Section 6

STEERING SYSTEM

6-1. GENERAL.

E20-258, E30BS

removal, disassembly, cleaning, inspection, reassembly and installation procedures. System checks and adjustments are given at the end of this section.

6-2. This section contains the overhaul instructions for the major components of the manual and power steering systems. Overhaul instructions include (where appropriate)

Manual Steering System

© Copyright Hyster Company 1976

Manual Steering System

SYSTEM DESCRIPTION

6-3. The steering system consists of a steering wheel assembly, steering column assembly, steering gear and pitman arm assembly, drag link, steering axle assembly, spindles and wheel hubs. The two-section steering column connects through a universal joint and flexible coupling to the steering gear

and pitman arm assembly. The steering gear assembly is a conventional worm and sector gear unit. The pitman arm connects the output shaft of the gear assembly through a drag link to the steering axle center arm. Tie rods connect the center arm to each wheel spindle assembly.

STEERING WHEEL ASSEMBLY

6-6. REMOVAL AND DISASSEMBLY. (See Figure 62.)

a. Disconnect the battery connector.

b. Carefully pry off the horn button cover.

c. Remove the three screws securing the base plate, then remove the base plate.

d. Slip the rod, with the holder attached, up out of the shaft. The holder is threaded on the rod and “locked” with adhesive.

e. Back off the 5/8-inch UNC steering wheel nut to the end of the shaft.

f. Remove the steering wheel using a steering wheel puller.

6-7. INSPECTION. (Refer to Table 6-1.)

COMPONENTS

6-4. DESCRIPTION. (See Figure 6-2.)

6-5. The steering wheel assembly consists of the steering wheel, horn button cover, base plate and a rod with attached holder to operate a column cover mounted horn switch. When the horn button cover is depressed, it operates the rod to trip the horn switch. The steering wheel is splined to the steering column and secured by a lockwasher and nut.

6-8. REASSEMBLY AND INSTALLATION. (See Figure 6-2.)

a. With the steering wheels straight ahead, install the steering wheel with one spoke pointing to the 12 o’clock position. Install the washer and nut on the shaft.

b. Install the rod, with the holder attached, into the shaft.

c. Install the base plate and secure with the three screws.

d. Install the horn button cover by forcing the cover “ring” into position in the holder.

FIGURE 6-2. STEERING WHEELSTEERING COLUMN ASSEMBLY

6-9. DESCRIPTION. (See Figure 6-3.)

6-10. The horn switch is located near the base of the upper shaft and is operated by mechanical linkage. A cast upper column housing with an integral instrument panel supports the steering wheel and mounts to the truck cowl. The upper column shaft is supported by two ball bearings. A plate directly below the instrument panel provides access to the instruments and electrical connections. A lower column cover encloses the lower shaft and the flexible coupling. The flexible coupling connects the lower shaft and steering gear drive shaft.

6-11. REMOVAL. (See Figure 6-3.)

a. Remove the access plate below the instrument panel and the lower column cover.

b. Tag and disconnect all wires to the column electrical components.

c. Remove the pinch bolt securing the flexible coupling to the steering gear drive shaft.

d. Support the column assembly and remove the four nuts and washers securing the column casting to the truck cowl.

e. Lift the assembly while working the flex coupling off the steering gear shaft. Remove the assembly from the truck. 6-12. DISASSEMBLY. (See Figure 6-3.)

a. Remove the steering wheel as specified in paragraph 6-6. Tilt the assembly up (steering wheel end down) to remove the small spring from the center of the upper shaft.

b. Remove the three screws securing the upper column cover. Remove the cover with the KEY and horn switches attached. Carefully feed the wires past the lower bearing housing.

c. If the universal joint and lower shaft or the upper shaft are to be replaced, loosen the universal joint pinch bolt and nut. Remove the universal joint and lower shaft from the upper shaft splines.

d. If the lower shaft or flexible coupling are to be replaced, remove the pinch bolt and remove the coupling from the lower shaft.

e. Use suitable snap-ring pliers to remove the two snap rings on the steering wheel side of the upper bearing.

f. Press the pin out of the switch flange to allow the flange free movement on the shaft.

g. Remove the two capscrews, nuts and washers securing the lower bearing housing to the column casting.

h. Carefully slide the upper shaft down (as mounted on truck) out of the upper bearing. Then, remove the remaining upper bearing snap ring, switch flange and spring from the shaft.

i. If necessary, remove the spring retainer pin, lower bearing retainer, lower bearing and lower bearing housing from the shaft.

6-13. INSPECTION. (Refer to Table 6-1.)

