SEPTEMBER

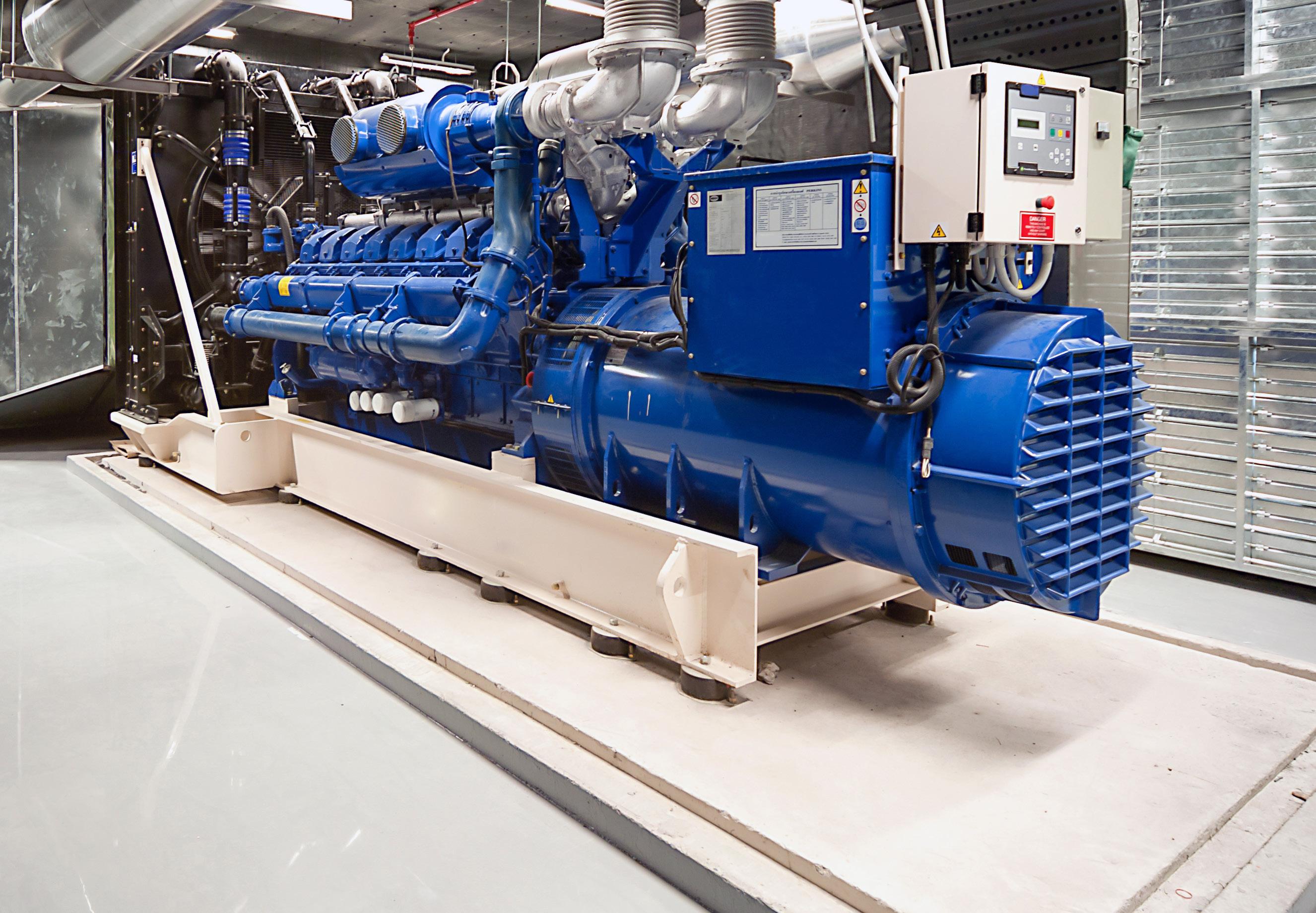

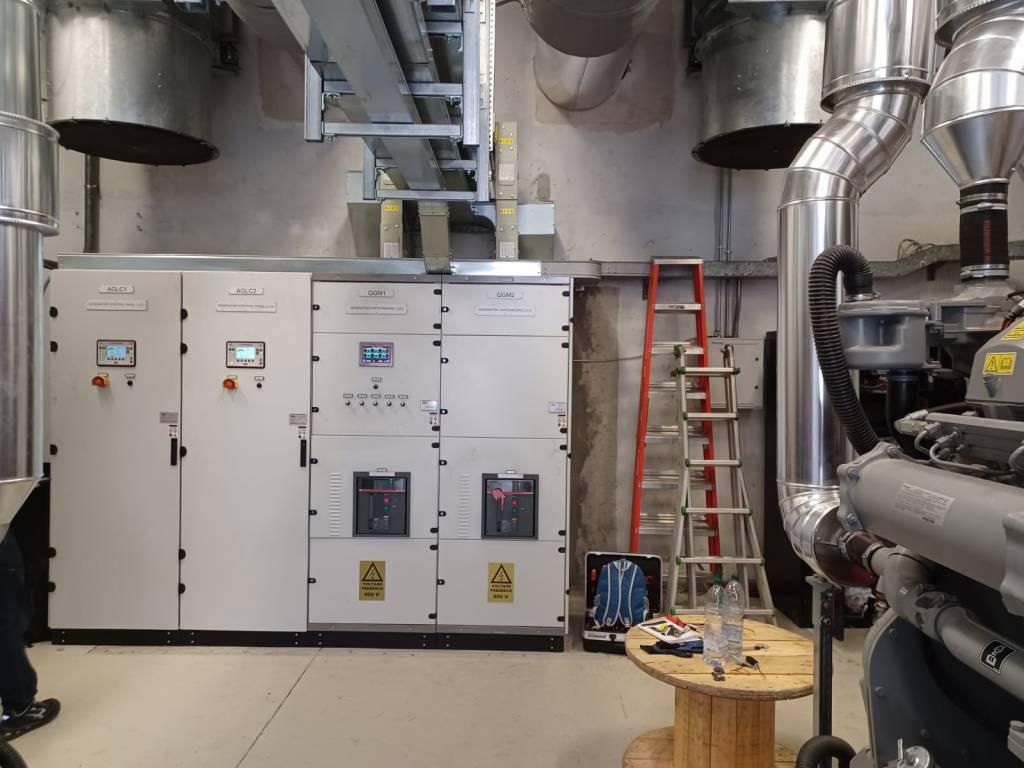

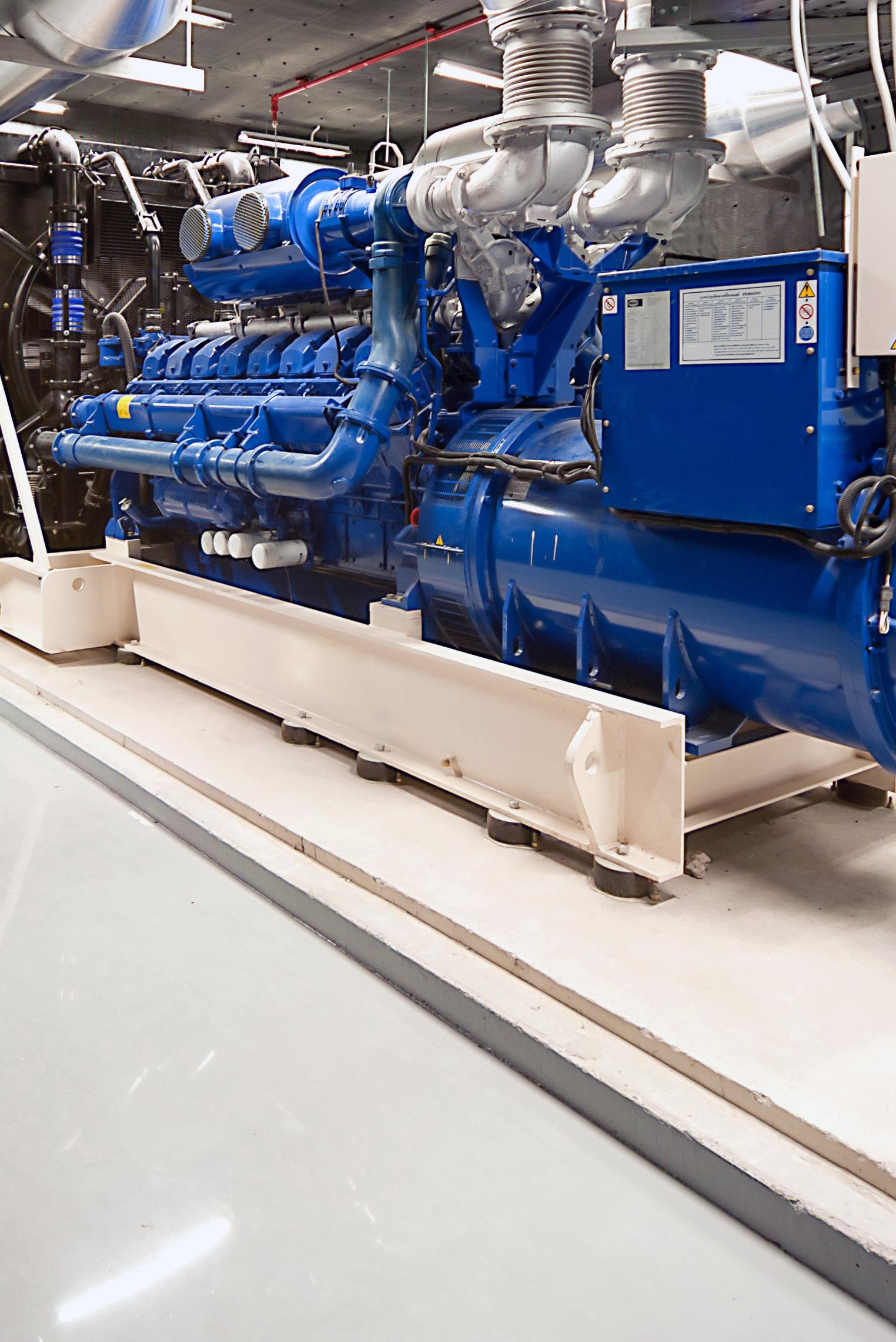

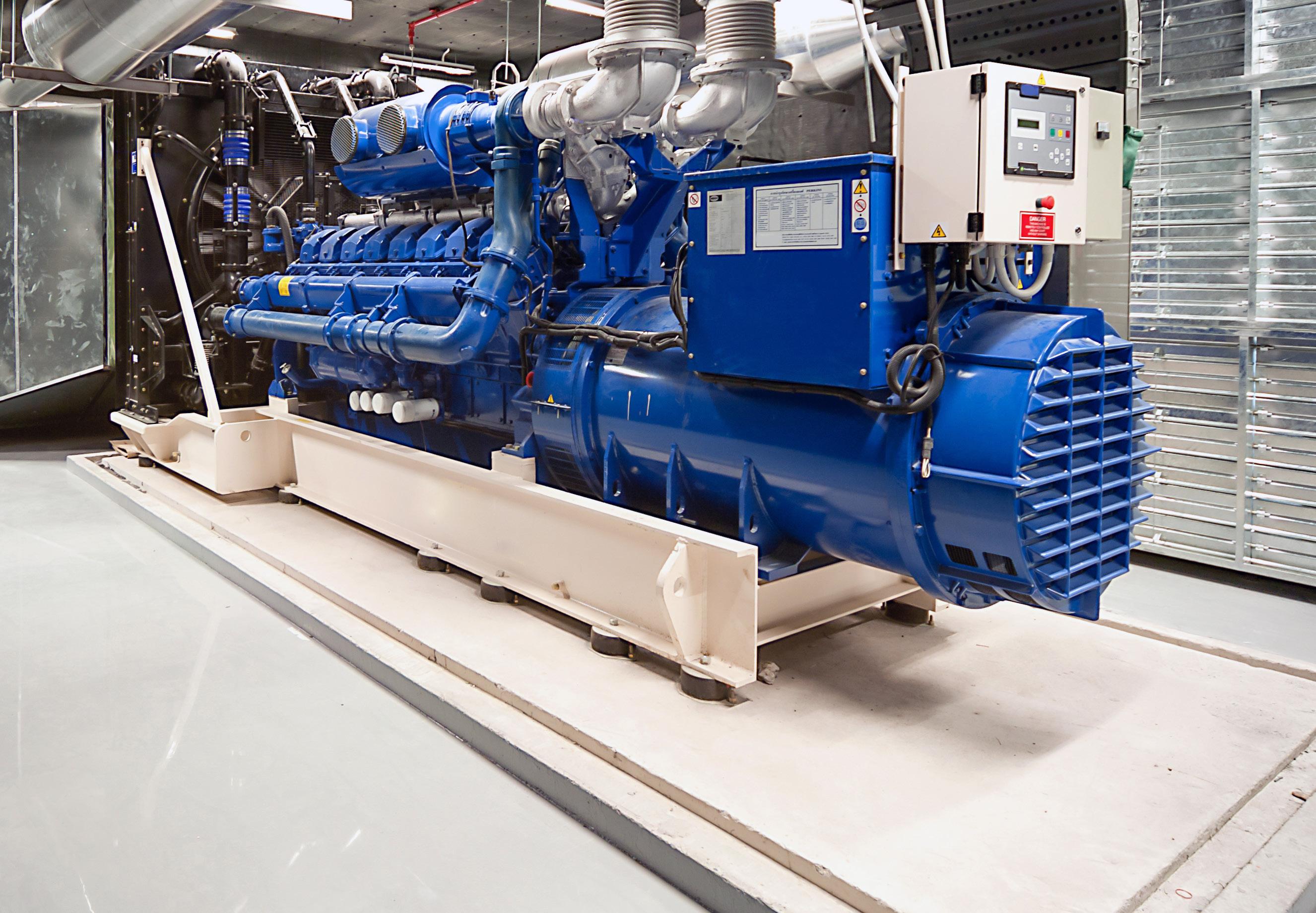

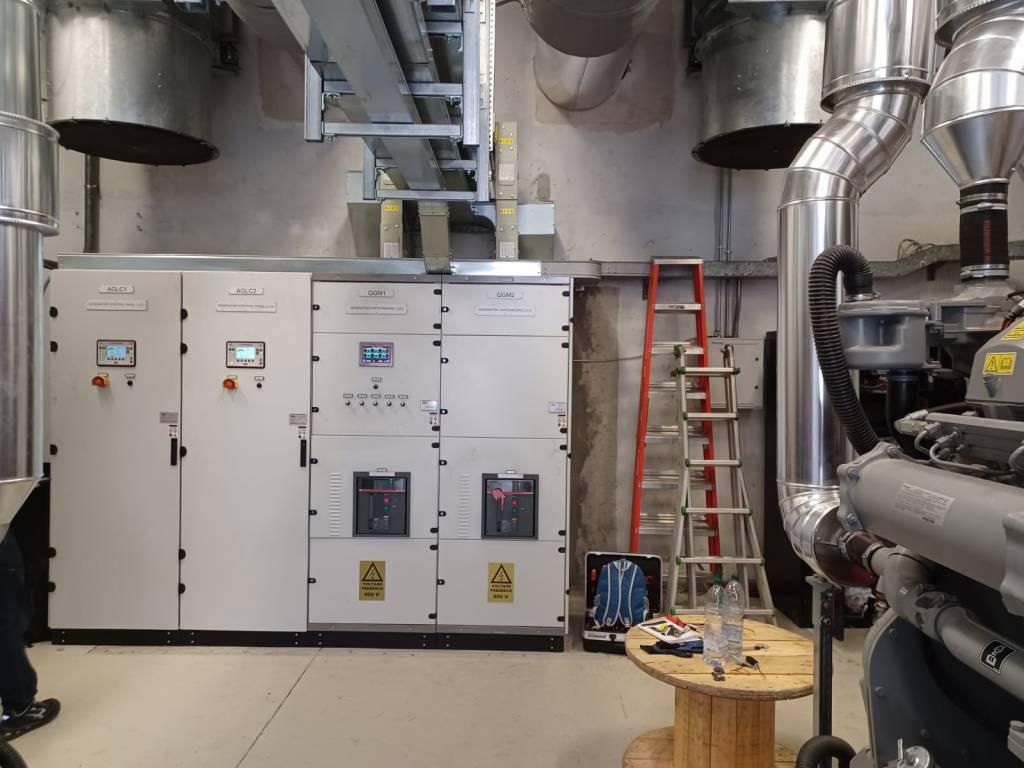

A new Cummins C2000D5 standby generator with custom-built acoustic container has been installed on the roof of a six-storey building in the middle of Dublin City, Ireland.

