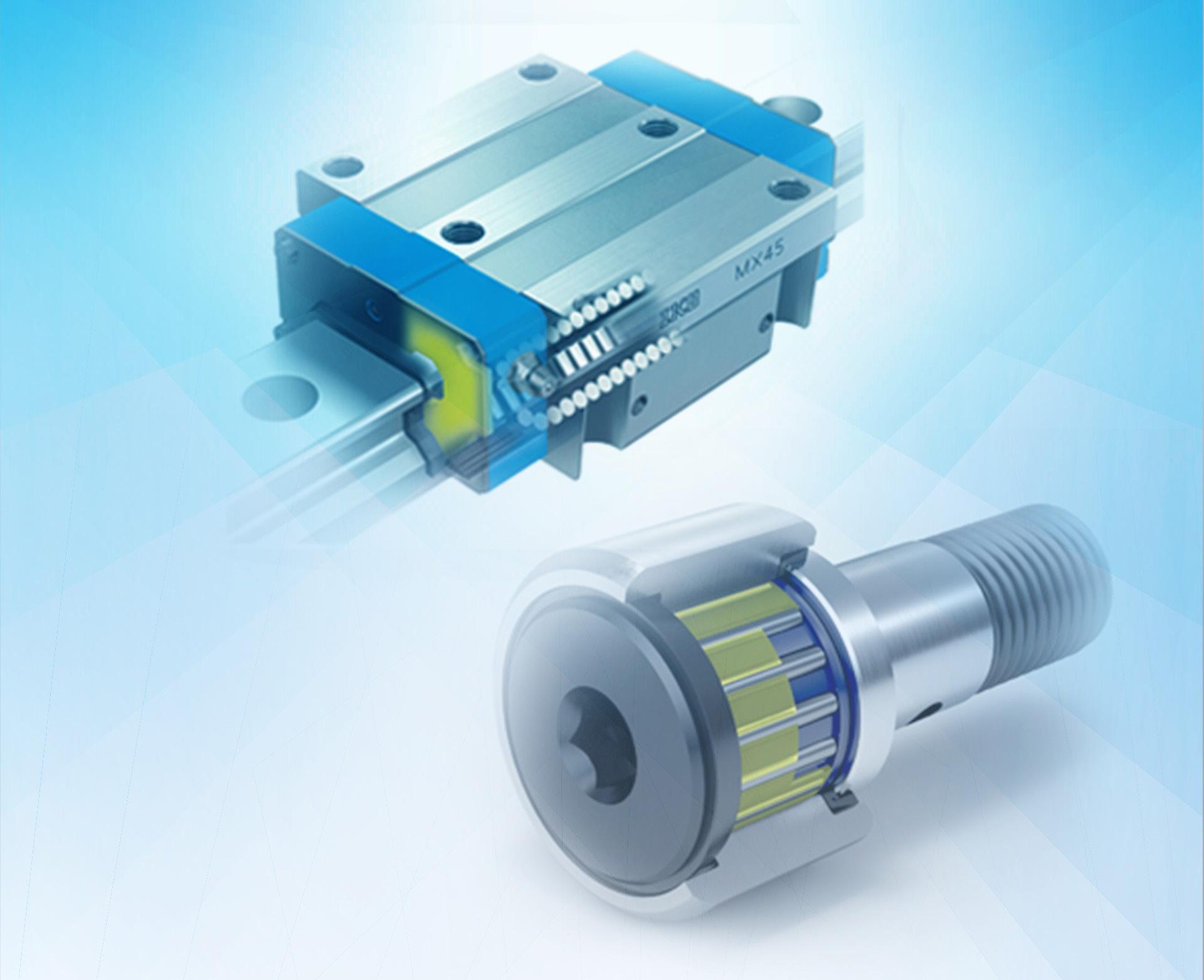

THK is a leading manufacturer of high quality and ultra precise miniature linear guides, ball screws, cross roller rings and actuators for a wide range of industries, including industrial automation, medical, aerospace, semiconductor, machine tool and robotics.

LM Guides - SRS Series - Featuring patented THK Caged Technology, the SRS Miniature LM guides perform with smooth and quiet motion, long-term maintenance free operation, increased speed and accuracy, low dust generation and a long life.

Cross Roller Rings - RAU Series - THK Micro Cross Roller Ring Series RAU are compact and lightweight and even more rigid than a double row angular contact ball bearing type. Spacer retainers enable smooth movement and high rotation accuracy.

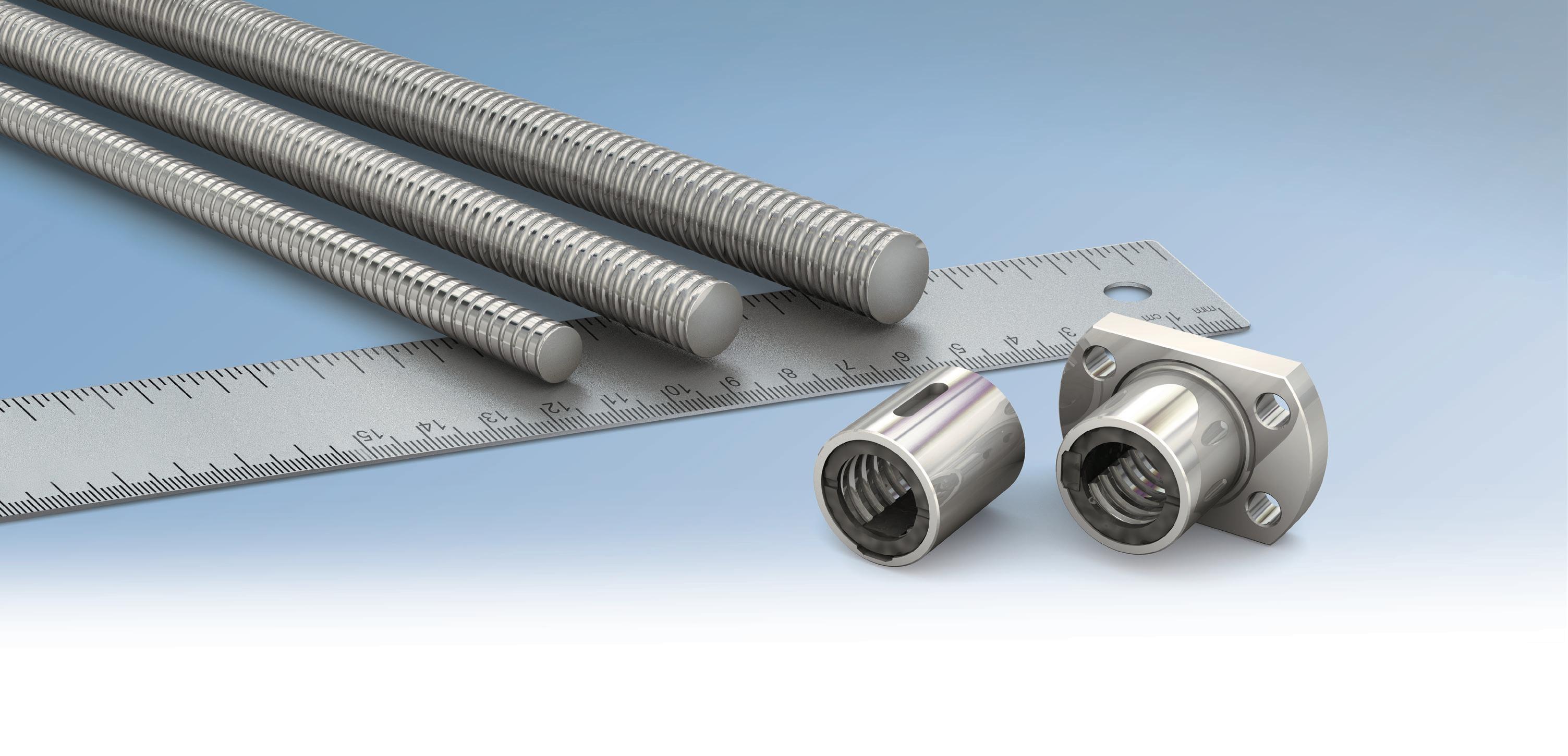

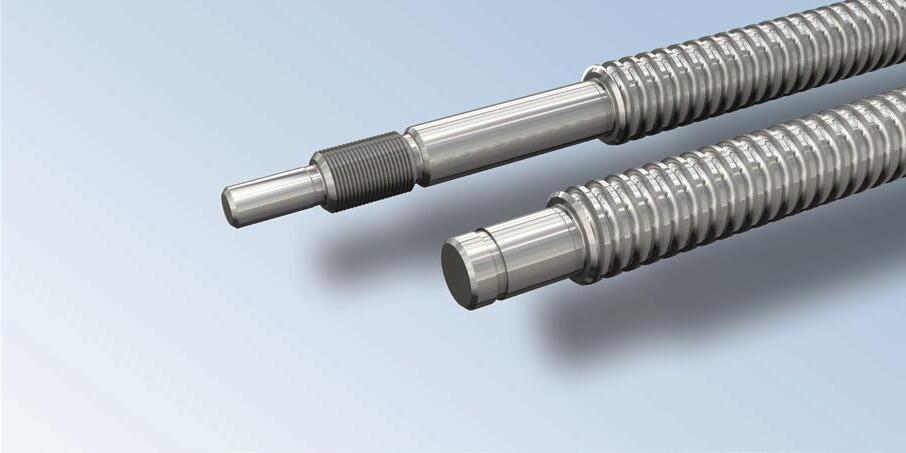

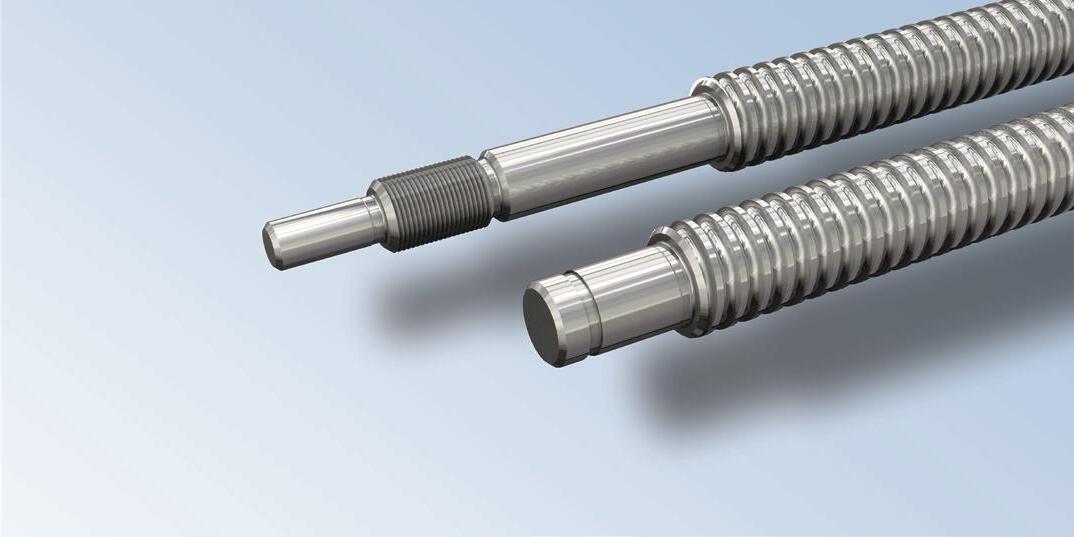

Ball Screws - BNK and MTF Series - BNK with finished shaft ends and MTF Roll-Formed screw shaft are known for their high accuracy, low noise, smooth movement and long-term maintenance free operation.

Actuators - KR Series - KR Actuators consist of LM guide units on the ends and ball screw unit in the center making them highly rigid and highly accurate in a minimal space.

To learn more, call us at 847-310-1111 or visit www.thk.com.

SRS BNK MTF

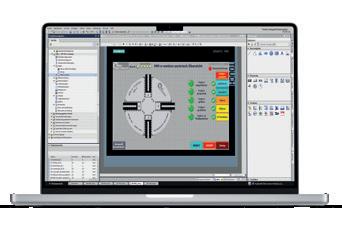

CONFIGURATION SOFTWARE with thousands of ready-to-use objects

The NEW C-more CM5 HMI series o ers low-cost, high-performance HMIs in sizes from 4 inches (only $340.00) to an impressive 22 inches (only $2,299.00). With an amazing 1.6 GHz processor in the larger units (10” and above) and 90 Mbytes of memory, these HMIs provide better trending, extra data storage, faster communication, improved le types, and 16.7 million screen/object color options.

All CM5 panels have serial and Ethernet ports (dual Ethernet ports on 10” or larger models) that support many of the most popular industry protocols, including EtherNet/IP, MQTT, and Modbus. The included USB ports provide in-an-instant connections for keyboards, barcode scanners, memory storage, etc. and the embedded SD-card slot provides easy project transfers or up to an additional 2TB of data storage (depending on model) for important log les.

Plus, all C-more HMIs come with FREE, powerful, easy-to-use programming software and FREE technical support!

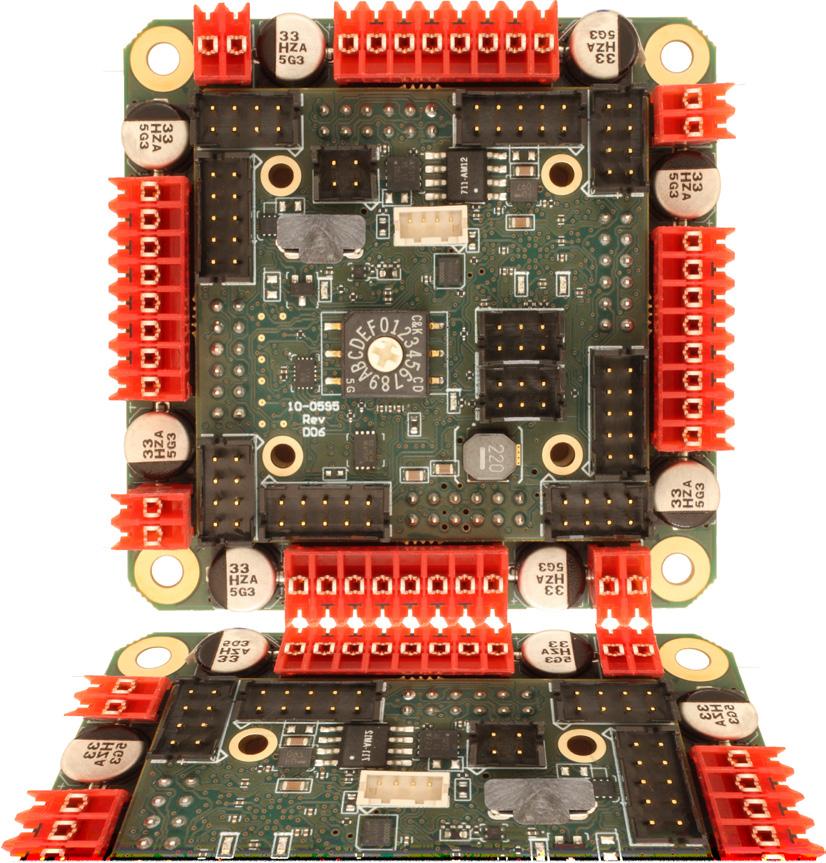

- brushed or bldc motors - 5 amps per axis - 16 analog inputs - 16 on/off drivers - home and limit in - live tech support - made in the USA

I remember feeling chronic discomfort in my shins as my teenage tibias attempted to get me up to average height. It was a nice try, but five-foot-two was all they could muster. Fortunately, most engineering and writing careers don’t have a minimum height requirement.

Today’s fast-paced world pressures us to grow quickly and strategically or fall behind. But too often, growth goes by doppelganger of “change,” which can paint a very different picture in people’s minds. A common sentiment is that change is scary, but growth is good. And the difference is rooted in a person’s outlook and approach.

At the recent Additive Manufacturing Users Group (AMUG) Conference, Todd Grimm, long-time AMUG committee member, shared insights from sponsors and the board of directors. Aside from common themes around automation, sustainability, materials, and workforce development, one trend from GoEngineer struck me — the 3D printing industry is growing into “adulthood.”

“They have seen that we have transitioned from moody teens who know it all to adulthood. To the contemplative… Not can I do it, but should I do it, and how should I do it,” said Grimm.

However, growth is not without discomfort and challenge, which can inhibit people’s stamina and willingness to try. Tali Rosman, startup advisor and entrepreneur-at-residence at Toronto Metropolitan University, touched on this during a recent Design World interview. Rosman has worked at Stratasys, led Xerox’s former 3D printing subsidiary, Elem Additive, and now serves as a business advisor with expertise in advanced manufacturing. She said resistance to change is common in all industries, but especially in manufacturing, which is characteristically traditional and conservative.

“Resistance to change and the lack of faster adoption are not unfounded. There is a lot of merit to them,” said Rosman. “There might be a lack of awareness of how much progress has been made … The other thing is trusting

the technology. We have to provide tools and give them confidence. So, I fully understand where it’s coming from and the barriers we need to address.”

Last year, Rosman participated in an Engineering Research Visioning Alliance (ERVA) event to identify challenges that engineering research can address to move U.S. manufacturing forward. ERVA described three grand challenges — material supply chains, tools and processes, and data and quality assurance — in its report, Engineering the Future of Distributed Manufacturing. During our interview, Rosman explained how 3D printing technology makes distributed manufacturing possible and enables startups to get a piece of the pie.

“If anything, 3D printing is the great balancer for small and medium-sized businesses to compete against larger companies. Maybe not for all the volume, but you can compete for some of the contract,” Rosman said.

For any size manufacturer, perseverance is an elixir. Despite the pangs of disruption, those willing to confront change and leverage it for growth will survive and thrive.

“It’s more of riding the tail of this dog that’s running through an economic downturn,” said Grimm. “We have challenging times, but the takeaway is that there’s an extremely bright future for additive manufacturing. So, if you love this industry, if you want to make it your longterm career, rest assured … this industry is going to continue on and make significant impacts.”

The same can be said for many other future-focused industries, including healthcare, agriculture, and renewable energy. Whether we call it “change” or “adulthood,” we all have to manage our growing pains as we mature. DW

By: Paul Heney • Editorial Director

By: Paul Heney • Editorial Director

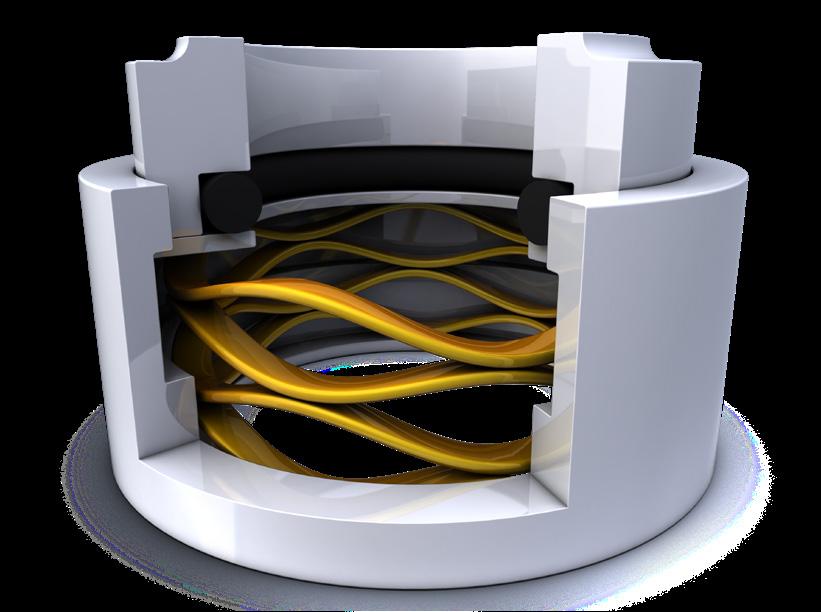

Freudenberg Sealing Technologies’ newest production facility in Parets del Vallès, Spain (near Barcelona) is a fully carbon-neutral plant. The facility manufactures automotive components and replaces an existing plant at the same location. The company said it is boosting its production capacity by 15%. In all, more than 11 million euros have been invested in the new production facility.

