With Covid-19 continuing to exert a significant impact on the country as a whole and in particular construction, it is easy to forget the other pressures and challenges affecting the wider industry.

It is timely, therefore, that the Construction Leadership Council has constituted a dedicated Brexit Working Group, in advance of the expiration of the transition period with the European Union at the end of the year.

Brexit seems to have fallen down the agenda in recent months for many. But the Working Group aims to produce and signpost business guidance and information to help the construction industry get ready and be prepared to maintain business continuity at the end of the transition period.

The Group will also aim to identify critical issues facing the construction industry (in the event of no agreement) that the Government should address in advance of the expiry of the transition period as well as championing opportunities for the construction sector in the numerous ongoing trade deal negotiations (EU+ROW).

In addition, the existing workstreams of the CLC will also take on Brexit-readiness related work, helping to produce guidance on matters including procurement and contracts.

Andy Mitchell CBE, Co-chair of the CLC said: “The CLC has a leading role to play in getting our business ready for the changes that will come at the end of the transition period. While businesses contend with the fallout from COVID-19 and adjust to the new ways of working, the clock continues to tick on reaching an agreement with the EU.

“Whether we reach an agreement or not, our relationship with our European neighbours and the rest of the world will change and we’ll be doing all we can to help the industry adapt, adjust and rise to meet the Prime Minister’s ‘Build, Build, Build’ ambition.”

James Butcher, Head of Policy at the National Federation of Builders, who is co-ordinating the Brexit Working Group added that four key areas that we believe are critical for business continuity as we enter a new post-Brexit world with more details coming in September.

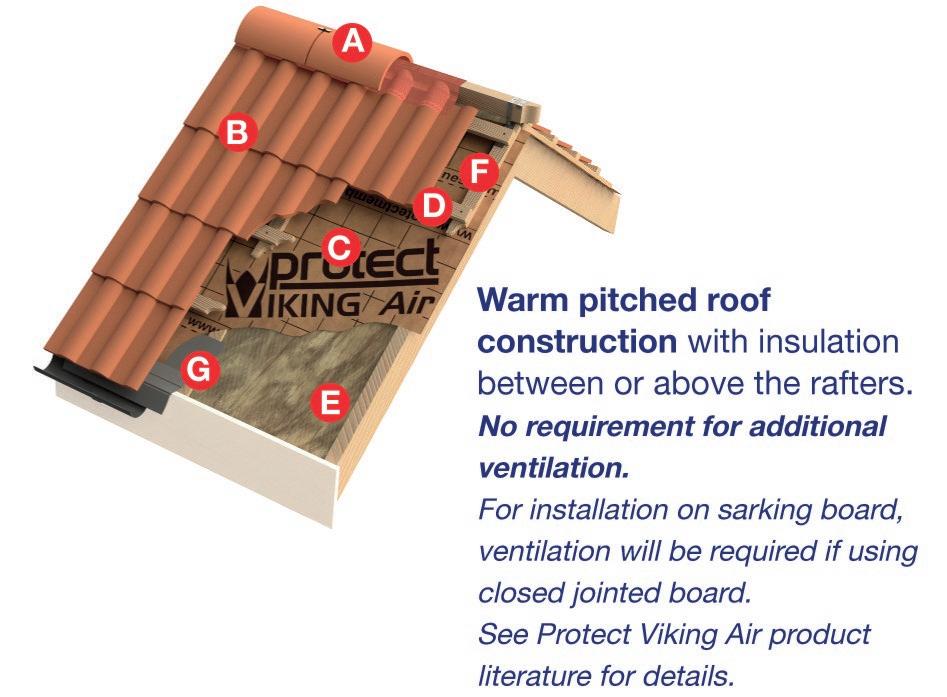

This next generation pitched roofing membrane offers class leading air and vapour permeability, ventilating the roof space for the ultimate in condensation control. Independently certified by BM TRADA, the underlay provides strong wind uplift resistance up to Zone 4 at 345mm batten gauge to BS 5534. To read more about Viking Air, see page 24 or visit www.protectmembranes.com/vikingair.

After four months in negative territory, the RIBA Future Trends Workload Index rose to +3 in July, from –17 in June.

Nearly a third (31%) of practices anticipate a workload increase, 42% expect workload to remain the same and 28% expect a decrease.

In July the Staffing Index also rose by 5 points, with 75% of practices saying they expect the level of permanent staff to remain the same over the next three months and 8% (rising from 4%) anticipating the need to employ more permanent staff. Despite this, 17% still expect their staffing levels to decrease over the next three months.

All sectors returned slightly more positive balance figures. The private housing sector rose significantly to +17 (from -3 in June), the commercial sector rose to -15 (from -32), the community sector to -14 (from -19) and the public sector to -4 (from -12).

While there was increased optimism about workloads over the next three months, 62% of respondents still expect profits to fall over the next year and within that, 7% consider that their practice is unlikely to remain viable.

The findings from this month’s survey also show:

• 20% of architectural staff have been furloughed

• 1% of architectural staff have been made redundant

• 1% have been released from a ‘zero hours’, temporary or fixed-term contracts

• 18% of staff are working fewer hours (and they are most likely to work for smaller practices)

• 26% of projects are still on hold since March

• 22% of projects which remain active are at stages 5 or 6 of the RIBA Plan of Work

RIBA Head of Economic Research and Analysis, Adrian Malleson, said: “While July’s findings might show the first glimpse of positivity we’ve seen for a while – with practices seeing a specific increase in private residential enquiries as home working continues – architects still face a particularly challenging market.

“For some, their current workloads mainly consist of pre-pandemic commissions and the source of future work is uncertain.

“As the UK enters its first recession in 11 years, we can expect further caution from clients to commit to new projects, and confidence in future workloads may be affected.

“It remains our fundamental priority to support our members through this difficult time with resources and economic intelligence to help overcome immediate hurdles and build future resilience.”

The total value of construction contract awards in July 2020 was £6.3 billion which compares to £3.1 billion in June and £1.6 billion in May, underlining the magnitude of the growth trend for contract awards over the last two months.

The number of awards has also increased in July to 860 which is an increase of 80.3% on June. The residential and infrastructure sectors accounted for over 50% share of total contract awards. The latest edition

of the Economic & Construction Market Review from industry analysts Barbour ABI, highlights levels of construction contract values awarded across Great Britain.

Every sector had at least 33% growth in July, compared to June, with up to 98% growth in certain sectors. The residential sector contract awards increased by 65.9% on June, Infrastructure climbed 75.4% and education contract awards increased by 43.5%.

Construction work is recovering after the impact of lockdown with less disruption to site work, more project-starts, and more contract awards anticipated as the industry gets back to work.

Looking back at activity over the three months to the end of June, industry analysts Glenigan said this is very welcome news. The sheer scale of the impact of lockdown is astonishing, with the value of projects starting on-site 45% down on a year ago!

Despite the immediate and obvious impact of the pandemic, the development pipeline improved during the second quarter, with the value of overall approvals 15% up against a year ago. The rise was driven by a 51% jump in the value of major projects securing planning approval. The value of underlying detailed planning approvals slipped by 2% against the preceding three months on a seasonally adjusted basis and was unchanged on a year ago.

The decline in construction activity plummeted by 30% against a year earlier according to the latest data published by the ONS.

Residential work suffered the greatest disruption with private new work, social new work and housing RM&I output falling by 43%, 42% and 40% respectively. In contrast Infrastructure and public non-residential output saw declines of ‘just’ 14% and 15%.

The disruption to work on-site was greatest during April. Output during May rose by 8% against the preceding month as more sites re-opened, although output was still 40% down on a year earlier.

The CIPS Construction Index suggests that construction activity improved further during June. At 55.3 the June index points to a marked increase in total construction output against the preceding month. Any figure above 50 figures indicates a rise in output.

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Introducing the new pre-assembled airbrick system from Manthorpe. Allows for an extraction system be conveniently built into the brickwork, eliminating the need for retrospective core drilling. Unique, extendable telescopic pipe to suit the thickness of the wall and ducting connection. Product supplied finished therefore no assembly requirement. Build Thru…air into the masonry as it proceeds. Provides easier and quicker installation to match the demands of on-site construction.

