3 minute read

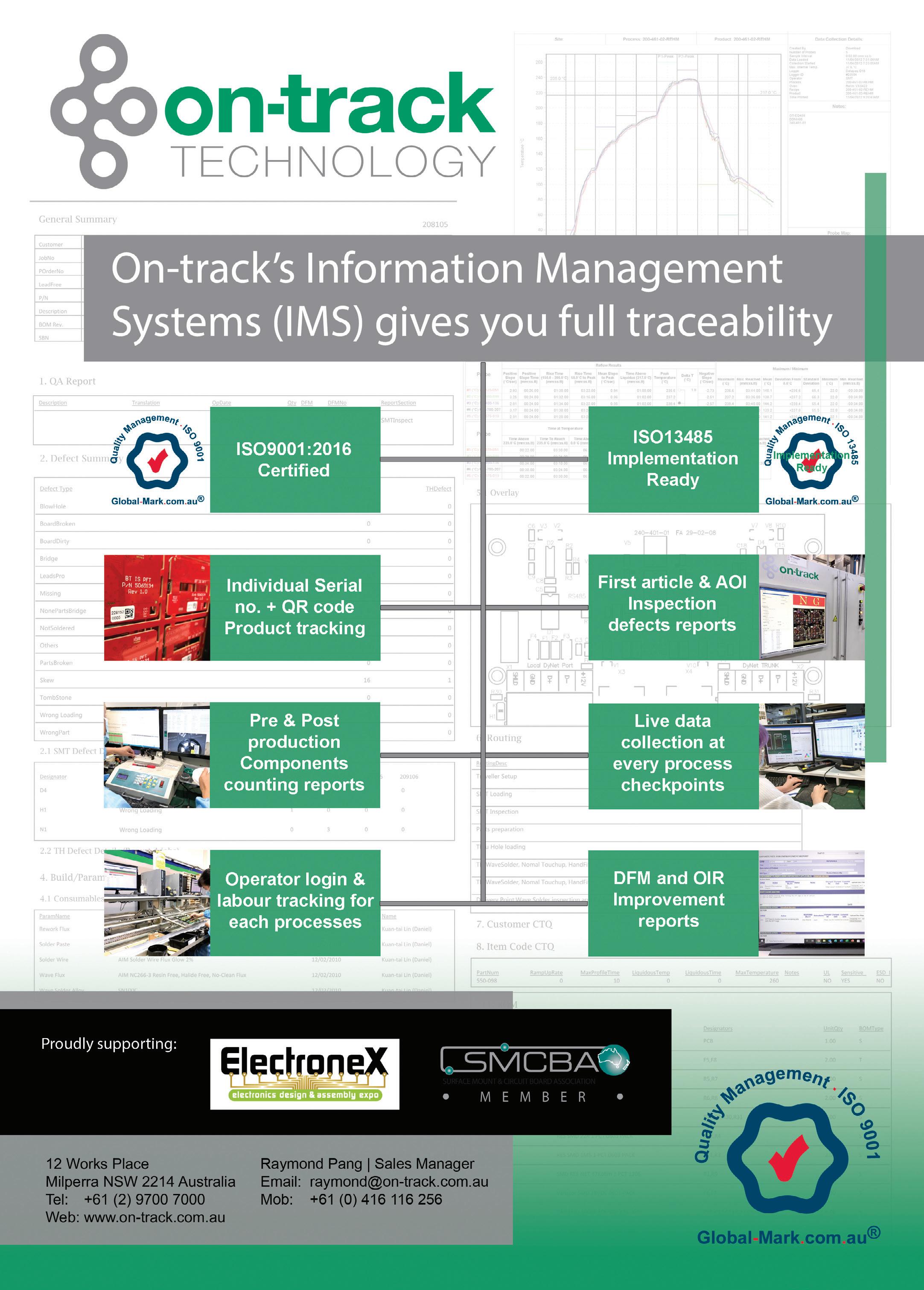

Scientists create ‘armour’ for quantum technology

©stock.adobe.com/au/BAIVECTOR

Westwick-Farrow Media A.B.N. 22 152 305 336

www.wfmedia.com.au

Researchers at the ARC Centre of

Excellence in Future Low-Energy Electronics Technologies (FLEET) have led the development of socalled ‘body armour’ for extremely fragile quantum systems, which will make them robust enough to be used as the basis for a new generation of low-energy electronics. Their work has been published in the journal Advanced

Materials.

