From keeping life support machines running to enabling surgeons to carry out essential operations, Scania Power Solutions deliver the engines for backup generators that literally help save lives. With hospitals needing nothing less than 100% reliability, our engines are designed to kick-in flawlessly when they’re needed most. When it has to work, it has to be Scania.

SPEAK TO OUR SCANIA POWER SOLUTIONS TEAM TODAY – CALL 0845 034 3034

Publisher/Sales DIrector

Neb Saric neb@wipmagazines.com

Publishing & Events Director

Richard Teasdale richard@wipmagazines.com

Managing Editor

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager

Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales

Bob Liu Shanghai, China bob.liu@ronco.com.cn

US Sales & Subscriptions

Jelena Milojevic power@wipmagazines.com

Austrian & German Agent

Mario Dobresko power@wipmagazines.com

Power Media International Group, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0) 1403 888019

www.powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468 7100)

www.wipmagazines.com

www.powermediagroup.co.uk

Russian forces destroyed the Trypillia Thermal Power Plant (TPP) in Kyiv Oblast because Ukraine had run out of missiles to defend it during an attack, President Volodymyr Zelensky said in an interview this month.

The Trypillia TPP was completely destroyed in a Russian strike on Ukrainian energy infrastructure on April 11, leading to the 100% loss of Centrenergo’s generating capacity. This has left Ukraine with only a 12 Gigawatt grid capacity.

Russia launched 11 missiles in the direction of the plant, according to Zelensky. Ukraine was able to shoot down the first seven, and four “destroyed Trypillia.”

The plant is located less than 30 kilometres south of Kyiv and was the main power supplier to Kyiv, Zhytomyr, and Cherkasy oblasts.

Russia has stepped up targeted attacks on Ukraine’s energy infrastructure, overwhelming local air defences and destroying some of Ukraine’s largest coal-fired power stations.

For the past two winters, Ukraine has withstood a barrage of Russian airstrikes seeking to disable its energy infrastructure, plunge its citizens into darkness and use the freezing temperatures as a weapon of war.

“The enemy’s tactics have changed – unfortunately, not for the better for us,” Svitlana Grynchuk, Ukraine’s deputy energy minister,commented.

“RUSSIA HAS NOW PUMMELLED UKRAINIAN POWER STATIONS ACROSS THE COUNTRY.”

In the first two years of war, Russian attacks were more scattered, firing salvos of missiles to target large swathes of Ukraine’s energy system. Now, the strikes are becoming more precise and concentrated, with dozens of missiles and drones raining down on a single target.

“In such a short period of time – in a few weeks of these massive Russian attacks – almost all of our year-long efforts to rebuild and repair were destroyed in a few days, in a few attacks,” Grynchuk explains.

The turning point came in late March 2024, reports Oleksandr Kharchenko, director of the Kyiv-based Energy Industry Research Center (EIRC). On that day, Russia launched one of its largest missile and drone attacks on Ukraine’s energy infrastructure, targeting at least 10 of the country’s regions and briefly leaving more than 1 million households without electricity.

DTEK, Ukraine’s biggest private power company, has indicated that Russia has caused “serious damage” to two of its plants, and that approximately 80% of the power-generating facilities it runs had been destroyed by Russian strikes.

“Rather than continuing to focus their attacks on Ukraine’s transmission systems, from late March 2024 Russia began launching massive attacks on our energy generation infrastructure,” said Maxim Timchenko, CEO of DTEK.

AIDAN TURNBULL

“Unfortunately, the enemy has evolved his tactics and is now using high-precision weapons.”

Managing Editor

STEAM TURBINE MARKET WORLDWIDE

The global steam turbine market size was valued at US$16.27 billion in 2022 and is projected to register a compound annual growth rate (CAGR) of 2.5% from 2024 to 2030, reports the market research company Grand View Research.

An increase in the number of power plants is likely to be commissioned to compensate for the energy deficit and this is expected to propel the demand for steam turbines in the coming years. The U.S. has emerged as the largest market in North America in 2022. There has also been an increase in the number of combined-cycle natural gas plants in the country.

19 GAS-ENGINED GENSETS BEING USED IN AN ENERGY PROJECT ON LAKE KIVU, RWANDA

Lake Kivu in Rwanda is the scene of an unusual Lenergy project. The Rwandan lake of 2,400 km2 and a depth of 490 m has methane deposits which are used for eco-friendly energy generation. The construction of a power plant, comprising 19 MWM TCG 2032B V16 gas gensets began in 2019 and began generation last year.

GLOBAL MARKET FOR STEAM TURBINES 2024-2030 TRENDS & DEVELOPMENTS

20MW FUEL CELLS TO POWER THE NEW BRITAIN ENERGY & INNOVATION PARK, USA

Bloom Energy is supporting the potential for more advanced manufacturing in the state of Connecticut with solid oxide fuel cells for power storage. The fuel cells power up to 20MW of electricity as part of the New Britain Energy & Innova tion Park, which will include a new data centre.

Bloom Energy’s solid oxide hydrogen fuel cell technology is uniquely positioned to accelerate both the production and the usage of hydrogen.

£27 MILLION IN ORDERS FOR NEWLY-DEVELOPED 30KW FUEL CELL GENSETS

AFC Energy, the UK-based developer of hydrogen fuel cell generators, said it had £27 million worth of orders for its 30kW fuel cell gensets. The orders include supply arrangements for its 50/50 joint venture with Speedy Hire – Speedy Hydrogen Solutions – and its sales agreement with TAMGO covering Saudi Arabia, the Middle East and North Africa, as well as orders with global contractor Acciona.

20MW GAS POWER PLANT FOR ROMANIA’S NATIONAL ELECTRICITY GRID

Racari, Romania: 6 x INNIO Group Jenbacher

Type-6 engines have been supplied to support Romania’s national grid supplies. With the first phase of the Clarke Energy and Navios peaking plant project in Romania now fully commissioned, the company has announced that the second phase is now well underway in Racari.

45MW NATURAL GAS POWER PLANT PROVIDED FOR GUATEMALA, SOUTH AMERICA

Bergen Engines, a leading producer of medium speed engines and generating sets, has provided 5 x Bergen B35:40V20AG2 gensets to the a strategic consortium led by Sampol Ingeniería y Obras (SAMPOL), a multinational applied engineering company specialised in energy efficiency,

OPTIMISING DIESEL GENERATORS TO REDUCE EMISSIONS

When we talk with customers, what do they need to consider when choosing a generator?

Once they have understood the application for the generator, and the requirements for how much power is needed, a good next step is to review the regulations for their region, reports KOHLER.

EDITOR’S LETTER

08-14

NEWS REPORTS (p.8-14).

International News + details on PowerEx Live Midlands and PowerEx Live London Exhibition. Held at the prestigious Park Plaza, Westminster Bridge, London, 09:30 – 16:00 on Thursday, December 12th, PowerEx Live London aims to offer the perfect networking opportunities for a host of professionals across the Genset, CHP and Renewables sector.

MARKET REPORT - STEAM TURBINE MARKET

WIP looks at predictions for the STEAM TURBINE market 2024-30.

28-31

ASSOCIATION NEWS

Associations: MEGSA, UKGSA, EGSA, Europgen & Italcogen

NEW PRODUCTS

Don’t miss some of the best new products for March 2024

CLASSIFIED DIRECTORY OF EQUIPMENT & SERVICES

Listings of key companies in the industry. 34

ENGINE MANUFACTURERS GUIDE

OEMs manufacturing engines today.

Anyone who knows gensets, knows that Mecc Alte is unrivalled for our knowledge and expertise worldwide. From alternators to controllers, we are the Power from Within, giving you the ultimate choice of kit that you need, all backed up by the support and impartial advice you only get from the world’s leading independent alternator specialists. Take 360° control. Talk to Mecc Alte.

The world’s largest independent producer of alternators 1 – 5,000kVA

The TEDOM Poland team recently visited the site of one of its landmark installations at ZGH Bolesław. This location features three TEDOM Quanto 4000 CHP units, each with a 4.3 MW capacity, contributing to a total output of 12.9 MW of electricity.

A spokesman commented: “This project is a testament to our commitment to energy efficiency and sustainability and reflects a significant milestone in our journey towards a greener future.”

The Quanto series CHP units offer a very high output. One such unit can reliably supply heat to an entire housing estate of 250 apartments, including an adjacent primary school. At the same time, it produces enough electric power to cover the consumption of a town of two thousand people. Other key applications include industrial plants, quarries and mines.

Jubaili Bros Nigeria recently delivered a Top Tier 2028 kW gas generator to Metal Manufacturing Nigeria Ltd to power its manufactoring processes and provide energy from its CHP system.

Metal Manufacturing Nigeria Ltd. (MMNL) was established in November 2010 with a vision to establish a fully integrated manufacturing facility for Battery & Lead Oxide.

The company began with the recycling of battery scrap to pure lead and lead alloys. Pure lead and lead alloys are exported to various parts of the world and generate Forex earnings for Nigeria. The company i ntegrated vertically to use pure lead to produce Nigeria’s first Indigenous battery with the brand name StarPlus. The company has an existing state-of-the-art manufacturing facility at Ikorodu Sagamu Road, Vill: Gbara, Sagamu LGA, Ogun State, Nigeria.

The group is extremely versatile and is said to maintain stringent ethical standards.

Its product quality meets the international specifications optimum for the production of pure lead, lead alloys, and batteries. The company, directly and indirectly, employs over one thousand people.

A Jubaili Bros company spokesman commented:

“With this green fuel generator, we’re bringing uninterrupted power solutions to the industrial sector.”

