F u e l A c t i v e F u e l S t o r a g e S o l u t i o n s G r e e n o x A d B l u e S o l u t i o n s t / a T e n n a n t s D i s t r i b u t i o n G e n e r a t o r P o w e r L t d H e n d y P o w e r H J S E m i s s i o n T e c h n o l o g y H M S I n d u s t r i a l N e t w o r k s L t d I D E S y s t e m s I n d u s t r i a l P o w e r S y s t e m s I n s t i t u t i o n o f P o w e r E n g i n e e r s I P U G r o u p K a l e A u t o R a d i a t o r K a r l D u n g s L t d L e r o y S o m e r / N i d e c L i s t e r P e t t e r E n g i n e C o L t d M e c c A l t e M E M S P o w e r G e n e r a t i o n M H M G r o u p M i r a t e c h M o t e u r s B a u d o u i n P i l l e r P o w e r S y s t e m s P r a m a c G e n e r a c U K L t d P r e h e a t E n g i n e e r i n g R o c h e s t e r S e n s o r s U K L i m i t e d S c a n i a S T A M F O R D l A v K T e k s a n T r i a n g l e C a b l e s ( U K ) L t d T u r b i n e S e r v i c e s L t d T V R U K P o w e r N e w s V o l v o P e n t a W A S P P o w e r a n d F i l t r a t i o n S o l u t i o n s W E G ( U K ) L t d W e r n i c k P o w e r S o l u t i o n s W o r l d w i d e I n d e p e n d e n t P o w e r Y o r P o w e r L t d

NOV/DEC 2022 1 UK POWER NEWS NOV/DEC 2022 S P E A K E R S & T O P I C S FREE ENTRY TO 25 SPEAKERS, 51 EXHIBITORS & FREE LUNCH 8 D E C E M B E R 2 0 2 2 , P A R K P L A Z A H O T E L , W E S T M I N S T E R , L O N D O N T H DATA CENTRES Ian Bitterlin EMISSIONS Richard Payne ENERGY STORAGE Ian Bitterlin HYDROGEN Dr Michaela Kendall DIESEL & GAS GENERATOR MARKET OUTLOOK 2024 Romain Mocaer STAGE V COMPLIANCE AND CONSIDERATIONS Dave Philips NOISE REDUCTION John D Kerr SUSTAINABLE CRITICAL POWER SYSTEMS Keith Maclean Martin FUELS Red Diesel Bernard Gospel G99 PROTECTION AND G99 GENERATOR COMPLIANCE Ian Wassman THE COST OF CONTAMINATION Matthew Hide CHP AND COGENERATION MARKETS Dave Andrews DISTRICT HEATING FOR MOST OF THE UK Far Better than Hydrogen Gordon Taylor STORED FUELS The challenges relating to stored fuels in critical standby applications Mike Benzies/Nathaniel Fuller ENGINES & TURBINES IN WIND AND SOLAR DROUGHTS Professor Mark Barrett GREEN HYDROGEN Richard Lowes ON DEMAND LOW PRESSURE HYDROGEN GAS Dave McGrath DIRECT AIR CAPTURE OF CO2 Andy Erlam HEAT PUMPS WITH DISTRICT HEATING Richard Hanson Graville RENEWABLES AND FLEXIBILITY MARKETS Colin Mallett HOW TO INSTALL HEAT PUMPS CORRECTLY Brendon Uys HEAT NETWORKS Dr Andrew Cripps BEYOND SPACE HEATING & COOLING Dr. Bill Bordass ENABLING A ZERO CARBON FUTURE Terje Eriksen E X H I B I T O R S A K S A P o w e r G e n e r a t i o n E u r o p e B V A M C M e c a n o c a u c h o A p r o v i s A V I n d u s t r i a l P r o d u c t s B e r g e n E n g i n e s A / S B G G U K L t d C a b e l C l a r k e E n e r g y C r e s t c h i c D u r r U n i v e r s a l E d i n a E m i n o x L t d E n r o g e n

O P E N I N G T I M E S : 9 3 0 1 6 0 0 S P O N S O R E D B Y : www.powerexlive.co.uk

Publisher/Sales Director: Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor: Aidan Turnbull aidan@wipmagazines.com

Accounts Manager: Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager Sarah Hallows sarah@wipmagazines.com

Far East Sales: Bob Liu Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China Mobile:+86-013817410089 Email: bob.liu@ronco.com.cn

Austria & Germany agent Mario Dobresko power@wipmagazines.com

Contributors

HMS Industrial Networks, Kohler, Baudouin, Cummins Inc, MWM, Rolls-Royce, AKSA, Bergen Engines, Genesal, Yellow Power, INNIO, Veolia, Generac, Fluence, Ansaldo Energia, Doosan Skoda, Energy Dome, ABB, Generator Power, Bergen Engines UK, Wernick Power, STAMFORD AvK, Clarke Energy, AKSA, Crestchic, Durr Universal, Industrial Power Systems, IPU Group, Leroy Somer|NIDEC, Cummins

45+ leading companies from the European energy sector will be supporting PowerEx Live with their technical presentations

More than 45 of industry’s power equipment companies will be presenting at PowerEx Live. Here is a brief rundown on some of their achievements to date.

* Arnold Magnetics Corporation will be exhibiting - for over 60 years it has provided exceptional support to its extensive military and high grade industrial customers worldwide.

As a technology innovator of AC to DC Power Supplies, DC to DC converters, Power Distribution Units, Rack Mount Power Systems, Transformer Rectifiers and Custom EMI Filters, our broad portfolio of products range from rugged, configurable and modular, offthe-shelf power solutions, to standard AC front ends.

PowerEx Live in London

LATEST TIMES, TOPICS & SPEAKERS AT POWEREX LIVE HELD ON DECEMBER 8th, 2022, IN WESTMINSTER, LONDON

GENSETS Live – Starts at

10.00-16.00

10.00 - 10.30 - FUELS - Red Diesel – Changes to rebated fuelsBernard Gospel

10.30 - 11.00 - DIESEL & GAS GENERATOR MARKET OUTLOOK2024 - Romain Mocaer

11.00 - 11.30 - DATA CENTRES – Emergency standby generators for applications - Ian Bitterlin

11.30 - 12.00 - HYDROGEN - UK Fuel Cells & Hydrogen Technology Supply Chains -Dr Michaela Kendall 12.00 - 12.30 - EMISSIONS – The Application of Emissions Legislation - Richard Payne 12.30 – 13.00 - ENERGY STORAGE – Tech for large scale applications ie. Batteries - Ian Bitterlin 13.00 - 13.30 - STAGE V COMPLIANCE AND CONSIDERATIONS - Dave Phillips

13.30 - 14.00 - NOISE REDUCTION – Reciprocating Engines Noise – Power Generation - John D. Kerr 14.00 - 14.30 - STORED FUELS - The challenges relating to stored fuels in critical standby applications. Are existing OFTEC regulations really suitable for our industry? -Mike Benzies/Nathaniel Fuller

14.30 - 15.00 - SUSTAINABLE CRITICAL POWER SYSTEMS -Keith Maclean-Martin

15.00 - 15.30 - G99 PROTECTION AND G99 GENERATOR COMPLIANCE - Ian Wassman 15.30 – 16.00 - THE COST OF CONTAMINATION - Matthew Hide

ENGINE MANUFACTURERS AT POWEREX LIVE

Edina is one of the UK’s leading power generation specialists and an EPC solutions provider for the engineering, installation and maintenance of gas-fired distributed power plants, standby mission critical generation, and battery energy storage systems.

*Lister Petter Engine Co. is a world-renown engine manufacturer with 150 years of history. Just this year it has released a new series engineSTARLITE. The 16-83kW rated power is being recognized and is commonly used in gensets.

UK POWER NEWS

Published by:

Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0)1403 888019 Fax: +44 (0)1403 220751

powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year.

Please send address changes to UK Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

*Turbine Services is a global provider to owners and operators of industrial gas turbines. Its primary specialisation is in the heavy duty frame range of General Electric designed gas turbines. *Pramac-Generac has continually evolved and transformed, expanding its product portfolio and becoming the global benchmark for the production of generators and warehouse material handling equipment, says the company.

PRAMAC’s diverse business lines ensure the company is a leading player in a wide variety of global markets.

SPONSORS

CHP Live – Starts at 10.15 – 16.15 10.15 - 10.45 - DISTRICT HEATING FOR MOST OF THE UK - Far Better than Hydrogen - Gordon Taylor 10.45 - 11.15 - ENGINES & TURBINES IN WIND AND SOLAR DROUGHTS - 100% zero carbon energy for the UK - Cost and feasibility? - Professor Mark Barrett 11.15 - 11.45 - GREEN HYDROGEN - Wake up to the hype around green hydrogen for heating – where might it realistically have an application – engine power generation in wind and solar droughts? -Richard Lowes.

11.45 - 12.15 - ENABLING A ZERO CARBON FUTURE - Hydrogen & future fuels as an engine-based power plant installation can supply reliable power for over 30 years, machinery chosen today must be able to operate on the least GHG intensive fuel that is available now and be able to transition to the green fuels as they become available. - Terje Eriksen 12.15 - 12.45 - ON-DEMAND LOW PRESSURE HYDROGEN GAS –a perfect feed gas for engines and Fuel Cells. - Dave McGrath 12.45 - 13.15 - DIRECT AIR CAPTURE OF CO2 - for methanol engine and turbine fuel – is this the way forward? - Andy Erlam 13.15 - 13.45 - HEAT PUMPS WITH DISTRICT HEATING, CHP AND HEAT PUMPS - running the BEIS SRBI project to deliver open control systems for renewables including a number of field trials from domestic installs through to heat networks - Richard Hanson-Graville 13.45-14.15 - RENEWABLES AND FLEXIBILITY MARKETS - Colin Mallett 14.15-14.45 - HOW TO INSTALL HEAT PUMPS CORRECTLY - so they work properly and have a good winter and seasonal COP - Brendon Uys 14.45-15.15 - HEAT NETWORKS: recent progress and their future potential as part of decarbonising heat and the role of engines CHP in the transition - Dr Andrew Cripps 15.15-15.45 - BEYOND SPACE HEATING & COOLING - Dr. Bill Bordass 15.45/16.15 - CHP AND COGENERATION MARKETS - Dave Andrews.

SEE PAGES 4 & 7 for more on the complete lineup of speaker times with Genset + CHP topics. For free registration and attendance go to www.powerexlive.co.uk

*WEG manufactures a complete line of generators for the most diverse applications. It also makes alternators for generator sets. WEG is experienced in designing and supplying generators for applications such as steam turbines, gas turbines and other machines.

*YorPower - based in the UK YorPower assembles, supplies and delivers a generator somewhere in the world nearly three times a day. The company provides backup power, typically by supporting the mains with a generator for businesses and end-users so that, in the event of a power-cut, commerce can operate without interruption. The company reports that it celebrated its 30th successful year in the generator sector in 2021.

*BGG UK is a Bruno Group company. Bruno Generators Group (BGG) is recognised as one of the leading manufacturers of high specification rental diesel powered generators. Ranging from 6.5 kVA to 2000 kVA prime power, with a full range of super silent canopies and containers.

