THK is a leading manufacturer of high quality and ultra precise miniature linear guides, ball screws, cross roller rings and actuators for a wide range of industries, including industrial automation, medical, aerospace, semiconductor, machine tool and robotics.

LM Guides - SRS Series - Featuring patented THK Caged Technology, the SRS Miniature LM guides perform with smooth and quiet motion, long-term maintenance free operation, increased speed and accuracy, low dust generation and a long life.

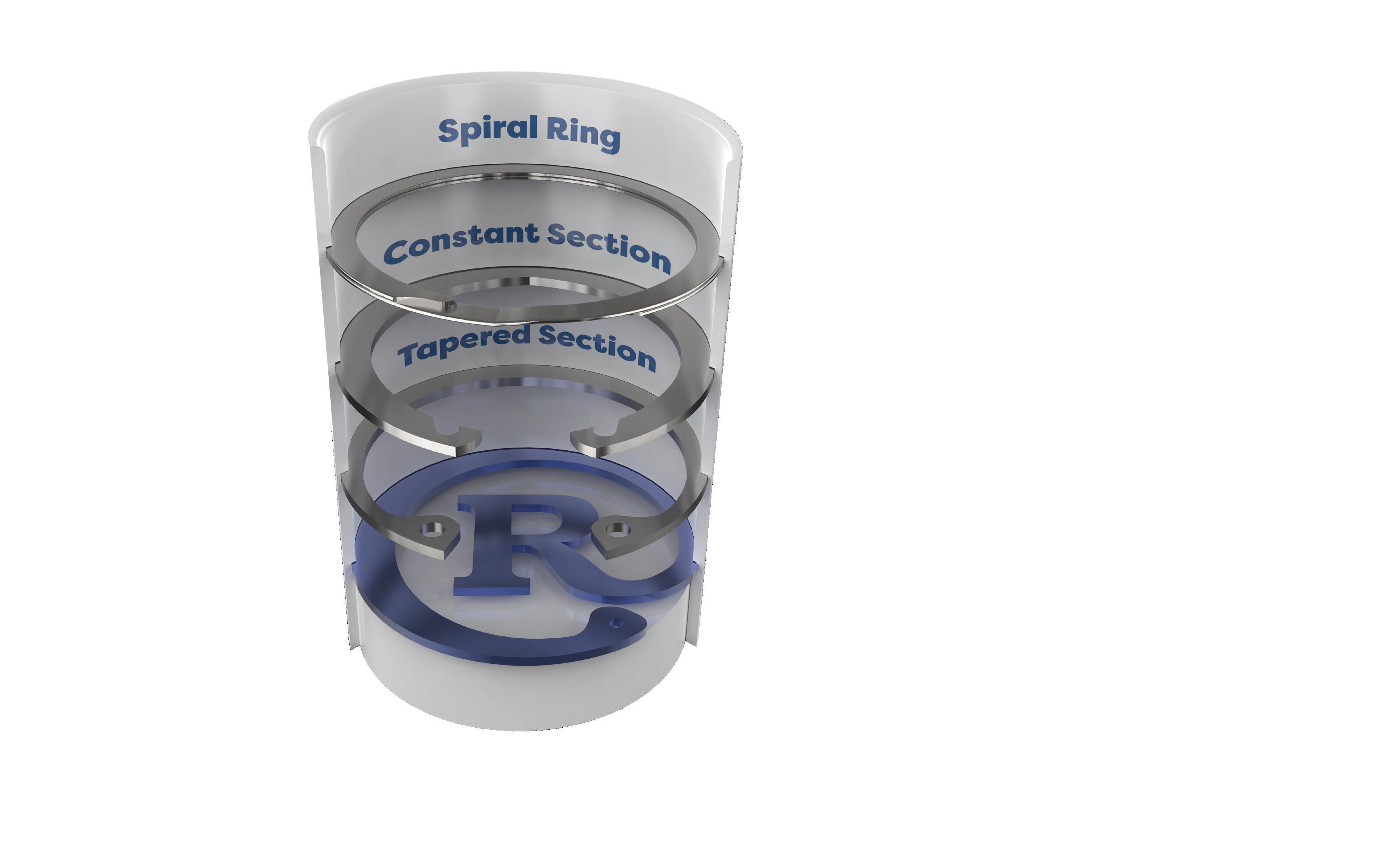

Cross Roller Rings - RAU Series - THK Micro Cross Roller Ring Series RAU are compact and lightweight and even more rigid than a double row angular contact ball bearing type. Spacer retainers enable smooth movement and high rotation accuracy.

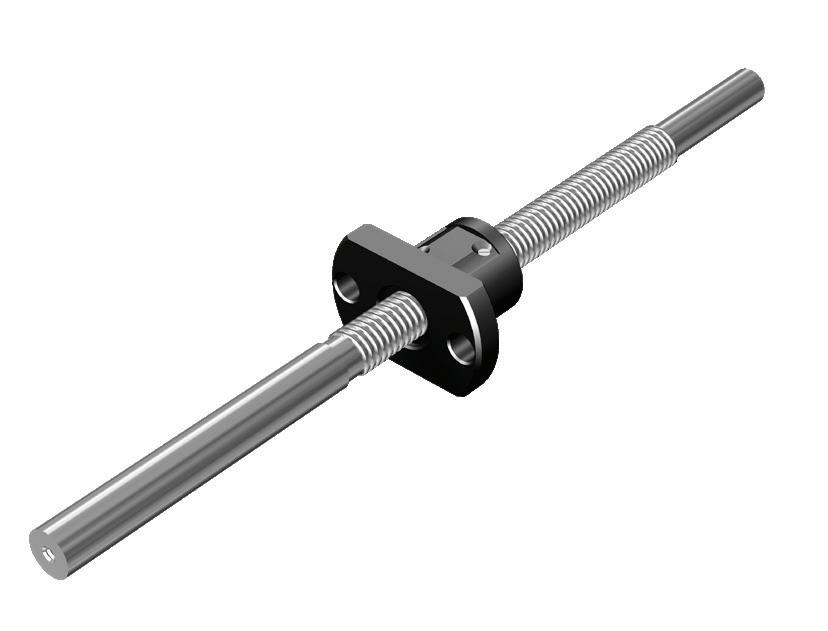

Ball Screws - BNK and MTF Series - BNK with finished shaft ends and MTF Roll-Formed screw shaft are known for their high accuracy, low noise, smooth movement and long-term maintenance free operation.

Actuators - KR Series - KR Actuators consist of LM guide units on the ends and ball screw unit in the center making them highly rigid and highly accurate in a minimal space.

To learn more, call us at 1-800-763-5459 or visit www.thk.com.

SRS MTF

(100W)

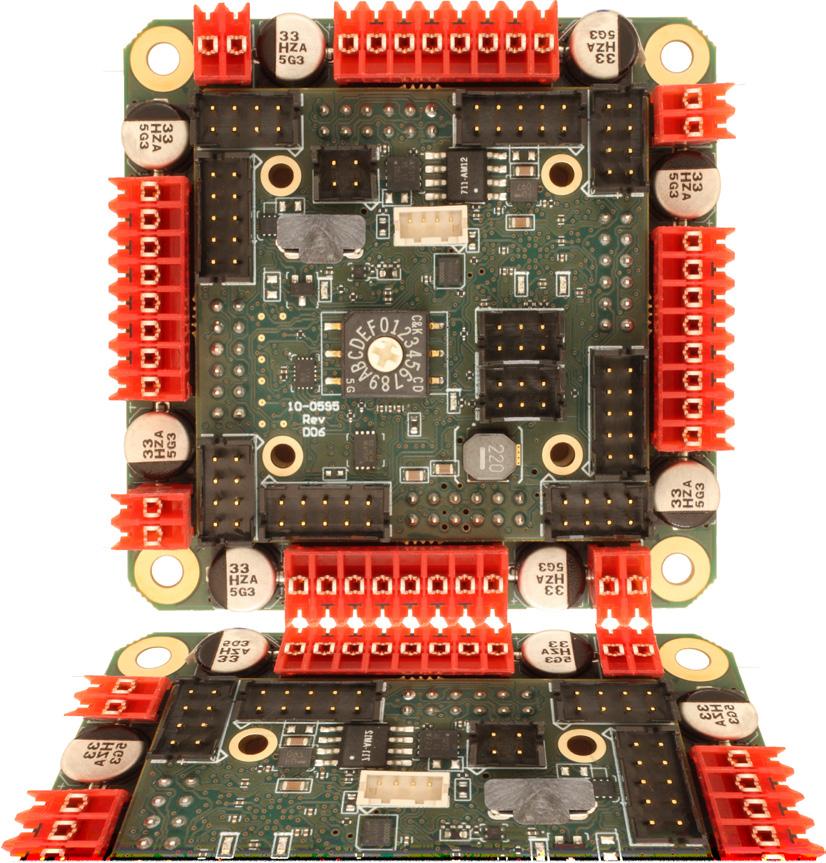

Starting at $964.00 (100W system with cables and I/O breakout)

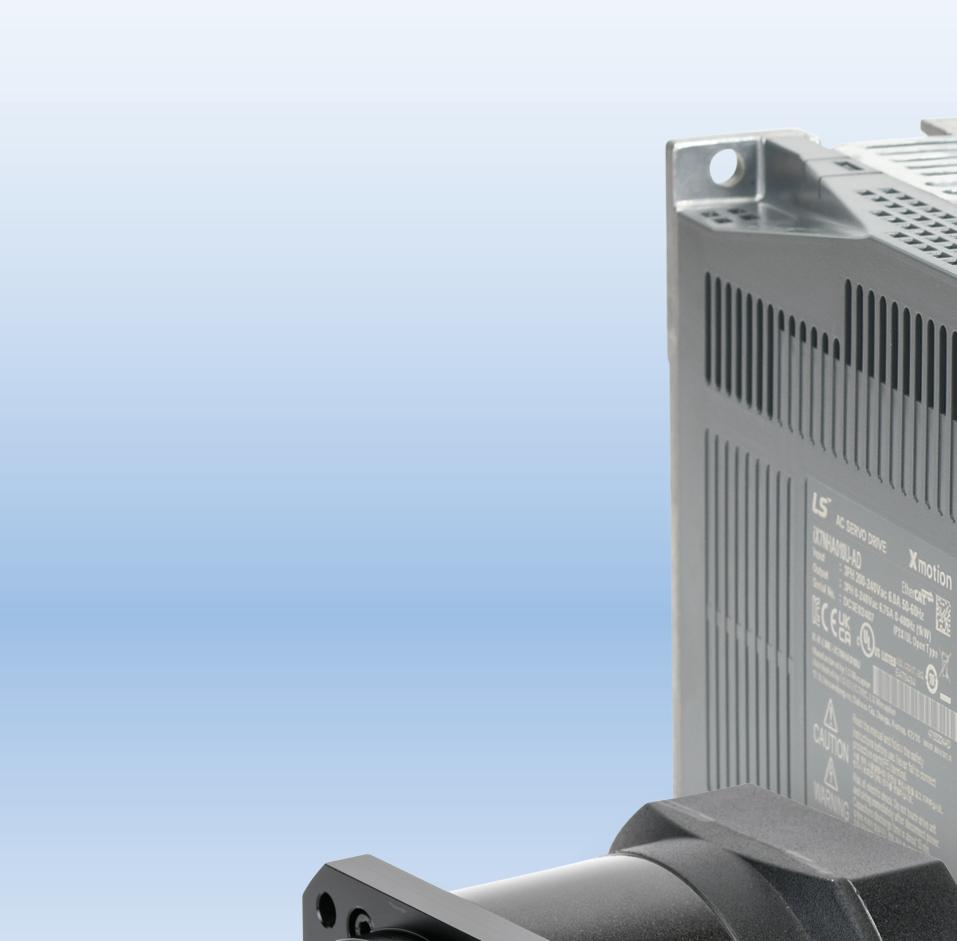

LS Electric iX7 servo systems offer advanced multi-axis motion control along with EtherCAT networking. The EtherCAT protocol provides extremely fast, real-time, deterministic, and synchronized communication for high precision motion.

• 9 standard servo systems from 100W to 3.5kW

• Multiple input power options:

• 110VAC single-phase up to 400W

• 230VAC single-phase up to 2.2k

• 230VAC three-phase in all sizes

• Use with any CANopen over EtherCAT (CoE) compatible PLC/host controller or one with ModbusTCP capability

• Fully digital with 1kHz velocity loop response

• 45-day money-back guarantee

• One-year warranty

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Need an EtherCAT controller?

LS Electric® XGB PLC CPUs starting at $299.00 (w/FREE software)

The LS Electric XGB PLC controls up to 16 axes of EtherCAT® motion with several positioning methods including linear, circular, helical, and ellipse interpolation. Seven homing routines are also available and the FREE software offers a graphical interface so you can see the motion in action! The XGB series PLC is a perfect control solution for:

• Palletizers

• Pick-and-place applications

• Rotary tables

• Flying cutoff systems

• Precision machining tools

• Automated welding systems

• and much more

Systems with a 4-axis EtherCAT positioning module starting at $691.00 (not including servo system(s))

316

316

- brushed or bldc motors

- 5 amps per axis

- 16 analog inputs

- 16 on/off drivers

- home and limit in - live tech support

- made in the USA

I’m going to veer off the normal engineering focus of this column for a month to dabble in a scientific field that’s close to my heart: astronomy. We’re a month out from this year’s big heavenly spectacle in the U.S., the total solar eclipse on April 8th. This eclipse will sweep across the country from Texas to Maine, giving people close to the centerline almost four minutes of totality.

First attracted to astronomy in the mid-1980s with the passing of Halley’s Comet, I was soon swept up in the excitement leading up to a total solar eclipse in Baja California in July 1991. I saved up enough money in college to travel to see that eclipse and was awestruck. I’ve seen two more since, but I have been waiting for most of my life for the 2024 eclipse to come to me, and my hometown of Cleveland.

You may recall the “Great American” eclipse in August 2017, which swept across the nation from Oregon to South Carolina, affording so many people the opportunity to see this incredible event. My family drove to Tennessee to see it. But afterward, I was crestfallen to hear reports from so many friends that they saw it, too — “It was more than 97% here” or “We were right near the center, it was more than 90% covered at maximum for us ... pretty cool.”

The key to total solar eclipses is the total part. One of the strangest coincidences about life here on Earth is that our Moon is 400 times closer to us (on average) than the Sun, but the Sun is 400 times larger. Thus, the two objects have about the same apparent size in our sky. There’s no law of physics that

says this must be so. In fact, in a few billion years, the Moon will be noticeably smaller when viewed from the Earth’s surface. But this coincidence of apparent sizes today means that the geometry of the moon basely covering the sun is somewhat rare and provides an incredible spectacle when it happens.

Totality, when 100% of the sun is covered, is the magic part. You no longer need to use the darkened glasses (as long as you know how much time is left before the sun peeks out again), and you can see fiery red solar flares; the sun’s outer atmosphere, the corona; and brighter stars and planets. The leadup to this 100% coverup can include a drop in temperature, windy conditions, strange moving light bands on the ground, and animals behaving strangely. You’ve spent your entire life observing (actively or passively) sunsets and twilight — and having that 45-minute process compressed into a minute or so is mindbending and astounding.

But again, if you aren’t in the narrow, hundred-mile-wide band of totality, you’ll miss all that. The difference between 99% and 100% is everything. In the years since the 2017 eclipse, I’ve finally found the words to explain this to friends who missed totality back then:

“If you drove 99% of the way to your favorite restaurant and then turned around and came home — and I asked you how the meal was — would you reconsider your choice?”

I hope you all are able to make your way into the shadow of the moon on April 8th, and let’s all cross our fingers for clear skies that day! DW

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

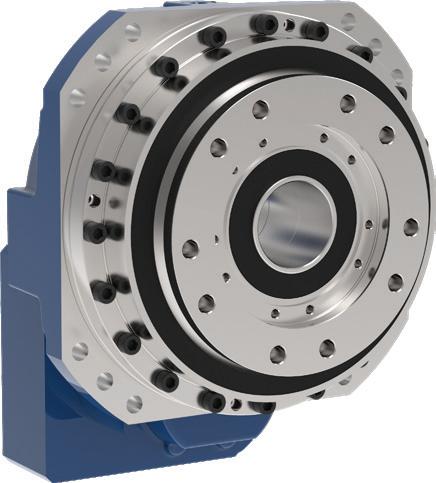

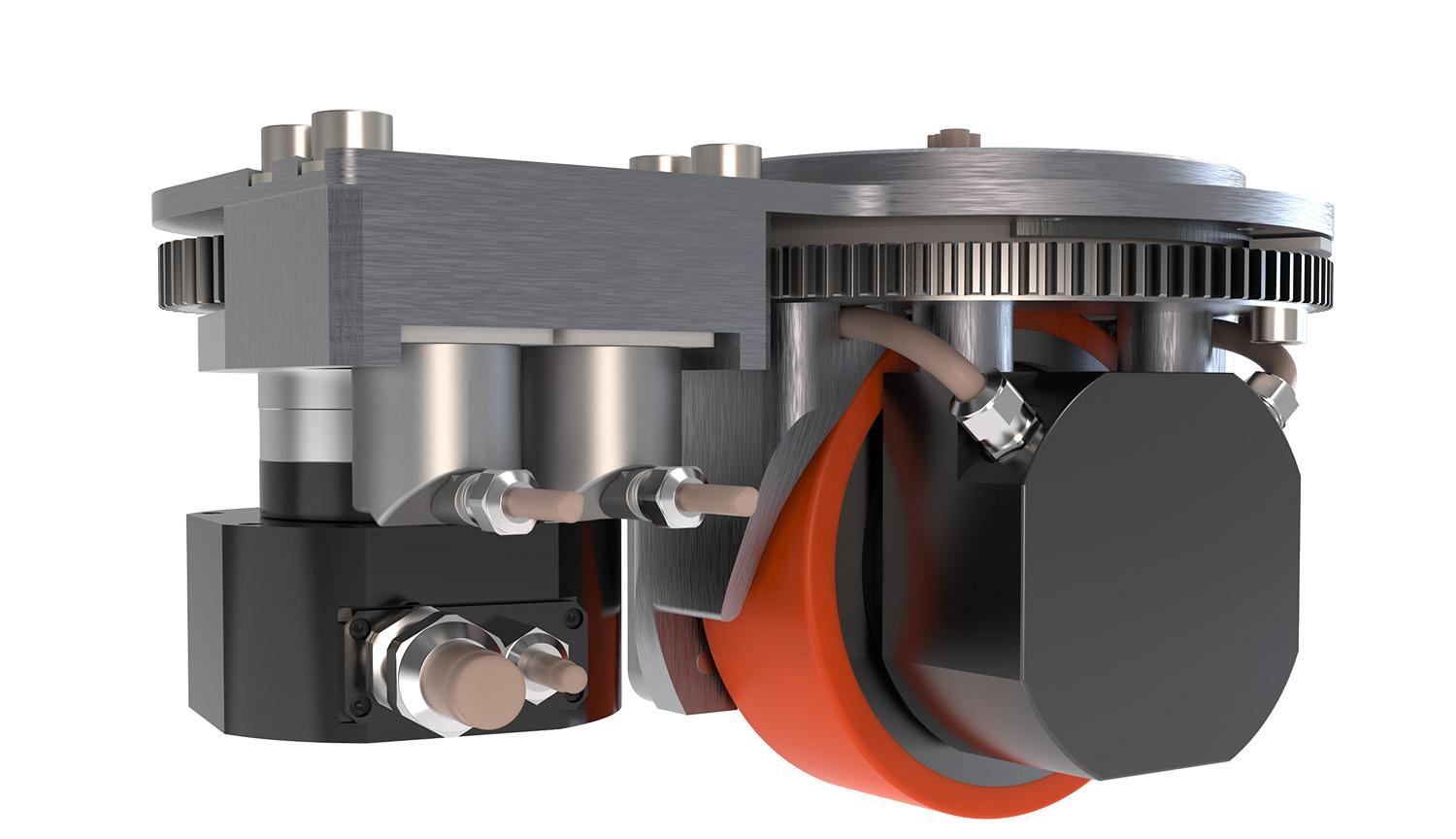

GPL Robotic Planetary

Backlash ≤0.1 arcmin for the life of the gearbox

Vibration-free for high positional accuracy

GSL Strain Wave

Backlash ≤0.5 arcmin

Harmonic-type gearing

High torque density

Easy integration

GCL Cycloidal

Backlash ≤1.0 arcmin

Impact resistance 5x nominal torque. Available with integral pre-stage

GML Planetary

Backlash ≤10 arcmin

Servo ready. Heavy duty bearings. Rotating hub design eliminates overhung load, ideal for pulleys or wheel drives

GAM robotic gearboxes are designed with the flexibility to fit your application. Rotate the flange or outer housing, add a housing cover, a motor adapter, or a pre-stage gearbox.

