John Deere Operations Center Mobile takes remote management of your field operations and equipment to the next level. The Operations Center Mobile app connects with John Deere Operations Center, empowering you to evaluate expected vs. actual performance of job execution and machine utilization. Powered by an easy, reliable connection between you and your machines through JDLink™ Connect, the Operations Center Mobile app allows you to monitor completed field activities to determine the productivity and quality of each field for a given operation like Seeding, Application, Harvest, and Tillage. Or, enter the activities on non- JDLink™ Connect enabled machines by entering the details manually so that all crop records can be kept in one easy to use tool for reference. The Operations Center Mobile app is truly your solution to view machine and agronomic data anytime and anywhere. Access insights that help you proactively manage your day to day tasks to improve logistics and productivity, as well as increasing confidence that work across the operation is being executed as planned.

Features include:

• View John Deere Operations Center information Plan tab makes it easy for operators to get Work Setup details right in the field by entering plans ahead of time and sending them to equipment

• Easily Analyze all Seeding, Application, Harvest, and Tillage data across your organization

• Dashboard of area worked by operation type and field summary cards

• Field operation performance including quick view maps

• Correct data for elements like variety, product or field size View fields and field boundaries View agronomic information while in poor cell connectivity Add completed work for a complete crop record of activities on the field

• Manage Flags on the map

• View today’s Location History for each machine

• View machine location, hours, fuel levels and performance and efficiency measurements

• Link out to map app for driving directions to machines or fields View machine security and health alerts including diagnostic trouble codes (DTCs) View operator’s in-cab display with Remote Display Access (RDA)

• Partner view of John Deere Operations Center to support growers

Features include:

• Explore Operators Manuals for Deere equipment

• Find parts using equipment model or serial number

• Access work optimization guides and tools

• Contact Western Tractor

View John Deere Operations Center equipment in one place View connected devices

Harvest Data attributes documented and displayed

• Ground speed

• Moisture

• Dry Yield

Wet Yield

Relative Grain Loss

Fan Speed

• Rotor Speed

• Threshing Speed

• Chaffer Opening

• Sieve Opening

• Average Dry Yield

• Average Wet Yield

Average Moisture

• Add equipment to your organization by scanning the serial number

The John Deere Equipment Mobile app allows you to manage, maintain and keep your equipment running. With it, you can prepare equipment for work, access key information from the Operator’s Manual, and find the parts you need.

The app also connects with John Deere Operations Center using JDLink™ Connect, providing an easy, reliable connection between you and your equipment.

Equipment Mobile is your solution to access insights that help you proactively manage day-to-day operations and improve productivity.

• Access machine information – serial number, model year, and software version Connected equipment capabilities such as fuel and hours

John Deere Connect Mobile is a mobile application downloaded onto an iPad to monitor, optimize, and ensure high quality operations; and the best job possible. The Connect Mobile app connects to the machine through a WiFi network to document and display quality, productivity, and agronomic data about the operation. The app works in conjunction with either the GreenStar™ 3 2630 or Generation 4 4600 & 4640 CommandCenter™ displays.

The John Deere Connect Mobile app can be used for planting, spraying, and harvesting operations; and requires no additional hardware with MY18 and newer Connect Mobile ready machines. Other equipment can be fitted with Connect Mobile with an additional field kit. Contact your dealer for details.

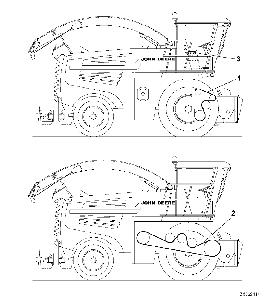

1 AutoTrac™ RowSense™

Take corn harvesting to the next level on a variety of combine platforms. By fusing GPS data from the StarFire™ receiver with data from the universal row sensor, this system delivers hands-free guidance, increasing combine productivity and reducing operator fatigue.

When you put it on your multi-use account. Ask us for details!*

3 QuickLub® Automated Lubrication System

5

Achieve better residue distribution with a wider platform. Adjust your spread width from 35 to 50 ft. (10.6 to 15.2 m). Spreads residue evenly.

See us for details.

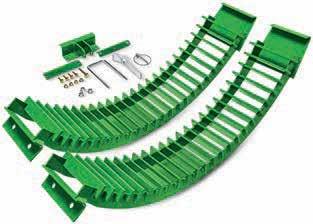

2 Concave Insert Bars

Switch from harvesting large grains to small grains in record time with our easy attachment system.

BH84308 9870 Combines

BH84294 S550 and 9570 Combines

Talk to us today about how attachments can Add More to your combine experience.

ActiveYield™ Retrofit Kit

Save time and labor plus increase wear life. The Quicklub system automatically meters small amounts of grease to moving combine parts at set intervals while in operation.

See Dealer 50 through S Series Combines

4 Additional Grain Tank Sensor

This optional, additional grain tank level indicator helps detect a full grain tank when on side slopes.

BH81598 60 and 70 Series Combines

BXE10270 S Series Combines

6

See Dealer S660, S670, S680 and S690 Combines

Extra-Wide Straw Spreader

Add to a standard straw spreader (twin-disk widespread with integrated chaff spreader) to increase your spread width up to 40 ft. (12.2 m). Recommended when you don’t need fine sizing of crop residue.

BXE10648 9050 Series, 9660, 9760, 9860, 9670, 9770, 9870, S660, S670, S680 and S690 Combines

ActiveYield renders quality yield data by measuring grain weight in the grain tank as it fills. Combines utilize the weight information to continually calibrate yield systems throughout harvest to provide operators optimized system accuracy and reliable yield data.

Part numbers and applications:

BXE10503 MY12-MY-15 S-Series Combines

BXE10797 MY16- S-Series Combines

Center Section Seal Kit

Center Section Seal Kit: Minimizes grain loss when direct-cutting Canola and can be utilized for other small grain crops with up to 45 percent decrease in losses from the center feed section compared to previous models.

Part number and applications: BXE10851 600D, 700D Series

Additional Grain Tank Sensor

The fast easy way to let you know when your combines grain tank is full on slopes and hills.

In-cab mobile devices mounting brackets

We’ve made it easier and more convenient for you to have hands-free access and improved viewing of your iPad, iPhone, or other mobile device from the seat of your cab. They’re easily accessible and don’t interfere with visibility and machine controls. Even better, they’re customizable to ft your specific cab needs.

Part number: KXE10454 Foot Pegs

Pull-Down Sun Shade

Improve operator comfort with this simple upgrade. Foot pegs can be installed on all S-Series Combines going back to MY12.

This kit reduces wrapping of crop material in tough, wet, viney crops such as soybeans, peas, straight-cut edible beans, and canola. The reel tine flip-over kit also increases visibility to the front of the draper.

The pull-down shade for the front windshield improves operator visibility on sunny days by blocking the sun’s bright light and reducing glare. The pull-down sunshade allows the operator flexibility in the amount of window coverage desired through an infinitely adjustable range of movement.

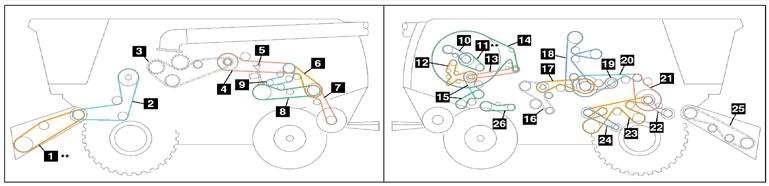

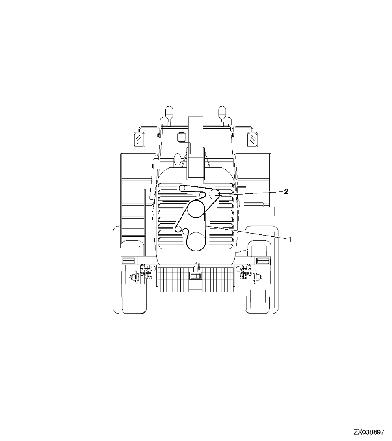

*HXE175042 1 Front end secondary drive (fixed)

(1000, 1100)

HXE168680 14 Rotary screen

HXE125617 15 Fan drive belt

1100)

(1000, 1100)

(1000, 1100)

(1000, 1100)

(1000, 1100)

(1000, 1100)

(1000, 1100)

(1000, 1100)

** Feederhouse Variable drive pictured

HXE45928 1 Var Fdr Hse (High Torque)

HXE50398

H203474

HXE95935

H229018

H156796

AXE53952

AXE79735

HXE45928 1 Var Fdr Hse (High Torque)

H218726 1 Var Fdr Hse (Hvy Duty)

HXE47152 1 Fixed Fdr Hse Drive

HXE50399 1 Var Fdr Hse (High Torque-FORE AFT)

H229019 1 Fixed Fdr Hse Drive (5Speed)

1 Fixed Fdr Hse (Std Duty)

2 5 Speed to Fdr Hse

H174885 1 Fixed Fdr Hse (Hvy Duty & Hi Torq)

1 Fixed Fdr Hse (Hvy Duty & Hi Torq-FORE AFT)

2 E-Clutch to Fdr Hse (Hvy Duty)

3 Unloader-Chain (150% Unload Rate)

2 E-Clutch to Fdr Hse (Std Duty)

MY 12/13/14/15/16 (S660, S670, S680, S690)

HXE124868

MY12/13 (S660, S670)

MY14 (S670, S680)

MY15/16 (S660, S670)

MY14/15/16 (S660, S670)

MY12 (S650)

MY13/14/15/16 (S660)

MY 12/13 (S670, S680, S680HM, S690,S690HM)

MY 14 (S670, S680, S690, S690HM)

MY15/16 (S670, S680, S690)

MY 15/16 (S670, S680, S690) (5Speed--FORE AFT)

MY 12/13/14/15/16 (S660, S670, S680,

3 Unloader-Chain (400BU, 3.8BU/SEC) S690)

MY15/16 (S660, S670, S680, S690)

MY12/13 (S650, S660)

MY 12/13/14/15/16 (S660, S670, S680, S690)

MY 12/13/14/15/16 (S670, S680, S690)

MY 12/13/14 (S660)

MY 12/13/14/15 (S660, S670)

MY 12/13/14/15/16 (S680, S690)

AXE53952 3 Unloader-Chain (#60H Roller Chain) MY 16 (S660, S670)

(3HC) FC S680HM, S690,S690HM)

MY 14 (S660, S670, S680, S690, S690HM)

MY15/16 (S660, S670, S680, S690)

H241000 6 PTO to Chopper Jackshaft MY12/13 (S670) 4HC - 9.0L XFC

H240888 6 PTO to Chopper Jackshaft MY 12/13 (S680, S680HM, S690, 4HC - 13.5L XFC S690HM)

