Humanitarian organizations are sounding alarm over the crisis in Sudan, warning the conflict has created “one of the worst humanitarian crises in recent memory” as the national power grid fails and fuel and food supplies begin to run out.

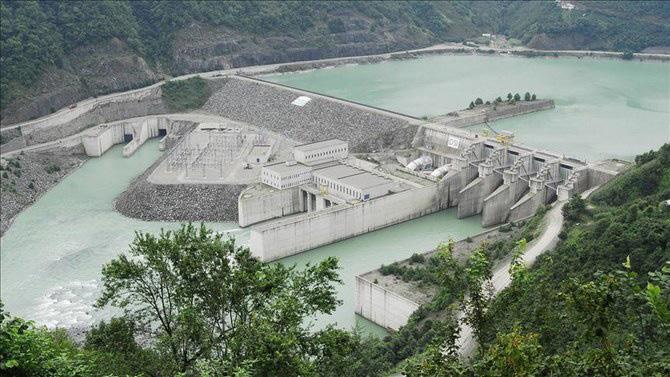

Sudan is a country with immense renewable energy potential, possessing major hydropower resources based on its location on the river Nile and other watersheds, a high windspeed mainly in its northern and western region, and high levels of solar radiation throughout the country.

“SUDAN IS ON COURSE TO BECOME THE WORLD’S WORST HUNGER CRISIS WITH AROUND 18 MILLION PEOPLE FACING TOTAL STARVATION.”

War has now severely affected its power grid with many of its major cities relying on generator sets and dwindling diesel supplies. The largest electricity consumer in Sudan was previously the domestic sector, approximately 57%. But in 2011 Sudan lost its oil-rich south (South Sudan) in a referendum, thermal generation was ruled out for power generation; Sudan lost 60% of its biomass energy resources, 75% of its oil reserves, and 25% of its hydropower capacity. The total potential for hydropower in Sudan is estimated at 4,860 MW, with an annual production of 24,132 GWh but no-one is exploiting this. Sudan has five hydropower plants with a total capacity of 1923 MW - but an unknown number of these are now destroyed or non-functional.

Fighting erupted in Sudan on April 2023 after tensions linked to a planned transition to civilian rule. General Abdel-Fattah Burhan, commander of the Sudanese Armed Forces (SAF) and General Mohammed Hamdan Dagalo, head of the Rapid Support Forces paramilitary group (RSF) - once allies - are now engaged in a vicious and ongoing power struggle.

Even before the war ramped up Sudan recorded growing electric grid transmission and distribution losses, due to deteriorating equipment, which were put at between 5% and 19% respectively five years ago. In 2019 Sudan was assessed as one of the top 20 access deficit countries with more than 46% of its population lacking access to electricity. More than 70% of Sudan’s population is lacking access to electricity now and that figure is growing ever higher every day.

Edem Wosornu, Director of Operations and Advocacy at the United Nations Office for the Coordination of Humanitarian Affairs (UNOCHA) has publicly warned of a “fast-reaching and fast-deteriorating situation of food insecurity” in Sudan following 11 months of conflict.

Only when peace comes can Sudan fix the issues with its transmission and distribution losses - this requires investment in grid reinforcement technologies and an upgrading of the existing infrastructure as well as placing the renewable power plants close to load centres in Khartoum.

TWO DIESEL GENSETS FOR CASABLANCA

Two HFW-400 T5 400 kVA generator arrive in Morocco.

16

KOHLER has supplied four 400 K.V.A KOHLER generators. 13

Genesal Energy has just reinforced the safety of the energy supply in one of Tanzania’s main factories which produces brown sugar for direct consumption with the following sets: 2x GEN2000YC + GEN1100YC.

FOUR 400 KVA DIESEL GENSETS FOR A KEY LIVESTOCK PROJECT IN NORTH AFRICA

17

BANK IN MALI INSTALLS DIESEL GENSET

Teksan has delivered a 1100 kVA diesel genset to the Banque du Développement du Mali in Mali where it will supply both prime and backup power as needed.

CAR & GENERAL TRADING LTD

of Dar Es Salaam. Kenya, has supplied 4MW FAT for IX Africa Data Centre in Kenya/ The set was successfully tested in UAE.

Multiple data centre clusters are emergingin the African continent, including those in nations such as South Africa, Kenya, Ghana and Nigeria. Ethiopia is a particularly interesting market, as it has significant opportunity for deregulation and growing broadband availability, as well as many competitive advantages that put it in a strong position to expand despite recent suggestions of political instability.

BIA BURKINA SARL is the dealer responsible for negotiating the sale and installation of 2 x 1029 Kva C1100D5B + 2 x 750 kva C825D5A diesel gensets to the Sofitel Cotonou Marina, a five-star hotel in Benin, which has exclusively chosen the Cummins brand of genset.

The Cummins C1100D5B 1100 kVA 3-phase open diesel generator is powered by a Cummins KTA38-G14 engine and has a Stamford HCI6K alternator. The KTA38-Series is the result of years of technical development and improvement to bring customers a future proof diesel engine which keeps pace with ever-changing generator set requirements. The KTA38-Series is widely acknowledged as one of the the most robust and cost-effective diesel engine in its power range for the generator set market.

The Cummins C825D5A 825 kVA 3-phase open diesel denerator features a Cummins VTA28-G6 engine and Stamford S6L1D-C4 alternator. The VTA28-Series is recognised globally for its performance under even the most severe climatic conditions, and widely acknowledged as the most robust and cost effective diesel engine in its power range.

Key design features include two large capacity aftercoolers for more efficient combustion, dual camshafts for precise control valve and injector timing, a cooling system boasting a more even flow of coolant around the cylinder liners, valves and injectors, and Cummins PT self-adjusting fuel system for overspeed protection independent of the main governor.

