You can now receive your industry news in a range of formats: Newscast, Website, Social Media, and a magazine. So whatever your preference is for catching up with the latest innovations and news in the industry, there is a Window News format to suit everyone.

We aim to keep readers up-to-date with the latest industry news, trends, technical innovations and suppliers. Our web format means that we can be in the right place at the right time – wherever that may be.

The contents of Window News are provided for general use only and do not constitute general advice and should not be relied upon.

Views/opinions, replies and specific advice expressed by external persons are not necessarily those of Window News and are not subscribed to by Window News. To see the full terms and conditions please visit: http://www.windownews.co.uk/window-news-disclaimer/ Privacy Policy: http://www.windownews.co.uk/window-news-privacy-policy/

Publisher Gerald Batt Tel: 01255 850245

E-mail: gerald@windownews.co.uk

Editorial E-mail: edit@windownews.co.uk

Production E-mail: production@windownews.co.uk

Copyright © 2024 PO Box 13225. Frinton-on-Sea, CO13 3BT www.windownews.co.uk

Cover picture: Glazing The Workplace Of The Future, read more on page 100

Surgit Singh, the owner of Aluco Aluminium Ltd and Ventiss Ltd, has announced the acquisition of 100% share ownership of Evolution Home Improvements Ltd. Evolution, a specialist in timber alternative manufacturing, is based in Biggleswade, Bedfordshire.

In recent times, Evolution was under the ownership of UK Windows and Doors Group and more recently Everest 2020 Ltd (now in administration). This marks a significant milestone as prior to this Surgit was the co-founder of Evolution in 2004 before selling the company to

Masco in 2014.

Evolution is renowned for its high-quality timber alternative products. The company has earned a strong reputation for its exceptional craftsmanship and innovative designs in the window and door industry.

Taking control of Evolution once again, Surgit Singh, along with his experienced management team, aims to reclaim Evolution’s position as the market leader in the timber alternative industry. The strategic focus will be on innovation, sustainability, and

fostering long-term relationships with all stakeholders, including staff, customers, and suppliers.

Partners from ReSolve, the business advisory firm, were appointed as joint administrators to Everest 2020 Limited on 24 April 2024, of which Evolution was a subsidiary. This sale by the administrators to Mr Surgit Singh secures the future of the business as well as the jobs of all its employees.

Chris Farrington, Partner at ReSolve and joint administrator to Everest 2020, commented:

“We are pleased to have completed the sale of Evolution to Mr Surgit Singh, one of the original founders of the business. We were able to move quickly, securing the future of the business and over 60 jobs. We wish Surgit and Evolution all the best for the future.”

Anglian Home Improvements (trading as ASHI Group Ltd) has today completed a transaction which sees it acquire the customer order book, brand and intellectual property, and certain other assets from Everest 2020.

Cameron Gunn, Chris Farrington and Lee Manning, Partners at ReSolve, were appointed joint administrators to Everest 2020 Limited (“Everest” or the “Company”) on 24 April 2024.

The transaction ensures that where possible Everest 2020 customers impacted by the Company’s insolvency will have the opportunity to have their home improvement projects carried out in full by Anglian Home Improvements.

Anglian Home Improvements manufactures a wide range of home improvement products at its factory in Norwich, and is responsible for the employment

of circa 1,500 people across the UK. It has over 40,000 living space orders under warranty and 400,000 orders of windows and doors under warranty. These products are installed throughout Britain from the North of Scotland to Cornwall.

Anglian says it is proud to achieve the Made in Britain accreditation, which showcases the best in British manufacturing. As a company that has been manufacturing its own products for over half a century, Anglian is proud of its British heritage and says it is focused on raising the standard across the industry.

Peter Mottershead, executive chairman of Anglian Home Improvements, said: “Since the announcement last week that Anglian had reached agreement with the joint administrators to take on the Everest 2020 order book, our customer service teams have been working hard to make contact with all customers impacted to review the status of their orders and where possible progress their project. Having been manufacturing and installing home improvements for around 60 years, we are looking forward to helping them transform their homes.”

Cameron Gunn, joint administrator of Everest and senior partner at ReSolve, commented: “We are pleased to have completed the transaction with Anglian which will provide much needed certainty to customers over their home improvement projects. We will continue to provide support to the affected employees throughout this process.”

A team comprising Chris Farrington, Lee Manning, Nadeem Sweiss, Andrew Lawrie and others at ReSolve were supported by Jeff Roberts and Andrew Titmas from Memery Crystal. Anglian Home Improvements were advised by Jatinder Bains, Malcolm Walton, Alex Green and Rosie Duckworth from Macfarlanes.

A high-profile roundtable event hosted by Glass Express Midlands, and including government representation, resulted in the Glass & Glazing Federation (GGF) and the Council for Aluminium in Building (CAB) agreeing to work closer together to provide a unified voice to policy makers.

Held at a central London location, and attended by representatives from different parts of the supply chain, the round table event set out to discover what better regulation looks like how representatives can create positive benefits for glazing and the wider construction industries.

“The in-depth discussions were very well-informed, and the delegates all shared their frustrations of poorly managed projects,” Glass Express Midlands’ managing director Arun Photay said. “Many of these frustrations could be attributed to a lack of visibility of project details, and of

a sometimes confused regulatory framework.

“To have two of our industry leaders agree to closer cooperation and speak to government with a unified voice is an excellent result.”

Eddie Hughes MP, who was previously the Minister for Rough Sleeping and Housing at DLUHC (Department for Levelling Up, Housing and Communities), told delegates that difficultto-work elements of Building Regulations often came down to communication between government and industry.

“Government Ministers and Civil Servants endeavour to work with all interested parties to ensure that Building Regulations are workable,” he said. “In the case of the glass and glazing industry, I think a single unified body representing the interests of all parties is a sensible idea.

“I look forward to working closely with glass and glazing industry to develop stronger and more meaningful partnerships.”

John Agnew, managing director of the GGF Group of Companies, recognised that providing a unified voice is what government wants to see.

“And with support from other like-minded trade associations we will be better able to represent the views of the sector,” he said.

“Today we have committed to creating that unified voice with CAB. This is new ground, and we are looking forward to developing our strategy together over the coming months.”

Nigel Headford, CEO of Council for Aluminium in Building, said it was important to overcome historic challenges to create a ‘bigger voice’.

“We have a lot of members, and some of our members cross over,” he said. “And to represent them properly, I think we need to join together and target the right level in the decision-making process.

“We’re membership bodies. So, for me, it’s about working for them and being able to lobby for them and to bring their concerns to a higher level. And together with other trade organisations in construction, we can do that.”

Three key aims emerged from the event: to create a unified voice, inviting representatives from various trade bodies within the glass and glazing industry; to develop a voluntary code of conduct; and to promote the use of technology to prove compliance.

“There is an avenue here where we can produce a document that can be presented to government,” Arun said. “I think what really came out of this discussion is how we want to do something that’s holistic, where all the different parts of the industry come together like a jigsaw puzzle, and we present that one solid document on how we move forward to the government so that we do have a voice.”

glassexpressmidlands.co.uk

Trade aluminium fabricator Fentrade has reported a 20% increase in sales compared to the same period last year. Chris Reeks, managing director of Fentrade, said: “The growing strength of the aluminium market is reflected in our sales and we’re seeing a significant uptake in commercial projects across the board.”

Chris notes that Fentrade’s commercial order book encompasses projects of all sizes and in all sectors.

In the education sector, the company has been involved in two major projects involving complete window and full façade replacements. It’s a trend that is already set to continue, with future projects booked in for the summer holiday months.

Smaller scale projects are also increasing in number. Commercial entrance doors and emergency access products are particularly popular, with installers working with local authorities, retailers and main contractors.

Looking forward, Fentrade are quoting for a high volume of individual projects including for care homes and the MoD.

Chris commented: “Our strong sales pipeline reflects a buoyant commercial sector and we’re delighted to be playing our part in helping our customers to secure and deliver these contracts.”

The fabricator manufactures Kestrel and Jack Aluminium for its commercial products, with the AluK SL52 curtain walling and the GT55 ground floor treatment range also proving popular.

Alongside the product range, Fentrade claims customers also benefit from the company’s depth of experience. Chris commented: “Our team has over 30 year’s fenestration experience, so we understand what customers need. We always communicate fully with every customer from quote to delivery.”

www.fentradealuminium.co.uk

Keystone Market Research has announced the release of the second edition of its quarterly UK Consumer Fenestration Trends report, sponsored by Epwin Window Systems, offering insights into changing preferences and homeowner buying priorities in the fenestration market.

