www.therobotreport.com A Supplement to Design World • April 2024 ISSARONOW ADOBE STOCK

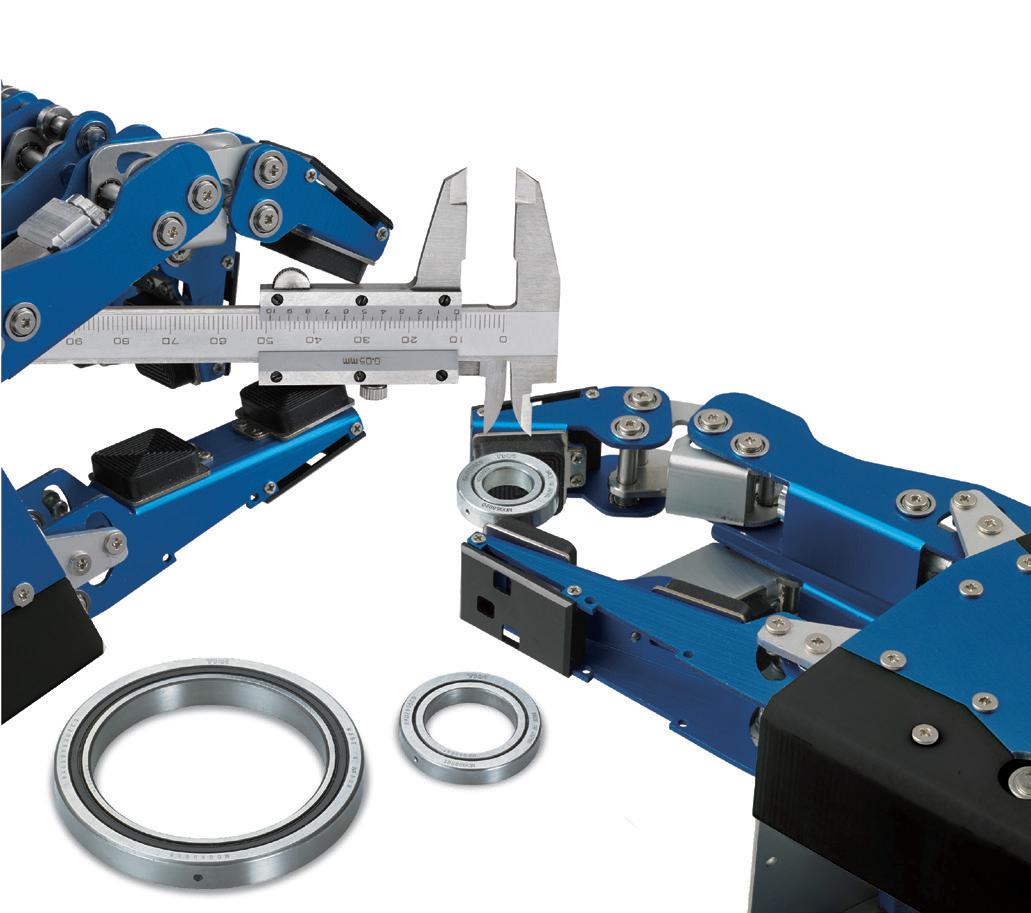

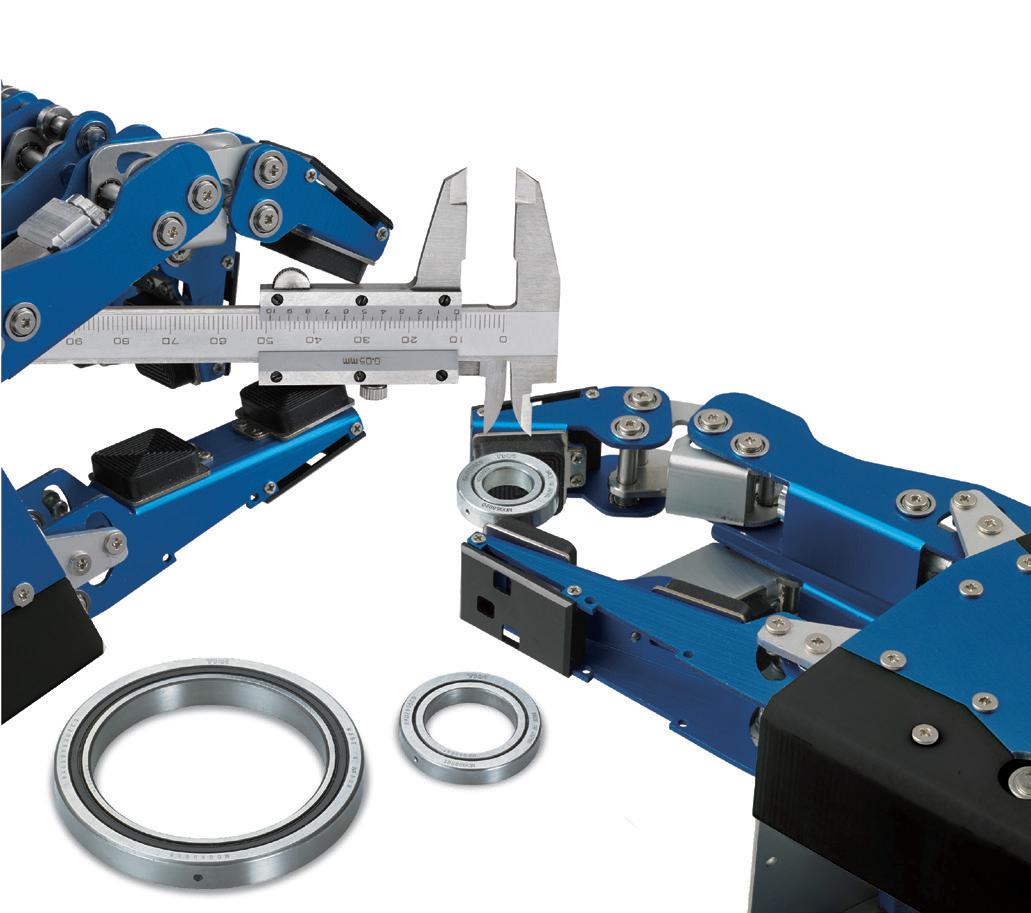

Quality Linear Motion Solutions from THK

THK is committed to meeting the worldwide demand for linear motion products. We manufacture, assemble, and ship across North America from our location in Hebron, Ohio. We’ve also ramped up our automating processes at existing facilities, including our U.S. manufacturing plant, where over 70% of THK Robotics Components are manufactured. Automated processes at this state-of-the-art facility enable increased production while maintaining the high standard of precision associated with THK products. To learn more, visit www.thk.com

LOCAL MANUFACTURING WORLD-CLASS LINEAR

1–2 Week Delivery of Select LM Guides and Actuators QUICK SHIP COMPONENTS THK Manufacturing in Hebron, Ohio

MOTION

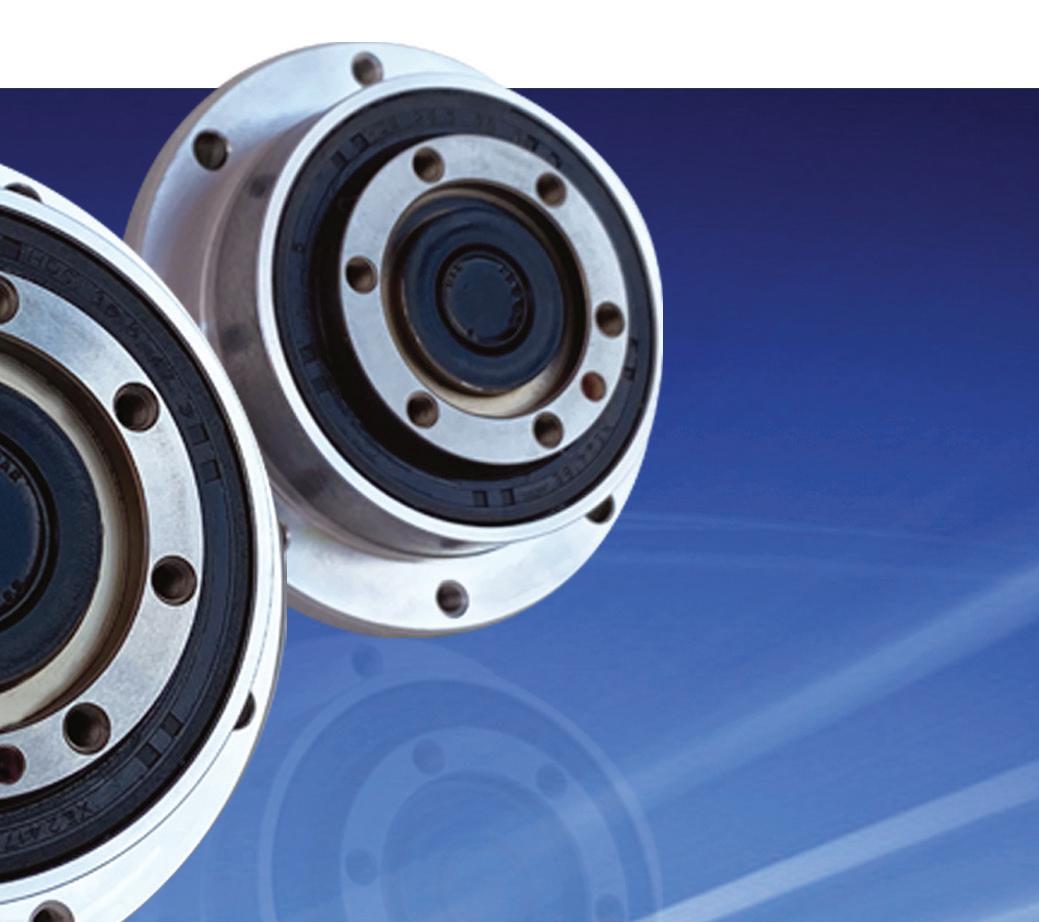

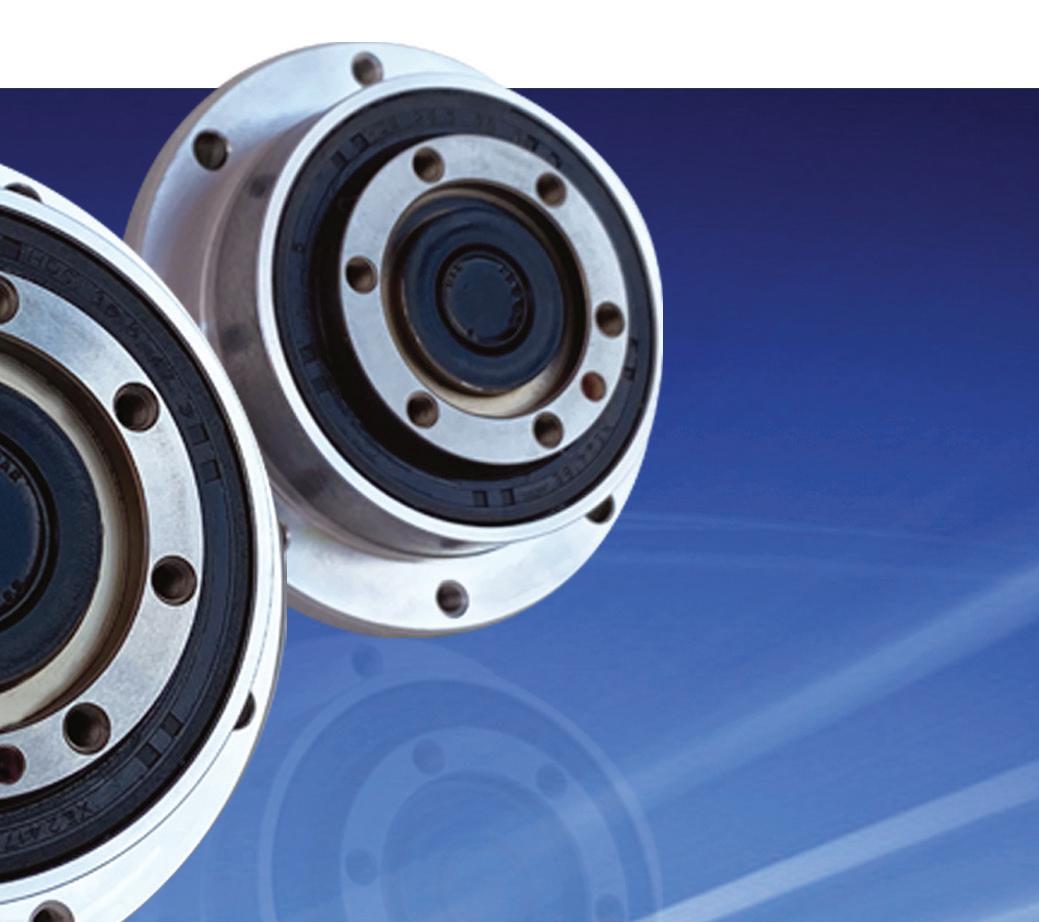

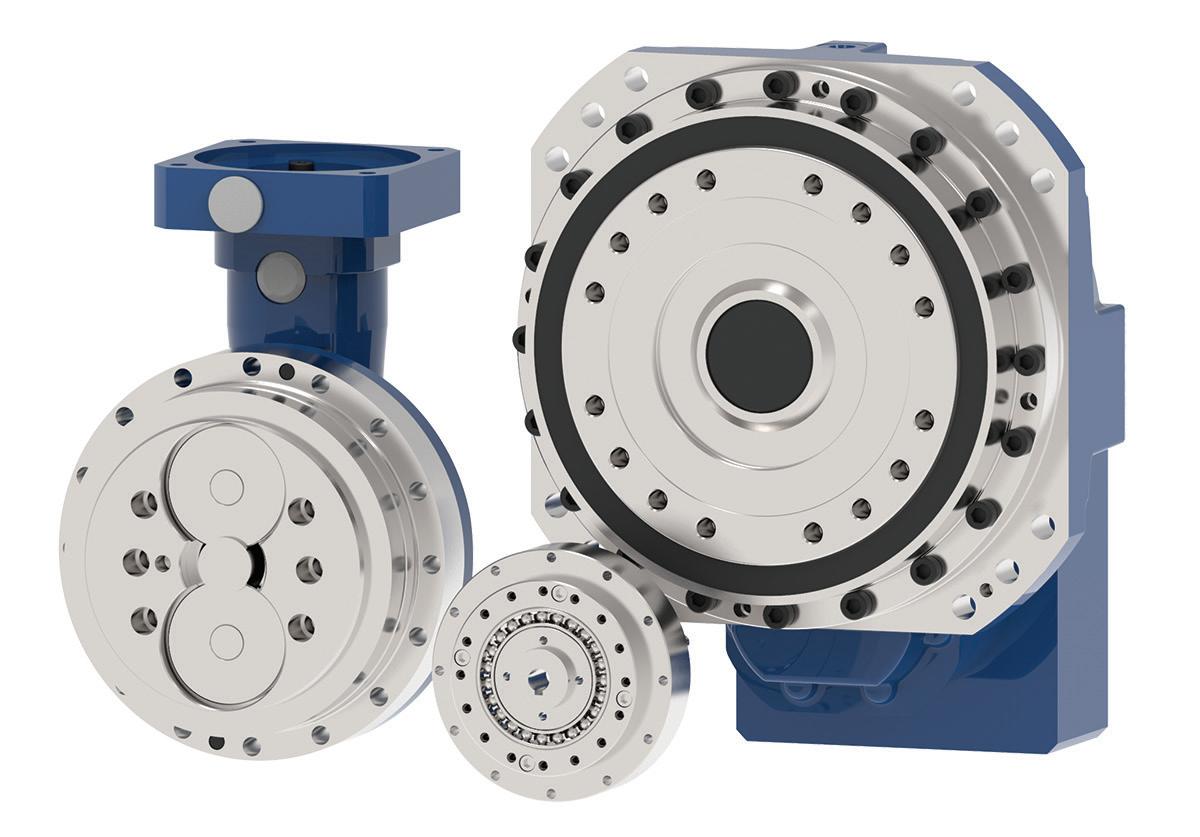

Ultra-Lightweight, Compact Gear Units

Introducing a new series of ultra-lightweight gear units featuring a newly engineered lightweight structure with an ultra-compact shape. Ideal for use on end of arm axes for small industrial and collaborative robots, the CSF-ULW is also well suited for general industrial machinery where weight is a critical factor. The two smallest sizes, 8 and 11, are available today. Other sizes coming soon!

