The Architectural Association Visiting School (AAVS) is an expansive global architecture program and network, embracing diverse forms and objectives that collectively enrich the ongoing discourse of architectural education. Since its inaugural program in Dubai in 2008, the AAVS has welcomed thousands of students across more than 100 Visiting Schools on five continents. Each workshop leads participants on a journey of discovery, immersing them in the geographic and cultural fabric of their unique settings and facilitating engagement with local expertise. These workshops address pressing architectural, technological, cultural, urban, and social issues, creating a distinctive and essential learning experience in contemporary architectural education.

At its core, the AA Visiting School is about fostering learning, exploration, collaboration, and experimentation. It brings together an international cohort of partners, including schools, cultural institutions, local teachers, and practitioners, to redefine the shape, expectations, and potential of architectural education. These partnerships give participants a chance to learn from experts, share ideas, and challenge traditional boundaries in architecture.

DLAB exemplifies this mission by advancing digital design integration across multiple design, architectural, and analytical platforms, paired with both foundational and advanced construction methods. Within its intensive timeframe, DLAB emphasizes the evolution from

digital concepts to tangible forms through fabrication and assembly, offering participants a fully immersive, hands-on experience. Through this approach, students gain insights into how to transform digital ideas into physical realities, bridging the gap between theory and practice in a very practical way.

One of DLAB’s core goals is to share essential design processes and encourage critical thinking. Theoretical sessions and seminars equip participants with essential tools, aiming to help them navigate the computational, theoretical, and physical dimensions of the methods explored during the program. This approach to learning is as much about understanding design principles as it is about applying them, allowing students to test and refine their ideas as they progress.

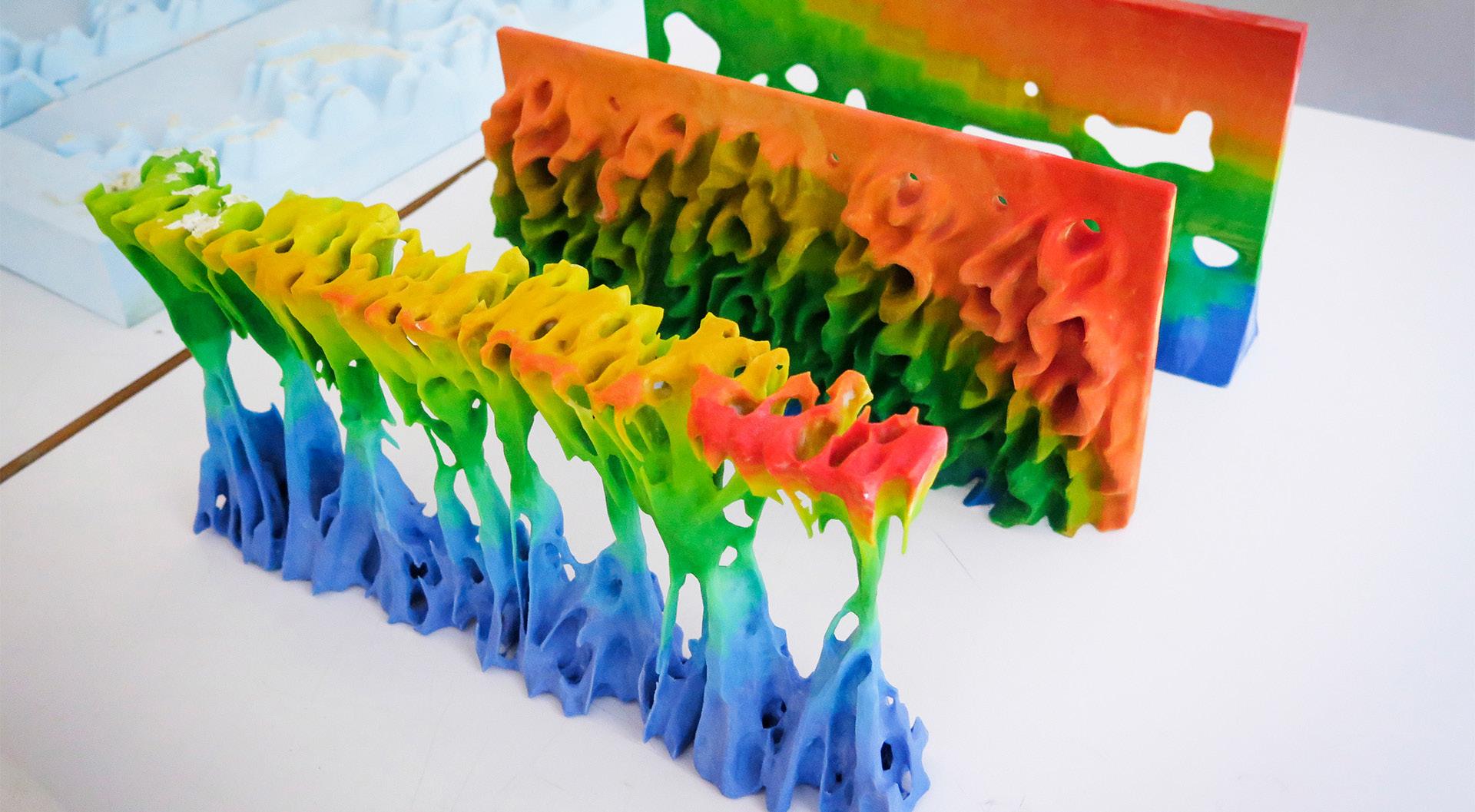

In 2025, AA DLAB will explore the intersection of sustainability, material re-use, and advanced fabrication by focusing on the integration of robotic 3D printing and the upcycling of materials. The objective of this exploration is the innovative use of 3D printing to bridge the gaps between found materials, transforming them into cohesive architectural structures. The research agenda highlights the reduction reduces material waste by integrating discarded or locally sourced elements into the design process. By leveraging the precision and adaptability of 3D printing, the research aims to demonstrate how advanced technologies can advance sustainable practices of building environmentally conscious structures.