The latest edition looks at the shifts in homeowner views compared to the initial survey, uncovering intriguing swings that are shaping the industry. To maintain a balance between new content and tracking homeowner

views over time to build up trends, each report presents the data results from a different angle to ensure that the information is as easy to understand and apply to your business as possible.

While the first report offered a comprehensive overview of overall results at a product level, the Spring edition takes a closer look at regional preferences. By examining each area in turn, readers gain valuable awareness of the unique needs of local audiences, highlighting both similarities and variations across regions.

As shown in the Winter report, online search and visibility are playing an increasingly crucial role in consumer decision-making. Therefore, this edition also features expert guest advice from Laura Trowbridge on maximising opportunities in this area.

Charlotte Hawkes, director of Keystone Market Research, comments: “Feedback on our inaugural report was overwhelmingly positive, with companies praising its strategic value and user-friendly format. Our annual subscribers are finding the Spring report to again be an invaluable resource, with comments on how interesting it is to see the changes in homeowner preferences quarter by quarter and how useful it is for generating installer support content. Building on the first edition results, we’ve packed this latest release with unique homeowner insights and practical guides to empower fenestration businesses and we’ll continue enhancing the format based on customer feedback to ensure we’re delivering ongoing value.”

Looking ahead, the Summer report will analyse results by homeowner profiles, aiding companies in gaining deeper insights into their target audience and enabling them to adapt their marketing efforts effectively. Meanwhile, the Autumn report promises to be the most thorough yet, drawing from the views of over 4000 homeowners by that point – the largest published dataset of its kind – to provide a comprehensive overview of UK homeowner views on fenestration products. Additionally, it will include the first look at anticipated homeowner-indicated spend levels on home improvement in 2025.

The second report is available now, with single report or annual subscription purchase options. For more information, please visit www.keystonemr.co.uk

•

•

• Hybrid timber-foam core to combine thermal efficiency and strength

• Aluminium sheets add rigidity and reduce moisture ingress

• Slab painted to order for a perfect finish in a wide range of colours

•

Deceuninck has installed 2,200 solar panels onto the roof of its Calne manufacturing facility, generating a total of 895,762 kWh of clean energy.

The renewable energy source not only reduces Deceuninck’s reliance upon fossil fuels for its operations, but also significantly reduces CO2 emissions by

498,507kg a year, according to the company.

Darren Woodcock, operations director at Deceuninck, said: “The solar panels went live on 15th March. We only experienced around four hours of operations downtime whilst the inverters were connected. It was a seamless installation.

Darren Woodcock

Darren Woodcock

“We have every aspect of the roof that could be covered in panels, covered. The solar energy will help us offset rising energy costs, but will also generate huge environmental savings, further reducing our CO2 emissions, and allowing fabricators to benefit from the saving.”

Deceuninck has established a lead on sustainability based on its’ commitment to the Science Based Targets (SBTi) programme, claims the company, with a headline pledge to cut the CO2 emissions from its own operations (Scope 1&2) by 60% by 2030 from a 2021 baseline.

Research by Deceuninckshows that while fabricators and installers want to lower their carbon footprint, many struggled to know where to start and were put off by the complexity involved in the process.

As a result of Deceuninck’s new renewable energy usage, fabricators can now increase their own sustainability simply by purchasing Deceuninck products and benefitting from the work done upstream in the supply chain, says the company.

In addition to allowing window companies to measure their carbon footprint through its innovative Carbon Calculator, Deceuninck has also provided guidance on how companies can lower their own CO2 emissions – and how a more sustainable approach can help them win more business.

This includes a Sustainability Marketing Toolkit, with headline positional statements drawing on Deceuninck’s commitments under Science Based Targets; own-branded-printable sustainability brochures; plugand-play website content; e-shots; social media assets; presenter decks; and video content; door-drop leaflets; sustainability logos; showroom pull-up banners, wall decals; and flyers.

“We are going to be able to display the number of trees that we have saved every day by cutting our CO2 emissions through using clean energy in our reception area”, said Darren.

“This is a clear, tangible way of communicating our savings to our customers, in the same way that our customers can benefit from the free, substantial messaging and resources available within our Marketing Toolkit.”

www.deceuninck.co.uk

AT Precision, manufacturer of bi-folding door components and ancillary products, has announced a significant advancement for its Recycled Thermal Reinforcement (RTR) bars.

Following their introduction six months ago, the company says they have successfully upgraded the RTR bars to ensure compatibility with a much wider range of window and door systems.

Manufactured from 100% recycled uPVC, AT Precision’s RTR bars offer exceptional strength and enhanced thermal performance for windows and doors. They are renowned for their quick and easy installation and boast a minimum lifespan of 35 years, claims the company.

“The initial launch of the RTR bars was a resounding success,” says sales director Michael Hewitt. “We saw strong interest from fabricators due to the product’s environmental credentials, performance benefits, and ease of use. However, we recognised the need to expand compatibility to reach a wider customer base.”

The company recently launched its own in-house uPVC recycling scheme, complete with a factory expansion and a £370,000 investment in a new extrusion machine. atprecision.co.uk

Eurocell claims to have achieved 32 per cent recycled PVC-U in extrusion in 2023, up from 27 per cent in 2021 – setting what it describes as ‘a new bar for recycled materials in the design and manufacture of its PVC-U windows and doors’.

Eurocell’s dedication to sustainability is demonstrated through its innovative manufacturing processes, where its profiles division blends raw PVC resin with recycled materials sourced from the company’s cutting-edge recycling plants located in Selby, North Yorkshire, and Ilkeston, Derbyshire.

These facilities are pivotal in transforming factory offcuts and old window frames, which would likely end up in landfill, into reusable raw materials. In 2023 alone, Eurocell’s recycling operations saved the equivalent

of approximately 3 million window frames from landfill. The business operates a closed-loop recycling system to ensure that waste PVC-U can be reused, significantly reducing environmental impact.

Sandra Gaspar, head of recycling at Eurocell, commented: “The increase to 32 per cent in the proportion of recycled materials in our extrusion process, is a testament to our ongoing commitment to sustainability and demonstrates how we are leading the way in PVC-U recycling.

“By integrating more recycled content into our products, we not only reduce our carbon footprint but also provide our customers with high-quality, sustainable building solutions. We are helping the industry reduce waste and lower its carbon footprint, which is what we want our forward strategy to help deliver as we look to make

further inroads in our recycling operation.”

Looking ahead, Eurocell has set an ambitious target to increase the proportion of recycled PVC-U in its products to 40% by 2030. The company’s recycling initiatives also extend beyond its own operations and they are actively working with third-party sites to optimise material recovery and reduce waste, aiming to increase the percentage of waste recycled to 88% by 2025 and to 93% by 2030.

Eurocell says it facilitates efficient PVC-U recycling for installers and fabricators through its closedloop recycling system. By offering reliable and timely collections from any UK site, Eurocell ensures that PVC-U waste is managed responsibly. The service includes all aspects of waste management, from collection and transport to documentation, with waste transfer notes provided to demonstrate responsible handling – a testament, says the company, to why the home improvement specialist won “Best PVC-U Manufacturer & Recycler 2023 – UK” at the Design and Build Awards 2023.

www.eurocell.co.uk

Epwin Window Systems is renowned for its commitment to sustainability. This commitment is in clear evidence in its recent investments in using recycled material in its manufacturing processes.

Phil Parry, technical director at Epwin Window Systems, commented: “Forecasts suggest that demand for PVC in Western Europe will increase at a rate higher than GDP between 2024 and 2028. This will put

pressure on raw materials and we are taking the lead on being prepared for that shift. Our latest investments enable us to produce class-leading, sustainably manufactured systems efficiently while also building our capacity for future growth.”

The company has installed numerous Krauss Mafai coextruders and multiple twin strand Greiner Red Line tools and downstreams. These investments have allowed the

company to introduce additional co-extruded profiles that use post-consumer recycled PVC-U into its product offer. The material is all reprocessed in the UK from recycled window profiles with a demonstratable chain of custody, something that means Epwin Window Systems is already aligned with proposed future legislation.

This year, the company will introduce multiple new Optima mainframe tools that will incorporate a recycled core that won’t be visible when manufactured. On average, each section will contain 45% recycled content.

