In what has been yet another turbulent 12 months for the country as a whole, 2021 is ending with an increasingly challenging environment for the wider construction industry.

The global pandemic, Brexit and material and staff shortages have all combined to provide barriers to the period of growth many industry analysts were predicting earlier in the year.

There is also growing annoyance that Government is simply not listening to the industry and surging ahead with new initiatives and programmes without proper consultation. Now, as 2021 draws to a close, the Construction Leadership Council has written to The Rt Hon Michael Gove MP, Secretary of State, Department for Levelling Up, Housing, Communities & Local Government and The Rt Hon Kwasi Kwarteng, Secretary of State, Department for Business, Energy & Industrial Strategy to draw their attention to urgent industry concern in connection with the introduction of the UK CA Mark.

The CLC says it has been working on issues with Government department teams for some time and welcomed the recent extension to the transition period to 1st January 2023.

However, despite the cooperation by industry and Government, serious issues remain that have the ability to cause considerable disruption to the construction sector and the levelling-up agenda.

The letter states: “Our main cause of concern is that for a significant range of construction products there is limited or no capacity for these tests to be carried out in line with the UK Construction Product Regulations. There must be a significant expansion of facilities with the incumbent recruiting and training of staff, who must all then receive authorisation by UKAS, before more products can be put through the new process. Unfortunately, this expansion of capacity is not happening quickly enough.

“If the current situation prevails, these products will not be available on the UK market after the January 2023 deadline. The inability to certify radiators in the UK, for instance, could delay the construction of over 150,000 homes in a single year and will also delay the switch to low carbon heating.”

If the UK as a whole has any hope of building a sustainable recovery platform and hitting necessary targets, the Government must resolve to listen and learn more during 2022.

Paul Groves || Group Editor

The NEW Aquaboost iBolt and iMatic range of high fl f ow, high head, cold water pressure and flow boosting solutions. Designed to optimise space and provide a very quiet, simple to install solution for domestic and commercial applications.

Explore the full range at stuart-turner.co.uk/aquaboost

The Royal Institute of British Architects (RIBA) has published its annual summary of business trends in the architecture and construction sectors.

The RIBA’s annual Business Benchmarking report tracks the turnover and salaries of RIBA Chartered Practices, indicating how architecture practices compare to others on a broad spectrum of criteria.

This year’s report assesses the period 1 May 2020 - 1 May 2021, therefore reflecting how RIBA Chartered Practices responded to the challenges presented by the Covid 19 pandemic.

A key finding is that overall practice revenue was down by 15% compared to the 2020 report, with reductions of over 30% in revenue from work on offices, culture and entertainment, and sports and leisure. There was also a downturn of 14% in revenue from international work that was felt particularly hard by practices with 100+ staff.

Despite revenues dropping, results show that practices preserved profitability. This has been achieved through a combination of a reduction in expenditure and adapting to the market.

Staff numbers have fallen by 11% and Chartered Practices have pivoted to where the work is: one-off houses, domestic extensions and alterations. Revenue from those work sectors increased by 3%, which is impressive compared with the 15% fall in revenue from all other sources. RIBA Chartered Practices reported they were working on just as many jobs as before the pandemic and bid for more work than the previous year, while maintaining the same competitive success rate.

Adrian Malleson, Head of Economic Research and Analysis at RIBA: “This year’s Benchmarking report is the first comprehensive assessment of the effects of the pandemic on RIBA Chartered Practices. With revenue and staffing being down, at first sight, this year’s report is punishing reading.

“Yet practices have once again proven their ability to adapt to market changes. The pandemic has accelerated that adaptation; change to business’ strategy was needed in weeks or days, rather than months or years. Practices rapidly and successfully responded to new client requirements, new markets, and a need for new ways of working. Through the worse economic and societal shock in memory, practices have preserved their profitability.

“As we look forward, the RIBA Future Trends survey suggests there is reason for guarded optimism. Although the twin pressures of Covid and Brexit continue to weigh down upon the supply side of construction, the demand side is holding up. A recovery in architects’ work has been led by private housing and is now broadening; as 2021 draws to a close, the commercial sector is also picking up. We hope the worst of the Covid storm is over, and practices can look forward to greater stability in 2022.

“Through ongoing research and consultation we are actively monitoring trends and opportunities on behalf of our members as they navigate the forthcoming months and years. Architects are well equipped to add real value mid and post-pandemic, as we reimagine the built environment and the future of the workplace and homes. We will continue to offer high quality support to our members and enabling them to thrive wherever they live or work.”

A key construction milestone has been reached on CARGO Work, a stand-out Grade A workspace at Bristol’s Wapping Wharf, with a new flythrough film offering a sneak peek of how it could look.

With space for up to 230 people across 20,270 sq ft of cutting-edge office space, the striking new CARGO Work building is being created within the stone walls of the disused J S Fry warehouse, which were formerly part of the old Bristol Gaol.

The steel frame is now complete and installation of the concrete floor slabs underway, with completion expected in the

coming weeks. This work is paving the way for the creation of stylish, contemporary, open-plan offices which will include a

Mosaic Architecture + Design has secured detailed planning permission and listed building consent for the redevelopment of 50 Bothwell Street in the heart of Glasgow city centre into an ambitious development providing refurbished office accommodation with a subdivision of ground floor retail and with a new café and business hub at street level.

50 Bothwell Street has lain vacant since 2017. Along with comprehensive internal alterations creating a light-filled and activated atrium, the proposals include plans for an exciting redevelopment of the fifth and sixth floors within the roof to create impressive office floorplates, flooded with natural light and landscaped roof terraces for outside enjoyment and appreciation of the local skyline.

In a new report the Public Accounts Committee says the Green Homes Grant Voucher Scheme “underperformed badly”, upgrading only about 47,500 homes out of the 600,000 originally envisaged and delivering a small fraction of the expected jobs.

The project accounted for just £314 million of its original £1.5 billion budget, and £50 million of that was administration costsmore than £1,000 per home upgraded.

The PAC is also “not convinced that BEIS has fully acknowledged the scale of its failures with this scheme”. The scheme’s failure “continues government’s troubled record of energy efficiency initiatives and risks damaging the Department’s future efforts to harness both consumer and industry action to deliver Government’s net zero commitments”.

The Scheme was implemented as an urgent response to the COVID-19 crisis, aiming to support jobs at a time of significant risk for the economy while also reducing carbon emissions from homes – but the 12-week timescale to implement it was unrealistic and BEIS proceeded with it despite its own Projects and Investment Committee rejecting its business case.

The result was “a scheme with poor design and troubled implementation”.

By August 2021, 52% of homeowners’

voucher applications were rejected or withdrawn, and 46% of installer applications failed. The Scheme’s primary aim was to support jobs but its design and duration limited its impact on employment, and its abrupt closure may have in fact led to redundancies.

Dame Meg Hillier MP, Chair of the Public Accounts Committee said: “It cost the taxpayer £50 million just to administer the pointlessly rushed through Green Homes Grant scheme, which delivered a small fraction of its objectives, either in environmental benefits or the promised new jobs.

“We heard it can take 48 months - 4 years - to train the specialists required to implement key parts of a scheme that was dreamed up to be rolled out in 12 weeks. It was never going to work at this time, in this way, and that should have been blindingly obvious to the Department. That it was not is a serious worry.

“I am afraid there is no escaping the conclusion that this scheme was a slam dunk fail.

“We will need this massive, step change in the way our homes and public buildings are heated, but the way this was devised and run was just a terrible waste of money and opportunity at a time when we can least afford it.”

The failure of the Green Homes Grant Scheme was a disappointment and the Government must learn from these findings to ensure similar, future schemes work better for industry and consumers, says the Federation of Master Builders (FMB).

Brian Berry, Chief Executive of the FMB said: “It is not surprising to read the Public Accounts Committee’s damning assessment of last year’s Green Homes Grant Scheme. By the experience of our own members, the FMB echoes the Committee’s criticisms and know that the scheme was too short-term in outlook. Critically, it did not allow sufficient time for builders to upskill and gain the necessary accreditations. For those that did make the leap, they ended up spending large sums of money only to have the scheme pulled from under their feet.

“This stop-go green initiative undermined certainty for both the public and builders in trying to stimulate demand for energy efficient home improvements. The Government needs a National Retrofit Strategy which sets out a clear, longterm plan to upgrade our existing homes and would go some way to restore faith in green initiatives with the public and industry.”

DRU Maestro 60 Tall gas fires are available in front, 2-sided and 3-sided options. With a maximum height of 1.2 metres, they are suitable for new-build or refurbished developments.

And with the exclusive DRU Fire app, you can control the flame picture and gas consumption with ease.

DRU is the only UK fireplace supplier to provide a fully comprehensive, RIBA approved online CPD course for this important product range. The course covers gas and wood burning fires, with essential guidance on fuel options, flue types and energy efficiency directives.

Visit: ribacpd.com/dru

DRU Maestro 60 Tall front gas fire

DRU Maestro 60/2 Tall 2-sided gas fire

DRU Maestro 60 Tall front gas fire

DRU Maestro 60/2 Tall 2-sided gas fire

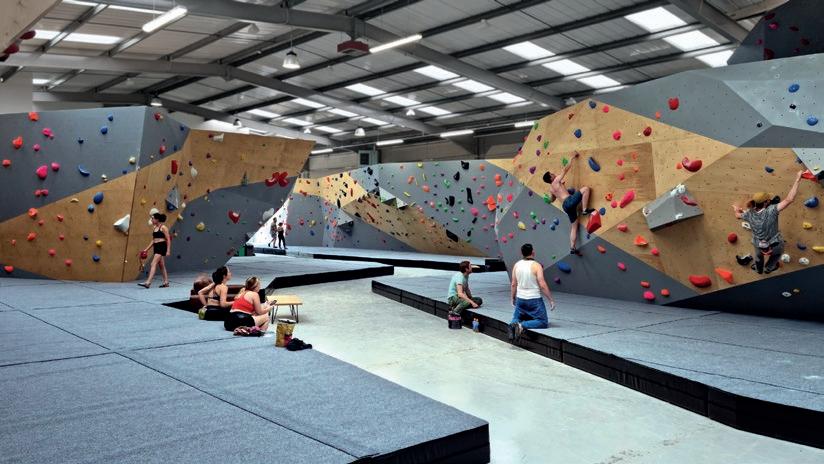

A QuickZone conventional fire alarm system from UK manufacturer, Advanced, has been installed at BlocHaus Climbing, Manchester’s newest bouldering wall.

