As a recognised and valued British brand across many industries, we believe in delivering exceptional customer service supported by our continual investment in infrastructure, technology and people. With the support of our trusted supply chain partners and the commitment of our colleagues and customers, there has never been a greater opportunity than now to support British Manufacturing.

Great British Manufacturing, here now and for the future - home of...

Contact us for more information.

Century House, Premier Way, Lowfields Business Park, Elland, West Yorkshire, HX5 9HF

T: +44 (0) 1484 658341 E: info@decorativepanels.co.uk www.decorativepanels.co.uk

There is little doubt that 2020 has been a year of change, not least due to the on-going pandemic.

But adoption of new Building Regulations, changes to planning, new investment programmes, the continuing public inquiry into Grenfell Tower, and Brexit, are all leading to a considerable shift for the industry as a whole.

It is also a time of change for us as publishers. This industry shift is also having implications for the way we work, as will the pandemic and the fact that the way people are working on a dayto-day basis is also changing.

Through regular engagement with our readers and advertisers we know our printed title remains an important source of information for the industry. But we have taken the opportunity to refresh our magazine brand.

We have given the magazine a bold and vibrant new design with the aim of showcasing both product-based and project-focused material more effectively. We will still be providing the same informed and detailed technical information our readership requires, but we are doing so in a more dynamic and accessible way.

We will also look to provide more industry-based views and opinions as we see more changes and shifts taking place in the months to come.

The magazine will continue to complement our online and social media output, which is updated on a daily basis to give a more immediate and valuable resource and which also helps feeds into the features and product-based information we cover in more detail in the printed title.

Above all, we recognise the importance of continuing to listen to the industry. Changing working patterns and behaviours will influence our multi-format approach, how people wish to access information and exactly what kind of detailed technical information they require will always help shape what we do.

Accessing information in this day and age is never an issue. But we will continue to work to ensure the information we provide is relevant and accurate and will help the industry to progress and adopt best practice.

The time for change is here and the aim should always be to improve. We will continue to work to improve our publications and online provision as the industry itself adapts to new ways of working, accessing information and setting new benchmarks for quality.

Paul Groves || Group Editor

Bulmer

Coleford

Forterra Plc www.forterra.co.uk

H.G. Matthews www.hgmatthews.com

Ibstock

Ketley

Matclad Ltd www.matclad.co.uk

A survey of 100 construction companies across the UK conducted by the MHA Association of accountancy firms reveals a stark divide in how construction companies have fared during the COVID-19 crisis.

While almost half of companies (49%) said the impact of COVID-19 has been substantial, over four in ten (44%) said it has had only minimal impact on their business. Only 5% stated the damage was critical. The division is also apparent in terms of expectations for the future. Almost a third (32%) said business activity was now back to normal, or nearly back to normal, while 30% believe it will take over a year to return to pre-pandemic levels.

Robert Dowling, Head of Construction and Real Estate at MHA said: “The sector was in relatively good shape going into the pandemic. The future however is very uncertain. Government projects are now the most likely source of revival for the

sector; housebuilding, although currently buoyed up by strong demand is likely to suffer from a rise in unemployment and commercial building is unlikely to thrive, with many companies questioning whether they need as much office space as before.

“The fact that companies have had such different pandemic experiences means any future government relief must be properly targeted; not everyone needs help and there is no blanket solution for the companies that do need assistance.

“In particular the government needs to be mindful that big infrastructure projects tend to benefit larger companies the most, and even disadvantage small ones by sucking in materials and labour. The smaller players must not be neglected when it comes to new contracts especially as, broadly speaking, they have coped less well with the pandemic.”

Changing Streams calls on construction to join fight against plastic

A new not-for-profit organisation, Changing Streams, has been established by an entrepreneur from Liverpool in a bid to remove plastic from the construction industry. Neal Maxwell, who has worked in the construction industry for more than 30 years, founded the organisation alongside researchers from the University of Liverpool, after a trip to the Arctic left him appalled by the levels of plastic pollutants in the Arctic Ocean.

He is now appealing for UK and international businesses across every

industry, especially those involved in the built environment, to join him in his mission to eradicate the use of plastic on a global scale. This includes contractors, material manufacturers, the A&D community, surveyors and property owners, as well as any company or individual who believes in this cause.

The construction sector is the second largest producer of plastic waste in the UK, after packaging. It is estimated the building trade generates 50,000 tonnes of plastic waste each year, 40% of which is sent to landfill.

Changing Streams is bringing together experts from across the construction, scientific and environmental communities, to facilitate research and development programmes to drive a reduction in plastics in buildings and throughout the built environment supply chain.

Building Design Partnership (BDP), an international architecture firm, was appointed to design a new 11-storey cancer centre in the heart of Liverpool –the city’s first dedicated cancer hospital that comes as part of a £162 million investment in cancer centres in the region.

With cleanliness, hygiene and inclusive design in mind, BDP turned to PPG Architectural Coatings to provide a Johnstone’s Trade paint specification for Clatterbridge Cancer Centre – Liverpool.

The new cancer centre has been designed to complement the existing Clatterbridge centres in Wirral and Aintree. It incorporates state-of-the-art facilities for radiotherapy, chemotherapy, diagnostics and imaging, outpatients, daycase treatments, bone marrow transplant, a Teenage & Young Adult Unit, clinical therapies, and a wide range of cancer information and support services.

The centre will care for a total population of around 2.4 million people from across Merseyside, Chester and further areas, as well as carry out clinical trials of new cancer treatments.

BDP collaborates with PPG on Clatterbridge Cancer Centre

A new Delivery Hub is to be established to direct the housebuilding industry’s response to meeting the government’s environmental targets.

Following the Home Builders Federation’s second Housing and Environment Summit, a new cross-sector Future Homes Task Force has announced its plans, with the Hub set up to drive the industry’s intention to deliver net zero, “environmentally positive” new homes.

The Task Force - consisting of representatives from across the sector including in housebuilding, government, utility provision and suppliers - met with wider industry leaders at the virtual summit to further discuss the challenges surrounding the environmental agenda for the industry.

HBF said that to meet the “high level ambitions” surrounding tomorrow’s new homes, with their improved fabric efficiency, ways of being powered and impact on their environment, the industry needed an

overarching masterplan to co-ordinate the various issues and regulatory requirements. The Task Force will develop this masterplan, which will be based on the government’s main environmental targets: on net zero, the natural environment, resources, water and air quality.

Stewart Baseley, HBF’s executive chairman, said: “The environmental agenda is an absolute priority for the UK’s housebuilding industry and one on which we are committed to leading the way.

“We have been set a huge challenge by government, but it is one we are determined to deliver. We will work with government and stakeholders to set ambitious but deliverable goals that will ensure we make our contribution to environmental targets and achieve our ambition of net zero homes and a net zero industry.

“The work of the Task Force will help deliver homes that we can all be proud of as a nation and future generations will thank us for.”

The Royal Institute of British Architects (RIBA) is pleased to announce that Sir David Adjaye will receive the 2021 Royal Gold Medal, one of the world’s highest honours for architecture.

The Royal Gold Medal is approved personally by Her Majesty The Queen and is given to a person or group of people who have had a significant influence ‘either directly or indirectly on the advancement of architecture’.

Coventry University’s Building, Town and Country Planning course has been named as the best of its type in the Guardian University Guide 2021 subject rankings.

The subject category covers the study of all aspects of buildings except design, from construction to location, and encompasses the university’s BSc (Hons) Quantity Surveying & Commercial Management, BSc (Hons) Building Surveying, and BSc (Hons) Construction Management degrees.

The courses sit within the School of Energy, Construction and Environment, which boasts a strong portfolio of industry-related

research, particularly in the areas of low carbon building technology, sustainable construction materials and engineering education, ensuring students stay abreast of new technologies and emerging issues.

Professor Michael Fitzpatrick, Pro-ViceChancellor (Engineering, Environment and Computing) said: “Our staff possess impressive academic and professional experience in the industry, while our students have demonstrated a strong work ethic and discipline for success. It is no wonder that we boast successful alumni working for some of the most prestigious names in the relevant industries.”

Sir David Adjaye has achieved international attention for an exceptional body of work over 25 years. Drawing on his cited influences including ‘contemporary art, music and science to African art forms and the civic life of cities’, his completed projects range from private houses, exhibitions and furniture design, through to major cultural buildings and city masterplans. From the start of his career he has combined practice with teaching in schools of architecture in the UK and the USA, including professorships at the universities of Harvard, Michigan, Pennsylvania and Princeton.

