The government has started 2022 with a major proposal to reset the approach to building safety with a plan to protect leaseholders and make wealthy developers and companies pay to fix the cladding crisis.

Secretary of State for Levelling Up Michael Gove has given the industry two months to agree to a financial contributions scheme to fund the new plan, otherwise, if necessary, the government will impose a solution in law.

In addition, a new dedicated team is being established to pursue and expose companies at fault and to force them to shoulder the burden of making buildings safe.

Despite the move signally a significant shift in the Government’s response to the cladding crisis, the familiar complaint remains that the devil remains in the detail as regards new proposals. Even those groups representing leaseholders gave the announcement a largely lukewarm response.

RIBA President, Simon Allford, welcomed the fact that the new plan should provide some welcome relief to the many homeowners who have unduly suffered at the hands of our flawed building safety regime. “We remain concerned however that the new funding mechanism will not raise enough money to fully address the widespread fire safety or structural defects that exist up and down the country,” he added.

“The extension of the Defective Premises Act will also seriously impact the availability of insurance for the entire construction sector, impacting not only architects who are needed to help design remedial works, but also others who have never worked on high-rise housing projects.

“While the new collaborative procurement guidance signals progress, that too will require much stronger Government oversight to prove effective, because despite awareness of risks, too many construction projects confuse cost, value and safety.

“To help the construction sector to move forward, the Government must, accepting of its role as the regulator that allowed this crisis to arise, devise and enforce a properly funded and sustainable solution.”

The next two months ahead of Mr Gove’s deadline could prove very interesting. In the meantime, everyone at TSP Media would like to wish you a Happy New Year and we look forward to a successful 12 months.

Groves || Group Editor

Strong. Natural. Versatile. The product of hundreds of millions of years of heat and pressure, slate is one of the most sought-after construction materials on Earth – and not just for roofing.

Slate cladding looks stunning, and can last the best part of a century.

It can lend tasteful, traditional aesthetics to heritage buildings, and bring sleek, minimalistic aesthetics to contemporary ones.

It’s safe, water-resistant, and far more sustainable than the alternatives – and so, if you want a beautiful, reliable natural cladding solution, speak to SSQ today!

Want to find out more? Speak to SSQ. Call us today on 020 8961 7725 or email info@ssq.co.uk www.ssqgroup.com

Stuart

have a range of automatic variable speed ‘In-Tank’ integrated cold water booster systems offer a compact, submersible, very quiet and simple to install solution for a range of commercial applications. The booster sets are controlled by our advanced variable speed control panel and different configurations are available offering maximum flow rates ranging from 4.4m3/h (75l/min) – 29m3/h (480l/min) (Per Pump) and maximum head pressures ranging from 1.0 – 16 bar.

The House of Lords’ Built Environment Committee has published its report, ‘Meeting housing demand’, which concludes that the Government must address barriers to building much needed new homes.

Too many people currently live in expensive, unsuitable, and poor-quality homes and housing supply needs to be increased to tackle the housing crisis now.

Key points highlighted in the report include:

• The role of SMEs in the housebuilding industry has collapsed. SMEs should be supported by reducing planning risk, making more small sites available, and increasing access to finance.

• The population is ageing and by 2050 one in four people in the UK will be over 65. The country needs more specialist and mainstream housing suitable for the elderly.

• Uncertainty and delays to planning reforms have had a ‘chilling effect’ on housebuilding and created uncertainty for housebuilders and planners. We need more up-to-date local plans, and these need to be simpler, clearer, and more transparent. Planning departments need more resource to avert an emerging crisis.

• The Government’s own figures show that skills shortages accounted for 36% of all construction vacancies and 48% of all manufacturing and skilled trades vacancies. Skills shortages must be addressed, through broadening the base of talent, upskilling and reskilling, including for the green skills needed to address climate change. The Apprenticeship Levy needs urgent reform. We call for

the New Homes Ombudsman’s powers to be robust and adequately enforced to ensure homes are built to high standards of quality and design.

• Government must change its approach to spending on housing. Over time the money spent on housing benefit should be invested in increasing the social housing stock. Right to Buy schemes are not good value for money: increasing the housing supply would be a more effective use of funding.

Baroness Neville-Rolfe Chair of the House of Lords Built Environment Committee said: “The Government’s ambitious target of 300,000 new homes per year will only be met if Government takes action to remove the barriers for housebuilders, particularly for SMEs who 35 years ago built 39% of new homes but now build just 10%.

“The planning system needs urgent reform. Currently, less than half of local authorities have an up-to-date local plan: more councils need simple, clear and transparent local plans. Any new planning system will only work if local planning authorities have the resources and staff to implement it.

“Skills shortages in the construction, design and planning sectors must be addressed to unlock the required development, including the green skills needed to address climate change.

“Uncertainty and the absence of a clear policy direction has only exacerbated housing problems. Our report provides a package of proposals to help deliver much needed housing and address the critical undersupply of new homes.”

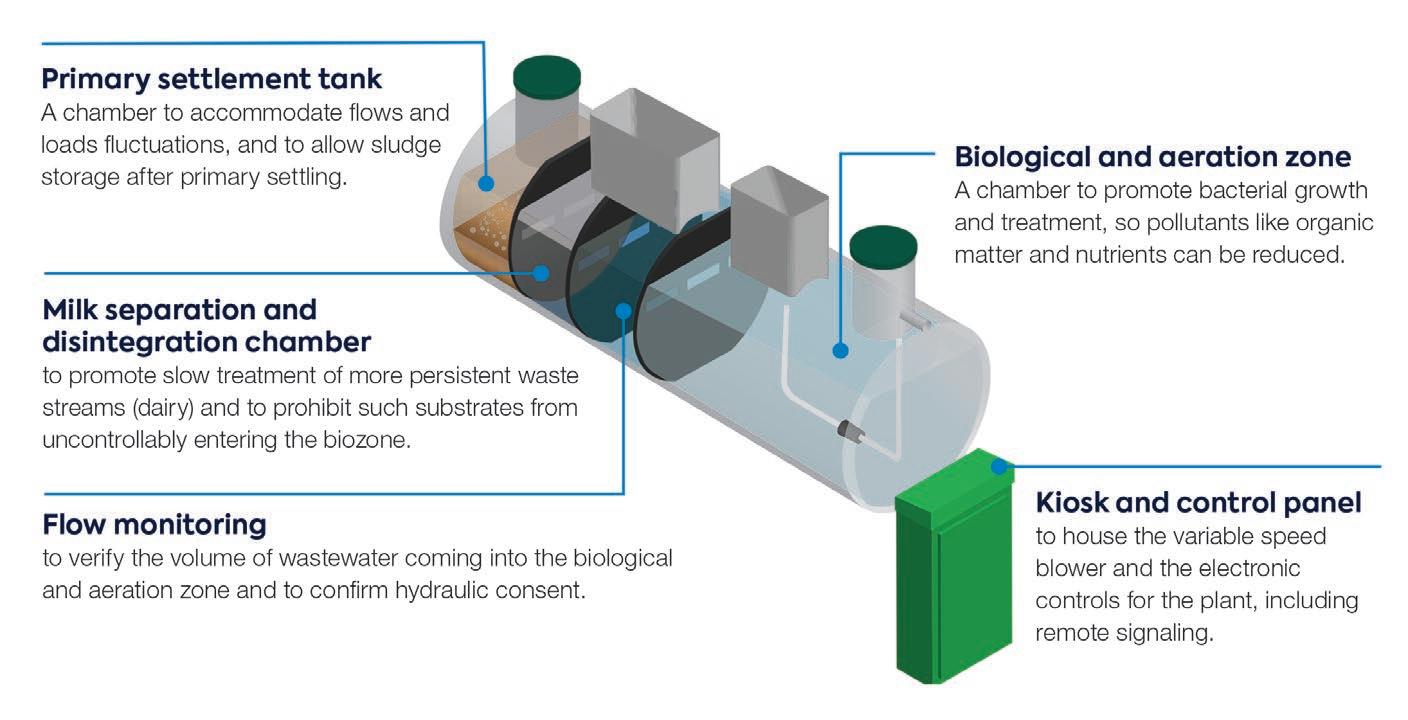

Following the publication of the Heat and Buildings Strategy, funding awards have been allocated to a suite of low carbon heat network projects.

Heat networks have been identified by the Government as a key technology and the Strategy placed particular emphasis on the use of heat pumps in the delivery of low carbon heat.

The announcement combines these two technologies across four projects. The variety of projects that have secured funding really demonstrate the adaptability and flexibility of heat pump technology when deployed in heat networks.

The successful heat network schemes announced all utilise heat pump technology and bring the total amount awarded via the Heat Networks Investment Project to over £250 million.

Ken Hunnisett, Triple Point Heat Networks Investment Management said: “The Heat and Buildings Strategy made clear that both heat networks and heat pumps are central to the Government’s decarbonisation efforts.

“So, it is fantastic to see so many schemes already stepping up to combine these solutions in such innovative ways to access heat under our feet, in the air around us, in our waterways and even within our sewerage system.

“Not only will these inspiring projects deliver carbon savings, but they prove that heat pump technology is adaptable and can contribute to a smarter, more flexible future energy system.”

Lord Callanan, Department for Business Energy and Industrial Strategy said: “Changing the way we heat our homes and workspaces is key to tackling pollution and today’s investment into new heat networks across Worthing, London, Bristol and Liverpool will ensure these areas are placed at the heart of the UK’s green industrial revolution.

