MAKER SPACE

CASE STUDY REVIEWS 22/23

/ Teaching and Learning

/ Research and Enterprise

/ Student Experience and Engagement

/ STEM Outreach and Impact

/ Teaching and Learning

/ Research and Enterprise

/ Student Experience and Engagement

/ STEM Outreach and Impact

Engineering is at the forefront of innovation; it is pushing the boundaries of what is possible and shaping the world we live in. In this pursuit of excellence, Morson Group - a global engineering recruitment and workforce solutions company based in Eccles, Salford, has established a transformative partnership with The University of Salford and its Maker Space.

Becoming a STEM Changemaker in our region, Morson Group’s commitment to STEM education is evident. Through initiatives like the esteemed Gerry Mason Engineering Scholarship programme, they are granting talented students access to education unburdened by financial constraints, providing graduate placements, industry mentors, and the establishment of the Morson Group STEM Foundation. This powers our collective mission to empower promising young minds towards engineering futures and lifelong STEM learning opportunities.

The Maker Space is a cutting-edge facility, boasting industry-standard equipment and stands as a flagship for hands-on learning, prototyping, and additive manufacturing on campus. After successfully relocating to the new School of Science, Engineering, and Environment (SSEE) building in September 2022, the 300m2 Maker Space move was a remarkable achievement. It involved intricate transfers and recommissioning of specialised equipment, coupled with advanced machinery procurement to expand our factory floor in the Morson Engine Room.

Equipped with state-of-the-art technologies including 3D printers, laser cutters, robotic kits, and advanced software, we are proud to have expanded our technical abilities. The facility now includes CNC Lathe and CNC routing machines, TIG welding, sandblasting, and enhanced surface finishing widening in-house part production possibilities.

A newly integrated computer-aided design suite and functional AV system empower students to move beyond lectures to delve straight into prototyping, tinkering, and problem-solving. Guided by our expert technicians, the Maker Space offers pivotal resources and mentorship. This bridges the gap between theoretical learning and practical application, ensuring a seamless transition from theory to real-world practice.

The technology enhancements have transformed the Maker Space into a facility that engages students and staff from all across campus, utilising our industry-standard machinery and expertise on a regular basis.

Mike Walsh Maker Space Manager

Mike Walsh Maker Space Manager

In making the digital transition from our annual Maker Space Case Studies hardcopy brochures to an online magazine format, we are taking a significant step toward showcasing our maker contributions to student and staff projects, research, and innovation. This launch also serves as a dynamic preview of the future energised by our collaborations. I would like to extend my gratitude to Morson Group, Morson Projects, the Maker Space team, and our esteemed colleagues and partners who trust in our maker culture making it possible for us to succeed in our ‘Make in Salford’ journey.

Dr. Maria Stukoff, Maker Space Director

As anyone passionate about anything will know, the desire to keep driving forwards can sometimes cheat us out of the opportunity to learn from looking back. By taking time to reflect on our efforts and their outcomes, we renew our enthusiasm and sharpen our direction. With that in mind, I’m proud to welcome you all to the very first Maker Space annual brochure, commemorating the first year of the Morson Group STEM Foundation, led by the Maker Space at The University of Salford.

This publication showcases the Morson STEM Foundation’s efforts to empower the next generation of aspiring engineers through STEM learning activities. It highlights the hard work and dedication of the Maker Space team, who help to inspire and support students as they develop the industry skills employers need today, and it explores some of the award-winning academic research and innovation that has been conducted at the University of Salford.

I am particularly proud of our enduring commitment to the Gerry Mason Engineering Scholarship programme, which holds great significance for our family. Since 2017, when my late father launched the programme, we have supported over 53 scholars, helping them reach their potential, regardless of socio-economic background, gender, race, or any other area of ‘difference’. As we look back on their remarkable transformations and outstanding achievements, we remain steadfast in our mission to cultivate a society where opportunities are accessible to all. With this vision at our core, in 2022 we were thrilled to embark on a new partnership with IntoUniversity Salford to enable long-term support to young people aged 7-18, helping them to discover their focus, build their capabilities and ultimately have the opportunity to reach their full potential.

