Fibre AdaptiveComposite Systems

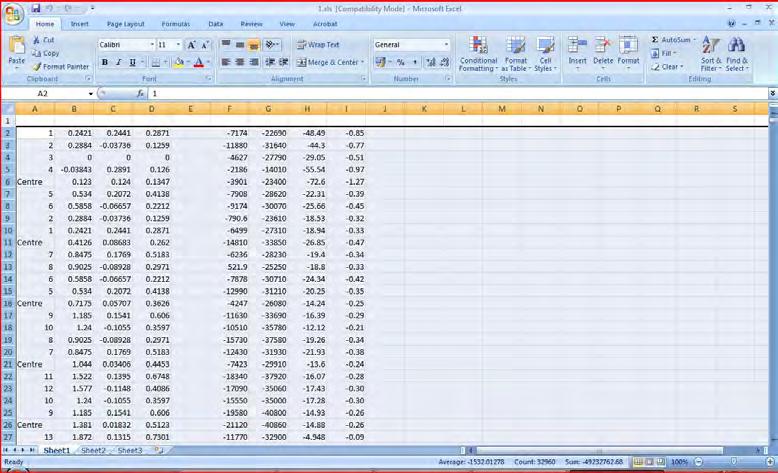

Maria Mingallon | Konstantinos Karatzas [MSc]

|

|

|

Sakthivel Ramaswamy [MArch] Emergent

Technologies + Design

Architectural Association

London

2008/09

ARCHITECTURAL ASSOCIATION SCHOOL OF ARCHITECTURE GRADUATE SCHOOL PROGRAMMES

COVERSHEET FOR COURSE SUBMISSION 2008/2009

PROGRAMME: Emergent Technologies and Design

TERM: Autumn 2009

STUDENT NAME(S): Konstantinos Karatzas, Maria Mingallon

SUBMISSION TITLE MSc Dissertation | Fibre Composite Adaptive Systems

COURSE TUTOR Mike Weinstock, Michael Hensel

SUBMISSION DATE: 12/10/2009

DECLARATION:

“I certify that this piece of work is entirely my/our own and that any quotation or paraphrase from the published or unpublished work of others is duly acknowledged.”

Signature of Student(s):

Date: 12/10/2009

1

Contents

Biomimetics Research 9

Organisation Strategies in Nature Thigmo-Morphogenesis

Fibre

Nature

Smart Systems

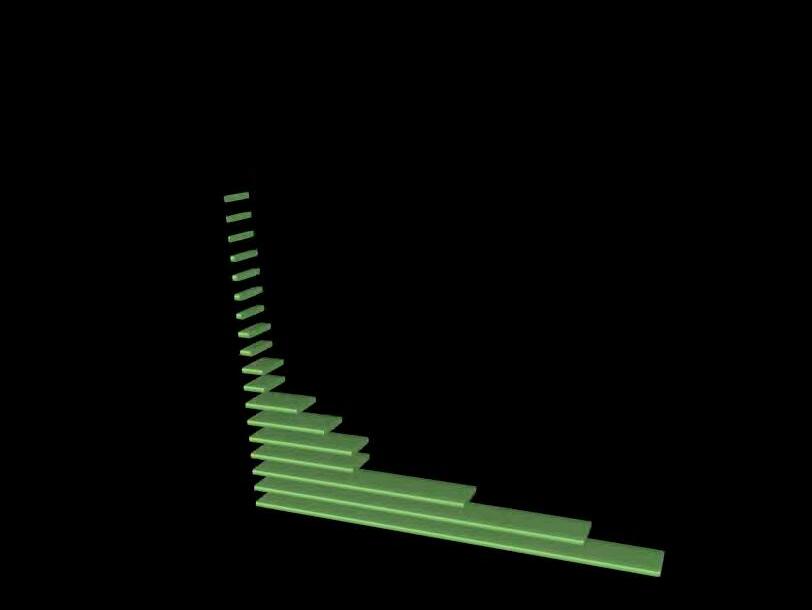

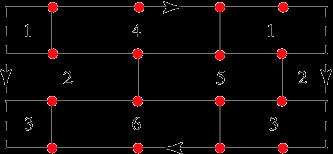

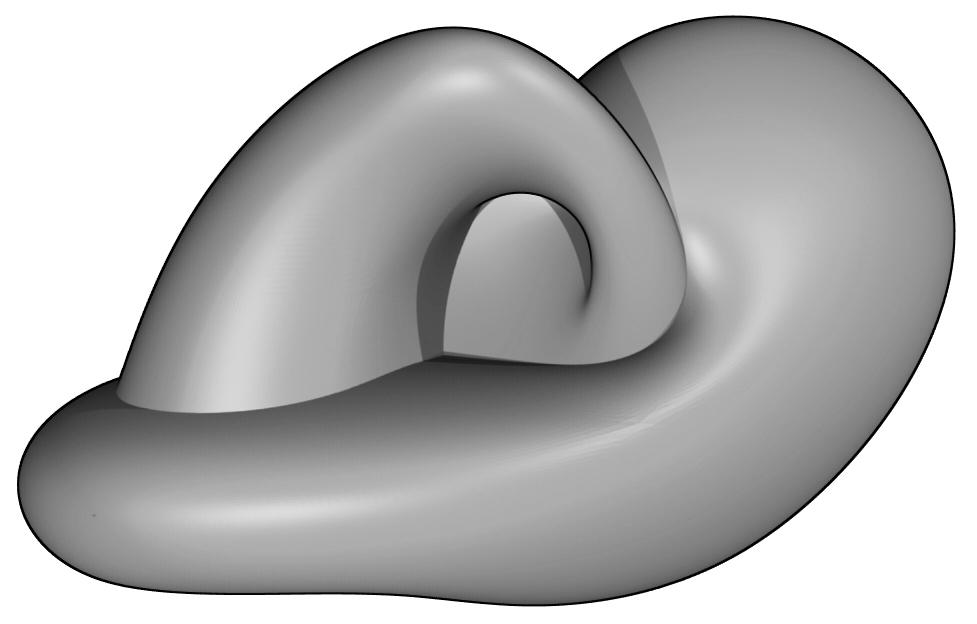

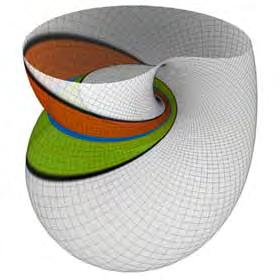

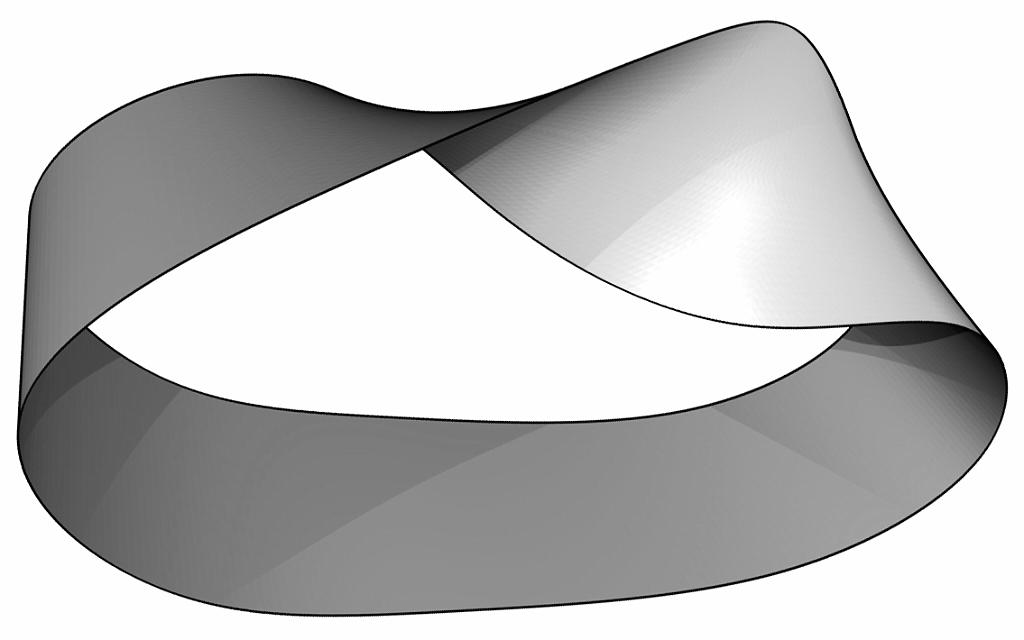

Technology 27 Base Material Sensing Actuation Energy Control 3 Experiments 49 Preparation Actuation Actuation +Control Sensing + Control Sensing + Actuation + Control 4 Geometry 81 Local Geometry 83 Precedents Topology Actuation Global Geometry 115 Precedents Morphology Material configuration 5 Environmental Performance 141 Global Morphology Local Geometry Information Processing 6 Conclusion + Further Research 149 Appendixes 155 A: Technology B: Geometry C: Manufacturing Bibliography 241 Illustration Credits 244 Glossary 245

Adaptive Systems in

Precedents

2

Acknowledgments

We would like to thank our tutors; Mike Weinstock for his involvement and invaluable guidance, and Michael Hensel for his help and encouragement. George Jeronimidis, for his immense help in developing our research and performing the physical experiments. His research on biomimetics is the foundation for this project. We would also like to thank Stylianos Dristas, for his essential input in evolving the geometry. Prof. Kevin Kuang and W.J.Cantwell for sharing their knowledge and research on shape memory alloys and fibre optics. Finally, we would like to thank Evan Greenberg, Tryfon Mantsos, Trystrem Smith and all our Emtech colleagues for their support and feedback.

Abstract‘Thigmo-morphogenesis’ refers to the changes in shape, structure and material properties of biological organisms that are produced in response to transient changes in environmental conditions. This property can be observed in the movement of sunflowers, bone structure and sea urchins. These are all growth movements or slow adaptations to changes in specific conditions that occur due to the nature of the material: fibre composite tissue. Nature has limited material; remarkably all of them are fibres, cellulose in plants, collagen in animals, chitin in insects and silk in spiders. Natural organisms have advanced sensing devices and actuation strategies which are coherent morphomechanical systems with the ability to respond to environmental stimulus.[1.0]

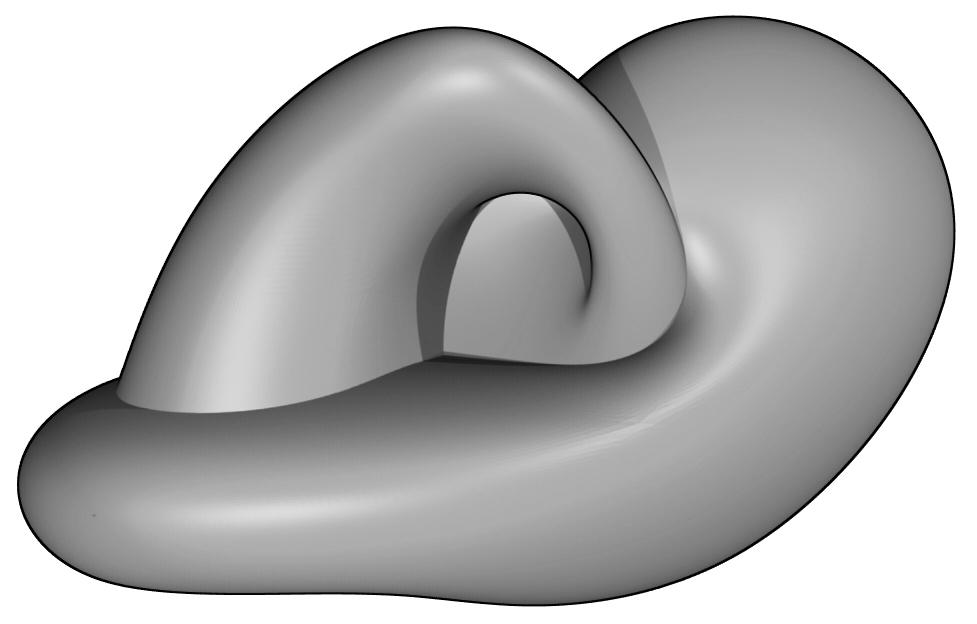

Architectural structures endeavour to be complex organisations exhibiting highly performative capabilities. They aspire to dynamically adapt to efficient configurations by responding to multiple factors such as the user, functional requirements and the environmental conditions. Existing architectural smart systems are aggregated actuating components assembled and externally controlled, whose process of change is essentially different from that of Thigmo-morphogenesis. For example in a leaf, the veins account for its form, structural strength and nourishment, nevertheless they are an integral part of the sensing and the actuation function. This process of a coherent self-autonomous multi-functionality could be termed as ‘Integrated functionality’. Emulating such a Morpho-mechanical system with sensors, actuators, computational and control firmware embedded in a fibre composite skin is the core of this research.