Systems in the new building are powered entirely by green electricity, with 25% coming from photovoltaics on the roof of the plant. Furthermore, the facility employs an energy-efficient and eco-conscious cleaning technique for exhaust air from coating processes through microorganisms. These metabolize the hydrocarbons in the solvents into water and CO2. This eliminates the need for an additional

heating medium — no gas has to be burned to purify the exhaust air. As a result, the new production facility is one of the most modern and sustainable sites for Freudenberg.

“This is a highly innovative plant that is carbon-neutral, thus aligning with both present and future automotive industry standards,” said Carlos Arnau Calduc, Freudenberg Sealing Technologies VP. “Investing in the new

plant in Parets del Vallès is the best example of Freudenberg’s commitment to both the automotive industry and to Spain as a business hub.”

The new plant, at 6,800 square meters, is home to 171 employees. The Parets del Vallès site was established in 1973 and the company has been producing damper seals there since the beginning. Roughly 80% of the production volume remains in Europe and goes primarily to Spain and Poland, with some parts shipped to Germany. The remainder is exported to America and Asia.

The new production facility brings Freudenberg another step closer to its climate targets: to reduce relative CO2 emissions by 30% from 2020 to 2025, measured in tons per million euros of sales. By 2030, the company aims to fulfill its electricity needs entirely through renewable energy sources, aspiring to carbon neutrality by 2045.

“We know that we can only achieve our climate targets if we move forward quickly and decisively. This means that we want to rapidly conserve energy by continuously optimizing our products and technologies, reducing waste, and improving the energy efficiency of buildings. For us, sustainable management means using materials and energy consciously and minimizing CO2 emissions during production,” said Dr. Matthias Sckuhr, CTO and COO. DW

MOTION CONTROL

Discrete automation with motion systems and complementary forms of warehousing technologies remain core to reshoring and making supply chains more robust in the years since COVID-19.

Trends in linear motion

SENSORS

What are the six microphone polar patterns used for?

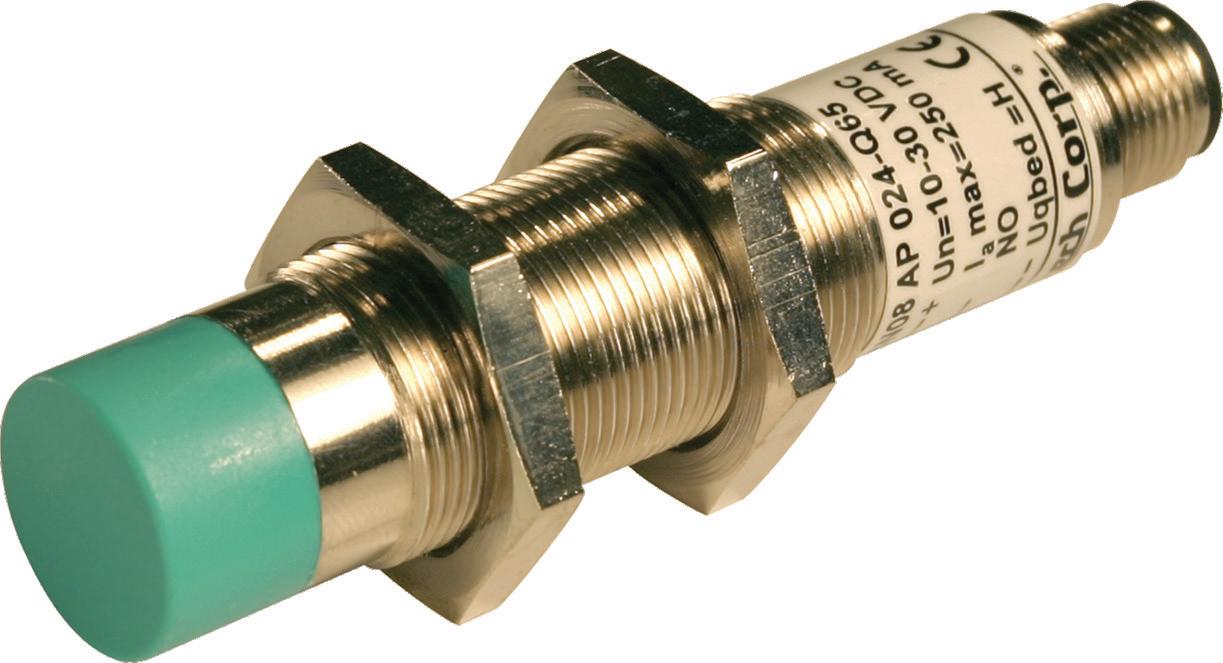

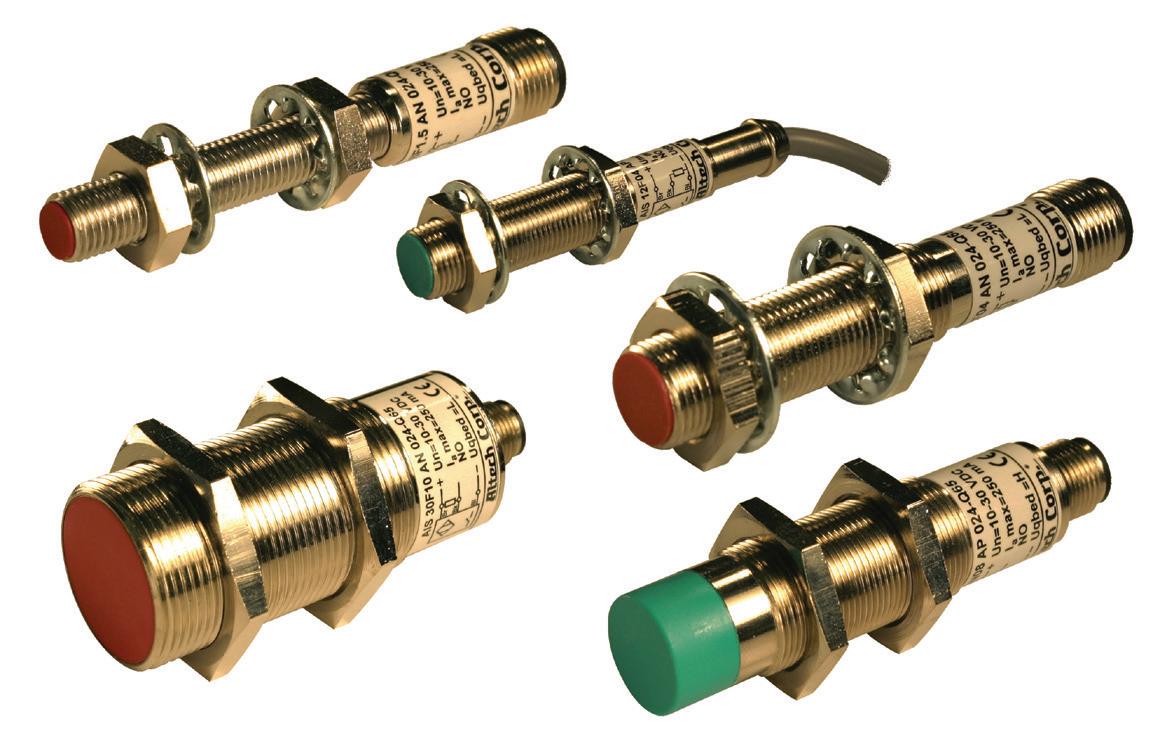

These sensors help keep personal mobility devices under “control.”

COUPLINGS ELECTRONICS LINEAR

Automation over the last several years has expanded use of electric linear actuators to leverage their technological advancements in smart homes, aerospace, defense, and industrial applications. In fact, the global linear actuator market could (in large part because of electric options) surpass U.S. $52.67B this year and grow at a compound annual growth rate through 2030,

How to reduce emissions for Stage V diesel engines

Stage V is an EU emissions standard for non-road mobile machinery with spark or compression ignition engines.

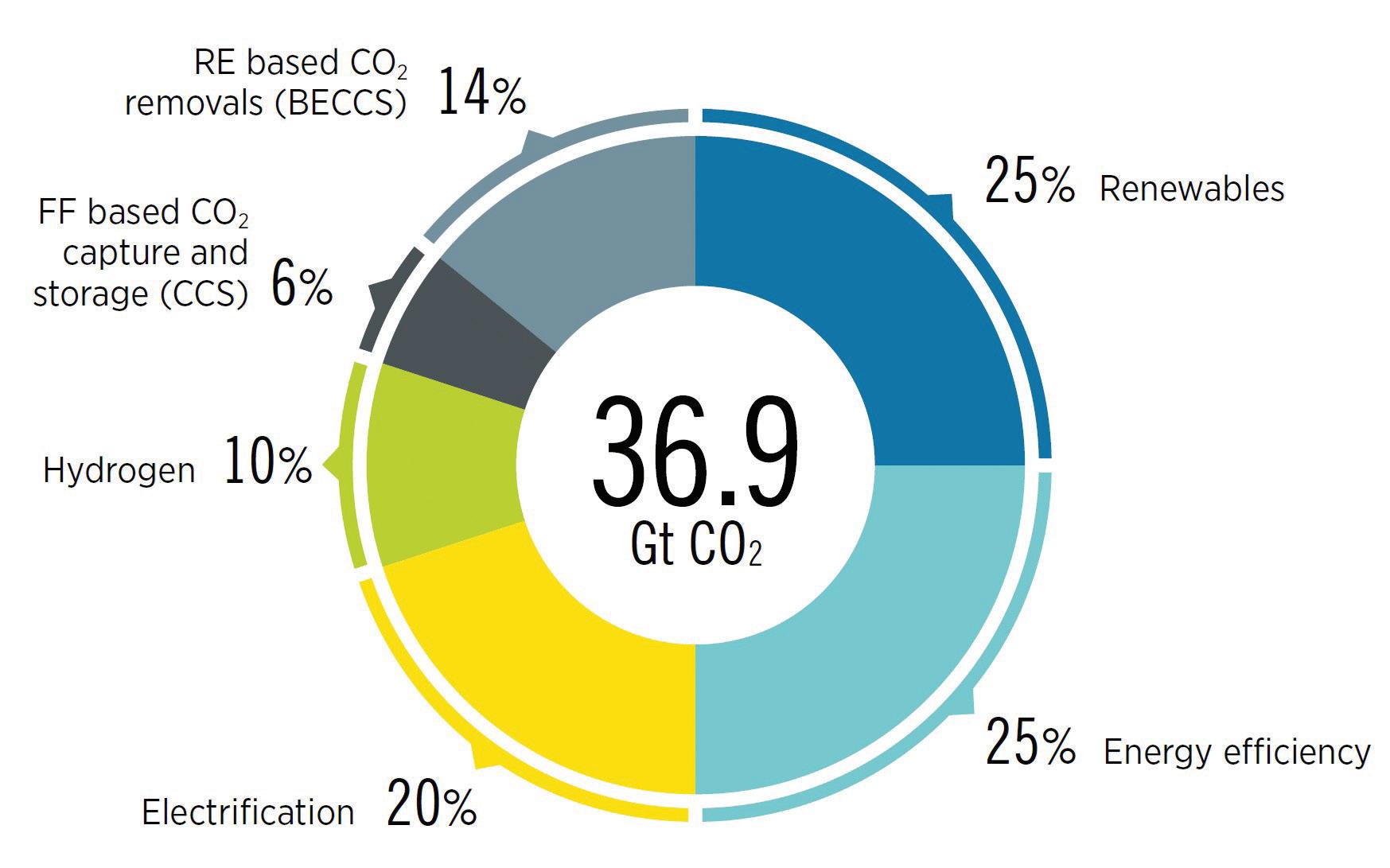

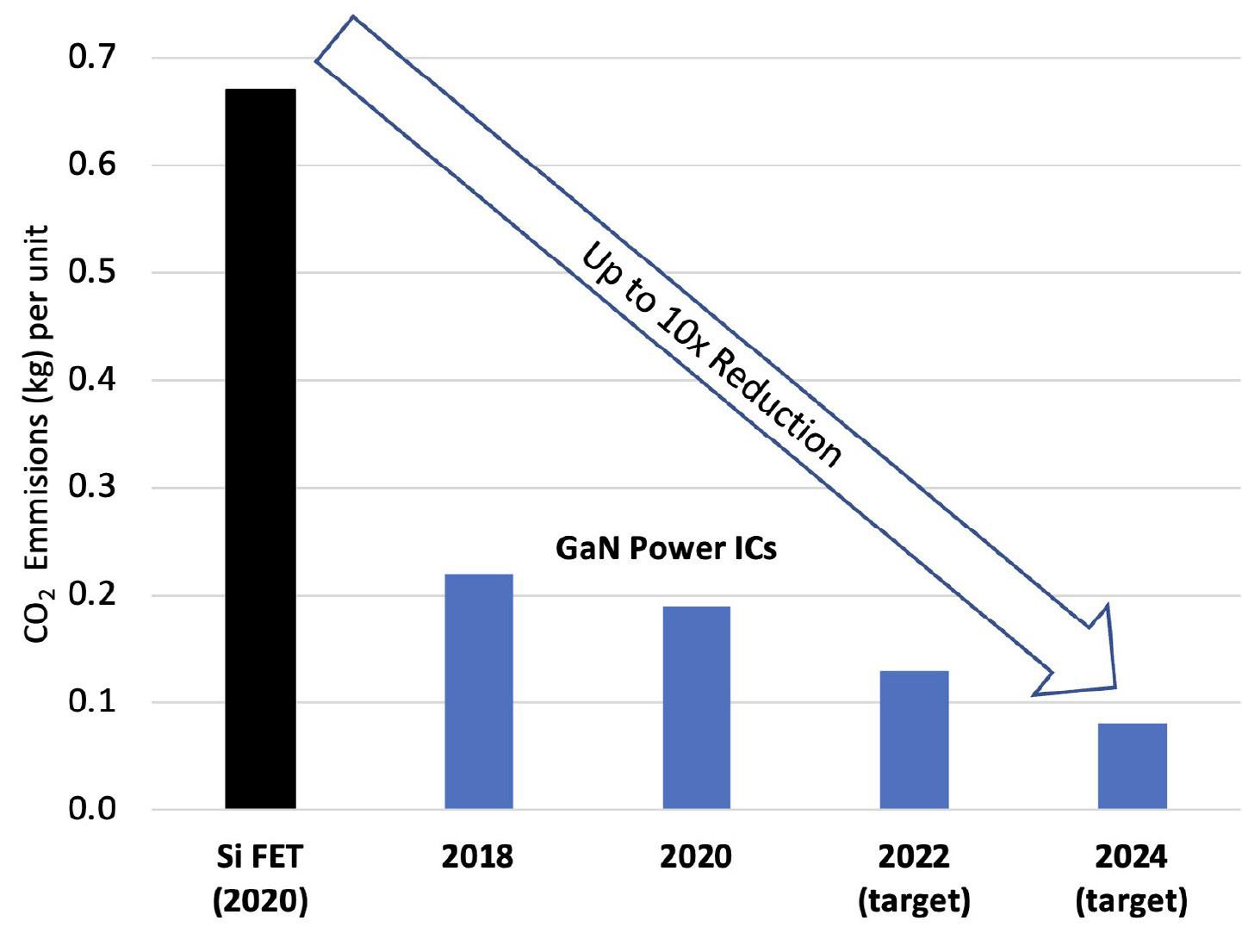

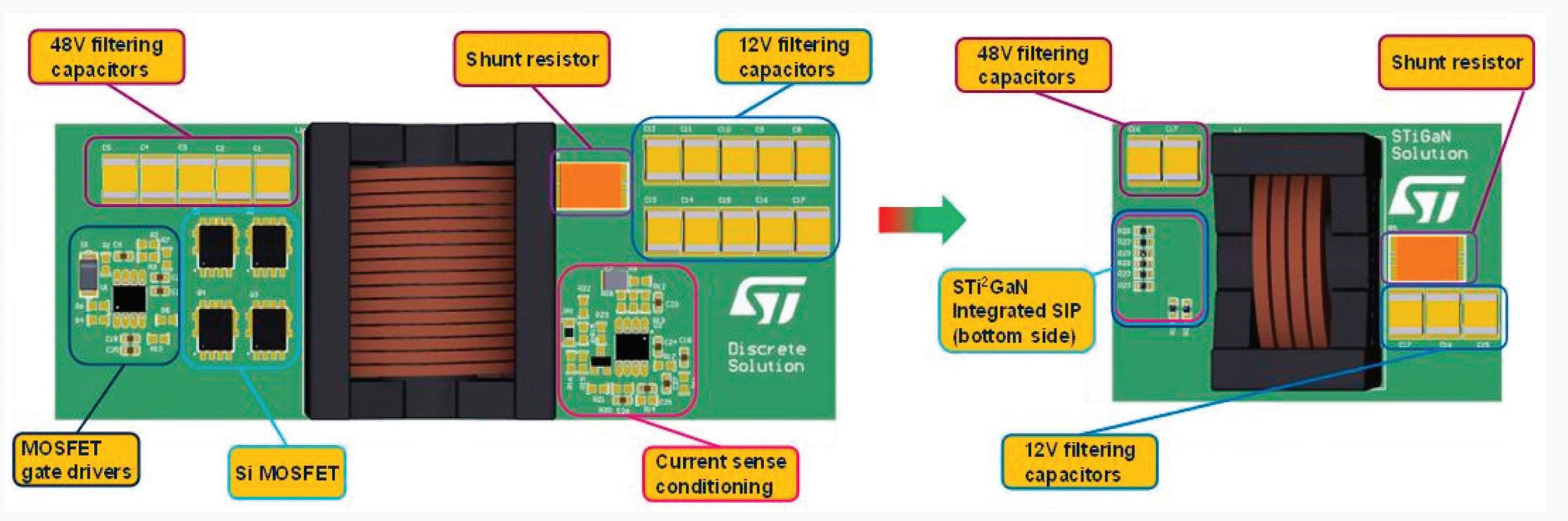

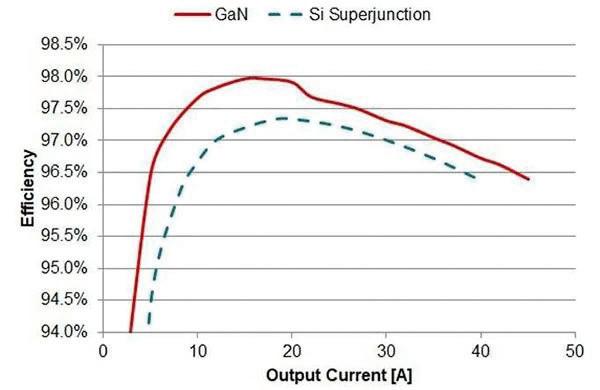

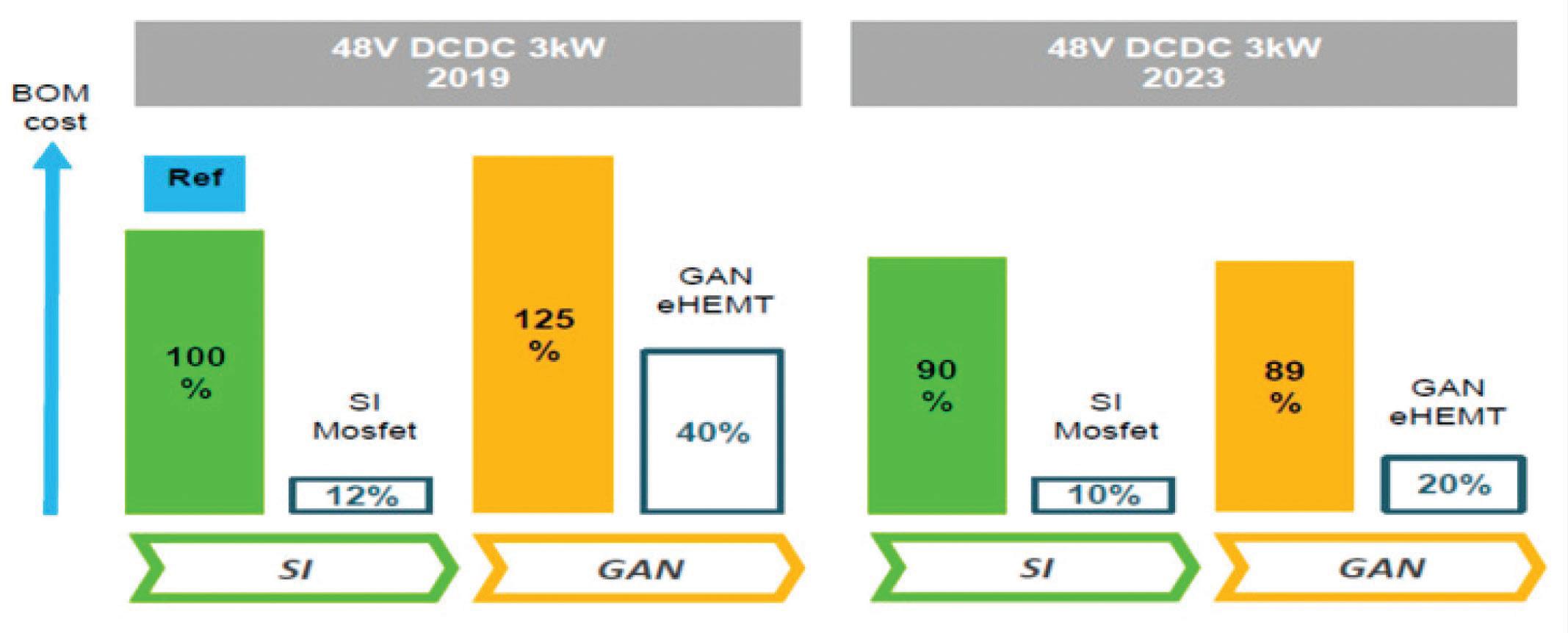

Can gallium nitride (GaN) recude CO2 emissions?

