IAM Robotics originally developed a complete solution that included a 3D scanner, enterprise software and mobile manipulator robot.

| IAM RoboticsI recently reported on IAM Robotics launching an automated solution designed for person-to-goods (P2G) warehouse workflow. The company is entering a new chapter focused on the hottest segment of autonomous mobile robot (AMR) applications and one that has already been proven through the efforts of companies like Locus Robotics and 6 River Systems.

The rebirth of IAM Robotics is significant because it is the latest chapter in what was a valiant attempt to commercialize mobile manipulators. It’s also a poignant lesson in failed market fit and knowing when to pivot as a robotics startup.

A classic garage startup

IAM Robotics started in Vlad Altman’s Pittsburgh basement and quickly moved to a local township garage building to model a working warehouse. Co-founder Tom Galuzzo had a passion for mobile robots and a robotics degree om Carnegie Mellon University. At the time, the idea of putting a robot arm onto a mobile platform and using it to pick items om shelves was one of the remaining “holy grail” challenges in robotics.

It was also a year a er Amazon’s historic acquisition of Kiva Systems for $775 million – the potential for robotics in warehousing was in the spotlight. It took until 2015 for IAM Robotics to raise its first seed round and introduce its Swi robot on the promise of automated picking in the warehouse.

This was when IAM Robotics first appeared on my radar as an innovative solution for goods-to-person workflows in the warehouse. At the time, I was leading product management for the mobile robot business at Adept Technology, and no other vendor in the market was commercializing a mobile manipulator for warehousing applications.

The company was pushing the boundaries of robotics technology, simultaneously solving the problems of vision-guided mobile manipulation and developing strategies for AMR perception, obstacle avoidance, and the challenges of battery-supported operations.

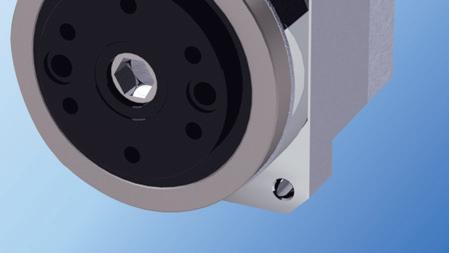

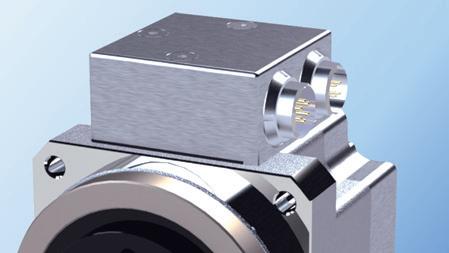

The IDT Series is a family of compact actuators with an integrated servo drive with CANopen® communication. They deliver high torque with exceptional accuracy and repeatability, and feature Harmonic Drive® precision strain wave gears combined with a brushless servomotor. Some models are available with a brake and two magnetic absolute encoders with the second providing output position sensing. This revolutionary product line eliminates the need for an external drive and greatly simplifies cabling, yet delivers high-positional accuracy and torsional stiffness with a compact form factor.

• Actuator with Integrated Servo Drive utilizing CANopen®

• 24 or 48 VDC nominal supply voltage

• A single cable with only 4 conductors is needed: CANH, CANL, +VDC, 0VDC

• Zero Backlash Harmonic Drive® Gearing

• Panel Mount Connectors or Pigtail Cables Available with Radial and Axial Options

• Control Modes include: Torque, Velocity, and Position Control, CSP, CSV, CST

What immediately struck me about the Swift robot was that it didn’t pick up individual items from bulk SKU bins stored in the warehouse. Rather, it worked by picking from stock that was stored in organized rows on a shelf, not unlike what you might see in the frontof-house retail space of your corner drugstore.

I had never seen a warehouse space with products organized in neat product rows like this, and that was my first red flag about the viability of Swift. To make the system work, Swift required a 3D model of each product SKU. With the 3D model, the robot’s vision system could then identify the item on the shelf and determine the correct pose of the robot to acquire the item.

The company developed a novel 3D item scanning station called “Flash” that would ingest a new product SKU, image it and add it to the 3D library of items that Swift could now handle.