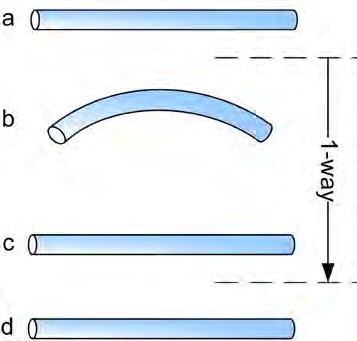

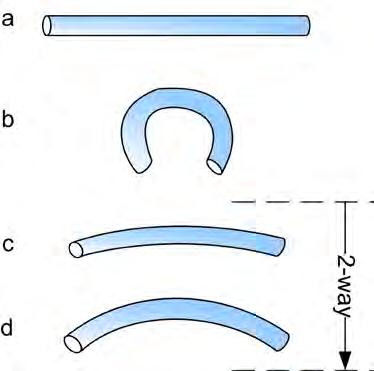

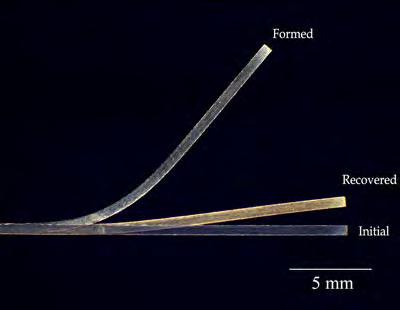

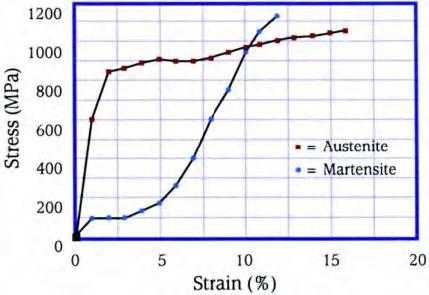

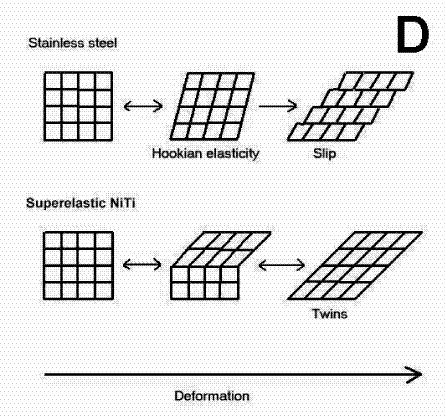

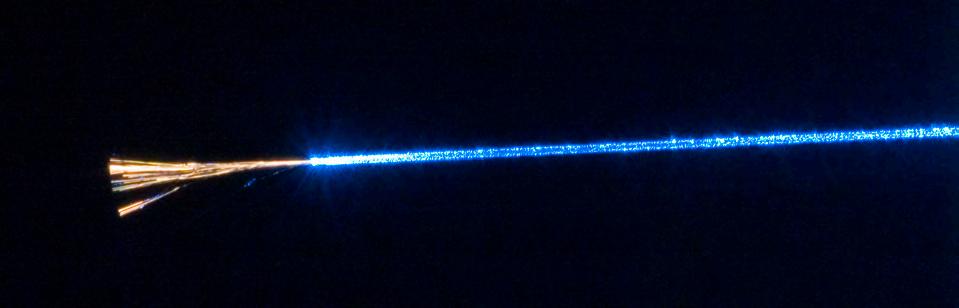

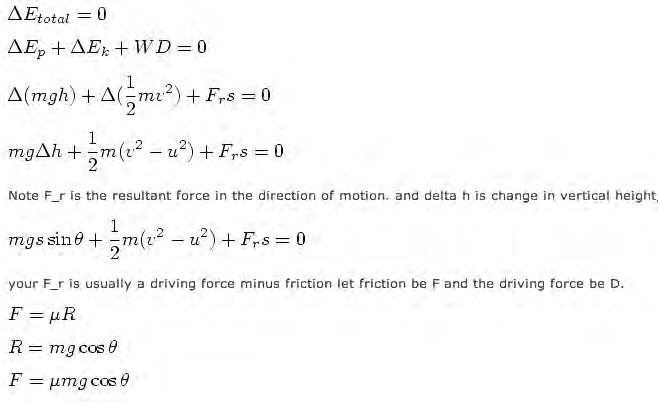

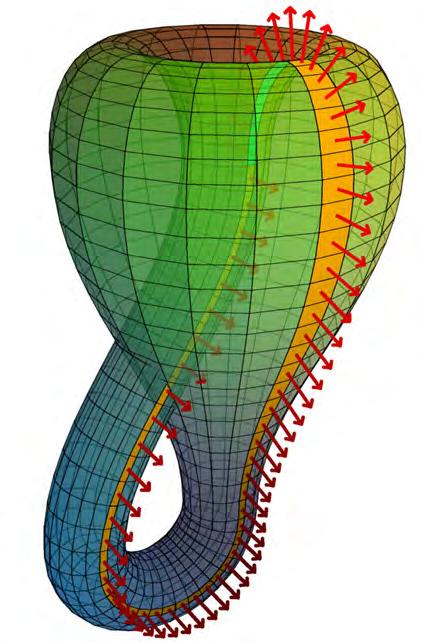

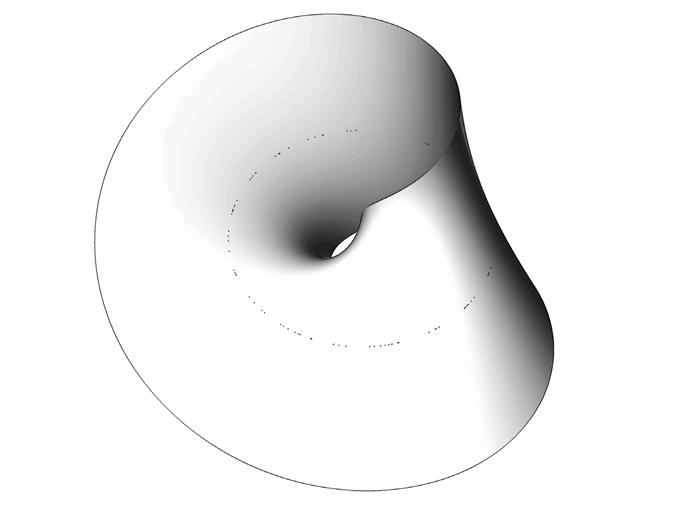

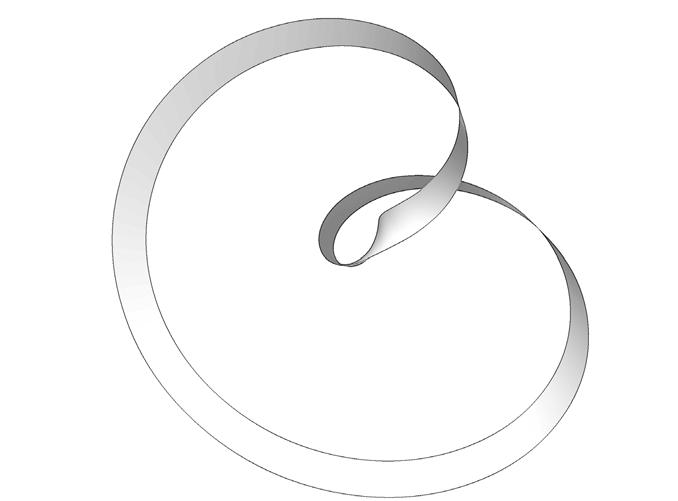

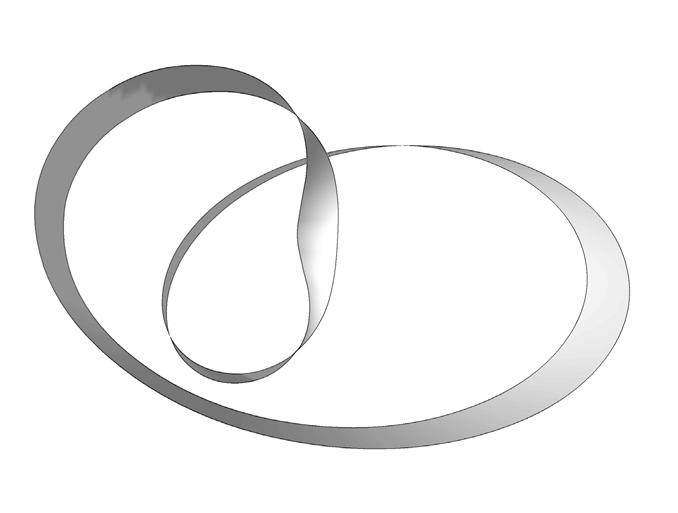

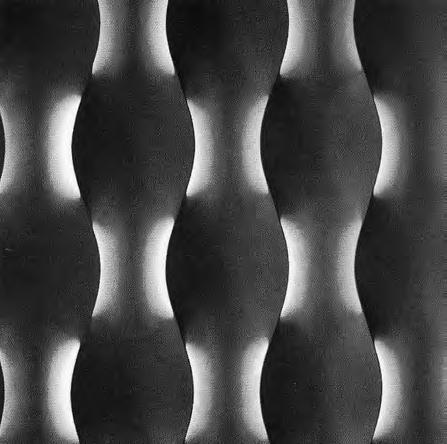

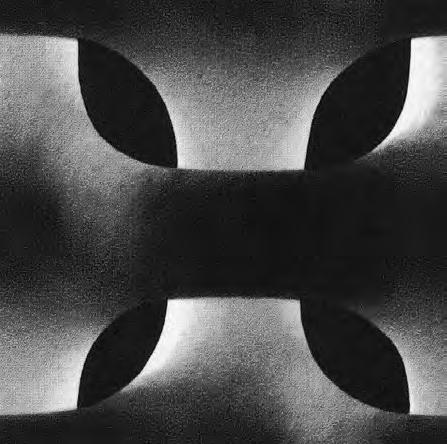

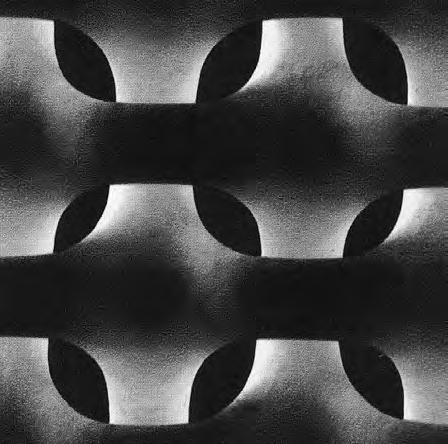

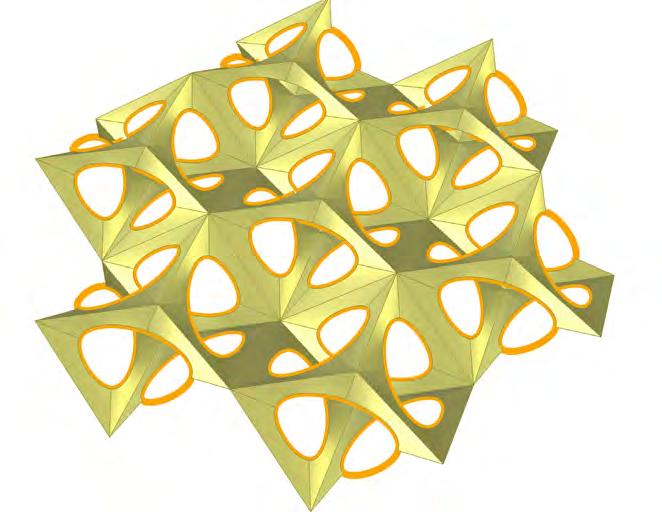

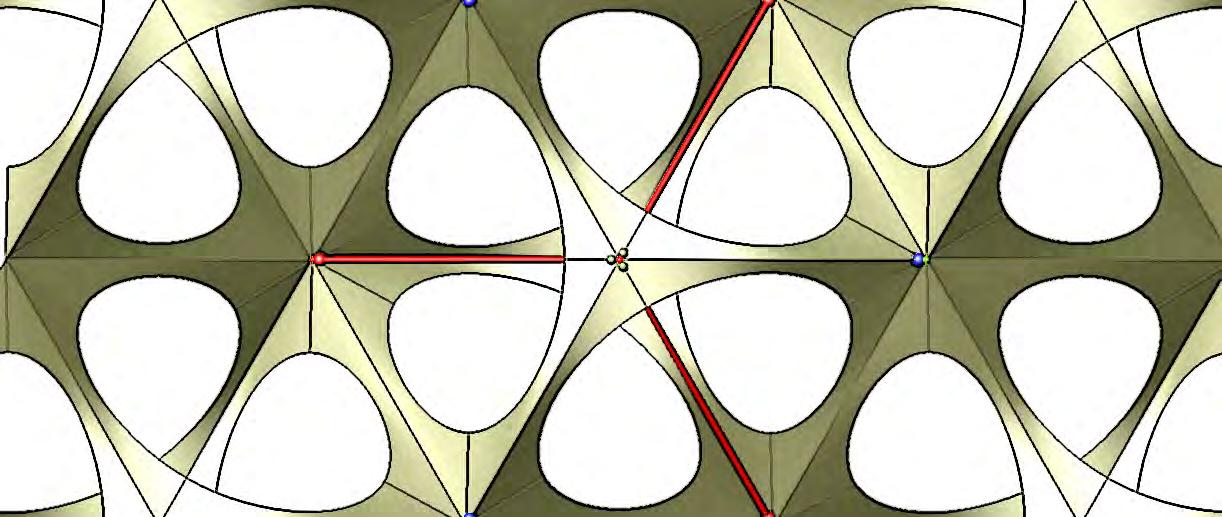

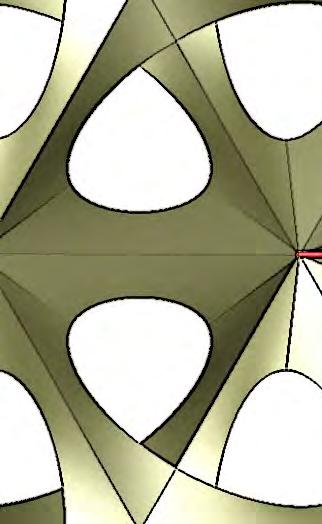

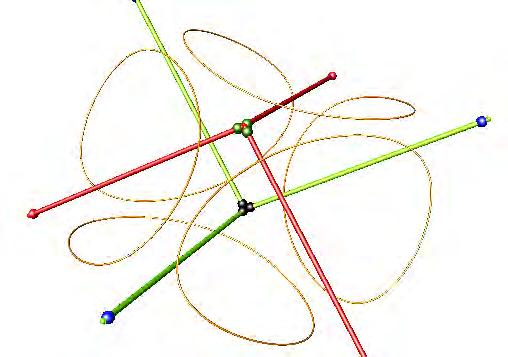

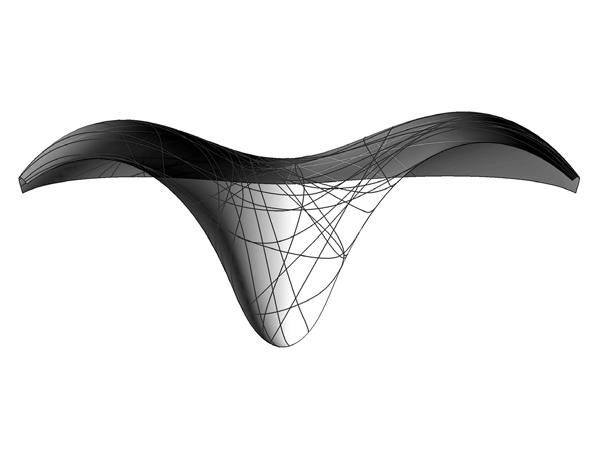

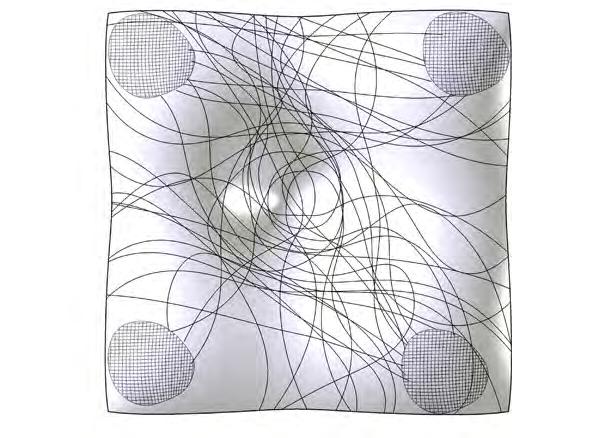

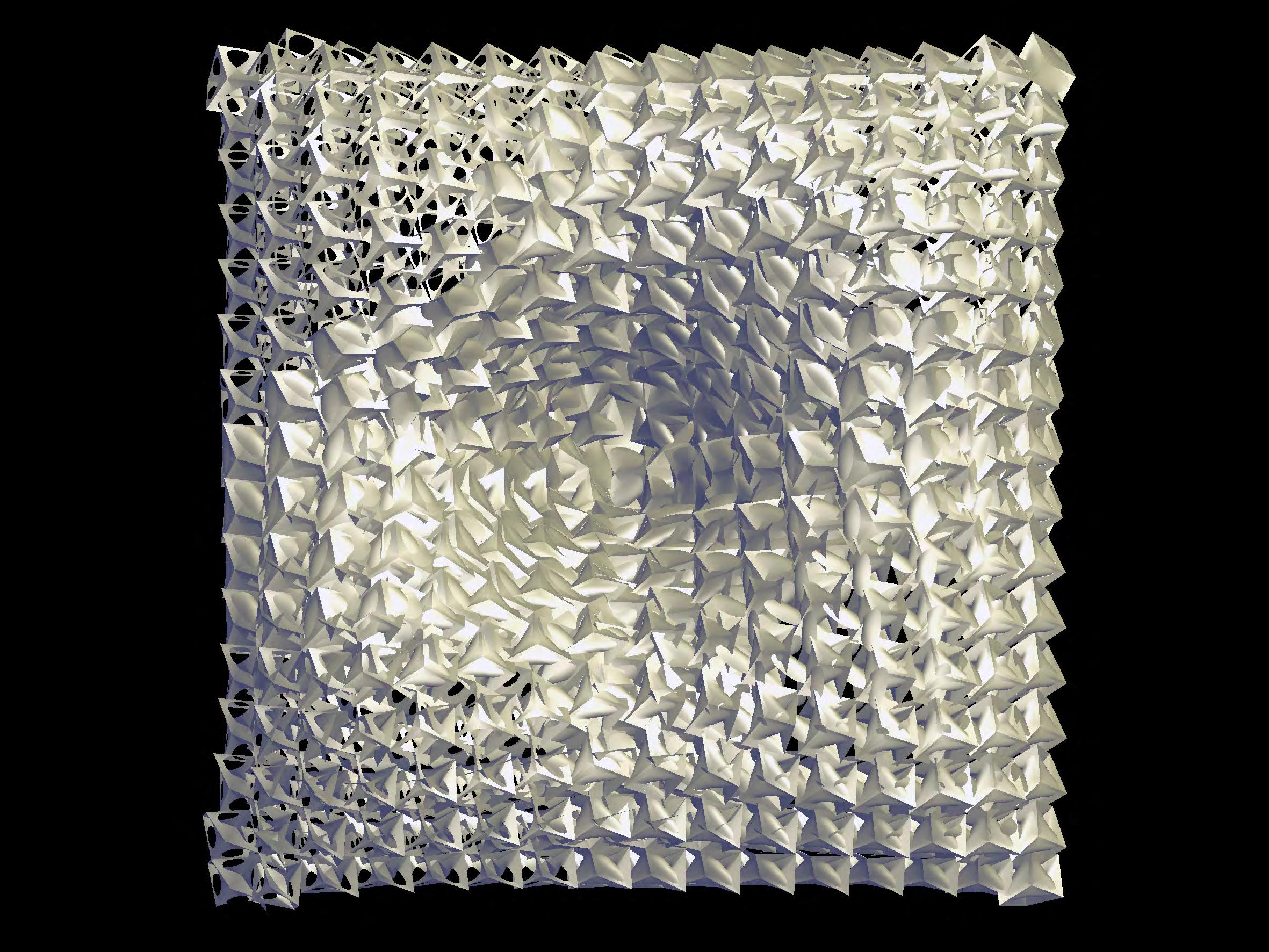

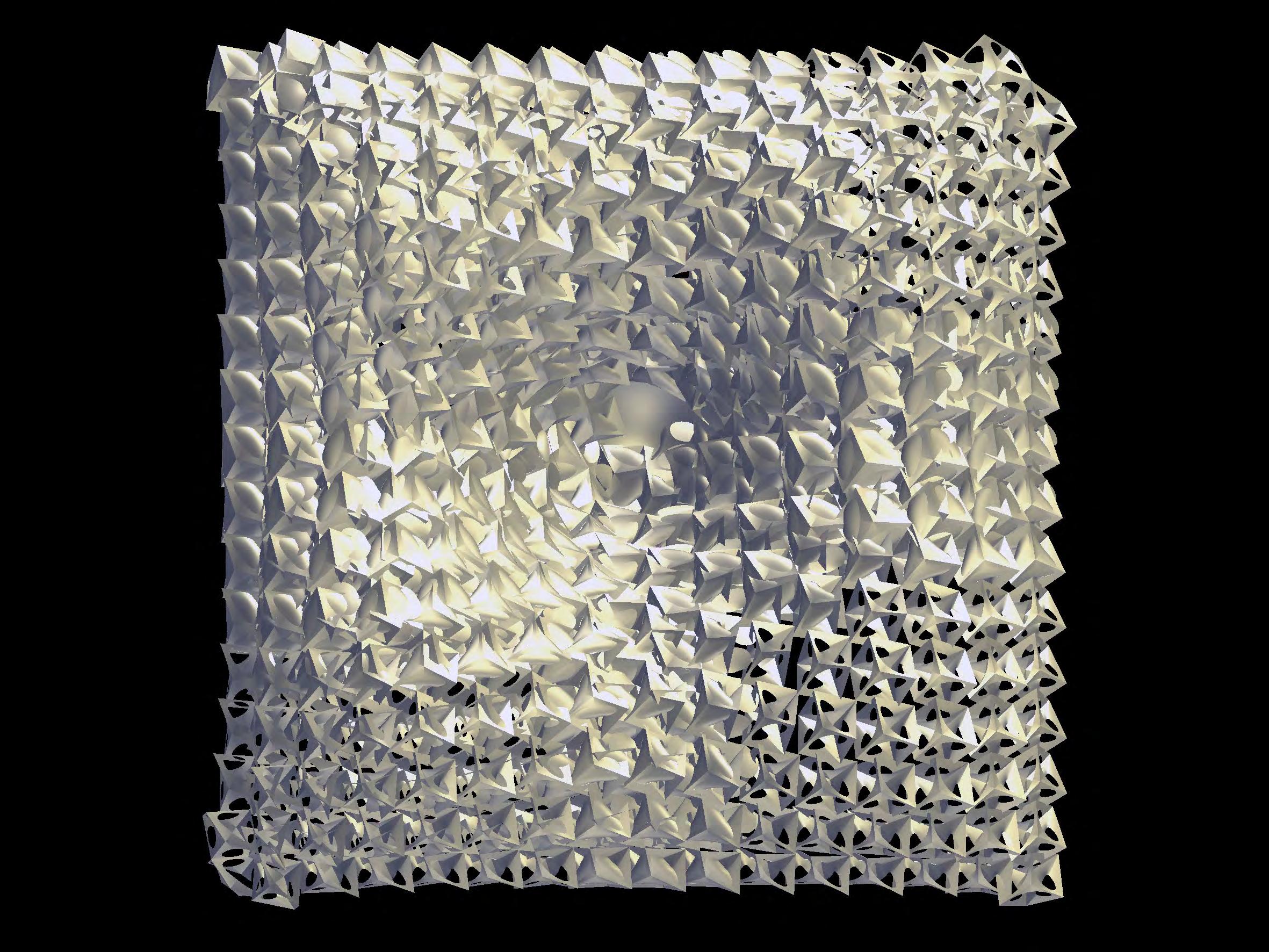

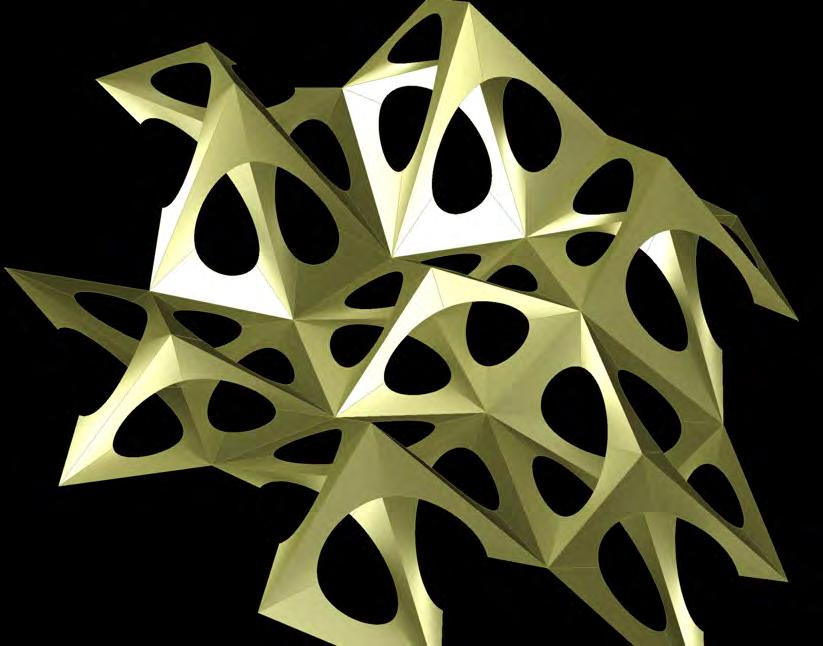

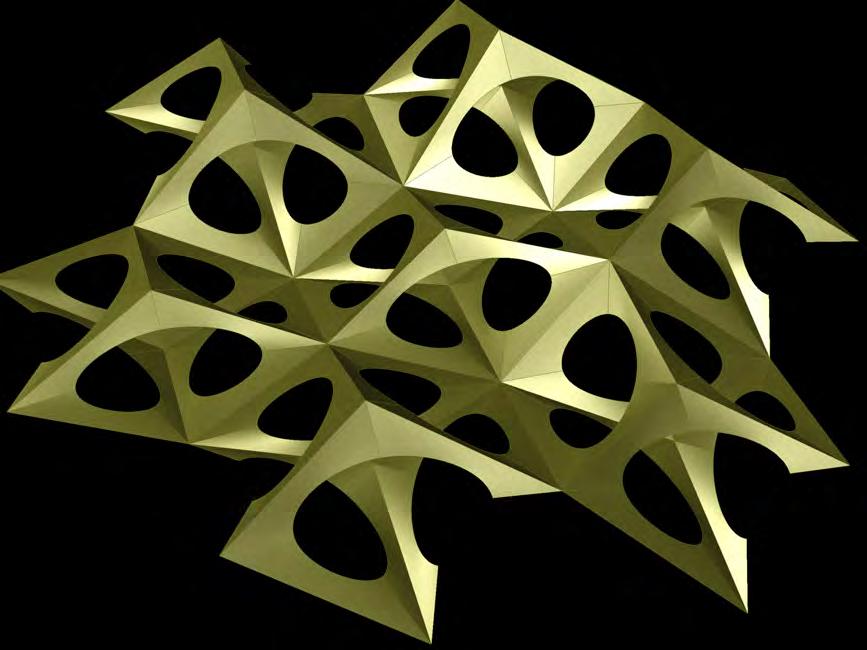

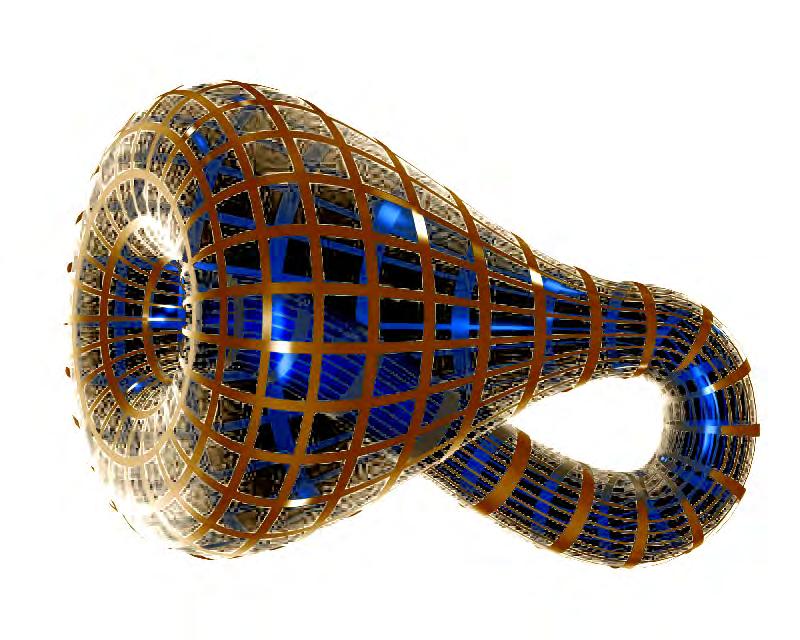

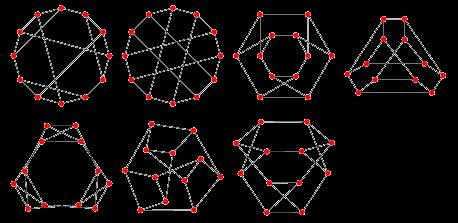

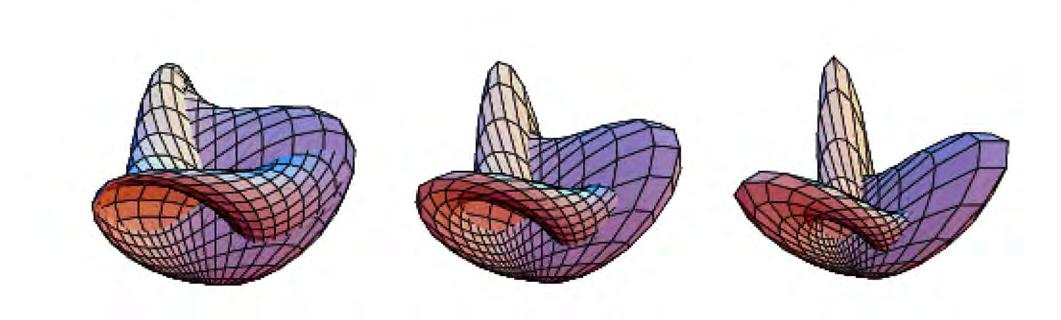

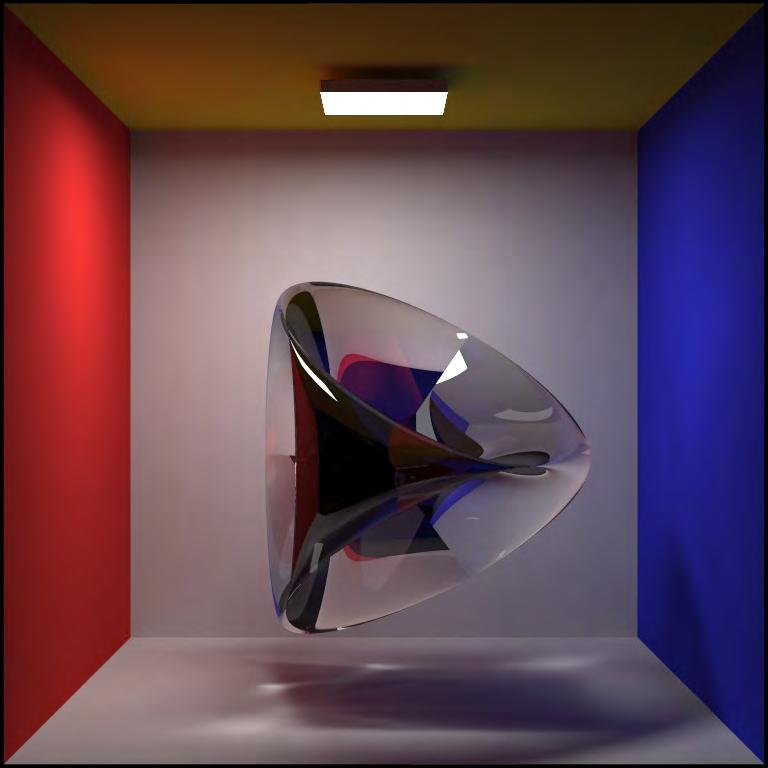

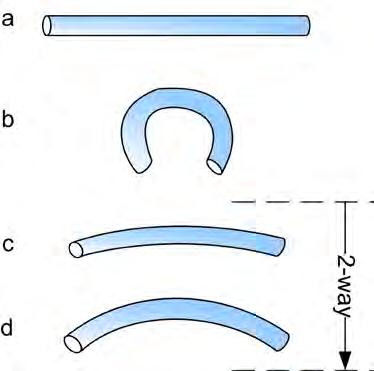

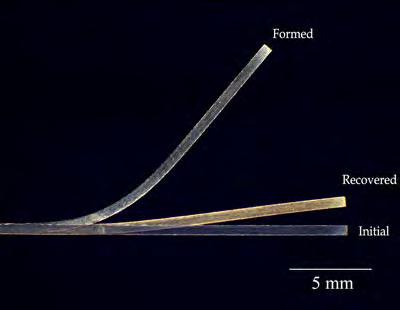