Mike Walsh Maker Space ManagerI extend my thanks to the entire Morson Group team, the Maker Space at The University of Salford, and our esteemed partners for their unwavering commitment to the success of these STEM initiatives. Together, we are inspiring the engineers of the future.

Ged Mason, OBE, CEO Morson Group

Morson Engine Room and Maker Space is a digital fabrication facility for rapid prototyping with robust, industrial-grade machinery. With this space, students gain hands-on experience in design, assembly, and inspection fostering seamless skills alignment with industry needs.

MORSON ENGINE ROOM

/ OMAX Maxiem 1515 Waterjet cutter with a 5-axis head

/ Hass UMC-500 5-axis milling machine

/ AXYZ Flat-bed CNC router for full sheet size timber and light metals

/ Haas ST-15Y CNC lathe with Y axis

3D PRINT HIVE

/ Fused Filament Fabrication (FFF)

/ Stereolithography (SLA)

/ Selective Laser Sintering (SLS)

/ Metal printing (Metal X ADAM)

LASER CUTTING

/ Epilog Fusion CO2 and fibre laser cutters

CLEAN ROOM

/ Electronics development area

/ Digital and optical microscopes and metrology instruments

/ Nikon Altera Coordinate Measuring Machine

/ 3D Laser Scanner

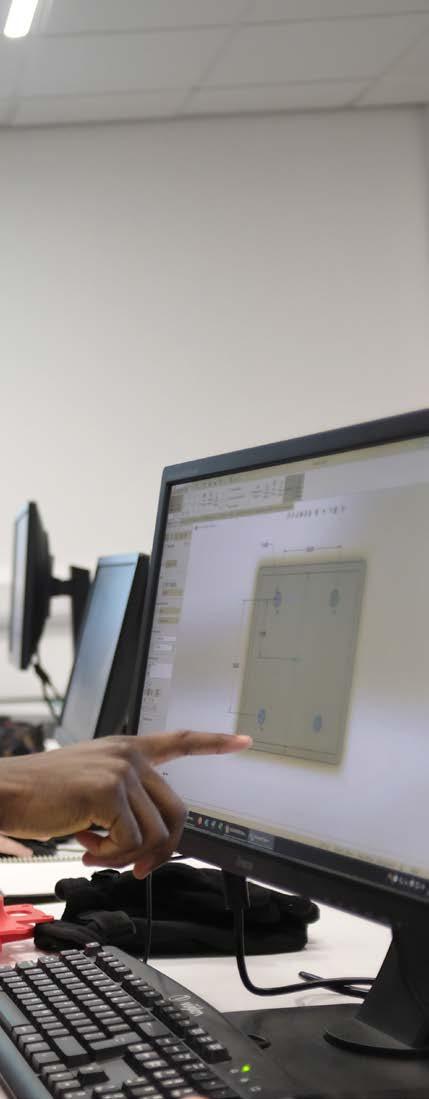

CAD SUITE

/ 14 x computer terminals

/ Software applications including Fusion 360, Solidworks, Microsoft Office and Adobe Creative Cloud

What a great space to apply our coursework into real world practice.

Education and engineering are undeniably intertwined when it comes to cultivating a skilled workforce for the future. At Morson Projects, we are fortunate to witness the remarkable impact of our industry-university partnerships in championing STEM (Science, Technology, Engineering, and Mathematics) skills through the Maker Space and the Morson Group STEM Foundation.

It has been a fantastic journey witnessing the growth and development of the Maker Space facilities. With a dedicated and innovative facility spanning 300m2, our industry-university partnership has flourished. The Maker Space serves as a platform for showcasing the pivotal role of technology and skills in exposing students to the latest industry-standard practices. Seeing their progress and the spark of inspiration in their eyes as they work with advanced tools is truly rewarding for us at Morson Projects.

Partnerships between industry and universities benefit students immensely. By engaging with the Maker Space, Morson Projects fosters a collaborative mindset and networking opportunities. This allows students to interact with industry professionals, and mentors to expand their professional networks. Morson Projects provide valuable insights into industry trends, best practices, and practical application of STEM principles. Our partnership with the Salford Racing Society also highlights how industry skills are directly applied to engineering and students’ final-year projects. These collaborations empower students to gain real-world skills, industry exposure, and prepare them for successful careers in their chosen fields.