His practice, Adjaye Associates, was founded in 2000 and today has studios in Accra, London and New York, with projects across the world.

Fluctuating

Wilo provide energy efficient solutions for pressure boosting, including the Wilo-SiBoost Helix VE to enable a consistent and reliable supply of water specific to the requirements of each application.

Wilo UK have a number of stocked booster sets with short lead times, built on site in the UK each one can be tailor-made to your own requirements.

Fire safety glass is integral to ensuring a building’s compliance with building regulations. However, with three different fire glass classifications available, each with its own performance characteristics, there can be confusion regarding which classification should be specified and where.

Andy Lake, UK Projects Director at Pyroguard, explained: “Fire safety glass can have multiple applications and classifications within a mid or high-rise building, all working together to form a vital part of a its passive fire protection.

“Detailed within Building Regulations and, more specifically, Approved Document B: Fire Safety, compartmentalisation involves the creation of fire-resistant compartments within a building, ensuring that, in the unfortunate event of a fire, it would be contained within a designated area.

“According to BS EN 13501-2, there are three main classifications of fire safety glass to be aware of: E (Integrity), EW (Integrity & Radiation) and EI (Integrity & Insulation).”

E offers the base level of fire performance and is also the minimum requirement stated by the UK Building Regulations. While it provides an effective barrier against smoke and flame, it does not prevent the transmission of heat.

EW represents a step up in the level of protection offered. Fire glass that achieves the EW classification will maintain the same level of protection against smoke and flame as E

but, in addition, will also deliver a reduction in the amount of radiant heat transmitted to the protected side. Specifically, EW keeps the amount of radiant heat to below 15kW/m2

The EI classification offers the highest level of protection. As well as providing a robust barrier against smoke and flame, EI also delivers a significant reduction in the amount of heat transferred through the glass, keeping the average temperature of the unexposed side to below 140°C. In simpler terms, this means that there could be a raging fire on one side of the glass, with temperatures above 800°C, and yet you could make an escape on the unexposed side, remaining protected from the heat.

“Of course, it is important to remember that, while the type of protection offered is determined by the product’s classification, the length of time for which this protection can be maintained will vary,” he added. “Typically, with fire rated glass, from 30 minutes all the way up to 180 minutes.

“As aforementioned, compartmentalisation is integral when considering a building’s passive fire protection scheme, meaning that the classification of fire safety glass required will likely differ depending on whether it is to form part of the compartment barrier, is to be installed within the compartment or is for elsewhere on a building. The creation of safe areas, for example, such as a data

centre, museum archive or evacuation zones within a hospital are likely to require higher levels of passive fire protection, such as EI classification fire safety glass.

“With no two construction projects the same, it is important that architects, specifiers and contractors continually consult the Building Regulations throughout the design and specification process. Only then can they correctly determine what level of performance and classification of fire safety glass is required for each individual application and area within a project.

“Of course, the classification stated in the Building Regulations is the minimum requirement and so architects may also choose to specify a higher classification of fire safety glass.

“Having an understanding of the three fire glass classifications and their performance characteristics is key if architects are to make more informed specification decisions. As demonstrated, despite E being the minimum requirement stated by Building Regulations, it is clear that there are applications where higher performance products would be better suited. In fact, Pyroguard has witnessed a recent shift within the industry with more customers installing EW and EI glass, perhaps signalling an increased awareness of higher performance products and a greater duty of care in project design and building maintenance.” Pyroguard

Karen Wilding, marketing manager for the leisure & hospitality sector at Forbo Flooring Systems, explains why the unparalleled combination of high performance benefits and the extensive range of designs that flocked flooring offers, makes it the ideal solution for creating the ‘wow factor’ within the interiors of ski resorts.

With the winter ski season just around the corner and travel restrictions starting to be lifted, the coronavirus pandemic has forced the entire industry to rethink its operations to ensure that resorts are as clean and safe as possible. While this may include increased sanitisation procedures, social distancing measures and perhaps even the demise of après-ski bars to avoid large crowds, the interior design of ski facilities should be well-thought through so that skiers can still enjoy their experience.

When it comes to the specification of floor coverings, there are a number of factors to consider. The choice of flooring should not only be hygienic and easy to clean and maintain, but products should also be comfortable, durable, waterproof and quick drying in areas of high foot traffic coming in from the snow. Aesthetics are also important in order to create attractive environments. With all of this in mind, flocked floor coverings provide the perfect solution as it is well suited to areas where durability and cleanability are essential.

Flocked floor coverings have seen a huge rise in popularity in recent years, thanks to the advances in technology that are challenging traditional perspectives. Neither a carpet, nor a resilient floor covering, electrostatically flocked flooring solutions offer the best of both worlds. Like resilient floor coverings, they are safe, durable and washable, but they also offer the appearance, comfort and sound-absorbing properties similar to a textile flooring.

Advanced digital printing techniques have extended the range of vibrant colours and patterns that flocked flooring can be manufactured in, giving rise to a host of new design opportunities. Providing the ultimate printing surface, specifiers can make a bold statement or muted complement, depending on the client’s requirements. Choose from wood-like aesthetics and floral styles to linear outlines and geometric patterns in a range of tile, plank and sheet formats or even have bespoke designs printed and create standout, one-of-a-kind destinations for end users to enjoy.

Thanks to its precision-driven and unique manufacturing process, flocked floor coverings are truly different to any other type of flooring on the market in terms of performance. There are products available with a pile density of over 70 million fibres per sqm on an impermeable PVC backing; this makes the floor incredibly easy to clean and the tightly packed fibres reduce the potential for soiling deposits. The impermeable PVC layer is waterproof and ensures that nothing will seep through the product into the subfloor. Indeed, this makes it more hygienic and longer lasting than other textile floor coverings.

In terms of reducing maintenance downtime, which is vital in ski facilities, flocked floor coverings are also quick drying in comparison to other textile floor coverings. What’s more, specifiers should look for options that can provide low in-room impact noise performance (Class A) as well as good

impact sound reduction, to create quiet relaxing environments for end users to wind down after a day on the slopes.

Available in a wide range of colours and designs, all whilst being able to withstand extreme wear and high traffic, Forbo Flooring Systems’ Flotex flocked flooring offers a unique blend of qualities that will complement any ski resort interiors project. Flotex is also the only textile floor covering to be awarded with the prestigious Allergy UK Seal of Approval™, as with the correct cleaning and maintenance regime it will not harbour dust mites – contributing to a better indoor environment for all.

Whether you’re working on a UK ski facilities project or specifying for ski resorts across the world, by liaising with a reputable flooring manufacturer, specifiers can achieve comfortable, durable and functional interior spaces.

Paul Williams, Domus Ventilation Product Manager, looks at implications of the future homes standard.

The current Building Regulations Part F, which covers ventilation, has been in place since 2010 but over the years key issues have been identified and concerns voiced over the failure of homes to comply.

All that is about to change with a revision to the regulations in line with the government’s plans for the Future Homes Standard, which focuses on increasing the energy efficiency requirements for new homes.

The expectation is that an average home will have 75-80% less carbon emissions than one built to current energy efficiency requirements, so it’s a big leap and will require big changes.

Increased Ventilation

Part L (Conservation of fuel and power) and Part F of Building Regulations are very closely linked. If we are to achieve the type of low energy buildings laid out in the Future Homes Standard, new homes will need to become even more airtight than they are now to reduce energy wastage.

Without sufficient ventilation though, these homes can become overheated and the air uncomfortable and unhealthy to breath. Consequently, Part F will also need to change to ensure the right level of ventilation is supplied to ensure good indoor air quality and user comfort. And that change means increasing the level of ventilation.

Mechanical ventilation, in the form of intermittent extract, continuous extract (MEV systems) or supply & extract (MVHR systems), are recognised as the most proficient means of ventilating a modern property. The revised Building Regulations are expected to increase the minimum airflow through these systems to each bedroom by 6 l/s. This has been introduced in concern over insufficient ventilation in bedrooms overnight if doors are kept shut. The other expected change here is an increase in the background ventilation from 2500mm2 to 5000mm2 in extract-only systems.

Natural ventilation systems, i.e. background ventilation, will remain an option under the new regulations, but only for less airtight homes with a design air permeability of ≥ 5. However, this will most likely mean the use of much larger grilles - far from aesthetically pleasing! – as ventilation will be determined on a room by room basis, rather than based on the whole property.

