The CPA main scenario for construction output in 2020 is a 14.5% fall as the construction industry shows promising signs of recovery from the coronavirus pandemic.

Demand for new private housing and private housing repair, maintenance and improvement as well as strong growth in the infrastructure sector, are expected to support recovery for the industry towards the end of this year and into the next following historic falls in output during lockdown.

The prospects, however, of both a deterioration in labour market conditions along with a potential ‘No Deal’ Brexit deal at the end of December mean that the upcoming winter will be decisive for how far such a recovery can be sustained.

The Construction Products Association’s (CPA) Autumn Scenarios continue to expect a tick-shaped economic recovery as the most likely outcome, with output for construction rising by 13.5% in 2021 from the sharpest fall on record in 2020. The easing of lockdown measures over the summer was accompanied by a rush to meet pent-up demand, particularly in private housing and refurbishment work that couldn’t take place as sites were closed. With social distancing integrated on construction sites, productivity was also able to pick up.

CPA’s Economics Director, Noble Francis, said uncertainty continues to loom for the commercial sector. “If working from home becomes more engrained in society, footfall in city and town centres will decline leading to a lack of demand for office and retail space. Equally, a critical winter lies ahead for the wider economy,” he added.

“The key risks to the construction industry remain a potential second national lockdown and a ‘No Deal’ Brexit, which are illustrated in the CPA’s other scenario. Either would lead to a second dip in the UK economy and construction output.

“A free trade deal agreed in principle with the EU, with the details determined over time, would at least give some degree of confidence for what is still a fragile economic recovery. In addition, construction recovery so far has been highly reliant on government either directly through spending in infrastructure or indirectly through policy stimulus to boost housing. Government has an extra responsibility, therefore, to deliver on its announcements and ensure construction recovery does not stall in the next 12 months. We certainly aren’t out of the woods yet.”

•

•

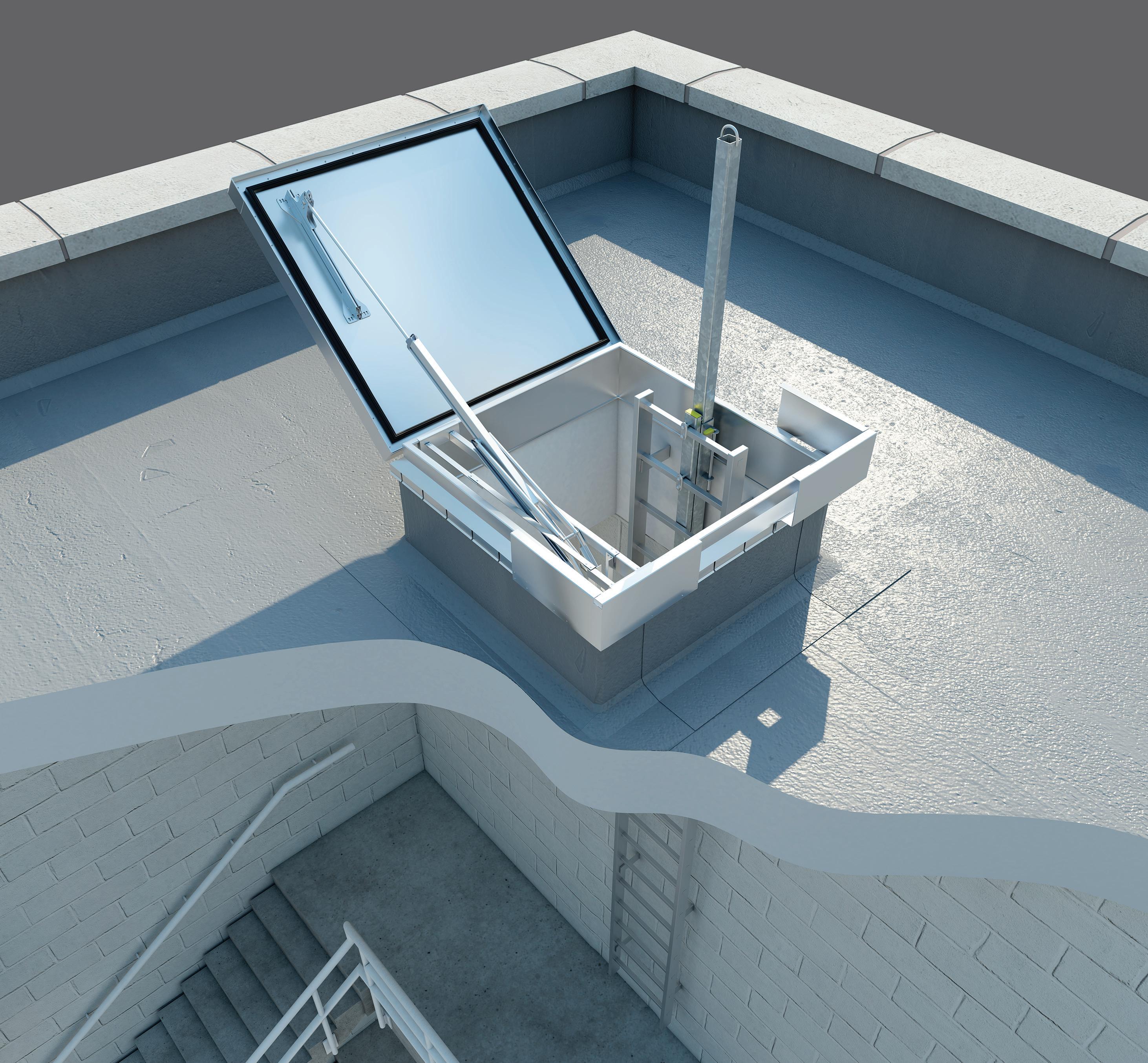

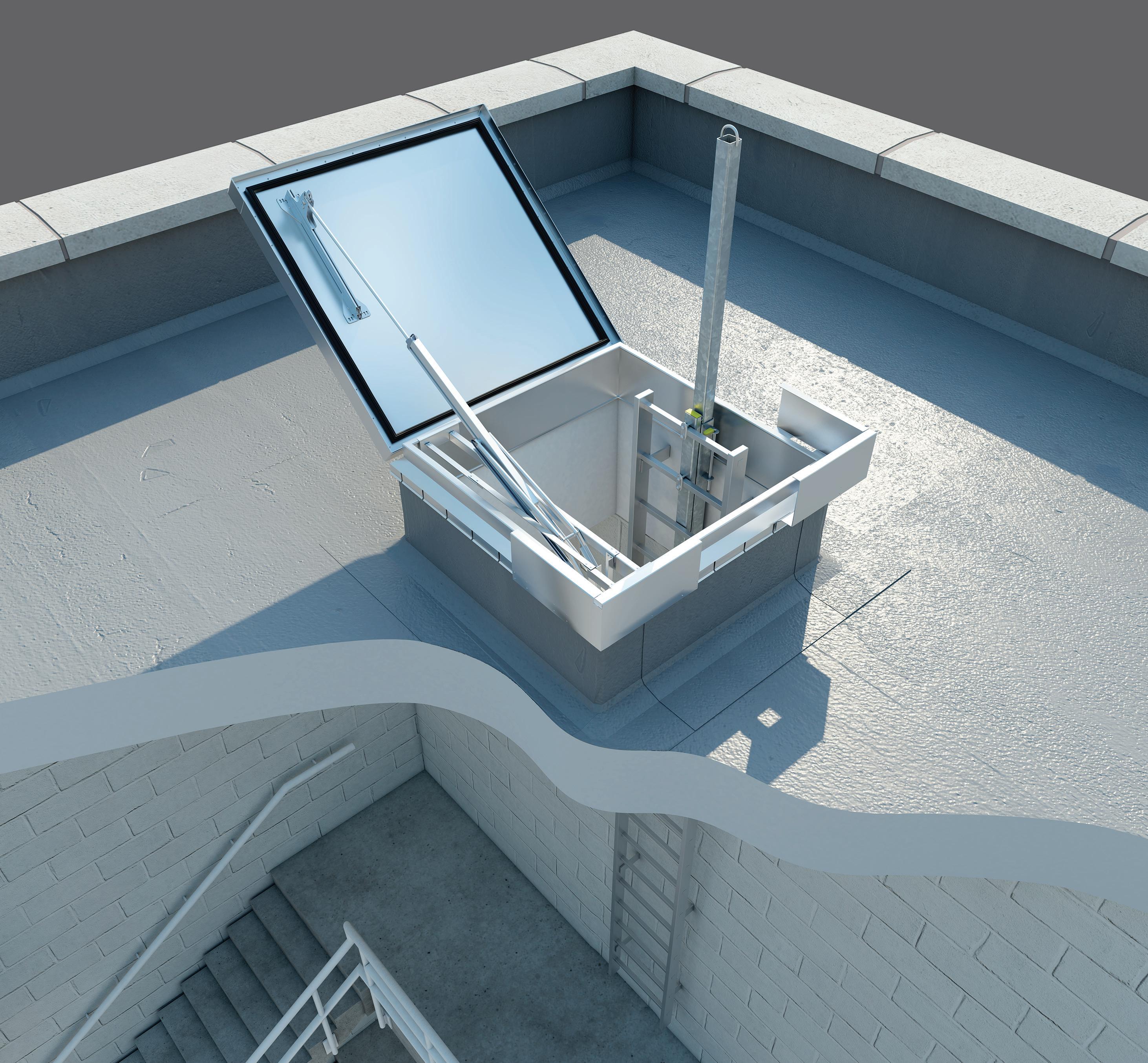

That hatch with the ladder running up to it? Yes, it’s a Bilco smoke vent. You may know it as one of the best smoke vents on the market; CE-marked, self-actuating in less than a minute, excellent thermal properties, and so on. But simply add a fixed ladder with the optional LadderUp® Safety Post, and you also have a safe exit out onto the roof.

So the next time you specify a smoke vent, make sure it’s a Bilco.

The University of Huddersfield’s Barbara Hepworth Building has been named as the Project of the Year at the prestigious Education Estates awards.