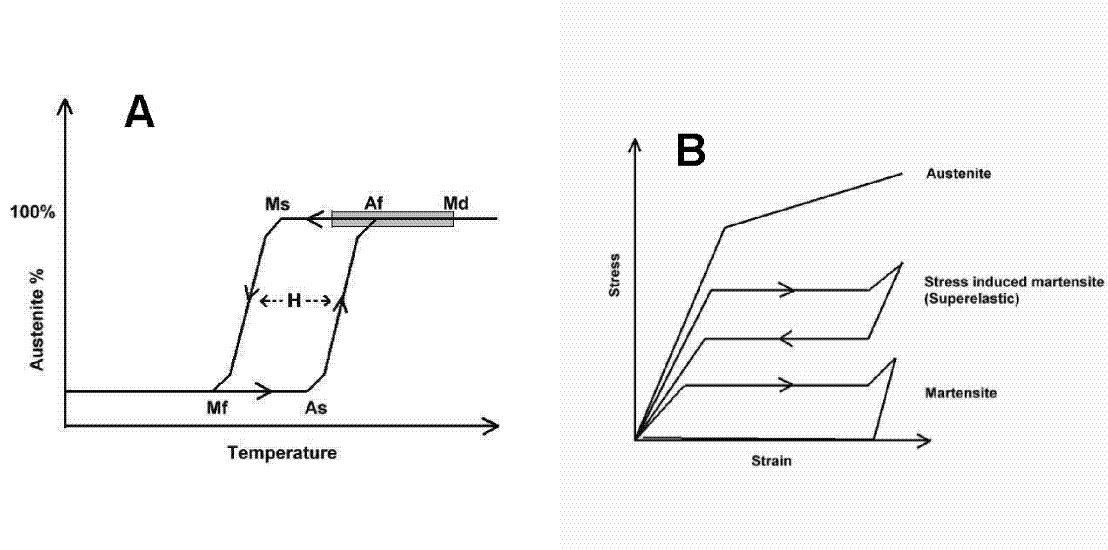

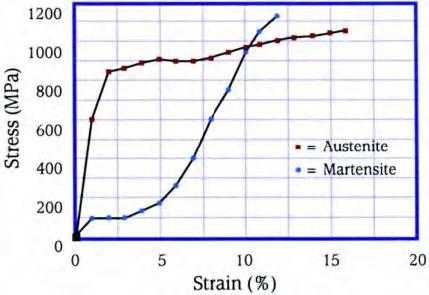

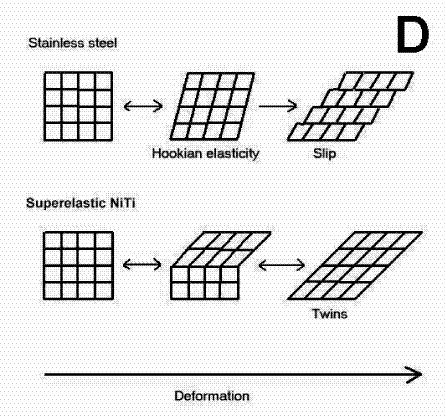

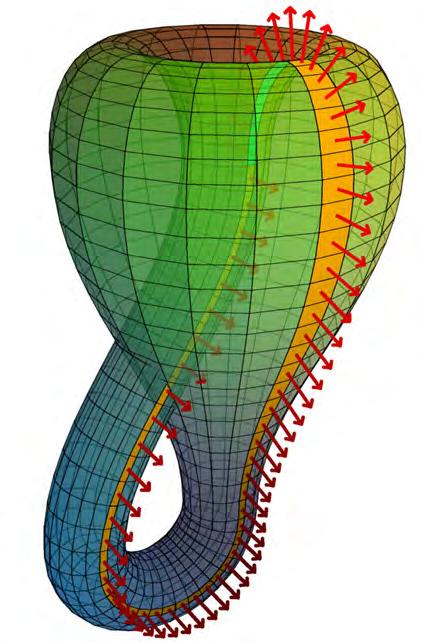

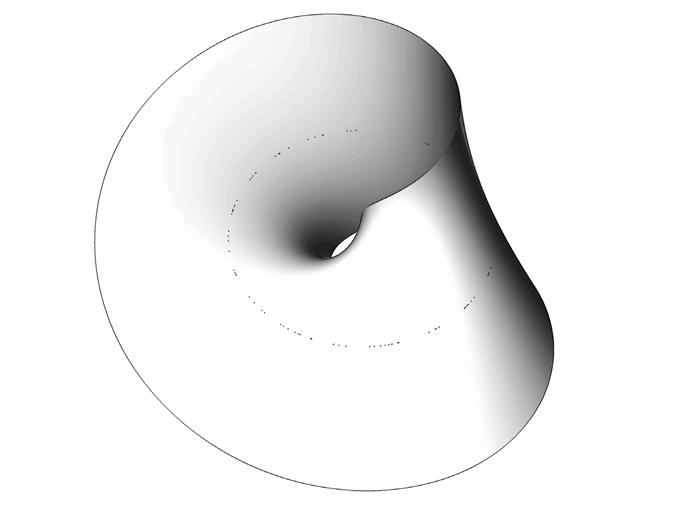

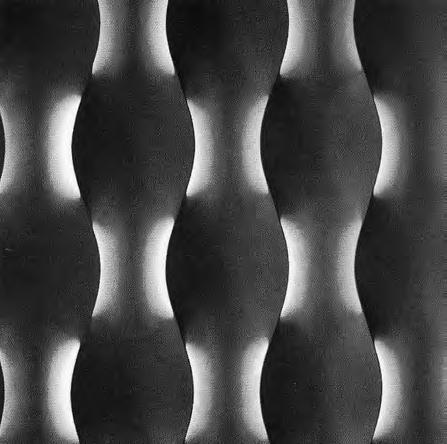

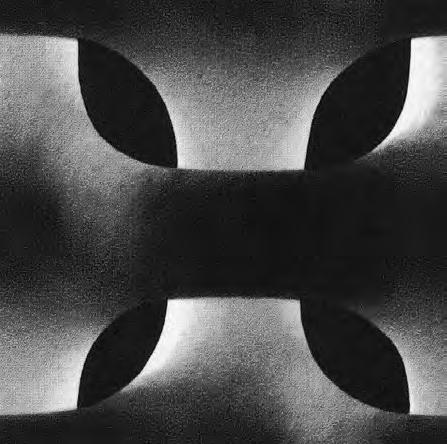

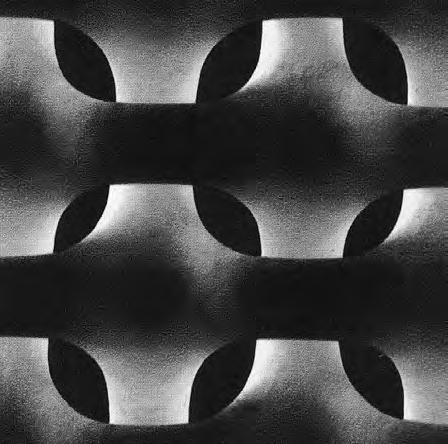

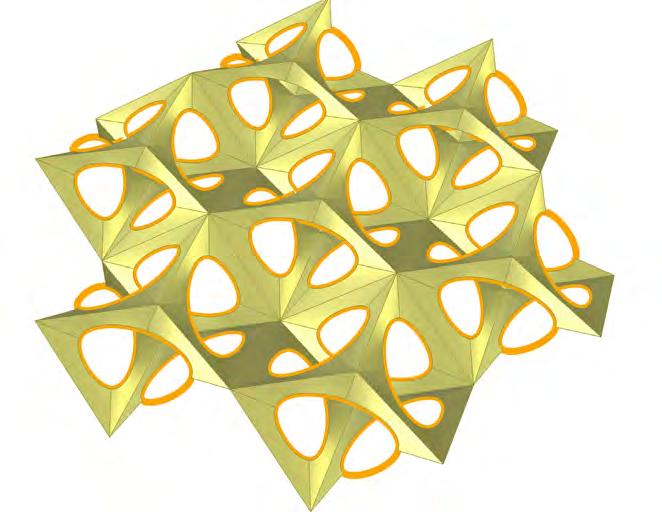

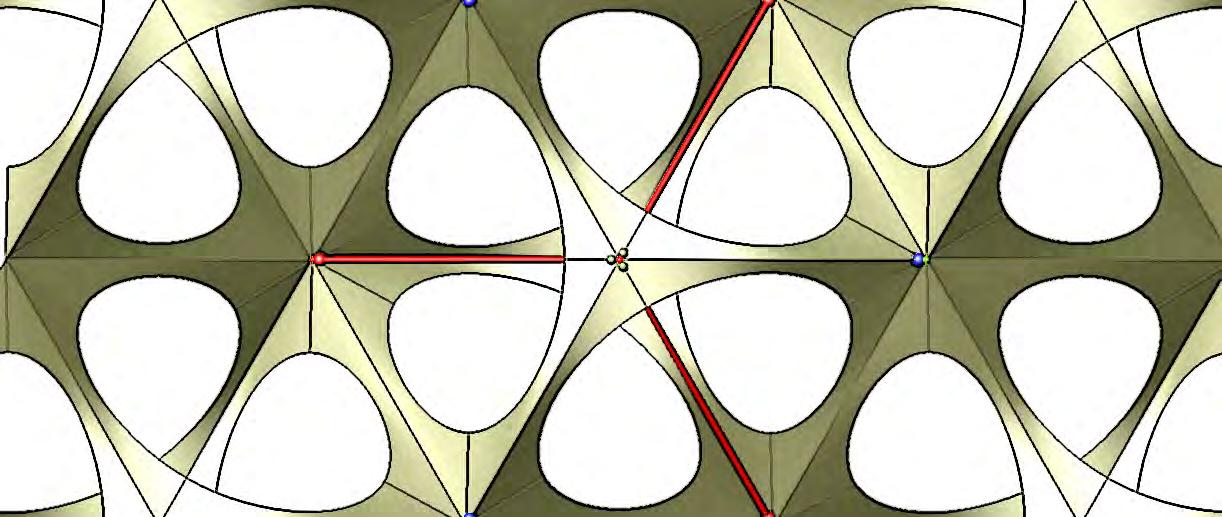

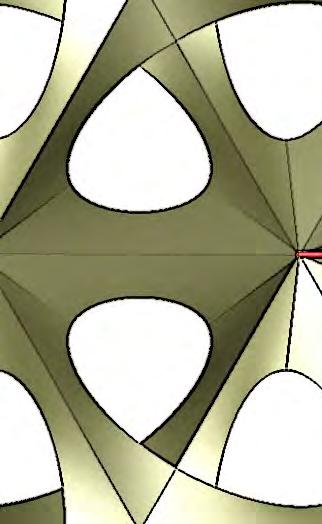

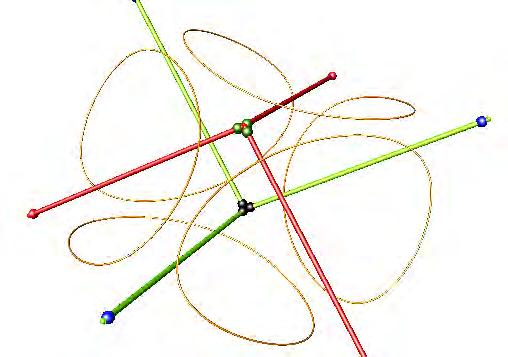

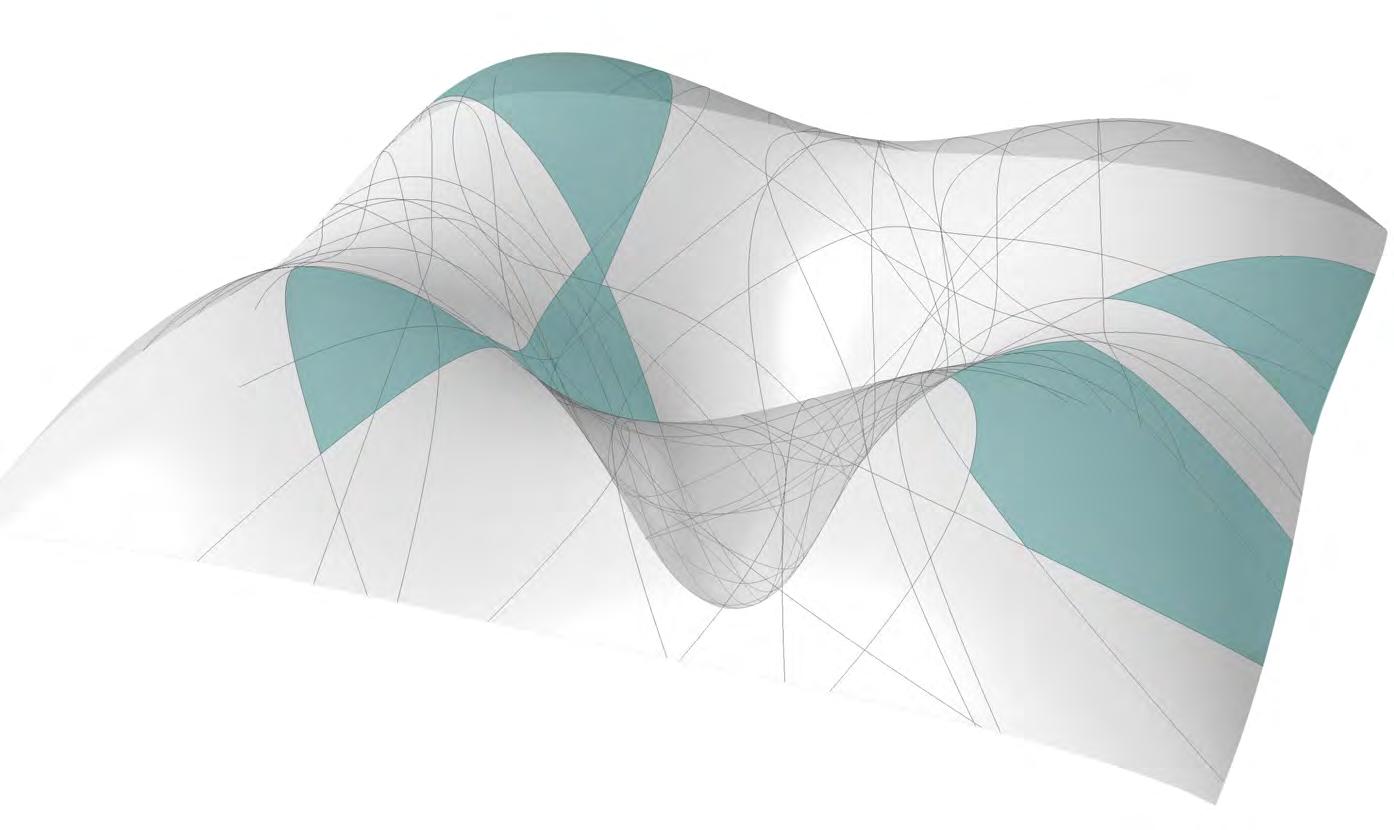

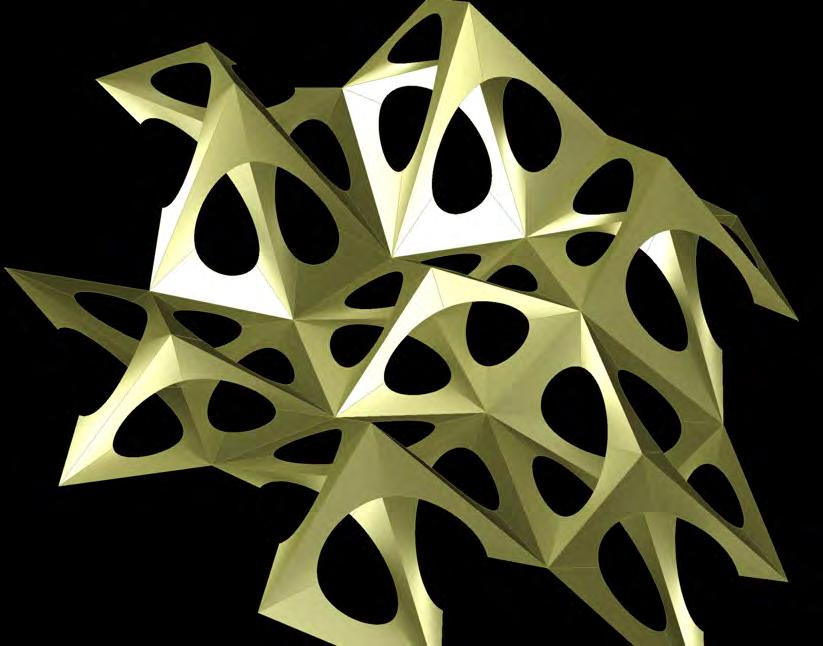

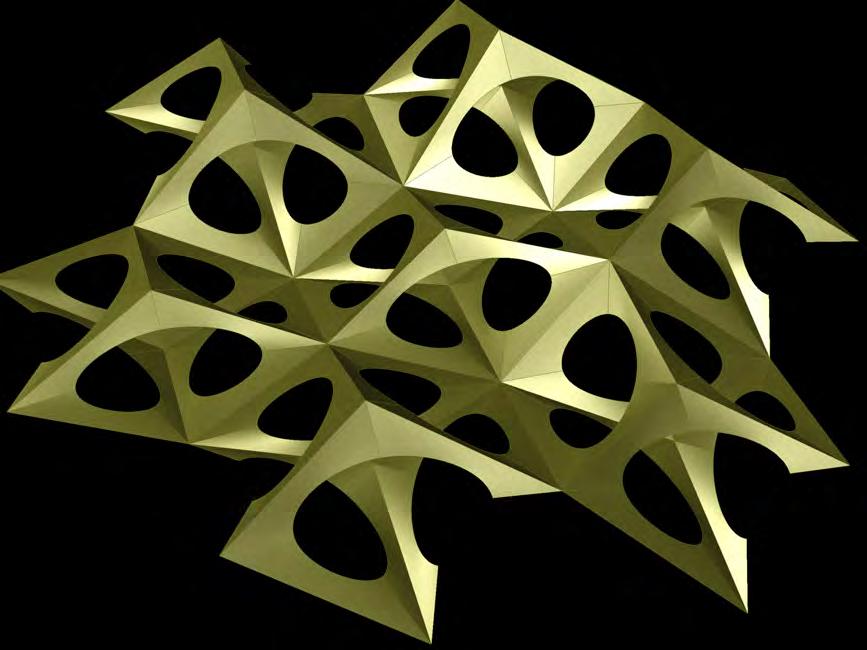

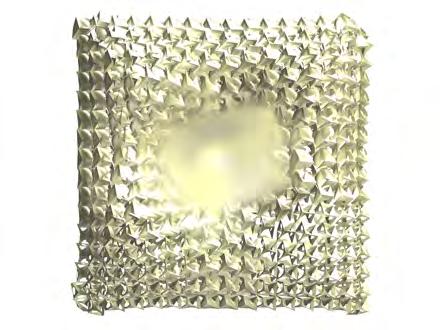

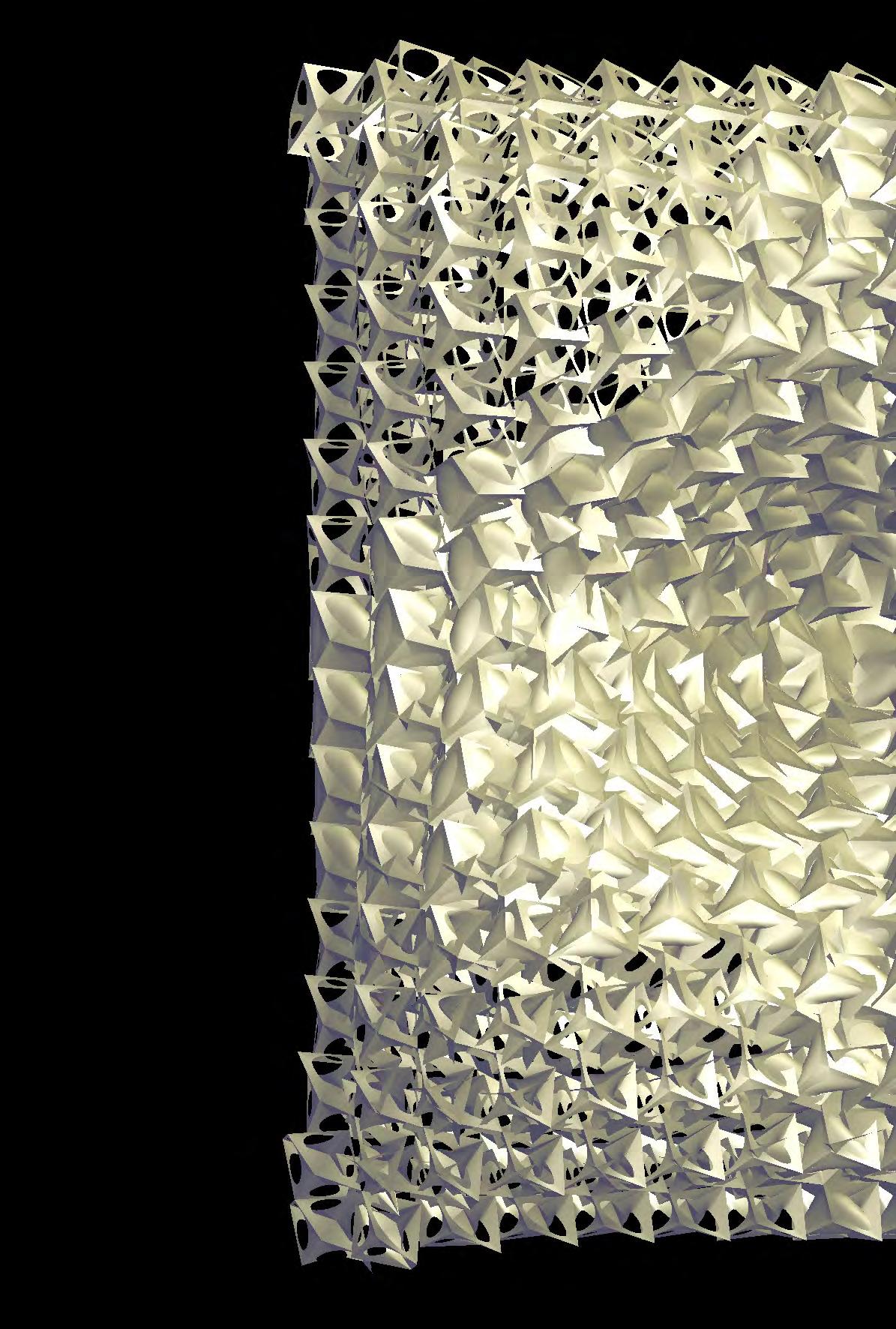

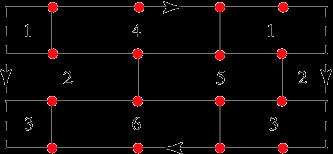

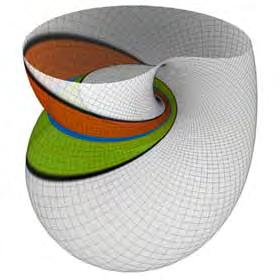

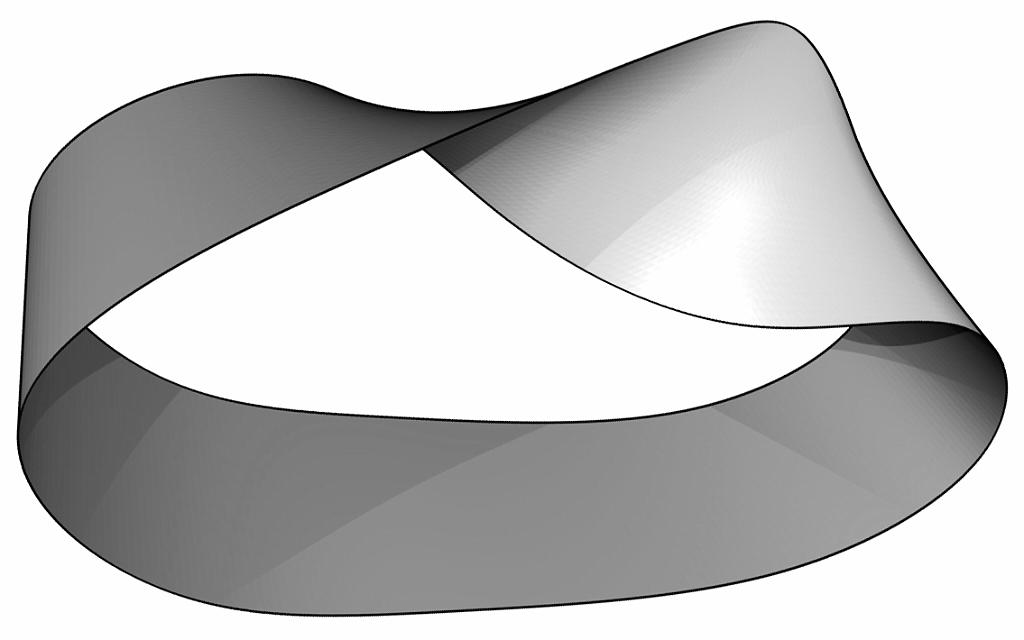

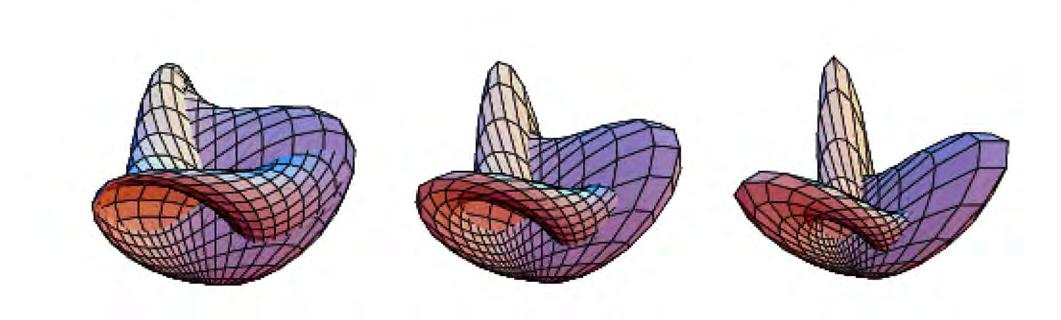

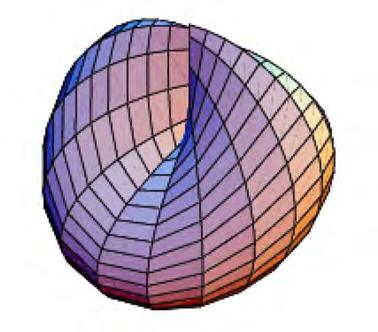

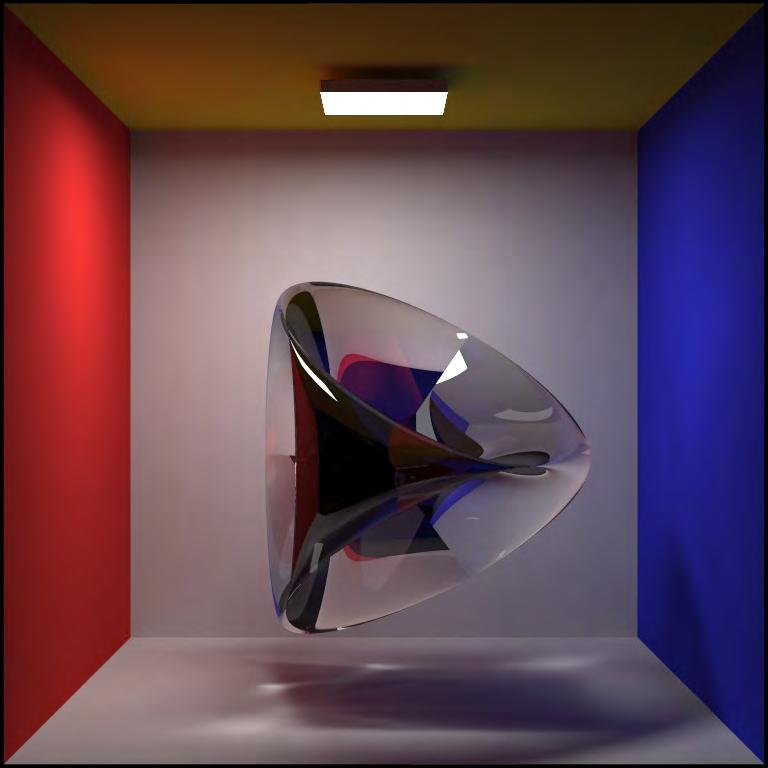

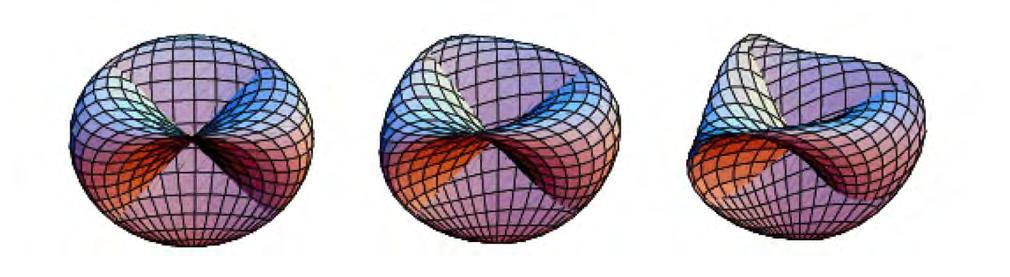

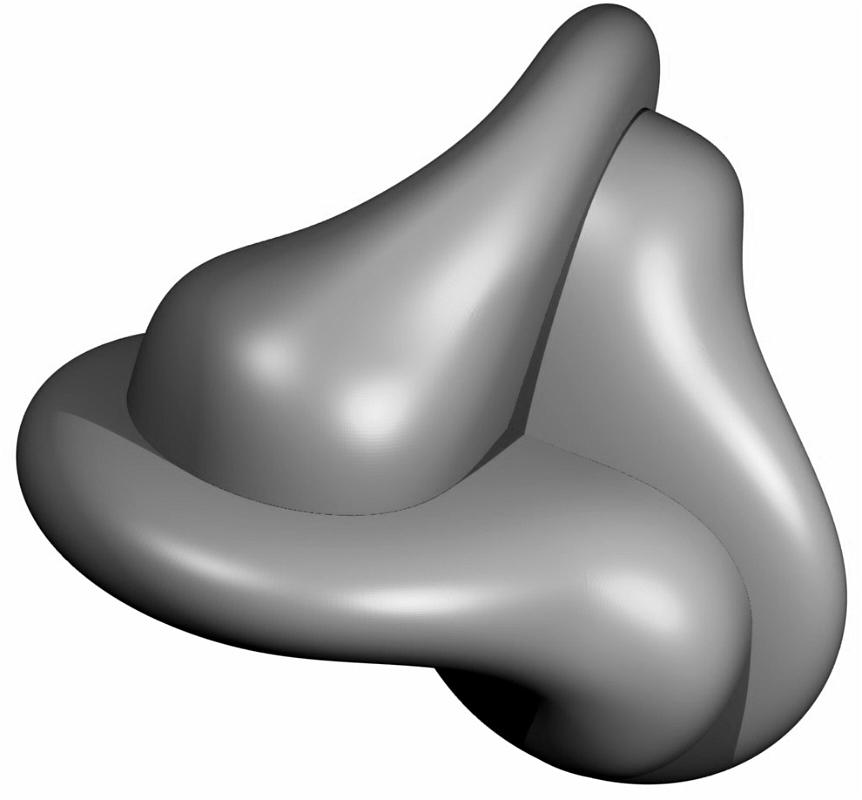

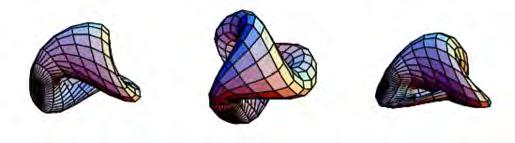

Performative abilities and intelligence of the fibre composite adaptive system proposed, springs from the integrated logics of its material behaviour, fibre organisation, topology definition and the overall morpho-mechanical strategy. The basic composite consists of glass fibres and a polymer matrix. The sensing function is carried out through embedded fibre optics which can simultaneously sense multiple parameters such as strain, temperature and humidity. These parameters are sensed and processed as inputs through artificial neural networks. The environmental and user inputs, inform the topology to dynamically adapt to one of the most efficient configurations of the ‘multiple states of equilibrium’ it could render. The topology is defined as a multi-layered tessellation forming a continuous surface which could have differentiated structural characteristics, porosity, density, illumination, self-shading and so on. The actuation is carried out through shape memory alloy strips which could alter their shape by rearranging their micro-molecular organisation between their ausentic and martensitic states. The shape memory alloy strip is bi-stable, but a strategic proliferation of these strips through a rational geometry could render several permutation and combinations creating multiple states of equilibrium, thus enabling continuous dynamic adaptation of the structure.

