Wärtsilä has signed a contract with EDF Renewables UK and Ireland to deliver a new grid-scale energy storage facility in Sundon, Bedfordshire.

The 50 MW/100 MWh project will form part of a new ‘Energy Superhub’ in the region. Construction will begin in spring 2023. The new lithium-ion storage facility can store enough electricity to power around 100,000 homes for two hours, and will support electric vehicle (EV) charging and the electrification of public transport.

The project is intended to enable increased renewable energy integration and intermittency management, in addition to strengthening the resiliency of the electricity system, automatically charging and discharging to balance supply and demand.

Matthew Boulton, director of Storage and Private Wire at EDF Renewables, commented: “We are working with local councils to accelerate the rollout of Energy Superhubs, helping to unleash the potential of renewable energy and enable local people to reap the benefits of net zero through better access to low-carbon transport.”

Wärtsilä has provided

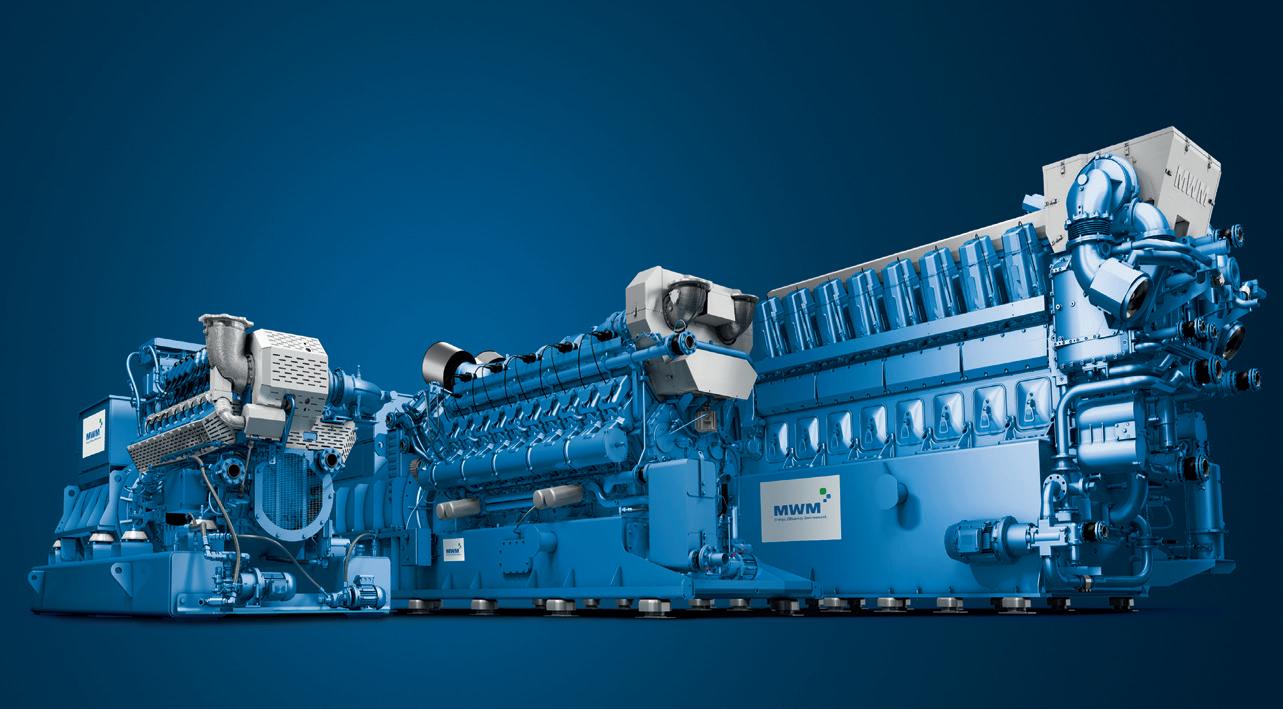

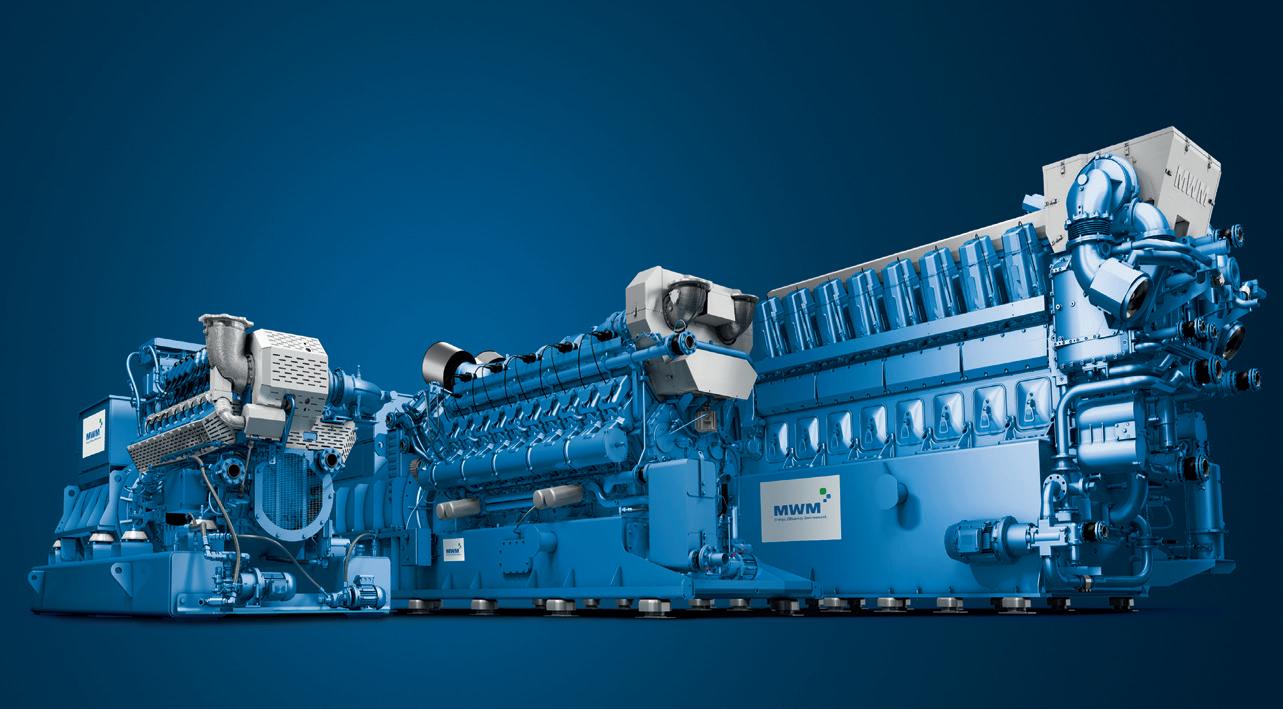

HYDROGEN - CLIMATEFRIENDLY ALTERNATIVE MWM reveals retrofit kits for the gas engines of the TCG 3016, TCG 3020, and TCG 2032 series.

NOxMASTER IN ACTION

December 2022 saw the Agriemach engineering team transporting and installing gear for a site requiring a 16.8MW SCR retrofit.

New grid-scale energy storage facility to be built in Sundon, Bedfordshire

its proprietary GridSolv Quantum system and GEMS Digital Energy Platform, in addition to the power conversion system and commissioning for the project.

GEMS provides the data and insights to instruct trading parties and performance for comprehensive asset management. Wärtsilä’s installed energy storage technology base in the UK now exceeds 424 MWh.

The previous projects with

The previous projects with EDF Renewables (formerly Pivot Power) in Oxford and Kemsley in Kent were delivered in 2021, and two projects in Birmingham and Coventry are currently under construction. Wärtsilä has also delivered other energy projects in the UK, such as a 50 MW/100 MWh project first site for SSE in Salisbury.

KEEPING THE TRAINS RUNNING

FirePro has worked hard to help minimise the key fire risks from high voltage cabling for the Eurostar highspeed rail service

1 UK POWER NEWS JAN/FEB 2023

NOxMASTER • SCR NOx Reduction Systems

MCERTS Test Equipment • Diesel Particulate Filters

Oxidation Catalysts +44 (0)1342 713743 www.Agriemach.com Data Centre Emissions Compliance Retro-Fit & New Exhaust System Installations Design • Manufacture • Installation Commissioning • UK & Europe Service & Support AGRIEMACH LTD TM

•

•

Page 18

Page 23

Page 24

CES20001_Anzeigen_MWM_TCG3020_235x55mm_EN__RZ1_0_mg.indd 1 09.09.22 11:44

The all-round talent.

www.mwm.net/gas-engine-TCG-3020

JAN/FEB 2023 1

Publisher/Sales Director:

Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor:

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager:

Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent Mario Dobresko power@wipmagazines.com

Contributors

MWM, Scania, Genesal, Mitsubishi, Edina, ForePower, Agriemach, Cabel, Innio, FirePro, Gencat, Octopus Energy, Data Centre World, UKGSA, Perkins Engines, DSE, Flow-Rite Controls, Trystar, PUNCH Flybrid, Shenton Group, Advantage Utilities, SSE Renewables, Genquip Groundhog, Peter Brotherhood, Tamini Transformatori, Yellow Power Ltd, HMS |Industrial Networks, Genovate Power Solutions, Neptune Energy, Mitchell Power Systems. ****************

UK POWER NEWS

Published by: Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK Tel: +44 (0)1403 888019

Fax: +44 (0)1403 220751

powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to UK Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

Largest UK virtual power plant could ‘slash bills for everyone’

Octopus Energy has announced that the combined capacity of car batteries on the tariff has now surpassed 100MW, enough energy to power a city the size of Leicester for an hour.

