MWM

If you have concerns about fuel

speak to an

about our

can offer everything you need to keep your fuel in peak condition from environmental compliance through OFTEC surveys to subsequent remedial recommendations, installation of polishing systems and scheduled maintenance routines. And, as a leading OEM in fuel systems, we are in a unique position to design and manufacture the solution most tailored to your needs.

With decades of experience in the global Oil and Gas sector, operating in some of the world’s most demanding ATEX environments, we fully understand the hazards and challenges you may face – which is why you can rely on our pro-active and undiluted support at all times.

place on 8th December, 2022, at the prestigious Park Plaza Hotel,

London, PowerEx Live 2022 is organised by the Power

Group Ltd. The event has attracted 45+ leading

25+ key power speakers from the Critical Power

a free-to-attend conference with refreshments and lunch

free today for your entry to PowerEx.

www.powerexlive.co.uk

the Critical Power sector include: Generator Power, Bergen Engines UK, Wernick Power, Cummins Generator Technologies, Clarke Energy, Aksa, Crestchic, Durr Universal, HMS Industrial Networks, Industrial Power Systems, IPU Group, Leroy Somer|NIDEC, Mecc Alte, BGG UK, Scania, MHM Group, Volvo, YorPower, Edina, Eminox, Teksan, Lister Petter Engine Co, MEMS, AMC, WEG, Moteurs Baudouin - and many more.

Register for free: attendees have the chance to learn from energy experts within several key fields: Gen-Sets, CHP, District Energy, Engines, Emissions, Rental, Hydrogen, Distributed Energy, Fuels, Grid Codes, Data Centres, Batteries, Energy Storage, Fuels, Noise Reduction, Gen-Set Statistics and Industry Consultants.

PowerEx covers the CHP, Gas & Renewables sectors which includes promoting alternators & Gen-Sets. Leaders in the energy field - such as Clarke Energy & Edina - are exhibiting. More than 12 of the speakers are dedicated to these specific areas of the market.

The two conferences take place under one roof in one day, with 25+ quality speakers. Lunch & refreshments are provided free to all attendees.The AMPS Awards for Excellence (black tie) event is also being held in the evening at the same location.

PowerEx Live has won a solid reputation as a quality networking and industry event held at a Covid-secure venue in the heart of London, with excellent rail, tube and road links. PowerEx itself is organised by one of the leading publications companies in the field of power generation and energy today, the Power Media International Group Ltd. The Claverton Energy Group is providing additional speakers for the PowerEx Live event taken from from academia, consultancies and the public and private sector and has engaged other industry experts involved with the broader energy spectrum [see Page 8, 11 & 12 for Conference details]. We look forward to you joining us on 8th December, 2022, in London.

AIDAN TURNBULLPOWEREX LIVE TAKES PLACE IN WESTMINSTER LONDON ON DECEMBER 8TH, 2022. IT IS PROBABLY THE BEST AND MOST COMPREHENSIVE ENERGY CONFERENCE YOU’LL ATTEND ALL YEAR

Future Market Insights says that - despite the lower cost of diesel generator sets - the gas generator set sector will experience a higher rate of demand within generator set market share. A rising awareness of environmental issues is leading to cost reduction, energy efficiency, and the utilisation of cleaner sources, say the marklet analysts. Globally, market worth is put at US$ 2.67 billion.

In Western Europe AB InBev beers are being brewed with 100% renewable electricity, following the opening of a 148 MWp solar park near Granada, Spain with partners BayWa r.e. and VERBUND.The solar park was officially opened this month in an inauguration ceremony attended by local and international stakeholders and guests, reports WIP.

INNIO has announced the launch of its next generation Jenbacher Type 3F engine. This forms part of INNIO’s commitment to empower the transition to net zero with flexible, scalable, and resilient energy solutions and services. The new and improved Jenbacher Type 3F engine offers customers proven robustness and reliability while delivering up to two percentage points of efficiency boost, the engine line’s highest efficiency ever and delivers efficiency as high as 43.3%.

. 3,300 KWE COGENERATION SYSTEM SUPPLIED TO A CERAMIC MANUFACTURER

AB ENERGY SPA has supplied and installed a methane-fuelled ECOMAX 33- a 3,300 KWE CHP system - to a site in Maranello (MO).Italy, owned by Gruppo Cerdisa Ricchetti, leader in Italy in the production of quality ceramic coatings. The installation was carried out by the White Energy Group who specified an ECOMAX 33 supplied by AB.

Teksan reports that two 1,650 kVA diesel generators have been successfully installed and commissioned for the Inter Mattrid Beverage Company Ltd. Based in Cambodia. Each set features 1,650kva Standby Perkins Engines / Leroy Somer Alternators with synchronized system in IMB. The Inter-Mattrid Beverage (Cambodia) Co Ltd’s US $78 million brewery/beverage plant has been approved by the Council for the Development of Cambodia (CDC).

GAS GENSETS GENERATE ENERGY FROM WASTE DESTINED FOR LANDFILL MWM technology is behind the the largest kitchen waste treatment project in China at the Guangzhou Likeng treatment plant. This was successfully connected to the grid for power generation earlier in 2022. The Likeng comprehensive treatment plant is currently the largest environmental protection project for kitchen waste treatment in China.

Generac Power Systems and EODev, a French developer and manufacturer of zero-emission hydrogen fuel cell power generation systems, have announced a JV distribution agreement - Generac will now offer EODev’s GEH2 large-scale, zeroemissions hydrogen fuel cell power generator to the North American market. Generac said the distribution agreement signifies the continued growth and availability of alternative energy solutions for the industrial power sector.

Moteurs Baudouin has launched the 6F21 sixcylinder, 12.5-litre engine, a compact yet powerful model suited for intermittent-duty (815 hp/599 kW), light-duty (900 hp/662 kW) and high-performance duty (1000 hp/735 kW) applications. All three power options are rated at 2300 rpm.The choice of power ranges enables adaptability across a variety of lightduty applications.

Cummins has unveiled a new Euro 7 diesel engine which reflects its Destination Zero strategy. The X10, is what Cummins calls ‘a practical route to emissions reduction and decarbonization for applications which are not easily switched to alternative power solutions’. Cummins next-generation fuel cell technology is also available alongside the engine in 135 kW single and 270 kW dual modules.

www.wipmagazines.com www.powermediagroup.co.uk

This year’s PowerEx Live Conference is happening once again at Park Plaza Hotel, Westminster, London - opening time: 9.30am – 16.00pm.

A key event in every company’s energy calendar, the free-to-attend one-day Conference boasts 24+ speakers who are leaders in their respective fields.

The venue also includes dedicated Gen-Set + CHP / Renewables Live areas. At the same hotel location the AMPS Awards for Excellence event is also being held.

This is an excellent opportunity for all AMPS members to come along and make a day - and a night of it.

The Conference at the prestigious Park Plaza Hotel, Westminster, London, is being organised by the Power Media International Group Ltd.

This event has already attracted the participation of 45+ leading companies and 25+ key power speakers, from the Critical Power sector.

This is a free-to-attend Conference with refreshments & lunch provided for everyone. The 45+Exhibitors from the Critical Power sector at the show currently include:

Edina, Clarke Energy, Generator Power, Bergen Engines UK, Wernick Power, STAMFORD AvK, AKSA, Crestchic, Durr Universal, HMS Industrial Networks, Industrial Power Systems, IPU Group, Leroy Somer|NIDEC, Mecc Alte, BGG UK, Scania, MHM Group, Volvo, YorPower, Eminox, Teksan, Lister Petter Engine Co, MEMS, AMC, WEG, Moteurs Baudouin, Turbine Services Ltd and PramacGenerac UK Ltd along with many more companies.

The AMPS Awards for Excellence (black tie) event is also being held in the evening at the same location. There are only 40 tickets left for the Awards night and over 25 different companies are attending. Register for PowerEx free at: www.powerexlive.co.uk

Opening time: 9.30am – 16.00pm. Visit: www.powerexlive.co.uk

DATA CENTRES –Emergency standby generators for applications

- Ian Bitterlin

ENERGY STORAGE – Tech for large scale applications ie. Batteries -Ian Bitterlin

HYDROGEN - UK Fuel Cells & Hydrogen Technology Supply Chains -Dr Michaela Kendall DIESEL & GAS GENERATOR MARKET OUTLOOK -Romain Mocaer

NOISE REDUCTION – Reciprocating Engines Noise – Power Generation -John D. Kerr

SUSTAINABLE CRITICAL POWER SYSTEMS

- Keith Maclean-Martin FUELS - RED DIESEL – Changes to rebated fuels - Bernard Gospel CHP AND COGENERATION MARKETS - Dave Andrews G99 PROTECTION AND G99 GENERATOR COMPLIANCE

- Ian Wassman/Hassaan Minhas

EMISSIONS – The Application of Emissions Legislation

- Richard Payne STAGE V AND BEYOND - Dave Philips STORED FUELS - The challenges relating to stored fuels in critical standby applications. Are existing OFTEC regulations really suitable for our industry?

- Mike Benzies/Nathaniel Fuller

ENGINES & TURBINES IN WIND AND SOLAR DROUGHTS - 100% zero carbon energy for the UK - Cost and feasibility?

- Professor Mark Barrett GREEN HYDROGEN - Wake up to the hype around green hydrogen for heating – where might it realistically have an application – engine power generation in wind and solar droughts?