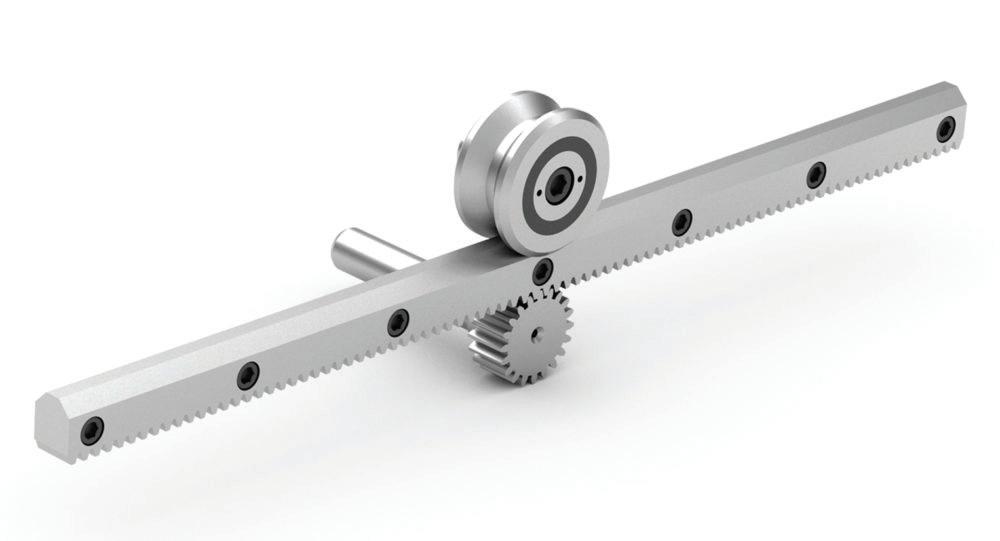

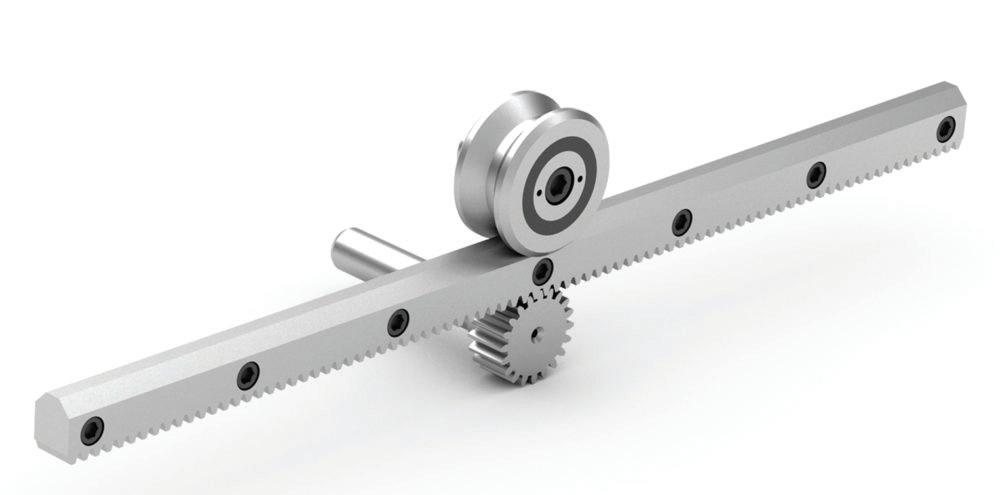

GAM offers a full range of robotic and servo gearboxes, along with rack & pinion, servo couplings, and linear mount products for motion control and robotic applications. With our broad product offerings, as well as the in-house engineering design experts and U.S. manufacturing capabilities to develop customized solutions, we can help with your application.

GAM Can.

www.gamweb.com

BXR Brakes

· Up to 480 in-lbs static

· Up to a 1.125'' bore

· 19 watts or less

· Produced for over 10 years

Our Innovative design features a very thin profile, reducing weight and space.

For more information:

Call: 800.533.1731 www.mikipulley-us.com

Late last Spring, my family and I decided to grow our first garden. We tilled dirt, built fencing, and wasted no time planning for our future backyard bounty. It was a disaster. There is not a green thumb among us, and apparently, optimism and good intentions are no substitute for sunlight and viable soil. Could technology have helped me? Perhaps one of the many gardening apps available at the touch of a button? It got me thinking.

What if this little undertaking wasn’t just a summer hobby? What if this was my livelihood? For folks in commercial agriculture, results are mandatory. The good news for farmers is that many experts think the Ag industry is about to undergo a substantial technological transformation for the better. Earlier this year, the Association of Equipment Manufacturers (AEM) listed Ag’s tech transformation as one of their 4 Equipment Manufacturing Trends to Watch In 2024. In the article, AEM Director of Agriculture Austin Gellings wrote that the advances will be considerable and not limited to mere improvements in existing agriculture technology.

“Agriculture is experiencing a seismic shift related to its underlying technologies, incorporating advancements from other industries while also leading the way in its own evolution.”

As technologies like automation and robotics become industry standard, the integration of AI and machine learning will likely follow suit. Gellings believes this may be just the beginning.

“While providing for more integration and connectivity, these

systems are also leading to other new challenges and opportunities. One is actual connectivity to equipment, allowing for the transfer of data to the cloud and its use in offline decisionmaking by end users.”

Additionally, in a Global AgTech Initiative article titled, 5 AgTech Trends to Watch in 2024, Agmatix CEO Ron Baruchi explained that Generative AI will be responsible for generating significant actionable data for farmers.

“These tools enhance crop management by analyzing big agronomic data, providing AI-supported insights to optimize production practices. This helps farmers understand patterns affecting the performance of crop varieties and production on their specific farms and tracks climate trends to help farmers become more resilient to the changing climate.”

These advances in interconnectivity won’t be without challenges (cybersecurity firms must be salivating), but the rewards seem to more than outweigh the risks. Better soil health, improved water and air quality, better labor conditions, and more, are just a few of the benefits we might see soon. So, while I myself won’t be setting up a stand at the farmer’s market anytime soon, it’s good to see that our agriculturalists might have some new tools at their disposal for the upcoming growing season. I’m interested to see how it plays out. I wish them luck.