Octopus Energy says its “virtual power plant” is helping to deliver clean electricity to the grid which can “bring down bills for everyone”.

The UK’s third largest energy provider has a smart tariffIntelligent Octopus - which allows customers with the Octopus Energy app to set the time (and amount) they want their electric vehicle (EV) charged by. This then automatically charges the cars when there is abundant, with low-cost, clean energy. When there is less strain on the grid, the company says it helps balance out demand and supply on the network. This comes as National Grid warns about pressure on the grid becoming so intense that it may have to roll out organised blackouts this winter if temperatures plummet while energy imports from Europe drop.

As one of its operational tools to avoid this emergency worstcase scenario, the grid has previously warmed up coalfired power plants to provide a backup source of power. According to Octopus Energy, this is “paid for by consumers through their energy bills”.

New engine platform is more fuelefficient & powerful

After a decade of engineering, Scania’s latest engine platform is more fuel efficient and powerful, has a significantly increased lifespan and a large reduction in CO2 emissions, reports the company.

Joel Granath, Senior Vice President and Head of Power Solutions at Scania, tells UKPN: “This is our most fuel-efficient engine ever, with more torque, more power and up to 50 percent longer base engine lifespan. It’s a game-changer for Power Solutions.”

There are two new engines with varying power outputs for customers to choose from. The six-cylinder, 13-litre engine ranges from 368kW to 450kW, which delivers up to 11 percent more power and up to 21 percent more torque over the current generation engines. While the five-cylinder, 11-litre engine ranges from 202kW to 368kW.

The new engine platform from Scania continues the performance and reliability that customers expect from Scania, with increased reductions in CO2 emissions. The next generation inline engine platform also sets a new standard for Power Solutions - improvements include: new power outputs, longer service intervals and a major reduction in CO2 emissions

Built using cutting-edge technology, the new Scania engines start better from cold, and enjoy longer service intervals and operating lifespans over the current generation. For example, the time between overhauls can be up to 25,000 hours.

Some of the other new design features include making the engines easier to service, more precise cooling, a more rigid engine block and cylinder head, and a more robust engine transmission with optimal gear strength.

Fuel efficiency is improved thanks to the enhanced gas exchange system, reduced internal friction and increased turbocharger efficiency. The engines feature a seven percent improvement in fuel consumption with the new 13-litre engine compared to the current generation. This equates to around four litres of diesel saved per hour at full load.

Henrik Nilsson, Scania’s Director Product Management, Power Solutions, said: “Our mindset throughout the development of the new platform has been to ease the transition for our customers while positively impacting fuel efficiency and product performance.”

By utilising Scania’s leading position in trucks, buses and coaches, the technology is now filtering through to Power Solutions, reports the company. It also meets the latest legislative demands and is compatible with biodiesel and HVO. Both engines go into serial production in 2024 for heavy equipment and power generation sets.

DATA CENTRE WORLD ExCel, London, March 8-9, 2023

Data centres are the beating heart of the digital economy. There are more than 7 million facilities world-wide, and the demand for more shows no sign of slowing down. Spending by operators and end users is rising beyond $200 billion, and investments are doubled year-on-year in 2021. The greater attention on the data centre industry also comes with the pressure to ensure sustainable practice and energy security. At Data Centre World, 1000s of operators and end-users join forces to carve out successful strategies and find solutions that future-proof your next generation of data centres. Join thousands of C-Level leaders innovators working towards a shared goal to empower a more sustainable, secure, and successful data centre future. You will be in great company, as 54% of attendees are C-Suite and key decision-makers. Carve out strategies and discover solutions on the buzzing exhibition floor featuring ABB, Anord Mardix, Mitsubishi Electric, Riello UPS, Schneider Electric, VID Fire-Kill, and more. Shape the community’s future directions in conversation with over 100 influential speakers discussing key topics like achieving net-zero, cost-effective management, ensuring resiliency, and efficient design. VIP and C-Suite visitors will also get access to bespoke appointments, providing a space to discuss your specific business needs.

www.datacentreworld.com

2 JAN/FEB 2023 UK POWER NEWS NEWS NEWS www.powermediagroup.co.uk

Edina has delivered its third University of York CHP plant

Newcastle University makes a splash with wave energy

Plans to turn wave motion into a source of renewable energy are underway as Newcastle University looks to install a prototype Wave Energy Converter (WEC) in the North Sea.

The MU-EDRIVE project is part of eight projects funded by the Engineering and Physical Sciences Research Council (EPSRC), part of UK Research and Innovation (UKRI) to build on the UK’s leading role in marine wave energy.

Edina, a recognised on-site power generation and energy storage solution provider has delivered its third Combined Heat and Power (CHP) project at the University of York, a leading educational institution.

The latest CHP plant comprises a 2.3MWe MWM TCG 3020 V20 gas engine and associated equipment and joins two existing CHP plants rated 1.56MWe each also engineered, installed, and maintained by Edina.

The additional CHP plant is part of on-going energy-efficiency measures to manage energy costs, improve sustainability, and on-site energy resilience for the University. NG Bailey, a leading independent engineering, and services business awarded Edina the contract to design, engineer, and install the CHP plant.

The 2.3MWe CHP plant is containerised within an attenuated acoustic enclosure engineered at Edina’s in-house packaging facility and was recently delivered to site and positioned within a purposebuilt energy centre situated on the University East Campus.

Adam Bloom, Head of Sales, Edina, said: “This project is unique in the way we created bespoke artwork around three sides of the container perimeter to visualise the internal components and workings of the CHP plant. This requirement forms part of an expansive learning initiative designed to engage the university students and staff on the energy-efficient technologies powering their campus and facilities whilst educating the university’s engineers of tomorrow.”

Edina commissioned the CHP plant in late 2022, and is cunder contract to provide long-term assetcare coverage to ensure plant operation, energy security and availability.

The University’s latest CHP plant accompanies the sites existing two CHP plants to provide the University with a total power output of 5.4MW electrical capacity.

CHP is the cogeneration of heat and electricity from a single fuel and is a highly efficient form of energy conversion using gas engines. Combined Heat and Power can save up to 30% on primary energy costs when compared to the separate purchase of electricity from the electricity grid and gas for use in on-site boilers.

As a recognised CHP supplier and total solutions partner, Edina manages the end-to-end delivery of CHP plants from design, engineering, installation, commissioning, and ongoing asset-care requirements, helping reduce risk, interfacing, and ambiguity - all from one point of contact.

Looking at the gas genset

The MWM TCG 3020 gas genset effectively balances efficiency and reliability. It delivers up to 18 percent more output than its predecessor, though its dimensions are almost the same. Additionally, the new model features long service intervals with up to 80,000 operating hours until the next general overhaul (if the gas quality is high) and a total efficiency of more than 87 percent (with natural gas).

Owing to their high reliability and profitability, the new gas genset with an output of 1,380 to 2,300 kWel are ready for the challenges of Industry 4.0. Thanks to the use of the digital power plant control TPEM (Total Plant & Energy Management), they are able to reach their full performance for maximum plant availability, capacity, and usability.

Higher Efficiency and Performance

•Compared to the predecessor model, the TCG 3020 features the same size, a more compact design, and up to 18 percent more output.

•State-of-the-art technologies enable an output of 1,380 to 2,300 kWel and application-optimized engine types

•Improved electrical efficiency of up to 45 percent (natural gas)/43.6 percent (biogas), total efficiency of more than 87 percent (natural gas)/86 percent (biogas)

•Flexible use for various applications and gas types, such as natural gas, biogas, APG, and propane gas.

The tried and tested TCG 3020 series has been supplemented with a new variant. In the Z configuration, the MWM TCG 3020 V20 gas engine runs on propane; in this way, the engine delivers a high performance density even at high altitudes. To ensure high quality and availability of the plant, the TCG 3020 V20 Z has undergone an extensive text cycle. The genset is available for parallel operation with the most important grid codes and for island-mode operation with improved load response.

Wave energy is a concentrated form of solar energy. The sun heats land which results in hot air rising and causing wind, as the wind blows across the sea surface, it creates the oscillating up-down movement which can be used to generate electricity.

Led by Newcastle University’s Dr Nick Baker, MU-EDRIVE is a collaboration between Dr Serkan Turkman and Professor Jeff Neasham at Newcastle University and Professor Markus Mueller from the University of Edinburgh.

It follows the successful collaboration between Edinburgh and Newcastle on the MEC-EDRIVE project funded by EPSRC as part of a previous wave energy funding call.

MU-EDRIVE aims to demonstrate the marinisation and upscaling of All Electric Drive Trains for wave energy converters.

The Newcastle team will install a generator and power converter to a buoy mounted 3km off the Northumberland coast at Blyth in Spring 2024 for a 12-month period.

Once installed, the prototype WEC will provide vital operational data while testing the newest corrosion and anti-fouling technologies which will progress the understanding of the robustness of WECs in situ.