Teplo Těšín a.s is a water & waste treatment company located in the Czech Republic. In late 2023 a Quanto 1000 CHP unit powered by natural gas, featuring an electrical output of 1 MW was installed at a Teplo Těšín plant located at the Hrabinská housing estate in Český Těšín.

A spokesman commented: “The primary goal of this investment is to decrease heating expenses. Teplo Těšín a.s. intends to progressively offer this advantageous heat price to all of its customers. The TEDOM Quanto 1000 CHP unit is currently reducing heating costs in Český Těšín.”

The cogeneration unit is equipped with a 100 cubic-metre storage vessel, which serves to mitigate the imbalance between heat production and customer consumption.

This enables the storage of heat during the day, which can be used at night when the CHP unit is not operational due to lower electricity prices. The electricity generated will be supplied to the grid, providing an additional source of income for the CHP operator.

The town of Český Těšín and Teplo Těšín a.s. are already enjoying the advantages offered by this technology. Deputy Mayor Jan Pekař says that thisproject enables the town to reap the benefits of new legislation about the use of CHP in the nation’s urban environments .

Two MWM TCG 3020 V20 gas engine generator sets (4.6 MW of electrical energy and 4.5 MW of thermal energy) have been supplied to Uzbekistan by MWM distributor İltekno.

The equipment was installed at a site operated by JSC Thermal Power Plants. The MWM gas engines now generate energy for the Chilanzar district since the combined heat and power (CHP) plant was commissioned.

In 2023, İltekno signed a contract with JSC Thermal Power Plants (TPP), which is responsible for generating and supplying power to businesses and the population of Uzbekistan. JSC Thermal Power Plants currently has eight thermal power plants, five thermal power cogeneration plant centres, one of them Tashkent Heat Center LLC, and three organizations providing services to enterprises of the industry.

In 2022 JSC Thermal Power Plants produced 55.5 billion kWh of electricity and 5.3 million Gcal of heat energy. In 2023, the company planned on generating 54.3 billion kWh of power and 5.1 million Gcal of thermal energy. To achieve this plan, TPP signed a contract with İltekno for the installation of cogeneration power plants in six districts of city of Tashkent, namely Chilanzar, Mirzo Ulugbek, Yakkasaray, Sergeli, Olmazor, Yashnobod, Uchtepa and Yangihayot.

The first project was Chilanzar project, which was successfully completed in early November ‘23. İltekno supplied, installed & commissioned two MWM 3020 V20 natural gas engine generator sets with an output of 2.3 MWel and two natural gas boilers with 12.5 MW.

MWM

Efficient, low-maintenance and highly available.

The MWM product portfolio comprises gas engines and gensets in the output range from 400 kWel to 4,500 kWel . Power plants with an output of 100,000 kWel and more are technically feasible. The units are designed for maximum electrical and thermal efficiency, low operating and service costs, and high reliability and availability. Thus, they reach efficiency levels of more than 90 percent.

Himoinsa, part of the Yanmar Group, has reported the acquisition of Hispano Acústica, a specialist provider of acoustic engineering solutions. Under the deal, the company will be rebranded as HiAcoustic.

It is expected that the deal will allow HiAcoustic to extend its offering of soundproofing systems to more global customers. The company works across a range of applications, including acoustic booths and screens, through to sound-absorbent treatments for generator sets and installation rooms.

For Himoinsa, which is based in Murcia, Spain, the addition will add a new support feature to its portfolio and the capability to deliver ‘360-degree solutions’ for customers.

Francisco Gracia, president and CEO of Himoinsa., said: “This acquisition certainly reaffirms our commitment to the design, production and commercialisation of innovative solutions for the market.”

Volvo Penta is now marketing two of its latest products: its new 17-litre D17 generator set engine and its newly-designed battery energy storage subsystem (BESS) technology.

With the addition of the 705-kWe D17, Volvo Penta has grown its power node offering to cover from 200 up to 700 kW. The compact, inline six-cylinder engine incorporates a slightly larger engine block that allows for the added displacement, said Darren Tasker, vice president of Industrial Sales, Volvo Penta. A modernized fuel injection system with a common rail design is engineered for fuel efficiency. Dual-stage turbochargers and heavy-duty steel pistons provide a dense power set up.

The engine delivers an optimised power-to-weight ratio within the same footprint as the D16.

“This was a joint development between the Volvo Group companies,” Tasker said. As such, it was important to maintain the mounting positions for the engine, cooling connections, turbo position, air filters, etc.

“We kept that all the same as the 16-litre so from an installation perspective, our customers will see no change. It’s a cost-effective, simple way of getting to that higher power node without a significant engineering investment,” he explains.

The dual-speed (1,500/1,800 rpm) engine is suited for a variety of applications but will be initially targeted to standby and prime power gensets.

“We’re going to start by selling this into the power generation market,” Tasker reports. “The second step would be to develop a variable-speed version of the engine so we can sell it into the off-highway markets.”

A 1-MW PEM ME450 electrolyzer supplied by Germany’s H-Tec Systems will be utilized by Spanish green hydrogen project developer SailH2 in the “HUB LA ISLA H2” green hydrogen pilot project in the region of Sevilla, Andalusia, by SailH2.

The 1-MW ME450 PEM electrolyzer will be used as part of a pilot project examining a variety of different applications for green hydrogen. SailH2 plans to invest 25 million Euro into building a pilot centre for production and distribution of green hydrogen. It has ordered the ME450 PEM electrolyzer to produce up to 136 tons of green H2 per year in combination with a 1.5-MW PV plant in the first phase of the HUB LA ISLA H2 project.

The pilot project will be the first commercial hub of green hydrogen in Andalucía and will be located at the industrial site Poligono Industrial Isla in Dos Hermanas, a city district of Sevilla. The site construction works are scheduled to be finalized by Q3 2024, with H-Tec Systems set to deliver the electrolyzer in September 2024.

The pilot project will examine a variety of different applications for green hydrogen, such as power-to-mobility, power-to-industry and power-to-gas in the 4- to 20 -MW range. The PEM electrolyzer will be applied in the initial phase (Phase 1 Power-to-Mobility), during which SailH2, with the support of Agencia IDAE through the Moves Singulares II grant, will combine1 MW of hydrolysis power with 1.5-MW photovoltaic power produced at a near-site PV plant.

The hydrogen plant utilising the electrolyzer will produce up to 136 tons of green H2 per year.

Eduardo Almagro, CEO of SailH2, and CEO of H2Green La Isla, said, “We chose the ME450 PEM electrolyzer for our project because it is a proven product with best-in-class performance.”

South 8 Technologies has reported completing a successful demonstration of its LiGas liquified gas electrolyte with low-nickel, cobalt-free battery cells.

The LiGas electrolyte uses widely available non-toxic and non-corrosive gases which are held under pressure in a liquified state. The company said that this electrolyte can be contained in standard cylindrical cells.

The California-based company said that the LiGas electrolyte has already shown ‘excellent performance’ in conventional graphite/lithium-nickel-manganese-cobalt oxide (LNMO) cells.

Cold-weather performance is said to be enhanced using the LiGas electrolyte, which also supports faster charging than standard cells.

As part of the development process, South 8 demonstrated full compatibility with a 4.6 V commercial LNMO cathode. Energy retention at -20°C (-4°F) was measured at 96%. This compares to less than 5% retention for standard liquid LNMO electrolyte at the same temperature. Further testing showed 87% energy retention at -40°C.

“LNMO is a future cathode material, promising the safety of LFP (lithium iron phosphate) and energy of NMC (nickel manganese cobalt),” said Cyrus Rustomji, Chief Science Officer at South 8. “The challenge has been the electrolyte: conventional solutions break down at LNMO’s high voltage. LiGas does not. LiGas gives excellent low temperature performance and greatly reduces thermal propagation.”

Romain Mocaer 11:00-11:30

PowerGen Statistics “European generator & Data Center market outlook”

Ian Bitterlin 11:30-12:00

“Forecasting Data Centre power growth” Consultant

Dr Michaela Kendall 12:00-12:30 Adelan Latest developments on Hydrogen

Steve Peal 12:30-13:00 YorPower

“Running Your Business in Todays Modern World”

11:00-11:30 Dave Andrews

Claverton Energy

CHP, District Heating, Grid plus Latest Technologies on alternative fuels

11:30-12:00 Eric Lewis Consultant

“How to combine existing and new systems in an optimised future GB AC Grid”

12:00-12:30 Dr David Toke

How Britain can achieve 100% renewables energy supply 100% Renewable UK

12:30-13:00 Paul Woods

How district heat systems integrate w/ a renewable grid using low-cost heat storage capability Consultant

Steve Hone 14:00-14:30

Data Centre Alliance CEO

Your Introduction to the booming Data Centre Sector

Mark Acton 14:30-15:00

Head of Technical Due Diligence (Future-Tech)

“Data Centre Sustainability, Energy Efficiency, Metrics and Reporting”

Venessa Moffat 15:00-15:30

Channel Partner Manager, EMEA

EkkoSense AI

Does AI + data centre + power consumption = dead planet?

Ian Bitterlin 15:30-16:00

Using Data Centres to support the Power Utility Consultant

14:00-14:30 Josh Collins

Discussing a range of renewable energy solutions SAV Systems

14:30-15:00 Prof. Pearson

Star Refrigeration Limited

Large water source heat pumps and rivers

15:00-15:30 Dave Andrews

Claverton Energy

CHP, District Heating, Grid plus Latest Technologies and where the market is heading along with alternative fuels

Socomec has developed a compact version of its Sunsys HES L battery energy storage system (BESS), the Sunsys HES L Skid.

The new designis said to improve overall efficiency, while reducing installation, transport and maintenance costs. The new power solution is suitable for powering EVs, commercial/industrial buildings and microgrids.