The next phase of this project is the installation of a fuel system for HVO fuel.

On August 25th, 2023, Cummins Inc. announced approval of its entire line of diesel high horsepower engines across all ratings for use with unblended paraffinic fuels (EN15940), often referred to as renewable diesel, including hydrotreated vegetable oil (HVO).

Utilising renewable diesels like HVO are shown to reduce net greenhouse gas (GHG) emission by up to 90% compared to conventional diesel, dependent on the exact feedstock and fuel pathway.

This approval applies to all high-horsepower (19L-95L, V903, ACE) engines for all applications in use across a variety of industries, such as mining, marine, rail, defense and oil & gas.

All industrial engines currently in the field can be fuelled with 100% renewable diesel, or any blend of renewable and traditional diesel, with no engine modifications required. Any

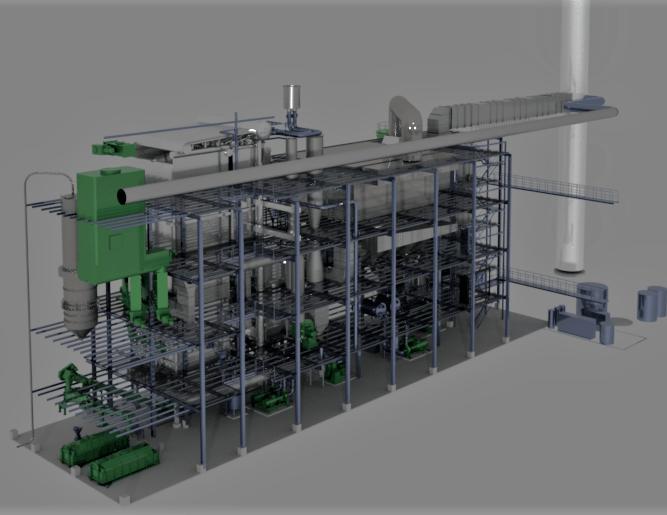

FINLAND’S LATEST BIOHEAT PLANT

KPA Unicon, a Partnera Group company, has supplied Kuhmon Lämpö Oy with a key bioheat plant.

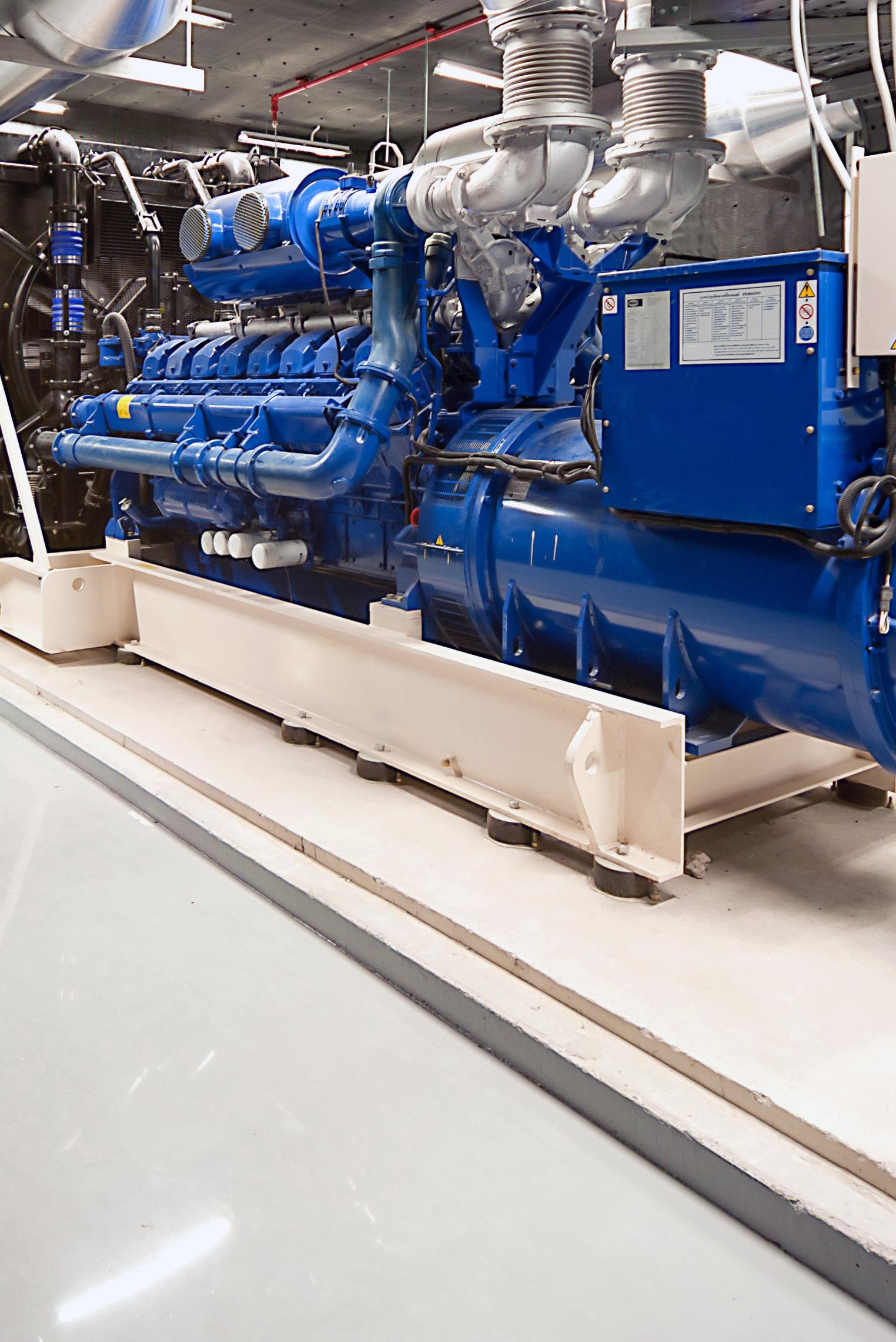

BIOGAS PLANT POWERS 4,000 HOUSEHOLDS

A newly-built biogas plant in Lozovo (North Macedonia) uses two TCG 2020 V12 gensets from MWM.

18

NEW ELECTROPAK GENERATOR IS RELEASED

The latest 2806J-E18TAG1 is a new engine which delivers a powerful package with ease of integration.

24

2,000 KVA

HVO GENERATOR FOR DUBLIN ROOFTOP

renewable diesel used must meet the EN15940 standard, as defined by the European Committee for Standardization (CEN).

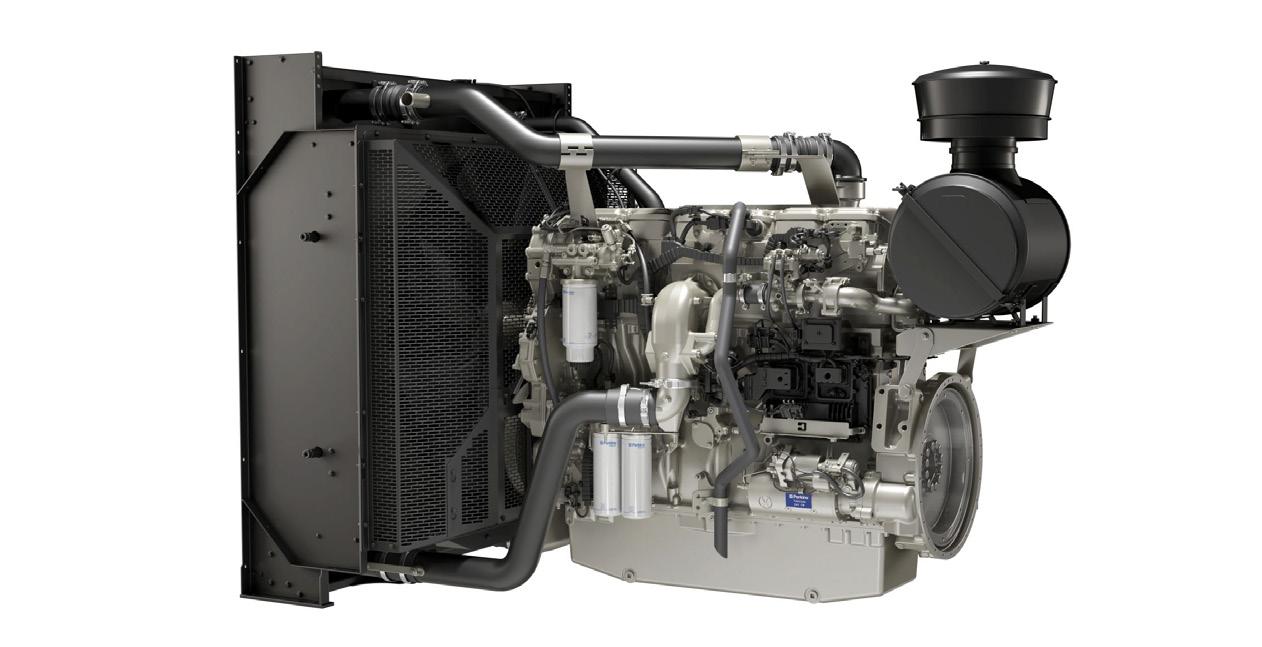

The Cummins C2000D5 is a 2000 kVA Three Phase Auto Start 50Hz Open Diesel Generator featuring the Cummins QSK60-G3 engine & Stamford PI734F alternator.

Suitable for standby, prime or continuous duty power, the Cummins 2000kVA is said to offer optimum

performance in any setting. The generator’s heavy-duty, turbocharged, four-cycle engine delivers a consistent and reliable source of power while producing only a low level of emissions.

Page 14

Page

Page

Page 14

Page

Page

2023 1 EURO POWER NEWS SEPTEMBER 2023

www.mwm.net/gas-engine-TCG-3020 CES20001_Anzeigen_MWM_TCG3020_235x55mm_EN__RZ1_0_mg.indd 1 09.09.22 11:44 We designed and built your genset –and we know it like no other. Entrust the service to the one who knows best: the manufacturer. www.mwm.net/en/services CES22027-Anzeigen_MWM_Service_V1_95x145mm_EN_1_0_RZ_sm.indd 1 08.03.23 09:23

The all-round talent.

Publisher/Sales Director:

Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale

richard@wipmagazines.com

Managing Editor:

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager:

Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent Mario Dobresko power@wipmagazines.com

Contributors

MWM, EUROPGEN, Teksan, Perkins, Margen, TEDOM, Europgen Power, Ansaldo Energia, Edina, NGEN, GE Vernova, Ausonia, Stamford, Doosan Skoda, ABB, MEGSA, Volvo Penta, INNIO, Green Biofuels, Dagartech, Eurogen, Koc Holdings, Ford Motor, LC Energy Solutions, Margen, Siemens Energy, FATA, GE, DAMCO, KOHLER Power, De Watergroep, AKSA Energy, Zwart Techniek, DTEK, Anglo Belgian Corp., VM Motori, EMSA Generators, Van Twist, Coelmo

EURO POWER NEWS

Published by: Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0)1403 888019

Fax: +44 (0)1403 220751

powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to Euro Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

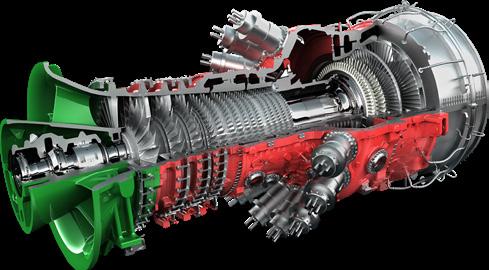

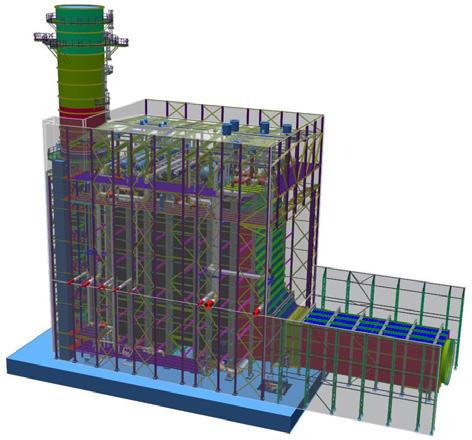

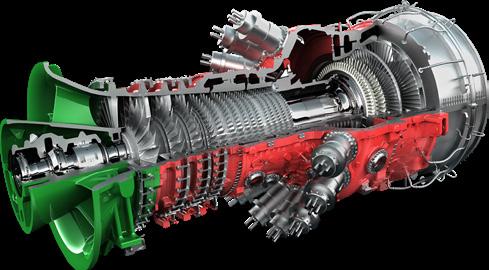

GT36 TURBINES CHOSEN FOR GERMANY

RWE, the leading German power producer, chooses Ansaldo Energia GT36 turbine as part of the company’s decarbonisation and energy transition plan. Capable of powering over 500,000 households, with potentially zero-emissions, Ansaldo Energia’s largest and best performing gas turbine is planned to power a combined cycle plant at the existing Weisweiler site, supporting the country’s energy transition.

RWE, the leading German power producer, has chosen Ansaldo Energia H-class GT36 turbine as part of the company’s decarbonization and energy transition plan. RWE has signed a contract with the consortium formed by Ansaldo Energia and Técnicas Reunidas for the construction of a hydrogen- ready combined cycle power plant.

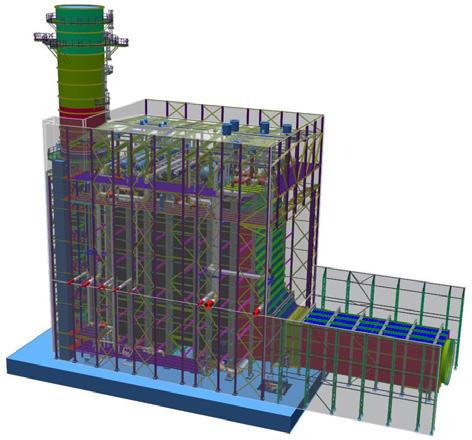

Ansaldo Energia is to supply the entire power island, the heart of the plant, which includes a GT36 gas turbine and related generator, a steam turbine and related generator, HRSG, condenser, and auxiliary systems.

Ansaldo Energia’s GT36 is already capable of operating with a blend of 50%vol hydrogen thanks to its unique sequential combustion system, with the potential to upgrade to 100% hydrogen. The planned new plant with a capacity of 800 MW and an efficiency of 62% will be built on RWE’s existing site in Weisweiler, near Cologne. Currently, there are four lignite-fired steam power plants in Weisweiler, which have to be closed under the German Coal exit law.

The planned CCGT will help to power Germany while reducing climate-changing emissions. RWE will take the final investment decision for the planned CCGT after Germany has finalized the regulatory framework to ensure economic viability for H2 ready gas fired power plants that the country is currently working on and after all necessary permits are received.

Austria installs a BESS made up of Megapacks

EPN DIARY

POWEREX LIVE 2023 - THURSDAY 7TH DECEMBER, LONDON, UK

PowerEx Live 2023 at London’s Park Plaza Hotel, will be held on Thursday 7th December, 2023.

Developer NGEN Smart Grid Systems has completed a 10.3MW/20.6MWh standalone battery storage project in Austria. The facility is claimed to be the largest in the country.

The Slovenia-headquartered company has installed the project in Ardnoldstein, which is now grid-connected and participating in the electricity market,.

The battery energy storage system (BESS) is made up of Tesla Megapacks, the EV giant’s grid-scale lithium iron phosphate-based (LFP) product, and a total of €15 million (US$16.2 million) was invested into the project.

Roman Bernard, CEO of NGEN Smart Grid Systems GmbHtold EPN: “The focus is initially on supporting the Austrian transmission network. But the system also opens up exciting opportunities for building a local energy community market and integrating active electricity consumers.”