“The new networks of air source heat pumps will deliver affordable, low-carbon heat and energy across the nation’s homes, universities residences, and business units, while opening up huge job and investment opportunities, making our thriving cities and seaside towns greener places to live, work, and visit.”

The creation of the Uniclass Advisory Board (UAB) is announced with a remit to advise on potential improvements to Uniclass 2015, a classification system used to organise information across all construction industry disciplines, helping to make interoperability between software platforms easier, to aid with better outcomes.

Meeting quarterly, UAB will be made up of a cross-section of relevant stakeholder organisations, including representatives from bodies who supply, consume and procure construction data. Specifically, UAB will explore and advise upon Uniclass in relation to digital construction’s evolution and maturation alongside the evolving need for data security around sensitive assets, buildings and infrastructure.

UAB’s member organisations include Association of Cost Engineers (AcostE), Chartered Institute of Architectural Technologists (CIAT), Chartered Institute of Building (CIOB), Institute of Asset Management (IAM) and UK BIM Alliance (UKBIMA).

Fiona Moore will be UAB’s chair, who

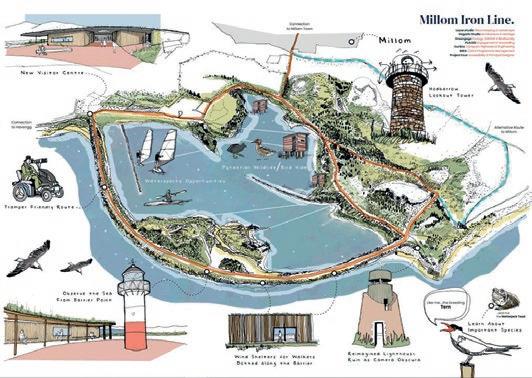

Design partner for Millom’s Iron Line announced

The design partner for a project that will see an area of Cumbria’s coastline transformed has been announced following a global search.

The Iron Line is a scheme that will see the uniquely beautiful sea wall and coastal lagoon enhanced to provide an inspirational and fully inclusive route across RSPB Hodbarrow. Layer Studio was selected as the design partner to take the project to the next stage, with the panel saying Layer Studio’s Stage 2 submission was sensitive to place, heritage, ecology, culture, and community.

The team is led by renowned landscape architects and includes a specialist in projects that require engagement with the local community. Work to create the design proposal for The Iron Line will take place over the coming weeks and months.

currently oversees the technical delivery of the Government & Industry Interoperability Group (GIIG). NBS experts Sarah Delany and Tina Pringle will also be sitting on the board, providing expert technical advice and insights.

Commenting on the creation of UAB, Fiona Moore said, “Those implementing information management processes and the technologies that facilitate them know first-hand how important having a shared way to classify every aspect of a construction project is. The pace of adoption of digital construction is speeding up and that’s why we need to ensure that naming conventions and approaches are robust and reflect what’s happening in the field. That’s why the creation of an industry wide panel in the form of the UAB will help to continuously improve Uniclass and make sure it continues to be an important part of driving up construction quality.”

UAB attendee, Tina Pringle, Director of Digital Information, NBS and a member of the team who devised Uniclass 2015 said, “Uniclass 2015 is a powerful system as it provides a unified classification system for the construction sector. It delivers a hierarchical suite of tables that allow for ‘things’ of all

sizes to be classified from an individual screw through to a university campus or road network. It allows for buildings, landscape, and infrastructure to all be classified using one system. As you can see it’s very powerful, yet as digital construction evolves so must Uniclass. This advisory board is going to be a powerful way to ensure that the system remains fit for purpose as digital construction matures.”

Uniclass is a consistent classification structure for all disciplines in the construction industry.

It contains tables classifying items of any scale, from a large facility such as a railway, down to products such as a CCTV camera in a railway station. The classifications within the tables allow buildings, landscape and infrastructure to be classified under one unified scheme.

Uniclass is an essential way of identifying and managing the vast amount of information that’s involved in a construction project, and it’s a requirement for BIM projects, as set by the BS EN ISO 19650 series of standards.

One of the most comprehensive surveys of Small and Medium Enterprise (SME) housebuilders in the UK, conducted by the Home Builders Federation (HBF), Close Brothers Property Finance and Travis Perkins has found:

• Planning remains a significant barrier to increasing housing delivery over the next 12 months, with 94% of SME housebuilders seeing delays in securing planning permission or discharging conditions stifling housing supply.

• With all out elections in 2022 effectively shutting down planning system, conditions are expected to worsen.

• 78% of housebuilders also see the supply and cost of materials as major barrier to delivery (up 20% from last year).

• 59% see the supply and cost of labour as a major barrier (up from 19% last year).

The survey, now in its second year, takes a deeper look at how the Covid-19 pandemic has changed the landscape for housing delivery via SMEs and includes an in-depth focus group this year, which drills down into the key findings from the survey.

The construction industry is, and will continue to be, a key driver of economic recovery as we move back towards

normality, and it is critical that SME builders are able to play their part in this recovery and also create a more diverse sector, with a thriving local and regional network of home building firms.

Stewart Baseley, executive chairman of the Home Builders Federation said: “Recent decades have seen a collapse in SME builders numbers and the survey shows the considerable challenges the sector continues to face. Every single SME I speak to is suffering badly from delays to the planning process.

“SMEs are literally having to put their businesses on hold whilst Local Authorities delay the start of construction as their planning departments don’t have adequate capacity to process applications effectively. Allied to concerns on materials and staff, planning delays threatens the demise of even more SME builders.”

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Secretary of State for Levelling Up, Housing and Communities Michael Gove has warned developers that they must pay to fix the cladding crisis that they caused as he overhauls the government’s approach to building safety.

Mr Gove has written to industry giving them a deadline of early March to agree a fully funded plan of action including remediating unsafe cladding on 11-18 metre buildings, currently estimated to be £4 billion.

He warns he will take all steps necessary to make this happen, including restricting access to government funding and future procurements, the use of planning powers and the pursuit of companies through the courts. He adds that if industry fails to take responsibility, the government will if necessary impose a solution in law.

The Secretary of State is also due to make an oral statement to the House of Commons announcing plans to protect innocent leaseholders, who are trapped in unsellable homes and face excessive bills to

Cllr David Renard, housing spokesperson for the Local Government Association, said it was right that no leaseholder should have to pay the costs of making their homes safe and the Secretary of State’s threat to use the legal system to ensure developers meet their responsibilities to leaseholders is a positive step in the right direction.

However, he added, leaseholders are not the only innocent victims of the construction industry’s failure to build safe homes.

“The construction industry must also be made to fix the fire safety defects it has built into blocks owned by councils and housing associations,” he continued.

fix dangerous cladding defects. Mr Gove will also unveil a package of measures to restore common sense to the industry and end the situation of buildings being declared unsafe when they are not.

In the letter, Secretary of State for Levelling Up, Housing and Communities Michael Gove says: “Our home should be a source of security and pride. For too many of the people living in properties your industry has built in recent years, their home has become a source of misery. This must change.”

Mr Gove adds: “It is neither fair nor decent that innocent leaseholders, many of whom have worked hard and made sacrifices to get a foot on the housing ladder, should be landed with bills they cannot afford to fix problems they did not cause.

“Government has accepted its share of responsibility and made significant financial provision through its ACM remediation programme and the Building Safety Fund. Some developers have already done the right thing and funded remedial works and

“Unless the Government forces the industry to act – or provides taxpayer funding – we are concerned that the costs of fixing social housing blocks will fall on council housing revenue accounts and housing associations.

“This will reduce the funding available to meet the Government’s ambitions for improvements to social housing, net zero and the provision of new social housing, leaving tenants and those on the waiting list to suffer the consequences of decades of industry failure and poor regulation. Like leaseholders, council tenants and those on the waiting list are innocent victims and the Government needs to help them too.”

In the letter, the Secretary of State asks companies to agree to:

• make financial contributions to a dedicated fund to cover the full outstanding cost to remediate unsafe cladding on 11-18 metre buildings, currently estimated to be £4 billion

• fund and undertake all necessary remediation of buildings over 11 metres that they have played a role in developing

• provide comprehensive information on all buildings over 11 meters which have historic safety defects and which they have played a part in constructing in the last 30 years

I commend them for those actions. But too many others have failed to live up to their responsibilities.”

The vast majority of 11-18 metre buildings are safe and others that do have combustible cladding may also be safe or can be made safe through effective use of existing or new fire safety measures, such as sprinklers and alarms. There are, however, a small number of residential buildings with unsafe cladding which must be addressed.

Mr Gove says developers must take forward all necessary remediation work at paceprioritising those with greatest risks first and in all cases finding the quickest and most proportionate solution to make buildings safe.

He calls on industry to enter an open and transparent dialogue with the government to hear their proposals, starting with a roundtable with the largest residential developers and trade bodies. The government will invite leaseholders and those affected by the Grenfell Tower tragedy to the table to discuss solutions at appropriate junctures to ensure discussions are not taking place behind closed doors.

The government will announce a decision on which companies are in scope for funding contributions following discussions with industry but expect it to cover all firms with annual profits from housebuilding at or above £10 million.

