In its latest quarterly forecast, The Construction Products Association (CPA) forecasts that output in the industry will grow by a robust 4.3% in 2022, slowing to 2.5% in 2023 compared to the 13.3% seen in 2021.

This demonstrates the remarkable resilience of the sector to the initial Covid-19 lockdown and the end of the Brexit transition period in 2020.

Housebuilding, the largest sector within the UK construction industry, is expected to remain buoyant while infrastructure will be the major driver for growth. Projects already underway in all sectors give great confidence for the forecast figures.

Product supply issues, a major challenge in 2021, have eased recently, but may still cause problems, particularly in the peak spring period and particularly for smaller building companies.

While supply issues have eased off over the past six months, the CPA still considers these to be the biggest challenge to overall growth. Questions over sufficient materials, products, labour, HGV drivers and imports will be at the forefront of industry minds. These challenges are not spread equally across the sector, with smaller specialist sub-contractors feeling the pressure more.

Noble Francis, CPA Economics Director, offered this insight into the supply chain issues: “Major house builders and main contractors are less affected as they have better visibility of medium-term demand and can plan and purchase well in advance; plus, they are the larger customers of the manufacturers, builders’ merchants and importers.

“Smaller firms, however, have found that availability issues have delayed projects and, consequently, revenue streams whilst sharp cost increases have hit margin, harming their viability even though they have strong workloads. Overall, the latest indications are that supply issues have eased recently, which is a positive sign, although it is still early in the year and before industry activity tends to ramp up in the Spring.”

Paul Groves || Group Editor

The Construction Leadership Council has set out four priorities to deliver a better UK construction sector in 2022.

The Council has picked issues where there is the greatest need for collaborative industry action, and the greatest opportunity to deliver positive change. The four priorities for 2022 are:

• Net Zero Carbon

• Building Safety

• Meeting the Skills Challenge

• Implementing the Construction Playbook

The announcement of the four priority areas comes as the CLC publishes its Annual Review for 2021.

Having established itself as the leading force for the industry in 2020 with its response to Covid-19, in 2021 the CLC built on this success. It led UK construction’s work ahead of the COP26 climate change summit with CO2nstructZero, while also responding promptly to the emerging threat of materials shortages to improve product availability nationwide. It launched a single hub for all new entrant jobs –TalentView Construction – while setting out the first ever Skills Plan for the whole UK construction industry.

Among its objectives this year it is targeting apprenticeships, aiming to return numbers to pre-Covid levels to meet future skills needs. It will publish quarterly data to show the sector’s journey to zero carbon. On Building Safety, it will work with partners

to roll out frameworks to ensure that those working on buildings have the competence to build and maintain them safely. And it will continue its work to promote the Government’s Construction Playbook, boosting awareness and implementation among clients and suppliers.

CLC co-chair Andy Mitchell CBE said: “Having lit the spark in 2020, and watched it grow last year, the CLC can deliver transformational change for UK construction in 2022. We know that some of the threats facing our sector are daunting, but we are now working together as a sector, talking on challenges with a united approach. I hope that when we come to write our Annual Review for 2022 the whole sector will be able to judge us by our successes in delivering real change.”

CLC co-chair and Construction Minister Lee Rowley MP said: During 2021, the industry demonstrated its ability to adapt to manage the ongoing challenge of COVID-19, and also its willingness to improve, and to start to tackle the need to transform the sector so it can consistently deliver betterperforming, safer and more sustainable buildings and infrastructure.

“However, we can’t rest on our laurels. We will continue to face challenges during 2022.

“Only by working together collectively, will we continue to meet these challenges, and truly build back better, faster and greener for future generations.”

Plans have been submitted to regenerate a brownfield site in the centre of Hemel Hempstead with 56 new homes and a purpose-built headquarters for homeless charity, DENS.

On behalf of Dacorum Borough Council, multi-disciplinary design practice, rg+p has designed and submitted plans for a complete redevelopment of the Paradise Depot site, which is located off St Albans Road, east of the town centre.

Currently occupied by the DENS office and foodbank as well as other commercial/ industrial premises, the intention is for the site to become an asset for the town.

“Paradise Depot occupies a central location within Hemel Hempstead; there are plenty of amenities nearby, it’s easily accessible by public transport and is bordered by a public park so is entirely suited for a modern, mixed-use development,” explains Grant Giblett, the project’s lead and rg+p’s director.

“Our design has sought to create a real sense of place, not just somewhere to live and work, but an attractive, sustainable environment that will wholly benefit the community.”

New data shows that the house building sector is getting smarter as it continues its journey toward more, better quality, and increasingly sustainable homes.

This dashboard – now in its third yearshows how the house building sector is making progress against key targets.

In 2020, despite the challenges of Covid 19, house builders have cut the time taken on site to build a house by nearly a quarter, while waste has been reduced by 15 per cent.

The dashboard draws on data developed by RICS, BRE, Cast, NHBC, CITB, LC Journey and Mott MacDonald and Ekkist. It is intended to demonstrate the performance of the housing sector, and encourage developers, local authorities and housing associations to develop the evidence to demonstrate the power of smart construction.

A key aim was that suppliers and customers could then use the information to make data driven decisions to improve productivity, sustainability and health and safety in manufacturing and construction.

Three new measures have been introduced:

• Digital maturity of the housing sector

• Apprenticeship levels

• Circular Economy

Simon Cross, Chair of the CLC Metrics, Demonstrations and Business Case Working Group said: “Our dashboard shows the significant outcome-based improvements by the housing sector in this health affected year, but there is still a long way to go, including a necessity to focus on digital maturity, designing for people’s health and increasing pre-manufactured value

”I feel sure that combining a digital and MMC approach, whilst considering whole life performance will drive the UK housing sector to world class status.”

Set amongst the picturesque coastline of Torquay, South Devon, the Royal Terrace Gardens are a popular tourist attraction frequented by locals and visitors alike.

Multi-award-winning lighting design practice Michael Grubb Studio was commissioned by Torbay Council to develop ‘Lightplay’ - a new, permanent, lit interactive route along the seafront.

The overall concept devised by Michael Grubb Studio is to encourage visitors to enjoy the gardens and take inspiration by extending the notion of sunset so as to bring a sense of health, happiness and enjoyment that comes with the warmth of evening light.

The Chartered Institution of Building Services Engineers (CIBSE) has published revisions to its Technical Memorandum 54: Evaluating operational energy performance of buildings at the design stage. The revisions bring the guidance up to date by taking account of regulatory changes and advances in best practice.

CIBSE TM54 provides building designers and owners with guidance on how to evaluate operational energy use once a building’s design has been developed. It covers all energy uses, both regulated and unregulated.

The 2022 revision is cited as a method which can be used to meet the new requirement for large new non-domestic buildings to produce an energy forecast as stipulated in the latest revision to Approved Document L, effective from 15 June 2022.

The main evaluation principles remain the same as in the original document, with a step-by-step approach and scenario testing to improve the robustness of the design proposal calculations and advice to clients.

The revision takes account of advances in modelling expertise across the industry

and the increased emphasis on highperformance buildings. It encompasses steady-state modelling as well as dynamic simulation and provides guidance on how to select the most appropriate modelling approach, and level of detail, for each project. The document makes clear that the methodology could be applied to any building, whether domestic or nondomestic.

There have been a few key changes in the lift industry over the past twelve months. While supply chain issues have impacted the industry as elsewhere, we look forward to issues that specifiers should know about and implications in the Buildings Safety Bill. Nick Mellor, MD of LEIA and LIFTEX explains.

Due to come into force this year, the Building Safety Bill is expected to deliver the biggest improvements to building safety in nearly 40 years. While the initial focus will be understandably on higher risk residential buildings, the Building Safety Act will introduce (either directly or through secondary legislation) a new building safety regulator. It will also introduce new management roles to manage safety in high rise buildings and new competence requirements on the principal designer and principal contractor.

The use of lifts in the event of fire and for the evacuation of disabled people is being widely considered as an important element of building safety. The London Plan requires at least one evacuation lift per core (or more, subject to capacity assessments) to be provided for the safe and dignified emergency evacuation of people who require level access from the building.

Until other standards are published, BS 9999 includes the only description of an evacuation lift in British Standards and the design and construction of the building elements which protect and power it.

While this, and forthcoming standards, might improve the evacuation lift provision in new buildings, improving the building safety of existing buildings is likely to pose further challenges.

This is a word we are likely to hear more of as we move towards being more sustainable. In fact, speaking on behalf of Actuate UK at the Construction Leadership Council’s COP26 session, Michelle AghaHossein MCIBSE raised this issue. She highlighted that the ‘fabric first’ approach is needed as 80% of buildings in existence today will still be in use by 2050.

This means that whether we are looking at moving to net zero or improving building safety, the improvement of existing lifts will be a major part of meeting these challenges.

Digital switch – from analogue telephone lines to fibre

Analogue telephone lines (with copper conductors) are being replaced by fibre connections to provide broadband connections to commercial and domestic users. BT Openreach has an objective for all buildings to be on fibre connections by the end of 2025 when support of existing analogue lines will cease.

This has very significant implications for the specification of lift alarms communication system since many of these use analogue telephone lines and might not work directly on a new fibre line even with a suitable “analogue telephone adaptor” (ATA). Fibre lines will typically not be battery-backed.

At present, a solution is typically a GSM solution incorporating a batterybackup. Since 2G and 3G are also due to be withdrawn in the coming years, we recommend a 4G solution.

Project: Silverstone Interactive Museum Architect: cube_design ltd Suppliers: TECHNAL; SFS; Central Fabrications; Mather & Co; QG Architectural Aluminium Specialists

Award-winning architecture practice cube_design ltd is behind the Silverstone Interactive Museum is a £22m motorsport exhibition located at the world famous Silverstone Circuit in Northamptonshire.