The project was initially going to be built in Klagenfurt near a new substation, but local opposition forced NGEN to choose a new location. The Arnoldstein site was settled on thanks to it being an industrial site as well as 14MW of availability at the nearby Gailitz substation.

As well as Austria, NGEN is also deploying large-scale projects in Croatia and its home market of Slovenia, totalling 50MW/100MWh and 70MW/140MWh in size respectively, with 1GW of projects overall in development in Europe. Energy-Storage.news has been told by a local source that the Croatia project is the largest in the country. Bernard said that NGEN’s 100MW/200MWh of energy storage in Slovenia “cover half of the system services that serve the grid.”

The Tesla Megapack is said to significantly reduce the complexity of large-scale battery storage and provides an easy installation and connection process. Each Megapack comes from the factory fullyassembled with up to 3 megawatt hours (MWhs) of storage and 1.5 MW of inverter capacity, building on Powerpack’s engineering with an AC interface and 60% increase in energy density to achieve significant cost and time savings compared to other battery systems and traditional fossil fuel power plants.

Using Megapack, Tesla can deploy an emissions-free 250 MW, 1 GWh power plant in less than three months on a three-acre footprint – four times faster than a traditional fossil fuel power plant of that size. Megapack can also be DC-connected directly to solar, creating seamless renewable energy plants.

PowerEx Live 2023 aims to offer the perfect networking opportunities for professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With conference speakers at the top of their respective fields alongside premier display space in a world class venue, this event becomes a priority for all those in the power and energy markets. Exhibit with us at this prestigious venue in December 2023.

The ‘GEN-SET LIVE’, ‘CHP LIVE’ and ‘CHP & Renewables LIVE’ conferences will run parallel with prime exhibitor space available in adjoining rooms. Take your products to your customers with the opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets. The choice of stands are allocated on a ‘first-comefirst-serve’ basis, so please contact us today and prepare for the highlight of the UK’s Power & Energy calendar for 2023. The venue is situated on London’s iconic South Bank, Park Plaza Westminster Bridge London is just a short walk from Westminster and Waterloo. Station.

2 SEPTEMBER 2023 EURO POWER NEWS NEWS NEWS www.powermediagroup.co.uk

****************

3.3MW

Anew plant room is currently being developed for a pharmaceutical company based in Ireland to house the hydrogen-enabled 3.3MWe Combined Heat and Power (CHP) plant powered by a single MWM gas engine as part of the site’s expansion.

Once in commercial operation, the CHP plant will deliver financial and carbon savings whilst maintaining energy resilience and offering power flexibility. Onsite generation technologies such as Combined Heat and Power (CHP) from Edina can provide a long-term solution for manufacturers looking to reduce energy costs, improve resilience, and reduce their dependence on grid-imported power.CHP is an energy-efficiency technology that cogenerates electricity and heat or steam from a low-carbon, renewable or hydrogen-blend fuel source. Manufacturers benefiting from CHP have typically saved up to 30% on their energy costs when compared to the separate purchase of electricity from the grid and gas for use in on-site boilers.

Rising energy costs are anticipated to be the biggest cost facing manufacturers in 2023, according to a recent survey published by Make UK - the industry body representing manufacturers in the UK. The Executive Survey 2023 – Cost Competitive and Confidence, which collated views from over two hundred senior executives across the manufacturing sector, reported an overwhelming 70% of manufacturing leaders believe energy costs are expected to increase significantly this year, with a further 20% expecting a moderate increase in 2024.

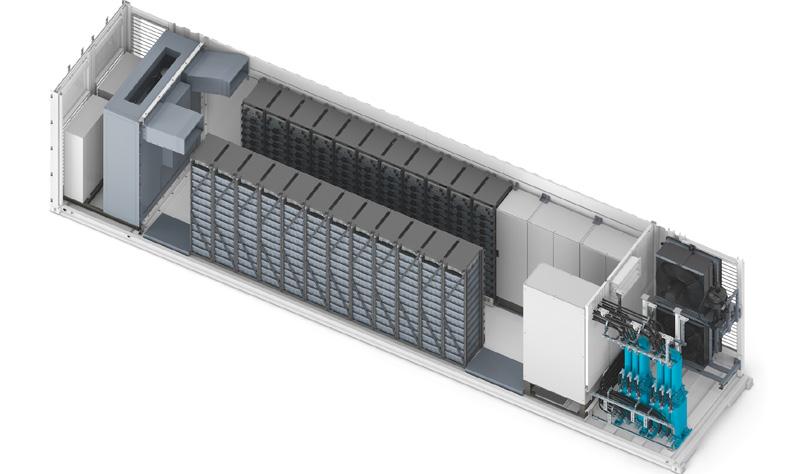

BESS project developed

In 2022 UK infrastructure projects developer ForePower selected Edina to deliver a 10MW battery energy storage system (BESS) project for its engineered, system-integrated turnkey solution. Edina, a key UK-based onsite power generation solutions provider for hydrogen-ready Combined Heat and Power (CHP) plants, standby power generation and battery energy storage systems (BESS), subsequently announced that it had won its first contract with UK developer ForePower for its systemintegrated BESS solution based in Doncaster, South Yorkshire.

Now this project has been fully realised, ForePower provides National Grid with the ability to stabilise the electricity network with its portfolio of assets. Funded by Nash Business Capital Ltd, the 10MW 1-hour duration BESS project is based in South Yorkshire, UK, where it will provide a range of balancing services to the electricity grid to ensure power security, system flexibility and accelerate renewable energy integration.

Edina’s modular outdoor battery energy storage solution is fully integrated and prefabricated with lithium iron phosphate (LFP) battery cell chemistry, liquid-cooled thermal management system, skid-mounted inverter systems, battery management system and UL certified fire detection and suppression systems. Edina has provided the full engineering, procurement, and construction (EPC) and system integration scope of work to included detailed design, engineering, project management and installation, plant commissioning and discussions are underway to undertake long-term plant maintenance.

Hugh Richmond, Edina CEO, told WIP: “This is our first battery storage development with ForePower, and we are delighted to be working with such an enthusiastic and forward-thinking company. This project is a significant milestone for the evolution and growth of Edina, who was traditionally a gas engine supplier and developer but has now added another ‘string to its bow’ by developing standalone and hybrid power solutions and full EPC contracts.”

Andrew Foreman, ForePower’s Founder and Projects Director, Steven Thorpe, agree. They commented: “It’s an exciting time for the UKs energy mix and it is a great the opportunity to work with Edina. We look forward to working with Edina on this project to help build our relationship and build out our current portfolio of assets.”

The project allows ForePower to access the Capacity Market, Fast Frequency Response, and other grid services markets.

Edina specialises in the engineering, installation and after-care support of low carbon and hydrogenready gas-fired Combined Heat and Power (CHP) plants, mission-critical standby generation, and integrated battery energy storage systems. ForePower Ltd, develops and operates battery storage and renewable assets to balance the supply and demand across the UK.

1,500 KVA FOR A MAJOR TELECOM PLAYER IN ITALY

A 1,500 kVA diesel generator with Perkins engine and Stamford alternatorhas been supplied to italy by Ausonia.

The gensets has been factory tested - this was successfully concluded and the genset is now ready to go for branding and delivery to site. This 1500 kVA green genset has been designed by Ausonia S.r.l. to guarantee a max noise level of 60 dB(A) at 7m while running in parallel operation with an existing genset at a Test Plant of a major telecom player in Italy.

Ausonia reports that it is able to deliver bespoke power systems, whose specs can include, among others, customised control panels and switchgears, super-silent soundproof canopy / container, specific IP protection degrees, Medium Voltage Power Output and ATEX-compliant features for the entire power plant and relevant accessories.

A company spokesman comments: “The proven field experience of Ausonia in designing, manufacturing, supplying, installing and maintaining power generators, allows customers to rely on a serious energy partner, who can assist them from the initial engineering phase to the final commissioning onsite, with a dedicated support during the entire product lifecycle.

“Thanks to its high technological know-how, Ausonia is ready to propose bespoke energy solutions, tailored around the specific needs of its customers. The entire Ausonia portfolio of energy solutions for Telecoms is designed according to the highest market standards.”

Ausonia reports that it has has developed a wide range of different solutions specifically designed for the Telecomms market.

In order to meet the specific needs of the Telecommunication industry, Ausonia R&D’s activity has been successfully oriented to reduce OPEX and CAPEX, to extend the Product’s Life Cycle, to increase its reliability and to achieve significant environmental benefits, says the company.

Willing to move ahead from product manufacturer to solution maker, in 2003 Ausonia created MediPower with specific skills and a dedicated structure, in order to manage all service activities related to the gensets’ world with a customer focused “energy supply approach”.

Thanks to the dynamic and flexible nature of its young and innovative organization, MediPower became a leader for the italian off-grid BTS energy supply, servicing a market share of more than 85%. MediPower is able to provide a turn-key approach for a “Full OPEX” solution, based on a daily fee. Ausonia’s product design and production capabilities, joined with MediPower’s full service skills,

SIMPLE CYCLE PLANT IN IRELAND HAS 8 TURBINES

GE Vernova’s Gas Power business has signed contracts for both the supply and the operation and maintenance activities of a simple cycle power plant consisting of eight GE LM2500XPRESS aeroderivative gas turbines from the Electricity Supply Board of Ireland (ESB) for its facility in Shannonbridge, County Offaly, Ireland. This project follows GE’s recently announced 200 MW emergency

power plant construction project at North Wall in the Dublin area. Similar to ESB’s North Wall Power Plant, which is powered by six GE LM2500XPRESS, the Shannonbridge Power Plant will support the Irish grid when needed. The LM2500 family of aeroderivative gas turbines, including the LM2500XPRESS, boasts over 120 million operating hours, several times the operating experience of its competitors.

EURO POWER NEWS SEPTEMBER 2023 3 NEWS NEWS

CHP PLANT FOR A PHARMACEUTICAL COMPANY IN IRELAND

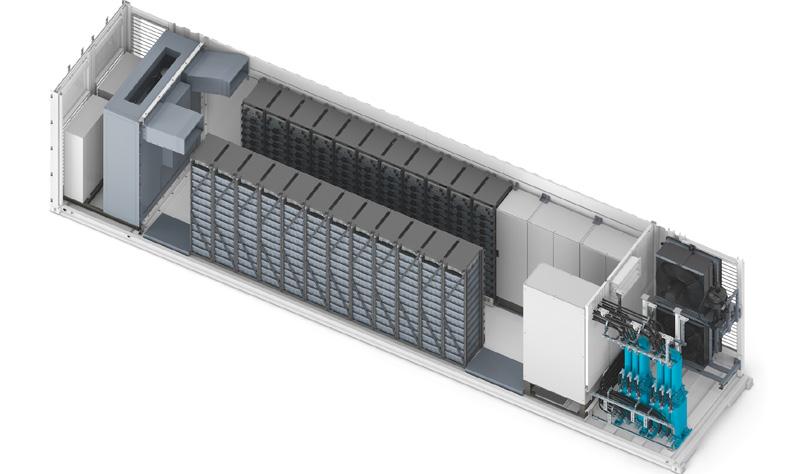

168 BATTERY RACKS (30MW) FOR GRID FREQUENCY REGULATION

NEW MOVES ACCELLERATE RENEWABLE ENERGY USAGE

In line with the Green Deal and REPowerEU plans the European Parliament has just voted to boost the deployment of renewable energy.

The update of the Renewable Energy Directive (RED), already agreed upon between MEPs and Council, raises the share of renewables in the EU’s final energy consumption to 42.5% by 2030. Member states should strive to achieve 45%.

The legislation will accellerate procedures to grant permits for new renewable energy power plants, such as solar panels or wind turbines, or to adapt existing ones.

National authorities should take no longer than 12 months to approve new renewable energy installations, if located in so-called “renewables go-to areas”. Outside such areas, the process should not exceed 24 months.

target for innovative renewable energy technology of at least 5% of newly installed renewable energy capacity, as well as a binding framework for cross-border energy projects.

The European Parliament has pushed for stricter criteria on the use of biomass to ensure that the EU does not subsidise unsustainable practices. Biomass harvesting should now be done in a way that prevents negative impacts on soil quality and biodiversity, says the EU.

Almost 100 battery racks with the mtu Energy Pack QG have been installed in Vlissingen in the Netherlands for the Dutch company SemperPower BV, and more battery racks will be added soon. In total the large-scale battery storage system consists of 168 battery units with an output of 30 megawatts and a storage capacity of 63 megawatt hours. It will be put into operation at the end of September. The storage system will be used for grid frequency regulation in the Netherlands and will thus serve to integrate electricity from renewable energy sources into the public grid.

“We see it as our task to accelerate the energy transition. We do this by using energy storage systems that store sustainable energy in times of surplus and release it when the market needs it. We are delighted to have found Rolls-Royce as a partner who, with its high-quality solutions, is pulling in the same direction as us,” explained Dennis Schiricke, CEO SemperPower B.V. The order also includes general contractor services, as well as the construction of the building and other infrastructure. Semper Power develops and operates energy storage systems for wind and solar farm developers, distribution grid operators and industrial customers.

The large-scale battery storage system, with a capacity of 30 megawatts and a storage capacity of 60 megawatt-hours, is used for grid frequency regulation in the Netherlands to integrate electricity from renewable energy sources into the public grid.

When fully charged, the system has the capacity to supply 8,000 households with electrical energy for an entire day. The mtu QG EnergyPack storage solution from the Rolls-Royce business unit Power Systems consists of 168 battery units, 7 inverters and the intelligent control platform mtu EnergetIQ. When commissioned in spring 2023, it will be the largest energy storage system in the Netherlands and one of the largest in the EU.

Rolls-Royce has recently begun supplying mtu EnergyPack QG large-scale storage solutions to go with its battery container solutions. These consist of modular units for capacity and power and can be flexibly configured to any size. The components include integrated battery cabinets and the intelligent control system mtu EnergetIQ. They are mainly used for grid services, energy trading and the integration of renewable energies.

Due to their modular design and high energy density, they can be flexibly adapted to project-specific services and capacities.

The mtu EnergetIQ control platform ensures optimum performance and flexibility.

“We are taking another step with our customers towards net-zero greenhouse gas emissions,” said Andreas Görtz, President Sustainable Power Solutions.

In the transport sector, renewables deployment should lead to a 14.5% reduction by 2030 in greenhouse gas emissions, by using a greater share of advanced biofuels and a more ambitious quota for renewable fuels of non-biological origin, such as hydrogen.

MEPs have also ensured that member states set an indicative

DEMOSATH SUPPLIES POWER TO SPAIN’S GRID

Saitec Offshore Technologiesin collaboration with RWE and Kansai Electric Power (KEPCO) - has revealed that its floating offshore wind project DemoSATH has begun supplying power to the Spanish grid.

In August 2023 DemoSATH was installed offshore at the BiMEP testing area at Armintza in the Basque Country. Subsequently, the connection of the existing static seabed cable to the motionabsorbing dynamic cable, and the link to the platform itself was successfully completed. This enabled the transmission of power to the grid via the BiMEP substation. The platform, located 2 miles off the Basque coast, features a 2 MW

turbine. As a result, floating offshore wind technology is being introduced as a new renewable generation technology in Spain’s energy mix for the first time.

The commissioning marks the beginning of a two-year operational period to gather data about the behaviour of the SATH technology, developed by Saitec Offshore Technologies, and the monitoring of the systems installed on the platform.

4 SEPTEMBER 2023 EURO POWER NEWS NEWS NEWS

SIZE, FIND AND CONFIGURE YOUR GENERATOR INSTANTLY WITH POWER CENTRE FROM FG WILSON

Power cente is the ultimate tool when planning your project, enabling you to instantly size a generator that will meet your power needs, find inventory near you in stock and configure a generator set to meet your project specifications.

Start today at power.fgwilson.com

SIZE, FIND AND CONFIGURE YOUR GENERATOR INSTANTLY WITH POWER CENTRE FROM FG WILSON

Power cente is the ultimate tool when planning your project, enabling you to instantly size a generator that will meet your power needs, find inventory near you in stock and configure a generator set to meet your project specifications.

