Introducing Dark Chocolate Barista Mini Chips in NEW 5LB. bags. Convenient and versatile, these mini chips deliver decadent chocolate flavor to your most delightful treats—steam with milk for a delicious hot mocha, blend in frappés for an extra chocolatey treat or create a magical topping for ice cream and beverages with just a little sprinkle.

Order FREE samples at 800.877.9338 or professionalproducts@ghirardelli.com

MOCHA SALES WITH GHIRARDELLI ON THE MENU.

©2022 Ghirardelli Chocolate Company

EDITORIAL

EDITORIAL DIRECTOR, FOOD NEWS MEDIA: Danny Klein danny@qsrmagazine.com

MANAGING EDITOR, FOOD NEWS MEDIA: Nicole Duncan nicole@qsrmagazine.com

DIRECTOR OF CUSTOM CONTENT: Peggy Carouthers peggy@qsrmagazine.com

CUSTOM CONTENT ASSOCIATE EDITOR: Charlie Pogacar charlie@qsrmagazine.com

CUSTOM CONTENT ASSOCIATE EDITOR: Kara Phelps kara@qsrmagazine.com

CONTENT EDITOR: Ben Coley ben@qsrmagazine.com

STAFF WRITER: Trevor Griner Trevor@qsrmagazine.com

ART & PRODUCTION

ART DIRECTOR: Tory Bartelt tory@qsrmagazine.com

ONLINE ART DIRECTOR: Kathryn “Rosie” Rosenbrock rosie@qsrmagazine.com

GRAPHIC DESIGNER: Erica Naftolowitz erica@qsrmagazine.com

PRODUCTION MANAGER: Mitch Avery mitch@qsrmagazine.com

ADVERTISING

800.662.4834

NATIONAL SALES DIRECTOR // EXTENSION 126 : Eugene Drezner eugene@foodnewsmedia.com

NATIONAL SALES MANAGER // EXTENSION 149 : Edward Richards edward@foodnewsmedia.com

NATIONAL SALES MANAGER // EXTENSION 141 : Amber Dobsovic amber@foodnewsmedia.com

NATIONAL SALES MANAGER // EXTENSION 148 : John Krueger john@foodnewsmedia.com

SALES SUPPORT // EXTENSION 124 : Tracy Doubts tracy@foodnewsmedia.com

CIRCULATION WWW.QSRMAGAZINE.COM/SUBSCRIBE

CIRCULATION COORDINATOR: N. Weber circasst@qsrmagazine.com

ADMINISTRATION

GROUP PUBLISHER, FOOD NEWS MEDIA: Greg Sanders greg@foodnewsmedia.com

PRESIDENT: Webb C. Howell

MANAGER, IT SERVICES: Jason Purdy

ACCOUNTING ASSOCIATE: Carole Ogan

ADMINISTRATION

800.662.4834, www.qsrmagazine.com/subscribe

QSR is provided without charge upon request to individuals residing in the U.S. meeting subscription criteria as set forth by the publisher.

REPRINTS THE YGS GROUP TOLL FREE: 800.290.5460

FAX: 717.825.2150

E-MAIL: qsrmagazine@theygsgroup.com www.qsrmagazine.com/reprints

Sponsored content in this magazine is provided by the represented company for a fee. Such content is written to be informational and non-promotional. Comments welcomed. Direct to sponsoredcontent@foodnewsmedia.com

As we were planning our 2022 calendar, the notion of a climate issue gave me some pause, I have to admit. Not that I’m not a believer in the topic, but I just wasn’t sure where to go with it. In some ways, it reminded me of diversity and a conversation my colleague Ben Coley and I had with Dr. James Pogue a few months back. James is the president and CEO of JP Enterprises, a company that helps coach inclusivity at the leadership and team level. One of their banner phrases is, “The Right Kind of Uncomfortable.” We talked about that framework and the role of media in all of it. How it often can feel forced or fake, and in turn, sail the intended impact. So, in the end, you’re left trying to further a message and yet do it for the right reasons. It’s a complex line.

My initial response to a magazine dedicated to climate and the industry’s role in it was, “what can we at QSR bring to the table that hasn’t been talked about already?” My boss’ answer was simple: We need to stir the conversation. You can’t expect or promote change without giving a voice to it. And that’s really where I began. Who were the thought leaders and innovators in this space, from the back ( page 36 ) to the front ( page 28 ) of it. I asked Just Salad chief sustainability officer Sandra Noonan what mattered to her. And what was going to matter next year ( page 20 ). Throughout our conversation, from the circular economy to food waste, the notion of leading from an uncomfortable position kept surfacing. Namely, I floated a pretty common theme in her direction—“are customers asking for this?” Noonan’s answer wasn’t what I expected and she quickly dispelled it. While the

answer has hints of “yes” in it, and you can read stats to back that up all over Google, the larger implication and directive is that it doesn’t matter.

Whether or not surveys and random polls return that point, Just Salad was going to invest, and invest heavy, in sustainability and climate-centric initiatives. On the topic of reusables, for instance, Noonan put it this way: “It’s a matter of operators’ ability and willingness to participate; it’s a matter of policy; and it’s a matter of shifting public opinion. When those three reach a critical level, we will hit a tipping point.” But Just Salad isn’t waiting around.

Noonan admitted an inflection wasn’t quite in sight, which is why the company incentivizes climate-friendly behavior like some brands might a visit. Use a reusable bowl, get a free topping. On the brand’s app there’s a carbon label filter that recently allowed Just Salad to discount pricing for an Earth Day deal. The idea of rewards and loyalty evolving into sustainability programs is something Noonan says the brand is headed toward, and she thinks others should, too.

“To be clear, we don’t come in every day and say the customer wants more sustainability from us,” Noonan said. “We come in every day and we say we’re doing sustainability. And brands need to lead.”

Dressed down, it’s the message I was given to make this issue happen. While we might not all be eager or ready to take sustainability steps or have debates, the answer isn’t to shelve it for further review.

Danny Klein, Editorial Director

Danny Klein, Editorial Director

It’s not a topic every restaurant is comfortable talking about, but that might just be the point.

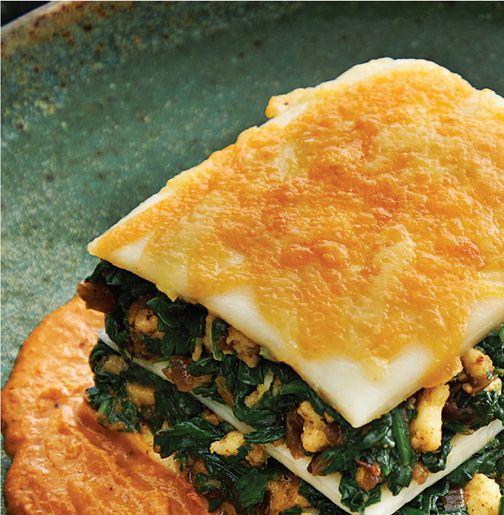

CHEF MANISH TYAGI BELIEVES WHOLESOME , SUSTAINABLE CALIFORNIA DAIRY INGREDIENTS Y MAKE HIS SIGNATURE INDIAN FUSION DISH THAT MUCH MORE COMPELLING.

CHEF MANISH TYAGI has a lways done things his own way. That was never more evident t han when , in t he midst of the pandemic, he opened his restaurant , Aurum , in Los Altos , California. It was a risky move, coming at a time when more independent f ullservice restaurants were shutterin g rather than opening.

But Aurum has been a smash h it in t he Bay Area, t han k s in large part to T yagi’s innovative takes on traditiona l Ind ian d ishes. Tyagi’s artistr y is on full display in Aurum’s best-selling d ish : a spinach and paneer past a dubbed “I’m Not Pasta.” The entreé uses thinly-sliced Real California paneer cheese to mimic lasagne noodles, sandwiched around a fi lling of brown garlic, fenu g reek leaves, and California

mozzarella. The lasagne-like creation is cooked and then plated atop a spicy tomato sauce and fi ni shed wit h ba sil oi l and ch i l i t h read s.

“At any Indian restaurant, you’ll fi nd a paneer d ish ,” Tyagi says. “But I don’t do any Indian dish the way you’d fi nd it in a tra d itiona l Ind ian restaurant. I add my own st yle to it. It’s a ver y old culture and cuisine, but there’s always room to present it as a new version. So when somebody sees ‘I’m Not Pasta’ on the menu, there’s a sur prise element to it , but the color, texture, and taste of the dish speak for themselves.”

T he R EAL Ma kers video series spotlights chefs using California dair y

he bel ieves it’s a h ig her qua l it y product than chefs can fi nd elsewhere He also believes in sustainable practices , alsobelievesinsustainablepractices a nd, accordin g to the California Milk Advisor y Board, California farmers

a re more than halfway to a statewide goal of 40 percent less methane emissions by 2030. The California dair y industry’s carbon footprint has shrunk

4 5 percent over the past 5 decades, and about 40 percent of a Cali fornia dair y cow’s diet consists of by products from food and fiber production—like almond hu ll s and grape pomace—keepin g

t hese by products out of landfi lls and reducin g the amount of water needed

to grow additional feed by around 1.3

t rillion gallons per year.