MY 14 (S660, S670, S680, S690, S690HM)

H X E 124869 7 St r Chopper J'Shaft to Str Chopper MY 12/13 (S660, S670, S680, (2HC) FC S680HM,S690,S690HM) MY 14 (S660, S670, S680, S690, S690HM)

MY15/16 (S660, S670, S680, S690)

H240974 7 Str Chopper J'Shaft to Str Chopper MY 12/13 (S660, S670, S680, (3HC) XFC S680HM,S690,S690HM)

MY 14 (S660, S670, S680, S690, S690HM)

H240972 7 Str Chopper J'Shaft to Str Chopper MY 12/13 (S660, S670, S680, (1HC) XFC

HXE15556 8 Discharge Beater 1HC S680HM,S690,S690HM)

MY 14 (S660, S670, S680, S690, S690HM)

HXE124870

MY 12/13/14/15/16 (S660) 8 Discharge Beater 2HC Set

MY 12/13/14/15/16 (S660, S670, S680, S690)

HXE69280 9 ATB - AFTERTREATMENT MY 14/15/16 (S660, S670) BLOWER DRIVE) 9L

HXE69281 9 ATB - AFTERTREATMENT MY 14 (S680, S690, S690HM) BLOWER DRIVE) 13.5L MY 15/16 (S680, S690)Key Model

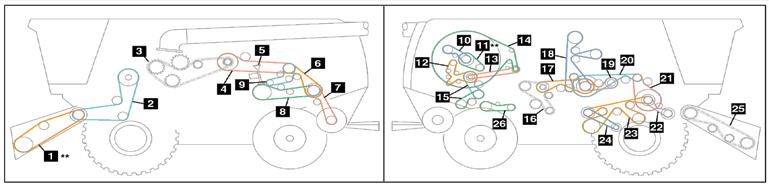

*Class VI, VII, and VIII combines only

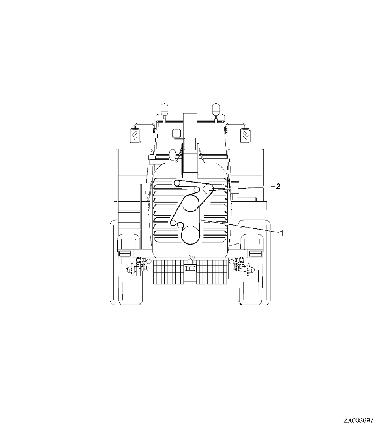

**Engine fan Variable speed pictured

Part

HXE71061 10 AIR COMPRESSer Drive MY16 (S680, S690) (13.5L iT4 & FT4)

HXE71043 10 AIR COMPRESSOR Drive MY16 (S660, S670) (9.0L iT4 & FT4)

HXE32548 11 Engine Fan Belt 13.5L MY 12/13 (S680, S680HM, S690,S690HM) MY 14 (S680, S690, S690HM) MY15/16 (S680, S690)

HXE22617 11 Engine Fan Belt Variable 9.0L MY 12/13/14/15/16 (S660, S670)

H238831 12 Engine Alternator Belt 13.5L MY 12/13 (S680, S680HM, S690,S690HM)

MY 14 (S680, S690, S690HM) MY15/16 (S680, S690)

H238822 12 Engine Alternator Belt 9.0L MY 12/13/14/15/16 (S660, S670)

H238867 13 Rotary Screen Drive (Engine Side)

H221273

MY 12/13/14/15/16 (S660, S670, S680,S690)

MY15/16 (S660, S670, S680, S690) 14 Rotary Screen Drive (Screen Side) MY 12/13 (S550, S660, S670, S680, S680HM, S690,S690HM)

MY 14 (S660, S670, S680, S690, S690HM)

MY15/16 (S660, S670, S680, S690)

HXE38073 15 Vacuum Fan Drive 13.5L MY 12/13 (S680, S680HM, S690,S690HM) MY 14 (S690, S690HM)

MY15/16 (S680, S690)

HXE68015 15 Vacuum Fan Drive 9.0L Upper MY 12/13/14/15/16 (S660, S670)

HXE68016 15 Vacuum Fan Drive 9.0L Lower

AXE17053 16 Tailings Rethresher Chain

AXE23140 16 Tailings Rethresher Chain

H240895 17 Tailings Rethresher Belt

MY 12/13/14/15/16 (S660, S670)

MY 12/13 (S670, S680, S680HM, S690,S690HM)

MY 14 (S670, S680, S690, S690HM)

MY 15 (S680,S690)

MY 12/13 (S680, S680HM,

MY 14 (S670, S680, S690, S690HM)

MY15/16 (S680, S690)

H218645 18 Clean Grain Elev MY 12/13 (S550, S660) MY 14 (S660, S670) MY15/16 (S660)

H223230 18 Clean Grain Elev Mod HD MY 12/13 (S670, S680, S680HM, S690, S690HM)

MY 14 (S670, S680, S690, S690HM) MY15/16 (S670, S680)

HXE20763 18 Clean Grain Elev 2HB MY 12/13 (S690) MY 14 (S690, S690HM) MY15/16 (S690)

H154731 19 Tailings Elev MY 12/13 (S550, S660) MY 14 (S660) MY15/16 (S660, S670)

H154723 20 P'Shaft to Elev J'Shaft MY 12/13 (S550, S660, S670, S680, S680HM, S690, S690HM) MY 14 (S670, S680, S690, S690HM) MY15/16 (S670, S680)

AH150678 21 P'Shaft to Feed Accelerator J'Shaft MY 12/13 (S660, S670, S680, S680HM, S690, S690HM) MY 14 (S660, S670, S680, S690, S690HM) MY15 (S660, S670, S680, S690)

HXE95511 22 Feed Accel-Std Spd Hi-Cap 440/800 RPM

HXE152482 22 Feed Accelerator-Slow Spd Kit 320/790 RPM

HXE82335 23 Shoe Drive (Gates)

HXE102288 23 2HC Shoe Drive(Gates

HXE15594 24 Cleaning Fan (Std Spd)

HXE99294 24 Cleaning Fan (w. 2HC shoe drive)

AXE80366 25 FH Right Hand chain drive

HXE88564 21 P'Shaft to Feed Accelerator J'Shaft MY16 (S660, S670, S680, S690)

AXE80368 25 FH Right Hand chain drive

H240895 26 Overshot Beater

MY 12/13 (S550, S660, S670, S680, S680HM, S690,S690HM) MY 14 (S660, S670, S680, S690, S690HM)

MY15/16 (S660, S670, S680, S690)

HXE54503 22 Feed Accelerator Hi Spd Hi Cap MY 12/13 (S550, S660, S670, S680, S680HM, S690, S690HM) MY 14 (S660, S670, S680, S690, S690HM)

MY 12/13/14/15/16 (S660, S670, S680, S690)

MY 12/13/14/15 (S660, S670, S680, S690)

MY16 (S660, S670, S680, S690)

MY 12/13/14/15 (S660, S670, S680, S690)

MY16 (S660, S670, S680, S690)

MY 12/13 (S550, S660, S670, S680, #60H, 189 LINKS S680HM, S690,S690HM)

MY 14 (S660, S670, S680, S690, S690HM)

MY15/16 (S660, S670, S680, S690)

MY15/16 (S660, S670, S680, S690) #60H, 181 LINKS

MY 12/13 (S670, S680, S680HM, S690, S690HM)

MY 14 (S670, S680, S690, S690HM)

MY15/16 (S670, S680, S690)

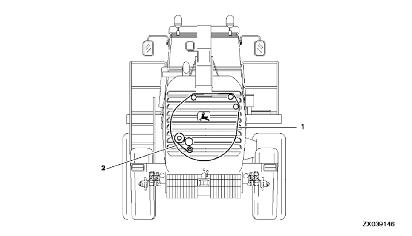

Part

H174885 1 Fixed speed feederhouse 9870, 9860 (extra heavy-duty)

H229019 1 Fixed speed feederhouse 9870, 9770 (multi-speed feederhouse drive)

H203474 1 Fixed speed feederhouse 9770, 9670, 9860, 9760, 9660

H218726 1 Variable speed feederhouse drive 9770, 9670, 9860, 9760, 9660

HXE45928 1 Variable speed feederhouse drive 9770, 9670, 9860, 9760, 9660 (high speed)

H201334 1 Variable drive feederhouse 9660 (standard capacity)

HXE95935 2 Header and reel pump 9870, 9770, 9670, 9860, (variable speed) 9760, 9660

H229018 2 Header and reel pump 9870, 9770 multi-speed feederhouse drive

H156796 2 Header and reel pump 9770, 9670, 9860, 9760, 9660 speed)

AH160080 3 Unloading auger system 9870, 9770, 9670, 9860, 9760, 9660

HXE147321 4 Variable rotor drive 9870, 9770, 9860 (705798-)

HXE150557 4 Variable rotor drive 9670, 9760, 9660

H207851 4 Variable rotor drive 9860 (-705797)

HXE10501 5 Countershaft, discharge beater, 9870, 9770 and chopper, heavy-duty

H201596 5 Countershaft, discharge beater, 9860 and chopper, heavy-duty

HXE10556 5 Countershaft, discharge beater, 9870, 9770, 9670 and chopper, standard-duty

HXE15671 5 Countershaft, discharge beater, 9860, 9760, 9660 and chopper

H223212 6 Straw chopper 9870, 9770

H232997 6 Straw chopper 9670

H235564 6 Straw chopper 9760, 9660

H220747 6 Straw chopper 9860

H217352 6 Straw chopper, premium grain 9860

H219182 7 Discharge beater 9860, 9760, 9660

H219182 7 Discharge beater 9870, 9770, 9670

R503505 8 Alternator 9870, 9860

DZ118855 8 Alternator, 95 amp 9760, 9660

Part

DZ118861 8 Altenator, 185 amp 9760, 9660

HXE32806 8 Alternator, 200 amp 9770, 9670, 9760, 9660

DZ119641 9 Engine fan 9870, 9860

H213353 10 Rotary screen drive, engine side 9870, 9770, 9670, 9860 (715601-), 9760 (715501-), 9660 (715401-)

H206807 10 Rotary screen drive, engine side 9860 (-715600), 9760 (-715500), 9660 (-715400)

H221273 11 Rotary screen drive, screen side 9870, 9770, 9670

H175628 11 Rotary screen drive, screen side 9860 (-715600), 9760 (-715500), 9660 (-715400)

H214241 11 Rotary screen drive, screen side 9860 (715601-), 9760 (715501-), 9660 (715401-)

