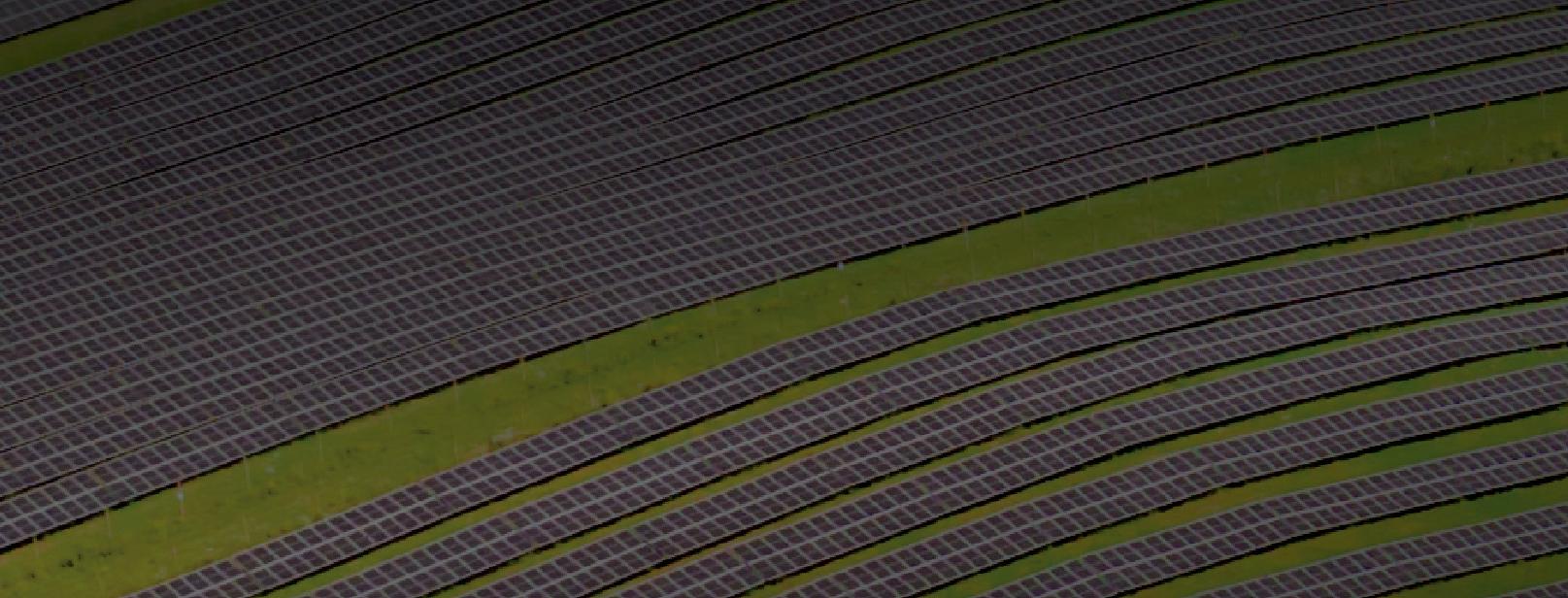

As North America’s most diversified steel and steel products company, Nucor is committed to delivering quality, on-time reliability, and sustainability to the renewable energy market. Our Energy Solutions team is your partner in optimizing the design and installation of your next solar and wind projects.

Let’s work together to make your next project a success.

Following solar policy is like scheduling a flight right now — with the shortage of airline workers, extreme weather and other factors, you don't want to get your hopes up that you’ll arrive on time, and if you actually do, you're ecstatic. The odds are high that there will be cancelations and rescheduling along the way.

Such was the case with the solar priorities that SEIA and other industry advocates have been aiming for ever since President Joe Biden took office in 2021. Solar incentives began popping up in new legislation and federal policy platforms, starting with a standalone storage tax credit and 10-year ITC extension in March 2021, followed by a solar production tax credit in September 2021. Then in the Fall, to the industry's delight, the Build Back Better Act was introduced, containing most of those priorities and solar manufacturing tax credits.

That didn't end well. But even after Sen. Joe Manchin made it clear he wouldn't support the bill in December 2021, the solar industry remained positive about getting these priorities to the White House. SEIA’s president and CEO Abigail Ross Hopper said after the Manchin statement that the organization still believed strongly that members of Congress would continue to press ahead.

And press they did — both the solar industry and members of Congress kept working behind the scenes to include solar legislation in budget reconciliation. After yet another hiccup in July 2022, with Manchin again saying he couldn't support reconciliation legislation in its current form, he and Sen. Chuck Schumer shocked the country by announcing a surprise deal two weeks later that included almost every single solar policy request from the industry.

Now, these federal solar incentives are law. They include a 10-year ITC extension, standalone storage ITC, domestic manufacturing incentives and many more provisions that are expected to transform the industry. Solar installers and developers will greatly benefit from long-term certainty and a path to more

American-made, non-tariffed solar products; and American homeowners, nonprofit organizations, tribes and more will benefit from tax credits that make going solar more affordable for more people. Read my story on everything the law does for the solar + storage industry on page 26, and follow Solar Power World over the coming months as we dive even deeper into each element that will impact your solar business. Although it was unpleasant to spend hours researching the fine print of bills only to see them languish over the past year and a half, it's all the more gratifying when the legislation finally reaches the president's desk. In the end, it was well worth it to book that flight. SPW

Kelsey Misbrener Managing Editor kmisbrener@wtwhmedia.com

PUBLISHER Courtney Nagle cseel@wtwhmedia.com 440.523.1685

EDITORIAL

Editor in Chief Kelly Pickerel kpickerel@wtwhmedia.com @SolarKellyP

Managing Editor Kelsey Misbrener kmisbrener@wtwhmedia.com @SolarKelseyM

Associate Editor Billy Ludt bludt@wtwhmedia.com @SolarBillyL

VP of Creative Services Mark Rook mrook@wtwhmedia.com

Art Director Matthew Claney mclaney@wtwhmedia.com

Senior Graphic Designer Allison Washko awashko@wtwhmedia.com

Graphic Designer Mariel Evans mevans@wtwhmedia.com

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

MARKETING (CONT.)

Digital Production/ Marketing Designer Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Webinar Coordinator Halle Sibly hkirsh@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com

Digital Media Manager Patrick Curran pcurran@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Front End Developer Melissa Annand mannand@wtwhmedia.com

Digital Production Specialist Nicole Lender nlender@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

IN-PERSON EVENTS

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

Videographer Manager Bradley Voyten bvoyten@wtwhmedia.com

Videographer Garrett McCafferty gmcca erty@wtwhmedia.com

Videographer Kara Singleton ksingleton@wtwhmedia.com MARKETING

VP of Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

Digital Marketing Coordinator Emily Gillespie egillespie@wtwhmedia.com

Events Manager Jennifer Kolasky jkolasky@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

WTWH Media, LLC : 1111 Superior Avenue, Suite 2600, Cleveland, OH 44114 Ph: 888.543.2447 | Fax: 888.543.2447

SOLAR

SOLAR

by-lined articles express the views of the author and not necessarily of the publisher or publication. Every e ort is made to provide accurate information. However, the publisher assumes no responsibility for accuracy of submitted advertising and editorial information. Non-commissioned articles and news releases cannot be acknowledged. Unsolicited materials cannot be returned nor will this organization assume responsibility for their care.

SOLAR POWER WORLD does not endorse any products, programs, or services of advertisers or editorial contributors. Copyright©2022 by WTWH Media, LLC. No part of this publication may be reproduced in any form or by any means, electronic or mechanical, or by recording, or by any information storage or retrieval systems, without written permission from the publisher.

SUBSCRIPTION RATES: Free and controlled circulation to qualified subscribers. Non-qualified persons may subscribe at the following rates: U.S. and possessions, 1 year: $125; 2 years: $200; 3 years $275; Canadian and foreign, 1 year: $195; only U.S. funds are accepted. Single copies $15. Subscriptions are prepaid by check or money orders only.

SUBSCRIBER SERVICES: To order a subscription or change your address, please visit our web site at www. solarpowerworldonline.com

SOLAR

POSTMASTER: Send address changes to Solar Power World; 1111 Superior Avenue, 26th Floor, Cleveland, Ohio 44114.

After more than a year of stops and starts, landmark legislation for the solar + storage industry has become law in the form of the Inflation Reduction Act. All solar sectors will see new or expanded tax incentives.

The patented M18KD gearless, dual-axis tracker from Mechatron Solar is the highest-yield solution in the industry. With the smallest land use footprint, it's the uniquely winning design solution for C&I and utilityscale installations.

Benefits include:

40% higher yield than fixed tilt installs with the same number and type of panels

20% higher yield than single axis installs with the same number and type of panels

15%+ yield boost from bifacial panels, depending on substrate

Supports up to 40 KW of solar, compatible with all PV module types

Sustains up to 135 mph winds due to elliptical tube design and double-band brake system

High survivability due to self-slippage under extreme wind conditions

Operating temperature range -20°C (-68°F) to +70°C (158°F)

Quick and easy installation with patented zero-backlash gearless drive mechanism

Rural-to-urban applications with 360° range of motion and 0-60° degree elevation

Reliable 99.6% up-time, measured for over a decade across thousands of installs

Typical payback time is 3 years or less with the lowest LCOE in the industry

Bankability Report by Black and Veatch & Certified to UL 3703 Tracker Standard

See detailed specs at www.mechatron-solar.com or scan the QR Code

With a new law in place, Massachusetts solar installers can now sell larger residential projects that still qualify for net metering.

New CPUC proposed decision on NEM 3.0 expected by September 29

Sacramento, California

After many months of solar industry protests, the California Solar & Storage Association is expecting the CPUC to release its proposed decision on net metering in the state on or before September 29. The CPUC issued an initial proposed decision in December 2021 that would have added new grid-use charges and shifted to a net billing structure.

Boston, Massachusetts

Gov. Charlie Baker signed climate legislation in Massachusetts that included significant investments in solar power. Most notably, the law doubles the size of residential solar projects eligible for net metering to 25 kW and establishes incentives for pollinator-friendly commercial-scale projects.

Consumers Energy adjusts community solar rules to expand access

Jackson, Michigan

Michigan utility Consumers Energy reached a settlement with stakeholders to expand opportunities for residential and business customers to purchase renewable energy. The new provisions include an “anchor tenant” option that allows a central tenant, like a school or business, to host community solar projects.

