SPECIFICATION

This month’s features:

Sector Reports:

• Retail Construction

• Roofing, Cladding & Insulation

Features:

• Ceilings, Partitions & Boards

• Lifts, Stairs, Balconies & Balustrades

• Bricks, Blocks & Pavers

• External Works & Landscaping

This month’s features:

Sector Reports:

• Retail Construction

• Roofing, Cladding & Insulation

Features:

• Ceilings, Partitions & Boards

• Lifts, Stairs, Balconies & Balustrades

• Bricks, Blocks & Pavers

• External Works & Landscaping

Discreet watertight joint with Hydrolock® Grout free

Multipanel bathroom panels are precisely engineered and equipped with a unique Hydrolock® tongue and groove joint which allows seamless installation in any wet room or bathroom, reducing bathroom installation costs by up to £30/m2

Driving around the circumference of the Earth 628 times is equivalent to the CO2 reduction in Multipanel being used instead of tiles.

New Towns Taskforce can be a planning blueprint

The Government has appointed Sir Michael Lyons as Chair of the newly established ‘New Towns Taskforce’, and Dame Kate Barker serving as Deputy Chair.

Sir Michael noted that the taskforce “will work closely with local leaders, communities as well as the wider development and investment sectors to make sure these new towns are built in the right places.”

Richard Beresford, Chief Executive of the National Federation of Builders (NFB), said: “We applaud the Labour government for reviving the new towns policy. From stimulating regional growth and boosting construction worker capacity, to creating affordable housing in unaffordable regions and designing the places of the future, new towns are a strategic policy mechanism.

“There are considerable opportunities to involve local employers, investing regional contractors and SME builders in the process, particularly as policies, such as the subdivision of large sites, already exist to achieve that in practice.”

The new towns programme will include the creation of largescale new communities built on greenfield land and separated from other nearby settlements, as well as numerous urban extensions and urban regeneration schemes. Each new settlement will initially contain at least 10,000 homes but will be able to deliver more in the future.

All new towns will be well connected, well designed with all necessary infrastructure, and aim to deliver 40% affordable housing. The final shortlist of locations will be announced before the end of August 2025, with the first taskforce meeting scheduled for September.

The TCPA’s chief executive, Fiona Howie, said: “The detail of the ‘New Towns Code’ will be important in setting expectations for these new communities from the start. They need to be well-connected and well-designed, and this must include being exemplars in relation to net zero, nature and supporting health and wellbeing.

“Making sure new development is in sustainable locations will therefore also be a key to success. Infrastructure that is delivered upfront is vital – and this needs to include social infrastructure if we are to create thriving communities in the long term.”

Paul Groves || Group Editor

● Opening speed over 4.0 m/s*

● Maximum transparency with 90% of the door leaf surface*

● Carbon neutral option for all construction project products, including industrial doors and high-speed doors

* Dependent on door size

A natural roofing material forged over 500 million years ago, Riverstone phyllite continues to be sought-after by architects worldwide. Today, phyllite offers brand new possibilities for contemporary construction. Now you can choose Riverstone for your cladding, flooring and roofing projects. PLUS create a seamless finish with our NEW matching block ends, hip ends, ridge tiles and caps.

• Entirely natural material

• Boasts exceptional durability and water absorption.

• Attractive grey colour with a unique phyllitic sheen

• Cladding, flooring, roofing and roof ridges also available

• Accessible alternative to indigenous slate

• Assessed to the US testing standard ASTM C406, awarded an S1 rating, indicating it will last a minimum of 75 years.

• 100-year weathertightness guarantee

• Non-combustible

• W1-T1-S1 in BS EN 12326

Want to find out more? Call 020 8961 7725 or email info@ssq.co.uk

The Royal Institute of British Architects (RIBA) has published the findings of its latest Future Trends Survey, a monthly report of business and employment trends affecting the architects’ profession.

The June 2024 findings show that, over the next three months, architects anticipate higher workloads, and, with the RIBA Staffing Index hitting a two-year high, practice staff recruitment is expected to increase. This suggests that practices are preparing for long-term growth.

RIBA Head of Economic Research and Analysis Adrian Malleson said: “The

profession’s outlook is positive for a third consecutive month - a welcome recovery after the the negative outlook that characterised the second half of 2023 through to the start of 2024. Nevertheless, the recovery in the architects’ market is tentative, and significant numbers of practices remain pessimistic.

“We are yet to see the effect, if any, of Labour's widely anticipated general election victory – stay tuned for next month’s report. Commentary received in June indicates an improving market for some but a mixed picture overall. The general election, while bringing a sense of change, also brought

The new extension at Marseille Provence Airport welcomed its first passengers in June this year.

Designed by Foster + Partners in association with Rougerie + Tangram, the landmark project establishes an overall masterplan for the future by restoring the clarity of Fernand Pouillon’s original 1960s terminal and Richard Rogers' airside development.

The design significantly improves the travel experience by reorganising passenger flows through a set of simple, bright, and easy to

navigate spaces. It features a new Coeur –heart in French – that rationalises arrival and departure sequences within a single building, creating an intuitive progression through the terminal for passengers.

Norman Foster, Founder and Executive Chairman, Foster + Partners, said: “Our terminal extension in Marseille is inspired by the clarity of Fernand Pouillon’s original work – we continue the main space of the concourse and the structural rhythm of the façade to future proof the airport for the decades to come.”

a level of uncertainty. While practices continue to report that the planning system is dampening workloads and hampering project delivery, a small number of practices report an improvement in planning application progression.

“Some relay fewer enquiries and downward pressure on public sector work, while others describe a growing order book and steadying private housing workloads.

“We will continue to report our findings to the Government and work with other built environment bodies to monitor these trends.”

Plans for a state-of-the art government office development in York have been given the go-ahead.

The application to construct a six-storey, 195,000 sq ft government hub, put forward by partners the Government Property Agency (GPA), Homes England and Network Rail, was approved by the City of York Council Planning Committee.

Earmarked for completion in 2027/2028, the hub will be home to up to 2,600 civil servants. Building features include solar panels, air source heat pumps and a green roof, as well as 230 cycle spaces and a planted pedestrian area.

The development includes 135,000 sq ft of flexible office space, with ground floor retail and ancillary space.

The hub is the first part of York Central – a major initiative to redevelop a substantial area of land close to York city centre and boost the regional economy.

Enquiry 4

The Construction Leadership Council has published a research report into the views of senior managers in construction product manufacturers about digitisation.

The research consisted of telephone interviews with C Suite individuals in manufacturing companies who supply products into the UK construction supply chain.

It shows that:

• Most manufacturers do not see digitisation as a major concern.

• Over half see no need to digitise.

• Most provide product information largely via pdf or hard copy only.

• Only 8% have ever made or commissioned a BIM object, yet

• A considerable majority think digitisation increases profitability.

• The research shows that the requirement for digitised product information set out in the Building Safety Act and the Golden Thread guidance is not reaching product manufacturers.

Cala Homes has completed its first net-zero-carbon enabled home at its Hampton Lakes development in Peterborough.

Residents will soon move into the fourbedroom property, offering the opportunity for the business to learn about the technical viability and user experience of sustainable

Manufacturers face a challenging journey to digitise and will require specific support and motivation to make the necessary changes.

Richard Robinson, President, UK & Ireland at Atkins Réalis said: “Eighty per cent of the 80 manufacturer leaders interviewed for this research understood the importance of digitisation, however only a few placed digital highly in their priorities, well behind other pressing concerns.

“We also found that digital transformation journeys are fragmented, and our investment into digital is sometimes misplaced due to a poor understanding of what is possible and what it means to digitalise. I urge you to read this report and consider how it can influence your policy decisions.”

The research was carried out by the Plain Language Group, the author of several other publications aimed at understanding manufacturers’ role in the digital transformation of the construction industry and assisting in the process of digitising construction product information.

The NHBC Foundation has published a new report; The UK’s progress towards a Passivhaus standard in new homes.