The statement follows the Secretary of State ordering the suspension of Rydon Homes, who are linked to a company responsible for the refurbishment of the Grenfell Tower, from the government’s Help to Buy scheme.

Mr Gove also condemned the Mercedes F1 team sponsorship deal with Kingspan, a company connected to the crisis.

House on the Hill, a strikingly contemporary extension to a Georgian farmhouse in Gloucestershire, designed by Alison Brooks Architects, has been named RIBA House of the Year 2021.

To complement its arresting new wing, the 18th century stone farmhouse, which overlooks the Wye Valley in an Area of Outstanding Natural Beauty, has also been meticulously restored. Together the farmhouse and extension create an extraordinary new home for the owners and their art collection. The threestorey farmhouse has been converted into one vast gallery space that seamlessly integrates with the contemporary extension.

Larger than the original house, the new twostorey wing is set back, partially embedded into the hillside, with its dark tones and cladding pattern inspired by the nearby Forest of Dean.

On the ground floor, the kitchen, living and dining areas flow into each other and onto exterior terraces. With the kitchen in the centre, overlooked by a gallery on the floor above, the space is flooded with natural light, and offers up panoramic views of the surrounding landscape, including into a new, bespoke dry-stone-walled garden.

The home’s main staircase doubles-up as a gallery and leads up to two bedrooms, an office and a further terrace.

From the skylights to the walls and the cruciform-steel-columns, the angles throughout the house are intentionally skewed and undulating, echoing the topography of the adjacent meadows, and drawing the eye onwards to new and surprising focal points. Niches, benches and recesses add to the fluidity and playfulness of the space and provide practical areas to display the owner’s art.

Ground and air source heat pumps and solar panels work together to reduce the building’s overall energy consumption, and the new wing has an extensive green roof planted with native wildflowers to reduce rainwater loss. As part of the renovations, the surrounding grounds have also been revitalised with new wildflower meadows and orchards, bordered by hedges that have been repaired and renewed with pollen-rich species of plants. >>

>> RIBA President, Simon Allford said: “This geometric design skilfully fuses together the old with the new – connecting two architectures separated by over 300 years. Intriguing and distinguished, House on the Hill is the impressive result of a ten-year collaboration between the homeowners and their architect. This is an extraordinary labour of love in architectural form.

Every detail has been meticulously considered and exquisitely finished, resulting in a truly remarkable home that enhances its unique setting.”

Architect, Alison Brooks said it was a honour to win RIBA House of the Year amongst an accomplished shortlist of beautiful projects.

“I see private house commissions as a rare opportunity to test new ideas in a concentrated form – they are the built equivalent of writing an essay,” she explained. “So, this accolade is a testament to my client’s belief in the value of architecture and their willingness to embrace the new. I’m grateful for their trust in me and my team of talented architects, in Akera Engineers and the brilliant team of builders and gardeners whose skilful contributions produced this remarkable house and gardens, that together reveal a new way of living in the landscape.”

RiddleChair of the RIBA House of the Year 2021 jury, architect Amin Taha, said: “Some decades in the making, the replacement of a very large 1970s shed housing a pool and ancillary spaces with Alison Brooks Architects lower scaled and fragmented form impressed the jury, in a highly competitive year with contenders excelling in sustainability, craftsmanship, reuse, economy of means and thought-provoking sensitivity.

“House on the Hill balanced these where others may have, for instance reused but at disproportionate cost, or crafted but

to no innovative end. The jury felt Alison Brooks Architects had applied their longresearched process of subtly breaking down the rigid and spatially predictable grid with gentle inflection. Adding depth of scale and richness of experience to the existing house, and through the new extension, transitioning with ease into the beautifully landscaped gardens.

“It is a model of architectural approach applicable to all scales, resulting from the architects’ long practiced ideas and the clients’ successful collaboration.”

The versatility and choice available within the Encasement column casings range has been driven by the demands of architects and specifiers seeking to create a stylish finish to building interiors and exteriors.

Akey element in the design freedom provided by the range is the choice of materials available to meet different specifications and applications. From Circa and Quadra preformed plywood casings, through to Polyma GRP and Gypra GRG, as well as Encasement’s Forma metal range, each allows an array of specification options to be accommodated, including shapes, sizes and finishes.

Used extensively in a broad range of sectors, including transport, health, education, retail, hotel and leisure, as well as commercial refurbishment and building re-purposing projects, the column casings range also offers the option of standard or bespoke manufactured solutions.

Projects such as Tetrosyl’s Rochdale offices; Cardiff Premier Inn, Porsche West London and Farnborough Sixth Form College, have all taken advantage of the design versatility provided by the material and finish options alongside the company’s bespoke manufacturing capabilities, which enable specific project requirements to be met.

In addition, Encasement column casings have been installed on countless projects throughout the UK to provide aesthetic and practical solutions for concealing structural columns and steelwork, while also helping create stylish decorative interiors.

Alongside its wide product range, Encasement also offers a supply and install service, that enables the company to maintain complete control over the installation while also providing dedicated solutions to meet the needs of any column casing project. Encasement – Enquiry 10

A magnificent Grade 1 Listed Tudor Manor House situated within beautifully landscaped gardens and farmland in the heart of Worcestershire.

Due to the building being built in the thirteenth century, it has been added and adapted to over the years and was fitted with a more traditional gravity fed system with large tanks situated in the roof spaces. This meant that much of the property was relying on the head of water to push through the system and feed a high number of outlets. This meant that showers in a number of rooms were very poor and also flow during peak usage was also poor.

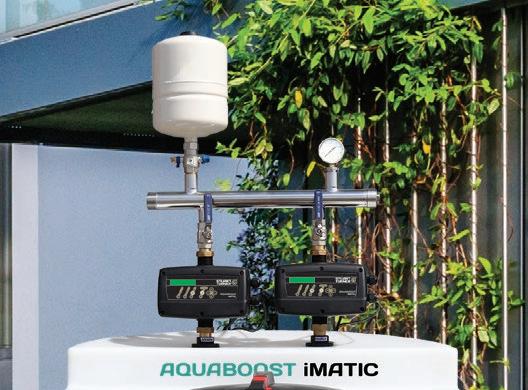

Christopher Hughes from CRH Plumbing & Heating was called into this property in Worcester back in 2019, Chris got in contact with Conor Reeves from Stuart Turner to discuss the best way to go about creating a solution. It was decided that the best course of action was to fit an Aquaboost In-Tank 1000 litre (Two Piece) Twin Pump Booster Set - ABI-0303-2S-SPC/M-1000-2. The reason for this is it is maintenance free, fit and forget and due to it having submersible pumps meant it is water cooled and low noise.

The two piece construction was also ideal as it allowed the tank to be installed in a much more desirable location within one of the two plant rooms. With the access limited due to the nature of the building, being able to construct the tank on site allowed for a smoother installation and no building alterations to accommodate it.

The new system is providing better pressure and flow to all 8 bathrooms, not to mention all the other outlets. With new flow rates being adaptable by programming of the system controls the desired outputs can be achieved based on the customers and the buildings requirements.

“Stuart Turner are one of the few companies who offer a product like an itank and help with the fitting and installation process which gives it a more personal feel” said Christopher Hughes.

Full details of the Stuart Turner Aquaboost Range can be found at stuart-turner.co.uk/aquaboost, or you can call 01491 572 655 for more information.

Stuart Turner – Enquiry12

Stuart Turner are one of the few companies who offer a product like an itank and help with the fitting and installation process which gives it a more personal feel

The NEW Aquaboost iBolt and iMatic range of high flow, high head, cold water pressure and flow boosting solutions. Designed to optimise space and provide a very quiet, simple to install solution for domestic and commercial applications.

The ‘Sky-House’ development, at Oughtibridge Mill to the north of Sheffield, comprises forty high-specification homes. The term ‘Sky-House’ being derived from the spacious feel of the properties, which benefit from unrivalled views and offer bright and airy living, complete with riverside balconies.

Designed by CODA Architecture, it is built very much with sustainability in mind and minimising any risk of thermal bridging at the balcony detailing is critical. The load-bearing structural thermal break that easily achieves this; and most effectively helps the project meet compliance with the necessary Building Regulations (and the impending Future Homes Standard criteria) is the Schöck Isokorb. Specifically it is the Schöck Isokorb T type SK for concrete-to-steel connectivity

that is incorporated at Oughtibridge Mill.

This is a complete system thermal break. It is unique in being the only formally UK approved product that satisfies the load-bearing and thermal insulation requirements for this type of application, providing assurance to the enduser that the safest product has been selected for their building needs.

The avoidance of thermal bridging is extremely important for a number of reasons. Any local heat loss will result in more energy being required to maintain the internal temperature of the building.

Also, low internal surface temperatures in the area of any thermal bridge can cause condensation and this in turn is likely to result in structural integrity problems. Mould growth too is a possible risk, which in a residential situation can cause asthma and allergies.

Oughtibridge Mill ‘Sky-House’ is an award winning scheme – recipient of the Development of the Year (fewer than 50 homes) at the Insider Yorkshire

Property Industry Awards 2021. It is part of a wider scheme for 320 new homes that will enable the regeneration of this former industrial mill site. It had been a flourishing paper mill from Victorian times until its closure in 2007 and renovation of the old mill building for use as a mixed-use food hall, community hub and leisure facility is underway. To reference the industrial history of the area, a sensitive contemporary design style features saw-toothed roofs on the three and four-bed townhouses. All Isokorb products are fully compliant

In addition to its comprehensive range of Isokorb solutions for concrete-to-steel, concrete-to-concrete and steel-to-steel – Schöck also offers a maintenance free alternative to wrapped parapets. All products meet full compliance with the relevant UK building regulations and have the security of independent BBA Certification, which provides NHBC approval. The temperature factor requirement (fRSI) used to indicate condensation risk, which for residential buildings must be equal to, or greater than, 0.75 is also easily met by incorporating the Isokorb.