A large proportion of homes do not comply with current Building Regulations requirements which indicates the regulations are either being flouted or are not being understood and implemented. To tackle the latter, ventilation standards are being simplified in relation to a property’s air

permeability through the recommended use of continuous Mechanical Extract Ventilation (MEV) and continuous supply & extract ventilation (e.g. Mechanical Ventilation with Heat Recovery - MVHR) for properties with any level of air tightness. Furthermore, whole house ventilation design calculations, will now only require the number of bedrooms and floor area to be taken into consideration, removing the need to predict occupancy rates, which removes guess work.

For some, the changes to Parts L and F of the Building Regulations don’t go far enough in reducing carbon emissions and energy consumption. For now though, these changes are heading your way and, when it comes to ventilation, it’s a carrot and stick approach: it’s easier to understand and implement, but ventilation rates are increasing and proof of system effectiveness will be required.

Ventilation – Enquiry 11

carrot and stick

A large proportion of homes do not comply with current Building Regulations requirements which indicates the regulations are either being flouted or are not being understood and implemented.Domus

Our renowned 4000 Series riser doors have always been specified by architects for delivering the highest standards in third party fire certification without compromising on architectural design.

Unlike the rest of the industry, we fire test our riser doors from both sides to ensure legal compliance and still achieve 240 minutes certified fire rated performance.

Given the choice, why would you specify anything less?

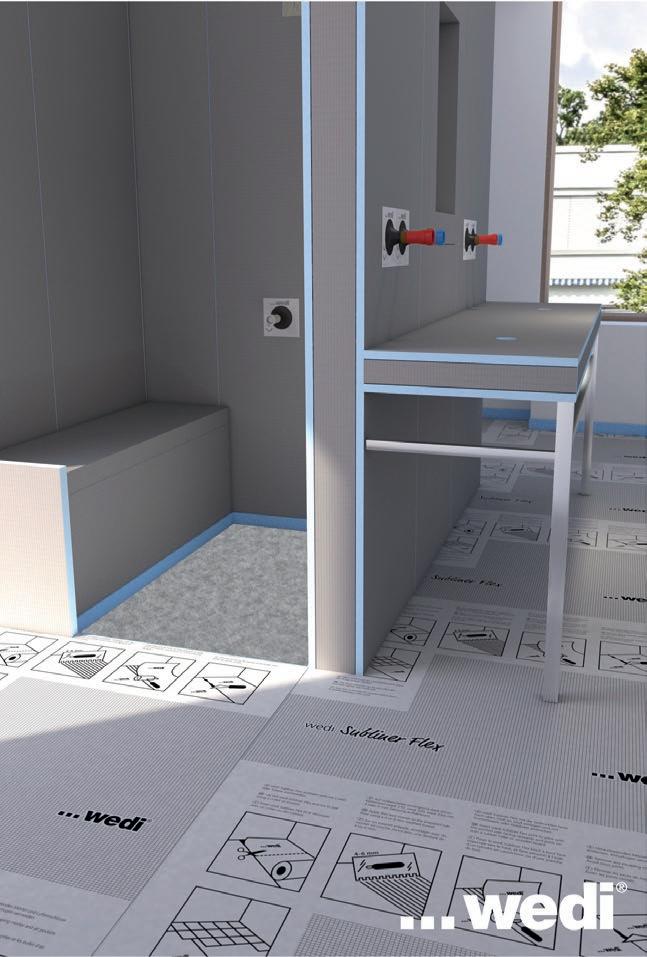

Getting the waterproofing basics right is an absolute must when it comes to creating a wetroom, but it is equally important to produce the perfect finish too.

Schlüter-Systems creates products which work best when used together, as well as providing solutions for the variety of challenges architects and specifiers face on a daily basis.

Schlüter ®-DITRA 25, an uncoupling membrane, serves as a waterproofing membrane and a vapour pressure equalisation layer, protecting tile or natural stone coverings from cracking or debonding. The same features can also be found in the underfloor heating system Schlüter ®-DITRAHEAT-E, making it ideal for heated floors and walls in wetrooms with tile and stone coverings.

The tile and stone covering in the shower area must be sufficiently sloped to allow for appropriate drainage.

This is where Schlüter-Systems’ newest launch Schlüter- KERDI-SHOWER-LTS comes into its own. The preformed shower tray has been created with a 1 in

80 slope to work harmoniously with the linear drainage system Schlüter ® -KERDILINE-G3.

The KERDI-LINE-G3 drain complies with BS EN 1253, providing a constant 50 mm water seal and anti-blockage based on an 8mm ball bearing test.

To create the desired finish, Schlüter ®TRENDLINE finishing profiles are available in a variety of different colours and textures, giving you full flexibility to

complement the chosen tile effortlessly. This can be achieved by offsetting the colour to make a statement with the tiles, or for visual flow using one tone of tile, matching the colour of your profile to it.

If a shelf is required after the project is finished, the Schlüter®-SHELF range is the perfect solution as it avoids the need to drill through finished coverings and the waterproofing beneath.

Schlüter-Systems – Enquiry 13

Flex-R is one of the UK’s largest suppliers of EPDM materials and cold-applied roofing systems. This year the company celebrates reaching a significant milestone in their history, 20 years supplying to the roofing industry. We speak to Trading Director Duncan Winter, who has been involved with the company since it first started, to find out how the Flex-R has changed over the years.

Flex-R all started back in 2000 with the decision to launch a new, unknown roofing system, EPDM, into the UK market. Flex-R always believes in supplying reliable products and we worked with the pioneers of rubber roofing, Carlisle SynTec, to exclusively distribute RubberBond Fleeceback. In fact, we believe in the product so much we still supply it today.

It’s taken a lot of work to get EPDM established into the market. We must be doing something right because in the last five years sales have almost doubled, impressive growth for an unknown product!

However, it’s not all about EPDM. We also supply LQD-R2, a cold applied liquid waterproofing system and last year we launched another innovative roofing product, GE Silicones, a flexible liquid membrane.

Roofing products are only one element of our service. Flex-R has an experienced team with the technical knowledge to work with clients throughout the entire process from design and specification to purchase, delivery and installation. We can advise you at each stage of your project, matching the right system to your specific requirements.

We know that a project can only succeed by delivering high standards of workmanship. For this reason, we also set up our Specialist Registered Installer (SRI) scheme which trains contractors on

how to use our products. Our technical team are always on hand to answer any questions that may come up during the installation.

Flex-R are constantly looking at ways to share their expertise on roofing projects. We support academies through the Continuous Improvement Funding process and using our knowledge we have recently developed our second RIBA approved CPD on roof refurbishment.

Flex-R – Enquiry 14

Award winning Studio Moods is the off-the-shelf bespoke LVT solution from IVC Commercial, making one-off feature floors more affordable.

Using nine geometric shapes, including four new XL formats over the original collection, combined with wood, stone and colour looks, Studio Moods presents 107 off-the-shelf QuickShip patterns that make it fast and easy to select a floor personalised to your project. Alternatively, you can use the 69 building blocks used for all QuickShip patterns to create your own design or go completely bespoke across 160 looks from just 75m2

From classic chevron and herringbone in surprising stone effects, through to patterns involving multiple formats, Studio Moods is all about versatility and creativity. Wood combined with stone, giant hexagons in solid colours next to dark oak; this is an LVT collection that brings personality to workplace, retail, hospitality and leisure, PRS and PBSA projects.

“The original Studio Moods collection has proved itself as the ideal solution for creating stunning feature areas in a wide variety of projects,” says David Bigland, managing director, IVC Commercial. “Now with the new Studio Moods, we’ve refined the concept, so designers have access to a wider variety of patterns, bigger scale and new wood, colour and stone looks; all easily and quickly accessible from stock through our QuickShip programme.”

Using IVC Commercial’s 55 specification ensures that Studio performs wherever you choose to install it. Suitable for receptions, breakout zones and feature areas; as well as anywhere else that demands style and performance; the floor is durable and easy to maintain, efficiently made in Belgium using renewable energy and features 30% recycled content.

Designed and manufactured in the UK, Powermatic controlled, concealed door closers deliver exceptional performance as well as a host of benefits that surface-mounted closers cannot match:-

• Genuine independent third-party certification

• Closing speed and latching action adjustable without removing closer from door

• Certified for use on one-hour and half-hour fire doors

• Contributes towards the achievement of accessibility requirements (AD M)

• The only CERTIFIRE jamb-mounted door closer

• Improves aesthetics and reduces risk of damage from vandalism or tampering

• Perfect for social housing, hotels, health, care homes, secure accommodation, commercial and many other situations.

