22 minute read

Mail Bag

from WorkBoat May 2021

by WorkBoat

Happy to see the Jones Act strengthened

Ienjoyed Pam Glass’ short Inland Insider column about the Jones Act boost in the February issue. I’m glad to see it being strengthened instead of being watered down.

I was fortunate to be a Coast Guard senior marine inspector during the time of security rules coming in and the era of working hard to clean up the foreign and domestic vessel eet. I saw rsthand when companies we might call “shady” try to cut corners and use the cheapest means available to conduct business. That of course is what the Jones Act protects.

Over the years I saw the good effects from removing some very bad vessels and companies from visiting U.S. waters by enforcing standards. Also were those trying to skirt the pollution laws. We have got to be good detectives of piping systems and OWS (oily water separator) systems.

The same thing happened in the towboat industry over last several years, slowly forcing substandard vessels out of service and bringing others up to standard for those companies that wanted to bother getting it right.

I noticed a few companies that were adept at keeping track of USCG command turnovers. They would request one time load line exemptions for moving large equipment, then go to a different command or waiting for a change of command to do it again, over and over. Using our system correctly we discovered the ploy and were able to put a stop to it. It was also similar with Jones Act exemption requests.

Thank you for your column. I have always been a strong supporter of U.S. shipping and conducting inspections of our domestic eet, with an eye toward helping them see the need for regulation adherence instead of trying to get away with whatever. I retired from the USCG after 31 years but still do damage surveys and similar work. The main point is that I’m glad to see the strengthening of the Jones Act.

Samuel Boucher

A Marine Inspection Services Team LLC Sterling, Alaska

WorkBoat encourages readers to write us about anything that appears in the magazine, on WorkBoat.com or pertains to the marine industry. To be published, letters must include the writer’s address and a daytime phone number.

Email: workboat@cox.net

WORLD-CLASS VESSEL DESIGN HIGH-VALUE SHIPYARD SUPPORT TRUSTED CONSULTANT SKILLED GOVERNMENT CONTRACTOR

WIND FARM SUPPORT VESSEL

ACCOMMODATION TRANSFER VESSEL

SERVICE OPERATION VESSEL

BMT ACTIVE FENDER SYSTEM™

65 FT

RIGHT WHALE-COMPLIANT WIND FARM SUPPORT VESSEL

GLOBAL LEADERS IN SHIP DESIGN FOR THE OFFSHORE WIND INDUSTRY 703-920-7070 | INQUIRIES@BMTDP.COM | WWW.BMT.ORG

On the Water

Disappearing buoys — Part II

By Joel Milton

The red buoys and others that have disappeared from along the East Coast served a legitimate purpose: to allow vessels running along the coast to have physical navigation markers to help x their positions and maintain overall situational awareness, thereby reducing the risk of grounding.

Maritime safety authorities, company policies, educational curricula, industry best practices, etc., point out the obvious: that any aid to navigation (ATON) could be off-station, malfunctioning, sunk, destroyed or otherwise compromised. Therefore, ATONs should never be relied on for “safe” navigation. Likewise, you should never rely on radar, or your depth sounder, or your GPS receiver, navigation plotter, or ECDIS. In short, you should rely on nothing whatsoever because everything is prone to failure. It’s a disingenuous circular reasoning cycle that serves more as a way to assign liability than anything else. Mariners too, as amply demonstrated by history, are prone to failure. So are those who regulate and oversee us, and trainers and educators.

The fact is that to varying degrees at various times we must rely on all of these things in varying combinations as circumstances change. Ideally you want to have as many options or resources available as possible, so that you avoid getting boxed in and having to rely too much on any one of them. Or just one of them. Nevertheless, sometimes that’s exactly where you may nd yourself. Single-point failure is the bane of human endeavor, but we’re still very prone to it.

Virtually every act of modern human activity, particularly commerce, has become totally dependent on a 100% reliable, fully functioning Global Positioning System — and this seems to be acceptable and accepted. But today, however, take away someone’s smartphone and they just might never make it home.