Aggressive international sustainability goals call for more efficient power converters. Here’s a look at how GaN designs can reduce greenhouse gases and long-term operating costs.

Help us honor the companies that have provided the most leadership in engineering

It has been a fascinating decade for all businesses, including manufacturers. We’ve seen the difficult supply chain issues brought on by the worldwide pandemic, along with a shortage of qualified workers and the strong reshoring trends in many industries. If nothing else, this helps to show how resilient manufacturers can be.

These companies represent the best and brightest, and they reflect the continued vision, integrity, and creativity of their design (and manufacturing) engineers.

We think they deserve recognition from you, too. Vote online for one or more of the companies listed through October.

FOLLOW THE WHOLE TEAM @DESIGNWORLD

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Senior Editor Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael

Associate Editor Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

CREATIVE SERVICES

VP, Creative Director Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Art Director Allison Washko awashko@wtwhmedia.com

Senior Graphic Designer Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Graphic Designer Shannon Pipik spipik@wtwhmedia.com @wtwh_shannon

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

WEB DEV / DIGITAL OPERATIONS

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Digital Marketing Coordinator Meagan Konvalin mkonvalin@wtwhmedia.com

Webinar Coordinator Emira Wininger ewininger@wtwhmedia.com

Webinar Coordinator Dan Santarelli dsantarelli@wtwhmedia.com

EVENTS

Events Manager Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

VIDEO SERVICES

Videographer Kara Singleton ksingleton@wtwhmedia.com

Videographer Cole Kistler cole@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

WTWH Media, LLC 1111 Superior Ave. 26th Floor Cleveland, OH 44114

Ph: 888.543.2447

HUMAN RESOURCES

Vice President of Human Resources

Edith Tarter etarter@wtwhmedia.com

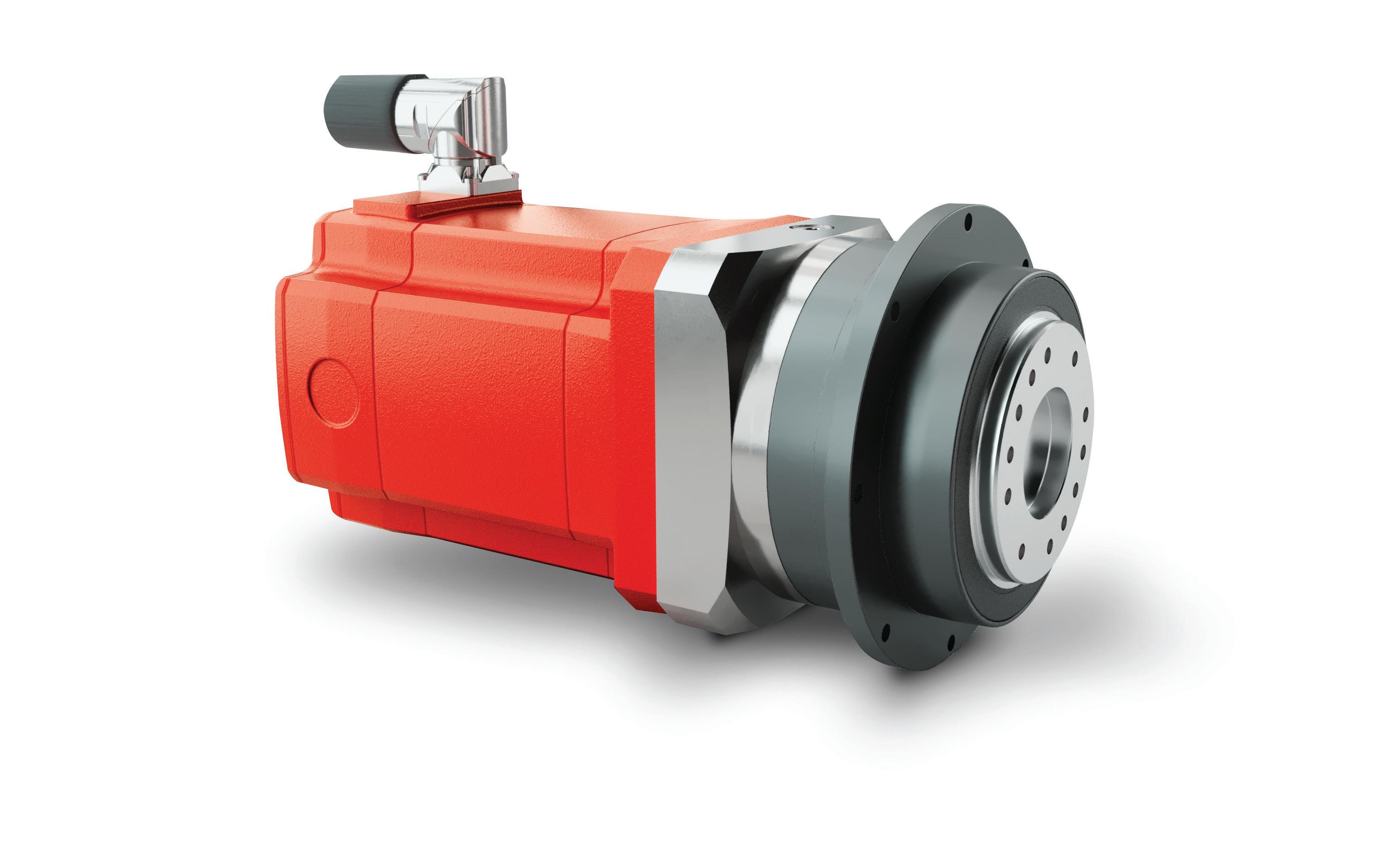

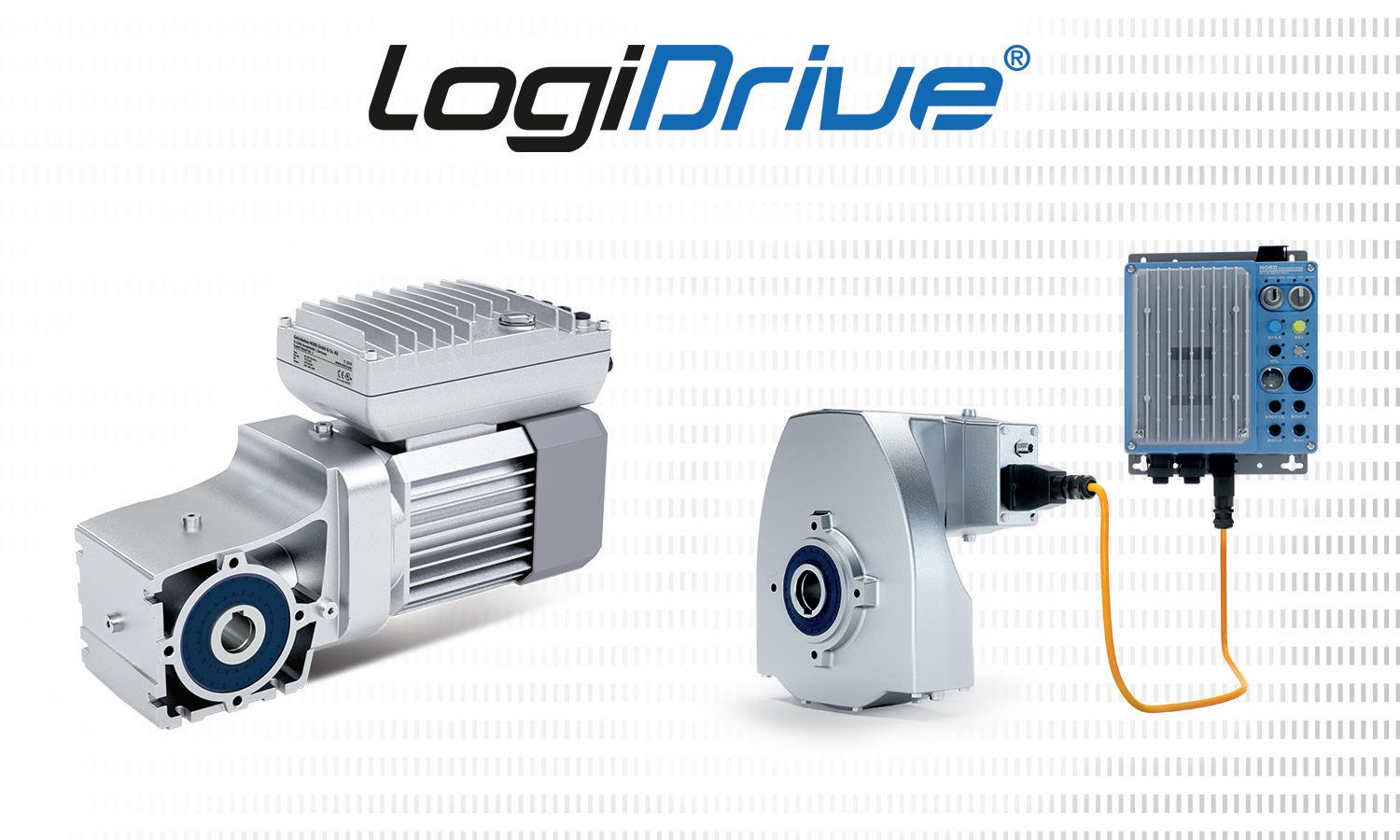

Servo motors and gear units from SEWEURODRIVE offer a high degree of dynamics and performance with a compact design, making them excellent for confined spaces. Multiple frame sizes and torque ratings makes them the perfect fit in material handling, hoist and gantry applications, and a wide variety of

machine automation applications. Their modular design allows for direct gear unit mounting without adapters or couplings. Pair that with the option of single-cable technology and you’ve got a flexible, precise servo drive solution.

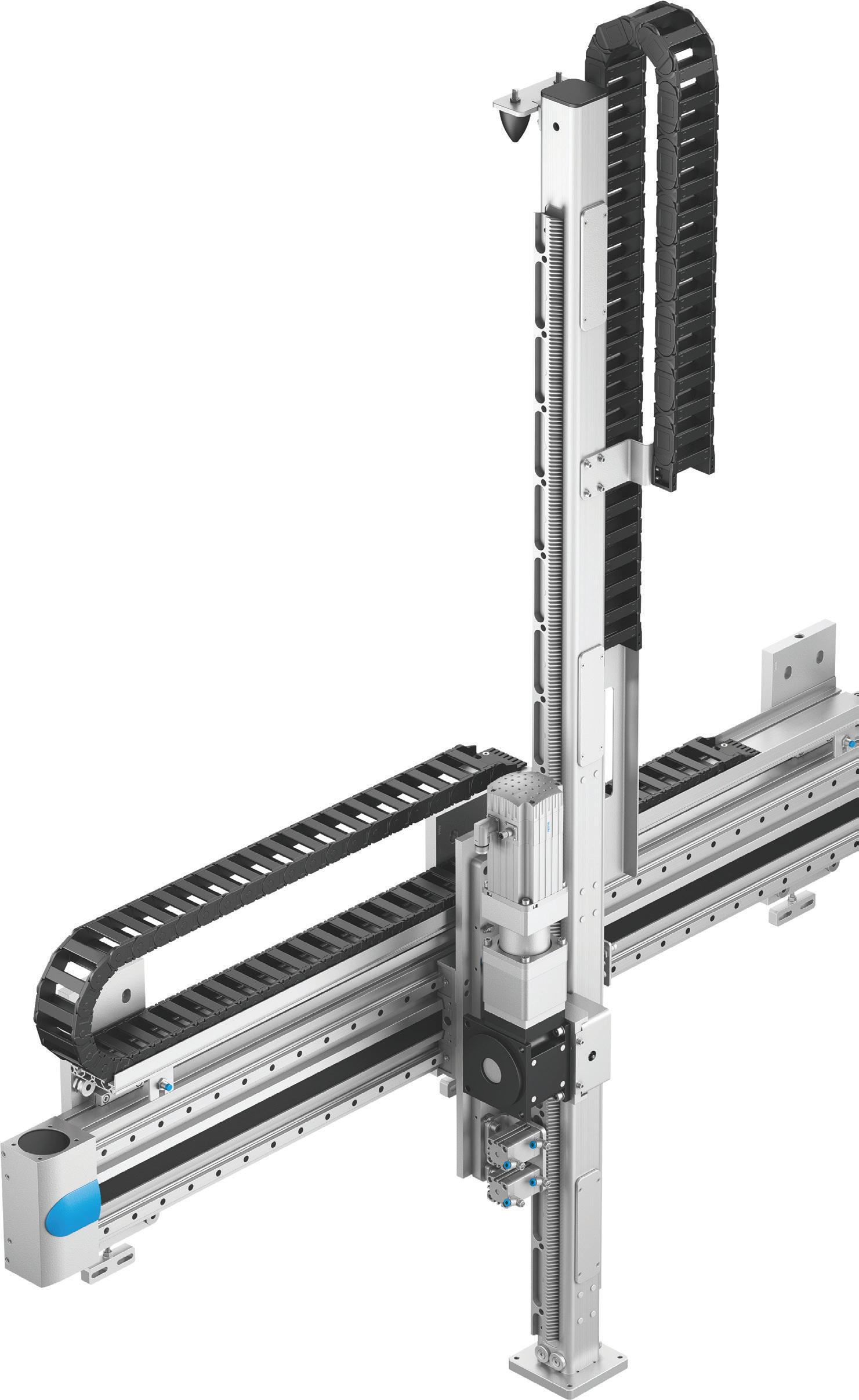

Cartesian gantries are known for accuracy and speed, whether handling a small load over a long reach or a heavy load over short distances. Compared to six-axis robots that can lose accuracy and lift capacity at the periphery, gantries cover the entire workspace with equal accuracy, speed, and performance at each point on the X and Y axes. Cartesian palletizers also have a smaller footprint and often cost less than six-axis robotic palletizers.

Festo introduced a heavy-duty Cartesian gantry for palletizing with a lift capacity of up to 440 lb, Z-axis stroke lengths exceeding 8 ft, and a speed of up to 5 ft/s. With online design tools, offthe-shelf servo drives, motors, other components, and quick assembly kits, this palletizing solution shortens project time and reduces engineering and assembly costs.

Materials of: CARBON, ALLOY and HARDENED ALLOY STEELS

Materials of: ALLUMINUM and CORROSION RESISTANT STEEL

manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly.

Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

Offering easy integration in manufacturing and packaging production lines.

Robust, high-rigidity electric actuators provide the core of this new solution. These actuators include a cantilevered Z-axis EHMH rack and pinion actuator for loads up to 440 lb and an ELCC-toothed belt actuator with ball bearing guides for loads up to 220 lb. For an X-axis solution, the EGCHD heavy-duty toothed belt or ball screw actuator is suitable for most heavy-duty applications.

OEMs, system integrators, and end users can use the free Handling Guide Online (HGO) tool to specify a gantry in as little as 20 minutes. Engineers input application parameters, such as distance, speed, torque, and weight, and HGO outputs solutions based on performance and cost. HGO ensures interoperable components that are accurately sized for the system, as matched components lower risk and improve performance.

Modular Design

Hygienic Features

Low-Maintenance

At the end of the specification session, HGO provides 2D and 3D CAD files, a parts list, a quotation, and an expected delivery date. The CAD files allow system design to continue while the gantry’s ready-toassemble kit is prepared.

Combined with HGO, the Festo Motion Control Package (FMCP) software designs the control panel, which arrives pre-built. Users connect the cables and program the robot using function blocks, and crews can complete the initial setup in hours or days.

Other key components in the Festo Cartesian palletizer include the compact CMMT-AS servo drive that now features multiprotocol capabilities — one drive for EtherNet/IP, PROFINET, EtherCAT, and Modbus TCP protocols. For control, a single CPX-E Codesys-based controller can manage multiple synchronized gantries while communicating with third-party controllers. Festo’s CDPX HMI features an IP67 rating for on-unit mounting, increasing ease of use and reducing space in the control panel. DW

Festo www.festo.com

Though encoders are useful for measuring rotation, many production processes need to measure linear position or speed. Measuring wheels and accessories, combined with encoders, can be a convenient and accurate way of measuring linear motion in applications such as conveyor systems or manufacturing rolled products. Recent enhancements to Posital’s programmable encoders make it simpler to configure wheel-equipped encoders to meet an application’s exact requirements.

Wheel encoder assemblies measure speed and position directly from a moving surface, avoiding errors due to gear backlash or hysteresis that can arise when encoders are connected directly to rollers or drives. For cut-tolength applications, measuring product position directly from the surface of materials, such as fabric, paper, wire, or sheet metal, can improve accuracy and reduce scrap losses. Posital’s measuring wheel-encoder combinations provide resolutions as fine as 0.1 mm/pulse for all wheel sizes.

Posital’s IXARC incremental encoders are programmable, where

software parameters define the encoder resolution and can be modified with no changes to mechanical components. Engineers can set commonly used resolutions, such as 1000, 1024, or 2048 pulses per revolution (PPR) or as high as 16,384 PPR. Likewise, output drivers can be set to either Push-Pull (HTL) or RS422 (TTL) to ensure compatibility with PLCs. The wheel-encoder sets can be customized to exact application requirements and reconfigured onsite through software updates.

Measuring wheels are available with 200 mm, 500 mm, or 12-in. circumferences. Four rim treatments are available: knurled aluminum, smooth polyurethane, and two tread patterns for the polyurethane tire. Posital also has several spring-loaded mounting brackets and pivot arm assemblies designed to minimize slippage by maintaining a steady contact pressure between the wheel and a moving surface. Pivot arms accommodate large lateral movements and feature adjustable spring tension for optimal contact pressure. DW

Posital • www.posital.com

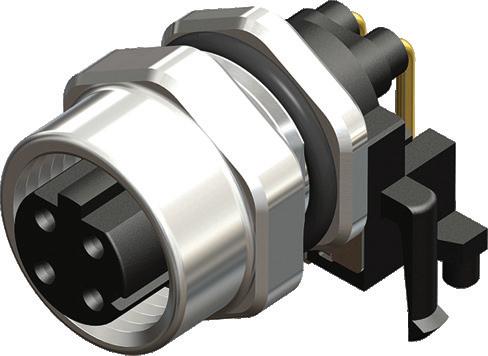

After passing UL’s Solid Particle Protection and Liquid Ingress Protection Tests per IEC Standard 60529 (Sec. 4.2, 13.4, and 14.2.4), Interpower’s C14 inlet Face Seal Kit as well as its Plug Seal Kit was given an Ingress Protection rating of IP54 per UL’s test report. The IP “5” rating (solid particle ingress level), prevents corrosive dust and solid particles from reaching the terminals, which could create loss of electrical continuity and disable machinery.

