TCG www.mwm.net/tcg-2032-en 2032

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh marine environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime, so you can be sure of reliable power generation, regardless of the operational conditions and compliant with all marine classifications. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

FOR FURTHER INFORMATIO N VISIT WWW.MECCALTE.COM

METHANE EXPLOSION IN THE US HIGHLIGHTS THE DIFFICULTIES OF USING THE GAS AS A GENSET FUEL

ISSUE #246

Publisher/Sales DIrector

Neb Saric neb@wipmagazines.com

Publishing & Events Director

Richard Teasdale richard@wipmagazines.com

Managing Editor

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager

Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales

Bob Liu Shanghai, China bob.liu@ronco.com.cn

US Sales & Subscriptions

Jelena Milojevic power@wipmagazines.com

Austrian & German Agent Mario Dobresko power@wipmagazines.com

Power Media International Group, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0) 1403 888019

www.powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468 7100)

An estimated 18,000 cows were killed and one person injured after a methane (CH4) explosion ripped through a dairy farm at South Fork Dairy near Dimmitt, Texas, USA, on April 10th, 2023. Officials suspect a machinery malfunction in the facility may have ignited methane gas. Investigators believe that the deadly explosion began with a machine known as a ‘honey badger’, described as a “vacuum which sucks the manure and water out”. Methane is produced naturally on dairy farms by cows through enteric fermentation and manure storage, and the incident underscores the difficult issue of safely harvesting methane as an alternative fuel for generators.

To achieve reduced electricity costs in a low-emission future, gas is used as fuel for power generation/power plant. Methane gas is an abundant supply resource and has proven to be a cost-saving alternative fuel.

Methane gas engine reduces a user’s carbon footprint, the amount of greenhouse gases including carbon dioxide (CO-2) released into the atmosphere, is a global priority and part of a larger plan to combat climate change.

Methane gas provides a superior alternative to conventional fuels. Switching to methane gas fuel from gasoline or diesel is known to effectively reduce CO2 emissions by up to 30%.

Biogas used today in gensets typically refers to a mixture of different gases produced by the breakdown of organic matter in the absence of oxygen.

Biogas as a fuel can be produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste or food waste. It is a renewable energy source and, in many cases, generates a reduced carbon footprint. Biogas can be also produced by anaerobic digestion with anaerobic bacteria, which digest material inside a closed system, or fermentation of biodegradable materials.

The biogas used for genset is primarily composed of methane (CH4) and carbon-dioxide (CO2) and may have small amounts of hydrogen sulphide (H2S), moisture and siloxanes. The gases methane, hydrogen, and carbon-monoxide (CO) can be combusted or oxidised with oxygen. This energy release allows biogas to be used as a fuel for power generation. The general term biogas mainly refers to low BTU gas, including digester gas, landfill gas and sewage gas etc. Storing and utilizing methane can be tricky and poses potential problems. Unfortunately, the abundance of this fuel is paralleled by a current lack of resources for collecting methane in a reliable manner. Methane remains difficult to handle safely, making it potentially unwieldy and dangerous.

AIDAN TURNBULL Managing Editor

AIDAN TURNBULL Managing Editor

APRIL 2023 3 WORLDWIDE INDEPENDENT POWER

www.powermediagroup.co.uk

www.wipmagazines.com

EDITOR’S NOTES

“

“THE INCIDENT UNDERSCORES THE DIFFICULT ISSUE OF SAFELY HARVESTING METHANE AS AN ALTERNATIVE FUEL FOR GENERATORS.

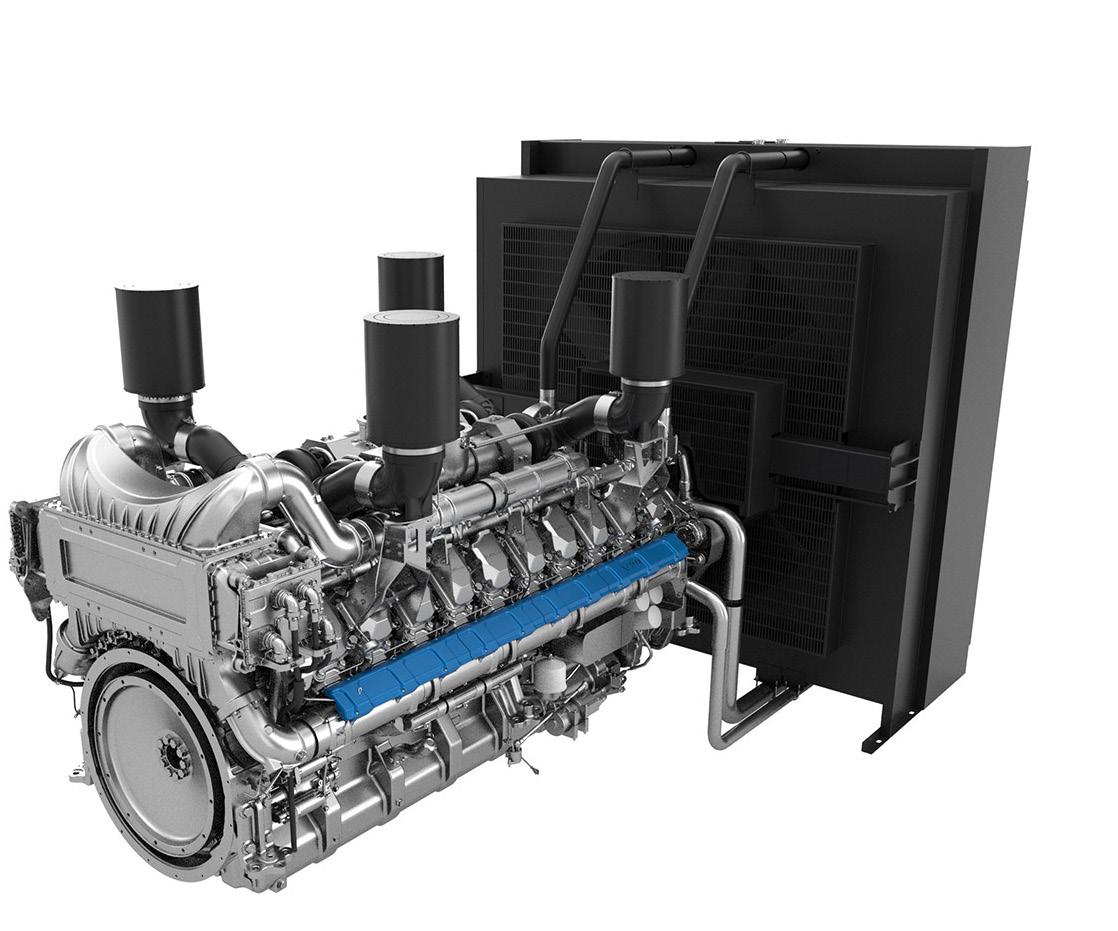

TCG www.mwm.net/tcg-2032-en 2032

p. 16 | MARKET REPORT

GAS GENERATOR MARKET SIZE & SHARE ANALYSIS

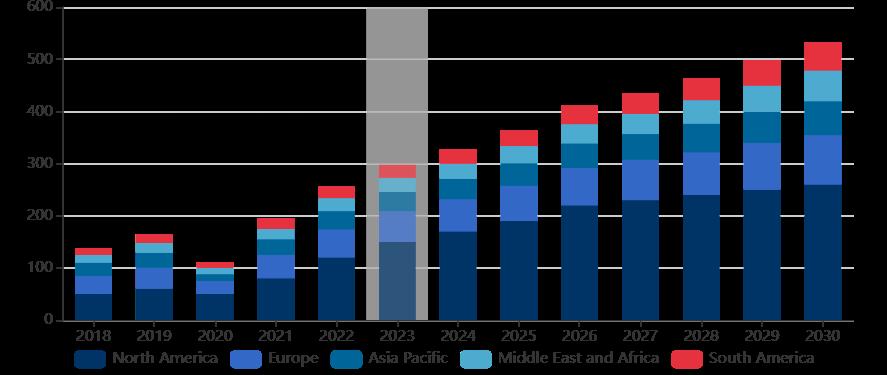

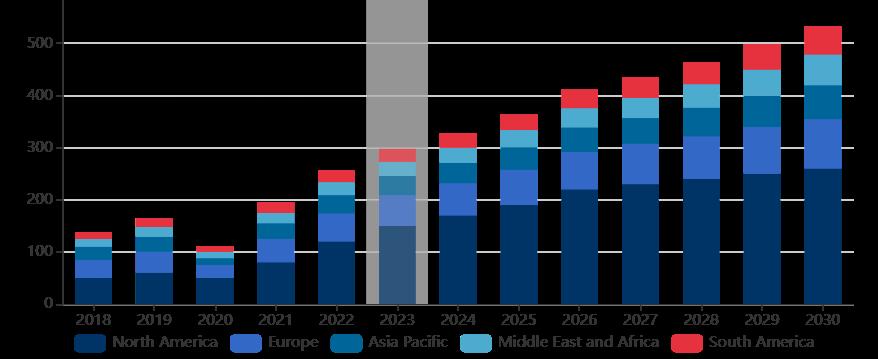

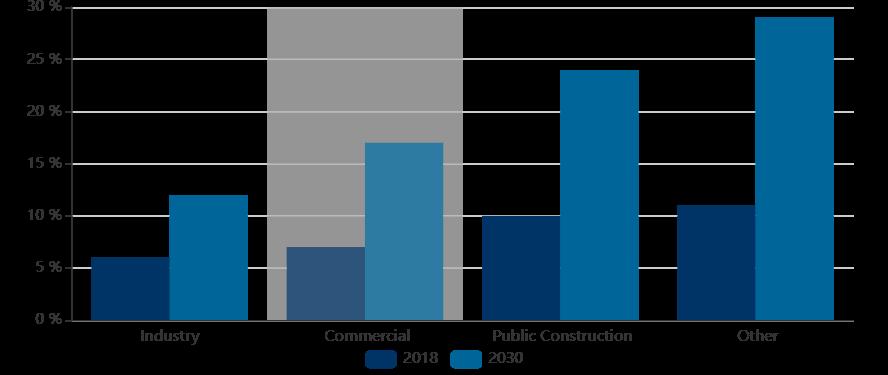

The gas generator market is segmented by capacity rating (less than 75 kVA, 75-375 kVA, and above 375 kVA), End User (Industrial, Commercial, and Residential), and geography (North America, Europe, Asia-Pacific, South America, and Middle East & Africa), explains Mordor Intelligence, a key market analyst. The gas generator market is expected to register a CAGR of more than 4.2% during 20222027. The COVID-19 pandemic generally had a negative impact on the gas generator market.

p. 17| GENSETS

DIESEL GENSET FOR THE HIRIWADUNNA WATER TREATMENT PLANTIN SRI LANKA

The National Water Supply and Drainage Board (NWSDB) uses TEKSAN generators at many of their Water Treatment Plants and Pump Houses across Sri Lanka. Thanks to a new installation the Hiriwadunna Water Treatment Plant is now powered by a TEKSAN 1000 kVA container generator, meeting all its essential energy requirements.

p. 20| GENSETS

2,250 KVA DIESEL GENSET FOR A CANCER HOSPITAL IN SPAIN

Electra Molins was recently involved in the installation of a 2,500 kVA genset in a Cancer Hospital in Spain. This new genset comes with a Baudouin 20M33 engine and a Mecc Alte alternator. It is equipped with an MP15 synchronization and closed loop transfer control panel, the same type which Electra Molins technicians previously installed.

p. 23 | GENSETS

TWO 2,100 KVA DIESEL GENSETS FORM A BACKUP POWER SYSTEM FOR A NATURAL GAS CYCLE POWER PLANT IN TURKEY

ARKEN Generators has supplied and commissioned a backup power system for a natural gas cycle power plant. Involving two ARKEN 100 kVA diesel gensets, the power system has been installed in airconditioned special containers with IP-55 insulation class, 80dbA acoustic feature at 1 mt, fire detection and dry fire extinguishing system. Double-walled flame arrester fuel tanks in the generator sets have an automatic, motorized valve filling system.

p. 19| GENSETS

ENERGY PROJECT ON LAKE KIVU, RWANDA

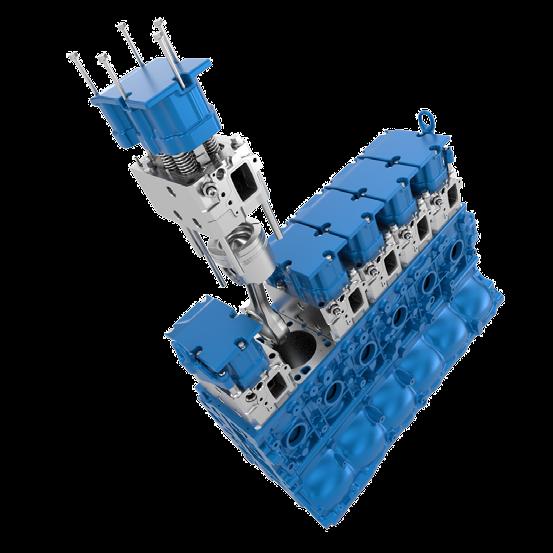

Lake Kivu in Rwanda is the scene of an unusual energy project. The Rwandan lake of 2400 km2 and a depth of 490 m has methane deposits that are used for eco-friendly energy generation. The construction of a power plant comprising 19 MWM TCG 2023B V16 gas engines started in 2019. The 19 MWM TCG 2032B V16 gas engines form the core of the power plant on the shores of Lake Kivu.

p. 21 | GENSETS

DIESEL GENSETS (4 X 3250 KVA) INSTALLED IN A DATA CENTRE IN SOUTH KOREA

Four KD3250UE generators and customised a master control panel were provided to synchronize a power system for data centre customer in South Korea. Kohler Engineers supported the company’s partner in Korea, Coastal Power, on the Site Acceptance Test and Integrated System Test; this was carried out in the presence of the customer.

p. 24 | ENGINES

ENGINES SUPPLIED TO PUERTO RICAN LIFE-SCIENCE COMPANY FOR USE IN A KEY POWER PLANT

Bergen Engines has supplied two Bergen Engines’ B36:45L 3.3 MW medium speed (720 rpm) units to power plants belonging to a life-science industry company in Puerto Rico. A company spokesman commented: “Bergen Engines will supply two medium-speed units for power plants in Puerto Rico. The client has signed a power purchase agreement for two new efficient energy power plants.”

For reader enqurires and subscriptions visit our website at www.wipmagazines.com | powermediagroup.co.uk 4

GAS GENSET MARKET 2023-2028

p. 25 | GENSETS

THREE 800 KVA DIESEL GENSETS FOR ONE OF THE KUWAIT OIL COMPANY’S KEY SITES IN THE UAE

JUBAILI BROS - KUWAIT has provided three JP 800kVA synchronized generating sets for delivery and installation at one of the Kuwait Oil Company’s exploration sites. The 800kVA silenced generators are built to exacting specifications to ensure industry leading performance. Designed primarily for the rental market, they are tough & ultra-reliable. Fitted with Deep Sea panels, they offer a wide range of settings to suit all applications.

p. 27 | GENSETS

TAILORED EMERGENCY POWER FOR A COGENERATION PLANT IN GERMANY

Genesal Energy’s latest project is a 2000-2200kVA medium voltage (6300 V) GEN2200HC generator set for a cogeneration plant in Germany. This is located in an area with very adverse weather conditions such as very cold winters and intense rainfall, it required a very special and careful design to guarantee smooth power supply. In this type of facility, a permanent power supply is crucial.

P.28| CHP

1MW BIOGAS-FIRED GENERATOR FOR A TAPIOCA STARCH FACTORY, KAMPHAENG PHET PROVINCE, THAILAND

A 1MW biogas-fuelled Jenbacher 320 gas turbine been installed and commissioned in Khlong Khlung district, Kamphaeng Phet province, Thailand, to power a key tapioca starch factory, reports the installer SOUER. Starches manufactured here are used in brewing and as thickening agents.