Start today at power.fgwilson.com

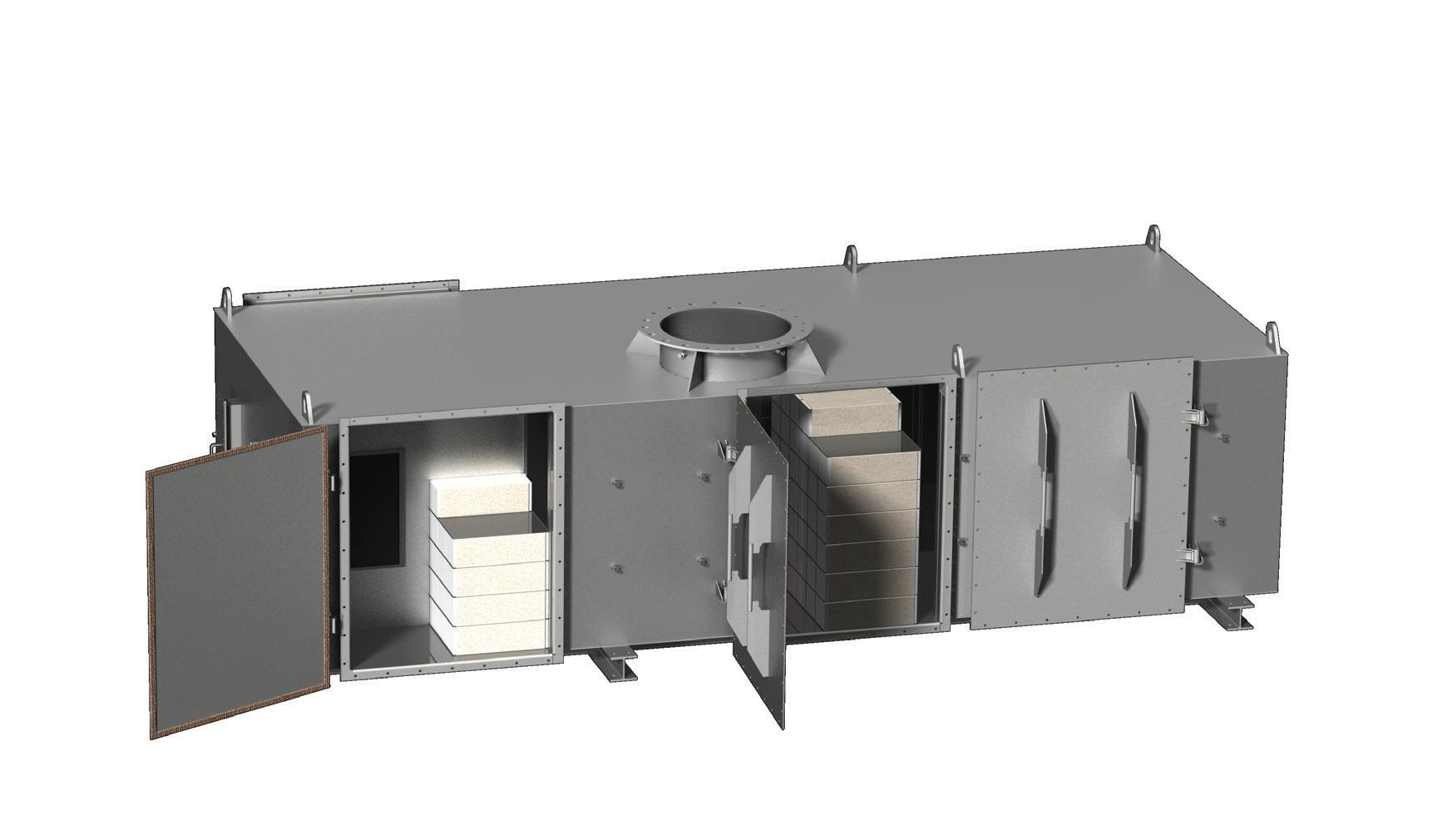

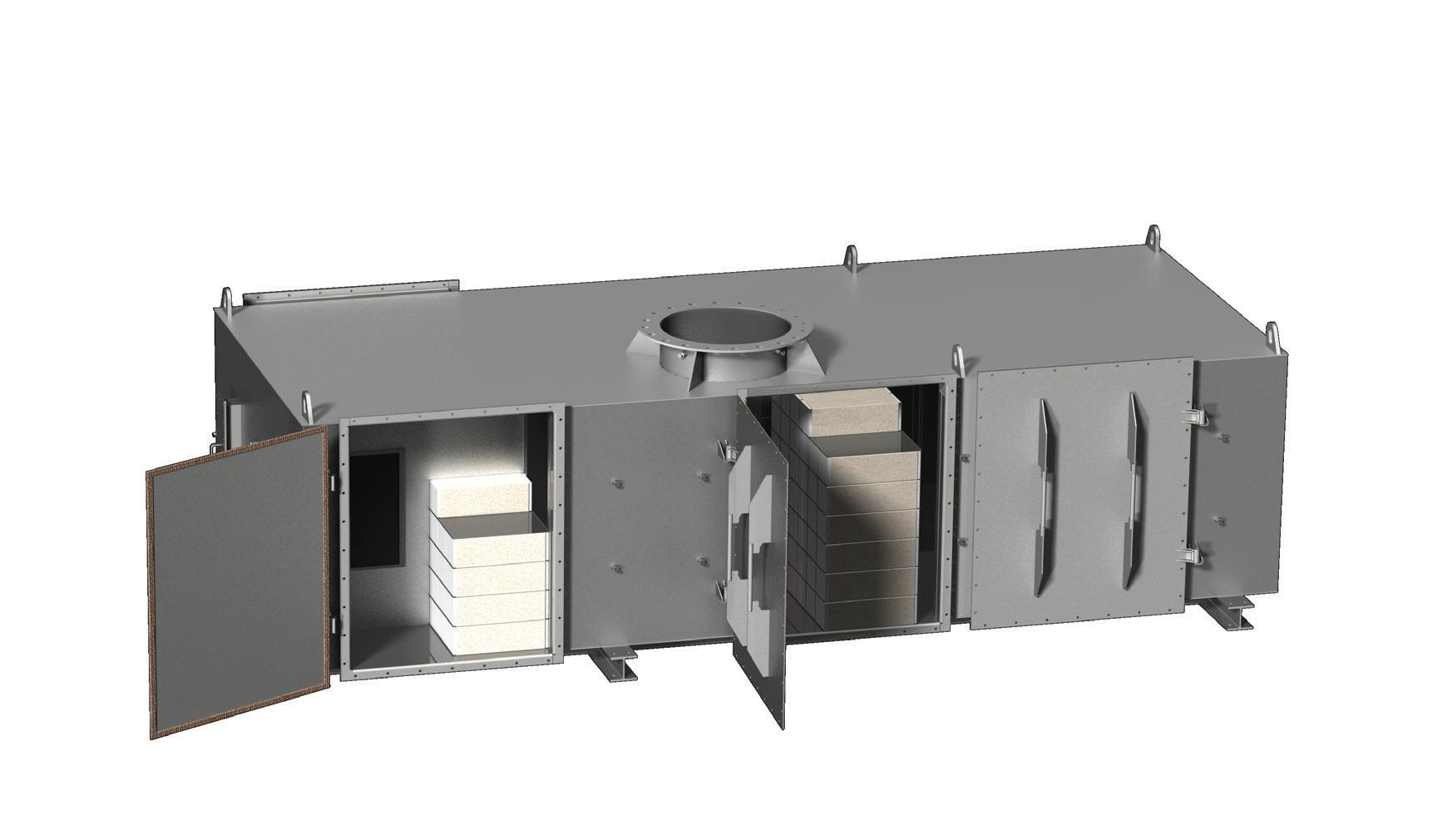

The MIRATECH® MIRA-CUBE

Best Available Technology (BAT)

EU Stage V / MCPD / 44.BlmSchV

Designed to Offer an Integrated Pre-packaged Emission Solution.

Includes:

SCR - NOx Reduction

DPF - PM10 Reduction

OxiCat - CO / HC / CH2O Reduction

Silencing - Integrated Attenuation

• Designed for Data Center/multiple engine sites

• Suitable for diesel and gas engines 1000 to 4000kW

• Compact design fits on generator enclosures or inside engine rooms

• Retrofit capability + easy install principle.

• Flexible inlet/outlet locations to simplify pipe routing

• Integrates proven passive LTR™ lowtemperature regeneration DPF (260°C regen)

• For natural gas applications, can be supplied as SCR or SCR/Oxidation

• Future-proof your GenSets vailable as SCR-only / DPF-ready - additional catalysts may be added later in order to meet future requirements

• Silencing can be upgraded for stricter sound targets with additional incorporated layers lmSchV target compliant

™

+44(0)7786 819 157 | MIRATECH ENGINEERED TO PERFORM™

DPF Access Outlet Oxidation Elements SCR Access CATALYTIC ENGINE SOLUTIONS • ENGINE & PROCESS SILENCERS • GAS TURBINE

BALWIN1, BALWIN2 AND DC34 POWER TRANSMISSION CABLE PROJECTSPREFERRED BIDDER IDENTIFIED

GERMANY TO BUILD & OPERATE 24GW H2 PLANTS

Prysmian Group, a world leader in the energy and telecom cable systems industry, has been selected by Amprion as preferred bidder for the two Offshore Grid Connection Systems BalWin1 and BalWin2 and the underground cable project DC34.

The preferred bidder agreement provides an obligation on the parties to negotiate in good faith the outstanding items of the projects with a target to execute the final contracts by 15 January 2024. Prysmian is committed to reserve the required production and installation capacity until the aforementioned date. The contracts are valued in aggregate at around 4.5 billion euros.

The three projects are part of the Germany’s overall plan to install 70 GW of offshore wind energy by 2045 and will support the transmission of the energy generated in the North Sea to consumers in the Western and Southern regions of the country.

“This agreement is a huge step towards realizing these three important projects in time. Thus, the major components for our offshore projects are secured until 2030”, commented Hendrik Neumann, CTO of Amprion.

“Prysmian is highly committed to the development of greener and smarter power grids, supporting Amprion as one of our key customers in it’s important energy transition targets” commented Hakan Ozmen, EVP Projects BU, Prysmian Group.

BalWin1 and BalWin2 will transmit each up to 2 GW of energy from the future offshore wind farms to be located in the German North Sea BalWin Cluster to the grid connection points in Wehrendorf (Lower Saxony) and Westerkappeln (North Rhine-Westphalia) and thus supporting the energy transition in the industrial heart of Germany.

Each cable system consists of 2 single-core ±525kV HVDC copper cables with XLPE insulation for the submarine sections and P-Laser insulation for the land underground sections, plus a dedicated metallic return cable and a fibre optic cable. BalWin1 will utilize approx. 1,070 km of cables along a 358 km route, whereas BalWin2 will use approx. 1,100 km of cables over a route of 376 km.

DC34 (Number 82 of the Federal Requirement Plan Act) as part of the Rhein-Main-Link will instead connect the substation in the area of Ovelgönne/Rastede/Wiefelstede/Westerstede (Lower Saxony) to a second substation in Bürstadt (Hesse) to transmit up to 2 GW of energy produced by the offshore wind farms in the North Sea to consumers in the Rhine-Main metropolitan area.

The cable system will consist of two single-core ±525 kV HVDC copper cables with P-Laser insulation, including a dedicated metallic return cable. DC34 will consist of up to 2,100 km of cables for this cross-Germany route.

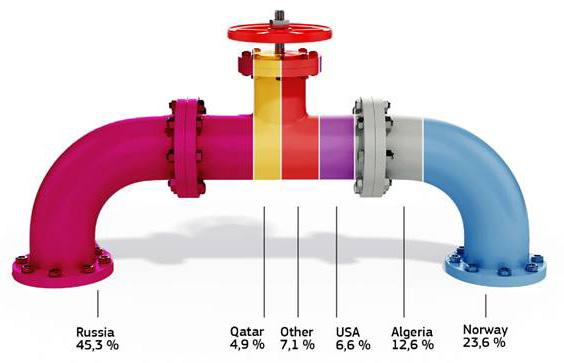

H2-READY POWER PLANTS BY 2030

RWE plans to build hydrogen-ready gas-fired power plants at its own former power plant sites in Germany by 2030 to help achieve the goal of phasing out coal.

The company has awarded the contract to an international consortium, which has laid the foundation for building a hydrogen-capable combined cycle gas turbine power plant with an output of 800 MW at its Weisweiler site by the end of 2029.

The approval planning for the plant is to begin immediately. The ordering of the power plant components and the commissioning of the construction will be subject to a final investment decision.

Roger Miesen, CEO RWE Generation, commented: “With the commissioned approval planning, we advance to keep open the chance of completion by 2030. To achieve [the phase out of coal] the political course needs to be set quickly: only when the hydrogen grid connections are secured and the economic operation of the power plants is made possible by suitable framework conditions, can we make final investment decisions.”

The European Commission has set important framework conditions for planned German state support to build and operate about 24 gigawatts (GW) hydrogen power plants and fossil gas units which will later be converted to hydrogen, reports the economy ministry (BMWK). The ministry and Commission have worked out a “common understanding” for support to build such gas-fired power plants, which the government considers a necessary supplement to intermittent renewables to secure the electricity supply. “The progress made [in the talks] with the European Commission are an important first step, even if this does not mean that the intended measures have already been approved by the European Commission under state aid rules,” said the ministry. The

official state aid consultation process will continue after the summer break. Over the past few months, Germany and the EU agreed on important legislation to speed up renewable energy expansion, said economy minister Robert Habeck.

“Now it is a matter of initiating the conversion of our power plant fleet to hydrogen and thus set the course to achieve climate neutrality for the entire electricity sector.” Habeck said the results of the talks with

RECORD-BREAKING CABLE CONTRACT AWARDED

A major turnkey contract, valued at €1.43 billion, has been awarded to Nexans for the section of the EuroAsia Interconnector which links Greece and Cyprus.

As a critical part of a broader project to connect the grids of Greece, Israel, and Cyprus, the 525kV HVDC cable will be the longest and deepest interconnector in the world with a bipole length of 2x900 km, and will run across the Mediterranean sea floor at depths of over 3000 metres.

Subsea HVDC mass impregnated cables will be manufactured in Nexans’ facilities in Halden

(Norway) and Futtsu (Japan), and will be installed by its cable laying vessels Nexans Aurora and Nexans Skagerrak.

The EuroAsia Interconnector will have the capacity to exchange up to 1000 MW among the three nations with the capability of increasing to 2000 MW. It will end the energy isolation of Cyprus by creating an energy highway between Europe and Asia, and will be the largest interconnector project in history. Pole One is expected to be completed in 2028 and Pole Two in 2029.

EURO POWER NEWS SEPTEMBER 2023 7 NEWS NEWS

HYDROGEN BLEND TESTS PROVE THAT ENGINE TECHNOLOGY CAN DELIVER FUTURE-PROOF POWER SOLUTIONS

IRSCHING 6 GAS-FIRED PLANT GETS OFFICIAL GO-AHEAD

Wärtsilä’s hydrogen blend tests at WEC Energy Groups A.J. Mihm power plant have proved that engine technology can deliver future-proof power solutions for decarbonised operations. The unmodified Wärtsilä 50SG engine supplied power to the grid throughout the three-day testing period, achieving a 95% load with a 25 vol% hydrogen blend, improving engine efficiency and reducing greenhouse gas emissions while staying compliant with NOx emissions. A 100% engine load was attainable with a 17 vol% H2 blend.

The tests were validated by Electric Power Research Institute (EPRI), who led the assessment and confirmed that blending hydrogen with natural gas for use in existing Wärtsilä engines is feasible, safe, and reliable. The EPRI report states that this class of engines maintain higher efficiency compared to simple-cycle gas turbines while co-firing hydrogen, resulting in lower relative CO2 output.

The Wärtsilä 50SG gas engine is a four-stroke, spark-ignited gas engine generating set. High efficiency in a small footprint combined with great reliability and flexibility makes this solution ideal for flexible baseload and balancing applications, reports the company.