Aim

Self-organisation is a process through which the internal organisation of the system adapts to the environment to promote a specific function without being controlled from outside. Biological systems have adapted and evolved over several billion years into efficient configurations which are symbiotic with the environment.

To emulate this self-organisation process by developing a fibre composite material system that could sense, actuate and hence efficiently adapt to changing environmental conditions is the primary aim of this research.

Hypothesis

Form, structure, geometry, material, and behaviour are factors which cannot be separated from one another. For example, the veins in a leaf contribute to the overall form of the leaf, its structure and geometry. At the micro scale the fibre material organisation compliments to the responsive behaviour of the leaf. Therefore, the veins display an integral coherence within the multiple functions they perform which could be termed as ‘Integrated Functionality’. Integrated Functionality occurs in nature due to multiple levels of hierarchy in the material organization.

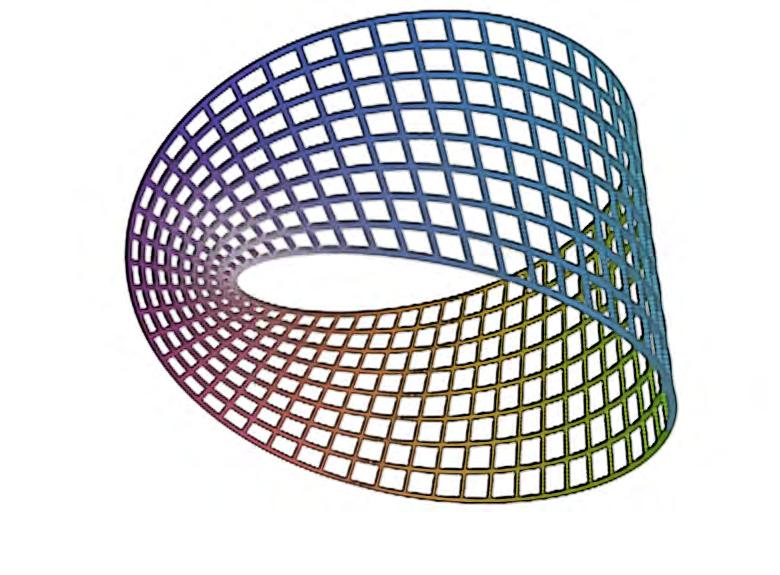

The premise of this research is to integrate sensing and actuation functions into a fibre composite material system. Fibre composites which are anisotropic and heterogeneous offer the possibility for local variations in their material properties. Embedded fibre optics would be used to sense multiple parameters and Shape memory alloys integrated into composite material for actuation. The definition of the geometry, both locally and globally would complement the adaptive functions and hence the system would display ’Integrated Functionality’.

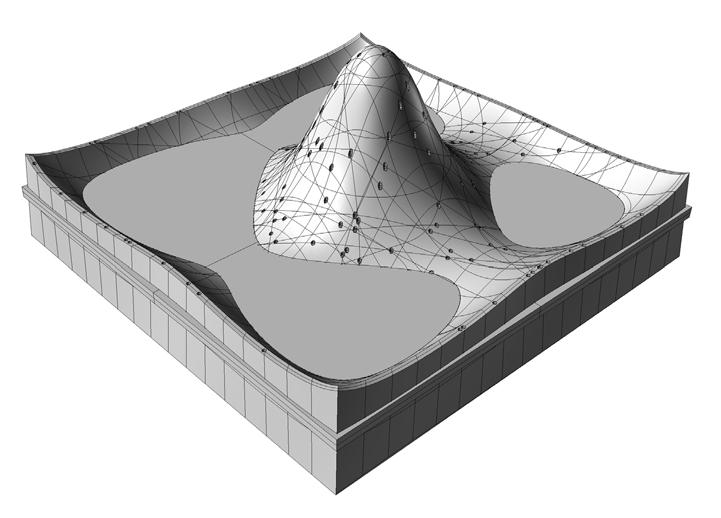

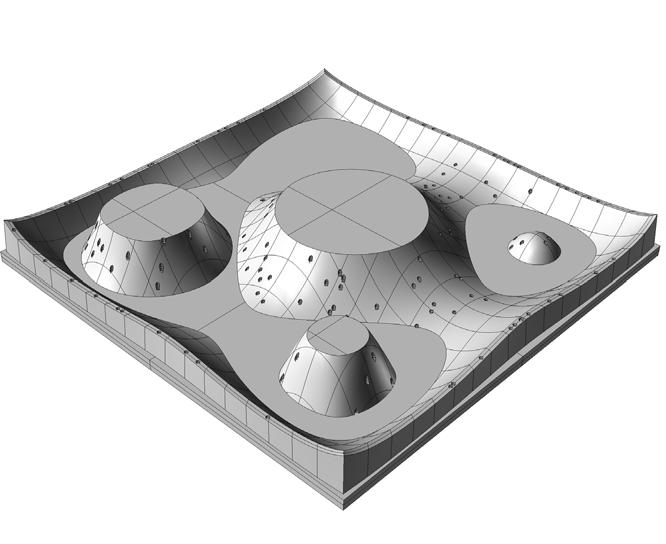

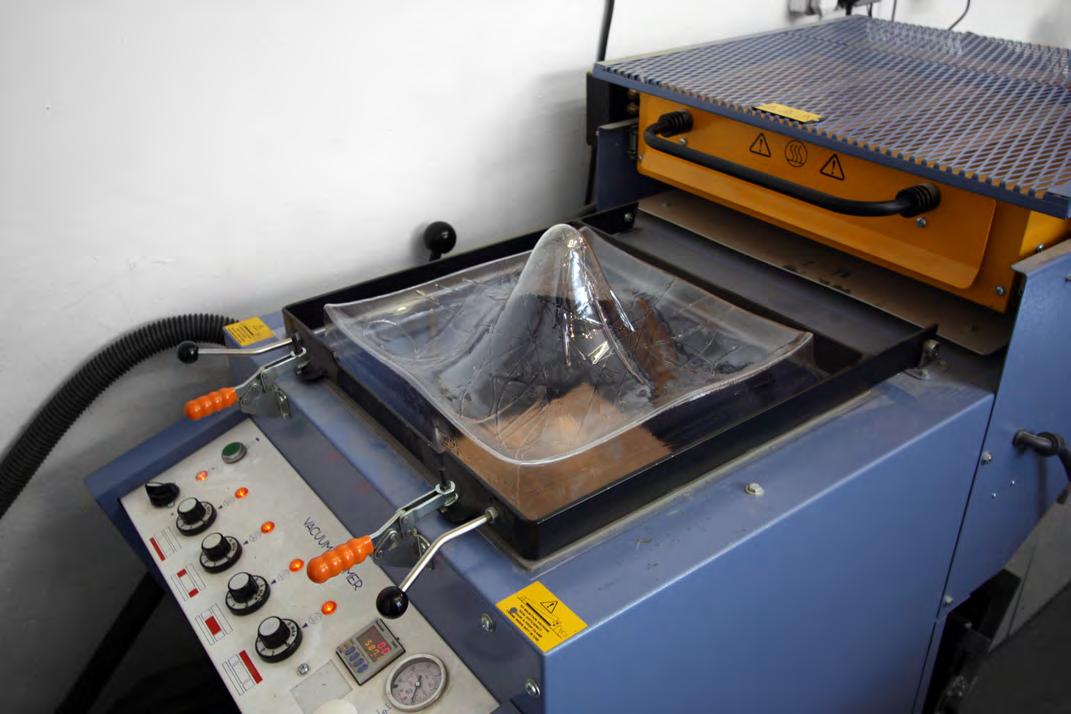

0.1 - Images from top, Showing the form of hibiscus leaves, Structure at the bottom of lily pad, Vein pattern of a leaf, Microphoto of stomatawhich aid photosynthesis,

8

1 Biomimetics Research

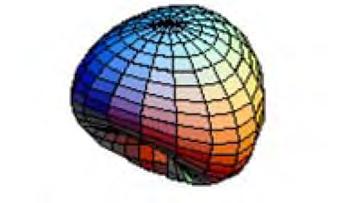

This chapter is a comprehensive study of adaptive systems in nature. Fibre organisation strategies in biological systems , which allow for changes in shape and material properties with respect to transient changes in the environment are investigated. The process of Stimulus-Response co-ordination, in biological organisms range from simple to complex configurations. Such configurations of sensing devices, actuators and controllers are studied, both in biology and man-made precedents.