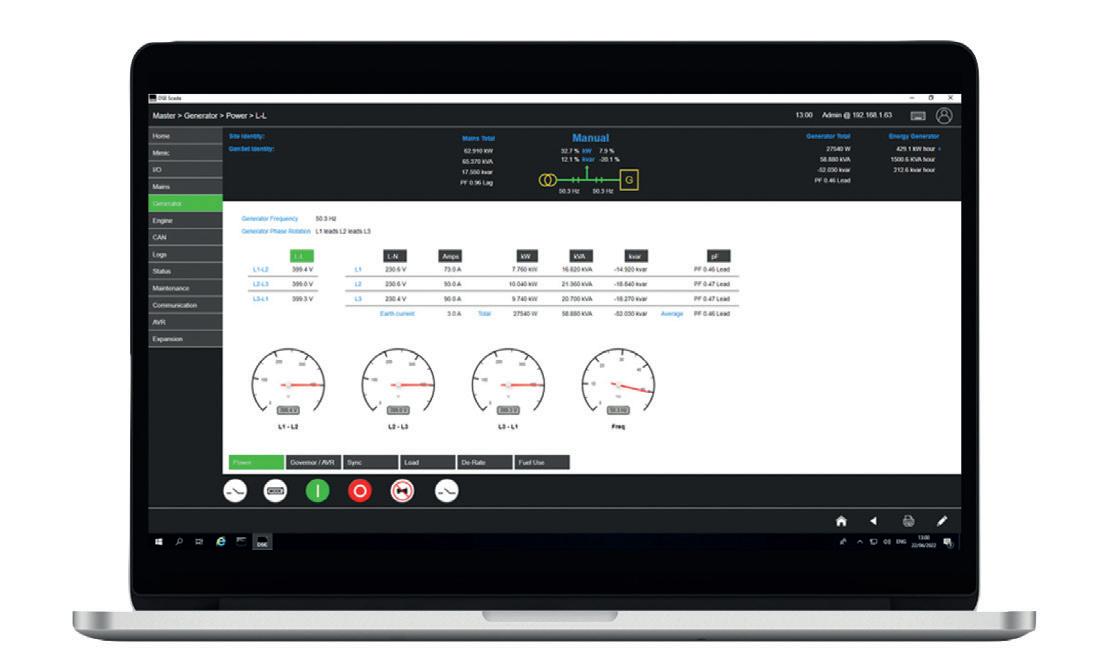

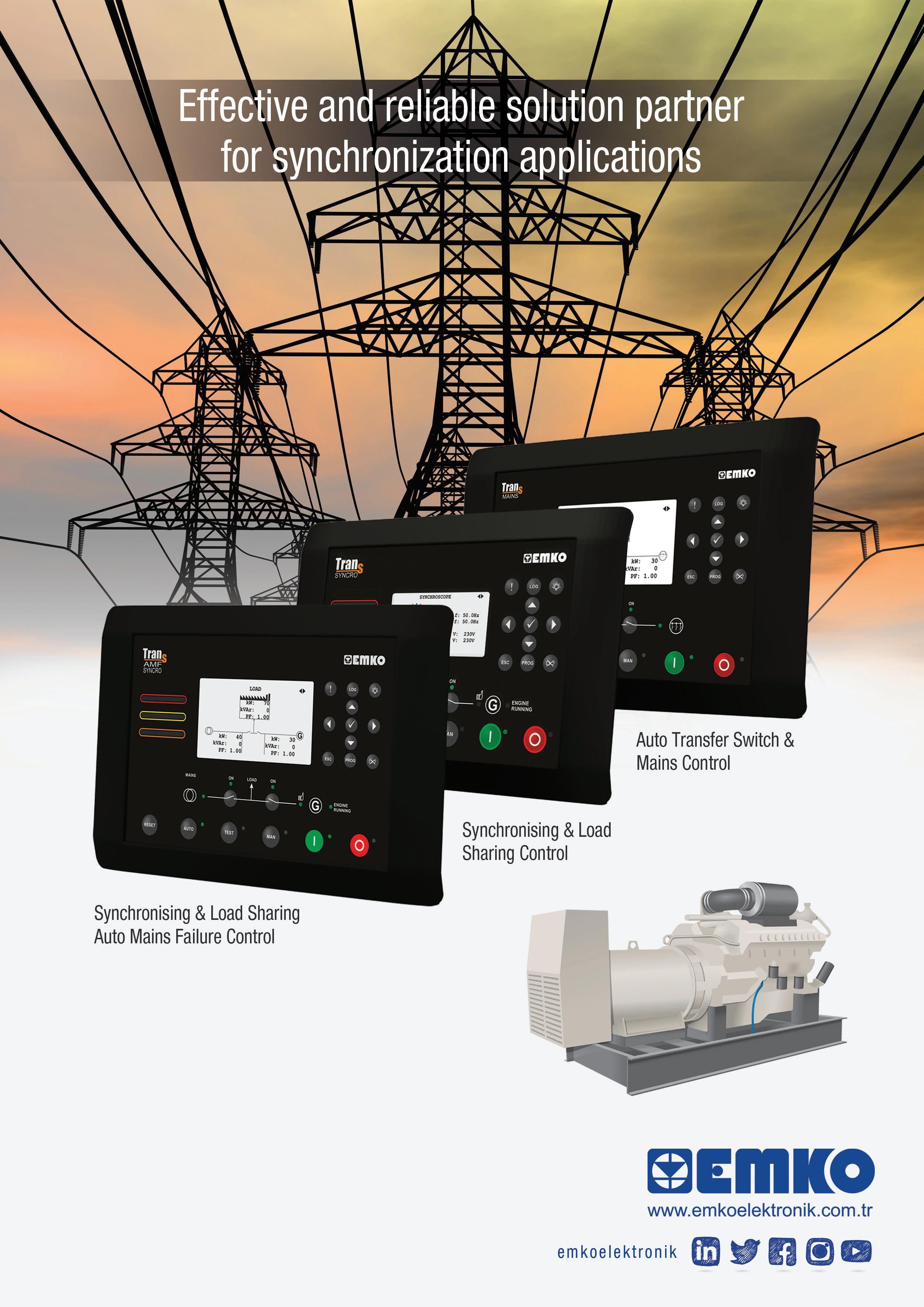

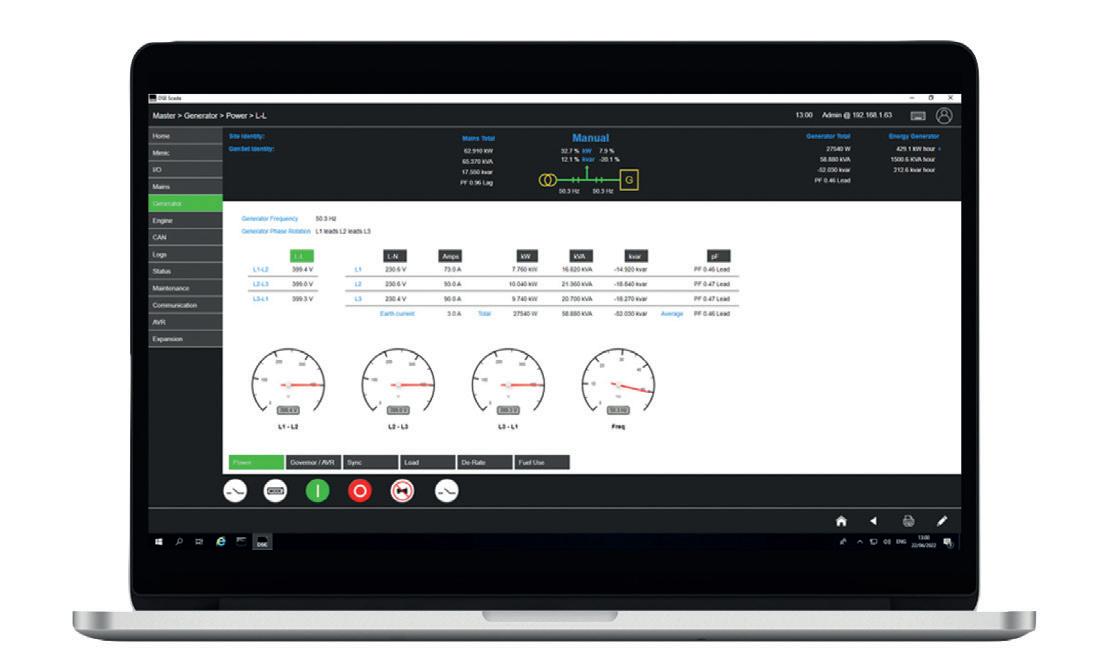

P.30| CONTROLS

ADVANCED PARALLELING & CONTROL PLATFORM

Deep Sea Electronics Ltd. (DSE) has released the G8 Series – Advanced Paralleling Controller Platform, developed to meet future industry demands, including complex paralleling applications such as data centers, hospitals, rental and industrial sites. The new controller platform introduces ‘nextgeneration technology’, says the company.

www.wipmagazines.com www.powermediagroup.co.uk

5

APRIL 2023 6 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk 03 FEATURES EDITOR’S LETTER 03-14 NEWS REPORTS International News + details on PowerEx North Exhibition & Conference (p.9) 16 MARKET REPORT - GENSET MARKET WIP looks at predictions for the gas-powered genset market 2023-28. 31 ASSOCIATION NEWS Associations: ADE, ACE and iPowerE 32 33 CLASSIFIED DIRECTORY OF EQUIPMENT & SERVICES Listings of key companies in the industry. 34 ENGINE MANUFACTURERS GUIDE OEMs manufacturing engines today. NEW PRODUCTS Don’t miss the best new products for 2023 16 31 31 32 3 GAS GENSET MARKET

The all-round talent.

Discover the new models

State-of-the-art components providing more power: the compact design, a focus on a wide range of applications and high efficiency values make sure of that. Controlled by the smart and secure TPEM (Total Plant & Energy Management), the new TCG 3020 series offers highest profitability and reliability.

www.mwm.net/gas-engine-TCG-3020

TWO 100KVA DIESEL GENSETS BOUGHT FOR A KEY HOSPITAL SITE IN ABU DHABI

660 KVA DIESEL GENSET FOR MINING SUPPORT

Grupel recently supplied a diesel generator for mining support in Conakry. Guinea, West Africa. Conakry is the capital and largest city of Guinea. A port city, it serves as the economic, financial and cultural centre of Guinea. Its city population is about 2 million and its electrical grid has been known to suffer outages.

The diesel generator plays a key role in ensuring an energy supply to the mining sector. The power generator in question has 660kVA of power and is composed of a Perkins engine, a Leroy Somer alternator, and a DeepSea controller. The new genset has some extra components, such as:

-Temperature, oil level and fuel sensors, in order to ensure the easy monitoring of the equipment and its safe and efficient operation

-Water and air filters, crucial in environments prone to dust, dirt and other particles, as is the case of mines and a manual oil pumping system, ideal for safe storage, distribution and hauling.

Bauxite, iron ore, gold, and diamond mining represent key markets for Guinea and are relatively well developed with many foreign companies operating nationally.

Two 1100KVA Bahmani NGT1100 diesel gensets specially designed for standby applications were recently supplied by the Bahmani Group to one of the key government hospitals in Abu Dhabi.

The sets feature Perkins engines and are now providing vital backup power for the facility in case of a mains power failure in the local grid.

Producing reliable power at 1100 kVA, 50 Hz, each NGT 1100 GC diesel generator set is built to meet ISO 8528-5 transient response requirements and to accept 100% rated load in one step; this generator set type also offers a low fuel consumption system and accepts 100% Block Load and a demonstrated capability to pick up large onsite loads.

The NGT Gen set is equipped with DSE controller (DSE7320), made in the UK by one of the world’s top manufacturers.

An advanced and user-friendly controller, it helps to maintain the set’s low fuel consumption, saving on fuel spend. Its compact and rugged design also saves on transport and storage costs.

3,000 KVA DIESEL GENSET FOR THE TEXTILE INDUSTRY IN SRI LANKA

Trade Promoters Limited (TPL), sole distributor for Cummins in Sri Lanka and the Maldives, has provided a 3000kVA Cummins generator to Texlan Center (Pvt) Ltd.

This is the single largest generator TPL supplied in Sri Lanka and marks a major milestone for the TPL company, as the number one suppliers of generators in Sri Lanka.

Texlan is an Italian-owned group of companies backed by over 40 years of experience in the hosiery industry. The first plant in Sri Lanka was established over 30 years ago and has been growing ever since.

THREE NEW KD SERIES INDUSTRIAL GENERATORS HAVE BEEN LAUNCHED

Kohler expands its industryleading KD Series™ line of industrial generators with two new models, KD700 and KD750 for 60hz markets. These generators feature a new KOHLER 18L advanced diesel engine (KD18L06) that can also run on Hydrotreated Vegetable Oil (HVO) as a renewable fuel source.

These new models join a proven series of gensets which continues to provide the highest power density and best fuel consumption at more nodes than competitors between 700-4000 kW, offering cost savings to users. The new KD units are designed to power mission critical applications, including airports, hospitals, and healthcare facilities, water treatment plants and mid-sized data centres.

The KD700 and KD750 join Kohler’s industrial generators which are engineered to use HVO fuel. HVO provides a cleaner and more sustainable alternative to conventional diesel and biofuels. No adaptation is needed and both HVO and diesel can be mixed together. HVO is also highly stable, with no sensitivity to oxidation, so it can be stored long-term. It enables to offset carbon emission by up to 90% by using renewable waste products.

Kohler’s KD Series has proven performance excellence, designed to deliver extreme durability and ultimate reliability in a variety of emergency and prime applications. KD Series generators are engineered to last, with better fuel economy and a small footprint. When paired with Kohler’s global sales and support network the KD Series lineup provides an industry-leading solution that secures customers’ critical operations. And when service is needed, Kohler has a global dealer and distribution infrastructure consisting of more than 800 facilities offering 24/7 parts availability. For additional details about the KOHLER KD Series, please visit www.KohlerPower.com.

Additionally, Kohler has announced an upgrade to its KD800 for 50hz markets with the integration of this new KD18L06 engine, coming to market in summer of 2023.

Founded in 1873 and headquartered in Kohler, Wisconsin, Kohler Co. is one of America’s oldest and largest privately held companies, comprised of more than 40,000

APRIL 2023 NEWS 8 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

PowerEx Live North Networking & Conferences

- 2-day event

- Tuesday 27 June 2023 - The Mere Golf Resort & Spa, Knutsford, Cheshire

on Wednesday 28th June, 2023

ABOUT THE VENUE:

The Mere Golf Resort & Spa Club

Tel. 01565 830155

Chester Road, Knutsford, Cheshire, WA16 6LJ www.themereresort.co.uk

DATE:

Wednesday 28th June 2023

- GOLF DAY Competition

FIRST TEE: 12.30 – 13.20 (2 tee Tee off or Shotgun start at 13.00) Singles & COMPANY Team Stableford (18 holes)

FORMAT: Bacon Rolls & Tea/Coffee refreshments on arrival

Club Lounge & Bar Post round drinks. 16.30-19.00

Three Course Meal in Evening from 19.30-late with Presentation and Prizespossible After dinner speaker.

PRICE: £139.00pp (£5 sweep competition optional on the day)

Guests - £157.00pp (inc. ball sweep comp. on the day)

*Sponsorship All teams so far have sponsored a hole for only £115. This will include a Company promo plaque on the tee box plus your logo on 2/3 pull ups promoting around the event.

There are just 72 places available on a first-come-firstserved basis. 2 Tee tee off or Shotgun Start (18 hole same time start at 12.00).

There will be networking opportunities with many PowerEx companies and delegates attending.

Your place will be confirmed on receipt of payment. Final deadline for booking is coming soon. We expect to be sold out – so BOOK EARLY and don’t miss out.

There are negotiated discounted prices at The Mere Hotel & Spa. Join your fellow players in the bar for a post dinner drink or two.

Contact: Richard Teasdale

- Group Events Sales Director.

Email: richard@wipmagazines.com

Tel: 07814 172007

GREEN ESSENTIALS: The 18-hole, 6,882 -yard, par-71 course at The Mere was designed by James Braid, and created out of 150 acres of Cheshire parkland in 1934. Today, the Championship course holds a reputation as one of the best-maintained and highest-quality golf courses in the North of England.

PowerEx Live North Networking & Conferences Event with 6 speakers on Tuesday 27th June, 2023.

