MILLBROOK PROVING GROUND & NOxMASTER™ Agriemach has provided Selective Catalytic Reduction Systems for this key site.

UNIVERSITY OF YORK RECEIVES ITS 3RD CHP UNIT

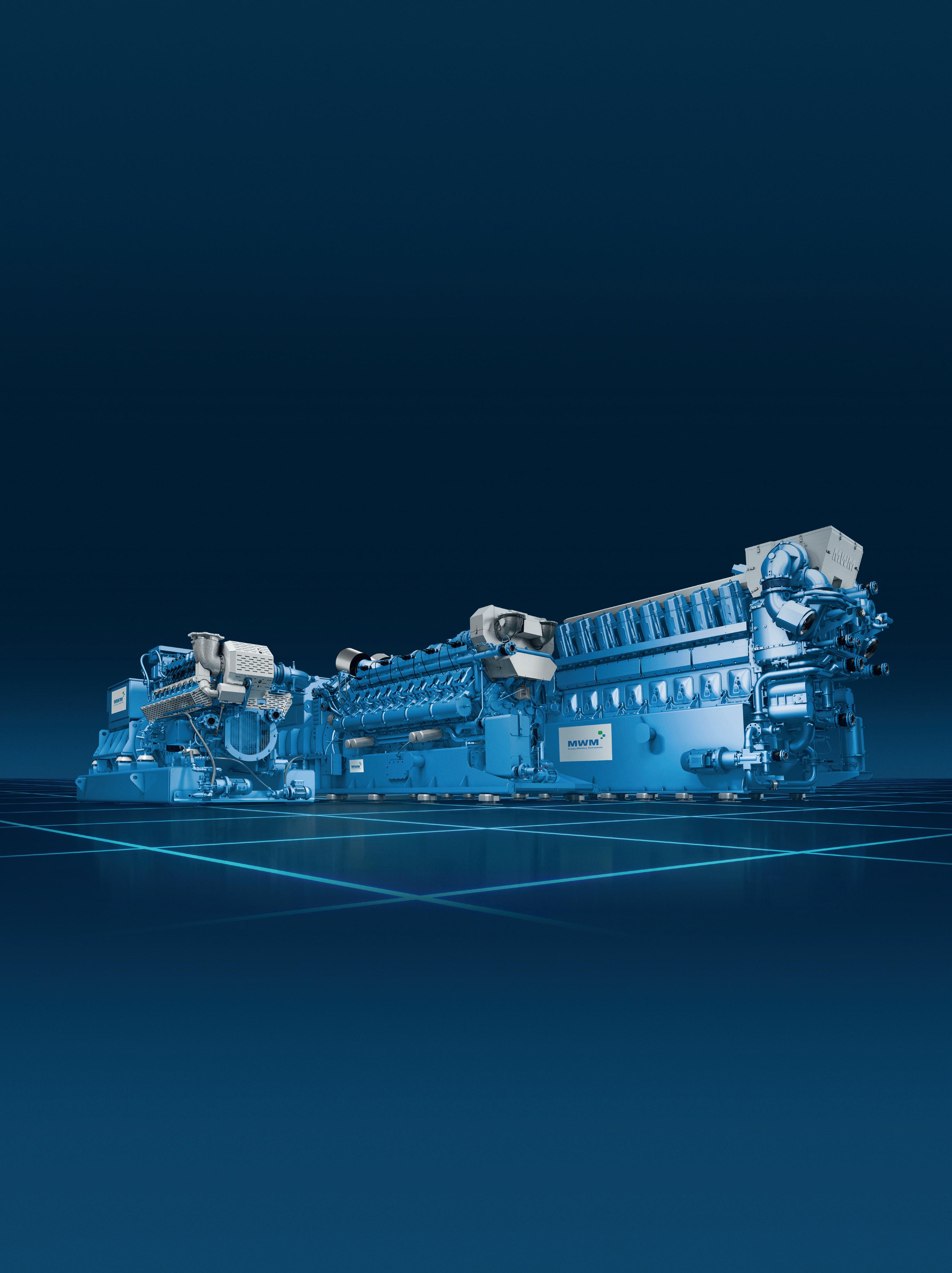

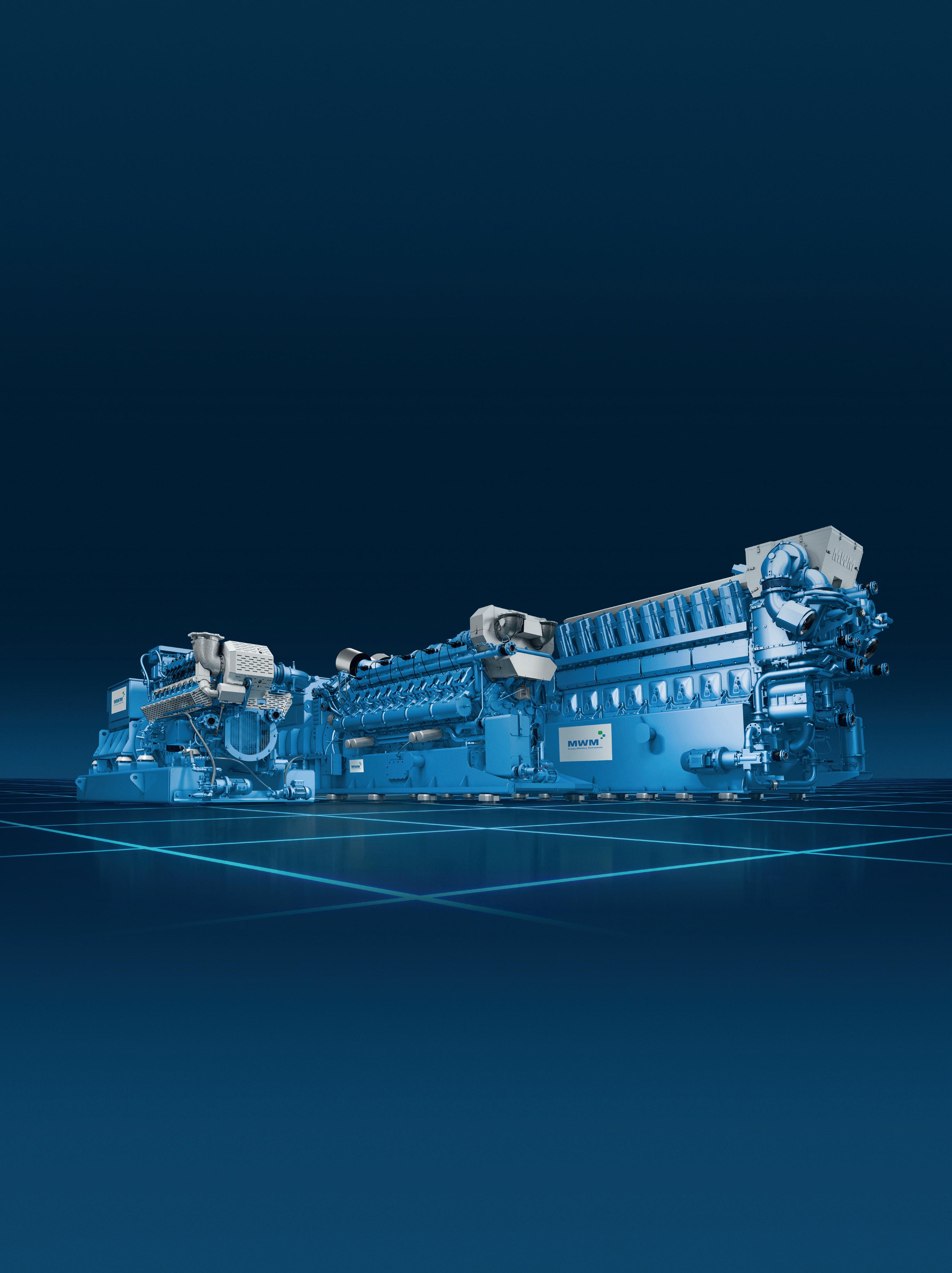

The MWM TCG 3020 V20 is part of the site’s energy centre, which supplies the campus with power.

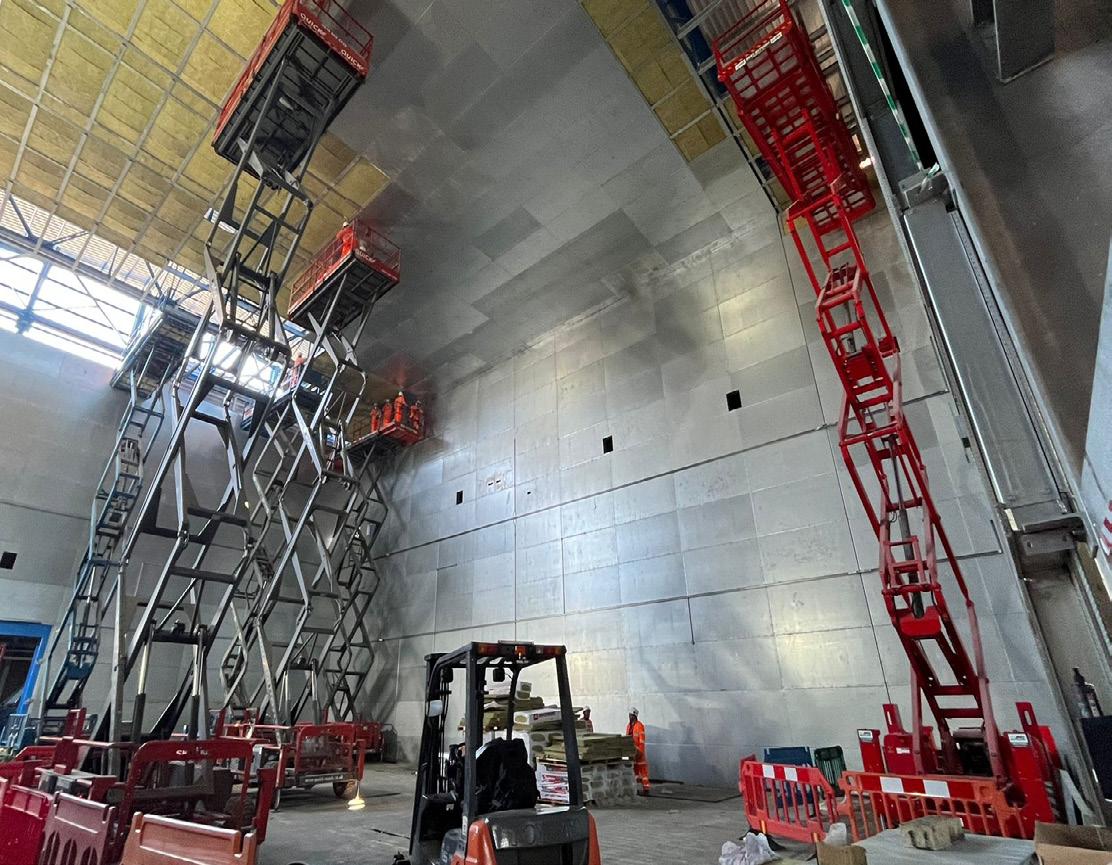

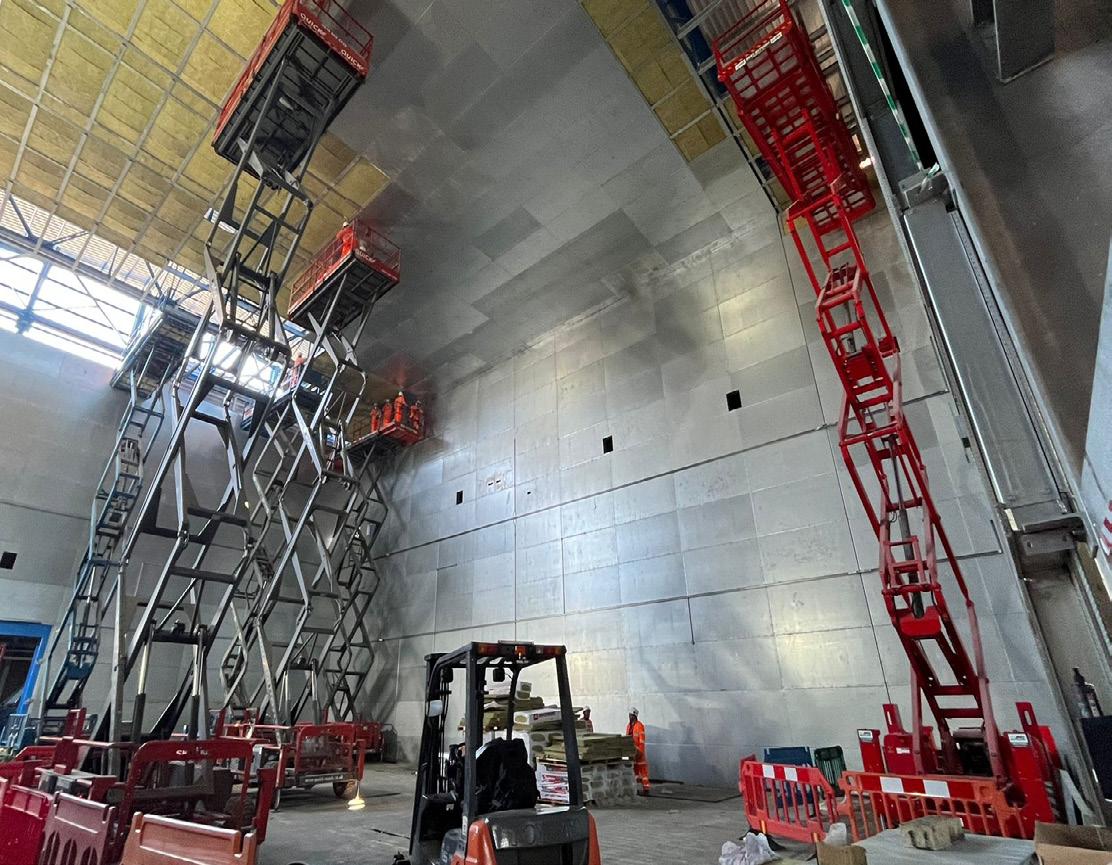

KEY FIRE PROTECTION

The Sellindge substation in Kent suffered a major fire but Promat has built-in future fire protection security.

