trends 2023

DESIGNWORLDONLINE.COM MOTIONCONTROLTIPS.COM MARCH 2023

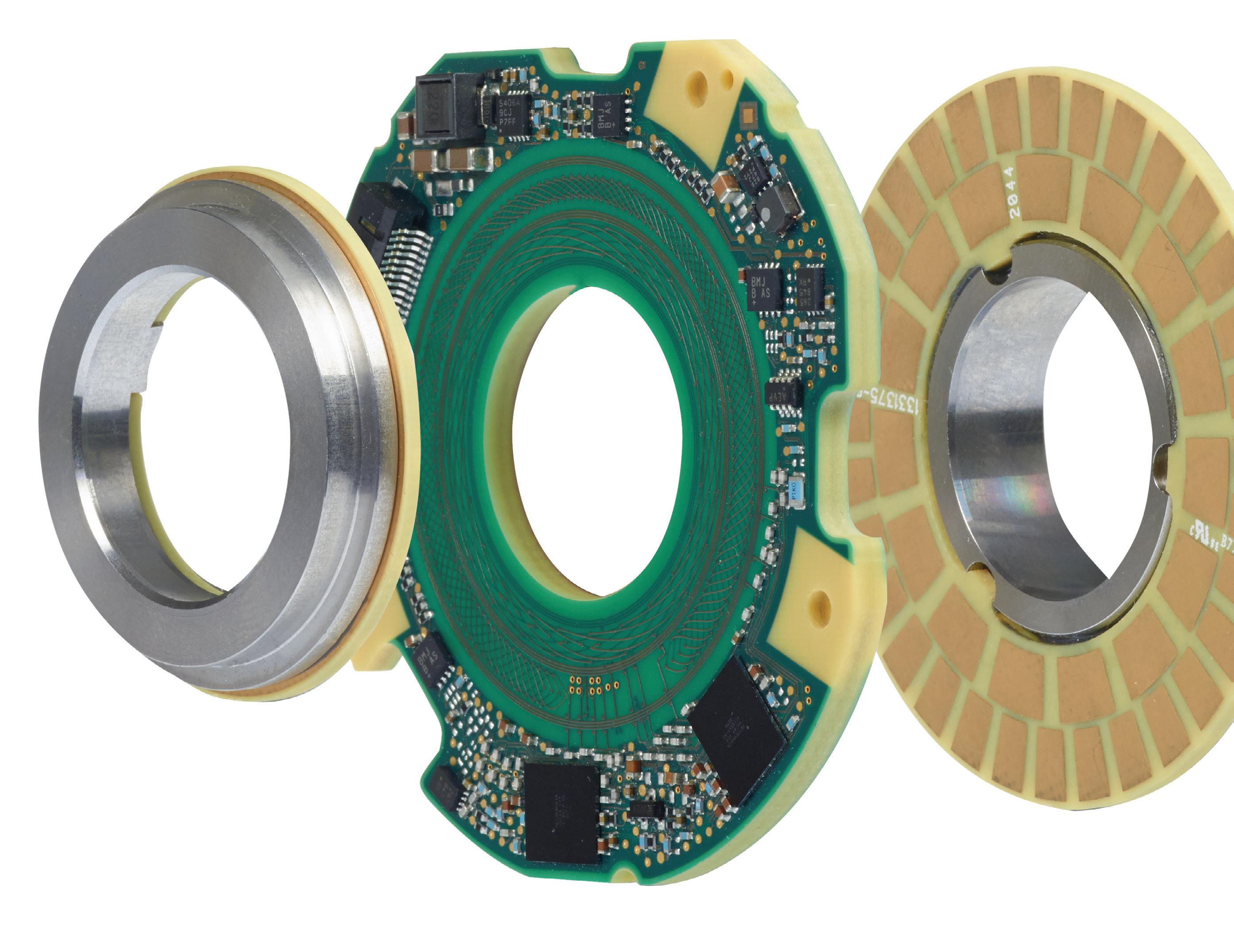

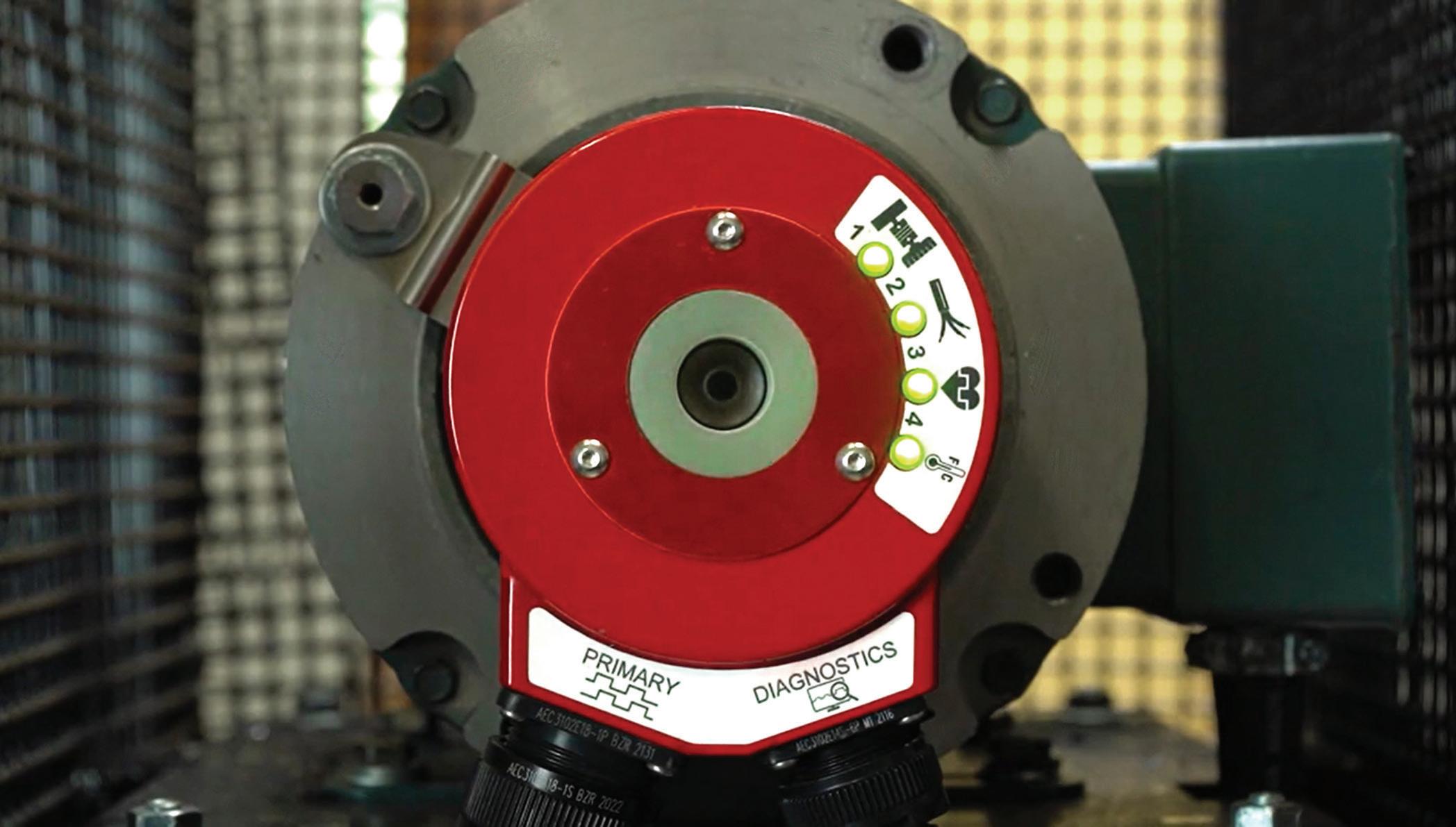

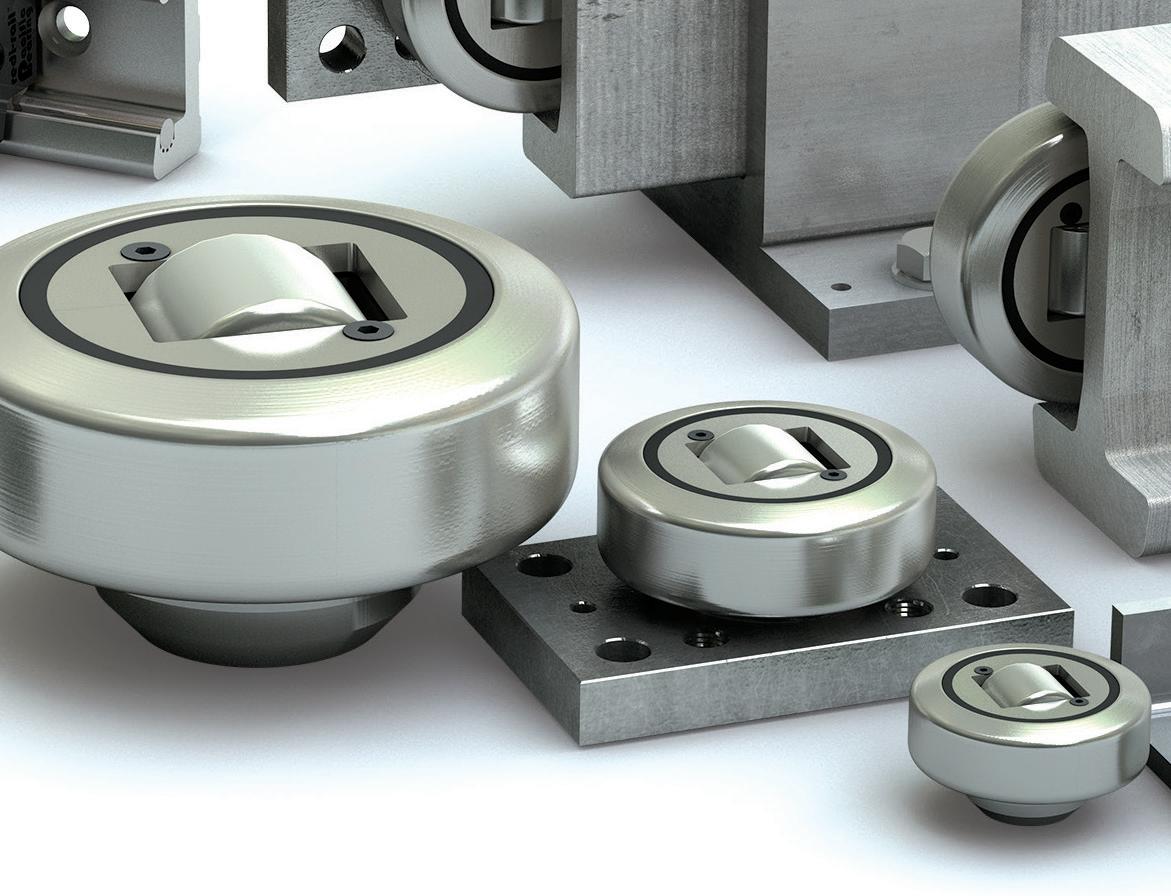

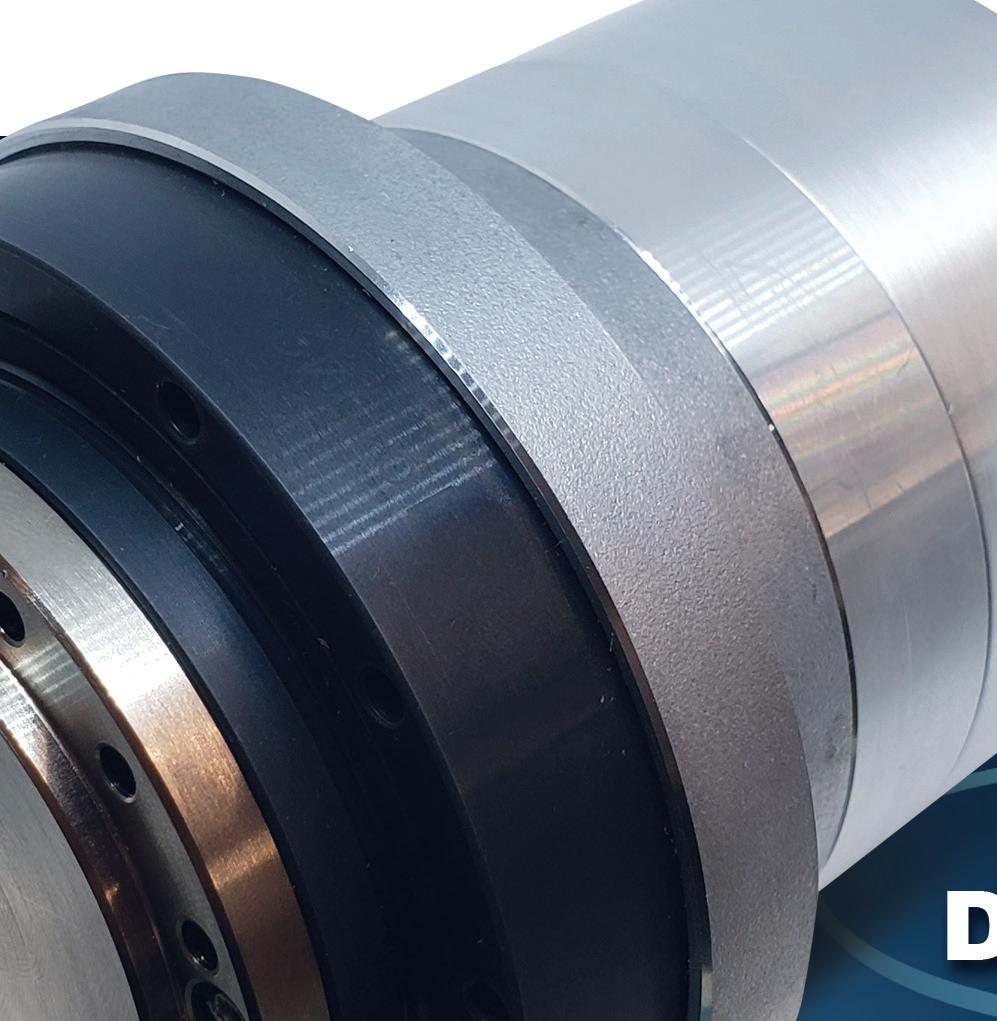

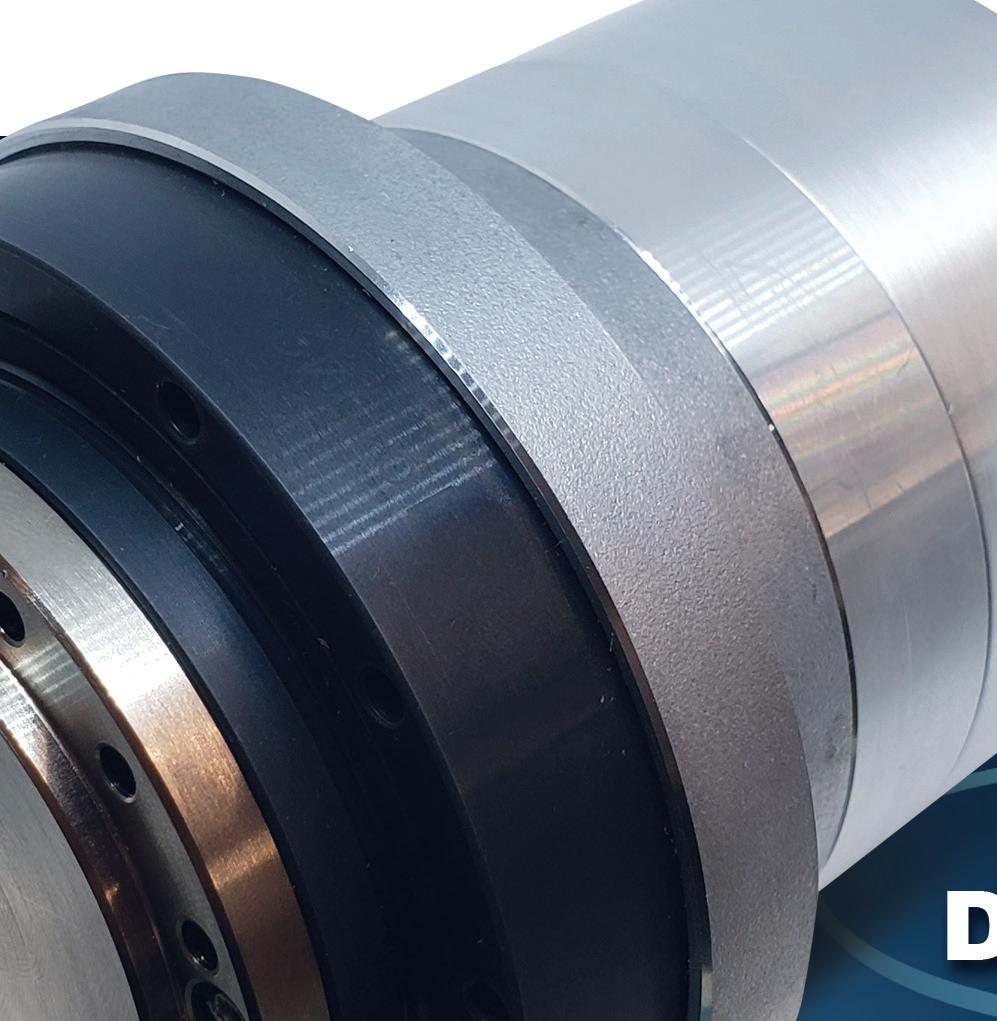

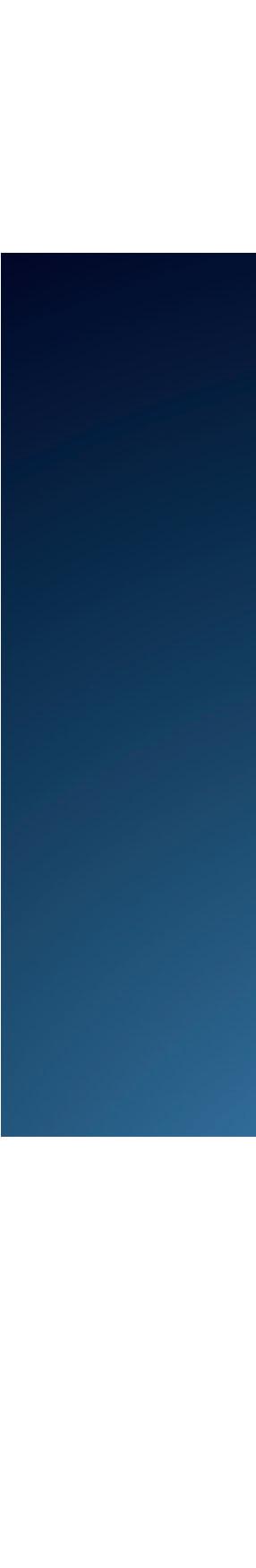

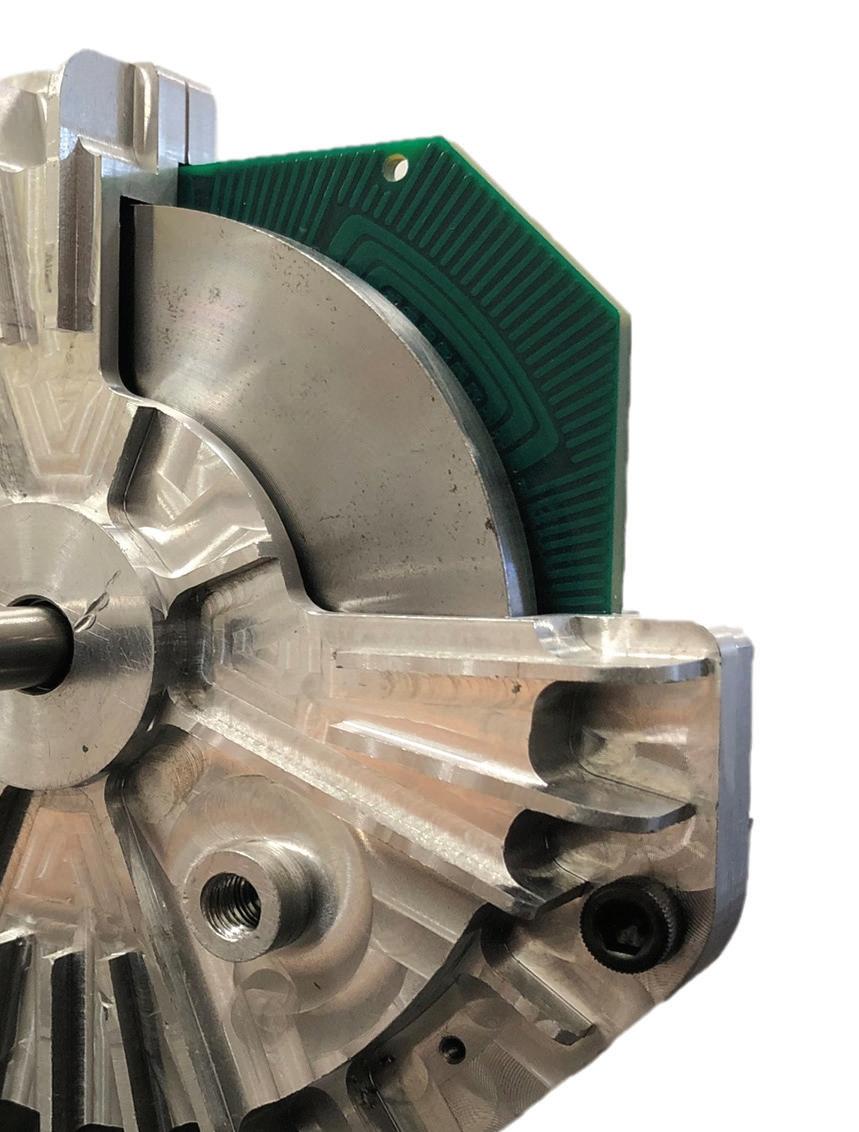

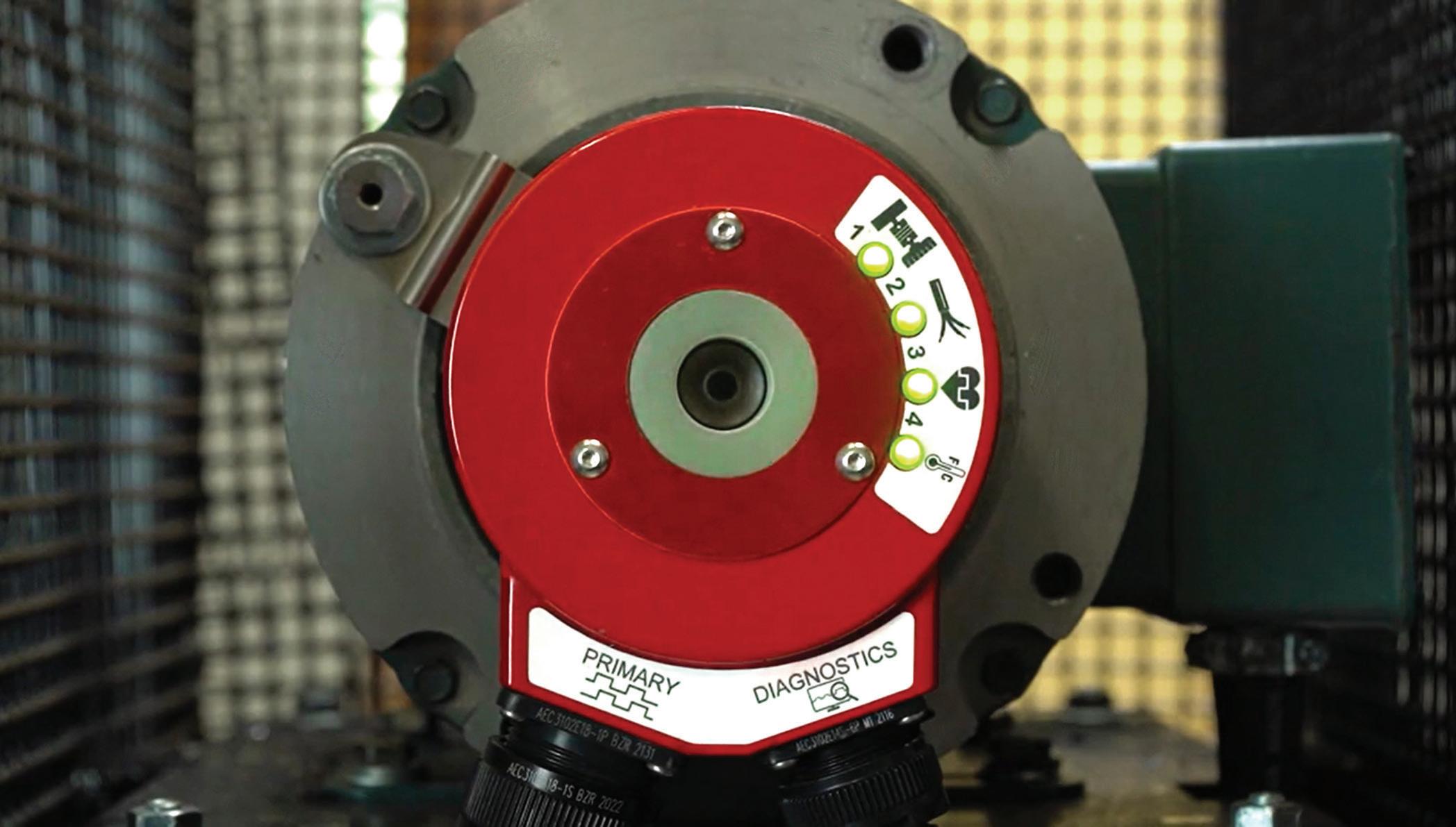

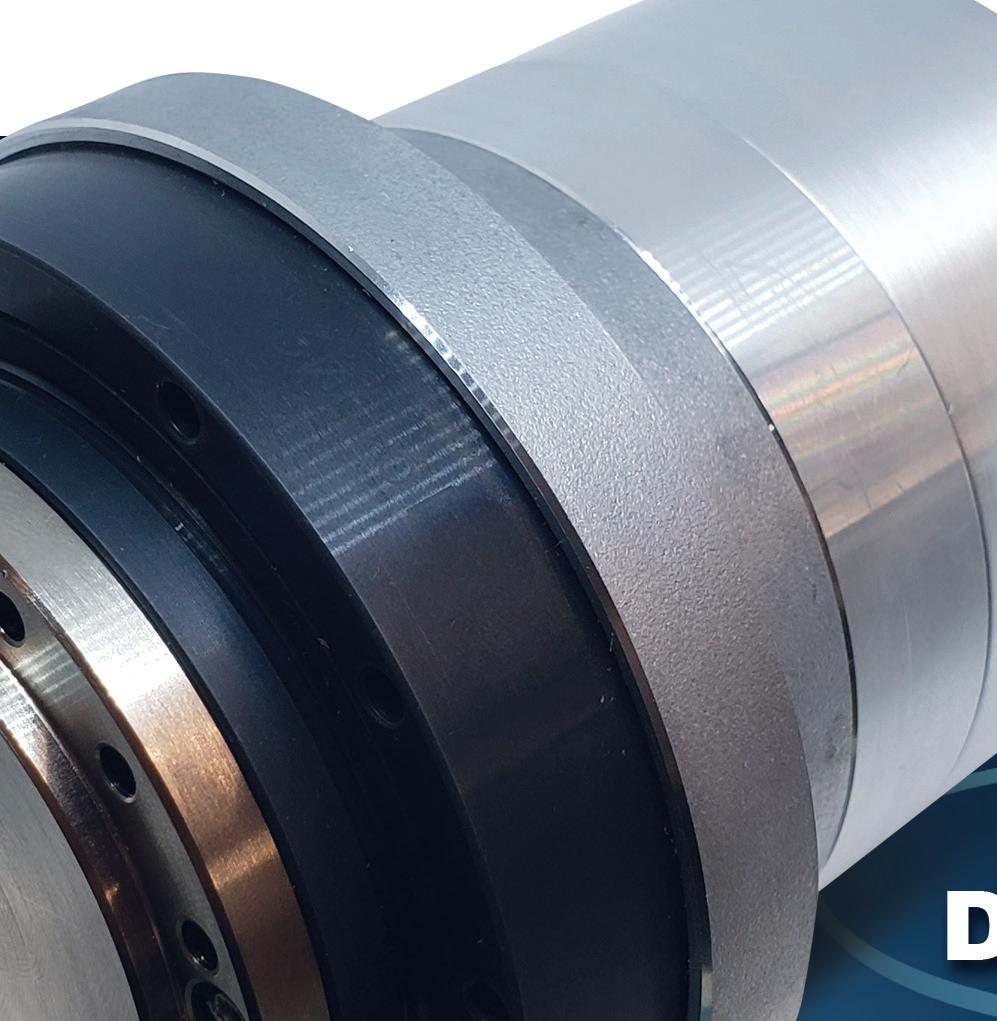

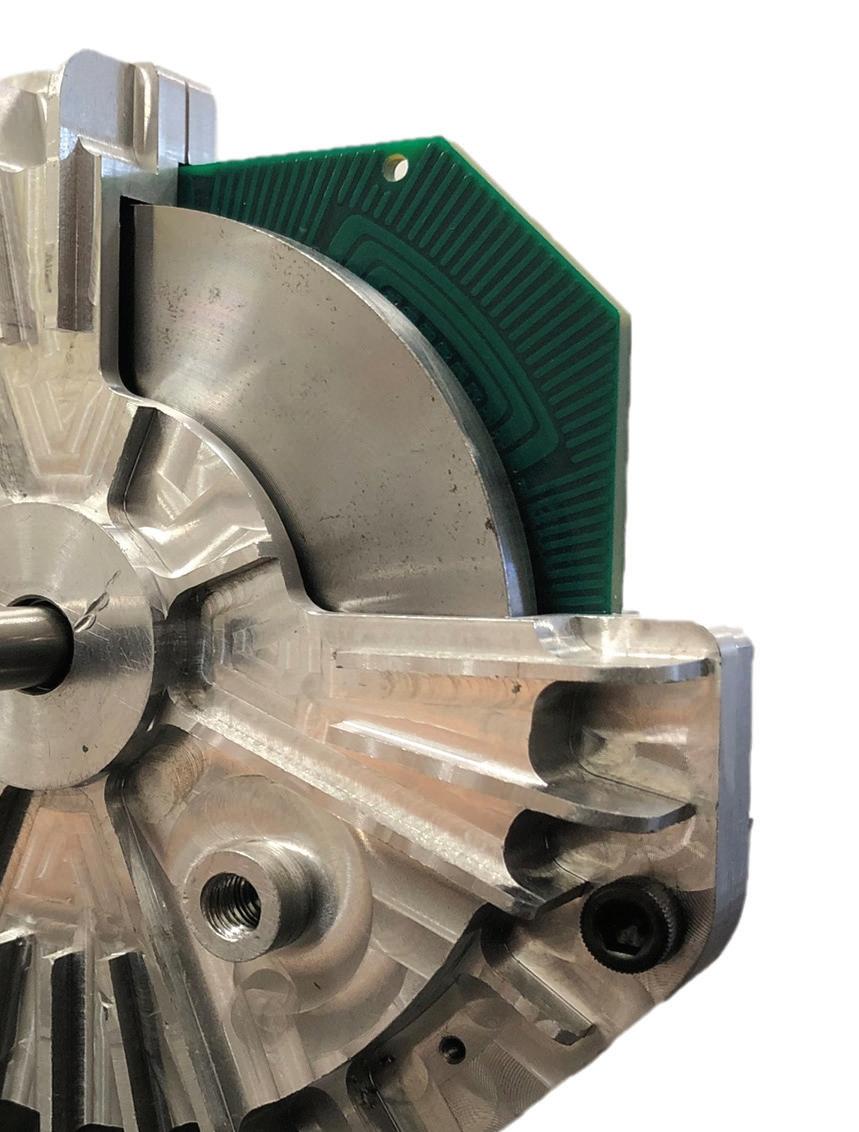

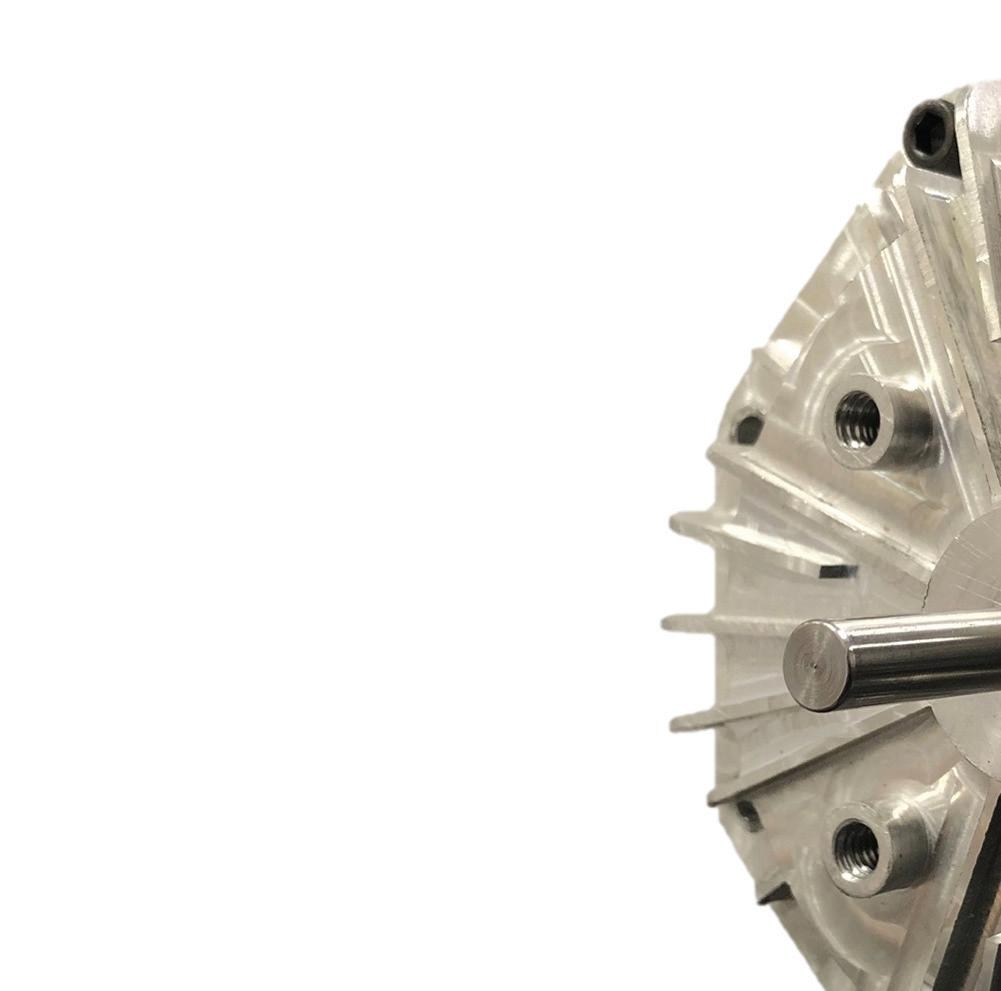

SHA Rotary Actuator with Integrated Servo Drive

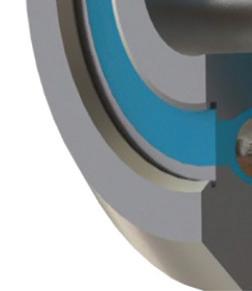

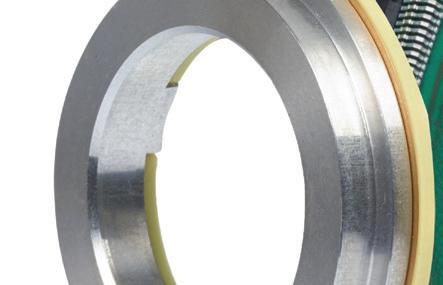

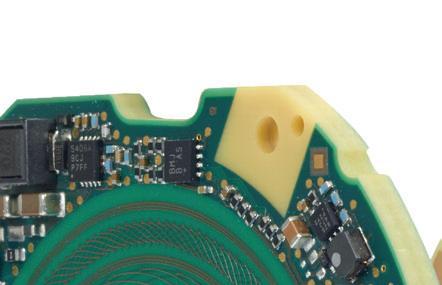

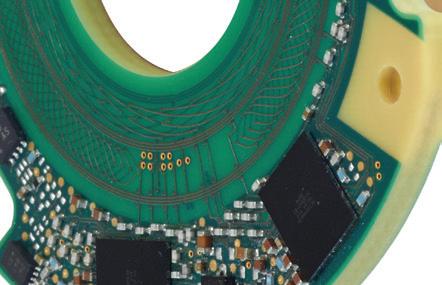

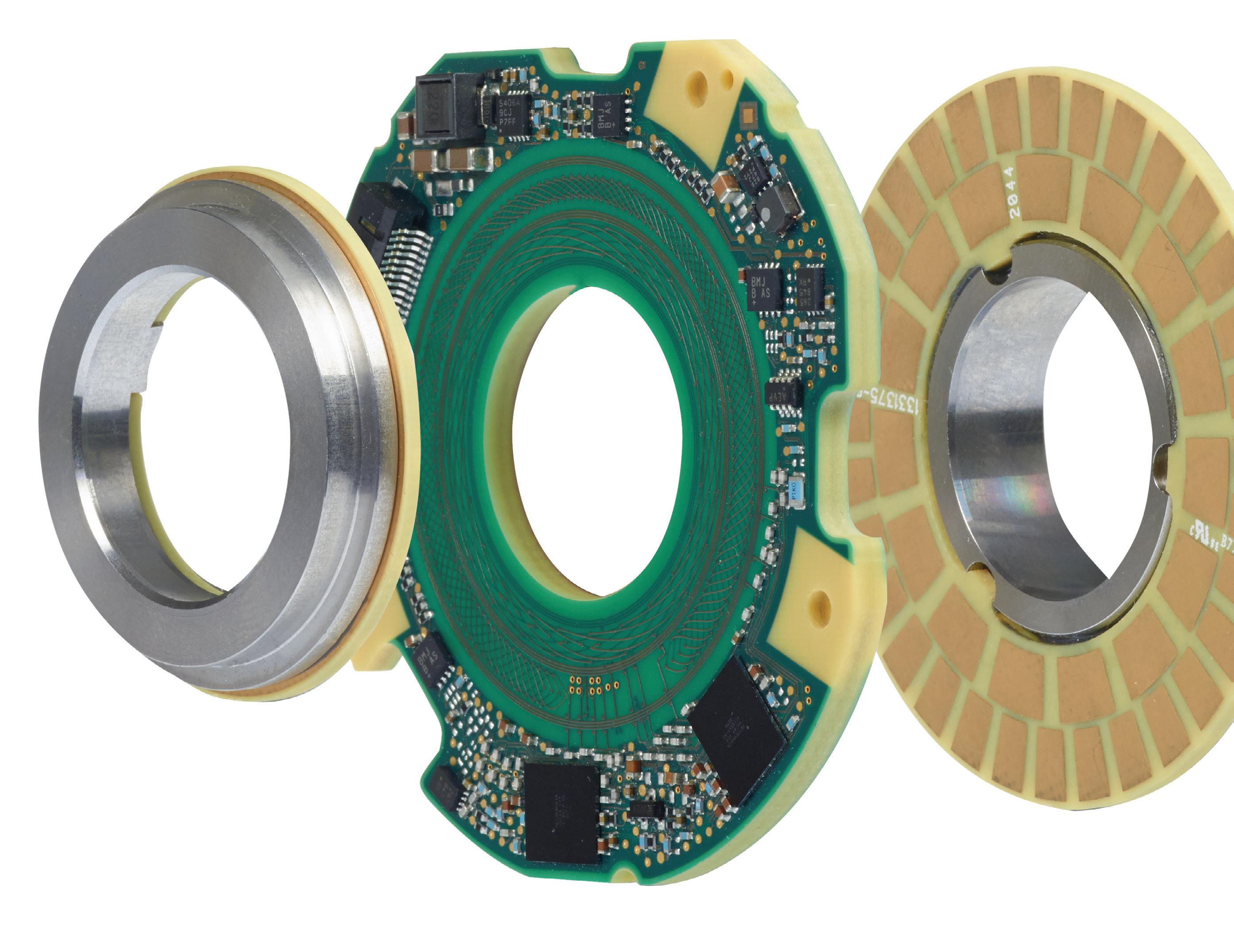

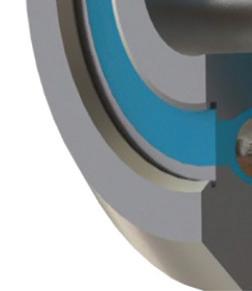

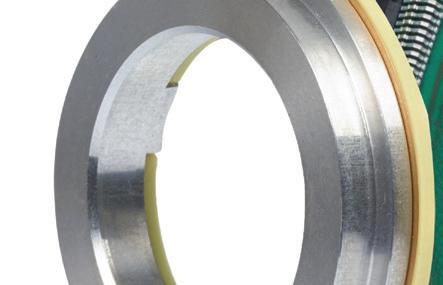

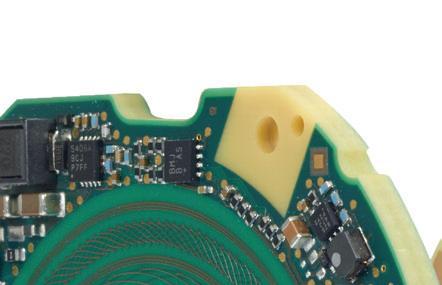

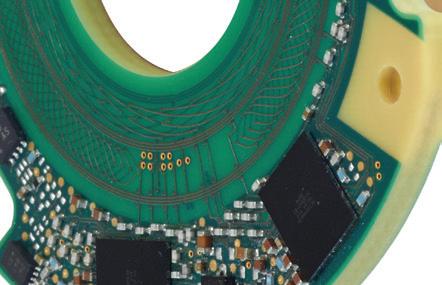

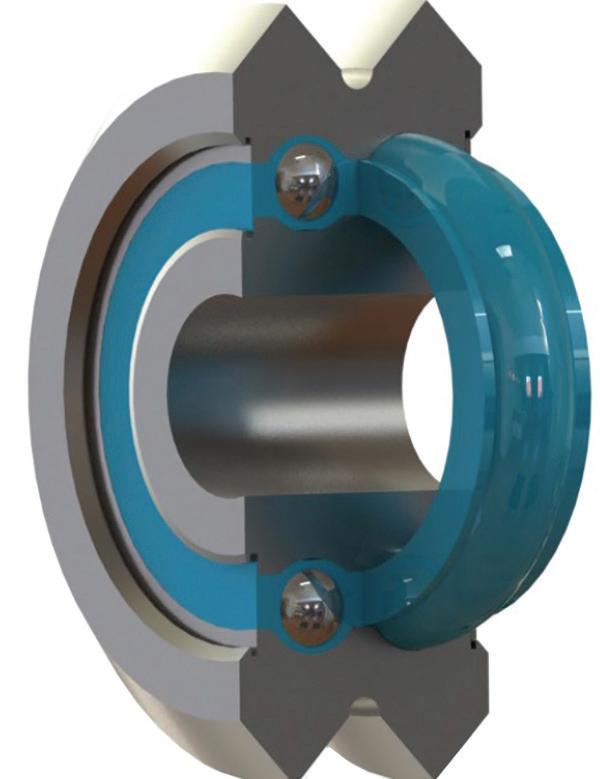

The SHA-IDT Series is a family of compact actuators that deliver high torque with exceptional accuracy and repeatability. These hollow shaft servo actuators feature Harmonic Drive® precision strain wave gears combined with a brushless servomotor, a brake, two magnetic absolute encoders and an integrated servo drive with CANopen® communication. This revolutionary product eliminates the need for an external drive and greatly simplifies wiring yet delivers high-positional accuracy and torsional stiffness in a compact housing.

• Actuator + Integrated Servo Drive utilizing CANopen® communication

• 48 VDC nominal supply voltage

• A single cable with only 4 conductors is needed: CANH, CANL, +48VDC, 0VDC