10.30 start with Coffee/Tea. pastries, Networking until 11.30 -16.30

11.30 first paper. There are 6 speakers on Gensets, CHP, Fuels, Sustainability, Data Centres, Hydrogen and Energy Storage Systems

Complimentary Lunch 13.30-14.30

Free to attend 10.30-16.30

PAPERS & TOPICS TO DATE:

DATA CENTRES / Sustainability (Finning) / Fuel Alternatives / Genset Statistics (Romain Mocaer) / Noise (Durr Universal) / Rentals (HSS Abird) / Hydrogen / Energy Storage

DATA CENTRES - “ Powering improved data centre operation and efficiency” - Paul Smethurst takes an abstract look into why gensets are key to operating the IT load and, more importantly, how to prevent losing the critical load being a total DATA CENTRE disaster .“

FINNING UK SPEAKER - Sustainability in the power generation industry - a look at the varying options available to combat market restraints, demand and growth - this includes a look at the alternative fuels available, what’s possible now and any options in the future.

This POWEREX LIVE NORTHERN NETWORKING EVENT takes place the day before the GOLF DAY on 27th June, 2023, with 6 SPEAKERS on CHP, GENSETS, FUELS, ENERGY STORAGE, DATA CENTRES, HYDROGEN. The Conference itself is FREE TO ATTEND with morning pastries, coffee/tea and Lunch provided.

EXHIBITION COSTS - 27th June, 2023

*Table tops cost just = £600.00 - Limited availability of 8-10 tables. Sponsorship opportunities available on request.

* GOLF DAY event on Wednesday 28th June 2023 costs £139.00 pp+VAT and Accommodation at discounted costs is now available to book. Contact: Richard Teasdale - Group Events Sales Director. Email: richard@wipmagazines.com

Tel: 07814 172007

9 WORLDWIDE INDEPENDENT POWER NEWS APRIL 2023 www.wipmagazines.com www.powermediagroup.co.uk

NEWS 9

APRIL 2023

PowerEx Live North Golf Day - to be held

POWER YOUR BUSINESS

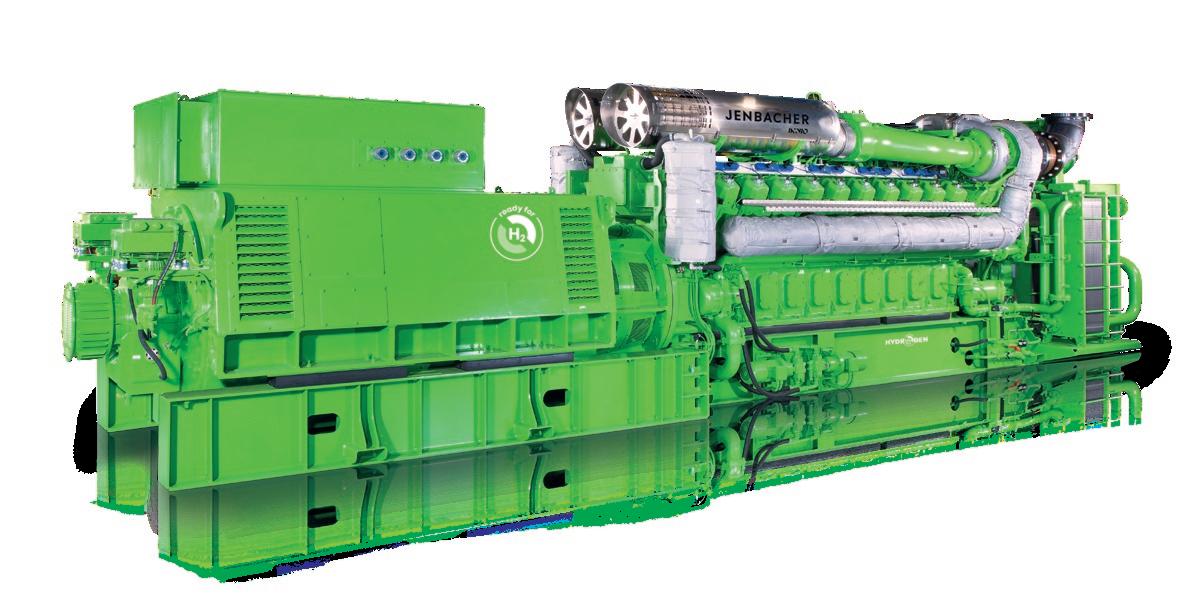

With efficient energy and economics

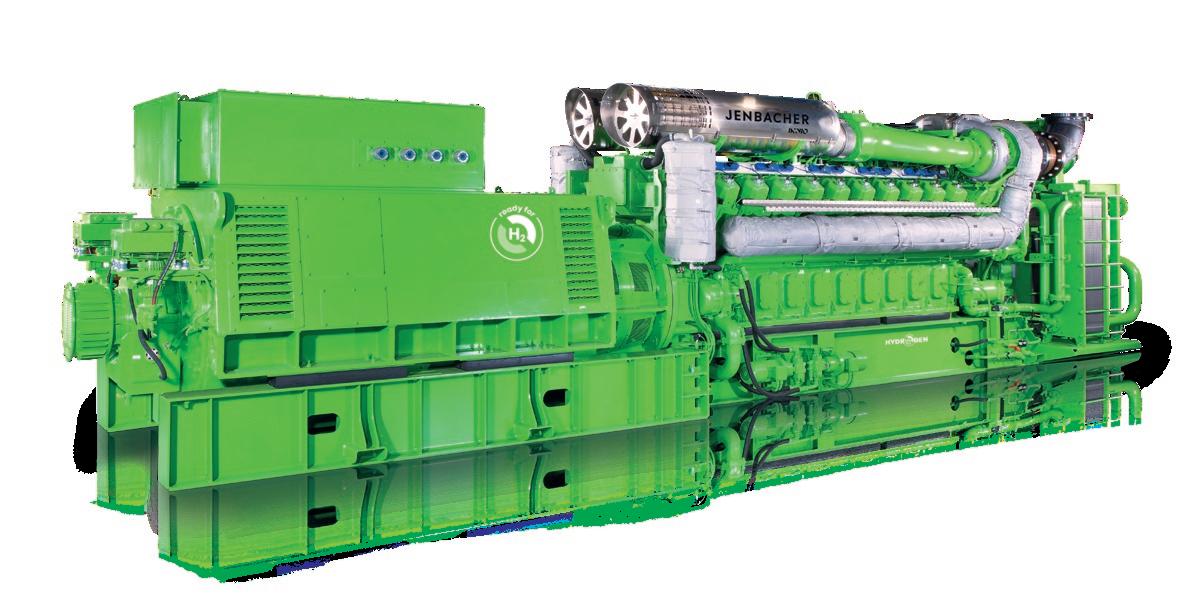

INNIO* is among the world’s leaders in CHP and CCHP solutions.

Power your business with INNIO’s flexible and innovative Jenbacher* CHP and CCHP energy systems, which deliver power, heat and/or cooling for your local site. With up to 95 % total efficiency, cogeneration can reduce your energy consumption and CO2 emissions by more than 30 % compared to the separate generation of power and heat for significantly lower energy costs. Combined with heat storage, you can operate your asset flexibly. INNIO’s CHP and CCHP systems run on a wide range of gases with the option of converting to CO2-free H2** operation once that fuel is more readily available.

Let us support your transition journey. innio.com

* Indicates a trademark.

** Optional scope on demand.

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME.

IN BRIEF

5MW CHP POWER PLANT PROJECT FOR A STARCH MANUFACTURER BASEDIN ISRAEL

500 KVA DIESEL GENSET FOR THE STATE-OWNED MAHIYANGANAYA HOSPITAL IN SRI LANKA

A 500 kVA diesel-powered generator is now in operation at the state-owned Mahiyanganaya Base Hospital - its role is to supply essential power during power outages.

The engine, manufactured in Germany, has been supplied by a company called NATIVEWAY which is based in Sri Lanka.

A company spokesman commented: “All our customers trust the FMTU brand because of its superior quality and reliability. MTU is the generator of first choice for many hospitals due to its manufacturing excellence and super silent sound level of 75 dB(A) @ 1m. Nativeway is the exclusive distributor for MTU diesel generators in Sri Lanka, Bangladesh and Maldives. We have installed many such MTU Generators at state-owned enterprises across Sr Lanka.”

AB’s manufacturer Gruppo AB - Energy Sustainability is working in co-operation with Rimon Energy Ltd and AB ENERGY ISRAEL on a CHP plant for a site owned by Galam.

Galam, a starch manufacturer, is looking for a power plant which offers dependable high energy efficiency. The 5MW cogeneration plant can offer three tons of steam per hour produced from the residual heat of the engine. Galam’s work involves the supply of a variety of starches to the food, construction, paper and tissue, textile, corrugated board, adhesives and binders’ industries in the region.

1.3MW CHP POWER SYSTEM SUPPLIED FOR A MAJOR GREENHOUSE PROJECT BASED IN ALBERTA, CANADA

SIEMENS has shipped a 1.3MW CHP unit to Green Marble, the largest greenhouse operation in Alberta, Canada. This is an additional unit to provide standby support paralleled to work seamlessly with an existing 12.0 MW CHP plant.

Fuel efficiency levels of up to 90% can be achieved with a SIEMENS

Combined Heat and Power (CHP) plant, thanks to the heat utilization features, says the company. For businesses, this naturally means lower costs to produce the same amount of heat and power.

CHP is one method of mitigating environmental impacts – an overall reduction of energy costs by up to 30% while simultaneously achieving a 15-40% decrease in carbon emissions speaks for itself. Profitability can be further increased for industrial applications by exporting excess power to the local grid.

With hundreds of cogeneration plants installed worldwide, Siemens Energy reports that it has a proven track record of providing best-in-class products, services, and solutions for CHP.

Standing at a gargantuan 3.1 million square feet (72 acres), Big Marble is the largest greenhouse in Alberta. It’s home to over 496,000 cucumber plants; 385,400 tomato plants and 47,000 grow lights. A spokesman commented: “We also use 680 km of radiant hydronic heating pipes and a 7 million litre heat recovery system for ultra-efficient operation in winter months and a mechanized louvre system to cool off plants during warm spring and hot summer days. This ensures that our produce is grown from the healthiest and most vibrant plants you’ll find anywhere.”

FLEMISH COMPANY PROVIDES

La Liberté is a key water & waste treatment centre in Suriname, South America, which has been designed, developed and built by De Watergroep.

The project will provide safe drinking water for around 30,000 people. Vandaele Power has just delivered a H-1750 KVA diesel genset mounted in a 40ft steel container to provide backup power for the site’s pumping systems.

De Watergroep is the first Flemish water company to develop an installation of this size in the region.

A spokesman for Vandaele Power comments: “Generator sets we supply for fixed installations stand out for their reliability and fast response.

“These are gensets which can establishing communication

with the grid or with other generators, being able to work in parallel, if the application requires it. They can efficiently supply continuous or backup power with immediate response time to guarantee continuous power supply in the event of power outage.”

Vandaele Machinery / VD Power is an accredited contractor class 6 for P1 and P2. This recognition is mandatory to be allowed to install e.g. backup power generators or to carry out large projects in the public sector. The company is VCA certified and is a member of SIGMA.

11 WORLDWIDE INDEPENDENT POWER NEWS APRIL 2023 www.wipmagazines.com www.powermediagroup.co.uk

1,750 KVA DIESEL GENSET INSTALLED AT A WATER & WASTE TREATMENT SITE IN SURINAME, SOUTH AMERICA

IN BRIEF

1,000 KVA DIESEL GENSET FOR THE HIRIWADUNNA WATER TREATMENT PLANT

Sri Lanka’s National Water Supply and Drainage Board (NWSDB) uses TEKSAN Power generators at many of its water treatment plants and pump houses across Sri Lanka.

The Hiriwadunna Water Treatment Plant recently installed a TEKSAN 1000 kVA container type power generator for its essential energy requirement. This water treatment plant (WTP) provides safe water to about 40,000 consumers living in Rambukkana and Kegalle area. The service area is a mountainous area with altitude varying from 200m to 300m. The treated water complies with the Drinking Water Standard of Sri Lanka, SLS 614-1983. TEKSAN is a leading European brand manufactured in Turkey in accordance to European standards. The TEKSAN brand is trusted by customers due to its reliability and high standards.

TWO KD 3500-E 3,500 KVA DIESEL GENERATORS FOR A PHARMACEUTICAL PROJECT IN BELGIUM

Two Kohler KD 3500-E diesel gensets have undergone FAT testing at Kohler France. They have been designed and built to provide emergency power for a revolutionary pharmaceutical project in Belgium.

Powered by the Kohler KD83V16, 3800HP strong with a key displacement of 83470cc and 16 cylinders in V. KOHLER G-Drive diesel engines produce industry-leading power output in a package which enables a smaller generator set footprint while delivering best fuel consumption at more nodes than any competitor between 800 and 3250 kW. That means higher performance at reduced operating cost.

The engine architecture, injection system and engine management of G-Drive engines are elements which have been designed to achieve optimal generator set performance while meeting all worldwide emission requirements.

Turbochargers have been designed for maximum power and optimal combustion. They are specifically matched to each engine and engineered to provide the required amount of air at all times, which reduces fuel consumption and enables operation at high altitudes. The common rail fuel system generates up to 2200bar injection pressures for maximum efficiency, optimizing the combustion pressure curve.

ROTARY UPS

Installed in late 2022, two 600KW Weichai Baudouin diesel generator sets continue to provide Guiyang IHG hotel in China, with emergency backup power, reports Taizhou Tontek Power Technology Co., Ltd.

A spokesman commented: “The customer requested that the 600KW Weichai Baudouin generator sets run in parallel and specified the Baudouin engine 6M33D725E310(675/725KW). The sets also feature Stamford alternators S5L1D-H41 (600kW) and Smartgen controllers HGM9510.”

Manufactured in factories located in France and China, Baudouin engines offer ISO 9001 and ISO/TS 14001 certifications and meet the highest demands for both quality and environmental management.

Baudouin engines also comply with the latest IMO, EPA and EU emission standards, and are certified by all major IACS classification societies around the world. Baudouin’s production philosophy rests on three key principles: the engines are durable, robust and built to last. These are the hallmarks of every Baudouin engine, reports the company.. From standby power generators powering banks and hospitals to prime and continuous generators powering mines and oil fields a number of applications in China rely on Baudouin ‘s power to stay up and running.

AUSONIA S.r.l. has provided the equipment and systems integration for seven 1750 KW diesel-fuelled rotary UPS into a complete 12,25 MW backup power solution. This has a technical output@11,5kV for a petrochemical facility based in Malaysia. Uninterruptible Power Supplies, with battery backup, provide a few seconds to a few minutes, or up to a couple of hours, of backup power to immediately replace power from the mains in case of failure.

While these short periods of time can give facilities time for an external generator to start and come online, or time for personnel to perform proper equipment shutdowns, UPS are suitable for short periods of time and can support power outages

for a limited time without transferring the load to a

separate generator backup system.

Diesel rotary uninterruptible power supply devices (DRUPS) combine the functionality of a battery and plus a diesel generator for long term uninterrupted power without requiring a power transfer.

A DRUPS can have enough fuel to power the load for days or even weeks in the event of failure of the mains electricity supply.

Established in 1932, Ausonia is a key genset manufacturing company based in Italy, offering a range of gensets up to 3300 kVA in capacity.

APRIL 2023 NEWS 12 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

SEVEN 1750 KW DIESEL

SYSTEMS SUPPLIED TO A MAJOR PETROCHEMICAL FACILITY IN MALAYSIA

GUIYANG IHG HOTEL, CHINA, HAS A RELIABLE, INDEPENDENT POWER SUPPLY THANKS TO TWO 600KW WEICHAI BAUDOUIN DIESEL GENERATOR SETS

UK SPACE AGENCY BACKS POWER PLANTS ON THE MOON

Rolls-Royce has secured funding from UK Space Agency, which is backing research by R-R into how nuclear power could be used to support a future Moon base for astronauts.

Researchers at Rolls-Royce are working on the Micro-Reactor programme to develop a technology which could provide the power needed for humans to live and work on the Moon. Nuclear power, says R-R, has the potential to dramatically increase the duration of future Lunar missions and their scientific value.

The UK Space Agency has announced £2.9 million of new funding for the project, which will deliver an initial demonstration of a UK lunar modular nuclear reactor. This follows a £249 000 study funded by the UK Space Agency in 2022.

Rolls-Royce plans to have a reactor ready to send to the Moon by 2029. Relatively small and lightweight compared to other power systems, a nuclear microreactor could enable continuous power regardless of location, available sunlight, and other environmental conditions.