H223230 12 Clean grain elevator 9870, 9770

H218645 12 Clean grain elevator 9670, 9860, 9760, 9660

H154723 13 RH jackshaft, rear 9870, 9770, 9670, 9860, 9760, 9660

AH150678 14 RH jackshaft, front 9870, 9770, 9670, 9860, 9760, 9660

H154731 15 Tailings auger and elevator 9870, 9770, 9670, 9860, 9760, 9660

H230909 16 Cleaning fan 9870, 9770, 9670

H206048 16 Cleaning fan 9860, 9760, 9660

H215389 16 Cleaning fan, slow speed 9870, 9770, 9670

H211601 16 Cleaning fan, slow speed 9860, 9760, 9660

HXE82335 17 Shoe fan and conveyor augers 9870, 9770, 9670, 9860, 9760, 9660

HXE54503 18 Feed accelerator, high speed 9870 (730101-), 9770 (730101-), 9670 (730101-)

H221733 18 Feed accelerator, high speed 9870 (-730100), 9770 (-730100), 9670 (-730100), 9860, 9760, 9660

HXE152482 18 Feed accelerator, slow speed 9870, 9770, 9670, 9860, 9760, 9660

HXE95511 18 Feed accelerator, standard speed 9870, 9770, 9670, 9860 (715601-), 9760 (715501-), 9660 (715401-)

H221731 18 Feed accelerator, standard speed 9860 (-715600), 9760 (-715500), 9660 (-715400)

HXE45928 1 Var Fdr Hse (High Torque)

HXE50399 1 Var Fdr Hse (High Torque-FORE AFT) MY18 (S760, S770)

H218726 1 Var Fdr Hse (Hvy Duty)

H229019 1 Fixed Fdr Hse Drive (5Speed)

HXE47152 1 Fixed Fdr Hse Drive

(5Speed--FORE AFT)

HXE50398

H229018

HXE95935

MY18 (S760)

MY 18 (S770, S780, S790)

MY18 (S770, S780, S790)

H174885 1 Fixed Fdr Hse (Hvy Duty & Hi Torq) MY 18 (S760, S770, S780, S790)

2 5 Speed to Fdr Hse

2 E-Clutch to Fdr Hse (Hvy Duty)

AXE79735 1 Fixed Fdr Hse (Hvy Duty & Hi Torq-FORE AFT)

3 Unloader-Chain (400BU, 3.8BU/SEC)

MY18 (S760, S770, S780, S790)

MY18 (S770, S780, S790)

MY 18 (S760, S770, S780, S790) MY 18 (S780, S790)

AXE53952 3 Unloader-Chain (#60H Roller Chain) MY 18 (S760, S770)

AH160080 4 Unloader-Belt matched set MY 18 (S760, S770)

AH233198 4 Unloader-Belt Hi Cap matched set MY 18 (S780, S790)

HXE150557 5 Rotor Dr (Std Duty)--Carlisle MY 18 (S760, S770)

HXE147321 5 Rotor Dr (Hvy Duty-Lrg Shv)--Gates MY 18 (S780, S790)

HXE124868 6 PTO to Chopper Jackshaft (3HC) FC

HXE15556

HXE124870 8 Discharge Beater (1HC) 8 Discharge Beater 2HC Banded

HXE69280 9 ATB - AFTERTRE ATMENT BLOWER DRIVE) 9L

HXE69281 9 ATB - AFTERTRE ATMENT BLOWER DRIVE) 13.5L

MY 18 (S760, S770, S780, S790)

H X E12486 9 7 Str C hopper J Shaft to Str C hopper M Y 1 8 ( S 760 , S770 , S780 , S79 0 ) (2HC) FC

MY18 (S760) MY 18 (S760, S770, S780, S790)

MY 18 (S760, S770)

MY 18 (S780, S790) Model

**Engine fan Variable speed pictured ** Feederhouse Variable drive pictured

HXE71061 10 AIR COMPRESSer Drive (13.5L iT4 & FT4)

HXE71043 10 AIR COMPRESSOR Drive (9.0L iT4 & FT4)

HXE32548 11 Engine Fan Belt 13.5L

H221273

HXE22617 11 Engine Fan Belt Variable 9.0L

H238831 12 Engine Alternator Belt 13.5L

HXE68016 15 Vacuum Fan Drive 9.0L Lower

AXE54619 16 Tailings Rethresher Chain

H154731 19 Tailings Elev

H223230 18 Clean Grain Elev Mod HD

HXE20763 18 Clean Grain Elev 2HB

H154723 20 P'Shaft to Elev J'Shaft

MY 18 (S780, S790)

MY 18 (S760, S770)

MY 18 (S780, S790) MY 18 (S760, S770)

H238822 12 Engine Alternator Belt 9.0L MY 18 (S780, S790) MY 18 (S760, S770)

H238867 13 Rotary Screen Drive (Engine Side) MY 18 (S760, S770, S780, S790)

HXE38073 15 Vacum Fan Drive 13.5L MY 18 (S780, S790)

HXE68015 15 Vacuum Fan Drive 9.0L Upper MY 18 (S760, S770)

MY 18 (S760, S770)

MY 18 (S780, S790)

H240895 17 Tailings Rethresher Belt 14 Rotary Screen Drive (Screen Side) MY 18 (S760, S770, S780, S790)

MY 18 (S780, S790)

H218645 18 Clean Grain Elev MY 18 (S760)

HXE152482 22 Feed Accelerator-Slow Spd Kit 320/790 RPM

HXE54503 22 Feed Accelerator Hi Spd Hi Cap

HXE95511 22 Feed Accel-Std Spd

HXE102288 23 2HC Shoe Drive (Gates)

HXE99294

AXE80366 #60H, 189 LINKS

MY 18 (S770, S780)

MY 18 (S790)

MY 18 (S760, S770)

MY 18 (S760, S770, S780, S790)

HXE88564 21 P'Shaft to Feed Accelerator J'Shaft MY18 (S760, S770, S780, S790)

MY 18 (S760, S770, S780, S790)

MY 18 (S760, S770, S780, S790)

AXE80368 25 FH Right Hand chain drive #60H, 181 LINKS

H240895 26 Overshot Beater

MY 18 (S760, S770, S780, S790)

MY 18 (S760, S770, S780, S790) 24 Cleaning Fan (w. 2HC shoe drive) MY18 (S760, S770, S780, S790)

25 FH Right Hand chain drive MY 18 (S760, S770, S780, S790)

MY 18 (S760, S770, S780, S790)

MY 18 (S770, S780, S790)

This camera is a plug-and-play solution for 2017 and newer John Deere S-Series combines factory fitted with mounts and wiring for cameras overseeing the unloading auger, grain tank, and rear view.

• Compatible with Greenstar 3 2630 & CommandCenter GPS

• Direct plug & play

• Mounting bracket features 4-hole bolt pattern for direct fitment

• Includes all mounting hardware (not shown)

SPECIFICATIONS

• Weatherproof

• Color video with audio, Image mirroring capable

• 110° Viewing Angle

• Automatic Infrared Illuminators allow night vision to 32’

These cameras and cables are not compatible with standard CabCAM™ camera observation systems

To learn

Stalk rolls:

NUMBER ITEM/DESCRIPTION

HXE11079 Opposed LH

HXE11080 Opposed RH

HXE11081 Fluted LH

HXE11082 Fluted RH

HXE41139 Intermeshing LH

HXE41140 Intermeshing RH

HXE41141 Opposed LH

HXE41142 Opposed RH

HXE41143 Fluted LH

HXE41144 Fluted RH

H150691 Knife, left-hand

H104091 Tapered hard-faced, left-hand

H104090 Tapered hard-faced, right-hand

Deck plates:

H94952 Left-hand, right-hand

N102069 Left-hand

N102068 Right-hand

AH147773 Hard-faced, left-hand (hydraulic)

Auger:

H84583 Auger paddle

H149629 Auger paddle

AN102010 Bearing, row unit and cross auger

AFH205780 Cross auger idler sprocket

H166582 Ear gate

NUMBER ITEM/DESCRIPTION

Gathering chain and guides:

AH208978 Gathering chain, chrome pin

AH234578 Gathering chain, chrome pin

AH233138 Gathering chain, black pin, import

AH233139 Gathering chain, black pin

AN102009 Gathering chain, black pin

AH229064 Gathering chain, black pin, import

AH136671 Gathering chain, chrome pin

H118945 Chain guide

H151211 Chain guide

Gathering chain sprockets:

H233287 Drive sprocket

AXE36872 Drive sprocket

AH231386 Idler sprocket

AXE18770 Idler sprocket

H85252 Drive sprocket, upper

AH101219 Drive sprocket, lower

AN102448 Drive sprocket, lower

H154270 Hard-faced: left-hand and right (manual); right-hand (hyd.)

600 Series (-745100)†

600 Series (-745100)†

600 Series (-745100)†

600 Series (-745100)†

600 Series (745101-)†

600 Series (745101-)†

600 Series (745101-)†

600 Series (745101-)†

600 Series (745101-)†

600 Series (745101-)†

40 and 90 Series*

H150139 Straight futed, left-hand 90 Series

H150138 Straight futed, right-hand 90 Series

H150690 Knife, right-hand 40 and 90 Series*

and 90 Series

and 90 Series

Series (466451-)

Series (-466450)

Series (-466450)

Series

Series

Series MY12

and 90 Series*

and 90 Series*

and 90 Series*

and 90 Series (660709-)

Series (-660708)

Series MY08-11

Series MY12

Series MY08-11

Series MY12

and 90 Series

Series

Series (466450-) and 90 Series*

Series (-466450) and

Unlike long cutterbars, our sectionalized knives are easy to transport in the bed of your truck. Plus, splice and joint kits allow for lightning-fast assembly and an extra strong hold; no drilling required. Available for 3-inch and 4-inch knife drive systems.

Middle

Tail section:

Joiner Section:

AXE28958 Small-wire,

AXE28960

AXE28962

AXE28964 Large-wire, mid/rear

AXE28965 Extended wear, large-wire, front

AXE28966

AH210894 KIT–60 Series Latch

NUMBER

*Does not ft 9560 STS or S550 Combines. **Required for frst-time installation on 50 Series STS.