For t hese reasons, Tyagi rel ies on Real California Cheese and trusts that it performs as well or better than anyt hin g a restaurant could make in house.

“ I like California dairy for both its consistenc y and taste,” T yagi says. “And because it’s f rom here, the taste is California.”

BY CHARLIE POGACARFor more, visit realcaliforniamilk.com/foodservice

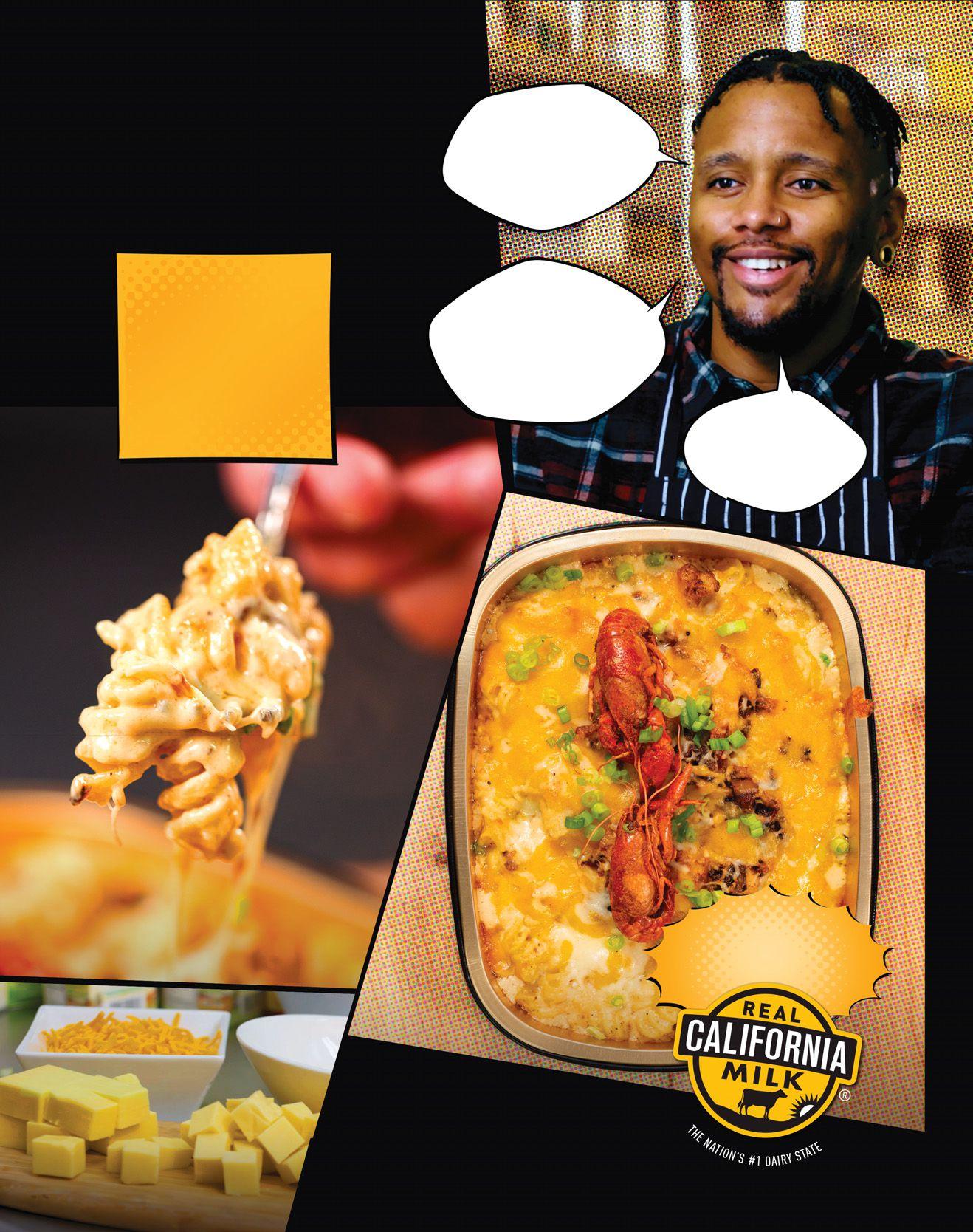

I FOUNDED THE BLACK FoOD COlLECTIVE TO BRING LIGHT TO SMAlL BUSINEsSES AND HELP THEM GROW.

InNOVATION BUbBLES UP AT CHEF RASHAD ARMSTEAD’S OAKLAND GHOST KITCHEN.

WE’RE “DELIVERYONLY,” SO FLAVOR IS EVEN MORE IMPORTANT, AND CALIFORNIA CHeESES MAKE MY FoOD TASTE THAT MUCH BEtTER.

I USE FIVE OF MY FAVORITES IN THIS JAMBALAYA MAC & CHeESE!

Domino’s (and its marketing materials) found a home in this past season of “Stranger Things.”

Domino’s created an immersive ordering experience for guests that was out of this world.

MIND-ORDERED PIZZA? Domino’s made this otherworldy notion a reality in May around the premiere of “Stranger Things’” new season. The brand’s “mind-ordering app” placed test subjects inside Hawkins National Lab in Hawkins, Indiana, transporting them to the center of the show, circa 1986. Users could explore the lab, uncover Easter eggs, use telekinetic powers to gain control of certain objects, and place a Domino’s Easy Order. The chain deployed facial recognition and eye-tracking technology so guests could use their “powers” to order pizza by making certain facial expressions and head movements.

“We’re geeked to launch this first-of-its-kind mind ordering app, just in time for the premiere of ‘Stranger Things’ new season,” says Kate Trumbull, Domino’s senior vice president of brand and product innovation. “Now hungry customers and ‘Stranger Things’ fans across the U.S. will get a taste of what it’s like to be Eleven, and they may find some hidden surprises along the way, such as the Noid or Demogorgon.”

SHORT ORDER

Food waste can fast become a convoluted debate. There are enough statistics and survey points to bury even the most informed operator. So we’ve cut through some of the noise to bring you a collection worth highlighting.

Ahalf a pound of food is wasted per meal in restaurants, whether it’s from what is left on a customer’s plate, or in the kitchen itself (GreenBlue).

U.S. restaurants generate an estimated 22–33 billion pounds of food waste each year. About 4–10 percent of food purchased by restaurants is wasted before reaching the consumer (NRDC)

WHERE OUR WASTE COMES FROM:

HOMES

43%

U.S. food waste is responsible for the equivalent of the emissions of 37 million, or one in seven, cars (Natural Resources Defense Council)

Roughly 85 percent of the food that isn’t used in a typical restaurant is thrown out. With more than 42 million food insecure people in our country, there’s no mystery why this is a problem (GreenBlue) reducing food waste by 15 percent could provide enough sustenance to feed more than 25 million people, annually (USDA)

America wastes roughly 40 percent of its food (NRDC)

While the world wastes about 1.4 billion tons of food every year, the U.S. discards more food than any other country in the world: nearly 80 billion pounds every year (EPA) That equates to 219 pounds of waste per person.

RESTAURANTS, GROCERS, FOODSERVICE COMPANIES (Feeding America)

MANUFACTURERS

The restaurant industry loses $162 billion annually thanks to wasted food (USDA).

55%

2% 16% 40% 40% 85%

On average, diners leave 17 percent of their meals uneaten and 55 percent of edible leftovers are left at the restaurant (Cornell University Food and Brand Lab)

The biggest concerns for most restaurants when it comes to food donations (41 percent of respondents in a ChefHero survey) are liability and transportation

TRASH BIN WITH FOOD WASTE: ADOBE STOCK LIGHTFIELD STUDIOS, FOOD SCALE: ADOBE STOCK DESIGNER, VEGETABLES IN BOWL: ADOBE STOC K BY PRIYANKA, CAR: ADOBE STOCK RASHADALIYEV, FOOD WASTE: ADOBE STOCK BY PRIYANKA, MAP OF USA: ADOBE STOCK BY HL, TRAS H BIN ICON: ADOBE STOCK BY JANIS ABOLINS, PAN: ADOBE STOCK BY MISSBOBBIT, HOME: ADOBE STOCK SATHAPORN, STORE: ADOBE STOCK TELMANBAGIROV, BARN: ADOBE STOCK MARTIALRED, FACTORY: ADOBE STOCK / MARC, MONEY: ADOBE STOCK JACARTOON, SALAD: ADOBE STOCK PRIYANKA, FOO D DONATIONS: ADOBE STOCK BSD STUDIO, RISK LEVEL ICON: ADOBE STOCK LYSENKO.A, COURIER: ADOBE STOCK LEREMY 10 JULY2022 | QSR | www.qsrmagazine.com

BY AMANDA BALTAZAR

BY AMANDA BALTAZAR

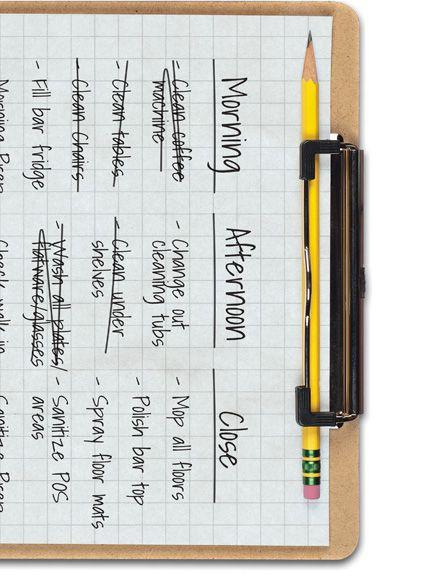

Just over a year ago, fast casual Kitava hired Preethi R as culinary director. One of her day one tasks? Reduce waste.