• Suitable for anti-ligature applications

• Completely concealed when the door is closed

www.concealeddoorclosers.com

Tel 0121 766 4200 info@samuel-heath.com

When you need a “one-off” solution, it pays to turn to British manufacturing pioneers.

This has proven to be the case for leading global data and media company Bloomberg, when the roof on one of its main warehouse facilities in London began leaking. Hambleside Danelaw rose to the challenge and could not only manufacture to the profile required, but could deliver a comparatively small quantity, costeffectively.

Bloomberg’s real estate management company called in Weatherproofing Advisors to remedy the problem. Teamwork between Weatherproofing Advisors, cladding manufacturer Joris Ide and rooflight manufacturer Hambleside Danelaw delivered more than a roof that no longer leaks- the new solution has improved internal energy efficiency in heat and light, lowered the carbon footprint, and enhanced the working environment within the building.

“We had to address the leaks resulting from lack of maintenance over the 20 years or so since the unit was first built, and do so without interrupting or disrupting daily operation,” explained Weatherproofing Advisors contract manager Ben Orton. “An improved thermal performance was an additional consideration in our original brief. By over-cladding the roof, and replacing the old GRP rooflights with new Zenon double skin factory assembled units, we improved

the U value, and have reduced the amount of artificial light required. Even whilst the work was going on, the staff were telling us they didn’t need the lights on as much!”

The original metal roof was composite with a 50mm box depth, and 20% rooflight area. The entire roof was overclad with Joris Ide metal sheet to JI32.167.1000 profile, and rooflights replaced with Hambleside Danelaw’s Zenon rooflights, comprising Zenon Pro 24 outer sheet and Zenon Evolution LC1 as the liner. The rooflight combination delivers a minimum 56% light transmission and a U value of 1.3W/m2K- well within the limit set under Building Regulations.

“Hambleside Danelaw was the only GRP rooflight manufacturer prepared to work with

us, to develop and manufacture a specific profile to the quantity we needed,” added Ben Orton. “Its advanced manufacturing processes means it could not only do that, but do it cost-efficiently. The client is a lot happier- they have a roof with no leaks and that’s easier to maintain going forward, better natural light and thermal performance, and a better working environment.”

Hambleside Danelaw has a history of British innovation, now spanning five decades. With its Zenon being one of the UK’s top three brands in GRP industrial rooflights.

CE marked Zenon Pro sheet is a nonfragile thermosett GRP available in a range of weights and fire ratings. Zenon Evolution is a unique material manufactured by a pioneering process with continuous filaments of GRP that produces a greater strength: weight ratio than traditional GRP yet uses less resin which results in less embodied carbon. The combination will deliver excellent light transmission and thermal performance for 25-30 years.

Full details and further rooflight configuration can be found here: https://www.hamblesidedanelaw.co.uk/zenon-rooflights/.

Hambleside Danelaw – Enquiry 17

Coventry University is laying the groundwork for future developments in STEM (Science, Technology, Engineering and Mathematics) with a new, state-of-the-art postgraduate facility, completed with a building service specification featuring premium performance Kingspan Kooltherm Pipe Insulation and Kingspan Therma Duct Insulation.

The Beatrice Shilling Building is the third collaboration between Coventry University and designers. The four-storey facility provides a range of cutting-edge facilities including a specialist rapid prototyping area, laser facility and science and technology labs. Constructed by Speller Metcalfe, the new building is linked to the undergraduate teaching block, ECB1, through a covered bridge on the third floor.

As part of its commitment to reduce its carbon emissions by 20% relative to a baseline period of 2008-9, the University has developed a sustainable building framework which focuses on full lifecycle emissions and costings for new buildings. The Beatrice Shilling Building was the first to be constructed under this framework and this contributed to the specification of over 7000 m Kingspan Kooltherm Pipe Insulation for all domestic, heating and chilled water service pipework across the building whilst 400 m2 Kingspan Therma Duct Insulation was fitted on external ductwork. The complete thermal insulation package was supplied and installed by Cilex Insulations.

Kingspan Insulation – Enquiry 18

Cost-e ective, permeable car parking solutions

Designed for everyday use, busy car parks Can be part of a SuDs installation scheme

Engineered for the long-term Works well with a gravel or grass nish Ideal for emergency access routes

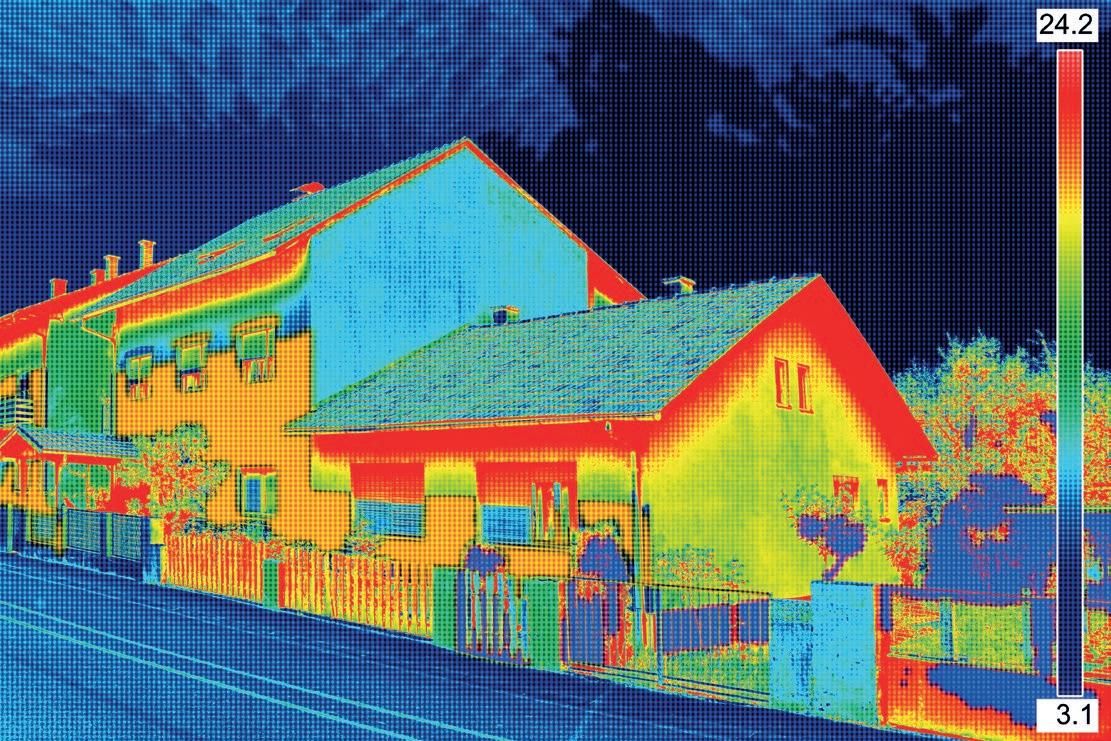

A well-insulated building means a healthier, quieter and more energy e icient environment with better comfort levels, lower heating bills and a reduced carbon footprint. And nothing does a better job of insulation than Icynene – the first name in spray foam insulation.

Icynene expands 100-fold when applied, sealing all gaps, service holes and hard to reach spaces, completely eliminating cold bridging and helping reduce energy bills.

What’s more its open cell structure lets the building breathe naturally.

Icynene. It’s the modern way to insulate buildings, old and new.

For more information on the benefits of Icynene visit icynene.co.uk

Polypipe Building Services has devised an above ground drainage system that can negotiate the small footprint of a landmark tall building in the centre of Manchester.

Polypipe supplied its Terrain P.A.P.A.® (Positive Air Pressure Attenuation) and Pleura air admittance and control systems for use on the 28 storey Axis Tower, situated near the city’s popular Deansgate Locks, and the pioneering Beetham Tower.

The building is positioned between a canal and locks, a critical city centre junction between Whitworth Street and Lower Moseley Street, as well as the tram tracks serving Deansgate Castlefield station –meaning it has a tight footprint.

The development is 93 metres high and is currently the 12th highest building in a city which is currently experiencing a dramatic growth of tall building developments.