These latest investments build on a long track record of using recycled content.

As part of its manufacturing process, Epwin Window Systems recycles waste bar length into RCM (recycled composite material). These RCMs are made up of 100% recycled PVC-U and provide the perfect blend of product performance and sustainability.

These investments and innovations are all part of a wider programme of initiatives designed to put sustainability front and centre of all business practices.

Phil concluded: “As an industry, we have a lot to celebrate when it comes to sustainability. Since 2000, through the VinylPlus initiative, our industry has recycled 8.1 million tonnes of PVC. In the process, we’ve saved 6.2 million tonnes of CO2 and created over 1,600 direct jobs in recycling plants. As our latest investments show, here at Epwin Window Systems we’re committed to continuing this progress, leading the way and doing everything we can to make sustainable business practices the new norm.”

Quanex company Edgetech have spent decades making buildings more thermally efficient – and in doing so, have helped cut carbon emissions around the world, claims the company.

However, as well as supplying the spacer bar products needed to manufacture highly energy efficient windows, in recent years the company’s attention has increasingly turned to reducing its own carbon footprint.

According to the company, this year these efforts have seen Edgetech significantly reduce its usage of plastic packaging, Manufacturing plastic is a major contributor to carbon emissions worldwide, and effectively recycling and disposing of it poses an ongoing challenge.

Similarly, the company is shifting to the use of glueless boxes in its spacer manufacturing, again reducing its reliance on a material with a significant environmental impact.

In doing so, the firm is taking steps to cut the embodied carbon of its spacer products – the total carbon emitted in the process of manufacturing, transporting and installation of a product, then its lifetime after installation.

Managing director Chris Alderson comments: “Edgetech, like Quanex more generally, is firmly committed to cutting carbon emissions –both by manufacturing some of the world’s leading spacer products, and reducing our own carbon footprints.

“Simply looking at the carbon emitted during day-to-day operations is no longer enough in an era where companies and countries around the world strive for net zero.

“Embodied carbon accounts for 11% of annual greenhouse gas emissions, and 28% of building sector emissions –and by cutting these, we can help steer construction into a greener future.”

www.edgetechig.co.uk

Victorian Sliders, sash window manufacturer, has announced the appointment of Nick Evans as its new chief executive officer.

Nick, who joined the company in August 2023 as strategic development director, brings considerable experience to lead the business through its next phase of growth.

Originally from a financial services background, Nick spent over 25 years in corporate banking, predominantly in mergers and acquisitions, working alongside private equity in a wide range of sectors including key investments in the building products space.

This was followed by 7 years in a private equity backed business where he made a number of acquisitions and held the role of COO.

This breadth of experience positions him perfectly to help Victorian Sliders achieve its ambitious plans for the future.

“I’m thrilled to take on the role of CEO at Victorian Sliders,” Nick comments.

“The company has made significant strides in product quality and customer service over the past three years with the backing of proven growth funders BGF, and I’m excited to build upon that success.”

“Our business model provides us with control and visibility over the end to end process from extrusion to final assembly.

“This, coupled with our continued investment in our premises and technology, allows us the flexibility to deal with the smaller end of the market right the way through to something of the scale of a university, whilst maintaining our exceptional product quality.”

Nick continues: “We are continuing to invest in technology to provide our customers with more product options and shorter lead-times, whilst also focussing on our environmental impact.

“Our R&D team is working on some new releases for the second half of this year. It’s an exciting time for the business, our people and our customers.”

www.victoriansliders.co.uk

The shared ideals and values of improving standards and quality in the market, has culminated in a strategic partnership between Gutmann and The Joinery Network to create a new Gutmann Lignum woodaluminium window and door system.

The new timber-aluclad product has been specifically designed by aluminium specialists, Gutmann, and The Joinery Network to suit the UK’s housing stock. The system benefits from the certification and Secured By Design accreditation awarded across the comprehensive Lignum range of windows and

doors.

Paul Barden, Gutmann director UK & Ireland, says: “The Joinery Network is a natural partner for Gutmann as we share a vision of producing top quality, sustainable window and door

systems. Working together we have utilised each other’s strengths and knowledge to develop a high-performance product, ensuring the aesthetics were right for UK homes and buildings.”

Luke Piper, founder partner for The Joinery Network, adds: “Joinery manufacturers and installation companies have been asking us for a timber aluclad window and door range that fits in with UK houses. The new Gutmann Lignum suite represents a significant addition to our fully Document Q certified offer. It’s been brilliant working with Gutmann to develop this new range, and it will give our members more choice and opportunities to promote truly sustainable windows and doors.”

www.thejoinerynetwork.co.uk

BDC Aluminium is reaping commercial dividends as a result of its longstanding decision to offer windows and doors using Stellar –the aluminium system from Epwin Window Systems, according to the company.

The fabricator, which supplies high-end fenestration products for both domestic and commercial projects, is continuing to see strong and sustained demand for its Stellar range which includes fully flush, bifold and patio doors,

as well as fully flush, casement windows.

Andrew Speakman, group commercial director at Rocal Endurance, BDC Aluminium’s parent company, explains: “BDC has been fabricating the Stellar system since 2020 and throughout that time it has remained a consistently sought after choice.

“We attribute this enduring popularity to the fact that the system delivers win-win benefits for the installer and for the property owner or occupier.”

The entire system is internally glazed meaning glass can be fitted from inside the property with no requirement for scaffolding whilst patented knock-in beads expedite the glazing process and provide the added benefit of neater interior gasket lines. In addition, flat rebates simplify the fitting of glazing packers. Plus, Stellar frames are flat backed, making it easier to position them perfectly, and its flush doors have fully adjustable hinges, enabling adjustments to be made once the

door is in place, according to the company.

Stellar window and doors are also PAS 24 certified and offer exceptional thermal performance. This contributes to a more comfortable living environment, lower heating costs, reduced environmental impact, and levels of energy efficiency that comply with Approved Document Part L. Stellar is even an advantageous choice for the fabricator too.

The fact that it is a pre-gasketed system reduces waste and cuts fabrication time by up to 20%. Further time savings stem from an innovative reverse butt joint, which eliminates the need for dummy sashes and reverse adaptor profiles, from a reduced requirement for chevrons and corner ties, and from the use of faster to fit espags rather than shoot bolts on Stellar windows, claims the company.

Andrew Speakman, group commercial director, BDC Aluminium commented, “As well as quicker fabrication and shorter order lead times, Stellar also employs common and interchangeable components across the system, reducing stockholding.

“Stellar has always sat perfectly within the wider BDC Aluminium offer as it epitomises our focus on providing the very best products backed by equally high standards of service and support”.

“As it is manufactured with a focus on continuous improvement, it continues to evolve and to offer new benefits that keep pace with changing market conditions, legislation, and consumer demands.”

He concludes: “We’ve enjoyed impressive success with the Stellar system to date. We look forward to building on that long into the future.”

www.bdcaluminium.co.uk

Pioneer Trading Company, which manufactures the Deceuninck range of windows, doors and conservatories to the trade throughout the UK, has renewed its membership with Secured by Design (SBD). It has also added Gerda Engineered Entrance Doors, for which the Essex-based firm has exclusive distribution rights for the UK and Ireland.

Products covered under the agreement include Deceuninck doorsets, casement and flush sash windows, and Gerda Optima 60, Thermo Premium and Thermo Prime doorsets.

Tina Beal, group sales director for Pioneer Trading Company, said: “We are delighted to continue our long association with Secured By Design, which ensures that we continue to manufacture and sell windows and doors that meet the highest standards of security and performance in our industry.

“Of key importance is the

inclusion of Gerda Engineered Entrance Doors, on our Police Preferred Specification Accredited Product List. With their aluminium outer frames and steel facings Gerda overcome the inherent problems of bowing and warping that composite doors suffer from and offer superior security. They sailed through the PAS 24 tests prior to us obtaining our SBD Accreditation.”

As well as high levels of security, Gerda Doors also offer ‘superior’ U values, ranging from 1.3 W/m2K for glazed designs, as low as 0.74 W/m2K for the Gerda Altus door which exceeds Passivhaus standards.

For Secured By Design Lyn Poole said: “Pioneer Trading Company has been with us for 16 years with membership dating back to 2008. I am delighted that they continue to feel that having the membership benefits them.”

https://pioneertc.com

Steel window and door manufacturer, Crittall Windows, has unveiled a thermally enhanced rolled steel window and door system.