“Food waste is huge, and in a company it’s a cost,” says the culinary director. So as she worked on the menu, R looked at the yield of every ingredient and what the concept could get out of it—“truly get out of it,” she says.

Food waste is a growing problem, and food is the largest contributor to landfills, where it produces methane, a greenhouse gas even more potent than CO2. But many counter-service brands are taking every effort to curb the growing problem.

Kitava, a two-unit brand based in San Francisco, sells food

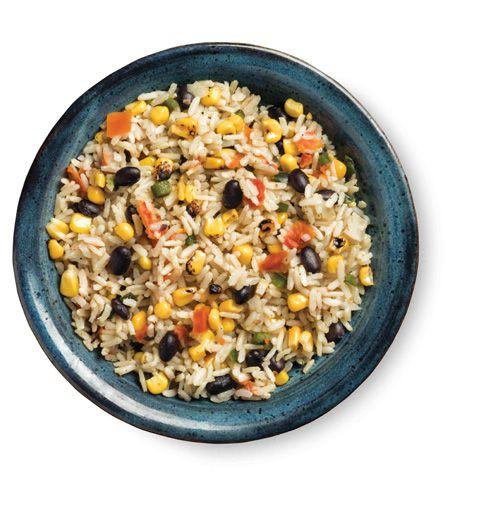

through ghost kitchens. Its cauliflower florets go into three different dishes—za’atar cauliflower and hummus; za’atar cauliflower (fried florets); and the mezze harvest bowl—and the stalk is shredded for cauliflower rice.

Avocados were proving to be a problem since they were inconsistent with brown spots, so R blitzes the problem areas into a sauce with lime and cilantro, and it’s added to the tacos and eliminated waste. As an added bonus, this boosts the nutrition of the tacos.

Kitava also takes care to use every part of herbs. Stems of softer herbs like parsley or cilantro go into a green goddess dressing;

heartier herbs are added to stock. This broth also contains chicken bones and leftover vegetable scraps—onion, carrot, celery—and cooks overnight, then is blended with ginger and turmeric.

R removed items from the menu, as well as added them. Shredded carrots in some of the bowl menu offerings added a nice earthiness but didn’t last long enough, so now the concept pickles them. “They last longer, they bring a great texture, feel, taste, and health benefit,” she points out.

Fat Choy, in New York City, is also as zerowaste as possible.

Chef and owner Justin Lee developed several menu items to reduce food waste through repurposing.

“At Fat Choy we put in the extra work to make the most out of every part of the plant,” Lee says. “So much goes into growing and transporting that plant, it seems wasteful to only use the most ‘desirable’ parts. Hopefully we can show people simple techniques they can easily adopt into their lives.”

Fat Choy is a vegan, “Chinese-ish” restaurant, through which Lee hopes to encourage people to eat less meat, while still being omnivores.

Lee had a lot of waste of stalks and leaves from his salt and pepper cauliflower. So he now cuts up the cauliflower cores very small and thin and fries them along with the florets. “By understanding they’re more fibrous we can fry them and increase our yield from that product,” Lee says. And he grinds up the leaves in the food processor along with stems from collard greens and uses them in sticky rice dumplings.

Mushrooms also have more than one use. Lee uses the caps of king oyster mushrooms in specials such as “Fun Guy Stew” and “Fun Guy Salad,” but can’t include the woody stalk. Instead, he braises and purees them and they add flavor to sauces, along with acting as a thickening agent. This goes into both dishes as well as soups such as stone soup, and hot and sour soup

And in perhaps the most innovative idea, Lee is confit-ing ginger skins and scallion roots then blending them into a paste. “We use that to flavor fried rice or to start up a braise or a soup, so that’s a really useful technique,” Lee says. Other scraps go into stock or flavored vinegars. He steeps jalapeño cores and seeds—or whatever he has on hand—in vinegar than uses it to make a house hot sauce. “It changes slightly in flavor depending on the season and what scraps we put into it,” he says.

Lee enjoys the task. “This is a different challenge—to make scraps taste good. The first step is to put everything into a stock, but we’re taking further steps and making that into solid food,” he says.

What is tricky is knowing how much of this to share with customers and do it in a non-preachy way. Lee is aware using food scraps might encourage some guests to come back and might deter others. “Every now and then on Instagram we might talk about it. The idea behind Fat Choy is this menu can exist anywhere in the world,” he says.

Shouk is an Israeli street food fast casual with three locations in Washington, D.C., and one in Bethesda, Maryland.

“We run at little to no waste,” says cofounder and CEO Ran Nussbächer.

He achieves this by having a very limited set of SKUs and using them to create as many menu items as possible. “We’re fairly aggressive in keeping it tight,” he says. “We’re always asking ourselves what more we can do with what we have. We try not to bring in anything that’s single-use because if it’s a perishable item and I’ve ordered too much of it I can’t use it for anything else. If I have two or three items with the same perishable item I’m unlikely to run into that problem.”

Oyster mushrooms, for example, are used in two very different ways and customers don’t even realize they’re the same, he says. The mushrooms are seasoned and grilled for mushroom schawarma; and breaded and deep fried for fried schouk’n. “The profile of the dishes couldn’t be any different,” Nussbächer explains. “That way we are able to have the flexibility to use the product for both without any leftovers.”

Likewise with chickpeas, which are used in hummus, falafel, and the Shouk veggie burger. “They all taste different and feel different. We have a fairly limited set of SKUs and we’re fairly aggressive in keeping it tight.”

Shouk’s menu is 100 percent plant-based, which means, Nussbächer says, “that our products aren’t as perishable as animal proteins. We have more time on items; a tomato doesn’t go bad as quickly as a steak and if goes beyond 24 hours that’s OK.”

Nussbächer also enjoys the challenge of being as zero-waste as possible. “It’s good for the planet, good for business,” he says. q

Both a commercial real estate broker and a longtime restaurant operator, Josh McBride is better equipped than most with insights into the quick-service site selection process. And, as the industry evolves at a rapid pace, there’s been no better time to revisit some of the fundamental calculations that should be on every operator’s mind when looking for real estate.

Below is an edited version of a conversation between McBride and QSRmagazine.

What is your background in the restaurant and real estate industries?

“I began my restaurant career with Chickfil-A in 2004, where I served for over 9 years, including as an owner-operator. I also spent time as vice president of development for what was, at the time, the largest Pieology Pizzeria franchisee group. More recently, I co-founded Hogwood BBQ in Franklin, Tennessee—one of the highest-rated BBQ restaurants in the Nashville area.

Since launching McBride Real Estate a few years ago, I’ve brokered over $50 million in

perform for the dinner or weekend business. Operators should ideally look for sites with high counts for both categories.”

retail and restaurant leases across the Southeastern U.S., and have evaluated over 1,000 raw land development opportunities, resulting in a net lease asset sale value of over $75 million”

What are key things franchisees and operators should look for when targeting sites?

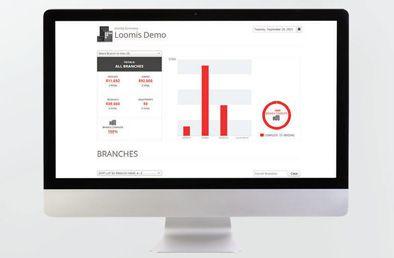

“When analyzing an opportunity, there is nothing more critical to understand than how the restaurants in the immediate vicinity are performing. There are some very sophisticated software programs today that can provide operators with real-time customer traffic data that wasn’t accessible 5 years ago. Operators should use these tools to understand how their competitors are performing at a specific location and then target the sites with the highest probability for success.

Employee population in a trade area typically correlates to how the restaurant should perform in the breakfast and lunch dayparts. Residential population in the trade area typically correlates to how the restaurant should

What are key things franchisees and operators should inquire into when negotiating commercial real estate?

“Aside from rent, a big concern for most restaurant operators is their initial cash investment in the space. Borrowing is getting more expensive while, at the same time, construction costs continue to rise. A secondgeneration restaurant space can be a very good option, if you can find one.

For new developments, the operator can submit a work letter to the landlord. This work letter could include stipulations like having a grease trap, patio with railing, upgraded electrical panel, and high tonnage HVAC installed. Most franchisors should be able to provide a detailed landlord work letter for their brand.

Rent and investment are the two most critical items in the landlord proforma as well, so compromise is key. Operators should expect to pay a premium in rent if the landlord is prepared to invest additional capital in their restaurant buildout.”

At a time with little margin for error, an expert shares insights on targeting the right locations. /BY CHARLIE POGACAR

In the 10 years since, Cousins Maine Lobster has grown to roughly 40 food trucks nationwide and a handful of restaurants, from Maine and Massachusetts to California and Nevada.