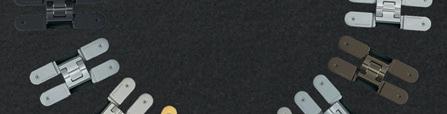

SIMONSWERK UK is proud to announce that the TECTUS range of concealed hinges has been approved for the Warrington fire CERTIFIRE certification scheme.

CERTIFIRE is an independent third-party certification scheme that assures fire protection products’ performance, quality, reliability, and traceability. The scheme is recognised by regulatory authorities worldwide, it is an internationally respected mark of fire safety and one of the most authoritative in the industry.

Following stringent tests and further assessments, the TECTUS is the only CERTIFIRE approved multi-axis concealed hinge on the market.

Robin Guy Managing Director says “The certification is a fantastic asset to the range; it gives both our customer and the end-user the confidence and reassurance that the products carry the mark of a reputable third-party certification body. It gives assurance as to the performance of the products, particularly following the understandable stringent requirements on products to meet additional fire test standards due to recent tragic events.

The certification underlines SIMONSWERK’S commitment to the highest quality standards and the products performance reliability”.

SIMONSWERK are Europe´s leading Hinge Manufacturer with a history spanning more than 130 years in the manufacture of brass, aluminium and stainless-steel hinges for doors and windows. The range includes the renowned fully concealed TECTUS hinges and the popular TRITECH solid brass hinge with concealed bearings.

SIMONSWERK UK – Enquiry 15

The exceptional variety of finishes offers maximum design options. The hinge system TECTUS can be seamlessly integrated into every door or by design stand out in contrast.

www.simonswerk.com

Supporting and driving the sustainability of the built environment and manufacturing sector is key to reducing the world’s energy usage and carbon emissions. At Polypipe Building Services, a range of exciting developments are underway including advancing the circular economy and tackling climate change. But what other areas is Polypipe Building Services focusing on?

Asustainable built environment can be circular and holistic, with focuses on longevity and low-carbon technologies. It is at the heart of the built environment’s future, particularly as the built environment is responsible for half of all global energy use and half of all greenhouse gas emissions.

Manufacturers that place sustainability at the heart of what they do put themselves in a better position to reap the benefits. According to a report from MAKE UK, nearly a fifth of manufacturers are going much further with imaginative and cutting-edge energy efficiency projects. Businesses are starting to look past the immediate cost saving drivers towards sustainability for the long term, which is not only attracting investor confidence, but the brightest and best employees.

Here at Polypipe Building Services, we are excited by all the developments that are happening in relation to sustainability. Genuit Group – of which Polypipe Building Services is a part of – has highlighted the main approaches from a sustainability perspective including:

• Advancing the circular economy

• Developing sustainable solutions

• Tackling climate change

• Investing in an engaged and diverse workforce

• These key approaches have been the basis for the action we’re taking at Polypipe Building Services.

There are many exciting things happening at Polypipe Building Services from a circular economy perspective. We are currently aiming to use larger amounts of recycled materials in both of our main product families – i.e., our Terrain brand (PVC) and FUZE (HDPE).

As part of the aim to use more recycled materials, Polypipe Building Services is looking at areas such as material science and development; working with our partners to make sure that the systems we create

are kitemarked and certificated. We are using more recycled material where the standards allow to adopt a circular economy. Wherever the standards allow us to use recycled material, we’re making sure we are optimising that.

At Polypipe Building Services, we are identifying solutions that are more innovative. One of our key solutions is our Advantage offering, where we take individual components and produce a fabricated stack, which is far more sustainable as you have less waste, less offcuts, and less work onsite. Advantage is certainly helping with sustainable solutions for drainage and water supply.

Additionally, Polypipe Building Services is focused on reducing greenhouse gas emissions in compliance with SECR reporting. Streamlined Energy and Carbon Reporting (SECR) requires companies to report on their energy usage and the associated greenhouse gas emissions. These are divided into three Scopes, known as Scope 1, Scope 2 and Scope 3.

Scope 1 emissions are direct emissions from controlled or owned sources and Scope 2 is defined as indirect emissions that are a consequence of your organisation’s activities. In line with SECR reporting, Polypipe Building Services is focusing on

using more economical transport methods, machines that are more efficient and greener aerodynamic vehicles.

Sustainability is a real buzzword for environmental health. But sustainability can also be related to the health of a company and its positive working culture.

Here at Polypipe Building Services, it’s key for us to cultivate a nurturing work environment. A sustainable business is highly desirable for both prospective and current employees. Not only are we investing in more training hours for staff development, we are following a total wellbeing calendar this year to focus on the health of our people.

Whilst it is important for us to focus on sustainable solutions that drive efficiency and innovation, a huge part of being a sustainable business is ensuring employee happiness. From professional development, to quizzes, socials, healthy food and drink, Polypipe Building Services is committed to creating a healthy and engaged community.

Sustainability is having a huge impact on the built environment and manufacturing sector. For many businesses, the change it is putting into motion is enabling greater efficiencies and innovations, not to mention a larger focus on the wellbeing of staff.

Polypipe Building Services– Enquiry 17

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Manufacturers that place sustainability at the heart of what they do put themselves in a better position to reap the benefits. According to a report from MAKE UK, nearly a fifth of manufacturers are going much further with imaginative and cutting-edge energy efficiency projects.