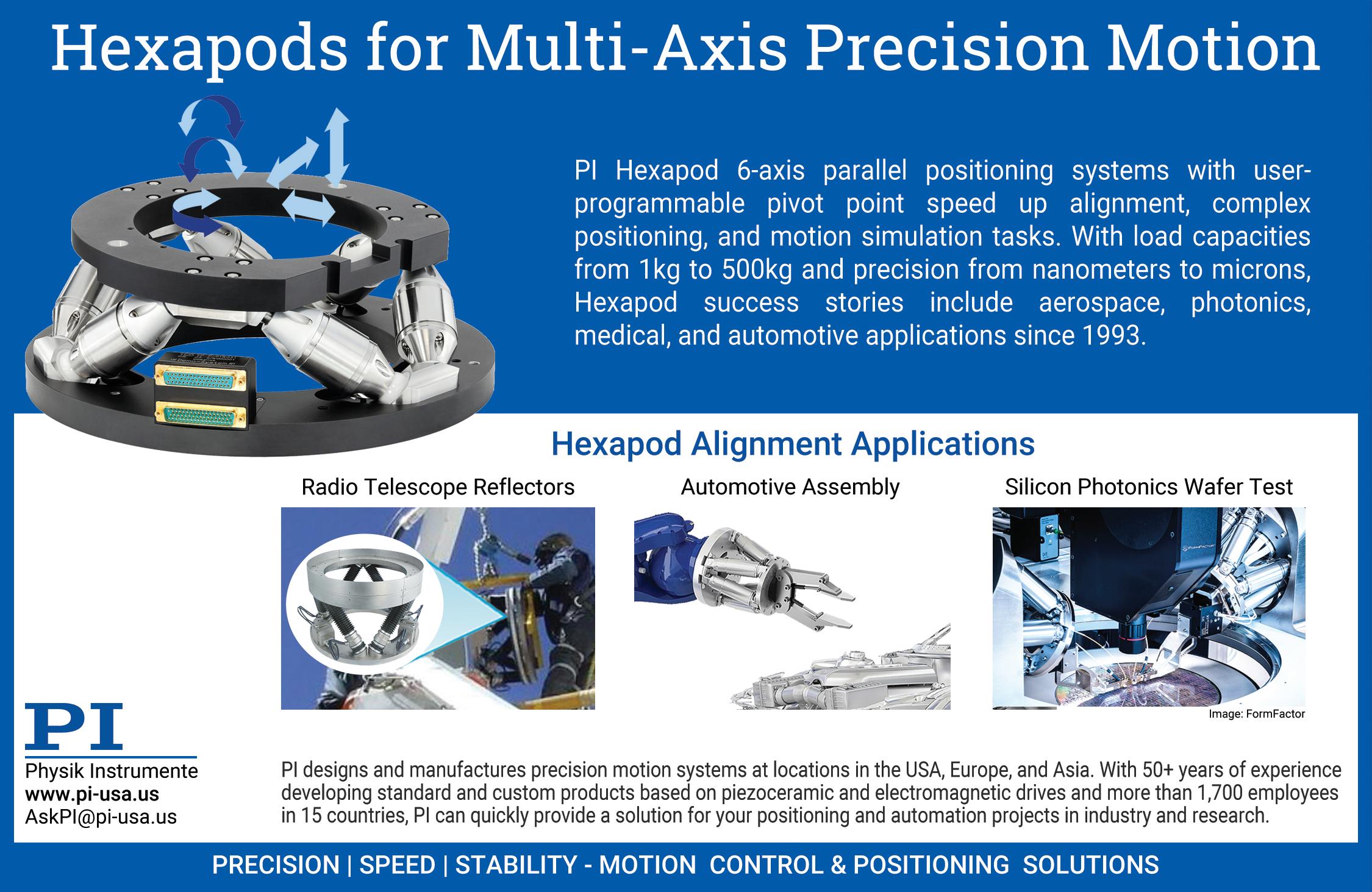

Six-axis nanopositioning systems are often used in photonics alignment and semiconductor inspection applications. They are notably precise, versatile, and can manipulate objects at the nanometer scale.

Physik Instrumente (PI) has released a unique planar XY-theta-Z nanopositioning stage based on air bearings and direct drive motors. Unlike conventional multi-axis stages, the A-361 employs only one moving platform shared among all three axes. One of its advantages is the ultralow, 40-mm profile with an integrated vacuum chuck to accommodate wafers or other samples. Engineered as a parallel-kinematic multiaxis system, this stage delivers precision in a compact package. Incorporating noncontact components ensures frictionless operation, ultra-high precision, and a completely

maintenance-free, virtually infinite service life. The built-in positionlocking capability proves useful for operations requiring utmost stability with zero servo jitter. Due to the contact-free operation and lack of lubricants, the XY-Theta stage is suitable for clean room applications.

For applications requiring precision motion in six axes, the A-361 XYTheta stage can be integrated with the A-523 Z Tip/Tilt stage, creating a compact six degrees of freedom nanopositioning system with only 100 mm total height. DW Physik Instrumente • www.pi-usa.us

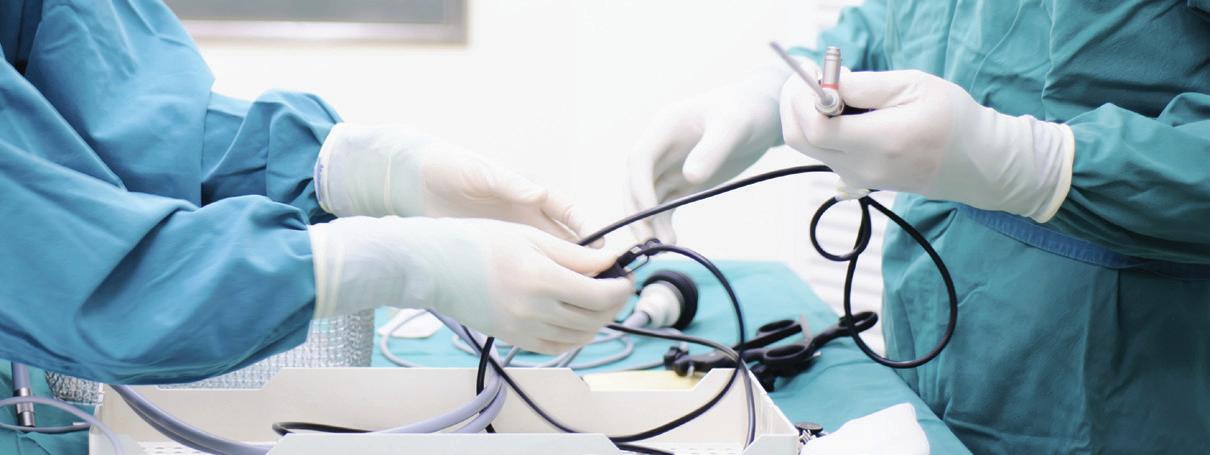

Turn your design challenges into next-generation, marketleading medical devices with our extensive manufacturing capabilities and engineering expertise. We have facilities in Fremont, CA and Santa Ana Sonora Mexico.

Categories:

Video Cables

Patient Monitoring Cables

Sensor Probe Cables

RF Generator Cables • Robotic Surgery System Cables • Aesthetic Surgery Cables

• Single Use Cables

For wheelchair users, engineering and accessibility can often help offer vastly improved mobility. Working on these challenges is New Zealand-based Omeo Technology. The manufacturer specializes in what it calls “personal mobility devices,” and the engineering and technology it is built on enables its users to have a freedom and control that was previously unavailable.

The Omeo

The Omeo personal mobility device provides hands-free control, beach and other off-smooth or -paved surface mobility, a zero-degree turning radius, and substantial power and speed capabilities. Hands-free control is achieved with an active seat control that enables the user to move the Omeo forward, back, left, and right by leaning in the seat.

The drive and tires are designed to work on sand, gravel, dirt, and smooth surfaces. Zero-degree turns let users roll through tight spaces indoors or outdoors which could be a non-starter for conventional wheelchairs. The run time on a single charge of the battery gives the Omeo a range of up to 31 miles and at speeds of up to 12.4 mph. Why does such sportiness matter? Well, in just one user’s case, it lets him roll alongside his wife while she goes for a multi-mile jog. Participating in activities that were once out of reach can be lifechanging.

The technology behind the Omeo To understand how the Omeo works, it helps to start with the Segway — the device on which the Omeo platform is based.

The Segway is a personal transporter device designed for a rider to be

standing up and steering by leaning left, right, forward, or back while holding a handlebar. The handlebar contains an angle sensor at its base to detect the angle of the handlebar and its left or right direction of tilt. The handlebar, together with the sensor, is referred to as LeanSteer by Segway. There are sensors on the platform for riders to stand on to detect their forward or backward lean — both in direction and degree. Two controller boards under the rider’s platform accept inputs from the batteries, motors, LeanSteer sensors, rider platform sensors, rate, and gyroscopic tilt sensors.

Omeo has re-engineered the motion controls to adapt the functionality to a seated rider.

A seated rider controls the Omeo’s motion by shifting their weight about a central pivot point using sensors under the seat to detect a forward, backward, left, or right weight shift around that

After passing UL’s Solid Particle Protection and Liquid Ingress Protection Tests per IEC Standard 60529 (Sec. 4.2, 13.4, and 14.2.4), Interpower’s C14 inlet Face Seal Kit as well as its Plug Seal Kit was given an Ingress Protection rating of IP54 per UL’s test report. The IP “4” rating (liquid ingress level) prevents liquids from “splashing” into the terminals causing possible arcing, which could lead to shortcircuiting which may damage equipment, or possibly create fires or even electrocution.

Toll-Free Phone: (800) 662-2290

E-mail: info@interpower.com

Business Hours: 7 a.m.–5 p.m. CST Order Online! www.interpower.com ®

point. Omeo calls this Active Seat Control (ASC). There is also a joystick so riders can choose between one of these control input methods. In either case, the sensors and joystick use angle sensors to generate output control signals that are sent to two controller boards with microprocessors and software stored in memory to process these signals.

Omeo can only be started in joystick mode with the stabilization legs extended to ensure the rider’s safety. Once a rider is ready, they can retract the legs and switch to ASC mode.

Two Novotechnik SP 2800 angle sensors are used in the Omeo for motion control. They both have redundant circuits to maintain operator control even in the unlikely event of a failure of one of a sensor’s circuits.

When a user moves the Omeo joystick in one direction, the angle sensor converts this movement to an electrical signal. That signal is sent to a controller in the Omeo’s base. The

joystick is spring-loaded to maintain a neutral position unless a rider moves it. The joystick is used for turn information only and not forward or backward motion input. Only one sensor is needed to assess the position of the joystick.

The second angle sensor is coupled to the Omeo’s seat and is used by the ASC for left or right tilt input. The seat is also spring-loaded to maintain a neutral position unless the rider shifts their weight, thereby changing their center of gravity. Omeo has also engineered hydraulic dampening into the seat to smooth out seat motion for the rider and enable the Omeo to be steered in a consistent and highly controlled manner. This is achieved by a needle valve that restricts the flow of hydraulic fluid between two cylinders on each side, under the seat, and supported by a mechanical pivot point.

There are two modes of operation with the Omeo that enable riderless operation. In the first case, called Walker

Balance Mode, a user may want to roll the Omeo without a rider while walking behind it. One example in the manual describes moving the Omeo up or down a ramp. The second is called Free Wheel Mode and is used when moving the Omeo without powering the wheels is desired.

The Omeo has front and rear lights for travel in low light. It measures 35 x 25.6 x 39-in. (l x w x h). With the off-road kit, the width is 34-in. It comes with a Railblaza attachment port that accepts add-on accessories, including storage compartments, cup holders, umbrellas, or fishing pole holders. Its maximum combined rider and cargo capacity is up to 250 lbs. The weight of the Omeo itself is 172 lbs with batteries, and it has a ground clearance of 3.4-in. Omeo specifies that it will operate on a slope of up to a 20 to 25° incline and 30° decline — with sufficient traction. DW