DESCRIPTION

AH124852

and 94-9650

AXE12921

unloading

STS and

MODEL/TYPE

AH164070 Vertical unloading, regular unload rate, high wear

AXE17156

AXE18070 Vertical unloading, high unload rate, high wear S660-S690, S760-S790

AH124852 Vertical unloading 94-9600, CTS, 94-9610, and 94-9650

AXE12921 Vertical unloading 96-9860 STS and 96-9870 STS

AH164070 Vertical unloading, regular unload rate, high wear 50 Series STS, 95-9660 STS, and 95-9670 STS

AXE17156 Vertical unloading, regular unload rate, high wear S660-S690, S760-S790

AH146840 Vertical unloading, regular unload rate, high wear 50 Series STS, 95-9660 STS, and 95-9670 STS

AXE17155 Vertical unloading, regular unload rate, standard wear S660-S690, S760-S790

AH112435 Horizontal unloading (inner) 8820, 94-9600, CTS, 94-9610, 94-9650, 959660, 50 Series STS, 9560 STS and 9570 STS

AXE56290 Horizontal unloading (inner) 96-9860 STS, 96-9870 STS, and S660-S690

AH143731 Horizontal unloading (outer) 6620, 94-9600, CTS, 94-9610, 94-9650, 9560, and 50 Series STS

AH146840 Vertical unloading, regular unload rate, high wear 50 Series STS, 95-9660 STS, and 95-9670 STS

AXE17155 Vertical unloading, regular unload rate, standard wear S660-S690 $ 601.16 $ 553.09

AH203021 Horizontal unloading (outer) 96-9860 STS, 96-9870 STS, and S660-S690

AH218485 Clean grain loading 94-9650, CTS, 95-9660, 96-9860 STS, 9670 STS, 9770 STS, S660, S670, S760 and S770

AH112435 Horizontal unloading (inner) 8820, 94-9600, CTS, 94-9610, 94-9650, 95-9660, 50 Series STS, 9560 STS, and 9570 STS $ 722.30 $ 664.49

AH233419 Clean grain unloading S670-S690, S780-S790

AXE56290 Horizontal unloading (inner) 96-9860 STS, 96-9870 STS, and S660-S690 $1,515.75 $1,394.49

AXE18081 Grain tank, cross front, high unload rate, high wear S660-S690, S760-S790

AH143731 Horizontal unloading (outer) 6620, 94-9600, CTS, 94-9610, 94-9650, 9560, and 50 Series STS $ 950.96 $ 874.89

AXE18077 Grain tank, cross front 94-9500, 94-9510, CTS, 94-9550, 9560, 50 Series STS, 96-9760 STS, 95-9670 STS, S550, and S660

AXE18078 Grain tank, cross rear, regular unload rate, high wear 94-9500, 94-9510, CTS, 94-9550, 9560, 50 Series STS, 96-9760 STS, 95-9670 STS, S550, and S660

AH203021 Horizontal unloading (outer) 96-9860 STS, 96-9870 STS, and S660-S690

$1,368.75 $1,259.29

AXE18082 Grain tank, cross rear, high unload rate, high wear S660-S690, S760-S790

AH218485 Clean grain loading 94-9650, CTS, 95-9660, 96-9860 STS, 9670 STS, 9770 STS, S660, and S670 $ 672.81 $ 618.99

AH233419 Clean grain unloading S670-S690 $ 889.72 $ 818.49

AH162442 9600 and 9610

NUMBERMODEL/TYPE

AXE18077 Grain tank, cross front 94-9500, 94-9510, CTS, 94-9550, 9560, 50 Series STS, 96-9760 STS, 95-9670 STS, S550, and S660 $ 874.69 $ 804.69

AH162058 9050 and 9060 Walker and CTS

AH87747 6600, 6620, 7700, 7720, and 8820 (-464350)

AXE28559

AH134818 8820 (464351-)

AXE18081 Grain tank, cross front, high unload rate, high wear

S660-S690 $ 958.94 $ 882.19

AH162441 9400 and 9410 CTS and CTS II

AH162442 9600 and 9610

AH162058 9050 and 9060 Walker and CTS

9650, 9750, 9660, 9760, 9860, 9570, 9670 STS, S550, S660, and S670

$ 931.84 $ 857.29

AXE28560 9770, 9870 STS, S670, and S680

$416.49

AXE16681 S690

AXE18078 Grain tank, cross rear, regular unload rate, high wear 94-9500, 94-9510, CTS, 94-9550, 9560, 50 Series STS, 96-9760 STS, 95-9670 STS, S550, and S660

AXE28559 9650, 9750, 9660, 9760, 9860, 9570, 9670 STS, S550, S660, and S670

$401.79

AXE17053 S680 and S690

S660-S690 $ 958.94 $ 882.19

AXE10556 S680 and S690

AXE18082 Grain tank, cross rear, high unload rate, high wear

AH148021 9050 Series STS, 95–9860 STS, 95–9870 STS, S550, S660, and S670

$198.09

AXE72667 S780 and S790 Clean Grain

AXE47615

AXE28560 9770, 9870 STS, S670, and S680

S780 and S790 Tailings

$630.69

AH148021 9050 Series STS, 95–9860 STS, 95–9870 STS, S550, S660, and S670

With the correct concave configuration, you can enhance combine performance in a wide variety of crops and conditions. Use the concave guidelines below to determine how you can increase the threshing capacity of your John Deere STS or S Series combine For specialty and seed crops, always use the best-rated concave configuration.

With the correct concave configuration, you can enhance combine performance in a wide variety of crops and conditions. Use the concave guidelines below to determine how you can increase the threshing capacity of your John Deere STS or S Series combine For specialty and seed crops, always use the best-rated concave configuration.

SMALL GRAINS (WHEAT, BARLEY) RICE SMALL

CORN SOYBEANS

CROP TYPE

CROP TYPE

CROP TYPE

(WHEAT, BARLEY)

FOOD CORN MILO/SORGHUM, SUNFLOWERS (CONFECTION)SUNFLOWERS (OIL)

POPCORN, FOOD CORN

MILO/SORGHUM, SUNFLOWERS (CONFECTION)SUNFLOWERS (OIL)

SMALL WIRENOT RECOMMENDEDNOT RECOMMENDEDNOT

SMALL WIRENOT RECOMMENDEDNOT

1. Large-wire concaves are not recommended for corn with moisture above 25 percent. Matting of green, leafy material significantly reduces separating capacity.

2. Optional threshing inserts are available to improve threshing ability in tough threshing varieties or conditions.

1. Large-wire concaves are not recommended for corn with moisture above 25 percent. Matting of green, leafy material significantly reduces separating capacity.

4. Optional concave cover plates are available to improve threshing ability and sample cleanliness (white caps, snapped heads, unthreshed pods). Recommended for tough, damp, hard-to-thresh conditions only. Removal of every other wire is recommended for best grain quality results.

5. Optional Kondex® MaxThresh™ Concave in the first section to improve threshing.

2. Optional threshing inserts are available to improve threshing ability in tough threshing varieties or conditions.

3. Optional concave threshing inserts are required in the first concave to improve threshing ability. Tough threshing conditions may require additional threshing inserts in the second and third concave sections.

3. Optional concave threshing inserts are required in the first concave to improve threshing ability. Tough threshing conditions may require additional threshing inserts in the second and third concave sections.

THRESHING INSERTS

4. Optional concave cover plates are available to improve threshing ability and sample cleanliness (white caps, snapped heads, unthreshed pods). Recommended for tough, damp, hard-to-thresh conditions only. Removal of every other wire is recommended for best grain quality results.

6. Optional Kondex® MaxRound™ Concave in the first section to improve threshing.

5. Optional Kondex® MaxThresh™ Concave in the first section to improve threshing.

6. Optional Kondex® MaxRound™ Concave in the first section to improve threshing.

Concave Inserts (9560, 9570, S550):

BH84294 Set of 2 John Deere

BH84308 Set of 2 John Deere

Concave inserts provide the additional threshing action required for harvesting small grains with the round bar concaves. Concave inserts are easy to install and remove as you switch between crops.

Concave Inserts (9650, 9750, 9660, 9760, 9860, 9670, 9770, 9870, S650, S660, S670, S680, S690):

Exclusive to John Deere, Revolution™ concaves provide more versatility to match varying crops and conditions. Plus, they are light and easy to change and install. Available for S-Series and STS Combines.*

BXE11144 MaxThresh™ Kit

BXE11145 MaxRound™ Kit

AXE76998 Plate, Concave Front Lip

AXE76999 Concave, Half Width, MaxThresh

AXE77000 Concave, Half Width, MaxRound

BXE11457 Kondex Revolution Small Grain Bundle

BXE11458 Kondex Revolution Coarse Grain Bundle

AXE91114 Single Kondex Revolution MaxThresh Small Slot Concave

*Not available for 9560 STS, 9570, or S550 Combines.

The sectionalized concave covers help to provide additional threshing in the concave area when harvesting hard-to-thresh-type cereal crops. They can also help to reduce white caps and increase grain tank cleanliness.

BH84534 Small Wire and Large Wire Covers

BH84535 Round Bar Covers

Separator grate covers are used to reduce chaff load and alter distribution of material to cleaning shoe. Up to 20 covers may be used. Covers are recommended in small grains but should not be used during corn harvest. Part numbers BXE10645 (Standard Grate) or BXE10646 (HD Grate).

BXE10645 Covers (Set of 4)

BXE10646 HD Covers (Set of 20)

The HD separator grate is a welded separator grate while the standard separator grates are single-piece casted steel. HD separator grates are stiffer and more robust than the standard separator grates for increased performance in tough threshing crops like tough straw and green stemmed beans.

All threshing elements listed below are available in kits of (3) only. To maintain rotor balance, all three must be installed in a row around the circumference of the rotor.

All threshing elements listed below are available in kits of (3) only. To maintain rotor balance, all three must be installed in a row around the circumference of the rotor.

NUMBER DESCRIPTION

KXE10755 LH Threshing Element Kit

NUMBER DESCRIPTION

KXE10756 RH Threshing Element Kit

KXE10755 LH Threshing Element Kit

KXE10756 RH Threshing Element Kit

All separator tines listed below are available in kits of (2) only. To maintain rotor balance, both must be installed in a row around the circumference of the rotor.

NUMBER DESCRIPTION

KXE10959 Extended Wear Kit

All separator tines listed below are available in kits of (2) only. To maintain rotor balance, both must be installed in a row around the circumference of the rotor.

NUMBER DESCRIPTION

KXE10959 Extended Wear Kit

Kondex® Revolution™ concaves are made exclusively for John Deere by Kondex and are manufactured using laser cladding high-wear additive, which extends product life by 2–3 times! These concaves give more versatility to match varying crop conditions, especially in tough threshing or high moisture crops.

Kondex® Revolution™ concaves are made exclusively for John Deere by Kondex and are manufactured using laser cladding high-wear additive, which extends product life by 2–3 times! These concaves give more versatility to match varying crop conditions, especially in tough threshing or high moisture crops.

