Uniper’s hydrogen projects in Wilhelmshaven, the “Green Wilhelmshaven Electrolyser” and the “Green Wilhelmshaven Terminal”, have been selected by the European Commission for the list of Projects of Common Interest (PCI).

With this, Uniper is recognised as part of cross-border infrastructure projectswhich link energy systems across EU countries. These projects benefit from both accelerated authorisation procedures and funding, supporting the realisation of EU’s energy and climate goals.

With an electrolyser capacity of up to 1 GW, the large-scale “Green Wilhelmshaven Electrolyser” will tap into the region’s renewable energy resources to boost the domestic production of green hydrogen.

The “Green Wilhelmshaven Terminal” ammonia import terminal paves the way for the import of renewable ammonia by ship and the conversion and feed-in of hydrogen into the European hydrogen network on a large scale.

Both projects underscore Uniper’s commitment to achieving a climate-neutral European Union by 2050,

POLAND & CHP

A CHP plant with an MWM gas genset ensures high mushroom yields all year round for the food producer, the Hajduk Group.

POWER PLANT PROVIDES BALANCING SERVICES

INNIO & Clarke Energy have supplied six new INNIO Jenbacher generators to Romania.

SWISS GENSETS

Elcos has provide 1250kVA of standby power capability to a Swiss operation & has specified a unique kind of alternator for its gensets.

in line with the Paris Agreement goals. They form a crucial part of the trans-European energy infrastructure, facilitating the functioning of the internal energy market, security of supply, competitive energy markets, energy efficiency and savings, and the development of new and renewable forms of energy.

to generate 16,000 MWh of renewable electricity per year. This has been awarded a “Renewable Energy Sources Act” subsidy. Page 18

20

Page 26

In addition, a 19 MWp PV plant will be built on an area of around 14 hectares and is expected to generate

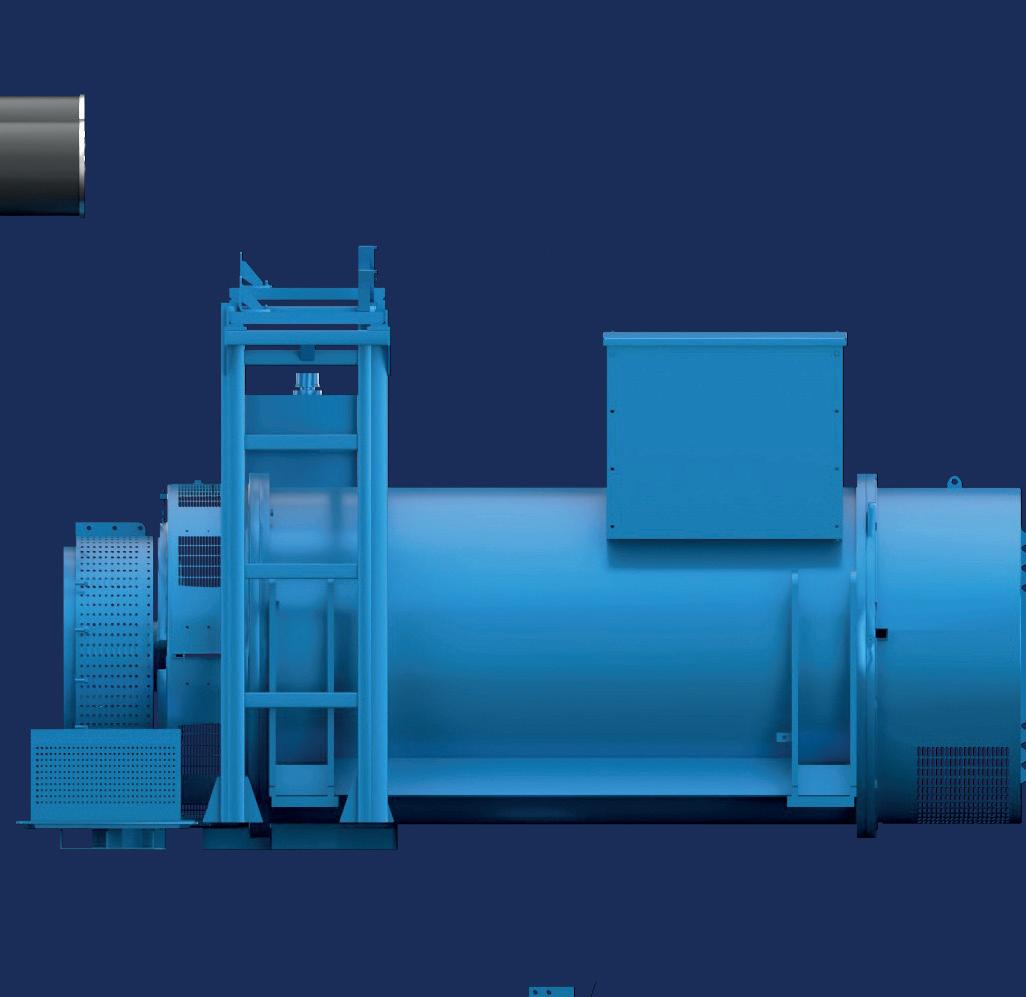

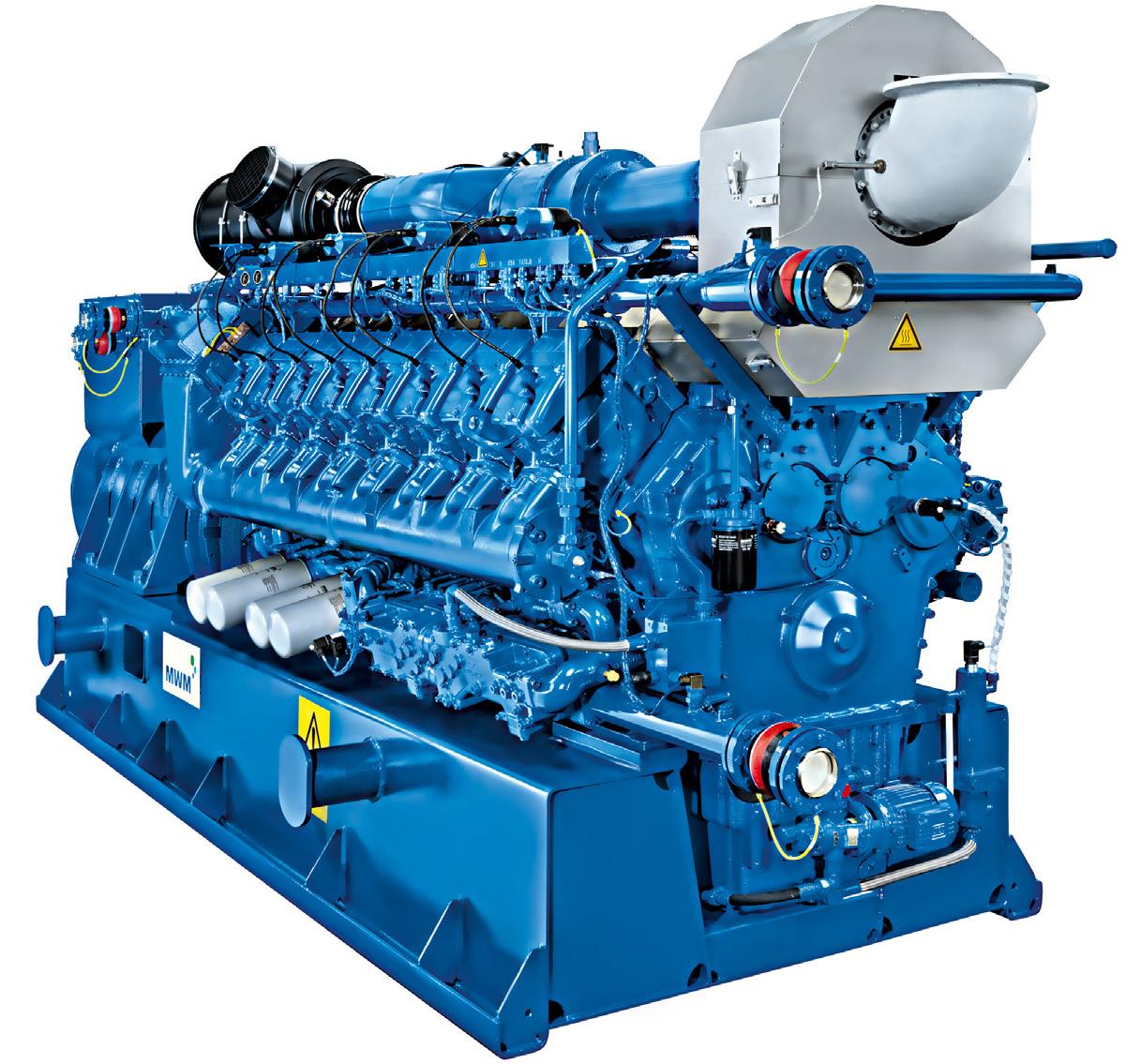

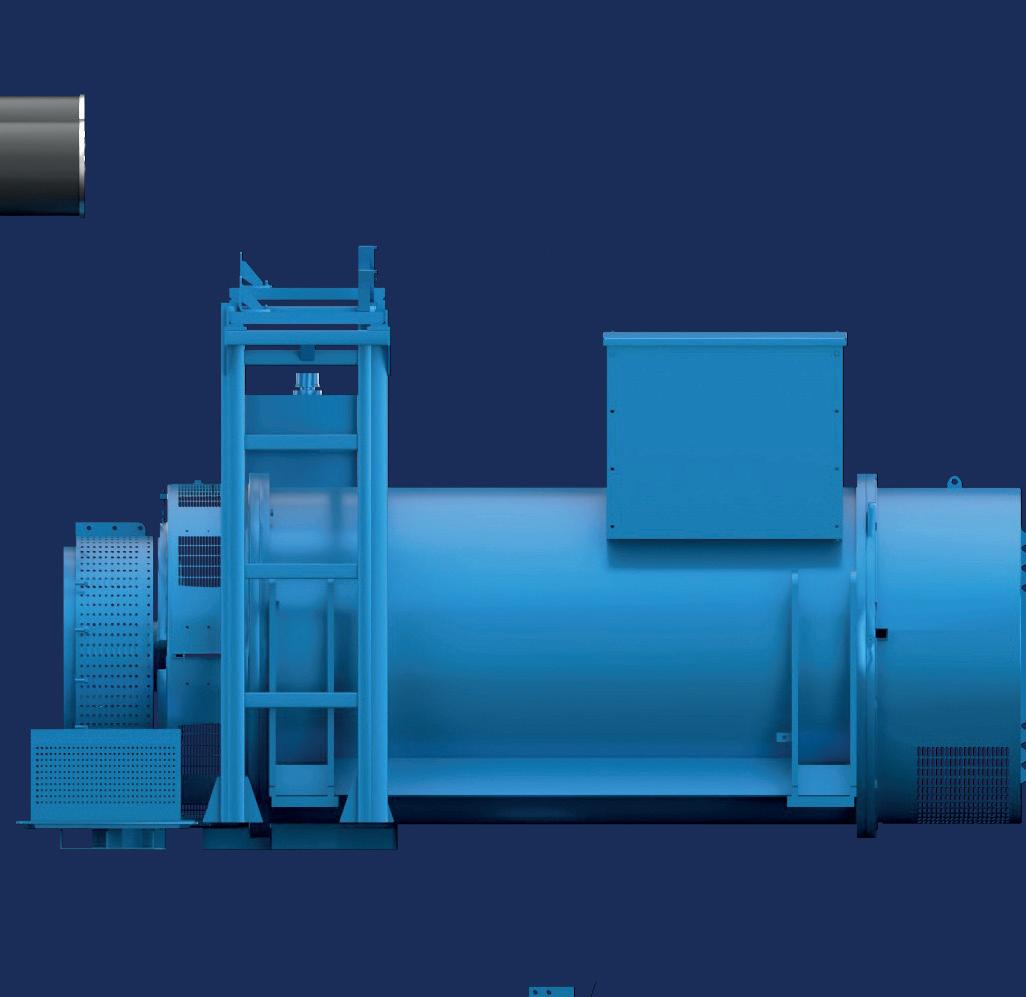

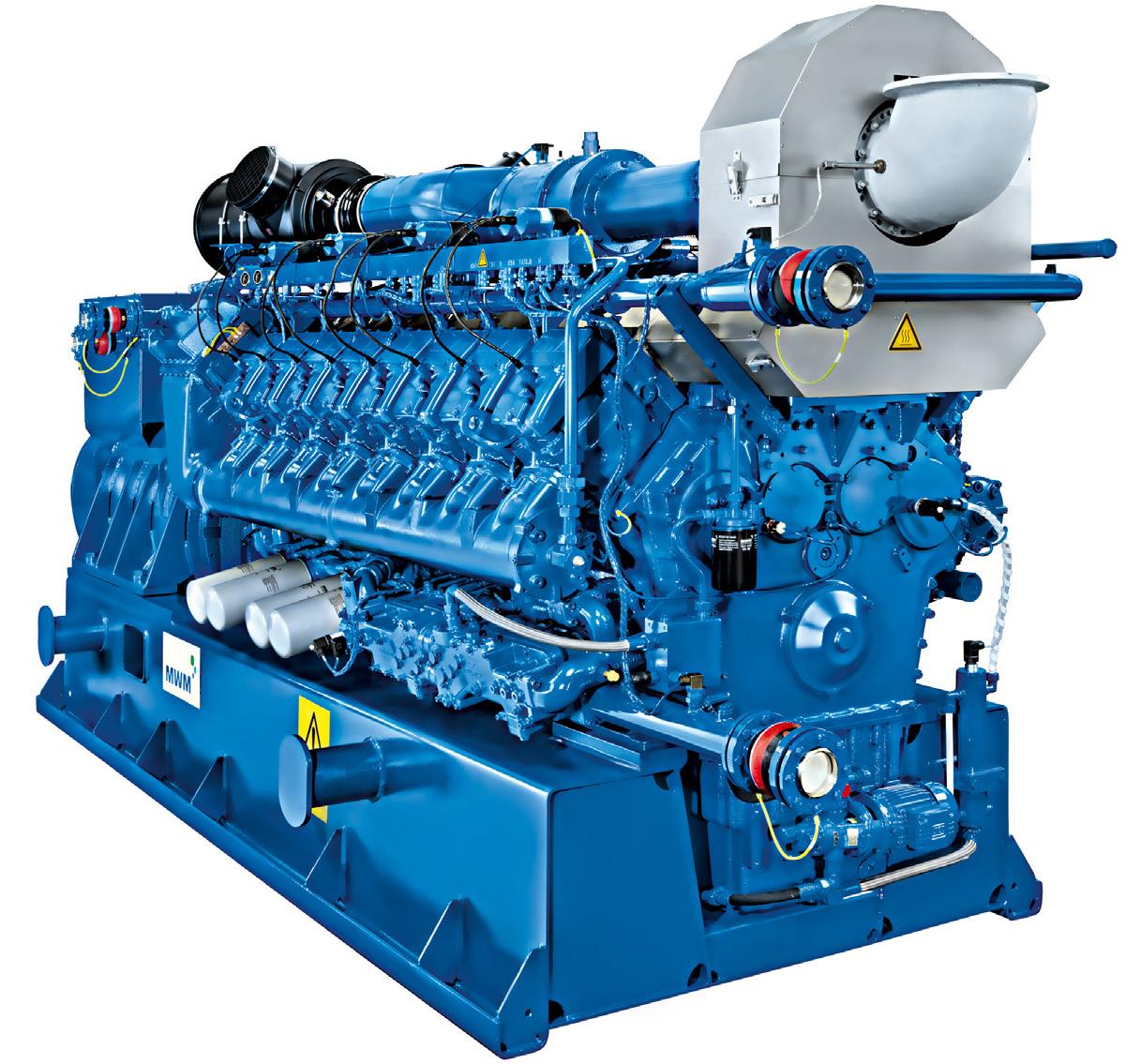

MWM. Maximum Availability and Performance of MWM CHP and gas power plants: MWM gas engines and generator sets, including our original spare parts, are designed for top performance and efficiency. Governed by the same regulations as production parts, our spare parts ensure hassle-free operation, adhering to high-quality and availability standards.

www.mwm.net/spareparts

ORIGINAL

SPARE PARTS. 100%

MWM

QUALITY. 100%

CES20001-Anzeigen_MWM_Ersatzteile_95x145mm_EN_1_0_RZ_sm.indd 1 20.03.24 11:01

Page

EUROPEAN COMMISSION APPROVES ENERGY SITE MAY-JUNE 2024 1 EURO POWER NEWS MAY-JUNE 2024 MWM gensets. Efficient, low-maintenance and highly available.

CES20001_Anzeigen_MWM_3er Range_235x55mm_EN_2_0_RZ_sm.indd 1 16.05.24 13:52

www.mwm.net/en

Publisher/Sales Director:

Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor: Aidan Turnbull aidan@wipmagazines.com

Accounts Manager: Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu

Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent

Mario Dobresko power@wipmagazines.com

Contributors

MWM, EUROPGEN, Perkins, TEDOM, Stamford, MEGSA, Volvo Penta, INNIO, KOHLER Power, AKSA Energy, Coelmo, Genmac, Baudouin, Mecc Alte, Genesal Energy, Clarke Energy, MTU, Rolls-Royce, Coelmo, Volvo Penta, MAN Energy, SailH2, Damen naval, HIMOINSA, Yanmar, HIAcoustics, Przedsiębiorstwo Energetyki CieplnejKW SEY OY, Cummins, Lukas Hospital, ELCOS, AKSA ****************

EURO POWER NEWS

Published by:

Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0)1403 888019

Fax: +44 (0)1403 220751

powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year.