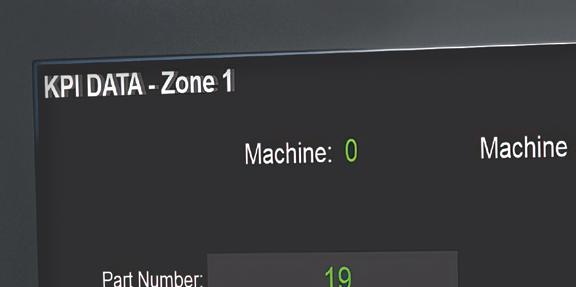

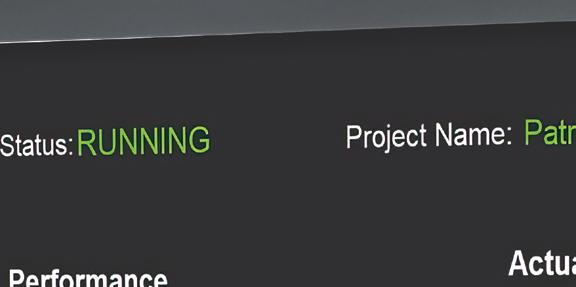

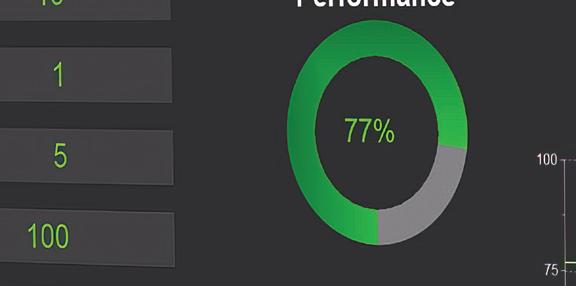

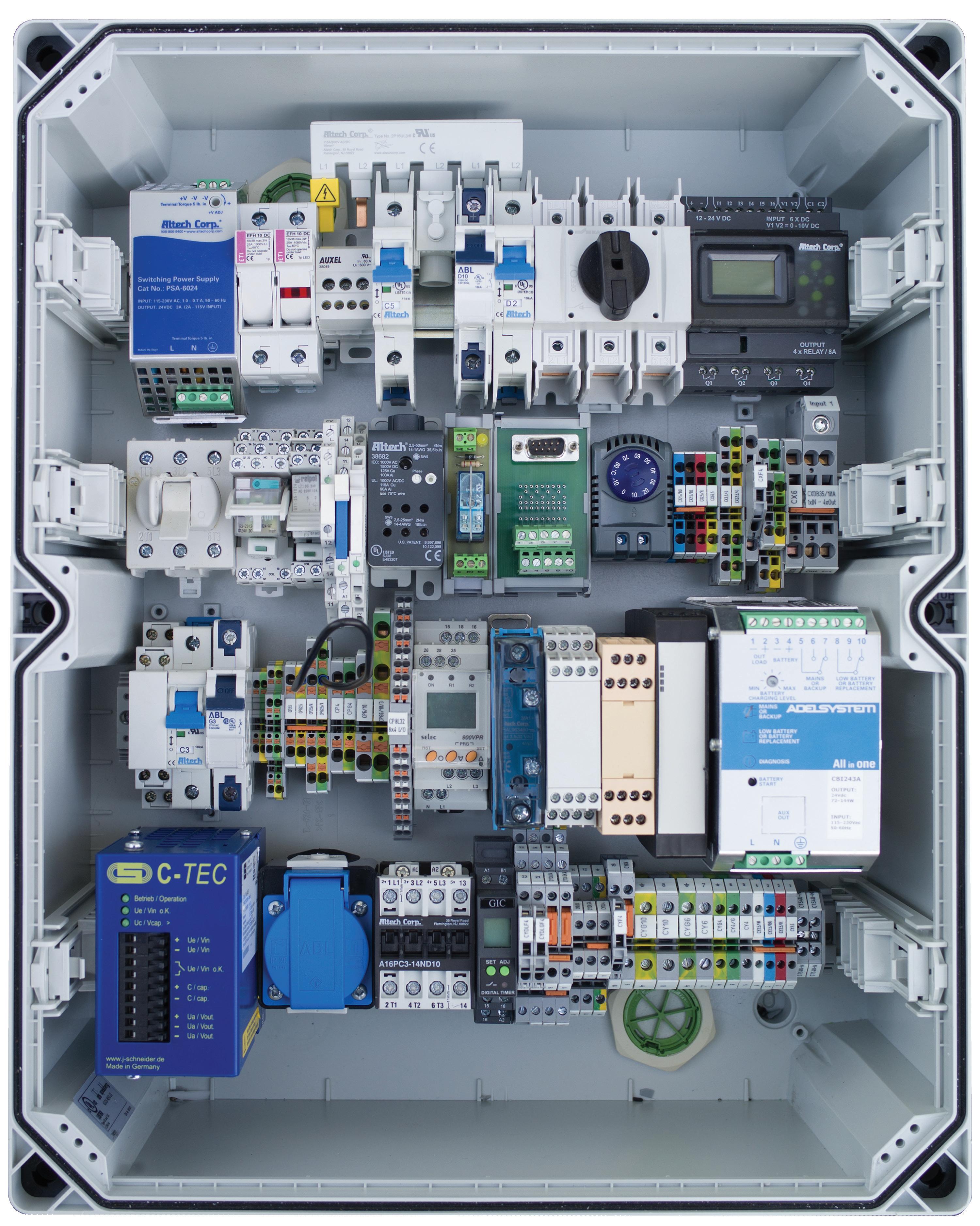

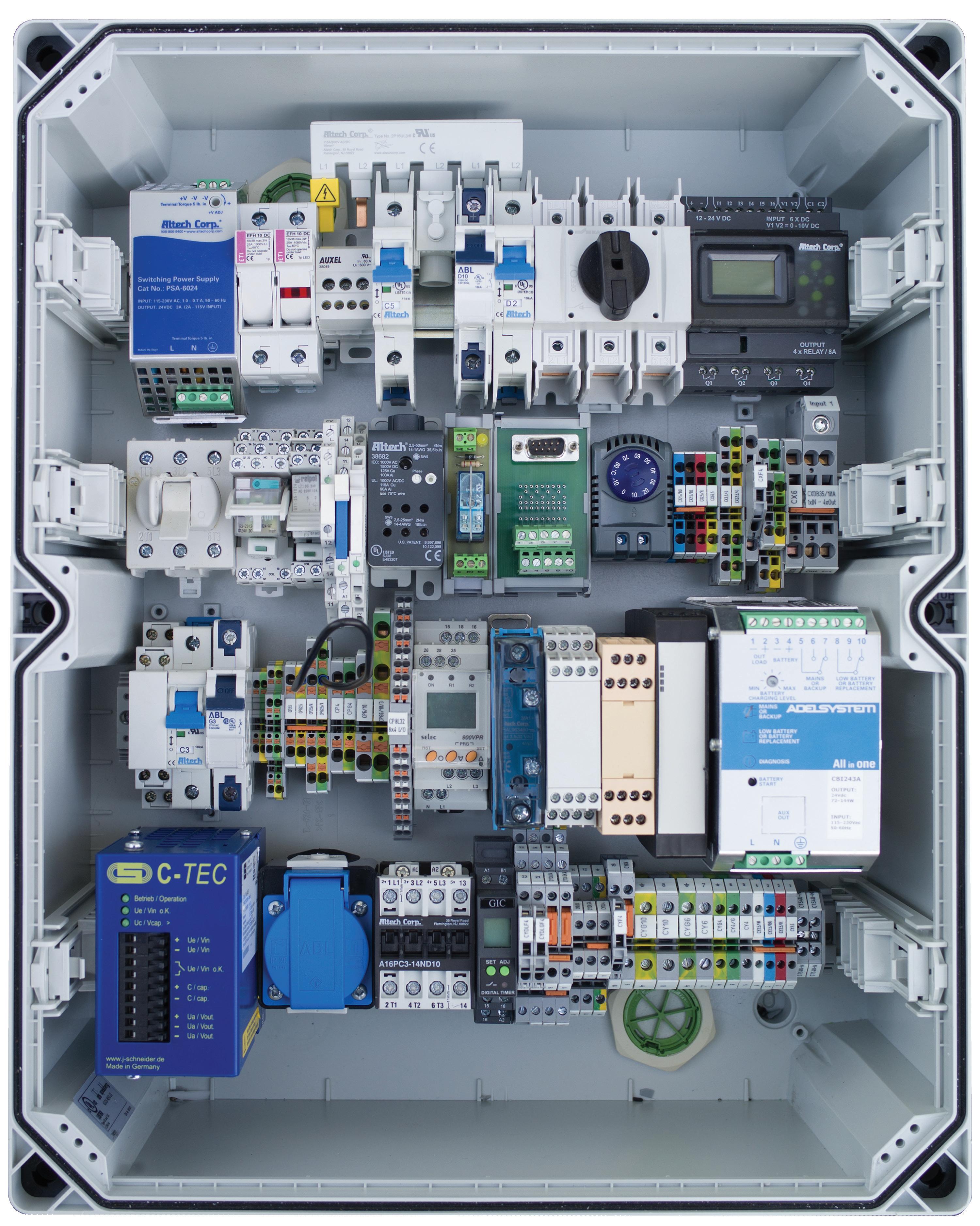

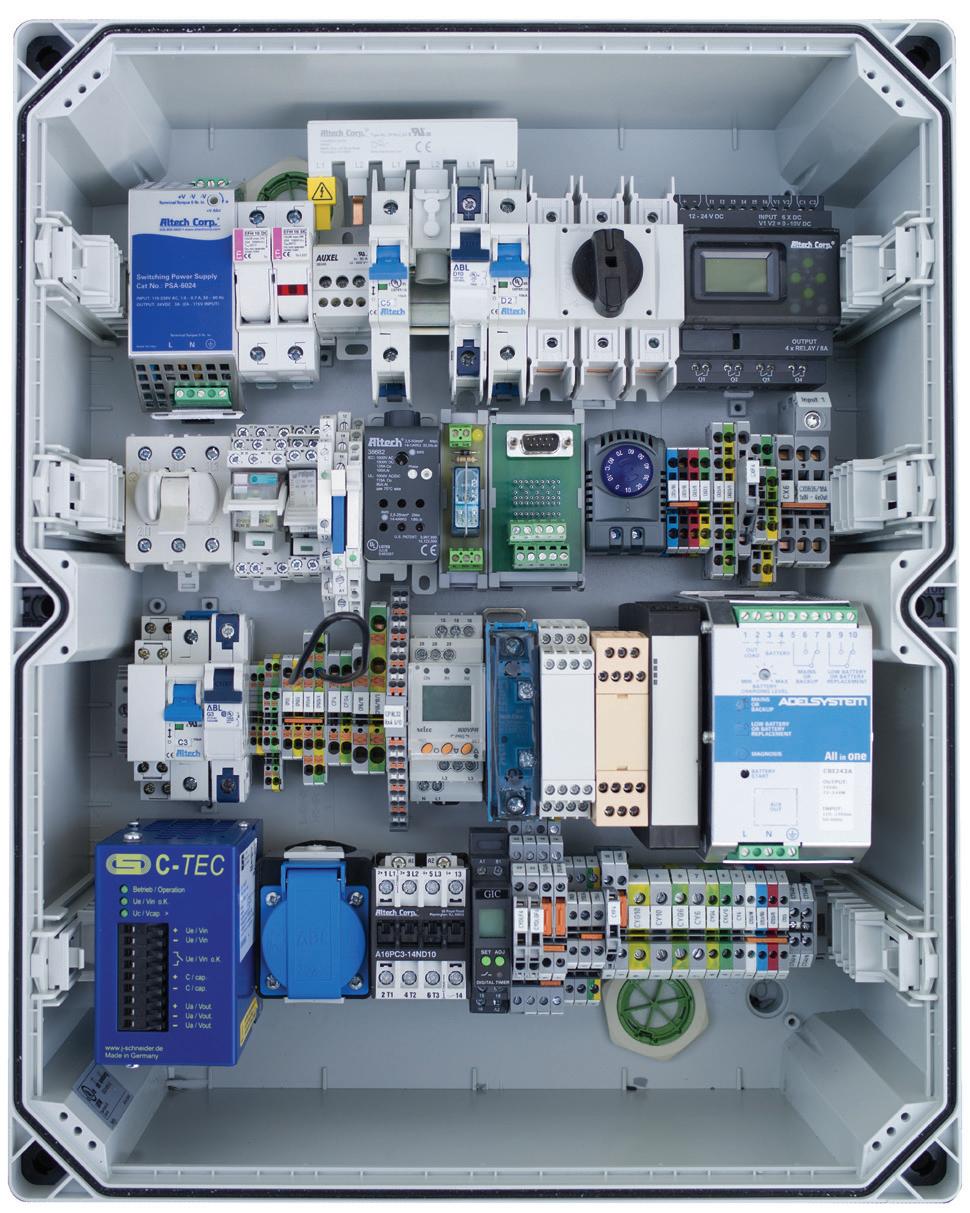

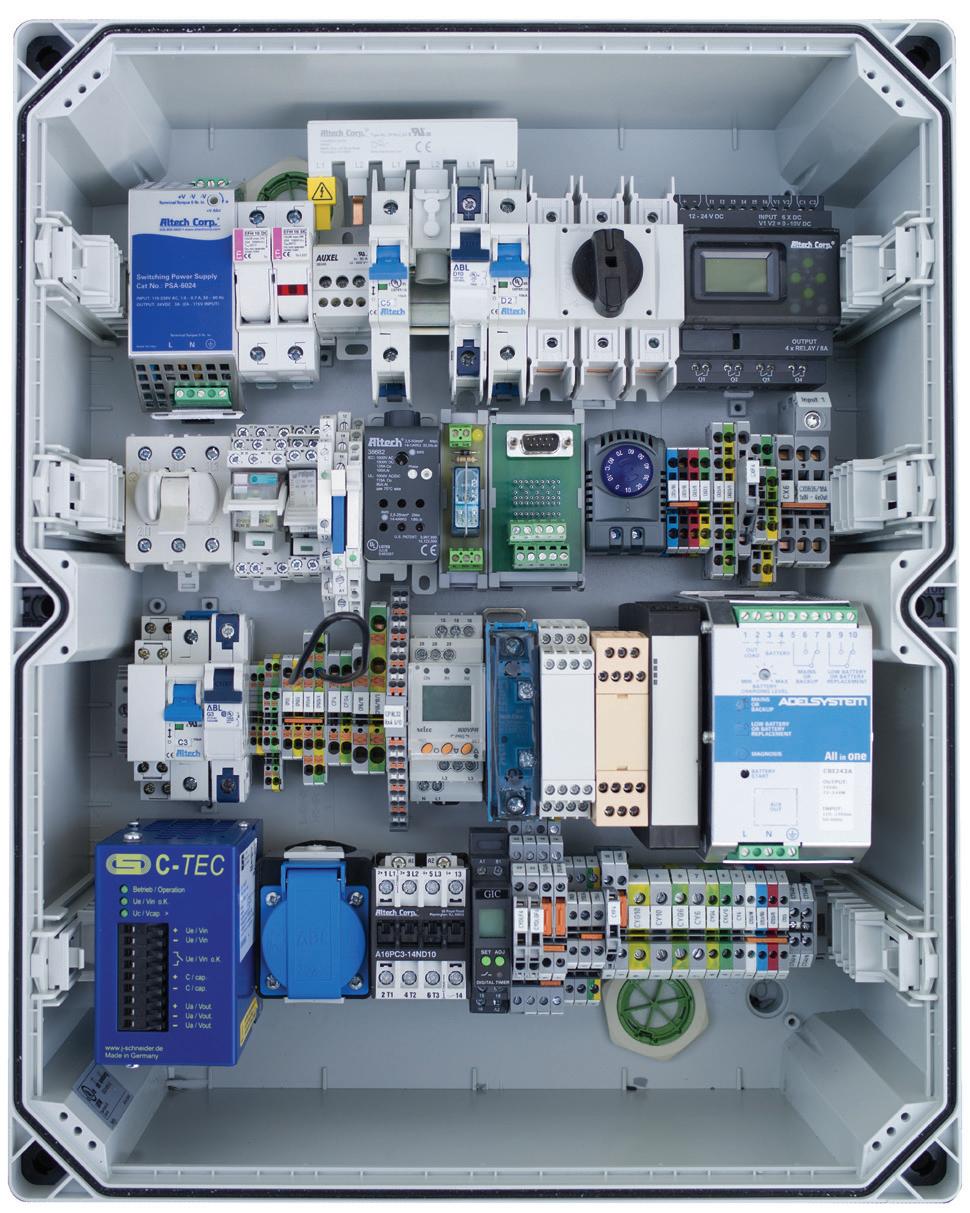

When it comes to industrial automation applications, there has long been a degree of separation between “control” and “visualization” functions. Programmable logic controllers (PLCs) and human-machine interfaces (HMIs) have evolved technologically over decades to perform distinct but closely related operational roles. A closer look reveals why this has been the case historically, and it can also show how uniting both PLC control and HMI visualization roles into an all-in-one PLC and HMI (PLC+HMI) device can be the best solution for certain industrial automation applications (Figure 1).

Control and visualization differences

As digital controllers first superseded hardwired automation decades ago, they were architected with programming and execution concepts designed to ensure reliable monitoring and operation of critical devices on machinery and equipment. For industrial applications, the PLC was

particularly adapted to work in harsh environments, interact with all the common signaling voltages and types, and provide the required rigorous programming instructions. Sometimes, these instructions mimicked physical elements, such as electrical contacts and drum sequencers, but at other times, they advanced into more esoteric areas of math and logic.

Original operator interface methods for PLCs were primarily oriented around panel-mount devices like buttons, switches, lights, and indicators. But as digital displays and PCs developed, they were quickly adapted into more capable graphical HMIs. The focus of HMI configuration was on accessing PLC data and displaying it in a useful manner for operators, while also empowering them to interact with the data via virtual pushbuttons, data entry fields, and other means.

Both PLCs and HMIs perform important industrial automation roles, even though the core functionality of

essential visualization, I/O, controller, and communications connectivity in an ultra-compact industrial form factor, making it a leading choice for many applications across diverse industries.

each is very distinct from the other. Close interaction between PLCs and HMIs is essential, yet developers often must pursue two parallel development paths before eventually integrating the two different work products. In some applications, the additional physical space demanded by separate PLCs and HMIs becomes a concern, as well as integration issues, cost, and complexity. For these and other reasons, and depending on the application, designers should consider an all-in-one PLC+HMI device to best meet their industrial automation needs.

Automation can be better together

Combined PLC+HMI devices have been available for many years and usually fit a targeted use case of smaller input/ output (I/O) count applications with significant physical space constraints. Certain devices have been based on PLCs with some visualization capabilities added, while other examples are created from HMIs with selected control functionality incorporated.

The idea of selecting a combined PLC+HMI device is attractive to

suitable control and visualization capabilities for many applications.

designers for many applications, but few implementers will be willing to sacrifice the control, visualization, and overall performance they have come to expect with individual devices. New solutions address this issue, and here are some of the key considerations for evaluating a combined PLC+HMI.

A lack of installation space is one of the main driving factors for moving to a combined PLC+HMI automation solution (Figure 2). This concern becomes increasingly important as equipment footprint shrinks, machines are more highly instrumented, and automated functionality increases.

PLCs demand real-time I/O scan performance, while HMIs require computational processing adapted for graphics presentation. Reconciling these two different purposes in a single central processing unit (CPU) is possible, but a better approach for PLC+HMI units is incorporating two CPUs, with one dedicated to each role. The two CPUs can be designed to communicate natively with each other so that users will experience the best computing performance and streamlined connectivity.

Users will also expect a PLC+HMI to feature the full PLC instruction set, including PID analog loop control, without any limitations that would negatively impact implementation. Because PLC+HMI is commonly used for small to medium applications, best practice is for the device to incorporate a reasonable number of built-in I/O. The I/O types should be a selection of discrete and analog inputs and outputs suitable for the most common 24VDC, 0-10VDC, and 4-20mA signaling voltages or currents. High-speed inputs and RTD inputs provide even greater design flexibility. Relay output versions can provide a higher current-carrying

option, while transistor output versions can operate at higher speeds and even work as pulse train outputs for motor drives. For slightly larger applications, the ability of a PLC+HMI to use expansion modules to increase the I/O count is a plus.

An HMI display touchscreen can represent a vulnerable weak point because it is exposed to the environment and user interaction. For this reason, only industrial-grade hardware will serve; designers should look for devices rated for operation in extreme temperatures and washdown environments. However, older technologies have used membrane pads or infrared light, making them susceptible to damage and false operation due to dirt or water drops. More modern HMIs are now incorporating projected capacitive touch panel (PCAP) advanced technology, which is similar to what is used for smartphones and tablets (Figure 3). The tech has been toughened to resist water and scratches while maintaining multitouch high performance, and resisting false signals due to dirt and water droplets on the screen face. Users can even interact with a PCAP display while wearing thin gloves.

VESA-mount enclosures designed for the installation of standard displays, panel PCs, HMIs and touch screens (e.g. Siemens, Beckhoff and B&R). Four sizes with a slim profile just 3.740" deep. VESA MIS-D 100 mounting for VESA control arms or brackets. Accessory wall and pole mounting kits.

Order your own custom version!

Since PCAP has a glass surface and uses fewer layers than older tech, it has muchimproved brightness and clarity. PCAP also works well with slim bezels, resulting in the maximum possible display area for a given installation footprint and a very shallow mounting depth clearance requirement.

Advanced connectivity, simplified software

As the intelligence level increases for automated machines, users need ever more connectivity options for the control and visualization platforms, with Ethernet the de facto standard for today’s equipment. Industrial protocols such as Modbus TCP can be used to access many common types of field devices, while IT-type functionality such as the FTP protocol, SMTPS secure emailing, custom web page hosting, and even X, formerly known as Twitter, integration can provide many ways for the automation system to interact with host systems and remote users.

To ensure easy implementation, users should investigate the programming/ configuration development environment. A single integrated development environment harmonizes the PLC programming and HMI configuration effort, streamlining developer work. Users should also look for ease-ofuse features such as an intuitive drag-anddrop interface, built-in symbol libraries, and unlimited no-cost updates for the life of the product.

PLC+HMI as the adaptable answer

Individual PLCs and HMIs have a long history of excelling throughout all types of industrial applications. While prudent designers may have fair concerns about whether a combined PLC+HMI might introduce some types of compromises, the fact is that modern hardware architectures, the latest PCAP touch display technology, and well-designed software have overcome many of these challenges.

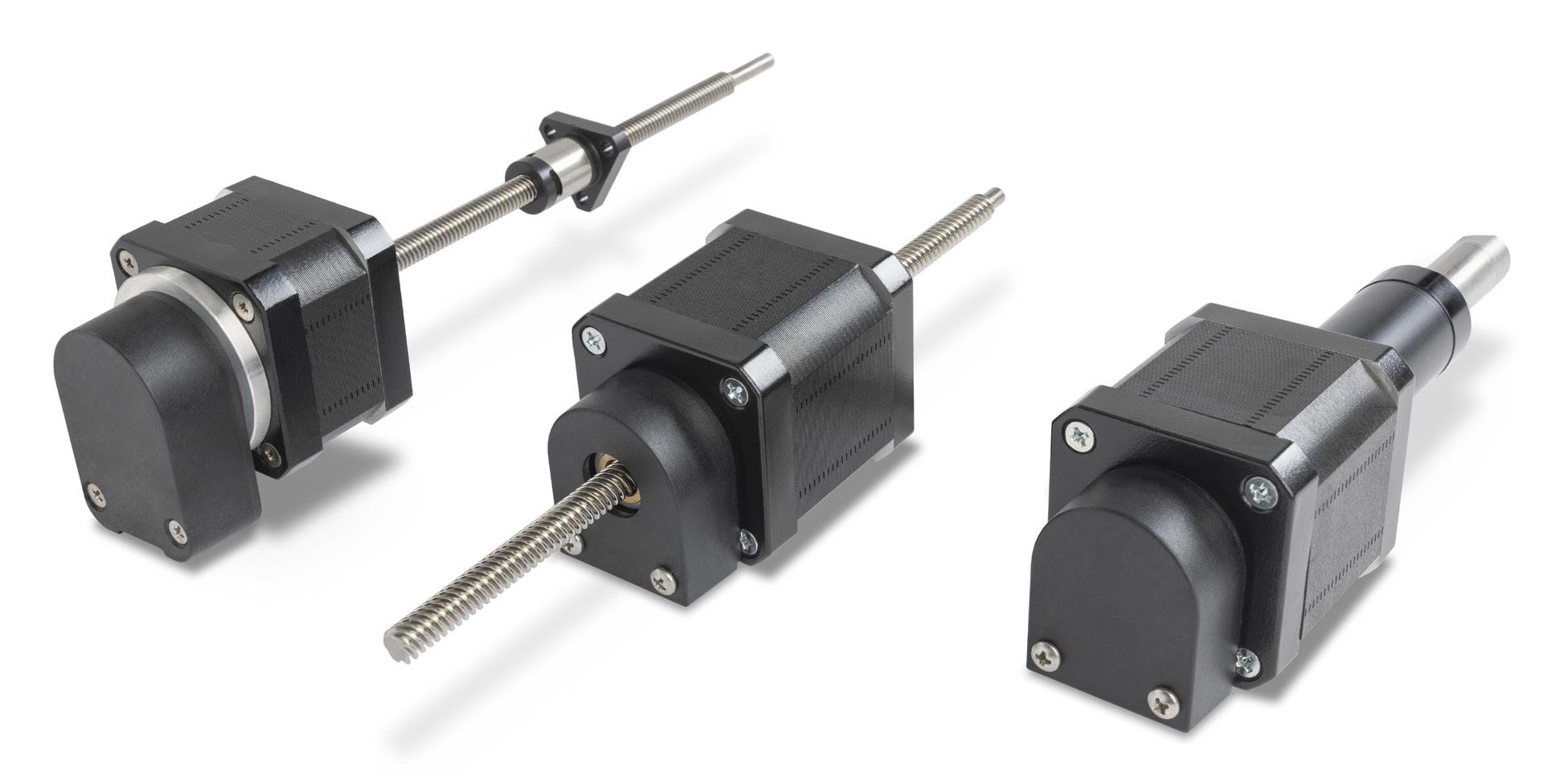

• Available Sizes Flange and Cylindrical Nuts

• Machined Journals

• State of the Art Metrology and Inspection

• Integrated Ball Screw Motors

- NEMA 08, 11, 14, 17, & 23

• Applications

- Medical Lab Automation

- Optical Sensor Adjustments

- Pick and Place

- Packing Line Push Systems

- Measurement Systems

- Mechanical Automation

• Customization Available

Opened in 2015 and then expanded in 2018, the Festo Regional Service Center in Mason, Ohio, now fills three buildings covering 565,000 square feet on a 47-acre campus and serves North America. The center’s automated storage and retrieval system, shown here, end-to-end is 35 miles long with automated material handling equipment that can accelerate faster than a sports car.

Discrete automation with motion systems and complementary forms of warehousing technologies remain core to reshoring and making supply chains more robust in the years since COVID-19.

We recently asked several industry experts about trends they’re seeing in this space. Here’s what they had to say.

Is your company developing new relationships with local and regional suppliers?

Giunta: The North American Market continues to be valuable as a global manufacturing center. Reshoring is critical to meet the demands end customers need to ramp up quickly in a post-COVID market with a reduced workforce and a rapid need for automation.