For more information, visit www.manthorpebp.co.uk/thruair

Construction product manufacturers have signalled a shift in their investment intentions towards e-commerce sales as they respond to their worst quarterly performance since the 2008/09 recession.

The poor performance for product manufacturers in Q2 of this year comes against a backdrop of construction site closures, manufacturing shutdowns and widespread economic uncertainty in response to the public health measures implemented on 23 March.

The Construction Products Association’s State of Trade Survey for 2020 Q2 reports that 81% of heavy side manufacturers reported a fall in sales compared to Q1. Sales of light side products were reported to have decreased by 68% of manufacturers. Both were the lowest balances since 2008 Q4. Heavy side products are typically used in the early, structural stages of construction, whilst light side products are typically used in the later, finishing stages of building.

Manufacturers expect the recovery to cautiously begin in Q3, with 13% of heavy side firms and 9% of light side firms anticipating a rise in sales in the next quarter, on balance. Furthermore, investment intentions signal that the sudden change in trading conditions has elicited a broader change in manufacturers’ priorities. 53% of heavy side producers and 50% of those on the light

• 81% of heavy side firms and 68% of light side firms reported that construction products sales declined in Q2 compared with the previous quarter, the weakest balances in nearly 12 years.

• On balance, 13% of heavy side manufacturers and 9% of light side manufacturers anticipated a rise in sales over the next three months.

• Half of heavy side firms anticipated a decline in headcount over the coming year, the lowest balance since 2009 Q2.

side anticipate increased investment in e-commerce over the next year, in contrast to expectations of reducing investment in structures, such as new factories.

Rebecca Larkin, CPA Senior Economist said: “As we emerge from an unprecedented economic shutdown, the extent of its impact on construction and construction product manufacturing is now clear in the sharp decline in sales in Q2. Within the quarter it’s likely to have been a tale of two halves, with manufacturing lines closing in response to pauses in site activity in April and early May, followed by a phased restart as construction gradually resumed from mid-May. The light side appears less affected, adding to reports that the return to work is focusing on completing existing projects, particularly in housing, commercial and industrial. Uncertainty over the economy, the appetite for new project starts and potential longerterm structural changes in demand mean that industry’s questions now move away from the question of how low can it go, to how quickly it can come back.”

The Royal Institute of British Architects has announced three joint winners of Rethink: 2025 – an international design competition seeking designs for our post-pandemic world.

Rethink: 2025 invited architects and students to consider what life and our built environment could look like by 2025. Entrants were given seven categories from which to generate ideas, including the future of: healthcare spaces, remote learning, high density living, public transport, high streets vs online shopping, international travel and the use of technology to monitor and control population.

The winners are:

Get Everyone In, Benjamin Holland, Olivia Dolan, Katie Williams - This proposal draws on two issues which have been amplified by the pandemic – the need to house people who are homeless and the prediction that many office spaces will become permanently redundant. Bringing these issues together, it suggests that empty office spaces can be re-used and repurposed to house homeless people.

Streets are Made for Walking, People Matter - This proposal uses Holloway Road, an arterial road in North London, as an example of what could be done in any city to redesign its streets to make high quality public space for those living either side of such traffic corridors.

Greater London Agriculture, Tim Rodber and Dominic Walker - This proposal seeks to transform London’s metropolitan area into an ecologically diverse, agricultural landscape, addressing the premise that industrialised food production has made us vulnerable to diseases transmitted from animals to humans.

• A balance of 23% of light side firms also expected a fall in their labour force over the next year.

• On the heavy side, 20% of firms expected to reduce investment in structures over the next 12 months, the lowest balances in the survey’s history. 18% of firms on the light side expected a decline.

• 53% of heavy side firms and 50% of light side firms, on balance, also anticipated increased investment in e-business over the next year.

As we emerge from an unprecedented economic shutdown, the extent of its impact on construction and construction product manufacturing is now clear

Magrini baby changing units provide a hygienic and safe place for changing your smallest customers. The contemporary style incorporates extra-deep sides providing an intrinsic safety barrier and the units have a unique hinge system preventing small fingers from being trapped.

Magrini baby changing units are available in a choice of colours to suit modern commercial washrooms.

The National Federation of Builders (NFB) Major Contractors Group (MCG) has thrown its support behind the #ConstructionDeclares movement, the first and currently only trade association representing main contractors to do so.

#ConstructionDeclares is a global petition uniting all strands of construction and the built environment. It is both a public declaration of the planet’s environmental crises and a commitment to take positive action in response to climate breakdown and biodiversity collapse.

The declaration includes eleven points that the signatories commit to, including pledging to reduce embodied carbon by at least 40% by 2030, based on the World Green Building Council call to action.

The Major Contractors Group of the NFB represents main contractors with turnover of £40m+. Last year, the group published a landmark report entitled ‘Transforming Construction for a Low Carbon Future’ positing that main contractors were uniquely placed to influence clients and their supply chains in delivering a low carbon future.

The Group intends to publish a second report later this year which will act as a

handbook for main contractors on how to decarbonise their businesses and projects.

Commenting, Mark Wakeford, Joint Managing Director of Stepnell Ltd and Chair of the NFB MCG said: “The construction industry directly accounts for 10% of the country’s emissions and influences 47% of all emissions.

“The structure and nature of our fragmented industry makes rapid and coordinated change difficult but as main contractors we have a uniquely influential position between the client and the supply chain.

“We’ve taken the step of issuing our declaration on the climate emergency as well as pledging our support for a reduction in embodied carbon. A low carbon future for construction is not just a reality but a necessity and we’re determined to show that contractors can commercially embrace decarbonisation, delivering a profitable service and securing our planet’s future”.

The NFB MCG is encouraging all main contractors to sign up to the declaration. The Group is currently undertaking research into main contractor’s decarbonisation efforts to date which will help form the insight into its future reports.

The RIBA has responded to the Government’s White Paper – ‘Planning for the Future’ – outlining reforms to the country’s planning system.

The Government has set out plans to overhaul outdated planning system and reform the way the country builds and it plans to streamline process, cut red tape and harness technology to deliver homes faster.

It insists that valued green spaces protected for future generations, with more building on brownfield land and that “building beautiful homes with communities at heart of new planning system” is the main priority. There will also be a 30% discount through First Homes, with an emphasis on key workers.

But RIBA President, Alan Jones, said: “While there’s no doubt the planning system needs reform, these shameful proposals do almost nothing to guarantee the delivery of affordable, well-designed and sustainable homes. While they might help to ‘get Britain building’ – paired with the extension of

Permitted Development – there’s every chance they could also lead to the creation of the next generation of slum housing. The housing crisis isn’t just about numbers, and deregulation won’t solve it.

“If the government is serious about addressing the dominant position of large housebuilders and the lack of quality social housing, the Secretary of State needs to make changes to the tax system, look at why land approved for development lies untouched for years, and give local authorities power and resource to promote and safeguard quality.

“The commitment to make all new homes carbon neutral by 2050 also needs be bought forward radically – we simply cannot go on building homes that damage the environment and leave people at risk of fuel poverty for another thirty years.

“These reforms might seem radical, but they won’t even scratch the surface when it comes to building the homes we need.”

A state-of-the-art medical centre in Milton Keynes has now reached completion thanks to national contractor Willmott Dixon.

The £9.5m facility, which is due to provide additional health care capacity for residents within the Western Expansion Area of the city, was handed over in July 2020.

The now complete Whitehouse Medical Centre – delivered on behalf of Milton Keynes Council – will serve around 22,500 people living nearby and will also be a base for Thames Valley Police.

Procured via Major Works England and Northern Ireland - a part of the Scape National Construction framework - the project is visually striking thanks to its design by Race Cottam Associates.

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

preSelect from FAKRO.

The beautifully designed, award winning roof window that offers all the benefits of a top hung or centre pivot at the flick of a switch. Find inspiration at fakro.co.uk/preSelect

Product guarantees are an important feature of the construction industry’s supply chain, often assisting specifiers in their purchasing decisions and providing additional assurances. Jonathan Arnold, technical manager at Tata Steel discusses the issue here.

Published in the midst of much scrutiny upon the construction industry, the Hackitt review into Building Regulations and Fire Safety provided a stern assessment of the industry, as well making a series of robust recommendations and guidance. A key focus of the report was the need to think about building construction differently; to start viewing buildings as a single system, encompassing a series of sub-systems, and for the Building Regulations framework to start treating building as such.