While the concept is still relatively young, the regulations it abides by to obtain product are more than 100 years old, says Annie Tselikis, who leads marketing and franchisee engagement. She refers to the Maine lobster business as the “gold standard in sustainability.”

“This industry has been sustainable since before the word was ever a buzzword,” says Annie Tselikis, a 15-year veteran of the Maine lobster industry.

There are roughly 4,500 licensed lobster fishermen in Maine, and the entry/ exit procedures are strict. If one wanted to start fishing tomorrow, they would have to undergo a two-year apprentice program with a licensed fisherman, the majority of which would be documented fishing time on the water, in addition to gear work and learning navigation.

FOUNDERS: Jim Tselikis and Sabin Lomac

HEADQUARTERS: Portland, Maine

YEAR STARTED: 2012

ANNUAL SALES: $54,757,000 (in 2021)

TOTAL UNITS: 36 trucks and seven brick and mortar restaurants

FRANCHISED UNITS: 38 Franchised units total

COUSINS JIM TSELIKIS AND SABIN LOMAC SPENT much of their formative years—weekends, summers, and holiday breaks—hanging out with family members and enjoying lobster, a staple in the state of Maine.

The two went their separate ways in college, but reconnected years later in Los Angeles. They instantly fell into old habits

and were reminded of all those great times they had as kids. But it was more than just reminiscing; the passion for Maine and its lobsters ran deep, and the cousins felt there was opportunity to spread that familial love to the rest of the country.

In 2012, the idea ballooned into a Cousins Maine Lobster food truck in L.A., and not too long after, they found themselves being courted by ABC’s Shark Tank.

“We said no twice, and then eventually, an executive producer called and said, ‘you guys will be making the worst decision of your lives if you don’t do this,’” Jim Tselikis recalls. “So about 2.5 months into business, we were on the set of Shark Tank . We had targeted Barbara [Corcoran], believe it or not, and that is who we eventually did our deal with.”

After that, they would be eligible for a lobster license, but they would likely sit on a waitlist in most parts of the state for at least 10 years. That’s because the Maine Department of Marine Resources, which manages the fishery, will not let new fishermen into the industry until some come out. And usually, those licenses aren’t given up until someone is in a nursing home or passes away.

“I have friends that have sat on the waitlist for 10 years,” Annie Tselikis says. “That is a big deal.”

Once a person is in the fishery, they start with 300 traps and can add 100 each year until the 800 maximum. In terms of actual lobster, the industry is intently focused on maintaining the next generation. For instance, fishermen return egg-bearing females to the water and

From Shark Tank to a nationwide fleet of food trucks, sustainability has always been at the heart of the growing fast casual.

In the company’s report, it noted it had removed artificial colors and sweeteners from food. Moore says the company is dedicated to providing guests with high-quality, fresh, and delicious products, and the decision to remove artificial colors and sweeteners emerged a decade ago “to ensure our menu delivered guests the highest-quality food possible with only the best ingredients.”

The drinking straw initiative was first considered by Noodles back in 2021. “We are constantly looking at all elements of our business, and the conversation around compostable straws came up about a year ago,” Moore says. “Before implementing the new straw, we tested it to ensure it would uphold our high standards and we were pleased with the quality and our guests’ reactions.”

With climate concerns weighing more and more on consumers’ minds today, Colorado-based Noodles & Company decided to generate its first impact report, which was released in October. As the company notes, the report outlined the initiatives taken “in the areas of food, people, planet, and community” to improve the world and offer environmentally sustainable solutions to the fast casual’s business model.

One way it will affect change is through disposable paper drinking straws, and more green-conscious updates are also happening across Noodles’ more than 450 locations nationwide.

“As a values-led company, we believe in transparency, and it is important to us to share our journey as well as our path forward,” says Danielle Moore, director of communications. “Our first report served as a baseline to show what we’ve accomplished over the past 25-plus years and where opportunities lie moving forward. As a female, I was especially proud to see that females comprise 56 percent of our operations team and 50 percent of our executive team, and I am continually proud of Noodles’ dedication to inclusion and diversity.”

Last fall, Noodles announced a partnership with Hoffmaster Group Inc., a 66-year-old company known for specialty disposable tabletop products in brands like Linen-Like, FashnPoint, and CaterWrap. Its brand of Aardvark Straws are certified BPI-compostable, FDAapproved, naturally degradable, and made in the U.S. Martin Stone’s original patent on paper straws dates back to 1888, and the straws were re-introduced into the marketplace back in 2007 when Aardvark saw a growing need because of the anti-plastic movement that included restaurants, hospitals, and other service industries. Indiana-based Precision Products Group Inc. was asked by Aardvark to create a straw that was more environmentally friendly. Hoffmaster purchased Aardvark in 2018.

“[ Hoffmaster] is a leader in developing environmentally friendly products, and we were very impressed with the quality of their straws and the other products they offer,” Moore says. As reported this past January, this change will remove nearly 21,000 pounds of plastic from the company’s waste stream annually.

Last year also found Noodles developing a fresh plan to reduce water and energy usage. The company began installing a new dripper system chain-wide that Moore says reduces water usage by more than 30 percent. The dipper wells Noodles recently installed have restricted waterflows, which will improve the amount of water usage into each location using them. The company is also exploring new high-efficiency faucets it hopes to bring to

With custom programming, one-touch operation and precision performance, Vitamix® machines empower employees to achieve perfectly consistent results every time – even the first time.

It’s just one reason we’re the industry’s most trusted blending partner.

See what else sets us apart at VITAMIX.COM/OURDIFFERENCE

Sandra Noonan doesn’t typically cold email CEOs. But she recognized something about Just Salad the company itself likely didn’t. In the emerging conversation on circularity, the New York City-based salad chain was a decade ahead.

This was 2019, about 13 years from when Nick Kenner and childhood friend Rob Crespi debuted the brand as a way to serve healthy, quick food in a market that lacked accessibility. The goal, as Kenner said then, to become the “Trader Joe’s of fast food,” or a restaurant where organic on the menu didn’t signal breaking the bank.

A year earlier, Noonan read an article in the New Yorker on the Great Pacific Garbage Patch (the largest of five offshore plastic accumulation zones in the world’s oceans) and was disgusted. She took one statistic, in particular, to mind—a finding in Science Magazine that claimed 275 million metric tons of plastic waste was generated across 192 coastal countries. “I had a, ‘I did not sign up for this moment’ as a consumer,” Noonan says. “And started doing more research and learned that only 9 percent of all plastic has ever been recycled, according to scientific literature.”

It made her think of Just Salad. In addition to Kenner’s aim to bulldoze barriers to healthy food, he devised a reusable container prototype in hopes of limiting the plastic salad vessels stuffing waste baskets throughout the city.

Kenner and Just Salad execs oversaw the program, yet they also were trying to run a growing restaurant chain that had scaled to about 40 stores (there are 60 today). Naturally, one often preceded the other.

Just Salad’s Sandra Noonan is proof one fast casual is taking environmental issues to heart. But she’s ready to start a broader

Earlier in her career, Noonan served as VP of digital strategy at Morgan Stanley’s Institute for Sustainable Investing. She also worked as a reporter with Bloomberg, independent marketing consultant, and adjunct instructor at NYU’s School of Professional Studies. But when she came upon Just Salad’s reusable bowl, Noonan was spending all of her free time on an advocacy group she founded in 2019 called Zero Waste NYC, which had grown to a few hundred members.

“He answered within a day,” Noonan says of her email.

Kenner told Noonan to come by and trade thoughts. So she slipped out of work one day and took the subway to Just Salad’s Manhattan HQ. “I didn’t really know what I was doing there,” she says. “But I said listen, I am really passionate about this reusable bowl program … I realized that he was totally engrossed in what I was saying.” A few months later, Kenner asked Noonan to join in. She accepted on the spot, which is how the fast casual became one of the few ( it’s challenging to find any ) restaurant brands in America to employ a chief sustainability officer in its C-suite.

What Noonan wanted to accomplish from the outset was increase the cultural relevance of reusables—to tell Just Salad’s story and how it all connects with a broader dilemma. In a 2021 report by United Nations Environment Programme, an estimated 931 million tons of food waste was generated in 2019, globally. The U.S. throws away more than any other country in the world, with nearly 80 billion pounds of food wasted per year, an estimated 30-40 percent of the country’s entire food supply.

Nearly 9 million tons of single-use food service items are used every year, too, equivalent to the weight of 25 Empire State Buildings.

Circling the restaurant sector, per the USDA, the industry loses $162 billion annually thanks to wasted food.

Right away, Kenner asked Noonan to help Just Salad along many of these fronts, starting with composting. And it’s only gained over the years. Eco-labeling; a Sustainability Champion program for in-store staff; becoming the first U.S. chain to display carbon labels on its menu.

Before exploring some of Just Salad’s nuanced directives, it’s worth pulling back.

Noonan says the chain, and restaurants as a whole, are only scratching the surface on storytelling when it comes to climate. It’s taken years, but the ceiling is nowhere in sight.

