NSW and ACT 2024 Welding Excellence Award Winners Announced >>>

Victoria and Tasmania 2024 Welding Excellence Award Winners Announced >>>

Geoff Crittenden wins ‘Leader of the Year’ at the 2024 Endeavour Awards >>>

NSW and ACT 2024 Welding Excellence Award Winners Announced >>>

Victoria and Tasmania 2024 Welding Excellence Award Winners Announced >>>

Geoff Crittenden wins ‘Leader of the Year’ at the 2024 Endeavour Awards >>>

Geoff Crittenden Chief Executive Officer 1800 189 900 g.crittenden@weldaustralia.com.au

TRAINING

Guy Brooks, General Manager, Training Operations 0488 743 322 g.brooks@weldaustralia.com.au

MARKETING

Michelle Tagliapietra, Executive General Manager, Sales & Marketing 0437 106 726 m.tagliapietra@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104 d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Executive General Manager, Technical Services 0487 487 170 d.yalniz@weldaustralia.com.au

ENGINEERING

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991 v.blain@weldaustralia.com.au

NEW SOUTH WALES

Arya Sharifian, Welding Engineer 0419 414 901 a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991 v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, General Manager, Engineering – QLD, ACT, NSW, NT 0491 491 888 r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Ian Mackay, Business Development Manager 0493 027 882 i.mackay@weldaustralia.com.au

Weld Australia is calling for immediate action against the Victorian Government’s offshoring of steel for major infrastructure projects. The Victorian Government has already decimated the local steel manufacturing industry, costing jobs, investment, and threatening the sovereign capability of Australia’s manufacturing sector.

In the last six to 12 months, Victorian industry has seen a massive increase in the volume of imported fabricated steel. Evidence suggests that since the beginning of the year, over 28,000 tonnes of steel has been offshored. The North East Link project is a critical example of this issue. It was recently revealed that the Bullen Flyovers, consisting of 11,000 tonnes of steel bridges and girders, were awarded to an overseas fabricator.

Despite earlier reassurances made by the Victorian Government to Weld Australia members, these contracts were awarded to a Chinese company—that is banned from operating in the US—to meet project timelines that allegedly could not be met by a single local fabricator. Weld Australia finds this rationale deeply concerning because it is simply untrue.

Over the course of the last two to three years, the Victorian Government has worked with local industry and disseminated supplier briefings that outlined a massive influx of work, calling for local fabricators to reserve capacity for 2025. Our members have repeatedly told us that they have actively scheduled this project work into their targeting and forward forecasts. As a result, local manufacturers have not pursued work on other projects, or in other industries.

Now, the Victorian Government has done a backflip, sending the bulk of the work straight offshore. How can local industry expect to operate with any kind of surety if their own government can’t stay true to its word? Our local industry is being held to ransom by duplicitous politicians.

The public should be concerned for their safety. How can an imported fabricated steel structure meet the quality compliance requirements imposed by the Victorian Department of Transport and Planning? According to the Department’s own specifications, fabricators must be AS/NZS 5131 Certified to CC3 for such structures, yet it remains unclear if overseas

fabricators meet any kind of quality standards—let alone these stringent standards. Do members of the general public feel safe driving over steel bridges not knowing whether the welds will hold?

This situation raises serious questions about adherence to the Victorian Government’s own Local Jobs First Policy. The Policy merely requires “maximisation” of local steel content without a clear percentage requirement.

A concerted effort by governments to achieve a 90% domestic share of steel content in government projects would increase local steel supply by 3.4 million tonnes in total over the next five years, an average of 690,000 tonnes per annum, contributing $4.3 billion to real GDP over the next five years, assuming an average steel price of $1270/t. This price is 10% higher than the projected average import price, in line with Canada’s local content policy.

Victorian steel fabricators are struggling against the influx of imported steel, particularly from Vietnam and China, which is up to 40% cheaper than locally fabricated steel. Companies across the state are reporting sharp downturns in available work, leading to redundancies, reduced work hours, forced annual or long-service leave, and operational cutbacks.

Prominent local fabricators in the Australian market have reported a staggering reduction of approximately 60% in government tender availability. This downturn has already forced numerous redundancies, cut operational hours to as little as three to four days per week, and halted major investments in production capacity. The impact extends to apprenticeships and future investments. Companies are reconsidering training programs, shelving capital investments, and struggling with tax and interest burdens.

We are witnessing a race to the bottom. How can our local steel industry compete when imports are priced below our own raw materials?

Weld Australia demands urgent action from the Victorian Government. The government must adhere

to its own Local Jobs First Policy, ensure clear local content requirements, and protect local steel jobs. The Victorian Government needs to stand up for our manufacturing sector. These cheap imports are undermining local industry standards, taking away jobs, and compromising the quality of our nation’s infrastructure.

The government must take urgent and immediate action to protect the livelihoods of thousands of workers and steel fabrication industry in Australia. We must have clear requirements for local steel content and stronger adherence to quality standards to ensure that Victorian fabricators can compete on a level playing field.

Over the last month, we celebrated the winners of the 2024 New South Wales and ACT Welding Excellence Awards, and the winners of the Victoria and Tasmania Welding Excellence Awards. On behalf of the Weld Australia team, I’d like to congratulate all the winners, runners up and highly commended.

The 2024 Welding Excellence Awards showcase the exceptional talent of welders and fabricators across New South Wales, the ACT, Victoria and Tasmania. We are excited to honour both individuals and businesses who are driving advancements in welding through their commitment to quality, safety, and innovation. The

winners this year embody the pursuit of cutting-edge, sustainable solutions that enhance project outcomes while reducing risks, alongside initiatives that broaden and deepen the skilled workforce within the welding sector.

The winners of the 2024 New South Wales and ACT Welding Excellence Awards are:

Company Of The Year - Fabrication

• Winner: NWEC

• Runner Up: Macfab Engineering

• Highly Commended: JB Specialist Engineering

Company Of The Year - Indigenous

• Winner: IndigeFab

Project Of The Year

• Winner: MC Quality Control for Glencore’s Colombian operations

Health and Safety In Welding

• Winner: APEX Welding Safety (AWS)

Company Of The Year Supplier

• Winner: Kemppi

• Runner Up: Coregas

Training And Education Award - Organisation

• Winner: Welding Quality Management Systems

• Winner for VET Schools: Shepherds Park Education and Training Unit

• Runner Up: Zeal Features

• Highly Commended: TAFE NSW

Welding Professional Of The Year - Welding Coordinator

• Winner: Sungmook Park from TSS Engineering

• Runner Up: Joel Mennie from MC Quality Control

Welding Professional Of The Year - Welding Inspector

• Winner: Terry Morton from MC Quality Control

Welding Professional Of The Year - Welding Supervisor

• Winner: Emil Dionisio from E&C Welding Inspection and Services

• Runner Up: Mark Lamb-Crane from MC Quality Control

Young Tradesperson Of The Year

• Winner: Holly Collins from Assure QC

• Runner Up: Joshua Kassissieh from BW Fabrication

• Highly Commended:

• Thomas Affleck from AD McCallum and Son

• Ethan Galea from West-Trans Equipment

Tradesperson Of The Year

• Winner: Chris Todd from Ventia

• Runner Up: Thomas Askew from Empire Industrial Engineering

Training And Education Award - Individual Teacher

• Winner: Francesco Prestia from TAFE NSW

• Runner Up: Craig Taylor from TAFE NSW

For full details on all the award winners, see the article on page 10

The winners of the 2024 Victoria and Tasmania Welding Excellence Awards are:

Victorian Company Of The Year - Fabrication

• Winner: Hanlon Industries

• Runner Up: Steel Mains

Tasmanian Company Of The Year - Fabrication

• Winner: Jayben Group

• Runner Up: Incat

Victorian Project Of The Year

• Winner: ACCIONA for PPG’s Plant C Manufacturing Facility

• Runner Up: Pure Piping for Moderna’s ‘Project Resilience’

Tasmanian Project of the Year

• Winner: Crisp Bros & Haywards for the Fyans Street Rail Bridge

Health and Safety In Welding

• Winner: Structural Challenge

Company Of The Year Supplier

• Winner: Migomag Welding Supplies

• Runner Up: Coregas

Victorian Training And Education AwardOrganisation

• Winner: Chisholm TAFE

• Runner Up: Ringwood Training

• Highly Commended: Australian Institute of Engineers

Tasmania Training And Education AwardOrganisation

• Winner: TasTAFE

Welding Professional Of The Year - Welding Coordinator

• Winner: Krishna Annapureddy from Alstom

• Runner Up: Kim Temple from ITEST (Independent Testing & Inspection Services)