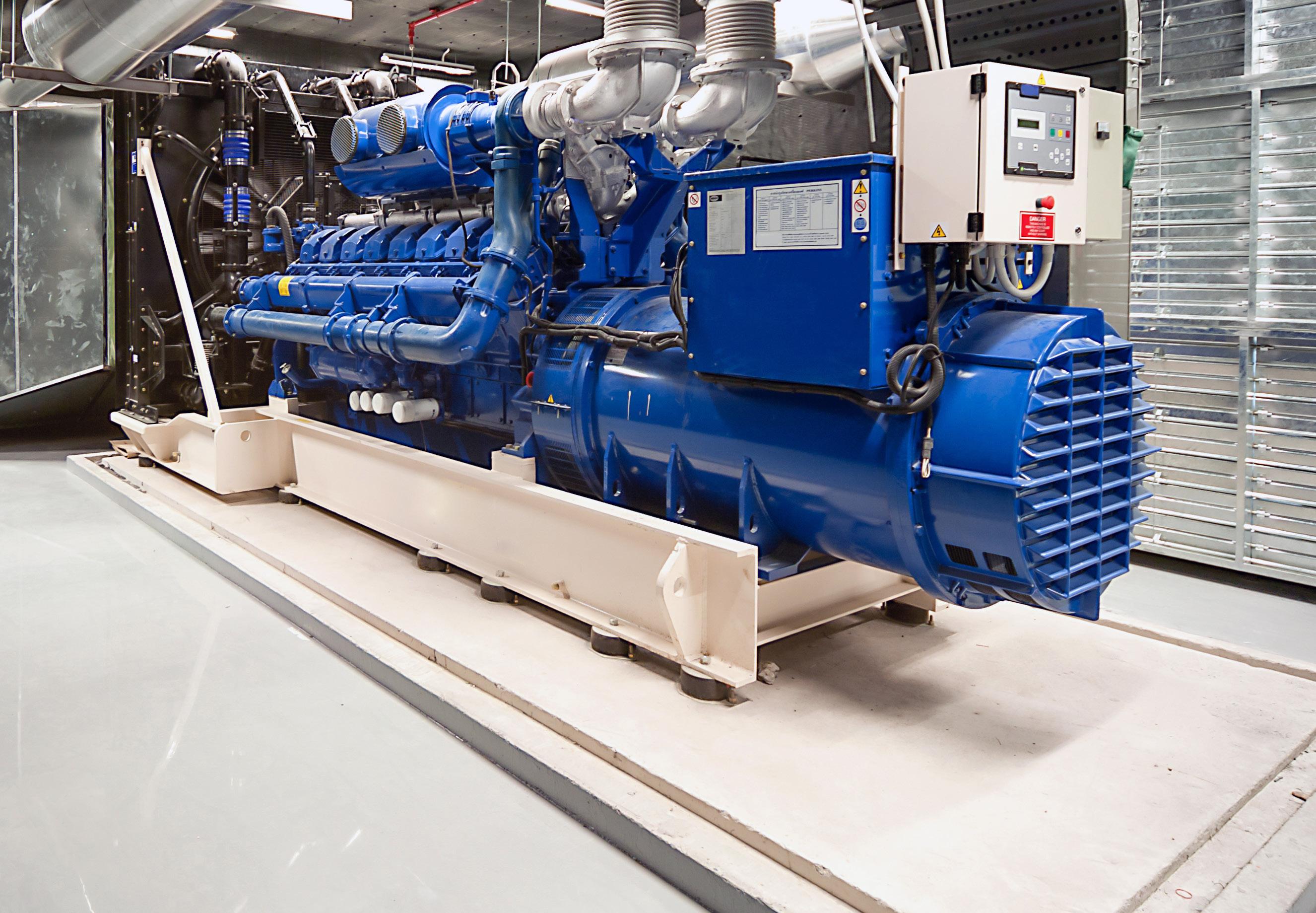

A data centre in South Africa recently purchased four mtu Series 4000 generator sets which had to be installed in an area facing severe space constraints.

MTU’s innovative layout plan featured two generators located on the ground floor - and two on the first floor.

All radiators placed remotely on the second floor. Complex rigging and pipework were installed to resolve the spatial challenges. The mtu Series 4000 gensets are designed to operate in a trouble-free way while offering the highest power quality eve under extreme conditions.

According to mtu they have proven their resilience again and again in continuous operation and with full loads in the heat, cold, and dust, as well as with frequent load changes.

In addition to their well-known longevity, their low-maintenance construction and long service intervals also ensure costeffectiveness.

They minimize expenses and downtime and ensure that all equipment is fully operational again in record time. The gensets are said to offer the highest possible power output for each frequency, rating and application group.

EMSA JENERATOR has supplied a a 2250 kVA genset powered by a Baudouin engine and a Stamford alternator, supplying electricity to three villages in Morocco.

The E BD EM 2250 series diesel generator set features a BAUDOUIN heavy duty diesel engine, 4 cycle, water-cooling system. It is turbocharged with aftercooler induction, an ECU governor system and a 12/24 volt self-starter and charger alternator. The set comes with a changeable air, fuel and oil filter & flexible fuel pipe.

Other useful features include an oil discharge valve and extention pipe, an Industrial type silencer, plus an exhaust spiral or

compensator. There is a maintenance-free battery, an engine block water heater (in automatic models). The set is supplied with diesel gen-set maintenance and operating instructions and an electrical circuit diagram.

The genset is powered by a rugged & reliable 16M33G2250/5 engine.

The continuous need to provide reliable and durable engines for land-based power generation, and the high-seas has led to the development of the popular 16M3 engine, says the company.

The Baudouin range of G Drive engines is available from 15 kVA to 2500 kVA. The generating sets are widely used today across commercial & residential sectors.

The European Union plans to invest 60 million euros (US$63 million) in upgrading one of the Uganda’s largest hydropower plants, helping partially plug a financing gap for the country’s ageing energy infrastructure, a top diplomat have said.

The Nalubaale and Kiira hydropower plant complex located at the source of River Nile at Jinja in Uganda’s east produces about 380 megawatts (MW) and is Uganda’s oldest power plant, commissioned in 1954.

Nicen Industries Limited, one of the largest paint manufacturers in Aba Nigeria, is celebrating its first year of successful operation for a gas power plant from Clarke Energy & INNIO.

The plant was originally installed in April 2023 to improve operations amid unreliable grid supply and has lived up to expectations. Chris Eze, Managing Director at Nicen Industries reports that the decision to install the energy resilient power plant was “one of the most rewarding decisions the company has taken since it was founded in 1990”.

Clarke Energy supplied and commissioned the 1MW solution which included the complete front end engineering design, installation and project management and currently provides maintenance support to the plant.

Ioannis (Yiannis) Tsantilas Managing Director of Clarke Energy Nigeria commented: “The 1MW power plant solution delivery in 2023 reflects the Clarke Energy commitment towards improving the manufacturing and processing value chain in Aba and the south-eastern part of Nigeria.

“Clarke Energy partnered with NICEN in its vision to improve its costs of manufacturing durable plastics and high-quality decorative paints that are affordable and competitive in the local market.”

Spain’s Transport Minister, Oscar Puente, has indicated that a 17.2-mile underwater tunnel linking Spain with Africa will become a reality within the next 20 years. This Fixed Link Project for the Strait of Gibraltar was first discussed 40 years ago and is seen as a strategic key for both Spain and Morocco, as well as Europe and Africa.

The project is likely to include a high-speed rail link stretching for about 26 miles. A 17.2-mile-long underwater tunnel and a 6.3-mile underground tunnel are also being proposed, reports Moroccan stateowned media SNRTNews. As of 2023, the completion of Morocco’s first national high-speed rail line from Casablanca to Tangiers has led to renewed interest in a tunnel that would connect the line to Spain’s own high-speed network. It has been suggested that the tunnel might reach a maximum depth of 1,558 feet and that construction could take around 15 years.

Once built the tunnel complex would need two major electricity substations to be built. These would be connected to the Moroccan and Spanish grids to supply the 25,000 volts on a daily basis for railway traction and the 21,000 volts (three-phase) needed for other fixed equipment.Electrical power supplying the tunnels, drainage pumps, lighting and the trains, could be provided by substations located on each side of the Strait of Gibraltar.

This means In the event of any loss of power from one side, the entire system can be supplied from the other nation’s grid.

A second scenario involves a crossing between Point Oliveros and Point Cires: this plan features deep piers and a length of 14 kms (9m).

Farouk Benabdoun, Vice President of North, West and Central Africa of Siemens Energy, will participate as a speaker at Invest in African Energy (IAE) 2024 – a two-day forum connecting Africa’s leading energy projects with operators, investors and service providers.