Still, the juncture at hand holds promise. One reason being sustainability, reusables, and other environmental top-

ics got buried over the past couple of years by COVID-19. Just for restaurants, the rush to serve off-premises guests—often with single-use plastics—raced ahead on the priority chart. But similar to how consumers tapped comfort food early and have begun to return to health-minded goals, the same is true of watching their environmental impact, Noonan says.

A study from Unilever showed 72 percent of U.S. diners care about how restaurants handle food waste. Forty-seven percent added they’d spend more at restaurants with an active food recovery program.

While that might be anecdotal in scope, Noonan says hard data is where change is really beginning to unfold. It’s central to sustainability communication with customers, she adds, almost to the point where calling this directive “storytelling” doesn’t fit anymore. “It might imply spinning a story,” Noonan says. “That’s not what we’re talking about at Just Salad.”

In 2021, as part of an internal audit guided by SASB (Sustainable Accounting Standards Board) standards, Just Salad estimated 91 percent of its disposable food service packaging was made from recycled and/or renewable materials, and 90 percent of its packaging was recyclable, reusable, and/or compostable. In an effort to provide multiple ways for customers to access reusable packaging solutions, Just Salad expanded its partnership with Deliver Zero to offer reusable containers for pickup and delivery orders on DoorDash and Caviar. Through Deliver Zero, customers can choose to have their order built in a reusable DeliverZero container. Then, they can return it to the Just Salad location they ordered from or any store within the DeliverZero network.

Here’s an example: It took Just Salad roughly a year to run a third-party environmental impact assessment with the New York State Pollution Prevention Institute at the Rochester Institute of Technology to measure its reusable bowl benefits compared to disposable containers. The goal being to capture the “break-even point,” or number of times the bowl must be used for its impact to be less than fiber disposable bowls. To do so, the LCA evaluated the carbon emissions and water use associated with each bowl at each stage of its life cycle.

The LCA showed, on average, Just Salad’s reusable bowl resulted in lower global warming ( greenhouse gas emissions ) and water consumption impacts than disposable fiber bowls after two uses.

Alter three, the global warming impact was equivalent to 42 percent of the impact of the fiber bowl. Four in and it dropped to 34 percent. With water consumption, the impact after three uses measured to 55 percent that of the fiber bowl, while after four, it fell to 46 percent, on average.

Perhaps the most concise and repeatable way to explain it—and share with guests—is a customer who washes and reuses their bowl once per week for an entire year could create 89 percent fewer greenhouse gas emissions and use 78 percent less water, on average, compared to the same number of uses of disposable fiber bowls, according to calculations published in Just Salad’s impact report.

NEXEO takes communication beyond the drive-thru and into key areas of your restaurant, increases efficiency with voice commands and one-to-one conversations, and seamlessly supports Automated Order Taking. And that’s just the beginning.

It was a painstaking, lengthy effort, Noonan says. Yet invaluable. Just Salad has offered reusable bowls since the opening of its first location, making it home to one of the longest running programs in the U.S. restaurant industry. How could the brand turn a trait into a movement?

Over the years, Just Salad’s “MyBowl” guests purchase the signature blue bowl for $1, and the chain gives them a free topping each time they use it.

The impact last year measured at more than 3 tons of single-use plastic bowl waste avoided. Keeping to a Big Apple theme, you could have stacked enough single-use plastic bowls to create a tower 15 times taller than the Empire State Building.

Also, amid the pandemic, Just Salad launched a pilot program at a Murray Hill store that offered guests a way to access reusable bowls for online pickup orders. Just Salad’s “BringBack” platform enabled customers to receive their online salads in a green reusable bowl and return it to a restaurant, where Just Salad employees took care of the washing. The brand expanded the platform to Midtown and initial analysis found BringBack users ordered from stores twice as frequently per week versus non-BringBack guests. As this scales, Just Salad plans to make it available on the company’s mobile app.

The data story, however, continues to thread throughout. Not just in Just Salad’s decision-making, but also in the way it’s courting customer frequency.

Leaders met with Anna Keller, a PhD candidate in environmental psychology at the University of Central Lancashire, who has published research on the various stages of behavior change during an individual’s transition from single-use to reusable cups, to tap her methodology. Just Salad then surveyed customers and found 65 percent were interested in using fewer single-use containers, yet either have not started reducing, did not know how, or didn’t think it was possible.

BRING YOUR OWN CUP: Last year, Just Salad relaunched its Bring Your Own Cup (BYOC) program for smoothie orders, giving customers the choice to avoid single-use paper cups.

SINGLE-USE UTENSIL OPT-OUT: On the Just Salad app and orderjustsalad.com, customers are asked to indicate yes or no for disposable utensils. Just Salad offers a 10-cent discount on delivery orders that optout of utensils. In 2021, the utensil opt-out feature on orderjustsalad. com avoided over 2,200 pounds of unnecessary waste.

DINE-IN BOWLS: Often in fast casual, customers receive their orders in disposable packaging even if they plan to dine on-site. Just Salad continues to introduce dine-in bowls at locations with sufficient seating capacity.

Just Salad also enlisted the help of eco-rapper and content creator, Hila the Killa, to leverage influencer marketing.

To put it plainly, Just Salad is spreading its message with more ammo than ever. “Data is the foundation of good story telling,” Noonan says. “And I think before Just Salad had a CSO, it didn’t have the bandwidth or resources to do that. …

I think the next two or so years at Just Salad we’re going to be able to talk about the benefits of reuse in a much more data-cen-

tric way.” Noonan does want to make one point clear, though—Just Salad doesn’t show up and say, “the customer wants more sustainability from us.” Although feedback and demand are always golden eggs to chase in hospitality, a topic like sustainability—akin to diversity—is one that idles if there’s no driving force. “We come in every day and we say, ‘we’re doing sustainability,’” she says. “And brands need to lead.”

This is a critical notion, Noonan adds, in understanding where restaurants go from here. Simply by having a CSO, Just Salad is sending a message that’s it’s going to try to skate ahead versus responding only when consumers ask for it.

However, there is an intersection. “For 16 years, we’ve had a very loyal cohort of consumers who have used the reusable bowl millions of times,” Noonan says.

Would Just Salad have witnessed this kind of activity and stability if not for the fact it gives free toppings away? The answer returns to Noonan’s point about the brand’s need to carry the sustainability banner on its own back.

The program owes some measure of its success, arguably a good deal of it, from the fact it offers an incentive to guests for doing something that’s not necessarily convenient.

But that’s not a negative spin, Noonan explains. Rather, it’s something she hopes more restaurants adopt. The pay-off is worth the price tag.

The company’s September 2020 call to introduce a seven-item “Climatarian Menu” that allowed customers to calculate greenhouse gas emissions with build-your-own salads, offers a blueprint. Come October, Panera Bread started doing something similar, although there were visible differences, like the unit of measurement Just Salad was using, kg CO2e. When guests ordered an item online at Just Salad, they saw the estimated carbon footprint compared to that of a quarter-pound beef patty, for context.

On the incentive note, the day Just Salad’s “Eat for the Earth” campaign launched, it changed the price of its Climatarian Menu items to reflect their individual carbon footprints. So a salad with a carbon footprint of 0.41 kg CO2e cost $4.10.

This year, any salad or warm bowl was $8.99 for customers

using reusable bowls. Online or via the app, if they filtered by Climatarian, guests found a selection of low carbon-emitting salads at that price point. Again, nudging consumers at a cost Just Salad is more than willing to write a check for.

Rewarding guests for eating on the low end of the carbon footprint scale almost surely will pop up again for Just Salad, Noonan says.

Logistically, Just Salad’s Climatarian dietary filter sits alongside vegan, keto, gluten-free, and paleo offerings, giving customers a shortcut to identifying the brand’s lowest-impact options. Fast Company named it one of 2021’s “Wor Changing Ideas.”

More recently, Just Salad’s carb o labels achieved compliance with inte national greenhouse gas (GHG) emission protocols ISO 14040/14044 and the Br i ish PAS 2050 standards.

The brand’s partner, Planet FWD, cal culates the carbon impact of the individu components of each salad, including bu not limited to, individual ingredients and packaging materials, which is where t h final emissions value comes from. Ju Salad calculates miles traveled by each ingredient based on their origin.

Noonan describes the overall arc as “cradle to grave,” meaning it starts from extraction of raw materials and ends at the end-of-life for all the inputs required to create a single unit of product.

REFORESTATION:

Just Salad funded the planting of 12,000-plus trees through Mastercard’s Priceless Planet Coalition.

ENERGY:

The company reduced average annual energy use by 7 percent, achieving reductions as high as 20 percent in some months, through a four-store pilot program with Budderfly.

REGENERATIVE AGRICULTURE:

Just Salad raised $15,000 to support regenerativeagricultureprojects

“On reusables, it’s a matter of operators’ ability and willingness to participate,” Noonan says. “It’s a matter of policy. And it’s a matter of shifting public opinion. When those three reach a critical level, we will hit a tipping point.”

One way to get there could be through one of the industry’s fastest-growing avenues—rewards. Relevant pre-virus but ignited by a landscape of mass digital adoption, restaurants are using loyalty and digital channels to accelerate data gathering and brand experience. Can these turn into sustainability outlets?

ANIMAL WELFARE: The fast casual met its goal of sourcing 100 percent of eggs from hens raised cage-free.