6-14. REASSEMBLY. (See Figure 6-3.)

a. If removed, install the lower bearing in the bearing housing and install the housing with bearing retainer on the column. Install the spring retainer pin (1/4-inch pin) and large spring on the upper shaft.

b. Insert the steering wheel end of the upper shaft in the lower hole (as mounted on the truck) of the column casting. Install the switch flange (flange portion toward lower bearing) and the upper bearing bottom snap ring on the upper shaft.

Manual Steering System

FIGURE 6-3. STEERING COLUMN COMPONENTSc. Align the lower bearing housing and lower bearing retainer mounting holes and install the two mounting capscrews, washers and nuts finger tight.

d. Install the upper bearing over the shaft and secure it to the shaft and column casting with the two (internal and external) snap rings.

e. Tighten the lower bearing mounting capscrews and nuts.

f. Align the holes of the switch flange with the slot in the shaft and install the switch flange pin.

g. Insert the KEY and horn switch wires in the upper column cover opening and between the lower bearing housing and the column casting inner surface. Remove all slack and install the upper column cover.

6-15. INSTALLATION. (See Figure 6-3.)

a. If the flexible coupling was removed

from the lower shaft, install it on the lower shaft. Install, but do not tighten, the socket head pinch bolt.

b. If the universal joint and lower shaft were removed from the upper shaft, install the universal joint on the upper shaft and tighten the pinch bolt.

c. Place the steering column assembly in position on the truck while sliding the flexible coupling down over the steering gear shaft splines.

d. Install the four lockwashers and nuts to secure the upper casting to the truck cowl.

e. Install the lower pinch bolt in the flexible coupling and tighten both pinch bolts securely.

f. Connect all wires as tagged. Install the lower column cover and the access panel below the instrument panel.

g. Install the small spring in the center of the upper shaft, then install the steering wheel as specified in paragraph 6-8.

STEERING GEAR ASSEMBLY

6-16. DESCRIPTION. (See Figure 6-4.)

6-17. The steering gear assembly consists of a worm shaft (20), ball nut (24), sector gear (8), and a pitman shaft (5). Two sets of worm balls (23) in the ball nut act as rolling threads between the ball nut and the worm shaft. Gear teeth on the ball nut mesh with the sector gear. The steering ratio between the worm shaft and the pitman shaft is approximately 28:1.

6-18. When the steering wheel is turned, the steering column assembly rotates the worm

shaft. This causes the ball nut to move up or down on the worm shaft. Movement of the ball nut causes the sector gear and pitman shaft to rotate forward or back, depending upon the direction of steering wheel rotation. A pitman arm is splined onto the pitman shaft to provide the steering gear assembly output. Clearance between the ball nut and sector gear is adjustable by a screw (12) located on the outside of the gear assembly.

6-19. REMOVAL. (See Figure 6-5.)

6-20. DISASSEMBLY. (See Figure 6-6.)

6-21. CLEANING.

6-22. Clean all parts of the steering gear assembly with cleaning solvent. Use compressed air to dry, then store in a clean area until reassembled.

6-23. INSPECTION. (Refer to Table 6-1.)

6-24. REASSEMBLY. (See Figures 6-4 and 6-6.)

a. Place the steering gear worm shaft (20, Figure 6-4) flat on a workbench and slip the ball nut (24) over the worm shaft. The ball guide holes in the nut (24) must be up and the shallow end of the sector gear teeth toward the pitman arm end of the shaft. Align the grooves in the worm and ball nut by sighting through the guide holes.

b. Drop the worm balls (23) into one of the guide holes while turning the worm gradually away from the hole. Continue turning until the ball circuit is full from the bottom of one guide hole to the bottom of the other guide hole (or until stopped by reaching the end of the worm).

NOTE If the balls are stopped by the end of the worm, hold down the balls already dropped into the ball nut with a blunt, clean rod and turn the worm in the reverse direction a few turns. The filling of the ball circuit can then be continued. It may be necessary to work the ball nut back and forth, holding the balls down first in one holethen the other.

Manual Steering System

FIGURE 6-6. DISASSEMBLY OF THE STEERING GEAR ASSEMBLY (SHEET 1 OF 2)

FIGURE 6-6. DISASSEMBLY OF THE STEERING GEAR ASSEMBLY (SHEET 1 OF 2)

UPPER BEARING

Thank you very much foryourreading.Please Click Here Then Get MoreInformation.

NOTE: If there is no response to click on the link above, please download the PDF document first and then clickonit.