Doing away with those physical buoys removes yet another layer of protection — removes options for the navigator. While it’s likely to be inevitable that we continue to follow the technological advancement trajectory without questioning it, this change should not pass unnoticed or without comment.

Joel Milton works on towing vessels. He can be reached at joelmilton@yahoo.com.

Captain’s Table

Should we be optimistic about 2021?

By Capt. Alan Bernstein

Our yearlong struggle with the coronavirus pandemic has dragged on for so long that many of us have almost forgotten about how things were before. The waiting has been the worst — waiting for Covid tests, waiting to be vaccinated, and waiting for some sign that life is beginning to return to normal.

During the pandemic, business planning has been a hitor-miss proposition.

For BB Riverboats, business in 2020 was cut by approximately 90%. Often I wish for the proverbial crystal ball to help see what the future holds for my business, employees, and crew.

One day news reports signal improvement in suppressing the spread of the virus, then reports on following days show an uptick in infection rates. With these uctuating reports, should we still expect a resurgence in business this spring? Or should we just cross our ngers and hope for the best? Should we be optimistic about the future or should we be concerned?

I have chosen to be optimistic. This is the only way I know how to cope with all of the dysfunction and uncertainty associated with the Covid-19 pandemic.

It has been a year full of anxiety. I am not a health care professional, but I believe that optimism is critical if you are going to successfully work through the issues that have caused the anxiety in the rst place.

I believe that the worst is behind us now and tomorrow is a new day with exciting opportunities to build back our businesses.

When I was a teenager, I remember my father telling me that when you are in business you need to put a smile on your face, be cheerful and be nice to people. Most of all, you must respect your customers’ needs and wants. If you do this, then you will come out ahead every time.

I am enthusiastic about 2021. Our phones are ringing again, our social media is active, online sales are good, and demand for private events is decent.

I am con dent that we will continue to move forward. Many passenger vessel operators from around the country feel the same way as I do.

This is a good sign. After all, the key to success is simple: be optimistic, smile, and life will get better.

Alan Bernstein, owner of BB Riverboats in Cincinnati, is a licensed master and a former president of the Passenger Vessel Association. He can be reached at 859-292-2449 or abernstein@bbriverboats.com.

Energy Level

Operators to restrain production growth

By Jim Redden, Correspondent

After years of unrestrained production growth — spending be damned — scal discipline has taken hold as once reluctant operators bow to investor pressure and resist their notorious tendency to call up rigs and completion crews at the slightest uptick in prices.

“If oil prices continue to improve this year, we will not increase capital in support of production growth,” Occidental Petroleum Corp. President and CEO Vicki Hollub assured analysts in a Feb. 24 call. Occidental holds drilling rights to some 1.6 million acres of shale-targeted acreage in the Permian Basin in west Texas and southeast New Mexico. Even as West Texas Intermediate (WTI) benchmark prices reached a two-year high of $67.87 bbl in early March, estimates compiled by the Energy Information Administration (EIA) show Occidental is far from alone. The seven shale plays the EIA tracks were expected to collectively produce just under 7.5 million bpd in April, roughly 1.2 million bpd less than aggregate April 2020 shale oil production when Covid-induced demand destruction aggravated a crude

JAN. '21 FEB. '21 MAR. '21 MAR. '20 WTI Crude Oil 52.78 61.55 60.93 21.03 Baker Hughes Rig Count 16 17 12 18 IHS OSV Utilization 18.9% 19.1% 19.8% 29.3% U.S. Oil Production (millions bpd) 10.9 10.0* 11.1* 13.0 WTI Price U.S. Prod 1000s bopd GOM Rig CountUtil. Rate % Sources: Baker-Hughes; IHS Markit; U.S. EIA *Weekly Estimated

20 18 16 14 12 10 8 6 4 2 0 GOM RIG COUNTGOM Rig Count

3/20 3/21

1 2 3 4 5 6 7 8 9 10 11 12 13

glut and sunk WTI prices to previ- Dakota: “Demand recovery is takously unheard of negative territory. ing longer, spare supply remains and