“That’s what we’re getting toward,” Noonan says. “Rewarding a customer for reusable bowl usage in our app is something we want to do, and we plan to. So I think that the industry has to get creative about integrating sustainability.”

And beyond the output and tangible efforts, Just Salad’s structure is one other chains can take heed of. The fast casual’s marketing and brand departments not only report to Kenner, they report to sustainability as well. It’s not a matter of sustainability reporting to marketing, which is more common, but rather vice versa. “That sets the tone for the organization,” Noonan says.

Noonan recalls having these conversations with Kenner in November 2019, just a few months into her role. Just Salad had cleared some early, pillar ideas, like composting, and were swapping thoughts on how to further talks about the relationship between food and environmental sustainability.

“During that conversation, we were like yeah, there’s been a lot of talk about eating locally. It’s wonderful. Should we be talking about that more?” Noonan says. “And I looked at the data and I was like, huh, it says that approximately 10 percent of a food’s carbon footprint is related to the miles it travels.”

The bulb flashed: Eating local wasn’t the end-all to achieving a low carbon footprint. And perhaps the nutrition label in general was a bit outdated. “Maybe now we need something that takes planetary health into account, too,” Noonan says.

Broadly, she hopes Just Salad is putting a dent in public awareness that consumers, as eaters, affect climate change. Noonan speaks with other quick-serves and CEOs about reusables, she says, and partners where the brand can. She adds there’s plenty of willingness industry-wide to get on board, but reusables “are a tough nut to crack for a lot of operations.”

It requires training, procedures, and it can’t flip on overnight.

The result is every marketing initiative gets scrutinized through the lens of sustainability. This runs up and down the ladder. Every time a new employee joins the company, HR sends an email introducing them and asks for a sustainability tip to share for their welcome.

Noonan believes greenhouse gas footprints, at the corporate level, is where the next topic is going. With the SEC proposing a new regulation that publicly traded companies vastly expand their climate disclosure, quantifying scope 1, 2, and 3 emissions is becoming table-stakes. Just Salad last year, for the first time, completed a greenhouse gas emissions inventory, conducted by the consultancy Green Places, across the entirety of its operations. The company also invested in store waste audits showing significant progress toward diverting more than 90 percent of daily waste from landfills, and started selling surplus food via Too Good to Go to achieve quantifiable reductions in wasterelated emissions.

“I think that a number of emerging companies will make it easier for small- to medium-sized restaurants to understand their carbon footprint and use data to surgically attack the areas that are most responsible for their environmental footprint,” Noonan says. “And that is generally your supply chain.”

“So we cannot lose sight of the big picture,” she adds. q

It’s not easy being green, but green is increasingly essential. In a 2021 survey of roughly 2,000 executives, two in three said environmental issues are “significantly important to them personally.”

In that same survey, conducted by the IBM Institute for Business Value (IBM-IBV), 39 percent of the organizations said environmental sustainability was already a top priority in their company and, within three years, 53 percent expect it will have become a top priority.

In the consumer-focused, labor-strapped restaurant industry, the significance of environmental sustainability is a driving force behind brand integrity, corporate responsibility, and bottom-line success. Becoming green-savvy and green-sincere is at the heart of attracting and retaining both consumers and employees.

Across 7,000 consumers surveyed this spring by Censuswide and Deliverect, 43 percent said they are willing to pay more at restaurants that have visible sustainability practices and more than half, 56 percent, would choose a restaurant that uses eco-friendly packaging and does not have singleuse plastic.

That said, more than half (again 56 percent) also doubt restaurants are being transparent about their sustainability practices.

Environmental practices and improvements impact recruiting and retention as well: Additional research from IBM-IBV that was released in April reported two-thirds of the workforce are more likely to apply for and accept jobs with environmentally and socially responsible organizations, and nearly half of the respondents said they would accept a lower salary to work at those organizations.

Conveying corporate commitments, policies, and quantifiable results are critical. The IBMIBV research also found that, while 86 percent of companies have a sustainability strategy, only 35 percent have acted on that strategy. In restaurant organizations, the challenges and opportunities for transitioning talk into action come in many shades of green. Among the environmental impacts most often targeted for improvements are packaging and recycling, food waste, greenhouse gas (GHG) emissions, and water usage.

Restaurants are learning how to be green-savvy and green-sincere.

/

CONNIE GENTRY

“What companies are finding, and certainly it has been Wendy’s experience, is that this overall corporate responsibility area has become a heightened focus for all the right reasons,” says Liliana Esposito, chief corporate affairs and sustainability officer at Wendy’s. “Consumers and investors care about it, and taking corporate responsibility is the right thing to do in terms of making sure we are improving the impact; but what has also become apparent is that the companies that focus on these areas and put meaningful effort and resources behind them perform better. At Wendy’s we have seen this is absolutely a benefit—it is not always easy and there is work to do to make sure you are improving your impact, but it is the right thing to do.”

Wendy’s is aggressively tackling multiple areas to achieve improvements and address its global footprint, but meeting environmental targets is not feasible in a single leap, it’s done through baby steps and long-term commitments.

For instance, the company set a goal in 2020 to sustainably source 100 percent of its customer-facing packaging by 2026. At the end of 2021, 48 percent of Wendy’s customer-facing pack-

The most widely discussed environmental initiative across all industries centers around goals to reduce GHG emissions, typically referenced as a target of net zero, with benchmarks of 2030 and 2050 often cited. In October, McDonald’s Corp. announced a goal to cut its GHG emissions to net zero by 2050.

Wendy’s has been actively working through its goals and timelines for reducing its GHG emissions, relying heavily on the Science-Based Targets initiative (SBTi) [sciencebasedtargets.org].

“We have completed the first couple of steps and a key part is, within the last year, for the first time we recorded our Scope 1 and Scope 2 greenhouse gas emissions to the CDP Climate tool,” Esposito says. “We also conducted a life cycle assessment of our Scope 3 initiatives and reported those results. Going forward, we will continue to report on Scope 1 and 2 and continue to add Scope 3. By the end of next year, we’ll have assigned base targets for reduction of emissions across those three scopes and timeframes will be set as well.”

CDP is a not-for-profit charity that operates a global disclosure system for monitoring and tracking global progress toward

environmental sustainability. In 2021, more than 13,000 companies disclosed, up from fewer than 3,000 companies in 2010 and just 300 in 2004. CDP rates the companies based on their positive impacts toward climate change; in 2021, 200 companies made the CDP “A” list. No restaurant companies were among those 200; Wendy’s earned a “B” rating. [ CDP.net]

Restaurant companies like Wendy’s face a difficult challenge because the majority of their GHG emissions are attributed to Scope 3. In the simplest terms, Scope 1 and 2 emissions are owned or controlled by the company; whereas Scope 3 emissions are considered consequences of the company’s actions but occur from sources that are not owned or controlled by the company, such as supply chain vendors or franchise operators.

Only about 5 percent of Wendy’s restaurants are company-owned, and 99 percent of the chain’s GHG emissions fall into Scope 3.

“With our franchisees, we are still setting reduction targets, but we know a key part of that will be reducing the emissions of our restaurant operations and, in many cases, that will be directly related to energy use in the restaurants,” Esposito explains. “Over the last five years we’ve been part of the U.S. Department of Energy’s Federal Buildings Challenge; all our company restaurants participate as well as about 12 franchisees, about 1,000 restaurants total. There has been the benefit of being able to work together around the benchmarking and measuring of electricity and other energy uses, as well as the associated GHG emissions that go along with that. We have voluntarily taken on a commitment to reduce that energy capacity by 20 percent by 2025.”

Working together with franchisees is a win-win as it improves the footprint of each restaurant’s environmental impact and it reduces costs overall. The same holds true on the supplier side, and Esposito notes that the company’s goal to responsibly source its top 10 food categories by the year 2030 includes both environmental and social components.

“We are actively reaching out to our suppliers to share with them what our footprint looks like and the role that they play in that footprint,” she says. “We will be partnering with them to understand what their contribution to that footprint is and what sort of reductions they can make to help us meet our reduction targets. In many cases, our Scope 3 will be their Scope 1, and many of those suppliers have set their own targets for GHG

emissions and, even those that have not set targets are certainly working on efficiencies.”

Where more than 6,500 of Wendy’s 6,949 restaurants are franchise-owned, Chipotle’s 3,000 restaurants are 100 percent company-owned and operated, so its percentage of Scope 3 is lower than restaurant operations that are heavily franchised. Roughly 93 percentage of Chipotle’s GHG emissions fall into Scope 3.

“We have committed to reducing our absolute Scope 1, 2, and 3 greenhouse gas emissions by 50 percent by 2030, from a 2019 base year,” says Laurie Schalow, chief corporate affairs and food safety officer at Chipotle. “To keep ourselves on track with our 2030 goal, we have also committed to reducing our Scope 1 and 2 GHG emissions by 5 percent by the end of 2022.” Additionally, Chipotle has formed an internal climate steering committee “to guide decision-making, determine reduction targets, and drive strategy forward to reduce emissions in the most carbon-intensive functions of the business.”

Another topic raised throughout conversations of climate control is water conservation. It’s a concern for all restaurant operators and, in particular, for those where their footprint extends into drought-prone, high-risk geographies.