• Zero Backlash

• High Accuracy

• Ultra Lightweight

• Ultra Compact

• Reduction Ratios 30:1~100:1

• Super Flat Configuration, 19mm (size 8); 21.5mm (size 11)

• Outer Diameter: φ 42.5mm (size 8);

φ 50.5mm (size 11)

• Weight: 90g (size 8), 150g (size 11)

NEW! Harmonic Drive is a registered trademark of Harmonic Drive LLC. 42 Dunham Ridge, Beverly, MA 01915 | 800.921.3332 | www.HarmonicDrive.net

RBR50 AWARDS RECOGNIZE INNOVATION AND EXCELLENCE IN ROBOTICS

A CLOSER LOOK AT THE NOTABLE WINNERS OF THE RBR50 ROBOTICS INNOVATION AWARDS

The RBR50 Robotics Innovation Awards have honored industry leaders for the past 12 years. And now we’re taking the RBR50 to the next level.

We introduced three new categories in 2024 – Robot of the Year, Application of the Year, and Startup of the Year –and will be holding the inaugural RBR50 Gala on May 1 from 6-8 PM at the end of Day 1 of the Robotics Summit & Expo.

The RBR50 Gala offers a chance to connect with the world’s leading robotics innovators. It’s also an evening of celebration to honor leading roboticists and their impressive achievements.

You can find profiles of all of this year’s RBR50 winners on The Robot Report

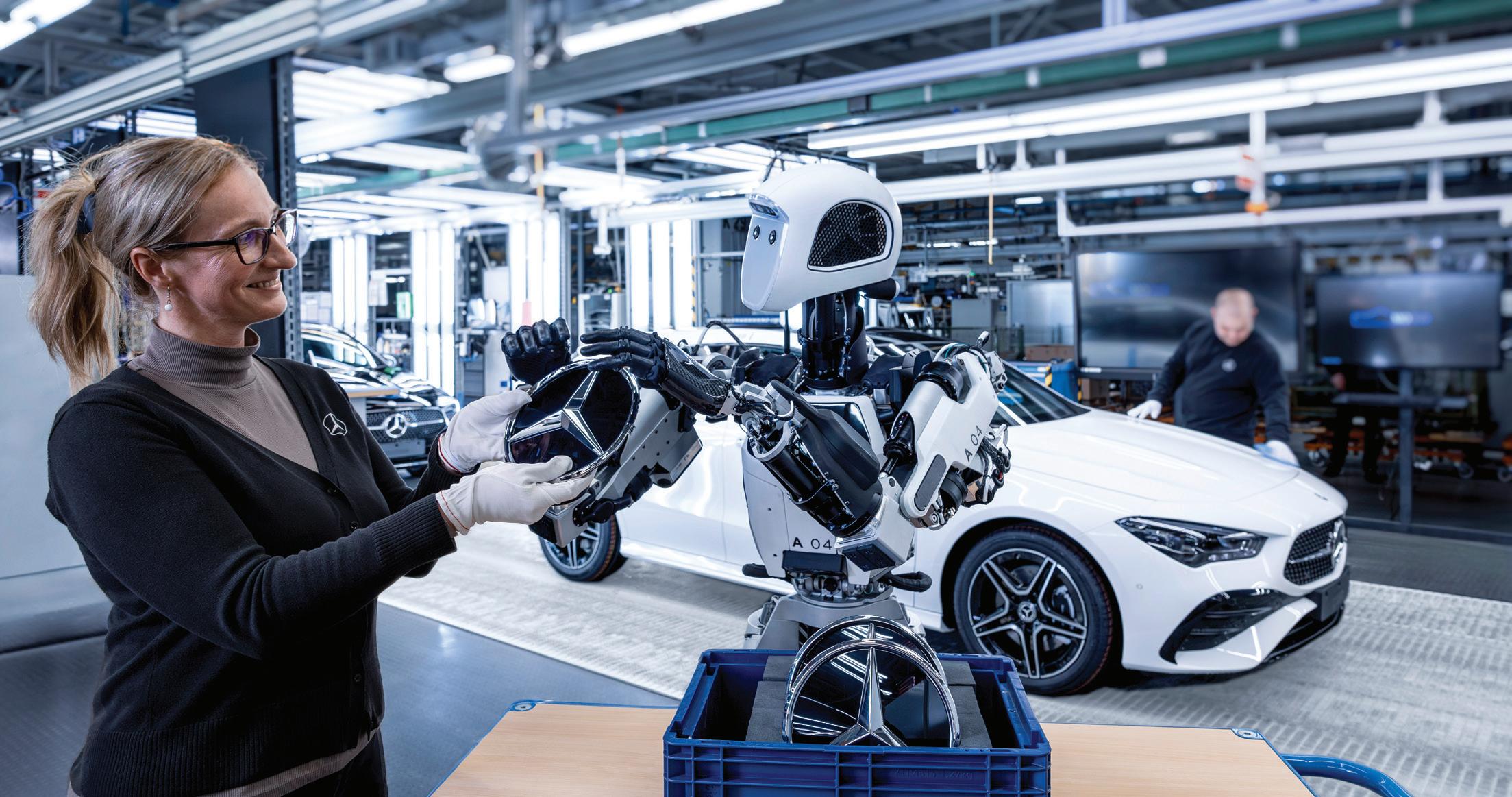

Digit is Robot of the Year 2023 was the year of humanoids, and Agility Robotics has taken an early lead with commercial trials. The company’s Digit humanoid stole the show at ProMAT, where it demonstrated its ability to pick up totes from a shelf, walk over to a conveyor, and place the totes onto the conveyor.

At the time, Agility said the demo was based on a real customer use case. Later in 2023, the company announced pilots with two major customers:

Amazon and GXO Logistics, which claims to be the world’s largest pureplay contract logistics provider. Digit is 5 ft, 9 in. (175 cm) tall, weighs 143 lb. (64.8 kg), and can carry up to 35 lb. (15.8 kg).

Digit’s potential flexibility gives it an edge over other types of robots, including autonomous mobile robots (AMRs) with top modules, according to Adrian Stoch, chief automation officer at GXO.

“The real application here is endto-end product flow throughout the warehouse,” he said. “Until now, solutions have been mostly discrete applications: goods-to-person, sorters, wearable tech. Solving discrete problems in one part of the puzzle.”

We’ve never seen a humanoid perform real tasks in a commercial setting until now. Humanoids have long

Agility Robotics’ Digit humanoid

been relegated to research labs, but the goalposts began to seismically shift in 2023.

Continuing the year of the humanoid, other developers made the 2024 RBR50 list, including Apptronik for Apollo, Boston Dynamics for Atlas, and Figure for Figure 01. All are taking different approaches to locomotion, manipulation, and control, so it will be interesting to continue following these innovators.

Autopicker wins Application of the Year

Cincinnati-based Brightpick, which spun out of Photoneo, was named the inaugural Application of the Year winner. In 2023, Brightpick unveiled Autopicker, which it said is the first commercially available AMR that can pick and consolidate orders directly in warehouse aisles.

Autopicker combines a mobile platform, a robotic arm, machine vision, and artificial intelligence for e-commerce fulfillment. The innovative system’s patented two-tote design enables it to retrieve orders from bins on shelving and pick items to one of its totes. This reduces the need for associates to spend time traveling with carts.

The robot can fulfill orders for everything from cosmetics and

•

•

STEVE CROWE

EXECUTIVE EDITOR

THE ROBOT REPORT

iNTRODUCTION

RBR50

.

www.therobotreport.com 2 THE ROBOT REPORT April 2024

VISUAL GENERATION | ADOBE STOCK

pharmaceuticals to e-grocery items, electronics, polybagged apparel, and spare parts. To do this, Autopicker uses proprietary 3D vision and algorithms trained on more than 500 million picks, as well as machine learning to improve over time.

“On the AI side, this was not possible five to six years ago,” Jan Zizka, co-founder and CEO of Brightpick, told The Robot Report.

“The serious breakthroughs enable machine learning to generalize to unseen items.”

Other companies recognized for warehouse systems included Amazon Robotics, Exotec, Geek+, Instock, KUKA, Mujin, Sereact, and Simbe Robotics. Not only does this demonstrate the demand in this sector, but also the potential of automating new applications.

Electric Sheep named Startup of the Year

Every year, we see robotics startups with promising technologies shut their doors for good. It’s often very difficult to find funding to keep the business running while iterating on a robot and demonstrating its value to new customers.

However, San Francisco-based Electric Sheep’s unique business model allows it to bring in revenue as it takes

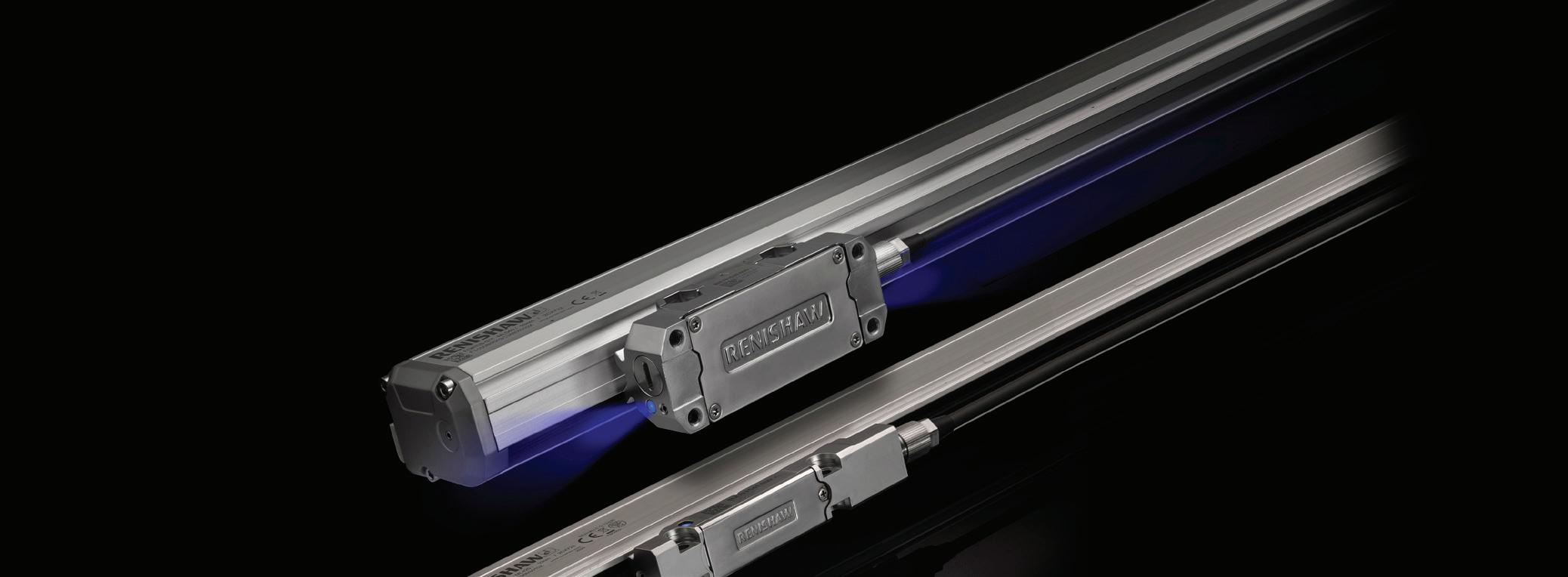

Superior encoders for position and motion control

With a comprehensive line up of encoder solutions, Renishaw brings the expertise needed to address your manufacturing challenges. Whether your application calls for optical, magnetic or laser technology, our encoders achieve the highest levels of accuracy, durability and reliability. Powerfully positioned for innovative motion control.

its time deploying its technology. This business model led to it being named Startup of the Year.

Electric Sheep develops autonomous robots for outdoor maintenance. Its flagship robot is an autonomous mower backed by the company’s ES1 foundation model. Instead of selling or leasing the robots to commercial landscaping businesses, Electric Sheep is becoming vertically integrated by purchasing landscaping companies. This allows it to get to know how these businesses operate and where the robots can best be

RBR50 iNTRODUCTION

partner for innovative manufacturing www.renishaw.com/encoders usa@renishaw.com Renishaw Inc., West Dundee, IL 60118 © 2024 Renishaw Inc. All rights reserved. See us at: Robotics Summit & Expo Booth #114

outdoor maintenance

Your

Brightpick’s Autopicker autonomous robots for

deployed while still bringing in revenue. Once Electric Sheep has decided where the robots can do the most work, its team can start integrating them into operations.

Since implementing this strategy, Electric Sheep said it has grown revenue by eight times. Last year, the company acquired four landscaping businesses, and it said this strategy is key to its longterm plan.

RBR50 winners innovate in several areas

In addition to humanoids, warehouse automation, and a new model for commercialization, this year’s RBR50 demonstrated the growing relevance of generative AI to robotics.

The availability of large language models (LLMs) like OpenAI’s ChatGPT is making new breakthroughs possible.

For example, Sereact released PickGPT, a robotics transformer that combines LLMs with the company’s computer vision technology. The technology allows robot operators to instruct the company’s pick-and-place robots using natural language. Agility Robotics and Boston Dynamics produced interesting demos using generative AI, while Toyota Research Institute is building large behavior models to enable robots to more quickly learn new tasks.

Other notable winners include Harvard University’s development of a soft exoskeleton that helped a 73-yearold man with Parkinson’s walk without freezing. And Seattle-based startup Glidance developed a robot that offers autonomous mobility assistance for the visually impaired. RR

SPONSORS

A NEW GENERATION OF ROTARY ENCODERS

Meet POSITAL’s Updated and Improved IXARC Encoders

New TMR sensor technology and upgraded processors offer enhanced performance and better energy efficiency.

Incremental encoders are programmable for extra versatility: Resolution and communications interfaces are can be easily customized to meet your exact requirements.