• Zero Backlash

• Panel Mount Connectors with radial and axial options

• Dual Absolute Encoders

• Output Encoder: 16bit (65,536 cpr) resolution

• Input Encoder: 17bit (131,072 cpr) resolution

• Control Modes include: Torque, Velocity, and Position Control, CSP, CSV, CST

Simplify.

Harmonic Drive is a registered trademark of Harmonic Drive LLC. CANopen is a registered trademark of CAN in Automation. 42

| 800.921.3332 | www.HarmonicDrive.net

Dunham Ridge, Beverly, MA 01915

trends 2023

DESIGNWORLDONLINE.COM MOTIONCONTROLTIPS.COM MARCH 2023

: Agile machines with adaptive automation

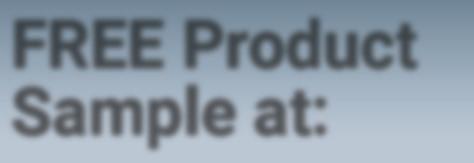

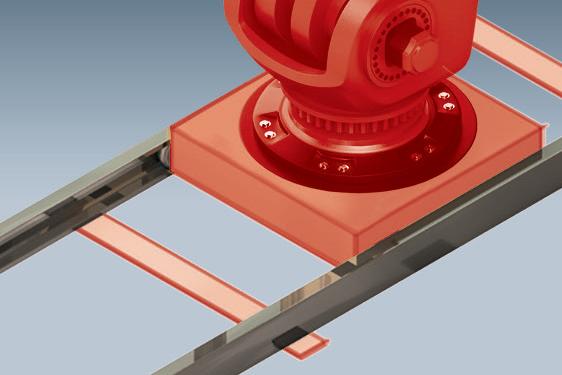

Flying 2D product transport with up to 6 degrees of freedom

XPlanar enables new dimensions of freedom in product and material handling: Levitating planar movers fly over flexibly arranged planar tiles accommodating nearly any track layout and path planning.

Individual 2D transport at up to 2 m/s

Processing with up to 6 degrees of freedom

Transport and processing in one system

Wear-free, hygienic and easy to clean

Free arrangement of planar tiles enabling totally customized machine and process layouts

Multi-mover control enables parallel and individual product handling

Fully integrated into the powerful and standardized PC-based Beckhoff control system

(TwinCAT, PLC IEC 61131, Motion, Measurement, Machine Learning, Vision, Communication, HMI)

For use across all industries: assembly, packaging, food/bev, pharma, laboratory, entertainment, …

AT11-19US

Lifting by up to 5 mm Levitating planar movers Velocities up to 2 m/s Tilting by up to 5° 5° 360° rotation 360° Scalable payload kg Scan to experience XPlanar in action