Nearly 4.3 million bpd of April inventories remain elevated. It makes production is expected to ow from no sense to grow into this market the Permian Basin, where Diamond- environment, so we’re choosing to stay back Energy operates exclusively and at a sustaining level for the year,” said has no plans to open the taps full bore. CEO Ryan Lance. “We are still operating in a marMar-20 Meanwhile, like their offshore ket supported by supply that’s been Apr-20 counterparts, companies with leases purposefully withheld to allow global May-20 on federally owned lands in New inventories to decline as demand recovers from the depths of the global pandemic. Diamondback continues to see no need to grow oil production into this arti cially undersupplied Jun-20 20-Jul Aug-20 Sep-20 20-Oct Nov-20 Mexico, Colorado, Wyoming and elsewhere, had to contend with President Biden's Jan. 27 freeze on new leasing of government-owned lands. One of those, Cimarex Energy Co., market,” said CEO Travis Stice. Dec-20 admitted to “overreacting” by im-

And this from ConocoPhillips Jan-21 , mediately diverting all activity from which holds shale assets across Texas, Feb-21 New Mexico to privately owned Texas Wyoming, Oklahoma and North 21-Mar properties.

18 17 12 11 12 13 14 13 13 17 16 17 12

The Toughest Boats on Earth Choose ZF

zfmarinepropulsion.com // 1-833-ZF-WRENCH

Inland Insider

Reducing carbon emissions

By Pamela Glass, Washington Correspondent

The head of the American Waterways Operators said the maritime industry needs to be actively involved in initiatives to reduce carbon emissions, or others will make policy decisions that will affect their shipping operations well into the future.

“As an industry, we need to be at the table or we will nd ourselves on the menu,” Jennifer Carpenter, AWO’s president said at a March conference organized by Marine Log.

The shipping industry is under increasing pressure worldwide to decarbonize its operations and reduce carbon emissions, and reaching these goals is “the biggest industry challenge of our era,” said Carpenter.

And reducing the industry’s carbon footprint is not only being pursued by the Biden administration and Democrats in Congress.

“It’s our industry’s customers, its end users, its banks and investment houses, it’s the international community,” she said. “And we need to expect that transportation — and maritime — will be in the crosshairs.”

She cited numerous recent initiatives: Biden’s goal of reaching a net-zero-carbon U.S. economy by 2050 and moves by the International Maritime Organization to eliminate greenhouse gases from shipping this century and cut them by 50% from 2008 levels by 2050.

Further, she said a group of governments and maritime advocacy organizations working in international trade has submitted a plan to the IMO to create an International Maritime Research and Development Board, a $5 billion program to fast-track research and development into decarbonizing technologies that would be nanced by a $2-per-ton fee on marine fuel.

Carpenter said the tug, towboat and barge industry faces dual challenges of being “an industry whose vessels rely on fossil fuels for propulsion, and as one that transports (safely and ef ciently) more than 400 million tons of petroleum, petroleum products and coal each year. We need to be cleareyed about both of those challenges.”

She said the inland navigation industry should consider this as an opportunity to “build on our position as the lowest carbon-emitting mode of surface transportation. Maritime is today, and can be in the future, a key part of the solution to reducing greenhouse gases from transportation.”

It’s imperative for the industry to engage now, both in technology development and in public policy, “because while this is a long-term challenge that won’t be solved overnight, decisions will be made in the near term that will affect our industry for years to come.”

“We need to be an active contributor to the development of public policy that spurs rather than constrains innovation, and enables our industry to survive, adapt and thrive for the long haul,” Carpenter said.

Pamela Glass is the Washington, D.C., correspondent for WorkBoat. She reports on the congressional committees and federal agencies that affect the maritime industry, including the Coast Guard , Marad and Army Corps of Engineers.

Nor’easter

Offshore wind industry is still short on vessels

By Kirk Moore, Contributing Editor

Awhirlwind of events this spring pushed the offshore wind industry’s hopes to the forefront, with the Biden administration’s March 29 announcements that it would seek $3 billion in federal funding to support industry development and start as many as 10 more environmental reviews this year for East Coast projects.

