5 minute read

Evaluating isolation techniques in dc/dc converters

Steve Roberts | Recom Power

Different isolation methods give different results. It’s important to know what to expect from converters that separate their input and output in a specific way.

Isolation in dc/dc converters has numerous uses besides just protection against electric shock. There are various grades of isolation that low-power dc/dc converters implement in different ways.

Many dc/dc converters use an internal transformer to electrically (galvanically) separate the output from the input. This separation makes dc/dc converters versatile. Outputs that float with respect to the input prevent ground loops and reduce the potential for noise in electrical systems. Moreover, the output polarity can be freely chosen. And, of course, the isolation barrier can prevent electric shock and reduce other hazards caused by faults.

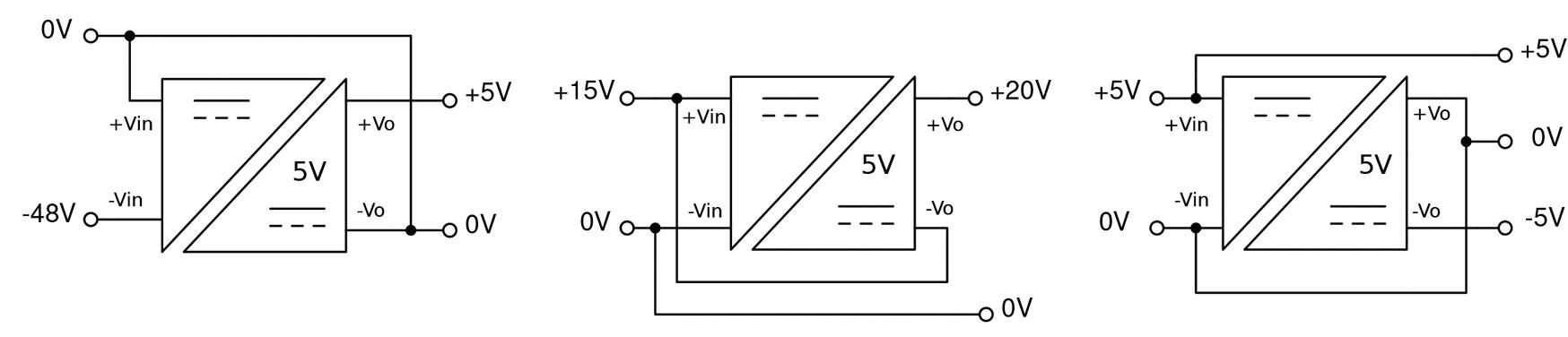

Because the output is isolated from the input, the choice of the ‘zero’ reference voltage for the input or output side is also arbitrary. For example, an isolated dc/dc converter with a 5-V output can be used to change voltage level and polarity (e.g. +5-V out from -48-V in), add to an existing voltage (e.g. generate +20 V from a +15-V supply) or create a dual output from a single supply (e.g. ±5 V from +5 V).