The limitations of viewing and considering building products in isolation, as opposed to assessing how the individual materials will react and work in unison, are perhaps widely apparent. After all, no building product will be installed in solitary confinement. Instead, it will form part of a wider system in conjunction with other products and materials, all of which could potentially have an effect on the expected levels of performance.

Sadly, therefore, while a specifier may be more attracted to building envelope products with a robust guarantee from the manufacturer, reassured by the promise of quality and performance, there is still an element of risk involved. Not only this but, in the unfortunate event of a claim, the process can be very time-consuming, with the potential for blame-passing and also issues in detecting the single product and manufacturer or supplier at fault.

By way of comparison, taking a system approach to building construction involves using a proven solution, where components in the building envelope have been tested together, as one, to demonstrate their proven performance. After all, it stands to reason that since building components are not going to be installed in isolation, they should not be considered or specified in isolation either. This process and approach is key in order to prevent the overall building from being negatively affected or compromised by components failing to function together.

So, how does this translate to the guarantee? Compared to individual product guarantees, which by their very nature can be limiting, and even then, can often come with various restrictions or conditions, a system guarantee provides assurance of the building

envelope as a whole. Not only does this provide architects, specifiers and indeed building owners with greater peace of mind that the components will perform together as expected, but also that, in the unlikely event of a problem arising further down the line, rectifying the issue would be a simpler and more streamlined process.

As well as the challenges of reducing risk and ensuring that a building’s individual components will deliver the required and expected levels of performance, another obstacle that architects and specifiers can be faced with is value-engineering. A theme that also featured in the Hackitt review, valueengineering is an all too common occurrence on the UK’s construction sites; a process where the original specification is altered as the construction sequence progresses, with inferior, unproven products finding their way onto a project. Taking a system approach to specification and construction can reduce this risk, with the building envelope components specified and approved for use together,

helping to ensure that the originally designed performance is maintained and initial good intentions aren’t diluted.

Those who transform their mindset and begin taking a systems approach to construction can also be assured of high levels of support from manufacturers. For example, some building envelope system suppliers provide tailored technical advice and support, not just at the specification stage, ensuring that each proposed system specification will achieve the highest levels of performance possible, but also continuing through to ensuring this is adhered to on-site.

While taking more of a system approach to construction was just one of a series of recommendations within the infamous Hackitt review, it is well worth considering. Its advantages are widely evident, perhaps even more so when specifying the fabric of a building envelope, with it being integral to the success of the overall structure. Architects and specifiers will be provided with the assurance that the building components will work together, and even complement one another; an assurance that then translates through to the longevity and performance of the overall structure and also into the building system guarantee.

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Tim Sandberg, category manager for below-ground drainage at Marley Plumbing & Drainage, explores the benefits of sustainable drainage systems (SuDS) and how flow control units can be key in protecting communities from flood risks.

While us Brits are well-known for talking about the weather and its unpredictability, extreme weather events are becoming more common. In fact, extended periods of extreme winter rainfall are now seven times more likely to occur than in the previous decade, with climate change reportedly increasing the risk of floods in England and Wales by at least 20%. Such extreme weather events are predicted to become only more frequent in the coming years, with the Met Office and Government’s 2019 ‘UK Climate Projections’ report forecasting future increases in the intensity of heavy summer rainfall events and significant increases in the heavy hourly rainfall intensity experienced during the Autumn months.

With our existing drainage infrastructure evidently unable to cope with such heavy and sustained rainfall events, as demonstrated by the devastating flash floods earlier this year, it is clear that specifiers and developers need to start considering alternative rain and surface water strategies, such as Sustainable Drainage Systems.

SuDS are a collection of water management practices and systems designed to mimic natural drainage processes and better control, manage and utilise the stormwater. There are numerous forms of SuDS, such as retention ponds, rainwater harvesting, green roofs, pervious surfaces and attenuation tanks.

Depending on the individual site, ground conditions and project requirements, a combination of these systems can be carefully selected and incorporated within a development’s green infrastructure and surface and stormwater strategy.

Vortex flow control units are another example of a SuDS and work in conjunction with attenuation tanks. Installed underground, rain water is directed into the attenuation tank, off and away from the surface level. The vortex flow control unit is then installed beyond the attenuation tank. As the name suggests, the flow control unit works to control the rate at which stored water is released into natural water courses or underground sewer systems during a storm event, using the proven vortex principle. This protects both the underground drainage pipework from becoming overwhelmed by the amount of stormwater entering the system during such an event and also the ground from becoming over-saturated – two factors that are known to lead to surface water flooding and flash floods.

In order to ensure a system is specified that will offer long-term performance, it is important that specifiers consider the material from

which the flow control unit is manufactured, as well as various additional features, such as inlet filters, which protect the system against potential blockages or silt-build up.

Some flow control units, such as Marley Plumbing & Drainage’s Flowloc, are also manufactured with a range of different size orifice plates. These provide further, more tailored control over the water flow rate, allowing the developer to match the maximum allowed discharge rate with that required by the local water authority.

As we continue to feel the effects of climate change and extreme rainfall events become more frequent, Sustainable Drainage Systems are set to play an integral role in protecting communities from surface water flood risks. By considering SuDS, such as flow control units and attenuation tanks, at the design and planning stage of a project, specifiers can help to futureproof the development, creating a drainage strategy that will work to better manage and control the levels of stormwater, as well as reduce the pressure on our existing drainage infrastructure.

Marley Plumbing & Drainage

With our existing drainage infrastructure evidently unable to cope with such heavy and sustained rainfall events, it is clear that specifiers and developers need to start considering alternatives.

There’s never been a better time to build. Materials, construction techniques and fire safety have reached a pinnacle unthought of in times past. Architecture and design continue to push into brave new frontiers –with masterpieces like the the Shard in London or the Louvre in Abu Dhabi becoming a more regular addition to the world.

So, with all the advances in the art and science of construction, are we now able to make a fireproof building?

There’s no way to make a building completely fireproof. Even though there are stringent fire regulations for new builds, they can still be poorly designed, or even ignored.

But even with every possible safety measure implemented and agonised over, ruling out a fire would be impossible. The ideal, least likely to catch fire building would be highly impractical and unaffordable to the extreme. Imagine a structure carved from a single piece of stone, moulded entirely in concrete – and crucially, filled with nothing but inert materials.

No wood, fabric, paper or plastic could enter the building, because they’d represent a fire risk. Even if you remove every element of accidental fire risk, there’s still malicious damage and arson to think about. Advertising a building as “completely fireproof” could serve as an invitation to test the claim out. A well-planned fire could damage and stress even the strongest stone structure, and water penetration could take decades to resolve.

A building made for the sole purpose of resisting fire would, of course, technically be safer than a standard build – but that safety gain would be at the expense of usability, design and just about everything else. Achieving exemplary fire safety standards isn’t a case of removing all risks – because that’s not possible. It’s about good planning, excellent design and a proper fire strategy.

Fire curtains can be applied to any architectural design: office blocks, high rise buildings, retail environments, heritage buildings, airports –even high risk industrial facilities.

Keeping fire at bay starts at the design stage. Compartmentation is an essential part of design – and it can still be achieved in an open-plan environment.

Fire curtains make this possible by slowing the spread of fire down, protecting fire escapes for longer periods in the event of a fire.

Fire curtains are ideal for both small spaces and for large, open-plan areas. When fire curtains are factored into the design stage of a building, they can be recessed into walls and ceilings, making them all but invisible. Even retrofitted curtains can be made to fit in perfectly with their surroundings,

and we specialise in the manufacture and installation of fire curtains for historic and heritage buildings.

At Coopers Fire, we’re always developing, testing and improving our products. To find out more about our industry-leading fire curtains or to enrol in one of our educational online CPD seminars courses, visit www.coopersfire.com

Coopers FireKeeping fire at bay starts at the design stage. Compartmentation is an essential part of design – and it can still be achieved in an open-plan environment.

Our renowned 4000 Series riser doors have always been specified by architects for delivering the highest standards in third party fire certification without compromising on architectural design.