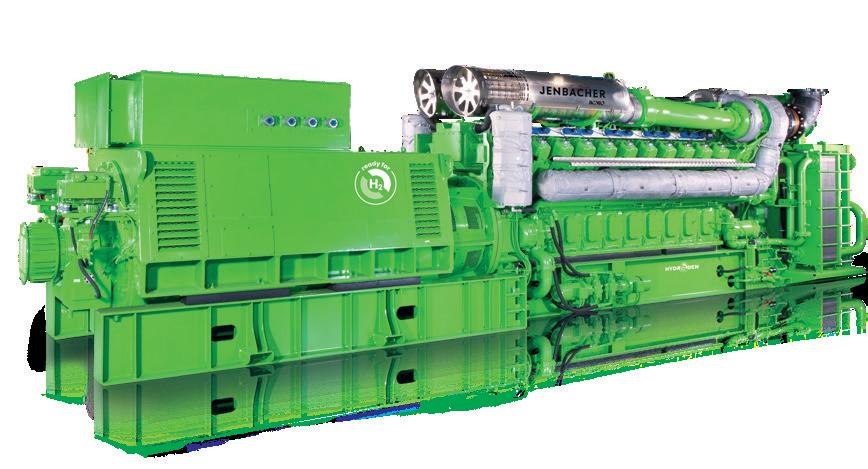

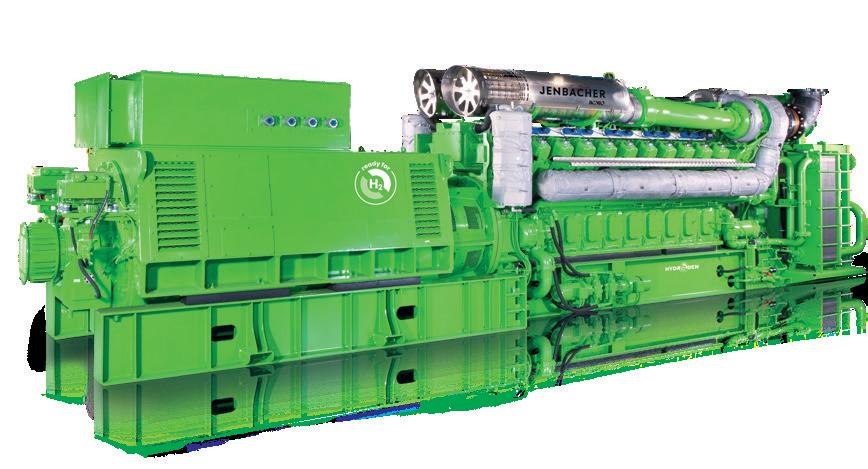

Clarke Energy will act as EPC contractor, engineering, installing and maintaining 50MW of hydrogen ready INNIO Jenbacher gas engines to VPI’s expansion at Immingham energy hub, as part of its energy transition investment.

Development of VPI’s new energy hub on the South Humber bank of the UK has reached a significant milestone with contracts awarded for nearly 350MW of fast-response, flexible power generation.

The developers have already submitted planning and permitting applications for the company’s Carbon Capture plant.

VPI’s combined heat and power (CHP) station at Immingham, North Lincolnshire has been a local landmark for nearly 20 years, providing power to the electricity system and steam for adjacent refinery businesses since it was opened in 2004.

Now, following a contract signature with key contractors, expansion is underway with the construction of additional, rapidly-deployable generation capacity to meet peaks in demand which cannot currently be met by

50MW OF HYDROGEN READY GAS ENGINES FOR A CHP STATION AT IMMINGHAM

renewables, reports the company.

VPI’s investment in capacity vital to the success of the energy transition includes a 50MW gas reciprocating peaking facility, installed by Clarke Energy, which will be operational early next year, and a 299MW open cycle gas turbine (OCGT), expected to enter service by summer 2025. Both installations will use established technology which has a track record of highly efficient and reliable

More transparency, more value.

operation to support the energy transition whilst maintaining security of supply. They are also capable of being converted to run on a proportion of hydrogen once industrial scale production is established. In addition to the new power facilities, decarbonisation of the existing CHP is also taking a major step forward.

With MWM Remote Asset Monitoring.

Remote Asset Monitoring (RAM) is the new digital application from MWM that enables you to continuously monitor your plant. The system displays the status of your MWM fleet in a well-structured, transparent manner, allowing you to act with foresight and more effectively.

www.mwm.net/ram

1

CES20001_Anzeigen_MWM_RAM_95x145mm_EN_2_0_RZ_sm.indd 1 21.03.22 12:58

Page 15

Page

24

Page 26

UK POWER NEWS MARCH/APRIL 2023 www.mwm.net/en-3016 CES20001_Anzeigen_MWM_TCG 3016_235x55mm_EN_2_0_RZ_sm.indd 1 21.03.22 12:53 MARCH/APRIL 2023

Publisher/Sales Director:

Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor:

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager:

Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent

Mario Dobresko power@wipmagazines.com

Contributors

MWM, Agriemach, AF Switchgear, Eland Cables, ABB, Hitachi Energy, Mitsubishi, Promat, Durr, Aggreko, Woodward, Generac, Cummins, Gravitricity, Veolia, All-Energy Exhibition, Advantage Utilities, EnerSys, CMP Products, Kohler UPS, University of Warwick (UoW) Interdisciplinary Biomedical Research Building (IBRB), Mocean Energy and TEXO Engineering & Fabrication (TEXO E&F), Weatherhaven, Yorpower, Perkins, KOHLER UPS, National Grid, SP Energy Networks, UK Power Networks, The Generator Company.

UK POWER NEWS

Published by:

Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK Tel: +44 (0)1403 888019 Fax: +44 (0)1403 220751

powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to UK Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

GRAVITY ENERGY STORAGE FOR A DECARBONISED GRID WITHIN

THE UK

Gravity energy storage can form part of ‘virtual power plants’ – helping deliver stable power as European countries strive to decarbonise their electricity grids.

Underground energy storage specialists Gravitricity have signed a collaboration agreement with Czech electricity flexibility aggregator Nano Energies to develop commercial routes to market for their gravity storage technology. Gravitricity - the Edinburgh storage firm - has unveiled plans to transform the former Darkov deep mine in the Czech Republic into a massive gravity energy store. This could be a pathfinder for projects Europe-wide.

Gravitricity plans to store energy by lowering and raising a single massive weight suspended in the Darkov mine shaft.

Stanislav Chvála, CEO of Nano Energies, [top] explains: “Gravitricity’s technology is able to respond to grid fluctuations very quickly and flexibly in terms of megawatt volume. We could thus involve them in our virtual power plants, which help balance the grid in the way that nowadays primarily coal and gas-fired power plants are able to do. He explains: “It is a longlife technology, well suited to integration with existing grid infrastructure. It can cycle rapidly from charge to discharge without any loss of performance over many years, and it delivers extremely fast response times of less than a second.”

He concludes: “This makes it a very attractive package to grid operators seeking grid balancing and fast frequency response services.”

Nano Energies specialises in delivering energy services to countries across Europe including Croatia, Hungary, Slovakia and Romania as well as the Czech Republic. They bring together a range of electricity sources including cogen units and solar parks.”

Energy initiatives for NHS Foundation Trusts from Veolia

Veolia has marked 85 years of providing energy management to the healthcare sector with major new projects to help decarbonise two acute hospitals for the University Hospitals Birmingham NHS Foundation Trust, one of the largest teaching hospital trusts in England which treats over 2.8 million patients each year.

Using a £22 million investment from the Salix Public Sector Decarbonisation Scheme (PSDS) Phase 3a, and additional Trust funding, the Good Hope Hospital and Queen Elizabeth Hospital Birmingham will gain from an extensive range of energy upgrades that will further cut carbon emissions.

The works are being delivered through the Energy Performance Contract with Veolia that was awarded through the Carbon Energy Fund framework, which provides project management and technical support to the projects. Designed using the whole building approach, these will help the Trust achieve the NHS net-zero goal by saving 3,847 tonnes of CO2 each year.

Located in Edgbaston, the Queen Elizabeth Hospital Birmingham will lower its carbon footprint by 2086 tonnes per year through conversion from the use of steam for heating, and replacing this with a hot water system backed by the integration of a 1MW multi-stage heat pump system. To ensure the efficiency of the new system 2,000m2 of roof insulation will be installed and the control systems optimised. Installation of a 314kWe solar array will further help to decarbonise the hospital’s electricity supply, by adding renewable power, and electricity consumption will be reduced by fitting more than 2962 LED luminaires in the buildings.

Upgrades at the Good Hope Hospital in Sutton Coldfield will mirror those being implemented at the Queen Elizabeth hospital with a similar conversion from steam to hot water heating. To achieve a total annual saving of 1760 tonnes of CO2 the hospital will use a 650kW multi-stage heat pump system, new efficient hot water boilers, installation of 9,500m2 roof insulation, and new building energy management systems.

Electricity use will be cut by 1992 LED luminaires that will replace existing internal lighting. These measures will add to the efficiency of the existing combined heat and power based supply that has been delivering financial savings and efficient energy, secure generation since 2013.

10 - 11 May 2023

Scottish Event Campus, Glasgow, UK

All-Energy Exhibition

and Conference is the meeting place for the renewable and low carbon energy community.

Our goal is to connect suppliers of renewable and low carbon energy solutions and policymakers to developers, investors, buyers, and a number of professionals from around the world, facilitating business and knowledge exchange right there on the show floor and will welcome professionals from a variety of sectors like hydropower, offshore/onshore wind, bioenergy, marine renewable energy, and others, coming from the UK, France, Germany, China, USA, Italy, and beyond.

Commenting on these latest decarbonisation projects for the NHS, Gavin Graveson, Veolia Senior Executive Vice President Northern Europe Zone said: “As the NHS became the world’s first health service to commit to reaching carbon net zero, these projects will help the Trust meet this target by cutting reliance on fossil fuels and will advance their progress to eliminate carbon emissions by 2045.

He concludes: “Our whole building approach, and expertise gained over 85 years of delivering energy efficiency to healthcare, will deliver major benefits including savings on critical energy costs, reduced emissions, and enhanced patient facilities.

“By working in partnership we will enable the Trust to meet their sustainability goals and deliver a net-zero future for healthcare in the UK.”

Registration for the UK’s largest renewable and low carbon energy exhibition and conference – All-Energy and the co-located Dcarbonise – is now open. The duo of events will be held at SEC Glasgow on 10 and 11 May 2023. Attendance at the major exhibition; the far-ranging conference; and the everpopular Giant Networking Evening is free of charge to all with relevant business or academic interests. As Jonathan Heastie, Portfolio Director Energy & Marine, RX Global who own and organise the duo of co-located events, explained: “The All-Energy and Dcarbonise exhibitions boast a veritable, and constantly growing, list of key organisations; and the conference programme will be looking at the wide range of highly relevant topics affecting, and of interest to, generators and users of all forms of renewable and low carbon energy.

