We are a company that started almost two decades ago with a vision to provide practical and long lasting solutions to the burgeoning paper industry in India by creating a fusion of chemistry applications and local industry environment and requirements.

INDUSTRIES WE SERVE

Developing

Packaging & Board

Printing & Writing

Recycled Fiber Enzymes Tissue Textile Water & Waste Water

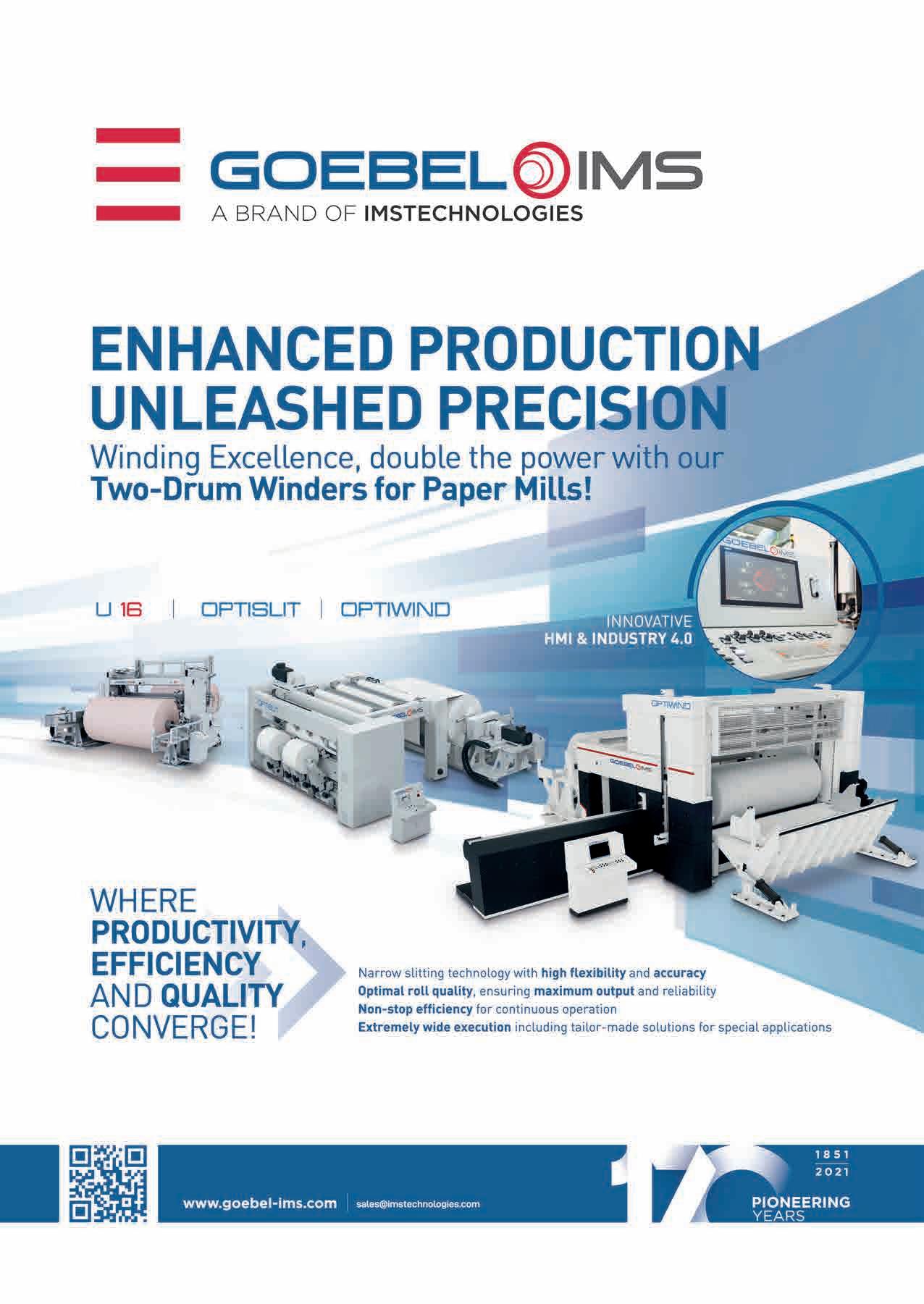

OUR PRODUCT RANGE

Odor control HIGH

Internal Sizing & Surface Sizing

Retention and Drainage

Dry Strength Resin

Paper Machine Deformer and DE-AERATION

Surface Additives

Felt Cleaning and Conditioning Program

Microbiological & Deposit Control Program

Wet Strength Resin

Stickies Control program

Deinking chemicals

Enzymes

Starch(Native, Modified cationic/oxidized)