According to the company, this latest product is a patent pending adaptation of the company’s iconic Corporate W20 steel profiles which have been adapted, by state-of-theart CNC machinery, to attain UW & UD values of just 1.4 W/m²K.

The new system also achieves a thermal gradient across the profile equivalent to that of thermally broken steel section. Plus, the innovative co-extruded dual weather seals deliver superior weather performance,

helping to secure this product’s high-performance credentials.

The new Corporate W20 TE system has a life expectancy in excess of 60 years, meets current UK Building Regulations – including Approved Document L – and is galvanised and powder coated in any RAL, BS or bespoke shade to increase durability and prevent corrosion. The traditional elements of a steel window have been maintained within the revolutionary system which still features impressive slim sightlines, design flexibility and the stunning aesthetic of the original Corporate W20 rolled steel system, claims the company.

Russell Ager, MD at Crittall Windows, said: “The launch of this new steel system is game changing for the industry. Manufactured to the highest quality, this traditional steel window meets modern performance and makes the perfect addition to any commercial or residential project.

“As a team we’re proud to announce that the inherent strength and robustness of steel has not been compromised in this new system. This means Corporate W20 TE can be specified for the most demanding new build or replacement applications.

“At Crittall Windows, we’re dedicated to delivering excellence and thanks to the expertise and knowledge of our incredible team we’ve been able to create a new steel system that not only looks fantastic but delivers exceptional performance.”

https://bit.ly/4cab7it

Steel reinforcement and profile roll-forming specialist Anglo, has launched a new campaign to drive up standards in the supply of galvanised steel.

Galvanising applies a layer of zinc to each face of the steel, which stops rust forming on the surface by creating both a physical barrier from the elements and electrochemical corrosion protection for bare steel exposed by small nicks and scratches.

The thicker the coating of zinc on a steel reinforcement, the longer its service life, a critical element in window and door manufacture, says Anglo.

Available on loan at no charge –regardless of who they buy their steel reinforcement from – the

Anglo Galvanised Steel Meter scheme allows fabricators to independently test that zinc coatings are to specification.

David Evans, managing director at Anglo, said it was launching the scheme in response to growing concern among manufacturers that steels were out of specification.

“The number one concern of those people we have spoken to is the zinc coating level on the product they’re ordering, because it has a big bearing on the ultimate quality and durability of that product when it’s installed.

“We’ve decided to offer fabricators in the UK, whether they’re Anglo customers or not, access at no cost to a galv meter

so that they can verify in-house the thickness of the galv coating that they believe they’re getting is what they’re getting.

The electronic meters employ the principle of electromagnetic induction for measuring the thickness of a non-magnetic coating such as zinc on a magnetic substrates such as steel, giving a clear digital read out of the galvanised zinc coating thickness.

To take a measurement all fabricators need to do is make sure the sure the surface of the steel is dust and dirt free and take measurements at multiple points along the steel, the average of which gives an indication of the coating thickness.

David explained: “The galv meter is very, very simple. It’s a digital meter, needs very little technical training. It’s simply a case of pushing the probe against the material in a range of spots along the metal to get an average reading.

“We’re also supplying a conversion chart. So, you can convert from that measurement given by the meter in microns which will translate directly then into the equivalent Z-coating of the galv.”

Anglo supplies galvanised window and door steel reinforcement in full bar length or cut-to-size Investment and the evolution of its offer now means that orders are delivered in three-days, with many of its customers receiving twice weekly drops.

“We have full traceability through the entire production process”, David continued. “This includes certification from the UK steel mills we source product materials from as well as certifying the product all the way through the production cycle.

“Our customers need the

assurance that the quality of the reinforcement they’re getting is what they’re in turn certifying to their customer”, David said.

“And what customers of Anglo can be certain of is they are getting that quality.”

Anglo was acquired by the global metals engineering giant, the Amari Metals Engineering Group in 2021, triggering a major

investment programme and multi-million-pound restructuring of the business.

This has included its new doublesided roll-forming line, the most advanced roll-forming line in the UK. It features 24 forming stations, allowing Anglo to roll complex sections – in gauges ranging from about 0.8 mm, and everything in between up to 2mm.

Made for Trade (MFT) says it has launched its KwikCollect service to enhance the efficiency and productivity of tradespeople.

According to Made for Trade, the KwikCollect service is a solution in the trade sector that helps tradespeople manage their time more effectively, avoid unnecessary delays, and ultimately stay ahead of the competition.

Orders can be placed via a customer’s KwikQuote

account, or if you don’t have one MFT says setting one up is user-friendly and the whole process from ordering to collection of products is seamless.

So how does the KwikCollect process work? According to Made for Trade:

• Using your KwikQuote account, place your order online

(Check that your products meet its KwikCollect criteria).

The line also rolls directly from the coil, punching and cutting ‘on-the-fly’ as part of a continuous process, delivering significant efficiency gains, while investment in dedicated toolsets for each product brings increased precision to manufacture.

To arrange a galvanised steel meter on free loan from Anglo, please email enquiries@angloeuropean.net

• Select ‘KwikCollect’.

• Once your order is processed, you will receive a confirmation email.

• If you order before 2 pm, you can collect your order on the same day next week!

• On arrival at the factory collection point, present your collection note.

• To avoid any storage fees, make sure you collect your order before ten days is up.

Made for Trade states that standard colours and selfcleaning glass are available in the KwikCollect service. However, laminated glass, blind glass and triple glazing are not included in the KwikCollect service.

MFT says customers will be able to manage their schedules easier with KwikCollect via the flexibility of collecting products without constrained delivery windows.

A spokesperson for MFT said: “If you want to complete your building projects faster and hold a significant competitive advantage, more rapid turnaround times and access to those important Korniche products, the KwikCollect service will certainly place you in pole position.”