The 6000m2 £22 million Silverstone Interactive Museum building was built with a contribution from the National Lottery Heritage Fund. It consists a fully refurbished WWII aircraft hangar and a new two storey extension, which serves as the entrance to the exhibition.

The hangar, which is an important part of Silverstone’s heritage as a former Royal Air Force base, is the only one remaining on the site and one of only two such examples in the UK.

“The aim with the design of the Silverstone Interactive Museum was to create an iconic building that would provide an impressive statement at the entrance to the circuit,” explained Jane Lock-Smith, Managing Director at Cube Design.

“To enhance the visitor experience, the exhibition area within the hangar was designed as a ‘black box’ to remove external influences. We wanted the extension area entrance to be a contrast to this with natural light and views out across the famous track. >>

The Silverstone Experience includes:

• A permanent 4000m² exhibition that takes visitors on an exciting two hour journey through motor racing past, present and future.

• A Collections and Research Centre, offering museum and archive accredited storage for

the unique British Racing Drivers’ Club (BRDC) archive and other motor sport collections as well as a specialist library and learning space for school groups.

• A series of themed tours stopping off at iconic parts of the circuit.

>> “The TECHNAL curtain walling was a key part of the design. We had worked with TECHNAL on a number of projects before and so we were confident its products could deliver what we needed.

“The large expanses of glass at the front and rear of the building provided an excellent contrast to the finish and materials of the rainscreen cladding that dominates the exterior of the building.”

The Silverstone Experience takes visitors

TECHNAL’s curtain walling and Stormframe STII aluminium doors have been used to create an impressive, lightfilled entrance to the state of the art Silverstone Interactive Museum building.

The high performance, low profile glazing allowed the design concept to be realised while meeting the project specific technical requirements.

Alongside the TECHNAL curtain walling and doors, the Silverstone Interactive Museum building features a combination of opaque polycarbonate rainscreen cladding and an iridescent aluminium cladding that has green and pink tones depending on the light.

The exposed location of the Silverstone Interactive Museum meant that airtightness and thermal efficiency were also design considerations. The TECHNAL aluminium curtain walling system features a thermally broken construction and high levels of wind and weather resistance.

on an exciting two-hour journey through motor racing past, present and future.

The hangar has been fully refurbished and features a colour shifting cladding system, creating an iridescence that forms the most dynamic backdrop; the original structure is sympathetically exposed internally, giving the visitor a visual clue to it’s historic use as a hangar.

The latest technology has been utilised to tell the amazing stories of the people that have been part of the site’s history, from

medieval monks and World War II air crew, to the racing drivers, riders, engineers and marshals of today.

The new extension offers first class views over the track and houses a Collections and Research Centre, offering museum and archive accredited storage for the unique British Racing Drivers’ Club (BRDC). It incorporates other motor sport collections, as well as a specialist library and learning space for school groups.

It’s a triple crown for Steve Marshall who has not only taken over as Managing Director of Strand Hardware, but also its two sister companies – Strand Technologies and AliMet Fabrications.

The industry stalwart has taken the helm of the three Midlands companies following a 24-year career at GEZE UK where, for the past two years he served as Operations Director, following roles in the service and commercial teams.

However, his new challenge has taken him full circle – he began his career as an estimator for an aluminium door and window fabrication company (James Gibbons) before moving into the world of automatics (Newman Tonks followed by Horton Automatics).

Steve’s appointment is a significant step change for Strand Hardware and demonstrates a resounding belief in his abilities. It will be the first time that the company has seen day-to-day operations managed by someone outside the family-run firm. Strand was founded by Jonathan Franks in 1991 and his daughter, Catherine, took on the role of Managing Director in 2005. She will continue to help steer the ship in her new role as Chair of Strand Hardware.

Steve said it was an exciting challenge and continued: “They are three fairly different companies which at the same time complement each other. My work at GEZE UK has given me a background in door hardware, albeit that Strand Hardware has a different range of specialist products, but I know a lot of people in the industry that are customers of Strand already.

“All three are really, really exciting, and I’m looking forward to working with the teams, helping them develop and achieve further growth.”

Cubicle and washroom systems from Telford based casing and enclosure specialist, Pendock, provide a comprehensive range of solutions for most single or multi-cubicle installations, as well as IP panels systems.

Already used in a range of sectors, including education, retail, health, leisure and public buildings, five systems are available under the Pendock Washroom brand, which include the Classic; Classic Plus; Robust; Ultimate and Education – as well as modular IP panels and bespoke solutions.

The Classic range is manufactured from 18mm thick MFC (melamine faced

chipboard) and is designed for use where economy and simplicity are key factors, while the Classic Plus uses the same core, but is faced with high pressure laminate. Both models are edged with 2mm PVC.

Designed for high traffic and wet areas, including high humidity zones, Robust cubicles are produced from 12mm compact laminate (CL), which provides excellent value, durability and design flexibility to meet the demands of most washroom projects.

Pendock’s Ultimate cubicles are also manufactured from 12mm CL with a radiused edge. The range provides an exceptionally wide choice of options and can be specified with any finish or colour combination

to meet exact interior design or project requirements.

The dedicated Education range covers washrooms from nursery through to further education and are available in 18mm MFC or HPL, as well as 12mm CL in a range of colours and finishes including special options for early years and schools through all key stages.

For complete design versatility, every aspect the IP panel system and bespoke washroom range can be specified, including the core material, finish colours, graphics, panels and door sizes, as well as pilasters and ironmongery.

Vanity units, back panels and accessories are also available across the range, alongside DDA and Approved Document M compliant options, allowing specifiers to maintain design consistency and integrity, whilst providing high levels of versatility and cost-effectiveness.

Pendock – Enquiry 12

Two fault-tolerant networks of MxPro 5 fire panels from UK manufacturer, Advanced, have been installed as part of a fire system upgrade at the Manor House & the Ashbury Hotels in Devon.

Set in 500 acres on the edge of Dartmoor National Park, the two hotels offer a combined total of 421 rooms as well as the Ashbury Hotel’s renowned 99hole golf course.

As part of a site-wide upgrade to the Manor House and Ashbury Hotels’ fire systems, 11 of Advanced’s flagship MxPro 5 fire panels in 1, 2, 4 and 8-loop variants have been installed to provide industry-leading protection for the resort’s staff and its thousands of annual guests.

Phil Calvey, Regional Sales Manager for the South West, said: “This project is a classic example of our fire protection solutions making life easier for installers and end users alike. We are thrilled to hear Castle Technical Solutions speak so positively of their retrofit experience.

“Our MxPro 5’s high-speed networking capabilities come into their own when protecting large-scale sites such as this resort, where there is a need for

complex cause and effect programming, without compromising overall system performance.”

MxPro 5 is the fire industry’s leading multiprotocol fire panel and was recently certified by FM Approvals to the EN 54 standard. It offers customers a choice of four detector protocols and a completely open installer network, backed up by free training and support.

MxPro 5 can be used in single-loop, singlepanel format, or easily configured into highspeed networks of up to 200 panels covering huge areas.

www.advancedco.com

Advanced –Enquiry 13

More than any other sector, the UK government has backed the construction industry as the leading force in driving economic growth and achieving financial stability, following the significant disruptions caused by COVID-19. Here Marcus Parnham, Commercial Director at Profab Access, explores how the building products industry is evolving to successfully support professionals in achieving an increased and more efficient rate of construction, whilst simultaneously meeting greater requirements for testing and certification.

The building industry often leads the way out of economic crises, with 2021 being no different. Last year’s Queen’s Speech set out the government’s regulatory agenda and included new legislation on infrastructure and housing, which were specifically designed to place construction firmly in the vanguard of the nation’s economic recovery.

However, government investment alone will not enable the construction industry to thrive. The repercussions of the last year have created greater focus on the role of innovation and product development, as professionals increasingly require new and enhanced building components that streamline the specification, installation and maintenance stages, without compromising on quality, compliance or aesthetics.

This has led to the design and manufacture of a new generation of building products that reimagine traditional building practices to create new ways of working that increase on site efficiencies and reduce associated cost and resource implications, whilst also providing the highest possible standards in certification and safety.

In order to successfully achieve this, manufacturers have had to re-assess established installation methods to identify how building components can be reimagined to support professionals in working smarter and quicker when on site. However, these products must also enhance the proficiency of the specification stages by being supported by essential certification and accreditation documentation to evidence compliance with relevant regulations.

As part of this, it is critical that the products are installed into an approved construction in a method consistent with the sample originally tested. For example, with regard to doorsets, the installation process potentially poses a number of risks to the overall fire integrity of a wall construction through variables such as the packer type and intumescent mastic bead application.

To overcome this potential gap in compliance, professionals should look to

work with manufacturers that are taking this commitment to third party testing and certification even further through latest advancements in technology and product design, which are providing a revolutionary approach to the installation and maintenance processes.

For example, Profab Access has identified an opportunity to reduce the level of components required to not only shorten fitting times, but provide the highest possible standards of fire integrity to futureproof a development against potential legislative changes. Its INTEGRA 4000 Series Riser Doors are now supplied with an expertly engineered PRECISION adjustable frame, which completely transforms the installation process for construction professionals and streamlines the specification process for architects and specifiers.

The unique construction of the patented PRECISION adjustable frame, which enables the frame to be fully adjusted to meet the specific dimensions of each structural opening, also includes an integral intumescent strip to provide fire stopping between the wall and frame. This not only eliminates the requirement of packers and the reliance of the correct thickness of intumescent mastic bead, but most importantly ensures the compliance and adequacy of the entire installation, as its fire integrity performance has been sufficiently documented by an independent assessor.

As a result, this also subsequently increases the efficiencies of installation and removes any potential margins for error, whilst also providing a complete trail of due diligence with both current and future requirements as the frame has undergone rigorous CERTIFIRE third party testing and certification provided by Warrington Fire as part of the entire doorset.