The Edinburgh team will design, build and test a magnetic gear in

partnership with Mocean Energy to demonstrate upscaling of electrical power take off systems. The project will also show how marinisation and magnetic gearing technology can be scaled up to larger power levels and integrated more fully into wave energy converters.

Dr Nick Baker, Reader in Emerging Electrical Machines & Senior Lecturer at Newcastle University, commented: “With regards to achieving the ambitious goal of net zero by 2050, it is essential to look at the energy system as a whole.”

He explains: “Wave energy originates from solar energy as the sun heats the land, the land heats the air to create wind and wind creates waves. Wave energy can therefore be considered as ‘energy dense’ and could be a significant factor in moving away from traditional energy sources.

“The upscaling aim of the MU-EDRIVE project will help to reduce costs of energy production as devices get larger, making the energy both easier and more affordable for access and usage.”

He concludes: “It’s hard to know what a wave energy device will look like in 10 years’ time. Thinking back to 10 years ago, offshore wind turbine technologies were in their infancy - this could be the same for wave energy now.”

Solving the contaminated fuel conundrum with fuel pickup system

Contaminated fuel can be a major issue for power generation businesses and operators. Unplanned downtime can be disruptive and costly in any sector, but for power generation in particular, it can be critical.

Genquip Groundhog provide a wide range of welfare accommodation units to the construction sector.

Like many operators and service providers, Genquip Groundhog experienced significant problems with fuel contamination through poor quality fuel delivery, inadequate cleanliness during refuelling and unreliable operator practices. Fuel contamination can quickly lead to fuel filter blockages, premature injector wear and generator failure.

Based in Cardiff, FuelActive invented an innovative floating fuel pick-up system, avoiding contamination that overwhelmingly is found at the bottom of the tank. This globally patented system delivers the cleanest fuel available to the engine, preserving critical engine components. This is particularly important for stage V engines which have particularly low tolerances to contamination.

UK POWER NEWS JAN/FEB 2023 3 NEWS NEWS

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime across the whole product lifecycle, so you can be sure of reliable power generation, regardless of the operational conditions. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

TOGETHER WE POWER THE WORLD

FOR FURTHER INFORMATIO N VISIT WWW.MECCALTE.COM

Agroup of scientists has reported that they were able to guide lightning bolts using laser technology for the first time. In new work published in the journal Nature Photonics, international researchers said that laster-induced filaments, formed in the sky using short and intense laser pulses, can guide lightning discharges across “considerable distances.”

The authors said that they believe their experiment would lead to progress in lightning protection and lightning physics. The demonstration was conducted on Säntis mountain in Switzerland during the summer of 2021 but the research behind it has only just been published.

Using a high-repetition-rate terawatt laser, the equipment was set up next to a telecommunication tower said to be one of Europe’s structures most affected by lightning.

In tests conducted on the summit of the Säntis, the scientists found that the discharge could follow the laser beam for several dozen metres before reaching the tower of the operator Swisscom. The laser was activated every time storm activity was forecast between June and September and the area had to be closed to air traffic in advance.

Intense laser pulses, at 1,000 times per second, were fired at thunderclouds to redirect lightning strikes. The tower was hit by at least 16 lightning flashes, four of which occurred during laser activity. All four strikes were intercepted.

“The guiding of an upward negative lightning leader over a distance of 50 meters was recorded by two separate high-speed cameras. The guiding of negative lightning leaders by laser filaments was corroborated in three other instances by very-high-frequency interferometric measurements, and the number of X-ray bursts detected during guided lightning events greatly increased,” tone of the researchers told the media. The device is the size of a large car, weighing more than three tons and uses lasers from the German manufacturing company, the Trumpf Group. With the University of Geneva scientists also playing a key role, the experiments were conducted in collaboration with aerospace company ArianeGroup.

This concept, which was first proposed in the 1970s, has worked in laboratory conditions, but not in the field until now. The University said in a release that it took nearly a year to analyze the data that was collected, rprovding that the laser could guide lightning effectively in practical tests.

“The data analysis also demonstrates that the [Lightning Laser Rod (LLR)], unlike other lasers, works even in difficult weather conditions – such as fog (often found at the summit of Säntis), which can stop the beam – since it literally pierces the clouds,” said a university spokesperson. The next step is to increase the height of the laser’s action even further, with the long-term objective to use the LLR to extend a 10-metre lightning rod by 500 meters.

“This work paves the way for new atmospheric applications of ultrashort lasers and represents an important step forward in the development of a laser-based lightning protection for airports, launchpads or large infrastructures,” the researchers have said.

The economic effects of lightning damage to property are large, varied, and widely spread across society. In addition to loss of life and health, there are direct and indirect costs from lightning which affect a wide spectrum from individual homeowners and small businesses to large companies such as oil refineries as well as national heritage sites. Unfortunately, even in developed countries, little systematic research has been done on these areas, and research that has been completed has often been considered proprietary by industry or insurance companies. There are few models to predict losses and no routine monitors to measure them. As a result, figures for economic damages may be fraught with reporting errors.

During 2007-2011, for example, U.S. local fire departments responded to an estimated average of 22,600 fires per year which were started by lightning. These fires caused an average of nine civilian deaths, 53 civilian injuries, and US$451 million in direct property damage per year. Most of these fires occurred outdoors, but most associated deaths, injuries, and property damage were associated with home fires initiated by lightning strikes.

A spokesman for the UK POWER NETWORK comments: “Lightning can sometimes damage electrical equipment and cause power cuts. We keep in close contact with the UK Met Office so we are well prepared.”

new power station

Peter Brotherhood was approached by one of its customers to assist in the creation of a waste-to-energy plant. With the project being in its infancy the backing of the concept was deemed to require evidence of the ability to raise and use steam on a small scale prior to approval of the larger scale project.

A small steam turbine had already been identified by the customer to use as a proof-of-concept, however the turbine had not run for a long time and parts were missing. At this point Peter Brotherhood provided their services for dismantling and inspecting the Skinner steam turbine to identify all repair and new spare parts requirements.

A spokesman comments: “The unit was received into our workshop for a full detailed inspectionto be carried out to include rotor concentricity checks, all bearing and seal clearances and relevant dimensions recorded, NDT of all required items and inspection of governor and

tripping mechanism.”

A detailed inspection report was issued to the customer outlining additional components and repairs required before the unit could be rebuilt. This included new control valve components, seal and bearing components and over-speed trip mechanism components to include a new UG Woodward governor.

The rotor was balanced to ISO1940 grade G2.5 to provide a serviceready rotating element, the seal and bearing housings were then aligned during the trial fit of the rotor and the bearings blued for contact pattern achieving the require percentage coverage.

The new trip and control valve components were fitted together with all new seal components allowing the unit to be finish assembled with all required dimensions and clearance data recorded. Although it was possible for the unit to have trial run on steam this was not required by the customer and the unit was painted utilising high temperature paint and packed for shipping.

Give Your Transformer An Extra Life

To ensure a long working life of its transformers for steelworks, Tamini Trasformatori has implemented an advanced real-time remote control and history data analysis solution for preventive maintenance. At the core of the system developed by W2W solutions lies the eWON Flexy IIoT gateway using MQTT technology. Remote assistance for transformers is often provided in the field of energy distribution networks while it is still very new when it comes to metallurgy. Tamini Trasformatori designs transformers for networks and steelworks. The function of the transformers for steelworks is to prevent alternating cycles of high energy stress (electric current and power). Their operation must be continuously monitored; otherwise,

there is a risk of deterioration and damage to the system. Sophisticated algorithms first analyse the transformers historical data. Then a compilation of trends reveals the process status and predicts future conditions. The data which the monitoring system is based on include: the system data (voltage, current, temperature of cooling water, etc.), and specific machine data (temperature, oil levels, alarm signals, gas content in oil, the absorption of various components, position and number of actuations of the switch, etc.).

UK POWER NEWS JAN/FEB 2023 5 NEWS NEWS

Steam turbine overhaul for client helps to develop wasteto-energy ‘proof of concept’ and enables the key development of a

Scientists report they have diverted lightning strikes using lasers

Generator Sets

Gensets provide a valuable technology through integrating generators and engines to produce power for site equipment and operations, explains Dr. James Crosby, Head of Sustainability at Advantage Utilities.

Most commonly, this equipment delivers a critical backup electricity supply for facilities across the world to remain operational in the event of discontinuation in their centralised/grid-sourced power. Furthermore, it also provides several industries which operate remotely from the grid a source of electricity without undertaking time-consuming and capital-heavy grid connection programmes.

At present, the most ubiquitous form of genset is fuelled by diesel, whereby an engine becomes powered by the combustion of a stored volume of this diesel. Crudely speaking, this engine is then integrated with a generator and produces an electrical output. Additional common fuels for these engines include liquid petroleum gasoline (LPG) and liquid natural gas (LNG). These can be thought of as ‘brown’ gensets, as they come from highly-pollutive non-renewable fuels.

A key benefit of these gensets, aside from providing a backup power solution, is their relative independence of highly volatile wholesale gas and power markets. This is outlined by the graph below, showing the relative wholesale pricing of power (blue) and Brent crude (red) over the past 5 years. For the purpose of this argument, this relative volatility is best observed since June 2021, with brent crude varying from ~$75/barrel to ~$135/barrel (i.e. median variance of ~29%) whereas wholesale electricity has varied from ~£150/mWh to ~£850/mWh (i.e. median variance of ~70%).