2 MARCH/APRIL 2023 UK POWER NEWS NEWS NEWS www.powermediagroup.co.uk

****************

All-Energy Exhibition and Conference

THE RENEWABLE FUTURE OF FUELLING GENERATORS

Dr James Crosby, Head of Sustainability at Advantage Utilities looks at how gensets integrate generators and engines to produce power for a site. Most commonly, this can be in the form of backup electricity or the supply of power to remote locations.

“Currently, the most ubiquitous fuel which is used to power these generators are diesel and natural gas,” explains Dr Crosby. “In their cheapest form, diesel and natural gas come from fossil fuels and are highly pollutive throughout their entire lifecycles (i.e. extraction, refinement, transportation, and combustion). However, they are certainly affordable relative to alternative fuel sources and have highly efficient output.”

In spite of this, the ubiquitous nature of diesel and natural gas as fuel sources for gensets will have to be addressed by many firms utilising them. As emissions have risen and global average temperatures increased, the sustainability agenda has, for good reason, grown. This is highlighted by the UK NetZero 2050 pledge, he feels.

Dr Crosby asks the question: “This, therefore, poses the key question for businesses – how can we enhance the sustainability of our gensets without compromising its performance or increasing the running costs? Unfortunately, there is no perfect answer. Instead, there is a staged option.”

Option 1 – Do nothing and buy carbon credits

“This is my least favourite option. It does have the benefit of fulfilling superficial sustainability targets without a significant increase in cost or compromising performance. However, it is not addressing a generator’s emissions, merely masking them.,” explains Dr Crosby.

Option 2 – Substitute existing fuels for green gas and green diesel

He comments: “For the interim, this is my favourite option. Green gas is a catch-all phrase, however here it is being referred to as biomethane. Biomethane behaves akin to grid gas (methane) at the point of combustion. Therefore, there is little/no compromise on the performance of the genset. However, as biomethane is obtained by anaerobic digestion from organic waste, it has substantially less emissions than grid-sourced methane. The key negative of this fuel is the cost. Although not dramatically higher, obtaining green gas through the grid is approximately 10% to 30% more expensive.”

Green diesel is otherwise known as HVO (hydrogenated vegetable oil) and is an alkene (as is diesel) which is directly substitutable for traditional diesel. Therefore, it has the benefit of near indistinguishable performance relative to traditional diesel. Furthermore, it comes from the treatment of organic waste materials (e.g. vegetable oils etc…), which as a result has 90% lower emissions at the point of consumption. The key drawback is the price of this fuel. In terms of p/l, HVO is typically 30p to 40p more expensive.

Option 3 – Hydrogen

Dr Crosby feels this is probably the fuel with the most industrial commentary and hope. Hydrogen is set to be a renewable source of fuel with a competitive performance output relative to existing fuels, and is set to become affordable.

He concludes: “However, this is also the fuel which has the most uncertainty around it. Grid-scale and decentralised supply of hydrogen is a huge obstacle for this technology and the exact volumes and timescales for rollout are uncertain. Therefore, this ‘perfect’ solution is one which remains a long-term ambition.”

“In conclusion, the future of fuelling gensets will require modernisation and enhanced sustainability for the supply of fuel to fall within the Net Zero 2050 targets. However, the mechanisms which businesses choose to employ this will be subjective and become a factor of balancing costs with their own green agenda. Overall, this author concludes the best short-term solutions will be from Green Gas

UK NO LONGER HAS A ONESIZE-FITS-ALL BATTERY INDUSTRY

EnerSys® provides a complete, turnkey portfolio of solutions that can be tailored to meet the customer’s exclusive power demands.

The company handles anything from traditional flooded lead acid to advanced Thin Plate Pure Lead (TPPL) and Lithium-ion battery technology as well as the latest charging systems and battery management tools to the largest network of service providers.

“When engineering our products, we try to place ourselves in our customers’ shoes and develop solutions that will help address their operational pain points which often include scheduling disruptions due to labor issues, productivity inefficiencies from limited battery options and a general lack of knowledge on how to right-size their fleet,” said Harold Vanasse, Senior Director of Marketing, Motive Power Global at EnerSys®.

“As we all know, no two operations are the same. It’s no longer a ‘onesize-fits-all’ battery industry and that is why we’ve created our exclusive EnSite™ modeling software. It eliminates the guesswork with data-driven, actionable intelligence that identifies the ideal battery and charging combination to optimize a customer’s operations.”

In addition to the Company’s signature line of sustainable, virtually maintenance-free NexSys® TPPL and NexSys® iON batteries and legacy lead acid battery solutions, the company has recently released a wireless charging setup.

The full array of EnerSys® battery management tools, including the

Wi-iQ® battery monitoring device, the Truck iQ™ smart battery dashboard, and the E-Connect® mobile unitds are amonst other products being promoted by the company.

Today, EnSite™ modelling software can be the first step to enhanced productivity and a lower Total Cost of Ownership (TCO, reports the company.

A spokesman comments: “Before EnSite™ modeling software, finding the most efficient power solution for your material handling equipment meant relying on hand calculations and guesswork. “But with EnSite™ modeling software, we use your application data to determine which battery and charger combination will be optimal for your operation’s needs and goals.”

He concludes: “We work with you to collect a range of data about your application. Then we use your data in our EnSite™ modeling software to find a solution that meets your requirements for the lowest TCO for your operation.”

UK CABLE GLAND MANUFACTURER IS AWARDED ISO 50001 ENERGY

CMP Products, leading manufacturer of cable glands, cleats and accessories, has been awarded ISO 50001-energy management certification by Bureau Veritas, demonstrating the company’s commitment to responsible energy management and efficiency.

To achieve ISO 50001 certification, CMP was required to establish its processes, procedures and set benchmarks to ensure efficient energy usage and to implement continuous improvement when it comes to energy management.

Three third parties audited CMP over a five-day period, who visited the company’s manufacturing headquarters based in Cramlington, UK to analyse all the documentation and processes relating to energy

management, speaking with various team members and witnessing processes in practice. The ISO 50001 certification now forms part of CMP’s integrated management system, which covers ISO 9001, ISO 14001 and ISO 45001.

Michael Walton, Health Safety and Environmental Manager, said: “CMP is committed to achieving net-zero by 2040, and this certification forms an important part to demonstrate that we are making progress towards achieving this goal, through responsible energy management. As part of this certification, we must continue to monitor and develop our energy management with third party audits assessing our progress and maintenance on a yearly basis, to ensure we continue to adhere to the standards.”

UK POWER NEWS MARCH/APRIL 2023 3 NEWS NEWS

Noise control experts Keeping your world clean, quiet, and safe. Dürr Universal is a global leader in the design and manufacture of inlet and exhaust systems for gas turbines and reciprocating engines in the OEM and retrofit markets. www.durr-universal.com Dürr Limited United Kingdom Phone +44 1455 8944 88 Email solutions@universalaet.com

KEY POWER SYSTEM PROTECTION AT THE UNIVERSITY OF WARWICK

TWO 60KVA GENERATORS SUPPLIED FOR RAPID DEPLOYMENT SHELTERS

Over the past month YorPower was asked to provide a quotation and plan to supply and deliver two 60kVA units by Weatherhaven Global Solutions (Weatherhaven).

A spokesman comments: “Weatherhaven is expert at designing, planning and implementing shelter and camp solutions across the world. The company provides military camps, mobile medical shelter systems, and commercial camps, varying from mining to construction setups. It’s always great to work with companies that offer a service which helps people in need.”

the island.

Echoing the ethos of YorPower, Weatherhaven is keen to do what it can to help the environment.

All of its shelter designs are lightweight and compact, which helps reduce fuel consumption and transport time. These principles fall in line with YorPower’s aim to become the first Carbon-Neutral company in the industry.

TheUniversity of Warwick’s (UoW) Interdisciplinary Biomedical Research Building (IBRB) brings together 300 biomedical researchers from across the School of Life Sciences and Warwick Medical School to fight human diseases.

Its focus is on understanding the origins and mechanistic basis of diseases of the body and brain, with the aim of finding new ways to extend healthy life spans. Today its power systems are protected by a Kohler PowerWAVE 8000DPA system.

The IBRB builds on UoW’s existing world-class research in neuroscience, microbiology and infection, cell biology, and disease models, supporting and facilitating interdisciplinary biomedical research of the highest quality. Representing an investment of over £50m, the IBRB provides the two schools with a world-class environment in which to train future generations of biomedical researchers.

Following the Covid-19 pandemic, a Kohler PowerWAVE 8000DPA 100kVA was installed in the IBRB’s services room located in the basement. This UPS system was commissioned to support a network of critical power outlets throughout the building. These are used for designated equipment that must continuously function throughout a power disturbance, including analytical and monitoring systems that form part of critical experimental equipment.

Based on the initial load, a 100kVA system was selected with 20-minutes battery autonomy, an external bypass switch, cable box for top entry cabling plus site load bank testing to confirm everything was working and delivering what it should.

Comments Paul Holland, Electrical Design Engineer, University of Warwick:“We set out to find a reliable partner able to demonstrate innovative, low energy and low maintenance solutions with a commitment to sustainability. The Kohler PowerWAVE 8000DPA systems was chosen because of its superb energy efficiency, allowing us to keep running costs low.

“The small footprint and an innovative, fully modular design improve resilience compared to standalone UPS systems by removing single points of failure. The design also enables 100 KVA to be installed now and another 80kVA to be installed later in 20kVA steps – both future-proofs the building and further-proofs the building and further reduces running cost compared to buying and running at 180kVA unit right from the outset.”

If the protected equipment were exposed to a power failure, it would result in months of research being lost, key results invalidated, and crucial samples destroyed. Ultimately, this would lead to a significant delay in the research of diseases for the general public.

With the designated KUP system in place however, power dips will not result in equipment resets, and any spikes will be prevented from reaching and damaging sensitive components. If the power fails completely, the battery backup system will immediately begin supplying power until the mains power is restored or the onsite standby generator comes online. Featuring energy efficiency of up to 95.5%, low THDi and a near unity power factor the PowerWAVE 8000DPA UPS system achieves this whilst minimising environmental impact and ensuring a low cost of ownership.

The Kohler PowerWAVE 8000DPA system, coupled with KUP’s support, provides an efficient, dependable, and innovative solution as expected by the University of Warwick Estates Team and will be there to support the critical research being undertaken whenever power disturbances threaten to interrupt it.

The PowerWAVE 8000DPA is said to be ‘ideal’ for low to medium and high density power applications such as commercial fit-out

Widely proven, highly reliable three-phase UPS built for low to medium, high density power protection applications, it features a resilient modular design using proven Decentralised Parallel Architecture (DPA) technology. The PowerWAVE 8000DPA offers high energy efficiency, 99.9999% availability and flexible scalability in either a tower or rack-mountable solution. Essentially, it offers capacities from 10kVA to 200kVA in 10 or 20kVA modular steps, and a parallelable frames up to 400kVA. The equipment is available as tower (ST) or 19” rack-mountable (RI) solution.

This particular project required YorPower to deliver two 60kva Perkins diesel generators to an island in the Indian Ocean - here they now support the power systems serving rapid deployment shelters manufactured and installed by Weatherhaven. These shelters can hold kitchens, dry goods, mobile hospitals and other relevant facilities. The generator sets were shipped in a container, alongside two battery chargers, six additional sockets and two road trailers for easy transportation once they arrive on

YorPower Group Sales Director, Jordan Kincaid said: “This is a great project for YorPower to take part in. Knowing that these generators will travel the world providing power to the volunteers supporting third world countries and war-torn areas is extremely rewarding.”

UK WAVE ENERGY EXPERT STRIKES NEW DEAL WITH TEXO E&F

Wave energy specialists Mocean Energy and TEXO Engineering & Fabrication (TEXO E&F) have signed a Memorandum of Understanding for TEXO E&F to become Mocean’s preferred fabrication, assembly and loadout contractor for its Blue Star and Blue Horizon wave energy converters.

Aberdeen headquartered TEXO E&F was chosen by Mocean Energy after a competitive tendering process and is already providing technical support to design Mocean Energy’s products for manufacture. The intention is that a formal fabrication and assembly contract will be agreed, following design completion.