Throughout 2022, the entire sector, from building products manufacturers, right through to specifiers and contractors, must continuously challenge themselves to review existing building practices to support successful innovation and collaboration, in order to drive the industry forward and set the economy on a stable footing in the years ahead.

For further information on Profab Access and its range of riser doors, access panels, and steel doors, call +44(0)1827 719051 or visit www.profabaccess.com.

Profab Access – Enquiry 14

The superior airtightness performance qualities of the Wraptite® air barrier system from the A. Proctor Group will enhance a new state-of-the-art development at St Dunstan’s College - a coeducational independent school in Catford, London.

Contractor Willmott Dixon will deliver the new Junior School, STEM building and Sixth Form Hub at St Dunstan’s.

Designed by Bond Bryan Architects, the new development will be sited adjacent to the existing historic Headmaster’s House and connected by a glass atrium. Phase one includes a new junior school with specialist facilities for art, music and performance, and phase two includes the construction of the STEM Centre and Sixth Form Hub.

A vital element of the design and construction is to maximise the energy efficiency of the new buildings: Wraptite airtightness membrane, the only self-adhering vapour permeable air barrier certified by the BBA, will form a crucial part of the solution.

The inclusion of Wraptite within the facade will ensure “asdesigned” performance, narrowing the gap between as-designed and actual energy performance and reducing the likelihood of potential failures to meet required airtightness levels.

Wraptite is a self-adhesive breather membrane applied externally, quickly and efficiently as part of the rainscreen system. The selfadhesive Wraptite membrane fully bonds directly to the substrate, requiring no mechanical attachment and little seals or tapes to suppress air leakage around junctions or penetrations.

Wraptite combines the critical properties of vapour permeability and airtightness in one self-adhering membrane, providing high levels of protection to the building fabric beneath the cladding. As a result, the Wraptite system allows the substrate beneath to dry quickly and moisture vapour to escape and reduces the likelihood of mould, mildew, condensation, timber distortion and metal corrosion.

Wraptite is compliant with Part B regulation changes and also has BBA approval for unrestricted use in buildings over 18m in England and 11m in Scotland.

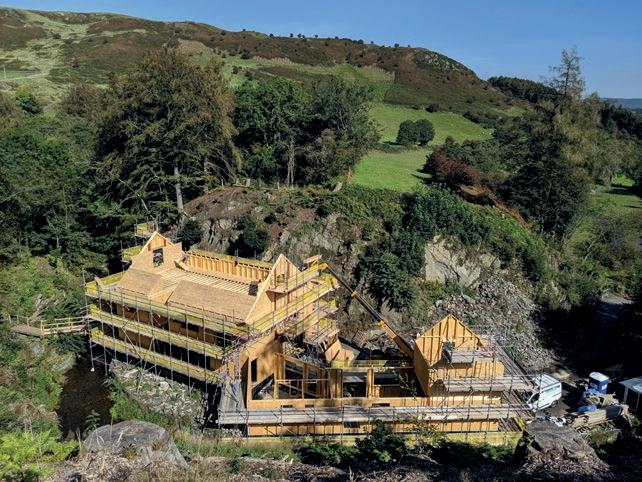

Spray foam insulation from Huntsman Building Solutions [HBS] has been used in the transformation of a collection of derelict industrial buildings into a stunning, architect-designed self-build home in rural Cumbria.

The buildings dated back to the late 18th century and once formed a mill producing blacking, a material used to coat the insides of casting moulds for a range iron goods, made at a nearby foundry.

Architect Robert Glass and his partner Ruth Grimshaw who now practice at Tape Design in Ulverston, had decided to move back to the South Lakeland area of Cumbria following years in the city. Robert had known about the site since his early 20’s and had always wanted to build a home there. In January 2015, they approached the owner and after finally gaining planning approval, bought the site in November 2017.

The site was challenging with narrow, single-track access. A fast-flowing beck which originally provided power for the mill ran through the site and the surrounding land was completely overgrown, almost reclaiming the tumble-down stone structures that had laid abandoned since the 1950’s.

None-the-less, the potential was clear to Robert and Ruth and plans were drawn up to transform the buildings into one stunning, four-bedroom home of 218sqm with a further 90sqm of workshop and office facilities. A 90sqm roof terrace was incorporated into the main house structure, providing recreational space and views over the surrounding woodland canopy.

A key criterion in the construction of the buildings was control of the internal environment to minimise heating costs, so achieving a high degree of air tightness and the incorporation of a mechanical ventilation and heat recovery system [MVHR] into the finished structure was required.

It is estimated that around 40% of a building’s heat loss is caused by air leakage - essentially draughts - so an insulation system that works to prevent air leakage,

A completed section of the building prior to trimming back of the breathable foam insulation to accept plaster boarding.

effectively creating a sealed environment was essential in order to minimise heat loss.

Following detailed research, an open cell spray foam insulation solution from Huntsman Building Solutions [HBS] was chosen. Their H2 Foam Lite product not only promised outstanding levels of air tightness and thermal efficiency but also allowed the building to “breathe” and move with the timber framed inner structure.

The site runs through a steeply wooded valley with a fast-flowing beck that provided water power to the mill.

Huntsman supplies its products exclusively through a trained and authorised contractor network and the spray foam installation was handled by Preston based contractor Heatlok Insulation.

Greg Raby of Heatlok explained that HBS spray foam insulation systems were developed in Canada to cope with their severe winters and are now widely used in the UK in both the residential and commercial sectors.

He also explained that spray foam insulation is an inherently elastic material so it moves with the building without cracking and causing gaps. It’s also able to fill the small voids in the structure where conventional rigid board insulations are almost impossible to fit effectively.

Unlike the urethane foams of 20 years ago, modern spray foams such as HBS H2 Foam Lite uses water as the blowing agent. This means that the reaction between the two components produces a small amount of CO2 which causes the foam to expand. Cells of the foam burst and the CO2 is replaced by air.

According to Huntsman Building Solutions, H2 Foam Lite E is currently the only spray

foam insulation system to carry the prestigious BBA [British Board of Agrement] Certification.

From an environmental perspective, H2 Foam Lite claims a Global Warming Potential of 1 and an Ozone Depletion Potential of 0 [Zero]. Furthermore, it doesn’t emit any harmful gases once cured, another important factor in the choice of insulation. “Ruth is very sensitive to chemicals in the air, the fact that H2 Foam Lite is becomes inert after a few seconds, with little or no off-gassing after installation, made it the perfect choice for us” said Robert Glass.

H2 Foam Lite was used in the external wall and roof areas to create a highly thermally efficient structure. External walls are a combination of 250mm outer leaf of Lakeland stone facing with 140mm thick timber frame inner leaf with spray foam filling. Inner 50mm thick battening allowed an extra 90mm thickness of foam insulation giving an overall thickness of wall insulation of 230mm.

Where timber cladding was used to visually soften the exterior appearance, wall sections comprised 22mm thick larch cladding, facing a 140mm thick timber frame supporting structure with foam insulation infill. Similarly, 50mm thick inner

Below: The Mill reconstruction gradually comes to life – the 90 sqm roof terrace will provide recreational space and stunning views over the surrounding tree canopy.

Above: The external combination of Lakeland stone and larch cladding blends beautifully with its surroundings.

battening allowed an extra 90mm thickness of foam insulation giving an overall thickness of wall insulation of 230mm.

Roof areas also received high level of insulation. Pitched roof areas are timber clad over a glass fibre water-proofing layer that overlays 18mm OSB [oriented strand board] fixed to 145x50mm rafters with foam infill. Foam filled 50mm thick inner battening gives an overall thickness of insulation of 230mm. Flat roof areas beneath the roof terrace received additional treatment with 300mm thick foam sprayed around the perimeter where the roof and walls meet, to fully seal any potential gaps.

Robert and Ruth acted as both designers and main contractors for the reconstruction process, a huge task whilst continuing to run their Architectural Practice, engaging and managing trades as required over the Covid disrupted build programme.

The mill transformation began in January 2018 and is due to be completed in the spring of 2022. The four-year project was the subject of a Channel 4, Grand Designs programme lead by Kevin McCloud and was broadcast in autumn of 2021.

Huntsman Building Solutions – Enquiry

Aico are delighted to announce the launch of their very own awards ceremony – the Community Awards.

Designed to recognise excellence within social housing and the local community, the Aico | HomeLINK Community Awards have 11 different categories, all of which are now open to entries, from College Initiative of the Year to the Rising Star Award, the Women in Fire Safety Award to the Best Distributor of the Year, including a Corporate Social Responsibility Initiative award.

Entries close on Thursday 31st March 2022 with finalists announced in early April, ahead of the awards ceremony taking place in May. The inaugural ceremony will be held at the International Convention Centre, Birmingham with host George Clarke, architect, and TV presenter, renowned in the industry.

With an evening of celebration, recognition, and entertainment, the Aico | HomeLINK Community Awards will celebrate the achievements of inspirational individuals and organisations working within social housing and the local community; innovating, demonstrating excellence, and putting people first.

Managing Director Neal Hooper comments “We are passionate about

supporting the sector as well as our communities, and showcasing inspirational people, organisations and initiatives is a great way to champion excellence, share knowledge and collaborate in the creation of safer homes. Corporate Social Responsibility (CSR) is such a crucial focus for Aico | HomeLINK, forming a key part of our ethos, which is also why we have launched these awards. It is vital that CSR is advocated, encouraging more involvement from people and organisations in supporting their local communities.”

All colleagues are very excited about the inaugural Aico | HomeLINK Community Awards, Neal goes on to say “We are very much looking forward to seeing all of the entries celebrating the achievements of inspirational individuals and organisations working within social housing and the local community; innovating, demonstrating excellence and putting people first.”

To find out more about the Community Awards and to enter, please visit: www. aico.co.uk/events/communityawards2022/

Aico – Enquiry 18

We are passionate about supporting the sector as well as our communities, and showcasing inspirational people, organisations and initiatives is a great way to champion excellence, share knowledge and collaborate in the creation of safer homes.

wedi is and has been the industry leader of innovative tilebacker solutions in Europe for over 38 years.