Welding Professional Of The Year - Welding Inspector

• Winner: Brett Sutton from Ulbricht International

• Runner Up: Brendan Farley from Pure Piping

Victorian Welding Professional Of The YearWelding Supervisor

• Winner: Joel Sibraa from Furphy Engineering

• Runner Up: Li Tian from TMC Australia

Tasmania Welding Professional Of The YearWelding Supervisor

• Winner: Matthew Swinden from Elphinstone

Young Tradesperson Of The Year

• Winner: Iesha Swan from Hanlon Industries

• Runner Up: Kynan Smith from Pure Piping

• Highly Commended: Ned Sweeney from Hanlon Industries

Tradesperson Of The Year

• Winner: Farokh Banihashemi from Shadbolt Group

• Runner Up: Grayson Cooper from Chisholm TAFE and Energy 360

• Highly Commended: Ernesto Locsin JR from Structural Challenge

Victorian Training And Education Award - Individual Teacher

• Winner: Rodney Bentvelzen from Chisholm TAFE

• Runner Up: Joe Haley from TAFE Gippsland

Tasmanian Training And Education AwardIndividual Teacher

• Winner: Michael Schnackenberg from TasTAFE

For full details on all the award winners, see the article on page 16

Geoff Crittenden

CEO, Weld Australia

GEOFF CRITTENDEN NAMED ‘LEADER OF THE YEAR’ AT THE 2024 ENDEAVOUR AWARDS

The Manufacturers’ Monthly Endeavour Awards 2024 was an outstanding night for many who gathered to celebrate the contributions and achievements of Australian Manufacturing.

Held in Melbourne in early November, the awards allowed those in attendance to celebrate just some of the many successes seen recently within the industry.

Geoff Crittenden, Weld Australia’s CEO, won the ‘Leader of the Year’ award at the 2024 Endeavour Awards.

“Over the last 50 years, I’ve learned one crucial lesson: it’s not about you; it’s about the people who work with you,” said Crittenden.

“I want to take this opportunity to thank my team at Weld Australia. They are absolutely fantastic, and without them, leadership means nothing.”

Following feedback from local Victorian members, Weld Australia distributed a media release two weeks ago that called for immediate action against the Victorian Government’s offshoring of infrastructure projects in favour of cheap, unsafe imported steel. Journalists at the Herald Sun undertook an investigation, interviewing government representatives, local Weld Australia members and Geoff Crittenden (CEO, Weld Australia).

As a result, the Herald Sun ran a front page article on 22 October detailing how Victorian manufacturers are preparing to cut jobs, saying they’ve been betrayed by “duplicitous politicians” who are allowing steel to be shipped in from China and abroad for Big Build projects.

Local steel fabricators say they were promised a lucrative pipeline worth hundreds of millions of dollars from the Big Build, only to see some orders disappear overseas. The state’s most expensive road project, the $26bn North East Link, recently sourced 11,000 tonnes of steel from China – part of an $80 million package – for bridge structures at road interchanges.

Winners named at Queensland and NT Welding Excellence Awards, published by AuManufacturing

Top welders, fabricators recognised at 2024 Queensland and NT Weld Australia Awards, published by Australian Manufacturing

Welding Excellence Awards spotlight QLD and WA winners, published by Manufacturers’ Monthly

Weld Australia names winners at NSW & ACT Welding Excellence Awards, published by AuManufacturing

Welding achievements spotlighted at Weld Australia’s 2024 NSW & ACT Awards, published by Manufacturing Monthly

Celebrating VIC & TAS at Weld Australia’s 2024 Welding Excellence Awards, published by Manufacturing Monthly

Weld Australia names Welding Excellence Awards winners from Victoria and Tasmania, published by AuManufacturing

Stand among industry leaders at the 21st annual Endeavour Awards, published by Manufacturing Monthly

Celebrating industry achievements: Highlights from the 2024 Endeavour Awards, published by Manufacturing Monthly

Welding industry is grappling with work shortages and rising costs, says new Weld Australia report, published by Manufacturing Monthly

Did you know that Weld Australia offers a whole range of resources for members, as well as the broader welding, fabrication and manufacturing industries?

From Guidance Notes and a detailed Member Directory, through to our discounts and regular calendar of events, there are sure to be some resources that can help you in your business or career. We’ve included just a small sample of our resources opposite.

Weld Australia memberships for 2025 are now due for renewal. You can renew your membership via Weld Australia’s member portal. If you need any assistance, feel free to contact David Choudry (Membership Manager, Weld Australia) via d.choudry@weldaustralia.com.au or 0417 878 104

TECHNICAL GUIDANCE NOTES > SAFETY ALERTS >

Safe Work Australia has reduced general welding fume exposure limits from an 8 hour time weighted average (TWA) of 5 mg/m³ to 1 mg/m³, reflecting the dangers of even low-level fumes. This is in addition to existing limits for specific hazardous components like chromium and nickel.

Skill, quality, and professionalism took centre stage earlier this month as the winners of the 2024 New South Wales and ACT Welding Excellence Awards were announced in Sydney. Hosted by Weld Australia, the Excellence Awards are the most prestigious event on the welding industry calendar. These awards honour and highlight the exceptional work of local welders, fabricators and educators contributing to the industry’s growth.

This year, the awards were held at Rydges World Square in Sydney and saw the best and brightest from the New South Wales and Australian Capital Territory welding industry come together to acknowledge the incredible calibre of work achieved over the past 12 months.

Geoff Crittenden (CEO of Weld Australia) said, “The 2024 Welding Excellence Awards showcase the exceptional talent of welders and fabricators across New South Wales

and the ACT. We are excited to honour both individuals and businesses who are driving advancements in welding through their commitment to quality, safety, and innovation. The winners this year embody the pursuit of cutting-edge, sustainable solutions that enhance project outcomes while reducing risks, alongside initiatives that broaden and deepen the skilled workforce within the welding sector.”

NWEC won the 2024 Company of the Year Award - Fabrication. NWEC is a specialist in steel fabrication, painting, installation, construction management, and welding resource supply, with over 40 years of experience serving Australia’s petrochemical, mining, aviation, rail, road, gas and heavy industry sectors. Known for its exceptional quality and consistency, NWEC stands out by combining top-tier fabrication and welding services with comprehensive quality, safety, environment, and project management systems.

The Runner Up of the Company of the Year Award – Fabrication was Macfab Engineering, and a Highly Commended Award went to JB Specialist Engineering.

Indigefab won the 2024 Company of the Year Award – Indigenous. Indigefab is a progressive and proud 100% indigenous-owned and operated business, established in 2023, under parent company Absolutions Group. It draws on over 25 years of experience across all sectors of the construction industry with a focus on delivering exceptional metal fabrication services Australiawide. Notably, Indigefab has become the preferred partner to supply and fabricate sunshades structures for NSW schools across the state manufacturing 30 to 40 structures every year.

MC Quality Control won the 2024 Project of the Year Award for Glencore’s Colombian operations. MC Quality has worked with Glencore in Australia for nearly a decade, focusing on improving welding QA/QC processes and enhancing the structural reliability of their mining equipment. Glencore’s Colombian operations asked MC Quality to help address similar issues, expanding the use of Australian expertise in an international context. In this project, MC Quality audited a workshop with 500 employees and conducted welding inspections on new and in-service mining equipment – navigating language barriers and demanding environmental conditions to ensure quality and reliability in line with international standards.

APEX Welding Safety (AWS) won the 2024 Health and Safety in Welding Award. A passionate advocate for welders’ health and safety in Australia and New Zealand, AWS has published numerous welding safety whitepapers and industry reports, and welding fume control frameworks. As a company that specialises in welding fume safety equipment, its goal is to raise awareness and education around the important issues that welders face. AWS also played a major role in campaigning for the 2024 legislative change to the workplace exposure standard for welding fume.

Kemppi won the 2024 Company of the Year Award –Supplier. Kemppi is a leading multinational manufacturer and supplier of welding solutions, including the design, development and production of welding equipment, accessories, and safety gear as well as digital solutions and consulting and training services. Since its inception 1949, the Kemppi has pioneered and shaped the welding industry by solving welding challenges – such as being the first to move from analog to digital welding technology,

and introducing the world’s first universal welding management software and digital welding procedure specifications.

The Runner Up of the Company of the Year Award –Supplier Award was Coregas.

