Publisher/Sales DIrector

Neb Saric neb@wipmagazines.com

Publishing & Events Director Richard Teasdale richard@wipmagazines.com

Managing Editor Aidan Turnbull aidan@wipmagazines.com

Accounts Manager Alison Williams accounts@wipmagazines.com

Business Development Manager Kurt Ellmer power@wipmagazines.com

Far East Sales Bob Liu Shanghai, China bob.liu@ronco.com.cn

US Sales & Subscriptions

Jelena Milojevic power@wipmagazines.com

Austrian & German Agent Mario Dobresko power@wipmagazines.com

Power Media International Group, Power Media International Group Ltd First Floor Suite 1 5 Sanford House Medwin Walk Horsham West Sussex RH12 1AG, UK

Phone Number +44 (0) 1403 332888

Mobile No +44 (0) 7539 791169

www.powermediagroup.co.uk © Worldwide Independent Power (ISSN 1468 7100) www.powermediagroup.co.uk

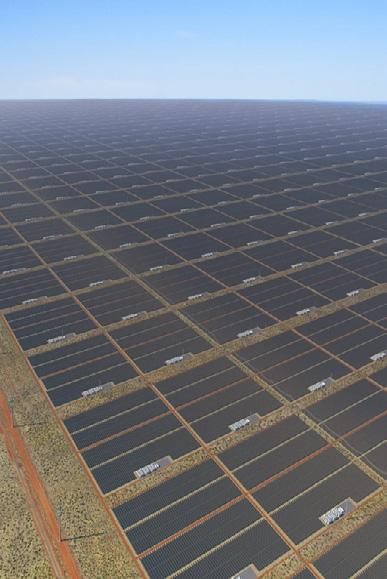

SunCable’s Australia-Asia PowerLink is a renewable generation and transmission project which aims to build a brighter, more sustainable future for Australian people and businesses.

Australia’s abundant renewable resources will be harnessed to support decarbonisation of the Northern Territory and Asia-Pacific region. They will power new green industries and cities, drive new economies and, support communities across the footprint of the project.

Over two stages of development, SunCable’s AAPowerLink project aims to deliver up to 6GW of 24/7 green electricity, of which 4GW will go to green industrial customers in Darwin over two stages; and 1.75GW will go to to customers in Singapore via a 4,300km subsea cable through Indonesia.

The AAPowerLink is the world’s largest renewable energy & transmission project in development and is projected to be one of the largest economic industrial developments in Australian history.

The Australia-Asia Power Link encompasses five key infrastructure components:

1. Solar precinct: located in the Northern Territory

2. Overhead transmission line: approximately 800km HVDC overhead transmission line (OHTL) from the solar precinct to subsea cable beginning at Murrumujuk (Gunn Point, north-east of Darwin)

“

THIS HISTORIC POWER CABLE CONNECTION WILL LINK AUSTRALIA WITH THE ASIA-PACIFIC REGION.”

3. Darwin converter site: terminal location for the OHTL and converts electricity from HVDC to HVAC for connection to Darwin, before being converted back to HVDC for transmission to Singapore

4. HVDC subsea cable system: approximately 4,300km in length from Darwin converter site to Singapore via Indonesian waters

5. Singapore converter site: The HVDC power is converted via a Voltage Source Converter (VSC) to connect to the local Singaporean electricity network.

SunCable is working closely with governments and communities in Australia, Indonesia, and Singapore, and partnering with scientists, engineers, infrastructure experts and First Nations Traditional Land Owners to make the dream of a brighter, renewable energy future for the Asia-Pacific region a reality.

SunCable is owned by a consortium led by Grok Ventures. The AAPowerLink project is being developed by SunCable’s executive leadership team. In a world first SunCable was recently granted Conditional Approval by the Singaporean Government’s Energy Market Authority (EMA) to import green electricity via its flagship project the Australia-Asia PowerLink (AAPowerLink).

AIDAN TURNBULL Managing Editor

12

1.015

An AKSA AD1015 , 1015 kVA/812kW Standby Power diesel-fuelled genset with canopy has been supplied to an industrial client located in Zhejiang, China. Powered by a Hyundai engine this is a high quality, reliable and complete power unit of compact design, easy start and easy maintenance.

The set has been fully-engineered with a wide range of options and a sound proof canopy. Every AKSA generating set is subject to a comprehensive test program which includes full load testing, checking and provision of all control and safety shut down functions testing, says the manufacturer. Features of the set include a heavy-duty HYUNDAI diesel engine, Turbocharged intercooled.

18

A RENEWABLE HYDROTREATED VEGETABLE OIL NOW POWERS

SINGAPORE’S DATA CENTRES

Since July 2024 ST Telemedia Global Data Centres (STT GDC), one of the world’s fastest-growing data centre providers has used Hydrotreated Vegetable Oil (HVO) as a fuel in its data centres power generators in Singapore.

20

HYDROGEN GAS WILL BE SHIPPED FROM MALAYSIA TO MEET ASIA’S COMBINED CYCLE GAS TURBINE NEEDS

Senoko Energy, one of Singapore’s largest energy companies, and Gentari, a clean energy solutions provider, have signed a Memorandum of Understanding (MoU) to embark on a collaborative effort to explore the importation of hydrogen gas from Malaysia to Singapore.

21

CLASSIFIED DIRECTORY

2 X 1,000 KW DIESEL GENSET FOR A GUANGXI HOSPITAL PROJECT

Earlier this year EvoTec provided robust 1000KW 400V generators as the backup power solution for a hospital project in Guangxi, China. Engineered with precision to ensure reliability during emergencies.

These tailored solutions have been designed to meet the unique demands of healthcare facilities, reports the company. EvoTec was established in May 2011, specializing in the development and manufacturing of industrial/marine three-phase synchronous Low, Medium and High Voltage alternators and permanent magnet alternators.

16

7.5MW GAS-BASED POWER PLANT TO SUPPORT NASIR FLOAT GLASS INDUSTRIES IN BANGLADESH

Innio and Clarke Energy have supplied five JGS 420 to the industrial sector in Bangladesh. This is a Jenbacher 420 A V20-cylinder power generation solution. Said to be the most powerful solution in the Type 4 engines family, with power output up to 1,429 kW and electrical efficiency up to 41.9%, the gas-powered genset is described as a ‘great fit’ as a single unit application or power plant for several megawatts, when flexible operation is needed. The J420 D/E genset delivers a robust concept with a compact footprint with a 0.6-metre reduction in length.

22

ENGINE MANUFACTURERS GUIDE

GMMCO Ltd has announced that on Friday, 20th September, 2024, it unveiled the newly-launched FG Wilson 4000 Series Gensets - “a product which brings together the dual advantage of FG Wilson’s Made in India world-class technology and the trusted service assurance of GMMCO,” says the company.

The event, held in Bangalore, brought together industry experts and leaders from the region, who ‘engaged in insightful discussions on the power and reliability these gensets bring to the table’.

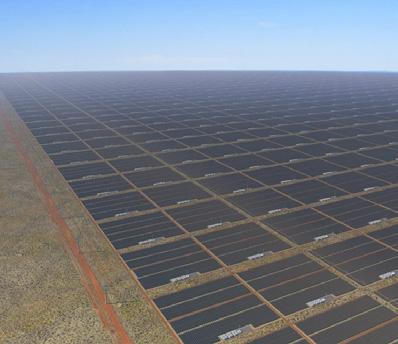

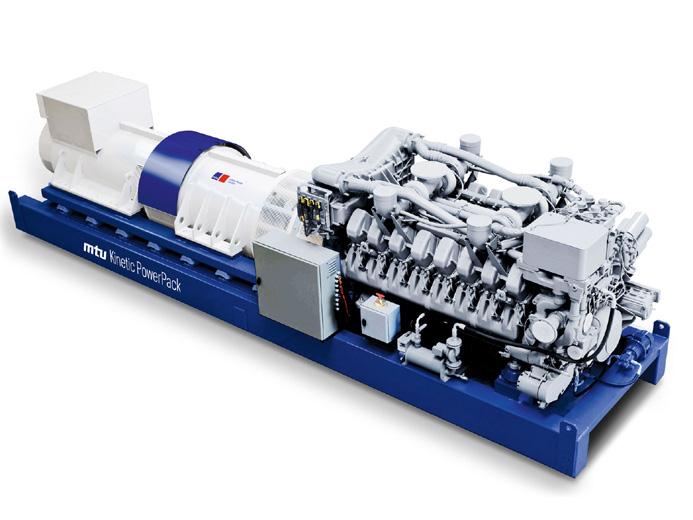

Rolls-Royce is supplying its mtu emergency gensets to a global provider of hyperscale data centre solutions in Japan. A total of 31 MTU emergency gensets and a complete mtu EnergetIQ control system will be provided to the hyperscale data centre located near Osaka.

