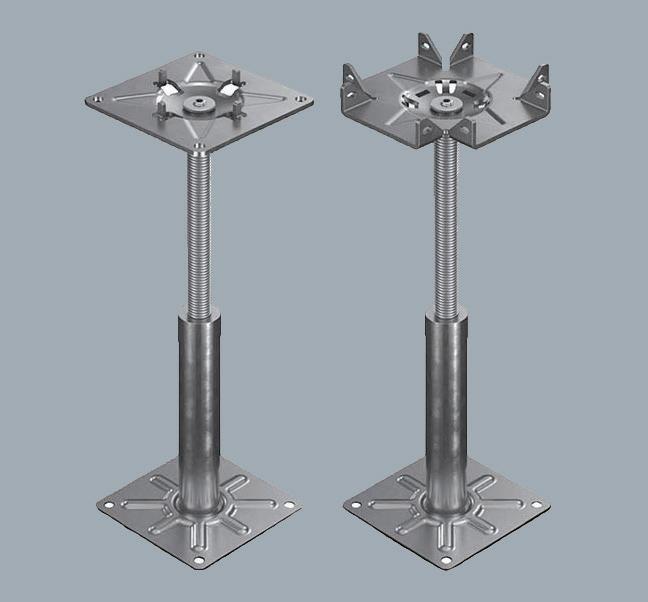

With a vast choice of finishes available for any Design scheme, including larger formats and co-ordinating internal tiling, Levato Mono porcelain paver system is perfect for balconies, roof terraces, garden decks and piazzas. Key benefits include; high slip resistance & load bearing, fade & wear resistance – so low cost ongoing maintenance. Both of our self-levelling support pedestals promote a fast cost-effective installation process for use on delicate waterproofing or covering tired slabs. The tilting head adjustment compensates slopes up to 5% even with multiple falls. If a Fire rated pedestal is specified then the FRSL range has Class A1 classification or the SL polypropylene type which have their own key features; secure height locking, non- slip acoustic dampening pads and large height range (28 to 550mm).

Anew white paper has been published that sets out how the entire built environment sector can unite behind a single, agreed standard to determine, demonstrate and recognise construction product competence (CPC).

The white paper ‘Built environment – proposed construction product competence standard – white paper’ has been developed by Competence Steering Group (CSG) Working Group 12, led by the Construction Products Association (CPA).

The CSG was tasked with responding to the competence issues raised in Dame Judith Hackitt’s report ‘Building a Safer Future’ and the subsequent requirements set out in the Building Safety Act following the Grenfell Tower fire.

All industries of the built environment sector use construction products, but their misuse can lead to dangerous and potentially fatal outcomes. Ensuring those who use construction products are competent is vital to producing buildings and a built environment that is safe, and efficient and performs as required. However, there is currently no universal way to demonstrate that an individual has the correct competence for the tasks they are accountable and responsible for.

This white paper confirms that radical change is needed in the area of construction product competence. Individuals who supply, use, or otherwise work with construction products need to be properly assessed and deemed competent to do so. This would include those from manufacturing, merchants, design, contractors, maintainers, and many others from right across the supply chain.

The proposal for a new standard comprising five core levels of competence, as well as a methodology that defines how these can be mapped consistently by the different industries to their competence frameworks. The white paper also proposes that the standard be added to the existing BSI 8670 series, which specifies requirements for competence frameworks for individuals working in the built environment.

Peter Caplehorn, CPA Chief Executive, says: “Dame Judith Hackitt rightly pointed out that our industry needs to take responsibility for competence and work in a non-siloed manner. Now the Building Safety Act is making clear that regulators will no longer tolerate an industry that does not evidence its competence. The CPC levels have been designed to provide a single framework for everyone to work to, and I would urge the industry to read this white paper and get involved in testing it together.”

Paul Groves || Group Editor

Britain’s modular construction companies are moving at speed to deliver widescale change in the housing market unseen in the UK for generations, according to new research published by Make UK Modular. ‘Greener, Better, Faster: Modular’s Role in Solving the Housing Crisis’, shows that while innovation has left the construction industry largely untouched till now, precision engineered homes, factory-built in areas where employment is required and delivered to regions of the UK where housing is scarce, are set to revolutionise the sector and help solve Britain’s growing housing crisis.

Factory engineering means modular homes can be built to consistently high sustainability standards, delivering savings of 55% on energy consumption compared to the average UK home and cost 32% less to heat than a traditional new build.

This translates to savings of up to £800 a year for a three bedroomed family home, and energy reduction rises to 60% for single or two person households living in smaller properties.

Foster + Partners has completed the new headquarters for DJI, the world’s leader in civilian drones and creative camera technology.

Located in the Nanshan District in southwest Shenzhen, China, the two towers – 44 and 40 storeys respectively – are set to become

Modular manufacturers already produce 3,300 homes a year, one in 60 of all new houses in the UK and by 2025, and with the right support, this could grow to over 20,000 new modular buildings each year.

Modular manufacturers have chosen to build over 40 factories in post-industrial provincial towns or cities, creating over 3,000 jobs and delivering £700m of investment to lowgrowth, low employment areas – a figure which could easily double with some simple Government support.

Steve Cole Director of Make UK Modular, the trade body for modular housing said: “There is a housing success story in this country, and it is modular. This report shows definitively that modular is now a significant player in the UK housing market. Government must capitalise on this as opportunities to transform our broken housing market into the most sophisticated in the world do not come around every day.

“Government must accelerate modular delivery, building on the investment made and the jobs created, by removing the remaining barriers holding the industry back.”

With the launch of the Better Social Housing Review in June bringing an increased focus on the importance of refurbishing ageing public housing stock, Polypipe Building Services has announced the launch of a white paper offering guidance on one of the most complex and time-consuming RMI challenges –drainage system replacement.

Following government debate regarding the condition of some social housing in the UK, the independent Better Social Housing Review has been established to make practical recommendations to social housing providers to tackle problems from damp issues to communication with tenants. This has placed a renewed focus on how RMI projects can deliver best value and minimise disruption for residents.

the ‘heart of innovation’ for the company and form a creative community in the sky.

Across the two towers, office and research spaces are arranged in floating volumes cantilevered from central cores by large megatrusses and circular profiled steel suspension rods.

Given the nature of the work involved, drainage system replacement can often represent a large portion of such projects. As Graham Hicks, Project Development Manager at Polypipe Building Services explains, this means specialist focus is needed: “Replacing the drainage stack in a large residential building is a significant piece of remedial work, and inevitably means a period of time where residents are unable to use sinks, toilets and other facilities.

“Furthermore, given the nature of older buildings there has usually been a degree of renovation or reconfiguration work already undertaken which means planning exactly what needs to be replaced and how can be extremely complicated.”

“Getting drainage replacement right can often be make or break as to whether an RMI project overruns or causes unexpected disruption to residents. That’s why we have launched our latest white paper that gives specialist advice on what should be considered for this type of work.”

Based on case studies from recent public sector RMI projects, the white paper outlines key considerations for building owners and contractors so they can ensure drainage system replacements are carried out as efficiently as possible – helping to support the drive to improve the condition of the UK’s social housing stock.

The Pendock Radius range provides architects and specifiers with the perfect solution for concealing interior or exterior columns & structural steelwork with decorative, durable and practical column casings. Incorporating both standard and bespoke shapes in a range of materials, finishes & sizes, Radius offers unrivalled versatility and choice. They can also be installed by our experienced teams to ensure the perfect fit and finish are achieved.

The Radius range includes:

Material: Ply/MDF; aluminium; stainless steel; GRP and GRG Shape: Circular; square; rectangle; ellipse; triangle; polygon and bespoke Finish*: Site-finish; HPL; PPC; brushed; polished, textured; patterned and Gelcoat

*Dependent on material

Pendock Radius is part of our extensive casings, enclosures and decorative architectural products range, which combines aesthetics with practicality and design flexibility.

www.pendock.co.uk e: technical@pendock.co.uk t: 01952 580590

CIBSE is launching an addendum to TM65, the embodied carbon calculation methodology published in 2021.

TM65 Embodied carbon in building services: Using the TM65 methodology outside the UK (TM65LA) is designed to create global consistency on how the embodied carbon of building services equipment can be assessed.

TM65 provides a methodology to estimate the life cycle embodied carbon of products used in building services engineering where no environmental product declaration (EPD) is available. Many of the methodology’s inherent assumptions in the 2021 publication are specific to the UK.

This addendum aims to complement TM65 by defining how local addenda can be developed. As such, it sets out how the methodology can be adapted to be used outside of the UK. It is not a standalone document and cannot be applied without first understanding TM65.

Housing provider A2Dominion has signed a contract with award-winning housebuilder, The Hill Group, to deliver a scheme of 125 units to house a minimum of 340 key workers at the John Radcliffe Hospital in Oxford.

Due for completion in October 2025, the residential scheme replaces the existing Ivy Lane accommodation and includes seven new apartment buildings, ranging from three to five storeys high.

Designed to meet the needs of the Trust’s staff, the site is made up of 68 apartments and 57 cluster units, each shared unit comprises of either four or five bedrooms and a communal kitchen.

This contemporary scheme also includes facilities such as management offices, a meeting area, bike and car parking, and landscaped communal green open space for residents to enjoy.

To ensure that the CIBSE TM65 methodology is globally valid and globally consistent, CIBSE supports the creation of local addenda to TM65 that are specific to localities outside of the UK. This document aims to assist in the creation of these local addenda.

Primary authors, Louise Hamot and Clara Bagenal George (Integral Group) said: “The aim is to create global consistency with relevance locally.

“The TM65 methodology inherently relies on a set of assumptions that might differ in different countries for supply chain or geographical reasons. This guide sets the rules for creating consistent local addenda. A local addendum can be developed for a continent, a country, a state, a city or a region. The overarching methodology would be the same but applied with local assumptions and local carbon factors.”

CIBSE TM65LA was authored by Louise Hamot and Clara Bagenal George (Integral Group), with contributions from Dr Joe Jack

Williams (Feilden Clegg Bradley Studios); Dr Julie Godefroy (CIBSE); Leonardo Poli (Integral Group); Louise Wilkinson (Integral Group); and Simon Wyatt (Cundall).