Mocean Energy is based in Edinburgh and Aberdeen and

specialises in designing and delivering wave energy converters to power ocean equipment and the grid with clean, carbon-free, renewable energy. They are developing two wave energy technologies: Blue Star, a device that will power a range of subsea equipment, including autonomous vehicles and control systems; and Blue Horizon, a much larger machine designed to generate grid-scale electricity in off-coast wave farms.

UK POWER NEWS MARCH/APRIL 2023 5 NEWS NEWS

FLYING HIGH AFTER 30 YEARS: MAINTAINING POWER AT HEATHROW, GATWICK & STANSTED

NEW LONDON CANCER TREATMENT HOSPITAL INSTALLS GENSET

Millions of UK passengers fly across the world today - unaware that behind-the-scenes UK Power Networks Services has kept three major airports running smoothly 24/7, 365 days a year for 30 years. In 1993 the company acquired the ground-breaking contract to own, operate and maintain critical electricity infrastructure for Heathrow, Gatwick and Stansted, some of the busiest airports in the world.

This long-term partnership and collaborative approach has benefitted all parties throughout the years as passenger numbers have continued to soar from across the globe, further enhanced by expansions to each airport including Heathrow Terminal 5, Gatwick Pier 1 and Stansted Substation 100.

In total, the portfolio of assets that UK Power Networks Services manages across the three sites includes more than 500 substations, around 600 electrical transformers plus a vast amount of high and low voltage cabling and expert engineers based in each airport.

David Mitchell, director of UK Power Networks Services told UKPN:” It means a lot to us that we have served the airport industry for this significant period. I am proud to see some of the major works that have been undertaken in this timeframe. The partnership with our airport clients has allowed us to jointly develop and manage a world class range of aviation support services.

“A big responsibility of ours throughout the years has been minimising disruption and increasing efficiencies across all airports. Every output that occurs through these airports is underpinned by our remarkable teams running the critical power infrastructure.”

Philip Heathcote, head of markets, added: “This anniversary is hugely momentous to us. What we do is unseen by the passenger. People only notice what we do if it stops working and we fix it.” The company’s 429 employees will celebrate the milestone by holding modest events at each airport this month – and enjoying anniversary cupcakes.

Now the company is working with the airports to achieve net zero, a phrase that was not in common parlance 30 years ago. Already aiding Heathrow in achieving the Carbon Trust Level 3 award, further net zero projects are in delivery.

UK NATIONAL GRID ENERGISES THE WORLD’S FIRST T-PYLONS

Electricity is now flowing to homes and businesses through the first new pylon design in the UK for nearly 100 years. This represents a major milestone in National Grid’s Hinkley Connection project to connect 6 million homes and businesses in the South West to home grown, low carbon energy.

The T-design, with a single pole and cross shaped arms, is around a third shorter than the traditional design with a smaller ground footprint. The T-pylons, along with a new substation and underground cabling, are now incorporated into National Grid’s electricity transmission network delivering electricity in Somerset and across England and Wales.

National Grid has successfully energised 36 of the world’s first T-pylons between Bridgwater and Loxton in Somerset. The new shaped pylons have been constructed as part of the £900 million Hinkley Connection Project, a new 57 km high-voltage electricity line that will connect six million homes and businesses to new sources of home grown, low carbon energy and help the UK to meet its net zero by the 2050 target.High-voltage electricity - up to 400,000 volts - is now passing through the T-pylons, a newly constructed electricity substation at Sandford.

The Generator Company was approached to provide a standby generator power package for new state-of-the-art hospital dedicated to advanced cancer treatment and surgery services in central London.

Following a government announcement to invest £250 million towards a vital cancer treatment and surgery facility, one of the UK’s leading construction companies was awarded the contract to design and build, using the process of BIM (Building Information Modelling), a new state-of-the-art hospital dedicated to advanced cancer treatment and surgery services in central London.

In 2016 The Generator Company was contacted with a view to undertaking the design, delivery and installation of a new standby power package for this new stateof-the-art NHS cancer treatment facility, currently one of only two to be built in the UK; the other based in Manchester. The advanced 31,500sqm, 11 storey building consists of five storeys below ground and six above. The height of the building, including below ground is 58.5 metres, making it equivalent to London’s Tower Bridge.

The first stage of the project

required temporary standby power to support site during the construction of the building providing back-up power for equipment, machinery and welfare facilities. Following discussions on the power needs for the build it was agreed to supply a 700kVA temporary containerised standby generator with a daily storage tank that would be housed on a gantry, with the welfare cabins, adjacent to the site. The generator was delivered, craned onto the gantry and commissioned by the commissioning team.The second stage of the project was to supply standby power to support 100% of building load to include all equipment within the building and the critical life safety system of the building incorporating the Proton Beam equipment. In line with the initial requirements of the end-client, TGC proposed two 1500kVA generators sized on the load profile information available at the time for the new cancer treatment equipment, boilers, UPS system and other essential plant. Ultimately, the proposal was modified on request of the endclient due to changing of suppliers during the tender process, with the generator resized to 1 off 2500kVA with an oversized alternator.

‘BLACK START’ RESTORATION TO THE UK POWER GRID

A consortium led by SP Energy Networks is launching a worldleading project to demonstrate the potential of using offshore wind to provide ‘black start‘ restoration services to the electricity grid thanks to funding from energy regulator, Ofgem. Black start is the better known name for Active Electricity System Restoration Service – the procedure used to restore power in the event of a total or partial shutdown of the electricity transmission system – and which has traditionally relied on fossil fuels like coal and gas. The BLADE Black Start Demonstration from Offshore Wind project – funded through the Strategic Innovation Fund

and supported by UKRI/IUK –will explore how offshore wind can transform that process and maximise the benefits of the huge amount of green electricity that will be produced in UK waters to push power on to the network in the event of a shutdown. It follows SP Energy Network’s groundbreaking work in the demonstration of black start services from distributed energy.

6 MARCH/APRIL 2023 UK POWER NEWS NEWS NEWS

POWER YOUR BUSINESS with

efficient energy and economics

INNIO*’s flexible, scalable, and resilient Jenbacher* CHP and CCHP energy systems deliver power, heat and/or cooling for your local site while supporting your decarbonization efforts. Yielding up to 95% total efficiency, cogeneration can reduce your energy consumption and CO2 emissions by more than 30% compared to the separate generation of power and heat, significantly lowering your energy costs. Combined with heat storage, you can operate your asset flexibly. Jenbacher CHP and CCHP systems run on a wide range of gases with the option of converting to H2** operation once that fuel is more readily available.

Join us on our path for a sustainable future! jenbacher.com

* Indicates a trademark.

** In general, “Ready for H2” Jenbacher units can be converted to operate on up to 100% hydrogen in the future. Details on the cost and timeline for a future conversion may vary and need to be clarified individually.

SOLUTIONS. EVERYWHERE, EVERY TIME.

ENERGY

MORRISTON HOSPITAL’S HIGH PERFORMING SOLAR FARM

NET ZERO INNOVATION PROJECTS WIN £1 MILLION IN FUNDING

The energy crisis means the UK’s first direct wired solar farm developed to power a hospital will generate far greater savings than could have been predicted. It went live in October last year and is expected to produce a fifth of Morriston Hospital’s energy consumption every year. Even during the winter months there have been days when it has generated enough to power the entire hospital – and on occasions with electricity to spare to export to the National Grid. This is despite only operating during the shortest days of the year.

The £5.7m solar farm was built thanks to a loan scheme set up by the Welsh Government to decarbonise the public sector by 2030, and is repayable on an invest to save basis. It is estimated that the hospital has already saved an estimated £120,000 in electricity bills since it was switched on in November, and is projected to save 1000 tonnes of carbon and £500,000 per year in bills when fully operational. It has already produced 30,000 kWh surplus energy that’s been sold back to the energy grid at a profit to the hospital.

Visiting the 4MW project on Brynwhillach Farm, which is linked to Morriston by a 3km private wire, Minister for Climate Change Julie James said last month: “We want our energy to come from community owned and locally run renewable energy sources in Wales. This will ensure our supply is resilient, reliable and reasonable for both our planet and our pockets.

“We have bold ambitions to decarbonise the public sector by 2030. Morriston Hospital - which depends not only on the powers of its staff, but also the energy hungry machines to keep their patients alive and well - have blazed the trail in their switch to renewables, which makes sense both financially and to the health of the people of Wales.

“Our addiction to fossil fuels is proving harmful, volatile and no longer viable. In Wales we will continue to accelerate our investment in renewable energy and energy efficient measures such as those adopted at Morriston hospital, and call on the UK Government to support a socially just transition to Net Zero as we respond to the climate emergency.

“The IPCC have rung the clarion call for our planet, now we must listen and respond to the science.”

Chair of Swansea University Health Board, Emma Woollett, said:“I am delighted that the solar farm’s performance has already exceeded our initial expectations. The health board’s aim is to reduce its carbon footprint and maximise opportunities to use renewable energy sources.

“The solar farm will play an important part in achieving that aim, but there is also an additional benefit in terms of cost savings. It is not only lowering our electricity costs every day, but on some days covering 100% of our electricity needs.

“With the current volatile situation with energy prices, this really shows that the investment and the long-term thinking on behalf of the health board has paid off.”

It has estimated that the Solar Farm has saved an estimated £120,000 in electricity bills since going live in November 2021.Since being switched on, the 10,000-panel solar farm has produced enough energy to power 190 three-bedroom houses for a year, or to boil almost 200,000 kettles.The four megawatt farm was anticipated to reduce the hospital’s electricity bill by around £500,000 a year. But with world energy prices spiralling, the actual savings could be almost double that figure.

A few years back, Swansea Bay University Health Board was awarded £13.6 million, on an invest-tosave basis, to bring down its energy costs and reduce its carbon footprint by around 5,000 tonnes a year.

The money was awarded through Re:Fit, a national programme, supported by the Welsh Government. Following an extensive selection process, the health board selected Vital Energi as its partner.

Phase one, a range of energy conservation measures at Morriston and Singleton hospitals and other health board premises, was completed last year at a cost of £7.7 million. The solar farm was developed on a 14-hectare site at a cost of £5.9 million.

Nearly £1m has been awarded from a scheme established by regulator Ofgem to the UK National Grid’s electricity transmission and distribution networks. The money will go towards eight innovation projects. These rojects include investigating technology to increase power flow capability on existing overhead lines, and exploring using electric vehicles to help restore power supplies to vulnerable customers in the event of an outage.

The proposals were submitted to Ofgem as part of a scheme to encourage innovation and help transform the UK’s energy systems in line with net zero targets.

Eight National Grid-led projects exploring innovation in the electricity transmission and distribution networks have been given the green light to progress to the first ‘discovery’ phase of Ofgem’s Strategic Innovation Fund (SIF) programme.

The ambitious innovation projects are intended to provide critical learnings and research to help inform the future development of a net zero energy system at the same time as delivering significant benefits to consumers.

National Grid Electricity

Transmission has been awarded £396 000 for three projects that will help develop a net zero electricity network, including investigating technology to increase power flow capability on existing overhead lines, development of a long-term strategy to remove electrical insulating gas sulphur hexafluoride (SF6) from the network, and a project to assess whole energy system resilience.

National Grid Electricity Distribution has been awarded £500 000 for all five of the projects it applied for through the fund, one of which will investigate using electric vehicles to help restore power supplies to vulnerable customers should there be a power cut.

The other four projects will explore the impact of thermal energy efficiency on network loads, the use of digital solutions to support regional network planning, flexibility opportunities across different utilities and the role of digital technologies in developing a local smart energy system. National Grid’s electricity distribution business will also be collaborating on a further four SIF projects – two with Wales & West Utilities and two with National Grid Electricity System Operator

UK SETS NEW RECORD IN POWER FROM WIND TURBINES

New statistics released by the Government show that Britain’s wind farms set new annual electricity generation records in 2022, producing enough power to meet the needs of 22.8 million homes.

The figures, published by the Department for Energy Security and Net Zero, reveal that wind generated nearly a quarter of our electricity last year (24.6%, 80.2 terawatt hours), up from 21% (64.7TWh) in 2021 and an all-time annual high.

Offshore wind provided a record 13.8% of our power (45.0TWh), up from 11.5% (35.5TWh) in 2021. Onshore wind also generated a record annual amount of electricity (35.1TWh), providing 10.8%. The

growth in offshore wind generation was driven by the addition of 3,193 megawatts of new turbines in British waters last year, while just 318MW of new onshore wind was added, mainly due to planning barriers for onshore wind.

Renewables overall produced 41.4% (134.8TWh) of our electricity. Low carbon sources (renewables and nuclear) generated a record 56% of UK power.