According to Rolls-Royce, this is one of the largest data centres in Japan with a designed capacity of 45.9MW. Rolls-Royce Solutions Japan has already installed and commissioned eight of the 31 container gensets, which are based on 20-cylinder MTU Series 4000 engines.

The remaining emergency generators will be added gradually as the data centre’s capacity increases. The MTU containers compactly contain the diesel engine with a generator, a switchgear and include the mtu EnergetIQ control and monitoring system.

mtu EnergetIQ, the Energy Management System (EMS) from Rolls-Royce Power Systems, uses artificial intelligence to control microgrids. This predicts the user’s load profile. Based on past data, it can accurately predict when how much power will be needed.

A spokesman comments: “The new mtu EnergetIQ Manager can be considered as the brain of your power plant. It controls groups of power generation and storage assets and the distribution of power all the way from generation to your load. The mtu EnergetIQ Manager handles island installations and grid parallel installations to offer applications from response market to emergency power.”

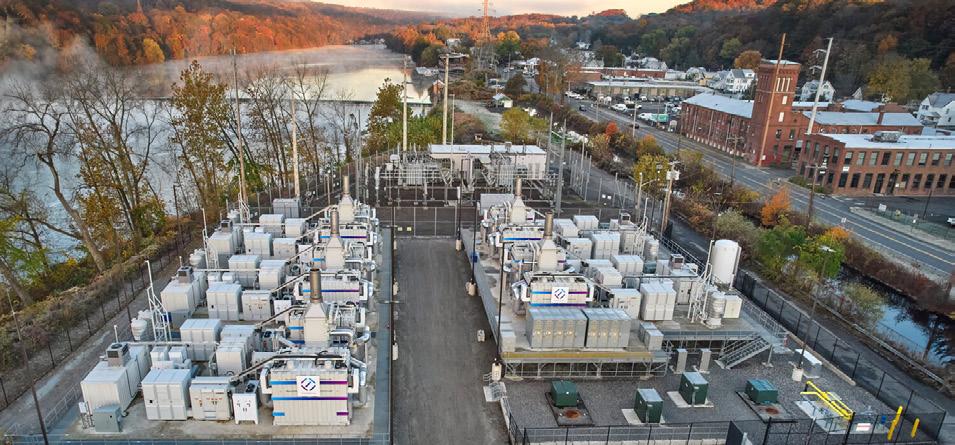

42 X 1.4MW FUEL CELL MODULES NOW SUPPORT AN INDUSTRIAL

Fuel Cell Energy has supplied and installed 42 X 1.4MW fuel cell modules at the premises of a company based in South Korea.

FuelCell Energy fuel cell modules were supplied to Gyeonggi Green Energy (GGE) to support an upgrade of its Hwaseong Baran Industrial Complex fuel cell power platform in South Korea.

Earmarked as the ‘largest’ fuel cell power platform in the world, located in Hwaseong-si, the plant has the capacity to produce 58.8MW of electricity, capable of powering around 135,000 homes. It can support Korea’s Hydrogen Econ -

omy Roadmap, which plans to supply 15GW of power from fuel cells by 2040. Under the terms of the contract FuelCell Energy receives approximately US$160m. The deal is a significant milestone for supplying clean power to the Korean market and includes a seven-year service agreement which commits FuelCell to servicing the site’s fuel cell modules until 2031. In May 2024 FuelCell Energy and Gyeonggi Green Energy first announced an agreed deal for the purchase of forty-two 1.4-megawatt upgraded carbonate fuel cell modules. These were destined for the Hwaseong Baran Industrial Complex’s fuel cell power platform.

On April 10th, Weichai generator sets registered a record 30,000 hours of operation at the KohSichang Power Station in Thailand.

Tan Xuguang, Chairman of Shandong Heavy Industry Group and Weichai Group, alongside Chen Muxiong, Chairman of Thailand’s Namsang Company, jointly witnessed this significant milestone. They unveiled the plaque commemorating the 30,000 hours of operation for the Weichai 12M33 generator set and Tan Xuguang presented customers with a Lifetime Quality Assurance service commitment certificate.

During the event, Chen Muxiong shared his experience of Weichai’s vital power generation product in the power

station: “Weichai’s power generation products have efficiently provided electricity security for the local residents of KohSichang in Thailand. We thank Weichai very much for its ongoing round-the-clock technical service support and express hope for further collaboration between the two parties to develop more high-quality products tailored to the local market in Thailand, aiming to serve customers better.”

Tan Xuguang comments: “ The Weichai KohSichang Power Station project began operating in 2019 and has been running safely for 5 years, surpassing 30,000 hours of operation, which has established a remarkable example of co-operation.”

Work is continuing as scheduled on PetroVietnam Power Corporation’s Nhon Trach 3&4 Power Plant in Ong Keo Industrial Park in the Nhon Trach district, approximately 70 kms southeast of Ho Chi Minh City, Vietnam. In 2022 the project placed its first H-Class gas turbine order in Vietnam. Once in commercial operation in 2025, Nhon Trach 3 & 4 is expected to deliver over 1.6 gigawatt (GW) of electricity, and it will be the first power plant fuelled by liquefied natural gas (LNG) in the country. Vietnam is keen to end its reliance on coal which fuels around a third of its electricity output.

GE Vernova Inc. has commenced commercial operations at Tongyeong Eco Power’s Tongyeong combined cycle power plant in Gyeongsangnam-do, South Korea.

The new one-gigawatt (GW) LNG-fueled plant site, including one 200,000-cbm LNG storage tank, is located at Anjeong Industrial Park in Tongyeong City, and it delivers the equivalent electricity needed to power approximately 1 million Korean households.

For the project, GE Vernova provided two 7HA.02 gas turbines, one STF-D600 steam turbine, two Heat Recovery Steam Generators (HRSG) and three H65 generators. In addition to the equipment, GE Vernova is expected to provide maintenance services for the 7HA.02 gas turbines and generators for the next 17 years.

“GE Vernova is committed to bring more affordable, reliable and sustainable power generation technology to South Korea and we are confident that the adoption of GE Vernova’s advanced HA technology, combined with their total plant services offering, will play a significant role in moving the country towards becoming an energy self-reliant nation,” said Tongyeong Eco Power.

YTL PowerSeraya Pte Limited, a subsidiary of YTL Power International Berhad, has announced an order for a 9HA.01 gas turbine, which will power a new 600 megawatt (MW) hydrogen-capable combined cycle power plant at Pulau Seraya Power Station (PSPS) on Jurong Island, Singapore.

This facility will mark the first hydrogen-blended, natural gas-fuelled plant in Singapore, supporting the nation’s energy goals.

Working in partnership with POWERCHINA and SEPCO III, the project is being run by a consortium to deliver the engineering, procurement, and construction (EPC) contract for the combined-cycle plant, which is expected to be operational by 2027.

The project, which includes the STF-A650 steam turbine, W88 generator, and a triple-pressure Heat Recovery Steam Generator (HRSG) with reheat, was initiated in a groundbreaking ceremony led by John Ng, Group CEO of YTL PowerSeraya, and attended by Dr Tan See Leng, Minister for Manpower and Second Minister for Trade and Industry, as part of the Singapore International Energy Week (SIEW).

“By 2027, we aim to expand our power generation capacity on Jurong Island with one of the most advanced natural gas technologies, capable of utilising hydrogen, to help meet Singapore’s electricity needs and ensure energy security,” said John Ng, Group CEO of YTL PowerSeraya.

“We are honoured to support Hyundai Development Company (HDC)’s Tongyeong Eco Power in its approach to providing more efficient power and thermal energy from Liquefied Natural Gas” said Ramesh Singaram, President and CEO, Asia of GE Vernova’s Gas Power. “The start of operations at Tongyeong Combined Cycle Plant marks a significant achievement that underlines our commitment to delivering efficient energy solutions.”

ChemOne Group, the developer of the Pengerang Energy Complex (PEC) has confirmed that the PEC (Pengerang Energy Complex) is on track to be fully operational by 2027 at the aromatics project in Johor, Malaysia.

aspirations, and construction planning reviews focused on achieving fastest time to Project Start-Up, currently targeted for around the end of 2027.

“Our collaboration on this 600MW hydrogen-capable combined cycle gas turbine (CCGT) project is a significant step forward in Singapore’s energy transition. The latest hydrogen and gas turbine technology expertise supports our commitment to reducing greenhouse gas emissions while ensuring efficient power production in Singapore. Together, we are setting the stage for a more sustainable energy future, helping Singapore achieve a lowcarbon future with increased energy resilience.”

Meetings with the project’s technology provider and EPCC contractor, Honeywell UOP, at its HQ in Des Plaines (Chicago), USA, has ensured secure maximum plant efficiency, lowest energy requirements, and lowest carbon footprint, reports the company.