Unlike the rest of the industry, we fire test our riser doors from both sides to ensure legal compliance and still achieve 240 minutes certified fire rated performance.

Given the choice, why would you specify anything less?

As we tentatively step out of lockdown, Pat Jefferies, Commercial Director at Abloy UK, outlines how hands-free access control can play a vital part in building public confidence and safety.

Now we’re confronted by the ‘new normal’, we can more easily see the challenges still before us. Notably, research has indicated almost a third of people oppose the reopening of venues, and only 38% feel safe going back to work. What’s more, three in four are concerned about a second wave.

Like every other sector, we should balance public health and the need to get the economy moving again. It may be odd to think that we can affect behavioural change, but the access control is integral to the way people interact with, and use buildings.

We have the opportunity to build confidence in the community by giving them safest experience possible. So how can the security industry adapt and meet the new demands with these new procedures in mind?

The answer is to turn to a mix of access control technologies – old and new – to enhance safety measures such as social distancing, sanitary stations and controlled access.

Though automated access has existed for a long time, it’s never been more important or in demand as it’s a simple measure that businesses can introduce to help protect their customers and employees.

Likewise, contactless entry combines the benefits of door automation and access

control. Presenting a digital key or card to a reader not only signals for it to open but will also notify you when the door is once again secure. This allows compliance and will also generate an audit trail.

Smartphones also work well as keys, preventing cross contamination as people don’t need to touch anything other than their own device.

Meanwhile, dynamic lockdown technology, which is usually only implemented in emergency situations, can be repurposed to monitor capacity and reduce overcrowding. This can prevent ingress once a certain capacity is met, while still allowing egress with the automatic door system.

It’s also important to remember, despite many other pressing priorities, that every solution must be compliant. Though escape

While remaining open to supply essential markets in the Republic of Ireland, RSPL recognised the urgent need to implement new safety measures to protect customers and staff.

RSPL approached Abloy UK to supply automatic door operators to give visitors hands free access and egress. The

doors may be hands free, they still require a compliant escape device for emergency situations.

As a sector, we should actively promote solutions which can help organisations to operate while reducing the risk of infection. We don’t know what the next few months will bring, so implementing hands-free access will allow you to prepare and react to any future safety measures.

For further information on products and services available from Abloy UK visit www.abloy.co.uk, call 07884 548080, or email info@abloy.co.uk.

specification links with the building’s access control and door entry system to ensure that staff and visitors can access the building and collect supplies safely.

The automated doors work in conjunction with face recognition technology, temperature screening cameras, a visitor density control system, and ‘no-touch’ door releases.

The continual growth of the UK’s student accommodation sector has seen SALTO chosen to secure Teeside University’s new Cornell Quarter development which is planned to open to students in October.

Part of the University’s campus master plan which will see £300 million invested in the campus up to 2026, the £21.4 million Cornell Quarter is a new 300-bedroom residential complex arranged across 48 cluster apartments. Each of these comes complete with communal facilities and a proportion of rooms are designed for students with special mobility needs.

Wates Construction was appointed to build the new development and went with SALTO for its great product range and market leading reputation in the higher education sector. SALTO has now completed installation of 350 doors in Cornell Quarter using its XS4 One handle sets. Smart, secure, innovative and easy to install, the XS4 electronic escutcheon needs no hard wiring and provides a totally wire-free networked electronic locking solution with a great range of features. It is specially designed to fit on most standard doors, and work with the majority of Scandinavian, European and ANSI mortise locks and tubular latches.

Security measures in universities as well as colleges and schools need to be robust and effective but unobtrusive. Parents need to trust educational institutions to look after their children, so it is vital that they provide effective 24/7 security and ensure both students and staff are safe and protected at all times. This is especially true in a campus

housing environment, where many of the students are living away from home for the first time.

Building entrances, classrooms, lecture rooms, libraries, laboratories, staff rooms, sports centres, student housing and more can all be protected by smart access control that allows access to specific rooms or areas for selected periods only, with doors auto locking at pre-specified times as necessary. And, if required, they can also incorporate special features such as SALTO AMOK electronic escutcheons that enable classrooms and facilities to be quickly locked down during a security or other emergency event.

USERS & DOORS - Maximum number of users per door: 4 million. Maximum number of doors per system: 65,000. Access levels: unlimited.

KEYLESS & MOBILE ACCESS - Users can open doors with convenient and flexible credentials; by smartphone, PIN number, or smart keycard.

SMART ACCESS - No costs for lock replacement from lost keys. Saves valuable time and resources across the organization.

Jack Cowburn, Account Manager at SALTO says “Good security for student accommodation is paramount. So having SALTO access control installed as one of the security measures at the university will help them maintain a safe, secure environment for students staff and the university community alike.”

For more information: www.saltosystems.com

SALTO Systems

Good security for student accommodation is paramount. So having SALTO access control installed as one of the security measures at the university will help them maintain a safe, secure environment.

Bostik has supplied a host of subfloor preparation and flooring adhesive products for use on the refurbishment of the Arts & Design Building at the University of Suffolk.

The products, combined with Bostik’s expert advice, enabled a faultless installation of the new floor coverings in the building.

Ipswich-based Top Floors was appointed by main contractor RG Carter to strip out the two-storey centre’s rubber stud tiles, which were installed when it was built in the early 1990s, and replace them with 700m² Altro Walkway vinyl and 500m2 of Burmatex Tivoli carpet tiles as well as new nosings for the staircases.

The company primed the subfloors using the versatile Bostik Universal Primer. This was then followed by Bostik’s two-part Screedmaster Ultimate smoothing compound, which offers excellent workability and flow characteristics.

To bond the vinyl floor coverings in the corridors and on the staircases, Top Floors applied Bostik’s BEST flooring adhesive. Suitable for an array of different floor types including vinyl, Bostik’s BEST dries rapidly to form a strong bond. It also offers best-inclass handling characteristics, excellent coverage rates and good resistance to plasticiser migration – one of the most common issues with vinyl flooring.

For the carpet tiles in the rooms, Bostik specified its Laybond Carpet Tile Tackifier. The key benefit of this is that Laybond Carpet Tile Tackifier is designed to provide a permanently tacky film when dry.

Finally, Top Floors installed 100 new Quantum nosings on the building’s stairs using the high-strength Sticks Like Turbo adhesive from Bostik brand EVO-STIK.

Supplied in a cartridge, EVOSTIK Sticks Like Turbo is a high performance, fast setting grab adhesive that sets in just 15 minutes.

Ask housebuilders what they value in suppliers and most say meeting their needs reliably. Successful builders learn to be agile. They respond to what’s selling well and don’t plan sites too far in advance, and need the same agility from their suppliers, plus quality, support and reliable deliveries. So, being able to integrate a national supply chain to meet their requirements locally is critical.

Freefoam, a specialist manufacturer of PVC-UE roofline and external cladding, PVC-U rainwater systems, and interior decorative panelling, has strong ties with housebuilders. Success in new build comes from understanding their needs. We don’t push product through an owned-network of trade counters but work closely with independent stockists and merchants to supply them. Together with our national network of stockists, we have the scale, logistics, expertise and service to supply housebuilders with consistent quality on short lead times. It’s a national-local approach we call ‘The Power of Many’.

Simon Parrott, Freefoam Newbuild Manager explains: “We cater to all size of builders and developers and understand each newbuild customer has specific requirements. So, we offer extensive support to stockists and their housebuilder customers, from a scheduling service (vital for housebuilders working to strict timescales) and technical support in the specification process right through to regular, reliable deliveries and on-site assistance when needed.”

Choice, quality and service guaranteed We’ve invested in manufacturing and logistics to operate at scale to provide a wide range of products on short lead times, with very good OTIF (On Time In Full) figures. That’s one of the reasons stockist

PCP Cladding uses Freefoam. Andy Loasby, PCP Director of Sales explains: “We supply Freefoam products predominantly to the newbuild market and chose Freefoam because we offer a good range of products with the full support of our supplier.”

Keith Clarke, Senior Buyer at housebuilder and developer Chartway Group agrees: “We chose Freefoam because of the range, colours and sizes that come with a 10-year guarantee.

“The service and support from Freefoam and PCP Cladding are very good. It’s important when we place an order that we get the stock on site as soon as we ask for it, and Freefoam together with PCP Cladding always deliver on time.”