The eye-catching home of the School of Art, Design and Architecture won Project of the Year (Colleges and Universities) from the awards that are partnered with the Department for Education.

And the University also performed excellently elsewhere at the awards, with Sovereign Design House winning a Highly Commended in the Refurbishment of the Year category.

The Barbara Hepworth Building was completed in 2019, and features a dramatic flying cantilever design that has seen it quickly become a local landmark. Built on a sloping, canal side location that required a great deal of work prior to the building’s construction began, it has already won several awards including Constructing Excellence’s Building Project of the Year in 2019.

Sovereign Design House is a former bath house for foundry workers that was built in the 1950s on land adjacent to the Barbara Hepworth Building. It re-opened as a café, exhibition space and gallery earlier in 2020 following a restoration project that, like its neighbour, also involved partners in construction firm Morgan Sindall and architects AHR.

“The Sovereign Design House is fantastic addition to the University’s facilities and exhibition spaces,” said Nic Clear, Dean of the School of Art, Design and Architecture. “This beautifully developed project has preserved a unique building from Huddersfield’s industrial past by keeping exterior intact and retaining features from its original function as a factory bath house.

“It provides a vibrant public café and a gallery space that will help the School of Art, Design and Architecture showcase student and staff work, as well as providing an exciting opportunity to exhibit work from nationally and internationally recognised artists and designers.”

Developer Glenbrook on behalf of Latimer, Clarion Housing Group’s development arm, has commenced construction on a new £70 million, 280 apartment residential scheme at MediaCityUK which is set to complete in 2022.

The build for sale scheme is being delivered in partnership with MediaCityUK and is located on a former surface car park immediately adjacent to Booths’ food store in the heart of the internationally renowned MediaCityUK development.

Contractor Bowmer + Kirkland has been appointed to deliver the 231,000 sq ft Sheppard Robson designed building ranging in height from 14 to 17 storeys.

The scheme received detailed planning consent in February this year and will provide 132 one-bedroom, 136 two-bedroom and 12 three-bedroom apartments. Demonstrating its commitment to delivering varied ownership opportunities, alongside 180 apartments for private sale, Latimer will be offering 100 homes for sale on a shared ownership basis.

Queensgate Investments and Rockwell has now been given the green light by the Greater London Authority (GLA) for the redevelopment of the Kensington Forum, to provide a world-class hotel and serviced apartment scheme alongside 62 genuinely affordable homes and substantial public realm improvements.

Designed by SimpsonHaugh, the new scheme will replace the existing 906 room hotel with an exceptional high-quality development providing outstanding visitor accommodation for the future including restaurants, bars, health spa and conference facilities, vital to supporting London’s continued role as a world city and major global destination.

The Good Home Inquiry, launched in July 2020, has three experts joining the panel alongside the Chair, David Orr CBE.

The Inquiry will take a fresh look at how to improve the quality of England’s homes and respond to the rapidly changing age profile of the population.

Recommendations will be targeted at policy makers, housing providers, homeowners, landlords, and others with the aim of making it easier to upgrade, maintain and improve homes across the country, as well as to build good-quality homes that are fit for the future.

The Inquiry is commissioned and supported by the Centre for Ageing Better but led by an independent panel, chaired by David Orr. The Inquiry is expected to report initial ideas for policy reforms and changes in practice early next year.

The three panelists are: Victor Adebowale, a non-Executive Director of the CoOperative Group, Founder and Chairman of Collaborate CIC, Co-Founder and Chairman of Visionable and Owner and Director of Leadership in Mind;

Vidhya Alakeson, the founding Chief Executive of Power to Change, an independent trust established in 2015 to support the growth of community businesses across England as a means to creating more prosperous and cohesive communities; and Pat Ritchie, chief executive of Newcastle City Council and former chief executive of the Homes and Communities Agency (Homes England).

David Orr, Chair of the Inquiry said: “This Inquiry has launched at a crucial time with the effects of the pandemic impacting all aspects of our lives – but particularly housing as we spend more time than ever in our own homes.

“Far too many of our homes are cold, damp and unsafe. Too many people already die needlessly because of this. Covid-19 has thrown into even sharper relief the need to make improvements quickly. As an Inquiry team we are keen to drive change as soon as possible.

“It is vital that England’s housing stock is improved so that we have more decent, accessible and affordable housing for everyone.”

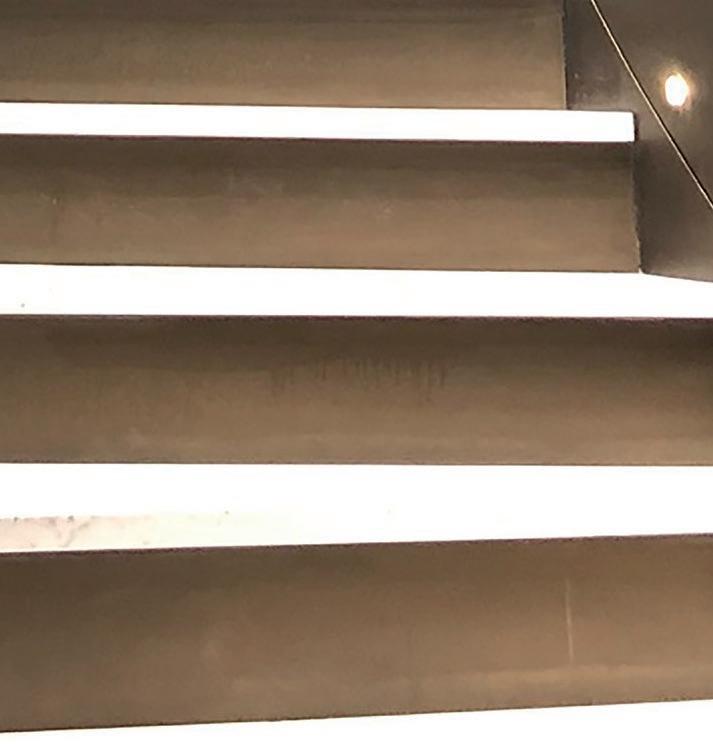

A new modular council development in Newhaven, East Sussex, is being hailed as a ‘game changer’ for social housing and a window on the future of residential schemes.

The entire development consists of 36 modules constructed within the Boutique Modern factory in Newhaven and craned into place.

The 13 one and two-bed apartments are equipped to the highest specification, in terms of standard and desirable features, sustainability credentials and fire safety standards that effectively future proof the development against all anticipated toughening of regulations post-Grenfell enquiry.

Every apartment has its own 2.1kWh solar PV installation and 2.7Kw battery to store electricity generated during the day for use at peak times. The modules are also super insulated, meaning they are 40% more energy efficient than traditional homes. Mechanical ventilation and heat recovery systems are installed in each apartment, maintaining a healthy fresh air supply within each home.

Each apartment constitutes a one-hour fire compartment, and every habitable room has

a MIST fire suppression system installed. They also feature Automatic Opening Vents, so in the event of a fire every walkway window and the roof vent in the stair core will automatically open, allowing smoke to clear.

A communal fire alarm system is integrated with the fire brigade or monitoring company. It detects any fault and activates within seconds.

The 58 AMP Jurors have made their decisions and the Architecture MasterPrize is pleased to announce the winners of the 2020 edition of this prestigious award, in both professional and student categories.

Two programs were open this year, celebrating the greatest architectural designs and products of the year: Design of the Year Award; and Architectural Product Award.

Four projects were chosen as top winners in each discipline and received the titles “Design of the Year” / ”New Discovery of the Year” in Architecture, Interior Design and Landscape Design, and “Architectural Product of the Year”, by the jury panel of renowned architects, academics and industry experts based on the criteria of design excellence and creativity.

For the first time this year, the jury also awarded the “Best Of Best” distinction to projects which were shortlisted for the Design of the Year title: 70 projects received this special mention.

The AMP 2020 professional top winners:

• Architectural Design Of The Year: He Art Museum by Tadao Ando Architect & Associates (pictured).

• Interior Design Of The Year: Nocenco Cafe by Vo Trong Nghia Co

• Landscape Design of The Year: Thammasat Urban Farm Rooftop by Landprocess

• Architectural Product of the Year: Thinline 2500 Sliding Door by Styline

New council homes ‘raise the bar’

Leading manufacturer of water pumps and pump systems, Wilo Group, has been announced as one of the top 50 Sustainability & Climate Leaders.

With a target of providing 100 million people with access to drinking water by 2025, Wilo is heavily incorporating sustainability into its approach and working to provide intelligent, efficient and climate-friendly solutions.

To find out more about Wilo’s energy efficient products, visit: wilo.com/gb/en

The Royal Institute of British Architects (RIBA) has published findings of its COVID-19 student survey, focusing on how architecture students have been affected by the pandemic.

Headline findings from the survey, which was completed by 398 architecture students, revealed:

• Students are under significant stress 58% of respondents told us that their mental health had deteriorated because of the COVID-19 crisis and 39% said that their physical health had deteriorated. 45% were feeling isolated and 39% were not keeping in touch with their peer group.

• Job roles have been directly impacted by the pandemic 10% of students had a job offer at a practice but it was withdrawn, 9% have lost a part-time role and 5% no longer wish to become an architect.

• Students are concerned about their future career 48% worry about being able to get a job as an architect when they complete their studies.

• Online teaching and learning is not a replacement for in-person learning 83% stated that online teaching and learning is suitable for only some parts of the curriculum and 81% would be put off applying to a course that’s entirely online. However, 58% feel it is good preparation for the digital future.

• Home working doesn’t suit everyone 25% say that where they live is not adequate for them to work in and 25% say their equipment is not adequate for the work they need to do.

• Money is a concern 41% don’t feel they have the money they need to get by and the same amount are worried about their family’s finances.

RIBA Director of Education, David Gloster, said: “The education and training of aspiring architects is crucial to the future of architecture in the UK and around the world. However, the findings of our latest COVID-19 survey paint a concerning picture for architecture students - and those who teach them - demonstrating how much the pandemic has impacted those hoping to enter the profession.