Welding Quality Management Systems (WQMS) won the 2024 Training and Education – Organisation Award. WQMS are structural cracking and weld repair management experts, providing a holistic suite of solutions, services, training, software and supplies for crack and weld repair management of fixed and mobile structures. They worked with IBSA to create and develop the Cert IV level unit MEM05069 Perform Advanced Weld Repair and Maintenance to meet broad industry needs for an accredited VET unit for maintenance welding. WQMS has also helped develop a training package for Muswellbrook TAFE, including a detailed learner guide, e-modules, practical assessment, and coaching for upskilling.

The Runner Up of the Training and Education –Organisation Award was Zeal Features. A Highly Commended Award went to TAFE NSW, and the Winner for VET Schools was Shepherds Park Education and Training Unit.

Sungmook (Mac) Park from TSS Engineering was named the 2024 Welding Professional of the Year –Welding Coordinator. Sungmook Park is a skilled IWSqualified Welding Coordinator at TSS Engineering. With over 20 years of experience in the welding and fabrication industry, Sungmook has significantly contributed to various high profile projects. His key achievement is leading his team to successfully implement a comprehensive quality system that not only met but exceeded client expectations. Sungmoo’s dedication to continuous improvement and professional development him apart as a leader in the field.

The Runner Up of the Welding Professional of the Year –Welding Coordinator category was Joel Mennie from MC Quality Control.

Terry Morton from MC Quality Control won the 2024 Welding Professional of the Year – Welding Inspector Award. Terry is a Welding Inspector and Supervisor at MC Quality, bringing over two decades of experience in the welding and fabrication industry. His extensive background as a Special Class Welder has allowed him to work on large-scale projects, such as major industrial shutdowns and international collaborations. In his current role, Terry has led quality control efforts for projects both in Australia and overseas, including work with Caterpillar in Batam and at the Cerrejón mine in Colombia. His deep knowledge, strong work ethic, and commitment to quality make him a deserving winner for this award.

Emil Dionisio from E&C Welding Inspection and Services was named the 2024 Welding Professional of the Year – Welding Supervisor. With a trade

background in boilermaking and pressure welding, Emil is a highly skilled Welding Supervisor. He has been involved with notable projects around Australia in structural piping, oil and gas, and power stations, including CBP WestConnex and Sydney Gateway. Emil is committed to mentoring new welders and apprentices, and promoting a positive working culture for both welders and midmanagement level. He also volunteers on the NSW Committee for Weld Australia.

The Runner Up of the Welding Professional of the Year –Welding Supervisor category was Mark Lamb-Crane from MC Quality Control.

Holly Collins from Assure QC won the 2024 Young Trades Person of the Year category. Holly is a fully qualified tradesperson working in gas and power generation across NSW. A ticketed pressure TIG welder, she started out in the food industry where she fabricated and welded many stainless-steel components and piping, before moving into the hydrogen industry and then power generation. In her short time, Holly has already demonstrated commitment and dedication to the craft, overcoming challenges and working hard to get the job done – making her an inspiration to young women in the welding profession.

The Runner Up for Young Trades Person of the Year category was Joshua Kassissieh from BW Fabrication. There were also two Highly Commended Awards:

• Thomas Affleck from AD McCallum and Son

• Ethan Galea from West-Trans Equipment

Chris Todd from Ventia was named the 2024 Trades Person of the Year. Chris started with Ventia as an apprentice in the project services workshop and has worked his way up to become the Leading Hand. He has played a key role in the delivery of multiple projects across both structural and piping, including the fabrication of a nearly 1000m 300NB bunker oil pipeline and 200-300NB high-pressure steam pipework to supply a turbo alternator. Chris also takes pride in passing on his knowledge to the next generation, training apprentices how to accurately align and check their fabrication prior to welding.

The Runner Up for Trades Person of the Year category was Thomas Askew from Empire Industrial Engineering.

Francesco Prestia from TAFE NSW won the 2024 Training and Education – Individual Teacher Award. Francesco is Head Teacher of Metal Fabrication and Welding at TAFE NSW, overseeing six campuses in the Riverina. He coordinates and delivers the Certificate 3 in Engineering to over 100 apprentices, and Certificate 4 in Engineering to 30 students across the state using virtual classrooms and face to face delivery. Francesco is also passionate about offering pathways for school students into trade areas, with a focus on metals and manufacturing: this year alone, he has organised and taught eight programs introducing school students to trade careers. The Runner Up in this category was Craig Taylor from TAFE NSW.

A safe and healthy work environment boosts productivity and efficiency. Moreover, a clean and safe workplace enhances employee morale and job satisfaction, leading to higher productivity levels. Investing in fume control systems is not just about compliance; it’s also about fostering a productive and motivated workforce.

“There is no universal single product that covers in all applications and work environments. A solution should be designed to the specific workshop conditions,” said Bartosz Glogowski (Automation Solutions Manager at Lincoln Electric).

As Kristian Kruger (Technical Manager Applications at Lincoln Electric) suggested, “It’s important to ensure effective fume control at the source, it’s recommended to capture and manage fumes as they are generated. Suitable methods include local exhaust ventilation (LEV) systems, such as hooded fume extractors or on-gun fume extraction. The captured fumes should be filtered and vented outside the workshop whenever possible.”

“Welders should also use personal respiratory protection, especially when their head is near the weld plume. Powered Air Purifying Respirators (PAPRs) provide excellent protection in most welding scenarios.”

“In addition, the ventilation for overall workshop is also crucial to protect the entire workforce, the Circulator from Lincoln Electric is a flexible self-contained system to capture and filter any weld fume that is present in the overall workshop,” said Glogowski.

Investing in these technologies ensures welding operations remain safe, compliant, and environmentally friendly.

Glogowski added, “The best fume mitigation strategy depends on the specific situation and type of fumes being produced”. However, some general strategies for reducing fumes include:

1. Welding process/technique/consumables – Weld fume creation can be reduced by implementing equipment and process technology together with the correct welding consumables.

2. Reduction of fume at source.

3. Personal protection for directly exposed welders.

4. Welding automation with local extraction. With automation we can embrace fumes locally, to unable spreading them around the workshop.

5. Central extraction Push-Pull type or Standalone Filtration systems to continuously keep right fume exposure levels, as we are not always possible to collect all the fumes at source.

“Effective welding fume control is essential for safeguarding worker health, meeting regulatory standards, enhancing productivity, and reducing environmental impact. By prioritizing fume control, companies can foster a safer, healthier, and more efficient work environment,” said Kruger.

This article was supplied as part of a sponsorship package.

Skill, quality, and professionalism took centre stage earlier this month as the winners of the 2024 Victoria and Tasmania Welding Excellence Awards were announced in Melbourne. Hosted by Weld Australia, the Excellence Awards are the most prestigious event on the welding industry calendar. These awards honour and highlight the exceptional work of local welders, fabricators and educators contributing to the industry’s growth.

This year’s ceremony was held at Crowne Plaza, drawing together the brightest talents from the Victorian and Tasmanian welding sectors. The event celebrated the outstanding achievements and workmanship demonstrated over the past year.

Geoff Crittenden (CEO of Weld Australia) said, “The 2024 Welding Excellence Awards celebrate the outstanding skills and achievements of welders and fabricators

throughout Victoria and Tasmania. We are thrilled to recognise both individual professionals and forwardthinking companies that are shaping the future of welding through their dedication to excellence, safety, and innovative practices. This year’s winners exemplify the drive for advanced, sustainable solutions that improve project outcomes and mitigate risks, while also fostering initiatives to expand and enrich the skilled talent pool in the welding industry.”

Hanlon Industries won the 2024 Company of the Year Award – Fabrication for Victoria. Hanlon Industries is a second generation Australian business, specialising in steel fabrication. Operating across road, rail, airports, and commercial developments, Hanlon provides comprehensive in-house solutions that include concept design, project management, manufacturing, and construction. They are also recognised for their community involvement and support, actively engaging with local organisations to provide apprenticeship opportunities, foster emerging talent, and promote diversity within the workforce.

The Runner Up of the Company of the Year Award –Fabrication for Victoria was Steel Mains.

Jayben Group won the 2024 Company of the Year Award – Fabrication for Tasmania. The Jayben Group is an original equipment manufacturer that specialises in power train products and light to medium industrial plant and equipment—including R&D, engineering, manufacture, domestic and international distribution, and continuous improvement. Headquartered in Burnie, Tasmania, and with operations in Royal Park, South Australia, Jayben develops their own branded products and bespoke solutions to an expanding group of businesses throughout Australia and Asia.