Our unique partnership also extends beyond technical knowledge. Through direct engagement and sharing experiences, we ignite a passion for engineering and STEM careers in students. Morson Projects has supported, recruited, and employed recent Salford University graduates, helping them flourish as professional engineers. By pioneering such exceptional industry partnerships and working in collaboration with the University and the Maker Space, we help shape the future of engineering right here in Greater Manchester.

The Morson Maker Space is not just a place to tinker with tools and technology; it is a hub of innovation where young minds come alive and the next generation of engineers is nurtured. This space is not only shaping their technical skills but also fostering a mindset of collaboration, resilience, and creativity. The Morson Maker Space is where we forge the path to a brighter future, paving the way for a new era of engineering excellence.

Andy Hassall, Associate Director, Morson Projects

The Maker Space is passionate about bringing digital fabrication skills into curriculum. We work with students to provide them with the opportunity to apply their coursework in a more tangible way, and to aid their understanding of design and iteration.

This is a safe place for students to fail, fail fast and cheap, while realising what went wrong, to improve their projects and to learn in a supportive and open environment.

During the academic year 2022-23, we saw more final year students using the Maker Space to create prototypes for their projects. These case studies showcase how aeronautical engineering students utilise the Maker Space in designing and building working prototypes for a flexible wing, demonstrating practical applications of their written concepts.

Project - Flexible and moveable leading edge of wing design, including custom designed and programmed electronic control of the position of the wind tunnel model over Bluetooth.

Kelly developed a flexible wing prototype which uses small servo motors to control the position of silicone rubber leading edge components. Apply the use of Formlabs Fuse 1, OMAX Maxiem 1515 Waterjet Cutter, AXYZ CNC Router the Maker Space technical team helped Kelly develop Arduino programming and circuit development skills to develop a wireless control mechanism which uses Bluetooth to communicate between a controller and the wing model.

There is no easy way to get wired parts in and out of the wind tunnel while it is in operation, so a wireless control mechanism presents an innovative solution to this problem. Kelly utilized 3D printing processes, including the new Formlabs Fuse nylon powder printer, to create the static parts of the wing model and molds for the silicone rubber sections of the leading edge. Additionally, he employed a waterjet cutter to shape a steel and carbon fiber sheet for mounting all the components. The TIG welding facilities in the Maker Space were also used to attach mounting points for connecting the prototype to the wind tunnel.

Without the Maker Space, I believe I would have been lost in my Final Year Project. Being a practical-oriented engineer, the Maker Space equipped me with essential skills, and they provided direction on various ideas I had at the time. Having someone approachable and supportive is essential, and the Maker Space has fulfilled that role perfectly.

Without access to the Maker Space my challenging final year project would not have been possible, I would not have been able to create my testing jig and my moulds would have been difficult to manufacture. I have been able push the limits of my ability to the next level. I would like to thank the Maker Space especially Aidan and George who have taught me how to use all the machinery available and with this amazing maker team behind students, anything is possible.

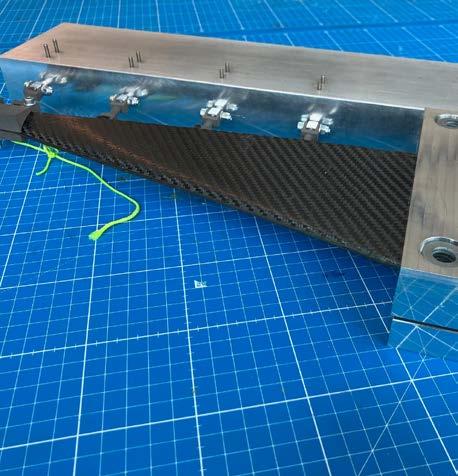

Project - Building a scale model of a Concorde wing to test the role of composites in flexing of airframe components.

Tom’s project stress tests a composite version of a Concorde wing. This requires a complex jig to simulate the fixedpinned conditions found in a real-world application using the Haas UMC-500 CNC Mill, AXYZ CNC Router, Haas ST-15Y CNC Lathe, in order to proof test the load conditions that would be experienced during flight. This ambitious final year project involved four complex CNC machined components, two machined tooling board mould halves, and waterjet carbon fibre composite reinforcing ribs. Tom has been using the 5-axis mill in both 3-axis and 5-axis mode and can competently start up, program, setup and run the machine with little input from staff.