The development site has a footprint of just 3,200 square feet, as the base of the building is small, but the structure

cantilevers out to the upper floors of the building. This provided a challenge in managing water from the top of the building, through the bottom of the structure, without relying on an extensive network of pipes. The design of the system also required a reduction in additional secondary stack pipework.

Polypipe Building Services worked with primary contractor Russell WBHO and Quartzelec to develop the system and advised the use of the Terrain P.A.P.A.® and the Terrain Pleura air admittance valves to supply a complete drainage ventilation system.

The positive pressure reduction device is used to mitigate the effects of positive air fluctuations in the drainage pipework system, such as when a toilet is flushed on an upper floor.

The use of Terrain P.A.P.A.® system allowed for the use of less pipework, while maximising the use of the available floor space within the building structure.

The application of the Terrain Pleura Regulators balances negative air pressure fluctuations within the drainage system.

Polypipe’s early involvement in this project ensured we could deliver a high quality above ground drainage system and water supply system.

The regulators are also easy to install allowing for efficient management of onsite skilled labour, which is essential during projects relying on meeting strict deadlines.

Gary Gardner, Head of Building Services at Russell WBHO, said: “Polypipe’s early involvement in this project ensured we could deliver a high quality above ground drainage system and water supply system.

“We managed the project from design to inception so it was important we worked with a drainage specialist that could meet and exceed the demands of this project with its unique structural requirements.”

Jonathan Greenwood, Strategic Project Manager, Polypipe Building Services, said: “Working with Russell WBHO andQuartzelec, the Polypipe team was able to devise a water management solution that worked within the constraints of the project footprint, negotiated the challenge of gravity management, and met all building specification and regulations.”

The Axis Tower opened to residents in 2020.

Polypipe – Enquiry 21

Polypipe Building Services is your specialist commercial construction partner – investing in the future, developing and delivering systems that support you in creating safe and sustainable commercial buildings. We harness our ingenuity and creativity to deliver class-leading solutions and product sustainability. And we’re with you every step of the way – providing technical support as well as on-the-ground assistance. We do all of this, to bring you more. More Innovation. More Expertise. More Support. More Polypipe.

AJ Specification Award winning project ‘The Forge’ in London E6 epitomises the way forward in rainwater management in the UK.

‘This project demonstrates good design team collaboration and joined-up thinking,’ said the judges . ‘It responds to the city’s challenge – of not being able to put things in the ground – and uses specification to turn the scheme on its head, with a high-quality outcome.’

A key constraint of the original planning consent for this residential scheme was the site’s limiting maximum discharge rate for surface water of 3.3 litres per second – resulting in the scheme sitting within what’s known as a ‘critical drainage area’, and posing significant design challenges in terms of drainage.

Radmat’s Blue40 Roof systems provided a key element of the source control and attenuation required by the sites Sustainable Urban Drainage System (SuDS) strategy; attenuating rainwater rather than draining it quickly.

A comprehensive roofing system incorporating waterproofing, insulation, blue roof and green roof systems all wrapped up in a single source guarantee that eliminates warranty risk or split liability – Radmat Blue40 Visit our website or email: techenquiries@radmat.com for further information.

www.radmat.com

Photo: Ben Luxmoore

The Forge, Upton Park, uses an innovative Blue40 Roof System that restricts and delays runoff from the site, equating to 60% of the equivalent green field flow rate.

ARCHITECT: RM_A ARCHITECTS

Photo: Ben Luxmoore

The Forge, Upton Park, uses an innovative Blue40 Roof System that restricts and delays runoff from the site, equating to 60% of the equivalent green field flow rate.

ARCHITECT: RM_A ARCHITECTS

With more than 40 years experience in the design, manufacture and installation of architectural casing solutions, Encasement Ltd is ideally equipped to support a range of decorative casing requirements, whether it’s high quality products, technical information or specification details.

The company’s extensive range provides aesthetic and practical solutions for concealing structural columns and steelwork, as well as wall lining solutions and building services casings to assist architects, specifiers and contractors with interior and exterior projects.

To provide the maximum design versatility and choice, the Encasement column casings range includes the ‘Circa’ and ‘Quadra’ products, manufactured from pre-formed plywood, as well as the ‘Forma’ metal range and the ‘Polyma’ and

‘Gypra’ casings, which are moulded from glass reinforced plastic (GRP) and glass reinforced gypsum (GRG), respectively.

Designed to meet the broadest scope of specifications, installations and project requirements, the range also provides an exceptional choice of standard and sizes and shapes, as well bespoke options and a diverse palette of finishes for each column casing type and material.

While all Encasement column casings are suitable for interior use, the ‘Polyma’ and ‘Forma’ ranges are also widely used for

SIMONSWERK UK Ltd are delighted to announce the opening of a new London showroom at 45 Great Sutton Street in the heart of Clerkenwell. Conveniently located right in the heart of London’s design district.

The UK is a key market for the SIMONSWERK Group with London being known for its trendsetting community of architects and designers who work on global projects. The new London showroom has been created to provide our customers, architects, and designers with the opportunity to experience our products first-hand. The goal is to showcase our products and inspire and share our expertise, as well as to offer a meeting place to discuss projects, product demonstrations and CPD presentations. Ideally located just a short walk from Farringdon tube station. The showroom is nestled in the heart of a thriving design community near trendy restaurants and bars.

SIMONSWERK share the showroom with Wilkhahn a leading German manufacturer of office furniture. The showroom is split over two levels where the entire TECTUS Concealed hinge system and the TRITECH solid brass product range will be available to see. SIMONSWERK

exterior retail projects, due to their inherent weather resistance and durability.

For integrated and versatile interior finishing, Encasement’s Vecta system includes high quality wall linings and lift lobby linings, as well as bulkheads, reveals, soffits and skirting. Widely used in retail, transportation and commercial projects, Vecta provides an outstanding finish to any project, whether it is used for decorative purposes, concealing structural components or providing protection in high traffic areas.

Encasement – Enquiry 24

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Protect Viking Air, our new air and vapour permeable roofing underlay, has arrived. And with it, your opportunity to specify an independently certified product with a higher airflow rate than any competitor, without the need for additional roofspace ventilation when a well-sealed ceiling is installed. What’s more, with wind uplift resistance up to Zone 4* at 345mm batten gauge to BS 5534, Viking Air outperforms the rest, ensuring wide coverage across the UK and throughout Ireland.

We believe it’s a breakthrough in air and vapour permeable technology in its own right. And as part of the wider Glidevale Protect family of class leading roofing products, it adds even more to a total solution of underlay options that offers all the choice you need.

Domestic or commercial. Warm roof or cold. New build or refurbishment. Whatever your pitched roofing project, Glidevale Protect gives you complete control.

Visit: protectmembranes.com/vikingair to find out more. Or contact info@glidevaleprotect.com / 0161 905 5700 quoting ‘Viking Air’.

GLIDEVALE PROTECT, 2 Brooklands Road, Sale, Cheshire M33 3SS. Tel: 0161 905 5700 Fax: 0161 905 2085 Email: info@glidevaleprotect.com Web: protectmembranes.com *Meets Zones 1-4 without need for additional counter batten or integral tape. Achieves unrestricted use for wind uplift - Zones 1-5 at 310mm batten gauge or when installed on sarking board.

When Premier League football team, Aston Villa FC, decided to transform one of the hospitality lounges at Villa Park – it was in need of practical flooring that could cope with a high level of footfall and provide excellent slip resistance – Amtico Spacia 36+ stepped up to the spot!

Designer and main contractor Benchmark was tasked with converting the North Stand’s existing lounge and 18 small hospitality boxes into a brand-new suite – The Gas Lamp. The brief was to create a modern, yet history-fuelled space, while offering superb views of the pitch.

For the bar area, Benchmark chose a contemporary and welcoming aesthetic, while paying homage to the 145-year-old club’s history and founding story of four members meeting under a gas lamp to form Aston Villa FC. The aim was to create the perfect space for fans, friends and family to meet up before heading to the lounges for the match. Neutral oak tones and mid-grey concrete hues, from Amtico’s Spacia 36+ collection, were chosen as the main flooring solution for the open-plan bar, as well as the hospitality boxes, corridors and stairs.