- Richard Lowes/David Cebon

ON-DEMAND LOW PRESSURE HYDROGEN GAS – a perfect feed gas for engines and Fuel Cells. - Dave McGrath

DIRECT AIR CAPTURE OF CO2 - for methanol engine and turbine fuel – is this the way forward? - Andy Erlam

HEAT PUMPS WITH DISTRICT HEATING, CHP AND HEAT PUMPS - running the BEIS SRBI project to deliver open control systems for renewables - Richard Hanson-Graville RENEWABLES AND FLEXIBILITY MARKETS - Colin Mallett

DISTRICT HEATING FOR MOST OF THE UK - Far Better than Hydrogen? - Gordon Taylor HOW TO INSTALL HEAT PUMPS CORRECTLY - so they work properly and have a good winter and seasonal COP - Brendon Uys

HEAT NETWORKS: recent progress and their future potential as part of decarbonising heat and the role of engines CHP in the transition

- Dr Andrew Cripps

BEYOND SPACE HEATING & COOLING - Dr. Bill Bordass

ENABLING A ZERO CARBON FUTURE - Hydrogen & future fuels as an engine-based power plant installation can supply reliable power for over 30 years, machinery chosen today must be able to operate on the least GHG intensive fuel which is available now and be able to transition to the green fuels as they become available.

- Terje Eriksen

Register free for PowerEx Live at: www.powerexlive.co.uk

We’re ready for H2. Get ready, too!

At INNIO*, we are continuously innovating flexible, scalable, and resilient energy solutions to help you generate and manage energy efficiently and sustainably.

Our Jenbacher* engine technology is an investment in the future. It can be converted to run on traditional gas-hydrogen mixtures and up to 100% hydrogen when hydrogen becomes available. Installing our “Ready for H2”**-designed gas power plant now will enable you to convert it to 100 % hydrogen operation later, delivering a sustainable energy solution that works for you today and accelerates a greener tomorrow!

Let us support your transition journey. innio.com

Indicates a trademark.

Optional scope on demand.

More than 45+ of industry’s power equipment companies will be presenting at PowerEx Live.

* Generator PowerLtd, the Yorkshire based generator hire and purchase specialist, has celebrated a successful milestone - 25 years in business.

MD Stephen Cardwell said:“ There is no secret to the success of Generator Power. It’s all about monitoring competition and ensuring you can offer the best service and innovation so that you can offer something different to make you stand out from competition.”

* Bergen Engines UK provides iconic medium-speed liquid fuelled and gas-fuelled reciprocating engines for marine and land based applications. Its engines can be found operating in some of the most demanding and hostile environments on earth, both on land and at sea.

Arnold Magnetics Corporation - for over 60 years it has provided exceptional support to its extensive mili tary and high grade industrial customers worldwide. As a technology innovator of AC to DC Power Supplies, DC to DC converters, Power Distribution Units, Rack Mount Power Systems, Transformer Rectifiers and Custom EMI Filters, our broad portfolio of products range from rugged, configurable and modular, off-the-shelf power solutions, to standard AC front ends, Plug and Play DCDC Converters and custom power designs.

*Turbine Services is a global provider to owners and operators of industrial gas turbines, offering an employee skill-base in excess of 2,000 man-years of experience in gas turbine maintenance solutions.

Some of the world’s key energy equipment manufacturers are represented at Powerex Live:

* Leroy Somer|NIDEC is a world leader in electromechan ical and electronic drive systems and the world leader in industrial alternators. Founded in 1919, Leroy-Somer is a French company employing 6,200 people in 28 production units and 470 points of sale and service worldwide.

* Mecc Alte - as an alternator supplier, the company has proven expertise and experience in research, design, lowcost manufacturing and development capabilities. With manufacturing taking place in Italy, the UK, India and China, coupled with high market capabilities and a powerful world wide capacity, it offer a fast and reliable alternator solutions service to customers all over the world.

*BGG UK is a Bruno Group company. Bruno Generators Group (BGG) is recognised as one of the leading manufacturers of high specification rental diesel powered generators. Ranging from 6.5 kVA to 2000 kVA prime power, with a full range of super silent canopies and containers.

* Scania - used as primary or back-up power for everything from events, remote locations and construction sites to critical functions in data centres and hospitals, Scania power generation systems deliver reliable power where clients need it, when they need it.

* MHM Group is a leading supplier of power generation, advanced solarhybrid-gensets, fluid storage, lighting towers and engine drive welders and product-related accessories for the UK and Ireland.

The company says not only does it build the finest medium speed engines available, Bergen also supplies generator sets, provides modular power generating plants and partners for complete turn-key microgrid power solutions.

* Wernick Power Solutions says it can cater for any temporary power need. Alongside a fleet of over 1,600 generators ranging from 6 to 500kVA, the company can supply loadbanks, distribution boards, fuel tanks, ca bling, and storage. Using minute-by-minute telemetry, Wernick can ensure a continuity of supply and help clients to reduce their carbon footprint.

* STAMFORD AvK - utilising wire-wound technology and with an output extending from 7.5 to 5,000kV the company is probably best-known across the power industry for its genuine STAMFORD® alternators. These are are designed for delivering superior efficiencies in marine, oil and gas auxiliary, UPS, telecoms, CHP, construction and other continuous or standby power applications.

STAMFORD® alternators are available with a choice of SAE adaptors to ensure easy coupling to a wide range of prime movers. All STAMFORD® S-Range is fitted with CoreCooling™ Technology.

* Clarke Energy provides distributed power plant solutions with market leading engineering, installation and maintenance support. The was recently involved in an NZ project supplying EnviroWaste Services Limited with a fourth Jenbacher biogas engine, the Jenbacher J320. This reduces the carbon footprint and increases green energy supply across New Zea land’s power grid.

* AKSA - being one of the first manufacturers of natural gas generator sets of the world, Aksa Generators feels it holds supremacy with respect to synchronised sets. Aksa Generators is manufacturing more sound proof, environment-friendly generators with lower fuel consumption for use around the globe.

Among the prestigious companies attending PowerEx Live is

* Crestchic - specialising in load bank manufacture since 1983, With sales and rentals offices in the UK, North America, Singapore, Netherlands, France, Germany, India and Dubai, Crestchic feels it has earned the title of the largest load bank specialist in the world.

Crestchic load banks have been operationally successful in all seven con tinents and are reliably testing power supplies every day in locations and climates all round the world, from temperate to jungle, desert to snow, off-shore to high altitude.

* Dürr Universal is a global provider of custom-engineered ancillary equipment and solutions to the power generation, oil and gas, industrial processing, rail transportation and backup power markets.

* HMS Industrial Networks create products which enable industrial equipment to communicate and share information. HMS stands for Hard ware Meets Software™, the two core components of its solutions.

* Industrial Power Systems - from industrial battery chargers, modular DC systems and inverters to AC UPS, power converters and green mobility chargers, the Italian manufacturer has built up a reputation based on the impeccable quality of its industrial power components and is still known for this quality today.

* IPU Group has a long history of serving the power generation industry in the UK and globally. The company is a UK distributor for products including ComAp generator and industrial controls, Powerstart starter motors, Parker Racor filtration, Hotstart engine heaters, Woodward solenoids and GAC engine governors. IPU’s new laboratory offers an oil and fuel testing service which delivers exceptional response time and economy. IPU also designs, manufactures and exports ranges of IPU-branded products including Diesel Defence fuel polishing units.

Pramac-Generac will be exhibiting at PowerLive in London on December 8th, 2022.

The company says it has continually evolved and transformed, expand ing its product portfolio and becoming the global benchmark for the production of generators and warehouse material handling equipment., Today, PRAMAC manufactures a complete and flexible product range which satisfies the full spectrum of energy needs to suit customers world wide. 2016 saw PRAMAC become part of the Generac group forming the world’s third largest generator and lighting tower producer.

Hyliion Holdings Corp. has told WIP that its a definitive agreement to acquire the KARNO hydrogen and fuel agnostic-capable generator from GE Additive, part of General Electric (GE), for US$37 million, is a ‘game-changer’.

Hyliion will acquire the generator technology and integrate the Cincinnati-based engineering team which created the KARNO system into its operations.

Hyliion plans to use the KARNO generator tech in its electric powertrain recharged by an onboard generator. In late 2023, the company intends to release the Hypertruck ERX powertrain leveraging an onboard natural gas engine as the generator.

Many of the companies appearing at PowerEx Live have long and fruitful careers. One such company is Moteurs Baudouin - for over 100 years, Baudouin has designed and manufactured the highest quality diesel and gas engines for marine and power generation applications spanning 18 – 4125 kVA. Its Network supports customers in over 130 countries with specification, commissioning, service and genuine spare parts.

* Teksan Generator designs and produces optimum diesel generators, natural gas and biogas driven gen erator sets, mobile generator sets, portable generator sets, cogenera tion and trigeneration packs, hybrid power systems for customer needs all around the globe.

* Eminox designs & manufactures exhaust aftertreatment systems for heavy-duty vehicles and equipment such as gensets. Its sustainable engineered solutions achieve the latest, global emissions standards working in partnership with clients.

Deere & Co. announced its next steps in meeting the growing demand for batteries as a sole- or hybrid-propulsion system. In addition to the production facility in Austria, John Deere is making an immediate investment in two additional locations. The plan is to increase the production capacity expansion of Kreisel Electric – the battery technology specialist in which John Deere recently acquired majority ownership.

The significant capital commitment will bring an increase of over 2 GWh to Kreisel battery production capacity, beginning with the opening of a new facility at Deere’s Saran factory, the primary manufacturing location for John Deere engines in the European Union. In parallel with this project, John Deere will also invest in battery assembly in the United States to support the growth of its customers and Deere products.

“This investment will put a strong focus on the industrialisation and automation of the entire production process, as well as research and development capacities at Kreisel HQ in Rainbach,” said Jennifer Preston, global director, John Deere Electric Power.

Deere said that by leveraging the established expertise at Saran, Kreisel will have access to world-class supply chain management, manufacturing engineering, quality assurance, logistics coordination and cutting-edge automation solutions. The funds from the investment will primarily be deployed within the mobile commercial and industrial solutions as well as the charging infrastructure division of Kreisel.