Muliturn absolute models feature updated Wiegand sensors and a new ASIC for optimized batteryfree rotation counting

More NEXTGEN product announcements coming soon!

5 THE ROBOT REPORT April 2024 www.therobotreport.com

www.posital.com

Editorial Director The Robot Report

Crowe Executive Editor The Robot Report

Wessling Associate Editor The Robot Report

Oitzman Editor The Robot Report

Eugene Demaitre

Steve

Brianna

Mike

Organization Category

ABB Robotics Application

Advanced Construction Robotics Application

Agility Robotics Robot of the Year

Amazon Robotics Technology

Ambi Robotics Technology

Apptronik Technology

Boston Dynamics Technology

Brightpick Application of the Year

Capra Robotics Application

Dexterity Application

Disney Technology

Doosan Technology

Electric Sheep Startup of the Year

Exotec Application

FANUC Business

Figure Technology

Fraunhofer Institute for Material Flow and Logistics Technology

Gardarika Tres Application

Geek+ Business

Glidance Application

Harvard University Application

ifm efector Technology

igus Technology

Instock Technology

Kodama Systems Application

Kodiak Robotics Application

KUKA Business

Locus Robotics Application

MassRobotics

Accelerator Business

Mecademic Technology

MIT Technology

Mujin Application

Mushiny Technology

Innovation

Modular industrial robot arms offer game-changing flexibility

IronBOT makes rebar installation faster, safer

Digit humanoid gets feet wet with logistics work

Amazon strengthens robotics portfolio with heavy-duty mobile robot

AmbiSort uses real-world data to improve picking

Apollo humanoid features bespoke linear actuators

Atlas shows off unique skills for humanoid

Autopicker applies mobile manipulation, AI to warehouses

Hircus AMR bridges gap between indoor, outdoor logistics

Dexterity stacks robotics and AI for truck loading

Disney brings beloved characters to life through robotics

App-like Dart-Suite eases cobot programming

Vertical integration positions landscaping startup for success

Skypod ASRS scales to serve automotive supplier

FANUC ships one-millionth industrial robot

Startup builds working humanoid within one year

evoBot features unique mobile manipulator design

Develops de-mining robot for Ukraine

Upgrades PopPick goods-to-person system

Provides independence to visually impaired individuals

Exoskeleton improves walking for people with Parkinson’s disease

Obstacle Detection System simplifies mobile robot development

ReBeL cobot gets low-cost, human-like hand

Instock turns fulfillment processes upside down with ASRS

Startup uses robotics to prevent wildfires

Autonomous pickup truck to enhance U.S. military operations

Robotic arm leader doubles down on mobile robots for logistics

Mobile robot leader surpasses 2 billion picks

Equity-free accelerator positions startups for success

MCS500 SCARA robot accelerates micro-automation

Robotic ventricle advances understanding of heart disease

TruckBot accelerates automated truck unloading

Intelligent 3D sorter ramps up throughput, flexibility

www.therobotreport.com 6 THE ROBOT REPORT April 2024

Organization Category

Mushiny Technology

NASA Technology

Neya Systems Technology

NVIDIA Technology

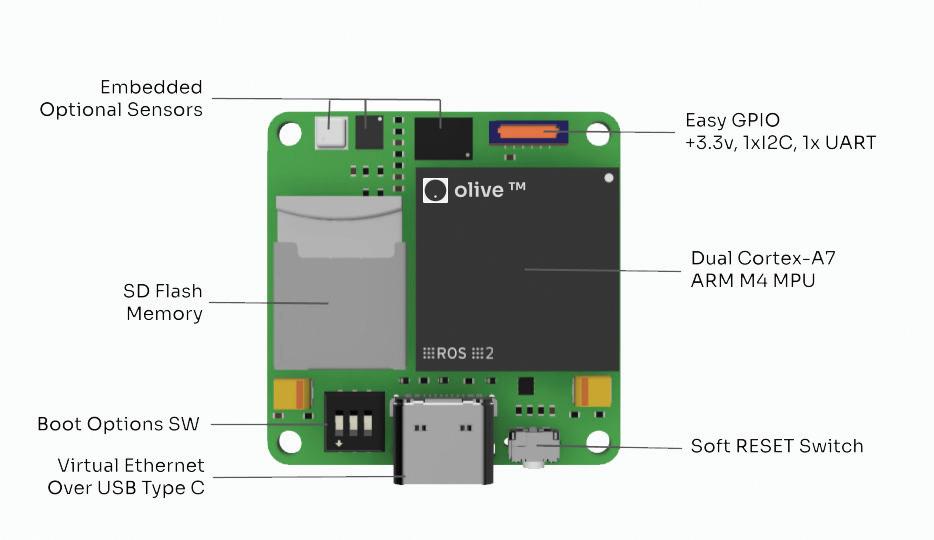

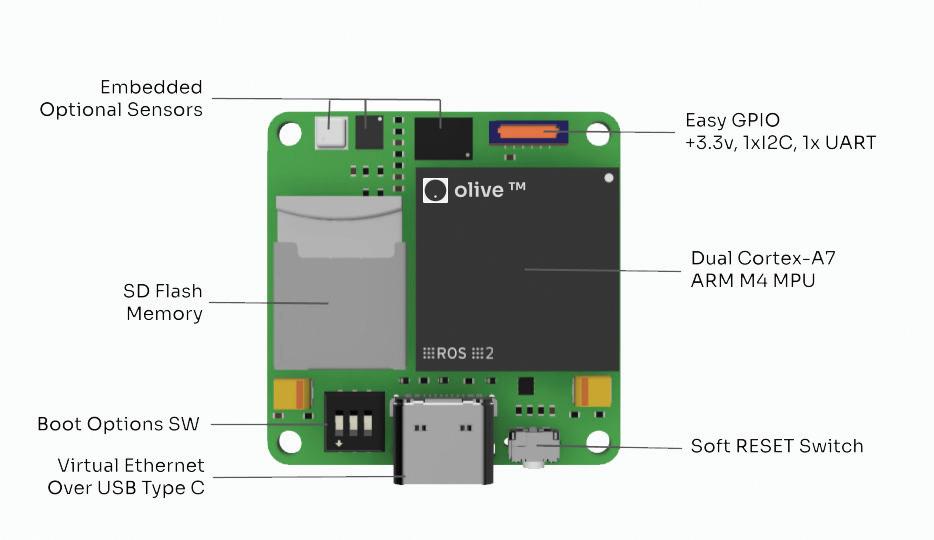

Olive Robotics Technology

OpenAI Technology

Opteran Technology

Renovate Robotics Application

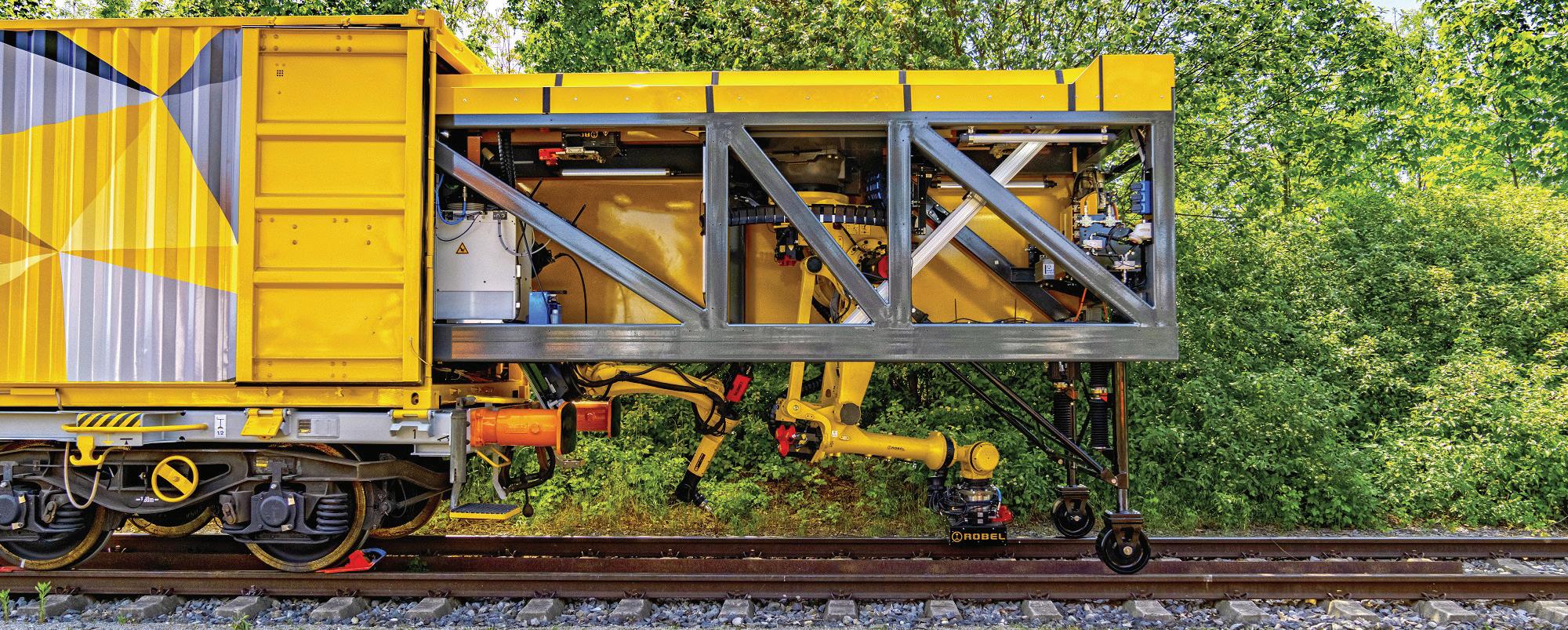

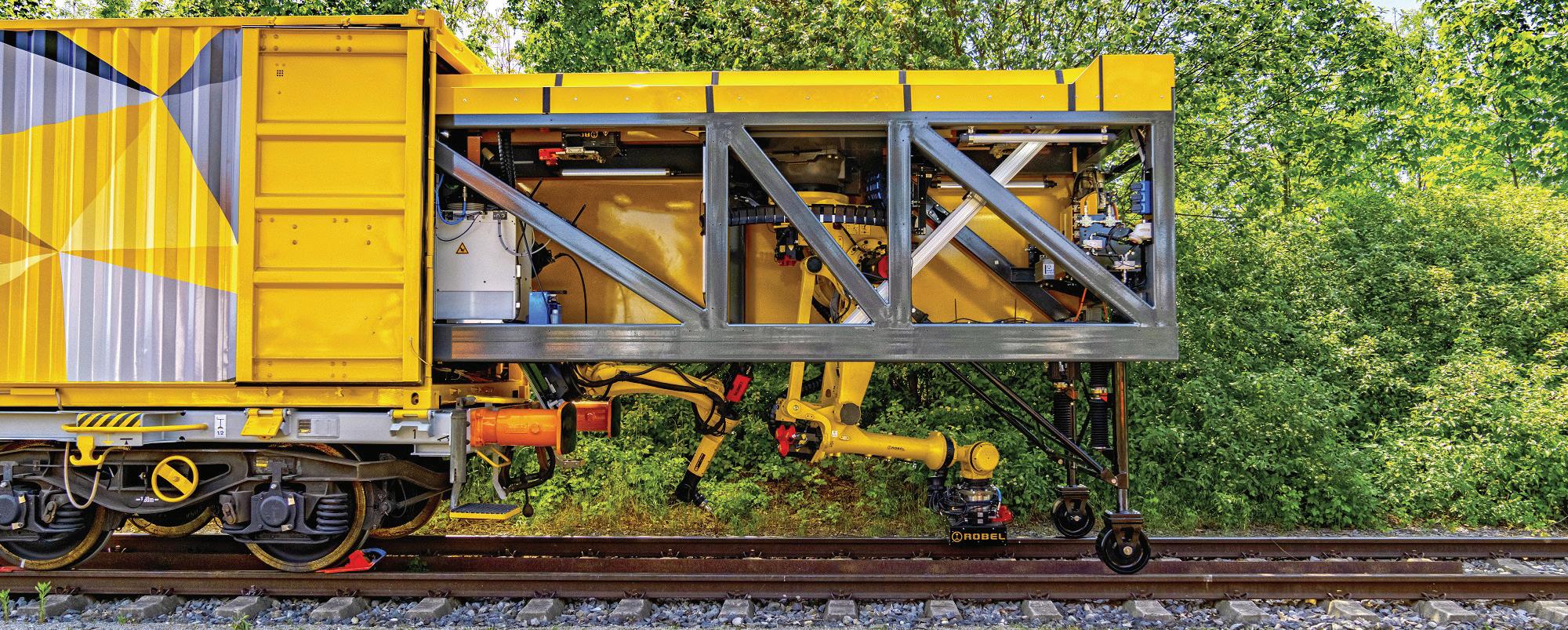

Robel Application

Robust AI Technology

Rockwell Automation Business

Sereact Technology

Simbe Robotics Application

Slip Robotics Application

Symbotic Application

Toyota Research Institute Technology

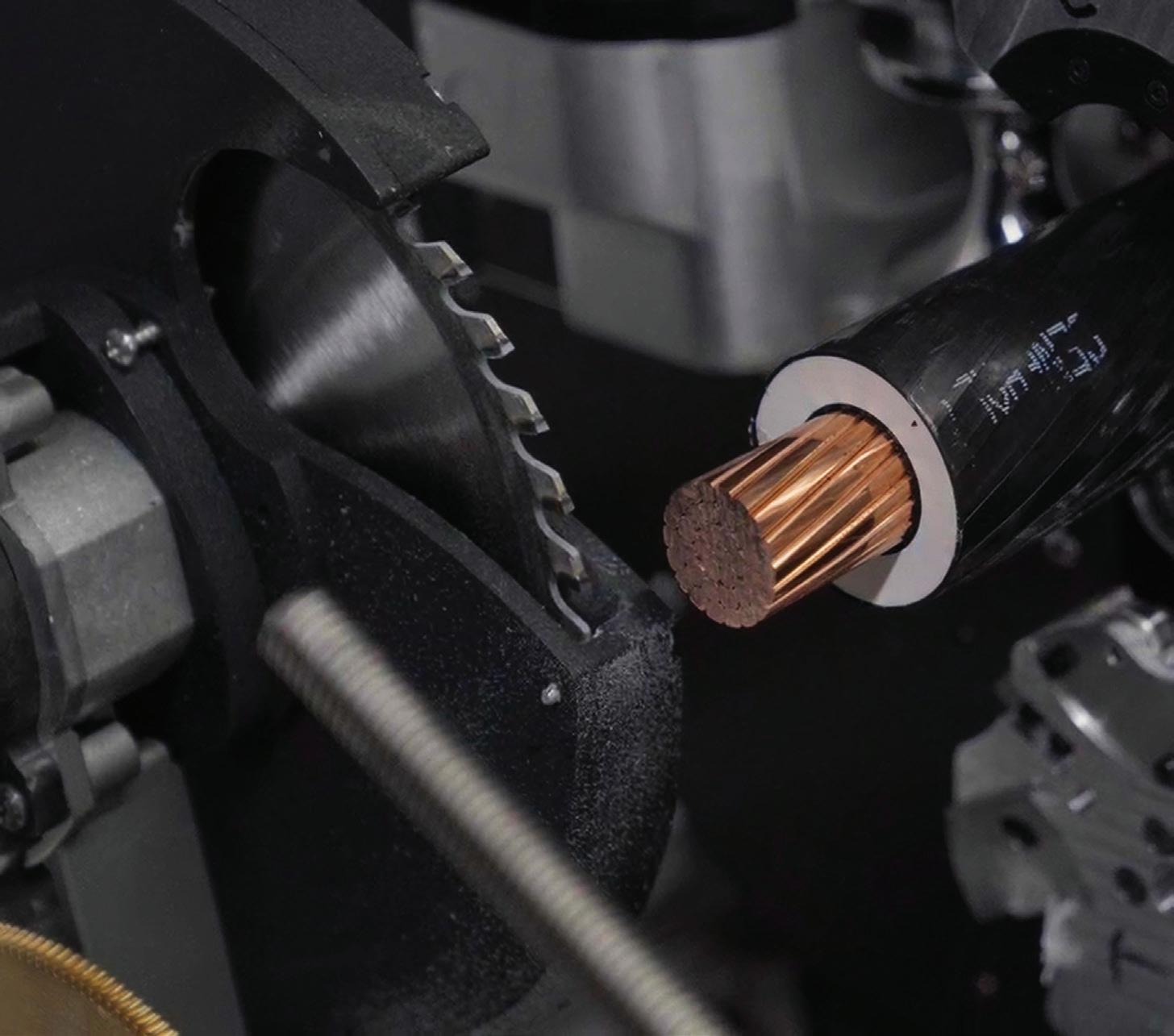

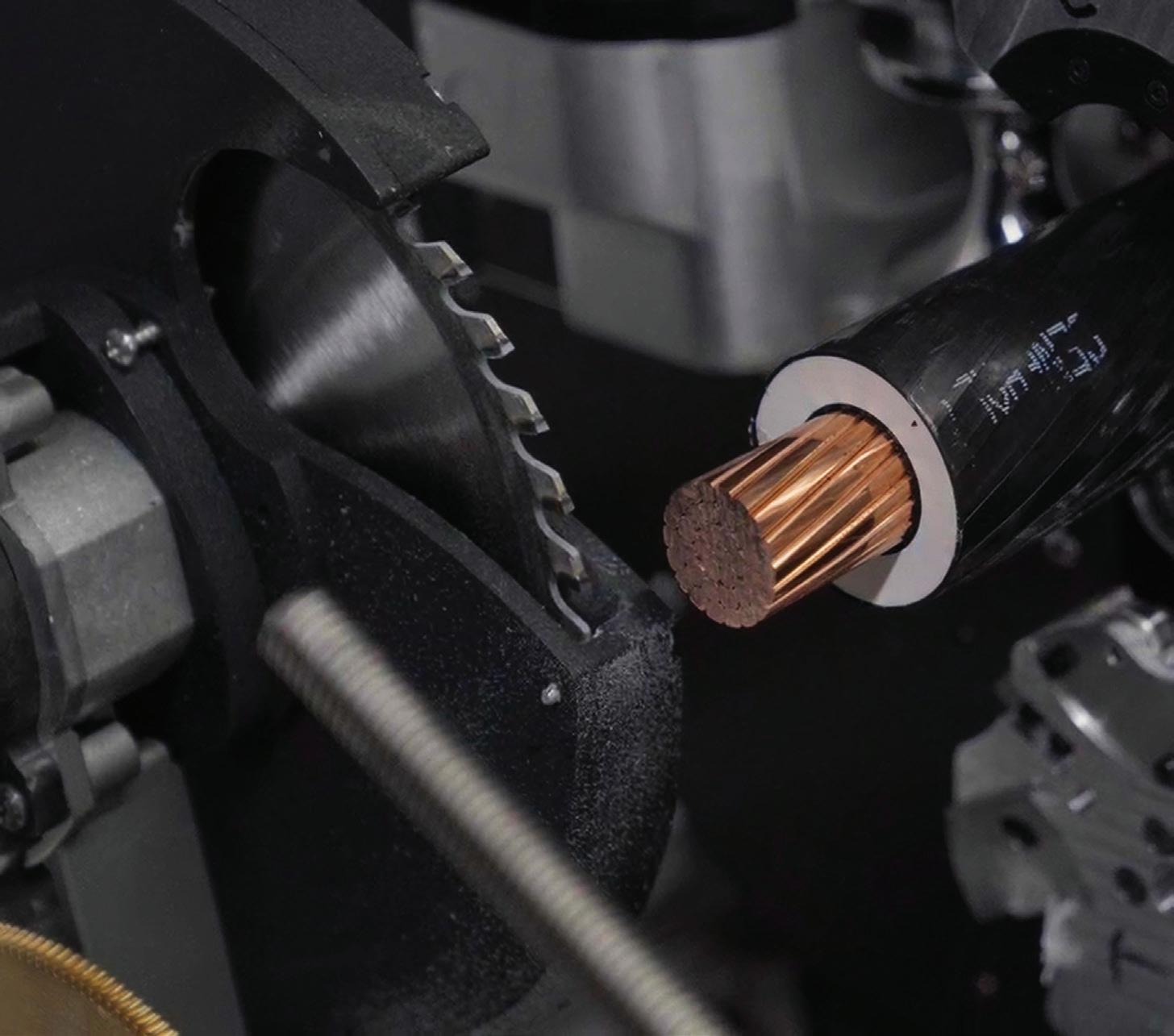

ULC Technologies Application

Universal Robots Technology

Innovation

Intelligent 3D sorter ramps up throughput, flexibility

MOXIE completes historic oxygen-making mission on Mars

Development of cybersecurity standards harden AGVs

Nova Carter gives mobile robots all-around sight

EdgeROS eases robotics development process

LLMs enable embedded AI to flourish

Applies insect intelligence to mobile robot navigation

Rufus robot automates installation of roof shingles

Automates railway repairs to overcome labor shortage

Carter AMR joins DHL’s impressive robotics portfolio

Adds OTTO Motors mobile robots to manufacturing lineup

PickGPT harnesses power of generative AI for robotics

Scales inventory robotics deal with BJ’s Wholesale Club

Simplifies trailer loading/unloading with heavy-duty AMR

Walmart-backed company rides wave of logistics automation demand

Builds large behavior models for fast robot teaching

Cable Splicing Machine improve safety, power grid reliability

Cobot leader strengthens lineup with UR30

www.therobotreport.com 8 THE ROBOT REPORT April 2024

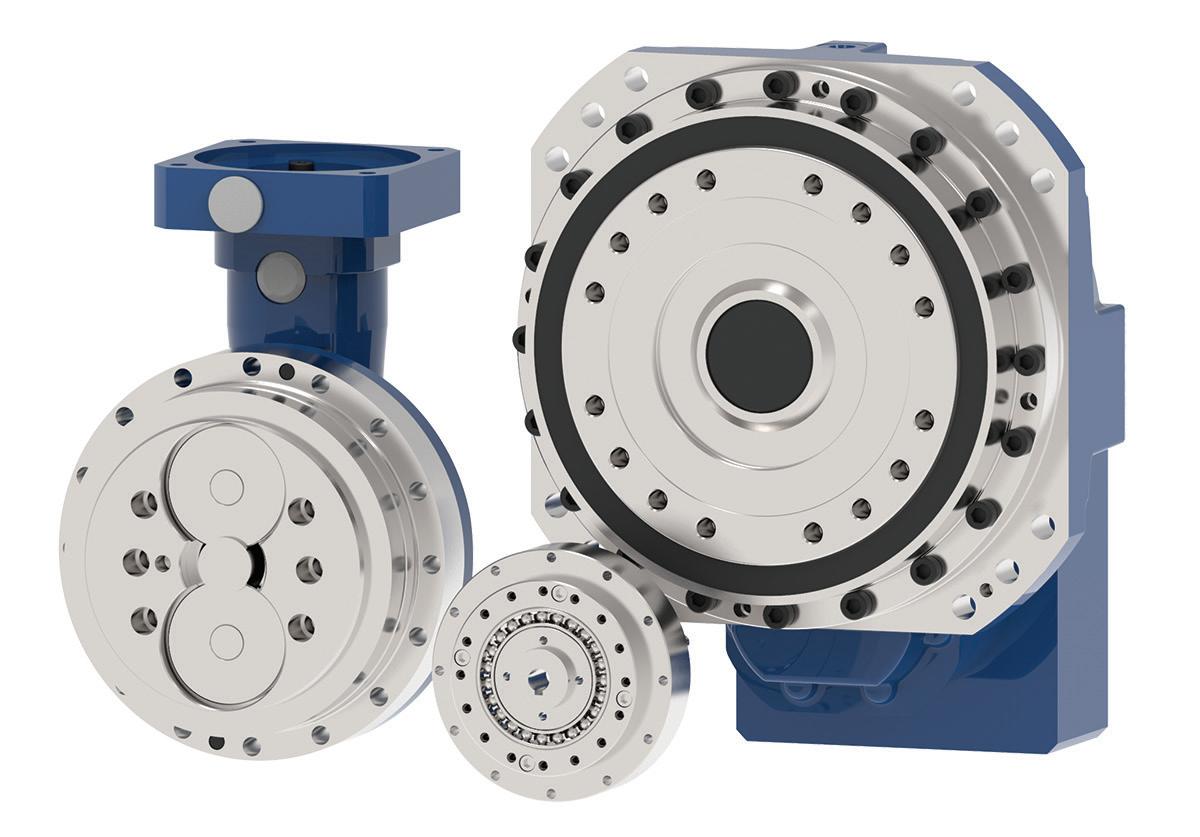

GAM’s broad range of standard robotic flange gearboxes, servo gearboxes, rack and pinion, and other automation products, along with our engineering expertise and manufacturing flexibility, provide the building blocks for the right solution to your specific application. GAM Can. ®

www.gamweb.com/custom | info@gamweb.com | 888.GAM.7117 Collaborate with GAM and make your job easier.

Miniature

Zero-Backlash,

Standard NEMA 17 Inline Planetary Gearbox Standard 35 mm Spiral Bevel Right Angle Gearbox Standard Size 017 Strain Wave Zero-Backlash Gearbox

- Customer Collaboration

Medical Robotics Application:

Right Angle,

Robotic Flange Gearbox

GAM

ABB modular industrial robot arms offer game-changing flexibility