The site features new Honeywell UOP technologies designed to meet the project’s low carbon

Based on UOP’s recent technical innovations, the PEC is likely to have a 30% lower carbon footprint than UOP’s similarly installed plants.

Alwyn Bowden, CEO of Pengerang Energy Complex Sdn Bhd, comments: “Crucial meetings with our partners has seen us continue to beat industry standards when it comes to the project’s carbon intensity. We look forward to conquering further benchmarks as we finalise our lineup of top-tier contractors.”

Delta, a global leader in power management and provider of IoT-based smart green solutions, recently highlight its integrated technology portfolio at the seventh edition of Industrial Transformation ASIA-PACIFIC (ITAP 2024) at the Singapore Expo. Delta presented its modular and integrated portfolio which has been specifically engineered to tackle some of the most pressing challenges in today’s industrial world, such as labour shortages, space optimisation, and the need for more efficient power dispatch and renewable energy smoothing.

Two of the company’s most innovative products - the DIATwin Virtual Machine Development Platform and its Energy Storage System (ESS) were featured - both designed to drive operational efficiency and reduce the environmental footprint of industries across the Asia-Pacific region.

Delta’s Energy Storage System (ESS) was of special relevance, demonstrating how smart energy management can contribute to a more sustainable future. The ESS has been designed to balance energy demand and optimise the use of renewable energy sources, providing reliable power storage for homes, businesses, and utilities. By integrating advanced battery technology with cloud management, Delta’s ESS helps users reduce energy costs while supporting environmental sustainability. This solution plays a crucial role in smoothing renewable energy supply, enhancing grid reliability, and lowering carbon emissions.

“Delta is at the forefront of developing integrated solutions that drive energy efficiency and sustainability,” said PS Tang, General Manager of Delta Electronics, Singapore. “Our focus on advanced technologies ensures we deliver smarter systems for a greener future, addressing the growing demand for clean energy.”

ABB Electrification Service has brought to market a breakthrough digital monitoring solution for power and distribution transformers in collaboration with Danish start-up Oktogrid. ABB Ability Asset Manager for Transformers (TRAFCOM) will enable industries to swiftly modernise outdated electrical grids, ensuring they can handle increased power demands with enhanced performance, reliability and availability.

This next generation transformer sensor is quick and easy to fit, requiring no screws or tooling for installation. Instead, the TRAFCOM sensor can be mounted magnetically to the transformer within 15 minutes, transmitting data to the cloud almost immediately, significantly reducing the need for any maintenance downtime.

It works independently of transformer type, make, and age, enabling customers to benefit from real-time monitoring capabilities all within a single, unified interface as part of an endto-end asset management system.

Mahmoud Abdelkhalek, Global Product Manager, ABB Electrification Service, said: “We know there are many electrical network transformers out there, which have never been monitored in 15-20 years, due to the high costs and complexity of installing sensoring technology. ABB Ability™ Asset Manager for Transformers overcomes these barriers as a simple and cost-effective way to modernise the grid.”

TRAFCOM offers a 4-in-1 proposition, measuring temperature and humidity, surface temperature, magnetic field, vibration, acoustics, and partial electrical discharges. The monitoring solution allows customers to understand a transformer’s condition in real time, enabling them to detect anomalies early, anticipate and avoid failures.”

SunGreenH2, a leading innovator in green hydrogen production technology, has announced the signing of two pivotal partnerships with key partners, including a Strategic Manufacturing Partnership Agreement (SMPA) with MMI Systems and a Memorandum of Understanding (MOU) with H2E International.

These agreements mark significant milestones in the company’s commercialisation journey to scale up production capacity in Singapore and expand its commercial footprint into Malaysia, as well as new markets in and beyond Southeast Asia.

The first strategic partnership was signed with H2E International Pte. Ltd, a renewable energy project developer based in Malaysia.

This collaboration on renewable energy and off-grid/decentralised electrification projects in Malaysia will focus on developing and deploying hydrogen electrolyser and fuel cellbased renewable energy solutions for rural communities and facilities.

In addition, it will also establish an electrolyser system assembly facility in the country. This is part of the broader mission to transform rural electrification across Malaysia,.

The UFR1001E system- disconne relay monitors voltage and frequenc y in single or three -phase networks

Presetting per G99/98, values as per the standard pre programmed

• Under and over voltage monitoring 40…520 V Under and over frequency monitoring 45…65 Hz

• Monitoring of Rate of Change of Frequency (ROCOF, df/dt)

• Monitoring the voltage quality (10 minute average value)

• Response time adjustable 0.05 … 130.0 s, individual setting for each limit

• Fail-safe, with monitoring of the connected section switch

Suppor ts the mains synchronisation when using generators

• Measurement 3 phase 3 or 4 wire systems or single phase

• Self-test

• Third Par t Independently tested Compliant to G99/98 by Bureau Veritas

KEPPEL has commissioned ABB to upgrade one of the turbine control systems at the 1,300 MW Keppel Merlimau Cogen (KMC) combined cycle gas turbine on Jurong Island in Singapore, to improve efficiency and reliability. The scope includes replacing the existing Egatrol 8 turbine control system with Egatrol X, which is based on the ABB Ability™ System 800xA® flagship distributed control system (DCS) and modern AC800M portfolio.

Transferring full functionality from the existing application to the updated solution allows the customer to avoid downtime and install the control system in the shortest possible time.

The project involves upgrading DCS components while keeping the overall structure as far as possible. Instead of having to rebuild the entire system in one go, ABB will provide a flexible, customised approach whereby older components are replaced as and when needed. This prevents unnecessary downtime, avoids the costs associated with loss of operation, and ensures a stable, reliable energy supply with high availability.

All control settings are adopted through an in-house software code conversion process, eliminating time-consuming adjustments of system parameters. The user interface, based on System 800xA, only requires minor adjustments, which eliminates operator retraining. The hardware design, featuring ABB’s latest I/O evolution kit, significantly reduces commissioning time and eliminates the risk of re-wiring errors. As part of Singapore’s commitment to achieving net zero emissions by 2050, the government is driving business transformation through grants for energy efficiency and emissions reduction. It is also investing in low carbon technologies to make progress in the energy transition.

NEW DATA CENTRE OPENS IN MALAYSIA

Asia Pacific & Japan (APJ) hyperscale data centre specialist, AirTrunk has officially opened its flagship Malaysian 150 megawatt (MW) hyperscale data centre in Johor Bahru, named AirTrunk JHB1 (JHB1).

The initial phases of JHB1 will provide over 50MW of capacity for its large technology customers. The development was completed in over four million work hours with no major safety incidents, reinforcing AirTrunk’s company-wide commitment to upholding the highest levels of safety at its construction sites, says the company.

Spanning 10.3 hectares, JHB1 is strategically located in Johor Bahru at the southern tip of the Malay Peninsula. Servicing a major cloud availability zone, the data centre offers strong domestic and international connection to regional technology hubs including neighbouring Singapore, with an end-to-end cross border connection strategy.

Along with its industry-low design Power Usage Effectiveness (PUE) of 1.15, making it one of the most efficient data centres in the country, the new state-of-the-art facility features an AI-ready design with AirTrunk’s first deployment of direct-to-chip liquid cooling technology alongside traditional indirect evaporative cooling (IEC) and high-density racks.

This pioneering approach reduces energy consumption by up to 23%. The company launched its liquid cooling approach in July 2024, following five years in research and development.

Earlier this year, AirTrunk also announced the first renewable energy Virtual Power Purchase Agreement for a data centre for 30MW of renewable energy, with developer ib vogt, under Malaysia’s Corporate Green Power Programme. The allocation was the maximum available for an individual developer with a secured offtaker. JHB1 is also equipped with a solar-panel roof, able to provide over 1MW of power for this phase, making it one of the largest onsite solar deployments for a data centre in Southeast Asia.

AirTrunk Founder & Chief Executive Officer, Robin Khuda said: “The rapid and safe delivery of JHB1 is a pivotal step in the adoption of AI in Malaysia and AirTrunk’s growth as a trusted partner for our customers in the APJ region. With a commitment to innovation and sustainable growth, combined with a program of investment in energy availability and renewable electricity, Malaysia is fast becoming a key tech hub in the Asia Pacific & Japan region.

MANUFACTURER HELPS TO ALLEVIATE THAILAND’S WATER

In the water crisis of July 2024 Cummins Custompaks were being used for water management by technical teams in Thailand.

Sixty Cummins Inc. CustomPaks have been in use in Thailand as part of a critical water management plan aimed at easing a Summer water crisis – an issue which has caused enormous economic and social damage and stirred conflict among communities.

Kittithanapat Engineering Co. (KTP), has been involved in Thailand’s water management systems since 1996.