At the core of the business is the continued drive to adapt and develop its products and system solutions to meet the ever growing challenges of the construction industry.

Primarily focused on 100% waterproof wet room solutions, wedi is more than able to handle requirements for offsite POD manufacturing, even for the spa & wellness industry. Dedicated to people and the environment, wedi is a certified EcoProfit operation with certified energy (ISO 50001), environmental (ISO 14001) and quality (ISO 9001) management systems.

Its products are manufactured with 100% green energy and with at least 25% recycled XPS foam material in a completely environmentally friendly process. What‘s more, wedi building boards and shower elements have internationally recognised environmental product declarations that provide quantitative information of the environmental footprint throughout the entire life span of these products. They

are waterproof to the core and have the best thermal (0.036W/ mK) and vertical weight load (133kg/m 2) capabilities amongst XPS tile backers and produce very little dust when worked on, hence contribute to a safer working environment.

Its seamless, Top design surfaces do not only provide a sleek, modern finish in place of traditional tiling, but are made of a unique mineral composite: a mixture of 50% resin and 50% stone powder derived of old, recycled materials such as frames, pipes, textiles and waste of marble fabrications. Thanks to this special combination, they have an organic, warm feel tackling surface condensation and can be fully recycled at the end of their lifecycle.

No need to sacrifice quality or style - for environmentally-friendly projects choose wedi throughout.

Committed to its present clientele, to future generations and nature, wedi continues to set high standards in the tilebacker industry. Plan green, think blue – know your XPS –find us on stand F32 on Futurebuild 2022!

wedi – Enquiry 19

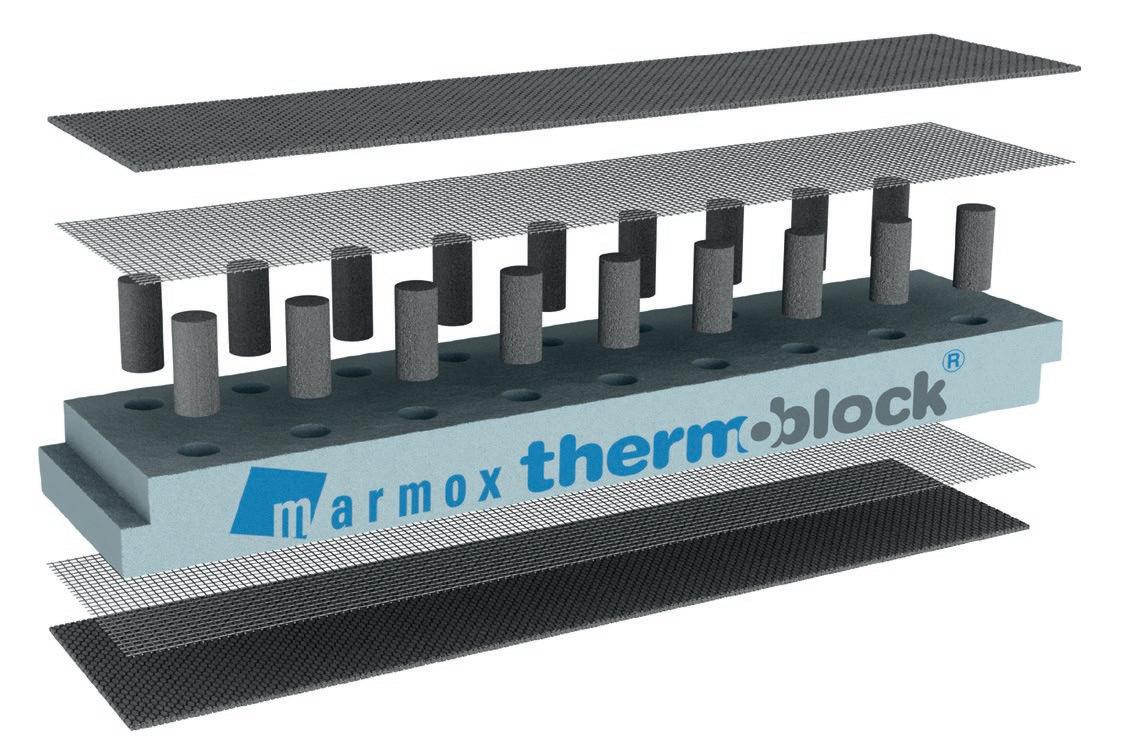

Fully in step with the sustainable construction goals of Futurebuild, Marmox will be exhibiting its well proven and versatile Thermoblocks on stand K10 from March 1st to the 3rd.

The easy to install product is widely used to tackle the issue of coldbridging around the floor/wall junction at the base of perimeter and internal walls, beneath both masonry and timber frame constructions, while it also finds applications at intermediate floor levels, beneath parapet walls and even in the construction of swimming pool surrounds.

Thermoblocks are available in widths of 100, 140 or 215mm and are formed from sections of XPS (extruded polystyrene) encapsulating two rows of high strength, epoxy concrete mini-columns.

These are attached at either end to the top and bottom layers of glass-fibre reinforced polymer concrete, to ensure a good bond with the rest of the structure

Marmox’s technical sales team will be on hand to explain how specifying Thermoblocks can avoid having to adopt the punishing default value under SAP and therefore help achieve Part L compliance in a practical and economic manner.

Visitors can also gain an insight into the performance benefits of Marmox 360 multipurpose adhesive and other products in the manufacturer’s extensive range.

Marmox – Enquiry 20

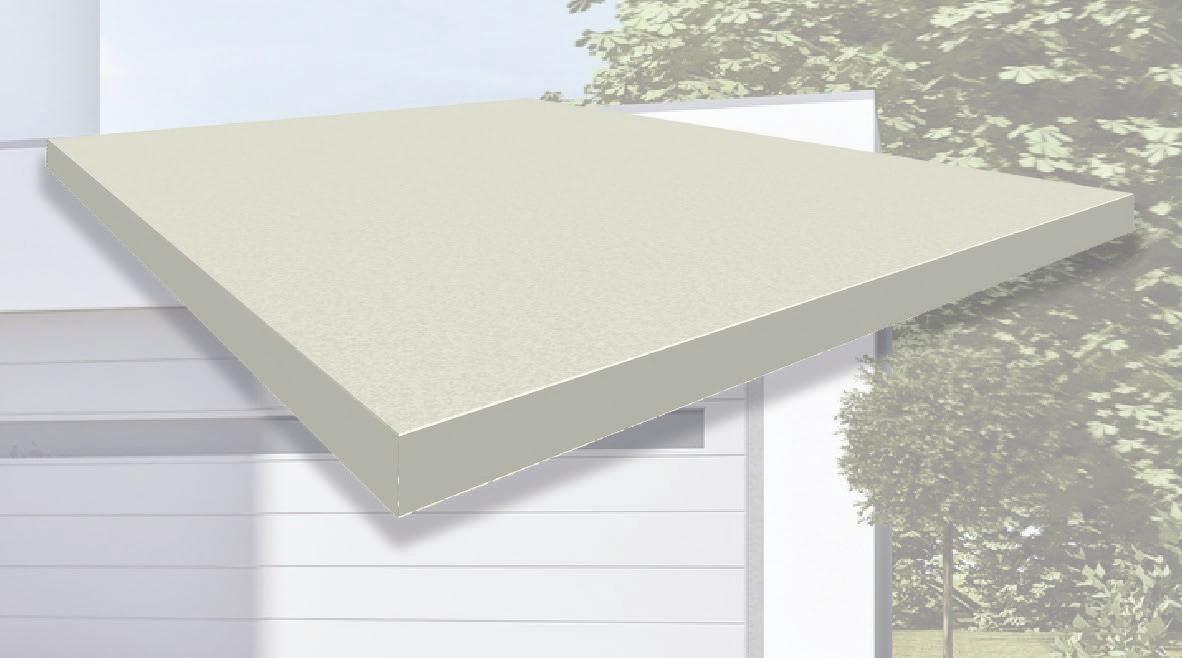

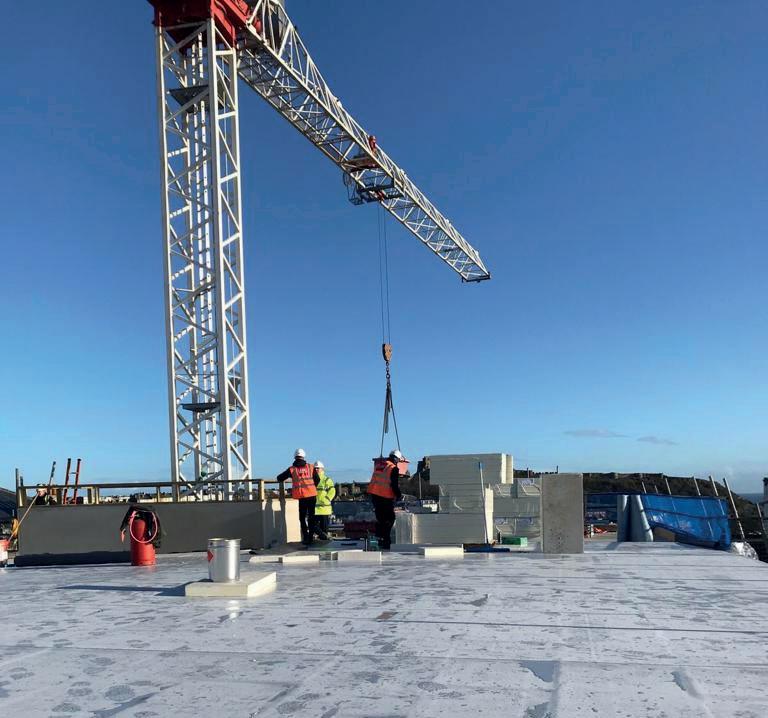

The upkeep of public sector buildings, such as educational settings, is crucial to sustaining happy and healthy communities, writes James Wilkinson, Design Team Manager at flat and tapered roof insulation specialists, Gradient.