Please send address changes to Euro Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

European Hydrogen Bank auction provides €720 million

The European Commission is awarding nearly €720 million to seven renewable hydrogen projects in Europe, selected through the first competitive bidding process under the European Hydrogen Bank.

The funds for this auction come from the revenues of the EU Emissions Trading System.The winning bidders will produce renewable hydrogen in Europe and will receive a subsidy to bridge the price difference between their production costs and the market price for hydrogen, which is currently driven by non-renewable producers.

The European Hydrogen Bank is therefore contributing to the scale-up of cleaner fuels which will contribute to the decarbonisation of European industry. The renewable hydrogen they produce will be used in sectors such as steel, chemicals, maritime transport and fertilisers.

The 7 selected projects were the winners of an oversubscribed auction which attracted 132 bids in total.

Together, the winning bidders plan to produce 1.58 million tonnes of renewable hydrogen over ten years, avoiding more than 10 million tonnes of CO2 emissions.

The selected projects are located in 4 European countries. They submitted bids between €0.37 and €0.48 per kilogram of renewable hydrogen produced, and also met the other qualification requirements. The subsidy the 7 projects will receive ranges from €8 million to €245 million.

The seven selected projects will now start preparing their individual grant agreements with the European Climate, Infrastructure and Environment Executive Agency (CINEA). These agreements are expected to be signed by November 2024 at the latest. Selected projects will have to start producing renewable hydrogen within a maximum of 5 years after signing the grant.

NEW GENSET PICKED FOR PARIS RAILWAY SUBSTATION

Genmac, an Italy-based company, with its rich history spanning over four decades, has established itself as a trusted name in the generator manufacturing industry and has now won a pretigious contract with France’s railway sector.

With a power range offering from 2 to 2645kVA, Genmac serve a diverse range of customers, including those in the construction, residential, emergency services, mining and hospital healthcare sectors.

Genmac recently approached STAMFORD | AvK with a specific standby power requirement for a Paris train station substation in Archeres, France. The total power requirement for the project, including grid supply, was 400kVA at 400V, 50Hz.

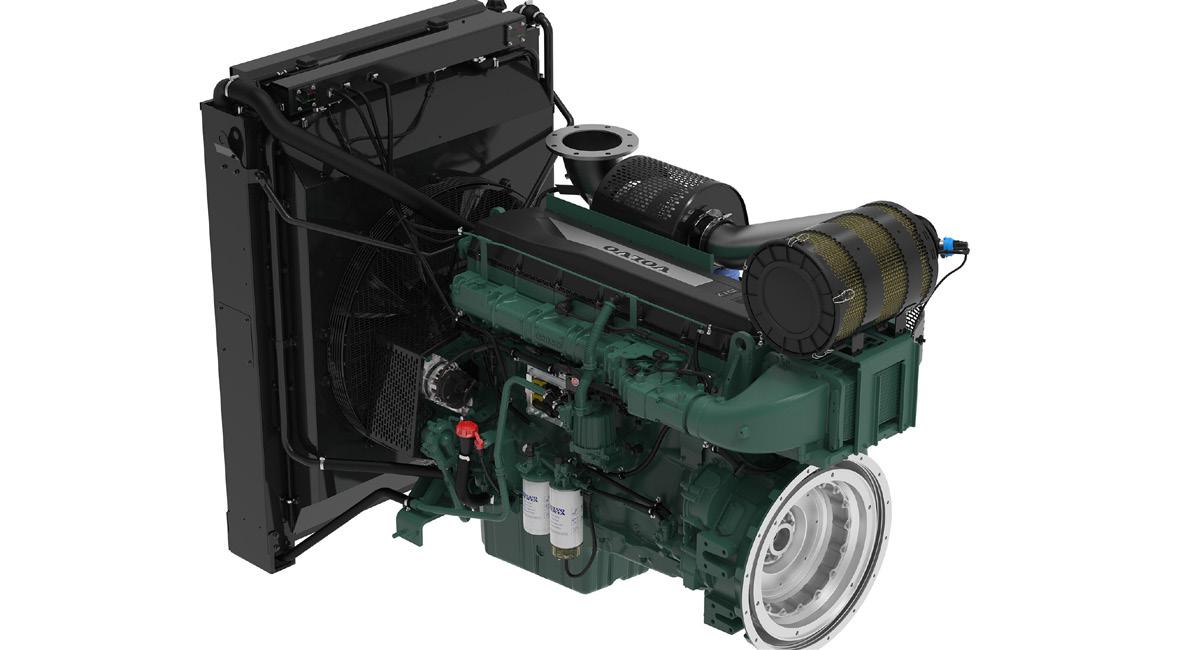

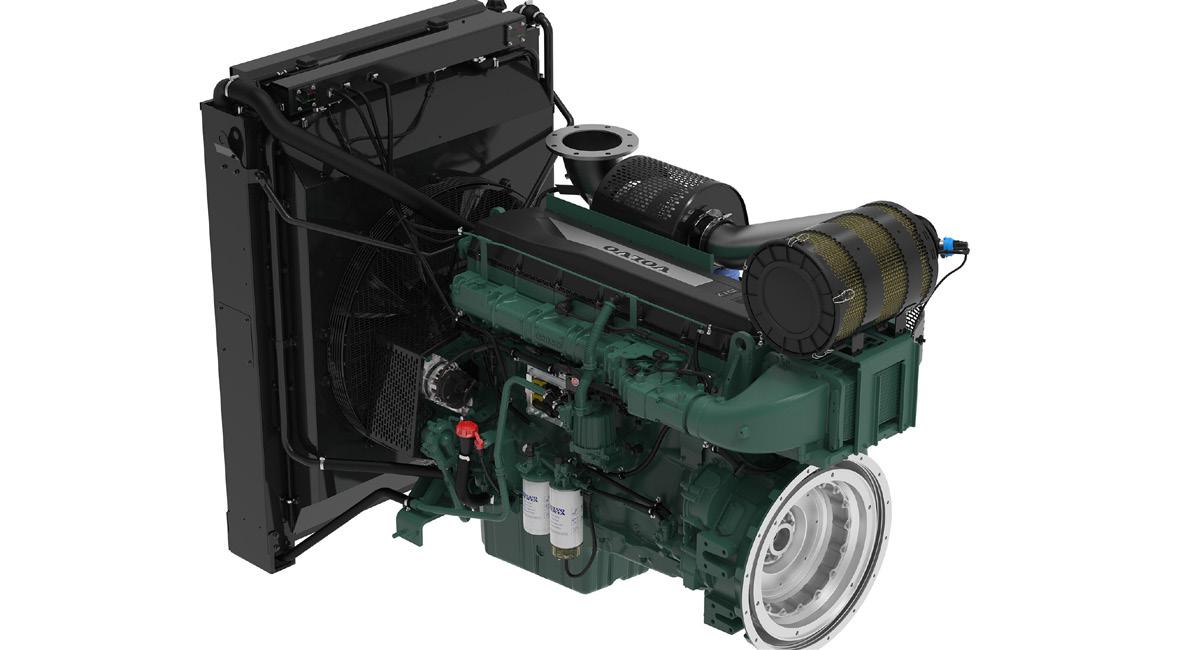

STAMFORD | AvK supplied the STAMFORD S4 alternator with a twin AVR AS440. The generator design considerations included environmental factors, size, altitude, temperature, and ingress, coupled with the VOLVO TAD1344GE engine.

The Volvo Penta TAD1344GE is a 6-cylinder engine with a displacement of 12.78 litres. It has a weight of 1325 kilograms and a bore of 131 millimetres. The stroke of the engine is 158 millimeters. The minimum power output of the engine is 354 kilowatts, while the maximum power output is 389 kilowatts. The engine operates at a speed of 1500 RPM.

The Volvo TAD1344GE is regarded as an efficient diesel engine with a turbocharger and air cooled exhaust manifold. The 6-cylinder in-line engine also includes an electronic high pressure fuel injection system and an overhead camshaft which improves the efficiency and lowers the fuel consumption of the engine.

The total displacement of the Volvo TAD1344GE is has a total displacement of 12.78 litres. The 6 cylinder engine has an oil system capacity of 36 litres and a net coolant capacity (engine and radiator) of 44 litres. The generator efficiency of the engine is 93% . Using this engine at 50Hz/1500 RPM will produce a prime power output of 411 kVA and a standby power output of 452 kVA. Using this engine at 60Hz/1800 RPM will produce a prime power output of 455 kVA and a standby power output of 501 kVA.

The wet weight of the Volvo TAD1344GE engine alone is 1325 kg. The dimensions of the engine 2206 x 1114 x 1391 mm.

The diesel engine can be coupled with an alternator to make a powerful diesel generator that can be used for a range of power hungry applications across the globe.

EPN DIARY

POWEREX LIVE 2024 ON THURSDAY 12 DECEMBER, LONDON, UK

PowerEx Live 2024 at London’s Park Plaza Hotel, will be held on December 12th, 2024.

PowerEx Live 2024 aims to offer the perfect networking opportunities for professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With conference speakers at the top of their respective fields alongside premier display space in a world class venue, this event becomes a priority for all those in the power and energy markets. Exhibit with us at this prestigious venue in December 2024.

The ‘GEN-SET LIVE’, ‘CHP LIVE’ and ‘CHP & Renewables LIVE’ conferences will run parallel with prime exhibitor space available in adjoining rooms. Take your products to your customers with the opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets. The choice of stands are allocated on a ‘first-comefirst-serve’ basis, so please contact us today and prepare for the highlight of the UK’s Power & Energy calendar for 2024. The venue is situated on London’s iconic South Bank, Park Plaza Westminster Bridge London is just a short

2 MAY-JUNE 2024 EURO POWER NEWS NEWS NEWS www.powermediagroup.co.uk

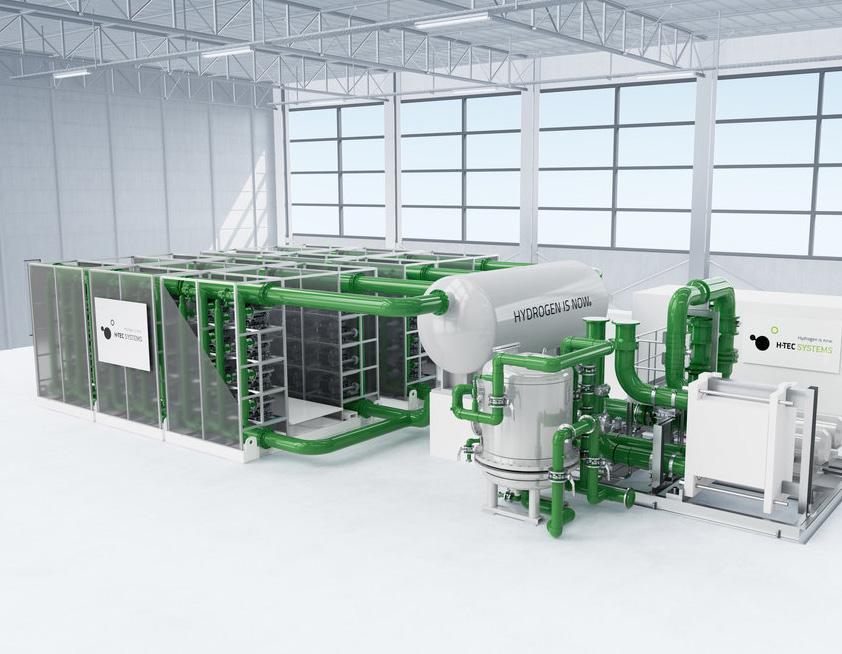

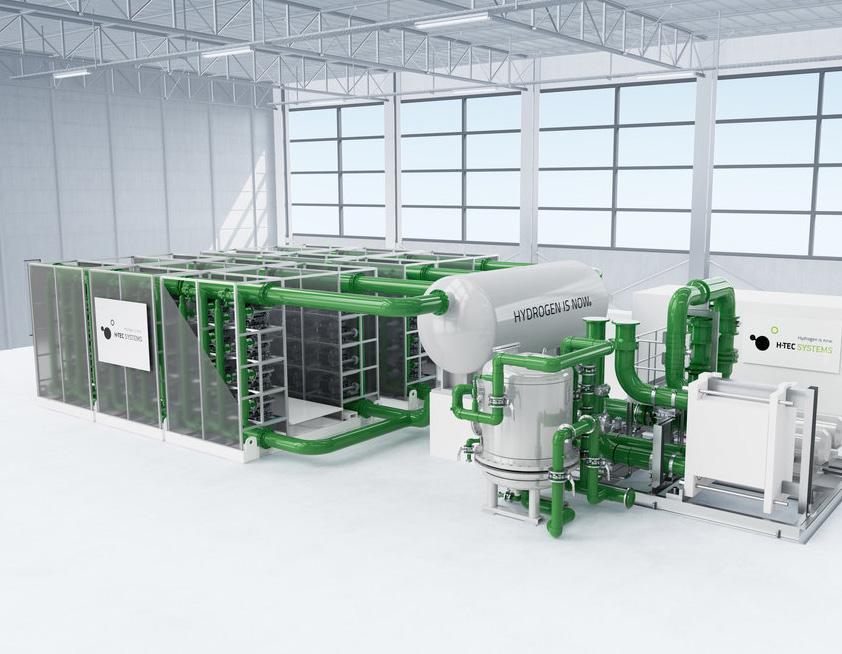

GREEN HYDROGEN PILOT PROJECT DEPENDS ON 1MW

PEM ME450 ELECTROLYZER

A1-MW PEM ME450 electrolyzer supplied by German manufacturer H-Tec Systems will be utilised by Spanish green hydrogen project developer SailH2 in the “HUB LA ISLA H2” green hydrogen pilot project in the region of Sevilla, Andalusia, by SailH2.

The 1-MW ME450 PEM electrolyzer will be used as part of a pilot project examining a variety of different applications for green hydrogen. SailH2 plans to invest 25 million Euro into building a pilot center for production and distribution of green hydrogen. It has ordered the ME450 PEM electrolyzer to produce up to 136 tons of green H2 per year in combination with a 1.5-MW PV plant in the first phase of the HUB LA ISLA H2 project.

The pilot project will be the first commercial hub of green hydrogen in Andalucía and will be located at the industrial site Poligono Industrial Isla in Dos Hermanas, a city district of Sevilla. The site construction works are scheduled to be finalized by Q3 2024, with H-Tec Systems set to deliver the electrolyzer in September 2024.

The pilot project will examine a variety of different applications for green hydrogen, such as powerto-mobility, power-to-industry and power-to-gas in the 4- to 20 -MW range. The PEM electrolyzer will be applied in the initial phase (Phase 1 Power-to-Mobility), during which SailH2, with the support of Agencia IDAE through the Moves Singulares II grant, will combine1 MW of hydrolysis power with 1.5MW photovoltaic power produced at a near-site PV plant. The hydrogen plant utilizing the electrolyzer will produce up to 136 tons of green H2 per year.

Eduardo Almagro, CEO of SailH2, and CEO of H2Green La Isla, said, “We chose the ME450 PEM electrolyzer for our project because it is a proven product with best-in-class performance that eliminates the risk of power supply fluctuations in our project. With its strong technology and service capacities through the international service network of MAN ES, H-Tec Systems is the most competent and reliable partner for the next phases of our project.”.

In 2025, phase 2 will explore the production and distribution of 680 tons of H2 for decarbonizing local industrial production processes with an electrolysis power of 5 MW.

“In the innovative regional hydrogen hub project, our electrolyzer is used to supply local mobility projects for decarbonizing the industry. We are very pleased to be a technology partner for this futureoriented project and to actively contribute to the energy transition in Spain,” said Jorge Menéndez García, Sales Manager at H-Tec Systems.

The H-TEC SYSTEMS ME450 electrolyzer is a proven turn-key solution for the easy and efficient production of green hydrogen. In the space of just one standard 40-foot container, enough hydrogen can be produced to refuel 90 cars daily. Each ME450 has an electrolysis capacity of 1 MW and can produce 450 kg of high purity hydrogen per day. Thanks to a multiple stack design, high plant availability, excellent spare parts availability, and our extensive range of services, risks can be minimized, and costs reduced. The proven design and technology make the H-TEC SYSTEMS PEM electrolyzer ME450 reliable and future-proof.

Modular, skid-mounted, ready-to-install, the Modular Hydrogen Platform (MHP) enables the industrial production of green hydrogen by combining single 10-MW blocks to multi-MW systems - thanks to the scalable, modular system.

The MHP is a scalable platform for industrial production of green hydrogen based on PEM technology. 10-MW blocks can be combined into multi-MW systems for projects with an electrolysis capacity from 10 to more than 100 MW.