DW Mike Santora msantora@wtwhmedia.com

Mike Santora msantora@wtwhmedia.com

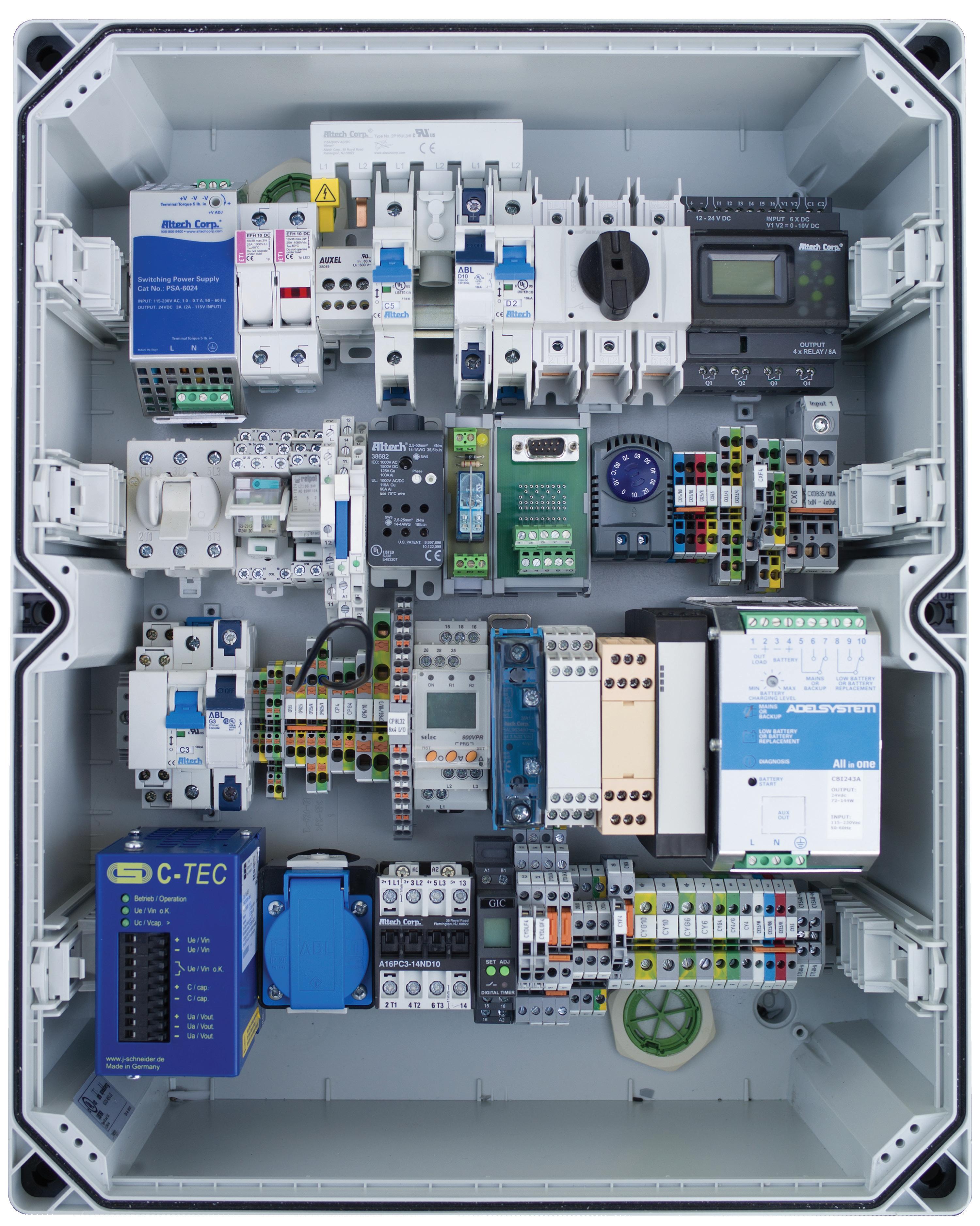

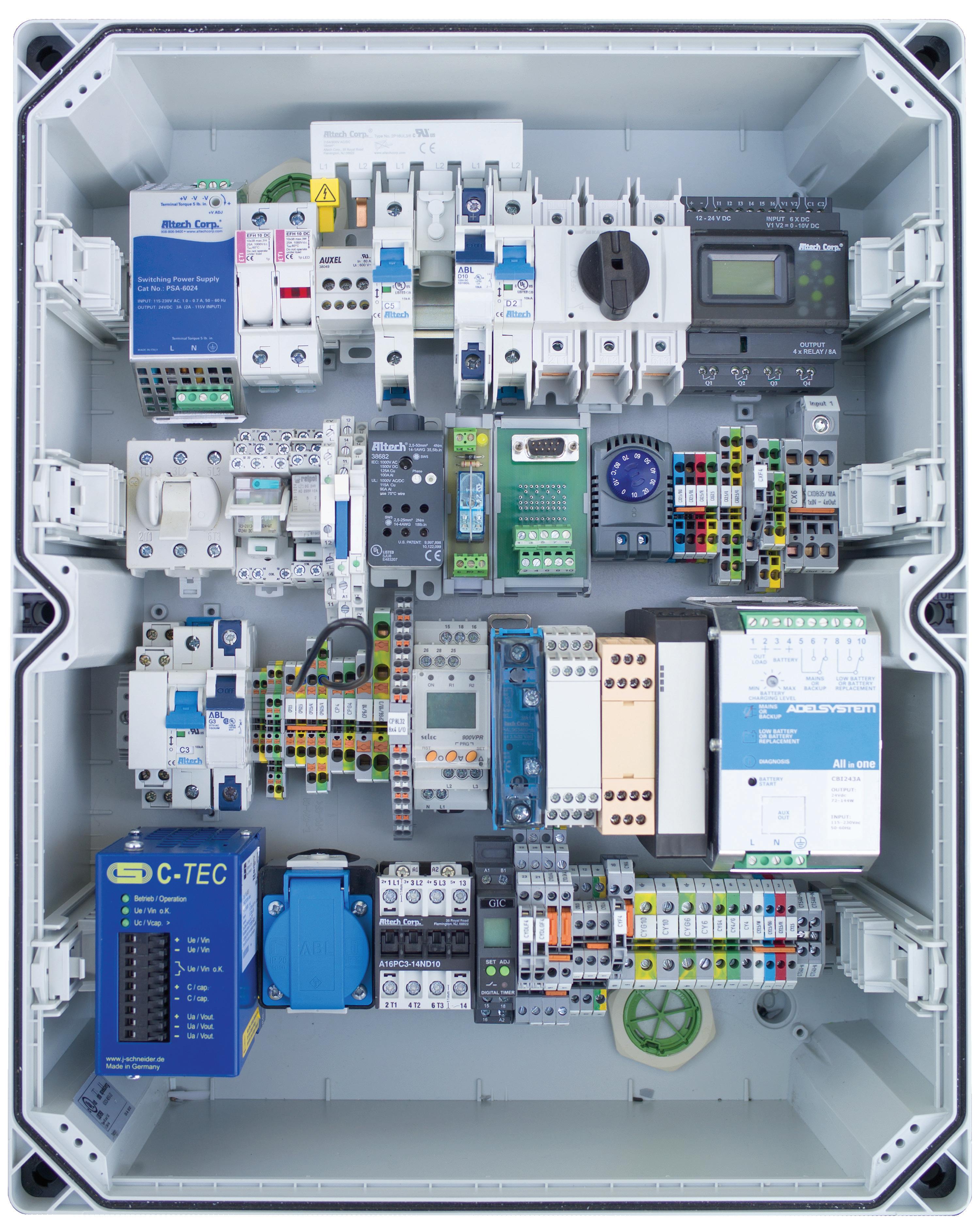

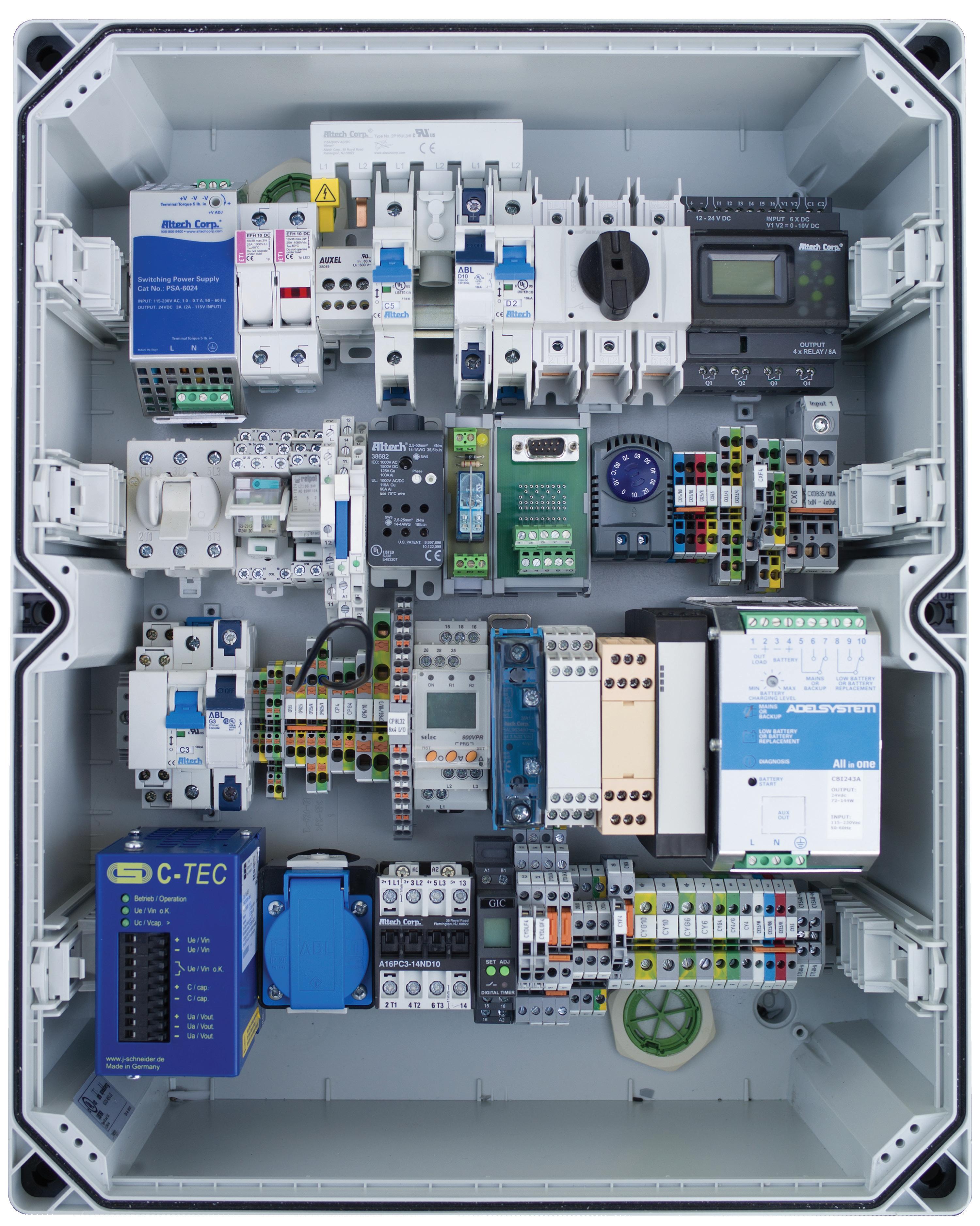

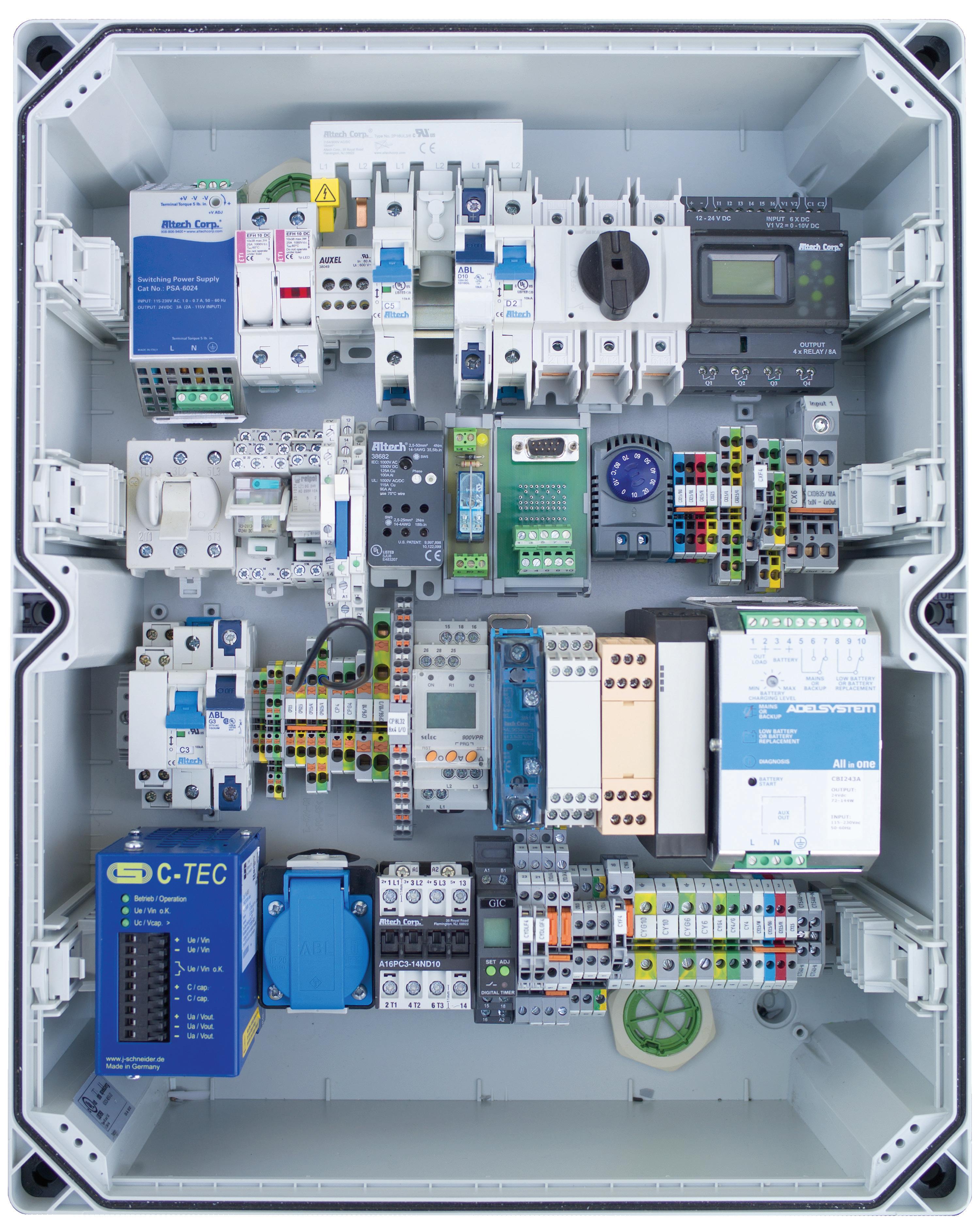

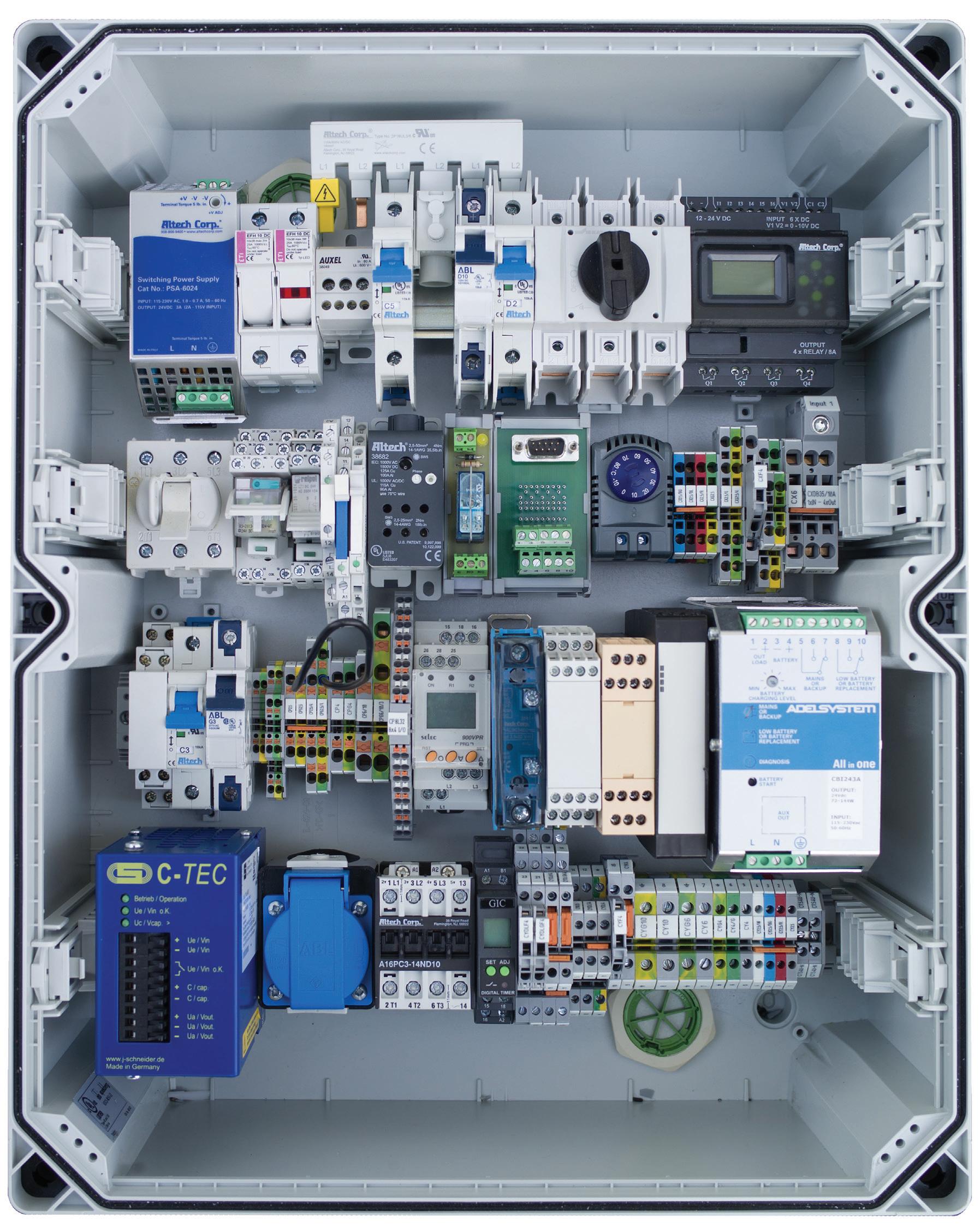

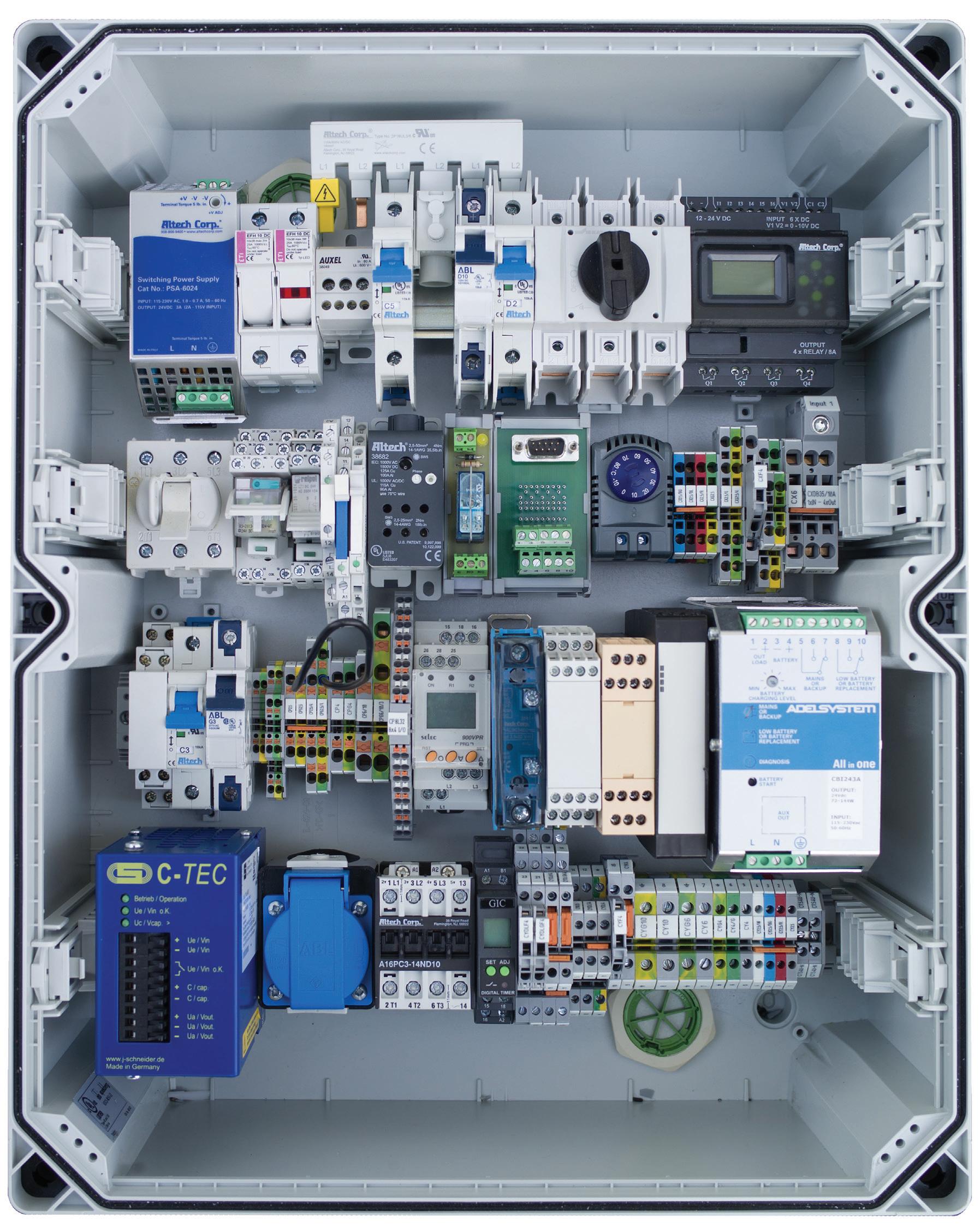

Trends in drives and controls

Drive and control technology has moved fast in the last decade. We asked leading industry experts to get us up to speed on the trends of today, and what to expect in the near future.

Without a cam follower, a cam would not be of much use, as cams must make contact with followers to transfer rotary motion into linear motion.

Help us honor the companies that have provided the most leadership in engineering

It has been a fascinating decade for all businesses, including manufacturers. We’ve seen the difficult supply chain issues brought on by the worldwide pandemic, along with a shortage of qualified workers and the strong reshoring trends in many industries. If nothing else, this helps to show how resilient manufacturers can be.

These companies represent the best and brightest, and they reflect the continued vision, integrity, and creativity of their design (and manufacturing) engineers.

We think they deserve recognition from you, too. Vote online for one or more of the companies listed through October.

EDITORIAL

VP, Editorial Director Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Senior Editor Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael

Associate Editor Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

CREATIVE SERVICES

VP, Creative Director Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Art Director Allison Washko awashko@wtwhmedia.com

Senior Graphic Designer Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Graphic Designer Shannon Pipik spipik@wtwhmedia.com @wtwh_shannon

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

WEB DEV / DIGITAL OPERATIONS

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Digital Marketing Coordinator Meagan Konvalin mkonvalin@wtwhmedia.com

Webinar Coordinator Emira Wininger ewininger@wtwhmedia.com

Webinar Coordinator Dan Santarelli dsantarelli@wtwhmedia.com

EVENTS

Events Manager Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

FINANCE

Controller

Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

VIDEO SERVICES

Videographer

Kara Singleton ksingleton@wtwhmedia.com

Videographer Cole Kistler cole@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative

Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative

JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative

Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager

Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer

Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist

Elise Ondak eondak@wtwhmedia.com

WTWH Media, LLC

1111 Superior Ave. 26th Floor Cleveland, OH 44114 Ph: 888.543.2447

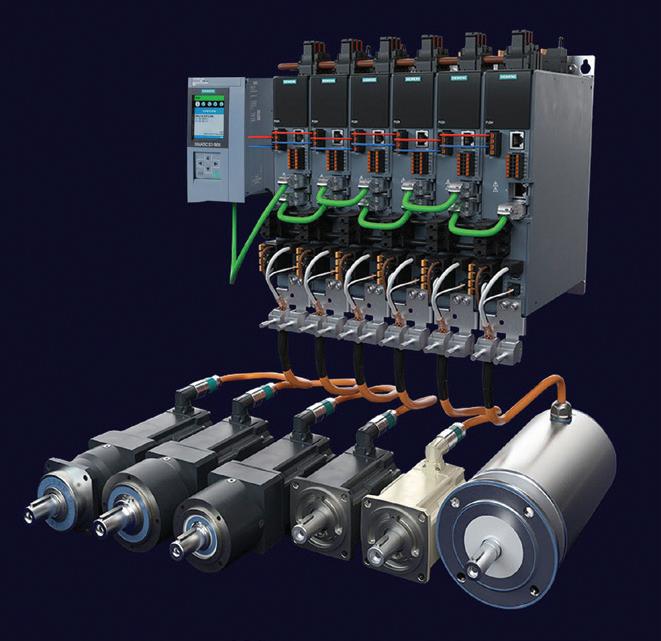

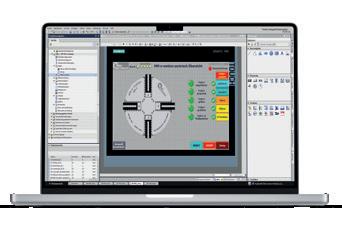

Servo drive systems are crucial in packaging applications as they offer precise, flexible, and efficient control over machine motion. Siemens has recently updated its well-known Sinamics S210 servo drive system with a new hardware architecture and V6 software generation, suitable for high dynamics applications ranging from 50 W to 7 kW.

The new generation of Sinamics S210 includes a second encoder interface and an optional connection to a direct measuring system that compensates for mechanical looseness and tolerances. This leads to significant improvements in precision, enabling more applications. It also complies with SIL3 (EN 61508) and PL e (EN ISO 13849-1) requirements, providing

Basic and Extended Safety Integrated functions and new Security Integrated functions with user management and access protection.

Apart from the Profinet IRT, the Sinamics S210 system also offers communication via EtherNet/IP. The servo system can connect to thirdparty controllers, providing a more comprehensive range of applications,

especially in the U.S. market. With its new 3C3 (H2S and SO2) coating, it is highly robust and resistant to aggressive environmental influences and challenging production conditions.

The EPOS single positioner is now a technology function module that implements high-precision motion control positioning tasks in the converter. Calculating positioning tasks directly in the drive reduces computing power in the controller, enabling it to compute more complex tasks or a larger number of drive axes.

Engineers can use the DriveSim Advanced simulation software to create a digital twin of the Sinamics S210 system in the TIA Portal, allowing them to commission the drive system virtually in advance and perform engineering tasks. The digital twin also enables virtual training and demonstrations and helps optimize real machines. The integrated Web server supports the new Web server platform and operating philosophy of the new Sinamics inverter generation (Sinamics S200 and Sinamics G220). The Web server enables efficient commissioning, fast diagnostics, and maintenance from tablets, PCs, and other devices. DW

Siemens • siemens.com

Tomorrow-R1 and Tomorrow-R2, the world’s first commercially built weather-radar satellites, were launched last year and orbit 550 km above Earth. These pathfinders include active and passive sensors for global weather forecasting, climate observation, and near realtime scans of precipitation and atmospheric profiles for any point on Earth. But to make use of all the data, they need reliable antennas.

Vitesse Systems announced the successful delivery of its first additively manufactured satellite antenna integrated into the Tomorrow-R1 satellite. The antenna was designed and tested at Vitesse Systems’ Longmont location (previously Custom Microwave). Since acquiring the business in 2021, Vitesse Systems has invested in two additional metal additive manufacturing machines and increased its design engineering capacity to streamline the development of complex antenna solutions. Vitesse Systems has also developed a range of proprietary finishing processes that enhance the surface characteristics of its antenna solutions, overcoming the limitations previously associated with additively manufactured antennae.

The company began working with satellite developer Tomorrow.io in 2020. As the team developed the preliminary antenna design, they realized they could optimize radio frequency (RF) performance and reduce the overall mass of the antenna with additive manufacturing.