The Maker Space encourages collaboration between academics, students, and industry partners to enhance practical learning. In this process, prototyping is a powerful tool for understanding how ideas and designs work together for coursework, research projects, and innovation. “Prototyping and rapid iterative design are key to successful projects”, says Senior Technician Aidan Dunbar. “Students can test small, independent sections of a project quickly, uncovering design flaws and validating nascent concepts well before finalising their project plans.” By developing hands-on skillsets, students will be able to showcase real-world solutions to coursework concepts in their final projects.

The North of England Robotics Innovation Centre (NERIC)

I had the incredible opportunity to work closely with the Morson Maker Space and work at North of England Robotics Innovation Centre (NERIC). NERIC is a dedicated hub for industry collaboration and innovation in robotics and automation. It provides access to specialised equipment, a purpose-built facility, and extensive support services. Through NERIC, assistant technical consultants like myself and companies can seamlessly integrate robotics, automation, and digital technologies, leading to the development of truly ground-breaking applications and products.

To realise my master’s project, I embarked on an inspiring journey at the Morson Maker Space. I was driven by the goal of designing a control system for an electromechanical actuator to be implemented in an innovative prosthetic ankle for lower limb amputees. My vision was to revolutionise prosthetics by incorporating an innovative control system method to improve amputee mobility. The Maker Space became an invaluable partner, providing essential support and training to bring my ideas to life. The Maker Space’s innovative resources have played a pivotal role in shaping my project research. It exemplifies how collaborative environments are instrumental in turning ideas into reality.

Thanks to the Maker Space’s resources, I received training on the Mark Forged Mark Two 3D printer, allowing me to print essential components using carbon fiber - an indispensable material for my prosthetic ankle design. Notably, I became the first student to complete the Maker Space’s 5 Axis CNC Mill training, gaining expertise in machining intricate aluminium components. This skill proved instrumental in realising my prototype. Through the Maker Space’s unwavering support, I successfully completed my prototype - a significant milestone for my project.

During my studies, I worked part-time as an Assistant Technical Consultant at the North of England Robotics Innovation Centre (NERIC). The objective of this role is to contribute to NERIC’s mission of promoting innovation and collaboration in the robotics and automation industries in order to improve their efficiency and productivity.

I highly recommend the Maker Space. The staff’s passion for their work is evident in their teaching approach, and they possess excellent technical knowledge in various manufacturing and engineering domains. The Maker Space enables researchers to achieve their project goals effectively. I wholeheartedly recommend it.

Amidst Covid-19 challenges, the University’s Podiatry Clinic embraced innovation in teaching methods. Limited by social distance measures, they sought alternative solutions to demonstrate essential techniques to students while adhering to guidelines. Inspiration struck when Susan Millidge, a Podiatry Technician at the School of Health and Society, learned about teaching aids developed in Australia and New Zealand. Susan Millidge collaborated with the Maker Space team to develop prototype teaching aids tailored for Salford students. Typically costing around £500 per model, the Maker Space’s expertise and resources enabled significant cost savings by manufacturing the aids in-house.

George Dodgson, Lead Technician at the Maker Space, harnessed the potential of 3D scanning equipment by using an existing foot model from the Podiatry Clinic to create a detailed digital replica. This digital model was then transformed into a physical prototype through 3D printing. In collaboration with the Podiatry Technical Team, iterative improvements were made with models being carefully fitted with lifelike latex skin to enhance realism. The interior was also designed with a flexible piece to mimic the natural movement and bend of a foot. Using almost lifelike models, this innovative approach enhanced the learning process for students.

Looking ahead, the next generation of models will embrace diversity and inclusivity, with plans to create models in multiple skin tones. Using this approach demonstrates the commitment to providing accessible and representative teaching aids to all students and is an excellent example of how the Maker Space can provide enterprise support. The continued exploration of creative ideas and technologies promises to foster further advancements in podiatry education at the University of Salford.