The Wärtsilä 50SG gas engine offers unique fast-starting capability, which enables rapid response to fluctuations inherent to renewable generation. The solution also supports user decarbonisation with its low greenhouse gas emissions and capability of hydrogen blending. Wärtsilä engine power plants can be delivered both as EPC and Equipment Delivery contracts.

A company spokesman comments: “The Wärtsilä 50SG is a four-stroke, spark-ignited gas engine generating set. High efficiency in a small footprint combined with great reliability and flexibility makes this solution ideal for flexible baseload and balancing applications. It offers unique fast-starting capability, which enables rapid response to fluctuations inherent to renewable generation.

AWIRS POWER PLANT WILL BE REPLACED WITH A 875MW FACILITY

The Awirs power plant (Flémalle, Belgium) will be replaced by 2025 with a new 875 MW combined cycle thermal power plant.

Its operator, ENGIE, entrusted John Cockerill with the design and supply of the heat recovery boiler. It will be the largest and one of the most efficient boilers of this type ever installed in the world.

The new gas-steam combined cycle power plant in Flémalle will be commissioned in mid-2025. The site, which from the 1970s hosted the largest thermal power plant in Wallonia, is in a deconstruction phase. It will be upgraded to build a brand-new power plant.

With a capacity of 875 MW, it will be able to supply electricity to nearly 700,000 households. It will achieve an efficiency of over 63%, one of the highest in the world for a gas/steam combined cycle power plant, thanks to the John Cockerill boiler, which will produce a third of the power plant energy. With an optimised vertical design, John Cockerill’s Once Through Boilers (OTB) are said to offer a reduced carbon footprint, increased cycle efficiency, and reduced emissions.

The official go-ahead has been he official go-ahead for the commissioning of the new Irsching 6 gas-fired power plant near Ingolstadt.

The 300 MW plant was built by Uniper, and will be operated by Uniper in the future. It will serve exclusively as a security buffer for the power supply – the plant will not be available to the market, but will only be connected when system security is at risk.

The project was put out to tender by the transmission system operator TenneT, which will request the plant as needed in the future.

Uniper was awarded the contract for construction and operation at the end of 2018. The final commissioning of this power plant, known officially as ‘special grid-related equipment,’ will take place as soon as final occupational safety checks and corresponding documentation have been completed. Trial operation was successfully completed on 1st August, 2023.

The Irsching power plant is located near the town of Vohburg on the Danube in the Irsching district.

It consists of a total of six independent units, of which the two oldest – Irsching 1 and 2 – have already been shut down.

Unit 3 has been classified as system-relevant by the Federal Network Agency and is available to

the network operator as a reserve to ensure network stability.

The very efficient CCGT plants Irsching 4 (“Ulrich Hartmann”) and the joint-venture power plant Irsching 5 (Uniper share: 50.2 percent) are in market operation and are sometimes started up and shut down several times a day. With an efficiency of around 60 %, both units are among the most efficient combined cycle plants in Europe.

The plants are also regularly used by TenneT in the so-called redispatch procedure. Together, the Irsching power plant units make up the largest power plant site in Bavaria with over 2100 MW of installed capacity.

As the Transmission System Operator (TSO) for the Netherlands, and a significant part of Germany, TenneT owns and operates over 25,000 kilometres of high-voltage lines and cables.

A spokesman comments: “We deliver electricity to 43 million domestic and business users, safely and reliably, 24-hours-a-day and 365-days-a-year.”

The company designs, builds, maintains and operates a highvoltage grid stretching across land and sea.

This carries electricity from where it is made – including a rapidly increasing proportion of wind and solar energy – to where it is used.

Biblis features 11 gas-fired turbines of 34MW each

Biblis, Germany’s latest 300-megawatt gas-fired grid reserve plant is run by transmission system operatorAmprion.

The new plant, built just south of a nuclear power plant, now provides a stable capacity of 300 MW. However, this capacity is not deployed in the market, but can be called up by the grid operator Amprion to ensure grid stability in an emergency.

The eleven gas turbine units first fired up in June 2022. After successfully completing a performance test, the plant has been in operation since March 2023

- just 24 weeks - to be ready for use by Amprion. Biblis employs an innovative concept with 11 gas-fired turbines with a nominal capacity of 34 MW each, to ensure performance with a high level of redundancy. Gas turbines of this type are also used in aviation and can therefore reach the required load after start-up without delay.

8 SEPTEMBER 2023 EURO POWER NEWS NEWS NEWS

MILESTONE EMISSIONS TARGET ACHIEVED BY ELMO RIETSCHLE PLANT IN GERMANY

TRANSPORTING LIQUID H2 ACROSS EUROPE

GTT, an expert in containment systems used to transport and store liquefied gases, has received an Approval in Principle (AiP) from ClassNK for a concept of a membrane type containment system for liquefied hydrogen (LH2).

The company said the ability to transport hydrogen in liquefied form at -253°C is one of the technological challenges to build a reliable, efficient and competitive hydrogen supply chain and move towards a carbon-free future.

systems for the transport of liquid hydrogen is a key element in accelerating the energy transition.

GTT’s R&D teams are determined to push back the technological frontiers so that this solution is viable and rapidly available to the maritime transport and energy players.”

Aglobal manufacturer of compressors, blowers, pumps and vacuum products will cut emissions by 60% this year, seven years ahead of its environment target. Ingersoll Rand will achieve the milestone at its Elmo Rietschle plant in Bad Neustadt, Germany, thanks to innovative solar-powered technology worth over $1 million.

The plant will finalise the significant installation of a photovoltaic system this summer. Containing 2,796 modules and spanning 10,000 square metres, the system will be connected to the factory roof by a specially selected panel supplier who has extensive experience of undertaking projects on this scale.

It is expected that around 5.66 MWp of CO2-neutral solar energy will be generated daily in summer and around 566 kWp in winter, enough to power the entire facility and provide a surplus of 500,000 MW, which the company will supply to the local community via the public grid. The photovoltaic system is capable of generating up to 1GW of solar energy per year.

The project demonstrates Ingersoll Rand’s commitment to improving its environmental impact and will aid the company’s mission to ‘Make Life Better’ for all, taking the company from a consumer to a producer of electricity, most notably renewable power.

Additional sustainability credentials of the initiative include 500 tonnes per year of CO2 savings, as well as 10,000 square metres of surrounding green land which has been preserved thanks to the roof-top installation.

The design phase was quickly approved internally within one week by CEOs, a testament to their commitment to climate action. Planning permission and certifications from local power suppliers took a further three months, including assessments to ensure the roof could withstand the additional weight of the large panels. Finally, the execution stage is scheduled to be completed within six months; less than a year from start to finish in total.

Along with a dedication to protecting natural resources, Ingersoll Rand recognises the importance of corporate social responsibility to customers and as such, reducing its carbon footprint throughout the supply chain. The business was recognised for its industry-leading sustainability efforts this year, by both the Dow Jones Sustainability World Index (DJSI World) and the Dow Jones Sustainability North America Index (DJSI North America).

This is the second major investment in recent years at this particular site, with the first being a capacity enlargement estimated at €500,000 which facilitated accelerated growth in the market, due to the Elmo Rietschle plant being the largest manufacturer for liquid ring vacuum pumps and side channel blowers in Europe.

Other factories within the organisation have also implemented the solar technology with plans to continue rolling it out to additional branches, as part of a global strategy to mitigate climate change at both a local and national level, for generations to come.

This is just one aspect of Ingersoll Rand’s journey to achieving total carbon neutrality: other green directives scheduled for the near future include switching from gas to electrical power within manufacturing processes, such as production heating systems (a timely requirement given the recent gas supply shortages) and installing electric vehicle charge points on sites to support the expected burgeoning adoption of eMobility.

Juergen Schneyer, Operations Director, Ingersoll Rand commented: “We operate as sustainably as possible and are committed to helping our customers do the same through efficient products and production processes. When we reduce our environmental impact, so too do our customers as they are part of the wider value chain. Ingersoll Rand is incredibly proud to have been listed on the DJSI World and DJSI North America indexes, which highlight our corporate, environmental, and social goals, along with our actions to change the cultural mindset across the different industries we supply.”

To this end, GTT has developed a scalable containment system, which can be adapted to any size of LH2 carrier without major design modifications, as well as the cargo handling system, the design of which has been validated on the basis of ClassNK rules accompanied by a risk analysis.

“We are proud to have obtained this new approval in principle from ClassNK, whose in-depth technical and regulatory knowledge, as well as the solid experience in the hydrogen field, demonstrate the relevance of GTT’s technology in this domain,” said Philippe Berterottière, chairman and CEO of GTT.

“We are convinced that the development of containment

Masaki Matsunaga, corporate officer and director of Plan Approval and Technical Solution Division of ClassNK, said the AiP for the LH2 cargo containment system and cargo handling system followed a review in accordance with rules and guidelines dedicated to LH2 transportation as well as verification of the risk analysis’ results.

“Anticipating that hydrogen transport will play a significant role in a carbon-free society, we are delighted to participate in GTT’s pioneering initiative through our expertise in safety assessment,” Matsunaga said.

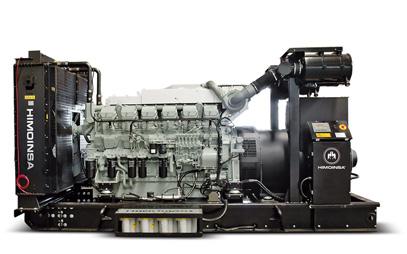

1,000 KVA DIESEL GENSET FOR PARIS, FRANCE

An HTW1035 T5 generator provided with an MHI engine and STAMFORD alternator has been installed at a commercial site in Paris, France.

A spokesman for HIMOINSA commented: “We had installed a rental generator of 1000 KVA on a logistics platform in the Paris region a few months ago. Our service provider, ATM Levage, was involved with organising the installation of the Himoinsa HTW 1035 T5 supply generator. We made the electrical connections of the generator set as well as a 300 kw load bank. Commissioning has been completed.”

The Emissions STAGE 2 HYW-35 T5 model is a diesel Three Phase

Yanmar -engine soundproofed genset. This offers:

Prime Power (PRP): According to ISO 8528-1:2018, Prime power is the maximum power which a generating set is capable of delivering continuously whilst supplying a variable electrical load when operated for an unlimited number of hours per year under the agreed operating conditions with standard maintenance intervals and procedures.

10 SEPTEMBER 2023 EURO POWER NEWS NEWS NEWS

POWER YOUR BUSINESS

On your path to net zero

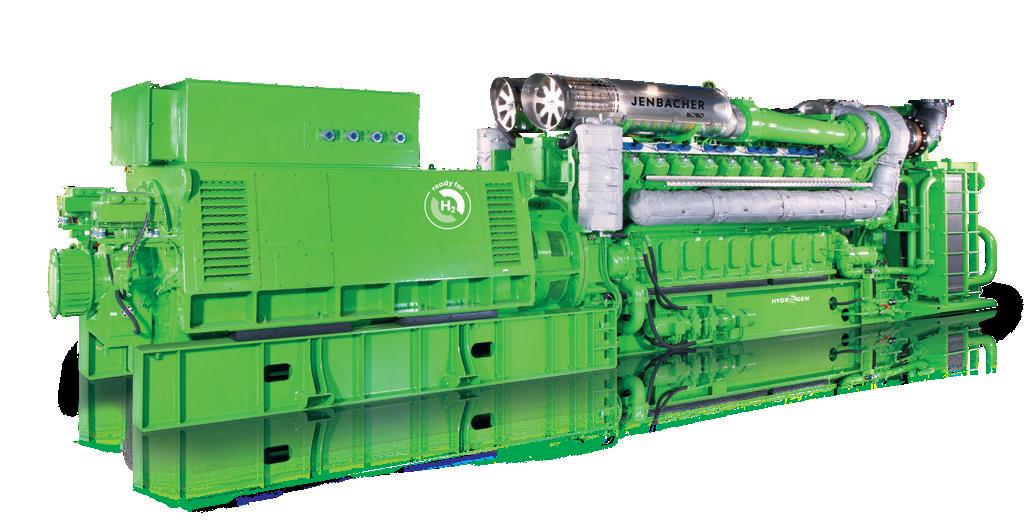

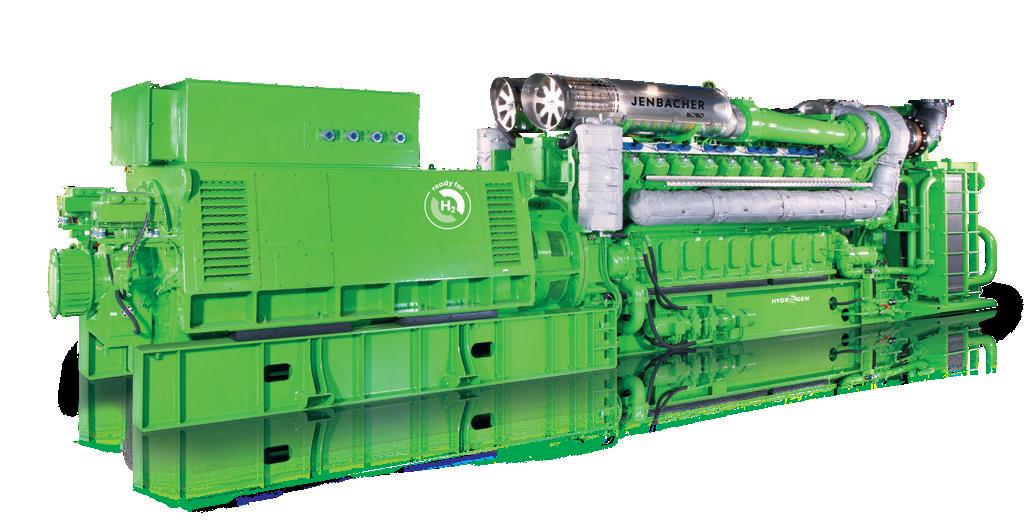

INNIO*’s flexible, scalable, and resilient Jenbacher* CHP and CCHP energy systems deliver power, heat and/or cooling for your local site while supporting your decarbonization efforts. Yielding up to 95 % total efficiency, cogeneration can reduce your energy consumption and CO2 emissions by more than 30 % compared to the separate generation of power and heat, significantly lowering your energy costs. Combined with heat storage, you can operate your asset flexibly. Jenbacher CHP and CCHP systems run on a wide range of gases with the option of converting to H2** operation once hydrogen is more readily available.

Join us on our path for a sustainable future! jenbacher.com

* & indicates a trademark.

** “Ready for H2” means the genset can generally be converted to 100% H2 operation in future. Details on cost and timeline of a future conversion package may vary and need to be clarified individually.

Jenbacher is part of the INNIO Group

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME.

INCREASING ENERGY EFFICIENCY & REDUCING THE TOTAL ENVIRONMENTAL FOOTPRINT AT AN INDUSTRIAL SITE IN NORWAY

UKRAINE IS SEEKING €2.4 BILLION IN FUNDING

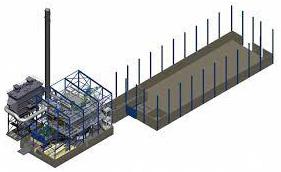

Clarke Energy France, a leader in the engineering, installation, design and maintenance of decentralized power generation solutions, has presented an innovative project designed to recover blast furnace gas at an industrial site in Norway. This turnkey solution will enable the ferromanganese plant to increase its energy efficiency and reduce its environmental footprint.

Clarke Energy is an expert in gas-fired power stations and combined heat and power technology. As a turnkey solutions provider, the company offers a complete package to industrial companies wishing to produce their own energy and reduce their carbon footprint.

Located in Sauda, in south-west Norway, the ferromanganese production plant of Eramet, a French mining and metallurgy group, is forced to flare blast furnace gas. Thanks to Clarke Energy’s solutions, this resource will now be used to produce electrical and thermal energy.