In the future, it will become incredibly important to transition from ‘brown’ fuelled gensets towards ‘green’ fuelled gensets. As a UK market, we have committed to achieving net-zero by 2050. Therefore, using non-renewable and highly pollutive fuels as a source of power is directly opposed to this mantra. As far as strict ‘gensets’ are concerned (engines integrated with generators), the focus must be on the fuels powering the engine. The most obvious immediate examples of these fuels are in the form of natural gas from renewable origins (e.g. anaerobic digestion units), biodiesels (e.g. hydrotreated vegetable oil - HVO), and hydrogen. In terms of kg of CO2 produced per kg of combusted fuel, these renewable options are more favourable. However, technologically speaking, it is a non-trivial matter. This is because the current engines which have been manufactured for generations are highly efficient. at combusting non-renewable fuels to create power (kW). This technology has not been directly translated to these alternative fuel sources. As a result, the volumes of renewable fuels required to generate the output from non-renewable fuels are far higher and/or more expensive. As a result, the comparative CO2/kWh generated between renewable and non-renewable fuel types is not as dramatically different and the £/kWh generated is far higher.

In reality, the future role of the traditional genset may become that of a supplemental technology for backup and decentralised power. This is directly related to the emergence and continued development of the battery energy storage systems (BESS) being integrated with renewable power generators.

These BESS can be integrated with renewable generators such as mobile solar PV systems and wind turbines. However, the current pricing of BESS and realised kWh output from mobile solar PV modules and wind turbines means this emerging technology is still far from widespread adoption. Furthermore, as far as risk is concerned, it also brings in additional market forces which are less impactful on wholesale oil and wholesale power markets (e.g. commodities such as critical rare earth elements (i.e. lithium) and semiconductors).

Dr. James Crosby concludes: “Over the next 10 years, it is my opinion that the traditional ‘brown’ genset will still represent an important component for backup and decentralised and relatively low-risk power supply. However, going forwards we will see a transition to more efficient ‘green’ gensets and ultimate replacement by BESS devices integrated with renewable power generators, e.g. solar PV & wind turbines.”

Greener, cleaner and more effective power using flywheels

The latest innovation in generator technology, the flywheel power system, is tipped to revolutionise the industry, making systems greener, cleaner and more cost effective.

The flywheel power system is an item of next generation kit which works by capturing energy which is normally wasted during a machine or vehicles use and storing it in a highspeed energy storage flywheel.

The stored energy can then be cycled back through the machine and used in its running, saving fuel, improving performance and reducing emissions.

Genny Hire, a diesel-generator rental company based in the North East of Scotland, is excited to have put in an order with Silverstonebased PUNCH Flybrid for the flywheel power system.

A spokesperson Lorna from Genny Hire explains: “My main reason for making an ongoing investment in this technology is that both our customers and we ourselves want to reduce our energy consumption. “We always want to provide the best solutions for our customers, and we are hearing more and more that people want to reduce their carbon footprint and up their green credentials – and we are only too happy to help with that.”

For the company, the big impact this year is the fuel element, for reasons which need little explanation, though Genny Hire’s customers have been particularly iaffected by the move from red to white diesel.

She says: “Everyone wants to reduce their emissions, but also, understandably, their costs. So from that point of view we have taken a good look at how we can help them achieve that. To our mind this solution will do that.”

Tobias Knichel from PUNCH Flybrid explains: “Typically, a lot of energy is wasted through applications which use generators because they have what is known as ‘dynamic profiles.’ By this we mean that they use a lot of power intermittently in bursts, which uses a lot more energy than a steady supply of energy.

“We were originally in F1 racing – which is of course extremely dynamic, and there’s a lot of wasted energy. But for industrial applications, you can really bring that energy profile right down. Lorna says this chimes exactly with Genny Hire’s aims, and that the company is putting its money where its mouth is, as Genny Hire is keen to implement PUNCH Flybrid’s solution across its own company, as well as in the generators it hires.

500 KVA genset for a residential development project

January 2023: The Shenton Group team has been involved in a recent contract to secure the 500 kVA diesel generator package on the ‘135 Park Street’ development. The company is supplying and installing a 500kVA generator in a bespoke enclosure at 135 Park Street, a prestigious commercial project underway in Southbank, London SE1. The site has full planning consent for the demolition of the existing Emerson Building and the development of 150,000 sq ft of new Grade A office space built to the highest sustainability standards with the target of creating a net zero carbon building.

The new building, designed by Squire and Partners, will comprise

11 upper floors of high quality, Grade A office with a ground floor retail unit and complemented by 14,000 sq ft of affordable workspace at lower ground, ground and first floor. Occupiers will benefit from access to a wide range of amenities including a roof top communal terrace overlooking the Thames and the City of London, as well as cycle storage for 284 bicycles.

6 JAN/FEB 2023 UK POWER NEWS NEWS NEWS

and Componentry: Outlining the transition from ‘brown’ gensets to ‘green’ gensets

PURE ENERGY

We have the power to boost your projects with sustainable energy solutions of the best quality and with personalised service.

Pure energy is an attitude, it’s in our character to innovate, developing more sustainable and efficient generator sets adapted to your needs. Always with a quality and attention to detail that make the difference. We are the energy that gives you everything!

We are the energy that gives you everything.

genesalenergy.com

DIESEL, GAS AND HYBRID GENERATOR SETS | ENGINEERING AND CUSTOMIZATION SERVICE | WIDE RANGE OF ENGINES AND ALTERNATORS | FROM 5 TO 3.900 KVA | WORLDWIDE COVERAGE

Six natural gas mtu gensets are destined for Nottingham

Pioneering project highlights how compliance can be achieved

UK System Integrator Yellow Power Ltd’s specialist team has packaged six natural gas mtu Series 4000 CHP engines for a client, Landmark Power Holdings. Yellow Power Ltd designs, supplies, and installs new and used diesel and gas fuelled power generation systems. The company excels in designing and integrating reliable and robust turnkey installations into a customer’s energy infrastructure.

The Series 4000 CHP systems are destined for the Rhodesia Power project in north Nottinghamshire, a 10 MWe gas generation and carbon capture plant that will support the national grid (and potentially local businesses) and convert the captured carbon into food grade CO2.

The new Series 4000 natural gas genset offers the highest power density in its class. Designed with cutting-edge technology, the new Series 4000 natural gas genset is optimized for maximum performance and low emissions to deliver an economical, reliable, and sustainable source of power.

A significant reduction in nitrous oxide emissions makes the natural gas genset a perfect fit for independent power producers (IPP) and combined heat and power (CHP) applications. With part-load performance down to 35% and a fast start option, the gas genset’s operational flexibility is also ideal for demand response applications. Low emissions - 250 mg/Nm³, 500mg/Nm³, (@5% O2)NOx – are achieved without external aftertreatment, even meeting the new expected German unburned THC emissions legislation (<1300mg@5%O2).

The natural gas genset has an effective engine power of 130 kWm/cylinder – the highest power density in its class thanks to its compact design and small footprint. It offers superb performance at high temperatures and high humidity for use anywhere in the world and delivers 30% more power than its predecessor.

All natural gas genset components are fine-tuned to ensure long service lives and deliver maximum uptime. Long service intervals and easy-to-maintain components mean low maintenance costs. Fast availability of spare parts and low engine oil consumption also help keep the new gas genset lifecycle costs lower overall, with cylinder head lifetimes potentially equivalent to TBO. The natural gas genset achieves efficiencies of up to 44.4%, delivering a significant improvement in fuel/energy utilization at high temperatures.

Deal involves certifications and certified training for UK industrial networks

HMS Industrial Networks Ltd, a wholly-owned subsidiary of HMS Networks AB, has acquired all shares in Control Specialists Ltd, located in Manchester.

Control Specialists is a key partner to Procentec – an HMS’ offering in monitoring and diagnostics of industrial networks. They deliver certifications and certified trainings related to industrial networks in the United Kingdom. Control Specialists is expected to realize a turnover of 0.5 MGBP in 2022 and will be integrated into HMS Industrial Networks Ltd during 2023 to further strengthen the Procentec training offering.

HMS Networks AB is a market-leading provider of solutions in industrial information and communication technology (Industrial ICT). HMS develops and manufactures products under the Anybus®, Ewon®, Intesis® and Ixxat® brands.

Development takes place at the headquarter in Halmstad, and in Ravensburg, Nivelles, Bilbao, Igualada, Wetzlar, Buchen and Delft. Local sales and support are handled by branch offices in the UK, Germany, USA, Japan, China, Singapore, Italy, France, Spain, the Netherlands, India, Sweden, South Korea, UAE and Australia, as well as through a worldwide network of distributors and partners.

Six months ago Eminox, a leading designer and manufacturer of emissions reduction technologies and Speedy officially joined forces to improve air quality. The pioneering project has already highlighted how compliance can be achieved as part of public and occupational health strategies in advance of stringent emissions legislation. The partnership has seen Speedy’s generators retrofitted with an Eminox exhaust aftertreatment system which has cost-effectively upgraded power generators from Stage IIIa to Stage V compliant standards.