Newly opened, BlocHaus Climbing boasts an array of facilities at its East Manchester site, including 130 climbable boulders, routing roof and on-site café.

As part of the active fire protection for the site, the 4-zone QuickZone conventional fire panel from Advanced has been installed alongside Hochiki conventional heat/smoke detectors, Apollo conventional call points and Roshni conventional sounders.

Responsible for the design, installation and commissioning of the fire system at BlocHaus Climbing were Manchester-based, Surefire Protection Ltd. Surefire installed the QuickZone panel alongside music

shutdown integration to ensure clear audible notification for all building users in scenarios where the system goes into alarm.

Michael Rouse, Fire Alarm Supervisor at Surefire Protection Ltd, said: “As long-term partners of Advanced, we’ve worked with its solutions for many years and are confident in their capability to deliver high standards of protection throughout sites large and small. We only specify Advanced fire panels due to their quality, reliability and standard of technical support, and we firmly believe they offer the best solutions available for open protocol systems.”

QuickZone is the conventional and twin-wire fire system from Advanced that is quick and simple to install and manage and ideal for installations that have less complex programming and configuration requirements. Offering eight panel variants across the QuickZone and QuickZone XL product lines, the panels will support 2 to 32 zones, are approved to EN 54 parts 2 and 4 and support comprehensive false alarm management.

Space-saving, sustainable, cost-effective and seamless design: these are just some of the buzzwords manufacturers are now using to describe their products as they strive to compete within a market which is moving at an unbelievably fast pace.

Because vertical platform lifts are cost effective, energy efficient, easier to install than passenger lifts and take up much less space than fitting a ramp, they provide an ideal access solution.

Drive systems differ according to the manufacturer but the one thing they all have in common is energy efficiency. They are either hydraulic, chain driven or screw and nut. All types of platform lifts travel at 0.15 m/s.

Sean O’Sullivan, Managing Director of the Platform Lift Company, said: “Platform lifts for commercial environments are now designed to be compact. They have incredibly small footprints - as little as 1560mm deep x 1250mm wide - but remain compliant with Part M of the Building Regulations. A vertical platform lift also requires much less head space than a passenger lift, making them ideal for the reuse of buildings. For example, a standard

platform lift requires 2.2 metres from the finished floor level – the distance from the floor up to the top of the shaft when the lift is at its highest point. A cabin style platform lift will need a little more head space of 2.5 metres.

Ease of installation is where vertical platform lifts win hands down against a traditional passenger lift. They can be installed by creating a pit as little as 50mm in the floor. If a pit cannot be created, it is possible to fit a ramp to the front of the shaft on the ground floor level. The selfsupporting shaft is freestanding and doesn’t require any fixings, making it a great solution for heritage buildings with sensitive wall fabrics. Building work is minimal compared to a passenger lift

Neil

“Surefire’s

demonstrates our solutions’ versatility. Not only will you find our panels installed throughout airport terminals, hospital complexes and university campuses, but also smaller, less complex sites, such as offices, retail outlets and activity centres. Whether you opt for the simpler QuickZone panel, or the feature-rich QuickZone XL, Advanced can deliver the conventional system you need.”

Advanced – Enquiry 7

and platform lifts can be installed within a three-to-four-day period.

Visually, vertical platform lifts have evolved dramatically. Vertical platform lifts have fast become an interior design feature as well as meeting modern building requirements such as energy efficiency and accessibility.

“One last thing to mention is that you don’t always need to replace a platform lift as they can be easily upgraded to improve running costs or refurbished.

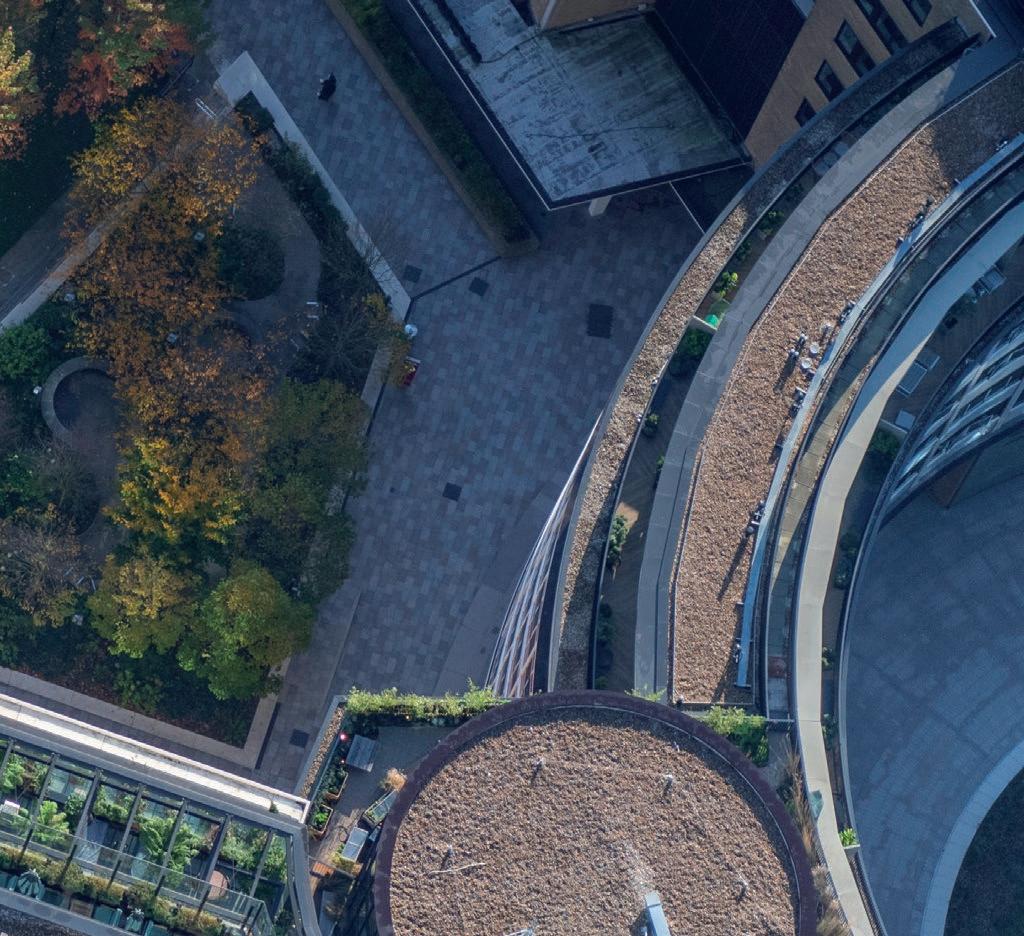

Able to host international conferences, industry leading exhibitions and live performances, The Event Complex Aberdeen (TECA) opened in 2019 to wide acclaim for both its facilities and the structure’s stunning appearance.

Aberdeen City Council expects the TECA development to boost the country’s economy by £63 million a year.

The main building, constructed at a cost of cost £333 million, has already hosted acclaimed bands and crucial business conferences, most notably the Offshore Europe Expo in 2019.

Representing a key element in the council’s long-term strategy, the extensive structure was designed by the highly regarded Keppie architectural practice and built by Robertson Construction.

In order to achieve an outstanding 55 dB sound reduction figure, the roof features a bespoke Kalzip system comprising 14 separate components, including rock mineral wool slabs for acoustic attenuation; while the 1mm gauge, 65/400 profile version of the manufacturer’s world renowned aluminium roofing system, with a stucco embossed finish, weathers the system.

The manufacturer’s ability to offer site rolling further facilitated the installation of 100+ metre lengths of the profile direct onto the roof structure, thereby avoiding the need for overlaps anywhere over the arena and enhancing the weather resistance of the envelope.

In addition to preventing noise disturbance from music events, the facility’s proximity to Aberdeen Airport, with its numerous commercial flights and helicopters ferrying workers out to the North Sea oil and gas platforms, further raised the bar on acoustic performance for the 15,000 capacity arena.

Keppie were appointed in September 2014 to progress the concept design for the masterplan of the new TECA and a 200bed hotel. The concept theme of ‘ripples in the landscape’ influenced the design development of the architecture and the landscaping of the wider site. >>

• The new TECA is 30.5 metres high, and just over 418 metres long

• It would take Usain Bolt 40.8 seconds to run this length

• The area of roof cladding at the new TECA is equivalent to 5 Pittodrie football pitches

• The rows of seating at the new TECA Arena would stretch for over 6,000 metres if placed end to end

• It would take 89 Olympic swimming pools to fill the Subterranean Space

• 8,300 tonnes of steel have been used in the construction of the new TECA

• The Arena alone could hold up to 718 billion Smarties

Kalzip duly provided a 25-year guarantee for the completed installation, though the system will deliver a minimum 40 year service life. With more of the material employed for cladding walls and the other roofs to the exhibition complex, a total

of 27,000 m2 of the 65/400 stucco embossed profile were supplied for the contract: the success of which has led to further work with Robertson Construction such as at Bertha Park in Perth.

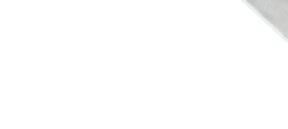

>> The heart of the new TECA provides visual amenity with the formation of a new Central Square enclosed by the TECA, Subterranean Car Park and Hotel Quarter. This square is a key social gathering space reinforced with high quality materials and opportunities for public art. It has a distinctive, people-centred environment forming a backdrop for informal activities, a meeting place, and a setting for special events and outdoor concerts.

The new exhibition and conference facilities consist of a 9,000 sqm arena to accommodate a maximum of 15,000 people, 6,000 sqm of flexible exhibition space and a further 31,500 sqm, 1250 space subterranean car park that doubles as exhibition space for events such as the biennial oil and gas Offshore Europe Exhibition. A further 10,000 sqm of external exhibition space can also be utilised.

The new TECA has been designed to provide a range of flexible spaces comprising a multipurpose arena that provides flexibility to host a large range of exhibition, entertainment and sporting events, a multipurpose sub-divisible exhibition hall, and a range of conference facilities.