In recent years it has been working closely with authorities such as the Royal Irrigation Department, The Department of Water Resources, Bangkok Metropolitan Authority and others.

To help KTP meet its often urgent requirements, Cummins DKSH (Thailand) recently supplied 60 Australian-built CustomPaks – 45 powered by Cummins’ X15 engine rated at 600 hp, and 15 powered by the QSL9 rated at 325 hp. These fully self-c ontained powerpacks are emissions certified to Tier 3.

The CustomPaks are coupled to hydraulically-driven, large-volume submersible water pumps sourced by KTP from US company Moving Water Industries (MWI); KTP is the exclusive distributor in Thailand for these MWI Hydroflo pumps.

A26 MW offshore wind turbine has been manufactured by China’s Dongfang Electric Corporation in Fuzhou, Fujian Province in eastern China. DEC regards the new offshore WTG as ‘the world’s largest in both capacity and size’.

Designed toi cope with wind speeds of 8 m/s and above, the turbine is said to feature strong resistance to typhoons and corrosion. The centre of its hub stands at 185 metres, while the rotor diameter exceeds 310 metres. With average winds of 10 m/s, a single unit can generate 100 GWh of clean energy every year.

Three 7HA.03 gas turbines will be installed at The Kansai Electric Power Company, Inc.’s Nanko power station in Osaka, Japan.

Advanced 7HA.03 power generation equipment will replace the existing ageing conventional LNG power generation assets (consisting of three boilers and three steam turbines). The upgrade is expected to increase power plant efficiency, while reducing its carbon-dioxide emissions.

Japan has set ambitious targets to achieve net zero by 2050 as per the latest Nationally Determined Contribution (NDC) plans.

Japan’s energy system is in transition, and the nation is keen to achieve its decarbonisation goal by establishing further nvestments in lower carbon generation sources and also through the support of “Economic Efficiency”, one of the three “S+3E” pillars within the revised national 6th Strategic Energy Plan (including also “Safety plus Energy Security”, and “Environmental Sustainability”).

“The plant is expected to deliver up to 1.8 gigawatts (GW) of electricity to the grid in total and to be the among the most efficient in the country,” reports Ramesh Singaram, President and CEO, Asia of GE Vernova’s Gas Power.

“In addition, 7HA.03 gas turbine technology currently has the capability to burn up to 50% by volume of hydrogen when blended with natural gas, with a technology pathway to 100% over the next decade. We look forward to bringing this advanced technology to Kansai Electric, with whom we have a longstanding relationship built on years of mutual respect and trust, to help revitalize the Japanese power industry with more efficient and more sustainable technology, in alignment with the country’s energy goals.”

GE Vernova is a key player in Japan’s energy transition, having provided power generation technology for Japan for more than 130 years. To date, the company delivers more than 50% of Japan’s heavy duty gas power capacity and supports the country’s growing renewable and nuclear energy needs.

Eco Wave Power has sold a wave energy generation unit to I-Ke International Ocean Energy, a subsidiary of leading maritime engineering company Lian Tat Co/ The deal means that Eco Wave Power’s wave energy will soon be providing Taiwan with ‘green power’.

I-Ke’s plans for the first stage of the project include the development of a 20 MW wave energy power station in Taiwan. Construction will begin with a 100 kW pilot and expand in stages to a total targeted installed commercial capacity of 400 MW, reports the company.

CY Huang, the chairman of Lian Tat, commented: “Taiwan is an island country with a coastline of 1,566 km - its has a high potential for the installation of marine energy.

“The construction of Eco Wave Power’s project is relatively easy, and I believe that it will be a significant stepping-stone for the development of green electricity in Taiwan.

“We have already completed the site selection process and once the 100 kW demonstration site is built, with positive results, our target is to expand it to 20 MW, and we will continue to push up to more than 400 MW of wave energy installed capacity.”

Most of the experts have suggested that Taiwan’s north-eastern coastal area offers the most potential area for wave energy generation. The peak density of wave power occurs in autumn and winter for most of Taiwan’s sea area, except for the southwestern coast where peak seasons occur in spring and summer. These results imply that the wave power in Taiwan’s sea area is dominated by monsoons.

The CebuCables International CCI Project Team has recently delivered urgently-needed electrical bulk materials to a 60MW Solar Power Plant in Toledo, Cebu.

According to the company, the delivery required airlifting overnight and involved the supply of 25kV rated Elbow Connectors, HV termination kits, plus Bi Metallic Connectors from various stocking warehouses overseas.

“With direct access to manufacturer’s facilities and distribution centres in Asia Pacific, our team was able to arrange immediate delivery of the items to the solar project,” reports a company spokesman.

The solar power plant stands on a 73-hectare property in Barangay

Talavera In Toledo City, southwest of Cebu.

This is where the first Toledo Solar Energy Corp. (FTSEC) was constructed in October 2015 by Citicore Power Inc. (CPI).

The facility is located just 800 metres from NGCP’s Calung-Calung substation. It remains the only operating solar power plant in Cebu although there have been efforts in the past by investors to establish similar power facilities in the province Cebu is where most of the load is located in Visayas. There are a few solar power plants being constructed in Negros but demand in the area is relatively limited. The main demand for power is focused on Cebu where there are increasing investments and industries.

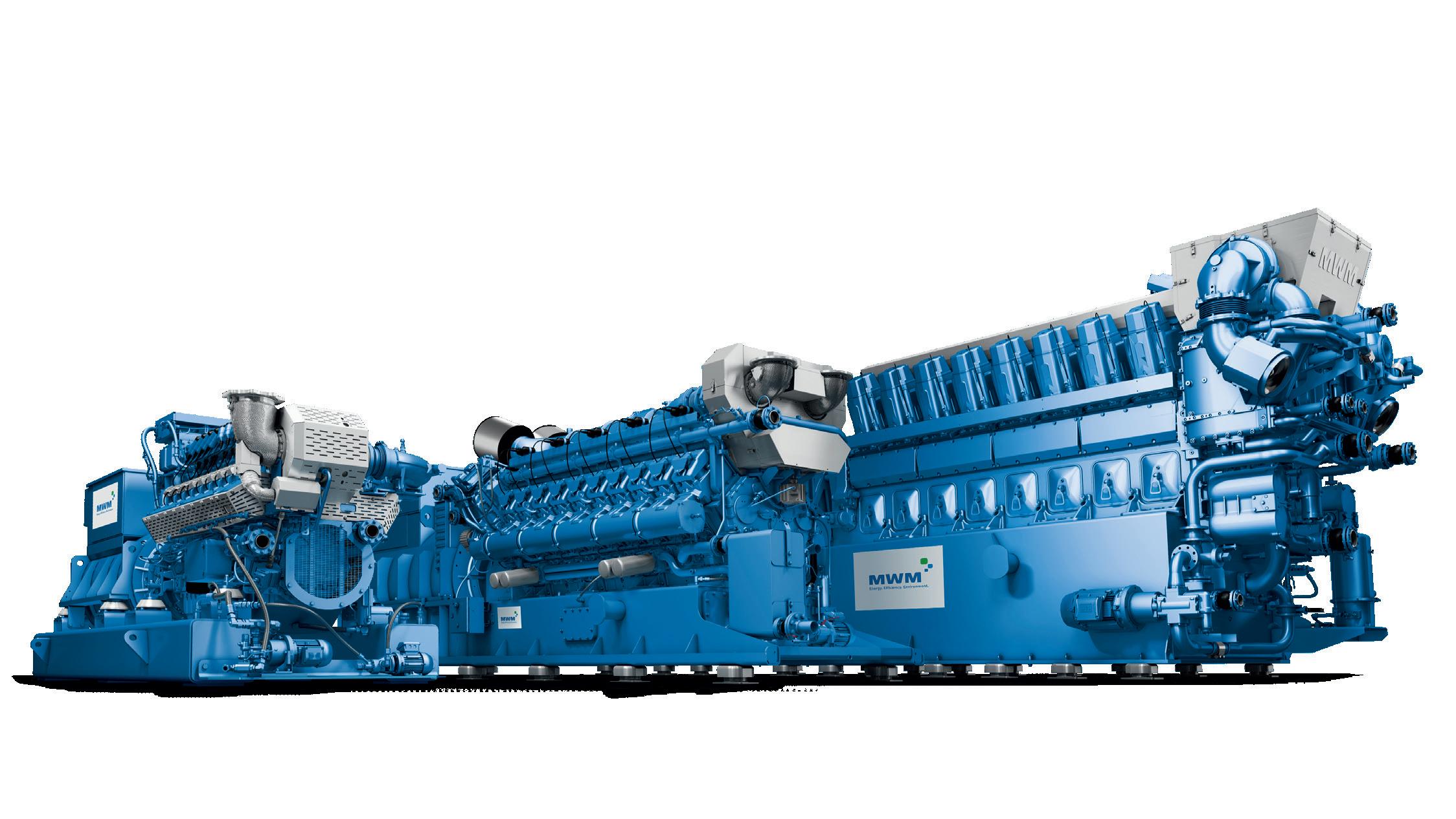

New variants of the TCG 3016, TCG 3020 and TCG 2032 series enable natural gas operation with hydrogen admixture of up to 25 vol.%. Retrofit solutions for existing plants are also available.

www.mwm.net/25H2-Kits

An AKSA AD1015 , 1015 kVA/812kW standby power diesel-fuelled genset with canopy has been supplied to an industrial client located in Zhejiang, China.