2 NOV/DEC 2022 UK POWER NEWS NEWS NEWS www.powermediagroup.co.uk

****************

*******

Technical input at the event

Scania is a key manufacturer represented at PowerEx Live. Its products are used to generate primary or back-up power for everything from events, remote locations and construction sites to critical functions in data centres and hospitals, Scania power generation systems deliver reliable power where clients need it, when they need it.

* MHM Group is a leading supplier of power generation, solar-hybrid-generators, fluid storage, lighting towers, engine drive welders and product related accessories to the UK and Irish rental markets for both purchase and rehire.

* Generator Power Ltd, the Yorkshire based generator hire and purchase specialists, has celebrated a successful milestone - 25 years in business. MD Stephen Cardwell said:“ There is no secret to the success of Generator Power’ continues, it’s all about monitoring competition and ensuring you can offer the best service and innovation so that you can offer something different to make you stand out from competition.”

* Bergen Engines UK provides iconic medium-speed liquid fuelled and gas-fuelled reciprocating engines for marine and land based applications. Its engines can be found operating in some of the most demanding and hostile environments on earth, both on land and at sea.

Not only does the company build the finest medium speed engines available - says the manufacturer - Bergen also supplies generator sets, provides modular power generating plants and partners for complete turnkey microgrid power solutions.

* Wernick Power Solutions says it can cater for any temporary power need. Alongside a fleet of over 1,600 generators ranging from 6 to 500kVA, the company can supply loadbanks, distribution boards, fuel tanks, cabling, and storage. Using minute-by-minute telemetry, Wernick can ensure a continuity of supply and help clients to reduce their carbon footprint.

* STAMFORD AvK - utilising wire-wound technology and with an output extending from 7.5 to 5,000kV the company is probably best-known across the power industry for its genuine STAMFORD® alternators. These are are designed for delivering superior efficiencies in marine, oil and gas auxiliary, UPS, telecoms, CHP, construction and other continuous or standby power applications.

STAMFORD® alternators are available with a choice of SAE adaptors to ensure easy coupling to a wide range of prime movers. All STAMFORD® S-Range is fitted with CoreCooling™ Technology.

* Clarke Energy provides distributed power plant solutions with market leading engineering, installation and maintenance support. The was recently involved in an NZ project supplying EnviroWaste Services Limited with a fourth Jenbacher biogas engine, the Jenbacher J320. This reduces the carbon footprint and increases green energy supply across New Zealand’s power grid.

* AKSA - being one of the first manufacturers of natural gas generator sets of the world, Aksa Generators feels it holds supremacy with respect to synchronised sets. Aksa Generators is manufacturing more soundproof, environment-friendly generators with lower fuel consumption for use around the globe.

* Crestchic - specialising in load bank manufacture since 1983, With sales and rentals offices in the UK, North America, Singapore, Netherlands, France, Germany, India and Dubai, Crestchic feels it has earned the title of the largest load bank specialist in the world. Crestchic load banks have been operationally successful in all seven continents and are reliably testing power supplies every day in locations and climates all round the world, from temperate to jungle, desert to snow, off-shore to high altitude.

* Dürr Universal is a global provider of custom-engineered ancillary equipment and solutions to the power generation, oil and gas, industrial processing, rail transportation and backup power markets. For more than half a century, OEMs, EPCs, packagers and end-users have relied on Universal to engineer acoustic and emission / filtration systems to meet their specific needs and provide unparalleled support across the entire energy generation lifecycle.

* HMS Industrial Networks create products which enable industrial equipment to communicate and share information. HMS stands for Hardware Meets Software™, the two core components of its solutions. HMS enables valuable data and insights from industrial equipment, allowing customers to increase productivity and sustainability.

* Industrial Power Systems - from industrial battery chargers, modular DC systems and inverters to AC UPS, power converters and green mobility chargers, the Italian manufacturer has built up a reputation based on the impeccable quality of its industrial power components and is still known for this quality today.

* IPU Group has a long history of serving the power generation industry in the UK and globally. The company is a UK distributor for products including ComAp generator and industrial controls, Powerstart starter motors, Parker Racor filtration, Hotstart engine heaters, Woodward solenoids and GAC engine governors.

IPU’s new laboratory offers an oil and fuel testing service which delivers exceptional response time and economy. IPU also designs, manufactures and exports ranges of IPU-branded products including Diesel Defence fuel polishing units. OilLife extended oil life systems and hydraulic, air, spring and nitrogenstarting systems. All products are backed by technical expertise and service.

Alternators, emission controls and genset manufacturers

Alternator manufacturers at the show include the following companies:

* Leroy Somer|NIDEC - a world leader in electromechanical and electronic drive systems and the world leader in industrial alternators. Founded in 1919, Leroy-Somer is a French company employing 6,200 people in 28 production units and 470 points of sale and service worldwide.

* Mecc Alte - as an alternator supplier, the com pany has proven expertise and experience in research, design, low-cost manufacturing and development capabilities. With manufacturing taking place in Italy, the UK, India and China, coupled with high market capabilities and a powerful worldwide capacity, it offer a fast and reliable alternator solutions service to customers all over the world.

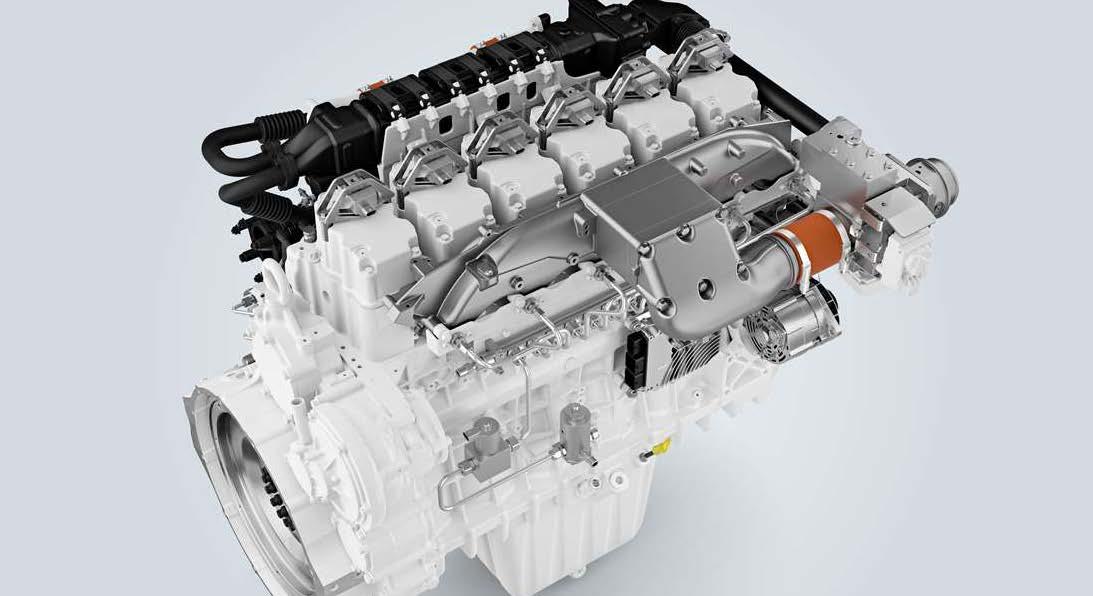

Engine manufacturers at PowerEx Live include:

* Moteurs Baudouin - for over 100 years, Baudouin has designed and manufactured the highest quality diesel and gas engines for marine and power generation applications spanning 18 – 4125 kVA. Its network supports customers in over 130 countries with specification, commissioning, service and genuine spare parts.

* Teksan Generator - also present - designs and produces optimum diesel generators, natural gas and biogas driven generator sets, mobile generator sets, portable generator sets, cogeneration and trigeneration packs, hybrid power systems for customer needs all around the globe.

* Eminox designs and manufactures exhaust aftertreatment systems for heavy-duty vehicles and equipment such as gensets. Its sustainable engineered solutions achieve the latest, global emissions standards. Working in partnership with you, we create effective new products and

technologies, bridging the gap to a net-zero carbon future.

From concept through to manufacture, the Eminox in-house team of experts understands that every industry has different requirements, says the company.

Its existing solutions for diesel, gas, hybrid, and bio-methane for on- and off-road applications are available for engines from 50kW – 10MW. The future product technologies its is developing, support fuels including hydrogen and ammonia.

* MEMS Power Generation sparked into life in 1978 as an electrical engineering company. Since then this company has grown to become one of the leading specialists in temporary power solutions, operating one of the country’s largest diesel generator rental fleets. In a recent high-profile contract, MEMS helped out following a generator failure at one of the UK’s leading independent healthcare providers.

In addition, the hospital affected by the power outage also runs three specialised neurological rehabilitation residential centres, providing care for residents with complex neurological conditions. Hence the hospital needed a reliable supplier like MEMS to provide a rapid power supply to ensure they stayed online. The MEMS team swiftly provided a 500kVA temporary diesel generator to give ample power to the hospital.

ESSENTIAL FACTS ABOUT YOUR VISIT TO POWEREX LIVE 2022

One of the key facets of the PowerEx Live event is the opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets. T his world-class venue offers optimal trade opportunities - a chance to meet regional and global buyers, distributors and contractors in the heart of London.

The venue - the Park Plaza hotel - is easily accessible by car: 200 Westminster Bridge Rd, Lambeth, London SE1 7UT, UK. It can also be reached simply by tube/train and is just a short walk from London

Waterloo Station and from the Houses of Parliament.

There is a 250+ guest space In the exclusive Park Plaza where PowerEx Live will be held.

Five restaurants and bars are available within the hotel for attendees.

There will be two Conferences held under one roof with buffet and bar area for all visitors. Lunch and refreshments will be provided for everyone attending.

Don’t forget the event is only open: 09:30 - 16.00pm.

The Conference moderator is Dave Andrews - Claverton Energy.