ABB Robotics released its first modular industrial robot arms in 2023. Its fifth generation robots expanded the company’s large robot range with four new models. These models, however, include 22 different variants to offer ABB’s customers more choices, increased coverage, and greater performance.

The IRB 6710, IRB 6720, IRB 6730, and IRB 6740 have payloads ranging from 150 kg to 310 kg and reaches from 2.5 m to 3.2 m. What makes these robots innovative is that all 22 models are based on the same modular design. All of the components are standardized across all model platforms, including

Organization Name: ABB Robotics

Country: U.S.

Website: abb.com

Year Founded: 1974

Number of Employees: 500+

Innovation Category: Technology

the base, lower arm, upper arm, and wrist. All of the robots having the same footprint means installation is faster, more convenient, and more flexible.

All of the modules, or building blocks, share the same linkages or interfaces, allowing ABB to offer a greater range of robot models more efficiently. The company said these modules help it maintain a more manageable supply chain of components, allowing it to deliver builtto-order robots far more quickly and economically.

The result is shorter lead times for customers and more flexible robots. Customers can order an ABB robot

model that exactly matches the specifications of their application. And if things change in the future, they can simply change out robot components to modify the robot’s capabilities.

This lets ABB’s customers know they’re not sinking money into something that won’t be able to adapt as their business grows. For example, within the electric vehicle industry, manufacturers will likely need to ramp up production in the coming years. These manufacturers can choose from a wide range of ABB robots to ensure they have the right variant to handle batteries of varying sizes. RR

www.therobotreport.com 10 THE ROBOT REPORT April 2024

www.ids-imaging.us

IronBOT makes rebar installation faster, safer

Rebar is a steel bar used as a tension device in reinforced concrete or masonry. It’s an essential part of many construction projects, but it can be time-consuming and labor-intensive to install. According to OSHA, 61% of construction accidents are due, in part, to rebar.

Last year, Advanced Construction Robotics released its second rebarinstalling robot, IronBOT. While its first robot, TyBOT, self-ties horizontal rebar intersections, IronBOT lifts, carries, and places rebar. IronBOT can lift up to 5,000-lb bundles of rebar in a transverse or longitudinal orientation without requiring any heavy lifting from crew members.

IronBOT doesn’t require any preprogramming, pre-mapping, calibration, or BIM input. Once it’s on site, it can begin working within four to eight hours, the company claimed. It also automates rebar placement based on the customer’s spacing requirements.

IronBOT completed its inaugural project alongside TyBOT in February on the Port St. Lucie West Boulevard Bridge in Port St. Lucie, FL. The robots completed the project alongside Shelby Erectors, a construction company that specializes in building bridges.

The team originally estimated that rebar installation would take 14 days, but when augmenting Shelby’s crew with robots, the same amount of work took only seven days. During the pilot

Organization Name: Advanced Construction Robotics

Country: U.S.

Website: constructionrobots.com

Year Founded: 2016

Number of Employees: 1-10

Innovation Category: Application

project, IronBOT placed 147,032 lb of rebar, and TyBOT completed 58,068 ties over 6.5 production shifts.

IronBOT can work at any time of day or night, even in the rain. With the robot, workers can steer clear of rebar installations, ensuring their safety and

freeing them up to do higher-level tasks on the construction site. Its flexible design means it can work on almost any construction site and can be installed quickly, making it a potential gamechanging robot for the construction industry. RR

www.therobotreport.com 12 THE ROBOT REPORT April 2024

more

EXPO

Sponsorship opportunities are available for future DeviceTalks and Robotics programs. For

information, contact Colleen Sepich. 857.260.1360 | csepich@wtwhmedia.com SUMMIT &

DISCOVER THE LATEST ADVANCEMENTS IN

Agility Robotics’ Digit humanoid wins inaugural Robot of the Year Award

2023 was the year of humanoids, and it all started thanks to Agility Robotics. Its Digit humanoid stole the show at ProMat, where it demonstrated its ability to pick up totes from a shelf, walk over to a conveyor, and place the totes onto the conveyor.

At the time, Agility said the demo was based on a real customer use case. Later in 2023, Agility announced pilots with two major customers: Amazon and GXO Logistics, which claims to be the world’s largest pure-play contract logistics provider. Digit is 5 ft 9in (175cm) tall, weighs 143 lbs, and carries up to 35 lbs.

In October, Amazon and Agility announced Digit was being tested at Amazon’s robotics research and development facility outside of Seattle. The initial use of Digit is to help employees with tote recycling, a highly repetitive process of picking up and moving empty totes once inventory has been completely picked out of them.

In December 2023, GXO announced Digit is being tested on logistics tasks at a SPANX facility in Georgia. Digit is moving totes filled with products off of autonomous mobile robots (AMRs) and onto a conveyor. Agility said at the time that Digit will communicate with the AMR fleet manager in the future.