Socomec believes that BESS are expected to play a ‘crucial’ role in grid stability and reliability as markets increase uptake of renewable energy sources.

Socomec’s new design allows for six battery cabinets to be daisy-chained per installation. All cabinets are shipped assembled and mounted to a skid system.

This allows ease of transport between sites.

Once in place, the BESSs need an AC power (as required) and a communication connection.

The Sunsys HES L Skid joins the high-power HES XXL, which was unveiled in October 2023.

PowerEx Live Midlands 2024, will be held on Thursday, June 27th, 2024. It aims to probe and discuss all the trends, opportunities and challenges for the GENSET, CHP & ENERGY industries.

At the Conference - PowerEx Live Midlands 2024 - the exhibit space is within the same room - and in a different room the (DCA) datacentre alliance will be holding seminars and presentations.

PowerEx Live will be hosting some of the foremost energy speakers in the country with the most recent and cutting-edge content within the energy industry - see OPPOSITE PAGE.

This regional UK event - with an associated Golf Tournament held the day before the event (June 26th) - offers all key sector players in the North of England an opportunity to assess new trends, connect and develop all under 1 roof over the course of 1 day. The official PowerEx Live 2024 Golf Tournament is held at the Belfry Hotel & Resort at Royal Sutton Coldfield, West Midlands, UK, on Wednesday 26 June, 2024.

Alongside several restaurants and bars, events and meetings spaces, a leisure club and The Belfry Spa, the site of the PowerEx Live 2024 Conference also features three courses, including BRABAZON golf course. These are recognised as world-class, having previously hosted The Ryder Cup more than any other venue in the world and home to this year’s Betfred British Masters.

Sponsorship opportunities are available at £135 per hole. There are Prizes – Nearest the pins on every Par 3 and 2 Longest Drive holes. This is also a great networking event and an opportunity to meet people from the Power & Energy Industries.

Final deadline for booking: April 26 2024. Please email enquiries: richard@wipmagazines.com or power@wipmagazines.com

1,600 KVA DIESEL GENSET FOR THE BIA CARGO TERMINAL FACILITY IN SRI LANKA

A Cummins model C1750D5E generator, boasting a powerful 1600kVA capacity, will soon be available for operation at the BIA Cargo terminal facility in Sri Lanka.

A spokesman for the airport said: “This milestone underscores our commitment to reliability and efficiency, as well as the trust our valued customers place in Cummins products.”

The 175 kVA Three Phase Silent diesel generator is powered by a Cummins QSB7-G5 (Stage IIIa) engine has a Stamford UCI274F alternator. The QSB7 incorporates the latest diesel engine technology, including a high pressure common rail fuel system for greater fuel efficiency, lower noise and reduced emissions. Features of the engine include Full-Authority Electronic Controls and pptimised engine operation - the electronics will deliver critical information for controlling costs, reducing maintenance and allowing seamless integration with other components.

Holset HX35 Wastegated Turbo - the Wastegated design optimises transient response. There is also a Low-Maintenance Fuel Filter Assembly - the fuel filter incorporates an integral water separator and water-in-fuel sensor; 500-hour filter life with easy top-load replacement using standard Fleetguard® filters.

These Coolpac Integrated Design - products are supplied complete with cooling package and air cleaner kit for a complete power package. Each component has been has been specifically developed and rigorously tested for G-Drive products, says Cummins.

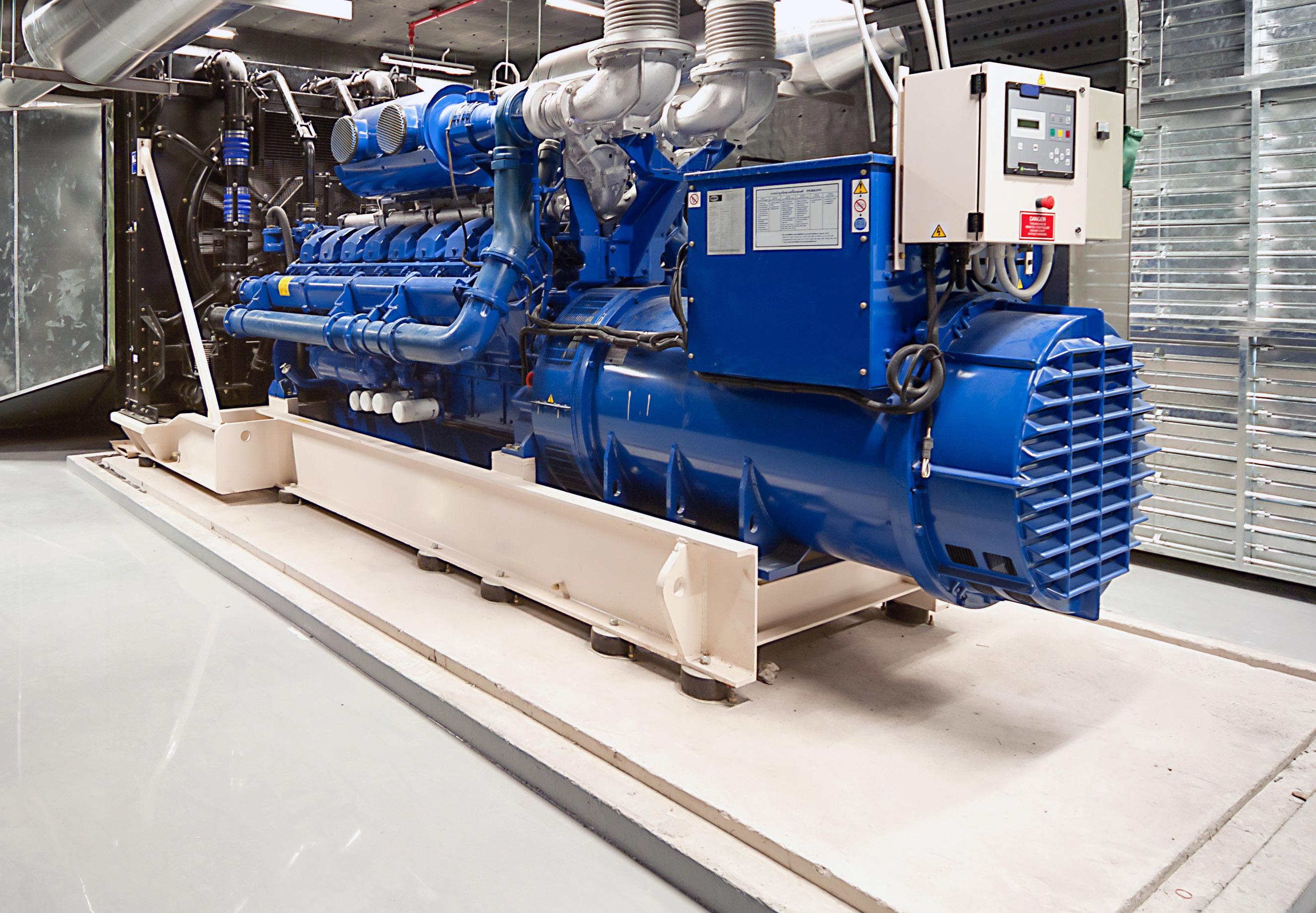

Four MTU 20V Series 4000 gensets (each with a capacity of 3290kVA) have been deployed to provide emergency backup power mtu partner AVK|SEG (UK) Ltd, a leading provider of critical power solutions. It recently installed four mtu 20V Series 4000 gensets (each with a capacity of 3290kVA) to support a facility in the UK banking sector.

Powered by HVO, a drop-in fossil-free replacement for diesel fuel, the systems not only provide robust and efficient emergency power, but also support the customer’s carbon neutral goals.

Before being despatched to the site, the systems underwent a rigorous FAT program, which included a cold start test, functional tests, a heat run over several hours and load step testing as per ISO 8528-5 class G3 to ensure peak performance. The AVK|SEG team will provide service and technical support to ensure optimal operation and ongoing customer satisfaction.

HVO (Hydrotreated Vegetable Oil) is made from sustainably sourced renewable raw materials and its use can make a real contribution to climate protection. It has excellent storage properties, and systems powered by it see lower particulate and nitrogen oxide levels and an emissions reduction of up to 90%. It is already being used in many mtu engines.

1-3 May

Global Electric Power Tech 2024 Seoul, South Korea

8 - 9 May

Decarbonisation Technology Summit Europe 2024 Institution of Engineering & Technology, Stevenage, UK

8-10 May

PowerGen India 2024 New Delhi, India

14-16 May

Power Uzbekistan 2024 Tashkent, Uzbekistan

15 - 16 May

All-Energy Exhibition and Conference 2024 Scottish Event Campus, Glasgow

15 - 16 May

Battery Cells and Systems Expo 2024 NEC, Birmingham

15-17 May

Future Energy Asia 2024 Bangkok, Thailand

16-17 May

Innovation Forum Energy 2024 Zurich , Switzerland

20-21 May

The Power & Electricity Show Philippines 2024 Manila, Philippines

21 - 22 May 2024

Renewable Energy Revenues Summit 2024 Conference Hilton London Tower Bridge, London

21 - 22 May

Utility Week Live 2024 NEC, Birmingham

22-24 May

Power & Energy Kenya 2024 Nairobi, Kenya

27-29 May

Lisbon Energy Summit & Exhibition 2024 Lisbon , Portugal

29-31 May

China International Exhibition on Gases Technology Hangzhou, China

3-5 June

SNEC PV Power Expo 2024 Shanghai, China

24-26 June

CHINA G-POWER 2024 Shanghai, China

26 Jun 2024

PowerEx Live 2024 Golf Tournament

Belfry Hotel & Resort, Royal Sutton Coldfield

27 Jun 2024

PowerEx Live MIDLANDS Conferences & Networking Event

Belfry Hotel & Resort, Royal Sutton Coldfield

25-27 Jun HILLHEAD 2024 Buxton, Derbyshire

28 July 2024:

PowerAid Charity Football Day - UKGSA Event Coalville Football Club

11-12 Sept

Tanzania Energy Congress 2024 Dar es Salaam, Tanzania

17-19 Sept

Nigeria Energy 2024 Lagos, Nigeria

19 Sept 2024

Cricket at Trent Bridge UKGSA Hospitality Event

24-28 Sept

ENERGY SHOW 2024 Shanghai, China

23 - 24 Oct 2024

Renewable Energy Scotland Event 2024 Scottish Event Campus, Glasgow

6 - 7 Nov 2024

NIBS Battery Conference Telford, Shropshire

12 - 13 Nov 2024

Future Energy Wales 2024 International Convention Centre Wales, Newport,

20-21 Nov 2024

DATA CENTRES IRELAND

RDS Dublin

12 Dec 2024

PowerEx Live London Park Plaza Westminster Hotel, London SE1 7UT

The global steam turbine market size was valued at US$16.27 billion in 2022 and is projected to register a compound annual growth rate (CAGR) of 2.5% from 2024 to 2030, reports the market research company Grand View Research.

