SIP BUILD UK AND HEMSEC

Creating sustainable buildings for our future: Hemsec and SIP Build UK work together to build a shared vision

TIMBER INDUSTRY NET ZERO ROADMAP 12 How the timber sector can meet the needs of an increasingly low-carbon world

TIMBER

EXPO 2023 18 Boost your timber business profile at the UK’s largest showcase for timber in construction

20

23

SPRING 2023 www.timbermedia.co.uk ISSN 2515–8686 (PRINT)

CONSTRUCTION

landed! Our NEW pre-primed OSB is a blank canvas, perfect for applying for marketing messages and graphics. With all the inherent properties of our popular OSB3, SterlingOSB Zero PrimedPlus has a primed textured finish, and is designed for promotional messages, screening, exhibition stands, walkways and hoardings, inside or out.

Pre-primed board, ready for graphics NEW PRODUCT

Just

SterlingOSBZero.com

02 News

The latest news and views from across the industry.

14 First Steps to a Net Zero Future

Commissioned by TDUK, the Timber Industry Net Zero Roadmap aims to understand how the timber sector can better meet the needs of a low-carbon world.

16 CATT Gets Digital Update

BIM and digital tools are pivotal to the new Centre for Advanced Timber Technology, the purpose-built facility designed to demonstrate advanced timber technologies.

20 Cover Story: SIP Build UK and Hemsec

SIP BUILD UK and Hemsec have joined forces to work on a shared vision for creating sustainable timber buildings

22 Boost Your Timber Business Profile

Timber Expo is the UK’s largest and only dedicated showcase event for timber in construction and is thriving on the back of a successful show last year.

24 Optimum Energy Performance

Dara McGowan, director at Partel explains how a fabric first approach and timber frame homes can deliver excellent thermal and airtightness standards.

28 Safety at All Costs

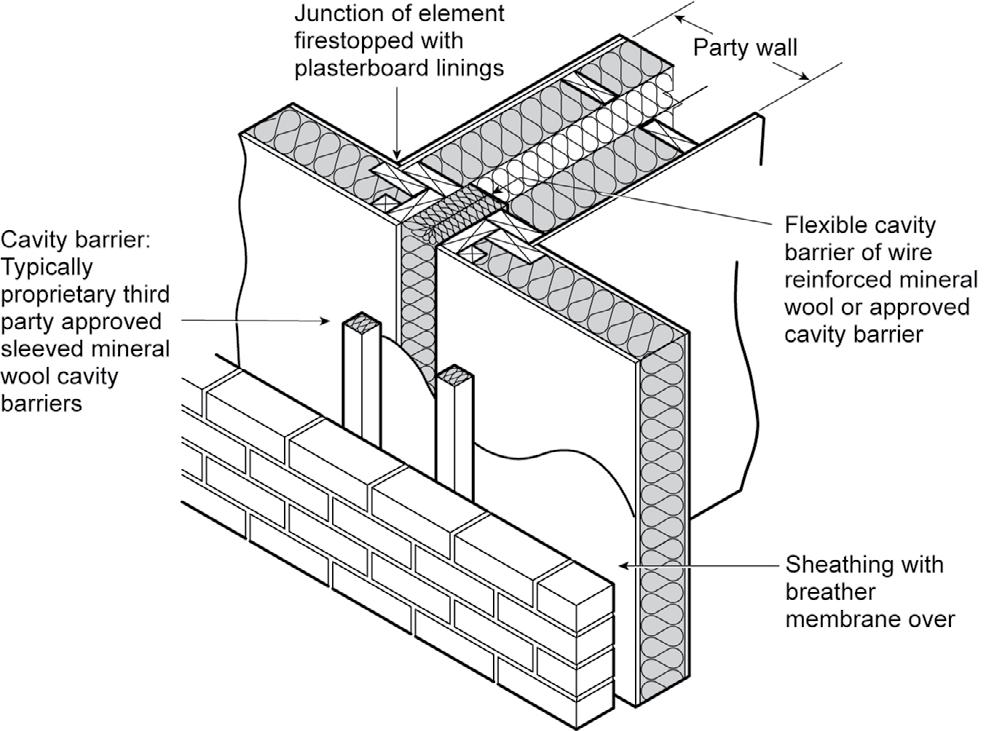

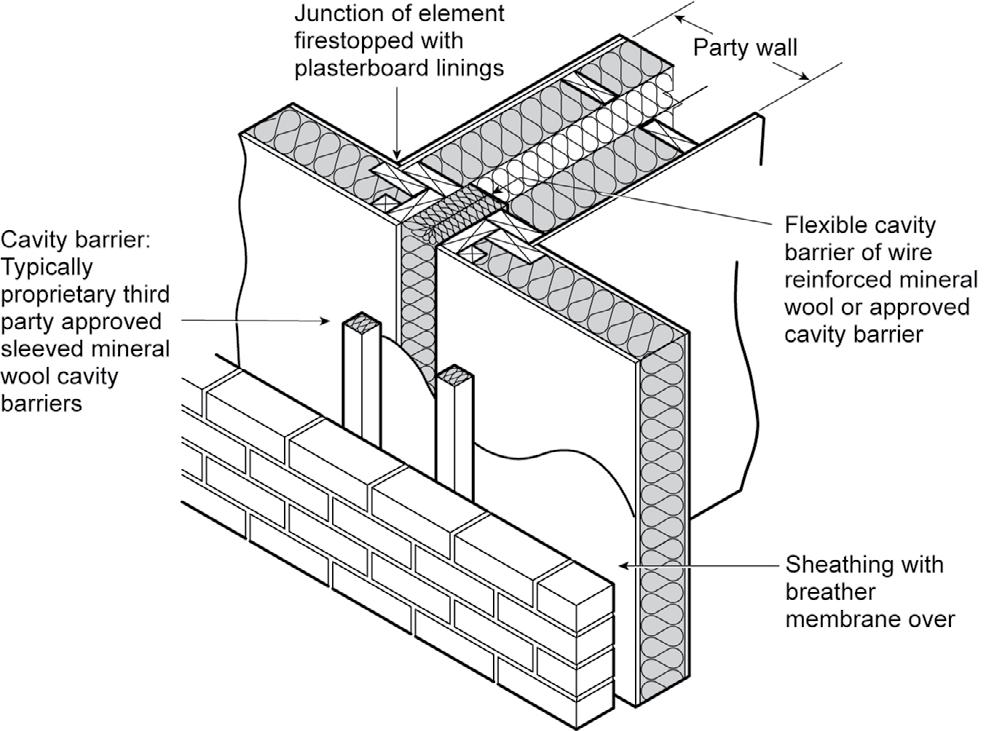

Robin Lancashire, senior timber frame consultant at BM TRADA, explains key considerations to bear in mind when designing and installing timber frame cavity barriers.

32 Modular Roofing for Charles Church

Smartroof’s offsite manufactured modular ‘room in roof’ system has met the highly technical demands of a curved row of terraced townhouses.

34 Timber Home Concepts

A concept house at Salford University is part of a project designed to accelerate progress towards low carbon and net zero housing.

The Perfect Partner for the Timber Industry

Managing Editor: Terry Hanlon

terry.hanlon@timbermedia.co.uk

01925 872371

Artwork: Pete Awad

artwork@timbermedia.co.uk

Follow Timber Media:

@Timber_Media

Registered address: 9 Viaduct Street, Newton-le-Willows, Merseyside WA12 9PL

Company registered in England and Wales. Company Number 10839173.

Timber Construction Magazine Spring 2023 01 www.timbermedia.co.uk @Timber_Media

20 22 16 14 02

32 28 34 24

TIMBER CONSTRUCTION ISSUE 23 CONTENTS

Timber Trader UK magazine 185 x 62 Liz nov2022.indd 1 15/11/2022 17:33:38

combilift.com

New climate change hub launched for forestry sector

The Climate Change Hub – which centralises the latest resources, information and guidance on climate change adaptation to support landowners, woodland managers and forestry practitioners in addressing climate change threats – was launched by Defra, Forest Research, Scottish Forestry and Welsh Government on 20 February.

The Climate Change Hub, managed by Forest Research, centralises and distils the latest information and UKFS (United Kingdom Forestry Standard) guidance on climate change adaptation to encourage uptake of adaptive practice by forest and woodland owners and managers. It provides concise information about risks from the changing climate, how to identify suitable adaptation measures and examples of how other managers are implementing adaptive practice.