The Runner Up of the Company of the Year Award –Fabrication for Tasmania was Incat.

ACCIONA won the 2024 Victoria Project of the Year Award for PPG’s Plant C manufacturing facility. ACCIONA was engaged to perform the structural, mechanical, and piping works package for a new waterbased paint manufacturing facility known as “Plant C” at PPG’s site in Clayton, Victoria. ACCIONA’s scope of work included the fabrication of all piping/tubing and structural supports comprising of mild steel structural frames and stainless steel pressure piping/vessels. At its peak, the ACCIONA team consisted of over 100 personnel – navigating a complex design process to deliver a first-of-its-kind plant.

The Runner Up of the Project of the Year Award for Victoria was Pure Piping.

Crisp Bros & Haywards won the 2024 Tasmania Project of the Year Award for the Fyans Street rail bridge. The Fyans Street rail bridge is a level crossing removal project being undertaken by the McConnell Dowell Downer Joint Venture. Crisp Bros & Haywards were contracted to fabricate the 550t centre steel section, including two 32 metre long, 4.2 metre high I beams weighing more than 125t each, and two 16 metre long I beams weighing over 65t. Specialist fabrication and transport equipment was required to safely and efficiently weld, rotate and transport sections of this scale.

Structural Challenge (SC) won the 2024 Health and Safety in Welding Award. Structural Challenge (SC) is a Victorian-based steel fabrication company known for their strong commitment to quality and innovation. Since its inception, SC has established itself as a leader in the industry with a focus on health and safety in every aspect of its operations. Their dedication to maintaining a safe work environment is reflected in their comprehensive health and safety management plan, active engagement in continuous safety improvement, and a work culture of safe and lean manufacturing.

Migomag Welding Supplies won the 2024 Company of the Year Award – Supplier. Migomag Welding Supplies specialises in providing high-quality welding solutions across a broad range of sectors, including construction, manufacturing, and infrastructure. Over the past 30 years, the Migomag brand has become renowned for their comprehensive suite of welding machines and welding consumables, and advanced capabilities in both manual and automated welding processes. With state-of-the-art facilities and cuttingedge technology, the company demonstrates an unwavering commitment to advancing the welding industry through innovation, exceptional quality, and customer satisfaction.

The Runner Up of the Company of the Year Award –Supplier Award was Coregas.

Chisholm TAFE won the 2024 Training and Education – Organisation Award for Victoria. Chisholm TAFE’s Engineering Department is a premier training provider, delivering an array of courses designed to equip students with the skills and knowledge necessary for a successful career in engineering, fabrication and welding. Training over 1000 students annually, Chisholm TAFE boasts an impressive 97% retention rate for apprenticeship delivery – catering to a diverse student body from various genders, age groups, and cultural backgrounds. The department has a particular focus on encouraging women in trades.

The Runner Up of the Training and Education –Organisation Award for Victoria was Ringwood Training. A Highly Commended Award for Victoria went to the Australian Institute of Engineers.

TasTAFE won the 2024 Training and Education –Organisation Award for Tasmania. TasTAFE Metals and Manufacturing provides training to approximately 800 students across campuses statewide – supporting employment and workforce development. The dynamic educational model places students’ needs and industry requirements at the centre of delivery, with the ability to quickly develop programs from scratch to help businesses expand into new manufacturing sectors. A big supporter of WorldSkills, many TasTAFE teachers assist with running and judging regional and national competitions.

Krishna Annapureddy from Alstom was named the 2024 Welding Professional of the Year – Welding Coordinator. Krishna is a highly skilled Metallurgical Engineer and International Welding Engineer with 12 years of experience across the heavy fabrication industry. He has successfully handled major excavator, construction, and railway projects from design through to delivery. As the Responsible Welding Coordinator of Alstom Dandenong factory, Krishna did an exceptional job of leading possibly the largest welding team in Australia, managing and coordinating nine welding engineers, supervisors and inspectors.

The Runner Up in this category was Kim Temple from ITEST (Independent Testing & Inspection Services).

Brett Sutton from Ulbricht International won the 2024 Welding Professional of the Year – Welding Inspector Award. Brett is a qualified boilermaker and welder who exemplifies competency in practical welding, service pressure equipment inspection, and welding supervision. He is skilled in developing welding procedures and quality systems; managing teams and liaising with engineers, tradespeople, and management; and maintaining inspection and test plans for outages, in line with industry standards. Brett has also demonstrated a commitment to fostering a culture of continual improvement at Yallourn Power station to improve morale and welding quality.

The Runner Up in this category was Brendan Farley from Pure Piping.

Joel Sibraa from Furphy Engineering was named the 2024 Welding Professional of the Year –Welding Supervisor for Victoria. Arriving at Furphy as a metal fabricator tradesman in 2015, Joel quickly positioned himself as a future leader of the company – moving to QA/QC Officer and on to a range of supervisory roles across different departments. In addition to his well-rounded knowledge, exceptional people skills, and can-do attitude, Joel has a keen interest in sharing his expertise with up-and-coming tradesmen, apprentices and other new staff – making him instrumental to the business.

The Runner Up in this category for Victoria was Li Tian from TMC Australia.

Matthew Swinden from Elphinstone was named the 2024 Welding Professional of the Year –Welding Supervisor for Tasmania. With over seven years of dedicated service at Elphinstone, Matthew has contributed significantly to the organisation’s success – progressing through various team leader and coordinator positions across multiple projects. He has recently been engaged in defence sector initiatives, particularly the LAND 8116 project which involves largescale machine and structure fabrication and assembly for Defence OEMs. Matthew’s proven track record highlights his ability to lead teams, solve challenges, and set new benchmarks for welding excellence.

Iesha Swan from Hanlon Industries won the 2024 Young Trades Person of the Year category. Since starting her boilermaking apprenticeship with Hanlon Industries in 2023, Iesha has consistently outperformed her peers, earning the title of the best at her level every year at trade school. She has quickly become an essential part of the team, known for her ability to not only handle her own tasks with precision but also assist seasoned boilermakers with fabricating and designing complex steel structures. Iesha’s contributions have been integral to the successful completion of several key projects at Hanlon Industries.

The Runner Up in this category was Kynan Smith from Pure Piping. A Highly Commended Award went to Ned Sweeney from Hanlon Industries.

Farokh Banihashemi from Shadbolt Group was named the 2024 Trades Person of the Year. Farokh has twenty years of experience as welder in the oil and gas, fabrication, and shipbuilding industries in Iran and Australia. Specialising in process piping and structural shipbuilding, Farokh is an outstanding and highly-skilled welder who is always able to deliver projects of high specification within time and quality requirements. His productivity and workmanship quality set an example to other welders at Shadbolt, who regularly train with Farokh to advance their own exotic welding skills.

The Runner Up for Trades Person of the Year category was Grayson Cooper from Chisholm TAFE/Energy 360. A Highly Commended Award went to Ernesto Locsin JR from Structural Challenge.

Rodney Bentvelzen from Chisholm TAFE won the 2024 Training and Education – Individual Teacher Award for Victoria. With a distinguished career spanning 30 years, Rodney has significantly contributed to the welding and fabrication industry through his exemplary teaching and industry involvement – from organising welding exams and competitions to integrating new technology into his teach practice. Rodney’s impact extends beyond the classroom, playing an active role in the Victorian Engineering Senate committee and Victorian TAFE Teachers of Mechanical and Fabrication streams to promote collaboration and best practices among training providers.

The Runner Up in this category for Victoria was Joe Haley from TAFE Gippsland.

Michael Schnackenberg from TasTAFE won the 2024 Training and Education – Individual Teacher Award for Tasmania. Michael is a highly-respected TasTAFE teacher, with 35 years of trade experience and industry recognition including the 2004 National Gold Medal for Construction Steelwork. In addition to overseeing the delivery of the AS1796 program in the North West, Michael mentors and supports his fellow teachers to ensure they have a deep understanding of welding codes requirements. His passion and enthusiasm for teaching inspire and engage students, creating a positive and productive classroom environment.

For 42 years, Gentronics has been supplying the welding industry with high quality products and services, catering specifically to the needs of the welding and fabrication industry, from ship building to panel beaters, mining, education and every thing in between.

As sales and service agents for the biggest brands available in Australia we stock over 12,000 items, and are able to source and supply almost anything required to solve the most complicated workshop problems, right through to the simplest of day-to-day needs.