Freefoam’s eight colours in roofline and 10 for cladding is a big advantage to housebuilders and lets them cater for more unusual requests. George Petts, Business Development Manager at Freefoam stockist Willmott’s says: “Freefoam’s product range is excellent, and Colormax® is without doubt the best in the industry. Freefoam is quick to react and their range has developed as a result of demand in the marketplace.”

Andrew Weldon, Senior Site Manager at Barwood Homes says: “The quality of Freefoam’s products is great. We never get any complaints from the carpenters who fit it, which is usually a sign that the product is very good.”

“Freefoam values our customers as much as we do”

Freefoam’s collaborative approach benefits stockists’ customers as much as housebuilders. We took the strategic decision not to compete with stockists, but to give them the support and service to compete for housebuilder customers to grow their business. Courtney Robertson, Area Sales Manager at stockists General Building Plastics elaborates: “We trade on our independence, and it’s important to us that Freefoam is an independent supplier. Freefoam wants us to grow and helps us win newbuild business. They don’t have trade counters so we know we can go after new business without stepping on anyone’s toes.

“Freefoam provides unrivalled support for newbuild. They give us really quick turnaround on tenders. They’re also quick to help if there’s any issue on site. We’ve worked with Freefoam since 1994, and it’s down to the quality of products and consistency of supply. Freefoam’s choice of products, cladding and coloured products is a big benefit for housebuilders and gives them a competitive edge.

“But the real reason our relationship is so strong is they value us and our customers. Freefoam works with us as a business, recommending us as a newbuild supplier and passes on leads – some of which we’ve converted into quality, repeat customers.”

Courtney concludes: “Freefoam give us unrivalled back office support and are always there to help with any issues on-site. Freefoam want us to grow, and our newbuild business has grown over the past 10 years. I don’t think we could have done this without Freefoam.” >>

>> Willmott’s, a leading independent plastics supplier in Reading supplies housebuilders in the South East, and its long-standing success with Crest Nicholson comes from a deep understanding of the housebuilder’s needs.

George Petts, Willmott’s Business Development Manager says: “Freefoam and Willmott’s is a real partnership and we supply Freefoam to nearly all our housebuilder customers. There are sites where only Freefoam is used. Partnership with Freefoam demonstrates how easy it is to succeed.”

Oliver Dodd, Site Manager at Crest Nicholson confirms: “We’ve used Freefoam fascia, soffit and cladding. We work closely with Willmott’s and they’re renowned for their excellent customer service. Willmott’s have won supplier of the year award for the past few years.”

Stuart Hume, Senior Buyer at Crest Nicholson adds: “Delivery service from Willmott’s is excellent, with next day delivery. They’re always helping sites out when urgency is key.”

When Willmott’s identified an opportunity to reduce waste for Key Partnership Homes, a developer that works with housing associations to design and supply high-quality affordable housing across the South Midlands and Home Counties, Freefoam developed specifications for a bespoke solution. The solution, a 6-metre cladding board, significantly reduced waste for the developer.

We’ve built these national supply chain partnerships around the needs of housebuilders and developers so our stockist customers can outperform competitors and grow their businesses. To compete successfully for new build, the supply chain has to integrate and synchronise as a single entity, supplying housebuilders through the channel that works for them. So, via a national stockist or local supplier they get the same fantastic service. That’s why we call it the Power of Many. Success is seeing customers prosper, because when they grow, we grow.

For more information contact Freefoam on 01604 591110, visit www.freefoam.com and follow @freefoam. Freefoam

Building products manufacturer Glidevale Protect has launched Viking Air, an air and vapour permeable (LR) roofing underlay for cold and warm pitched roofs.

Air and vapour permeable membranes are becoming an option of choice for specifiers due to the ability of the underlay to provide airflow and ventilation into the roof space of the dwelling. Protect Viking Air delivers the solution to this requirement through class-leading air and vapour permeability. This reduces the risk of condensation in line with BS 5250, without the need for additional ventilation, subject to a well-sealed ceiling, which is acceptable to the NHBC.

Viking Air’s resistance to wind uplift ensures suitability for use in wind zones 1-4 at 345mm batten gauge to BS 5534, with no need to tape laps or use additional counter battens. When the membrane is installed at 310mm batten gauge or on sarking, it also meets wind zone 1-5 requirements, ensuring unrestricted use across the UK and Ireland.

Tough and durable yet easy to handle, even in low temperatures, Viking Air offers a unique grid design to make precise cutting simple.

The underlay can be laid straight over the ridge without cutting material short, ensuring the roof is instantly watertight during the construction stage, and, because the membrane is hydrophobically treated, it provides extra water shedding properties and a high resistance to water penetration. The product is independently certified by BM TRADA.

“We believe we’ve created a new era of air permeability performance and a gamechanger with Protect Viking Air,” says John Mellor, Senior Product Manager, “it adds a next-generation, technically advanced option to our existing portfolio, which we have built up over many years. We’re confident that whatever the specification, we have the complete solution or combination of products that give our customers the right mix of performance and value, every time. Whatever the project, wherever the location Glidevale Protect has it covered.”

Viking Air forms an integral part of Glidevale Protect’s roofing membrane family.

This includes LR vapour permeable and airtight options, alongside impermeable HR underlays which can be twinned with Glidevale Protect ventilation products and accessories, giving specifiers and contractors a single source solution, whatever their pitched roof challenges.

To discover more about Protect Viking Air, visit protectmembranes.com/vikingair, contact info@glidevaleprotect.com or 0161 905 5700 quoting ‘Viking Air’. Follow our Glidevale Protect LinkedIn page for all the latest news.

Glidevale Protect

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

Protect Viking Air, our new air and vapour permeable roofing underlay, has arrived. And with it, your opportunity to specify an independently certified product with a higher airflow rate than any competitor, without the need for additional roofspace ventilation when a well-sealed ceiling is installed. What’s more, with wind uplift resistance up to Zone 4* at 345mm batten gauge to BS 5534, Viking Air outperforms the rest, ensuring wide coverage across the UK and throughout Ireland.

We believe it’s a breakthrough in air and vapour permeable technology in its own right. And as part of the wider Glidevale Protect family of class leading roofing products, it adds even more to a total solution of underlay options that offers all the choice you need.

Domestic or commercial. Warm roof or cold. New build or refurbishment. Whatever your pitched roofing project, Glidevale Protect gives you complete control.

Visit: protectmembranes.com/vikingair to find out more. Or contact info@glidevaleprotect.com / 0161 905 5700 quoting ‘Viking Air’.

GLIDEVALE PROTECT, 2 Brooklands Road, Sale, Cheshire M33 3SS. Tel: 0161 905 5700 Fax: 0161 905 2085 Email: info@glidevaleprotect.com Web: protectmembranes.com *Meets Zones 1-4 without need for additional counter batten or integral tape. Achieves unrestricted use for wind uplift - Zones 1-5 at 310mm batten gauge or when installed on sarking board.

The world’s thinnest inverted roof insulation just got thinner

Shopping centres are at the heart of most major cities across the UK. As popular, high-traffic destinations, these buildings require regular upkeep in order to maintain a high-end finish. One such example is Resorts World in Birmingham, a modern shopping, dining and entertainment destination that attracts visitors from across the Midlands and beyond.

When tasked with renovating Resorts World, architects and interiors practice Alexander Owen Architecture (AO) and painting contractor, Bagnalls, turned to PPG Architectural Coatings and its paint brand Johnstone’s Trade for its wide range of colour.

After analysing the space, they decided on a large-scale art installation to transform the look of Resorts World. For the final finish, AO wanted to incorporate a subtle sheen to the surface to give the colour transitions fluidity, and with such high footfall at the centre, the chosen product would need to be hard wearing. Collaborating with Bagnalls, Johnstone’s Trade Eggshell from PPG was specified for this unique project.

Discussing their approach, James Webster, co-founder of AO Architecture, said: “This was a brief with a lot of scope and an opportunity to make a real impact for Resorts World and their guests.

“With the atrium located at the heart of the building and being so architecturally dynamic,

it was the obvious place to start considering potential interventions. After analysing the architecture in three dimensions as well as how people flowed up, down and across the space, we developed an architecturallyresponsive visual art piece that celebrates the structure, form and organisation of the building, as well as the flow of people within it. In this sense it’s not simply art applied to the surface of the architecture, it’s art entirely driven by the architecture itself.”