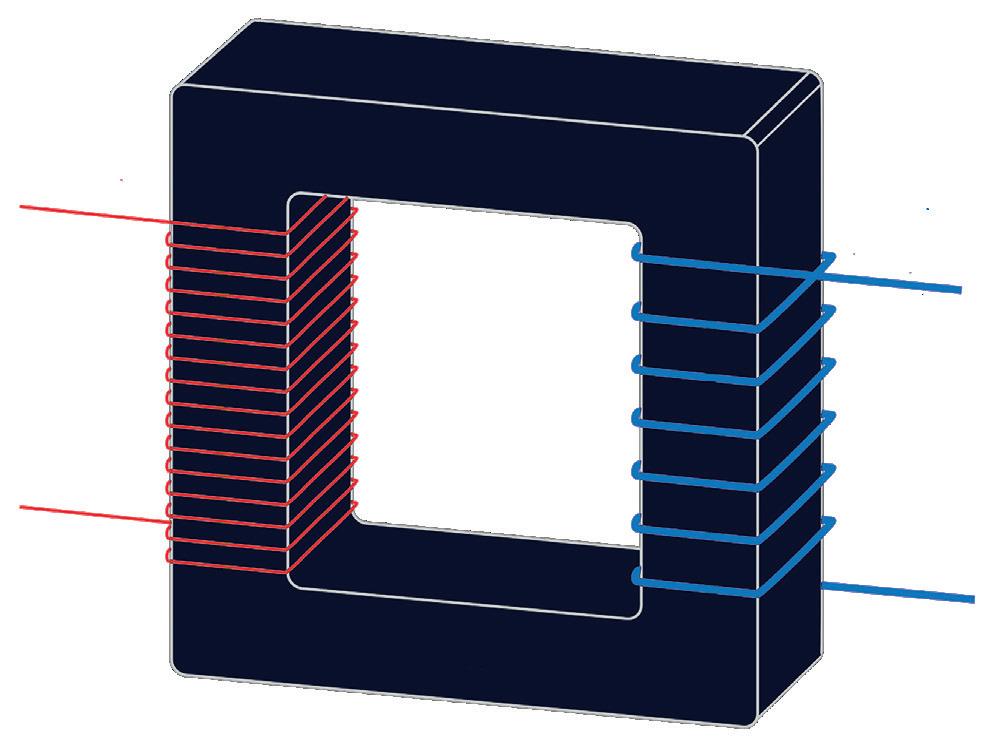

An example of a ring core transformer with functional isolation.

The isolation grade depends on the robustness of the isolation barrier. For dc/dc converters, the most commonly used classes are:

Functional - The output is isolated, but there is no protection against electric shock. Basic - The isolation offers shock protection as long as the barrier is intact.

Supplementary - An additional barrier to basic, required by agencies for redundancy.

Reinforced – A single barrier equivalent to two layers of basic insulation.

The RECOM RP-xxxx series uses potted-core transformer construction to offer 5.2 kVdc isolation test voltage rating in a compact SIP7 package (19.6 x 10.2 x 7 mm). This makes the RP series one of the most reliable high-isolation dc/ dc converters in the RECOM portfolio, used in demanding applications ranging from military aircraft to high-voltage test equipment.

IN AN ISOLATED SUPPLY

It is useful to explore how these classes translate into practical transformer construction. For functional isolation, the transformer primary and secondary windings are typically wound directly over one another, relying on the thickness of the wire lacquer for insulation. This method has the advantage of being inexpensive and yielding a compact transformer which, despite the small size, can withstand up to 4 kVdc isolation testing but with limited duration and as a non-repetitive test.

Typical applications for functional isolation converters include non-safety-critical systems. Here the isolation is primarily used to prevent ground loops, block conducted interference paths, or to provide a change in functional ground reference voltage. In these applications, an isolation fault would not injure anyone or seriously damage the equipment, or (usually) stop the application from working. The isolation helps prevent interference and boosts reliability, but is not safety-related.

A RECOM REM1 medical-grade dc/dc converter in a compact SIP7 case uses a reinforced transformer construction which lets it be medically certified to the IEC/ EN/UL 60601-1 safety standard with 4 kVac/1 min. isolation, 2 x MOPP (Measures of Patient Protection) and 250 Vac working voltage isolation.

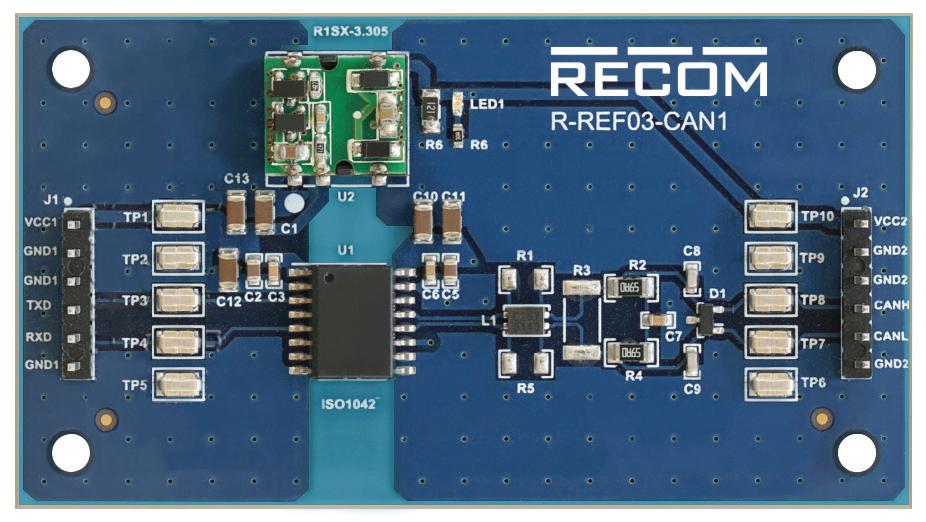

A good example is a CAN-bus data communication system. The CAN-bus specification does not specify that the bus wiring must be isolated. But in practice, isolating the interface eliminates many potential sources of error or interference with the data transmission. As both ends of the bus are isolated, the transmitter and receiver can sit at different ground potentials without problem. Any electrical interference is ignored by the differential bus topology, without the danger of external fields inducing an overall current flow in the wiring. This is one of the reasons why isolated CAN-bus systems are often used in heavy industrial automation plants and production processes.

Examples of isolated dc/dc converter applications include those that invert the polarity of a dc supply, boost a dc output, and provide a ± output from a single supply.

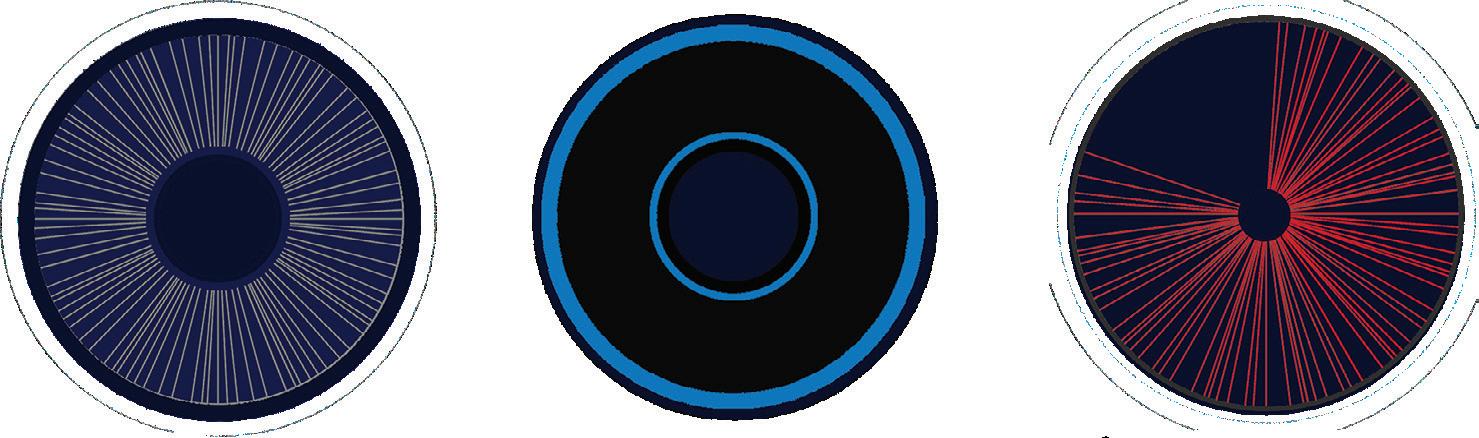

Basic isolation grade requires secure insulation between the primary or secondary windings, rated at the system voltage - lacquer insulation on winding wire is insufficient as pin-holes can be present. In a basic-insulation-grade transformer, the input and output windings are not wound directly over one another, but are separated by a minimum distance or with a physical barrier, such as an agency-approved insulating film. This method can be used in larger transformers where there is enough room to add layers of tape between the windings.

For compact dc/dc converters, it may be a challenge to provide basic isolation without making the transformer too big. One technique uses a separation bridge to physically separate the windings. In addition, manufacturers may coat the ferrite ring core with plastic so it is also independently isolated from the windings.

Another way of making a basic-insulated transformer uses a potted core. In this method of construction, the ferrite core with one winding (usually the primary) is placed in a plastic pot which is then filled with epoxy. A lid is fitted and then the second winding is wound around the whole construction through the hole in the middle. The insulation doesn’t depend on the lacquer around the transformer wires. Instead, it is independently ensured via the plastic pot and epoxy filling.

An evaluation board that uses a RECOM SMD dc/dc converters to provide isolated bus power.

Production processes ensure that the quality and thickness of epoxy and lid meet the minimum agency requirements for basic insulation at the stated system voltage. Although more complex to manufacture, this ‘potted-core’ method gives a very compact transformer with a reliable and consistent insulation performance which does not deteriorate with time.

With reinforced isolation, input and output windings are separated by a larger distance or at least two physical barriers, each equivalent to a basic insulation rating. The multiple layers of insulation make the transformer bulkier, however, which limits the amount of miniaturization possible. One way around this problem is to use triple insulated (TIW) transformer wires which are already classified as offering reinforced insulation.

The RECOM RxxPxx and RxxP2xx series use a bridge-design transformer type of construction which is production-tested up to 6.4 kVdc, in a compact SIP8 package (19.5 x 12.5 x 9.8 mm).

REFERENCES Recom Power, www.recom-power.com