There is no single recommended approach to climate change adaptation, as each woodland has different objectives and conditions. To enable managers to make informed decisions for their own woodlands, the Climate Change Hub also includes detailed guidance through the decision-making process, step-by-step, including information about the online tools available to support risk management and species choice.

Forestry Minister Trudy Harrison said: “Trees and tree management are crucial parts of our plan to reach Net Zero by 2050, and resources such as the Climate Change Hub support the forest industry to make better, more informed and ultimately more sustainable decisions when it comes to tree planting and woodland management.”

Forestry Commission Chief Executive Richard Stanford said: “Climate change will affect our trees, wood and forests. We need to ensure that our management practices ensure they thrive for the long term to ensure all the benefits they provide are maximised.

The Climate Change Hub will allow all of us to see this critical information in one place for the first time, enabling land managers and foresters to make the best decisions for our planet on tree and forest management.”

Scottish Forestry’s Chief Executive Dave Signorini said: “Trees have a significant role in climate change adaptation and resilience, providing habitats for wildlife, reducing flooding, and absorbing carbon dioxide from the atmosphere, and we want to help people understand how best to achieve that. The new Climate Change Hub will help empower the forestry sector here in Scotland to sustainably manage woodland and forests to deliver benefits for our environment, economy and communities.”

Wales’ Minister for Climate Change, Julie James, said: “This project will provide up-to-date research and guidance that will help the forestry sector and woodland planners plant and manage woodland in a flexible way. It’s another key project that will help us in Wales meet our Net Zero commitments and I look forward to seeing how it progresses.”

Woodland owners are encouraged to plant and manage more diverse and resilient woodlands of varying ages and species in the face of climate change. To counter future extreme weather risks from severe storms to drought, forests and woodlands should have a broad range of trees at different ages, from seedlings to trees to vary the size of our trees.

The Climate Change Hub supports the government’s wider Net Zero strategy and follows commitments set out within the recently published Environmental Improvement Plan to improve our mitigation and adaptation to climate change.

More at www.forestresearch.gov.uk

Timber Construction Magazine Spring 2023 02 www.timbermedia.co.uk @Timber_Media

TIMBER CONSTRUCTION NEWS

Celtic Offsite teams up with Premier Forest Group

Caerphilly-based social enterprise, Celtic Offsite, has teamed up with one of the UK’s leading timber suppliers, Premier Forest Products, as part of their ambitious plan to develop a Welsh supply chain to reduce its carbon footprint and support the local economy.

Celtic Offsite, part of the United Welsh Group, manufactures low carbon homes by producing high quality, sustainable timber frame structures, complete with factory fitted insulation and windows, to build up to 250 low carbon homes a year.

Premier Forest Products was initially approached by Celtic Offsite to supply Oriented Strand Board (OSB) for sheathing for timber frame panels, plywood and chipboard. However, thanks to Premier’s growing product offering, they have recently started supplying roof trusses, engineered floor joists and Laminated Veneer Lumber (LVL) for structural beams, taking Celtic Offsite ever closer to their goal of using Welsh suppliers for more of their manufacturing work.

Neil Robins, Managing Director of Celtic Offsite said: “We are actively committed to making the areas in which we work better and more environmentally sound. We have been certified as a Climate Positive Business by Earthly, meaning we will remove more greenhouse emissions than we produce. One of the ways that we will do this is by working with local suppliers who have a similar mindset to our own. We have been so impressed by the service and quality of the products

supplied by Premier Forest that we have consistently increased the range of items that we order from them.”

Co-founder and CEO of Premier Forest Products Terry Edgell said: “As an organisation, we firmly believe that the use of timber should be at the forefront of sustainable housing development. At the moment, wood in construction is the only commercially viable carbon capture and storage system so, simply by using more wood in construction, we can turn our built environment into a weapon against climate change. It is so inspiring to be working with an organisation in Wales that not only recognises the benefits of using timber but is actively working to build a sustainable supply chain, hopefully changing the way that homes are built.”

Premier Forest Products is a vertically integrated timber operation engaged in the importation, sawmilling, processing, merchanting, and wholesale distribution of timber and timber products from its 12 sites in the UK. As part of its commitment to the local community, Celtic Offsite offers an on-site training suite to provide skills development and apprenticeships for green construction jobs. Celtic Offsite has also achieved PEFC certification for the chain of custody of forest-based products and was awarded Gold by the Structural Timber Association (STA) in their latest audit.

Timber Construction Magazine Spring 2023 03 www.timbermedia.co.uk @Timber_Media

TIMBER CONSTRUCTION NEWS Yes we do, in fact that’s all we do! So, when you’re planning your next marketing campaign drop me an email at terry.hanlon@timbermedia.co.uk or call me on 01925 872371. Magazine advertising, e-marketing, web advertising and our new comprehensive Products & Services listings can all be found on our website www.timbermedia.co.uk DO WE LIKE TIMBER?

More at www.unitedwelsh.com

New vice chair for the Trussed Rafter Association

Luke Roberts, managing director at Donaldson Timber Engineering has been appointed vice chair of the Trussed Rafter Association (TRA). Luke brings with him over 22 years’ experience in the trussed rafter industry having started his timber engineering career in 2000 with National Hickman as an I-joist designer. Following roles with Walker Timber Group and FJI-Joists, Luke was appointed business development director at Donaldson in 2017 and managing director in 2019.

“The TRA plays an important role in our industry, and I am keen to get involved and play my part in the future of our trade association,” said Luke. “With recruitment, training, and our journey towards net zero being high on the agenda, I want to help get TRA members engaged so we can knowledge-share and benefit from the collective strength we have as an organisation.

“The recent launch of the TRA’s designer development programme (DDP) is testimony to the progress the TRA is making in creating a route for young designers to gain professional qualifications. The advances in the technical, and health and safety aspects of our work are also very exciting and so it’s a great time for me to take up this opportunity.”

TRA chief executive Nick Boulton welcomed Luke to the team saying: “Luke’s leadership of one of our larger members and his experience in all his previous roles will be an asset to our organisation. At a time when there is such economic uncertainty, a skills shortage, a housing crisis and the need to tackle climate change, I look forward to seeing how together, the TRA can help shape the future of modern methods of construction as a sustainable solution.”

Luke’s appointment was announced at the TRA’s members meeting and networking event in Hinkley in December. The Trussed

Rafter Association (TRA) represents the trussed rafter and metal web joist industry in the UK and Ireland. Members include the principal manufacturers of trussed rafters, metal web joists, suppliers and professionals involved in roof truss and engineered wood floor joist design and manufacture.

More at www.tra.org.uk

SEMA Group acquires Compass Software

SEMA Group, the world’s leading provider of CAD/CAM software in the fields of timber construction, stair design and sheet metal work, announced at the end of January the acquisition of Compass Software GmbH, a leading manufacturer of CAD/CAM/CNC software for stair design, timber and window construction.

Compass Software GmbH, founded over 30 years ago and headquartered in Dortmund, Germany, supports several thousand customers in over 30 markets worldwide with planning tools, connections to CNC machines of numerous machine manufacturers and MES systems for workshop organisation around the topics of stair design, timber and window construction. Optimising production-critical workflows and providing the right solution for the customer is part of the Compass Software DNA. This includes not only the use of the latest VR technologies, but also a fully integrated manufacturing process through the MES solution PROKON.

For the building industry, which is facing fundamental changes and challenges in the areas of digitalisation and process coordination like hardly any other industry, the alliance of the two companies is a strong signal. Both companies are already contributing considerably to BIM co-ordination processes for all trades involved that enable their own customers to achieve above-average increases in productivity and improvements in cost and schedule adherence for the industry.

“The SEMA Group is pleased to welcome Compass Software GmbH, a team with valuable and extensive expertise in stair design and digital manufacturing,” said Alexander Neuss, CEO, SEMA Group. “The complementary capabilities of both companies will give our customers access to high innovation and sophisticated technologies.”

This deal represents a strategic expansion of the SEMA Group portfolio. It is expected to further advance our strategic goal of offering a platform for industrialised timber construction by bundling innovative power, which offers customers a unique user experience in addition to consistent workflows. The mutual customers now have the possibility of integrating other trades into their daily business through the highly innovative solutions from the SEMA Group portfolio.

More at www.sema-soft.de

Timber Construction Magazine Spring 2023 04 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

New appointment at Scotts Timber Engineering prioritises dynamic growth

Thrapston-based Scotts Timber Engineering is building upon last year’s commercial success with its latest employee promotion. Billy Richardson has been appointed group head of sales, after spending 18 months as equestrian sales manager at sister company, Scotts of Thrapston.