The final design includes a series of dynamic forms in varying colours that draw visitors up and around the three-storey atrium, fluidly changing shape where escalators and structure intersect.

With such a large-scale design, it was important for painting contractor Bagnalls that the specified product would not only be easy to apply, to keep in line with timescales, but also be a financially viable option. Johnstone’s Trade Eggshell offered both these qualities. Its hardwearing formulation for interior wood and metal surfaces provides a smooth and even surface that is washable

for a long-lasting finish, reducing maintenance requirements. Moreover, with a coverage of 20 sq m, the product goes a very long way – a key objective of this project.

The design itself involved a range of over 20 vibrant colours, including neon highlights, which were digitally created by the architecture team. >>

This was a brief with a lot of scope and an opportunity to make a real impact for Resorts World and their guests.

>> As Johnstone’s Trade Eggshell can be tinted to the wide selection of colours from the PPG Voice of Colour range, it was more than able to accommodate their vision. Working with the architects, PPG’s colour consultant team colour matched to the closest corresponding shades from the palette. These included pinks and purples, such as Kenny’s Kiss, Cleopatra’s Gown and Mystic Iris, as well as Electric Mint.

With misunderstandings around inclusive design potentially leading to discrimination charges, costly legal disputes and damaged brand reputations, ASSA ABLOY Opening Solutions UK & Ireland has published a free new white paper advising architects and specifiers on the standards door opening solutions need to meet.

Titled Inclusive design – why should you care?, the new white paper provides best practice advice on how to ensure door opening solutions can meet the requirements for inclusive building designs, and the risks of not complying with these.

Inclusive design is a key consideration for most architects and specifiers today, ensuring any barriers that might prevent an individual from using an environment freely and easily are removed. This approach must be reviewed in line with the guidelines governing inclusive design, which includes Approved Document M, the Equality Act 2010 and, crucially, BS 8300-1 and 8300-2:2018, which sets out how buildings should be designed, constructed and maintained to create an accessible and inclusive environment for all. It applies to both new builds and refurbishments.

“Inclusive design is viewed by most architects and specifiers nowadays as a nonnegotiable,” explains Eryl Jones, Manging

Director of the ASSA ABLOY Door Hardware Group.

“While it is the owner that ultimately bears responsibility for the design of a building, should a legal dispute arise then an architect or specifier would be called upon to explain why a solution was recommended. In the event of a discrimination claim, those that can demonstrate that they have adhered to standards such as BS 8300-1 and 83002:2018 will be on safer ground than those that cannot.

“Our new white paper aims to offer architects and specifiers a helpful and informative overview of why inclusive design is so important, what the guidelines governing this state, and the considerations that they need to think about when specifying a door opening solution. This means they can be confident when recommending door opening solutions for projects, ensuring everyone

SAS International was recently chosen to provide a modern, open cell ceiling for the canteen area at Wix.com’s European headquarters in Dublin.

The renovation of the building supports the significant expansion of the Isreali software company in Ireland. With a staff of 140, the canteen space was designed to be a fun social hub, with ample space for individuals to relax during breaks.

SAS800 was selected to meet the client’s requirements to bring texture and interest to the space. This manifested most vividly in the unusual bespoke pastel colour - RAL 3012. This was chosen to mirror the darker tone of the floor area. Together, both colour blocks define the dining space.

– from the elderly to those with a disability and children – can access and use a building and its facilities safely.

“Furthermore, with some architects and specifiers potentially facing clients that might want to do the bare legal minimum when it comes to inclusive design, the white paper also helps outline why the approach is not only the right thing to do from a social point of view, but the impact it can have commercially too.

“Market drivers such as an ageing population and consumer buying power mean brands that prioritise inclusive building design can enjoy greater consumer loyalty and spending opportunities, as well as increased differentiation, credibility and brand awareness. We hope that the findings included in the white paper can help support this case for architects and specifiers, when having these conversations with clients.”

This suspended metal ceiling also accommodates spot lighting and air conditioning grills.

Chris Carey, Designer at SAS who worked on the project said: “The client chose SAS due to their ability to deliver a bespoke product within a demanding fitout programme.

“The tight timescale was challenging, but we were delighted that all was achieved on schedule to the highest SAS standard."

SALTO Systems, a leading manufacturer of electronic access control solutions, has released the SALTO Neo Cylinder – a new electronic cylinder that offers more features and better functionality than any other cylinder on the market.

The compact SALTO Neo Cylinder is designed for doors where fitting an electronic escutcheon is not possible or required and can be installed on standard doors, server racks, gates, cabinets, electric switches, sliding doors and more. It’s available in an extensive range of models to suit almost any kind of door – from Europe to ASIA to the Americas.

The SALTO Neo Cylinder provides an effective and convenient way of securing a building or assets. The clutch system is energy efficient, dropping power consumption to impressively low levels resulting in 100,000 / 130,000 operations from just one set of batteries. Standby power consumption is also reduced, further extending battery life.

The IP66-rated SALTO Neo Cylinder is weather-resistant, making it especially

SALTO Systems, a leading manufacturer of electronic access control solutions, has become the first company to achieve the BSI Enhanced Level IoT Kitemark™ for access control systems.

The IoT is typically a network of smart devices and systems that can be connected, enabling data to be exchanged to provide services, efficiency and innovation. Its technology can positively enhance lives and businesses, but the complexity of IoT also means that those of criminal intent may attempt to access it to steal data, hack cameras, enter buildings or otherwise breach security.

The UK government’s Department for Digital, Culture, Media and Sport has assessed the growing threat of this and created a Code of Practice (CoP) for IoT security, in collaboration with the National Cyber Security Centre (NCSC) and other experts from academia and industry.

BSI (British Standards Institution) has been part of this collaborative work to give

clarity on best practice for IoT security, subsequently developing a scheme to assess connected/IoT devices. The scheme determines whether a product has the appropriate security controls for its intended use and is suitably supported throughout its intended life. This cyber/physical security scheme forms the security element of the BSI Kitemark for IoT/Connected products.

The Enhanced Level IoT Kitemark™ demonstrates that a connected product has a higher level of security controls in place than the market standard for its type and is generally suitable for higher value or risk applications. Assessment to this level involves BSI’s most in-depth and exacting testing and analysis.

To achieve certification, the SALTO XS4 One access control solution had to meet

suitable for outdoor use, even in the harshest of environments. Inside the tough Neo Cylinder exterior is the absolute latest in electronic lock technology. Certified to the highest security standards, and incorporating ever-higher quality and reliability, the SALTO Neo Cylinder offers value far beyond security, however. It also provides greater control over the door by offering users access to audit trails, reports, alerts and so much more.

Using smart keys and mobile technology the SALTO Neo Cylinder enables users to manage access rights – quickly and keyless – which is more secure than using mechanical keys. Additional flexibility, convenience and operational efficiency are provided by the Neo Cylinder’s wireless technology.

the requirements of a Quality Management System such as ISO 9001 to demonstrate functional, safety and interoperability performance.

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

INVISTA, makers of Antron® nylon 6,6 commercial carpet fibre, released today its sustainability and wellbeing report, “The Antron® Brand on Sustainability”.

The report, available in digital and video format, reinforces the brand’s sustainability vision and includes testimonials from interior designers, flooring professionals and end users detailing their experience with the Antron® brand and sustainability.

Antron® fibres offer permanent built-in performance so carpets can work harder,

clean up beautifully, and resist crushing, matting, staining and soil. This longevity drives real sustainability and supports longterm value. The total cost of ownership of carpets made with Antron can be 250% less over the life of the carpet. Carpets made with Antron® nylon can last up to 75% longer than a majority of competitive carpets. This product longevity supports long-term value and cost savings captured from not having to replace carpet prematurely.

“Over the years, most of us have experienced the trend toward short-lived disposable products, and this trend is counter to real sustainability,” said Anthony Green, Vice President of Global Commercial Solutions for INVISTA.

“We believe carpets should be durable, not disposable. Antron® fibres are designed consistent with the belief that the longer our product lasts, the more sustainable it is.”