Coating thickener

Coating lubricant

Dispersants

Antisclants

Flocculants

Coagulants

Pulp mill Cooking-aid

Pulp mill Wash-aid

Haber’s Sensor Solutions: Revolutionizing the Pulp & Paper Industry

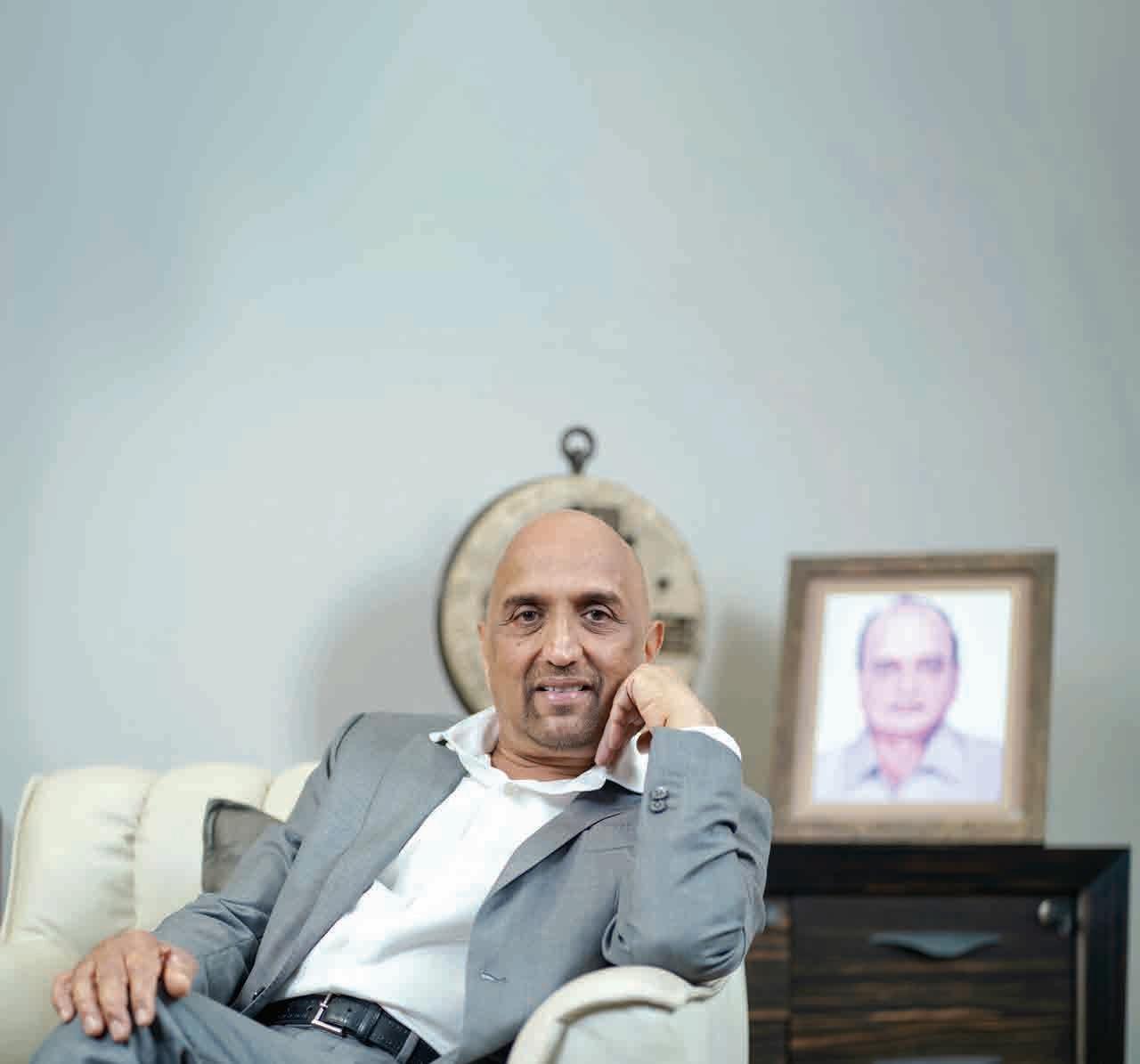

As the pulp and paper industry continues to seek ways to enhance operational efficiency and sustainability, advancements in technology are playing a crucial role. In an interview with Paper Mart, Dr. Claudy D’Costa, Head of the Sensor R&D Division at Haber, who previously presented on the impact of artificial intelligence on filtrate turbidity testing (FTT) at IPPTA, discusses how Haber is integrating sensor technology and machine learning to monitor fiber morphology, offering potential benefits to Indian pulp & paper industry.

Dr. Claudy D’Costa, Head of the Sensor R&D Division, Haber

Paper Mart: Could you start by explaining your role at Haber and what the company is focusing on in the pulp and paper industry?

Claudy D’ Costa: As the Head of the Sensor R&D Division, my role involves developing and implementing advanced sensor technologies tailored to the pulp and paper industry. As a team, we are focused on developing sensor solutions that go beyond mere monitoring; they must provide actionable insights. By combining deep industry knowledge with cutting-edge sensor technology, we’re building tools that will revolutionize how paper mills operate. We’re not just developing sensors; we’re solving problems. Imagine having real-time data on fiber characteristics, that directly correlate to paper strength or smoothness. That’s the kind of impact we’re aiming for. It’s about empowering paper mills to make data-driven decisions, reduce waste, and produce higher-quality products.