Tomorro.io recently reported that its satellites now demonstrate high levels of accuracy over a wide range of precipitation rates and types. With AI playing a significant factor in weather forecasting capabilities, the datasets fueling AI are proving to be the differentiating performance factor. DW

Vitesse Systems • vitessesys.com

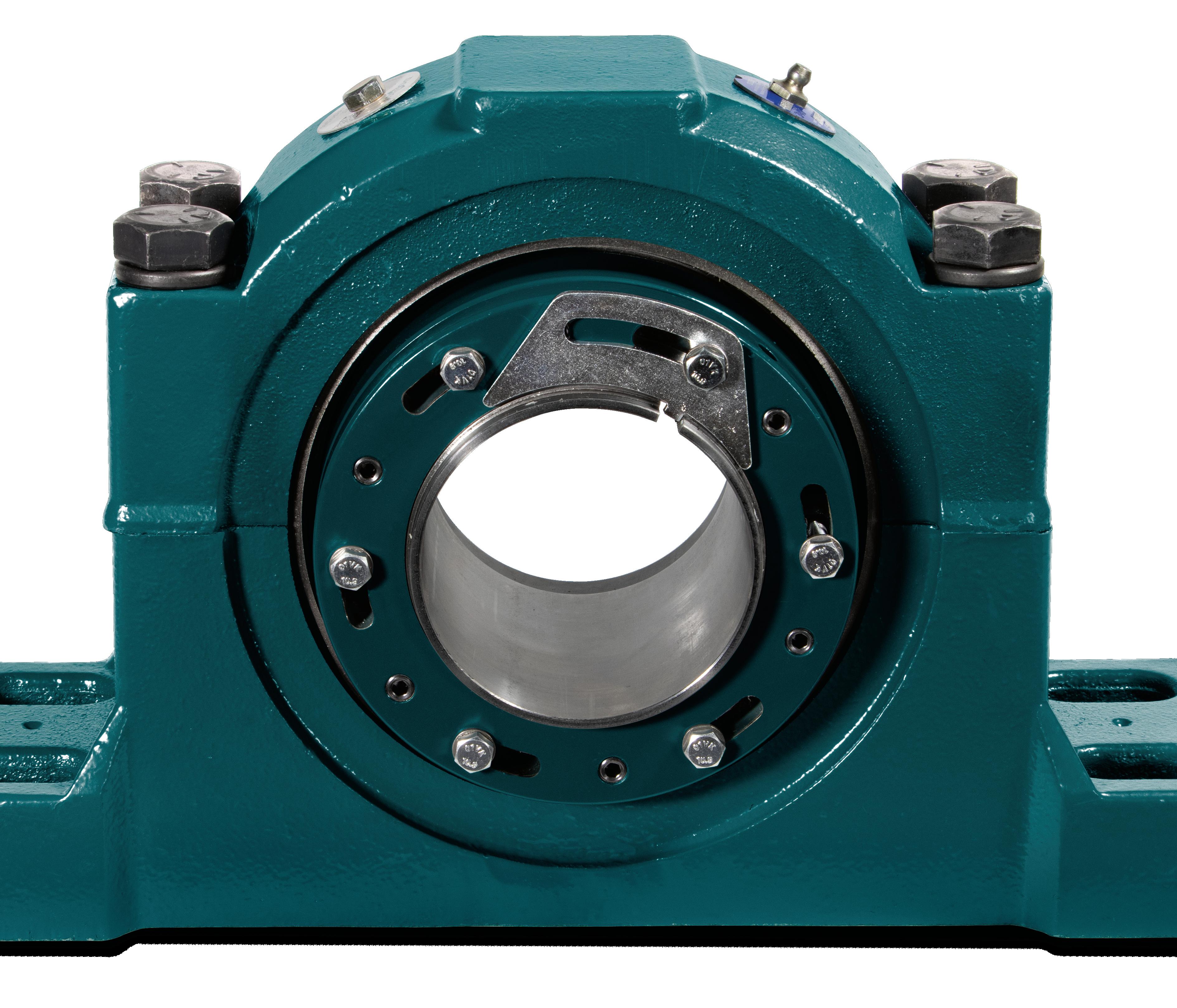

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly.

Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

Emerson recently collaborated with Sartorius, an international biopharmaceutical company, to natively integrate Sartorius’s Biostat STR Generation 3 family of bioreactors with Emerson’s DeltaV distributed control system (DCS). A manufacturing plant’s DCS provides critical automation of operations for faster, safer production. Life sciences companies often struggle to connect process equipment to their plant’s automation system because engineering and configuring equipment is complex and time-consuming. Biostat STR Generation 3, natively-integrated with a plant’s DeltaV DCS, eliminates this complexity for one of the most frequently used components of biopharmaceutical manufacturing. The bioreactors are specifically designed and pre-engineered with DeltaV components from the ground up by Sartorius. The configuration toolkit developed by Emerson and Sartorius has a library of templates that provide standardized configuration.

By integrating Emerson software and technology into our new Biostat STR DeltaV variant, we help our customers rapidly bring their operations online.

Using the library, teams can integrate bioreactors into their control system quickly and easily out of the box. Commercial manufacturing sites expect to save up to 80% of their equipment integration time, helping them take advantage of the enhanced features and diagnostics inherent in the DeltaV DCS more quickly and easily. The increased automation reduces the need for manual operation, ultimately increasing quality and speeding up time-to-market.

“One of the biggest barriers to fast delivery of new treatments is the time it takes to connect new equipment to the plant’s control system,” said Nathan Pettus, president of Emerson’s process systems and solutions business.

Biostat STR Generation 3 bioreactors integrated with Emerson’s DeltaV DCS are built with technologies, including DeltaV Electronic Marshalling with CHARMs devices, to reduce wiring and configuration work during installation. The bioreactors can integrate seamlessly with Emerson’s DeltaV PK Controller and S-Series and M-Series controllers. Built-in templates provide standardized configurations for the most common uses, allowing teams to use standard setups out of the box to bring operations online rapidly and safely and allow them to change those operations quickly to meet shifting market needs.

“The biopharmaceutical industry requires modular and scalable bioprocess equipment to help quickly and easily manufacture the treatments patients around the world are waiting for,” said Mario Becker, head of bioreactor technologies at Sartorius. “By integrating Emerson software and technology into our new Biostat STR DeltaV variant, we help our customers rapidly bring their operations online.”

The easy configuration and integration of the Biostat STR Generation 3 bioreactors integrated with the DeltaV DCS helps life sciences manufacturers build a connected plant, a core strategy of reaching level 3 of the Biophorum Digital Plant Maturity Model.

In addition, increased access to advanced automation strategies and diagnostics from the DeltaV DCS helps prepare the plant for the more predictive technologies necessary to meet level 4. Each step change in digital maturity brings plants closer to autonomous operations. DW

Emerson • Emerson.com

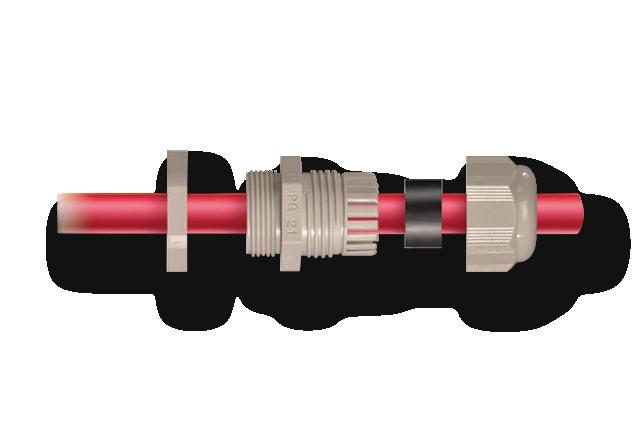

Subsea applications are characterized by constantly harsh conditions and extreme environments. In marine environments, various applications involve propeller shafts and components for underwater robots and telecommunication systems. However, in the presence of water, salt, and harsh elements, selecting just any bearing won't suffice — it's crucial to choose the right one for optimal performance and durability.

The World Corrosion Organization has reported that the global annual cost of corrosion amounts to $2.2 trillion, equivalent to more than 3% of the world's gross domestic product (GDP). When a bearing in a subsea industrial application begins to experience corrosion, it sets off a chain of detrimental effects.

First and foremost, the corrosion accelerates wear on the bearing’s raceways, rolling elements, and cages. This heightened wear and compromised surface integrity increases the bearing's susceptibility to the intrusion of abrasive particles and contaminants. These contaminants can further exacerbate wear and damage in critical components such as seals, gears, and other bearings.

Swift intervention and corrosionresistant bearings are vital to mitigate these risks and ensure the integrity and longevity of subsea equipment.

The lifespan of a bearing can be significantly affected when fully submerged, depending on the material composition. Take 440-grade stainless steel bearings as an example. While they exhibit high resistance to fresh water and weak chemicals, they are

prone to rapid corrosion when exposed to salt water or fully immersed in water.

440 grade stainless steel bearings struggle to withstand the corrosive nature of these environments, even with external protection such as passivation, leading to reduced performance and premature failure.

Passivation involves a metal finishing process that uses nitric acid or citric acid to eliminate free iron from the surface. This chemical treatment results in a protective oxide layer, reducing the likelihood of chemical reactions with air and preventing corrosion. However, in a marine environment, without protection from the elements, the passivated metal will eventually corrode. So, which material is best for subsea applications?

Ceramic bearings excel in corrosive environments, although they may

come at a higher initial cost. Ceramic bearings, such as Si3N4 bearings, don’t react with saltwater and many harsh chemicals, which can add consistent performance even when they are permanently submerged.

Reduced friction and wear

Ceramic bearings offer significantly lower friction coefficients than their steel counterparts, reducing energy consumption, improved overall system efficiency, and increased lifespan.

Zirconia (ZrO2) and silicon nitride (Si3N4), for ceramic bearings, have excellent corrosion resistance. These materials have a low friction coefficient, so they can even be used without lubrication in lower-speed applications. The exceptional hardness of ceramic materials also contributes to lower wear rates, extending the service life of

the bearing and reducing downtime for maintenance and replacements.

Resistance to debris and contamination

Subsea environments often expose bearings to debris, sand, and other contaminants. Traditional steel bearings will suffer from accelerated wear and failure under such conditions.

Because of their much greater hardness, ceramic bearings exhibit improved resistance to particle intrusion, although care should be taken to prevent contaminants from entering any bearing to ensure reliable operation. This feature lessens the risk of failure and enhances the durability of subsea equipment.

In applications such as subsea telecommunication systems, the choice of bearing is critical to ensure reliable and efficient signal transmission across undersea fiber optic cables.

One of the critical benefits of ceramic bearings is their non-magnetic properties, which play a crucial role in preventing electromagnetic interference with signal transmission. As subsea telecommunication systems rely on precise data transfer over vast distances, any magnetic interference could lead to signal disruptions and data loss.

By using non-magnetic ceramic bearings, these systems can maintain the integrity of their signal transmission, ensuring uninterrupted communication between continents and enhancing the overall reliability and performance of subsea telecommunication networks.

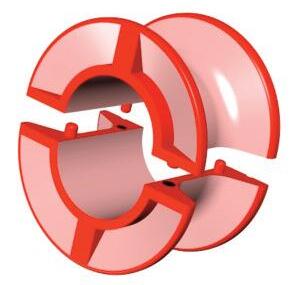

Full ceramic bearings, made from zirconia or silicon nitride with PEEK cages and seals, offer superior corrosion resistance in marine applications. Since ceramic bearings are not affected by seawater, they can be used in marine environments where they are permanently submerged and can cope with higher loads.

Ceramic bearings are mainly used in environments that are too hostile for steel bearings, where heavy shock loads are unlikely — due to the brittle nature of ceramics. SMB Bearings ZrO2 bearings possess several advantageous properties. They are non-magnetic and non-conductive, making them suitable for various applications.

Additionally, they exhibit high corrosion resistance against a wide range of chemicals. Their waterresistance further enhances their suitability for marine applications, particularly in fully submerged scenarios or situations where the load or speed exceeds the capabilities of 316 marine grade bearings.

Because corrosion comes at a high cost, and can cause wear and tear on bearings, choosing the most suitable bearing material at an early stage can help subsea operators prevent downtime, unplanned rework, and costly replacement parts. Investing in ceramic bearings, which are completely corrosion-resistant and have a long lifespan, will help avoid disturbing the application and maintain a steady workflow.

SMB Bearings • www.smbbearings.com

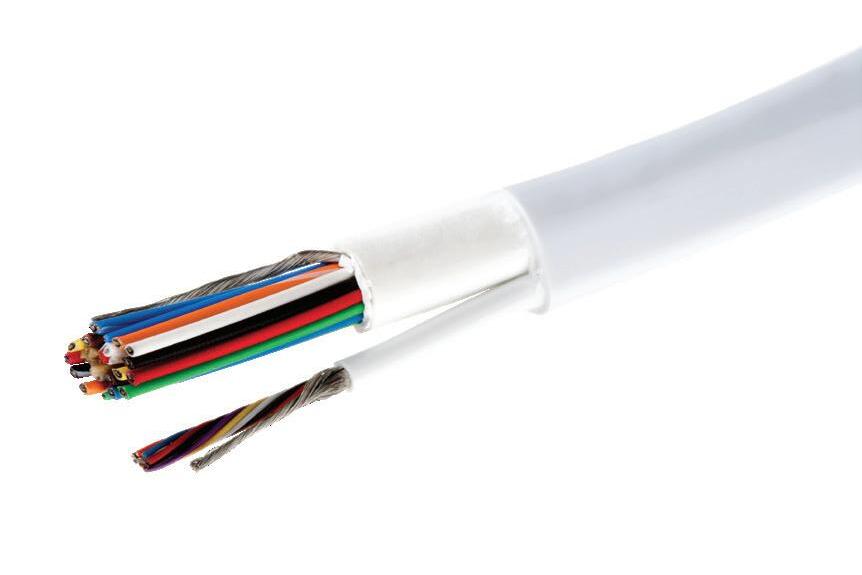

Interpower North American and international cord sets

Interpower manufactures state-of-the-art electrical cord sets for global markets with no minimum order requirements. Interpower cords and components are

in accordance with its product quality plan: hipot testing, continuity testing, and ground testing with multiple inspections. Interpower offers value-added options such as lengths, colors, packaging and labeling!

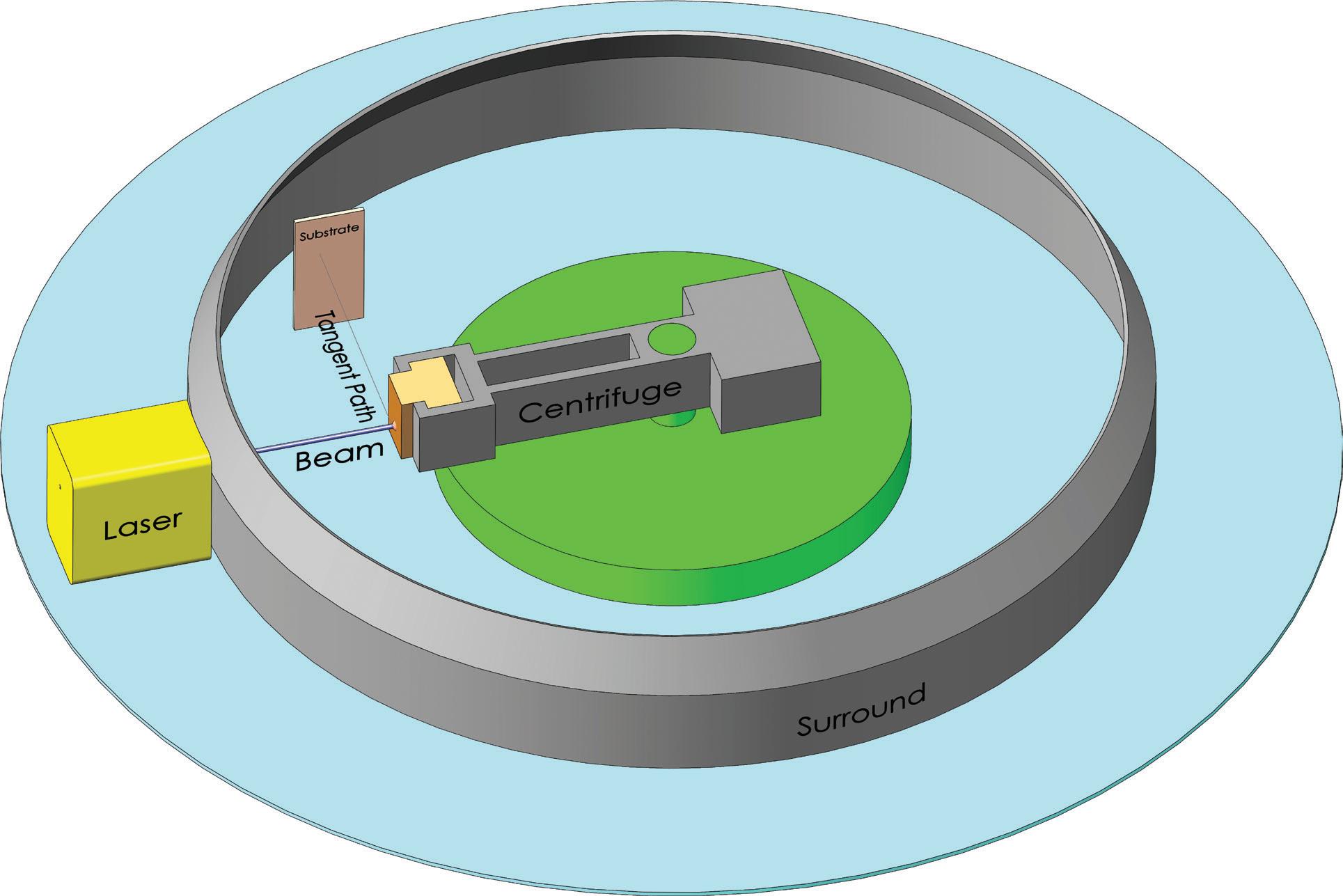

The tangential laser-centrifuge process is suitable for manufacturing small and very detailed parts, such as microchannel cooling devices used as heat sinks for CPUs typically performed in vacuum or clean room environments. Inserts for injection molding dies with tiny channels can also benefit from the tangential machine process by focusing the laser on very small areas to remove metal. Conversely, conventional machining uses very small bits that can easily break while removing material. This technology allows for making deep holes without debris precipitation on the sides of the hole that ablation machining produces.

Tangential machining removes material and can deposit material, such as in 3D printing. Using a spinning

mass of material with a pulsed laser, microdroplets directed in a straight line can be deposited on a substrate to build up material layers. Through precise control of the substrate position, complex parts can be formed. Since the laser can pulse in femtoseconds, the material stream can be deposited faster than current 3D printer technology.

Tangential Systems background

Lasers have been used for both cutting and machining. Light from the laser heats the workpiece material, which must be removed. For laser cutting, the molten material, dross, is usually blown from the cut with a jet of air or gas and can spray on surfaces that then require cleaning. In laser machining, the laser pulses are short and powerful. The

intense laser light ablates material, which ejects as a vapor plume that condenses and precipitates on surfaces. The vapor can also create byproducts that can be noxious. Thus, removing the heated debris requires additional technologies to mitigate.

The Tangential System (Patent US7933680B2) provides significant advantages by attaching the workpiece to a centrifuge. The laser-heated material is removed instantly by centrifugal force. The released material can fuse to a substrate to form a separate object (using the released material for 3D printing).

Advantages of the Tangential System include:

• High-speed material removal. The Tangential System removes material at more than twice the rate compared to typical high speed CNC machining.

• No tooling. Instead, the material is energized and released by a laser, eliminating the time to change tools.

• Materials to be formed. Lasers can inherently process a vast multitude of materials, including plastics, metals, composites, glass, and minerals. The type of laser can be matched with the material to achieve good energy absorption.