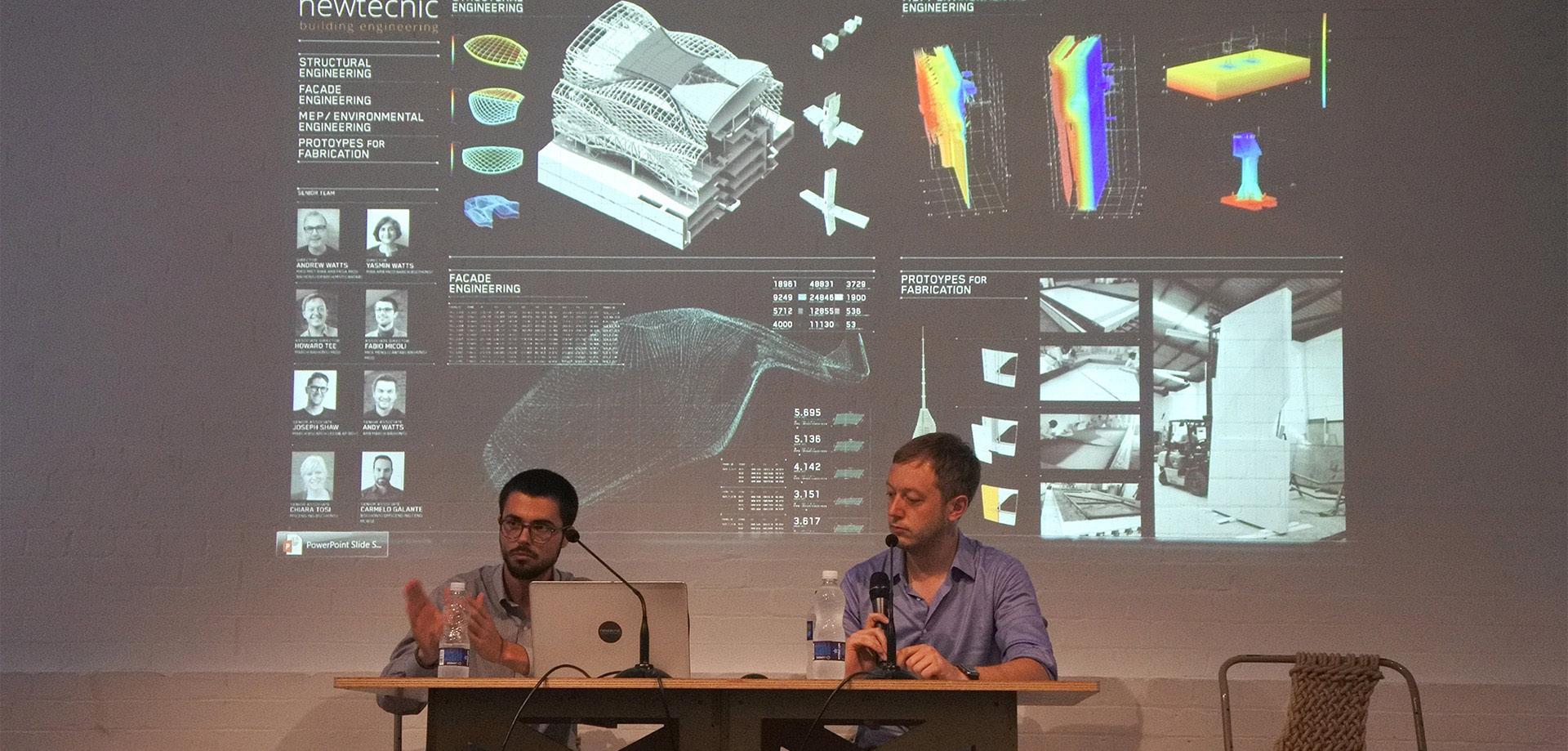

DLAB experiments with the integration of advanced computational design, analysis, and large-scale prototyping techniques. The programme continues to build on its expertise on complex architectural design and fabrication processes, relying heavily on materiality and performance. The programme brings together a range of experts - tutors and lecturers – from internationally acclaimed academic institutions and practices, including AA Emergent Technologies & Design (EmTech) Post-Graduate Programme staff. The research generated at DLAB has been published in international media - ArchDaily, Archinect, Bustler - and peer-reviewed conference papers, including SimAUD (Simulation in Architecture and Urban Design), eCAADe (Education and research in Computer Aided Architectural Design in Europe), Design Modelling Symposium (DMS).