The role involves heading up the sales divisions for both Scotts Timber Engineering and Scotts of Thrapston. “Scotts has significantly invested in sales in recent months,” said Billy. “Which has enabled us to secure some great projects with major housebuilders and specialist developers. Now it’s my job to build upon that success, using the proven tactics I demonstrated in equestrian sales, and further increase our market share.”

Business development sits at the heart of Billy’s new role, as does driving both companies forward in relation to their net zero journey. Billy says: “Product development and securing

projects within new markets is a key priority. We’re constantly developing new products that push new boundaries and enable us to continue to achieve record-breaking growth. In the region of 75% of my time is spent on achieving our business development goals.

“In the meantime, we’re firmly focused on helping our clients and the company make the transition to net zero. We have conducted a full audit and calculation of the company’s carbon emissions and are mapping out our carbon reduction targets for the years ahead. We’re currently working on developing new timber car ports that provide solar-powered charging for electric vehicles and are looking to transition to an all-electric fleet for our own staff. These innovations are just the start and come in addition to us only working with sustainable, PEFC-certified timber.”

Prior to joining Scotts, Billy worked in sales and business development within the building

materials and glazing industries. Overall, he has more than a decade’s relevant experience. James Scott, managing director of Scotts, said: “This promotion means our sales operations across both companies are in very capable hands. Given his corporate background and in-depth knowledge of the business, Billy has the expertise and experience to help us drive continued growth in a way that also improves all aspects of our sustainability.”

More at www.scottste.co.uk

Timber Construction Magazine Spring 2023 05 www.timbermedia.co.uk @Timber_Media

TIMBER CONSTRUCTION NEWS

BM TRADA launches new series of 2023 technical timber webinars

BM TRADA has announced a new programme of technical timber webinars which will be delivered throughout 2023. They will focus on one of three main areas of discussion: timber frame, technical timber and fundamentals of timber.

Benefitting from refreshed content and new topics on strength grading; modified woods, plywood and other panel products; and degrading micro-organisms, the webinars are set to provide a valuable educational resource for stakeholders across the construction industry.

Ben Sharples, commercial lead for timber services at BM TRADA, comments: “Provided it is ethically sourced, timber is an inherently sustainable construction material that uses

a fraction of the carbon in its source to end-use process when compared with other construction materials and products, not to mention its ability to sequester carbon too. With the UK construction industry tasked with reducing its carbon emissions in line with government net zero targets, timber is likely to have an increasingly prominent role to play over the coming years.”

The next series will feature three technical timber sessions covering misconceptions when strength grading solid timber (27 April), modified woods and panel products (11 May) and understanding wood degrading insects and microorganisms (25 May).

The final series will consist of four webinars discussing timber fundamentals starting

with timber origins (2 November), before covering quality (16 November), moisture (30 November) and protection (14 December).

Ben Sharples continues: “While timber is likely to further increase in prominence as a primary construction material over the coming years, it can also be found in countless architectural and heritage projects, all of which are covered by a strict code of practice. We hope that by offering such an extensive programme of educational content we will be able to support all stakeholders, irrespective of the age or condition of a project, and help add clarity to some of the most persistent technical timber misconceptions.”

More at www.bmtrada.com

Timber Construction Magazine Spring 2023 06 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

DOUGLAS FIR

THE TIMBER SPECIES OF THE FUTURE.

RICH RESERVES OF DOUGLAS FIR: France is the number one producer of Douglas Fir in Europe. Second in the world!

Great mechanical properties so the ideal construction material as glulam, finger-jointed or CLT

Naturally durable heartwood to Use Class 3.2 so can be used outdoors without treatment.

Sap can be pressure treated grey or brown up to Use Class 3.2.

Versatile: perfect for use as cladding or decking.

PIVETEAUBOIS

Technical centre

LAMWOOD total engineered timber production: 100,000 m3/year.

PERMANENT STOCK OF 3,000M3 of GL24h Douglas Fir, Spruce and treated Pine in 13m lengths.

STATE OF THE ART MACHINING AND CUT TO LENGTH SERVICE available for all your projects.

Timber Construction Magazine Spring 2023 07 www.timbermedia.co.uk @Timber_Media NEED MORE INFORMATION? CONTACT YOUR EXPERT: Elisabeth PIVETEAU | +44 (0) 7821 807 788 | elisabeth.piveteau@piveteau.com

Cinema «Les Fauvettes»Architect : Françoise RAYNAUD Come and see us at Stand J52 at Futurebuild

TwoTwenty employee ownership secures ‘perfect future’

Derbyshire-based staircase manufacturer TwoTwenty has announced its sale to an employee ownership trust (EOT). The transition of TwoTwenty, along with its holding company Elephant Holdings, to a business that is 100% employee-owned is believed to be the first such deal in the UK timber engineering sector and secures the jobs of 40 staff.

No funding or contributions have been required from any employee to fund the purchase of the business by the EOT, and under the terms of the deal, all staff are expected to benefit from significant tax-free bonuses in future years as well as deciding the company’s future strategy and growth plans. All the existing senior leadership team will remain closely involved in the business as trustee directors.

Ali Wright, founder of TwoTwenty, will become chair of the EOT, saying: “We passionately believe that our colleagues are the thing that make TwoTwenty successful, so becoming an EOT secures the perfect future for this business. As a small business, in reality we only have a few options for the next phase of growth. We did not want to pursue a trade sale as that does not secure the long-term future for our staff. We did not want to pursue an external investor or management buy-out because of the huge pressure and obligation it brings on future performance.

!We could not simply share the ongoing profits of TwoTwenty with our employees as that would make us unsaleable, and I certainly couldn’t imagine exiting by just closing down such a strong and vibrant company. In effect, we

are a family business whose employees are not related, so to create an EOT resonates with every value we have ever aspired to. It creates a legacy for us, provides security for all the staff, and allows us to handsomely reward every employee for the hard work and effort they put in.”

Steve Chapman, director at TwoTwenty, commented: “The Employee Council will be the thing that really makes the magic happen. The engagement and ongoing buy-in of our staff will transform the ability of TwoTwenty to capitalise on the huge opportunities ahead. It also allows us to make a 10% pay rise for everyone and to introduce a new scheme that facilitates a minimum of 22.5% higher pension contributions for each employee. These commitments can genuinely change the lives of our employees and their families.”

According to the Employee Ownership Association, the benefits of companies becoming employee-owned include improved productivity and employee engagement and more resilient regional economies. There are now more than 1,000 employee-owned companies in the UK.

More

Donaldson Timber Systems secures OSHA framework agreement

achieve Buildoffsite Property Assurance Scheme Plus (BOPAS Plus) in recognition of the quality and durability of its offsite build systems. With DTS’ state-of-the-art open and closed panelised systems – Alpha, Delta or Sigma ll – works can still be carried out on site, ensuring that social value potential is reached within the communities served.

Donaldson Timber Systems (DTS), has secured a position on the Off-Site Homes Alliance (OSHA) national construction framework for volumetric (CAT 1) and panelised (CAT 2) Modern Methods of Construction (MMC). The framework is valued at £2 billion. DTS will deliver offsite timber panelised system build for Category 2 housing over four years.

Working closely with 23 local authorities and housing associations nationally, DTS will design, manufacture and install timber frame wall panel building systems that meet build speed, fabric performance, building design and cost requirements. With a fabric-first approach that achieves net zero operational carbon, housing providers can use DTS’ timber systems to create sustainable, resilient, and affordable homes that meet the Future Homes Standard.

Earlier this year, DTS became one of the first manufacturers to

Mike Perry, Business Development Director, Donaldson Timber Systems, said: “By securing a position on the OSHA MMC Cat 1 and Cat 2 Framework, we can build upon our strong relationship with affordable housing providers nationally and bring them along on DTS’ timber frame, fabric-first journey. We look forward to facilitating greater efficiency and value for clients who procure via this framework and supporting OSHA’s mission to deliver 20,000 homes with MMC technology.”

Matthew Harrison, Chief Executive of OSHA member Great Places Housing Group, said: “We’re delighted to be working with Donaldson Timber Systems on the new OSHA framework. We’re confident they will be able to work with us and the OSHA clients in delivering the sector’s extensive development ambitions. We were pleased with the positive response from the market and received high quality proposals and substantial social value pledges for our communities. We are now looking forward to mobilising the framework and working together on new projects to realise our ambitions of delivering much-needed affordable homes.”