Active in over 50 African countries, Siemens is a global leader in energy technology and leads innovative energy initiatives across the continent, with a focus on power, renewable energy and hydrogen.

In November 2023, Siemens signed an MOU with Germany company DAI Infrastruktur to develop a 2-million-ton-per-annum green ammonia project in Egypt,

supplying key electrolyzers, auxiliary plant systems and critical equipment.

By late 2028 the plant will export green ammonia to German and European off-takers and supports Egypt’s plans to develop a domestic green hydrogen industry.

In Nigeria, Siemens is spearheading plans to upgrade and expand Nigeria’s current power infrastructure, having signed a power project deal to deliver 11,000 MW to the national grid by 2030. Meanwhile, Siemens Gamesa has installed more than 3.4 GW of wind power capacity in Africa, representing around half of the African continent’s total capacity.

Zanzibar receiveS electricity from mainland Tanzania through undersea cables, but due to challenges in electricity generation on the mainland - as well as transmission concernsZanzibar is looking for alternative sources.

Under an EU-funded project, a consortium (led by Stantec) is providing technical assistance to support and guide the Zanzibar authorities towards a strategic approach and economically viable investments.

After analyzing the costs and benefits of each proposed technology, engineering teams have determined viable options and possible combinations of alternative energy sources.

Stantec has also supported the establishment of a legal and regulatory framework. It has also provided an action plan and implementation schedule, helped where needed, and - ultimately - has raised awareness about renewable energy and energy efficiency with the Zanzibar population. The next step is Implementing renewable energy projects, reports the company.

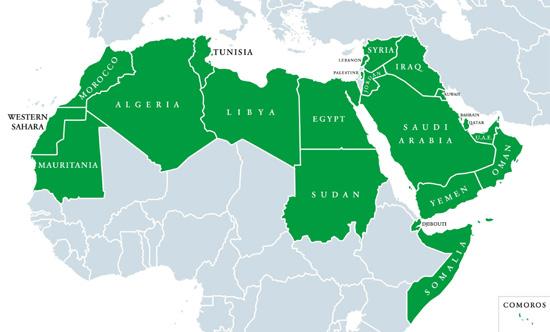

Richard Teasdale, President I CEO of the Association, explains: “MEGSA - MIDDLE EAST GEN-SET ASSOCIATION has gone from strength-to- strength with 50+ companies taking advantage of the new membership joining options, including Bahmani, Jubaili, Technopower, Staunch Machinery plus many other OEMs.

“Research shows that the Middle East Gen-set & North Africa (Generator) market is expected to register substantial growth (3.7% CAGR) owing to the rising population and inadequate generation of power supply between 2022-2030.

“Additionally, increasing number of chemical and power projects in Saudi Arabia and in the UAE is likely to further expand the growth of the market.

“MEGSA’s ambition is to be a strident voice for the Middle East standby and independent power sector as the key professional trade body for the Middle East Gen-Set sector and its associated products diversification backed by upsurge investment of government in infrastructure will undoubtedyl boost the growth of the industry and region,” he explains.

“This is where MEGSA as an association comes to the fore. Its ambition is to be a strident voice for the Middle East standby and independent power sector as the key professional trade body for the Middle East Gen-Set sector and its associated products,” he explains.

One of the Association’s aims is to provide regular annual member events as networking opportunities. The Association is already in the enviable position of being at at the forefront of industry knowledge-sharing, offfering its members huge digital marketing opportunities and regular social media updates and interaction. MEGSA provides business opportunities and new contacts through different networking events.

Membership benefits include:

• Many Networking Opportunities

• Annual Statistical Report Free

• MEGSA Quarterly Publication

• Newsletters to over 10,000 in the Middle East region

• Professional advice & body knowledge

• Social Media promotion to over 7,000

• Membership badge of approval

• Company logo on the MEGSA homepage

• A MEGSA stand @ MEE promoting MEGSA and to visit/use as a base when visiting shows sponsored by the Association

• MEGSA can help in the transition to more sustainable options – “Net Zero”

• At Middle East Energy - MEGSA is an official supporting Media Partner and also the official UK sales agent

• 3 x 1 page, colour adverts - Free advertising to run in the “Official Association Publication” and “MEP - Middle East Power” magazine.

• Incentivised joining costs - Be part of our Inaugural year and Join for the 1st year @ £2450.00 or 2 years @ £1950.00 each year (Inaugural year incentivised joining prices)

• The voice of the Middle East Generating-Set industry

• There is also an Official Media Partner Power Magazine available free for all members. Richard Teasdale concludes: “Our mission is to serve our members and the industry by encouraging the sharing of knowledge in the field of the diesel and gas engine power generating sector, Distributed Energy, Power and Energy. MEGSA has a real voice thanks to the Association’s links with various media & marketing entities. Accordingly, it can offer real & profitable Networking Opportunities.”

All enquiries - you can take up membership by visiting: www.megsa.org

The Dekemhare 30-megawatt photovoltaic solar power plant project in Eritrea is being financed by a US$ 49.92 million grant comprising US$ 19.5 million from the African Development Fund (ADF-15) and US$ 30.42 million from the Transition Support Facility (TSF).

The project involves the construction of a 30-megawatt solar photovoltaic power plant with a battery backup system. This is expected to contribute to increasing generation capacity and grid energy to 185 MW and 365 gigawatt-hours/year, respectively.

Part of the grant will also be allocated to technical assistance and capacity building to improve the operational performance of the grid and ensure the sustainability of the results achieved and the overall development of the Eritrean power sector. The contracts include includes the design, construction, supply and installation of a 30 MW grid-connected solar photovoltaic power plant with a 15 MW/30 MWh battery energy storage system, a 33/66 kV substation and a 66 kV transmission line connected to the existing transmission line between East Asmara and Dekemhare, located about 1 km from the project site.

Responding to demand with the same old designs and power grid dependency is simply not sustainable for Africa anymore, reports Ed Ansett, Founder & Chairman, i3 Solutions Group.

Two of Africa’s biggest economies suffer regular power grid blackouts. South Africa continues to grapple with a formidable energy challenge caused by a strained and unreliable power grid prone to rolling outages. In Nigeria, the grid crisis has reached alarming levels, with two total grid collapses occurring within a single week in September 2023.

Such grid instability poses a significant hurdle for data centre development, as these are facilities that require constant and uninterrupted power. The situation is being exacerbated by ageing infrastructure, maintenance issues, and a surge in energy demand.

Power and connectivity can mean different things in different markets in Africa. Of Africa’s 1.2bn population, roughly half, 600 million people don’t have a dependable networked electricity supply. In Sub-Saharan Africa, two-thirds of people have no regular access to electricity.

This is being changed through the development of off-grid power systems. Much of this off-grid solar power is largely used to charge the more than 1bn mobile phone handsets as people rush to get connected and online.

According to the GSMA The Mobile Economy Sub-Saharan Africa 2022 report there will be 613m unique mobile subscribers by 2025 covering 50% of the population (of which 41m will be 5G connections). Mobile is forecast to generate $154bn in economic value by 2025. Nigeria boasted 199.6 million mobile connections as of March 2022, according to the West African country’s Communication Commission (NCC).