The system is ready for indoor installation on pre-assembled skids. It is equipped with integrated process water treatment and an electrical power supply. Optionally, the system can be supplemented with fresh water and hydrogen treatment, as well as process heat recovery or oxygen utilization as required. The MHP electrolyzer is said to stand out with its unrivalled system efficiency, high availability, and proven maintenance concept, which result in low hydrogen production costs and

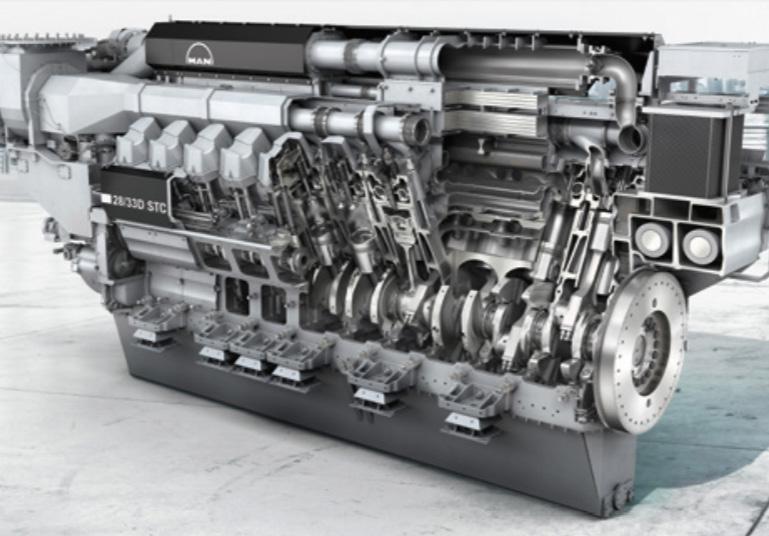

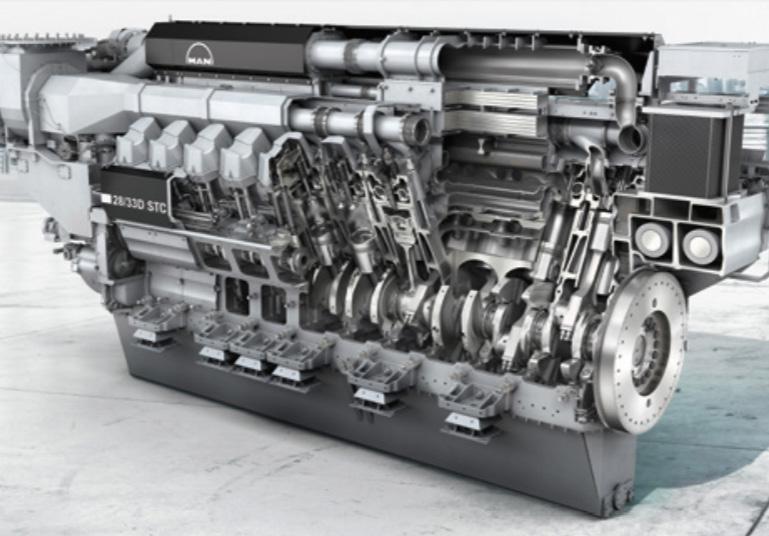

DUTCH & BELGIAN NAVY FRIGATES GET NEW GENSETS

Damen Naval has contracted MAN Energy Solutions to supply the diesel engines and gensets for a series of new anti-submarine warfare (ASW) frigates.

The order covers delivery of eight MAN 20V28/33D STC marine engines and 16 variable speed 16V175D-MEV naval gen sets with sound enclosures and plant auxiliaries.

These will be fitted to four new ASW frigates which are to be built for the Dutch and Belgian navies.

“The MAN 20V28/33D STC engines are considered to be one of the most powerful and fuel-efficient 1,000 rpm diesel engines in the world and we believe they are the best solution for the ASW frigates,” said Roland Briene, MD at Damen Naval.

This is the second recent contract between the two companies. In September 2022, MAN Energy Solutions was selected to supply

engines for the F126 frigates Damen Naval is building for the German Navy.

ASW frigates are designed to sail with as little noise as possible, both to support submarine detection and to avoid detection by submarines. The 175D gen sets are key to this, while also meeting requirements for shock, noise and vibration.

The ASW frigates will replace the current Karel Doorman-class multipurpose ships built by Damen Naval between 1985 and 1991. The engines and gensets are scheduled for delivery in mid-2025.

ACQUISITION OF ACOUSTIC ENGINEERING SOLUTIONS ADDS NEW SUPPORT

Himoinsa, part of the Yanmar Group of companies, has reported the acquisition of Hispano Acústica, a specialist provider of acoustic engineering solutions. Under the deal, the company will be rebranded as HiAcoustic.

It is expected that the deal will allow HiAcoustic to extend its offering of soundproofing systems to more global customers. The company works across a range of applications, including acoustic booths and screens, through to sound-absorbent treatments for generator sets and installation rooms.

For Himoinsa, which is based in Murcia, Spain, the addition will add a new support feature to its portfolio and the capability to deliver ‘360-degree solutions’ for customers.

“This acquisition certainly reaffirms our commitment to the design, production and commercialisation of innovative solutions for the market,” said Francisco Gracia, president and CEO of Himoinsa.

While now owned by Himoinsa, HiAcoustic will remain a fullyindependent company. As such, its acoustic solutions will be available to third-party custom

EURO POWER NEWS MAY-JUNE 2024 3 NEWS NEWS

3MVA CONTAINER GENSET SOLUTION PROVIDES BACKUP POWER IN FINLAND

KWSET OY recently provided a larger-than-average container solution for backup power for an industry customer in Finland. The container provided was 15 metres long and features a CUMMINS 3MVA emergency power genset inside. Compact and neat busbars were installed between the generator in the container and the circuit breaker switchboard.

Busbars have proved an excellent alternative to traditional cables, saving space and time during the installation, especially in high power classes. The busbar trunking also offers cost-effectiveness and a clear installation result, says the company. his Cummins® commercial generator set is a fully integrated power generation system, providing optimum performance, reliability, and versatility for stationary standby, prime power, and continuous duty applications.

The QSK60 Cummins heavy-duty engine from CUMMINS is a rugged 4- cycle, industrial diesel delivers reliable power, low emissions and fast response to load changes.

- Alternator - Several alternator sizes offer selectable motor starting capability with low reactance 2/3 pitch windings, low waveform distortion with non-linear loads and fault clearing short-circuit capability.

- Permanent Magnet Generator (PMG) - Offers enhanced motor starting and fault clearing short circuit capability.

- Control system - The PowerCommand® digital control is standard equipment and provides total genset system integration including automatic remote starting/stopping,precise frequency and voltage regulation, alarm and status message display, AmpSentryTM protective relay, output metering and auto-shutdown at fault detection and NFPA 110 Level 1 compliance.

- Cooling system - Standard and enhanced integral set-mounted radiator systems, designed and tested for rated ambient temperatures, simplifies facility design requirements for rejected heat.

- NFPA - The genset accepts full rated load in a single step in accordance with NFPA 110 for Level 1 systems.

- Uptime Compliant - Meets the requirement of a Tier III and IV data center site by being rated to run for unlimited hours of operation when loaded to ‘N’ demand for the engine generator set.

- Data Centre Continuous (DCC) - Applicable for supplying power continuously to a constant or varying electrical load for unlimited hours in a data centre

GENSET UNIT FOR LUKAS HOSPITAL IN GERMANY

The Lukas hospital in Neuss, Germany, has just ordered a special genset unit from Genesal Energy.

Genesal Energy specialises in offering the healthcare sector highly innovative energy solutions with all the warranties in terms of design, manufacture and maintenance.

Its generators are known for their capabilitieis: they can start up in record time – in the event of a failure in the network – securing the operation of ORs, ICUs and other equipment.

The high quality and innovation behind Genesal-manufactured generator sets has led their to design projects for hospitals all over the world and one of the latest orders has been for the Lukas Neuss one in Germany.

The Lukas Hopsital A required a special emergency unit compliant with local emissions’ regulations for ‘combustion engines and water protection’. The genset had to be able to operate at low temperatures. Features of the genset include: -Power panel integrated in the container.

-WHG compliant.set -Leak detector in the container rooms and in the double-walled tank.

- Motorised air inlet and outlet louvres.

-Interior space heaters.

The Lukas Hospital in Neuss belongs to the Rheinland Klinikum. As the largest clinic in the RheinKreis Neuss, the facility makes a decisive contribution to medical care in the region. The hospital enjoys a nationwide reputation, thanks to the excellence of its numerous certified centres which focus on the field of cardiovascular medicine, surgery and neonatal medicine.

FOUR DIESEL GENSETS FOR A DATA CENTRE IN ITALY

ELCOS has supplied four 650 kVA Super Silent - Parallel mode diesel gensets to a data centre site in Italy. The gensets are powered by Doosan engine and feature STAMFORD | AvK alternators.

The ELCOS Super Silent Gen Sets is a versatile range built to cover the widest application field and customizable to any needs. They offer the maximum level of performance in the event of a sudden power failure.

These gensets grant a reliable power supply and optimise the load thanks to an MC4 control panel.

The Super Silent range covers from 10 to 250 KVA, equipped with engines and premium brand alternators.

ELCOs was also responsible for providing ORSHA Airport on Belarus with a GE.PK.450\400.BF+011 genset and a GE.PK.400\350. BF+011, equipped with Perkins engines and Stamford alternators. These two power generators are powered by a 3000 lt external tank. The tank is placed in separate room inside the container and in addition is equipped with a solenoid valve with adjustable timer.

4 MAY-JUNE 2024 EURO POWER NEWS NEWS NEWS

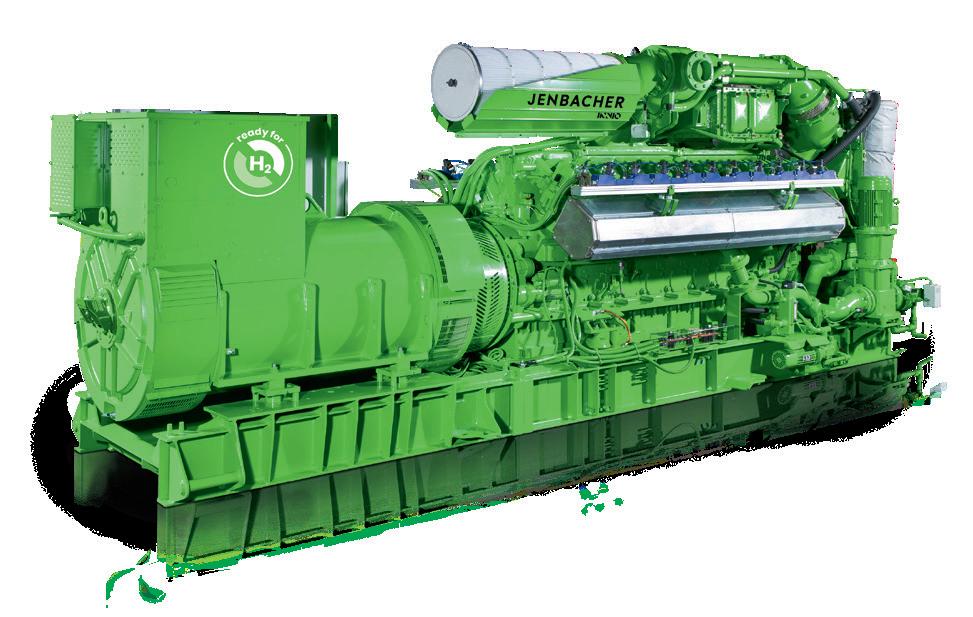

HYDROGEN Enabling your transition to a green future

We're ready for H2. Get ready, too!

At INNIO* Group, we are continuously innovating flexible, scalable, and resilient energy solutions to help you generate and manage energy efficiently and sustainably.

Our Jenbacher* engine technology is an investment in the future. It can be converted to run on traditional gas-hydrogen mixtures and up to 100% hydrogen when it becomes more readily available. Installing our “Ready for H2”**-designed power plant now will enable you to convert it to 100% hydrogen operation later, delivering a sustainable energy solution that works for you today and accelerates a greener tomorrow!

Let us support your transition journey. jenbacher.com

* & indicates a trademark.

** In general, “Ready for H2” Jenbacher units can be converted to operate on up to 100% hydrogen in the future. Details on the cost and timeline for a future conversion may vary and need to be clarified individually.

Jenbacher is part of the INNIO Group

May 21 - 22, 2024

Booth: B82

ENERGY

SOLUTIONS. EVERYWHERE, EVERY TIME. World Hydrogen Forum

POWER READY TO ENERKIT

RELIABLE, PRE-ASSEMBLED HIGH PERFORMANCE POWER SOLUTION

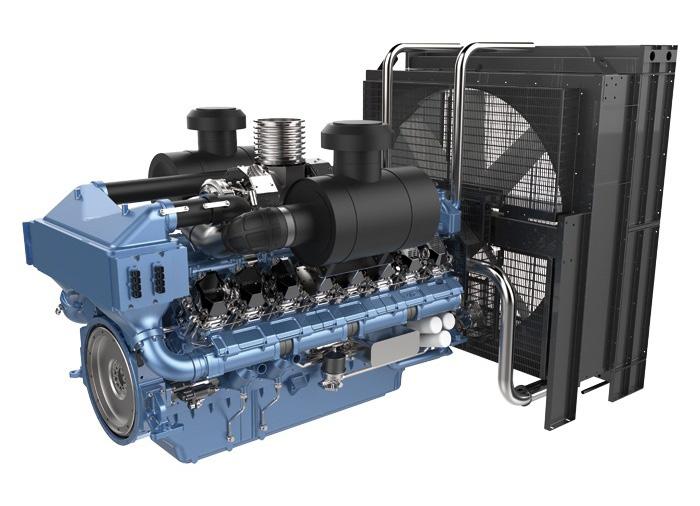

ENERKIT DIESEL FROM 1500 kVA – 4000 kVA

UPTIME INSTITUTE COMPLIANCE | HVO TESTED | BEST IN CLASS LEAD TIME

GLOBAL SUPPORT NETWORK | TAILORMADE OPTIONS

DURABLE. ROBUST. BUILT TO LAST. BAUDOUIN.COM

ITALY-BASED OEM ACQUIRES CONTROLLERS GIANT AS PART OF A NEW SMARTECH™ INITIATIVE

In a strategic expansion of global capacity, Mecc Alte has acquired SICES’ controllers business worldwide. For the past three months all SICES controller design, manufacturing and logistics resources have formed part of Mecc Alte’s expanded global SMARTECH™ offer to genset designers and manufacturers.

Commenting on the takeover, Mario Roberto Carraro, President and CEO of Mecc Alte, said: “In the heart of the energy transition and the decentralisation of power, we have embarked on a transformative journey, transitioning from a focus on single industrial alternators to embracing genset controls and components that together help create next-generation power solutions. This strategic shift is both a response to industry trends and a proactive commitment to shaping a sustainable future for energy.”

The move follows a sustained period of cooperation between the two businesses, with SICES controllers incorporated into Mecc Alte products since 2021. Mecc Alte sees the acquisition as an essential response to a changing energy landscape.

“Genset controls are a pivotal solution as power generation becomes decentralised with the rapid expansion of renewable sources of energy. These sophisticated control systems provide not only efficiency in power generation but also the intelligence to adapt to varying energy demands. By integrating advanced technologies such as these and future controllers, and linking them to Mecc Alte’s highly successful range of products, we aim to empower our clients with the ability to optimise power generation and contribute to a more sustainable energy grid,” said the head of Mecc Alte’s SMARTECH™ division Miles Revell.

As one of the world’s leading manufacturers of alternators, Mecc Alte is well-positioned to expand its reach. The SICES acquisition builds on other advanced capabilities, such as advanced rotating electrical machines, advanced power generation systems, and LV industrial alternators with specialised custom products such as liquid cooled PMG machines. The range also includes MV and HV alternators and many unique multipole solutions optimised specifically for their given solution.

“This acquisition, in line with our company’s transition within the wider energy landscape enables us to transfer our knowledge and expertise gained across multiple energy sectors to new and exciting markets,” said Jonathan Stokes Mecc Alte’s Group Marketing Director. “Market evolution means traditional singular systems are being replaced by mixed and complex multi-dimensional systems where the integration of digital technology is essential. As we continue to navigate the complexities of the energy transition, we stand proud as pioneers in the journey towards a decentralised, responsible, and more sustainable energy landscape.”

Laura Curioni, SICES CEO, said: “We’re delighted that Mecc Alte will be able to continue to develop and expand the controllers technology that we created while we focus on other key aspects of our business. Through our previous partnership, it’s clear that Mecc Alte has a very clear grasp of both the technology and its strategic potential.”

Mecc Alte’s SMARTECH™ will continue to be designed and developed in its Italian plants, with production also expected to start in the company’s Indian facilities. Mecc Alte’s global supply chain will provide support to customers worldwide, incorporating previous SICES distributors where needed.

GENSETS PROVIDE 3,300 KVA FOR SOUTH INKAI URANIUM MINE IN KAZAKHSTAN

AKSA has provided 2 x 1,015 kVA + AD-TP1260 (1260 kVA)3,300 KVA for the South Inkai Mine is a uranium mine located in Kazakhstan. This is part of the Inkai mining complex, which plays a significant role in global uranium production, with Kazakhstan being top global uranium producer.

AKSA’s installed backup power generators, include 2 units 1015 kVA diesel generator sets and TwinPower AD-TP1260 (1260 kVA), provide the necessary power for reliable operation of equipment and processes at the field. AKSA’s equipment helps to minimise the risk of downtime, which is critical

for the efficiency of uranium mining tofday. Kazakhstan has 15% of the world’s uranium, and in 2011, Kazakhstan was responsible for 35% of world production. There are 17 uranium mines in the country, however, maximum output is capped at 20,000 tons per year. Currently, 50 deposits are located in six provinces.