The administration’s new goal of 30,000 megawatts of offshore generation by 2030 includes opening another 800,000 acres in the New York Bight for possible wind leases. The Bureau of Ocean Energy Management (BOEM) initiated an environmental review of Ørsted’s planned 1,100-MW Ocean Wind project off New Jersey.

Meanwhile a record of decision from BOEM was expected soon on the 800-MW Vineyard Wind project. The developers announced their plan for construction using Belgium-based DEME Offshore’s wind turbine installation vessel (WTIV), supplied from New Bedford, Mass., by U.S.- ag Foss Maritime tugs and barges.

For now, that so-called “feeder” business model is a necessary work-around for wind developers contending with a tight worldwide supply of WTIVs, and the dictates of the Jones Act for using U.S. vessels and crews to move cargo between U.S. points.

But it won’t last for long, said Karl Humberson, director of project construction for Dominion Energy, the Virginia-based utility company developing offshore wind and building the rst U.S.- ag WTIV.

“A feeder barge solution will work, we’ve seen it work, we’ve used it ourselves,” said Humberson, whose company built the twin turbines, 12MW Coastal Virginia Offshore Wind pilot project as its precursor.

“But when you look long term … there’s a reason Europe and Asia have

moved to purpose-built vessels,” Humberson said during a March 31 webinar, “Operating on the (Wind) Farm” presented by WorkBoat. “As much as a feeder barge solution can work, I think the real question is, is it the optimal way to do the work?”

Instead, Humberson said that Dominion of cials decided, “Okay, this is what the industry needs.” Dominion’s 472'×184'×38' WTIV, under construction by Keppel AmFELS at its Brownsville, Texas, shipyard, will be one of the largest in that class, with a Huisman main crane boom length of 426' and lifting capacity of 2,200 tons – enough the handle the next generation of 12- to 14-MW turbines standing over 800 feet tall.

The ship is “actually not for the Dominion project. We’re building it for the industry,” Humberson stressed. “The vessel is a merchant vessel. It is there for people to use.”

That is a sensible plan, said Rafael Riva, vice president of commercial operations at Lloyd’s Register. “You need to keep operating a $400 million asset,” said Riva, whose organization is working on a Jones Act-compliant WTIV design for the U.S. market. “These ships don’t get built overnight … the planning really has to start now.”

“We can’t look at the U.S. market in isolation,” added Ross Gould, vice president for supply chain development with the Business Network for Offshore Wind. With larger turbines and more projects in the pipeline worldwide, “that is going to mean a lot of new construction” to serve both those markets and the U.S., he said. “Some of my colleagues have called 2021 ‘the year of the vessel,’ ” Gould added.

“The charter rates are going to get higher and higher to bring these (foreign WTIV) vessels over to do the work,” said Charles Donadio, president of Atlantic Wind Transfers, which operates crew transfer vessels for Dominion and Ørsted. “I think we’ll see a few more of these feeder vessel scenarios happening until we get some purpose-built vessels here in the U.S.”

For the Coastal Virginia Offshore Wind pilot project, Dominion had Belgium-based Jan De Nul Group install the two turbines with its WTIV Vole au Vent. The major Siemens Gamesa turbine components from Europe were carried by the at deck carrier BigRoll Beaufort from Esbjerg, Denmark, to Halifax, Nova Scotia.

Contributing Editor Kirk Moore was a reporter for the Asbury Park Press for over 30 years before joining WorkBoat in 2015. He has also been an editor for WorkBoat’s sister publication, National Fisherman, for over 25 years.

After more than 50 years of commercial boat building, Yank Marine is ready to step into the future of offshore wind!

Link to Video

https//vimeo.com/497356264/184cd7fba4

Yank Marine Services, LLC

487 Main Street, Dorchester, NJ 08316 Phone: 856-785-0100 •50 ton Marine Travelift •820 metric ton Marine Travelift!

Yank Marine, Inc.