Another well-known PowerEx exhibitor is MEMS Power Generation which sparked into life in 1978 as an electrical engineering company. Since then this company has grown to become one of the leading specialists in temporary power solutions, operating one of the country’s largest diesel generator rental fleets.

* Volvo - independent supplier, Volvo Penta provides industrial power generation engines that are constructed with reliable efficiency and unmatched load acceptance at their core.

Flexible, easily installed and fuel efficient – backed by an extensive aftermarket sup port – they will supply power, ease of operation and peace of mind.

*Edina is a leading power generation specialist and EPC solutions provider for the engineering, installation and maintenance of gas-fired distributed power plants, standby mission critical generation, and battery ener gy storage systems.

* Lister Petter Engine Co. is a world-renown engine manufacturer with 150 years of history. Just this year it has released a new series engine - STARLITE. The 1683kW rated power is being recognized and is commonly used in gensets.

* WEG manufactures a complete line of generators for the most diverse applications. It also makes alternators for generator sets WEG is experience in design ing and supplying generators for applications such as steam & gas turbines.

*YorPower - based in the UK YorPower assembles, supplies and delivers a generator somewhere in the world nearly three times a day. The company provides backup power gensets for many applications.

Aggreko has created a new ‘energy transition’ business unit in North America to invest in low emission power technologies. The division will focus on ‘middle market’ opportunities to develop, own and operate clean energy and sustainable infrastructure through long-term investment and partnerships. ‘Middle market’ typically means businesses in the US$10 million to $1 billion range, reports the company.

The division, called Aggreko Energy Transition Solutions, will be led by Jerry Polacek as President. He is a former Managing Director of GE Capital, CEO of Energy & Investment Capital, and most recently, Managing Director of Ecofin, an investment company focused on sustainable business and managing US$2 billion in funds.

Polacek is joined in the leadership team by two other former Ecofin executives: Matthew Ordway will be Chief Operating Officer and Prashanth Prakash has been apppointed Chief Commercial Officer.

Aggreko reports: “The three have a proven history of developing, constructing, originating, and managing value-added renewable energy infrastructure.”

The company said the power market in the US has proven to be an attractive one for renewable energy over the last decade, given its large size, an ageing conventional generation fleet, and policy support for clean energy. It said the recent Inflation Reduction Act’s US$369 billion allocation would accelerate the decarbonisation of the US power grid.

Perkins Engines Company Ltd. is participating in two projects under the UK government’s Red Diesel Replacement Competition, which supports low-carbon technologies, fuels and systems for industry. Funding for the competition has been made available through the government’s £1 billion Net Zero Innovation Portfolio, which looks to accelerate the commercialisation of low-carbon technologies and systems.

Projects which are part of the competition will build on research and development activities to improve power system efficiency while also minimising environmental impact –further enhancing the portfolio of technologies available to reduce greenhouse gas (GHG) emissions across the off-highway sectors. By complementing its technology, Perkins said the projects will help to advance its engines’ capability to operate on an array of lower car bon intensity fuel types in addition to 100% hydrotreated vegetable oil (HVO) to EN15940 and biodiesel up to B20.

Perkins is serving as the lead organisation working closely with Loughborough University and Flogas in development of an internal combustion engine which runs on renewable dimethyl ether (rDME). rDME is a non-toxic aerosol propellant which can be synthesised from biomass, residues and waste.

DME fuel has several properties which make it attractive for use in diesel engines, including a very high cetane number and the ability to provide comparable energy efficiency and power ratings to traditional diesel engines. Its sootless combustion can further reduce particulate matter (PM) emissions from modern diesel engines, enabling PM limits to be achieved with simplified exhaust aftertreatment.

According to Perkins, DME can use the existing LPG infrastructure with minimal change. Flogas and Loughborough University will provide a practical demonstration of delivery and storage of DME as well as engine performance and capability.

In a second project, Perkins is partnering with Mahle Powertrain, Clean Air Power and the University of Nottingham to demonstrate a number of solutions based on ammonia and hydrogen as fuels for decarbonising heavy-duty engines.

By developing flexible fuel capability, the consortium plans to demonstrate combinations of fuels ranging from dual-fuel diesel with hydrogen and/or ammonia or hydrogen.

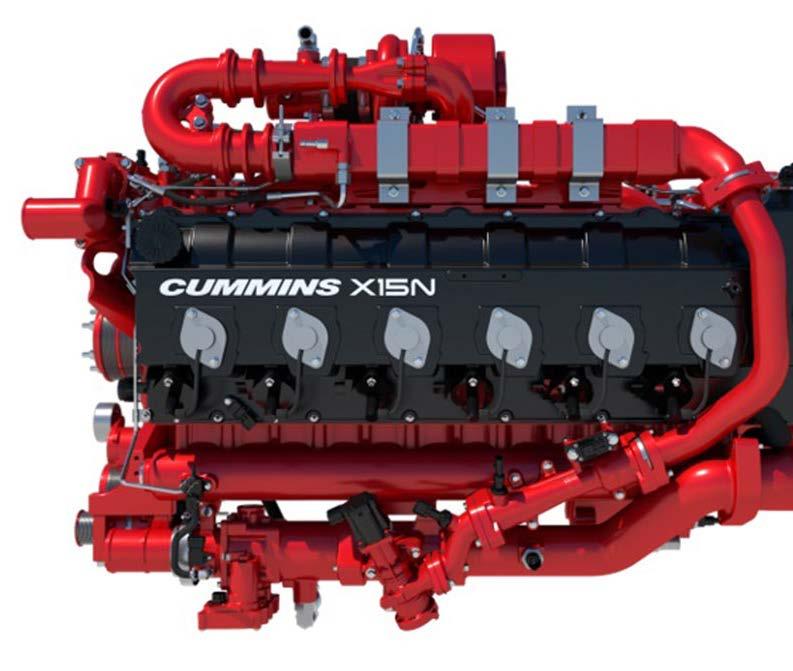

Werner Enterprises has signed a letter of intent to purchase 500 Cummins 15-L hydrogen internal combustion engines.

In early 2022 Werner announced plans to validate and integrate Cummins’15 L natural gas and Cummins’ X15H hydrogen engines, both part of Cummins’ fuel agnostic platform, into their fleet.

said Werner’s chairman, president and CEO, Derek Leathers.comments: “At Werner, we’re committed to a 55% reduction in greenhouse gas emissions by 2035 because we recognize the important role our sustainability efforts play.

“Our customers are showing increased interest in more sustainable choices in the marketplace, and we see significant potential in utilising Cummins’ fuel agnostic platform.”

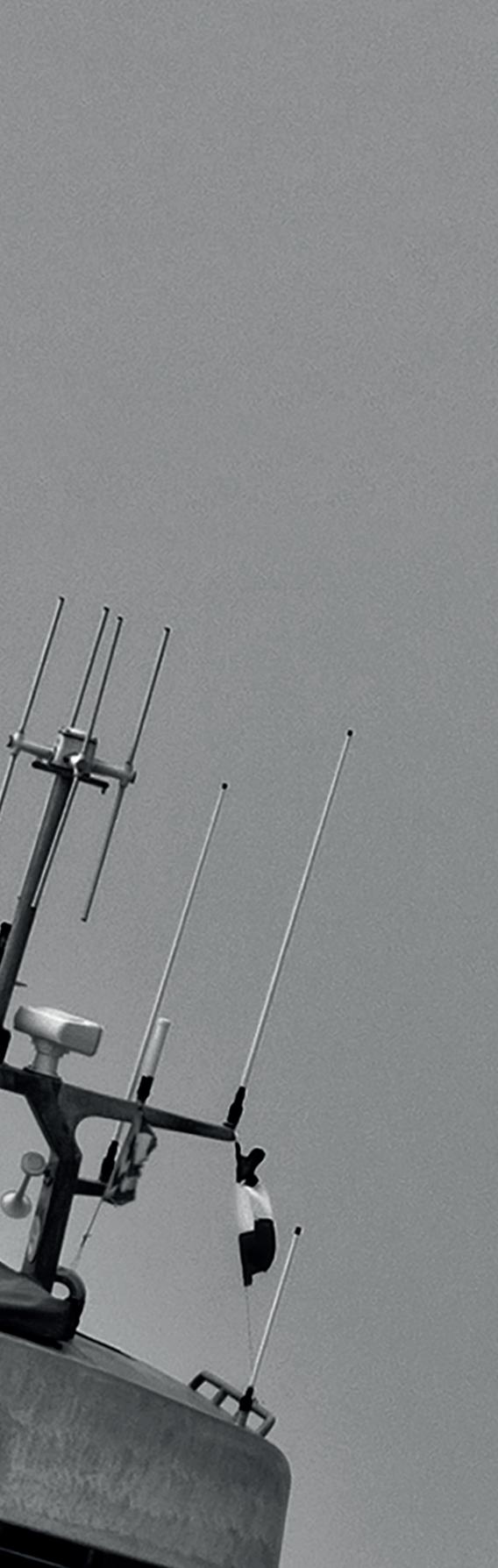

Volvo Penta variable-speed marine generator sets enable vessels to be built with smaller battery banks and charged on the move.

Volvo Penta has launched a new range of variable-speed marine genera tor sets that it said will allow shipyards to more easily and cost-effectively install hybrid-electric modular propulsion systems in marine vessels by enabling the vessels to be built with smaller battery banks and charged while on the move. Because of their modular installation, the gen-sets are also reported to be the most compact solutions available that meet the latest IMO Tier III regulations.

Russia has unleashed a fresh wave of missile strikes on power plant sites in cities and towns across Ukraine this month as Vladimir Putin seeks to shut down the country’s electricity, heating and water supplies ahead of winter.

Missiles rained down on power facilities from Odesa, the Black Sea resort in the south, to Kovel, a medieval town near the Belarus border in the north, leaving about 40% of the national energy infrastructure out of action.