Antron

ATAG Commercial has launched a new range of technologically advanced, high efficiency gas boilers, comprising the company’s first ever floor standing unit –the XL-f – as well as the wall-hung XL-w. Boasting the exceptional levels of quality and performance for which ATAG Commercial is renowned, the new boilers offer greater flexibility in terms of installation, as well as ease of maintenance. The new XL-f and XL-w ranges both offer outputs of 70 to 200kW from a single boiler and up to 1.6MW in cascade, all models benefit from an excellent footprint to power ratio.

Forbo’s integrated flooring scheme creates the ‘wow’ factor

Kingspan Kooltherm K103 Floorboard has been installed in the ground floor of an expansive new development, providing high quality office space at the heart of Cheltenham’s growing Business Quarter. In developing the design, the architects looked to raise the bar in terms of energy performance, setting rigorous thermal performance targets for the building envelope including a maximum ground floor U-value of 0.14 W/m2K. To deliver this, they specified over 1,000m2 of Kingspan Kooltherm K103. The rigid thermoset phenolic insulation board has a thermal conductivity of just 0.018 W/mK across all thicknesses, the lowest of any commonly used floor insulation.

Kingspan Kooltherm

With the help of Forbo Flooring Systems’ integrated portfolio of solutions, the Bioscience Filtration Division of Parker Hannifin in Birtley, County Durham, was transformed into a contemporary, uplifting and dynamic workplace environment.

Labelled ‘Project Rejuvenate’, the scheme designed by Blake Hopkinson Architecture was awarded top marks in the annual Fly Forbo 2019/20 competition.

On the ground floor in the reception area and general circulation spaces, the natural aesthetic with true to life embossing of Forbo’s Allura Flex Wood Luxury Vinyl Tiles (LVT) in Oyster Seagrass were installed to create a striking and sophisticated finish.

The tackified loose lay LVT was also installed alongside Tessera Layout and Outline carpet tile planks (100 x 25cm) in the meeting areas and open plan concourse.

Made from 97% natural raw materials, Marmoleum Concrete differentiates itself from Forbo’s classic Marmoleum flooring as the solid marble design and accent colours are specially designed to be combined with their ‘shimmer’ counterpart.

Forbo’s Surestep Original in Elephant ticked all of these boxes and was used throughout the facilities, as well as in the wet rooms, offering a fresh alternative to conventional safety flooring. What’s more, in both the main and staff entrances, Coral Brush entrance flooring in Hurricane Grey was installed for its exceptional ability to absorb moisture and remove dry soiling. Forbo Flooring Systems

Kingspan finds its place on grade-a office development

American owned DocuSign is a leading global technology company with a new cutting edge tech hub and EMEA HQ at the heart of Dublin’s ‘Silicon Docks’.

To help meet the client’s architectural ambitions and the acoustic challenges posed by the mix of interior spaces, Rockfon acoustic ceiling systems are fitted throughout.

Rockfon Mono Acoustic is a unique product which combines the elegance of a seamless ceiling with high performance characteristics, previously thought only possible with modular suspended ceilings. The ceiling tiles are installed and completed with acoustic render creating an elegant, smooth-white, monolithic surface which provides high light reflection and light diffusion, reducing the need for artificial

light. Whether flat or curved, direct or suspended installation, the innovative system allows for easy integration of all services and offers Class A sound absorption to significantly decrease echo and reverberation.

Danny Reilly of certified Rockfon Mono Acoustic installer Reilly Ceilings: “Sound reverberation levels in the glazed meeting rooms had the potential to be very high. Therefore, DocuSign needed the best performing sound absorption product available. Rockfon Mono’s smooth appearance meant it didn’t interfere with the room aesthetics and the client is delighted with the end result.”

Attenuated 1200x300mm Rockfon Tropic® acoustic ceiling tiles, installed by The Castle Group, are used to great effect throughout thoroughfares and communal spaces.

Both Tropic and Mono installations went to plan, using the versatile Chicago Metallic grid.

Rockfon Tropic features Class A sound absorption, high light reflectance, excellent fire performance and superior resistance to bacteria, with no visible deflection in high humidity.

Rockfon

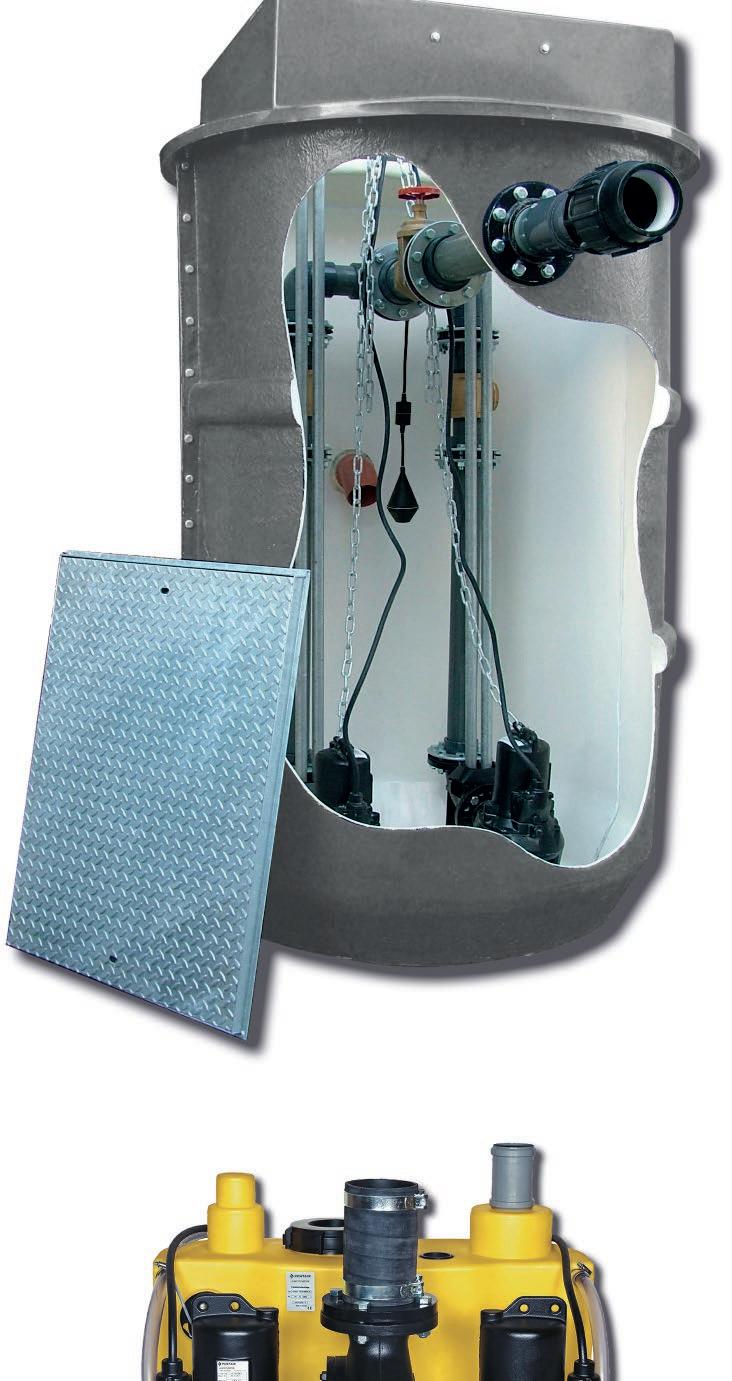

Wilo-Padus UNI,

Submersable Drainage Pump.

The flexible drainage pump for a diverse range of fluids. The Wilo-Padus UNI is the ideal entry-level model for wastewater transport in small commercial buildings. The pump can be used flexibly as a portable device or in a pump chamber. Hydraulics made from corrosion-free composite material provide high levels of reliability for universal use in the pumping of a diverse range of fluids. By utilising Wilo-Control switchgears, the Wilo-Padus UNI can also be integrated into existing building management systems.

Features & Benefits:

Exceptional reliability owing to corrosion-free hydraulics for universal applications and various fluids

Easy installation thanks to its low weight, integrated capacitor at the AC motor and threaded flange

Optimum efficiency and high operational reliability owing to improved hydraulics

Quick maintenance facilitated by direct access to the sealing chamber and pump housing

Long maintenance intervals thanks to double mechanical seal and large volume sealing chamber

Clog-proof thanks to the integrated strainer

For more information please contact our sales team.