Adrian Stoch, GXO’s chief automation officer, said Digit’s potential flexibility gives it a nod over other types of robots, including AMRs with top

Organization Name: Agility Robotics

Country: U.S.

Website: www.agilityrobotics.com

Year Founded: 2015

Number of Employees: 101-500

Innovation Category: Robot of the Year

modules. “The real application here is end-to-end product flow throughout the warehouse,” he said. “Until now, solutions have been mostly discrete applications: goods-to-person, sorters, wearable tech. Solving discrete problems in one part of the puzzle.”

For companies operating fulfillment centers with a wide product mix or fluctuating demand, the potential

flexibility of humanoids could help fill the ongoing labor crisis.

We’ve never seen a humanoid perform real tasks in a commercial setting, until now. Humanoids have long been relegated to research labs, but the goalposts began to seismically shift in 2023. Congratulations to Agility Robotics for winning the inaugural Robot of the Year Award. RR

www.therobotreport.com 14 THE ROBOT REPORT April 2024

Amazon strengthens robotics portfolio with heavy-duty AMR mobile robot

Amazon is the world’s largest user of industrial robots. It has deployed more than 750,000 robots to help fulfill customer orders. According to the Seattle-based e-commerce giant, more than 75% of all customer orders globally are delivered with the help of robots.

That number is only going to increase going forward with the introduction of robots like Titan, Amazon’s new mobile robot. Titan can transport heavy-duty payloads up to 2,500 lb. (1,133.9 kg). That is two times more than Hercules, which is Amazon’s most broadly deployed mobile robot.

Organization Name: Amazon Robotics

Country: U.S.

Website: amazon.jobs/en/teams/amazon-robotics

Year Founded: 2003

Number of Employees: 501-1000

Innovation Category: Technology

Titan integrates several technologies from Amazon’s other mobile robots for battery management, computer vision, obstacle detection, and user control. It can also integrate with other robots Amazon uses throughout its facilities by using familiar hardware components to manage its operating system “as it plans, executes, and interfaces with other technologies.”

Amazon said its SAT1 fulfillment center in San Antonio, Texas, is the first to deploy Titan. It will work with other robots to move heavy objects, including small household appliances or pallets of pet food and gardening equipment, and allow

people to focus on new tasks.

While there are other heavy-duty mobile robots on the market, Amazon developing and deploying Titan in its facilities proves these robots are ready for primetime. Titan increases the number of SKUs Amazon can move via robotics, meaning it could be another game-changing robot for Amazon, joining the likes of Hercules, Pegasus, Proteus, Robin, and more. Titan is a continuation of Amazon’s decades of robotics research to better serve its customers and create a better workplace for its employees. RR

15 THE ROBOT REPORT April 2024 www.therobotreport.com

Ambi Robotics leverages real-world data for more flexible picking solution

Ambi Robotics released its AmbiSort B-Series in 2023, an updated version of its flagship robot with some impressive new features. With robots deployed across the U.S. in over a dozen states, and running through the entire 2022 peak holiday season, Berkeley, Calif.based Ambi Robotics was able to leverage the extensive real-world data it gathered to add new capabilities to AmbiSort.

AmbiSort B-Series is the company’s entry into automated induction, middlemile sortation, and reverse logistics. The new sort-to-gaylord system can handle up to 1,200 sorts per hour. Additionally, it can be used in various use cases,

Organization Name: Ambi Robotics

Country: U.S.

Website: ambirobotics.com

Year Founded: 2018

Number of Employees: 101-500

Innovation Category: Technology

such as reverse logistics, zone skipping, and AI-vision quality control, making it one of the more configurable systems available in today’s market.

This new system is built around the AmbiSort bin-picking capabilities the company introduced with its previous A-Series robot. It includes an industrial robot, an overhead vision system, and AI-driven perception software.

All of Ambi Robotics’ solutions run on its proprietary operating system, AmbiOS. This system teaches robots in simulation and transfers its deep neural network advancements to physical world systems by leveraging breakthroughs in Sim2Real technology.

The company makes its system even more robust with AmbiAccess. This platform comes with a suite of operation-enhancing applications to make customers’ lives easier. This new customer portal doesn’t just provide data visibility, it gives customers comprehensive insights and advanced analytics and leverages historical data and trends.

In all, Ambi Robotics’ AmbiSort B-Series builds on the company’s already successful system to provide customers with more flexibility, more capabilities, and a better understanding of their current operations. RR

www.therobotreport.com 16 THE ROBOT REPORT April 2024

Apptronik releases humanoid robot with bespoke linear actuators

In August 2023, Apptronik released Apollo, the company’s first commercial version of a bipedal humanoid robot. Apptronik is no stranger to the development of legged robotics, having built multiple generations of exoskeletons for the U.S. defense department.

These projects helped the company develop the kinematics, mechanical and electrical expertise to support the venture into bipedal robotics.

Organization Name: Apptronik

Country: U.S.

Website: apptronik.com

Year Founded: 2016

Number of Employees: 101-500

Innovation Category: Technology

The company's primary intellectual property is linear actuation. Apollo includes several linear actuators for its leg and arm joints. Apollo uses linear actuators for joints such as the elbow and knee, in contrast to competitors who have opted for rotary motors and gear trains.

By offering a sixth generation of motors, Apptronik has surpassed rivals like Tesla in this area. Not only does this improvement make things cheaper,

it also makes the supply chain more reliable and the manufacturing process more scalable, which is important for expanding Apollo's uses beyond factories. Building a low-cost linear actuator is a big step forward for Apptronik that will make this growth possible. RR

17 THE ROBOT REPORT April 2024 www.therobotreport.com

Atlas demo unique manipulation, mobility skills for humanoid

With all the momentum around commercializing humanoids, it seems many have forgotten about Boston Dynamics’ Atlas. The prototype has always served as an R&D platform, with certain technologies eventually making their way into the company’s other robots, Spot and Stretch.

In January 2023, Boston Dynamics released a video showing Atlas performing a task at a mock construction site inside its Waltham, Mass. headquarters. A “construction worker” atop a scaffold left his toolbag on the ground. Instead of hopping down to get the tools himself, Atlas brings the tools to him.

Atlas, using a claw gripper, picks up and manipulates a wooden plank to create a bridge for itself onto the scaffold. It then picks up a toolbag, runs onto the scaffold, spins around, and throws the toolbag up to the construction worker. Atlas then pushes a wooden box off the scaffold and flips and twists its way to the ground.

“The dream of humanoids is that they should be able to do all the things that we do, right?” Scott Kuindersma, Boston Dynamics’ team lead on Atlas, said in a behind-the-scenes video about the construction site demo. “A humanoid robot will be well suited for applications like manufacturing, factory work, construction - [places] where a humanoid form factor actually fits very

Organization Name: Boston Dynamics

Country: U.S.

Website: www.bostondynamics.com

Year Founded: 1992

Number of Employees: 101-500

Innovation Category: Technology

well, with its bi-manual nature, its ability to stand upright, move heavy things around, and work in spaces that were traditionally designed for humans to do work in.”

At press time, Boston Dynamics hadn’t disclosed any plans to

commercialize Atlas. But this video, and many previous ones, should be a reminder about Atlas’ leading mobility and manipulation skills. And if a commercial version of Atlas ever comes to market, it’d likely jump to the front of the pack. RR

www.therobotreport.com 18 THE ROBOT REPORT April 2024

Autopicker applies mobile manipulation and AI for warehouse flexibility

Organization Name: Brightpick

Country: U.S.

Website: brightpick.ai

Year Founded: 2021

Number of Employees: 101-500

Innovation Category: Application of the Year

Each picking and mobile manipulation have been challenging for robotics developers. In 2023, Brightpick unveiled Autopicker, which it said is the first commercially available autonomous mobile robot (AMR) that can pick and consolidate orders directly in warehouse aisles.

Autopicker combines a mobile platform, a robotic arm, machine vision, and artificial intelligence for e-commerce fulfillment. The innovative system’s patented two-tote design enables it to retrieve orders from bins on shelving and pick items to one of its totes. This reduces the need for associates to spend time traveling with carts.

The robot can fulfill orders for everything from cosmetics and pharmaceuticals to e-grocery items, electronics, polybagged apparel, and spare parts. To do this, Autopicker uses proprietary 3D vision and algorithms trained on more than 500 million picks, as well as machine learning to improve over time.

Based in Cincinnati, Brightpick is a business unit of machine vision provider Photoneo.

“On the AI side, this was not possible five to six years ago,” Jan Zizka, co-founder and CEO of Brightpick, told The Robot Report. “The serious breakthroughs enable machine learning to generalize to unseen items.”

Brightpick also offers a goods-toperson option for heavy or hard-to-pick items. Autopicker can raise its bins to waist height for ergonomic picking.

By working with standard shelves, the AMR can be deployed in less than a month, and warehouses can reconfigure storage as needed. The system also supports pallet picking, replenishment, dynamic slotting, buffering, and dispatch. It can store up to 50,000 SKUs.

Last year, Brightpick went from raising additional funding to deploying Autopicker at Netrush, Rohlik Group, and other customers. The system is available for direct purchase or through a robotics-as-a-service (RaaS) model. RR

19 THE ROBOT REPORT April 2024 www.therobotreport.com

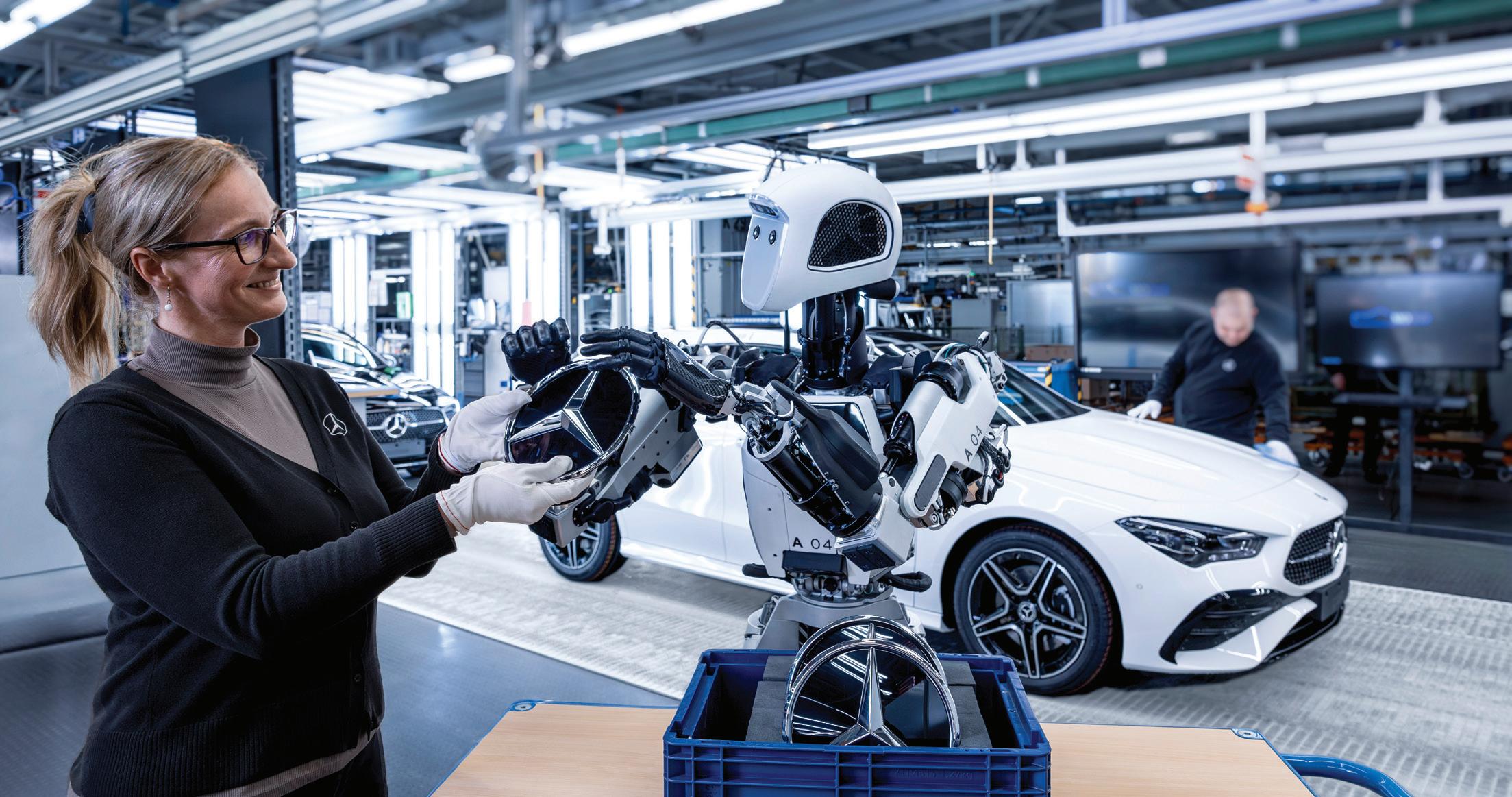

Capra Robotics bridges gap between VELUX’s indoor, outdoor logistics

Capra Robotics introduced the Capra Hircus, an autonomous mobile robot (AMR) designed to navigate challenging terrain with ease, thanks to its patented kinematic model and four-wheel chassis. This robot can carry various types of loads while moving across rough and uneven surfaces.

The Hircus AMR has the unique

Organization Name: Capra Robotics

Country: Denmark

Website: capra.ooo

Year Founded: 2019

Number of Employees: 11-50

Innovation Category: Application

keep it on its path. The system uses cameras for obstacle detection and avoidance.

VELUX, a Danish window manufacturer, had the challenge of transporting payloads and material weighing up to 500 kg within and between their manufacturing facilities in Skjern, Denmark. The company sought a unified solution to address this issue.

The Capra Hircus, in combination with a detachable cart solution from partner ROEQ, proved to be the ideal

fit for VELUX's requirements. The Capra solution has been incorporated into current operations, with tasks from the central management system sent to the robot through the Capra Fleet Manager using the standardized VDA5050 interface.

Workers can stage and queue raw materials, work in process, and finished goods on the carts, and then schedule the robots to pick and move between manufacturing areas.

The movement process is completely automated as the robot autonomously controls gates and doors along the way, giving them access to the outside world, and then back indoors once they arrive at their destination.

VELUX said it sees immense potential in bridging the gap between indoor and outdoor transport. It added that integrated gate control, automated pick-up and drop-off, and wireless charging were among the reasons Hircus was the obvious solution to this end. RR

www.therobotreport.com THE ROBOT REPORT April 2024

Dexterity stacks robotics and AI for truck loading

Loading trucks and trailers is a thankless task, requiring workers to repeatedly move boxes of all sizes. Dexterity Inc. has been working with FedEx Corp. and Sagawa Express Co., among others, to automate this process.

Truck unloading requires people or robots to pick from the top and work their way down. By contrast, loading is like “playing 3D Tetris with up to 50-lb. boxes,” said the Redwood City, Calif.based company.