GSMA Intelligence data also showed that there were 108.6 million cellular mobile connections in South Africa at the start of 2022, equivalent to 179.8 per cent of its population.

Egypt’s 98.29 million mobile users during the first quarter of 2022, represents 93.4 per cent of its population. Yet currently in central Africa, 39% of the population lives outside a mobile broadband coverage area. This figure is 16% for West Africa, 13% for East Africa and 12% in Southern Africa. In all, it is estimated that 43 per cent of the entire African population is still without smartphone access.

Africa is not just a story of remoteness and rurality. Africa’s 10 largest cities amount to 55 million people living in the continent’s biggest metros. Building and running the data centres required to support the businesses in these metros and how they serve a growing and ever more connected population means facing up to new challenges from dealing with unreliable grids to finding sustainable energy.

The data centre sector should look to the ‘leapfrogging’ efforts of the power and mobile sectors of off-grid power and network rollouts. In the power supply areas, industrial microgrids are being built around a combination of renewable sources (where available) and on-site engine-based power generation.

Power companies are onto the huge opportunities for leapfrogging outside the major cities – avoiding vast and costly fixed power line investment by jumping straight to solar and wind for power generation and building community, rural, and networked microgrids.

Leapfrogging is not a panacea but it shows that in power and telecoms, new thinking in supply and demand is facilitating rapid adoption and expansion.

ED ANSETT

The $2.9bn Julius Nyerere dam’s first 235MW turbine has begun producing power, and a second unit is expected onlineshortly, says the government.

After considerable delay the 2.1GW megaproject has begun fulfilling its potential to supply national and regional demand . Despite this positive development there are long-standing questions about whether the transmission infrastructure can be overcome.

A drought has forced a reduction in electricity generation in Zambia, prompting the state-owned power utility Zesco to begin rationing electricity. An eight-hour daily electricity rationing programme started on 11th March, 2024, in response to a reduced level of generation from Zesco’s drought hit hydroelectric power (HEP) plants.

In response to the Presidential declaration of the drought national disaster and emergency in Zambia, the United Nations (UN) is working with Zambia’s government in preparing a drought response plan to support affected households in 84 severely affected districts across seven provinces.

Drought is already affecting the Ngonye Falls Hydroelectric Project, a sustainable run-ofriver scheme previsouly generating 180MW of renewable, low cost electricity. .

It is the same story in Zimbabwe where the majority of Zimbabwe’s hydropower resources lie along the Zambezi river. The country previously relied on 80% of its hydropower demands from the Kariba South Bank power station on the Zambezi river. The potential hydropower was previously estimated for the Zambezi river is put at around 18600 GWh per annum. Current conditions mean much less is being generated owing to inadequate rainfall;

Voith has won the order to supply equipment for the large-scale hydropower plant Caculo Cabaça in Angola, West Africa.

The order comprises all electrical and mechanical equipment, including the installation of four Francis turbines with an output of 530 MW each, an additional Francis turbine with an output of 52 MW, generators, control and auxiliary systems and a customised training concept.

The hydropower plant on the Kwanza River is around 250 km southeast of the capital Luanda in the province of Kwanza Norte. Caculo Cabaça is set to be connected to the grid there with a total capacity of 2172 MW before the end of the decade. The pilot tests have recently been completed. Following commissioning of this power plant, around two-thirds of Angolan energy will come from hydropower.

The order volume for Voith amounts to more than US$1 billion. The company arranged a long-term, tailored financing package with attractive terms and conditions for the Republic of Angola. This was implemented with the support of the German government and specialists at Euler Hermes.

MITSUBISHI HEAVY INDUSTRIES has been awarded a contract for a 3.5 MW natural gas fired power station - once installed it will be the main power source for the state of the art - Pocari Sweat NG factory in Nigeria. A company spokesman comments: “We would like to take this opportunity to thank our partners Mitsubishi Turbocharger and Engine Europe for the support shown to win this deal. This is just the start for more big projects to come to the Nigerian market. We don’t sell generators, we sell power solutions.” Pocari Sweat is a soft drink

beverage being manufactured in Nigeria.

Pocari Sweat is the product made by Otsuka Nigeria Nutraceutical Company Ltd. Otsuka says it is dedicated to creating new products to bring better health worldwide. The factory is based in Ogun, state, western Nigeria. This area was created in 1976 and comprises the former Abeokuta and Ijebu provinces of former Western state, the latter carved out of former Western region in 1967. Ogun is bounded by Oyo and Osun states to the north, Lagos state to the south, Ondo state to the east, and the Republic of Benin to the west.

Aprimary power plant is being readied at the Eko Atlantic City development in Victoria Island, Lagos, thanks to the arrival of the first batch of generators.

The contract is the work of the distributor MIKANO who first struck a deal with HHI-EMD for the supply of six gas engine generator sets. These HYUNDAI HiMSEN 20H35GV engines will provide 56.4MW in the first phase of this partnership with a plan to extend to a total of 500MW.

The genset manufacturer HHI-EMD has become the forerunner in the sector of engine power generation as well. A great number of its domestic and overseas engine power plants have given superb performance, contributing to the HYUNDAI’s high reputation.

Special features of the HYUNDAI gas engine genset are as follows: H35/40G(V) rated power at 100% load Heat Rate & Electrical Efficiency

720 rpm / 60 Hz Rated Output (kW) Engine Type Heat rate In-line type Electrical In-line type Efficiency Vee type.

The genset conforms to ISO 3046/1 reference conditions and is optimised to TA luft legislation at the reference condition. There is a monoblock cast iron engine block with a combustion air chamber.

Each cylinder had a split type camshaft and each camshaft is jointed by screws. Each piece of camshaft has an intake cam and an exhaust cam. Surface hardening has been provided for the each cam profile. The gear wheel for driving the camshaft, as well as the gear wheel for connection of governor drive, are mounted on the flywheel side. The front end block is located on the free end of the engine.

Extreme miller timing for the intake cam has been applied to reduce NOx emission and prevent knock combustion. Variable Cam Timing (VCT) has been proven to be a very effective method in PFI (Port Fuel Injection) engines for improved fuel economy and combustion stability, and reduced emissions. In DISI (Direct Injection Spark Ignition) engines, VCT is applied in both stratified-charge and homogeneous charge operating modes.

The heat rate & electrical efficiency at generator terminals, without engine driven pumps and with +5% tolerance, are within normal parameters, says Hyundai. Fuel gas L.H.V. is 35 MJ/Nm³ with M.N. 80. The set is arranted at 100% load only.

Studies conducted in the past conceptualised Miller cycle by early inlet valve closure (EIVC) using high values of boosted air pressure through two-stage

“Power is everything in a development like Eko Atlantic City”

turbocharging. These studies showed that extreme values of EIVC in conjunction with increased boost pressure resulted in a remarkable reduction of engine-emitted NOx up to 50% without deterioration of brake specific fuel consumption (BSFC) compared to conventional diesel engine operation.

Various methods have been proposed in studies to materialise Miller cycle in diesel engines but it has not been clarified which is the best combination of methods for simultaneous reduction of diesel-emitted specific CO2 and NOx emissions.