Biden signs Inflation Reduction Act with many solar and storage provisions

Xcel Energy can now cap the amount of clean energy on sections of grid

St. Paul, Minnesota

The Minnesota Public Utilities Commission approved changes to the state’s interconnection rules allowing Xcel Energy to cap the amount of clean energy installed on a section of the grid. The Interstate Renewable Energy Council found this change increased the number of sections of the grid closed to new renewables by 4%.

Mississippi raises solar netmetering cap and creates new rebate program

Missouri strikes down property tax exemption for certain solar systems

Jefferson City, Missouri

Missouri’s Supreme Court struck down a 2013 state law exempting large solar projects from property taxes, according to the Associated Press. The court said the tax break was not allowed under the state’s constitution, so now some solar project owners could owe back taxes.

Biden Administration announces new grant funding for solar job training, manufacturing

Jackson, Mississippi Washington, D.C. Washington, D.C.

President Joe Biden signed the Inflation Reduction Act after climate provisions were revived by Senators Chuck Schumer and Joe Manchin. The bill includes a long-term extension of the solar ITC, standalone storage credits, direct pay for nonprofit entities, solar manufacturing tax credits and much more.

Illinois Commerce Commission approves detailed roadmap to reach 40% renewables by 2030

Springfield, Illinois

The Illinois Commerce Commission approved a long-term plan that outlines the steps the state must take to reach 40% renewables by 2030. This includes a roadmap for how the state will expand the Illinois Solar for All low-income program using a dedicated $70 million now available each year.

The Mississippi Public Service Commission recently raised the state’s net-metering participation cap and added a $3,500 state rebate for homes and small businesses that go solar. The commission also announced higher rebate payments to households earning up to 250% of the federal poverty level.

New Mexico’s hard-fought community solar legislation now in jeopardy

Santa Fe, New Mexico

After a yearlong, stakeholder-involved process establishing community solar rules in New Mexico based on 2021 legislation, the Southwestern Public Service Company filed a motion that could potentially stall the program for years. Advocates are asking for the Supreme Court to dismiss the case and move forward with the program.

The Biden Administration announced a slate of new initiatives and $56 million in new funding to spur innovation in solar manufacturing and recycling. The administration separately announced a $10 million investment in expanding community solar access and solar job training opportunities in underserved communities.

Georgia Public Service Commission approves 200 MW of new solar projects

Atlanta, Georgia

Georgia’s Public Service Commission voted to expand solar arrays throughout the state by 200 MW and increase energy storage deployment. The commission also voted to establish a DG Working Group — with five out of 20 seats going to solar developers — to work toward the goal of streamlining solar project approval.

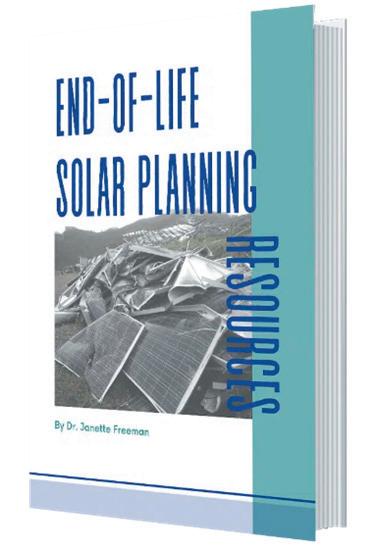

It’s common for technologies to leave the solar market. The industry is constantly growing and changing, and not every manufacturer survives.

What’s uncommon is for a solar technology that’s been dormant for half a decade to resurface under a new name.

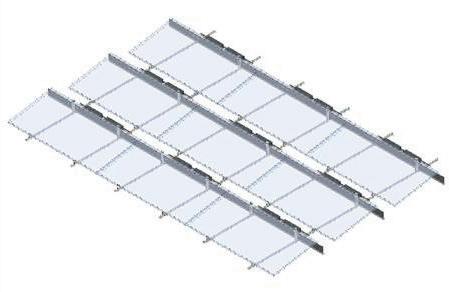

In 2017, solar racking and module manufacturer tenKsolar shuttered. Today, its technologies are available again from a new company called Global RAIS.

Greg Cox, co-founder and president of Global RAIS, and his business partner Todd Broome are responsible for reviving tenK’s proprietary interconnected-cell solar modules and kit-based racking. Cox is an environmentalist and former solar contractor who used the “dual-tilt” systems in the past, installing several projects using tenK technology on buildings belonging to Broome.

tenK was founded in 2008 and shuttered nine years later. The manufacturer was known for its prepackaged “wavelets” primarily installed in the commercial market. Solar panels, racking and microinverters were sold together as kits.

Many tenK systems began failing after deployment due to a microinverter manufacturing issue that caused water damage. One report said that in 2015, 100 installations in Minnesota alone were malfunctioning.

tenK was addressing the microinverter failures when it went out of business in 2017 for an unrelated issue. Global RAIS plans to help previous tenK customers replace faulty inverters with its current, compatible microinverters.

As tenKsolar was closing its doors, Cox was in the middle of several projects, so he acquired some of the company's remaining product inventory.

"I was curious as to what was going to happen with the technology," Cox said. "It was a really good technology, and I was sad to see it go away."

So, he and Broome formed a company to purchase the intellectual properties belonging to tenK. By that point, tenK had ceased all operations, sold the rest of its inventory and laid off its employees. But the former owners still had possession of the technology’s IP and patents.

Cox and Broome pitched the former tenK owners on acquiring the technology, which included 30 patents relating to solar module and racking design. The pair officially acquired tenK’s IP in June 2019 and prepared to

revive the dormant solar technology as soon as investors were secured. But then COVID-19 hit.

"COVID was actually a blessing in disguise for us, all of the devastation notwithstanding," Cox said. "It’s allowed us to really rethink and strategize and position ourselves to be successful. Clearly, we’ve learned lessons from what tenK went through and we’ll not repeat some of the same processes. I’m a big believer in needing to walk before we run."

The company name Global RAIS is a reference to one of the key patents on tenK's technology. It stands for “Redundant Arrays of Integrated Solar.” What differentiates Global RAIS's solar panel technology is its solar cell structure.

"Rather than being serial-based architecture where every cell is connected to the next cell and so forth — and you build voltage as you add cells and add modules — this IP allows us to build everything in a matrix fashion," Cox said. "So, each cell is connected to the next cell in multiple pathways."

This means that individual cells in Global RAIS panels can still perform without hindrance from neighboring cells that are underperforming; whereas solar cells with typical connections can underperform if neighboring cells experience performance loss, like shading or microcracks.

Global RAIS demonstrated the durability of its panels in a side-by-side test with a

I was curious as to what was going to happen with the technology. I was sad to see it go away.

competing module brand by simulating shading and damaging the panels with a baseball bat, bullet holes and even by throwing a whole kitchen sink at each panel. Due to its parallel cell structure, the Global RAIS module continued to produce power throughout the test.

This ability to operate through shading and other obstructions is what makes Global RAIS panels suited for commercial rooftops with HVAC systems casting shade throughout the day, Cox said. The company is so unconcerned with shading, Global RAIS’s system is designed to work with shadows.

The dual-tilt racking places panels back-to-back at 26° and 16° angles in each row. With those varied panel angles and the compact nature of the racking, inter-row panel shading is unavoidable during the day. But Global RAIS is betting

that the ability to pack more panels onto a surface and mitigate that inevitable shading means these systems will outperform traditional arrays.

“It allows us to put a much higher density of potential energy generation in a smaller footprint because of the shading,” Cox said. “In traditional solar, you’ve got to account for that shading. We don’t need to deal with that, so we can pack a much higher amount of power in a smaller footprint.”

The system can be designed in east-west, north-south or any orientation off-azimuth, and it can be mounted to the ground. The panels and racking are sold together as one package and can’t be mixed and matched.

Global RAIS modules are currently using Northern Electric Power BDM-800 microinverters with customized firmware

In traditional solar, you’ve got to account for that shading. We don’t need to deal with that, so we can pack a much higher amount of power in a smaller footprint.

that adapts to their low-voltage output, but the company is exploring other collaborations too. DC-coupled storage integration is made simple with Global RAIS’s module-level electronics package, which features configurable voltage controls that eliminate the need for an additional battery management system.

“That storage-ready module, that’s a key component. If there’s one thing that’s really convinced us that we should come back to the market now, it’s this direct-tostorage piece,” Cox said.

Reviving a solar technology that left the industry years ago has made Cox reflect on the choices that led to tenK’s demise. He saw an opportunity to fill a niche in the market with this hardware that he loved enough to pursue the patents, but he also recognizes opportunities at an institutional level to operate differently.

Global RAIS is pursuing a B Corp certification, which will mean flattening corporate governance among employees, being transparent about the company’s

performance and, of course, prioritizing sustainability within the company and all the way up the supply chain.

The company is also planning to install solar systems for clients that provide critical public services during natural disasters, like food banks and medical centers.

"We seek to do good with this product, and we need to do good with this product in places where this is going to make a huge difference to how people live,” said Robin Cox, chief sustainability

officer at Global RAIS. “In a lot of places, you need reliable, readily available clean energy, so the B Corp certification allows us to do that within the same corporate structure."

After pursuing and acquiring the rights to a dormant solar technology, reestablishing manufacturing operations and emerging from a pandemic, Global RAIS solar modules and racking are once again a reality. The company has sold its first projects, but this is just the beginning of its re-entry into the solar market.

“We don’t have a magic mirror,” Robin Cox said. “We don’t know what the future holds, but we teach and learn better by doing it ourselves. As the company grows, our intent is to do it different and figure it out along the way.”

SPW

THE Inflation Reduction Act, packed with incentives for the solar + storage industry, was signed by President Joe Biden on August 16. Solar advocates believe the sector will boom thanks to the long-term certainty provided by this law.

“The changes to the ITC are monumental. They are things that will create a longer runway for clean energy growth in America,” said SEIA president and CEO Abigail Ross Hopper. “The ITC, as we know, is the No. 1 policy driver in the solar industry and has helped us build the industry to what we have today.”

Here’s what’s in the IRA.

The personal income tax credit for solar power is raised to 30% and extended by 10 years, with stepdown beginning in 2033. Standalone residential batteries over 3 kWh, purchased after December 31, 2022, are also eligible for the 10-year, 30% ITC. There is no direct pay option for residential projects.

Commercial solar incentives in the IRA fall into two categories based on project size.

Commercial projects under 1 MWAC can receive the 30% ITC with

no prevailing wage or apprenticeship requirements to receive the full benefit.

