SMART GLASSES: A VISION IN MANUFACTURING SAFETY

TOP TIPS: STARTING A DRUG AND ALCOHOL PROGRAM

EXCEEDING COMPLIANCE: THE POWER OF WHS SOFTWARE

SMART TECH: INCREASING SAFETY AROUND MACHINERY

August 2023 | Vol.17 No.4 PP 100007391

Welcome to the August issue of Safety Solutions — and isn’t it difficult to believe that we are already more than halfway through 2023? This edition’s features include machine safety in the manufacturing industry, compliance software, and drugs and alcohol.

Although safety within the manufacturing industry has improved over recent years, the risk of serious injury is still very real. Sojung Lee explores how smart glasses, when combined with industry-proven augmented reality solutions, can be effective at helping operators to use machinery safely. Along with smart technology, compliance software has become a powerful tool within the WHS manager’s arsenal. This software can help to enable a shift from simply achieving organisational compliance, to undertaking proactive safety and risk management. Manuel Seidel outlines five key areas where compliance software provides significant value in transforming organisational safety. Finally, how effective is your organisation’s drugs and alcohol program? In our “Top tips” segment, Glenn Dobson outlines the importance of proactive management of substance abuse in the workplace and offers five tips for implementing a comprehensive workplace drug and alcohol testing program. We are always happy to receive editorial contributions — so if you would like to submit an article, case study or new product for possible inclusion in a future edition of Safety Solutions, please feel free to get in touch on the email address below.

Steed Editor, Safety Solutions ss@wfmedia.com.au

Steed Editor, Safety Solutions ss@wfmedia.com.au

AUGUST 2023 - SAFETY SOLUTIONS 3 www.safetysolutions.net.au FROM THE EDITOR

Amy

August 2023 Vol.17 No.4 PP 100007391 TOP TIPS: STARTING A DRUG AND ALCOHOL PROGRAM EXCEEDING COMPLIANCE: THE POWER OF WHS SOFTWARE SMART TECH:INCREASING SAFETY AROUND MACHINERY SMART GLASSES: A VISION IN MANUFACTURING SAFETY CONTENTS SAFETY SOLUTIONS AUGUST 2023 4 In the news 8 Smart glasses: A vision for manufacturing safety 14 Top tips: Starting a workplace drug and alcohol testing program 22 Mastering workplace safety: The power of WHS software 26 How smart tech increases safety around machinery 33 Six steps to ensure mining contractor safety 35 Psychosocial harm at work on the rise Your copy of Safety Solutions is available as an online eMag. READ ONLINE! www.safetysolutions.net.au/magazine 100007391 SMART GLASSES: A VISION IN MANUFACTURING SAFETY Cover image ©stock.adobe.com/au/kckate16;

IN THE NEWS

SWA RELEASES GUIDANCE TO REINFORCE TOWER CRANE SAFETY

Safe Work Australia has released a model code of practice for tower cranes that provides practical guidance for PCBUs and other duty holders about managing the work health and safety risks of working with tower cranes. Tower cranes are high-risk plant, with a number of risks associated with their operation. These risks include structural or mechanical failure or collapse; contact or collision with other plant, structures or people; arcing or flashover from an energised overhead or underground electric line; and extreme weather and related damage or failure and collapse.

Other hazards include falling objects, falls from height, noise, fatigue, and extreme weather and related damages. There are often multiple PCBUs and duty holders involved in managing risks of tower cranes in the workplace. Each may have responsibility for the same health and safety matters, either because they are involved in the same activities or share the same workplace.

The model code of practice includes guidance on what to do before using a tower crane and while using the crane, and how to inspect and maintain a tower crane.

WORKER FATALITIES PROMPT SAFETY REMINDER ABOUT INDUSTRIAL GATES

SafeWork NSW has reminded those who own industrial gates to get them checked after a number of serious incidents, including two deaths. While industrial gates can effectively protect property at home or on worksites, they can be extremely dangerous if not properly maintained as they can weigh hundreds of kilograms. A lack of maintenance can cause them to fall or become unhinged and can cause serious injury or even death.

A 64-year-old worker died in 2020 after an electric industrial gate weighing nearly 260 kg fell on him as he was trying to manually open it. The gate and surrounding fencing had been damaged and was yet to be repaired. From 2017 to 2022, there have been 17 serious injuries to workers involving industrial gates, including two worker fatalities. The top cause of injuries by falling industrial gates are a fractured pelvis and a fractured vertebra.

SafeWork NSW inspectors are checking industrial gates at construction, agricultural, transport and warehousing worksites. Individuals may be fined up to $720 and businesses up to $3600 for gates that pose a threat to the safety of workers and the community.

Head of SafeWork NSW Natasha Mann said it is important that workers and members of the public are kept safe from falling industrial gates. Mann urged employers to pay specific attention to the condition of industrial gates in their workplace or face the consequences if their gates pose a threat to worker safety.

“If industrial gates are not regularly inspected and maintained, the risk of serious injury increases dramatically. Worse still would be if someone was injured or killed in a preventable incident due to your negligence. If you own an industrial gate, answer this question — When was the last time you checked your gate?” Mann said.

FREE LUNG HEALTH CHECKS OFFERED TO FORMER MINERS

Former and retired Queensland mine and quarry workers are encouraged to take advantage of free lung checks to detect mine dust lung diseases. The free lung health check program, administered by Resources Safety and Health Queensland (RSHQ), provides a free check every five years, for life.

In the last year, the total number of mine dust lung disease cases for current and former workers diagnosed since 1984 has risen to 400. The majority of new cases are former workers who have received a free lung health check from their local, RSHQ-approved doctor, or from Health of Australia’s HEART 5 Mobile Health Unit. The unit was launched in February 2022 as part of a commitment of the Palaszczuk government.

More than 150,000 chest X-rays have been completed for current and former workers since 2016. Dean Barr, Executive Director (Occupational Health) of RSHQ, said ongoing checks are important because most dust lung diseases can develop many years after workers retire from the industry. “The checks include chest X-ray and spirometry and, when required, other followup investigations such as high-resolution CT scans,” Barr said.

The HEART 5 Mobile Health Unit is visiting Ipswich, Moranbah, The Gemfields and Emerald in August. Former workers can book a free lung health check from the HEART 5 or their local authorised doctor by contacting the Mine Dust Health Support Service on 1300 445 715.

4 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

iStock.com/Charday Penn iStock.com/shaunl iStock.com/Believe_In_Me

INNOVATIVE IMMERSION THERAPY TO BE PROVIDED ACROSS AUSTRALIA

Workplace road accident survivor Pete Wilson from Determined2 launched Immersion Therapy in Adelaide eight years ago. The company has now announced a collaboration with leisure provider Belgravia Leisure, which will help Determined2 offer accessible immersion therapy services across Australia. The collaboration with Belgravia Leisure will see Determined2’s Immersion Therapy expand first into Melbourne’s Watermarc Facility, with plans to then expand into at least 10 other aquatic facilities across the country and New Zealand over the next five years.

This expansion means that distance will no longer be a barrier for those living with an injury or a disability outside of Adelaide who require access to this novel allied health service. With guidance from specially trained Accredited Exercise Physiologists, Immersion Therapy offers the freedom of movement within a weightless underwater environment using SCUBA equipment.

Underwater, participants with a range of disabilities and injuries who find it difficult to walk on land can walk, swim and even dance, with participants reporting improved movement, reduced pain and enhanced mental and social health after their sessions. Determined2’s services in Adelaide have been funded by the NDIS, for people with workplace injuries (WorkCover), motor vehicle injuries, returned service personnel and people supported by an aged care package. The program has benefited people living with autism, anxiety, depression, multiple sclerosis, spinal cord injuries, amputations, soft tissue injuries and a range of other conditions. Wilson said the service is designed to reach as many people as possible.

“With Immersion Therapy being delivered within Belgravia facilities by qualified allied health professionals, we truly believe they will now be able to include everyone in evidenced-based physical exercise and activities, especially to those who for a long time have been excluded,” Wilson said.

Training of exercise physiologists will begin in Adelaide in August, with the first participants to receive immersion therapy at Melbourne’s Watermarc venue in October.

METAL MANUFACTURER FINED AFTER FATAL CRUSH INCIDENT

Victorian metal manufacturing company Rapid Perforating Pty Ltd has been convicted and fined $280,000 after a machine operator died at its Epping factory in February 2021. The company pleaded guilty to a single charge of failing, as far as was reasonably practicable, to provide or maintain plant that was safe and without risks to health.