8 MARCH/APRIL 2023 UK POWER NEWS NEWS NEWS

[Above] Des Keighan, Swansea Bay UHB Assistant Director, Estate, Swansea Bay UHB Chair, Emma Woollett, Scott Lutton, from Vital Energi and Welsh Government Minister for Climate Change, Julie James, at the Morriston Hospital solar farm.

MWM gensets. Efficient, low-maintenance and highly available.

The MWM product portfolio comprises gas engines and gensets in the output range from 400 kWel to 4,500 kWel . Power plants with an output of 100,000 kWel and more are technically feasible. The units are designed for maximum electrical and thermal efficiency, low operating and service costs, and high reliability and availability. Thus, they reach efficiency levels of more than 90 percent.

www.mwm.net/en

BIOMASS ENERGY SYSTEM IS FUELLED BY WASTE PALLETS

THE UK HAS THE CAPACITY TO PRODUCE CHEAPEST ELECTRICITY IN EUROPE, SAYS ENERGY MINISTER

ABlackCountry pallet and packaging company has invested more than £1 million in a new renewable energy plant as part of its ongoing drive to lower its carbon footprint. Nicklin Transit Packaging, one of the UK’s largest independent pallet and packaging firms, has installed the biomass energy system at its main manufacturing site on the Woods Bank Estate, in Wednesbury.

The plant will be fuelled using the waste generated by the company’s manufacturing processes and the resultant energy will help to heat buildings across the site as well as its kilns used in the manufacture of timber products. The company said it would eradicate the need for natural gas for heating and burn the 1,000 tonnes of timber waste created by the plant annually, therefore reducing the need for skips and thousands of haulage miles necessary to remove the waste to landfill or repurposing plants.

The new plant will also enable Nicklin to increase its services to customers by enabling it to collect their waste timber.Managing director David Nicklin, who is the fourth generation of his family to run the company since it was founded in Birmingham in 1913, said the move towards renewable energy was part of its plans to become a more sustainable business.

He said: “The looming climate crisis is the biggest challenge facing society and every individual and business has an obligation to do all that it can to ensure that it is taking steps to minimise its own impact on the environment.

“In recent years, we have taken a range of steps to reduce our carbon footprint, from investing in a fleet of electric forklift trucks to introducing LED lighting across our Wednesbury plant but the biomass investment will be a real game changer in terms of our aspirations to achieve the lowest net carbon position possible for our business.

He concludes: “This is our biggest-ever single investment as a business and reflects not just our commitment to being the best possible business we can be but also our resilience against the backdrop of the challenges everyone has faced in recent years and our confidence going forward.”

EMERGENCY POWER FOR ONE OF SCOTLAND’S RECYCLING PLANTS

Genesal Energyhas been involved in the construction of one of the most modern and sustainable municipal waste treatment plants in Scotland. It transforms non-recyclable municipal waste into clean energy thanks to the design, manufacture and supply of a customised generator set.

The manufacturing process was carried out after carefully studying the project, analysing every technical aspect of the future plant until the right solution to guarantee the electricity supply at all times and in any situation was found, reports the company.

The project was made-to-measure, which is essential in this kind of plants designed to run alongaside the conventional public electricity grid. The client was seeking a medium voltage generator set capable of powering the plant in an emergency and with the capacity to start the gas turbine at any time of the year.

Once an analysis was carried out, Genesal’s technical team designed a Black Start medium voltage generator (GEN1500YC) which is used to start a turbine after a programmed shutdown.

Now up-and-running the generator is able to directly supply medium voltage power (11000V).

The Minister of State for Energy Security and Net Zero has said publicly that the UK has the potential to boast the most competitive electricity prices in Europe,. Graham Stuart MP has stressed the significance of reducing emissions to limit global warming and protect the most vulnerable populations.

The Minister of State for Energy Security and Net Zero Graham Stuart MP said: “I think the UK has got a tremendous opportunity. When we took over the COP Presidency only 30% of global wealth was covered by net zero pledges.

“By the time we’d finished it was 90%. If you look at the UK and you see all our offshore wind, we’ve done a tremendous job of developing under this government.

“That’s why I think going forward there’s a real chance that we could actually have amongst the most competitive electricity prices in Europe.”

The Energy Minister also highlighted the opportunity for

economic and industrial growth, particularly in regions such as the Northeast, the Northwest, Scotland, and Wales, through the expansion of renewable energy.

By doing so, the Minister believes the UK can achieve its net zero targets, lower energy costs and provide benefits to individuals and families across the country.

The Energy Minister said: “I think net zero, although it’s seen as some sort of green conceit by some, actually offers an opportunity for economic renaissance for the UK and industrial renaissance.”

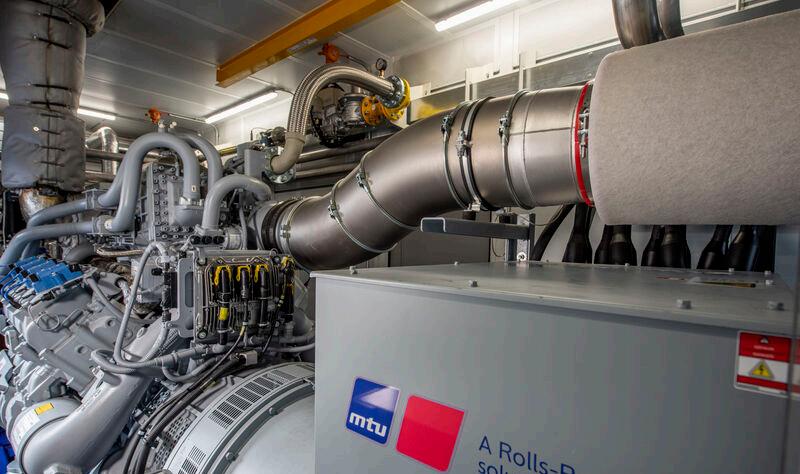

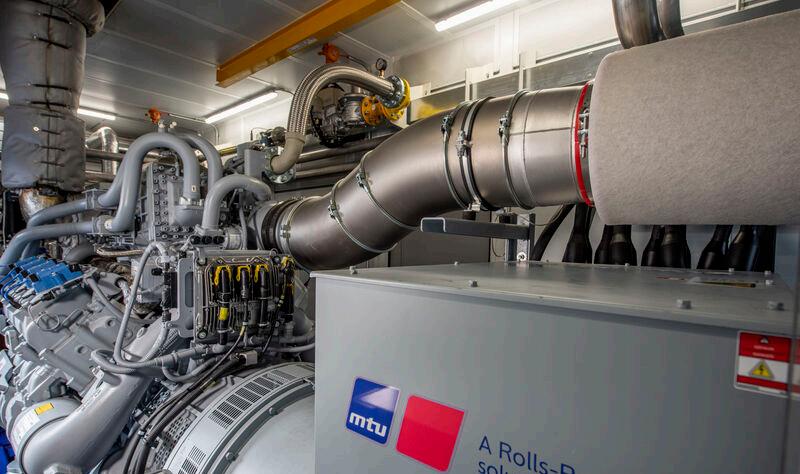

3 MW COGENERATION SYSTEM FOR BIGGLESWADE LOGISTICS PARK

A CHP unit based on MTU 8V 4000 gas engines has been installed at a logistics park in Biggleswade. A company spokesman told UPN: “We supplied ogeneration units with 8V 4000 gas engines providing a total output of 3 MW from the main power source for the site.

“Together with two emergency gensets, two battery storage systems - both also mtu productsand a PV system, they make up a microgrid with intelligent control of the energy supply.”

The mtu Series 4000 natural gas engine fachieves an efficiency factor of 87.1% by optimising the

utilisation of heat. The combined heat and power plant allows users to adapt heat generation flexibly to satisfy grid stability power production demands in any factory environment. The customer was offered a special container as a solution to reduce CHP noise emissions.

10 MARCH/APRIL 2023 UK POWER NEWS NEWS NEWS

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime across the whole product lifecycle, so you can be sure of reliable power generation, regardless of the operational conditions. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

FOR FURTHER INFORMATIO N VISIT WWW.MECCALTE.COM

PowerEx Live North, Networking & Conferences2-day event - Tuesday 27 June, 2023, to be held at The Mere Golf Resort & Spa, Knutsford, Cheshire

PowerEx Live North is a Networking & Conferences Event with 6 speakers on Tuesday 27th June, 2023.

10.30 start with Coffee/Tea, pastries. Networking until 11.30 am first paper. 11.30-16.30. There are 6 speakers on Gensets, CHP, Fuels, Sustainability, Data Centres, Hydrogen and Energy Storage Systems

Complimentary Lunch 13.30-14.30

Free to attend 10.30-16.30

PAPERS & TOPICS TO DATE:

DATA CENTRES / Sustainability (Finning) / Fuel Alternatives / Genset Statistics (Romain Mocaer) / Noise (Durr Universal) / Rentals (HSS Abird) / Hydrogen / Energy Storage

DATA CENTRES - “ Powering improved data centre operation and efficiency” - Paul Smethurst takes an abstract look into why gensets are key to operating the IT load and, more importantly, how to prevent losing the critical load being a total DATA CENTRE disaster “

FINNING UK SPEAKER - Sustainability in the power generation industry - a look at the varying options available to combat market restraints, demand and growth - this includes a look at the variety of alternative fuels available, what’s possible now and any likely options in the future.

This POWEREX LIVE NORTHERN NETWORKING EVENT takes place the day before the GOLF DAY on 27th June, 2023, with 6 SPEAKERS on CHP, GENSETS, FUELS, ENERGY STORAGE, DATA CENTRES, HYDROGEN

The Conference itself is FREE TO ATTEND with morning pastries, coffee/tea and Lunch provided.

EXHIBITION COST - 27th June, 2023

*Table tops cost just = £600.00 - Limited availability of 8-10 tables. Sponsorship available on request.

* GOLF DAY event on Wednesday 28th June 2023 costs £139.00 pp+VAT and Accommodation at discounted costs is now available to book.

Contact: Richard Teasdale - Group Events Sales Director. Email: richard@wipmagazines.com

Tel: 07814 172007

UFR1001E G99/98 compliant Loss of Mains Relay

PowerEx Live North Golf Day - to be held on Wednesday 28th June, 2023

include a Company promo plaque on the tee box plus your logo on 2/3 pull ups promoting around the event.

There are just 72 places available on a first-come-first-served basis. 2 Tee tee off or Shotgun Start (18 hole same time start at 12.00).

The UFR1001E system-disconnection relay monitors voltage and frequency in single or three-phase networks.

• Presetting per G99/98, values as per the standard pre programmed Under and overvoltage monitoring 40…520 V

• Under and over frequency monitoring 45…65 Hz

• Monitoring of Rate of Change of Frequency (ROCOF, df/dt)

Monitoring the voltage quality (10 minute average value)

• Response time adjustable 0.05 … 130.0 s, individual setting for each limit

Fail-safe, with monitoring of the connected section switch (can be switched off) 2 automatic restarts on error

• Supports the mains synchronisation when using generators

Measurement 3 phase 3 or 4 wire systems or single phase

• Self-test

Third Part Independently tested Compliant to G99/98 by Bureau Veritas

Tel: +44 (0) 1206 575755

Email: sales@tvri.co.uk www.tvri.co.uk

TVR Instruments Limited 143 Butt Road, Colchester CO3 3DP Essex, United Kingdom

ABOUT THE VENUE:

The Mere Golf Resort & Spa Club Tel. 01565 830155

Chester Road, Knutsford, Cheshire, WA16 6LJ www.themereresort.co.uk

DATE: Wednesday 28th June 2023

- GOLF DAY Competition

FIRST TEE: 12.30 – 13.20 (2 tee Tee off or Shotgun start at 13.00) Singles & COMPANY Team Stableford (18 holes)

FORMAT: Bacon Rolls & Tea/Coffee refreshments on arrival

Club Lounge & Bar Post round drinks. 16.30-19.00

Three Course Meal in Evening from 19.30late with Presentation and Prizespossible After dinner speaker.

PRICE: £139.00pp (£5 sweep competition optional on the day)

Guests - £157.00pp (inc. ball sweep comp. on the day)

*Sponsorship All teams so far have sponsored a hole for only £115. This will

There will be networking opportunities with many PowerEx companies and delegates attending.

Your place will be confirmed on receipt of payment. Final deadline for booking is coming soon. We expect to be sold out – so BOOK EARLY and don’t miss out.

There are negotiated discounted prices at The Mere Hotel & Spa. Join your fellow players in the bar for a post dinner drink or two.