H35/40G(V) gensets provide an automation system for engine safety, control and indicating based on programmable logic controller. The system is independently installed in each engine and also can be connected to the remote system, for example main switch board of engine control room via hard-wired communication cables.

Gas engines like these are able to operate with more stability than other gas turbine under different ambient temperatures.

The HYUNDAI gas engines are said to offer a shorter start time compared with gas turbines.

These HYUNDAI gas engines also offer higher efficiency and lower emission rates in energy production, reports the company.

www.hyundai-ec.com

“Eko Atlantic City will be one of the most impressive sites in developed Africa”

Two HFW-400 T5 400 kVA soundproof generator set each powered by an C13TE3A FPT IVECO engines and each with a MECC ALTE alternator have been delivered to Casablanca Finance City In Morocco.

Casablanca Finance City (CFC) is an African financial and business center committed to the continent’s future. ts goal is to attract international institutions and investors to invest and operate in North, West, and Central Africa, using Casablanca as a gateway to access this region.

The centre offers three main business categories:

-Financial Companies: These include banks, insurance companies, and other financial institutions operating Morocco or abroad.

-Professional Services Providers: Offering legal, consulting, and other specialized services.

-Regional or International Headquarters of Multinationals: Providing a strategic base for global companies.

CFC reports it consistently ranks as a top financial center globally, providing comprehensive administrative support to its members.

Each of the genset has a C13TE3A FPT IVECO engine offering ISO 8528 standard certification of excellent performance related to load acceptance.

Each engine has an accurate fuel delivery system designed to achieve top performance terms of load response and top power with the minimum fuel consumption: C87 with very compact 2nd generation Common Rail SystemC10 & C13 with electronic controlled unit injectors.

The engines offer the option to switch from 1500 rpm to 1800 rpm. This feature is said to be user-friendly thanks to interface card.

Designed to cope with freezing nightime desert climates the C13TE3A has a minimum cold starting temperature without auxiliaries down to -10°C (with grid heater down to -25°). Tier 3 performance is achieved without external EGR or VGT, says FPT. The engine is turbocharged with air-to-air charge cooled air system with 4 valves per cylinder to increase the engine efficiency through the optimisation of thermodynamic performance in terms of load response & fuel consumption.

These CURSOR family engines adopt combustion chambers and high pressure injection system optimised to reduce oil dilution. The C13TE3A offers optimum engine design in terms of mechanical clearances, piston rings and oil system calculation, reports FPT.

The C13TE3A has an engine ECU (Electronic Control Unit) with CAN-BUS control & monitoringinterfaces can be used for advanced real time diagnosis.

The engine also offers multiple injections, balancer counterweights incorporated in crankshaft webs, rear gear train layout, camshaft in crankcase, suspended oil pan and ladder frame cylinder block.

There is an Integrated CCV (Closed Crankcase Ventilation) system and engine design oriented to high component integration. Water-oil cooler, oil and water pumps are completely integrated in the engine block, reports the manufacturer.

The HFW-400 T5 400 kVA is a watercooled three-phase soundproof genset which is compliant with the following directives:

• EN ISO 13857:2008 Machinery safety.

• 2006/95/EC Low voltage.

• 89/336/EEC Electromagnetic compatibility.

• 2000/14/EC Sound Power level. Noise emissions outdoor equipment. (amended by 2005/88/EC)

• 97/68/EC Emissions of gaseous and particulate pollutants. (amended by 2002/88/EC & 2004/26/EC. With its 4-stroke diesel engine

(injection type) it has a turbocharged aftercooler. It offers a Total Oil Capacity of 35-litres ands collant capacity of 68-litres. The gensets also feature a dry air filter and an electronic Engine Governor. Standard equipment with the unit includes:

• Diesel engine, 4-stroke, water cooled, provided with electric start 12V or 24V.

• Radiator with pusher fan

• Decanting water pre-filter

• Mechanical engine regulation (up to model HFW160) or electronic (from model HFW-200)

• HWT / LOP senders (from HFW250)

• Low coolant level sensor (from HFW-200)

• Hot & mobile components (exhaust, fan etc) and radiator guards.

• Exhaust engine outlet and industrial silencer of -15dB(A) & oil sump extraction kit.

The generator features 4-poles, Serie Star winding connections, SAE1 - 14”Frame Mounting, Class H insulation, and an IP23 e.nclosure (according IEC-34-5)

casablancafinancecity.com

www.fptindustrial.com

www.himoinsa.com

Italy-based COELMO is well-known worldwide for producing rugged and highly-reliable generating sets designed and produced for professional applications covering a range from 3 to 4,000 kVA.

These robust reliable gensets can be personalised and provided with accessories which allow them to be adapt to a variety of different industry sectors, making them an ideal choice for demanding users.

COELMO was recently involved in the design, supply, installation and commissioning of one 2,000 kVA generating set (model BTD16M33) and three other 1,400 kVA Coelmo generating sets (model BTD12M33) in ESP, 50Hz, 400 V, 1500 rpm. These have been supplied to an important hydrocracking complex located in Assiut, Egypt.

These COELMO gensets are equipped with:

- Baudouin engine 16M33G2000/5 - 12M33G1400/5

- Mecc Alte alternator ECO46 VL4 - ECO46 1L4

- 40 ft container, 85 dB(A) 1m

- Parallel control panel with remote start (Comap)

- Motorised circuit breaker

- Fire detection and CO2 extinguishing system

- 1,000-litre fuel tank with leakage collection tank.

The ECO46 VL4 has many product features designed into the alternator. Self-regulation is obtained through a digital electronic regulator that is fed by an auxiliary winding. The manufacturer, Mecc Alte guarantees an almost constant supply from the generator – under any possible operating condition. In the design a rotating inductor is fitted with a damper cage.

The manufacturer guarantees an almost constant supply from the generator – under any possible operating condition.

“WE ARE PROUD TO HAVE OUR HIGH-QUALITY GENSETS

ASSOCIATED WITH THE ASSIUT HYDROCRACKING COMPLEX, PART OF EGYPT’S KEY NATIONAL ENERGY DEVELOPMENT PROGRAMME, AND LOOK FORWARD TO SUPPORTING ITS POWER NEEDS FOR YEARS TO COME.” - COELMO

The windings have a 2/3 pitch in order to reduce the harmonic content of voltage. The entire series is manufactured according to, and complies with, the most common specifications such as CEI 2-3, IEC 34-1, EN 60034-1, VDE 0530, BS 4999-5000, CAN/ CSA-C22.2 No1495- No100-95.

The ECO46 1L4 alternator fitted to the other gensets is also from the ECO46 range - which has many special product features designed into the alternator. Self-regulation is obtained through a digital electronic regulator which is fed by an auxiliary winding.

A rotating inductor is fitted with a damper cage. The windings have a 2/3 pitch in order to reduce the harmonic content of voltage. The entire series is manufactured according to, and complies with, the most common specifications such as CEI 2-3, IEC 34-1, EN 60034-1, VDE 0530, BS 4999-5000, CAN/ CSA-C22.2 No1495- No100-95.