The worker, who had been working at the factory for a month, was operating a turret punch — a large machine used to perforate sheets of metal. Co-workers found the worker pinned between the machine’s travelling carriage, which moved metal sheets around the turret, and one of the two tables placed at the front of the machine and bolted to the ground to support the sheet metal as it slid out. The man died at the scene with severe crush injuries to his torso and arms.

An investigation by WorkSafe Victoria found a lack of guarding around the danger area presented an immediate health and safety risk, and the fixed table created a trapping space with the moving carriage. It was reasonably practicable for the company to have installed a presence-sensing system, such as a light curtain, to the front of the turret punch and physical barriers with designated access points at the rear, or a presencesensing system that encompassed the enter perimeter of the machine.

WorkSafe Executive Director of Health and Safety

Narelle Beer said workers will continue to die or suffer horrific injuries while employers fail in their duty to ensure machinery is appropriately guarded.

“This worker was only 46 when his life was cut short due to a lack of guarding. Last year 311 manufacturing workers were injured seriously enough in incidents involving machinery to make a workers compensation claim. So far this year there have been 142 such claims. WorkSafe will not hesitate to prosecute duty holders who fall short of their obligation to keep their workplaces safe,” Beer said.

AUGUST 2023 - SAFETY SOLUTIONS 5 www.safetysolutions.net.au IN THE NEWS

iStock.com/Phynart Studio

A participant undertaking Immersion Therapy.

IN THE NEWS

SWA SEEKS FEEDBACK ON EXPOSURE TO NON-THRESHOLD GENOTOXIC CARCINOGENS

Safe Work Australia is seeking to understand whether nonthreshold genotoxic carcinogens (NTGCs) are present in Australian workplaces, in what quantities, and for what purpose, through a survey. NTGCs are carcinogens that can cause cancer by interfering with normal body processes and altering DNA. No safe exposure level or dose can be established for NTGCs based on current scientific knowledge, with any exposure posing a risk of cancer.

The review of the Workplace exposure standards for airborne contaminants identified 33 chemicals as NTGCs with evidence of use in Australian workplaces. Further information is sought from stakeholders to inform decisions around how NTGCs should be regulated to protect workers from exposure to these carcinogens.

Safe Work Australia is also seeking stakeholder feedback about the regulatory requirements in place under the model WHS laws to protect workers from exposure to carcinogens in Australian workplaces.

The survey can be completed on Safe Work Australia’s online consultation platform Engage by Friday 8 September 2023.

SAFEWORK SA LAUNCHES VEHICLE HOIST SAFETY CAMPAIGN

SafeWork SA has launched an awareness and compliance campaign focusing on vehicle hoists in automotive workshops. The sixmonth campaign targets high-risk plant such as vehicle hoists and pressure vessels, which are a common cause of serious injuries in automotive workshops.

In 2011, a worker died after being found crushed beneath a vehicle hoist at an automotive workshop in Wingfield. An investigation found that an unsafe system of work and the poor condition of the hoist were the primary factors, prompting an earlier proactive campaign.

The 2023 campaign will provide a health check regarding vehicle hoists in automotive workshops, with the data collected being compared with the results from the 2011 campaign.

SafeWork SA inspectors will visit a range of automotive workshops throughout the state, auditing the safety control measures in place for vehicle hoists and pressure vessels to protect workers from risk of injury. A vehicle hoist self-assessment tool is available on SafeWork SA’s website to help workplaces identify risks. If non-compliance is identified during the audit and cannot be remedied while the inspector is onsite, a statutory notice will be issued. Inspectors will also provide advice, information and education about vehicle hoists and pressure vessels.

WELDING SAFETY AT THE FOREFRONT FOR INDUSTRY, GOVT AND STATUTORY BODIES

Industry, government and statutory bodies across Australia are working together to ensure that appropriate strategies are in place to reduce welder exposure to fumes and prevent long-term health effects.

To assist, Weld Australia is developing two online welder safety training courses. One course is tailored for welders, while the other is aimed at welding engineers and supervisors. They cover a range of activities, from electric arc welding and flame cutting, to topics like welding fume safety and welding in confined spaces, at heights, or in hot and humid conditions. These courses will be completed towards the end of the year and made freely available by the Weld Australia website.

“All welders should receive training on methods to mitigate the effects of metal fume, including positioning themselves to reduce exposure and investigating less toxic alternatives where possible. Education is the key to ensuring a safe and productive working environment for everyone. Employers need to invest in thorough and up-to-date training for all their employees to ensure that they understand the risks associated with welding, the mitigation strategies they can use, and the equipment available to prevent accident and injury,” said Geoff Crittenden, CEO of Weld Australia.

6 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

iStock.com/IPGGutenbergUKLtd

iStock.com/Phonix_a

iStock.com/Kittisak Kaewchalun

SMART GLASSES: A VISION FOR MANUFACTURING SAFETY

8 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

iStock.com/Catalin205

Sojung Lee, President – Asia-Pacific, TeamViewer

While safety in the manufacturing industry has greatly improved over the last several decades, the risk of serious injury is still real.

Augmented reality (AR) can be instrumental in protecting workers and ensuring that they operate equipment safely. Smart glasses, when combined with industry-proven AR solutions, allow workers to use both hands to complete tasks, which is crucial in an industry where safety is paramount. For example, it’s far safer for a logistics worker to climb a ladder with both hands instead of juggling a hand scanner with one hand and using the other to try and maintain balance at an elevated height.

Moreover, the glasses can provide alerts pertaining to situations that raise concerns from an ergonomic standpoint. This is especially relevant in industrial settings where heavy parts need to be constantly handled. By directly displaying warnings on the glasses, the risk of injury can be greatly reduced. At the same time, smart glasses can display step-by-step instructions to remind workers of hygiene protocols, or warn workers about temporary restricted zones, such as tests in laboratories.

The changing manufacturing landscape

AR is transforming the manufacturing industry by bridging the gap between the physical and digital realm. Factories aren’t solely rooted in the past — in fact, they also play a large role in the future. With the rise of Industry 4.0 and the transition to Industry 5.0, driven by greater business demands and the use of data, factories are experiencing a transformative wave of technological advancements. Among these technologies, AR stands out as an essential component and the driving force behind the future of manufacturing.

AUGUST 2023 - SAFETY SOLUTIONS 9 www.safetysolutions.net.au

AUGMENTED REALITY

In the dynamic Australian manufacturing landscape, the industry has faced significant challenges in recent times, including a widespread skills gap and an aging workforce. And, as retirement looms for some of the most experienced workers, it has become increasingly important to find innovative ways to transfer their invaluable skills to the next generation of workers. Manufacturers are therefore looking to intelligent new technologies that address these challenges and help to power safer and more efficient operations for frontline manufacturing teams.

Streamlining processes

The human element is still essential to production processes; however, manufacturers face the challenge of reducing human errors that can lead to worker injuries, as well as maintaining the quality of their products and avoiding costly mistakes. AR-enhanced smart glasses allow frontline workers to digitise manufacturing processes. These glasses replace error-prone paper lists or manuals and provide step-by-step guidance for machine assembly. With the glasses on, workers can see all the necessary information at their fingertips while keeping their hands free to work. Also, AR-enabled cameras and sensors assist in making sure the production process meets safety and quality standards.

In addition, smart glasses allow remote experts to guide onsite workers in troubleshooting and repairing machinery, minimising production losses or delays and reducing the need for onsite service visits. Workers can receive real-time instructions and support, empowering efficient problemsolving and reducing operational downtime.

Enhanced training capabilities

Manufacturers can leverage AR to deliver enhanced training for their workers, which is particularly important to maintaining safety in an industry that frequently welcomes new employees with little to no prior experience. By equipping smart glasses with AR solutions designed for manufacturing, companies can augment the onboarding process and deliver learn-on-the-job experiences.

Smart glasses have the ability to simulate hazardous scenarios, which enables workers to practice safety procedures and responses in a controlled environment, enhancing their preparedness and reducing accidents on the job. This also helps alleviate pressure on stretched management teams who may have limited resources to provide comprehensive training to new staff.

SMART GLASSES HAVE THE ABILITY TO SIMULATE HAZARDOUS SCENARIOS, WHICH ENABLES WORKERS TO PRACTICE SAFETY PROCEDURES AND RESPONSES IN A CONTROLLED ENVIRONMENT.

New employees can also receive real-time visual guidance and instructions directly in their field of view — through step-by-step instructions, 3D models and annotations onto the physical environment, eliminating the need for traditional training manuals or classroom sessions. This enables employees to learn and perform tasks such as new processes, replicating repairs, or inspection steps — simultaneously and without handling any equipment — while also learning new skills much more quickly than they would with a classroom-based, theoretical approach.