A newly constructed head office in Newcastle City Centre has raised the bar for its delivery of social value.

One Strawberry Lane, the new home for Home Group, one of the UK’s largest housing organisations, has returned a 44% social value score – up to three times the national average for a similar sized project.

Research last year by Social Value Portal and SCAPE show that the average social value scores for construction projects range between 13% - 25%, with the lower score correlating to larger developments.

Home Group worked alongside developers

Ask Real Estate and contractor BAM Construction to draw up an agreed plan to ensure the project delivered to the highest standard.

In particular, the One Strawberry Lane project has delivered significantly against the local spend criteria.

More than £16m has been reinvested within 30 miles of the project, with majority of the local spend supporting micro, small, and medium enterprises (MSMEs).

The Building Engineering Services Association (BESA) has urged the government to include reducing energy demand as part of its strategy for economic growth and review of net zero policy. It said a strong focus on energy saving could help the Prime Minister Liz Truss achieve her aim of delivering net zero in a ‘pro-business and pro-growth’ way and could play a key role in improving energy security and make the country more resilient to financial and climate shocks.

The Association said it was important that former energy minister Chris Skidmore considered demand-side energy measures as part of his three-month review of the UK’s net zero strategy commissioned by new Business and Energy Secretary Jacob Rees Mogg.

“There is a lot of focus on finding new sources of energy and driving investment in major infrastructure projects like nuclear and fracking, but cutting energy

consumption should come first,” said BESA President Rab Fletcher.

“A national programme of building refurbishments and retrofits could dramatically reduce the need for spending on new energy developments, stimulate a massive market, and move us several strides further along the path to net zero,” he added.

Fletcher pointed to a new study from the Institute for Government (IfG) that estimated a national energy efficiency retrofit scheme for buildings could cut domestic energy bills by £27bn a year.

The report warned that the current energy price freeze did not consider what would happen in the longer term, with the UK likely to experience fluctuating gas and electricity prices for the rest of this decade. This will make us vulnerable to price shocks because we depend on gas-fired electricity generation and gas heating and have an inefficient building stock.

While BESA welcomed the government’s intervention to freeze the cap on energy bills at £2,500 for two years, it is concerned this could delay vital action on energy saving.

It urged the government to use the time to deliver radical policy changes to promote energy efficiency and low carbon building services.

“Liz Truss and her team deserve praise for putting bold measures in place to get consumers and businesses through the early stages of the current energy crisis, but this is a long-term problem and high gas and oil prices are with us to stay,” said BESA President Rab Fletcher.

“Now is not the time to pause energy efficiency and carbon saving strategies. On the contrary, we should use this period to press the accelerator and use the new energy landscape as a once in a generation incentive to invest in energy efficiency on a dramatic scale.”

Singapore has a new skyline addition with the completion of CapitaSpring – a 280-meter-tall high-rise oasis that continues the city’s pioneering vertical urbanism with a diverse neighborhood of restaurants, office space, a serviced residence and sky gardens from the ground all the way up to the 51st floor.

Currently among the city’s tallest towers, CapitaSpring is designed by BIG-Bjarke Ingels Group and CRA-Carlo Ratti Associati who collaborated on its architecture, public space, and digital user experience (respectively).

At multiple elevations, the vertical elements comprising the building’s exterior are pulled apart to allow glimpses into the green oases blooming from the base, core, and rooftop “sky garden.”

A new development of 21 homes on Mayton Street in Openshaw has completed, creating a new benchmark for family social housing in the city. The all-electric development consists of 15 houses for social rent and 6 made available for shared ownership.

The homes were constructed using a sustainable timber panellised system manufactured off site and make use of air source heat pumps for hot water heating.

The wider development also benefits from solar-powered street lighting.

Building work for the Mayton Street development was started by John Southworth Builders in August 2021, and after 12 months the project has been completed.

One Manchester is working toward the zero carbon Manchester ambition to become a zero carbon city by 2038 at the latest.

The New York St John Creative Centre, designed by Architects Tate + Co, is a purpose-built, three-storey creative space where bold architecture meets innovative facilities.

Tate + Co were the architects and lead consultants for the project, employing the design team on behalf of the client.

This team included MCAG/RLF as Quantity Surveyors, Contract Administrators and Project Managers, Atelier One as Structural Engineers, Atelier Ten as MEP and Lighting Consultants, Colour Landscape Architects, McKenzie Town Planning, Sound Space Vision as Theatre and Acoustic Consultants and the Sensory Trust as Access Consultants.

The building was constructed under a traditional contract by Kier.

The Creative Centre for York St John University is a low-energy building that provides a permanent new home for the University’s music and computer science courses, featuring specialist spaces for performance, creative writing and media production students.

Three main concepts formed the foundation of the design approach.

First, it is a genuinely sustainable building, both in operational and embodied carbon terms, with a substantial timber frame and simple climate control.

Second, the main atrium space unites all the building elements together, reflecting the latest thinking in higher education to create ‘third spaces’ for cross-disciplinary collaboration.

Finally, the Centre makes the most of its proximity to York Minster connecting the University to the heritage of the surrounding city.

Throughout the atrium, recital hall and critical listening room, views to the Minster are carefully framed, reinforcing this picturesque view across the stunning historic site. >>

>> “Low embodied carbon materials, such as glulam and CLT, were used for the construction of the Centre, as part of a ‘fabric-first’ approach using Passivhaus principles to achieve a BREEAM Excellent rating,” explained Tate + Co.

“Working alongside environmental design consultant Atelier Ten, the project’s eco credentials were achieved by using tripleglazing, making the building air tight, providing simple operation systems – such as openable windows – and a mixed mode ventilation system with both mechanical and natural ventilation in teaching rooms.

The building is extremely functional and flexible, for example the 2,000m2 of teaching space are column-free internally with modular servicing to allow easy re-configuration in the future should the university’s requirements change.

The 180 capacity auditorium was designed with SSV Theatre Consultants to facilitate teaching as well as performances, with a level access technical level.

“And the building connects to the natural environment through its use of natural materials and integration with a campus wide landscape masterplan which Tate + Co developed with Colour Landscape Architects.”

In June, Chancellor of the university, BBC Broadcaster Reeta Chakrabarti, cut the ceremonial ribbon to mark the centre’s launch.

Vice Chancellor of York St John Professor Karen Bryan said: “Sustainability is very important to our student body.

“We have an aim to half our energy consumption, to re-use wastewater – those sorts of issues are very important to us. We deliberately employed an architectural company with expertise in that area.

“We also wanted the building to be modern – but to have a connection with the traditional architecture and landscaping in our grounds.”

Epwin Window Systems is the UK’s largest and most established British manufacturer and supplier of cutting-edge PVC-U and aluminium window and door systems. It’s also the home of two of the country’s most widely specified PVC-U commercial window and door systems, Spectus and Optima.

Our window, door and curtain walling systems have been specified and installed in thousands are commercial

projects throughout the UK. And with our ongoing commitment to sustainable design and high-quality construction we have the

products, longevity and stability to remain the system partner of choice for commercial projects. >>

But none can match the excellence of a system that is truly complete

THE UNIFOLD GUTTER LINING SYSTEM.

Having faced and solved every problem experienced in its long life with consummate ease UNIFOLD remains THE GOLD STANDARD to which others aspire!

UNIFOLD – Unrivalled excellence in Gutter Lining Technology.

Epwin Window Systems has developed two heavyweight PVC-U window and door systems for the commercial sector, Spectus and Optima.

Spectus products have been specified in the commercial sector for over 40 years. It’s a complete system with product solutions to meet the requirements of diverse architectural styles and different building materials.

Award-winning Optima is the country’s most widely specified window and door system. Following in the footsteps of its predecessor, Profile 22, it is used on projects of all sizes across all sectors.

Spectus and Optima are part of a wider portfolio of cutting-edge PVC-U and aluminium window and door systems. These include PatioMaster, the UK’s best-selling PVC-U sliding door system, and Stellar, the multi-award-winning aluminium window and door system.

Epwin Window Systems’ PVC-U windows and doors are all designed to maximise thermal efficiency and meet regulatory requirements, helping you to meet your environmental targets. Our products have a lifespan of more than forty years. At the end of their life, they are recyclable up to ten times.

We were the first UK systems house to achieve the VinylPlus® Product Label, the labelling scheme that makes it easy for customers and markets to identify the most sustainable and high-performance PVC-U products.

We hold BES 6001 accreditation for responsible sourcing of construction products, and our manufacturing facilities meet the requirements of BS EN ISO 14001 Environmental Management.

Our complementary specification support forms an essential link between architects, specifiers and approved manufacturing partners regardless of the size or scale of the commercial project.

It gives you access to technical expertise and practical support, including drawings, technical calculations and stakeholder liaison, to ensure you have met the exacting standards of every aspect of your window and door schedule. We also embrace the latest technologies, and we have products in bimstore.co and NBS Source.

Our Approved Commercial Partners gives you peace of mind you’re working with manufacturers and installers with the expertise and experience to take on the biggest commercial projects.

As well as having industry-recognised credentials and considerable commercial experience, Approved Commercial Partners are skilled in fabricating and installing Epwin Window Systems products, ensuring projects are completed to the highest of standards, on time and on budget.

Our 40-year track record of working with public and private sector organisations speaks for itself. Across new build and refurbishment contracts, our products are chosen for housing developments, social housing projects, hospitals, educational establishments and more.

Our products are specified because our size and strength make us a reliable partner. We help you deliver cost-effective and inspirational projects that protect homes and buildings and the people who live and work in them.

To discover more visit www.epwinwindowsystems.co.uk

In our approach to building refurbishment, it is crucial to recognise that we cannot simply upgrade thermal insulation without addressing the balance of moisture movement and air leakage. In doing so, we can ensure that the most optimal upgrade solutions are achieved. Strategies to upgrade the energy performance of existing buildings must therefore be carefully considered, and considered holistically, as actions affecting one aspect of the building may have unforeseen consequences in another. Designers must therefore have a good understanding of the materials being used both in the upgrade process and the original construction.

When considering the insulation of buildings, we usually refer to U-Values. A U-Value quantifies the rate of heat loss through a building element such as walls, roof, windows, and doors. The lower the U-Value is, the slower the heat generated by the heating system will escape the building, and the less energy input is required to maintain a comfortable internal temperature.