Contact: Richard Teasdale

- Group Events Sales Director. Email: richard@wipmagazines.com Tel: 07814 172007

GREEN ESSENTIALS: The 18-hole, 6,882 -yard, par-71 course at The Mere was designed by James Braid, and created out of 150 acres of Cheshire parkland in 1934.

Today, the Championship course holds a reputation as one of the best-maintained and highest-quality golf courses in the North of England. Surrounded by mature trees, flowering banks and with stunning views over the Mere Lake, the course offers all the charm of the Cheshire countryside.

12 MARCH/APRIL 2023 UK POWER NEWS NEWS NEWS

12 APRIL 2023 UK POWER NEWS NEWS NEWS

• COMPLETE POWER PLANT • RIG SAFE – ATEX GENERATORS • COGENERATION PLANT • FIRE FIGHTING PUMPS • PROCESS AND INJECTION PUMPS • DIESEL / GAS / HFO UNITS POWER STATIONS – BESPOKE UNITS BGG UK Limited · Delta House · Tendring Heath · Nr. Clacton · Essex · CO16 0BU Tel 01255 830355 · info@bgguk.com · www.bgguk.com A BRUNO GROUP COMPANY ENERGY SOLUTIONS

Engine Cooling Solutions

Jacket

For engines rated up to and in excess of 1 MW.

Induction

For engines rated up to 850 kW.

Lubrication Oil

Engine & transmission oil coolers

Heat recovery for engines rated up to 8900 kW, with up to 30 bar oil pressure.

Exhaust Gas

Exhaust gas heat exchangers

For engines rated up to 1 MW, recovering up to 673 kW of heat.

Efficient, cost effective cooling solutions for Engine Driven Gen-sets, Pumps, HPU’s and Compressors; Co-Generation Systems; Off Highway Vehicles; Fire Protection Systems, plus Marine Engines, Transmissions and Gen-sets.

Water Header tank heat exchangers

Air Water cooled intercoolers

www.ej-bowman.com for

our technical sales team on +44 (0) 121

5401, or email sales@ej-bowman.com BOWMAN® 100 YEARS OF HEAT TRANSFER TECHNOLOGY EJ Bowman (Birmingham) Ltd Chester Street, Birmingham B6 4AP, UK Tel: +44 (0) 121 359 5401 Fax: +44 (0) 121 359 7495 Email: sales@ej-bowman.com www.ej-bowman.com Don’t Compromise on Performance PremiumTower™ Standalone Three-phase UPS From 10kW - 250kW SWISS MADE Phone: 01420 82031 Email: sales@centiel.co.uk Web: centiel.co.uk PremiumTowerTM offers an on-line operating efficiency of 96.6% in double conversion mode minimizes running costs and reduces the Total Cost of Ownership.

Visit

full details of the extensive range, call

359

Selective Catalytic Reduction Systems for Millbrook Proving Grounds

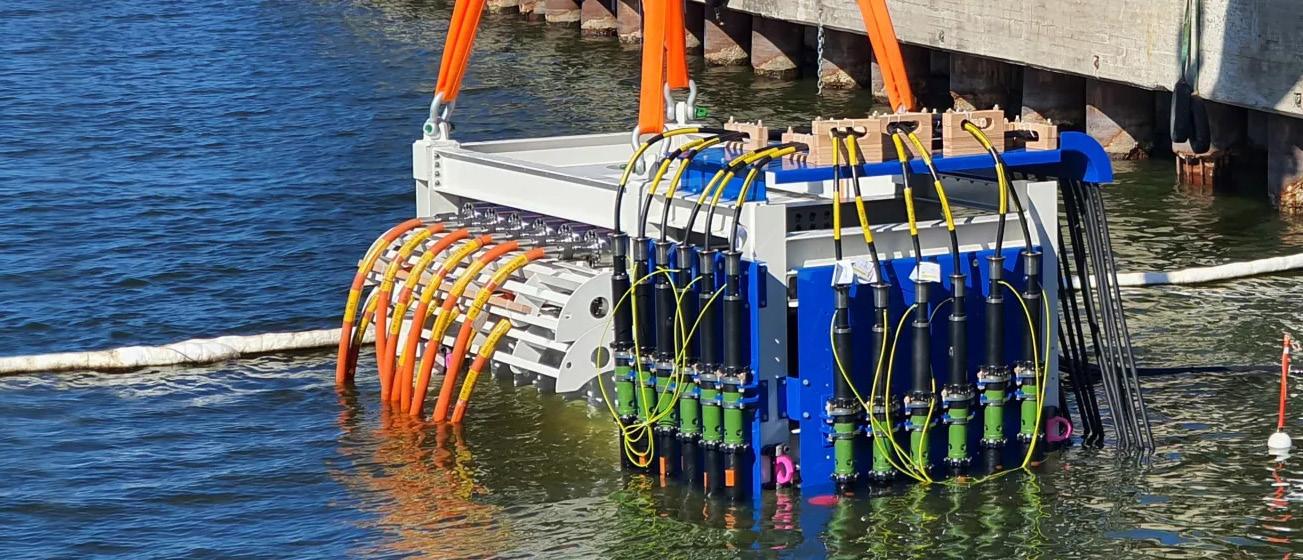

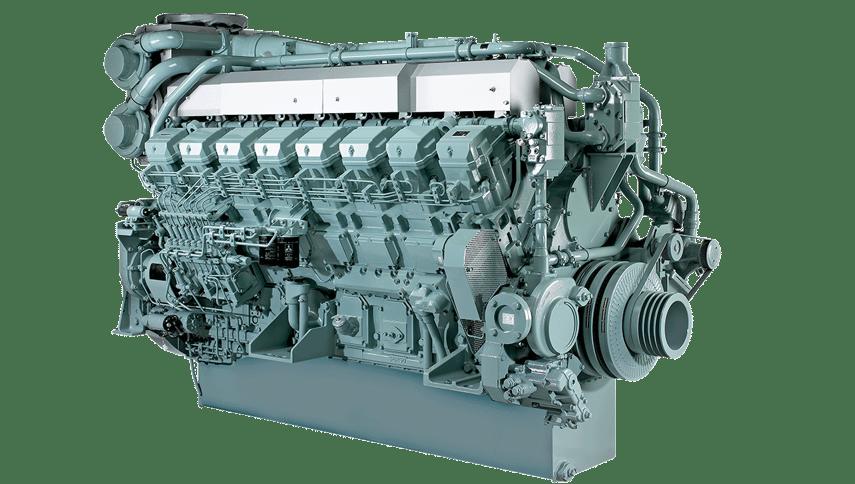

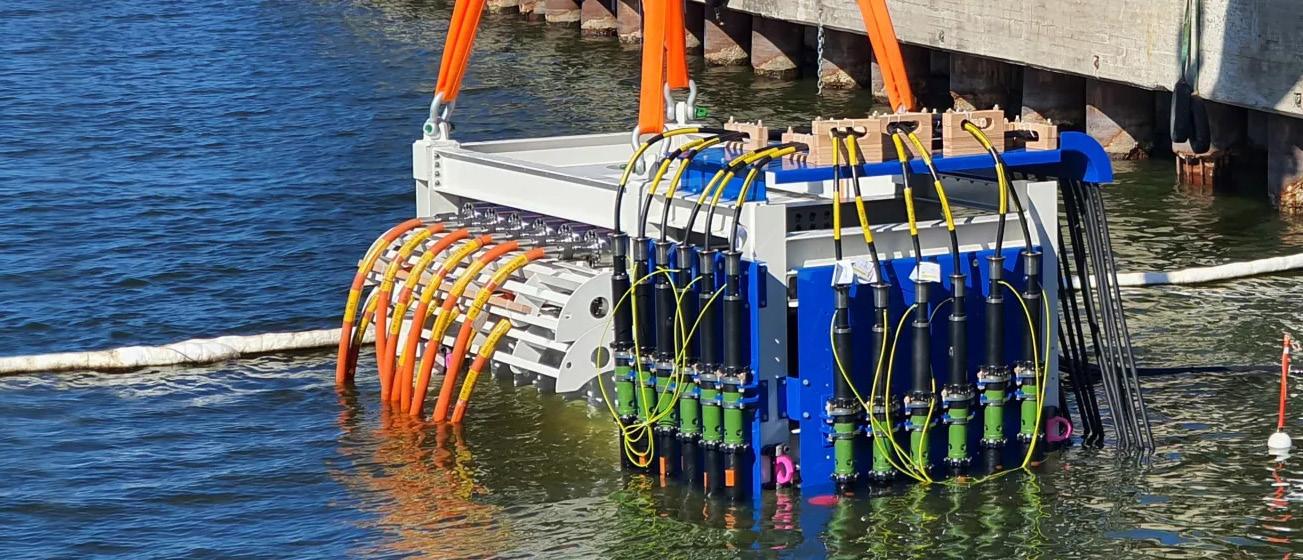

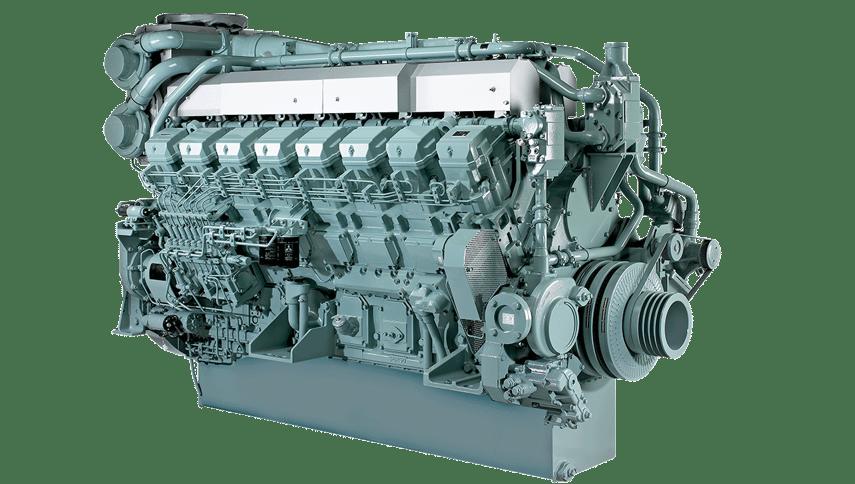

Another pair of NOxMASTER™ Selective Catalytic Reduction Systems were successfully commissioned for Mitsubishi S12R-PTA diesel engines operating at Millbrook Proving Ground at their Hybrid and Electric Vehicle Battery Testing facility, reports the manufacturer, Agriemach.

The 1.1MWe diesel generators deployed at Millbrook Proving Ground in Bedford now meet permit conditions for NOx, bringing them down from 1790 mg/Nm3@15%O2 to under 190 mg/Nm3@15%O2 – A 90% reduction of NOx emissions.

This is achieved by monitoring the raw and treated NOx emissions using an Agriemach closed loop dosing system control - Also by monitoring the operating temperature, backpressure and the engine load. With all of this information fed to the NOxMASTER™ controller, it allows for very precise dosing of urea as the reductant and a high NOx reduction efficiency.

The NOxMASTER™ dosing system is an industrial based control system for industrial applications, which allows it to be used for variable load operating profiles such as this. The controller monitors the operating conditions and reacts according to these ever changing load conditions.

This is vitally important to ensure no overdosing of the reductant which on other more basic systems would produce an over injection of the reductant and an undesirable Ammonia slip. Many permit conditions for operators prohibits

ammonia slip - this is why this level of accuracy and control is so very important. Not only that, by offering a higher efficiency over dosing control this ultimately reduces the amount of the reductant used which reduces the overall consumable cost. Permit conditions met –Consumable costs are lower.

Not only does the NOxMASTER™ system reduce the NOx emissions from this diesel generator by over 90% - But it also has silencing functionality designed and combined into the SCR Urea Mixing section which allows the integrated silencing element to produce attenuation down to 80 dB(A)@1m – On other applications it has been known to reduce down to 65 dB(A)@1m with system integration.

Space is always at a premium and the overall footprint is always requested to be optimised whilst accommodating the engines maximum allowable backpressure.

Engineering solutions with integrated functionality is a service Agriemach prides itself on and the company has a vast amount of longrunning applications for emissions reduction across the UK and Europe. The best engineered solutions are specifically what the company offers to clients.

The test facility at Millbrook conducts hybrid and electric (EV) battery testing to assess the life of battery cells, modules and packs; determine battery safety in a wide range of situations including crash events. The site validates the performance of automotive batteries under a range of environmental conditions.