Adaptive Systems Precedents Smart Systems

Thigmo-Morphogenesis

Fibre Organisation

Fibre Organisation Strategies in Nature

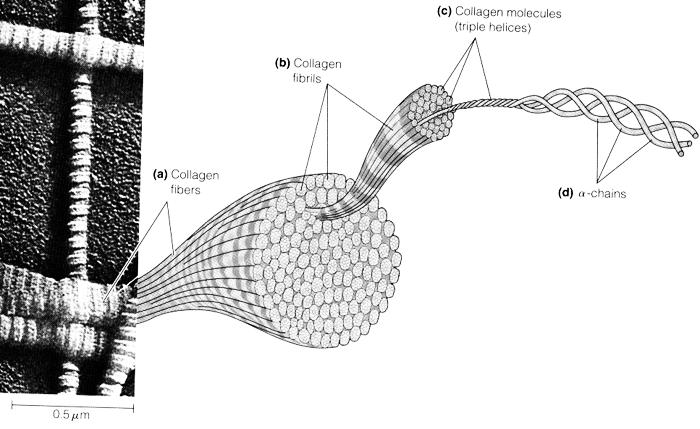

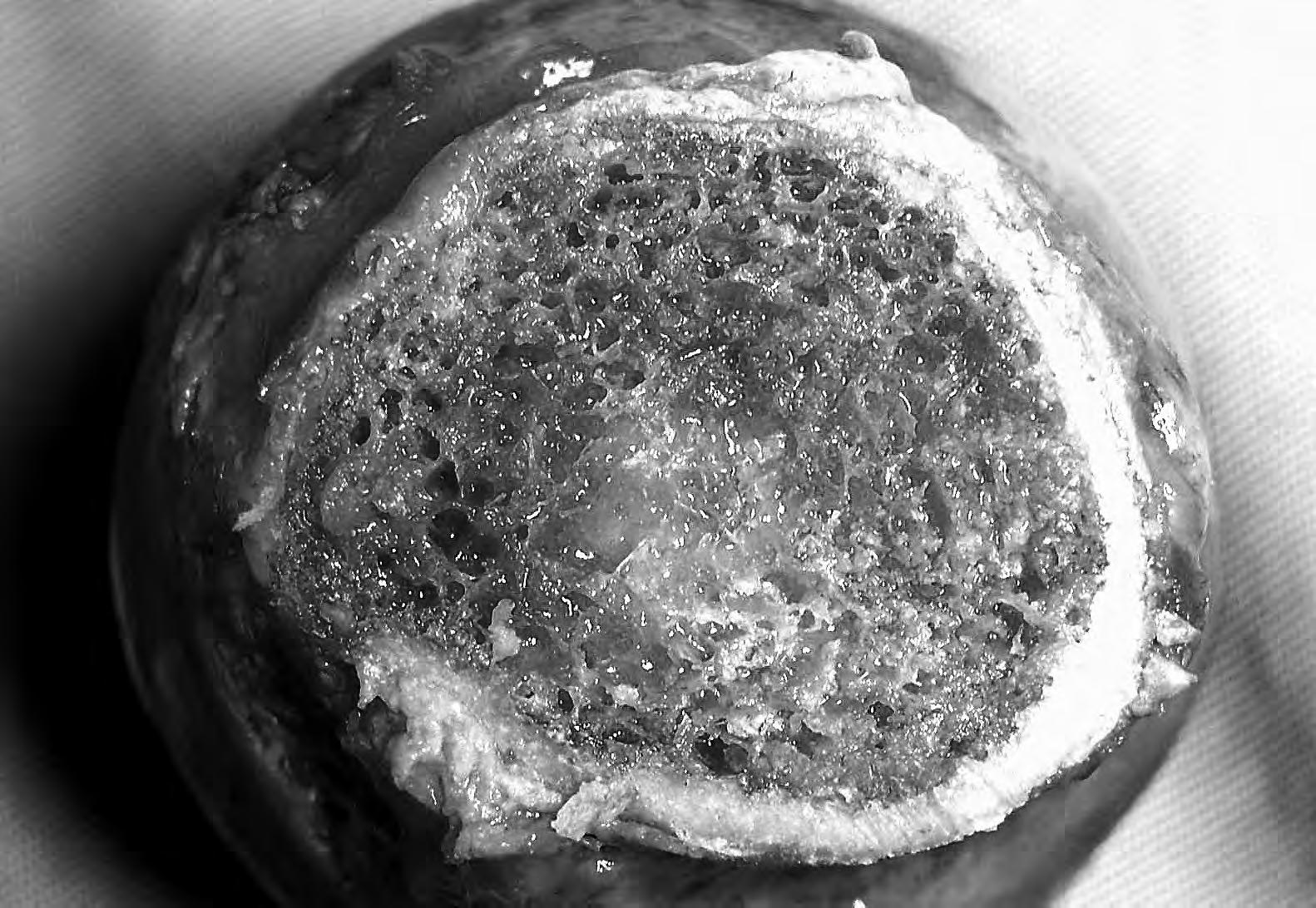

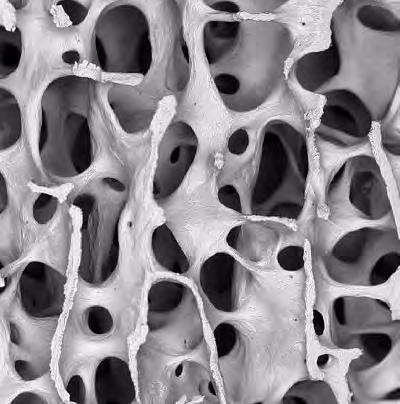

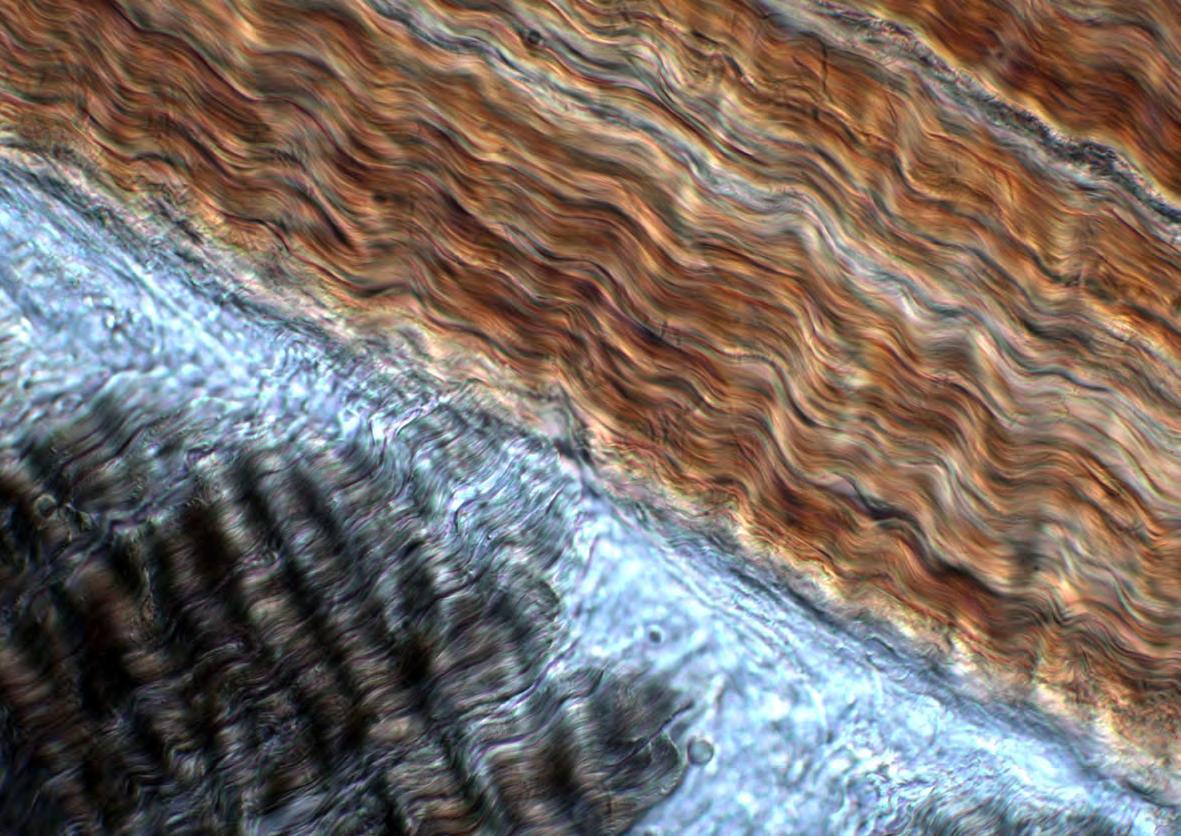

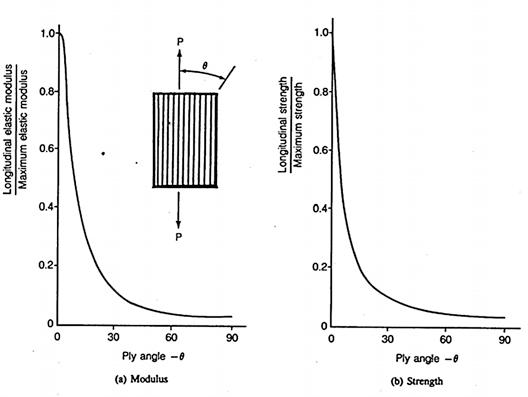

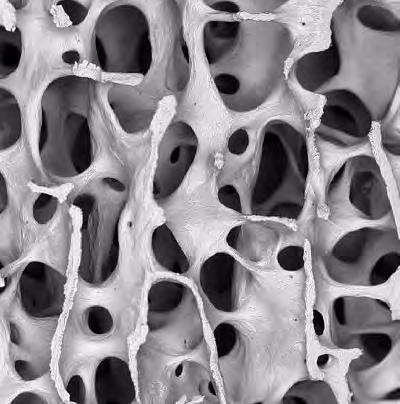

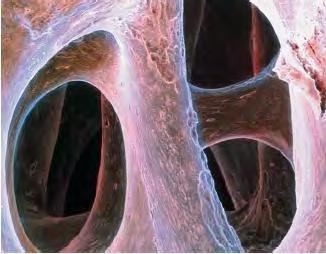

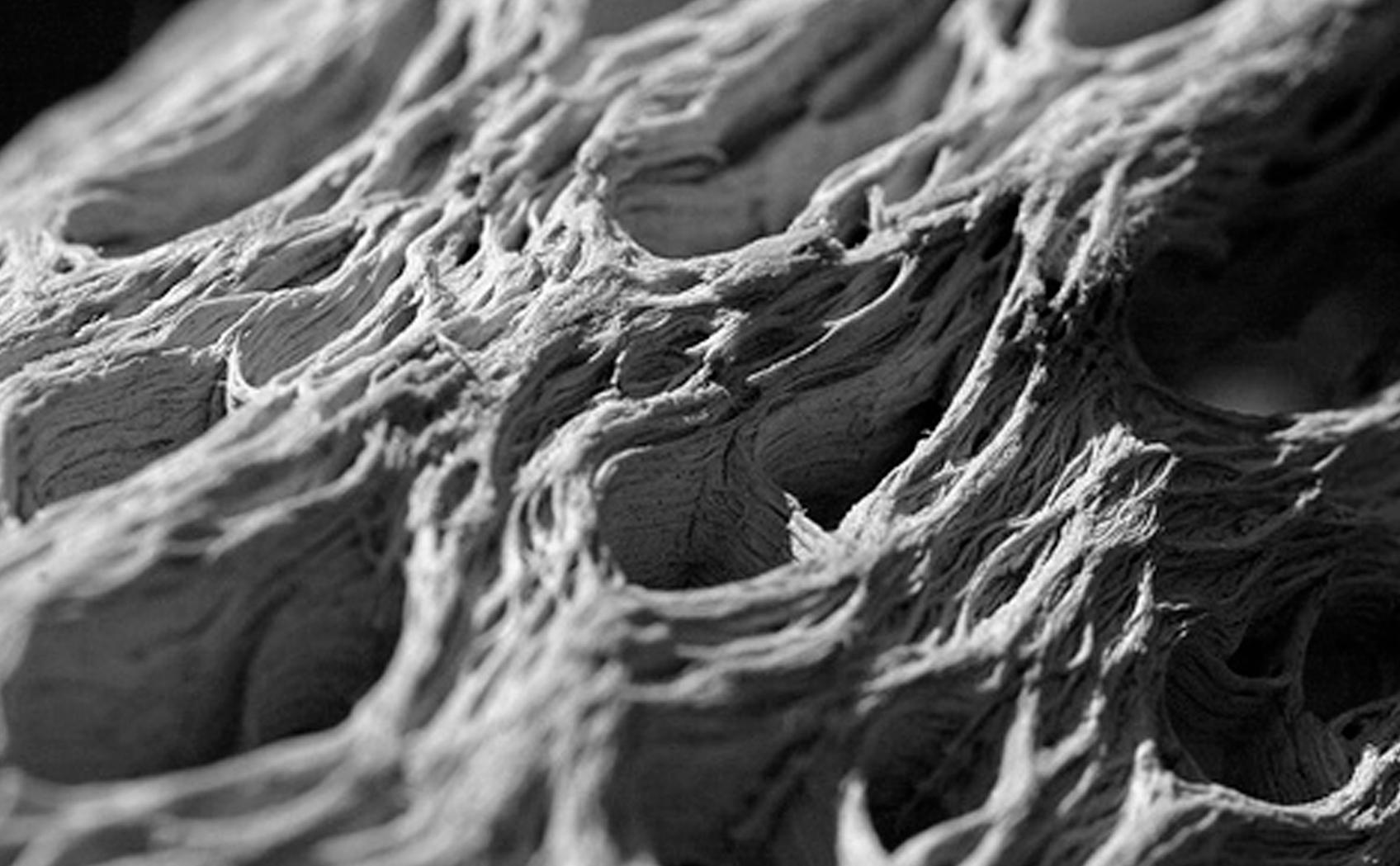

Biology makes use of remarkably few materials and nearly all loads are carried by fibrous composites. There are only four types of fibers: cellulose, collagen, chitin and silks. These are the basic materials of biology and they have much lower densities than most engineering materials. They are successful not so much of what they are but because the way in which they are put together. The bulk of the mechanical loads in biology are carried by these polymer fibres. The fibres are bonded together by various substances such as polysaccharrides, polyphenols and so on, sometimes in combination with minerals such as calcium carbonate (eg.mollusk shells) and hydroxyapatite (eg. bone). The organisation of the fibres and the degree of interaction between them provides the means of tailoring their properties for specific requirements. For example, It is the same collagen fibre that is used in low modulus and highly extensible structures such as blood vessels, intermediate modulus tissues such as tendons and high modulus, rigid materials such as bone. [1.1]

The reason for all biological organisms being made of polymers is probably that the synthesis of long polymer chains based on carbon, oxygen, nitrogen and hydrogen makes use of readily available chemicals and can be controlled by enzymes at low temperatures. The man-made counterparts of these biological fibrous materials are high-performance fibres such as nylon, aramid and highly-oriented polyethylene. The use of fibres for making structural materials offers a great deal of scope and flexibility in design. Fibres and fibre-reinforced materials have an inherent property of anisotropy of physical and mechanical properties and heterogeneity. If properly exploited, they can provide higher levels of optimisation than would be possible with isotropic, homogeneous materials because

stiffness and strength can be matched to the loads applied, not only in magnitude but also in direction.

In biology this is extremely common and happens as a result of “growth under stress”. The magnitude and direction of the loads that the organism experiences as it develops provide the blueprint for the selective deposition of new material, where it is needed and in the direction in which it is needed. The best known examples of this are the “adaptive” mechanical design of bone and trees. In bone, material can be removed from the under stressed parts and re-deposited in the highly stressed ones ; in trees a special type of wood, with different cellulose microfibril orientation and cellular structure are produced in successive annual rings when mechanical circumstances demand. Growing a structure by producing and organising fibres under the control of the loads that it has to carry is extremely efficient.

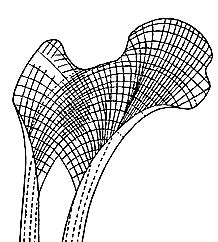

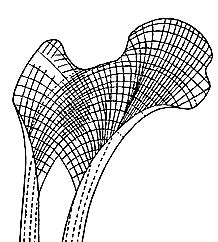

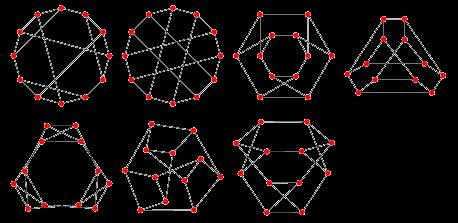

Numerous patterns of load-bearing fibre architectures are found in nature, each one of them being a specific answer to a specific set of mechanical conditions and requirements. In a sense there are no general design solutions in biology but case specific ones, governed nevertheless by common general principles. In conventional engineering practices this process is replaced by stress and structural analysis which is not always accurate and often very complex. In recent years, numerical techniques based on Finite Elements have provided new tools to simulate the adaptive design of nature and this approach has proved to be very successful. [1.2]

10

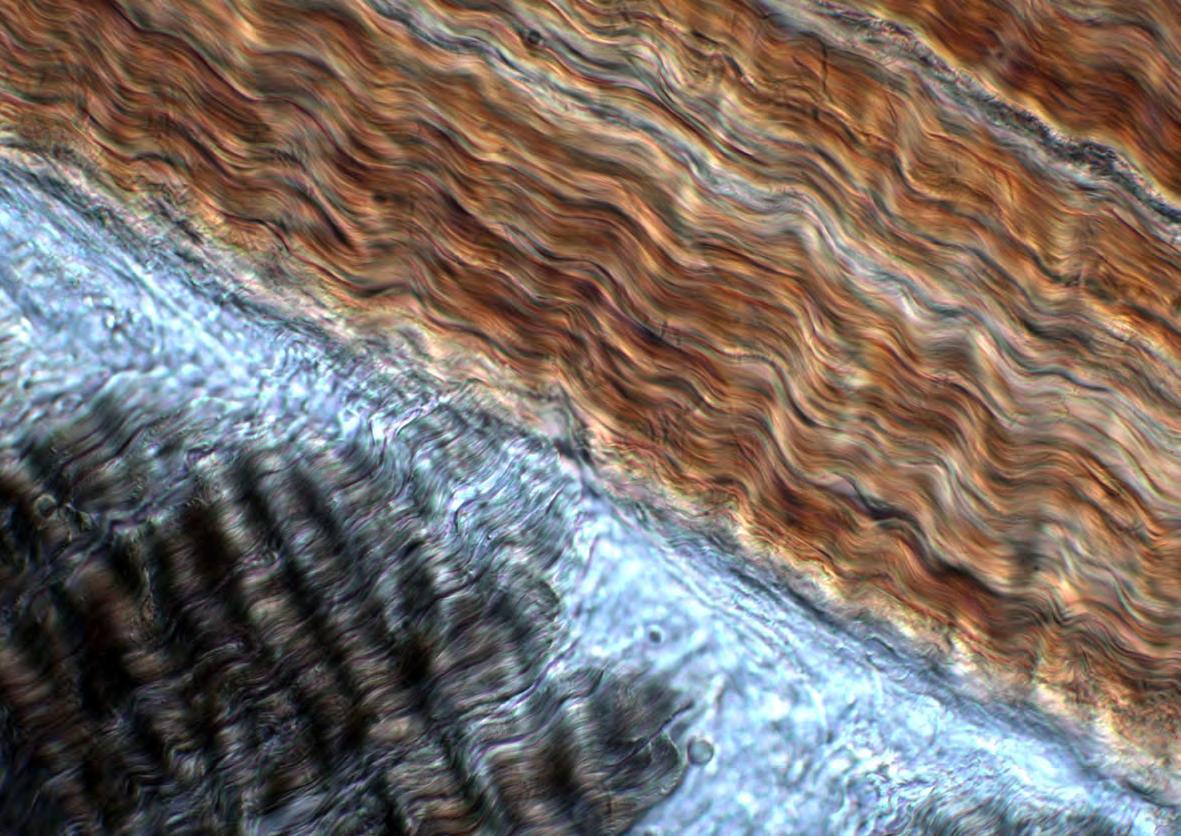

1.1 - Four basic types of fibres in nature, namely, collagen, cellulose, chitin and silks.

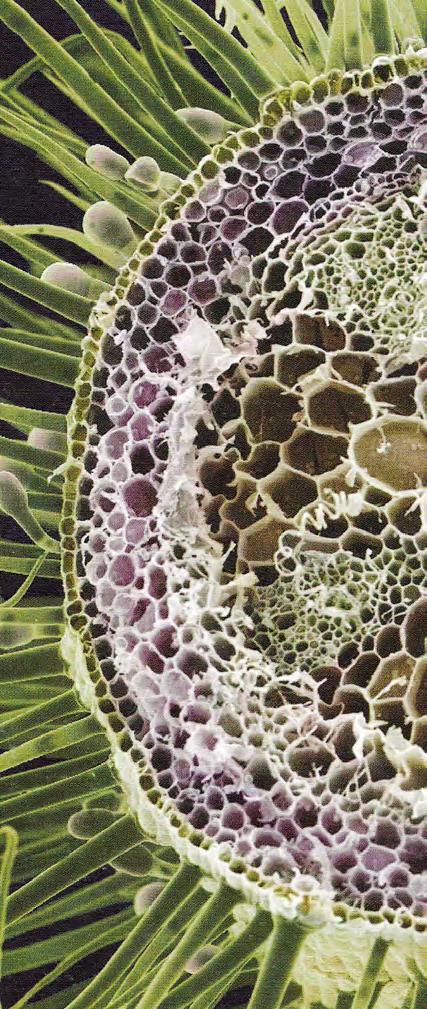

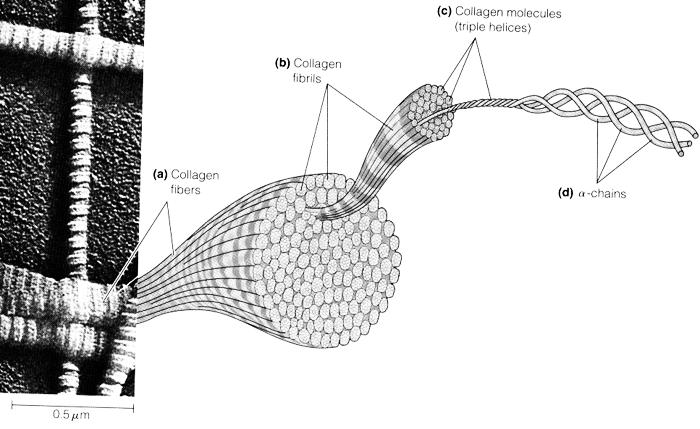

Collagen- The fibre material composition of the human femur shows the close packing of fibres in parts which are highly stressed.

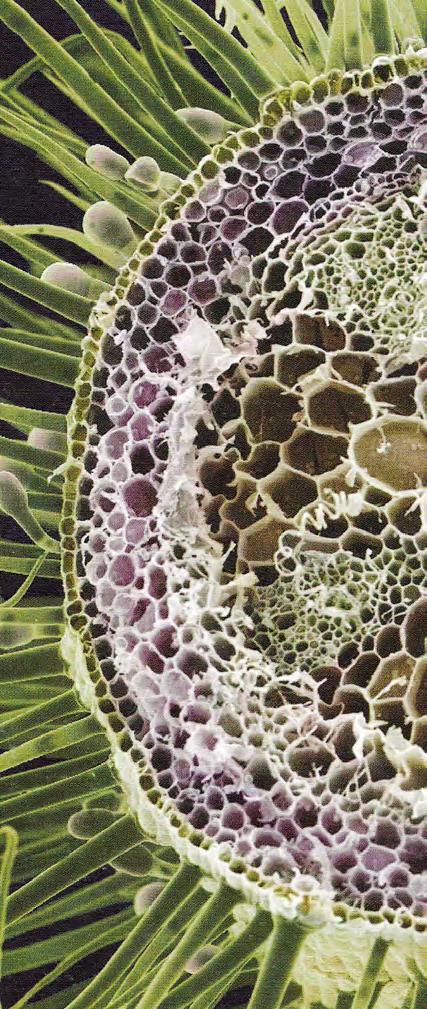

Cellulose- The section through the stem of a germanium reveals the closely packed bundles of vessels and cells. The geometrical arrangement of closepacked integration produces a complex structure, strong but flexible and capable of differential movement. The large pale tubes in the centre are xylem vessels that transport water and nutrients up from the root. The five bundles of pale green vessels are phloem cells, part of the vascular system for the distribution of carbohydrates and hormones, and the smaller purple cells on the perimeter are parenchyma cells, which are thin walled and flexible and can increase and decrease in size by taking up or losing water. These changes cause deformations, which is how the plant achieves movements such as bending towards light or turning around an obstacle

11

Collagen

Cellulose

Chitin

Silks

material hierarchies

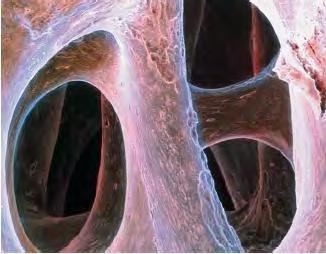

Fibres are most efficient when they carry pure tensile loads, either as structures in their own right such as ropes, cables, tendons, silk threads in spider’s webs or as reinforcement in composite materials. Being slender columns, fibres cannot carry loads in compression because of buckling, even when partially supported laterally by the matrix in composites. In the case of polymer fibres, micro buckling at the micro-fibrillar level within the fibre results also in very poor compressive strengths. This problem is common to both man-made and biological composites. Since nature had no alternatives to fibres as building blocks, it had to find ways of offsetting the low efficiency of fibres in compression in order to expand life beyond the limits of squidgy invertebrate species or aquatic environments. There are four solutions available in nature to this problem: pre-stress the fibres in tension so that they hardly ever experience compressive loads; introduce high modulus mineral phases intimately connected to the fibres to help carry compression; heavily cross-link the fibre network to increase lateral stability, and change the fibre orientation so that compressive loads do not act along the fibres.