O’Grady: Yes, we’ve accelerated the localization of our supply base and have established new relationships with new vendors. Really, we’ve just accelerated a trend that was already underway. As we grow within the North American Market, the economics behind decisions about where value is created within our production processes evolves. For instance, we used to sell several hundred pieces of a certain product per month. Now we sell tens of thousands of that same part monthly.

Now the math that drives our sourcing decisions favors more local procurement of raw materials. Similarly, when we look at instability in global supply routes and other risk factors, the math dictates more safety stock to buffer against these variables. In cases where it makes financial sense to remove those variables from the equation, local sourcing and production is often the answer.

Beyond these constantly evolving supply questions, Festo has also decided to invest even more heavily in the North American market by deploying new R&D capabilities in Ohio and Boston to let us more quickly and accurately assess and meet end user demands.

Sizemore: While we were already in process of localizing our supplier base when COVID hit, we placed a lot of focus on gaining quicker results. We were able to localize more vendors, setup alternate suppliers, reach agreements with customers and suppliers to alleviate risk.

Mooij: During the past two years, a combination of factory onshoring and labor shortages has accelerated

• Brian Burke: Product manager III • BishopWisecarver Corp.

• Chris Caldwell: Product manager –material handling • Yaskawa Motoman

• Brian Dengel: General manager • KHK USA Inc.

• Michael Giunta: VP of sales and marketing • Macron Dynamics Inc.

• Richard Halstead: President • Empire Magnetics Inc.

• Mike Korkowski: Operations manager • LinMot USA

• Josh Leath: Senior product manager — thermal • Yaskawa Motoman

• Todd Mooij: Applications engineering manager • BRECOflex CO. LLC

• Sean O’Grady: Sales operations director • Festo

• Dave Prezzano: Global head of goto-market • HP Personalization and 3D Printing

• Gian Sachdev: Marketing head – Americas demand generation • Cognex

• Andrew Sizemore: Supply chain director

• Festo

• Julian Torres: Demand planning manager

• Festo

• Yoshi Umeno: Industry manager — global medical and robotics • Kollmorgen

• Patrick Varley: Product marketing manager — robotics • Mitsubishi Electric Automation Inc.

• Ori Yudilevich: CTO • MaterialsZone

innovation and catapulted what were once dream concepts, such as 3D house printing and vertical farming, into fledgling commercially viable industries. These exciting industries leverage the same timing belt technology that BRECOflex CO., L.L.C. already manufactures for the rapidly expanding automated warehousing, solar, and EV production industries.

Lights-out production is only possible when maintenance due to lubrication and timing adjustments are eliminated. Timing belts eliminate this periodic maintenance, and offer an ideal combination of high accuracy, speed, low mass, long life, and low cost. Next generation belt technology such as BRECOmove has helped make these new industries a reality with its energy-conserving tooth facing, and unprecedented stiffness for the highest possible timing belt accuracy.

Transitioning from concepts to viable production in these new fields requires applying a different set of rules and design efficiencies. This is best achieved when pairing equally innovative components with your winning machine design.

Caldwell: In most cases, where reshoring is discussed, the decision involves moving the manufacturing of an item back from a low-wage country into a higher standard-of-living area. Robotics allow for a greater portion of the manufacturing process to be completed by capital equipment, by either doing the process directly, or by supporting other capital machines to keep them running at full capacity. By driving a larger portion of the production to equipment, the human capital can be reassigned to the more fulfilling roles of overseeing multiple work cells, rather than functioning as a lineworker.

What industry effects of COVID-19 have proven to be permanent?

Sizemore: Our capabilities are back to pre-crisis levels. In fact, in many cases, the lessons learned, and tools developed to help us work through the supply crisis have made us stronger and are now a standard part of our daily operation, as opposed to tools that we’ve put in the proverbial closet to dust off for the next supply challenge.

B. Burke: The prices of our products needed to increase because of cost increases from nearly every supplier, particularly when metals or metal products are involved. Price increases in the range of 3% to 5% were commonplace within the last year. Our company engaged in supply chain diversification to expand our list of qualified suppliers to maintain competitive costs.

Varley: Like most manufacturers, we are seeing increased component costs. Mitsubishi Electric

design in the material and size you require. From prototype to production, we'll provide you with the perfect spring solution for your application.

Automation is working with our suppliers to lessen any cost increases that need to be passed on to our customers. So far, we feel that we have been able to keep cost increases to a minimum and hope to continue to do so.

Prezzano: The pandemic is proving to have a lasting impact on the way the manufacturing and industrial sectors operate. A new normal has been established with volatile conditions from labor and inventory shortages to a turbulent economic climate forcing companies to implement new strategies to stay afloat. As such, a greater focus will be placed on onshore manufacturing, enhancing supply chain resilience, and adopting just-in-time

production in sectors dependent on mass production in 2024 and beyond. With traditional manufacturing methods that were heavily relied on prepandemic failing to rise to the occasion in this new industrial ecosystem, additive manufacturing will further cement itself as a critical tool to be leveraged throughout the production chain. As more businesses look to enhance their operations to withstand ongoing change, the market for 3D-printed goods and services will continue to grow, resulting in an expanding network of service bureaus, industry partners, and breakthrough tools and solutions that ensure production workflows remain optimized. With the rapid advances seen in technology today, we can expect solutions like 3D printing to continue to gain traction across industries and

meet the needs of manufacturers that traditional manufacturing methods cannot provide in this ever-evolving manufacturing landscape.

O’Grady: Overall demand from the market is still quite lumpy as we see the ripple effects of the crisis. But the only constant is change. Rather than trying to predict how the supply chain will evolve, we’re focusing on accelerating our ability to flex and adapt so that we can continue to stay ahead of the evolution of the markets that we serve and those that serve us.

Sizemore: We’ve improved forecasting with our customer and supplier base by using analytics and product focus. Fast tracking our vertical integration supply chain strategy also provides more reliable end-to-end lead times.

What trends do you see in data digitalization for automated operations?

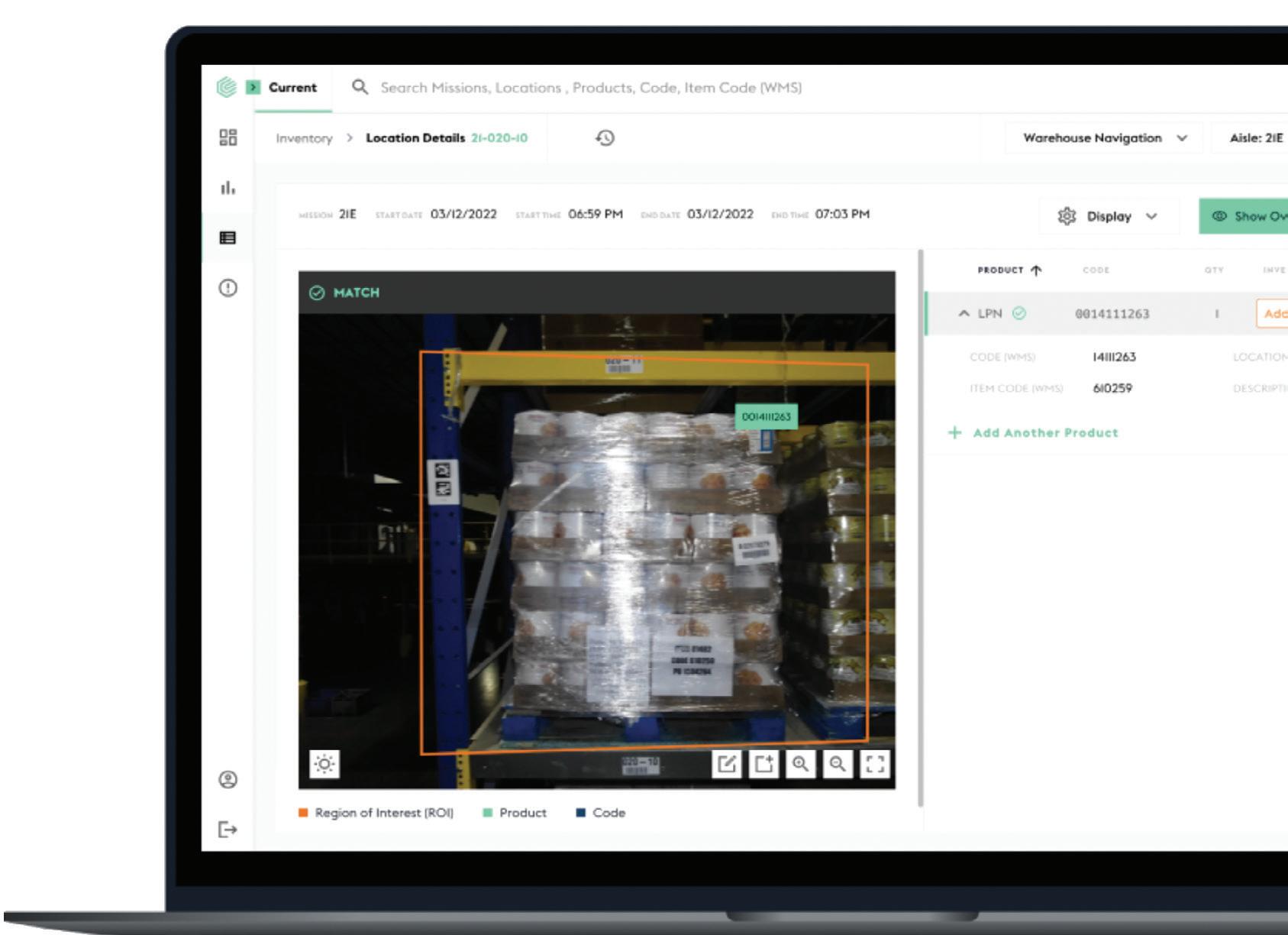

Torres: With the explosion of online commerce, coupled with the continual advancement of supply chain science overall, the innovation happening in this space is vast. The vast diversity in warehouses’ size and complexity for different products means digitalization solutions are rapidly proliferating.

Caldwell: Warehouse digitalization provides a huge potential benefit, especially as the warehouse becomes more automated. Optimizing storage locations and allocation based on realtime or predictive velocity of products, improving packing algorithms to reduce voids in packages, and bundling products in smarter ways to reduce or eliminate shipping damage are just some of the immediate benefits. Moving towards lights-out operations is a goal, but with data and smarter automation in many cases large percentages of

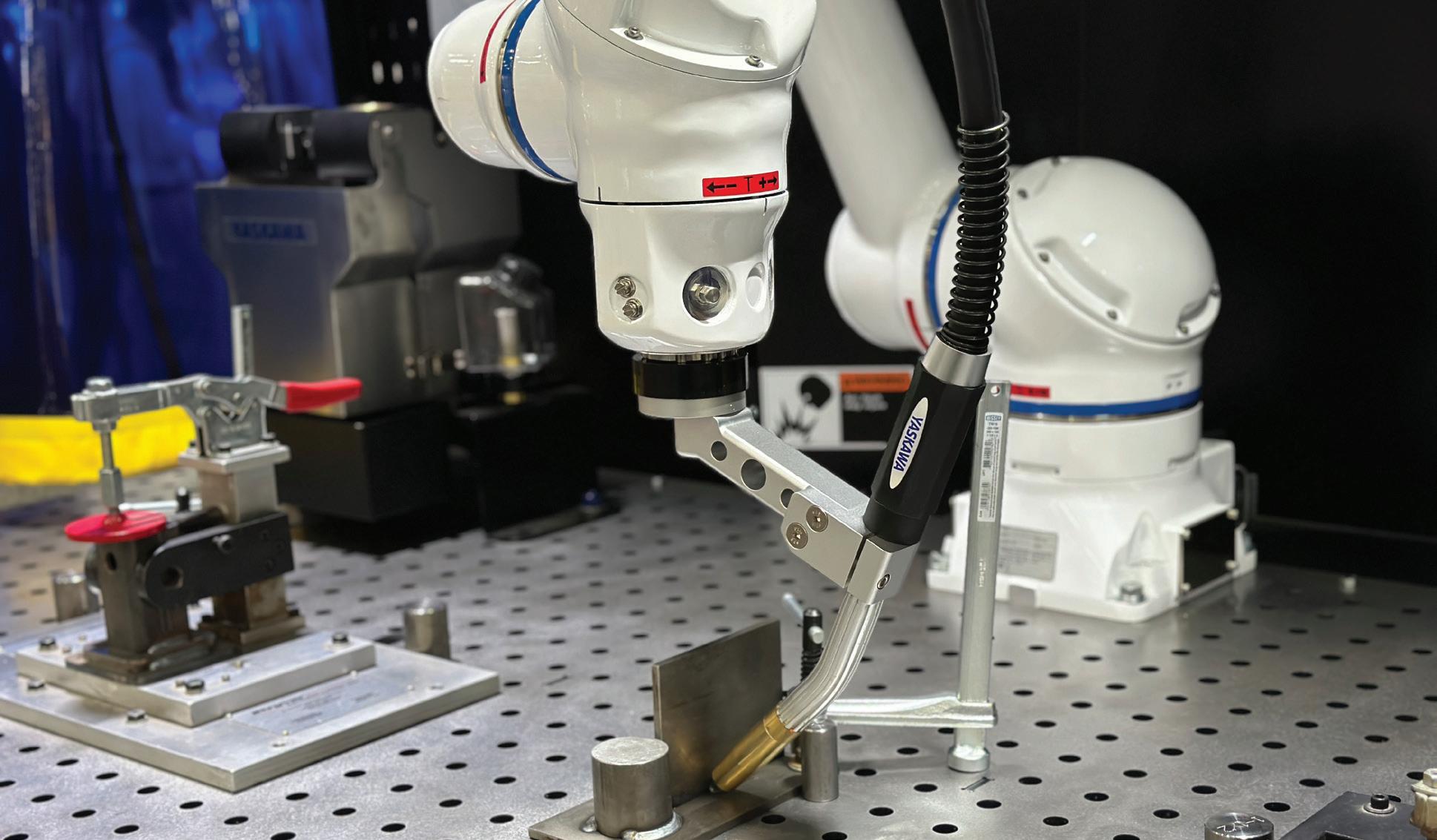

The ArcWorld HC is a simple, complete, and cost-effective way for customers with low volume fabrication needs to automate their welding process. | Yaskawa

the ugly side of warehousing (cycle counts, relocating products, reassigning bin locations, shelf-life management) can be completed fully automatic and during an off-shift. This keeps the traditional workforce effective, efficient, and fulfilled. Beyond the automation side, warehouse digitalization also allows machine learning to recommend discontinuation of slow-moving or obsolete (SLOB) inventory.

Yudilevich: By enhancing efficiency in data management, analysis, and experimentation, MaterialsZone enables R&D professionals to work more effectively, mitigating the impact of labor shortages. This approach accelerates innovation and maximizes the output of skilled personnel, contributing to overall workforce productivity in the face of ongoing labor challenges.

Torres: We’ve accelerated preplanned upgrades to our enterprise planning software and associated analysis tools. Together, this new suite of tools lets us include a wide variety of inputs in our planning algorithms. In addition to traditional inputs such as historical consumption and customer input, we’re now able to use economic modeling data in our forecasts. For instance, we know that historical performance of food and beverage OEMs in western states has historically aligned very closely with certain economic indexes. While staying mindful of the difference between correlation and causation, we can consider future trends in these indexes as an input into overall planning. Once we’ve aligned the demand picture, we rely on our planning software to

connect the market expectation into actual production plans. The data is realtime and interconnected so our demand planners can directly collaborate with our supply planners. The power of data science and real-time data software in supply-chain planning is transformational, just as it is in so many other aspects of our society.

Prezzano: Increased digitization across factory lines and the introduction and implementation of emerging technologies will continue to establish itself as an industry standard. We have seen traditional manufacturing methods struggle to maintain sufficient levels of production as mass-personalization transitioned from a nice-to-have to a must have to retain customers in a highly competitive industrial ecosystem. 3D-printing technology is extremely flexible in that it can enable quick and cost-effective short runs. By centralizing machinery and data input into one additive manufacturing system, users can benefit from all that local manufacturing has to offer, including reduced lead times. More recently we have seen our industry shift to cloud-based solutions requiring specific procedures to effectively encrypt and secure the transmission of sensitive design data. As more companies implement digital solutions into their production flow, we anticipate ongoing integration of additional endto-end encryption and data protection tools within comprehensive 3D printing solutions to continue safeguarding against unauthorized replication and counterfeiting.

Torres: We believe the question of digitalization for warehousing is vital to

The following is an excerpt from a recent roundtable in which Jürgen Berger and Matthias Eick of HELUKABEL, Steffen Quadt of SEW-EURODRIVE, Frank Sangel of Sangel Systemtechnik (now of HELUKABEL), and Martin Schleef of the Fraunhofer Institute for Manufacturing Engineering and Automation discussed (among other things) how automation is traditionally associated with the loss of jobs. For the complete story, visit helukabel.us and click Newsroom.

Schleef: Some people like to claim the goal of automation is to reduce costs by cutting down on staff. But this argumentation is unconvincing: There are many professions where companies are finding it difficult to recruit anybody at all and this is almost forcing them to go down the automation path. Rather than being a threat, automation is a guarantee of jobs. For many activities would no longer be possible if automation didn’t make up for the lack of staff.

Quadt: Automated industries also need qualified professionals, sometimes more than before. The job specification is only different. The skilled trades industry is in a similar situation. In my opinion, politicians must do more here to address this shortage.

Berger: That’s exactly what I think. Here in Germany for example we depend on immigration so we should make more of an effort to integrate foreign skilled personnel. There’s a lot of catching up to do.

Eick: But the skills shortage is not unique to Germany. We’re also finding it more and more difficult to recruit suitable people for several jobs in other countries, for example in Eastern Europe.

Quadt: Automation has another major plus point: it removes the need for people to do tiring, monotonous or dangerous work that nobody wants to or is allowed to do any more. We should use people’s other strengths, for example, their flexibility. As a society, it’s our responsibility to encourage qualifications and professional development rather than preserve outdated jobs and activities. We don’t depend on raw materials for our prosperity in Central Europe but on technologies and our ability to develop and exploit them.

the supply chain in terms of managing the flow of goods from production centers and ultimately to customers. However, warehouse systems need to be integrated with forecasting and planning.

What of the persistent labor shortages?

Dengel: Our company has been using cobots in production for the past 10 years, and most of our machines operate with one or more cobots.

Leath: Logistics and food production are two things that can’t just stop due to limited occupancy in these facilities. However, with continued labor shortages (that started before COVID) these areas continue to need workers and are adopting automation faster than others.

Sachdev: Our customers tell us that one advantage of automation is that it helps them address labor shortages by moving valuable workers into higherpriority jobs, and letting automation take over inspection or sorting tasks that previously required a dedicated person. As machine vision becomes more capable and expands to more applications, companies can reduce the impact of labor shortages by shifting employees into the most critical roles.

Prezzano: Automating processes throughout the production line is pivotal to be competitive in today’s manufacturing landscape defined by labor shortages as well as other supply chain and economic headwinds. Additive manufacturing is already opening the door to a newly reimagined factory floor thanks to 3D printing’s ability to enable complex part designs, improve efficiencies, and provide unique material offerings. However, HP saw that customers could derive even more value from our additive manufacturing technology if automation solutions were available to further simplify processes and reduce steps along the production line.

HP recently launched the HP Jet Fusion 3D Powder Handling Automation Solution and the HP Jet Fusion 3D Automation accessory, both of which are compatible with the HP Multi Jet Fusion 5200 Series 3D Printers using PA12. When utilized together, these solutions bring automation and streamlined production steps to the forefront of any production line by leveraging improved modularity and increased flexibility. This means that factories can operate independent of human intervention, allowing for production to continue into costly night and weekend shifts, minimizing reliance on labor while increasing production volume.

Korkowski: LinMot is part of an automation project and therefore will address areas of operations where it is difficult to retain certain manual operational labor pools.

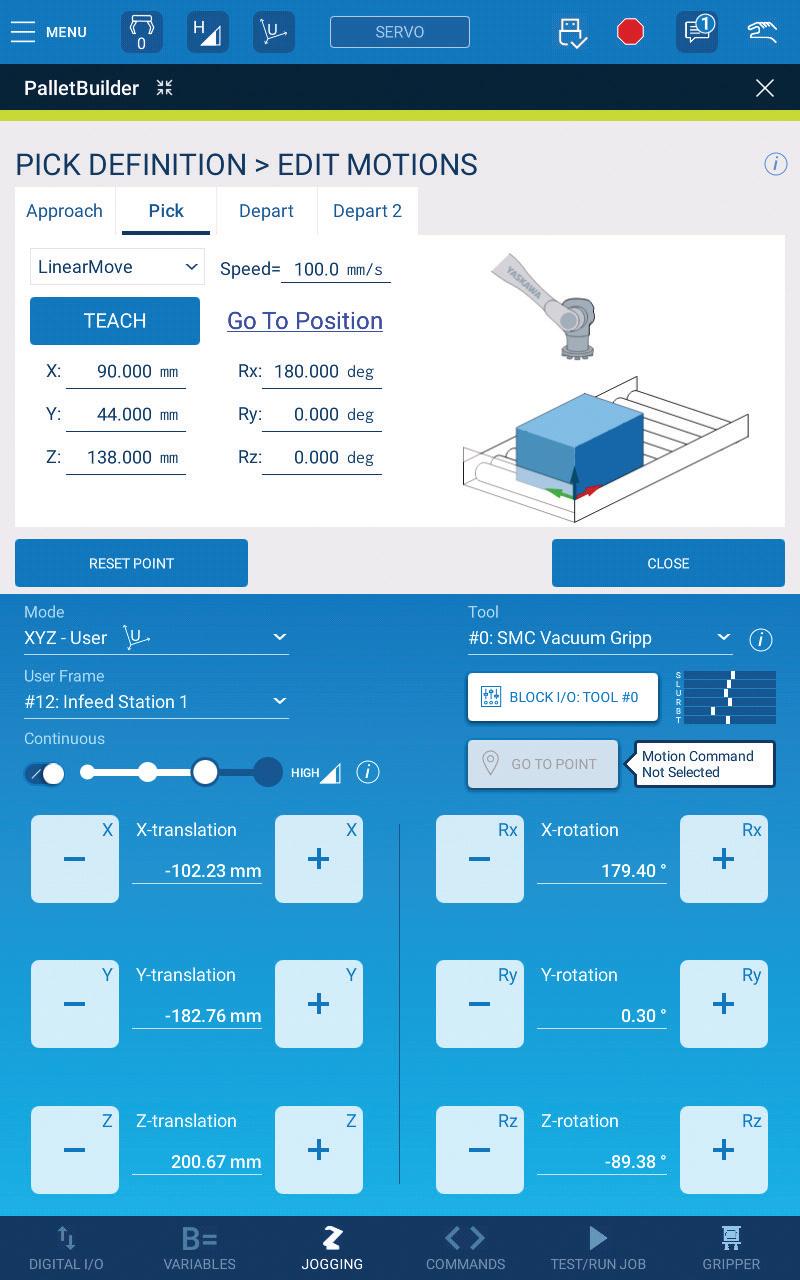

Leath: According to late-2023 data, unemployment is 3.7% or so. There are also currently two job openings for every person looking for a job. The only way to expand our current workforce is through robotics in applications that can be automated. We continue to focus on ease of use to make robotics more approachable for customers who have been waiting to adopt the technology. These are things like the Smart Pendant, that uses simple left, right, up, down commands and applications such as PalletBuilder that let engineers build entire palletizing programs without INFORM code knowledge.

Sachdev: One lasting impact of the COVID-19 pandemic is the increased use of robotic automation in packaging and logistics. Many manufacturers moved to automated solutions during the pandemic, both to address labor challenges and to reduce contamination risks. For example, food and pharmaceutical industries use pick-

and-place robots to reach high efficiency and quality production targets while minimizing contamination risks. Those pick-and-place robots need reliable machine vision to guide their activities, which is where we come in.

Umeno: Kollmorgen plays an essential role in powering the robots that are addressing the global labor shortage crisis. Through our innovative solutions, Kollmorgen empowers the next generation of robots to alleviate labor shortages, boost productivity, and pave the way for a safer and more efficient future. From the heavy-duty demands of industrial robots to the growing focus on collaborative robots, Kollmorgen’s industrial-grade motors and drives deliver the power, reliability, and safety needed for diverse applications. In manufacturing, Kollmorgen equips industrial robots with unmatched precision and repeatability for intricate

tasks, while our lightweight and compact motors seamlessly integrate into collaborative robots, fostering safe human-robot collaboration. Kollmorgen focuses on subsegments that support the labor shortages including industrial robots, Cobots, exoskeletons, outdoor robots, and the cutting-edge world of humanoids.

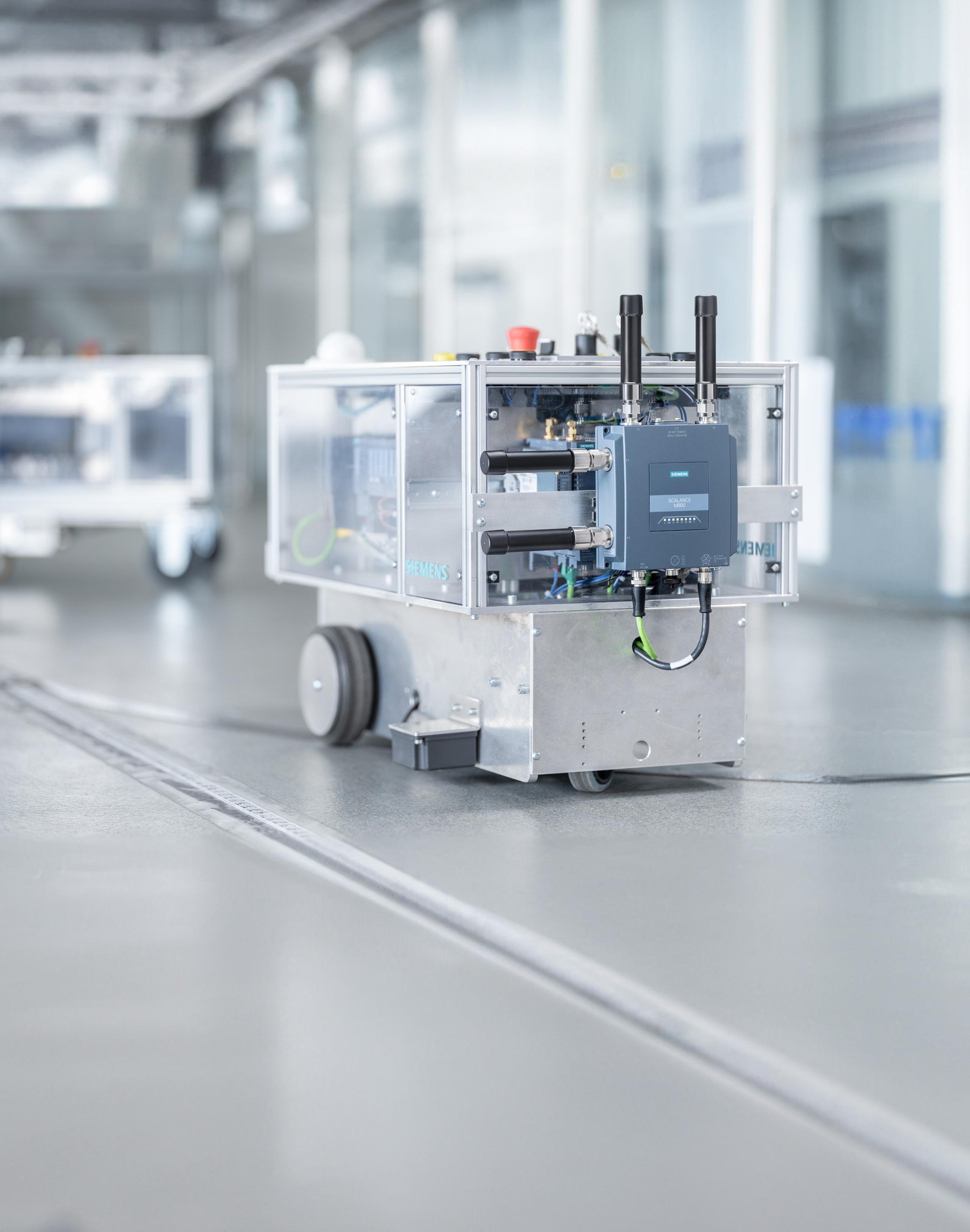

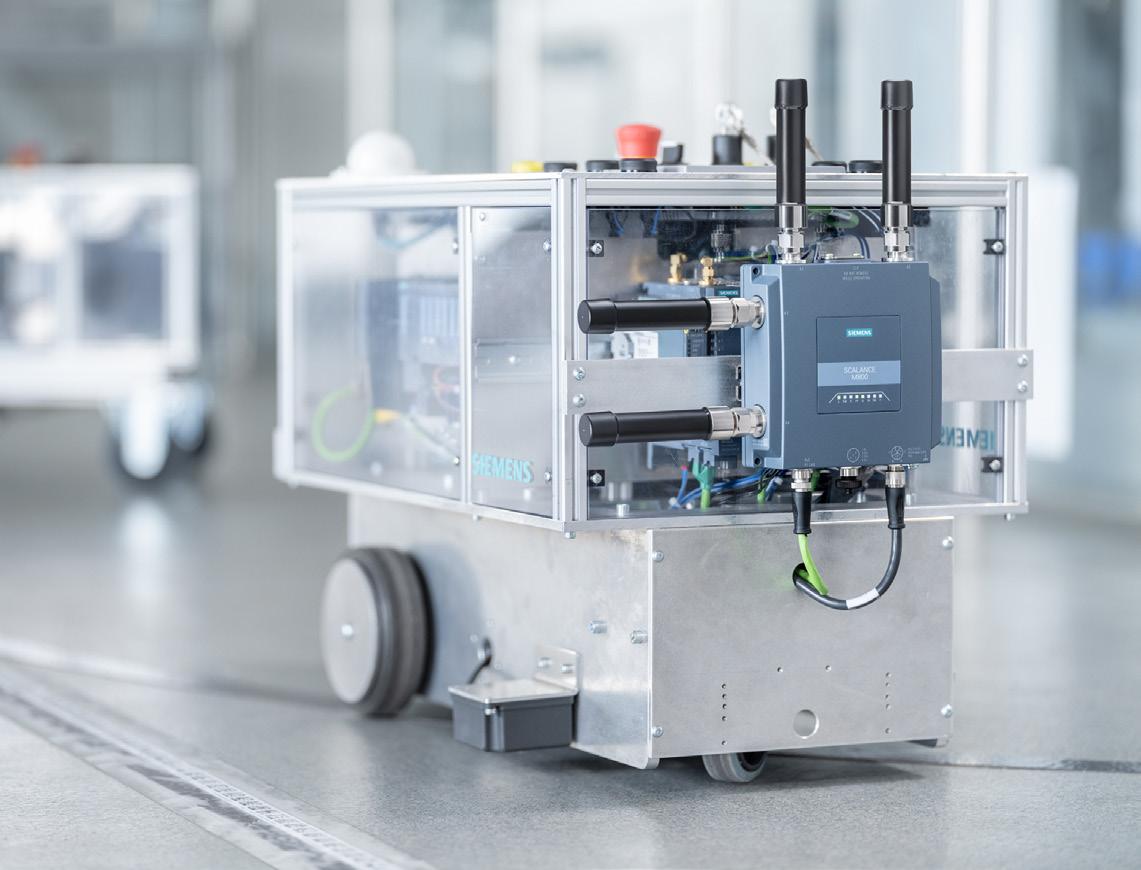

Prezzano: To continue exploring the ways additive manufacturing can allow companies to maximize workflow productivity with improved automation capabilities, HP has worked alongside long-standing partner Siemens on a proof-of-concept demonstration. The demonstration leverages HP’s Jet Fusion 3D powder handling automation and automation accessory with Siemens Automation Hardware and Software, including Siemens SIMOVE for Autonomous Mobile Robots (AMR) within flexible Production Systems. This

solution has been implemented at HP’s Center of Excellence in Barcelona, acting as a hub for HP’s collaborative efforts with partners and customers on research and development, application development, and production use cases.

Umeno: We provide cutting-edge offerings including the game-changing TBM2G frameless motors that offer lower joint weight, high load-carrying capacity, energy efficiency, faster movements, and greater smoothness of motion to the designs of cobots. From intricate assembly to delicate welding and precise painting, Kollmorgen empowers cobots to excel in diverse tasks, even in spaceconstrained environments.

Varley: For many years, and increasingly so recently, the robots manufactured by Mitsubishi Electric Automation have been used to address persistent labor shortages. Two of our more recent

successes come from very different industries: stainless steel machining and food production. For the machining application, by implementing our robots, the user was able to increase their CNC machine efficiency from 70% to over 95% and know that this output wasn’t subject to fluctuations in labor availability. It allowed them to take on more orders without having to add machines or staff. For the food production application, chronic staffing shortages and absentee rates impacted their ability to produce and ship their products. This led to missing deliveries and the need to cancel or reduce their orders for the ingredients needed to make their products. In both cases, automation was not replacing workers: it was allowing more predictable production and deployment of workers to higher value tasks.

Leath: Like many of the robotic welding suppliers, we have developed a solution with a cobot on a flexible worktable complete with arc flash, fume, and speed and separation safety. This lets operators with lowvolume fabrications have a simple and cost-effective way to automate those weldments.

Varley: Cobots and robots both address the same issues facing today’s manufacturer’s regarding productivity, capacity, and labor issues but in slightly different ways. Both types of robots have applications that they are well suited for and tasks that they do not address as efficiently as the other type. Robot manufacturers such as Mitsubishi Electric Automation that make both types of robots are in the best position to help manufacturers make the robot style choice that will benefit them the most.

Reconsider stainless-steel machining. In one operation the company owner was looking for ways to bring production back to the US for some of their components. It had to be done in a cost-effective manner and the 70% machine utilization rate wasn’t high enough for long term justification. Once they deployed the robots and saw the increase in machine utilization, the decision to reshore manufacturing of those parts was easily justified from both cost and deliverytime perspectives. We have numerous other examples of this type of effort that Mitsubishi Electric Automation is supporting with our robots and other automation components.

and

Halstead: While robots appear to be a cost-effective solution, the backlash to come from labor groups has yet to be addressed. Even so, robots will for many good reasons eventually dominate manufacturing, but the rollout is going to take longer than projected. DW

Automation over the last several years has expanded use of electric linear actuators to leverage their technological advancements in smart homes, aerospace, defense, and industrial applications. In fact, the global linear actuator market could (in large part because of electric options) surpass U.S. $52.67B this year and grow at a compound annual growth rate through 2030, according to Grand View Research.

MEET THE EXPERTS

• Eric Rice: Product Market Manager – Electric Automation • Festo

• Carl White: Engineering manager — industrial automation • Schaeffler Americas

• Darren O’Driscoll: Product market manager — core products • Festo

• Dave Beckstoffer: Industry manager • Portescap

• Ulrich Mayr: VP — industrial automation • Schaeffler Americas

• Matt Palmer: Product line manager – linear units • Thomson Industries

• Mike Korkowski: Operations manager • LinMot USA

We recently asked several industry experts what markets they see driving this adoption. The responses were diverse. Several experts indicated increased use of electric actuators and related linear-motion components in North American and European off-highway equipment and aircraft to replace hydraulics and pneumatics. Others cited the proliferation of smart actuators (integrating encoders and other feedback along with onboard electronics for controls) as key to new DX designs. Such actuators increasingly feature enhanced connectivity for streamlined commissioning, automated optimization, and predictive-maintenance functions.

Pre-engineered and integrated linear-motion variations are now commonplace in myriad industries — especially where end users require advanced subassemblies such as stages, gantries, and XY tables for captive use or application-specific electric actuators.

their own linear solution or specify and buy a made-to-order subassembly is determined largely by the amount of time available for design and the number of machines built using that design. For long design cycles where many repeat machines will be built, machine builders can benefit from designing and building their own linear-motion solution. The long design cycle affords the time to find and specify the individual components of the axis — including the linear bearings, drive technology (ballscrew or belt, for example), support rails, carriage materials, and so on. This process lets machine builders

Without the time to optimize each component or the financial return on investment of many repeat machine sales, a made-to-order subassembly is the quickest path to a successful design. Here, three Festo servo-controlled linear axes are designed for fast assembly and can be shipped as a kit. | Festo

• Michael Giunta: VP of sales and marketing

• Macron Dynamics Inc.

• Yugi Ikeuchi: General manager — engineering and app development

• IKO Intl.

• Charles Isaac: Product line manager – linear bearings and guides | Thomson Industries Inc.

• Alex Marques: Product manager • Bishop-Wisecarver Corp.

• Jim Marek: Senior director of engineering | Thomson Industries

Rice: Machine builders save time and money by outsourcing the design of motion subassemblies such as linear axes and multi-axis gantries. Whether a machine builder will design and build

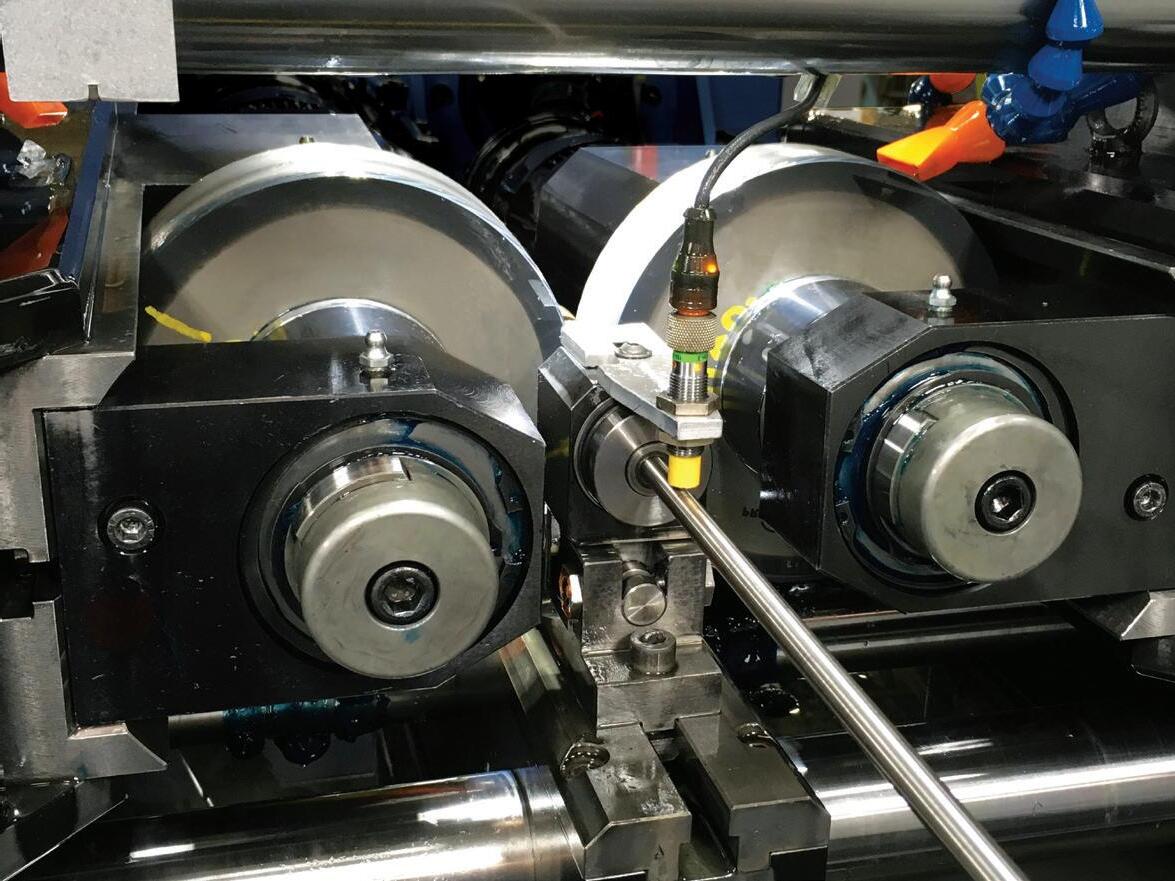

Linear bearings see unwavering use in linear-motion applications.| Thomson

optimize each component to meet a price-to-performance ratio and satisfy performance requirements for the machine at the lowest cost possible. Special attention must be paid to multiaxis solutions where complexity quickly increases with the number of axes.