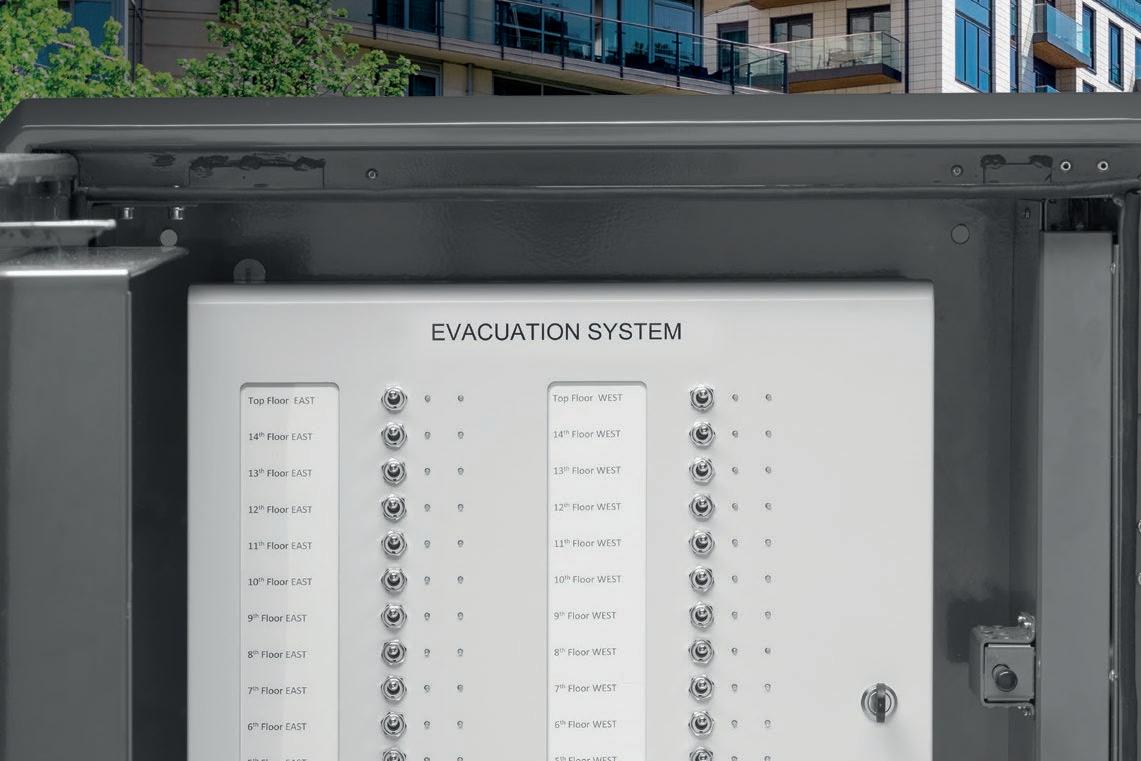

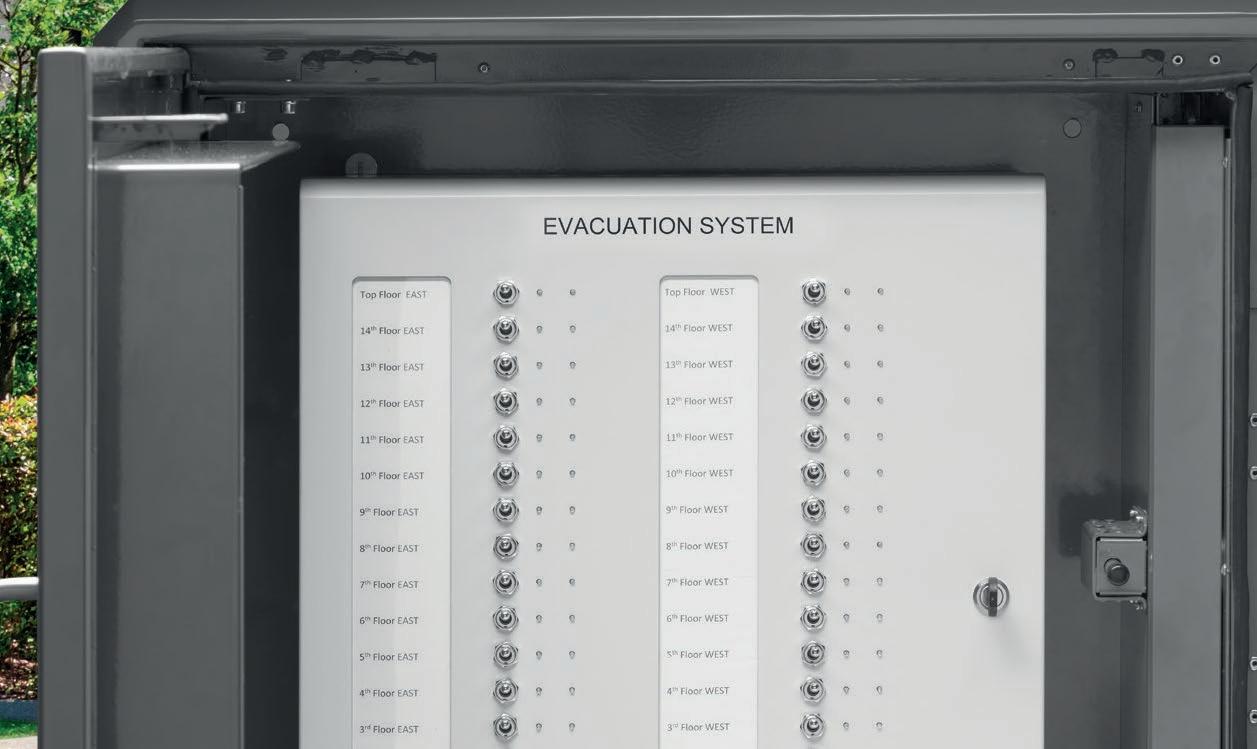

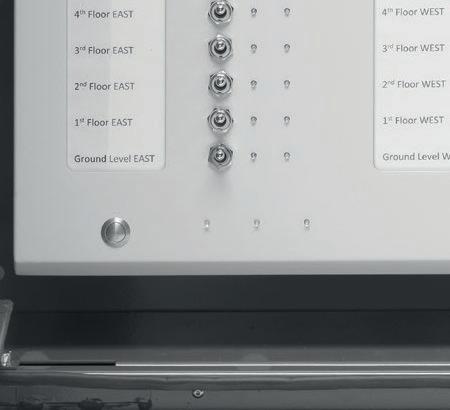

Combining robustness and reliability with speed and simplicity, EvacGo’s wired, wireless and hybrid options provide freedom to create the best possible evacuation alert solution, as specified by your local fire and rescue service.

Failing to meet new life safety rules is high risk; choosing Advanced leaves nothing to chance.

Hotels typically have a considerable demand for domestic hot water (DHW) which contributes to their reputation as a high energy user.

But sustainability is increasingly a must in the hotel industry, bringing both an improved reputation that attracts more sustainably minded guests and reducing operational costs through greater energy efficiency.

One means of improving efficiency is to move towards greater electrification and the use of heat pumps. However, due to the unique requirements for hot water in hotels, there are a number of challenges to taking a wholly electric approach to hot water generation in hotels – namely system losses, legionella control and space.

Let’s consider the DHW usage. This is usually characterised by an extremely high peak in the morning for guests’ showers followed by a long period of low demand. Typically, a second peak will occur towards the end of the day with end of service in the hotel restaurant and the cleaning down period for the kitchens.

If the system were designed around wholly electrical supplies, a larger thermal store would be required to meet peak demand, due to longer recovery times. This would then have a financial impact, as operational costs would rise compared with a conventional system based on direct-fired gas water heaters.

Legionella control would also be a consideration as only a small portion of ASHPs can at present efficiently generate temperatures high enough to store domestic hot water above legionella temperatures (60ºC or higher).

From a logistical standpoint, finding sufficient space to store the large storage vessels could prove problematic. After the months of lockdowns and restrictions, hotels may well prefer to use this space to provide an additional room for paying guests.

So what are the options? Many hotels use traditional direct-fired water heaters as one

of the most efficient means of meeting the sudden peaks in hot water demand as they can deliver large volumes of water in a short time. A major benefit of this approach is that it reduces energy loss between peak periods as the system will only use energy when hot water is required.

As a first step, any non-condensing water heaters should be upgraded to condensing units. Condensing water heaters are around 20% more efficient than the non-condensing variety, so it follows that the greater the demand for hot water, the greater the savings.

If we then integrate a heat pump and condensing water heater in a hybrid design, 52% of the peak load can be met by renewable pre-heat, achieving a significant emissions reduction compared with a 100% natural gas approach.

This method also greatly reduces the requirement for storage described in the wholly electric approach.

Let’s consider a hotel that requires 6,000 litres of DHW in a 90-minute peak period with eight hours between each peak. >>

The Marley Plumbing & Drainage Golf Classic has evolved. Join us for just £46 per two-ball team – play in your region, make friends and build networks on your way to the Grand Final. We do the matching so you can enjoy playing golf in this famous five round tournament. Share green fees and compete toward the September 2022 Grand Final at the fabulous Slaley Hall Hotel, Golf Resort and Spa. Finalists enjoy free championship course golf, gala prize-giving dinner and luxury overnight stay. Simply visit www.thegolfclassic.co.uk email info@thegolfclassic.co.uk or call 01892 752300 now to enter. Entrance closes at the end of March 2022 with the 1st round in April.

>> The electrical supply on site suits a maximum heat output of 45kW which can be used to pre-heat a small storage vessel – 2,000 litre storage in this example –sized to deliver half the peak demand. The storage vessel, which can be charged in between the peak periods, then feeds the direct-fired water heater which will meet the peak hot water demand.

The hot water demand is met efficiently and more sustainably, with no issues surrounding system losses, legionella control or space.

The Automatic Door Suppliers Association (ADSA) is hosting a series of free bite-sized online training sessions to raise awareness of the legal responsibilities around operating automatic doors. They cover different areas of law and regulation including installation, health and safety at work and fire safety.

The ease and convenience of automatic doors in premises is a given – they enable accessibility, improve the flow of foot traffic, provide functionality and contribute to an aesthetic finish – but what if they go wrong?

Who is responsible for ensuring their safety – a specifier, an installer, a landlord or occupant? In reality, every one of

these people has a role to play, with legal responsibilities that need to be met.

It begins with the architect and specifier. Not all automatic doors are suitable for every environment. For example, automatic swing doors may not provide the right solution for a building in an exposed location with high wind speeds, such as the coast. So, design calculations are essential.

Ensuring that an identified automatic entrance solution is fit for purpose and suitable for the requirement and the constraints of its specific location is just the start however. Even with the right door in the right place, a risk assessment needs to be undertaken to identify potential hazards and put safeguards in place to minimise risk of injury from impact, crushing, sheering or drawing-in.

Solutions are many and varied, from humble warning signs to the installation of pocket screens, barriers and sensors. Consideration should also be given to limiting leaf force through the application of a standard or low energy safety system, especially if the process of entering the building may incur delay, for example, where queues are anticipated.

The door manufacturer must ensure that all new machinery put into service is safe and all equipment should be

marked accordingly, with UKCA if supplied in Great Britain and CE markings when exported to the European

The installer must play their part in delivering an assured evidence trail, including the production of a technical file which documents the process, checks and balances that have been undertaken. This would include technical drawings, design calculations, electrical and control schematics and test results. ADSA’s Technical Bulletin 014 provides an example of what should be included.

Darren Hyde, ADSA’s Technical Manager, says: “Automatic doors have become so common place that many people take them for granted. Every time we go into a commercial building or residential premises designed for multiple occupancy, we most likely walk through an entrance with powered pedestrian doors.

“They’ve become such a part of daily life that we often fail to recognise them – they are an expected fixtures and fittings - but they are machines with the potential to injure if they are poorly maintained or go wrong. That’s why it is vital that we know what responsibilities are placed on us by law and are methodical in undertaking them.”

As the UK’s ONLY dedicated water leisure exhibition, SPATEX 2022 at the Coventry Building Society Arena (Tuesday 1 to Thursday 3 February), is bursting with inspiration and information. Showcasing the very latest products, trends and innovations from around the world and hosting a free seminar programme, it’s the beginning of your exciting journey into water leisure.

Free to attend, SPATEX 2022 provides architects, specifiers, builders, developers with ALL you need to know about water features, spas, hot tubs, saunas, steam rooms, swimming pools, enclosures, tiling as well as the more functional elements like chemicals and heating and ventilation.

One hundred plus companies, including all the world’s major suppliers and manufacturers, cover every conceivable aspect of water leisure, for both the domestic and commercial sectors.

Saving energy is high on the exhibition’s agenda and you can expect to see lots of new products supporting a low energy, low carbon footprint. Following the pandemic, many of the stands will feature two years’ worth of launches as well as those making their 2022 debut.