A follow-up to research it undertook more than ten years ago examining whether Passivhaus could address climate change objectives, this report considers why the delivery of Passivhaus at scale remains a considerable challenge, as well as highlighting where progress has been made.

technology in a ‘lived in’ home. Through monitoring data, including qualitative feedback from the residents gathered throughout the summer and winter months, Cala will gain valuable insights into the practicalities of implementing these technologies and, importantly, the user experience of sustainability features in an occupied home.

Importantly, the report also considers the cultural shift needed to construct homes to this standard alongside the end user and what they need to know about living in a low energy home. The original research, published in 2012, was undertaken in the context of the Government’s commitment to deliver zero carbon homes from 2016 onwards. A decade later, however, homeowner concerns have markedly shifted; recent energy price increases have made them more aware of the running costs of running their homes and a need to reduce energy consumption. This means the benefits of Passivhaus are potentially more important than ever.

Despite the benefits, this report reveals the progress of Passivhaus development in the UK has been slow, with only 2,900 fully certified buildings constructed in the UK. Yet there has been a notable shift in how building regulations incorporate key Passivhaus principles to enhance existing standards.

The report explores the concerns raised by house builders about the feasibility of developing homes at volume to Passivhaus standards. It also looks at the barriers to adoption and highlights the opportunities being brought forward through government policies across the UK.

CIC has published a set of policy recommendations for the new Government.

The recommendations are contained in a new publication, ‘Building A Safer, Healthier and More Sustainable Future for All’, which outlines some of the actions the new Government can take to empower the country’s economic growth, as well as enhance the nation’s health and wellbeing by ensuring a better built environment for everyone.

The Government has set out its legislative priorities for the upcoming Parliamentary term and CIC is urging it to consider the exceptional benefits a well thought out plan for construction and the built environment can bring.

The recommendations have been formulated with the individual assistance of CIC members as well as collectively through CIC committees. As the representative forum for the professional bodies, research organisations and specialist business associations in the construction industry, CIC has drawn from its wide experience and direct engagement with government on a wide range of areas including planning, housing, building safety, net zero and future skills.

The University of Cambridge, working with BDP, has announced ambitious plans to restore the Grade II* listed History Faculty Building by James Stirling, which is also the home of the Seeley Library.

This landmark project will restore and revitalise one of the iconic ‘Red Trilogy’ – the triumvirate of highly significant university buildings designed in the 1960s by prominent, post-war architect, James Stirling.

It presents a once in a generation opportunity to provide a new range of enhanced learning and working environments at the heart of the University’s Sidgwick site while improving the building’s accessibility, safety and comfort and provide a new range of learning and working environments at the heart of the University’s Sidgwick site.

The comprehensive refurbishment will safeguard the use and enjoyment of the building; repairing and upgrading building fabric and replacing services to improve thermal comfort, while introducing a range of carbon saving and climate resilient measures.

CIC members collectively represent approximately 500,000 individual professionals and 25,000 firms of construction consultants.

CIC Chair, Dr Wei Yang commented on the publication saying: “With buildings meant to last generations, we need a highquality built and natural environment that benefits everyone.

"A long-term mission-driven commitment will bring improved energy, food, and water security, provide safe and sustainable homes, enhance local amenities, foster healthier families, and protect against global heating and biodiversity loss through blue and green infrastructure.”

CIC Chief Executive, Graham Watts said: “As the new government looks to hit the ground running on planning, infrastructure and housing, we would urge them to consider the broader advantages our industry can provide. Construction is a vital tool for growth and there are clear benefits to the public purse of addressing our climate obligations early, working with industry to improve building safety and getting a skills plan in place to deliver on national objectives for housing and infrastructure.”

West Leigh has won the Best Commercial Project category at the Steel Window Association (SWA) Awards 2024 for its sensitive and painstaking work on the restoration of a former Victorian wallpaper factory in West London.

Voysey House in Chiswick had previously been refurbished in the 1980s with the work featuring the ever-popular W20 window, in the large pane format. All the architecturally important curved heads had been panelled to save money, severely detracting from the period styling of the property, which the client wanted to renovate as offices.

Voysey House will now be re-occupied by one of the most renowned interiors brands worldwide who originally built the manufacturing facility extension in 1902.

For whatever mode you’re in

Introducing Modal X, our groundbreaking innovation from our new cutting-edge dual block plant at St Ives.

Crafted with precision and designed for unparalleled versatility, Modal X redefines the standards of contemporary paving.

X Endless design options with an extensive choice

X Utilises MaxiMix® technology

X Suitable for both trafficked and pedestrian areas

Learn more

Project: Shoreline, Folkestone

Architects: ACME

Suppliers:

Knauf Insulation; Leviat; Ancon; Uform; CEF

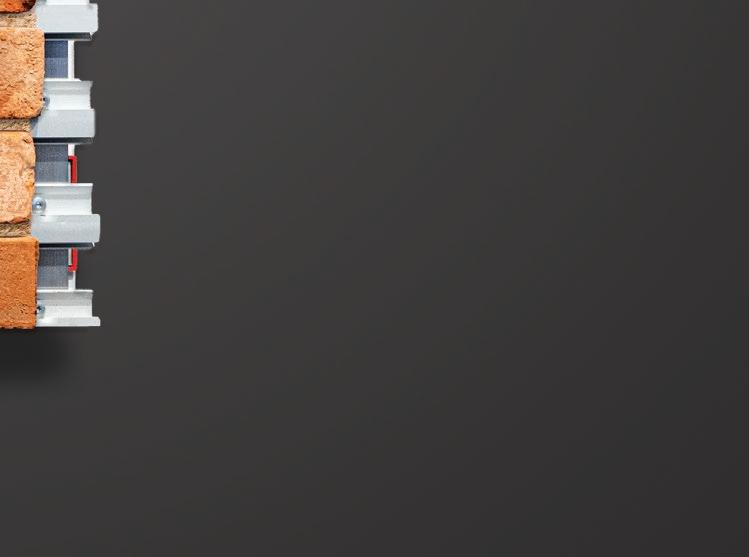

Occupying a prominent position on the Folkestone beachfront, Shoreline is a contemporary take on the traditional Edwardian curved terrace and the first phase of an impressive masterplan, designed by ACME architectural practice.

This impressive residential building is the first step in creating a vibrant new community along the historic seafront for the Folkestone Harbour & Seafront Development Company.

Situated at the foot of the historic Leas Lift and coastal park, Shoreline’s 84 luxury homes benefit from a prime position with uninterrupted views onto the beach and across the sea, stretching as far as the French coastline on a clear day.

It is the first phase of a landmark project that will provide up to 1,000 new homes, shops, bars and restaurants as well as attractive public and green spaces, including Leas Square and Marine Parade along the seafront in Folkestone.

Overcoming a multitude of challenges along the way, this incredibly beautiful, unique building sits upon robust foundations of over 200 piles, driven to a depth of 27 metres making the foundations as deep as the building is high.

Constructed with a reinforced concrete frame, Shoreline’s flowing curved form echoes the shape of the waves, pebbles and coast. Built to endure the ever-changing weather patterns experienced on the UK’s coastline, every detail of Shoreline has been meticulously considered.

The facade’s white glazed bricks, sourced from La Paloma in Spain, reflects the changing colours of the sea and sky according to the weather and the time of day.

‘Standardised’ was never going to be an option and as such over 24 different specially designed bricks were required to achieve the complex geometry. Metal used on the exterior of the building is rust-proof, whilst wall ties beneath the facade are made from the same marine grade materials found on deep sea oil rigs, ensuring longevity and sustainability. With the design of the balconies proving problematic in terms of their load bearing weight, engineers implemented lighter-weight aluminium support systems that seamlessly integrated into the building's curved design.

There were also five different balcony designs each bespoke to mirror the shape and curve of the structure.

The coping stones on the parapet walls were individual in size and shape requiring special moulds.