“It is particularly worrying to see the impact COVID-19 has had on the mental and physical health of students, and we encourage those struggling to seek help as needed. At this challenging time, students need our support more than ever.

“While it has been encouraging to see recent government plans to make architecture apprenticeships more accessible, we will continue to call for a re-evaluation of the education process, to make architecture more inclusive postpandemic.”

InsideOut have unlocked the potential of a complex sloping site in Tulse Hill, south-east London, to deliver a bold contemporary residential development of 22 homes.

The efficient high-density scheme challenges topography to create a new raised ‘ground’ which maximises the amount private and communal open space, while providing a mix of high-quality spacious accommodation, including apartments, duplexes and mews houses.

The project represents a milestone for the practice in being the first project of this scale to reach completion from a diverse range of large-scale multi-unit residential schemes that are currently underway.

The material palette respects the local context while adding some vibrancy amid the neighbouring housing schemes. The simple architectural forms are enhanced with high-quality textured brickwork which provides a material tactility to the simplicity.

In contrast, offset and oversized windows with exaggerated splayed metal reveals animate the façade, while large recessed

Multi award-winning London architecture firm, Adams+Collingwood Architects, has delivered a stunning new headquarters for the Royal College of Midwives (RCM).

The ‘calm and bold’ brief provided the opportunity for the talented team of architects to blend the RCM’s rich history with a contemporary workspace that would promote collaboration and flexibility.

The resulting design is bright, elegant and contemporary, delivering a range of lightfilled, flexible working spaces. A dropped floor delivers the wow factor and adds drama to the space, while also dividing it up practically and providing discreet storage under the higher-level floor.

balconies located at the corners lighten the volume allowing daylight to spill into the depths of the apartments.

Social distancing measures will continue to have a significant impact. Access solutions can make a huge difference by minimising physical contact and reducing the spread of germs, whilst providing reliable security. Stephen Littlewood, Senior Projects Lead for entrance systems at dormakaba explains more.

With facilities reopening in the wake of continuously evolving social distancing measures and guidance, business owners will be looking to operate as conventionally as possible whilst minimising the spread of viruses and bacteria. To do this, the building must firstly be reviewed to pinpoint the most common contact points and solutions implemented in these areas in order to reduce potential risk.

The review will likely find that the most common high contact areas are the entrances and exits. Reducing the number of manually operated doors can help to minimise contact at these access points and leading suppliers will be able to offer effective, quick to install solutions.

For example, manual swing doors can be converted to automatic operation by swapping standard door closers for automatic swing door operators and installing required sensors. Not only will this minimise common contact points at the entrances and exits, this will also improve accessibility into and through the building.

Leisure facilities can also benefit from integrating a gated solution as opposed to the typical turnstile access that is often utilised in these buildings. These can operate with card reader access, using Radiofrequency identification (RFID) access media, or even Bluetooth Low Energy (BLE) enabled smartphone access. The latter is even more beneficial as this will negate the need for leisure workers to provide separate cards, minimising physical contact – with the added bonus that patrons are far less likely to lose their phone than a fob or key card.

Secure areas of the building, such as staff only areas or lockers, can also easily be

upgraded from traditional cylinder locks or coded keypads to contactless, digital versions that utilises the same technology as that used on the entrance gate.

Specifiers can also advise business owners that this has further advantages in terms of convenience and control, as the individual readers and cylinders can be integrated into a single system security management system.

This will improve the control of access rights and traffic within certain areas of the establishment and also offers the opportunity to maintain a detailed log of access to key areas, for enhanced security.

Button operated automatic doors can also be improved by replacing the standard push-pad with a touch free sensor, that typically uses microwave detection to activate the door when the user moves their hand in front of the sensor.

Reducing physical contact with fire doors is a further consideration, yet any solution must remain compliant with the Building Regulations and fire safety legislation. Standard fire door closers can be replaced with compliant electro-magnetic hold-open or free-swing door solutions, allowing doors to remain open during busy footfall periods, therefore limiting contact with the door surface. Upon activation of the fire alarm or the unlikely event of a power failure, the doors will close automatically, meaning they remain fully compliant.

There are a range of solutions available to help improve the hygiene of facilities and reduce common contact areas. Many of the solutions will also improve ease of access and can enhance security, whilst complying with existing building legislation.

The building regulations governing fire safety continue to be reviewed and are likely to become stricter and farther reaching. For specifiers, it makes sense to choose non-combustible soffit insulation to protect people, property and yourself, argues Luke Davies, Rock Mineral Wool Product Manager at Knauf Insulation.

The current focus on building fire safety from the government, the public and the industry is a welcome one. The most high-profile change to date is the revision to Approved Document B mandating non-combustible materials in certain high-rise residential applications.

It made sense for the government to start here given the risk profile, but the public and regulators alike are asking whether there are other building elements that require closer scrutiny. Consider the calls for the ban on combustible materials to go further from all quarters; including RIBA, the Fire Brigades Union and the Association of British Insurers.

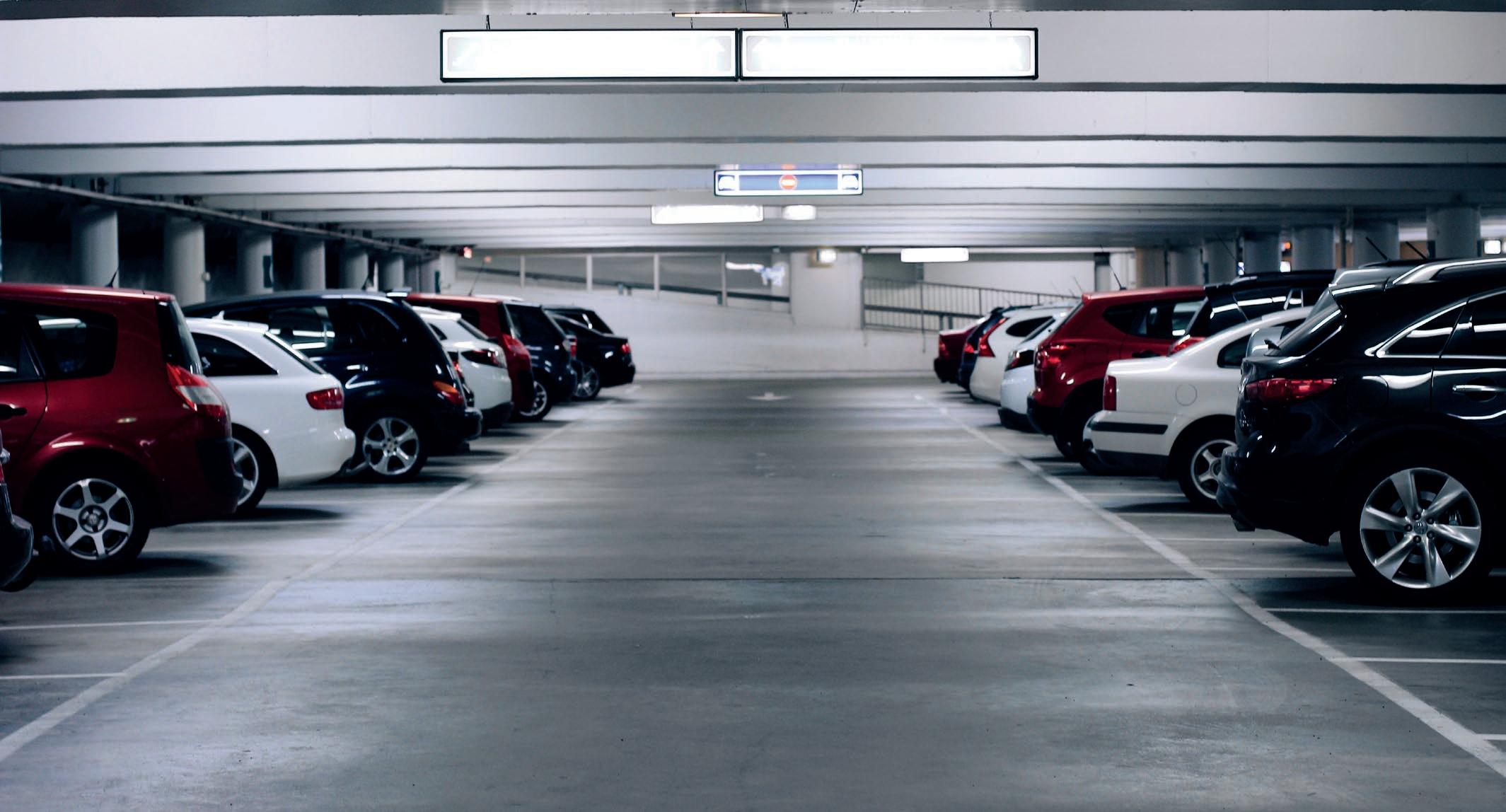

Large scale soffits – such as those found in stadiums, car parks and commercial units –could be next in line.

Historically, these soffits would be uninsulated, with non-combustible concrete abundant. But with the drive for improved thermal and acoustic insulation, many soffits are now being insulated – either during construction or renovation – for the comfort of those occupying the space above and below.

If this insulation is combustible, it could be adding unnecessary fire risk and associated smoke to the building, to potentially devastating effect. So, even before building regulations change, specifiers should be asking whether they can do more to create safer soffits.

Consider the fatal fire at Monica Wills House in Bristol in 2006. A blaze started

in a vehicle in the car park underneath the newly-completed development of 121 retirement flats. The fire spread quickly to other vehicles, then up the exterior wood cladding panels and through the uPVC windows on the upper floors.

The soffits in the car park had been sprayed with a foam insulation. In a subsequent test for the coroner’s report, Avon Fire & Rescue indicated that the fire “was assisted in propagation and smoke evolution by the presence of the foam insulation”.

Safer soffits don’t just protect people, they protect property too. In car parks, fire damage can rack up multi-million pound bills. For example, the Liverpool Echo Arena car park fire on New Years Eve 2017 destroyed 1,400 vehicles and resulted in insurance losses estimated at £20M.