The Baudouin PowerKit 16M33G2000/5 ESP/PRP/DCP/

COP Diesel Engine Engine and block features a cast iron cylinder block with inspection door per cylinder, cast iron cylinder liners, wet type and replaceable valves guides and seats. There are separate cast iron cylinder heads with 4 valves. The engine has hardened steel forged crankshaft with induction-hardened journals, crank pins and radius, plus lube oil-cooled light alloy pistons with high-performance piston rings

The cooling systems have radiator and hoses supplied separately and two separate circuits: the high temperature circuit equipped with thermostatically-controlled system with two gear driven coolant pumps, while the low temperature circuit equipped with belt-driven coolant pump.

An advanced lubrication system features full flow screwable oil filters, lube oil purifier with replaceable cartridge and a water-cooled lube oil cooler. The fuel system has a high-pressure common rail system with one high pressure pump gear.

www.coelmo.com

www.meccalte.com

baudouin.com

Ten 20V 4000 L64 FNER gas generators with rated power of 2500 KW and with up to 84,000 hours lifetime to major overhaul (TBO) have been supplied to Egypt. These have a rated power of 2500 KW and offer up to 84,000 hours lifetime to major overhaul (TBO).

The next generation Series 4000 natural gas genset offers the highest power density and the highest kilowatt-per-square-foot ratio in its class. Based on the successful Series 4000 engine, it delivers from 776–2,535 kW, and has been optimized for hot and humid environments like those found in Egypt.

Designed with cutting-edge technology, the new Series 4000 natural gas genset provides maximum performance and low emissions to deliver an economical, reliable, and sustainable source of power.

The gas genset come with Performance Assurance Certification (PAC)- Generator Set Tested to ISO 8528-5 for Transient Response - verified product design, quality and performance integrity- all engine systems have been prototype-and-factory-tested

The generators accept Rated Load in One Step Per NFPA 110 - ermissible average power output during 24 hours of operation is approved up to 85%.

Standard features of the 20V 4000 L64 FNER gas generator includes a 2-year standard warranty, a 20V4000 diesel engine, 95.4-litre displacement, Common Rail Fuel Injection, 4-Cycle configuration and a complete range of accessories.

The generator elements includes

- Brushless, Rotating Field Generator

- 2/3 Pitch Windings

- PMG (Permanent Magnet Generator) supply to regulator

- 300% Short Circuit Capability

The Digital Control Panels offer the following:

- UL Recognised, CSA Certified, NFPA 110

- Complete System Metering

- LCD Display

The gas generator cooling system provides:

- Integral Set-Mounted

- Engine-Driven Fan.

A significant reduction in nitrous oxide emissions makes the natural gas genset a perfect fit for independent power producers (IPP) and combined heat and power (CHP) applications.

With part-load performance down to 35% and a fast start option, the gas genset’s operational flexibility is also said to be ideal for demand response applications.

A Heat Recovery Unit with the genset also provides the basis for optimised auxiliary efficiencies.

Low emissions - 250 mg/Nm³, 500mg/Nm³, (@5% O2)NOx are achieved without external aftertreatment, even meeting the new German unburned THC emissions legislation (<1300mg@5%O2).

The natural gas genset has an effective engine power of 130 kWm/ cylinder – the highest power density in its class thanks to its compact design and small footprint.

It offers ‘superb performance at high temperatures and high humidity for use anywhere in the world and delivers 30% more power than its predecessor’, reports the manufacturer.

All natural gas genset components are fine-tuned to ensure long service lives and deliver maximum uptime. Long service intervals and easy-tomaintain components mean low maintenance costs. Fast availability of spare parts and low engine oil consumption also help keep the new gas genset lifecycle costs lower overall, with cylinder head lifetimes potentially equivalent to TBO.

The natural gas genset achieves efficiencies of up to 44.4%, delivering a significant improvement in fuel/ energy utilisation at high temperatures.

A spokesman comments: “The gas-powered Series 4000 gives you more power in less space while reducing fuel and maintenance costs, especially designed for hot and humid conditions.”

Ignition systems for individual cylinders allow for the most efficient level of operation for all cylinders, even with variable CH4 content. The ignition system gives information on the state of the spark plugs.

The system is equipped with a data logger providing access to digital solutions, including remote monitoring, fast and reliable service support and – coming soon – further features such as predictive failure prevention and operational optimisation.

Each generator has a Motor interface panel (MIP) with stand-alone mtu Module Control (MMC).

The MMC provides all the functions necessary for controlling the system. All the auxiliary drives required for the CHP system can be operated from here.

The integrated power circuitry minimizes the customer’s need for cabling on site.

www.mtu-solutions.com

KOHLER has been involved in the supply, installation, and commissioning of four 400 K.V.A KOHLER generators for a livestock project in Egypt .

Each state-of-the-art generator ensures uninterrupted power supply, providing peace of mind and comfort to the project for many savings, says the company.

Each generator has also been equipped & automated with a fuel system, Since the 1920s, Kohler Co. has become one of the world’s leading manufacturers of power generators.

The company has continued to specifically design generators to suit every application, offering clients a solution which suits their needs.

The KV400C2 is one KOHLER 400 kVA generator which can be supplied with an optional automatic transfer switch which will allow the detection of a power outage and then turn the generator on automatically. Being a 100% European manufactured product, this will ensure its effectiveness and reliability in the protection of your facility.

The KV400C2 features a special engine: the VOLVO TAD1341GE-B – along with the TAD1342GE-B and TAD1343GE-B variants these represent are powerful, reliable and economical generating diesel genset engines built on the dependable in-line six design, offering durability and low noise.

They are designed for easiest, fastest and most economical installation and are field-tested to ensure highest standard of durability and long life.

Well-balanced to produce smooth and vibration-free operation with low noise level, the gensets maintain a controlled working temperature in cylinders and combustion chambers as each the engine is equipped with piston cooling.

The engine is also fitted with replaceable cylinder liners and valve seats/guides to ensure maximum durability and service life of the engine.

Low exhaust emission The state of the art, high-tech injection and charging system with low internal losses contribute to excellent combustion and low fuel consumption.

The TAD1341GE-B, TAD1342GE-B and TAD1343GE-B engines are emission-certified. An electronicallycontrolled viscous fan drive is available giving substantially lower noise and fuel consumption. Easy service and maintenance Easily accessible service and maintenance points contribute to the ease of service of the engine.

Benefits and features of the KV400C2:

* Industrial water cooled DIESEL engine

* Electric starter & charge alternator

* Standard air filter

* Schneider or ABB electric circuit breaker, adapted to the short-circuit current of the generating set

* Single bearing alternator IP 23 T° rise/ insulation to class H/H

* Welded steel base frame with 85% vibration attenuation mounts

* 4 lifting points on the chassis, lifting bar on the top included from 165 kVA ESP or optional

*Highly durable QUALICOAT certified epoxy paint

*Frame height optimized to allow it to be moved safely by forklift

* Enclosure made of new high-quality European steel with enhanced corrosion resistance

* IP 64 locks, made from stainless materials

* Enclosures and base frames tested and analyzed by the French Corrosion Institut

* 100% of tanks tested for permeability

* Personal protection ensured by

protective grilles on hot and rotating parts

*Separate 9 dB(A) silencer

*Fuel tank welded inside the genset frame

*Retention bund included for gensets up to 110 kVA ESP

*Charged DC starting battery with electrolyte

*Emergency stop button on the outside

*Flexible fuel lines & lub oil drain cock

*Exhaust outlet with flexible and flanges

* Premium performances

* Robust base frames and highquality enclosures

* Protection of installations and people

* Approved in line with the most stringent standards

* Premium level engines, in-house or from strong partners

* High power density, small footprint

*Low temperature starting capability

* industry leading motor starting capability.

kohlerpower.com

Teksan has delivered a 1100 kVA diesel genset to the Banque du Développement du Mali which in 2018 was voted Best Bank in West Africa. Teksan diesel generators incorporate the best engine brands available and the Teksan TJ1100PE 1100 kVA diesel generator is known for its reliability & economy thanks to its robust Perkins 4008TAG2 engine.