Not just an exhibition, SPATEX hosts a double programme of free seminars on all three days. The technical workshops hosted by ISPE

(Institute of Swimming Pool Engineers) offer vital information such as new standards and guidance that affect all disciplines involved in the development of water leisure projects and CPD points and a certificate of attendance are available for all attendees.

For example: Wednesday Feb 2 14.15 –14.45 Arena 1 Protect yourself – Protect your Business– an overview of the types of insurance pool builders and engineers should consider including liability and professional risks, personal accident and tools.

Wednesday Feb 2 12.30 – 13.00 Arena 2 Promising to be of particular interest to architects is the talk by Devin Consulting (experts in the design and engineering of water features) on discussing their role in the construction of the world-famous London Sky Pool, completed in June. Spanning 17m across the rooftops of two high rise apartment buildings 35m in the air, this amazing all-acrylic structure is part of the Embassy Gardens development in Nine Elms, London for Ballymore EcoWorld, opposite the new American Embassy building.

SpaFlo

Tap into a unique pool of free expert advice for your projects - SPATEX 2022 is fortunate to count the industry’s many esteemed associations amongst its supporting partners. There’s no better place to seek advice from an expert. Please come to the SPATEX Help Desk at the entrance to the exhibition hall, if you need pointing in the right direction.

Registration is FREE here and view SPATEX’s impressive list of exhibitors and details of the free double seminar and workshop programme.

SPATEX 2022 – Tuesday 1 to Thursday 3 February. The Coventry Building Society Arena, Coventry CV6 6GE is easy to get to - just 500 yards off the M6 and within two hours commuting time of 75%of the population, it offers 2,000 free on-site car parking spaces.

www.spatex.co.uk

SPATEX – Enquiry 21

External noise has been kicked into touch by a bespoke secondary glazing system, supplied by Granada Glazing, at the historic Stock Exchange Hotel in central Manchester owned by two prominent footballers.

Former Manchester United stars Ryan Giggs and Gary Neville have turned what was once the Manchester Stock Exchange into a 4-star luxury boutique hotel.

Due to the hotel’s city centre location on Norfolk Street close to the Royal Exchange Theatre, noise insulation from traffic and late-night revellers was a key requirement to create a quieter, more comfortable experience for guests. The original singleglazed timber box sash primary windows were retained due to the building’s listed status and a desire to retain the stone building’s character.

Granada Glazing’s aluminium secondary glazing was specified to attenuate external noise without impacting on the visual aesthetics of the guest accommodation.

Working directly with their client, Granada Glazing’s technical team designed,

Forbo Flooring Systems has refreshed its market-leading Coral entrance flooring collection which can stop up to 95% of dirt and moisture from entering a building and can reduce cleaning time by up to 65%. The update comprises two new products, a new adhesive free construction, as well as a colour refresh for the existing ranges. Coral Grip is a robust dirt and grit remover for inside and outside use, ideal for areas leading to and from leisure or sports environments, while Coral Interior is a unique concept that completes an entrance flooring system.

Flooring Systems – Enquiry 23

manufactured and installed Heritage Hinged casement units to blend discreetly with the existing primary windows.

Powder-coated in a white high gloss finish, the slimline aluminium frames support 6.8mm acoustic laminated glass that was crucial to meet the required noise reduction level.

Secondary glazing is the proven costeffective, efficient and discreet solution to cure issues with external noise, thermal efficiency and enhance security in buildings of all ages. When correctly installed, secondary glazing can make buildings up

to 80% quieter by reducing noise levels up to 54dB.

A total of 31 windows on the front streetfacing elevation were treated in this first phase, increasing both acoustic and thermal insulation.

22

Radisson RED London Heathrow and Radisson Hotel & Conference Centre London Heathrow, the largest hotel at the airport, have been equipped with the latest high-performance CIAT and Toshiba HVAC technology as part of a major refurbishment.

The solution was provided by Toshiba Carrier UK Ltd (TCUK). CIAT and TCUK are part of Carrier Global Corporation (NYSE: CARR), the leading global provider of healthy, safe, sustainable and intelligent building and cold chain solutions.

The recently rebranded four-star hotel is now served by a high-performance CIAT Floway® 5000 air handling unit (AHU), ensuring outstanding comfort for guests and low-running costs for the hotel.

The Floway AHU is equipped with a counter-flow plate exchanger that manages airtight air flows between fresh and extracted air. This recovers up to 80% of the energy that would otherwise be lost from the building via exhaust air, transferring it to incoming fresh air to temper it, boosting efficiency and further enhancing occupant comfort.

By minimising leakage from the system to negligible levels, CIAT Floway units achieve Eurovent’s top air-tightness rating, L1, and deliver a 60% improvement on leakage rates for lower-rated L2 rated systems, which covers the majority of air handling unit systems available.

CIAT – Enquiry 24

Forbo

Situated in the heart of Gloucestershire is the stunning Thornbury Castle, the last Tudor Castle to be built in England. Once owned by Henry VIII, it is now a high-end luxury hotel and popular venue for weddings and other grand events. This impressive renovation project saw multiple bedrooms and guest bathrooms refurbished and extended.

Due to its historic roots, there needed to be a balance between creating new facilities whist retaining the charm of the famous, Grade I listed building. Schlüter-Systems were able to help with this tricky task, offering a full system solution using Schlüter-KERDI products to ensure waterproofing within the guest bathrooms, which were designed and specified by Childs Sulzmann Architects.

For areas of high moisture, waterproofing is an essential consideration, and it takes on an even greater significance when it comes to preserving historic buildings such as Thornbury Castle. To meet this requirement, a selection of Schlüter products were utilised to create a fully tanked system. This included the BBA-certified Schlüter-KERDI-BOARD

tiling substrate and sealing components

Schlüter-KERDI-KEBA sealing band, KERDICOLL-L sealant adhesive and Schlüter-KERDI KERECK which was used for internal corners.

To provide entry level within the shower area, Schlüter-KERDI-SHOWER sloped shower tray and SchlüterSHOWERPROFILE-S tapered profile were installed beneath the tiles.

If you’re involved in the design and specification of bathrooms within heritage buildings, waterproofing will ensure the building is preserved for generations to come so please get in touch to find out how we can help.

Schlüter-Systems – Enquiry 25

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

The completion of a stunning new Hilton hotel at Silverstone is another step nearer and leads the way featuring the superior high-performance Wraptite® external airtightness barrier.

The impressive new hotel, located trackside, overlooks the starting grid for the home of the iconic British Grand Prix. Facilities include 197 guest rooms, a rooftop terrace and the offer of race-day hospitality experiences.

KKA Architecture designed the hotel, with Metclad Contracts appointed as the specialist envelope contractor for the project.

Wraptite airtightness membrane from the A. Proctor Group, specialists in supplying highperformance products to protect buildings, was selected by Metclad to maximise airtightness and energy efficiency, perfectly balanced with the crucial requirements of vapour permeability.

Wraptite self-adhesive breather membrane is applied externally, quickly and efficiently as part of the rainscreen system. Incorporating the Wraptite System helps

ensure “as-designed” performance. Its inclusion narrows the gap between asdesigned and actual energy performance whilst reducing the likelihood of possible failures to meet required airtightness levels.

Traditionally air barriers have been fitted internally. The internal installation of an air barrier necessitates accommodating building services such as electrical, lighting, heating and drainage systems, thereby increasing the gap between as designed and built. However, the Wraptite membrane fully bonds externally to virtually any substrate, requiring no additional mechanical attachment, seals or tapes to suppress air leakage around junctions or penetrations.

The high vapour permeability of Wraptite allows the substrate beneath to dry quickly and moisture vapour to escape and reduces the likelihood of mould, mildew, condensation, timber distortion and metal corrosion.

Wraptite is the only self-adhering vapour permeable air barrier certified by the BBA and combines the critical properties of vapour permeability and airtightness in one self-adhering membrane. Quite simply, providing a winning performance in advanced membrane technology for buildings.

A. Proctor Group – Enquiry 26

Visitors to the GPO food hall at Liverpool’s Metquarter are assured of a great atmosphere, thanks to the local air movement specialist with an international reputation, Gilberts.

Double deflection grilles from the Blackpoolbased ventilation manufacturer have been fixed into the distinctive oval ducting running the length of the main food hall

in the Metquarter. The grilles ensure a consistent flow of fresh air without draughts nor transfer of aromas from one zone to another from the 12 independent kitchens in the converted former General Post Office.

The strategy has been designed and installed by JD Engineering M&E contractor to the brief from development management company Queensberry and restauranteurs The Milestone Group.

To balance ventilation, extraction and odour control requirements within the space constraints, JD Engineering proposed flat oval ducting to run the length of the retail area, with Gilberts GHV double deflection grilles strategically positioned along the sides. Adjustable blade dampers, fixed horizontally to the front and vertically to the rear of the grilles circulate the conditioned air.

The design delivers 70% free ventilation area, deflecting incoming air vertically and horizontally to optimise rapid mixing and entrainment without draughts. Gilberts’ GECA removeable core eggcrate grille and GX extract valves also feature.