To function properly, Swift also had to autonomously handle product replenishment, putting items onto the warehouse shelves in those neat and organized rows. The idea to replenish the shelves autonomously looked great on an ROI spreadsheet, but Swift wasn’t fast

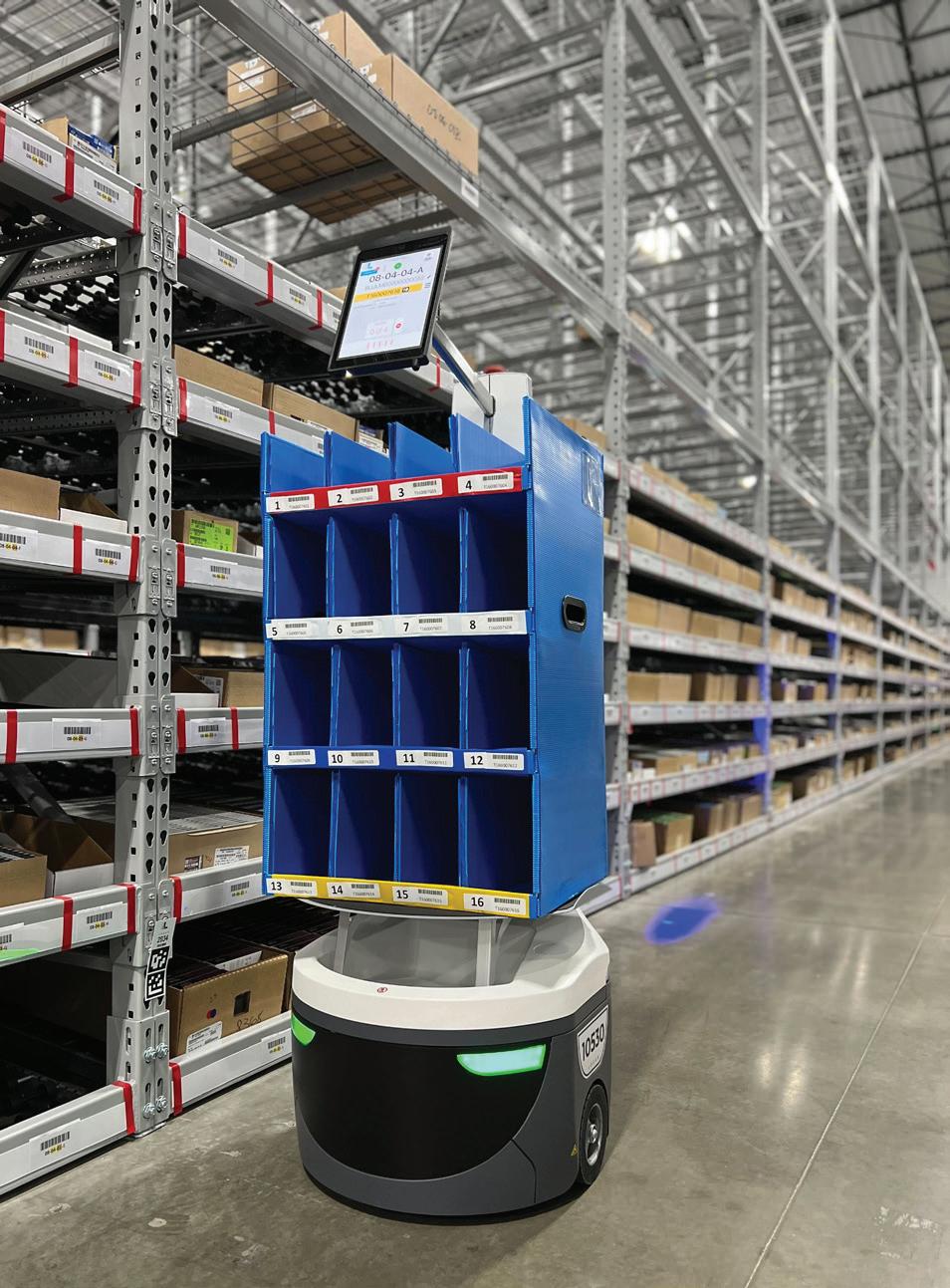

IAM Robotics’ new solution directs the human associates with information about which item to pick and where to place the item for a customer order. The Lumabot then moves items to a pack-out station.

enough (compared to human warehouse associates) at replenishing the shelves in the real world. It also couldn’t easily work side-by-side with human associates in warehouse aisles due to its working dimensions.