Combining and aligning axes, cable management, and moment loads in multiple directions are just a few of the additional considerations.

With shorter design cycles or when the number of machines built is lower, the economy of scale diminishes, and made-to-order subassemblies are a more practical solution. Without the time to optimize each component, or the financial return on investment of many repeat machine sales, a made-to-order subassembly is the quickest path to a successful design. The machine builder can be confident that the subassembly is built with high-quality components and can rely on the manufacturer to guarantee performance characteristics.

For multi-axis solutions, the manufacturer will have already designed the mechanical interfaces between axes, supplied a robust cable management solution, and calculated the various moment loads via their sizing software to ensure a high performing and costeffective solution.

Laiewski: An increasing number of companies are losing experienced engineering talent and are struggling

to find new talent for future growth. For this reason, more companies are now outsourcing the design and manufacturing of single or multi-axis subassemblies to specialists with the requisite core competencies. Linear and rod-style actuators are prime example of these types of subassemblies.

C. White: In-house engineering design and calculation services are increasingly in demand. Specific component suppliers typically have better software capabilities that are focused on their products. To create a competitive edge, companies are creating very specialized analysis tools to provide more accurate results and ensure the life of the product selected by the customer.

Electric and pneumatic linear actuators complement burgeoning forms of conveyance in automotive and electronics-manufacture — including linear transfer systems that allow the execution of automated assembly tasks directly on the transfer-system conveyance medium. Elsewhere, linear actuation boosts manufacturing with unbeatably accurate workpiece handling and positioning. Compactness is often a top objective for application-specific electric and pneumatic solutions.

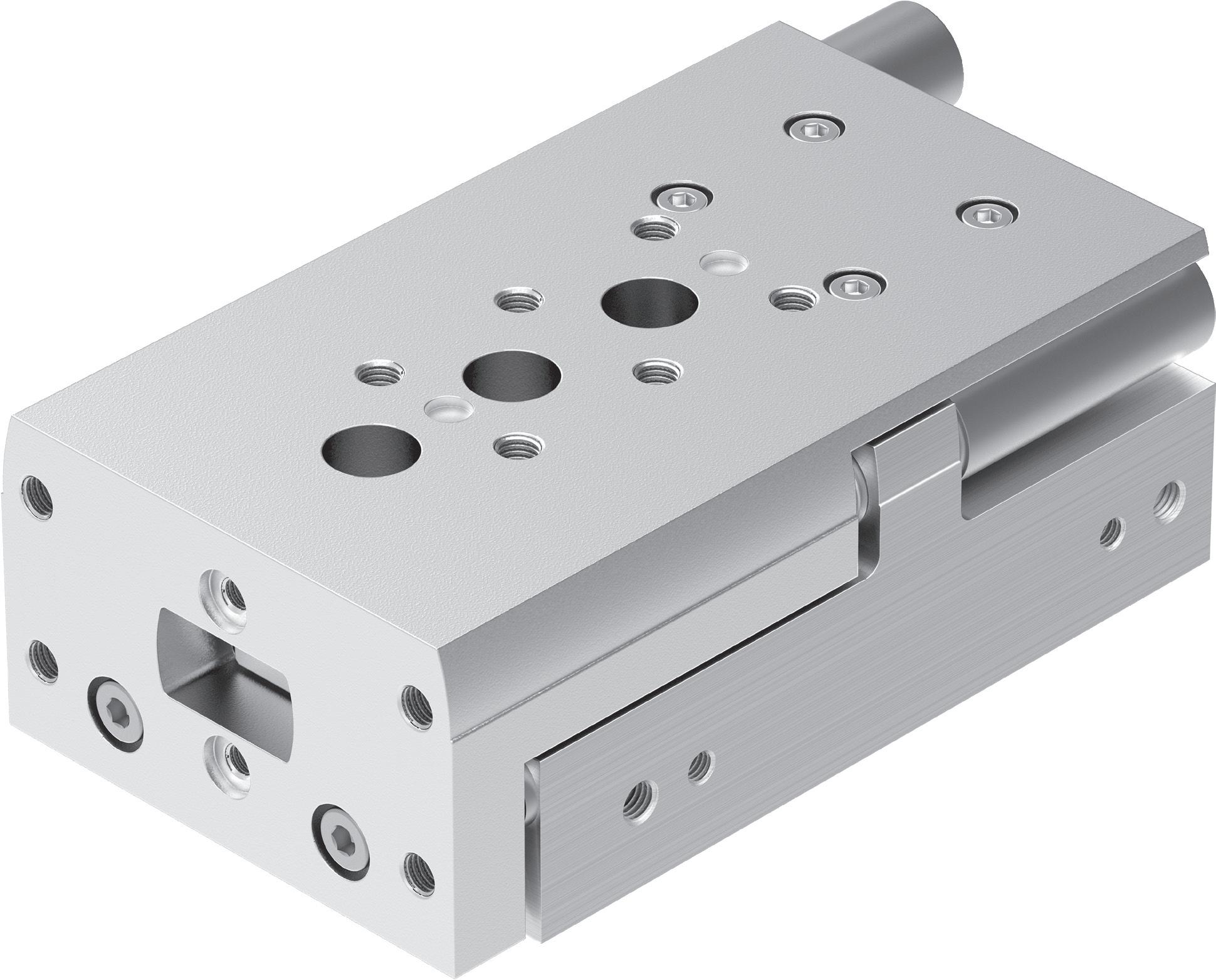

O’Driscoll: Many industry segments use short and compact actuators, but these are key in automate machinery for packaging, light assembly, and electronics industries. Here, smaller machines and higher component density are prized.

Festo couldn’t achieve the desired space optimization while meeting ISO 6432 8 (25-mm bore single-rod) or ISO 21287 (compact sized 20 • 100-mm bore). While important for interchangeability, these two ISO norms essentially dictate components’ overall dimensions and mounting interface. As a workaround, Festo developed new space-optimized versions of two popular actuator types — DSNU-S round cylinders and ADN-S ultra-compact short-stroke cylinders.

The DSNU-S round-body cylinder is up to 40% more slender and 3.5 cm shorter than DSNU ISO types of the

same bore size and stroke length … plus is lighter and allows direct mounting. Likewise, the ADN-S is up to 45% shorter and lighter than comparable Festo ADN ISO cylinders.

Both of these relatively new actuators (along with others in Festo’s Core range) are also now offered in the F1A version. This designation represents a line suitable for new applications such as lithium-ion battery cell production where content by mass of less than or equal to 1% copper, nickel, and zinc is required.

Delicate applications have increasingly adopted use of linear actuation based on leadscrews; at the other end of the application spectrum, more position-intensive applications (and those needing exceptional power density) have spurred increased use of roller screw-based designs.

Beckstoffer: The emergence of biologics to provide therapy regimens for patients is driving development of new and differentiated drug-delivery devices. The utilization of a leadscrew to drive the syringe is becoming more popular for these devices. Coupled with a motor and gearbox, these customized drive systems perfectly fit the form factor required for patient comfort and mobility.

Mayr: The strong growth in rollerscrew use is being driven by the emerging market for humanoid robotics. Specifically, roller screws offer the high power density needed to fit into space and weight-constricted designs. The same applies to the rotary joints that currently use strain-wave gearboxes for

their space efficiency. Additional benefits can be realized by utilizing integrated force and torque sensors which provide highly accurate positioning feedback.

Rice: The strong growth in the use of roller screws is driven by the need for higher forces from linear axes. Ballscrews provide excellent force and accuracy performance but cannot reach the high forces available from larger pneumatic and smaller hydraulic actuators. Roller screws bridge the force gap in many applications, allowing machine builders to avoid the costs and maintenance requirements of compressed air and hydraulics.

Despite increased migration to electric-based linear motion, pneumatics remain indispensable.

O’Driscoll: Precision and compactness have become increasingly important in end user and machine builder applications. Reducing the weight and footprint of components while maintaining required performance is essential. The launch of Festo’s DGST offers the most compact slide on the market. In addition to precision,

end-position accuracy, and high feed force, the DGST offers a new price competitiveness previously impossible with Festo’s past mini-slide portfolio.

Precision and accuracy were not synonymous with pneumatics in the past until the development of the mini-slide, also known as slide table in the market. With industrial and consumer goods leaning more and more on electronics, the need for compact, precise, and high-speed automation equipment has been growing year after year. Industries in light assembly, testing, and packaging all demand a mini-slide-type solution. After all, even when electric axes are used in handling systems, it’s still quite common to find pneumatics at the final positioning and gripping stages. Mini-slide functions include those for precision pushing, picking, insertion, and positioning tasks. Guided movements of small and large payloads (up to 17 kg) are possible with the DGST mini-slide due to twin piston actuation.

Unique to the DGST and the slide market is the way in which the yoke and slide plate are machined as one part. Prior to DGST, all mini-slides including Festo’s range were built with a two-piece assembly incapable of

providing the accuracy today’s machine builders commonly demand. The new design provides the highest degree of precision.

The key point here is that many machine builders require a high level of dimensional control over parallel and perpendicular mounting surfaces of the mini-slides. When that dimensional control is not to the design requirement, machine builders resort to machining their own sub plates or shims — which in turn adds time and cost to projects.

Linear motion components often prove a more pragmatic choice than six-axis arrangements for roboticizing workcells in industrial settings. Surveyed market experts indicated there’s been increased use of use of Cartesian assemblies in place of manual operations for consumer, laboratory automation, and medical applications. Options abound, so engineers are cautioned to compare all specifications.

Palmer: The market for linear stages and linear motion systems has become highly competitive in recent years. There are many players in each region, all with relatively small market shares. Because design engineers specifying these products have so many options, and because the products typically consist of an assembly of standard linear motion products, it can be difficult to see any obvious differences between linear motion suppliers and their products.

Encoders provide real-time feedback on load position. | Thomson

Precision and compactness have become increasingly important. | Festo

However, as a design engineer it’s important to pay close attention to the details that may seem minor but ultimately have a large impact on the life and performance of the product. Some examples include polymerbearing material properties, linear unit sealing solutions, linear rail sizes and specifications, load capacity and life ratings, repeatability, environmental ratings and certifications, and customizability.

Mayr: As demand for robots and cobots continues to increase, vertical and horizontal linear actuation kits are being developed to expand the reach of these robots … thereby making them more versatile while providing higher utilization rates.

Korkowski: We now offer linear-motionbased pick-and-place robots. These are customized with specific pick-and-place

options — including force sensors, MagSpring-based load compensation, cleanroom certification to ISO4, and optional holding brakes. The robots are sustainable products that customers request as a single simple part number; they easily interface with our drives and reduce installation costs and maintenance as well. Now, we also offer electric linear-based gripper modules. Once design engineers add gripper modules to the pick-and-place robot, they have a complete automation solution … all with one-stop shopping.

Giunta: In the recent past, linear robotics and gantries were overlooked at a starting point for solving automation problems due to the popularity of six-axis robots. Most North American companies are evaluating automation for continuous-duty applications but are quickly finding the price of entry into this solution does not provide a fast enough ROI.

In contrast, gantry assemblies offer a lower price point, larger range of motion, and a higher payload capacity that six-axis robots for most pick-andplace applications.

Ikeuchi: IKO has teamed with AutomationWare to offer electric cylinders for longer travel and heavy load applications. What’s more, newer robotic joint modules allow for customized multi-axis robot

configurations. Robot joint-specific J actuators and T actuators are available and have begun to gain adoption. What’s more, electric cylindrical actuators are available with a variety of options and short turnaround times — even with some customization. In addition, our precise low-profile miniature positioning stages, NT-V linear-motor, and servo or stepper-driven TM15 are seeing use in optical projects. Over the last year, IKO has also increased its ability to ship from U.S. inventory … and that helps support fast-paced development.

There is no substitute for the linear bearings that accompany linear drives.

Isaac: Certain linear bearings continue to be specified in linear-motion applications even with newer technologies available. When considering load capacity and speed compared to cost, the benefits of both linear ball bushing bearings and plain bearings can outweigh other linearguidance options. The added flexibility of material choices means these linear bearings can also be used in a range of applications. As a result, we continue to see strong demand for these proven technologies.

Marques: As linear motors have become more popular, we’ve seen a lot of interest in our HepcoMotion GFX offering that features a hardened steel guidance system and uses high-speed high-precision Beckhoff linear motors. Many applications use variable speeds, multiple carriages acting in tandem, or programming the carriages to queue to optimize throughput and decouple processes with varying cycle times.

O’Driscoll: The market for guided drives is growing as more engineers become aware that it is easier and more convenient to buy a single product that combines the benefits of linear movement and guiding than buying both functions separately, the DFM from Festo is such a product.

Guided actuators are found in widespread use in applications involving lifting, pressing, pulling, pushing, clamping, stopping, restraining, holding,

cutting, separating, and more. They come in many sizes and variants, can hold almost any tooling, deliver stroke lengths up to 400 mm, are extremely robust, and can apply great force where required.

From an industry perspective, guided actuators have widespread use in light assembly and handling, automotive Tier 1 applications, and the food and beverage industry. Guided actuators are suitable for literally any application that requires a linear actuator rigid enough to handle external torque or lateral loads.

The key to a guided actuator is ultimately the robustness. With DFM from Festo, design engineers get industry-leading rigidity and options to provide the right solution to satisfy the most critical requirements. If the need is based on high lateral or offset loading but price is a concern, then DFM offers a plain bearing guide solution, identified by GF in the type code. If superior stiffness and the least possible deflection is critical for positional accuracy, then DFM offers a recirculating ball bearing guide solution, identified by KF in the type code.

The key point here is that either way, both GF and KF versions are readily available in the DFM core range of standard strokes for quick delivery.

The linear motion market is seeing a surge in demand.. | Thomson

Growing emphasis on energy-efficient automation heavily relies on electric linear actuation, especially in home automation for control of lighting, HVAC, and smart-building functions, according to Grand View Research. Linear motion systems in mobile designs (including electric vehicles for motorized interior elements) have also driven demand for more efficient assemblies.

Marek: The linear motion market is seeing a surge in demand driven by the need for reliable and energy-efficient motion control across various industries. Material handling, factory automation, transportation, robotics and medical are just a few of the markets driving that demand.

Machinery and its subsystems connected through sensors and controls allow realtime monitoring of machine performance. This facilitates the harmonization these subsystems to drive optimum machine performance while providing datasets for predictive maintenance. Thomson has developed a family of smart electric linear actuators in increasingly higher power ranges that are rapidly replacing hydraulic, pneumatic, and manually operated axes on various types of machinery. DW

Figure 3: This studio microphone has selectable polar patterns, including cardioid, omnidirectional, and bidirectional. | Shure

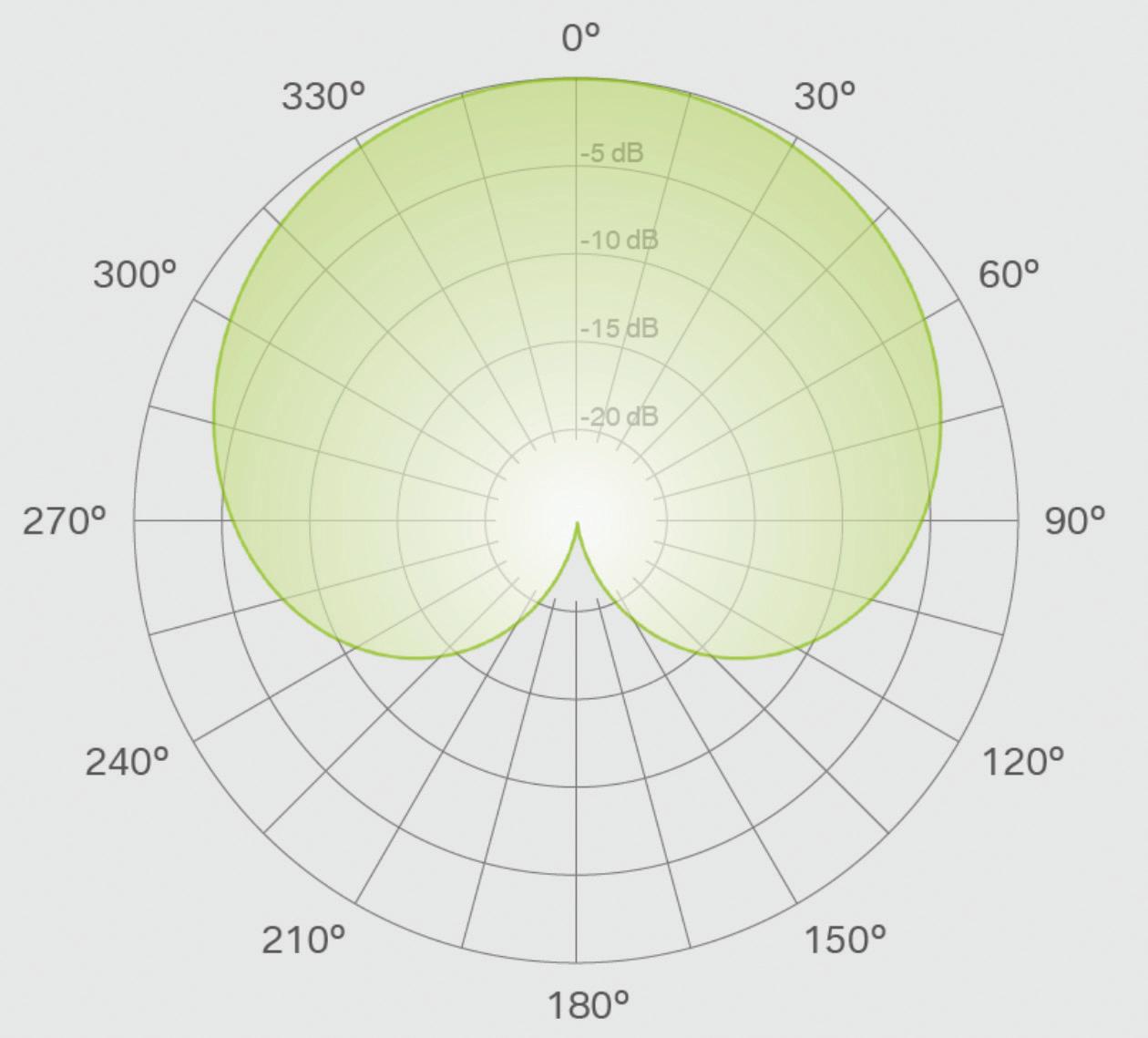

Microphone polar patterns, sometimes called pickup patterns, define microphone sensitivity in different directions. The various polar patterns are used for controlling sound pickup and isolating the sound source, or sources, of primary interest from surrounding sources. There are six common microphone polar patterns: cardioid, supercardioid, hypercardioid, omnidirectional, lobar, and bidirectional.

Polarpatterns are represented by graphs that show the relative sensitivity of the pickup in a 360° field surrounding the microphone. The front of the microphone (onaxis) is defined as 0°, and behind the microphone (off-axis) is defined as 180°. The polar pattern consists of a series of concentric circles that define microphone sensitivity in 5 dB decrements (Figure 1).

Characteristics of the six microphone polar patterns include (Figure 2): Cardioid is the most common polar pattern. It picks up sound most efficiently from directly in front of the microphone and excludes sounds from the sides and back. These microphones have an optimal pickup area of about

130°. The cardioid, also called offaxis, is least sensitive at 180°. They can isolate individual sound sources, reducing feedback from surrounding sources, and their directionality supports cleanly picking up sounds in noisy environments.