Powered by a Hyundai engine, this is a high quality, reliable and complete power unit of compact design, easy start and easy maintenance.

The set is fully-engineered with a wide range of options and a sound proof canopy. Every AKSA generating set is subject to a comprehensive test program which includes full load testing, checking and provision of all control and safety shut down functions testing, says the manufacturer.

Features of the set include a heavy-duty HYUNDAI diesel engine, four-stroke, water cooled, turbocharged intercooled, a direct injection fuel system & ECU governor system with a 12/24 V D.C. starter and charge alternator.

The set features a replaceable fuel filter, oil filter and dry element air filter, a cooling radiator and fan, plus a Starter battery (with lead acid) including Rack and Cables, a flexible fuel connection hoses and manual oil sump drain valve, an industrial capacity exhaust silencer and steel bellows - there is also a jacket water heater (for automatic models.

The set comes with a brushless, single bearing system, flexible disc, 4 pole alternator which meets insulation class H. This has a standard degree of protection IP21 (*IP22/IP23 is available) and is self-exciting and self-

“

SUPPLIED TO AN INDUSTRIAL CLIENT LOCATED IN ZHEJIANG, CHINA, THE AKSA AD1015 , 1015 KVA/812KW STANDBY POWER DIESEL-FUELLED GENSET IS POWERED BY A HYUNDAI ENGINE. THIS IS A HIGH QUALITY, RELIABLE AND COMPLETE POWER UNIT OFFERING COMPACT DESIGN, EASY START AND EASY MAINTENANCE.”

regulating. The alternator is impregnated with tropicalised epoxy varnish and comes with a solid state Automatic Voltage Regulator and Stator winding with 2/3 pitch for improved harmonics.

The Aksa AD1015 features a control supervision and protection panel mounted on the genset base frame.

The Auto Mains Failure Control Panel provides Control with AMF module, a Static battery charger, an Emergency stop push button.

The DSE7320 MKII here is a powerful, new generation Auto Mains (Utility) Failure genset control module with a highly sophisticated level of new features and functions, presented in the usual DSE user-friendly format.

This is said to be suitable for a wide variety of single, diesel or gas genset applications.

In another recent announcement AKSA has supplied the Golcuk State Hospital in Turkey with three of its 1.915 kVA diesel generator sets, each fitted with Mitsubishi engines. The package offers a total of 5,745 kVA in terms of power. Each genset features

a heavy-duty Mitsubishi diesel engine (four-stroke, water-cooled, direct injection fuel system plus Mechanical Governor system).

Each genset comes with 12V D.C. starter and charge alternator, replaceable fuel filter, oil filter and dry element air filter, cooling radiator and fan.

The package includes a Starter battery (with lead acid) including Rack and Cables, flexible fuel connection hoses and manual oil sump drain valve, Industrial capacity exhaust silencer and steel bellows, Jacket water heater(at automatic models) plus operation manuals and circuit diagram documents.

Golcuk Hospital was established in 2014 as part of the MEDAR HEALTHCARE GROUP - it now has four hospitals in Golcuk, Gebze, Sakarya and Istanbul Atasehir. Its role is to engage and serve their communities with excellence, and grow toward a healthy future. Golcuk hospital features a dynamic team of physicians, experts in their fields, along with a professional and caring healthcare staff.

www.aksapowergen.com

Jenbacher off-grid power solutions even help data centers go net-zero

INNIO Group‘s Jenbacher engine power plants can help you secure reliable power – even in regions with no grid or where grid reliability is a concern. And with renewable energy sources such as hydrogen, Jenbacher “Ready for H2”* generators can put you on the road to net zero.

Let us support your transition journey. jenbacher.com

* In general, “Ready for H2” Jenbacher units can be converted to operate on up to 100% hydrogen in the future. Details on the cost and timeline for a future conversion may vary and need to be clarified individually.

Jenbacher is part of the INNIO Group

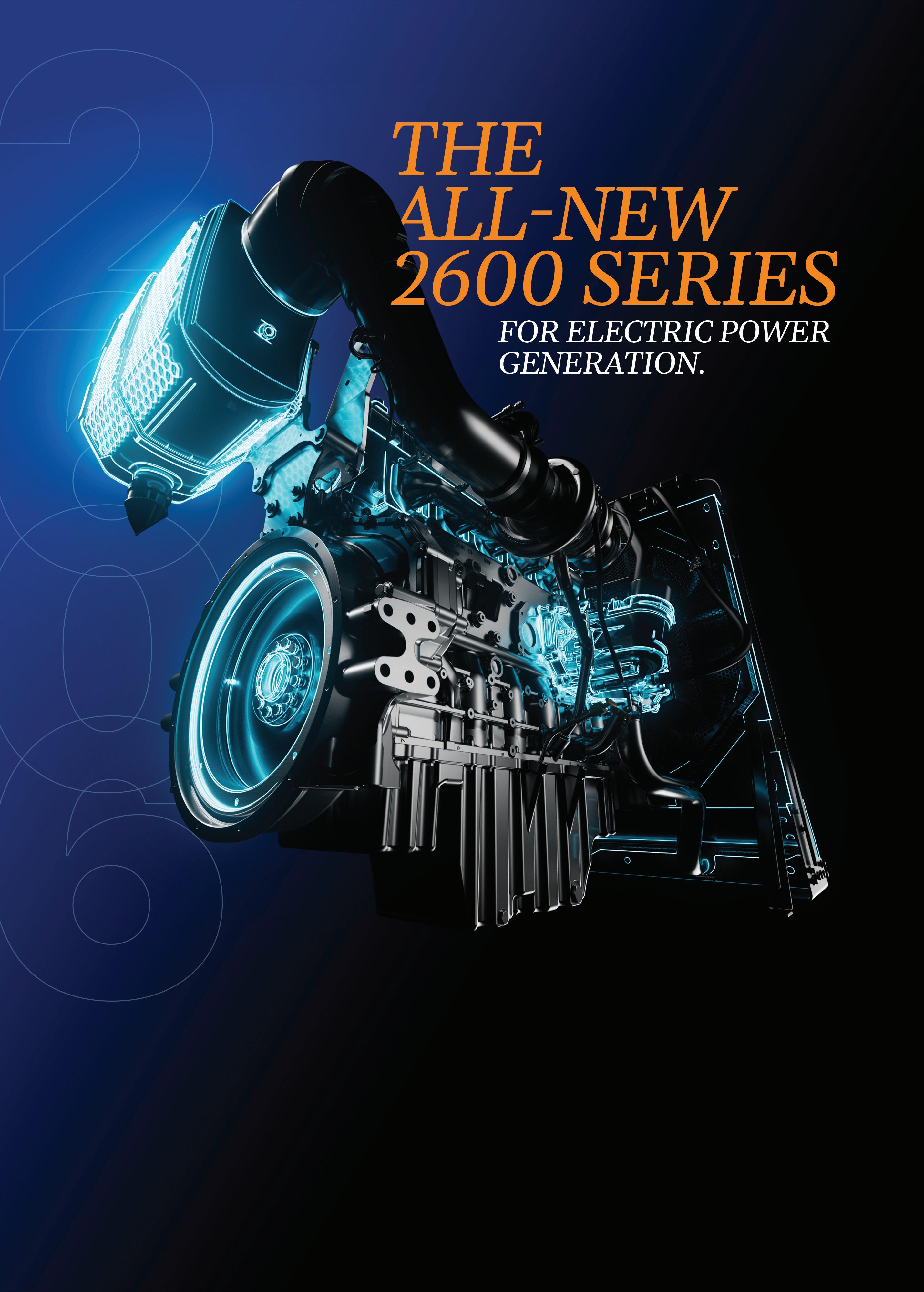

The Perkins® 2606A-E13TAG, 12.9 litre engine can generate up to 572 kW of dependable engine power to be used for generator set electrical output up to 625 kVA – offering flexible, dependable performance.

Scan the QR code to learn more. Together, we power ahead.