NUMBER DESCRIPTION

BXE11581 Small Grains 4-pc. Bundle

BXE11582 Coarse Grains 4-pc. Bundle

AXE90830 LH Single Kondex® Revolution MaxThresh™ Half-Width Concave

AXE90831 RH Single Kondex® Revolution MaxThresh™ Half-Width Concave

NUMBER DESCRIPTION

AXE90832 Single Kondex® Revolution MaxRound™ Half-Width Concave

BXE11581 Small Grains 4-pc. Bundle

BXE11582 Coarse Grains 4-pc. Bundle

AXE90830 LH Single Kondex® Revolution MaxThresh™ Half-Width Concave

AXE90831 RH Single Kondex® Revolution MaxThresh™ Half-Width Concave

AXE90832 Single Kondex® Revolution MaxRound™ Half-Width Concave

NUMBER DESCRIPTION

BXE11375 Round Bar Standard Wear Concave Kit

BXE11376 Round Bar Extended Wear Concave Kit

BXE11577 Small Wire Standard Wear Concave Kit

BXE11578 Small Wire Extended Wear Concave Kit

BXE11579 Large Wire Standard Wear Concave Kit

BXE11580 Large Wire Extended Wear Concave Kit

John Deere OEM Concave’s reputation for reliability, optimal threshing and separation is long standing. They also allow for versatility in crops and finetuning performance via use of inserts, cover plates or combining with Kondex® Revolution™ concaves.

NUMBER DESCRIPTION

AXE90486 Round Bar LH Insert

AXE89573 Round Bar RH Insert

NUMBER DESCRIPTION

BXE11382 Concave Cover Kit

Concave inserts provide the additional threshing action required for harvesting small grains with the round bar concaves. Concave inserts are easy to install and remove as you switch between crops.

The sectionalized concave covers help to provide additional threshing in the concave area when harvesting hard-to-thresh-type cereal crops. They can also help to reduce white caps and increase grain tank cleanliness.

Elevator chains should be checked for stretch and adjusted or replaced as required. The rubber paddles can develop rounded corners and edges, resulting in grain leakage.

X-Series chopper knives deliver value by offering superior residue management, enhanced chopping performance, reduced maintenance requirements, improved harvesting efficiency, and seamless integration with existing equipment.

NUMBER DESCRIPTION

KXE10761 Straight Blade

The 6-Pitch conveyor chain has 1 slat for every 6th chain link (total 51 slats). This provides better grain quality and is tied to the round bar concave. The 12-Pitch conveyor chain has 1 slat for every 12th chain link (total 27 slats). This provides better feeding and is tied to small and large wire concaves.

NUMBER DESCRIPTION

AXE91154 Conveyor Chain, 6-Pitch

AXE91155 Conveyor Chain, 12-Pitch

X-Series augers deliver value by improving harvesting efficiency, preserving grain quality, enhancing productivity, ensuring long-term reliability, and offering seamless integration with existing equipment.

NUMBER DESCRIPTION

AXE98517 Lower Clean Grain Auger

AXE89023 Loading Auger

AXE92496 Vertical Unloading Auger, High-Wear

Separator grate covers helps balance the shoe load and improves capacity in very dry small grain conditions by reducing the chaff load to the cleaning shoe. Typically one bundle covers 1 grate on each rotor, however, may need 2 covers in extreme dry crop conditions.

NUMBER DESCRIPTION

BXE11383 Separator Grate Cover Kit

Lose less profit to the land with a Grain Saver Belt

Aftermarket Upgrade from John Deere. Unlike standard draper belts, grain saver belts feature a unique crosshair design that traps free grain and gets it into your tank. As a result, more grain ends up where it belongs to make your operation more profitable.

Grain saver belts are available for John Deere 600FD-Series draper heads and up. (See page 13 for ordering details.)

Upgrade your combine’s performance today.

Upgrade your combine’s performance today.

4.5L

John Deere DEF ensures you can be confident you are getting a high-quality product that will provide unsurpassed performance while protecting your equipment investment. Simplify your operation by integrating John Deere DEF into your fluidmaintenance routine.

• Compatible with all engines using selective catalytic reduction (SCR) aftertreatment technology

• Nontoxic, nonhazardous, and nonflammable

• Dispense nozzle included with each jug

• Drums outfitted with 2-in. bung opening for direct-pump or closed-system dispensing valve and drop-tube installation

• Totes include integrated closed-system dispensing valve and drop tube

• Forklift tubes beneath tote cage for ease in handling

• ISO 22241 compliant for DEF-handling procedures

• American Petroleum Institute (API) certified

Container Sizes

John Deere Engine Rate

Typical Usage Rates Dispensing Pumps

• DEF pump with 20 ft. (6.1-m) hose

• Poly, manual or stainless steel, auto shutoff nozzle

• Closed-system dispense coupler

• Hookup ready

• Valve and dip tube (ordered separately)

Dispensing Unit

• Durable polyethylene molded tank withprotective hard cover

• Removable 12-volt, self-priming transfer

• 20 ft. (6.1-m) hose

• Poly manual nozzle

• Delivers 7–10 U.S. gpm (26–37 Lpm)

• Store out of extreme temperatures

• Freeze point: –11°C (12°F)

• Keep out of direct sunlight — solar heating may raise the temperature of the fluid which could cause the urea to break down, making it less effective

• Store in sealed containers — make sure the tamper-proof seal stays intact on totes and drums

• Purchase DEF in quantities that will be consumed within 12 months

This guide moves the location of the twine closer to the center of the bale. It’s especially useful when baling slick grasses and straw.

BE24157 557, 558 and 559

BE24158 447, 457, 448, 458, 449 and 459

Automatically roll bales away from the baler on level or moderately rolling terrain – eliminating backing up.

This kit protects your pickup over uneven terrain with smooth ground gauging and adjustable pickup-tooth-to-stubble-height.

1

2

3

5

6

7

8

9

10

12 -

1 - Starter Roller

2 - Lower Drive Roller

3 - Front Idler Roller

4 - Upper Drive Roller

5 - Front Tension Arm Roller

6 - Take-up Arm Roll

7 - Upper Gate Roller

8 - Lower Gate Roller

9 - Gate Roller

10 - Rear Tension Arm Roller

11 - Top Idler Roller

12 - Center Tension Roller

13 - Belt Staggering Roll

- AFH205792 | LH - AFH207783

- AFH205792 | LH - AFH207783

AE74209 - Short E86147 - Pin | AE53298 - Lacing

AE74210 - Long E86147 - Pin | AE53298 - Lacing

| AE59200 - Netwrap

207925 | AFH207855 - Netwrap

1

2

3

4

5

6

7 -

8 -

9

10 -

11

12 -

13

AFH210848 - Short

1 - Starter Roller

2 - Lower Drive Roller

3 - Front Idler Roller

4 - Upper Drive Roller

5 - Front Tension Arm Roller

6 - Take-up Arm Roll

7 - Upper Gate Roller

8 - Lower Gate Roller

9 - Gate Roller

10 - Rear Tension Arm Roller

11 - Top Idler Roller

12 - Center Tension Roller

13 - Belt Staggering Roll

- AFH215561 | LH - AFH207783

- AFH215561 | LH - AFH207783

AFH210848 - Diamond Tough Pro Short E86147 - Pin | AE53298 - Lacing

AFH210849- Diamond Tough Pro Long E86147 - Pin | AE53298 - Lacing

AE74177 - Diamond Tough Short E86147 - Pin | AE53298 - Lacing

AE74178 - Diamond Tough Long E86147 - Pin | AE53298 - Lacing

1 - Starter Roller

2 - Lower Drive Roller

3 - Front Idler Roller

4 - Upper Drive Roller

5 - Front Tension Arm Roller

6 - Take-up Arm Roll

10 - Rear Tension Arm Roller

11 - Top Idler Roller

12 - Center Tension Roller

13 - Belt Staggering Roll

- AFH215561 | LH - AFH207783

- AFH215561 | LH - AFH207783

AFH210848 - Diamond Tough Pro Short E86147 - Pin | AE53298 - Lacing

AFH210849- Diamond Tough Pro Long E86147 - Pin | AE53298 - Lacing

AE74177 - Diamond Tough Short E86147 - Pin | AE53298 - Lacing

AE74178 - Diamond Tough Long E86147 - Pin | AE53298 - Lacing

7 - Upper Gate Roller AE46606 E127309 AE54311

8 - Lower Gate Roller AE46606 E127309 AE59200

9 - Gate Roller AFH204893

NUMBERDESCRIPTION

Round Baler with Regular Pickup:

E67036 6-in., 4-Coil with Bolt

A-E67036 Baler Tooth*

A-E74678 Baler Tooth*

E79475 7 1/4-in.

A-E79475 Baler Tooth*

Round Baler with MegaWide™ Pickup:

E74678 6-in., 5-Coil with Allen-Head Bolt

APPLICATION

A-AFH202304 Tooth, Pickup (Square Wire); Set of 4 Teeth with Hardware

410, 430, 500, and 510 Model Balers

410, 430 (SN <710000), 500, 510, and 530 (SN <710000)

330, 335, 375, 430, 435, 530, and 535 Model Balers

330, 335, 385, 435, 6-, 7-, 8-, and 9-Series Round Balers

E90881 Left-Hand 6-, 7-, 8-, 9-, and 0-Series Round Balers

FH304576 Middle, MegaTough™ Square Tooth6-, 7-, 8-, 9-, and 0-Series Round Balers

Large Square Baler Pickup:

6-, 7-, 8-, 9-, and 0-Series Round Balers

E90880 Right-Hand 6-, 7-, 8-, 9-, and 0-Series Round Balers

FH324064 Pickup Tooth L330 and L340

*Check machine serial number for correct parts.

NUMBERDESCRIPTION

E88848 Stripper*

FH304576 Middle, MegaTough™ Square ToothL331 and L341

330, 335, 375, 430, 435, 530, and 535 Model Balers

CC32669 Center Stripper (Wide Pickup) 435, 535, 540, 545, 550, and 6-Series Round Balers

FH311772 Center Stripper 8- and 9-Series Round Balers

FH311994 Inside Stripper (Rock Ejector) 7-, 8-, and 9-Series Round Balers

A-FH311994 Stripper, Rock Ejector; MegaWide™ Pickup 7-, 8-, and 9-Series Round Balers

FH311995 Outside Stripper 6-, 7-, 8-, and 9-Series Round Balers

* Fits models 330, 335, 375, 430, 435, 530, 535 balers.