An increase in the number of power plants is likely to be commissioned to compensate for the energy deficit and this is expected to propel the demand for steam turbines in the coming years.

The U.S. emerged as the largest market in North America in 2022. An increase in the number of combined-cycle natural gas plants in the country as they are reliable sources of energy is one of the prominent reasons for the rising demand for steam turbines in the U.S.

Policymakers in the country are focusing on developing sustainable energy generation plants. This is anticipated to surge the number of steam turbine installations in the U.S. in the coming years.

The increasing focus of the government in the U.S. on establishing energy-efficient and clean power generation plants is also contributing to the surge in the number of CHP installations in the country.

Rising demand for combined heat and power across North America is expected to drive the growth for the market in the region over the forecast period.

Policymakers in the UK are focusing on reducing carbon emissions and carrying out energy-efficient power generation.

This has resulted in the formulation and stringent implementation of various environmental and emission norms in the country. Steam turbines are employed in industrial applications for use in CHP units.

The COVID-19 pandemic hindered the growth of the market for steam turbines globally owing to the unavailability of steam turbine parts which delayed their production and cause logistic issues.

This further results in delays in ongoing steam turbine installation projects. A reduction in new orders for turbine installations occurred owing to the diversion of funds by steam turbine buyers to sustain the COVID-19 crisis.

Steam turbine manufacturers have taken subsequent steps to provide turbines to end users with ongoing projects. Vendors are opting for digital tools and are following social distancing norms and using PPE to carry out new power plant installations. Based on capacity, the market for steam turbines has been segmented into up to 150 MW, 151 to 300 MW, and more

“THE DEMAND FOR LARGE CAPACITY STEAM TURBINES IS EXPECTED TO SEE A DECLINE DUE TO THE TRANSITION TO RENEWABLE AND CLEAN ENERGY TECHNOLOGIES FROM COAL-BASED POWER INFRASTRUCTURES.”

than 300 MW accounted for the largest share of 61.61% in the global market in 2022.

Up to 150 MW capacity steam turbines are expected to witness significant growth on account of increasing demand for industrial CHP units.

CHP units are getting popular across various process industries on account of their superior efficiencies than single units. CHP also serves as a source of direct power, electricity, and heat, and it has observed a surge in demand in the recent past.

Due to high demand of small steam turbines in small- and mid-sized combined cycle power plants (CCPP), combined heat and power (CHP), petrochemicals, biomass, and concentrated solar power (CSP) solutions, the segment is expected to have the highest growth over the

forecast period.

In addition, vendors manufacturing steam turbines are more focused on the small steam turbines category due to high demand from steel, cement, chemical, and other industries.

The demand for large capacity steam turbines is expected to see a decline due to the transition to renewable and clean energy technologies from coal-based power infrastructure in countries across the globe.

However, increasing demand for uninterrupted power supply from developing countries such as China and India is expected to add to the market value of large capacity steam turbines over the forecast period. www.grandviewresearch.com

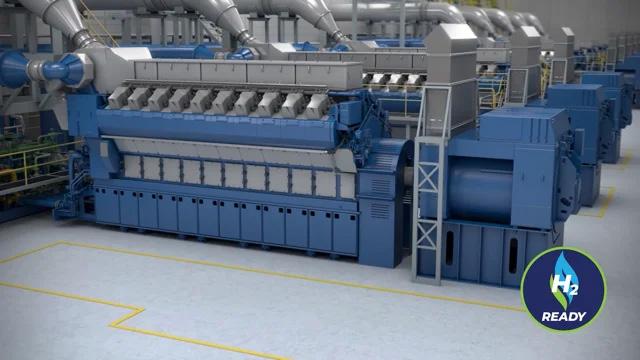

Lake Kivu in Rwanda is the scene of an unusual energy project. The Rwandan lake of 2,400 km2 and a depth of 490 m has methane deposits which are used for eco-friendly energy generation.

The construction of a power plant, comprising 19 MWM TCG 2032B V16 gas gensets began in 2019. Now, the plant using MWM gas engines is operational.

These gas gensets form the core of the power plant on the shores of Lake Kivu, which has an output of 76 MW.

Methane is extracted from the depths of the lake by means of a suction system and transported to the shore through pipelines of a length of up to 17 km. At the surface, the methane is processed and ‘sweetened’ in scrubbing towers in order to improve the quality of the gas.

Since July 2023, methane extracted from the lake is being used to produce energy for Rwanda.

It was a long journey for the MWM gas gensets which travelled from Hamburg to Rwanda. The ship voyage was followed by a trip of 1,600 km on both desert and savanna tracks from Mombasa to Rwanda.

“By means of extensive controls, we made sure that the MWM gas gensets ran perfectly when the power plant was ramped up,” explained Thomas Mattil, the project manager responsible for the plant.

Today, a total of 19 MWM TCG 2032B V16 gas gensets form the core of the power plant, which has an output of 76 MW.

The central plant switchboard of the highly complex power plant is the largest ever set up at a customer by Caterpillar Energy Solutions for the MWM brand.

The plant switchboard is used for the central control of the MWM gas gensets, cooling water modules, and other components on land. In July 2023, all 19 MWM TCG 2032B V16 gas gensets began producing sustainable energy for Rwanda.

“This energy project on the shores of Lake Kivu is undoubtedly one of the world’s most exciting and innovative projects for the energy supply with MWM gas gensets”, said Mattil.

An ambitious energy project Lake Kivu in Rwanda - a body of water about five times the size of Lake Constance - forms the basis for this nationwide energy supply project.

The lake hosts major methane deposits which can be used for eco-friendly energy generation purposes. The methane will fuel one of Rwanda’s largest power plants, which, in turn, will supply the landlocked country with energy.

According to estimates of the Swiss Federal Institute of Aquatic Science and Technology (Eawag), some 300 km³ of carbon dioxide and 50 to 70 km³ of methane are dissolved in Lake Kivu.

Methane - the main component of natural gas - is a key fossil energy source.

The colourless and odourless gas in the lake can escape to the surface in an uncontrolled manner, which not only harms the environment and contributes to global warming. It also represents an acute danger for humans. Scientists and businesses want to harness the gas hazard from Lake Kivu before disaster strikesand produce power from the gas.

The MWM TCG 2032B V16 gas gensets transform the methane gas, which is harmful to the environment,

into useful electrical energy.

“In this way, our gas gensets greatly contribute to the reduction of climate-damaging methane gas, while at the same time producing clean energy,” explains Rene Ludvik, Director for MWM.

The gas-water mixture is transported up to the surface of the lake through pipes. At the surface, the methane is processed in scrubbing towers. In this way, the gas is upgraded for the energy generation, enabling the extraction of even more electrical energy. The carbon-dioxide is sent back down to the depths of the lake.

The Lake Kivu project will supply Rwanda with energy for several decades. According to the Swiss Federal Institute of Aquatic Science and Technology (Eawag) of the ETH, the 55 km³ of methane present can be transformed into power worth some US$20 billion, based on today’s energy prices.

“We are pleased to be able to deliver a significant contribution to this sustainable, extraordinary energy project with our MWM gas engines, thereby supporting Rwanda’s economic growth”, says Ludvik.

Bloom Energy is supporting the potential for more advanced manufacturing in the state of Connecticut with solid oxide fuel cells for power storage. The fuel cells power up to 20MW of electricity as part of the New Britain Energy & Innovation Park, which will include a new data centre.

“Fuel cell usage is ramping up again worldwide after pandemic delays and will likely gain new importance as a way to store energy and hydrogen produced by wind and solar generation,” said Joel Rinebold, former director of energy at Connecticut Center for Advanced Technology (CCAT).

A company spokesman comments: “Bloom Energy’s solid oxide fuel cell technology plays a critical role in advancing the hydrogen economy for a greener future. Dozens of countries have committed to net-zero emissions goals in the coming decades.

“Hydrogen energy is required to reach these deep decarbonization goals. It is estimated that 30% of energy-related CO2 emissions are hard-to-abate with electricity alone, providing a massive opportunity for hydrogen.”

He concludes: “The hydrogen economy is advancing across numerous sectors including power generation, transportation, industrial energy, building heat and power and feedstock. Bloom Energy’s solid oxide hydrogen fuel cell technology is uniquely positioned to accelerate both the production and the usage of hydrogen.”