4.8MWE COGENERATION PROJECT FOR A DISTRICT HEATING PROJECT IN POLAND

Poland -based Przedsiębiorstwo Energetyki Cieplnej & Lubartów Sp. z o.o. have installed four CG170B-12 cogeneration units as part of a district heating system.

The investment includes four CG170B-12 cogeneration units with a total capacity of 4.8MWe and a thermal capacity of approx. 5.2MWt.

The units are equipped with complete heat collection installations, including heat from flue gases, the necessary accompanying infrastructure and a power connection with a length of approx. 2 km.

A spokesman comment: “Thanks to this implementation, the PECLubartów will reduce CO2 emissions, gain energy production from renewable sources, and will generate electricity and heat in highefficiency cogeneration conditions”. Poland’s district heating operators have struggled with major destabilisation in the fuel supply market, which affected in particular gaseous fuels, the bulk of which was imported from the east. However, the market does seemed to have turned a corner now and installations are on the rise..

EURO POWER NEWS MAY-JUNE 2024 7 NEWS NEWS

US$1 BILLION IN INFRASTRUCTURE DAMAGE AFFECTING UKRAINE’S ELECTRICITY GRID, SAYS MINISTER

Ukraine needs key electricity imports from five European countries after reporting significant energy infrastructure damage from Russian strikes, Ukraine’s energy ministry has said.Imports are expected to rise to 19,484 megawatt hours (Mwh), beating the record of 18,649 Mwh at the end of March 2024 after the first wave of Russian attacks on Ukraine’s energy sector.

The Energy Ministry said that, with the country facing a significant deficit in the system, it plans to import power from Romania, Slovakia, Poland, Hungary and Moldova on Monday.

The grid operator has said that emergency assistance from the European Union had already been provided, adding that power curbs for industrial consumers are expected imminently.

“Restricting consumption is a necessary measure to maintain the stability of the power system after the fifth targeted missile attack on power plants this year,” the operator has said.

A recent attack on Ukrainian energy infrastructure caused serious damage at three thermal power plants, piling more pressure on the country’s power grid. Russian missile and drone attacks on Ukraine’s energy sector have intensified since March 2024, dealing significant damage and causing blackouts in many regions.

The attacks have resulted in more than $1 billion of damage to the sector, said Ukrainian energy minister German Galushchenko. Thermal and hydropower facilities as well as power transmission systems have been specific targets, resulting in the loss of about 80% of Ukraine’s thermal power generation capacity and increasing reliance on its three nuclear power plants, which produce about 50% of the country’s electricity.

In February 2022 Ukraine’s electric grid operator disconnected the country’s power system from the larger Russian-operated network to which it had always been linked. The long-planned disconnection was meant to be a 72-hour trial proving that Ukraine could operate on its own. The test was a requirement for eventually linking with the European grid, which Ukraine had been working toward since 2017.

Ukraine’s connection to Europe - which was not supposed to occur until a year later- became urgent, and engineers aimed to safely achieve it in just a matter of weeks. On March 16th, 2024 they reached the key milestone of synchronizing the two systems. It was “a year’s work in two weeks,” according to a statement by Kadri Simson, the European Union Commissioner for Energy.

RESTRICTIONS TO CURRENT POWER GRIDS & STORAGE WORRY GREECE

Greece’s Helleniq Energy says it remains committed to its plan to install more renewable capacity in the coming months but has said that It was concerned about restrictions related to power grids and a lack of energy storage.

Helleniq, Greece’s biggest oil refiner, operates solar and wind parks with a total capacity of 381 megawatts with plans to increase that to 1 gigawatt within the next 18 months, Chief Executive Officer Andreas Shiamishis said when commenting on first quarter results.

Tapping its abundant solar and wind potential, Greece has been investing heavily in green energy projects in recent years but progress has outpaced much-needed upgrades of its power grid and the building of facilities to store renewable energy. As many European grids are decades old and need adapting from generation by large, fossil fuel power plants to wind and solar power generation, Europe will need to invest 84 billion euros (US$634.63 billion) in upgrades this decade, according to European Union estimates.

DIRECT CURRENT PLATFORMS TO BE BUILT IN NORMANDY

The Chantiers de l’Atlantique, TSO RTE and the Hitachi Energy consortium have reached an agreement to build the first of a number of offshore direct current platforms and onshore converter stations for the Normandy (Centre Manche 1 & 2) and Oléron Island offshore wind farms.

The deal reflects a new development of offshore farms and wind farm locations in France - very few European nations are currently building large offshore high voltage direct current converter stations.

These platforms will be larger and have a higher power capacity (1250 MW) than the alternating current equipment of the first French offshore wind farms, underscoring the scale-up needed in the production of offshore renewable electricity.

This latest generation of offshore wind farms is regarded as more powerful and located further away from the coast, taking advantage of the stronger and more favourable wind currents available.

In order to connect these offshore farms to the mainland grid, it is necessary to use a technology capable of transporting electricity over very long distances.

In Normandy and Oléron, the high voltage direct current (HVDC) transmission systems championed by Chantiers de l’Atlantique and Hitachi Energy will enable the

integration of more than 3.5 GW of renewable energy into the RTE network.

RTE, the project owner, selected the Chantiers de l’Atlantique and Hitachi Energy consortium after an international call for bids.

Chantiers de l’Atlantique’s experience includes more than a dozen offshore platforms built for wind farms in France and throughout Europe.

Hitachi Energy’s expertise in HVDC technology is recognised globally and has been selected for the IFA2 and Bay of Biscay interconnections, Great Britain – France and Spain –France respectively.

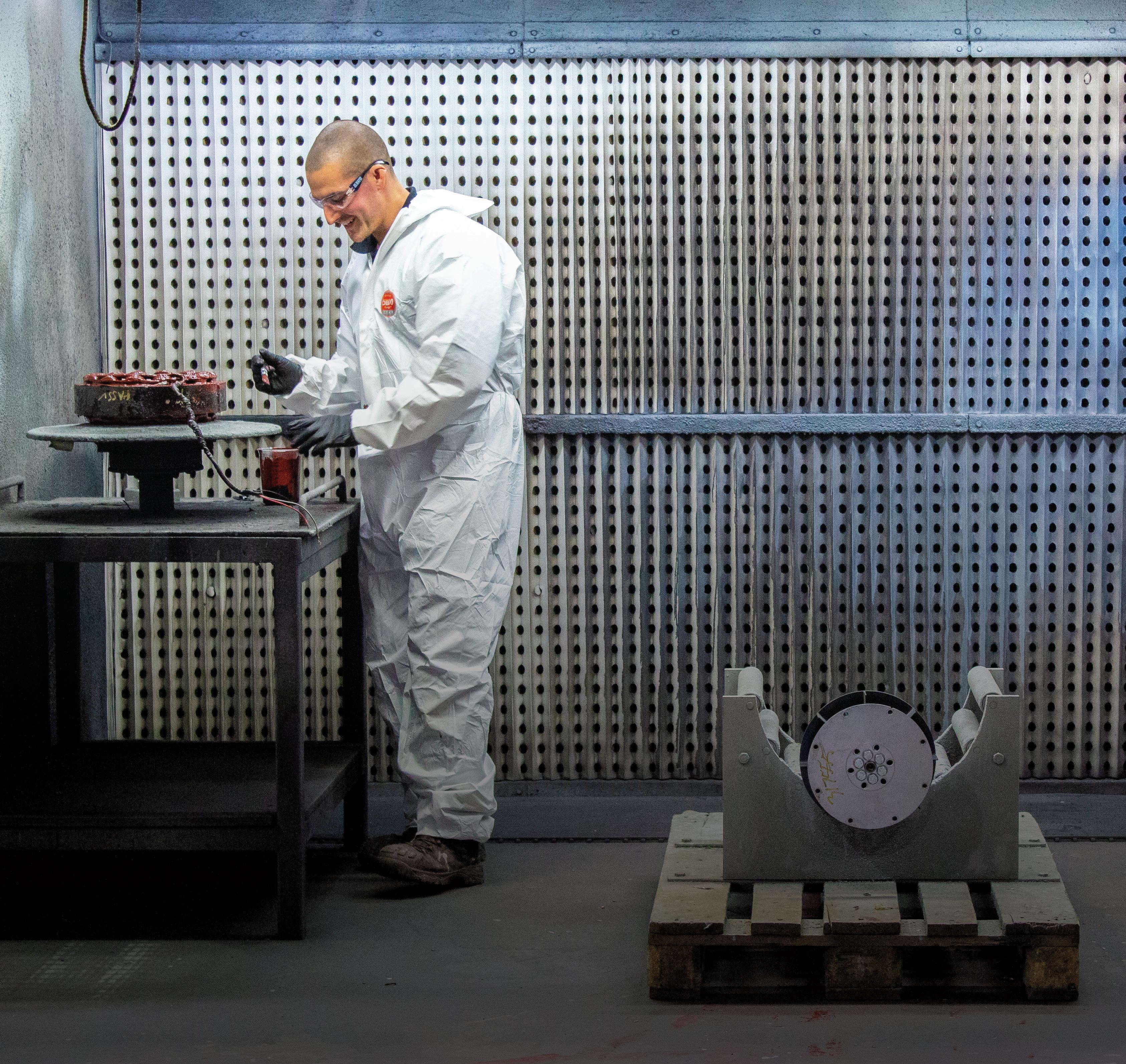

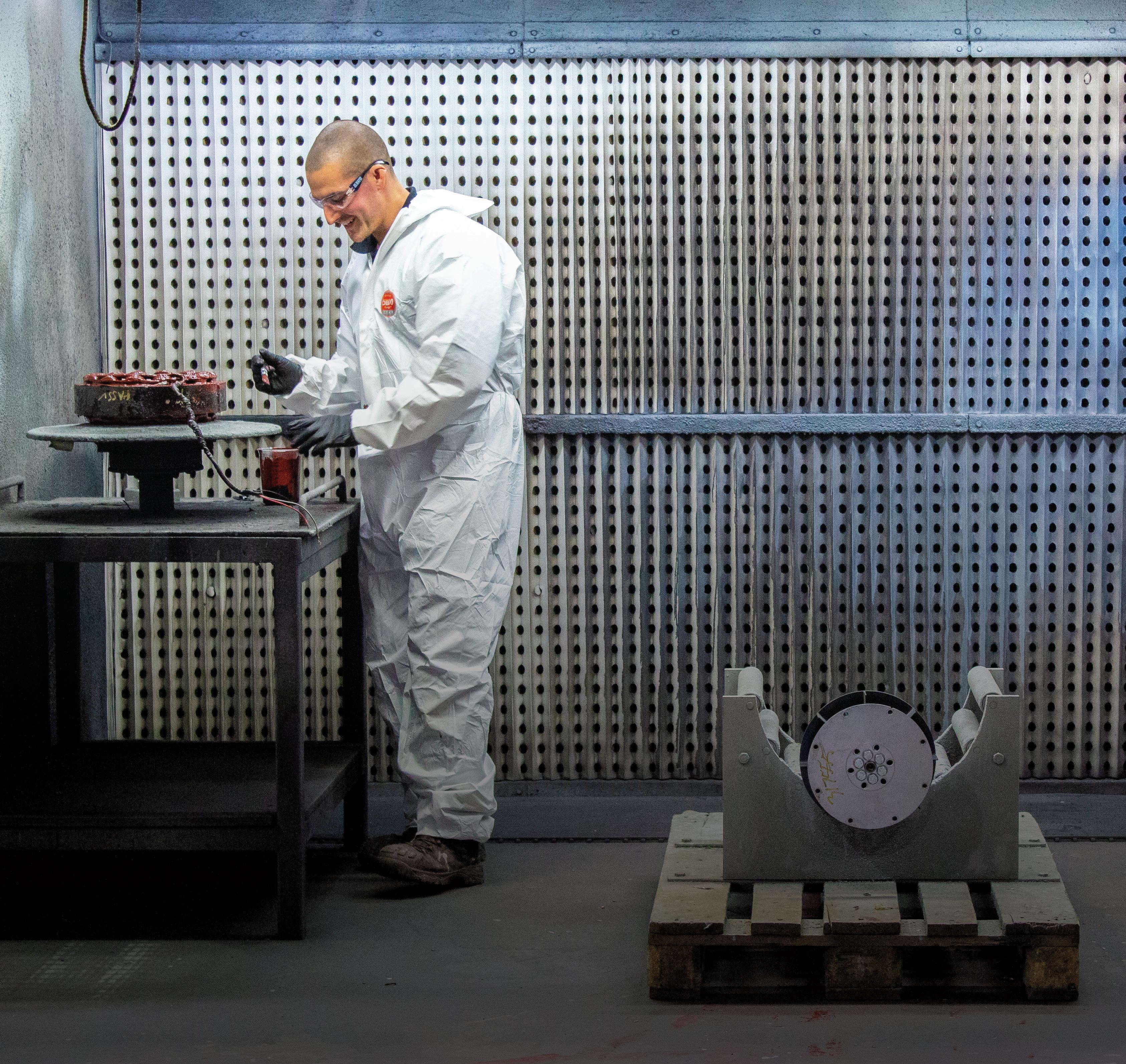

Construction of the three offshore platforms will be carried out in Saint-Nazaire, where Chantiers de l’Atlantique will double its production capacity, investing nearly €100 million in this expansion.

The company is set to acquire Europe’s largest paint cell, with a total area of 4600 sq m, and capitalise on its state-of-the-art industrial facilities, including its slipway equipped with gantry cranes lifting up to 1400 tons.

ITALY HALTS PV PANELS ON SOME AGRICULTURAL LAND

Italy’s new rules, part of a broader package of measures to protect farming and fisheries, have included a ban on the installation of photovoltaic systems with modules placed on the ground in areas classified as agricultural.

“We put an end to the wild installation of ground-mounted photovoltaic panels),” Agriculture Minister Francesco Lollobrigida told the media after the cabinet meeting that approved the measures.

Agricultural lobbies - key supporters of Prime Minister Giorgia Meloni’s right-wing government -- had long

called for limitations to the panels, saying they were incompatible with cultivation. In contrast, ecoassociations now accuse the government of undermining green goals agreed with partners from the G7 wealthy nations. Italy has committed to triple installed renewable energy capacity by 2030 and will phase out coal-fired power.

8 MAY-JUNE 2024 EURO POWER NEWS NEWS NEWS

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime across the whole product lifecycle, so you can be sure of reliable power generation, regardless of the operational conditions. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA FOR FURTHER INFORMATIO N VISIT WWW.MECCALTE.COM

TWO MTU 20V 4000 DS2750 GENERATOR SETS WILL FORM THE OFFICE COMPLEX POWERPLANT OF THE EUROPEAN COMMISSION IN LUXEMBOURG

Apowerplant is being provided for the Jean Monnet 2 building, the future office complex for the European Commission in Luxembourg City. This is a massive project that will house around 3,600 officials.

Once integrated by Energolux, two 2500 kVA gensets will provide emergency power to all securityrelated facilities within the building, as well as the technical systems required for its operation. The successful tests guarantee their reliability and performance in critical scenarios.

The company reports a satisfied customer and is said to ‘be proud to be part of building the infrastructure which will support the core activities of the European Commission’. Rolls-Royce/mtu has already announced the successful completion of Factory Acceptance Tests at Ruhstorf in Bavaria for two mtu 20V 4000 DS2750 generator sets, designated for the site.

Each diesel engine 380V – 11 kV/50 Hz provides prime power for stationary emergency use. The fuel consumption is optimised and the 16V4000G34F features water charge air cooling.

- Engine-generator set tested to ISO 8528-5 for transient response

- 85% load factor

- Verified product design, quality and performance integrity

- All engine systems are prototype and factory tested

Accessories available for each genset include:

- Control panel

- Power panel

- Circuit breaker/power distribution

- Fuel system

- Fuel connections with shut-off valve mounted to base frame

- Starting/charging system

- Exhaust system

- Mechanical and electrical driven radiators

- Medium and oversized voltage alternator.

Each engine-generator set is designed and manufactured in facilities certified to standards ISO 2008:9001 and ISO 2004:14001. The generator set complies to ISO 8528 and meets EC 60034-1, ISO 8528-3; IEC 60044-1. With each engine comes a declaration of conformity; EN55011, group 1, cl. B ; each sets meets NFPA 110.

Power rating: System ratings: 2600 kVA; accepts rated load in one step per NFPA 110; generator set complies to G3 according to ISO 8528-5; the generator set exceeds load steps according to ISO 85285. The engine is the Model16V4000G34F.

The Jean Monnet 2 building (also known as JMO2) is a future office complex for the European Commission under construction on Boulevard Konrad Adenauer in the European district of the Luxembourg City quarter of Kirchberg, Luxembourg (cost: €526,300,000). The complex will be composed of a welcome pavilion and two office buildings to be completed in two phases respectively; an 8 storey 180 metre long block and a 24-storey tower, connected at the basement and second storey levels. The construction site combines some of the plot of the previous building with an adjacent former open air car park. Upon completion, the Jean Monnet 2 building will enable the European Commission to consolidate the majority of its Luxembourg-based staff on one site.

NEW ENGINE TECHNOLOGY FOR H2 GENERATION PLANT IN GAMPERN, UPPER AUSTRIA

A combined heat and power plant in Upper Gampern, Austria, has just commissioned the world’s first 100% hydrogen storage facility in a porous underground reservoir.