Gilberts Blackpool – Enquiry 27

TECHNAL’s curtain walling and Stormframe STII aluminium doors have been used to create an impressive, light-filled entrance to the state of the art Silverstone Interactive Museum building. The high performance, low profile glazing allowed the design concept to be realised while meeting the project specific technical requirements. Alongside the TECHNAL curtain walling and doors, the Silverstone Interactive Museum building features a combination of opaque polycarbonate rainscreen cladding and an iridescent aluminium cladding that has green and pink tones depending on the light. The system features a thermally broken construction and high levels of wind and weather resistance.

TECHNAL – Enquiry 28

Gilberts helps create the right ambience at the MetquarterSilverstone museum benefits from Technal

There are many aspects to address at the initial design stages when specifying flooring for healthcare environments, with hygiene, safety and functionality all leading factors. Here Howe Green's Business Development Manager, Chris George, discusses the types of floor access covers professionals should choose to ensure a successful specification.

For professionals researching floor access solutions for installation throughout healthcare buildings, ensuring the product achieves a safe, flat finish, whilst also providing permanent and convenient access to underfloor services with minimum disruption, is crucial to achieving long term suitability of the installation.

However, with hospitals and healthcare facilities being inundated with patients and visitors as a result of COVID-19, there has been a significant increase in the frequency of cleaning routines, in addition to dedicated sanitation measures.

This has highlighted the importance of floor access covers that also facilitate the highest standard of hygiene, by being easy to clean and maintain, whilst simultaneously being resistant to rust and corrosion, without impacting overall functionality and performance.

Due to the nature of healthcare applications, flexible floor finishes are typically specified, with vinyl, linoleum and rubber popular considerations. When choosing floor access covers to install in conjunction with these types of flooring, professionals should specify resilient access covers that deliver an impermeable and flat installation.

Aluminium floor access covers can provide a high standard of resistance to harsh cleaning chemicals, without compromising on the overall strength and longevity of the floor access cover.

Whilst ensuring floors are consistently sanitised is crucial, guaranteeing the flooring's safety and durability is also essential to eliminating the potential for visitors to trip whilst moving around the building. Slips and trips account for more than half of all major accidents to members of the public, due to incorrect or poorly maintained installations.

Professionals should here consider flexible floor access covers with crimped corners that enable the cover and frame to lie flat, whilst double seal designs also provide the strongest seal possible to prevent the ingress of water, achieving a sanitary and permanent joint.

Ensuring the correct load bearing of the access cover is also crucial to guarantee it withstands the heavy frequency of footfall, in addition to wheeled traffic, such as patient beds or sack trolleys.

Howe Green’s high-performance Visedge® Series provides permanent and convenient access to underfloor services. Featuring an aluminium construction that includes a weldable PVC securing edge, the frame section can be bonded and welded to the cut edge of the sheet flooring to form an impermeable, flat and hygienic joint.

Providing permanent, easy access to underfloor services using lifting keys, the access covers are manufactured in the UK to meet the most demanding site requirements in the shortest lead times possible.

Installed in a number of healthcare facilities across the country, Howe Green’s Visedge® Series features in the Queen's Hospital in Romford, Southmead Hospital in Bristol, and Chase Farm Hospital in Enfield, to provide easy access to under-floor services whilst achieving a safe, hygienic and flush finish.

Ashwood House is a development of Manhattan-style apartments in the desirable Surrey commuter town, Camberley. Situated in a converted 1960s office block, developer Berkeley Homes Southern Ltd needed to ensure the 116 luxury flats were as energy efficient as possible.

This was a particular concern for the properties situated above the first floor car park, which has open walls to allow adequate ventilation of exhaust fumes. As a result, the specification stipulated a U-value of 0.25 W/m²K.

How the insulation looked was an important part of the brief as Berkeley Homes wanted a solution that would be aesthetically pleasing. Knauf Insulation’s Rocksilk® Soffit Linerboard Standard features a black glass veil facing, so no additional finishing was required. This meant that RPN Ltd has been able to install the slabs perpendicular to the ring beam to create a quilted effect across the ceiling.

The other specification factors were thermal performance and fire safety. Knauf Insulation’s Technical Support Team undertook U-value calculations to determine that 130mm Rocksilk® Soffit Linerboard Standard would be required. It

is manufactured from Rock Mineral Wool, has a thermal conductivity of just 0.034 W/ mK and is designed to insulate structural soffits in applications such as open sided car parks.

It is non-combustible with the best possible Euroclass A1 reaction to fire

classification, so will not contribute to the development or spread of a fire should it occur. Rocksilk ® Soffit Linerboard Standard also has excellent sound absorption characteristics so will help to ensure that residents are not disturbed by the noise of cars parking beneath their flats.

Sherwin-Williams has announced an expanded product portfolio for High Performance Flooring, consisting of a new naming system for its epoxy range and a range of colour palettes for its highly regarded family of resin flooring products serving industrial and commercial markets.

In addition, Sherwin-Williams is launching a new website dedicated to High Performance Flooring, enabling customers to more easily find – and be inspired by – the flooring systems, products and design features appropriate to their projects and applications.

The website is designed not only for applicators, contractors and owners, but also for architects and designers. Therefore, it is equipped with tools for design and specification, as well as product applications. The extended range of system guides means that a wide range of solutions are available to suit different budgets and requirements through all industrial sectors.

The new portfolio naming system, colour palettes and website are part of a global launch showcasing the company’s dedicated expertise in high performance flooring. This flooring category encompasses a wide spectrum of

seamless resin industrial and commercial floors that are not only highly durable, but also aesthetically appealing, and suitable for stadiums, arenas, schools, universities, healthcare facilities and manufacturing.

The new product portfolio naming system brings together product families from several previous product lines. The portfolio is organised by chemistry (e.g., epoxy, polyurethane comfort floor, polyurethane cement, polyaspartic etc.) and further subdivided by function (e.g., heavy-duty flooring for food facilities, clean rooms, aviation hangars).

When Gloucestershire NHS Commissioning Group decided to replace an existing healthcare facility in the centre of Gloucester, over 3000m2 of flooring from international flooring specialist Gerflor was specified to complete the project to the highest standards. The project would demand high quality flooring that could meet and exceed the rigorous demands of this new healthcare facility head on.

The main contractor Kier Construction would, through Newcastle-based ADP Architecture, specify a mixture of Gerflors’ Taralay and Tarasafe flooring solutions to produce the final high-quality flooring finish that the new build healthcare project would require.

The new health centre, in Quay Street in Gloucester, has replaced the previous Quayside House, which was built in the 1960s and had a planned 30-year lifespan. The new building includes two three-storey GP surgeries capable of serving more than 17,500 patients, a pharmacy, office space and ground floor parking.

Gerflor have an enviable history in designing and manufacturing high quality flooring for the healthcare market. It’s a reputation built on expertise, knowledge, and innovation. With over 60 years’ credible healthcare experience, Gerflor is a respected manufacturer of innovative, high performance, design-led, and sustainable solutions for flooring, and interior finishes. As hygiene and infection control go hand in hand, with Gerflor’s trusted surface treatments decision makers can be assured that their healthcare products can stand up to any rigorous maintenance regime, together with delivering a durable, hardwearing solution that also looks stunning.

Kier, a leading provider of construction and infrastructure services was appointed by Gloucestershire County Council to deliver phase one of its Quayside regeneration masterplan. Andy Bolas, Gloucester Office Operations Director at Kier Regional Building Central, commented: “We are delighted to have been appointed to deliver Quayside House. This achievement builds on our existing relationship working

on the Gloucestershire County Council Framework.”

David Chatfield, Senior Quantity Surveyor, Kier Construction Regional Building Western and Wales commented, “Quayside House was secured by Kier for one of our key local customers, where the new building utilised existing foundations.”

Gerflor recognised that cleaning and hygiene is even more important than ever, so it was vital to work with ADP Newcastle to specify the right flooring solutions for the healthcare environment at Quayside House. This collaboration would see 1500m2 of Gerflor’s Taralay Premium and Taralay Impression Compact installed within the internal walkways and communal spaces at Quayside House. The project required a ‘no-nonsense’ approach to deliver safe yet durable flooring for the walkways, clinical areas, and treatment rooms, so Gerflor’s Taralay Impression Control safety flooring was also specified, alongside Tarasafe Ultra safety flooring for the storerooms and toilet locations.

The actual installation of the Gerflor flooring would need to be of the highest standards as set by Kier Construction. The delivery of the outcome would be the responsibility of Bristol-based Gollop Contract Flooring.

Director, Letisha Gollop, of Gollop Contract Flooring Limited said, “We Initially tendered for the project and then agreed a final price

which enabled us to secure the contract. The Gerflor products we used were specified by the architects.” On installation, their Contracts Manager for the project Paul Watts added, “Considering we had to work to an extremely tight schedule around other trades the Gerflor products were all extremely easy to lay with absolutely no problems. We understand that the flooring is performing really well and surpassing the clients’ expectations on all fronts.”

David Chatfield finally commented, “Although specified to us by ADP Architecture we would definitely choose to deliver Gerflor flooring again on other contract and in particular healthcare projects.”

Letisha Gollop concluded, “We have specified Gerflor innovations many times before and would definitely choose Gerflor again, particularly now that many of their best sellers are stocked and are readily available in the UK for a fast turn around.”

Andy Gordon, Healthcare Specification Manager - North commented “This was a greatly prestigious project to be involved in, alongside our architectural and installer partners. The client is absolutely delighted with the final outcome, both in terms of the fast turnaround of the project and the technical performance of the products installed”. Gerflor

As a company member of FIRAS Warringtonfire, Harrison Thompson’s range of products and services can help with the up keep and repair of fire doors using best practice guidance.