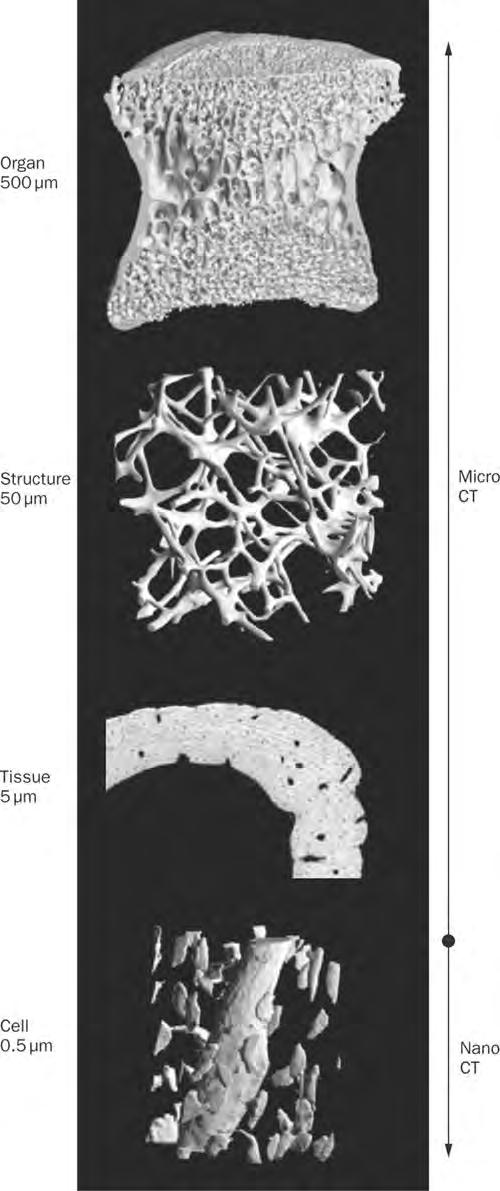

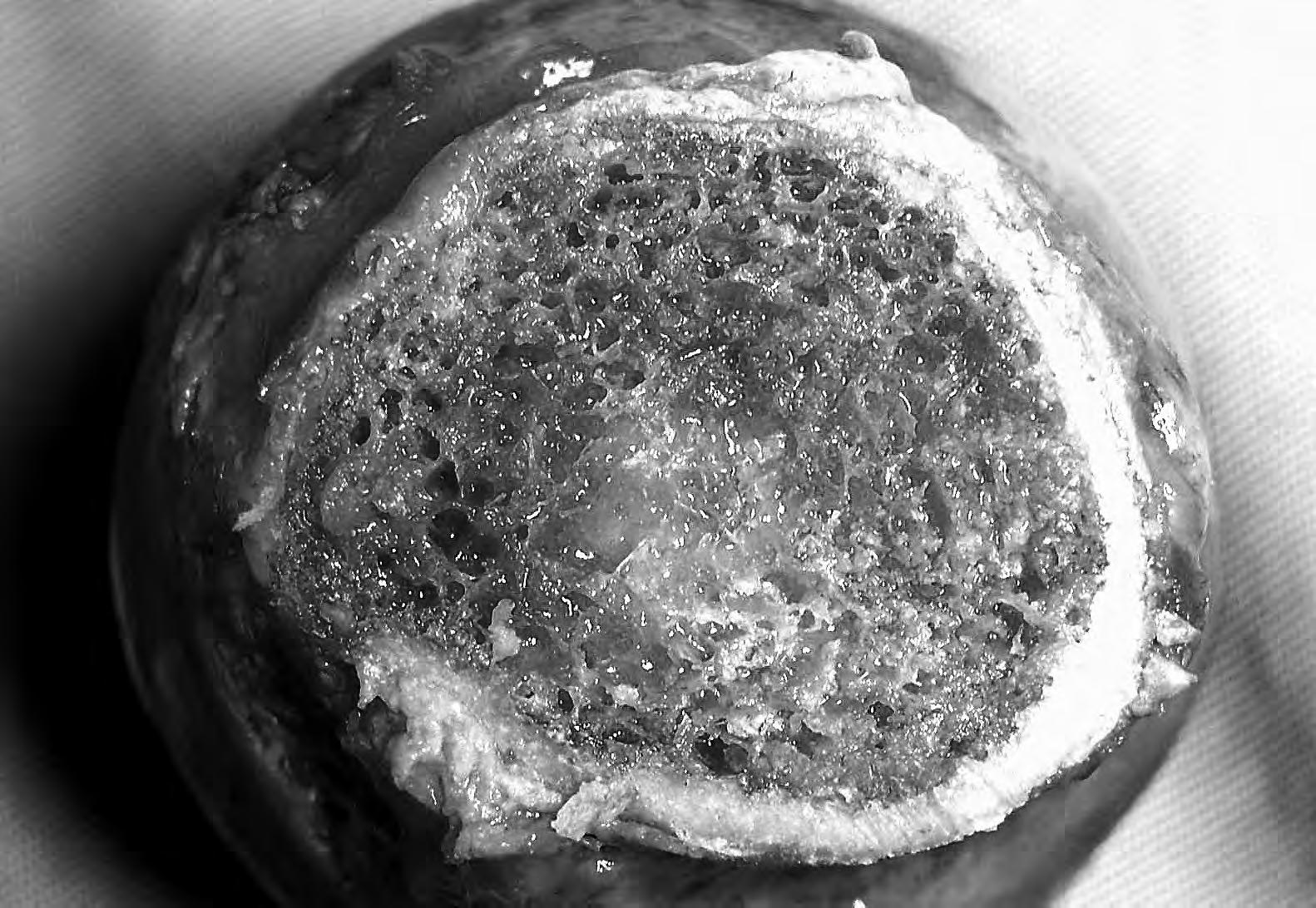

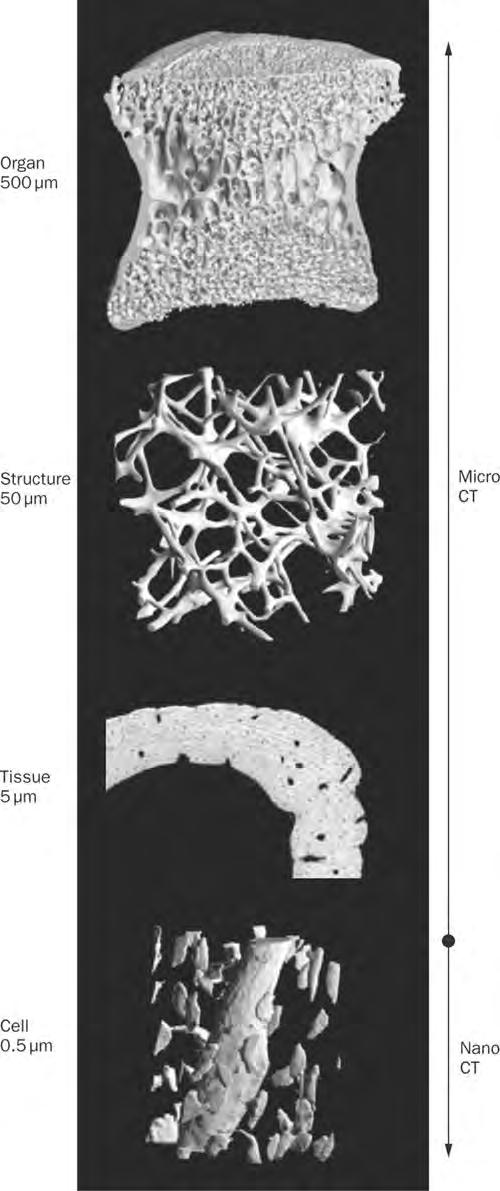

Jim Gordon, says in ’ The New Science of Strong Materials and Structures’, when one is dealing with very heterogeneous fibre reinforced composite systems, the distinction between materials and structures becomes one of convenience rather that of fact. This distinction becomes even more elusive in biology because between the polymer macromolecular chains at the nano metre level and the functional organ at the millimetre or metre levels there is a multiplicity of structures which represent different levels of aggregation of the load bearing materials. These hierarchical

organisations are the rule rather than the exception in all biological composites. They are probably the result of growth by successive deposition of fibres and other materials. They are difficult to analyse because of their complexity but, by varying the degree of interaction between sub elements within a hierarchical level and between levels, stiffness, strength, toughness, etc. are modulated, tailored and optimised for specific requirements. This kind of integrated sub-structuring is a common theme in biology, far more subtle and extensive than in any manmade material or structure. [1.3]

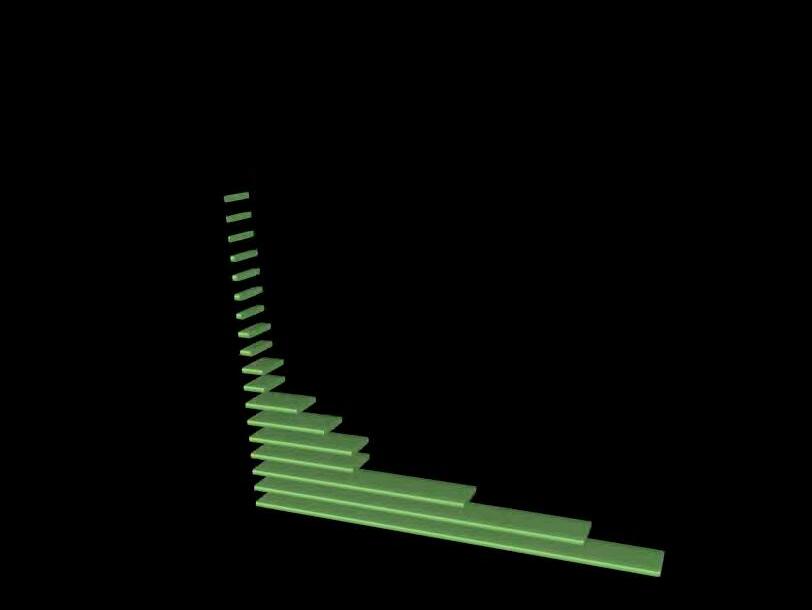

Familiar biological materials such as tendons, bones, muscles, skin and wood provide amazing arrays of hierarchies spanning in typical dimensions from 10-9 metres at the molecular level, to typically 10-3 - 10-2 at tissue level and 100 and beyond at the organ level. In trees, for example, the representative diameter of the various sub structures covers a range from 101 metres at the diameter of trunk down to 10-8 metres diameter of cellulose protofibril; i.e. ten orders of magnitude with perhaps eight hierarchical levels: organ (trunk), tissue (wood), wood cell, laminated cell walls, individual walls, cellulose fibres, microfibrils and protofibrils.

12

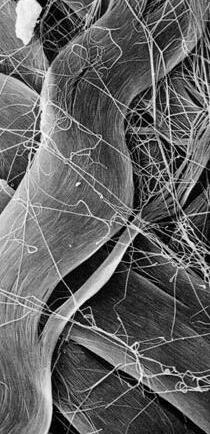

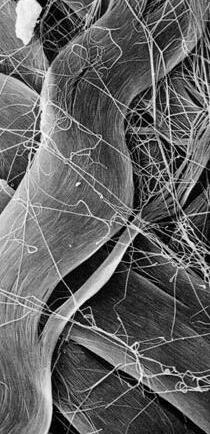

1.2 - The upper image shows collagen fibres of various sizes in a scanning electron microscope. At bottom a much higher magnification image from a transmission EM shows characteristic “banding” pattern of individual fibrils that make up the larger anatomic fibre.

Fibre

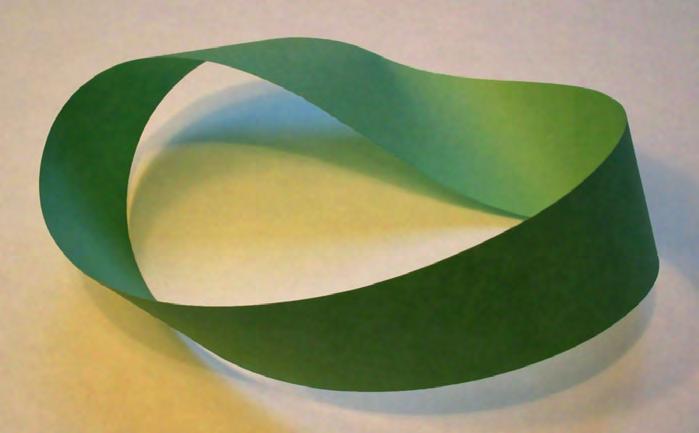

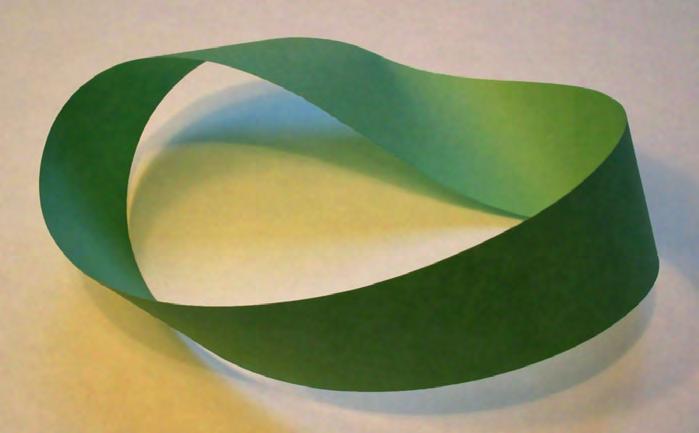

Thigmo-morphogenesis

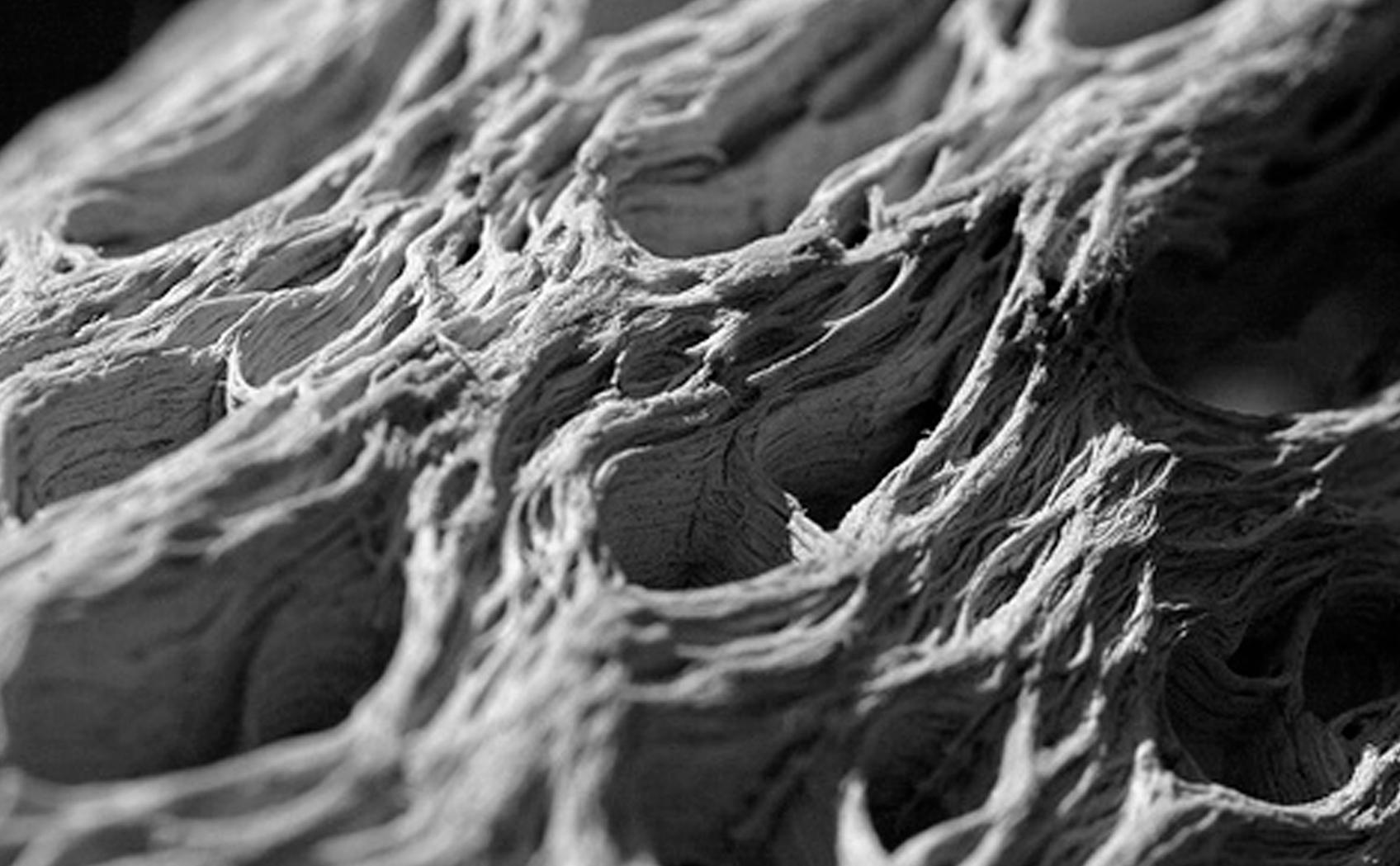

Thigmo-morphogenesis refers to the changes in shape, structure and material properties that are produced in response to transient changes in environmental conditions. We are all familiar with the fact that many plants are capable of movement, sometimes slow as in the petals of flowers which open and close, tracking of the sun by the sunflowers, the convolutions of bindweed’s around supporting stems, snaking of roots around obstacles, sometimes visible to the eye as in the drooping of leaves when mimosa pudica is touched, exceptionally very rapid, too fast to be seen as in the closing of the leaves of the venus flytrap.

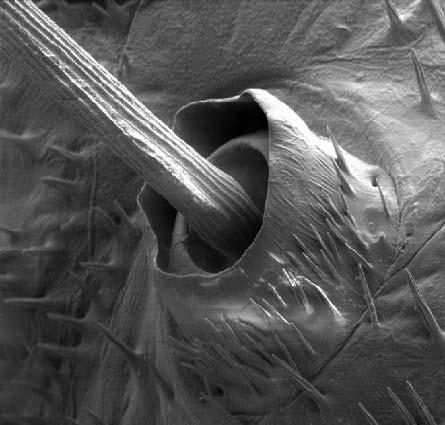

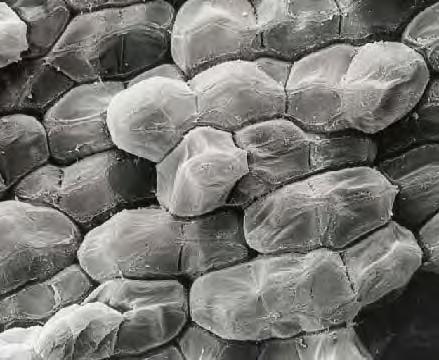

In all these examples, movement and force are generated by a unique interaction of materials, structures, energy sources and sensors. The materials are the cellulose walls of perenchyma cells ,nonlignified, flexible in bending but stiff in tension; the structures are the cells themselves and their shape with the biologically active membrane that can control the passage of fluid in and out of the cells; the energy source is the chemical potential difference between

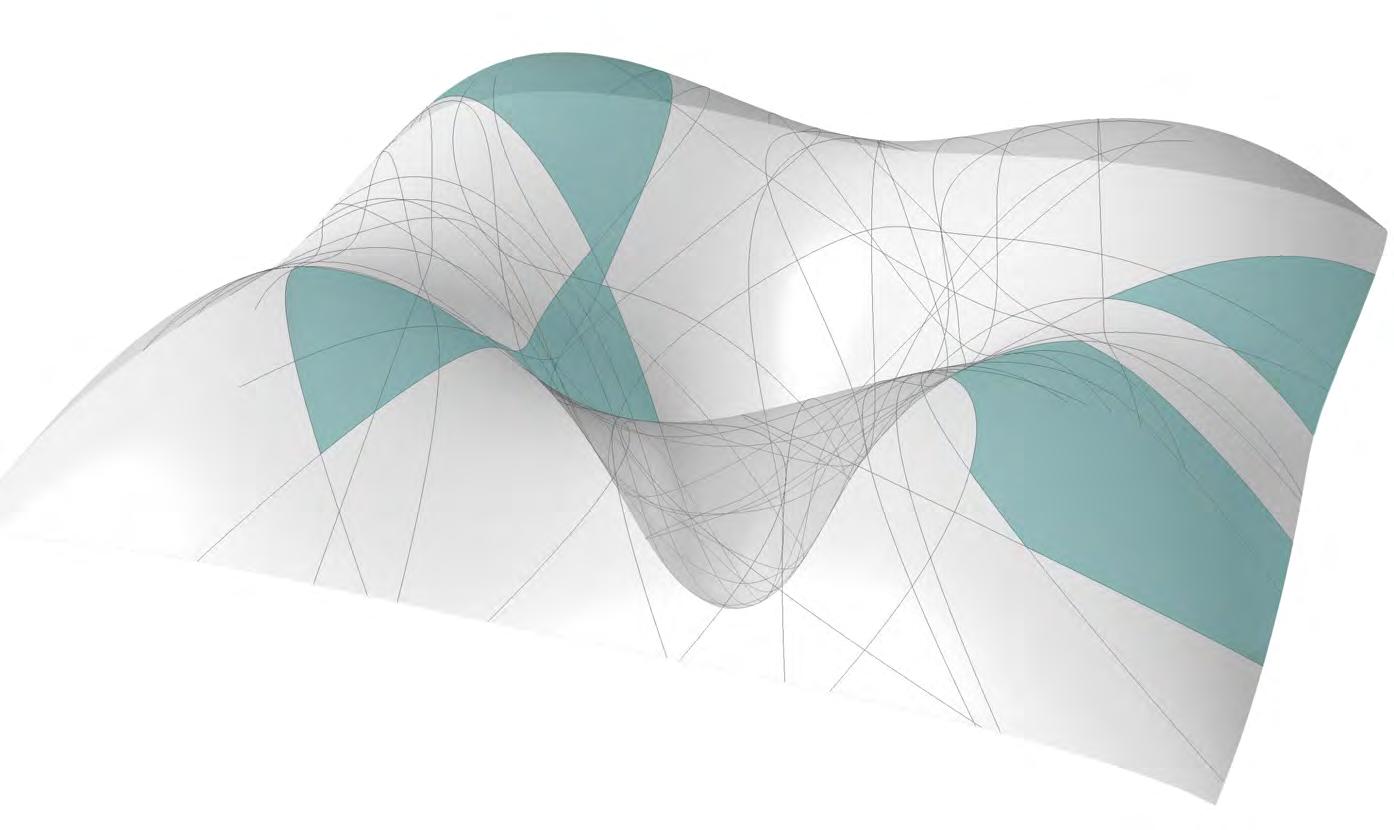

the inside and the outside of the cells; the sensors are as yet unknown. These systems are essentially working as networks of interacting mini hydraulic actuators, liquid filled bags which can become turgid or flaccid and which, owing to their shape and mutual interaction translate local deformations to global ones and are also capable of generating very high stresses. Similar mechanisms can be seen in operation when leaves emerge from buds and deploy to catch sunlight. How to package the maximum surface area of material in the bud and to expand it rapidly and efficiently is the result of very smart folding geometry, turgor pressure and growth. [1.4]

13

1.3 - Undisturbed delicate leaves of the sensitive plant,

Mimosa pudica when lightly touched, responds to stimulus.