Commercial projects over 1 MWAC can receive the 30% ITC if prevailing wage and apprenticeship metrics are met. These labor requirements will take effect for projects that begin construction 60 days after the Dept. of Treasury defines the metrics. Companies that begin construction before the 60 days are over are exempt from meeting the requirements to reach the full 30%.

After the 60-day period, commercial projects over 1 MWAC will receive a 6% base credit, with 24% more available if projects meet those

additional labor requirements to make a total of 30%.

Both prevailing wage and apprenticeships are closely based on union labor. A prevailing wage is set by states and is the basic hourly rate of wages and benefits paid to a number of similarly employed workers in a given geography, according to The Center for American Progress. Some states do not have established prevailing wages, according to Pari Kasotia, senior director of policy at DSD Renewables, so the Dept. of Labor will need to create guidance for those scenarios.

Apprenticeships too are typically union-led programs. The IRA dictates what percentage of a project’s workforce must be made up of apprentices, starting with 10% for projects beginning

construction in 2023, increasing to 12.5% in 2024 and 15% in 2025.

“I cannot underscore [enough] the need to ensure appropriate levels of training programs to meet the growing demand for labor that would come from this bill,” Kasotia said.

After 2025, the continuation of the commercial solar and storage ITC for the following seven years is contingent on whether the solar sector and electric sector meet the Treasury Dept.’s greenhouse gas emission goals. The credits will continue until the electric sector’s emissions have dropped 75% below 2022 levels.

Commercial solar and storage projects are also eligible for a number of adders

I cannot underscore [enough] the need to ensure appropriate levels of training programs to meet the growing demand for labor that would come from this bill.

that can take that credit even higher.

Those adders include:

• 10% for meeting domestic content standards, meaning a certain percentage of any manufactured product is made in the United States;

• 10% for siting projects in “energy communities,” meaning places with brownfield sites or coal plant closures;

• Up to 10% for projects smaller than 5 MWAC that are located in low-income communities or tribal lands; and

• Up to 20% for projects smaller than 5 MWAC that qualify as residential building projects or economic benefit systems.

The 5-MWAC cap for some of the adders could be especially fruitful for

community solar projects, which are usually under that size and often serve those incentivized communities.

“There are ways to increase the credit up to 50 to 60%, but, obviously, the details would matter,” Kasotia said. “Ensuring that you are able to cleanly check all of these boxes is important, so the guidance from Treasury will dictate a lot of those details on what it looks like to receive these bonus credits.”

Projects under 5 MWAC can also now receive the ITC for interconnection costs.

The IRA now allows commercial solar developers to choose whether to collect the ITC or PTC on any given project. The

PTC is currently at $0.026/kWh for 2022 and rises with inflation.

While the Investment Tax Credit (ITC) is based on the upfront cost of a solar project, the Production Tax Credit (PTC) is based on the output of the project. The ITC is available in the year a project is placed in service, while the PTC can be claimed every year over the 10-year credit period beginning when the project is placed in service, according to Kevin Pearson, partner and tax attorney at Stoel Rives.

The PTC is especially attractive for high-output, low-cost projects — for example, huge utility-scale arrays.

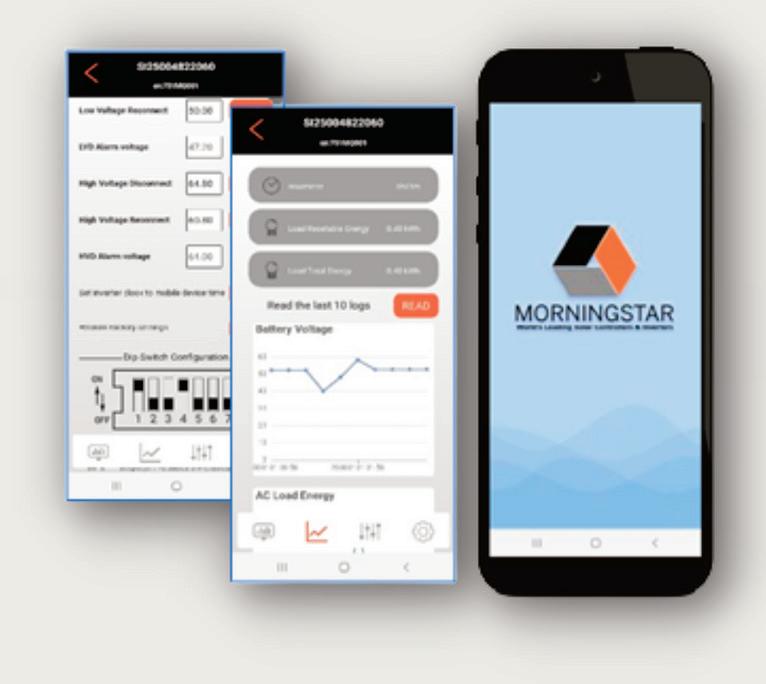

As the leader in solar charge controllers since 1993, SureSine is the inverter line our customers asked us to build. And our competitors will wish we hadn’t.

ureSine starts with the same industry-leading quality and performance standards of our charge controllers and adds a long list of advanced inverter features and technologies: full communications capabilities, wireless utility apps, seamless system integration, multiple AC wiring options, and more. We also built-in the safety, noise and performance standards required to achieve industry-leading NRTL conformance certifications—a unique advantage in this class of inverters.

capabilities, wireless utility apps, seamless system integration, multiple AC wiring options, and more. We

With six power classes ranging from 150 to 2500 Watts offering models with 120, 127 or 230V output and 12, 24 or 48V DC input options, there’s a Morningstar SureSine perfect for your next project

Commercial storage projects larger than 5 kWh are now eligible for the ITC, with the same structure as the commercial solar ITC — with prevailing wage and apprenticeship requirements to reach the full 30%.

In the past, storage had to be paired with solar to receive the ITC. A battery could only take advantage of the solar ITC if it was at least 75% charged directly from the PV asset it was paired with for five years. That meant the paired batteries couldn’t perform many of the additional demand arbitrage functions they were capable of, lest they forfeit the ITC.

The IRA changes that structure, allowing batteries to perform their full breadth of functions while collecting tax credits.

“I like the fact that the bill took the electric system as a whole and provided incentives for each technology that is set to play a significant role in a clean energy grid — solar, storage, wind, electric vehicle infrastructure, interconnection. I’m really glad that they made sure that storage could be combined either with solar or as a standalone system,” Kasotia said.

The IRA now allows for transferability of tax credits after 2022, including both the PTC and ITC. In the past, only a few banks and insurance companies had enough tax liability to

finance large solar projects. The ability to transfer tax credits could allow individuals to finance solar projects through investment funds and other mechanisms, according to Pearson. This new provision could mean smaller projects that can’t get financing from the big banks could get financed by individuals instead.

“That’s a totally groundbreaking concept,” Pearson said. “It’s a very effective way to encourage people to invest in these projects.”

The IRA includes manufacturing tax credits for a number of solar components, from solar panels to trackers and inverters (see sidebar on left). SEIA has already

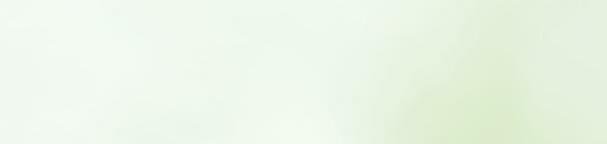

It starts out as best-in-class. And gets better from there

Introducing GenStar MPPT: the industry’s first fully-integrated solar DC system controller

Out of the box, GenStar is an overachiever —an all-new design with “lithium DNA.” Standard features include advanced communications and control, powerful load control, and oversized PV array input capability. On top of that, our innovative ReadyRail architecture makes it easy and cost-effective to add a solar professional’s “wish list” of advanced features and control technologies, including battery metering/monitoring, lithium battery communications and control, signaling and advanced load control, and more. Our snap-in ReadyBlocks make GenStar fully futureproofed for evolving system needs.

With three models up to 100A maximum current GenStar’s ready to bring success your next critical project

Shown with optional ReadyBlocks installed

Snap-in ReadyBlocks enable advanced features to be built-in and fully integrated, instead of wired outside the system as accessories

• Residential solar ITC: 30% until stepdown starts in 2033

• Residential storage ITC for batteries over 3 kWh: 30% until stepdown starts in 2033

•

• Commercial solar projects: 30% ITC until 2025. Credits in 2025 and later are contingent on whether the Dept. of Treasury determines carbon reduction goals are met

• Prevailing wage and apprenticeship requirements to receive full 30%

• These requirements take effect for projects that begin construction 60 days after the Dept. of Treasury defines the metrics

• These requirements do not apply to projects under 1 MWAC

• Commercial storage ITC for batteries over 5 kWh that are placed in service after 2022: 30% ITC until 2025. Credits in 2025 and later are contingent on whether the Dept. of Treasury determines carbon reduction goals are met

• Prevailing wage and apprenticeship requirements to receive full 30%

• These requirements take effect for projects that begin construction 60 days after the Dept. of Treasury defines the metrics

• ITC adders available (for both commercial solar and storage)

• 10% for domestic content usage

• 10% for siting in “energy communities”

• Up to 10% for projects smaller than 5 MWAC located in low-income communities or tribal lands

• Up to 20% for projects smaller than 5 MWAC that qualify as low-income residential building or economic benefit systems

• Projects under 5 MWAC can receive ITC for interconnection costs

• Commercial solar projects can choose whether to receive the PTC or ITC

• PTC is currently at $0.026/kWh for 2022 and rises with inflation

• Credits are transferable after 2022, potentially allowing individuals to invest in projects

suggested that the tax credits in IRA could spur upwards of 30 GW of new solar panel manufacturing capacity in the United States.

Although individual tax refundability did not make it into this bill, direct pay for some nonprofit entities is expected to boost the benefits of solar for these organizations.

The IRA extends direct pay to nonprofit organizations, other community organizations, rural electric cooperatives, Native American tribes, school systems, units of state and local government, the Tennessee Valley Authority and other entities.