The development has allowed equipment to be deployed where regulations such as London NRMM Low Emission Zone, Clean Air Zones (CAZ) and Medium Combustion Plant Directive (MCPD) are enforceable, and on pioneering projects such as HS2 sites across the country.

“It was a pleasure last year to welcome the new Group Managing Director at Speedy Services, Danny Johnson, to our headquarters in Gainsborough so he could experience first hand the realworld results of our market leading approved retrofit emissions control solutions for power generators.

We have been working together and delivering a positive impact for public health and emission control by achieving Stage V equivalent compliance through upgrading gensets in their portfolio,” comments Andy Meakin, Chairman, Eminox. The retrofit solution is available and has been rolled out on Speedy generators between 60kva to 250kva encompassing a wide range of commercial and domestic applications. I

n addition, the upgrade has taken place at Speedy locations to minimise lead and down times.

“Eminox is the first to market with such technologies, and their knowledge and expertise is secondto-none. Working with them to retrofit our gensets for our hire market, and to support the health of operators and the general public health on construction sites across the UK, is imperative as we strive to support the move towards net-zero targets,” explains Danny Johnson, Group Managing Director, Speedy Services. This pioneering project will deliver far reaching benefits across all applications of power generation, and the move to wider compliance of Stage V equivalent emissions regulations, confirms Eminox.

New partnership offers CCTV and asset monitoring

Genovate Power Solutions, a company which specialises in the delivery, operation and maintenance of large-scale energy projects, and Crest Energy, a company which owns and operates energy sites, have announced a 5-year partnership.

The deal will see Genovate providing operations and maintenance services across the Crest Energy sites. The assets include hundreds of generators with a total generating capacity of 120MWe.

Genovate has considerable experience in the operation and maintenance of such energy projects and through the partnership with Crest Energy will offer around-the-

clock CCTV and asset monitoring, a 24hr-emergency response facility, regular testing and will also undertake repairs in the installations.

Alan Dempsey, CEO of Genovate Power Solutions said: “We’re pleased to be working with Crest Energy on these projects and we will continue to provide unbeatable service to them and our other customers.”

8 JAN/FEB 2023 UK POWER NEWS NEWS NEWS

AsUK government incentives for renewable energy decline, investing in large on-farm anaerobic digesters to export power to the national grid is making less economic sense. Instead some UK dairy farmers are following a trend seen on the continent for smaller, simpler, slurry-only units, designed mainly to meet a farm’s heat and electricity needs. The UK has just 18 slurry-only AD plants running, but the number is rising and could soon double with 20-30 further units at the planning stage. David Kaner, CEO of Advanced Anaerobics, explains that government energy production incentives had previously made bigger plants attractive.

“The Feed-in Tariff (FiT) for electricity and the Renewable Heat Incentive (RHI) encouraged the rapid expansion of AD with more than 280 plants on farms,” says Dr Kaner. These are mainly large and, as well as manure, need purpose-grown crops or other waste material to generate energy. Typically they produce 500kW per hour from a combined heat and power (CHP) generator, he says. Few UK farms need more than 50kW per hour of electricity so these large plants were put in to capitalise on government payments by exporting the bulk of energy produced to the national grid.

FiTs for small scale AD plants were cut from 14p/kWh in 2011 to 6.65p/kwh from 7 October 2016. Government consultations on the future of FiT and RHI suggest further cuts and the removal of incentives for energy from purpose-grown crops. The FiT will be discontinued for new plants commissioned after the end of Q1 2019. A further disincentive for larger units is limited grid export capacity.

“In large parts of the country capacity is no longer available or has become unaffordable. Timed and capped connections are also becoming the norm,” says Dr Kaner.

So large units dependent on energy crops are becoming harder to justify on single farms. However, a slurry-only anaerobic digester uses just the manure and slurry available on the farm. Each tonne of organic dry matter in slurry can produce 300-400cu m of biogas.

A 300-cow unit can collect enough slurry to support a 50kW plant, avoiding the input cost of energy crops and better matching the electricity requirement of the farm. Several companies offer commercial AD plants for slurry-only use, mainly in the size range 10-50kW.

The capital cost of a typical 50kW unit is about £400,000. It is still a significant investment but is a fraction of the multi-million pound bill for a larger plant. Each livestock farmer should look carefully at the operational benefits, economic case and environmental impact of processing slurries and manures by slurry-only AD, Dr Kaner advises. But slurry-only plants of smaller size could find a successful niche as a solution to a farm energy problem and provide other benefits, he adds.

Dairy farmer John Jamieson, who farms at Woodhead, near Annan in Dumfries and Galloway, has invested in a 50kW anaerobic digester designed to process 24t of fresh cow slurry a day. The slurry from his 320-milking cows produces a total of 1,200kWh of electricity per day (50kWh x 24hrs).

Around 500kWh each day is used on the farm, reducing electricity purchases, and the balance is exported to the grid, for additional revenue. Mr Jamieson plans to use surplus heat from the plant on the farm, securing further payments under the RHI. Another benefit of the smaller-sized plant has been simplified planning and permits, says Mr Jamieson. As it does not need additional crop or other material brought in, there is no requirement to qualify the farm as a consented waste management site.

“The lack of imported feedstocks avoids the need for truck movements on rural roads and digestate from the plant can be spread on land without additional onerous restrictions,” he says. Mr Jamieson applied for his FiT in September 2014 – before the government made swingeing cuts – and secured payments of 12.46p/kWh.

Combined with savings on his electricity bill and a provision for payments under the RHI, this offers him a payback estimated at 60 months. fter reviewing several options, he chose to finance the plant with support from the farm’s existing bank. But a major consideration with a small plant is the operating cost, Mr Jamieson warns.

The CHP generator requires routine maintenance and periodic engine rebuilds. Over a 20-year lifetime, the operating costs of the plant as a whole will exceed the initial capital cost.

Construction of the SlurryGen-50 system supplied by Advanced Anaerobics Ltd started in July 2015 and initial commissioning followed in September. It is now routinely producing in excess of 1,100kWh per day of electricity, against the theoretical maximum of 1,200kWh per day, he reports.

Powering new integrated hubs in the North Sea

Neptune Energy has signed a Memorandum of Understanding with Ørsted and Goal7 to explore powering new integrated energy hubs in the UK North Sea with offshore wind-generated electricity.

Integrated energy hubs have the potential to combine multiple energy systems, including existing oil and gas production assets, carbon storage and hydrogen production facilities.

They could extend the life of producing fields and support the economic case for electrification with renewable energy.

The agreement will see the companies examine the potential to supply renewable electricity from Ørsted’s Hornsea offshore windfarm projects to power future Neptuneoperated hubs in the UK North Sea.

Neptune Energy’s director of New Energy, Pierre Girard, commented: “Neptune has submitted three applications under the recent Carbon Dioxide Appraisal and Storage Licensing Round, and securing the licences would enable us to develop future proposals for integrated energy hubs in the UK North Sea.

“In parallel, the agreement with Ørsted and Goal7 will support research into the potential use of wind-generated renewable electricity to power these hubs, which could comprise new and repurposed offshore assets and bring together hydrogen production and carbon injection facilities.”

The North Sea Transition Authority is due to award storage licences early in 2023.

Neptune Energy plans to spend more than US$1 billion1 over the next five years securing energy

supplies for the UK and speeding the transition to net zero. Neptune currently operates around 11% of the UK’s gas supply from fields in the UK’s Southern North Sea and the Norwegian North Sea. t is one of the UK’s lowest carbon producers, with the carbon intensity of its production at 1.7 kg CO2/boe compared with the industry average of 20 kg CO2/boe2.

Following the publication of the Government’s British Energy Security Strategy in 2022, Neptune will accelerate investment to increase energy supply to the UK. Ørsted currently develops, constructs, and operates offshore and onshore wind farms, solar farms, energy storage facilities, renewable hydrogen and green fuels facilities, and bioenergy plants. Ørsted is recognised on the CDP Climate Change A List as a global leader on climate action and was the first energy company in the world to have its science-based net-zero emissions target validated by the Science Based Targets initiative (SBTi).

Headquartered in Denmark, Ørsted employs approx. 7,700 people. Ørsted’s shares are listed on Nasdaq Copenhagen (Orsted). In 2021, the group’s revenue was DKK 77.7 billion (EURO10.4 billion).

University of Edinburgh renews its generator contracts

Following a competitive Tender exercise two years ago, Mitchell Power Systems was awarded the Generator Maintenance contract for the prestigious University of Edinburgh which it has maintained successfully for two years.

The University of Edinburgh is a public research university. Granted a royal charter by King James VI in 1582 and officially opened in 1583, it is one of Scotland’s four ancient universities and the sixth-oldest university in continuous operation in the English-speaking world.

The 4-year contract, which commenced on 1st September 2021, has so far involved the planned maintenance of 46 generator sets ranging from 3 kVA –2MW. In addition to annual servicing

and loadbank testing Turner Power Generation (a division of Mitchell Powersystems) has also provided a 24-hour emergency call out service and support the University staff during annual planned generator black start test events. This contract - which expires in 2025 - followed on the back of a series of contract

UK POWER NEWS JAN/FEB 2023 9 NEWS NEWS

Slurry power could still save us all?