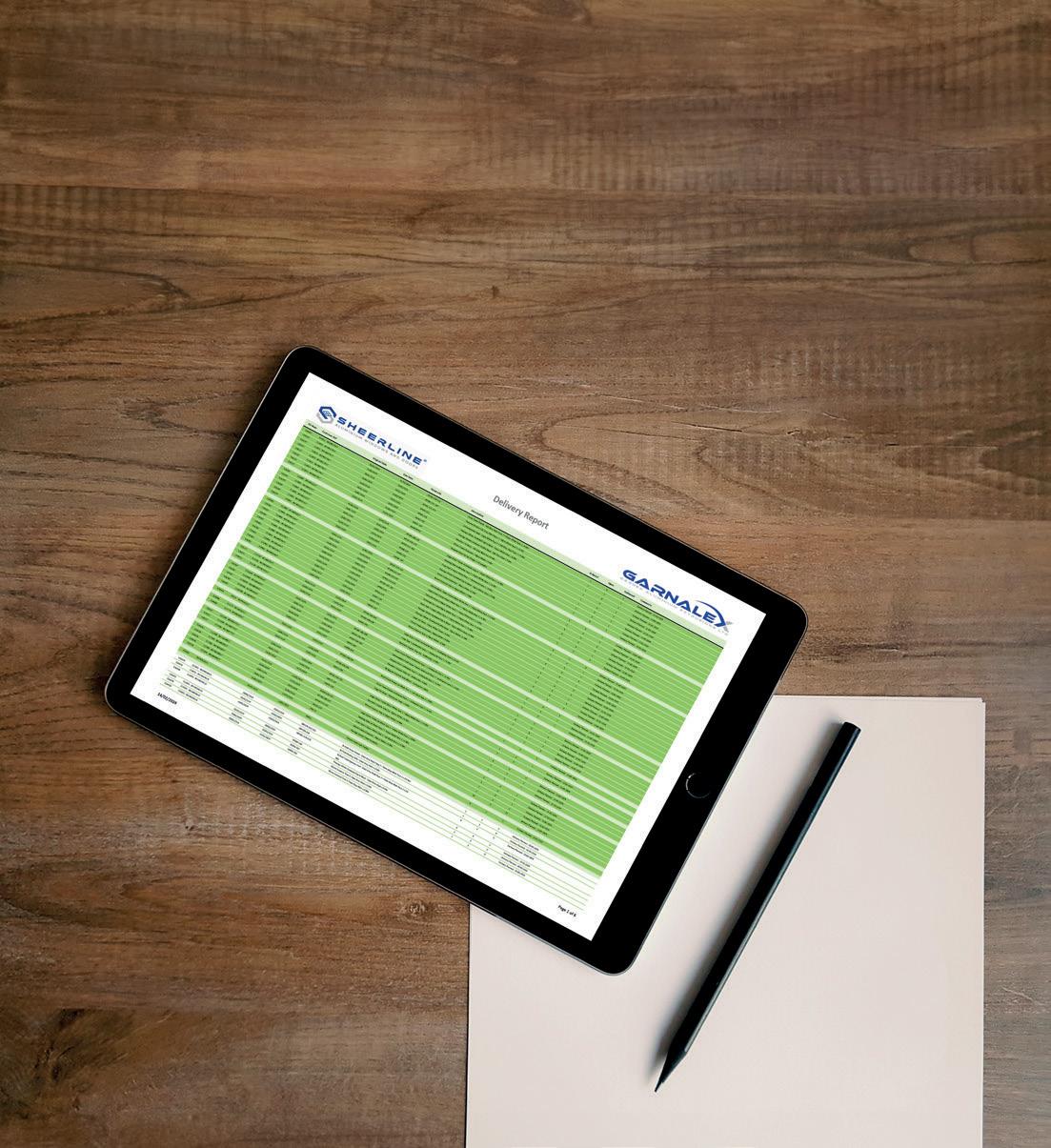

Sheerline has revealed how vertical integration, internal communications, and a focus on providing an agile service have enabled it to achieve an OTIF (on time, in full) of 99.1% in February, followed by 99% in March – helping maintain high levels of customer satisfaction.

While benchmarking OTIF to assess performance is not uncommon for manufacturers, Sheerline tracks a particularly harsh standard, monitoring at full order level, not by item.

This means that if a single item is missing from any order (that may contain dozens of items), the full order counts against the overall OTIF score.

Delivery reports are sent the day before orders are due to be delivered and contain everything the customer needs to know. This includes an itemised list of the products being delivered, which is split by their orders. Not only does this give customers full visibility of what is being delivered and when, it also helps them to plan their production effectively, splitting everything down by individual customer projects if required.

The driving force behind this achievement is the key goal shared across all departments: customer satisfaction.

Alongside its single site, vertically integrated state of

the art manufacturing, this enables Sheerline to offer 5-day lead times on standard colours across its entire range.

Steve Musgrave, Sheerline operations director, commented: “Receiving an OTIF of just over 99% in February is an enormous achievement for the team, but we cannot let complacency set in. Our challenge now is to improve further and then maintain those levels, so customer satisfaction remains high.”

“We’re passionate about continuous improvement, striving for perfection and the highest possible standards across every element of the business, which is why our processes receive the same attention as our products. Ultimately, the result is happy customers, who know what they’re getting, when they’re getting it, and that they can depend on us,” he added.

www.sheerline.com

An expanding window and door trade counter network has introduced Rapierstar branded fasteners to its product portfolio.

Europlas (PVCu) is a division of the Rooms & Views Manufacturing Group, which produces more than 1,800 windows and doors every week at its factories in North and South Wales, and Scotland. Rapierstar is supporting Europlas as it expands its current network of trade counters throughout South Wales, including Buckley, Flintshire, and Winsford, Cheshire, with new branches also coming

soon in Scotland and another in South Wales.

Europlas branches supply a wide range of exterior and interior products to the window, door, roofing and joinery markets, plus hardware and tools, making the Rapierstar brand a perfect fit. The business is set up in a way that ensures each counter can combine a personal customer service with experienced advice and large product ranges from industry leading brands, including Liniar, Floplast, Soudal, Kestrel, Supalite, Classic Bond EPDM &

Ronjack .

Amongst the Rapierstar products now available at Europlas are StarFix masonry fixings and StarTurn universal woodscrews. StarFix provides a plug-free screw for the efficient installation of PVC-U window and door frames in a single process, with no need to set fiddly plastic plugs first. And StarTurn is a range of screws in numerous sizes designed primarily for use in wood, with ease of use and secure fixing assured thanks to Rapierstar’s optimised thread design and head form.

Gavin Burton, operations director at Europlas said: “Partnering with Rapierstar will bring us a number of benefits which I believe will be important for the next era of our

business. Their position as the market-leader for window and door fasteners is evident in the quality of their sales, customer service and technical support that we’ve already experienced, and their commitment will certainly help us to maintain our high standards as we grow.”

Kevin Jennings, technical consultant at Rapierstar added: “We’re delighted to be partnering with Europlas and that its growing customer base can now source Rapierstar fasteners from their trade counters alongside other major brands in the construction market. The business has an excellent reputation for providing quality products that its customers can rely on, both in terms of their performance and availability, and we will be working closely with them to ensure their sales of Rapierstar branded screws are maximised.”

www.rapierstar.com

Euroglaze has added Rehau Rio flush window and doors to its list of Secured By Design (SBD) accredited products – giving trade customers what it believes is yet another reason to choose the Barnsley based fabricator as their one stop shop for Rehau frames.

Euroglaze already holds the PAS24: 2022 Secured By Design accreditation on its Rehau Total 70 windows and doors, as well as on the majority of Liniar windows and doors it also fabricates.

Martin Nettleton, Euroglaze’s managing director, says SBD accreditation is an ever important part of its offering to trade customers – and more than justifies the investment it makes in testing and SBD membership.

He explained: “We’ve seen demand increase steadily over the past few years for all our flush sash windows and doors – including Rehau Rio and Liniar Flush, so it makes perfect sense for us to offer Secured by Design options to give us

and our customers a valuable competitive edge.

“Security remains high on consumers’ list of priorities and of course SBD is the instantly recognisable logo which they know and trust.”

Alife Hosker from Secured by Design added: “I am delighted that once again Euroglaze have renewed their SBD membership. They have recently transitioned to PAS24: 2022 Police Preferred Specification and have an ongoing programme to add to this.”

As well as being Rehau’s longest continuous customer in the UK, Euroglaze also offers what it says is the most comprehensive range of Rehau products of any trade fabricator– with Heritage vertical sliders, Rauferno fire rated windows and the new Rehau Slinova patio all available.

Euroglaze says its highly experienced sales and customer service teams can give expert advice on the best products for every application.

www.euroglaze.co.uk

At its Annual General Meeting on 16 May 2024, members of the British Plastic Federation’s council re-elected existing President Nigel Flowers for a further year and elected a new vice president: chief executive of Rehau UK and Ireland and Scandinavia, Martin Hitchin.

Martin Hitchin gained a degree in Combined Engineering at Coventry University before going on to do post graduate training in China, followed by an MSc at North London University in Polymer Science and Engineering. He has since worked in the manufacturing and construction sector for 35 years. Martin started working with Rehau in 1988 as an Applications Engineer. After numerous promotions he was made CEO at Rehau in 2007, where he has overseen steady evolution of the company and positive growth. Martin is also the vice chair of New Model Institute for Technology and

Engineering (NMITE), a start-up engineering university in Hereford.

Commenting on the appointment, BPF director general Philip Law stated: “We are very pleased to have Martin Hitchin as the new vice president of the British Plastics Federation. His election is very well deserved. Martin has had a very distinguished career and is a highly valued member of the BPF Council. I am sure that he will be an excellent vice president, helping the BPF to continue to provide value to its members and promote the varied interests of our industry.”

Director of Sumitomo (SHI) Demag Plastics Machinery UK and BPF president Nigel Flowers stated: “I happily welcome Martin Hitchin as vice president. His experience in several areas of plastic processing will be invaluable. Martin has a background in working with

windows, pipes, automotive and also recyclers, so really offers a wealth of knowledge we can all benefit from.”

Newly-elected BPF vice president Martin Hitchin added: “It is an honour to be voted in as vice president of the BPF. I have been involved with the trade association for many years and am aware of the wide variety of work it does to champion our industry. The work of the BPF Council helps to shape the approach and priorities of the organisation. I look forward to my new role and am keen to support the existing ambitions of the current president, Nigel Flowers.”

The BPF’s AGM also provided key updates about the trade association, which has experienced encouraging growth. In 2023, it welcomed 49 new members, taking membership up to 592 companies from across the entire UK plastics supply chain.

The BPF’s 2023 Annual Review, outlining its activities for its many groups and committees in detail, is available to view or download on the BPF’s website.

www.bpf.co.uk

Colour coating specialist Kolorseal Ltd is introducing a new Quality Assurance Certificate for customers to pass onto the end user which will add further substantiation to the company’s existing 10 year quality guarantees.