After a pilot phase validated in 2021/22, Eramet’s Norwegian site has decided to invest €19 million in an energy recovery unit proposed by Clarke Energy. This unit, equipped with the latest-generation INNIO Jenbacher gas engines, will use the lean gases recovered to increase the plant’s energy efficiency by more than 30%. Clarke Energy is providing a complete package, including raw gas treatment, electricity generation, connection to the medium-voltage grid and the heat recovery process. The specific composition of the recovered gas – whose energy comes from the hydrogen it contains –demonstrates Clarke Energy’s expertise in the conditioning and recovery of specialty gases.

“We are proud to be involved in this fantastic project, which is in line with Clarke Energy’s sustainable strategy. It’s another contribution from our company to the energy transition and the global net-zero initiative,” comments Didier Lartigue, Managing Director of Clarke Energy France. The project has the support of the Norwegian authorities and aims to develop and deploy environmentally friendly technologies, by recovering the gases emitted by the furnaces and reducing electricity consumption. The project, worth a total of €32 million, also includes the installation of a complete heat recovery process to supply thermal energy to the local district heating system in the municipality of Sauda (population 5,000), and to improve the plant’s overall efficiency by enhancing the quality of raw materials. In addition, engine exhaust gases will be fed into a carbon capture and storage (CCUS) plant, helping to reduce greenhouse gas emissions and produce a low-carbon alloy.

NEW 5MWH CONTAINER PRODUCT OFFERS A COMPACT ESS2.0 CAPACITY

Hithium has announced a new 5 MegaWatt hours (MWh) container product using the standard 20-foot container structure. The more compact second generation (ESS 2.0), higher-capacity energy storage system will come pre-installed and ready to connect.

It will be outfitted with 48 battery modules based on the manufacturer’s new 314 Ah LFP cells, each module providing 104.5 kWh capacity and designed to meet the needs of large utility scale systems. Due to the more compact design, the 5 MWh container will provide an energy density of 117 Wh/l. That is 46% higher than the 80 Wh/l that can be seen in standard systems based on 280 Ah cells. The product will also be technically compatible with most top inverter brands’ power control systems, or bidirectional inverters. The new energy storage system, named the “HiTHIUM ∞Block,” comes with the company’s mature multi-level, liquid-cooling technology, which keeps cell temperature variation below 3° Celsius. Intelligent thermal management also enables the system to optimize battery power and reduce internal energy consumption. Further safety features include multi-level fault detection systems, cell monitoring, gas and smoke detection, and automated fire extinguishing.

DTEK, Ukraine’s largest private energy company, has announced plans to transform its warshattered electricity network in areas surrounding the capital Kyiv by building a smart grid capable of better withstanding military assault and able to accelerate Ukraine’s energy transition.

The Kyiv regional power grid (which excludes the capital itself) was extensively damaged in spring 2022 as Russian forces advanced towards Kyiv city and again after October 2022 when Russia deliberately targeted Ukraine’s civilian energy infrastructure.

After Ukrainian forces liberated areas near the capital in the first months of the war, DTEK crews from around Ukraine immediately moved in to reconnect customers. Although they restored power in

just 45 days, the network remains in need of extensive repairs and major upgrades to allow it to match modern European standards.

DTEK Grids, the grid operating business arm of DTEK, is seeking €2.4 billion of funding in a 10 yearproject to transform the region’s power infrastructure. The plans, which must be approved by Ukraine’s Ministry of Energy, envisage building a smart grid with 20,000 km of new overhead and underground cables, 250 substations, 6,000 transformers and almost a million smart meters.

Key advantages include:

-A resilient smart grid infrastructure which still works even if one segment is damaged or destroyed.

-Stronger connectivity to power produced from renewables.

-Digital Twin technology allowing engineers to model the network.

PHOSPHATE & LITHIUM DEPOSITS DISCOVERED IN

A huge phosphate rock deposit discovered in Norway contains enough minerals to meet the global demand for batteries and solar panels for the next 100 years, according to the mining company that controls it.

Norge Mining said up to 70 billion tonnes of the nonrenewable resource may have been uncovered in south-western Norway, alongside deposits of other strategic minerals like titanium and vanadium. Phosphate rock contains high concentrates of phosphorus, which is a key component for building

green technologies but currently faces significant supply issues. Phosphorus has become an essential component in lithium-iron phosphate batteries in electric cars, in BESS systems, in solar panels and in computer chips.

Russia previously controlled the world’s largest ultra-pure phosphate rock deposits, with the European Union warning that these “critical raw materials” have a high supply risk.

The EU is currently almost entirely dependent on imports of phosphate rock from the rest of the world, according to a report

12 SEPTEMBER 2023 EURO POWER NEWS NEWS NEWS

Leaders in complete power solutions

A full service approach to temporary power provision

Power solutions for every environment

Established in 1950, we were one of the first providers of temporary power hire in the UK. Over the past 70+ years, we’ve worked on a complete range of projects. We have the equipment, expertise and experience to handle specific power requirements for any industry.

WOODLANDSPOWER.COM | UK: 0845 600 3335 | INTERNATIONAL: +44 138 644 2622

Hire Sales Service & Maintenance Contingency Planning

BIOHEAT

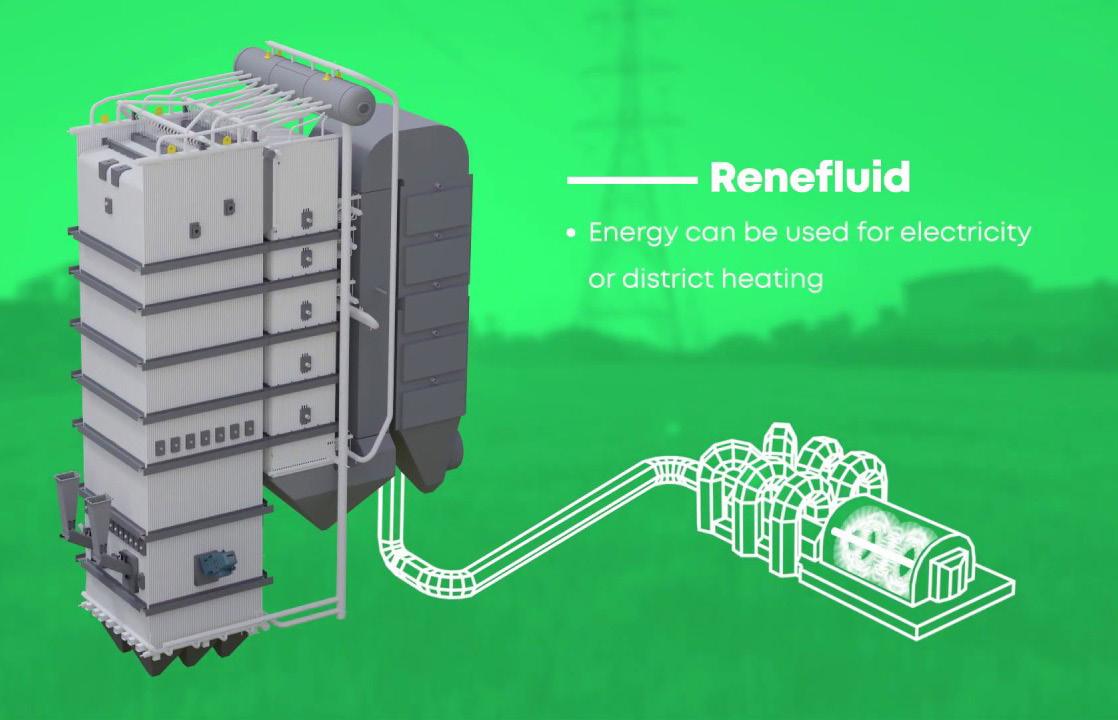

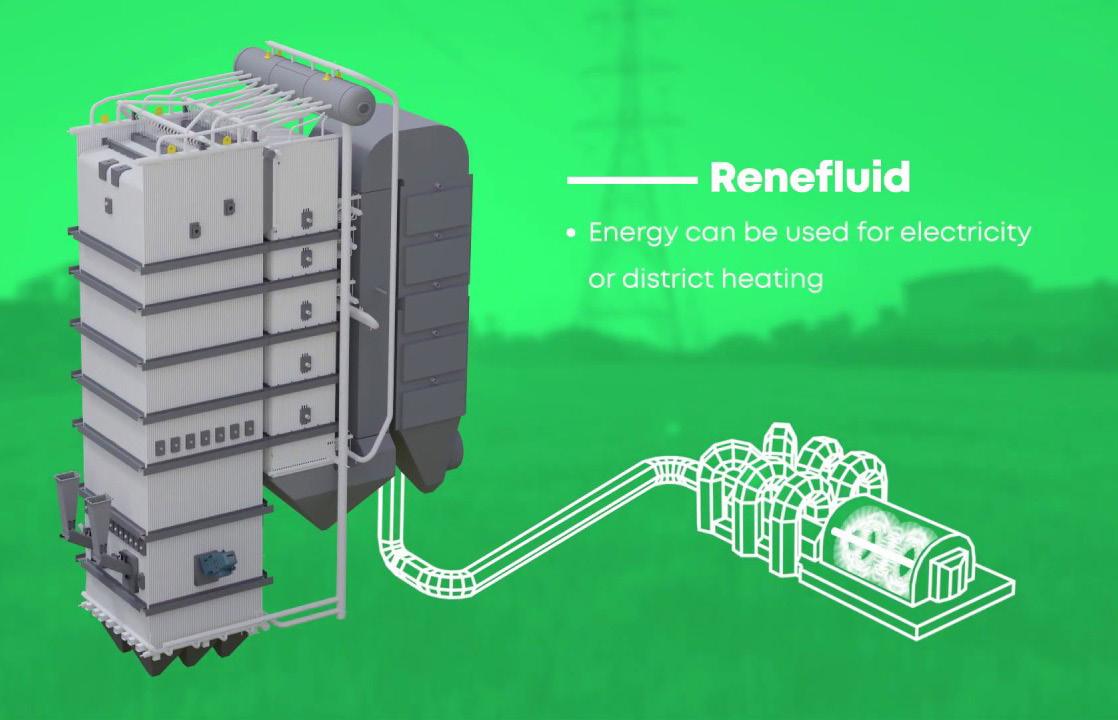

Finland’s latest bioheat plant opens in Autumn 2023

The new 5 MW Unicon Renefluid bioheat plant installed by KPA Unicon will produce heat for the City of Kuhmo and Kuhmo Oy’s sawmill. The plant will use bark, sawdust, and woodchips as fuel.

“The boiler investment will enable an increase in the production capacity of Kuhmo Oy’s sawmill and the expansion of the district heating network in the city of Kuhmo,” said Janne Heikkinen, Managing Director, Kuhmon Lämpö.

Included within the turnkey solution is the Unicon Renefluid fluidized bed (FB) boiler, electrical and automation, a modular boiler building, and fuel handling.

The bioheat plant also includes KPA Unicon’s own bag filter, which ensures that the plant’s emissions are clean and the air quality in the surrounding area remains good.

According to KPA Unicon, a bag filter is “a costeffective way” to effectively remove hazardous particles from the flue gas.

“The increase in heat production is both technically and logistically environmentally friendly and energy-efficient, as the biomass used in the plant comes from a sawmill on the same site. The boiler investment will also improve the security of district heating supply and maintenance planning in the future,” explains Heikkinen.

The plant has already been equipped with KPA Unicon’s PlantSys digital service platform and the plant will have a secure remote control room system (PlantSys Operation) as well as a digital operating log (PlantSys Diary) and a reporting system. The system will be fully

supported for years to come. During the warranty period, the plant iwill be optimised and monitored with the help of artificial intelligence (AI).

“Together with Kuhmon Lämpö Oy, we get a welldesigned entity that will complement Kuhmon Lämpö Oy’s district heating and sawmill’s heat production by utilising the sawmill’s by-products as biomass. Bag filter, on the other hand, ensures a cleaner environment and better air quality, said Jukka-Pekka Kovanen, Managing Director, KPA Unicon.

Last year, KPA Unicon was awarded a contract for a biomass boiler refurbishment project in Sweden. The company was chosen by energy utility Katrinefors Kraftvärme AB (KKAB) to modernise an existing biomass boiler unit at KKAB’s combined heat and power (CHP) plant in Mariestad.

The Katinefors Kraftvärme CHP plant supplies steam for Metsä Tissue’s paper mill in Mariestad, district heating for Mariestad, and power for the grid.

The KKAB plant consists of two CHP units, 37 MWth/9 MWe and 28 MWth/7 MWe that were commissioned in 2002 and 2015 respectively, and uses paper mill sludge as fuel in the former unit and recycled wood in the latter.

Four 15 MW oil-fired boilers, of which two are hot water boilers for district heating and two are steam boilers. make up the reserve and backup for the plant.

The technology and the modernization focussed on the 37 MW boiler which was originally delivered in 2002 by a third party and is based on KPA Unicon’s fluidized bed (FB) technology.

The 28 MW boiler, an Unicon Reneflex boiler, was initiually supplied by KPA Unicon in 2015.

The work was completed in the Autumn of 2022 and has had significant and positive impact on the plant’s fuel flexibility and usability.

“When we made the decision to update the boiler after 20 years of operation, we compared the current technology to the boiler which KPA Unicon delivered in 2015 and its operating experience. The goal of the redevelopment is to achieve the same high usability that we have on the Reneflex boiler with better environmental performance,” commented Johan Nilsson, Managing Director, KKAB. KPA Unicon’s Swedish contract included the modernisation of the 2002 boiler’s fluidised bed, renewal of the bottom ash removal system, starter, and load burners as well as the circulating gas system. KPA Unicon has been tackling the world’s toughest energy problems for nearly three decades. From renewable, clean-energy solutions like our biomass boiler plants to operational modifications that increase the efficiency of existing energy plants, KPA Unicon is inspiring and facilitating the world’s transition to clean energy.

www.kpaunicon.com

14 SEPTEMBER 2023 EURO POWER NEWS GENSETS 14 SEPTEMBER 2023 EURO POWER NEWS

As part of an installation contract to be completed in Autumn 2023, combustion technology provider KPA Unicon, a Partnera Group company, has supplied the district heating company Kuhmon Lämpö Oy with a bioheat plant for a facility in Kuhmo.

“ The increase in heat production is both technically and logistically environmentally friendly and energy-efficient, as the biomass used in the plant comes from a sawmill on the same site. The boiler investment will also improve the security of district heating supply and maintenance planning in the future.”

Janne Heikkinen, Managing Director, Kuhmon Lämpö.

Noise control experts Keeping your world clean, quiet, and safe. Dürr Universal is a global leader in the design and manufacture of inlet and exhaust systems for gas turbines and reciprocating engines in the OEM and retrofit markets. www.durr-universal.com Dürr Limited United Kingdom Phone +44 1455 8944 88 Email solutions@universalaet.com

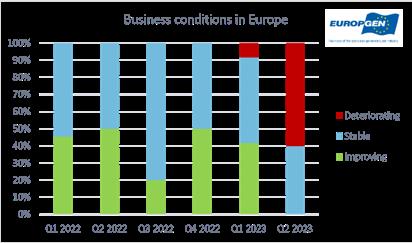

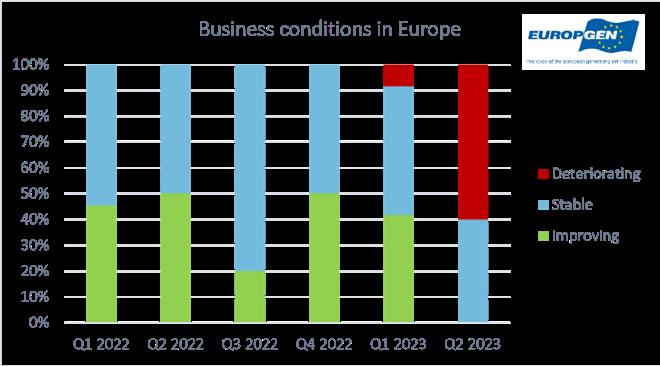

THE 2023 & 2024 GENERATOR MARKET

2023 appears to be a transition year for generators below 750 kVA. After more than two years of post-COVID recovery, and double-digit growth (+22% in 2021, +15% in 2022), the year 2023 should grow at a lower rate (+6%). Above all it should experience a much weaker second half of the year, and a slight decrease is expected in 2024, reports

The main drivers of growth are currently at a standstill, even if large disparities exist depending on the region and segment.