The future of manufacturing with AR

AR has quickly become one of the cornerstones of the new industrial revolution. What is referred to as the Industrial Metaverse

offers significant potential to support frontline workers on factory floors across several industries, including automotive, aerospace, and food and beverage packaging. Already, many manufacturers are reaping the benefits of AR for quality control, maintenance and repair, streamlined workflows, and remote onboarding and training to improve productivity and safety, while also tackling the skills gap. As the industry evolves, and as technologies continue to advance at a rapid pace, smart glasses using AR — which can effectively overlay virtual objects on the physical world — are poised to have an even greater impact on manufacturing, driving heightened workplace safety, efficiency and innovation in the years to come.

TeamViewer www.teamviewer.com/en-au/

10 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

AUGMENTED REALITY

©

Stock.Adobe.com/au/seksan mongkhonkhamsao

Safety overshoe

The Gaston Mille Visitor’s Overshoe is a patented accessory that slips over the top of the wearer’s personal footwear. It features a 200-joule impact protection steel toecap with a moulded protection tongue that is designed to shield against splashes, cuts, dust and abrasion. The slip-resistant half-sole helps to provide stability on slippery floors.

The removable and interchangeable strap allows the product to be adaptable to different heights and it can even be worn with heels.

The overshoe has flexible material to fit just about any urban-style shoe. Since there is no direct contact between the foot and the safety overshoe, it can be re-used by multiple people, providing a hygienic solution for visitors to warehouses and other worksites.

The safety overshoe is available individually or as a kit of five pairs.

Trading Downunder www.tradingdownunder.com.au

Evaporative cooler

The Big Ass Fans Cool-Space evaporative cooler offers a portable and eco-friendly alternative to other cooling methods. Unlike common A/C or refrigeration units, the evaporative cooler uses only water and air movement to create a cool environment.

Evaporative cooling is an innovative approach to beating the heat. By directing airflow through a saturated media, the evaporative cooler transforms sensible heat into latent heat. This means that instead of relying on energy-intensive compressors and refrigerants, it leverages the natural process of water evaporation to absorb and remove heat from the air. The result is a cool and comfortable space that keeps occupants at ease.

The evaporative cooler is designed to be effective in a range of climates, making it a versatile solution for various environments. Evaporative cooling offers high cooling efficiency in hot, dry and well-ventilated spaces.

The evaporative cooler offers rapid relief from heat in notorious hot spots commonly found in racking aisles, packing lines and loading docks.

Big Ass Fans Australia Pty Ltd www.bigassfans.com.au

Personal duress alarm

MySafe Pod is a small and light all-in-one personal safety device. The personal duress alarm features fast 4G connectivity, with 1-way or 2-way voice calls, multiple location technologies, discreet SOS and worker down alerts.

The alarm allows automatic calls to nominated persons, as well as SMS for up to 10 emergency contacts, with alert details and map link. There is also the option to have it monitored 24/7.

The alarm features 4G LTE cellular technology, voice status prompts, Bluetooth 5, a charging dock and 48 hours of battery life with a low battery confirmation. It is designed to vibrate to confirm an alert has been sent and also features worker-down and non-movement alerts. The alarm comes with multiple location technologies, including GPS, GNSS and Wi-Fi, and is water resistant to IPX6 standard.

My Safe Work mysafework.au

12 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

TOP TIPS:

STARTING A WORKPLACE DRUG AND ALCOHOL TESTING PROGRAM

Glenn Dobson, CEO, The Drug Detection Agency

Proactive risk management is essential in all industries. Drug and alcohol use in the workplace is a serious issue that has negative consequences for employees, employers, a business’s bottom line and reputation, and the public.

Implementing a comprehensive and robust workplace testing program can help to reduce drug- and alcohol-related risks and create a safer, more productive work environment.

The need for workplace substance testing programs

Substance use in safety-sensitive workplaces can significantly increase the risk of physical harm, injury or even fatality. Drug and alcohol testing programs help employers identify and mitigate risks and deter substance use. Comprehensive policies and programs also provide employers with information to make informed hiring decisions and provide pathways for employee rehabilitation and retention.

Testing helps foster a productive environment with high morale, and positively contributes to a business’s reputation. It sends a message to prospective clients that the business takes credibility and

14 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

reliability of services seriously. Below are five tips for implementing a comprehensive workplace drug and alcohol testing program.

1. Consult an expert on policy development

Leading businesses consult an expert when developing a substance use policy, to ensure it is clear and fit for purpose. Experts understand the complex nature of workplace drug and alcohol policies and practice. They help ensure that a policy is compliant with legal and regulatory requirements, that it promotes health and safety effectively and that it protects employee rights.

A good policy has a purpose and scope, and covers types of testing, reasons for testing and procedures around engaging testing. If an organisation uses pre-employment, random, reasonable cause, post-incident, client requirement and rehab testing, it needs to be covered. The policy should be explicit about testing methodologies and explore post-testing pathways and plans. There should be scope for reviewing results, including engaging a Medical Review Officer and rehabilitation options — all while protecting confidentiality.

Drug and alcohol policies also need to cover known and emerging drugs as well as prescribed medications.

2. Implement employee education and training

Management and employee education is crucial to the success of a drug and alcohol testing program — it is no use having a policy that’s unknown or misunderstood. Education ensures understanding of expectations, rights and obligations under the policy. When the benefits of safety are effectively communicated, it encourages buyin and creates a culture of awareness and responsibility. Training sessions are a great way to teach management to identify risks and engage appropriate courses of action.

3. Ensure best practice testing procedures

Testing procedures should be clearly defined and adhere to best industry practice. It is important to use an independently accredited provider and a certified lab, as this ensures samples are taken and analysed accurately in accordance with the relevant standards. This removes doubt and helps your business to withstand potential litigation.

Lab testing can accurately identify both the type and amount of substances in a person’s system; this is particularly important when it comes to prescription medications. Different tests can reveal different information, for example an organisation may wish to use oral fluid or urine testing for random and post-incident testing, as this provides an indication of recent drug use. Hair testing is considered best practice for pre-employment testing as it can reveal patterns of habitual use.

4. Factor in return to work and rehabilitation programs

Workplace drug and alcohol programs should have structured approaches for addressing positive test results, and these need to be clearly communicated to employees before testing. Employees should be advised of their right to have the “B” sample independently analysed if they dispute the initial lab analysis and/or engage an independent Medical Review Officer. If an employee has a good record and is willing to engage with the employer, a rehabilitation program may enable the organisation to keep valued workers.

5. Regularly undertake program maintenance

Leadership must regularly evaluate the program to ensure its effectiveness. A good testing partner captures, secures and delivers accurate and real-time data to help review testing outcomes from incidents. They identify patterns and areas for improvement and give a business access to instantly actionable information. Leadership should also consider feedback from employees, supervisors and stakeholders to encourage buy-in, and consistent and effective testing.

Comprehensive substance-use policies are essential for safetysensitive workplaces and benefit both the employer and employee. If an organisation is looking to roll out a new substance policy, or review its current policy, engaging an expert is recommended. Experts help with policy development and effective education.

Further, using an independently accredited tester means organisations will get legally robust, accurate testing practices that provide them with actionable information. Regularly reviewing the program with management is vital to keep up it up-to-date, compliant and relevant to the workplace. Whatever methods are chosen, there is no denying that drug and alcohol testing programs contribute to safer workplaces.

TDDA - The Drug Detection Agency www.tdda.com

AUGUST 2023 - SAFETY SOLUTIONS 15 www.safetysolutions.net.au

DRUGS AND ALCOHOL

iStock.com/courtneyk

Universal lockout devices

Circuit breaker lockouts function by isolating the switch to prevent accidental start-up of equipment when being worked on during construction, installation or maintenance. This in turn helps to safeguard all workers onsite and prevents accidents from happening in the workplace. Universal lockout devices made by Cirlock are designed to suit most applications.

The UCL-1 will lock out most miniature style circuit breakers (MCBs). Simply clamp the device onto the toggle of the MCB in the OFF position using a small screwdriver. Place any of the Cirlock padlocks through the device with a danger tag to complete the lockout. Many circuit breakers are different in shape and have different toggles; however, Cirlock offers a number of assorted products in its universal lockout range to suit all types of breakers to allow users to perform maintenance work safely.

As well as the UCL-1, the UCL-4 will lock out most miniature style circuit breakers, and the UCL-2 and UCL-5 can be used to lock larger type moulded case breakers. Most Cirlock UCL devices are made from tough nylon plastics.