More at www.donaldsontimbersystems.com

Timber Construction Magazine Spring 2023 08 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

at www.twotwenty.co.uk

International Timber joins STARK Group

International Timber has joined STARK Group. The acquisition first announced on the 12 December confirmed that International Timbers’ parent company had reached an agreement to sell International Timber to STARK Group. This sale has completed, and International Timber are now wholly owned by STARK Group.

International Timber has now joined one of the fastest growing merchants and distribution groups in Europe and a business completely focused on its expertise in distributing building materials for tradespeople. The International Timber brand name, much recognised and respected by those in the industry will continue and International Timber will become part of the UK subsidiary of STARK Group, STARK Building Materials UK.

Paul Martin, managing director of International Timber, said: “STARK Group is a leading distributor of building materials across Europe and their business will bring their experience of successful growth. They have a culture of sharing best practice and will be supporting our plans to deliver the solutions, services and great experience that will help customers grow and make their life easier. So it’s great for our customers and for our suppliers who are also a critical part of our success.

“Customers won’t notice any immediate change, as it’s very much business as usual and we will continue to trade as normal for customers. Over time we will be working closely with STARK, sharing and building on our great plans for our customers. We have a lot of opportunities now to share best practice with STARK and learn from their business and operations elsewhere in Europe. They have a tremendous track record of growth and delivering a great experience to their customers. We’ll be spending time seeing in what ways we can learn from this experience to support our local customers.”

STARK Group CEO Søren P. Olesen said: “We are very pleased to have completed this acquisition in great time and look forward to welcoming the International Timber colleagues and branches to STARK. We have a strategy that successfully focuses on professional tradespeople and the renovation and maintenance market together with specialist distribution for a range of customer segments.

“Entering the UK market is a great opportunity for our combined business to share best practice across the Nordics, Germany, Austria and the UK making life even easier for tradespeople. We’re delighted to now be a major employer in the UK, with 9,000 colleagues, where we will continue to operate as a good corporate citizen, placing a strong emphasis on sustainability, valuing and caring about our new UK employees and supporting UK growth and building decarbonisation.”

More

DURABILITY FOR YOUR GROUND CONNECTIONS

ALU START is the aluminium profile for ground connection of CLT and timber frame walls of any size. A unique system for tracking, levelling and raising the timber wall from the ground. It protects against capillary rising damp and transfers all shear, tensile compressive and lateral forces to the foundation without the need for additional plates. The strength values are validated by comprehensive and reliable calculation models in accordance with the CE marking according to ETA-20/0835.

www.rothoblaas.com

Timber Construction Magazine Spring 2023 09 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

at www.internationaltimber.com

More ‘regular’ timber import patterns seen in Q4 2022

The gap between record 2021 volumes and low 2022 volumes began to close in November, with imports resembling more regular winter totals reported Timber Development UK (TDUK) in January.

The disparity in total volumes between 2021 and 2022 was just 14% in November 2022, compared to 22% in October and 21% in September. The reduced disparity between 2021 and 2022 was seen most clearly in the softwood category, where a 182,000m3 gap in October was reduced to 72,000m3 in November.

Overall, imports in 2022 have been significantly lower than the records set last year, with totals from January to November 2.4 million m3 lower than the same period in 2021. Only hardwood has seen growth in 2022, up 13% compared to last year.

TDUK head of technical and trade, Nick Boulton, said: “Totals in Q4 are beginning to resemble the levels of previous years, with the large disparity seen between 2022 and 2021 starting to close. These more ‘regular’ volumes, however, are largely due to reduced winter demand in previous years rather than increased volumes this year, with the timber market often winding down for the festive season.

“Overall, volumes have been low in 2022, with healthy stock levels and market uncertainty being reflected in this year’s import patterns.

Looking forward, 2023 is set to be another tricky year for the timber trade, with the CPA predicting reduced activity in crucial private housing and RM&I sectors. The CPA has predicted a shallow recession in 2023, with demand likely to pick up again in 2024. Demand for timber is also likely to increase significantly in the long-term, as the UK looks to reduce emissions in the built environment and achieve net zero by 2050.”

Accoya® TV adverts launched on Sky

Accsys, the manufacturer of Accoya wood, has launched a new UK national advertising campaign, ‘Lasts a Lifetime’, highlighting the high performance of Accoya wood to homeowners. The campaign features the first UK TV commercial to promote Accoya® wood.

The commercial aired from the 27 February on Sky, supported by digital advertising including YouTube and other social media channels. The campaign launched with a commercial on Sky TV targeting a subset of the homeowner market audience. This will be supported by digital ads running through the spring. The commercial was produced by RD Content.

The commercial on Sky is expected to reach an audience of more than 3.1 million homeowners with an advert frequency of 5.5 million. It follows a young family’s life through the lens of an Accoya window, charting the ups and downs of a relationship between a father and his daughter over the years. The window acts as a constant in their ever-changing lives.

George Neel, communications, marketing and ESG director at Accsys, commented: “As we move into the warmer months many people are considering replacing their windows and doors. Windows

and doors are one of the biggest investments to add value to a home and choosing the right material is key. We want to ensure homeowners understand the durability and reliability benefits of Accoya and know that it lasts a lifetime.”

More at www.accsysplc.com

Timber Construction Magazine Spring 2023 10 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

www.timberdevelopment.uk

More at

Timber Construction Magazine Spring 2023 11 www.timbermedia.co.uk @Timber_Media

Thermally modified wood made from British-grown timber

use intense heat to reconfigure locally grown wood into a more durable, stable and consistent material. And by using British species we’re investing in local woodlands.

is made in Wiltshire by the team at Vastern Timber. Brimstone is a beautiful range of thermally modified British wood for cladding, decking and joinery. Call us +44 (0)1793 853281 Email sales@vastern.co.uk Website brimstonewood.co.uk Instagram @brimstonewood

Transforming British Woods

We

Brimstone

Vastern Timber celebrates a hat trick of awards

Vastern Timber, the UK’s largest hardwood sawmill and creator of Brimstone Wood, is celebrating three recent award wins. Over the last few months, the team has picked up awards for ‘Best Cladding’, ‘People’s Choice’ and ‘Changing Attitudes’.

Build It Magazine’s ‘Best Cladding’ award

The team’s winning streak began with the Build It Magazine’s ‘Best Cladding’ award for Brimstone. This innovative cladding product uses British-grown timbers – like poplar, ash and sycamore – and transforms them into durable external cladding using thermal modificationBrimstone received the award for best cladding system or product. Not the best product compared to other timbers, or other British made products, but the best in class, which was a real endorsement for the team.

Alliance of Sustainable Building Products’ People’s Choice award

Brimstone’s second gong came from the Alliance of Sustainable Building Products’ People’s Choice award. The team were delighted to be recognised here due to the ASBP’s focus on important ‘pillars’ of sustainability – ethics and transparency, health and wellbeing, low carbon and resource efficiency.

In Tom’s pitch for the people’s prize, he said “we developed Brimstone as a local alternative to imported timber cladding. We source most of our timber from within 100 miles of our sawmills which reduces imports and roadmiles. By using thermal modification, we’re able to transform British timbers that aren’t normally durable (such as poplar, ash and sycamore) into long-lasting products for the construction industry.”

Confor Changing Attitudes award

Last but not least, the Confederation of Forest Industries awarded Vastern’s MD, Tom Barnes, with the Changing Attitudes award. The

judges highlighted Tom’s work on the National Wood Strategy for England and the ‘Wood for the Trees’ series, about the future of forestry, “promoting greater understanding and awareness of the sector” which has had over 70,000 views.

Trudy Harrison MP, the Forestry Minister, presented Tom with the award. Vastern Timber are delighted with their wins, but Tom says they are looking beyond the award shelf. “The wins are great, but our work is about much more than awards. What really matters is our mission to promote local timber, and our ongoing collaborative efforts to support local woodlands.”

More at www.vastern.co.uk

Timber Construction Magazine Spring 2023 12 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

Sidey launch training academy

Fenestration specialist Sidey is set to officially launch its Training Academy. In response to the declining skilled labour market, the company decided to create the Sidey Training Academy and begin an associated Modern Apprenticeship Program with the intention of growing its workforce and promising long term security of employment, to those engaged within it.

The event will see Sidey open the doors to its Training Academy to local schools, colleges, and councillors so they can speak with the team about Sidey’s Modern Apprentice Installer program and how the company supports the Young Persons Guarantee. Donna Montgomery, Sidey’s Community Benefits Manager commented: “Sidey’s Training academy extends beyond the physical space created next door to our Perth showroom, it encompasses the resources invested every single day in coaching, mentoring, and training our apprentices to become exceptional members of our team.