The Overhead Valve (OHV) 1500rpm engine produces 1100 kVA / 808 kW of prime power effortlessly and has been designed to be quiet, rugged, and durable.

The Teksan TJ1100PE has a close-fitting acoustic canopy, long run bunded fuel tank, its best at home when used for the construction industry, hire fleets, outdoor events, or for standby power applications.

The genset has a prime power rating of 1100 kVA / 808 kW and standby power rating of 1100 kVA / 808 kW.

This canopied diesel generator is extremely compact and robust, so can be stored with ease with minimum effort.

With a generous bunded fuel tank of 1650-litres, the Teksan TJ1100PE diesel generator is perfect for a wide variety of projects and applications.

With an easy-to-use configuration this diesel generator gives an excellent balance between performance and price, reports the manufacturer.

In Teksan generator sets, leading engine brands that have state of the art technology and have compliance with ISO 8528, ISO 3046, BS 5514, DIN 6271 standards, being used.

These engines offer low fuel consumption, provide accurate speed settings, mount to the fuel pump, also have mechanic or electronic type governors.

The alternators used inside them are appropriate according to EC 60034-1; CEI EN 60034-1; BS 4999 5000; VDE 0530, NF 51- 100,111; OVE M-10, NEMA MG 1.22. standards.

The engines have a bearing system which does not need maintenance, with an electronic type voltage regulator providing voltage settings.

The standart control panel, used in Teksan generator sets, ensures comfortable and safe usage.

Al measured and statistical parameters, operating modes, notice and alarms and condition of generator, are monitored easily from the control panel.

Based on the front of the panel’s metal body the electronic control module and the emergency stop button are easy to reach.

The panel’s metal body is made of steel sheet and is painted with electrostatic powder paint. Teksan offers panel design and solutions which comply with special requirements of customers as well as quality standard panels.

Teksan’s chassis is manufactured from steel which complements its rigid structural design and antivibration mounts: it reduces vibration levels to minimum.

The chassis contains lifting lugs making transportation and positioning easier.

In less than 1600 kVA power generator sets, the fuel tank is integrated in design. In chassis with more than 1600 kVA power generator sets, a rectangular type fuel tank is provided separate from the generator set . Both types of fuel tank have an individual level indicator.

Each genset’s cooling system consists of a quality industrial-type radiator, expansion tank and cooler fan, to keeps the set’s interior temperature constant and at a

proper level.

TEKSAN Dropover Canopy Type Generator Sets

Teksan manufactures drop over canopies for outdoor installations. with features as follows;

*Compatible with 2000/14/EC directives, certified noise emission level,

*2 or 4 points transport possibility according to cabin size,

*Hidden exhaust inside the canopy,

* Emergency stop button located on the canopy,

* Improved air suction channel to ensure homogenous cooling in the canopy,

* Radiator air outlet and exhaust with designed towards above.

* Lid on cab to help with easy filling of radiator water and antifreeze.

*Improved paint system which protects against corrosion and rust.

*Improved performance in terms of sound insulation.

* Demounted parts which make transportation and maintenance easier.

* The TJ-509-T MK3 is a nextgeneration controller combining multifunctionality and wide range of applications.

The Perkins 4008TAG2 is a turbocharged, air-to-air charge cooled, 8-cylinder in-line diesel engine. Its premium design and specification features provide economic and durable operation as well as exceptional power-toweight ratio, improved serviceability, low gaseous emissions, overall performance and reliability essential to the power generation market. Individual four valve cylinder heads give optimised gas flows, while unit fuel injectors ensure ultra fine fuel atomisation. www.teksan.com

MWM Solutions Provider Green Power International has installed an MWM gas genset for a plastics manufacturer in Nigeria. The MWM TCG 3020 V16 gas genset went live on January 5, 2023 and produces 1,840 kWel of electricity for the company.

The Panar Group of Companies has been a leading plastics manufacturer in Nigeria since 1978. The company is one of the country’s largest suppliers of jars, plastic pipes, and preforms.

Green Power International Pvt. Ltd. had already installed an MWM TCG 2020 V12 K1 gas genset for the company back in 2014. Since its go-live, the MWM engine with an output of 1,000 kWel has completed 50,000 operating hours producing energy for consumption by the Panar Group of Companies.

Along with the MWM TCG 2020 V12 K1 gas genset, the MWM TCG 3020 V16 gas genset installed by Green Power International produces energy for the Panar Group of Companies.

The two gas gensets are based in two separate cogeneration power plants. Since its installation in January 2023, the MWM TCG 3020 V16 gas genset has been operating continually. Together with the MWM TCG 2020 V12 K1 gas genset, it generates enough energy to meet the company’s high production requirements and ensure smooth operations.

The service team of Green Power International takes care of the regular maintenance of the systems of the Panar Group of Companies in order to ensure uninterrupted energy supply.

Thanks to the high reliability and availability of the two MWM gas gensets, the production process has not suffered any interruptions since the gensets went live.

The MWM TCG 3020 is considered the all-rounder among MWM gas gensets. It is suitable for various application areas and gas types, e.g. natural gas, biogas, APG, and propane gas.

Moreover, the MWM 25H2 kit is offered for the conversion of natural gas gensets for operation with a hydrogen admixture of up to 25 vol%. Apart from delivering an output range from 1,380 to 2,300 kWel, the MWM TCG 3020 gas genset stands out with high reliability, efficiency, and availability.

The MWM TCG 3020 gas genset effectively balances efficiency and reliability.

The genset delivers up to 18% more output than its predecessor, though its dimensions are almost the same.

Additionally, it features long service intervals with up to 80,000 operating hours until the next general overhaul (if the gas quality is high) and a total efficiency of more than 87% (with natural gas).

Apart from the 50 Hz variant, the TCG 3020 V20 gas genset is also offered as 60 Hz variant.

Owing to their high reliability and profitability, the gas gensets with an output of 1,380 to 2,300 kWel are ready for the challenges of Industry 4.0.

Thanks to the use of the digital power plant control TPEM (Total Plant & Energy Management), the gas gensets are able to reach their full performance for maximum plant availability, capacity, and usability.

Here is what the gas genset offers: - State-of-the-art technologies enable an output of 1,380 to 2,300 kWel and

application-optimised engine types

- High electrical efficiency of up to 45 percent (natural gas)/43.6 percent (biogas), total efficiency of more than 87 percent (natural gas)/86 percent (biogas)

- Flexible use for various applications and gas types, such as natural gas, biogas, APG, and propane gas, hydrogen admixtures, and other gases.