Rolls-Royce will be working alongside a variety of collaborators including the University of Oxford, University of Bangor, University of Brighton, University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) and Nuclear AMRC.

The funding means Rolls-Royce can further strengthen its knowledge of these complex systems, with a focus on three key features of the MicroReactor; the fuel used to generate heat, the method of heat transfer and technology to convert that heat into electricity.

The potential applications of Rolls-Royce MicroReactor technology are wide-ranging and could support commercial and defence use cases in addition to those in space. The aim is to create a world-leading power and propulsion capability for multiple markets and operator needs, alongside a clean, green and longterm power source.

The partnership with Rolls-Royce comes after the UK Space Agency recently announced £51 million of funding available for UK companies to develop communication and navigation services for missions to the Moon, as part of the European Space Agency’s Moonlight programme, which aims to launch a constellation of satellites into orbit around the Moon, primarily for communication and navigation purposes.

Diesel generators with Cummins KTA50-G3 & KTA19-G4 engines and Leroy Somer LSA50.2M6 & TAL0473C alternators have been supplied by Ghaddar Machinery to the Ministry of Energy in Sierra Leone, West Africa.

Ghaddar Machinery Co. through its dealer in Sierra Leone delivered the first batch of a project of total capacity of 14 MW consisting of multiple units synchronized together. Those will ultimately be distributed across seven power stations across the country.

The Cummins KTA50-G3 package is a fully integrated, robust power generation system that sets new benchmarks in performance, reliability and efficiency for Standby and Prime Power applications.

It contains the following features: Design: 4 cycle, 60° Vee, 16 cylinder diesel, turbo charged, charge air-cooled; Bore: 159 mm; Stroke: 159 mm; Displacement: 50.3 L; Cylinder block: Cast iron; Battery capacity: 2 parallel strings of 2 x 12 V, 75 A/hr; Battery charging alternator: 35 A; Starting voltage: 24 V negative ground; Fuel system: Direct injection; Fuel filter: Spin on fuel filters with water separator; Air cleaner type: Dry replaceable element with restriction indicator; Lube oil filter type(s): Spin on full flow filter, plus a standard cooling system: 50°C ambient radiator.

Each genset has a Leroy Somer LSA50.2M6 - this is a high performance and reliable industrial alternator for all types of generator sets (power 1100 - 1640 kVA). The LSA range is ‘the name that built the legend’ says the manufacturer: reliable, high performance alternators with a wide range of options and customisations to match all requirements. LSA alternators are regarded as flagship products. They are designed for demanding applications, for grid-connected projects or aboard ships with their LSAM variants. The Leroy-Somer TAL 0473 All-purpose industrial 4-pole alternator is considered suitable for all standard generators sets applications. The TAL 0473 is the latest addition to the range based on the .3 platform. It replaces the TAL 047 and benefits from improved performance, offering kVA/50Hz - kW/60Hz | Continuous / 40°C.

13 WORLDWIDE INDEPENDENT POWER NEWS APRIL 2023 www.wipmagazines.com www.powermediagroup.co.uk

14MW POWER STATION FOR THE MINISTRY OF ENERGY IN SIERRA LEONE

IN BRIEF

LAUNCH OF A NATURAL GAS ENGINE COGENERATION SYSTEM (2000 KW)

Mitsubishi Heavy Industries Engine & Turbocharger (MHIET) is launching a new natural gas engine cogeneration system with a power generation output of 2000 kW.

The new SGP M2000 package encloses a 16-cylinder natural gas-fired engine modeled G16NB which has an electrical efficiency of 44.3%, the highest level in the world for a 2,000kW-class, the company said. The SGP M2000 was released in the Japan market from April 1st, 2023.

Compared to MHIET’s existing 1000 kW gas engine cogeneration system, SGP M2000’s electrical efficiency is 1.8 percentage point higher, which means CO2 emission rate involved in power generation is less. It also features compactness. SGP M2000 is able to give twice as much output as MHIET’s existing cogeneration system with an engine of the same displacement.

CONSTRUCTION OF NYBRO ENERGI BATTERY STORAGE UNIT IN SWEDEN IS UNDERWAY

US$5.5 BILLION INVESTMENT INTO NEW BATTERY MANUFACTURING COMPLEX

LG Energy Solution is putting US$ 5.5 billion into building a battery manufacturing complex located in Queen Creek, Arizona, USA. The complex will consist of two manufacturing facilities – one for cylindrical batteries for vehicles and the other for lithium iron phosphate (LFP) batteries for energy storage systems.

It marks the largest single investment ever for a stand-alone battery manufacturing facility in North America. It is also more than four times the amount the company initially announced last year to manufacture cylindrical EV batteries in the same location. The cylindrical battery manufacturing facility is expected to start mass production in 2025, mainly supplying EV makers in North America.

The company also plans to invest US$ 3.2 billion in building a cylindrical battery manufacturing facility with a capacity of 27 GWh, and US$ 2.3 billion in an LFP battery facility with the capacity of 16 GWh. Work will being on both facilities later in the year. Once complete they will have an output totalling 43GWh.

With the new battery manufacturing complex, LGES will boost its production capacity in major product segments, develop more cohesive partnerships with its customers in both EV and ESS sectors. It will , cut back on current logistics costs by bringing its key manufacturing facilities closer to its core markets and customers.

A project involving the installation of the Nybro Energi battery storage unit in Sweden is now underway. The 12MW/12MWh one-hour system is being installed by Soltech Group’s division of clean energy solutions for the Swedish municipal energy provider.

The project is expected to reach its commercial operation date (COD) by the end of 2023.

The transmission system operator (TSO), Svenska Kraftnät, will receive frequency regulation services from the battery energy storage system (BESS). The BESS may also eventually supply power to the grid during periods of high demand.

The project’s owner will be Nybro Energi. “We were one of the first energy companies in Sweden to invest in large-scale battery storage of this kind,” said the company’s CEO Hakan Dahlgren. “When we have more renewable energy sources we will need to store this energy and stabilize the grid, so we can see a market for these solutions.”

Soltech Energy Solutions recently announced 2MW projects for an EV truck charging park (Scania) and a solar PV plant. Both are in the Swedish battery storage market. It also established another project at a solar PV plant in September at a cost of US$1.4 million.

The Italian UPS leader, Riello UPS, joins other major players in the sector to promote the ongoing development of Italy’s national data centre industry

Riello UPS, a brand of the Riello Elettronica group, a world player in the production of uninterruptible power supplies and photovoltaic inverters, has announces its entry into IDAthe Italian Data Centre Association. This is the first Italian association which has been eastablished to bring together manufacturers and operators of Data Centers in Italy.

Strengthened by experience and know-how gained in the protection of data centres around the world, Riello UPS is now contributing to the objectives of the association. Established with the aim of uniting the most important

companies in the sector, the IDA aims to put enhance Italy’s position as an ideal location for data centres at a global level.

Riello UPS has been carrying out projects related to data centres for some years now.

A company spokesman commented:

“The company has been working to inspire, create and support events and initiatives in this area. For , example, with its Site Preparation Forum.

“It has also encouraged the creation and development of networks of operators with complementary skills and know-how who operate in this sector.”

APRIL 2023 NEWS 14 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

RIELLO UPS BECOMES A MEMBER OF IDA, THE ITALIAN DATA CENTRE ASSOCIATION

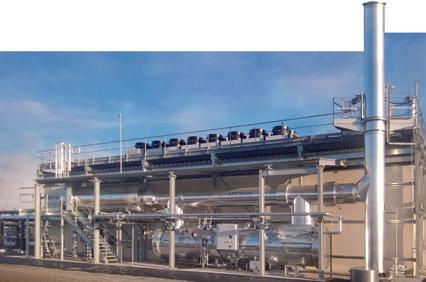

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

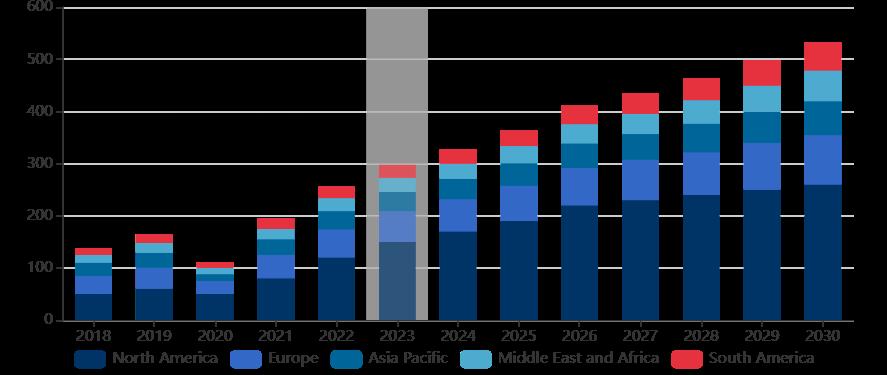

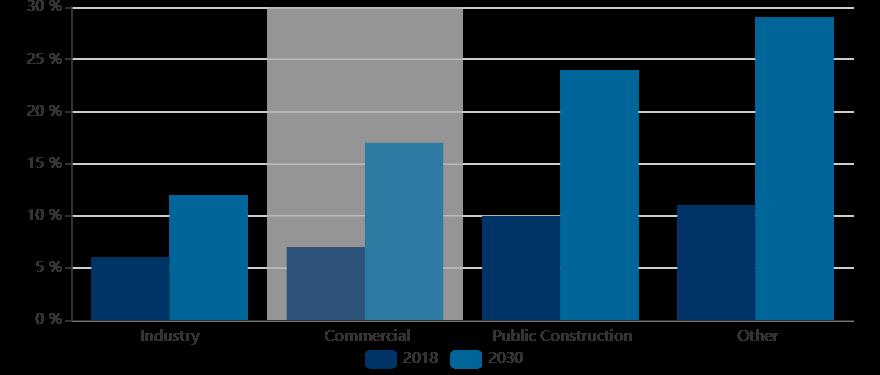

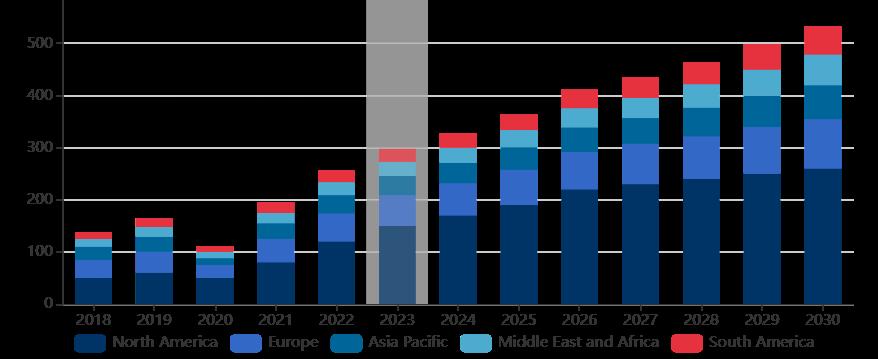

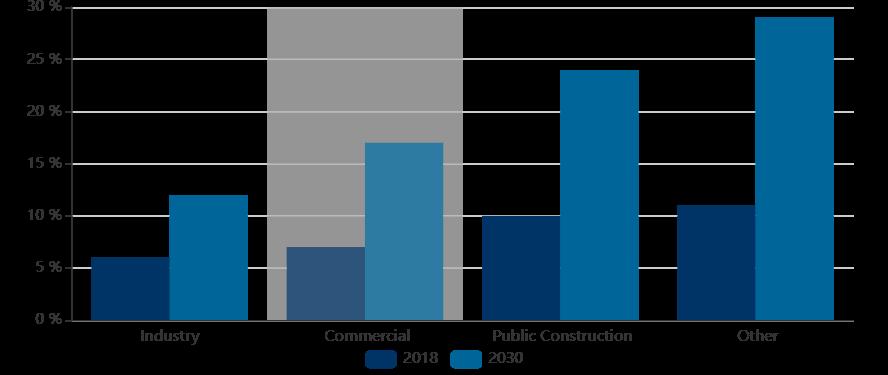

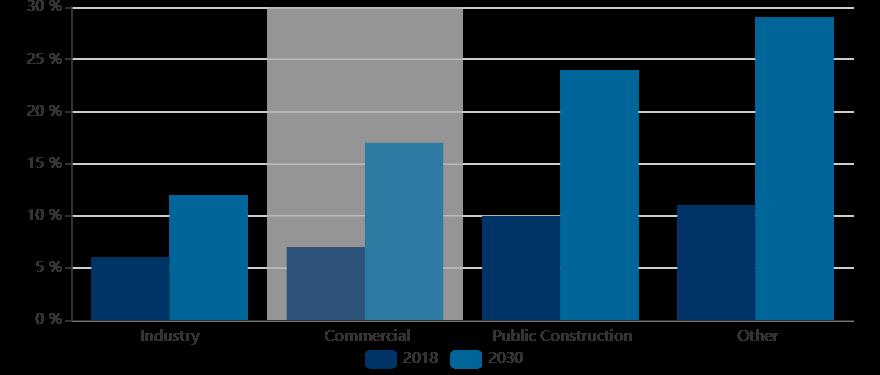

GAS GENERATOR MARKET SIZE & SHARE ANALYSIS - GROWTH TRENDS & FORECASTS (2023 - 2028)

The gas generator market is segmented by capacity rating (less than 75 kVA, 75-375 kVA, and above 375 kVA), End User (Industrial, Commercial, and Residential), and also by geography (North America, Europe, Asia-Pacific, South America, and Middle East & Africa), explains Mordor Intelligence, a key market analyst.

The gas generator market is expected to register a CAGR of more than 4.2% during 2022-2027. The COVID-19 pandemic had a negative impact on the gas generator market across the world due to the reduction in power demand, mainly from customers in the industrial and commercial sector, as many manufacturing plants and retail businesses were closed during the Covid lockdown.

Factors such as increasing awareness regarding natural gas as a clean and reliable fuel, increased concerns over diesel maintenance and refuelling issues, decreasing natural gas fuel prices, and the general desire to be more environmentally-responsible have supplemented the demand for gas generators in recent years.

Moreover, to counter the high-pollution emission risk, several countries have been implementing stricter emission norms pertaining to diesel generator emissions and are promoting the usage of eco-friendly gas generators.

However, the lack of gas grid connectivity via pipeline, resulting in hindered fuel supply, is expected to act as a challenging factor to overcome the gas generators market in the coming years.

Below 75 kVA capacity generators are estimated to have the largest market share during the forecast period, supported by the increase in demand from telecom, retail, and other commercial buildings and residential sectors.

The commercial and industrial sectors of the emerging economies, the residential sector of developed economies, and the increasing need for power in defense operations are expected to create significant opportunities for market participants in the near future.

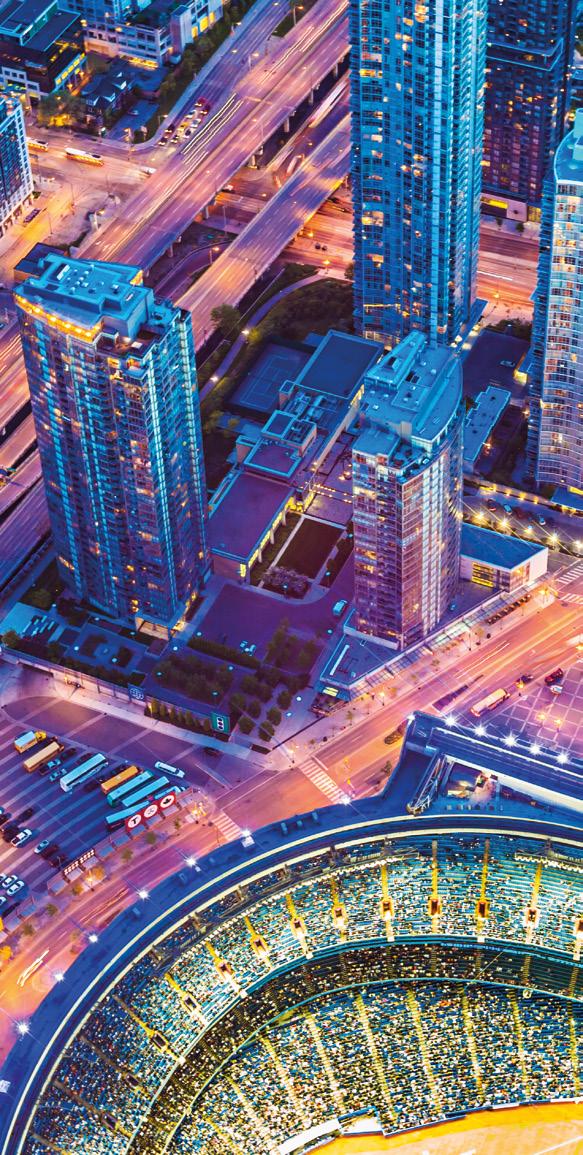

North America is expected to be the largest market during the forecast period for gas generators, with the majority of the demand expected to come from the United States and Canada.