“In 2021, we developed a program to assess our water risks,” Schalow says. “We are in the process of completing our water risk assessment and then will develop programs to address water usage across our supply chain, ingredients, and restaurants. This assessment will allow us to better understand where our key water risks and impacts lie, and to advise the next steps for water stewardship projects in our facilities and supply chain.”

Similarly, Wendy’s has been focused on water improvements. After completing its own water risk assessment, Esposito says, “we identified that about 40 percent of our restaurants globally exist in areas that are considered moderate- to high-risk, and geographically its exactly where you would expect.”

Perhaps surprisingly, the vast majority of those sites, 85 percent, are located in the U.S.

The company joined the Department of Energy’s Better Buildings Water Challenge in 2019, and set a goal to reduce water usage in company-owned restaurants within the U.S. by

20 percent by 2029, compared against a 2018 baseline.

“Last year we reduced it by 21 percent on the company side, and one franchised unit reduced their water usage by 31 percent, and they operate in Florida, which is a critical area,” Esposito continues. “There is no silver bullet solution, but after monitoring and measuring, certain solutions will make sense in different areas. One of the tools we’ve implemented at several of our company restaurants is metering technologies, so we can identify how water is being used and compare it to water usage in similar locations. In other cases, we’re using landscaping monitors and sensors that identify when it’s raining so the restaurants don’t turn sprinklers on when the ground is wet.”

Incremental, common sense adjustments can add up to sustainability success, but in growth-oriented business models, the organization’s success can further complicate progress toward environmental initiatives. In 2020, Chipotle set a goal to reduce its overall waste 5 percent by 2025. In 2021, due to the company’s rapid growth, overall waste actually increased by 7.5 percent.

However, Chipotle did implement significant steps toward waste reduction and the company recorded some relevant milestones. In 2021, Chipotle diverted 2.6 million cubic yards of waste through recycling, composting, and waste-to-energy. Specifically, the company composted 107,900 cubic yards of waste in 2021 and turned 68,490 cubic yards of waste into energy. The company also achieved a 50 percent landfill diversion rate.

Wendy’s is also making strides toward its goal of sourcing 100 percent sustainably packaged costumer-facing products by 2026, having taken its overall customer-facing packaging

Shake Shack, which has 369 restaurants across 32 states and 15 countries, launched a test last year of compostable, plastic-free, and carbon-negative straws. The pilot test, which was conducted in select markets, indicated that a single Shake Shack restaurant reduced carbon emissions by 4,146 metric tons in a single month simply by using the carbon-negative straws, which were sourced from Restore Foodware.

In a similar initiative implemented in fourth quarter 2021, Shake Shack reduced its cardboard usage by more than 1,000 pounds weekly by increasing its burger case pack by 4.5 pounds per case. The company has also begun testing solar panels in five locations, is using LED/motion-sensor lights and energyefficient equipment in many stores, and is evaluating adding EV charging stations in the future.

There is no single action or answer to positively impact the climate, as Esposito notes, “It’s a combination of different things. One of the things Wendy’s has done is renovate our restaurants to use more energy-efficient equipment, HVAC systems, lighting ( most have converted to LED in the parking lot ), and building materials. We use a double-sided grill for most of our restaurants, and we’re actually rolling out a new model that is more energy efficient. We’ve also converted to a ware wash machine at several hundred restaurants and these are more energy efficient as well as more water efficient.”

Looking to the future, Wendy’s plan for new construction as well as remodels includes EV stations in the schematic. Although there are only a few EV stations currently in place at Wendy’s stores, it is something that can be incorporated as the use of hybrid and electronic vehicles rises.

The move to corporate responsibility has translated directly into corporate accountability. At both Wendy’s and Chipotle, executive compensation is now tied to the achievement of ESG ( environmental, social, and governance ) goals.

At Chipotle, Schalow notes, “The 2022 annual incentive bonus for our officers can be positively or negatively impacted by up to 15 percent based on the company’s achievement of our ESG goals.”

And at Wendy’s, Esposito says: “This year, for the first time, 10 percent of the annual incentive compensation for our executive population, which is vice president and above, will be tied to the achievement of ESG goals.”

from 42 percent sustainable in 2019 to 48 percent in 2021. Most notably, the sourcing of cups and lids improved from 6 percent sustainable materials to 19 percent sustainable in 2021, and the category of straws, cutlery, napkins, and liners improved from 69 percent sustainable materials to 73 percent.

Even restaurant operations with hundreds of stores instead of thousands can have a substantial impact. New York-based

Key to achieving the goals is employee engagement, and that is an area that she has been most pleased with at Wendy’s: “This is a team sport, it is not something that one person or one department can impact, I’ve been pleased at how much energy there is within our organization for focusing on these initiatives, whether food, or footprint, or people-related. If anything, we have more ideas than we can implement in terms of how to move forward. so that’s really encouraging.” q

Connie Gentry is a regular contributor to Food News Media and the former editor of FSR magazine. She is based in North Carolina.

In the early days of the pandemic, George Frangos wouldn’t say that his fine casual Farm Burger was sitting pretty, per se, but it was definitely faring better than most. This good fortune was due in large part to the concept’s core values. When Frangos and cofounder Jason Mann opened the first location in Decatur, Georgia, in 2010, collaboration with nearby farmers and ranchers was paramount. The brand’s sourcing practice not only yielded a higher quality product, it also kept dollars in local agriculture.

A dozen years and about as many locations later, Farm Burger’s direct-to-the-source approach shielded it from some of the early chaos of COVID-19.

“As you had disruptions to the meat industry and supplies with processors and big slaughterhouses being shut down and COVID outbreaks and everything, we didn’t have those issues because we work directly with farmers and directly with small processors and really have a vertically integrated chain around our proteins,” says Frangos, who is also the brand’s president. “Our prices held tight, and we didn’t have any problem with supply. We were actually in a strong position, kind of unknowingly so.”

Recent bottlenecks and shortages have restaurants reevaluating their supply chains—and sustainability might just be part of the solution.

/

/

But the extent of these supply chain repercussions was not immediately visible. Instead, they unspooled gradually, casting ripples up the supply chain. As orders from restaurant clients ebbed, manufacturers and distributors curbed output and, in some cases, laid off employees. When orders started to ramp up again, there was a shortage of not only product, but workers, too.

Farm Burger felt the effects of the second phase of this reaction. It struggled to source sustainable paper and recyclable products; when it succeeded, the price could be double the usual amount. As of this spring, Frangos says the brand ( like many restaurants ) is still navigating a shaky landscape, with product availability changing on a near-weekly basis. Furthermore, it’s experiencing delays on specialty products like goat cheese. When demand faltered, farms bred fewer goats; now they’re having to grow the herds once again.

All too common quagmires like this have restaurants rethinking how they source ingredients and other products. Sustainability also comes into play, and not just for altruistic reasons. A shorter supply chain, as with Farm Burger, offers more control and dexterity for when the next disruption occurs. It also provides a baked-in narrative that curries favor with a growing number of consumers.

“For the operator, it’s wise to centralize their purchasing and localize it because they feel like they control it better, with fewer inputs and maybe more knowledge about those places they’re sourcing from,” says Laurie Demeritt, CEO of market research firm, the Hartman Group. “So I think there are good opera-

about reducing the carbon footprint. And still for other people, it might mean something else,” says Aaron LaMotte, vice president of supply chain management for North America for foodservice and facilities management company Sodexo. “So, sustainable sourcing over the last 10 years has become more of a focus from a broad perspective. We’ve had a lot of key stakeholders in the industry share with us how important it is to them.”

Just as restaurants might become overwhelmed by the many faces of sustainability, their partnering companies must also juggle multiple initiatives. LaMotte says one of the trickiest tasks for distributors and management companies is the beingeverything-to-everyone conundrum. One restaurant client might pursue sustainability by curbing their energy consumption, while another chases the same goal but by reducing their carbon footprint. All aspects of sustainability lead back to a central goal, but the entry points can be far apart. The broader Soedxo’s customer base, the broader its approach to sustainability has to be, LaMotte says.

A number of restaurants also employ a holistic methodology in building greener supply chains. For nearly four decades, Southern California–based concept Rubio’s Coastal Grill has sourced wild Alaskan pollock for its tacos. The whitefish, which has a mild, cod-like taste, is considered one of the more sustainable species, a reputation that has elevated its appeal in recent

tional reasons for doing this … but there’s a lot of other rich narratives about that sense of place, about money circulating locally, about supporting humans that are local.”

Nevertheless, sustainability in the supply chain encompasses more than local sourcing. It’s also about the path a product takes from its point of origin to the restaurant. The products themselves are another facet, whether they’re ingredients or packaging, the latter of which has faced increased scrutiny amid the pandemic-era spike in single-use disposables.

“We don’t have a universal definition as to what sustainable sourcing is. For some people, that might be local sourcing, buying in the communities in which we live. For some people, it’s

years. Accreditations from Alaska Responsible Fisheries Management and Best Aquaculture Practices guide the brand in its vendor selection. It also collaborates with organizations like the Monterey Bay Aquarium and Marine Stewardship Council.