This innovative strategy not only ensured successful teaching amidst challenging circumstances but also nurtured inventive solutions. By amalgamating insights from diverse fields and harnessing the advanced technologies accessible at the Maker Space, the University showcased its dedication to delivering top-tier education while embracing the prowess of makers to adeptly navigate the intricate challenges posed by the pandemic.

I have really enjoyed working with George on this collaboration and it has been very beneficial to the student experience. To our knowledge we’re the only podiatry school in the country to have these teaching aids.

We take real pride in the way we support innovation in our teaching approach through our maker expertise. Collaborating with the School of Health and Society proved to be a genuine success in developing real-world solutions to assist Susan Millidge in creating classroom teaching aids.George Dodgson, Senior Technician, Maker Space Susan Millidge, Podiatry Technician

This year, over 130 IntoUniversity students participated in four dynamic STEM workshops hosted by the Maker Space. Powered by the Morson Group STEM Foundation, pupils from across different school levels were able to explore the exciting world of engineering and actively take part in the STEM revolution. Every maker workshop is carefully designed to stimulate creativity, technology skills, and engineering aptitude.

IntoUniversity is a national charity, offering a safe space to learn, support disadvantaged students to strengthening their aspirations and achieving their future goals. A partnership between the University of Salford and the University of Manchester helped establish the IntoUniversity at the Beacon Centre in Salford, receiving widespread industry support. The centre tailors its guidance for students aged 7-18, cultivating passions, honing essential skills, and fostering goal attainment.

In the Maker Space workshops, students assembled and raced remote-controlled cars, studied mechanics and electronics, built electric torches, and experimented with 3D printing. The immersive experience encouraged meaningful connections among 7-18-year-olds by encouraging them to share their experiences. Tailored evening sessions extended to parents and guardians provided a glimpse into universitylevel engineering courses, demystifying STEM subjects using Lego bricks, to overwhelmingly positive responses.

We take great pride in collaborating with the Morson Group STEM Foundation to tackle STEM skill shortages head-on. The Morson Maker Space provides a creative environment for students to test out digital tools and engineering skill in a safe environment and fuel their passion for future STEM careers.

At IntoUniversity, we have been delighted to run a number of successful workshops with the Maker Space both at our learning centre and in the Maker Space itself. We have had a wide variety of students and families engage with hands-on engineering activity supported by Morson Group. These STEM based workshops allowed students to see the practical application of engineering skills in a fun context while building real-life practical skills and give insight into what a career as an engineer might look like. Students leave feeling inspired and excited about careers in STEM.

Rachel Norton, Maker Space Project Manager

Basic Art and Electronics Workshop.

This workshop welcomed thirty students from Year 6 to combine arts, craft, and electronics to create their own “Minecraft” inspired paper torch, which lights up at the touch of a button. The Maker Space worked in collaboration with Mako Create who offer a range of creative, tech-based educational workshops and helped deliver this hands-on engeering learning experience.

Ignition Workshop.

In partnership with the University of Salford’s student racing team, sixty Year 8 students visited our campus and learned about our technical facilities. During the Maker Space event, participants got to race remotecontrolled race cars using parts they manufactured.

Bespoke STEM workshops for Parents/ Guardians Session with a mixed age group of children.

To help demystify STEM skills and careers, these sessions introduced students with their parents and/ or guardians to university life and taught simple civil engineering and construction principles. Teams worked together to construct the tallest Lego tower, using the designated bricks. By adding forces to their Lego structures, the challenge simulates real-world engineering and construction principles. Reflecting on their accomplishments and challenges during the activity provided participants the opportunity to strengthen their problem-solving abilities.

Making use of cutting-edge technology, the Maker Space creates a multidisciplinary environment to foster knowledge exchange and enhance learning experiences.

In line with the University’s visionary approach to cultivating innovative industry partnerships, we nurture futureready talent, powered by the Morson Group STEM Foundation, equipped with the skillsets required for tomorrow’s industries - today!

MAKER SPACE

School of Science, Engeering and Environment

Room 00.12

University of Salford

Manchester M5 4QJ

makerspace@salford.ac.uk

www.salford.ac.uk/our-facilities/maker-space