Manual Steering System

c. Lay one-half of the ball guide (15) groove up on the bench and place the remaining balls in it. The number of remaining balls should just fill the guide. Close this half of the guide and plug each open end with lithium-base, Mobilux EP1 lubricant (or equivalent) to prevent the balls from dropping out.

d. Push the ball guide into the guide holes. If the guide does not push in all the way, tap lightly on the ball guide with the handle of a screwdriver.

e. Fill the second ball circuit as specified in steps b through d. Secure the ball guide to the ball nut with the clamp retainer screws (16). Be sure to use lockwashers under the screws.

f. Rotate the ball nut on the worm and check for smooth operation. If the ball nut sticks or binds in any area, remove the ball guides and check for damage at the ends of the guides.

g. Install the lower and upper worm thrust bearings (14 and 21) onto the worm shaft and insert the shaft and ball nut assembly into the steering gear case.

CAUTION Do not allow the ball nut (24) to rotate to the end of the worm shaft (20). Damage may result to the ball guides (15).

h. Apply non-hardening Permatex (or equivalent) to the threads of the adjuster lock-nut (17). Assemble the cup and adjuster plug (18) and the worm thrust bearing grease seal (19) onto the worm shaft (20), then place the partially assembled unit in a vise with the worm shaft horizontal.

i. Tighten the adjuster plug (18) until all end play is removed from the steering gear worm shaft (20). Tighten the adjuster locknut (17).

j. Coat the threads of the side cover capscrews (3) and the lash adjuster (12) with

non-hardening Permatex (or equivalent). I)o not apply the compound to the internal threads, and do not allow the compound to contact the side cover bushing (9).

k. Start the pitman shaft (5) into the side cover bushing (9), then use a screwdriver to turn the lash adjuster (12) counterclockwise to pull the pitman shaft into the side cover bushing as far as it will go.

l. Rotate the steering gear worm shaft (20) by hand until the ball nut is about centered on the shaft, then handpack the steering gear case with lithium-base, Mobilux EP1 lubricant (or equivalent).

m. Tape the serrations on the end of the pitman shaft (5) to prevent seal damage. Install a new gasket on the side cover and carefully lower the pitman shaft assembly part way into the case. Ensure that the case is completely filled with lubricant. Lower the pitman shaft assembly the rest of the way into the case.

n. Make sure some lash exists between the ball nut and the sector gear, then install the side cover capscrews and tighten to 30-foot-pounds (40 N.m).

o. Adjust the steering gear assembly as specified in paragraphs 6-150 and 6-152.

6-25. INSTALLATION. (See Figure 6-5.)

6-26. Installation is essentially the reverse of removal. Align the scribe marks made in step 1 during removal. Position the steering gear shafts and pitman arm as shown in Figure 6-5 step 4. When tightening the allen-head capscrew that blocks the steering gear in place (see step 2, Figure 6-5), tighten the capscrew only until it touches the gear. case. Excessive torque on this capscrew can damage the steering gear case. Adjust the pitman arm stops as specified in paragraph 6-153.

TIE RODS AND DRAG LINK

b. The rod ends have right or left-hand threads and may be removed from the rod by loosening the locknut and unscrewing the rod end.

6-30. Cleaning.

6-31. Wash the rods in cleaning solvent, then blow dry with compressed air. Lubricate the rod end wear surfaces with multipurpose grease.

6-32. Inspection. (Refer to Table 6-1.)

6-33. Installation. (See Figures 6-7 and 6-11.)

6-27. TIE RODS. (See Figure 6-7.)

6-28. The two tie rods are connected between the center arm of the steering axle and the wheel spindles. The drag link rotates the axle center arm, and the tie rods rotate the spindles. The tie rod ends are adjustable to vary the rod length for wheel alignment. The tie rod end lube plugs may be removed for periodic lubrication or may be replaced with grease fittings for heavier applications.

6-29. Removal.

a. Remove the cotter pin and the castle nut for the tie rod. A special puller can be used to remove the tapered stud from spindle arm. Another method to loosen the tapered stud is to hit the spindle arm with a large hammer. Hold another hammer behind the spindle arm and hit the spindle arm near the side of the tapered stud. DO NOT hit the threads or the nut of the tie rod.

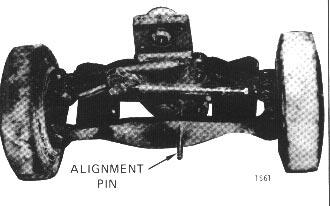

a. Position the rear wheels so that they are straight ahead (parallel with the truck center-line). Lock the axle center arm in position by inserting an alignment pin as shown in Figure 6-9.

b. Install the rod end with the left-hand threads on the center arm using the castellated nut and lock pin. This will place the lube plugs to the rear. Tighten the nut to 79 foot-pounds (107 N.m) torque dry before installing the pin.

c. Screw the tie rod onto the installed rod end, then screw the second rod end onto the opposite end of the tie rod.