Seafood might be at the crux of Rubio’s sustainability practices, but it’s not alone.

“Our focus on sustainability ranges from our seafood to land proteins to packaging,” says Angela Scheufele, director of supply chain for Rubio’s. Napkins, paper towels, and tissue are made of 100 percent compostable fiber. Last year, the chain used more than 122 metric tons of recycled fiber in these products.

But, the pandemic disrupted Rubio’s otherwise stable supply

chain. Shortages across the board—product, labor, transportation—plus commodity inflation and volatility have made for a challenging two years. The experience reinforced not just how important Rubio’s vendor relationships are but also the value of having backups.

“We have always believed in the benefit of dual sourcing when it makes sense, but now it is more important than ever given current conditions. We are prepared to pivot quickly if needed,” Scheufele says. “For example, we approved wild ono [wahoo] as a temporary alternative to our wild mahi mahi as mahi has been in short supply this season.” Rubio’s is also testing wild hake ( a pollock substitute ) at its Arizona restaurants as a precautionary step.

On the operational front, Rubio’s is working to incorporate GS1 global traceability standards and RFID (radio-frequency identification) technology. While conversations around traceability often pertain to food safety, GS1 barcodes can help verify sustainability claims and cut down on so-called greenwashing.

Beyond tracking technology, restaurants are also taking other steps to shorten products’ transit distances. During the pandemic, Rubio’s worked with its distribution partner to optimize freight lines to the restaurants—with locations in California, Nevada, and Arizona—and temporarily trim the number of deliveries when business was slow.

Even prior to 2020, New England–based Oath Pizza practiced the idea of doing more with less, something that has proved especially advantageous as of late.

“Oath has always been selective about the products and the menu we offer. Through some really thoughtful selection and cross-utilization, we’ve been able to put together a menu that caters to all tastes,” says Pam McMorrow, director of supply chain and product innovation. Indeed, the fast casual offers vegetarian, plant-based, gluten-free, and dairy-free options.

“Another piece of it is we’re really mindful about the impact on the planet when we’re making our decisions on what we bring in,” she adds, offering Oath’s use of humanely raised Applegate proteins and recyclable packaging for non-pizza dishes as examples.

But even the versatility of Oath’s ingredients couldn’t shield it from gridlocks along the supply chain.

“The biggest things were product deliveries being delayed and complete product outages; if it wasn’t coming in late, it wasn’t coming in at all,” McMorrow says. “We had to find alternative methods for deliveries like direct shipments or drop shipments straight from the manufacturers.”

She adds that thanks to a nimble team, Oath has been able to take many of these disruptions in stride. Like Rubio’s, it also sought alternatives to products that were tied up in transit or unavailable. In many cases, the substitutes were closer to home.

Before COVID, about 75–80 percent of its products were domestically produced since Oath would import some specialty items, like gourmet cheeses, from overseas. Now, McMorrow estimates the portion has grown to 95 percent. The switch also saved money by eliminating trade tariffs and shortening the shipping distance. Through it all, the brand was able to maintain its standards; as a bonus, the less time in transit also translated to a fresher product with a longer shelf life.

McMorrow says the final piece was turning to creative workarounds with ingredients that, while still fresh and high quality, might not be what was needed. For example, if crusts arrived that weren’t the right size for a pizza, the restaurants would cut them into squares and use them as croutons on the caesar salad.

“We put laser focus on product inventory—or par levels— based on accurately forecasted sales, and we completely tightened up our purchasing practices to bring in only the amount of product needed,” she says. “By doing that, we reduced the amount of stock in our restaurants and the amount of product in the supply chain. It also reduced the risk of having extra that could go to waste.”

Distributors are also adopting a repurpose mentality. In late March, US Foods became one of the first major broadline food distributors to join the Upcycled Food Association, an organization whose members salvage ingredients bound for landfills and incorporate them into food products.

US Foods’ first foray into upcycling is the Hilltop Hearth Pub Grain Hamburger Bun, which uses spent grain flour. A byproduct of beer brewing, spent grains not only find new life as flour, they also infuse the buns with a mild, earthy, and sour flavor.

One area of sustainability that McMorrow says tends to be overlooked are the chemicals used along the supply chain and in the restaurants.

“I don’t think people realize how damaging it can be if you’re using the wrong products, how damaging it can be to just pour it down the drain. That drain goes directly to our water supplies in some cases or watersheds, and it’s not often thought about,” she says. “Restaurants have to do their homework on those choices; you have to know what’s in these chemicals and how their contents affect the environment.”

In addition to third-party accreditation groups, manufacturers and distributors are creating their own initiatives as a way of vetting products for their restaurant clients. At US Foods, this culminated in the Serve Good program, which launched in 2016. To be part of Serve Good, products must not only have claims of sustainable sourcing or waste reduction, they must also arrive in eco-friendly packaging.

Because so many factors are involved in meeting the criteria, US Foods divided them into five categories: agricultural practices, sustainable seafood, animal care, responsible disposables, and waste reduction. “Almost all of the products under the Serve Good umbrella have the reassurance of some third-party certifier. So we’re working with Non-GMO Project Verified, USDA Organic, Marine Stewardship Council, Forest Stewardship Council,” says Hannah Koski, director of corporate social responsibility at US Foods. “Some of these third party certifications have a long history, but then others are new, and we’re excited to be able to incorporate those as well.”

In just six years, Serve Good has quadrupled the number of products (under US Foods Exclusive Brands ) in its stable to 770.

The broadline distributor is also making strides in how these items are transported. In California, its distribution centers are moving to 100 percent renewable diesel. In Texas, it’s converting compressed natural gas trucks to use renewable natural gas fuel. US Foods is also bringing 15 electric trucks into the fold. All three agenda items are slated to be completed by year-end.

“How [a product] is delivered is also really important,” Koski says. “We flagged a lot of initiatives both in our buildings and in our routes to improve our efficiency and reduce our environmental impact overall.”

Steps like these aren’t going unnoticed by consumers. While the average person might not be aware of initiatives at companies like US Foods and Sodexo, they do pay more attention

to the efforts of consumer-facing businesses, like restaurants and retailers. Whether the restaurant is building sustainability practices in-house ( as with Farm Burger ) or collaborating with third-party partners, the messaging resonates—perhaps even more so now than pre-2020.

“I think one of the things the pandemic did was just shine more of a light on the food supply system, and that’s everything from the growers to the producers and distributors to the folks who work in foodservice, who are making the food, who are delivering the food,” the Hartman Group’s Demeritt says. “Knowing some of those stories and those narratives about not just what’s in your product, but also where those ingredients are coming from is a good starting point.”

That’s one step all restaurants can take in both better understanding their own supply chain and communicating those details to customers, she adds. In terms of sourcing, the terrain has yet to stabilize, making it hard for many operators to refocus on their own sustainability practices. For this reason, Sodexo’s LaMotte recommends that restaurants stay on their toes as conditions continue to evolve.

“I would say that we’re not out of this yet. [ With] things like the bird flu situation that’s happening right now and the labor market that continues to have constraints and inflation being such a front-of-mind issue for all of our operations team, I don’t think we’re out of some of the more difficult parts of all of this yet and we may not be for the better part of the next year or so,” he says. “It behooves everybody to be patient and work to the best of their ability with their supply chain professionals.”

Building relationships has been the bedrock of the hospitality sector from the very beginning, and if anything, the adversity of the past two years reinforced how important the people side of the industry truly is. The restaurant-customer dynamic has been frequently spotlighted, but the ties between operator and farmer, rancher, distributor, manufacturer, etc. are just as vital to foodservice’s longevity.

Over its 12-year history, Farm Burger has cultivated relationships with many small businesses as it expands into new markets. After a COVID-necessitated pause, the restaurant is continuing this practice. In January, it debuted a location in Athens, Georgia, that had been delayed since 2020.

Prior to opening, the Athens store had suppliers locked in for its proteins, like grass-fed beef, and other menu staples, but it’s still searching for producers of ancillary items, with the goal of local, organic ingredients supplanting conventional ones.

Building these relationships takes time, but for brands like Farm Burger, it’s worth the effort, whether from a business standpoint or a sustainability one.

“When we go into new markets, there’s this learning curve. You don’t always know all the proper smaller- medium-size providers or growers or farmers or cheesemakers. It always takes time, and sometimes they find you. Sometimes when you get into a market, 3–6 months later, you find new local connections,” Frangos says. “That’s an exciting part of it, but it never happens the day we open.”

Autonomous technology has begun to emerge, offering operators and customers a more environmentally friendly—and cost-effective—approach.

BY TREVOR GRINERFifteen years ago, the first-generation iPhone hit the U.S. market. The sleek, paradigm-breaking design captured the imagination of consumers. Touch screens, apps, and other features would soon become a standard for mobile technology.

Today, innovation is advancing at an even faster clip. And it’s particularly evident in foodservice—a sector long considered a laggard to tech evolution—where futuristic solutions are popping up on the back-end of a global pandemic. Autonomous delivery being one of them.

Driverless delivery vehicles, drones flying through the sky with pizzas and groceries, and automated robot servers gliding through dining rooms, are all now realistic functions, as much as it might sound like an episode of “The Jetsons.”