Bloom Energy’s Solid Oxide Fuel Cells (SOFC) have been deployed in 100s of applications across healthcare, data centres, critical manufacturing, retailers and more.

“HYDROGEN IS ESSENTIAL TO MEET GLOBAL DECARBONISATION GOALS BY 2025 ACROSS INDUSTRIES. THE INTERNATIONAL RENEWABLE ENERGY AGENCY (IRENA) ESTIMATES THAT BY 2050, CLEAN HYDROGEN COULD MEET 12% OF ENERGY CONSUMPTION AND COULD MITIGATE SEVEN GIGATONS OF CO2 EMISSIONS ANNUALLY. H2-FED POWER PLANTS ARE NECESSARY TO PRODUCE GREEN RENEWABLE ELECTRICITY WHILE STILL MAINTAINING A RELIABLE GRID.

The same proven hydrogen fuel cell technology which has powered natural gas fleet is being used to generate combustion free emissions free and carbon-free electricity from hydrogen.

The technology enables highlyefficient, distributed power generation with the same focus on reliability that Bloom has demonstrated over the last 15 years, reports the company.

Bloom’s hydrogen fuel cells provide a combustion-free method of generating resilient, sustainable, and predictable electricity.

Hydrogen fuel cells run on pure hydrogen and provide 24/7 “always-on” power reliability without harmful emissions.

Fuel cells are a flexible, scalable, and distributed power technology which can be sited in a compact footprint. Bloom’s hydrogen fuel cells offer superior efficiency compared to other fuel cell

technologies, and leverage the same solid oxide platform that has over 700 installations globally.

Advantages of the fuel cells

• A highly efficient, zero-carbon, distributed energy solution

• Produced by a company with a proven track record in fuel cell technology with 15+ years’ experience

• Superior performance compared to alternative technologies.

In five to 10 years, green hydrogen is expected to be widely available. By one estimate, global green hydrogen capacity is expected to rise 280 times by 2030, with the price falling 40% by 2025.3

In the U.S., the U.S. Government in June 2021 launched the Hydrogen Energy Earthshot initiative, aiming to reduce the cost of clean hydrogen to $1 per kilogram in just one decade.

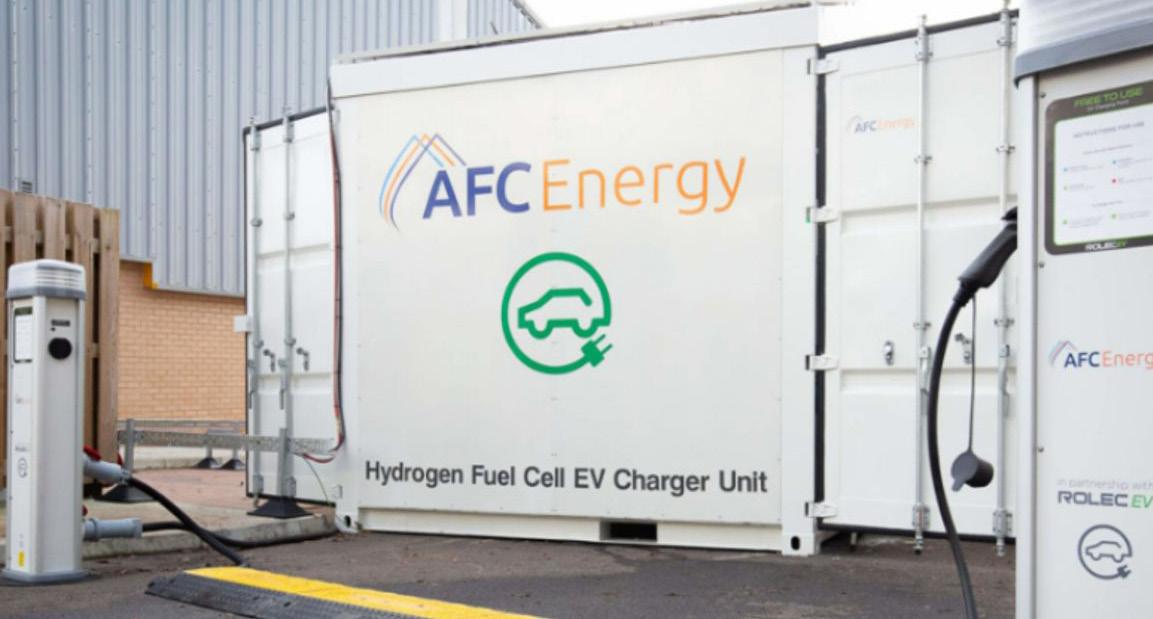

AFC Energy, the UK-based developer of hydrogen fuel cell generators, said it had £27 million worth of orders for its 30kW fuel cell gensets. The orders include supply arrangements for its 50/50 joint venture with Speedy Hire –Speedy Hydrogen Solutions – and its sales agreement with TAMGO covering Saudi Arabia, the Middle East and North Africa, as well as orders with global contractor Acciona.

AFC said Speedy had committed £2 million in orders with first year sales with the company projected at £4.7 million. This year will see the first deliveries to all three customers.

TAMGO is owned by Zahid Tractor, the largest distributor of construction equipment in Saudi Arabia and a Caterpillar dealer.

The company said in its annual results for the year to 31 October 2023 that it had completed supplier qualification work for all the key components of the gensets and was targeting suppliers who could scale up to more than 1000 units annually.

Adam Bond, chief executive of AFC Energy, reports that its key aims in 2023 had been to validate its business model, customer demand, its technology and its route to market. He commented: “Twelve months later, our contracted order book, multiple routes to market and successful product deployments highlight the tangible successes achieved by AFC Energy over the year.”

He said demand from customers to displace diesel generators has never been stronger; “driven by government policy, tendering requirements, carbon

“LOWERING THE TOTAL COST OF OWNERSHIP OF FUEL CELL GENERATORS IS A KEY PREREQUISITE TO INDUSTRY-WIDE ADOPTION. LAST YEAR, FIELD DATA SUGGESTED THAT AFC ENERGY’S H-POWER TOWERS WERE, OPERATIONALLY, ONLY 14% MORE COSTLY THAN DIESEL GENERATORS BASED ON EUROPEAN HYDROGEN PRICES, HIGHLIGHTING THE IMPORTANCE OF FUEL EFFICIENCY IN GENERATOR PERFORMANCE.”

reduction commitments and emissions based regulations.

“Together with our new distribution partners, including Speedy Hire and TAMGO, we are confident of the company’s robust commercialisation strategy,” he said.

Last month AFC Energy reported that its S Series Fuel Cell had achieved improved efficiency and operating cost reductions. Milestones included:

* A16% reduction in hydrogen fuel consumption from the 2024 30kW H-Power Generator versus the 2023 H-Power Tower;

* A significant lowering of 2024 H-Power Generator’s operating cost to customers, which builds on the 50% reduction in 2024 generator capital cost (per kW) relative to the 2023 H-Power Tower;

* Performance measured during recent Speedy Hydrogen Solutions FAT and is compared to “in the field” data received from customers during

H-Power Tower deployments in 2023; According to the company the data demonstrates the highly efficient performance of the S Series aircooled generator technology driven by its distinct integration of both proprietary fuel cell stack and generator balance of plant design.

Adam Bond concluded: “Lowering the total cost of ownership of fuel cell generators is a key prerequisite to industry-wide adoption.

“Last year, field data suggested that AFC Energy’s H-Power Towers were, operationally, only 14% more costly than diesel generators based on European hydrogen prices, highlighting the importance of fuel efficiency in generator performance and reducing this cost gap.

“AFC Energy’s high efficiency, high power dense S Series fuel cell generators are setting the standard for industry’s transition to a hydrogen- fuelled future”.

www.afcenergy.com

Bergen Engines, a leading producer of medium speed engines and generating sets, has provided 5 x Bergen B35:40V20AG2 gensets to the a strategic consortium led by Sampol Ingeniería y Obras (SAMPOL), a multinational applied engineering company specialised in energy efficiency, renewables, and digitization, in Guatemala. Bergen has delivered a state-of-the-art 45MW power plant to Petén.

Petén, located in the country’s north region, is bounded by Mexico to the north and west and by Belize to the east.

It constitutes more than one-third of the country’s territory. Petén is a low limestone plateau, varying in elevation between 500 and 700 feet (150 and 210 metres) above sea level at the base of the Yucatán Peninsula.

Except for areas of savanna vegetation, the region is covered by dense tropical rainforests. Few rivers penetrate Petén, for most of the heavy rainfall is drained underground. Guatemala.

The energy project, slated for completion in 2025, marks a significant milestone in Guatemala’s energy landscape as it introduces the country’s first mid-scale power plant operating on natural gas.

The owner of this groundbreaking power plant is Innova Energy, a CEC company, a forward-thinking group committed to driving positive change in the energy sector.

With the collaborative efforts of Bergen Engines and SAMPOL, Innova is set to usher in a new era of sustainable and efficient power generation for Guatemala.

The power plant will be equipped with 5 x Bergen B35:40V20AG2 gensets, renowned for their exceptional performance, efficiency, and notably low emissions of NOx, CO, and UHC. Developed by Bergen Engines,

“THE PROJECT, SLATED FOR COMPLETION IN 2025, MARKS A SIGNIFICANT MILESTONE IN GUATEMALA’S ENERGY LANDSCAPE AS IT INTRODUCES

THE COUNTRY’S FIRST MID-SCALE POWER PLANT OPERATING ON NATURAL GAS. THE OWNER OF THIS GROUNDBREAKING POWER PLANT IS INNOVA ENERGY, A CEC COMPANY, A FORWARD THINKING GROUP COMMITTED TO DRIVING POSITIVE CHANGE IN THE ENERGY SECTOR.”

these gensets strike a unique balance between power generation capabilities and environmental impact, aligning with global efforts to reduce carbon footprints.