An insulation system that is correctly specified, designed and installed is key to a satisfactory outcome, as failure in relation to any one of these elements could lead to costly, long-running maintenance. Such an issue could cause disruption to important work being carried out in a school, which would be rightly seen as unacceptable to most people. Therefore, when it comes to refurbishing flat roofs in these places, it’s vital regulation levels of thermal performance and weathertight protection – including the installation of high-performance insulation – is achieved as rapidly and cost-effectively as possible.

Correct specification will go a long way to ensuring a desired result in terms of flat roof insulation - a system that will withstand the test of time and the elements. There is, however, no room for error at any stage of the process, particularly where publicfunded schemes involving the health sector are concerned.

Tapered insulation offers the best of both worlds when upgrading a flat roof which is showing signs of wear and tear. When installed as part of a flat roof’s waterproofing build-up, tapered insulation’s multifunctional design not only enhances a building’s overall thermal performance, it manages a roof’s water run-off to ensure it flows into the appropriate outlets or gutters. If water is not properly dispersed from a roof, its weight will lead to deflections forming and increase the risk of ponding. This additional weight will fast-track the waterproofing system’s wear and tear, thus increasing the likelihood of a worst-case scenario: water-based structural damage, one of the most common forms of building failure. Therefore, a well-appointed tapered insulation scheme can extend the life of the building itself, hence the importance of selecting a system, whether single-layer or multi-layer, that is specifically designed to suit a particular application.

In terms of specifying an insulation system that meets industry standards by taking into account issues such as water run-off, pitch size, wind load calculation, falls and weight

ratio, the Single Ply Roofing Association (SPRA) code of practice offers excellent guidance. This is freely available online and ideal for installers and specifiers requiring insulation as part of a single-ply system. Similarly, BS: 6229: 2018, the standard that defines best practice in flat roof design and maintenance, provides a learned reference for performance requirements across a range of applications.

Bonded under factory-controlled conditions, single-layer tapered insulation systems are the time and cost-effective alternative to multi-layer solutions: they are ready to install once delivered to site. The insulation within the single-layer bond will have been monitored for its minimum pull-off performance, leaving installers with the relatively straightforward task of installing it – in one block – to the roof, followed by the waterproofing. This not only guarantees the insulation will perform as-designed, it significantly reduces application times and material waste. Therefore, whilst a multi-layer solution might appear, on paper at least, to be a more cost-effective option, the benefit is negated by the additional hours it takes to bond and install the insulation layer-bylayer; a process that is eliminated with a pre-bonded single-layer system. >>

As a company member of FIRAS Warringtonfire, Harrison Thompson’s range of products and services can help with the up keep and repair of fire doors using best practice guidance.

Yeoman Shield Fire Door Services offer fire door installation, repair, maintenance and the fitting of Yeoman Shield fire rated protection products - all carried out by accredited fixing operatives.

The benefits of technology are clear to see Carl Brunger, Building Services BIM Manager at Polypipe Building Services, lists the benefits of technology and highlights the positive difference technology is making to its sector.

“The difference digital solutions can make to the construction industry are numerous,” he says. “According to an article published in BIM+, technology can have a hugely positive impact on the industry’s productivity and efficiency levels, safety, and profitability. In non-residential construction, 10 years of full-scale digitalisation could save up to $1.2trn in the design, engineering and construction phases, and $0.5 trn in the operations phase.

“For manufacturers in particular the benefits are significant, especially in terms of project delivery and speed, and the quality and accuracy of products produced. Here at Polypipe Building Services, technology is ensuring that the products we make are of the highest quality, a key area of focus in the industry.

“Quality is only going to get more crucial as the likes of the Building Safety Bill gains momentum. One of the main elements of the bill is the Building Safety Regulator, which is designed to implement and oversee a stringent regime for higherrisk buildings and drive improvements in building safety and performance standards in all buildings.

“The Golden Thread of Information will be a pillar of this bill, with the regulator seeking a clear trail of accurate, up-to-date building data to check its safety. This in turn is set to increase transparency and accountability in the sector.

“With this in mind, the importance of information cannot be overstated. The advantage of the digital world is that companies can pull information all into one BIM model so it is there from the get-go. In the next few years, clear concise and easy data management will be fundamental for manufacturers, including Polypipe Building Services.

“At Polypipe Building Services we have implemented approaches that ensures information can be made more visible. As stated, from a manufacturing point of view this is key.

“We have a group initiative that enables us to agree what our BIM standpoint is to make sure we are aligned with the rest of the industry and ensure we innovate. We also have a manual which guides the group as to the things we want to achieve and what we should be following with regards to the standards. These approaches essentially make sure we are the best we can be.

“To further assure quality, Polypipe Building Services does as much as we can in-house. One of the key problems in the BIM world is outsourcing, as the guarantee and quality are compromised both in terms of process

and product. This in-house control means we know exactly what the customer and project is. It also gives us clear visibility of our products within that model. This feeds back into assuring that all-important Golden Thread of Information.

“Furthermore, our MecFlow system has been produced under the BIM Kitemark, an accreditation which ensures that our digital content meets regulations. We also utilise digital laser scanning onsite for our components to ensure we can scan products and compare it to digital models. This allows us to take that physical information and put it back into the digital world for customers to use. The scans ensure that we are producing the right products that were specified.”

When Cardiff High school needed a high-quality multi-use sports flooring solution for their main hall, they chose international flooring specialist Gerflor to supply 700m2 of their world class Taraflex® Multi-Use vinyl sports floor in ‘Wood Natural’. The project would also be further enhanced by Gerflor supplying an Isolsport underlay and their ubiquitous Taraflex® Bateco moveable protective covering which would ensure that the Taraflex® sports floor installed would remain protected during non-sporting activities.

Although Cardiff High School was established in its current form in 1970, its origins go back much further to the foundations of the three schools that merged to form the present school. The school’s curriculum and co-curricular activities, wellbeing programs, sporting, and cultural programs, as well as experienced staff, ensure that Cardiff High School students have a broad and well-rounded education within a caring and accepting environment. Their main sports hall plays a huge part in the school’s overall daily activities with sport featuring very highly in the school’s curriculum.

The contracting responsibility for the new replacement sports floor would be undertaken by a well-established and respected Welsh flooring contractor.

Floor Furnishings Limited are a Cardiffbased flooring contractor who have been conducting flooring contracts throughout the UK for a wide range of clients since 1961. It is an enviable history of commitment in supplying and fitting quality flooring.

Nick Jefferies, Company Director, Floor Furnishings Ltd commented, “We originally had an enquiry directly from the school. We chose Gerflor as we have an excellent long-standing relationship with them.” On installation Nick Jefferies went on to say, “Gerflor’s Taraflex sports floor was extremely easy to lay. The Isolsport underlay also supplied by Gerflor, enabled us to lay the Taraflex Multi-Use directly over the existing concrete floor, this was a real benefit as the project was on a very tight schedule, due to the hall being required for exams.”

The flooring install in the sports hall was finally completed with appropriate line marking by Biddle Sport Ltd. A company renowned for their sports floor maintenance and court marking services.

The Taraflex® Multi-Use sports floor installed at Cardiff High School is a P1 category sports flooring, designed with both sport and non-sport use in mind, making it ideal for multi-purpose areas. Taraflex® Multi-Use protects users with excellent shock absorption and impact protection of 25% to 35%. Yet it’s tough enough to protect itself against non-sport demands often found in many education environments such as the movement of tables, chairs, and exercise equipment.

This is due to improved indentation resistance and recovery through Gerflor’s new innovative CXP HD+ foam technology.

As the main hall would also have to facilitate other non-sports activities including archery the school also opted for Taraflex® Bateco which is a moveable solution for protecting multi-sports floors falling on non-sporting activities. It can be unrolled over the floors and rolled up again before resuming sports activities. Taraflex® Bateco is made from 100% post manufacturing recycled waste.

Commenting on the Cardiff High School project Tony Thorne, Gerflor Specification Manager, South Wales said, “When the initial query came to us from Nick Jefferies at Floor Furnishings, we organised a site survey with the school to determine which of our world renowned Taraflex sports floors would be the best fit for the pupils, sports played, together with non-sports use such as exams and also as importantly, the budget.”

Tony Thorne added, “With an abundance of legacy installations locally in South Wales, we had plenty of previous Taraflex installations to fall back on as examples of similar sports floors. Therefore, the school were able to see our floors in action and were able to speak with independent stakeholders on how easy they are to maintain and their low life cycle costs. Taraflex Multi-Use was then selected for this installation due to its high level of impact protection and indentation resistance. We then worked alongside Biddle Sport to provide the centre circle logo which really elevates the whole sports hall. “

Nick Jefferies commented further, “The client is extremely happy with the final result and overall performance of the Taraflex floor. Biddle Sports also produced a logo for the centre circle on the finished floor which looks absolutely superb.”

Nick Jefferies ended by saying,” Gerflor’s support from the start of this project to the finish was brilliant. We have specified Gerflor products before with tremendous success and would definitely choose them again.”