•

• Available for nonprofit entities, state or local governments, the Tennessee Valley Authority, rural electric cooperatives or tribal governments

• No direct pay available to residential projects

•

•

• Thin-film or crystalline silicon PV module: 7¢/WDC

• Thin-film or crystalline silicon PV cell: 4¢/WDC

• Thin-film or polysilicon PV wafer: $12/m2

• Solar-grade polysilicon: $3/kg

• Polymeric backsheet: 40¢/m2

•

• Torque tube (defined as: rotated by a tracker drive system): 87¢/kg

• Structural fastener (used to connect a tracker’s mechanical/drive system to the foundation, torque tubes to drive assembles, or segments of torque tubes to one another): $2.28/kg

Before this direct pay provision, nonprofits typically had to partner with tax equity entities to be able to afford a solar installation. The tax equity partners owned the systems and received the tax benefits through power purchase agreements.

“That comes at a cost that cuts into the benefits the direct beneficiary of the system would otherwise get if they owned it themselves,” said Andie Wyatt, policy director and legal counsel at GRID Alternatives.

Some organizations seeking small or otherwise less profitable solar installations may have been unable to find tax equity partners at all in the past.

•

• Central inverter (>1 MWAC capacity): 0.25¢/WAC

• Utility inverter (>125 kWAC, <1 MWAC): 1.5¢/WAC

• Commercial inverter (>20 kWAC, <125 kWAC): 2¢/WAC

• Residential inverter (<20 kWAC): 6.5¢/WAC

• Microinverter (<650 WAC and connects with one solar module): 11¢/WAC

“The reason the industry as a whole was arguing that [nonprofits] should get direct pay is because there’s not an infinite pool of tax equity to partner with. Partners want the highest returns, and that kind of cuts against the most equitable projects a lot of the time,” she said.

•

• Battery cell (>12 Wh capacity): $35/kWh

• Battery module (>7 kWh): $10/kWh

• Electrode active materials (cathodes, anodes, anode foils, solvents, additives, electrolyte salts): 10% of cost of production

Direct pay could bring solar power and its many benefits to far more organizations that do not pay taxes.

“It just gives us more options and gives the communities we work with more options to consider how to structure and benefit from clean energy projects,” Wyatt said.

Some organizations may still be interested in PPAs for the convenience of giving a third party the responsibility of maintaining a system through its lifetime. But many could reap far more benefits from direct ownership.

“Having these entities be able to access the systems directly and own the systems if that’s what they choose is a huge step forward for energy sovereignty,” Wyatt said.

She expects there to be much implementation work to come, as well as a need for education to inform organizations about the incentive and how to take advantage of it. GRID stands ready to help with that outreach.

“There’s going to need to be a lot of networking, outreach and education, not just top-down from the IRS and the Dept. of Energy, but any organization, including GRID, that has the capacity to work with our partners to spread the news of how these [incentives] work,” she said. “There’s also going to be a lot of implementation work at state and local levels and in federal agencies as they build this all out. It’s going to be just a tremendous few months to be involved in climate policy.” SPW

Technology evolves quickly. Keep up with CPS America 250/275kW 3-phase string inverters designed to work with solar sites from 2MW to 2GW.

Significant design flexibility for solar plants of all sizes

More granular data analytics and monitoring

Available now, without the long lead time.

When maintenance is required, only 275kW is impacted versus 5MW, minimizing harvest loss. Get back up and running quickly with service performed by local electricians instead of waiting for highly specialized manufacturer’s technicians.

Welcome to a new era in solar with CPS America string inverters. www.chintpowersystems.com

Ready for a new era in solar?

Visit us at RE+ • September 19-22, 2022 • Booth 2804

capsule days.

THE Ulysses S. Grant Cottage National Historic Landmark is a preserved time capsule of the 18th president’s final days. Built in 1872 atop Mt. McGregor in eastern New York state, the cottage was where Grant wrote his final memoirs before succumbing to throat cancer. Today, the building contains many of the late president’s belongings to preserve the history of the man who led the Union army to victory in the American Civil War.

historical preservation, the New York State Office of Parks, Recreation & Preservation installed a 30-kW off-grid solar + storage system to power the cottage and affiliated historical site facilities.

Continuing a 150-year legacy of Office facilities.

Prior to Grant’s arrival at Mt.

McGregor in 1885, the site was also home to a mountaintop resort. The cottage and remaining buildings were outfitted with an early form of electricity

made by a steam-powered generator. It powered lights in the hotel buildings, including the cottage.

Grant Cottage maintains that record for electrical history by being the first facility in the New York Parks network powered by an off-grid solar array.

Down the mountain from the cottage is the Mt. McGregor Correctional Facility, a former prison and tuberculosis sanitorium that was decommissioned eight years ago and has been vacant ever

powered generator was a power line that ran from the prison up the mountain to supply electricity for the cottage site, but its electrical infrastructure was degrading and the cost to repair was substantial.

In one year, the Grant Cottage had experienced 12 power outages.

“This site has its inherent challenges, and those challenges increased when the prison closed,” said Ben Kemp,

operations manager for the Friends of

lights

Grant Cottage. “In our perspective — both the parks department and ours — our main object must be preservation first. It has to be, because if you have nothing here — if you can’t keep the lights on, if you can’t keep the heat on — everything would degrade, and you’d have nothing to show people. There would be no historical value if things fell apart.”

The access road up to Grant Cottage is a 700-ft climb, with the actual site

standing at an elevation of about 1,000 ft. So, the parks department was faced with either replacing electrical lines up the side of a mountain for a historical site that is only open 110 days a year or seeking alternative energy sources that could take the cottage off the grid, like solar and energy storage.

replacing the cottage off the grid, like solar and October, and that was one of the reasons system,

“We basically run May through October, and that was one of the reasons they zeroed in on this site as a candidate for an off-grid system, as opposed to

many of the other parks and sites in New York,” Kemp said. “A lot of them stay open year-round and have a heavier draw on the system.”

Construction on the Grant Cottage solar project began in November 2020 and finished in April 2021. The historical site is closed to the public during that time because Mt. McGregor experiences heavy snowfall throughout the winter, making road access more difficult. Those conditions caused some construction delays as well.

The solar array was entirely constructed by a workforce of state employees from the Office of Parks, Recreation and Historic Preservation, the Department of Environmental Conservation and the New York State Energy Research and Development Authority. The only outside hire made for this project was a concrete contractor.

“We talked to everyone, and we asked if they were physically comfortable doing this kind of work and being out in the weather and carrying and moving stuff,” said Rodney Wiltshire, head engineer of the Grant Cottage solar project and a former employee at the

New York Natural Heritage Trust.

“That was basically the requirement. Then I trained every single person that was there and put them to work, and I supervised. I did some work, but I was basically running around the entire time making sure people were doing things right — and they learned.”

Wiltshire has installed PV solar since 2007, primarily through his company Empire Solar & Electric. He was contracted by the parks department to design and oversee construction on the Grant Cottage project.

For the five months of construction, state employees worked onsite building this array, enduring the natural challenges of the climate and elevation. There was constant snowfall and snowmelt conditions to contend with, as well as widely varying temperatures in the springtime when days would start with freezing temperatures and end much warmer.

Much of the ground on Mt. McGregor is full of bedrock and exposed

Grant on the cottage porch days before his death. Library of Congress

shale. The solar array was installed atop a shale deposit along the access road before reaching the cottage. A 15-ft cliff at the edge of the shale deposit made installation conditions even trickier.

Heavy machinery like a telehandler, forklift and crane were brought up the mountain to hoist system equipment to the site, and an excavator was needed to dig trenches to run conduit to the site's

IN THIS SPECIAL EDITION OF CONTRACTOR’S CORNER, Scott Francis, technical sales manager for Westex: A Milliken Brand, talks through the latest in industry-relevant safety codes that should inform the personal protective equipment selection process and the steps to selecting PPE for an industry like photovoltaic solar. Since 1941, Westex has produced flameresistant and arc-rated fabrics used in PPE across many industries.

Below is a portion of the company’s Solar Spotlight podcast with Solar Power World, but be sure to listen to the full episode on your favorite podcast app.

Can you tell me about some of the basics around NFPA 70E and the arc flash hazard?

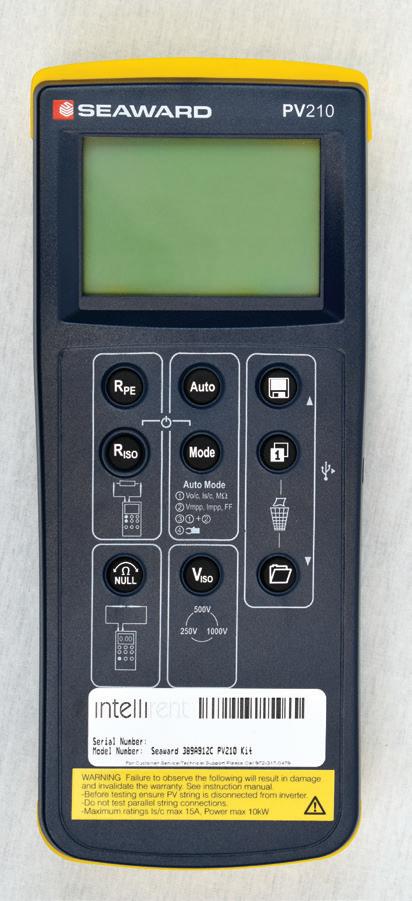

NFPA 70E is the standard for the arc flash and shock protection and provides guidance on how to assess the risk associated both with arc flash and shock hazards and both AC and DC electrical equipment; and on how to select the appropriate arc flash and shock PPE. Now, regarding the arc flash hazard in the solar power industry, both AC (alternating current) and DC (direct current) equipment applies with the DC arc flash hazards present in the PV, the photovoltaic cells of the solar equipment before the inverter and the potential arc flash hazard after the inverter. Since additive arc flash analyses for both AC and DC currents are not available, appropriate arc-rated PPE needs to be determined based on DC or AC arc flash analysis, which determines the estimated incident energy in calories per-squarecentimeter or determines the PPE category if the PPE category method, which is NFPA 70E, is used.

Select arc-rated clothing PPE that has an arc rating — the arc rating is also measured in calories per-square centimeter — select PPE with an arc rating higher than the estimated instant energy listed on the label, or PPE with an arc rating that meets the PPE category method requirements.

According to the NFPA 70E, when and why should risk assessment be reviewed?

Per NFPA 70E, arc flash risk assessment should be reviewed every five years, or when there has been a change made to the electrical system. This includes checking and updating the accuracy of equipment labels so the appropriate PPE is properly called out on the label. Of course, that’s the why: To protect workers. Make sure that the appropriate arc-rated, arc-flash PPE is indicated on the equipment label. Again, that is done when an accurate incident energy is listed on the label, or the appropriate PPE category is listed on the label if they’re utilizing that method. What method you’re using depends on what’s going to be shown on the label. That’s the key thing.