SAMPOL’s design for the plant With years of experience in similar projects, SAMPOL will build a low-consumption, high-availability design for the plant with Bergen Engines’ performance at the focus.

An advanced digital control system will allow Innova Energy to monitor and supervise the facility remotely from their offices in Guatemala City.

In a pioneering move for the region, the power plant will utilise locally produced natural gas.

This departure from imported coal, diesel, or heavy fuel oil commonly used in Guatemala underscores the commitment to environmental sustainability.

“This project represents a significant step forward in Guatemala’s energy matrix,” said Theodore Lorentzos, Head of Sales for the Americas at Bergen Engines. “By harnessing the power of natural gas in a locally produced and sustainable manner, we are not only pushing the boundaries of technological innovation but also contributing to Guatemala’s broader energy transition goals,” concludes Lorentzos.

Racari, Romania: 6 x INNIO Group Jenbacher Type-6 engines have been supplied to support Romania’s national grid supplies. With the first phase of the Clarke Energy and Navios peaking plant project in Romania now fully commissioned, the company has announced that the second phase is now well underway in Racari.

Phase 2 will supply an additional 20MW and 6 x INNIO Group Jenbacher Type-6 engines to the plant, which will be dedicated to the balancing services of Romania’s national electricity grid.

The full EPC project delivered by Clarke Energy’s team in Romania is scheduled to be commissioned in summer 2024 and it will be supported by a long-term maintenance contract with the client, Navios Investment SRL.

The result of continuous enhancements and extensive experience, the Jenbacher Type 6 engines are an advanced and reliable addition to INNIO’s product line.

The 1,500-rpm engine speed results in a high power density with low installation costs, and its precombustion chamber achieves high efficiency with low emissions. There have been 6,400 engines delivered since 1989 (J624 since 2007).

Type 6 engines incorporate features designed to enhance heat recovery, assure stable combustion, reduce emissions, and increase efficiency - taking the Jenbacher line to new levels of performance.

A centrally-located purged pre-combustion chamber helps provide optimal ignition conditions. The spark plug ignition energy is amplified in the pre-combustion chamber, facilitating stable and reliable combustion.

Miller valve timing creates reduced compression temperature and an increased safety margin to

knocking limits, providing improved ignition timing and high efficiency.

Combined Heat and Power Module (CHP Module) solutions like these allow customers to generate power and heat simultaneously at a very high total efficiencies, reaching 90% and even more.

Last year the INNIO Group provided five Jenbacher J920 FleXtra engines will power a 50MWe combined heat and power project in Bydgoszcz, Poland, for PGE Energia Ciepła S.A. (PGE).

The five Jenbacher CHP unitsgenerating a total of 52.6 MWe - each consisted of a generator, a turbocharger, and an auxiliary module.

Additionally, under a 10-year service agreement with PGE, the Jenbacher team provides maintenance and assembly work, as well as start-up and operator training.

subsidiary Polimex Energetyka Sp. z o.o. to implement the design, construction, installation and all other aspects of the building process.

The project stipulated the construction of a turnkey cogeneration power plant, electrode water boiler, standby/peak boiler, and steam generator.

“INNIO Group’s technology is helping to achieve the transition to net zero by replacing coal power plants, resulting in eliminating over 70% CO2 per power plant,” said Dr. Olaf Berlien, president and CEO of INNIO Group.

“Our ‘Ready for H2’ engines help ensure that PGE assets will be able to deliver carbon-free power and heat well into the future when hydrogen is more readily available.”

WITH ITS PRODUCT BRANDS JENBACHER AND WAUKESHA AND ITS DIGITAL PLATFORM MYPLANT, INNIO OFFERS INNOVATIVE SOLUTIONS FOR THE POWER GENERATION AND COMPRESSION SEGMENTS THAT HELP INDUSTRIES AND COMMUNITIES GENERATE AND MANAGE ENERGY SUSTAINABLY WHILE NAVIGATING THE FAST CHANGING LANDSCAPE OF TRADITIONAL AND GREEN ENERGY SOURCES.”

The “Ready for H2“ CHP plant will be fuelled with gas, replacing coalfuelled power plants tpreviously in use.

The Jenbacher team worked with engineering and construction firm Polimex Mostostal S.A. and its

Power and heat generation is an important aspect of PGE’s strategy to decarbonise its district heating operations. With the operational efficiency of the Jenbacher combined heat and power solution, PGE’s transition from coal-fueled power generation to natural gas helps support the Polish government’s phase-out of coal and to reduce carbon emissions.

www.clarke-energy.com

www.innio.com

The climate crisis means that all organisations are under significant pressure to comply with environmental regulations and to achieve corporate sustainability goals.

Anything that uses fossil fuels will, rightly, be subject to increased scrutiny, to see how its emissions can be reduced.

The diesel generator is in this category, as it emits carbon dioxide (CO2) and other gases. But it’s proven technology that delivers reliable, high performance emergency backup power. A generator starts up quickly, in 10 seconds or less, and has a well-established fuel supply infrastructure.

Diesel generators are the backbone of a resilient energy solution. So how can we ensure that we minimize their emissions, and hence their impact on the environment?

When we talk with customers, what do they need to consider when choosing a generator?

Once they have understood the application for the generator, and the requirements for how much power is needed, a good next step is to review the regulations for their region.

For North America, installations are regulated by the US EPA. The EPA Tier 4 requirements have made good progress in reducing emissions, and we’re now also seeing pockets of specific air quality management districts (AQMD) with stricter regulations.

This includes California, Virginia, and other areas of the East Coast. It’s key to understand those local regulations and make sure to pick a technology that is going to meet the specific requirements in that area.

In the EU, there are similar requirements about emissions, including Stage V. There is a directive called MCPD (Medium Combustion Plant Directive) which aims to reduce harmful components like NOx from generators and other mid-size equipment (rated between 1 MWth and 50 MWth). In practice, this directive is adapted in each individual country.

Another new trend that we’re starting to see is customers that simply want to be better. They want to provide the greenest solution or use the best available technology, and to go beyond what the legislation demands, for example by adding an additional after treatment system to their generator.

Once a customer has understood their application and the environmental legislation that applies to them, they can review their options to reduce emissions, if required. Let’s look at a few technologies that can help.

One of the biggest opportunities to reduce generator emissions is by switching from fossil diesel to renewable fuel. In particular, hydrotreated vegetable oil (HVO) can provide an effective alternative to diesel, which can help reduce overall greenhouse gas emissions.

HVO is usually made by the hydrogenation of vegetable oil, adding hydrogen to molecules, or by hydrocracking, using hydrogen to break big molecules into smaller ones. Also known as green diesel or renewable diesel, using HVO instead of conventional diesel reduces net CO2 emissions by up to 90%.

Since HVO is similar in grade and quality to conventional diesel, it can be used without modification

of infrastructure, or any need to buy new engines. It is compatible with the standard mix of petroleum-derived diesel fuels, so it can also be blended with fossil diesel – thus increasing flexibility for the end-user. It is easy to store and handle, and can be kept for years without major degradation.

HVO is made from waste products and residues that don’t impact agricultural land use, including vegetable oils, animal fats, and used cooking oils. It could also be made from photosynthetic organisms such as algae in the near-to-medium term.

Compared to traditional first generation biofuels, HVO is also a superior, cleaner-burning fuel, which helps reduce emissions across its lifecycle. The generator transient re sponse time when using HVO is also similar to the performance achieved with conventional diesel, meaning the genset can respond quickly enough when called upon. HVO is more cost ly than traditional diesel, but prices are expected to drop.

Let’s look at an example of how HVO can reduce CO2 emissions. With a typical 1000-kilowatt generator that is running 100 hours each year on fossil diesel, that’s the equivalent of about 16 cars per year. If we do the same calculation for HVO, it’s equivalent to less than two cars per year .

In the development phases of gensets, there are naturally trade-offs involved in emission reductions, to ensure everything is being done to

optimize emissions specifically for each application.

This typically starts with the easiest options, which for engines means in-cylinder technologies such as EGR (exhaust gas recirculation) and combustion optimization to ensure that we’re getting the most efficient use of the engine.

When considering more stringent emissions requirements, that is where additional equipment may be needed. And this is where technologies such as Selective Catalytic Reduction (SCR) and Diesel Exhaust Fluid (DEF), which can reduce NOx emissions to negligible levels, come into play.

Adding these extra technologies does involve additional cost and additional equipment, and also comes with regulations and specific protections that the engine must have to ensure that the emissions equipment is functioning as we expect it to.

With all these approaches to help improve emissions, what’s exciting is that we see minimal impacts from a performance perspective. We’re not seeing derating on the engine, or worse transient performance.

Overall, there are no major impacts to the performance of the genset.

By taking a pragmatic approach, using one or more of the approach es discussed in this article, users of diesel generators can minimize their emissions, without noticeable cost or performance reductions.

The first official edition of the UKGSA Association magazine has been published - it is distributed free amongst the membership of now over 50+ members including key companies and associations in the UK Power & Energy sectors.

Launched in December 2023, UK GEN-SET & CHP ASSOCIATION (UKGSA) is pledged to serve its members and the industry by encouraging the sharing of knowledge in the field of Gen-Sets and CHP throughout the entire independent standby power and energy sectors.

The Association’s additional aim is to promote the interests of the Generating Set industry for UK Manufacturers, Suppliers & Distributors, Service Providers, Rental Companies and Power-related providers.