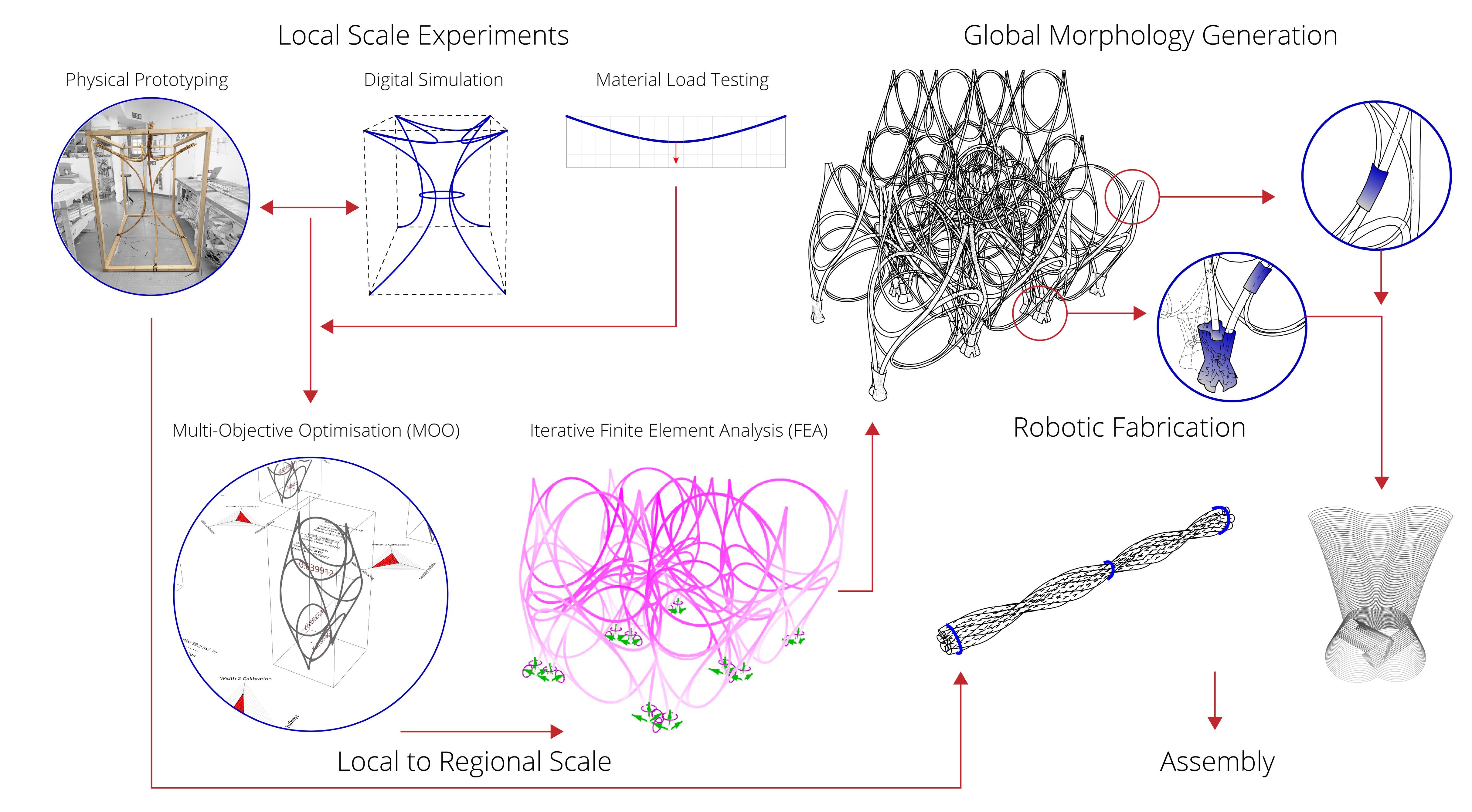

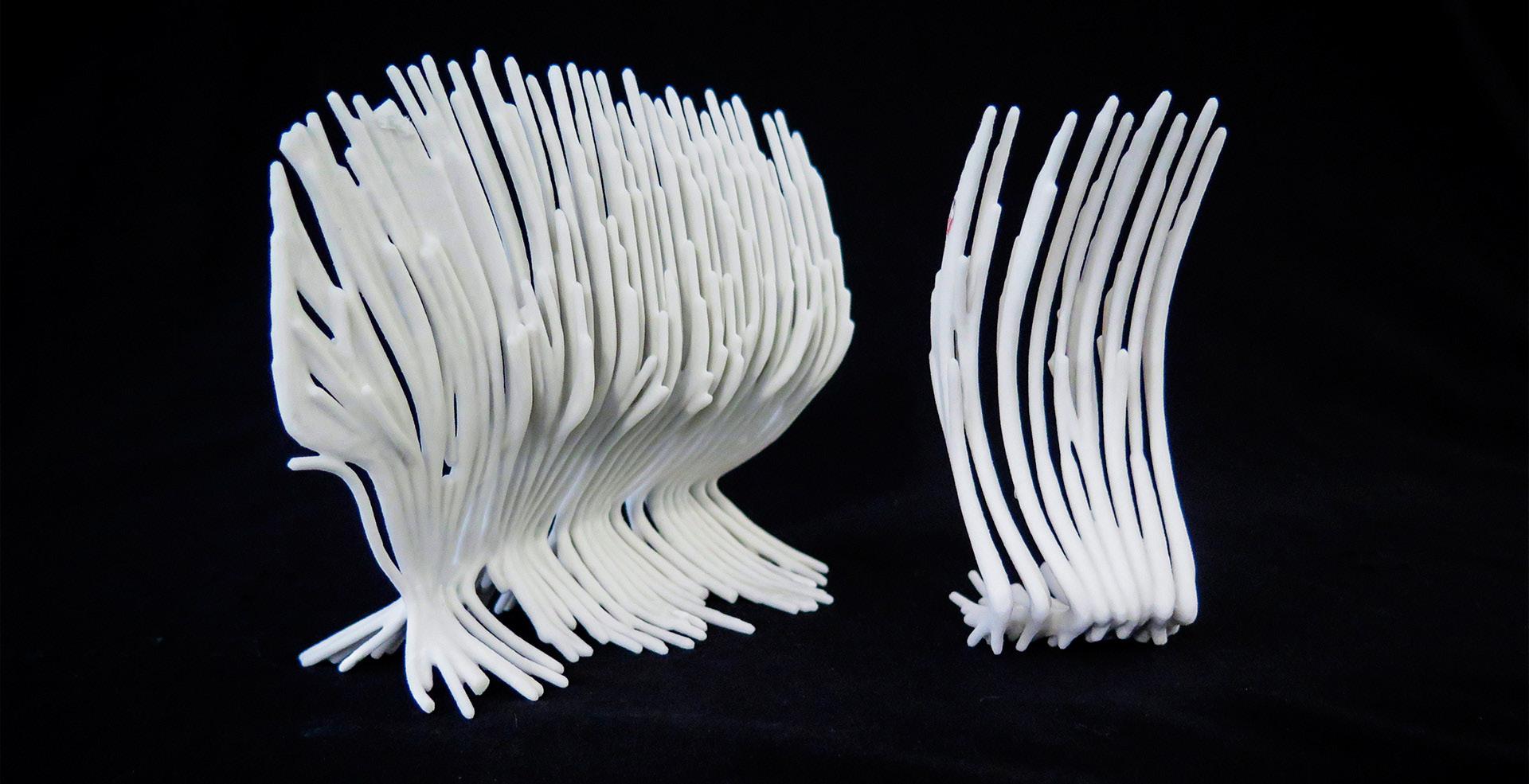

DLAB investigates on the correlations between form, material, and structure through the rigorous implementation of computational methods for design, analysis, and fabrication, coupled with analog modes of physical experimentation and prototype making. Each cycle of the programme devises custom-made architectural processes through the creation of novel associations between conventional and contemporary design and fabrication techniques. The research culminates in the design and fabrication of a one-to-one scale prototype realized by the use of robotic fabrication techniques, with the aim of integrating form-finding, material computation, and structural performance. DLAB is a three weeklong full-time programme

that takes place at AA London HQ’s unique atmosphere. The participants benefit from the facilities of the AA where they are able to access the library, bookshop, and the various workshops (metal, wood, digital, photo, and more).

The programme is structured in two stages; initially, participants are introduced to core concepts related to material processes, computational methods, and various digital fabrication techniques during the initial stage. During the second stage, participants propose design interventions based on the skills and knowledge gained during the previous phase, supported by scaled study models and prototypes. Finally, the fabrication and assembly of a full-scale architectural intervention with the use of robotic fabrication techniques unify the design goals of the programme.

The programme enriches the academic experience with a series of expert-led lectures and industry visits that provide students with valuable insights into the architectural profession. Lectures from renowned practices such as Grimshaw Global, Foster + Partners, PLP Labs, Mamou-Mani Architects, AKT II, BuroHappold Engineering, Zaha Hadid Architects, and TU Delft have previously been featured.

Student life at DLAB is active and engaging, thanks to its London base, which offers access to one of the most dynamic architectural hubs in the world. Participants benefit from the city’s vibrant architectural scene, including office visits to leading firms and exposure to cutting-edge practices.

The Architectural Association’s DLAB is a forward-thinking architectural workshop that has operated since its inception in 2010. By combining advanced computational techniques with hands-on material experimentation, DLAB bridges the digital and physical realms of architectural design and fabrication. Over the years, it has gained recognition for its cutting-edge approach to exploring generative design, material computation, and large-scale fabrication.

DLAB’s ethos is rooted in the synthesis of computation, robotics, and materiality, exploring new ways of designing and constructing at the intersection of architecture, technology, and craftsmanship. Each year, participants from around the globe gather at the AA’s London facilities to engage in a three-week long intensive program. The outcomes are full-scale architectural prototypes that demonstrate innovation in design and fabrication.

The central location of the programme in London not only provides access to state-of-the-art facilities but also immerses participants in the city’s vibrant architectural scene. Visits to renowned architectural offices and exposure to leading industry experts are key components of the programme.

Experimentation and Key Materials:

Concrete

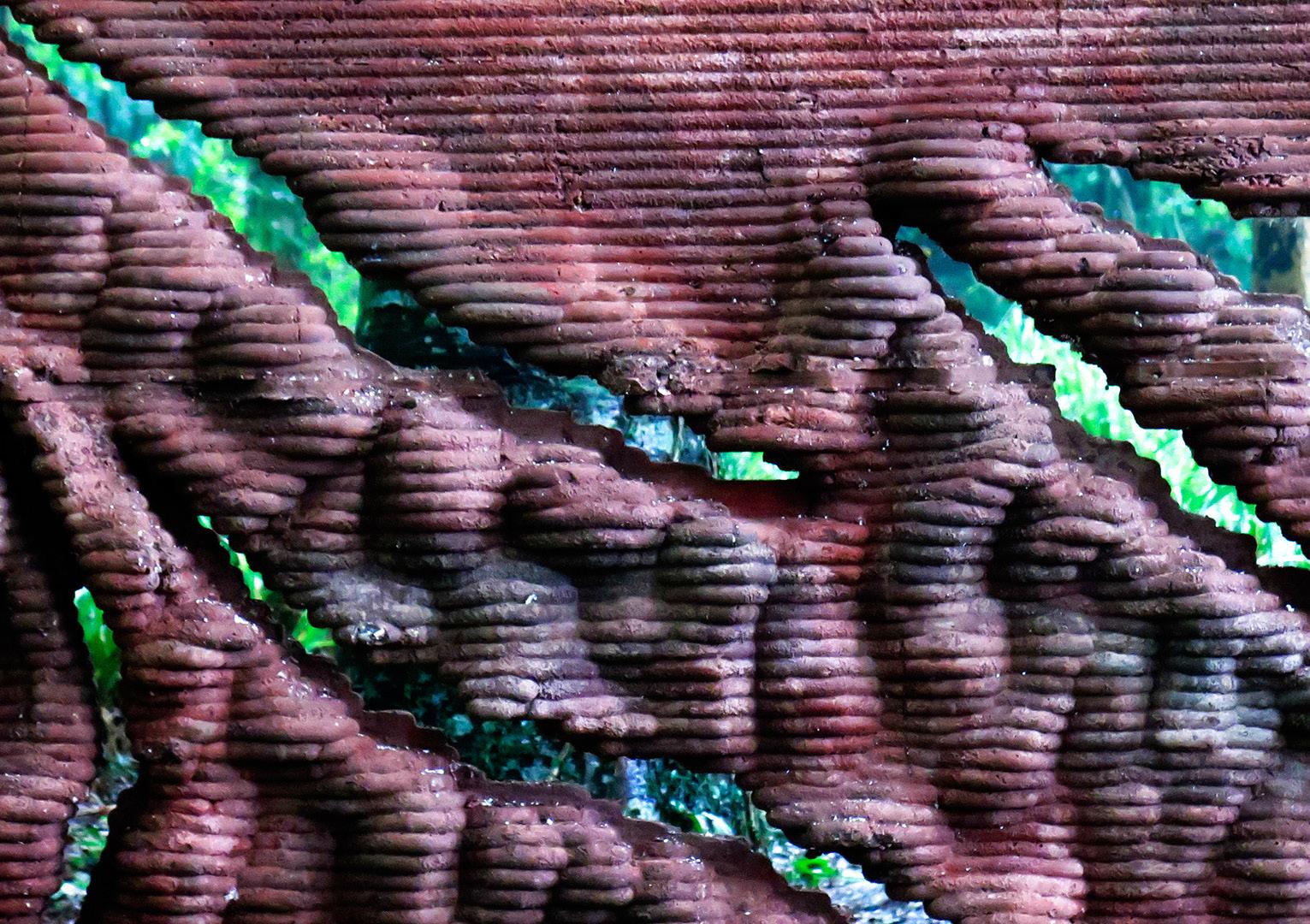

Concrete has been a primary material of ex-

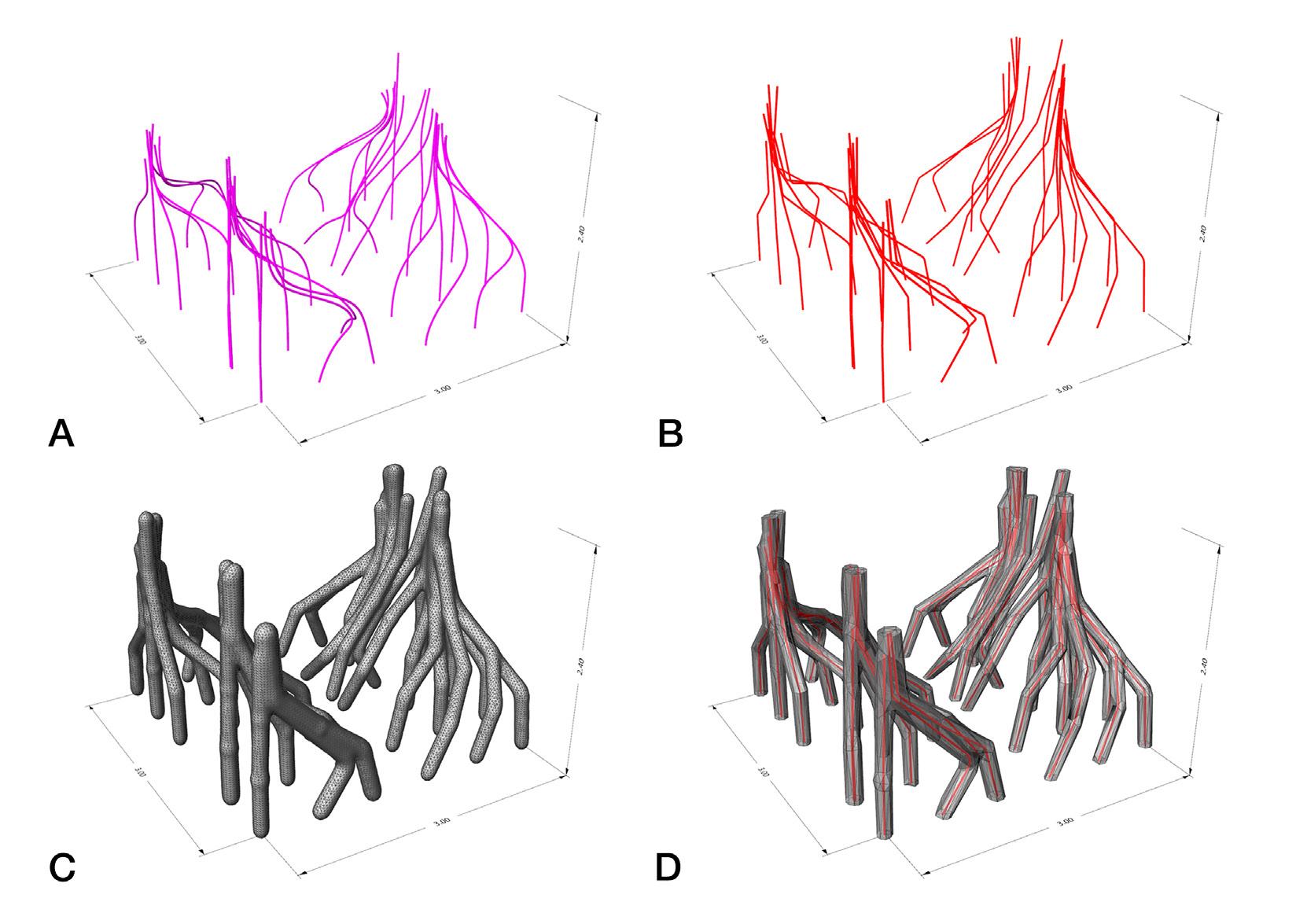

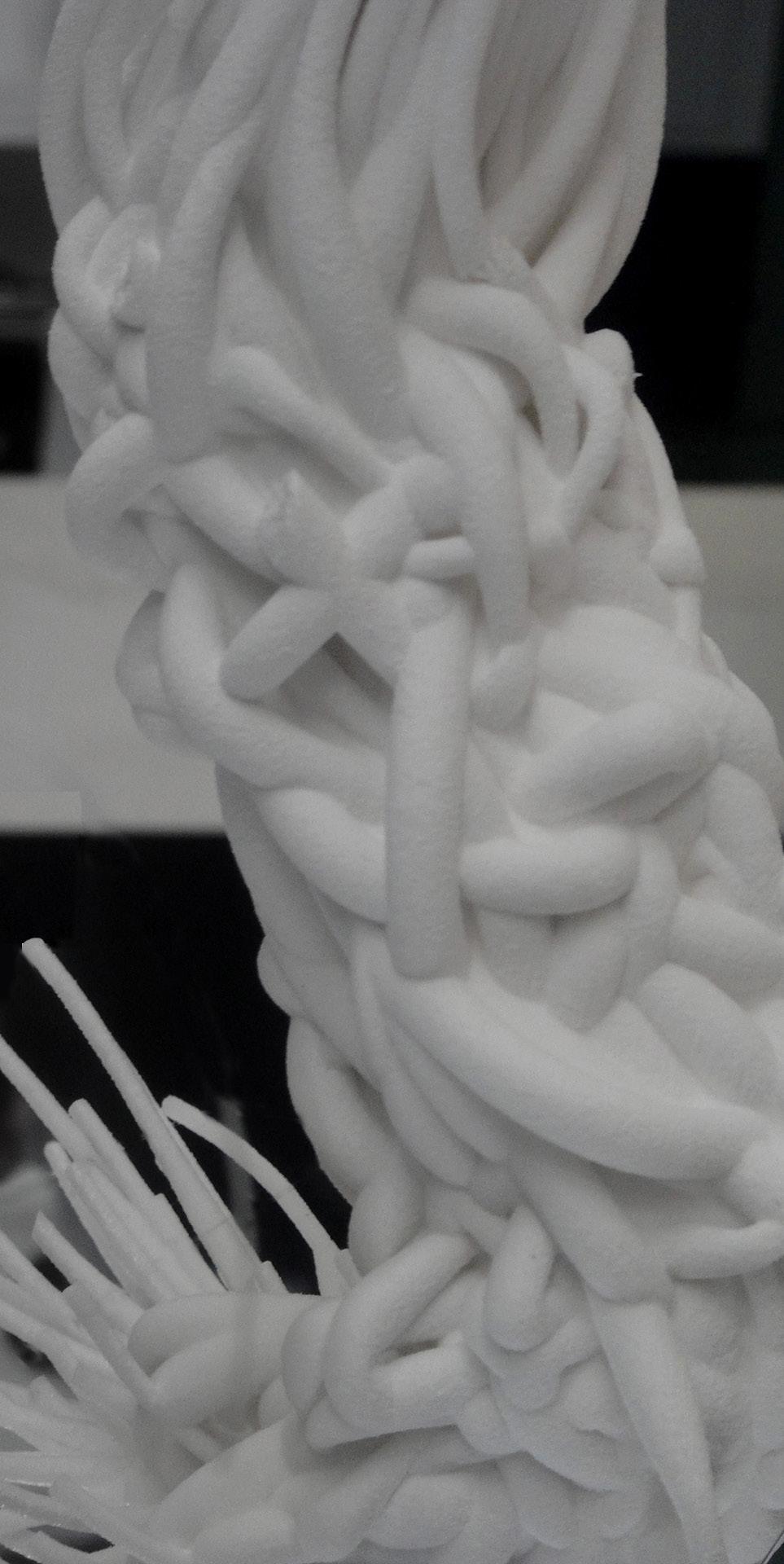

perimentation in multiple cycles of DLAB. Projects like Callipod (2014), InFlux (2015), and Weave.X (2016) focused on exploring the fluidity and structural behaviour of concrete. Techniques such as fabric formwork, earth scaffolding, and expanded polystyrene (EPS) formwork were employed to challenge traditional casting methods. Weave.X investigated robotic rod-bending protocols and integrated computational workflows to produce interwoven concrete structures. Computational simulations, including FEA analysis, informed the optimization of concrete structures, while robotic fabrication advanced the precision and complexity of formwork designs. These projects highlighted the architectural potential of concrete in creating highly efficient, non-conventional forms with limited resources and time.

