6 minute read

Boosting power & efficiency at the UK’s Coryton plant with two High Efficiency upgrades

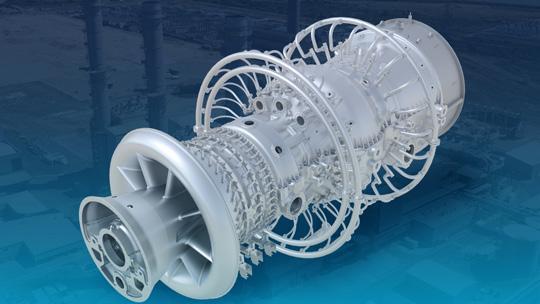

Continuing to keep customers’ gas turbine fleets competitive in the UK’s energy marketplace, GE Vernova’ Gas Power business has announced an order from InterGen, one of the largest independent power producers in the UK.

The order is for two High Efficiency (HE) upgrades to modernize the Coryton Power Plant. The 800 megawatt combined cycle power plant, located 30 miles east of London on the River Thames, is powered by two GT26 gas turbines. The upgrades will be installed in 2025.

GE’s HE upgrade utilizes technology breakthroughs across gas turbine, compressor and combustor that will help Coryton Power Plant deliver approximately additional 77 MW of power output. The upgrade will also increase the units’ efficiency, and extend ongoing maintenance intervals.

In addition, the modernization is expected to result in a reduction of approximately 67,500 tonnes equivalent of carbon emissions each year, in line with the government’s goals to lower the carbon footprint in the country, by requiring less fuel to produce the same amount of power compared to the plant’s current output.

“Ar InterGen we continue to invest in the energy transition by boosting flexible generation to ensure the stability of grids as renewable generation increases, while developing advanced solutions that keep the lights on, at a manageable cost for our customers- and we see GE as a reliable player and technological innovator to drive these goals forward,” said Jim Lightfoot, InterGen’s CEO.

“We selected GE’s HE upgrade because of its excellent part load efficiency and its fuel-flexible combustion system.

“With this innovative upgrade, we expect that our power station will benefit from improved efficiency and increased output, in line with our goals.”

Natural gas-fired power plants like Coryton are said to be the lowest emitting fossil fuel power plants, whether measured based on CO2, SOx, NOx, particulate matter, or mercury.

GE is advancing flexible, efficient and reliable gas power generation solutions, because of their fundamental role to complement renewables towards a more sustainable energy future.

GE has invested significantly in the development of this upgrade, which was introduced in 2019. This technology combines the best from both GE’s F- and H-Class fleets with additive manufactured parts and innovations in aerodynamics.

Launch of industry first CO2 asessment tool for gas turbine rotors assessment tool for gas turbine rotors

EthosEnergy, which specialises in services and solutions for rotating equipment in the energy and industrial sectors, has launched the industry’s first life cycle assessment (LCA) solution for gas turbine rotors. This enables full visibility of environmental impact and a reduction in CO2 emissions.

Developed in partnership with Politecnico di Torino and Politecnico di Milano, the new CO2 assessment tool – EcoView™ - provides comprehensive environmental insights across each phase of the rotor life cycle. These evaluations quantify the carbon and financial reductions which can be achieved from maintaining existing equipment compared with purchasing new.

Massimo Valsania of EthosEnergy told UKPN: “Having a transparent view of CO2 emissions across the entire life cycle, and how to tackle these, is a key factor in the world’s energy market and driving towards net zero carbon emissions.

“EthosEnergy’s expert team took the initiative to research and explore a pioneering solution which provides emission and maintenance insights for companies across the world to action – implementing a positive change for energy operations.

“By enabling ESG reporting and compliance, we are supporting the energy industry to achieve a fair energy transition. We play an active part in the circular economy, offering attractive solutions for our customers and the wider supply chain.”

Eden Project North: Plans for £125m 2-dome development in Morecambe

2.5MW solid oxide fuel cells for a leading hydrocarbon company

Bloom Energy has supplied 2.5 MW of Bloom’s solid oxide fuel cells to a leading hydrocarbon company based in Dorset, UK. The company recently signed an agreement with Perenco to install 2.5 megawatts of Bloom’s solid oxide fuel cells at a key site owned by Perenco.

Perenco is a leading independent hydrocarbon company, producing 500,000 BOE of oil and gas per day from its operations in 14 partner countries.

important step as we continue to reduce our emissions wherever we work. We look forward to a successful initial deployment at Wytch Farm and to then expanding the use of the technology into other global operations sites.”