Leading the industry, we offer expert knowledge in all Welding Processes, Automation, Laser Technology, Generators, Engine Driven Welders, Turning Rollers, Positioners, Compressors, Benders, Notchers, Fume Control, and Safety Equipment. Whether you require equipment or consumables for MIG, TIG, MMA, Laser, CNC, Welding Wires, or even Gas Cylinders and refills, we have the solution.

Gentronics endeavors to stay ahead of the curve in welding technology, and provide detailed product training when new developments are made within the industry. With the machinery advancements and changes to safety laws that further protect the health of welders, we provide the specialised products, and the knowledge behind them to ensure an exceptional service is provided at all times.

Pulse Welding

Pulse welding is a specialized welding technique where the amperage, or electric current, alternates between high and low points throughout the welding process.

This fluctuation in current enables welders to achieve sufficient penetration in the material while minimizing overall heat input. By controlling the heat more precisely, pulse welding reduces distortion, which is especially useful when working with thinner materials that are prone to warping or overheating.

Additionally, pulse welding often results in a cleaner, more aesthetically pleasing weld bead with minimal spatter. This not only improves the visual appeal of the finished product but also reduces the need for post-weld cleaning.

Gentronics provides a full range of pulse welding machinery, as well as in-depth informative demonstrations to display the capabilities of this advanced process.

With the legislation changes addressing welding fume exposure now in full swing, there has never been a better time to familiarise yourself with the new regulations, and the actions in which to take towards them.

A huge part of this is ensuring the correct welding fume control measures are taken, and sufficient equipment is available to protect both the welding operators, and

the people subjected to the area they are working in.

Gentronics offers solutions to Welding Fume exposure mitigation in all forms including the latest in PAPR (Powered Air Purifying Respiratory) Welding Helmets and fume extraction technologies.

On-the-go welding has never been more accessible with the introduction of Battery Powered Welding and Generator units within the welding industry.

This technology has seen huge improvements in development over the last few years, and has now successfully made its way to the Australian market. With the ability to weld without restriction of power cords, the portability of these machines is second-to-none.

We carry an extensive of range of both battery powered welding machines and generator units to ensure access to power and welding, anywhere, any time.

Choose Gentronics as your trusted partner for all your welding needs including Sales, Service, and Hire. Experience the reliability, expertise, and personalised attention that sets us apart. Together, let’s take your projects to new heights of success.

This editorial was supplied as part of a paid sponsorship package.

Cobot welding is reshaping the manufacturing industry, offering a flexible and cost-effective automation solution for businesses of all sizes. Unlike traditional fixed robotic work-cells, collaborative robots (cobots) are compact and lightweight, allowing them to be easily moved to various job locations. This adaptability enables companies to optimise production layouts and efficiently adapt to evolving operational demands. With lower capital investments and exceptional versatility, cobots boost productivity whilst simultaneously reducing production costs.

OLP Robotics Director Russ Melville started his career as a first class welder and spent many years “on the tools”. Drawing on this experience and deep process knowledge, OLP Robotics have focused on delivering turnkey welding automation solutions to customers Australia-wide. Our goal is to deliver world-class solutions and support to enable the success of our customers.

The cobot welding system is a tool for welders. The WeCobot software, designed with welders in mind, features a clean and intuitive interface, allowing users to quickly gain proficiency without prior programming knowledge. Initially hesitant, operators quickly gain confidence, often reporting impressive production results on the very day of training. Many welders find satisfaction in using the system, noting the high-quality outcomes they achieve. This positive experience encourages them to explore broader applications for the technology.

Despite its user-friendly interface, WeCobot does not compromise on functionality. It includes the best suite of features we’ve seen on the market, including weave patterns for positional welding, through-arc

seam tracking (TAST), program repeats, and advanced multilayer welding controls—equipping users to tackle various welding tasks with ease.

One of the key advantages of cobot welding is enhanced working conditions. New regulations surrounding weld fume exposure necessitate safer working environments. Cobots remove operators from direct exposure to welding arcs, and allow them to manage multiple units or engage in other tasks away from hazardous areas. Coupled with on-torch fume extraction solutions, cobot welding significantly improves operator safety.

In a climate of labour shortages, cobot welding offers business owners an accessible and effective strategy to regain control and future-proof their operations. The versatility of these systems means one investment can be adapted for multiple uses and scaled according to business needs. By bringing welding in-house, companies gain better control over costs and timelines, efficiently managing workloads without adjusting headcount.

A recent customer study illustrated the efficiency of cobot welding, revealing cycle times of just 16 minutes compared to 45 minutes for manual welding, leading to labour savings of over $11,000 on a single job. This time saving allowed the company to redirect resources to enhance other workshop activities. Additionally, programming a cobot took only 10.6 minutes, compared to three hours for an industrial robot, underscoring the ease of use and suitability for low batch production.

For further information, visit: www.olp-robotics.com.au/ wecobot-welding

This article was supplied as part of a partnership agreement.

ProQM Pty Ltd, established in 2013, has built a reputation as a leader in construction quality management across Australia. From its headquarters in Narre Warren, Victoria, ProQM delivers specialised inspection and surveillance services, with expertise in structural steel welding, precast concrete manufacturing, and coatings inspection.

Serving diverse sectors including infrastructure, energy, and renewables, ProQM ensures that projects adhere to the highest standards and comply with Australian regulations.

ProQM’s NATA accreditation under ISO/IEC 17020 highlights its commitment to quality and integrity. The company’s team of internationally certified inspectors and specialists leverages advanced tools, such as the QMaster™ software. This real-time reporting system enhances transparency, providing clients with secure and continuous access to project data. The ability to swiftly identify and address potential issues minimises delays and rework, ensuring that projects remain efficient and cost-effective.

ProQM’s expertise has positioned it as a trusted partner in major infrastructure projects, including the West Gate Tunnel and the North East Link. Their meticulous approach ensures strict adherence to design and safety specifications, contributing to successful project outcomes. ProQM’s comprehensive inspection services span across all stages of construction, from initial planning and surveillance through to project completion, making them a key player in improving quality and safety standards throughout the industry.

Beyond their technical expertise, ProQM is dedicated to fostering positive community impact. They actively support social initiatives, such as sponsoring the National Association for Women in Construction (NAWIC) Awards and offering mentorship programs aimed at empowering women in the construction sector. These efforts reflect ProQM’s commitment to diversity, inclusion, and strengthening the industry’s future.

With over 25 years of combined industry experience, ProQM is also a leader in technical training. Their Technical Awareness Training programs provide industry professionals with in-depth knowledge of Australian standards, regulatory compliance, and construction practices. These tailored training sessions enhance the skills and proficiency of participants, ensuring they are equipped to manage complex projects successfully. This commitment to knowledge-sharing reinforces ProQM’s role as an industry leader, helping clients achieve compliance and elevate project quality.

ProQM’s relentless pursuit of excellence is evident in their continuous refinement of processes and investment in team development. Their client-focused approach, combined with an unwavering dedication to quality and compliance, makes ProQM an invaluable partner in the Australian construction sector. By driving improvements that benefit communities and ensure project success, ProQM continues to shape a stronger, more resilient industry landscape.

This article was supplied as part of a paid sponsorship package.

In the world of welding, precision isn’t just a preference—it’s a necessity. And that’s where WeldaToolz™ enters the scene, redefining quality in precision measurement for welders and metal fabricators. Designed for professionals who rely on accuracy, WeldaToolz combines rigorous engineering with a commitment to consistency, delivering gauges that bring an elevated level of assurance to every weld.

In an industry where the smallest miscalculation can result in costly rework, tools that offer exact measurement become invaluable. WeldaToolz™ brings forward a solution, backed by NATA-certified testing, guaranteeing that our gauges meet the highest standards in accuracy. With our range, welders no longer must guess at critical dimensions; they can trust their tools to deliver reliability on every project.

The WeldaToolz™ Range: Crafted for the Working Professional

Our lineup offers a selection for every need, whether you’re performing a quick inspection or a detailed analysis. Details below:

2-PCE Stainless Steel Fillet Welding Gauge

Compact, durable, and laser-etched for clarity, this gauge offers quick and accurate measurements of popular weld fillet sizes. With its stainless-steel build, it’s an essential tool for any welder on the go.

3-PCE Stainless Steel Fillet Welding Gauge

Ideal for MIG, TIG, and STICK welds, this versatile set includes three essential gauges, all packed in a

convenient protective pouch. The design prioritises portability without compromising the accuracy welder’s demand.

Tri-V Stainless Steel Welding Gauge (NAKA Style)

Engineered for multi-purpose verification, this gauge measures weld joint preparation angle, root gap, plate thickness, and more. Its polished stainless-steel construction ensures durability, and it comes with a handy plastic carry case for convenience.