What are the two methods for selecting PPE with the proper arc rating?

The first table, which is 130.5(C), assists in estimating the likelihood of an occurrence of an arc flash in AC or DC systems for certain tasks on various equipment types and conditions in a “yes or no” format. If the column reads no, you really don’t have a risk. It’s unlikely something’s going to happen, you really don’t need PPE. If the answer is yes under the likelihood of occurrence column with that task and equipment type and condition, an arc flash is likely to occur. It’s not that it might occur or could occur, it’s likely to occur. You need to take on additional protective measures, which is usually going to include the use of PPE. You move on to determine the PPE, you move to a second table.

The second table I talked about, the arc flash PPE category table, has the listed parameters for both AC and DC systems that dictate if these systems can be used. If your parameters don’t meet you can’t really use these. So, they cannot be utilized, the incident energy analysis, also known as the “arc flash study,” is performed. In the solar industry, due to the generation of 1,000 VDC, the incident energy analysis method is used for the DC before the inverter since the 1,000 VDC parameter exceeds

the 70E PPE category maximum voltage parameter of 600 V. It lists 600 V in the tables. Well, if you’re at 1,000 V, you can’t use the tables.

If I am selecting the PPE for my team, how do I know which of these two methods I should use?

As I mentioned previously for the PPE category method that can be used, basically for the series of three tables in 70E to be used certain electrical parameter requirements must be met. If the electrical system parameters, such as available fault current and clearing time maximums, are exceeded or the working distance is shorter than the minimum distance, the “incident energy method” shall be required to be used. All else being equal, selecting PPE based on the incident energy analysis method is more e ective at ensuring worker safety than the PPE category method.

PPE is one of the controls that is most susceptible to human error. The best hazard assessment with the most accurate arc flash incident energy information on the label does no good if human error, which is also lack of human performance, takes place and the arc flash holding PPE is not worn at the appropriate time. Certainly, there is various ways of getting workers to buy into wearing arc flash PPE. But human performance, or lack thereof — human error — also a ects the risk assessment method and when to revisit the assessment. Complacency is a safety killer, and it can occur in the assessment procedure or the reassessment procedure. SPW

load center. Workers had to bring plenty of other tools up with them to get the job done too.

“We probably spent a half-hour every single day just lugging hand equipment tools up and down there,” Wiltshire said.

After the crew cleared some trees from the location, they ballasted the array with pour-in-place concrete footers set atop the shale. Piers were placed in each of the concrete blocks and IronRidge racking was attached on top of them. Boring into rock wasn't feasible for the array's anchors, but the state employee installers still had to drill through rock elsewhere during construction.

Conduit had to be run into another building that had granite walls that were about 20 in. thick. Installers had to bore a hole 4 in. wide for the conduit, and Wiltshire said it took five days

get through the wall, breaking three diamond-tipped drill bits in the process.

“I think that it shows that something like this, that this kind of design does have an application,” Wiltshire said. “We’re not saving the world here; we’re not providing refuge. It’s just a historical site and a visitors’ center, but this application can be used anywhere you need power that is remote, off-grid and in a location that’s very difficult to install on. And it can be done with virtually untrained but willing labor.”

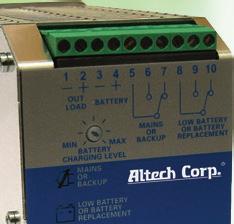

The system is composed of REC 380W modules, six OutBack Power FLEXmax 100 charge controllers, OutBack Radian 8048 inverters, MidNite Solar combiner boxes and DC disconnects and two EnerSys PowerSafe XL lead batteries, which are housed in a small storage unit next to the array.

The completed array is visible from the back porch of the cottage when leaves have fallen from the trees. Kemp said the distance of the system from the historic site was intentional to maintain an image from that period of President Grant’s life, when the lights in the cottage were still powered by steam-generated electricity.

Solar has been powering the Grant Cottage for about a year-and-a-half now. The site is expanding, and the parks department is prioritizing solar as its primary energy source with new facilities.

“It’s become a model for other parks in the state of New York, but it’s also a model for our own site,” Kemp said. “Now we immediately look at solar as the main option for the infrastructure expansion here. It’s changed the direction of the historical site.” SPW

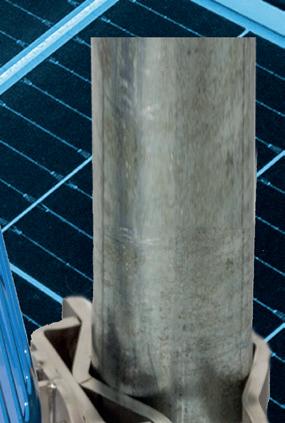

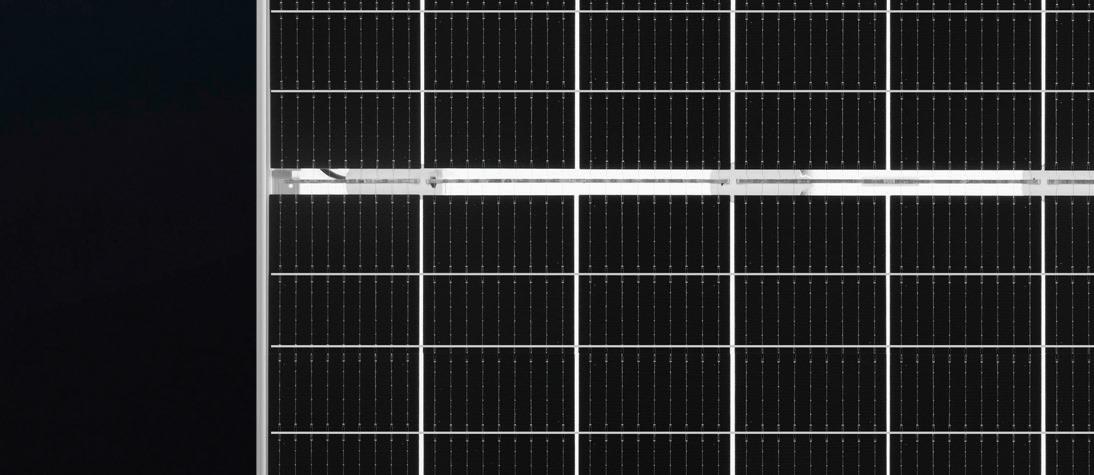

While the sun has forever been affiliated with solar power, so too has the aluminum frame. Some solar PV panels have gone frameless with cells sandwiched between two pieces of glass, and other more flexible designs use polymers to keep electrons protected. But for every other solar panel with a frame out there, chances are it is made of aluminum. For environmental and practical reasons, there’s now growing momentum to explore other framing material options.

Aluminum likely became the dominant material choice for panel frames back when the industry started because it is lightweight and has excellent corrosion protection.

“It was the safe bet 40 years ago, but it’s not the right choice for what is going to be huge growth in solar for the next 40 years,” said Gregg Patterson, CEO of steel frame startup Origami Solar. The company’s argument for switching to steel framing: aluminum is expensive and has a huge carbon footprint.

There are some facts to back this up. According to a July 2022 review of the global metals market, cold-rolled steel was averaging $0.93/lb while aluminum was holding near $2.45/lb. According to Risen Energy, which recently added a steel frame option to its popular Titan

solar panel line, it takes 13.5 MWh of thermal power to produce one tonne of aluminum (equivalent to 11.2 tonnes of CO2), while it only takes 4.5 MWh to make one tonne of steel (1.8 tonnes of CO2). And with nearly all aluminum frames coming from China, a country that relies on coal-powered electricity, solar panel frames have a dirty energy origin.

“The aluminum frame is the most expensive component of a module after the solar cells,” Patterson said. “[With steel] you get cheaper, cleaner, higher performance and it can be domestically sourced. It hits virtually every aspect of what the industry is looking to do now.”

Steel could be the framing material of choice for the solar industry of

the future. It’s inherently stronger than aluminum, so it will more easily support the added size and weight of large-format modules. And with new corrosion coating advancements, steel is better able to withstand the increasingly temperamental elements associated with climate change.

Risen Energy is so far the only module manufacturer that markets a steel-frame option. The Chinese company reinforces its steel frame with a corrosion-resistant zinc-aluminum-magnesium coating to improve strength, cosmetics and lifespan. According to spec sheets, the only difference between a 670-W utility-scale Titan solar panel with a steel frame and one with an aluminum frame is the steelframed model is 1.5 kg (3.3 lb) heavier.

More than anything, Risen looked at frame alternatives due to aluminum’s large carbon footprint.

“Whatever your belief,” said Luke Sun, president of Risen Energy, in a press release, “environmental pollution and carbon dioxide emissions affect us all. It is simply not good enough for us to proclaim that we are making an impact of reduction of these elements by providing and using solar PV modules, we must do more. Moving to this uniquely constructed module is a step in the right direction.”

Market intelligence firm Boundless Impact Research & Analytics completed an environmental impact report for Origami Solar earlier this year and found that replacing just 10% of the solar industry’s conventional aluminum frames with steel frames would result in a greenhouse gas emission reduction of approximately 30 megatonnes between 2022 and 2030. This is

equivalent to the emissions from eight coal-fired power plants for an entire year.

Origami Solar has already built over 4 km of frames to show steel’s similarity to aluminum and will begin third-party testing. Steel suppliers have been secured; Origami now just needs module companies to sign on. Patterson said many are interested, especially since Origami’s manufacturing process can provide domestically produced steel frames that are cost-competitive with aluminum imports from China.

“Our goal is to drive adoption of frames and work with the module companies and then the racking and tracking companies to figure out how we can improve the installation costs so we drive solar in the right direction so it can scale to what the world needs. We've got to start getting off of that Chinese supply chain,” he said. SPW

LG Chem is testing its engineering plastic LUPOY as an aluminum frame replacement. The polycarbonate plastic is mixed with glass fiber to produce a flame-retardant material that maintains its shape even during temperature changes. The material is already used in household electronics and automotive applications, but LG Chem thinks it would work well as a solar panel frame. The plastic has the same level of durability as aluminum but is half the weight.

“Solar panel frames made of plastic have many advantages that differentiate them from existing frames, such as ease of installation, and therefore have great market potential,” said Steven Kim, leader of the engineering materials division at LG Chem, in a press release.

LUPOY has not yet been successfully used in any solar panel designs.