PM: What motivated Haber to concentrate on sensor technology and machine learning for the pulp and paper sector right now?

CC: Our focus on sensor technology and machine learning really comes

from wanting to tackle some of the big challenges in the pulp and paper industry. Traditional methods often have trouble with things like raw material variability and process inconsistencies. By using advanced sensors and machine learning, we can provide real-time, precise data that helps mills make smarter decisions and fine-tune their operations. It’s not just about having better technology; it’s about offering solutions that address these core issues and drive real improvements. We’re committed to innovation and want to ensure that our solutions make a tangible difference in how the industry operates.

PM: Can you go into more detail about how Haber is developing these sensor technologies?

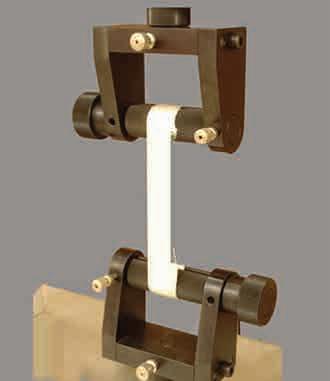

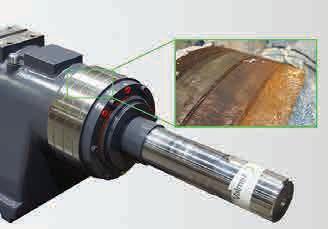

CC: At Haber, we’re taking a handson approach, revolutionizing the way fiber morphology is looked at, by blending advanced optical sensors with machine learning. Here’s how it works: We place these high-precision sensors throughout the production line to keep a close watch on key fiber properties like length, diameter, and fibrillation. The sensors capture detailed, high-resolution images and data, which we then analyze in real-

time using machine learning. This lets us spot trends and predict the best process settings on the go, so we can adjust things like refining intensity and chemical dosages as needed. It’s all about tackling those long-standing industry issues and boosting both the quality of the product and the efficiency of the process.