Power analysts suggest that Putin is trying to weaponise winter in Ukraine by freezing the nation into submission – just as he is weaponising his control over energy supplies in Europe by driving up prices.

The new range will initially include models extending from the 190 kWe D8 to the 545 kWe D16. Their Volvo Penta water-cooled diesel engines can run on HVO 100 fuel, reducing CO2 emissions by up to 90% compared to standard diesel, according to the company.

A typical installation of the technology includes using the variable-speed marine gensets to power electric drives with or without battery packs.

This direct current (DC) grid system can be upgraded with alternative power sources plus has fewer components, resulting in reduced vessel weight, particularly when compared to batteries as the sole energy carrier, said Volvo Penta. The modu lar installation also cre ates the option to use the minimum number of engines to deliver power, enabling the gensets to run in the efficiency ‘sweet spot’.

Two 1,100 kVA diesel generators with Perkins engine and Leroy Somer alternators have been supplied to a metal factory in Touggourt, southern Algeria. Electra Molins has been responsible for the supply and commissioning of the EMU-1100 kVA generators to north Africa.

From the 3-cylinder 1103 range to the 6-cylinder 1106 range, the Perkins® 1100 Series engine gives unparalleled performance, reports the company. The engines feature exceptional reliability and low cost of ownership.

Their trusted performance reflects the thousands of hours of valida tion in the real world, says Perkins, working with agricultural, construction and electric power providers who value the company’s reputation and expertise.

Electric power engines in the series achieve regulated and unregulated emission standards globally. Within the 1100 Series of industrial engines are mechanical and electronic units up to Stage IIIA/ Tier 3 equivalent emissions standards.

Each genset is fitted with an MP15 panel - this is an automatic startup panel for the generating set in the event of a mains failure. It is the standard equipment with the most benefits and features in the market, easy to use, very reliable and robust.

It controls the mains supply, starts up and shuts down the set auto matically, handles the switching and controls the correct operation of the genset at all times.

The programmable control module includes three microprocessors which specialise in electrical measurements, the generating set logic and communications. Standard equipment includes radiator and fan, an electronic speed governor and special protection for parts.

FPT Industrial’s multi-en ergy approach is reflected in its new XC13 which uses the Cursor X concept as multi-energy, modular and multi-application engine platform.

The XC13 is FPT Industrial’s first multi-fuel single base engine.

From diesel to natural gas – including biomethane – hydrogen and renewable fuels, the base engine has been designed with multiple versions to offer maximum component standardization and easy integration into the final product.

FPT Industrial said the engine is compatible with a range of market requirements and emissions regulations, with limited impact on installation.

The diesel version delivers ratings to 600 hp (447 kW) and torques up to 2102 lb. ft. (2850 Nm), resulting in 5% more power and 14% greater torque compared to the cur rent Cursor 13 engine.

The natural gas version de livers up to 520 hp (382 kW) and 1844 lb. ft. (2500 Nm),

which is 13% more horse power and 25% more torque than the current Cursor 13 Natural Gas.

CO2 emissions reductions stand at 9% for the diesel unit and 10% for the methane model, but the latter can achieve net-zero CO2 emissions when fuelled by biomethane, FPT said.

Since 2012, PowerLink group has launched GXE, GRS series PowerLink gas gensets, powered by PowerLink, are equipped with cost-effective engine and high-quality spare parts, covering power range from 10kw to 350kw with open type, soundproof type, mini container type and container type for your selection. Our units are distributed in Europe, South America, Russia, Southeast Asia, the Middle East and other countries. They are providing continuous and stable power on the project sites, bringing excellent benefits to owners and investors.

According to a 308-page report from Future Market Insights, the global generator set market is forecast to be worth US$ 4,445.8 million by 2032, up from US$ 2,677.9 million in 2022, registering a CAGR of 5.2% during the forecast period, explains Nikhil Kaitwade, Principal Consultant.

To prevent the disruption of daily business activities due to power outages, the norm increasingly is to use a generator set to provide backup electricity supplies.

Despite the lower cost of diesel generator sets, gasfuelled generator sets are anticipated to witness a higher demand across the genset market share.

The potential of generator sets to supply the required output voltage, and output frequency broadens the motor generator set market size.

The revival of mining activities implemented legislation is also driving demand for generator set. An expansion in seaborne trades and the construction of new vessels also contributes to the marine diesel generator market, further expanding the market trend.

Rising awareness of environmental issues begets cost reduction, energy efficiency, and utilisation of cleaner sources drives the sales of generator sets.

Generally businesses want to avoid any external dam age to grid infrastructure and will more readily adopt gensets to provide backup power.

There is an increasing significance and requirement for reliable emergency power supply and this also encourages demand for generator set which can offer a consistent electricity supply. There is a growing customer demand for zero downtime.

The genset market size is growing as a reflection of the increasing reliance on electronics and electrical equipment to sustain day-to-day operations across a myriad of end users.

There is a rising utilisation of products in the commercial sector such as business complexes, telecom towers, hotels, and educational institutionsthis is also influencing demand for sets.

Because mobile towers need to accommodate a diverse consumer base suppliers will often recommend backup gensets to augment grid-based energy supplies. The launch and expansion of large industries and retail stores also demand a consistent power supply, further increasing adoption of generator sets. The requirement for 200-330 kVA generator sets increases thanks to growing infrastructure development projects.

The growing severity and frequency of weather-related disasters is making the installation of backup power units more important.

Industry has also reported an increasing need for standby power supplies serving the automotive and pharmaceutical manufacturing industries.

Businesses generally are keen to avoid the huge financial, product and reputational losses endured by industry, They are more likely to take advantage of the easy transportation and portability of generator sets to install them on premises.

Internationally, there are growing concerns over issues like energy security and the consumption of fossil fuels - this is fuelling the adoption of hybrid-fuel gensets.

The shale gas boom and the increasing availability of natural gas is also promoting the growth of the

generator set market.

Lack of availability of direct power supply in rural or remote places mean that gensets are often the only practical way to provide power.

A high level of carbon emissions has initiated stringent regulations, hindering the sales of gensets.

The integration by governments of clean energy alternatives may hamper theadoption of gensets

Certain countries are investing in renewable power sources, and setting high green energy targetsthis also curbs sales.

Fast-paced technological developments mean that solar panels are becoming more affordable. Renewable energy power generation has the same effect.

www.futuremarketinsights.com

Across Western Europe AB InBev beers are being brewed with 100% renewable electricity, following the opening of a 148 MWp solar park near Granada, Spain with partners BayWa r.e. and VERBUND.

The solar park was officially opened in September at an inauguration ceremony attended by local and international stakeholders and guests.

The project is one of the largest cross-border solar energy deals in Europe to date and covers 14 of AB InBev’s breweries in Western Europe and more than 50 brands across 12 countries, including Budweiser.

The 161-hectare Solar Park Pinos Puente will generate approximately 260 gigawatt hours (GWh) of emission-free electricity per year with a planned total capacity of 147.6 megawatts-peak (MWp).

Through the 10-year VPPA deal made between AB InBev and BayWa r.e., the solar park forms part of one of the largest Pan-European corporate solar power deals in history.

This will see the brewer of brands such as Budweiser, Corona and Stella Artois, supplied with 250 gigawatt hours (GWh) of renewable electricity per year, which will come from the VERBUND solar park and a second expected to be connected to the grid by the end of this month.

This is enough electricity to brew over 10 billion beers per year or enable an electric car to drive around the whole of Europe 1.2 million times.

The deal, which enables AB InBev beers across Western Europe to be brewed with 100% renewable electricity, covers 14 of its breweries in Western Europe and more than 50 brands across 12 countries, including Budweiser.

It will play an instrumental role in supporting the brewer’s 2025 Climate Action goal and its ambition to achieve net zero across its full value chain by 2040.

Erik Novaes, Vice-President Procurement & Sustainability Europe, AB InBev said: “With a global energy crisis and the growing impact of climate change keenly felt across much of Europe this Summer, we are focused to be building climate resilience and driving forward our push towards decarbonisation.”

Cybelle Buyck, Vice-President Legal & Corporate Affairs Europe, AB InBev, adds: “Our global purpose, a future with more cheers, represents shared prosperity, for our communities, for the planet and for our company. Sustainability is a foundational part of our company and we are immensely proud to see the park open and to embark on this next chapter with our

partners.”

In 2016, AB-InBev was granted approximately € 800 000 for the LIFE BEVERAGE project forming part of its ambitious dream to create a cleaner world.

These LIFE programs contribute to the achievement of the objectives of the Europe 2020 strategy and embed sustainability and social responsibility throughout the company’s entire value chain, explains AB InBev.

The boiling step is the most energy-consuming step in the brewing process, which consumes up to 20 % of the total heat required and generating high levels of greenhouse gases.

Previous research at AB-InBev led to the publishing of the patented technology of “Method for treating a wort in a boiling kettle”.

Fuel and water consumption can be drastically reduced in this process step by a disruptive innovation; using atmospheric air as the ultimate green resource. Bubbling nitrogen gas into the liquid will simulate the effect of boiling, without the heat requirements.

As one of the world’s leading brewers, AB-InBev feels it has an important role to fulfil in addressing

serious environmental changes such as water scarcity, resource depletion and climate change.

With the LIFE BEVERAGE project the company wants to reduce the emission of greenhouse gases caused by beverage production through a new process technology which will be piloted at breweries in Belgium and UK.

A company spokesperson commented: “We are passionate about our brewing traditions, but understand that traditional brewing processes often stand at the gateway to transformational change. The fundamental principles of the most energy consuming step in the brew ing process are being questioned and carefully reverse-engineered.

“In this way AB-InBev aims to lead the way in the transition towards a new standard for a more eco-friendly and sustainable brewing process.