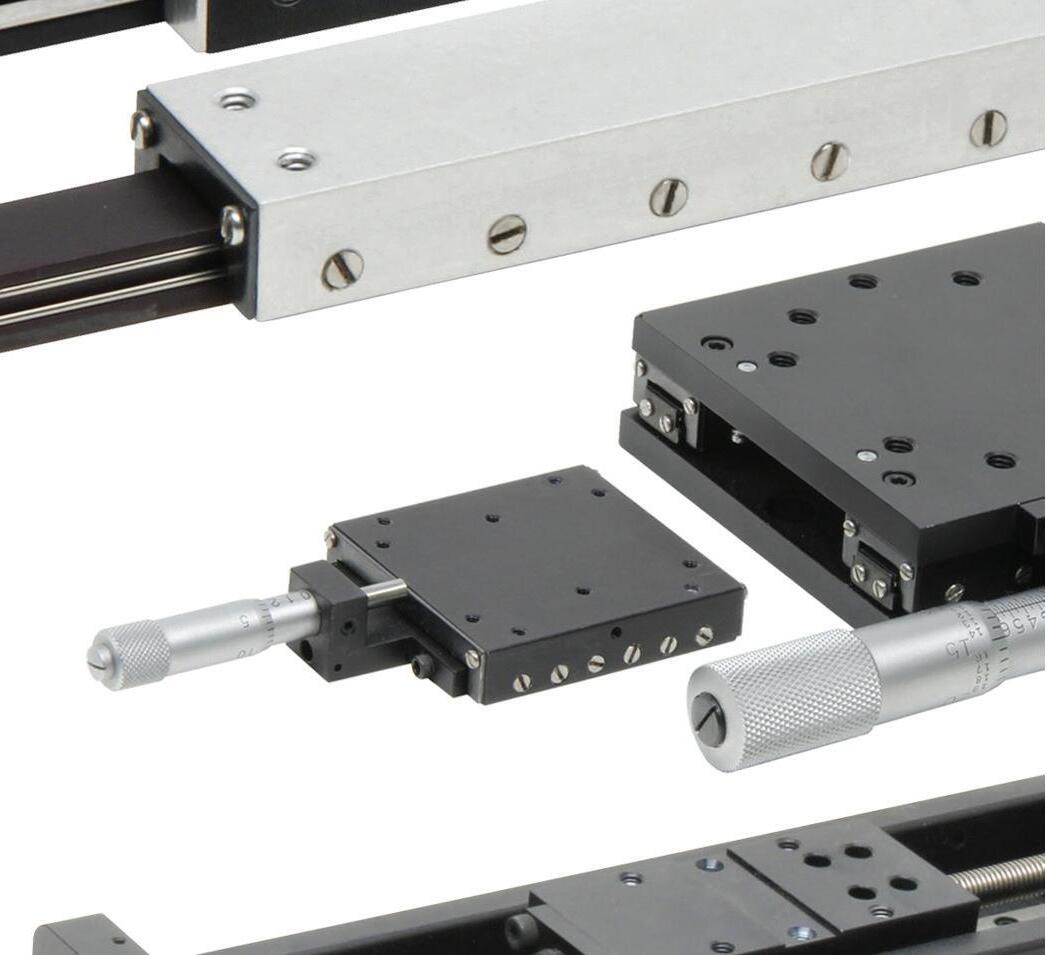

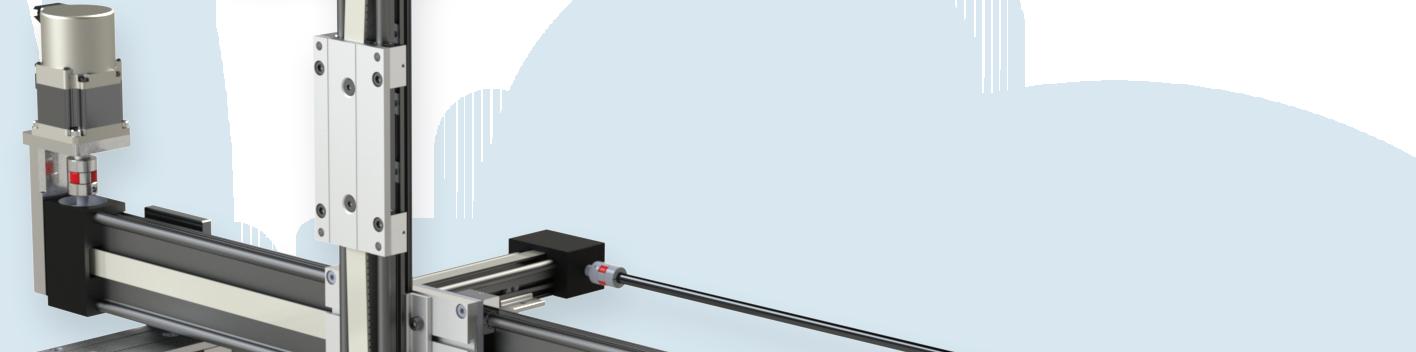

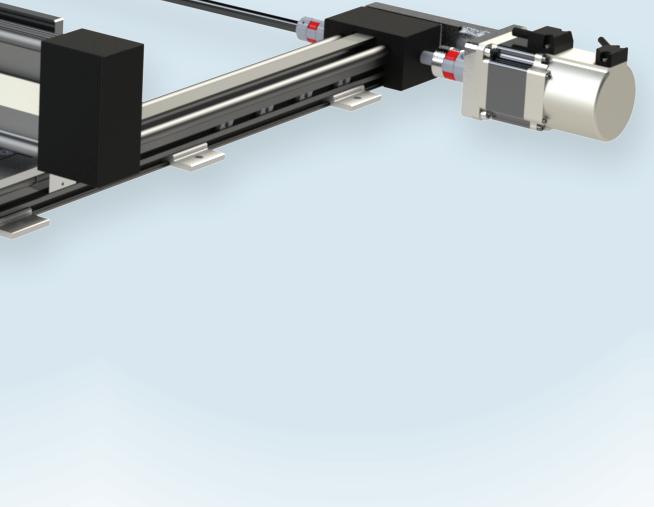

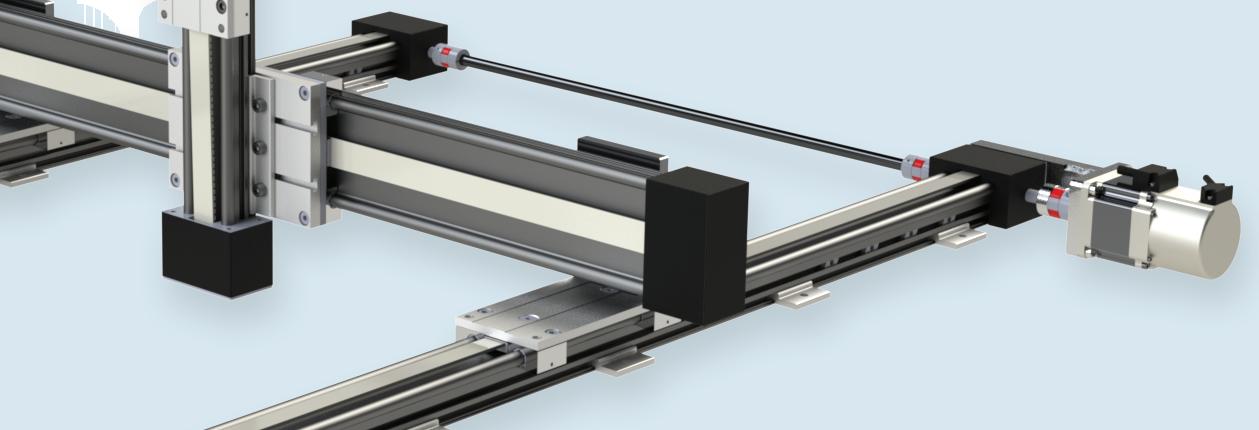

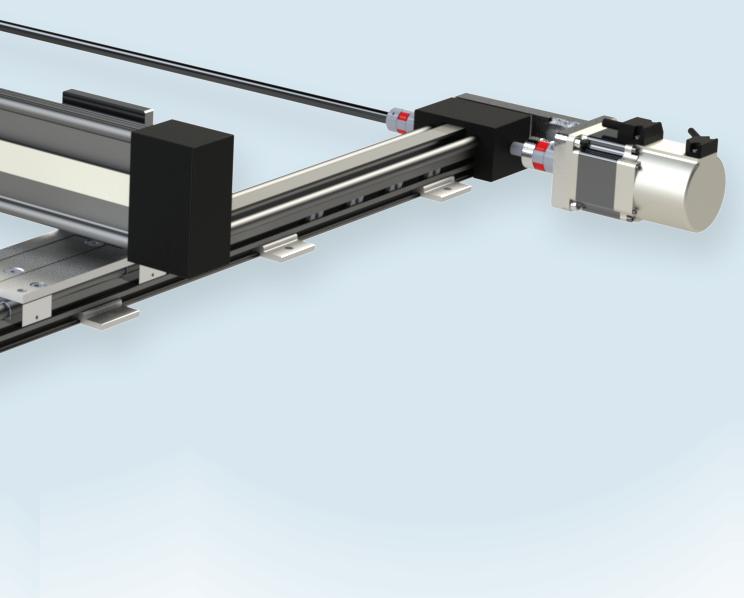

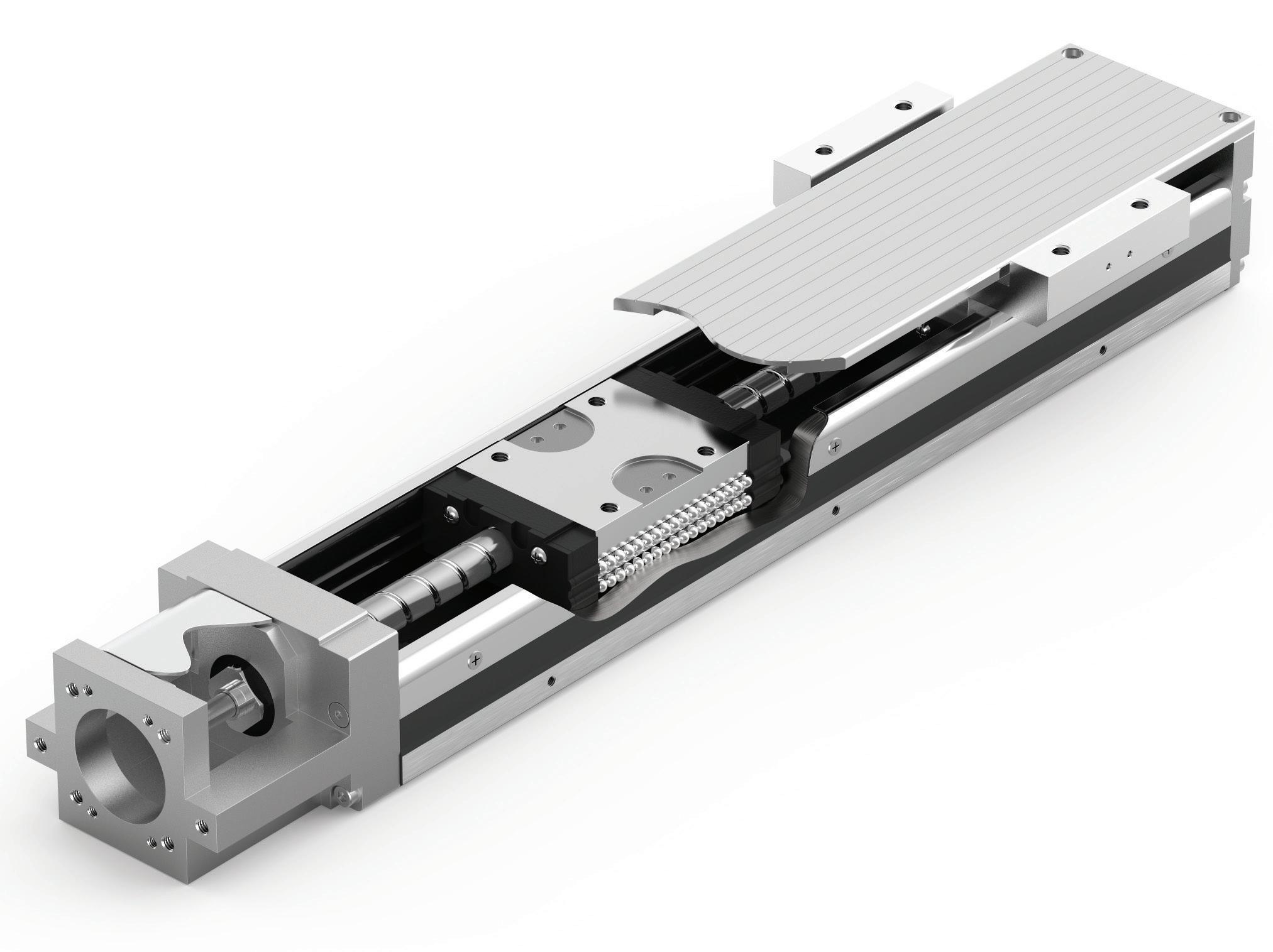

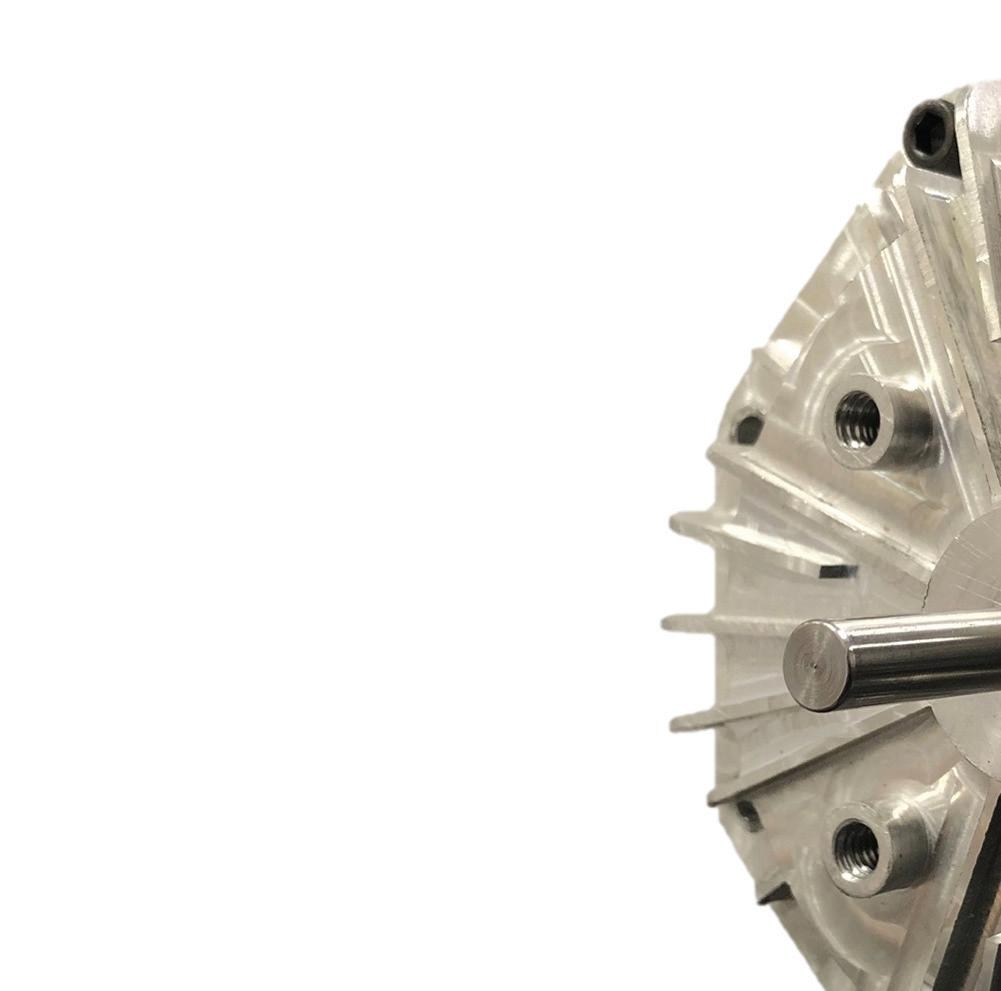

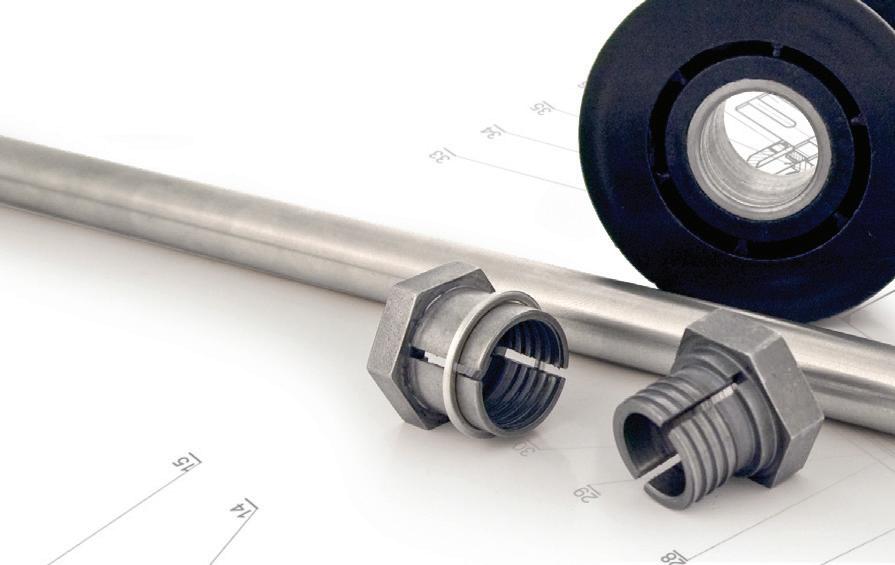

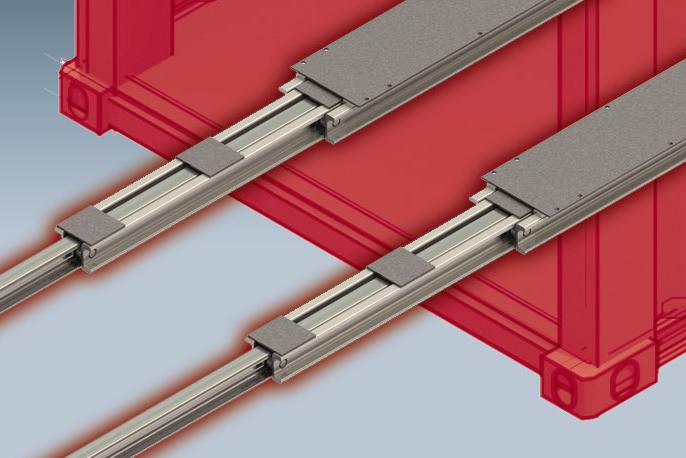

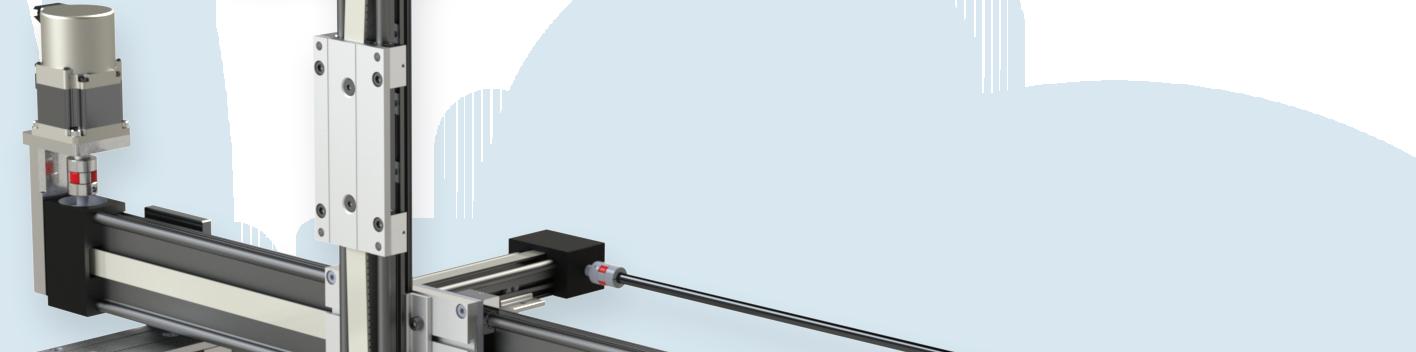

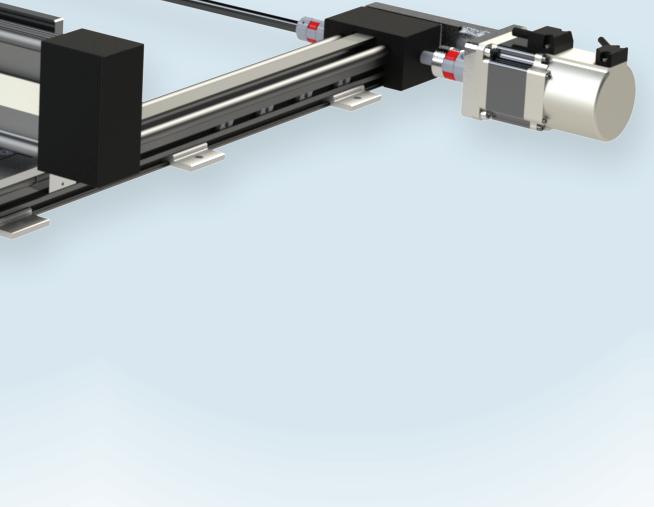

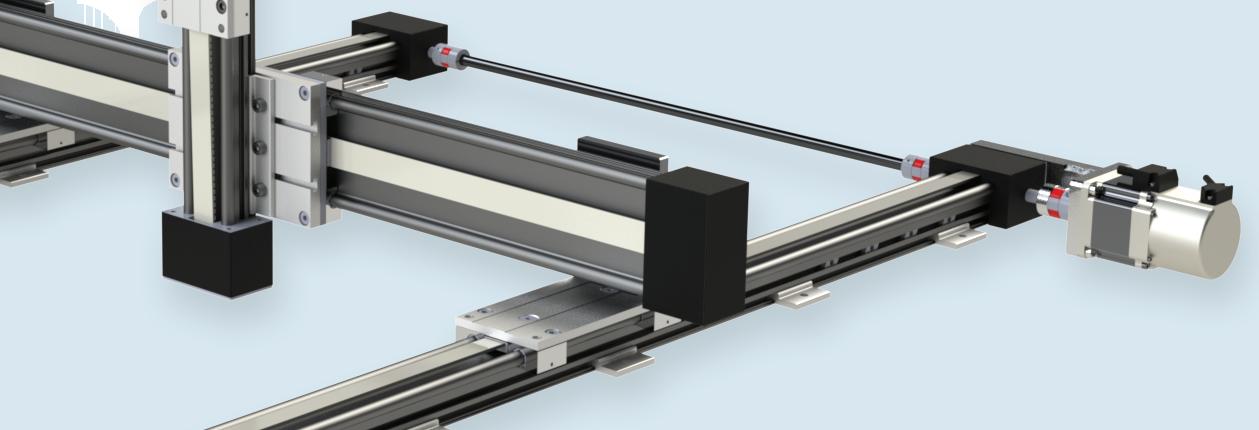

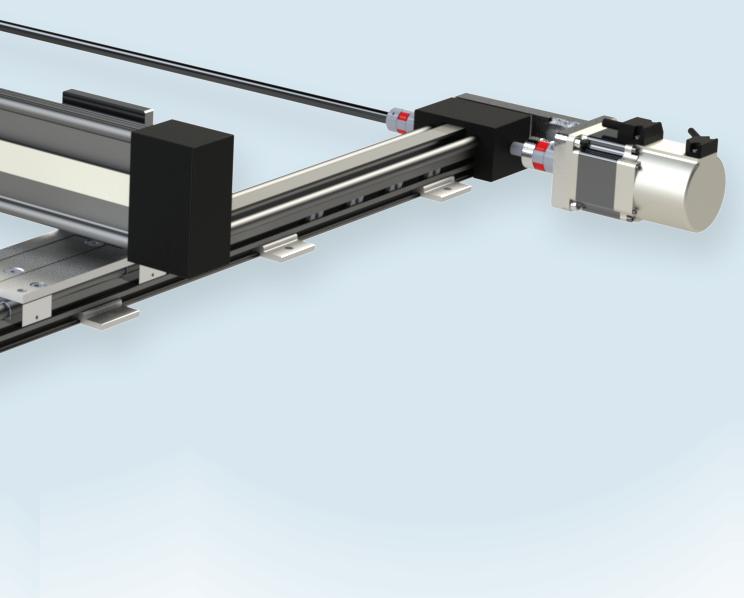

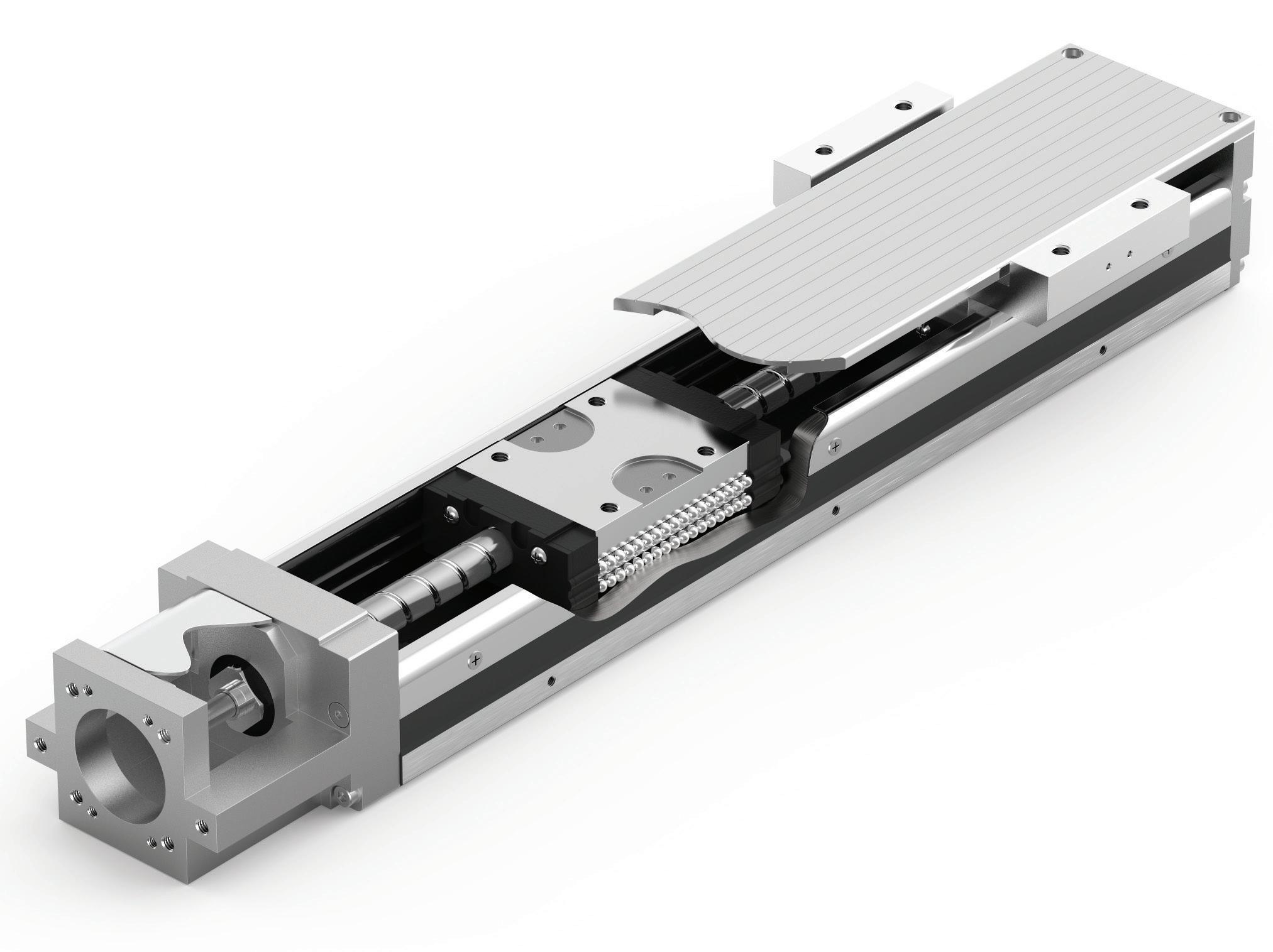

Linear Motion Actuators

Starting at $355.00 (SAW1040-05-B)

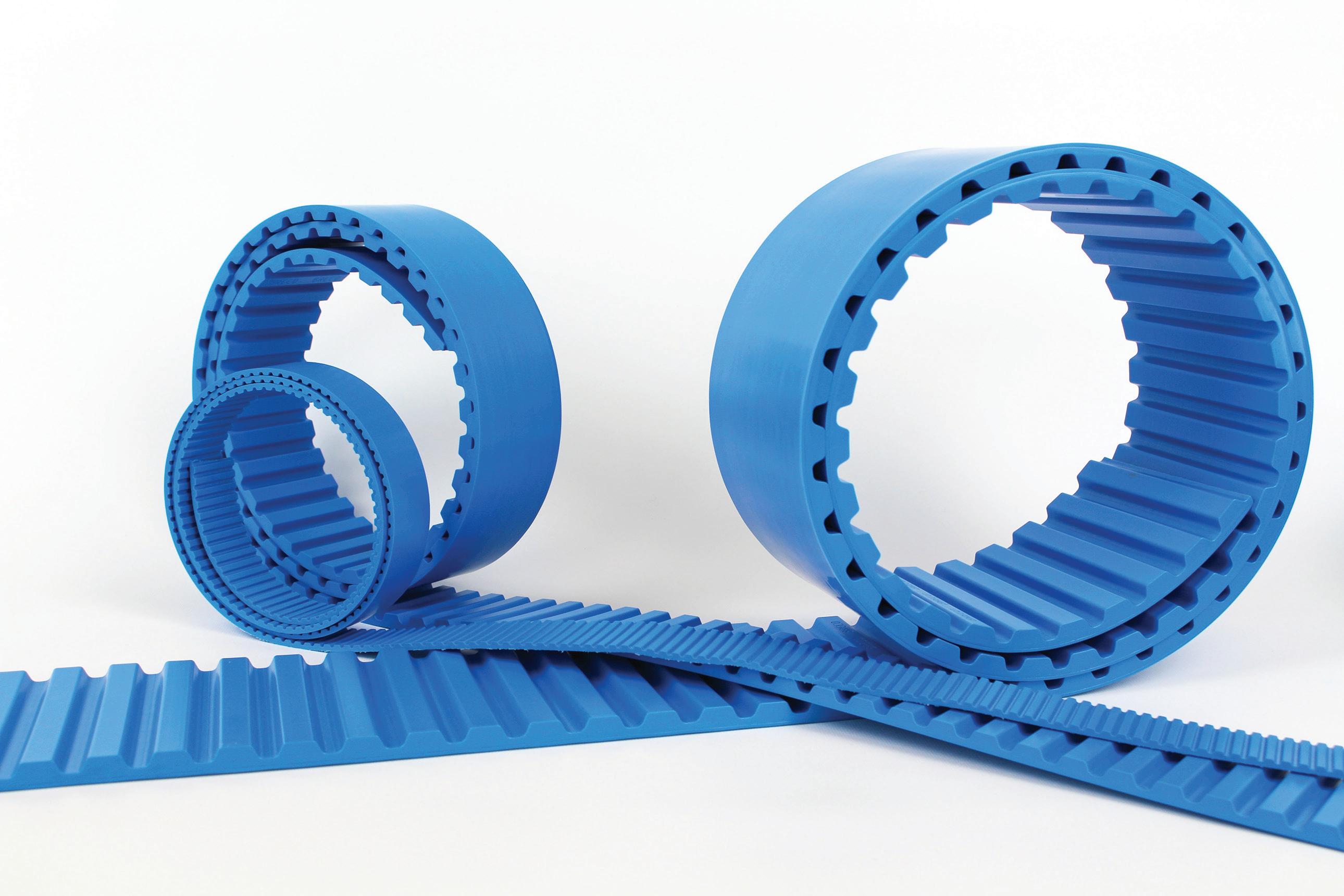

igus XYZ gantries offer an economical solution for creating a motion system with up to 3 axes of motion. These systems are available with belt driven or lead screw driven slides. They are easy to assemble, are stackable, and can be used as a single axis, double axis, dual drive axis, or as a complete 3-axis XYZ system.

Features:

• Maintenance and lubrication free

• 14 belt driven actuators from 200mm travel length to 1000mm travel length

• 13 lead screw driven actuators from 100mm travel length to 750mm travel length

• Rails made from durable 6061-T6 aluminum with hard anodized finish

• Motor mounts for SureServo and SureStep motors

• T-slots in rails allow switches and sensors to be easily installed

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2022 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405 Gantry Components for Less Rugged industrial actuators & slides for demanding 24/7 applications Research, price, buy at: www.automationdirect.com/linear-motion Also Available Precision Gearboxes (for Stepper & Servo) Stepper Systems SureServo2 Servo Systems

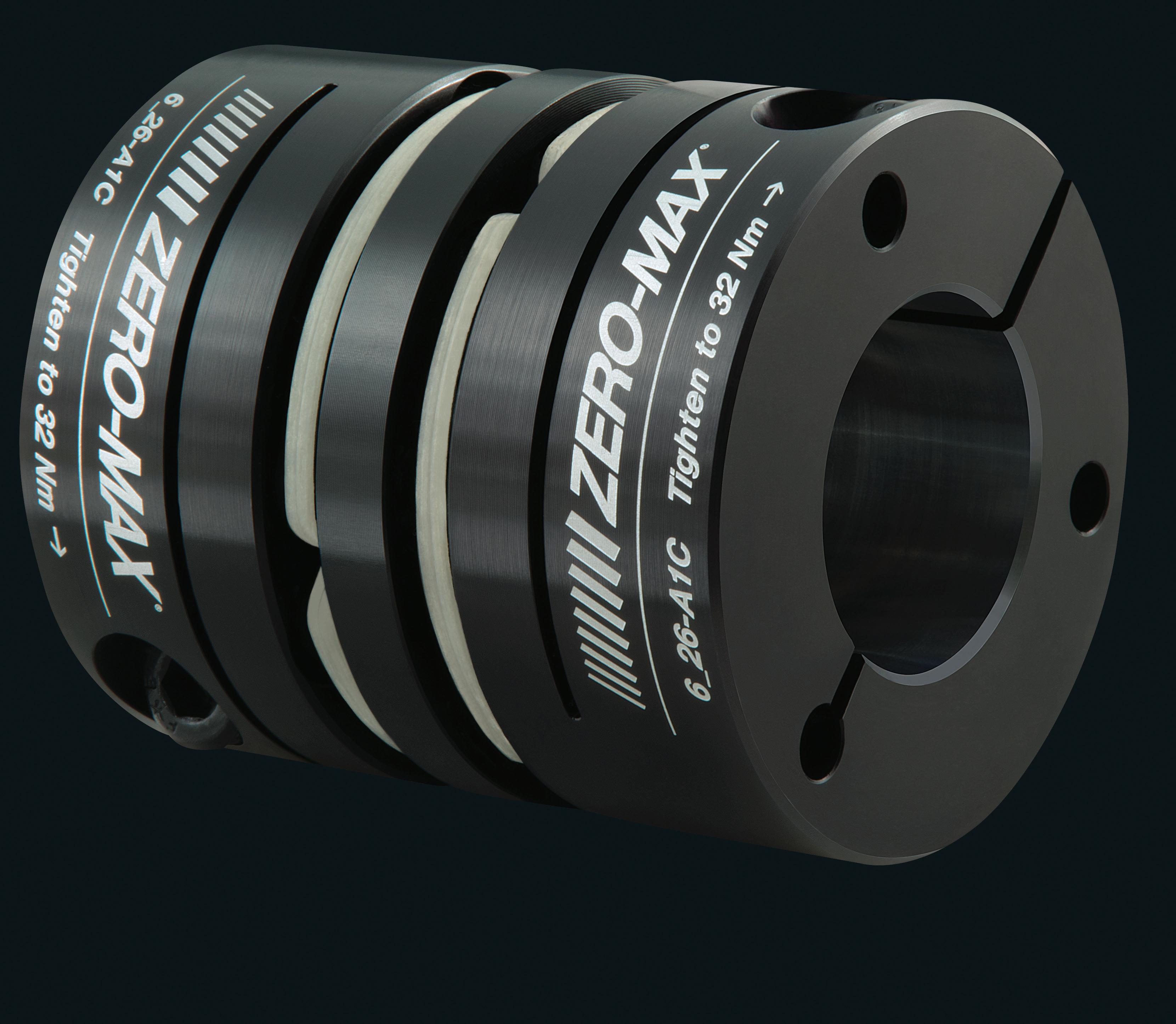

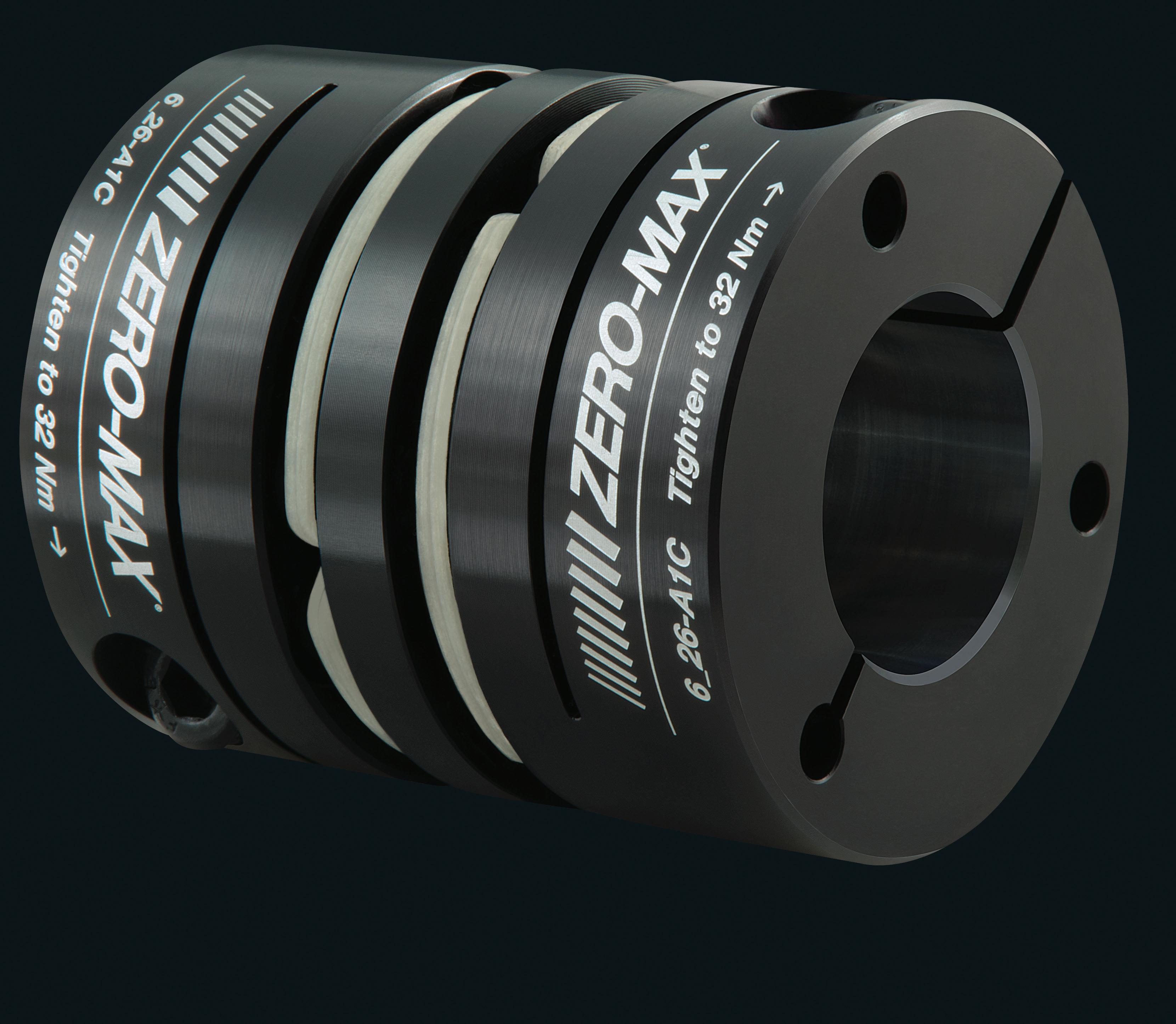

Single-Flex, Double-Flex, Floating-Shaft Solutions • Standard Models / Fully Customizable • Engineering Assistance / Fast Delivery www.zero-max.com 800.533.1731 PRECISE.ROBUST.AVAILABLE.

volume 9 number 1

6 STAFF

8 SUPPLY-CHAIN & LABOR ISSUES

In its wake, the COVID pandemic left lingering supply-chain issues that are still affecting manufacturing and other automated industries. Now some slowdowns at least have cleared.