Half Moon Stainless Steel Welding Gauge (CAM Style)

Offering versatility in both inches and millimetres, this gauge measures preparation angles (0° to 60°) and various depths. With general linear measurements up to 50mm (2 inches), it’s a must-have for detailed inspections. A protective pouch ensures easy transport.

More than just tools, WeldaToolz™ gauges are built with reliability and precision in mind. Every product comes with a Conformance Certificate of Accuracy, a testament to our commitment to quality. For welders, this certification provides the peace of mind that their measurements are precise, backed by rigorous standards and engineering integrity.

WeldaToolz is not just a choice; it’s a statement of professionalism that redefines what welders can expect from their precision measurement tools. This article was supplied as part of a paid sponsorship package.

Need help or further details? Contact events@weldaustralia.com.au

Calling all welders, welding supervisors, inspectors, managers, company owners, and anyone involved in the welding industry in Albany, WA.

Mathew Lee (Senior Welding Technologist, Weld Australia) will cover the latest changes to welding fume exposure limits. On 18 January, Safe Work Australia announced that Work Health and Safety Ministers have agreed to an immediate reduction in the workplace exposure standard for welding fumes, from an 8-hour time weighted average (TWA) of 5 mg/m3 to 1 mg/m3. All necessary controls must be implemented to meet this higher standard.

Don’t miss this opportunity to network, learn, and engage with industry leaders and peers. This event is FREE for all to attend, secure your place now.

Perth: 3 to 5 December 2024

Brisbane: 10 to 12 December 2024

Facilitated by US expert, Jim E. Meyer, this three day course provides an introduction to the ASME B31.3 Process Piping Code. It covers the requirements of B31.3 for design, analysis, materials, fabrication, testing and inspection of process piping systems. It explores the rules for various components including fittings, connections, bends, valves and specialty components.

Other topics include dimensions and ratings of components, fluid service requirements for joints, piping flexibility and support, welding, heat treatment, bending and forming, brazing and soldering, assembly, erection, examination and inspection.

Brisbane: 2025 - Date to be confirmed

The ASME code is the American Society of Mechanical Engineers (ASME) standard that regulates the design, development and construction of boilers and pressure vessels. ASME Section IX specifies the requirements for the qualification of welders and the welding procedure specifications.

The course will be facilitated by Walter J. Sperko, P.E., the President of Sperko Engineering Services, a consulting firm specialising in metal fabrication technology. He has particular experience in piping and pressure vessel fabrication, installation, maintenance and repair. Mr. Sperko is also a past-Chairman of the ASME Welding, Brazing and Fusing Standards Committee IX and a member of ASME Subcommittee III, Nuclear Components.

This course is intended for people who are involved in writing and qualifying welding and brazing procedure specifications, qualifying welders, brazers and operators, reviewing suppliers procedures, auditing or reviewing inhouse procedures and qualifications and estimating jobs which impose the requirements of Section IX. Welding Engineers, quality assurance personnel, auditors, testing laboratory personnel, maintenance personnel and jurisdictional inspection personnel will find this course interesting, exciting and beneficial.

With a relaxed, informal setting, Weld Australia’s Industry Drinks Nights are designed to foster connections, inspire new ideas, and cultivate partnerships among Australia’s top welding professionals. Hear from Geoff Crittenden (CEO, Weld Australia) and other industry experts.

Industry Drinks Nights are FREE for Weld Australia members; and $55 for non-members. Cost includes drinks and canapés.

Victoria - Sponsored by Cigweld

• Date: Thursday 27 February 2025

• Time: 6:00pm to 9:00pm

• Venue: Byblos Bar & Restaurant

• Address: 18-38 Siddeley Street, Docklands VIC 3008

New South Wales - Sponsored by TAFE NSW

• Date: Thursday 27 March 2025

• Time: 6:00pm to 9:00pm

• Venue: Cargo Bar

• Address: 52-60 The Promenade, King Street Wharf, Darling Harbour, NSW 2000

For information, contact events@weldaustralia.com.au

Outsource Institute have honed their own training by delivering training directly and through partnerships with the likes of Weld Australia, Custom Fluid Power, Workforce Success, RPR Trades, Solidus IQ and

To address skill shortages in Australia, governments are offering various funding options and incentives to minimise shortages, focus on high-demand jobs in critical industries, and increase the number of individuals with formal post-school qualifications.

“Vital government funding through Outsource Institute advice has proved invaluable. Their commitment to quality matches ours,” said Carl Quarterman, Managing Director,

Outsource Institute can help guide you through the available government funding and the criteria. On top of that they can also help with financing. Stay ahead of the curve while building it.

If you’re ready to commit to a better future and explore funding and training opportunities, reach out to Outsource Institute Training and Development

This article was supplied as part of a paid sponsorship

Weld Australia recently hosted Q&A Career Path Night at Chisholm TAFE in Melbourne. It was an insightful evening, during which attendees learnt all about becoming a boilermaker and the various opportunities available in the welding sector.

They had the chance to hear about first-hand experiences from professionals at different stages of their careers, including an apprentice, tradesperson, welding supervisor, welding inspector, welding coordinator, non-destructive testing technician, and mechanical testing technician.

The speakers included:

• Victor Blain, who gave an opening introduction and hosted the event as MC

• Mathew Billman, who gave a description of the career pathways available in welding

• Bonnie Inkster, an apprentice of the year who described her work on race cars chassis

• Blake McDonald, who spoke about his work on exotic materials and opportunities in Finland and Malaysia

• Andrew Joiner, an expert in destructive and non-destructive testing who spoke about his career and experience

• James Johnson, who has extensive career on iconic projects and responsible welding coordinator

It was a great evening, with amazing speakers who shared some very interesting projects. It was clear how proud all of the speakers are about their work and career, and how passionate they are about welding.

The Q&A session was very informative. There were 40 attendees including some younger students at the stage of deciding what they would like to study. The students had the opportunity to hear positive and diverse experiences from a variety of people involved in the welding industry. It was a great evening promoting opportunities and careers in welding.

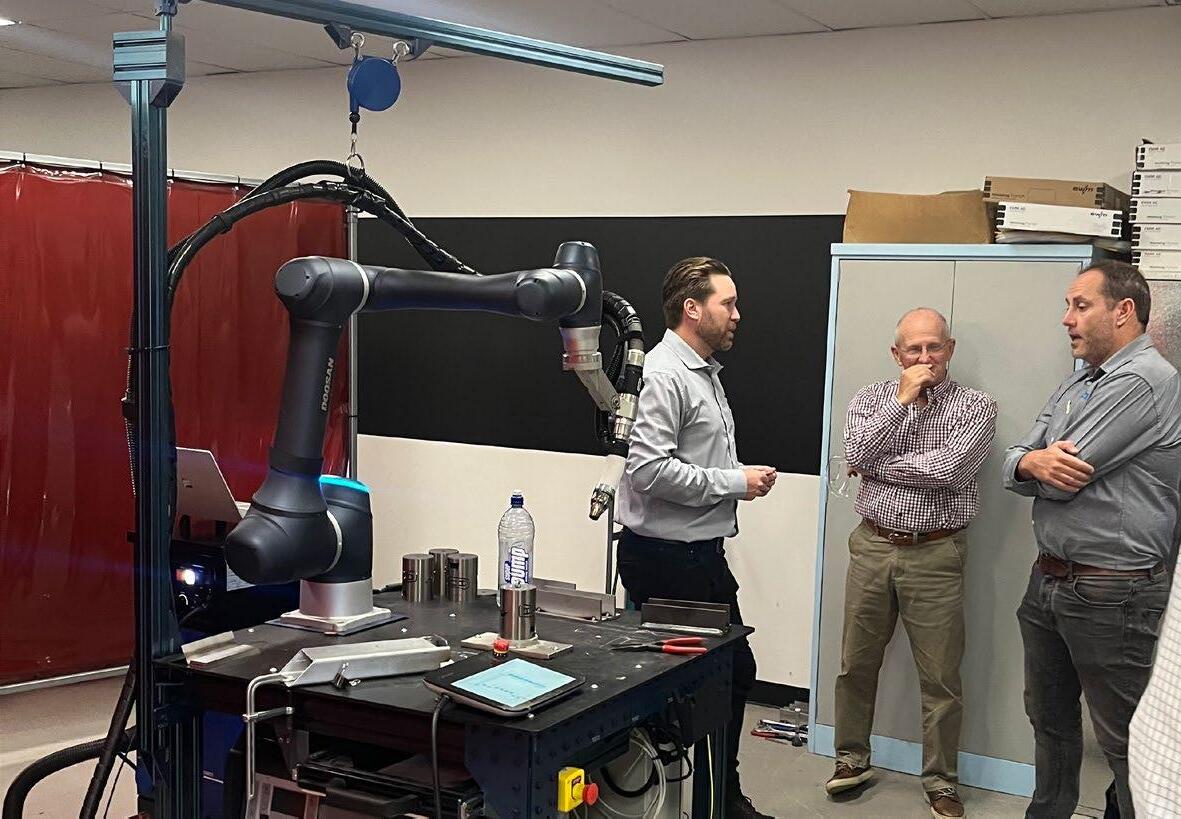

Weld Australia was recently involved in a cobotics roadshow. The exciting, interactive events in both Brisbane and Melbourne showcased the benefits of cobot welding and its applications in welding. The roadshows included:

• Live Demonstrations of cobots in action as they seamlessly integrated into welding processes.

• Expert Insights: Valuable insights from companies who have successfully implemented cobotic welding solutions.

• Q&A Sessions: Attendees had their questions answered by experts and learnt from real-world cobotics experiences.

• Hands-on Experience: Attendees experienced the future of welding training with the state-of-the-art Soldamatic training cobot.

Weld Australia hosted these events in conjunction with the Australian Cobotics Centre, BOC, Diverseco and Industrial Robotics. They were held at Swinburne University’s Intelligent Robotics Lab in Melbourne, and BOC’s Manufacturing Applications Technology Centre at Rocklea in Queensland.

As part of the WorldSkills Australia 2024 Regionals competitions, TAFE Queensland’s Toowoomba campus hosted the first-ever WorldSkills Augmented Reality (AR) Welding VET in Schools (VETiS) Competition over two days in October.

This groundbreaking event featured 20 TAFE at School students competing on state-of-the-art Augemented Reality (AR) welders supplied by TAFE Queensland’s industry partner, Weld Australia. Toowoomba students were the first in the country to compete in this new category, showcasing their skills in a virtual environment.

“This is the very first time we’ve had an augmented reality version of this WorldSkills welding competition,” said Weld Australia Regional Training Manager, Adam Coorey.

The AR welding machines are currently used for training activities and have the ability to score two commonly used industrial welding processes – Gas Metal Arc Welding and Manual Metal Arc Welding. During the competition, the machines assessed competitors’ fine motor skills including position, angle, and speed consistency, as well their ability to set up the welding parameters, and their use of safe welding practices.

“In addition to the students and teachers being able to view real-time results, this technology offers a safer environment when compared to using real welders in a welding bay with Personal Protective Equipment.”

“It’s also a great opportunity for young people to learn more about welding before deciding to pursue a trade career in engineering or manufacturing.”

TAFE at School student, Sam Russell, is part way through a Certificate II in Engineering Pathways (MEM20422) at the Toowoomba campus and he welcomed the opportunity to compete in his first WorldSkills regional competition. “The experience of using an AR welder is still the same, except it’s not as hot,” explained Sam.

Completing a TAFE at School course is providing Sam with foundational industry skills and knowledge in preparation for a future trade career at no cost as he’s eligible for VETiS funding. Graduating from a TAFE at School course can also count towards Sam’s Queensland Certificate of Education (QCE).

“I would like to do a boiler making trade after school and work in the mines,” Sam said

By the end of November, more than 500 regional WorldSkills Australia competitions would have run Australia-wide across 64 skill areas, which cover a diverse range of industries including construction and building, information and communications technology, manufacturing and engineering technology, social and personal services, creative arts and fashion, and transport and logistics.

Regional medallists may be eligible to progress to the WorldSkills Australia 2025 National Championships at the Brisbane Convention and Exhibition Centre to be held in Brisbane from 12-14 June 2025.

Those fortunate enough to be crowned best in their skills area at the Nationals may have the opportunity to represent Australia internationally at WorldSkills International Shanghai 2026.

Weld Australia’s Excellence Awards are one of the most prestigious events on the welding industry calendar. The Awards embody and promote the highest standards of craftsmanship, quality and professionalism. The 2024 Welding Excellence Awards are a fantastic opportunity for welders, fabricators and educators across Australia to showcase their people and their operations. Winners will be awarded in each state for each of the award categories below. Register now to attend the awards ceremonies.

Company of the Year: recognises superior performance across a comprehensive range of business metrics. There are three categories: Fabrication Company, Supplier, and Indigenous Company.

Welding Professional of the Year: recognises professionals making a valuable contribution to the industry with a high level of skill, knowledge or craftsmanship. There are three categories: Welding Coordinator, Welding Supervisor, and Welding Inspector.

Project of the Year: recognises excellence in welding and fabrication projects, with a focus on exceptional craftsmanship, a commitment to quality standards, environmental sustainability and innovation.

Health and Safety in Welding: recognises organisations leading the way in encouraging and promoting health and safety, and ensuring the health and safety of their team.

Trades Person of the Year: recognises tradespeople who are making a valuable contribution to the industry with a high level of skill and dedication. There are three

• Western Australia: Thursday 21 November at Burswood on Swan, 1 Camfield Drive, Burswood

• South Australia: Thursday 28 November at Kooyonga Golf Club, May Terrace, Adelaide

categories: Young Trades Person, Young Indigenous Trades Person, and Trades Person.

Training and Education Award – Organisation: recognises the outstanding achievements of a STEM or VET provider or program, based on delivery of quality, innovative training, involvement with industry, retention of students, and corporate social responsibility.

Training and Education Award – Individual Teacher: recognises the outstanding achievements of a STEM or VET teacher based on quality of delivery, innovation, knowledge, strong links with students, and dedication.

WITH THANKS TO OUR SPONSORS

Star apprentices from the engineering industry were presented awards at the 2024 TAFE QueenslandSkillsTech CSQ Apprentice Awards.

The best and brightest engineering industry apprentices were recognised at the 2024 TAFE Queensland –SkillsTech CSQ Apprentice Awards on Thursday 10 October at the Royal International Convention Centre in Bowen Hills, Brisbane in a night to remember for attendees.

Drawing a crowd of 350 attendees made up mostly of apprentices, their employers, and guests, with industry sponsors and TAFE Queensland staff also in attendance, the event showcased the nation’s top training provider’s very best apprentices across 14 trade categories along with two employer categories.

On the night, there was the Weld Australia Engineering and Manufacturing Apprentice of the Year and the CTIAQ Recreational Vehicle Apprentice of the Year, each awarded to apprentices already showing promising signs as industry leaders for the future.

Lachlan Kemble from MIGAS Apprentices and Trainees won the Weld Australia Engineering and Manufacturing Apprentice of the Year thanks to his tremendous work ethic and dedication to his trade, with the winner already noting his desire to complete further TAFE Queensland study following his apprenticeship. QUEENSLAND’S

Cigweld recently gave away a top-of-the-line multi process welding inverter worth a whopping $8,175 + GST to a lucky Weld Australia member. We’d like to congratulate Steve Parkes (Leading Vocational Teacher TAFE at School, TAFE Queensland) on taking home this fantastic prize.

The new BlueVenom XF353 is a 3-in-1 multi process welding inverter that has been specifically engineered to be narrower in size for easy access in tight and constrained areas but also as a modular arc station. The XF353 can deliver awesome arc characteristics in the most popular processes of MIG (QuickSet and manual modes, gas and gasless operation, single and double pulse MIG with the optional PulseMate™), STICK (MMA with VRD for extra safety) and TIG DC-Lift welding modes. For details on the BlueVenom XF353, visit Cigweld’s website

TAFE Queensland – SkillsTech General Manager

Stephen Gates said the 2024 TAFE Queensland –SkillsTech CSQ Apprentice Awards was, above all else, an opportunity to encourage reflection on the achievements of Queensland’s future industry leaders.

“Every year, this event gives us the opportunity to promote rewarding excellence and engage the employers who train apprentices with us to think about what their apprentices’ best assets are,” Mr Gates said.

“I was lucky enough to be involved in the judging process and it was remarkable to hear about the achievements of our apprentices and their individual stories. There is no one pathway to success in a trade career and that was exemplified by our winners in 2024.”

Novarc Technologies Inc., a full-stack robotics company specialising in the design and manufacturing of cobots and computer vision AI for automated welding applications recently launched NovEye™ Autonomy (Gen 2), a real-time vision processing system that constantly improves weld quality based on data collection and model enhancement to fully automate the pipe welding process while maximising productivity and delivering the highest quality welds.

“NovEye Autonomy (Gen 2) is an industry-first as we have developed the intelligence to fully-automate the welding process,” said Soroush Karimzadeh, CEO of Novarc. “This is an accomplishment that has resulted from years of data collected through machine learning, and we are extremely excited to be able to offer this solution to the industry.”

NovEye Autonomy (Gen 2) is the only AI machine learning real-time vision processing system that constantly improves welds based on data collection and model enhancement. NovEye Autonomy gets smarter as it continuously improves through a terabyte-scale library of welding videos, ensuring unmatched precision and reliability.

The software is embedded in the control system of the cobot and controls the weld pool in exactly the same way a human welder would, allowing the boring, repetitive welds to be delegated to the robot.

The autonomous welding process enables uninterrupted welding due to NovEye Autonomy (Gen 2’s) multi-pass and multi-layer autonomous welding system, which is able to handle real-world pipe fitting inconsistencies like HiLo and varying root gaps. NovEye Autonomy (Gen 2) can immediately detect and adapt welding parameters to maintain weld integrity.

“NovEye Autonomy (Gen 2) is a truly adaptive welding solution with real-time vision processing and an advanced, complex sensory system,” said Karimazadeh. “It’s powered with advanced, real-time control due to its sophisticated AI, and powerful hardware.”

Fabricators and contract manufacturers in Australia and New Zealand are held to strict standards to provide sophisticated welds for industries such as aerospace, food and beverage, mining, energy, pharmaceutical, shipbuilding, chemical processing, and water treatment and desalination. All of these industries stand to benefit from NovEye Autonomy (Gen 2) which enables high quality welds with zero operator intervention, maximising productivity and minimizing errors.

NovEye Autonomy (Gen 2) can also easily integrate into existing manufacturing processes of customers across a range of industries. The Spool Welding Robot - the hardware component of NovEye Autonomy - is designed with a very small footprint, but a very long reach, enabling it to fit in almost all fabrication shops, and easing the adoption of automation.

Automation is a very big milestone for the welding industry, dramatically reducing human exposure to all welding hazards as it positions the operator several meters away from the welding arc and noxious welding fumes.

With NovEye Autonomy (Gen 2), operators can program the weld, and observe the weld away from the arc, reducing the risk of exposure to dangerous fumes and radiant heat. As well, muscle fatigue is reduced as the welding process is fully automated: ultimately, a win-win for the welder and the pipe shop, delivering X-ray quality welds, every time, with zero operator intervention.

NovEye Autonomy (Gen 2) is the result of years of data collected from Novarc’s fleet of SWRs at customer sites in Australia, North America, Europe and the Middle East, and has undergone extensive internal and external testing to ensure all of the features are performing and the weld quality meets ASME standard to ensure unmatched precision and reliability.

This article was supplied as part of a paid partnership agreement.

Rockpress recently underwent audits for both AS/NZS ISO 3834 and EN 15085. Rockpress has been in business since 1972. In the 50 years since then, the company has grown to become one of Brisbane’s most highly-regarded steel fabrication suppliers. While Rockpress can supply ‘off the shelf’ materials in steel and other metals, their real expertise is in manufacturing and fabricating custom-made work, either for one-off projects or in quantities for high volume demand.

Rockpress boasts more than 12,000m2 under roof floor space. All of these capabilities mean Rockpress is more than capable of handling work of any size or volume.

Rockpress recently won the 2024 Project of the Year Award for the LAND 907 project. The LAND 907 Phase 2 program, led by Thomas Global Systems, aimed to enhance the training capabilities of the Australian Defence Force (ADF) through advanced simulation technology. Rockpress’ role was crucial in the development and delivery of the M1A2 Immersive Tactical Trainer (ITT) Mission and Support System, creating a synthetic combined arms training environment that mirrors real-world combat situation.

Chess Engineering also underwent their first surveillance audit after their recertification to ISO 3834.2 at their new premise in Leppington, New South Wales.

Chess Engineering offers leading engineering solutions in Sydney and Perth. Our group of mechanical engineers specialise in fabrication, machining and fitting tasks. We span industry sectors, from structural steel to specific parts for rail, mining, food and defence.

Chess Engineering is firmly established as a reliable steel fabricator, manufacturing to Australian standards of quality and safety. They conceptualise, design, fabricate and install all metals including mild steel, bisalloy, stainless, aluminium, titanium, and so on. Their capacity and technology covers an array of markets including specialisation in: rail rolling stock and track; mining; infrastrucutre; food and beverage; flame proofing; mobile cranes; and general engineering.

Weld Australia would like to congratulate everyone who qualified in October.

• Ninu James

IW INTERNATIONAL WELDING INSPECTORBASIC (IWI-B)

• Ali Halakooee Shirazi

• Ambrose Keogh

• Ardin Masson Court

• Aristotle Bombales

• Clint Harris

• Damien Ebenwaldner

• Desmond Lee

• Jiho Jeon

• Mohsen Forouhideh

• Nathan Henry

• Niall Temple

• Sean Supierz

AS 2214

• Anthony Burke Millard

• Chayce Douglas

• Ethan Doidge

• Jacob Emmerson

• Kwang Hee LEE

• Reece Penman

• Tyson O’Toole

AS 1796 CERTIFICATE 2

• Connor Munckton

• James Haseldine

• Neil Flanagan

• Thomas McDonald

AS 1796 CERTIFICATE 3E

• Benjamin Moore

AS 1796 CERTIFICATE 4

• Connor Munckton

• Fletcher Stasinowsy

• Jack Mattern

• James Haseldine

• Neil Flanagan

• Thomas McDonald

AS 1796 CERTIFICATE 5

• Connor Munckton

• James Haseldine

• Neil Flanagan

• Thomas McDonald

• Aniwat Koetmolee

AS 1796 CERTIFICATE 7

• Reid Saunders

AS 1796 CERTIFICATE 8G

• Aniwat Koetmolee

AS 1796 CERTIFICATE 10

• Darren Ritchie

• Robert Tierney

• Vipin Mohan

AS 1796 CERTIFICATE 11

• Jared Fitzclarence

• Peter Reimann

• Willard Chiweshe

Do you need to book an exam through WeldQ? We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2024, making planning ahead as simple as possible. Upcoming exam dates include:

• Wednesday 13 November: National Welding Supervisor Exam Papers A B1 & B2

• Friday 15 November: IWI S - WIE-S (Session 6) Online exam

• Friday 22 November: National Welding Supervisor - Paper B1 exam - F2F Melbourne

• Monday 2 December: National Welding Supervisor - B papers exam - Session 10

• Wednesday 4 December: WTE-B/WTE-S Online Exam

• Wednesday 11 December: National Welding Supervisor Exam Papers A B1&B2

• Friday 13 December: IWE/T - EA4/TA4 Online Exam

For further information about exams and qualifications, simply email our team via: qnc@weldaustralia.com.au

WELDING SUPERVISORAS 1796 CERTIFICATE 10

Starts 21 January 2025

Welding Supervisors understand the factors that influence welding quality, how to oversee welders effectively, and the variables that help maximise productivity. The AS1796 Certificate 10 meets the requirements of AS 1210 for pressure vessels and AS/NZS 1554.1 for welding of structural steel.

WELDING SUPERVISORAS 2214

Starts 21 January 2025

In this highly engaging course, you’ll cover the welding theory needed to meet the requirements specified in AS 2214 for welding high quality applications using carbon and low alloy steel. It covers welding safety, equipment, practice, production, testing, inspection and more.

IIW INTERNATIONAL WELDING INSPECTOR STANDARD

Starts 29 January 2025

This course provides advanced knowledge of welding and inspection theory and application, including NDT, mechanical and visual inspection techniques, inspection procedures and acceptance criteria, identification of weld imperfections associated with pre-production, fabrication, and post fabrication.

IIW INTERNATIONAL WELDING INSPECTOR BASIC (IWI-B)

Starts 29 January 2025

This course provides general knowledge of welding, inspection theory and application, including: NDT, mechanical and visual inspection techniques, inspection procedures and acceptance criteria, Identification of weld imperfections. It’s run online over five weeks.

IIW INTERNATIONAL WELDING SPECIALIST

Starts 4 February 2025

The IWS course is a globally recognised International Institute of Welding (IIW) qualification. You will gain comprehensive knowledge in the following topics: welding processes and equipment, materials and their behaviour during welding, construction and design, an fabrication, application engineering.

IIW

Starts 13 March 2025