Register free for PowerEx Live at: www.powerexlive.co.uk

UK POWER NEWS NOV/DEC 2022 3 NEWS NEWS

GENSET LIVE

begins at 10.00am

BERNARD GOSPEL

POWEREX LIVE CONFERENCE SPEAKERS GENSET-LIVE

Coffee

FUELS - RED DIESEL - CHANGES TO REBATED FUELS

10.00-10.30

Technical Secretary AMPS The Association of Manufacturers of Power generating Systems He looks at the issues surrounding red diesel a gas oil which is a cheaper alternative to regular diesel, and it is not subject to the same environmental regulations

This means that it can be used in engines that are not as efficient as those found in passenger cars In the UK red diesel is also called “rebated gas oil”

ROMAIN MOCAER

10 30-11 00

DIESEL & GAS GENSET MARKET OUTLOOK

Romain will speak about the diesel & gas generator market in 2021 and the coming years: which territories and which segments are recovering faster, and what is the outlook for the next few years Generally speaking, the generator industry has been affected by the COVID 19 crisis but it has also strengthened some segments that were already growing strongly, such as data centres He will look at where the major sources of growth are for the generator market

IAN BITTERLIN

11.00-11.30

DATA CENTRES – Emergency standby generators for applications

With more than 52 years in engineering including 32 years’ experience in data centre power and cooling, Ian is a former CTO for Emerson Network Power in EMEA and Visiting Professor to the University of Leeds, and now an Expert Witness for HKA Global An author of many technical papers on critical power and cooling with presentations and keynote speeches

Dr MICHAELA KENDALL 11 30 12 00

HYDROGEN UK Fuel Cells & Hydrogen Technology Supply Chains

Adelan is the longest running fuel cell technology company, with over 50 years’ experience in the UK hydrogen industry landscape Not all fuel cells use hydrogen Adelan has developed fuel cells which use common, cheap fuels with non fossil replacements This talk will describe recent advances in the global hydrogen economy and project the role of UK fuel cells

RICHARD PAYNE

12.00-12.30

EMISSIONS – The Application of Emissions Legislation

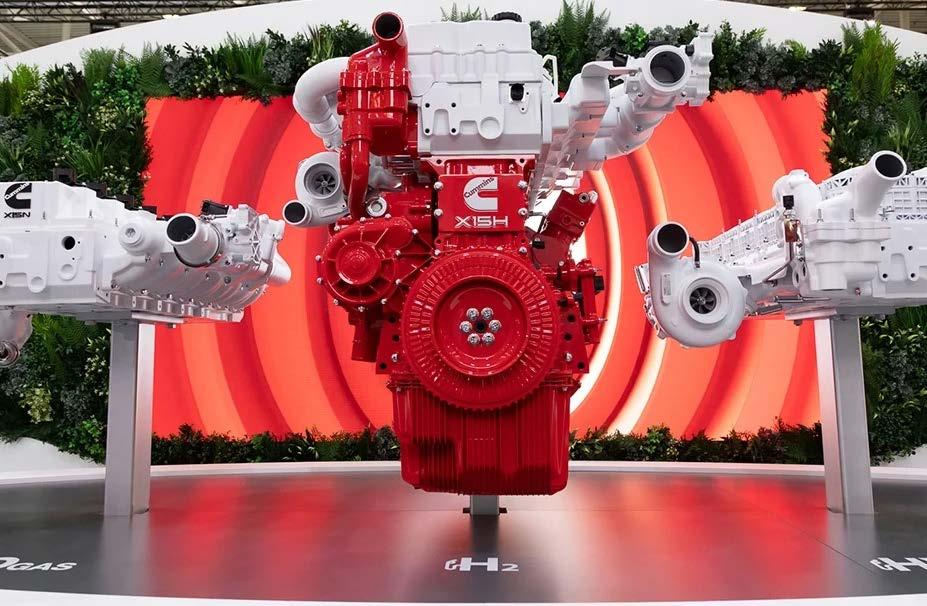

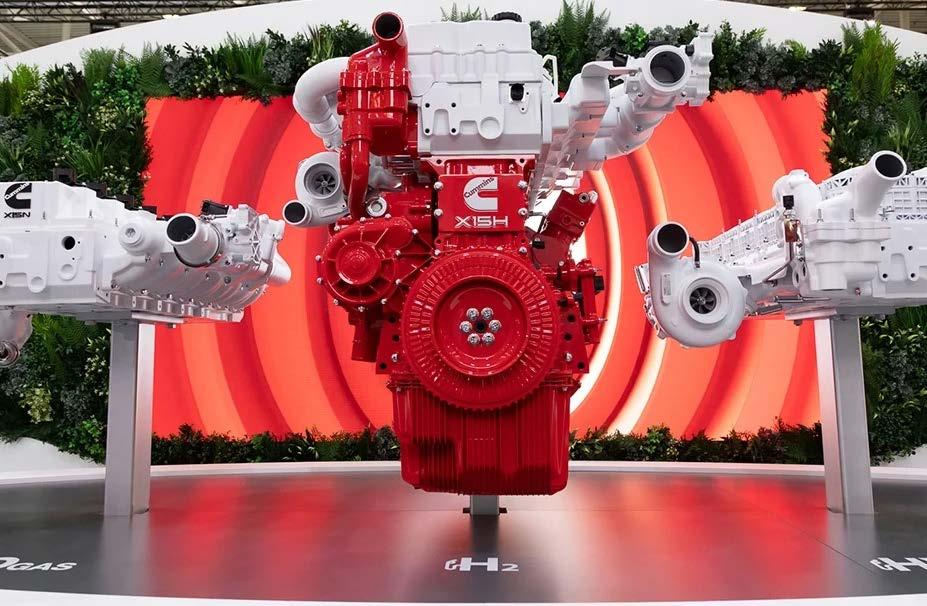

As Off Highway Regulatory Affairs Director PEM Europe at Cummins, Richard is responsible for influencing, understanding and communicating all aspects of exhaust emission and noise regulations that affect non road diesel engined products which are sold into Europe

IAN BITTERLIN

12 30-13 00

ENERGY STORAGE Tech for large scale applications ie Batteries

An author of many technical papers on critical power and cooling with presentations and keynote speeches made around the world, Ian is a Fellow of the IET and Member of CIBSE A formerTechnical Chair of the Data Centre Council of techUK and Chair of the DCSG of the BCS

& Networking 9.00am 10.00am

DAVE PHILLIPS

STAGE V COMPLIANCE AND CONSIDERATIONS

Dave Phillips is Engineering Director at Eminox Ltd, formerly Head Of Development and then Product Development Manager before that

He has a PhD in Organic Synthetic Chemistry plus a BSc in Chemistry from Swansea University

Eminox is well known for providing sustainable engineered solutions which meet and exceed stringent emissions control demands

JOHN D KERR 13 30-14 00

NOISE REDUCTION Reciprocating Engines Noise

An introduction to acoustics on stationary power generation applications

• What we hear and how sound is measured

• The acoustical characteristics of the sound and how they relate to the applications

• Topography and the effects on sound

• How silencers work and how they are sized

John is a Customer Engineer for Durr (Universal)

MIKE BENZIES 14 00 14 30

NATHANIEL FULLER

STORED FUELS The challenges relating to stored fuels in critical standby applications.

Are existing OFTEC regulations really suitable for our industry?

Mike Benzies is the IPU Group Business Development Director

KEITH MACLEAN MARTIN 14 30pm 15 00

SUSTAINABLE

CRITICAL POWER SYSTEMS

Sustainable critical power systems helping to achieve decarbonisation but without grid reliance

Sustainable power is planned to be delivered through the mass electrification of systems, reliant on decarbonised generation sources feeding the National Grid Organisations want to control their critical power needs, but this may sacrifice decarbonisation goals Take control of sustainable critical power needs

POWEREX LIVE - CONFERENCE SPEAKERS

IS SPONSORED BY

13.00 13 30

MATTHEW HIDE 15 30 16 00 THE COST OF CONTAMINATION With the transition to Stage V engines in progress, the requirement for clean fuel has never been more critical Matthew Hide will discuss the causes of fuel contamination, the impact and the importance of good fuel management to mitigate against downtime and capital inefficiency IAN WASSMAN 15 00 15 30 G99 PROTECTION AND G99 GENERATOR COMPLIANCE Ian is Product Manager G59 Relays at the IPU Group The IPU Group IPU Group designs and makes high quality engine starting, fuel polishing, emissions solutions and components for critical diesel and gas engine applications The company’s solutions provide reliability & confidence wherever they are needed

Jenbacher S Oil 40 increases drain intervals by on average 80% extends filter life Specially developed for Jenbacher non-natural gas engines life Lower operational costs High TBN retention Exceptional condemning limits Longer engine life Excellent protection and anti-wear properties Jenbacher S Oil 40 Oil D - 0.8 % Ash Oil C - 0.9 % Ash Oil B - 0.5 % Ash Oil A - 1% Ash 0 500 1000 1500 2000 2500 3000 3500 4000 Oil life (hr) 80% more Oil life in INNIO’s Jenbacher J320 gas engine running on non-natural gas(1) Based on > 9,000 condition monitoring samples. Engineered by www.Q8Oils.com/Jenbacher-S-Oil-40 © 2021 INNIO - INNIO and Jenbacher are trademark applications or registered trademarks of INNIO or one of its affiliates. (1) The displayed results are based on the experience of a limited number of engines during field tests. Actual results can vary depending on the type of engine, its maintenance, operating conditions and quality of prior lubricant used. Please consult the technical instructions from INNIO Jenbacher for specific guidelines.

Essential electromechanical repair and rewind for alternators, pumps, motors and so much more.

Designed to assist your business and extend the life of your equipment.

Call: 01572 755 168 Email: info@cabeluk.com www.cabeluk.com

The

Specialists CERTIFIED QUALITY SYSTEM

Electromechanical

We go further

WINDING REWINDING SERVICE &REPAIR SUPPLY 24/7 ALL BRANDS

CHP LIVE

begins at 10.15

GORDON TAYLOR

10.15-10.45

DISTRICT HEATING FOR MOST OF THE UKFar Better than Hydrogen

Gordon is a Director, Subsurface at RPS Energy RPS

Energy has over 15 years’ experience in the market place and recognises the importance of building a bespoke utilities package for all its clients

Professionalism and a personal approach are two of the company’s core values with each client being appointed a nominated energy consultant to walk them through the process, from initial appointment to contract and beyond

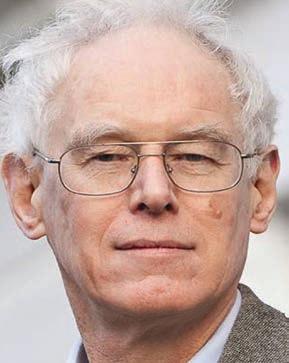

PROFESSOR MARK BARRETT 10 45-11 15 ENGINES & TURBINES IN WIND AND SOLAR DROUGHTS

100% zero carbon energy for the UK Cost and feasibility?

Mark Barrett has a PhD in Energy Modelling and is Professor of Energy and Environmental System Modelling at the UCL Energy Institute, which he joined in 2006 He has 45 years experience of modelling energy and transport systems working as a civil servant, con sultant, company director and academic He has developed models to aid policy development

RICHARD LOWES

11.00-11.45

GREEN HYDROGEN - Wake up to the hype around green hydrogen for heating where might it realistically have an application engine power generation in wind and solar droughts?