£27million contract to cut carbon and energy costs for Eastbourne District General Hospital

Veolia, working through its specialist energy team, has been awarded a £27m energy management contract to upgrade the 459-bed Eastbourne District General Hospital, part of East Sussex Healthcare NHS Trust. The contract, which extends to 2040, includes a multimillion pound construction project during 2023 that will deliver wide ranging energy upgrades and target carbon savings of 4,129 tonnes per year.

Delivered through Veolia’s Building a Zero Carbon Future programme, with funding provided through the Public Sector Decarbonisation Scheme for affordable, low carbon energy efficiency upgrades across the public sector, the scheme is one of the first to to take a whole building approach. This utilises a holistic approach that accounts for how facilities and the energy delivery systems interact with each other, while maintaining an indoor environment that enhances patient care.

A secure energy supply is essential to maintain a modern patient care environment for the hospital which has 457 beds and treats more than 470,000 patients per year. To meet this energy demand and achieve carbon and energy cost savings Veolia will manage projects covering the design, delivery, and installation of a range of energy upgrades. These will guarantee the hospital meets the NHS carbon reduction targets for 2030 and is supported by a 24/7 operations and maintenance contract.

The energy plant upgrades include desteaming the site, solar arrays giving a total of 1.1MWp renewable electricity, improved ventilation systems, and a dual stage heat pump system to supply 3.2 MWth of low carbon heat with N+1 redundancy that gives system availability in the event of component failure. To ensure that this heat is efficiently used the project covers fitting of 17,300m2 of insulated roofing, replacing older single glazed windows with 4,540m2 of high efficiency double glazing, and 12,972 m2 of insulating cladding.

Commenting on this latest development, John Abraham, Chief Operating Officer - Veolia UK & Ireland - Industrial, Water & Energy said:

“Using the whole holistic building approach is part of our Building a Zero Carbon Future programme, and is key to advancing healthcare energy efficiency, cutting carbon emissions and providing cost savings that can be redirected to patient care. By targeting annual carbon savings of 4,129 tonnes, we are actively supporting the NHS decarbonisation programme and delivering lower cost energy for the healthcare sector.

“We look forward to working with the teams at East Sussex Healthcare NHS Trust and helping them achieve their environmental goals.”

Chris Hodgson, Director of Estates and Facilities at East Sussex Healthcare NHS Trust, said: “This project will make a significant contribution to the trust’s goals to reduce our organisational carbon footprint. As well as the significant carbon savings that the project will deliver, the additional cladding and insulation to the hospital will create a more comfortable environment for both our patients and our staff”.

Veolia has been working with East Sussex Healthcare NHS Trust since 2009, and currently provides energy and facilities management to over 100 hospitals in the UK. These support the healthcare for around 8.1 million inpatients each year, and reduce CO2 emissions in the healthcare sector by 120,000 tonnes.

In becoming the benchmark company for ecological transformation, Veolia is committed to tackle climate change, resource depletion, biodiversity collapse, and pollution.

By expanding the use of existing solutions, and developing new innovative solutions, the company is accelerating the process to radically change patterns of production and consumption and prioritise ecology.

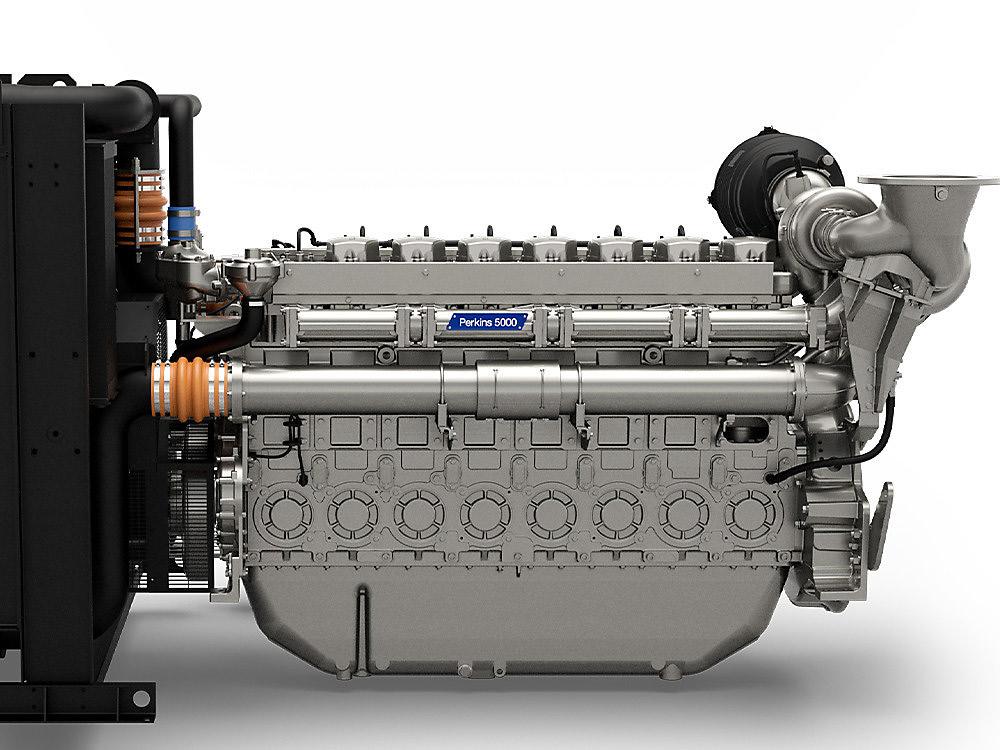

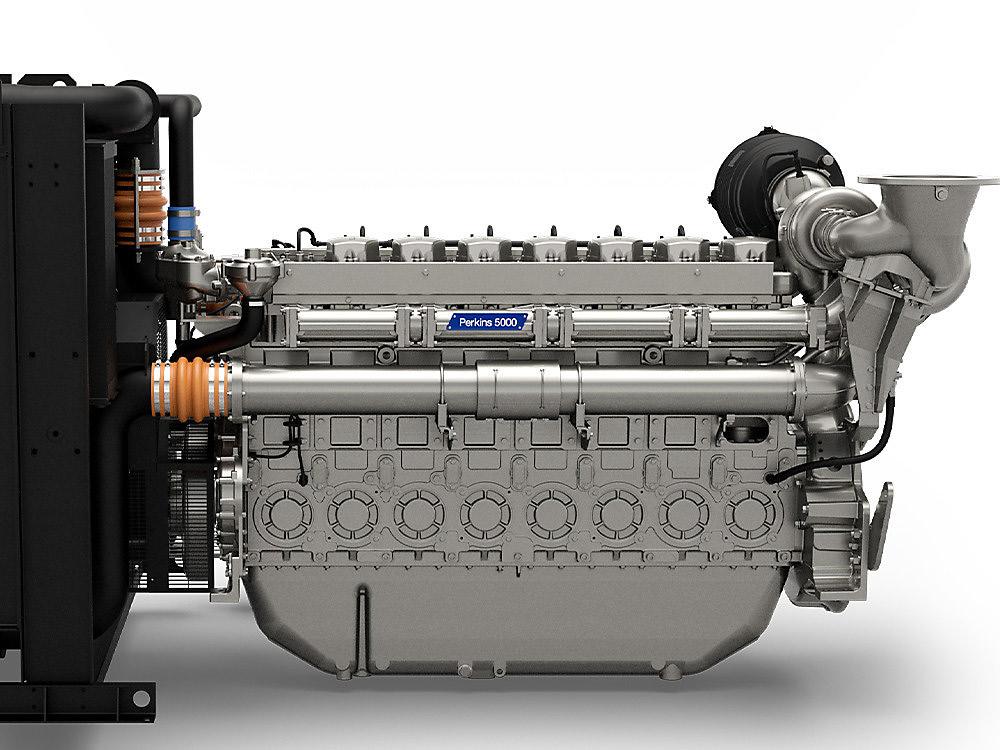

Impressive top-end overhaul of a 3000 Series engine

Bells Power Services Ltd recently carried out a top end overhaul to include head gaskets and all core plugs ending with a successful load test on a Perkins 3012 CV12 engine.

This job was critical to the client and was undertaken successfully under very strict time constraints as requested, all without the loss of backup power or disruption to the business.

The PERKINS 3000 Series embraces V8 and V12 engines suited to power generation and to the heavy end of the industrial power market.

The range comes in either electrounit or electropaK form (inclusive of radiator and fan). The 3012 range is also available as an Industrial Open Power Unit with industrial ratings.

Gas-powered spark ignited variants are also offered by the manufacturer.

Following the top end overhaul the client was ‘extremely happy with

the end result’, reports Bells Power Services.

It was all achieved five days ahead of schedule - from the switching plan through to the final load bank tests on both standby generators.

The Bells engineering team also recently completed three major service programmes for a Londonbased client: two full services involving FG Wilson P2250-1E gensets and a full service on a FGW P175-3.

These generator sets are considered field-proven and trusted to provide reliable power for a variety of critical applications including mini power stations, data centres, large factories, airports, hospitals and large retail stores etc.

Available with a 50 ° C package option, to ensure efficient operation in high ambient temperatures, this range is often customised with bespoke enclosures, cooling systems and specialised control systems.