Mosquito Landing Road, Tuckahoe, NJ 08250 Phone: 609-628-2928 •75 ton Marine Travelift •300 ton Marine Travelift

WorkBoat Composite Index

Stocks post another strong month

After rising almost 14% in February, the WorkBoat stocks posted another strong month in March, gaining 175 points, or almost 6%. For the month, winners topped losers by a 9-4 ratio.

In late March, shipbuilder Gulf Island Fabrication reported its 2020 fourth-quarter and year-end results. Consolidated revenue for the fourth quarter was $57.6 million, compared to $79.4 million for 2019’s fourth quarter. The year-over-year decrease was primarily attributed to the company’s fabrication and services division and, to a lesser extent, its shipyard division.

“This past year brought unprecedented challenges, including the effect of the Covid-19 pandemic on labor availability and productivity negatively impacting our results as well as crude oil volatility, which reduced the volume of work in our traditional end markets,” Richard Heo, Gulf Island’s president and CEO, said during the company’s March 29 quarterly conference call.

However, Heo said the company “substantially strengthened our foundation” over the past year through the consolidation of resources and process improvements, and expanding its end market focus to reduce reliance on the offshore oil and gas industry.

During the quarter, Gulf Island completed its final two harbor tugs, delivering the last tug in January. This allowed the company to close its Jennings, La., and Lake Charles, La., facilities, consolidating its shipyard operations into the Houma, La., location. This should “further improve our resource utilization, centralize key project resources and deliver additional cost savings,” Heo said. — David Krapf

STOCK CHART Source: FinancialContent Inc. www. nancialcontent.com

INDEX NET PERCENT COMPARISONS 2/26/21 3/31/21 CHANGE CHANGE Operators 342.55 332.84 -9.71 -2.83% Suppliers 5,013.51 5,391.31 377.80 7.54% Shipyards 2,777.31 3,081.47 304.15 10.95% Workboat Composite 3,027.23 3,201.94 174.71 5.77% PHLX Oil Service Index 55.78 53.70 -2.08 -3.73% Dow Jones Industrials 30,932.37 32,981.55 2,049.18 6.62% Standard & Poors 500 3,811.15 3,972.89 161.74 4.24% For the complete up-to-date WorkBoat Stock Index, go to:

www.workboat.com/resources/workboat-composite-index

Insurance Watch

Keep claims hassle-free

By Chris Richmond

Insurance is often one of your company’s biggest expenses and one that you hope is rarely needed. But please don’t think that reporting a claim is going to adversely affect your policy’s premium. Even if you think that the incident is minor and not worth reporting, a quick call to your agent can prevent some major hassles down the road.

Here are a few things to remember to keep a claim hasslefree. • First, report the claim to your agent. Alerting your agent does not re ect negatively on you. In fact, insurance adjustors appreciate this type of reporting because it gives them a baseline right at the time of the claim. Recording the essential facts in a timely fashion helps greatly in case something develops from the incident six months down the road. And, as a bonus, you get to touch base with your agent. • Second, should the claim involve damage to property, keep the damaged items secure so they will not suffer any further damage. If you have to make emergency repairs, document the damage rst so an adjustor can see it. You don’t want the damage to get worse due to your inattention.

• Third, save receipts. Once repairs start on your vessel or property, the bills will accumulate. Keep all associated receipts and send them to your agent who will then forward them to the adjustor. If you are doing repairs yourself, keep track of your own time. • Were there witnesses to the accident? Record their names and contact information. Did anyone take photos or video with their cellphone? Are there security cameras which could have captured the event? All of these can help you with your claim.

Finally, we are back to where we started. Report your claim. Too often I hear from a client that something happened six or eight weeks ago. The time to call your agent is right after the incident occurs so, with your assistance, the adjustors can start their investigation and document all the facts. Strike while the iron is hot and get all the facts down while they are fresh in your mind, and in the mind of any witnesses. You will be happy that you did.

Chris Richmond is a licensed mariner and marine insurance agent with Allen Insurance and Financial. He can be reached at 800-439-4311 or crichmond@ allenif.com

We take the heat, so you don’t have to.

Cool. Because you need it. We deliver cool based on your reality. So no matter where you operate, hot waters and heavy loads will never slow you down.