Cirlock also offers a pack of three different size UCLs for use across all types of plant equipment, complete with a free screwdriver. When used with a personal padlock, the devices can lock out circuit breakers of most sizes as well as fuse holders. Personal padlocks are sold separately.

The Cirlock UCL-1 is made in Australia from recycled materials. Cirlock www.cirlock.com.au

Portable pedestrian warning system

The BodyGuard portable pedestrian safety warning system is a solution designed for situations where traditional vehicle-mounted systems are impractical. With its batterypowered design and quick magnetic attachment, it’s a versatile choice for worksite safety.

The portable pedestrian safety warning system is designed to protect pedestrians and workers with an adjustable safety exclusion zone that ranges from 1.5 to 9 m, thereby preventing accidents and minimising risks in dynamic work environments.

The magnetic attachment system facilitates set-up without any vehicle modifications. When a person wearing a BodyGuard Tag breaches the safety exclusion zone, the portable unit activates strobe warning lights and a powerful siren, providing clear and immediate alerts to nearby individuals.

The user’s BodyGuard Tag vibrates simultaneously with the visual and audible warnings, providing an unmistakable signal to steer clear of danger. The system is designed to be easily moved between vehicles, making it suitable for contractors or temporary work situations. The tag is designed to increase safety on any site without the need for permanent installations.

BodyGuard Safety Solutions

www.bodyguardsafety.com.au

Smart watch

Active Environmental Solutions (AES) has launched Reactec’s R-Link smart watch across Australia. Designed and manufactured in the UK, the smart watch brings together workplace wearable technology and cloud-based Reactec Analytics software to help organisations prevent risks across a range of sectors including construction, rail, ports and mining.

The wearable device is designed to help employers to understand, monitor and mitigate exposure to vibration and the risk from dangerous proximity to moving vehicles in operating environments.

AES’s range of safety sensing technologies for harsh operating environments uses on-person monitors and software solutions to measure air quality, noise, silica dust, heat, radiation, light and exposure to vibration.

The smart watch protects teams from immediate site safety hazards, such as collisions involving people and plant, and also long-term health risks like hand-arm vibration syndrome (HAVS).

Active Environmental Solutions

www.aesolutions.com.au

16 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

Using AI adaptive learning to reduce worksite risks

In today’s rapidly evolving workplace, developing and maintaining the skills and competencies of employees — combined with challenges in skills shortages and productivity across the workforce — presents a significant challenge. Every employee or contractor brings unique knowledge gaps, which can lead to increased risk, reduction in safety outcomes and reduced productivity.

Organisations across a range of sectors and environments are now leveraging AI adaptive learning to address these gaps effectively and efficiently. Drawing on 25 years of cognitive research, Area9 Lyceum’s four-dimensional learning platform Rhapsode, powered by AI, has emerged as a transformative solution. With over 30 million learners across various industries, Rhapsode recreates a personal teacher experience that evaluates and supports learners. It adjusts in real time, recognising the areas where there is competency and teaching/adjusting to help support the gaps in knowledge. By evaluating learners using a vast amount of data, comprising over eight billion data points, Rhapsode acts as a personal tutor, guiding individuals through their training and addressing their specific knowledge gaps. This has been used in a range of workplaces to improve competency, increase employee engagement, reduce risk and save thousands of hours in standard training, which directly flows to productivity.

The introduction of Rhapsode has yielded results in multiple industries, including construction, mining, manufacturing and utilities. For instance, the Australian Rail Track Corporation (ARTC) integrated Rhapsode into its contractor safety management program, resulting in not only a reduction in total recordable injury frequency rate (TRIFR), but also behavioural changes on the engagement of contractors across ARTC sites. By utilising Rhapsode’s adaptive learning capabilities alongside a blended learning approach, the ARTC effectively enhanced worker safety and reduced incidents.

Implementation of the technology at John Holland, an infrastructure, building, rail and transport contractor, also exemplifies the transformative impact of Rhapsode. By adopting Rhapsode as part of its e-learning approach, John Holland not only saved thousands of hours in training time but notably, an

improvement in safety performance. Rhapsode’s adaptive learning approach allowed John Holland to address individual knowledge gaps efficiently, thereby further supporting their culture of safety and effective risk mitigation.

The impact of AI adaptive learning on operational competency is particularly noteworthy. By tailoring training content to each learner’s needs, Rhapsode ensures that employees and contractors acquire the necessary skills and knowledge for their roles. This personalised approach not only improves productivity but also enhances learner engagement, leading to greater safety outcomes. As a result, organisations see improvements in both lag and lead key safety metrics such as behaviour and TRIFR and overall operational efficiency.

18 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au CASE STUDY

Images courtesy of John Holland.

area9lyceum.com

Area9 Lyceum

Constructed using an impermeable full dip coating that creates a barrier to keep hands dry during wet handling tasks. 18-gauge Cut Level D Graphex yarn, doesn’t compromise on fit or function. Superior dexterity for all tasks that require precision and protection from cuts.

Also

Scan GFPR

to request a sample

AUGUST 2023 - SAFETY SOLUTIONS 19 www.safetysolutions.net.au 400 Liquid 18 Gauge Cut Level D GFPR Graphex® Precision LQR CE 719275 Australian Standard AS/NZS 2161.2:2020 AS/NZS 2161.3:2020 AS/NZS 2161.4:1999 Lic. BMP 760806 4X42D EN 388:2016 X1XXXX EN 407:2020

Superior Cut Protection GraphexGloves.com

This is liquid precision. This is redefining cut resistance. This is Graphex® Precision LQR. available in thermal

20 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

WORKPLACE HEALTH & SAFETY SHOW EXHIBITOR LIST

GUANGZHOU J&Y SAFETY PRODUCTS MANUFACTURER CO. LTD. K12

GUANGZHOU JUNYUE FOAM EARPLUG CO. LTD. E31

HAINA SECURITY TECHNOLOGY (ZHEJIANG) CO. LTD D07

HEART AND BRAIN WORKS LTD. J01

HEIGHT SAFETY ENGINEERS D14

HSE GLOBAL F07

IKON SERVICES AUSTRALIA CC09

INDUSTRIAL ATHLETES AUSTRALIA E27

INDUSTRY UPDATE MANUFACTURING MEDIA G01

AUGUST 2023 - SAFETY SOLUTIONS 21 www.safetysolutions.net.au

ABSORB ENVIRONMENTAL SOLUTIONS I24 ACTEVATE H15 ACTIVE ENVIRONMENTAL SOLUTIONS A07 AESC J26 AFFIRMER E30 AIMWELL G03 ALCOLIZER TECHNOLOGY G08 ALL PREPARATION EQUIPMENT F29 APEX WELDING SAFETY I37 A-SAFE AUSTRALASIA PTY. LTD. B11 ASCOM G06 AUSTRALIAN INSTITUTE OF HEALTH AND SAFETY A08 AUSTRALIAN SCAFFOLD & ACCESS PTY. LTD. B05 AUSTRALIAN SECURITY TECHNOLOGY E15 AUTOMATION SYSTEMS AND CONTROLS F11 BASTION PACIFIC PTY. LTD. K24 BIOSYMM D19 BLACK DOG INSTITUTE J37 BLACKWOODS C18 BRADY AUSTRALIA PTY. LTD. J25 BUFF SAFETY B01 CENTRE FOR WORK HEALTH & SAFETY B15B CIRLOCK C15 CLEAN STREAM TECHNOLOGIES I14 CM3 CONTRACTOR MANAGEMENT PTY. LTD. E09 COMSAFE TRAINING SERVICES FIRE AND RESCUE NSW D12 COTEWELL J09 DONESAFE G24 DOUGLASS HANLY MOIR PATHOLOGY –COMMERCIAL SERVICES H25 DURESS E06 EARTHMOVING TECHNOLOGY SOLUTIONS G28 ECOPORTAL E12 EMONA INSTRUMENTS E28 EMP ONSITE F20 ENABLEORG I26 ESSENTIAL WORKSAFE K01 ETISCOPE E13 EVERYDAY MASSIVE I19 EXCITE SAFETY J30 GLOBUS GROUP D24 GOOD FEET AUSTRALIA C12 GREATEAGLE SAFETY PRODUCTS J32 GREATGUARD SAFETY PTY. LTD. D01