The curved structure also demanded bespoke windowsills; each unit scanned as a 3D image. The bespoke finish is most certainly not limited to what the public eye can see with communal areas clad with acoustic walls and terrazzo floors to ensure quality radiates throughout.

Private roof terraces are included for the beach houses and penthouse apartments and all units have the exclusive use of a private communal garden above the undercroft car park that promotes natural daylight through carefully placed openings to provide a secure and pleasant environment with EV charging points and sufficient headroom for all modern vehicles.

Martin Sandall, Managing Director of Jenner, who completed the project, said: “As a Folkestone based main contractor, we are delighted to have been able to deliver the initial phase of the transformative Folkstone seafront development.

“Shoreline Crescent is a truly spectacular interpretation of an English seaside crescentshaped apartment building. Whilst its coastal location presented a number of construction challenges, from ground engineering through to the selection and installation of materials, the exceptional quality of the finished building stands as testament to the remarkable work of the entire project team.”

From initial concept through to articulation of its architecture by utilising stateof-the art construction techniques and products of the highest specification, the project serves as a prime example of how the built form positively impacts upon a region.

While it’s designed to look spectacular, it’s also important that the façade delivers the performance required of modern buildings. With this in mind, the architect specified the Knauf Through Wall System for the rainscreen façade.

The system is BBA certified, demonstrating it complies with the relevant building regulations. It also gives the architect

reassurance that the different elements of the wall build-up have been designed to work together and have been tested both individually and as a system.

The Knauf Through Wall System comprises all the components needed for a highperformance façade build-up. The system can be used with a wide range of external finishes, ensuring that the architect still has design freedom.

Another factor was fire safety. Products are non-combustible with the best Euroclass A1 reaction to fire classification. So, they comply with legislation that bans the use of combustible material in

the external walls of relevant residential buildings over 18m tall. In addition to thermal and fire safety performance, mineral wool has an open structure, so it is highly effective at absorbing sound. This means the insulation will also contribute to the acoustic performance of the external wall build-up.

Both products are manufactured with ECOSE Technology, Knauf Insulation’s unique bio-based binder that contains no added formaldehyde or phenol. It is made from natural raw materials that are rapidly renewable and is 70% less energy-intensive to manufacture than traditional binders, so it is more environmentally friendly.

In the ever-evolving realm of retail, attention to detail is paramount, with every element contributing to the overall customer experience. Among these elements, flooring holds a unique position, silently shaping the ambience and aesthetics of a retail environment.

Gerflor, a pioneer in innovative flooring solutions, has a number of design-led, fast-track, high performance solutions that are transforming the way retailers renovate their front of house locations.

The Creation 70 Connect collection, allows retailers to refresh or replace their floors without disrupting their operations, with no need to close their premises. Whether it's a luxury boutique, a busy supermarket, or a cosy convenience store, this advanced superior technical tile enhances the overall shopping experience. It provides exceptional comfort underfoot, delivers outstanding acoustics, is extremely hard wearing, it can cope well with rolling loads and the collection is available in striking & contemporary finishes.

A remarkable aspect of the Creation 70 Connect range is its commitment to sustainability. The flooring is 100% recyclable and incorporates 55% recycled

content, aligning perfectly with the growing demand for eco-friendly solutions in the retail industry. Retailers can effectively enhance their brand's image by opting for flooring that reflects their dedication to a greener future.

Within Gerflor’s fast-track flooring portfolio, you can also find the GTI Max and Attraction collections, that offer a range of unique benefits. These products can be effortlessly installed over many types of existing surfaces, making the process fast and hassle-free. Moreover, their quick and simple maintenance routine ensures that the floors remain immaculate, allowing retailers to concentrate on their core focus: delivering exceptional customer experiences.

Gerflor's design-led, fast-track solutions have genuinely redefined the concept of retail flooring. By eliminating the need for store closures during flooring refurbishments, retailers can seamlessly continue serving their customers with minimal disruption on site.

As the retail landscape continually evolves, Gerflor remains a steadfast partner, providing cutting-edge flooring solutions that adeptly keep pace with changing trends, while unwaveringly maintaining a focus on quality and innovation.

Gerflor – Enquiry 7

Education Estates® is the UK’s leading learning environments event - bringing the whole community together: from policy makers and responsible bodies to specifiers and the supply chain.

The event comprises a two-day conference over 7 themed stages, an exhibition showcasing some of the most innovative solutions around and an awards ceremony celebrating excellence in the sector.

The exhibition is free for all to attend or register as a private sector delegate to attend the conference.

Design, Construction, Delivery

Good Estate Management

Policy & Funding

Refurbishment & Retrofit

Special Educational Needs & Disabilities

Sustainability

Book now at educationestates.com to ensure you don’t miss out on your opportunity to join the largest gathering of education specifiers in the UK!

“Education Estates® is the national conversation around the education estate.”

Crawford Wright, Head of Architecture and Design: Schools and Colleges

at the Department for Education

SPONSOR PARTNERS

LIEBIG Ultraplus heavy duty anchors have demonstrated in a project to create a new lifting bridge over the River Yare in Great Yarmouth that post-installation anchoring can offer performance equivalent to that of cast-in anchors, whilst also being better suited to the complexities of modern construction processes.

The £121m Herring Bridge project is an excellent example of how the application of innovative products is enabling major civil engineering projects to be delivered more efficiently in a shorter timescale.

The twin bascule bridge’s construction process involved building cofferdams on both banks of the river. These house the machinery and mechanism required to lift, hold and lower each leaf of the bridge, all of which had to be securely anchored to the concrete.

As with many major civil engineering projects involving the kind of ‘design and build’ process used here by main contractors BAM Farrans, the team did not have the luxury of the ‘ideal world’ approach where anchors are cast-in to the concrete. Construction of the cofferdams had to commence as soon as the project received the green light, which meant there was no scope for the extended design time that cast-in anchors would have demanded.

The design team, therefore, explored the potential for a post-installation anchoring solution to attach the baseplates of the bridge’s operating mechanism. Crucially, any anchors would have to be suitable for the concrete conditions within the cofferdam design and offer a very high load capacity.

Yorkshire-based engineering specialists

Qualter Hall were consulted to help identify a post-installation anchor that would meet this demanding criteria, which they found with LIEBIG Ultraplus anchors.

For the Herring Bridge project, the design required EJOT to produce and deploy possibly the largest post installed mechanical anchors ever used in a civil engineering project. Two lengths of M36 size Ultraplus anchors were produced, with the longest being 1.45m in length and the shortest 1.09m, with both lengths being used on the same baseplates in an unconventional yet successful design approach.

It was an approach that, despite being incompatible with the product’s ETA (European Technical Assessment), satisfied the requirements of the globally respected ACI (American Concrete Institute) Building Code.

The Ultraplus anchor’s design is unique in the way that it transfers stress into the concrete extremely effectively. It also does this in a way that differs significantly from ‘normal’ postinstalled anchors and other undercut anchors, including those intended to work like cast in anchors.

Demonstrating compliance with the ACI Building Code enabled Ultraplus anchors to be deployed in this bridge construction project with confidence and ensure a post-installation approach could be utilised. The advantages that stemmed from this meant the bridge’s design and construction time could be reduced, with subsequent cost benefits.

Find out more at www.ejot.co.uk/ cast-in_vs_post-install_anchors

Images:

1: How three common anchoring approaches compare – left to right: a standard undercut anchor provides compression of the concrete by partial expansion forces being created at the bottom of the anchor. A typical cast-in place anchor allows compression of the concrete to be achieved between the cast-in washer plate and the concrete. With a LIEBIG Ultraplus Anchor, compression of the concrete is achieved between the undercut and the concrete surface.

2: LIEBIG Ultraplus anchors securely angled to support the hydraulic mechanisms of the bridge decks as well as the tail locks that hold the Herring Bridge in its raised and open position.

3: LIEBIG Ultraplus undercut anchors are manufactured by EJOT UK to a consistently high standard at its Yorkshire facility.