“Apprentices work towards a level 5 SCQF through vocational training over a 12–18-month period. In tandem, our bespoke Milestones training plan clearly sets out the competencies required to fulfil their role, against which they are assessed monthly, provided with

constructive feedback and goals to work towards. Apprentices will regularly spend time in our Feus Road Training Academy, which provides a safe space, in a closely supervised, supportive environment to practice new skills before they are refined on-site.”

The Sidey Training Academy building contains timber kits accommodating various styles of windows and doors, with replaceable subframes to allow apprentices to remove and refit repeatedly. There is textured render, cladding, a bay frame, roofline, and hand/power tools to work with. A large television screen and comfortable seating area provides an area for inductions, presentations, and training sessions.

Donna continued: “Our apprentices have varied backgrounds, sourced from Council led employment programs and in future, college graduates of Joinery/Carpentry NPA courses. Each apprentice has a drive to succeed and pride in their work, a strong foundation upon which Sidey can build, passing on knowledge accumulated with almost a centuries experience in the fenestration industry.”

More at www.sidey.co.uk

SterlingOSB Zero ‘Primed for Action’ across the board

Panel product manufacturer, West Fraser, has introduced a new ready-primed version of its industry-leading SterlingOSB Zero board which is ideal for use in a wide range of situations from site hoardings through to building exhibition stands and other installations where appearance is important.

SterlingOSB Zero PrimedPlus is being produced in 18mm thick, squareedged sheets measuring 1220 mm wide by 2440mm long. The top face is primed with a UV putty and the sides are sealed to reduce water ingress, leaving the sheets ready for decoration or the application of graphics. The high-quality surface is smooth while the structure is free from knots or voids and from an environmental perspective the ‘Zero’ in the name assures specifiers that the product contains no added formaldehyde.

West Fraser’s Dom West, Sales Director for UK and Ireland, commented: “SterlingOSB Zero is the first UK manufactured OSB with zero-added formaldehyde to deliver health as well as several other technical benefits, making it superior to softwood plywood as well as particleboard. The factory-primed, ultra-smooth surface presents a blank canvas for marketing messages and other types of promotional display. Being rugged and weather-resistant, the SterlingOSB Zero PrimedPlus boards can be used outside for security applications, such as screening or walkways while we’re already getting strong interest from the hospitality sector and shopfitting specialists, as well as housebuilders and other contractors.”

SterlingOSB Zero PrimedPlus is CE-marked and complies with the Forestry Stewardship Council (FSC) and BBA Agrement requirements.

The boards are supplied in packs of 50 to cover a total area of approximately 150m². Right across its range, West Fraser has been making substantial investment in reducing the environmental impact of its production processes including signing new contracts with its energy suppliers to ensure that all its power comes from renewable sources that are covered by REGO (Renewable Energy of Guaranteed Origins) certification.

For peace of mind, the boards also conform to European E1 emission standard, comply with BS EN 622: Parts 1 and 5.

For further information, call 01786 812 921 or visit uk.westfraser.com

Timber Construction Magazine Spring 2023 13 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

First Steps to a Net Zero Future

The Timber Industry Net Zero Roadmap commissioned by TDUK aims to accelerate the productivity,

and innovation of the timber sector to better meet the needs of a low-carbon world.

The Roadmap was published in January 2023 following a comprehensive effort to map and measure carbon emissions across the whole supply chain. Produced in collaboration by Timber Development UK (TDUK) in collaboration with 11 UK timber trade associations and organisations, its first step is to outline the size of the challenge, using 12 months of expert analysis to show that the timber supply chain is responsible for 1,575,356 tonnes CO2e territorial emissions –around 0.35% of the UK’s total.

The report acknowledges that this is very low compared to other manufacturing industries such as UK steel production, which is responsible for 12 million tonnes CO2e (2.7% of UK emissions), and concrete, which is responsible for 7.3 million tonnes CO2e (1.5% of UK emissions). However, the opinion of the organisations involved in the Roadmap is that the industry must start its journey to net zero from the position that no emissions are acceptable.

With a range of pathways set out in the Roadmap for the industry to achieve net zero by 2050 – at the very latest – the document has been made freely available for all businesses in the timber supply chain to adopt, alongside a set of 10 high-level policy recommendations. These are:

1. Industry should align to GHG protocol to report Scope 1 & Scope 2 emissions by all non-SME operators by 2023

2. Set industry standard to compile full scope carbon footprints (inc. Scope 3) by 2025

3. Reduce road-going transport emissions intensity by 25% by 2030, and 50% by 2035

4. Reduce processing/manufacturing emissions intensity by 50% by 2030

5. Reduce forestry emissions intensity by 50% by 2040

6. Reduce Scope 1 & 2 carbon intensity of the industry by 90% by 2045

7. Reduce Scope 3 carbon intensity of the industry by 90% by 2050

8. The industry will develop a specific circularity/resource efficiency roadmap by 2024 to accelerate the activity in this key area

9. Nature-based solutions (combined with the above reductions) focused on permanent carbon removals to be used for offsetting

10. The industry will support targets/initiatives to increase domestic production and expansion of the domestic woodland stock.

The Roadmap also seeks to address the 3,655,715 tonnes CO2e of imported embodied emissions that come from the processing of wood products in their country of origin. This figure, taken together with territorial emissions, would make the timber industry responsible for about 0.68% of the UK’s total emissions.

Of the total consumption emissions, 49% of these emissions are from the transport of timber products, and 34% are embodied in imported materials. The remaining 17% are from the UK production processes within the industry, and waste.

One of the key aims of the Roadmap, according to TDUK Sustainability Director Charlie Law, is to challenge the misconception that as the timber supply chain comes from a low-carbon base, there are few opportunities for the timber supply chain to influence their emissions.

“There are some really quick wins outlined in the Roadmap for businesses – wherever you are in the supply chain – which can be put into practice now,” says Charlie. “If you reduce your carbon, you reduce your costs. You can change the energy source for heat for your factory processes, reduce the waste from your product manufacture, or reduce your energy use by using better lightbulbs – there are literally thousands of ways both big and small you can start reducing your emissions.

“This includes for the single biggest contributor to the timber industries carbon profile – transport. While there aren’t yet many fully electric HGV options to remove these emissions, there are ways to be more efficient in your current operations. And if you’re using less diesel, you reduce your emissions and your fuel costs.”

The most important first step, he says, is making sure you can accurately count your carbon emissions. This is why the Roadmap is being rolled out with both free, and recommended, tools to help businesses better understand their emissions profile.

Charlie adds: “Once you have an emissions profile for your business, you see not just your environmental impact, but also your operational inefficiencies. From here you can start your business on a pathway to be more competitive in a low-carbon market.”

The 11 UK organisations who collaborated with TDUK on the report are: The Alliance for Sustainable Building Products (ASBP), British Woodworking Federation (BWF), Confederation of Forest Industries (Confor), National Merchant Buying Society (NMBS), Structural Timber Association (STA), Timber Decking and Cladding Association (TDCA), Timber Packaging and Pallet Confederation (Timcon), Trussed Rafter Association (TRA), Wood Protection Association (WPA), Wood Panel Industries Federation (WPIF), and Wood Recyclers Association (WRA).

Timber Construction Magazine Spring 2023 14 www.timbermedia.co.uk @Timber_Media

You can download the roadmap for free from www.timberdevelopment.uk

FEATURE TDUK

sustainability,

FSC and UKTR Training for TDUK

IIn January, FSC UK joined the Soil Association at The Building Centre, London for a one-day training workshop for Timber Development UK (TDUK) members on FSC and UK Timber Regulation (UKTR).

“It was great to have in-person exchange and dialogue with FSC-UK. We are very grateful to have this opportunity and hope to continue this direct exchange in the future so we can jointly help certificate-holders and TDUK members prepare for their upcoming ventures,” said Xiao Ma, TDUK

The workshop provided explanation and discussion of the FSC system, how it works and relates to the UKTR and what the auditors will look for in both systems.

The workshop was aimed for anyone wishing to improve their understanding on FSC and UKTR and to also prepare importer members of the TDUK ahead of their annual audit on UKTR (RPP). The workshop was delivered by staff members from FSC UK and an auditor from the Soil Association.

“This event was a great reminder of the value of face-to-face meetings,” said Rosie Teasdale, FSC UK “There will always be a place for

online meetings now but it was so good to be able to hear first-hand the experiences, challenges and questions from certificate holders and other stakeholders in person. We also appreciated the willingness of the participants to throw themselves into the activities with such enthusiasm!”