Another concern for the viability of Swift was that the target segment of “warehouses with highly organized shelves” was just too small. The majority of warehouses and distribution centers store bulk items contained in bins or boxes on the warehouse shelves. Bulk storage is simply the most efficient and cost-effective method of using precious warehouse space.

Lastly, the inability of Swift to pick items from bins (the “holy grail” application) ultimately sealed its fate. In the warehouse, humans are very adept at pulling individual items from bulk storage. This realization led the company to rethink its portfolio.

Creation of an AMR platform

Fast forward to 2020, and IAM Robotics made the first pivot with the design and launch of its Bolt AMR, using all of the knowledge and experience gained from engineering Swift. The goal of Bolt was to offer a standard AMR base that could be deployed into any AMR application. This

was a competitive market with a large number of established vendors, including companies like OMRON, Fetch Robotics, MiR, OTTO Motors and others.

Unfortunately, this was also the start of the pandemic. While e-commerce was exploding in popularity (along with the demand for automated support for warehouse labor shortages), there were also hundreds of AMR competitors on the market with standard AMR platforms. The novel innovation for Bolt was a swappable battery that could be quickly changed with minimal downtime of the AMR. But it wasn’t enough.

In 2021, the company restructured, hired CEO Lance Vandenbrook, let go of many of the original mobile manipulation-focused engineering teams, hired the necessary enterprise so ware engineering team and entered a self-imposed “stealth mode” to retool.

The company recently re-emerged with a new person-to-goods (P2G) warehouse workflow, leveraging all of the intellectual property om its early days in AMR development and adding a new, robust, fully featured enterprise workflow layer on top.

The new Pyxis (pronounced pix-us) solution is designed to be competitive with existing P2G solutions such as Locus Robotics and 6 River Systems. The focus for IAM Robotics has changed om being a mobile robotics company to a warehouse workflow company, managing the tasks of both human associates and mobile robots.

The company launched a new AMR called Lumabot, taking the Bolt AMR base and outfitting it with a payload of fixed shelves and pick/put-to-light

guides. Human associates interface with the solution through a wearable that communicates customer orders, quantity and SKU locations.

Lumabot robots move autonomously to the pick location where humans pull individual items om bins and place them in outgoing customer order bins. The Lumabots then take assembled customer orders to pack out stations for final consolidation, packaging and labeling.

The Pyxis solution manages the operations of all of the human associates in the warehouse, together with the fleet of Lumabots to manage customer order picking and consolidation. The system is designed to be deployed in either greenfield or brownfield opportunities and offered as a robots-as-a-service (RaaS) business model. RR

These connectors deliver exceptional performance in harsh environments, ensuring long-lasting durability. Whether in industrial automation, medical robotics, or for Rovers and Legged Robots, LEMO connectors provide the ability to connect sensors, actuators, and control systems seamlessly.

• Light weight

• Durable

• Compact

• Ergonomic

At the beginning of the pandemic, the team at ABB Optical struggled with recruiting new associates to perform their manual warehouse processes. Here’s how Locus Robotics came to the rescue.

ABB Optical Group is a leading provider of optical products, services, and business solutions in the eye care industry. They operate through three business pillars: ABB Contact Lens, ABB Labs, and ABB Business Solutions.

ABB is focused on the future of eye care professionals, helping them succeed by making practices more efficient and assisting providers to effectively navigate market changes. ABB Optical is headquartered in Coral Springs, Florida and most recently opened a National Logistics Center in Hebron, Kentucky.

At the beginning of the pandemic, the team at ABB Optical struggled with recruiting new associates to perform their manual warehouse processes. They looked at a number of automation solutions to improve their productivity

and employee satisfaction while ensuring the right item is picked and packed for customers.

“We looked at A-frame automatic dispenses and pickto-light systems, but space constraints were a factor,” said Tom Calhoun, senior vice president of operations, ABB Optical. “One of my colleagues knew someone in the automotive industry that used LocusBots, so we went to see them, and it just made sense for our warehouse.”

Quick implementation speed and cost efficiency were also important points of consideration for ABB Optical when selecting an automation solution.

Locus Robotics, a Wilimington, Mass.-based developer of autonomous mobile robots (AMRs), deployed a warehouse execution platform and 114 AMRs along with a suite of dashboards

Locus Robotics recently announced its AMRs have picked more than two billion units, reinforcing its position as a leading robotics provider for the warehouse and logistics industry.