Yeoman Shield Fire Door Services offer fire door installation, repair, maintenance and the fitting of Yeoman Shield fire rated protection products - all carried out by accredited fixing operatives.

Interface, a worldwide commercial flooring company and global leader in sustainability, has unveiled a refresh of its popular Heuga 727 product. This mainstay collection has been one of the company’s most popular ranges since its launch in 2010.

The refreshed collection features 48 colours ranging from soft greys and warm neutrals, to lush blues and greens, and vivid reds and oranges. The rich variety of tones ensures interior designers and fit-out companies can find flooring to suit their space, either as a single block colour or by combining multiple options.

Heuga 727 is also compatible with other Interface carpet tiles, LVT and nora® rubber flooring, enabling maximum creativity in flooring design. The tiles use CQuest™Bio backing – a non-vinyl, non-bitumen backing made with a bio-composite, containing bio-based and recycled fillers which are net carbon negative.

Mandy Leeming, design director EAAA at Interface, said: “Heuga 727 has been enduringly popular for 11 years thanks to its high quality, excellent durability and valuefor-money price point, so we’ve refreshed the colours available to reflect changing and emerging trends. The new palette features 48 colours ranging from soft greys and neutrals to intense primary tones. There really is something to suit every mood board and

design theme. As with all Interface carpet tiles, Heuga 727 is carbon neutral across its full product lifecycle and verified through our Carbon Neutral Floors programme™ – part of our ongoing commitment to reduce our carbon impact, restore the planet and reverse global warming.”

Over the past 11 years, Heuga 727 has been a firm favourite of fit-out companies

and interior designers, appearing in offices, education facilities and other workspaces across the country.

Interface is a global flooring company specializing in carbon neutral carpet tile and resilient flooring, including luxury vinyl tile (LVT) and nora® rubber flooring.

Interface – Enquiry 31

The new branch was opened as part of the leading designer clothing brand’s exciting expansion strategy, and portraying Flannels’ reputation for luxury through the interior design was a vital element of the brief.

The vision was brought to life with the use of CTD Architectural Tiles’ Lisbon range, with the tiles laid in a basket weave pattern to create an eye-catching feature floor. The Lisbon range can be used for both floors and walls, and is the ideal choice for the store – which is expected to have high footfall – due to its highly non-slip porcelain surfaces.

Using geometric symmetry in the tile layout created a classic look, while the choice of colours contrasted the store’s dark aesthetic. The end result is an aesthetically-

pleasing store interior that is as practical as it is stylish.

To discuss how CTD Architectural Tiles can assist with your tile inspiration and specification for your next project, contact

Glass moveable walls are today’s ‘en vogue’ method of creating light, airy, flexible space with specifications from architects and interior designers at an all-time high.

According to Mark Cowley, who heads up the glass division of leading moveable wall specialist, Style, the demand for glazed partitioning systems has rocketed and seems set to continue.

“Glass moveable, folding and partitioning walls offer such a wide range of applications that we’re seeing their popularity significantly intensify in the new build and refurb sectors,” said Mark.

Style has further strengthened its partnership with the dormakaba Group earlier in 2021 by securing the exclusive UK distribution of its interior glass Horizontal Sliding Walls (HSW) range.

The partnership means that Style now has sole UK distributor rights of the full suite of glass moveable wall

solutions from dormakaba/Hüppe at a time when the market is seeing unprecedented growth.

“The timing for extending that longstanding partnership with the dormakaba Group for its interior glass Horizontal Sliding Walls (HSW) range was perfect,” continued Mark. “We can now fulfil our customers’ requirements in totality with a complete end-to-end process for acoustic and nonacoustic glass systems, with manual, semi-automatic and fully automatic operation.”

Style – Enquiry 33

info@ctdarchitecturaltiles.co.uk or call 0800 021 4835. For more information and to view our full tile collections, please visit www.ctdarchitecturaltiles.co.uk

CTD Architectural Tiles – Enquiry 32

With the opening of a larger central facility, cork specialist Granorte is providing improved support for its UK network of retail and commercial customers. Providing some 10,000ft2 of warehouse space, as well as a new sample centre, showroom and offices, Granorte’s new Telford headquarters provide retail and commercial clients with improved service and support. Giving improved stock levels across the company’s range of cork walls, floors, furniture and design objects, the facility is centrally located for efficient distribution across the UK. A showroom displaying Granorte wall, floors, award-winning furniture and display objects will also be available.

Granorte – Enquiry 34

Leading commercial tile supplier CTD Architectural Tiles worked with Argent Design and EB Design to complete the latest store for luxury clothing chain, Flannels, in St Helens.The construction sector is currently facing one of its biggest transitions to date. As specifying and installing building products that go above and beyond minimum levels of compliance is paramount to ensuring the long-term safety of a building, here Marcus Parnham, Commercial Director at Profab Access, discusses the importance of adequate product testing and certification.

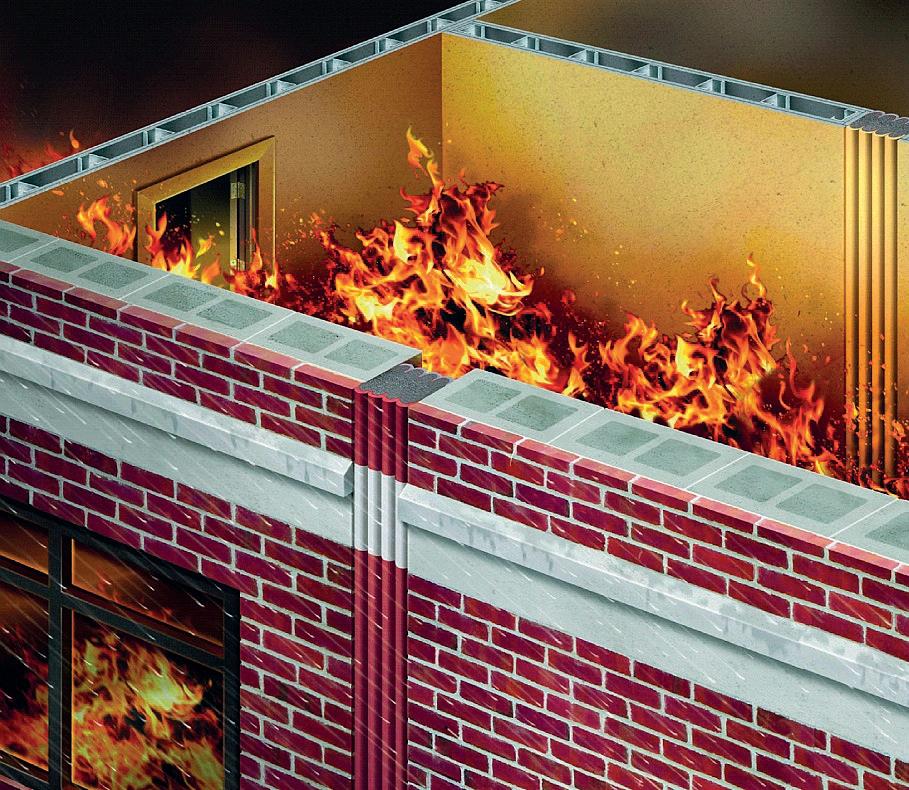

The Grenfell Inquiry, the release of the Building Safety Bill and the formation of the National Construction Products Regulator are driving a step change throughout the construction sector regarding approaches to product testing and certification.

No longer will just meeting current standards and regulations be acceptable. In this new era of accountability, it is imperative that the industry sets the standard for achieving a proactive and comprehensive approach to building safety.

First raised in Dame Hackitt’s Independent Review of Building Regulations and Fire Safety, the fire-resistance of a product should be tested in ‘real-world conditions’ to ensure that all performance figures stated by the manufacturer are factual and represent the final installation.

Whilst some manufacturers may currently only conduct product assessments via a third party, others have responded to Dame Hackitt’s findings and have adopted a proactive approach to the testing, certification and verification of their products.

Profab Access has led the way in increasing standards within this area, being the first manufacturer in the UK to bi-directionally fire test its riser doors via an independent third party. As the riser door is physically tested in both directions, it offers the highest levels of fire safety, as professionals can be confident the riser door will withstand exposure to fire and smoke from both directions for the certified time period.

Following Dame Hackitt’s guidance, it is also critical that the riser door is installed into an approved wall construction in a method consistent with the sample originally tested. In practice, the installation process poses a number of potential risks to the overall fire integrity of a construction, through variables such as packer type and intumescent mastic bead application.

To overcome this possible gap in compliance, professionals should look to work with manufacturers that are taking this commitment to third party testing and certification even further, through latest advancements in technology and product design.

This includes the new PRECISION adjustable frame, which is supplied as standard with Profab Access’ INTEGRA 4000 Series Fire Rated Riser Door. The product’s unique construction enables the frame to precisely adjust to the specific dimensions of each structural opening, without the need for packers, dramatically reducing fitting times and superseding current building regulations.

The frame also eliminates the need for intumescent mastic bead application as a secondary operation on site, as it utilises a factory applied integral all-in-one smoke, intumescent and acoustic FS1000 seal, to provide fire stopping between the frame and the wall. This eliminates the reliance