Richard is actively involved in researching, analysing and communicating around the government policies needed to transform the way we heat homes and buildings In 2021 he moved to the Regulatory Assistance Project where he has focused on applied heat technology

TERJE ERIKSEN

11 45 12 15

ENABLING A ZERO CARBON FUTURE Hydrogen & future fuels as an engine based power plant installation can supply reliable power for over 30 years, machinery chosen today must be able to operate on the least GHG intensive fuel that is available now and be able to transition to the green fuels as they become available Terje Eriksen, Regional Sales Manager at Bergen Engines, will be sharing insights on the opportunities & challenges with hydrogen

DAVID MCGRATH

12.15-12.45

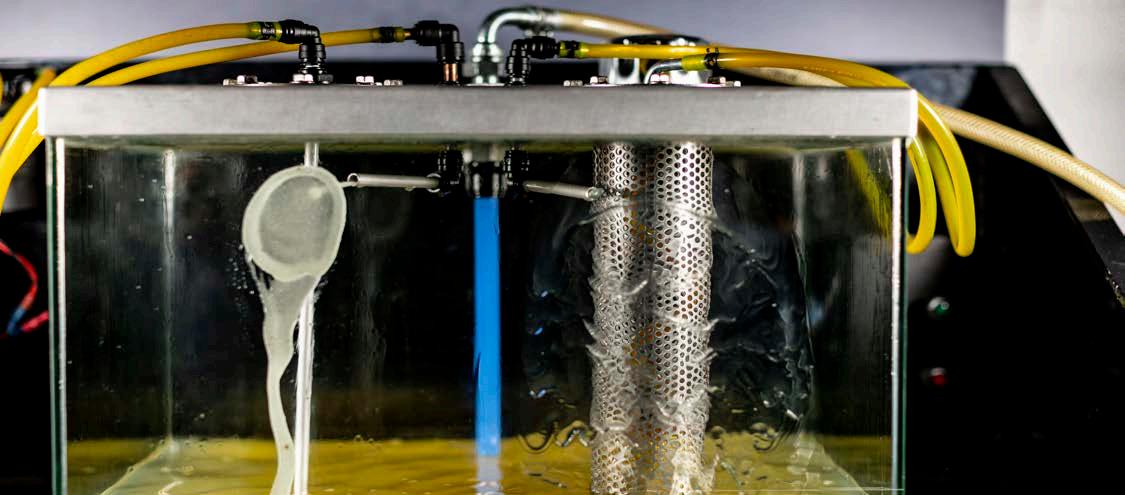

ON-DEMAND LOW PRESSURE HYDROGEN GAS – a perfect feed gas for engines and Fuel Cells

A 2/3rd Methanol and 1/3rd H2O mix through a unique reformer can deliver low pressure hyrogen gas on demand The H2 mix is a low pressure gas for PEM Fuel Cells Fuel cell anodes are immune to trace methanol unlike trace ammonia which is very harmful These deliver H2 gas for loads between 50kW to 500kW

ANDY ERLAM

12 45-13 15

DIRECT AIR CAPTURE OF CO2 for methanol engine and turbine fuel is this the way forward?

Marine main propulsion? Hydrogen or batteries?

Neither The only solution is carbon neutral methanol CNP has developed technology to use Direct Air Capture and its unique, patented electrolyser to produce a synthetic methanol suitable for marine use

Networking 9.00am 10.15

RICHARD HANSON-GRAVILLE 13.15 14.45

HEAT PUMPS WITH DISTRICT HEATING & CHP running the BEIS SRBI project to deliver open control systems for renewables including a number of field trials from domestic installs through to heat networks

Richard Hanson Graville is Technical Manager at Thermal Integration Ltd & 2nd Generation HIU and Thermal Store designer He is Head Of Research And Development for Thermal Integration Ltd where he deals with the development of renewable storage systems and communal heating interface systems

COLIN MALLETT

14 45-14 15

RENEWABLES AND FLEXIBILITY MARKETS

ICT for Smart Energy and Internet of Things, he founded Trusted Renewables Limited (TRL) in 2008 As a company he reports we are deeply involved in Smart Energy, IoT and M2M R&D exploiting secure, trusted and/or blockchain architectures My team has completed numerous Innovate UK IoT and smart energy R&D projects and consultancy projects with international companies

BRENDON UYS

14 15 14 45

HOW TO INSTALL HEAT PUMPS CORRECTLY so they work properly and have a good winter and seasonal COP

Brendon is Managing Director of Heacol, a well established local Renewable Heating firm based in Cumbria which has been providing services since 2007 It specialises in Eco Friendly heating, by installing new heating systems using heat pumps which can provide the same benefits as a new boiler

DR ANDREW CRIPPS 14 45pm 15 15

HEAT NETWORKS: recent progress and their future potential as part of decarbonising heat and the role of engines CHP in the transition Andrew is Technical Director, Heat networks and Sustainability at Triple Point, Visiting Professor, Sustainable Building Engineering, Loughborough University Former Regional Director of sustainability AECOM He was previously based in St Albans with the AECOM (formerly Faber Maunsell) development

DR BILL BORDASS 15.15-15.45

BEYOND SPACE HEATING & COOLING

Dr Bill Bordass is the Research and Policy Adviser for Usable Buildings Trust this is a charity which collects information about building performance, improves awareness of techniques for building evaluation, extracts lessons and attempts to influence clients, designers, builders, suppliers, occupiers, management and government It provides technical assistance

DAVE ANDREWS

CHP AND COGENERATION MARKETS

15 45 16 15

Chairman of the Claverton Energy Think Tank, Dave has been involved for many years with projects which focus on Combined Heat and Power (CHP) developers who are addressing environmental issues, legislation and emissions of CHP installations on a worldwide basis

POWEREX LIVE - CONFERENCE SPEAKERS

IS SPONSORED BY

Coffee &

POWEREX LIVE CONFERENCE SPEAKERS CHP-LIVE

More than 22 million diesel engines have rolled off company production lines

TECHNOLOGY ENSURES MAXIMUM UPTIME FOR GENSETS

Perkins Engines Company Limited celebrates 90 years of being in business. During the company’s lifetime, more than 22 million diesel engines have rolled off our production lines, initially from the UK, and now from manufacturing facilities on four continents.

Around the world, more than 3 million generators are powered by Perkins’ 5-2500 kVA engine range. Many feature the Perkins® 4000 Series, which is designed for standby and prime electricity generation. With models from 6 to 16 cylinders, diesel models achieve regulated and unregulated emissions standards globally.

A company spokesman commented: “By working in collaboration with over 800 original equipment manufacturers in the agricultural, construction, electric power generation, industrial and materials handling industries, we tailor our engines to meet their needs and exacting standards. With eight stateof-the-art manufacturing facilities, we ensure all our engines meet the same quality standards in every location. Supported by a global distribution network and digital aftermarket solutions, we work to deliver power and service to serve our customers. With more than 22 million engines manufactured powering over 5,000 different applications across the world, our engines truly are the heart of great machines.”

Perkins is also proud to report that its Aurangabad facility has achieved a major milestone after its 10,000th 4000 Series engine rolled off it own dedicated production line. Initially built to meet customer demand across Asia for the complete range of 750 to 2500 kVA 4000 Series engines, the state-of-theart production facility now serves Perkins’ customers around the world.

Located at the Shendra Industrial Estate in Aurangabad, India, equipment powered by Perkins Aurangabad built engines currently generate reliable power solutions for hospitals, airports, universities, real estate, data centres and large manufacturing industries.The 10,000th engine to come off the line was a 4012; one of 530 different variants that can be produced on the manufacturing line, which first started production in October 2015. “We are overjoyed to have achieved this important milestone,” said Jawed Ahmed, facility manager. “These engines are meeting our customers’ needs in the field and are a testimony to the hard work and dedication of our employees at Aurangabad.”

Biomass boiler project reduces environmental impact for UK company

A £1m upgrade of the biomass heating systems at Hill’s Panel Products is currently taking place at the company’s Oldham HQ in the UK. The company was one of the first businesses to join the government’s Renewable Heat Incentive (RHI) program- set up to minimise the effects of climate change - when it was launched almost 10 years ago.

The scheme works by rewarding firms with financial support when they employ renewable energy technologies.

The work to install two new, more powerful and efficient boilers, and associated extractors, has already started and the state-of-the-art system is expected to be fully operational later in the autumn. The new installations will combine to work in the same way as the existing biomass systems, which reduce HPP’s carbon footprint by collecting wood waste via an extraction system. It is then stored in huge silos to fuel boilers heating production warehouses, in addition to supplying heat needed for the manufacturing process.

HPP’s Marketing and Business Development Director, Dan Mounsey, comments: “Our infrastructure was ageing so we wanted to update it for greener, more efficient options. These new boilers will reduce our carbon footprint to the point that we don’t use any fossil fuels to heat those warehouses at all.

“The big difference between old and new is the new feature ceramic filters that extract exhaust gases before they leave the boiler. It means the emissions are much lower, which is better for the environment, while creating more heat output.”

Contaminated fuel can be a major issue for power generation businesses and operators, explains FuelActive.

Unplanned downtime can be disruptive and costly in any sector, but for power generation in particular, it can be critical.

Genquip Groundhog provide a wide range of welfare accommodation units to the construction sector. Whether mobile or static, the onboard generator is a crucial component of a welfare unit set-up, ensuring cabins have an uninterrupted supply of power whenever required.

Like many operators and service providers, Genquip Groundhog experienced significant problems with fuel contamination through poor quality fuel delivery, inadequate cleanliness during refuelling and unreliable operator practices.

Fuel contamination can quickly lead to fuel filter blockages, premature injector wear and generator failure. This in turn results in unplanned downtime, increased maintenance costs and an unsatisfactory service for customers.

Based in Cardiff, FuelActive invented an innovative floating fuel pick-up system, avoiding contamination that overwhelmingly is found at the bottom of the tank.

This globally-patented system delivers the cleanest fuel available to the engine, preserving critical engine components. This is particularly important for stage V engines which have particularly low tolerances to contamination.

As a ‘fit-and-forget’ technology, there is no maintenance requirement once installed and any contamination and water that collects at the bottom of the tank can be drained during routine servicing.

FuelActive products have a standard five-year warranty and have been proven on a wide range of equipment, from 6kVA Generators to 400t haul trucks at 4 Megawatts.

The versatile system is compatible with all fuel types including HVO and can be installed on generators, mobile fuel bowsers (fuelcubes) and bulk tanks.

Having trialled the pick-up on several power generators, Genquip Groundhog decided to install FuelActive on all of its dieselpowered units.

“We’ve fitted FuelActive as standard for about 10 years now and since that time, the company has accumulated more than 10 million operating hours across the fleet with zero fuel-related breakdowns,” said Peter Beach, Sales and Marketing Manager at Genquip Groundhog.

Newcastle International Airport’s solar project is key

Vital Energi has begun work on the construction of Phase 1 of Newcastle International Airport’s solar farm project which will begin generating clean energy by early 2023.

Earlier this year, planning permission was secured for a total of four phases, providing in the region of 16MW of energy.

Phase 1 will provide approximately 3MW.This first phase will be a £3.6m investment, of which 50% is funding from the European Regional Development Fund (ERDF).

The start of the project marks a major milestone in the Airport’s ambitious strategy to achieve Net Zero emissions by 2035, ahead of the majority of airports across

Europe which have plans to become Net Zero before 2050, and ahead of the Government’s Jet Zero strategy target of 2040. The site for the scheme is situated on Airport owned land to the south of the eastern end of the Airport runway.

The scheme will include areas of tree planting to screen the view of the solar farm from the surrounding roads and public rights of way.