INFOSIGN

J12 INTEGRITY

I02 INTELLIGENT

G21 JB'S WEAR J08 JEA TECHNOLOGIES F24 JOBFIT HEALTH GROUP J15 KALLIBR TRAINING F22 LICENCES 4 WORK B07 LIVINGSTONE INTERNATIONAL F06 MARTOR AUSTRALIA I36 MAXISAFE F31 MAYO HARDWARE D03 MCCUE J22 MCM ELECTRONICS J36 MEPACS G19 MILWAUKEE TOOLS AUSTRALIA C24 MOBILE SCREENING D28 MOLEMAP AUSTRALIA & NEW ZEALAND J14 MSZ INTERNATIONAL K09 MY SAFE WORK E18 NLR RESTORATIONS BB09 NOGGIN F03 NOISE MEASUREMENT SERVICES K32 OUTDOOR SOLUTION AUSTRALIA C09 OZHELP FOUNDATION D26 PARAMOUNT SAFETY G12 PATHTECH K14 PERMARK INDUSTRIES (AUST.) PTY LTD K31 PINNIP (XIAMEN) IMPORT & EXPORT CO. LTD. I20 PLANT ASSESSOR G18 PREVENTURE G09 PRYME HEALTH C07 QINGDAO EXPORTPPE CO. LTD. G31 RECKITT BENCKISER PLC BB08 RELIANCE MEDICAL I12 REOGUARD A04 RISE EQUIPMENT H30 ROAD SENSE AUSTRALIA I18 SAFEGUARD COMMERCIAL FLOORING H32 SAFETY CHAMPION G07 SAFEWORK NSW B15A SC JOHNSON PROFESSIONAL DD09 SCHMALZ AUSTRALIA J20 SHANGHAI DASHENG HEALTH PRODUCTS MANUFACTURING CO. LTD. H14 SKYTRUST C20 SLIP-LESS SERVICES PTY. LTD. K28 SONIC HEALTHPLUS F02 ST JOHN AMBULANCE NSW H27 STEEL BLUE D06 SUHYUNTECH CO. LTD. F05 SURF LIFE SAVING SERVICES H24 TALEB MEDICAL D18 TEG RISK J11 TRANSPORT FOR NSW I30 TRU BRANDS H20 ULTIMATE LED LIGHTS D20 VACUUM LIFTING AUSTRALIA J24 VERGE SAFETY BARRIERS H21 VIDERSITY E08 VITALITY WORKS H17 WASTE INITIATIVES K30 WERNER CO AUSTRALIA C06 WF MEDIA K33 WHS MONITOR E20 WINC H03 WORK HEALTHY AUSTRALIA C14 WORK REHAB F30 WORKING AT HEIGHT ASSOCIATION A06 WORKPLACE EMERGENCY MANAGEMENT H26 WORKSAFE GUARDIAN G20 WORKSTRONG HEALTH SOLUTIONS I27 WORX INDUCTIONS E19 WUHAN BESTAR INDUSTRY CO. LTD. H04 WUYI ROSUN GARMENT MFG CO. LTD. I23 XIANTAO ZHONGYI SAFETY & PROTECTION PRODUCTS CO. LTD. J13 ZHEJIANG BOYANG COMPRESSOR CO. LTD. D09 ZHEJIANG KANGLONGDA SPECIAL PROTECTION TECHNOLOGY CO. LTD. J33 ZHEJIANG WILDWIND PPE TECH CO. LTD. G30 Information was correct at the time of printing. EVENTS

PTY. LTD.

HEALTH & SAFETY

BIO SOLUTIONS

MASTERING WORKPLACE SAFETY THE POWER OF WHS SOFTWARE

Workplace health and safety (WHS) software has emerged as a powerful tool in promoting organisational safety — helping to enable a shift from simply achieving compliance to undertaking proactive safety and risk management. But there is more to WHS software than meets the eye.

On the surface, WHS software appears to merely help organisations achieve their compliance obligations. Of course, regulations exist for a reason, but today’s WHS software providers offer so much more than just ticking boxes. With systems that are entirely integrated to offer all staff one single platform for all their safety needs, organisations can enhance their staff engagement, transform their communication across the board and achieve the WHS gold standard of a stronger safety culture.

Ultimately, the value of WHS software is that companies can move from a net zero, compliance-based focus, to a synergistic, organisation-wide transformation in culture, mindset and wellbeing. This article explores the five key areas where WHS software shines.

1. Software’s role for data and trends

One of the key aspects of effective safety management is the collection and analysis of near-miss and event data. While incident data is fairly obvious to collect and assess for weak spots, near-misses are arguably more important, especially for proactive risk management. Near-misses are incidents that nearly caused harm, but did not result in injury or damage. They’re the close calls, where something could have gone wrong — but didn’t.

Near-misses are data goldmines. Highquality WHS software can use data input from near-miss events to help identify where significant risks lie, before the harm occurs. Using software to spot trends — eg, frequent occurrences of people slipping on a patch of floor — helps managers notice the weak spots and fix them, before someone is seriously hurt.

WHS software plays a crucial role in this process, facilitating one centralised platform to which staff can report all incidents — making it faster and easier to input data. It also empowers organisations to adopt a proactive approach to risk management, helping to support the implementation of risk controls, by providing a systematic framework for recording and tracking their effectiveness. This negates the need for outdated Word documents and complicated spreadsheets.

With WHS software, safety leaders can simply and easily monitor the status of their imparted risk controls, ensuring that they are in place and functioning as intended.

2. Proactive engagement

When workers find their WHS software platform accessible and easy to use, they will engage in more proactive reporting, completing the lifecycle of risk manage -

22 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

Dr Manuel Seidel, Founder & CEO, ecoPortal

ment. Any platform that’s a hassle to use is instantly off-putting, and detracts from the process of entering data.

An easy-to-use, enjoyable platform built with the end-user in mind, means that workers are more likely to want to record near-misses and incidents. With the tap of a button, useful data is inputted, and the business is better for it. Improving the user experience is a critical part of why WHS software helps to transform organisational safety. If data entry is a job that takes hours, then it detracts from other work that staff could be focusing on, and is far less likely to be completed.

3. Transforming the risk management lifecycle

Risk management in any organisation is a continuous process — a feedback loop, using controls set in place, to help monitor, record, track and review risks of varying degrees within the workplace environment.

The beauty of WHS software solutions lies in their ability to offer tools and frameworks that help to conduct comprehensive risk assessments within the workplace. These tools and frameworks aid risk management

Case study

As businesses grow, a centralised platform is essential for safety leaders to keep up. xLam, a manufacturer of sustainable building products, noticed that an effective WHS software solution was paramount to maintaining stability and structure during a rapid growth phase of the business.

As xLam expanded to the Australian market, its safety needs required more than a fragmented, siloed system. Now, using a WHS software that proactively improves its risk management, the team boasts an organic, yet effective safety culture, where reporting has increased tenfold.

Several initiatives were started as a result of integrated incident data. The team realised that a trend was forming, with an influx of near-miss data involving forklifts. With insights derived from the specifics of the recorded nearmisses, they decided to put blue lights on all their forklifts. These lights would shine when the forklift was five metres away from any machine, helping to alert workers about increasing risk. It was no surprise that the company’s near-miss rate dropped soon afterwards.

© Stock.Adobe.com/au/gorodenkoff

by helping organisations to track and monitor the effectiveness of their implemented risk controls over time.

By streamlining the entire risk management process, WHS software seamlessly helps organisations maintain a genuine, proactive approach to safety, and offers the opportunity to continuously improve safety measures.

4. Moving beyond compliance to positive contribution

While compliance with safety regulations is an essential and noble pursuit, solely focusing on compliance limits what an organisation can achieve by investing in health, safety and wellbeing. Compliance is centred on box-ticking to achieve certifications and meet standards, but health and safety is inevitably more than this.

WHS software encourages and facilitates a proactive, safety-oriented culture. If employees are engaged with the platform available to them, they’re more likely to actively participate in safety initiatives, thus improving the overall safety climate.

Using seamless, smooth systems helps the holistic functioning of the organisation

too, with lasting positive contributions to the business in the form of reduced turnover rates, increased employee satisfaction and productivity.

Employees who feel valued and safe are more likely to be engaged and motivated, leading to not just compliance with ISO standards, but improved organisational performance.

Transforming safety

WHS software unlocks significant value in transforming organisational safety. By leveraging the capabilities of WHS software, organisations can move beyond mere compliance and adopt a proactive approach to risk management. The collection and analysis of near-miss data, the engagement of employees, and a positive safety culture are all cornerstones of effective safety management.

Without a doubt, it’s imperative that organisations embrace WHS software as a proactive tool, to sustain improvements across the board in workplace safety.

ecoPortal www.ecoportal.com

AUGUST 2023 - SAFETY SOLUTIONS 23 www.safetysolutions.net.au

COMPLIANCE

White paper: welding fume product controls

An Australian scientific study has compared the effectiveness of different welding fume product control methods in reducing exposure to welding fume.