If you are interested in arranging FSC training for you or your organisation, visit uk.fsc.org/contact-us/training for more information or email training@fsc-uk.org

Is your timber really green?

Timber Construction Magazine Spring 2023 15 www.timbermedia.co.uk @Timber_Media

ADVERTORIAL FSC

* Contains public sector information licensed under the Open Government Licence v3.0. © FSC / Paintbrush (Renovo) FSC® F000231

people than ever

about the environmental impact of the products and services

buy,

research shows that

be

the world’s most trusted forest management solution. Choose FSC. uk.fsc.org/construction

certification offers credible assurance that the timber and forestbased products you trade support responsible forestry.

More

are concerned

they

but

40% of green claims made online could

misleading (CMA*). Choose

FSC®

CATT Gets Digital Update

Designed by Bond Bryan, the 2,500sqm building comprises five studios, event and breakout spaces, two large workshops and amenities including a café and dedicated quiet space. Part of the New Model Institute for Technology and Engineering (NMITE) second campus at Skylon Park in Hereford, CATT utilises a hybrid structure that combines timber and steel.

A combination of techniques

The studio space is constructed with cross laminated timber (CLT) panels for the external walls and ceiling, internal and external glulam beams and timber insulated closed panels. The workshops are constructed with steel frames and include a combination of timber and metal cladding.

Designed using Design for Manufacture and Assembly (DfMA) principles, the timber and steel panels, frames and beams were manufactured offsite before being delivered to site for assembly. The timber frame was also designed so that it can be dismantled and reused in the future.

Aditi Saxena at Bond Bryan was the project architect and sustainability lead on the scheme. “The brief was a building of two halves,” she explained. “NMITE wanted to showcase as many ways of using timber as possible, so we combined a number of design approaches within the one building, including the use of offsite manufacturing techniques. NMITE focuses on teaching students in practical environments so there was also a desire to leave parts of the building interior exposed to show the mixture of different materials and how it was all put together.”

A live testbed

The core concept for the project was to create a ‘Living Lab’, where research and testing could take place in a real-world environment. A number of sensors have been embedded within the building to measure thermal, acoustic, and structural performance, including thermocouples, accelerometers, and strain gauges. Results are being fed back into digital models to compare predictions with actual performance.

One of the tests involves looking at the structure itself. Working with Stora Enso, the CLT supplier, 48 sensors have been installed to monitor moisture within the building. It is hoped that the results can be used by industry professionals as well as insurance and warranty providers to better understand how the materials behave.

Sustainable and efficient

An exemplar in timber technology and design, the CATT has biophilic design principles at its heart. The buildings are orientated to maximise natural light and minimise heat gain. The studio spaces face west and have solar shading provided via external timber battens. They also benefit from northlights that bring in natural light. In contrast, the workshops have slim slot windows to minimise solar gain from the south.

The building also houses the Centre for Advanced Manufacturing (CAM). Originally conceived as two separate buildings, the disciplines were combined into a single building to maximise the budget and provide the most efficient use of space.

“It was a project that continuously evolved,” adds Aditi Saxena. “It was a new centre for new courses that had never been taught, so there

Timber Construction Magazine Spring 2023 16 www.timbermedia.co.uk @Timber_Media

FEATURE BIM & DIGITAL DESIGN

BIM and digital tools are pivotal to the new Centre for Advanced Timber Technology (CATT), the purpose-built facility designed to demonstrate advanced timber technologies and teach the next generation of engineers.

was a lot of collaboration about what the end result might look like. Graphisoft’s Archicad was extremely useful for this process. It allowed us to develop the 3D form quickly and agree the spatial massing before we went to detailed design. We built the whole model in Archicad within three days which is very fast. We then added more technical detail as the design progressed.”

This speed of use and ability to work effectively on different design concepts was a major help when discussing options with the client, added Aditi Saxena. “Because the project involved the use of various materials and construction techniques between different parts of the building, we needed a way to demonstrate the options as we went along. Archicad helped us to do this efficiently. We would use different layers for options and then toggle between them in meetings. Once decisions were made we just deleted the old layers to refine the final model.”

Co-ordinating the design

Using multiple construction techniques meant that the team at Bond Bryan had to co-ordinate with two separate structural engineers, one for the steel elements and one for the timber.

Brad Stenson, architectural technologist at Bond Bryan says: “We incorporated their models directly into Archicad using IFC, which helped us to visualise what we needed to do in one place. This included working with the supply chain early on to convert 2D drawings so that they could be used directly in the model, saving us lots of design time.

“There’s so much flexibility within Archicad – it opens a different way of modelling and building. When you model in 3D everyone in the room understands the design straight away, which helps collaboration and speeds up decision making.

“For example, the 3D fly around camera is very useful. It helped the contractor to understand what the building would look like and was an instant hit. And, when we wanted to highlight specific areas, the graphical overrides made it very easy. The built-in link to Solibri made it simple to check the model and avoid clashes. It also helped us to decide where best to leave services exposed to allow the students to see what they’re learning about in practice.”

CATT welcomed its first intake of students in September 2022. It is hoped that industry organisations will also use the space for CPDs and events, helping to forge links between education and the sector.

More at www.nmite.ac.uk

Timber Construction Magazine Spring 2023 17 www.timbermedia.co.uk @Timber_Media

FEATURE BIM & DIGITAL DESIGN

www.graphisoft.com/uk

Time to Talk Timber

Boost your timber business profile and benefit from special discounted deals on all shell scheme exhibitors with extra show promotion and coverage inside Timber Media’s publications.

Timber Expo 2023 will see the 11th edition of the event and is co-located with UK Construction Week – the UK’s leading trade event for the industry, attracting 30,000 visitors.

So where can we help?

Timber Media has teamed up with Media 10 and will play an active part in promoting the 2023 show. Timber Expo will be supported by a heavyweight national trade marketing campaign. The co-location with UK Construction Week ensures a guaranteed audience, and the targeted messaging through digital advertising and trade press will deliver those trade professionals who specify or buy timber products.

Timber Media can exclusively offer an ‘all in one stand package’ on the 6sqm and 15sqm shell scheme stands to make it easier and cheaper for companies to get involved. For both size stands this includes:

• Carpet, walling and nameboard

• x1 data capture device

• x1 table and x4 chairs

• Lockable cupboard and literature rack

• Track with spotlights with x1 electrical socket

• Visitor data captured and delivered to you

• x3 month company profile on: www.ukconstructionweek.com

Costs: 6sqm stand - £3,000+vat and 15sqm stand - £7,000+vat

Should you wish to book a specific stand outside the ‘all in one package’ we can give you a discount of 15% off all sizes of shell scheme stands, but with the ‘all in one package’ it’s just turn up and start exhibiting…EASY! We will also be sending fortnightly visitor promotion e-shots to our database of 5,000 dedication timber professionals

“As businesses start to move on past the pandemic, there is a lot more interest in meeting face-to-face to discuss plans for the future and understand how timber plays such an important part in achieving the 2050 net zero carbon targets. There has never been a better time to get together and talk timber so please get in touch to find out more.” Terry Hanlon, managing director, Timber Media.

Timber Expo is the UK’s largest and only dedicated showcase event for timber in construction. Backed by trade bodies including the Timber Development UK (TDUK), the Structural Timber Association (STA), the Builders Merchant Federation (BMF), it is the most comprehensive representation of the timber industry anywhere in the UK.

Timber Expo brings together award-winning architects with clients and contractors to showcase best practice in timber construction projects. It is the must-attend annual event for anyone working with timber products in the built environment. The exhibitor profile includes structural timber frame, sawmills, merchants, glulam, SIPs, CLT, fixings and fastenings, timber cladding, doors and windows, mouldings, skirtings and flooring products.

All of Timber Media’s visitor promotion activity is in addition to that of the show organiser, Media 10. Throughout the year you can follow developments on Timber Expo in all the Timber Media publications and there is a range of joint advertiser/show exhibitor options that can be discussed.

To discuss your involvement in the show in more detail get in touch now with Terry Hanlon at terry.hanlon@timbermedia.co.uk

Timber Construction Magazine Spring 2023 18 www.timbermedia.co.uk @Timber_Media

FEATURE TIMBER EXPO 2023

Head for Heights

Taylor Lane Timber Frame recently introduced its Top Hat Gantry Walkway method – a new work at height technique for use when constructing roofs which require top hat trusses. The method was developed in-house with the aim of moving the procedure up the hierarchy of control measures when working at height – from fall arrest to fall prevention, with the creation and use of a safe work platform.