The launch of the Certificate of Authenticity takes guarantees to the next level for the homeowners as it reinforces the high standards associated with Kolorseal and by association its customers, according to the company.

Deborah Hendry, managing director, Kolorseal comments, “Today, people have very high expectations when it comes to modernising their homes. Equally, when it comes to selling properties, homeowners are looking for advantages and assurance certification really helps.”

Deborah continues, “Whether it is for an internal or external appearance on a window or door, or a roofline product that requires matching, it is important for consumers to feel reassured. As a brand Kolorseal is recognised for its quality, however it’s important for homeowners to know that when choosing their ideal colour it will mean something.

The Assurance Certificate from Kolorseal will give added peace of mind alongside our existing guarantees. This gives the whole chain from fabricator, to installer and on to the end user more confidence when making colour choices.”

Unique Window Systems is preparing for the next chapter in its ongoing success story.

The award-winning company has rebranded, unveiling a new identity which will help to position it for further evolution and expansion.

Sunil Patel, joint managing director at Unique, explains: “Unique’s previous brand identity has served us well having been in place since our incorporation almost 20 years ago. During that time, we have enjoyed incredible success and growth, which includes our turnover surging from £20.8 million to £39.2 million between 2020 and 2022.

“Times and design styles change however, and it’s important for us as a business to change with them. Our new brand identity is more reflective of the company we have become and better epitomises our position as a large, highly professional, and qualityfocused organisation.”

The new Unique brand is undergoing a soft launch, being introduced gradually as existing assets and materials are replaced or updated.

The business decided to adopt this approach as part of its wider environmental policies. A hard launch had the potential to create unnecessary consumption and waste.

As part of the rebrand, the Unique Window Systems name remains and is now complemented with the addition of a distinctive U brand mark.

In addition, a new corporate font is being adopted whilst the company’s corporate colours are evolving slightly to retain a connection to the previous brand identity and to preserve existing brand equity.

A new strapline is also being introduced. ‘Our future in fenestration’ reflects the breadth of the Unique offer which caters for customers in the commercial, new build and trade sectors. It also highlights the fact the business is on a collective journey with these customers to shape a mutually beneficial future.

Unique’s new brand was developed by WeBuildBrands – the specialist marketing consultancy for the fenestration, construction, and home improvement sectors

Concluding, Sunil adds: “The introduction of the new Unique brand is an exciting development and a clear statement of intent. We may have achieved a great deal to date but we’re not about to rest on our laurels.

“Instead, we are committed to seeking out opportunities in every area – from our brand identity to our fabrication processes – to drive enhancements that are beneficial to us, our partners, our customers, and the eventual property owners and occupiers who live with our products on a daily basis.”

Unique Window Systems https://www.uws.co.uk/

Five-year anniversaries are traditionally celebrated with a gift of wood, but aluminium would be a much more appropriate choice for AluK and Fentrade as they mark five years in partnership together.

Fentrade chose AluK as its aluminium systems supplier during its early months of start-up fabrication and, after exceeding its first year target by 15%, it has gone from strength to strength ever since. It has built a reputation for precision manufacturing, reliable deliveries and helpful and intelligent customer support and, as a result, has a growing customer base, an expanding workforce, and a well-equipped, extended factory,

according to the company.

Based in Newport, trade manufacturer Fentrade supplies retail and commercial installers with all their aluminium needs. From the outset, it has fabricated windows and doors in AluK’s hugely versatile 58BW and 58BD systems, alongside BSF70 bifolds and BSC94 inline and lift and slide patios. Latterly, these ranges have been extended with the thermally efficient HI range of profiles, says the company.

It has recently added the new SL52 curtain walling system to its offering and is gearing up for the new AluK S140 Lift and Slide patio

door and the Quik Clip clip in bead.

Chris Reeks, Fentrade’s founder and managing director commented: “The customer service and technical teams at AluK are particularly helpful to us. We get great communication from the customer service team so we can always keep our customers informed and up to date, and the technical team provide a fantastic resource for answers to any design and manufacturing queries.

“Over the past couple of years, we’ve worked more closely with AluK’s projects team as well, and they have helped us secure some significant new contracts and supported our move into commercial work.”

Russell Yates, AluK’s managing director added: “Fentrade is a great example of how a fabricator can leverage maximum benefit from their partnership with us. From free training for their fabrication team to access to our design studio to demonstrate AluK products to their customers, they have made full use of the resources we offer.

“In marketing terms, they have also aligned themselves firmly with AluK and that has helped them win business from installers who like and trust our products.”

Chris Reeks added: “From an installer’s perspective, Fentrade is an easy company to do business with. For instance, we check every single order and query anything that doesn’t look right before it becomes a problem, we deliver on time and in full and we keep customers informed every step of the way. The support we get from AluK helps to make that possible and we have the confidence of knowing that they will go on supporting us as we continue to grow.”

uk.aluk.com

fentradealuminium.co.uk

Safeware, the specialist hardware division of Epwin Window Systems is celebrating the 21st anniversary of its iconic Safeware range of multi-point door locks. Since the inception in June 2003, the Safeware range of feature rich door locking solutions remain a popular choice with Epwin fabricators, demonstrating their timeless

appeal and innovative design.

With an impressive record of over 1.5 million sold to date, Epwin Window Systems says Safeware door locks have retained their popularity over the years. Specifically designed for use on PVC-U and composite doors, its reputation for highquality mechanisms and

precision design ensures ease of use, reliability and durability, adds the company.

During its 21-year tenure, the lock has developed into a suite of multi-point door locks, suitable for all market sectors.

Paul Hinds, head of sales at Safeware, said: “The family of Safeware multi-point locks is renowned for prioritising security. Over the years, the range has evolved in line with market demands but the fundamental design principles have remained the same, demonstrating how ahead of its time it was when we launched it in 2003.”

The exclusive Safeware 7 multi-point lock was designed in collaboration with Yale. Paul said: “The Safeware 7 is a seven-point lock incorporating three hooks and four precompression rollers. It is designed to give optimum security with ease of operation. The lock is supplied with a one piece keep which features several innovations that are unique to Safeware, saving on manufacturing time and allowing simple, quick and effective installation.”

The latest addition to the range is the development of SensCheck, an integrated smart door sensor, in collaboration with Yale.

Paul said: “We were the official launch partner of Yale SensCheck back in 2022. Yale SensCheck allows homeowners the option of being able to check the status of their doors on their smart devices and mobile phones with instant connected security status for peace of mind. Since the launch, Yale SensCheck has proved popular with our customers, helping them to tap into this growing domestic interest and creating valuable upselling opportunities.”

epwinwindowsystems.co.uk

Nationwide Windows and Doors has made the switch with their composite door glazing cassette system having adopted DoorCo’s pre-foamed Flip system.

DoorCo say they have paved the way in the cassette world with the launch of their system in 2021, which had a rework at the end of 2023 to roll out further improvements. The system comes with ‘Foam in Place Technology’, is available in 3 different profiles, and now features a simple corner and connector system which offers improved security and weatherability, adds the company.

Speaking on making the change, John Whalley, Nationwide’s managing director, tells us, “We’ve been impressed watching the rise of the Flip system from DoorCo over the last couple of years. It’s been a journey of innovation and has evolved into a product that addresses a lot of the complex needs of the industry.”

Dan Edwards, Nationwide’s production director, continued, “The system is both streamlined and extensive. The pre-foamed gasket removes the need for glazing tape and the corners and connectors coming prescrewed makes the whole system extremely quick and easy to use. However, the simplicity of the fitting does not extend to the offering, which is vast.

“The range includes 3 different profiles and a full selection of standard colours and stains, which match the most popular door colours. This level of variety makes Flip a system that ticks every box.”.

Talking about this new arm to their partnership, DoorCo’s managing director Dan Sullivan tells us: “Nationwide are a much-valued customer of ours and we really respect their perspective and opinions.

“We launched Flip around 3-years ago now and have been working hard on continually innovating the system to ensure it can be everything that everyone in our industry needs and wants.

“We’re really pleased that the team at Nationwide will be utilizing Flip in their production lines on upcoming projects. We’re confident that the system is at a point where it’s hugely exceeding market standards and will provide Nationwide’s end customer with the best product possible. We’re looking forward to working with the team as they make the switch and hearing from their experiences of using it.”.