Energy efficiency has become a crucial aspect of modern home design and construction. With rising energy costs and growing environmental concerns, there is a significant push towards building homes that use less energy for heating, cooling, and powering appliances. Energy-efficient homes not only reduce utility bills for homeowners but also contribute to a lower carbon footprint, supporting global sustainability efforts.

Nick Worrell, Marketing Manager at Stormking, a UK designer and manufacturer of Glass Reinforced Plastic (GRP) building components, explores the role GRP can play in creating more energy-efficient homes: “Glass Reinforced Plastic (GRP) is a composite material made of plastic reinforced with fine glass fibres. Known for its durability, lightweight nature, and versatility, GRP has become an increasingly popular material in construction. Its unique properties make it an excellent choice for creating energy-efficient homes. GRP provides superior thermal insulation, reduces heat loss, and improves overall energy efficiency in buildings.

“GRP’s thermal insulation properties are one of its standout features. The material's structure helps to significantly reduce heat transfer, maintaining stable indoor temperatures regardless of external weather conditions. This insulating capability means that homes built with GRP components require less energy for heating in the winter and cooling in the summer, resulting in substantial energy savings.”

Leading the GRP revolution

Stormking has been at the forefront of developing innovative GRP products that enhance energy efficiency in homes. Some of their notable products include GRP Bay Window Roofs, offering superior insulation and weather resistance; GRP Dormer Roofs, providing effective thermal insulation and aesthetic appeal; and SmartStack Chimneys, reducing heat loss and improving energy efficiency.

for

Stormking works closely with builders and architects to create bespoke GRP solutions tailored to specific energy efficiency goals. Their custom-designed GRP components are engineered to meet the unique requirements of each project, ensuring optimal performance and sustainability.

These bespoke solutions not only improve energy efficiency but also contribute to the overall quality and durability of the buildings.

Nick concludes, “As the demand for energyefficient homes continues to grow, the use of GRP in construction is set to increase. Ongoing advancements in GRP technology will likely enhance its insulating properties and expand its applications in home building. Stormking’s commitment to innovation

and sustainability positions them as a leader in this field, driving the future of energy-efficient home construction with cutting-edge GRP solutions.”

Further information about Stormking and its range of GRP building solutions can be found at www.stormking.co.uk or by calling 01827 311 100.

Dirk Stefan Polte, Managing Director of FIEGER GROUP, explains whether he still promotes the former seal of approval with his customers - and what this has to do with a policy of “driving with the handbrake on”.

Dirk Stefan Polte has been in charge of FIEGER Group since 2019 and with his team is striving for growth within the strategy >>FIEGER – Next Level<<.

Polte’s career began over 30 years ago as a reserve Army Officer and led him to train and study in all three world regions: EMEA, The Americas & Asia Pacific.

Question: On your company’s homepage you write FIEGER Louvre Windows are what people imagine Germany Engineering to be from the phrase “Made in Germany”. What characteristics were you referring to exactly?

Answer: Our values of quality and reliability are recognized across the world and are strongly embedded in our company. FIEGER louvre windows stand for iconic design, durability and quality.

We’ve been in business for almost 25 years and our first louvre windows are still working perfectly. Standardised endurance tests confirm the extraordinary reliability of our products. Our engineers always strive to achieve a greater degree of precision and often higher than the required test standards.

German punctuality builds confidence in our delivery and product promise. All this is achieved by setting clear objectives, hard work and a high level of staff involvement.

Q: What is “Made in Germany” worth today?

A: Previously at international exhibitions our products would virtually be snatched out of our hands.

Today we have to meet the challenges of a new more volatile and uncertain world. Business development and sales necessitate more red tape, European and international certification, knowledge of supply chains as well as trading conditions regarding customs and statistics.

International competition doesn’t sleep, products from areas such as Shenzhen are available at a fraction of German prices. That complicates international competition, where the entry-level price is often still what decides matters.

We argue for the Total-Cost-of-Ownership as well as promoting the use of CO2 reduced aluminium, production in Germany simply means ever-increasing administrative effort and costs. The “Made in Germany” label alone isn’t sufficient to compensate for these disadvantages.

Q: How are worldwide events and changes making themselves felt?

A: Let’s take Brexit as an example. Previously I could export directly from my despatch department in Germany to our subsidiary in the UK. Today I have to use an export agency who on each occasion takes 50 to 100 Euros extra as well as an import agency who also takes between £50 to £100 a time. That best illustrates the obstacles we face. Brexit, as well as other rapid global changes, has had a considerable effect on our business.

Q: What other hurdles do you face?

A: When we consider the area of product licences and certification, they play a particularly important role. In spite of our European certification, we had to obtain American certification for a large project in Boston for Harvard University, which incurred even greater expense.

In this case, the scandal surrounding exhaust gas emissions involving the German motor industry didn’t help to instil confidence. Compliance with regulations still varies greatly around the world. Perhaps Germany should not always be at the forefront until the same rules applies to everyone.

This article was first published in the magazine of the Industrie und Handelskammer (Chamber of Commerce) for the Rhine Main Neckar region in Germany. Written by Matthias Voigt, translated by Lindsay Eccles.

7 Conference Stages | 150+ Exhibitors | 3000+ Attendees | 700 Awards Guests

Education Estates® is an annual event that brings together the education community: from policy makers and responsible bodies to specifiers and the supply chain. The event showcases the best educational projects over the last year - the concepts behind them, the expertise employed in creating them and the real-life experiences of learners using the space.

Held in partnership with the Department for Education, Education Estates® is the UK’s leading learning environments event and the only event of its kind focussing on the funding, design, build, maintenance and management of schools, colleges and universities. Designing for learners requires a collaborative approach and a special skill set - the ability to balance functionality, technology, sustainability and inclusivity. This is the fundamental principle behind Education Estates®

• Learn: a 2-day conference over 7 themed stages

• Explore: an exhibition showcasing some of the most innovative solutions around

• Celebrate: an awards ceremony celebrating excellence in the sector

Event Director of Education Estates®, James Lee, is excited for the upcoming event: “This year is the biggest and best yet! Each stage is a conference in its own right, enabling delegates to focus 2 full days on 1 key area of interest or select sessions across all 7 stages and gain a broader understanding of the challenges and opportunities in the sector. The event is particularly poignant this year and interest in the event is at an all-time high, generating the highest ever number of registered attendees.

With record numbers of exhibitors across many exhibitor types including architects, contractors, consultants and the supply chain, you can be sure to meet specifiers in their abundance at Education Estates® 2024. Be part of the conversation – join us on 15-16 October!”

The Education Estates® Awards sells out every year. The shortlist has been released and the winners will be announced on the night by popular comedian, Hugh Dennis. New for this year is the Education Estates® People’s Awards, recognising incredible talent and passion in education.

Programme Highlights:

• Climate adaptive school grounds: a new frontier - Matt Robinson, Learning through Landscapes

• Acoustic Design Watchlist - What the Building Bulletins don't cover! - Emma Greenland, Anderson Acoustics

• Building Quality from design to handover - Nick Coke, WT Partnership, Linda Stevens, CIOB & Jo Marchant, The Boxing Academy

• Does Design Review Deliver for Education Development? - Matthew Blythin, DHA & Catherine Ward, HLM; Enhancing Higher Education Spaces Through Data-Driven Insights - Becky Hayward, Buro Happold

• The integration of academia and community and commercial spaces

- Robert Hopkins, AHR & Tim Hosker, University of Huddersfield

• Education in the Secure Environment

- Dave Clark, Lincolnshire County Council & Lorna Crowther - Managing/ Regional Lead Architect, Kier Design

When: 15-16 October 2024

Where: Manchester Central How do I register: Register at: www.educationestates.com How do I book a stand: Call 01892 351626

Private sector attendees can register to attend the exhibition for free or book as a delegate for access to all 7 conference stages – book before 6 September to benefit from the early booking rate. Public sector attendance is free*

Education Estates® 2024 Sponsor Partners: Arcadis, AtkinsRéalis, Clevertronics, Galliford Try, iAM Compliant and TG Escapes modular eco-buildings.