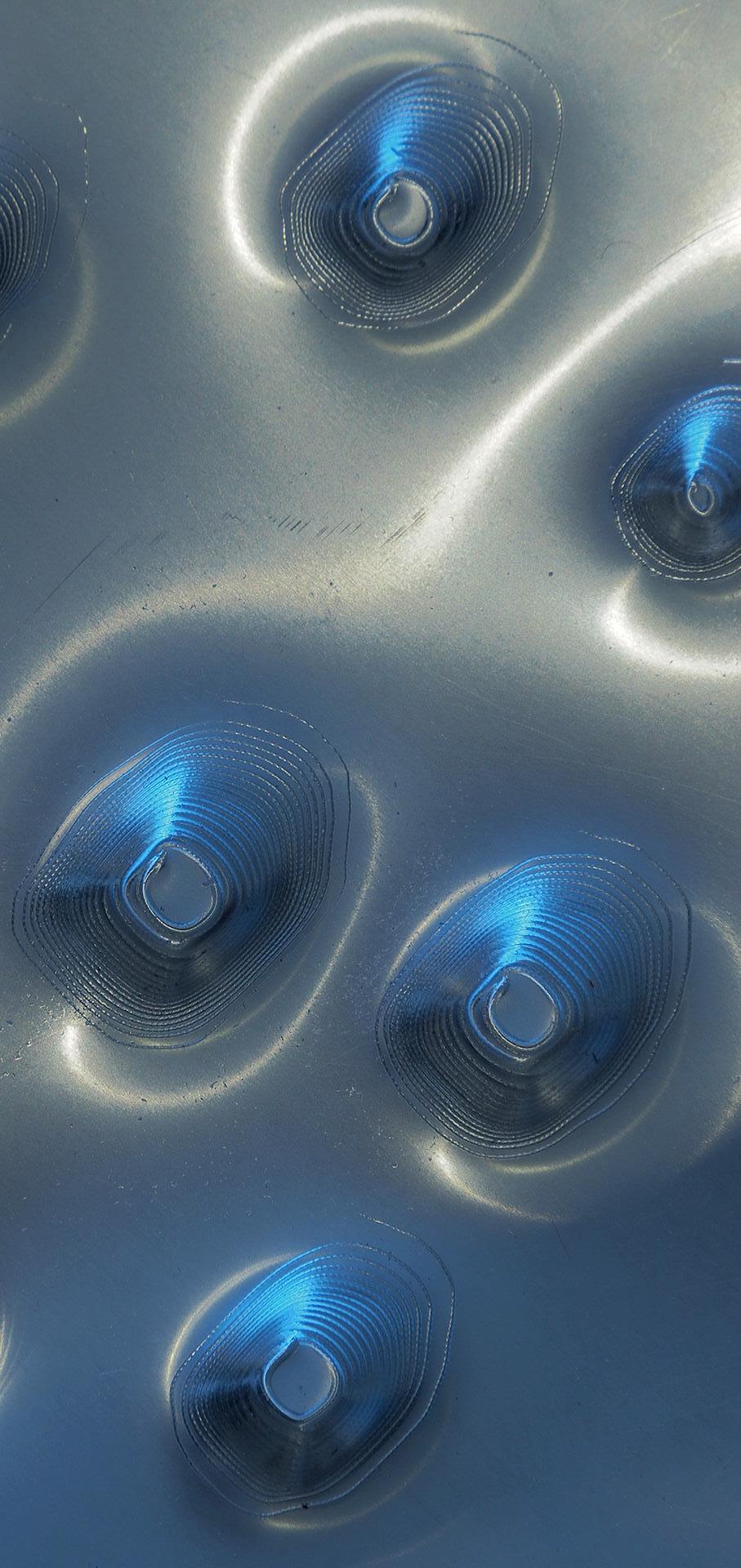

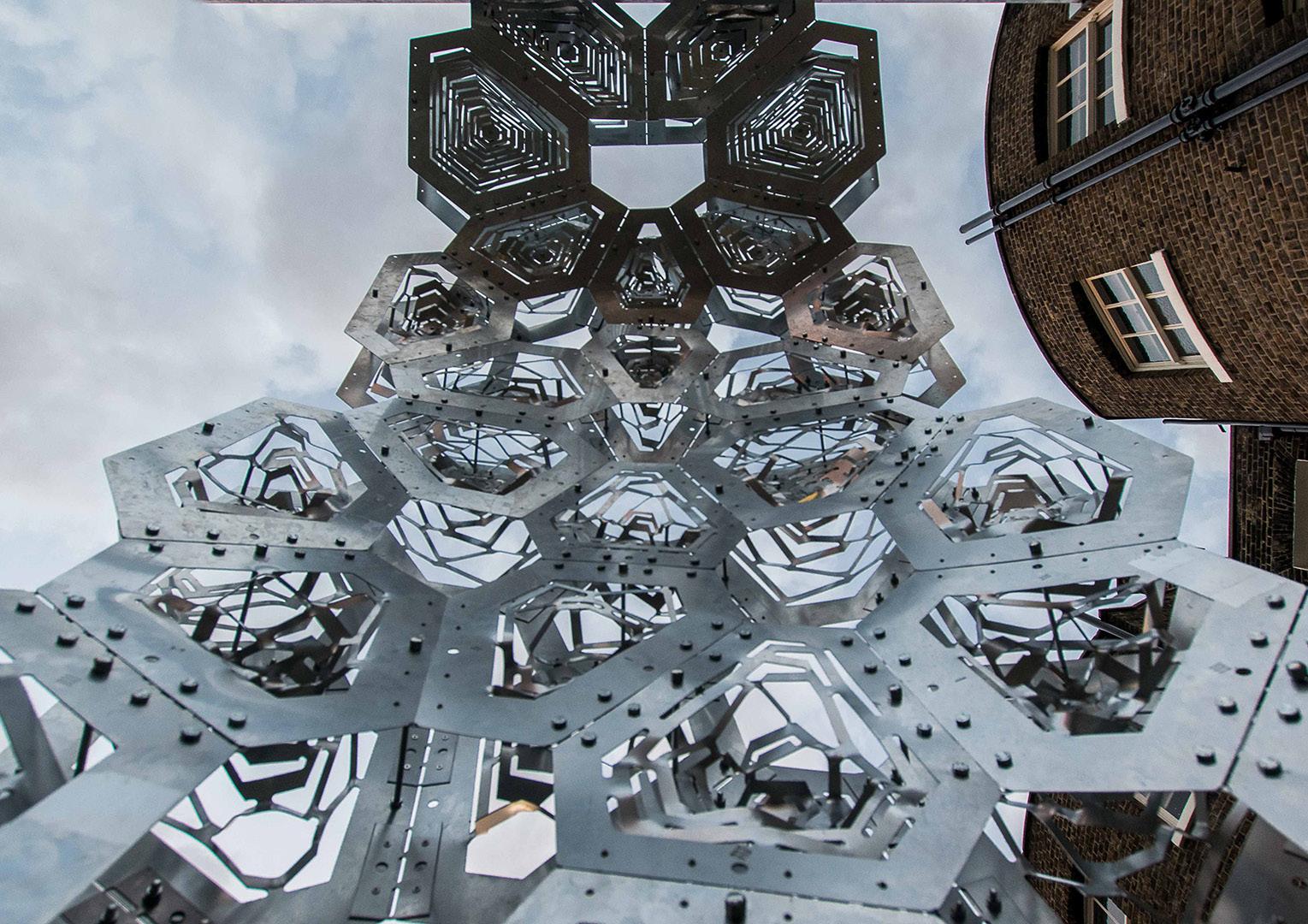

Metal sheet experimentation emerged as a key theme in cycles like 2017 and 2019. This research stream focused on robotic incremental sheet forming and metal expansion techniques, leveraging the malleability and strength of metals to create lightweight, structurally efficient components. Expanded metal sheets and incrementally formed panels were fabricated using industrial robots, allowing for precise, context-responsive geometries. By integrating computational design and robotic toolpath generation, these projects advanced the architectural possibilities of metal for cladding and spatial enclosures.

In 2022, DLAB explored the use of thin plywood, emphasizing robotic active bending techniques to create innovative structures. The focus was on thin plywood plates, where participants explored elastic bending and twisting to create sustainable and transportable designs. The research focused on the versatility of plywood and timber materials in architectural applications. The project highlighted the potential of integrating active bending with robotic fabrication to achieve intricate geometries that are easy to transport, assemble, and disassemble.

Rattan

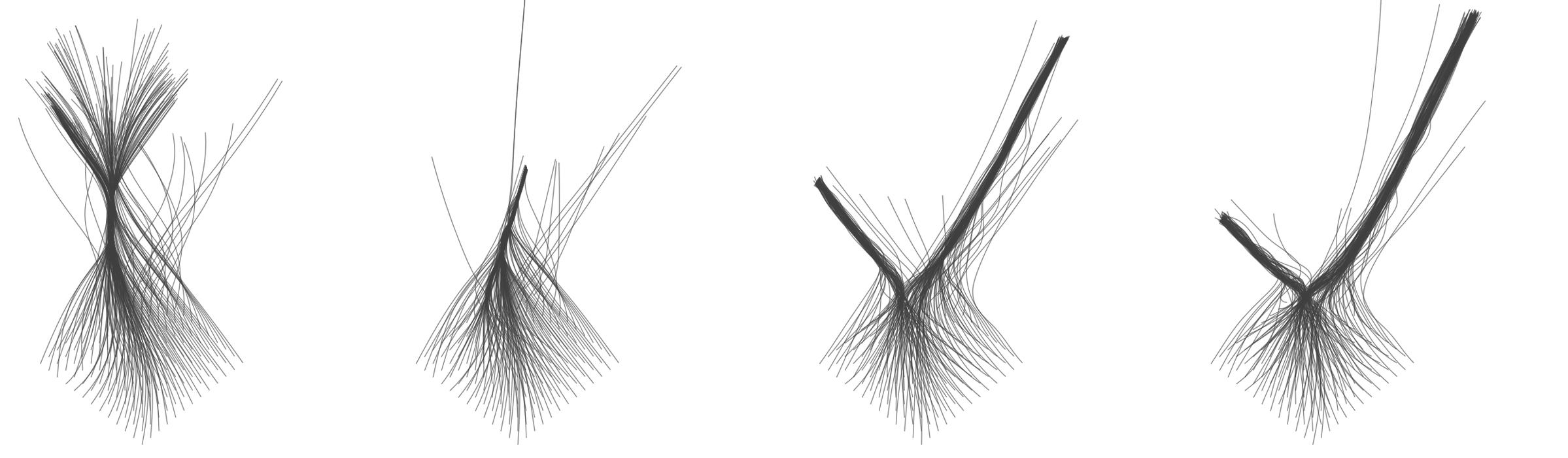

DLAB 2023 introduced rattan canes as a renewable and biodegradable material for architectural exploration. Through robotic bundling and twisting techniques, participants created lightweight structures that emphasized sustainability and minimal waste. Robotic fabrication played a crucial role in achieving precision in the bundling and assembly processes. Computational tools were used to simulate and optimize the arrangement of rattan bundles, ensuring structural stability while minimizing material usage. The workflow combined generative design algorithms with physical prototyping to refine the properties of rattan in architectural applications. The integration of natural materials with computational design workflows underscored the programme’s highlight on environmentally conscious innovation.