Earlier this year EvoTec provided robust 1000KW 400V generators as the backup power solution for a key hospital project in Guangxi. Engineered with precision to ensure reliability during emergencies, these tailored solutions have been designed to meet the unique demands of healthcare facilities, reports the company. EvoTec was established in May 2011, specializing in the development and manufacturing of industrial/marine three-phase synchronous Low, Medium and High Voltage alternators and permanent magnet alternators.

EvoTec is located in Lujiang High-Tech Development Zone in Hefei City, Anhui Province in China. The area covers a vast area of about 90,000m². More than 30,000m² of modern production plants and office facilities have been built in the vicinity so far. The annual production capacity of the factory is 30,000 alternators of various sizes.

EvoTec alternators satisfy the requirements of the standard IEC 60034-1, reports the company. EvoTec has been awarded the certificates of ISO 9001, ISO 14001, ISO 45001, CE and China Classification Society (CCS). EvoTec alternators have the rated power from 6.8 to 10,000kW, voltage from 110 to 15000V, frequency of 50Hz or 60Hz, and IP class from IP21 to IP57, which meet the various power requirements of customers around the world.

EvoTec says that it is committed to independent R&D and technological innovation, has independent intellectual property rights and independent brands (EvoTec and BESTAGEN), and its products have obtained 63 national authorised patents (18 invention patents). In 2015, it was rated as a national high-tech enterprise in China.

In 2022, EvoTec was further rated as a National Specialised and Innovative ‘Little Giant’ Enterprise. EvoTec has established one of the largest generator R&D centre in China. It is responsible for the new product R&D and providing personalised & customised services.

EvoTec offers its customers technical assistance services for all pre-sales and after-sales support. As a leading generator manufacturer EvoTec Power’s products have a “Short Structure Design”, more than 100mm shorter than similar motors. The excellent performance of ventilation and heat dissipation enables its products to extend their service life.

With enclosure characteristics up to IP55, it can withstand extreme environments. EvoTec has long-term and reliable operation experience in data centres. The leading power factor of EvoTec generator is stable and reliable. The ability to bear the large-capacity nonlinear loads is strong. EvoTec generators have the advantages of higher efficiency, lower temperature rise, and better performance in parallel and grid-connected operation, offering better dynamic performance with various power systems.

EvoTec uses the international leading generator electromagnetic design technology to optimise

efficiency performance parameters of its products. The power generation efficiency of EvoTec generator is higher than the peers by 0.5%1%. EvoTec generators have the advantages of higher efficiency, lower temperature rise, and better performance in parallel and gridconnected operation, better dynamic performance. The power factor of EvoTec generator can be advanced to 0.9 stable operation, which has the advantages of stronger capacity of nonlinear load and good match with various power systems.

Performance indicators of EvoTec generators are better than national standards and reach the international advanced level.

Typhoon Jongdari was a strong, long-lived and erratic cyclone which affected Japan and East China in late July and early August 2018.

When Typhoon Jongdari battered Guangdong, Guangxi and other regions with heavy rain, resulting in flooding disaster, EvoTec played a key role in organising personnel to clear and dredge affected areas, working tirelessly to ensure flood prevention & rescue efforts. Thanks to EvoTec’’s efforts rapid and effective drainage greatly reduced the threat of flooding and its high-flow drainage pumps were able to play a critical role in the flood rescue efforts.

evotecpower.com

Innio and Clarke Energy have supplied five JGS 420 to the industrial sector in Bangladesh. This particular model chosen is a Jenbacher 420 - a V20-cylinder efficient power generation solution.

Said to be the most powerful solution in the Type 4 engines family, with power output up to 1,429 kW and electrical efficiency up to 41.9%, the gas-powered genset is described as a ‘great fit’ as a single unit application or power plant for several megawatts, when flexible operation is needed.

The J420 D/E genset delivers a robust concept with a compact footprint with a 0.6-metre reduction in length compared to previous Type 4 genset versions.

The new Jenbacher J420 D/E unit is based on the company’s proven Type 4 platform of more than 6,000 delivered engines generating about 7 GW of power worldwide.

Leading the way with next-generation technology innovation, the new J420 D/E delivers as much as 4% more output - up to 1,560 kW - and up to 1% point of additional electrical efficiency compared to respective J420 B versions. The unit features a Jenbacher gas-piston engine for biogas or natural gas. The entire plant is tested on a special testing stand in Jenbach, Austria. Perfect reliability is ensured by Jenbacher’s unique quality system.

Combined Heat and Power Module (CHP Module) solutions like these allow customers to generate power and heat simultaneously at a very high total efficiencies, reaching 90% and even more.

The equipment offers: -Engine and alternator installed on the frame -Control panel, gas train -Heat exchangers including exhaust gas heat exchanger

CHP Modules can generate hot water or steam at various parameters and can be integrated with your existing heat infrastructure. Users can select the option that fits your project’s needs among the heat recovery schemes provided by Jenbacher. The scope of supply can be extended further with various balance of plant options (BOP). CHP Modules can be installed inside a building or inside a container.

A company spokesman comments: “Clarke Energy in Bangladesh is proud to support Nasir Float Glass Industries Ltd. with the installation of a 7.5MW gas-based power plant featuring INNIO Group’s Jenbacher gas engines. This project enhances energy efficiency and ensures continuous, reliable power for their manufacturing unit in Bangladesh.”

INNIO has supplied more than 25,000 Jenbacher engines with a total capacity of more than 37 GW worldwide and has a wide customer base in Asia.

INNIO previously supplied Jenbacher engines to Del Monte Philippines, Inc. (DMPI), a leading producer, distributor, and marketer of premium-quality healthy food and

beverage products.

In 2015, the electricity grid proved too unreliable for the fruit cannery manufacturing plant and blackouts were frequent.

Faced with an energy shortage that year, DMPI turned to INNIO Group’s Jenbacher combined heat and power (CHP) technology for reliable – and more efficient – heat and power as well as a sustainable way to deal with pineapple waste.

DMPI chose to build a biogas digester and CHP plant designed to generate savings through electricity and heat generation.

Now wastewater from the pineapple processing is converted to biogas for the facility’s new CHP plant. Installed in 2015. Two Jenbacher J420 engines running on biogas provide 1,411 kW of electricity and 1,594 kW of thermal energy which preheats the boiler feedwater. Biogas also powers a Jenbacher J320 that was added in 2019 to provide an additional 1,059 kW of electricity.

Located far from the grid, the CHP plant operates in island mode, saving the expense of grid connection.

Even during an energy shortage elsewhere, the plant provides both electricity and heat, and the containerised units’ compact design means a smaller footprint.

www.jenbacher.com www.innio.com www.clarke-energy.com

Anyone who knows gensets, knows that Mecc Alte is unrivalled for our knowledge and expertise worldwide. From alternators to controllers, we are the Power from Within, giving you the ultimate choice of kit that you need, all backed up by the support and impartial advice you only get from the world’s leading independent alternator specialists. Take 360° control. Talk to Mecc Alte.

The world’s largest independent producer of alternators 1 – 5,000kVA

Since July 2024 ST Telemedia Global Data Centres (STT GDC), one of the world’s fastest-growing data centre providers has used Hydrotreated Vegetable Oil (HVO) as a fuel in its data centres power generators in Singapore - HVO is now the renewable fuel of choice replacing conventional diesel fuel for backup generators.

STT GDC is the first data centre operator in Singapore to deploy HVO for use in backup generators across its facilities in Singapore, starting with deployment of an initial 50,000 litres.

HVO is a renewable diesel alternative produced from waste fats and vegetable oils. As a drop-in fuel, it is compatible with most existing diesel engines without modification.

HVO significantly reduces carbon emissions, which reduces greenhouse gas (GHG) emissions and with less impact on air quality, as compared to traditional diesel, making it a cleaner and more sustainable option for backup power generation.

“At STT GDC, we are committed to implementing innovative solutions that not only enhance our operational efficiency but also contribute to a sustainable environment,” said Lionel Yeo, CEO – Southeast Asia, ST Telemedia Global Data Centres.

“The deployment of HVO in our operations is a significant step towards achieving our sustainability goals and supporting Singapore’s emissions targets.

“As our business grows, we want to continue to embed sustainability into every facet of our business, while at the same time, support the industry’s efforts to accelerate the use of renewable fuel sources.”

This initiative aligns with STT GDC’s broader global sustainability goals to be carbon neutral by 2030.

This includes taking proactive measures to reduce absolute emissions by exploring more sustainable fuel sources such as HVO.

The strategy is part of the company’s broader approach to incorporate advanced biofuels and other green and renewable energy sources into its current energy mix.

STT GDC sources HVO from fuel supplier Neste, which has issued Proof of Sustainability that the HVO delivered reduces GHG emissions by up to 90% over its lifecycle, compared to fossil diesel.