*This includes those directly employed in schools, colleges, universities, government and local authorities (including governors and independent schools).

Education Estates® – Enquiry 12

Custom House is a major regeneration scheme in Newham, East London. A project which Schöck has been heavily involved in from the outset; initially providing full design support and installation training.

The project is designed to Passivhaus standard, so the need to effectively eliminate any risk of thermal bridging at various points of the design detailing was crucial.

As Europe’s leading supplier of innovative load-bearing insulation products, this is where Schöck really came into its own –with high performance solutions for the columns, balconies and parapets. Known as the Custom House kickstart project and designed by Adam Khan Architects and Haworth Tompkins (for which they received a Housing Design Award) it is part of a wider masterplan by Adam Khan Architects.

The main delivery partner is The Hill Group and the scheme overall consists of three mansion blocks, ranging in height from four to eight storeys. This first stage though will deliver 95 affordable homes, along with commercial space, community growing space, communal gardens and a high-quality accessible public realm.

The columns presented a special challenge It is estimated that around 40% of all structural thermal bridges in buildings are caused by walls and columns; and these are calculated to be responsible for at least 10% of the heating energy loss. The recently introduced Schöck Sconnex range is a unique solution to this problem, allowing walls and columns to be directly and permanently insulated.

There are three product variations, the type W, type P and type M. Specifically, the Sconnex type P is the product used at Custom House. It consists of a thermal insulation element and a reinforcement element, both of which are required to withstand the bearing load. The thermal insulation element has a pressure resistant support structure, made of light weight concrete and polypropylene fibres, all in a 100mm thick insulation layer.

Its performance significantly reduces heat flow, but importantly, also eliminates the need the for the traditional solution of using cumbersome flanking insulation. On this occasion though, quite apart from effectively isolating the rectangular columns from the rest of the building, there were challengingly high load requirements. To meet these demanding loads, it was necessary to incorporate multiple Sconnex type P units at the head of each column – the first time this particular design solution has been used in a UK project.

Parapets are as prone to thermal bridging problems as balconies

Preventing thermal bridging at the Custom House parapets was also a critical consideration for such a high performance development, because as with balconies, parapets can allow conductive materials to transfer energy through the thermal barrier. Conventionally, in the majority of cases, the method of insulating parapets and parapet walls is to wrap the perimeter of the wall with an insulation barrier.

However, the Schöck Isokorb XT type A used here offers a solution that is both more costeffective and more thermally efficient than conventional wrapped parapets. Its 120mm insulation thickness results in low psi-values and therefore significantly reduces heat loss – and there is no wrapping required. An added benefit being there is no risk of any additional thermal bridging through balustrade fixings. Other key factors are durability –and significantly water impermeability – so there is no risk of expensive maintenance or restoration due to waterproofing problems.

High performance solution for the concrete balconies

For the concrete balconies at Custom House the tried-and-tested Schöck Isokorb XT Type K has been incorporated to meet Passivhaus standards. The XT type K with compression module HTE-Compact and 120 mm insulation thickness, is a load bearing thermal break element for free cantilevered balconies. It is the company’s most efficient thermal break ever, offering 30% more thermal performance than the standard Schöck Isokorb T type K.

The widest range in Europe

All of the Schöck products used at Custom House (the Sconnex type P, the XT type A and the XT type K) are certified by the Passive House Institute in Germany. With the Sconnex type P being the only column connection certified by the Institute.

The fully compliant Schöck Isokorb range, whether for Passivhaus or standard solutions, offers the widest selection of structural thermal break solutions from any European supplier. In the UK, the range enables projects to meet full compliance with the necessary Building Regulations (and the impending Future Homes Standard criteria where relevant).

There is also the security of independent BBA Certification, which provides NHBC approval.

Contact Schöck on 01865 290 890; or for full details of the entire product range visit the solutions page on the website at www.schoeck.com/en-gb/solutions-uk

Images:

1. Custom House – courtesy of Adam Khan Architects.

2. To meet these demanding loads, it was necessary to incorporate multiple Sconnex type P units at the head of each column – the first time this particular design soluti-on has been used in a UK project.

3. Graphic of a conventional Sconnex type P unit in position.

4. Graphic of the XT type K in position.

5. Graphic of the XT type A in position.

– Enquiry 13

Delivering improved illumination and durability, Ansell Lighting has upgraded its popular Raptor Twin Spot emergency light.

Offering superior performance and reliability, the newly enhanced version ensures optimal safety and visibility in emergency situations.

Ideal for large open spaces such as warehouses, open plan offices and retail environments, the compact, modern Raptor Twin Spot now offers an impressive 500 lumen output on standard models or 700 lumen output on high output models. Ingress protection (IP) standards have also been upgraded with Raptor now delivering IP65 across all models.

Solid maple the perfect backdrop at flagship showroom

British furniture company Ercol has selected Junckers solid maple flooring for its flagship showroom in Princes Risborough, Buckinghamshire.

Adding a natural element to the space, Junckers hardwood flooring is a durable option with a polished appearance - the perfect backdrop the many iconic designs Ercol is known for. Installed throughout the 1,300 m2 display showroom, Junckers’ solid maple flooring has an elegant, light colouring in an even tone and a subtle grain pattern. Maple is one of the hardest wood species available, capable of withstanding the wear and tear of heavy footfall, a critical characteristic for retail interiors.

Junckers – Enquiry 15

Available in both black and white finishes, Raptor’s two moulded polycarbonate heads can be individually adjusted for complete versatility and controlled direction of light. To aid installation side conduit entry positions have also been added to enhance flexibility and ease of wiring.

Powered by a long-lasting LiFePO4 lithium battery, which protects against short circuits, over-charging, and mechanical damage Raptor is a highly reliable emergency light. Its pulse charging nature enhances product lifetime, whilst the low parasitic load of the lithium battery reduces power consumption, leading to lower costs and a reduced carbon footprint. Raptor also comes with a five-year product and battery warranty.

which includes a self-test feature as standard. This ensures reliable operation and easy maintenance, providing peace of mind and enhanced safety in emergency situations.

Alongside standard and high output options, Raptor is also available with DALI emergency

StoVentec glass meets unique design brief

A glass rainscreen system manufactured by Sto in four different designs has been used as part of the £21m transformation of an indoor entertainment centre.

Located in Manchester city centre, the Printworks is home to bars, restaurants and leisure facilities including a cinema, gym, bowling alley and indoor golf.

Ansell – Enquiry 14

Working in partnership with specialist contractor Craft Interior, Sto helped architects CDA bring their design vision to life using the StoVentec Glass A rainscreen system. This cladding system comprises tempered safety glass which is bonded to a carrier board to produce bespoke composite panels, available in any size, shape, colour or finish. The panels are secured to Sto’s bespoke hidden-fix subconstruction, combining both stainless steel and aluminium components. “Originally, we just wanted to use a metal cladding system throughout, but for

various reasons, couldn’t find a viable product,” explains David O’Connell, Senior Architect at CDA. “We then began speaking with Sto about what we were looking to achieve aesthetically. We soon realised that StoVentec Glass could open up more creative options allowing us to use glass cladding on a much wider scale.”

In addition to meeting the aesthetic design brief, the StoVentec Glass A rainscreen system provides significant safety benefits.

> IDEAL FOR RETAIL LOCATIONS AND FIRE ESCAPE ROUTES

> FIRE-RATED AND SAFETY GLASS FOR BUTT-JOINTED PARTITIONING, ALUMINIUM AND SOLID TIMBER SYSTEMS

> ANTI-VANDAL GLASS

> A SPECIALIST CUT-SIZE SERVICE FOR GLASS PARTITIONS

> LARGE FORMAT GLASS AND IGUS

> TECHNICAL HELP & SUPPORT

#TRUSTTHEEXPERTS

Roof pitches are integral to both the aesthetic appeal and functionality of buildings. Ardit Strica, Technical Manager at Onduline Building Products, offers insights into low-pitched roofs, their challenges, and the benefits of sub-roof systems.