How can we improve the U-Value of a given element? Using a wall as an example, we add thermal insulation boards or blankets to keep the heat in.

A specific thickness of any material has thermal resistance, and to work out a U-Value, we add all the R-Values in the wall together and take the inverse of the result. This inverse calculation means that the more insulation we add, the greater the improvement to the U-Value.

Not all materials insulate equally well, though, and to determine that, we use a value called the thermal conductivity or Lambda value. For example, materials like bricks or metal have high thermal conductivity, while insulation like mineral wool or rigid foams has far lower conductivity. The thermal conductivity of a material is usually independent of its thickness, making it ideal to use as a comparison tool.

Combining all this information, we take the thicknesses of our materials and divide those by their thermal conductivity to get R-Values. We then add those R-Values together and take an inverse to get the U-Value. Finally, the U-Value is adjusted for any penetrations like structural elements, called repeating thermal bridges, any fixings or air gaps present, and a few other correction factors to give us a final U-Value for the element.

The next step is to take all our U-Values, weight them by area, and derive an overall average for the entire building. Finally, this average is adjusted to account for non-repeating thermal bridges like corner junctions, floor zones, etc., resulting in our complete heat loss model.

Modern new build homes typically have wall U-Values of around 0.2 W/m2K, whilst traditional older properties with solid walls will be more like 2.0 W/m2K, an order of magnitude worse, which will have a significant effect on the heating bills of the property and the quality of life of the occupants. This has substantial impacts where occupants are in fuel poverty or belong to a vulnerable social group such as the elderly. For such groups, poor thermal insulation can lead to health problems, so it’s essential that upgrading such homes is a priority.

In historic buildings, this priority will need to be balanced against retaining architectural features, maintaining the character of the building and aesthetic qualities, and ensuring the internal spaces remain large enough to be fit for purpose.

There are many types of insulations on the market, with a wide ranges of thermal conductivities However, there are some challenges when considering the right choice for refurbishment projects or historic buildings.

Firstly, older buildings typically benefit from highly vapour permeable insulation. The traditional building materials used in these older properties, such as lime-based mortar and plaster,

have very different hygrothermal properties from their modern equivalents. Adding insulation of low permeability, such as rigid foam, can result in damaging moisture problems for two primary reasons.

Adding any insulation will reduce the temperature of the existing wall masonry, making it more likely that condensation will occur to the inside as there will be less heat penetrating from the living spaces to warm up the masonry.

Secondly, some insulation types, such as rigid foams, can prevent the drying out inwards into the building, further compounding the problem. If not adequately accounted for in the design, this moisture accumulation can continue unchecked, increasing issues with dampness and mould over time and, in extreme cases causing the masonry to degrade due to freeze/thaw cycling.

Permeable insulation prevents moisture from being trapped in the construction and does not disrupt the established balance of moisture flows within the building fabric to the same degree. However, traditional moisture vapour permeable insulation, such as mineral fibre, tends to be very bulky. This results in another challenge in historical refurbishment: preserving interior space.

The relatively high thermal conductivity of mineral fibre, wood fibre or natural wool means achieving modern thermal standards can require up to 200mm of thickness. This thickness is often not practical to incorporate into an existing space.

On the other hand, aerogel composites such as Spacetherm® can maintain permeability while dramatically reducing the required depth. This makes Spacetherm ideal for use in rooms with limited floor area, at door and window reveals, and in other areas where retaining existing features would otherwise limit the use of thick and bulky insulation.

Aerogel is a very low-density solid developed in the 1930s but has only recently found mainstream uses. Aerogel is a gel in which the liquid is replaced by gas without shrinking via a complex process called supercritical drying.

The silica aerogel used in Spacetherm insulation is essentially puffed up sand, best described as being to sand what a Rice Krispie is to rice. The resultant structure is 97% air, entrapped in nano-sized pores, and while a superb thermal insulator, it is very brittle in its raw state, limiting its practical applications. However, Spacetherm takes this aerogel and embeds it into a fibrous mat to achieve excellent thermal performance and robust flexibility. The thermal conductivity of 0.015 W/mK makes it among the best thermal insulants in use today, which, combined with its high vapour permeability, makes it ideal for refurbishments. Furthermore, Spacetherm is also hydrophobic, meaning it actively repels liquid water.

Spacetherm can be used directly in the blanket form utilising its inherent flexibility to fit around curved or uneven wall surfaces, or it can be laminated to a variety of panels and lining boards for more specific applications. Because the aerogel insulation blanket contains no blowing agents, it does not release harmful gasses into the building over time, nor does its performance degrade, with extensive testing showing no loss of thermal performance over 50 years.

So, considering all the above, the risk of condensation, counterintuitively, is lowest when we omit the vapour control measures and limit the insulation thickness. The additional detail regarding moisture movement can be assessed by hygrothermal assessment which allows the designer to quantify and manage the specific risk associated with the proposed thermal upgrade.

Decorative architectural casings are now a common feature in contemporary building design as they provide a versatile, effective and stylish method of concealing structural steelwork, concrete support columns and building services.

This method of production allows a high degree of design versatility with shape; size and colour options all open to specification to meet bespoke project requirements, as well as standard profile options.

Projects, such as Kia Motors’ flagship London showroom, Premier Inn’s recently completed hotel in Cardiff Bay and Birmingham’s Dental Hospital, illustrate the versatility of ‘Polyma’ and ‘Forma’ column casing solutions and suitability for bespoke solutions.

The combination of practicality, versatility and aesthetics have been at the centre of the wide range of projects undertaken by the Encasement Ltd, covering many business sectors including retail, education and healthcare, as well as hotel, sport & leisure and commercial refurbishment and building re-purposing projects.

Key to this project diversity is the number of options available to specifiers. These include several materials, as well as an array of finishes and the ability to select from standard shapes and sizes or create bespoke manufactured designs.

As a result, Encasement casings have been specified and installed by many well-known brands, including Porsche; TATA; Premier Inn; Kia Motors; Halfords and Tesco together with a wide range of retail outlets, hospitals, universities, leisure projects and office buildings across the UK.

The company’s products include the pre-formed plywood Circa and Quadra ranges, together with the Forma metal range. Alongside these, the Polyma GRP and Gypra GRG casings are moulded from glass reinforced polymer and glass reinforced gypsum, respectively.

The range is completed by Metza, which is a specialised solution for use with mezzanine floors that provides up to 2 hours fire protection to the floor support columns. Whilst all Encasement’s column casing are suitable for interior use, Polyma and Forma are also widely used for exterior projects, due to their inherent weather resistance and durability.

Available in aluminium or stainless steel, Forma casings can be specified as circles, with diameters from 250mm up to 1000mm, plus square, rectangular or hexagonal forms, as well as unique custom profiles. The choice of finishes is also extensive. In addition to RAL colour PPC coating options, numerous brushed, anodised, embossed and textured finishes are also available.

Durability and colour choice are also features of Polyma GRP moulded casings.

Circa and Quadra plywood casings are designed purely for interior use and are manufactured from UKTR compliant sustainably sourced timbers. Within each range, circular and square profiles can be specified in a wide range of sizes, as well as extended circles and rectangular profiles that use additional pre-sized infill panels to give greater design versatility.

A wide choice of finish options is available with decorative high-pressure laminate (HPL) being the most popular.

In addition to resisting damage, scuffs and scratches, HPL provides specifiers with an extensive range of finish options, including plain colours, wood grains and metallics, as well as textured and real wood veneers. Circa is also available as an unfinished plain casing for on-site painting and decoration.

Among the many Circa installations are Liverpool University, Gateshead International Stadium and Gatwick Airport’s South Terminal are major installations while typical Quadra projects include Farnborough College 6th Form Centre, Worksop Bus Terminal and the Dame Kelly Holmes Sports Centre.

A magnificent Grade 1 Listed Tudor Manor House situated within beautifully landscaped gardens and farmland in the heart of Worcestershire.

Due to the building being built in the thirteenth century, it has been added and adapted to over the years and was fitted with a more traditional gravity fed system with large tanks situated in the roof spaces. This meant that much of the property was relying on the head of water to push through the system and feed a high number of outlets. This meant that showers in a number of rooms were very poor and also flow during peak usage was also poor.

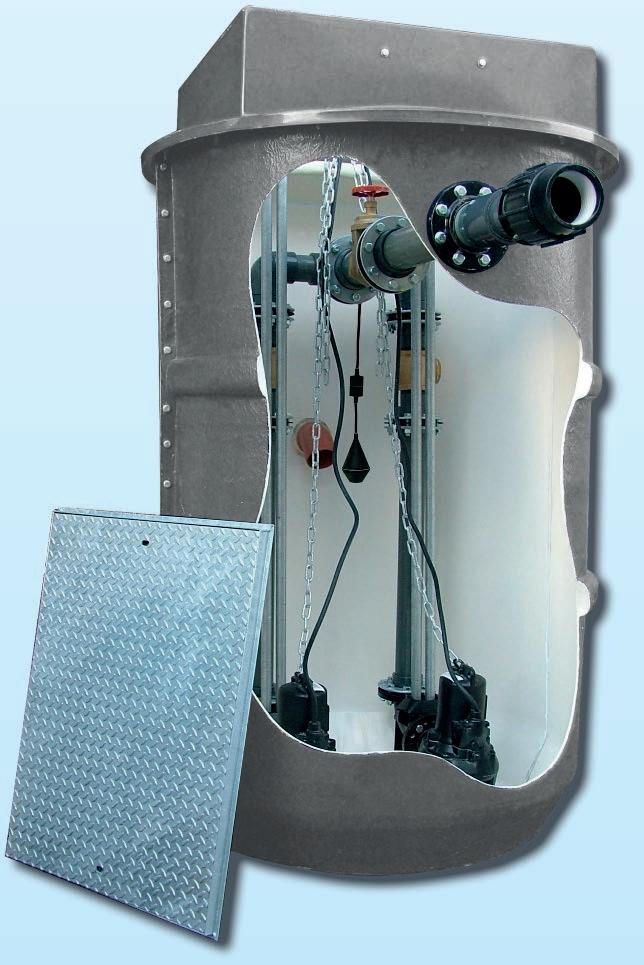

Christopher Hughes from CRH Plumbing & Heating was called into this property in Worcester back in 2019, Chris got in contact with Conor Reeves from Stuart Turner to discuss the best way to go about creating a solution. It was decided that the best course of action was to fit an Aquaboost In-Tank 1000 litre (Two Piece) Twin Pump Booster Set - ABI-0303-2S-SPC/M-1000-2. The reason for this is it is maintenance free, fit and forget and due to it having submersible pumps meant it is water cooled and low noise.