He concludes: “LIFE BEVERAGE technologies for two different production methods are be ing piloted in Jupille and Magor breweries to enable roll-out to all AB-InBev breweries worldwide.”

Linz Electric is an Italian company specialized in the production of synchronous alternators up to 1500kVA. Linz Electric’s Mission is to create the most efficient solution to lead customers to success through Made in Italy quality products, flexibility in process and quick and complete service. Linz Electric’s Alternators: Energy for your Success.

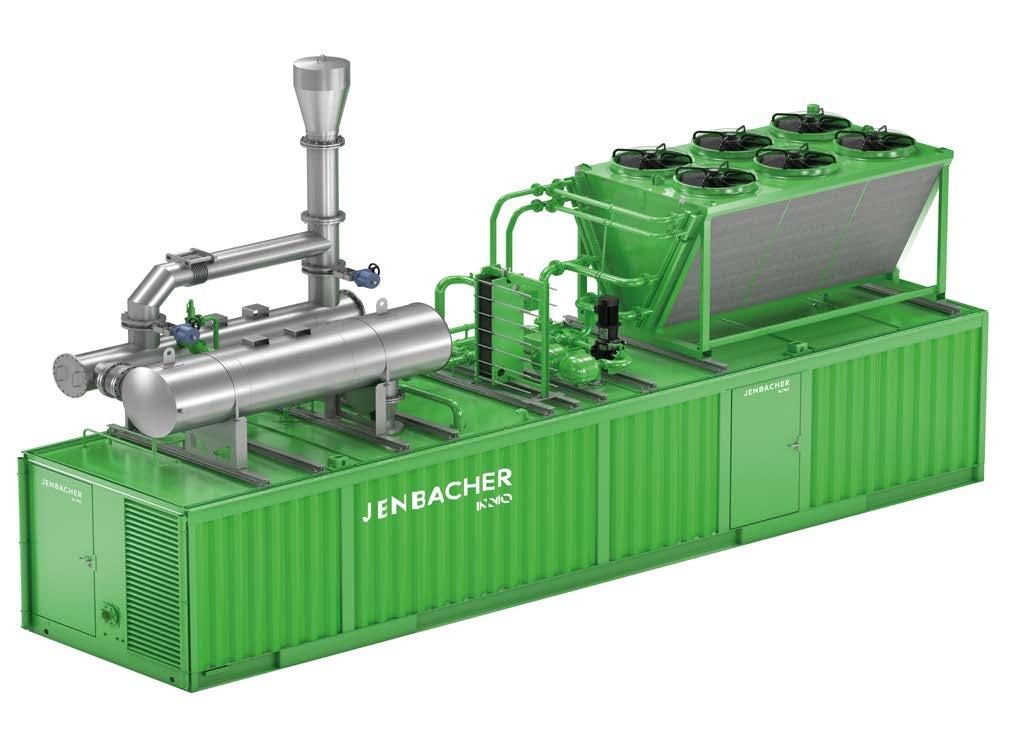

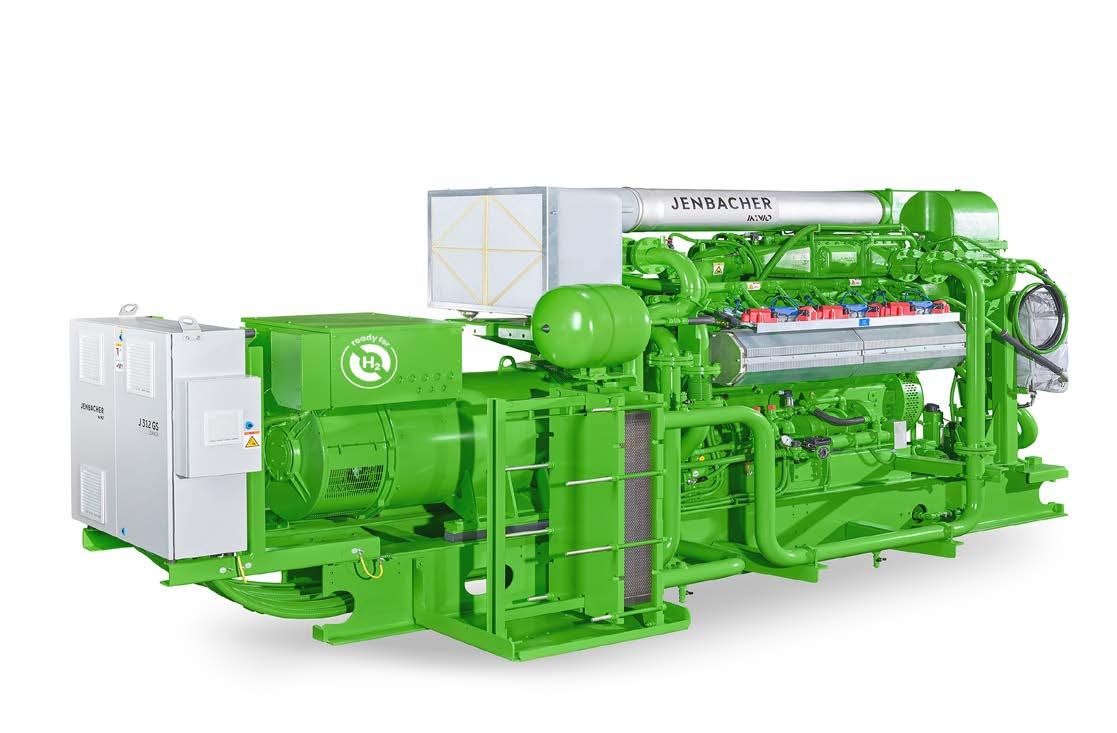

INNIO has announced the launch of its next generation Jenbacher Type 3F engine. This forms part of INNIO’s commitment to empower the transition to net zero with flexible, scalable, and resilient energy solutions and services.

The new and improved Jenbacher Type 3F engine offers customers proven robustness and reliability while delivering up to two percentage points of efficiency boost, the engine line’s highest efficiency ever.

In addition to delivering efficiency as high as 43.3% when operating on pipeline gas, the Type 3F engine is optimised for reduced total hydrocarbon (THC) emissions, future-proofed fuel flexibility, and enhanced serviceability.

Moreover, the latest 3F technology is offered with a “Ready for H2” option and retrofittable for most of the installed Type 3 fleet.

“INNIO’s innovative engine technology is engineered to help drive industries and communities to net zero power generation. INNIO’s hydrogen-ready Jenbacher 3F technology is the latest energy solution committed to a climate-neutral, greener and more secure energy future,” said Dr. Olaf Berlien, president and CEO of INNIO.

“We have been working with the Jenbacher Type 3 engines for over twenty years. Given our positive experience with the upgrade of the first engine to the new Jenbacher 3F generation model in 2020, it was an easy decision for us to implement this current upgrade. Thanks to the improved fuel usage of the Jenbacher 3F generation engine, we have been able to both increase

our profitability and to reduce our environmental footprint,” commented Thomas Roth, head of power & engineering at Dominikust-Ringeisen-Werk and operator of one of the field test plants.

Building on the Jenbacher Type 3 more than 35 years of experience and more than 11,000 engines worldwide the new generation of the Jenbacher Type 3 brings numerous advantages to customers such as:

• Future-proof fuel flexibility with a “Ready for Hydrogen” option that facilitates a transition from traditional fuels today to H2 operation in the future, once H2 becomes readily available

• Greater efficiency of up to two percentage points improved fuel usage

• Lower THC emissions and greater efficiency lead to a smaller environ mental footprint

• Reduced oil cost that reduces consumption while providing longer lube oil lifetime and lower engine oil life-cycle costs

• Convenient upgrade for currently installed engines, ideally applied

during minor/major overhaul

The Jenbacher Type 3F is available for applications in 50 Hz countries and will be available in 60 Hz countries in 2024.

INNIO is a leading energy solution and service provider which empow ers industries and communities to make sustainable energy work today.

www.innio.com

THE JENBACHER TYPE 3F ENGINE IS OPTIMISED FOR GREATER EFFICIENCY, REDUCED TOTAL HYDROCARBON EMISSIONS, FUEL FLEXIBILITY AND SERVICEABILITY.

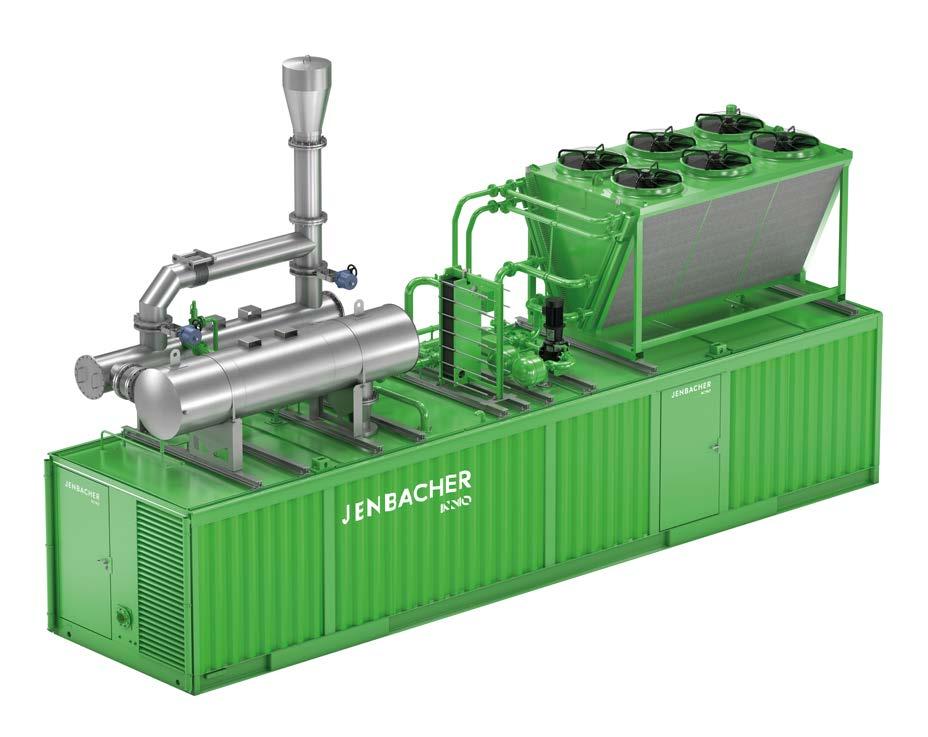

AB ENERGY SPA has supplied and installed a methane-fuelled ECOMAX 33- a 3,300 KWE CHP system - to a site in Maranello (MO).Italy, owned by Gruppo Cerdisa Ricchetti, leader in Italy in the production of quality ceramic coatings.