As large areas formed part of the emergency escape route, Building Control requested that the flooring had high slip resistance. To meet these requirements, Benchmark opted for Amtico’s Spacia 36+ Luxury Vinyl Tile (LVT) safety floor, which boasts enhanced slip resistance for the lifetime of the product and antimicrobial

technology, which protects against bacteria including MRSA and E.coli. The collection is available in tiles and planks, offering greater design possibilities including Parquet. This allowed the design team at Benchmark to successfully achieve a stylish and practical space, creating walkways and specific zones using the collection’s Featured Oak and Metropolis Smoke in contrasting laying patterns.

Paul Smith, projects director at Benchmark, explains why Amtico was specified: “The Gas Lamp was an important project for Aston Villa FC, Levy UK and Benchmark, bringing an underused area up to high quality hospitality use. Due to the layout of the space, a large

proportion of the floor areas were on an escape route and needed to have slipresistant properties to meet the requirements of Building Control. The Spacia 36+ range allowed the flooring to be stylish, functional and cost effective.”

Products: Featured Oak, laid in Large Parquet, and Metropolis Smoke, laid in Uniform Tile, both from the Amtico Spacia 36+ safety floor collection.

For more information about Amtico and its latest ranges of LVT and carpet, please visit www.amtico.com/commercial.

Amtico – Enquiry 27

The Spacia 36+ range allowed the flooring to be stylish, functional and cost effective.

Located in one of the most vibrant parts of London, lies the stunning Ham Yard Hotel. Centred around a pedestrian thoroughfare connecting Great Windmill Street and Denman Street, Ham Yard Hotel has everything guests could want on its doorstep, from an eclectic nightlife of buzzing bars and restaurants to quirky shops and quaint cafes.

Built on a plot that has been vacant for a number of years, the site has had a creative past. During the 1920s Ham Yard was home to the Hambone Club for writers and musicians.

Numerous plans had been put forward over the years to develop the site, all were rejected until permission was granted for Firmdale hotels to redevelop the area. They went on to create 91 individually designed hotel bedrooms and 24 apartments, along with a 1950s style bowling alley, theatre and restaurant.

Although new double glazed windows were installed throughout the building, the corner of the hotel on Great Windmill Street still suffered high exterior noise levels. The introduction of secondary glazing is one of the most effective ways of combating outside sound. A reduction of 45dB is

possible when there is a gap of at least 100mm.

A total of 37 openings have been treated in three different unit styles. The secondary glazing was finished in a dark grey colour to match the existing primary windows, making them as unobtrusive as possible. Acoustic laminated glass was also used, which absorbs the external noise levels, to support in creating a peaceful and tranquil atmosphere.

As testament to the detailed planning throughout the design and build phases, Firmdale’s efforts were rewarded with the hotel gaining a BREEAM ‘Excellent’ rating. Established in 1966 and Royal Warrant Holder since 2004, Selectaglaze has a wealth of experience working on many building types, from new build to Grade I Listed buildings. Selectaglaze offers a

A hattrick of fenestration solutions from Senior Architectural Systems alongside a great team performance from supply chain partners Elite Aluminium Systems Ltd and Buckingham Group has played a key part in the delivery of two new football stadiums.

At the new LNER Community Stadium in York, Senior has provided a highperformance fenestration package comprising its SF52 slimline aluminium curtain walling, thermally-efficient SPW600 aluminium windows and SPW501 and SD commercial doors, all fabricated and installed by Elite Aluminium Systems Ltd.

Designed by Holmes Miller Architects, the new landmark benefits from the versality of Senior’s product range enabled the project team to meet the various requirements for the building and its different users.

The flexibility offered by the SF52 aluminium curtain walling also enabled

comprehensive free advisory service to help with any specification queries, as well as RIBA approved CPDs.

For further information, please contact Selectaglaze on 01727 837271, e- mail: enquiries@selectaglaze.co.uk or visit: www.selectaglaze.co.uk

Selectaglaze – Enquiry 29

Senior and Elite Aluminium Systems Ltd to collaborate to develop a bespoke solution for the impressive façade of the new Brentford Stadium in West London.

Installed to the main entrance, the system was modified to offer a 80mm sightline with a 29mm glazing rebate, complete with specially fabricated pressure plates and caps, and was integrated with Senior’s automatic SD aluminium commercial doors. On the pitch side elevation, Senior’s standard SF52 system has been installed alongside the robust low U-value PURe® Commercial Door, which is Senior’s largest and strongest system to date. To complete the fenestration package, Senior’s SPW600 aluminium casement windows were installed and fabricated to include automatic opening vents.

Designed by AFL Architects and constructed by Buckingham Group, the new stadium for Brentford Football Club and London Irish rugby club boasts a capacity for some 17,250 spectators.

Senior Architectural Systems – Enquiry 30

Bustling night life on its doorstep; Ham Yard Hotel still offers a peaceful night’s sleep with Selectaglaze

We’re breaking through obstacles in sanitary engineering with the introduction of Geberit BIM NOW. Providing you with simple, intelligent geometry enhanced models with specific BIM parameters for easy planning. Download the Geberit catalogue plug-in for Autodesk Revit now and you’ll have direct access to the latest, up-to-date data for all Geberit products.

geberit.co.uk/BIM

With a successful track record of working in the hotel and leisure sector, Senior Architectural Systems has supplied the full aluminium fenestration package for the new Hilton Garden Inn hotel located at Doncaster’s famous racecourse.

Designed by KKA Architecture, the new hotel features Senior’s slimline aluminium curtain walling, thermallyefficient windows and robust commercial doors which have been installed by supply chain partner Danum Windows Ltd for main contractor Galliford Try.

With both Senior and Danum Windows being based in South Yorkshire, the use of a local supply chain has helped reduce the financial and environmental cost of the build and contribute to a timely delivery. The new hotel is also the latest contract that Senior has undertaken for global hotelier Hilton and

follows the successful completion of similar high-profile schemes such as the Hilton Garden Inn at Manchester’s Emirates Old Trafford cricket ground.

Located overlooking Doncaster’s iconic racecourse, home of the St Leger Stakes which is the UK’s oldest horse race dating back to 1776, the new Hilton Garden Inn hotel has been designed to offer luxury accommodation and exceptional views of the surrounding scenery.

The extensive use of Senior’s slim profile SF52 aluminium curtain wall system

Designed for maximum hygiene and cleanliness, Viega has introduced two new touch-free flushing technologies for urinals in public facilities such as offices, transport hubs and sports stadiums.

The concealed and infrared flushing solutions are available in a variety of design options and are protected against vandalism.

For the concealed flushing solution, a sensor is installed inside the urinal siphon, which registers the change in flow and temperature when the urinal is in use. This will trigger the flushing mechanism automatically, delivering exceptional hygiene for the user. In addition, the whole system is concealed behind a wall, protecting it from any form of damage or vandalism.

Adaptability is another important consideration for public sanitary facilities. The concealed flushing system offers the option to set a one or three litre flush depending on the requirements. A dynamic option is also available that will automatically detect high frequency use and

reduce the flushing volume from three litres to one. Depending on the selected setting, additional hygiene flushing can also be triggered automatically after 24 hours.

The infrared technology system offers another option to deliver maximum hygiene with touch-free flushing. The system is installed behind the wall together with the compatible Viega Prevista Dry urinal element. Once installed, only the flush plate with its integrated sensor is visible. The flushing mechanism will trigger when a user stands in the detection range of the infrared sensor for at least eight seconds, preventing unnecessary activation.

The detection range, flushing volume and duration can all be adjusted in line with expected use and specific requirements.

Viega – Enquiry 33

alongside the use of its SPW600 aluminium window inserts, helps to create a bright and welcoming interior and provides various vantage points from which to watch the sporting action.

Senior’s high performance SPW501 aluminium doors have been installed to provide access to private balconies which overlook the racecourse, with the manufacturer’s automatic SD aluminium commercial doors providing safe and secure access to the main entrance and reception areas.

Senior Architectural Systems – Enquiry 32

In June, Prime Minister Boris Johnson promised to ‘build, build, build’, saying that he wanted to use the crisis caused by the pandemic to tackle this country’s great unresolved challenges and get uk construction moving. Health construction is destined to be one of the main sectors to benefit.

With a view to streamlining the planning system, reducing unnecessary bureaucracy and speeding up development, major planning system reforms were announced by the government at the beginning of August, reports industry analysts Glenigan.

Under the new rules, land will be designated in one of three categories: for growth, for renewal and for protection.

“Land designated for growth will empower development - new homes, hospitals, schools, shops and offices will be allowed automatically”, Robert Jenrick said. New homes and hospitals will be granted automatic outline planning permission, cutting time for developments to proceed to slight as well as cutting costs for developers.