“The decision to now deploy HVO in our operational data centres is the culmination of a period of thorough testing with our partners to validate compatibility and performance and reflects our confidence around the reliability of the HVO supply chain in Singapore,” comments Lionel Yeo.

Amongst its key products, Neste offers MY Renewable Diesel which utilises Neste’s patented NEXTBL technology and 100% renewable raw materials.

Neste describes itself as ‘the world’s leading producer of renewable diesel and sustainable aviation fuel and a forerunner in providing renewable feedstock solutions for the polymers and chemicals production. This is made possible by our proprietary NEXBTL™ technology.’

This is a unique platform which allows the company to turn a wide variety of renewable fats and oils into premium-quality renewable products, such as fuels and feedstock for polymers and chemicals production.

A company spokesman comments: “The core and the aim of our processing technologies is to ensure flexible intake of different raw materials and have optionality to produce various different end products while having best-in-class operational performance.

“We constantly develop technologies which increase the energy efficiency and diminish the carbon footprint of traditional oil refining. Our know-how in refining difficult raw materials has a long history. Over the years, our engineers have had to find ways of refining challenging low-quality crude oil into transportation fuels. This knowledge laid the foundation for

Thanks to Neste, hydrotreated Vegetable Oil (HVO) is now used as a fuel in generators in Singapore’s data centre sector. HVO is now the renewable fuel of choice replacing conventional diesel fuel for backup generators.

developing our unique refinery platform that can process a great variety of fats and oils from many renewable sources’.”

ST Telemedia Global Data Centres (STT GDC) Philippines recently announced that the first phase of operations for its highly anticipated STT Fairview 1 data centre is also on track to be ready for service by Q2 2025.

Upon full completion, the STT Fairview campus will be the largest data centre in the Philippines, with a total IT capacity of 124MW. Designed to accelerate the nation’s digital transformation and meet the rising demand for AI workloads, the STT Fairview campus is carrier-neutral and will feature seamless connectivity options while incorporating advanced energy-efficient technologies for sustainable operations.

“We remain committed to delivering on our project timelines.

Last year, we projected that STT Fairview would be ready in the first part of 2025, and we are on schedule to deliver the initial capacity by Q2 2025,” Carlo Malana, President and CEO of STT GDC Philippines tells IPA.

STT GDC Philippines continues to see strong demand for its services, maintaining impressive capacity utilisation.

www.neste.com ww.sttelemediagdc.com

Membership Benefits

• Training Days

• Exhibiting at 15+ Shows

• Member Networking Events

• 62,000+ Digital Association

Magazine Distribution

• Founder Member Badge

• Association Magazine x2

Free Adverts

• Annual Statistics

• Quarterly Newsletter

• Hospitality Days

• Access link to White Papers

+ lots more...

Senoko Energy, one of Singapore’s largest energy companies, and Gentari, a clean energy solutions provider, have signed a Memorandum of Understanding (MoU) to embark on a collaborative effort to explore the importation of hydrogen gas from Malaysia to Singapore.

Following the MoU, both parties will explore the feasibility of importing hydrogen gas from Malaysia to Singapore, with plans to integrate it into Senoko Energy’s existing and new combined cycle gas turbine assets, enhancing their efficiency and environmental performance. The hydrogen will be supplied by Gentari through a 20-year supply agreement, expected to commence by 2029.

Through this collaboration, Senoko Energy aims to explore the reduction of carbon emissions by 18,000 tCO2e annually in the first phase, which is equivalent to taking about 4,000 cars off the roads.

This number could potentially increase to 535,000 tCO2e in subsequent phases (equivalent to 119,000 cars). In line with Senoko Energy’s ambition to be the first in bringing in hydrogen to Singapore for power generation, this partnership underscores the company’s commitment to sustainable energy solutions, Singapore’s national hydrogen strategy and contribution to Singapore’s 2050 Net Zero target.

On the partnership, Frederik Baerts, President & CEO, Senoko Energy, said: “Senoko Energy is extremely excited to be embarking on this partnership with Gentari, which represents a significant milestone in our commitment to advancing the energy transition. Hydrogen has the potential to play a critical role in

reducing carbon emissions, and so together, we are taking a bold step towards creating a more sustainable energy landscape and low-carbon future.”

The collaboration confirms Gentari’s position as a leading supplier of green molecules in the region, in line with its aim to become a large-scale hydrogen producer and go-to industry partner for hard-to abate sectors including industry, chemicals, maritime and aviation.

Michèle Azalbert, Chief Hydrogen Officer, Gentari, comments: “This partnership with Senoko Energy is a key step in building a hydrogen backbone for Southeast Asia.

“Cross-border infrastructure like this pipeline connects production and demand centres as we accelerate green hydrogen adoption across the region. Gentari firmly believes hydrogen is crucial to decarbonising multiple sectors on the path to Net Zero, and we’re encouraged by stakeholder support and rising demand for low-carbon hydrogen derivatives.”

Senoko Energy’s collaboration with Gentari is part of its ongoing efforts to support Singapore’s plans for a low-carbon future. Other initiatives include an MoU signed between Senoko Energy and City Energy back in June 2023, which also aimed to

explore hydrogen opportunities, as well as SolarShare 2.0, the first commercially-available peer-to peer grid scale trading platform for solar energy in Singapore.

Concurrently, Senoko Energy is exploring green electricity import, the installation of the latest H-Class Combined Cycle Plant and on-site solar PV.

Today, the most efficient plants available in an H-class combinedcycle (CC) application are as follows: 63.08% gross CC efficiency at Chubu Electric’s Nishi Nagoya power plant in Japan (7HA, 60Hz), and 62.22% net CC efficiency at EDF’s Bouchain power plant in France (9HA, 50Hz).

Gentari is developing Malaysia’s hydrogen economy through several initiatives including an ongoing collaboration with Tenaga Nasional Berhad to conduct feasibility studies on green hydrogen development as well as a partnership with Sarawak’s SEDC Energy to develop a hydrogen production hub in Sarawak.

Beyond Malaysia, Gentari is also developing clean ammonia projects in India – independently and with partners, targeting commercial production of more than 5 million tonnes per annum (MTPA) before 2030. www.senokoenergy.com www.gentari.com

GENTARI IS DEVELOPING MALAYSIA’S HYDROGEN ECONOMY THROUGH SEVERAL INITIATIVES INCLUDING COLLABORATION WITH TENAGA NASIONAL BERHAD TO CONDUCT FEASIBILITY STUDIES ON GREEN HYDROGEN DEVELOPMENT AS WELL AS A PARTNERSHIP WITH SEDC ENERGY TO DEVELOP A HYDROGEN PRODUCTION HUB.”

INNIO is headquartered in Jenbach (Austria), with other primary operations in Waukesha (Wisconsin, U.S.) and Welland (Ontario, Canada).

INNIO Jenbacher gas engines

Headquarters: A-6200 Jenbach (Austria) T +43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.gejenbacher.com

Manufacturer of gas driven generator sets and cogeneration systems in a power range from 0.25 to 3 MW.

Model Fuel rpm Pel Pth

JMS 208 GS g 1,500 330 358 JMS 208 GS g 1,800

m3N. Dry exhaust gas; based on 5% O2. For engines with 1,200 rpm please contact GE Energy’s Jenbacher product team.

TAD1242GE 352 409

TAD1640GE 393 462

TAD1641GE 433 509

TAD1642GE 485 570

INNIO Jenbacher gas engines

Jenbacher* product portfolio 2022

R Schmitt Enertec GmbH

56743 Mendig, Germany T +49 2652 9351810

F +49 2652 9351822

info@rschmitt-enertec.com www.rschmitt-enertec.com

1) ISO

Manufacturer of gas driven engines,generator sets and cogeneration systems in the range from 100 - 500 kW.

at 1,500

and

A team of more than 3,500 experts provides life-cycle support to the more than 54,000 delivered engines globally through a service network in more than 80 countries.

INNIO Jenbacher gas engines

Headquarters: A-6200 Jenbach (Austria) T +43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.gejenbacher.com

Manufacturer of gas driven generator sets and cogeneration systems in a power range from 0.25 to 3 MW.

Model Fuel rpm Pel Pth

Manufacturer sets and cogeneration from 100 -

RSE Engines for Model

M06-G/B T0D41

M06-G/B TID41

RSE Engines for natural gas and biogas

according to ISO 3046at p.f. = 1.0 according to VDE 0530 REM 2) Heat recovery with a tolerance +/- 8 %

M06-G/B T2D41

M08-G/B TID41

Model fuel Freq. Electric output

M06-G/B T0D41 g 50 140 kW

3) NOx @ 5 % O2 dry Requirements for technical data: All data according to full load, and subject to technical development and modification

M06-G/B TID41 g 50 200 kW

* Indicates a trademark.