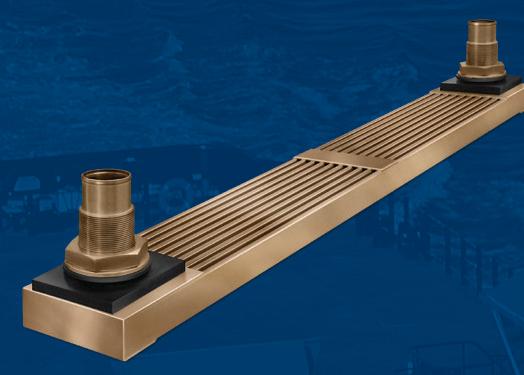

GRIDCOOLER® Keel Cooler

• One Piece Head Design maintains greater structural integrity. • Higher Silver Content Braze Joints resist fatigue and maintain the strength of surrounding material. • Better Penetration at Braze Joints places more braze material with less heat, making joints stronger. • 2-Year Warranty on Copper Nickel

GRIDCOOLER Keel Coolers:

Industry-leading design, craftsmanship and materials create industry-leading products. • 70 Years of Experience with

Fully Assembled Packaged

Keel Coolers:

Our focus is and always has been heat exchangers.

WEKA Boxcooler®

• Over 20 Years of Experience with Copper Nickel Boxcoolers offering longer product life cycle than standard coated tube units. • Manufactured in the USA and The Netherlands: provides the greatest product availability. • Weka Guard and Protector eliminate the need for bulky and costly copper sacrificial anodes.

Tranter® Heat Exchangers

• Tranter Heat Exchangers product offerings make Fernstrum your single source for multiple stage cooling systems. • Tranter Superchanger plate and frame heat exchanger provides a range of options in pattern, size and material for a wide variety of applications. • Tranter Platecoil provides an efficient and cost effective alternative to traditional pipe coil heating for bulk cargo, ballast and other applications.

Join us for Inland Marine Expo May 24-26th at booth #323

fernstrum.com | 1.906.863.5553 | sales@fernstrum.com | ISO 9001:2015

Legal Talk

The requirements for seamen status

By Daniel J. Hoerner

In February, the U.S. Court of Appeals for the Fifth Circuit issued a signi cant ruling on the test for seaman status. However, unlike most cases on this issue, the challenge to the employees’ classi cation did not deal with their legal rights and remedies under the Jones Act. Instead, it stemmed from a claim by an able-bodied (AB) seaman and his co-workers for overtime wages under the Fair Labor Standards Act (FLSA).

The FLSA requires that any employee who works over 40 hours a week must be compensated at a rate not less than one-and-a-half times his regular wage. However, traditional seamen are exempt from this rule. In Adams v. All Coast LLC the workers claimed that they were not seamen within the meaning of the law because the majority of the work they performed was not maritime in nature and did not contribute to the operation of their employer’s vessels. Rather, they spent at least 80% of their work time operating cranes and assisting with the transfer of cargo to and from vessels while the vessels were jacked up and stationary. The remainder of the time was devoted to vessel operations, and the workers ate, slept and performed most of their tasks aboard vessels.

In reversing the district court’s summary judgment holding that the workers were, in fact, seamen based on their work aboard a eet of commonly owned vessels, the Fifth Circuit looked to case law addressing the meaning of a seamen in the context of Department of Labor regulations. Those criteria de ne a seaman as an employee who (1) is subject to the authority, direction and control of a vessel’s master, and (2) whose service aids the vessel as a means of transportation.

In Adams, the crewmembers did not meet the second element of this test. Rather than serve the vessels’ transportation function, the crew worked on vessels mainly to load and unload cargo. Consequently, this group of workers did not satisfy the requirements for seaman status as de ned under Department of Labor standards and were, therefore, entitled to overtime wages under the FLSA.

Daniel J. Hoerner is a maritime attorney with Mouledoux, Bland, Legrand & Brackett LLC. He can be reached at 504-595-3000 or dhoerner@mblb. com.