One of the big differences between 2022 and 2023 is the stock levels at distributors. In just a few months, we went from a situation where demand was much higher than supply (long lead times, shortage of components) to a situation where supply is now higher than demand.

The local Chinese market being very affected by the real estate and construction crisis, and Europe (which was boosted in 2022 by Ukrainian imports and fears of an energy crisis) are having a significant negative impact on the market in this end of 2023 and 2024.

Outlook by application

On a global scale, the main market drivers for sub 750 kVA generator sets are the industrial and construction sector, the Telecom market, agriculture, rental and residential generators. Here are their trends for 2024.

- Mobile and rental groups: The market is expected to take a break in Europe, after two years of post-COVID recovery where rental companies have invested massively in new fleets, and the outlook for the construction market calls for great caution. In North America, the mobile market seems to be holding steady at very high levels.

- Industry and construction: In general, the residential construction sector should decline

in most regions, and the non-residential construction sector should show very contrasting growth depending on the region: sustained in Southeast Asia and to a lesser extent in North America, it should suffer in China, Europe and Latin America.

- Telecom: Although the development of 5G still benefits this segment, growth will be very moderate in 2024 because certain markets (USA) have invested massively in past years, except in Asia where growth should be more sustained.

Forecast by region

- Europe: This is the region that is expected to suffer the most at the end of 2023 and beginning of 2024. After two years of very strong growth, driven recently by the consequences of the conflict in Ukraine and the energy crisis, the main vectors of growth are at a standstill. (Ukrainian imports, fears of an energy crisis, decline in construction) and product stocks are high at distributors. The market is expected to record a double-digit decline in most countries in 2024.

- China: The local Chinese market will continue to suffer in 2024 as residential housing projects will continue to decline while growth in infrastructure projects may moderate.

Businesses are suffering from the slowdown in the global economy and falling exports. On the other hand, Chinese exports of generator sets are booming and have doubled in two years.

- South East Asia: It is one of the regions that

areas such as Ukrainian imports, fears of an energy crisis, decline in construction.etc.

should do well in 2024, thanks to the growth of construction infrastructure projects in the key countries (Indonesia, Vietnam, Philippines).

Roads, railways projects as well as the relocation of the capital in Indonesia are some of the key examples where investment in construction projects and infrastructure is ongoing.

- India: 2023 is a transition year for generators below 800 kW with the implementation of the CPCB IV+ emissions standard.

Government spending on infrastructure and the country’s economic outlook provide optimism for sustaining the growth of the Indian market.

- Africa & Middle East: growth prospects are subject to significant downside risks due to, persistently tight global financial conditions and elevated geopolitical risk especially in Africa.

However two countries should be the pillars of growth in these regions: Saudi Arabia thanks to the giant construction and infrastructure programs that have started, and South Africa.

South Africa still suffers from blackouts and the national emergency generator market still very strong.

- North America: growth has been mainly driven by the mobile segment and investments in new fleets.

Although fears exist in the residential market, the non-residential construction sector is expected to continue its growth thanks to the positive impact of government-related infrastructure investments.

- South America: After a year of strong growth in 2022, the South American market is expected to take a break in 2023-2024.

Inventory levels are high among distributors and the construction sector is slowing down despite substantial infrastructure programs.

16 SEPTEMBER 2023 EURO POWER NEWS EUROPGEN

Romain Mocaer.

In Europe the main vectors of growth are at a standstill in

EUROPGEN CO-SIGNS THE JOINT INDUSTRY POSITION PAPER ON DIGITAL DECLARATION OF CONFORMITY (DoC)

In Europgen news: The signatories of Joint Industry Position Position Paper (DoC) believe that it is necessary to clarify in the Blue Guide that the term “accompany” in relation to documentation can, unless the provision of the paper format is specified in sector-specific legislation, be taken to mean either providing the DoC on paper or digitally. This would ensure a harmonised use of digital DoCs across all EU relevant legislation.

The Position Paper is available via a link on the official website.

BATTERIES AND WASTE BATTERIES REGULATION

On 28th July 2023, the EU Batteries and Waste Batteries Regulation (Regulation (EU) 2023/1542) was published in the Official journal.

The Regulation strengthens sustainability rules for batteries and waste batteries and will regulate the entire life cycle of batteries to ensure their safety, sustainability and competitiveness.

The Regulation will apply to all batteries, including all waste portable batteries, electric vehicle batteries, industrial batteries, starting, lightning and ignition (SLI) batteries and batteries for light means of transport (e.g. electric bikes, e-mopeds, e-scooters).

The regulation prescribes end-oflife requirements, including extended producer responsibility, collection targets and obligations, as well as targets for the recovery of materials.

The new Regulation introduces labelling and information requirements (applicable from 2026) and an electronic “battery passport” and a QR code (applicable from 2027). Furthermore, the Regulation prescribes tight due diligence rules for operators who shall verify the source of raw materials used for batteries placed on the market.

An exemption from the due diligence rules is provided for SMEs.

The Regulation will enter into force 20 days following its publication in the Official Journal

of the European Union. The Regulation is available via a link on the official website.

ENVIRONMENTAL IMPACT OF WASTE MANAGEMENT – REVISION OF EU WASTE FRAMEWORK

The Commission has published a call for evidence about The Waste Framework Directive.

The stakeholders are invited to give their feedback. All feedback received will be summarised by the European Commission and presented to the European Parliament and Council with the aim of feeding into the legislative debate.

The feedback period is open from 7 July 2023 to 22 September 2023 and is available via a link on the official website.

“ EU Directives Working Group

Working Group leader:

Stuart Hawkins –Cummins

EUROPGEN MARKET TRACKER

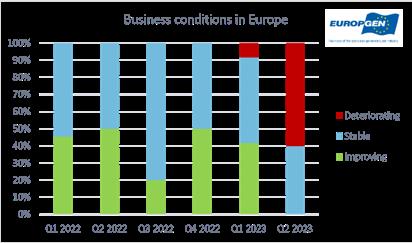

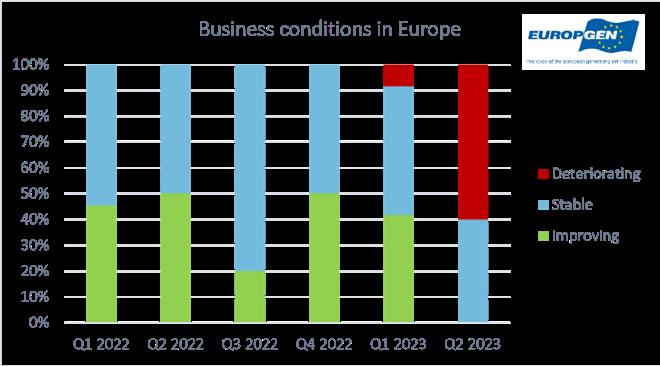

On 20 July, EUROPGEN has published the Q2 2023 quarterly Market Tracker survey. The goal of this study is to publish Q2 2023 trends regarding the business conditions in Europe.

We communicate these results on our website and social network accounts, and will send the next survey at the end of September 2023.

EUROPGEN – NEW MEMBER

EUROPGEN is delighted to welcome EODev as a new member!

EODev develops and industrializes sustainable, reliable, and affordable hydrogen-based energy solutions. We are looking forward to working with them on the H2 topics.

MEETINGS & EVENTS

Next meetings

*EUROPGEN Technical Committee meeting, Paris, 21th September 2023

*EUROPGEN Executive Committee meeting, Paris, 22nd September 2023

ABOUT EUROPGEN

Europgen is a cross-border organisation registered as an official lobbying organisation in the EU. It brings together Europe’s most

Objective: EU Directives Working Group reviews and monitors European regulations related to Product Safety. This working group is monitoring and providing feedback into the consultations on the revision of the Machinery (MD), Low voltage (LVD) and Electromagnetic Compatibility (EMCD) directives.

Current topics: The consultant’s report on the effectiveness and applicability of the MD to new machinery technology such as Artificial Intelligence (AI) & Cybersecurity.

prominent corporate companies and trade associations in order to form a powerful and unified voice for the European generating set industry.

OBJECTIVES:

To promote the interests of the European generating set industry in its relations with customers, suppliers, EU regulatory authorities and government organisations.

To negotiate and liaise with European institutions, appropriate associations and organisations involved in the genset industry

To facilitate the agreement of European and International Standards for genset products and related services.

To ensure the highest standards for the genset industry’s products and services

To provide a forum for the exchange of non-competitive information.

KEY ACTIONS:

To lobby in accordance with the EU’s code of conduct.

To inform and influence any new framework guidelines for network codes.

To be a first warning system for any legislative guidelines that will affect the industry.

To provide advice, guidance, information and representation for the generating set industry.

EUROPGEN MEMBERSHIP

Membership is open to any companies, trade associations, and any trading partner within the power industry in Europe representing the generating set industry at a national level.

MAIN TERMS OF THE ASSOCIATION

The Association is registered as an official lobbying organisation in the EU. Transparency registration number : Number: 05847066277-30.

EUROPGEN has the following bodies:

The General Assembly

The Executive Committee

The President

The Secretary General

The Treasurer Working Groups

The affairs and policies of the Association are directed by the Executive Committee. Key decisions will be made by consensus.

EUROPGEN ASSOCIATION, 17 Rue de I’amiral Hamelin, 75783 Paris Cedex 16, FRANCE

EURO POWER NEWS SEPTEMBER 2023 17 EUROPGEN

Europgen is a cross-border organisation registered as an official lobbying organisation in the EU.

GAS GENSETS

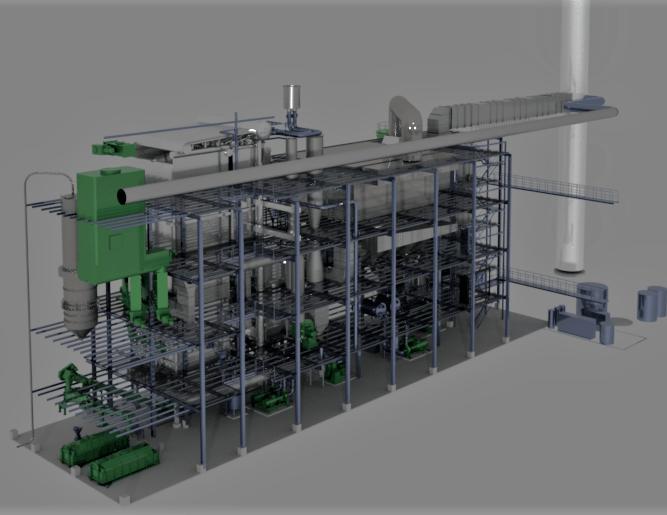

NORTH MACEDONIA BIOGAS PLANT POWERS 4,000 HOUSEHOLDS

Gensets of the medium MWM series, TCG 2020 and TCG 3020, are very popular, for example, in hospitals, data centres, shopping centres, biogas plants or in the food industry. With a power range between 1 and 2.3 MW, the gas gensets of this series are ideally suited for decentralised energy projects.

A newly-built biogas plant in Lozovo (North Macedonia) supplies reliable electrical energy to around 4,000 households with its two TCG 2020 V12 gas gensets. Construction of the plant began in December 2020, and power generation started precisely two years later.

Highly efficient 1 MW gas gensets

The MWM gensets supplied for this project were of the high-efficiency 1 MW design. The engines, powered exclusively by renewable energy and organic waste, also provide 2.1 MW of thermal energy.

But that’s not all: approximately 30,000 tons of natural fertilizer are produced annually as a byproduct of biological processes and used in local agriculture.

The power plant, an investment of Bio Enterprise, was planned and realized by the engineers and technicians of Feroinvest and EMS (Energy Maintenance Solutions).

Feroinvest is known in North Macedonia and beyond for its expertise in renewable energy.

Biogas is usually produced by the anaerobic digestion of organic waste in a so-called digester. Instead of allowing the waste to decompose uncontrollably and release gases into the atmosphere, it is stored in an oxygen-deficient environment, such as a covered lagoon or stainless steel tank.

From there, methane is extracted and used as fuel to generate heat and electricity.

This way, biogas plants can convert organic waste into energy and valuable byproducts such as fertilizer. In addition, biogas plants can continuously generate electricity, which is particularly valuable given the current shift to renewable energy.

Large tomato producer relies on MWM gensets

Wonderplant S.A, one of Greece’s largest tomato producers, also relies on cogeneration with MWM gas gensets Made in Germany. The Greek vegetable grower produces up to 15,000 tons of tomatoes annually. For the “Wonderplant 2” project and the associated expansion of the greenhouse area, MWM Benelux B.V. installed another cogeneration unit in 2021, powered by

“The Wonderplant2 cogeneration plant has an annual electrical capacity of 76,800 MW and an annual heat generation of 83,200MW.

The CHP plant ensures that around 15,000 tons of tomatoes can be harvested annually under optimal conditions.

The site produces enough tomatoes to feed the average demands of 500,000 people.”

eight MWM TCG 2020 V12 gas generator sets.In 2011, the first greenhouse of the vegetable grower Wonderplant S.A, with an area of 105,000 square meters, was built.

In 2013, the first cogeneration plant with four MWM TCG 2020 V20 gas gensets with a total capacity of eight MWel was installed by MWM Benelux B.V. to manage the greenhouse. Since then, the MWM gensets have been in continuous operation and have completed over 70,000 operating hours.

In 2018, the greenhouse area was expanded by another 55,000 square metres.

To handle the increased demand for heat and electricity following the expansion of the greenhouse area, MWM Benelux B.V. 2021 installed a new cogeneration plant, including flue gas cleaning for Wonderplant.

The CHP plant is powered by eight MWM TCG 2020 V12 gas gensets with a total output of 9.6 MWel and 10.4 MWth. Both CHP plants have a total capacity of up to 17.9 MWel. The greenhouses can be optimally heated thanks to the new CHP plant with the MWM gas gensets.

Sufficient tomatoes for a big city

The cogeneration plant of “Wonderplant 2” has an annual electrical capacity of 76,800 MW and an annual heat generation of 83,200 MW. After the commissioning of the plant in 2021, the Greek MWM distributor A.EI.M.A S.A. has taken over the maintenance and service work for Wonderplant.

The CHP plant ensures that around 15,000 tons of tomatoes can be harvested annually under optimal growing conditions.

With an average per capita consumption in the European Union of 31 kilograms per year, the company produces enough tomatoes to supply a major city with around half a million inhabitants. This also includes the demand for tomatoes for ketchup or sauces.

www.mwm.net

18 SEPTEMBER 2023 EURO POWER NEWS 18 SEPTEMBER 2023 EURO POWER NEWS GAS GENSETS

Gas gensets produce electricity and heat reliably on a decentralised basis and contribute significantly to power generation, reports MWM.