The two piece construction was also ideal as it allowed the tank to be installed in a much more desirable location within one of the two plant rooms. With the access limited due to the nature of the building, being able to construct the tank on site allowed for a smoother installation and no building alterations to accommodate it.

The new system is providing better pressure and flow to all 8 bathrooms, not to mention all the other outlets. With new flow rates being adaptable by programming of the system controls the desired outputs can be achieved based on the customers and the buildings requirements.

“Stuart Turner are one of the few companies who offer a product like an itank and help with the fitting and installation process which gives it a more personal feel” said Christopher Hughes.

Full details of the Stuart Turner Aquaboost Range can be found at stuart-turner.co.uk/aquaboost, or you can call 01491 572 655 for more information.

Stuart Turner – Enquiry 15

Stuart Turner are one of the few companies who offer a product like an itank and help with the fitting and installation process which gives it a more personal feel

Gerflor further increases its product category with the launch of their brand-new 2022 Creation LVT Collection, providing a tantalising all-in-one approach for designers and architects. Simply put, it’s a game changer!

Gerflor knows that designing and manufacturing products that are durable and easy to customise are key to ensuring that designers, specifiers, and architects can have a myriad of choices at their fingertips. This new 2022 Creation LVT Collection Gerflor now offers a range of solutions are extremely durable and simply beautiful to look at.

Aimed at architects, specifiers, decision-makers, and professionals, the new 2022 Creation LVT Collection provides a complete flooring solution targeted at four levels of traffic intensity. Creation 30 (Class 31) Creation 40 (Class 32) Creation 55 (Class 33) and Creation 70 (Class 34).

One spectacular innovation for the 2022 Creation Collection is a new RIGID clip system that has better performance characteristics and is available as two options: Creation Solid Clic and Creation Rigid Acoustic (with built-in underlay) for improved everyday comfort.

The all-new Creation Solid Clic installation system is now even easier to install providing the right balance between flexibility and rigidity for simpler installation and long-life use.

Creation 55 Solid Clic supplies the best rigidity and comfort in a single product. It comes with Duocore 2.0 which is more rigid to cope with renovation demands while offering acoustic comfort when walking. The exclusive new Clic system makes it quieter for installation whilst

areas are still in use, together with keeping the possibility of replacing any planks and is much easier to install on an underlay.

Creation Rigid Acoustic-This innovation delivers an Interlocking Rigid LVT with inbuilt acoustic underlay, delivering excellent acoustic performance due to the 19DB built-in underlay, increased tolerance for installation on tiles than Creation Solid Clic on joints measuring up to 8mm. Provides a 100% angular interlocking system which is similar to a laminated floor and is exclusive to Creation 40 providing a 30% lighter rigid acoustic LVT for easier installation and a reduced carbon footprint.

Also, new for this year is the innovative Protecshield™ Treatment from Gerflor which preserves the beauty of the floor-covering over the years preventing dirtying and wear over time and offering overall optimal protection.

In addition to protecting against external damage during day-to-day use, this new system makes maintenance much easier and cost effective.

Commenting on the new collection Nav Dhillon, UK Marketing Manager,

Gerflor said, “As we continue to innovate, the new 2022 Creation LVT Collection from Gerflor has opened up a whole new world for designers, specifiers, and architects by providing a raft of new design themes and alternative fitting methods in an allin-one approach. The new 2022 Creation LVT Collection also boasts a brand-new protection system- Protectshield™ which guards the beauty of the floor over the years.”

Learn more about Gerflor solutions, ask for a free sample or contact us to speak to a specialist today by calling 03332 412901, emailing contractuk@gerflor.com, or visiting gerflor.co.uk for the latest innovations.

Gerflor – Enquiry 17

Set deep within Delamere Forest, emerges a beautiful rural retreat, offering guests the chance to connect with nature among the trees. Forest Holidays create holiday cabin locations across the UK in unique and stunning forest locations, providing people with an opportunity to connect with nature.

Delamere Forest is the latest addition and includes Marley AntiSlip Plus® timber decking. Set amongst a 2,400 acre mixed broadleaf and evergreen forest, 66 spacious woodland cabins, each with their own outdoor decking area and hot tub are accessed by walkways and bridges, to offer guests a tranquil rural escape. Marley talked to Forest Holidays about Delamere and why they specified anti-slip timber decking.

In keeping with the woodland surroundings, Forest Holidays were looking to use natural timber products, choosing to specify a treated timber decking that would reinforce the organic sense of place between the forest, timber cabins and walkways. Natural timber products can be one of the most sustainable choices when specifying building materials. Marley timber decking is made using sustainably sourced European Redwood timber, with full chain of custody and supplied with PEFC™ certification to meet the Forest Holidays specification.

It goes without saying that safety for visitors is the utmost priority, so specifying anti-slip products, both indoors and out is a necessity. Each of the holiday cabins contain a hot tub on their outdoor decking area, providing a unique space for guests to wind down in the open air. For Forest Holidays, they also needed to ensure that the decking specification met the anti-slip criteria.

Mark Sheppard, Head of Procurement at Forest Holidays said, “We took the decision to use anti-slip decking back in 2017 after running a series of small trials across our sites. With hot tubs included in our decks, as well as decking used in our raised walkways, bridges and central areas, we couldn’t afford not to. Now we start with the ultimate spec, so we can ensure the safety of our guests whist reducing the risks associated with wet floors.”

AntiSlip Plus® utilises our anti-slip technology which comprises of two grey bauxite inserts. These inserts enable the deck boards to be

used when wet and score very highly, using the Health and Safety Executive's (HSE) test method, in both wet and dry conditions.

By making changes to site practice as well as moving to an anti-slip decking product, Forest Holidays have been able to extend the life of their deck boards by a number of years, which has prompted them to roll it out across their 11 UK locations.

www.marley.co.uk/decking

Marley – Enquiry 18

Keeping the leisure world secure and safe

Ojmar, the world-leading European manufacturer of innovative high performance electronic and mechanical locks, is delighted to introduce OTS® PULSE, the latest addition to its well-known family of locks.

Specifically designed for the Corporate and Leisure markets, OTS ® PULSE is the ultimate touch-free, wireless networked locking solution that operates in highly secure cloud software. It uses the latest battery technology providing a life of up to 10 years before needing a simple battery replacement. This makes it one of the most efficient, longest-lasting systems available on the market.

As Covid infection rates continue to rise, so the use of keyless and keypad-free lockers

has become more important in the battle to reduce cross-contamination and infection. Smart touchless locking systems provide maximum flexibility and safety for the user.

OTS® Pulse is a perfect solution for this type of application. Fully plug-and-play, online, self-managed and wireless, OTS® Pulse will help your leisure facility be adaptable and flexible at minimal cost. It is designed to minimise the risks of cross-contamination for areas with a high turnaround of visitors and for quick and easy installation without complex and costly hardwiring. It does not require any expensive servers, just a simple standard internet connection managed through a PC, tablet or smartphone.

Ojmar – Enquiry 19When Edinburgh Gin wanted to open its latest pop-up store in Edinburgh city centre, they tasked Exhibeo VM to design a store which reinforced the company’s branding, whilst creating a lasting visual impact. Using a colourful, textured look to elevate the customer experience and entice shoppers into the store, Exhibeo VM specified Forbo Flooring Systems’ adhesive-free Modul’up range in the Coral Terrazzo colourway, to bring the vision to life. The glossy pink theme is aided by Forbo’s adhesive free Modul’up flooring solution in the contemporary Coral Terrazzo colourway – a pattern and texture that is slightly reminiscent of the ingredients used to distil the gin.

Forbo

Forbo

Flooring Systems – Enquiry 20

Artcore is modulyss’ latest soft flooring concept, built to shape and transform spaces like never before. Inspired by transitions seen in nature, Artcore includes four different patterned collections – all Cradle to Cradle Certified® Gold – that offer an opportunity to rewild the interior world, creating unique patterned transitions that reconnect us with nature, restoring balance and wellbeing. Artcore is inspired by the transitions that modulyss designer Joris Peutz noticed in nature – the space between two states, where a material or an environment changes from one thing to another. Artcore consists of four different designs: Core, Mezzo, Litho and Etch.

modulyss – Enquiry 21

In

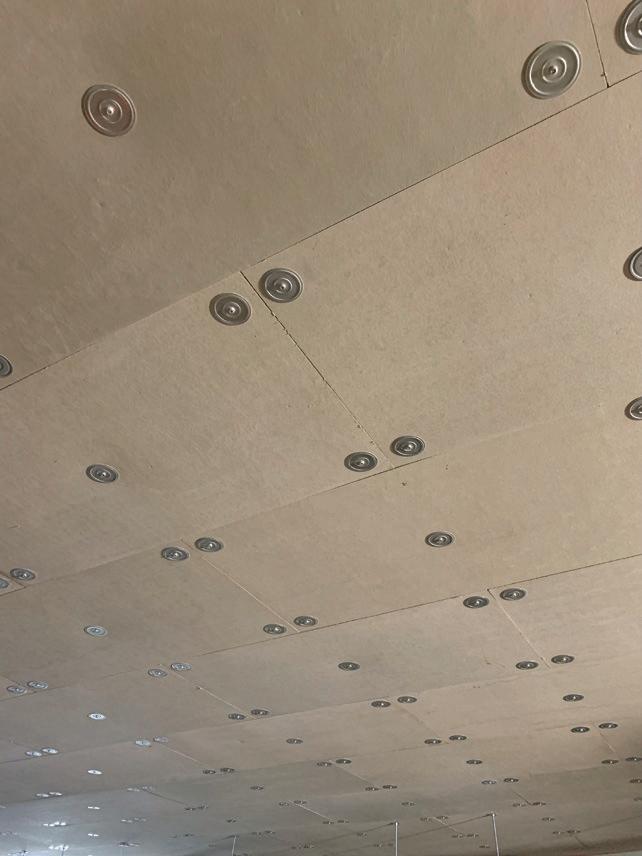

After three years of renovation work, Hall L, Terminal 2E now has a new 8,000m2 of solid wood grid ceiling in matte white lacquer, which was designed and manufactured by

The wood wall is also testament to Hunter Douglas’s commitment to quality, with 1,000m2 of white, delineated and nano-perforated walnut wood planks, finished in clear varnish.