• Shapes and setups. Virtually any shape can be formed using this system as long as the working

surface is visible to the laser beam.

• Machine mass and energy. In the Tangential System, all that touches the workpiece are laser beams. Thus, the entire system can be made of lightweight materials.

• Minimal heat affected zone. The centrifuge instantly removes all hot material from the surface. Therefore, heat in the debris has no time to warm the surrounding work.

• Precision. Debris is instantly removed so the new shape can be measured virtually and concurrently with material removal.

• Efficiency. The laser only needs to provide enough energy to release the material, which lowers the energy requirement of the laser. Additionally, some of the energy used to rotate the centrifuge can be retrieved through regenerative braking. The total energy required for material removal is minimized. As a further benefit, the removed material can be concurrently used to manufacture additional forms.

• Cleanliness. The debris is removed from the workpiece in a specific path. The debris material can then be used to form another object or stored for later use. The minimal heat used minimizes noxious gases and byproducts.

• Concurrent subtractive and additive manufacturing. The material released by the laser can be directed to add the hot material to a separate structure.

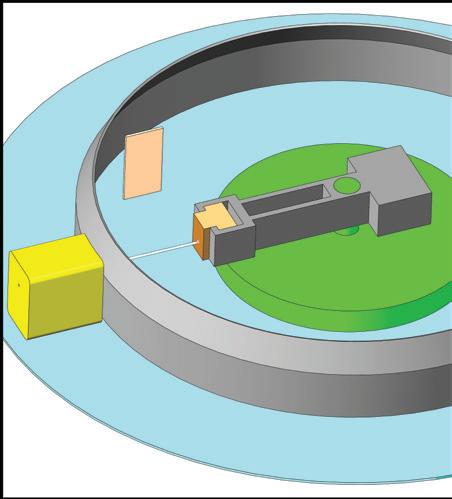

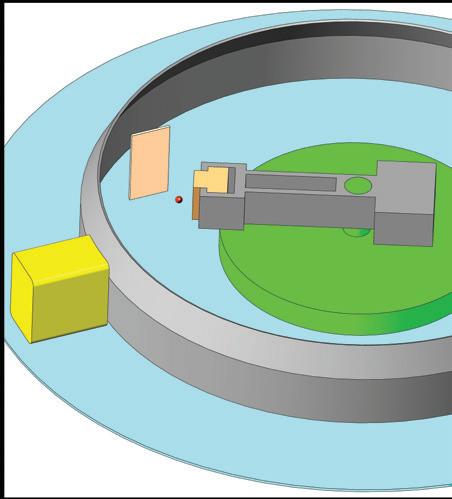

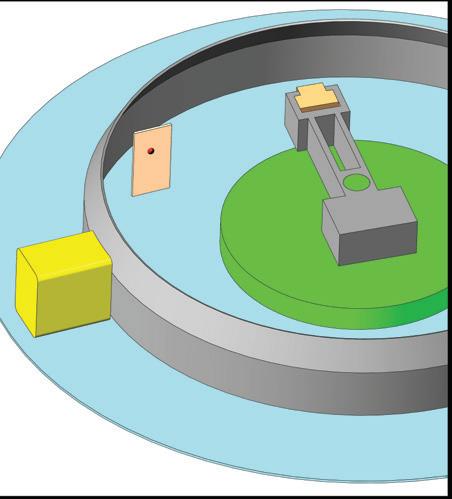

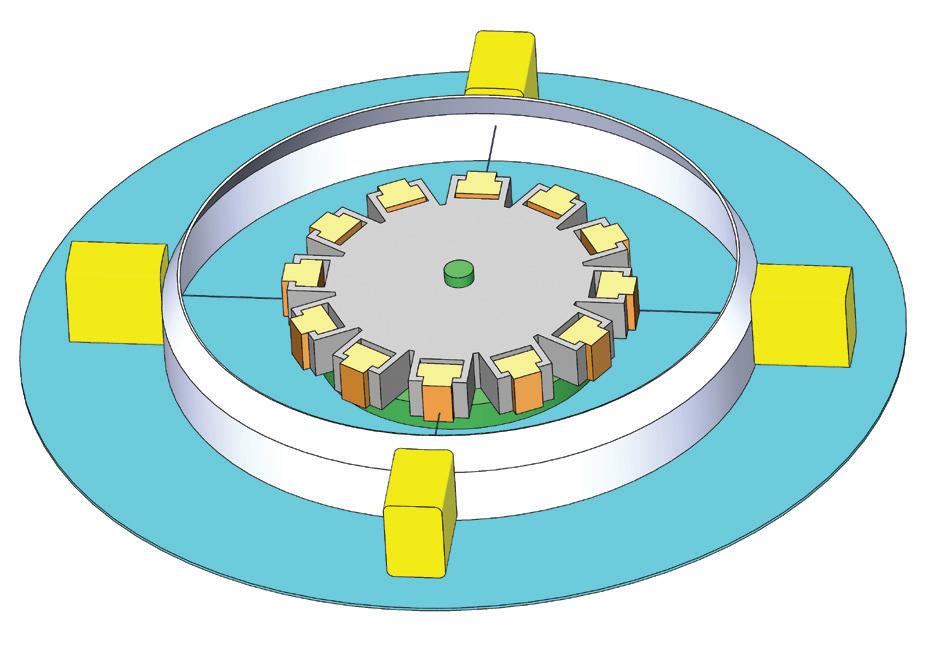

How Tangential System manufacturing machines work

The Tangential System can perform material removal and addition

concurrently. Material removal is performed by attaching a solid workpiece to a centrifuge. When the centrifuge turns, centrifugal force acts on the workpiece and creates radial acceleration, which can be many times the acceleration of gravity. As the centrifuge spins, a laser beam focused on the workpiece adds energy to the bonds that hold the material together. As the bonds are weakened, the heated material is released and travels in a tangential path away from the workpiece. The released material is typically hot and travels at high speed. A substrate placed in the tangential path acts as a target for this material. With each turn of the centrifuge, additional material is added to the substrate in a directed and controlled manner. As a result, formed objects can be created concurrently — first, from the workpiece on the centrifuge as the material is removed and then on the substrate as the material is deposited.

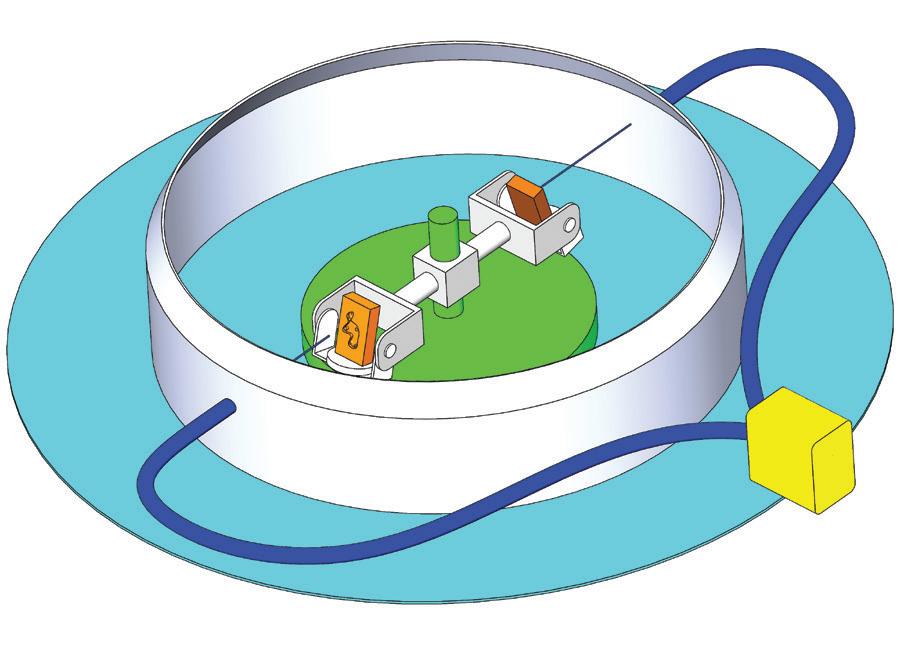

Figure 1 shows the basic components of the machine, Figure 2 shows the process in four steps, and Figure 3 shows configurations that can be made from the basic design.

This manufacturing technique can be used in many applications because of its ability to process any type of solid in an accurate, precise, fast, and efficient manner. The Tangential System provides the technology for material removal rates many times that of traditional technology. This energy-efficient system can effectively process many types of materials and does not require investments in cutting tools or heavy machinery. In

conventional machining and laser ablation machining, vibration and the explosive removal of material induce stresses in the workpiece material, changing the material properties and the heat-affected zone. The Tangential System does not have these side effects and can produce detailed features in fragile materials that would otherwise be impossible to manufacture. Advanced additive manufacturing can also be achieved where composite materials are formed in product construction.

Additionally, there is a need for both subtractive and additive manufacturing in space applications. A machine for these tasks must have low mass to enter orbit, and the Tangential System meets such requirements. Further, it provides the flexibility to process a variety of materials and construct composite structures while using minimal energy. DW

Thelast decade has seen advancements in controls and motor drive technologies to boost efficiency, safety, and ease of use. Now commonplace are drives that:

• Let end users leverage autotuning functions for faster commissioning

• Detect and correct for vibration issues — including the shaping of power into motors to avoid resonances

• Spur increasingly compact motors to beyond rated speeds

• House sensing capabilities and memory to support predictive maintenance initiatives

• Perform realtime monitoring for continual efficiency optimization

• Sport safely limited speed and safedirection features.

Controls on the other hand are the basis of software-based automation in applications requiring flexible solutions for frequent changeovers; digitaltransformation connectivity; and distributed control using ruggedized control components. We recently asked industry experts for their own observations and insights into the most important drive and control trends today. Here’s what they had to say.

T. Burke: Products in general are becoming more sophisticated and competitive. For example, servodrives are now equipped

with torque measurement and encoder technology that is so accurate that it can automatically detect vibrations, manage acceleration, and deceleration. At the same time, improvements in components and manufacturing processes are delivering greater tolerances and quality in hardware. In the case of communications, the latest technology is gigabit Ethernet and the ability to schedule communications through time sensitive networking (TSN). CC-Link IE TSN is a leading performance industrial Ethernet network technology available in a broad range of vendor products.

Worsnopp: Two trends in servodrives we’re seeing include ease of integration and advanced safety. From the sizing and selection of servos to their configuration and programming, machine builders today expect the use of servodrives to be easier than ever. After

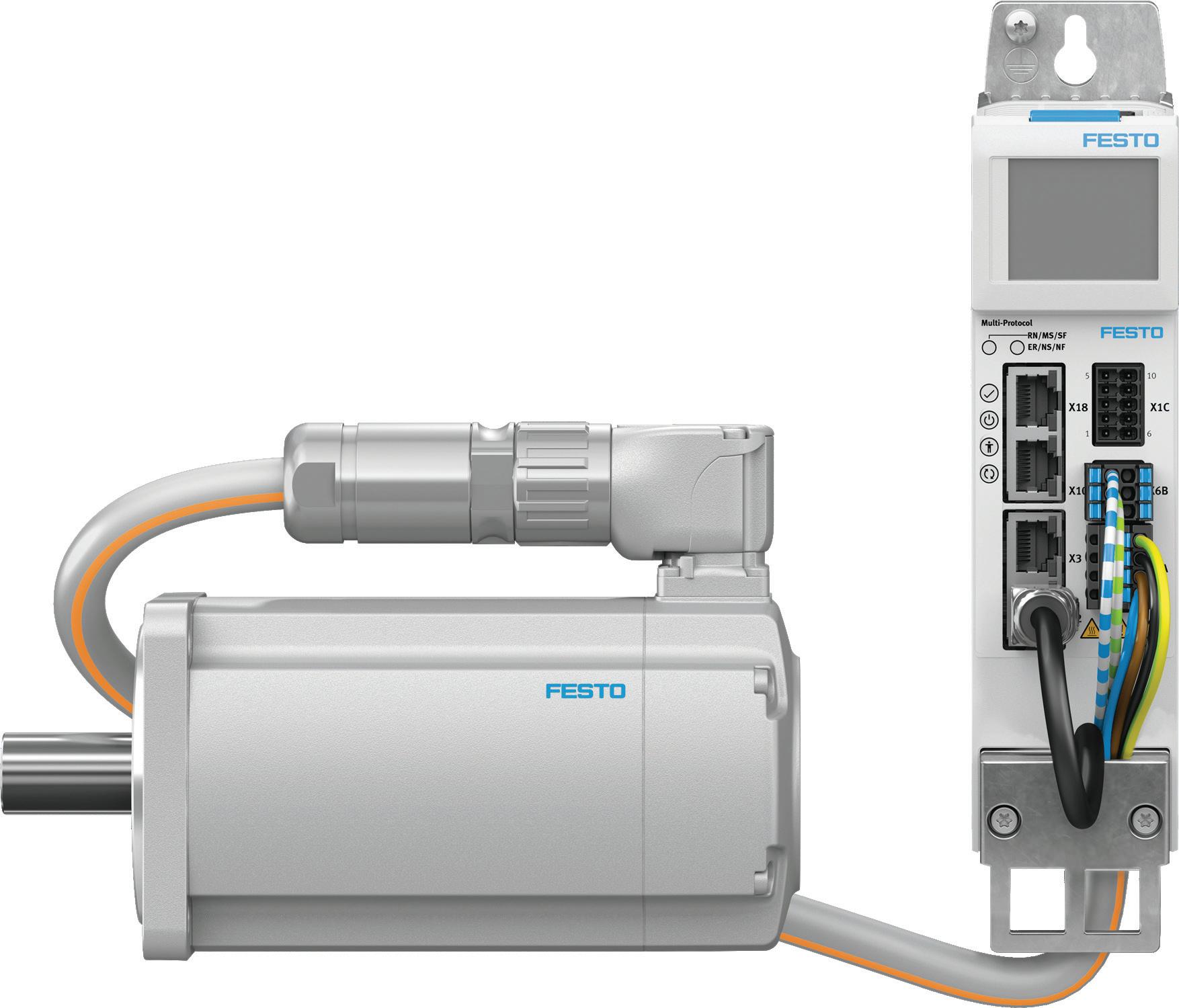

all, we’re all surrounded by consumer technology such as smartphones, smart TVs, and cars that are exceptionally easy to use. This leaves us all with the impression that technology should be accessible. Manufacturers have also improved servodrive buying processes. For example, Festo provides easy-touse tools for sizing servo axes and configuring their servodrives along with function blocks to simplify servodrive programming.

Guitart: Rockwell Automation and Infinitum are jointly developing a motor system combining Rockwell’s PowerFlex drive technology and Infinitum’s high-

Festo provides easy-to-use tools for sizing a servo axis and configuring servodrives. Festo units feature function blocks to simplify programming the servodrives. Shown here are the EMMT servomotor and CMMT-MP multiprotocol drive.

With encoders so essential to motor drive systems for position feedback, velocity control, and error correction, safety capabilities, and diagnostics, it’s no surprise their design and application have advanced as well. Here’s what four industry experts had to say on this.

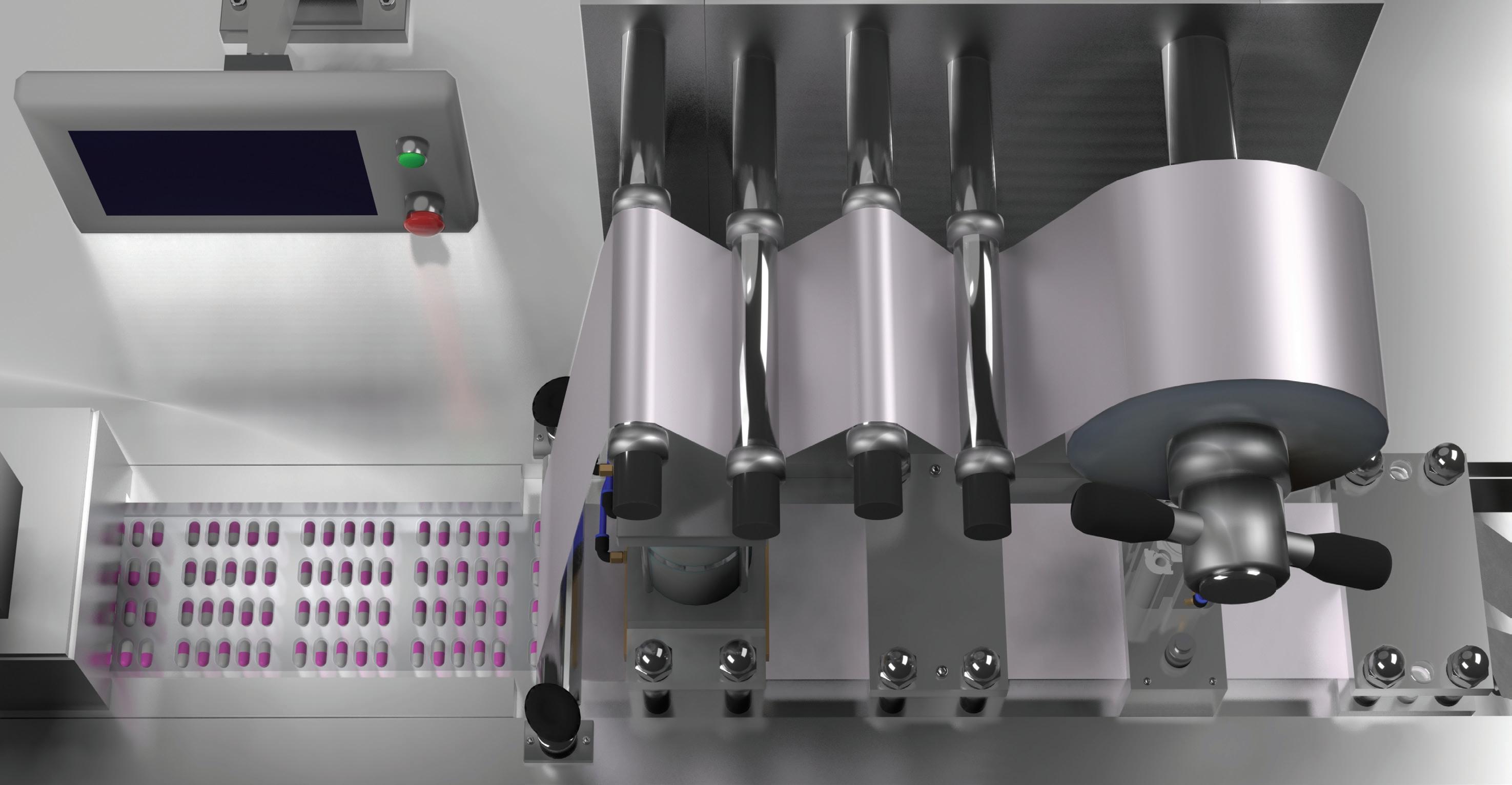

Brimage: Encoders provide realtime feedback on load position, which is critical for high-precision, linear motion applications. We’ve seen increased application of encoders due to linear motion systems requiring more precision than ever. The demand for highprecision systems in medical, life sciences, and factory automation is saddled with demand for more compact systems as well.