A continuous concourse connects all public functions, creating the possibility to use the

Easy to maintain Rockfon Colorall is made from a lightweight non-hygroscopic stone wool.

It will not harbour microorganisms, provides excellent sound absorption, humidity resistance up to 100% RH, demonstrates superior thermal and fire safety characteristics and is fully recyclable.

The Rockfon MaxiSpan grid specified for TECA is perfect for large single spans – typically up to 3m – enabling greater flexibility and freedom to install and maintain the services. It is ideal for use with a variety of tiles including long planks to create a more seamless appearance than traditional grids by using fewer components which can be combined in many configurations to suit a wide range of tile dimensions.

Rockfon System MaxiSpan enables optimum design freedom due to the variety of edges. It is available in lay-in, tegular and concealed configurations –with its main runners being 75mm deep, providing higher stability.

building for simultaneous performances or events. This route becomes a journey featuring merchandise units, bars and food & beverage units activating the ground floor concourse. This animated frontage will be viewed from the external Central Square through the main façade, and dramatic, transparent main entrance.

The proposals have been developed following detailed discussions with TECA and incorporate the input of expert, external advice.

“Our plans have evolved to provide a building that maximises operational benefits and flexibility whilst enhancing the user experience,” explained Suzanne Mackrell, Project Associate.

The frames have been finished in a RAL 7016 Anthracite Grey semi-gloss colour, inside and out, while the fenestration systems have been designed to withstand local wind loads of almost 2,200 Pascals. Their design included the use of bespoke 6.5 metre long mullion sections for some screens; while the contract also included the supply and installation of several WICLINE 65 Evo doorsets, used as access doors and emergency escape exits for both the hotel and the Arena.

WICTEC is fully tested for weather resistance and fire performance and is readily adaptable to almost any architectural style thanks to the availability of diverse profile types.

“The project has been a key part of our practice for over five years. It has reinforced our growing Arena and Stadia Portfolios, leading to several opportunities in other locations.

“Our team has become experts in the technical design criteria essential to ensuring the user experience is world-class. The new TECA has involved many Keppie team members bringing their unique skills and expertise to bear at various times or as a full-time commitment.

“I’m immensely proud of all at team Keppie in delivering this fantastic facility. It’s been an incredible team effort and I’m absolutely delighted to have been part of it.’”

Robust wall elements with a thickness of 100mm and a width of 900 or 1200mm are ideal for use as free-standing walls.

Wedi Sanwell Wall elements are not only waterproof to the core but are also fully customisable: the height and width is easy to adjust to required dimensions and the size of the integrated niche can also be modified to suit. Simply bond to floor & wall with wedi 610 adhesive sealant and after reinforcement of joints it’s ready to tile or plaster.

wedi building boards - 50, 60, 80 & 100mm wedi’s 100% waterproof tile backer boards from 50mm thickness are also approved for use as shower partitions. They can be used for creating up to 1200mm long separation walls when attached on 2 sides, but once attached to a wall, floor and a solid cementitious ceiling structure the length becomes limitless. Besides standard sizes (2500x600mm), there are XL (2500x900mm) and XXL (2500x1200mm) formats especially developed for this purpose - by reducing the number of joints, they simplify the installation process enormously. Benefits of both solutions: various formats in many different sizes, significantly shorter installation time, strong enough to support shower doors, radiators & shelving and the final height can be shortened during tiling.

wedi – Enquiry

wedi – Enquiry

10

For more information 01708 39 80 22 sales@brundle.com www.fhbrundle.co.uk

A living space is often seen as the vibrant social hub of a home – somewhere to have a catch up and a cup of tea, a place to entertain guests or the ideal spot to relax after a busy day.

For a luxury residential property in Longfield, Kent, the perfect opportunity to create ambiance with the help of a backlit feature wall using multiple products from Schlüter-Systems presented itself, ensuring that the large and open living room could be a place to welcome guests.

Taking advantage of the high ceilings and natural light available, a 5m tall porcelain tile feature was mounted to one of the walls. Already a beautiful space to begin with, this eye-catching element elevated the area with the help of Schlüter-LIPROTEC lighting profile, framing the feature for a stunning focal point within the room.

Schlüter-KERDI-BOARD in 19mm thickness was used to build the wall out and sufficiently prepare the area for the addition of the tile feature. The lightweight backerboard is a perfect substrate for tile and stone installations, and the easy to cut material makes it ideal for bespoke projects such as this one.

The project was undertaken by Daniel Berry of ATD Design Solutions who comments, “To create a stand-out feature using tiles, there needs to be a reliable substrate which will ensure the structure will last for years to come. This was easily achieved using KERDI-BOARD.”

The LED profile Schlüter-LIPROTEC-WS produced an indirect lighting element to accentuate the structure and provide a statement finish. It also softened the

look of the tile, making any harsh edges disappear to ensure a warm and welcoming environment. An array of different colour variants are available with the LIPROTEC lighting profile, giving the client creative control of their living space.

To finish the tiled wall off with style and ensure long-term protection of the impressive feature, the Schlüter-QUADEC cross brushed aluminium finishing profile in quartz grey was installed around the tile edges. This profile was also used in the design of a smaller feature with the same tiles, this time creating a backdrop for a television mounted to the wall.

Daniel adds, “When the client advised they wanted something eye-catching in the main living space, it was an obvious choice to suggest a feature wall with LIPROTEC which would create the wow-factor they were after. The profile is easy to install and creates the perfect soft lighting effect which looks great alongside the chosen tile.”

Using these popular Schlüter products in unique ways that benefitted both the form and function of each area meant that multiple features were added to the home with ease.

Schlüter-Systems – Enquiry

A listed art deco building exemplifying reinforced concrete construction has been refurbished with Crittall Windows helping to ensure its original appearance was maintained.

Victor House was built in 1937, designed by architect Peter Lind, as a headquarters for the British Reinforced Concrete Engineering Company on the site of its extensive cement works at Pitstone, Leighton Buzzard.

The two-storey building was conceived as a showcase to demonstrate how concrete could be used in modern construction. Its reinforced concrete frame and clean lines, with white walls and window frames, made it a prime example of the ‘international modern’ style, a British version of art deco. Its heritage importance was recognised in 1993 when it was listed Grade II.

When the cement works closed and was subsequently demolished Victor House survived as the only original building on the site which became the Pitstone Green Business Park. At this point it was purchased and refurbished by property company LaForet and won a design award from Aylesbury Vale Council.

After initial use as an office for a legal firm the building became vacant but failed to re-let as prospective tenants wanted a more open-plan layout. Also, single glazed windows contributed to large heating bills.

LaForet sought permission to convert the offices into eight apartments and architects EHW Ltd carried out negotiations with local planners who insisted that the upgraded double glazed windows should match the original fenestration as closely as possible. Crittall Corporate W20s, finished in white, were specified as a result. The building has been renamed Portland House as a reference to its original connection with the manufacture of cement.

•

•

Garador is now offering Secured by Design (SBD) accreditation, across nearly all of its sectional garage door range. The highly regarded SBD status is being offered as a free upgrade on all Garador sectional garage doors, ordered from October 2021 onwards, that meet certain eligibility requirements.

In order to gain the Secured by Design accreditation, the product and installation must meet strict criteria. These include the Garador sectional garage door being a 42mm Premium insulated model, without windows, fitted behind the opening and automated by a GaraMatic operator.

Once the door is installed, all that needs to be done is for the fitter to fill in a simple form which includes the installer, customer and door details.

Garador will then send out an official Secured by Design accreditation pack with registration label and badge.

The GaraMatic operator, which forms an important part of the Secured by Design accreditation, is engineered with an anti-lift kit to prevent forced entry. This utilises a mechanical lock built into the operator boom, and because it is mechanical the door cannot be forced open even during a power cut. Another noteworthy security

feature of the GaraMatic operators is the bi-directional radio system that uses the same 128-bit encryption employed by banks for online banking security. This technology makes the system even more secure and ensures a more reliable signal and extended range.

Home security remains a concern for homeowners, specifiers and housing developers alike, and there continues to be a strong demand for high-security

To qualify for Secured by Design status, the Garador sectional garage door must meet each of the following conditions:

• 42mm insulated premium sectional garage door (Classic uninsulated models are not eligible).

• Fitted behind the opening.

• No windows in any of the door sections.

• Electrically operated with a GaraMatic operator.

• Only official Garador parts and products must be used, and they must be installed in accordance with the manufacturer’s instructions.

Please refer to the installation instructions for a more detailed list of requirements: https://bit.ly/3lLWOrU

Garador’s Managing Director, Neil Discombe comments “Secured by Design accredited products are well known for having extra layers of security and so we expect this new feature to be well received by our customers.”

Neil continues “We have always been proud of the quality of our sectional garage doors. This new Secured by Design accreditation confirms that they are robust and secure.”

Garador already offers a selection of steel up & over garage doors with Secured by Design accreditation, as part of its Guardian range. The addition of SBD sectional garage doors will extend the company’s SBD product offering, giving customers the possibility of ordering a garage door that’s thermally insulated and electrically automated with a GaraMatic operator. Attributes that are not currently available in the Guardian Range.

When picking out a door design and colour, customers can choose from the full range of fully insulated Georgian and Linear

Premium sectional garage doors are 42mm thick, filled with insulating polyurethane foam and come with intermediate seals between every section joint to enhance thermal efficiency

designs, as well as all the standard RAL colours.

To find out more about Garador’s SBD sectional garage doors, please visit www.garador.co.uk or call 01935 443722.

Garador – Enquiry 15 products which offer an even greater level of protection.

Secured by Design is renowned throughout the building industry, providing a recognised standard for high-security products that reduce crime.

The Secured by Design badge is a clear indication that the product has a much higher level of security and has undergone rigorous testing to withstand an attack from a burglar.

As soon as the garage door is closed, the mechanical lock automatically engages in the operator boom, preventing forced entry

Winner of the Large Projects category of the UK Passivhaus Awards 2021, the first phase of Agar Grove, in Camden – anticipated to be the UK’s largest resi-dential Passivhaus development when completed – tackles occupant wellbeing, climate action pledges and fuel poverty.

In meeting such high levels of sustainability, a key element is the avoidance of thermal bridging; and one of the most effective countermeasures has been in-corporated – Isokorb technology from Schöck.