8 NOV/DEC 2022 UK POWER NEWS NEWS NEWS

WHEN FAILURE IS N OT A N O P T I O N Complete Generator and UPS Solutions from are available UK-Wide and via Export. Group Ltd Generator & UPS Sales: 01977 688 155 yorpower.com Generator & UPS Maintenance & Repair: 0345 200 9888 ppspower.com

TOTAL CONTROL FROM EVERY PERSPECTIVE

Anyone who knows gensets, knows that Mecc Alte is unrivalled for our knowledge and expertise worldwide. From alternators and controllers to an integrated generator system, we are the Power from Within. From prime power to standby power, data centre, renewables, telecoms and more, Mecc Alte delivers complete intelligent systems with digital AVR to identify fuel efficiencies and every component working perfectly together. All backed up by the support and unbiased advice you only get from the world’s leading independent alternator specialists. Take 360° control. Talk to Mecc Alte.

The world’s largest independent producer of alternators 1 – 5,000kVA

FOR FURTHER INFORMATION VISIT WWW.MECCALTE.COM

Approval for RES Drum Farm Energy Storage Project in Scotland unanimously

The UK could be exploiting more geothermal energy

The UK has a potential heat output of 100GW of geothermal energy, up to 2.2GW of which could be developed by 2030 This represents about 15% of the UK’s 2020 renewable heat target. Geothermal energy is a source of low-carbon, homegrown, renewable energy. It is available throughout the UK and can provide heat or power all year long independent of weather conditions.

powerful and abundant renewable on Earth,” explains Araque, “much more so than wind, solar, nuclear, and all fossil fuels combined.”

Araque was joined by Kathy Hannun, co-founder and president of Dandelion Energy, a company whose aim it to use geothermal energy to heat and cool residential homes.

RES has received planning consent to build a new energy storage project in north east Scotland following Moray Council’s Planning and Regulatory Services Committee decision to unanimously approve the scheme, in line with the case officer’s recommendation.

Drum Farm Energy Storage System is situated on land at Drum Farm, near Keith in Moray, Scotland. The new 49.9 MW facility will store electricity at times when generation exceeds demand, and release electricity back to the grid network when demand exceeds generation. It will facilitate the deployment of new wind, solar and other renewables which will be central to achieving the Government’s net zero commitments as well as enabling more energy to be generated domestically, improving security of supply.

Alan McMahon, Head of Energy Storage at RES, comments: “Energy storage is an essential part of the UK’s future energy system and will be crucial in enabling the rollout of zero and low carbon energy. We are very pleased with Moray Council’s decision which allows Drum Farm Energy Storage System to play its part in supporting the UK’s net-zero emissions target while ensuring the safe and reliable operation of the grid network.”

Drum Farm Storage System has been specifically located as close as possible to the existing Keith electrical substation where the project will connect to the wider grid network. The project, which includes an upgrade to the adjacent Core Path, has been designed to include planting of new native trees, hedgerows and wildflower grass areas which will not only reduce potential visibility of the scheme but also help to enhance biodiversity by providing wildlife corridors and vital resources for mammals, birds, and insect species.

An attenuation basin, as well as allowing safe and contained storage for excess rain and storm water, could deliver significant opportunities for further biodiversity net gain.

Employing over 100 people in Scotland alone, RES has developed and/or constructed 21 wind farms with a total generation capacity of 597MW. RES also operates its Global Control Centre providing 24/7/365 monitoring for assets across the planet from its offices in Glasgow.

One of the first to enter the battery storage market, RES says it is driven by the potential of the technology to enable more renewables on the grid and create a smarter energy system. Since then the company has established itself as one of the world’s leading energy storage technology integrators, according to global rankings.

RES reports it has the real-world experience of delivering over 300MW of projects across nine electricity markets. It offers behind-the-meter solutions for corporate and industrial clients looking to integrate storage with onsite solar while RES maintains a solar + storage programme itself.

Broxburn is one of RES’s best-known Energy Storage Project s. This is a 20MW project in West Lothian, Scotland, developed and built by RES and commissioned in 2018. Capable of responding in sub-second timescales, it balances electricity demand and supply across the network to maintain a stable frequency. The first of its kind in Scotland, the battery provides Enhanced Frequency Response (EFR) services and plays an essential part in National Grid’s ongoing move to a more flexible energy network for the UK. The use of energy storage at strategic points on the network will allow for a greater penetration of renewables and avoid costly grid upgrades, leading to cost benefits for all consumers.

RES Energy storage projects include our proprietary energy management system, RESolve. Developed in-house by RES experts, this state-of-the-art software has been proven to maximise potential revenue streams for clients.

RESolve has been deployed in 10 different electricity markets, functioning in 21 different ways to generate revenue. This opens up a world of opportunity for solar plus storage or standalone projects. One of the key strengths of the software is its flexibility, adapting to a variety of system architectures and enabling modular updates to account for changing market conditions and new opportunities to supply services. RESolve is also built to deliver portfolio or fleet level integration to support owners of multiple projects.

Last month RES announced the sale of Aberarder Wind Farm to SSE Renewables. The 12-turbine project located in Strathnairn, near Inverness in the Scottish Highlands has a consented capacity of 49.9 MW.

Aberarder Wind Farm is located directly adjacent to the operational 94 MW Dunmaglass Wind Farm, a project that was also developed by RES.

Aberarder received planning consent in 2017 and once complete the wind farm will contribute to a more secure and diverse energy supply for Scotland and the UK.

It currently delivers less than 0.3% of the UK’s annual heat demand, using only a fraction of the estimated available geothermal heat resource. There is the potential to increase this proportion significantly, but this will require long-term government support to develop a route to market and overcome high upfront capital costs and geological development risks.

At the SOSV Climate Tech Summit 2022, held last October, Carlos Araque of Quaise Energy revealed that his company is developing a unique drilling technique to reach the hot rock some two to 12 miles beneath the Earth’s surface.

“In addition to being clean and global, geothermal provides a baseload energy source that’s available 24/7, even if it’s cloudy out or there’s no wind. It’s also the most

Araque believes that by the end of the decade Quaise will create power from a coal- or gas-fired power plant which has been converted to geothermal.

“You feed in geothermal steam instead of steam from a fossilfuel boiler. That in a brushstroke decarbonises the power plant, and you can repeat that 10,000 times over with other plants.

“You leverage the oil and gas industry,” says Araque. “I think of them as a ready-made workforce, supply chain, and regulatory framework.that can push this into the world at the scale that’s required.”

Kathy Hannun, co-founder and president of Dandelion Energy said: “It’s hard to advance our building stock and change all of the buildings that already exist to geothermal because]they’re all slightly different and there’s a lot of complexity to manage.”

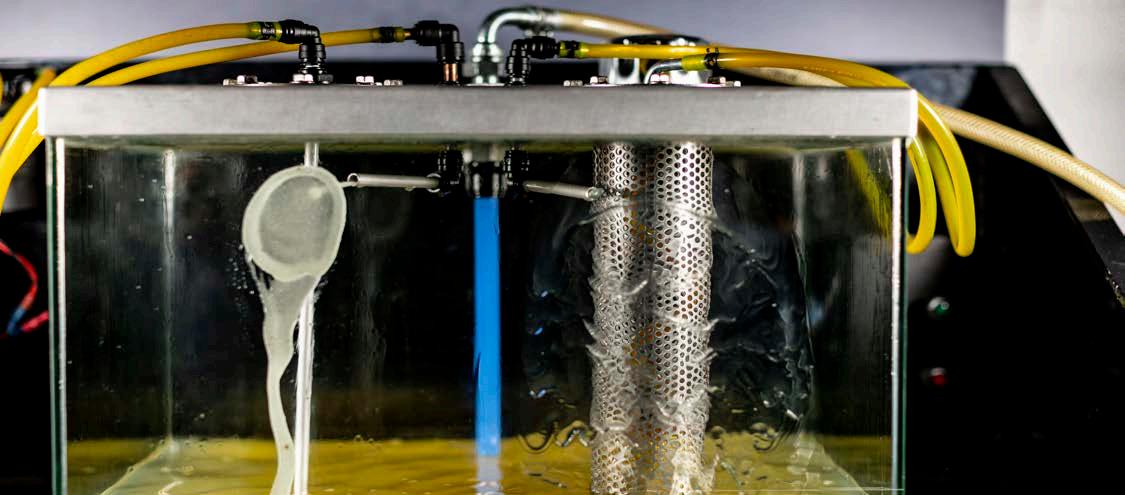

Feed coffee grounds to microalgae and you get low emission biodiesel

Around 98 million cups of coffee are drunk each day in the UK, contributing to a vast amount of used coffee grounds which must be processed as general waste, often ending up in landfill or incineration.

However the researchers at Aston University discovered that waste coffee grounds provide both nutrients to feed, and a structure on which the microalgae (Chlorella vulgaris sp.) can grow.

Dr. Vesna Najdanovic senior lecturer in chemical engineering and Dr .Jiawei Wang were were involved with the team which cultivated algae which was then processed into fuel. As a result, they were able to extract enhanced biodiesel that produces minimal emissions and good engine performance, and meets US and

European specifications.

The research paper “Enhancing growth environment for attached microalgae to populate onto spent coffee grounds in producing biodiesel,” appears in the November 2022 issue of Renewable and Sustainable Energy Reviews.

“There is no reason to doubt that one day our generators might be run on biodiesel derived from some of the tons of coffee waste typically discarded every day in the UK,” commented one industry analyst.

UK POWER NEWS NOV/DEC 2022 11 NEWS NEWS

New 7MW gas peaking project in Somerset has already gone live

Biomass company helps the UK reduce Greenhouse gas

Edina UK Ltd is behind a 7MW gas peaking project recently completed in Somerset using MWM engines. Gas-fired peaking plants, often known as peak-lopping or peaker plants, are power plants designed to balance the fluctuating power requirement in the electricity network and operate during periods of high level demand for electricity or shortfalls of electricity supply.

This demand and supply variation is due to the increase in renewable energy sources (wind and solar) connected to the electricity grid as part of the UK’s effort to cut CO2 emissions. As such, these intermittent and unpredictable renewable sources of power pose a risk to increased fluctuations in energy supply.

The Digest of UK Energy Statistics (DUKES) recent report published and updated in 2019 by the Department for Business, Energy & Industrial Strategy states that renewables’ share of UK generation was at a record level of 33.0% up from 29.2% in 2017. This has grown significantly since 2000 when renewable generation was just 2.6% Peak-lopping power plants provide important balancing services where weather conditions prevent output either when the wind isn’t blowing or the sun isn’t shining. Peaking plants address this imbalance and reduce stress on the electricity grid, providing power stability – to potentially avoid blackouts and maintain the security of electricity supply. Unlike base load power plants, reserve peak-lopping plants operate in standby mode when not in use and are called to operate by the electricity grid when there is a demand to supply electricity.

Offshore wind in the Celtic Sea approches gigawatt scale

Equinor has released its plans for developing gigawatt scale floating offshore wind in the Celtic Sea, in view of the upcoming Celtic Sea floating wind seabed leasing round.

Regarded as a pioneer in floating offshore wind, as the developer and soon to be operator of two of the world’s first floating offshore wind farms, Equinor is keen to develop new floating opportunities in the Celtic Sea.