The installation was carried out by the White Energy Group who specified an ECOMAX 33 supplied by AB. The cogeneration plant will save 1,400 TOE during the company’s production cycle, equal to a reduction of 2,800 tons of CO2 emitted every year.

“In looking for ways to to reduce the environmental impact of an energy-intensive company like ours, the support of White Energy Group and partners has been very important,” comments Marco Fregni, CEO of Cera miche Ricchetti. “

This was a plant which was built quickly and without impeding the normal activities of the facility. This allows us to cut both costs and emission pollutants.”

The ECOMAX - Model 33 - Methane Gas Cogeneration Plants from ABB is part of the ECOMAX Natural Gas line available to the industrial and commercial sector cogen eration plants fuelled with methane gas, which combine structural compactness and versatility with high energy performance.

Thanks to the savings on fuel costs for producing electricity and heat, cogeneration represents a competitive advantage for companies which decide to use it, points out AB ENERGY - there is also the security of a constant supply of the energy necessary for the different processes to consider as a benefit.

Through the solutions of the ECOMAX® Natural Gas Line it is possible to produce electricity and heat starting from a single fossil source, natural gas. Electricity can be used for industrial use, for civil heating or for cooling and air conditioning systems (trigeneration).

A spokesperson comments: “AB specialists identify the plant which is most compatible with the energy needs and with the technologies already present in the company. Great flexibility is guaranteed by the nature of ECOMAX® and the generation solution is distributed as a modular package. This has brought innovation all over the world.”

The technology offers the following advantages:

*Easy configuration, which meets the needs of all markets

*Ease of transport and installation

*Time and risk optimization in the installation and commissioning phase

*Interconnection with existing plant systems

*Availability of service assistance even in difficult situations.

ECOMAX® is said to offer the ideal solution for the efficiency of energy-intensive structures.

Suitable for many industrial, tertiary and service sectors, cogeneration responds effectively to the needs of energy-intensive realities, characterized by high consumption of heat and electricity.

In fact, a cogeneration plant simultaneously produces electricity and thermal energy from a single energy source inside an integrated system. This is why we use the phrase combined heat and power.

Therefore, using the same fuel (natural gas) to generate two energy carriers (electricity and heat) makes it possible to increase the effective use of the source fuel up to 85%, with the resulting reduction in energy costs and CO₂ emissions, compared to the separate production of electricity and heat.

The use of the heat generated during the process, which would otherwise be lost, allows cogeneration to obtain the highest levels of energy efficiency and performance, with the advantage of being able to manage energy production continuously, reliably and safely.

A cogeneration plant consists of an Otto cycle engine, powered, in this case, by natural gas, which produces mechanical energy that is conveyed through an alternator to generate low voltage electricity, which is then transformed into medium voltage electricity.

Heat recovery takes place on two fronts:

* from the engine cooling water, using a plate-type heat exchanger that allows obtaining high-temperature water;

*from the flue gas fumes, which, being close to 400°, can be used to produce hot water, superheated water, steam or diathermic oil through a boiler, or be used pure in the process.

Energy produced includes electric power (to be sold to the network) and thermal energy.

The simultaneous production of electricity and heat allows a reduction of over 30% in the consumption of raw energy sources, bringing the total efficiency of the process to 85%.

Since the energy produced will be used mainly by the company that produces it, transmission and distribution losses that occur when electricity circulates on normal electricity networks are also avoided.

Cogeneration from natural gas allows a significant commitment towards protecting the environment: the greater efficiency of the energy production process leads to less CO2 and greenhouse gas emissions, with a consequent reduction in the environmental impact.

Cogeneration is an ideal solution for areas which are frequently affected by blackouts or with low performance or non-widespread networks.

www.gruppoab.com

Teksan reports that two 1,650 kVA diesel generators have been successfully installed and commissioned for the Inter Mattrid Beverage Company Ltd. Based in Cambodia.

Each set features 1,650kva Standby Perkins Engines and Leroy Somer Alternators.

The Inter-Mattrid Beverage (Cambodia) Co Ltd’s US $78 million brewery/beverage plant has been approved by the Council for the Development of Cambodia (CDC).

Accordingly, the multi-million dollar brewery is being constructed in DeiIth commune’s Sdao Kanleng II village, Kien Svay district in Kandal province.

The company’s slogan is: “Mattrid Beer is brewed with the finest ingredients and the latest technology from Europe to YOU for the best-testing beer.”

According to the manufacturer, the Teksan generator sets feature state-of-the-art technology and have compliance with ISO 8528, ISO 3046, BS 5514, DIN 6271 standards. These engines offer low fuel consumption, provide accurate speed setting and or der. They are mounted to the fuel pump and also have mechanic or electronic type governors.

The sets use alternators which pass necessary test process and found appropriate according to EC 60034-1; CEI EN 60034-1; BS 4999-5000; VDE 0530, NF 51- 100,111; OVE M-10, NEMA MG 1.22. standarts, have bearing system that does not need maintenance, with electronic type voltage regulator providing voltage setting.

The control panels ensure comfortable and safe usage. All measured and statistical parameters, operating modes, notice and alarms and condition of generator, are monitored easily from the control panel.

On the front of the panel’s metal body there is an electronic control module and the corresponding emergency stop button and the panel’s metal body are made of steel sheet painted with electrostatic powder paint.

Teksan says it offers panel design and solutions which comply with the special requirements of customers as well as quality standard panels.

The chassis of each genset have been imanufac tured from durable steel. Thanks to its rigid structural design and anti-vibration mounts, it reduces vibration level to minimum. All chassis units contain lifting lugs. The chassis design is said to make transportation and positioning easier.

In gensets offering less than less than 1600 kVA, the fuel tank is integrated with the chassis. In gensets offer ing more than 1600 kVA a rectangular-type fuel tank is

provided with generator set seper ately. All types of fuel tank from the Teksan range offer a fuel level and indicator.

The Cooling System in the genset consists of quality industrial type radiator, expansion tank and cooler fan - these keep the temprature of generator set’s equipments constant at a proper level.

The TJ-509-T MK3 is a nextgeneration genset controller combining multi-functionality and wide communication capabilities together with a reliable and low-cost design.

The same controller provides syn chronisation, load share, AMF, ATS, Remote Start, Engine Control and Remote Display Panel functionalities.

The module comes ready for remote monitoring over GSM or Ethernet with plug-in communication modules.

Various plug-in modules provide unlimited expansion capabilities allowing to meet any special requirement. The unit complies and mostly exceeds world’s tightest

safety, vibration and environmental standards for the industrial category.

Software features are complete with easy firmware upgrade process through USB port.

The Windows-based PC software allows monitoring and programming through USB, RS-485, Ethernet and GPRS.

The Rainbow Scada web monitoring service allows monitoring and control of an unlimited number of gensets through any web browser.

Teksan is an engineering and technology company which produces uninterrupted energy solu tions. It specialises in the manufacture of diesel generators, natural gas and biogas generator sets and cogeneration and trigen eration systems which provide 90% energy efficiency, mobile lighting towers, hybrid power systems, biogas solutions, and microgrid systems. It also offers a rental-mobile genera tor product range operating in 130 countries worldwide.

www.teksan.com

China has demonstrated its technical capabilities in producing energy from waste treatment in a number of recent projects. MWM gas gensets offer many advantages in terms of sustainable and clean decentralised energy supply. In addition to natural gas, they can be operated with a variety of biogases and reliably generate electrici ty, heat and, if required, cooling.

As the population grows, so does the amount of waste. At the same time, the challenges to disposing of it sensibly are increasing.

In several recently installed projects in China, MWM gas gensets are helping to produce energy from kitchen waste.

Recently, the largest kitchen waste treatment project in China - namely the Guangzhou Likeng comprehensive treatment plant - was successfully connected to the grid for power generation.

The Likeng comprehensive treatment plant is currently the largest environmental protection project for kitchen waste treatment in China, with an average daily treatment capacity of about 1,000 tons.

The project will treat about 350,000 tonnes of kitchen waste every year, with an estimated annual power generation of about 48 million kWh and a carbondioxide emission reduction of more than 15,000 tonnes per year.

The main processes of the project are Pretreatment + Anaerobic digestion + Wastewater Treatment + Biogas Power Generation.

The kitchen waste containing a large amount of organic matter will produce biogas after anaerobic fermentation and decomposition. After purification by the pretreatment system, the biogas will enter the gas genset for power generation.

MWM distributor PAUWAY has provided three MWM TCG 2020 V20 biogas generating units (single unit out put power of 2000kW) for the project.

All of the energy generated will be ‘self-utilised and surplus electricity connected to grid power’, reports the company.

PAUWAY is also in charge of the design and subsequent maintenance of all power systems for this project.

MWM supports urban green, lowcarbon and sustainable development in Qingdao In Qingdao, China, kitchen waste will also be used to generate energy in the future.