Apitched roof, per British Standard BS 5534, has a pitch between 10° and 75°. Roofs under 20° are generally low-pitched, while those below 10° are considered flat. The choice of roof pitch is influenced by material availability, cost, aesthetics, construction ease, weather conditions, and local building codes. Client preferences and architectural designs also play crucial roles as the pitch affects the building's exterior look.

Practically, roof pitch must handle various loads, including snow, wind, and dead and live loads, making it essential to adapt to local weather. The roofing material, such as concrete, clay, or slate, further dictates the pitch. Low-pitched roofs face specific challenges, especially regarding effective water drainage.

Low-pitched roofs, commonly used in extensions, offer aesthetic advantages but come with challenges like slow water runoff and limited tile options. Unlike steep roofs that easily shed water, low-pitched roofs can experience water pooling, leading to leaks and potential damage. The limited availability of suitable tiles also challenges designers and builders.

Recent changes in permitted development rights have increased the appeal of lowpitched roofs, allowing homeowners to

renovate and extend properties more freely. Lowering roof pitches can create additional ceiling space, aligning with the trend of property extensions. While flat roofs save space and offer contemporary aesthetics, pitched roofs that match the main property enhance visual cohesion. Low-pitched roofs in extensions enable the use of matching tiles, ensuring uniformity.

Sub-roof systems address the tile limitation for low-pitched roofs, revolutionising roofing design and functionality. Acting as the primary waterproofing layer under the tiles, sub-roofs allow for using tiles below their minimum pitch. British Standard BS 5534 highlights the need for weatherproof sub-roof systems when recommended pitches can't be met.

Sub-roof systems shift the traditional roofing dynamics, making tiles a secondary defence against water ingress. This innovation permits using various tiles, including concrete, slate, and clay,

at pitches as low as 10°. Options like flat sub-roofs with non-breathable felt on a rigid sarking board and corrugated sub-roofs with bituminous sheets offer different solutions, with the latter enhancing ventilation to minimise moisture build-up and timber rot.

The popularity of sub-roof systems stems from their flexibility in roofing projects. They allow the use of different roof tiles, improving both aesthetics and functionality. These systems are particularly beneficial for heritage sites and older properties, enabling the use of existing or reclaimed tiles while providing additional water protection.

An example of an innovative sub-roof system is the ISOLINE LOW LINE solution. It's the only sub-roof system in the UK BRE tested and BBA accredited for pitches as low as 10° with a 30-year guarantee. Made from approximately 50% recycled material, this lightweight bituminous underlay sheeting fits under roof tiles, shielding them from elements like wind and rain, offering a durable waterproofing solution.

As the construction industry evolves, innovations like sub-roof systems are crucial in addressing roofing challenges and expanding design possibilities. Creating visually appealing, functional, and watertight low-pitched roofs opens new avenues for architectural creativity and sustainable construction. Understanding these concepts allows professionals to make informed decisions, ensuring the success and longevity of their projects.

Designed by the world-renowned Hopkins Architects, a new facility has been created to provide The All England Lawn Tennis Club in Wimbledon with a dozen new courts: six indoor and six outdoor clay courts; as well as new facilities for members and players competing in the annual Grand Slam tournament.

Replacing the existing facilities opposite the main site in SW19, the new courts have been constructed with a hybrid structure featuring a steelframed, double-curving roof which represents an early adoption of the revolutionary new Flexicon sub-structure and fully formable XT panels developed by Kalzip.

These very versatile new systems have the capacity to offer architects far greater

freedom of expression in terms of roof geometry than conventional standing seam and other commercial roofing solutions. In fact, they make possible the use of roof geometry which would previously have been confined to leadwork or PVC mouldings.

Kalzip can take the initial design from the architect or engineer as a Revit model and import/convert it into the industry standard Rhino surface modeller. The basic roof deck along with its supporting beams and purlins is then taken as the sub-structure upon which to design the tubular Flexicon 80/2.5 0mm members, which will in turn carry the different options of XT sheets.

The particular challenges presented by the long, double-curving roof to Wimbledon’s indoor courts – aside from the complex geometry – were the need to roll all of the different sheet lengths and types on site; and the requirement to create a mock-up in the All England Club’s corporate colour and finish which could be used as part of the

process to gain planning approval. Liaison with the project architects during the precontract period, based on their original aspirations regarding the tightness of the roof curves, resulted in some smoothing of the spherical shapes in order to respect the minimum radii which can be practically rolled on site by the manufacturer’s Portable Rollformers.

Kalzip also carried out a value engineering process whereby the use of the more expensive XT profiles was confined to the dome-like centre section, thereby introducing lap joints which then allowed the lower levels to be formed from standard profiles. The colour was a PVF2 finish in RAL 6007.

The Flexicon sub-structure creates an insulation zone that is nominally 225 mm deep, though this varies due to the structural deck being faceted, and therefore not actually parallel to the XT and other capping sheets.

CUPA 12 has been installed as part of a roof refurbishment project at Parkstone, a stunning Edwardian residence on the edge of Roundhay Park, Leeds. The natural Spanish slate was specified as it's a high-quality product with more than one hundred years of lifespan.

Situated on the prestigious Park Avenue alongside Roundhay Park and next to Soldiers Field, where battalions mustered during the First World War, Parkstone is a striking Edwardian residence converted into five luxury apartments.

The original plan for the roof was to reuse the existing tiles; however, this was not feasible as the 100-year-old tiles had incurred too much wear and tear. Siobhan Atkinson, the main client on the project commented: “We had to make a very big decision about what we were going to replace the roof with. In the end we selected Spanish slate from CUPA PIZARRAS as Yorkshire Heritage Roofing were able to advise us on the product’s environmental impact, the variations in colour available and how it would be in-keeping with the other properties located nearby.”

Roofing contractor Ian McCarthy from Yorkshire Heritage Company presented the management company with five slate options from CUPA PIZARRAS. Ian wanted a natural slate that would provide a smooth, flat finish and always recommends CUPA PIZARRAS slate over other companies’ products.

"When I trained as a roofer, we used CUPA PIZARRAS products, so it is my go-to company for roof slate," explains Ian. "The quality is excellent, and there are different gradings, sizes and colours to choose from. It's great to be able to go to a customer and say, 'I have exactly what you're looking for.'"

CUPA 12 e was chosen for the project as it met the high standards demanded by the client. Tested and certified to T1 (thermal cycling), S1 (sulphur dioxide) and W1 (water absorption) levels, CUPA 12 won’t discolour, split or crack and as such can be guaranteed for 100 years, offering excellent piece of mind for the building’s residents. The dark grey slate is widely known as being among the highest quality natural slate on the market today. The slates feature thin laminations and a smooth matt surface split to an average thickness of 3.5mm, 5mm and 6mm. Furthermore, the slate requires minimum maintenance.

The re-roofing work was a complex challenge. Although all CUPA PIZARRAS slate comes precut and pre-holed, there were areas where the slate had to be cut to size to accommodate dormer windows, as well as the building’s distinctive chimneys. In addition to CUPA 12, the extensive work included upgraded insulation throughout, hydraulic lime mortar pointing and flaunching to the chimney stacks, new leadwork and clay capped angle ridges to finish the roof. While initially sceptical about Yorkshire Heritage's proposal to introduce a striking red clay ridge to contrast the grey slate, the apartment owners all agree that the aesthetic blend is fantastic.

"I have used other Spanish slates before, but the quality is often poor. CUPA 12 is easy to cut and lay, with minimal breakages or wastage," concludes Ian. “The uniform thickness of the slate makes them easier

to install, while the dark grey, even colour, provides a striking, decorative finish.”