The methods analysed were On-Gun Fume Extraction (LEV), Hooded Capture Extraction (LEV), and Welding Helmet with a Powered Air Purifying Respirator (PPE). The scientific study was published in the Safety journal in 2023.

AWS has now released a white paper — The Effectiveness of Welding Fume Product Controls — based on the results of this scientific study. This white paper discusses the results and then provides clear and practical guidance on how best to control welding fume.

Welding fume has been linked to a myriad of short-term and long-term adverse health effects, including multiple forms of cancer. To that end, many studies have concluded that “welders run an increased risk of lung cancer of up to 43% when compared with those who have never welded or been exposed to welding fume”1

There are countless studies that conclude that welding fume is bad for health, yet there seem to be very few that can give us practical guidance on how to effectively control welding fume exposure. Studies have done an effective job in defining the problem; however, few have been able to identify and compare the relative effectiveness of available product control solutions.

AWS Pty Ltd

www.apexweldingsafety.com.au

Conveyor covers

Harsh environmental conditions can cause irreversible damage to conveyor belts, their components and the material itself. In order to avoid downtime and repairs, K-AllShelter Conveyor Covers have been designed to provide complete coverage of the conveyor. The conveyor belt covers are manufactured using a range of optional materials and engineered as a waterproof, durable barrier. They can be custom made to suit all belt widths and models.

The environment can be a harsh and relentless place for conveyors and their moving materials. Extremely windy conditions can blow the material away — and in some instances, can flip the belting over. Precipitation in any form (rain, sleet or snow) can alter the consistency and quality of the conveyed material, leading to screen blinding and clogging issues as well as chute hang-up and blockage. If precipitation is intense enough, material can be washed away. Heat and humidity are also factors that can interfere with material quality and flow. Damaging UV rays can shorten belt life.

Covering the conveyor is beneficial to operators from a safety perfective. Moving parts are covered effectively, and dust is contained safely within the covers. The conveyor covers feature a dust-tight seal that prevents dust from escaping and causing health hazards for operators. This also prevents dust from entering the conveyor system and causing damage to its components.

Kinder Australia Pty Ltd www.kinder.com.au

24 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

[1] 2019 Honaryar MK, Lunn RM, Luce D, et al. Occup Environ

Med.

Safety glove

The Graphex Rogue was developed out of a requirement across the mining, trade and construction industries to have a glove that provided cut resistance, dexterity and the ability to have free movement in the wrist when working with hand and power tools, particularly in and around machinery.

The thin, lightweight and comfortable Cut Level F certified glove is engineered from Graphex 18-gauge yarn with additional thermoplastic rubber impact protection and a short wrist to facilitate movement. Due to the dexterity of the 18-gauge Cut Level F yarn, there is no longer a need to doff cut-resistant hand protection or compromise on the cut level when performing intricate tasks.

Regular cuffed gloves can be restricting, especially when handling power tools or working in confined areas with a risk of catching the glove. To combat this issue, many workers cut the wrist off regular gloves, compromising the gloves’ performance and creating more of a hazard with loose fibre strands. For this reason, the task-specific hand protection solution was produced to provide safety and protection. The safety glove is finished with a hook and loop closure for a secure fit and black piping is stitched into the end of the glove to ensure no loose or frayed edges.

Certification is a cornerstone of the Graphex range, with independent testing and regular third-party factory audits to enhance wearer safety.

Private Brands Pty Ltd

www.privatebrands.com.au

AUGUST 2023 - SAFETY SOLUTIONS 25 www.safetysolutions.net.au

HOW SMART TECH INCREASES SAFETY AROUND MACHINERY

Workplace health and safety is a critical consideration for Australian businesses, especially when the workplace involves heavy vehicles, machinery and other mechanical elements, such as those prevalent in heavy industries.

Across manufacturing, construction, mining, transportation, and oil and gas, workers are required to work from great heights, in confined spaces and/or with hazardous chemicals, while often also risking accidents with vehicles and machines. Recent data shows that 38% of Australian workplace fatalities are caused by vehicle collisions, while 23% are caused by being hit by falling or moving objects. Falls from a height represent 11% of fatalities and 7% are caused by being trapped by moving machinery. The remaining 21% of workplace fatalities are attributed to other mechanisms.1

A large number of organisations working across heavy industries have taken steps towards digital transformation, with many investing in new tools and solutions that will help to streamline efficiencies and improve operations — including by reducing risk to human workers. However, more needs to be done to improve the safety of workers within these industries. The answer lies in leveraging innovative smart technologies.

Heavier technology investments help heavy industries

Companies that operate in industries such as manufacturing already use technologies like sensors and detectors, robotics and mobile apps across their operations to improve the efficiency of activities and improve worker safety.

26 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

Frank Baldrighi, Business Development Manager – Australia and New Zealand, Getac

However, while these are all delivering essential benefits to operations, they are only just starting to scratch the surface of how innovative technologies can be used to improve workplace health and safety. There are three key areas where more improvements can be made by investing further in the use of smart technologies:

1. Virtual and augmented reality

Interest in virtual reality (VR) and augmented reality (AR) is growing, with its application already seeing results across the education, automotive and medical industries. 2 When it comes to heavy industries, VR and AR can provide significant benefits to users, including through improving training and better preparing workers for possible dangers. Using AR and VR allows organisations to better train workers regarding complex and dangerous tasks, by exposing them to potentially hazardous environments, scenarios and incidents without ever actually placing them in harm’s way. This helps to better prepare workers while decreasing the risk of accidents and injuries.

2. Wearables

Wearables are becoming increasingly common across various sectors, as they can be used in numerous ways to deliver benefits for workers in heavy industries. For example, wearables can be used to monitor worker fatigue — alerting them as to when they need to take breaks according to fatigue data. They can also help to reduce the risk of workers’ exposure to health

risks and high temperatures onsite, or even to monitor workers’ posture or noise levels.

Wearables that are supported by sensors can also alert workers when they are standing too close to machinery or not properly following safety protocols — which can reduce the potential for workers to experience clothing or body parts becoming entangled in heavy machinery and equipment. Additionally, wearables can help organisations to more effectively monitor lone workers, locate all workers in the event of an emergency and even potentially prevent collisions between workers and machines.

3. Robotics and automation

Perhaps one of the most effective technologies in heavy industries to reduce worker risk and improve safety is the use of robotics and automation. These technologies eliminate workers’ exposure to dangerous tasks by using automated machines, drones and vehicles. Robots can independently manage dangerous tasks, such as those requiring work in confined spaces or from great heights, which eliminates the risk of workers being exposed to these dangerous scenarios.

The combination of robotics with AR and VR applications can be an especially powerful tool, as organisations can remotely control, maintain and even repair equipment at a distance. Workers operate devices and machines remotely without being in the dangerous situation themselves, which helps to improve productivity without increasing worker risk.

Strengthening worker safety with artificial intelligence and big data

Underpinning each of these innovative applications is the continued use of artificial intelligence (AI) and big data. AI and data analysis can help organisations strengthen their use of innovative technologies and further protect their workers from dangerous situations. Using worker data based on wearables can help them improve rostering by reducing the potential for fatigue. Additionally, combining robotics and automation with AI and data from monitors, cameras and sensors, for example, can eliminate the risk of collisions between autonomous vehicles and workers.

While technology is not the be-all and end-all for heavy industries, it can go a long way towards improving worker safety onsite. And, for the best results, organisations must also ensure that the technologies they invest in are supported by the robustness and durability that their dangerous and diverse working conditions require. The latest technologies need to comply with relevant industry and organisational regulations while also meeting the standards of the workplace itself. Ensuring businesses operating in heavy industries invest in robust technology can help to eliminate the potential for technologies themselves becoming a risk factor.

1. https://www.safeworkaustralia.gov.au/doc/key-work-health-and-safetystatistics-australia-2022

2. https://accumulate.com.au/virtual-reality-statistics-australia-2023/

Getac Technology Corp www.getac.com

AUGUST 2023 - SAFETY SOLUTIONS 27 www.safetysolutions.net.au

MACHINE SAFETY iStock.com/NanoStockk

Battery storage solution

Tesvolt and Denios have partnered to present the Power Safe, an all-in-one solution that combines a battery storage system and fire protection. The Power Safe product line also meets the safety requirements in commercial and industrial settings; eg, in operations located in water conservation areas or regions that are at a risk of forest fires, or as required by some insurers. Products in this line feature cases offering F90 fire resistance rating and are available in various sizes, from small-scale 80 kWh solutions to large energy storage systems with several megawatt hours.