Dexterity has developed DexR, a two-armed robot that uses machine vision, force sensing, and integrated motion planning to pick up a range of items, from stiff cardboard to soft plastic. The mobile system also uses machine learning to get better at packing trailers over time.

The system can autonomously drive in and out of trailers as it loads or unloads. DexR does not require presequencing to stack boxes into stable walls, the company said.

“Based on feedback from our operations team, we have been looking for a solution that helps alleviate the challenges of truck loading,” stated Rebecca Yeung, corporate vice president of Operations Science and Advanced Technologies at FedEx. “Collaborating with Dexterity AI to combine the latest in AI and robotics

Organization Name: Dexterity

Country: U.S.

Website: dexterity.ai

Year Founded: 2017

Number of Employees: 101-500

Innovation Category: Application

supports our operations team while meeting growing customer demand.”

Dexterity noted that DexR integrates with existing warehouse doors and conveyors, and it can operate at speed in tight spaces. The company said it has built on its experience in singulation and induction, palletization and depalletization, and robotic print and apply.

In addition, Dexterity provides fleet management and data analytics capabilities. It is working with Sumitomo as a distributor for its robotics-as-aservice (RaaS) offering in Japan, with a goal of deploying 1,500 systems by 2026. RR

21 THE ROBOT REPORT April 2024 www.therobotreport.com

Disney develops new approach for building robotic characters

Disney Research has long been at the intersection of imagination and cuttingedge technology. And it outdid itself again in late 2023 when it unveiled a new robot that wandered through Disneyland California’s Star Wars: Galaxy’s Edge. The robot didn’t have a name yet at press time, but it seems to be inspired by the BD-1 from the Star Wars Jedi: Fallen Order video game.

Moritz Bächer, associate lab director at Disney Research in Zurich, led development of the robot. It combines modular hardware, learning software, and 3D printing. The robot’s head has four degrees of freedom to look up, down, around, and tilt. It also has five degree-of-freedom legs with hip joints that allow it to walk while dynamically balancing.

And the robot can do more than walk. Disney Research engineers and Walt Disney Imagineering Research & Development animators worked closely together to ensure that it can convey emotions by strutting, prancing, or trotting around. To do this, the company developed a reinforcement learning-based pipeline that relies on simulation to combine and balance the vision of an animator with legged locomotion.

Disney is exploring how its robotic characters can enhance the park experience for customers. And these recognizable, charismatic robots could be just the tip of the iceberg.

Organization Name: Disney Research

Country: U.S.

Website: disneyresearch.com

Year Founded: 2008

Number of Employees: 101-500

Innovation Category: Technology

Disney’s researchers said its new development techniques should significantly reduce the time needed to train a robot on new behaviors. Bächer claimed Disney can now develop new robotic characters in months rather than years.

We’ve never seen robots like these before, but we could soon start seeing more robotic versions of Disney’s most beloved characters interacting with us in its parks. RR

www.therobotreport.com 22 THE ROBOT REPORT April 2024

Doosan Robotics’ app-like DartSuite eases cobot programming

Organization Name: Doosan Robotics

Country: South Korea

Website: www.doosanrobotics.com

Year Founded: 2015

Number of Employees: 101-500

Innovation Category: Technology

How is a robot like a smartphone? Both are platforms that can be programmed for multiple tasks. However, mobile apps allow users to tap into a wide range of activities, while robots typically require experienced engineers for specialized applications by industry. By contrast, Doosan Robotics’ Dart-Suite aims to provide a “holistic and democratized environment for users of all types.”

The robot ecosystem is intended to enable users of collaborative robots to download an app, install it, and use it, all without prior expert knowledge. DartSuite allows for multitasking.

For example, a coffee shop could use a single cobot to act as a barista in

the morning, prepare lunch menus at midday, and serve beer as a bartender in the evening. In addition, Dart-Suite allows robots to be used across fields, such as food and beverage, logistics, agriculture, and manufacturing.

Doosan noted that Dart-Suite, which it developed last year, has an integrated development environment (IDE) that allows customers to create modules for their specific needs. The IDE includes drag-and-drop artificial intelligence functionality to reduce the time of development by as much as 80%, as well as to cut the cost of integration.

While many robots today get software updates through wired connections or

USB, Dart-Suite provides over-the-air (OTA) updates for easier management of operating systems and software.

The company developed a recycling system with Dart-Suite that it dubbed “Oscar the Sorter,” which was later recognized by the Consumer Technology Association. TDK Qeexo applied machine learning and vision plus the compliant grippers to materials handling.

Dart-Suite can increase the range and number of tasks that cobots can do, expanding the number of industries that can deploy automation. RR

23 THE ROBOT REPORT April 2024 www.therobotreport.com

Vertical integration positions Electric Sheep for long-term success

Every year, we see robotics startups with promising technologies shut their doors for good. It’s often very difficult to find funding to keep the business running while iterating on a robot and demonstrating its value to new customers.

However, San Francisco-based Electric Sheep’s unique business model

Organization Name: Electric Sheep

Country: U.S.

Website: sheeprobotics.ai

Year Founded: 2019

Number of Employees: 51-100

Innovation

Category: Startup of the Year

allows it to bring in revenue as it takes its time deploying its technology. This business model led to it winning our inaugural Startup of the Year Award.

Electric Sheep develops autonomous robots for outdoor maintenance. Its flagship robot is an autonomous mower backed by the company’s ES1 foundation model. Based on recent

advances in generative AI, ES1 is a learned-world model that enables reasoning and planning for the company’s robots.

Instead of selling or leasing the robots to commercial landscaping businesses, Electric Sheep is becoming vertically integrated by purchasing the landscaping companies. This allows Electric Sheep to get to know how these businesses operate and where the robots can best be deployed while still bringing in revenue. Once it’s decided where the robots can do the most work, the team can start integrating them into operations.

Electric Sheep’s strategy isn’t just about revenue. The businesses it acquires can provide crucial data used to make ES1 more effective. And because this data will be coming from businesses that ES1 will be at work in, the company’s robots can start working from the moment they hit the ground.

Since implementing this strategy, Electric Sheep said it has grown revenue by eight times. Last year, it acquired four landscaping businesses, and it says this strategy is key to its long-term plan. By ensuring that the startup always has revenue coming in, and finding a unique way to acquire essential industry-specific data, Electric Sheep has set itself apart from other startups. RR

www.therobotreport.com 24 THE ROBOT REPORT April 2024

Exotec Skypod ASRS scales to serve automotive supplier’s SKU volume

Many warehouse operators are struggling with increasing complexity, and recent innovations in automation promise to help them adapt and scale their businesses. Exotec has developed the Skypod modular hardware and software for flexible storage and picking.

Lane Automotive provides highperformance automotive parts and accessories. The Watervliet, Mich.based company carries more than 660 bands, stocks over 100,000 SKUs in its distribution center, and offers more than 2.2 million parts from its catalog that serves four primary sales channels.

Lane Automotive needed to exceed fulfillment deadlines to meet carrier pickup times. It also needed to handle a

Organization Name: Exotec

Country: France

Website: www.exotec.com

Year Founded: 2015

Number of Employees: 500+

Innovation Category: Application

wide range of products and ease worker strain.

“The seasonal nature of our business generally sees its peaks between March and June,” said James MacEachern, chief operating officer of Lane Automotive. “This volume could stress our operational capacity.”

Last year, Exotec deployed Skypod to help Lane Automotive modernize fulfillment operations, building on its experience in the grocery, retail, e-commerce, and third-party logistics (3PL) markets.

“What was unique about this deployment is that Lane carries a lot of SKUs for very specific needs - racing, drag racing, and off-road - but it has

small inventories for each,” said Stanislas Normand, managing director of Exotec North America. “That’s where Skypod creates value instead of standard warehouse fulfillment solutions.”

The automated storage and retrieval system (ASRS) uses robots to move goods between high-density storage racks and ergonomic picking stations.

Skypod has streamlined inventory tracking, reduced the need for Lane Automotive employees to walk five to seven miles per day, and eliminated the need for heavy lifting since products are now picked directly into their shipping cartons. The company said it expects to see at least a sixfold increase in throughput. RR

25 THE ROBOT REPORT April 2024 www.therobotreport.com

FANUC ships one-millionth industrial robot

FANUC has been a pioneer in automation and robotics for nearly 50 years. And in August 2023, it reached another milestone with the shipment of its one-millionth industrial robot. The robot sold was a FANUC R-2000iC/210F that is designed to lift heavy payloads up to 210 kg in a variety of applications.

FANUC developed its first robot in 1974, called “FANUC ROBOT MODEL 1." FANUC used the robot on its own production line. Today, FANUC offers 200+ industrial and cobot models that are used in production facilities worldwide to assemble, handle, package, paint, and weld products of every shape and size.

FANUC uses its own robots to make robots, controllers, and machine tools to give itself a leg up on some of its competitors. "When customers visit FANUC’s headquarters in Japan, they are amazed to see the highly automated assembly lines and leave feeling confident in our ability to solve their production problems,” the company has said.

This landmark sale highlights FANUC's commitment to quality and reliability over the years, earning the trust of manufacturers worldwide to help drive their businesses forward. FANUC’s robots have consistently delivered exceptional performance, efficiency, and durability, setting the standard for excellence in robotics.

This milestone also reflects the role robotics plays in modern manufacturing. Robots from many companies have revolutionized production processes across a range of industries. By automating repetitive tasks, streamlining operations, and improving efficiency, Fanuc’s robots empower manufacturers to enhance productivity, reduce costs, and stay competitive in today's dynamic marketplace. RR

Organization Name: FANUC

Country: Japan

Website: www.fanuc.com

Year Founded: 1958

Number of Employees: 500+

Innovation Category: Business

www.therobotreport.com 26 THE ROBOT REPORT April 2024

Figure AI builds working humanoid within 1 year

Organization Name: Figure AI

Country: U.S.

Website: www.figure.ai

Year Founded: 2022

Number of Employees: 11-50

Innovation Category: Technology

Since exiting stealth mode in January 2023, Sunnyvale, Calif.-based Figure AI has swiftly navigated toward commercializing a humanoid under the leadership of founder and CEO Brett Adcock, a seasoned entrepreneur with two successful startups behind him.

Figure’s team includes industry veterans like CTO Jerry Pratt from IHMC, who boasts 20-plus years of experience developing humanoids. The company has also hired employees from Apple, Auris, Boston Dynamics, Nimble Robotics, Rivian, Tesla, and other leading technology companies.

The blistering development path that Figure demonstrated throughout the year is a testament to building and equipping a top-notch team with the right tools to be successful.

The company achieved dynamic bipedal walking with its Figure 01 humanoid in less than one year, which the company claims to be one of the quickest turnarounds in humanoid history. Figure 01 features dexterous manipulation capabilities and, like other humanoid developers, is being designed for logistics applications such as tote moving as potential tasks early on.

During a visit in October 2023, The Robot Report observed Figure’s meticulous approach to product prototyping and sophisticated development infrastructure, highlighting the team's prowess in iterative design and debugging. The integration of a fully dissected robot for software development and electrical system troubleshooting underscores the depth of expertise within Figure's ranks, showcasing the company's maturity despite its relative youth.

Starting in October, the company began to show progress through key milestones, including manipulation tasks, untethered walking, and real work demonstrations. RR

27 THE ROBOT REPORT April 2024 www.therobotreport.com

evoBot offers unique design for autonomous mobile robots

evoBOT is the kind of robot that stands out the moment you look at it. Its unique and seemingly simple design doesn’t resemble any other autonomous mobile robot (AMR) on the market today. Designed at the Fraunhofer Institute for Material Flow and Logistics, the robot consists of two wheels and gripper arms. If you’re looking at it head-on while it’s zooming around without any cargo, the robot simply looks like an arch with wheels attached at the bottom.

The robot uses these arms to grip boxes by applying pressure from each side, and it maintains balance as it zips across airports. It keeps its balance using a dynamically stable system based on the principle of an inverted pendulum, which means it doesn’t have an external counterweight. Its ability to balance makes it able to move on different and uneven surfaces.

evoBOT can reach a maximum speed of up to 60 km/hour (around 37 MPH) and can transport a load of up to 100 kg (over 220 lbs). It can handle hazardous goods, transport parcels for longer recurring distances, relieve employees during lifting and overhead work, procure materials, and provide support during the loading and unloading of an aircraft.

Last year, evoBOT completed its first test run at the Munich Airport. There, it performed a practical test in the cargo terminal and on the apron of the airport. These tests further proved how versatile the system is, setting it up for potential deployments in numerous industries. evoBOT’s innovative design sets it apart from its AMR counterparts, and it has the capabilities to back that up. RR

Organization Name: Fraunhofer Institute for Material Flow and Logistics

Country: Germany

Website: www.iml.fraunhofer.de/en/fields_of_ activity/material-flow-systems/iot-andembedded-systems/evobot.html

Year Founded: 1981

Number of Employees: 500+

Innovation Category: Technology

www.therobotreport.com 28 THE ROBOT REPORT April 2024

Ukrainian tractor automation company develops demining robot

Ukraine-based Gardarika Tres is a manufacturer and distributor of agricultural equipment that focuses on precision farming systems and was founded in 2014. The company started an autonomous tractor navigation brand called Efarm.pro in 2023.

At the end of January 2023, according to reports, about 250,000 square kilometers of Ukrainian agricultural land had become a minefield.

These explosive devices must be cleared from the fields. However, there is a lack of trained personnel and appropriate equipment to do the job. Accelerating the demining process will provide an opportunity to quickly restore the country's economy, industry, and agrarian entrepreneurship, and save people's lives.

The Efarm.pro brand developed an unmanned system to remove mines from fields. The system includes a drone, an autonomous tractor, and a demining attachment that can withstand explosions. The demining solution is driven remotely from a safe distance to ensure there are no humans in harm’s way.

The demining solution scans the field with a drone equipped with appropriate sensors to target demining areas. These areas are subsequently defused by running the autonomous tractors together with certified sappers. The innovation with the solution is to employ a mature autonomous navigation system for tractors with a hardened mine sweeper to explosively remove any mines within a field and return it to productive growing for farmers.

The tractor is equipped with additional armor plates, designed for use in vehicle structures for mine protection and improvised explosive devices. This ensures that the solution can work its way through the field without the need to stop and repair after a mine is set off. RR

Organization Name: Gardarika Tres

Country: Ukraine

Website: efarm.pro/demining_ukraine

Year Founded: 2014

Number of Employees: 11-20

Innovation Category: Application

29 THE ROBOT REPORT April 2024 www.therobotreport.com

Geek+ upgrades goods-to-person system

Geek+ unveiled its latest PopPick mobile robotics solution for order fulfillment in early 2023. PopPick's upgraded goods-to-person system offers mobility and versatility, eliminating infrastructure investments. With the capacity to handle goods of all sizes, it optimizes order fulfillment for third-party logistics providers (3PLs) and retailers, addressing the surge in e-commerce demands.

The system, built around autonomous mobile picking robots, achieves automatic docking of order containers, presenting goods to operators for efficient picking. PopPick boasts impressive metrics, including up to 650 totes picked per hour, a 50% increase in warehouse storage density, and doubled throughput capacity. Geek+ said its solutions prioritize safety and scalability, with modular designs allowing for easy expansion during peak seasons.