RAG’s ‘Underground Sun Storage’ deals with up to 4.2 gigawatt hours of electricity produced in summer can be kept ready for winter in the form of green hydrogen.

Commissioning of the highly efficient, flexible Jenbacher hydrogen CHP plant in the 1 MW range has been taking place.

In winter, electricity can then be generated on-demand from the green energy reserves, and the waste heat can be used for heating purposes.

In this trailblazing project, INNIO and RAG are augmenting the entire value chain, focusing on seamless coordination between the generation, conversion, storage, and – most notably – supply of green energy.

In Gampern, Upper Austria, INNIO and RAG are demonstrating what can and must be done to manage the energy transition by securing a reliable supply of green energy throughout the year. The hydrogen cogeneration plant is a

key building block for the entire hydrogen ramp-up, because flexible, quick-start CHP plants can not only generate electricity as needed, but also produce the heat that is so important in winter.

This significantly improves efficiency while also facilitating the heating transition.

INNIO Group is a leading energy solution and service provider that empowers industries and communities to make sustainable energy work today. With its product brands Jenbacher and Waukesha and its digital platform myPlant, INNIO offers innovative solutions for the power generation and compression segments that help industries and communities generate and manage energy sustainably while navigating the fastchanging landscape of traditional and green energy sources.

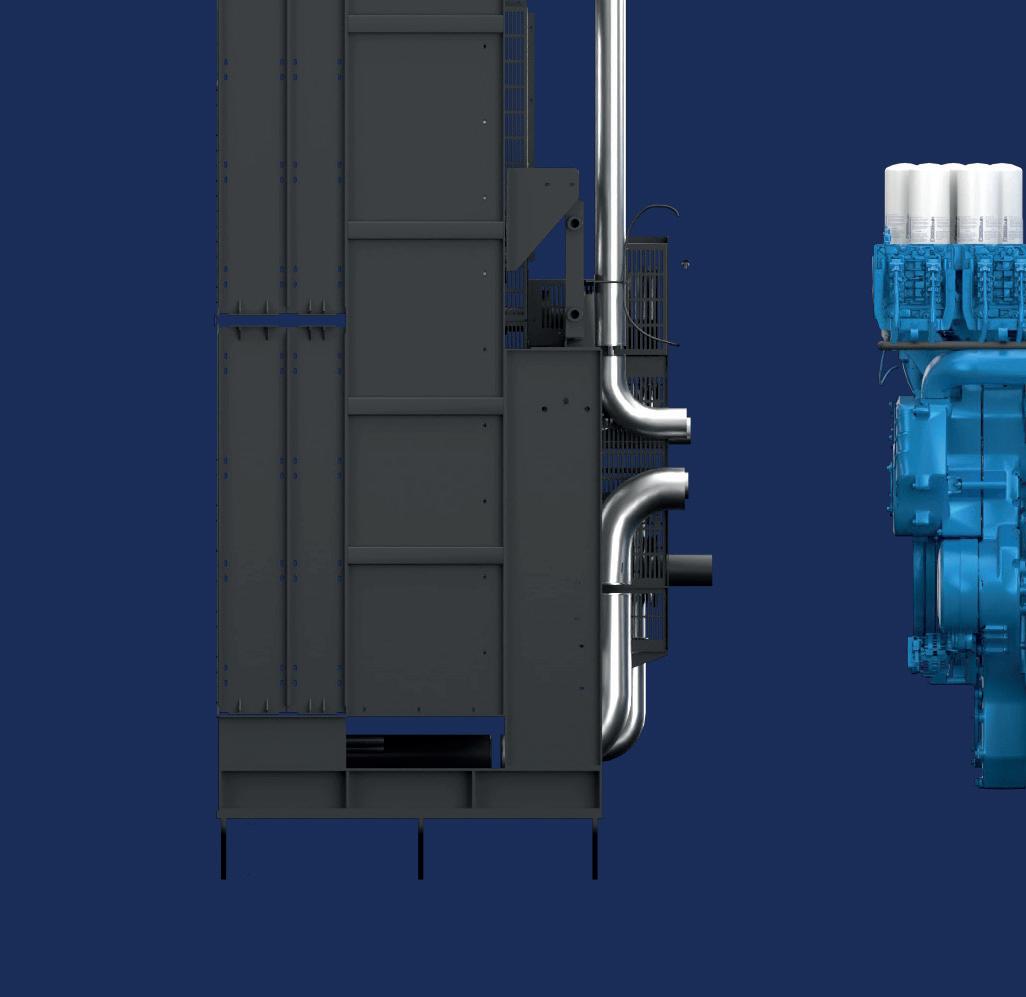

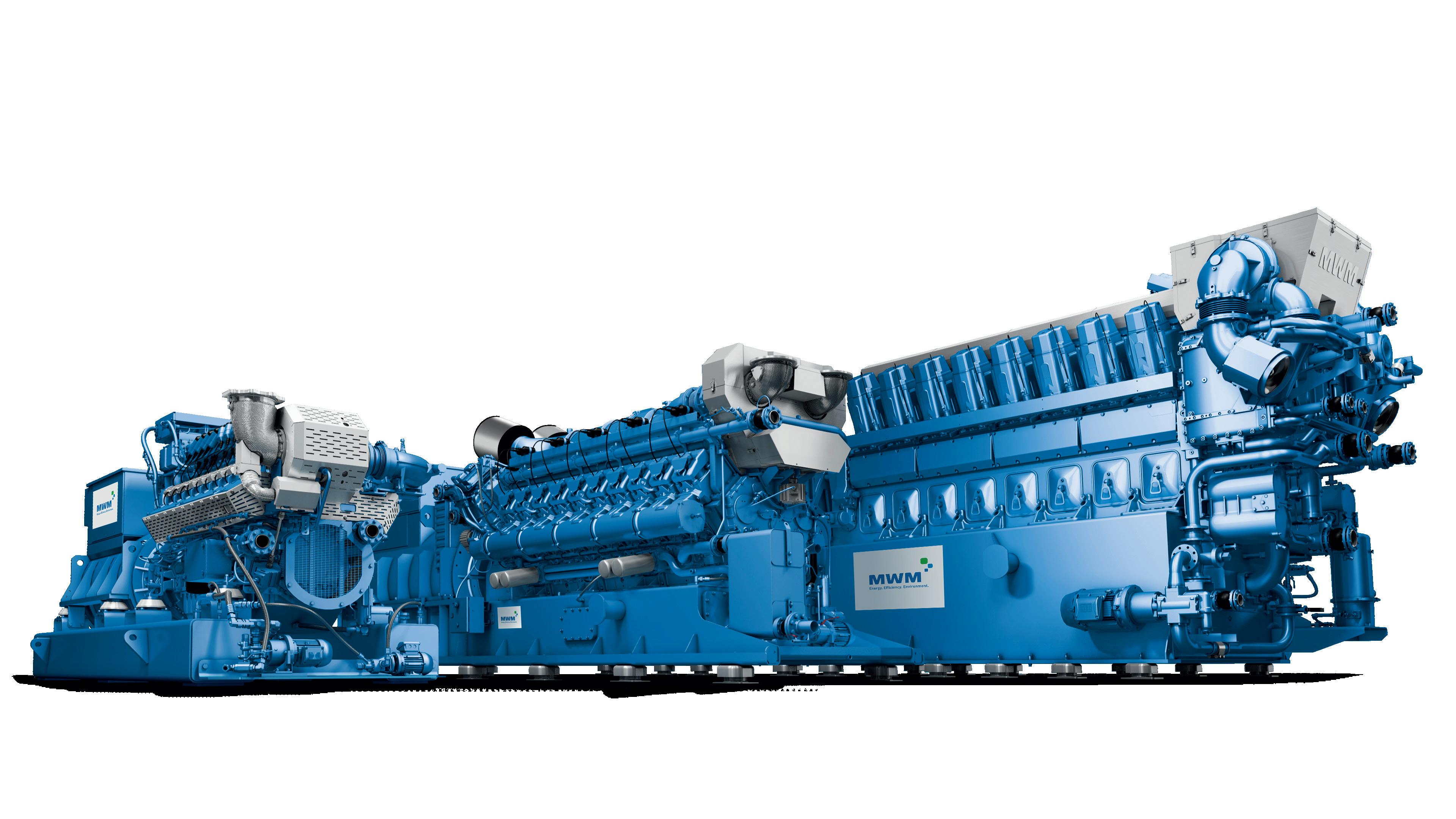

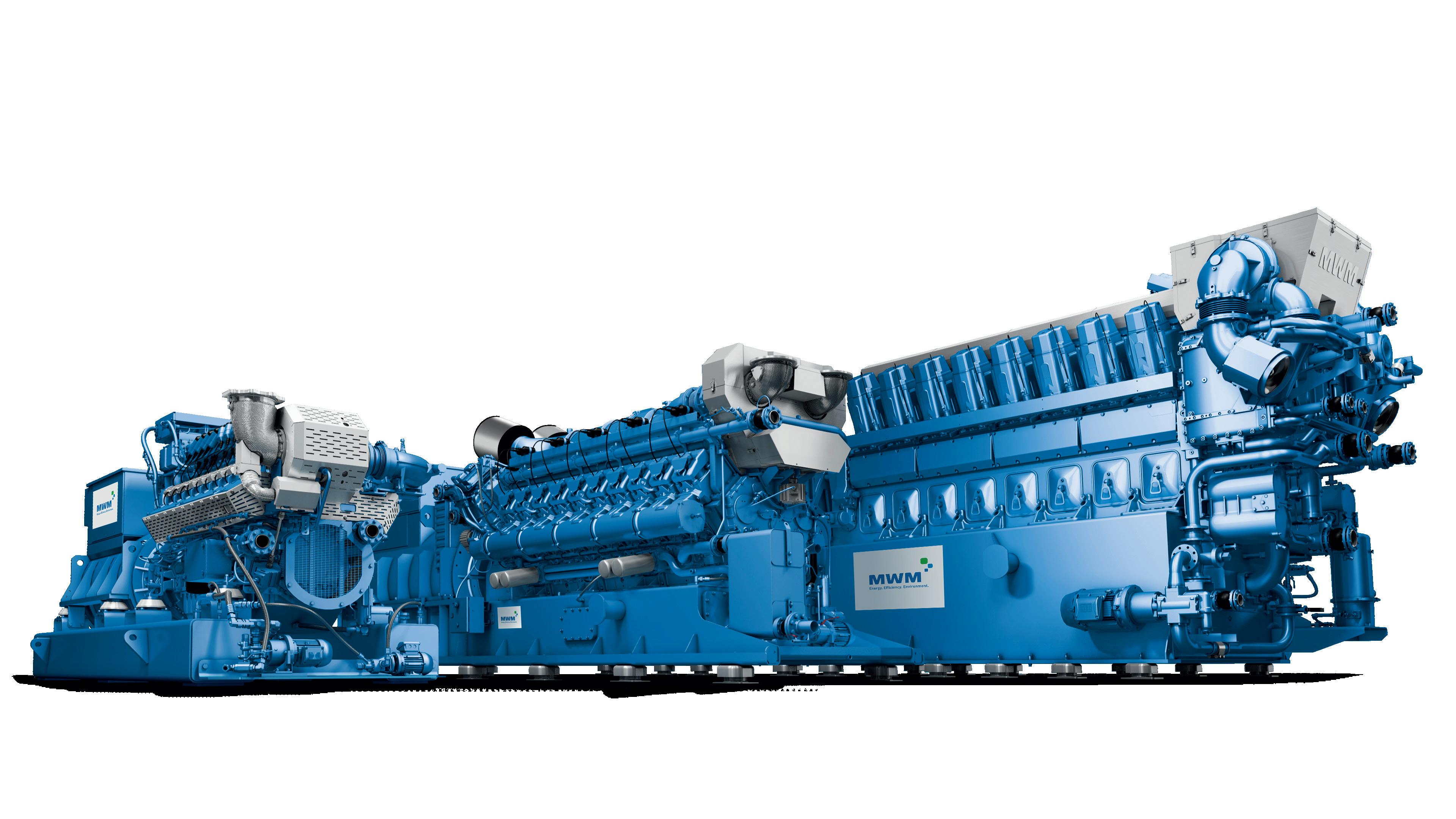

3MWE EUROPEAN-MADE GAS GENSETS ARE NOW POWERING A PLANT BELONGING TO A MAJOR SYNTHETIC

TEXTILE PRODUCER

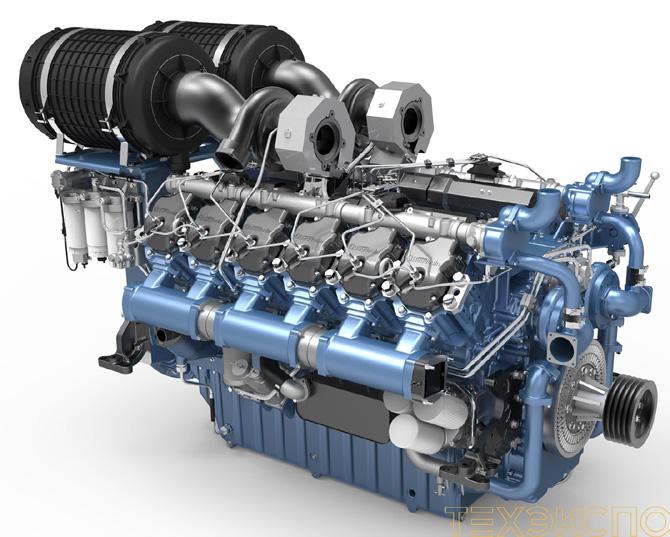

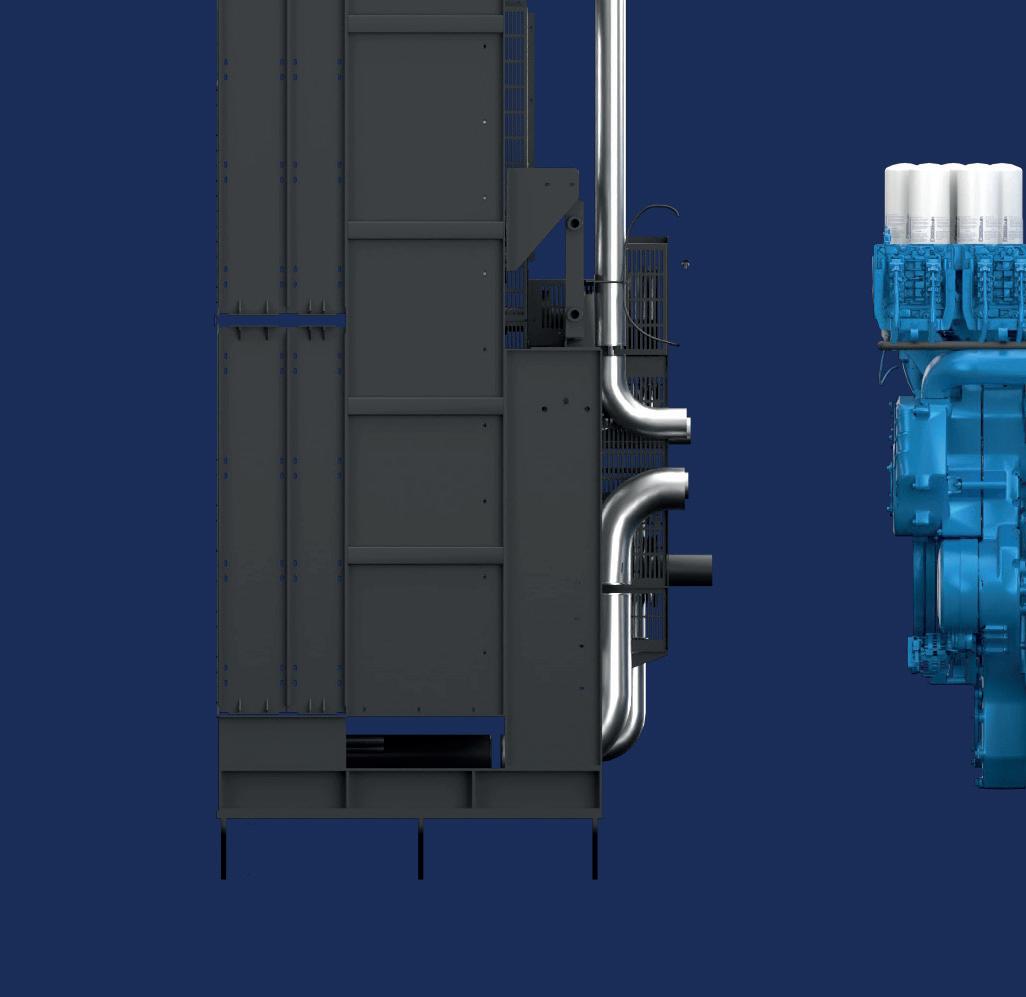

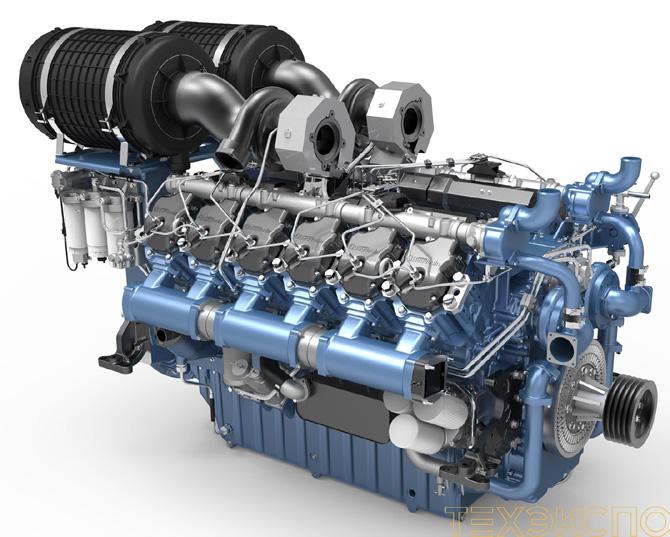

Five units of MWM (TCG 3020 V20) gensets were commissioned at one of the biggest synthetic textile industries based in Mirsharai, Chattogram.