The Crown Estate has already scheduled a seabed leasing round in the Celtic Sea in 2023.

The purpose of the Celtic Sea seabed leasing scheme is to facilitate the development of the floating offshore wind industry in the UK and encourage investments in the UK supply chain.

Catherine Maloney, Head of Business Development, UK Offshore Wind, commented: “Equinor has been operating in the UK for nearly 40 years and we are

delighted to see new and exciting opportunities emerging in the Celtic Sea.

“Our team is working hard to mature our plans in Wales and South West England, as engagement with local communities is critical to Equinor’s project development of offshore wind.”

She explains: “Equinor is highly experienced in developing floating wind: it has installed the world’s first floating wind turbine, the world’s first floating offshore wind farm and is now building the world’s largest floating wind farm.”

She concludes: “We are committed to industrialising floating offshore wind and the Celtic Sea is an optimal region for further development of this important technology.”

More than 630,000 tonn of GHG (Greenhouse Gas) emissions were avoided in the UK in 2021 thanks to the efforts of Esken Renewables.

This conclusion was recently published in a report undertaken by Logica Consultants.

Esken Renewables receives waste wood from the construction industry and household waste and recycling centres which would otherwise be sent to landfill where it would release methane gas over time.

Esken takes that waste wood to instead produce biomass fuel and last year treated and supplied 1.1 million tonnes of it to biomass plant customers - helping the UK to avoid GHG emissions equivalent to taking 135,746 cars off the road.

Including other types of biomass, Esken Renewables supplied 1.4m tonnes of fuel which its biomass

plant customers used to generate an estimated 1,880,000 MWh of electricity. This represents 2% of the UK’s domestic energy use and is sufficient to power around 650,000 homes.

Compared with using gas-fired turbines creating power through biomass plants means the UK was able to avoid 714,000 tonnes of GHG emissions in 2021 from fossil fuels.

The combined GHG emissions savings of avoiding waste wood going to landfill and using it to generate renewable energy meant that the UK avoided around 1.344MTCO2e in FY22.

Richard Jenkins, Chief Executive, Esken Renewables comments: “We are immensely proud of our role in the UK circular economy and our contribution to reducing greenhouse gas emissions such as methane.”

Hydrogen is the way forward for the UK says the North West Hydrogen Alliance

The North West Hydrogen Alliance (NWHA) is urging the UK government to accelerate the use of hydrogen as an alternative heating source for homes, as the nation faces the challenge of reducing emissions from buildings and securing energy supplies over the winter.

Decarbonising domestic heat is one of the biggest challenges facing the UK as it looks to deliver on its net zero commitments.

Heat is responsible for almost half of UK final energy demand and buildings are re sponsible for nearly 20% of all UK emissions.

In the latest report - ‘Hydrogen Heat in the North West’ - the NWHA states that using hydrogen for heating could cut average household emissions by 2.4 tonnes of CO2 each year, reducing residents’ carbon foot print by 35%.

In the North West, if just 50% of the region’s homes used hydrogen heating, this would save three millions tonnes of CO2 each year.

The North West region is home to the leading hydrogen and carbon capture project HyNet North West, which will deliver amongst the lowest cost CO2 transport and storage infrastructure in the UK by extensively repurposing existing onshore and offshore assets.

The project can deliver nearly 40% of the government’s new national 2030 target for low carbon hydrogen production. Able to benefit from the existing regional technical

skill base in engineering, chemicals production, refining and offshore oil and gas, HyNet North West is planning to be operational from 2025.

The North West is already making significant strides in developing a hydrogen economy. Whitby in Ellesmere Port, Cheshire has been shortlisted to be the first UK Hydrogen Village, which would see around 2,000 homes move to 100% hydrogen.

Cadent, British Gas and Cheshire West and Chester Council, the partners in the project, recently opened a Hydrogen Experience Centre - the North West’s first hydrogen demonstration facility open to the public.

12 NOV/DEC 2022 UK POWER NEWS NEWS NEWS

Contact enquiries@eminox.com or visit retrofit.eminox.com • Cost effectively upgrade your existing power generators • Future-proof your assets, extend genset life • Eminox fit onsite, minimising downtime • Systems available for gensets up to 7MW Meet Stage V emissions standards Approved Retrofit Solutions for Stage V equivalent compliance

the power to rescue

From ploughing through angry seas to reach people in distress to simply patrolling the coastline, Scania Power Solutions deliver engines designed to perform in any situation. Each one has been developed to deliver impressive power and immediate response when they’re needed most. When it has to work, it has to be Scania. SPEAK

scania.co.uk/powersolutions

TO OUR

SOLUTIONS TEAM TODAY –

SCANIA POWER

CALL 0845 034 3034

New study to assess the feasibility of green hydrogen as a planet-friendly fuel

Manufacturer helps to develop waste-to-energy concept

Peter Brotherhood of Peterborough was recently approached by one of its customers to assist in the creation of a waste-to-energy plant.

With the project being in its infancy the backing of the concept was deemed to require evidence of the ability to raise and use steam on a small scale prior to approval of the larger scale project.

A small steam turbine had already been identified by the customer to use as a proof-of-concept, however the turbine had not run for a long time and parts were missing.

At this point Peter Brotherhood provided its services for dismantling and inspecting the Skinner steam turbine to identify all repair and new spare parts requirements.

The unit was received into the Peter Brotherhood workshop for a full detailed inspection to be carried out. Following approval to proceed and receipt of all required components Peter Brotherhood’s technical team commenced the repairs and rebuilding of the unit.

coverage.The new trip and control valve components were fitted together with all new seal components allowing the unit to be finish assembled with all required dimensions and clearance data recorded.

Uniquely, Peter Brotherhood is able to offer small steam turbine repairs which are bespoke to both the individual unit and the customer’s needs, whilst providing high quality workmanship through utilising OEM engineering processes and standards.

By utilising the engineering team all repairs are covered by a full OEM warranty. Repairs carried out in the recent project included shaft refurbishment, rotor shaft replacement, reblading, provision of new componentsand bearing refurbishment/replacement. The unit will now be installed at a specific site and the trip mechanism and control system tested during the commissioning of the unit. This will happen once the remainder of the plant is erected and fully commissioned.

EON and a consortium of industry partners, academics and local authorities are jointly launching a new study to assess the feasibility of green hydrogen as a planet-friendly fuel for power generation using renewable sources in industry and supporting the transition to a cleaner economy.

The initial feasibility study, funded by the Department Business, Energy and Industrial Strategy and its Net Zero Innovation Portfolio (NZIP), will be based at E.ON’s Blackburn Meadows renewable energy park. It will explore the potential of generating hydrogen from biomass which can be used as an alternative to fossil fuels in South Yorkshire’s energy intensive steel industry.

Project partners include major industry near the Blackburn Meadows site, with strong interest from steelmakers in testing the use of hydrogen as a way of switching away from natural gas in heating and forging processes. They include Forgemasters and Forged Solutions, working alongside Chesterfield Special Cylinders and supported by Glass Futures and the AMRC/University of Sheffield.

Michael Lewis, E.ON UK CEO, said: “Hydrogen will play a significant role in our energy future, mainly powering energy-intensive industries and long-distance transport. It sits alongside the drive for heat pumps meeting domestic heating needs and a greater role for district energy schemes in urban areas.

“Our Blackburn Meadows plant is the perfect example of a range of technologies coming together to provide a solution for an entire city and generating green hydrogen for Sheffield’s world-renowned steelmakers means an economic win for them, greater security of their energy supplies as well as better air quality for the city and accelerating Sheffield’s energy transition to net zero.”

Cllr Mazher Iqbal, Co-Chair of the Transport, Regeneration and Climate Policy Committee, at Sheffield City Council, said: “Sheffield City Council are delighted to hear that E.ON’s application to BEIS’s Industrial Hydrogen Accelerator has been successful. Sheffield has a target to reach net zero by 2030. Emissions from our industrial and commercial sector make up about 28% of the city’s overall emissions and we’re encouraged by E.ON’s proposal to generate green hydrogen here in Sheffield.

“The funding they’ve now secured will build the knowledge and commercial business case of using hydrogen to support the decarbonisation of our steel industry and help futureproof their energy security.”

He concludes: “We recognise the significant investment that E.ON has already made in the city to deliver a local renewable energy system facility alongside a district heat network and an industrial scale battery storage system. We look forward to supporting them during this next phase of feasibility.” and project development of their HYDESS project.”

Professor Mohamed Pourkashanian, leading the project for the University of Sheffield, said: “To reach a hydrogen economy there will be many barriers, not least in fully understanding and investigating the technical challenges faced in switching to hydrogen as a fuel, and how it will integrate into our existing infrastructure. This project takes a vital step in making this technology a reality for industrial partners.”

The rotor was balanced to ISO1940 grade G2.5 to provide a service ready rotating element, the seal and bearing housings were then aligned during the trial fit of the rotor and the bearings blued for contact pattern achieving the require percentage

“The repair was an interesting challenge for us, although we are used to carrying out these types of overhauls having a piece of equipment that was not 100% complete when it arrived in our workshop provided us with the hurdle of identifying all of the missing parts, we were able to ascertain the shortfall in items and provide genuine OEM components for the rebuild.”

commented Lee Oliver, Aftermarket Manager, Peter Brotherhood.

UK’s first geothermal business wins funding as part of Net Zero Open Innovation Programme

CeraPhi Energy, based in Great Yarmouth, has been awarded funding as part of the Net Zero Technology Centre’s 2022 Open Innovation Programme.

The programme, aimed at developing technology which will reduce emissions offshore, accelerate clean energy production and enable delivery of the UK’s net zero ambitions, was launched in early 2022 with successful finalists announced last month.

The award and subsequent funding will enable CeraPhi Energy to focus on a programme of work demonstrating how oil and gas

liabilities can be repurposed into geothermal assets for net zero targets with the project expected to start by the end of 2022, Karl Farrow, CEO of CeraPhi Energy, commented: “This is our second award from the Net Zero Technology Centre (NZTC)”.

“It’s a great achievement and reward for a lot of hard work.

UK POWER NEWS NOV/DEC 2022 15 NEWS NEWS

GIVE YOUR TRANSFORMER AN EXTRA LIFE

Remote assistance for transformers is often provided in the field of energy distribution networks while it is still very new when it comes to metallurgy.

Tamini Trasformatori designs transformers for networks and steelworks. The function of the transformers for steelworks is to prevent alternating cycles of high energy stress (electric current and power).

Their operation must be continuously monitored; otherwise, there is a risk of deterioration and damage to the system.

Continuous data monitoring for preventive maintenance

Sophisticated algorithms first analyse the transformers historical data. Then a compilation of trends reveals the process status and predicts future conditions.

The data which the monitoring system is based on include: the system data (voltage, current, temperature of cooling water, etc.), and specific machine data (temperature, oil levels, alarm signals, gas content in oil, the absorption of various components, position and number of actuations of the switch, etc.). The solution calls

on advanced and smart instrumentation capable of providing data in real-time to collect these specific data from the machine.