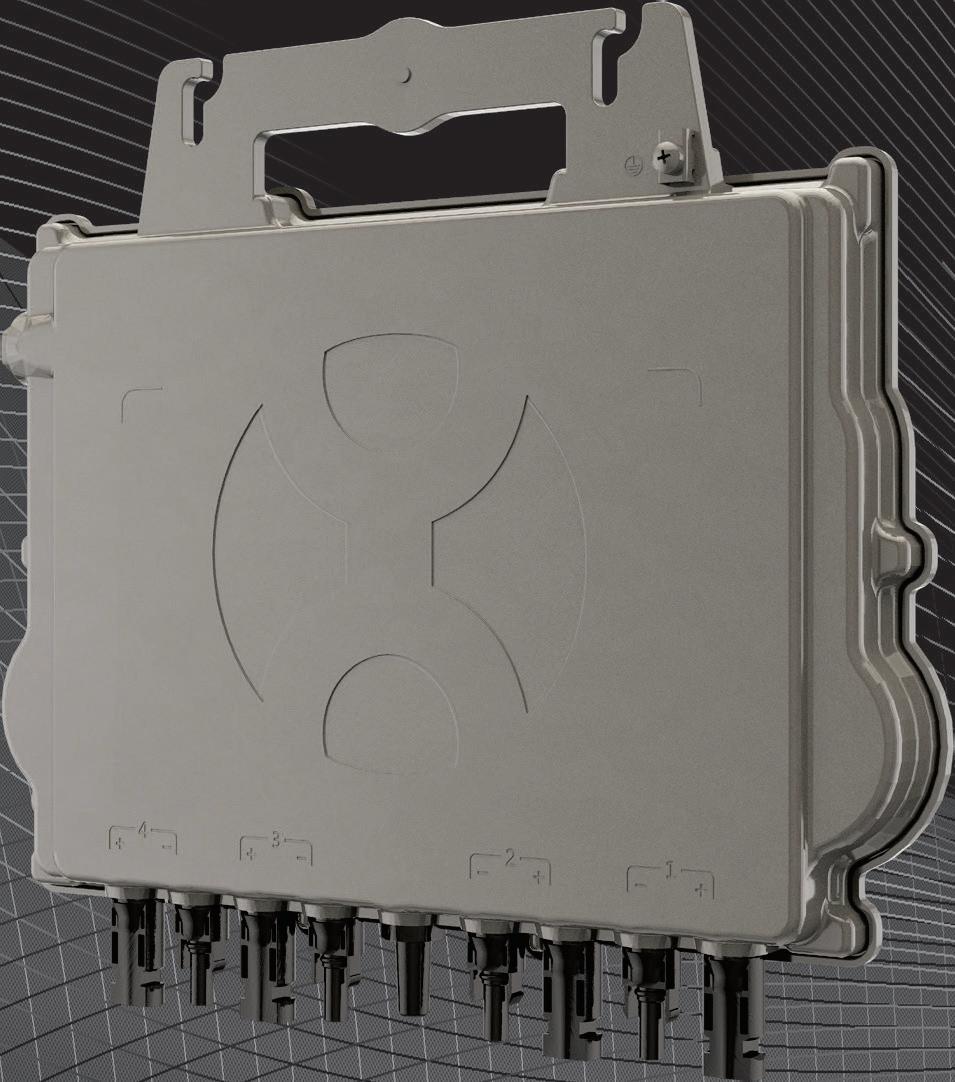

SolarEdge’s optimizer-based systems are UL 3741-certified.

Ever since the 2017 National Electrical Code (NEC) was published, rooftop solar contractors have faced potentially time-intensive and costly safety requirements for module-level rapid shutdown. The code requires installers to use module-level power electronics capable of lowering each module’s voltage to 80 V or less within 30 seconds of rapid shutdown initiation to protect first responders. On smaller residential systems, rapid shutdown devices might add a few extra minutes of install time and minor additional cost, but on huge commercial rooftops, they create a much larger challenge.

The 2017 code did include other ways besides using MLPE to satisfy this

safety requirement, but they weren’t as easily attainable.

"Everybody is doing MLPE because that, up to recently, was the only way to meet the requirement, and right now it's probably still the easiest way to meet the requirement primarily because of equipment availability, AHJ acceptance [and] firefighter acceptance," said Ryan Mayfield, founder of solar design firm Mayfield Renewables.

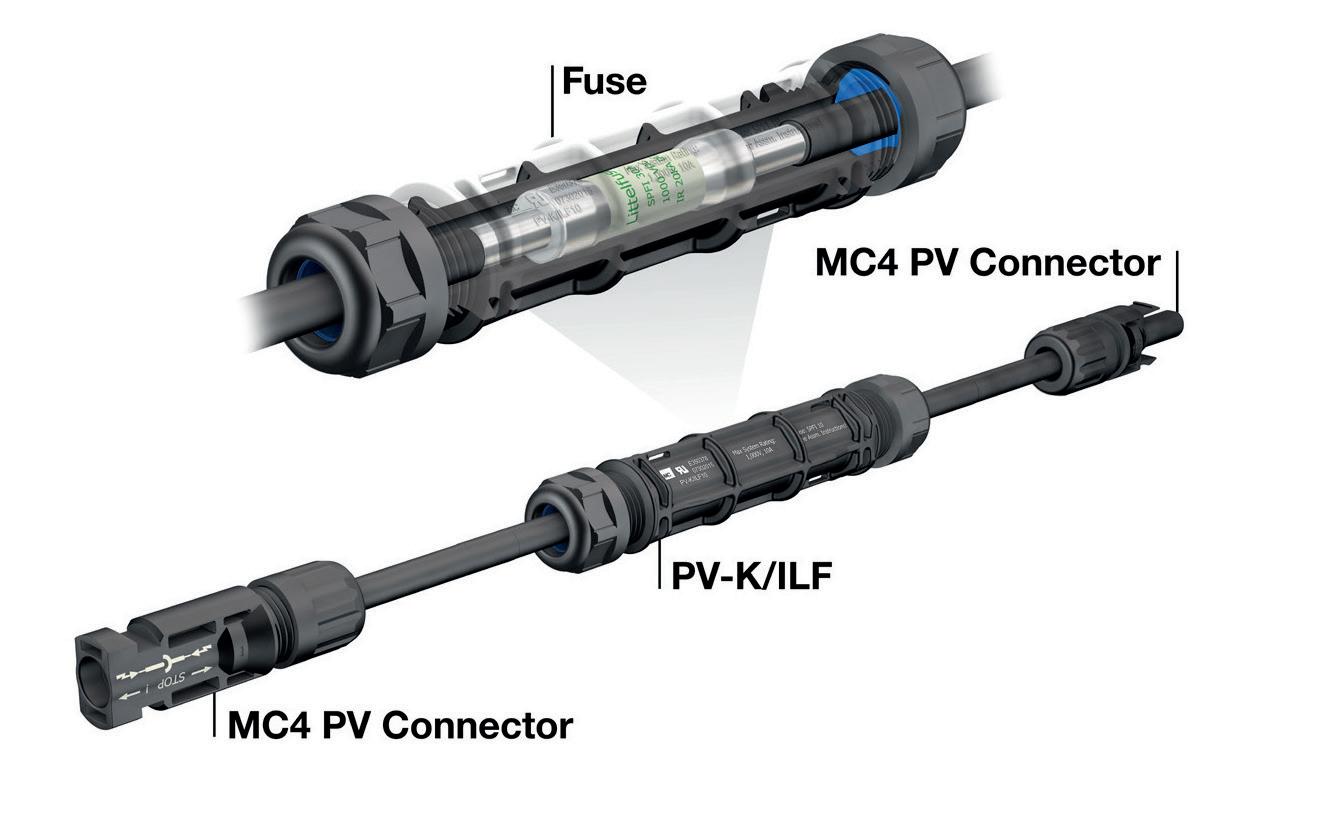

That won't be the case for much longer. With manufacturing and testing finally in place, installers have a new option to satisfy fire safety requirements on solar rooftops — PV Hazard Control systems.

This option, listed as UL 3741, has been included in the code since 2020, but only now are products getting tested and certified to the standard.

To achieve UL 3741 certification, products must pass a series of tests designed to simulate situations firefighters may encounter on a solar rooftop. The testing analyzes what happens when first responders fall on damaged solar panels while wearing typical protective gear. There's no prescribed combination of solar products to satisfy this new rating; the merits of each submitted product or product combination are scrutinized during testing.

The goal of the new standard is to make rooftop arrays safer for firefighters in

It can’t shake your hand, but it can shake up your solar business.

Find out how Aurora AI can estimate your customer’s consumption, create a solar design in 30 seconds, and help you close on the spot.

an emergency. Some in the industry say 3741 certification is much more rigorous and scientific than rapid shutdown certification.

"I don't know if I'll get anybody ever on record from the code-making panels, but I have heard over and over again that 80 V was semi- pulled out of the air," Mayfield said. "[3741] is based on a collective science and a collective agreement from the firefighter community [and] the electrical community.”

So far, at least one system by SMA and Sollega and one by SolarEdge have passed UL 3741 testing. The SMA collaboration uses the company's Sunny Tripower CORE1 inverters paired with Sollega's FastRack 510 mounting system — made of polymer material.

"[SMA] thought we were a good candidate given that our racking is polymer and non-conductive, and we worked together to achieve it," said Elie Rothschild, sales manager at racking manufacturer Sollega. "What we've shown through the UL 3741 certification is that there's a high degree of safety to prevent the firefighters from interacting with the array in any way that would cause them to become part of the current path and thus be subject to a shock hazard."

[3741] is based on a collective science and a collective agreement from the firefighter community [and] the electrical community.