Serving as lead author on the study was Matthias Wurdack, a PhD student at the Australian National University (ANU) and FLEET. He explained that protection is crucial for thin materials such as graphene, which are only a single atom thick — essentially twodimensional — and so are easily damaged by conventional layering technology.

With this in mind, the team created a protective layer by exposing to air a droplet of liquid gallium, which immediately formed a perfectly even layer of gallium oxide on its surface just 3 nm thick. By squashing the droplet on top of the 2D material with a glass slide, the gallium oxide layer can be transferred from the liquid gallium onto the material’s entire surface, up to centimetres in scale.

“The protective coating basically works like a body armour for the atomically thin material; it shields against high-energy particles, which would cause a large degree of harm to it, while fully maintaining its optoelectronic properties and its functionality,” Wurdack said.

Because this ultrathin gallium oxide is an insulating amorphous glass, it conserves the optoelectronic properties of the underlying 2D semiconductor. The gallium oxide glass can also enhance these properties at cryogenic temperatures and protects well against other materials deposited on top. This allows the fabrication of sophisticated, layered nanoscale electronic and optical devices, such as light emitting diodes, lasers and transistors.

“We’ve generated a nice alternative to existing technology that can be scaled for industry applications,” Wurdack said.

The work also promises lower-energy alternatives for electronics and optoelectronics, by harnessing the superior performance of 2D semiconducting materials such as tungsten disulfide, which was used in this study. As explained by team leader Professor Elena Ostrovskaya, also from ANU and FLEET, “Two-dimensional materials have extraordinary properties, such as extremely low resistance or highly efficient interactions with light.

“Because of these properties, they could have a big role in the fight against climate change.”

Using 2D materials to make more efficient devices will have advantages beyond reduced carbon emissions, with Wurdack saying, “2D technology could also enable super-efficient sensors on spacecraft or processors in Internet of Things devices that are less limited by battery life.”

Wurdack said he and his team “hope to find industry partners to work with us to develop a protective layer printer based on this technology that can go into any lab, like a lithography machine”.

“It would be exciting to see fundamental research like this find its way into industry,” he said.

Head Office Unit 7, 6-8 Byfield Street, North Ryde Locked Bag 2226, North Ryde BC NSW 1670 Ph: +61 2 9168 2500

Editor Lauren Davis wnie@wfmedia.com.au

Publishing Director/MD Geoff Hird

Art Director/Production Manager Julie Wright

Art/Production Veronica King, Colleen Sam

Circulation Dianna Alberry, Sue Lavery circulation@wfmedia.com.au

Copy Control Mitchie Mullins copy@wfmedia.com.au

Advertising Sales Group Sales Manager Nicola Fender-Fox – 0414 703 780 nfender-fox@wfmedia.com.au

Account Manager Sandra Romanin – 0414 558 464 sromanin@wfmedia.com.au

Asia Tim Thompson - 0421 623 958 tthompson@wfmedia.com.au

If you have any queries regarding our privacy policy please email privacy@westwick-farrow.com.au

Subscriptions: For unregistered readers, price on application.

To register, visit www.electronicsonline.net.au/subscribe

Printed and bound by Dynamite Printing Print Post Approved PP100007394 ISSN No. 0728-3873

All material published in this magazine is published in good faith and every care is taken to accurately relay information provided to us. Readers are advised by the publishers to ensure that all necessary safety devices and precautions are installed and safe working procedures adopted before the use of any equipment found or purchased through the information we provide. Further, all performance criteria was provided by the representative company concerned and any dispute should be referred to them. Information indicating that products are made in Australia or New Zealand is supplied by the source company. Westwick-Farrow Pty Ltd does not quantify the amount of local content or the accuracy of the statement made by the source.