Protecting lives will always be the primary driver for improved fire safety, with protecting property a valuable secondary benefit. But in an industry where value engineering and competitive tendering put pressure on the specification, it’s worth also highlighting the benefits to the specifier and

others in the construction supply chain. The construction industry has an opportunity to build trust by treating fire safety not as a minimum regulatory requirement, but as a core consideration on all projects. The solution is simple. Specifiers should reduce risk by specifying non-combustible Rock Mineral Wool insulation in every exposed soffit.

That means selecting products with a Euroclass A1 Reaction to Fire Classification rating. Although products with an A2 rating are sometimes classed as being of limited combustibility, their suitability depends on how they perform in terms of smoke and flaming droplets. An A2 product can have the worst possible smoke production rating of s3, which means it produces substantial amounts of smoke. This is not an issue for A1-rated products.

Only Mineral Wool insulation offers the unique performance combination of thermal, fire safety, acoustics and comfort that you need to create safe, sustainable and resilient buildings that tick every box. Knauf

Nordic Brass copper alloy cladding, sunscreens and ceilings help to define a new museum designed by architects BIG (Bjarke Ingels Group) in the Swiss Jura mountain region.

The Musée Atelier for Audemars Piguet houses the watchmaker’s collection of timepieces. Located in the Vallée de Joux, home to the company since 1875, the new building is linked to the original workshop and slotted discretely into the hillside landscape with a grass roof.

The plan form is conceived as a pair of parallel spirals, referencing mainsprings – the beating heart of the complicated mechanical watches that the company is famed for. The spirals are formed of structural glazing, highly-insulated from the outside and creating column-free space to allow visitors extensive views of the landscape and interior. The watch reference also extends to the restrained materiality of the building, as many watch parts are made from brass.

Externally, a band of Nordic Brass cladding crowns the curved glass facades. Then, a transparent brise-soleil screen extends down over the tops of glazing and clerestory windows, protecting them from the sun. The sunscreen comprises interlaced Nordic Brass ribbons, adding depth and varying transparency from different viewing angles. It was carefully adapted to the changing curvature of the plan, as well as differing height requirements for solar protection around the building.

Internally, perforated panels of Nordic Brass clad ceilings track the gently sloping

terrazzo flooring with brass joints. The ceiling also acts as a cooling medium with the Nordic Brass providing efficient thermal conductivity.

Copper and its alloys enjoy unique characteristics particularly in terms of safety, sustainability and long-term performance. With an ‘A1 (non-combustible material)’ fire classification to EN 13501-1, copper is inherently fire-safe and suitable for cladding tall buildings, using appropriate constructions. It is also, therefore, rated ‘Class 0’ surface spread of flame, making it suitable for wall and ceiling surfaces. Particularly important today, copper is nontoxic and its inherent antimicrobial qualities make it ideal for touch surfaces.

The extensive Nordic Copper range of architectural copper products is available from Aurubis, part of the world’s leading integrated copper group and largest copper recycler. It includes Nordic Standard ‘mill finish’ and Nordic Brown pre-oxidised copper offering lighter (Nordic Brown Light) or darker shades of brown determined by the thickness of the oxide layer.

The extensive Nordic Blue, Nordic Green and Nordic

Turquoise ranges have been developed with properties and colours based on the same brochantite mineralogy found in natural patinas all over the world. As well as the solid patina colours, ‘Living’ surfaces are available for each with other intensities of patina flecks revealing some of the dark oxidised background material.

Copper alloys include Nordic Bronze and Nordic Brass, which can also be supplied pre-weathered. The innovative Nordic Royal is an alloy of copper with aluminium and zinc, retaining its golden colour. A wide choice of Nordic Decor mechanically applied surface treatments is also available.

For more information visit: www.nordiccopper.com or email: g.bell@aurubis.com

Aurubis – Enquiry 14

The sunscreen comprises interlaced Nordic Brass ribbons, adding depth and varying transparency from different viewing angles

Smartphones in the workplace have the potential to improve employee mobility, job satisfaction and productivity. Pip Courcoux, Sales and Product Manager at Abloy UK, looks at how we should integrate them into our IT systems to create more flexible and efficient security solutions.

Smartphones became mainstream in 2008, and since then no piece of technology has had a bigger impact on the way we live our lives. We use them to stay connected to our friends and family, our home, look after our personal wellbeing and even our entertainment.

The numbers reflect this, with 78% of people owning a smartphone – rising to 95% of all 16-24-year-olds – and 95% of people use them every day. This is only expected to rise with the introduction of 5G, as users benefit from more reliable, faster connections.

However, while consumer use continues to grow, many organisations haven’t been as fast to tap into the uses and benefits smartphones can provide – in particular when they are embedded within a company’s infrastructure.

Though smartphones are a ready-made productivity tool in all our pockets, they seldom reach their full potential in workplace. For the past decade, this technology and its benefits has passed by the access control sector. But we should always be looking for the next ‘big thing’

that will make our lives – and work –more efficient.

How would it work?

I believe that the next generation of access control systems will rely much more on smartphones. They are capable of so many functions that have become a central part of businesses network infrastructure.

A simple to operate smartphone app is the perfect platform for keyless technology – as long as it is encrypted to the highest standards. This will allow businesses to increase the flexibility and efficiency of their on-the-ground teams, such as short-term contractors.

Meanwhile, a keyless access control system replaces traditional keys and lock cylinders by giving people access by using a key card, smartphone or a fob. This type of access control is becoming much more commonplace in every type of organisation

as the technology becomes more sophisticated and affordable.

Smartphone usage continues to increase. Organisations could even stop using traditional key management and deployment systems altogether. Alternatively, employees could access an app which will grant them permission through a network to access restricted areas, including padlocked remote sites.

This type of innovation will lead to a more streamlined, flexible and efficient infrastructure where anyone, anywhere in the world, can receive an activation code via SMS. They would also be able to display a list of access credentials, connect to a lock and use their phone to unlock it, receive rights from backend services, or even install a firmware update.

To build trust, keyless technology users should demand maximum security. This could include a number of authentication systems, such as the correct electronic access combined with biometric authentication, requiring a pin and facial recognition technology. It’s possible to achieve this without relying on internet access, allowing the process to function even in remote sites.

At Abloy UK, we are creating a portfolio of solutions which are backward compatible. This means that when you work with us, you can be confident that our products will be compatible and seamlessly integrate with one another.

Smartphones will also play a vital role in the world of hybrid integration. This is a framework to allow for more innovative and efficient integration with less risk. A hybrid integration platform pulls third party systems together to utilise common APIs and technologies, and in many cases the smartphone could fulfil this role.

A smartphone app could serve as the middleware to bridge the operating systems, databases and other applications. Furthermore, if this is done many times over using all the smartphones within a business, it would create wide scale benefits.

In fact, we’ve probably only realised a fraction of the value that smartphones can bring, providing the edge computing and connectivity necessary for true digital transformation – all for a manageable cost.

To reach their full potential, they should also integrate with cloud technology. This hugely increases their flexibility and allows users to connect from anywhere in the world and also means that companies don’t need to rely on establishing their own costly and complicated networks between locations.

The system can be improved further by integrating with mapping software, such as OS Cloud, so operators have access to a live database that monitors and manages all users at all sites. It also presents an opportunity for significant financial saving, as often the cloud utilises a multi-tenancy, shared production environment, splitting the costs across many organisations.

At Abloy UK, we are creating a portfolio of solutions which are backward compatible. This means that when you work with us, you can be confident that in addition to providing robust security our products will be compatible and seamlessly integrate with one another.

CLIQ® technology from Abloy is the perfect tool to help critical infrastructure sites overcome operational obstacles, by providing a system that manages, monitors and maintains security for sites which span large geographical areas.

The one-key solution allows staff to have their own key, while being granted access to assets only when and where they are needed. This small change can have a big impact, by reducing the need for risk

assessments and minimising in person key collections or attended visits.

These keys can also be activated through a smartphone using CLIQ® Connect technology and Bluetooth Low Energy (BLE): a revolution that brings remote access control into the mobile era. Using this technology, the keys and wire free products can even yield a realtime audit trail and grant access rights to the user while they are on-site.

Though traditional keys will always have their place, smartphones are a big part of the future. They will help organisations meet regulatory compliance, provide cost savings, improve operational efficiencies, reduce health and safety incidents and ensure assets are maintained and kept secure.

Integrating smartphones into our infrastructure will build up trust in the security sector, allowing the industry to benefit from the same convenience that consumers have had for years. For further information on products and services available from Abloy UK, visit www.abloy.co.uk or email info@abloy.co.uk. Abloy UK – Enquiry 17

As a leading international supplier of load-bearing thermal insulation products and reinforcement technology solutions, Schöck continues to optimise its digital portfolio service for planners; with the focus very much on improved digital workflow using web applications and BIM objects.

In addition to the Isokorb thermal break range – which offers three distinct levels of detailing – the updated CAD/BIM library also now offers the Bole punching shear reinforcement range and Dorn single-shear and heavy duty dowels.