Throughout the 493 home redevelopment, brick and reconstituted stone façade materials predominate, with stone banding providing depth and a quality finish to the balconies that run the full width of the façade. Balconies are always likely to pose a risk when it comes to thermal bridging and it

is here that the design detailing involves the first of the Schöck load-bearing structural therrmal break types used at Agar Grove –the XT type K. Thermal bridging is a frequent cause of increased heat and energy loss and also condensation, which is likely to result in mould formation, building damage and even consequent health implications. The Isokorb XT type K for concrete-toconcrete applications is one of the most technically advanced countermeasures for incorporation into Passivhaus projects and features a compression module HTECompact and 120mm insulation thickness. Designed for free cantilevered balconies, it

transfers negative moments and positive shear forces.

The second Schöck product at Agar Grove protects against any thermal bridging risk at the parapets – without any wrapping being required. With most parapets, the conventional method is to wrap the perimeter of the wall with an insulation barrier. However, the Schöck Isokorb XT type A is a product that requires no wrapping and which offers a more costeffective and more thermally efficient solution. Its installation results in low psi-values, significantly reduced heat loss, greater freedom of design – and there is no risk of any additional thermal bridging through balustrade fixings. Other key benefits are durability and water impermeability, so there is no maintenance required due to waterproofing problems.

Not only does the Isokorb range provide a number of solutions to meet Passiv-haus standards, it also exceeds the requirements of the Future Homes Stan-dard, helping the industry move towards the Governments 2050 net zero carbon targets. In addition to concrete-to concrete and maintenance free parapets, there are solutions too for concrete-to-steel, steel-to-steel – and innovative technology from Schöck even enables the retrofitting or renovation of balconies. Products meet full compliance with the relevant UK building regulations and there is also the security of independent BBA Certification, which provides NHBC approval. The requirement that the temperature factor used to indicate condensation risk (fRSI) must be greater than, or equal to, 0.75 for residential buildings, is easily met by incorporating the Isokorb.

As a company member of FIRAS Warringtonfire, Harrison Thompson’s range of products and services can help with the up keep and repair of fire doors using best practice guidance.

Yeoman Shield Fire Door Services offer fire door installation, repair, maintenance and the fitting of Yeoman Shield fire rated protection products - all carried out by accredited fixing operatives.

TN International (TNi), owner of Scottish insulation manufacturer Superglass, has acquired Chesterfelt Ltd, one of the UK’s best-known bitumen roofing manufacturers in a multi-million-pound deal.

With its regional headquarters for Western Europe and North America in Stirling, TN International is one of the world’s leading producers of roofing, waterproofing and insulating materials. The deal to acquire Chesterfelt adds production capacity to TNi’s building product portfolio, complementing the company’s ability to provide customers in the construction industry – particularly those based in the UK - with an integrated solution for the protection of buildings.

The addition of a UK-based production facility in the roofing sector will earn the environmental benefits of reduced transport miles and will also offer welcome service and logistics advantages to UK customers.

TN International supplies customers and end users across residential, commercial and infrastructure sectors, including schools, hospitals, and other public facilities.

Established in 1978, Chesterfelt has over 40 years’ experience manufacturing and distributing bituminous waterproofing products from a manufacturing and warehousing facility in Chesterfield, Derbyshire. The company employs thirty staff and supplies a wide variety of roofing projects from domestic properties to large industrial buildings.

There will be no job losses as a result of the acquisition.

TN International’s Superglass facility in Stirling has an annual production capacity of 60,000 tons of glass wool insulation, following a £37m redevelopment in 2019. In line with TNi’s focus on minimising its environmental impact and supporting the development of more sustainable built environments, the product is manufactured using over 80% recycled glass, and once installed can save hundreds of times the energy used to manufacture it.

Theresa McLean, Area Director of TN International for UK & Ireland, said: “Chesterfelt is a highly respected brand within the UK’s roofing market and will complement our existing manufacturing expertise for glass wool insulation in the UK. Increasingly our customers in

the construction industry are looking for whole building envelope solutions, and this acquisition is another key advance in TNi’s ability to meet those requirements. Alongside our broader suite of brands and products, we have the technologies to create ideal living and working environments, to safeguard people and property from the elements, and to reduce energy use and carbon emissions.

“Moreover, this acquisition is yet another indication of TN International’s belief in, and commitment to, the UK construction industry, following the recent £37m refurbishment of the Superglass plant. This acquisition, while important in itself, is

also a milestone in a much broader future investment plan in the UK market.”

Tom Yeo, Managing Director of Chesterfelt added: “We are delighted to conclude the agreement with TN International, which continues the success story of Chesterfelt. We are proud of the heritage and success of the Chesterfelt business, and the service we have provided to our customers over the last 43 years. We are confident that the range and scale of TNi make it a strong fit that will propel the Chesterfelt business and its people to even greater advances in the future.”

TN International – Enquiry 19

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

British manufacturer extends range of contemporary street lighting solutions with future-proofed luminaire that combines versatility and performance.

Leading exterior lighting solutions provider DW Windsor is proud to announce the launch of its latest product innovation, Daytona. With replaceable light modules, an elegant design and the power to adapt to the needs of its surroundings, Daytona is set to transform the illumination of urban spaces.

Daytona is an intelligent lighting solution that helps specifiers deliver the right light at the right time. Its modern design and advanced features make it ideal for a range of civic applications, including the illumination of urban and residential roads, pedestrian and cycle paths, and public spaces.

The need for versatile lighting and sustainability has never been more important for urban living and our environment. Daytona is a highly efficient, Connected Spaces ready solution with an outstanding service life to support the circular economy.

Recently completed, the £9m Cyber Quarter – Midlands Centre for Cyber Security, located in Skylon Park, Hereford Enterprise Zone, was designed by Associated Architects and built by Speller Metcalfe. TORMAX was contracted to the project by Aluminium Sashes to deliver a contemporary four-wing automatic revolving door to the main entrance.

Reliability and whisper-quiet operation is assured thanks to the world-class TORMAX 5201 door drive which combines a powerful, high-torque motor with impeccable design credentials to minimise maintenance requirements and ensure a long working life.

With a build-in height of just 140mm, the slim 5201 allows for a shallow canopy

The luminaire features interchangeable light engines that can be upgraded as new innovations come to market, whilst toolless entry and removable fixings ensure Daytona is easy to maintain.

Daytona is also DW Windsor’s first luminaire to be offered with Tunable White technology as standard, providing designers with a flexible solution for night-time illumination. The system can be specified with two separate transition ranges: 4000K to 2700K, or 3000K to 2200K, and the luminaire’s control system can be configured for multiple scenarios using a simple and intuitive app.

By automatically adjusting the luminaire’s colour temperature and brightness throughout the night, the innovative system can improve visual comfort, offering a sense of security whilst also minimising the impact on wildlife and biodiversity. For example, Daytona can be programmed to

begin illuminating at 3000K when night falls and transition to a warmer, softer 2200K overnight, when fewer road users and pedestrians are present.

The ability to manage light responsibly was a key consideration when developing the new Dark Sky friendly luminaire. To help minimise light pollution, Daytona has a 0% ULOR (Upward Light Output Ratio) and is compatible with the latest lighting control technologies, including a range of NEMA and Zhaga compliant sensors and network solutions.

DW Windsor – Enquiry 22

compartment allowing a truly minimalist entrance solution to be created. Further improving energy efficiency, system specific data is automatically captured, and door operation adapted to counter the impact of wind levels, or a build-up of dirt for example, ensuring the door continues to revolve with optimum performance.

Technologically advanced sensors are integrated within the system, ensuring uncompromising personal safety for every user. A world-leader, TORMAX has over 70 years of experience in the design, manufacture and installation of sophisticated automatic entrances, including sliding, folding and revolving door systems.

TORMAX – Enquiry 23

As part of the redevelopment of the University of Salford’s Waterside student residential village, accommodation provider Student Cribs has specified Showerwall bathroom panels to help create a stylish and modern living environment. Student Cribs specified Showerwall’s Emerald Subway design, which offers a stylish alternative to tiling, to add character and colour, creating modern bathrooms for the students. Part of Showerwall’s Custom Acrylic collection, the panels were specified for their ease of installation and hygiene benefits, with the grout-free design reducing installation times and eliminating hiding places for mould, dirt and germs, making them ideal for shared bathroom facilities.

Showerwall – Enquiry 24

We’ve combined our relentless pursuit of innovation with Zehnder’s German engineering to bring some new, heavy-weight lifting stations to the commercial and industrial sector. They’re available in one or two pump options and in single or three-phase specifications. So, it doesn’t matter if it’s a factory or an office block, we’ve got the power you need to get the job done.

New research reveals yet further hikes in materials costs, with the added energy and transportation crisis creating a perfect storm of limited raw materials supply, products and labour.

With the cost of steelwork up by a further 17% in the last three months alone and 38% over the last 12 months, contractors warn that the volatility of the market means that the supply chain can no longer forecast and fix building costs.

The research was carried out by the Southern Construction Framework (SCF), a leading construction procurement framework delivered by the public sector for the public sector in the South of England. Its latest quarterly report is based on data from July to September 2021 in partnership with its Main Contractors (BAM; GallifordTry; Isg; KIER; mace; midas; Morgan Sindall; Sir Robert McAlpine; Wates; Willmott Dixon).

In this quarter’s report, SCF’s Main Contractors have described the market volatility and the rate of price increases as ‘truly unprecedented’, with some referring to subcontractors fixing prices for just 24 hours, making planning across the industry impossible.

For Q3 alone, SCF’s Main Contractor’s supply chains have reported an average building cost increase of 12% across all trades - due to a combination of inflation rates across

numerous products and materials. The price of some raw materials, specifically metals, has continued to impact on the building costs of many trades and products. >>

DELABIE, expert in Water controls and sanitary ware for Public and Commercial Places, is saving water and energy, without compromising design, high-performance and responsible products.

More information at delabie.co.uk

>> Trades that have seen the greatest increase in Q3 when compared to the previous quarter include steelwork (17%), whilst over the last 12 months the greatest annual building cost increases have also been found in steelwork (38%).