The contract has involved 5 X TCG 3020 V20 units with a total capacity of 11.5 MWe.

Launched in 2019, the TCG 3020 offers more power and reduced oil consumption and can achieve an electrical efficiency of up to 45 percent.

The MWM TCG 3020 V20 gas genset achieves an output of 2.3MWe and offers a 15 percent performance increase from its predecessor model, the TCG 2020 V20. The new 3020 iteration benefits from reduced oil

consumption of 0.15g per kWe and high efficiency values, whilst also offering lower maintenance and installation costs. The flexible MWM TCG 3020 V20 gas genset is suitable for natural gas, biogas, landfill gas, and propane gas applications. The new MWM power genset enables an outstanding electrical efficiency of 45% for natural gas and 43.6% for biogas. electrical efficiency of 45 percent for natural gas and 43.6 percent for biogas.

10 MAY-JUNE 2024 EURO POWER NEWS NEWS NEWS

MWM 25H2-Kit

Operation with hydrogen.

New variants of the TCG 3016, TCG 3020 and TCG 2032 series enable natural gas operation with hydrogen admixture of up to 25 vol.%. Retrofit solutions for existing plants are also available.

www.mwm.net/25H2-Kits

DIARY - ENERGY EXHIBITIONS, SEMINARS &

7 -29 May 2024

Lisbon Energy Summit & Exhibition Lisbon, Portugal

3-5 June

Japan Energy Summit & Exhibition 2024 Tokyo, Japan

4-6 June

Caspian Power 2023 Baku, Azerbaijan

4 - 5 June 2024

UK Solar Summit 2024 Conference Novotel London West Hotel, London

11 - 12 Jun 2024

Energy Exports Conference 2024 Conference

P&J Live, Aberdeen

11-13 June 2024

European Sustainable Energy Week 2024 Brussels, Belgium

11-13 June 2024

Global Energy Show Canada 2024 Calgary, Alberta, T2G 2W1, Canada

19-21 June 2024

The Smarter E Europe 2024 Messegelände, Munich, 81823 , Germany

24 – 28 June

ASME Turbo Expo 2024

ExCel London, UK

21 - 22 May 2024

25-27 June

Reuters Global Energy Transition 2024 New York, USA

25 – 27 June Hillhead

Quarrying, Construction & Recycling Show Hillhead Quarry Buxton, Derbyshire SK17 9PR, UK

25 - 27 Jun 2024

InstallerSHOW 2024 NEC, Birmingham, UK

26-28 June

SPE Europe Energy Conference & Exhibition Turin, Italy

26 Jun 2024

PowerEx Live 2024

Golf Tournament

Belfry Hotel & Resort, Royal Sutton Coldfield, UK

Final deadline for Golf Tournament booking: April 30, 2024.

Please email enquiries to: richard@wipmagazines.com

27 Jun 2024

PowerEx Live MIDLANDS Conferences & Networking Event

Belfry Hotel & Resort, Royal Sutton Coldfield, UK

28 July 2024:

PowerAid Charity Football Day - UKGSA Event

Coalville Football Club, UK

14 Aug 2024

SR Solar Conference 2024 Conference

COSLA Conference Centre, Edinburgh, U

17 September 2024 - 18 September 2024

Solar & Storage Live Zurich Zurich, Switzerland

22 Aug 2024

York Races – Ebor Festival - UKGSA Hospitality Event, UK

19 Sept 2024

Cricket at Trent Bridge

UKGSA Hospitality Event, UK

24 September 2024 - 27 September 2024

WindEnergy Hamburg Hamburg, Germany

23 – 24 Oct 2024

The Showman Show, Newbury Showground, Berkshire, UK

23 - 24 Oct 2024

Hydrogen Technology Expo Europe Hamburg, Germany

24 Oct 2024

Smart Energy Conference & Exhibition 2024 ICC Belfast, Belfast, Northern Ireland, UK

OTHER EVENTS

23 - 24 Oct 2024

Renewable Energy Scotland Event 2024 Scottish Event Campus, Glasgow, UK

6 - 7 Nov 2024

NIBS Battery Conference Telford, Shropshire. UK

12 - 13 Nov 2024

Future Energy Wales 2024

International Convention Centre Wales, Newport, UK

13 - 14 Nov 2024

Future of Utilities: Smart Energy 2024 St Pauls, London, UK

13 - 14 Nov 2024

Energy Transition Summit 2024 London, UK

20-21 Nov 2024

DATA CENTRES IRELAND RDS Dublin, Ireland

3 - 14 November 2024

Solar & Storage Live Barcelona Barcelona, Spain

12 Dec 2024

PowerEx Live London Park Plaza Westminster Hotel, London SE1 7UT, UK

12 MAY-JUNE 2024 EURO POWER NEWS NEWS NEWS

26 Jun 2024 PowerEx Live 2024 Golf Tournament Belfry Hotel & Resort, Royal Sutton Coldfield 6

NOV 2024 NIBS DATA CENTRES IRELAND 20-21 NOV 2024 YORK RACES

AUG 2024 POWEREX LIVE - LONDON 12 DEC 2024 POWEREX LIVE - MIDLANDS 27 JUNE 2024

- 7

22

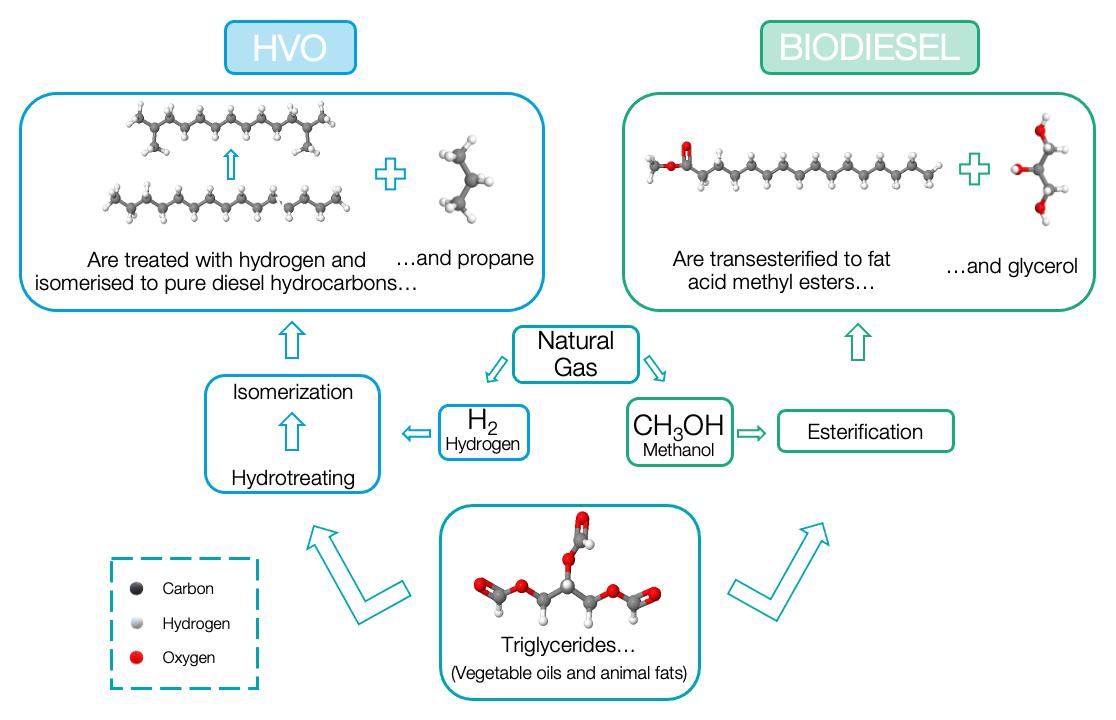

EUROPE’S FUEL OF THE FUTURE - IS IT LIKELY TO BE HVO?

HVO COMPARED WITH BIODIESEL

Hydrogenated vegetable oil is making its way into the market due to its numerous properties and is one of the paths towards the energy transition. In this feature Antia Míguez, Sustainability Coordinator at Genesal Energy, provides insights into this new fuel.

Electricity is by no means the main form of energy used, nor is it easy to bring electrification to all sectors, and although it is true that the advance of renewable sources is remarkable, these days 80% of the world’s primary energy demand is still based on fossil fuels, reports Antia Míguez, Sustainability Coordinator at Genesal Energy.

This is an issue, not only because of the high levels of emissions and their consequences on climate change, but also because of the finite nature of these fuels.

Genesal Energy is very aware that finding new sustainable fuels is an urgent priority for those sectors where electrification is not going to happen overnight.

Here is where HVO enters the scene. In recent years HVO has been positioning itself as one of the main alternatives to diesel.

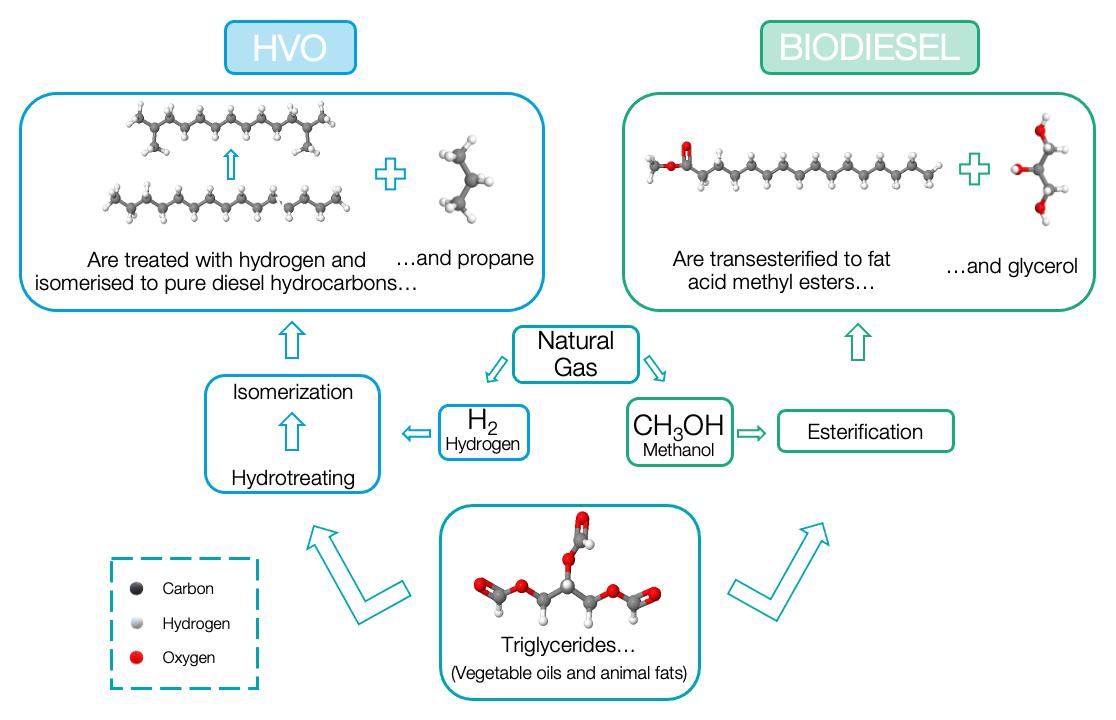

What is HVO?

Hydrogenated Vegetable Oil (HVO) is a secondgeneration biofuel. Although it has the words “vegetable oil” in its name, it can be produced from a variety of vegetable and non-vegetable sources:

- Used vegetable cooking oil (UCO - Used Cooking Oil).

- Waste animal fat.

- Tall oil, a byproduct of wood pulp manufacture.

- Non-food grade vegetable oils (rapeseed,

soybean and palm).

On their own, these oils are not considered effective fuels. However, through a process known as hydrotreating, it is possible to convert the fats in these oils into hydrocarbons almost identical to conventional diesel.

Is it the same as biodiesel?

No, biodiesel and HVO are different fuels. While both are based on triglycerides from vegetable oils and animal fats, biodiesel is made by esterification: the oily source is treated with an alcohol, usually methanol, and a catalyst.

This produces glycerine and a fuel made from fatty acid methyl esters or FAME (Fatty Acid Methyl Ester).

On the other hand, to obtain HVO, the oils are subjected to a hydrotreating process. Simply put, hydrogen is used to remove oxygen from the oil at high temperatures, splitting the fat molecules into separate chains of hydrocarbon molecules. The result is a stable fuel comparable to fossil diesel in both form and performance, making HVO superior to biodiesel as an alternative to fossil fuel.

What are the advantages of using HVO?

They include the following:

-If waste oils are used as source, and produced relatively locally, the use of HVO can result in a reduction of CO2e emissions by up to 90%.

- When burning HVO, emissions of carbon monoxide (COx) and other polluting particles are lower.

- Its service life is long: up to ten times longer than diesel.

- Its performance is maintained even at extreme temperatures (-30°C).

- It has good chemical characteristics. It is aromatic, low density, with a very high cetane number and no sulphur. In addition, its calorific value, and therefore its energy content, is higher than that of biodiesel.

- Unlike biodiesel, which needs to be blended with conventional diesel to work properly, HVO is a direct fuel, which can be completely replaced in most diesel units.

- Also in comparison, biodiesel is prone to degradation and needs very specific planning for storage. Only a single oil tank is needed to store HVO. In fact, conventional diesel tanks can be filled with HVO, and vice versa, so that if, for example, we are running on HVO, but it runs out and it is impossible to procure it quickly enough, we can switch back to diesel.

Different brands in the combustion engines and distributed energy worlds have already started to echo the benefits of HVO, certifying that their products are compatible with this biofuel.

For example, several companies have declared that all their Euro 5 and Euro 6 engines are compatible with the use of HVO.

“To

obtain HVO, the oils are subjected to a hydrotreating process. Simply put, hydrogen is used to remove oxygen from the oil at high temperatures, splitting the fat molecules into separate chains of hydrocarbon molecules. The result is a stable fuel comparable to fossil diesel in both form and performance.

If we have available an HVO that we know is not 100% sustainable - is it better to use it or to continue using fossil diesel? Do we look for an alternative, such as another type of biofuel or even a synthetic fuel?

These are difficult questions to answer that depend on many factors.

In order to facilitate decision making on the choice and use of fuels, Genesal Energy has created the “Greenesal Sustainability Assessment Scale for Fuels”

It is a tool that will allow us to evaluate the sustainability of fuels, so that it is not only easier to choose between the different options available, but it will also provide a clear idea of the real impact of each one of them.

In addition, the tool will fairly weight factors related to the three spheres of the sustainable development:

- Environmental sphere: raw material origin, GHG emissions, soil organic carbon, eutrophication, acidification, energy balance, biodiversity.

- Economic sphere: capital costs, operational costs.

- Social sphere: land rights, issues related to working conditions, relationship with local communities.

In this way, not only will it be possible to distinguish between different types of fuel, but it will also be possible to know which has a greater positive impact on the search for a sustainable future. genesalenergy.com

14 MAY-JUNE 2024 EURO POWER NEWS

BIOFUEL

30,000 KVA HVO GENSETS

FOR DATA CENTRES

With customers increasingly seeking sustainable products and new laws set to come into place, there’s no better time than the present to switch your diesel for HVO fuel to reduce up to 90% of net CO2 emissions. Ireland-based DE Power Solutions and Kohler Energy recently provided generators powered by HVO biofuel to major data centre sites across Ireland, reports EPN.

Kohler Energy and DE Power Solutions have jointly delivered hydrotreated vegetable oilcompatible (HVO) emergency generators with a combined output capacity of almost 30,000 kVA to customers in Ireland in a single week.

The deliveries represented the largest project commitment in Ireland across such a period. The HVO generators were supplied to three major data centre sites across Ireland: two international clients and also to the largest domestic data centre currently under construction.

The deliveries comprised:

* 4 x 4500 kVA, HVO renewable fuel generator, MV, containerised sets to site A

* 2 x 3100 kVA, HVO renewable fuel generator, LV, containerised sets to site B

* 2 x 2500 kVA, HVO renewable fuel generator, LV, containerised sets to site C

These HVO emergency generators are part of a much larger KOHLER Energy generator package on each site.

“Our thanks go out to the very professional team from Flynn Crane Hire for its excellent service on these projects, both in terms of logistics and first-class handling on site,” said Pat Cregan, DE Power Solutions . “Like DE Power, Flynn Crane Hire prides itself on quality and service, with particular emphasis on health, safety, and well-being.

“These installations further highlight how Kohler Energy is leading the way in the data centre market, with HVO-powered engines, excellent delivery times, the largest power node (4500 kVA) currently available in the data centre market, and direct project, design, planning and delivery.”