DoorCo’s prepped composite doors come with the Flip cassettes as a standard, but the system is also available for purchase via their distribution arm for fabricators to glaze with in-house.

For more information on Flip, visit: trade.door-co.com

For more information on Nationwide Windows & Doors, visit: nwd.co.uk

The Double Glazing & Conservatory Ombudsman Scheme (DGCOS) has published their Spring 2024 newsletter, which rounds up the news and initiatives the organisation has been involved with recently to offer valuable insights for installers and the wider industry.

“The DGCOS Newsletter is an important tool for us as a membership organisation to keep our stakeholders up to date with what’s happening, both at DGCOS and in the wider industry”, says Faisal Hussain, DGCOS chief executive. “From producing a mental health

focused podcast series with the National Home Improvement Council (NHIC) to adapting our registration options to include two and six year registrations, our latest newsletter is packed with information for the industry.

“As well as positive news, such as gaining the ISO 9001 certification for Quality Management, we’re never afraid to discuss the more difficult issues that we collectively face. It’s been a turbulent market for a while now and in the newsletter we discuss serious issues like the real implications of when an installer ceases to trade, as well as the impact the lack of

skilled installers coming into the industry has had on the quality of products and installations.

“On the other side, we discuss the powerful tools we have available to our members: data, benefits of teamwork and communication, and the importance of top-level customer service.

“DGCOS is committed to supporting our members through a wide range of initiatives, including our comprehensive Installer Journey Benefits, designed to help and support with their businesses, and our newsletter is a great example of the work we do.

“The DGCOS newsletter is available to view online here: shorturl.at/HLOSX” installers.dgcos.org.uk

It’s good to talk! So says the Automatic Door Suppliers Association which has just launched its own podcast – Tech Talk.

The series will feature conversations on topical issues facing the industry and interviews with those who work in it.

The first episode focuses on changes to BS EN 16 005 – a standard that defines safety in use and test methods requirements for power operated pedestrian door sets. It teases out the main changes of the update and responsibilities that fall upon manufacturers and technicians.

The 10-minute discussion is

hosted by ADSA MD Ken Price, in conversation with technical training manager Darren Hyde and head of operations Fae Ellor.

The monthly podcast is available through Apple and Android streaming services and can also be accessed through the ADSA website and social media channels. ADSA members can also access episodes through its online Academy.

Tech Talk has been introduced as an extension to ADSA’s existing communication channels and its availability on public streaming channels is intended to make it more accessible to “people on the go”.

Said Ken: “We felt that this was an ideal medium for many of our members, particularly technicians, who may be on the road travelling to different sites. Podcasts provide a bite-sized opportunity to raise awareness of key issues, in a way that can be informative and entertaining.

“People consume media in different ways and at different times – from their daily commute to when they are exercising. By producing Tech Talk as a podcast, we hope to highlight important issues, break them down and examine them in detail but in a way that is easy to access and provides a different take on a variety of subjects.”

It is planned that some episodes of Tech Talk will also be produced as video casts to incorporate visual requirements.

The first episode of Tech Talk can be accessed via ADSA. podbean.com/e/adsa-techtalk-updates-to-bn-16005 and through streaming platforms.

Made For Trade has been honoured with the King’s Award for Innovation 2024. This, says the company, shines a spotlight on its ‘revolutionary’ Korniche Roof Lantern.

Established in 1965, The King’s Award for Enterprise is the UK’s most distinguished business commendation. The award continues HM Queen Elizabeth II’s legacy and celebrates

businesses that pioneer innovation, sustainable practices, and social mobility.

Made For Trade’s achievement demonstrates its commitment to excelling and pushing boundaries within the home building industry. Korniche has established Made For Trade as a national operation despite its base in the Northeast of England. It has moved from a fabricator of third-party systems

Staff at Shelforce were presented with their King’s Awards for Enterprise crystal and charter for receiving the prestigious business award.

The Birmingham manufacturer received the King’s Awards for Enterprise in Promoting Opportunity (through social mobility) last year.

The King’s Awards for

Enterprise engraved crystal winner trophy was presented by The West Midlands’ Lord Lieutenant, Sir John Crabtree, who gave a short speech of congratulations and met all the team before having a tour of the factory.

The event was also attended by members of Birmingham City Council, including Wayne Davies, director of asset

to a business that designs, engineers, and builds its own products at scale. The Korniche Roof Lantern set a new paradigm in design and functionality.

Bradley Gaunt, Managing Director of Made For Trade, said: “As the managing director of Made For Trade, I’m delighted to announce that we’ve won the prestigious King’s Award for Innovation. At Made For Trade, innovation is our top priority. Winning this award validates our team’s hard work and dedication. It boosts our reputation and opens up new opportunities for growth and collaboration. Thanks to everyone at Made For Trade for their passion and commitment. Together, we’ll keep innovating and achieving success.”

www.madefortrade.co

management.

The team were also able to view the official The King’s Awards for Enterprise charter, which was signed by King Charles and Prime Minister Rishi Sunak and recognises ‘the outstanding achievement of Shelforce,’ and will be displayed in the reception at Shelforce’s headquarters.

Howard Trotter, Shelforce’s business manager, said: “It was a huge honour to welcome Sir John to the factory and it was brilliant for the team to be presented with the King’s Awards for Enterprise crystal and charter as our success is all down to them.

“Eleven years ago, the perception was that Shelforce was broken, and we would not survive, so to get to where we have and to receive the highest UK business honour is an unbelievable achievement.”

www.shelforce.com

The Joint Competency Initiative (JCI), in which the Automatic Door Suppliers Association (ADSA) is involved, is finalising its first framework for installers within the door, gates and shutter industry.

ADSA is working with the Door Hardware Federation (DHF) and the British Woodworking Federation (BWF) to establish the first of the “routes to competence” for the sector. This is due to be published this month.

The JCI was established in response to the Building Safety Act and is considered to be the most significant change to health and safety legislation within the construction industry

over the past 40 years.

The framework for installers includes skills required for the fitting of powered pedestrian doors of all types, steel and wooden fire-rated doors, gates and shutter systems including steel fire doors.

Ken Price, ADSA’s managing director, said that a “systematic process to identify what competence looks like” had been established over the past six months. This will be used to create the many frameworks needed across the industry.

Each of the organisations on the working group has undertaken a situational analysis to identify ‘where are we now’ and research

into training and qualifications needed for installer roles.

“Although we have found some excellent entry and specific skills training with regulated qualifications, we identified a gap around continuous professional development (CPD). This was mixed and largely unaccredited as installers moved through their career. We are all in agreement that this needs to be addressed and an accredited route to CPD created.”

The group recently began working with the Construction Industry Training Board (CITB) which already has established national occupational standards for the construction industry.

Added Ken: “We had a call from the CITB which had heard about the work we were undertaking and offered to help. Without a shadow of a doubt, this support has moved us forward and will help us deliver the whole project a lot faster than if we were doing it on our own.”

The group has identified up to 12 individual functions that each require a competency framework. This will include service and other skilled roles, such as procurement.

The JCI was initially formed by technical and procurement leads from BAM, ISG, Kier, Laing O’Rourke, Lendlease, Mace, Morgan Sindall, Multiplex, Sir Robert McAlpine, John Sisk, Skanska and Wates Group. Its vision has been to establish, “proportionate and practical requirements relating to both organisational and individual competence of those working in the glazing, cladding and roofing sectors”. This has led to the publication of a white paper, ‘Achieving Competence in the Building Envelope Sector’ which is available for download from ADSA’s website: https://bit.ly/4e3njTT

Our collection boasts an impressive array of colours that will seamlessly blend with any home decor.

With our stunning range of colours and finishes, you have the freedom to express your personal style and create a truly unique ambiance in every room.