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

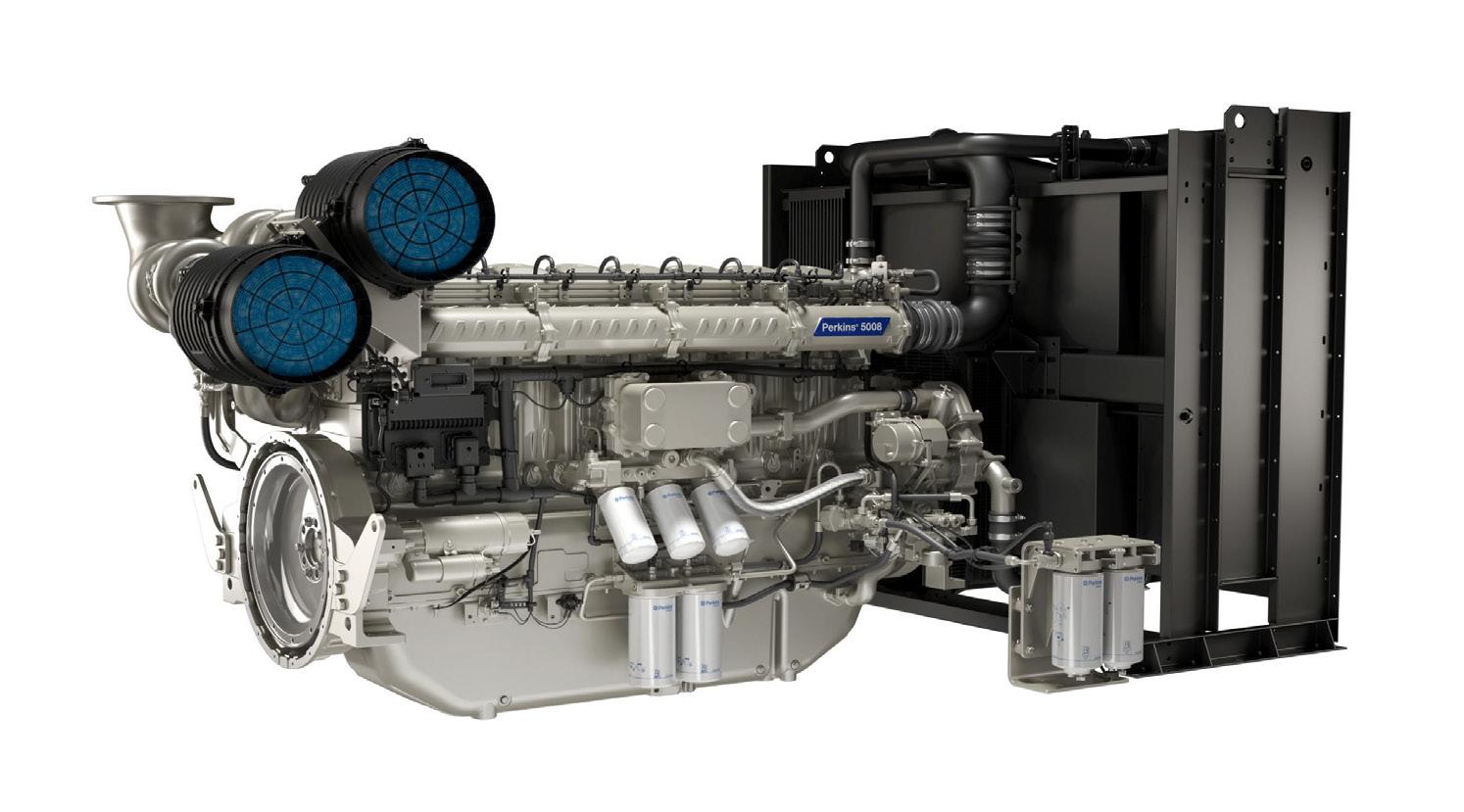

STAGE V ENGINES

2806J-E18TAG1 ELECTROPAK GENERATOR NOW RELEASED

maximising uptime.

Additionally, Perkins offers a powerful and growing portfolio of connectivity solutions that can help promote the optimal performance of diesel engines. Available as a standalone service from Perkins or easily integrated with generator equipment manufacturers’ offerings, connected engine capabilities deliver timely insights through a customisable dashboard of performance, fuel and oil consumption, and other vital engine data points that assist in maximising the uptime of Perkins-powered equipment.

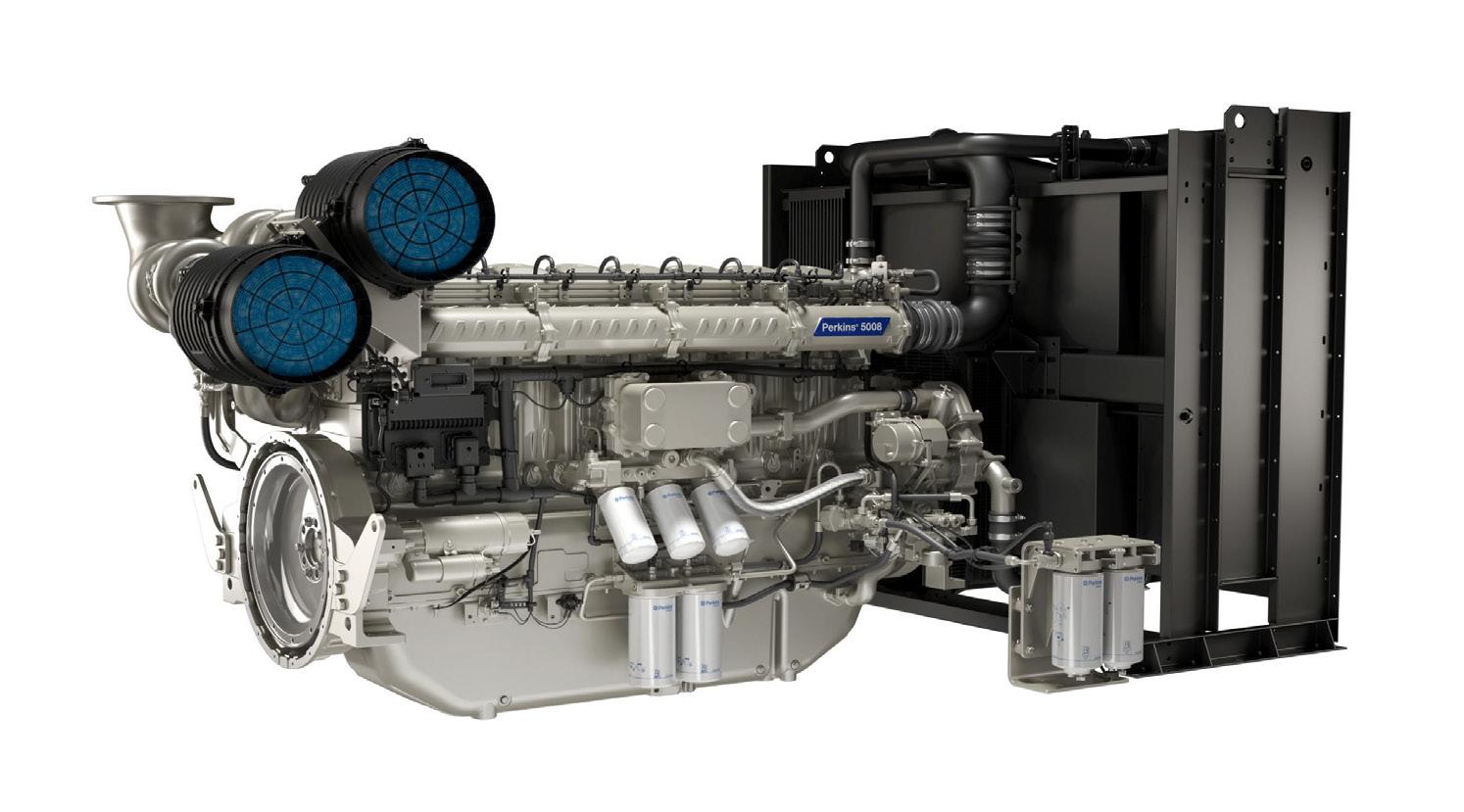

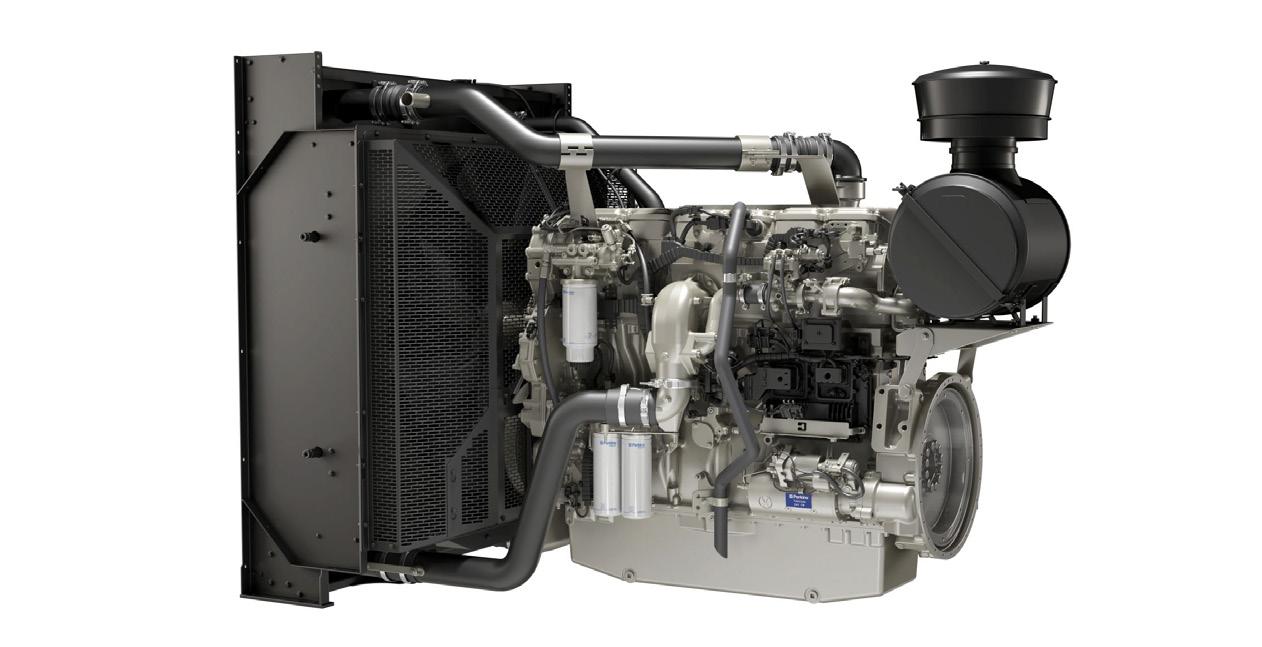

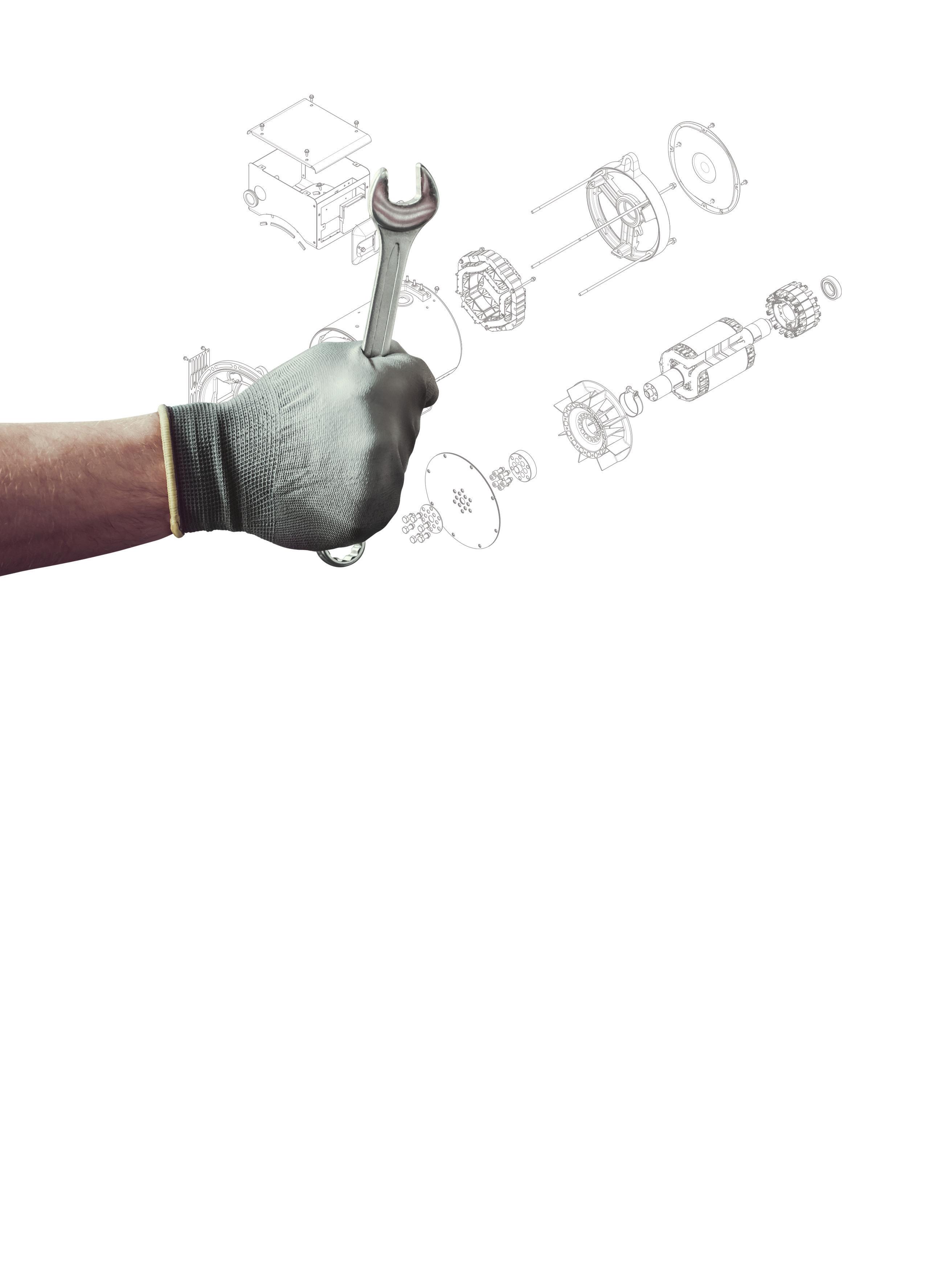

The 2806J-E18TAG1 is a new engine which delivers a powerful package and ease of integration, to meet the requirements of the electric power sector.

By achieving ISO 8528-5 G2 performance, the 2806J – which is available to order – provides excellent load acceptance in a wide range of electric power applications.

From a stationary prime source of power to a mobile unit serving the rental sector, the 2806J performs seamlessly, generating dependable power for everything from jobsites to critical installations including hospitals and data centres.

“Reliable electric power is not an option, it’s a fundamental need to keep operations running, whether that’s for standby when the mains power fails or to meet onsite prime power requirements,” says Jaz Gill, Vice President of Global Sales, Marketing, Service and Parts.

“Our engines are engineered and expertly crafted to provide reliable, stable and sustainable power for our customers, with the new 2806J

being the latest in a long line of products that also deliver a low total cost of ownership.”

For generator manufacturers and end users looking to reduce their greenhouse gas emissions, the 2806J can, subject to the fuel used meeting Perkins’ fuel specifications, run with biodiesel up to B20 based on a 20 percent dilution of biodiesel with standard diesel or on 100 percent hydrotreated vegetable oil (HVO).

The 2806J produces up to 610 kVA at 50 Hz and is switchable to 60 Hz, delivering up to 625 kVA.

The ElectropaK features the latest electronics with a single, on-engine electronic control module (ECM) that simplifies wiring harnesses, eases installation, supports future diagnostics and is fully capable of integration with customers’ telematics solution.

The ECM also manages all aspects of aftertreatment operation and regeneration without operator input. Regeneration occurs automatically with no impact to performance,

“ For generator manufacturers and end users looking to reduce their greenhouse gas emissions, the 2806J can, subject to the fuel used meeting Perkins’ fuel specifications, run with biodiesel up to B20 based on a 20 percent dilution of biodiesel with standard diesel or on 100 percent hydrotreated vegetable oil.”

These connectivity offerings are seamlessly integrated with expert maintenance and service capabilities from the Perkins global distributor network to prompt the proactive diagnosis and resolution of engine issues, helping technicians provide solutions and minimise downtime and repair expenses. The new 2806J-E18TAG1 joins the Perkins full line up of Stage V certified engines for electric power generation; 400 Series, 904 Series, 1200 Series, 1700 Series, and the 2000 Series, with power ranging from 4 kW @ 1500 rpm to 559 kW @ 1500 rpm. As with all Perkins engines, the new 2806J is supported by the global support network of 88 distributors covering 185 countries, ensuring stable and sustainable electric power when customers need it, where they need it and how they need it.

www.perkins.com

Building on its already comprehensive EU Stage V power offering, Perkins is announcing a new addition to the range – the 2806J-E18TAG1 ElectropaK. With over 90 years of design experience and more than 3 million Perkins-powered generator sets operating around the world, Perkins feels it truly understands the needs of the power generation industry.

20

TWO 1,200 KW GENSETS AT A HOSPITAL IN SIGONELLA, ITALY