PM: That’s impressive. How does Haber use machine learning and computer vision?

CC: Machine learning and computer vision are game-changers. We start by using high-precision optical sensors to collect detailed data on fiber characteristics throughout the production process. It allows us to monitor fiber properties with incredible accuracy. We can even spot tiny changes in fiber

NEWS

characteristics. The data from these sensors is fed into machine learning models that analyze it in real-time, helping us identify patterns and make predictions. This lets us adjust process parameters on the fly, ensuring that we maintain consistent fiber quality and enhance paper properties. Overall, it means a more efficient production process, less waste, and a more sustainable approach to manufacturing.

PM: It’s clear that technology is making a significant impact. How does computer vision contribute to improving the overall process?

CC: Computer vision really is transformative for our operations. It’s a technology many people encounter in their daily lives, like

the facial recognition you use on your smartphones and the DigiYatra system at airports, or your Aadhaarbased identification systems. In the pulp and paper industry, it lets us monitor fiber characteristics with outstanding precision. This leads to more consistent paper quality and fewer defects. By providing detailed and accurate data, computer vision helps us make better use of resources, cut down on waste, and lower operational costs. This not only boosts economic efficiency but also supports our environmental goals. For paper mills, this translates to significant cost savings and a more sustainable production process, allowing them to operate more economically while meeting their sustainability objectives.

Oji Holdings Subsidiary Buys Forest Plantation in Uruguay

Rohatyn Group has sold over 40,000 hectares of forest plantation in the Tacuarembó and Rivera departments in the northern part of Uruguay to Oji Uruguay Forest Company. The acquisition has reinforced Uruguay’s status as a prime forestry investment destination.

Jul 25, 2024

The Rohatyn Group, a global asset manager specializing in emerging markets and real assets, has announced the sale of over 40,000 hectares of forest plantation in the Tacuarembó and Rivera departments in the northern part of Uruguay to Oji Uruguay Forest Company (OUFC) S.A.S., a subsidiary of Japanese pulp and paper products manufacturer Oji Holdings Corporation - one of the largest forest, paper, and packaging companies in the world.

As per a release issued by the Rohatyn Group, the forestry assets, consisting of pine and eucalyptus plantation forests, were acquired by the TRG Forestry & Agriculture team in 2013. In December 2023, TRG entered into an asset transfer agreement with OUFC and subsequently closed the transaction on July 9, 2024.

During TRG’s ownership of the asset, the plantations were managed for solid wood production, developing commercial thinning operations with logs mainly destined for the export markets of China and India. The TRG F&A team was among the first to export logs from Uruguay via break bulk shipping. After closing, TRG will continue providing transitional management services to OUFC. TRG’s continued involvement in the management of the property aims to maximize value,

develop domestic processing in Uruguay, and help meet Oji’s environmental targets.

TRG Partner Ian Jolly commented, “TRG remains an enthusiastic investor in Uruguay plantations. This sale comes at the end of a planned investment period, during which we have been proud of the contributions we have made to helping the softwood industry develop, including the introduction of state-of-the-art softwood timber processing. TRG is honored to be assisting Oji with its move into Uruguay. The acquisition by such a well-respected global forestry company highlights the value of this resource and reinforces Uruguay’s status as a prime forestry investment destination. TRG looks forward to continuing its work in this country’s forestry sector.”