Two flat trucks carrying MWM gas gensets recently drove into a domestic waste comprehensive treatment park in Qingdao, officially kicking off the onsite construction phase of MWM distributor PAUWAY’s Qingdao kitchen waste power generation project.

In the next month, PAUWAY’s engineers will be responsible for the installation and commissioning of the equipment and help ensure the smooth operation of Qingdao’s first kitchen waste treatment project.

PAUWAY has delivered two MWM TCG 2020 V16 gas gensets for the project according to customer needs and field visits.

The power generation of a single generator unit is 1.56mW. After the unit is put into operation, it will meet the power demand in the park, and all the surplus power will be connected to the grid.

It is estimated that the annual on-grid power will be about 25 million kWh, thus reducing carbon emissions by more than 3300 tons and saving about 666,667m2 of landfill land.

This waste treatment park is an important part of Qingdao’s key environmental sanitation

infrastructure. It undertakes the task of waste disposal in the main urban area and high-tech zone and has the important function of ensuring the normal operation of the city.

After the completion of the project, the daily treatment of waste can reach 500 tons, which will make up for the shortboard of waste terminal treat ment capacity in Qingdao, and the waste treatment level will reach “domestic leading”, which will effectively promote the sustainable development of green and low-carbon in the city.

The MWM gas generator sets of the TCG 2020 series are perfectly geared to the challenges of a dynamic market environment. In the output range of 1,000–2,000 kWel, they meet the high requirements of a broad range of applications and guarantee efficiency, reliability, flexibility, and environmental sustainability, together with low lifecycle costs and high profitability.

Over the past 150 years, MWM has always taken “energy, efficiency, and environment” as its mission, continued to innovate, and is committed to the research and development and production of gas engines and generator sets which make efficient use of clean energy, to promote the application of green and clean energy with practical actions and contribute to the sustainable development of energy. www.mwm.net

THE MWM GAS GENERATOR SETS OF THE TCG 2020 SERIES ARE PERFECTLY GEARED TO THE CHALLENGES OF A DYNAMIC MARKET ENVIRONMENT. IN THE OUTPUT RANGE OF 1,000 – 2,000 KWEL, THEY MEET THE REQUIREMENTS OF A BROAD RANGE OF APPLICATIONS AND GUARANTEE EFFICIENCY, RELIABILITY, FLEXIBILITY, AND ENVIRONMENTAL SUSTAINABILITY AND LOW LIFECYCLE COSTS.

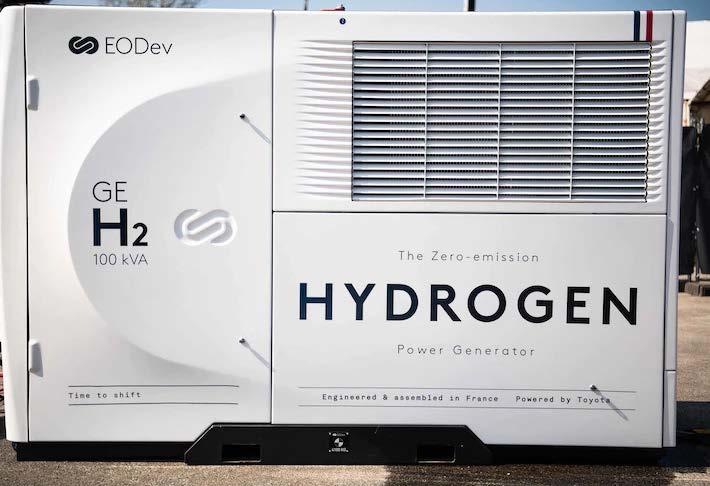

Generac Power Systems and EODev, a French developer and manufacturer of zero-emission hydrogen fuel cell power generation systems, have announced a JV distribution agreement. Under the terms of the deal, Generac will now offer EODev’s GEH2 large-scale, zero-emissions hydrogen fuel cell power generator to the North American market.

Generac said the distribution agreement signifies the continued growth and availability of alternative energy solutions for the industrial power sector, which addresses a market in transition to low-carbon and emission-free power solutions.

The collaboration also emphasizes Generac’s Pow ering A Smarter World strategic focus and expands EODev’s presence in the North American market with its advanced hydrogen fuel cell power generators.

Generac has placed an initial order for the GEH2 generators, some of which have already arrived in the United States.

Generac said its ability to manage in-house service and maintenance, rental solutions and client support teams across the country make it an ideal partner for EODev’s expansion plans in North America, as Generac can provide acquisition, installation and servicing of the GEH2 units.

“Generac Industrial Power is proud to partner with EODev to offer GEH2 hydrogen fuel cell power generators to North America,” said Erik Wilde, executive vice president of Industrial – Americas at Generac.

“Harnessing the power of hydrogen allows us to pro vide solutions that are engineered for the planet, while delivering value to customers committed to invest ments in carbon-free solutions.

“Hydrogen fuel cell power generators can play an important component in the expanding alternative en ergy space, and the GEH2 platform demonstrates our commitment to providing cutting-edge products that improve energy resiliency, optimize energy efficiency, and lead in environmental stewardship.”

The GEH2 uses a fuel cell and a lithium iron phosphate battery, reducing noise emissions and providing an instant start.

This combination of power enables the GEH2 to deliver up to 110 kVA of power. Developed for ease of use, the GEH2 system is equipped with event-driven electrical outlets, standardized frequency and voltage levels, as well as remote monitoring and data acquisition.

“We are delighted to have Generac further the EODev promise in the North American market,” said Jérémie Lagarrigue, chief executive officer of EODev. “Beyond their vast expertise, we share a common ambition to

accelerate the energy transition through our clean and innovative solutions.” market.”

The GEH2 technology was developed with the aim of easily integrating into all industries and environments. It is suitable for virtually all sites and sectors of activity, EODev said, whether customers are seeking energy autonomy, desiring a backup solution, or operating in a confined site or regulated zero-emissions zones.

A company spokesperson commented: In case of grid failure, or simply when the grid does not exist, the GEH2® electro-hydrogen generator brings you the energy you need, without CO2 emissions or fine particles. With the GEH2 and its record-breaking energy density, you benefit from instant power from 100kVA to 1MVA in an optimized volume.”

With a footprint of less than four square metres and an optimised mass, the GEH2 is equipped with the latest generation of fuel cells from partner Toyota, giving it exceptional durability and reliability. In relation to the power delivered, the most compact and efficient electro-hydrogen generator on the market, says the company EODev’s teams have carried out numerous developments over the

last few years in order to be able to mount the GEH2 in series and reach powers up to 1MVA, reports the company.

The GEH2 does not emit CO2, HC, NOx or other fine particles, says EO Dev - only hot water and filtered air. With the heat dissipated by the fuel cell, you can realize cogeneration, says the manufacturer.

The GEH2 is also capable of connecting with diesel or gas generators, and even the grid. It is this flexibility in its implementation which makes the GEH2 the ideal partner for the supply of autonomous decarbonated energy, says the company.

Thanks to its on-board intelligence, the GEH2 informs you if the hydrogen level is low or if a maintenance operation is required. If you wish, it can even warn our tech nicians directly. Its 4G connection allows continuous online monitoring of your GEH2 fleet via the cloud (location, usage profile, hydrogen reserve status, etc.).

To offer customers greater flexibility in work situations, a remote interface complements the unit’s touchscreen interface. This means that control and data acquisition are always at a user’s fingertips.

www.eo-dev.com www.generac.com

Moteurs Baudouin has launched the 6F21 six-cylinder, 12.5-litre engine, a compact yet powerful model suited for intermittent-duty (815 hp/599 kW), light-duty (900 hp/662 kW) and high-performance duty (1000 hp/735 kW) applications.

All three power options are rated at 2300 rpm.The choice of power ranges enables adaptability across a variety of applications, reports the company.

Steven Wang, CEO at Baudouin, comments: “The 6F21 is the first step toward a new series of engines of fering the best power in the market, and consolidating Baudouin as a trusted solution both for the commercial and pleasure market.”

He explains: “For larger applications, we are also preparing to expand the burgeoning F series with an eight-cylinder, 17 L version of the engine, coming later in 2022.”

The new 6F21 has a bore and stroke of 127 x 165 mm. It features a strengthened engine structure to withstand high torque and higher cylinder pressure of over 200 bar, plus includes a two-stage turbocharger system, two intercoolers and a common rail electronic fuel injection system operating at 2200 bar.

These features are packaged in the smallest engine ever released by the company; it measures just 1470 x 1100 x 1705 mm.

“We wanted to make an engine that is versatile for both the commercial and pleasure markets,” says Claudio Operti, chief engineer at Baudouin.

“This engine needed to be as compact as possible without compromising power, while at the same time keeping true to Baudouin’s DNA of offering robust and truly marine engines.”

The flywheel housing, oil sump, covers, brackets, supports and even heat exchanger bodies are all constructed from light alloys for reduced overall weight. Individual cylinder heads allow for easier maintenance even in the smallest engine rooms.

Fuel filters are mounted in the front for quick and easy servicing, and there is no need to dismantle any part of the engine in order to reach a component. The 6F21 complies with IMO II and EPA III standards, with IMO III and EPA IV following soon.

The 6F21 includes a strengthened engine structure to withstand high torque and a higher cylinder pressure of well over 200 bar.

A two-stage turbocharger system is also fitted on the engine, along with two intercoolers, and a high-end common rail system, operating at 2200 bar. The 6F21 delivers this genuine marine design with marine

marine components, such as individual cylinder heads which make maintenance easy even in the small est of engine rooms.

The fuel filters are mounted in the front to allow easy and quick maintenance, and there is no need to dismantle any part of the engine in order to reach a component, reports the manufacturer.

The 6F21 is one of the most compact engines in the market offering the most power at the same time.

Materials have been optimised to decrease the overall weight. Cast iron and steel are only used when stress and temperature demand it. Flywheel housing, the oil sump, covers, brackets, supports, and even heat exchanger bodies are all constructed from light alloys.