The planning changes may take some time to make a real difference, says Glenigan, but with a solid pipeline of infrastructure projects, the government is clearly boosting confidence for the sector, with many highvalue projects finally getting over the line thanks to government backing.

With increased demand on health services as a result of the Covid-19, both new-build

and refurbishments projects have become a priority. The need to ensure ease of movement around hospital rooms - as well as enhanced privacy and comfort – has seen P C Henderson’s Sirocco system specified on a number of projects.

Rene van den Biggelaar, Business Unit Manager at P C Henderson, said: “Our Sirocco sliding door system is extremely popular in healthcare applications due to its integrated hydraulic self-closing feature which ensures the door always comes to a safe and gentle close.”

On a recent project a system that worked well for both patients and staff was required and the company set up a test room during the build which was used for a number of months. This provided valuable feedback which led to some further customization of the product to ensure the best user experience.

“The contractor required a system which could work with a 1.35m wide doorensuring that even a hospital bed could be maneuvered through into the bathroom if required,” added Rene van den Biggelaar. “We achieved this by manufacturing a custom made 2850mm length of track to replace

the systems usual 2200mm track. We also designed a custom made stop which would allow the door to be held open half way across the opening - when only a small walk way was required.”

Sustainability is also high on the hospitals’ agenda The use of P C Henderson’s Sirocco system assisted towards this through its hydraulic self-closing feature which requires zero electric input. >>

With increased demand on health services as a result of the Covid-19, both new-build and refurbishments projects have become a priority.

>> Improved hygiene is always a priority for healthcare environments. The new DePuro Pro air purifier from Vortice has been successfully installed in two NHS hospitals in Essex as part of their fight against the spread of Covid-19. The twelve units have been installed in three dental rooms and nine treatment rooms in a project to improve the air quality in the hospitals and increase patient turn-around in a clean and safe environment.

The DePuro Pro unit comes in two sizes, it is a plug and play set up and uses two HEPA 14 filters which retain up to 99.995% of particulates including virus, bacteria and droplets within the air.

Meanwhile PAC, the world leading supplier of innovative access control solutions, has announced the availability of its new contactless and hands-free request to exit (RTE) button

Pete England, PAC’s global product manager, said; “Our new contactless RTE technology reduces the possibility of cross contamination and protects occupants, while also lowering the amount of surfaces that need to be regularly cleaned.”

Highly cost effective, as well as being quick and easy to install, the contactless

RTE button fits into a standard single-gang electrical backbox, with simple wiring into PAC controllers including the popular 512 and 212 devices, as well as the Easikey 99 and 250 products.

Where an existing push to exit button is in place, the contactless RTE can be retrofitted in minutes and its infrared technology is designed to prevent interference with other infrared devices located on-site. Housed in a stylish stainless steel faceplate, a

A state-of-the-art medical centre in Milton Keynes has been completed thanks to national contractor Willmott Dixon.

The £9.5m facility provides additional health care capacity for residents within the Western Expansion Area of the city.

The now complete Whitehouse Medical Centre – delivered on behalf of Milton Keynes Council –will serve around 22,500 people living nearby and will also be a base for Thames Valley Police. The ‘all in one'

prominent two colour LED changes from red to green when a successful request has been identified. It is also dust and water resistant to IP65 – something that is an important feature for use in harsh environments.

It limits the threat of transference of disease, infections and dirt between users and with an adjustable latch time from 0.5 to 20 seconds, it can also be used as part of a social distancing policy.

facility covers 30,400 sq ft and includes consulting rooms, minor surgery and recovery rooms, nurse-led treatment rooms, a pharmacy, ancillary clinical support rooms and multi-purpose/health education rooms. There is also space set aside for use by Thames Valley Police and an ambulance standby, alongside a café and car parking.

Procured via Major Works England and Northern Ireland - a part of the Scape National Construction framework - the project is visually striking thanks to its design by Race Cottam Associates.

A total of Advanced fire alarm control panels have been chosen to protect Wythenshawe Hospital, Manchester, one of the UK’s largest acute teaching hospitals.

Selected for their performance, quality and ease of use, 96 intelligent addressable MxPro 5 fire alarm control panels and 34 custom AdSpecials panels will be installed.

The system changeover to Advanced will involve the installation of new network cable across a live hospital environment as well as BMS integration, and the introduction of a graphics package to provide visual representation of the fire system to end users. The 34 custom-engineered, 6-loop panels with 600 zonal LEDs included

in the installation will be designed and manufactured by Advanced’s AdSpecials department. The network of Advanced panels will work with over 20,000 devices using Apollo and Hochiki protocol.

In addition, a full design review of the hospital’s existing false alarm management strategy will take place to ensure that the new system is programmed to effectively reduce unwanted alarms. The upgrade to the system will also see the introduction of ipGateway, Advanced’s fully interactive internet portal that presents the user with a detailed description of the current status of the fire system.

The new DePuro Pro air purifier has been successfully installed in two NHS hospitals in Essex as part of their fight against the spread of Covid-19. The twelve units have been installed in three dental rooms and nine treatment rooms in a project to improve the air quality in the hospitals and increase patient turn-around in a clean and safe environment. The DePuro Pro unit comes in two sizes, it is a plug and play set up and uses two HEPA 14 filters which retain up to 99.995% of particulates including virus, bacteria and droplets within the air.

Hospital benefits from P C Henderson’s Sirocco system

Sliding and folding door hardware manufacturer, P C Henderson, has been specified for a state of the art hospital build in Breda, Holland. The company manufactured a custom made 2850mm length of track to replace the systems usual 2200mm track. It also designed a custom made stop which would allow the door to be held open half way across the openingwhen only a small walk way was required. P C Henderson’s Sirocco system’s hydraulic self-closing feature requires zero electric input, whilst the sliding door gear caters for doors weighing up to 80kg.

P C Henderson – Enquiry 40

Technical advice and quality subfloor preparation products and flooring adhesives from Bostik have enabled the progress of the new 3,600m² three storey ward block at Norfolk and Norwich University Hospital.

To suppress the residual moisture in the subfloor, Nationwide Flooring Contractors used Screedmaster One Coat Membrane with Screedmaster One Coat Accelerator, Bostik’s singlecomponent additive for speeding up the cure rate of One Coat Membrane. It primed most of the subfloors using Bostik Universal Primer, before applying the high-flow, easy-trowelling Screedmaster Flow smoothing compound.

For areas likely to be affected by large medical equipment nearby, Bostik supplied its Screedmaster Epoxy Primer and fibre-reinforced Screedmaster Flex smoothing compound, which is specially designed for use where vibration and minimal thermal movement can be problematic.

For the skirting in the ward block, Nationwide used Bostik Roll, the company’s solvent-free, reinforced adhesive tape. As Bostik Roll is dry, there is no curing time required, making it perfect for time-sensitive projects. The fact that it is solvent-free also means it is ideal for healthcare applications, since there is less impact on building occupants.

Thanks to Bostik’s technical recommendations and first-class products, Nationwide Flooring Contracts was able to install the floor coverings, despite the challenges of the lockdown.

Bostik – Enquiry 41

A diverse product selection for a wide range of projects. Paul Groves looks at some of the highlights this month.

The need for a hygiene friendly finish doesn’t mean that interior projects have to compromise on design, at least not when it comes to laminated boards and HPL materials from UNILIN panels. These surfaces can be cleaned several times a day by 70% alcohol solutions without fear of damage, helping in the ongoing maintenance and daily hygiene of commercial environments.

In everywhere from schools and shops to offices and hotels and on everything from desks, tables and walls to doors and cupboards; UNILIN panels can provide a hygienic surface without sacrificing aesthetic integrity.

With the UNILIN Evola collection, specifiers can bring the feel and look of natural materials, brushed metals and terrazzo, explore the crisp ‘clean’ colours of pure white and bright fresh green, or embrace the soft-touch effect of Super Matt Black; creating surfaces that are at once beautiful and hygienic. With over 190 options, there’s really no limit to creativity.

Earthborn has introduced The Earth Collection, a palette of five harmonious new paint shades inspired by the natural world, themed around the earth, land, sand, sea and clouds. The Classic Earthborn colour card will remain unchanged for now; instead a simple bookmark is available displaying real painted swatches of the five new colours.

The new colours, and the full range of 72 shades on the Classic shade card, include Crocky Road; Up Up Away; Grassy; Skipper; and Sandy Castle. With Earthborn you get no acrylics or oils, but you get high quality and high performance and a full list of ingredients to help you make a more informed choice.