Kingsley Clarke, SCF Operations Lead said: “The cost of steelwork has shot up in the last year and in the next quarterly report due out in December, this is likely to be up again, given British Steel’s new surcharge in response to the mounting price of gas and transportation. Whilst it is temporary, a £30 per tonne price increase on already inflated costs is the last thing that contractors need in addition to all the additional knock-on challenges of materials and labour shortages and rising salaries.”

The knock-on effect is that trades have experienced an even greater increase in material and labour lead time during Q3 when compared to the previous year. The trade most impacted is steelwork at an additional seven weeks.

Adam Sanford, SCF Operations Lead added: “There is no easy way to solve the problems we face, but early collaboration is one way to help mitigate some of the crippling issues facing the industry. Early engagement with the Main Contractor means you can work together to ensure that design solutions incorporate current market pressures before detailed design. For SCF projects, our Main Contractors are committed to sharing early advice, even prior to appointment.

“We also recommend a transparent approach to project budgets, risk allocation and pricing to ensure an environment in which market risks can be effectively managed and mitigated, reducing uncertainty in procurement, and increasing certainty on costs.”

Nordic Brown pre-oxidised copper and larch cladding from Aurubis together define the natural character of a contemporary home, nestling amongst the treetops on the Island of Hirvensalo, part of the Turku archipelago in Finland.

Locally-based Sigge Architects’ design sought to reconcile their client’s need for a permanent working home combined with the essential characteristics of a Summerhouse for leisure. The Finnish Summerhouse epitomises ‘mökkielämä’ or ‘cottage life’, with its tradition of treading softly on the land and respect for nature. The three-storey building – known simply as ‘Villa L3’ – was envisaged as a deceptively simple modern structure with clean lines and a certain stature. A restrained palette of natural materials enables it to sit

comfortably in its elevated location within a gently sloping forest.

The Upper Level is conceived as a distinct copper-framed ‘box’ mass, oversailing the recessed Entrance Level ‘pedestal’. Here, Nordic Brown pre-oxidised copper was chosen, structured with vertical seams. It sits naturally alongside the larch batten cladding, which adds warmth, and responds to the exceptional natural surroundings.

Nordic Brown provides the same oxidised brown surface that otherwise develops over time in the environment. The thickness of the oxide layer determines the colour of the surface finish, with darker or lighter (Nordic Brown Light) shades of brown. Nordic Brown gradually changes over time to a stable dark chocolate brown.

The roll out of the W50 TB thermally broken steel frame system - which captures the classic appearance of the ubiquitous W20 profiles, while delivering contemporary standards of energy performance - has been gathering pace as building activity across the UK recovers from the disruption of the pandemic.

First introduced in 2016, W50 TB windows and doors are now being offered by most members of the Steel Window Association; and are finding applications in both high specification projects and the refurbishment of larger properties including hotels, offices and public buildings.

While the modern system, developed by the SWA in conjunction with European profile manufacturer, Ottostumm, echoes

the distinctive sightlines of the old W20 frames and offers similar light transmission to the building interior, the high-density polyurethane thermal break along with the flexibility to incorporate high performance glazing units up to 37mm thick, deliver greatly improved energy performance.

Having been tested during the early development stages to deliver a U-value of 1.5 W/m2K, the use of higher performance glass, warm edge spacer bars and argon or krypton gas filling can reduce this down much closer to a figure of 1.1 W/m2K. Meanwhile, hot dip galvanising and an extremely tough, factory-applied Interpon D polyester powder coat finish help ensure a long, low maintenance working life, in addition to steel windows’ renowned strength and security characteristics.

The traditional ‘stepped leg’ profiles can be employed to produce single or double casements as well as side hung and bottom hung options, which are fitted with dual EPDM gaskets to achieve an air permeability performance of 600 Pa to meet Class 4 standards. W50 TB windows and doors also offer very good acoustic performance.

The roofing and cladding industry continued to be blighted by material and skill shortages as well as spiralling cost increases in the second quarter of the year, according to the NFRC /Glenigan state of the roofing industry survey.

Four out of five (81 per cent) roofing contractors saw a deterioration in material availability in the second quarter of the year, with the most common shortage areas still being concrete roof tiles, followed by timber battens, insulation, general timber and clay tiles. Every single respondent to the survey reported that the price of materials went up in the previous quarter, with some reporting price rises as high as 300 per cent on some products.

Three quarters (76 per cent) of respondents also reported recruitment difficulties in the last quarter, up from 44 per cent in the first three months of the year. Almost half (47 per cent) of contractors struggled to find roof slaters and tilers, with 27 per cent finding it hard to even find general labourers. The shortage of labour is impacting wage rates, with 58 per cent of firms reporting rising labour costs.

The report also found:

• A net balance of 53 per cent of contractors saw an increase in their workloads against the first quarter;

• Scotland saw the strongest rise in workload after a subdued performance in the first quarter of the year. Firms in Yorkshire and the Humber saw a drop in workloads after above-average growth in the previous two quarters;

• Over a third (35 per cent) saw a rise in enquiries on the previous quarter;

• One in ten contractors (10 per cent) increased their headcount in the last three months;

• Whilst two thirds (65 per cent) of members had payment terms of 30 days or less, only 39 per cent of these were paid within that period.

NFRC’s Head of Policy, Philip Campbell, commented on the survey results, saying: “The second quarter of this year saw material shortages intensify further, with roofing contractors now reporting difficulty obtaining a whole range of products, not only tiles and timber but on materials as far-ranging as plastics and steel. Prices also continue to rise, with 100 per cent of respondents to this survey telling us their material prices went up in the last quarter. Contractors reported that some products had seen increases in the hundreds of per cent in recent months. It is critical that clients work with their supply chain to

provide flexibility in contracts to adjust for these unprecedented increases.

“The availability of labour has also worsened, with three-quarters of contractors now experiencing recruitment difficulties. Positive workloads have meant more firms took on staff in the last quarter, but there are simply not enough roofers out there to meet the demand. Staffing has proved difficult for contractors over the last quarter as a result of the ‘pingdemic’. One member has told us he has lost 1000 days of productive hours due to staff having to self-isolate." >>

The availability of labour has also worsened, with three-quarters of contractors now experiencing recruitment difficulties. Positive workloads have meant more firms took on staff in the last quarter, but there are simply not enough roofers out there to meet the demand.

>> “Workloads are set to continue to rise for the next quarter, and indeed the next year, which is encouraging, but the industry, clients, and government must all focus on addressing the ongoing material and skills crisis we are experiencing. If we don’t start resolving these issues now, we may see a detrimental impact of the growth we have seen coming out of the pandemic.”

Commenting on the survey findings, Glenigan’s Economics Director Allan Wilen said: “Construction continued to recover during the second quarter, with roofing contractors reporting a strong rise in workloads. Private housing and commercial repair, maintenance and improvement work and new house construction have been the best performing areas.

“Roofing contractors anticipate further, more broadly based growth over the next 12 months. However, the availability and cost of skilled labour and materials will be potential brakes on the pace of the recovery.”

Providing yet another façade solution for Coleg Cambria, one of the largest colleges in the UK, TECHNAL aluminium windows, doors and curtain walling have been specified and installed at the college’s flagship Yale Campus – the sixth Coleg

Cambria site to feature TECHNAL systems.

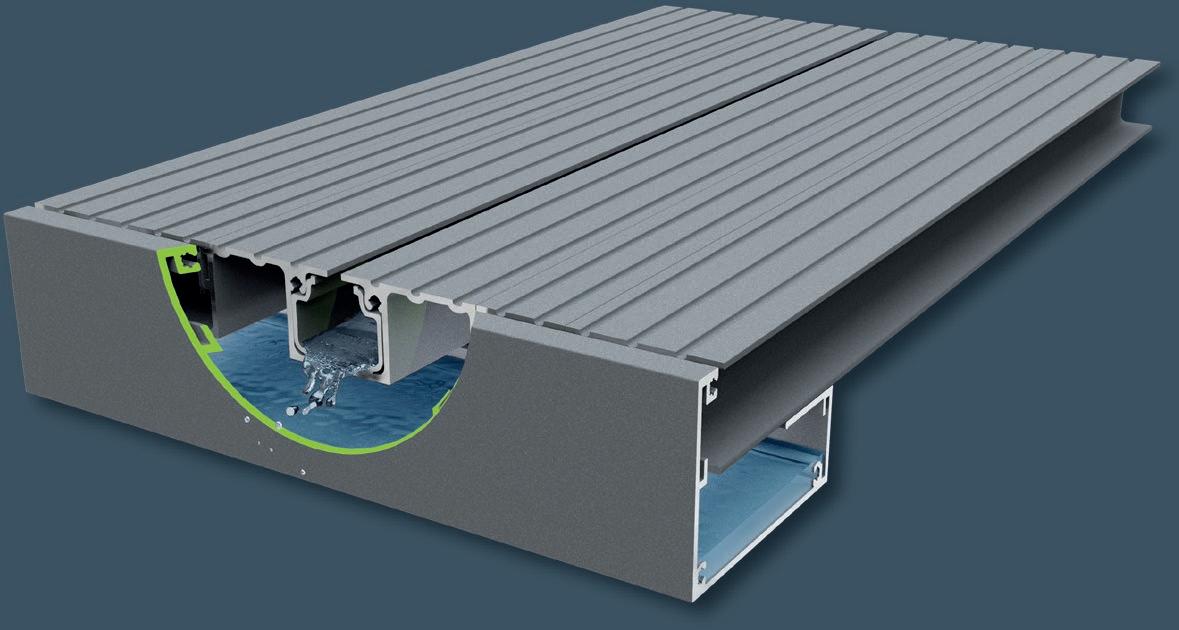

Constructed to BREEAM Excellent standards, the prestigious Yale Campus is the most recent project the team has worked on. Maximising daylight and ventilation, the glazed façade spans 1,200 sqm across the building. Specified for proven performance and thermal insulation, TECHNAL curtain walling offers a fully capped, mullion-drained solution. With an aluminium substructure width of 52mm, it creates a slim sightline while also providing the necessary strength and inertia requirements.

Contributing to higher credits for the critical Energy 01 part of BREEAM, which is concerned with the reduction of energy use and carbon emissions, TECHNAL A-rated Dualframe 75 Si windows offer exceptional energy efficiency. For the Yale campus, a U-value of 1.1W/m2K was achieved. As well as being inserted within the curtain walling, the windows have also been

fitted in a vertical panel format to create a striking rectangular pattern within the gold cladding.