The 6F21 is a smaller engine but delivers as much power as most of its bigger competitors. Measuring 1470 x 1100 x 1075mm, the 6F21 can easily fit in the smallest of engine rooms.

The 6F21 delivers a reliable, consistent performance regardless of the conditions. With this marine propulsion engine, Baudouin decided not to comprise power, consumption or reliability by using the best components in the market.

This new 6-cylinder, 12.5-litre engine produces up to 735 kW/1000 HP, enabling a best-in-class power

density in a very compact and light original design.

This level of performance was achieved through continuous technological evolution, says Baudouin.

The 6F21 is a high-power and light engine, but one that still promises a long life, with the reliability and robustness which Baudouin is known for.

Every 6F21 engine also has optimised maintenance for low total cost of ownership, and complies with IMO II and EPA III standards, with IMO III and EPA IV following soon.

The 6F21 is available in three duty ratings with continuous compact power. This includes best-in-class for power output at intermittent duty 599 kW/815 HP and light duty 662 kW/900 HP, and co-leader at the high-performance rating delivering 735 kW/1000 HP.

While overall, the engine is best-inclass for power density throughout all three duty ratings. This power range ensures adaptability across a wide spectrum of light duty applications.

Founded in France more than a century ago, Moteurs Baudouin is a market leader in quality diesel and gas engines for marine and power generation applications. Baudouin is owned by Weichai and has additional manufacturing based in China.

baudouin.comCummins has unveiled a new Euro 7 diesel engine which reflects its Destination Zero corporate strategy.

“We have to act now,” explains Jennifer Rumsey, Cummins president and CEO.

“Carbon once emitted to the atmosphere can’t be taken back and we can make the greatest impact by focusing on a dual path approach. Our estimated impact of doing just that is an additional 1.4 gigatons of cumulative carbon reduction – the equivalent of removing all trucks from the road for three years.”

Cummins said it will continue to advance its current internal combustion engine technology with further advancements in efficiency, as well as compatibility with cleaner fuels like hydrogen, biodiesel and hydrotreated vegetable oil (HVO).

The company has also made it clear it will continue to innovate zero-emissions solutions like hydrogen fuel cell and battery technology.

“We power some of the world’s most demanding and economically vital applications,” reports Rumsey. “There is no single technology that will work for all of our customers. We must advance solutions in a way that secures a sustainable future for the industries that keep the world running. That’s why we have developed a company with the broadest range of ultra-low and zero-emission technologies dedicated to commercial industry.”

In effect, Cummins’ next-generation advanced diesel platform, the X10, embodies a practical route to emissions reduction and decarbonisation for applications which cannot be easily switched to alternative power solutions.

The X10 is an ultralow emissions, 10-litre diesel engine. Designed to meet the Euro 7 emissions regulations, the engine is expected to be available in ratings from 235 to 331 kW (320 to 450 hp) with torque ratings up to 2300 Nm (1696 lb. ft.).

In a further development, at the IAA Transportation show, the world’s largest mobility show held in Hannover, Germany, Cummins last month showcased its fourth-generation hydrogen fuel cell engine.

Designed to meet the duty-cycle performance the fuel cell technology is available in 135 kW single and 270 kW dual modules.

Scania in Europe and Daimler have each announced collaborations with Cummins to develop and integrate these next-generation fuel cell engines. The systems use fourth-generation variable pressure technology to provide higher power density, power nodes and

and operating temperatures for easier system integration. They also have strong operating cycle efficiency and durability for a lower total cost of ownership.

“We know our customers have diverse needs and complicated duty cycles to support, which is why we focus on continued innovation and improvement,” said Amy Adams, Vice President of Fuel Cell and Hydrogen Technologies at Cummins.

Visitors at IAA also a drivetrain assembled with a newly introduced Cummins lithium iron phosphate (LFP) battery pack, Meritor’s 17xe ePowertrain and Meritor’s Power Control and Accessory System (PCAS).

Cummins recently added the ePowertain and PCAS solutions to its portfolio through its acquisition of Meritor.

The ePowertrain leverages market-leading technologies in the axle, motor and inverter, delivering performance, efficiency and pack aging advantages at a competitive cost. Additionally, the PCAS provides power where needed and control of necessary sub-systems while reducing packaging size and

simplifying integration.

Cummins is adding an LFP battery to its line of lithium-ion battery products. The LFP solution gives customers access to faster charging and longer-life batteries. By using a multi-chemistry strategy, Cummins is positioned to expand its manufacturing capacity further and diversify its supply chain, providing customers with more cost-effective electrification solutions.

“We are giving customers options to enable them to adapt to a zero-emis sions future faster,” said Brian Wilson, General Manager of Electrified Components at Cummins. “With the recent acquisition of Meritor and our new multi-chemistry approach, we will be able to tailor our solutions and offer a one-stop-shop for customers’ powertrain needs.”

Cummins’ portfolio includes four batteries, each of which targets a different duty cycle and use case and complement each other. In addition to the LFP option, this includes three nickel manganese cobalt (NMC) batteries – the BP95E, BP74E and BP30E.

www.cummins.com

National Grid ESO has increased the amount of money being offered to households and businesses to reduce their non-essential energy demand to help balance the grid over the winter period.

The Association for Decentralised Ener gy (ADE) notes this increased financial incentive is essential if the National Grid ESO’s (Electricity System Operator) Demand Flexibility Service (DFS) is to succeed in allowing the ESO to access additional flexibility when national energy demand peaks on cold winter days.

The service, expected to prove a critical tool in the ESO’s arsenal to prevent blackouts, will pay households to volun tarily reduce their energy usage at speci fied times, boosting the country’s energy security by ensuring demand never outstrips supply, such as in a situation where the UK is unable to import enough energy from the continent.

The ADE, which helped design the DFS alongside National Grid and industry, has previously called for the amount of money on offer to be increased to drive public involvement in the trial period of the scheme, which is set to launch on the 1st of November and will run for five months.

Sarah Honan, Flexibility Policy Manager at the ADE, said: “The DFS will allow households to take back control of their electricity usage to safeguard the fate of the grid, and be rightly rewarded for doing so. The launch of the service will be a hugely positive development, one that is absolutely critical if the UK is to avoid blackouts and grid interruptions over the course of what is sure to be a difficult winter period.

“Alongside industry, we said the ESO needs to put more money into this and they have listened. It is only right that households will be paid for providing this essential service to maintain the security of electricity supply.”

Welcoming the new strategy from the Construction Lead ership Council (CLC), ACE CEO Stephen Marcos Jones said:

“Over the last few years the Construction Leadership Council (CLC) has played an important role in bringing the industry together in the face of some of the most challenging circumstances ever faced.

“We’re pleased to support the new strategy which will help the CLC approach the new challenges we now collectively face. This includes reaching our Net Zero and biodiversity goals, the next generation delivery, building safety and in people and skills.

“ACE’s three year Blueprint, which we recently published, outlines our own complementary approach to this changing environment. We are looking forward to working collaboratively with the CLC for the greater good of the sector.”

Establishing investment zones in the UK Stephen Marcos Jones further comments: “We have called for an assured programme of projects from the public sector to drive growth and support jobs across the UK.

“This is why we were pleased to see positive steps announced last month on expediating 100 infrastructure projects and the establishment of new investment zones.

“While we await more detail of how the planning process will be simplified for significant infrastructure projects in forth coming legislation, the announcement that 100 projects have been earmarked for construction to start by the end of 2023 will be welcomed by our members and the wider industry.”

Monday 07 November - Workshop

Tuesday 08 November to 09 NovemberConference

Tuesday 08 November - Conference Dinner

VENUE: MeetPoint Midlands, Kegworth, Derby, DE74 2DA

This Conference - Power Technologies for the Energy Transition - builds on the established and acclaimed international IDGTE biennial Gas Turbine conference events first held 21 years ago. This IPowerE conference offers a unique opportunity to hear and discuss the latest devel opments relating to conventional technologies and innovative solutions set in the context of operation, development, and project execution

CPD - Attending will not only give you access to industry leaders, it will also make a notable addition to your CPD.

Monday afternoon’s workshop will be an interactive session led by industry professionals, including the Carbon Capture and Storage Asso ciation and AECOM, that will explore the update of the 2009 Carbon Capture Readiness (CCR) regulations which will ultimately be transformed into two ‘legs’ of ei ther demonstrating carbon capture or hydrogen readiness.

Please register your details using the linkhttps://ipowere.org/2022powerconference.html

Keynote Address:

-A Net Zero Grid - Requirement and ChallengesNational Grid

- Novel Testing Methods of a Full Hydrogen Combustor - Thomassen Energy

-Realising a Hydrogen Society - Mitsubishi -Battery Energy Storage: How Much is there in GB and What is it Doing? - Modo Energy

-Combined Heat and Power (CHP) Supporting the Journey to Net Zero - Clarke Energy -Water Electrolysers as Commodities for Decentralized Hydrogen Production - Plug Power -Synchronous Condensers with Flywheel for Supporting Power Grid Inertia:

- Achievements and Experience After First Year of Commercial Operation - Ansaldo - Post-Combustion Carbon Capture Develop ments in the Power Sector - AECOM

-Heat Recovery from Hydrogen ProductionRamboll

-Offshore Wind – Haliade-X - GE Renewables -Hinkley Point C: Helping Britain Achieve Net Zero - EDF

-The Value of Flexible Fuel Mixing in Hydro gen-Fuelled Gas Turbines – a Techno-Economic Study - Chalmers University of Technology (Sweden)

-Carrington - the 50 MW/300 MWh Renewable Energy Power Station - Highview Power -Hynet North West - Unlocking a Low Carbon Future - Vertex

There are only 40 tickets left for the Awards Night.