New 6F21 six-cylinder engine - a compact yet powerful model

Moteurs Baudouin has launched the 6F21 six-cylinder, 12.5-litre engine, a compact yet powerful model suited for intermittentduty (815 hp/599 kW), light-duty (900 hp/662 kW) and highperformance duty (1000 hp/735 kW) applications. All three power options are rated at 2300 rpm. The choice of power ranges enables adaptability across a variety of applications, reports the company.

The 6F21 is the first step toward a new series of engines offering the best power in the market, and consolidating Baudouin as a trusted solution both for the commercial and pleasure market.

A spokesman explains: “For larger applications, we are also preparing to expand the burgeoning F series with an eightcylinder, 17 L version of the engine, coming later in 2022.”

The new 6F21 has a bore and stroke of 127 x 165 mm. It features a strengthened engine structure to withstand high torque and higher cylinder pressure of over 200 bar, plus includes a twostage turbocharger system, two intercoolers and a common rail electronic fuel injection system operating at 2200 bar.

These features are packaged in the smallest engine ever released by the company; it measures just 1470 x 1100 x 1705 mm.

10 JAN/FEB 2023 UK POWER NEWS NEWS NEWS

Working Power Station project receives 166,555-litres in thermal stores

XC13 uses Cursor X concept asa multi-energy platform

FPT Industrial’s multi-energy approach is reflected in its new XC13 which uses the Cursor X concept as multi-energy, modular and multi-application engine platform.

regulations, with limited impact on vehicle installation.

Vital Energi Utilities Limited has provided two 166,666 litre thermal stores for the Woking Power Station Project. The thermal stores will be situated outside and become an architectural feature of the project. Vital Energi has been delivering the ThamesWey Energy’s Woking Power Station project which will create a state-of-the-art Combined Heat & Power energy centre providing low-carbon heating and power to local businesses and residents.

Woking Power Station’s energy centre will produce enough heat and power to supply the equivalent of 2,500 homes and it’s first customers will be the new Hilton hotel, shops and over 400 apartments currently being delivered as part of the Victoria Square development. The energy centre has been designed to be both scalable and highly flexible, capable of generating up to 10MW of heat, and adopting progressively lower carbon technologies over the next ten years.

The company has been collaborating with a specialist supply chain to provide multi-technology solutions whi h are flexible to achieve carbon reduction targets now and in the long term. Vital Energi has been working with industry specialists to research and develop future renewable technologies which will help clients to continue to reduce their carbon emissions. Energy generation technologies can be retrofitted into an existing building or in a new dedicated energy centre.

The company has also been supporting large-scale applications of heat pumps. These are relatively new to the UK and Vital Energi has successfully installed the UK’s largest water source heat pump at Queens Quay, Clydebank, which will see two 2.65MW heat pumps extract energy from the river Clyde to provide heat and hot water to surrounding homes and businesses.

Vital Energie is also delivering a retrofit heat pump project in Southwark where heat will be extracted from water using ‘open loop’ supplied Water Source Heat Pumps and when completed, the technology will become the primary heat source for the heat, supplying low carbon heat to 2,175 homes. in the Consort, Newington and Wyndham housing estates.

Heat pump heating systems take the ambient heat from a source, such as the ground, water or air, and then boost it to provide low-temperature heating and hot water. Importantly, each of these types of heat pump systems has the ability to provide cooling as well, making them useful for the warmer summer months when the heating would normally go to waste.

Unlike traditional heating methods, which often rely on carbon-intense fossil fuels, heat pumps are powered by electricity which can come from renewables, or directly from the national grid. This, combined with high coefficients of performance makes them an attractive choice for anyone looking to find a financially viable way to decarbonise.

A heat pump spokesman commented: “Everything around us contains thermal energy – or heat. Heat naturally flows from a warmer place to a colder place. To provide the heat energy in a home when outdoor temperatures are colder, we need heat to flow in the other direction – from a colder place to a warmer place. But how does it do it?

“When the pressure of a gas increases, the temperature also increases. When the pressure decreases, the temperature decreases. This relationship between pressure and temperature is the key to how a heat pump works. The gas is called a ‘refrigerant’ and a heat pump uses electricity to compress this refrigerant, increasing the pressure and therefore the temperature.

“As the refrigerant’s heat is transferred to your home through the heat exchanger, it cools down a little. The refrigerant is then allowed to expand so that it cools even further. It’s now cold enough to absorb more heat from outside and begin the process again.

“The heat delivered to the heat exchanger can then be used to heat your home. This would normally be done using a central heating system – but it could also be done using warm air in either an air-to-air heat pump or an exhaust air heat pump.”

The XC13 is FPT Industrial’s first multi-fuel single base engine. From diesel to natural gas –including biomethane – hydrogen and renewable fuels, the base engine has been designed with multiple versions to offer maximum component standardization and easy integration into the final product.

FPT Industrial said the engine is compatible with a range of market requirements and emissions

The diesel version delivers ratings to 600 hp (447 kW) and torques up to 2102 lb. ft. (2850 Nm), resulting in 5% more power and 14% greater torque compared to the current Cursor 13 engine. The natural gas version delivers up to 520 hp (382 kW) and 1844 lb. ft. (2500 Nm), which is 13% more horsepower and 25% more torque than the current Cursor 13 Natural Gas. CO2 emissions reductions stand at 9% for the diesel unit and 10% for the methane model, but the latter can achieve net-zero CO2 emissions when fuelled by biomethane, FPT said.

Greener power at new Tritax Symmetry development

BasePower has entered into its first joint enterprise project with Tritax Symmetry to supply clients at the new Symmetry Park Biggleswade development with uninterrupted greener, cheaper power solutions.

Located on a greenfield site where the grid is constrained, the new 2MW energy centre will augment the grid with renewable and resilient generation from a number of sources including rooftop solar PV, batteries and a Combined Heat and Power (CHP) plant.

The announcement is one of several joint projects between BasePower and Tritax Symmetry to provide greater resilience, more competitive energy and a pathway to fully net zero carbon in occupation. The project was specified, designed, procured and built by BasePower who will continue to develop energy systems in line with the evolving needs of the tenants.

Principal contractors included the Power Systems division of RollsRoyce, which installed mtu CHP systems, battery units and standby generators. Powersystems UK acted as the high voltage (HV) specialist partner for the electrical

infrastructure. Dan Poulson, co-founder at BasePower said: “The need for the creation of alternative energy resources has never been greater and we are proud to have been selected by Tritax Symmetry for this project in Biggleswade along with multiple energy projects on their other sites. Across our business we currently operate ten energy centres in the UK with a further 20 in development. Through their lifecycles we invest to enhance each site to deliver increasing levels of decarbonisation as client requirements evolve.”

UK POWER NEWS JAN/FEB 2023 11 NEWS NEWS

Diesel genset is now backing up the systems of a London investment bank

Data Centre outages are costing more, with power failure the number one culprit

A new 2,530 kVA diesel-powered genset with an MHI engine is now operating in the UK’s capital following its installation at the end of 2022. This 2530kVA 11kV genset is providing backup power for a major investment bank in London.

The MITSUBISHI series heavy duty diesel engine features a 4-cycle, water cooling system, turbocharged - aftercooler induction, an electronic governor system, a 12/24 volt self-starter and charger alternator, a changeable air, fuel and oil filter and a flexible fuel pipe.

Inside, the components include an oil discharge valve and extention pipe, an industrial-type silencer, exhaust spiral or compensator, a maintenance-free battery and an engine block water heater.

The MECC ALTE ECO46HV-2VL/4 alternator the set relies on has many special product features designed into it.

Self-regulation is obtained through a digital electronic regulator which is fed by an auxiliary winding. MECC ALTE says it guarantees an almost constant supply from the generator – under any possible operating condition.

A rotating inductor is fitted with a damper cage. The windings have a 2/3 pitch in order to reduce the harmonic content of voltage. The entire series is manufactured according to, and complies with, the most common specifications such as CEI 2-3, IEC 34-1, EN 60034-1, VDE 0530, BS 4999-5000, CAN/ CSA-C22.2 No14-95- No100-95.

Isle of Wight becomes the focus for tidal stream energy

A new study led by Dr Danny Coles, Research Fellow on the INTERREG V A France TIGER Project at the University of Plymouth, says that adopting tidal power alongside other forms of renewable energy can significantly enhance energy security and go some way to enabling communities to fulfil their clean energy ambitions.

Researchers found that installing tidal stream systems, in addition to solar and offshore wind farms, is around 25% more effective at balancing supply with demand than just relying on solar and wind technologies.

Using tidal technologies as part of a renewable energy mix can also reduce the space required for power-generating facilities, both on land and at sea, by around 33% and significantly reduce their visual impact since much of their operation is below the sea’s surface.

It can also help to reduce the

levelised cost of whole-system energy, relative to solar and wind systems, because it reduces the requirement to access expensive reserve supplies.

Published in the journal Applied Energy, the study focuses on the Isle of Wight.

The island plans to generate as much renewable energy as it consumes, and achieve net-zero emissions, by 2040. To achieve this, it will need to find ways to generate an average of 136MW of electricity through clean energy to meet its future projected annual demand.

Its primary source of power is currently a gas-fired power station and while solar power currently generates 80MW, plans for a nearby offshore wind farm were refused in 2015.

Findings from Uptime Institute’s 2022 Global Datacentre Survey highlight the fact that downtime in the data centre industry is becoming increasingly expensive, with the main cause identified as power failures.