We recently joined a number of other companies involved with the UK data centre sector at Data Centre World, 6th-7th March, 2024, for an immersive experience at the epicentre of infrastructure advancement. ExCel was definitely the place to discover groundbreaking solutions at an event which essentially powers the digital economy.

The exhibition also presented the chance for industry professionals to learn more about the one-day PowerEx Live Midlands Show being held on June 27th, 2024.

This will feature an unparalleled line-up of key speakers and industry exhibitors. They come together to present cutting-edge power generation technologies and high-quality services, setting the stage for innovative energy-generation strategies across the industry.

On June 26th, 2024 - the day before the PowerEx Live Midlands event - we are holding a special Golf Day on the Brabazon Course at the Belfry Hotel & Resort at Royal Sutton Coldfield, West Midlands. Book your Company 4 player team, 3, 2 - or individual person team places as soon as you can.

There are networking opportunities available with many UKGSA member companies. See www.ukgsa.uk for further details. At the end of 2024, on December 12th, we will be participating in PowerEx Live London, one of the UK’s premier energy conferences held in Westminster.

UKGSA has a serious, technical purpose but also offers a diverse range of UKGSA Hospitality Events, such as a day at the Cheltenham Races on March 12th, the 2024 Aintree Races - Grand National 11th April, Cricket at Trent Bridge on 19th September and on 28th July a PowerAid Charity Football Day at Coalville Football Club. UKGSA is also holding a day at York Races – Ebor Festival - on 22nd August 2024.

“So far 50+ key companies have joined UK GEN-SET & CHP ASSOCIATION and we very much look forward to expanding our membership and its activities during the course of 2024,” explains Richard Teasdale, the President I Chairman of UKGSA.

UKGSA is about connecting professional companies and professional people within the power generation sector. How to join? Simply go the website and fill out an online form. Visit: www.ukgsa.uk/membership

AJ POWER

ASHVALE ENGINEERING

BRUNO GROUP DQM LTD FINNING CAT GENERATOR POWER GENOVATE

GSM

GTI POWER GENERATION HIMOINSA

JUBILEE POWER LISTER PETTER

MEMS POWER GENERATION

MHM GROUP

P&I

POWERLINK

TEKSAN TESSARI ENERGIA

UNITED RENTALS YORPOWER

ASSOCIATION AFFILIATE MEMBERS

THE DISTRIBUTED ENERGY SHOW DATA CENTRE ALLIANCE IPOWERE

MIDDLE EAST ENERGY DUBAI

FOUNDER MEMBERS

THE DATA CENTRE TRADE ASSOCIATION POWERGEN STATISTICS

UK POWER NEWS POWER COMPONENT SUPPLIER MEMBERS

EDINA

HILLSTONE PRODUCTS

STAMFORD I AvK

AGRIEMACH

BOWMAN

CABEL

DURR UNIVERSAL

DUNGS

JENELEC

JEREMIAS

MECC ALTE

MIRATECH

PFS

REICH

SCANIA

TVR

STAMFORD AVK

HONORARY MEMBERS

MHFCN

MIDLANDS HYDROGEN & FUEL CELL NETWORK

Richard Teasdale, President I CEO of the Association, explains: “MEGSA - MIDDLE EAST GEN-SET ASSOCIATION has gone from strength-to- strength with 50 + companies taking advantage of the new membership joining options, including Bahmani, Jubaili, Technopower, Staunch Machinery plus many other OEMs.

“Research shows that the Middle East Gen-set (Generator) market is expected to register substantial growth (3.7% CAGR) owing to the rising population and inadequate generation of power supply between 20222030.

“Additionally, increasing number of chemical and power projects in Saudi Arabia and in the UAE is likely to further expand the growth of the market.

“MEGSA’s ambition is to be a strident voice for the Middle East standby and independent power sector as the key professional trade body for the Middle East Gen-Set sector and its associated products diversification backed by upsurge investment of government in infrastructure will undoubtedl boost the growth of the industry and region,” he explains.

“This is where MEGSA as an association comes to the fore. Its ambition is to be a strident voice for the Middle East standby and independent power sector as the key professional trade body for the Middle East Gen-Set sector and its associated products,” he explains.

“One of the Association’s aims is to provide regular annual member events as networking opportunities”.

The Association is already in the enviable position of being at at the forefront of industry knowledge-sharing, offfering its members huge digital marketing opportunities and regular social media updates and interaction. MEGSA provides business opportunities and new contacts through different networking events.

Membership benefits include:

• Many Networking Opportunities

• Annual Statistical Report Free

• MEGSA Quarterly Publication

• Newsletters to over 10,000 in the Middle East region

• Professional advice & body knowledge

• Social Media promotion to over 7,000

• Membership badge of approval

• Company logo on the MEGSA homepage

• A MEGSA stand @ MEE promoting MEGSA and to visit/use as a base when visiting shows sponsored by the Association

• MEGSA can help in the transition to more sustainable options – “Net Zero”

• At Middle East Energy - MEGSA is an official supporting Media Partner and also the official UK sales agent

• 3 x 1 page, colour adverts - Free advertising to run in the “Official Association Publication” and “MEPMiddle East Power” magazine.

• Incentivised joining costs - Be part of our Inaugural year and Join for the 1st year @ £2450.00 or 2 years @ £1950.00 each year (Inaugural year incentivised joining prices)

• The voice of the Middle East Generating-Set industry

• There is also an Official Media Partner Power Magazine available free for all members.

Richard Teasdale concludes: “Our mission is to serve our members and the industry by encouraging the sharing of knowledge in the field of the diesel and gas engine power generating sector, Distributed Energy, Power and Energy.

“The aim is to advance design, development, manufacture, application, operation and maintenance throughout the entire independent standby power and energy sectors.

“We will be actively promoting the interests of the Generating Set

industry for International Manufacturers, Suppliers & Distributors, Service Providers, Rental Companies and other Power-related providers during the course of 2024.

“We will also keep members abreast of the latest industry news within the Middle East sector. MEGSA has a real voice thanks to the Association’s links with various media & marketing entities. Accordingly, it can offer real & profitable Networking Opportunities. Make sure that you take advantage of the many benefits MEGSA has to offer.”

All enquiries - take up membership by visiting: www.megsa.org

* * *

2024 Middle East Energy Exhibition & Conference flooded

Unfortunately the 2024 Middle East Energy Exhibition & Conference in Dubai was cancelled due to issues beyond our control - namely the weather.

Speaking for MEGSA, Neb Saric commented: “We were not able to interact with customers and attend the other client meetings we had lined up at the Middle East Energy show. However, we do look forward to seeing everyone again soon.”

The UFR1001E system-disconnection relay monitors voltage and frequency in single or three-phase networks.

Presetting per G99/98, values as per the standard pre programmed Under and overvoltage monitoring 40…520 V

• Under and over frequency monitoring 45…65 Hz

• Monitoring of Rate of Change of Frequency (ROCOF, df/dt)

• Monitoring the voltage quality (10 minute average value)

• Response time adjustable 0.05 … 130.0 s, individual setting for each limit

• Fail-safe, with monitoring of the connected section switch (can be switched off) 2 automatic restarts on error Supports the mains synchronisation when using generators Measurement 3 phase 3 or 4 wire systems or single phase Self-test

• Third Part Independently tested Compliant to G99/98 by Bureau Veritas

Tel: +44 (0) 1206 575755

Email: sales@tvri.co.uk

TVR Instruments

The Commission has adopted a new delegated regulation on the first phase for establishing an EU-wide scheme to rate the sustainability of EU data centres.

As foreseen under the new, recast Energy Efficiency Directive, this secondary legislation requires data centre operators to report the key performance indicators to the European database by 15 September 2024 and then by 15 May in 2025 and subsequent years.

It follows extensive consultation with EU countries and stakeholders and a period for public feedback at the end of last year and a 2-month scrutiny period for the Council and European Parliament.

With data centres estimated to account for close to 3% of EU electricity demand and likely to significantly increase in the coming years, the scheme is intended to increase transparency and potentially to promote new designs and efficiency developments in data centres that can not only reduce energy and water consumption, but also promote the use of renewable energy, increased grid efficiency, or the reuse of waste heat in nearby facilities and heat networks.

The delegated act sets out what information and key performance indicators should be reported. It also defines the first sustainability indicators that will be used for the rating of data centres.

Under Article 12 of the recast Energy Efficiency Directive, data centres will also be required to publish information on their energy performance and sustainability (as detailed under annex VII).

The delegated act is also part of ‘promoting climate-neutrality actions for the IT sector’ that are foreseen in the Action Plan for the Digitalisation of the Energy Sector, published in October 2022.

The recent Energy Efficiency Directive recast sets a new binding target of reducing the EU energy consumption by 11.7% by 2030 relative to forecast energy consumption for 2030 made in 2020.

The directive identifies the key Information & Communication Technology (ICT) sector as a sector of increasing importance in this context.

Italcogen – Association and manufacturers and distributors of cogeneration plants It gathers within ANIMA CONFINDUSTRIA manufacturers and distributors of cogeneration systems, heat recovery and fuel cells in Italy.

In Italcogen all cogeneration technologies are represented, both powered by fossil sources and by biomass.

The sector represented by the association produces a turnover of 500 million euros, with an export/ turnover share of 18%. It therefore represents an important branch of the Italian chain of energy efficiency and technologies for achieving environmental objectives by 2030.

The market shares of our members represent peaks of excellence in some specific sectors of bioenergy, covering: - 85% of the Italian market for liquid biomass plants and for small-sized solid biomass plants (<3 MW);

- more than 80% of the European market and national & European positions relevant to the biogas sector.