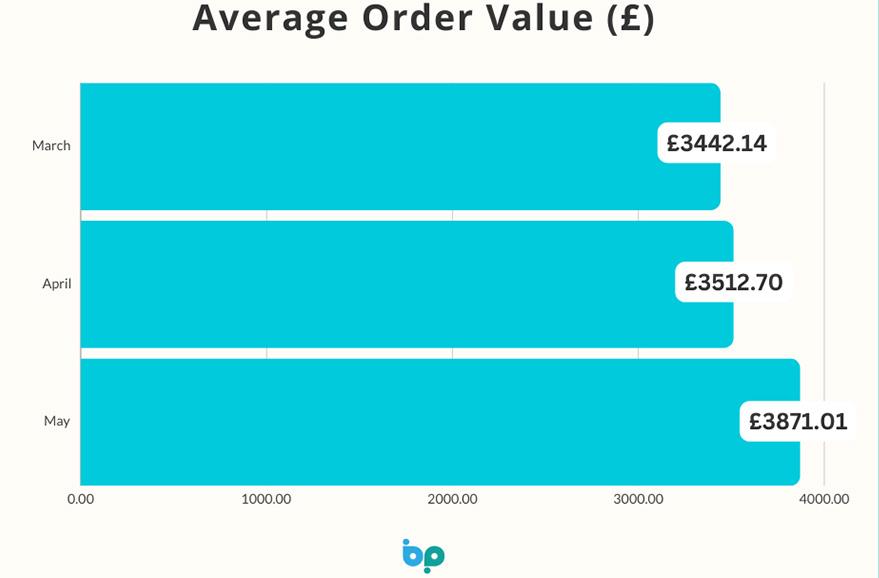

The Business Pilot Barometer offers a monthly analysis of the key trends defining window and door retail. It draws on real industry data collated by Business Pilot, the cloud-based business management tool.To find out more see www.businesspilot.co.uk/barometer

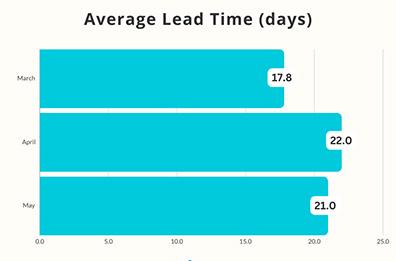

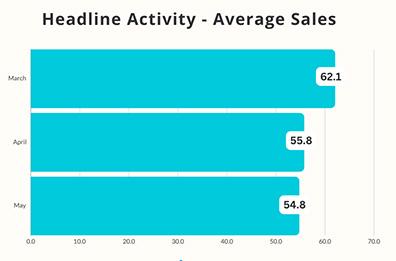

At a headline level, the average number of sales made by retail companies has fallen for the second consecutive month – down 1.8% to 54.8 in May 2024 when compared to April 2024.

This lacklustre performance is compounded by a drop in leads – down 3.8% to 111.5 in May 2024 when compared to the previous month.

These have been offset by a climbing average order value (up 10.2% to £3,871 in May, when compared to April) and a strong conversion rate (up 1.7% to 42.4% in the same period).

This supports the discussions many of us are having in the industry, which is that the volume market is quiet, and those who are buying windows and doors are choosing either whole house refurbishments, or higher value products (or both), and more people are serious about buying when they make enquiries.

Retail companies are also working hard to convert leads when they cross their desks.

Should we expect anything different? We are still a month out from a general election, and borrowing remains stubbornly high. It will be interesting to see if there is any movement on these statistics in two months’ time.

A bit of perspective is required when viewing the Business Pilot figures, because it is easy to use them to support your current view of the market.

Because we know that homeowner confidence is down, and that access to money is expensive, then it is difficult to see beyond a falling trajectory.

But if we step back a bit, we would see that in May both average sales (54.8) and average leads (111.5) were above the rolling 12-month average (which were 52.3 and 107 respectively). In other words, the market hasn’t suddenly taken a tumble, and – despite strong headwinds –opportunities are still available.

Instead of using market data to support preconceptions, it is best used combined with your own company data to help you make more informed decisions. Monitoring your own

sales conversion rates will give insight into the effectiveness of your sales team and their processes. And keeping track of your most popular product lines and active sales areas means marketing can be optimised so that you don’t waste money on a scatter gun approach.

With this in mind, it will be interesting to see how the second half of the year plays out. If you are using the data correctly, then you will be positioning your business for when the confidence does return, so that every opportunity is maximised.

Mike Parczuk, managing director of Sternfenster, doesn’t have a crystal ball, but there are plenty of signs that things are picking up. Here he explains why.

As a nation we’re too quick to talk ourselves down – you turn on the news, and it’s always bad.

This lack of positivity can be very damaging. For example, I think the economic prospects for the second half of the year will be better than the first. Inflation seems to be under control. We’ve got a general election, which normally means money is going to get thrown at everybody to try to win votes. And I think customers will be in a better position to part with their cash as interest rates come down, so there will be more consumer confidence in the market.

But I do think that our job as business leaders is not to talk everything down, and instead be a bit more positive. Yes, the market is tough, but we’ve been here before and we’ll be here again. It just means that we must work

harder and work smarter to win new business.

It’s a conversation we regularly have with our customers, because we have a range of tools that can help them win business and keep their operations running efficiently and profitably. For example, our EasyAdmin package can create professional looking quotes, track deliveries, and allow customers to have full oversight of their profit and loss.

We’ve seen that, since the start of this year, more of our customers are engaging with these tools, and they are doing better than those customers who don’t. Similarly, customers who want to learn more about our product ranges are engaging more successfully with homeowners, because they can more easily sell them a dream with a wide choice.

You can’t sit and wait for the phone to ring and expect the leads to come flooding in.

In fact, it is this mentality that fuels the race-to-the-bottom on price.

We are very proud of the range and the quality of our products, but we are a fabricator, like many others, who make and sell PVC-U and aluminium squares.

The differentiation between us all shouldn’t be price, it should be the added value and extra services we offer. As I’ve outlined above, this can be much more effective at generating leads and winning sales than simply cutting prices, because you are engaging with what the homeowner truly wants.

I hope that the conferences and summits that are becoming popular in our industry can address some of these issues, because I think that if we are a little more professional in our approach – doing the right things at the right time in the right way –then I think there is plenty of work out there for everybody.

With the right approach, the second half of 2024 will be better than the first.

For more information visit www.sternfenster.com Alternatively, join the conversation on LinkedIn: https://bit.ly/4e7pWEg

As the leaders in daylight solutions, we’re well-versed in the latest rooflight trends. And this year our flat glass is the must-have statement piece.

From stock to fully bespoke, linked units to electric opening, and even walk-on, we’ve got the most comprehensive range of flat glass products for all applications.

To see our exclusive range; visit www.whitesales.co.uk/flatglass or call 01483 917580

- 18 stock sizes in 3-5 days delivered to site

- Bespoke units from 3 weeks

- Fixed, manual & electric opening options

- Factory pre-glazed for faster installation

- Laminated inner pane & toughened outer pane as standard (double & triple glazing)

- Class 1 CWCT tested option

Aluplast’s director of sales and marketing Ian Cocken explains why attention to detail matters, and why we shouldn’t rule ourselves out of lucrative new opportunities.

As homeowners’ expectations of the window and door industry develops, and they expect more authentic detailing in their products, the role of systems supplier becomes ever more crucial.

First, fabricators need access to systems that meet the demand for on-trend styles and detailing, but they also need the support to meet that expectation. For example, they need to work with reasonably priced systems that

aren’t difficult to fabricate.

The volume market for windows and doors is showing little sign of significant growth before the year end, which is driving many more companies to target the higher value market. This includes the heritage sector, or properties that demand traditional features – ie, not PVC-U windows (typically white) with a 45-degree weld.

While the margins in this sector are clearly attractive, they can come at something of a cost.

Since this is not a volume sector, homeowners expect detail that elevates their home improvement

project above that of similar renovations, especially if their home is in an area with design restrictions.

Some profile designs are expensive, and others require methods of fabrication that use specialist machinery or patented techniques. Should window fabricators invest heavily in a market sector they have no experience in, with the aim of either bringing their customers with them or targeting new retail outlets?

Companies are definitely investing in this sector, but they don’t need to sacrifice their hardwon profits to do so.

I predict that even when the volume market picks up again, demand for windows with traditional features will remain strong, especially as more window retail companies include traditional-looking products in their ranges, and recognition grows.

Which means now is a good time to invest in this sector, and you can do it without breaking the bank.

For example, we recently unveiled our new mechanically joined flush window, which targets the market for authentic timber window replacements.

The unique mechanical join is the result of a significant period of product development, and it allows fabricators to create a realistic finish without investing in specialist tools or machinery.

Coupled with the deep bottom rail and woodec (the next generation timber-effect foil), the new mechanically joined flush window gives homeowners the opportunity to confidently replace timber windows while benefiting from improved thermal performance and a lifetime of low maintenance.