DLAB explores themes of generative design, material computation, and large-scale fabrication and assembly technologies. Participants are challenged to design and produce full-scale architectural structures that respond to structural, morphological, and contextual factors, exploring diverse material and geometric configurations.

In recent decades, the digital era in architecture has enabled a wide array of complex geometric assemblies. As digital fabrication evolves, architects face new opportunities and challenges in transitioning digital forms into physical constructs. Robotics in architecture have opened new possibilities for seamlessly merging digital and physical design processes, allowing for greater precision and versatility.

The program draws inspiration from structural principles found in natural systems, such as the efficient organization and adaptability observed in various fibrous assemblies. These principles highlight the benefits of redundancy and hierarchies in structural systems, offering robustness and flexibility in both organic and human-made constructs. Traditional building methods have long utilized techniques like bundling to enhance load-bearing capacity and structural efficiency, demonstrating how these approaches can be adapted to contemporary architectural needs.

Each year, participants are introduced to innovative design techniques, including the con-

trolled deformation of materials to achieve complex forms. Through these methods, they explore how material properties can lead to structurally efficient and aesthetically dynamic designs. Hybrid systems that combine various structural components offer potential for creating lightweight, adaptable structures, pushing the boundaries of material efficiency and architectural form.

In addition to using sustainable materials that embody lower energy and carbon footprints, DLAB emphasizes design solutions that minimize waste. Advanced computational methods, simulations, and structural analysis guide participants in developing material-efficient, environmentally conscious designs.

The finalized structures are designed for easy assembly and transport, aligning with the program’s focus on modular and adaptable construction. Throughout DLAB, participants engage in a series of digital and physical experiments to bridge the gap between digital concepts and physical outcomes. By iteratively testing digital designs through physical models, each team develops a scaled prototype that is ultimately realized at full scale as a working architectural prototype.

DLAB is an intensive, nineteen-day design program that requires full-time engagement from participants. The program is structured as an integrated design unit, guiding students through a unique brief that brings together experimental architectural knowledge, critical thinking, and innovative design research. By combining hands-on fabrication, computational experimentation, and collaborative learning, DLAB offers a transformative experience for emerging architects and designers.

The program is divided into two primary stages:

The first stage introduces participants to the core concepts, tools, and objectives of the program. During this initial phase, participants receive technical tutorials on essential computational tools, including Rhinoceros, Grasshopper, and Grasshopper add-ons, such as Robots, Kangaroo, and Karamba. These tutorials provide a foundation in algorithmic design and digital modelling, helping students acquire the skills necessary to translate complex concepts into viable architectural designs.

Alongside technical training, students attend design lectures led by experts from architectural practices and research institutions. These lectures introduce students to cutting-edge concepts, methodologies, and innovations within architectural research. By engaging with professionals who work at the forefront of dig-

ital design, participants gain insights into the systematic approaches shaping contemporary architecture and fabrication.

During this phase, each design team is tasked with developing a proposal for a full-scale, 1:1 architectural intervention. These proposals, intended for AA London’s outdoor area, must integrate structural, material, and contextual considerations. The teams present their initial concepts in interim pinups, allowing for feedback that helps refine their ideas. Stage 1 culminates with a final jury, where teams present their proposals as part of a design competition. Selected designs are chosen to proceed to Stage 2 based on predefined criteria, such as alignment with the research agenda, feasibility, and structural coherence. By the end of this phase, each team has produced a range of materials, including graphic illustrations, drawings, simulations, and scaled prototypes.

Stage 2: Full-Scale Prototype Fabrication & Assembly

In the second stage, DLAB shifts from design development to hands-on construction. All design teams collaborate toward a unified objective: fabricating and assembling a full-scale architectural prototype. This stage emphasizes the continuity between digital design and physical assembly, challenging participants to adapt their digital models to the practical demands of full-scale construction. Students utilize a combination of digital, robotic, and analog fabrication techniques to realize the full-scale proto-

type, engaging in every step of the fabrication and assembly processes.

The construction process incorporates AA’s Digital Prototyping Lab (DPL) and wood and metal workshops, providing students with the tools and environment to test their designs in real-world conditions. By engaging with both digital and manual fabrication, participants deepen their understanding of how digital workflows translate into architectural forms, learning to calibrate their design for factors such as material behaviour, structural integrity, and environmental constraints. This collaborative, full-scale fabrication exercise not only enhances students’ technical and problem-solving skills but also reinforces the importance of teamwork and adaptability in architectural practice.

Throughout both stages, students work in a studio environment where experimentation is key. Technical tutorials run parallel to design experiments, allowing participants to apply theoretical knowledge directly to hands-on projects. With a comprehensive timetable provided at the start of the program, students can anticipate and prepare for each phase, from concept ideation and tool mastery to full-scale construction.

Computation - Digital Fabrication

The computational approach in DLAB 2024 is rooted in generative design algorithms, explored within the algorithmic modeling environment of Rhino and Grasshopper alongside specialized Grasshopper add-ons such as Robots, Kangaroo, and Karamba. The program begins with technical tutorials, where students learn to understand algorithmic logic and coding as powerful design tools. This foundational knowledge equips them to develop computational models that align with the program’s agenda, setting the stage for hands-on experimentation and design. As participants progress, they are encouraged to explore iterative design processes, adjusting and refining their digital models based on feedback from both digital simulations and physical prototypes. This interactive approach reinforces their understanding of how digital tools can directly influence and shape physical outcomes.

Continuity of Workflow from Digital to Physical

One of DLAB’s primary objectives is to seamlessly integrate computational design and physical fabrication. As each design proposal takes shape, students will create physical models at various scales to test and refine their ideas. Participants have access to the AA Digital Prototyping Lab (DPL) and the AA Wood and Metal Workshop, where they can experiment with diverse materials and fabrication methods, including CNC techniques like laser cutting, milling, 3D printing, and robotic fabrication. This environment enables students to move

fluidly between digital simulations and physical prototypes, ensuring that their designs are informed by both computational accuracy and real-world feasibility. Each stage of this process provides valuable insights into material properties and fabrication techniques, allowing students to refine their digital designs in response to the challenges and possibilities encountered in physical production.

Full-Scale Fabrication & The “Analog Machine”

During the second phase of DLAB, students construct a one-to-one scale working prototype that utilizes techniques such as robotic bending and twisting. This full-scale fabrication serves as an “analog machine,” allowing students to observe the transformation of digital systems into functional, performative material assemblies.

Real-world constraints, including gravity, physical forces, and loading conditions, are crucial factors in the digital simulations, and students refine their models based on these variables to achieve structural integrity and aesthetic coherence in the physical realm. This handson process not only reinforces the connection between digital design and tangible outcomes but also helps students develop a keen understanding of structural performance and the impact of material behavior in real-world applications.

