8 minute read

THE POWER TO DELIVER

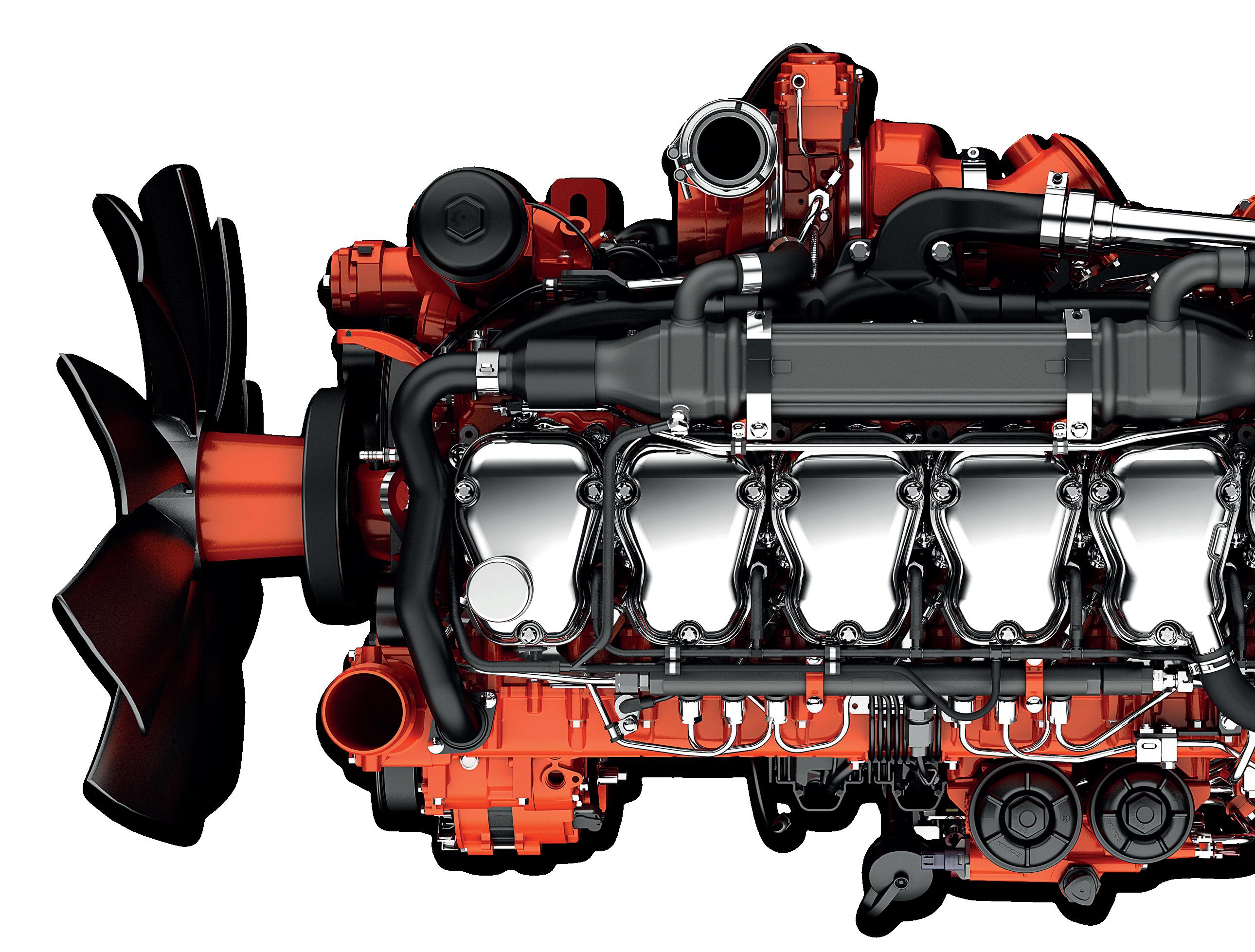

Whether it’s our flawless 9-series, 13-series or V8 16-series of engines, Scania Power Solutions will make sure you get it right. Our team have all the experience and sheer depth of knowledge to match the perfect engine to your power generator needs, every time. And because Scania Power Solutions lead the way in Stage V compliance, you can be sure that you’re choosing from a range of engines – from 202kW to 566 kW – that is not only super-efficient, reliable and economical, but sustainable, too. When it has to work, it has to be Scania.

SPEAK TO OUR SCANIA POWER SOLUTIONS

TEAM TODAY – CALL 0845 034 3034

NHS hospital facility in Cheshire installs a 1,650kVA diesel generator set to provide critical power onsite

Temporary energy supplier for the 44th Ryder Cup will be teeing off in September 2023

Now delivered , off loaded & positioned, another Teksan™ UK 1650 kVA containerised diesel generator solution is providing critical power for the NHS supply chain in Cheshire.

The Teksan TJ165BD 150kVA diesel generator offers reliability and economy thanks to the robust Baudouin 4M06G165/5 engine. The Overhead Valve (OHV) 1500rpm engine produces a dependable 150 kVA / 120 kW of prime power and has been designed to be quiet, rugged, and durable, reports the manufacturer.

The Teksan TJ165BD features a close-fitting acoustic canopy, long run bunded fuel tank and copes well with tough environments and a range of high and low temperatures.

It has a prime power rating of 150 kVA / 120 kW and standby power rating of 165 kVA / 132 KW. This canopied diesel generator is extremely compact and robust, so can be stored with ease with minimum effort. With a generous bunded fuel tank of 400 L, the Teksan TJ165BD diesel generator is perfect for your next project. With an easy-to-use configuration this diesel generator gives you a fantastic balance between performance and price.

Simply press the button and up it starts. The button start makes starting straightforward and easy. The Baudouin 4M06 is currently one of the most powerful engines from the 4M06 range, and in fact the highest powered to run at 50 Hz. The 6 cylinder, 2.3L engine has a turbocharger and is air to air after cooled. It is currently produced in France and China.

Genset details are as follows:

-Prime Power 150 kVA / 120 kW

-Baudouin Engine (4M06G165/5)

-Deep Sea Electronics 7320 control module

-Leroy Somer alternator

-3 Phase / Voltage 400V

Teksan generator sets comply with ISO 8528, ISO 3046, BS 5514, DIN 6271 standards, are being used. These engines with low fuel consumption, provide accurate speed setting and order, mount to the fuel pump, also have mechanic or electronic type governors.

All alternators pass the necessary test process and are appropriate according to EC 60034-1; CEI EN 60034-1; BS 4999-5000; VDE 0530, NF 51- 100,111; OVE M-10, NEMA MG 1.22. standards, have bearing system that do not need maintenance, with electronic type voltage regulator providing voltage setting.

The Control Panel ensures comfortable and safe usage. All measured and statistical parameters, operating modes, notice and alarms and condition of generator, are monitored easily from the control panel.

On the front of the panel’s metal body has electronic control module and the emergency stop button and the panel’s metal body is made of steel sheet and is painted with electrostatic powder paint. The chassis is manufactured from steel - thanks to its rigid structural design and anti-vibration mounts, it reduces vibration level to minimum. All chassis contain lifting lugs.

Apart from gensets with less than 1600 kVA power, the fuel tank is manufactured integrated to the chassis. In more than 1600 kVA power generator sets, a rectangular type fuel tank is provided with generator set separately. All types of fuel tank on offer from the company have fuel level and indicators.

The genset’s Cooling System System consists of quality industrial - type radiator, expansion tank and cooler fan, designed to keep the temperature of generator set equipment constant at a proper level. For more information visit: teksanuk.com

UK-based Aggreko will be the official temporary energy supplier for the 44th Ryder Cup teeing off in September.

Aggreko will provide power and HVAC across the event from all hospitality to both the opening and closing ceremonies. The Ryder Cup is one of the most iconic tournaments in golf and attracts tens-of-thousands of fans from all over the globe. This will be our fifth time supporting the European leg of the competition having previously supplied energy to the 2006, 2010, 2014, and 2018 editions.

It will be the first time ever power for the Ryder Cup will be supplied by a combination of resilient temporary generators and two solar arrays to further improve energy efficiency

“We are proud to continue our ongoing support of the Ryder Cup working with Ryder Cup Europe and the PGA of America for the event that’s on every golf fan’s calendar,” said Jono Rose, General Manager - Aggreko Event Services. “Every global sporting occasion presents its own set of unique challenges. Aggreko not only has the tools to solve these complex situations, but to do so in a way that continues to reduce carbon footprint and implement a flawless Ryder Cup event. Our team will be on the ground months ahead of the event to ensure we can meet every demand asked of us, so that the organisers can deliver yet another unforgettable Ryder Cup.”

ForePower invests in a 10MW battery energy storage system for South Yorkshire

In 2022 UK infrastructure projects developer ForePower ordered a 10MW battery energy storage system (BESS) project for its engineered, system-integrated turnkey solution.

ForePower invested in a systemintegrated BESS solution. to provide the National Grid with the ability to stabilise the electricity network via a portfolio of assets.

Funded by Nash Business Capital Ltd, the 10MW 1-hour duration BESS project is based in South Yorkshire, UK, where it will provide a range of balancing services to the electricity grid to ensure power security, system flexibility and accelerate renewable energy integration.

The modular outdoor battery energy storage solution is fully integrated and prefabricated with lithium iron phosphate (LFP) battery cell chemistry, liquid-cooled thermal management system and skidmounted inverter systems.

An innovative £10m district energy centre, situated in the heart of Helix - a landmark mixed-use development in Newcastle City centre, and one of the largest urban regeneration projects of its kind celebartes its third anniversary.

In 2020 Newcastle District Energy Centre scooped a prestigious RICS Social Impact North East’s ‘Infrastructure’ Award for the development.