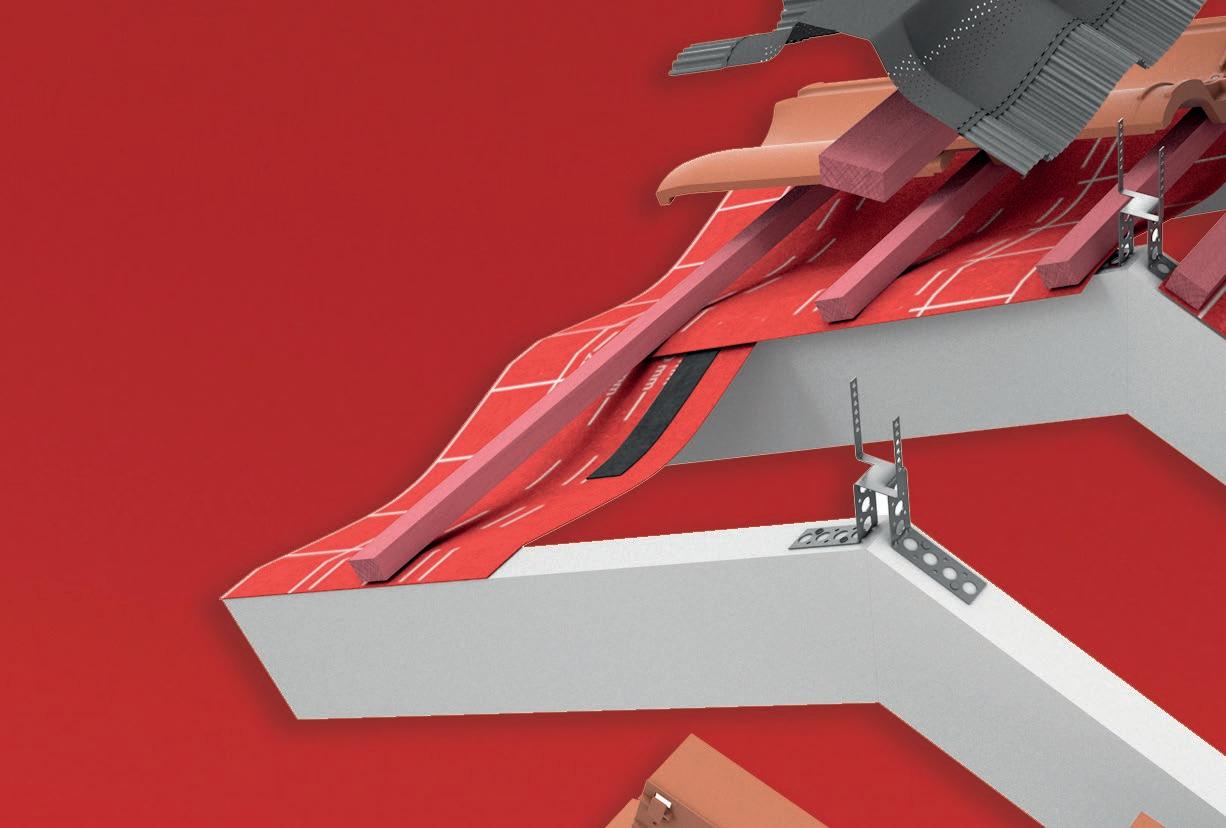

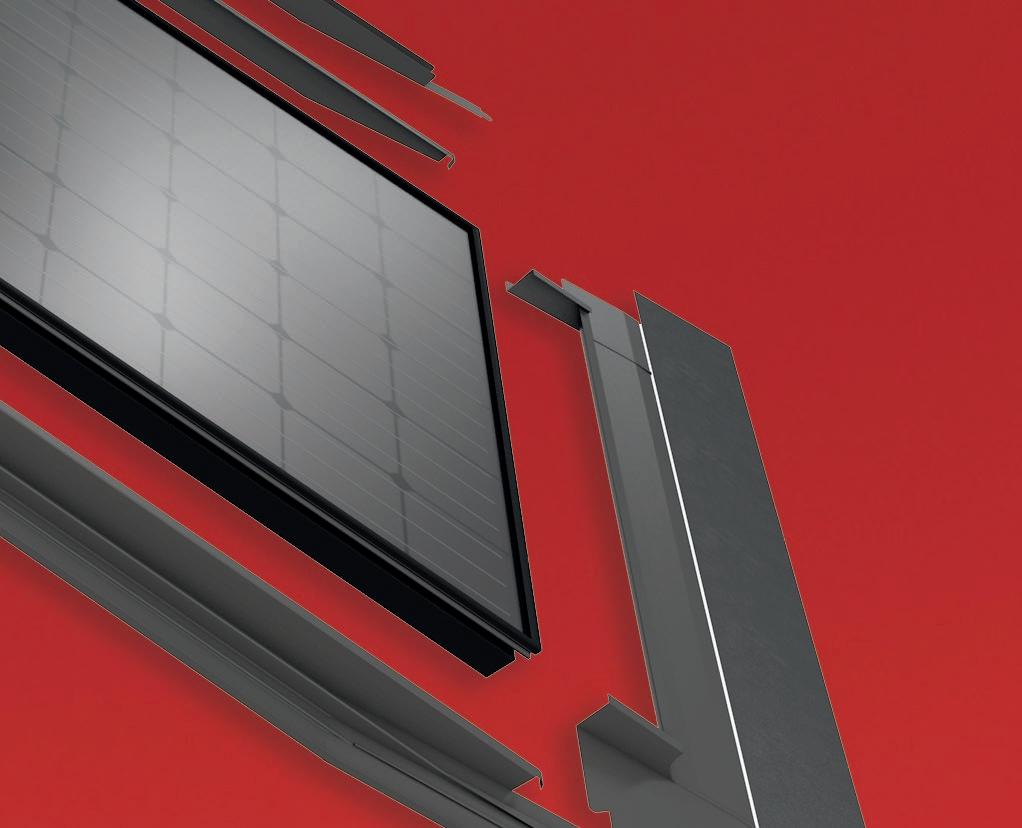

To aid the specification market as it seeks to design in renewable energy solutions needed for the homes of tomorrow, Marley has launched an enhanced solar panel providing superior aesthetic appeal, improve energy efficiency and greater power output.

The new Marley SolarTile® delivers a lean, low-profile aesthetic for both new build and retrofit projects and offers simple, quick and seamless roof integration.

Following significant research and development to design products that meet the needs of changing legislation, and carbon reduction targets, the enhanced panel is quick to install, and the increased efficiency allows for an install time of 45 minutes per kWp. The panel development gives specifiers the benefit of an increase in total power output from the roof area and makes roof-integrated solar a more cost-effective option, with fewer panels and roofing kits needed to reach the project energy target.

The aesthetic appeal of our integrated solar roofing solution has been further enhanced with the launch of the new panel, system flashing kits feature darker coloured flashings, enabling new solar installations to achieve a seamless blend between panel and flashings for total visual integration with the overall roofscape.

For every solar panel sold, Marley supports the planting of a tree through charitable

organisations across the world. This collaborative approach supports the longterm rehabilitation of natural ecosystems by teaming up with organisations with local expertise. Read more about Marley’s commitment to planet, people and process – www.marley.co.uk/sustainability

Stuart Nicholson for Marley, comments: “Our new enhanced panel further supports

specifiers as they look to provide sustainable, product-led design solutions for the homes of the future as well as retrofit projects that enhance the energy efficiency of older properties.”

For more information, please visit: www.marley.co.uk/solar

Marley – Enquiry 23

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

With one of the most comprehensive ranges of roof underlays and ventilation solutions available in the UK and Ireland, Glidevale Protect offers tried and trusted performance for any project. When you’re creating better buildings and healthy homes, choice really is everything.

Glidevale Protect is a specialist UK producer, offering ventilation solutions, condensation control and energy efficiency across the built environment.

For technical guidance or to book a presentation, contact us on +44 (0)161 905 5700, email info@glidevaleprotect.com or visit www.glidevaleprotect.com/choice

Specifying pitched roofing underlays for new build projects can be confusing with many options available, each offering various performance credentials. John Mellor, Senior Product Manager at Glidevale Protect, explains.

Amembrane should be designed as a hidden protector, operating as the secondary line of defence against wind driven rain or snow and providing strong wind uplift resistance in accordance with BS 5534. However, with roofing underlays often specified in isolation, the importance of the membrane type used, and the controlled ventilation needed to manage condensation risk is often overlooked.

Roofing underlays and ventilation must work hand in hand to provide a watertight structure and avoid condensation build-up within the roofspace. The choice of underlay for any pitched roof impacts the amount of ventilation required, so selecting a manufacturer well versed in appropriate guidance is paramount. Choice is an important factor here rather than a ‘one size fits all’ approach, with the membrane an integral component of the overall solution.

The ongoing commitment by Government to bring all greenhouse gas emissions to Net Zero by 2050 and improving energy efficiency in homes, means ventilation has never been more important. In the UK, the uplifts to Building Regulations Approved Document Part L (conservation of fuel and power) and Part F (ventilation) are due in June 2022, and will both form the transition to the Future Homes Standard. This means as homes are designed to be more airtight, it is vital to have appropriate ventilation, protecting against excessive moisture build-up, including within the roof.

So, with the undoubted importance of having a ventilation strategy, what different categories of membrane are available and how does this impact ventilation requirements, whether cold or warm roof?

The type LR underlay is airtight but allows water vapour to disperse into the atmosphere. For a cold roof solution on a dwelling sized roof, BS 5250 recommends high-level ventilation of 5000mm2/m, whether a well-sealed or normal ceiling is in place. Alternatively, where there is a well-sealed ceiling, a ventilation provision of only 3000mm2/m at low level is required. For re-roofing projects where the ceiling is not likely to be airtight, ventilation at low level should be increased to 7000mm2/m. In warm roof construction, the use of a type LR underlay will not require any additional ventilation, subject to a well-sealed ceiling and an air and vapour control layer (AVCL) being installed. If there is doubt about whether a ceiling is sealed at specification stage, further ventilation should be planned into the design.

The second type of LR underlay is both air and vapour permeable, ensuring airflow through the material and allowing vapour to escape to control the risk of condensation. Whilst an air permeable underlay may involve higher initial material costs, this is offset by no additional requirement to ventilate, saving labour and installation time. Air and vapour permeable membranes can be used without

additional ventilation, as accepted by the NHBC in their Technical Requirements R3 Document, related to cold roof construction. The only exceptions are where closed jointed sarking boards, or an airtight roof covering is used. In the latter case, it would be necessary to ventilate the batten space.