Beckstoffer: Motor feedback is always critical in medical applications, particularly drug-delivery devices, to ensure accurate dosing to the patient. With these devices getting smaller to enable patient mobility, feedback devices must continue to shrink in size while providing the proper counts per revolution. Magnetic encoder technology is allowing the size reduction for closing the loop for dc motors.

Brimage: In support of the industry pushing toward miniaturization, we have also seen an increased demand for smaller encoders. Thomson has a complete offering of stepper motor linear actuators with integrated encoders to enhance precision positioning control with a range of sizes that are compatible with small motors.

Soltero: We’ve observed a trend towards absolute encoders with analog outputs to help systems efficiently handle higher resolutions. In some cases, when customers seek to increase the resolution of their existing incremental encoder designs, they typically use a higher pole-count ring magnet (if one is currently used) as well as digital-output Hall-effect latches. This combination is employed because higher pole-count magnets produce a weaker magnetic field, necessitating a high-sensitivity Hall-effect latch. At some point, the design reaches a limit on the number of poles due to costs associated with the magnets and latches. Once this limit is reached, designers typically transition to absolute encoders with analog outputs.

Graham: The latest trend we’re seeing in motor feedback is encoders assuming more sensing tasks with a common communication channel back to the drive-control system through the encoder interface. Things such as temperature sensing, vibration sensing, and torque sensing are all possible to do with the integration of certain encoders. As we move to support these features, we’ve also improved our communication interface with EnDat 3.

efficiency Aircore EC motor system. The solution aims to help companies reduce their carbon footprint with a motor system that’s 50% smaller and lighter than traditional iron-core motors all while using 66% less copper and consuming 10% less energy. The motor and lowvoltage drive solution will be distributed through Rockwell to let global industrialsector clients deploy a sustainable motor system and cut energy consumption.

Worsnopp: It is still early in this trend, but we are seeing more requests for servodrives that incorporate advanced safety functions such as safe limited speed. Historically, servodrive safety was implemented outside the servodrive using safety relays and safety controllers. Over time, more safety functions have integrated into the servodrives themselves; this in turn saves machine builders time and increases machine reliability. For example, safe torque off (STO) is now a standard safety function included in many servodrives. STO

makes it possible for the machine builder to easily cut power to the motor … and that makes it safer for an operator using the machine.

As automation becomes more sophisticated, machine builders are likewise requiring more advanced safety functions that let them run their machine and reduce the risk of harming personnel. For example, with safe limited speed on a servodrive, it’s possible for machine builders to keep a machine in motion (typically at a safe reduced speed) and monitor that speed to ensure it’s prevented from accidentally moving too fast.

Advanced safety functions are becoming more common on servodrives, and we can expect to see more manufacturers offer them in the future.

Korkowski: LinMot’s Multi-Interface drive is compatible with Ethernet IP, PROFINET, EtherCAT, Powerlink, SERCOS, and CC-Link. As a single product to satisfy multiple designs, this

drive offers quick lead times. Our drives also feature process monitoring for pass or fail and force control as a software solution to support various design options.

Ledoux: We are seeing an increased demand in motor speed controllers to be installed in remote areas requiring outdoor packaging dedicated to the component instead of what is typically provided — a climate-controlled building.

Guitart: Integrated motor and drive solutions from Infinitum are making installation and serviceability in the field easier … and improving uptime and equipment reliability. For instance, new designs feature user alerts that identify specific problems for faster resolutions as well as removable access panels for easier access to terminals, connectors, and programming ports.

With conventional motors, it can take up to two weeks to have service requests fulfilled. New Infinitum motors are built for end user serviceability.

Infinitum can train a company’s internal technical service team to do repairs in about 15 minutes, so end users have more control and flexibility. In data centers and manufacturing lines where uptime is of key importance, this is a desirable and differentiating capability.

Luchars: ECM recently launched an integrated and customizable electric motor controller — a 5-kW Unum Potentia controller leveraging PCB Stator and PrintStator Motor CAD platform while helping deliver 98% efficiency. When combined with a PrintStatordesigned machine, the controller allows IE5 ultraefficiency electric-motor performance. With a near100% efficient controller versus one having 80% to 90% efficiency, the system consumes less energy than traditional alternatives.

The new motor controller will be available to PrintStator SaaS clients and partners for roughly a tenth the cost of controllers supporting similar electric-motor kW ranges. With this controller, engineers can fully integrate PrintStator designs and design a drive-controller perfectly tuned to the full electric system.

PrintStator software allows the custom design, manufacture, and integration of PCB Stator electric motors. The motor controller is customizable via PrintStator and structurally and thermally integrated to the resulting motor housing for a compact footprint (and full motorsystem optimization). In fact, the software can output motor-tuning parameters and translate those into a code file that uploads to the controller. This makes the motor system design truly plug and play. The controllers can run 3 to 8-kW motors board-component changes; the board footprint always stays same. The Unum Potentia controller also operates and 480 three-phase ac offers sensorless control of running motors down rpm; and (with its FETs) upwards of 100 kHz. DW

• Dave Beckstoffer: Industry manager • Portescap

• Kurt Ledoux: Business director — medium voltage drives • Yaskawa

• Lindsey Brimage: Product line manager – lead and acme screws • Thomson Industries

• Manny Soltero: Product marketing engineer • Texas Instruments

• Mike Korkowski: Operations manager LinMot USA

• Ramon Guitart: VP of engineering — electric motors • Infinitum

• Robert Luchars: Executive VP • ECM PCB Stator Technology

• Stuart Graham: Business Development Specialist • HEIDENHAIN Corp.

• Thomas Burke: Global strategic advisor • CC Link Partner Association (CLPA)

• Tom Worsnopp:

Without a cam follower, a cam would not be of much use, as cams must make contact with followers to transfer rotary motion into linear motion.

One of the most crucial components and systems within machinery is the cam and follower set. Cams are rotating elements that vary in shape and size and are typically attached to a rotating shaft. A cam follower directly contacts the cam, typically riding atop of it, and transmits the rotary motion of the cam into a linear motion.

As for the cam followers themselves, they are devices with a rotary bearing core that bears load while serving as the interface between independently moving machine sections. Another way to think of cam followers is that they are essentially a type of bearing, typically a needle or roller bearing, designed in a way to follow a cam lobe profile.

Perhaps the most well-known example of a cam and follower is that of a camshaft in a car. The goal of a cam is to convert rotary motion to linear motion and there are multiple types of cams, including cylindrical and plate varieties.

Cam follower bearings, also known as track followers, can come in various designs, but are generally made with an extra thick outer ring. This design allows cam follower bearings to handle high radial loads, while a soft core can accept extreme shock loads without threat of fracturing the part. Depending on the application, cam followers may require either ball or needle rollers or even special materials such as stainless steel or chrome.

The outer diameter (OD) of the cam-follower bearing assembly is its working face — typically made of steel, nylon, urethane, polyamide, or other engineered material. This OD mates with some machine surface; traditionally this was a mechanical cam of some type, such as the precision barrel of an indexing table. Such mechanically automated indexing tables have a motion profile cut into a cam drum that engages the followers, which in turn transmits the power to an output.

Cam followers assemble onto machines in one of two ways. Stud-type cam followers include a partially threaded shaft fixed to the follower inner diameter (ID) for assembly onto a machine frame with a nut or similar fastening device. Yoke cam-follower variations (identifiable by their open ID) often mate to machine frames via press fit at a hardened inner race usually held by the follower’s end plates. Because they’re not a cantilevered design, yoke followers exhibit minimal deflection. But stud cam followers are indispensable in an array of applications — including those that are subject to high loads.

The most common cam-follower design employs needle rollers to carry high radial loads; where applications require the axis to run at high speeds, a cage can separate the rollers.

Where loads are particularly high and the axis needs high dynamic load capacity, cam followers can include twin rows of standard rollers. In fact, some lightload cam followers are even built around simple plain (sleeve) bearings.

Note that cam followers differ from their rollerbearing cousins in a few ways. Because the latter are typically interference fit into assemblies, they get circumferential reinforcement from the surrounding machine frame or housing. In contrast, the outer race of a cam follower must be thick to prevent deformation, especially under the localized line of loading. In addition, many cam followers include lubrication ports and more ruggedized surface finishes to withstand exposure to environments during operation — particularly those that operate exposed on unprotected machine sections.

Many cam followers have flat OD profiles, while others (especially those for linear-motion applications) include crowned, edge-flanged, or vee-shaped ODs to engage tracks and rails that are engineered with mating geometry.

Crowned cam followers can compensate for ten times as much misalignment as traditional flat-profile cam followers.

Interested? Get your free sample now:

This press applies up to 3000 tons to

form composite automobile panels. Delta’s RMC does multi-axis control of position and pressure to keep every moving part in perfect synchronization.

Look to Delta RMC motion controllers and graphical RMCTools software to make complex motion design easier, smoother, and more precise.

For the complete case study featuring Wuxi LANLI Machine Tool Co. or others relevant to your industry or application, visit our website.

Watch our training videos to witness firsthand how Delta Motion can make your application work in perfect, precise harmony.

Some cam followers serve as track followers by engaging rails to deliver linear motion. These designs are increasingly common in automated storage and retrieval systems (AS/RS) and seventh-axis robot transfer units (RTUs).

That’s because cam-follower-based linear systems outperform the linear bearings known as profile guides where compactness and ultra-high accuracy are less important than ruggedness, quick and forgiving installation, high-speed reversals, and long life.

Applications for cam and follower sets range widely over many uses and industries, including in machine tools, industrial robots, electronic parts production, and office automation equipment. More specifically, cam followers are found in rotary indexing tables and turntable conveyors, longstroke RTUs, and an array of highly customized machinery. Cam followers also find use in assemblies that pair them with linear tracks and other engineered paths on customized assemblies.

More recently, new cam follower designs for limited space are being offered by manufacturers. For instance, IKO International’s CFC…B Series of short stud-type cam followers have a unique mounting structure that solves space limitations that often exist on the stud side of the assembly region, thereby satisfying mounting requirements without sacrificing performance.

The CFC…B cam follower’s mounting structure consists of a hexagon socket head bolt and a dedicated flange nut that not only creates a more compact cam follower, it reduces the required mounting space on the stud side by up to nearly 34% — far more than conventional cam followers. By providing greater design freedom, this cam follower family can enhance production efficiency for a wide range of applications across many industries such as robots, electronic devices, manufacturing, and automated equipment.

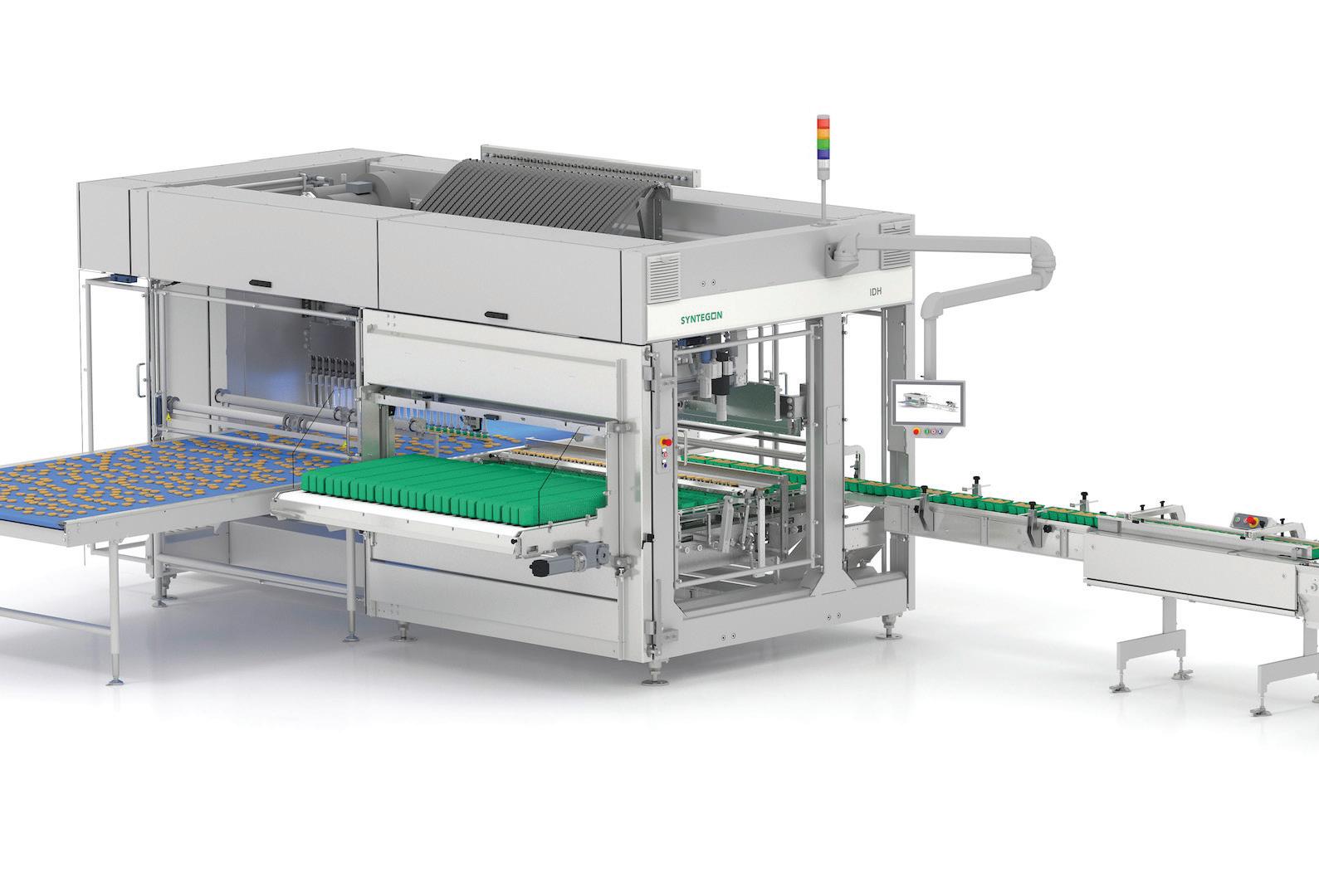

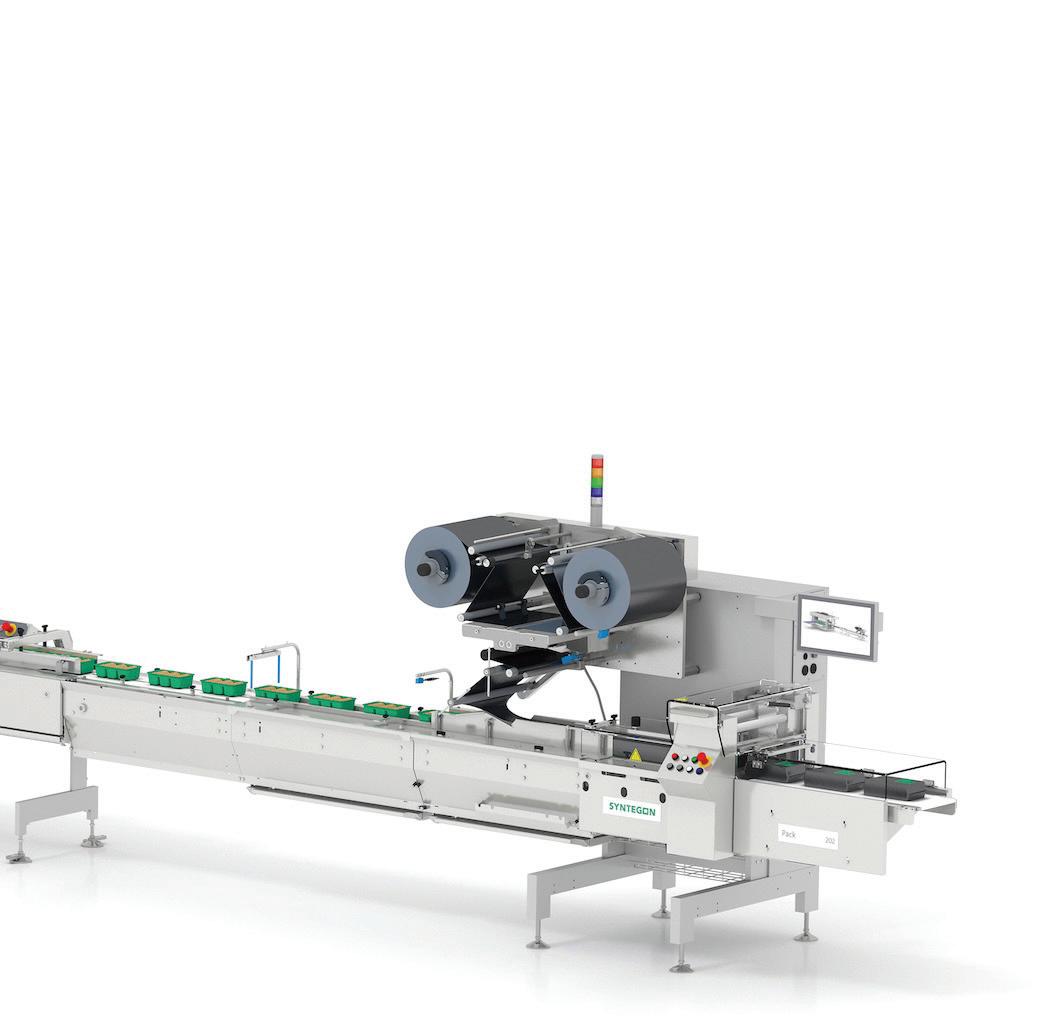

Packaging machinery uses cutting-edge automation, and it’s no wonder. Facilities that parcel products need to deliver high throughput, but modern consumers demand smart packaging in the form of no-fuss containers that protect everything from M&Ms to patio furniture. What’s more, there’s a continuous drive to customize packages and let consumer-facing companies wrap products for bulk distribution, single-item sales, and everything in between.

To satisfy these design objectives, packaging machinery over the last decade has become increasingly adaptive. That’s been evident in a range of motion components and fully integrated designs at recent Pack Expo events. More specifically, the newest adaptive machines are:

• Modular (so they can be reprogrammed if not physically reconfigured on the fly)

• Fitted with HMIs (to let operators feed high-level operational data into machines as needed)

• Based on components that satisfy the efficiency, safety, and networking standards of multiple regions.

At the core of all these sophisticated elements are motion-control and power-transmission mainstays. Most all packaging machines include mechanical frame and powertransmission elements (including linear motion drives and guides); motors and drives; and motion controllers not unlike those used for the last 40 years in mechanizing and automating equipment. However, the accuracies and other performance characteristics of these machines’ power-transmission elements have steadily evolved and improved to complement the latest servomotor offerings (synchronous ac and otherwise) as well as increasingly advanced electronic control capabilities.