M06-G/B T2D41 g 50 250 kW

M08-G/B TID41 g 50 260 kW

M08-G/B T2D41 g 50 333 kW

M12-G/B TID41 g 50 400 kW

M12-G/B T2D41 g 50 500 kW

M06-G/B T0D41 g 60 150 kW

M06-G/B TID41 g 60 210 kW

M06-G/B T2D41 g 60 250 kW

M08-G/B TID41 g 60 280 kW

M08-G/B T2D41 g 60 333 kW

M12-G/B TID41 g 60 420 kW

M12-G/B T2D41 g 60 500 kW

RSE engines for LPG

M06-PT0D41 g 50 115 kW

M06-PTID41 g 50 173 kW

M06-PT2D41 g 50 205 kW

M08-PTID41 g 50 233 kW

M08-PT2D41 g 50 260 kW

M12-PTID41 g 50 350 kW

M12-PT2D41 g 50 450 kW

M06-PT0D41 g 60 130 kW

M06-PTID41 g 60 173 kW

M06-PT2D41 g 60 205 kW

M08-PTID41 g 60 233 kW

M08-PT2D41 g 60 260 kW

M12-PTID41 g 60 350kW

M12-PT2D41 g 60 450 kW

m3N. Dry exhaust gas; based on 5% O2. For engines with 1,200 rpm please contact GE Energy’s Jenbacher product team.

TAD1242GE 352 409

TAD1640GE 393 462

TAD1641GE 433 509

TAD1642GE 485 570

M08-G/B T2D41

M12-G/B TID41

M12-G/B T2D41

M06-G/B T0D41

M06-G/B TID41

M06-G/B T2D41

M08-G/B TID41

M08-G/B T2D41

M12-G/B TID41

M12-G/B T2D41 RSE engines for M06-PT0D41

M06-PTID41

M06-PT2D41

M08-PTID41

M08-PT2D41

M12-PTID41

M12-PT2D41

M06-PT0D41

M06-PTID41

M06-PT2D41

M08-PTID41

M08-PT2D41 M12-PTID41

M12-PT2D41

Perkins Engines Company Limited

Peterborough PE1 5FQ

Contact name:- Simon Gray

Tel: +44 (0) 1733 583000

Perkins Engines Company Limited

Peterborough PE1 5FQ

Contact name:- Simon Gray

Tel: +44 (0) 1733 583000

Headquarters: A-6200 Jenbach (Austria) T +43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.gejenbacher.com

Email: gray_simon_j@perkins.com

Perkins is one of the world’s leading suppliers

Manufacturer of gas driven generator sets and cogeneration systems in a power range from 0.25 to 3 MW.

in dieselor 1000 kWE prime in gas.

SCANIA ENGINES

SE-151 87 Sodertalje Sweden

Tel +468553 81000

Fax +468553 898 12

E-mail engines@scania.com

Web www.scania.com

UK Contact – Mark Swindell

Scania GB Ltd

Tel +44 1908 329386

E-mail mark.swindell@scania.com

Diesel & Gas engines for power generation

m3N. Dry exhaust gas; based on 5% O2. For engines with 1,200 rpm please contact GE Energy’s Jenbacher product team.

Prime power 250kVA to 700kVA Stand by power 250kVA to 770kVA

TAD1242GE 352 409

TAD1640GE 393 462

TAD1641GE 433 509

Engine range prime power 50hz & 60hz at (70% mean load factor)

TAD1642GE 485 570

Scania produce diesel and gas powered engines for various Industrial and Marine applications,tionally low fuel consumption.

Perkins Engines Company Limited

Peterborough PE1 5FQ

Contact name:- Simon Gray

All models are available to meet current emissions requirements, Scania engines are now available to meet both Tier 4F and EU Stage V. Alternative fuels

Tel: +44 (0) 1733 583000

Email: gray_simon_j@perkins.com

Perkins is one of the world’s leading suppliers

Many of our engines can also operate on Bio-diesel conforming to EN14214 and HVO conforming to EN159540

R Schmitt Enertec GmbH

RSE engines for Woodgas

M06-HT2D41 g 50 122 kW

56743 Mendig, Germany T +49 2652 9351810

M08-HT2D41 g 50 166 kW

F +49 2652 9351822

M12-HT2D41 g 50 250 kW

Email: gray_simon_j@perkins.com

Perkins is one of the world’s leading suppliers

M06-HT2D41 g 60 140 kW

info@rschmitt-enertec.com www.rschmitt-enertec.com

M08-HT2D41 g 60 180 kW

M12-HT2D41 g 60 275 kW

Manufacturer of gas driven engines,generator sets and cogeneration systems in the range from 100 - 500 kW.

RSE Engines for natural gas and biogas

M06-G/B T0D41 g 50 140 kW

in dieselor 1000 kWE prime in gas.

SCANIA ENGINES

SE-151 87 Sodertalje Sweden

M06-G/B TID41 g 50 200 kW

Volvo Penta

Tel +468553 81000

M06-G/B T2D41 g 50 250 kW

405 08 Gothenburg, Sweden Tel +46 31 235460

M08-G/B TID41 g 50 260 kW

M08-G/B T2D41 g 50 333 kW

Fax +468553 898 12

E-mail engines@scania.com

Web www.scania.com

M12-G/B TID41 g 50 400 kW

Model Spec RPM kWm kVA

TAD530GE Diesel 15002) 75 85

M12-G/B T2D41 g 50 500 kW

UK Contact – Mark Swindell

TAD531GE Diesel 15002) 88 100

M06-G/B T0D41 g 60 150 kW

TAD532GE Diesel 15002) 113 130

M06-G/B TID41 g 60 210 kW

TAD550GE1) Diesel 15002) 76 86

M06-G/B T2D41 g 60 250 kW

Scania GB Ltd

Tel +44 1908 329386

E-mail mark.swindell@scania.com

M08-G/B TID41 g 60 280 kW

TAD551GE1) Diesel 15002) 89 101

TAD730GE Diesel 15002) 113 130

M08-G/B T2D41 g 60 333 kW

TAD731GE Diesel 15002) 132 152

M12-G/B TID41 g 60 420 kW

Diesel & Gas engines for power generation

M12-G/B T2D41 g 60 500 kW

TAD732GE Diesel 15002) 162 186

TAD733GE Diesel 15002) 175 201

RSE engines for LPG

Prime power 250kVA to 700kVA Stand by power 250kVA to 770kVA

TAD734GE Diesel 15002) 213 245

M06-PT0D41 g 50 115 kW

TAD750GE1) Diesel 15002) 114 131

M06-PTID41 g 50 173 kW

TAD751GE1) Diesel 15002) 13 152

M06-PT2D41 g 50 205 kW

Engine range prime power 50hz & 60hz at (70% mean load factor)

M08-PTID41 g 50 233 kW

TAD752GE1) Diesel 15002) 158 182

M08-PT2D41 g 50 260 kW

TAD753GE1) Diesel 15002) 173 199

TAD754GE1) Diesel 15002) 217 250

M12-PTID41 g 50 350 kW

M12-PT2D41 g 50 450 kW

TAD940GE Diesel 15002) 241 277

Scania produce diesel and gas powered engines for various Industrial and Marine applications,tionally

M06-PT0D41 g 60 130 kW

TAD941GE Diesel 15002) 280 326

TAD1341GE Diesel 15002) 271 315

M06-PTID41 g 60 173 kW

TAD1342GE Diesel 15002) 303 352

M06-PT2D41 g 60 205 kW

M08-PTID41 g 60 233 kW

TAD1343GE Diesel 15002) 325 378

TAD1344GE Diesel 15002) 354 412

M08-PT2D41 g 60 260 kW

low fuel consumption. All models are available to meet current emissions requirements, Scania engines are now available to meet both Tier 4F and EU Stage V.

M12-PTID41 g 60 350kW

TAD1345GE Diesel 15002) 388 451

TAD1351GE1) Diesel 15002) 279 324

M12-PT2D41 g 60 450 kW

TAD1352GE1) Diesel 15002) 314 365

RSE engines for Woodgas

Alternative fuels

M06-HT2D41 g 50 122 kW

TAD1354GE1) Diesel 15002) 328 381

TAD1355GE1) Diesel 15002) 355 413

M08-HT2D41 g 50 166 kW

TAD1640GE Diesel 15002) 392 461

M12-HT2D41 g 50 250 kW

Many of our engines can also operate on Bio-diesel conforming to EN14214 and HVO conforming to EN159540

M06-HT2D41 g 60 140 kW

TAD1641GE Diesel 15002) 430 505

TAD1642GE Diesel 15002) 503 591

M08-HT2D41

TWD1643GE Diesel 15002) 536 630

TAD1650GE1) Diesel 15002) 393 462

TAD1651GE1) Diesel 15002) 430 505 Engines are also available for1800rpm/60Hz