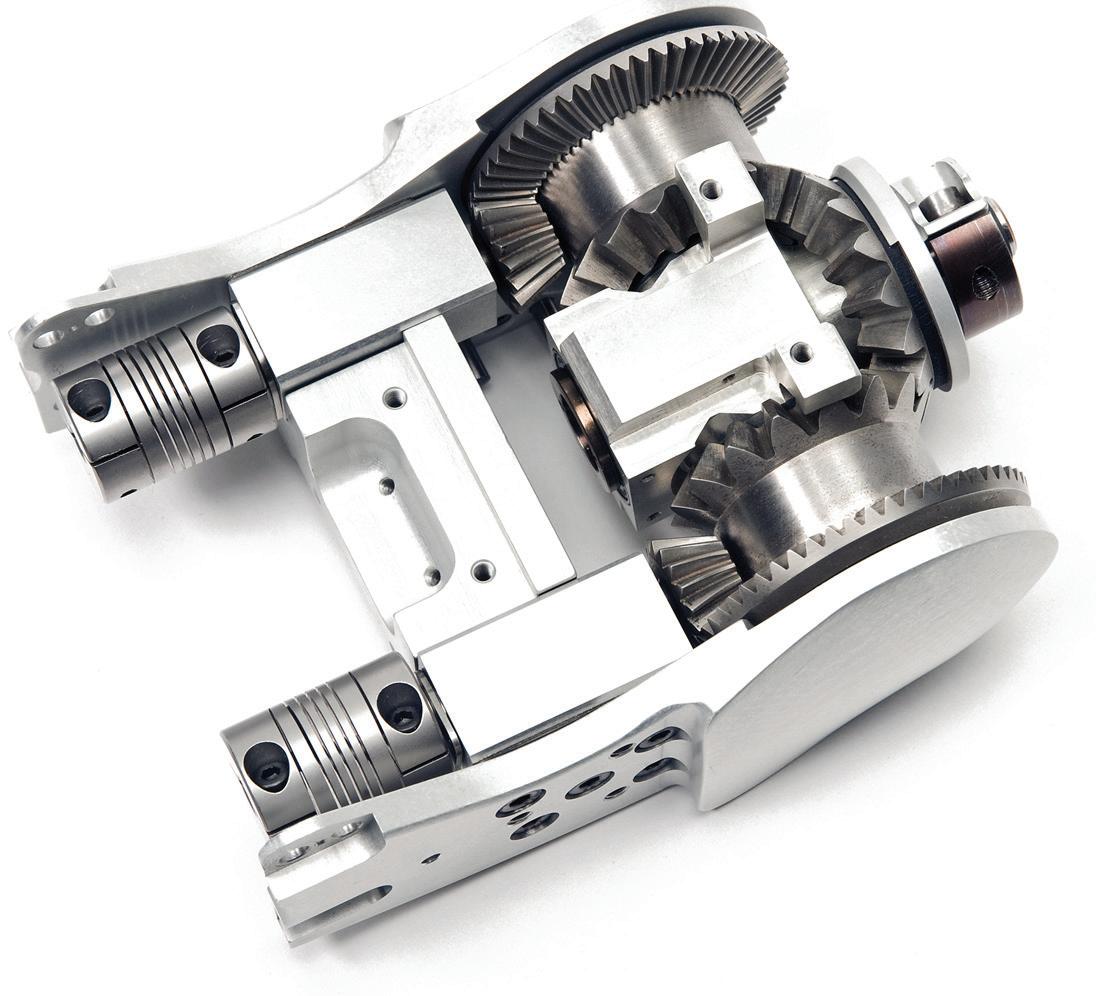

CGI Motion standard products are designed with customization in mind. Our team of experts will work with you on selecting the optimal base product and craft a unique solution to help di erentiate your product or application. So when you think customization, think standard CGI assemblies.

Connect with us today to explore what CGI Motion can do for you. copyright©2021

and actionable reporting tools at ABB Optical’s warehouses, including its National Logistics Center in Hebron, KY in October of 2022.

The Locus Robotics Origin is an intelligent autonomous mobile robot (AMR) that’s designed specifically for collaborative, high volume order fulfillment. It can carry up to 80 lbs. (36 kg.)

The Kentucky warehouse (100,000 square feet and holding 160,000 SKUs) was built with input from Locus to be a Locus-centric facility down to the aisle width that works best with LocusBots. “Locus Robotics has been a great partner as we make changes, and their help has been beneficial,” stated Calhoun.

In the healthcare industry, it’s crucial to capture lot numbers in real time for compliance. With Locus Robotics, ABB Optical tracks that information and ensures that the right item is picked out of the over 160,000 different SKUs they carry. Before choosing the Locus solution, ABB Optical had an order accuracy rate of well above 95%. Now, with the LocusBots, the accuracy rate is at 98%. LocusBots helped workers improve their average to 250+ units per hour (UPH), with some exceeding 500 UPH.

The warehouse associates at ABB Optical find it easy to work with the LocusBots as the displays are available in multiple languages like English or Spanish. These associates have told Calhoun that they have the easiest position in the warehouse, because the bots are selfexplanatory and simple to use.

The team plans to implement zone picking, which will enable associates to stay in one area instead of walking throughout the large warehouse. “The Locus Robotics solution is cost-efficient and provides real-time information on what’s moving and not moving to plan accordingly,” said Calhoun.

Locus Robotics recently announced that its AMRs have now picked more than two billion units, reinforcing the company’s position as a leading robotics provider for the warehouse and logistics industry. This new milestone comes just 11 months after reaching the industry-first landmark of 1 billion picks.

“Achieving the two billion picks milestone is an incredible accomplishment for our company and for our customers,” said Rick Faulk, CEO of Locus Robotics. “This event is a testament to the dedication and innovation of our incredible team and the dramatic productivity improvements we deliver to drive our customers’ growth and success.”

Reaching this milestone took just 358 days, with the last 100 million picks taking just 27 days – an average of 3.7 million picks per day. By comparison, it took more than six years to make the first billion picks, and 1,542 days to pick the first 100 million units. LocusBots have now traveled more than 37 million miles in customers’

| Locus Robotics

warehouses, the equivalent of more than 1,370 times around the Earth or 77 round trips to the Moon.

“Achieving the remarkable milestone of two billion picks demonstrates how Locus’s intelligent automation solution can transform warehouse operations,” said Keith Price, CIO of Concordance Healthcare, “We look forward to continuing to work with the Locus team to leverage the power of advanced robotics and automation to drive even greater warehouse fulfillment optimization in the years ahead.”

“Locus’s consistent innovation, user-centric approach, and genuine dedication to customer relationships puts them at the forefront of warehouse automation,” said Alan McDonald, vice president of continuous improvement at GEODIS. “This milestone is a testament to its technological leadership and synergistic collaboration. We look forward to building on our work together and driving even greater efficiency improvements in the future.”

The AI and data science-driven LocusOne platform serves as an enterprise-level fleet manager, overseeing complex warehouse

fulfillment workflows that support diverse use cases, clustering tasks to create optimal robot missions and reduce unproductive worker walking time. Locus’s unique multibot approach decouples workers from orders and tasks to dramatically improve worker productivity.

Proven at enterprise scale, laborchallenged 3PL, retail, health care, and manufacturing operators can seamlessly add robots to increase capacity or meet growth in any operation in just minutes to optimize productivity in their operations, reduce costs, and stay competitive in the rapidly evolving e-commerce landscape.

The LocusOne warehouse automation execution platform enables the orchestration of multiple robotic form factors at enterprise-scale within a single coordinated platform. It provides real-time optimization of tasks to be completed within the four walls and across multiple levels in warehousing and manufacturing environments. LocusOne optimizes robotic task allocation, route planning, and resource use, while delivering realtime business insights into warehouse operations.

Locus won an RBR50 Robotics Innovation Award earlier this year for surpassing the 1 billion pick milestone, which it achieved in September 2022. The milestone pick was made at a home improvement retailer warehouse in Florida, where a LocusBot picked a cordless rotary tool kit. Locus completed its billionth pick just 59 days after hitting its 900 millionth pick. To put this into perspective, it took Locus 1,542 days to pick its first 100 million picks.

Retailers and fulfillment warehouse operators are increasingly turning to AMRs to meet growing demand and mitigate labor shortages. Cost-efficient robots are a must-have as e-commerce volumes continue to increase.

And having been deployed at more than 200 sites worldwide, with some sites using as many as 500 LocusBots, Locus is a leading AMR provider that continues to create critical business value for its customers around the world, every day. RR

A Fluid Power World series of webinars focused on mobile hydraulic technologies.

Fluid power technologies are crucial in providing the power density, reliability and control required for mobile machinery. Fundamental Fridays is your platform to highlight technical solutions that enable OEMs to efficiently power, control and regulate machinery, especially as our industry responds to the need for more efficient and sustainable systems.

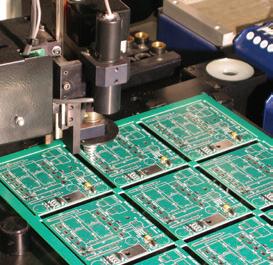

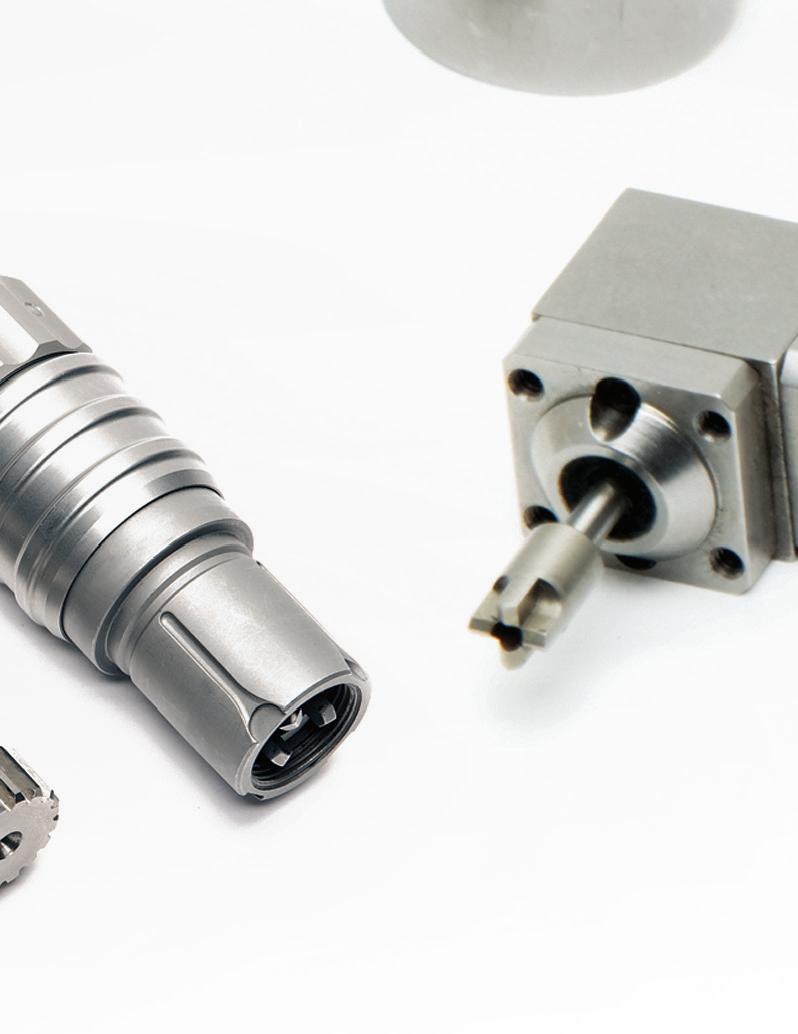

At CGI we serve a wide array of industries including medical, robotics, aerospace, defense, semiconductor, industrial automation, motion control, and many others. Our core business is manufacturing precision motion control solutions.

CGI’s diverse customer base and wide range of applications have earned us a reputation for quality, reliability, and flexibility. One of the distinct competitive advantages we are able to provide our customers is an engineering team that is knowledgeable and easy to work with. CGI is certified to ISO9001 and ISO13485 quality management systems. In addition, we are FDA and AS9100 compliant. Our unique quality control environment is weaved into the fabric of our manufacturing facility. We work daily with customers who demand both precision and rapid turnarounds.

CGI Inc. 3400 Arrowhead Drive Carson City, NV 89706

Toll Free: 1.800.568.4327

Ph: 1.775.882.3422

Fx: 1.775.882.9599

WWW.CGIMOTION.COM

GAM GAM

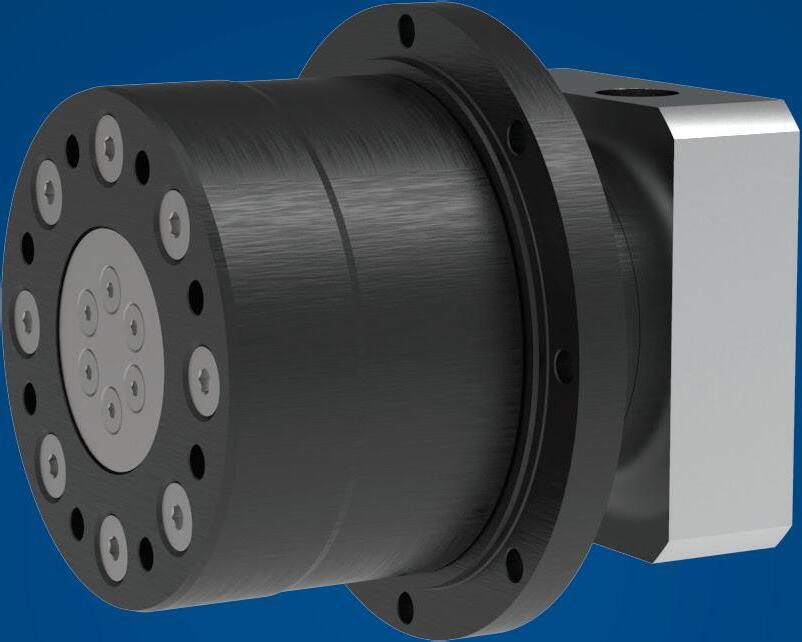

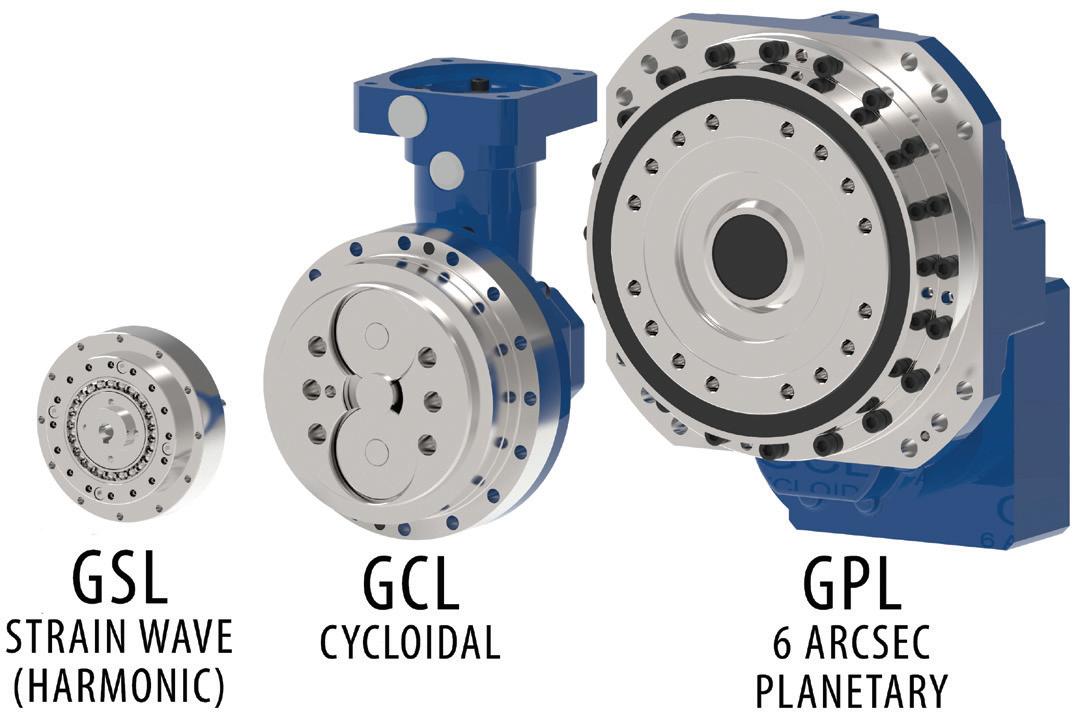

GAM provides a full range of robotic flange gearboxes

GAM’s extensive product offering includes three different flange gearboxes: Strain Wave (harmonic), Cycloidal, and the revolutionary Zero-Backlash Planetary. The GAM GPL zero-backlash planetary gearbox features a unique design ensuring backlash of ≤ 0.1 arcmin for the life of the gearbox. The GPL provides vibration-free motion and high positional accuracy for precise smooth path control and repeatability with a life of 20,000 hours. The GCL cycloidal gearbox provides precise point-to-point motion and high impact resistance of 5x nominal torque with the option of an integral pre-stage. The GSL strain wave gearbox uses harmonic-type gearing for high accuracy and drops in for popular competitor gearboxes. With three options, GAM can provide the zero-backlash gearbox for your precision application.

The SHA-IDT Series is a family of compact actuators that deliver high torque with exceptional accuracy and repeatability. These hollow shaft servo actuators feature Harmonic Drive® precision strain wave gears combined with a brushless servomotor, a brake, two magnetic absolute encoders and an integrated servo drive with CANopen® communication. This revolutionary product eliminates the need for an external drive and greatly simplifies cabling yet delivers high-positional accuracy and torsional stiffness in a compact housing.

www.Harmonicdrive.net

LEMO® is the industry leader in the design and production of precise custom interconnect systems. LEMO products are designed and manufactured according to rigorous and controlled processes. Inspection and traceability of products are systematically ensured in compliance with our standards. High-quality LEMO Push-Pull connectors are used in a wide range of challenging application environments, such as medical, test & measurement, research, defense & military, information systems, aerospace & autonomous vehicles, robotics, automotive, industrial control, nuclear, broadcast & audio-video, and communications.

https://www.harmonicdrive.net/products/rotary-actuators/integrated-actuators/sha-integrat

LEMO® has been designing precision connectors for over seven decades. Offering more than 90,000 combinations of products that continue to grow through customer-specific designs, LEMO® and its brands REDEL®, NORTHWIRE®, and COELVER® currently serve more than 100,000 customers in over 80 countries around the world.

LEMO USA, Inc. 635 Park Ct. Rohnert Park, California 94928

Ph: 707.578.8811

E-mail: info_us@lemo.com

Website: https://www.lemo.com/en

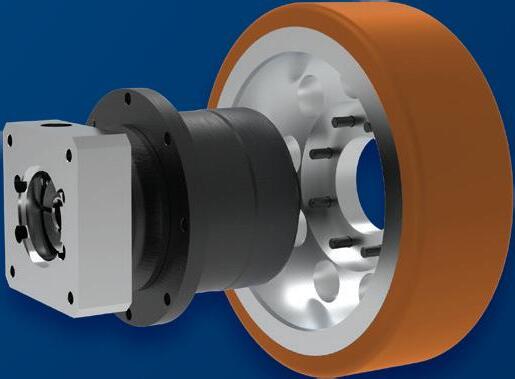

An automated guided vehicle (AGV) needs to do the job it is programmed to do; without error, quickly and efficiently

Motors for AGVs must be reliable and low maintenance and they need to be capable of being in operation 24/7 without loss of functionality.

What type of motor do you need for your AGV?

That depends on the type and size of the automated guided vehicle you have, and how much weight it will be expected to transfer at any one time. A motor that is too small won’t be able to function – or at least not for long – and one that is too big and powerful could cause functionality issues. The recommended motors for AGVs are brushless DC motors - they are powerful, quieter and low maintenance.

Parvalux’s brushless motors rarely need maintenance, and are highly efficient with a high starting torque, which means they are consistent in speed. This enables the timings of build on production lines and delivery times to be assessed more accurately. This makes reporting and assessing capacity for the warehouse easier.

Find out more at www.parvalux.com

Renishaw’s FORTiS™ delivers superior repeatability, reduced hysteresis, and improved measurement performance due to an innovative non-contact mechanical design that does not require a mechanical guidance carriage. It provides high resistance to the ingress of liquids and solid debris contaminants. It features an extruded enclosure with longitudinally attached interlocking lip seals and sealed end caps. The readhead body is joined to a sealed optical unit by a blade, which travels through the lip seals along the length of the encoder. Linear axis movement causes the readhead and optics to traverse the encoder’s absolute scale (which is fixed to the inside of the enclosure), without mechanical contact.

Parvalux 125 Dever Drive Taunton, MA 02780 USA

Phone: +1/508-916-6620

email: sales.us@parvalux.com

website: www.parvalux.com

Renishaw, Inc.

1001 Wesemann Dr. West Dundee, IL, 60118

Phone: 847-286-9953

email: usa@renishaw.com

website: www.renishaw.com