MWM hardware and software is provided from the same manufacturer for comprehensive plant control.

With MWM’s technology data analysis and optimum plant control are combined in a single systemIntegrated secure remote maintenance solutions which are always available.

There are long service intervals with up to 80,000 operating hours until the next general overhaul. Other benefits are low installation and operating costs through high performance and low oil consumption of only 0.15 g/kWhel. www.mwm.net

SIZE, FIND AND CONFIGURE YOUR GENERATOR INSTANTLY WITH POWER CENTRE FROM FG WILSON

Power cente is the ultimate tool when planning your project, enabling you to instantly size a generator that will meet your power needs, find inventory near you in stock and configure a generator set to meet your project specifications.

Genesal Energy has just reinforced the safety of the energy supply in one of Tanzania’s factories which produces brown sugar for direct consumption.

With a population of more than 63 million people, Tanzania’s agriculture is an important source of income, representing 25% of GDP, and sugar cane is one of its most profitable crops.

Within this sector, the Kilombero Sugar company is a heavyweight. Its projects to increase production in the medium and long term require solid infrastructures capable of withstanding any unforeseen power supply eventuality, the country having a very deficient electricity network.

Kilombero Sugar Company Limited is the largest producer of sugar in Tanzania under the Bwana Sukari brand name. The company is owned by Illovo Sugar Africa and the Government of Tanzania.

Kilombero Sugar operates two farms close to each other: Msolwa K1 and Ruembe K2. These are located on both sides of the Great Ruaha River and linked by a bridge.

Both farms are involved in brown sugar production and need a very reliable network to carry out their daily business.

The project developed by Genesal Energy for Kilombero Sugar focused on the design, manufacture and commissioning of three soundproof generator sets ( 2x GEN2000YC + GEN1100YC) with three different rooms each: engine-alternator room, control room and storage room.

Two soundproofed generator sets (GEN2000YC) were designed in 40 feet containers, guaranteeing an average sound pressure level of 85 dB at 1 m.

The container has 3 separate rooms: engine-alternator room, control room and storage room. In each genset a Baudouin engine has been fitted with a Mecc Alte alternator on an electro-welded steel base with anti-vibration blocks.

A 2000-litre, double-walled, certified tank has been installed inside the container.

A waterspray fire detection and extinguishing system was also installed in the group room and the storage room. CO 2 extinguishers were further installed in the control room which is air-conditioned.

The genset enclosures received C5 paint surface treatment, according to ISO12944. ISO12944 is the industry standard for corrosion protection of steel structures by protective paint systems.

Originally released in 1998, the standard is put together by representatives from key countries and companies involved in the protection of steel structures to build a mutually beneficial standard.

Execution:

Soundproofed Stationary 40HC Container.

Prime power: 1850 kVA

Standby power: 2000 kVA

Voltage: 400/230 V

Frequency: 50 Hz

RPM: 1500 RPM

Engine: Baudouin

Alternator: Mecc Alte

GEN2000YC for Tanzania’s sugar industry

In 2023 Genesal Energy supplied a 330kVA genset to an industry corporation operating in Kenya. This was a GEN330VI genset designed for a power plant & ancillary service applications. The 50Hz M (111-385kVA) offers PRP/STP (kVA)300/330 and is a soundproof three-phase dieselfuelled set with a FPT CURSOR87 TE4 engine and 1500 RPM.

The FPT Industrial Cursor87 ENT (294 kW) engine has a displacement of 8.7 litres and weighs 907 kilograms.

It is equipped with 6-cylinders, each with a bore of 117 mm and a stroke of 135 mm.

The engine has a maximum torque of 1700 Nm and a maximum power output of 294 kW at 2200 RPM. The GEN330VI genset weighs 3335kg and provides a voltage of 400/230415/240 - 380/220.

Three-phase generator sets of this type can be found in almost any power range and their intensive use and proven efficiency make them

more compact, more robust and more efficient than single-phase generator sets.

A three-phase generator is normally more compact than a single-phase generator as it can benefit from current effects and zero magnetic flux, which means that, to move the same power, less iron and copper are needed in electrical machines.

This makes them more efficient, both in the generation and transportation of electrical energy. Due to the construction of the magnetic circuits themselves, threephase generators tend to be more efficient, reports Genesal.

Whereas the single-phase motor has one pair of poles, the three-phase motor has three.

This makes the torque absorbed by the three-phase generator “rounder” and therefore, the mechanical transmission system, bearings and other parts not only suffer less wear, but are also more balanced.

INNIO Jenbacher gas engines

Headquarters: A-6200 Jenbach (Austria) T +43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.gejenbacher.com

Manufacturer of gas driven generator sets and cogeneration systems in a power range from 0.25 to 3 MW.

R Schmitt Enertec GmbH

56743 Mendig, Germany T +49 2652 9351810

F +49 2652 9351822 info@rschmitt-enertec.com www.rschmitt-enertec.com

Manufacturer of gas driven engines,generator sets and cogeneration systems in the range from 100 - 500 kW.

RSE Engines for natural gas and biogas

Ratings natural gas standard, NOx ≤ 500 mg/ m3N. Dry exhaust gas; based on 5% O2. For engines with 1,200 rpm please contact GE Energy’s Jenbacher product team.

TAD1242GE 352 409

TAD1640GE 393 462

TAD1641GE 433 509

TAD1642GE 485 570

Perkins Engines Company Limited

Peterborough PE1 5FQ

Contact name:- Simon Gray

Tel: +44 (0) 1733 583000

Email: gray_simon_j@perkins.com

Perkins is one of the world’s leading suppliers of off-highway diesel and gas engines, offering dependable cost-effective power up to 2500 kVA in dieselor 1000 kWE prime in gas.

SCANIA ENGINES

SE-151 87 Sodertalje Sweden

Tel +468553 81000

Fax +468553 898 12

E-mail engines@scania.com

Web www.scania.com

UK Contact – Mark Swindell

Scania GB Ltd

Tel +44 1908 329386

E-mail mark.swindell@scania.com

Diesel & Gas engines for power generation

Prime power 250kVA to 700kVA Stand by power 250kVA to 770kVA

Engine range prime power 50hz & 60hz at (70% mean load factor)

Scania produce diesel and gas powered engines for various Industrial and Marine applications, superior quality and reliability, offering exceptionally low fuel consumption.

All models are available to meet current emissions requirements, Scania engines are now available to meet both Tier 4F and EU Stage V. Alternative fuels

Many of our engines can also operate on Bio-diesel conforming to EN14214 and HVO conforming to EN159540

Alternator

Battery Charger

Controller

Governor (Actuator)

All the kit you need. All in one place. All in one box

We’ve taken the hard work out of complex sourcing for alternator, battery charger and controller components for your hybrid or industrial gensets.

You get high grade, precision-engineered, smart components that are proven worldwide with access to smart link integration through a singlesource with TheOne.

Instead of juggling different suppliers, multiple lead times and processing tons of paperwork, TheOne from MeccAlte gets it all done in one easy order. All of which makes it easier for you to innovate, create new opportunities and bring product to market more quickly.

Whatever you’re looking for, MeccAlte has TheOne you need.