A sopkesman for the association comments: “We promote the diffusion of cogeneration and thermal recovery in Italy, providing the member-companies with timely and constant support in the technical, regulatory-legislative and promotional fields to: - represent Italcogen technologies towards institutions; -clarify the regulations governing the sector;

-promote and encourage support actions for the national industry and for users in all construction and management phases; -offer adequate training to operators and maintenance workers.

September 15-17, 2024

The Electrical Generating Systems Association (EGSA) is the world’s largest organization exclusively dedicated to On-Site Power Generation.

The Association is comprised of 500 companies - Manufacturers, Distributor/Dealers, Contractors/Integrators, Manufacturer’s Representatives, Consulting & Specifying Engineers, Service firms, End-Users and others - throughout the US and around the world that make, sell, distribute and use On-Site Power generation technology and equipment, including generators, engines, switchgear, controls, voltage regulators, governors and much more.

Upcoming Events

Mon - May 13 - Advanced School - Charlotte, NC

Tue - Jun 11 - Load Bank Certification - Chicago Area

Mon - Jul 15 - Basic School - Virtual (Online)

Sun - Sep 15 - EGSA 2024 Fall Conference

Mon - Sep 30 - Basic School - San Antonio, TX

EGSA wishes to thank the following companies for their support of the Spring Conference. Revenues from the event help support ESGA’s operational programs.

CORPORATE PARTNER:

Gillette Generators

GOLD LEVEL

Mecc Alte

SILVER LEVEL

AKSA

ANA

GAC

GENERAL LEVEL

ASCO Power Technologies

Schneider Electric

Power Temp Systems

R Robinson

United Rentals, Inc. has announced that it will offer its customers zero-emission power systems with the introduction of POWRBANK battery systems in its rental fleet.

The company’s partnership with manufacturer POWR2 Energy Solutions represents a significant investment in sustainable worksite solutions for United Rentals customers in North America.

The POWRBANK is a portable energy storage system that integrates with diesel generators, enabling the user to significantly reduce generator run-time and reduce emissions, noise and fuel waste.

The system is comprised of high-density lithium batteries, inverters and load-sensing technology. The POWRBANK model designed for United Rentals is rated for 40KW to 60KW of power output and provides between 60KW and 120KW hours of storage.

David Scott, senior vice president, specialty operations, of United Rentals, said, “POWR2 is the type of sustainability partner we look for - innovative and willing to invest the time in understanding the unique demands of equipment rental. Hybrid power is a particular focus of ours as we explore adding more low- and zero-emission equipment to our rental fleet. Our introductions of reduced emission worksite solutions help our customers meet their own sustainability objectives.” www.unitedrentals.com

Bachmann electronic GmbH is launching a further enhanced version of its proven GMP232 controllerintegrated grid measurement and grid protection module.

With a frequency measurement accuracy of ≤ 1 mHz and maximum deviation of 0.1 % for measuring current and voltage, the GMP232/x2 meets even the most rigorous requirements of grid operators. The frequency measurement has been designed especially for the influences around the converters and the common grid faults that occur. Applications can directly access highly dynamic, interference-suppressed, or averaged frequency data as required.

Bachmann electronic GmbH has completely reworked its isolation concept, in order to simultaneously measure and protect large low-voltage generators or critical load feeders with both high accuracy and high costefficiency.

The GMP 232/x2 supports rated voltages up to the medium-voltage limit value of 1000 V.

www.bachmann.info

Sensor specialist Metis Engineering has released the results of independent testing covering its Cell Guard system, which is intended to deliver advanced detection of a thermal runaway event in battery packs.

The tests, which were carried out by Sandia National Laboratories, involved Metis’ Cell Guard system and products from two competitors; one intended for use primarily with battery-electric storage systems (BESS) and another for EV applications.

The results showed that Cell Guard detected possible thermal runaway signatures in less than a minute and up to seven minutes faster than the other test products.

The sensors produced by Metis have a wide range of sensing capabilities which support early detection. Where most commonly use temperature and voltage change to identify a potential runaway scenario, the Cell Guard sensors can detect volatile organic compounds (VOCs) emitted during cell venting – a precursor to thermal runaway.

In addition, the sensors can detect humidity and dew point (to help cooling), with the option of adding a three-axis accelerometer to measure shock loads.

One of the sensors in the test is designed to identify hydrogen as a signal for thermal runaway. But this is only produced at temperatures of around 200°C when the battery cathode starts to decompose - and just one minute before uncontrolled thermal runaway takes hold.

Early detection of thermal runaway is critical. It can allow preventative measures to be taken to stop a related fire, while also allowing time for the vehicle operator and any passengers to exit before the situation becomes more dangerous.

Joe Holdsworth, managing director at UK-based Metis Engineering, said: “We are delighted that our Cell Guard sensor has proven its mettle against two competitors in the market in an entirely independent and third-party test. Not only did our sensor detect a thermal incident in under 60 seconds, the CAN data it provides could be used to inform the driver to stop and evacuate the vehicle.”

Data collected by the Cell Guard sensors can also be used to complement information collected by the battery management system to give a more accurate estimation of overall battery pack health, which should help to support second-life for electric machines. www.metisengineering.com

INNIO is headquartered in Jenbach (Austria), with other primary operations in Waukesha (Wisconsin, U.S.) and Welland (Ontario, Canada).

INNIO Jenbacher gas engines

Headquarters: A-6200 Jenbach (Austria) T +43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.gejenbacher.com

Manufacturer of gas driven generator sets and cogeneration systems in a power range from 0.25 to 3 MW.

m3N. Dry exhaust gas; based on 5% O2. For engines with 1,200 rpm please contact GE Energy’s Jenbacher product team.

INNIO Jenbacher gas engines

A team of more than 3,500 experts provides life-cycle support to the more than 54,000 delivered engines globally through a service network in more than 80 countries.

R Schmitt Enertec GmbH

56743 Mendig, Germany T +49 2652 9351810

F +49 2652 9351822

info@rschmitt-enertec.com

www.rschmitt-enertec.com

Manufacturer of gas driven engines,generator sets and cogeneration systems in the range from 100 - 500 kW.

INNIO Jenbacher gas engines

Headquarters: A-6200 Jenbach (Austria)

+43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.gejenbacher.com

Manufacturer of gas driven generator sets and cogeneration systems in a power range from 0.25 to 3 MW.

1) ISO standard output, at 1,500 rpm/1,800 rpm and standard reference conditions according to ISO 3046at p.f. = 1.0 according to VDE 0530 REM

RSE Engines for natural gas and biogas

2) Heat recovery with a tolerance +/- 8 %

3) NOx @ 5 % O2 dry Requirements for technical data: All data according to full load, and subject to technical development and modification

* Indicates a trademark.

m3N. Dry exhaust gas; based on 5% O2. For engines with 1,200 rpm please contact GE Energy’s Jenbacher product team.

TINN00_07_Anz_Power_Sourcing_Guide_203x267_EN_2022.indd

R Schmitt Enertec GmbH

Perkins Engines Company Limited

Peterborough PE1 5FQ

Contact name:- Simon Gray

Tel: +44 (0) 1733 583000

Email: gray_simon_j@perkins.com

Perkins is one of the world’s leading suppliers

Perkins Engines Company Limited

A-6200 Jenbach (Austria)

Peterborough PE1 5FQ

Contact name:- Simon Gray

56743 Mendig, Germany T +49 2652 9351810 F +49 2652 9351822

info@rschmitt-enertec.com www.rschmitt-enertec.com

in dieselor 1000 kWE prime in gas.

Tel: +44 (0) 1733 583000

www.gejenbacher.com

Email: gray_simon_j@perkins.com

Perkins is one of the world’s leading suppliers

Manufacturer of gas driven generator sets and cogeneration systems in a power range from 0.25 to 3 MW.

in dieselor 1000 kWE prime in gas.

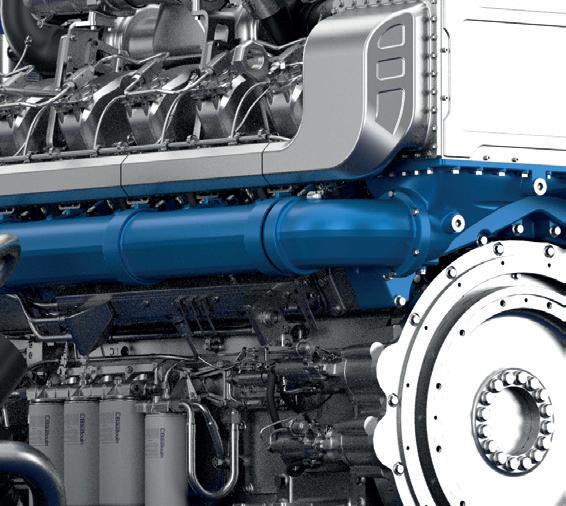

SCANIA ENGINES

SE-151 87 Sodertalje Sweden

Tel +468553 81000

Fax +468553 898 12 E-mail engines@scania.com

Web www.scania.com

UK Contact – Mark Swindell

Scania GB Ltd

Tel +44 1908 329386 E-mail mark.swindell@scania.com

Manufacturer of gas driven engines,generator sets and cogeneration systems in the range from 100 - 500 kW.

RSE Engines for natural gas and biogas

SCANIA ENGINES

SE-151 87 Sodertalje Sweden

Tel +468553 81000

Fax +468553 898 12

E-mail engines@scania.com

Web www.scania.com

UK Contact – Mark Swindell

Scania GB Ltd

Tel +44 1908 329386

E-mail mark.swindell@scania.com

Diesel & Gas engines for power generation

Prime power 250kVA to 700kVA Stand by power 250kVA to 770kVA

Engine range prime power 50hz & 60hz at (70% mean load factor)

Diesel & Gas engines for power generation