All in many common 2D and 3D formats. The BIM-compatible IFC files of these varied Schöck products can be used in all common BIM planning software such as Revit, Archicad or Tekla Structures. Digital product information is easily accessible for all those involved from planning to the construction site and can be efficiently integrated in a continuous, networked process. The Schöck CAD-Service platform is free of charge and available by visiting: https:// cad.schoeck.co.uk/?mandant=GB&CUL=en-GB

For the full range of Schöck product solutions contact the company on 01865 290 890 or visit the website at www.schoeck.co.uk

Schöck – Enquiry18

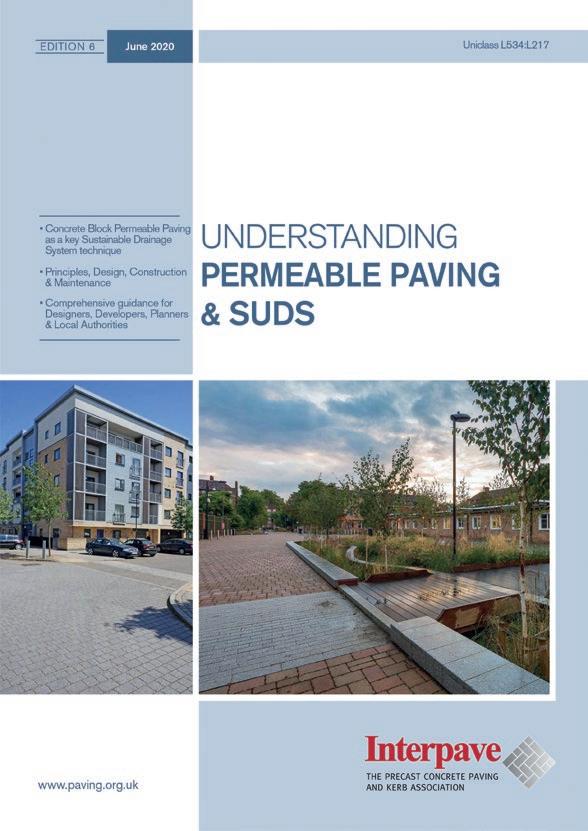

The trade association Interpave has published a new edition of ‘Understanding Permeable Paving and SuDS’, an essential introductory guide to all aspects of concrete block permeable paving for sustainable drainage systems (SuDS) – and much more.

Concrete block permeable paving is uniquely placed as an essential, multifunctional SuDS technique, providing an inherent drainage system that requires no additional land take for water storage. It combines proven engineering design solutions with water management replicating nature near the surface. And permeable paving is also very effective at removing pollution from surface water runoff, notably vehicle pollutants, identified in recent research as particularly harmful to our rivers.

The new edition explains how to use straightforward flow controls to maximise storage and other capabilities of permeable paving, offering further cost savings. But wider benefits of concrete block permeable paving are also discussed in the guide. It offers

‘cool pavements’ helping to reduce the urban heat island effect with evaporation of rainwater from the surface and within the paving. This enhances the already high albedo – or heat reflectance –offered by concrete block or flag paving generally.

One particular innovation covered in the latest edition of the guide is set to play a major role in the post-pandemic public realm. Retrofitting concrete block permeable paving as an overlay to existing streets offers a low-intervention technique to transform the public realm in response to the raft of recent active travel and open space initiatives.

www.paving.org.uk

Interpave – Enquiry 19

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Achieving thermal efficiency and low U-values using Glidevale Protect’s triple reflective wall membrane solution. See page 23 for more details.

Modular construction is often lauded as the answer to the country’s housing crisis. However, analysis of Glenigan construction data covering the past five years highlights that the sectors most keenly adopting modular construction are not private or social housing at all.

Over the past 5 years only 9% of private housing and 3% of social housing has been planned or built using modular construction.

This may change however, when clients look at the relative stability that modular showed during the first seven months of 2020 when only a relatively small 21% fall in modular project-starts was recorded, compared to the overall 39% decline in all construction-starts during lockdown.

Making up for lost time may also become a more urgent factor in wider adoption of modular construction as the speed of delivery, plus the ability to social distance more effectively is easier to manage and achieve with off-site construction.

And with Brexit concerns being exacerbated by the Prime Minister’s recent statement that leaving the EU with no-deal would be a “good outcome” for the country, the efficiency of modular construction with it’s higher degree of project certainty to some developments may help to mitigate some of the predicted construction material cost rises expected due to higher prices and shortages. Industry analysts Glenigan have outlined a number of reasons why modular construction in housing may be lagging behind other sectors. For example, the complexity and lack of standardisation of

modular solutions, the lack of rock-solid evidence that modular can match or out-performs traditional construction, plus the shortage of warranties available - up until very recently - that have made mortgage applications and insurance for property difficult to obtain.

But this could be about to change in the new social distancing and post Brexit world. If housing clients look more closely at the reasons driving the sectors that are most actively adopting modular construction, then there may be a dramatic uplift relatively soon.

The sector most active in flying the modular construction flag, accounting for 36% of all modular construction projects planned or constructed over the last five years, is the education sector.

Citing lower costs, increased speed of delivery and more flexibility to meet the demands of changing pupil numbers, plus a lower carbon footprint, schools have been the biggest customer of modular construction within the sector.

And both the office, and industrial sectors, are seeing the benefits too, with both accounting for 11% of all modular projects planned or constructed over the last five years.

Regionally, the greatest proportion of modular projects are located in London and the South East, accounting for 34% of all modular projects planned or constructed over the last five years.

Glenigan research has identified a 26% rise in the number of modular projects being started between 2017 and 2019, and the development pipeline has been firm over the last four years too, with planning approval granted on almost 1,000 projects a year.

While the number of approvals unsurprisingly fell back during the first seven months of 2020, earlier approvals will help to sustain the number of modular projects starting onsite during the second half of this year.

And once other sectors recognise the benefits achieved by the education, office, and industrial sectors, we expect an uptick in planning applications to follow.

Glenigan research has identified a 26% rise in the number of modular projects being started between 2017 and 2019.

An innovative combination of three reflective, insulating and low emissivity construction membranes from Glidevale Protect has been used to deliver the magic formula for a new build apartment scheme in Plymouth, Devon.

The installation of reflective wall membranes with strong thermal resistance has helped the project to achieve the key drivers of energy efficiency, reduced heat loss and a low overall U-value for the wall construction. Scheduled to be completed in Autumn 2020, the development named Victoria Views @ Arundel Crescent is the creation of a modern and luxury living space on disused land near the city centre, helping to regenerate the area and boost the economy. Incorporating 24 new build apartments built in timber frame, the housing stock features a range of styles with a mix of one, two or three bedroomed properties.

Timber PAK (SW) Ltd, a specialist timber frame manufacturer was appointed by housebuilder Harrington Homes (SW) Ltd to construct closed wall panels at their offsite factory in Ivybridge, Devon, followed by delivery and installation on-site. Through dedicated support from Glidevale Protect’s technical team, the three membrane solution working in harmony within the

wall panel was approved and utilised, helping Timber PAK to reduce insulation material costs and value engineer the build, providing no impact on labour cost. The confirmed wall make-up incorporated Protect TF InterFoil, a vapour permeable, reflective membrane installed back to back with Protect VC Foil Ultra, an internal air and vapour control layer on the warm side of insulation. With both reflective membranes facing independently into still airspaces, this ensured low emissivity performance and the creation of a radiant barrier to avoid heat loss in the structure. This was supported by the use of Protect TF200 Thermo, a reflective, external breather membrane to help create a radiant barrier within the external wall cavity. This membrane system achieved the client’s target U-value of 0.19W/m2K and resulted in no increase on overall wall footprint.

Ron Luker, Director at Timber PAK (SW) Ltd commented “The innovative idea to use TF InterFoil within a cavity designed into the closed panel allowed us to not only achieve

our target U-value but also save money on insulation material – a win win! The make up with the three membrane solution is now one of our standard wall types for clients and I would recommend this product combination for the more onerous new build specifications.”

The three reflective wall membrane solution from Glidevale Protect forms part of a comprehensive range of wall, ceiling and floor construction membranes alongside roofing underlays and accessories which are ideal for traditional and offsite construction, to help ensure the whole building envelope and internal structure to be controlled in terms of moisture management, condensation control and thermal resistance.

For more information visit www.protectmembranes.com, email info@glidevaleprotect.com or call 0161 905 5700, quoting ‘Victoria Views.’ Follow our Glidevale Protect page on LinkedIn.

Glidevale Protect – Enquiry 20

The superior airtightness performance of the Wraptite membrane from the A. Proctor Group is delivering huge benefits to both the in-factory and on-site construction of a series of new modular social housing for Anglesey Council.

Wraptite is the only self-adhering vapour permeable air barrier certified by the BBA. Applied externally on the outside of the structural frame, Wraptite simplifies the process of maintaining the envelope’s integrity, as there are less building services and structural penetrations to be sealed.

The high vapour permeability of Wraptite allows the substrate beneath to dry quickly and moisture vapour to escape, and reduces the likelihood of mould, mildew, condensation, timber distortion and metal corrosion. The self-adhesive nature of Wraptite means that it is easy to apply together with Wraptite Corners and the fact there is no requirement for mechanical fixings.

Specialist contractor Kenton Jones was commissioned by the Isle of Anglesey County Council to construct the new homes using a high-performance timber frame system. Managing Director, Kenton Jones explains how Wraptite was key to achieving a quality airtightness solution which was suited to modular build.

“After 10 years of building an open panel high-performance timber frame system, we moved to a factory insulated closed panel system which had the airtightness and VCL applied in the factory and simply taped onsite. This worked well when the airtightness layer was fully accessible before services were installed on site.

“In 2019 we built a new module factory and delivered our first set of modules early 2020, it was then we realised internal airtightness was going to be a difficult detail. When building modules that are fully factory finished internally but need to be craned together on-site to form the same dwelling both in a vertical and horizontal joint, we identified that there would be areas of the building which would remain inaccessible after installation on site.

“The first stage of the project was supplied with internal airtightness applied off-site that had very technical, vulnerable details to continue the airtightness around the dwelling within the small access areas left for finishing on-site after installation. This method proved very time consuming in the factory swapping from our usual airtightness board to flexible airtightness membranes between the modules. The cost of this was not sustainable so we needed to look for an alternative.

“We chose Wraptite to achieve the low value airtightness we required for the module system. The benefits of having the airtightness layer externally were a huge saving in time in the factory and impressive simplifying of details to achieve the same quality results. Wraptite was installed off-site in a factory environment for speed and ease and simply taped together on-site between modules to achieve the airtightness.

“Overall we saved time and money with Wraptite, we now have a set of high performance technical details for the airtightness in our module system which are easy to achieve and help maintain a robust quality control system.”

A. Proctor Group

Construction membranes may be hidden after the project is complete, but their role in ensuring proper heat, air and moisture movement through the building envelope and safeguarding the health of the building and occupants is essential.

Wraptite is a unique BBA-certified external airtightness solution. This membrane not only provides airtightness and vapour-permeability, its self-adhering installation method reduces programme length, installation costs and material waste.