The information that is gathered and appropriately processed allows for evaluation of the transformer performance together with the actions to be taken to optimise operation.

As a second step, the system enables Tamini Service personnel to take remote action and provide real-time support to the customer/user. Also, alarm thresholds can be defined by the Tamini specialists.

In transformer operating conditions, if the pre-alarm threshold is exceeded, notifications are automatically generated and sent to Tamini Service personnel, who take timely and proactive action to solve the problem.

In most cases, interventions can be done remotely, which drastically save time and costs relating to onsite travels.

An IIoT gateway fully adaptable to Tamini’s field requirements

For this IIoT project, W2W Solutions and Tamini decided to use eWON Flexy routers from HMS Industrial Networks with MQTT technology.

“ For this IIoT project, W2W Solutions and Tamini decided to use eWON Flexy routers from HMS Industrial Networks with MQTT technology. eWON Flexy is a combined remote access router and IIoT gateway designed to fully adapt to the requirements of many different industrial applications.

eWON Flexy is a combined remote access router and IIoT gateway designed to fully adapt to the requirements of many different industrial applications.

W2W solutions chose to build the remote-control architecture around this device mainly for the versatility of the product concerning hardware interfaces in the field.

What makes up eWON Flexy?

It is made up of combinable modules: choosing the most appropriate functions and protocols for your own needs, then connecting them, and finally, personalising the flow control and management applications.

With the need to interface analogue inputs, digital inputs, and Modbus/TCP and to send data wirelessly on a 3G/4G network, eWON was able to guarantee maximum integration of the parts.

. MQTT technology for data transfer

The Flexy device supports MQTT technology which is fully compatible with the CoIOTe Platform cloud system (www. coiote.io) developed by W2W Solutions.

MQTT is a very lightweight and reliable protocol that is catching on, thanks to the arrival of the Internet of Things.

The protocol is much appreciated as it guarantees data transfer even when connections are not entirely stable.

A successful IIoT project

Tamini has gained several advantages by implementing such remote monitoring and control system.

For starters, there is an opportunity to offer customers the possibility to continuously monitor their transformers with obvious improvements in preventive maintenance, transformer lifetime, and cost optimisation.

The real-time control of operating data enables a whole set of functionalities that provides energy efficiency. eWON Flexy’s versatility in interfacing with the field and the cloud has brought simplicity and performance to the system architecture.

The use of the MQTT protocol to transfer data has simplified communication and guaranteed lightness and stability in line with IoT directives.

www.ewon.biz www.hms-networks.com

16 NOV/DEC 2022 UK POWER NEWS NEWS NEWS

To ensure a long working life of its transformers for steelworks, Tamini Trasformatori has implemented an advanced real-time remote control and history data analysis solution for preventive maintenance. At the core of the system developed by W2W solutions lies the eWON Flexy IIoT gateway using MQTT technology, reports HMS Industrial Networks.

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

BACKUP SUPPLY FOR TWO HOTEL COMPLEXES

The GEN220FI + GEN110FI models are perfect for hotel complexes where the noise level must be very low to cut customer disturbance to the absolute minimum. Today the gensets provide a maximum noise level of 75 dBA and 70 dBA at one metre.

The GEN220FI model comes with Deep Sea 7310 MKII controller plus a Deep Sea 2157 module allowing alarm expansion.

There is a tailor-made external link box with connection plates designed according to the type, number and section of cables that will be connected by the client.

There are rain gutters above door frames and a protection mesh against the entrance of vermin. It has a 540-litre base frame integrated fuel tank including a collection tray with capacity to collect 110% the capacity of the actual fuel tank.

There is 50mm rockwool inside the canopy as part of the design to ensure a noise level of 70 dBA at 1 metre. The GEN110FI model, on the other hand, has been specifically designed to provide a noise level of 75 dBA at 1 metre.

The monoblock was mounted on an oversized canopy including double thickness rockwool in the walls and upper air outlet aiming to reduce noise to the level required by the client.

In addition to the reduced noise level feature, the design of the cabin was tailor-made insofar

as rain gutters were included in the door frames, as well as a protection mesh to prevent the potential entry of animals/vermin.

As part of the custom design for the client, Genesal incorporated its corporate branding on the outside of the canopy, which resulted in a personalised generator set.

The genset features a Deep Sea 7310 controller and Deep Sea 2157 module allowing alarm expansion. There is a tailor-made external link box with connection plates designed according to the type, number and section of cables that will be connected by the client.

The Deep Sea DSE7310 MKII is a powerful, new generation auto start genset control module with a highly sophisticated level of new features and functions, presented in the usual DSE userfriendly format.

Suitable for a wide variety of single, diesel or gas genset applications. Featuring a new Dual Core main processor and extended memory, the module provides faster and more powerful processing power, returning faster operational responses on intensive applications and increased functionality, with data logging facility.

Monitoring an extensive number of engine parameters, the module will display warnings, shutdown and engine status information on the back-lit LCD screen, illuminated LEDs, remote

PCs and via SMS text alerts (with external communication device).

The Deep Sea DSE2157 is an output relay expansion module providing 8 additional outputs to the control system.

Up to 10 x DSE2157 modules can be linked to together to provide increased output options.

Designed to give greater output flexibility for meeting complex industry generator control specifications. The module includes eight configurable relay contacts with LED indicators. These can be configured as 4 normally open and 4 normally closed. All configurations are controlled within the host control module.

One of Genesals’ tream members comments: “For these two new projects carried out in the UK we analysed the characteristics and needs of both buildings during the design process.

“After considering all the aspects we opted to manufacture a generator set of 200/220 kVA and another of 100/110 kVA.

“In addition to reducing the decibel level to the maximum - they provide a maximum noise level of 75 dBA and 70 dBA at one metre - these gensets were provided with great autonomy and, of course, were manufactured in accordance with British regulations.

“Our extensive experience in the British market, where we have an important portfolio of clients and projects in different business lines (CPD, health and hotel sector) are a good business card for clients. Our knowledge of the legislation in force in the UK provides security and guarantees the projects that we carry out in British territory.”

genesalenergy.com

18 NOV/DEC 2022 UK POWER NEWS GENSETS

Genesal Energy has manufactured and supplied two generator sets designed to guarantee the electricity supply in two hotels located in the north of England. The GEN220FI + GEN110FI models have a common feature: a low noise level to keep the guests happy.

“ In addition to reducing the decibel level to the maximum - the gensets provide a maximum noise level of 75 dBA and 70 dBA at one metrethese gensets were provided with great autonomy and, of course, were manufactured in accordance with British regulations. We have extensive experience in the British market.”