The installation of top hat trusses is a considered a hazardous working at height operation, the Taylor Lane Top Hat Gantry Walkway method designs out potential risk. A working platform or, in this instance, a gantry walkway can be made once the main roof section is braced, and a handrail is fixed within the gantry walkway to create a ‘safe’ place of work.

How does it work?

Wearing appropriate PPE throughout the procedure, the timber frame operative must first be clipped to the scaffold structure when accessing the gantry. Once the gantry

sub-deck is installed, four by one bracing provides handrail guardrails. These, along with an intermediate guardrail, are fitted in line with work at height regulations and fixed according to Taylor Lane’s engineering analysis document.

The guardrails are fitted when a leading edge is present to provide a safe gantry from which to carry out roof work. The top hat trusses can then be loaded out to the operative on the gantry from an operative on the scaffold. The Top Hat Gantry Walkway method is to be used in conjunction with Taylor Lane’s Risk Assessment Method Statements (RAMS).

Exceeding expectations

Speaking about the reason for top hat trusses and the development of the new method, Liam Hale, construction director at Taylor Lane Timber Frame said: “Top hat trusses are necessary when the trusses required for a build are too tall for standard manufacturing processes and/or transportation. The main body of the truss and

its topmost point (the top hat) are produced separately, taken to the site as two separate components, and then fitted in place. While this solves the problem regarding manufacture and delivery, it does present potential health and safety issues which come from the need to work at height.

“While we have always used the correct equipment and fall arrest in such instances, we felt that there must be a safer method, one which focusses on prevention of a fall. I am pleased to say that we have been successful in achieving this, developing a method that exceeds the basic requirements of the Work at Height Regulations 2005.”

For ease and better understanding, Taylor Lane has made a best practice video which gives a step-by-step guide to the new Top Hat Gantry Walkway method. It’s freely available to view on YouTube – search Taylor Lane Timber Frame. The video was filmed on site in Gloucestershire with the support of MF Freeman and Barecroft Carpentry.

More at www.taylor-lane.co.uk

Timber Construction Magazine Spring 2023 19 www.timbermedia.co.uk @Timber_Media

Health and safety is of paramount importance on any construction site and to add to protection at height, one timber frame company has introduced a new way of working.

FEATURE HEALTH & SAFETY

Creating sustainable buildings for our future, together

Hemsec and SIP Build UK announce their partnership with the aim of providing a cost-effective, end-to-end solution for the creation of energy-efficient building systems. With energy prices soaring and millions of UK households living in fuel poverty, we must consider the ways we construct now more than ever.

Many house builders are driving energy savings through a combination of materials and technology; however, we believe that a fabric-first approach delivers huge benefits for the homeowner and the environment. In addition, as building regulations change, a fabric-first approach will increase thermal efficiency to futureproof the build by considering the entire building envelope, with construction materials sitting at the heart of this.

Building with SIPs can significantly contribute to meeting Future Home Standards and Passivhaus standards, resulting in reduced days that require heating, significantly reducing energy bills. Additionally, when building with SIPs, homes are airtight, resulting in cooler homes during the warmer weather.

Through the partnership, Hemsec and SIP Build UK aim to build on existing synergies to provide high-quality sustainable building systems, with a focus on taking responsibility in today’s environment for the generations of tomorrow.

Sarah Gazzola, sales and marketing Director at Hemsec commented:

“At Hemsec, we are on an exciting journey to become a B-Corp certified company and therefore it is extremely important for us to build relationships with organisations where there is a synergy in our values and purpose. With a strong alignment in the direction we’re heading, we are looking forward to building on the relationship we have with SIP Build UK and hope to make a real difference in the construction industry through providing high-quality panels that contribute to an energyefficient future for homeowners.”

Chris Duckworth, managing director at SBUK Group, added:

“The future direction allows us to make the most of being a market leader with Nationwide Coverage, SIPs are regularly featured on Grand

Designs and other property programmes, we have seen demand soar in this marketplace. Energy efficiency is harder to achieve using traditional methods and the short supply of brick layers is moving many developers and builders towards Offsite Manufacture. Our partnership with Hemsec and our dedicated teams and systems enables us to continue our passion for better products and processes which aim to increase efficiency, quality, resident satisfaction, environmental performance and sustainability.”

About Hemsec

Hemsec is the UK’s leading independent and longest-standing composite insulated panel manufacturers. With over 90 years of experience in the industry, Hemsec has played a key role in shaping the use of insulated panels across many industries.

About SIP Build UK

SIP Build UK is part of the market leading SBUK Group. For over a decade SIP Build UK take great pride in the design and manufacture of high performance, thermally efficient buildings delivered and installed within budget on site on time. With extensive knowledge and years of experience they cover the length and breadth of England and Wales. Offering SIP, Timber Frame, Cladding and Light Steel Frame Systems they pride themselves on a consultative approach.”

More at www.sipbuilduk.co.uk www.hemsec.com

Timber Construction Magazine Spring 2023 20 www.timbermedia.co.uk @Timber_Media

Hemsec and SIP Build UK work together to build on a shared vision. Chris Duckworth, managing director told us more.

COVER STORY SIP BUILD UK & HEMSEC

For specifiers looking to adopt a SIPS approach – what are the key strengths and benefits of the panels – both from a commercial perspective and for self-build housing options?

Can you say a little about the way that SIPS cladding can provide both insulation and aid structural integrity and achieve high whole wall U–values?

SIPs cladding which can be a structural member as part of a system, wraps around a structural frame be it steel, oak, concrete or glulam. Wrapping around these frames with SIPs allows for extremely low u values to be achieved while minimising overall construction depths and thermal bridging in comparison to more traditional SFS style systems. A SIPs cladding wrap also removes the external finish from the critical path.

What key projects have you been working on over the last 18 months? Is there one in particular where you have really made a difference?

The specification of correctly accredited SIPs systems provides the specifier with an extremely predictable system removing variables from the project. Engaging with a company like SBUK group at the earliest stage allows for a predictability in thermal performance, cost and program time from the outset.

The increasingly stringent building regulation changes can still be achieved with an “of the shelf approach” guaranteeing thermal performance targets, while the offsite manufacture of systems allow for fast and predictable program times on site, reducing variables and therefore risk for the project overall.

The construction industry is under huge pressure to provide zero carbon design and adopt a more circular approach to material use – how are you ensuring high levels of sustainability, certification and streamlined offsite production processes?

Timber being Carbon Neutral and fantastic for Carbon capture allows the systems to be utilised to help future generations. All of our timber comes from sustainable sources and is PEFC marked.

The panelised SIPs are optimised for cutting using clever planning software, offcuts used for jointing splines and we try and utilise offcuts and trimmings from most of our manufacturing processes to further minimise waste.

Our QA process and system that we run for every item within the business allows us to regularly review and check the impact that that each element has.

We have recently featured on Channel 4’s Grand Designs – The Derbyshire Longhouse.

This was an extremely challenging project that required the meticulous design, manufacture and install of our SIPs to a complex Steel Frame. The Roof panels particularly as all angles were different on each roof plane, providing no square side as a starting point. This was a deliberate feature to create more interesting detailing and architectural flare.

This was achieved and excelled through our highly skilled and collaborative approach as without an exceptional understanding of SIPs and building systems this project would not have worked!

Timber Construction Magazine Spring 2023 21 www.timbermedia.co.uk @Timber_Media

COVER STORY SIP BUILD UK & HEMSEC

Boost Your Timber Business Profile

The UK’s largest event for the built environment, UK Construction Week (UKCW) is soon to start rolling out its programme for 2023.

Last year the show drew over 23,900 visitors from as far afield as Turkey, Brazil, Australia and Canada, and included a host of high-profile names including West Midlands Mayor Andy Street, Channel 4 presenter George Clarke, and BBC journalist and presenter Simon Jack.

Co-located within UKCW Birmingham was Timber Expo, which attracted over 2,000 visitors (8% of the total attendees) across the three days, including architects, local authorities, merchants, developers, housebuilders and contractors. Timber Expo is the UK’s largest and only dedicated showcase event for timber in construction. Backed by trade bodies including the Timber Development UK (TDUK), the Structural Timber Association (STA), the Builders Merchant Federation (BMF), it is the most comprehensive representation of the timber industry anywhere in the UK.