The report focuses on responses from more than 800 owners and operators of data centres, including those responsible for managing infrastructure at the world’s largest IT organisations.

While sustainability, efficiency gains, staff shortages and supply chain issues also dominate the report, the issue of power resiliency remains dominant.

Data indicates that the costs of outages are on the increase. A quarter of respondents reported that their most recent outage cost more

than US$1 million in both direct and indirect costs. This is a significant increase from 2021, reflecting a continuing upward trend over the last five years.

The report states: “Uptime’s 2022 annual survey findings are remarkably consistent with previous years. They show that onsite power problems remain the single biggest issue by a large margin.”

Backup power failure has been identified as the number one issue in 2023.

Further analysis in related research from the Uptime Institute identifies the biggest causes of power-related outages to be uninterruptible power supply failures, followed by transfer switch (generator / grid) and generator failures.

Work stalled at Scotland’s largest offshore wind farm

A project involviong the fitting of remaining turbines at Scotland’s largest offshore wind farm has stalled in February 2023.

Market analyst Esgian recently noted that “no jacket or turbine is being installed” at the Seagreen site, some 16 miles off the coast of Angus.

SSE Renewables subsequently confirmed that a planned break is ongoing – work to fit array cables is continuing.

The Seagreen Offshore Wind Farm is under construction around 27km from the coast of Angus in the North Sea.

A joint venture between TotalEnergies (51%) and SSE Renewables (49%), Seagreen will be Scotland’s largest and the world’s deepest fixed foundation offshore wind farm once complete.

Seagreen was consented with permission to install 150 offshore wind turbines.

114 turbines are currently being installed with a total installed generating capacity of 1,075MW and will be fully operational in Q2 2023. First power was achieved in August 2022 and is exported to the grid via a new substation at Tealing near Dundee.

The 114 turbines will provide enough green energy to power more than 1.6 million homes, equivalent to two-thirds of all Scottish homes. They will also

displace over 2 million tonnes of carbon dioxide from electricity generated by fossil fuels every year – similar to removing more than a third of all of Scotland’s annual car emissions and making a significant contribution to Scotland’s net-zero ambition by 2045..

The remaining 36 offshore wind turbines are consented but not yet constructed. The power will be exported to the grid via Cockenzie, East Lothian. Information relating to this connection can be found here.

In January 2022 the company submitted a Screening Report to Marine Scotland to i ncrease the size of the 36 consented turbines.

12 JAN/FEB 2023 UK POWER NEWS NEWS NEWS

The Electromechanical Specialists CERTIFIED QUALITY SYSTEM Call: 01572 755 168 Email: info@cabeluk.com www.cabeluk.com We go further Essential electromechanical repair and rewind for alternators, pumps, motors and so much more. Designed to assist your business and extend the life of your equipment. WINDING REWINDING SERVICE &REPAIR SUPPLY 24/7 ALL BRANDS

E CO - F R IENDL Y Don’t Compromise on Performance PremiumTower™ Standalone Three-phase UPS From 10kW - 250kW SWISS MADE Phone: 01420 82031 Email: sales@centiel.co.uk Web: centiel.co.uk PremiumTowerTM offers an on-line operating efficiency of 96.6% in double conversion mode minimizes running costs and reduces the Total Cost of Ownership.

EXHAUST TREATMENT

UGET 3+DPF fitted to a 3012TAG2A standby set at the Wales Millenium Centre, Cardiff

3012TAG2A standby genset located at the Wales Millennium Centre in Cardiff.

Based in St. Albans, GenCat has been trading in the exhaust after treatment industry since 2003, with a focus on heavy duty applications for NRMM, generating sets and materials handling equipment. Its products include a range of Diesel Particulate Filters (DPFs), Catalytic Converters, and key accessories include exhaust rain caps. The company says its mission is to ‘find the best solution to the application by offering the right equipment to do the job. From plant working in enclosed spaces, tunneling, offshore applications to standby power exhaust filtration’. In one recent contract GenCat engineers fitted a Bersy UGET 3+ DPF to a Perkins engine 3012TAG2A standby genset located at the Wales Millennium Centre (WMC) in Cardiff.

Located in Cardiff Bay, the centre is described as a ‘a home for the arts in Wales and a cauldron of creativity for the nation’.

The site covers a total area of 4.7 acres (1.9 ha) and comprises a large theatre and two smaller halls with shops, bars and restaurants. It houses Wales’ national orchestra and opera, dance, theatre and literature companies, a total of eight arts organisations in residence.

The main theatre, the Donald Gordon Theatre, has 2,497 seats, the BBC Hoddinott Hall 350 and the Weston Studio Theatre 250.

GenCat was called in by the WMC site managers to carry out an upgrade the exhaust system on a backup power generator.

The genset was based in the corner of a service area in the centre of the building. Within this courtyard area wwere many windows to offices and residential areas. Whenever the genset was started it generated a troublesome plume of smoke and this was a source of complaint.

To rectify the problem with the exhaust fumes GenCat installed two catalytic converters inside the canopy - and on the roof a UGET 3+ D1000 DPF has also been installed.

Here, a UGET 3+ diesel particulate filter now collects the particulate matter in the exhaust stream by means of physical filtration.

The UGET 3+ diesel particulate filter is capable of retaining particles as small as 0.3 microns, trapping all PM10 and PM2.5 matter and is capable of reducing up to 99% of particulate matter (PM) in the exhaust stream, reports GenCat.

“GenCat fitted a UGET 3+ DPF to a Perkins 3012TAG2A standby set at the Wales Millennium Centre, Cardiff. Two catalytic converters were installed inside the canopy and on the roof there is a UGET 3+ D1000 DPF. The remedy has overcome problems associated with exhaust fumes vented into a courtyard.”

The UGET 3+ is a non-regenerative type; it has a finite capacity of 1,000 grams before the filter cartridge requires replacing.

Applications for UGET 3+

The filter is suited to low usage applications such as standby generator sets or on equipment being used for short periods at a time. It is said to be particularly suited to equipment being used in confined spaces.

The filters can be bypassed, so that it is only used when required, i.e. inside tunnels and warehouses, electronic or manual bypass valves are available.

As the maximum operating temperature of the filter is 350°C, it is recommended that fitment of the filter is as far from the engine as possible, to avoid overheating.

The filter can be bolted to a frame or body and simply attached with a length of flexible exhaust pipe. The filter cartridge is fire resistant and incorporates a heat shield for protection from burns. There is minimal maintenance required for the UGET 3+ diesel particulate filter. At the end of the filter life the filter is removed and simply replaced with a new one.

Failure to do so will cause the filter to block, which in turn can damage or destroy the filter itself or cause damage to the engine due to increased backpressure. Filter life is estimated at 300-350 hours, depending on condition and maintenance of the engine.

A non-regenerative DPF was recently fitted to a Perkins 3012TAG2A Standby generating set in a similar contract, reports the company.

A standby set was located close to an industrial laboratory complex at a UK manufacturing facility.

Employees found that genset emissions on startup were entering the clean laboratory environment.

GenCat’s technical team installed twin catalytic converters to upgrade the complete the emissions control and the problem was completely solved.

www.gencat.co.uk

UK POWER NEWS

15

JAN/FEB 2023

Based in St. Albans, GenCat says its mission is to ‘find the best solution to the application by offering the right equipment to do the job. In one recent contract GenCat engineers fitted a Bersy UGET 3+ DPF to a Perkins engine

Hydrogen - one of the key instruments to effectively reduce emissions from energy generation

hydrogen. For example, this includes a wide range of flammability (enables lean mixtures), high autoignition temperature (similar to methane), low ignition energy (risk of premature ignition and flashback), and potential material incompatibilities (embrittlement of the steel).

The developers of the MWM gas gensets have mastered these challenges through ongoing research.

Green H2 as a clean fuel for gensets MWM has extensive experience in the use of gas gensets with hydrogen admixture.

Through the deployment of various MWM products and technologies in customer projects, MWM has implemented trend-setting projects with a hydrogen content of up to 60 percent.

MWM gas gensets are already capable of running with a hydrogen admixture of up to 10 percent without any technical modifications.

To reach current climate targets, energy consumption must be brought down and the availability of energy for the industry must be controlled in a flexible way, e.g. via flex operation of cogeneration power plants.

New laws and regulations including the 44th Federal Immission Control Ordinance (44th BImSchV) determine stricter emission limits for plants with firing systems, gas turbines, and combustion engines, which plant operators need to comply with and furnish evidence of their compliance.

The National Hydrogen Strategy also intends to speedily develop hydrogen technologies and ensure international market availability for the production and use of hydrogen in order to make the amount of hydrogen required for the conversion of application areas available as soon as possible.

Sustainably-produced green hydrogen can be used as a climate-friendly energy source for distributed power generation with gas gensets, as fuel for vehicles, as raw material for chemical processes, and for long-term storage.

Green and blue hydrogen: climate-neutral fuel and energy store

Compared to fossil fuels, the carbon emissions of sustainably produced hydrogen are much lower.

About 96 percent of the hydrogen produced around the globe is produced from natural gas, oil, and coal. Not all hydrogen types come from zero-carbon production. Distinction is made between green, blue, turquoise, and gray hydrogen.