Forming the building’s main glazed element, the curtain wall features multiple times including to the first floor creating a cantilevered section. Spandrel panels conceal structural work and the façade also includes an interesting glass fin detail to the building’s front and rear elevations.

Throwing light into the stairwell, the TECHNAL curtain walling has also been fitted at different panel heights with opaque glass to create a distinct corner feature while adding a contrasting level of transparency to the building’s design.

Springfield House has achieved healthy new roof, thanks to Welsh Slate. The reroof of a Grade II listed house that doubles as a healthcare building, is in the running for a national award.

Stoic Roofing and Construction's work on Springfield House at Northampton General

Hospital has put the specialist contractor in the eight-strong shortlist for "Best use of a heritage roof" in the 2021 Pitched Roofing Awards*.

A like-for-like replacement was required for Listed Building Consent, and this meant 441m2 of Welsh Slate's 500mm by

Barry Saltmarsh, Sales Director at natural slate experts SSQ, reflects on COP26, and how the materials he supplies can help construction cut its carbon footprint.

It’s been steadily growing in prominence for years – but after COP26, climate change has a bigger public profile than ever before.

In November, the world’s most powerful people gathered in Glasgow for the UN’s 26th conference on climate change.

Six years on from the Paris Agreement of 2015, that saw countries around the world commit to limiting rising global temperatures to 1.5 degrees Celsius, leaders convened to try and agree the radical action that would keep that goal alive.

But aside from the obvious fact that we all live on the same planet, and need a world that’s capable of supporting life, what relevance does any of this have to those of us working in and around construction?

It’s an uncomfortable fact that building has a huge environmental impact. According to the UK Green Building Council, Britain’s built environment causes around 40% of the country’s total carbon footprint, nearly half of which comes from the construction process itself.

In other words – if the UK has any chance of reaching its extremely ambitious target of cutting its carbon output to virtually zero by 2050, our sector is going to have to make drastic changes to the way it operates.

Changing the way we roof and build That process will inevitably involve changing the kinds of materials we use to construct the buildings of the future.

At SSQ, we’ve long been making the case for natural slate and phyllite as a much greener alternative to man-made roofing products.

Partly, that’s simply because natural materials last much longer. Tiles made of fibre cement and concrete, both extremely common around the world, can last up to thirty years, while clay tiles can last forty.

In all three cases, that’s considerably less than the lifetime of the average building.

By contrast, the best slate and phyllite can last over a hundred years (at SSQ, we guarantee our finest Ultra-grade Riverstone and Del Carmen products for a century).

That’s more than three times as long as some other commonly used materials – and means that quality slate often outlives the building it was originally installed on, and can then be recycled for use on other properties.

It’s also worth remembering that one of the most powerful ways to reduce the environmental impact of an activity is to simply do it less.

Choose a longer-lasting roofing material, and over a hundred year period, that roof will have to be replaced less often – which means less materials being transported around the world, less tradespeople having to drive their cars and vans to a site, and so on.

Natural, not man-made When it comes to sustainability, it’s almost

always true that natural materials are preferable to man-made ones, because the process of making those materials is often very polluting in itself.

To continue with the roofing examples – to make clay tiles, kilns are kept burning 24 hours a day, with inevitable impacts on the environment. Ceramic and porcelain tiles are even worse – the kilns have to be at higher temperatures.

This accounts for major differences in carbon intensity between different roofing materials.

Concrete tiles create 0.19kg of CO2 per kilogram. Clay tiles are worse – they produce 0.43kg per kilo. Natural slate, however, contains far less – between 0.0050.054kg per kilo.

Carbon offsetting However, even as natural slate suppliers, we know companies like SSQ unavoidably have an environmental impact.

It’s for that reason that, starting last year, we’ve begun investing to offset the carbon that we produce as a business.

Between January 1st 2019 and December 31st 2019, for example, our UK head office and our Argentinian quarry were responsible for producing 1,343 tonnes of CO2

We’ve responded by offsetting that carbon by supporting the Gold Standard VER East Africa Borehole project, which provides clean drinking water to people in impoverished parts of Sub-Saharan Africa –and offsetting 1,343 tonnes of carbon.

In response, the Carbon Neutral Organisation has presented us with a Carbon Neutrality Certificate, which you can view on our website.

It’s just the start of our efforts to cut our carbon footprint here at SSQ – but if dozens of other companies in our sector do the same, we can play a vital part in helping Britain achieve a cleaner, greener future.

If you’re interested in learning more, don’t hesitate to speak to SSQ today – call 020 8961 7725 or visit www.ssqgroup.com.

Homeowner and lecturer in Sustainable Architecture, Dr Stephen Finnegan is rising to the challenge of achieving a Net Zero Carbon (NZC) Victorian home in a leafy suburb of Liverpool. His objective is to minimise running costs, emit no carbon emissions in operation and run the entire property on electricity, largely generated through sustainable sources. Here, we take a look at the project.

The house, a large detached, brick-built property constructed at the turn on the 19th Century, is typical of the style of building of the period. Solid walls, high ceilings, a walk-in cellar and occupied roof rooms (historically used as servants quarters!). Heating the four-story property had originally been via open, coal fires in every room, including those in the roof prior to the installation of gas central heating.

Dr Stephen Finnegan, who is a lecturer in sustainable architecture at the University of Liverpool, plans to take the building back to a bare shell and incorporate as many energy

The electric dream house. A substantial brick built Victorian three story property

harvesting and low energy consumption systems as is practical in the restoration of the house. He will then carefully monitor energy and carbon usage with the overall target of Net Zero Carbon emissions.

His ultimate objective is to run the house entirely on electrical energy, through the incorporation of a solar PV system with a SunSynk battery storage system, an Air Source Heat Pump (ASHP), thermal store and monitoring kit (all of which will be provided by Dynamis Associates Ltd). This retrofit system will provide domestic hot water and underfloor space heating. An

electric vehicle charging point and a ‘time in use energy tariff’ will catapult the house into the 21st Century.

According to Dr Finnegan, it is well established that around 20% of UK carbon emissions are generated through heating, hot water and cooking in domestic properties. With over 60% of current housing stock built pre-1960 when little thought was given to heat-loss prevention, the challenge of reducing these emissions is significant.

New-build properties can be built to far more thermally efficient standards than their predecessors, so the Government’s target of slashing overall carbon emissions by 78% by 2035 puts real focus on older buildings where retro-fitting of heat loss prevention methods and reducing energy inputs, particularly of carbon rich sources such as gas, are so crucial.

In older properties, particularly like this house, built over 120 years ago, when energy costs were far lower and measures to prevent heat-loss through walls and roof were rarely considered, the challenge is even greater.

Dr Finnegan explains. “Our first big obstacle to overcome is heat loss prevention and this primarily focusses on improving insulation and air tightness”

Up to 40% of a building’s heat loss can be attributed to air leakage [what we would all understand as draughts], so it is vital that air tightness is included in any programme of measures designed to improve a building’s thermal performance. A so called ‘fabric first’ approach.

A breathable, sealed-box environment

Traditional insulation materials such as mineral wool or rigid board products can be time-consuming and expensive to retrofit and if not installed correctly can still lead to air leakage. It is almost impossible to achieve a completely airtight seal, whilst still allowing the building to breathe naturally.

“We needed a more efficient, modern method of insulation that provides a high level of thermal insulation and help us create a sealed ‘breathable’ box environment to give us better management of both heat input and ventilation. Electricity is already expensive and prices will only go upwards, so it’s vital that we do all we can to first minimise consumption, prior to the installation of any renewable energy technologies” said Finnegan.

Early on in the restoration programme, insulation specialists, Green Horizon Energy Solutions were brought in to advise on how best to minimise thermal loss. Director, Matt Lawford recommended the use of Foam Lite LDC 50, a breathable, spray applied ‘open cell’ insulation system from Huntsman Building Solutions [HBS].

Huntsman’s Foam Lite is a spray applied insulation system that expands quickly but gently, sealing all gaps, service holes and hard to reach spaces, virtually eliminating cold bridging and air leakage” explained Matt Lawford.

“As well as the entire roof area, we recommended applying spray foam insulation to the underfloor area of the timber ground floor. Up to 20% of heat can be lost through an un-insulated suspended floor and, with easy access from the cellar area, this gave us a quick-win in terms of heat loss mitigation” added Lawford.

Unlike the urethane foams of 20 years ago, modern spray foams such as Huntsman Building Solutions Foam Lite LDC 50 uses water as the blowing agent. This means that the reaction between the two components produces a small amount of CO2 which causes the foam to expand. Cells of the foam burst and the CO2 is replaced by air.

This “open cell” foam provides outstanding insulation properties but still allows the building to breathe naturally, without the risk

of condensation. HBS spray foam insulation systems were developed in Canada to cope with their severe winters and are now widely used in UK in both the residential and commercial sectors.

In the roof area, the original lath and plaster covering was removed from the underside to the pitched roof and 50mm section timber counter- battens installed. The roof had been re-slated in the 1960’s and the bituminous sarking felt covering was found to be in sound condition so no further remedial work was needed.

A thin layer of glass fibre was removed and HBS Foam Lite LDC 50 insulation sprayed directly on to the exposed felt to a depth of 120mm. After trimming flush, the ceiling was fitted with a Vapour Control Layer (VCL), re-boarded and skimmed.

With good access to the underfloor at ground level (via the basement), insulation was sprayed between the flooring joists

to a depth of 120mm, eliminating draught incursion to the rooms above.

The house restoration project began in early 2021 with a target for completion and occupation by the end of the year. An array of temperature, energy and relative humidity sensors are being installed as work progresses allowing a comprehensive programme of data collection covering air tightness, net electrical energy consumption, thermal performance and so on. These will be collated into a formal paper to be published by Dr Finnegan during the latter part of 2022. Alongside a live data feed open to the public and hosted by the Zero Carbon Research Institute www.zcri.co.uk. Which was founded by Dr Finnegan.