Though the accuracy and repeatability requirements of packaging equipment can be more modest than those for medical or semiconductor manufacture, the need for throughput is unrivalled — with many machines processing thousands of items per minute. Accompanying this need for high output is a need for reliability and consistency. That’s true whether discrete product pieces are of some consistent mass or (in the case of filling and packing) variable.

Consider the retail-ready packaging that some machines assemble — the product-packed pallets increasingly common in club stores such as Costco and BJs. The machines that put these shelf-ready displays together rely heavily on servo-driven stations and robotic arms that usually interface a conveyor. In a typical setup, the conveyor takes product to a station that orients individual units for grouping; then the modules travel on the conveyor to subsequent stations that group packs into patterns that let retailers use larger cartons for shipping, stacking, and displaying items once they’re in stores. Setup of such machines is almost always through HMIs.

In many cases, next-generation machines capable of assembling retailready displays must also incorporate sensors and networking fast enough to log dozens of mixed stock keeping units (SKU product codes) per minute.

For example, a maker of pita bread and sandwiches might employ servodriven cartoning machines to boost productivity and flexibility. For this application, vertical cartoner arrangements can assemble cartons having different item counts. For large retailers and club stores, this might involve four, six, 12, and 14-count cartons … necessitating a machine design that lets operators (via a touchscreen HMI) make speedy changeovers to different carton sizes — typically a dozen or more times a week. With modern drives and controls, such changeovers can take as little as 10 to 15 minutes.

In many cases, even the OEMs who build such cartoner packaging machines benefit from the automation and reduced mechanical part counts of servodrive-based equipment.

Automation in packaging has reduced labor costs and boosted efficiency for large makers of consumer goods. Now, smaller operations up and down the supply chain have also found ways to leverage automation’s benefits.

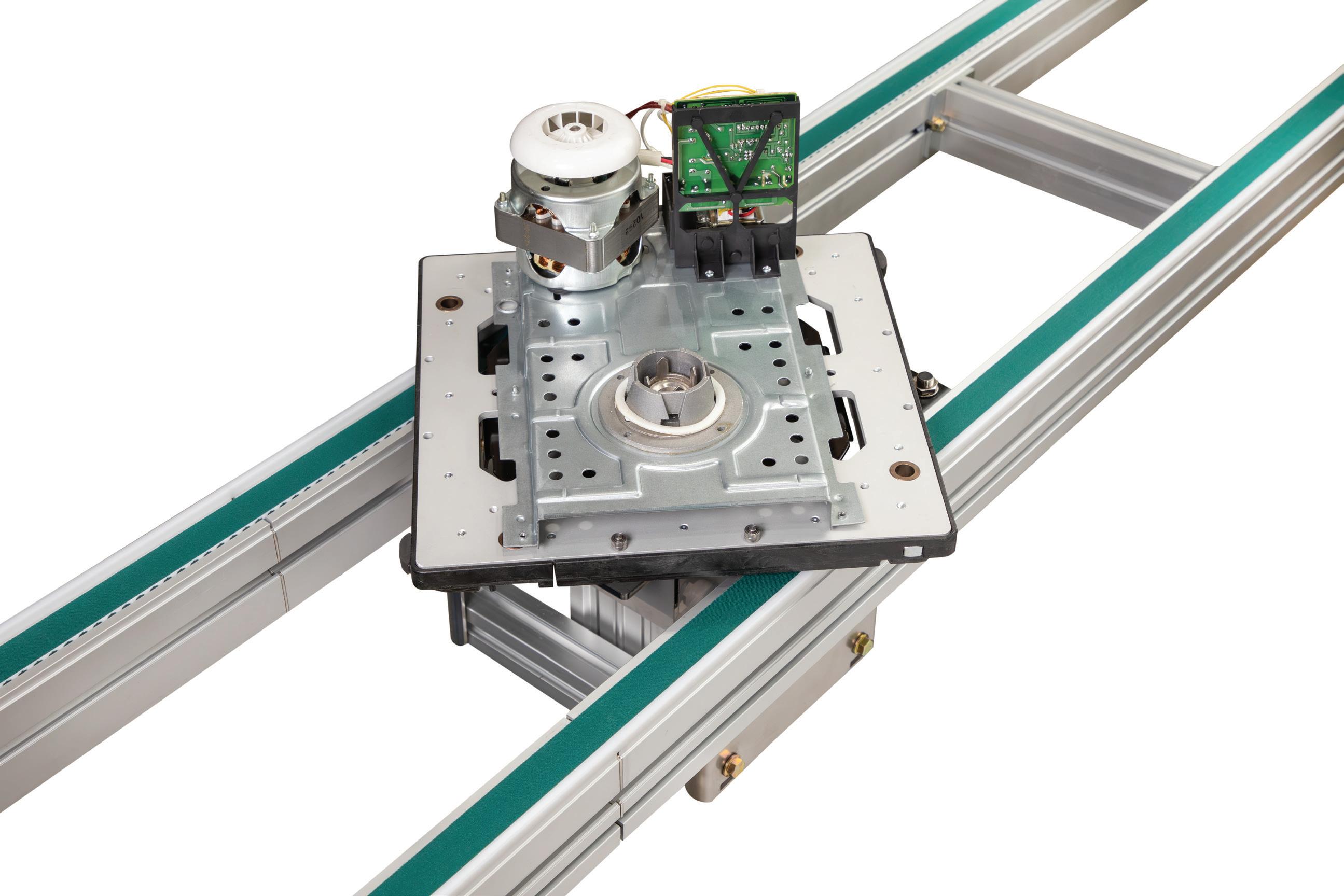

Just about any product made of metal, food, cosmetics, medical supplies, plastics, or boxes moves on a conveyor during manufacture. No wonder that conveyors come in all shapes and sizes — from belt widths of less than 2 in. (for moving extremely small parts) to several feet wide for transferring bulk substances.

Conveyors are classified by both their conveyance media and application: Some conveyors serve to transport bulk or discrete product in a steady stream with little interaction with transported goods along the way. These are ruggedized units optimized for high throughput. Slightly more demanding conveyor installations shuttle product between locations or machines. Still more demanding are

conveyors to move materials into or out of machines or stations. These actually require positioning capabilities to ensure proper handling of product. The most demanding conveyors run workpieces and other goods through assembly or other workstations and machinery without break. Many such conveyors for this demanding task employ custom workpiece pucks to steady product while machines perform work on the items.

Conveyors for moving arrays of discrete product — applications associated with motion control — take various forms. Some employ thin flat belt made of engineered fabric with nylon, PVC, styrene-butadiene synthetic rubber (SBR), or other durable synthetic materials.

Specially shaped motor-driven pulleys engage (with tensionmaintained friction) the conveyor belt and make it (and any product riding on it) advance. Benefits of this design include simplicity and costeffectiveness; thinness of conveyance medium for easier transfers off and onto the conveyor-belt ends

even for very small objects; the ability to withstand a wide range of temperatures; and customizable surfaces — for easy release of baked confections, for example.

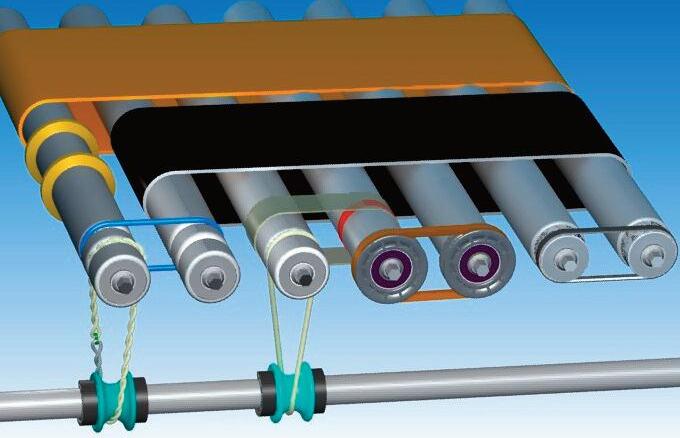

In other instances, conveyors consist of a series of both unpowered and powered cylindrical rollers. These roller-based conveyors work best for transporting flat-bottomed objects such as carboard boxes or molded part pucks.

Simple conveyors with only unpowered rollers work as manual conveyors (to let personnel push items along the low-friction conveying surface) or gravity conveyors which incorporate downward slopes — often as diverting-conveyor offramps to feed items to their final workplace or collection destinations. Here a competitive conveyor option is the ball-table conveyor — studded with freewheeling spherical rollers to let conveyed product freely glide along. The motorized rollers on roller-based conveyors can either couple to a gearmotor on the conveyor flank or directly integrate motors called drum

motors inside their cylindrical bodies — in turn usually made of steel or (if intended for washdown settings) stainless steel.

Conveyors to position items with moderate accuracy (say, for simple spacing of boxes) might employ only motorized rollers. In contrast, systems or sections of conveyor with laxer requirements (or relying on peripheral systems for final positioning functions) might gang a few unpowered rollers to each powered roller via cords or bands made of round polyurethane belt. These bands loop around and nestle into grooves on the powered and unpowered roller ends; tension keeps the round bands firmly set in their grooves and facilitates the transmission of power from motorized roller to ganged passive rollers.

Linear-motor conveyors, also called smart transport systems by those who aim to differentiate the offering, are costly but enable very sophisticated applications. Some modular linear-

Constant Force Lead Screw applies uniform pressure to the nut at all stages of travel along our quality CNC rolled lead screws. World class NEMA motors combined with an integrated lead screw make for one of the most accurate lead screw assemblies on the market.

Our miniature ball screw assemblies combine fine leads with small screw diameters, and utilize a compact internal ball return system to yield high precision linear motion for a range of small-scale applications. In addition, our ball screws are precision-rolled, making them a critical asset to laboratory machines, medical devices, and mechatronic applications.

transport systems can trim machine footprints by half when used to replace indexing and conveying equipment.

The movers on some such systems can travel independently of one another or in groups along several customizable rail systems. High dynamics and precision help the system excel in gapping and diverting applications — and a new hygienic version is aimed at pharmaceutical, biotech, packaging, and food and beverage environments.

Modular linear transport systems are not designed to replace other conveying systems. However, traceability with the system can reduce the scans required for each piece through an operation. Because movers are mapped as individual servo axes, controls never lose track of items being transported. Such

traceability in traditional architectures can require innumerable scanners ... so the component and labor reductions of intelligent transport systems are worthwhile in some cases.

Other options for conveyance of specialty goods are two-axis airbearing stages and planar motors. Air-bearing stages suspend the carried load on a cushion of air and for motion rely on linear motors— often with an ironless forcer design for smooth actuation. Driving is typically centered near the center of mass to maximize the straightness and minimize the angular errors of each motion. In contrast, planar motors use the electromagnetic behavior of its motors for both the movement and suspension of loads … which is why they’re occasionally called magnetic levitation or maglev stages. Some such

systems levitate the magnetic movers with six degrees of motion up to 5 mm above planar motor tiles.

Future packaging machines will also be judged by how well they integrate into so-called connected industry concepts. Here, the idea is to let design engineers build machines and networks to connect operational technology or OT — the drive, control, and even process and manufacturing components and software that they integrate everyday — with those of information technology or IT … here, the managerial, sales, ERP, supplychain, and inventory tools of an organization.

Several motion-component suppliers have over the last 15 years purchased or developed software to

let packaging-plant management and ERP-level data dictate what happens on factory floors. Others have established partnerships with Cisco and similar companies to offer these functions to OEMs and end users. Much of the integration here uses Ethernet to connect to IT data for IT/ OT convergence — relevant to many industries but particularly beneficial to packaging for the regulation of output to better meet demand … as well as product safety through tracking.

Formats for individual products— stand-up pouches, child-resistant (CR) packaging, anti-bacterial wraps, multifunction container lids, and custom-sized cartons — also continue to proliferate. In fact, market reports from the Flexible Packaging Association, a trade

association for converters of flexible packaging and industry suppliers, global use of specialty packaging has grown unabated over the last decade and now exceeds $30 billion. That’s thanks to better automation as well as advances in materials and processes. For example, some OEMs that build form-fill-seal machines for pouch products are switching from heat sealing to ultrasonic sealing, as the latter is more forgiving and efficient. Ultrasonic welding also improves beverage packaging. One technique from Germany-based Xolution (not to be confused with OXO) ultrasonically welds polypropylene lids to aluminum cans for a portable mug design that otherwise lets beverage companies can drinks by traditional means. OEM