Specify responsibly: It’s what’s on the inside that counts.

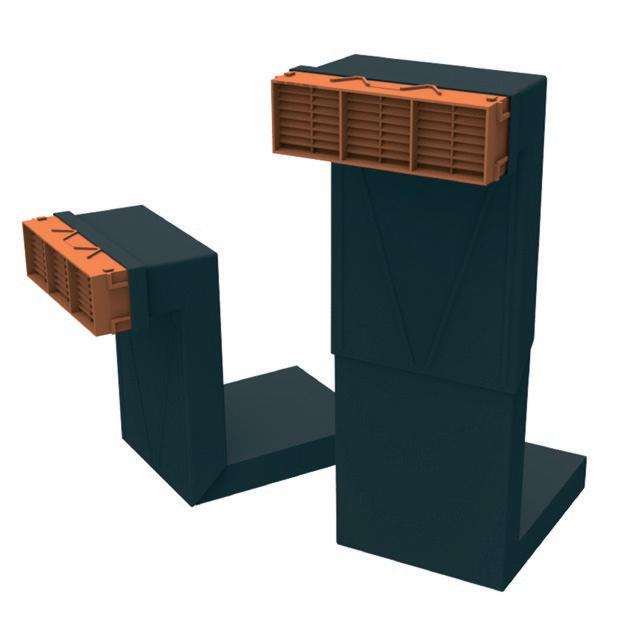

In Victorian times, suspended timbers tended to be used in most rooms, but rudimentary solid floors were still popular in areas such as kitchens and hallways. However, by the 1930s, solid concrete floors became the norm, right up until the advent of modern block and beam suspended concrete floors in the late 1990s.

Since then suspended concrete floors have become popular in UK house construction. It is an economical option due to off-site manufacture of the beams and blocks, fast assembly and little requirement for specialist labour or equipment. The installation of a beam and block floor is not usually weather dependent and therefore specifying this form of construction can reduce site delays that other methods might encounter.

With the increasing popularity of these modern methods of construction traditional vents are no longer considered practical. Increased depths of thermal insulation are being used in suspended floors along with an ever-growing width of wall cavities to accommodate the greater amounts of insulation placed within them, mainly driven by Part L of the Building Regulations and other standards. This has resulted in clear access vertically to the underfloor void being as much as 6 or 7 brick courses (525mm) below the level of an airbrick and potentially as much as 350mm horizontally from the outer face of the external leaf.

Subsequently, traditional, older designed Underfloor vents, are no longer able to fully penetrate through into the underfloor void on their own, making them prone to difficulties during installation, preventing ventilation of the floor void which can become a collection point for condensation, harmful and potentially explosive gases.

Consequently groundworkers face the daily challenge where very many underfloor ventilators will not be able to achieve this access without the use of additional vertical and horizontal extension sleeves, resulting in the fixing of the components being more time consuming and labour intense, which

not only increases the margin for errors in installation, but also has an impact on cost and the amount of components required.

Working with leading block and beam manufacturers and utilising the latest rapid prototyping techniques, Manthorpe’s development team were able to identify the features required to produce a more up-to-date solution. As a result of this collaboration, the G965 Dual Extended Telescopic Underfloor Vent eliminates the need for vertical extension sleeves, in most modern details, and on-site modifications to improve the joins between the vent and accessory units.

The Underfloor Vents are manufactured to offer the greatest vertical telescopic adjustment on the market between 5-8 brick courses, the standard being 3-5, the horizontal outlet can bridge an overall wall thickness of 350mm, so no additional extensions are required, in most modern details, keeping installation quick, simple and free of error.

Designed to meet the requirements of the relevant Building Regulations Approved Document C 4.19, NHBC Standards 5.2.10, BS5250:2011 and BRE guidance, the product is of a strong and durable nature for added assurance and integrity once in position, enabling our customers to reap the benefit of a well-designed, functional and userorientated product which meets modern building requirements.

For further information, or if you would like to see a sample, please contact Manthorpe Building Products on 01773 303030 or mbp.care@manthorpebp.co.uk

For demanding public sector environments that experience significant levels of pedestrian footfall, the correct specification of permanent floor access solutions is vital to not only providing secure and maintenance-free access to underground services, but also ensuring the highest levels of hygiene and safety at all times.

Here Chris George, Business Development Manager at Howe Green, explores the latest floor access solutions available to specifiers and architects to meet a diverse criteria of requirements.

For professionals working on renovation or new build projects within the education, healthcare and high-end hospitality sectors, there are a breadth of varying specifications that must be addressed at the design stages to ensure the long term suitability and compliance of the building components installed.

With regard to floor access covers in particular, durability and functionality are two of the first areas that must be considered. This includes assessing whether the materials used to construct the access cover can withstand the high frequency of pedestrian footfall and the subsequent weight loading requirement for the chosen environment.

Lightweight aluminium floor access covers offer both resilience and ease of use, whilst also being resistant to corrosion, a key requirement for the healthcare and education sectors due to the high level of cleaning and sanitisation required.

Compatibility with a wide range of flooring materials is also an important part of this stage of the specification process. Here professionals should look to specify solutions that are suitable for installation with all types of flexible floor finishes, including vinyl, linoleum, rubber and carpet.

The prevention of dirt and water ingress should also be considered to maintain the highest levels of hygiene. Here it’s recommended to explore access covers that have been specifically designed to bond and weld the sheet flooring to create an impermeable, flat and permanent joint.

Once the above criteria have been met, specifiers should then address the initial installation process, ease of use and ongoing maintenance of the floor access covers.

Due to their light weight, aluminium covers can be extremely versatile as they support quick and easy installation, which also delivering an accurate and unobtrusive finish that doesn’t require continuous upkeep.

The process of gaining access to underground services can also be streamlined through the use of lifting keys, which safely and securely raise the access cover to minimise any on-site disruption and also ensure compliance with all relevant health and safety guidance.

Finally, working with a manufacturer that supports bespoke specifications will also ensure each specific requirement is successfully met. This includes cover sizes, configuration of ducts and branches, along with various weight loadings.

Howe Green’s unique Visedge® Series is regularly specified for high profile healthcare developments including Queens Hospital, Romford, and Southmead Hospital, Bristol, whilst also being the access solution of choice for leading educational institutions including The University of Surrey and John Moores University, Liverpool.

The resilient floor access covers are the ideal choice for challenging healthcare, hospitality and educational environments due to the innovative double top edge seal construction, which provides the highest standards in hygiene and safety.

The Visedge® Series is manufactured to BS EN ISO 9001:2015 at Howe Green’s headquarters in Hertfordshire using CAD and C.N.C machinery.

For further information on the Visedge Series and Howe Green’s complete range of floor access solutions, visit www.howegreen.com or call 01920 463230.

Howe Green – Enquiry 25

The Plus range of finishes, specially formulated in the Mapei Research and Development laboratories, provides a complete solution for long-lasting protection of biological attack from mould and algae. Internal and external wall finishes with, superior performance thanks to Bioblock® technology.

Bull Products, a manufacturer of life-saving fire protection equipment, is taking site safety to new heights during the expansion of the University of Brighton’s largest campus.

Bull Products is helping to secure the safety of the workforce of leading construction company, Bouygues UK, as it delivers the multi-million development for Uliving, a student accommodation developer. The accommodation will provide over 800 student bedrooms and new fitness and social facilities at its Moulsecoomb campus.

Bull is protecting the site with the Cygnus Wireless Alarms including the Fire Call Point & First Aid Alarm. This market-leader temporary fire alarm and evacuation system offers heightened site safety, ensuring workers can distinguish if a fire or first aid alarm is raised. In the case of a first aid alert, each device beeps intermittently every eight seconds.

Matt Trigwell, Sales Director at Bull Products, says: “Our experience of installing our

wireless fire alarms in high-rise buildings means we are well suited to protect the University of Brighton throughout the different stages of development.

“A cause and effect functionality has been set up between zones which allows different personnel in each zone to escape in a controlled manner, therefore reducing accidents and trips during any evacuation.”

Bull Products’ fire extinguisher trolleys, equipped with fire extinguishers and alarms, also ensure all safety equipment is stored in one convenient place. An ideal solution for larger sites, the equipment can be moved around as the site develops, offering maximum site protection where and when it is needed the most.

Bull Products – Enquiry 27

Students at University of Salford will discover a new approach to being safe when the campus re-opens in September.

Gilberts’ “ first of its kind” Series 60 damper has been chosen by leading smoke control systems company Baiceir to protect the 14-storey Discovery Quay development.

Some 26 dampers- each capable of providing up to two hours’ fire integrityhave been incorporated into the common corridors to protect the two stairwells within the £24.5m building, comprising 400 student bedrooms and ancillary communal space.

Manufactured from galvanised steel with intumescent material and gaskets within, Series 60 has passed all relevant smoke and fire tests (EN12101-8 and EN1366-10), retaining its integrity and performance when incorporated into evacuation shafts and risers. Thus customers have the assurance

that they are meeting, if not surpassing, current Standards for smoke ventilation in multi-storey buildings- new build and refurbishments.

Believed to be the only vent of its kind designed and manufactured in the UK, Series 60 offers what Gilberts claims will the biggest standard range of EN12101-8 compliant fire-tested dampers. The initial launch provides seven sizes, from 440mm x 440mm up to 1000mm x 1125mm. The range will be extended by 1mm increments over the coming months.

Gilberts – Enquiry 28

Mul-T-Lock helps secure schools of the future

Security expert Mul-T-Lock recognises that every educational facility has a different security requirement and effective management is paramount. For schools that are looking to upgrade or extend their current master key suite, Mul-TLock offers a wide range of cost effective solutions to address the varying needs of education buildings. Mul-T-Lock has also recently launched a new antibacterial key solution, providing a more hygienic solution for education applications. MulT-Lock’s SMARTair access control system replaces keys with a wireless locking system operated by smartcards and even smartphones when used in conjunction with Mul-T-Lock’s Openow™ app. With SMARTair, lost cards can be cancelled, and replacement cards reprogrammed for increased security.