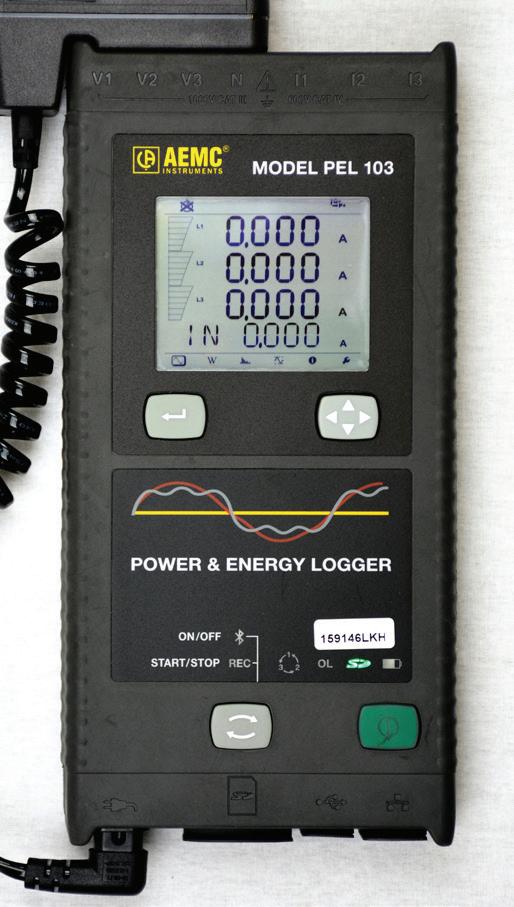

IN THIS SPECIAL EDITION OF CONTRACTOR’S CORNER, longtime photovoltaic panel manufacturer Jinko Solar discusses why the company has entered the storage market. Adam Detrick, U.S. director of product management and technical services at Jinko Solar, talks about how Jinko is standing out in a crowded storage market and the company reaching a major milestone in panel sales.

Below is a portion of the company’s Solar Spotlight podcast with Solar Power World, but be sure to listen to the full episode on your favorite podcast app.

Jinko just announced that it was the first module supplier in the world to deliver 100 GW. What does Jinko attribute to this broad success in the market?

Jinko’s core mission and vision in the U.S. market, or the global market really, is to the be the most trusted supplier. We have a very solid track record on execution, customer service and customer support, and I think that’s why people keep coming back to Jinko over the years. We deliver what we say we’re going to deliver, and that covers everything from on-time delivery to the reliability of the products, product performance and having a very robust customer service organization. All of which can be attributed to just very high customer satisfaction overall and Jinko’s success.

With all the success in solar, why the decision to start o ering a residential storage system?

Residential storage and solar go together very nicely, for a number of reasons. The global, and especially in the U.S., migration to work from home has really escalated the importance of grid stability and energy independence for homeowners. People are much more dependent on their homes for their work, and so having stable energy has become much more critical than it was in the past.

What di erentiates Jinko from the myriad of other residential storage o erings in these spaces?

It is a very crowded field in one way, and then not in another.

Number one, Jinko at a corporate level has very high commitment to storage in general. We foster very good supply chain relationships, so we have supply of the key components. One of the big issues out there right now is commodity constraints on a variety of materials that go into the storage systems.

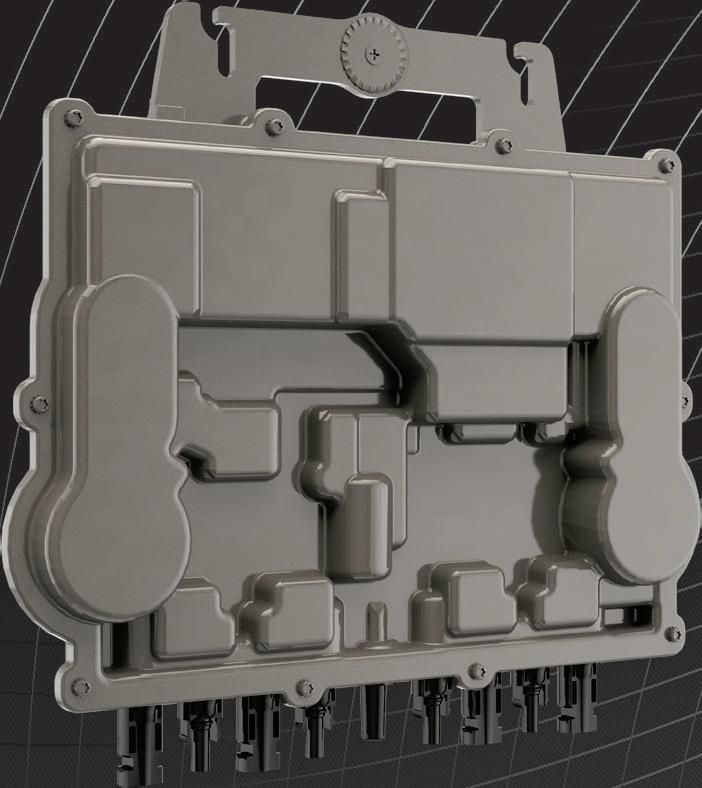

We really wanted to focus in on a single SKU. We have one system. It’s a DC-coupled system and we decided to do that because we really believe that it’s the best economic solution and the best value for the homeowner to combine the solar and storage as a DC-coupled system, because you get the synergies of the shared inverter and it keeps the balance of system component costs down.

What should installers and homeowners care about when purchasing a storage system?

Ultimately, as with most things, reliability would probably be number one. I would say strong customer support, what I just mentioned, is really a key aspect. It’s not only looking at the specifications of the system on paper — does this match the customer’s load profile and their energy usage? But is there a support network there if there’s questions or if something doesn’t come together as expected throughout the install process or if there’s confusion about how the application works.

We want to ensure that the homeowner has a really strong support network that’s consistent with Jinko’s mission and vision of being the most trusted supplier.

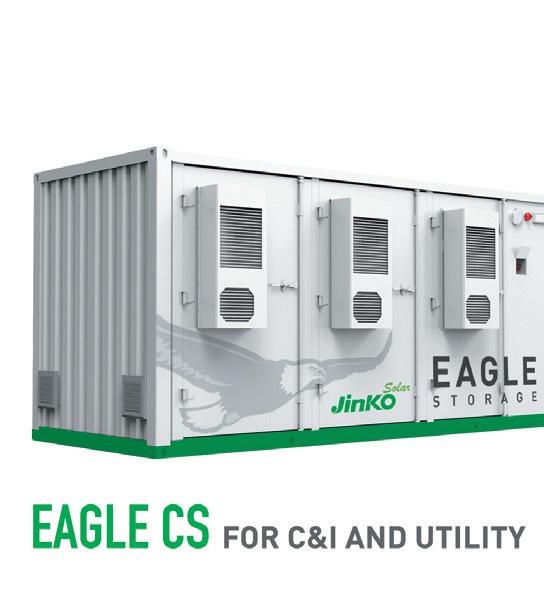

No, this year Jinko is also introducing the Eagle CS Storage System, which is geared toward commercial, C&I and utility applications. The Eagle CS is a fully integrated, scalable, turnkey AC-coupled energy storage system. We o er one- to four-hour battery duration, which can be configured for both C&I and utility applications. Jinko wants to bring the same level of high customer satisfaction and serviceability to commercial and utility storage as we do for residential solar and storage. SPW

In the SMA + Sollega system, wires are routed underneath both the modules and the non-conductive racking, which UL believed to be adequate to guard firefighters from a potential shock hazard when designed to specific requirements including using nylon zip ties with a necessary air gap to ensure wires do not come in contact with the aluminum module frames.

"This is going to require that we are installing it to a specific way and we're following the manufacturer's requirements so that we are meeting that standard," Mayfield said. "That's somewhat of the leap that we need to make sure that the industry hears and accepts and takes on if they're going to use this method."

Other UL 3741-certified systems are far less reliant on design for compliance. Systems like SolarEdge’s, which also passes rapid shutdown certification, use MLPE to lower the per-panel voltage enough to adequately protect first responders. The additional UL certification proves that this optimizerbased system does keep first responders safe in case of emergency.

“We don’t require any special restrictions or limitations, such as wire management, racking, inverter placement, special training, quality of work [or] ongoing array inspections to maintain compliance or other means to maintain limited access to dangerous high-voltage components,” said Jason Bobruk, director of code compliance, and Magnus Asbo, senior director of technical marketing at SolarEdge, in an email. “We reliably de-energize the entire system and remove the dangerous hazards altogether.”

All SolarEdge three-phase inverters paired with optimizers are listed as UL 3741-compliant when installed with any racking and wire management configuration.

Most rooftop racking systems are made of metal. With the non-conductive nature of Sollega's solution playing a large part in its hazard control system certification, it remains to be seen if metal racking systems will achieve UL 3741 certification.

"If you have a metal racking system, this is where it's going to get a lot harder, because as soon as you use the metal supports to hold the conductors, they're going to be in close proximity to the metal, which is going to be potentially energized," Mayfield said.

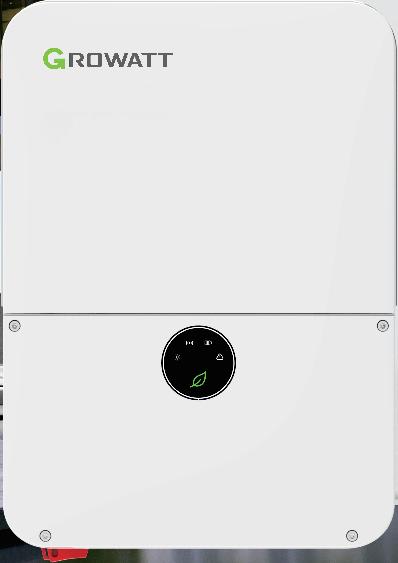

Solar Power World reached out to almost a dozen inverter manufacturers to see if they plan to submit products for UL 3741 testing. Yaskawa Solectria is looking into certification with both IronRidge and Sollega, while Ginlong Solis is in talks with Sollega as well. Chint Power Systems is planning to get all its 1,000-VDC inverter models UL 3741-listed. Fronius,

APsystems, Tigo Energy and Growatt said they do not have plans in the works, and GoodWe did not respond by press time.

What happens to rapid shutdown?

While the new standard is a welcome addition for installers, there's still a place for rapid shutdown systems in the mix. It will take some time for building departments to get comfortable with UL 3741 systems, and the current design constraints necessary for some products to meet the standard mean not all solar layouts will allow it.

In Sollega and SMA’s collaboration, for example, inverters must be mounted within 1 ft of the array to comply with its UL 3741 certification.

"Certainly, there will be systems that are difficult to design within those constraints. We think having both solutions available is the right approach," said Brett Henning, commercial product manager at SMA America.

Rapid shutdown device manufacturer Tigo Energy sees no reason to change what's working.

"Right now, Tigo has no plans to create solutions for the UL 3741 standard. Module-level power electronics remain the best solution for the marketplace because it has the flexibility of providing rapid shutdown and/or module-level monitoring and/or optimization," said James (JD) Dillon, chief marketing officer at Tigo. "We will certainly react to the needs of installers but have yet to hear a strong demand signal from the marketplace for this alternate standard."