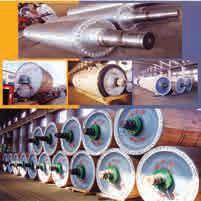

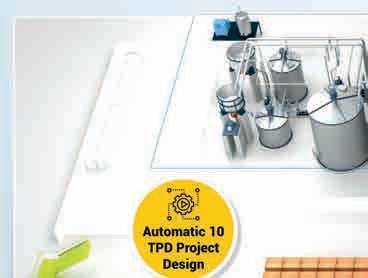

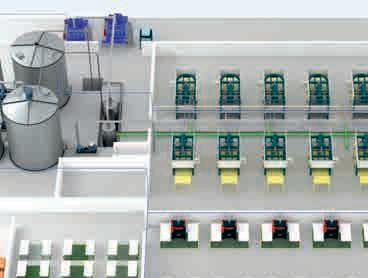

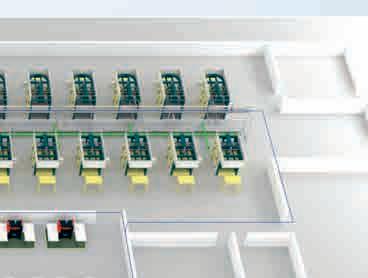

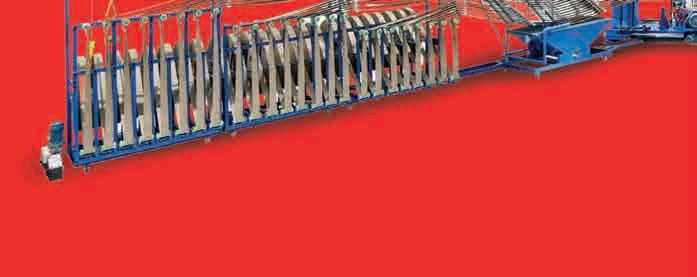

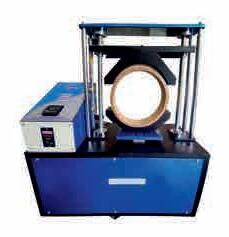

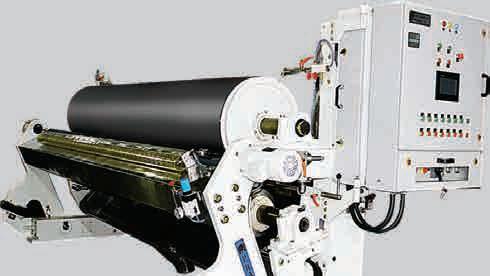

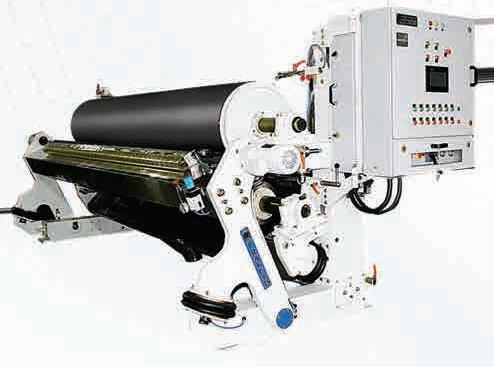

The competition in global pulp and paper markets is intensifying. There is a growing need for modernization and introduction of energy efficient and clean technologies for enhancing competitiveness.

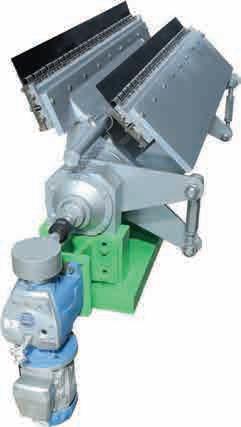

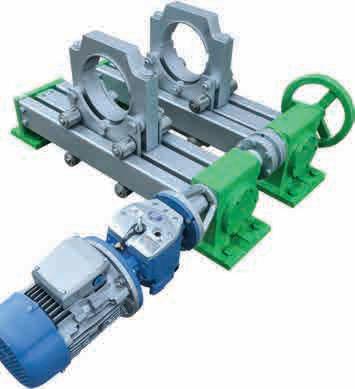

F-23, Industrial Area Delhi Road Saharanpur-247001, Uttar Pradesh, India Ph. 0132-2765146, Mobile: +91 9837009138, 9837028256 | Email: info@rcpapermachines.com Website: www.rcpapermachines.com PRODUCT OFFERINGS: Manufacturer & Exporter of Pulp & Paper Mill Machinery