3PLs have embraced PopPick as a solution that prioritizes high-density storage with high picking efficiency, as well as variable storage locations and rapid storage location alterations. The PopPick system helps retailers manage a large number of SKUs with different sizes and order frequencies. With its tailored solutions, PopPick enhances business-to-consumer and businessto-business choices across a variety of sectors.

Organization Name: Geek+

Country: U.S.

Website: www.geekplus.com

Year Founded: 2015

Number of Employees: 101-500

Innovation Category: Technology

Geek+'s commitment to R&D ensures continual innovation, catering to diverse industry needs. More than 1,000 global customers, including Fortune 500 clients, attest to the company’s market leadership. The adoption of mobile robotics not only enhances efficiency but also empowers workers, supplementing labor during shortages and enabling faster fulfillment.

As supply chains evolve, mobile robotics offer agility and flexibility, facilitating quick adjustments and efficient inventory management. PopPick epitomizes this shift towards automation, providing intuitive solutions that improve workforce productivity and optimize order fulfillment, ultimately securing a competitive advantage in today's dynamic market landscape. RR

www.therobotreport.com 30 THE ROBOT REPORT April 2024

Glidance provides independence to visually impaired individuals

In the United States, around one million adults are blind. Yet, only 2 to 8% use a white cane for navigation. Most instead rely on guide dogs or sighted companions, according to the Perkins School for the Blind. This reliance limits independence and mobility, a challenge Glidance, winner of the 2023 RoboBusiness Pitchfire Competition, aims to address through robotics.

The company’s flagship product, Glide, offers autonomous mobility assistance for the visually impaired, incorporating advanced guiding technologies and a unique mechanical design to foster independence. Providing haptic and audio feedback for safety, Glide's innovation garnered praise from industry experts, particularly for its potential to serve an underserved market segment. CEO Amos Miller, himself blind, brings a firsthand perspective to Glidance's mission.

Organization Name: Glidance

Country: U.S.

Website: glidance.io

Year Founded: 2023

Number of Employees: 2-10

Innovation Category: Application

The company plans to sell the device for about the cost of a new cell phone and offer subscription plans that enable feature updates and options that will make Glide easily configurable for each user's needs. With a battery life of up to eight hours and quick user adaptation, Glide promises to revolutionize mobility for the visually impaired. Founded by Miller and Mike Sinclair, Glidance represents hope for those seeking greater freedom and autonomy in navigating the world.

Miller noted that more than 50,000 individuals lose their sight every year, yet worldwide there are only 10,000 working guide dogs any year, leaving a huge gap and providing the opportunity for a device like Glide to make a huge difference in users' lives. It can cost up to $50,000 annually to train and care for a guide dog throughout its working lifetime with a person who is blind. RR

31 THE ROBOT REPORT April 2024 www.therobotreport.com

Exoskeleton improves walking for people with Parkinson’s disease

Organization Name: Harvard John A. Paulson School of Engineering and Applied Sciences

Country: U.S.

Website: seas.harvard.edu

Year Founded: 2007

Number of Employees: 500+

Innovation Category: Application

Researchers at Harvard John A. Paulson School of Engineering and Applied Sciences developed a soft exoskeleton to help a person with Parkinson’s walk without freezing. Freezing of gait (FOG) is a common, yet poorly understood, symptom of Parkinson's disease. It causes sudden and involuntary episodes of immobility that can occur during walking, often leading to falls and injuries. Traditional treatments for FOG, such as medication adjustments and physical therapy, have had limited success.

The researchers spent six months working with a 73-yearold man with Parkinson’s disease who, despite using both surgical and pharmacologic treatments, endured substantial and incapacitating FOG episodes more than 10 times a day. These episodes prevented him from walking around his community and forced him to rely on a scooter to get around outside.

The exoskeleton uses cable-driven actuators and sensors worn around the waist and thighs. Using motion data collected by the sensors, algorithms estimate the phase of the gait and generate assistive forces in tandem with muscle movement.

Without any special training, the patient was instantly able to walk without any freezing indoors and with only occasional episodes outdoors. He was also able to walk and talk without freezing, a rarity without the device.

Harvard collaborated on this with Boston University. The researchers said “this work suggests the potential benefits of a ‘bottom-up’ rather than ‘top-down’ solution to treating gait freezing. We see that restoring almost-normal biomechanics alters the peripheral dynamics of gait and may influence the central processing of gait control.”

The research demonstrates the potential of exoskeletons to treat FOG and offers hope to those with Parkinson’s disease. It could help them regain their mobility and independence. RR

www.therobotreport.com 32 THE ROBOT REPORT April 2024

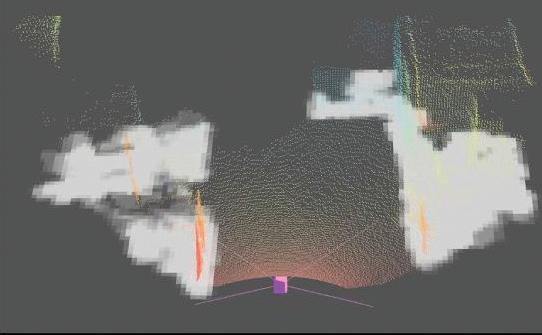

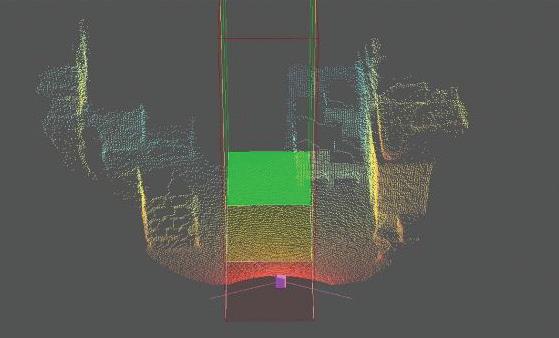

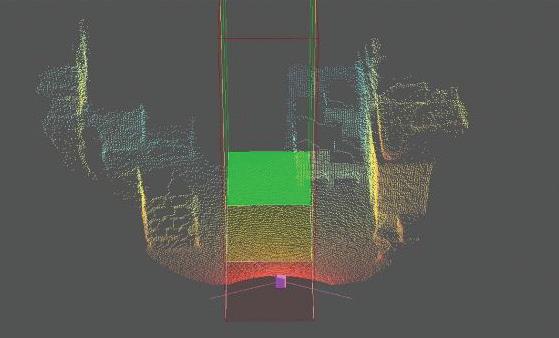

ifm simplifies mobile robot development with Obstacle Detection System

ifm efector’s Obstacle Detection System tackles the toughest hurdles of integrating 3D cameras into mobile robots, streamlining development, and reducing both capital expenditure and total cost of ownership. This increases a user’s return on investment and could help to democratize mobile robots, particularly for small and medium-sized enterprises (SMEs).

While mobile developers have effectively addressed person detection with standard safety LiDARs, collisions with objects beyond their view remain a challenge, potentially causing damage and hindering mission efficiency. Both automated guided vehicles (AGVs), which navigate using static path planning, and autonomous mobile robots (AMRs), which navigate using dynamic path planning, react differently to detected obstacles. However, both grapple with potential collisions. 3D cameras can offer a comprehensive solution, affording a complete view of the robot's path.

The ifm Obstacle Detection Solution reduces mobile

Organization Name: ifm efector

Country: U.S.

Website: www.ifm.com/us/en

Year Founded: 1985

Number of Employees: 101-500

Innovation Category: Technology

robot development time by providing a ready-made option for manufacturers, ensuring integration across diverse environments, and reducing facility integration time, irrespective of floor conditions.

Although mobile robots are gaining popularity as a tool to enhance workforce efficiency and address labor shortages, they have not yet achieved widespread adoption. ROI is one factor holding mobile robots back. Addressing this requires a shift in focus towards total cost of ownership (TCO), with significant development and deployment times emerging as the primary impediments.

By offering an obstacle detection solution priced at just $450 per robot, without recurring fees, ifm provides a viable “buy” option for developers and aims to redefine affordability and performance benchmarks for mobile robots. This approach enables manufacturers to concentrate on delivering value to end-users, catalyzing the integration of mobile robots into SME companies.RR

33 THE ROBOT REPORT April 2024 www.therobotreport.com

igus gives ReBeL cobot a low-cost, human-like hand

Organization Name: igus GmbH

Country: Germany

Website: www.igus.com

Year Founded: 1964

Number of Employees: 500+

Innovation Category: Technology

For all of the strides made in humanoid locomotion over the past year or so, there are still numerous applications for robotic manipulation to address. igus offers a finger gripper for its ReBeL collaborative robot arm to help developers.

The company designed ReBeL with its self-lubricating iglide plastics to be low-cost and easy to integrate so that innovators could focus on building the next generation of robots. End-of-arm tooling is already available for tasks such as assembly or inspection through the RBTX.com marketplace.

“As the ReBeL is very light and inexpensive with a weight of around 8 kg [17.6 lb.] and a price starting at $6,899, it is often used in humanoid applications,” said Alexander Mühlens, head of the low-cost automation business unit at igus. “For this reason, we have received several customer requests for a robot hand that can be easily connected to the ReBeL via plug and play.”

igus, whose U.S. headquarters are in Rumford, R.I., added that extensive testing has proved the longevity and flexibility of its hand. The ReBeL finger gripper can be controlled via various interfaces, including USB, TTL (5V) serial, and internal scripting.

The new end effector is compatible with all ReBeL models and is controlled by digital I/O at the tool center point. It can also copy human motion in teleoperation or imitation-learning applications.

The dexterous hand could be useful in university research, food service, and the entertainment industry. Small and midsize enterprises, which are already adopting collaborative robots for their ease of programming, can try to automate new tasks with low risk.

Following igus’ policy of openly listing its prices, the ReBeL finger gripper is available for $2,760. RR

34 April 2024

www.therobotreport.com THE ROBOT REPORT

Instock turns fulfillment processes upside down with unique ASRS

Instock came onto our radar when it became part of the Amazon Industrial Fund’s portfolio of robotics investments. This is the same fund that invested in Agility Robotics and many other notable companies.

Instock is taking a unique and flexible approach to automated storage and retrieval systems (ASRS). Most of these systems involve complex racking that moves bins around and places them onto autonomous mobile robots (AMRs) that bring those bins to picking robots or human pickers.

Instock doesn’t take this approach. Instead, the only moving part within the system is the AMRs, which pick up the bins themselves by gripping the bin wings and bringing them to workstations.

To travel between levels and maximize space, Instock’s AMRs drive along curved ramps placed at the end of the company’s modular racks. The AMRs then use magnets to drive upside down along the ceiling of the rack. When on the ceiling, the robot places itself above a bin and grabs from the top with its unique gripper. The AMRs can then use the ramps to travel to whatever level they need to be at to deliver the bin to picking stations. The AMRs use the same system to bring bins back to the racks.

Because the only moving part within the entire system is the AMRs, Instock’s ASRS is easy to fix when things go wrong. Similar systems might require the entire ASRS to be shut down while repairs are made to one module, but with Instock, users simply need to remove the malfunctioning robot for maintenance. Instock’s unique ASRS is more flexible and could require less maintenance than traditional systems. RR

Organization Name: Instock

Country: U.S.

Website: instock.com

Year Founded: 2020

Number of Employees: 11-50

Innovation Category: Technology

35 THE ROBOT REPORT April 2024 www.therobotreport.com

Kodama Systems uses robotics to prevent wildfires

In 2022, wildfires burned over 7.5 million acres of land in the U.S., according to the National Centers for Environmental Information. It’s a pressing issue in the U.S., and it will only get worse as the climate becomes hotter and drier.

While there are some robots deployed to fight these deadly wildfires, few are working to prevent them. This is where Kodama Systems comes in.

Historically, forests in the U.S. were less dense than they are today. Overstocked forests have resulted in greater competition for resources among plant life in these areas, making them more vulnerable to drought and other stressors. Scientific consensus also

Organization Name: Kodama Systems

Country: U.S.

Website: kodama.ai

Year Founded: 2021

Number of Employees: 1-10

Innovation Category: Application

suggests that these overgrown forests are a key contributor to the current wildfire crisis. An abundance of smaller, often weaker, trees is ready to burn.

To combat this overgrowth, government agencies have been increasingly investing in initiatives aimed at thinning out these forests. This is a labor-intensive task, as it requires a number of heavy machines to drive into the forest, cut down the trees, and then haul them out so they can be cut to size and delivered to sawmills to be processed.

Kodama Systems is working to add autonomy to the process. It creates teleoperation and autonomy kits for

the heavy machinery at work. The team started with the skidder, a piece of equipment used to haul cut-down trees out of the forest.

In 2023, the company deployed its teleoperation platform on a small forestthinning project in the Stanislaus National Forest. During this project, the company’s skidder autonomously dragged bundles of trees along skid trails to the project landing. In all, Kodama Systems creates technology for the labor-intensive and crucial work of thinning forests to prevent wildfires. RR

www.therobotreport.com 36 THE ROBOT REPORT April 2024

Autonomous pickup truck could enhance U.S. military operations

Kodiak Robotics unveiled in late 2023 its first autonomous test vehicle for the U.S. Department of Defense (DoD). A Ford F-150 truck is outfitted with Kodiak's autonomous system, Kodiak Driver, and is designed to handle complex military environments, diverse operational conditions, and areas with degraded GPS, as well as off-road variables like rocks, dust, mud, and water. The F-150 can be teleoperated if needed.

Since its founding in 2018, Kodiak has primarily focused on developing autonomous trucks. But the road to scaling autonomous vehicles has turned out to be longer than many expected.

Organization Name: Kodiak Robotics

Country: U.S.

Website: kodiak.ai

Year Founded: 2018

Number of Employees: 101-500

Innovation Category: Application

Working with the military could be a quicker path to revenue for Kodiak, which won a two-year, $50 million contract with the Army in December 2022.

Kodiak said it took less than six months to build the autonomous Ford F-150. If all goes well for Kodiak, it could become one of the Army’s future technology partners.

The Ford F-150 introduces new possibilities for enhancing military logistics and operations. Unmanned transportation of supplies and personnel offers the military greater flexibility, efficiency, and safety in fulfilling its mission-critical objectives.

This work also highlights the importance of a modular, vehicleagnostic autonomous driving system. The F-150 runs the same software as Kodiak's autonomous long-haul trucks and features Kodiak DefensePods, an adapted version of Kodiak's swappable SensorPods.

Kodiak Robotics said finding multiple use cases for its autonomous driving system is key to its future.

“Finding applications of technology that can apply to military use simultaneously with civilian and commercial use cases is the future. That’s where the efficiency is. That’s where the iteration is.” RR

37 THE ROBOT REPORT April 2024 www.therobotreport.com

KUKA releases next generation of mobile robots

KUKA has been a leading provider of industrial robot arms for years. It has also dabbled in the mobile robotics space. But in late 2023 it added some serious punch to its mobile robot portfolio.