For more information about the CUPA PIZARRAS range of products, including its CUPA 12 roof slate, please visit: https://www. cupapizarras.com/uk/roofing-slate-cupa-12/

CUPA PIZARRAS – Enquiry 18

Renowned Italian render manufacturer, Fassa Bortolo, has recently finished work on ‘Neyland’ a collection of residential properties developed by JG Hale Construction Ltd. This project, which won the ‘LABC Best Social Housing Development’ Award, was specified in collaboration with Fassa’s National Specification Manager, Stephen Gore.

The former Neyland School development encompassed the construction of 33 residences over three phases, including 8 one-bedroom flats, 2 bungalows, and a mix of two, three and four-bedroom homes. Additionally, the development integrated car parking, landscaping, living wall retaining structures, drainage systems, and associated engineering for highways.

Our client, JG Hale Construction Ltd, sought a cost-effective design solution for the project. Fassa Bortolo worked closely with Tom Bevan, Construction Manager, to achieve this goal while ensuring the development remained visually appealing.

The products used in this project were carefully selected to meet the specific requirements of new developments. Fassa Bortolo’s system, designed with this purpose in mind, included an initial base coat of KC 1, followed by FX 526, a universal pigmented primer undercoat. Additionally, Fassanet 160 mesh was incorporated to reinforce the structure, effectively reducing hairline cracking and enhancing overall durability. The system was completed with PX 505, an acrylic siloxane finish, known for its excellent weather resistance and long-lasting

protection against environmental elements. The colours were specifically chosen by the team from Fassa’s 365 topcoat range. BT 04, EP 36 and LR 19 were selected for their harmonious blend and ability to complement the architectural aesthetics of the Neyland development.

FASSA BORTOLO – Enquiry 19

Proctor Air, the roofing membrane for the future developed by A. Proctor Group, is being installed as part of the renovation of Manchester Town Hall.

Once construction work on the historic building, which is nearly 150-years old , is complete it will benefit from Proctor Air’s combination of vapour permeability and air permeability.

The scheme to redevelop the Grade 1-listed Town Hall is one of the biggest heritage projects in the UK.

At roof level, the restoration efforts include dismantling and rebuilding 30 of the 34 chimneys, and replacing 140,000 roof tiles. Removing the roof finish has afforded the opportunity to install a new pitched roof underlay.

The project architects specified Proctor Air, with Mac Roofing & Contracting Ltd carrying out installation. As an historic building, the Manchester Town Hall roof features many intricate details. The complexity of the roof forms, combined with the age and heritage value of the building fabric, means opportunities to provide modern roof ventilation are limited.

Catnic’s Urban Seam Façade receives BBA certification

The British Board of Agrément (BBA) has certified Catnic’s Urban Seam Façade, the limited combustibility wall system for use on buildings over 11 metres in height.

This provides assurance for specifiers and contractors that the complete façade system is compliant, helping to simplify the overall process and de-risk projects. As part of the BBA certification, and to demonstrate the structural integrity, durability and weatherability of the Urban Seam Façade system, Catnic carried out comprehensive full-scale testing in accordance with the Centre for Window and Cladding Technology (CWCT). It included wind loading, rain penetration and hard and soft body impact tests.

A key advantage of Proctor Air, as an air permeable low-resistance (APLR) membrane, is that it removes the need for separate roof ventilation. In fact, it provides a more uniform flow of air in the roof space than normal vents, ensuring there are no ‘dead zones’ where the complexity of the roof form could otherwise have restricted air movement.

Air permeability performance is important, but must work alongside good vapour permeability performance. With an Sd value of 0.015m and a vapour resistance of 0.075MNs/g, Proctor Air is one of the highest performing vapour permeable membranes on the market.

A.Proctor Group – Enquiry 20

‘Massive’ improvement in heat retention, comfort and aesthetic

The Mapetherm Mineral Wool External Wall Insulation (EWI) system from Mapei, has been installed as part of a Bristol City Leap (BCL) pilot retrofit scheme.

The EWI system was installed by Bristol-based ESW Construction Services Ltd. Following installation of a cavity fill system combined with the Mapetherm EWI, a u-value of 0.22 W/m2K was achieved, compared with a pre-retrofit rating of 2.06 W/m2K, demonstrating greatly improved heat retention and comfort.

Each of the 16 Easiform homes in Brentry features a non-standard concrete cast-in-situ construction. The scope of renovation works included replacement of roofing elements, renovation of chimney stacks,

insulation of cold roof space, internal ventilation works, cavity wall extraction, fenestration installation, cavity wall fill and a wide range of enabling works.

As part of the energy efficiency improvements, Mapetherm Mineral Wool - BBA 13/4977 certified high-density rock wool insulating panels for thermal insulations systems – were installed throughout the properties external walls, totalling over 1400 m2

“The Mapetherm system has been tried and tested on many of our projects. Mapei’s products are high quality, easy to use and the final results speak for themselves. The service we get from Mapei’s sales and technical team has always been first class and the support they offer on site is second to none,” commented Carlo Bonomini, ESW’s Commercial Manager.

Mapei – Enquiry 22

MERMET manufacturers of technical solar shading fabrics for internal and external use, helping you achieve your LEED & Breeam goals.

Are you seeking to achieve LEED and Breeam certification?

Did you know SOLAR SHADING is a critical component in achieving this?

Acoustic ceiling systems manufacturer OWA has extended its range of OWAtecta metal ceiling solutions with the introduction of the new S14 acoustic canopy.

Suitable for use across the sectors, including education, hospitality and commercial offices, S14 has been designed to enhance any contemporary open-plan interior space while offering class A sound absorption.

The standard rectangular-shaped 2m by 1m canopies come in one piece to create stunning ‘floating’ ceiling designs and have an integrated acoustic pad and suspension rods which make them easy to install and relocate. S14 can also be made to order to meet bespoke design requirements, including a variety of different sizes, shapes, colours, perforations and mesh patterns.

Offering a stylish metal alternative to glass or mineral wool, the S14 acoustic canopies are practical to handle, durable and easy to maintain. Sustainability has been considered throughout the product’s development, with OWA manufacturing the metal S14

The ambassador for quiet acoustics

Architects Common Ground Workshop completed a new hospitality development at 6 Embassy Gardens in Nine Elms, London.

Troldtekt wood wool acoustic panelling with a black finish was specified throughout the space, punctuated by a bespoke lighting track with drop-down custom-made LED light battens further emphasising the urban and industrial aesthetic look. Troldtekt panels were specified for their excellent acoustic properties and ability to dramatically reduce sound reverberation as well as their superior environmental credentials. The range is available in various sizes and structures, from extreme fine to fine. They can be supplied as natural wood or finished in almost any RAL or NCS colour.

Troldtekt – Enquiry 25

acoustic canopies using low carbon steel which is produced using cleaner, electric arc furnace technology. By reducing the amount of embodied carbon generated during the manufacturing process, and thanks to its simple construction which uses minimal metal suspension, OWA’s S14 acoustic canopy has the lowest carbon footprint of all of the company’s metal ceiling systems.

OWA is also committed to reducing waste on projects where the standard S14 acoustic canopies are specified as part of the initial Cat A fit out. Should the canopies no longer be required, OWA is offering a take back scheme so that the products can be re-used on other projects.

OWA – Enquiry 24

Premier League specifies first class moveable walls for offices

The London offices of Premier League have recently benefited from a refurbishment which included the installation of three, high specification, Dorma Hüppe moveable wall systems.

Style, the sole UK distributor for Dorma Hüppe, improved the flexibility of the main boardroom by installing a single glazed Variflex moveable wall down the entire length of the room, intersected with two solid Variflex moveable walls. This configuration allows the area to be divided into either one large room with a separate meeting room, or three individual rooms. For larger events, all three walls can be neatly stacked to one side, opening up the entire space.

The Premier League has responsibility for the football competition, its rule book and the centralised broadcast and other commercial rights. At its offices at the Brunel Building in London, Style worked with Minifie Architects and contractors, Parkeray, to create adaptable meeting space. The three Dorma Huppe walls all come with semi-automatic operation, ensuring the seals are applied to the correct pressure every time to optimise acoustic performance. The glazed moveable wall system offers a 52dB acoustic rating, and each solid wall a 57dB rating.