With a head office in Baldonnell, Dublin, and project and service divisions in Cork and Athlone, DE Power Solutions provides its

customers with a complete emergency power turnkey package offering a full range of on-site and off-site services such as design, delivery, installation, commissioning, maintenance, servicing, testing (such as load banking), and UPS supply.

Increasing

demand for HVO-powered generators

The project deliveries reflect the growing demand for emergency generators powered by HVO renewable fuel in Ireland and elsewhere as the shift to more sustainable mission-critical power intensifies.

HVO is made from waste products and residues such as vegetable oils, animal fats, and used cooking oils.

Since it is obtained from organic material from waste streams, HVO - unlike many firstgeneration biodiesels - does not contribute to deforestation. Also, it can reduce net carbon emissions by up to 90% across the lifecycle compared to fossil diesel, while delivering a 10% reduction in NOx.

In terms of the production process, impurities are first removed from the raw waste feedstocks. Then, the HVO is produced by hydrogenation and hydrocracking of the raw materials using hydrogen at high temperatures and pressures.

The end products are straight-chained hydrocarbons (paraffin) of consistent quality, similar to the chemical properties of fossil-based diesel.

The process is sufficiently flexible to convert a wide range of low-quality waste and residue materials to hydrocarbon-based drop-in fuels, making it a flexible diesel substitute for a broad range of diesel engine applications.

As the production process ensures that the final product is similar in grade and quality

to fossil diesel, HVO can be used in existing infrastructure, such as mission-critical generators, without any modifications.

And it has complete blending compatibility with fossil diesel, meaning the two fuels can be mixed directly in the tank without issue. HVO can be used immediately as the sole fuel supply for all KOHLER diesel generators, whether brand new or previously installed and in operation.

“A more local supply of HVO means reductions in carbon emissions usually associated with transportation. These investments help ensure a resilient supply chain for HVO. Increased supply will help reduce the price of the fuel –increasing its adoption rate in Ireland and elsewhere.”

There are also storage advantages. While first-generation solutions had a limited storage life of just six months, HVO is highly stable and not sensitive to oxidation, so it can be stored long-term. It is a high-cetane fuel, which provides advantages including better cold start, better combustion, and lower emissions. It can perform in harsh conditions down to -32°C, and with a minimum flashpoint of 61°C, it is safe to use in warmer climates.

Kohler Energy has approved its full range of advanced generators for use with HVO, supporting customers who are looking to decarbonise their operations as part of a transition toward zero carbon in the fight against climate change. Improved availability of HVO

The technical and performance characteristics of HVO mean it is becoming increasingly popular as a renewable fuel solution across a broad base of industries, including data centres.

Consequently, multi-million-dollar investments are being made in the global supply chain, and HVO is becoming more readily available.

New production facilities are regularly coming online. The use of waste feedstocks encourages shorter supply chains than first-generation biodiesels, which often rely on raw materials being shipped around the world.

A more local supply of HVO - closer to the end-user - means reductions in carbon emissions usually associated with transportation.

These investments help ensure a resilient supply chain for HVO, ensuring availability across markets. HVO can be produced in dedicated facilities that manufacture only HVO, or it can be coprocessed with fossil oil in refineries. Increased supply will help reduce the price of the fuel – increasing its adoption rate in Ireland and elsewhere. engines.kohlerenergy.com www.depower.ie

EURO POWER NEWS MAY-JUNE 2024 15

GENSETS

THE CONTINUALLY CHANGING FACE OF EUROPE

EUROPGEN is a cross-border organization registered as an official lobbying organization in the EU. It brings together Europe’s most prominent corporate companies and trade associations in order to form a powerful and unified voice for the European generating set industry. We detail the various working groups within Europgen, their aims & objectives.

T

he following is a brief rundown of the activities of the varrious groups which make up Europgen. The Europgen Emissions Working Group is headed by Working Group leader: Richard Payne – Cummins

The objective of the Emissions Working Group is to monitor EU and wider European exhaust emissions requirements for mobile and stationary generating sets.

Current topics: The prime mobile generating set legislation for the EU is the stage V non-Road mobile equipment regulation.

The prime stationary generating set legislation is the Medium Combustion Plant Directive (MCPD).

The MCPD sets baseline stringency and local regional or national legislation may set more stringent requirements. EUROPGEN monitors for these as much as is feasible. There can also be restrictions on the usage of mobile generating sets and EUROPGEN again monitors for these as much as feasible.

EUROPGEN works in conjunction with EUROMOT on these matters and future regulations. The liaison with EUROMOT is handled by the chair who is active in both associations.

Achievements:

EUROPGEN and other EU associations (FEM, CECE, CEMA, EGMF, EUnited) worked to obtain a 12-month extension deadline of the Stage V transition engines (<56kW and >=130 kW).

EU Directives Working Group

Working Group leader: Stuart Hawkins –Cummins

Objective: EU Directives Working Group reviews and monitors European regulations related to Product Safety. This working group is monitoring and providing feedback into the consultations on the revision of the Machinery (MD), Low voltage (LVD) and Electromagnetic Compatibility (EMCD) directives.

Current topics: The consultant’s report on the effectiveness and applicability of the MD to new machinery technology such as Artificial Intelligence (AI), Cybersecurity and robotics has been published.

Europgen is focusing on any changes to the definition or concept of Partly Complete machinery and the provision of Instructions as we move from paper to digital solutions.

Europgen has been represented at the Machinery Safety Working group by our experts selected from Europgen member companies, with the intention to monitor and influence revisions to the Machinery Directive that are relevant to the appropriate sector.

Standards Working Group

Working Group leader: François Lesaulnier –KOHLER

Objective: Standards Working Group reviews and monitors the applicable standards to generating sets. We aim to influence authors

To assist with GRID CODE compliance certification, different organizations such as CENELEC, ISO, FGW and UL are working on releasing test and certification standards.

standards to further the development and evolution by working in the interest of generator set manufacturers and their suppliers.

The working group also consists of members who actively influence the development of EN or ISO standards such as the ISO 8528 series. Some members are active either as chairmen or as members of working groups formed within the ISO TC70 committee.

Grid Codes Working Group

Working Group leader: Keith ChambersCaterpillar

Objective: The Grid Codes Working Group aims in constantly monitoring the grid code changes in Europe and updates any changes and their effects to generator manufacturers. The Working Group also consists of members who are actively influencing grid code compliance testing standards such as ISO 8528-6 and EN 50549-10.

Current topics: Grid regulations for power generating systems connecting to a national transmission/distribution system are now mandatory in many parts of the world and may require power generating facility to obtain third party certification ahead of grid connection.

To assist with GRID CODE compliance certification, different organizations such as CENELEC, ISO, FGW and UL are working on releasing test and certification standards to meet local grid code requirements.

Currently there is no one set of procedure to ensure that generating set can be certified to meet all individual European countries regulations.

Background: Introduced in 2009, the EU Third Energy package established a process for creating set of harmonized rules for the operation of the gas and electricity sector within Europe. These new network codes were intended

16 MAY-JUNE 2024 EURO POWER NEWS EUROPGEN

to ensure that the energy sector was secure and stable, whilst promoting decarbonization and creating competitive markets to benefit consumers.

The Requirement for Generators directive (RfG 2016/631) defines technical parameters required to be fulfilled by Power generation facilities when connected to grid. RfG 2016/631 is arranged in four tiers based on voltage connection and plant capacity.

The simplest requirements for the lowest capacity generators require controls on active power output and requirements gets stringent with increasing bands, with highest band requiring to operate through worst network faults.

This Directive came into force in 2016 and regional implementation of 2016/631 applies to all new connections and existing connections which are significantly modified.

The precise details of the requirements, including bandings have been left to national discretion. Entso-e is monitoring national level implementation and providing updates on its website.

ROHS

/ WEEE Working Group

Working Group leader: Ciaran O’Flaherty –Caterpillar

Objective: ROHS / WEEE Working Group reviews and monitors the chemical compliance status within Europe. It aims to influence authors of industry, legislative powers, and standards to further the development and evolution of generator sets and their components part by working in the interest of generator set manufacturers and their suppliers.

Current topics: Recent work includes working with EUROMOT industry body on the engine bearings lead exemption.

In the near future the EU RoHS directive will be recast; work is currently at an early stage in the European Commission but we are monitoring their proposals and providing input into any consultations they run, as well as participating in any working group set up by the European Commission.

Key areas that are monitored are Restriction

of Hazardous Substances (RoHS), Registration Evaluation Authorization and restriction of CHemicals (REACH), relevant aspects of the EU circular economy action plan, the EU Green Deal relevant to Generator Sets and the Waste Framework Directive.

Noise Working Group

Working Group leader: Arnaud Le Floch –KOHLER

Objective: in view of the evolution of the noise directives, the objective of this Working Group is to be informed of current or future changes and to actively influence the European Commission through our participation in the expert working groups of the European Commission and Orgalim.

Current topics: The next revision of the OND has been in preparation since 2015 and is intended to be more restrictive: lower allowed sound power levels and an increased constraint on powers greater than 400 kW.

As generator set manufacturers, we have to guarantee healthy products for customers but at the same time, we have to remain vigilant about the developments of the OND so that they do not become overly restrictive and remain realistic. The changes must be reasoned and acceptable.

If we look further, the European Commission takes now into account very precisely the harmful effects of transport noise on our health in a brand-new Directive, 2020/367/EC and the next step is the industrial noise, including generating sets.

Even if the generating sets will not be impacted in the coming years by this new directive, we can expect new regulatory constraints at the end of the 2020s, to consider the effects of noise on the health of users.

In addition, some members of the Noise Working Group are also involved in writing of ISO standards currently in progress (such as ISO 8528-10, which defines noise test codes for generating sets).

Background: the European Commission has more and more focused on the topic of noise over the past 20 years. All the generating sets manufacturers were significatively impacted when the OND came into force in 2000, with impacts on the design to reduce noise emissions and laboratory tests with additional costs. But we must keep in mind that it was also an opportunity to make our products better and allowed customers to distinguish between the manufacturers who have the know-how and the others.

EUROPGEN

“EUROPGEN

is a crossborder organization registered as an official lobbying organization in the EU. It brings together Europe’s most prominent corporate companies and trade associations in order to form a powerful and unified voice for the European generating set industry. Its role is to promote the interests of the European generating set industry in its relations with customers, suppliers, EU regulatory authorities and government organisations. It also negotiates and liaises with European institutions and appropriate associations.”

Cyber Security Working Group

Working Group leader: Vitor Lory- DEIF

Objectives: Provide a framework for the challenges met by today’s technology in cybersecurity aspects due to growing requirements.

Influence and provide customers with requirements and recommendations for testing aspects to meet the regulations and directives to demonstrate compliance.

Recommendation to a road map for Cybersecurity implementation to address speed to market aspect.

Energy Storage Working Group

Working Group leader: Massimo BrottoADE Power

Objective: The objective of the WG is to improve our understanding of European Directives and regulations, as well as to identify best practices and challenges for ensuring compliance.

EUROPGEN MEMBERSHIP

Membership is open to any companies, trade associations, and any trading partner within the power industry in Europe representing the generating set industry at a national level.

OBJECTIVES:

To promote the interests of the European generating set industry in its relations with customers, suppliers, EU regulatory authorities and government organisations.

To negotiate and liaise with European institutions, appropriate associations and organisations involved in the genset industry

To facilitate the agreement of European and International Standards for genset products and related services.

To ensure the highest standards for the genset industry’s products and services

To provide a forum for the exchange of non-competitive information.

To lobby in accordance with the EU’s code of conduct.

To inform and influence any new framework guidelines for network codes.

To be a first warning system for any legislative guidelines that will affect the industry.

To provide advice, guidance, information and representation for the generating set industry. The Association is registered as an official lobbying organisation in the EU. Transparency registration number : Number: 05847066277-30. https://europgen.eu/

EURO POWER NEWS MAY-JUNE 2024 17

Europgen is a cross-border organisation registered as an official lobbying organisation in the EU.

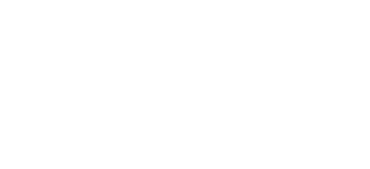

POLAND CHP PLANT PRODUCES ELECTRICITY & HEAT USING LIQUEFIED NATURAL GAS

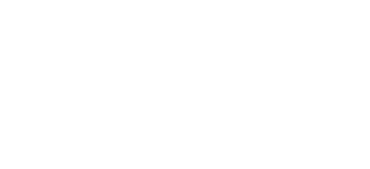

A CHP plant with an MWM gas genset ensures high mushroom yields all year round at moderate energy costs for the mushroom producer Hajduk Group Sp. z o.o. in Poland. Polygeneration makes it possible.

Poland is the world’s leading exporter of mushrooms and truffles, ahead of China (Statista 2022), and the market leader in European mushroom production.

One of Poland’s leading mushroom and mushroom substrate producers is the Hajduk Group Sp.z o.o. . Hajduk Group produces around 160 tonnes of mushrooms per week in four cultivation plants.

As mushrooms are energy-intensive in production, the company already invested in a CHP plant in 2018.

The cogeneration plant with an MWM TCG 2020 V16 gas genset was supplied by the official MWM distributor in Poland, Centrum Elektroniki Stosowanej CES Sp. z o.o..

Using polygeneration, the plant produces electricity and heat but also cooling and steam for mushroom cultivation.

Best conditions for mushroom cultivation

For a year-round harvest, mushrooms need stable growing conditions with the proper humidity and temperature. Typically, this means cooling in summer and heating in winter with the help of air conditioning.

Mushrooms are energy-intensive to produce. The energy costs of the production facilities, therefore, significantly impact the mushrooms’

final price. To keep these costs as low as possible, the polygeneration plant supplied by Centrum Elektroniki Stosowanej CES Sp. z o.o. is based on CHP. Liquefied natural gas is used as fuel.

Agricultural production plants far from conurbations and large cities often have limited connection options to the natural gas grid.

To operate a CHP plant, Hajduk Group relies on LNG for its CHP plant with a capacity of over 1.5 MWe. With this solution, polygeneration plants can be installed almost anywhere.

Engine exhaust heat for cooling

Thanks to the additional equipment, the CHP plant generates steam and cooling, electrical energy, and heat. The plant is powered by an MWM TCG 2020 V16 gas genset with an electrical output of 1,560 kW and a thermal output of 1,580 kW.

In the cooling halls where the mushroom substrate is produced, an absorption chiller uses the exhaust heat from the MWM gas genset to generate cooling for the halls.

The absorption chiller has a capacity of 720 kW. Steam is used to sterilise the refrigeration halls between production cycles.

For this purpose, the high-temperature heat of the exhaust gases is used in the steam generator,

“ In typical operation, the CHP plant with the MWM gas genset covers the entire demand for heating, cooling, steam, and electricity of the production facility at Hajduk Group. Part of the electrical energy is used on hot summer days for additional cooling. In winter, the halls can, in turn, be heated with heat from the CHP plant.”

which supplies 1,060 kg/h of steam at nine bar pressure. The hot water is also used for washing and other technological purposes.

CHP plant enables an independent and flexible energy supply

In typical operation, the CHP plant with the MWM gas genset covers the entire demand for heating, cooling, steam, and electricity of the production facility at Hajduk Group.

Part of the electrical energy is used on hot summer days for additional cooling. In winter, the halls can, in turn, be heated with heat from the CHP plant.

The polygeneration system offers flexibly controllable energy generation with a heat and cooling supply.

This allows Hajduk Group to maintain optimal production conditions for the popular edible mushrooms all year round while saving energy costs through the combined production of the different media.