KUKA introduced three new mobile robots in 2023: the KMR iisy mobile cobot, KMP 1500P, and KMP 600-S diffDrive. The new iisy model is a mobile manipulator that includes the LBR iisy cobot with a payload capacity of 11-15 kg and a mobile platform that can carry a supplementary load of up to 200 kg.

Organization Name: KUKA

Country: Germany

Website: kuka.com

Year Founded: 1898

Number of Employees: 500+

Innovation Category: Business

The KMP 1500P is built for heavy-duty applications and can transport up to 1.5 tons of material, while the new KMP600S model can move payloads of up to 600 kg.

KUKA’s AMRs are designed for a range of sectors, including the manufacturing, logistics, and automotive industries. Some of its older models are omnidirectional to ensure maximum freedom of movement and highprecision transport even with heavy loads. The company’s AMRs come with advanced sensor technology, no-code

programming, state-of-the-art battery technology, and higher energy density.

KUKA joins a long list of companies with strong mobile robotics portfolios. But KUKA is more of a household name than many of its competitors. And, again, it seems to be more serious about mobile robots with its “new AMR generation.” With these new models, KUKA continues to set itself apart from most other robotics providers by being a true one-stop shop for automation. RR

www.therobotreport.com 38 THE ROBOT REPORT April 2024

Locus Robotics surpasses 2 billion picks with AMRs

In August 2023, autonomous mobile robot (AMR) developer Locus Robotics surpassed 2 billion picks for its warehouse fulfillment customers. The milestone came just 11 months after it surpassed the 1 billion pick mark in 2022, for which it also won an RBR50 Robotics Innovation Award.

"Achieving the two billion picks milestone is an incredible accomplishment for our company and for our customers," said Rick Faulk, CEO, Locus Robotics. “This event is a testament to the dedication and innovation of our incredible team and the dramatic productivity improvements we deliver to drive our customers’ growth and success.”

Organization Name: Locus Robotics

Country: U.S.

Website: locusrobotics.com

Year Founded: 2014

Number of Employees: 51-100

Innovation Category: Application

It took Locus just 358 days to go from 1 billion to 2 billion, with the last 100 million picks taking just 27 days. That’s an average of 3.7 million picks per day. By comparison, it took more than six years to make the first billion picks and 1,542 days to pick the first 100 million units.

“Locus’ consistent innovation, usercentric approach, and genuine dedication to customer relationships put them at the forefront of warehouse automation,” said Alan McDonald, vice president of continuous improvement, GEODIS. “This milestone is a testament to its technological leadership and synergistic collaboration. We look forward to building

on our work together and driving even greater efficiency improvements in the future.”

Warehouse operators are increasingly turning to AMRs to meet growing demand and overcome labor shortages. And Locus Robotics continues to lead the way. Its AMRs support more than 120-plus of the world's top brands and are deployed at 300-plus sites globally. Locus enables retailers, 3PLs, and specialty warehouses to efficiently meet and exceed the increasingly complex and demanding requirements of today's fulfillment environments. RR

39 THE ROBOT REPORT April 2024 www.therobotreport.com

MassRobotics Accelerator positions startups for success

MassRobotics is the world’s first and largest independent non-profit innovation hub focused on growing robotics technology companies, scaling solutions, and championing robotics adoption. The MassRobotics Accelerator, Powered by Mass Tech Collaborative, empowers the next generation of robotics startups through non-dilutive funding, custom tailored curriculum, and personalized mentorship.

This is the first accelerator of its kind with equity-free programming committed to supporting and advancing robotics technology entrepreneurs and technical founders through a 13-week, in-person program based out of the MassRobotics headquarters in Boston. Mentors and

Organization Name: MassRobotics

Country: U.S.

Website: www.massrobotics.org

Year Founded: 2015

Number of Employees: 11-50

Innovation Category: Business

technical experts participating in the program include well-known robotics experts and entrepreneurs who are providing first-hand experience to help guide the 10 selected companies participating in the program.

The 10 startups include Apparel Robotics, brd BOT, Gopher Motion, Hominid X, Mapless AI, Oligo, Robotics 88, rStream, SIMPL Automation, and Yard Robotics.

These companies have access to world-class prototyping facilities as well as manufacturing experts who mentor companies on scaling. This is the first public/private accelerator of its kind.

More than 140 startups applied to this program, with applicants representing

more than 25 countries. The selection process was robust, ending with a selection committee composed of notable roboticists, entrepreneurs, and academics.

“Technical founders can often jump to product-building mode before intimately understanding their end user and customer. During this program, our startups will each complete at least 25 customer discovery interviews, in an effort to hone in on their customer pain and needs,” said Marita McGinn, director of the MassRobotics Accelerator. “Our goal is to help these brilliant technical founders bolster their business acumen through this curriculum.” RR

www.therobotreport.com 40 THE ROBOT REPORT April 2024

Mecademic accelerates microautomation with SCARA robot

Organization Name: Mecademic

Country: Canada

Website: www.mecademic.com

Year Founded: 2013

Number of Employees: 11-50

Innovation Category: Technology

Mecademic launched its micro-SCARA robot in 2023, offering high speed and repeatability in a small and flexible format. The new tabletop SCARA follows the Mecademic tradition of developing high-quality, high-precision, smaller-footprint robots for assembly applications in electronics and healthcare. Mecademic has carved out a niche in the industrial robotics market with two of the tiniest yet fully capable robots on the market today.

The new MCS500 SCARA robot boasts repeatability of 0.005 mm. It features an embedded controller in the base of the robot and eight digital I/O and various communication ports, simplifying integration possibilities. The robot can be programmed with Mecademic’s software or integrated with any other robot control software. Mecademic robot arms include external 24/36V power supplies and are equipped with embedded safety modules, E-Stops and a safety I/O interface.

This industrial robotic innovation fills a crucial gap in the automation market amidst the growing trend towards miniaturization, and will create a strong demand across various industries where space is a premium. Mecademic claims the MCS500 is the world's most compact and most precise SCARA robot with a reach of 225 mm and a maximum payload of 1 kg (2.2 lbs).

With fast cycle times and mounting flexibility, the MCS500 is ideal for a variety of applications. It can be mounted on a table or hung from an overhead mounting platform, depending on the application requirements. This robust robot is unique in that it offers a combination of simplicity, precision, and high performance in a small package. RR

41 THE ROBOT REPORT April 2024 www.therobotreport.com

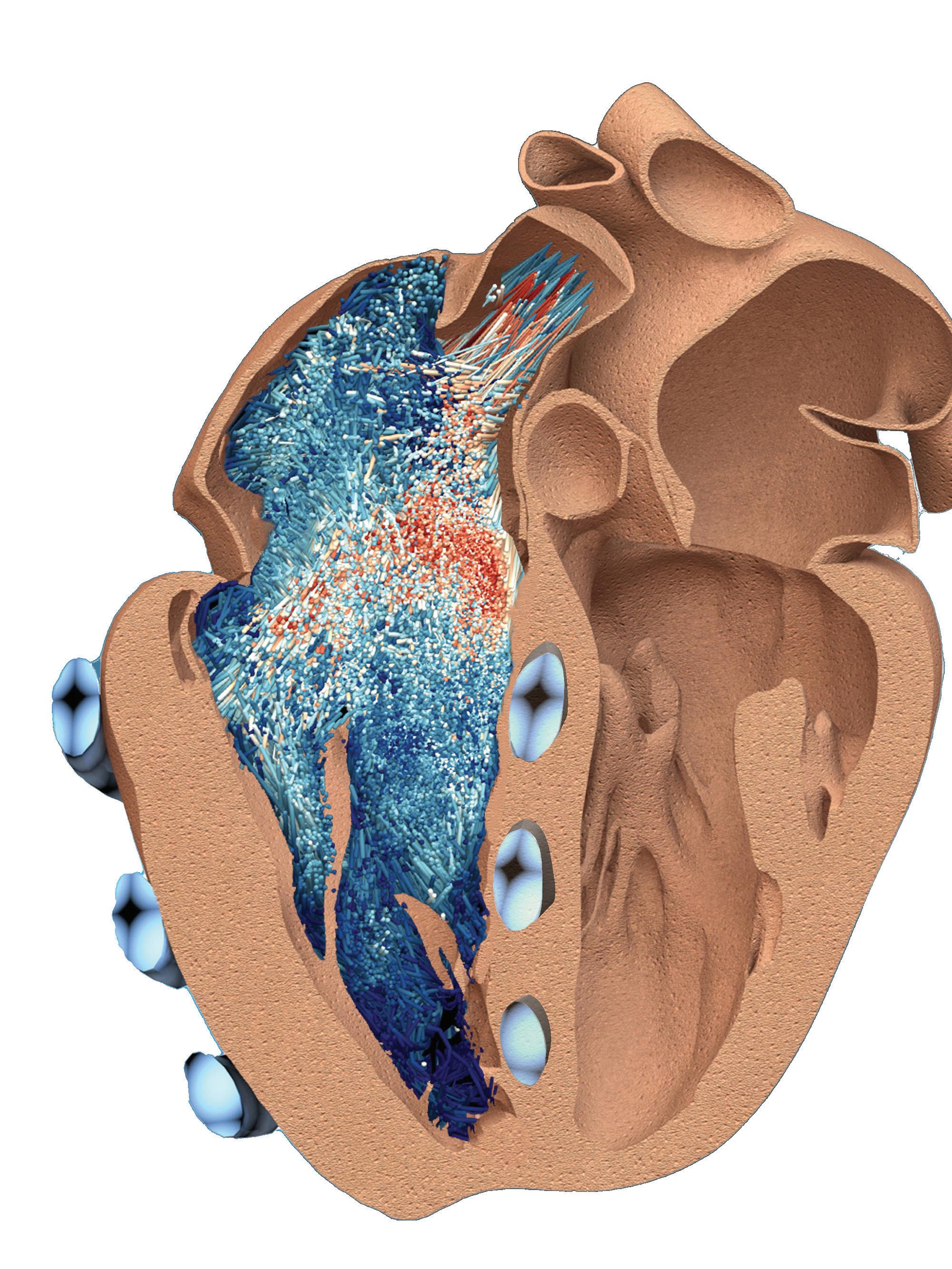

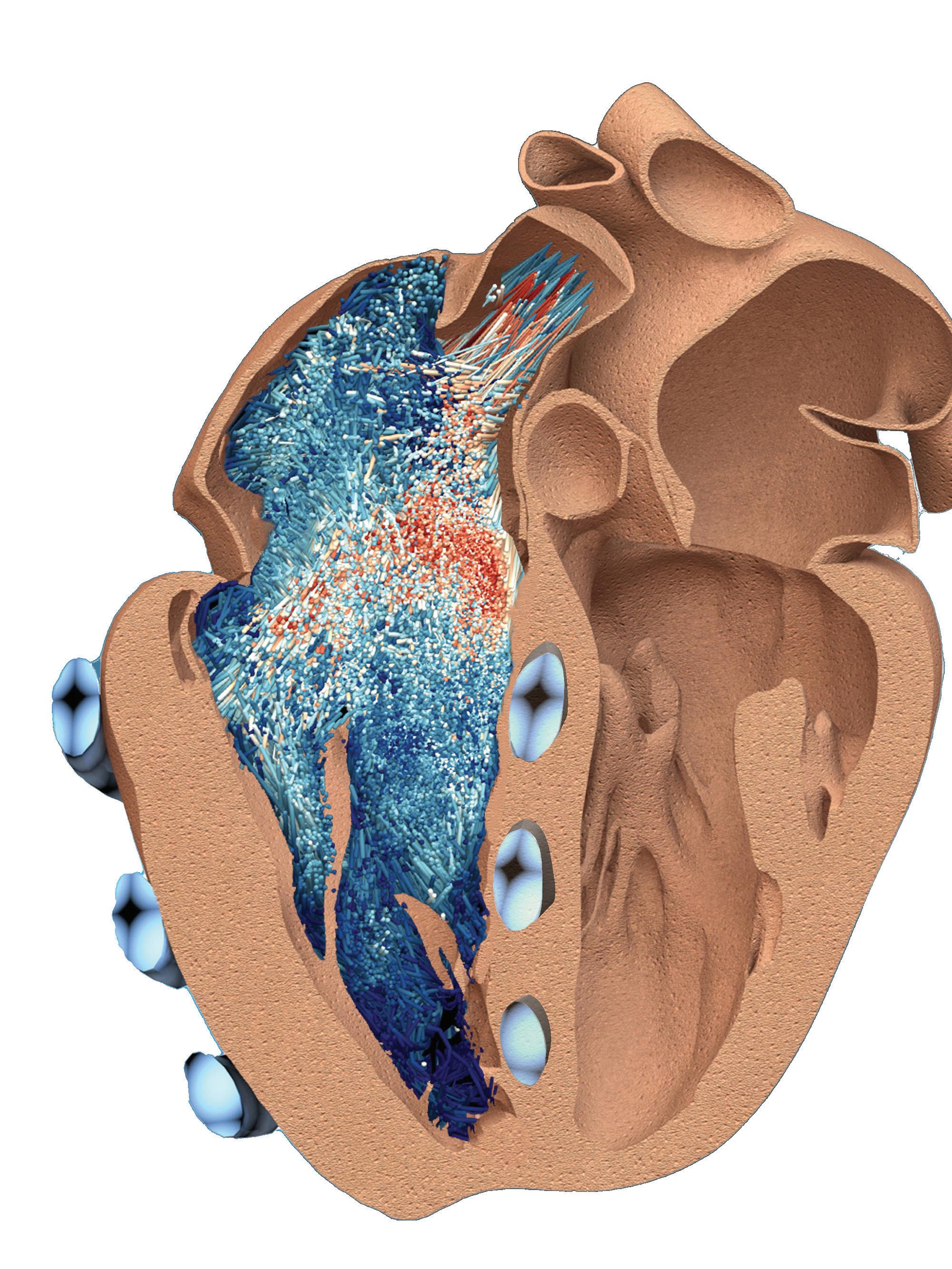

Robotic ventricle advances understanding of heart disease

MIT engineers developed a robotic replica of the heart’s right ventricle that mimics the beating and blood-pumping action of live hearts. The robotic right ventricle (RRV) combines real heart tissue with synthetic, balloon-like artificial muscles. It allows scientists to control contractions and observe the function of natural valves and structures.

The right ventricle is one of the heart’s four chambers, but its anatomical complexity has made it difficult for clinicians to accurately observe and assess its function in patients with heart disease.

Researchers said the RRV serves as a platform to study right ventricle disorders and test cardiac devices, providing insights into conditions such as right ventricular dysfunction, pulmonary hypertension, and myocardial infarction. They also said conventional tools often fail to capture the intricate mechanics and dynamics of the right ventricle, leading to potential misdiagnosis and inadequate treatment strategies.

MIT has also demonstrated the model's potential as a training tool for surgeons and cardiologists by implanting mechanical valves and ring-like medical devices to repair or replace malfunctioning valves. With plans to extend its performance and test implantable devices, the RRV represents a significant advancement in understanding and treating heart disease.

Organization Name: Massachusetts Institute of Technology

Country: U.S.

Website: www.mit.edu

Year Founded: 1861

Number of Employees: 500+

Innovation Category: Technology