Less than or equal to 75 kVA gas generators are used in the telecommunication sector, commercial complexes, small restaurants, small-scale industries, and petrol stations, primarily as backup power in grid-connected areas and as the main power source in off-grid areas.

WITH THE FALLING COST OF NATURAL GAS, THE USE OF NATURAL GAS ACROSS THE RESIDENTIAL SECTOR IS EXPECTED TO DRIVE THE GAS GENERATORS MARKET IN THE DOMICILE SECTOR.

The demand for less than or equal to 75 kVA gas generators is expected to increase, with the change in the landscape for small businesses, especially in the developing countries of Asia-Pacific and Africa, say the anlysts from Mordor |Intelligence.

As power failure is common in most parts of these regions, most households and shops prefer portable and affordable small generators.

The building and construction market is on the rise in India and China due to current government initiatives, such as smart cities and green building initiatives, which are expected to create the demand for gas generators during the forecast period, in turn, driving the market.

The purchase of less than 75 kVA gas generators is mostly based on price and requirement rather than efficiency as they offer key emergency backup power.

This has helped the small generator manufacturers to grow and capture the demand in developing countries, where residential construction projects and governmental investments in the tourism and agriculture industries are witnessing robust growth.

The natural gas industry in North America has undergone changes of unprecedented magnitude and pace, with natural gas consumption witnessing a 25% increase over the past 10 years and the availability of

abundant natural gas resources across shale regions is likely to increase demand for gas generators during the forecast period.

In 2020, approximately 40% of the operating electricity generating capacity in North America was contributed by natural gas, replacing coal as a prime source of energy supply. Hence, the increased use of natural gas for electricity generation bolsters market growth.

Severe weather patterns have caused disruptions to the wellestablished electricity transmission networks in the United States, increasing the demand for gas generators in recent years.

As the air emission norms are becoming more stringent in the United States, coupled with the environmental benefits, the demand for gas generators is expected to witness a significant increase, as compared to diesel generators, which are considered more polluting.

The United States enjoys one of the most developed gas-grid infrastructures in the world that ensures a steady fuel supply. With the falling cost of natural gas, the usage of natural gas across the residential sector is expected to increase.

This, in turn, is expected to drive the gas generators market in the residential sector for backup power applications in the coming years. www.mordorintelligence.com

APRIL 2023 16 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

MARKET REPORT

1,000 KVA DIESEL GENSET FOR SRI LANKA & TWO GENSETS FOR A CAMBODIAN BREWERY

The National Water Supply and Drainage Board (NWSDB) uses TEKSAN generators at many of their Water Treatment Plants and Pump Houses across Sri Lanka. Thanks to a new installation the Hiriwadunna Water Treatment Plant is now powered by a TEKSAN 1000 kVA container generator, meeting all its essential energy requirements.

A spokesman comments: “TEKSAN is a leading European brand manufactured in Turkey in accordance to European standards. The TEKSAN brand is trusted by our customers due to its reliability and high standards. Nativeway has installed many TEKSAN Generators at State Owned Enterprises across Sri Lanka.

In late 2023 two TEKSAN 1,650 kVA diesel generators were successfully installed and commissioned for the Inter Mattrid Beverage Company Ltd. based in Cambodia.

Each set features 1,650kva standby Perkins engines and Leroy Somer alternators with a synchronized system.

The Inter-Mattrid Beverage (Cambodia) Co Ltd’s US $78 million brewery/beverage plant has been approved by the Council for the Development of Cambodia (CDC). The multi-million Dollar brewery is being constructed in DeiIth commune’s Sdao Kanleng II village, Kien Svay district in Kandal province. The company’s slogan is: “Mattrid Beer is brewed with the finest ingredients and the latest technology from Europe to YOU for the best-testing beer.”

The TEKSAN generator sets feature state of the art technology and have compliance with ISO 8528, ISO 3046, BS 5514, DIN 6271 standards. These engines offer low fuel consumption, provide accurate speed setting and order, mount to the fuel pump, also have mechanic or electronic type governors.

The sets use alternators which pass the necessary test processes and have been found appropriate according to EC 60034-1; CEI EN 60034-1; BS 4999-5000; VDE 0530, NF 51- 100,111; OVE M-10, NEMA MG 1.22. standards. These have a bearing system which does not need maintenance, with electronic type voltage regulator providing voltage settings.

The control panels ensure comfortable and safe usage. All measured and statistical parameters, operating modes, notice and alarms and condition of generator, are monitored easily from the control panel, reports the manufacturer.

The front of the panel’s metal body features an electronic control module and the emergency stop button. The structure itself is made of steel sheet and is painted with electrostatic powder paint.

TEKSAN reports that it offers panel design and solutions which comply with special requirements of customers as well as other quality standard panels worldwide.

The genset chassis is manufactured from durable steel. Thanks to its rigid structural design and anti-vibration mounts, it reduces vibration level to minimum.

All chassis contain lifting lugs and are designed in accordance with customer specifications to make transportation and positioning easier.

In less than 1600 kVA power generator sets, the fuel tank is integrated with the chassis. Similarly, a rectangular-type fuel tank is provided with generator set seperately. All types of fuel tanks incorporate fuel level indicators.

The cooling system in each genset consists of quality industrial-type radiators, expansion tanks and cooler fans. These keep the temperature of generator set’s components at a constant and proper level.

The TJ-509-T MK3 is a next generation genset controller

combining multi-functionality and wide communication capabilities together with a reliable and low-cost design.

The same controller provides synchronization, load share, AMF, ATS, Remote Start, Engine Control and Remote Display Panel functionalities. The module comes ready for remote monitoring over GSM or Ethernet with plug-in communication modules. Various plug-in modules provide unlimited expansion capabilities allowing to meet any special requirement.

The unit complies and mostly exceeds world’s tightest safety, vibration and environmental standards for the industrial category.

Software features are complete with easy firmware upgrade process through USB port. The Windows based PC software allows monitoring and programming through USB, RS-485, Ethernet and GPRS. www.teksan.com

APRIL 2023 17 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk GENSETS

“

TEKSAN IS A LEADING EUROPEAN BRAND WHICH IS MANUFACTURED IN TURKEY IN ACCORDANCE TO EUROPEAN STANDARDS. THE TEKSAN BRAND IS TRUSTED BY OUR CUSTOMERS DUE TO ITS RELIABILITY AND HIGH STANDARDS. OUR DISTRIBUTOR NATIVEWAY HAS INSTALLED MANY TEKSAN GENERATORS AT STATE- OWNED ENTERPRISES ACROSS SRI LANKA.

EXHIBITION & CONFERENCE

27-28 JUNE 2023

SANDTON CONVENTION CENTRE, JOHANNESBURG

Headline Sponsor: Supporting Organisation:

To find out more and register visit: www.datacentres-africa.com

T: +44 (0) 20 8848 1912

Fuel

In-Line Heaters Hydraulic Oil Heaters Storage Tank Heaters Custom Heaters

UK manufacturers of the PEREGRINE and FALCON range of engine pre-heater solutions, we keep engines running in critical industry sectors High Quality - Durable - Reliable E: sales@preheat.co.uk preheat.co.uk

Fire Safety Generators Fuel Storage

Infrastructure. Services. Solutions

Diesel

and

As

Marine

Investment.