NUMBER DESCRIPTION

A-FH311995 Stripper, Outer; MegaWide™ Pickup 6-, 7-, 8-, and 9-Series Round Balers

In the field and need a part for your baler? With the John Deere Round Baler Wear Parts Box, you will have most of what you need to get back to baling fast. Whether you need something for your pickup, belts or bearings, it is probably in the Box. Light enough for two people to pickup and put in the truck, means you can take it to the field with you and have it when and where you need it. Ask your dealer about customizing this box for your personal needs and for older model or 5-ft. diameter balers.

BE32698 Round Baler Wear Parts Box For 8, 9, and Zero Series 6-ft. Diameter Balers

A-FH311772 Stripper, Center; Regular & MegaWide™ Pickup* 385, 630A, 630B, 640A, 640B, 645A, 645B, 6-, 7-, 8-, and 9-Series Round Balers

330, 335 (SN <915000), 375 (SN <915000), 430 (SN 710001>), 435 (SN <921150), 530 (SN 710001>), and 535 (SN <921939)

330, 335 (SN 915001>), 375 (SN 915001>), 385, 430 (Long tooth pickup only), 435 (SN 921151>), 530 (Long tooth pickup only), 535 (SN 921940>), 6-, 7-, and 8-Series Round Balers

TYPE

John Deere

A&I Products

John Deere

A&I Products

John Deere

A&I Products

John Deere

John Deere

A&I Products

John Deere

John Deere

John Deere

John Deere

John Deere

John Deere

A&I Products

John Deere

A&I Products

John Deere

A&I Products

John Deere offers two options for baler belts: DiamondTough™ and DiamondTough™ PRO

NUMBERDESCRIPTION

AFH215157

AFH215159

AE74209

AE74210

AE74177

AE74178

Did you know that not all baler belts are created equal? DiamondTough™ 1-ply baler belts are made with advanced technology and materials, designed to withstand the rigors of hay production in any crop or field condition. Our belts have a superior 1-ply design that eliminates the risk of delamination caused by multiple rubber layers. Unlike our competitors’ 3-ply design, we offer a larger single channel for our patented triple-weave technology. The three-step diamond tread design provides both built-in wear indicators and self-cleaning characteristics. As the diamond tread moves over the rollers, it stretches the concave, which releases the dirt and debris that could be trapped inside.

John Deere’s industry-leading DiamondTough baler belts feature:

1) Nylon-fill cords that provide superior puncture and tear resistance, along with excellent fastener-holding strength.

2) Excellent resistance to punctures and tears by inserting heavy-duty polyester straight-warp cords between the fill cords.

3) Polyester surface warp cords that resist abuse and increase flexibility over small baler rollers.

4) Nylon binder warp cords that help promote fabric integrity and abuse-resistant properties.

APPLICATION

DiamondTough™ Short 330, 335, 375, 446, 546, 447, 448, 449, 440E, and 547

DiamondTough™ Long 330, 335, 375, 446, 546, 447, 448, 449, 440E, and 547

DiamondTough™ Short 385, 6, 7, 8, 9, and Zero Series 5-ft. Balers

DiamondTough™ Long 385, 6, 7, 8, 9, and Zero Series 5-ft. Balers

DiamondTough™ Short 435, 535, 6, 7, 8, 9, and Zero Series 6-ft. Balers

DiamondTough™ Long 435, 535, 6, 7, 8, 9, and Zero Series 6-ft. Balers

NUMBERDESCRIPTION

AFH212598

AFH212599

AFH210848

AFH210849

Our DiamondTough PRO baler belts are more wear- and tear-resistant than many belts in the industry and are built with the following features:

• Built with a special rubber compound that offers excellent resistance to cutting, gouging, and abrasion — A step above standard DiamondTough, it’s the same compound used in rugged conveyor belt applications.

• Provide better performance in harsh baling conditions.

• DiamondTough PRO belts are highly recommended in abrasive conditions, such as when bailing corn stalks and peanut hay or when working in sandy soils.

DiamondTough™ PRO Short 7, 8, 9, and Zero Series 5-ft. Balers

7, 8, 9, and Zero Series 5-ft. Balers

PRO Short 7, 8, 9, and Zero Series 6-ft. Balers

DiamondTough™ PRO Long 7, 8, 9, and Zero Series 6-ft. Balers

Net Guides are a great addition for any round baler 6 series or newer! Net Guides bridge the gap between #10 and #12 rollers, to prevent the net from taking a detour and wrapping around the #11 roller. John Deere recommends installing 3 net guides (gap 2 4, 6) on a 5-ft. wide round baler or 2 net guides (gap 2, 4) on a 4-ft. wide round baler. Each Net Guide requires 2 chain links which are ordered separately (Part #AH223103).

NUMBER DESCRIPTION

FH345025 Net Guide

AFH223103 Chain Link

The all NEW John Deere Mega Roll is available in both CoverEdge™ and Edge to Edge®, which lasts up to 46% longer than a traditional-sized roll. With a larger roll, you have less downtime, less time spent reloading the baler with net, and enough net on one roll for a BIG day of bailing, more than 300 6' bales at 2 wraps of net on hay. Mega Roll® meets the maximum roll diameter for a John Deere Round Baler. Pair the new Mega Roll with a Net Lift Assist for even easier loading.

With more footage per roll, now you can make 10–15% more bales with each roll of net—for more baler productivity and less downtime. The new net is lighter and easier to handle, and priced right to reduce your cost per bale. It continues to give the same great bale coverage over the entire width of the bale, protecting the crop as well as helping to maintain the bale’s shape, making handling and storage much easier. Now that’s delivering the trouble-free baling you have come to know and expect from John Deere Netwrap.

John Deere CoverEdge goes right over the edge of the bale and snaps into place for better protection. With the elimination of shoulders, bales are perfectly shaped for better handling, transport, and storage. John Deere CoverEdge covers 15% more surface area of the round bale and protects the edges of the bale to help prevent rainwater penetration and moisture collection within the bale. It also improves the weatherability of the package. No loose “fluff” to pick up the moisture from rainfall. With John Deere CoverEdge, you can produce high-quality silage bales when wrapped with stretch film because the bale surface is smooth, eliminating air pockets in the bale.

John Deere XtraTwine™ Plus

Large Square Bales

Reduces your cost and increases your baler’s potential! Exclusively available through John Deere dealers. Features include:

• Uniform spool shape and consistent yarn to ensure trouble-free running in the baler

•Guaranteed length

•Unrivaled knotting performance

•Special UV light inhibitors to withstand intense exposure over long periods

•Unique color combination for bale identification

•Compatible with ALL large square balers

Extra spool length

Extra spool length for less spool changes, less waste, and higher efficiency.

Elevate your net wrap loading experience with the new Net Lift Assist and Net Lighting from John Deere. Increase field safety and efficiency by adding this attachment to your John Deere round baler. Our bolt-on design streamlines the installation and is compatible with 7-, 8-, 9-, and 0-Series round balers. Upgrade today for the ultimate loading experience.

Introducing the NEW John Deere Net Lift Assist — the ultimate solution for effortlessly loading net wrap on your round baler day or night. — Reliable and Durable. No cutting is required. A true bolt-on solution.

NUMBERDESCRIPTION

FH323281 Standard, Counterclockwise

FH323282 Standard, Clockwise

FH308234 High-Lift, Counterclockwise

FH308235 High-Lift, Clockwise

CC21780 Standard, Counterclockwise

CC21781 Standard, Clockwise

NUMBERDESCRIPTION

KN56151210 Angled Blade, Right Turning

A-76N942 Angled Blade, Right Turning

KN56151310 Angled Blade, Left Turning

A-76N941 Angled Blade, Left Turning

KN56451300 Angled Blade, Right Turning

A-76N226 Angled Blade, Right Turning

KN56451200 Angled Blade, Left Turning

A-76N198 Angled Blade, Left Turning

5TIDM411221 Angled Blade, Right Turning

5TIDM411222 Angled Blade, Left Turning

•Bend rather than break for safer livestock feed

•Burrs removed from holes for precise fit

10.5 degree Knives: Standard knife from factory.

APPLICATION

•Made from boron steel and heat treated for maximum strength

CC44004 Standard, Right-hand, Clockwise 270

CC44005 Standard, Left-hand, Counterclockwise270

DM1130, DM1140, DM1150, DM1160

DM1130, DM1140, DM1150, DM1160

DM1130, DM1140, DM1150, DM1160

DM1130, DM1140, DM1150, DM1160

DM1270

DM1270

DM1270

DM5050, DM5060, DM5070

DM5050, DM5060, DM5070

Note: Disc Mower Blades might fit Kuhn®, New Holland®, and other makes of Disc Mowers. Please see us for more details.

Engineered for optimal wear resistance and designed specifically for John Deere machines, these mower conditioner knives remain sharp and provide long-term, premium cutting quality.

270, 265, 275, 285, R160, R200, R240, R280, and R310

270, 265, 275, 285, R160, R200, R240, R280, and R310

265, 275, 285, 625, 630, 635, 830, 835, 916, 926, 936, 946, 956, 994, 995, and 500R

265, 275, 285, 625, 630, 635, 830, 835, 916, 926, 936, 946, 956, 994, 995, and 500R

265, 275, 285, 625, 630, 635, 830, 835, 916, 926, 936, 946, 956, 994, 995, and 500R

265, 275, 285, 625, 630, 635, 830, 835, 916, 926, 936, 946, 956, 994, 995, and 500R

Products

Products

Products

DM1270 A&I Products

18 degree Knives: High-twist design aids in maintaining excellent cut quality in downed crops or extremely heavy crop conditions.

•Knives are applied with rust-preventative oil or powder-coated for superior protection

NUMBER

630A, 640A, 645A, 630B, 640B, 645B

CC25176 Teeth

639 Standard Pickup

LCA105173 Teeth –

639, 649, 659 Premium Pickup

630A, 640A, 645A (-052096)

E65648 Stripper

630A, 640A, 645A (052097-)

FH311772 Stripper

630B, 640B, 645B

FH311772 Stripper

639, 649, 659 LCA104898 Stripper

630B, 640B, 645B

These service sets include all blades, scrapers, special bolts, and nuts. Number required to cover complete header is listed below. Heavy duty kits include tungsten carbide coated blades, which lasts three times longer.

High performance scrapers with convenient bolt-on design, allows you to use each side of scraper, saving maintenance costs.

If you notice teeth are blunt or damaged, replace with new points. Points must be installed in pairs on opposite sides of the drum.