While aesthetics were important, practicality was also key. Both halls had to have false ceilings

allow easy access to the plenum and Hunter Douglas tailored the solutions to the existing technical constraints.

The wall cladding was selected for its excellent acoustic properties, with nano-perforations that achieve a sound absorption value of 0.90 to 0.95.

Douglas Architectural – Enquiry

Douglas Architectural – Enquiry

22

There is a growing appreciation of how the design of healthcare buildings can impact the health and wellbeing of patients, their families, visitors and of course the staff, for whom the hospital is their working environment.

Research has demonstrated how interior environments can be adapted to improve the mental and physical wellbeing of those who occupy the space. This includes decades of research on the effects of colour, the impact of interior surface materials and the importance of creating a connection to nature.

As a result of this, many healthcare facilities are moving away from the sterile or institutional aesthetics that were common in older buildings in favour of designs that create a calming and relaxing environment.

As one of the key surfaces in a building, the flooring has a central role to play in creating a healthy indoor environment.

Firstly, the correct choice of colour for the flooring can help support how the room is used. Although how people respond to colour can vary based on their age, gender and cultural background; cooler tones, such as light greens, blues and purples are associated with a calm and relaxing atmosphere.

In contrast colours such as yellow and orange tend to be more energising and motivating. For hospitals, a soothing colour can be selected for the flooring in treatment and patient rooms that helps people to relax and recover. Meanwhile warm tones can be specified for staff areas to help create a mood-boosting environment to alleviate any stress and fatigue.

Furthermore, one of the most well studied aspects of healthcare design is the impact of nature and natural elements on health and healing, in an area of research also known as biophilic design. It is now almost 40 years since the now often cited study by Roger Ulrich was published.

The research found that surgical patients with a view of nature out of their window had shorter stays in hospital, required less pain medication and even suffered fewer complications.

Similarly, a study by the University of British Columbia found that the presence of wood surfaces in a room lowered sympathetic nervous system (SNS) activation.

This is the system of the body responsible for physiological stress responses and also has an effect on blood pressure, digestion and, importantly, healing.

This connection to nature is not only created through allowing views of the outside world but also in the shapes, patterns, textures and colours used in the interior design that evoke natural environments. With regards to flooring, there are often limitations on what materials can be used due to practical considerations such as acoustics, safety, hygiene, maintenance and cost.

However, there are options that still provide a sense of nature while meeting the functional requirements. These floor coverings, such as the Forbo Sphera Elite homogeneous vinyl range, take inspiration from nature in their textures and colours –greys, earthy tones, greens and blues – but have the durability required for high traffic environments.

Additionally, choosing a product with low Volatile Organic Compounds (VOC) emissions and phthalate free manufacturing can contribute to improved indoor air quality for a healthier environment. An increasing body of research is demonstrating the effect that design has on physical and mental health. As one of the largest single surfaces in a building, the correct choice of flooring can help to create an environment that supports health and healing, while meeting the practical requirements of healthcare flooring.

Catherine Seville-Clare, Group Customer Relationship Manager at Panaz, one of Europe’s leading suppliers of contract fabrics, discusses the benefits of specifying anti-microbial fabrics throughout healthcare facilities to mitigate the spread of viruses and deliver the highest standards of performance.

fabrics provide the required levels of comfort, durability and aesthetics.

Over the last two years, there has been a significant increase in demand for contract fabrics that successfully mitigate against the spread of virus and bacteria. By specifying upholstery and drapery that feature antimicrobial properties, professionals can support care home professionals in achieving the highest standards of hygiene.

is maintained, whilst simultaneously aiding cleaning and maintenance routines for care home professionals. In addition, professionals should ensure the fabric features an impervious waterproof layer for further protection.

The fire retardancy of the fabric is another leading consideration for healthcare, as the level of FR testing required changes depending on the end use. Whilst some design professionals may choose a retail fabric and have a FR treatment added, this may alter the texture and appearance and is not guaranteed to make it FR depending on the type of yarns involved. Many retail fabrics are not designed with contract specifications in mind, so often lack the durability required for a commercial environment.

When choosing contract fabrics for care home applications, there are a multitude of performance and design considerations that architects and specifiers must address at the initial design stage to ensure the long-term success and suitability of the installation. This includes achieving the highest standards of infection control, whilst ensuring the

This includes fabrics that feature fast-acting antimicrobial technologies, such as Shieldplus from Panaz, that have been applied during the manufacturing process via a method that creates an unbreakable bond with the fabric. This durable, safe to use technology providesprotection that fights against a broad spectrum of bacteria, fungi, viruses and parasites including Coronavirus, MRSA, C-diff Spore and Norovirus.

Because Shieldplus is non-migrating, it doesn’t leech into the environment, meaning it is active for the lifetime of the fabric as it won’t deplete in potency, even in high traffic areas. To ensure the chosen fabric is fit for purpose,

Whilst it’s essential the fabrics provide first class functionality, they must also feature calming designs, textures and constructions that facilitate feelings of relaxation and comfort to reflect an inviting home environment.

For communal areas, such as lounges and dining rooms, faux leather options such as vinyl, are low maintenance and easy to clean, choose a vinyl that features layers of protection to repel liquids and stand up to strict cleaning regimes, whilst at the same time allowing the fabric to breathe and be comfortable for the user.

architects should also consider stain resistance to ensure the original look and feel of the textile

architects should also consider stain resistance to ensure the original look and feel of the textile

The Sct. Hans Hospital in the Danish city Roskilde is a psychiatric facility specifically designed to provide the healthiest of environments for staff and patients and which has just won the prestigious Danish ‘Health Building of the year’ award.

Forming a larger extension to the original hospital, the new 21,000m2 complex, designed by KHR Architects, includes a new 126-bed psychiatric ward and therapy facilities built into the side of a hill and nestled within carefully landscaped grounds to provide privacy while maximising the views.

The use of nature and light along with modern and effective design and building materials makes for a calm, tranquil and light environment.

As part of the design, Troldtekt wood wool acoustic panels in different colours have been used for the ceilings to link various zones in the communal areas and activity rooms. In the therapy baths, the panels are a muted grey colour to exude a sense of calm. This choice of materials plays a key role as materials like wood adds warmth and naturalness. The materials, together with the good acoustics, contribute positively to the healing process.

Founded on the Cradle-to-Cradle design concept and recently attaining Gold certification,

Surfaces in healthcare environments undergo a lot of activity! Heavy footfall, transportation of heavy products and equipment, and increased levels of cleaning all mean that surfaces underfoot are subject to significant wear.

When resilient floors become damaged, new flooring is often the first, and sometimes the only option considered; yet this is very limiting and can lead to unnecessary expense and disruption.

The Bona Resilient Floor Solution totally transforms old, worn, unhygienic floors in the healthcare space without these issues. The results are so outstanding that it can easily be mistaken for a brandnew floor.

With its unique 3-step process, Bona’s Resilient Floor Solution offers a simple and effective solution to bring surfaces back to top condition, while also extending the life of the flooring itself. This approach delivers up to 50% less downtime, and is up to 50% cheaper than a brand new installation –saving significant funds from ever stretched healthcare budgets.

Founded in 1919, Bona is a family-owned, sustainably driven company that supplies products for installing, renovating, maintaining, and restoring premium floors. With the Resilient Floor Solution, Vinyl, PVC, linoleum, and rubber floors can be resurfaced quickly and cost-effectively.

Troldtekt’s natural and inherently sustainable panels are available in a variety of different surfaces and colours and contribute positively to a building’s BREEAM, DGNB and LEED ratings.

In addition to their high sound absorption and tactile surface, they offer high durability and low-cost lifecycle performance. Available in various sizes and in four grades, from extreme fine to coarse, the panels can be left untreated or painted in virtually any RAL colour.

Troldtekt – Enquiry 24

The new £15m ‘mock hospital’ at Nottingham Trent University’s Clifton Campus, which will help train healthcare professionals in a realistic hospital setting, has become the latest project to benefit from cladding panels from Proteus Facades. Pick Everard architects specified Proteus HR 1.0m Coil Pre Anodised Aluminium for the entire external element of the new Heath and Allied Professions Centre. The cladding panels were supplied in a mix of Bronze B40 Satin and Bronze B40 Brushed finishes. Proteus HR is an integrated, lightweight, high strength modular rainscreen cladding system with a honeycomb core that offers an optically flat panel.

Proteus Facades – Enquiry 26

Stuart Nicholson, roof systems director at Marley says sustainable roofing solutions can make a positive contribution to the sustainability challenge facing the construction industry. Product specification from an environmental perspective has never been easier thanks to innovative technology.

The race is on to find the construction solutions to support the nation’s decarbonisation ambitions. With the Climate Change Committee stating that the UK’s 28 million homes contribute around 14% of the country’s greenhouse gas emissions; building better, more sustainable and energy efficient homes must be a key priority.

The uplift changes to Part L of the Building Regulations now in effect in England marks an important milestone, setting the standard for thermal performance and energy efficiency for new builds. Part L is a welcome foundation towards achieving the energy performance requirements set out in the forthcoming Future Homes Standard.

When it comes to the built environment, eco-friendly roofscapes have a positive role to make towards overall sustainability objectives. A combination of material selection for roofs, together with innovative advancements in areas such as solar PV, means there is greater ability for specifiers to create roofing answers that chime with the sustainability agenda.

With targets set out in Part L to reduce carbon emissions in new homes by 31%, it is widely acknowledged there are several ways that this can be met. Currently one of the most costeffective is to combine an efficient gas boiler or renewable heat pump alongside a solar PV system that can harness the energy creating prowess of the sun on the roof.