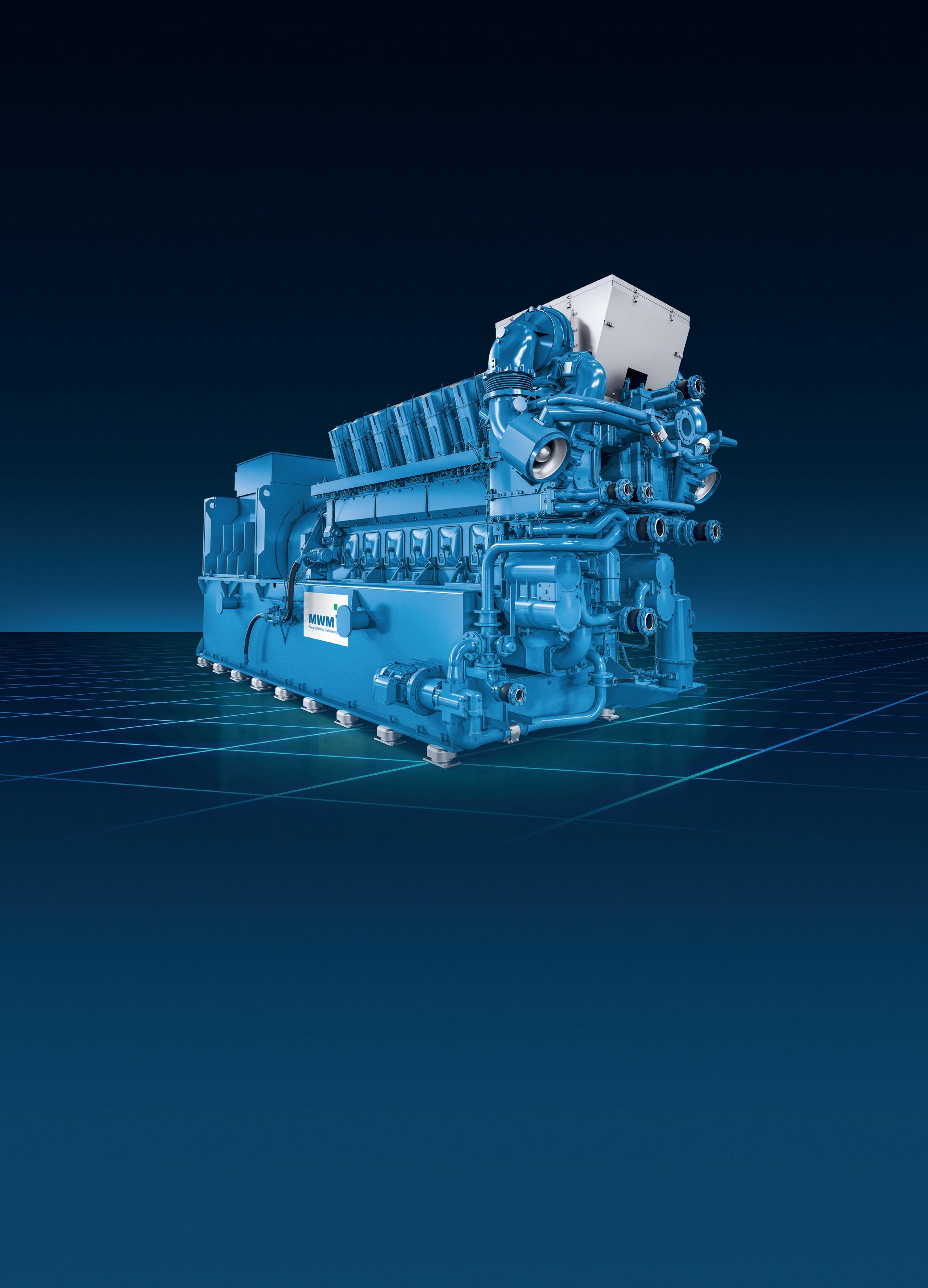

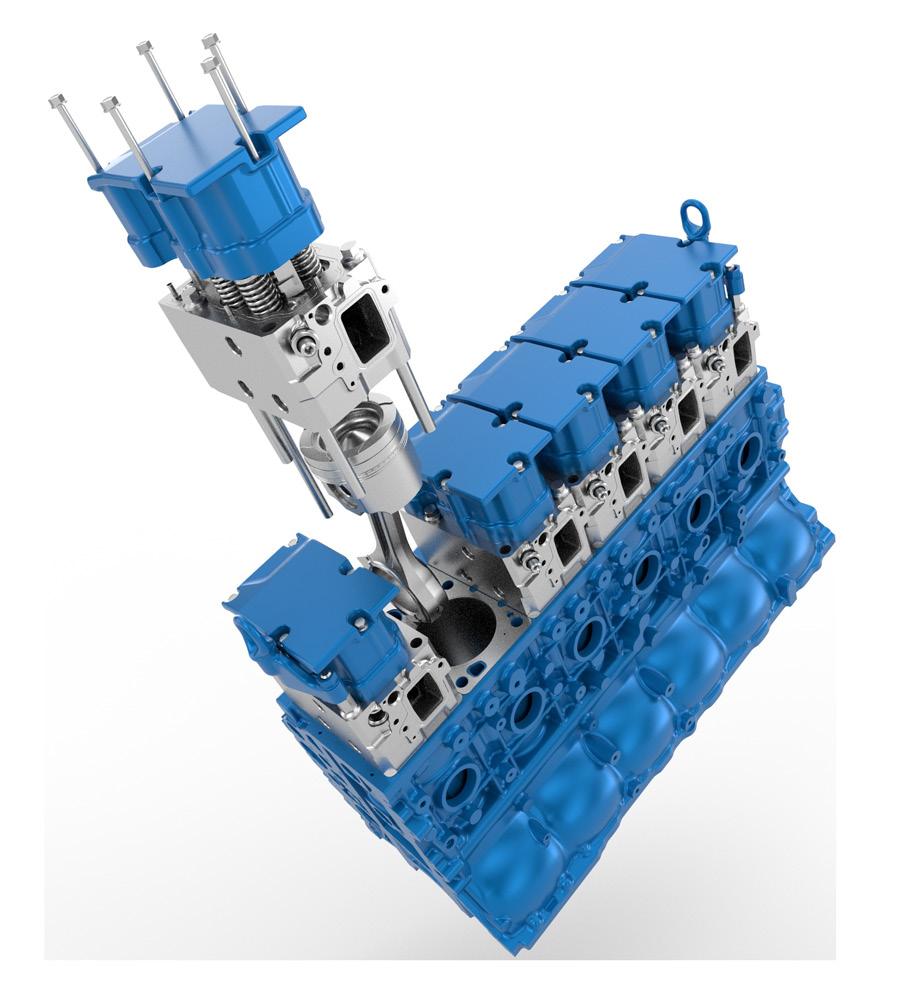

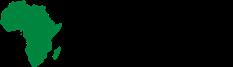

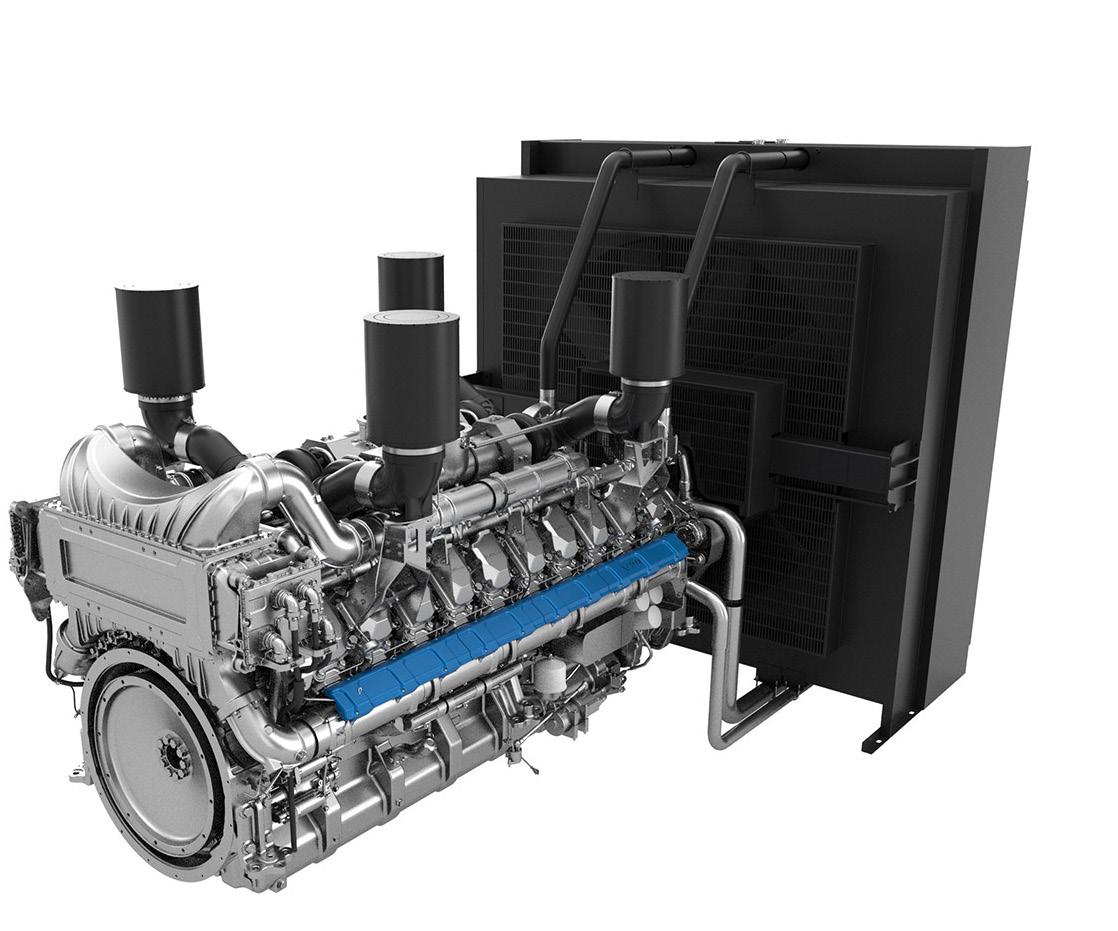

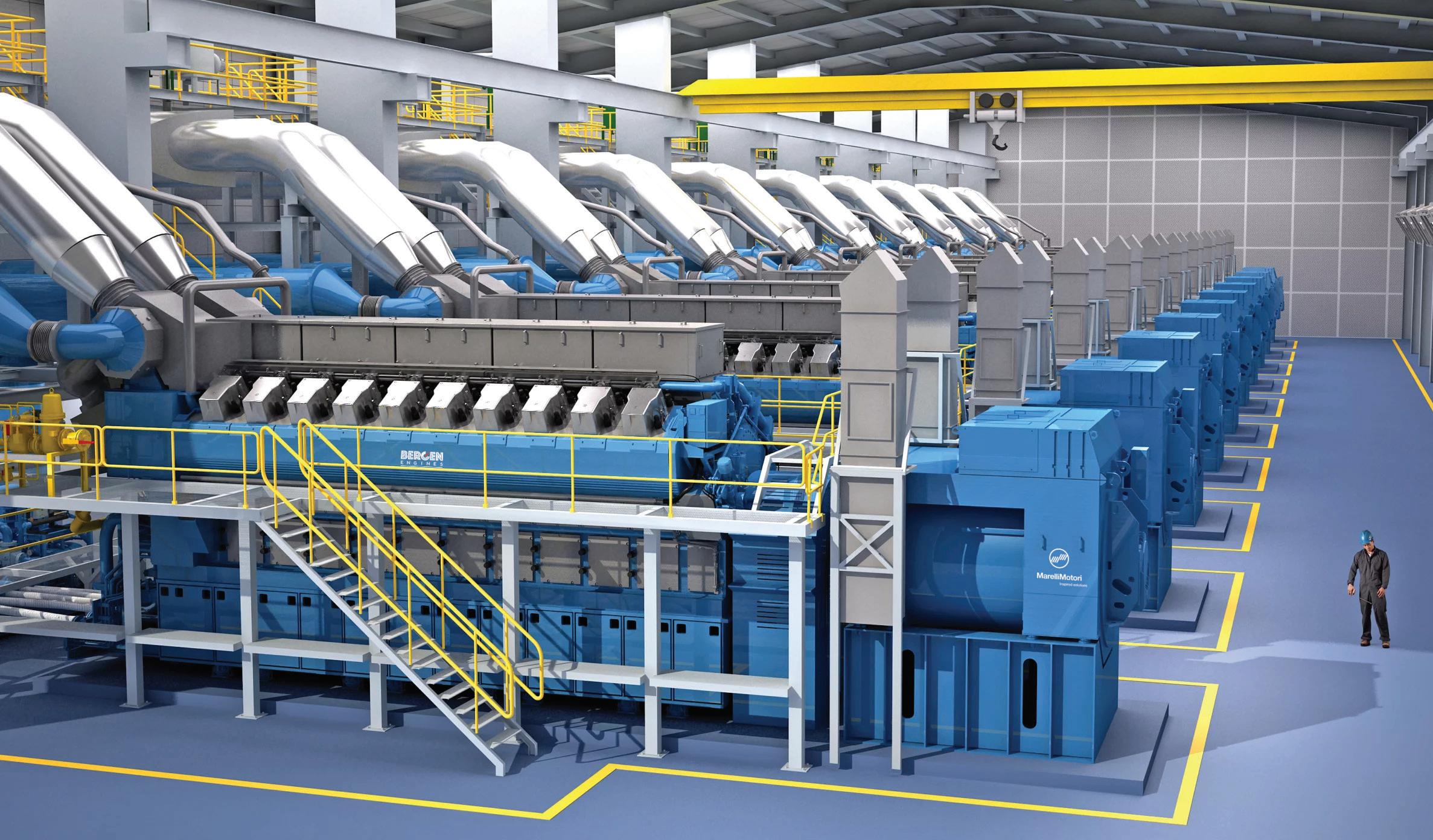

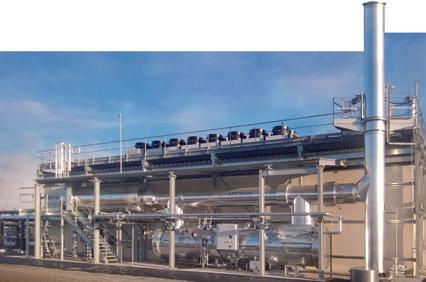

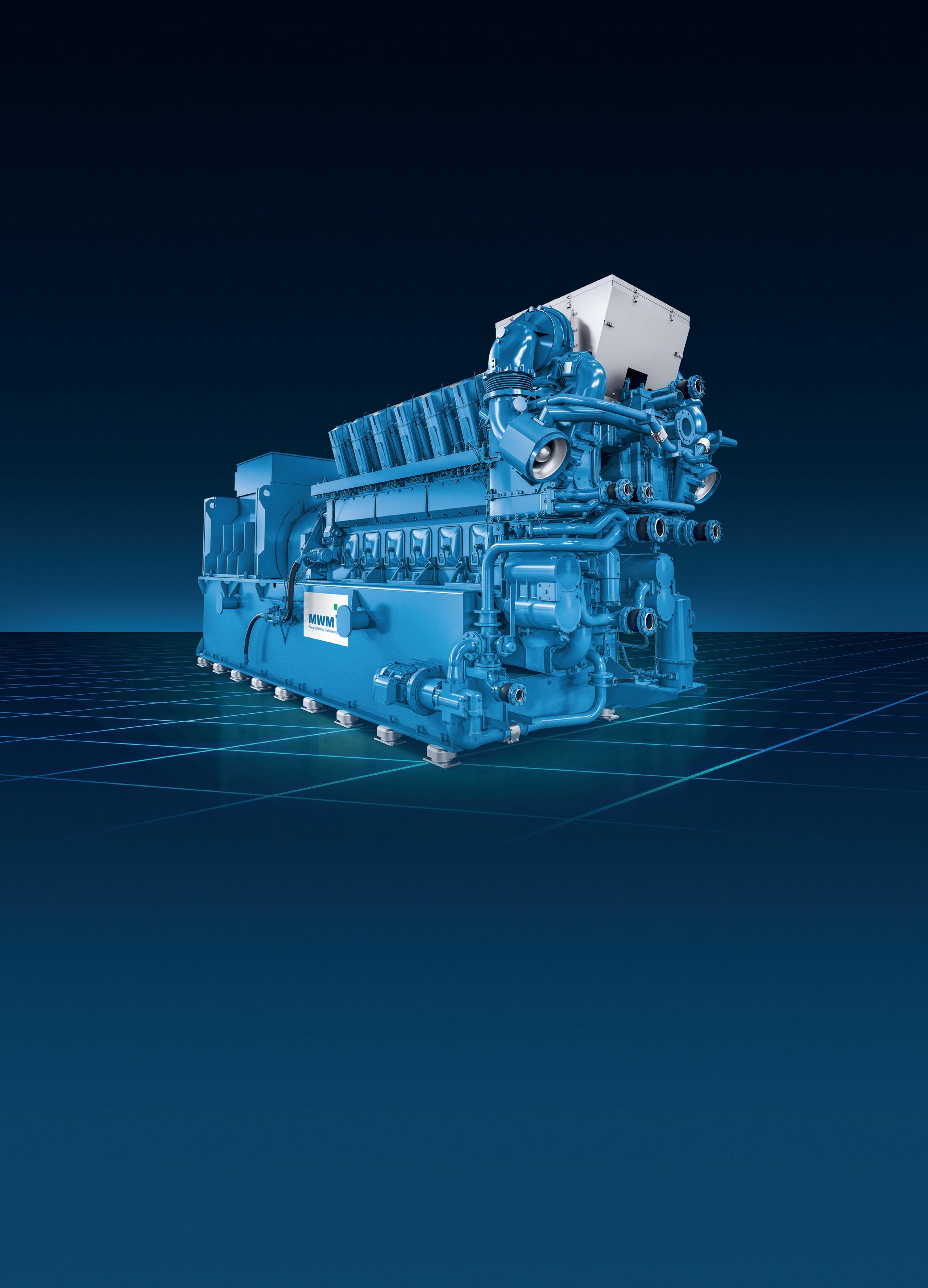

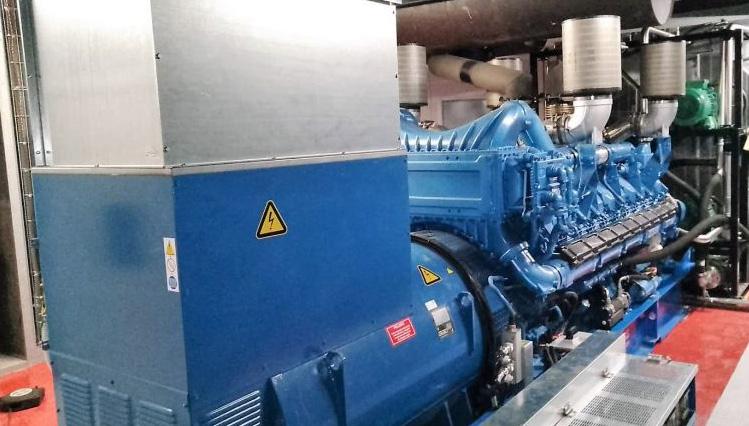

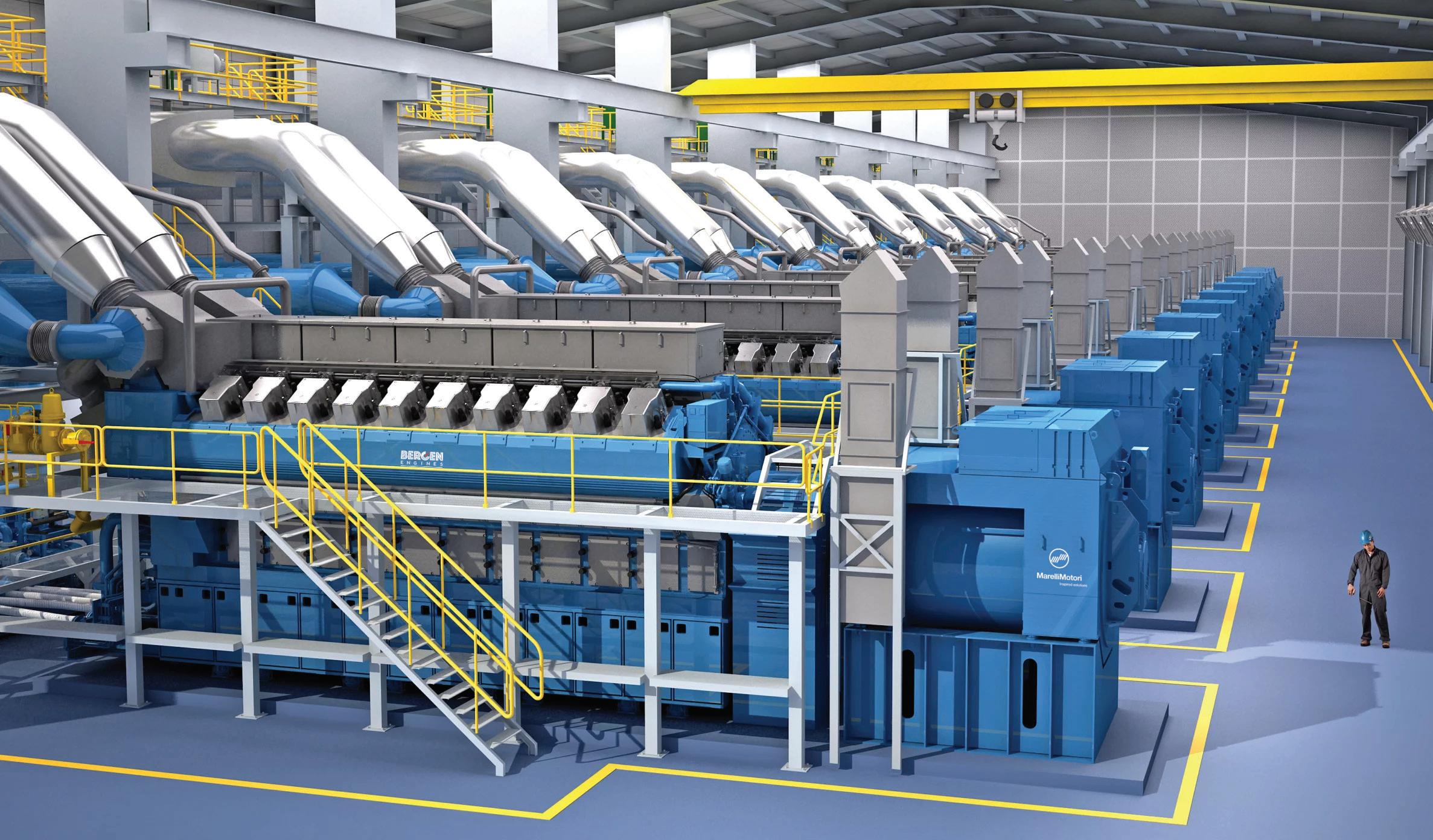

ENERGY PROJECT ON LAKE KIVU, RWANDA: POWER PLANT WITH 19 GAS-ENGINED GENSETS

Lake Kivu in Rwanda is the scene of an unusual energy project. The Rwandan lake of 2,400 km2 and a depth of 490 m has methane deposits which are used for eco-friendly energy generation.

The construction of a power plant, comprising 19 MWM TCG 2032B V16 gas gensets began in 2019. Now, the go-live phase of the MWM gas engines is imminent.

These gas gensets form the core of the power plant on the shores of Lake Kivu, which has an output of 76 MW.

Methane is extracted from the depths of the lake by means of a suction system and transported to the shore through pipelines of a length of up to 17 km. At the surface, the methane is processed and ‘sweetened’ in scrubbing towers in order to improve the quality of the gas.

From July 2023, methane extracted from the lake will be used to produce energy for Rwanda. The MWM commissioning engineers are preparing the power plant for its go-live debut onsite.

The first step is a mechanical preliminary go-live, which takes five days per MWM gas genset. Among other things, this includes an endoscopy of the cylinder combustion chambers, the filling of oil, and the review of the cooling water modules and peripheral parts such as pumps and valves.

The MWM gas gensets have made a long journey from Hamburg to Rwanda. The ship voyage was followed by a trip of 1,600 km on both desert and savanna tracks from Mombasa to Rwanda.

“By means of extensive controls, we make sure that the MWM gas gensets will run perfectly when the power plant is ramped up,” explains Thomas Mattil, the project manager responsible for the plant.

In the next step, the electric switchboard will be checked and commissioned. A total of 19 MWM TCG 2032B V16 gas gensets form the core of the power plant, which has an output of 76 MW.