The third category, type HR, is airtight and impermeable meaning water vapour is prevented from travelling through the material. Designed to overcome disadvantages of traditional type 1F felts, HR underlays are generally most cost effective. However, this has to be balanced against the additional ventilation provision required for both a cold and warm roof. Ventilation is imperative to avoid the risk of interstitial condensation forming on the underside of the underlay. As an example, for dwelling sized cold roofs with pitches over 15 degrees, a minimum of 10,000mm 2/m of ventilation is required at low level, in addition to 5,000mm 2/m at high level. For warm roofs, both high and low level ventilation is needed.

For guidance on the most appropriate roof underlay and ventilation combination for your project, visit www.glidevaleprotect.com/choice, contact Glidevale Protect’s Technical team on info@glidevaleprotect.com or call +44 (0) 161 905 5700.

Glidevale

Magply boards are being used as part of Sky’s efforts to create the world’s most sustainable film and TV Studios, Sky Studios Elstree.

Currently under construction by main contractor BAM and set to open in 2022, the build has recently included the use of 9mm thick Magply boards as part of a flat roof build up specified for the product’s proven fire-protection capabilities and all-round performance benefits.

Guaranteed Asphalt Ltd is installing their BBA Agrement certified hot melt flat roofing system over a reinforced concrete deck with the Magply boards being used to protect the mineral wool insulation. A total of 900m2 of 9mm Magply boards was supplied by Shield Membranes Ltd. a leading stockist of the IPP range.

Tyler Ellis, the Business Procurement Manager for Guaranteed Asphalt, explained: “We chose to use the Magply boards due to its non-combustible nature and installed the product as part of a non-combustible,

“The Magply boards were the top layer and allowed us to apply a hot bitumen

But none can match the excellence of a system that is truly complete

THE UNIFOLD GUTTER LINING SYSTEM.

Having faced and solved every problem experienced in its long life with consummate ease UNIFOLD remains THE GOLD STANDARD to which others aspire!

UNIFOLD – Unrivalled excellence in Gutter Lining Technology.

waterproofing called GuaraTEC Hot Melt Warm Roof System: which is accredited by the BBA.”

Magply – Enquiry 27

UNIFOLD ® Unrivalled excellence in gutter lining technology. www.gutterliners.com

The Construction Products Association has released a detailed response to the Government’s call for manufacturers to provide a significant financial contribution to the cladding crisis.

After initially welcoming the letter from Secretary of State for Levelling Up, Housing and Communities Michael Gove, the CPA’s chief executive has now written back to the minister committing the association and its members to pushing for a wider culture change within the industry as a whole.

But Peter Caplehorn also highlights the importance of ensuring that construction products are not routinely substituted from the original specification of a project and also that they are correctly installed. He maintains that this remains key to improving building safety.

In the letter to the CPA, the Secretary of State asks cladding and insulation manufacturers to agree to:

• make financial contributions this year and in subsequent years to fund remediation of unsafe cladding on 11-18 metre buildings. This is alongside the financial contributions the Secretary of State has requested separately from the residential property developer industry to cover

cost to remediate unsafe cladding on 11-18 metre buildings, currently estimated to be £4 billion.

• provide comprehensive information on all buildings over 11m which have historic fire-safety defects to which these companies have supplied products or services.

Mr Caplehorn says the CPA understands the need for industry to work with the Department for Levelling Up, Housing and Communities in an open and transparent way to address the need for remediation on buildings that are over 11 metres.

“We would welcome the opportunity to meet with you and your officials to clarify how this can best be achieved prior to a wider meeting involving both CPA members and relevant non-members,” the letter to Mr Gove states. “We are keen to help you and your officials ensure you have all the information on the entire sector that we have at our disposal.

“In addition to helping to meet the near-term needs of existing buildings, both ourselves

and our members are fully committed to changing the practices and culture within our sector and the wider construction industry that will be just as critical in the longer-term.

“In particular, we have:

• Assisted and fully supported Dame Judith Hackitt in her Independent Review of Building Regulations and Fire Safety, including with your officials and the Industry Response Group.

• Designed, developed and are now on the eve of launching the Code for Construction Product Information which we believe will prevent misleading marketing information about products being produced in future.

• Developed a competence process to raise the bar for all who work with construction products, including architects, builders, and manufacturers.

• Contributed to your team working on the new regulations and supporting Publicly Available Specification (PAS) documents. >>

• >> Continued to help across a wide range of activities, be that through the Construction Leadership Council, Building Regulations Advisory Committee, the British Standards Institution, Industry Safety Steering Group, and now with the Office for Product Safety & Standards.

• Developed with others a digital information process to ensure construction product information is reliable, clear and available to those who need it.

• Worked with colleagues through the CLC in respect of the current insurance issues that affect the whole sector, because in order to process the remediation work we need solutions in that area.

“The CPA has invested a considerable proportion of the Association’s time, resources and financial support, and will continue with all these activities to achieve the necessary reform and culture change.

“Your primary concern is understandably with the stock of existing buildings that have been identified as unsafe, and the appalling consequences for occupiers and home owners. We will help to the best of our ability. In addressing the key issues, it is important that the response is proportionate as you stated clearly in the House of Commons. Products can be incorrectly procured, installed and maintained by the builder/contractor in such a way as to make the building as a whole unsafe. Products are also routinely substituted by the builder/ contractor without clear records, again making the process of ensuring the building

is safe difficult and protracted.”

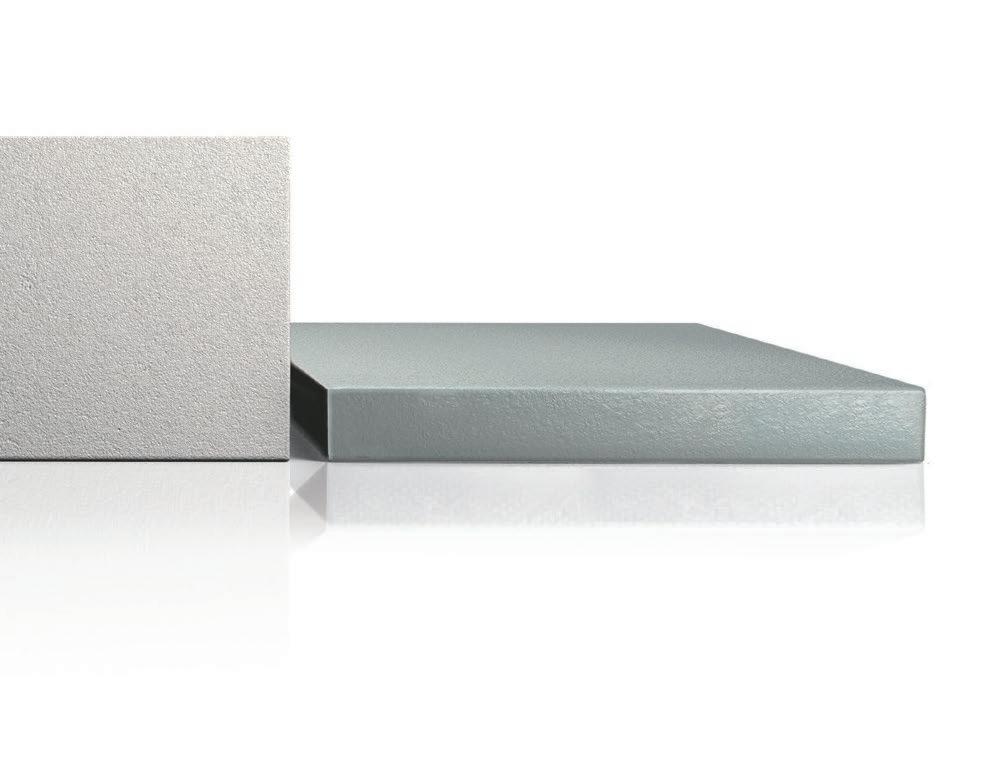

Insulation panels provide rapid protection Recticel PIR insulation is proving the ideal solution to ensure two new public school buildings attained regulation levels of thermal performance.

The huge project involves nearly 50 roofs – containing pitches of between 3.55° and 65° - and 60 dormer windows. Therefore, an insulation system that was rapid to install and offered superb thermal capabilities was essential to meeting the works programme’s strict time constraints. Recticel’s Eurothane GP insulation board met both requirements.

Waterproofing work on the new school buildings began in August 2020. The build-up comprised a vapour barrier, which was applied to a plywood deck, and breather membrane with a standing seam. For the insulation, TSH Architects in conjunction with contractor Salmon Solutions, and Recticel, specified 140mm Eurothane GP PIR insulation board. Despite this high-performance system’s lightweight

composition, it provides a thermal capability of 0.022 W/mK.

Eurothane GP boards fit easily between roof rafters to create a superbly flat foundation for a waterproofing finish. For the Charterhouse project, the boards were installed across a huge, 2,200m2 area. The prevalence of dormer windows provided an additional challenge, which was overcome due to Eurothane GP’s easy handling and cutting properties ensuring these features were quickly and effectively insulated against instances of thermal bridging.

Charlie Whitman, Project Manager and Surveyor at Salmon Solutions, said: “Recticel Insulation played a significant role in ensuring this vital project was completed to the agreed timeframe and to the highest specification. Lightweight and easy to handle, Eurothane GP insulation boards, were a pleasure to work with on this project. This benefit, along with their superb durability and consistent performance, ensured the boards were ideal when it came to selecting an insulation system which helped the roofing element of the impressive public school buildings achieve the required U-value.”

Despite the stop-start nature of the works programme due to coronavirus restrictions and inclement periods of weather, the Charterhouse building’s roofs are on track to be fully-waterproofed by the agreed completion date: August 2021. This is in no small part to Eurothane GP’s superb usability, resulting in a quick and easy installation that will futureproof these impressive structures against cold and damp for years to come.