Project Morecambe, previously known as Eden Project North, has been awarded £50m in the second round of the UK Government’s Levelling Up Fund. The funding allows the project to move into its next phase and begin the process of finalising the remaining funds required from private and philanthropic sources identified as part of the bidding process.

Eden Project Morecambe is being delivered for 2026 by the team behind the first Eden Project in Cornwall, alongside local partners Lancaster University, Lancaster City Council, Lancashire County Council and the Lancashire Enterprise Partnership. It will be situated on the former site of the Bubbles leisure complex with “shell-like” domes surrounded by outdoor gardens. Two restaurants are planned, with both featuring indoor and outdoor seating, and boasting views across Morecambe Bay. News sources suggest four gensets will provide backup power for HVAC, lighting and security systems onsite.

The £125m project on Morecambe Bay’s seafront is going ahead after years of development. Once completed in 2026, the Eden Project North is predicted to attract around one million visitors a year and directly employ more than 400 people.

The original Eden Project is a visitor attraction in Cornwall, currently features two huge enclosures consisting of adjoining domes (Rainforest and Mediterranean) which house thousands of plant species and each enclosure emulates a natural biome.

The ‘energy-friendly’ Eden Project is said to have contributed over £1 billion to the Cornish economy and had over 1 million visitors in 2019. The complex also uses Green Tariff Electricity – the energy comes from one of the many wind turbines in Cornwall, which were among the first in Europe - and now has its own geothermal energy source for its eventual electrical power and heating.

Multi-million pound project to refurbish overhead electricity lines is underway

A multi-million project to refurbish miles of overhead electricity lines is now up and running across Wrexham, Whitchurch and Crewe thanks to SP Energy Networks.

The £5.5 million project – covering a distance that’s equivalent to the length of a marathon – will modernise the network circuit between Legacy in Wrexham, Marchwiel through to Whitchurch and Crewe.

It will enhance the resilience and capability of the network in the region, ensuring it’s ready for the continued uptake of green energy solutions like electric vehicles and heat pumps.

SP Energy Networks serves more than 50,000 homes and businesses across the area, who will all benefit from this investment and the cleaner and greener choices it will allow them to make, while ensuring a resilient and reliable power supply.

The works are the first in a wider five-year investment programme, which will see SP Energy Networks invest £200 million in its 132kV network in England and Wales,and have been planned carefully with customers in mind to keep power flowing while the works are underway.

Mark Sobczak, 132kV General Manager at SP Energy Networks said: “It’s great to be out of the starting blocks and getting to work on this exciting project.”

The Bloom Energy Server® platform, to be delivered in late 2023, will be installed at Wytch Farm in Dorset, the largest onshore oil field in western Europe, where it will be used to support Perenco’s baseload requirements.

The agreement marks the first deployment of Bloom fuel cell technology in the UK.

“This is an important step that will demonstrate how our solid oxide fuel cell technology supports the resilience and sustainability goals of our energy-intensive clients,” Tim Schweikert, Senior Managing Director of International Business Development at Bloom Energy, told UKPN.

“Perenco has always been a pioneer in innovation and long-term investment in the countries where we operate,” comments Benoit de la Fouchardiere, Perenco CEO.

“This announcement is another

The third generation of fuel cells includes the solid oxide fuel cell (also known as SOFC), an all-solidstate device that efficiently and sustainably transforms chemical energy stored in fuel and oxidant into electrical energy at medium and high temperatures.

Similar to the proton exchange membrane fuel cell, solid oxide fuel cells are typically thought to be fuel cells which will be widely employed in the future.

A solid oxide fuel cell (SOFC) is an electrochemical device that uses the inclination of oxygen and hydrogen to react to transform the chemical energy in fuels into electrical energy. The solid oxide fuel cell runs on air and a gaseous fuel like natural gas or biogas. They are unique in that they produce heat and electricity with a high level of efficiency while emitting no harmful emissions.

Gensets provided for a key South London hospital

CTM Power Ltd, part of the CTM group, was involved in the supply design and commissioning of three 1.5MVA generator sets for a South London hospital. Also supplied was a generator control panel integrated to facilitate starting, paralleling and connection via LV switchgear.

Because the need for low nooise levels in the hospital envrions, noise attenuation measures were applied to the built environment.

The fuel supply system for the three backup power gensets included double-skin day tanks, all pipework, control panel and transfer pumps for the transfer of fuel from bulk tanks to over 150-metres away. CTM specialises in the supply of standardised & bespoke diesel and gas generating sets, UPS Systems, as well as weather, sound and blastproof containers and low, medium & high voltage containerised substations.