Housing provider Stonewater is taking full advantage of the excellent thermal efficiency of Kingspan Kooltherm K108 Cavity Board at its new affordable housing development The Bushels, in Mosterton, Dorset, creating homes that are cosy and cost-effective to heat.

With a thermal conductivity of just 0.018 W/mK, the cavity board is able to achieve compliant external wall U-values with an insulation depth of just 75 mm. The board’s reflective, low emissivity foil facing also increases the thermal resistance of the cavity, helping to retain heat during cooler months and reflect away solar radiation in the summer to guard against overheating.

Kingspan Kooltherm K108 produced at Kingspan Insulation’s Pembridge manufacturing facility is certified to BES 6001 (Framework Standard for the Responsible Sourcing of Construction Products) ‘Excellent’. The BRE has assigned the product a 2008 Green Guide Summary Rating of A+.

Protect Viking Air is a new air and vapour permeable roof underlay suitable for cold and warm pitched roof constructions from UK building product manufacturer Glidevale Protect. To help specifiers get to grips with the technical attributes of this new product, Glidevale Protect’s senior product manager John Mellor takes us through some commonly asked questions.

A. Thanks to the technology behind Protect Viking Air, this ensures top level performance is achieved in air and vapour permeability, delivering a high rate of uninterrupted airflow to eliminate the need for additional ventilation and reducing the risk of condensation in line with BS 5250.

The current BS 5250 guidance for an LR (vapour permeable) underlay used in a cold roof application is 5mm ventilation at ridge with either a well-sealed or normal ceiling. The NHBC permits the use of an air and vapour permeable roofing underlay such as Viking Air in a cold roof construction, without the requirement for additional ventilation based on the air permeability of the underlay providing suitable ventilation

– at least the equivalent of a continuous 5mm high-level slot. This is referenced in the NHBC’s Technical Requirements R3 document: ‘where the air permeability of the underlay can be shown to provide suitable ventilation, i.e. at least the equivalent of a continuous 5mm high-level slot, NHBC will accept that underlay without the need to provide any further ventilation.’

Protect Viking Air, categorised as an air and vapour permeable roofing underlay, can achieve the equivalent of 5mm high level ventilation and can therefore be used in cold roof construction without additional roof space ventilation.

In cases where there is an impermeable roof covering installed such as fibre cement or metal tiles, there will be a requirement for ventilation. In these cases, the batten

space needs to be ventilated with 25mm counter battens and ventilation provided – 25,000mm2/m at eaves or low level and 5,000mm2/m at ridge or high level. Alternatively, if closed jointed sarking with no gaps is used directly beneath the underlay, this will restrict the underlay’s permeability and airflow within the roof, so ventilation will be required.

Q. How air and vapour permeable is Protect Viking Air?

A. Protect Viking Air has been tested to BS EN 12114 with the underlay allowing for 78.71m³/m²/hr of air permeability @ 50 Pascals, achieving the best performance in the air permeable underlay market. The water vapour resistance has also been tested to BS EN ISO 12572, Method C and allows 0.04 MNs/g or 0.008 Sd (m) of vapour resistance, so is classed as a vapour

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

permeable underlay with low resistance (LR), ensuring the product also provides the best vapour permeability in the air open underlay category.

Q. Is a separate air and vapour control layer (AVCL) required with Protect Viking Air?

A. Whilst the installation of a separate AVCL is not a mandatory requirement when Protect Viking Air is installed on the roof, Glidevale Protect recommends the use of an air and vapour control layer on the warm side of the insulation, where this is achievable.

If the specification demands a belt and braces approach with a well-sealed ceiling, this offers benefits over an unsealed ceiling. As stated in BS 9250, the code of practice for design of the airtightness of ceilings in pitched roofs, a well-sealed ceiling can reduce air and vapour transmission into the roof by 70% which will save about 8-10% of the energy consumed in a typical house. Delivering this airtightness means energy efficiency is maintained, helping reduce overall energy bills for the homeowner.

If there are gaps in the ceiling such as around loft hatches, service pipes and light fittings, air and vapour may flow from the living area to the loft space. With heat and moisture passing through the gaps, this not only contributes to energy loss from the building but also creates a risk of warm air from the property meeting cold, which would result in the dew point being achieved and ultimately, condensation risk in the roof space. The ability to seal at this junction is down to the practicability of the design and the standard of workmanship involved in installation.

BS 5250, the code of practice for the control of condensation in buildings, recommends

requirements defined in BS 5250 for cold and warm pitched roofs.

To support the above guidance in BS 5250 and BS 9250, Glidevale Protect has a full range of products that can work hand in hand with Protect Viking Air (and indeed all Glidevale Protect roofing underlays), ensuring buildings are designed and constructed using a fabric first approach with the aim to minimise energy consumption. This includes both reflective and non-reflective air and vapour control membranes, sealing tapes and loft hatches which are designed to support the control of condensation and heat loss at this critical junction. The installation of these products

Q. In which wind zones is Protect Viking Air compliant?

A. Protect Viking Air can be used in wind uplift zones 1-4 at the widest batten gauge of 345mm, ensuring wide coverage in the UK and throughout Ireland and is superior to any alternative air permeable underlay product on the market. At 310mm batten gauge or when used on sarking board, Viking Air has unrestricted use, being suitable in wind uplift zones 1-5.

Q. Is Protect Viking Air independently third party certified?

A. Yes. Like all Glidevale Protect roofing underlays which are tried, tested and regularly installed over many years, Viking Air’s performance is backed up by full, third party, independent certification from BM TRADA’s Q-Mark Registration Scheme, giving confidence and reassurance in specification. Viking Air’s BM TRADA Q Mark Registration Schedule and Certificate can be downloaded from the Protect website.

To read more commonly asked questions, visit www.protectmembranes.com/vikingairfaqs.

For more product details about Viking Air, visit the website at www.protectmembranes.com/vikingair or contact Glidevale Protect’s Technical team on 0161 905 5700 or technical@glidevaleprotect.com.

Protect Viking Air – Enquiry 42

Ahmed El-Helw, founder and Managing Director of natural slate roofing specialists SSQ, charts the history of one of the world’s oldest and most enduringly popular roofing materials.

Hear the word ‘history’, and you probably think of castles, battles, and people in crowns and funny wigs. You almost definitely don’t think of bits of rock.

But bits of rock have a history too. In fact, they have the longest and most interesting history of all (admittedly, I’m biased – I’ve made slate and other architectural stone my life for the last forty years).

In our culture, we think something is ‘old’ after about a hundred years. But this is what’s so fascinating about raw materials like slate –materials we hardly ever think about, but have played a vital role in human civilisation.

They’re not hundreds of years old. They’re hundreds of millions of years old. They’re older than humanity itself – even older than the dinosaurs.

When life was underwater

For slate, the story began around 500 million years ago. Geologists call it the Paleozoic era, and it’s safe to say the world looked very, very different.

Most life on Earth was underwater. Africa was at the South Pole. It was during this period that the first plants appeared, although it’s thought they didn’t have leaves, and the first animals crawled out of the sea and began living on the land.

Back then, what would eventually become slate was just soft rock, like shale or mudstone – nothing especially interesting to look at. But then, it somehow got buried.

Over hundreds of millions of years deep in the earth’s crust, it was subject to incredible heat and pressure – which, gradually, made it change at a fundamental level.

Those processes gave it the characteristics that made it so popular with human beings, when we came along several hundred million

years later – it’s looks, it’s strength, and its ability to retain both even when it’s split extremely thin.

In one form or other, in fact, slate was in use from the earliest periods of human history. Neolithic hunters used it to tip wooden arrows and spears.

But it wasn’t for tens of thousands of years more that we started to realise slate’s potential for less grisly, more constructive purposes.

We know that the Romans quarried slate. They invaded Britain for the first time in 43 AD, and five years later they reached Wales for the first time. The Roman fort of Segontium, their biggest and most important in the region, had a slate roof.

In the centuries that followed, slate became a common sight on the roofs of military buildings – prized for its robustness.

Calder Abbey in Cumbria, founded in 1134, has a slate roof. So did Conwy Castle, which King Edward I had built between 1283 and 1289 at a cost of £10,000 (over £7m in today’s money).

And in 1445, 130,000 slates were ordered from the Isle of Bute to repair Dunbarton Castle.