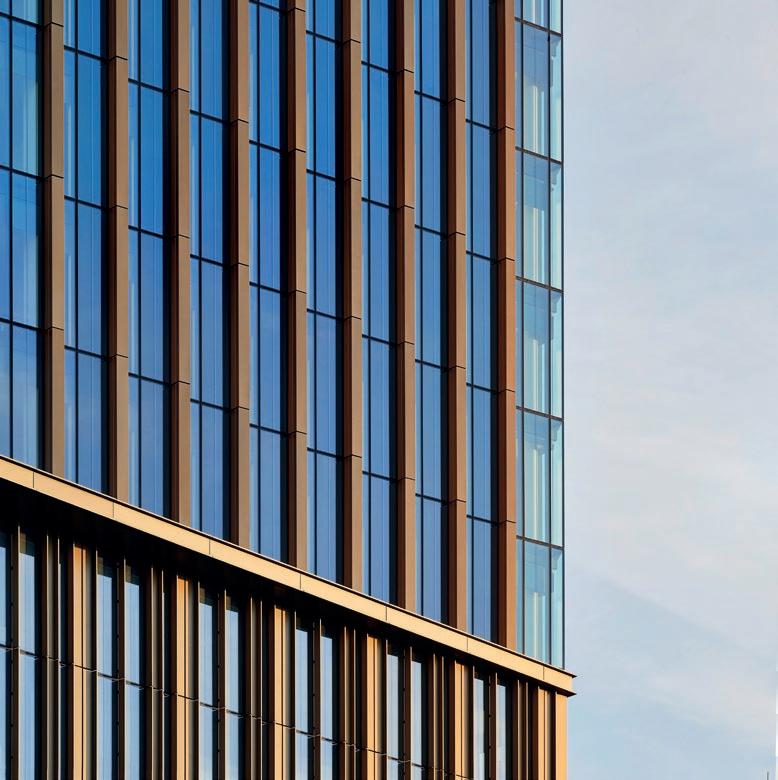

As the face of a building, facades are one of the most important design elements – and curtain walling can play a critical role. While it is easy to see the aesthetic benefits of selecting curtain walling over alternative materials, the benefits of this material can be extremely far-reaching.

Let’s explore five key reasons to include curtain walling in the design of modern buildings.

Curtain walling equips architects with the ability to create striking glazed facades through the use of off-the-shelf and bespoke systems. In practice, architects experience complete design freedom, safe in the knowledge that suitable curtain walling systems will be able to accommodate design considerations while still delivering the desired performance and functionality required of modern buildings.

Sustainability is a primary consideration at every stage of a building’s design, from

initial planning through to construction and even once occupied. Through its design, curtain walling can contribute towards the overall sustainability of a building thanks to the individual performance characteristics of specific systems, supporting functions such as cooling and ventilation through to energy efficiency.

To be successful, a building has to do more than look good – it needs to perform well and be functional for occupants. Comfort is a key consideration here, ensuring that interior spaces cater for the needs of those who use them. There are several layers to optimising comfort, including noise control, safety and security and daylighting. It is in

these areas where curtain walling can help buildings to excel.

4.

Often centre to the design of a building facade, aesthetics are integral. The trend to incorporate significant volumes of glazing into the building envelope is facilitated by curtain walling, delivering on a number of requirements, such as helping a building to fit into its surroundings, equipping it with a unique character and maximising views outwards.

As the most basic function of the building envelope, facades need to provide a barrier against external elements. To this end, systems are expertly engineered and rigorously tested to meet the demands of modern building requirements. This includes everything from Air, Wind and Water tightness through to thermal efficiency and building movement.

As specialists in the development of sustainable architectural glazing systems, Reynaers Aluminium offers a range of marketleading curtain walling solutions. To support architects in selecting the most suitable system for their design, Reynaers has also built a dedicated Consult Team to collaborate with architects from the outset of a project.

Find out more at www.reynaers.co.uk

Photos: ©Hufton+Crow

Reynaers Aluminium – Enquiry 32

Metalline are delighted to announce they have developed a new aluminium extruded plank system to add to their Unity rainscreen range.

Unity X-TRU is a cost effective cladding solution designed with simplicity and versatility in mind, making it the perfect solution for both new builds and the replacement of non-compliant ACM, HPL and timber cladding. The new X-TRU plank is functional with exceptional mechanical properties including strength, durability and fire-resistance and is particularly suited to buildings where dangerous timber cladding is present and needs replacing.

Available in a number of finishes, including wood grain, the X-TRU system is a unique way of transforming the exterior of a building and currently offers designers flat faced interlocking 100mm & 150mm planks. In addition to the wood grain effect finish, the extruded aluminium planks can be supplied in a variety of lengths and a vast array of powder coated or anodised colours to achieve A1 & A2 classifications. The panels offer a desirable fast track install and secret fix, connected by an interlocking male/female joint which can be easily fixed either horizontally or vertically to an adjustable support system. This drained and ventilated system creates a weather shield in front of a primary structure.

To find out more about the benefits of X-TRU planks, visit www.metalline.co.uk

Metalline – Enquiry 33

Enhance your façade with Metalline’s new non-combustible range of aluminium Spandrel panels.

Constructed using A1 non-combustible materials our Ultima Spandrel panels have been independently tested to EN13501-1 2018 and achieved both A1 and A2 - s1,d0 classification.

Nordic Copper offers an extensive range of natural surfaces and alloys that can be applied in numerous ways to clad a wide variety of building types from concert halls to social housing. A growing series of building studies – via www.nordiccopper.com – exemplify the best in contemporary architecture and showcase the diversity of surfaces, forms and applications available with Nordic Copper today.

Copper’s unique architectural qualities are defined by its naturally developing patina – which cannot be replicated successfully using other materials with surface coatings. Within a few days of exposure to the atmosphere, a copper surface begins to oxidise, changing from the ‘bright’ mill finish to a chestnut brown, which gradually darkens over several years to a chocolate brown. Continued weathering can eventually result in the distinctive green or blue patina seen on older roofs.

The Aurubis ‘Nordic Copper’ range provides all these surfaces straightaway. The processes involved are generally similar to those taking place over time in the environment, utilising copper mineral compounds, not alien chemical processes.

All these surfaces form an integral part of the copper, generally continuing to change over time, and are not lifeless coatings or paint.

The material is easily bent and formed, and there are no limitations on the length of copper sheet or strip because whole coils are treated on the production line, not just limited size sheets.

The Nordic Copper range includes Nordic Standard ‘mill finish’ and Nordic Brown pre-oxidised copper, offering lighter or darker shades of brown determined by the thickness of the oxide layer. The extensive Nordic Blue, Nordic Green and new Nordic Turquoise ranges have been developed with properties and colours based on the same brochantite mineralogy found in natural patinas all over the world. As well as the solid patina colours, ‘Living’ surfaces are available for each with other intensities of patina flecks revealing some of the dark oxidised background material.

Copper alloys are growing in popularity as well including Nordic Bronze and Nordic Brass – which can also be supplied preweathered. The innovative Nordic Royal is an alloy of copper with aluminium and zinc, giving it a rich golden through-colour and making it very stable. It has a thin protective oxide layer containing all three alloy elements when produced. As a result, the surface retains its golden colour and simply loses some of its sheen over time, as the oxide layer thickens with exposure to the atmosphere to give a matt finish.

A wide choice of Nordic Decor mechanically applied surface treatments is also available for various surfaces and alloys, particularly suited to interior applications.

Apart from traditionally-jointed, rolled material supported by a substrate, various other forms of copper for architecture are increasingly being explored by designers. For example, copper can be supplied in profiled sheets or extremely flat honeycomb panels, pressed to provide surface textures and modulation, or perforated, expanded or woven as mesh for transparency.

But there is more to architectural copper than meets the eye, with an unrivalled lifespan, no maintenance and full recyclability. With an ‘A1 (non-combustible material)’ fire classification to EN 135011, copper is also suitable for cladding tall buildings, using appropriate constructions. Low thermal movement makes it appropriate for any climates and locations, and it is non-toxic and safe to handle, as well as non-brittle and safe to work. And, importantly today, its inherent antimicrobial qualities make it ideal for touch surfaces internally as well.

The lifespan of copper roofing and cladding can be regarded conservatively as 200 years, subject to substrate and structure, and this is endorsed by experience. Naturally, this longevity has a significant beneficial effect upon comparative whole of life cost assessments. Copper’s longevity is due to a complex patination process. It ensures extreme durability with no maintenance and resistance to corrosion in virtually any atmospheric conditions. And, unlike some other architectural metals, copper does not suffer from underside corrosion.

In addition, copper requires no maintenance or decoration. As a lightweight and flexible covering, structural support demands are reduced, resulting in lower carbon and ‘whole of life’ costs. Copper is also fully recyclable utilising long-established practices – 97% of copper in construction comes from recycling – and has other impressive sustainability and environmental credentials. And, of course, copper retains a high scrap value at eventual demolition.

To explore inspirational Nordic Copper building studies, visit: www.nordiccopper.com/copper-stories/ or email: g.bell@aurubis.com

Weather-proof, UV resistant and with huge kerb appeal, Ceralsio Nero makes a striking impression when used as cladding on the exterior of a property.

The owners of the 1940s detached house in Hove, West Sussex, were keen to update the frontage while ensuring the finished look remained in keeping with the original Georgian features, ensuring the building continued to blend in with the street overall. To do this, the wood slat front common with this property type was replaced with Ceralsio Nero in a similar slat format, to give the house a new look with a modern twist that continue to works in harmony with its surroundings.

For installers Stone Specialist, this was the first time they have worked with the material, but with several neighbours making enquiries as a result, they are confident it won’t be their last. “The stone-effect Ceralsio panelling has modernised the building, giving it a facelift,” commented Chris Savage.

“It looks completely new and contemporary now and the client is very happy with the overall finish.”

Straightforward to fit, Ceralsio ceramic is a highly durable material that is made to