Assa Abloy – Enquiry 29

Devon-based luxury housebuilder, Bishopstone Homes, is currently creating Amberley Gardens, in Kingsteignton, Devon.

Creating high quality homes demands high quality, reliable materials and Bishopstone has once again chosen Norbord’s CaberDek flooring panels for the intermediate floors. CaberDek, part of Norbord’s CaberFloor range, is designed to withstand the elements for up to 42 days between laying the floor and fixing the roof.

Samples of CaberDek, and Norbord’s other construction panels, can be ordered on the website, www.norbord.co.uk. Head to the new housebuilder page on the website to download a selection of tools including a fully-interactive guide to all Norbord products and a checklist to make sure you have everything you need for your build.

The Jam Factory in Oxford, once home to Frank Cooper’s marmalade business, now comprises over 1,000 square metres of modern office space and a separate café and art gallery.

Member of the Steel Window Association, Cotswold Casements, has extensive experience in the repair, replacement and refurbishment of windows and was tasked with the responsibility of the fenestration. The Cotswolds-based metal window expert refurbished the windows offsite; the detailed

work undertaken included a polyester finish applied to the window sections. This was an impressive project taking around a year to complete and the reinstallation of over 100 refurbished windows has created a striking result.

Junckers has added further certification to demonstrate the sustainability of its wood flooring products. The Environmental Product Declaration, EPD, assesses Junckers’ manufacturing and material sourcing activities and the accreditation counts towards BREEAM, LEED and DGNB assessments.

The EPD sits alongside Junckers’ existing environmental and sustainability certification such as PEFC™, FSC® and the Danish Indoor Climate label.

An EPD presents data in relation to environmental impact, resource use, waste categories and output flow, simplifying the specification process by breaking down important data pertinent to achieving a building’s sustainability accreditation.

Norbord

Junckers is among the first wood flooring manufacturers to hold an EPD certification.

Group Editor Paul Groves takes a look at some of the latest innovations and case studies showing a range of products in use.Steel Window Association

Clear communication has been key to companies making a safe return from lockdown restrictions enforced by COVID-19. Acting with ‘integrity and professionalism’, the measures taken by Nationwide Windows have been described as ‘clear and concise’ and praised for raising ‘the bar even higher’.

“Nationwide were very proactive in sending us information early on from the onset of the coronavirus outbreak and throughout lockdown concerning the COVID-19 measures that they were adopting,” says Katie Waller, Programme Manager at Saxon Weald.

“They managed to reassure us, as a client, that they were following government guidelines, had put specific contingency plans in place and gave us further information and links to their website. The videos that they produced were both straightforward and informative and offered comfort in their processes at this worrying and unusual time.

“We have always been impressed with the way that Nationwide acts with integrity and professionalism. However, their recent communications have raised the bar even higher.”

Mark Lewis, Senior Commercial Manager at Sovereign, commented: “Nationwide has tackled this very difficult period with their usual excellent levels of communication and prompt responses.

“The decision to use videos as an aid for both staff and households was an innovative action that has been received really well. All requests by Sovereign have been dealt with in a ‘can do’ attitude by Nationwide.

“Nationwide are one of the leading contractors when dealing with change and new challenges with clear and concise guidance, method statements, risk assessments and preconstruction phase plans.”

Dante La Bella, Customer Services Manager at Abbey Developments Ltd, added: “Nationwide’s service is very efficient indeed even through these difficult times and communication is always excellent.”

“It was obvious to us from a very early stage that we needed to keep in regular contact with our customers and keep them informed of all the steps we were taking to make a safe return to operations,” says John Whalley, Nationwide Managing Director.

“It’s great to receive feedback like this as it shows that we’ve tackled this difficult situation in the best way possible in order to safely service our customers’ needs.”

For more information on Nationwide go to www.nwd.co.uk.

Nationwide Windows – Enquiry 30

We have always been impressed with the way that Nationwide acts with integrity and professionalism. However, their recent communications have raised the bar even higher.

Sliding and folding door hardware manufacturer, P C Henderson, has announced the launch of a new sliding barn door system which caters for bypassing doors weighing up to 40kg.

Available now - Rustic Bypass is the latest addition to the company’s wide range of sliding barn door style systems. Suitable for two bypassing doors, the new product is ideal for wardrobes, cupboards, pantries and large openings which have insufficient clearance space for bi-parting doors.

Stephanie Lee, Marketing Manager at P C Henderson, commented “Since launching our first sliding barn door system back in 2015 – we have continued to develop and enhance the range to include a wide choice of finishes, hanger designs and functionality options.

The products creative appeal has seen its popularity continue to soar- with customers becoming increasingly more imaginative with their installations. We’re delighted that we’re now able to cater for a whole host of other installations with this new bypassing variant”.

The system runs on one 3m track, making it extremely easy to installand is provided with all of the required components to hang two bypassing doors. Available in a stunning matt black finish the system caters for doors between 700 - 1400mm wide and 35 –40mm thick.

“Our Rustic product is a great way to create a bold design statement in a variety of applications including homes, offices, hotels, restaurants – anywhere. Aside from being a smart design choice, the system also comes with a host of practical benefits – allowing customers to get more square footage out of any room due to no space being taken up by a swing door”, continued Stephanie.

The system sits within P C Henderson’s Rustic sliding barn door family of systems which also caters for single and bi-parting doors in matt black and stainless steel. Visit www.pchenderson.com for more information.

Simplicity in design is often thought to be the secret to creating timeless fashions and one way to achieve that desired blank canvas, is by using flush white doors. This opportunity to rejuvenate and add a fresh clean look to interiors has now been given new impetus and inspiration with the introduction of the White Collection from Vicaima, a selection of quality interior doors for home, hospitality and commercial projects.

Bringing together some truly distinctive finish options in white, the collection demonstrates that this fundamental hue is not actually a single colour, but has in fact a myriad of sheens, surfaces and shades to suit every application. In addition, doors can be customised to allow even greater decorative freedom, with the inclusion of face grooves and inlays, together with many glazed patterns.

The White Collection includes Lacdor in White and Pure White shades, with its ultrasmooth lacquered paint finish; Dekordor SD

in White Smooth and Woodgrain finished foils; Dekordor HD White, a continuous pressure laminate for demanding areas and for those who still prefer to paint their own doors, Primed 2 Go, with its revolutionary surface that requires no face sanding or priming and which will accept paint straight onto its smooth face to achieve an excellent end result.

Where performance criteria is demanded, The White Collection is also available in fire, acoustic and security solutions. And as care for the environment is paramount

in our minds, everything is covered by FSC® certification. Products can be supplied as door only, door and matching frame assemblies or even as corresponding wardrobes.

For a copy of the new White Collection brochure or for further inspiration and trendsetting ideas, Visit the Vicaima website www.vicaima.com or contact info@vicaima.com Tel +44 (0) 7584 392770

Vicaima – Enquiry 34

Set in 74 acres of forest parkland and located on the shores of Lough Oughter in County Cavan Ireland, Killykeen Holiday Village provides 28 luxury log cabins for guests, as well as range of leisure facilities.

The site was acquired by Silvertown Properties Limited in 2016 and a year later the planning for a full refurbishment of the park’s log cabins began. Keen to work with local suppliers, Silvertown selected one of Smart Aluminium Systems’ specialist partners, Super Seal Window Systems Ltd, to deliver the window and door systems.

The requirement was for windows and doors to match the aesthetic of the existing steel fenestration systems, with a mixture of both onsite refurbishment work and off-site modular construction required. Smart’s Alitherm Heritage window and French door systems were chosen for the project, the range providing the perfect solution to meet both the project’s refurbishment and off-site modular construction requirements.

Designed to meet the aesthetic and performance needs of this prestigious project, the Alitherm Heritage system features the slim profiles and sight lines that are associated with traditional steel products, its timeless elegance being accompanied by outstanding thermal performance, durability and longevity.

Commenting on the completion of the work, Kenneth Taylor, Managing Director of Super Seal, said: “We are delighted to have been involved in such a great project, with these new and refurbished log cabins looking magnificent in such a spectacular setting.

“We worked closely with the teams at Silvertown and Smart to meet the specific requirements of the project, as well as with the construction teams both on and off site to deliver our work. The high quality Alitherm Heritage range provided the perfect solution to meet all the design requirements, and we now look forward to working with Silvertown on future stages of the park’s development.”