Millbrook offers a wide range of battery safety and abuse tests including for UN 38.3 and ECE Reg 100 and operates a state-of-the-art battery life and performance test facility in the UK.

It tests all major Lithium-ion chemistries and a range of other chemistries by simulating normal and extreme operating conditions. Millbrook provides a wide range of test methods to assess the life, safety and performance of vehicle batteries. These include:

•Pack life and performance testing

•Cell and module life and performance testing

•Battery shock testing

•Battery safety and abuse, including battery drop and nail penetration testing Millbrook also offers a range of electric machine and inverter tests and provides full vehicle test facilities including the ability to crash EVs and FCVs.

After completing a battery test, Millbrook’s skilled team safely strips them down to component parts, while measuring key parameters, such as distances, torques, voltages, and resistances. A detailed photographic record can also be provided. A highresolution video link allows real-time interaction.

www.agriemach.com

UK

NEWS

15 EMISSIONS

POWER

MARCH/APRIL 2023

“ Agriemach’s NOxMASTER™ dosing system is an industrialbased control system for industrial applications, which allows it to be used for variable load operating profiles such as this.

The controller monitors the operating conditions and reacts according to these everchanging load conditions.”

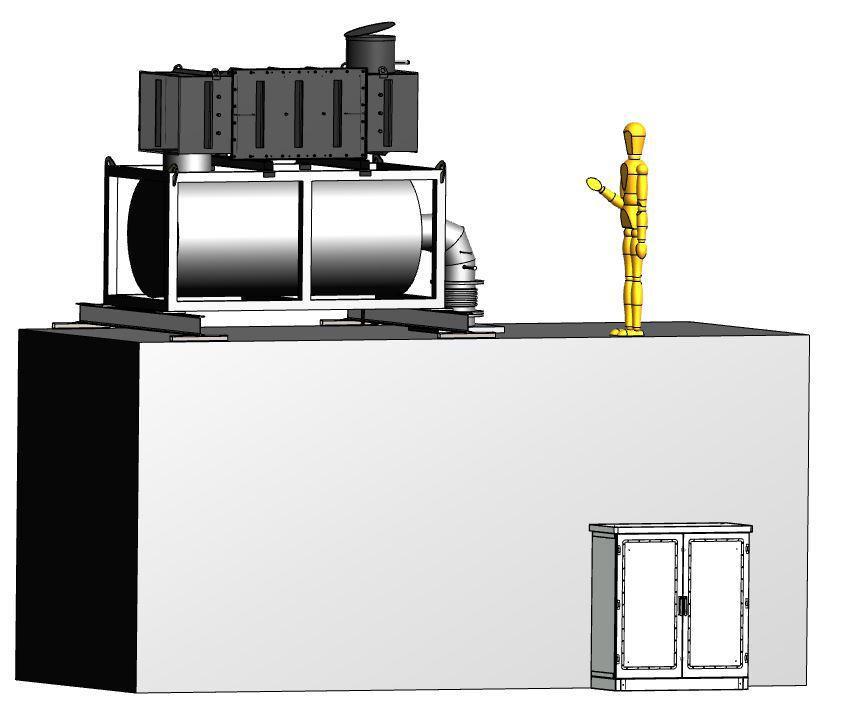

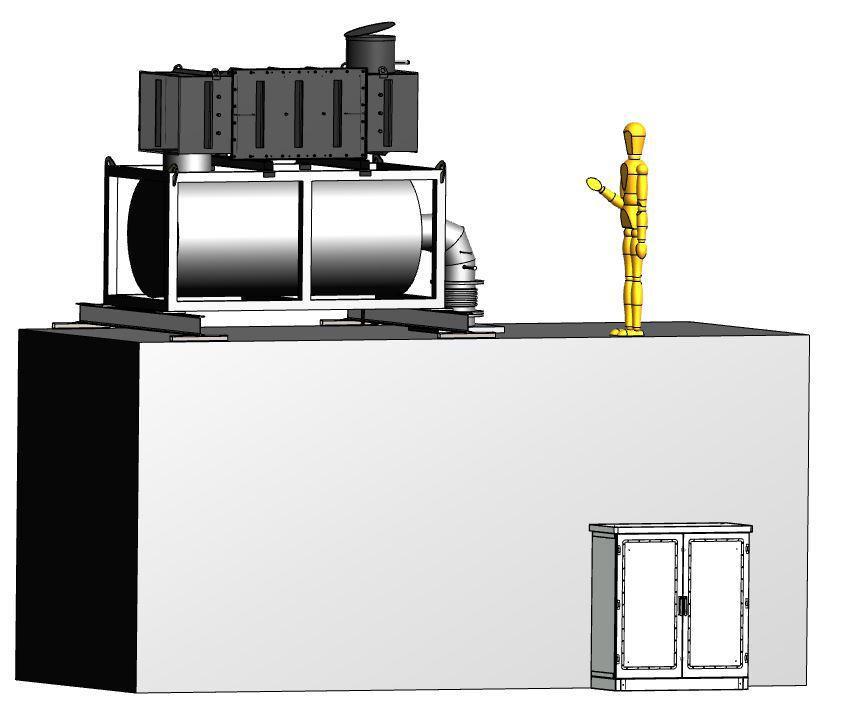

Two 2.5MW diesel gensets supplied to Datavita’s data

DTGen recently provided an emergency power solution at Datavita’s new data centre located at 177 Bothwell Street in Glasgow’s city centre. The company has supplied two 2.5MVA generators complete with

Based at Datavita’s new data centre in Glasgow the generators are located high in the city centre skyline on the building rooftop in bespoke acoustic enclosures.

Each generator runs off its own day tank with an auto fuel fill system in place from ground floor bulk storage tanks.

Joe Skillin, Major Projects Manager at DTGen, told WIP magazine: “Whilst we’ve delivered many power solutions for data centres throughout the UK, we’re delighted to be working with Datavita again, right here in Glasgow, following our successful delivery of the solution for Fortis data centre.

“As a company we provide a collaborative approach to solution sales and are trusted by a broad spectrum of customers to find the most cost effective and resilient standby power system.

“Delivering solutions to customers including hospitals, data centres, distribution centres, banking and utilities, we work with consultants, end users and contractors from initial design to project completion.”

He explains: “We have worked on single turnkey solutions through to the most complex of projects including 25 MVA of generators with high voltage alternators, complex controls, noise

attenuation, exhaust system and fuel package. Our dedicated solutions team has the specialist knowledge, experience and resource to advise and deliver your complete standby power solution.”

He concludes: “We carried out the installation in a live building, which presented a number of challenges, but the generators were craned into position during a weekend, and then it was all hands on deck working towards completing the installation.”

The new data centre is a highly resilient, purpose-built facility, and of tier III design, with 130 racks worth of space.

With excellent fibre connectivity and highly efficient cooling using green energy, the data centre now offers an exceptional level of physical security as well as flexibility for customers.

Graeme Logie, Operations Director at Datavita, said: “We know that DTGen has the experience and technical capabilities to safely and competently manage the city centre installation of the emergency power solution at our new data centre.”

Following the installation, DTGen’s project management team has continued to support Datavita and has ensured that the system

was fully tested and commissioned prior to handover.

This task was supported by DTGen’s technical department which has unrivalled knowledge and experience in the commissioning of standby power systems.

The company’s testing services include:

-UK’s largest test cell at DTGen HQ

-Onsite noise and emissions

-Onsite artificial load banks

-Simulated mains failure and IST

-System commissioning

-Project handover

Working in collaboration with its customers, DTGen provides a comprehensive design service ensuring the most challenging and complex of projects, no matter how large or small, are handled with professionalism, and delivered in the best possible way, reports the company.

Its current design services include:

-Survey and consultancy

-In-house Auto CAD to BIM

-Technical submissions

-Complete turnkey packages www.dtgen.co.uk

16 MARCH/APRIL 2023 UK POWER NEWS GENSETS

a control system to cover switching between both dual mains supplies and backup synchronising generators.

“ Whilst we’ve delivered many power solutions for data centres throughout the UK, we’re delighted to be working with Datavita again, right here in Glasgow, following our successful delivery of the solution for Fortis data centre.

- Joe Skillin, Major Projects Manager at DTGen

Generator group sells 1,200th Stage V emission-compliant genset into UK market

GENSETS

Bruno Generators Group (BGG) is recognised as one of the leading manufacturers of high specification rental diesel powered generators. Ranging from 9 kVA to 1320 kVA prime power, with a full range of super silent canopies and containers.

Bruno offers a wide range of products including hybrid and battery storage systems utilising their own in-group.manufactured battery management system.

BGG UK, based at Delta House, Tendring Heath, Nr. Clacton, Essex, has sold its 1,200th Stage V emission compliant diesel generator into the UK market.

With an outstanding reputation for RENTAL SPEC generators this represents a landmark achievement. for the company.

Available in both the GX rental range and the ultra- silent FUSTEQ range with patented VSi technology units are rated from 9 to 1320 kVA .

In keeping with the exacting build quality standards required for the rental sector all canopies are constructed from heavy duty hot

dipped galvanised sheet steel and powdercoated ensuring maximum durability.

The Stage V GX and FUSTEQ rental range is supplied with a number of key features.

The gensets are fully-bunded (all liquids) and have a bund alarm, a 3-way valve and an external fuel-tank sensor.

The gensets have been designed with a central lifting point, forklift pockets and are hardwired with microswitch protection over the Busbar door

There is a socket kit, a variable earth leakage circuit breaker and a DeepSea 7310 auto-start control panel, plus a DeepSea 8610 load-share option.

Included in the package: a battery isolator, a sump oil vac pump and DPF filter complete with LED status display.

There is also a SCR system for >60kVA. Options on the GX Series include:

* An engine heater (option)

*Racor filter (option)

*Battery charger option (option)

*Choice of control panel manufacturers (option)

“ BGG UK has sold its 1,200th Stage V emission compliant diesel genset into the UK. With an outstanding reputation for RENTAL SPEC generators. It provides both the GX rental range and the ultra- silent FUSTEQ range with patented VSi technology units rated from 9kVA to 1320 kVA

*Power locks (option)

*Road trailer (option)

*Remote monitoring system (option)

*Long run AdBlue management solutions. BGG’s ultra- silent FUSTEQ range features a fully-compliant Stage V engine with an ultra-silent compact canopy 53dBA @ 7m and patented VSi technology continuouslyrated up to 55˚C ambient.

The FUSTEQ comes with a compact hot-dipped galvanised powder coated canopy and a cooling system with independent electric fans and patented VSi technology . The genset is also fully bunded (all liquids) and features a bund alarm, a 3-way valve and an external fuel-tank sensor. There is a built-in central lifting point, forklift pockets and - like the GX Series - the genset has been hardwired with microswitch protection over the Busbar door.

There is a DeepSea 7310 auto-start control panel, plus a DeepSea 8610 load-share option. The genset comes with a battery isolator, a battery charger (option), a sump oil vac pump and a DPF filter complete with LED status display and an SCR system for >60kVA.

What do BGG’s current genset projects involve?

BGG projects are involved in supplying a wide range of industries from military, power utilities and water authorities. The group offers specialist expertise in the oil and gas sector, supplying ATEX, Rig-Safe and Zoned equipment..

BGG can provide equipment for:

-Single or Multiple Generator Operation

-Synchronising and Load-sharing

-Island or Grid Operation/ Black Start Functions

-Data Monitoring/Logging /SCADA

-LV /MV Circuit Breakers and NE

Resistors

-Control and monitoring of Ancillary equipment

-Emergency Shutdown panels

-ATEX and Hazardous Area Panels

BGG provides a comprehensive in-house customised Power Station and Projects power generation design service, guaranteeing the best solution to any specific application requirement. A company spokesman comments: “Our highly specialised team of mechanical and electrical design engineers work hand-in-glove with our sales project managers to ensure that the expectations of our customers are fully met and delivered in any agreed timeframe.”

www.bggukcom

UK POWER NEWS MARCH/APRIL 2023 17

The New GX Stage V RENTAL Series from BGG UK is a complete range of compliant generating sets up to 1320kVA with built-in adblue tank and DPF filtration systems. The FUSTEQ Series is known for its noise-reduction qualities, compactness and reliability. Both are making inroads into the UK market today, reports UKPN.

.”

Installing twin package substations at the Derby Velodrome

AF Switchgear has supplied several twin package substations for the Derby Arena and Velodrome, one of the largest projects undertaken in the East Midlands. The 5,000-seat arena features a 12-court sports hall, a gym, group exercise space and a cafe. As well as cycling, the venue hosts sports including basketball and doubles up as a concert venue. The indoor Velodrome is one of only five in the UK, reports UKPN.