In the Power Safe product line, storage systems come in a spatial system with dual-frame construction classified as REI 90 or REI 120 fire protection. It is designed to withstand fire, either internal or external, for at least 90 min, fulfilling the standards for safety certification required by approval authorities and reducing complex approval processes. This safety certification also allows the system to be installed without a minimum clearance between it and adjacent buildings. Moreover, Denios offers round-the-clock remote monitoring and will alert the operator immediately in the event of a problem with the system. An aerosol-based extinguishing system is also available for the spatial system.

The storage systems feature prismatic battery cells; the battery management system also monitors the voltage of each individual cell. This means the whole system is subject to constant plausibility monitoring. If the normalised range is exceeded, the system automatically switches to a safe state. Power Safe spatial systems with fire protection come with European Technical Assessment (ETA) and associated CE labelling. This offers enhanced planning and legal security for country-specific approval processes.

Tesvolt Australia

www.tesvolt.com.au

28 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

Comms system improves worker safety at heights

For a company operating in complex vertical and confined space environments, a robust communications system is key to keeping workers safe.

RISE Pacific is an expert company in rigging, access and rescue in the broadcast, aerial and stunt worlds, across live entertainment venues. It also has industrial, telecommunication and geotechnical solutions. While looking to source accessories and parts for its existing fleet of Motorola digital radios, it ultimately engaged D2N Technology Solutions to assist with utilising newer technologies for its on-site communication requirements.

Due to the danger factor within its line of work, RISE Pacific’s requirements were specific and comprehensive.

“Operating in complex vertical and confined space environments means communications are absolutely critical to our team’s safety and ability to efficiently achieve a given scope of works,” said Dane Boulton, Design and Sales Manager at RISE Pacific.

“What really interested us was the potential to deploy a solution that would allow constant duplex communication with all members of the work party. Not only does this allow our technicians to communicate even when both hands are busy using tools, managing ropes and operating rope access gear, it also removes the risk of a team member being blocked from passing an urgent message when a radio channel is busy. This is something that poses a major risk when comms systems are being relied upon as a primary means of communication in safety critical rope access and confined space operations.”

RISE Pacific also required a comms system that was both durable and compatible with an AS-approved hearing protection/ communications earmuff. In addition, it had to be able to maintain interoperability with the company’s existing fleet of digital Motorola radios. To meet these requirements, D2N proposed a comprehensive Riedel Bolero solution, one that is particularly well known for its reliability, flexibility and durability.

“The standalone Riedel Bolero system with audio interface and radio PTT input provided exactly what we were hoping to achieve, by allowing us constant duplex communication between our operators wearing wired or wireless Bluetooth 3M Peltor communications/hearing protection headsets and helmet attached earmuffs,” Boulton said.

“Not only did this provide our technicians hearing protection in noisy environments but also clear, articulate communications between them — regardless of whether they were one metre or hundreds of metres apart from each other. The beltpacks have proved incredibly durable in use, and the ability to interface with our existing fleet of Motorola MOTOTRBO radios allows us to easily scale the system up by providing radios to less critical members of the work party.”

RISE Pacific’s system is packaged in a rolling rack case that includes the Bolero system, NSA audio interface, radio interface and an IP camera system for monitoring of confined spaces and worksites.

For less complex jobs the company can easily package antennas and beltpacks in a small case for easier transportation to the site. Deployment is quick, with the antennas being connected back to the rack with a single ethernet cable handling both data and PoE power for the antenna.

“So far, we’ve utilised the system in complex confined spaces where our technicians have been separated vertically including in a 160-metre-deep ventilation and maintenance shaft which was a very harsh RF environment and on a working airfield where, even with an extremely high level of ambient noise, a ground team could clearly communicate with riggers working nearly 25 metres off from the ground in large boom lifts. Completing jobs of this nature smoothly and efficiently with clear communication between the team would not have been possible without such an effective means of communication,” Boulton said.

D2N Pty Ltd www.d2n.com.au

AUGUST 2023 - SAFETY SOLUTIONS 29 www.safetysolutions.net.au

CASE STUDY

Psychosocial hazard audits

Health and safety legislation across several Australian states requires PCBUs to identify psychosocial hazards and eliminate or reduce them as is practicable. Psychosocial hazards are aspects of work that can cause psychological harm to employees through repeated, prolonged or intense exposure. Examples include high or low workload, low role clarity, lack of support from manager, and bullying or harassment.

Heart and Brain Works offers psychosocial hazard audits that can help PCBUs identify over 30 hazards. The audits use quantitative and qualitative data to help clients understand the root causes of hazards. The company’s proprietary algorithm breaks down the risk of psychological health impairment so clients know the percentage of staff at risk. Heart and Brain Works provides a report that identifies areas of strength and areas where intervention is needed. The company also offers recommendations for actions and controls based on industry best practice.

Heart and Brain Works

www.heartbrainworks.org

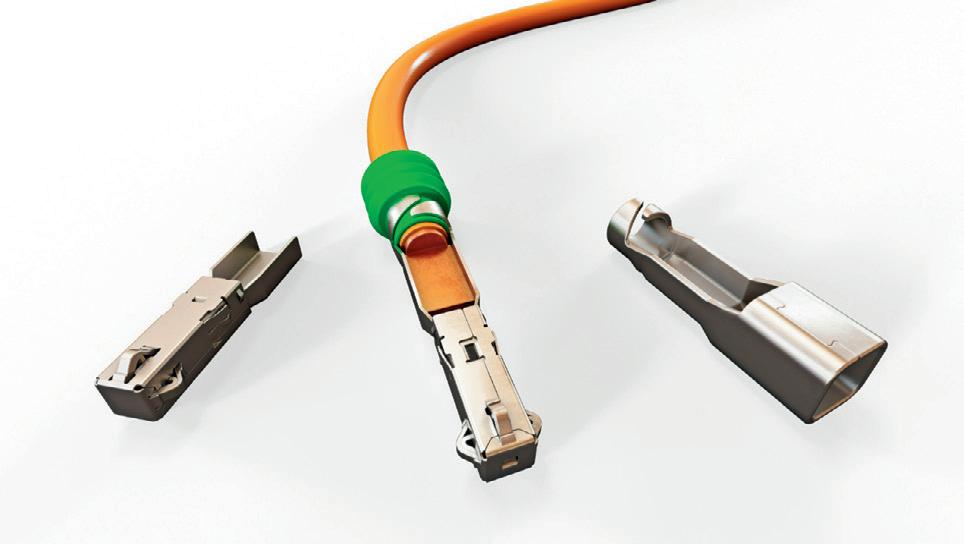

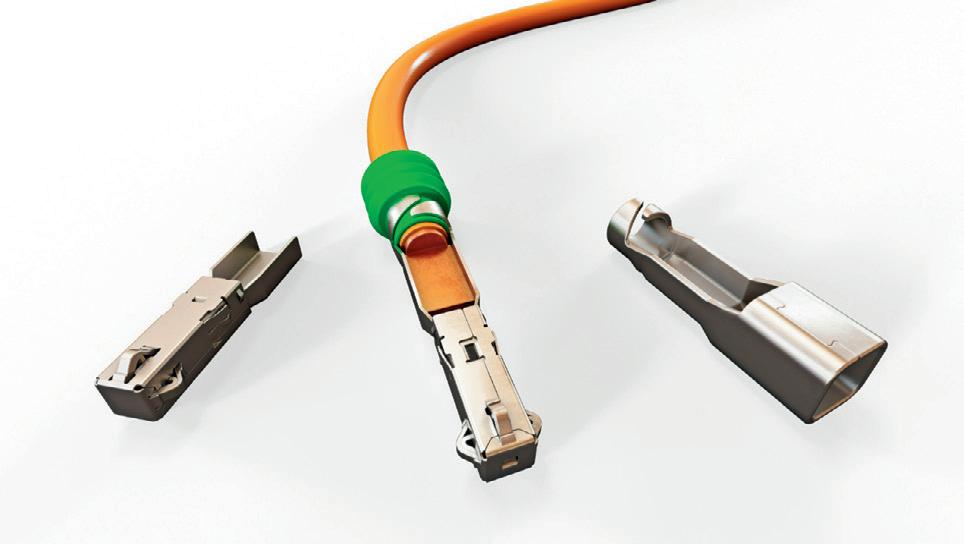

Lock box connectors

Eaton Corporation’s eMobility business offers specialised high-power lock box (HPLB) power connectors for use in current and future electrified and internal combustion vehicle solutions. The HPLB connectors offer a space-saving profile, cost savings and reduced manufacturing complexity. The HPLB connectors are designed to provide protection against the elements and corrosion, with the HPLB terminal system designed for high-current and high-temperature applications, up to 500 A and 125°C.