Learn mopre about Huntsman Building solutions: www.huntsmanbuildingsolutions.co.uk

Icynene – Enquiry 34

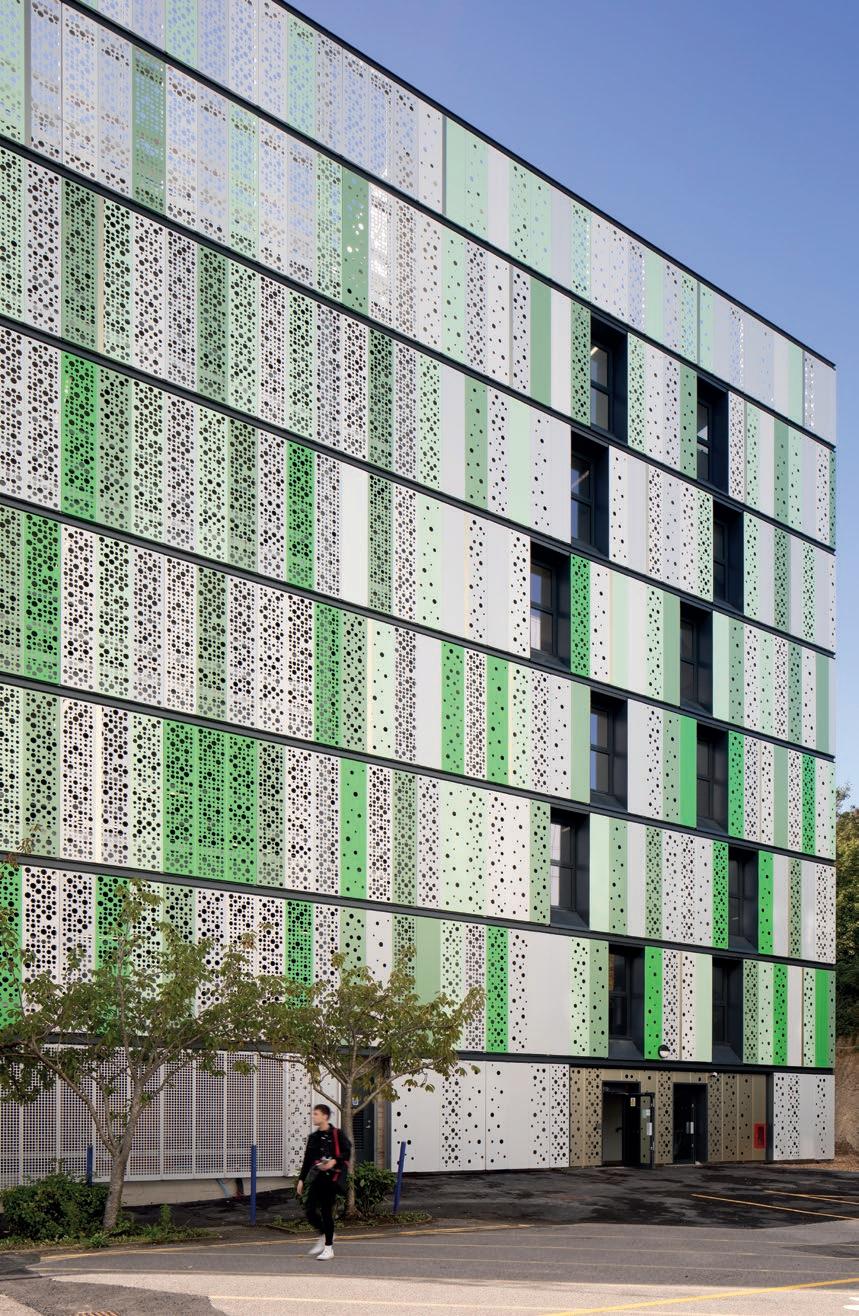

With 50 years’ experience in the car park sector, Berry Systems have developed a substantial breadth of expertise in many different areas, including cladding and facades. With the many different requirements which architects may have for a cladding project, whether for a car park or other buildings, new regulations and developments mean this is always changing.

There are more things to take into account than ever before. Specifiers must think about the practicality, aesthetics, safety and environmental impact when working on any project, making the task of finding a suitable solution much more challenging. However, Berry’s experience in cladding and façades means they can offer specifiers support from conception to completion.

Our wide portfolio of car park projects has seen us work with a huge range of popular cladding options, such as perforated panels, Sto glass and living walls, meaning whatever your requirements, we can provide you with a solution to meet your objectives. We work with architects and specifiers at an early stage, through our Design Advisory Service, meaning we can use our industry knowledge to help bring designs into reality and provide full project support in design, planning and installation.

All of this is showcased on our brand new website. We have created an easy-to-use platform which shows users how we can offer support from start-to-finish to provide a turnkey solution. It also contains information on all our products and services, with downloadable data sheets, as well as an entire section of case studies, which shows many of the notable developments we have worked on in the past.

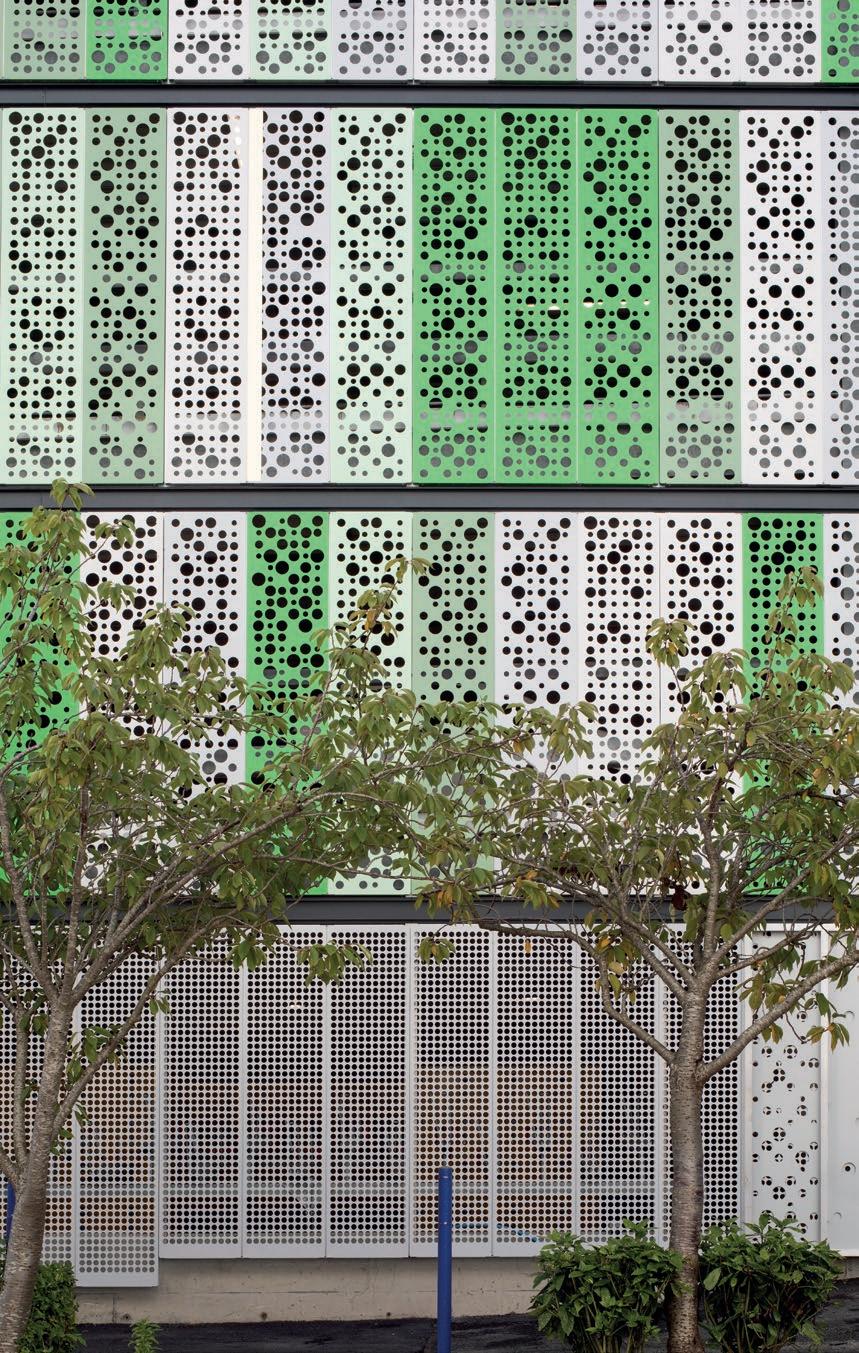

A great example of our cladding and façade expertise was highlighted with the award-winning project at Watts House car park in Brighton. We supplied and installed the perforated panels to create the façade, which was praised for its

outstanding aesthetics, as it won Best New Car Park at the British Parking Awards.

The client had several requirements and we contributed to the car park’s appearance by arranging the panels so they lightened as the height of the building increases, reducing the perceived mass. The façade also featured planter boxes at the top of the elevation, helping to improve the environmental impact of the structure.

Our early involvement in the design stage and close collaboration with the architects allowed us to provide a turnkey solution to meet the client’s requirements.

For complete support in your cladding and façade projects, we have the knowledge and expertise to work closely with architects and specifiers to help from design all the way through to installation, whatever your objectives.

To see the new website, go to www.berrysystems.co.uk or contact our team 01902 491100 for information on how we can support your project.

Berry Systems – Enquiry 35

New hub helps specifiers construct safe, comfortable and sustainable homes

Predictions suggest that an additional 9.3 million people will move to the UK’s cities by 20221, driving the trend for vertical construction to create more space for homes. In response, ROCKWOOL has developed a new high rise hub designed to support the specification of noncombustible stone wool insulation solutions for residential projects – ultimately helping specifiers to meet stringent fire safety, thermal and acoustic requirements while constructing high rise properties.

A central feature of the new hub is ROCKWOOL for High Rise Residential Projects, a comprehensive guide which explores the role of tall buildings in our

society and focuses on key high rise topics including fire safety, thermal comfort, energy efficiency, acoustic performance and sustainability. Containing specific building regulations guidance as well as stone wool insulation case studies, advice and best practice, ROCKWOOL for High Rise Residential Projects is the go-to resource for high rise developers and specifiers.