The project at the Derby Arena and Velodrome required fast-track manufacturing to enable a quick ‘power-on’ date. The substation needed to facilitate the heating and ventilation aspect during construction, purely to maintain a controlled ambient temperature to allow the wooden track to be laid and then settled.

Each AF Switchgear package substation consists of a cast resin transformer directly connected to a high voltage network (HV) on the primary side and then directly connected to the LV Main Switchboard from the secondary low voltage (LV) side.

The HV supply can come from either a siteowned HV circuit or HV ring which can connect to the primary side of the transformer via a HV

rated cable connection box, HV Switch, Circuit Breaker or Ring Main Unit (RMU). Package Substations are an efficient option to select when a large amount of power is required to feed a site with distributed LV especially when the customer site has access to a suitably rated high voltage power supply.

This high voltage power supply is usually fed from a Distribution Network Operator (DNO) owned and operated sub-station or as stated above a site-owned HV Network, depending on the situation.

A Package Substation like this is a fullyintegrated close-coupled system, which can save time, space and money when compared to a de-coupled system. The connections from a remote transformer may require a lengthy cable

or bus bar runs to reach the LV Switchboard, which can be expensive. Situating a cast resin transformer directly next to a suitably rated switchboard might be an attractive option.

AF Switchgear owns and operates its own in-house Fabrications and Paint Plant, meaning the company can design and build transformer housings complete with natural ventilation and forced ventilation systems. If the package has to be to be situated outside of a building, AF Switchgear can supply secure GRP and weather-proof type enclosures for this very purpose The transformer can be directly coupled to the LV Switchgear system via copper bus bars which is a more economical alternative to cabling, especially on larger systems

The operation of a Package Substation can be witness tested at an AF Switchgear site i.e. in a controlled factory environment booked via a Factory Acceptance Test (FAT)

In addition to manufacturing the numerous substations for Derby Arena and Velodrome, AF Switchgear also supplied substations and final circuit distribution boards for the Sir Chris Hoy Velodrome in Glasgow, the host venue for the Glasgow Commonwealth Games. The indoor arena section features a hydraulically operated 200m running track, jumping and throwing areas, and sports halls. The Velodrome houses a 250m high-banked cycle track with a multi-use infill area. The scheme also includes a community sports centre, four floodlit outdoor sports pitches and a 1km outdoor cycle track.

www.afswitchgear.co.uk

18 MARCH/APRIL 2023 UK POWER NEWS SWITCHGEAR

“ The AF Switchgear project at the Derby Arena and Velodrome required fast-track manufacturing to enable a quick ‘power-on’ date. The substation needed to facilitate the heating and ventilation aspect during construction.”

Meet Stage Vand MCPD equivalent emissions standards

Meet Stage V and MCPD emissions standards

• Cost effective upgrades for power generators up to 10MW

• Future-proof your assets, extend genset life

• Fully approved range available for 37-560kW

• Solutions for large back up power applications

enquiries@eminox.com | eminox.com

Technologies for a greener planet EMx Powered

Approved by

NHS Trust Hospital gets electrical infrastructure upgrade

Upgrade works at the UK NHS Trust hospital were long overdue, but the building that had been previously cleared for remedial works was suddenly required to provide Covid testing facilities.

The equipment in question was close to 50 years old - for context, the guidance on lifespan of an electrical cable is 25 years.

Whilst the equipment in question was still functioning, it was all, cables included, at risk of failure, taking out an essential part of the hospital’s power infrastructure.

The NHS Trust worked in conjunction with surveyors, consultants and construction managers to plan the scope and timetable of works.

One of the key suppliers called upon was Eland Cables, based in South Yorkshire, who worked with the team on specification before supplying low voltage armoured power cables and the accessories needed for connection and termination.

With reliability and longevity a key consideration, Eland Cables was chosen not just because the cables were readily available on a short lead-time (they were, in fact, in stock). The company has a world-class cable

testing laboratory that holds two of the highest accreditations in IECEE CBTL and ISO/IEC 17025, and the intensive testing as part of their QA protocols provided much needed peace of mind.

A spokesman for Eland Cables commented: “As a company we’re driven by people dedicated to excellence, and The Cable Lab, and our cable experts, are central to our customer commitment.

“Technical excellence means an ongoing commitment to product quality and compliance, testing hundreds of cables each week - both our own and from third parties - and remain vigilant of the issue of non-compliance and sub-standard cables that unfortunately still exists across the industry.”

The cables for the project

The cables in question for this project were armoured to provide mechanical protection – making them suitable for direct burial in the ground as well as running externally and internally.

Because it was being run internally, it was important that it was also a Low Smoke Zero Halogen (LSZH) and flame-retardant material sheathing the cable, offering protection in the

event of fire, as PVC materials emit dense black smoke and toxic halogen gases when burnt.

The company spokesman continued: “Matching the specification to the installation requirements is essential if you want to deliver both performance and sustainable operations.

“Quality and compliance are two of the biggest sustainability considerations in electrical cables – what you don’t want to do is have to keep returning to site for maintenance or dealing with premature failure.”

The cables were delivered to site using Eland Cables’ own fleet of HGVs that run on sustainable HVO biofuel, and their services include a cable recycling facility for old and waste cables so that the metals and plastic polymers, as well as the cable drums, can be continue to be used within the circular economy.

Consideraing sustainability issues Sustainability is a key consideration for the business, with Eland Cables pushing to reduce their own carbon emissions as well as calculating the embodied carbon in their products.

They hold accreditations including ISO 14064-1 Carbon Footprint Verification, Ecovadis Silver Medal status, having verified targets with the Science Based Targets Initiative (SBTI).

Eland Cables is also a signatory to the United Nations Global Compact Sustainable Development Goals (SDGs).

The spokesman said: “Our role is to make cable buying easy, helping our customers to make informed buying decisions based on sustainable procurement, and can serve as a blueprint for others to follow.”

www.elandcables.com

20 MARCH/APRIL 2023 UK POWER NEWS CABLES 20 APRIL 2023 UK POWER NEWS

The impact of the pandemic was felt in every corner of the NHS, including halting essential upgrade works to critical electrical infrastructure. Thankfully, many of these projects have now resumed, including one at a key UK NHS Trust Hospital where new generator sets and replacement power feeds to outbuildings have been installed, reports UKPN.

CABLES

“The NHS Trust worked in conjunction with surveyors, consultants and construction managers to plan the scope and timetable of works. One of the key suppliers called upon was Eland Cables, based in South Yorkshire, who worked with the team on specification before supplying low voltage armoured power cables.”

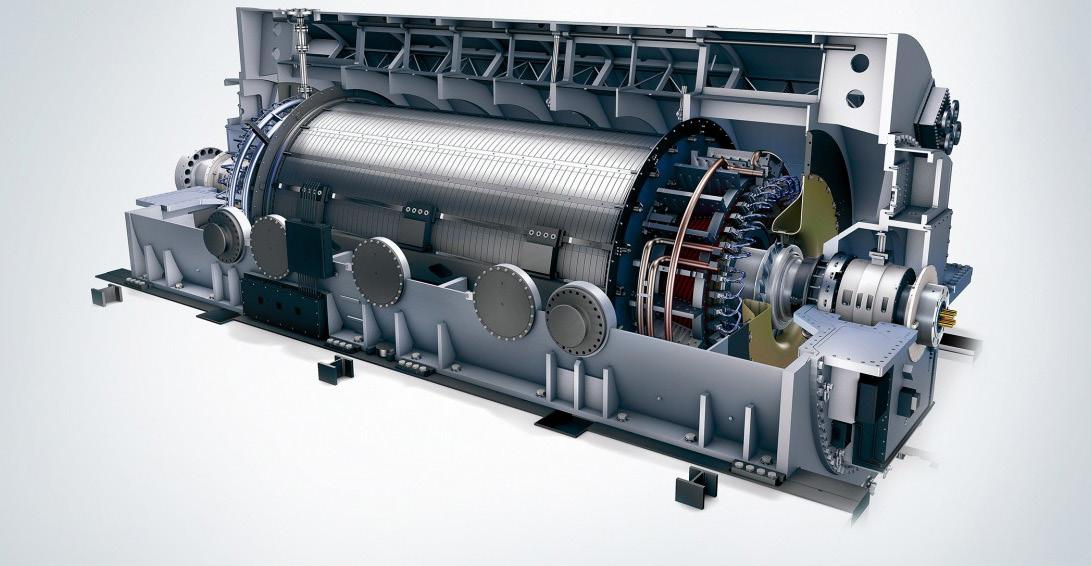

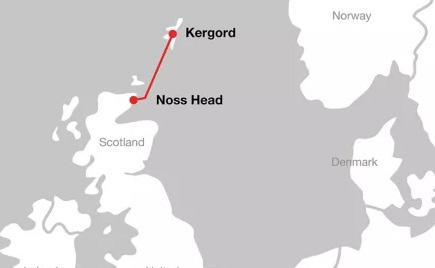

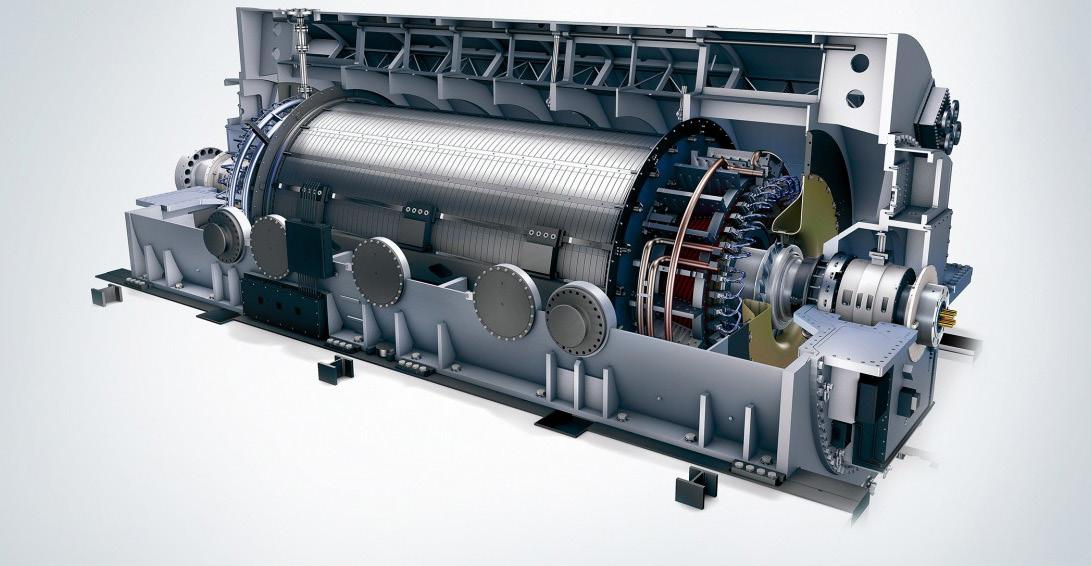

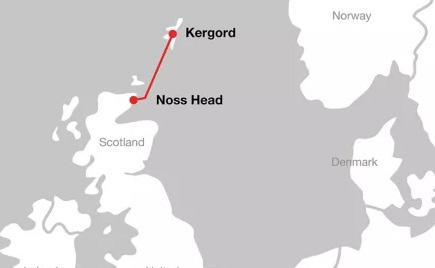

24 MVA SUBSEA TRANSFORMER NOW OPERATING IN THE NORTH ATLANTIC

In late 2022 Hitachi Energy supplied the world’s most powerful 24 MVA subsea transformer to OneSubsea, the subsea technologies, production, and processing systems business of Schlumberger. The transformers - now working for the past three months - form part of a large contract awarded to Hitachi Energy for the supply of two subsea OceaniQTM transformers, two input transformers and two step-up transformers.

The subsea transformers supplied by Hitachi Energy are submerged in waters to a depth of about 850 m and today power the OneSubsea multiphase compression system for the Shell Ormen Lange field.

Hitachi Energy has collaborated closely with ABB on the project. ABB has supplied its INSUBSEA Long Step-out solution to deliver power to the OneSubsea compressors and have overall system responsibility for the power scope of the project which includes delivering drives for seabed compressors that sit away from topside infrastructure.

The OneSubsea compression system is powered and controlled from the Nyhamna onshore gas processing plant, which is 120 km from the subsea location. This power stepout

distance sets a world record for transmitting variable frequency power from an onshore facility to equipment on the seabed.