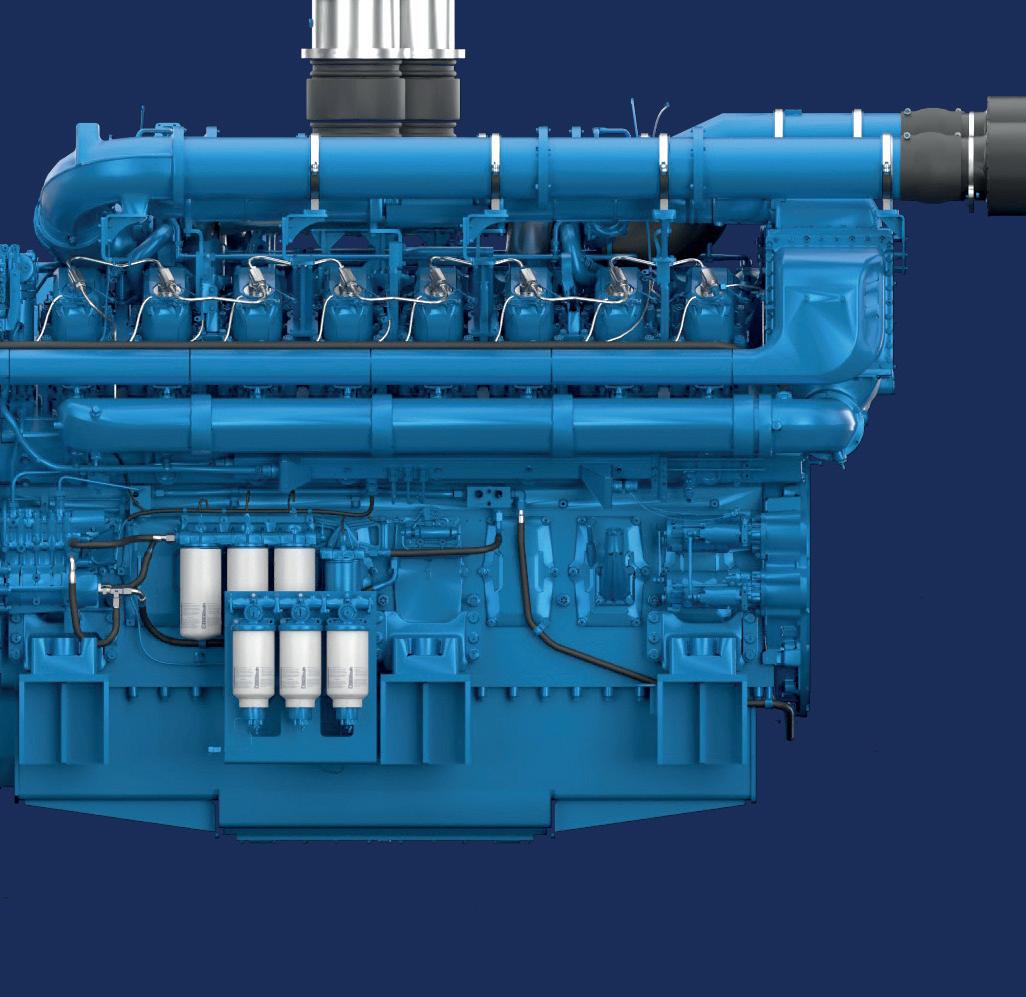

The MWM TCG 2020 V16 gas genset

The MWM gas engines of the TCG 2020 series are perfectly geared to the challenges of a dynamic market environment. Models in the output range of 1,000 – 1,560 kWel meet the high requirements of a broad range of applications and offer efficiency, reliability, flexibility and environmental sustainability, together with low lifecycle costs and high profitability.

Offering the best electrical and thermal efficiency in its class it runs on all gas types: natural gas, biogas, mine gas, landfill gas and sewage gas. www.mwm.net

18 MAY-JUNE 2024 EURO POWER NEWS

CHP

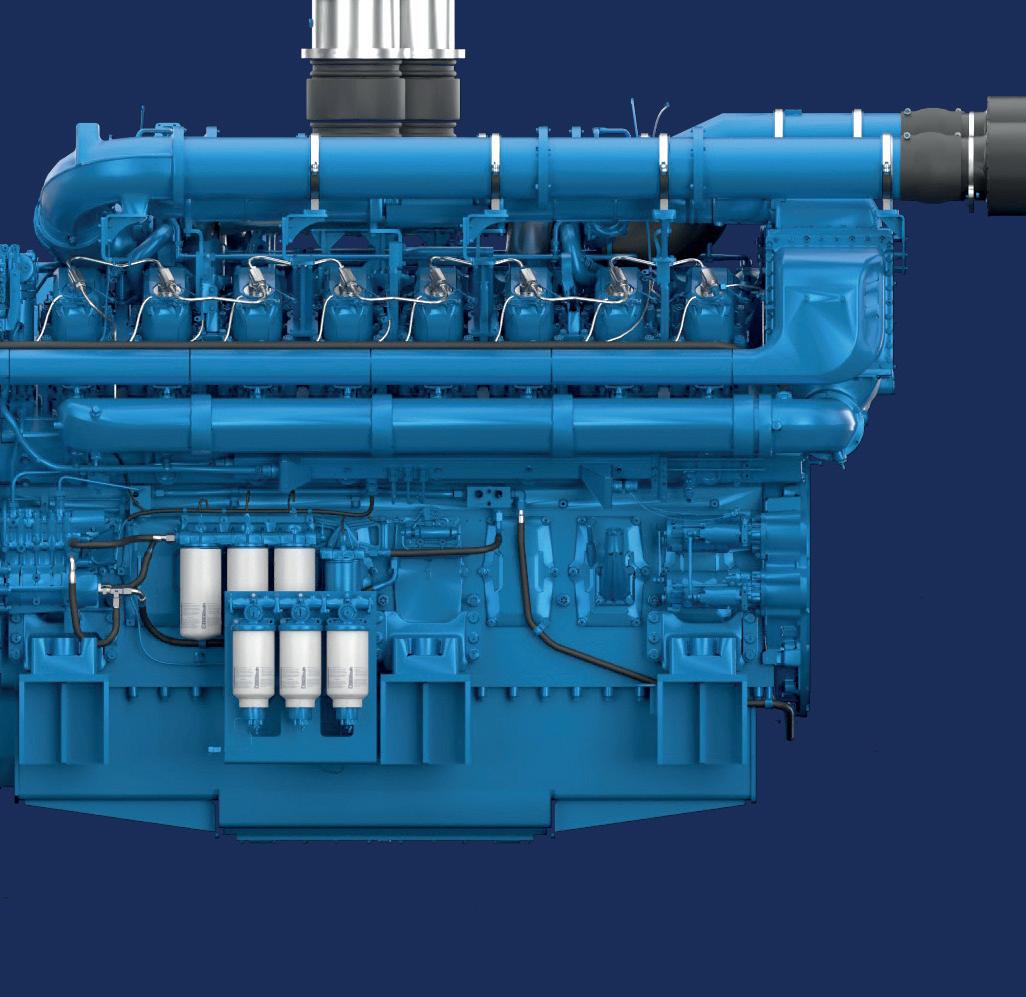

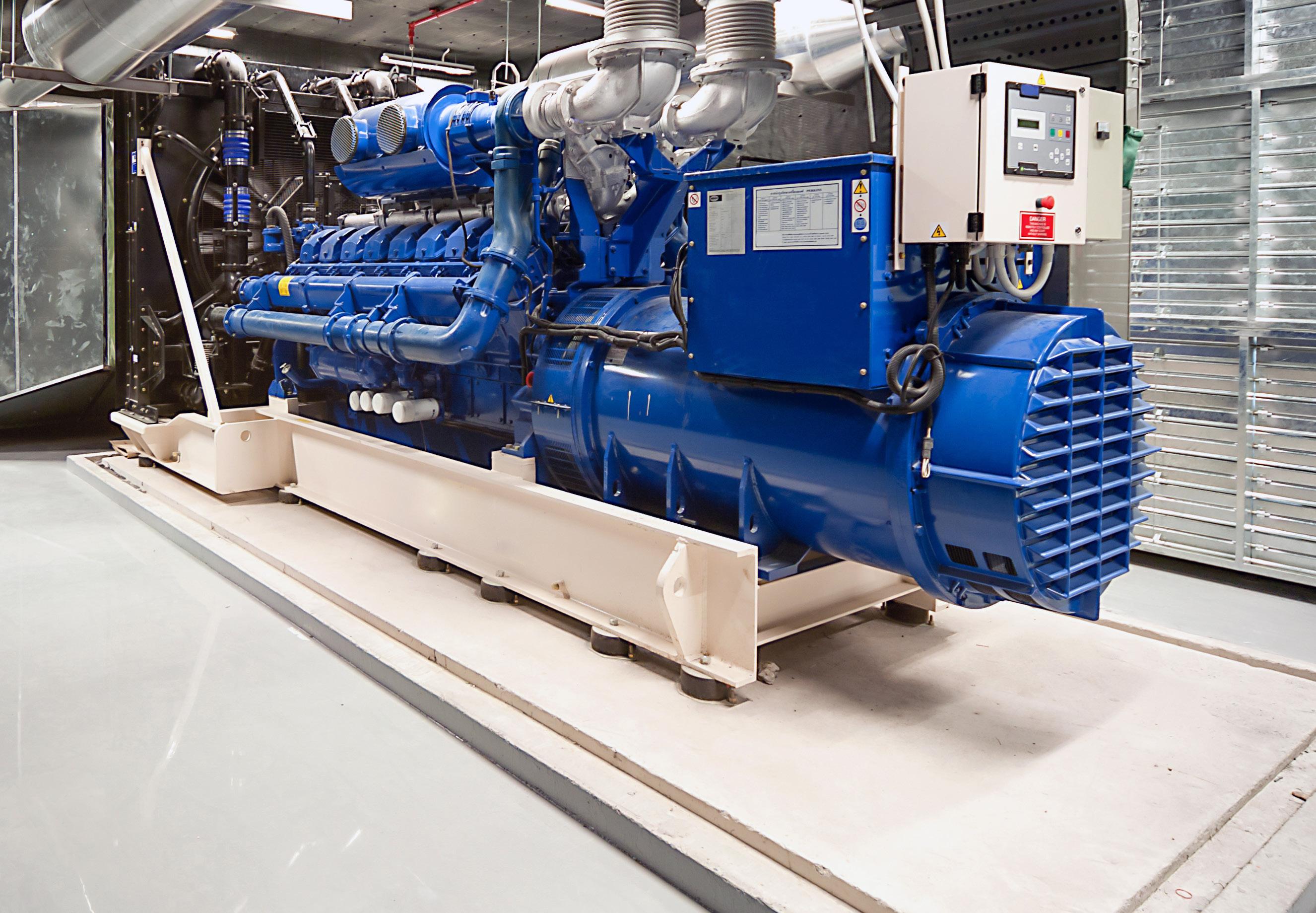

POWER PLANT PROVIDES GRID BALANCING SERVICES IN ROMANIA

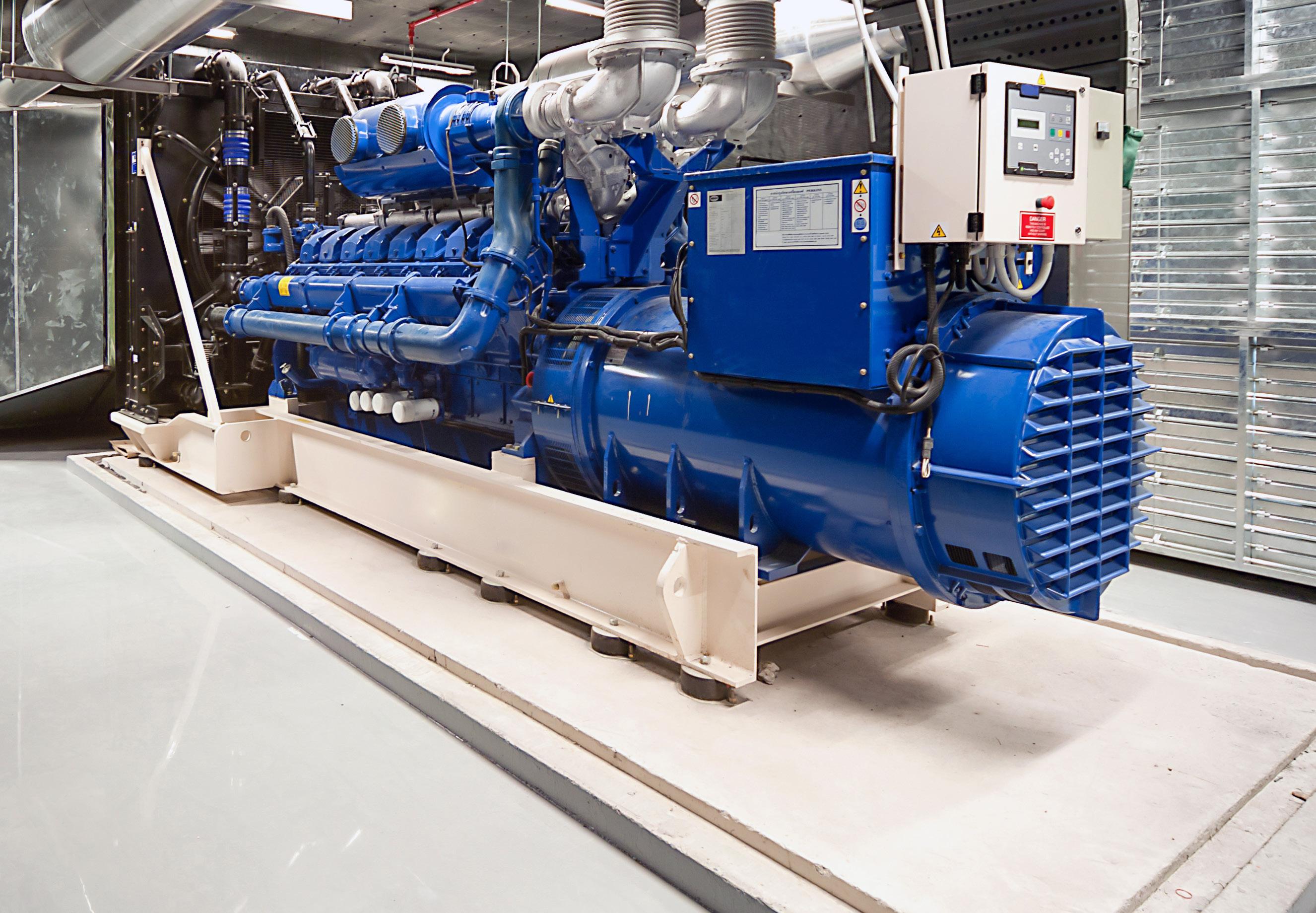

INNIO & Clarke Energy have supplied six INNIO Jenbacher generators to Romania’s energy sector. Romania has set ambitious targets for renewable energy, aiming to increase its share in the total energy mix. Wind energy has seen substantial growth, with numerous wind farms in operation, while CHP is becoming increasingly important, reports EPN.

The Six INNIO Jenbacher JMS 620 GS N.LC

– v.J02 generators have been supplied to Romania by INNIO & Clarke Energy.

Romania’s energy sector is poised to increasingly rely on hydropower, wind, and solar energy.

These renewable sources, however, are subject to the unpredictability of wind, sunlight, and drought conditions. This variability places significant pressure on the Transmission System Operator (CNTEE Transelectrica SA), which is tasked with ensuring the safety and stability of the National Electricity System.

As investments in renewables grow, enhancing investments in peaking / grid balancing capacities becomes critical to address the strains faced by the Transmission System Operator.

NAVIOS Investment, a company specialising in large-scale energy production investments, has recognized the shortfall in grid balancing capacities in Romania. In response, the company initiated investments in this sector starting in

2022. Clarke Energy Romania serves as the EPC contractor for two 20 MWel power plants developed by NAVIOS Investment.

Located in Racari, Dâmbovița County, these projects are designed to provide grid balancing services to the National Energy System of Romania.

The first phase of this project is now fully operational and is managed by Energy Innovative Solutions S.R.L (EIS), a subsidiary of NAVIOS Investment.

The second phase of the project is currently progressing in Racari and is overseen by Restore Energy SRL, another entity within the NAVIOS Investment SRL portfolio.

Client: Energy Innovative Solutions S.R.L Capacity: 20.15 MW

Location: Răcari, Dâmbovița, România

Industry: Grid Balancing (natural gas fuel)

Commissioned: Scheduled Summer 2024

Installation by: Clarke Energy Engine Type - 6 x INNIO Jenbacher JMS 620 GS

“The J620 is the Type 6 family’s “workhorse”, a V20-cylinder efficient power generation solution, with power output of up to 3,360 kW and electrical efficiency up to 45.9%. Type 6 engines are designed with features which enhance heat recovery, assure combustion & reduce emissions.

JMS 620 GS N.LC – v.J02 generators

The J620 is the Type 6 family’s “workhorse”, a V20-cylinder efficient power generation solution, with power output of up to 3,360 kW and electrical efficiency up to 45.9%.

Type 6 engines have been esigned with features which enhance heat recovery, assure stable combustion, reduce emissions, and increase efficiencytaking the Jenbacher line to new levels of performance.

* A centrally-located purged precombustion chamber helps provide optimal ignition conditions.

* The spark plug ignition energy is amplified in the pre-combustion chamber, facilitating stable and reliable combustion.

* Miller valve timing creates reduced compression temperature and an increased safety margin to knocking limits, providing improved ignition timing and high efficiency.

Combined Heat and Power Module (CHP Module) solutions based on the 620 are said to allow customers to generate power and heat simultaneously at a very high total efficiencies, reaching 90% and even more.

CHP Modules can generate hot water or steam at various parameters and can be integrated with an existing heat infrastructure. Users can select the option that best fits a project’s needs among the various heat recovery schemes provided by Jenbacher.

The scope of supply can be extended further with various balance of plant options (BOP) offered by Jenbacher. These CHP Modules can be installed inside a building or inside a container, depending on site requirements. www.innio.com

www.clarke-energy.com

Răcari, Dâmbovița, România

20 MAY-JUNE 2024 EURO POWER NEWS

CHP

The UFR1001E system-disconnection relay monitors voltage and frequency in single or three-phase networks.

• Presetting per G99/98, values as per the standard pre programmed

• Under and overvoltage monitoring 40…520 V

• Under and over frequency monitoring 45…65 Hz

• Monitoring of Rate of Change of Frequency (ROCOF, df/dt)

• Monitoring the voltage quality (10 minute average value)

• Response time adjustable 0.05 … 130.0 s, individual setting for each limit

• Fail-safe, with monitoring of the connected section switch (can be switched off) 2 automatic restarts on error

Supports the mains synchronisation when using generators Measurement 3 phase 3 or 4 wire systems or single phase Self-test

• Third Part Independently tested Compliant to G99/98 by Bureau Veritas

Start today at power.fgwilson.com

SIZE, FIND AND CONFIGURE YOUR GENERATOR INSTANTLY WITH POWER CENTRE FROM FG WILSON