When the time does come that most installers are looking for 3741-certified systems, Mayfield said there's still a role for the module-level rapid shutdown

makers. Instead of selling rapid shutdown devices on a one-per-module basis, manufacturers could certify MLPE that shut down up to four modules in series under the new PV Hazard Control listing, cutting down on cost, install time and potential O&M hassles.

Installers can expect to see even more options for fire safety compliance on rooftops in the near future.

"I think it's great that we're finally seeing manufacturers stepping up in order to provide hopefully what will be considered safer systems," Mayfield said. "I think that's going to help drive innovation within the industry, drive costs down and, hopefully, with the goal being putting up a safer system in the end because we can test to a standard." SPW

I think it's great that we're finally seeing manufacturers stepping up in order to provide hopefully what will be considered safer systems.

Sealing the holes required in most rooftop solar installations is one of the most critical steps in ensuring a waterproof installation. After drilling pilot holes into roof rafters, contractors will fill them with sealants such as MS polymer, silicone or butyl to prevent leaks throughout the array’s lifespan.

There isn’t a one-size-fits-all sealant in the solar industry, and selecting the proper waterproofing method depends on the AHJ, temperature and moisture/ precipitation levels in the environment where an array is being installed.

“You’re poking a hole in a perfectly good, sealed roof, and a solar installer does not want to be responsible for any

leaks,” said Rocky Stroud, national sales manager at rooftop sealant manufacturer Chem Link. “[Sealants have] been a learning curve for solar people because they’re not roofers, and this is very invasive to the roofing material.”

Sealants proven to meet specific environmental needs have long been available from solar and roofing product distributors like Chem Link. But how those sealants are applied is changing — and so is flashing, another crucial step in waterproofing a rooftop solar project.

Flashing used in general roofing projects is a metal sheet that creates an additional

barrier for waterproofing. It covers roof penetrations and is bonded to the roof using an adhesive or sealant.

“At the moment, the sealant is actually a ‘belt and suspenders’ approach to waterproofing,” said Sue Stark, senior manager of training at solar mounting manufacturer IronRidge. “We know that our mounts are waterproof without sealant, and only require it in the pilot hole, because the testing is done that way. However, most people will use sealant, and that’s more of a roofing manufacturer’s installation instruction than it is ours.”

Solar systems installed on comp shingle roofs often use a similar metal

flashing that slides underneath a layer of shingles. A “U” of sealant is applied to the bottom of the flashing to keep the metal sheet in place, diverting rainfall, snow and other moisture away from roof penetrations.

“The great debate is metal flashing vs. non-metal flashing, and there is no wrong answer,” said Johan Alfsen, senior director of training at solar mounting manufacturer K2 Systems. “Pick your flavor and do what you want, but at least these products are tested. Back in the day, they were just putting sealant all over the L-foot. I call that ‘goop and a prayer.’”

Recently, many solar racking manufacturers have developed topmounted attachments that go through the shingle and have a much smaller profile and fewer pieces than their metal flashing counterparts. Each top-mount has a different method for applying sealants, and some refer to it as chemical flashing, meaning the sealant is the primary waterproofing method on the attachment.

One example of chemical flashing is Unirac’s FlashLoc line of top-mounts, which is flashed by injecting sealant into a built-in reservoir that waterproofs the roof penetration it’s installed over. QuickBOLT’s flagship mount QuickBOLT2 uses proprietary Microflashing — a stainless steel compression-washer paired with EPDM rubber — to seal penetrations, and it can be installed with or without extra sealant. Then there are Roof Tech and K2 Systems, which use pre-installed butyl pads on the bottom of their over-the-shingle mounts that seal penetrations as bolts pass through the sealant.

“The brackets keep getting smaller, or at least engineered in a manner in which they’re lighter and less invasive,” Stroud said. “Personally, if it’s my roof, the fewer holes the better. But I also want

it to stay there, and I really don’t want it to leak, so I think the sealant is as important if not the most important thing from a longevity standpoint, because it’s the only thing keeping water from coming into your house.”

Many racking manufacturers pair sealants with their mounts. For those that don’t, there are a range of roofing sealants with different temperature, precipitation, movement and UV ratings. The simple way to select the right sealant for a specific environment is to read the product label and determine if it meets the conditions of a jobsite.

Each roofing sealant is rated to perform within a temperature range. Some sealant temperature ratings can go as high as 300°F, which is ideal for arid regions like the Southwest, where temperatures on a roof can

The great debate is metal flashing vs. non-metal flashing, and there is no wrong answer. Pick your flavor and do what you want.K2 Systems

reach and exceed 150°F. Despite the challenges of installing in those high-temperature conditions, sealant application tends to be more difficult in colder climates. “Anything below freezing is not recommended. Our rule is 32° and rising is fine. Thirtytwo degrees and falling, you’re probably not going to want to use a sealant,” Stroud said. “Chem Link’s a little unique where you can actually apply our sealants in sub-zero weather — they just won’t cure until it comes above 32°.”

Curing is the chemical reaction of turning a liquid into a solid material. One method is moisture curing, which means once the sealant is exposed, it will pull

moisture from the air and harden. While some sealants can bond in moist conditions, it’s not ideal to install them during rainfall. Alternatively, there are sealants that will not bond when exposed to moisture.

While a solar array is secured to a rooftop, there is still minor movement happening in the system. Matter exposed to the elements — whether that’s below freezing or higher temperatures — experiences thermal expansion and contraction, as well as other natural forces like wind that cause movement. That’s why it’s necessary to select a sealant that allows for movement without breaking. Sealant movement rating

is determined by percentage, and the recommended range is between 35 and 50%, according to Stroud.

“Everything is on the move,” he said. “You don’t want to use Liquid Nails or anything that’s glue, because it just means that whatever it’s stuck to, something is going to give, but it’ll be something that you don’t want to.”

Installers should also steer clear of sealants that are incompatible with specific roof materials. Chem Link recommends avoiding clear adhesives on asphalt roofing because when sunlight passes through a clear sealant, asphalt can leach into it and break down the adhesive over time. Opaque or solid-colored sealants are the safer choice.

UV ratings disclose how effectively a sealant will perform in direct sunlight. For a system that is built to be exposed to the sun, it’s necessary to invest in adhesives that can withstand those conditions.

“You should be looking at sealants that are made for professional roofing,” Stroud said. “You don’t want to use something that you’d use around your siding. There’s a big difference between caulking and sealants. It’s not just a word, but legitimately there’s just a big difference.”

Mounting models and configurations may change, but if there’s a roof penetration that needs waterproofing, then there’s a sealant that can handle it.

Bells and whistles are great, but sometimes the basic model is all that’s needed for energy storage.

When solar customers and power-concerned homeowners aren’t interested in or able to take advantage of load-shifting and demand arbitrage opportunities managed by energy storage systems, there are simpler products available today just for emergency backup. No longer do contractors have to suggest a gas generator or a bank of lead-acid batteries; many companies offer portable and powerful lithium-ion systems that can support customers looking for peace of mind during a blackout.

This category of energy storage is often referred to as “solar generators” and has been mostly marketed to adventurers on the go — those camping, traveling, tailgating and working off-

grid. These battery systems have lower capacities than stationary residential systems like the Tesla Powerwall and LG RESU, but they are expandable for specific power needs. They can be charged by portable solar panels or through the grid. Depending on the source of charging electricity, solar generators can be very clean. And best of all, they can be used to back up appliances and loads in the home at a fraction of the price of a stationary system.

Here are a few portable energy storage systems and solar generators that are increasingly regarded for emergency backup in the home.

Likely the most popular portable lithium battery system comes from Goal Zero. The company’s Yeti 6000X Portable

Power Station has an initial capacity of 6.071 kWh and uses NMC batteries with a 500-cycle lifespan at 80% depth of discharge (DoD). Yeti 6000X has 2 kW of continuous power and 3.5 kW of surge power. The station has seven output ports, but it can also be connected to a home’s electrical panel to support four essential circuits.

While Yeti 6000X is the company’s most powerful starting unit, Goal Zero offers many setups to accommodate various power needs. Customers just need one Goal Zero power station as a base, and then storage capacity can be expanded through cheaper lead-acid battery add-ons. Because of their size and weight, the lead-acid batteries are stationary, while the lithium power station is portable. The Yeti Tank Expansion Batteries come in a pair for 2.4 kWh of additional power capacity.

‘Solar

[lithium-based system] but expand the battery,” said Bill Harmon, GM at Goal Zero. “You can add as many [leadacid batteries] as you want. The customer can just plug them in. Suddenly, you have the portability of the lithium battery and the inexpensive lead-acid batteries sitting at

that Goal Zero has recently seen “almost an even split” between customers buying Yeti systems for home backup vs. outdoor recreation, but more than 70% indicate they intend to

“Our system is for all the people in the country who don’t have $15,000 to spend on an energy storage installation. And then when I’m done, all I have is something permanently installed in my home,” Harmon said. “Yeti is for those who are sensitive to what they’re

The Yeti 6000X is advertised online at under $6,000 with each two-battery lead-acid expansion priced under of a licensed electrician, Lycan can be connected to a

Propelling the transformation into the terawatt era with

Renogy reps told Solar Power World that while Lycan is a portable unit (it’s attached to wheels and is rated for outdoor use), most customers are just using it for emergency backup.

“Most customers use Lycan as their source of power generator via solar,” the rep said. “When used in home situations, customers install a sub-panel to divert part of their home’s appliances to be supported by Lycan instead of the grid.”

The 4.8-kWh unit has a continuous power output of 3.5 kW and a peak power output of up to 7 kW, with AC outlets directly on the system. It is equipped with circuit breakers and surge protection devices.

One additional benefit of the Lycan: It does not require a permit to install if it is used for a fully off-grid situation.

The system is advertised online at under $5,200.

Bluetti EP500

Bluetti, an off-grid power solutions company, has a line of solar generators and its own portable home battery backup system.

The Bluetti EP500 Solar Power Station is a 5.1-kWh system on wheels, and its LFP batteries have a 3,500-cycle lifespan at 80% DoD. Two units can be connected for up to 10.2 kWh of capacity. One EP500 has a 2-kW continuous power output rating with a peak of 4.8 kW.

A licensed electrician can connect the EP500 to a building’s main electrical box through the Bluetti Sub Panel.

A portion of the user’s manual does show how roof-mounted solar panels can charge the station, as long as they do

not use microinverters. EP500 comes with its own sine inverter, so that panel-level inversion would not work with the system.