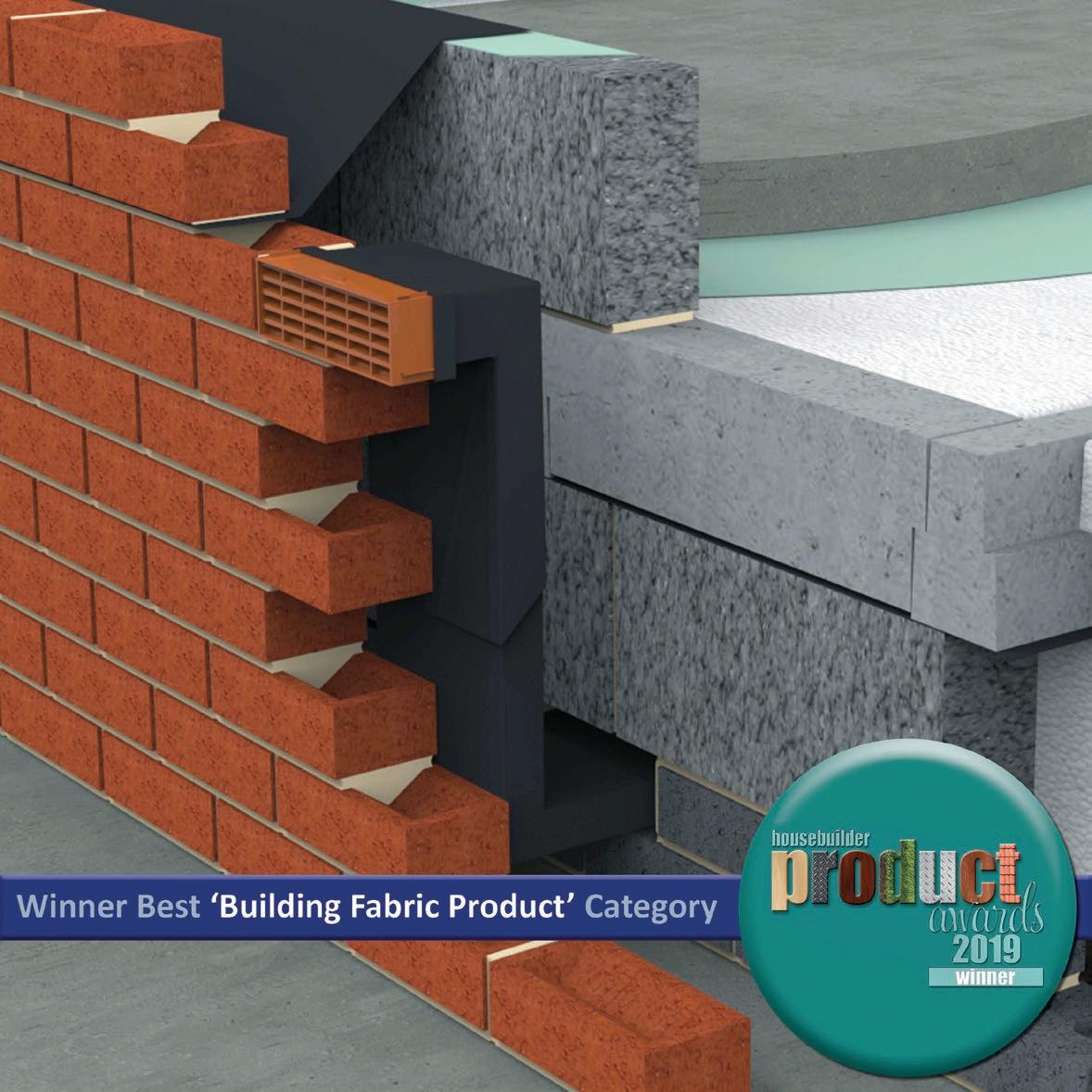

The Titon FireSafe Air Brick boasts a polyester powder coating, adhering to EN13501-1 classification A2-s1, d0 (reaction to fire), while its 1.2mm electrogalvanized sheet steel construction achieves the highest level of fire classification (A1 – “no contribution to fire”).

This ensures each Air Brick is noncombustible, as set out in Approved Document B (fire safety) Volume 1: Dwellings, 2019 edition. In addition to being salt spray tested to BS EN ISO 9227:2012 for corrosion resistance, the Air Brick has also been performance tested to BS EN13141-2:2010 (ventilation for buildings).

For added versatility, there are optional sizes; single brick sizes (204mm x 60mm), single brick and half (330mm x 60mm) and a double brick (204mm x 128mm), which can be connected to 204mm x 60mm and 220mm x 90mm regular, thermal and rigid ducting. All air bricks have depth options of 100mm, 400mm and 500mm. Bespoke lengths can also be produced upon request. Plus, the range contains a bezelled version

After weeks of hard work we are extremely proud to announce that our new website is live. We have listened to feedback and the new site includes much more product and specification information along with certification and fitting instructions for our range of high quality hardware for windows and doors designed for commercial buildings. We hope you enjoy our new look which is optimised for both desktop and mobile devices. Please visit our new site: www.strandhardware.co.uk

for use with exterior cladding (instead of brickwork), allowing the product to be installed throughout a variety of different applications.

Commenting on the new range, Lee Caulfield, Director of UK Sales (Ventilation Systems) at Titon, said: “In the aftermath of recent tragic, fire-related events, it has become apparent that various products within a building’s make-up need to be non-combustible. This has led to Titon developing a new, fire resistant air brick that improves dramatically on the design of traditional, plastic versions.

The flame-retardant properties of the Titon FireSafe Air Brick ensure it cannot contribute to a fire’s progression.”

The new products are coloured Terracotta, Sand, Grey, White or Brown,

while special paint finishes are also available, depending on the quantity required.

Titon – Enquiry 37

The Jam Factory in Oxford, once home to Frank Cooper’s marmalade business, now comprises over 1,000 square metres of modern office space and a separate café and art gallery. Member of the Steel Window Association, Cotswold Casements, has extensive experience in the repair, replacement and refurbishment of windows and was tasked with the responsibility of the fenestration. The Cotswolds-based metal window expert refurbished the windows offsite; the detailed work undertaken included a polyester finish applied to the window sections. This was an impressive project taking around a year to complete and the reinstallation of over 100 refurbished windows has created a striking result.

Steel Window Association – Enquiry39

The Schüco AD UP (Aluminium Door Universal Platform) door system combines the highest quality aesthetics with impressive thermal performance, outstanding watertightness, PAS 24 security and the ability to integrate smart building components. The AD UP door system offers a range of options for a multitude of applications and is based on two profile widths: the AD UP 75 (75mm) and the AD UP 90 (90mm). Both versions integrate seamlessly with the range of Schüco façade, window and sliding door systems. It has exceptional watertightness, up to E750, which ensures reliable performance even in a violent storm.

SchÜco – Enquiry 40

The NSG Group and University of Cambridge are collaborating on ground-breaking new glass applications, while using the latest technology to realise the future of manufacturing.

The Group, which owns Pilkington United Kingdom Limited, is currently working with the University’s Fluids in Advanced Manufacturing team (FIAM) to establish a way of printing conductive materials onto wide areas of curved glass surfaces.

Currently, conductive materials can only be effectively printed onto flat glass surfaces. If successful, this innovation is set to enable the printing of metallic nano inks at high precision across curved glass, introducing new applications for glass in automotive and architectural sectors by increasing the potential functionality of glazing. New uses include helping detect pollution, incorporating heating elements or as digital signage.

The research aims to see the conductive materials applied to curved glass surfaces, such as car windscreens, using inkjet printing technology at the final stage of the manufacturing process. This process will help make high tech curved glass more cost effective to manufacture, while helping it to be increasingly customisable for customers – boosting its marketability.

For the first phase of the research, the partners are using virtual reality to model and design a laboratory that uses robotic

technology to print the conductive materials onto curved glass surfaces. Using robots, printing the nano inks will be done with high precision and speed, while accounting for the curvature of the glass.

Dr Su Varma, R&D incubator academic programme director at the NSG Group European Technical Centre, said: “This is an exciting project that has the potential to extend the boundaries of glass’ use in car manufacturing and building design.

“It allows high-tech applications of glass to not be limited to flat surfaces, expanding opportunities for architects, while revolutionising the role that glass can play in vehicles.

“The project is our latest initiative working by the side of the University of Cambridge, a relationship that extends past the inauguration of the institution’s Pilkington prize in 1994, which recognises outstanding contributions made by academics and researchers to the University.”

Dr Ronan Daly, head of FIAM and senior lecturer at the University of Cambridge, said: “Smart technology applied to glass has the potential to perform a number of important tasks - from identifying the presence of bacteria on a hospital window to performing as a touchscreen display, for example.”

“Conductive materials can already be printed onto flat surfaces, and alongside the NSG Group we’re now overcoming the physical challenge of completing this for curved applications – this opens up new opportunities for designers to use glass technology to solve their modern design challenges.”

The pair are also co-funding a PhD student, James Macdonald, who is based at NSG Group’s European Technical Centre in Lancashire and at the Institute for Manufacturing, University of Cambridge, for researching new ways of patterning and printing on glass. Dr. Cristina RodriguezRivero from the Institute for Manufacturing is leading the printing-to-shape research. >>

This is an exciting project that has the potential to extend the boundaries of glass’ use in car manufacturing and building design.

>> Architectural glazing systems by leading UK manufacturer Kawneer were specifically selected for a £18.5 million extension to the UK's oldest business school for their ability to meet the building's design aesthetic and high-performance requirements.

Glancy Nicholls Architects were appointed to design a building that provided a cellular and multi-occupancy space for the school's academic staff, with student break-out spaces along with refurbished professional services, staff offices and enhanced café and catering facilities.

Glancy Nicholls director Simon Jesson said: "The Kawneer systems were selected by the sub-contractor to meet the stringent thermal performance requirements along with the high-quality detailing required by the planners.

"To maximise the daylighting the elevation incorporated large windows but also required user control of the ventilation as well as glare control. The system was able to provide the aesthetic requirements for incorporating silicone jointing to minimise the impact of the frame on the proportions of the windows.

"The relationship to the brickwork cladding, the stone and the glass-to-glass corners on the bay windows was managed efficiently with the necessary trims and recessed details to maintain a clean-looking façade."

The Kawneer glazing systems were installed by specialist sub-contractor and Kawneer dealer Duplus Architectural Systems.

Eyrise is providing instant solar shading at BAFTA 195 Piccadilly, as part of a comprehensive refurbishment to improve facilities and double the building’s capacity, enabling BAFTA to dramatically increase its charitable programme.

The British Academy of Film and Television Arts is installing recently developed smart liquid crystal windows to glaze two restored Victorian rooflights on a newly constructed top floor at its Grade II listed headquarters in London.

Proprietary Licrivision liquid crystal technology enables Eyrise glass to be tinted to provide solar shading immediately without compromising on natural daylight. The windows will provide lightwellness - visual comfort, thermal regulation and colour neutrality - for occupants on demand, while also helping to reduce energy consumption.

“New technologies are helping us transform and grow the infrastructure of our headquarters which in turn will enable us to expand our important work in supporting emerging and under-represented talent,” said Kevin Price, BAFTA’s Chief Operating Officer. “By raising the roof and re-integrating the rooflights with Eyrise’s innovative glazing, we are able to open up a bright new space and deliver a greater variety of initiatives, learning events and activities.”

The refurbishment will reveal the hidden rooflights, built in 1883, for the first time since 1975 when they were covered to create a dark space for a 227-seat cinema. Designed by Benedetti Architects, work on the project has already begun and is due to be completed in 2021.