Aside from the obvious sustainability advantages brought by harnessing the power generation of the sun to create a clean energy source, investing in the installation of solar PV can provide financial benefits also. Ahead of further price increases this winter, it is estimated that a 4kW solar PV system could generate electricity up to the value of £1,575 (based on a cost of 45p p/unit)*, offering homeowners significant savings on energy bills.

Solar PV technology is tried and tested, readily available and has become much more affordable in recent times. Indeed, such is the momentum behind the adoption of the technology, Solar Energy UK predicts the changes to Part L could lead to a fivefold increase in the number of new homes specified with solar technology.

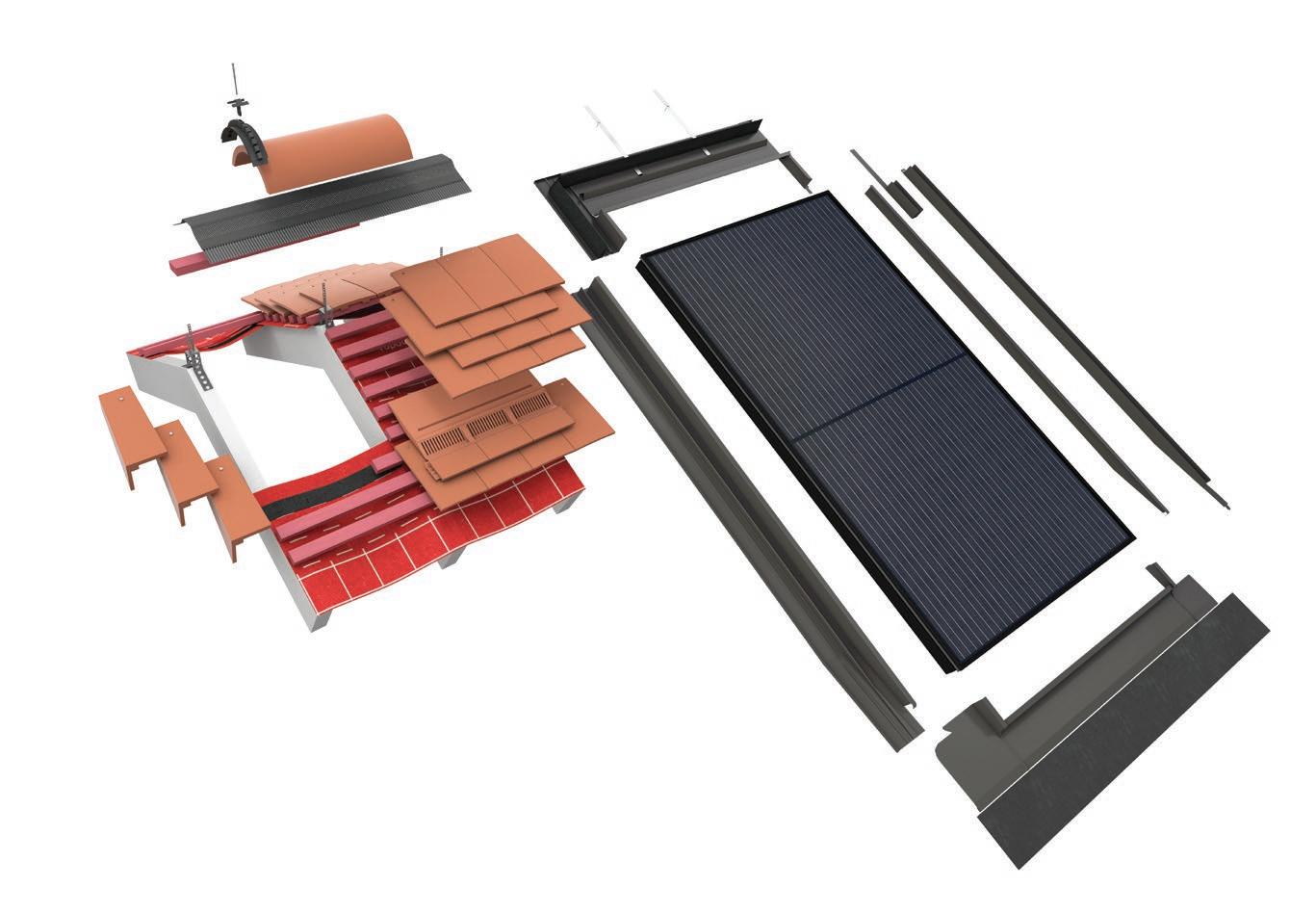

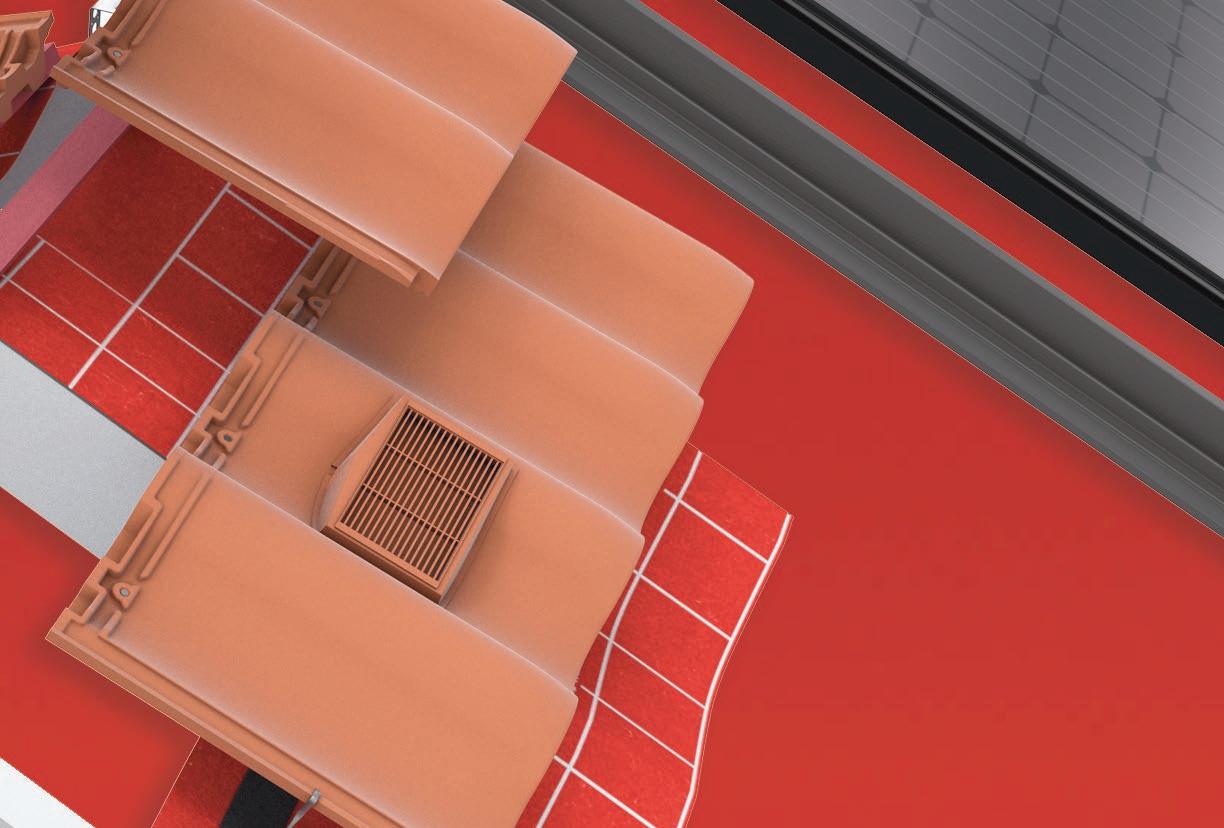

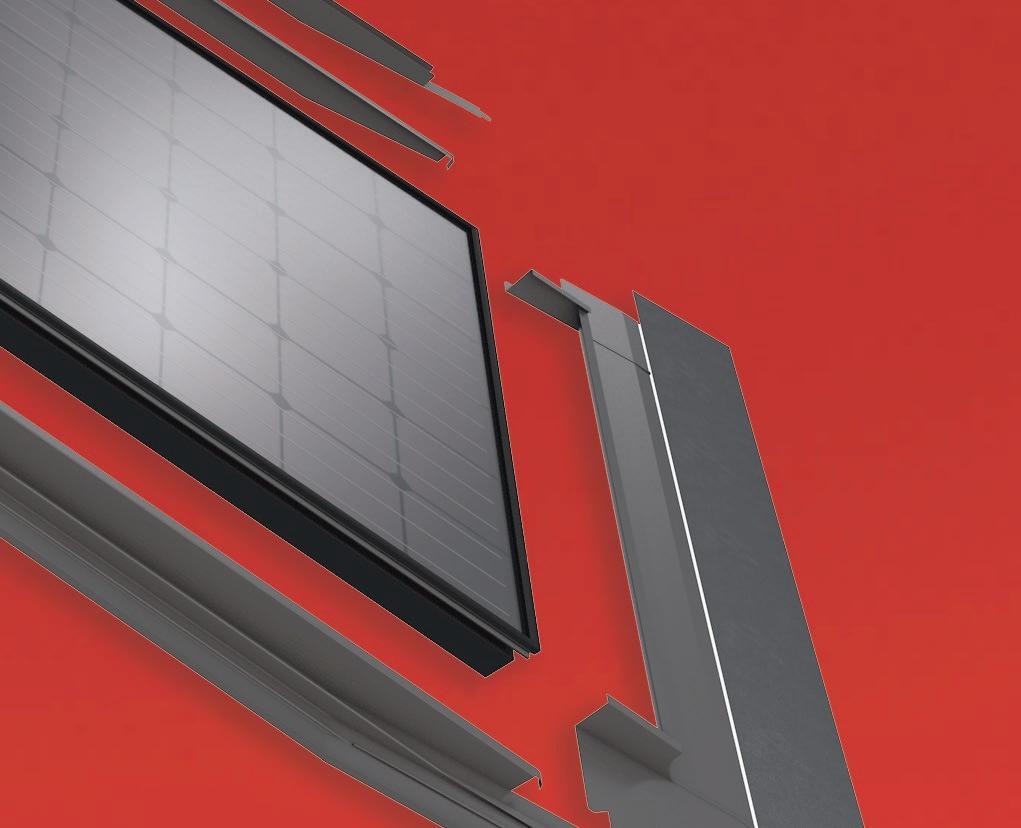

The ideal solution for both new and refurbishment projects, Marley SolarTile® enables integrated solar PV on a roof, offering a more visually appealing, cost effective and easier to install option.