POWER YOUR BUSINESS

With efficient energy and economics

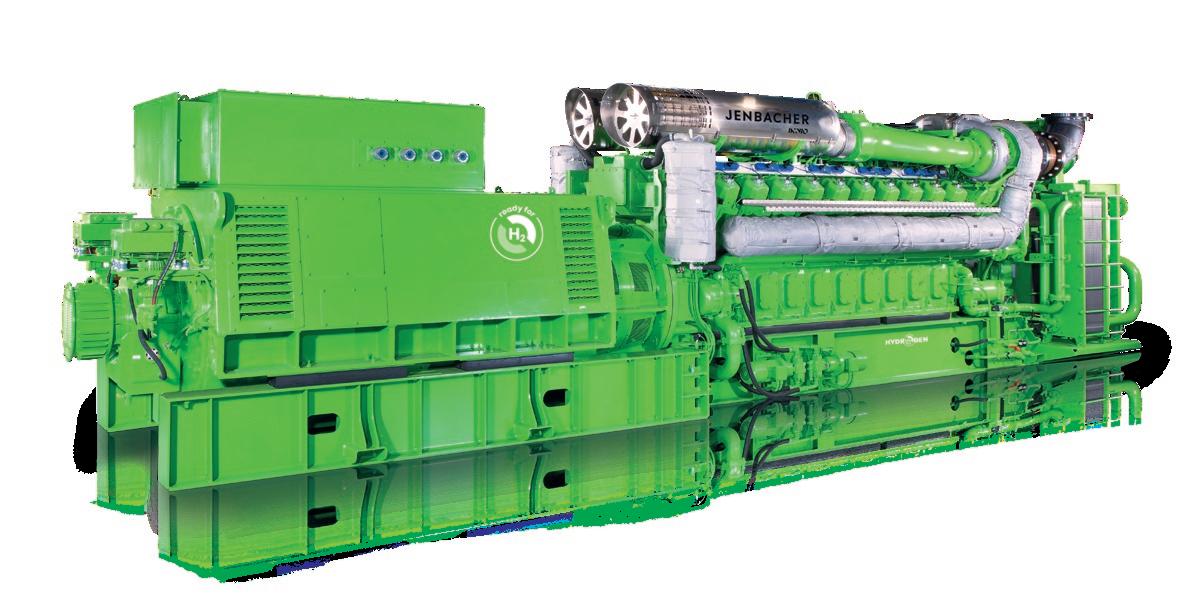

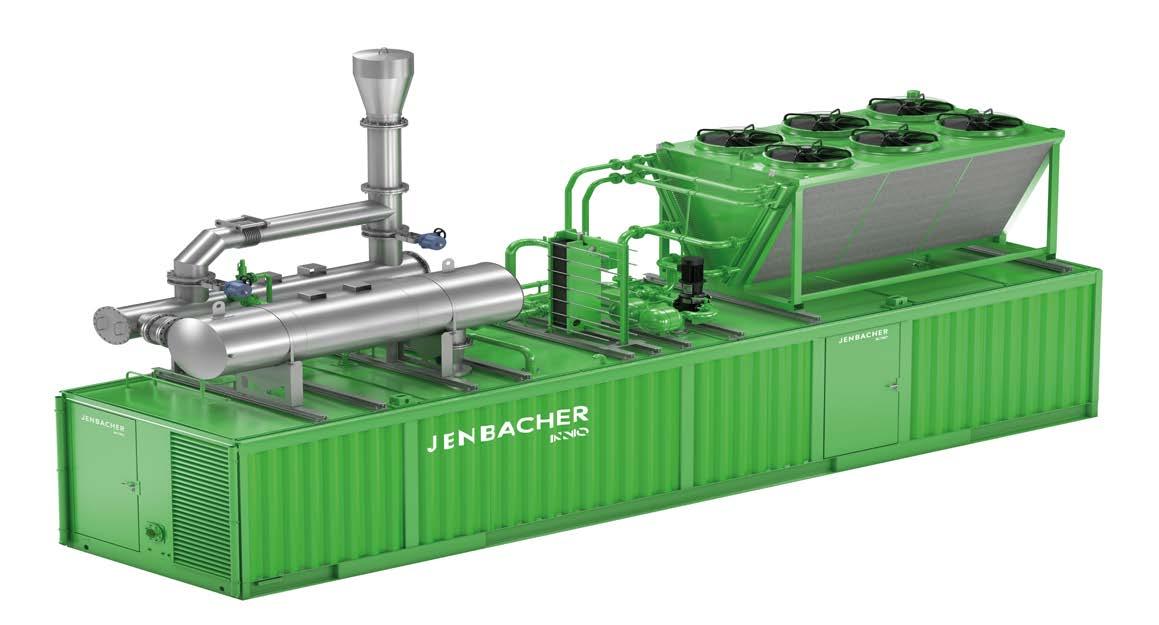

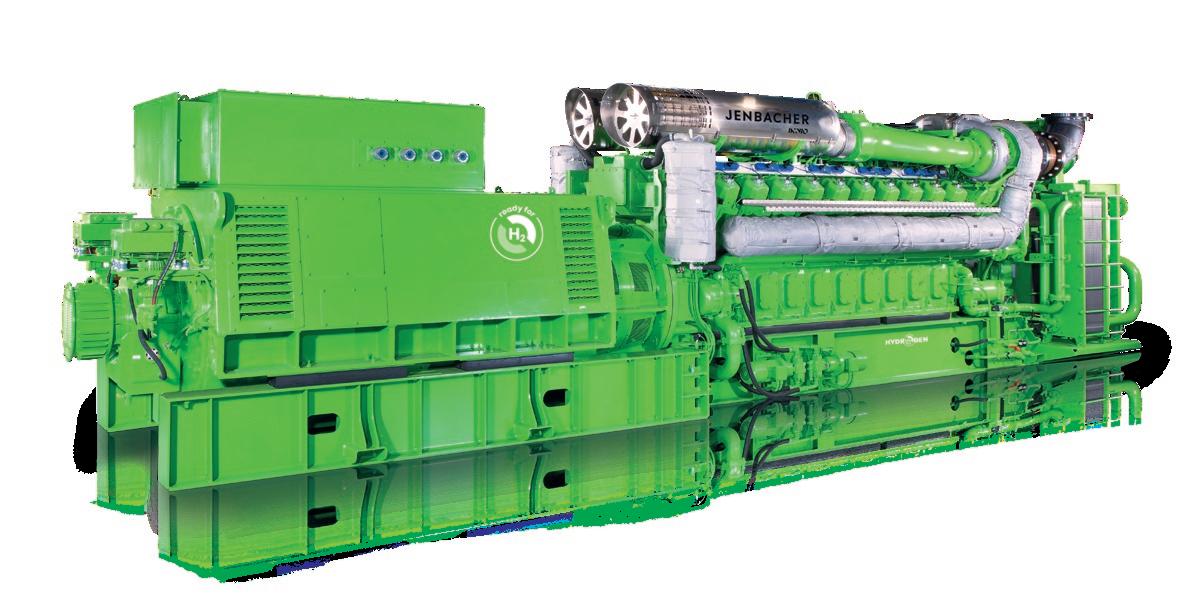

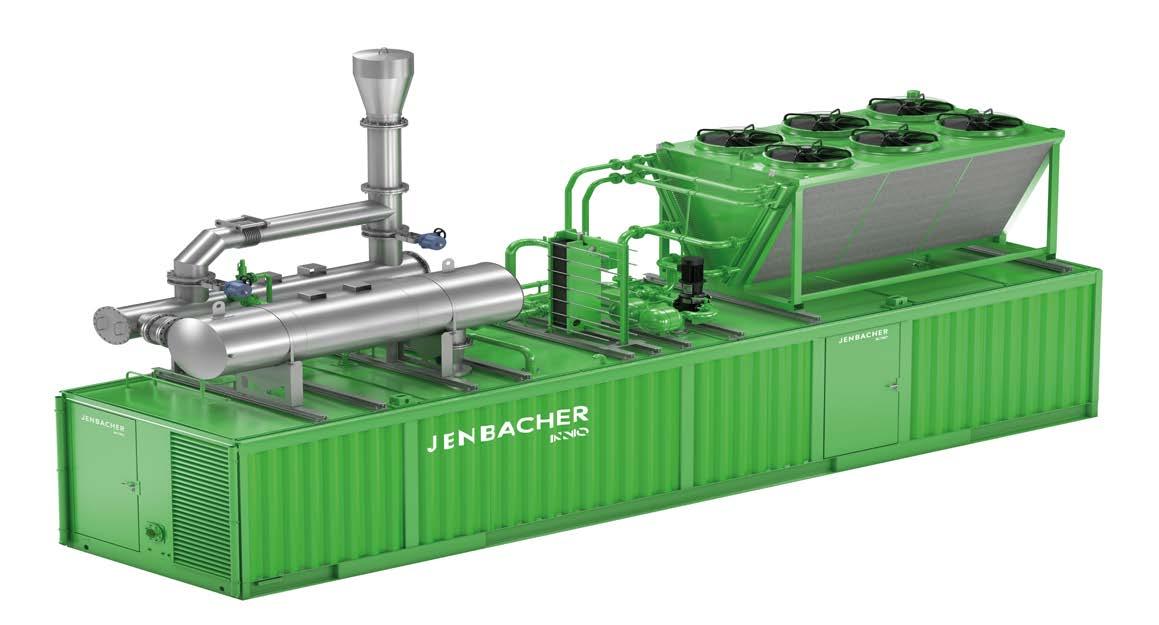

INNIO* is among the world’s leaders in CHP and CCHP solutions.

Power your business with INNIO’s flexible and innovative Jenbacher* CHP and CCHP energy systems, which deliver power, heat and/or cooling for your local site. With up to 95 % total efficiency, cogeneration can reduce your energy consumption and CO2 emissions by more than 30 % compared to the separate generation of power and heat for significantly lower energy costs. Combined with heat storage, you can operate your asset flexibly. INNIO’s CHP and CCHP systems run on a wide range of gases with the option of converting to CO2-free H2** operation once that fuel is more readily available.

Let us support your transition journey. innio.com

* Indicates a trademark.

** Optional scope on demand.

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME.

GAS GENERATOR SET GXE, GRS Series PowerLink Engine 10KW-350KW Since 2012, PowerLink group has launched GXE, GRS series PowerLink gas gensets, powered by PowerLink, are equipped with cost-effective engine and high-quality spare parts, covering power range from 10kw to 350kw with open type, soundproof type, mini container type and container type for your selection. Our units are distributed in Europe, South America, Russia, Southeast Asia, the Middle East and other countries. They are providing continuous and stable power on the project sites, bringing excellent benefits to owners and investors. www.powerlinkenergy.com | Tel: +44(0)1977 689100

SIX GAS-POWERED CHP ENGINES FOR NOTTINGHAMSHIRE

The Series 4000 CHP systems are destined for the Rhodesia Power project in north Nottinghamshire, a 10 MWe gas generation and carbon capture plant which will support the national grid (and potentially local businesses) and convert the captured carbon into food grade CO2.

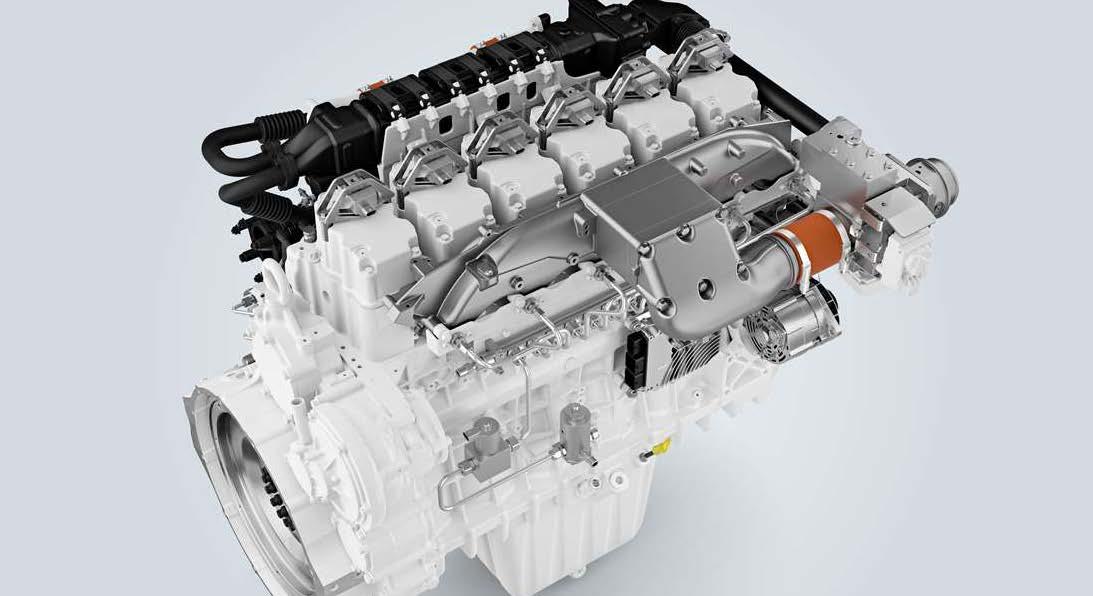

The new Series 4000 natural gas genset is said to offer the highest power density in its class. Designed with cutting-edge technology, the new Series 4000 natural gas genset is optimised for maximum performance and low emissions to deliver an economical, reliable, and sustainable source of power.

A significant reduction in nitrous oxide emissions makes the natural gas genset a perfect fit for independent power producers (IPP) and combined heat and power (CHP) applications.

With part-load performance down to 35% and a fast start option, the gas genset’s operational flexibility is also ideal for demand response applications. Low emissions - 250 mg/Nm³, 500mg/Nm³, (@5% O2)NOx – are achieved without external aftertreatment, even meeting the

new expected German unburned THC emissions legislation (<1300mg@5%O2).

The natural gas genset has an effective engine power of 130 kWm/cylinder – the highest power density in its class thanks to its compact design and small footprint. It offers superb performance at high temperatures and high humidity for use anywhere in the world and delivers 30% more power than its predecessor.

All natural gas genset components are finetuned to ensure long service life and deliver maximum uptime. Long service intervals and easy-to-maintain components mean low maintenance costs. Fast availability of spare parts and low engine oil consumption also help keep the new gas genset lifecycle costs lower overall, with cylinder head lifetimes potentially equivalent to TBO.

The natural gas genset achieves efficiencies of up to 44.4%, delivering a significant improvement in fuel/energy utilisation at high temperatures. The gas-powered Series 4000 gives you more power in less space while reducing fuel and maintenance costs, especially

The Series 4000 CHP systems are destined for the Rhodesia Power project in north Nottinghamshire, a 10 MWe gas generation and carbon capture plant that will support the National Grid and convert the captured carbon into food grade CO2. The new Series 4000 natural gas genset

designed for hot and humid conditions, reports mtu.

Features of the system include:

* Generator - Perfectly tuned to the engine and made by renowned manufacturers, the generator ensures a high level of reliability and optimum efficiency.

*Ignition System - Ignition systems for individual cylinders allow for the most efficient level of operation for all cylinders, even with variable CH4 content. The ignition system gives information on the state of the spark plugs.

* Digitally Connected - The system is equipped with a data logger providing access to digital solutions, including remote monitoring, fast and reliable service support and – coming soon –further features such as predictive failure prevention and operational optimization.

* Heat Recovery Unit - For this application, Yellow Power Ltd has designed a custom HRU solution carrying all circulation pumps and controls to allow seamless integration with other equipment utilised on the project.