| Tanteckken

| Tanteckken

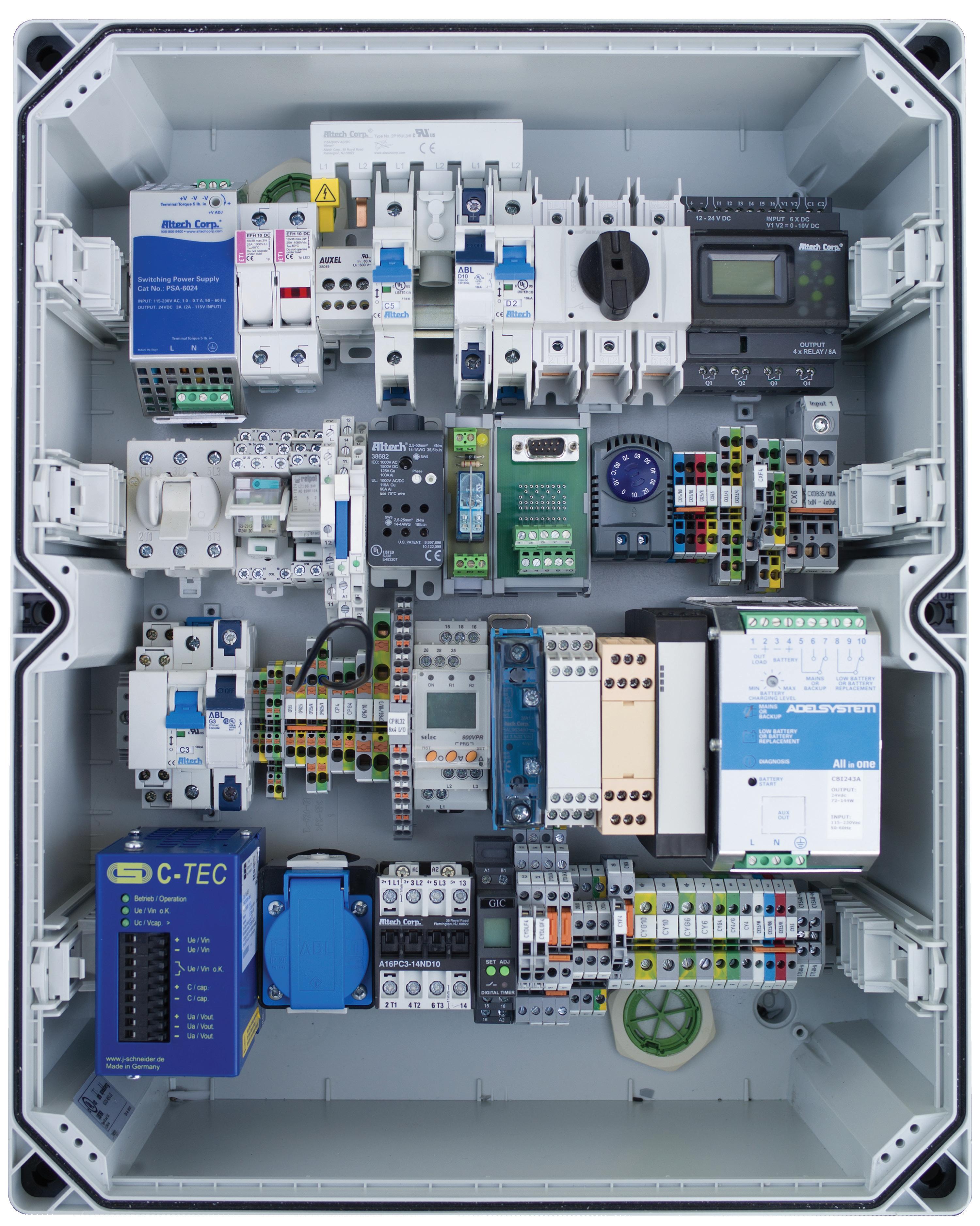

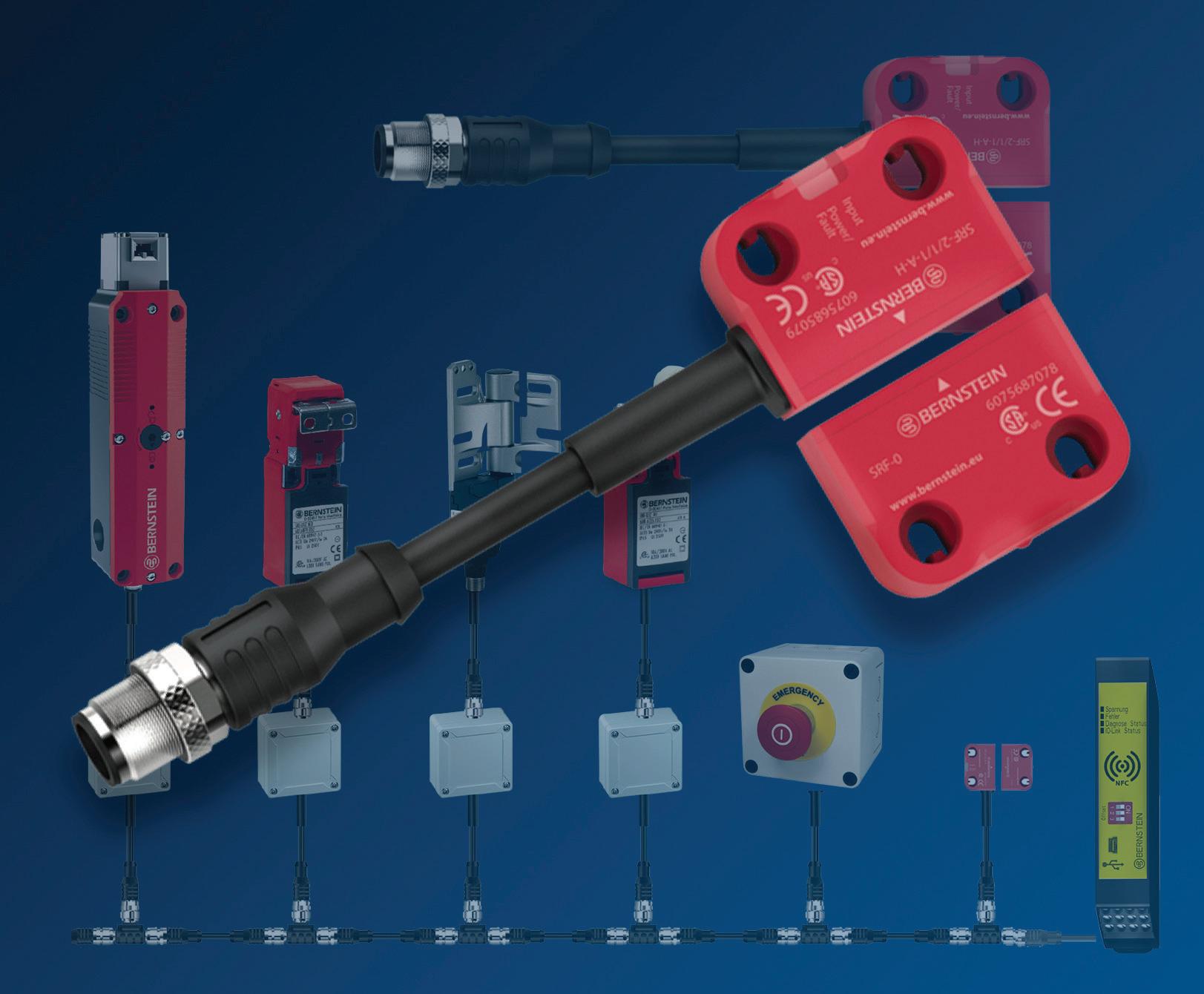

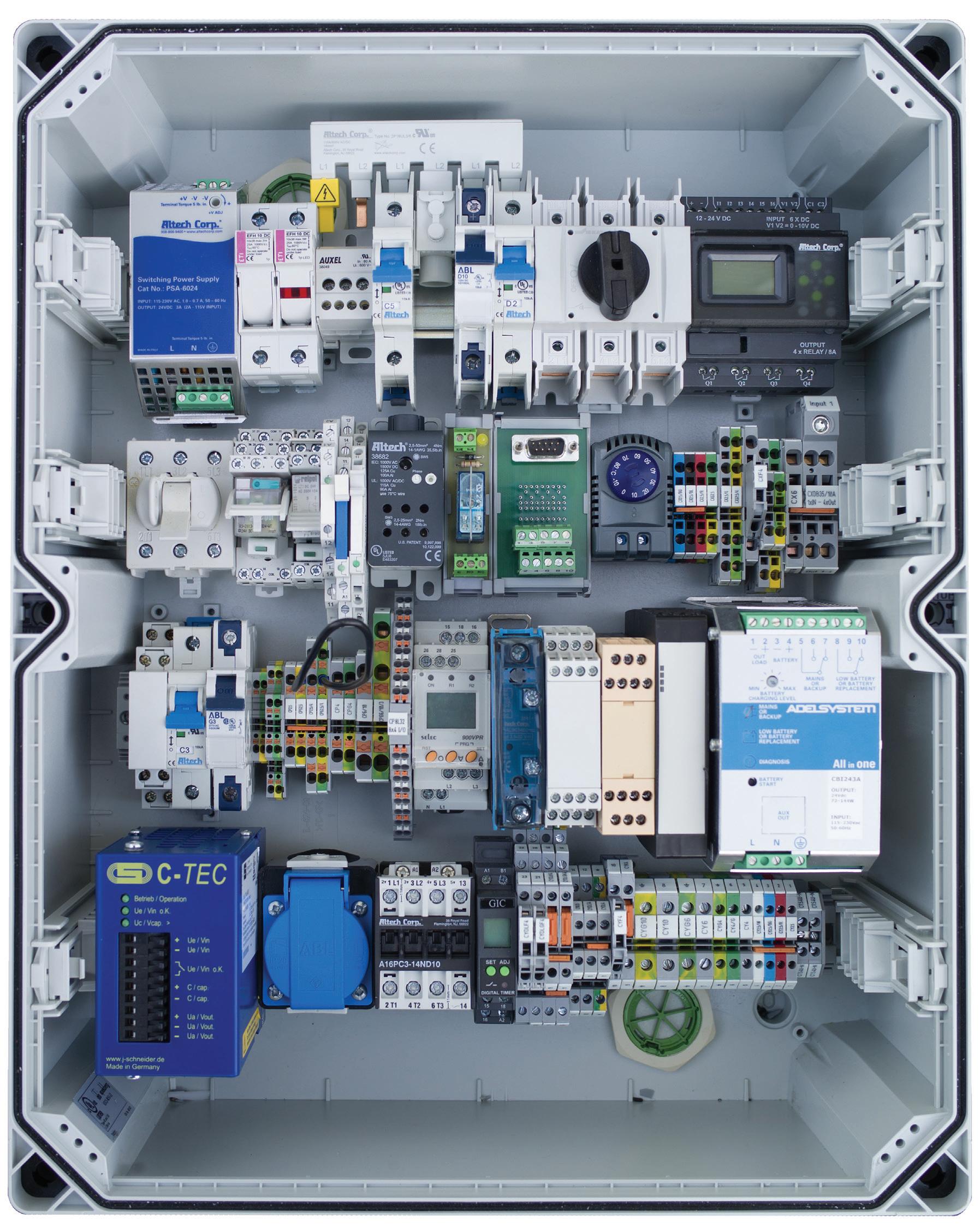

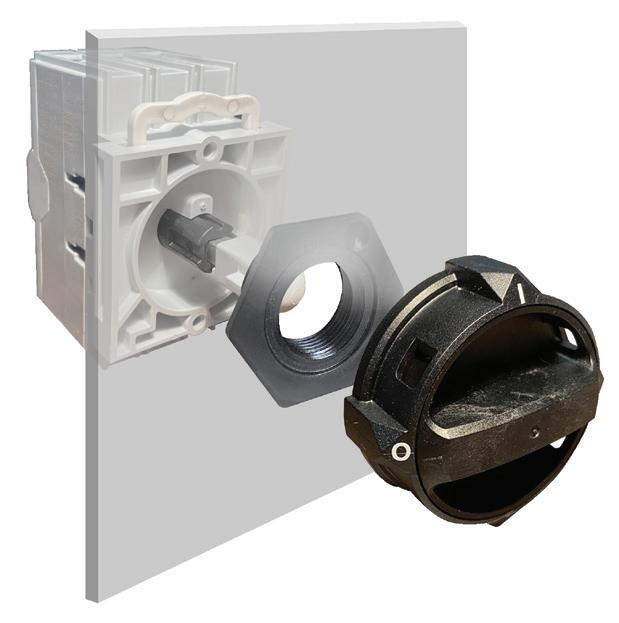

This system offers plug-in convenience allowing up to 32 switches to be run in series. The system features redundant cascading OSSD outputs which eliminates the possibility of fault masking (TR24119) and offers superior diagnostics and communication via IO-Link, NFC or PLC.

908-806-9400

908-806-9490 (FAX)

info@altechcorp.com

www.altechcorp.com

to ensure we stayed on track. So, they returned to remediate the floor some more, and it worked. We did all our receiving, got our pallets received, and then had to clear the floor again.

DW: Were there any other surprises or unplanned tasks?

Schulte: The AutoStore was built while we worked with other vendors. We had to get electrical to support what was going into the AutoStore. We had to get data run for the pick ports because each pick port needed its own data.

We had a huge ceiling fan right above the AutoStore, so we had to move it because we didn’t want it to hit anyone on the grid. We also had skylights above the AutoStore and hired roofers to cover them to avoid the risk of leaking.

Then, we found out about our fire suppression requirements. We needed

a fire pump, which was pretty expensive and something we didn’t expect. We also had to get a VESDA alarm system for very early smoke detection. If there's any smoke in the air, it triggers an alarm, the robots huddle together, and the AutoStore stops. We spent a lot of time and effort making sure that got done in our timeframe. We started talking to the fire suppression people in January 2023, and it was the last thing completed in the project. The final pump inspection occurred the week we went live, so it took the full 10 months to get the fire suppression done.

But we had a great group of contractors help us get ready. The electricians pretty much lived here for three months. We had a construction company build the pump room, and they were always here, as were the fire suppression people. So, we grew

great friendships and spent a lot of time together, supporting them and giving them what they needed to ensure the work got done well and on time. Having those people to work with is essential to ensure success.

The Kardex team started building about the week after the Fourth of July and was done toward the end of August. The grid was built quickly, and the people were here every day. The whole process and everything we’ve done with Kardex has been a great experience.

DW: How was the experience for anyseals employees?

Schulte: There was a lot of skepticism from employees while the machine was being built. They’d say, “There's no way this machine will be faster than us. We're so fast. We're going to be better than the machine.” Now that it’s installed, they're

trying to get as much stuff into it as possible because it makes picking much easier and faster. So, it's the flip-flop of people fighting it initially and then loving it at the end.

Overall, though, it was exciting for them. It was also quite tiresome, but we made it through. It’s important to have a great group of people to work with and engage your employees so they understand what's happening and that they're a big part of it. There was a lot of change and work to get through, but everybody's excited about it now.

DW: What are some other tips or lessons learned?

Schulte: Project costs are obviously a big factor, and with projects of this size, you usually have a lot of change requests. We went slightly over budget with only three change requests. For example, in the middle of the project, we decided to add an extra pick port before everything shipped from outside the country because it would be cheaper than ordering it later. There are also seismic towers that hold the grid in place. We planned on having six but needed eight to make the structure safe and sturdy. So, there was another slight change, but nothing shocking.

During the first two weeks of September, Kardex inducted all the bins.

Warehouse employees place parts on the scale, the scale interacts with the WMS, and employees fulfill the correct quantity. Leftover parts go back in the bin and then to storage. | anyseals

Our AutoStore has 20,000 bins, so we had truckloads coming in, which took about seven days. We can handle 5,000 more bins, so our AutoStore can hold 25,000 bins in total.

We went live in early October, two weeks ahead of schedule. The WMS went live first, then the AutoStore. From then, we started filling the bins, which can be challenging. It’s important to schedule the time and appropriate people to do the inbound and get inventory into the AutoStore. It’s hard to completely test until you have a good amount of inventory in the AutoStore. So, in the beginning, set up time to get as much inventory in there as possible. And if people are doing outbound, make sure you have people that can do inbound, too.

DW: How’s the system running now?

Schulte: We have 100% uptime. The WMS interaction with the system had a few little glitches, so good, strong communication between the interfaces is important. The WMS must speak to the AutoStore to ensure you successfully integrate the two.

Now, we're starting to put more inventory in and can look at our daily picks from the overstock and AutoStore areas. With the AutoStore, the average time for a bin to come to us is eight

seconds. Nobody could go through the warehouse and pick something in eight seconds.

Our business is unique because we don’t just grab products from the bin, and then the bin goes away. We grab a bag from the bin, place the parts on the scale, and weigh it to ensure we have the correct quantity. The scale and WMS are integrated, so the WMS knows the weight of each item and how many are needed to ensure the correct amount for each customer. So, the bin comes down, we take a bag from the bin, put the parts on the scale, then put the leftovers back into the bin, and the bin goes away.

Previously, our manual picks could take up to 15 minutes per pick because we had to get a lift truck to pull down the pallet, find the box on the pallet, and bring the bag to the scale counters. That could take five to 15 minutes, depending on the inventory's location. Once we weigh and count the customer’s parts requested, we label and send it to the shipping department. In the past, the parts we put back into the bin had to be returned to wherever we got it from. Now, we just leave the parts in the bin, and the bin goes away. So, we’re saving tons of time on the put-away as well.

One of the big things I learned is that the WMS is the brain, and the robots do whatever the WMS tells them to do. For example, when we have rush orders, we can’t wait to get through 200 picks before getting the rush order out. So, we learned how to prioritize within the WMS to ensure orders are shipped on time. Another recent challenge, as we’ve been putting inventory in the AutoStore, is when we call a bin down, we have another bin going out with that same inventory. So, who wins? Does it go inbound or outbound? It should always be outbound to ensure it gets to the customer, but we’ve been working through those learning factors. It’s been a challenge, but it’s been interesting to learn. AW

anyseals • anyseals.com

Powerful, multi-purpose solutions with easy installation and maintenance

High-speed, multi-code, multi-symbology barcode reading

Modular, standard structure gets you up and running faster

Advanced, real-time data and analytics

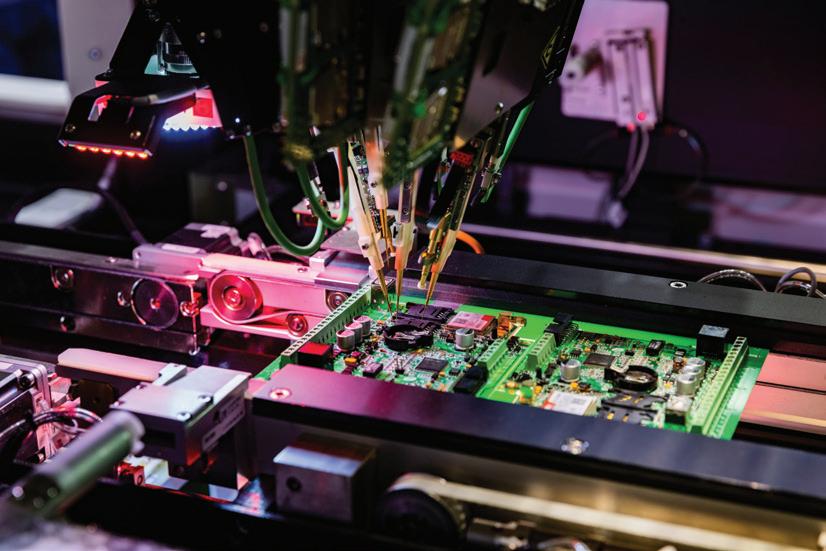

Mobile robot technology is moving fast, and generative AI is pegged to transform machine vision to enable more integrated solutions.

Vision systems are the bread and butter of AMRs and keep improving as technology evolves.

BY: RACHAEL PASINI SENIOR EDITOR

Advanced machine learning and visual processing are major trends in automated mobile robot (AMR) development. According to Gartner’s Emerging Tech Impact Radar, advanced computer vision and AI acceleration will be among the most important influencers within the next two years.

“In the past decade, machine vision changed a lot due to technological improvements. In the beginning stage, machine vision was rule-based, which is still very efficient. But about five years ago, deep learning highly improved accuracy and performance. Now, generative AI is changing machine vision again,” said Magic Pao, AVP of Industrial Cloud and Video Group at Advantech, during a keynote panel at the 2023

Advantech Industrial IoT World Partner Conference in Taipei, Taiwan.

Vision is critical for AMRs to navigate complex environments, avoid obstacles (including human workers), and identify and handle items correctly. AMR vision systems typically consist of:

• Cameras that capture image and video footage of the robot’s surroundings

• Other sensors, such as LiDAR and 3D sensors, that help the robot understand its surroundings, develop depth perception, and detect objects

• An onboard processor to analyze visual and sensor data. This processor runs computer vision algorithms to make sense of the

data, identify objects, detect anomalies, and determine the robot’s position and orientation. It may also run simultaneous localization and mapping (SLAM) algorithms to create maps and localize the robot within the maps.

• A communication interface to send and receive data to other robots or systems, such as a central control system

AMR vision systems must be highspeed and low-latency to be effective and ensure safe operation around humans. They also require technology to transmit and process large amounts of data over various distances. Therefore, Gigabit Multimedia Serial Link (GMSL)

In the past decade, machine vision changed a lot due to technological improvements... Now, generative AI is changing machine vision again

technology is often preferred because it can facilitate high-speed data transmission from cameras to the onboard processor and external devices and systems. It also allows data integration from multiple sensors and sources, enabling more complex, real-time decision-making. The latest generation, GMSL3, supports up to 12 Gbps and can transmit data up to 15 m from its host processor.

“We chose GMSL as our technology to empower our computing unit with visual capabilities,” said Jacky Liu, advanced computer vision head of Industrial Cloud and Video Group at Advantech. “It’s not a new technology and has already been widely used in the automotive industry with features such as high data rates and long-distance transmission. Its robustness and data integrity ensure reliable operation in challenging environments, and the scalability and synchronization allow you to run multiple data streams. With GMSL, our current video capture card can support up to eight channels, even 3D cameras, simultaneously.”

In early 2023, Advantech partnered with e-con Systems, an OEM camera solution provider, on a GMSL camera and AI computing system for automated guided vehicle (AGV) and AMR applications. The MIC733-AO is an industrial AI inference system based on NVIDIA Jetson AGX Orin. It has high AI performance of

up to 275 TOPs, a wide range of I/O interfaces for 5G/4G connectivity, and multiple video inputs, including two GMSL. The GMSL camera from e-con Systems transmits video data over long distances, and the solution can integrate multiple cameras into a single Jetson system.

“Today, the whole value chain is compressed, and each role is trying to integrate more things,” said Pao. “We integrate video acquisition software, called the Advantech CamNavi SDK, with NVIDIA ISAAC SDK and ROS2 (Robotic OS) into one software package. We don’t just pre-install them — we also pre-build and pre-train them. To adapt it for robotics, AMRs, and cobots, we just put application software on top and enable the solution.”

During the keynote panel at the World Partner Conference, Pao reiterated that generative AI is changing machine vision and that NVIDIA’s generative AI SDK is ready on the MIC-733-AO. With generative AI, vision systems can improve data augmentation, search functionalities, and image reconstruction. For example, a company may not have enough images to train an AMR to accurately detect item defects or damage. However, with generative AI, the system needs just a few images as examples and can generate numerous defect images with different aspects to retrain the AMR.

Autonomously transport materials up to 4,200 lb with the industry’s most comprehensive autonomous mobile robots and fleet management software.

$1.5M

saved in the first year at an aerospace facility

6x

throughput increase at a CPG facility

11 month

customer payback period at an automotive facility

“Accelerating AI from developer to deployment is very important,” said Elvis Lee, industrial AI platform manager of Industrial Cloud and Video Group at Advantech. “GPU performance has increased 1,000 times compared to five years ago, and data has increased 10,000 billion times within the past 10 years. The data is moving very fast compared to previous technology.”

While moderating an afternoon panel, Lee mentioned that NVIDIA recently surveyed its customers to understand what sensors and sensor interfaces they use in AMR projects. LiDAR sensors and USB, MIPI, Ethernet, and IR cameras are among the most popular. Mixed-sensor integration is also popular, but driver and compatibility issues and long integration times can delay projects.

“GMSL does not define a consistent camera parameter data structure, so people spend a lot of project time ensuring compatibility between the GMSL capture card and a device,” said Liu during Lee’s panel. “Currently, we are working on defining a camera parameter profile and plan to integrate it into our unit by the second half of 2024. We believe this will help customers easily select a camera, shorten the overall project time, and make the configuration more flexible.”

Advantech isn’t alone in its integration efforts, and as Pao noted, it takes the entire value chain to see widespread industry impact. “The whole value chain is very long. If you start from the chip vendor, system manufacturer, systems integrator, and toward the end user, it’s a long journey,” he said.

For example, on day two of the conference, Pyong W. Pak, CEO of Movensys, spoke about his company’s all-in-one software controller platform for AGVs and AMRs and how it opens doors for engineers.

“One thing that we've heard from our customers is that vision engineers do not know about motion control, and motion control engineers do not know about vision. So, we’re working on an all-in-one solution that ties vision and motion control,” said Pak.