NUMBER DESCRIPTION

Upper Front Feed Roll:

HXE64649 Wear Strip – Corn

HXE64652 Wear Strip – Grass

Z81671 Shaft

JD10071 Needle Bearing

AZ62417 Needle Bearing

AL28870 Seal

Upper Rear Feed Roll:

AZ71834 Feed Roll

HXE26048 Shaft

JD10458 Bearing

Lower Feed Roll:

AZ101149 Feed Roll

Z77138 Shaft (783 MM)

HXE32390 Shaft (728 MM)

AZ51405 RH Bearing

AXE10405 LH Outside Bearing

JD9467 LH Inside Bearing

Upper Front Feed Roll:

7700, 7800, 7750, 7850, 7950, 7780, 7980

John Deere feed rolls, wear strips, and bolts are made from heavy-duty, induction hardened stainless steel, which helps to minimize potential downtime. They are also demagnetized to prevent them from false tripping the metal detection system.

7200, 7300, 7400, 7500, 7250, 7350, 7450, 7550, 7180, 7280, 7380, 7480, 7580

AZ103443 Feed Roll with Replaceable Wear Strips

AZ103444 Feed Roll with Replaceable Wear Strips (7700/7800)

AZ103444 Feed Roll with Replaceable Wear Strips (7750, 7850, 7950, 7780, 7980)

HXE64650 Wear Strip – Corn

HXE64653 Wear Strip – Grass

Z81672 Shaft

JD10071 Needle Bearing

AZ62417 Needle Bearing

AL28870 Seal

Upper Rear Feed Roll:

AZ71837 Feed Roll

HXE26049 Shaft

JD10458 Bearing

Lower Feed Roll:

AZ101150 Feed Roll

Z102377 Shaft (848 MM)

AZ51405 RH Bearing

AXE10405 LH Outside Bearing

JD9467 LH Inside Bearing

NUMBER

DESCRIPTION

Knives and Mounting Parts:

Z63136 Corn Knife

Z62075 Corn Knife, Angled, Right-Hand

Z62076 Corn Knife, Angled, Left-Hand

Z69500 Grass Knife

Z102741 Grass Knife, Dura Line™ Coated

Z69650 Knife Bolt

Z60535 Cover Plate

HXE121397 Thread Bar

Z101528 Knife Bracket

Shearbars/Stationary Knife:

AZ53906 Corn

AZ103112 Grass

AZ57685 All Crop, Heavy-Duty

AXE37631 All Crop, Dura Line Plus

7700, 7800, 7750, 7850, 7950, 7780, 7980

Knives and Mounting Parts:

Z72500 Corn Knife

Z81123 Grass Knife

Z103040 Grass Knife, Dura Line™ Coated

Z69650 Knife Bolt

Z76801 Cover Plate

HXE121393 Thread Bar

Z101529 Knife Bracket

Shearbars/Stationary Knife:

AZ64735 Corn

AZ103113 Grass

AZ64737 All Crop, Heavy-Duty

AXE37632 All Crop, Dura Line Plus

7000, 7050, 7080 Series

Sharpening Stone:

AZ56626 Stone

NUMBER

DESCRIPTION

Spiral Band:

AXE40436 Standard

AXE40438 Dura Line™

Grass Chute:

AZ65662 Grass Chute, Bottom

Z78611 Stainless Steel Wear Liner

7700, 7800, 7750, 7850, 7950, 7780, 7980

Spiral Band:

AXE40437 Standard

AXE40439 Dura Line™

Grass Chute:

AZ65663 Grass Chute, Bottom

Z78792 Stainless Steel Wear Liner

7200, 7300, 7400, 7500, 7250, 7350, 7450, 7550, 7180, 7280, 7380, 7480, 7580

7200, 7300, 7400, 7500, 7250, 7350, 7450, 7550, 7180, 7280, 7380, 7480, 7580

7200, 7300, 7400, 7500, 7250, 7350, 7450, 7550, 7180, 7280, 7380, 7480, 7580

HXE29868 Paddles Straight – Normal Conditions (10 used)

HXE34827 Paddles Serrated – Gummy Conditions (5 used)

HXE34828 Paddles Serrated – Gummy Conditions (5 used)

Z67028 Blower BandStandard

Z105384 Blower BandDura Line™

7700, 7800, 7750, 7850, 7950, 7780, 7980

HXE29814 Paddles Straight – Normal Conditions (10 used)

HXE34825 Paddles Serrated – Gummy Conditions (5 used)

HXE34826 Paddles Serrated – Gummy Conditions (5 used)

Z73473 Blower BandStandard

Z105386 Blower BandDura Line™

NUMBER

7200, 7300, 7400, 7500, 7250, 7350, 7450, 7550, 7180, 7280, 7380, 7480, 7580

AZ104287 Chute

AZ104286 Wear Plate Kit

7700, 7800, 7750, 7850, 7950, 7780, 7980

AXE25702 Chute

AZ104208 Front Wear Plate Kit

AZ104209 Rear Wear Plate Kit NUMBER

7000, 7050, 7080 Series

AZ104282 High-Arc SpoutSpout without Wear Liners

AZ104285 High-Arc SpoutSpout Extension – Standard

BZ100238 High-Arc SpoutSpout Extension – 8-Row

BZ100239 High-Arc SpoutSpout Extension – 10-Row

AZ103510 High-Arc SpoutWear Liner – Bottom (848 MM)

AZ102629 High-Arc SpoutWear Liner – Bottom (Dura Line™)

AZ103381 High-Arc SpoutWear Liner – Middle (1,800 MM)

AZ103382 High-Arc SpoutWear Liner – Middle (1,800 MM) w/NIR

AZ101740 High-Arc SpoutWear Liner – Middle (2,000 MM) w/NIR

AZ54609 High-Arc SpoutWear Liner – Top

AZ101238 Low-Arc SpoutSpout – Bottom

AZ101239 Low-Arc SpoutSpout – Middle

AZ101240 Low-Arc SpoutSpout – Top

Z68680 Flaps Wear Liner – Bottom

Z105385 Flaps Wear Liner – Bottom (Dura Line™)

Z105390 Flaps Wear Liner – Bottom (Dura Line™) w/NIR

AZ54380 Flaps Middle Flap

AZ100715 Flaps Middle Flap (Dura Line™)

AZ53234 Flaps End Flap

AZ100714 Flaps End Flap (Dura Line™)

NUMBER TYPE

8100, 8200, 8300, 8400, 8500

DESCRIPTION

AXE49885 Upper Front Feed Roll Feed Roll

HXE93580 Upper Front Feed Roll Steel Wear Strip

HXE87701 Upper Front Feed Roll Plastic Strip

HXE100098 Lower Front Feed Roll Steel Wear Strip

8600, 8700, 8800, 9600, 9700, 9800, 9900

AXE14074 Lower Front Feed Roll Feed Roll

AXE85661 Upper Front Feed Roll Feed Roll

AXE66457 Upper Front Feed Roll Feed Roll (-516999)

AXE66457 Upper Front Feed Roll Feed Roll (517000-)

HXE93575 Upper Front Feed Roll Steel Wear Strip

HXE87459 Upper Front Feed Roll Plastic Strip

AXE77419 Lower Front Feed Roll Feed Roll

HXE100097 Lower Rear Feed Roll Steel Wear Strip

8000, 9000 Series

AXE66456 Upper Front Feed Roll Feed Roll (-516999)

AXE14946 Lower Rear Feed Roll Feed Roll

Z74128 Feed Roll Wear Strips HardwareNut

NUMBER TYPE

8100, 8200, 8300, 8400, 8500

AXE66456 Upper Front Feed Roll Feed Roll (517000-)

HXE87510 Feed Roll Wear Strips HardwareUpper Strip Screw

Z74127 Feed Roll Wear Strips HardwareLower Strip Screw

DESCRIPTION

HXE185152 Knives and Mounting PartsCorn Knife

HXE185150 Knives and Mounting PartsGrass Knife

HXE143972 Knives and Mounting PartsKnife Bolt

HXE121397 Knives and Mounting PartsThread Bar

HXE142406 Shearbars / Stationary KnifeCorn

HXE142407 Shearbars / Stationary KnifeGrass

8600, 8700, 8800, 9600, 9700, 9800, 9900

HXE53563 Knives and Mounting PartsKnife Bracket

HXE185151 Knives and Mounting Parts Grass Knife

HXE143972 Knives and Mounting PartsKnife Bolt

HXE121393 Knives and Mounting PartsThread Bar

HXE52928 Knives and Mounting PartsKnife Bracket

HXE142408 Shearbars / Stationary KnifeCorn Knife

HXE142409 Shearbars / Stationary KnifeGrass Knife

8000, 9000 Series

AXE17437 Sharpening Stone Stone

HXE172985 Shearbars / Stationary KnifeAll Crop, Dura Line Plus

HXE171640 Shearbars / Stationary Knife Corn, Dura Line

HXE169399 Shearbars / Stationary KnifeAll Crop, Dura Line Plus

On both front feed rolls (upper and lower) each wear bar is reversible (straight or serrated edge) so you can adjust the aggressiveness of crop feeding.

NUMBER DESCRIPTION

AXE41235 Standard

AXE42112 Dura Line™

HXE37067 Straight – Normal Conditions (10 used)

HXE34827 Serrated – Gummy Conditions (5 used)

HXE34828 Serrated – Gummy Conditions (5 used)

AXE35811 Standard

AXE42114 Dura Line™

NUMBER DESCRIPTION

8000, 9000 Series

High-Arc Spout:

BXE11033 Spout Extension – 10-Row

BXE11098 Spout Extension – 12-Row

HXE144911 Wear Liner – Bottom

HXE29814 Straight – Normal Conditions (10 used)

HXE34825 Serrated – Gummy Conditions (5 used)

AXE25517 Wear Liner – Middle

Low-Arc Spout:

HXE39391 Wear Liner – Top

AXE75118 Spout – Bottom

AZ101239 Spout – Middle

AZ101240 Spout – Top

AXE48208 Wear Liner – Bottom

AXE45366 Wear Liner – Top Middle Spout:

AXE28058 Wear Liner

AXE29779 Wear Liner (Dura Line™) Flaps:

AXE52630 Middle Flap

AXE55603 Middle Flap (Dura Line™)

AXE68374 End Flap

AXE68375 End Flap (Dura Line™)

HXE34826 Serrated – Gummy Conditions (5 used)

HXE144912 Wear Liner – Bottom (Dura Line™)

AXE49258 Wear Liner – Bottom (Dura Line™)

The John Deere kernel processor is induction-hardened rather than flame-hardened, like many competitors’ rolls. What does that mean to you? Hardening is much more consistent, resulting in a longer life and fewer repair costs. The hardening zones of a John Deere roll are shown in the illustration to the right.