Replacing a section of roof tiles, integrated solar PV provides a sleek appearance and acts as a seamless part of the overall roof aesthetic.

From an installation perspective, solutions such as Marley SolarTile ® can be effortlessly integrated with any of the existing tiles on a roofscape including all formats of concrete and clay rooftiles, as well as natural and fibre cement slates, making it an attractive and simple specification choice that supports the aims and ambitions of the Part L changes.

Finally, Marley SolarTile® is available as a key component of a complete roof system and offers the reassurance of a 15-year guarantee, as part of one. T

This means specification decisions needed to create sustainable roofs for the future can be made with total confidence in the knowledge they will continue to perform to a high level for years to come.

>> Setting the standard for safety Glasgow’s latest redevelopment project, located on Langside Road, is built upon the former site of the city’s Victoria Infirmary and consists of a large housing development that includes 413 flats, offices and retail space.

As part of the construction process, Bilco UK was commissioned to supply six ESW-50REM Smoke Vents, in addition to seven E-50TB Roof Access Hatches, to provide the highest standards of safety and efficiency, whilst being sympathetic to the project’s overall design.

Installed onto the roof areas of four blocks of flats by Scottish contractors, Procladd Small Works Ltd, Bilco UK’s ESW-50REM Smoke Vents were specified to provide essential ventilation in the event of a building fire. Featuring a linear actuator operating mechanism that opens the cover to 140 degrees within 60 seconds, the smoke vents ensure compliance with Building Regulations Approved Document B, BS9999 and EN12101-2.

The built-in wind deflector also provides protection against smoke being blown back into the vent in the event of a fire., whilst the newly-designed closed-cell EPDM sponge gasket helps meet Building Regulation air leakage targets by providing a better seal of the cover to the curb. With the addition of a fixed vertical ladder, the smoke vents can also be used by maintenance engineers for roof access.

Constructed with corrosion-resistant materials, Bilco UK’s E-50TB Roof Access Hatches were also installed to provide engineers with safe, regular and convenient access to the roof to conduct essential maintenance.

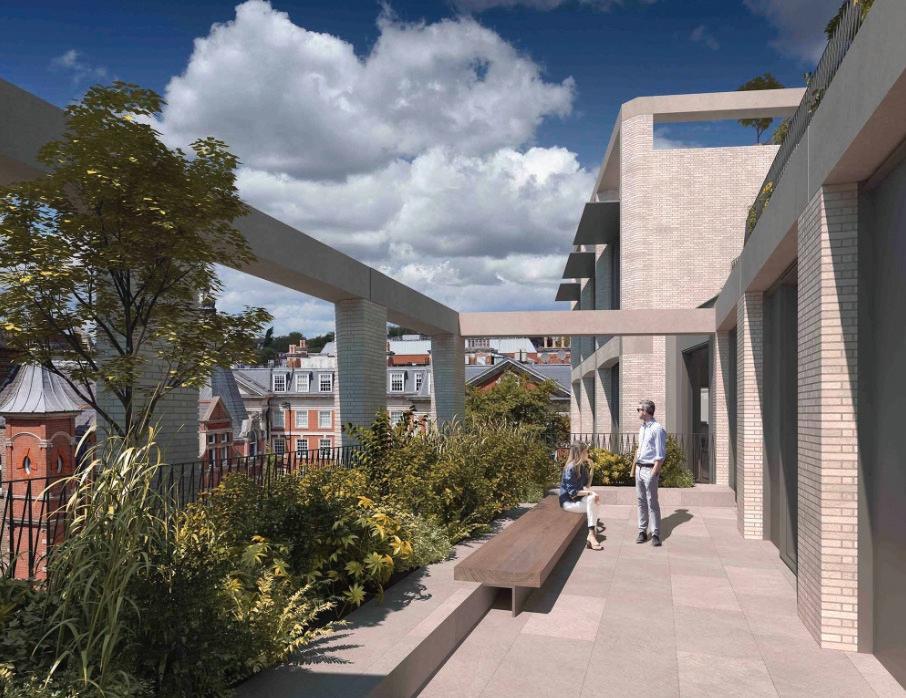

Taking the green route 127 Kensington High Street was formerly the site of the original, highly regarded Pontings department store. The store was demolished in the 1970s and replaced with two separate office blocks. To provide much improved mixed-use space, these structures were part removed leaving 30% remaining, and added to with extended areas and an additional two floors, as well as three levels of outdoor terracing.

The £53M project will provide primarily commercial space, with retail space on the ground floor and basement, as well as a new arcade entrance to Kensington High Street Underground station. has an environmental BREEAM rating target of excellent.

Green-tech were contacted by Elite Landscapes Ltd to quote for the tree planting in soft beds on the terraces, including anchoring systems, underground root ball irrigation, and for the larger trees, slow-release tree Irrigator bags.

Green-tech launched the tree Irrigator bag in 2020 in response to requests for a surface fed but slow-release irrigation system.

When using direct irrigation, either from above or using perforated rings around the rootball, there is always the risk of significant water wastage, whereby a lot of the water soaks straight down to the subsoil when delivered in one go, bypassing the root system that needs it.

Made from green PVC mesh cloth, with a permeable membrane in the base, the Tree irrigator bag can hold up to 60 litres in a single bag (95 when doubled up), which it slowly releases over a period of 5-9 hours depending on the conditions. It is very easy to fit post-planting, and simply wraps around the tree trunk and is zipped up, then filled via a filler opening at the neck.

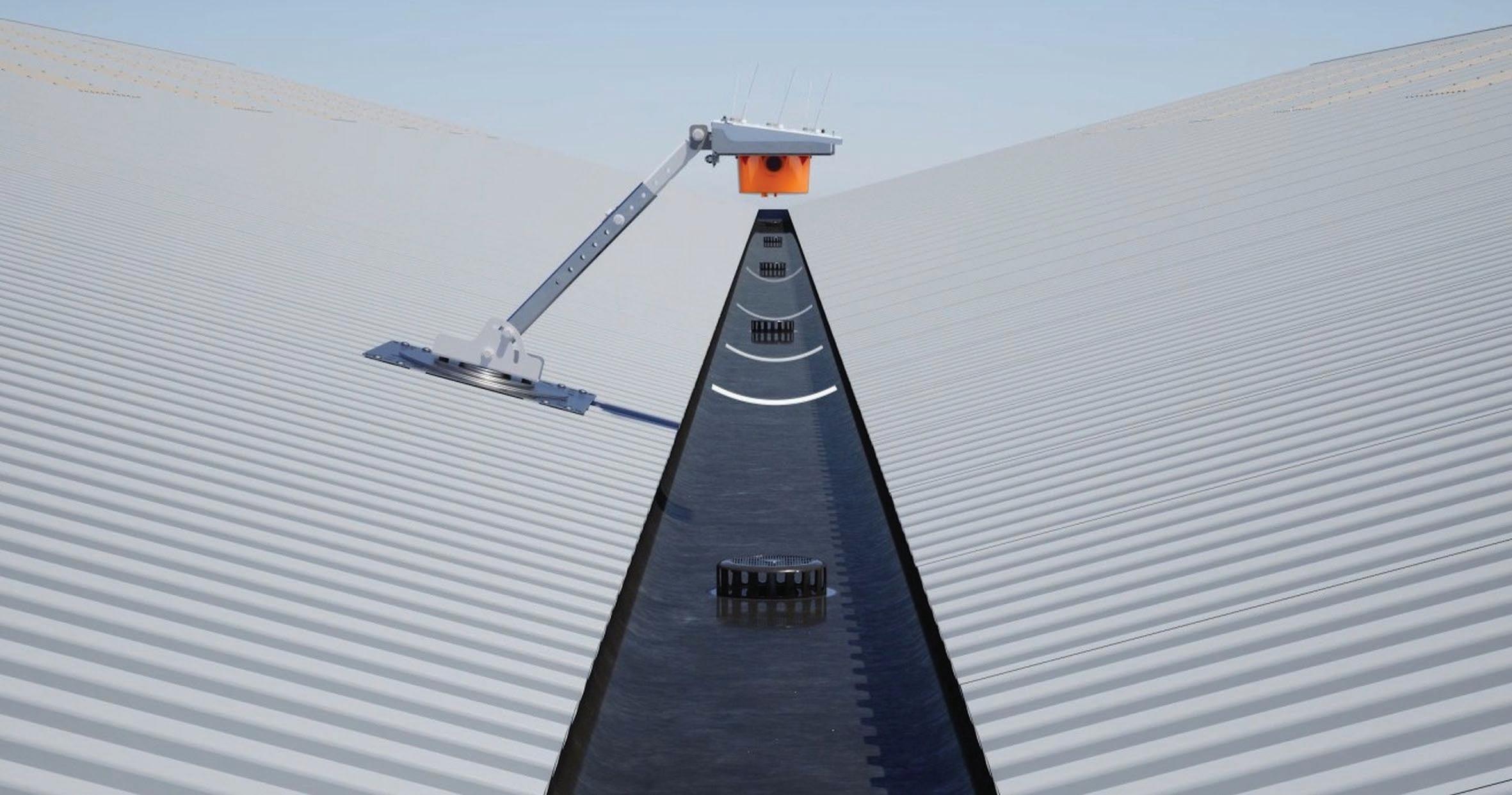

RoofCare is a new easy-to-install system which analyses drainage performance and generates alerts to highlight capacity issues. The system also helps the planning of evidence-based gutter and roof fabric maintenance programmes.

According to the Association of British Insurers in 2019, around 100,000 commercial buildings in the UK suffer roof leaks every year creating an annual cost to businesses of more than £800m.

Sharmans is the UK’s leading supplier of gutter and roof refurbishment systems and has been developing RoofCare for the past four years to deliver a new approach to gutter monitoring.