Timber Expo 2023 will see the 11th edition of the event and has been co-located with UK Construction Week since 2015. UK Construction Week won best UK Trade show in 2020 and is the UK’s leading trade event for the industry, attracting 30,000 visitors.

The show brings together award-winning architects with clients and contractors to showcase best practice in timber construction projects. It is the must-attend annual event for anyone working with timber products in the built environment. The exhibitor profile includes structural timber frame, sawmills, merchants, glulam, SIPs, CLT, fixings and fastenings, timber cladding, doors and windows, mouldings, skirtings and flooring products.

Nathan Garnett, UKCW event director, says: “It is crucial that timber, as a sustainable building material, is placed front and centre of the UK’s largest construction event. There is so much happening in the

construction industry right now that has put UK Construction Week into a unique position, whereby it can inform and educate the sector as it moves forward. There is a real sense of momentum now as we plan the next one, especially on meeting our next zero targets and creating long lasting culture change. A record number of companies have signed up for 2023 so we look forward to really growing the UKs largest trade show for construction.”

Timber Expo featured a programme of industry leaders, including architects, developers, housebuilders and merchants to name a few. They debated and discussed the sector tackling post pandemic supply issues, post Brexit challenges, the impact of the Ukraine conflict on timber supply chain and the drive to net zero as we strive to meet COP26 targets. The exhibitor profile includes structural timber frame, sawmills, merchants, glulam, SIPs, CLT, fixings and fastenings, timber cladding, doors and windows, mouldings, skirtings and flooring products.

Timber Expo will be supported by a heavyweight national trade marketing campaign. The co-location with UK Construction Week ensures a guaranteed audience, and the targeted messaging through digital advertising and trade press will deliver those trade professionals who specify or buy timber products. Throughout the year you can follow developments on Timber Expo in all the Timber Media publications and there is a range of joint advertiser/show exhibitor options that can be discussed.

Timber Construction Magazine Spring 2023 22 www.timbermedia.co.uk @Timber_Media

UKCW London will take place from 2-4 May 2023 at ExCeL UKCW Birmingham will run from 3-5 October 2023 at the NEC. More at www.ukconstructionweek.com FEATURE TIMBER EXPO 2023

Timber Construction Magazine Spring 2023 23 www.timbermedia.co.uk @Timber_Media WE MAKE MORE THAN CABINETS ONE OF THE LARGEST AND MOST MODERN FACTORIES IN ASIA ELEGANCE AND FUNCTIONALITY Over 400,000 sq ft of combined factory space and over 800 employees in Vietnam and China. Export capacity of over 400 containers per month. ISO 9001 and FSC Certified. KITCHEN CABINETS SUGI (JAPANESE CEDAR) LUMBER WALL PANELS DECKINGS SOLID COUNTERTOPS TWO FACTORIES IN ASIA FINGER JOINTED AND EDGE GLUED FOR A CLASSIC BUTCHER BLOCK LOOK www.OwenInternational.co.uk

Optimum Energy Performance

In order to meet spiralling energy costs and our climate change targets, new technologies and modern offsite construction methods can maximise energy savings through their structural components, whilst meeting the latest building standards.

Energy efficiency and the increase in fabric standards are at heart of the Future Homes Standard (FHS) which will ensure that all new homes built from 2025 will produce 75-80% less carbon emissions than homes delivered under current regulations. This will be achieved by having high levels of energy efficiency through a fabric first approach and low carbon heating systems.

A fabric first approach to design encourages the performance optimisation of the walls, roofs, windows, doors and floors. This approach allows the building to effectively retain heat and can greatly reduce the energy requirements necessary to maintain a comfortable indoor environment.

First pioneered by the Passive House Institute, this focus on the building fabric prioritises low U-values and minimal air leakage. The U-values of the notional building have been reduced in the recent regulation change (0.18 W/m2K for exterior walls for example) which highlights the move towards improved fabric performance. When the building fabric is well designed and insulated this will reduce the demands on renewable heating systems such as air source heat pumps which will only work effectively when the fabric is of a good standard.

Timber frame design

Offsite timber frame construction can provide the ideal fabric for buildings to achieve low energy demands and the new U-value requirements set out in Approved Document

L. Offsite manufacturers have had to respond to the reduction in U-value targets to ensure their system is compliant with new regulations, and end user demands for more energy efficient homes. In doing so, many timber frame manufacturers have reviewed their wall build ups in pursuit of an optimised solution.

While increasing insulation thickness is the

obvious solution to lowering U-values, this is not always cost effective. In addition, it increases the wall thickness which can impact footings, internal floor area and the erection processes. As an alternative, many manufacturers are exploring the use of reflective foil breather membranes and vapour control layers (VCL).

Reflective foil membranes are designed to perform their primary function (protect against wind and rain, or control water vapour) as well as improve the heat retention of a building element. When these membranes are installed adjacent to a cavity, they enhance the reflective value (R value) of that cavity – remember, the higher the R value, the better.

Open and closed panel timber fraes

The UK timber frame industry is made up of a mix of open panel systems and closed panel systems. Put simply, open panel systems typically install a breather membrane in the factory, but leave the internal side of the panel open, while closed panel systems apply internal sheathing to the panel, and in many cases, also install the VCL in the factory.

Both open and closed panel systems can benefit from switching standard membranes to reflective foil membranes. For example, one

of our existing customers had been building an open panel until recently. They were achieving a U-value of 0.21 W/m2K when using a standard breather membrane externally and no VCL. By swapping from a standard breather membrane to Partel ECHOFOIL EXO, they can reduce their U-value to 0.18 W/m2K. If they were to close the panel in the factory, and install Partel ECHOFOIL IZO as well, they would achieve a U-value of 0.16 W/m2K. Remember, this U-value improvement can be achieved without increasing the wall thickness. While this example is specific to this customer’s wall build up, it can give an indication of the benefit of using the Partel ECHOFOIL range in timber frame construction.

At a time when energy efficiency and net zero carbon is high on the agenda, offsite timber construction is being seen as one of the most attractive ways of delivering buildings that are high quality, sustainable and cost effective. The development of reflective foil membranes which offer high performance and can meet new the thermal and air permeability targets is set to revolutionise the way timber frame structures are designed and built.

More at www.partel.co.uk

Timber Construction Magazine Spring 2023 24 www.timbermedia.co.uk @Timber_Media

Dara McGowan, director at Partel explains the fabric first approach and how timber frame homes can deliver excellent thermal and airtightness standards.

FEATURE FABRIC FIRST

National Timber Systems rebrands panelised roof system as NTSROOF

NTS was formed in 2019 combining the design, manufacturing, and logistic capabilities of NTG companies Arnold Laver and NYTimber’s engineered wood products division.

With the rebrand NYTROOF, the original gable to gable supply only system developed by NYTimber and launched in 2015, has become NTSROOF with a new logo and delivery wrapping.

NTS will be introducing more innovative industry leading products soon as part of a NTSROOF range.

“The original NYTROOF was developed on the back of many years’ industry experience and expertise working closely with housebuilders,” said Philip Carney, National Timber Systems.

“We’re continuing that tradition providing a custom-designed off-site manufactured system that means contractors need to do less on-site. With the rebrand to NTSROOF we’re showing clearly that the products are available nationally from NTS.

“Over 7500 roofs have been supplied as NYTROOF to date and our customers include several national housebuilders.

“Demand continues to grow. Over the last year we have invested in our manufacturing sites and expect to have the capacity to produce 3000 roofs in 2023.”

As well as providing the advantages of off-site manufacturing, such as dimensional accuracy and safer working on-site due to less time at height, NTSROOF is robustdetails® approved which eliminates the need for on-site sound testing.

NTS has a turnover of almost £50m. There are 240 employees across the division’s four sites in Yorkshire, the North East and South West England and work is underway to open a new site in the Midlands. Other NTS products include gable and party spandrels, trussed rafters, engineered joists, and floor and roof cassettes.

More at www.nationaltimbersystems.co.uk

Timber Construction Magazine Spring 2023 25 www.timbermedia.co.uk @Timber_Media

National

Timber Systems (NTS), the specialist engineered wood products division of National Timber Group, has rebranded their panelised roof system, to bring it in as part of the NTS portfolio of products.

ADVERTORIAL NTSROOF

Top Reasons to Plan a Trip to FIT

FIT Show returns to the NEC for its ten year anniversary edition from May 23 - 25, 2023.

Over the last decade, FIT Show has firmly established itself as the number one event for the UK glass, glazing, windows, doors, hardware and components industry.

Here’s why FIT Show 2023 should be an essential fixture in your calendar this May: