MARCH-APRIL 2024

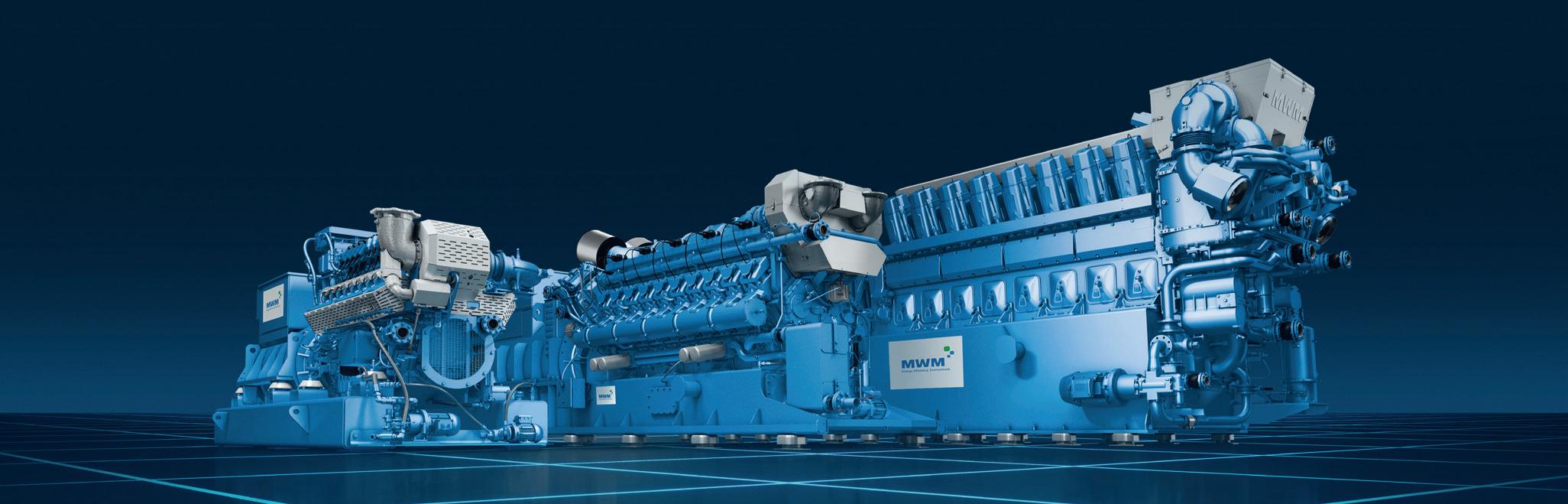

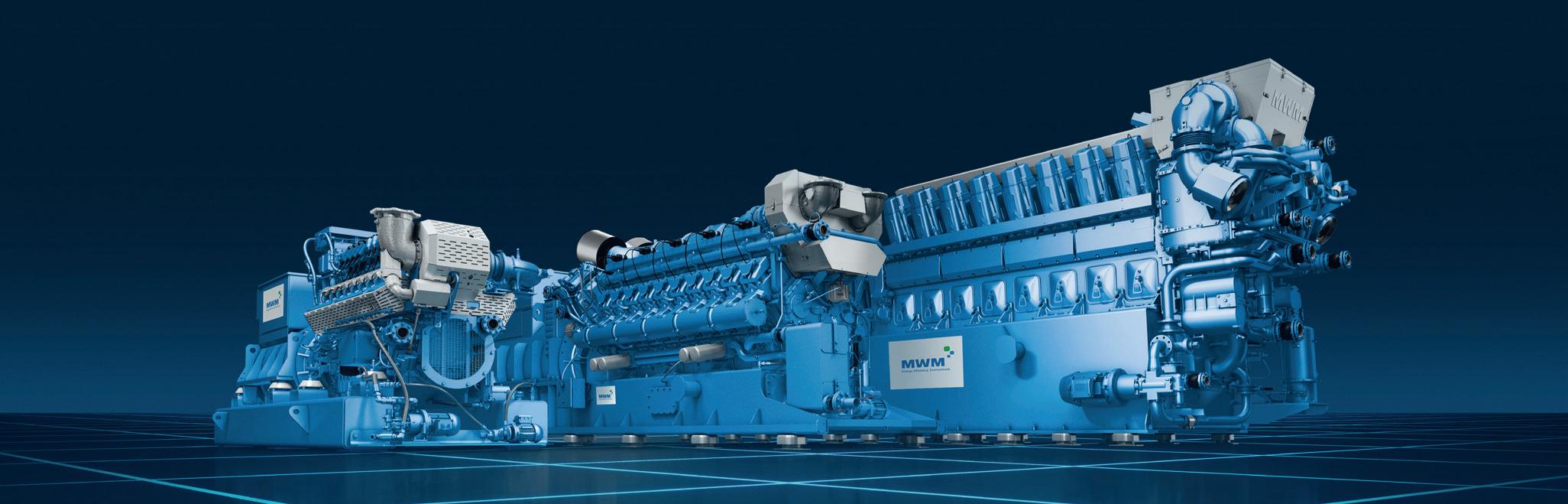

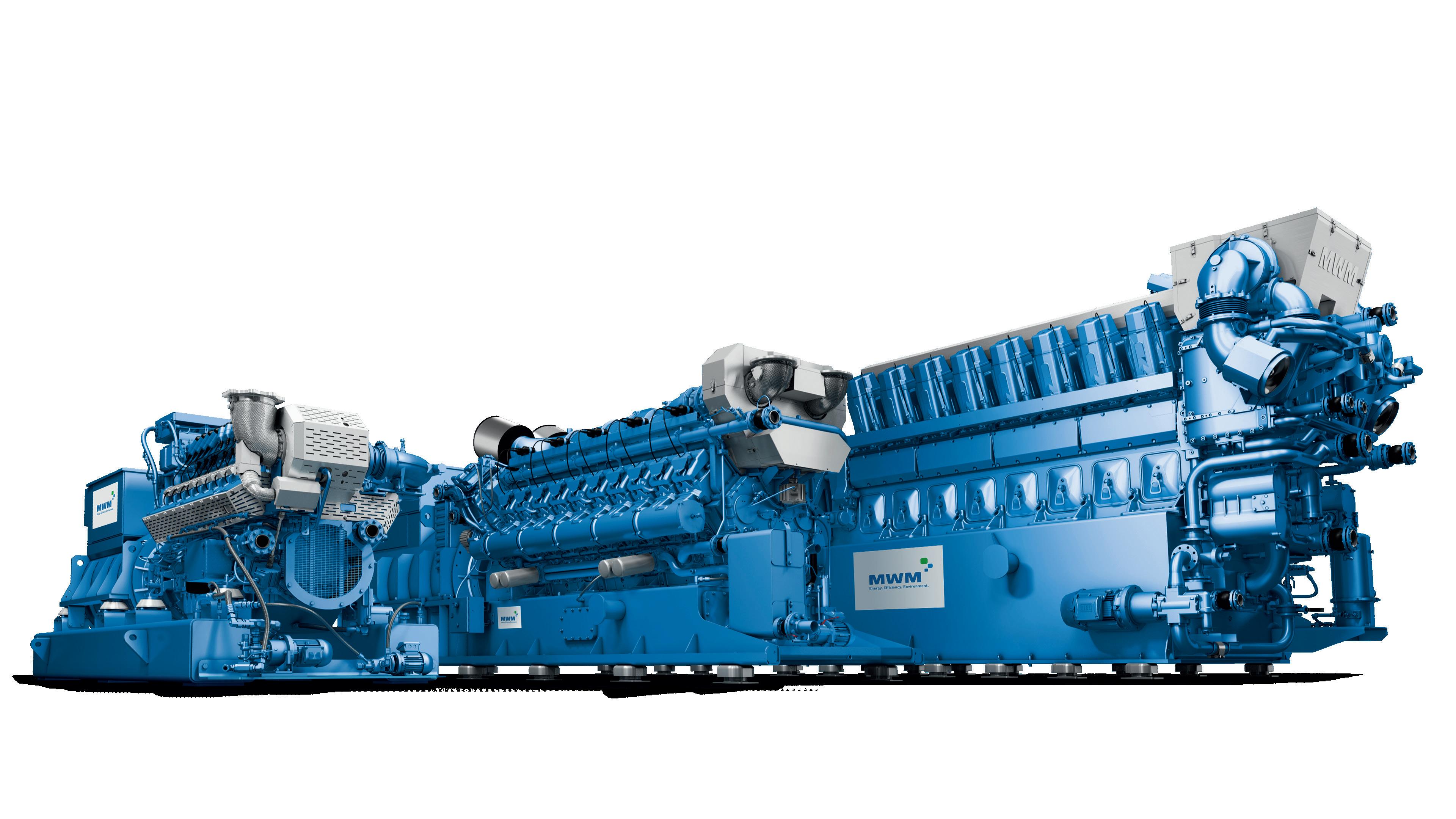

The all-round talent.

www.mwm.net/gas-engine-TCG-3020

UKGSA IS GROWING

More is always better - since its official launch in the UK in December 2023 UK Gen-Set & CHP Association has registered 50+ members [Page 2]: 24 Gen-Set members, 4 Founder Member companies, 14 Component Supplers & 8 Affiliates.

Finning Energy & Transportation has completed the installation of the exhausts to the gensets being used in a 20MW gas peaking project at Miners Road in thre city of Wrexham. The city represent the key administrative centre of Wrexham County Borough in Wales. It is located between the Welsh mountains and the lower Dee Valley, near the border with Cheshire in England.

Thw Wrexham site has been developed by Terra Firma Energy Limited. Assisted by Steve Foster Cranes. Finning oversaw the installation of the final six exhaust stacks, concluding the assembly work on the gensets.

The gas project went live in early February, this followed by the cold commissioning phase for the generators.

Additionally, a 10 MW co-located solar facility will be added to the site.

The Miners Road site, along with Terra Firma Energy’s portfolio of peaking assets, plays a vital role in the National Grid Electricity System Operator’s strategy for scalable power generation.

Recent threats of rolling blackouts and planned power cuts highlight the importance

CARRINGTON: It’s been a year since since Edina delivered a 10MW battery energy storage system (BESS) project in South Yorkshire. The EPC system integrated solution now supports grid infrastructure.

20MW GAS PEAKING PROJECT IN WREXHAM MAKES A KEY CONTRIBUTION TO GRID

of secure electricity supplies in the coming years.

Partnering with Finning CAT for the supply of generating sets ensures that Terra Firma Energy complies with the local planning authority and environmental permits’ noise and emission limits while maximising profit margins.

With the operating permit secured, the 23 MW power plant can now operate

for 8760 hours annually, significantly increasing profitability.

The project delivery team is overseeing the installation of all major generation items while works are carried out by both SPEN (Electric) and WWU (Gas).Terra Firma Energy’s Miners Road development is a significant milestone in meeting the UK’s electricity demands and ensuring a secure and reliable power supply.

PAN-UK DISTRIBUTION RELIES ON GENSETS

Two 830kVA generators have been installed at the new ASOS Distribution Centre based in Lichfield, Staffordshire near Birmingham

Maximum Availability and Performance of MWM CHP and gas power plants: MWM gas engines and generator sets, including our original spare parts, are designed for top performance and efficiency. Governed by the same regulations as production parts, our spare parts ensure hassle-free operation, adhering to high-quality and availability standards.

1

UK POWER NEWS MARCH-APRIL 2024

CES20001_Anzeigen_MWM_TCG3020_235x55mm_EN_RZ_2_0_sm.indd 1 20.03.24 11:01 ORIGINAL MWM SPARE PARTS. 100% QUALITY. 100% MWM.

www.mwm.net/spareparts CES20001-Anzeigen_MWM_Ersatzteile_95x145mm_EN_1_0_RZ_sm.indd 1 20.03.24 11:01

Publisher/Sales Director: Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor: Aidan Turnbull aidan@wipmagazines.com

Accounts Manager: Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu

Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent

Mario Dobresko power@wipmagazines.com

Contributors

MWM, mtu, RollsRoyce, Teksan, iPowerE, ACE, Cummins, Mecc Alte, Clarke Energy, INNIO, WBPS, UKGSA, MEGSA, IPowerE, KOHLER, CENTIEL, Forsa Energy, Green Frog Utilities, Eminox, Agriemach, UKGSA, Shention Group, UK Power Networks, Yellow Power, FirePro, Dumarey Flybrid, GenCat, Reheat, SSE, Clyde Hydrogen Systems, Conrad Energy, enfinium, HDI Hydundai Infracore, Voith, Antora Energy, Schneider Electric, Genpower, ADE, ACE,

UK POWER NEWS

Published by:

Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0)1403 888019

Fax: +44 (0)1403 220751

powermediagroup.co.uk © Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to UK Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

CHALLENGING POWEREX GOLF DAY COMES BEFORE POWEREX LIVE MIDLANDS

PowerEx Live Midlands 2024, will be held on Thursday, June 27th, 2024. It aims to probe and discuss all the trends, opportunities and challenges for the GENSET, CHP & ENERGY industries.

At the Conference - PowerEx Live Midlands 2024 - the exhibit space is within the same room - and in a different room the (DCA) datacentre alliance will be holding seminars and presentations. PowerEx Live will be hosting some of the foremost energy speakers in the country with the most recent and cuttingedge content within the energy industry..

This regional UK event - with an associated Golf Tournament held the day before the event (June 26th) - offers all key sector players in the North of England an opportunity to assess new trends, connect and develop all under 1 roof over the course of 1 day. The official PowerEx Live 2024 Golf Tournament is held at the Belfry Hotel & Resort at Royal Sutton Coldfield, West Midlands, UK, on Wednesday 26 June, 2024, is the date before the event.

The Belfry Spa, the site of the PowerEx Live 2024 Conference also features three courses, including BRABAZON golf course. These are recognised as world-class, having previously hosted major golfing championship events.

Sponsorship opportunities are available at £135 per hole. There are Prizes – Nearest the pins on every Par 3 and 2 Longest Drive holes.

This is also a great networking event and an opportunity to meet people from the Power & Energy Industries.

Final deadline for booking: April 30, 2024.

Please email enquiries: richard@wipmagazines.com or power@wipmagazines.com

VIRGIN MEDIA CENTRE IN KNOWSLEY REPLACES DRUPS SYSTEM WITH THREE STANDBY GENERATORS

The Virgin Media Technology Service Centre, a campus facility in Knowsley, UK, dealing with data centres and telecoms, was subject to technical upgrading of its supportive infrastructure to better enhance the power resilience to the site. This involved the supply and installation of two 2000kVA prime rated generators in N+1 configuration plus three bespoke fuel tanks.

The existing Diesel Rotary Uninterruptible Power Supplies (DRUPS) technology installed previously became extremely expensive to maintain, leading to the decision to upgrade the equipment.

Shenton Group was entrusted with this project due to an ongoing relationship with previous power installations for Virgin Media.

The project consisted of removing the DRUPS units, aligning these works with the installation of resilient UPS arrays to support the technical loads, replacing the DRUPS with three 2000kVA standby generators (1800kVa prime), and each generator having its own bespoke fuel tank.

All generators needed to be synchronised with three different incoming mains supplies in separate Low Voltage (LV) switch rooms; the site loads being shared and transferable between these sets for extra resilience, the resilience afforded via downstream change over devices.

Shenton Group opted for Comap control system as this would allow the generators to run in island mode and have forward and back synchronisation capability. The control system also required several breakers needing to be controlled in each LV room along with each generator.

Service continuity and supporting Virgin Media’s customer service expectations were the primary focus of the installation side. Due to the nature of the site and complex specifications, throughout the project, Shenton Group identified and upgraded other areas of infrastructure, aligning them into the resilience design for the site.

Shenton Group reported that it adjusted its works to meet the additional challenges encountered and were able to ‘resource and meet the needs of the developing project’.

To ensure power integrity and resilience was maintained throughout the project, Shenton Group supplied 5MW of rental generators, configured in an N+1 arrangement to provide resilience for the site.

Shenton Group also removed an underground 78,000-litre fuel tank. Whilst these works were underway, an opportunity arose to replace and upgrade all existing Schneider Air Circuit Breakers (ACB) within each LV room, a number of auto transfer switches, and a new LV switchboard in one of the electrical rooms.

Extensive building works were required throughout the project, including vast trenches for cabling roots and new concrete plinths to support the three new standby generators .

Don’t miss PowerEx Live held on 12th December, 2024, London

PowerEx Live 2024 - THURSDAY 12th DECEMBER, Location: LONDON, UK

PowerEx Live 2024 at London’s Park Plaza Hotel, will be held on Thursday 12th December, 2024.

PowerEx Live 2024 aims to offer the perfect networking opportunities for international professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With conference speakers at GEN-SET, CHP & ENERGY LIVE the top of their respective fields you can be sure to glean some valuable insights into the industry. The conferences are held alongside premier display space in a world class venue. This event has become a priority for all those in the power and energy markets. The conferences will run parallel with prime exhibitor space available in adjoining rooms. Do not miss this opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets.

The Power Hub Learning Zone

PowerEx Live 2024 will again feature a special Power Hub Learning Zone. The training experience will cover four subjects presented by different companies & speakers . The object is to teach, inspire and educate students, young people and fellow industry professionals about the importance of equipment familiarisation and other key aspects of the training experience within industry. This highlight of the UK’s Power & Energy calendar for 2024 is being held at . London’s iconic South Bank hotel, the Park Plaza, Westminster Bridge, London.

2 MARCH-APRIL 2024 UK POWER NEWS NEWS NEWS

****************

UK POWER NETWORKS MAKES A £15M TOWERING INVESTMENT

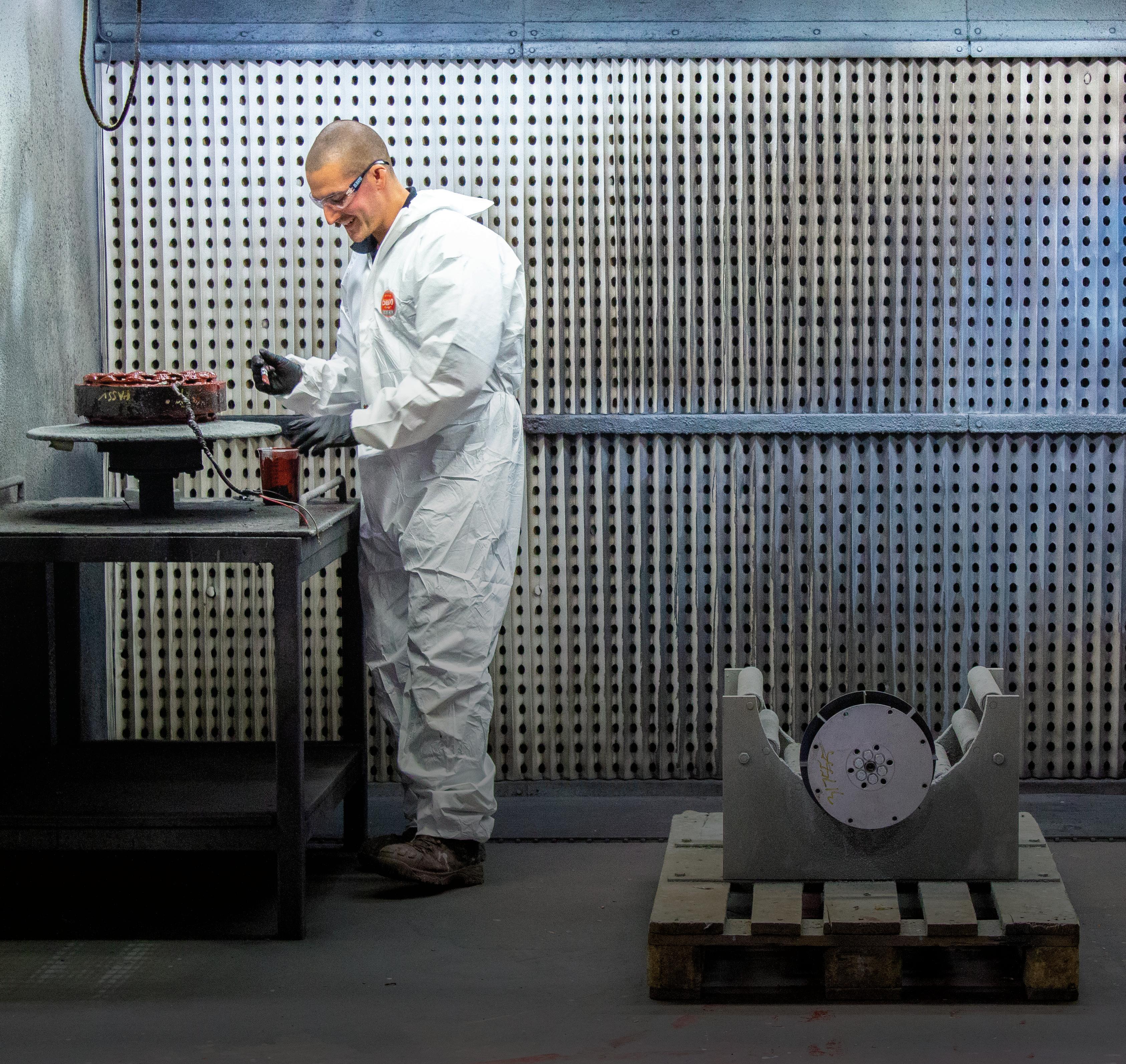

UK Power Networks is investing more than £15 million this year in upgrading and maintaining electricity towers across the East and South East of England.

The steel towers deliver electricity from the national grid to the distributor’s many substations which provide power for local communities. The voltage is at 132,000-volts when it arrives with UK Power Networks and is then reduced to 33,000-volts before it leaves and supplies electricity to around six million homes and businesses.

UK Power Networks, the largest electricity distributor in the country, looks after 46,000km of overhead lines and has 120,000 substations keeping the electricity flowing to 8.5 million homes and businesses. The multi million-pound investment will also see nearly 10,000 metres of overhead power lines replaced between the towers, to maintain reliability and future proof the network.

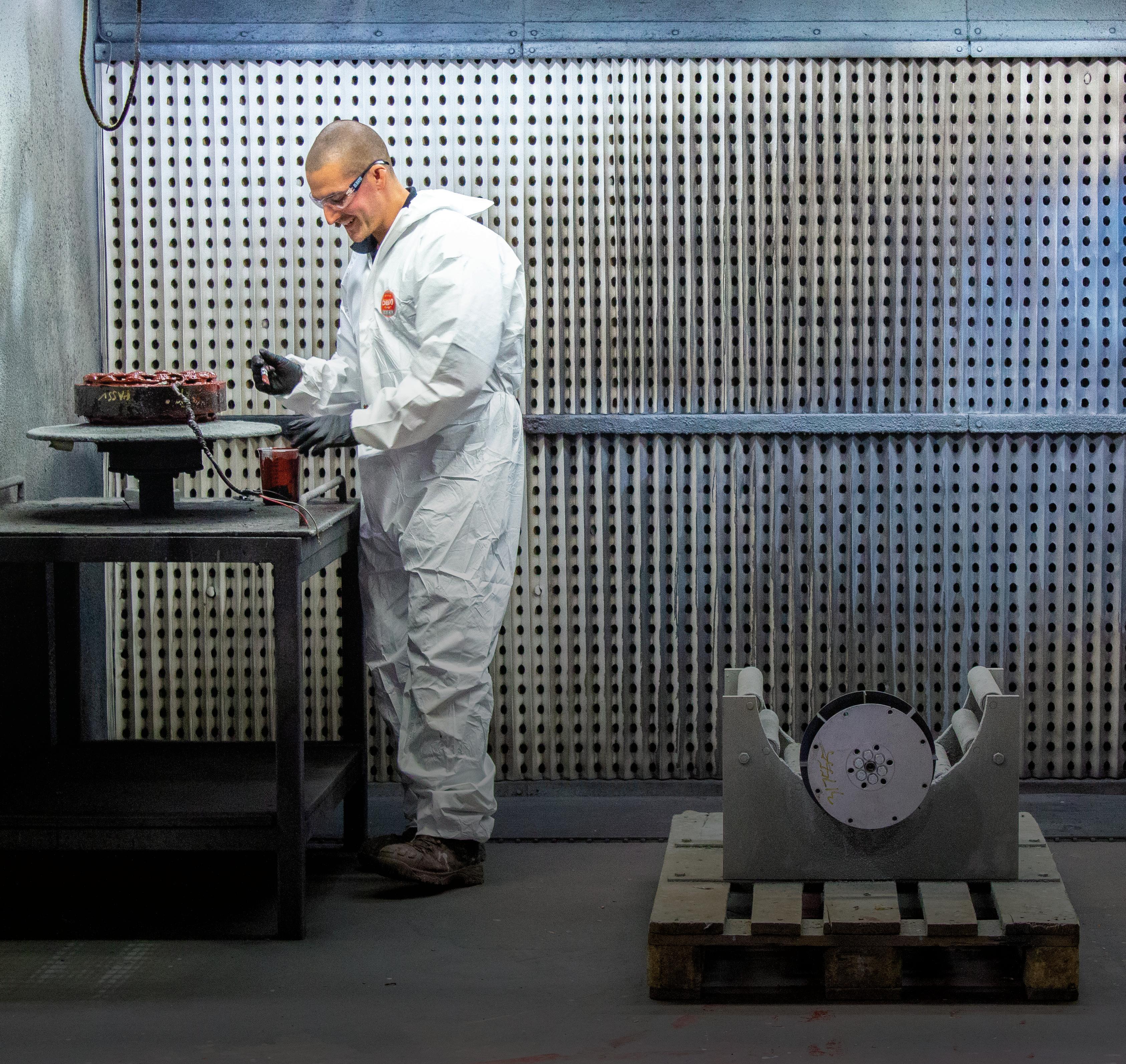

Part of the work will include repainting nearly 200 towers across Suffolk, Norfolk, Kent and East Sussex with a special anti-corrosion paint to protect them in all weathers.

Work has already begun alongside contractors Keltbray to ensure the towers are delivering a safe and reliable electricity supply to homes and businesses. Engineers are specially trained to climb the 30-metre high towers safely and members of the public are reminded to stay well clear of towers and substations as they carry live electricity in the overhead cables.

Colin Barden, UK Power Networks head of quality and supply said: “This work is a major part of an annual programme to ensure that our overhead lines continue to meet the requirements of our customers, as the modern-day usage of electricity increases.”

The work will future-proof local power supplies, as well as enabling more low carbon electricity generation to feed into the grid. As more people connect renewable energy, heat pumps and electric vehicles to local electricity networks, UK Power Networks plays a critical role in helping to enable the UK’s transition to a Net Zero economy.

UK Power Networks owns and runs the cables and substations which deliver electricity from the national grid to 8.5 million homes and businesses across London, the South East and East of England, serving approximately 20 million people.

As the country’s biggest electricity distributor, it has invested more than £6.4 billion in its electricity networks since 2011, focusing on safety, network reliability, sustainability and affordability by caring for vulnerable customers and keeping costs low.

It was named Utility of the Year in 2023, 2016, 2015 and 2012. It is also a founder member of the Levelling up Coalition, second on the UK Inclusive Companies list as well as one of only 5% of companies worldwide to achieve Platinum Investors in People status.

8.67MW LANDFILL GAS SITE UTILISES WASTE GAS POWER POTENTIAL WITH EIGHT G3516LE GENERATORS

A landfill site in the UK needed to replace its Ruston RK270GS generators which had been proving difficult to run and lacking in available spare parts.

The customer required the careful and multi phased re-engineering of a landfill gas power generation facility. This also had to be carried out whilst incurring the absolute minimum of downtime and interruptions to production.

Eight suitable G3516LE generators were selected from the client’s fleet of units. Located as far afield as Aberdeen and Norfolk, they were decommissioned and collected with their associated control systems and LV synchronising breakers.

They were then transported to YELLOW POWER’s Great Haywood workshops, where they were mounted in pairs onto specially designed steel bases that would not only accommodate the generator and control panels, but also support the overhead stainless-steel silencers once installed onsite.

Engine cooling systems were also engineered before pre-delivery to site, with both high and low temperature circuits configured to utilise plate heat exchangers which would then be integrated into the existing services and employ the Ruston radiators already on site.

Site preparation involved the phased removal of the 65-ton Rustons, along with their associated pipework and cabling back to clean

interface points. Civils were then modified to suit the new cabling requirements.

Conversion of the old 11kV breakers was also carried out, to allow them to be used as feeder breakers rather than synchronisation, this is now carried out at LV along with G59/3 mains protection at each generator.

Once preparations were complete, the pairs of generators were delivered, positioned and connected to each service in turn, including the utilisation of the old exhaust silencers to house individual flues for each engine.

Due to the difference in gas pressure required by the Ruston and G3516LE units, YELLOW POWER LTD was also commissioned to relocate and install a Haase gas plant from another site and install alongside the existing extraction facility. This was then dismantled once changeover was complete and commissioning finished to the customer’s satisfaction.

OVERHAUL & NEW FIRE DETECTION SYSTEM FOR NHS HOSPITAL GENERATOR

Hadley Wood Hospital is a dynamic new private healthcare facility located in High Barnet, North London.

The backup diesel generator set at the hospital required a complete overhaul, which included a new enclosure and fire suppression system. FirePro was the installer/ provider for Titan Fire & Security Ltd on this project.

Firepro’s role was to design, supply and install a new fire detection and FirePro fire suppression system, within a limited space enclosure. Everything about the project was limited - limited time scale, minimal space and limited budget - however there was quality and professionalism in abundance, says the company

“The client was impressed that we got the job done in under three days from start-to- finish,” explains Dean

Clark, Service Manager, Titan Fire & Security.

FirePro’s automatic fire suppression systems employ the patented FirePro Compound (FPC) technology that is the result of intensive and extensive R&D. FirePro systems have undergone tests and are certified according to the most stringent international standards and requirements. The modular, pre-engineered FirePro units efficiently and effectively protect conventional as well as specially-designed projects.

UK POWER NEWS MARCH-APRIL 2024 3 NEWS NEWS

The Atlas Copco portable Battery Energy Storage Systems, we call ZenergiZe offer a multitude of benefits, including low carbon footprint, reduced maintenance and servicing and improved sustainability. Whether you’re looking to enhance grid stability, manage peak loads,reduce operational costs or integrate renewable energy sources into your operations, we have the solutions to support your goals.

Revolutionise Your Energy World with ZenergiZe: “Store, Save, Sustain” ptuk.marketing@atlascopco.com 01442

350 www.atlascopco.com/en-uk/construction-equipment

222

PEAK POWER 200 FLYWHEEL SYSTEM PROVES ITS EFFECTIVENESS IN 2024 TEST

PUNCH Flybrid was recently rebranded to Dumarey Flybrid. A spokesman commented:

“Same group, same people, same product but a new brand that encapsulates our desire to continue our growth, to innovate further and to service our customers, with the same passion to work towards our vision of a future where sustainable mobility will be accessible to all.

“Dynamic duty cycles waste energy, and wasting energy is no longer acceptable. Our customers operate equipment which runs on dynamic duty cycles, where motors are constantly starting and stopping. Each time the motors start and stop, energy is wasted. Dumarey Flybrid helps our customers save energy, reduce power supply requirements and costs, and reduce their CO2 footprint. Our products help capture, optimise and reuse energy across a wide range of applications.”

Large industrial chillers have myriad uses across multiple industries. These systems are often deployed in remote or temporary locations where mains power is not available, requiring the use of temporary diesel power. In this case study, Carrier partnered with power provider WBPS and energy storage and management specialists Dumarey Flybrid to demonstrate significant cuts to power rental costs and CO2 emissions using the Peak Power 200 flywheel system.

The Model 522 CAR is a large industrial chiller from Carrier Rental Systems. It has a nominal capacity of 579 kW, and is typically powered by a 320 kVA diesel generator where mains power is not available. Given the typical applications, it’s normal for the generator to be run 24 hours per day. The model 522 has 8 hermetic scroll compressors controlled by a microprocessor. The startup of these compressors results in a brief spike in current, and the generator needs to be sized to cope with these spikes.

The Peak Power 200 flywheel system stores energy from the diesel generator during periods of low load, and can rapidly supply both real and reactive power when needed. This allows operators to reduce the size of the diesel generator required. The customer then makes three savings: Firstly, saving on the rental cost of a smaller generator. Secondly, the lower fuel costs associated with a smaller generator and finally they save CO2 emissions due to lower fuel usage. The combination of these factors makes the Peak Power 200 environmentally friendly and economically attractive.

For this application, a 330 kVA diesel generator (SDMO R330C5) and a Peak Power 200 flywheel system were provided by WB Power Services. The test setup involved heating a large tank of water to 60°C using an industrial boiler. When the tank reached the set temperature, the chiller was turned on with a set point of 7°C. The test was ended when the water reached 15°C. Data was recorded from both the flywheel and the generator for later analysis.

A spokesman said: “ The results of the application were very promising. Analysis of the data showed a maximum continuous current of 260 A. The flywheel sucessfully reacted to each motor start with a rapid injection of power to support the generator and minimise frequency and voltage drops. Although compressor starts were never simultaneous, the flywheel would be able to manage 5 of the compressors starting at the same time.

“The result is that on this application, the generator can be downsized from a 320 kVA to a 200 kVA. Savings for this are considerable, and are multiplied by the long running hours. We estimate that this downsizing would save around 650 litres of fuel per week. The customer would also see savings on generator rental, AdBlue usage and fuel deliveries. These more than offset the rental cost of the flywheel. On a typical 20 week rental, a user should see a net financial benefit, including flywheel rental costs, of approximately £13,400 as well as reducing their CO2 emissions by 34.4 tonnes.”

The spokesman concluded: “Dumarey Flybrid would like to thank the technical and commercial teams from Carrier Rental Systems UK and WP Power Services. Both provided equipment, logistics, and expertise to make this application a success.”

REGENERATIVE DPF WITH CATALYST FITTED TO A GENERATING SET

Based in St. Albans, GenCat has been trading in the exhaust after treatment industry since 2003, with a focus on heavy duty applications for NRMM, generating sets and materials handling equipment.

Its products include a range of Diesel Particulate Filters (DPFs), Catalytic Converters, and key accessories include exhaust rain caps.

The company says its mission is to ‘find the best solution to the application by offering the right equipment to do the job. From plant working in enclosed spaces, tunnelling, offshore applications to standby power exhaust filtration’.

In one recent contract GenCat engineers fitted a Bersy BPF R620 DPF with Catalytic Converter into the existing canopy of a Speedy generating set. The system replaced the original silencer unit and was expertly fitted by Western Tydens of Ivybridge, Devon before heading to the London NRMM LEZ zone. NRMM, particularly from the construction sector, is a

significant contributor to London’s air pollution. The NRMM Low Emission Zone uses the Mayor and London Borough’s planning powers to control emissions from NRMM used on construction sites. Like the Ultra Low Emission Zone, the NRMM Low Emission Zone requires that all engines with a power rating between 37 kW and 560 kW meet an emission standard based on the engine emission “stage”.

The BPF R620 system is constructed using recrystallized silicon carbide (SiC) filters with oxidation catalysts positioned in front. These filters serve a dual purpose:

- Particulate Filtration: They effectively retain more than 99% of solid particles emitted by diesel engines, thereby eliminating the typical black smoke associated with these engines.

- Emission Reduction: The oxidation catalysts help reduce unburned hydrocarbon (HC) and carbon monoxide (CO) emissions. Interestingly, this combination allows for an increase in nitrogen dioxide.

HEAT NETWORK PROPOSED FOR ALNWICK AREA

Northumberland Estates, in collaboration with Reheat, an Alnwick-based consultancy, and SSE Energy Solutions, is exploring the possibility of establishing a clean, eco-friendly energy network to supply local businesses and public spaces in Alnwick.

The study will explore low carbon heating for a large portion of Alnwick, which includes commercial consumers, public buildings, and new homes. The first area being considered includes Linnet Court, Lionheart Enterprise Park, Willowburn Retail Park and Willowburn Trading Estate on the southern edge of Alnwick. This area is typically made up of commercial, industrial and publicowned properties. The second area includes Alnwick Castle, The Alnwick Garden and Alnwick Infirmary.

Heat networks form an important part of the government’s plan to reduce carbon and Northumberland County Council’s energy masterplan. A heat network works by establishing a common heat source and ensuring that heat is distributed via insulated pipework to buildings on the network to provide their heat and hot water, instead of each building having its own individual heat source.

UK POWER NEWS MARCH-APRIL 2024 5 NEWS NEWS

BIOMASS IN ACTION: THE SNETTERTON RENEWABLE ENERGY CENTRE, NORFOLK, PROVIDES 44.2MW

BWSC is a leading O&M and technical service provider for power plants whose engineering expertise spans hydrogen plants, boiler-based waste and biomass plants, hybrid and engine plants.

To date, the company has designed more than 180 power plants and operated and serviced more than 3800 MW of base load generation equipment worldwide, and is keen about the role it will play in the future of the energy sector. BWSC reports that its Snetterton Biomass plant has been performing with a YTD availability above 96% and to secure similar high performance during 2024 a broad scope of works was included in the company’s outage - a key maintenance period - in late 2023, including more than 20,000 hours of work.

This outage involved a broad work scope, including: turbine gearbox replacement; extensive preventative tube replacement within the boiler; Wet ash conveyor overhaul; and a flues gas treatment plant overhaul, including catalyst super structure upgrades

Snetterton Renewable Energy Centre, Norfolk, has an an electrical capacity of 44.2MW, fuelled annually by 250,000 tonnes of baled straw supplied by local farmers, as well as woodchips. The plant is owned by a joint venture of Burmeister & Wain Scandinavian Contractor (BWSC) and a Danish infrastructure fund managed by Copenhagen Infrastructure Partners who together have put around £160M into the project.

The biomass plant’s operation is based on energy technology developed in Denmark.

The main part of the power plant is a boiler from Burmeister & Wain Energy (BWE), which is said to be the world’s largest water-cooled vibrating grate straw-fired boiler. The boiler house is 33m-high with the four elevations up to 35m-long. The building is a large braced frame with cross bracing inserted between the main columns, which are spaced at 5.7m intervals.

BIOMASS PROJECTS SUPPORTED WITH £26 MILLION FUNDING

The UK government has been actively supporting innovative biomass projects to enhance sustainable energy production, say new reports from Westminster Here are some key initiatives:

*£26 Million Funding for Biomass Boost:: The UK government has allocated £26 million to promote the production of sustainable biomass. This funding aims to power homes and businesses using materials like grasses, hemp, and seaweed. Biomass, derived from sustainably grown plant material, can be used as fuel for low-carbon energy. It plays a crucial role in achieving the UK’s commitment to net-zero emissions by 2050.

The selected projects will focus on enhancing biomass productivity through activities such as breeding, planting, cultivating, and harvesting organic matter. This includes water-based materials like algae and sustainable forestry operations1.

* Phase 2 of Biomass Feedstocks Innovation Programme: Under the government’s Biomass Feedstocks Innovation Programme, 25 projects across the UK have already received a share of £4 million in Phase 1. These projects explored ways to boost biomass production.

In Phase 2, these projects will evolve from the design stage into full demonstration projects. They will showcase innovative methods for growing biomass materials, which contribute to low-carbon energy.

BIOFUEL GENERATORS NOW SUPPORT THE UK BANKING SECTOR

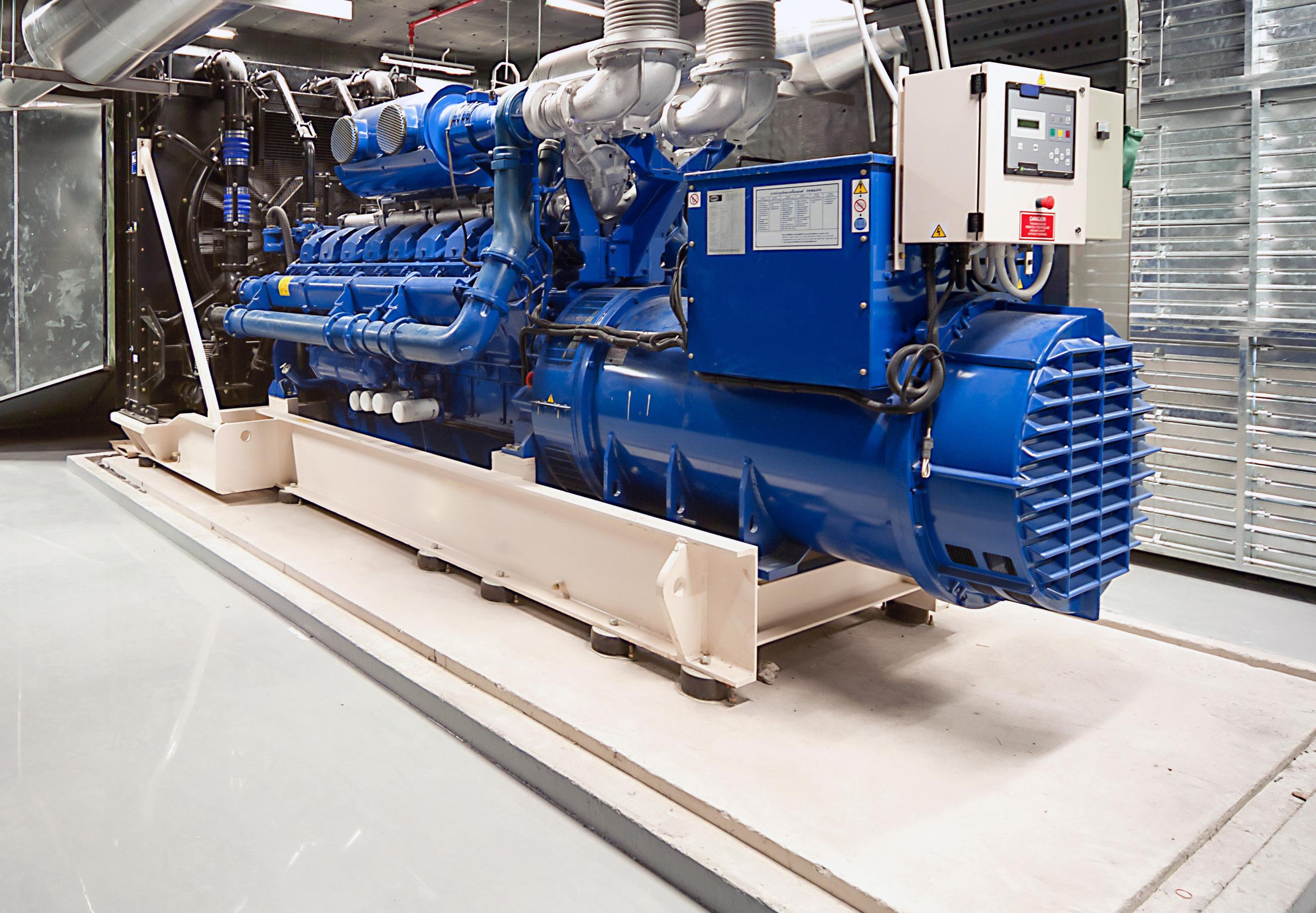

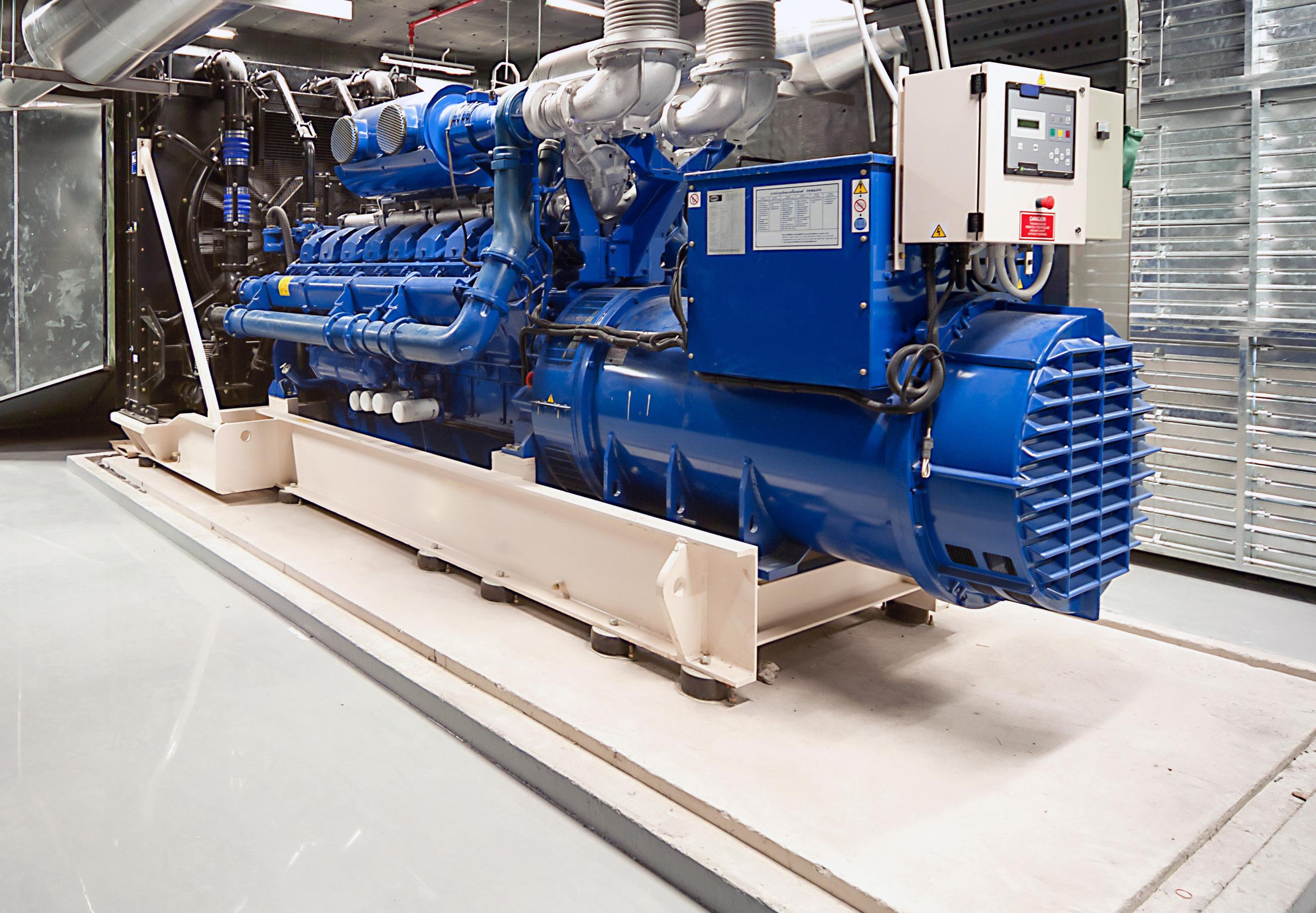

Rolls-Royce has supplied 4 x MTU 20V Series 4000 gensets (each with a capacity of 3290kVA) to the UK’s banking sector.

These gensets are already deployed to provide emergency backup power across many industry sectors around the world.

Partner company AVK|SEG (UK) Ltd, a leading provider of critical power solutions, recently installed these four mtu 20V Series 4000 gensets (pictured above) to support a facility in the UK banking sector.

Powered by HVO, a drop-in fossilfree replacement for diesel fuel, the systems not only provide robust and efficient emergency power, but also support the customer’s carbon neutral goals.

Before being despatched to site, the systems underwent a rigorous FAT program, which included a cold start test, functional tests, a heat run over several hours and load step testing as per ISO 8528-5 class G3 to ensure peak performance.

The AVK|SEG team will provide service and technical support to ensure optimal operation and ongoing customer satisfaction.

Hydrotreated vegetable oil, (HVO) is the next-generation low-carbon diesel. It is derived from used cooking oils, residue animal fats

from food processing, tall oil, and non-food grade crops. Biofuel, more generally, is a renewable source of energy that comes from plants, animals, or algae.

With the world shifting towards more sustainable practices to reduce climate change and protect the environment, HVO fuels have become a viable choice to help reduce diesel vehicle and plant emissions.

It is considered a paraffinic fuel, a new classification of cleaner transport fuels, and has almost zero sulphur and aromatics content. Made from sustainably and responsobly sourced renewable raw materials its use can make a real contribution to climate protection, research indicates.

It has excellent storage properties, and systems powered by it see lower particulate and nitrogen oxide levels and an emissions reduction of up to 90%.

Experts say waste-derived HVO is by far the most sustainable type of HVO and results in the lowest amount of greenhouse gas emissions.

It is already being used in many of mtu engines without any compromise to power delivery or service life, reports the company.

SANDWICH, KENT, THE BASE FOR A KEY BIOMASS PLANT

Now the Kent Renewable Energy Power Plant is fully operational at Sandwich in Kent it generates around 27MW of green electricity.

A spokesman comments: “Our plant burns locally sourced wood fuel to generate heat and power for Discovery Park and export electricity to the national grid. We generate enough electricity to supply the equivalent of 50,000 homes and save over 100,000 tons of CO2 every year.

“It’s difficult to visualise how much that is but would look the same as 165,000 really big hot air balloons

and the saving is equal to over 1 million plane flights to Paris. Around 15 – 20% of the clean, green energy we generate is supplied directly to the tenants of Discovery Park, who also benefit from the heat generated by the steam from our plant..”

6 MARCH-APRIL 2024 UK POWER NEWS NEWS NEWS

MWM 25H2-Kit

Operation with hydrogen.

New variants of the TCG 3016, TCG 3020 and TCG 2032 series enable natural gas operation with hydrogen admixture of up to 25 vol.%. Retrofit solutions for existing plants are also available.

www.mwm.net/25H2-Kits

GEN-SETS & DATA CENTRES CHP DISTRIBUTED POWER

Romain Mocaer 11:00-11:30

PowerGen Statistics

“European generator & Data Center market outlook”

Ian Bitterlin 11:30-12:00

“Forecasting Data Centre power growth” Consultant

Dr Michaela Kendall 12:00-12:30

Adelan

Latest developments on Hydrogen

Steve Peal 12:30-13:00 YorPower

“Running Your Business in Todays Modern World”

11:00-11:30 Dave Andrews

CHP, District Heating, Grid plus Latest Technologies on alternative fuels Claverton Energy

11:30-12:00 Eric Lewis Consultant

“How to combine existing and new systems in an optimised future GB AC Grid”

12:00-12:30 Dr David Toke

How Britain can achieve 100% renewables energy supply 100% Renewable UK

12:30-13:00 Paul Woods

How district heat systems integrate w/ a renewable grid using low-cost heat storage capability Consultant

COMPLIMENTARY LUNCH 13:00-14:00

Steve Hone 14:00-14:30

Data Centre Alliance CEO

Your Introduction to the booming Data Centre Sector

Mark Acton 14:30-15:00

Head of Technical Due Diligence (Future-Tech)

“Data Centre Sustainability, Energy Efficiency, Metrics and Reporting”

Venessa Moffat 15:00-15:30

Channel Partner Manager, EMEA

EkkoSense AI

Does AI + data centre + power consumption = dead planet?

Ian Bitterlin 15:30-16:00

Using Data Centres to support the Power Utility Consultant

14:00-14:30 Josh Collins

SAV Systems

Discussing a range of renewable energy solutions

14:30-15:00 Prof. Pearson

Large water source heat pumps and rivers Star Refrigeration Limited

15:00-15:30 Dave Andrews

CHP, District Heating, Grid plus Latest Technologies and where the market is heading along with alternative fuels Claverton Energy

WORLD’S LARGEST TIDAL POWER GENERATION SCHEME IS PLANNED FOR THE RIVER MERSEY, LIVERPOOL

Aplan to build a barrier across the River Mersey is starting to take shape. Liverpool City Region’s mayor, Steve Rotheram said: “There are still huge technical and financial challenges to overcome but Mersey Tidal Power has the potential to provide enough clean, green, predictable energy to power up to one million homes for over a century.”

The scheme involves building a structure to house 28 turbines driven by the flow of water in and out of the Mersey and generating electricity using the energy available from the difference in height of the tides, which can be up to 10 metres (33 ft) in Liverpool.” Total capacity is expected to be 700 MW, which would make this the largest tidal range scheme in the world.

The design will include sluice gates to allow water through when needed, which could help mitigate increased risks of flooding caused by climate change, as well as marine navigation locks to help keep the busy river traffic flowing.

At a meeting held in March 2024, the Liverpool City Region Combined Authority voted to initiate the formal planning process by drafting a scoping opinion, marking a crucial step towards realising the tidal power scheme. If realised, it could potentially generate clean energy for 120 years and create significant employment opportunities in both construction and operation phases.

Steve Rotheram explains: “We are under no illusions, we know there are still significant technical and financial challenges to overcome, but the plans we’ve agreed mark a huge step on our journey to bringing Mersey Tidal Power to life. Quite simply, the case for tidal has never been clearer – both for our economy and our planet.”

Over the past three years, the authority has conducted extensive technical groundwork to outline the scheme’s scope, which could be up and running within a decade, playing a huge role in the region’s push to be net zero carbon by 2040.

Councillor David Baines, Portfolio Holder for Net Zero and Air Quality, highlighted the significance of harnessing the River Mersey’s potential, emphasizing its role in diversifying the region’s clean energy mix and fostering economic resilience.

He comments: “Existing strengths in wind and solar power and emerging strengths in hydrogen mean that our city region is already leading the way in developing a cleaner and greener economy. Harnessing the power of the River Mersey to generate green and predictable energy for the next 100 years and more would be an incredible addition to our clean energy mix. We need to ensure we are extremely aware of our sensitive local ecology but just reaching this stage in the Mersey Tidal Power project has taken a huge amount of hard work allied with vision and would be a big step towards it becoming a reality.”

Prior to the scoping opinion being submitted the Combined Authority will now carry out a period of engagement, regionally and nationally, with stakeholders. Once the scoping opinion is received, the CA will hold formal consultations across communities and stakeholder groups.

The scoping opinion will be based on the creation of a barrage across the river. The report to the CA notes that a barrage option would be less expensive than a lagoon, requiring less material and lower levels of government support.

Submitting a scoping opinion is the first step towards preparing a Development Control Order (DCO) submission – a process which typically takes two to three years. The scoping opinion submission describes the project and asks the Planning Inspector to advise on the scope and breadth of surveys needed to complete the documents outlining the environmental impact of the scheme. The actual location of the barrage has yet to be determined- the Authority is currently looking into locations “closer to the mouth of the river that may align to regeneration aspects around Liverpool Waters and Wirral Waters,” said one source.

It is likely the multi-billion-pound project will be sent to the UK’s Planning Inspectorate later in 2024 for feedback on the kind of surveys needed to complete documentation relating to its environmental impact.

If the plan gets greenlighted the firstin-the-UK concept could generate as much as 2 TWh of electricity (opinions vary) annually for up to 1 million local homes - serving 30% of the region’s demand. Tidal range systems like this pull energy from the difference in water height between tides and the UK’s resources account for 5–15% of worldwide tidal range generation, say the experts.

DON’T MISS POWEREX LIVE MIDLANDS 2024 - IT WILL BE BE BIGGER & BETTER

PowerEx Live Midlands 2024, to be held on Thursday, June 27th, 2024, aims to probe and discuss all the trends, opportunities and challenges for the GENSET, CHP & ENERGY industries.

The organisers will be hosting some of the foremost energy speakers in the country with the most recent and cutting-edge content within the energy industry.

This regional event - with an associated golf tournament held the day before the event (June 26th)offers all key sector players in the North of England an opportunity to assess new trends, connect and develop all under 1 roof over the course of 1 day.

The conference is being held at a top-class venue offering optimal trade opportunities to meet both regional and global buyers, specifiers, OEMs, equipment distributors and contractors/ installers. The venue is at an awardwinning hotel and golf resort situated in the heart of the country at the Belfry Hotel and Resort in Royal Sutton Coldfield, West Midlands.The site offers 300+ luxurious bedrooms and suites.

Also available are several restaurants and bars, events and meetings spaces, a leisure club and The Belfry Spa. A key attraction is The Brabazon golf course.

This is recognised as world-class, having previously hosted The Ryder Cup more than any other venue in the world and home to the 2023 Betfred British Masters.

Be part of this unique and mustattend event held for all power professionals in the industry..

At the Conference - PowerEx Live Midlands 2024 - the exhibit space is within the same room and in a different room the (DCA) datacentre alliance will be holding seminars and

training on Data Centres. With limited space there are only a few tables available, therefore another 2 tables have been added to accommodate.These tabletop arrangements mean companies can take their products direct to customers with the additional opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets. The choice of stands at the Belfry Hotel is allocated on a ‘first-comefirst-served’ basis, so please contact us today and prepare for the highlight of the UK’s Power & Energy calendar in the Midlands for 2024.

Register for free at PowerLive Midlands 2024

In 2023 the Mere Golf & Spa Club, Knutsford, Cheshire, was the setting for the first Power Media International Group’s PowerEx Live regional conference & exhibition. This event was designed to give enhanced access for the power generation sector to companies with a primary focus in the region. This proved a major success as over 120+ delegates and exhibition personnel were registered. The 2023 event was described by one attendee as “business, education and excellent golfing all rolled into one.”.

Adam Thomas, CTO, also commented on the 2023 PowerEx Live event in Cheshire: “Thanks for running the event, it was a good place to network with other people in the generator industry.

For more details on the 2024 Powerex Live Midlands Conference, the Call For Papers and Exhibiting please visit: www.powerexlive.

UK POWER NEWS MARCH-APRIL 2024 9 NEWS NEWS

NEW WASTE TO ENERGY PLANT IN WEST YORKSHIRE WILL FEATURE CARBON-CAPTURE TECHNOLOGY

Enfinium, a leading UK energy from waste operator, has announced a significant step in its mission to decarbonise the UK’s unrecyclable waste by signing an agreement with global green technology company Hitachi Zosen Inova (HZI) to install the UK’s first carbon capture pilot plant at an energy from waste facility.

The technology supplied by HZI will be a scaled-down, containerised version of the CCS technology that could be applied to energy from waste facilities on a commercial scale. The unit will capture up to one tonne of CO2 per dayfrom enfinium’s operations at its Ferrybridge-1 site, in West Yorkshire. The trial will run for at least 12 months and will be operational from July 2024.

The pilot is the first of its kind mobilised in Europe, representing a significant milestone for HZI who intends to build on its world leading reputation in the energy from waste and renewable sectors by offering its clients new decarbonisation solutions.

The pilot will be used to demonstrate how carbon capture technology can be applied at energy from waste facilities to remove CO2 from the atmosphere. Through the pilot, enfinium will be able to compare different amine solvents and collect realistic data on performance, such as CO2 capture rate, energy consumption, and solvent degradation.

The pilot builds on enfinium’s broader ambitions to lead an investment of up to £800 million in Carbon Capture and Storage (CCS) at its Ferrybridge 1 & 2 facilities, which together would capture over 1.2 million tonnes of CO2 every year.1 With CCS installed, the UK’s largest energy from waste site would become one of the largest carbon removal projects in Europe.

Mike Maudsley, CEO of enfinium, told UKPN: “Installing carbon capture technology on energy from waste facilities is the only way the UK can decarbonise its unrecyclable waste. It also offers benefits including creating durable carbon removals, or negative emissions, at scale and generating reliable homegrown carbon negative power.

“This ground-breaking partnership with HZI will allow us to test multiple capture techniques that could in the future be deployed across our facilities at scale.”

Bruno-Frédéric Baudouin, CEO of HZI, added: “It gives us tremendous pride that with the support of the UK authorities and thanks to a strong collaboration with enfinium, we have the opportunity to help move the dial on the nation’s decarbonisation of its waste management infrastructure.

“The pilot will contribute significantly to our carbon capture knowledge base, which we are developing across several projects in Europe, and represents an important step not only towards to reducing CO2 emissions in our industry, but also towards making CO2 circular and driving down demand for fossil resources globally.”

“Minister for Investment and Regulatory Reform, Lord Dominic Johnson said: “The Government is making sure the UK continues to be an attractive choice for green investment, creating jobs and opportunities across the country as we transition to net zero.

“I’m delighted enfinium with HZI has chosen the UK for this pilot project – another win for our country and a huge step to enabling the decarbonisation of the UK’s unrecyclable waste.”

The announcement is the latest development in enfinium’s strategic partnership with HZI, who have provided engineering, procurement and construction (EPC) services to enfinium’s Ferrybridge 1 and 2 facilities. HZI is also acting as the EPC partner on enfinium’s £500m Skelton Grange facility in Leeds, which is due to be operational from 2025.

Enfinium is a leading UK energy from waste operator with four operational sites in the UK, in West Yorkshire, Kent and Flintshire, and two in construction.

Enfinium diverts 2.3 million tonnes of unrecyclable waste from climate-damaging landfill, putting it to good use by turning it into home grown energy, enough to power 500,000 UK homes. Enfinium’s ambition is to transform its facilities into local ‘decarbonisation hubs’ powered by the millions of tonnes of unrecyclable waste the UK will produce for decades to come.

Using existing energy from waste infrastructure, enfinium could contribute to heat networks, produce electrolytic hydrogen, or use carbon capture technology to provide durable, high quality carbon removals which will be critical for the UK to achieve net zero by 2050.

ORKNEY ISLAND COUNCIL BACKS NEW OFFSHORE WINDFARM PROJECT DEVELOPMENT

The Orkney Island Council is backing the West of Orkney Windfarm’s proposed multibillion pound offshore windfarm, located 30 km west of the Orkney mainland and 25 km north of the Sutherland coast, Scotland.

The offshore plans contain detailed information on how the windfarm will be constructed, including the proposed location of turbines and cable routes, and includes a comprehensive suite of environmental assessments based on survey data collected over two and a half years.

The final consent decision will be made by Scottish ministers following recommendations by the Marine Directorate Licensing Operations Team and taking into account comments made by statutory consultees, including Orkney Islands Council.

The project will incorporate up to 125 turbines on fixed foundations, providing an expected capacity of around 2 GW. The farm aims to deliver its first renewable power in 2029. It is being developed by a joint venture comprising Corio Generation, TotalEnergies and Renewable Infrastructure Development Group.

West of Orkney Windfarm development manager Jack Farnham explains: “The Scottish government has a stated ambition to deploy 8-11 GW of offshore wind in Scottish waters by 2030. As the first ScotWind project to enter the planning process, securing timely offshore consent from the Scottish government and onshore planning

permission from The Highland Council will be critical if Scotland is to meet this target, which will unlock significant inward investment and with it economic and social benefits to the far north”.

The developer has already supported a number of initiatives in the north of Scotland, including a £1 million research and development programme being led by EMEC in Orkney, a £900,000 education initiative led by UHI, and a £125,000 Fit 4 Renewables scheme led by ORE Catapult.

The West of Orkney Windfarm is involved with a £105 million investment initiative during the development phase of the project. This will fund the development of the supply chain which is planned to be enhanced to £140 million by match funding from third parties.

Orkney Islands Council is currently developing the Orkney Community Wind Farms project to generate significant income and harness Orkney’s natural resources.

The project consists of three developments – Quanterness, Hoy and Faray. Each wind farm sited in the area will contain six turbines which are 149.9 metres in height from base to blade tip. They are expected to generate nearly 90 megawatts per year. Additionally, the West of Orkney Wind Farm, developed by TotalEnergies, boasts an impressive installed capacity of 2 gigawatts, which can power the equivalent of over 2 million homes. These wind farms play a crucial role in advancing renewable energy and contributing to the UK’s Net Zero.

10 MARCH-APRIL 2024 UK POWER NEWS NEWS NEWS

HYDROGEN Enabling your transition to a green future

We're ready for H2. Get ready, too!

At INNIO* Group, we are continuously innovating flexible, scalable, and resilient energy solutions to help you generate and manage energy efficiently and sustainably.

Our Jenbacher* engine technology is an investment in the future. It can be converted to run on traditional gas-hydrogen mixtures and up to 100% hydrogen when it becomes more readily available. Installing our “Ready for H2”**-designed power plant now will enable you to convert it to 100% hydrogen operation later, delivering a sustainable energy solution that works for you today and accelerates a greener tomorrow!

Let us support your transition journey. jenbacher.com

* & indicates a trademark.

** In general, “Ready for H2” Jenbacher units can be converted to operate on up to 100% hydrogen in the future. Details on the cost and timeline for a future conversion may vary and need to be clarified individually.

Jenbacher is part of the INNIO Group

World Hydrogen Forum

May 21 - 22, 2024

Booth: B82

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME.

EVENTS DIARY

THE UKPN DIARY - EXHIBITIONS, SEMINARS & OTHER EVENTS

8 - 9 May 2024

Decarbonisation Technology Summit Europe 2024

Institution of Engineering & Technology, Stevenage

9 - 10 May 2024

International Conference on Renewable Energy and Conservation 2024 London, UK

14 - 16 May 2024

Africa Energies Summit 2024 Conference London

15 - 16 May 2024

All-Energy Exhibition and Conference 2024

Scottish Event Campus, Glasgow

15 - 16 May 2024

Battery Cells and Systems Expo 2024 NEC, Birmingham

21 - 22 May 2024

Utility Week Live 2024 NEC, Birmingham

21 - 22 May 2024

Renewable Energy Revenues Summit 2024 Conference

Hilton London Tower Bridge, London

21 - 22 May 2024

Utility Week Live 2024 NEC, Birmingham

4 - 5 June 2024

UK Solar Summit 2024 Conference Novotel London West Hotel, London

11 - 12 Jun 2024

Energy Exports Conference 2024 Conference P&J Live, Aberdeen

24 – 28 June

ASME Turbo Expo 2024

ExCel London

21 - 22 May 2024

25 – 27 June

Hillhead

Quarrying, Construction & Recycling Show Hillhead Quarry Buxton, Derbyshire SK17 9PR

25 - 27 Jun 2024

InstallerSHOW 2024 NEC, Birmingham

26 Jun 2024

PowerEx Live 2024

Golf Tournament

Belfry Hotel & Resort, Royal Sutton Coldfield

Final deadline for Golf

Tournament booking: April 30, 2024.

Please email enquiries to: richard@wipmagazines. com or power@wipmagazines.com

POWEREX LIVE - MIDLANDS

27 JUNE 2024

27 Jun 2024

PowerEx Live MIDLANDS Conferences & Networking Event

Belfry Hotel & Resort, Royal Sutton Coldfield

28 July 2024:

PowerAid Charity Football Day - UKGSA Event

Coalville Football Club

14 Aug 2024

SR Solar Conference 2024 Conference

COSLA Conference Centre, Edinburgh

22 Aug 2024

York Races – Ebor Festival

- UKGSA Hospitality Event

YORK RACES 22 AUG 2024

19 Sept 2024

Cricket at Trent Bridge UKGSA Hospitality Event

24 - 26 Sep 2024

Solar & Storage Live 2024 NEC, Birmingham

25 - 26 Sep 2024

World Energies Summit 2024 Strand Palace Hotel, London

23 – 24 Oct 2024

The Showman Show, Newbury Showground, Berkshire

23 - 24 Oct 2024

Renewable Energy Scotland Event 2024

Scottish Event Campus, Glasgow

24 Oct 2024

Smart Energy Conference & Exhibition 2024 ICC Belfast, Belfast

23 - 24 Oct 2024

Renewable Energy Scotland Event 2024 Scottish Event Campus, Glasgow

6 - 7 Nov 2024

NIBS Battery Conference Telford, Shropshire

6 - 7 NOV 2024 NIBS

12 - 13 Nov 2024

Future Energy Wales 2024

International Convention Centre Wales, Newport,

13 - 14 Nov 2024

Future of Utilities: Smart Energy 2024 St Pauls, London

13 - 14 Nov 2024

Energy Transition Summit 2024 London, UK

20-21 Nov 2024

DATA CENTRES IRELAND

RDS Dublin

20 - 21 Nov 2024

EMEX - The Net Zero & Energy Management Expo 2024 ExCeL London

12 Dec 2024

PowerEx Live London Park Plaza Westminster Hotel, London SE1 7UT 26 Jun 2024

12 MARCH-APRIL 2024 UK POWER NEWS

PowerEx Live 2024 Golf Tournament Belfry Hotel & Resort, Royal

Sutton Coldfield

DATA

IRELAND 20-21 NOV 2024

CENTRES

POWEREX LIVE - LONDON 12 DEC 2024

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

Project critical? Power generation emissions solutions Exceed MCPD regulations with the emissions experts Whatever the power needs, wherever located, we have a solution to reduce harmful PM and NOX Our retrofit team will plan and manage the installation of the exhaust aftertreatment system to your generator project Over 10,000 DPF + SCR systems installed worldwide enquiries@eminox.com | eminox.com Plan Install Commission

10MW EPC BATTERY ENERGY STORAGE SOLUTION BALANCES THE GRID

It’s been exactly a year since Edina delivered a 10MW battery energy storage system (BESS) project in South Yorkshire - an EPC, system-integrated solution designed to support the grid infrastructure and accelerate further deployment of renewable generation assets onto the network, reports UKPN.

The BESS site in Doncaster, South Yorkshire, comprises three modular outdoor skids with CATL lithium iron phosphate (LFP) battery cell chemistry, a liquid-cooled thermal management system, battery management system and UL certified fire detection and suppression systems.

Edina, an energy transition solutions provider for Battery Energy Storage Systems, hydrogen-enabled on-site flexible generation and Combined Heat and Power (CHP) plants, and Hydrotreated Vegetable Oil (HVO) Standby Power Generation, won this contract with UK developer ForePower for its system-integrated EPC BESS solution back in 2022.

ForePower provides National Grid with the ability to stabilise the electricity network with its portfolio of assets.

Funded by Nash Business Capital Ltd, the 10MW 1-hour duration BESS project in South Yorkshire, UK, provides a range of balancing services to the electricity grid to ensure power security, system flexibility and accelerate

renewable energy integration.

Edina’s modular outdoor battery energy storage solution is fully-integrated and prefabricated with lithium iron phosphate (LFP) battery cell chemistry, liquid-cooled thermal management system, skid-mounted inverter systems, battery management system and UL certified fire detection and suppression systems.

Edina provided all the full engineering, procurement, and construction (EPC) and system integration work in a project which included detailed design, engineering, project management and installation, plant commissioning and backed by a long-term service agreement.

Hugh Richmond, Strategic Adviser, Edina, said: “This was our first battery storage development with ForePower, and we were delighted to be working with such an enthusiastic and forward-thinking company. This project has This project has been a significant milestone for the evolution and growth of Edina, which was

“This was our first battery storage development with ForePower, and we were delighted to be working with such an enthusiastic and forward-thinking company. This project has been a significant milestone for the evolution and growth of Edina, which was traditionally a gas engine supplier and developer.”

- Hugh Richmond, Strategic Adviser, Edina

traditionally a gas engine supplier and developer but has now added another “string to its bow” by developing standalone and hybrid power solutions and full EPC contracts.”

Andrew Foreman, ForePower’s Founder and Projects Director, Steven Thorpe have jointly said: “It’s been an exciting time for the UK’s energy mix and has proved a great the opportunity to work with Edina. Working with Edina on this project has helped to build our relationship and develop our current portfolio of assets.”

The project has allowed ForePower to access the Capacity Market, Fast Frequency Response, and other grid services markets to support the national grid during periods of system stress.

The 10MW BESS solution joins Edina’s growing installed capacity within the battery energy storage and co-location market. Edina recently completed microgrid projects co-locating BESS, CHP, and standby power generation as part of a wider energy transition solution.

Edina has an installed portfolio of over 1,000MW capacity in the UK and Ireland, and is progressing a significant pipeline of 100MW battery energy storage capacity.

www.edina.eu

UK POWER NEWS MARCH-APRIL 2024 15 POWER STORAGE

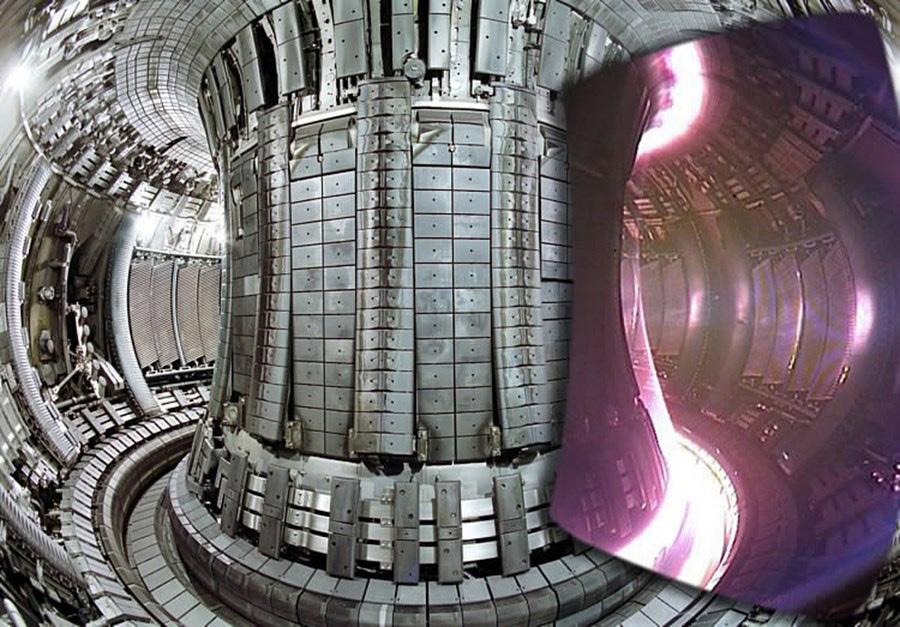

40.5MW GAS POWER GENERATION

SITE AT CARRINGTON

Forsa Energy’s newest flexible generation site at Carrington is now fully operational. Constructed by Clarke Energy acting as the principal contractor, Carrington is capable of exporting up to 40.5MW of electricity into the ENWL network. The site houses 9 X 4.5MW Jenbacher engines, each capable of ramping up to full capacity in just 5 minutes.

Carrington was awarded a Capacity Market contract by National Grid ESO in 2019 and will therefore contribute to the UK’s primary mechanism for ensuring a stable and secure supply of electricity.

Based on the proven design concepts of Jenbacher Type 3 and Type 6 engines, Type 4 engines are characterised by high power density and outstanding efficiency.

Enhanced control and monitoring provide easy maintenance capabilities, as well as excellent reliability and availability.

More than 6,400 engines have been delivered since 2002. Jenbacher Type 4 engines have the same design, emissions control, and waste gasto-energy capabilities as their Type 2 and Type 3 counterparts, plus high power density and outstanding efficiency in their power range. The high-power turbocharger allows optimal operation at higher air intake temperature and altitude.

A four-valve cylinder heads features enhanced swirl and channel geometry using advanced calculation and simulation methods, resulting in

optimal cooling and combustion conditions. The Type 4’s connecting rod reduces bearing wear and is said to be easy to maintain.

Applicable gas types for fuel include: natural gas, associated petroleum gas (flare gas), propane, biogas, sewage gas, landfill gas, coal mine gas, other special gases (e.g. coke, wood, and pyrolysis gases). INNIO and Clarke Energy have supplied nine of these 4.5MW Jenbacher engines.

Offering superior efficiency with an innovative engine concept, Type 4 engines save on fuel without sacrificing flexibility or reliability. The Type 4 is available in 50 and 60 Hz and features fuel and solution flexibility—making it an excellent choice for more than 10 different applications.

The 40.5MW gas powered generation plant was built by Clarke Energy acting as the principal contractor, Carrington is capable of generating up to 40.5MW of electricity into the ENWL network.

The sites’ nine 4.5MW Jenbacher engines are each capable of ramping up to full capacity in

“The Carrington 40.5MW gas-powered generation plant was built by Clarke Energy acting as the principal contractor, Carrington is capable of generating up to 40.5MW of electricity into the ENWL network. The sites’ nine 4.5MW Jenbacher engines are each capable of ramping up to full capacity in just 5 minutes.”

just five minutes.

Carrington was awarded a Capacity Market contract by National Grid ESO in 2019 and will therefore contribute to the UK’s primary mechanism for ensuring a stable and secure supply of electricity.

The project is a joint effort by Forsa Energy, INNIO, Clarke Energy, Green Frog Utilities, and ENWL.

With the backing of Tiger Infrastructure Partners, Forsa has a clear mandate to expand its portfolio of energy transition technologies.

To date Forsa has successfully developed, financed, and constructed 8 operational sites in GB, with a combined installed capacity of 196MW.

Forsa currently has a further 103MW of plant under construction and scheduled to energise over the next 6 months and an additional 250MW development pipeline of contracted sites.

Forsa says it is is well on its way to achieving its business target of 5-600MW of flexible energy generation capacity in the UK market.

www.clarke-energy.com

www.forsaenergy.com

www.innio.com

www.greenfrogutilities.co.uk www.enwl.co.uk

16 MARCH-APRIL 2024 UK POWER NEWS

GAS

POWER

Noise control experts

Keeping your world clean, quiet, and safe. Dürr Universal is a global leader in the design and manufacture of inlet and exhaust systems for gas turbines and reciprocating engines in the OEM and retrofit markets. www.durr-universal.com Dürr Limited United Kingdom Phone +44 1455 8944 88 Email solutions@universalaet.com

CAPABLE OF 25% HYDROGEN BLENDS:

THE TCG 3016 SERIES GENERATOR SETS

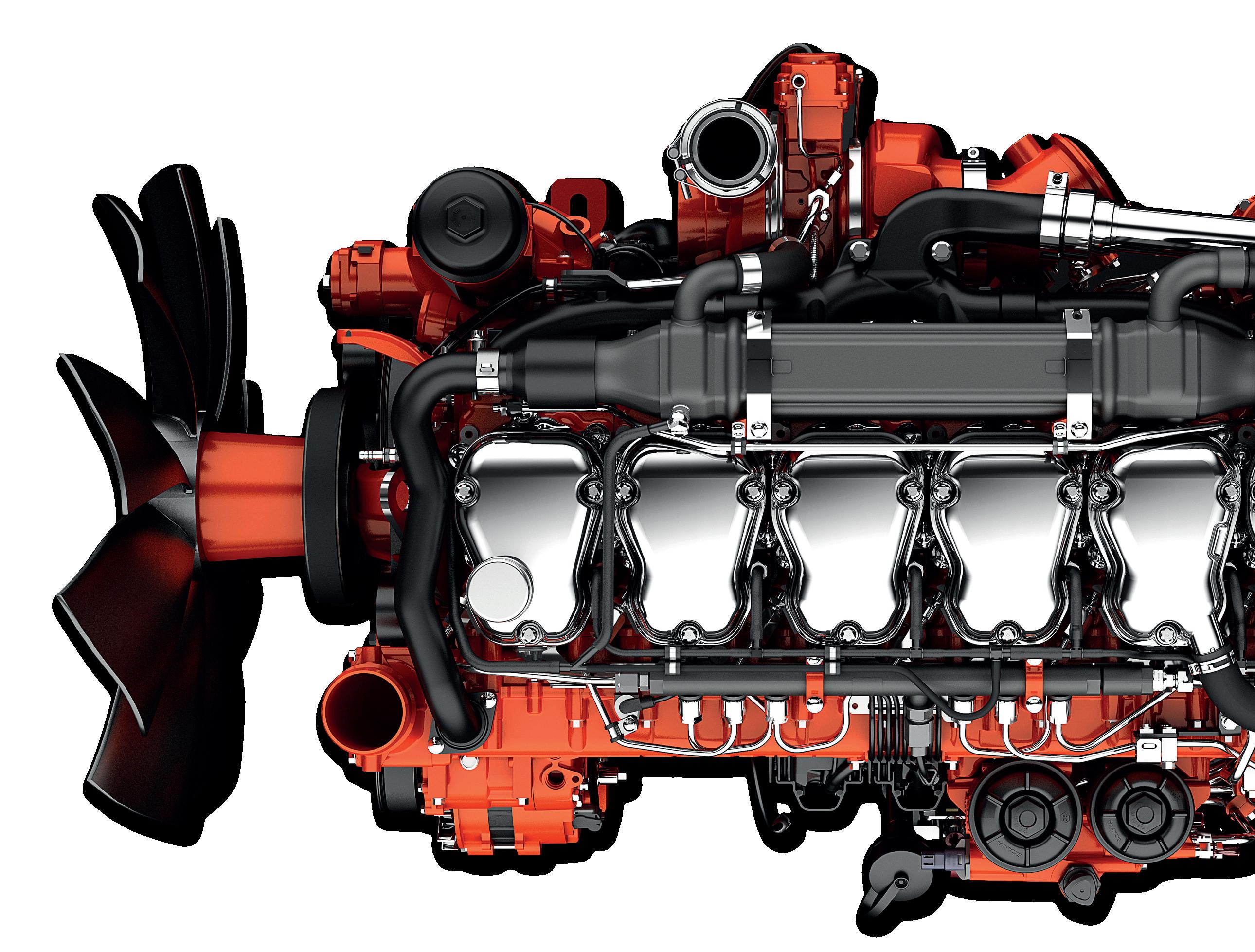

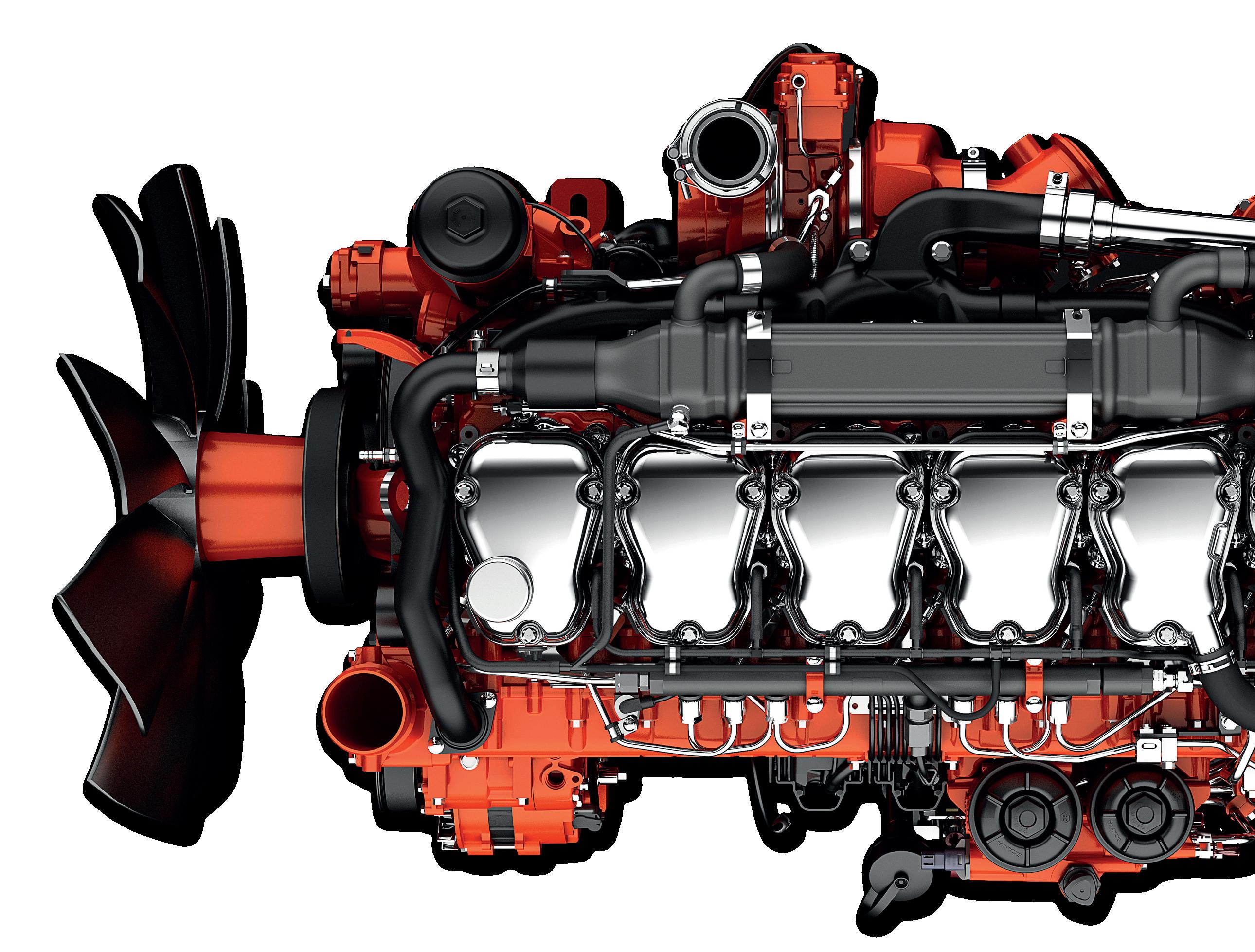

MWM has introduced gas gensets of the TCG 3016 series in the range from 400 kW to 1 MW - these can be operated on natural gas blended with up to 25% hydrogen, reports UKPN

MWM currently offers generator sets configured to enable operation on natural gas blended with up to 25% hydrogen for continuous, prime, and load management applications. Additionally, the company offers retrofit kits that provide hydrogen blending capabilities of up to 25% hydrogen for existing plants.

Reducing greenhouse gas emissions

Powerful hydrogen-based energy solutions

Renewable hydrogen fuel can help to reduce greenhouse gas emissions.

“We offer our customers hydrogenbased highperformance energy solutions that can help them reduce greenhouse gas emissions and use more sustainable energy sources,” explains Rene Ludvik, MWM Director.

MWM gas generator sets can already be operated with up to 10 percent hydrogen blends and are characterized by their high efficiency in decentralized energy generation.

MWM generators are traditionally at the

forefront when using alternative types of gas for power generation.

The generator sets can be configured to operate on a wide range of biogas fuels, including digestor biogas, landfill gas, and wastewater biogas.

The development and launch of hydrogen blended solutions address growing customer demand as the hydrogen supply infrastructure matures.

MWM is committed to helping customers meet their climate-related goals by providing products that facilitate the fuel transition, increase operational efficiency and reduce emissions.

The TCG 3016 gas genset from MWM introduces a new generation of gas genset technology to combine reliability, robustness, and maximum efficiency within the 400kWe – 1MW range.

The TCG 3016 gas genset is MWM’s smallest model offering greatly reduced installation and operating costs and includes the Total Plant and Energy Management (TPEM) control. This has been designed to ensure maximum reliability and availability.

“The TCG 3016 gas genset is MWM’s smallest version but features a TPEM (Total Plant & Energy Management) which eliminates the need for additional control systems. All power plant data for the genset, backup genset, and plant control are combined in one system, resulting in high efficiency through optimum control of the power plant.”

The TCG 3016’s improved oil management and optimised cylinder and turbo chargers set new standards in terms of durability and reliability.

The gas genset has the highest efficiency in its output class through unique combination of long maintenance intervals (80,000 operating hours for Natural Gas) and high efficiency (electrical efficiency up to 43.5 percent).

The TCG 3016 has a smaller setup area than comparable gensets due to its compact design and integrated tanks for daily refilling.

Due to the flanged genset concept, the vibration decoupling takes place directly between the gas engine and the base frame, helping to further reduce setup costs.

With a greatly reduced oil consumption of less than 0.1 g/ kWhe – the TCG 3016 gas engine boasts the lowest lubricant consumption in its class.

MWM, a part of Caterpillar Inc., stands for highly-efficient and more sustainable solutions for distributed power generation and manufactures gas gensets and power plants, as well as combined heat and power (CHP) plants.

Today, MWM tcommands a strong market position in the field of highly efficient, advanced distributed energy solutions. The company serves customers around the globe as a reliable partner for proven and sustained added value in the implementation of power plant projects.

MWM’s products are the result of more than 150 years of experience in the development and optimization of gas engines and generator sets for natural gas, biogas and other special gases.

For more information, please visit: mwm.net and caterpillar.com

UK POWER NEWS MARCH-APRIL 2024 19 GAS GENSETS

SMALL IS BEAUTIFUL WHEN IT COMES TO DATA CENTRES

AI or machine learning is about to change our lives. We are already starting to see it in everyday use through the surprising capabilities of ChatGPT, and now even LinkedIn asks us if we’d like to use AI to draft a social post? However, the power needed for AI is heavy duty and this will increase as our reliance on the new technology develops, exlains John Kreyling, Business Development Director, Centiel.

James Vincent, reporter at the Verge in his article How Much Energy does AI Consume.

He says: “Training a large language model like GPT-3, for example, is estimated to use just under 1,300 megawatt hours (MWh) of electricity; about as much power as consumed annually by 130 US homes.

“To put that in context, streaming an hour of Netflix requires around 0.8 kWh (0.0008 MWh) of electricity. That means you’d have to watch 1,625,000 hours to consume the same amount of power it takes to train GPT-3.”

Data centres are largely split into white space which houses servers and IT equipment and grey space which home UPS and switchgear.

AI will result in the need for more servers which will all draw a lot more power.

Estimates suggest that data centres with AI computing, will use High Power Density IT Racks, with designs looking to achieve potentially 30-40kW per Rack.

This is three-four times more power than a typical 7-10kW IT Rack. Suddenly, the infrastructure in the data centre will need to get physically bigger and more grey space will be required to support the increased power demand.

Data centres have the choice of larger

facilities or encroach into white space which will have an impact on revenues, or look at investing in supporting equipment with a better power density.

In other words,

Data centres have the choice of larger facilities or encroach into white space which will impact revenues, or look at investing in supporting equipment with a better power density.

In other words, UPS and associated equipment that is more powerful but has a much smaller footprint.

The challenge will become how to build a system which needs greater power but not expand the space needed for equipment to support it.

We are also increasingly seeing containerised power pods or E pods, which are bespoke containers being deployed. As well as creating more grey space close to the data centre, they are quick to build and can be developed in tandem with a new data centre development. Testing off site means a complete solution can be delivered ready to use.

Containerised power pod designs must also consider transportation and ensure operation and maintenance of equipment is adequate. Space is at a premium and so small is beautiful.

At Centiel we have developed ultra

John Kreyling

John Kreyling

compact frames for our latest UPS StratusPower to offer the highest power density within the smallest footprint but we also considered the space that is required to operate and maintain the UPS.

StratusPower only needs 900mm in front of the UPS to remove, maintain or replace the small 62.5kW modules.

Compare this to equivalent high power modular UPS that utilises larger 200kW + modules, that need in the region of 50% more space in front of the UPS.

“Space planning will become even more important, affecting how big and how much revenue the data centre can generate. Smaller, compact equipment will be needed as it will have a knock-on effect. We have designed StratusPower UPS to minimise footprints. It’s small but mighty, in various frames up to 1.5MW, with a power density of circa 1MW/m².”

They can weigh in excess of 250kg, needing slides and pallet trucks and a lot more space to manoeuvre to swap or maintain modules. The space needed to house batteries will also become influential. Oxygen free LiFePO4 batteries are a viable option, as they are up to 70% smaller than traditional VRLA batteries and 80% lighter.

Because of LiFePO4’s cycling capacity, they can also be advantageous in relation to Peak Shaving to achieve reduced energy taken from the grid at expensive (peak) times while batteries simultaneously discharge during high-rate demand, helping to reduce power consumption costs overall.

We have designed our sustainable StratusPower UPS to minimise footprints. It’s small but mighty, in various frames up to 1.5MW, with a power density of circa 1MW/m² to cope with this emerging challenge. It is also compatible with LiFePO4 batteries to fit into the smallest space possible.

StratusPower also offers a 30year design life so five years down the line, facilities will not be hit with component lifecycle replacements.

The system is fully scalable and can be enhanced through the years to ensure the latest tech is always on board, enabling the UPS to be upgraded or repaired rather than replaced to extend its useful working life.

Uniquely, StratusPower is also already hardware enabled, and with adaptations to the software/ firmware, is future ready to accept alternative, renewable energy sources. How we manage future energy use is a pressing challenge and AI is set to accelerate this problem.

Saving space within facilities will be just one issue and facilities will need to work with trusted manufactures and advisors who can all the environmental issues head on.

20 MARCH-APRIL 2024 UK POWER NEWS UPS

www.centiel.co.uk

UPS StratusPower

TWO 830 KVA DIESEL GENSETS FOR DISTRIBUTION CENTRE IN LICHFIELD

WB Power Services team just installed 2 x 830kVA Sync KOHLER generators at the new ASOS Distribution Centre in Lichfield, powering up this cutting-edge hub.

ASOS is one of the world’s leading online fashion retailers and has invested £90m in this brand-new state-of-the-art centre in Lichfield, Staffordshire; it has plans to employ 2,000 people at the site.

ASOS is an online retailer for fashion-loving 20-somethings around the world. ASOS customers can shop a curated edit of 85,000 products, sourced from 850 of the best global and local third-party brands and its mix of fashion-led inhouse labels

Its new 437,000 square feet, AEW and Allianz Real Estate joint venture warehouse is based at Fradley Park. Situated on the A38 with good road and airport links, the site serves ASOS’ customers in the UK and around the world.

Nick Beighton, CEO, ASOS, commented: “We’ve laid down the foundations for our future growth in Lichfield. This has been a significant investment in infrastructure and large-scale job creation and is a reflection of the confidence ASOS has in its future and the quality of the skills and talent available in this well-placed location. The site supports our ever-increasing customer demand and enable us to develop our offerings and delivery capabilities even further.”

WBPS offers a range of Kohler-SDMO 830kVA generators for sale. Said to be ideal for larger

applications, its high performing and reliable generators ensure the power keeps on flowing. Ideal for a variety of power requirements, the range of high-quality KOHLER generators are also suitable for prime and standby applications. Available on a short lead time and at a very competitive price, all generators can be supplied as part of a package. Along with flexible bespoke solutions, specialist generating sets can also incorporate acoustic enclosures, fuel tanks, duct work and exhaust flues and changeover panels, reports WBPS.

WBPS has an international reputation as a leading provider of critical power solutions, and is probably best known for the major expansion of its business portfolio in late 2023 when it acquired Hodgson Acoustics Company Ltd.

Operating under the Wilmott Group of companies, the newly acquired business sees the transfer of specialist container and acoustic solutions manufacturer to an associated company called Wiltech Acoustics Ltd. This strategic move came on the heels of a recent

“WBPS has an international reputation as a leading provider of critical power solutions, and is probably best known for the major expansion of its business portfolio in late 2023 when it acquired Hodgson Acoustics Company Ltd.”

development in the industry, where Hodgson Acoustics Ltd, based in Loughborough and Leicester, officially entered administration on September 20th, 2023.

With WBPS’s confirmed acquisition of the manufacturing company, the critical power service continued to solidify its commitment to innovation and customerfocused growth, whilst also placing WBPS and its related companies as firm forerunners in the power marketplace.

Following remarkable growth in all sectors of the business over the last few years, WBPS and its newest area of the business will continue to add to an already impressive portfolio of first-class services and products offered to their customers within the critical power sector in 2024.

Wiltech Acoustics Ltd empowers WBPS and its other companies within the Wilmott Group with complete control of the manufacturing process of its topquality and bespoke acoustic enclosures.

This strategic move has aligned with WBPS’s mission to offer comprehensive and innovative solutions to meet the everevolving needs of its clients.

Specialists in the industrial and power sectors of the business, Wiltech Acoustics Ltd commits to keeping the core premise of the company business the same, ensuring the design, engineering, and manufacturing capabilities at the very forefront.

Building on WBPS’s experience in the critical power marketplace, the 2023 acquisition also welcomed three significant production facilities to its group, in addition to the POD facility at Loughborough and Renewable production facility at Ilkeston.

Commenting on WBPS’s acquisition and its placement within the power marketplace, CEO of the Wilmott group and Managing Director of WB and Wiltech, Andrew Wilmott said: “We are extremely proud of our continued growth inside the manufacturing and power industries.

“With WBPS continuing to provide critical power services to some of the UK’s most important businesses and organisations, we are also focused in bringing the very best container and acoustic solutions to the forefront of our operations too.” www.wbpsltd.co.uk

22 MARCH-APRIL 2024 UK POWER NEWS

GENSETS

NEW LEGISLATION HAS IMPACT ON MEDIUM COMBUSTION PLANTS

The latest Medium Combustion Plant Directive (MCPD) legislation was amended in January 2024. Further changes are being introduced in January 2025; however action is required now to ensure compliance is achieved with the latest selective catalytic reduction (SCR) technology. Carlos Vicente, Retrofit and Aftermarket Director, Eminox, manufacturer of emissions solutions technologies, offers his views on what is expected of the power generation sector to achieve compliance, improve public health and reduce emissions.

What does the legislation mean?

In December 2018, the Medium Combustion Plant Directive (MCPD) was introduced into UK law to control exhaust emissions from medium sized combustion plant including power generators, explains Carlos Vicente. For power generators specifically, the directive sets emissions limits for Oxides of Nitrogen (NOx) with permits and compliance enforced by the Environment Agency (EA) in England, Scottish Environment Protection Agency (SEPA),Natural Resources Wales and DAERA Ireland.

January 2024 was the first significant change to MCPD legislation since its inception.

Now, all combustion plant with rated thermal input greater than 5MW must not operate without a permit. Compliance with emission limit values (ELVs) must also be achieved by gensets over 5MW from the 1st January 2025.

Further changes in requirements for emissions compliance are planned from 2030 pertaining to combustion plant with

rated thermal input between 1MW and 5MW.

However, for those who currently operate diesel-powered generators, there are emission reduction technologies available to effectively upgrade existing gensets, make them emissions compliant thereby improving air quality, and reducing the negative impact on public health by reducing NOx and particulate matter (PM).

How can compliance be achieved?

To achieve the current permit application requirements and compliance, operators, or applicants for new MCP sites or permits will now need to include the design, plans, and specification details for the exhaust aftertreatment system (EATS) as part of their application.