RoofCare’s innovative detector system provides early warning of imminent water ingression and alerts maintenance teams to potentially take action. The software predicts the need for gutter cleans and helps to ensure that cleaning takes place at the right time. Users of the system can view the performance of any of their roofs, utilising RoofCare on mobile devices or desktop computers 24 hours a day.

RoofCare’s Andrea Holbrook said: “Whether building owners or facilities managers employ a planned predictive maintenance regime or reactive strategy, our RoofCare system significantly enhances either approach.

“Our revolutionary system follows a fourstage process – analyse, diagnose, alert and plan – which provides protection across an entire roof portfolio and enables quick and easy monitoring.”

RoofCare is available on a flexible subscription basis which is either owner operated or provided by one of Sharmans’ expert contractors. It can also be integrated into existing computer-aided facilities management (CAFM) software or can function as a standalone system.

For further information visit www.roofcaregroup.co.uk

Sharmans – Enquiry 31

Our revolutionary system follows a four stage process - analyse, diagnose, alert and plan - which provides protection across an entire roof portfolio an enables quick and easy monitoring

The prestigious Forest of Arden Marriott Hotel in Birmingham has benefitted from a durable cold-applied liquid waterproofing solution thanks to Kemper System.

Asolution from the liquid-applied membrane specialist was used by contractors, Whitestone Property Services (Midlands) Ltd to refurbish the 254 sq.m roof at the high-end country club and hotel.

The existing single-ply roof, which comprised extensive plant and surface units, had experienced severe water ingress due to a number of vulnerable laps and seams around multiple penetrations.

Working during winter months, contractors specified Kemper System’s Kemperol V210M for its ease of application and fast curing properties, as well as its durability and versatility.

The cold-applied liquid solution was an obvious choice for this project. One of the main benefits is it can be applied

very quickly and easily using a roller. This provided the contractor with the speed and flexibility to complete the job on time as they had limited daylight working hours. The contractor also had to be respectful of the hotel’s guests as the building was still occupied during the refurbishment works.

This was a challenging project due to the vast amount of plant on the roof. A decision was made to overlay Kemperol V210M on top of the single ply. Another challenge was access – the contractor was unable to enter the hotel so the scaffolding was the safest option.

Transporting huge amounts of sheeting or other materials would have created health and safety risks, so Kemper System’s two-component solution adapted perfectly. Contractors erected an up-and-over

scaffold on the hotel’s roof to create a safe access route to the site.

The V210M liquid-applied membrane was applied ‘wet on wet’ in a single process using a reinforcement fleece. Once cured, the resin formed a seamless and elastomeric membrane that cannot delaminate.

As an extremely prestigious hotel a lot of thought had to go into the design and specification stages. Kemperol V210M is cold-applied, avoiding any risks relating to hot works, and can be applied quickly.

It is also UV stable and more suitable for complex details, providing a completely seamless membrane encompassing the entire roof area.

System – Enquiry33

One of the main benefits is it can be applied very quickly and easily using a rollerKemper

Situated in the heart of London sits the iconic 39-acre, grade II* listed Battersea Power Station, which has been subject to an incredible £9billion redevelopment project – one of the biggest schemes of this type anywhere in Europe.

One brand that is proud to have played a part within this ground-breaking project is Boughton, suppliers of stunning green roof substrates for the Power Station’s ‘Garden of the Elements’ project.

Positioned between the four chimney’s that have become synonymous with the Battersea development are three unique gardens that together make up the ‘Garden of Elements’, designed by Andy Sturgeon and brought to life by six-times BALI Grand award-winners, Willerby Landscapes.

Each garden is inspired by fire, water or air, harking back to the Power Station’s previous life. It is within these gardens, including the notable main podium garden ‘Boiler House Square’ that saw Boughton’s IN1 Intensive and Lightweight Green Roof Substrates, and Rootzone come into their own.

These garden spaces, full of cloud-like planting schemes are set within raised beds and tall grasses with vegetation designed to offer year-round interest with a mix of evergreens, Mediterranean and more exotic species. Boughton’s IN1 substrate was selected to

support this scheme thanks to its ability to support larger plants and to be installed at depths from 100 – 500cm, thanks to its sandy texture. Additionally, Boughton’s IN1 substrate offers significant moisture retention qualities, making it the perfect choice when so many plants are vying for attention within this three-hectare site. IN1 from Boughton continues to meet and exceed all G.R.O guidelines.

Elsewhere Boughton’s Lightweight Substrate was used to provide growing media where weight loading for the green roof needed to be lighter than traditional green roof schemes.

Finally, Rootzone completed the offering. Supplied as a ready-mixed solution, Rootzone

To make an enquiry – Go online: www.enquire2.com or post our: Free

provided better planting conditions throughout the scheme. Product was supplied in both bulk bags and 25L bags, meaning the Boughton team had to go above and beyond to tackle the logistically challenges that delivering to a central location presented.

Representative of one of the biggest projects Boughton has ever been involved in, it was vital that the team got it right.

Boughton – Enquiry 36

Virtually no roofing and cladding installers regard self-drilling fastener seal testing as the priority when working on building envelope installations, according to a survey by EJOT UK.

It asked installers to rank the importance of four things when thinking about installing a roof or façade – (a) choosing high-quality fixings, (b) regularly testing the quality of the seal, (c) picking the right screw gun and (d) using a properly set nosepiece.

Regular seal testing was the least important factor by a considerable margin with just 4% of respondents ranking it first, unlike ‘choosing high quality fasteners’ which was the runaway winner with 55% saying it was the priority.

The findings support EJOT UK’s goal to provide clearer and easier to access best practice and training for the use of self-drilling fasteners. Seal testing is one important stage of the process which can

get overlooked, despite being a really easy process, and the survey findings indicate that it is still not being given the focus it deserves.

Brian Mack, Technical Business Development Manager at EJOT UK said: “Installers have a lot to gain by making seal testing an integral part of every job where self-drilling fasteners are being used. Not only is it easy to do and low cost, but it is really effective at picking up quality issues that could prove financially and reputationally costly further down the line.

“But it does require two things – a good seal testing kit and some planning to work out how to make testing part of every project in a way that doesn’t cause disruption or add extra work.

“We can help on both fronts, in particular giving you the right kit through our VACUtest. This is an easy to use air pressure testing kit that works by creating a vacuum around the fastener head via a suction cup attached to a hose and a hand pump. And we’ve now produced a short video which shows exactly how easy it is to use.”

To find out more about installation and seal testing best practice for self-drilling fasteners, contact EJOT UK on 01977 687040 or email info@ejot.co.uk. Find out more at www.ejot.co.uk.

EJOT UK – Enquiry 38

Onduline, the light weight roofing systems and water-proofing specialist, is delighted to announce the launch of the installation guide for its new and unique under roof system, ISOLINE® LOW LINE - the only system in the UK to be BRE tested and BBA Accredited to as low as 10o with a 30-year guarantee.

Designed specifically for use on low pitch roofs, this lightweight bituminous underlay sheeting has been rigorously tested and is at least three times less likely to leak compared to a traditional tile system.

The installation guide explains what ISOLINE® LOW LINE is, the installations that it is suitable for, the benefits of the system and how it works. It then goes on to describe step-by-step fitting of the system with handy imagery and illustrations.

Ardit Strica, Technical Manager for Onduline Building Products, said: “We have received fantastic feedback from within the construction industry since the launch of ISOLINE® LOW LINE. As it’s the only bituminous corrugated under roofing system in the UK that can be used on a pitch as low as 10°, it is having a really positive impact on new and renovation projects alike.

“The launch of the brochure and installation guide on the Onduline website means that professionals have the opportunity to take a look at how ISOLINE® LOW LINE works, the benefits of the system, what projects it is suitable for and see step by step just how easy it is to install.”

With a corrugation height of just 24mm, ISOLINE® LOW LINE is fixed below the primary tile or slate roof covering, acting as the primary waterproofing layer of a roof. Thus, making roof tiles a secondary line of defence enabling the pitch of the roof to be much lower than the minimum as recommended by the tile manufacturer.

To view the installation guide for the ISOLINE® LOW LINE roofing system,

please click on the QR code or visit https://uk.onduline.com/en/professionals/ tools/installation/isoline-low-line-installation

Onduline – Enquiry 39

BMI Redland’s SpecMaster service provided a solution on this most difficult of projects. When Grade II Listed Victorian building Houldsworth Mill was repurposed into an apartment complex, tenants and owners were proud to live in a building of great local heritage.

They turned to the Redland SpecMaster service to provide a bespoke roof specification and 15-year weathertightness guarantee.

The client ordered a complete reroofing, including a full specification to ensure the quality and longevity of the roof from the ground up. They employed Karl Austerfield Roofing to carry out the complex re-roof, who turned to Redland as a tried and trusted supplier able to provide a complete solution and technical support to address the complexities of the project.

The challenge: Satisfying the conservation officers

Consisting of two twin pitched roofs with a glazed atrium separating them, the roofs had warm roof construction and were dotted with emergency exit Velux windows. The natural slate roof had been recovered using an interlocking slate tile system from another supplier, and had been installed in such a way that a myriad of water ingress issues had resulted.

However, the main issue that arose with the project was actually getting a refurbishment started. Many of the specifications that were drawn up as actionable solutions were rejected by conservation officers. Because Houldsworth Mill is a Grade II Listed Building, and the specified solutions would have affected the height or shape of the building in some way, even an increase in height of only 50mm was unacceptable and would have required planning permission.

As the roof is a warm roof, the construction from the ceiling up should have been a setup of plasterboard, followed by rafters filled with quilt insulation, followed by a 50mm air gap ventilated with eaves ventilation from the ridge. The failure was that the rafters running into the hips should have had high-level extract

ventilation, which they did not. The rafters should also have had vent tiles on both sides as they ran up the pitch of the roof - also missing. As neither of these existed, the roof was placing excess reliance on the insulation to stop condensation from forming. It was unable to do so and, therefore, water ingress issues were caused as a result.

Similarly, the insulation did not provide the levels of energy saving required by building regulations. So, the insulation levels needed to be increased. However, this would mean increasing the rafter sizes and therefore installing more ventilation tiles. From calculations conducted by the contractor, 80 vent tiles needed to be installed on the roof. This was denied by a conservation officer as installation of the vent tiles would increase the height of the building and would therefore require planning permission.