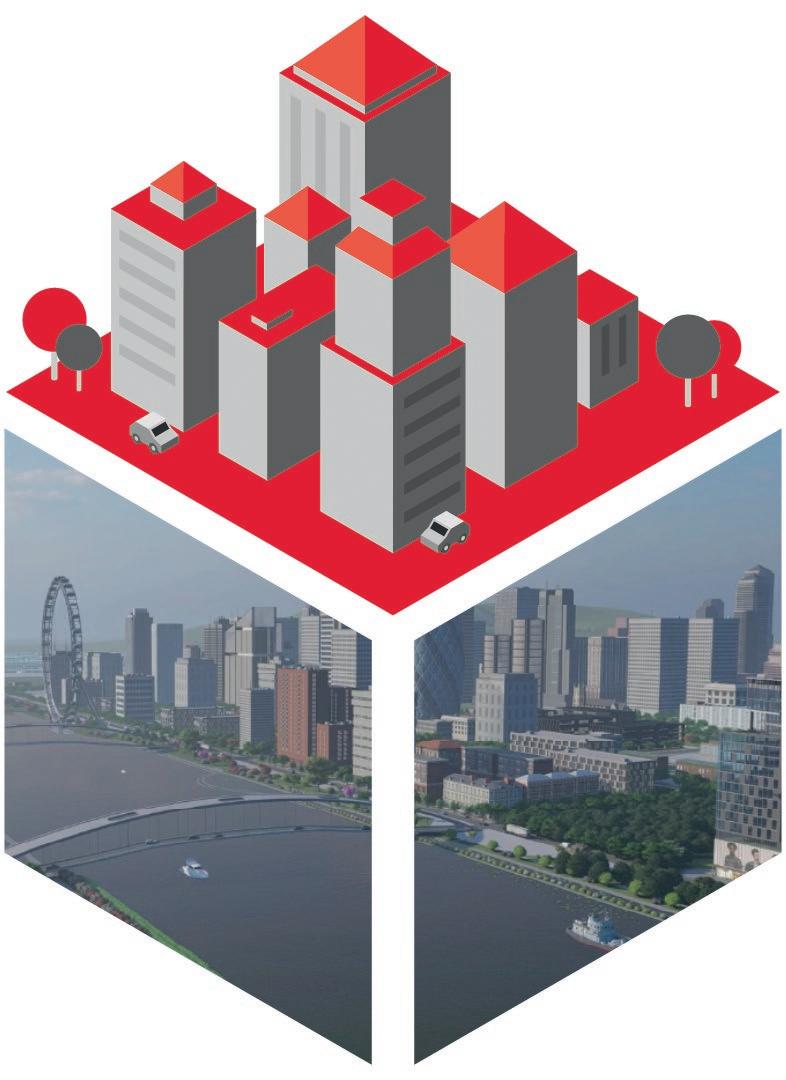

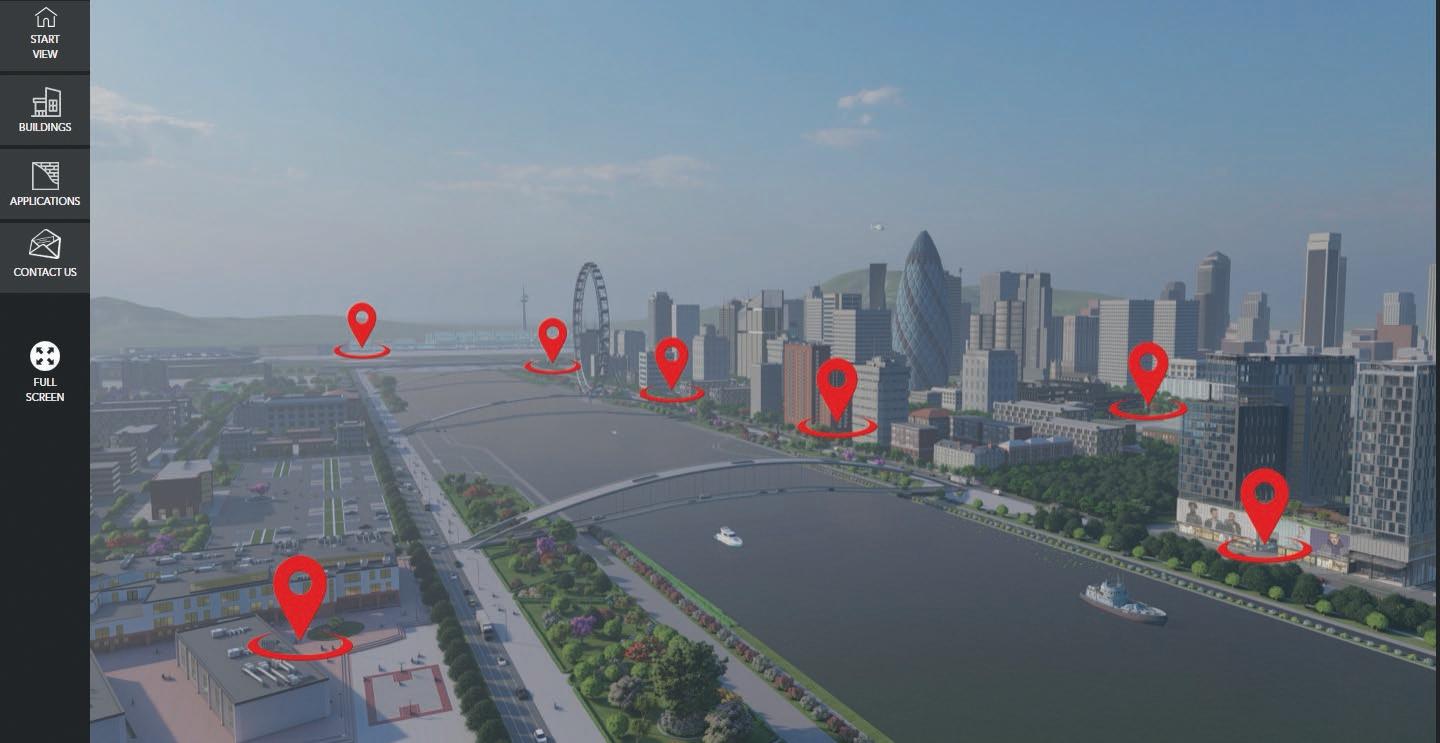

Through the high rise hub, specifiers can also access the ROCKWOOL Interactive City which features a virtual model of a multi-storey residential building with stone wool insulation solutions displayed in-situ. The cutting-edge 3D environment makes it easier than ever to visualise and select insulation solutions while keeping homeowners’ and tenants’ requirements in mind.

Through features like zoom, 360º views, pan-able application build-ups and augmented reality, the Interactive City helps users to explore the ROCKWOOL insulation range in an innovative and accessible manner.

For real world examples and inspiration of how stone wool insulation helps designers to create enjoyable high rise homes, visitors to the hub can also read a series of notable case studies featuring diverse developments including student accommodation and social housing.

Paul Barrett, Head of Product Management at ROCKWOOL, commented: “In launching the ROCKWOOL high rise hub, we’re making it easier for specifiers to access a host of resources specifically designed for residential homes at height.

"Specifying insulation solutions for high rise buildings isn’t always straightforward, so we’ve ensured that building regulations requirements and wider quality of life considerations are clearly presented.

“Ultimately, it’s about creating high rise homes which are safe, comfortable, futureproof and sustainable – and I’m confident that the high rise hub is a great place to start.”

Visit the ROCKWOOL high rise hub and download the ROCKWOOL for High Rise Residential Projects guide today: rockwool. com/uk/high-rise.

ROCKWOOL – Enquiry

The virtual 3D cityscape aims to inspire design, save time and lead to faster decision making

ROCKWOOL has further enhanced its range of resources for specifiers, contractors and building owners with the launch of the ROCKWOOL Interactive City, a 3D environment that makes visualising, specifying and learning about its non-combustible stone wool insulation easier.

Intuitively designed, the ROCKWOOL Interactive City allows users to explore its solutions across the whole of the built environment from housing and offices, to transport hubs and education in a single simulated space.

Through features like zoom, 360º views, pan-able application build-ups and augmented reality, the city provides a virtual ‘hands-on’ experience when it’s not possible

to touch, see or hear products in practice. Featuring a wide variety of applications, the tool can also be used to explore the versatility of ROCKWOOL’s solutions, understanding where its non-combustible products can enhance thermal, acoustic or fire performance in places users might not expect.

As well as saving specifiers’ time and aiding building design, these capabilities lead to smoother, faster decision making and a more collaborative process for project stakeholders.

“The Interactive City takes product specification to the next level,” said Paul

Barrett, Head of Product Management at ROCKWOOL. “As the whole of the built environment is covered, you can quickly and easily find out how to achieve any desired outcome with our stone wool insulation, whether that’s improved patient experience, increased student attainment, or a safer, warmer and quieter home.

“It’s also been created for complete flexibility. You can either browse the city or jump straight to the area or building you need, delving into substrate build-ups and system designs.”

The ROCKWOOL Interactive City has also been developed to help achieve the allimportant golden thread of construction data. Each 3D application provides a complete package of suitable ROCKWOOL solutions, with quick links to product documentation, installation guides and BIM objects that can be downloaded for use offline or integrated into construction modelling software.

The ROCKWOOL Interactive City can be found at rockwool.com/uk/interactive-city

ROCKWOOL

Market-leading roofing manufacturer Sika has now completed Extended Application Assessments, testing to CEN/TS 1187:2012 Test method 4 for the entire Sika Sarnafil range of PVC single ply membranes. Subsequently, the most common Sika Sarnafil roof systems are now all classified under BSEN 13501-5 as BROOF(t4).

Working closely with independent global fire safety testing, inspection and certification company Warringtonfire – part of the Element Materials Technology Group – Sika has undertaken significant investment to attain the BROOF(t4) classification across all PVC membrane systems. This covers a range of permutations, including membrane type, thickness of PIR insulation, up to a 70-degree pitch and on any structural substrate.

A project spanning over two years’ work, Sika has invested a substantial amount of time and resource, utilising the EXAP standard CEN/TS16459, which is available as a means of covering ranges of system permutations.

Dean Grady, project leader and Senior Product Engineer at Sika, comments on why Sika has opted to invest in this type of testing: “The market has become acutely aware of fire safety and it is looking to industry leaders to help. We have seen for a while now that specifiers, architects, clients and building control are increasingly insisting on fire test certificates that directly reflect the exact system being