SES Engineering Services (SES) was a key contributor to the successful delivery of the scheme in a ground-breaking joint venture between Newcastle City Council and ENGIE Urban Energy formed to create a 40-year partnership. The aim of the project was to tackle a city wide climate change challenge by implementing energy solutions across the city, the energy centre being the first development.

Today Newcastle Helix is a 24-acre landmark sustainable development on the site of the old Newcastle Brewery, and is one of the largest urban regeneration projects of its kind.

Designed to bring together industry leaders, businesses and top researchers, by creating a new innovation community, it is an exemplar of sustainable urban development, comprising prestigious commercial and residential space with first class research and education facilities, in the heart of a flourishing city.

At its heart is Newcastle District Energy Centre delivering heating, cooling and electricity through a distribution network to 10 buildings and approximately 500 future homes on the site. It has been calculated that the scheme is providing a carbon-emission saving of 30,650 tonnes over 40 years. Critically, the CHP energy centre is a key component of the city’s energy masterplan and is a significant contributor to achieving Newcastle City Council’s (NCC) ambitious green credentials and net zero carbon emissions target by 2030.

The project’s overarching value delivers at every stage and stands out because it both generates and supplies sustainable low-cost energy, provides significant emission savings until 2060 and beyondand sets the stage for the future development and the construction of further energy centres around the UK.

The energy system of Newcastle Helix includes the following infrastructure:

-11kV smart grid throughout the site

-Combined heat and power (CHP) district heating

-Electric vehicle (EV) fuelling station

-Low carbon heating

-Building-mounted solar photovoltaic

-Solar thermal photovoltaic (PVT), producing power and hot water

-The first University teaching building on site is Urban Sciences Building (USB). This is key to ongoing research at Newcastle Helix and is home to CESI HQ.

In the CESI & UNEW energy Lab, researchers are demonstrating projects developing exciting technologies, most of which will offer more efficient energy solutions to create a greener, lower carbon future. Recently, work in the lab has involved testing the rapid EV charger in a hybrid system of PV and BESS which is capable of charging an electric vehicle in around 30 minutes and has been developed for the Smart Hubs project.

The District Energy Centre provides affordable heating to all businesses and homes on Newcastle Helix via a network of underground pipes. Non-residential properties on the site also benefit from a cooling system and a bespoke electricity supply.

It is integrated with the smart electricity grid, smart meters and onsite electrical energy storage to allow the generation, distribution and consumption of heat and power to be closely monitored and managed. The Newcastle Helix development is in the vanguard of UK ‘Smart’ developments, providing a significant opportunity to showcase Newcastle Helix as a demonstration project which exemplifies the benefits of smart energy systems.

Keeping it clean at Glastonbury music festival 2023 with a new fuel filtration system for the generators

UK-based Agriemach provided a key service to one of the biggest music festivals in the world last month by ensuring site fuel supplies remained pure. Before the event began Agriemach supplied a vital Agriepure™ Fuel Filtration System is onsite to keep diesel fuel clean for onsite generator systems

Agriemach’s maintenance team supplied Worthy Farm with an Agriepure™ Fuel Filtration System before the event, making sure their Fuel was always clean and ready to use.

The Agriepure™ Filtration system is also HVO Compatible and is programmed to run every day ensuring the fuel is free of any Water & Particulates.

The Agriepure System has been developed to filter 25 litres of diesel per minute.

This system is generally used on small machinery, generators and tanks with small access points. It can be used for filtering any type of diesel in any type of tank.

System 1 uses 16mm hose on the suction and delivery sides, meaning that it is ideal for the smaller applications but while still producing 25 litres per minute of filtration.

The filter chamber holds a Racor Aquablock filter element which is coated with a resin. This filter will not allow any water past it. These filters also filter out particulates with the option of 2, 10 or 30 Micron.

Agriemach also offers reuseable MESH elements for applications with heavy particulate content.

At the bottom of each filter chamber is a system which uses centrifugal force. This system gets the diesel spinning and enables the larger contaminants to be pushed down into the clear bowl.

With the clear bowl being fitted, this allows you to see immediately; what type of contamination is in the tank. This also allows you to see which areas of the tank are most contaminated with sludge and rubbish, making the cleaning process more effective.

Bunnahabhain Distillery gets top sustainability award

Developed, built and operated by Dallol Energy in Scotland, the Bunnahabhain Distillery’s energy centre offers the first Net Zero distillation process on Islay.

The CHP system, finished in 2022, is fuelled with a mix of spent process malt (draff) and local woody biomass.

The Bunnahabhain clean burn biomass boiler is said to be one of the cleanest systems in Europe and whisky’s first example of three zoned biomass combustion coupled with NOx reduction technology.

According to the site managers

It saves 5500 tonnes of carbon emissions a year, representing a reduction of 95% over oil.

The biomass development has created a new forest economy and employment on the island.

The need for woody biomass fuel provides a local market for low value biomass which helps to finance the export of premium sawlogs, a largely uneconomic prospect up to now.

The project has also improved biodiversity and wildlife habitats through replanting.