Portable cable drum stand

The Adept Direct Portable Cable Drum Stand provides a versatile means of transporting drums of heavy cable across building sites.

The cable stand enables reels of cable to be correctly positioned to allow cable to pay out smoothly from each drum, without tangling.

The bright yellow powder-coated frames can be dismantled off the axle for transport and the 6 ″ pneumatic tyres can handle most construction site obstacles.

While the portable cable drum stand is mostly used for drums of cable, users have advised they are also suitable for unrolling anything off a drum: chain, rope, hose, air lines and more.

Adept Direct www.adeptdirect.com.au

Eyelet workers are traditionally manufactured by production line work ers wearing two sets of gloves for protection against high voltage and an air gun to tighten small nuts. If the connection is not precise every time it can result in a disruption in power flow. If the operator accidentally drops a nut into the component’s inner workings, it can short circuit the entire unit. The HPLB connectors can be installed by a ‘pick-and-place’ robot, to facilitate precise and safe connections. The HPLB also sits flush, unlike traditional connector terminals, reducing space requirements within the vehicle.

Eyelet terminals within vehicle electrical components are not sealed, potentially exposing them to road spray and salt, which accelerates terminal galvanic corrosion. Corrosion can mitigate the power flow, leading to system failure. The fully sealed connectors are also resistant to severe vibration and deliver a component service life that meets USCAR Safety Performance Requirements.

The HPLB terminal connectors are designed to lower temperature and provide extra current carrying capacity. The HPLB terminal system forms a connection that provides improved contact force throughout the component’s service life. Unlike traditional box and blade terminals, the connectors use Power Connections’ Connector Positive locks, which utilise an ‘inside-out’ contact system with internal spring pressure and multiple contact points. This configuration provides a stronger connection than that of conventional boxand-blade connectors where the female terminal spring squeezes the male blade, which loosens when exposed to heat and vibration, resulting in a loss of power flow continuity and the possibility of corrosion.

The connection also reduces heat radiating from the connection points by an average of 3.33°C per contact. Many modern vehicles have up to 120 such contact points, so leveraging HPLB connectors leads to temperature mitigation and improved vehicle performance.

Eaton Corporation

www.powerware.com

30 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

SIMULATION APPROACH TRAINING FOR EQUIPMENT OPERATORS

Field equipment productivity, such as loading and hauling equipment, is directly affected by the skills and ability of the operator. Skills gaps are generally present in a typical company workforce, where operators with lower proficiency are responsible for most incidents. These will prematurely fail the equipment, increasing the cost of maintaining the equipment. Therefore, training should be considered an integral part of an employee development program to ensure longevity and safety in the high-risk workplace.

Bestech Australia has supplied modern technical training equipment to local industries and training institutes in Australia and New Zealand. Our equipment includes hydraulic training systems, electrical testing boards and heavy equipment simulators, which are designed to prioritise safety in learning and teaching safe and correct operating procedures.

Training on the actual equipment provides a much more realistic experience. However, it is not suitable in many situations due to safety issues and a lack of diagnostic tools to support practical training. Heavy equipment simulators serve as costeffective training solutions and can act as pre-screening tools during hiring and recruitment campaigns.

In actuality, training new employees are integral and part of the hidden cost that can be easily overlooked. When a company recruits new operators, not all candidates possess the right aptitude to be trained as equipment operators. Evidence shows that approximately 25%–40% of the candidates that pass the initial screening were judged unsuitable to work as equipment operators. Simulators can be used as pre-screening tools to test for the candidates’ technical aptitudes, such as psycho-motor, sensory/perception and cognitive ability.

The SIMLOG equipment simulators include hydraulic excavators, forklifts, mining trucks, cranes and other equipment commonly found in construction and mining sites. These simulators have been commissioned in industrial training centers and TAFEs across Australia with technical support from our engineers.

SIMLOG’s heavy equipment simulator can be used as a training system for operators and pre-screen for technical aptitudes.

The number of simulation modules depends on the type of equipment or simulator. Each simulator is equipped with key performance indicators, allowing the instructors to grade the quality and productivity of students’ work. More importantly, students can learn independently without direct supervision from the instructors.

Training operators with good techniques and working habits lead to increased production efficiency, less wear and tear, and maximise the operating lifetime of the equipment. In the simulator, students will be put under the control of modern equipment with a realistic dashboard in a virtual worksite that mimics the real work environment. Training is delivered through a modular instructional design that teaches the skills to operate the equipment safely and efficiently.

For example, mining truck simulators consist of learning modules that teach operators how to drive the truck, turn the wheel effectively, and minimise the wear and tear on the tyres. Mistakes that occur during practice are counted and recorded. Both students and instructors can review these at the end of the exercise as part of their learning journey.

Choosing suitable training simulators depend on the individual training needs. The top-of-the-tier simulator can consist of multiple PCs, a motion platform, customised hardware/software interface with the particular model/make of the simulated equipment. In addition, it often comes with an ongoing annual subscription fee for the software module.

Safety must be the top priority in every workplace, and this can be achieved by training employees with adequate and upto-date technology. Setting up an in-house training centre can be costly, but it does not mean breaking the bank. Contact one of our specialists at Bestech Australia about your training needs at 03 9540 5100 or email enquiry@bestech.com.au.

Bestech Australia Pty Ltd

www.bestech.com.au

AUGUST 2023 - SAFETY SOLUTIONS 31 www.safetysolutions.net.au

SPONSORED CONTENT

Safety boots

Work boot manufacturer Steel Blue has released scuff-resistant versions of two of its popular boots, the Hobart and the Portland. The product lines of both have been extended to include versions of the boots featuring Steel Blue’s Scuff Cap, which is a durable, low-profile toe cap made from thermoplastic urethane (TPU).

The Scuff Cap, which has previously been added to Steel Blue’s Argyle, Parkes and Southern Cross work boot ranges, is designed to provide longerlasting protection of the boot without adding any weight. The Scuff Cap makes the boot resistant to abrasion and toe area damage because it covers more of the upper surface of the boot, while providing more low-profile protection than a Bump Cap. A Scuff Cap boot is suitable for people who are doing a lot of kneeling during their work that can damage or wear through the leather toes of their work boots.

The Hobart, an elastic-sided, steel-capped, pull-on boot, is suitable for the agricultural and horticultural industries, landscapers, emergency services workers and general trades. The Scuff Cap protected Hobart is available in black, sand and wheat and is already in stores.

The Portland is a high-leg (170 mm tall) lace-up work boot with a padded collar and tongue which is made from premium water-resistant leather. It’s particularly suitable for the mining industry. As well as adding the Scuff Cap, the new Portland has also been redesigned to include a zip. The Portland is available in black, sand and wheat.

All Steel Blue work boots are backed by a 30-day 100% Comfort Guarantee.

Steel Blue

www.steelblue.com.au

32 SAFETY SOLUTIONS - AUGUST 2023 www.safetysolutions.net.au

SIX STEPS TO ENSURE MINING CONTRACTOR SAFETY

Sue Bottrell, Legal Counsel of LinkSafe

Hazardous working conditions and complex operations demand rigorous safety protocols within the mining industry.

While companies employ numerous safety measures to protect their employees, a significant portion of the workforce in the mining sector comprises contractors. These contractors, often hired for specific tasks or projects, require special attention to ensure their safety and wellbeing.

This article will explore the importance of contractor safety in the mining industry, highlighting the challenges faced, and look at strategies that mining businesses can implement to mitigate risks and promote a culture of safety.

The significance of contractor safety

Contractors play an indispensable role in the mining industry, providing specialised skills and services necessary for efficient and timely operations. However, their transient nature of employment and varying levels of experience can create unique challenges where safety is concerned. The responsibility of ensuring contractor safety falls jointly on the mining companies and the contractors themselves. By prioritising contractor safety, mining companies can demonstrate their commitment to the wellbeing of all workers and foster a culture of safety throughout the industry.

Challenges and risks

Several factors contribute to the challenges associated with contractor safety in the mining industry. First and foremost, contractors may lack the same level of familiarity with mine-specific hazards as regular employees. This knowledge gap, combined with inad -

equate training and orientation programs, can significantly increase the risk of accidents or injuries.

Moreover, contractors often work under time constraints, striving to complete projects swiftly — often compromising safety protocols in the process. Lastly, ensuring consistent compliance with safety regulations among contractors can be challenging due to their diverse backgrounds and varying safety cultures.

Mitigating risks

To address the challenges and mitigate risks, mining companies must take proactive measures to prioritise contractor safety. The following strategies can serve as effective guidelines for achieving this goal: