RE+ 2023

2023 Pack - 88 Pieces

As North America’s most diversified steel and steel products company, Nucor is committed to delivering quality, on-time reliability, and sustainability to the renewable energy market. Our Energy Solutions team is your partner in optimizing the design and installation of your next solar and wind projects.

Let’s work together to make your next project a success. nucor.com/energy-solutions

PUBLISHER

Courtney Nagle cseel@wtwhmedia.com 440.523.1685

EDITORIAL

Editor in Chief Kelly Pickerel kpickerel@wtwhmedia.com @SolarKellyP

Managing Editor Kelsey Misbrener kmisbrener@wtwhmedia.com @SolarKelseyM

Senior Editor Billy Ludt bludt@wtwhmedia.com @SolarBillyL

CREATIVE SERVICES & PRINT PRODUCTION

VP of Creative Services Mark Rook mrook@wtwhmedia.com

VP/Senior Art Director Matthew Claney mclaney@wtwhmedia.com

Art Director Allison Washko awashko@wtwhmedia.com

Senior Graphic Designer Mariel Evans mevans@wtwhmedia.com

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist

Jamila Milton jmilton@wtwhmedia.com

MARKETING

VP of Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

Digital Marketing Coordinator Emily Gillespie egillespie@wtwhmedia.com

Digital Production/ Marketing Designer Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Webinar Manager Matt Boblett mboblett@wtwhmedia.com

Webinar Coordinator Halle Sibly hkirsh@wtwhmedia.com

ONLINE DEVELOPMENT & PRODUCTION

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com

Digital Media Manager Patrick Curran pcurran@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Front End Developer Melissa Annand mannand@wtwhmedia.com

Digital Production Specialist Nicole Lender nlender@wtwhmedia.com

Digital Production Specialist

Elise Ondak eondak@wtwhmedia.com

VIDEO SERVICES

Videographer Garrett McCafferty gmcca erty@wtwhmedia.com

Videographer Kara Singleton ksingleton@wtwhmedia.com

IN-PERSON EVENTS

Events Manager Jennifer Kolasky jkolasky@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

Events Manager Brittany Belko bbelko@wtwhmedia.com

CUSTOMER SERVICE

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service

Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

When the IRA was passed in 2022, it was pretty clear the solar industry was going to play an important role in this presidential administration. But seeing the president and vice president attend new solar factory openings over the summer to highlight their accomplishments really underscored that point.

In June, Vice President Kamala Harris attended an event at Qcells’ solar panel factory in Dalton, Georgia, to announce a deal between Qcells and community solar developer Summit Ridge Energy. Summit Ridge and Qcells entered a 1.2-GW module supply agreement that will boost community solar in the United States using mostly American-made panels.

“Since taking office, our administration has made the largest investment in solar energy in our nation’s history,” Harris said in Georgia. “We’ve strengthened domestic supply chains to make sure America has reliable access to parts and material to build a clean energy technology and economy. We provided tax credits to encourage companies to buy solar panels made in America. And we invested billions more to build and expand factories like this one.”

Following Vice President Harris’ visit, Enphase announced a special guest at its big U.S. manufacturing press conference in West Columbia, South Carolina. President Joe Biden joined the inverter maker in July to

kick off a contract manufacturing partnership with Flex to make U.S. microinverters.

“Since I took office, we’ve seen over 60 domestic manufacturing announcements all across the solar supply chain,” Biden said at the event. “By 2035, all electricity in America is going to be generated by clean energy — that’s a big deal.”

The IRA’s tax credits have indeed prompted a rush of U.S. solar manufacturing moves. In the past few months, solar panel and cell factory announcements have steadily rolled in, from Meyer Burger, Heliene, Canadian Solar and others. Mounting manufacturers too, like Nextracker and Array Technologies, have been expanding U.S. operations; while inverter announcements are lagging. It’s too soon to tell if some of these announcements will come to fruition, but the momentum is clear.

Another sign of a booming industry — this year’s biggest solar conference, RE+ in Las Vegas, is expecting another record-setting year, with upwards of 27,000 attendees. The solar industry is in this position thanks in large part to the IRA.

In this issue, we put together a special RE+ preview of the new products coming to the show

floor at The Venetian Convention & Expo Center and Caesars Forum. We also have stories about the other solar components helping contractors reach domestic content bonus requirements, and where the IRA stands on its one-year anniversary. It’s an exciting time to work in solar, and Team SPW is looking forward to catching up with many of you in person at RE+! SPW

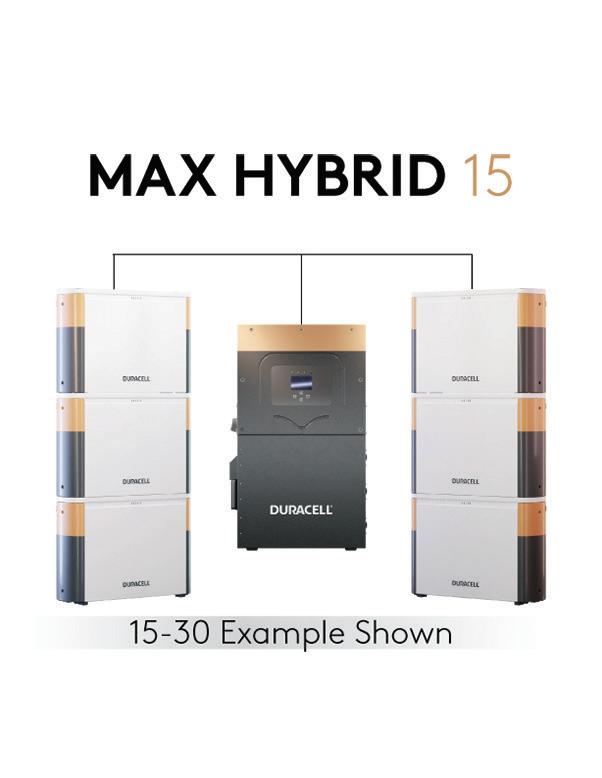

All-in-one solution for DC-coupled and AC-coupled systems

Battery ready feature for future battery storage extension

Integrate diesel generator to charge battery for optimal energy management

Backup power for home with dark start feature

Support multiple energy management modes

Comply with UL1741SA/SB, CA Rule 21&HECO

The solar industry’s largest tradeshow returns to Las Vegas in 2023. Check out our RE+ product preview to help navigate the show floor or see what you might be missing if you can’t make it to the desert. PAGE 63

Michigan’s largest utility agrees to raise distributed generation cap by 5%

Michigan utility DTE Energy reached an agreement with clean energy organizations including Vote Solar to raise its distributed generation cap from 1 to 6%. The plan was approved by the Michigan Public Service Commission on July 26 and could bring an additional 3.8 GW of clean energy to the grid by 2030.

statewide VPP program

The California Energy Commission approved a new statewide virtual power plant program to help boost the grid in times of high energy need. Homeowners and businesses with storage systems can opt-in to the program for a financial incentive, which has not yet been determined.

Two Republican state representatives introduced a bill in Ohio that would allow for the development of community solar facilities under a statewide pilot program. HB 197 would pave the way for 1,500 MW of community solar and award special grants to brownfield projects in the Buckeye State.

Does it feel like you’re rolling the dice when installing central inverters at solar sites? If something goes wrong, it can mean long waits for repairs by manufacturer’s technicians. Meanwhile, a significant piece of your site is not producing power.

Designed to work with solar sites from 2MW to 2GW, CPS America 250/275kW 3-phase string inverters take the chance www.chintpowersystems.com

out of energy harvest. Minimizing harvest loss and service wait times, the CPS 250/275kW inverter gets you back up and running quickly if maintenance is required.

And from design to service, CPS America has your back with a knowledgeable, responsive sales, application engineering, and service support team.

ST. PAUL, MINNESOTA

Gov. Tim Walz signed a bill into law that includes an $80 million investment in solar and energy storage incentive programs for the state of Minnesota. The law also expands the state’s Community Solar Garden program and adds new requirements for utilities to procure distributed solar.

WASHINGTON, D.C.

More than 125 groups are urging the U.S. Bureau of Reclamation to deploy solar power above the nearly 8,000 miles of canals owned and operated by the federal government. The groups say this effort would both generate clean power and reduce evaporative water loss due to climate change-induced droughts.

WASHINGTON, D.C.

FERC released a final ruling on new interconnection reforms meant to clear the backlog and prevent discrimination against certain energy sources. SEIA said the new rules will make it easier to add energy storage to projects that are already in the interconnection queue, an attractive proposition thanks to new IRA storage incentives.

WASHINGTON, D.C.

The Internal Revenue Service issued proposed regulations and frequently asked questions about the direct pay and transferability options in the Inflation Reduction Act. The guidance outlines who can go after these incentives and how to claim them on tax returns.

WASHINGTON, D.C.

The White House Council on Environmental Quality released a proposed rule that would accelerate environmental reviews and permitting in the interest of deploying more renewable energy on federal lands. The rule also aims to encourage early community engagement with new projects.

IREC released its Freeing the Grid interconnection grades, which rate each state in the nation on the quality of its interconnection policies. Of the 39 states and territories that have statewide interconnection procedures, only New Mexico received an A for its interconnection rules.

WASHINGTON, D.C.

The Dept. of Energy announced 12 projects selected for negotiation to launch training partnerships that expand the solar energy workforce in underserved and underrepresented communities across the country. The projects include two SPW Top Solar Contractors and the Amicus O&M Cooperative.

WASHINGTON, D.C.

The House Ways and Means Committee has proposed a repeal of the Inflation Reduction Act in its Build It in America Act. It’s unlikely to advance, but it’s the second attempt by the Republican-led House of Representatives to repeal the IRA this year.

The N.C. Clean Energy Technology Center found in its latest policy report that more state policymakers than ever are addressing equity issues through distributed solar programs and rate design. The report also found many states had developed new iterations of community solar programs in Q2 2023.

FERC interconnection reforms aim to increase efficiency, prevent energy source discriminationTHE UNITED STATES THE UNITED STATES

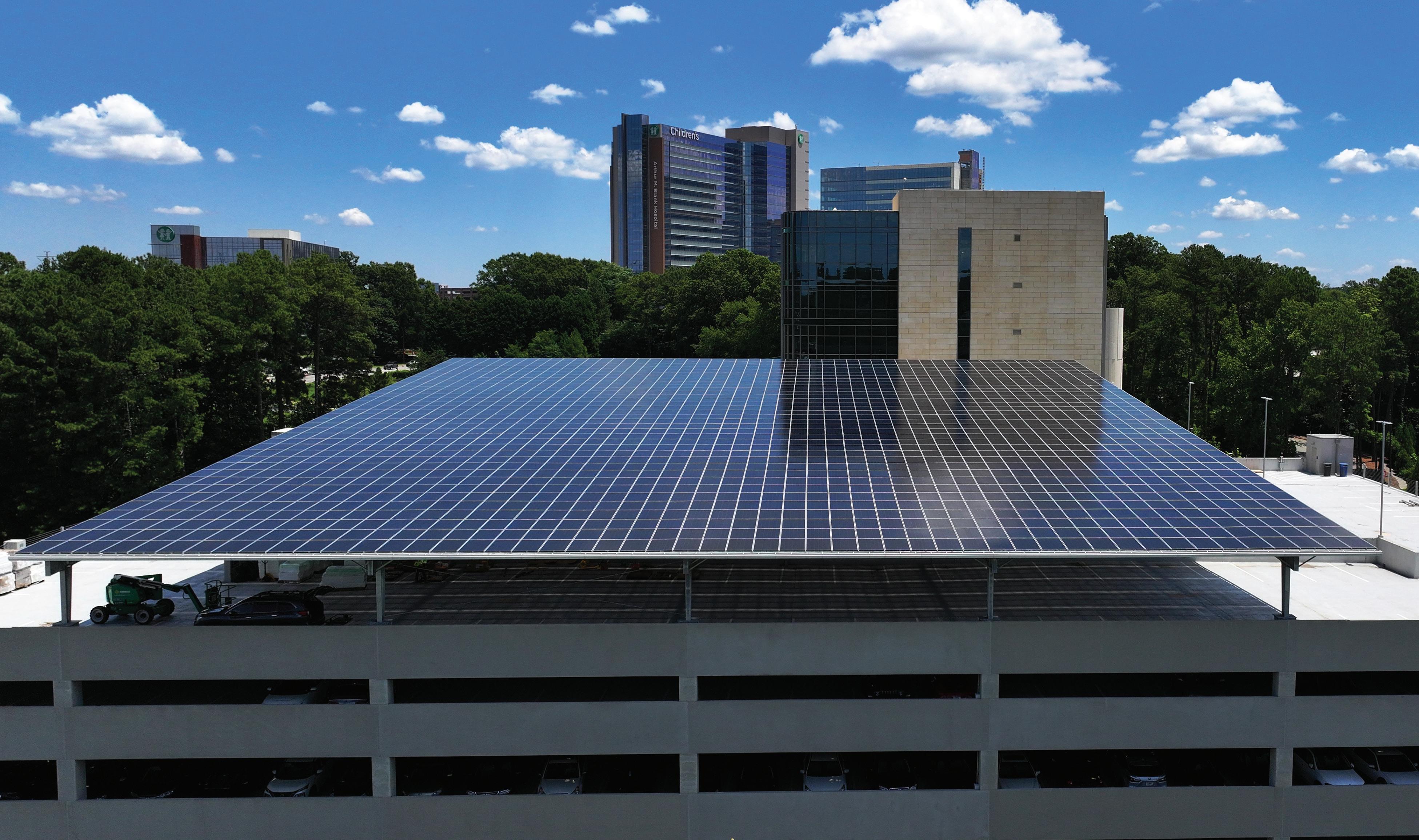

QUEST RENEWABLES DELIVERS AWARD WINNING SOLUTIONS WITH SUPERIOR AESTHETICS, INDUSTRY-LEADING SAFETY, AND TOTAL PROJECT EFFICIENCY

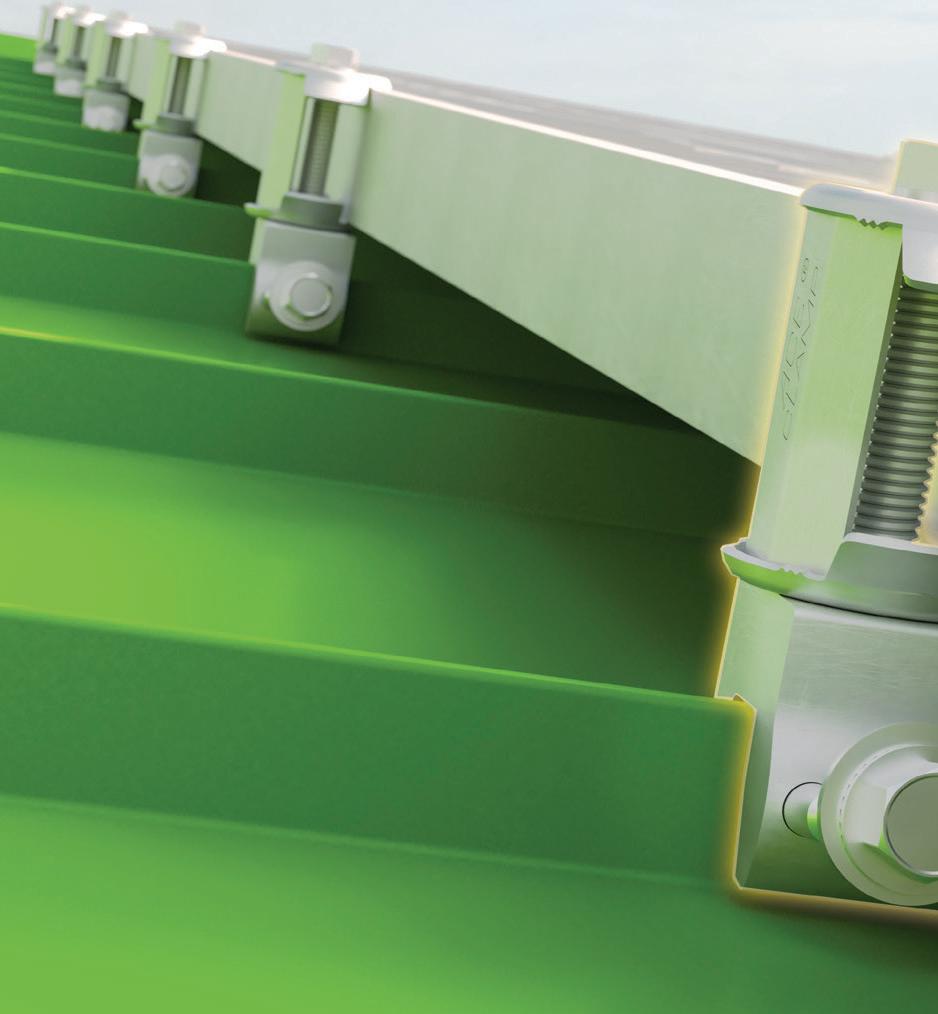

SOFTWARE PLATFORM FOR MONITORING SOLAR+ IN A DYNAMIC PV INDUSTRY

• One Platform to Monitor and Manage Your Portfolio of Installations

• Trusted Partner with 1+ GW of Solar

• O&M Work-order Management

• Asset Management

• PPA Billing

• Load Monitoring

• Monitor Batteries, EVs and Weather Stations

Learn how we can help create lasting value for solar companies and asset owners by leveraging our decade plus experience in the C&I solar space.

• Privately held and fully independent

• Hardware agnostic

• Best-in-class customer service

One Platform to Monitor Them All

VISIT US at RE+ in Las Vegas: Booth #7406 Sands Level 2 Ballroom

To schedule a demo visit www.manamonitoring.com

Mana contact: www.manamonitoring.com, info@manamonitoring.com

BILLY LUDT | SENIOR EDITOR

That concept also applies to residential and small commercial customers trying to install solar on their properties. While the cost of a solar project has dropped significantly in the last decade, it is still an investment of tens of thousands of dollars, even at a small scale. So, businesses, organizations and certain state and municipal governments have devised group

purchasing programs and cooperatives to give smaller customers the same purchasing power that developers have when building larger solar projects.

These solar purchasing cooperatives reduce the cost of a PV array by recruiting enough people in a community to go in on a multi-project agreement — like that three-in-one box of cereal. Combine that with the reinstated solar investment tax credit included in the Inflation Reduction Act, and customers can significantly subsidize the cost of a PV project.

Types of solar purchasing cooperatives

projects on multiple properties in a neighborhood, city or community, but uses different organizing entities to build the solar campaigns.

Solarize programs engage with local governments and community organizations to back development of these solar projects. Certain states and cities have their own Solarize programs to support interested residents. Those involved apply for grant funding in addition to applicable tax credits for solar installation, and the remainder of the cost is covered by customers.

The first Solarize campaign started in Portland, Oregon, in 2009. A group of residents sought solar installations for their neighborhood and “imagined that if they could organize a group of neighbors

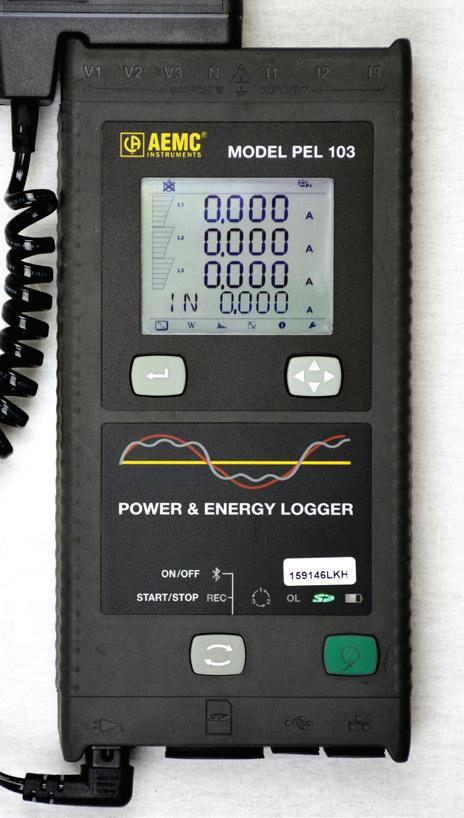

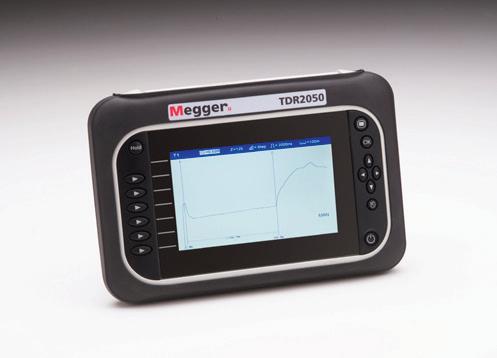

PV technicians working across a range of O&M activities can rely on the Megger tools when performing extremely critical jobs like ground-fault testing.

DLRO2X

Digital Low Resistance Ohmmeter

Provides technicians with a way to test to IEC62446 standard for the continuity of bonded conductors.

MIT2500

Insulation Resistance Tester

Perfect for segmenting out different sections of the array to identify ground fault locations.

DCM1500S

Digital Clamp Meter

Your go-to instrument for ground-fault locating. Check three points from line to line and use those points to locate the fault.

TDR2050

Time Domain Reflectometer

This two-channel fault locating instrument can be used on the ac side of a PV system. Its step function is used to improve detection of near-end faults.

DET2/3

Digital Earth (Ground) Tester

This instrument helps the technician accomplish the tests required on large or more complex ground systems. It’s designed to measure earth electrode resistance and soil resistivity.

Learn more about ground Fault testing in PV systems - scan the QR code to download our informative application note or visit: https://us.megger.com/groundpv

to ‘go solar’ together, they could collectively make an informed purchase and negotiate a volume discount,” according to The Solarize Guidebook from the U.S. Dept. of Energy.

Solar United Neighbors (SUN) has a similar origin story. The group started as a grassroots effort by founder Anya Schoolman, her son Walter and his friend Diego, to see if it was feasible to have solar installed on their home in Washington, D.C., in 2007. That curiosity turned into a local purchasing cooperative, resulting in new solar projects on 45 homes in the neighborhood.

“The boys were in middle school at the time, and they went up and down the neighborhood and canvassed that group. A lot of the lessons that we took from that we carry forward to today,” said Ben Delman, communications director of SUN.

Another group purchasing program, Solar CrowdSource, formed after founder Don Moreland witnessed Solarize programs playing out on the West Coast and wanted to bring similar tools to his home state of Georgia, where solar incentives were lacking. For the last eight years, Solar CrowdSource has brought solar projects to new communities by providing a framework and platform to host cooperative purchasing campaigns like Solarize.

“We are still plugging along with pretty much the same model, and that is recognizing that a lot of communities want to make solar more affordable and more accessible for homeowners and business owners, but to run a Solarize program, they don’t have a lot of the resources, the time, or even the subject matter expertise,” Moreland said.

There are a lot of shared practices among organizations like SUN and Solar CrowdSource, as well as stateand city-led Solarize programs. The first step for each is engaging with and educating the community.

That first Solarize program in Oregon wanted to create a group of savvy solar consumers capable of negotiating for a fair construction contract, which remains a primary goal for similar purchasing campaigns. The entities organizing these campaigns aim to garner enough support in a single community to create stronger purchasing power, but they also want the people participating to be informed on how the technology works, which can benefit them and solar installers.

“You’re getting a large group of interested and — maybe most important from the conversations I’ve had with installers — educated solar customers, so that we’re able to maybe save some of the time that you would have to spend walking people through the technology, the process and all that stuff,” Delman with SUN said. “By having a large group, we’re creating economies of scale that you’re having to do less marketing, you’re having to go to less permitting offices to pull permits. And so, saving some of that overhead, we’re hopefully helping installers grow.”

Groups will organize community

outreach events like meetings, informational sessions, open houses and workshops, and market the program through websites, flyers and social media. In addition to the solar technology, those community events can cover topics like financing and project options for commercial, nonprofit or low-tomoderate income homes.

After a group of stakeholders for the purchasing co-op is formed, the campaign must issue a request for proposals (RFP) to find a contractor willing to install multiple small-scale solar projects. If the program is run by organizations like SUN or Solar CrowdSource, they will handle the RFP process; otherwise Solarize programs can appoint a committee that will review and negotiate these contracts.

Procuring the hardware used on these solar projects is the contractor’s responsibility, but what components are selected is discussed and negotiated during the RFP period.

“It’s not always a race to the bottom,” Moreland said. “It’s about getting the best value and the highest-quality equipment for the lowest price. I’ve probably said that

a million times, but that’s essentially what we’re trying to accomplish.”

Each project contract is still between an individual homeowner and the solar contractor, but the group selects the installers to establish that bulk installation rate.

The length of a co-op program can range from several months to a year depending on the group that organizes it, the permitting and policy environment within a community, interconnection queues and hardware lead times.

Dennis Kill, a homeowner based in Westchase, Florida, a suburb of Tampa, participated in a SUN co-op purchasing program in 2019. He and his wife were already speaking to contractors to have solar installed on their home and heard

of the SUN campaign in their area.

“It was very simple, because you literally just told them you were going to put your name in the hat,” Kill said. “Then they did all the work.”

SUN provided details on the several company proposals it evaluated and rationale for the contractor chosen to complete these projects. After all that was secured, participants just had to coordinate when the installer could start the project.

As solar expands across the country, so do co-op purchase programs. SUN and Solar CrowdSource are always accepting inquiries from new communities seeking group solar installations.

After a program is complete and solar

is installed on many new properties, the people that formed the co-op have new knowledge about the technology, how it’s installed and the policies that either encourage or deter further development in their community. Delman even finds that co-op members often become new advocates for the solar industry.

“We help people go solar, we bring them together, we help them create community solar supporters, and then we’re able to activate them to fight for policies to help more people go solar, which ultimately helps installers’ bottom line,” he said. “You’ve got this really educated, active, interested group of people who are ready to go to the Public Service Commission and say, ‘Hey, get these utilities in line.’” SPW

KELSEY MISBRENER | MANAGING EDITOR

KELSEY MISBRENER | MANAGING EDITOR

ThisAugust marks one year since the Inflation Reduction Act was passed into law. The landmark legislation included dozens of incentives to boost solar energy deployment and bring manufacturing back to our shores. Since then, the Dept. of the Treasury

has been working feverishly to release guidelines on all the provisions included in the legislation and allow developers, installers, businesses and homeowners to take advantage of these new tax credits.

Solar Power World talked to Ben Norris, SEIA’s director of regulatory

affairs, to get a sense of where the IRA stands one year in and what’s still needed for the solar industry to capture all the benefits intended by the law.

This interview has been edited for clarity.

With on-demand environmental due diligence reports and comprehensive land data, you can mitigate your development risk in a few clicks of a button!

Minimize permitting development delays

Derisk your investment decisions

Accelerate land development

Solar Power World: So we’re coming up on the one-year anniversary of the IRA. What has been done, and what are we still waiting on?

Norris: It’s kind of crazy to think that we’re already coming up on the one-year anniversary. In many ways, it feels like a lot longer than that, just based on how much work we’ve had coming in our door and how much outreach we’ve been doing to our members. And yet, on the other hand, it does feel like we still have quite a bit of ways to go.

I’ll talk first about the biggest items we are anticipating through the end of the calendar year. One of the items that’s still outstanding that has really strong interest among our membership, which includes manufacturers, is guidance on the 45X provision. This is the production tax credit for certain clean energy inputs, including a number of enumerated solar energy components, so things like modules and cells, torque tubes, etc. (The production tax credits manufacturers can receive for producing Americanmade products.)

We have a lot of members that are really interested in utilizing this credit.

And this is, I think, sort of a “twofer” in solar. Not only does it mean more U.S. manufacturing jobs, but it also means a more robust supply chain for clean energy projects.

45X is a really critical piece of the IRA and it is an area that we have been talking to the administration about a lot lately. We’re really excited to hopefully get some guidance for some proposed rules in the next couple of months here.

We know it’s a big undertaking — the domestic content bonus credit provisions, for example, can be really technically complex. So we’re gratified that the Treasury Dept. is working closely with the Dept. of Energy on these very detailed, very technical elements of the IRA.

We think that by the end of the year, we will see some proposed rules on both the energy communities provision and the domestic content bonus credit provision. Some initial guidance was released on energy communities back in April, and then on domestic content back in May. But the notices that the IRS released were just initial guidance on both of those programs, so we’re looking forward to seeing those programs codified in rules.

Can you explain Treasury’s process in every one of these provisions?

Treasury, like any other agency, has some discretion on how to approach specific issues. They’ve actually taken slightly varying approaches on some of these matters already. To give you one example, on the prevailing wage and apprenticeship provisions, Treasury was very forwardleaning on getting initial guidance out, and has since noted that they intend to issue proposed rules at a later date.

However, if you look at something like domestic content, what Treasury technically did there was issue what’s called a Notice of Intent. That coupled initial guidance with a more concrete promise to issue proposed rules at some point in the future. And these all have the effect of sending some signals to the market about timing and sequencing, and what we could expect more information on at some point in the future.

So there are basically two phases, where they’re proposing some guidance and then getting feedback and coming back with final rules?

I think that’s the general overlay that we are looking at, but I also don’t want to suggest that “Step 1: Proposal, Step 2: Final Rule” is going to be the end-all-beall for the Inflation Reduction Act. Even if

We are confident based on the manufacturing investments all over the country that there should be bipartisan support for preserving the IRA.

we’re talking at this time in 2024, and let’s say we have new final domestic content rules, the Treasury Dept. would be free at some point thereafter to undertake a supplemental rulemaking process. There may be changes in the marketplace, or there may be changes in supply chains or in international trade that would counsel in favor of adjusting those rules. Agencies do that all the time.

When we think about IRA implementation, we’re definitely not just thinking about a year or two of regulatory activity. We’re really looking at this over the span of about a decade, which covers the life of some of these credits, but is also just part of good government. We know that this administration wants to get these things right. And that may mean three or four or more rulemakings and other sub-regulatory items.

Would you say that developers and installers have what they need at this point to utilize most of the provisions?

I think we are trending in that direction. I wouldn’t say that we have everything we need. 45X is a good example of where there is no guidance yet. And depending on how that guidance comes out, that could really drive or not drive investment in some of the key components enumerated in the text of the statute.

I’ve mentioned it a couple of times, but the domestic content bonus credit is proving particularly challenging for both developers and manufacturers to understand and utilize. We know that it’s initial guidance on a bonus credit, and if you’re going to get a bonus, you probably need to be going a few extra steps to enjoy the benefits. But now that we’re eight or nine weeks post-initial guidance, we’re still seeing some real challenges in developers actually being able to claim that.

It’s our hope that there may be some near-term action on amending that guidance, or perhaps even moving

very quickly to a proposed rule stage. We don’t want to see this credit go unutilized for a significant amount of time, and at least to my knowledge, it is unutilized at this point. So we’ve been working with the administration to express some of our thoughts on how the credit can be made more usable and more generally understandable. It’s a complex piece of guidance, and I don’t envy the Treasury Dept. at all. It was drafted in a way that forced Treasury to make some hard policy choices.

We want to make sure that at the end of the day, we are actually on-shoring our domestic supply chain through the use of the credit, and not leaving behind U.S. workers and the value that they add to the manufacturing that is occurring here and that will occur here as a result of all of the other provisions of the IRA working in concert.

How safe is the IRA, after there have already been two attempts by Congress to dismantle it?

It’s a great question, and I won’t pretend to be the government affairs expert here. We have a lobbying team here that is

working on this issue every single day; we have actually stood up a campaign to expressly defend the IRA from exactly the types of rollbacks that you’ve mentioned.

We are confident based on the manufacturing investments all over the country, including in both Democratic and Republican districts, that there should be bipartisan support for preserving the IRA. But if we were having this conversation in December 2024, and control of the Congress and the White House has flipped, the IRA would likely be at the top of the list for a new government to re-examine.

We don’t want to be in that scenario. Regardless of who’s in power, we want to make it clear that the IRA benefits all Americans; it benefits our entire economy; it benefits the global supply chain. And that’s what we’re going to be focusing on all the way up to and through the 2024 elections — to make sure that as much of it is preserved as possible. SPW

BOOTH # 7510

SEPTEMBER 11 - 14 TH

LAS VEGAS, NV

are mostly the same anywhere an installer is putting panels on a roof. They secure mounts and racking, attach modules and inverters and run wiring. It’s physically demanding work, but with the right experience, a solar installer could move anywhere in the country, pick up some panels and get them on a roof and quickly generating power.

The mechanical experience of installing based on their separate environments with

arrays in various regions may differ only slightly distinct temperatures and weather conditions.

The greater difference is in oversight from regional policies and permitting bodies.

Solar Power World case studies typically profile a single solar project and the unique challenges the contractor faced while building it. This case study will instead highlight solar arrays built by two contractors in California and Massachusetts and the many shared and separate experiences those companies encounter daily at a regulatory level.

Earth Electric is a solar installation company founded in California in 2009 that serves the greater San Jose area. PV Squared is a worker-owned solar contractor from Greenfi eld, Massachusetts, that has been in business since 2002.

This is what it’s like installing solar on opposite sides of the country.

Rate structure and interconnection in the biggest solar state Earth Electric completed a 7.38-kW residential solar + storage project in Morgan Hill, California, a rural community southeast of San Jose. The array uses an Enphase Encharge 10, a 10-kWh lithium-iron phosphate (LFP) battery that integrates with the manufacturer’s IQ8A microinverters; railbased racking with metal sheet fl ashing and mounts from IronRidge; and 410-W solar modules from Panasonic.

This project in Morgan Hill is one of the last to be included in the previous net-metering rates in the state, and it’s a model for what an ideal solar array will look like in California moving forward.

California remains the top-ranking state for total installed solar capacity in the United States, with part of that success owed to its net-metering compensation rates. But in April 2023, the state adopted new net-billing rates, called NEM 3.0, that have reduced export compensation based on utility time-of-use rates.

“It’s a big education process. The sales cycle is going to be longer and certainly there’s a lot less incentive to sign up to do solar. They need to add storage in order to get better coverage of their electricity bill, which is obviously a much higher contract cost. It’s radical and it’s concerning,” said Sheryl Lane, CEO and founder of Earth Electric.

Solar installers like Earth Electric are prioritizing energy storage sales on projects to counteract the solar compensation reduction. Lane said the company is changing how it’s modeling solar projects, sizing them to cover just under 100% of electrical usage, “because they’re never going to get a ‘zero’ bill anymore.”

Solar + storage is also a necessity in Earth Electric’s installation territory because of wildfire risk and rolling blackouts from regional utility PG&E.

Along with the longer payback period, Earth Electric has also struggled with project delays due to PG&E’s interconnection delays.

“PG&E is extremely unorganized,” Lane said. “We can figure out and overcome the building department and electrical components and all that, but PG&E is probably our biggest speed bump.”

In one instance, the utility required a transformer upgrade for a residential solar project built in March 2022. It took a year and three months before PG&E finally completed that process.

“They paid for and had their system installed and it sat there for over a year,” Lane said. “This is in the middle of a major city in California.”

PV Squared installed a 6.57-kW solar project on a 1930s home with a steep pitched roof in Greenfield, Massachusetts, in June. The array is composed of Hanwha Qcells Q.PEAK DUO modules, SolarEdge HD Wave 6-kW string inverters and IronRidge HUG Halo UltraGrip top-attached mounts.

On this project, and most others in Massachusetts, PV Squared had to

maintain an install crew that had a oneto-one ratio for licensed electricians to electrical apprentices during construction. The state mandates that solar projects must be built by licensed electricians with an apprentice to match, so PV Squared deploys crews with an even number of installers.

“For us, it’s much more expensive to install in the state, because licenses are hard to come by,” said Chris Dooley, team manager at PV Squared. “It does make it harder for us to participate in other states, because we just have to be able to cover our overhead and electricians are making $55 an hour.”

PV Squared runs an in-house apprenticeship program and pays for electrical schooling for those apprentices to become licensed electricians. Altogether, it’s a four-year process to complete, and PV Squared requires people who become licensed through the program to stay at the company for at least a year.

“We have a list of approved nonratio work, but it depends on where you’re working,” Dooley said. “You’re always going to be better off running in the ratio, because you can get in a lot of trouble and get your license taken with the state if you’re not.”

Currently, PV Squared has more licensed electricians on staff than apprentices but must maintain an even

ratio of electrician-to-apprentice on most projects. The company is trying to build a more diverse workforce by including people who identify as female and nonbinary on staff. But it hasn’t been simple hiring this way, because about 96% of current electricians in the United States are men. Even with that 96%, rooftop work may not be attractive to an aging population of skilled laborers.

“Solar installation, especially on a pitched roof, is physically challenging, and it’s hard on the knees and the joints,” said Josh Hilsdon, design and sales consultant for PV Squared. “Not that many 55-yearold electricians are excited about doing rooftop work. It just becomes a puzzle of: How do you get a licensed electrician to come work for you in a very competitive labor environment?”

Massachusetts has its electrician ratio requirement, while California has a changing net-metering policy and utilities slow to interconnect. But both states experience a gamut of permitting and inspection roadblocks that often increase solar project lead times.

The solar project Earth Electric installed in Morgan Hill, California, took about a month to complete, including reviews from the local building department and permitting approvals. In its experience with permitting and utility interconnection, that timeline is on the shorter end for Earth Electric.

“Once we started incorporating batteries and storage into the projects, that’s when we started running into the biggest challenges with trying to meet all of the various code requirements that we’ve got out here,” said Zach Shepard, general manager at Earth Electric. “Trying to make the fire departments happy, trying to make the building departments happy, trying to make it work with the equipment that we’re dealing with, too.”

Authority having jurisdictions (AHJs)

each have their own set of permitting criteria for approving solar projects. In some AHJs, both the solar and storage aspects of a single project would undergo fire and building inspections and require separate building permits.

PV Squared’s installation territory is between five counties in Western Massachusetts, and the contractor has installed in 50 different cities. Each of those cities has an inspector and building department with its own quirks and project requirements.

The company recently failed an inspection after installers placed a plaque showing the project layout on the north side of a building instead of how a firefighter would view it when entering the property, which is something the contractor hadn’t had issues with previously. Meanwhile, Earth Electric recently failed a few inspections for not including enough safety warning stickers.

“These kinds of little things get you returning to site, and you might have done 50 projects with the exact same thing, but either an inspector changes their mind or you’re working in the next town over and it’s just a different story,” said PV Squared’s Hilsdon.

Fire setbacks are another hurdle for both contractors, with no uniform approach to inspecting them among AHJs. Setback requirements already

existed in California and were just this year adopted in Massachusetts. Solar installers are required to place solar modules a designated distance from the edge of the roof and other roof obstructions.

Both Earth Electric and PV Squared will leave an 18-in. gap from the top of the array to the roof ridge and a 36in. walkway to navigate the roof. Fire setbacks are meant to prevent solar arrays from obstructing firefighters while on the job, but they can reduce project sizes.

“It seems like every year drops some new, painful wrinkle into the workflow, and this year fire setbacks are our current, new thing,” Hilsdon said. “We really are seeing everything from fire officials in one town saying, ‘I’m not interested in enforcing any setbacks and

you all can continue business as usual,’ to other towns saying, ‘We’re going to enforce this and the most conservative interpretation and not allow any reasonable exemptions.’”

Solar contractors are installing PV arrays from coast to coast. In every community within that span, they’re adapting to whatever regulatory hurdles they encounter to make these projects work. A solar project isn’t just a series of components working in conjunction to turn sunlight into electricity, it’s the culmination of construction expertise and regulatory knowhow that makes the grid greener a few kilowatts at a time. SPW

In Northwest Ohio sits a railway town that can trace its foundation to the boom of the locomotive in the early 1800s. Named after local railway engineer James Bell, the city of Bellevue is today home to the largest rail yard on the Norfolk Southern system. Moorman Yard is the junction of five routes heading in all major directions, and industrial parks surround the site for easy access to freight lines.

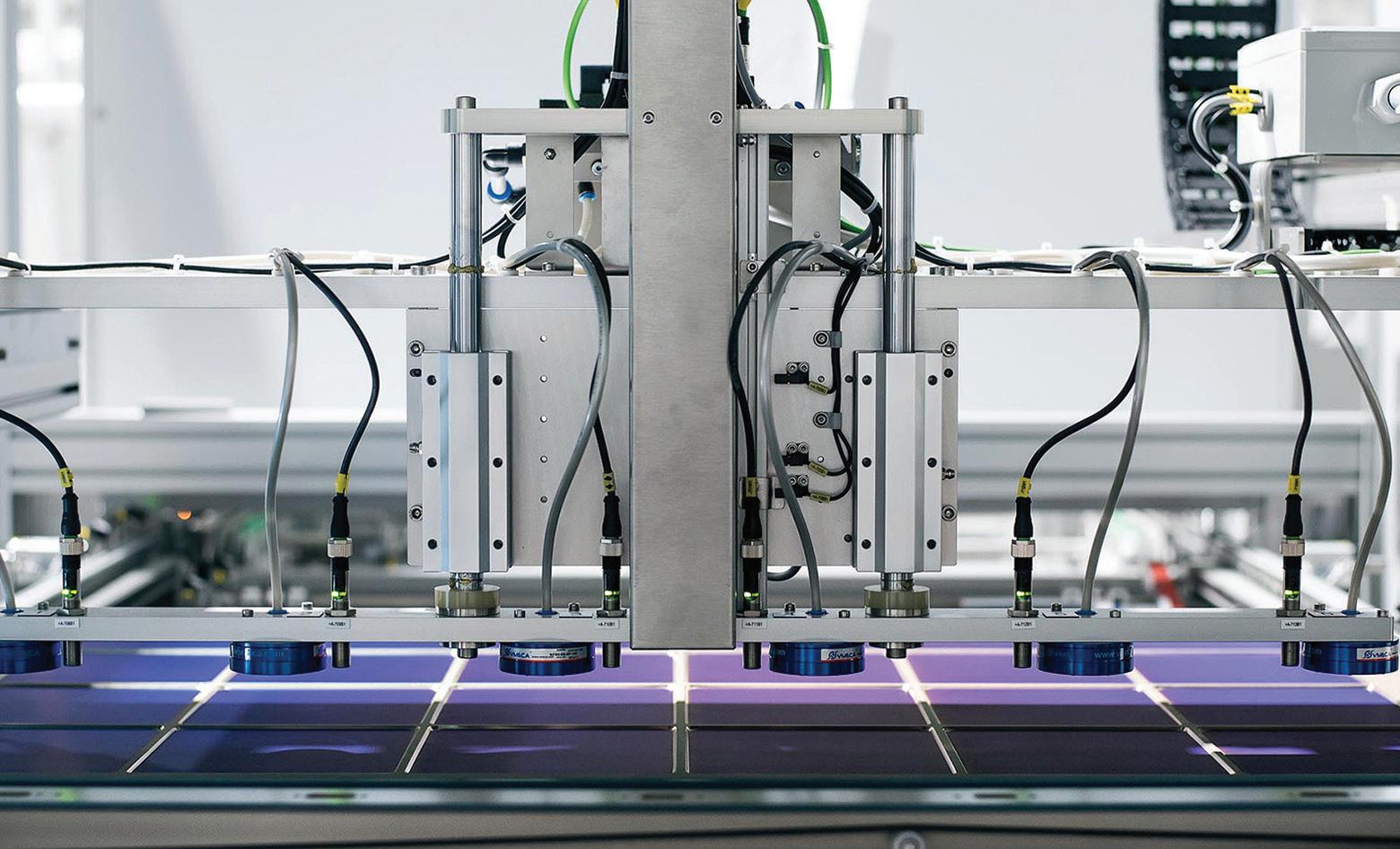

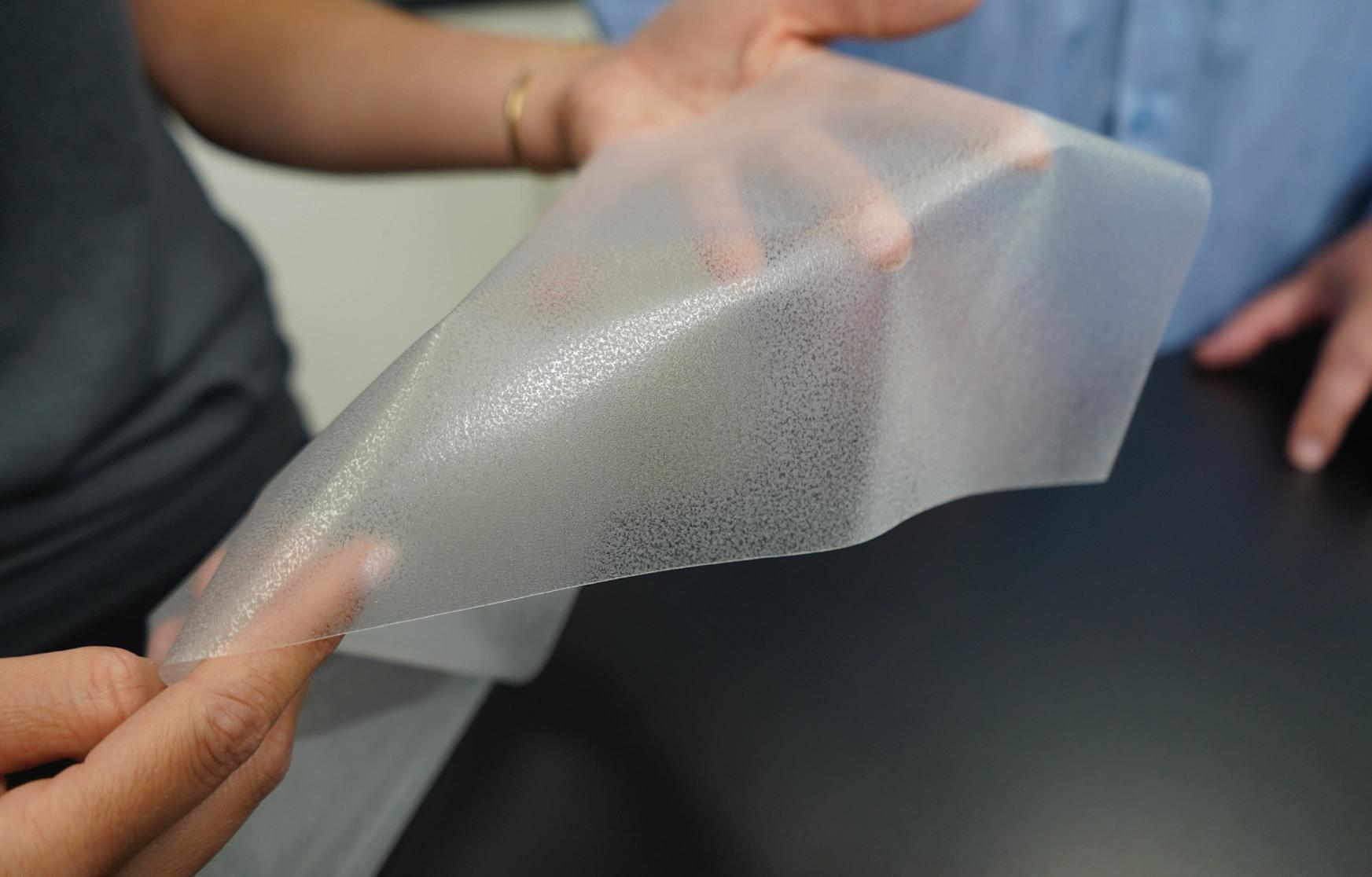

Just to the west of the vast rail hub is a 200,000-ft2 warehouse with an 80,000-ft2 climate-controlled “building within a building.” It’s here where four shifts of employees churn out product faster than they can ship. This is H.B. Fuller, the only domestic manufacturer of EVA sheets — an essential product for every type of solar panel made today.

“We’re not waiting [for final Inflation Reduction Act credit rules]. We’re committed to growing our business and growing it now,” said David McDougall, senior business development manager for PV at H.B. Fuller, on a recent Solar Power World visit to the Ohio manufacturing plant.

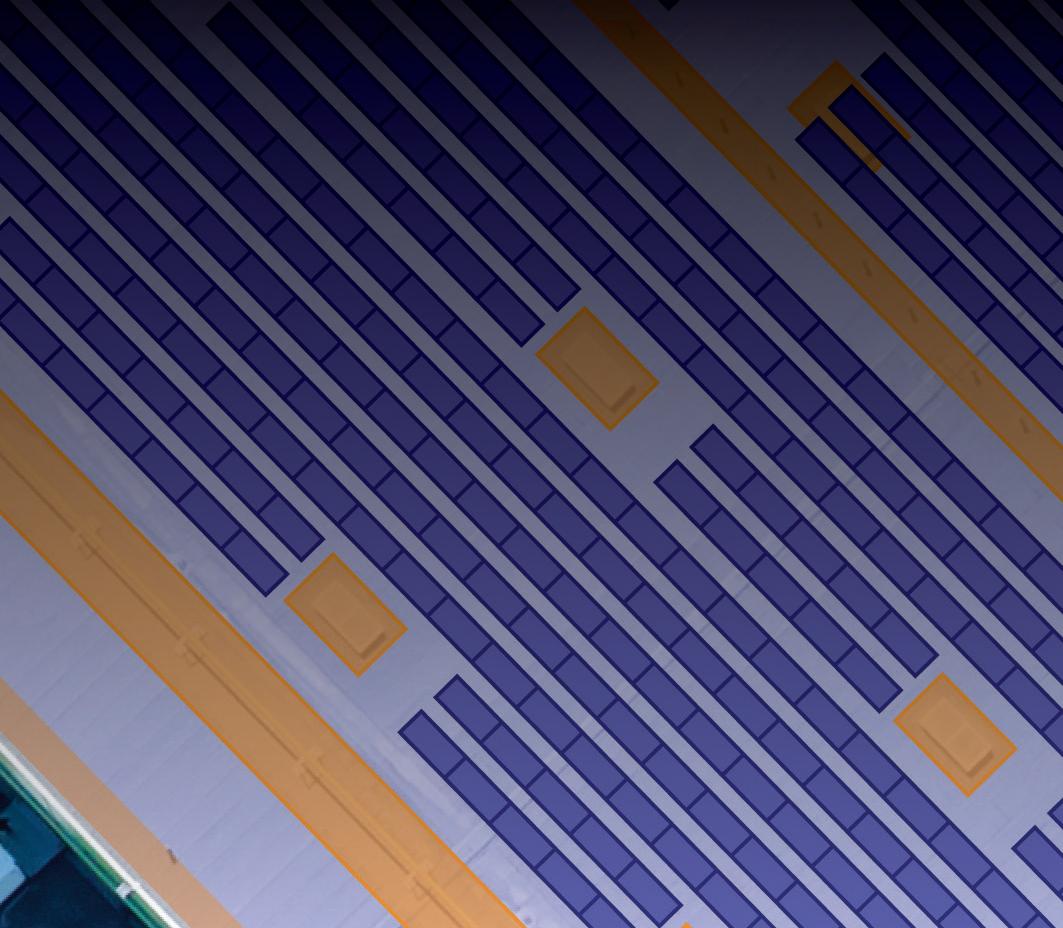

The solar encapsulant factory opened in July 2021 and has already almost doubled in size, with plenty of negotiating power to quickly expand further within the warehouse. H.B. Fuller makes ethylene-vinyl acetate (EVA) and polyolefin elastomer (POE) encapsulants that laminate solar cells, providing a moisture barrier

More manufacturers seek domestic materials to meet IRA requirements.

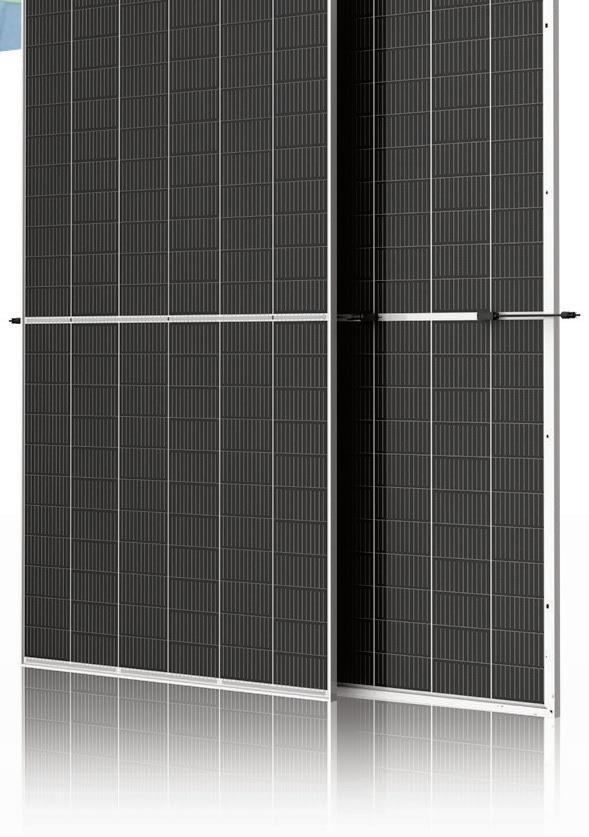

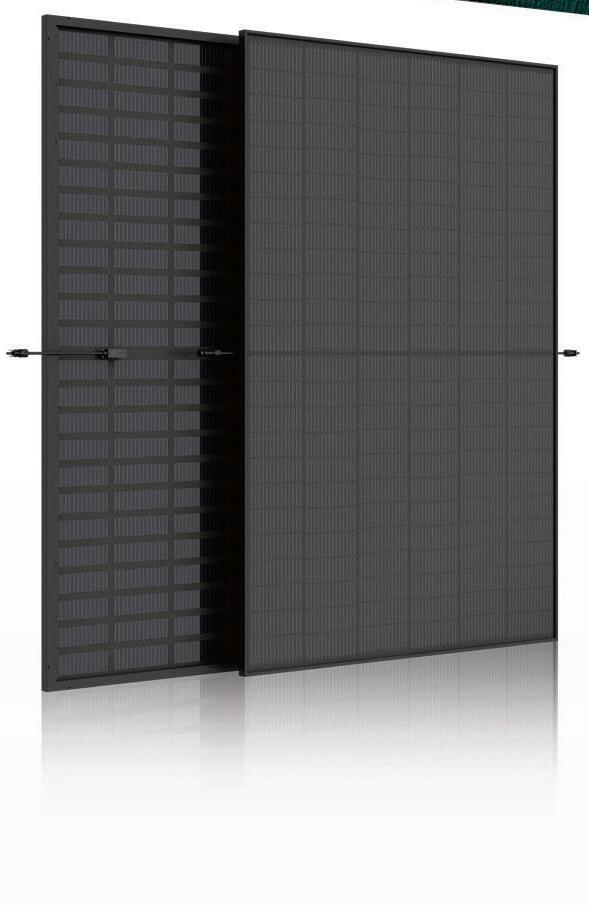

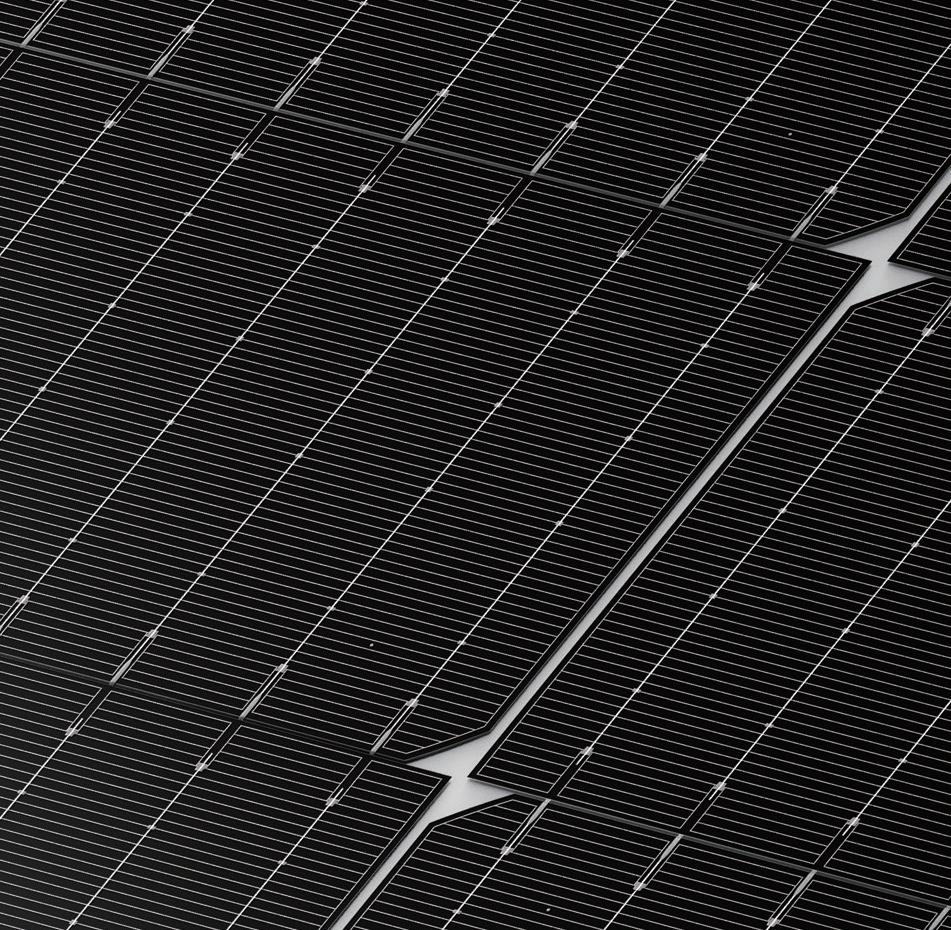

PHOTOVOLTAIC SOLAR MODULES continue to grow in wattage, and that often means increasing their size, too, but that doesn’t always have to be the case. In this episode of Solar Spotlight, Lucas Moura, product marketing manager for international module manufacturer Trina Solar, discusses the significance of the compact yet electrically potent n-type TOPCon solar module.

Below is a portion of Trina’s Solar Spotlight podcast with Solar Power World, but be sure to listen to the full episode on your favorite podcast app.

How are n-type modules changing the game for residential installers and homeowners?

Unlike utility and C&I solar industries, which are trending into larger format solar modules, the residential installers want something smaller and lighter modules, but they still want higher output wattages. So how do we square that circle? The Trina Vertex S+ n-type TOPCon cells is the higher power, smaller footprint module. Another big trend is the value-added benefit which is becoming an increasingly important di erentiators for installers. The manufacturer’s warranties, local support, a bankable partner become extremely important.

What are the technical aspects of n-type TOPCon modules that benefit homeowners and installers?

The takeaway is higher e ciency and lower degradation. We see a tremendous opportunity for cell e ciency growth with TOPCon. Don’t get me wrong, we had a great ride with mono-PERC, but we are at the very top of PERC technology e ciency. The higher e ciency TOPCon cells will allow for more power, better performance on the roof and ultimately will translate on a faster ROI.

What makes n-type di erent?

For you nerds out there, TOPCon is an acronym and it stands for “tunnel oxide passivated contacts.” The biggest di erence in it is the chemical composition — boron vs. phosphorous — which is used in the cells to improve the e ciency. The n-type is doped on phosphorous and eliminates the oxygen pockets and ultimately allows for lower degradation and higher e ciency compared to PERC cells.

How can installers decide what matters when getting n-type modules?

First is the module availability at multiple distributors. n-type is the direction the industry is going and installers need reliable access to

inventory. N-type TOPCon makes it easier for installers to install. Plus, the higher power and e ciency means they don’t have to install as many panels to generate the same power output. This ultimately saves them on BOS costs and installation times. It gives Installers the ability to choose the “best” part of the roof with more sun access, so they can get away from vents, pipes, chimneys or anything that might partially shade the modules.

What are a few concerns for homeowners as they decide what panels to put on their roof? Homeowners, they worry that the solar panels will fail and not perform to their expectations. That’s why the TrinaProtect 25/25 Warranty Program helps deliver that peace of mind for homeowners. While a 12- or 15-year might sound good, don’t settle for anything less than 25 years on a warranty. To the warranty point, a warranty is just a piece of paper unless the company that issued it is still around to honor it. So, you want to look into the company’s bankability. How long have they been in business, what do other industry experts have to say about them? SPW

THIS ADVERTORIAL IS SPONSORED BY WWW.TRINASOLAR.COM

before solar panels are finished with glass and backsheets at final assembly. Without the encapsulant, solar cells would float freely behind the glass.

Being the only EVA (the more popular and cost-effective of the two encapsulants) manufacturer in America was already a strong selling point for the growing U.S. module assembly industry, but the product became even more important to the domestic manufacturing conversation when the IRS included encapsulants as one of the subcomponents necessary for a solar panel to qualify for “domestic content” tax credits. Under incentives included in the Inflation Reduction Act (IRA), non-residential solar projects can receive a bonus credit if their products meet certain manufacturing requirements. For solar panels specifically, American manufacturers using American-made solar cells, frames, back rails, glass, encapsulants, backsheets, junction boxes, edge seals, pottants, adhesives, bus ribbons and bypass diodes would easily qualify for the full domestic content adder.

While the biggest beneficiary is the tax-paying entity that owns the project and can claim the domestic content bonus, Baker Botts partner Eli Hinckley said everyone in the solar project chain is interested in securing that “Made-inUSA” distinction.

“The person who’s going to own the asset is the person who cares the most. The other person that cares a lot is the tax equity [investor], because they understand what their investment will be, based on [additional credits]. Lenders care because that will provide the economic base for calculating the loan amount. EPCs care because it affects their pricing. The actual manufacturers care because it materially impacts what your selling price is going to be and what the demand for your product will be,” he said. “This is core to how everyone is thinking about value creation.”

While the details around what truly makes a domestic solar panel are still a bit sticky (is it all 12 of the mentioned subcomponents or a simple majority?),

if there was ever a time for U.S. solar panel assemblers to Americanize their bills of material, it’s now. Domestic subcomponent makers are ready to make that happen.

Exclusive deals in U.S. solar panel production are already flying. Hanwha Group has been securing its place as the most domestic silicon solar panel manufacturer it can be, with Korean backing. The entirety of REC Silicon’s American polysilicon supply will go to Hanwha’s Qcells ingot, wafer, cell and panel manufacturing operations in Georgia. The group will also be behind the country’s second EVA factory once it opens next year. Its subsidiary Hanwha Advanced Materials Georgia will establish EVA sheet manufacturing near the Qcells solar panel plants. Qcells is expected to be the main customer of Hanwha’s EVA capacity.

Meanwhile, the country’s first domestic junction boxes will be made

in Texas for one solar panel company. Houston-based solar panel assembler SEG Solar recently penned an agreement for American-made junction boxes with Chinese enterprise UKT New Energy. UKT will start a new factory in Texas to supply junction boxes exclusively to SEG.

“America’s solar company” First Solar has actively been domesticating its supply chains, making deals for American steel, copper mining and glass for its CdTe thin-film solar panels. First Solar entered an agreement with Vitro to restart an idled manufacturing line in Pennsylvania to exclusively make float glass for the specialty panels. Vitro had previously made glass for downstream automotive-glass finishing plants on the line, but a combination of events led to its shutdown in 2020. First Solar’s order will allow Vitro to hire 130 full-time workers after investing $93.6 million to update the line for solar needs.

“Vitro is making these investments because we see the great potential of the solar industry. As an ‘onshore’ float glass manufacturer, Vitro has the history, resources and technological capability to contribute to improving solar performance in the United States and beyond,” said Paul Bush, VP of technical services and government affairs for Vitro Architectural Glass.

These exclusive subcomponent supply agreements will provide solar panel companies with the easiest route to meeting domestic content requirements. Third-party verification will likely increase in the coming years, Baker Botts’s Hinckley said, so manufacturers can have credibility without opening their books. But so much more subcomponent manufacturing is needed than what is provided by these one-offs.

“The idea behind all of this was to try to build out the domestic manufacturing capacity for clean energy — we’ll create additional value if you meet these targets. We can support people building out new capacity, because there will be a premium for their products because you get this additional 10% tax credit,” Hinckley said. “You’re going to need multiple participants to support adequate domestic production.”

H.B. Fuller has no exclusive deals and is open to anyone. When asked if there was a minimum order-size limit the company would accept to supply some of the smaller U.S. panel assemblers, H.B. Fuller reps said that was up to how comfortable those companies were with limited-run pricing.

“We’re not turning away the small guys, because they will get big

someday,” McDougall said.

U.S. backsheet manufacturer Endurans Solar is another company without exclusive supply agreements. The company (which can also receive a bonus 40¢/m2 manufacturing credit from the IRA) is increasing its manufacturing capacity in New Hampshire to meet domestic demand and should announce a second U.S. manufacturing site before the end of Q3. Endurans does make specialty backsheets for American panel companies like Silfab, but no single manufacturer can supply the country’s gigawatts of demand, so it’s keeping its doors open.

“We’re excited that many more millions of solar panels will be manufactured and installed in the U.S. over the coming years, and we look forward to supporting the growth of U.S. solar panel manufacturers with our high-performance, sustainable and madein-America backsheets,” said Nathan Arbitman, president of Endurans Solar.

H.B. Fuller sees things the same. Its three manufacturing lines in Ohio have the capability of producing about 5 GW of encapsulants — barely onefifth of the country’s expected panel manufacturing aspirations. It takes 40 minutes for H.B. Fuller to finish one roll of the polymeric material; it takes a solar panel manufacturer four hours to use up the same roll. The adhesives giant is producing as quickly as it can in Bellevue and there’s always the opportunity to make even more.

“We are excited about the growth opportunities created by the IRA and believe we are well-positioned to capitalize and support this growth as the American market sees a resurgence of investment and new solar production capacity across the board,” McDougall said. SPW

Smooth solar installation requires the right workers, tools and maybe most importantly, training. Being prepared to work with increasingly complex solar power electronics can mean the difference between a quick installation and hours of troubleshooting.

Back when solar inverters were basic machines solely used to convert power from rooftop arrays, manufacturers offered only a simple paper instruction manual for system setup.

“One thing that drove me nuts is that there was no real information transfer from the manufacturer to me. It just showed up in a box and I was to put it up on a wall,” said Jeremy Sullivan, former installer and current senior director of worldwide training for Enphase. “Nobody was walking me through or guiding me as an installer through the process.”

But now, with inverters performing

more complicated interactions with the grid, batteries and other pieces of the smart home ecosystem, installation training must be more advanced.

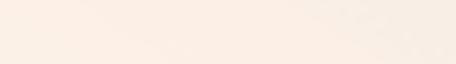

“It’s a different environment than just installing an inverter. We have realized that, so we’ve really put a lot of resources behind training and see that as a priority,” said Michelle Spina, sales education manager at SolarEdge.

Inverter training has come a long way in the last few years, but there’s still room for improvement. Manufacturers, installers and other training organizations are working in tandem to streamline this crucial step in the solar process.

The two most popular residential inverter brands in the United States, Enphase and SolarEdge, offer similar virtual training options for installers learning about their

equipment, ranging from interactive online demos to quick video refreshers.

Training begins with online certifications for a manufacturer’s products. Installers are not even allowed to work with some equipment, especially batteries, until they’ve completed trainings and received an official certification.

Both SolarEdge and Enphase host self-paced online learning platforms where installers can also earn continuing education credits from the industry’s specialized certifying body, NABCEP. These online courses have evolved to simulate real installations as closely as possible. SolarEdge’s EDGE Academy classes require installers to click through virtual installs, rather than just read about the steps.

“It’s not like they’re sitting there and just watching a PowerPoint. It’s hands-on

LONGi offers best-in-class solar technology, validated through rigorous independent testing and backed by world-leading R&D. With its improved efficiency, the Hi-MO � module effectively reduces the cost of equipment, module cleaning, land rental and maintenance.

Hi-MO � modules:

High-performance PV modules for utility power plants

Based on M10 wafer, best choice for ultra-large power plants

Advanced module technology delivers superior module efficiency

Excellent outdoor power generation performance

High-module quality ensures long-term reliability

To learn more, visit our website

and they actually have to click things to simulate the process. It is interactive,” Spina said.

Enphase calls its platform Enphase University, and offers training in sales, design and installation. Enphase University links to the company’s commissioning app, the Enphase Installer App, which ensures every user is certified to commission an inverter or battery.

In SolarEdge’s SetApp, installers go through a commissioning checklist on-site to ensure they’re hitting every step. If they need more information at any point, SetApp offers instructional videos that correspond to each checklist item.

Enphase is embracing short training videos and the popularity of YouTube for education too.

Enphase has recently rolled out a series of videos on its channel that answer very specific questions installers may have while working through an installation, like “How to replace an IQ Gateway’s serial number for a customer’s site using the Installer App.” The videos are about a minute long to help the installer get answers quicker.

SolarEdge’s YouTube channel currently offers longer-form instructional videos closer to formal training modules, but still aims to help contractors solve installation issues on their own.

“We’re seeing a lot of users wanting just short, quick things that are showing hands-on applications. YouTube videos are what people want to watch. So we are evolving and modifying our stuff based on what consumer needs are,” Spina said.

For more tactile learners, manufacturers offer a few different options for in-person inverter and battery training.

commissioning times on batteries. If you don’t have that training, a lot of times, those first 10 installs, you’re stumbling through them and it’s very timeconsuming,” she said.

In this smart-home era, where a residential system could include solar, storage, EV chargers and more, SolarEdge is also working to make it easier and quicker to install multiple products at once.

“We’re trying to bring and add efficiencies to the entire installation process. That’s a big thing we hear from installers — half of my team is sitting and waiting while the commissioning is updating or while there’s a firmware update, so what can you do in best practice during that time?” Spina said.

In addition to regular trainings at distribution centers, Enphase offers mobile training vans available to travel to installation companies for sessions.

“They can literally wire up our battery storage product and actually commission it, which is super wild by the way. Not all companies can do that,” Sullivan said.

“The first thing I did when I came to Enphase is I said we need more ‘for us, by us’ content for installers. I’m in the field, I want to know something right now. I don’t have my computer; I can’t sit down and take a training. I want something right in front of me. So I started a YouTube channel,” Sullivan said.

Both SolarEdge and Enphase offer in-person product training options to supplement online learning, with sessions held regularly at distribution centers across the country, like Greentech Renewables.

SolarEdge trainings are held for free once a month. Spina said she’s found contractors that prioritize hands-on training, especially for more complex battery installations, save time later.

“They’re down to under-30-minute

The biggest inverter players may have the funds and staffing to create comprehensive training programs themselves, but other manufacturers may not be in the same position. In those cases, large installation companies and other training providers are stepping in to fill the need.

NABCEP offers both general online courses on solar installation and design

We’re trying to bring and add efficiencies to the entire installation process.Suntuity

as well as training for specific products, including Sungrow, Fronius and Solis inverters.

National residential installer Suntuity Renewables also started its own training program to ensure consistent education for its over-400-person team of workers as new products hit the market.

“There’s very little hands-on training that’s available, other than the manufacturers sending their reps. If you don’t have the right training, it is a revenue loss for the companies installing, but more importantly, it is dangerous for the industry,” said Suntuity CEO Dan Javan.

“At the end of the day, you’re putting a power plant in someone’s home. If you don’t do it right, you’re going to burn someone’s house down,” he continued.

To boost install training, Suntuity has started a combination of online learning and in-person sessions at the company’s 10 regional offices.

“You’re starting off online, which gives you the fundamentals, but really the best practices need to be done inperson, where you can touch and feel the product,” Javan said.

Suntuity is now opening up its NABCEP-certified Suntuity University training model to other installers. Currently, the company has partnered with inverter manufacturer Hoymiles and smart electric panel maker Span to offer training courses. Those manufacturers pay Suntuity to host the online and inperson courses, which are then offered free to any installer who wants to learn.

The installation company is in talks with other manufacturers interested in hosting trainings through Suntuity as well. Javan thinks dedication to thorough training will be a make-or-break factor in inverter brand success as more players enter the market.

“Because the capital markets are tightening up, there’s margin compression that’s happening, which means now as a manufacturer…you have to justify what you charge,” he said. “What’s the additional value you bring to the equation? Training is one of them.”

Javan said he’s seeing other large solar installers starting training programs like this for internal purposes. He thinks this can only be a boon to the industry and will ensure higherquality installations.

“If we can now license our training programs to some of the training curriculums that they put together and crosscollaborate, I think that’s going to help the industry grow in general,” Javan said.

As systems become more complex and move toward whole-home electrification, thorough training for installers will only grow more important. SPW

Intensifying weather events related to climate change are affecting everyone globally. I experienced an especially turbulent summer in my little corner of Northern Ohio, an area considered one of the more climate-resilient locations due to its proximity to the Great Lakes

and lower risk of hurricanes and wildfires. But the summer of 2023 saw incredible wind gusts, intense hailstorms and flash flooding. I slogged through multiple long-term power outages and sudden flooding in my basement. My climate anxiety is at an all-time high, and I’ve

been exploring backup power options.

I believe I’m part of an untapped customer segment for solar and home energy contractors — homeowners who don’t consume a lot of power or have high enough utility bills to justify a traditional solar + storage system but are

still concerned about future power needs. I could easily get a natural-gas generator for emergency backup, but I want to be green and have a safer alternative for use inside the home.

In a moment of serendipity, clean energy company Nature’s Generator reached out to me the day after a lengthy power outage with the opportunity to test one of its solar generators. Through a comedy of errors, I was unable to test the unit due to its large size — the new Powerhouse Hybrid Platinum system is for full-home backup and comes with four full-size solar panels — and I’m one small solar editor with limited upper body strength. But the system still piqued my interest, and I wanted to learn more.

Nature’s Generator began

development of its flagship product in 2015 — a compact, solar-powered, portable generator. The original lead-acid Nature’s Generator system delivered 1.8 kW of electricity, and additional lead-based Power Pods could be added to fit a customer’s needs. It was an attractive option for off-grid situations, especially since the generator could be hooked up to portable solar panels and small wind turbines.

The product offerings from Nature’s Generator have expanded in recent years, and now the company manufactures larger, whole-home systems. The hybrid Powerhouse system is unique because it pairs lithium and lead-acid batteries — a setup not often attempted in whole-home backup.

The solution is anchored by one core lithium battery with an advanced battery management system, with the ability to add cheaper lead-acid batteries for more affordable, expanded power.

The Nature’s Generator Powerhouse Hybrid Platinum system consists of one LFP battery, expandable AGM lead-acid batteries, four 410-W solar panels and a 7.2-kW output. I talked with Lawrence Zhou, CEO of Nature’s Generator, to learn more about the unique system.

SPW: What is the Nature’s Generator company mission?

LZ: Nature’s Generator is a believer that consumers shouldn’t pay for equipment they don’t need, so every one of Nature’s Generator’s solar-power-systems are

expandable. This means people can grow their systems as their power needs grow. Keeping consumer cost low is very important to Nature’s Generator. The company was founded on the principle that electricity should be available and affordable to everyone. Having access to affordable, reliable electricity can be life-changing and, in some cases where powering medical equipment, food preservation or heating/cooling units are involved, lifesaving. We want our products to be affordable, because if they’re affordable they will be used to help people and help the environment.

Who is typically a Nature’s Generator customer?

We want to have our products available and affordable to everyone. Our customers tend to be people that appreciate a good “bang for the buck” — people who aren’t necessarily experts in solar but want to buy a product that gives them their money’s worth. We appreciate that ethic and, in turn, work hard to ensure our products match their expectations — high quality, high performance and high value but at an affordable cost.

The Powerhouse is a solar-powered and/ or wind-powered whole-home system. The Powerhouse system has a 7.2-kW, 120/240-V capacity and can power an entire home. Combined with our solar panels or our wind turbines, this generator is truly a powerhouse. This product was launched in 2022 and it’s a favorite of people looking to power an entire house with clean, renewable, climate-changefighting technology. And, of course, the Powerhouse system is expandable and can be augmented with additional power pods to increase wattage and running time further to fit the consumer’s needs.

The benefit of having wind charging is that, without fail, the sun sets each evening, but wind turbines can continue to power and recharge your Nature’s Generator even when it’s dark outside. Having the ability to recharge your Nature’s Generator systems with solar or wind power is a great added benefit, particularly for off-grid living.

What is the story behind the Powerhouse Hybrid Platinum system that can use both lithium and lead-acid batteries?

The Powerhouse Hybrid Platinum system was released in 2023. This specialty product was designed to save consumers money. This hybrid system can use both sealed lead-acid (SLA) and lithium-iron phosphate (LFP) batteries, giving consumers the benefits of both technologies. The LFP battery technology strengths include 6,000+ lifecycles, higher energy density and up to a 10-year lifespan. The SLA battery technology strengths include performing well in colder temperatures, high power output and an exceptionally affordable price. Plus, the hybrid Powerhouse allows consumers to upgrade without having to totally replace their old battery systems.

How are you able to use both lithium and lead-acid in the same system? What makes this possible is the Nature’s Generator “Eco-Intelligent Li” which is an intelligent battery management system. The Eco-Intelligent Li solves the problem of bias current and circulation in a parallel system and supports the mix of old and new lithium batteries and the intelligent mix of lithium and lead acid batteries which can give the user the best of both technologies as well as reduce system maintenance and upgrade costs — which improves the return on homeowners’ solar system investment.

One problem with many battery management systems currently on

the market for lithium batteries is the discharge and charge of lithium batteries may be inconsistent if connected in parallel — a connection pattern often used for batteries in solar-powered generator systems. This means that many existing systems will suffer poor safety performance, have low energy density, have a poor ability to achieve deep discharge and won’t adopt charging and discharging of other batteries when connected in parallel.

The Nature’s Generator EcoIntelligent Li battery management system solves these problems. It extends battery life and supports the mix of old and new LFP batteries and a mix of LFP and SLA batteries.

The Hybrid Powerhouse also uses the Eco-Intelligent Li system to solve the problem of the contradiction of energy consumption between lithium batteries. The Nature’s Generator battery management system adaptively adjusts the discharge current of old and new lithium batteries. The discharge current of a new battery is large, and the discharge current of an old battery is typically small. The Eco-Intelligent Li system provides a current sharing control strategy to ensure a common discharge of batteries, so the older batteries won’t just drain the new ones.

This means the Eco-Intelligent Li will support multi-module parallel connection, furnish a two-way automatic adjustment of output power, participate in intelligent peak shaving, support lithium and lead-acid batteries as well as the mixed use of old and new batteries, offer automatic matching of battery parameters to improve battery life and performance and allow for 100% utilization of battery capacity.

What are the advantages to the endcustomer for this hybrid system? This product was specifically designed to help customers reduce waste

and save money by allowing them to upgrade their systems without needing to completely replace their old systems. Now users can enjoy the lighter weight and longer (up to 10-year) life of LFP batteries, while still having the advantage of the higher power output and the high-low temperature performance of lead-acid batteries as well as their highly affordable price.

The Nature’s Generator Platinum Hybrid Powerhouse with its EcoIntelligent Li smart battery management system gives users the option to use both LFP and SLA battery technologies compatibly and simultaneously. This innovation will help increase the lifespan of homeowners’ solar investments, offering solutions to affordably buy, maintain, upgrade, extend and expand solar-powered generator systems. We like to say it’s a game changer. SPW

Combining a High-Voltage ba ery and inverter with a Smart Energy Panel, the Fortress Power Avalon HV ESS is truly an all-in-one, whole-home backup system.

• Manage system from mobile app

• Scalable up to 58.8kWh with a stackable, ultra-thin design

• 4 MPPTs for maximum e iciency (max 18.24 kW PV array)

• AC or DC Coupled with 200A pass-through & grid transfer switch

• Smart load management to control up to 12 circuits

• Integrated module level rapid shutdown transmi er

The eSpire Mini Energy storage system is a fully integrated, pre-configured turnkey solution for Large Residential and Light Commercial Projects (3Ph 208/480Vac @60Hz). The eSpire Mini has numerous applications such as Microgrid, backup, o -grid, dynamic peak-shaving, time of use, self supply, demand response and Virtual Power Plant (VPP). With AC and DC Coupling options, indoor and outdoor installation and Scalable capacity from 81-266kWh per unit, the eSpire Mini is perfect for your next project.

www.fortresspower.com

(877) 497-6937

sales@fortresspower.com

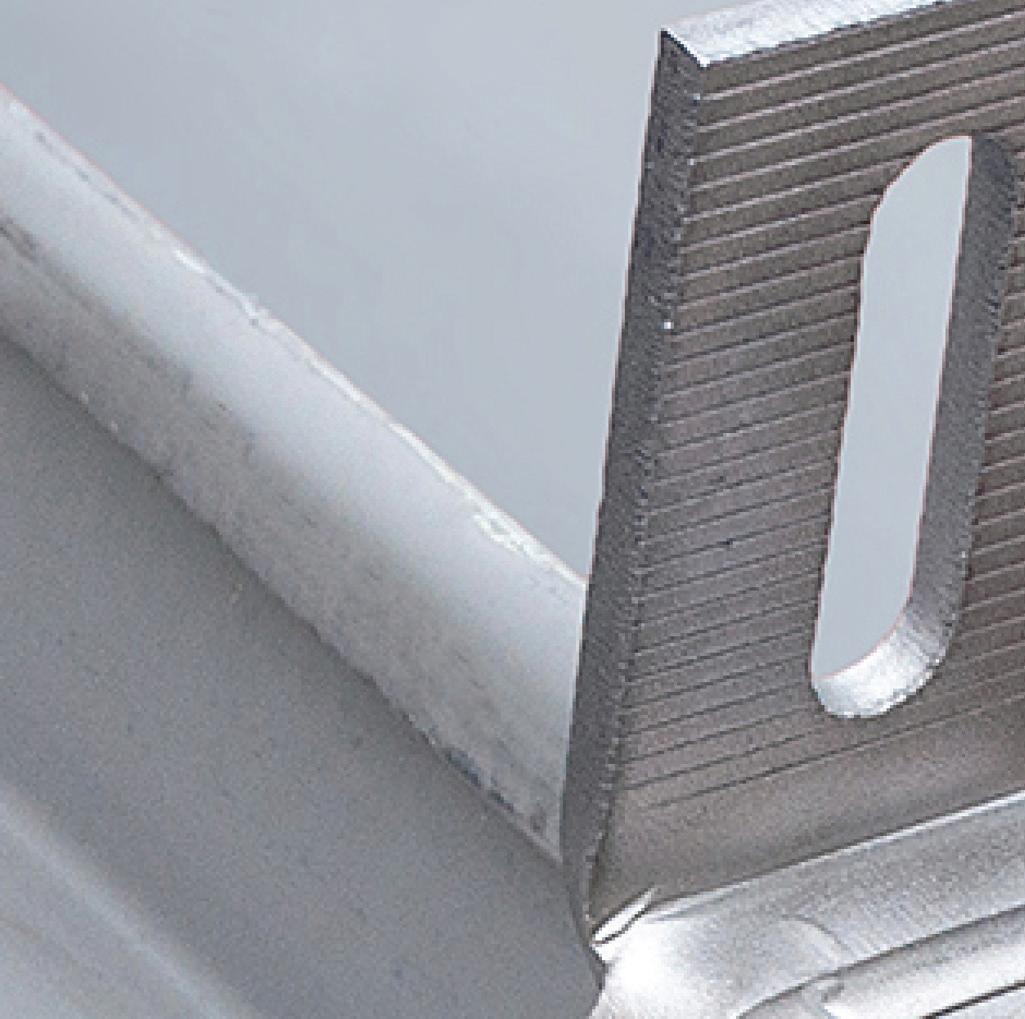

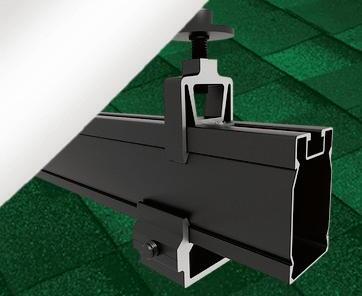

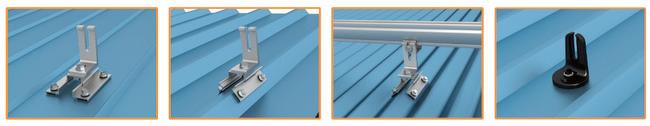

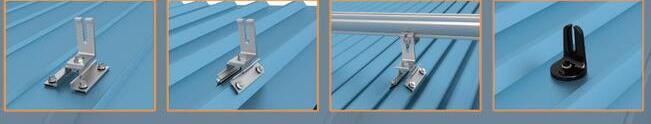

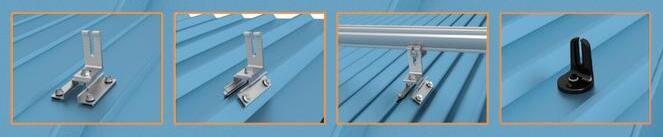

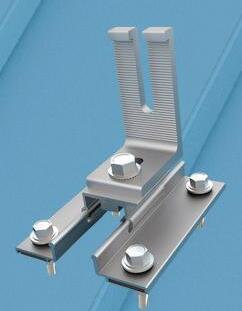

Every type of rooftop has its own quirks that contractors must consider when installing a solar project. Metal roofs come in a variety of profiles and material makeup that require specialized mounts to match them, but installing solar on these specialized roofs doesn’t have to be difficult.

Metal rooftops are a common covering choice for commercial buildings with a top built at a slight pitch, and they’re growing in popularity in the residential market too. The Dodge Construction Network, a construction industry analyst, released a report claiming residential metal roof adoption

increased from 12% in 2019 to 17% in 2021 in the United States.

Perhaps metal rooftops are a little louder during a hailstorm, but their durability contributes to a 70-year lifespan. Meanwhile, asphalt shingle roofs have an even shorter lifespan (15-30 years) than solar panels (25+ years).

“The metal roof is the only roof that will outlast the solar. You install solar on any other roof type — TPO, PVC, EPDM — if the roof is new when you’re installing the solar, it might last 15 or 20 years,” said Rob Haddock, CEO and founder of S-5!, a metal roof attachment manufacturer. “You’re going to have to dismantle the solar to replace the roof and that just shatters the financial pro forma of the solar.”

Installing metal is more expensive than a composite shingle roof but could make more economic sense for a building in the long-term. The three types of metal roof coverings are corrugated, standing-seam and stone-coated steel:

• Corrugated roofing comes in long sheets that run the length of a roof surface with built-in ridges, like rounded waves or trapezoids. Sheets are face-attached to the roof, meaning they use exposed fasteners to secure to a building.

• Standing-seam roofing is also manufactured in sheets, however, it is mostly flat except for interlocking channels placed on both sides of the roofing panel. These channels or ribs have hidden fasteners that secure each roofing panel in succession, leaving a protruding seam.

• Stone-coated steel roofing resembles clay tiles or shingles more than corrugated or standing-seam roofing. Smaller sheets of steel are formed into tile shapes and coated with stone granules.

Each of these roof types require different mounting techniques for solar projects. Mounting solar panels to corrugated roofing most closely resembles installing on comp shingle, since securing through penetrations is still necessary. On a corrugated roof, a lag bolt is driven through the sides of a trapezoid or

elevated portion of the roof, or the mount is secured straight down to the building structure.

Solar mounts for corrugated roofs are designed to follow their contours. S-5! manufactures a line of attachments for corrugated roofs that use fasteners with gaskets to waterproof each roof penetration.

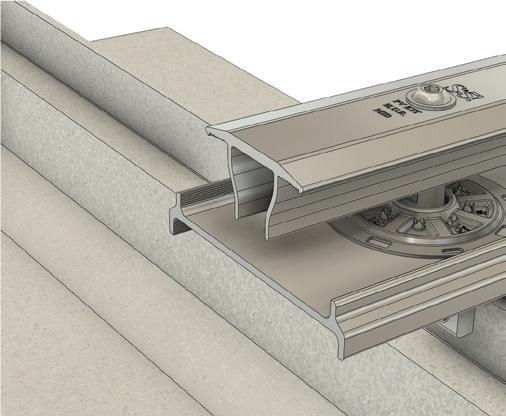

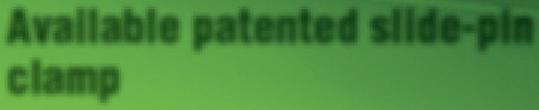

For a standing-seam roof, penetrations are rarely necessary. Solar mounts secure to the top of the seams using angled fasteners that drive into the surface of the vertical metal plane to create indents that hold a mount in place. These raised seams can also act as structural rails often seen on pitched-roof solar projects.

“You basically have rails on the roof that you can just grab, clip around and install,” said Mark Gies, director of product management at S-5! “You don’t need as much hardware because the hardware is kind of integral in the roof.”

Stone-coated steel roofing resembles clay tiles not only in shape but also in how solar is installed onto it. On a tile roof, installers must either remove a section of tiles or cut through the tile to reach the underlayment and attach a hook to the roof surface that protrudes through the gap between tiles.

“Usually, they’ll grind or chip out the tile material so that it can rest on top of the other tile like it’s supposed to, and the hook can come through it,” said Mike Wiener, marketing manager at QuickBOLT, a solar mounting manufacturer. “You don’t really worry about that with stone-coated steel because it’s metal and it’s overlapping. By design, it’s meant to have some wiggle room in between.”

With stone-coated steel, installers can bend and lift

that metal shingle without removing or breaking it, and similarly install a hook that extends past the shingle. QuickBOLT recently developed roof hooks that are designed for stone-coated steel roofs. The hook is shaped to work around the wooden batten that each row of stonecoated steel roofing is attached to.

Metal rooftops are primarily composed of steel, aluminum or copper. At a chemical level, there are metals that are incompatible when they touch each other, causing what is called a galvanic reaction that can spur corrosion or oxidation. For example, crossing steel or copper with aluminum can cause a galvanic reaction. Luckily, steel rooftops are sealed, so installers can use aluminum mounts, while there are brass mounts on the market that are compatible with copper.

“Aluminum will pock up, rust away and disappear,” Gies said. “Uncoated steel, just the environment will rust that. Whereas, you can have bare aluminum, because aluminum protects itself with an anodization layer.”

Running wires on a metal rooftop solar project shares most of the same tenets as wiring on other roof types. However, it’s more critical to keep wires

from touching metal roofs, Gies said.

Wiring a rail-based system follows the same steps as other roof types, where installers can use the rail to clip wires or as a channel for wire runs. With rail-less projects on standing-seam roofs, installers must clip strings to the module frames. Gies recommends determining string routes and clipping wires before solar modules even reach the roof.

“There’s more emphasis on preparation and the design of where the string’s jumpers are when you do rail-less on a metal roof,” he said. “It’s important to prepare the module ahead of time — that everything’s clipped and out of the way and nothing’s hanging. That’s good practice anyway, because then when you’re on the roof, installation is so much easier.”

Running conduit lines functions the same on metal rooftops as well. If wires are running inside, there’s a single penetration at the top of a roof with a junction box that runs wiring to the

designated load point indoors. Or if inverters are placed on the outside wall of the building, the wires can be directed there instead.

Despite metal being a conductive material, grounding a solar project on a metal roof is the same as any other style on the market.

“The roof is kind of out-of-scope,” Gies said. “You still have to bond and ground that system like you normally would, no matter if you’re on asphalt or whatever. Just do that the same way and don’t think about the fact that you’re on a metal roof.”

For building owners, the appeal of a metal roof is a long operating lifespan with a material built to withstand the elements. Solar installers building projects on these roofs have some material advantages over comp shingle and tile, but can encounter conditional risks.

The granules in comp shingles and

even stone-coated steel make it easier to walk and grip on these roofs. Corrugated and standing-seam roofs are smoother, and with rain or snow can be slick. That slip risk increases as a roof’s pitch gets steeper. Proper rooftop fall protection and anchor systems should be used when working on these special roofs.

Metal is also an inherently heavier material than comp shingle and, especially in commercial scenarios with larger roof spans, buildings cannot always handle additional weight atop them.

“That’s part of the challenge in that these steel buildings, they’re not built to take a lot of weight up top sometimes,” said Alex Deeter, senior sales and marketing engineer at SunGreen Systems, a commercial solar contractor from Pasadena, California. “So, depending on when it was constructed or what purpose it was constructed for, it’s figuring out what’s the lightest weight solution or how can we spread it out across the building.”

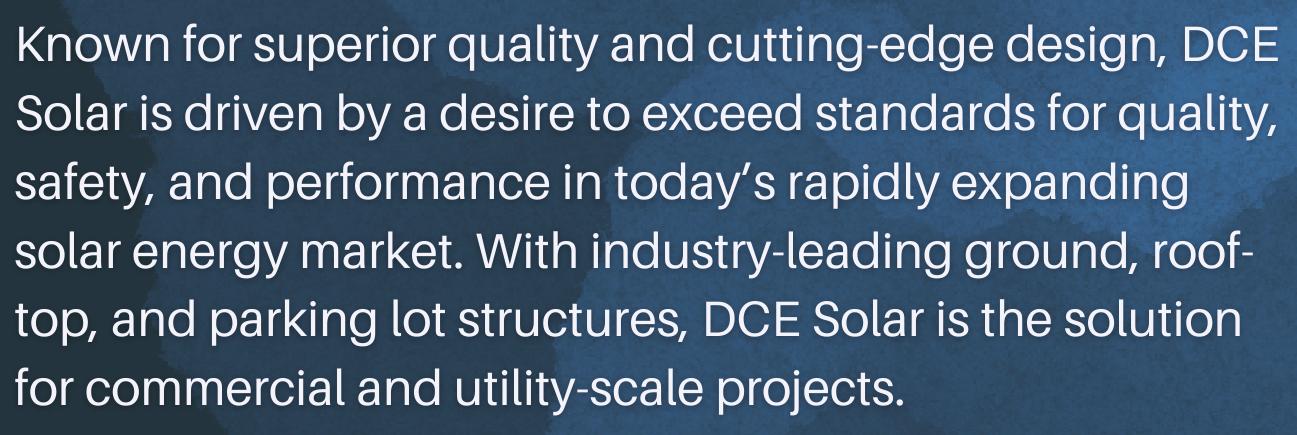

Despite these potential challenges, installers will no doubt encounter more solar projects on metal rooftops as more people choose this material for its durability and lifespan. With its unique considerations in mind, contractors can hone their installation practices like sharpened steel. SPW