Style – Enquiry 26

When only premium materials and construction quality will do: Hunter Douglas’s range of superior metal exterior ceilings will complete any project.

The vanguard of quality, they are designed to withstand even the harshest weather conditions and are ideally suited to environments such as car parks, stadiums, airports and office blocks. They are all ISO9001 and TAIM certified, providing assurance they are of the highest standard when it comes to production processes, material, machinery and finished product.

David Harris, general manager of Hunter Douglas Architectural UK, said: “Our systems are manufactured from a highperformance exterior grade aluminium alloy, with our exclusive protective exterior paint. We can provide large panels that are capable of enduring harsh conditions and high wind loads, typical of exterior applications.

“Our exterior systems are available in several different size profiles and in a range of standard colours, which makes them ideal for use in external canopies, soffits, car

parks, airports and stadiums. Both the panel and carrier systems are Cradle to Cradle Certified™ Bronze and can be fully recycled.”

The Linear system has a range of styles and applications that are suitable for a variety of settings. There are three closed systems:

• The Luxalon® Closed Ceiling system. Available in three widths – 75mm, 150mm and 225mm, they can all be combined and easily clipped on a universal carrier to create multiple designs possibilities.

• The Luxalon® wide panel system. The panels are 300mm wide and are designed for larger spaces, with panels manufactured up to 6m long to minimise the number of joints, while still being lightweight and easy to handle.

• The Luxalon® 84C Closed Ceiling system. There are box panels that are clipped on the carrier. The 84mm wide panels feature a flange that closes off the

16mm joint between the panels, while the 12.5mm deep recessed joint gives a linear direction to the ceiling plane.

Developed as a façade, but suitable for exterior applications, the Luxalon® MultiPanel Façade features neat closed joints, which give a smooth and uninterrupted appearance. Designers can combine the 150mm and 200mm panels to produce different effects.

Our three linear open ceilings enable architects and designers to create innovative and striking looks:

• The Luxalon® 70U ceiling system, for developments that need a stronger and impact-resistant finish, is a box panel with 70mm wide aluminium panels. These enable gaps between the panels, creating a directional effect.

• Our Luxalon® Linear Open 80B features slender box panels that are ideal when a directional ceiling is required. The joints between the panels can be open or closed.

• The Luxalon® Exterior 84R, which has 84mm round edged panels with 16mm joints that enhance the linear appearance. Combining the panels with join profiles provide a visually closed ceiling.

The V100 exterior ceiling is suitable for lightweight and open ceiling requirements. Ideal for reducing the room height while retaining original room volume, the V100 screen ceilings are engineered to dimensionally define the ceiling plane. They comprise vertically hung ‘floating’ panels and create unique visual patterns and lines. Our exterior metal ceilings are available in a wide range of colours and are finished in Hunter Douglas’s exclusive Luxacote® Exterior Coating. Comprising three layers – pre-treatment, primers and a UV and scratch-resistant topcoat – the coating enhances the ceilings’ strength and durability.

There’s a lot of consideration taken when designing public spaces, with small changes making a huge difference for those visiting the areas. Whilst these changes might not appear obvious to everyone; to those with impairments, they make day-to-day life much easier. With this in mind, the experts at Marshalls have revealed what stair nosing is and the difference it makes to public spaces.

Stair nosing is a safety feature installed on the edges of stairs. It is typically made of durable materials, such as metal or rubber, and is a contrasting colour to the stairs to enhance visibility. This contrast helps individuals, especially those with visual impairments, to identify a step and reduce the risk of falls.

Many falls on stairs result from someone misjudging the step tread and riser when climbing up and down the steps. So by creating a contrast between the step nosing and the colour of the step, people, particularly those with visual impairments, can differentiate between the tread and riser.

The sizes of external steps are tightly controlled, helping individuals form a habit when climbing steps as they know how

high they need to step. By maintaining consistency amongst external steps, people will be able to correctly judge the height of steps, creating an inclusive and accessible environment. With this in mind, stair-nosing enhances the visibility of steps to help people build a consistent habit and approach to climbing the stairs.

Regulations and guidance around stairnosing derive from the BS8300 standards and Building Regulations Part M. However, these requirements differ slightly when it comes to the width and positioning of the nosing strips. So, how can consistency and compliance be achieved?

Marshalls has recently developed a range of external concrete steps to incorporate a durable, permanently contrasting visibility

strip that meets the requirements of both Part M and BS8300 standards.

Light Reflective Value (LRV) is also an important consideration when designing external steps and choosing the correct materials for their construction. For those with visual impairments, the contrast between the step and the nosing must be at least a 30-point difference to create that visual differentiation. This means that no matter the sun’s intensity on the steps, there will still be a distinct colour variation between the steps and their nosing.

Mark King, a paving engineer at Marshalls has shared the following about the future of public spaces: “As we age, our eyesight naturally deteriorates - impacting how we interact with and experience the world around us. The population is undoubtedly living longer, therefore we can assume that a large number of people are living with visual impairments of varying severity.

“Steps are a very common landscaping method, creating transitionary spaces between indoor and outdoor environments and creating access between different heights in a space’s natural infrastructure. Therefore, it is important to acknowledge how this might impact an ageing population and ensure we are doing what we can to future-proof public spaces across the country.

“As there are over 2 million people in the UK currently living with sight loss, this isn’t limited to only those of an older age. Therefore, creating accessible and inclusive spaces for everyone is crucial.”

Stonework that stuns

As a long-established and well-respected manufacturer of high-quality cast stone, Haddonstone has created some of the most stunning stone structures for inspirational buildings past and present.

Haddonstone has always ensured its diverse range of standard products, as well as its continuous output of bespoke items, are manufactured to exceed industry standards, whilst also respecting the environment.

In fact, over 80% of the Building and Construction team's components are produced bespoke to meet their clients' precise requirements: involving the unique skillset of Haddonstone's CAD technicians, craftsmen in their moulds workshop, constant

monitoring of the mixes which fill them, and rigorous testing of the finished products.

The latter includes water absorption rate, compressive strength and tensile strength, as well as visual inspections and regular independent testing.

Haddonstone was commissioned to produce a large volume of high-quality architectural cast stonework for this stunning Georgian-style new build property in Henleyon-Thames, Oxfordshire.

With the help of Haddonstone's experienced team's help, the homeowner client integrated a number of beautiful façade stonework elements to the front elevation of the design. This included a smart portico featuring four smooth columns with Tuscan capital detailing and Juliette balcony to the front, and a further balcony to the rear featuring a balustrade.

Each component was manufactured in Haddonstone's TecStone (wet-cast limestone) in Portland colour.

The Housing Forum has welcomed the long-awaited technical guidance on second staircases in tall buildings.

The consultation on this guidance was released in December 2022, and the delay in publishing the response and technical guidance has led to uncertainty across the housing sector.

The Forum has been aware of many sites that have stalled because of the lack of information around what exactly is required (such as the maximum distance permitted between flat entrances and the staircases). It raised these concerns previously on behalf of members across the housing sector.

Publication of the technical details was therefore extremely welcome and will allow many stalled sites to resumefollowing redesign.

Clarity over the purpose of the second staircase and explicit statement from government that there may be situations when the ‘Stay put’ advice may need to be over-ridden is very helpful.

The transitional arrangements in theory allow buildings to be built to the current single-staircase requirements until September 2026. However, in practice this is unlikely to happen as planning permission is not being granted on single staircase buildings.

UK designed and manufactured lifts take pride of place in the Elizabeth Tower restoration project. By Dave Saunders, Head of Major Project Division at Stannah Lifts and John Newbold, Director at SVM Associates

For many decades, the Elizabeth Tower, the world-renown historic landmark adjacent to the Houses of Parliament in Westminster, has been displaying signs of age and exposure to pollution.