The central plant switchboard of the highly complex power plant is the largest ever set up at a customer by Caterpillar Energy Solutions for the MWM brand.

The plant switchboard is used for the central control of the MWM gas gensets, cooling water modules, and other components on land. By July 2023, all 19 MWM TCG 2032B V16 gas gensets will be ready to produce sustainable energy for Rwanda.

“If everything proceeds smoothly, the energy project on the shores of Lake Kivu will be one of the world’s most exciting and innovative projects for the energy supply with MWM gas gensets”, says Mattil.

An ambitious energy project Lake Kivu in Rwanda - a body of water about five times the size of Lake Constance - forms the basis for this nationwide energy supply project.

The lake hosts major methane deposits which can be used for eco-friendly energy generation purposes. The methane will fuel one of Rwanda’s largest power plants, which, in turn, will supply the landlocked country with energy.

According to estimates of the Swiss Federal Institute of Aquatic Science and Technology (Eawag), some 300 km³ of carbon dioxide and 50 to 70 km³ of methane are dissolved in Lake Kivu.

Methane - the main component of natural gas - is a key fossil energy source.

The colourless and odourless gas in the lake can escape to the surface in an uncontrolled manner, which not only harms the environment and contributes to global warming. It also represents an acute danger for humans. Scientists and businesses want to harness the gas hazard from Lake Kivu before disaster strikesand produce power from the gas.

The MWM TCG 2032B V16 gas gensets transform the methane gas, which is harmful to the environment,

into useful electrical energy.

“In this way, our gas gensets greatly contribute to the reduction of climate-damaging methane gas, while at the same time producing clean energy,” explains Tim Scott, Director for MWM.

The gas-water mixture is transported up to the surface of the lake through pipes. At the surface, the methane is processed in scrubbing towers. In this way, the gas is upgraded for the energy generation, enabling the extraction of even more electrical energy. The carbon-dioxide is sent back down to the depths of the lake.

The Lake Kivu project will supply Rwanda with energy for several decades. According to the Swiss Federal Institute of Aquatic Science and Technology (Eawag) of the ETH, the 55 km³ of methane present can be transformed into power worth some US$20 billion, based on today’s energy prices.

“We are pleased to be able to deliver a significant contribution to this sustainable, extraordinary energy project with our MWM gas engines, thereby supporting Rwanda’s economic growth”, says Scott.

www.mwm.net

APRIL 2023 19 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

GENSETS

2,250 KVA DIESEL BACKUP GENSET SUPPLIED TO A CANCER HOSPITAL IN SPAIN

Electra Molins has confirmed that the company was recently involved in the installation of a 2,500 kVA genset in a Cancer Hospital in Spain. This new EMT-3125 genset comes with a Baudouin 20M33 engine and a Mecc Alte alternator is equipped with an MP15 synchronization and closed loop transfer control panel, the same type which Electra Molins technicians installed in the existing genset (from another manufacturer) for parallel operation between the two gensets. The Baudouin 20M33 engine features a common rail system with one high pressure pump gear driven in the V angle of cylinder block.

There are two rails mounted on the sides of the engine, double wall, under inlet manifold. It features a Duplex fine filter and water separation filter assembly with transparent cup for better efficiency.

Electric fuel priming pump integrated in the filters support. Special rear mounted air filter with restriction indicator. Exhaust manifold shield for heat isolating

The four compressors feed a single water-air intercooler, mounted over the exhaust system flywheel housing, with vertical flow Special rear-mounted air filter with restriction indicator. Exhaust manifold and turbocharger

The closed loop transfer control panel is a key feature of this genset. The ability of a feedback system to modify the natural dynamics of a system and - in particular to stabilise it - is the basic architecture of any closed-loop system.

Systems in which the output quantity has no effect upon the input to the control process are called openloop control systems and open-loop systems are just that, open ended non-feedback systems.

The goal of any electrical or electronic control system is to measure, monitor, and control a process and one way in which the user can accurately control the process is by monitoring its output and “feeding” some of it back to compare the actual output with the desired output so as to reduce the error and if disturbed, bring the output of the system back to the original or desired response.

The quantity of the output being measured is called the “feedback signal”, and the type of control system which uses feedback signals to both control and adjust itself is called a Close-loop System.Closed-loop systems are designed to automatically achieve and maintain the desired output condition by comparing it with the actual condition. It does this by generating an error signal which is the difference between the output and the reference input. In other words, a “closed-loop system” is a fully automatic control system in which its control

action is dependent on the output. The Electar Molins genset includes the following sound and power systems:

*Air inlet silencer

*Air outlet silencer

*Exhaust silencer

*Soundproof door

*Silentblocks

*Load transfer panel

*Power cables outlet.

Electar Molins offers an MP15 automatic panel, a “standard item of equipment with the most functionalities in the market”. This is said to be easy-to-use, even by untrained personnel. It comes in different versions, depending on the customer requirements.

The design conditions include operating at extreme environmental temperatures, IP65 protection and great resistance to electrical disturbances such as overvoltage caused by atmospheric discharges. It is widely considered to be a very reliable and robust panel, reports the company.

The MP15-E panel is an auto-start control panel for the generating set on mains failure situations. It controls the mains supply, automatically starting up and shutting down the generating set, marshalling the switching process and controlling

the smooth running of the set at all times. The MP15-E5 panel makes it possible to carry out no break load transfers (i.e., without going through zero) not only from generating set to mains when mains resumes supply, but also from mains to generating set by automatic synchronisation and load transfer on ramp. This enables the user to test the generating set with the real load at any time, without the installations being affected by the supply being cut off.

The MP15-E5 equipment complies with the technical conditions established in the Spanish Low Voltage Electrotechnical Regulation ITC-BT-40 4.2 concerning no break load transfer. It can be set up for switching by means of motorised automatic circuit breakers or switching via contactors.

The MP15-DR panel is an auto-start control panel for a generating set that is activated by an external signal. This start signal normally comes from switch control equipment of the CON-2015 type (or similar) that controls the mains supply and gives the start signal to the generating set in the event of a mains failure. While the generating set is operating, the panel controls the smooth running of the set. electramolins.com

APRIL 2023 20 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

GENSETS

FOUR NEW DIESEL GENSETS (4 X 3250 KVA) INSTALLED IN A DATA CENTRE IN SOUTH KOREA

Four KD3250UE generators and customised a master control panel were recently provided to synchronise a power system for a data centre customer in South Korea.

Kohler Engineers supported the company’s partner in Korea, Coastal Power, on the Site Acceptance Test and Integrated System Test; this was carried out in the presence of the customer’s nominated Commissioning Agent. Kohler engineers also provided hands-on training to Coastal Power and its personnel at their workshop.

Each KOHLER diesel-powered generator set and its components are prototype-tested, factory-built, and production-tested before despatch.

The 60 Hz generator set offers a UL 2200 listing. The 60 Hz generator set meets NFPA 110, Level 1, when equipped with the necessary accessories and installed per NFPA standards. A three-year limited warranty covers all systems and components is also provided. Details on the genset are as follows:

-Standby Range (kW/kVA) 3250/4062;

-Prime Range (kW/kVA) 2950/3688

- Continuous Range (kW/VA) 2450/3062

-Frequency 60 Hz & Speed 1800 RPM

-Alternator Type: Brushless, Permanent-Magnet Pilot Exciter

Controllers are available for all applications involved with the KD3250UE gensets. In each genset, a low coolant level shutdown feature prevents overheating (standard on radiator models only).

An electronic, isochronous governor delivers precise frequency regulation, while there are multiple circuit

breaker configurations to suit a wide variety of applications

A pilot-excited, permanent-magnet (PM) alternator provides superior short-circuit capability, and each set offers NEMA MG1, IEEE, and ANSI standards compliance for temperature rise and motor starting.

Superior voltage waveform is achieved from two-thirds pitch windings and skewed stator; the brushless alternator with brushless pilot exciter provides excellent load response.

Each set is capable of a sustained short-circuit current of up to 300% of the rated current for up to 10 seconds and enables downstream circuit breakers to trip without collapsing the alternator field. The genset itself features selfventilated and drip-proof construction.

KOHLER’s KD range of standby generating sets runs from 800 to 4500kVA at 50Hz. The KD range offers the highest power level on the market in its category with the latest generation Kohler engine technology.

The flexibility and modularity of the KD SERIES generating sets make this the ideal range for tailored power solutions, perfectly suited to the most demanding applications and environments.

Common rail injection with electronic control enables optimisation of both fuel consumption and emissions.

Emissions optimised versions conform to EPA Tier 2 requirements at 50Hz and are EPA Tier 2 certified at 60Hz. EPA Tier 4 certified from 1250kVA – 3250kVA. With no DPF (Diesel Particulate Filter), no DOC (Diesel Oxidation Catalyst) and only SCR (Selective Catalytic Reduction).

The KD Series of gensets also features compact design. Ideal for space-saving, the KD SERIES has a

compact design and separate cooling for smoother installation.

Available with DCP power for data centres, the range includes a large number of options and accessories; control/command enclosures and containers, fuel tanks, silencers and circuit breakers.

Available with a wide variety of containerised gensets options, KOHLER’s gensets can be adapted to meet a client’s needs: Their standard dimensions mean they’re easy to transport, and the integrated fuel tank means they are ready to run. The gensets feature:

- ISO Containers – for emergency applications with no harsh environmental constraints

-CPU Containers – for the most demanding environments, these robust modular containers are designed to meet the most stringent of production applications

-Walk-in Enclosures – designed for data centres, these enclosures combine performance, reliability, strength, safety and modularity.

About the client

Coastal Power is a diversified company which specialises in all phases of key data centre decommissioning and equipment removal, providing turnkey solutions to the liquidation and sales of I.T. and facilities equipment.

A spokesman for the company comments: “Coastal Power provides complete equipment removal and environmentally-sensitive disposal of data centre and mission critical equipment.

“We appraise the value of the existing hardware onsite, enabling our clients to utilise their current infrastructure as a trade-in to help offset the purchase of new equipment.”

www.kohler-ups.co.uk

coastalpower.com

APRIL 2023 21 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

“ GENSETS

FOUR KD3250UE GENERATORS AND CUSTOMISED A MASTER CONTROL PANEL WERE PROVIDED TO SYNCHRONIZE A POWER SYSTEM FOR DATA CENTRE CUSTOMER IN SOUTH KOREA. KOHLER ENGINEERS SUPPORTED THE COMPANY’S PARTNER, COASTAL POWER.”

Noise control experts Keeping your world clean, quiet, and safe. Dürr Universal is a global leader in the design and manufacture of inlet and exhaust systems for gas turbines and reciprocating engines in the OEM and retrofit markets. www.durr-universal.com Dürr Limited United Kingdom Phone +44 1455 8944 88 Email solutions@universalaet.com

2,100 KVA DIESEL GENSETS PROVIDE BACKUP POWER TO A NATURAL GAS CYCLE POWERPLANT

ARKEN Generators has supplied and commissioned a backup power system for a natural gas cycle power plant in Iraq.

The project has involved supplying two ARKEN 2100 kVA diesel gensets.

The power system has been installed in airconditioned special containers with suitable IP-55 insulation class, 80dbA acoustic feature at 1 mt, fire detection and gas fire extinguishing system.

Double-walled flame arrester fuel tanks in the generator sets are supported by an automatic, motorised valve filling system.

The system features a test synchronisation system with each two mains coupled return and forward mains of both generators - it has the ability to communicate with the customer SCADA.

The SCADA Supervisory control and data acquisition is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of gensets and power processes.

It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery.

The operator interfaces which enable monitoring and the issuing of process commands, like controller set point changes, are handled through the SCADA computer system. The subordinated operations, e.g. the real-time control logic or controller calculations, are performed by networked modules connected to the field sensors and actuators.

The gensets feature engines provided by MITSUBISHI, one of the world’s leading engine brands. According to ARKEN, MITSUBISHI offers “a great service principle in terms of engine capacity working principle. These engines, which can be used in many fields, are constantly being developed with the designs of the best engineer teams.

The fact that the engines that have been used for years do not cause any problems and show high performance have made the brand even better.”

Key details:

-ST-BY: 2100 kVA

-Mounted air filter

-24 volt starter motor

-COMAP IG-NTC Controller

-Specially-installed LED lighting system that is not affected by temperature,

-Alternator windings and bearing temperature monitoring and protection system

-Alternator anti-condensation heater system

-Alternator differential protection system

-Selectable

- An oil level monitoring system has been installed while the engine is running. The system comes without break transfer (with one generator two mains)

- Test running with adjusted load as mains parallel.

- Running hours equalization of generators.

-Transmitters are used at oil pressure, oil temperature ,coolant temperature and fuel level measurements.

A working scenario involves one generator feeding a total load and the mains return generator is achieving synchronazation with both mains seperately.

The system is also capable of forward test synchronisation with mains at an adjusted load level. arkenjenerator.com.tr

ARKEN 2100 KVA DIESEL GENSETS. “

APRIL 2023 23 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

redundant battery system

GENSETS

“

ARKEN GENERATORS HAS RECENTLY SUPPLIED AND COMMISSIONED A BACKUP POWER SYSTEM FOR A NATURAL GAS CYCLE POWER PLANT IN IRAQ. THE PROJECT HAS INVOLVED SUPPLYING TWO