Ambitions of DLAB’s Design and Fabrication Techniques

1.Exploration of Generative Algorithms: Participants explore form-finding methods to design structures that balance functionality, aesthetics, and structural performance.

2.Material Computation: The program emphasizes simulating material behavior and organization, incorporating real-world constraints to create designs that are both innovative and viable.

3.Physical Models as “Analog Machines”: Physical models serve as iterative tests that bridge digital and physical experimentation, allowing students to calibrate digital simulations with tangible feedback from the material world.

4.Fabrication of a Full-Scale Prototype: The program culminates in the assembly of a fullscale working prototype, which integrates computational design, material exploration, and fabrication techniques to produce a structure that embodies the experimental and innovative ethos of DLAB.

This approach ensures that DLAB participants develop a comprehensive understanding of how computational and physical experimentation inform one another, preparing them for future design challenges where digital and physical processes are deeply intertwined.

Participants form dynamic design teams during the workshop, creating a collaborative space where students and tutors come together to address complex design challenges. DLAB fosters an environment of creativity and open-mindedness, encouraging participants to experiment with unconventional approaches, explore innovative techniques, and push the boundaries of traditional architectural thinking. Working in teams, students develop essential collaboration and communication skills as they share ideas, debate solutions, and work toward common goals. By deeply analyzing existing design problems, rigorously testing their ideas, and proposing unique interpretations, participants engage in an evolving process of design experimentation that values exploration over fixed answers. This process helps them develop resilience and adaptability—qualities essential in today’s rapidly evolving architectural landscape.

Students play an active role in the building and assembly of full-scale prototypes, gaining hands-on experience in a variety of fabrication techniques, including robotic fabrication. This practical, immersive approach to learning is at the heart of the DLAB experience. With access to the Digital Prototyping Lab and the wood and metal workshops, students bring their digital designs to life through physical models, experi-

menting with materials, and refining their methods. The program emphasizes the ongoing calibration between digital and physical experimentation, encouraging students to test and adjust their digital simulations based on the feedback and insights they gather from physical prototypes. This iterative process strengthens their understanding of both realms, allowing them to see firsthand how computational designs translate into real-world structures and adapt to material and structural constraints.

DLAB enriches the academic experience with a series of expert-led lectures and industry visits that provide students with valuable insights into the architectural profession. Renowned professionals from leading architecture practices share their experiences, guiding students through the latest developments and real-world applications of digital design and fabrication. These lectures complement the hands-on work in the studio, giving participants a broader perspective on how their experimental approaches connect to contemporary practice. Additionally, students have the opportunity to visit cutting-edge architecture firms and advanced fabrication labs, where they observe innovative workflows, tools, and processes in action. These office visits allow participants to gain practical knowledge of the industry, meet professionals, and build connections that may benefit their careers.

This section highlights key aspects of DLAB’s activities, showcasing the journey from conceptual ideas to full-scale installations while emphasizing the intellectual, technological, and hands-on dimensions of the program. Over the years, DLAB has brought together participants to explore creative design solutions through a blend of digital and physical approaches. From constructing prototypes to attending insightful lectures and engaging in collaborative teamwork, the program offers a well-rounded experience that encourages both practical skill development and thoughtful exploration of architectural challenges.

1) You can make an application by completing the online application form. If you are not able to make an online application, please contact the Visiting School Office.

2) AA Students are eligible to 20% Bursary, no CV, Portfolio or Cover Letter required. Please apply online with your login details and make a deposit payment, follow by contacting the Visiting School Office to request a concession code.

3) 50% Bursaries are also available for all participants that apply on or before the deadline Friday, 28 February 2025. Places for 50% Bursaries are limited, therefore this option requires a selection process. Please apply online by making a deposit payment £60, follow by sending your CV or Portfolio and a 200-word Motivational Statement to the Visiting School Office.

The AA Visiting School requires a fee of £1994 per participant, which includes a £60 AA Membership fee, payable by all participants.

For full applications, the application deadline is Monday, 14 July 2025.

Fees do not include flights or accommodation, but accommodation options can be advised. Students need to bring their own laptops, digital equipment and model making tools.

The AA recognises that the prospect of finding private-sector housing* upon arrival to London can be daunting, and has therefore enlisted the

The workshop is open to current architecture and design students, PhD candidates and young professionals. Software Requirements: Adobe Creative Suite, Rhino 7. No prior knowledge of software tools is required for eligibility. A CV or a portfolio is not required for the full application.

Private Practices: If you are interested to enhance your team’s skills with our specialised DLAB programme, contact our Visiting School team to request a meeting with the programme heads to discuss application options.

Fees

• Full fee including £60 Membership is £1994, or for existing Members is £1934.

• AA Students 20% Bursary: The full fee after the concession is applied is £1547.

• 50% Bursary for successful applicants:

The full fee for non-Members after the concession is applied is £1027, or for existing Members is £967.

Please note: The maximum price reduction is 50% for AA students or non-AA students with successful bursary applications. Bursaries are not accumulative for those eligible to multiple schemes.

The AA recognises that the prospect of finding private-sector housing upon arrival to London can be daunting, and has therefore enlisted the services of the University of London Housing Services (ULHS). The ULHS offers advice to

students regarding how to find accommodation, which areas to consider, pricing, contract checking, legal advice and more. They produce an annual Private Housing Guide and maintain an online database of available accommodation provided by registered landlords and letting agents for both groups and individuals. The ULHS also works with short-term accommodation providers and Private Student Halls of Residences.

Applicants can book an appointment for advice. You will need to provide ULHS with a copy of your unconditional offer letter from the AA.

All participants traveling from abroad are responsible for securing any required visas and the associated costs. Participants are advised to contact their home embassy early.

Student visas are not required for courses shorter than six months. How you apply for a Standard Visitor Visa depends on your country of origin. Applicants who require a visa to study in the UK should review the details and eligibility criteria for the Standard Visitor Visa, can be found on the gov.uk website.

Participants can apply for a visa up to three months before traveling to the UK. If a visa is required, a confirmation letter will be issued by the Visiting School office confirming enrolment in the program once full fees have been paid.

Note for nationals of Kuwait, Oman, Qatar or the United Arab Emirates: You can apply for an Electronic Visa Waiver.

All applicants are responsible for securing their own travel and health insurance and should ensure that their policy provides coverage for personal belongings such as laptops, equipment, tools, passports, etc. The AA takes no responsibility for lost or stolen property.

Note for EU, EEA, and Swiss Citizens:

The UK left the European Union on 31 January 2020. Applicants should complete the Brexit checker and review the guidance notes on healthcare for visitors to the UK from the EU. Applicants who are in the UK for less than six months will require a European Health Insurance Card (EHIC), which can be obtained from their home country. This card is not an alternative to travel insurance and will not cover any private medical healthcare costs or lost or stolen property. It is therefore important to have both an EHIC and a valid private travel insurance policy.

Note for international students:

As you will be in the UK for less than six months, you are not covered for National Health Service (NHS) services and treatment and must therefore obtain travel and health insurance from your own country.

Contact:

Architectural Association

36 Bedford Square

London WC1B 3ES

T: +44 (0)207 887 4014

E: visitingschool@aaschool.ac.uk

AA DLAB VISITING SCHOOL