16 THE DIGITAL TRANSFORMATION · AI · CONNECTIVITY

24 EV s · e BIKES & AGV s

30 MOTORS & GEARMOTORS · DRIVES

36 LINEAR MOTION—ACTUATORS · GUIDES · STAGES

We recently asked several industry experts about trends they’re seeing in the design and use of linear actuators, linear guides, and stages. Here’s what those experts had to say.

42 MOTION COMPONENTS IN THE FAST-FOOD INDUSTRY

46 ENCODERS · SENSORS & FEEDBACK

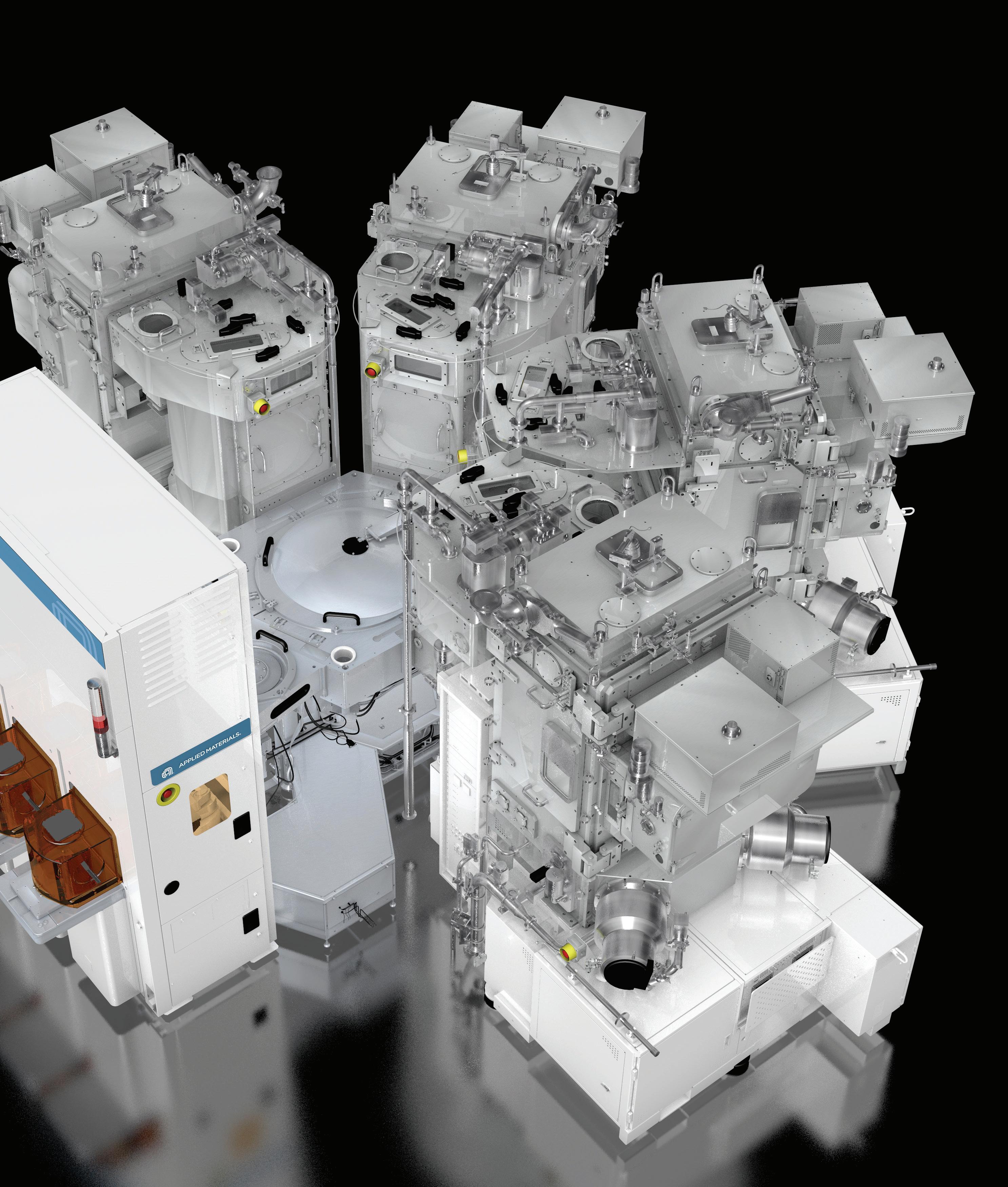

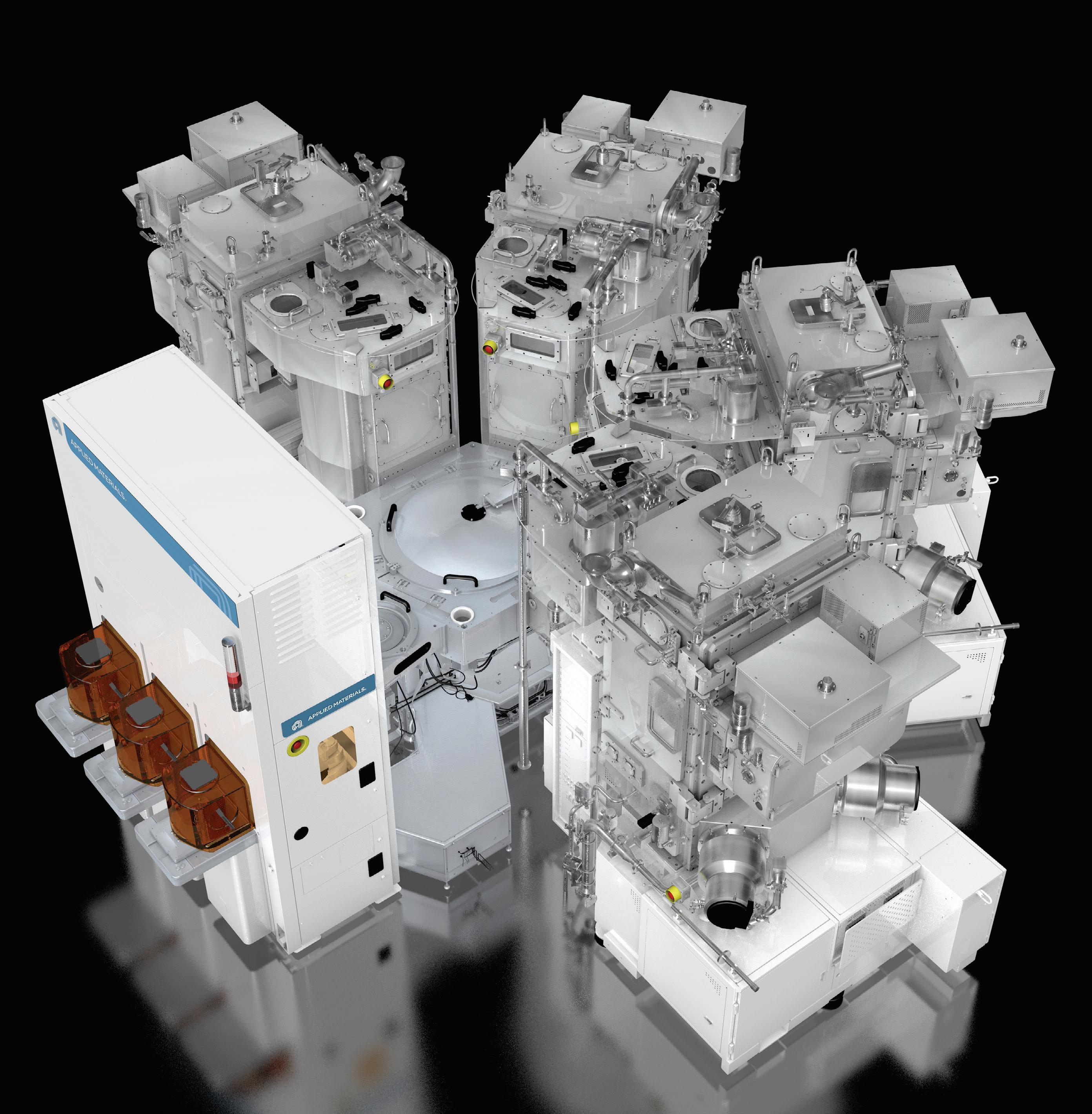

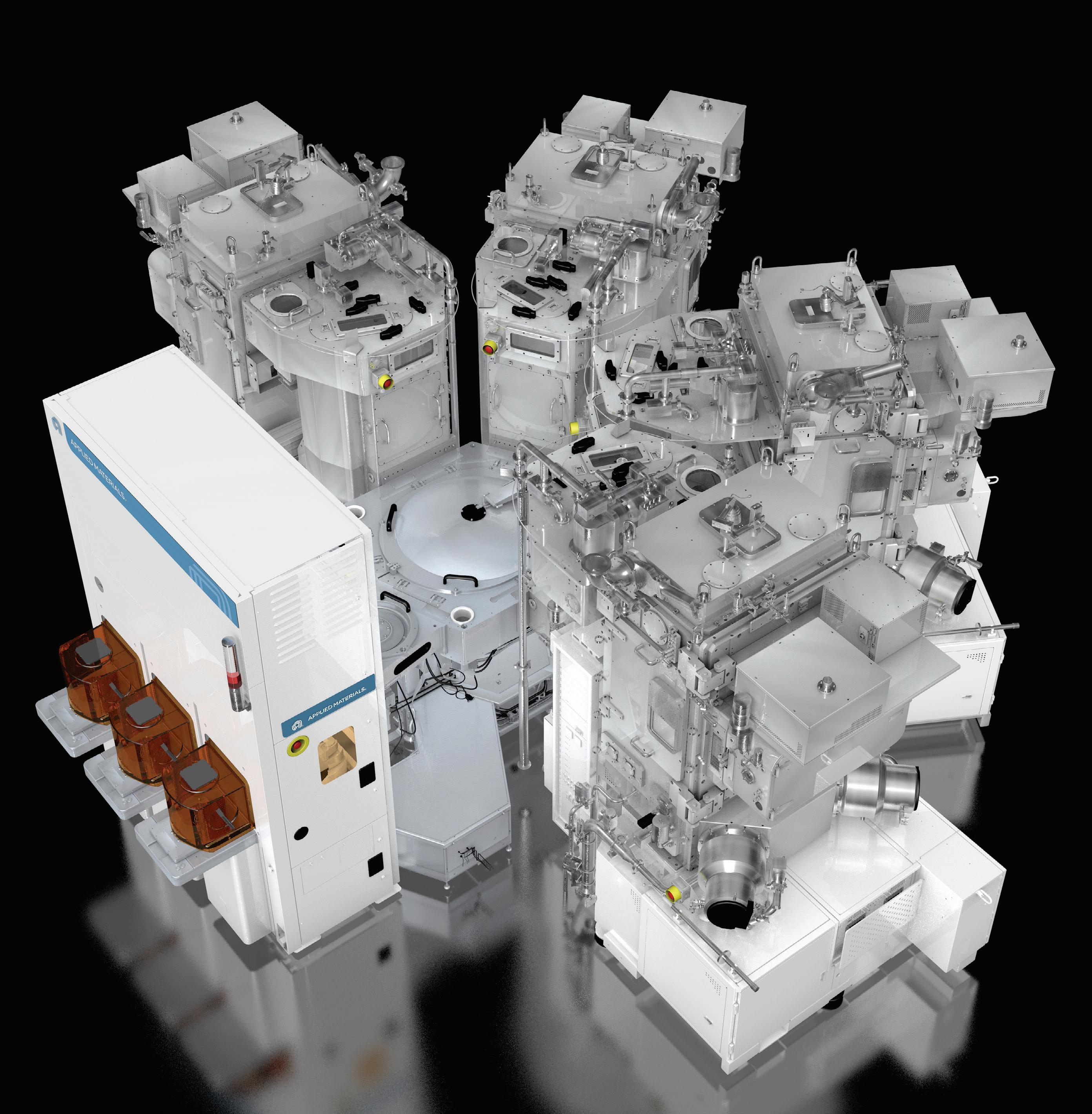

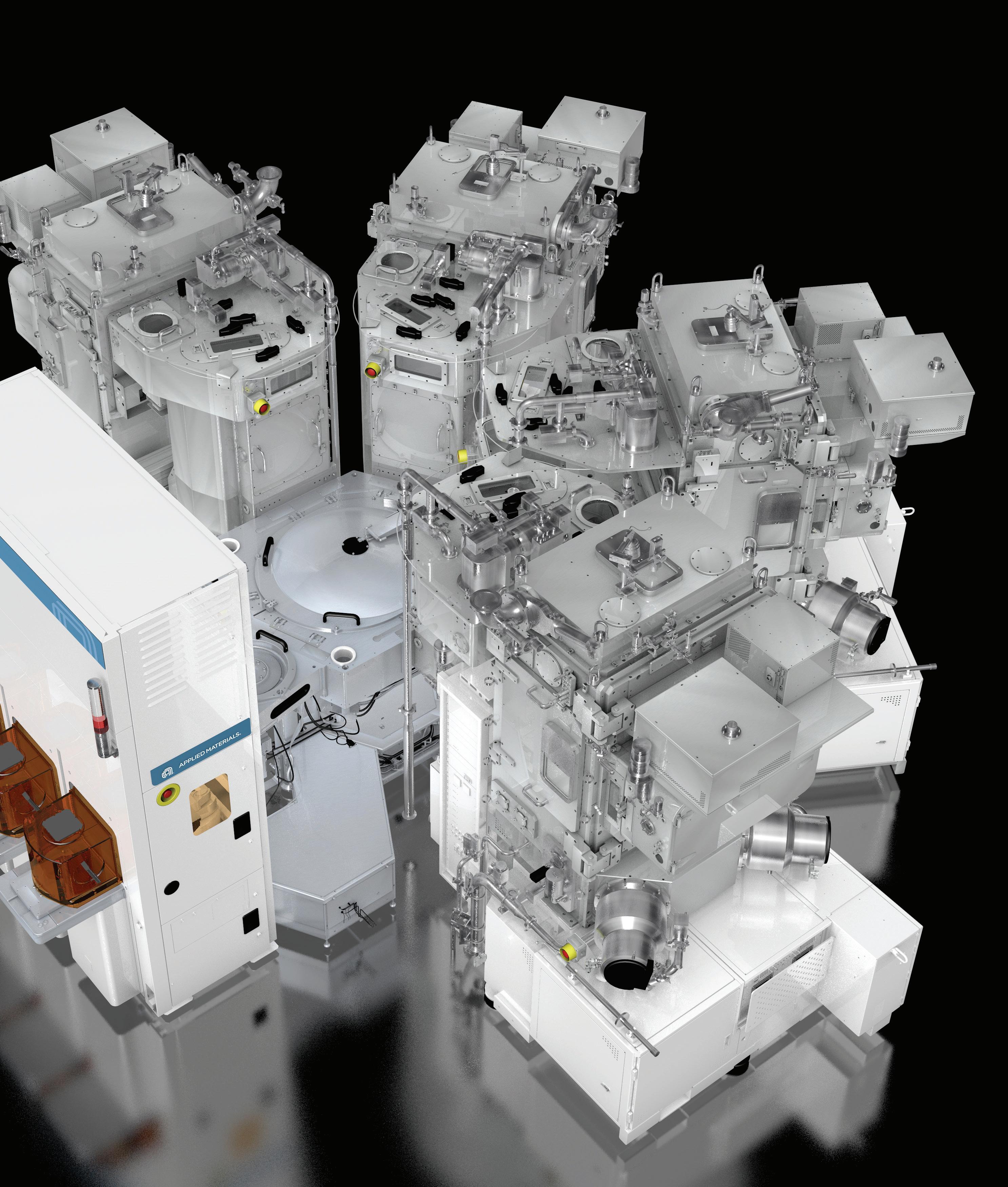

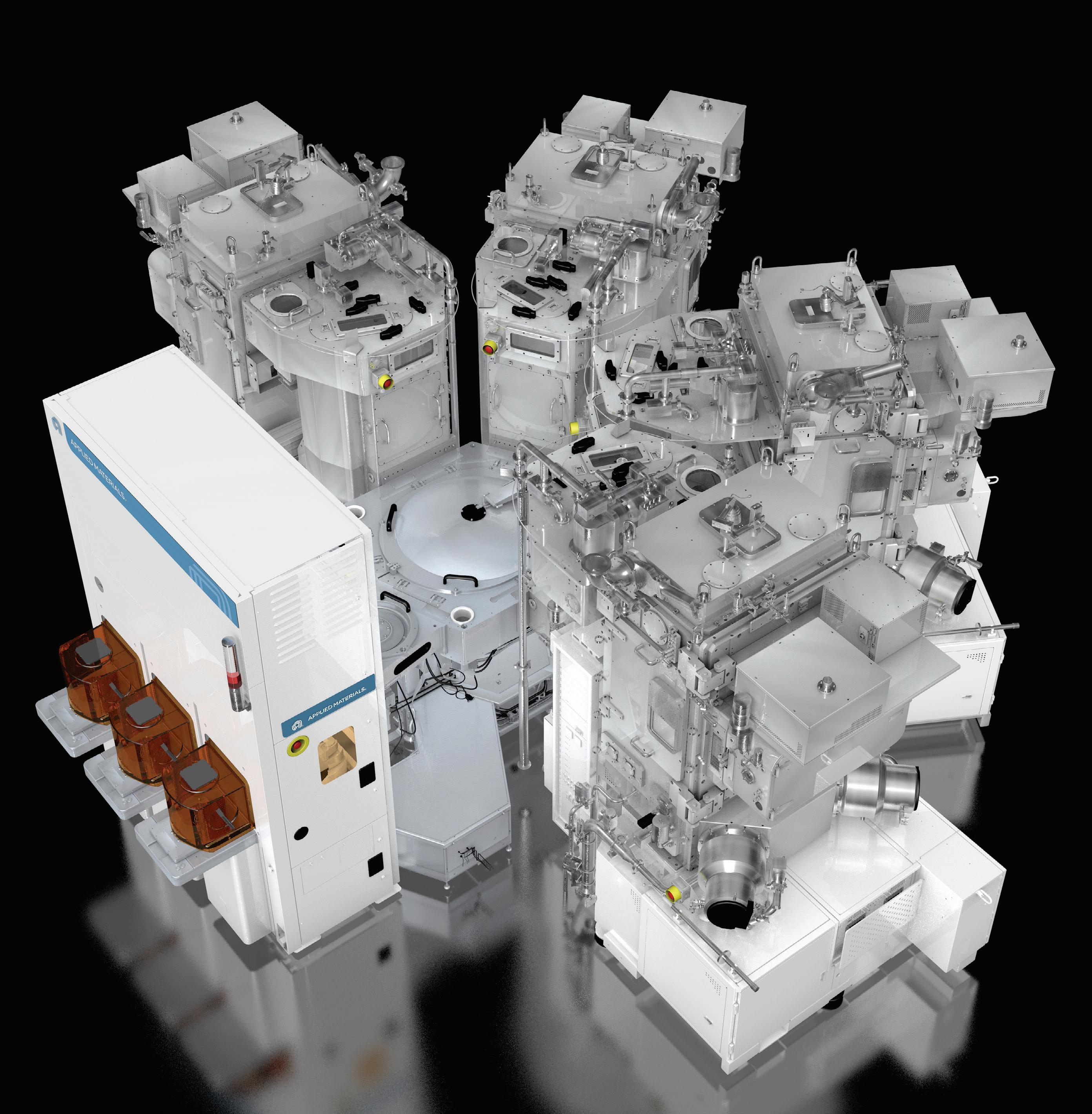

50 SEMICONDUCTOR PRODUCTION

Semiconductor products were more affected than any other by COVID-induced supply-chain issues felt around the world. International political tensions have only prolonged and exacerbated the problem.

58 AGRICULTURE & OFF-HIGHWAY AUTOMATION

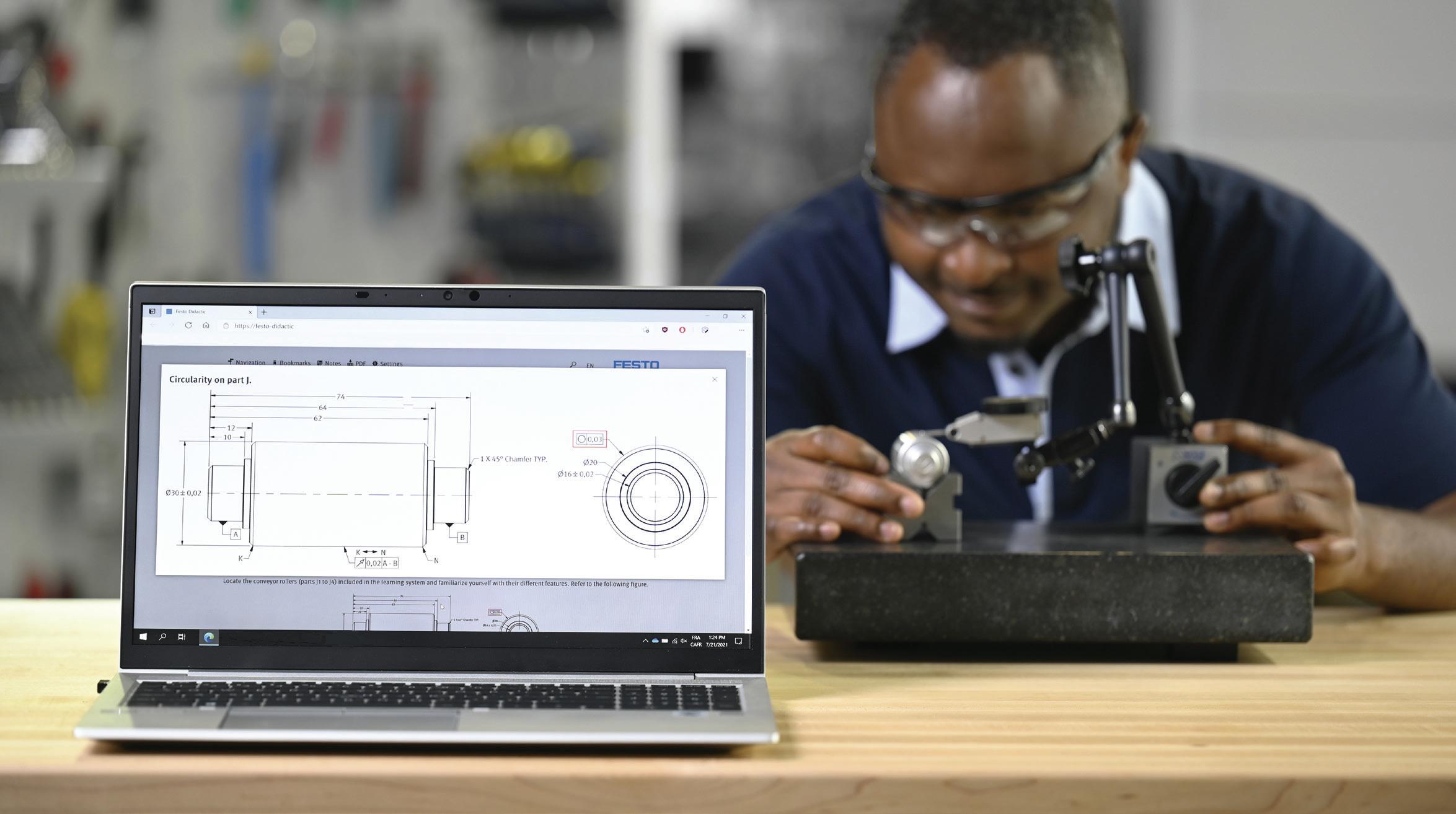

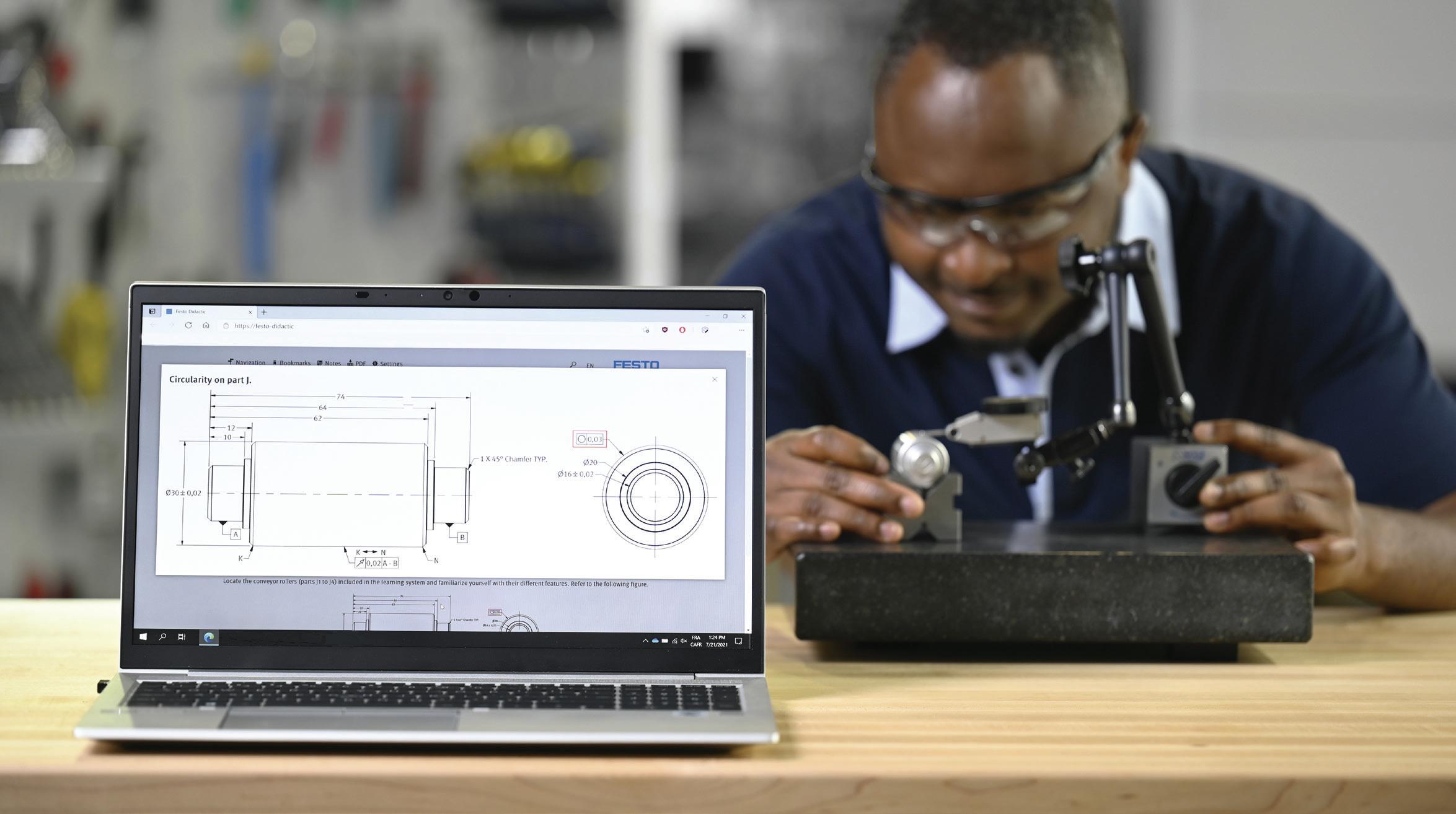

63 DESIGN SUPPORT · TRAINING & E-LEARNING

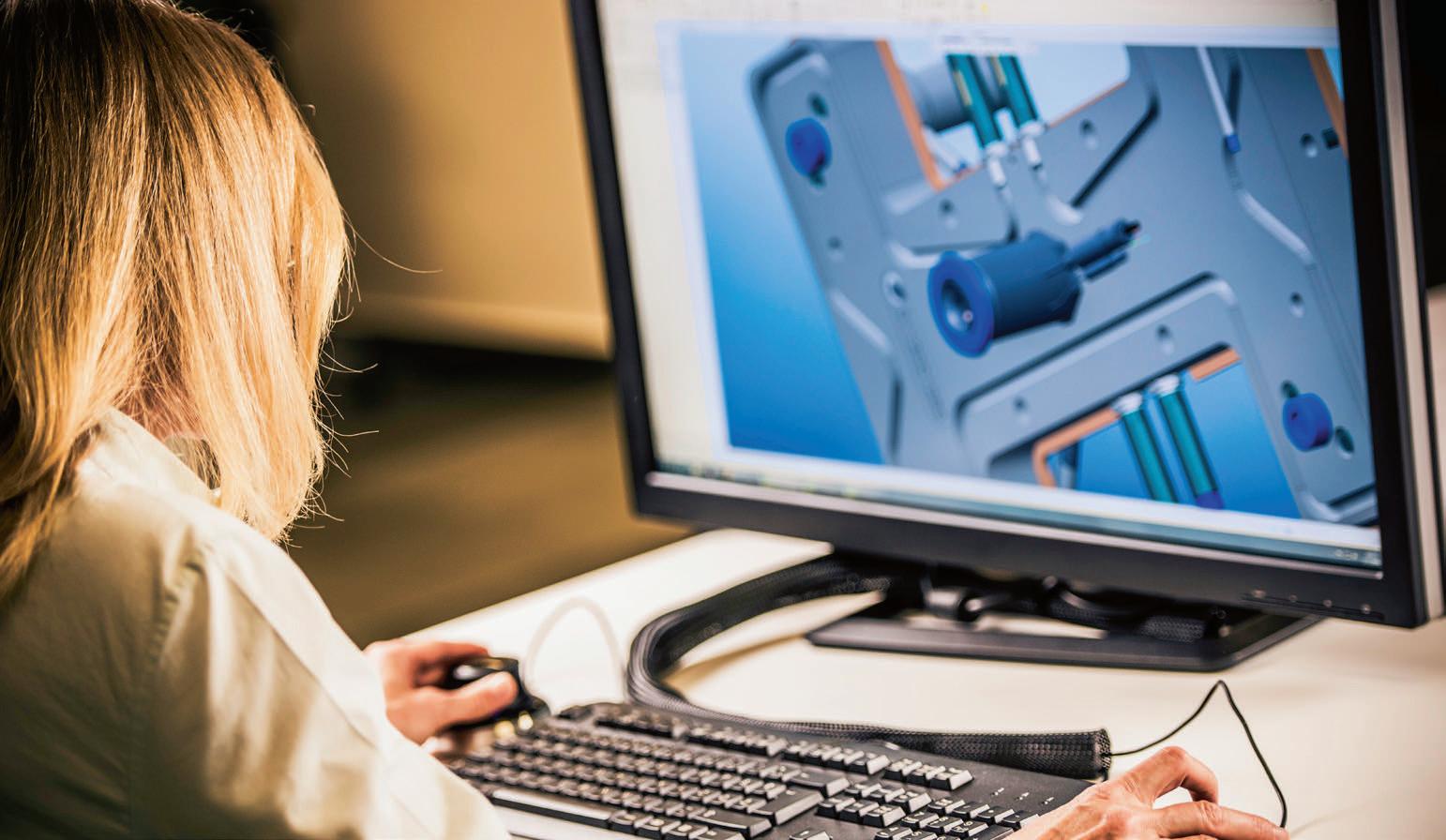

We recently asked several industry experts about trends they’re seeing in engineering training, software tools, and support. Here’s what those experts had to say.

68 AD INDEX

36

16

4 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com

CONTENTS

8 46 42

Tired

Automation made easy.

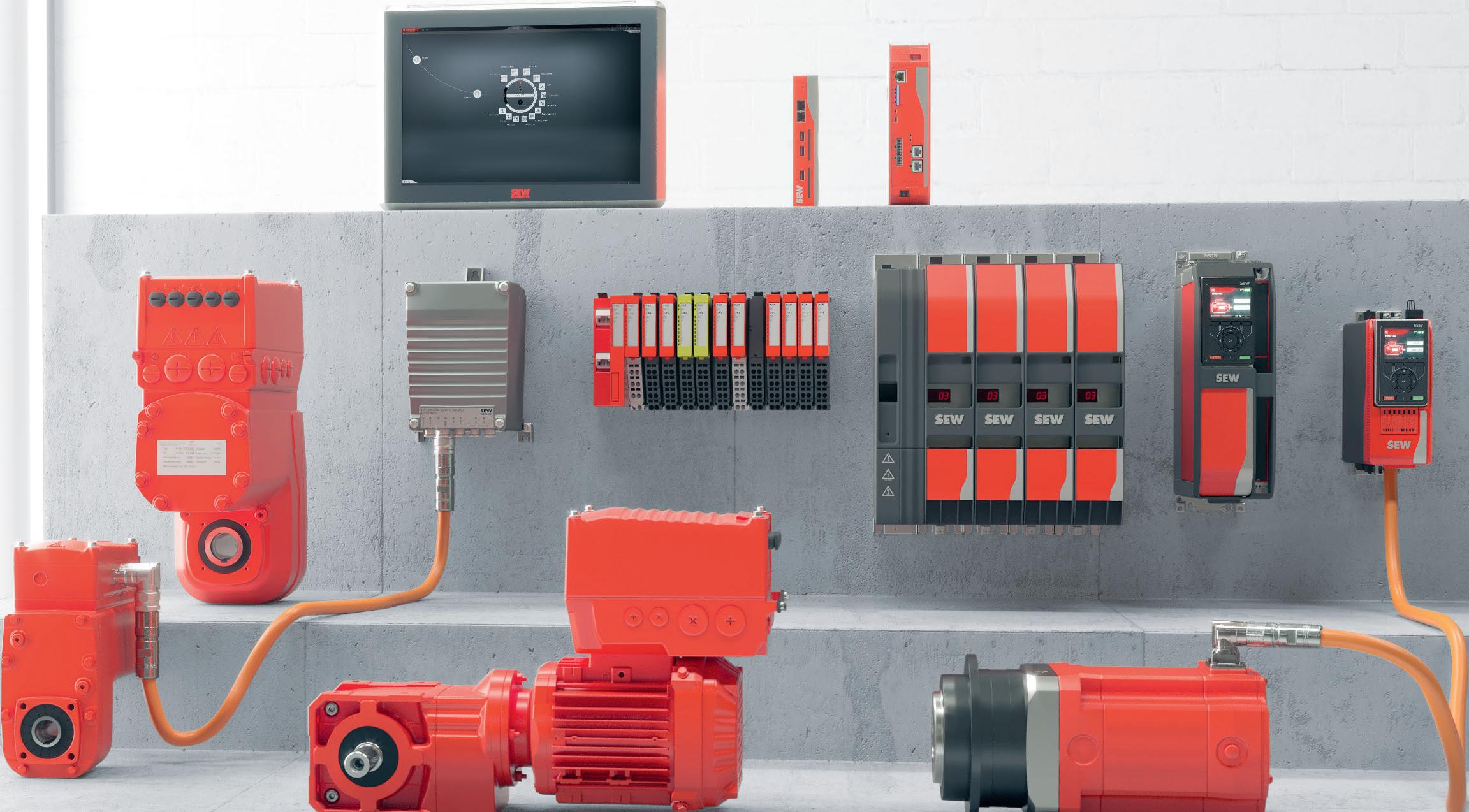

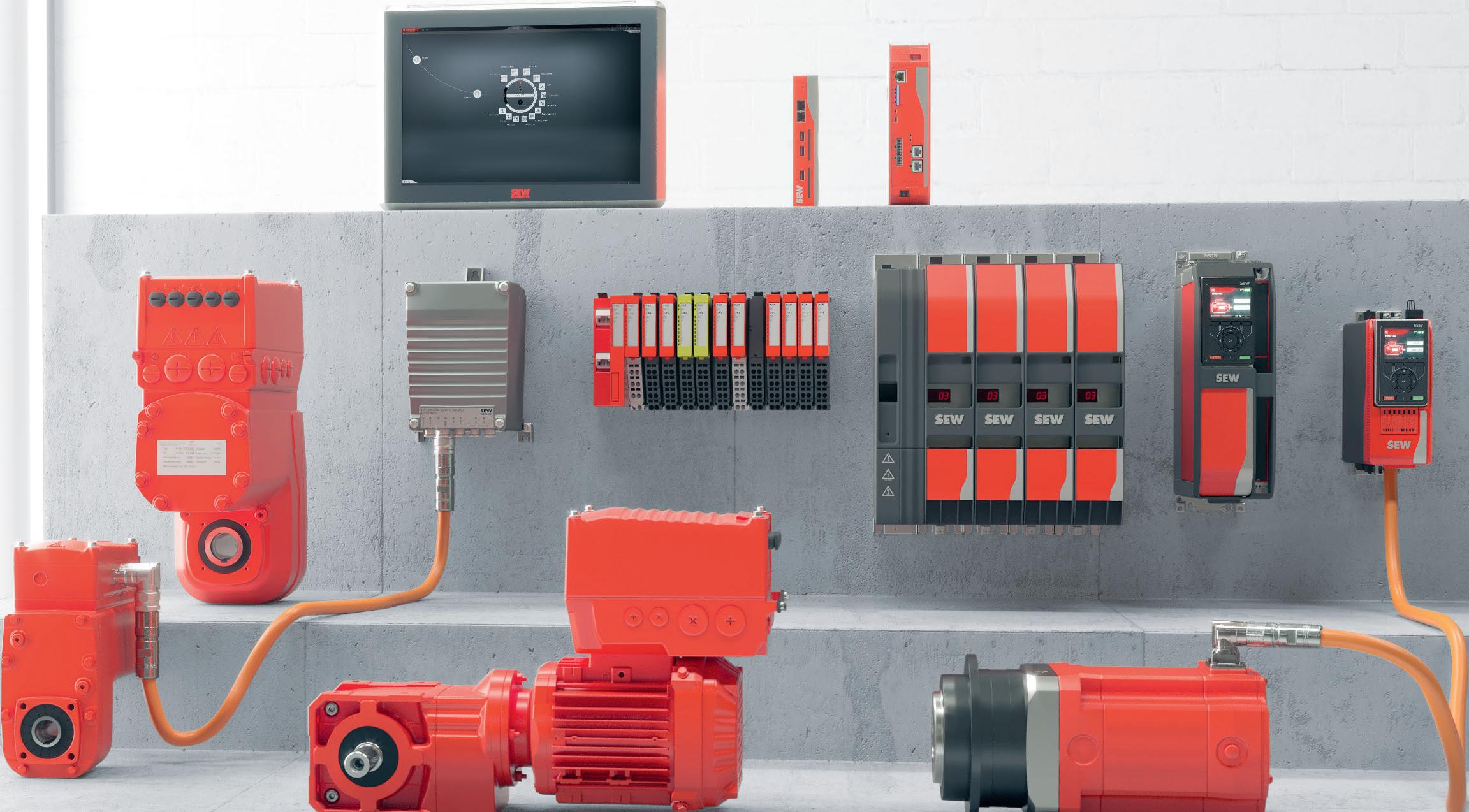

Check out our MOVI-C automation platform that features fully integrated drive components, control electronics and automation software – all from a single source –and all designed to work together perfectly! www.seweurodrive.com/movi-c

of compatibility headaches?

Design World’s Motion

An

DESIGN WORLD

follow the whole team on twitter @designworld

EDITORIAL

VP, Editorial Director Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Executive Editor Lisa Eitel leitel@wtwhmedia.com

@dw_LisaEitel

Managing Editor Mike Santora msantora@wtwhmedia.com @dw_MikeSantora

Senior Editor Miles Budimir mbudimir@wtwhmedia.com @dw_Motion

Senior Editor Mary Gannon mgannon@wtwhmedia.com @dw_MaryGannon

Senior Editor Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael

Senior Contributing Editor Leslie Langnau llangnau@wtwhmedia.com @dw_3Dprinting

IN-PERSON EVENTS

Events Manager Jen Osborne jkolasky@wtwhmedia.com @wtwh_Jen

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

VIDEOGRAPHY SERVICES

•

• Ball

•

• Couplings

•

•

•

•

Classroom installments cover topics including essential power-transmission and motion-control technologies for an array of OEM machines, powered end-user products, servo drives, and automated installations.

Videographer Garrett McCafferty gmccafferty@wtwhmedia.com

Videographer Kara Singleton ksingleton@wtwhmedia.com

CREATIVE SERVICES & PRINT PRODUCTION

VP, Creative Services Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Art Director Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Senior Graphic Designer Allison Washko awashko@wtwhmedia.com @wtwh_allison

Graphic Designer Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

ONLINE DEVELOPMENT & PRODUCTION

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com @wtwh_WebDave

Senior Digital Media Manager Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com VP, Strategic Initiatives Jay Hopper jhopper@wtwhmedia.com

WTWH Media, LLC 1111 Superior Ave., Suite 2600 Cleveland, OH 44114 Ph: 888.543.2447 FAX: 888.543.2447

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com @Taylor Meade Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Webinar Coordinator Halle Kirsh hkirsh@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

DESIGN WORLD does not pass judgment on subjects of controversy nor enter into dispute with or between any individuals or organizations. DESIGN WORLD is also an independent forum for the expression of opinions relevant to industry issues. Letters to the editor and by-lined articles express the views of the author and not necessarily of the publisher or the publication. Every effort is made to provide accurate information; however, publisher assumes no responsibility for accuracy of submitted advertising and editorial information. Non-commissioned articles and news releases cannot be acknowledged. Unsolicited materials cannot be returned nor will this organization assume responsibility for their care.

DESIGN WORLD does not endorse any products, programs or services of advertisers or editorial contributors. Copyright© 2023 by WTWH Media, LLC. No part of this publication may be reproduced in any form or by any means, electronic or mechanical, or by recording, or by any information storage or retrieval system, without written permission from the publisher.

Subscription Rates: Free and controlled circulation to qualified subscribers. Non-qualified persons may subscribe at the following rates: U.S. and possessions: 1 year: $125; 2 years: $200; 3 years: $275; Canadian and foreign, 1 year: $195; only US funds are accepted. Single copies $15 each. Subscriptions are prepaid, and check or money orders only.

Subscriber Services: To order a subscription or change your address, please email: designworld@omeda.com, or visit our web site at www.designworldonline.com

POSTMASTER: Send address changes to: Design World, 1111 Superior Ave., Suite 2600, Cleveland, OH 44114

MARKETING 2011- 2020 2013 - 2017, 2021 2014- 2016 2014 Winner

Classroom

Control

online reference series for design engineers. Each motion installment features current trends, videos, typical and emerging applications and FAQs. learn more at: www.designworldonline.com/mc2

Screws

Carriers

Cable

Conveyors

Motors

DC

Gearing

Motors

Integrated

Linear Guides

+ More MC² installments include stay up-to-date MC²

6 DESIGN WORLD — MOTION 3 • 2023

•

...All In Less Space

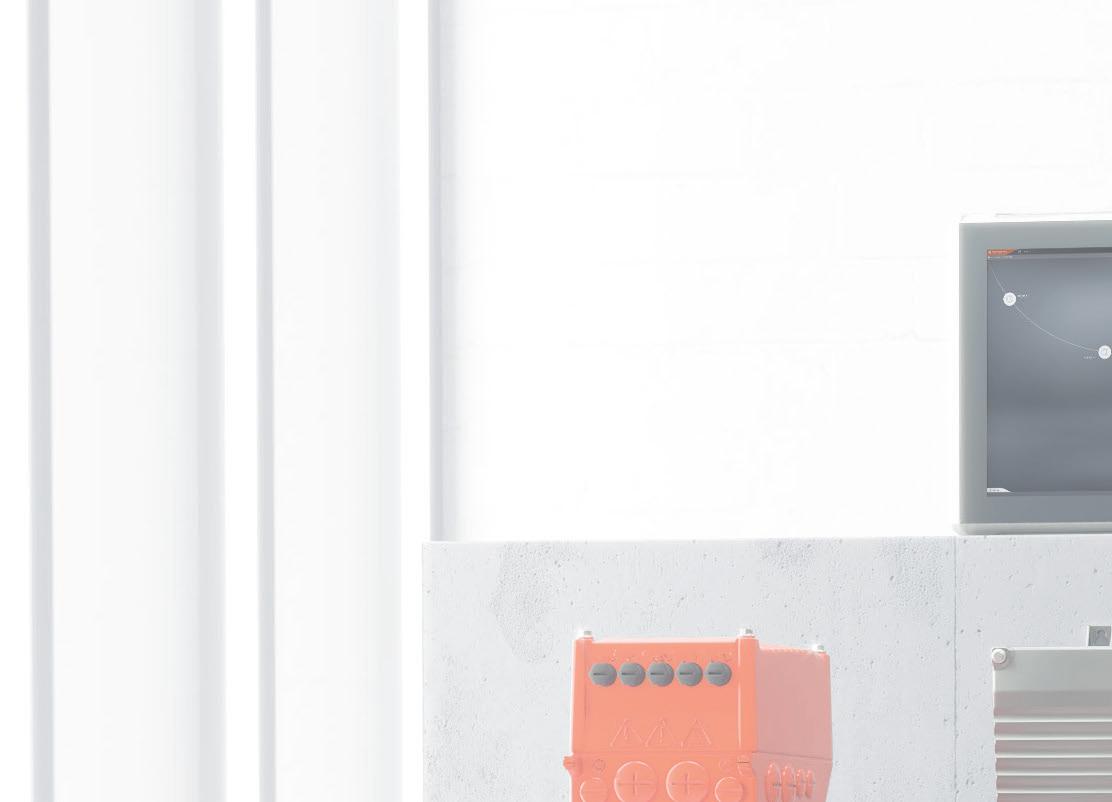

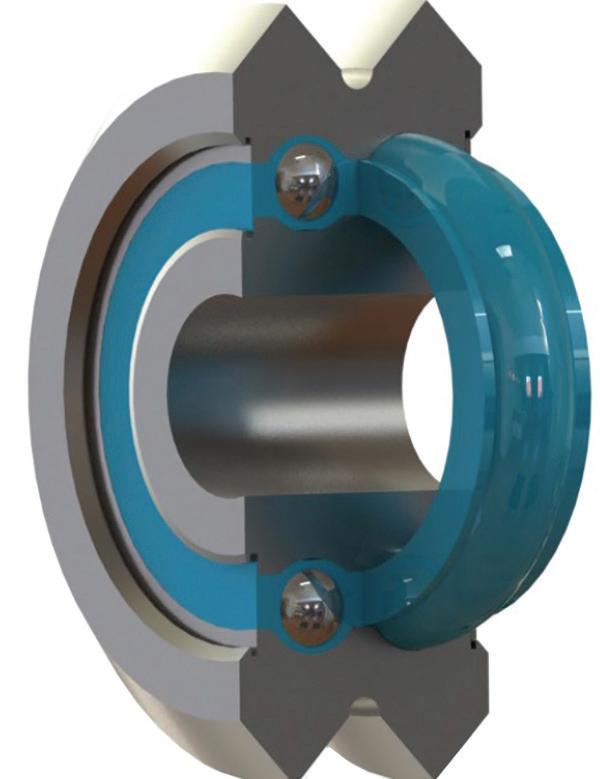

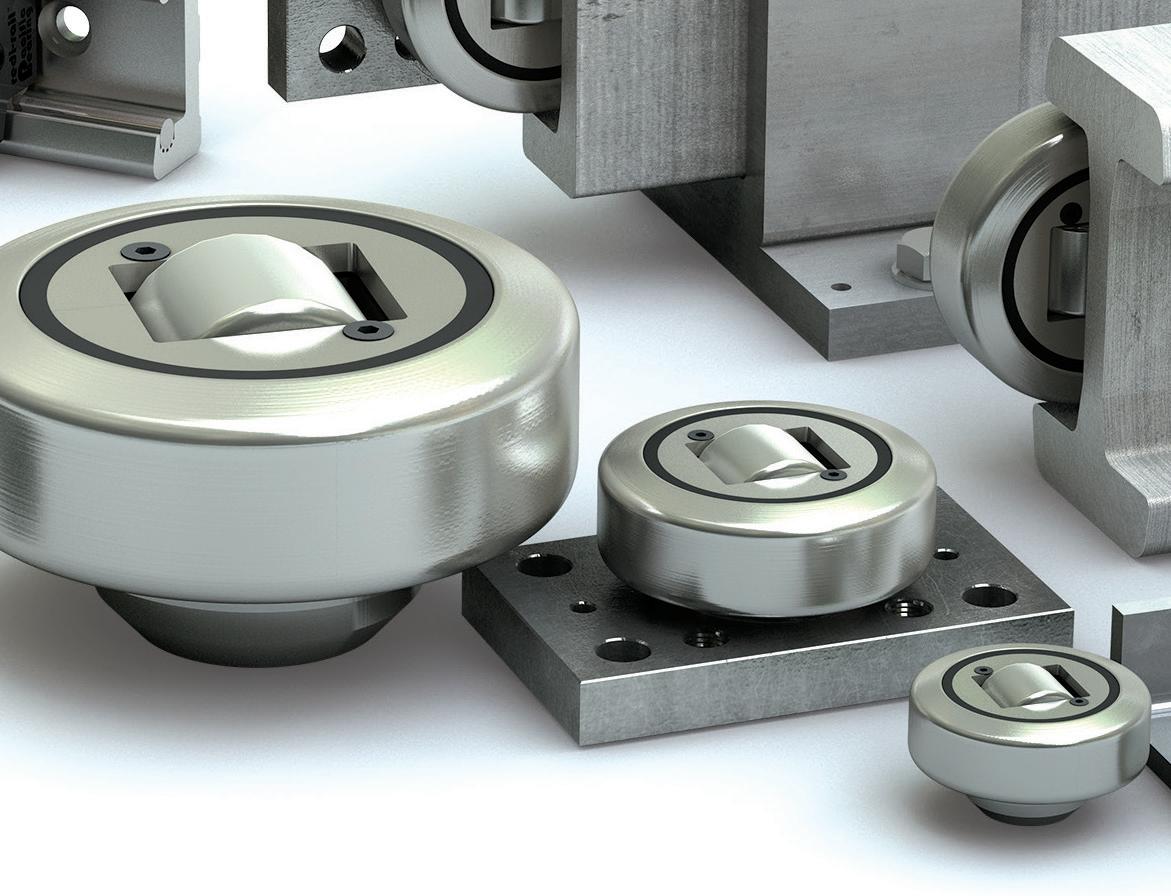

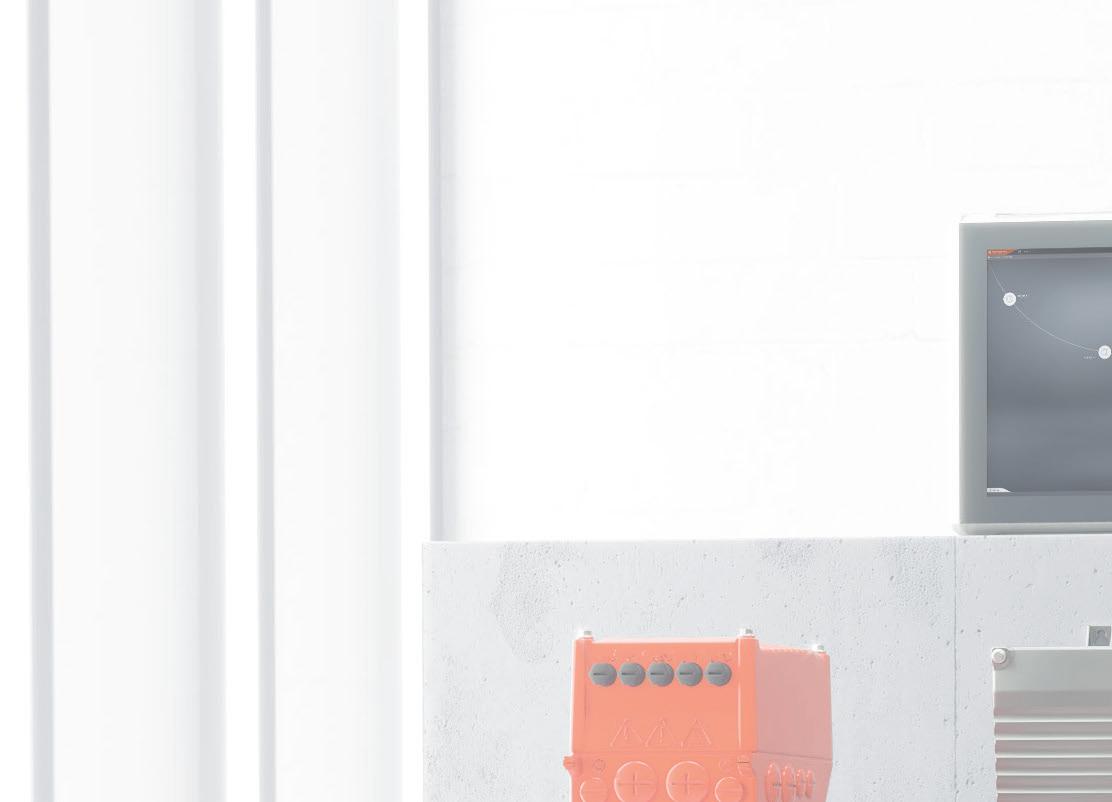

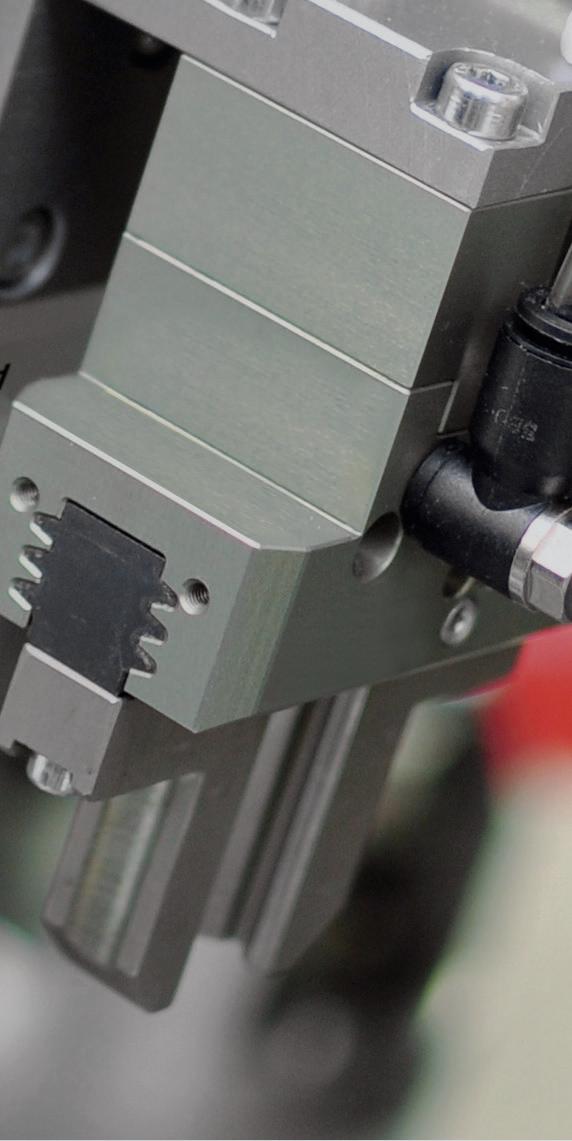

BG Actuator–Greater Loads, Precision & Rigidity

Why our single axis ball screw slide guide bests the competition:

Four ball circuits (not just two) for moreload and accuracy

Single, U-shaped rigid steel rail and base can be one-end supported

Circuits positioned closer to base for more stability

Balls have 4, not just 2, points-of-contact to guide block and rail for optimum stability

1. 2.

3. 4.

AUTOMATION INDUSTRY ADDRESSES SUPPLY-CHAIN AND LABOR ISSUES

In its wake, the COVID pandemic left lingering supplychain issues that are still affecting manufacturing and other automated industries. Now some slowdowns at least have cleared.

The last few years’ supply-chain issues have featured container ships waiting weeks for cargo unloading; empty shelves at stores; year-long waits for appliances; per-customer quantity limits on basic necessities; beleaguered online vendors struggling to maintain inventory; baby-formula fiascos; and various other back-ordered (and unavailable) parts and subcomponents in all industries. Today, shipments of goods have largely recovered, though data indicates the global supply chain in some markets continues to falter.

In fact, recoveries in shipping times and inventories may be due to the cooling effects of inflation and its discouragement of spending. Some predict the economic weakness of early 2023 will allow supply chains to recover and fully stabilize by 2024. But making business ventures even more challenging are the labor-shortage issues that have accompanied those on the supply side during COVID.

To be clear, most industry experts we surveyed for the 2023 Design World Trends issue don’t expect a fully normal supply chain or labor market for another year. Read on for the details.

Since the disruptions of COVID, which supply-chain issues have you seen persist or evolve?

Gallant: Raw material leadtimes are still longest, especially coming from Asia. However, we’ve seen significant improvement

8 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com design world trends

in logistics. Transit times have been reduced both internationally and domestically. We work with our customers very closely to plan out production timelines to ensure we factor in all manufacturing and logistical leadtimes.

Mowry: Most major supply-chain issues that peaked during COVID have improved. Notably, the availability of aluminum extrusions, which had severe leadtimes over the past couple of years, has recovered.

K. Walden: We’ve seen persistently longer leadtimes on raw materials — particularly for stainless steel and electronics items. So, we’ve implemented elevated stock holdings in strategic areas and established new suppliers and supply-chain options. We’ve also looked to re-engineer materials or production processes for leadtime reductions.

Gottlieb: We’ve seen supply-chain issues across the supply base and transportation sectors. It only takes one part to create a shortage on a final assembly, and we’ve experienced various issues from our vendors in market sectors mentioned in the news — semiconductors, materials — and those affected by transportation bottlenecks, cybercrime,

and natural disasters. Kollmorgen works aggressively to keep materials flowing through broker purchases and engineering redesigns.

Miller: Supply-chain issues have probably been the single most predominant challenge for our suppliers and customers over the past two to three years. Automation manufacturers’ leadtimes have skyrocketed industrywide — forcing customers to seek alternative solutions and, in some cases, make concessions where they normally would not.

Manufacturers also face obscene leadtimes for component parts and shortages — driving them to either work through brokerage firms (which drives up cost) or design in substitute components, often adding cost and complexity to the products they sell. Products with integrated microchips appear to be hardest hit in this area.

As a distributor and manufacturer of many motion control products, one way Motion Plus has worked to mitigate these challenges is to put extensive amounts of finishedgoods inventory on the shelf. We’ve done so on products like stages, motors, drives, and controllers, which are often highly configurable. There’s some risk in doing this, as it’s nearly impossible to cover every configuration option

- brushed or bldc motors

- 5 amps per axis

- 16 analog inputs

- 16 on/off drivers

- home and limit in

- live tech support

- made in the USA WWW.ALLMOTION.COM

supply-chain & labor issues

(Image courtesy of Sergii Sverdielov • Dreamstime)

(510) 471-4000 30097 Ahern Avenue Union City, CA 94587 Technical Support (408) 460-1345 See the EZQUAD SERVO in action!

4 AXIS SERVO from NEW! 9 DESIGN WORLD — MOTION 3 • 2023

2.25”

Custom Machine & Tool Co., Inc. 800-355-5949 sales@cmtco.com www.cmtco.com Precise. Reliable. Trusted. American Engineering | American Made © Custom Machine & Tool Co., Inc. Manufacturer of Power Transmission and Motion Control Components Timing Pulley Stock We guarantee your pulley stock order* ships within 72 hours or we pay the UPS ground freight charges. *Exclusions apply Email or call to get your Pulley Stock 72-Hour Shipping Program Catalog.

for every application/customer. However, we’ve found the 80/20 rule to be applicable here. If we stock the most commonly used options, they can usually work for most applications, and often customers are willing to accept a slight deviation to their exact part number if it means getting a product in days instead of weeks or even months.

T. Schroeder: In most sectors, the supply chain is starting to normalize. Suppliers have been catching up on backlogs, costs are starting to come down, and ocean freight costs have decreased. Electronics components are still lagging behind the rest of the sectors … and that’s causing complications and production delays. Companies are starting to transition back to a just-in-time inventory and reduce built-up inventory that was created during surging demands and supply chain uncertainty from COVID and recession worries.

Supplier diversification and strong supplier relationships have been critical … and will be critical through the next few years.

Varley: Many of our customers are still experiencing periodic component delivery issues. We’ve been working internally to increase production and meet the delivery dates that we provide to our customers.

Eidelberg: SAAR Inc. is active in exoskeleton product development and is experiencing no supplychain issues.

Sandys: With challenges due to supply chain shortages over the past three years, innovation stalled and temporarily took a backseat. However, with the worst behind us, we’re now seeing innovation escalate and even leapfrog where it would’ve been had the pandemic not happened. Now, the pace of innovation is on an unprecedented trajectory as new technologies are available to make designing products easier. In addition, the availability of parts is again expanding — along with the maker community’s sheer enthusiasm and excitement to innovate. These makers (and the ecosystem around them) are priming an innovation renaissance.

Gumas: Ruland has been fortunate that we’ve had no supply-chain disruptions. Our supply chain is primarily North American, which has limited the direct impact of availability — but not price.

In fact, we’ve always viewed our supply chain as critical to our ability to have industry-leading leadtimes and on-time delivery. The JIT model that many manufacturers have successfully implemented throughout the years was too risky for us in the event of an unforeseen

shortage. Our competency is the ability to quickly manufacture products, not manage a complex global supply-chain network.

How are you addressing any lingering supply-chain and labor problems?

Andaya: Procuring electronic components for products has been a struggle. Domestic labor shortages have also made maintaining experienced folks on the production line challenging. We’re addressing the supply-chain issues by sourcing some components from the open market and purchasing them well in advance. So, we’ve increased labor rates, and we’re in the process of adding a new production line with cobots.

Zaske: The last three years have been very dynamic for various reasons. 2022 was challenging with long supplier leadtimes, a tight labor market, inflationary pricing, and delayed deliveries. We’ve pulled a number of levers to address these issues, but one of the most important was our initiative to attract and retain employees. We organized a special group that helped us make several significant changes in a short period to stabilize and grow our workforce.

Andaya: Electric linear actuators and electric linear columns have been key to our growth in several markets. Because these actuators are intelligent, they can work on equipment compatible with collaborative robots (cobots) and logistics and warehousing equipment to reduce the labor needed for a given task. In fact, our products excel at assuming the mundane labor of operations involving repetitive motions.

Is

your company supplying robotics to address the manufacturing industry’s skilled labor shortage?

Mowry: We’re working hard to promote our line of linear actuators and Low-Cost Automation (LCA)

11 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com supply-chain & labor issues

Copia can display code in a web browser to help managers and new hires more efficiently communicate about a given codebase.

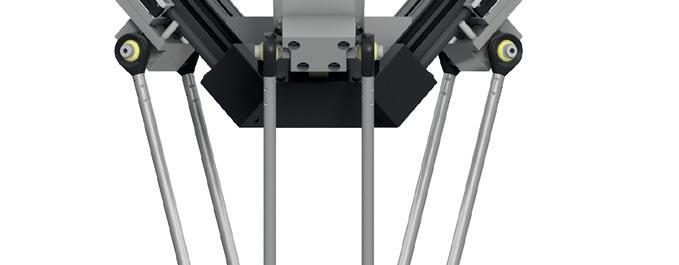

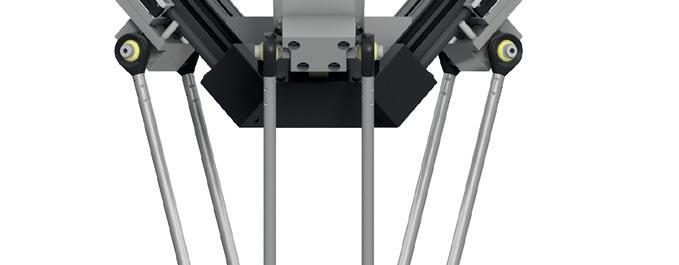

robots that help customers realize a rapid return on their investment … typically within six months. igus LCA robots include gantries, delta robots, articulated arms, and low-cost master control systems. Because we’re also a linear component manufacturer, we supply many parts that give engineers the flexibility to build their own lowcost robotic solutions.

Eidelberg: Our company focuses on reinforcement learning motion control technology of exoskeletons. We believe that reinforcement learning is the future of autonomous system control. It optimizes the real-time machine’s decision-making process in unpredictable environments to maximize intended performance.

Exoskeletons and humanoids are examples of such autonomous machines. Both are expected to increase the mobility and functionality of industrial employees as well as address a potential labor shortage. Tesla and Hyundai, for example, have spent billions of dollars developing reinforcement learning motion control technology for humanoid and other robots expected to support their manufacturing needs.

Varley: We’re seeing a strong increase in the amount of interest in our robotic and automation products. By automating processes, our customers are able to maintain steady production regardless of the impacts of the labor shortage.

Gumas: Ruland products are commonly used on robots, conveyors, and machine tools that help the modern manufacturer automate to solve skilled-labor shortages. For example, autonomous mobile robots or AMRs use couplings for the drive system; shaft collars to keep internal components in place; and vibrationisolation mounts to damp vibration during operation. These robots move throughout factories to transit parts, materials, and consumables — increasing the efficiency of current employees who no longer

have to manually move these items throughout the day. Ruland products are critical in such systems to address acute labor shortages and limit the long-term need for new employees.

What other automation technologies are helping address skilled labor shortages?

Kan: COVID hastened the pace at which companies aim to automate their processes. Projects that were perhaps considered five years out are (all of a sudden) a top priority. Our technologies help solve the

toughest automation challenges in contaminated and extreme environments. We’re also proud to automate dangerous workplace settings and reduce worker exposure to environments that may not be healthiest for direct human interaction.

Rice: Our Regional Service Center in Mason, Ohio, has a customersolutions department. This unit is experiencing exponential growth for its custom assembly and test-before-ship services. Festo’s internal systems and economies

12 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com

design world trends

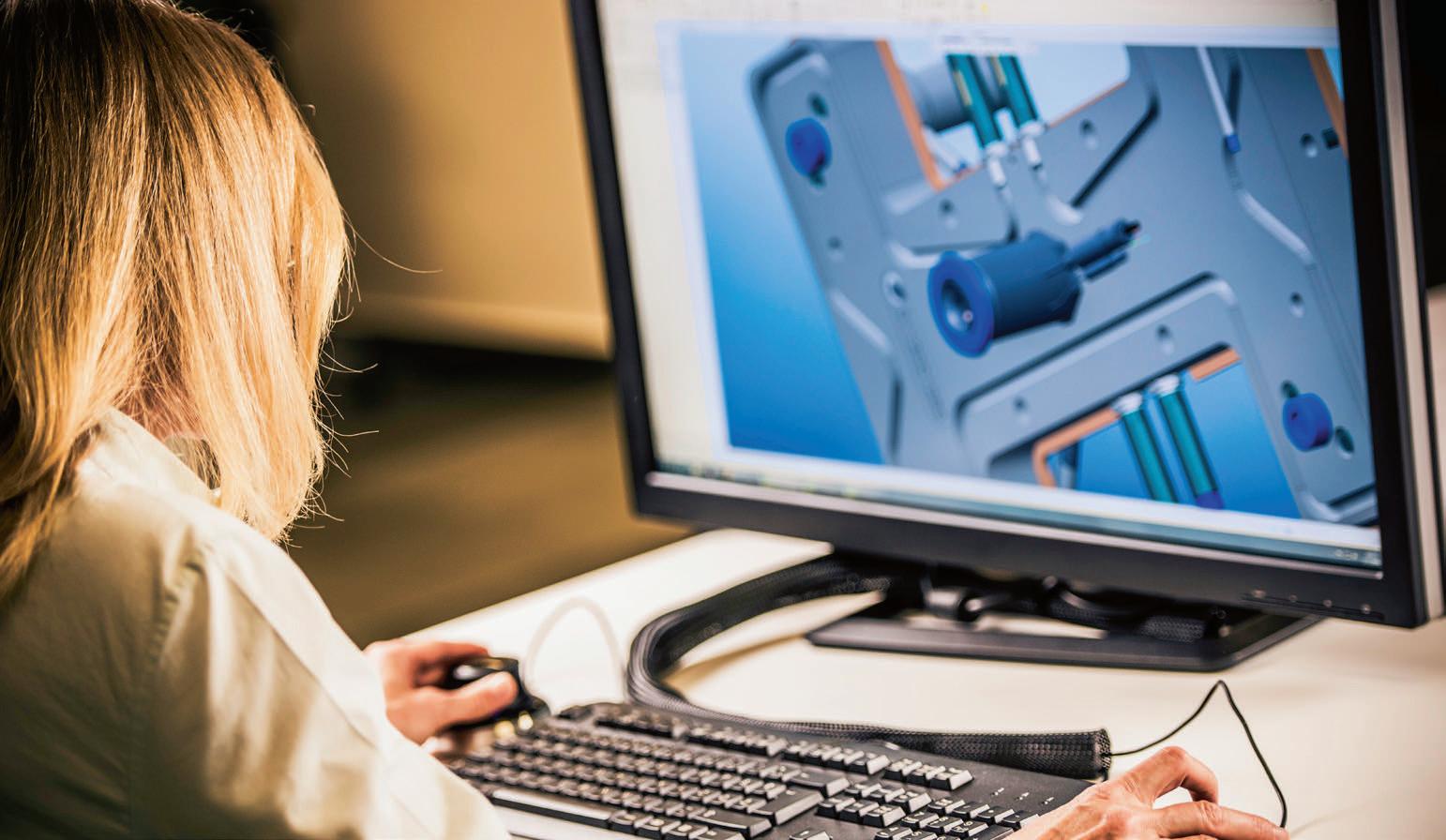

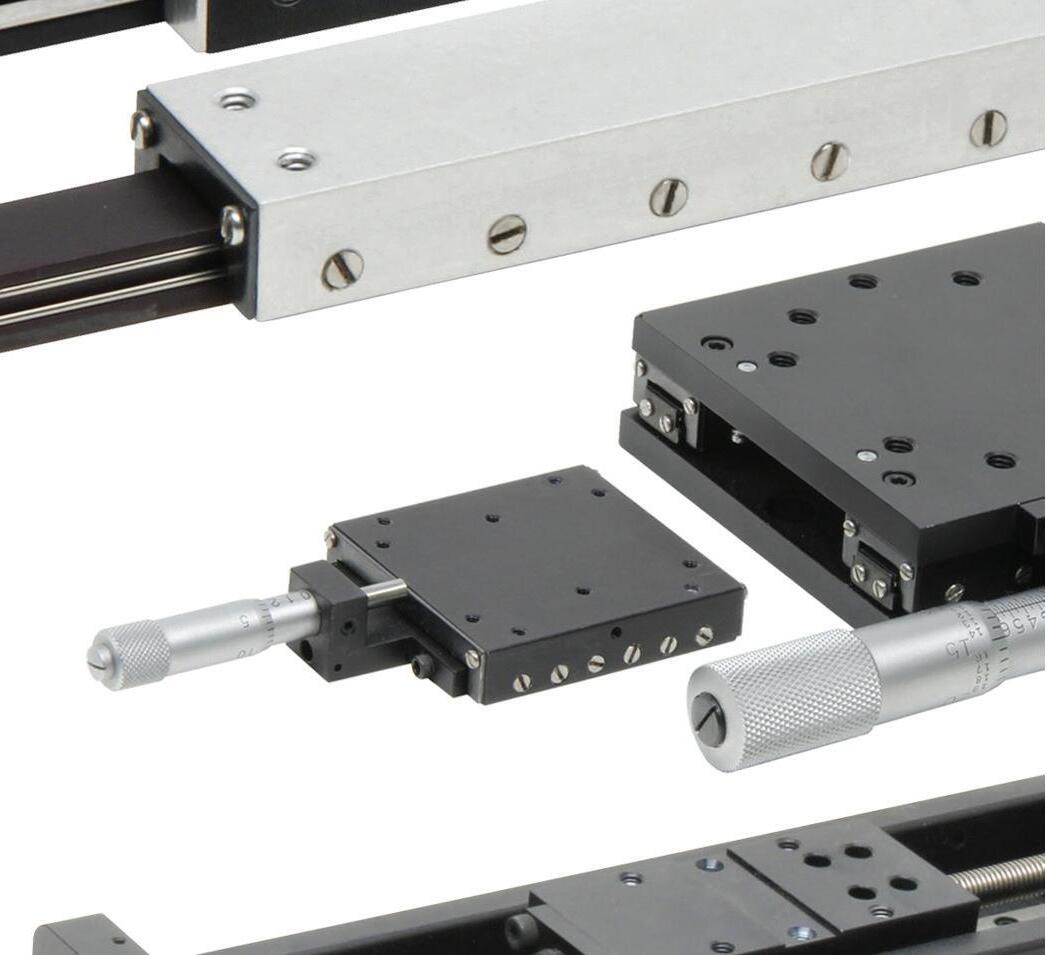

Festo industrial-automationbased XY tables and Cartesian gantries offer economies of scale and robustness unmatched by lab-device OEM systems. (Image courtesy of Festo)

of scale make these custom solutions practical, allowing OEMs to embed unique assemblies in their machines. These designs include custom air-preparation units, valve manifolds, and Cartesian systems. There’s no industry or system complexity for which we don't work with its customers. Our efforts revolve around motion automation.

Gluck: Copia Automation helps operations leverage in-house expertise to quickly onboard new hires. With Copia’s ability to show PLC code directly in a web browser, checking a colleague’s work is convenient and easy. New hires better understand the codebase, track changes, and contribute to the project without disrupting the work of other developers. Further, senior engineers can continuously review the new hire’s changes and directly comment on any concerns about rungs, blocks, and tags. Skills increase as senior engineers share their knowledge.

Andaya: In addition to helping our customers reduce the need for manufacturing labor, we’re able to make the work environment more attractive for existing laborers. We do this by using electric linear columns to make workstations ergonomic, which increases employee satisfaction and reduces workplace injuries.

K. Walden: Our company offers a broad range of motion solutions that are integral to automation. These include linear and curvilinear components, actuators, and even seventh-axis designs and more complex systems. Working in-house to automate our own production processes — and with our customers to solve their automation challenges — we’ve developed some great solutions.

Sharkey: The pandemic hastened demand for automated sample handling and fluid-dispensing systems in laboratory devices. Festo industrial-automation-based XY tables and Cartesian gantries offer economies of scale and robustness that lab device OEM systems simply cannot rival. Outsourcing lab device mechatronics enables the OEMs to concentrate on science — their value add — while relying on suppliers such as Festo to assemble,

13 DESIGN WORLD — MOTION supply-chain & labor issues better products. better solutions. (860) 769-5500 | info@mknorthamerica.com Find your next conveyor solution at Automate. May 22-25, 2023 | Detroit Booth 2207 Register for free using the link or QR and you’ll be invited to all of our special events at Automate. https://bit.ly/mkAutomate

test, and deliver drop-in solutions.

In 2018, Festo opened its LifeTech Technology Engineering Center in greater Boston. This center provides customers with consultative engineering services for their new product development and Festo with new product development in laboratory automation and microfluidics. During the pandemic, the team at the Festo Technology Engineering Center worked tirelessly with customers to meet expanding demand, and the center has grown its staff and capabilities accordingly.

Hansen: Adopting software solutions such as Epicor Kinetic (our manufacturing-specific solution) can bolster businesses’ competitive edge when hiring. As skill gaps and labor shortages continue, positioning a business as a forward-thinking organization — with tools in place to make potential new hires’ jobs easier — can be a deciding factor. Today’s high-value candidates are looking for places to work that are rich with new and intuitive technology. Enterprise software implementation combined with automation are the technology

MEET THE EXPERTS

building blocks manufacturers can employ to improve bottom lines while operating with a slimmer workforce.

Gottlieb: Kollmorgen’s motion control expertise is central to helping with the labor shortage. Our products are truly the brains, heart, and muscle of making global manufacturing safer and more efficient. Products such as the SafeMotion and Safety2G with Kollmorgen’s AKD2G servo drives (which follow IEC 61508) let production operators safely interact live with the machine under controlled and statistically reasonable conditions. In conjunction with a risk assessment and development from the machine builder, speed can be monitored with functions like SafeSpeed and SafePosition, while movement — or lack thereof under a SafeStop function set — is monitored via Safe Brake Control, Safe Brake Test, Safe Stop 1, and Safe Dynamic Brake. Resident safety in the servo drive allows for speed in monitoring and actuation at servo update-rate loop times.

Setup in the Kollmorgen Workbench aids the OEM with

James Gallant | Director of operations • ISL Products International Ltd.

Boaz Eidelberg | CTO • SAAR Inc.

Matt Mowry | Product manager — drylin linear bearings • igus Inc.

Adam Gluck | Founder & CEO • Copia Automation

Kelly Walden | V.P. of manufacturing • Bishop-Wisecarver Corp.

Tim Sharkey | Director of market management for electric automation • Festo

Chris Gumas | Director of marketing • Ruland Manufacturing

Pamela Kan | President and owner • Bishop-Wisecarver Corp.

Jeremy Miller | President • Motion Plus

Patrick Varley | Product marketing manager — mechatronics • Mitsubishi Electric Automation

Chris Gottlieb | Director — Drives and controls • Kollmorgen

Christine Hansen | Director of product marketing manufacturing • Epicor

Eric Rice | Product market manager — Electric Automation • Festo

Tom Schroeder | Executive V.P. • PBC Linear

Dave Walden | Applications engineer • PBC Linear

Nathan Andaya| Director — Techline strategic business unit • LINAK U.S.

David Sandys | Director of technical marketing • Digi-Key Electronics

Andy Zaske | V.P. of sales and marketing • Tolomatic

a programming methodology engineers know and with which they’re familiar. Fail Safe over EtherCAT (FSoE) combined with the installation of the Safe Encoder in the system’s servomotor save additional time for the OEM during initial machine wiring.

Hansen: While there are several ways technology is helping address the manufacturing labor shortage, most notable to Epicor customers is the way enterprise resource planning or ERP offers automation benefits that allow for continued operational efficiency from the shop floor to the top floor. For example, on the shop floor, software automation can help when connecting machines and automating the informationgathering process. This can improve efficiency — allowing more parts to be made with fewer resources, less machine time, and ultimately less labor.

On the other hand, automation can significantly assist top-floor operations such as onboarding or other tedious necessities that take

away from revenue-generating tasks. Refocusing those employees on projects that drive revenue for the company lets that company grow without hiring additional labor.

Miller: Automation will continue to play a key role in solving the growing demand and subsequent shortage of frontline workers in industry — especially as the trend of reshoring manufacturing back to U.S. locations continues to build. At Motion Plus, we manufacture and distribute automation products and solutions that are integrated into machinery used to reduce the burden on manual labor. Whether to maximize productivity for any particular repetitive operation (while also mitigating repetitive strain injuries) or just to optimize a particular process through the precise operation that only a motion control system can provide, it’s truly exciting to be part of the wave of automation driving manufacturing innovation now and into the future.

14 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com

design world trends

Low-Cost Automation (LCA) robots have a rapid return on investment for endusers who aim to automate simple processes. (Image courtesy of igus)

Better Performance. Smarter Motion.

Designing advanced semiconductor, electronics, or display manufacturing equipment? Challenge us with your high-performance OEM motion control application! www.acsmotioncontrol.com Meet the Intelligent Drive Module (IDM) Seriesdrives designed to maximize high-precision motion stage performance in high-tech manufacturing equipment. • Advanced servo control algorithms and performance optimization tools • High-frequency position-based I/O for device triggering and data capture

Single- and multi-axis models for single- and multi-axis stages

•

PART 1 OF 2: INDUSTRIAL CONNECTIVITY AND DIGITAL-TRANSFORMATION TRENDS

16 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com design world trends

Read Part 2 of this series here.

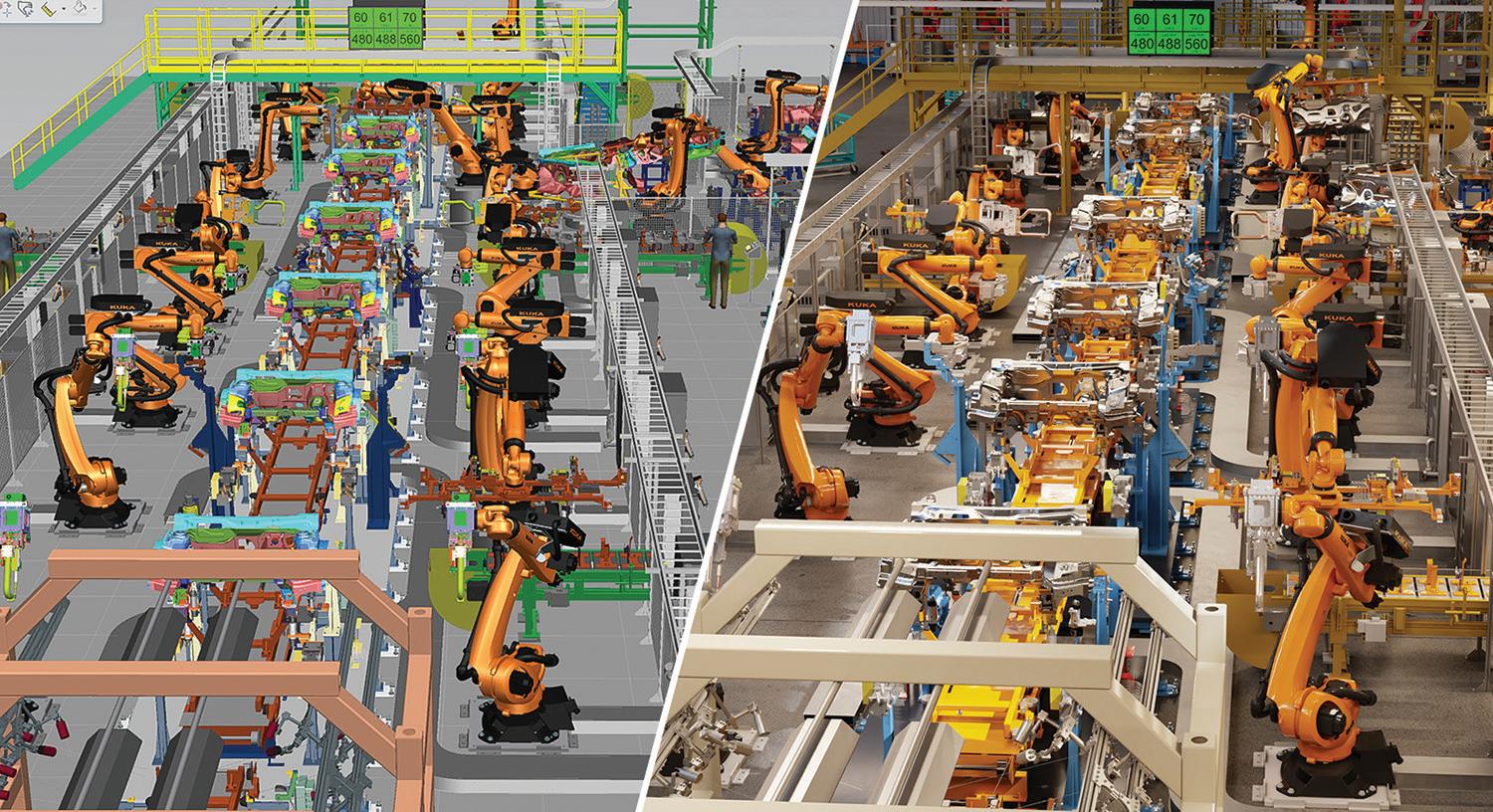

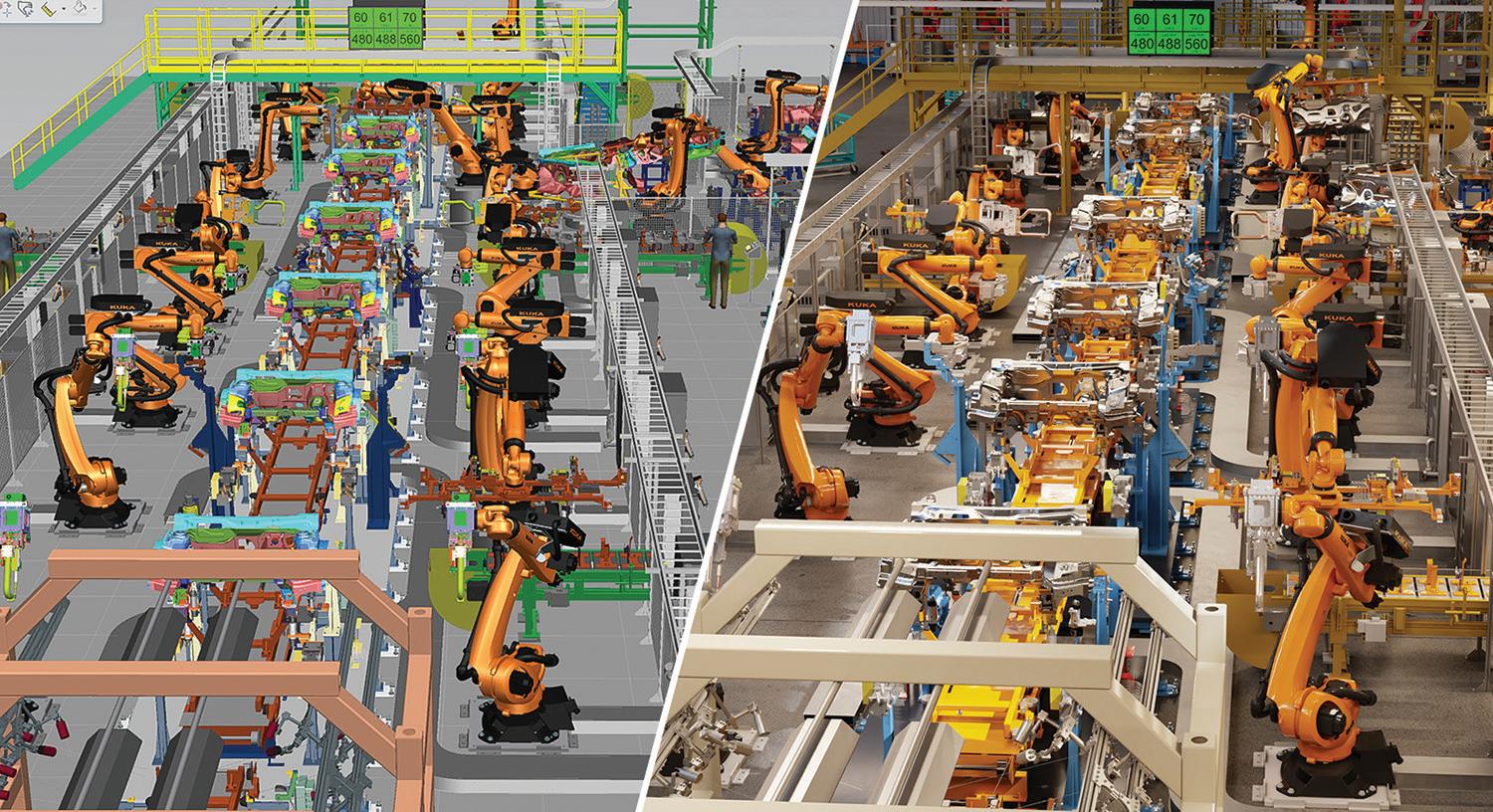

Together, NVIDIA artificial intelligence (AI) and Siemens industrial-automation tools now enable an industrial metaverse for the generation of digital-twins. More specifically, the companies have connected the open digital Siemens Xcelerator business platform and NVIDIA Omniverse 3D design platform for physics-based digital models and realtime AI to help companies make faster and more informed decisions to boost productivity. Adding Omniverse to the Xcelerator partner ecosystem is accelerating the use of digital twins.

Discrete automation’s edge devices include actuators, sensors, and connectivity components such as gateways and motor-mounted controllers. Many of these components feature computational capabilities to minimize data bandwidth and latency issues associated with legacy versions of centralized control. Their installation at the furthest reaches of automated equipment means their processing power is situated to filter and analyze data before it’s sent onward to central controls or connected cloud systems. But as our 2023 Trends panelists point out, the usefulness of such components ultimately relies on their interoperability with various machine systems.

Detail your involvement in efforts to promote standards for increased compatibilities and interoperability. Quintero: The pandemic, chip shortages, and supply-chain issues have forced endusers to be more receptive to working with various control vendors and not standardize on one. Openness to specifying controllers from an array of suppliers is rippling through the OEM community. One day an OEM may work on a Rockwell system, the next day Siemens, and the next day Beckhoff and Omron. Festo’s response has been to develop next generation multiprotocol solutions. For example, our new servodrive supports EtherNet/IP, PROFINET, EtherCAT, and Modbus TCP. OEMs benefit from having one multi-purpose drive and not having to commission a drive for every protocol. A single series reduces an OEM’s learning curve to a single system, lowers its inventory requirements, and simplifies support.

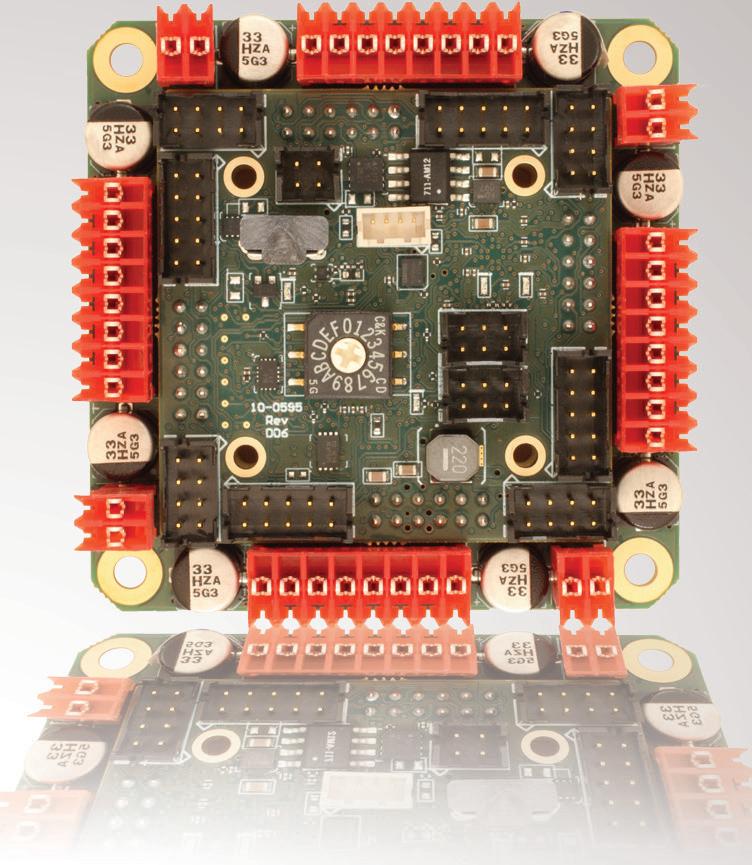

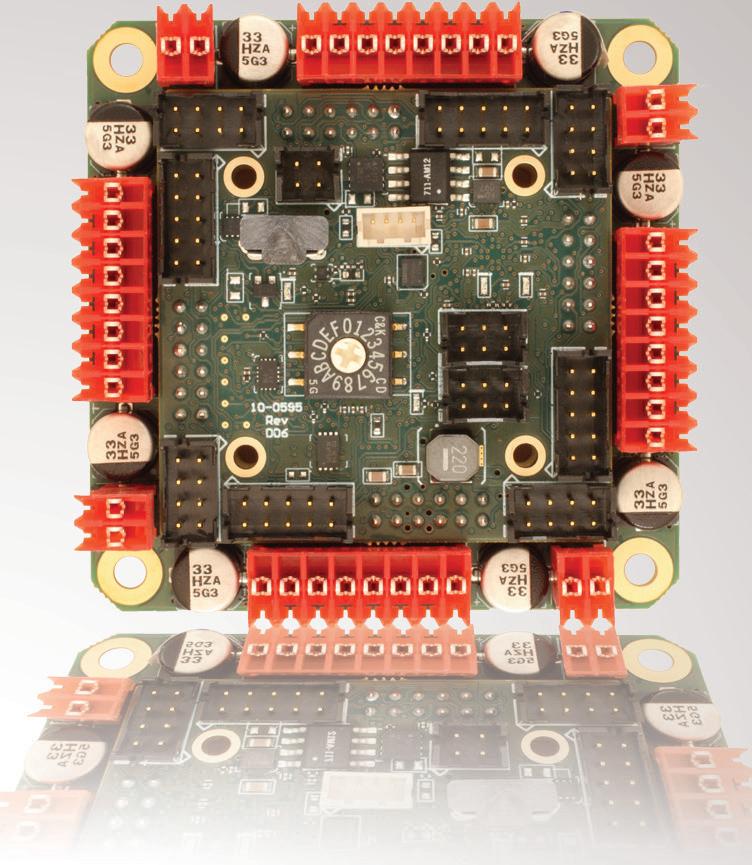

Patel: Improvements in PCB design and highdensity connectors has allowed maxon to develop low-profile micro-position controllers. The EPOS4 micro from maxon can provide 5 A continuously and 15 A peak and is available with CAN or EtherCAT communication.

Gottlieb: Kollmorgen belongs to the ODVA and EtherCAT global groups as well as ZVEI in Germany. We do plug fests to test regimens in and out of the groups, and I’ll say interoperability is really important — because design engineers have choices. Product and specification collaboration helps users maximize development and production efficiencies. So, a machine builder can use one servodrive with different protocol options — with one programming experience no matter the protocol to improve OEM time to market.

Product Finder helps you specify the performance characteristics, mechanical features and interface options you need.

POSITAL’s advanced production systems will custom-build devices that meet your requirements and ship them to you quickly. Minimum order quantity - one! For online purchases, try POSITAL’s new WebShop.

www.posital.com

YOUR ONE-STOP SHOP FOR POSITION AND MOTION SENSORS!

Encoders, Inclinometers, and Linear Sensors: Built to your specs!

the digital transformation • ai • connectivity 17 DESIGN WORLD — MOTION 3 • 2023

Sharkey: Endusers tell us that the benefits of multi-protocol components ripple through their organizations by making inventory, training, machine schematics, wiring, and part numbers more efficient. A single servodrive series and next-generation decentralized I/O help them more effectively serve a wide range of customer requirements. For example, the latest Festo servodrives come with a function-block software library. With PLCopen and other standards, the OEM commissions the drive in the same way for different PLCs. This is a timesaver and lowers the risk of programming errors.

Festo’s new drives can also be accessed via a standard web browser. On multiple-drive machines, OEMs program the drive once, and then the same file is used to set up the remaining files by uploading a parameter file via a web browser. Operators can view drive operation via the web browser; programming issues can be remotely handled, and remote operators can also guide maintenance personnel working on the drives.

Kan: We’re longtime members of the Power Transmission Distributors Association (PTDA) and the Association for High Technology Distribution (AHTD). These groups have created industry standards that make it easier to do business. More recently we’ve joined the Association for Advancing Automation (A3) to better serve in all areas of automation.

Gumas: Ruland has been a PTDA member for many years. The association recently announced it will license the Bearing Specialists Association (BSA) product information exchange (PIE) standard for bearings and add categories for shaft collars and couplings. Data normalization is critical for manufacturers to communicate with distributors, OEMs, and endusers in today’s economy.

For example, in our coupling line, the bore size can be called the bore, internal diameter, or shaft size. In everyday language, these terms are interchangeable. In internet speak, these are three different terms. When Ruland works with a distributor, they may use the term shaft size, and Ruland may use bore. Mapping analogous terms (even for straightforward attributes) can require significant human intervention. We have more than 500 attributes at Ruland — any of which can have this challenge.

The PIE seeks to normalize our industry’s language, so everyone works from the same template. Soon, manufacturers will be able to create one map to export their product information management (PIM) data to the PIE standard; then distributors, OEMs, and endusers will be able to create one map to import data to their PIM.

Normalization will significantly improve efficiency for engineers, maintenance personnel, and distributor personnel who use this data in their day-to-day work.

Quintero: The proliferation of control architectures is also

spurring more adoption of international standards. For example, Festo is a member of the PLCopen community and has adopted the IEC 61131-3 standard for programming languages such as structured text, ladder, and continuous function chart as well as motion control. We believe in a multi-vendor multi-protocol world, standards such as 61131-3 benefit everyone with less engineering time and greater ease of use.

Sophisticated connectivity for flatter architectures

When picturing a discrete automation installation, many engineers conjure the traditional automation-communications pyramid. Such architectures include data exchanges between field-level sensors and higher implementation layers with communications between controls — all ultimately linking into the pinnacle of the enterprise level. But several technologies have facilitated distributed and intelligent systems with flatter machinery communication structures:

• Today’s software (along with industrial apps not unlike those for consumer-grade mobile devices)

• Newer options such as cloud services — as one networking example

• Hardware such as programmable automation controllers (PACs) and smart field devices — as two component examples

As our panelists explain, these

technologies have changed the structure of the intelligent factory floor over the last decade.

What other connectivity and smart-factory trends have you seen over the last year?

Johannes: There’s a major drive to provide both Ethernet and USB protocols via ruggedized custom interconnects (not standard connectors) for medical, industrial, aerospace, and automotive designs. These are challenged by the need to support much longer transmission lengths than those satisfied by copper-based systems. So, non-return-to-zero (NRZ) and pulse-amplitude modulation (PAM) techniques are being applied to minimize attenuation and copper’s impact on signal integrity.

LEMO has rugged miniature circular connectors and systems to support USB 3.1 and Ethernet protocols for severe environments.

Quintero: The new Festo decentralized I/O is communications-protocol independent and offers a unified architecture for electric and pneumatic motion, digital and analog signals, and IIoT capabilities. It has a large capacity for components. Decentralized I/O also allows significant distance between components, which brings pneumatic valves closer to the point of actuation and improves response time of pneumatic actuators. Plus decentralized I/O can be located inside or outside a control cabinet.

Sharkey: Controllers are becoming smaller and more

18 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com

design world trends

powerful. This means that they have limited I/O capabilities. Such controllers benefit from decentralized I/O with one-wire communication back to the PLC for the system’s I/O. Plus decentralized I/O can help shrink the size of control panels by enabling greater numbers of components to be mounted on the machine.

Gottlieb: Motion controllers remain as necessary as always. Our PCMM controller powered by the Kollmorgen Automation Suite features a multi-axis EtherCAT master; supports five programming languages to satisfy any controls engineer; allows six digital inputs and two digital outputs; and allows the addition of extendable I/O. The PCMM’s pricepoint makes it suitable for single-axis machines and more complex machines to 20 axes.

Lassen: When copper’s maximum data rate has been reached, transitioning to fiber optics is necessary for both short and long-distance transmission — especially for digital 4K resolution video transmission. One of LEMO’s unique selling points is its ability to combine copper (power) and fiber-optic components within the same compact rugged connector housing. This makes it much easier for endusers to plug and unplug just a single connector rather than having to locate multiple connector elements.

A weak link when integrating fiber into a system is the exposed cabling used between the robust connectors. To address this, cables containing the delicate fibers and electrical conductors can be further protected with flexible armored jacket. For medical applications needing easy cleaning and handling, armored jacket (in products provided by LEMO’s Northwire division) can be extruded to provide a smooth surface.

Detail uses of Amazon Web Services (AWS), IBM Cloud, Microsoft Azure, or SAP Cloud services. Do you support MQTT-based systems?

Paczkowski: Emerson edge controllers and industrial PCs (IPCs) running PACEdge support MQTT communications, and a wide variety of other operational technology (OT) industrial protocols and IT-centric protocols. MQTT has become a leading way to transmit edge-sourced data to higher-level platforms, due to its low-bandwidth requirements and resilient communication methodologies.

Nandy: As the world is getting more connected, industrial automation and motion-control applications as well as controllers are becoming increasingly complicated. Each system connects via IIoT or edge communications to exchange data, report faults, log maintenance, and run live updates for enhancing as well as optimizing system performance. There’s no one-size-fits-all solution in this space. A complete solution includes the right software, communication protocol, security, and networking solutions to run on a wide range of hardware and systems.

Paczkowski: New equipment and projects can be developed with the latest PLCs/PACs, edge controllers, and IPCs to ensure they seamlessly communicate with each other and higher-level systems. However, there’s a massive installed base of automated equipment needing gradual upgrades. Emerson edge controllers and IPCs are well-suited to serve as the platform for such upgrades, or they can be layered on top of existing automation elements to add modern data handling, remote connectivity, and IIoT capabilities to legacy equipment. Gateways are another class of edge device suitable for complementing existing digital assets. They impart the ability to transfer data to higher-level onsite or cloud-based resources. In fact, engineers today have many options for adding gateway functionalities (and advanced computing) to new and legacy equipment.

Thompson: Spatial-data company Matterport is an ISV partner with Amazon Web Services and is listed on the Amazon Partner Network as well as the AWS Marketplace. Our partnership with AWS IoT TwinMaker has enabled:

Emerson offers a thoroughly integrated portfolio of hardware and software technologies to let engineers realize digital transformations of new and legacy equipment at every level — from edge-located field devices to control panels and control rooms … and even to the enterprise and cloud.

Rugged-environment LEMO connectors support USB 3.1.

Amazon Partner Network as well as the AWS Marketplace. data sources to optimize site visits and immediately

• The ability to create 3D scenes with spatial anchors linked to real-world data. Users can overlay equipment within a digital twin and then tag the space with anchors to connect models with a knowledge graph created and managed by AWS IoT TwinMaker. This knowledge graph allows integration of data such as heat mapping and controls into the digital twin.

• Better facility management by establishing realtime remote monitoring, process optimization, and historical root cause analysis. Endusers can connect to disparate data sources to optimize site visits and immediately assess issues.

20 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips .com design world trends

(Image courtesy of Festo)

.com | designworldonline

It’s now possible to build web apps on digital twins — including apps for training employees and apps to trigger notifications upon the detection of abnormal device data. With AWS IoT TwinMaker and Matterport, users can contextualize digital-twin data, gather insights and analytics, and access realtime and time-series replicas of their spaces anytime and anywhere.

Wireless industrial applications on the horizon

Increasingly, intelligent factory technologies (complementing Factory of the Future architectures) employ wireless connectivity such as 5G and edge computing to:

• Boost the flexibility of manufacturing

• Allow adaptive production planning

• Predict failures before critical work stoppages.

These capabilities minimize warranty, waste, and downtime costs while boosting worker safety, preferably while satisfying the objectives of machine builders and endusers.

What industrial applications for 5G do you predict over the next five years?

Wireless connectivity such as Wi-Fi, 5G, and WirelessHART has developed rapidly — both in terms of communication speed and available protocols. Physical installation of copper or fiber cabling is a significant expense with automation projects; once installed, wired infrastructure somewhat limits expandability and future flexibility. So, endusers are finding that modern wireless technologies provide a good way to address many localized networking needs while making it easy to expand or change installations in the future.

Emerson PACSystems and PACEdge products support wireless technologies and wired methods, so users have options for all implementation needs.

• Enhance operator and machine control through the entire range of motion without excess strength

J.

Inc. Magazine has called 5G the catalyst for the world’s fourth industrial revolution. Once 5G networks are operating at full capacity, I believe there will be two key benefits seen by industry and consumers.

First, the increased range offered by 5G networks will allow high-speed data to reach an increased percentage of the globe for more internet-connected devices and the ability to pass data back and forth to servers. Farmers, loggers, miners, wildfire firefighters, and others who operate in remote areas will be able to work in a connected world.

in autonomous of bandwidth.

This will enable a wide range of devices — including autonomous robots.

The second key advantage of 5G (and Wi-Fi 6 inside buildings) is high speed and bandwidth. The increased capabilities of Wi-Fi 6 and 5G will let devices become smaller and

• Perfect support of muscle power with forces from 2 to 2,923 lbs.

• Stainless steel options for wash down and sterile environments

• A variety of accessories allows for universal application

the digital transformation • ai • connectivity ACE Controls · Farmington Hills, Michigan www.acecontrols.com

21 DESIGN WORLD — MOTION

INDUSTRIAL GAS SPRINGS ARE THE SMART WAY TO LIFT AND LOWER

3 • 2023

Smart-factory. (Image courtesy of Dreamstime • Suwin Puengsamrong)

Schroeder:

requirements for harder material, SNCM220 and/or

normally used.

hardness is determined by production condition. expected hardness value is informed in a quotation of gears.

Gear precision grade table : mentioned equivalent grades are for reference only. grades completely match each other.

carburizing (case hardening), SCM415 is normally used.

SNCM420

15/05/21 14:20:18 259 Elm Place, Mineola, NY 11501 Phone: 516.248.3850 | Fax: 516.248.4385 Email: info@khkgears.us Largest selection of in North America Stock Metric GEARS

In Design World, we use many examples involving discrete automation to illustrate the possibilities of DX. Here, smart motion controls work by accepting sensor, switch, and encoder feedback and serving as (or triggering the signal-amplifying (amplifier) action of motor controls — all traditional functions. They also serve an additional role of connecting machines to enterprise-level systems.

last longer because the bulk of the processing power required will reside on a server, and data will be streamed to the device.

Consider how virtual reality (VR) and augmented reality (AR) technologies are electrically and computationally intensive — much more so than streaming. Offloading the processing to a server and converting devices to streaming devices will allow the spread of VR and AR, as field devices will become less costly (due to more modest processor and battery specs) and more ergonomic (due to their lighter weight).

What are your observations regarding IoT connectivity for mechanical components?

Morris: While bearings aren’t new technology, they’ve come a long way. Bearings can be metallic or plastic, and polymers all have different characteristics for use in

specific applications — including food-safe and medical applications where metallic bearings are not ideal. Ceramic bearings excel in hot, fast, and abrasive applications. Magnetic bearings, which use magnetic levitation to rotate around a shaft with no actual physical contact, eliminate wear and complement applications needing high speeds and low vibration.

Renewable energy has become a large industry. Wind turbines feature large bearings — typically slewing bearings. The medical industry employs bearings in stateof-the-art technology MRI machines

MEET THE EXPERTS

and CT scanners. Robotics have automated many processes; here, bearings complete rotating robotic arms and equipment to move robots vertically and horizontally. EVs also use various bearings, including ceramic bearings for their lightness and high speeds. Because large bearings can be quite costly (and have months-long leadtimes) predictive maintenance for them has become very useful — particularly with today’s supply-chain and leadtime issues. Performance data can be stored and sent to the cloud for in-depth analysis and then used for engineering improvements and improved maintenance schedules. Plus, all this data can be remotely monitored to reduce 24/7 maintenance-personnel needs by letting staff monitor and respond to issues at several sites at once.

Several products on the market today enable simple and affordable condition monitoring for bearings using sensor-collected data. The latter is analyzed, and the system alerts users to condition anomalies. Users can even monitor the data through mobile apps. Read Part 2 of this series by visiting designworldonline.com and searching on Gottlieb. Also look for a follow-up article in Design World on this topic.

Richard Johannes | Director of engineering and innovation • LEMO USA

Steven Lassen | Product & applications manager • LEMO USA

Sandro Quintero | Business development for electric automation • Festo

Will Morris | Category manager • RS Americas Inc.

Chris Gumas | Director of marketing • Ruland Manufacturing

Paul Thompson | V.P. solutions engineering • Matterport

Pamela Kan | President and owner • Bishop-Wisecarver Corp.

Chris Gottlieb | Director — Drives and controls • Kollmorgen

Jonathan Schroeder | Executive V.P. • PBC Linear

Bill Paczkowski | Senior product manager for PACEdge • Emerson

Pramit Nandy | Product marketing manager — 16-bit microcontroller division • Microchip Technology

Tim Sharkey | Director of market management for electric automation • Festo

Biren Patel | Business development manager — mobility solutions • maxon

23 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com the digital transformation • ai • connectivity

RFID OR BARCODES INTRALOGISTICS LOCAL FACILITY SHIPPING AND DELIVERY LOGISTICS AND DISTRIBUTION INTRALOGISTICS AUTOMATION NETWORK REMOTE SERVICES ERP MES INTERNET ROUTER SECURE WLAN SWITCH

END USERS MACHINES’ MOTORS AND DRIVES HOST CONTROLLER (PRESENT IN ADVANCED SYSTEMS) MOTION CONTROLLER BOARD OR CABLE CONNECTIONS

FIELDBUS

TRENDS IN EV s, AGV s, AND e BIKES

We recently asked several industry experts about the trends they’re seeing in the design and use of electric vehicles (EVs), scooters, eBikes, and autonomous ground vehicles (AGVs). Here’s what those experts had to say.

Gallant: We spec in our dc motors and gear motors into these types of EV, eBike, and AGV applications and

devices. For motion control, customers typically request one of our incremental magnetic encoders be added to our dc motor/gear motor in these applications. For any of our BLDC motor solutions, an additional motor controller is required. We provide standard BLDC motor controllers. For customers who desire a fully customized motor controller, we provide technical support to their electronic engineers during the PCB design.

24 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com design world trends

evs • ebikes & agvs 25 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com

Here is the interior of a machine that produces GBBatterie electric batteries. Festo components are used in this machine.

Festo components are used in the production of electric-vehicle batteries.

What are some new technologies being applied in mobile designs?

Rose: With input voltages supported from less than 10 Vdc to greater than 1000 Vdc, the dc-dc converters are used in small and low-voltage battery pack drones and bicycles through large and high voltage battery pack commercial buses and trucks. The ac-dc power supplies and the dc-dc converters are used in battery charging systems ranging from wall plug powered drones and bicycle chargers, to high-powered, fixed-installation chargers for cars, trucks, and buses.

More interesting than the numerous sensors in EVs is the power and communications technologies employed to enable the sensors and transfer enormous amounts of data from them. Power distribution in automobiles, trucks, buses, and aircraft is transforming to a similar situation as is used in data centers. It is becoming more common to have a 48 Vdc power delivery backbone employed with many branches and associated point of load dc-dc converters. The POL converters reduce the distributed voltage to the level required by each sensor or actuator. The weight and volume of copper required for power distribution is greatly reduced by implementing this topology.

Mowry: The more the EVs become autonomous, the more automation is being done inside the cab to make the experience better for the driver and passengers. We have seen new applications for our leadscrews in the automated opening of charging ports, power sliding windows in the back of pickup trucks, and linear systems that can change the position of the dashboard, steering wheel, or other parts of the interior to create more user space for the passengers.

Luchars: ECM’s PCB Stator electric motors are the central component for converting electrical energy to torque, horsepower, mechanical output, and forward motion in e-mobility applications. In fact, our coupling of printed circuit board, axial flux motor topology to a SaaS platform represents a new technology tool for electric mobility. ECM’s PCB Stator electric motors are lighter, faster, quieter, and achieve much higher efficiencies than conventional machines. We connect that to our motor CAD software, PrintStator, which offers unprecedented design flexibility. ECM’s SaaS platform takes discreet inputs: how much torque, power, and desired rotation speed‚ and converts those into a design for a custom PCB Stator used in axial-flux machines.

ECM’s motor designs in axial-flux air-core machines have maximum torque and superior power in a much smaller footprint. This presents numerous design and performance benefits for electrically powered applications, such as drones, e-bicycles, and certain marine vehicles. The most obvious upsides include reduced weight coupled to improved performance and greater battery efficiencies.

Schellenberger: Microchip Technology provides a range of semiconductor-based solutions for the e-mobility market. Our silicon carbide (SiC) solutions enable the high-voltage power conversion, regulation, and control necessary for propulsion in EVs, electric bikes, and scooters. Our AUTOSAR-ready digital signal controllers (DSCs) with a high-performance DSP engine and specialized peripherals result in stunning performance gains in digital power applications. Along with these core components, we also offer power management, connectivity, timing, and security solutions, among others, to help clients build a total system solution for E-Mobility applications.

In terms of sensing, LiDAR, radar, ultrasonic and camera-based systems lead the way for autonomous vehicles. Additionally, our inductive sensing solutions are key for motor control applications and position sensing for electric vehicles. On the drive side, the high-voltage systems needed for the propulsion of electric vehicles have created the demand for SiC MOSFETs and diodes that are capable of sustaining hundreds of volts.

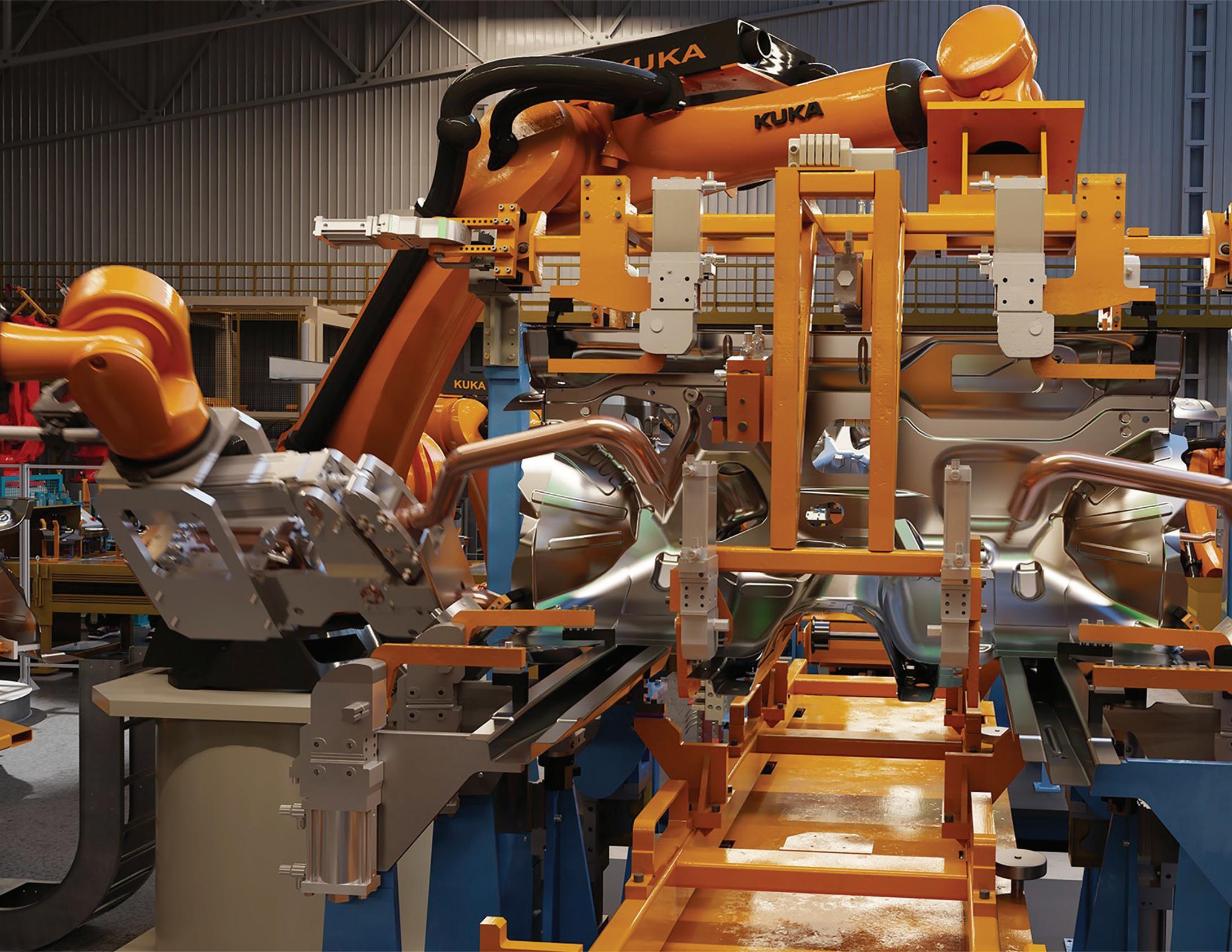

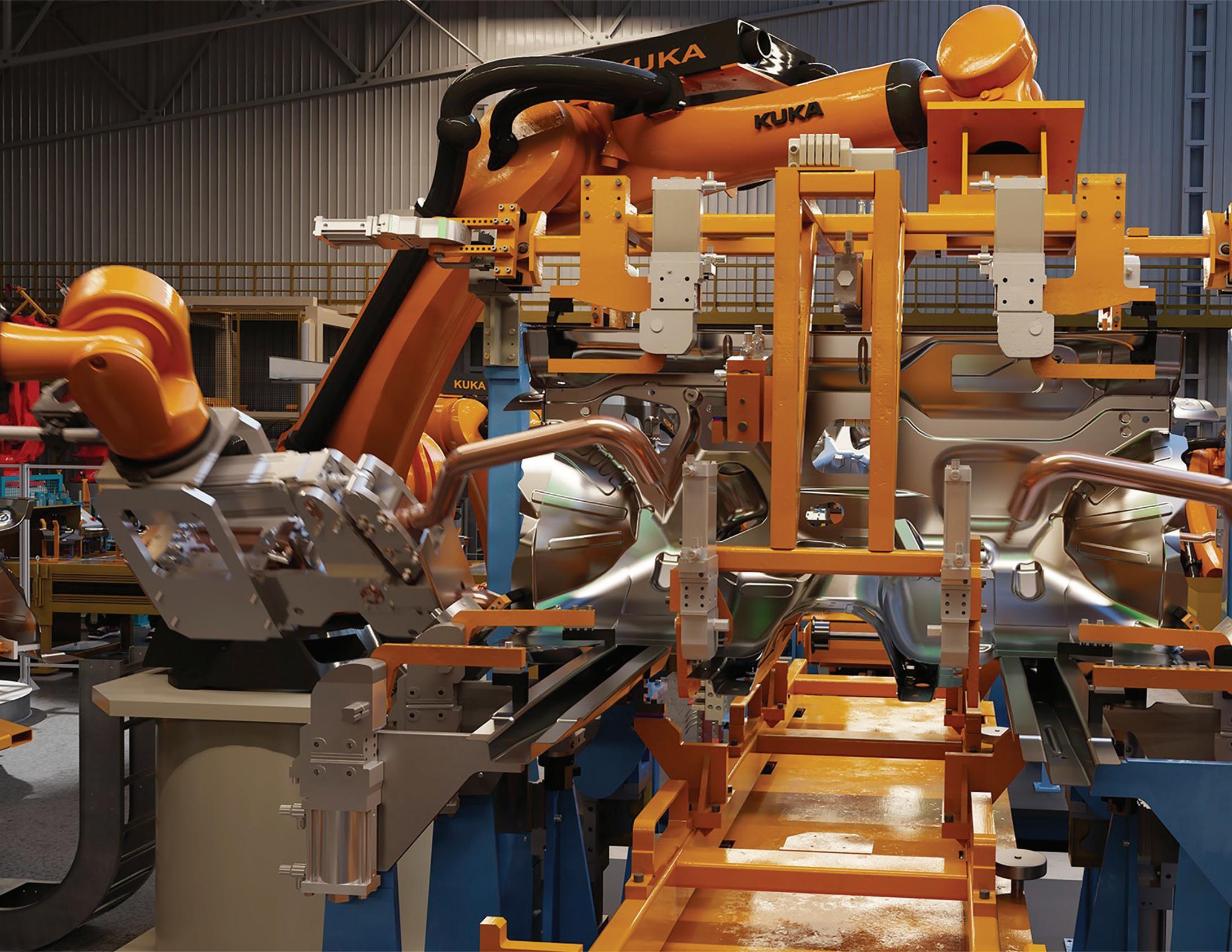

How about the manufacture of components that go into EVs?

Lin: Consider how motion control is used in EV battery production. There are two operation environments in battery manufacturing — in a dry room (dew point < -20° C) before the prismatic, cylindrical, and pouch-style batteries are sealed — and in the ambient factory environment, where the sealed assembly cells are placed in modules. After the cells are placed in modules, they are secured in the module with adhesive, pressed closed, and placed in an EV battery pack for installation into the vehicles.

26 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com design world trends

Jabil’s short-wavelength infrared 3D camera demonstrator operates at an 1130 nm wavelength making it a good fit for outdoor applications.

Festo Cartesian gantry robots are used for picking, placing, sealing, and pressing operations in the factory. Gantries, which are compact to begin with, use close to 100% of the work envelope, leading to a smaller footprint on the factory floor. Gantries require less guarding, which saves cost and space. The gantry motion is fast and accurate for the three-axis motion of picking and placing, sealing, and pressing.

To be competitive, EV battery OEMs must be better, faster, and offer superior systems in terms of performance. Festo developed the Handling Guide Online engineering productivity tool that reduces gantry design time from an industry average of two weeks to 20 minutes. With this free online tool, engineers enter basic application parameters such as mass, torque, and speed, and Handling Guide Online designs the optimum gantry. At the end of a design session, the engineer receives a 3D CAD drawing, a bill of materials, an estimated delivery date, and a quote for the cost of the system. With a 3D CAD drawing, the OEM can proceed with machine design while waiting for the gantry delivery and keep the project moving.

Festo delivers fully tested gantries, which are shipped as either quick-to-assemble kits or as fully assembled, ready-to-install systems. Each OEM receives a unique part number for the gantry for easy reorder and component identification. When the Festo gantry and control cabinet arrives, the OEM connects power along with the control cables and uses pre-installed function blocks to program the unit. The Festo Motion Control Package lets the OEM compress the standard commissioning time from one week down to one to two days.

Garbe: In EV battery production, there is enormous pressure for the rapid designing, building, and commissioning of automated machines for production. These machines must exhibit superior uptime, accuracy, data acquisition, and reliability. Along with growing consumer demand for electric vehicles, and the drive to be a market leader for automotive companies, the Inflation Reduction Act has spurred the industry to move even more quickly than before because of the tax incentives in the bill. There are immense production goals through 2030. The only way that auto manufacturers are going to reach these goals is through highly automated, reliable production methods. In electric-vehicle battery production, OEMs use linear-motion-based gantries for their accuracy versus six-axis robots. As a six-axis arm reaches farther from its base, the robots lose accuracy. A gantry maintains high accuracy within the entire work envelope. We find that OEMs in the battery industry do not want to buy components from multiple suppliers. Using numerous vendors complicates ordering in terms of time, inventory, and support for multi-component/multi-vendor systems and risks the components having interoperability issues.

Learning curves for programming and wiring also require higher internal resources. OEMs want their machines to be delivered and commissioned faster, reliably high performing, and easier to support. All of this leads to vendor consolidation. The Handling Guide Online reduces the delivery time of a gantry robot from an industry average of eight weeks down to three.

27 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com

evs • ebikes & agvs

What are some recent developments specific to eBikes and AGVs?

Patel: maxon has developed a lightweight mid-mounted drive unit that provides support when needed and can be integrated into the frame. The Bikedrive AIR drive unit weighs only 1.9 kg and has a Q factor starting at 155 mm and freewheel technology which provides no noticeable resistance. This means that when pedaling backward and riding unassisted, there is no frictional force to overcome due to the motor.

The low-profile drive unit allows racing, gravel, urban, kids, and mountain bike manufacturers to still use traditional frame designs.

For AGVs, maxon continues to develop integrated drives and has added to this offering with the release of the IDX 70. The IDX70 compact drives can easily be configured online and offer up to 87.5 Nm peak torque when combined with the 70-mm gearbox GPX70.

Umeno: Kollmorgen has provided many automation solutions to the production of batteries for EVs. Our success and expertise in supporting the large existing Asian market are being leveraged to support productions in Europe and North America. The coating process is critical in lithium-ion battery production. The manufacturers of coating machines rely on Kollmorgen’s direct drive technology to meet manufacturers’ requirements for a high yield.

Blasch: Jabil has developed a nextgeneration 3D camera with the ability to seamlessly operate in both indoor and outdoor environments up to a range of 20 meters. Jabil, ams OSRAM, and Artilux combined their proprietary technologies

in 3D sensing architecture design, semiconductor lasers, and germaniumsilicon (GeSi) sensor arrays based on a scalable complementary metal-oxidesemiconductor (CMOS) technology platform, respectively, to demonstrate a 3D camera that operates in the shortwavelength infrared (SWIR), at 1130 nanometers. The camera operates in the shortwave infrared, 1130 nm, greatly improving the signal-to-noise ratio used to calculate depth.

First, by targeting 1130 nm, the camera takes advantage of a gap in the sun’s solar spectrum, lowering the background noise impacting the ToF signal. Second, the magnitude of the signal can also be increased, as laser eye safety thresholds are higher at 1130nm than at either 850nm or 940nm. The result is a 3D camera capable of operation in bright sunlight, extended operating range, and better depth accuracy.

The key implication is that robotic platforms are no longer restricted to indoor operation. Given the high cost of autonomous mobile robots (AMRs) and other autonomous platforms, increasing their utility, safety, and reliability benefits everyone in the industry. Route planning

MEET THE EXPERTS

to avoid obstacles like windows or open bay doors, is no longer an issue.

Our goal, in collaboration with many component suppliers in the market, is to create low-cost 3D sensors enabling forklifts, AMRs, agricultural equipment, platforms in support of aircraft operations, and more whose performance is indifferent to environmental conditions. The use of 3D cameras at 1130nm can also be installed on AGVs, especially for collision avoidance. The use of 1130nm should be considered for AGVs that may want to move along loading bays, between buildings, or completely operate in outdoor environments.

Gottlieb: Kollmorgen is a key vendor in AGVs; we improve efficiency in manufacturing and warehousing without making significant investments. Market trends are for more direct-to-consumer shipments, and warehouse management strategies enabled by the most efficient tools will lift the winners to market share. We sell into the drones and EV market as well. Our products fit the bill for directdrive technology, drive accuracy and speed, and quicker time to market with consultative engineers.

Ian Blasch | Senior director — business development • Jabil

James Gallant | Director of operations • ISL Products International Ltd.

Jarod Garbe | Automotive industry segment manager • Festo

Chris Gottlieb | Director — Drives and controls • Kollmorgen

Lawrence Lin | EV batteries business development manager • Festo

Robert Luchars | V.P. of business development • ECM PCB Stator Technology

Matt Mowry | Product manager — drylin linear bearings • igus Inc.

Biren Patel | Business development manager — mobility solutions • maxon

Bruce Rose | Principal application engineer • CUI Inc.

Dave Schellenberger | Manager — automotive products business unit (Americas) • Microchip Technology

Yoshitaka Umeno | Global Market Manager — Medical and robotics • Kollmorgen Corp.

28 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com

design world trends

The figure of the plant highlights the ability of Jabil’s SWIR 3D camera demonstrator to capture depth information of an object partially illuminated by the sun and partially shaded from the sun.

SHA Rotary Actuator with Integrated Servo Drive

The SHA-IDT Series is a family of compact actuators that deliver high torque with exceptional accuracy and repeatability. These hollow shaft servo actuators feature Harmonic Drive® precision strain wave gears combined with a brushless servomotor, a brake, two magnetic absolute encoders and an integrated servo drive with CANopen® communication. This revolutionary product eliminates the need for an external drive and greatly simplifies wiring yet delivers high-positional accuracy and torsional stiffness in a compact housing.

• Actuator + Integrated Servo Drive utilizing CANopen® communication

• 48 VDC nominal supply voltage

• A single cable with only 4 conductors is needed: CANH, CANL, +48VDC, 0VDC

• Zero Backlash

• Panel Mount Connectors with radial and axial options

• Dual Absolute Encoders

• Output Encoder: 16bit (65,536 cpr) resolution

• Input Encoder: 17bit (131,072 cpr) resolution

• Control Modes include: Torque, Velocity, and Position Control, CSP, CSV, CST

Simplify.

Harmonic Drive is a registered trademark of Harmonic Drive LLC. CANopen is a registered trademark of CAN in Automation. 42

| 800.921.3332 | www.HarmonicDrive.net

Dunham Ridge, Beverly, MA 01915

MOTORS, GEARMOTORS, AND DRIVES

As automation continues to expand in existing as well as newer applications, the enabling automation technology is evolving to keep pace with these changes. Motors and drives are no exception. In particular, motors have gotten smaller to accommodate space and size restrictions in new, unique applications. There have also been changes to how motors are designed and built, with an increase in custom designs as well as motor and drive networking and connectivity.

We recently asked several leading industry experts about trends they’re seeing in motor, gearmotor, and drive technologies. Here’s what those experts had to say.

How is it that motor manufacturers can build motors of sizes impossible just a decade ago?

Beckstoffer: The miniaturization of motors over recent years has been accomplished by several key factors — design, materials,

and automation capability. From a design perspective, advances in simulation software provide engineers with the capability to evaluate smaller-diameter concepts to confirm feasibility. Engineers also continue to push the boundaries of size reduction through unique and patented motor features. This is further enabled by advances in materials, including higher power magnets, more conductive metals, and higher strength components.

All of this requires automation to precisely wind coils and complete the assembly of the miniature components of the motors. With the continual advances in these areas, motor manufacturers have been able to design and produce motors with continually smaller diameters and lengths.

Luchars: Customers typically come to ECM intending to remove gears from their design, as the geartrains in motor systems typically add size, cost, complexity, and noise to the system. Our partners are instead interested in a direct-drive solution. ECM is capable of running the direct drive analysis (in addition to various gear ratio designs) to explore the cost, size, and weight tradeoff of each. Because we can

30 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com design world trends

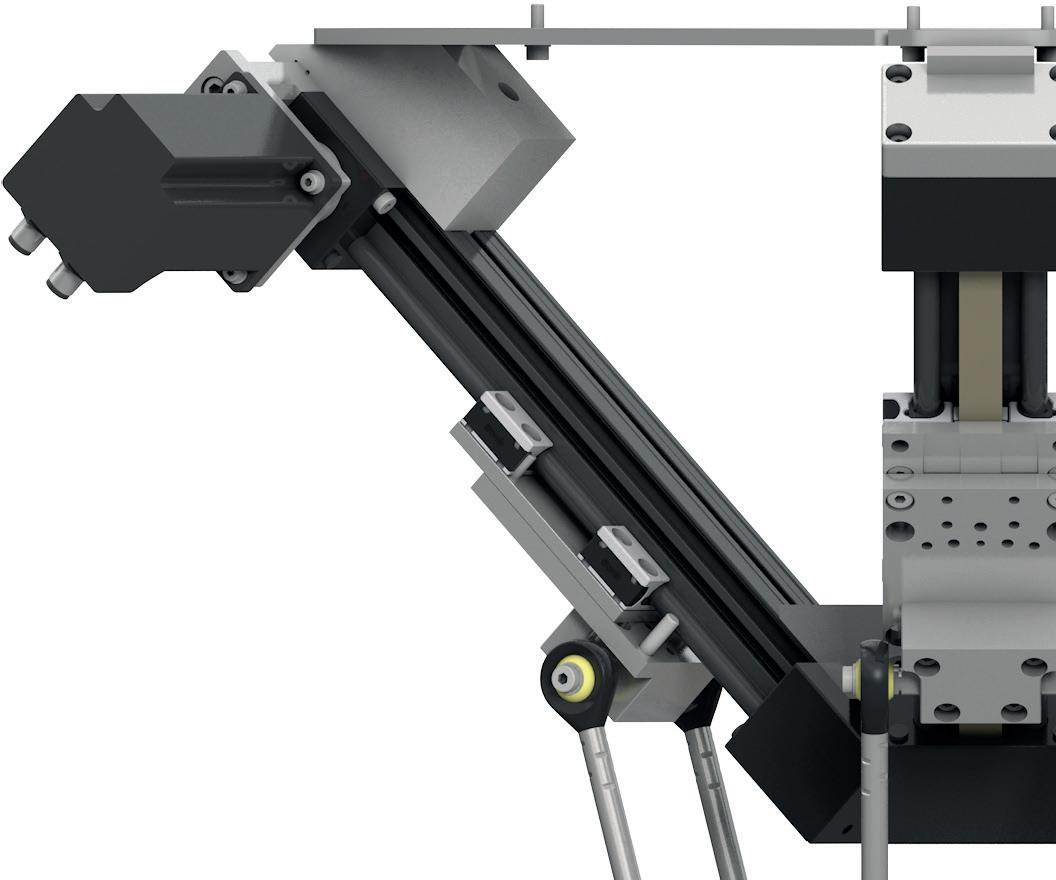

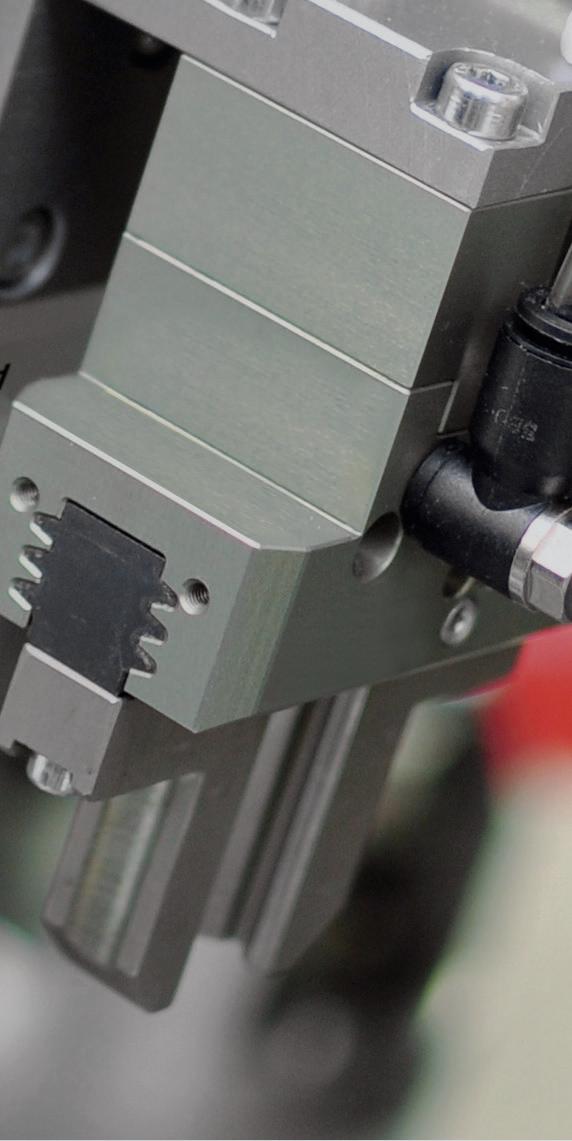

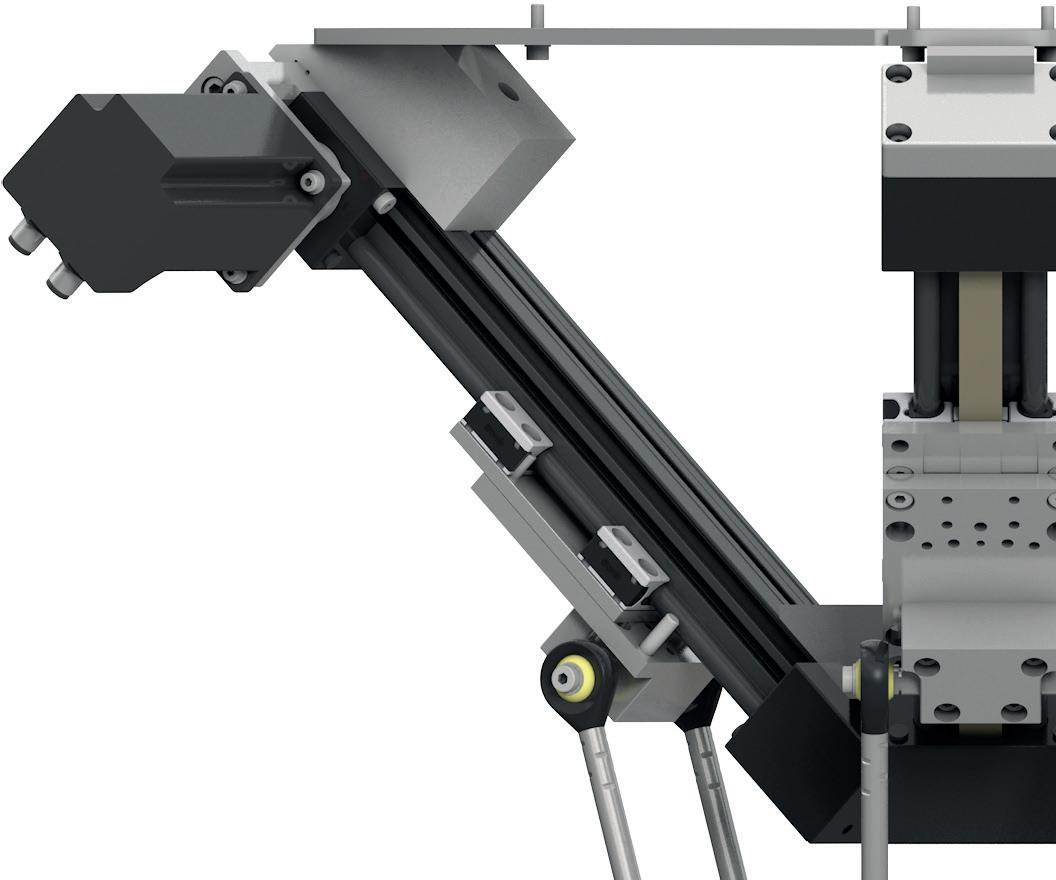

Festo CMMT-ST servo drives are mounted on the robot itself rather than on the gripper system, freeing up space on the gripper and making the design less complicated.

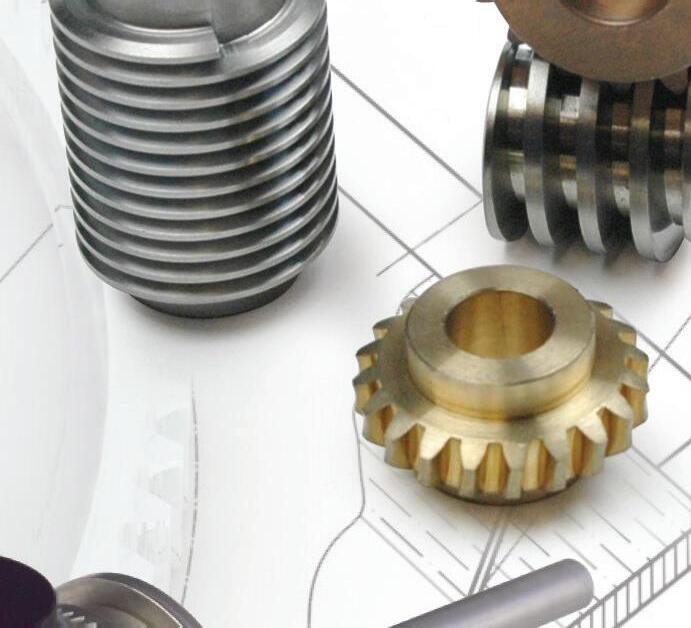

Advanced Products for Robotics and Automation

CGI Motion standard products are designed with customization in mind. Our team of experts will work with you on selecting the optimal base product and craft a unique solution to help di erentiate your product or application. So when you think customization, think standard CGI assemblies.

Connect with us today to explore what CGI Motion can do for you.

copyright©2021 cgi inc. all rights reserved.

CUSTOM SOLUTIONS

YOUR

ARE CGI STANDARD PRODUCTS

800.568.GEAR (4327) • www.cgimotion.com

execute rapid analysis of various gear systems, the optimal speedtorque combination can be quickly determined with high certainty. This lets us design suitable motorgeartrain-system combinations.

What are some new and unique motor applications you’ve recently supported?

Beckstoffer: Brushless dc (BLDC) motors provide operational advantages with their highspeed capability and electronic commutation. In addition, a slotless BLDC design enables rapid acceleration and deceleration due to the self-supporting cylindrical coil design. Short-term circulatory support devices assist the patient’s heart during a cardiac event or surgery, supplementing the pumping of blood throughout the body. The device needs to operate at high speed and be supremely responsive to the sinus rhythm of the heart, making BLDC slotless motors a good solution. The highpower density of these motors also ensures sufficient torque is available to respond to any changes in the patient’s condition.

Gallant: Brushless motors have become much more widely accepted and used over the past few years. Along with that, the development cost has dropped significantly, making them more affordable. We can offer brushless motors with planetary gearboxes as small as 22 mm in diameter. Brushless motors, by design are a little more susceptible to the elements with a better IP rating. We get about 50% of our new-customer requests for brushless motors vs. brushed motors.

found in almost any commercial or industrial application ranging from white goods to robotics to hunting equipment. We offer either planetary, spur, or worm gearboxes on our dc motors. Our motors are either brushed or brushless and coreless options are also available. Our planetary gearmotors can be as small as 12 mm in diameter, and worm gearmotors can get up to over 70 mm in diameter.

Patel: maxon has released a new family of frameless motors designed specifically with dynamic movements in mind. The DT series (Dynamic Torque) can be easily integrated into a range of applications, specifically when it comes to applications where speed can change instantly. The rotor and stator are delivered separately, without bearings or motor shaft, and are connected only during assembly. The features of the EC frameless DT motor series include minimal rotor inertia, excellent heat dissipation, compactness, and extremely simple integration. The flat design, high torques, and space for cable glands allow a high level of integration into a given application.

Gottlieb: Regarding design-based improvements, concentration on flux optimization produces motors such as the Kollmorgen AKM2G, which packs a punch of torque density and higher power in the same package as older generations of servomotors. Or consider the coming release of our AKMA washdown servomotor. It really is solving the problem of the food-grade paint motor being unacceptable in a food environment as the paint may peel but it is much

more economical than the sanitary requirement level of the AKMH hygienic motor. It will hit a real sweet spot.

Luchars: Regarding washdown or corrosive settings, ECM can fully enclose its motors, while keeping them cool, due to the patented qualities of our stators. PCB Stators use both the inactive and active copper in the PCB stator to conduct heat out through the aluminum housing, rather than requiring air to be drawn or blown through the stator windings‚ as occurs in a traditional wire-wound machine.

torque, and accuracy required in gantries. Festo also provides mechanical axes for a one-stop shop of interoperable products.

Luchars: Most brushed motor applications we have seen have been for cost-sensitive consumer goods. These, of course, have increased wear and decreased efficiency, but they are simple and cost-competitive. ECM can quickly use our software design platform, PrintStator, to understand whether a PCB Stator offering would be cost competitive. This saves a lot of time and resources that might

This is beneficial as it radically improves the sealing and protection of the internal motor components to limit the ingress of other foreign objects, debris, or harmful fluids.

Lin: EV battery manufacturers respond to the fact that Festo built its EMMT stepper motors and compact CMMT servo drives for interoperability in complex motion systems. The CMMT drives are compatible with all major Ethernet-based communications protocols for wide applicability. The EMMT/CMMT combination is suitabele for producing the speed,

MEET THE EXPERTS

end up being dedicated to a given project, only to later determine that the technology isn’t a good fit. If a PCB Stator machine is cost competitive, all the drawbacks of a typical brushed machine would be eliminated with a PCB Stator machine. ECM can design various motors, from constant-speed HVAC fans and blowers, to torque motors with resolution and torque requirements. This is another easy task from a modeling perspective to see how the torque production of an ECM machine compares to that of a traditional servo or stepper.

For the last few years, ECM

32 DESIGN WORLD — MOTION 3 • 2023 motioncontroltips.com | designworldonline.com

design world trends

This exploded view shows an ECM motor with a PCB stator used in a handwheel controller for camera control.

Biren Patel | Business development manager, mobility solutions • maxon Chris Gottlieb | Director, drives and control • Kollmorgen Dave Beckstoffer | Business development manager • Porttescap James Gallant | Director of operations • ISL Products International Ltd. Lawrence Lin | EV batteries business development manager • Festo Robert Luchars

| Vice president for business development • ECM PCB Stator Technology

An ECM employee holds a conventional copper wound stator (on the left) and an ECM PCB Stator (on the right) for comparison.