The John Deere kernel processor is induction-hardened rather than flame-hardened, like many competitors’ rolls. What does that mean to you? Hardening is much more consistent, resulting in a longer life and fewer repair costs. The hardening zones of a John Deere roll are shown in the illustration to the right.

NUMBER DESCRIPTIONAPPLICATION

Standard Triangle:

Standard Triangle:

AZ101800 2 Needed 7200–7500, 7250–7550, 7180–7580

AZ101800 2 Needed 7200–7500, 7250–7550, 7180–7580

AZ102602 2 Needed

AZ102602 2 Needed 7700–7800, 7750–7950, 7780–7980

7750–7950, 7780–7980

AXE43638 2 Needed 8100, 8200, 8300, 8400, 8500

AXE43638 2 Needed 8100, 8200, 8300, 8400, 8500

AXE43491 2 Needed 8600, 8700, 8800

AXE43491 2 Needed 8600, 8700, 8800

Saw Tooth Standard:

Saw Tooth Standard:

AZ101800 2 Needed

7200–7500, 7250–7550, 7180–7580

AZ101800 2 Needed 7200–7500, 7250–7550, 7180–7580

AZ102602 2 Needed 7700–7800, 7750–7950, 7780–7980

AZ102602 2 Needed 7700–7800, 7750–7950, 7780–7980

AXE43571 Front Roll 8100, 8200, 8300, 8400, 8500

AXE43572 Rear Roll 8100, 8200, 8300, 8400, 8500

AXE43571 Front Roll 8100, 8200, 8300, 8400, 8500

AXE43572 Rear Roll

AXE43163 Front Roll 8600, 8700, 8800

8100, 8200, 8300, 8400, 8500

AXE43182 Rear Roll 8600, 8700, 8800

AXE43163 Front Roll 8600, 8700, 8800

Saw Tooth Chrome:

AXE43182 Rear Roll 8600, 8700, 8800

AZ101376 2 Needed

Saw Tooth Chrome:

7200–7500, 7250–7550, 7180–7580

AZ101377 2 Needed 7700–7800, 7750–7950, 7780–7980

AZ101376 2 Needed 7200–7500, 7250–7550, 7180–7580

AXE43640 Rear Roll 8100, 8200, 8300, 8400, 8500

AZ101377 2 Needed 7700–7800, 7750–7950, 7780–7980

AXE43492 Front Roll 8600, 8700, 8800

AXE43493 Rear Roll 8600, 8700, 8800

AXE43640 Rear Roll 8100, 8200, 8300, 8400, 8500

32% Saw Tooth Chrome (Rear Roll Reversed):

AXE43492 Front Roll 8600, 8700, 8800

AXE43492 2 Needed 8600, 8700, 8800

AXE43493 Rear Roll 8600, 8700, 8800

Saw Tooth Whole Crop:

32% Saw Tooth Chrome (Rear Roll Reversed):

AZ102633 2 Needed

AXE43492 2 Needed 8600, 8700, 8800

7200–7500, 7250–7550, 7180–7580

AXE43641 Front Roll 8100, 8200, 8300, 8400, 8500

Saw Tooth Whole Crop:

AXE43642 Rear Roll 8100, 8200, 8300, 8400, 8500

AZ102633 2 Needed 7200–7500, 7250–7550, 7180–7580

AXE43494 Front Roll 8600, 8700, 8800

AXE43495 Rear Roll 8600, 8700, 8800

AXE43641 Front Roll 8100, 8200, 8300, 8400, 8500

Triangle Milo / Sorghum:

AXE43642 Rear Roll 8100, 8200, 8300, 8400, 8500

AZ54513 2 Needed 7200–7500, 7250–7550, 7180–7580

AXE43494 Front Roll 8600, 8700, 8800

AXE43643 2 Needed 8100, 8200, 8300, 8400, 8500

AXE43495 Rear Roll 8600, 8700, 8800

AXE43496 2 Needed 8600, 8700, 8800

Triangle Milo / Sorghum:

AZ54513 2 Needed 7200–7500, 7250–7550, 7180–7580

AXE43643 2 Needed 8100, 8200, 8300, 8400, 8500

AXE43496 2 Needed 8600, 8700, 8800

Z63136

Z62076

Z62075

Z102471

Z69500

Z60535

AZ53747

REFERENCEPART NUMBERDESCRIPTION

2 3040289 AC Belt

2 3040285 Fan Belt

1 AZ56225 1175 mm (sub from AZ50187)

2 217638 Water Pump Belt

3 Z58886 1120 mm

REFERENCEPART NUMBERDESCRIPTION

3 AZ43805 - 503552, 1160 mm

REFERENCEPART NUMBERDESCRIPTION

1 AZ39676 Fan Speed - 2055 mm, 1800 r/min

1 AZ39678 Fan Speed - 1896 mm, 2050 r/min

1 AZ61389 Grain Crop Kernel Processor - 2130 mm

1 AZ43804 Grain Crop Kernel Processor - 2140mm

REFERENCEPART NUMBERDESCRIPTION 1 Z48567 Rotary Screen Drive - 3485 mm

REFERENCEPART NUMBERDESCRIPTION

1 AZ39677 1962 mm

1 AZ61336 Grain Crop Kernel Processor

2 AZ51638 6375 mm, 1150 rpm

(dura line)

Z69500 Knife (package 10)

Z60535 Wear Plate

19M8610 Knife Bolt

AZ53747 Sharpening Stone ____ - 504991

AZ56626 Sharpening Stone 504992 - ____

Z63136

Z102471 Knife

Z69500 Knife

Z60535 Wear

AZ56626 Sharpening Stone

REFERENCEPART

REFERENCEPART NUMBERDESCRIPTION 1 DZ119640 1780 mm 2 L115660

NUMBERDESCRIPTION 1 AZ100806 Power Chute, 2356 mm 1 AZ100810 Kernel Processor, 2325mm 1 AZ100808 ___ - 510523, Kernel Porcessor, 1600 rpm 1 HXE13951 510524 - ___ , Kernel Processor, 1600 rpm

R124898

line)

REFERENCEPART NUMBERDESCRIPTION

1 HXE17071 1235 mm

2 REC541301100 1682 MM

3 REC541298700

REFERENCEPART NUMBERDESCRIPTION

1 AZ100806 Power Chute, 2356 mm

1 AZ100810 Kernel Processor, 2325mm

1 AZ100808 ___ - 510523, Kernel Processor, 2260 MM

1 HXE13951 510524 - ___ , Kernel Porcessor, 2440 mm

1 Z103479

1 AZ61336

1 AZ104276

2 R124898

BELT

Z63136

Z62076

Z62075

Z102471

Z69500

Z60535

19M8610

AZ56626

REFERENCEPART NUMBERDESCRIPTION

2 HXE15547 Rotary Screen Drive

REFERENCEPART NUMBERDESCRIPTION

PIN/LACING

Knife Corn

Knife (corn) L.H.

Knife (corn) R.H.

Knife (dura line)

Knife (package 10)

Wear Plate

Knife Bolt

Sharpening Stone

KERNELPROCESSOR

5 OPTIONAL AIR COMPR. DRIVE

OPTIONALAIRCOMPR.DRIVE

8100-8500PartNumber:HXE39119

8100-8200 9 L non EGR

8100-82009LnonEGR

8100-8200 9 L FT4

8100-82009LFT4

8300-8600 13,5 L non EGR

8300-860013,5LnonEGR

8300-860013,5LFT4

8300-8600 13,5 L FT4

8700-880019L

8700-8800 19 L

PartNumber:HXE43428

Part Number: HXE43428

8600-8800PartNumber:AXE25334

PartNumber:HXE90896

Part Number: HXE90896

Part Number: HXE41402

PartNumber:HXE41402

Part Number: HXE41402

PartNumber:HXE41402

Part Number: HXE81232

PartNumber:HXE81232

8100-8500PartNumber:HXE93098

8600-8800PartNumber:AXE52471

Part Number: Z103479

8100-8200

3 AIR SCREEN DRIVE

ALTERNATOR & A/C COMPRESSOR (mounted in back w/ 8700-8800) Part Number: HXE24688

VACUUM FAN DRIVE

Part Number: HXE64200

8300-8600 w/ CH Sp e ed 1100 rpm

8100-8600 w/ CH Sp e ed 1200 rpm

8700-8800 w/ / CH Speed 1100 rpm

8700-8800 w/ / CH Speed 1200 rpm

Part Number: AXE37395 Part Number: AXE17662 Part Number: AXE51063 Part Number: AXE41286 Part Number: AXE51876 POWER BELT

8700-8800 Additional belt for 24 V alternator P/N REC020699600 not shown here

ENGINE FAN DRIVE

8100-8600PartNumber:AXE33760

8700PartNumber:CQ40222

8100-8600 Part Number: AXE33760

8700-8800 Part Number: CQ40222

8800PartNumber:AXE33760

5 OPTIONALAIRCOMPR.DRIVE

8100-82009LnonEGR

8100-82009LFT4

8300-860013,5LnonEGR

8300-860013,5LFT4

8700-880019L

PartNumber:HXE43428

PartNumber:HXE90896

PartNumber:HXE41402

PartNumber:HXE41402

PartNumber:HXE81232

KERNELPROCESSOR

8100-8500PartNumber:HXE39119

8600-8800PartNumber:AXE25334

KERNELSTAR

8100-8500PartNumber:HXE93098

8600-8800PartNumber:AXE52471

Number: Z103479

POWERBAND FAN DRIVE

9600 -1650mm Part Number: AXE58124

9600 -1820mm Part Number: AXE33760

9700 - 9800 Part Number: AXE58124

9800 -9900 Heavy Duty Part Number:HXE137654

ALTERNATOR & A/C COMPRESSOR

9600 - Part Number: HXE79106

9700 - 9900 Part Number: HXE43428

9600 w/ CH Sp e ed 1110 rpm

9600 w/ CH Sp e ed 1200 rpm

9700 w/ CH Speed 1170 rpm

9700 w/ CH Speed 1350 rpm

9600 ser# -619548 Part Number: HXE64200

9600 ser# 619549- Part Number: HXE145224

9700 - 9900 Part Number: HXE145524

Part Number: AXE17662

Part Number: AXE51063

Part Number: AXE72269

Part Number: AXE72268

9800 - 9900 W/ CH Speed 1170 rpm

9800 - 9900 W/ CH Speed 1350 rpm

Part Number: AXE72695

Part Number :AXE72694

9700-9900 Additional belt for 24 V alternator P/N LW11347044 not shown

8100-8600PartNumber:AXE33760

8700PartNumber:CQ40222

8800PartNumber:AXE33760

9600 Part Number: HXE79106

9700-9900 Part number: HXE43428