13.2 MW CHP PROJECT FOR A KEY SECTOR OF PUERTO RICO’S LIFE-SCIENCE INDUSTRY

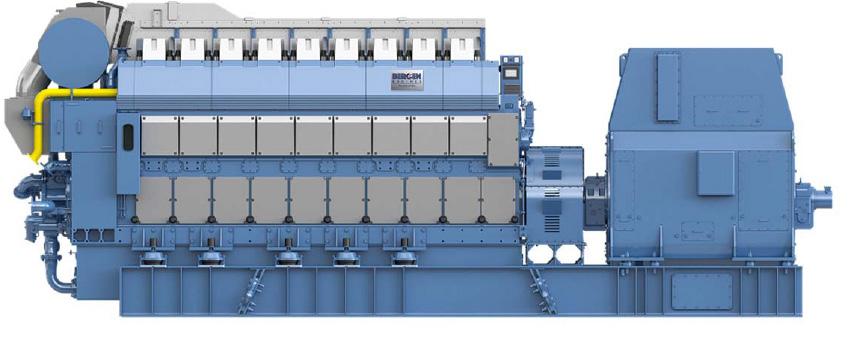

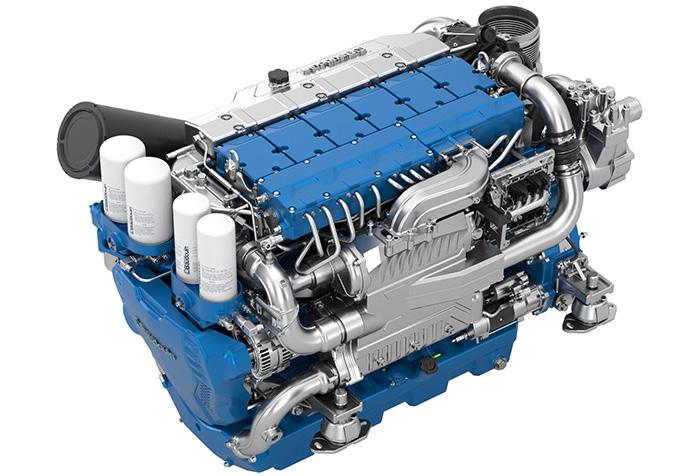

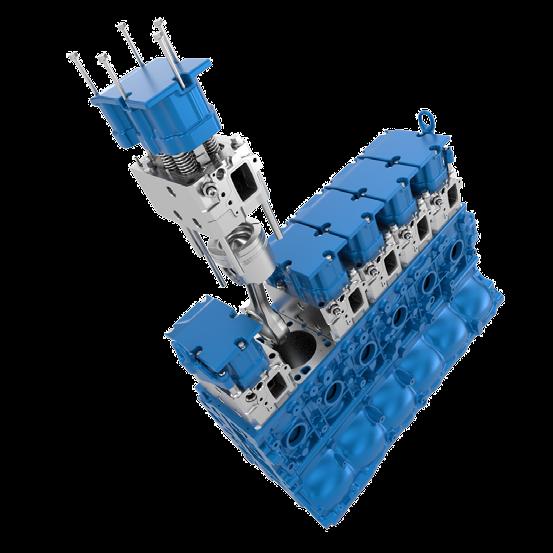

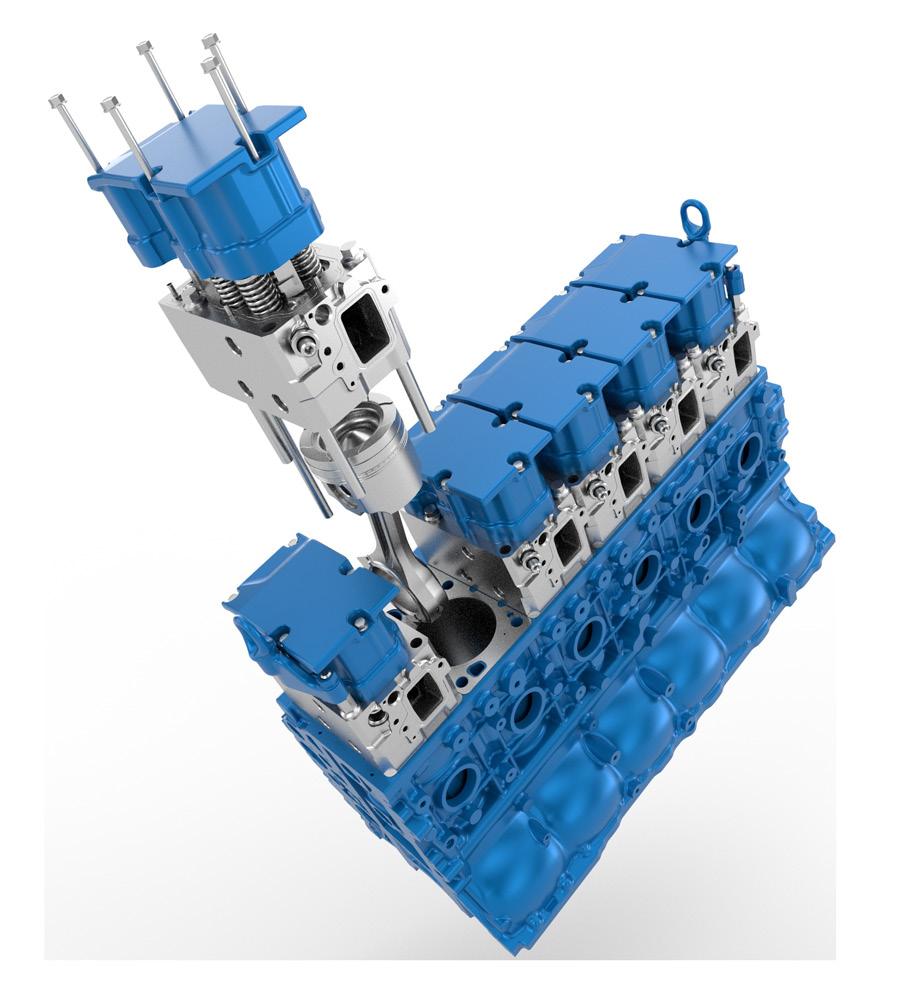

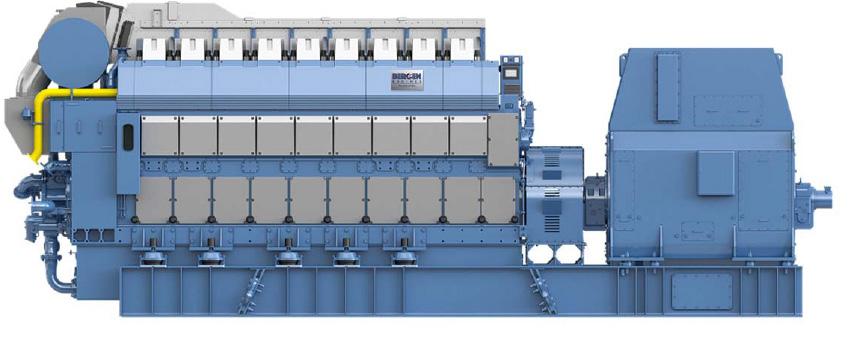

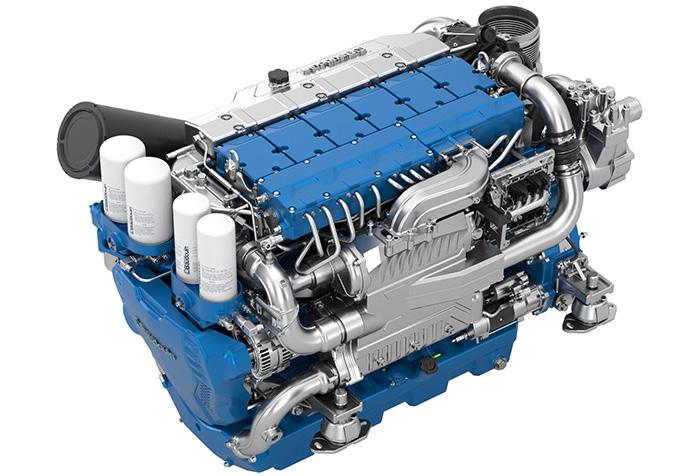

Bergen Engines has supplied four B36:45L 3.3 MW medium speed (720 rpm) units to power plants belonging to the life-science industry of Puerto Rico.

A company spokesman commented: “Bergen Engines will supply four hydrogen-ready medium-speed units to SAMPOL Group, a multinational applied engineering company, for two new energy-efficient power plants in Puerto Rico.”

“Each site will use two Bergen Engines’ B36:45L 3.3 MW medium speed (720 rpm) units in a hybridrenewable microgrid solution, which integrates solar photovoltaic technology, batteries, and baseload cogeneration for maximum use of renewable and cleaner energy.”

The B36:45 gas engine is a medium-speed lean-burn unit designed to produce up to 12 MW of mechanical power with optimised combustion technology and excellent load responsiveness. The design has been driven by stringent requirements for lower exhaust emissions, highest possible electrical and heat recovery efficiency, coupled with extreme reliability, reports Bergen.

A spokesman comments: “The B36:45L 3.3 MW medium speed (720 rpm) unit is a robust and powerful engine, delivering up to 600kW per cylinder, with world-class efficiency and reduced life-cycle costs. Our latest engine series is built on more than 80 years of experience.

“Our legacy, with all its valuable knowledge and experience, has been an important foundation for the development and testing of new technologies.”

The B36:45 gas engine is a medium speed propulsion engine and generating set (3,600 - 5,400 kW). The Bergen B-series is based on a modular design, which gives a flexible platform and at the same time carries forward the Bergen traditional values as a robust and reliable engine.

The selection of technology was achieved after consulting a broad range of operators, designers and shipbuilders, to establish the qualities they prize in an engine, reports the company. This engine series was first introduced to the market in 2014 as a diesel engine, and the gas version followed in 2018. It is available in several in-line or Vee cylinder variants for

both diesel and gas. Main benefits include:

-No lubricating oil separator needed

-Fast load response

-Cleaner engine room and no smoke emission

-Extremely low methane slip at all engine loads

-Cylinder Pressure Monitoring (CPM) for improved load control, and possibility for diagnostics per cylinder

-Exceptionally low emissions of NOx, CO2, SOx and particulate

-VVT – Variable Valve Timing for optimum response and load increase

-Gas safe (double wall piping)

-Possible conversion from gas to diesel and vice versa

-Wastegate turbocharger to ensure optimized fuel/air ratio at varying ambient conditions for lean-burn operation.

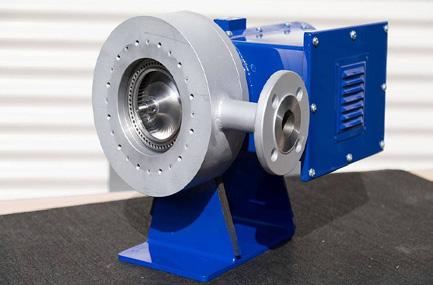

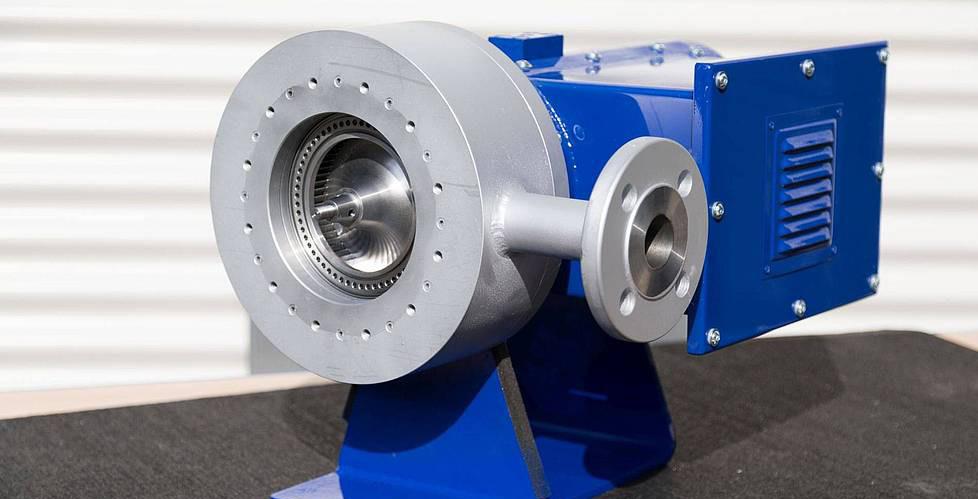

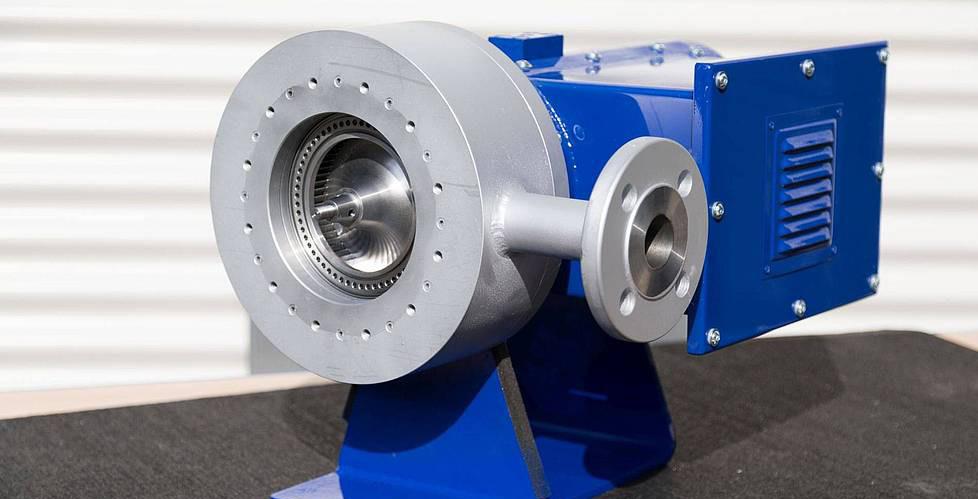

Bergen’s next-generation Marelli Motori MJH 1000 LB8 generator

In January 2022, Bergen Engines joined Langley Holdings plc sister companies Piller Power Systems and Marelli Motori in the newly formed Power Solutions Division. This began a collaboration between the companies that saw Marelli Motori start development of a new generator series to accompany Bergen Engines’ B35:40V20.

Within a year, the first Marelli Motori MJH 1000 LB8 generator was being assessed at the Bergen Engines facility in Bergen, Norway.

The first complete generator set was successfully tested with Bergen Engines and Marelli Motori engineers, marking a major milestone in the inter-company development project.

In a traditional generator set, both the engine and generator are attached to a common foundation. Due to this, the vibrations from the engine will spread to the generator which over time can cause damage due to excessive movement.

In developing this new generator, project engineers worked extensively to dampen these vibrations and mitigate movement of the Bergen V20 engine.

Using innovative computer modelling, the generator set was first divided into 1.3 million elements where Bergen Engines could study how the engine, generator and common foundation would be affected in a plant at full operation.

The results of this analysis showed a multitude of moving pieces that would twist and turn, if left without further development.

Bergen Engines has years of experience in optimising common foundations through an innovative development method which adds and removes excess materials.

This helps ensure the new generator set can tolerate the stress from all global and local mode shapes without damage.

www.bergenengines.com

APRIL 2023 24 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

GENSETS

KEY SITE IN THE UAE INSTALLS THREE HIGH PERFORMANCE 800 KVA DIESEL GENSETS

JUBAILI BROS - KUWAIT has provided three

JP 800kVA synchronized generating sets for delivery and installation at one of the Kuwait Oil Company’s exploration sites.

The 800kVA silenced generators have been built to exacting specifications to ensure industry-leading performance. Designed primarily for the rental market, they are tough and ultra-reliable, says the manufacturer. Fitted with Deep Sea control panels, the gensets offer a wide range of settings to suit all applications. They are simple to use and integrate all the features which customers require, says the company.

The sets feature hot-dip galvanised sound-attenuated enclosures, with sound-reducing abilities such as average 70 dBA @ 7 metres.

The gensets also have powder-coated grey-white 7035 surfacing (the enclosure shield is painted by electrostatic polyester powder paint - IP23 Protection class), forklift pockets complete with rubber bumpers, plus a 4-pole circuit breaker with variable earth leakage protection and on/off switch.

Quality componentry included in the genset manufacture includes a Deep Sea 8610 loadshare synch control panel, a battery isolator, a 1,300-litre bunded base fuel tank with three-way valve, CT for genset paralleling, a battery charger, plastic-coated locks and handles, a lockable canopy with common single key and a Cummins water separator filter.

A sump oil vac pump is supplied along with an oil pressure sensor, along with a water temperature sensor, and a central lift point. The set is hardwired via copper busbar and features microswitch protection and comes with a motorised MCCB and Racor filter.

Considering synchonisation in the generators

The genset synchronisation is fully automatic. After synchronization, the load is automatically shared and controlled according to the set proportion, increase or decrease output, add new units or stop online generating units parameters.

Equipped with a Deep Sea 8610 each set, the synchronising and load sharing control module is said to provide the user with complete and reliable protection against various gensets defaults, such as reverse power, over current, overload etc.

The DSE8610 is an effective intelligent mono display auto start load share control module packed with industry leading features to enhance multi-set control.

The module can be synchronised with up to 32 generators within the same system.

About the genset client and user

The customer - the Kuwait Oil Company (KOC) - is headquartered in Al Ahmadi - Kuwait and is a subsidiary of the Kuwait Petroleum Corporation, a government-owned holding company.

Kuwait is currently the world’s 10th largest petroleum and other liquids producer iand fifth-largest exporter in terms of volume of crude oil and condensates.

KOC is considered the backbone of

the economic and social development for the State of Kuwait. KOC ’operations and activities of exploring and producing oil make up nearly 90% of the national budget, which is still highly dependent on oil in its resources.

KOC announced four discoveries in the 2019-2020 fiscal year, two in the Cretaceous layer in Lower Burgan in Bahrah Field, the other two in the Jurassic layer located in Lower Marrat in Kahlolah Field, and Gotnia Anhydrite in Sabriyah Field.

Furthermore, KOC recently signed an offshore drilling contract to further explore Kuwait’s waters.

www.jubailibros.com

www.deepseaelectronics.com

APRIL 2023 25 WORLDWIDE INDEPENDENT POWER www.wipmagazines.com www.powermediagroup.co.uk

“ GENSETS

THREE JP 800KVA SYNCHRONIZED GENERATING SETS HAVE BEEN CHOSEN FOR DELIVERY AND INSTALLATION AT ONE OF THE KUWAIT OIL COMPANY’S KEY EXPLORATION SITES. THE GENSETS ARE BUILT TO EXACTING SPECIFICATIONS.”

TVR Instruments Limited 143 Butt Road, Colchester CO3 3DP Essex United Kingdom instruments ltd Tel: +44 (0) 1206 575755 Email: sales@tvri.co.uk www.tvri.co.uk

GENSETS SUPPLY TAILORED EMERGENCY POWER FOR A COGENERATION PLANT IN GERMANY

Genesal Energy’s latest project is a 20002200kVA medium voltage (6300 V)

GEN2200HC generator set for a cogeneration plant in Germany.

This is located in an area with very adverse weather conditions such as very cold winters and intense rainfall, it required a very special and careful design to guarantee smooth power supply.