Manual Steering System

NOTE Ensure that the two tie rod ends are evenly centered on the threads at eachend of the rod.

Adjust the tie rod length by turning the rod until the rod end can be installed into the wheel spindle without changing the position of the wheel. Secure the rod end in place with the castellated nut. Tighten the nut to 79 foofpounds (107 N.m) torque dry, then install the lock pin.

WARNING Ensure the alignment pin is removed before attempting to operate the truck.

6-34. DRAG LINK. (See Figure 6-10.) 6-35. Removal.

a. Remove steering axle as specified in paragraph 643.

NOTE The counterweight may be removed for easier for easier access.

b. Remove the cotter pin, then the castellated nut and washer from the pitman arm end of the drag link. Remove the rod end from the pitman arm.

6-36. Cleaning.

6-37. Clean all parts of the drag link with cleaning solvent and dry with compressed air.

6-38. Inspection. (Refer to Table 6-1.)

e. Install the opposite tie rod as previously described. Make sure that both wheels are straight ahead, parallel with each other and square with the axle. Adjust the tie rods as necessary to properly position the wheels. Tighten the rod locknuts.

f. After installation, check the rod ends for looseness. There should be no end play or vertical play in the tie rod ends. Remove the alignment pin from the axle and center arm.

6-39. Installation.

6-40. Install the drag link with the offset end toward the steering axle (see Figure 6-10). Position the steering axle under the rear of the truck and install the axle end of the drag link, then install the pitman arm end. Install the washers and 3/4-inch nuts. Tighten the nuts to the first alignment between 40 and 50 foot-pounds (55 and 68 N.m) torque. Install the steering axle as specified in paragraph 6-47. If removed, install the counterweight.

STEERING AXLE ASSEMBLY

6-41. DESCRIPTION. (See Figure 6-11.)

6-42. The steering axle supports the steering center arm and the two wheel spindles. It also provides a support for the rear of the truck. Rubber cushion mounts are installed on the

axle support plate to provide isolation and axle articulation. The axle is held in place by two large capscrews that extend through two retaining plates and the rubber mounts into the truck frame, The retaining plates are attached to the truck frame below the axle

FIGURE 6-10. DRAG LINK COMPONENTSsupport plate. These retainer plates prevent overstressing of the rubber mounts. The axle center arm and wheel spindles rotate on tapered roller bearings.

6-43. REMOVAL. (See Figure 6-12.)

NOTE Always remove the battery before elevating the rear of the truck. This will lighten the load on the stands and prevent possible battery damage.

a. Remove the rear counterweight.

b. Remove the nut securing the drag link end to the center arm. Do not attempt to remove the drag link at this time.

c. Block the rear of the truck off the ground, then support the steering axle using a suitable jack.

NOTE For easier removal of the large capscrews, the four retainer plate capscrews should be removed first.

d. Mark the two retaining plates with respect to the frame so that the plates are reinstalled in the same position. Remove the

four capscrews that secure the plates to the frame.

e. Alternately loosen the two long capscrews while lowering the axle assembly away from the frame. Make sure that the drag link does not bind in the center arm.

f. Remove the drag link end from the center arm.

6-44. CLEANING.

6-45. Clean the axle with cleaning solvent or steam clean. Pay particular attention to areas around machined surfaces. Apply a thin coat of lightweight oil to all machined surfaces.

6-46. INSPECTION. (Refer to Table 6-1.)

6-47. INSTALLATION. (See Figure 6-12.)

a. If the frame mounting pads were replaced, center the replacement pads 9.25 ± 0.003 (235 ± 0.8 mm) apart before tightening the pad mounting capscrews. Tighten the mounting capscrews to 70-80 foot-pounds (95-110 N.m) torque.

b. Insert the 4-1/2 inch (114 mm) long capscrew (with lockwasher) into the center hole of each retainer plate. Make sure that the match marks (made on the plates during removal) will align with the marks on the frame. This will make it easier to install the plates.

c. Support the axle on a suitable jack and position the axle close enough to the frame to start the two capscrews into the frame. Make sure that the drag link is loosely installed in the center arm.

d. Raise the axle toward the frame while alternately tightening the two long capscrews. Tighten the capscrews until the axle is in position on the frame with each retainer plate free to move for alignment.

e. Install the two placebolts that secure each retainer plate. Tighten these placebolts to 80 foot-pounds (110 N.m), then tighten the two large capscrews securely.