New Farnley Cricket Club in Leeds, when given the greenlight to open their bar and restaurant, wanted to ensure that their returning clientele would feel comfortable by providing facilities in line with the government guidance on Covid 19 safety.

Along with clear signage and establishing a one-way system through the club house, New Farnley CC commissioned protective screening from wall & door protection specialists Yeoman Shield.

To help protect staff and customers alike from viral loads that can be expelled by coughing, sneezing or shouting, Yeoman Shield installed a bespoke 800mm high screen using 4mm thick clear uPVC affixed around the bar with attractive chrome brackets and fixings.

Yeoman Shield portable protective screens were also supplied to help with the configuration and separation of dining tables and the social distancing of patrons whilst waiting in the expected queuing systems.

Being lightweight the screens can be moved around easily to accommodate requirements whilst being sturdy enough not to be knocked or tipped over.

The portable screens are available in a range of options such as clear or frosted uPVC or with the alternative of a clear top half giving a sense of space coupled with a through coloured, frosted or design printed bottom half.

The club’s Chairman, Mr John Baldwin, commented “It’s been great that Yeoman Shield were able to provide us with the right solution to our social distancing requirements to enable the club to re-open, which like other sports clubs, provide amenities to the local community.”

Yeoman Shield have also been providing similar solutions for Hospitals, Schools and Offices allowing visitors, students and

employees to return to safe environments. As the Covid-19 virus is not going anywhere soon Yeoman Shield have taken care in designing the screens to not only be attractive but long lasting.

Available in standard sizes or bespoke designs and sizes to suit any particular building requirement. For bespoke Hospital,

Office and School reception desk/worktops and mounted screens, a survey and installation service is available.

For more information go to www.yeomanshield.com or call 0113 279 5854

Yeoman Shield

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

As the need for the general population to become fitter increases local government and charitable organisations in England now provide a range of leisure services, including swimming, gym and other sports facilities. The provision of these facilities promotes social inclusion, community well-being and public health. It’s a real nod to future-proofing the health of the nation.

In East Lancashire, the local community benefit from a range of leisure and fitness activities supplied by the Pendle Leisure Trust who are the major provider of sport, arts, entertainment and health and community programmes throughout the Pendle area. The Trust is responsible for operating three leisure centres, a spa, golf course, athletics and fitness centre, a theatre and an arts, culture and enterprise centre.

When the main sports hall floor at the Pendle Leisure complex in Colne near Manchester needed replacing, they turned to international flooring specialist Gerflor to supply 540m2 of their world beating Taraflex® Evolution vinyl sports flooring in ‘Blue’ to deliver the looks, safety and performance they would ultimately demand. Gerflor is well-known as an official supplier for Olympic Games but also synonymous with sport and wellness since 1947.

The overall management of the new flooring installation would be the responsibility of property services company Liberata who have a satellite office in Nelson, Lancashire. Liberata offers a full range of awardwinning property services to both the public and private sector. With over 35 years of experience, they provide cost effective solutions strengthened with design excellence to ensure property assets are of the highest standard, together with delivering the best possible return for the client.

Bruce Corden, Facility Manager, Liberata Property Services commented, “Pendle Leisure Trust secured grant funding from Sport England with match funding from Borough of Pendle to refurbish the ‘dryside’ facilities at the centre.” On the main challenges surrounding the project Bruce

Corden added, “there was a real need to complete the works around the current use of the facility, and with minimum downtime.”

Taraflex® is available in 17 colours and three wood-effect designs. The improved Evolution product is now even safer, better performing and offers even more protection than before.

The greater protection has been obtained thanks to a total re-engineering of the CXP-HD™ foam technology that provides cushioning for exercise and sports play. Gerflor’s Taraflex® Evolution continues to be the market benchmark in sports floors with outstanding durability, improved comfort and protection offering a P1 category shock absorbency (25% to 35%) and a new 7.5mm thickness.

The product is treated with Protecsol®, which renders polish redundant and is triple action meaning no polish is ever required, it contributes to easy maintenance and is anti-friction burn and slide/grip. Taraflex® Evolution from Gerflor is also ideal for renovation works and is available with the DryTex™ System perfect for new construction or refurbishment projects with damp subfloors.

The responsibility for the installation would fall to Chorley-based CRT Flooring Specialists Ltd in Lancashire. They are a a professional Commercial Contract Flooring

and Hygienic Wall Cladding Specialist based in the North West, who pride themselves on their high quality workmanship and excellent personal service.

Ultimately Gerflor’s Taraflex® Evolution was a natural choice for the Pendle Leisure Centre as it is ideal for multi activity and multi-sports halls, providing both safety and comfort.

When it comes to creating a future-proof leisure centre, it seems by specifying Gerflor products you can be rest assured that you will have a world class solution to suit most budgets.

Gerflor

The Taraflex® Evolution sports vinyl product from Gerflor, has been installed and it looks stunning. It’s a highperformance product that’s got a world class pedigree.

new business development opportunities from specifiers, project teams, clients and key decision-makers in the education sector

best practice, and demonstrate your expertise that will help, and provide inspiration to education professionals for their upcoming/ current projects

Exhibit at Education Estates® and you will receive exposure at Education Estates® Digital Week this October, and either a shell or space only stand at Education Estates® 2021, maximising on branding exposure, lead generation and thought leadership.

To book a stand, please contact Rebecca today on 01892 779995 or rebeccastratten@stepconnect2.com

Stewart Dalgarno, Director of Product Development at Stewart Milne Timber Systems, discusses the wide benefits of adopting build systems for timber frame offsite construction in meeting housing targets sustainably.

“Using a fabric-first approach constructed within factory conditions helps to ensure the durability of systems, and from design to delivery, offsite construction represents an end-to-end solution as we look to adopt and champion construction practices which will speed up delivery, plug the skills gap, and, crucially, help to drive a low carbon sustainable economy,” he explained.

“Precision engineering in a specifically designed, automated factory environment where manufacturing conditions are optimum reduces margin for error and enables products of a consistently high standard.

“Offsite construction can have a transformational impact. With the UK currently experiencing a housing shortage and government statistics stating a further 120,000 homes are needed annually, offsite timber building solutions are essential in addressing the shortfall.

“There’s also growing recognition at government level of offsite construction’s wide application. At the same time, it is absolutely crucial that low carbon sustainability remains front-of-mind for developers. This is where the build fabric itself becomes just as important as the construction method.

“Timber is readily available, economically viable, and versatile. It’s also a natural carbon sink, delivering energy reductions of up to 33 per cent.

Offsite timber frame construction provides a superior thermal envelope, requiring minimal

maintenance and a fit-and-forget solution for the lifetime of the building - and with timber construction retaining and reducing heat demand, the resulting building becomes extremely fuel efficient.

“We were pleased to work with Taylor Wimpey on delivering a project which aided the regeneration of Barry Dockland in Wales. Taylor Wimpey sought an affordable offsite solution to provide the required number of units within budget and programme, utilising as much offsite production as possible. The decision was taken to therefore employ a pre-insulated timber frame external wall system using 100mm PIR insulation.

“The wall system was fitted in a controlled factory environment enabling a high level of quality and for the units to be insulated before the houses were watertight, resulting in the houses being completed more quickly.”

Offsite construction: an intelligent approach to building and tackling modern housing challenges

Two stunning sweeping Helical Kallisto staircase flights form the centre piece of the prestige residential development of an iconic former film studio.

The two four-metre diameter flights, weighing in at over eleven tonnes each, were designed by John Pardey Architects and manufactured by hand by Milbank in Essex for the refurbishment of Denham Film Studios in Buckinghamshire.

In its 1940s and 50s heyday, Denham Studios was a thriving film production studio producing classic British films such as Brief Encounter and Great Expectations. The site has now been lovingly developed to provide 224 conversion and new build homes, including 154 one, two and threebedroom apartments and 70 four and five-bedroom family townhouses.

The spectacular Kallisto stair cases, which spiral up through the central lobby with stunning marble clad steps, maintain the bold art deco theme with the clean lines and luxe finish redolent of the original building’s design. The architects had a clear design vision for the project, an effective balance of modern