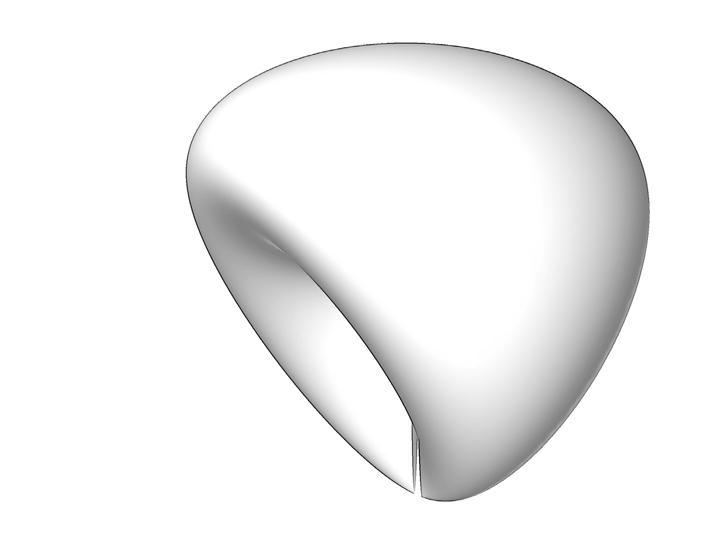

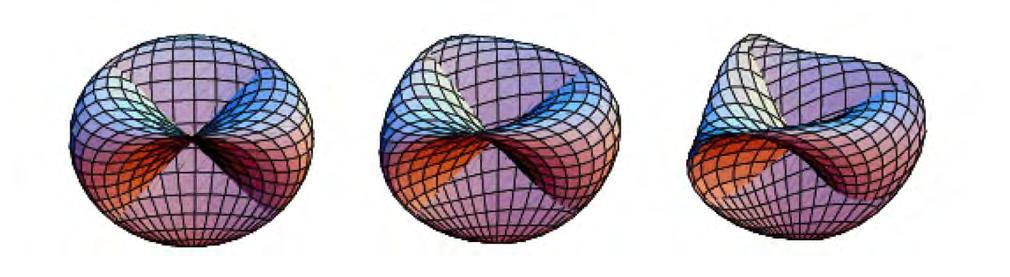

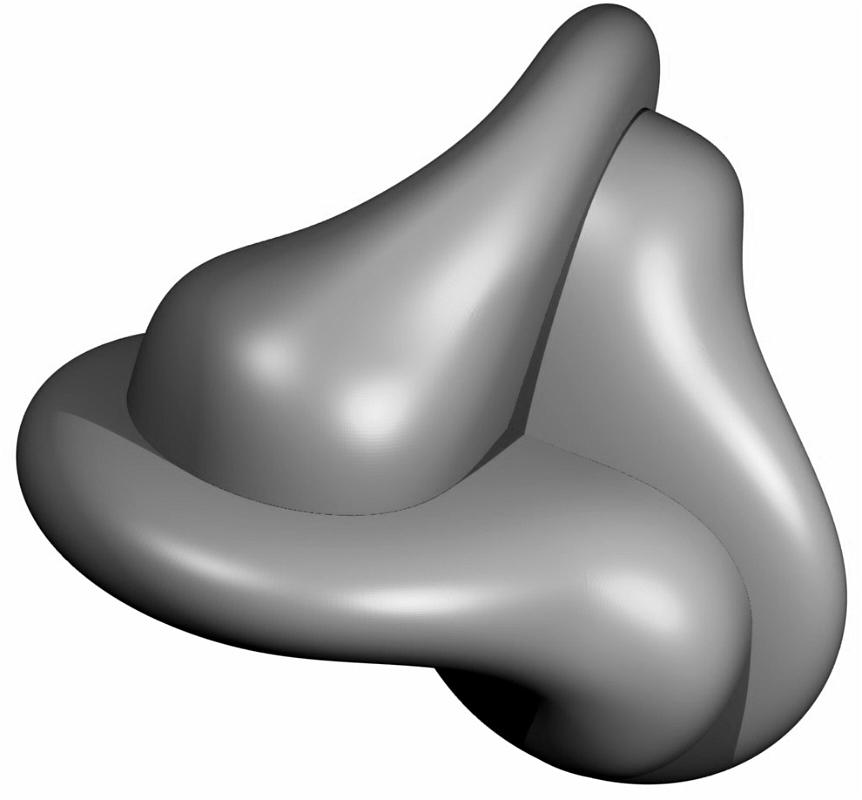

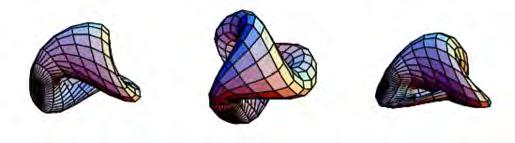

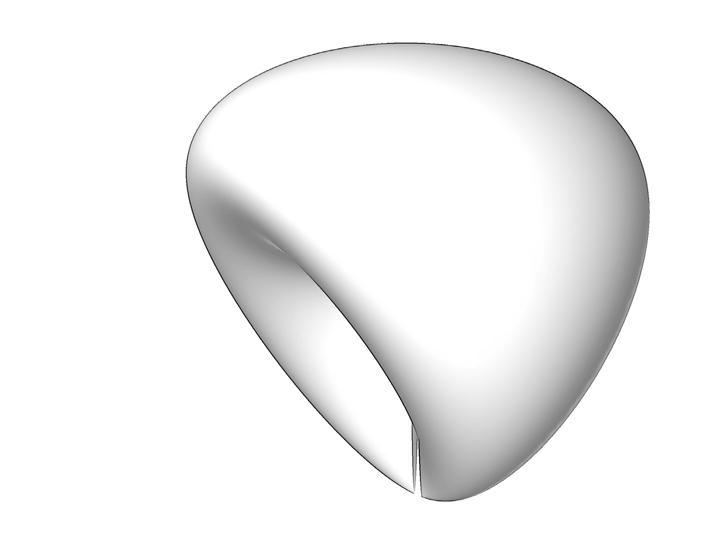

14

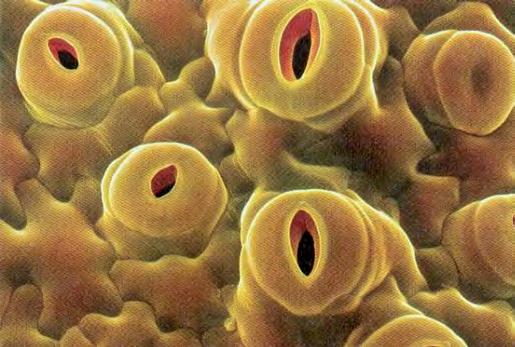

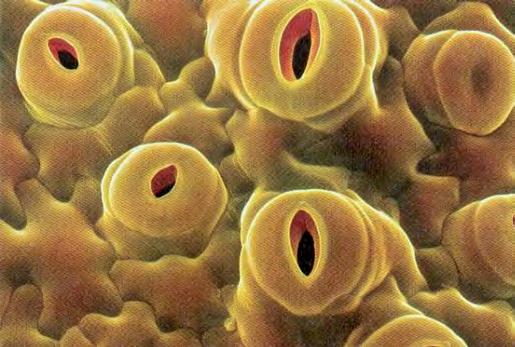

1.4 - Micrograph of stomata cells in a leaf, which open and close during the process of photo-synthesis in response to sun light.

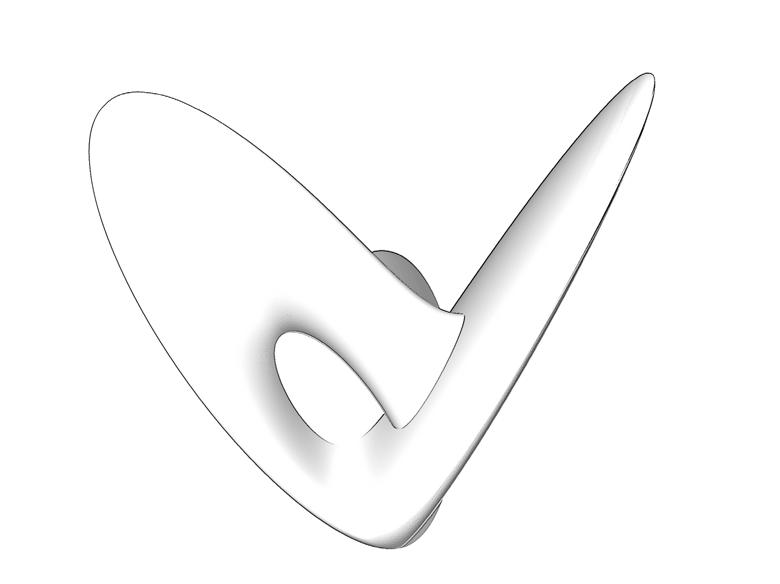

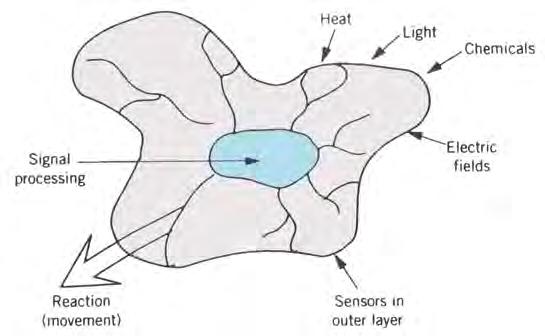

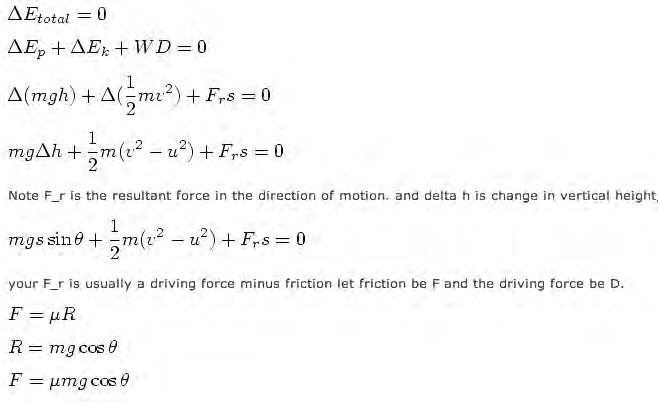

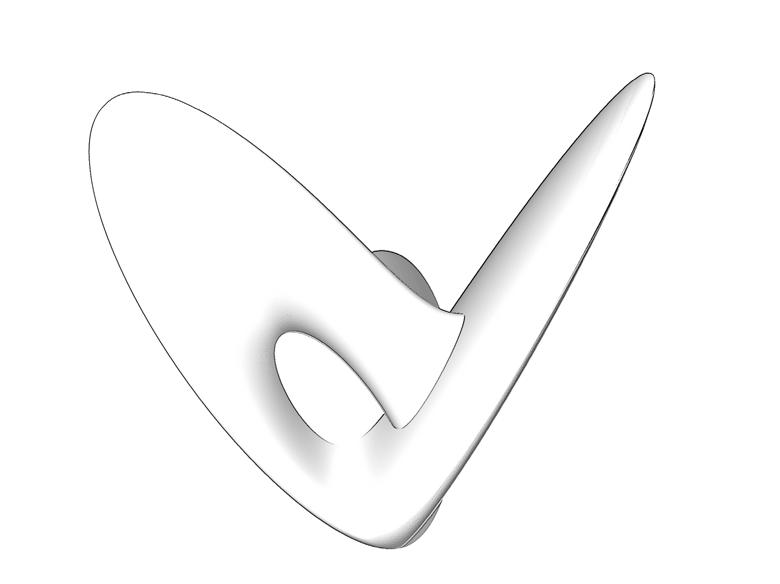

Energy Input (Stimulus)

Morpho-Mechanical Computation

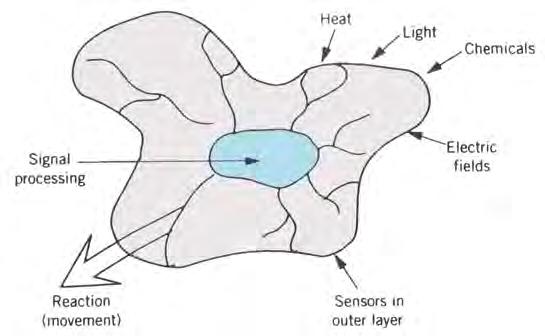

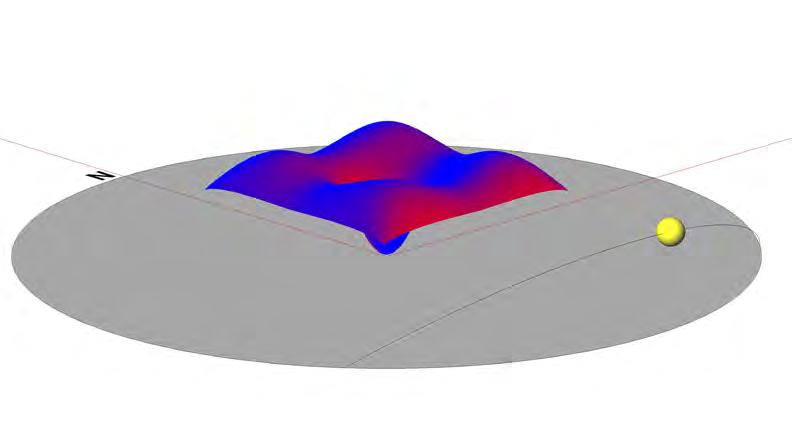

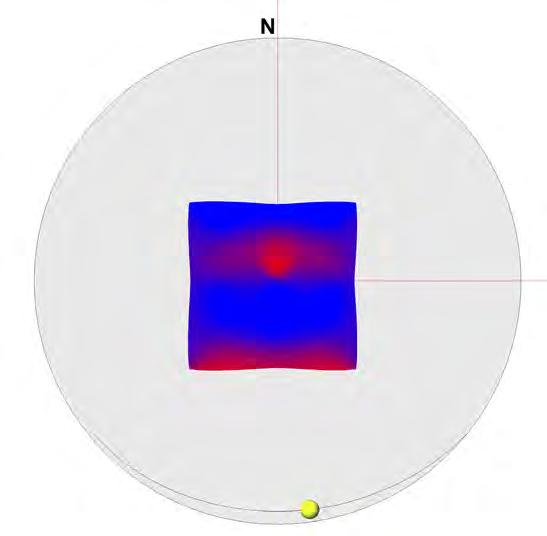

Adaptive mechanical design in biology deals with the design output arising from a set of inputs on the evolving or growing organ or organism. The inputs can be external and internal loads, environmental changes, etc., which are superimposed on the genetic information available. The evolutionary time-scale is a long one and what we observe as a response in biological organisms is the result of all these inputs over long periods of time. This complex process of sensing and actuation could be termed as ‘Morpho-Mechanical Computation’. The energy input or stimulus received from the environment is transduced into electric signals by biological sensing devices. The electric signals are further processed for an appropriate responsive behavior.

Two other aspects of ‘Morpho Mechanical Computation’ which

occur over much shorter timescales and which involve individuals as opposed to whole species, are Thigmo-morphogenesis, such as various forms of tropism, the opening and closing of stomata cells in leafs and bone-remodelling. What they show is the intrinsic design flexibility due to fibres and fibre architectures, hierarchies and the modulation of interactions between them, together with growth, converging to the a specific solution required for a specific situation. In order to adapt to the changes in circumstances, change in fibre orientations, modifications in structure and material properties and the shapes in local and global scales are altered. [1.5]

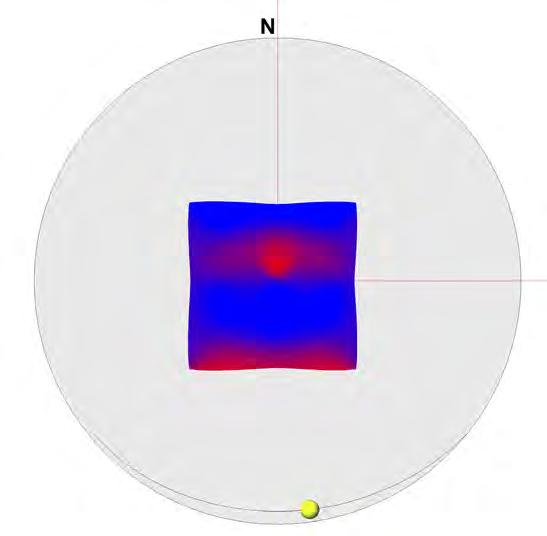

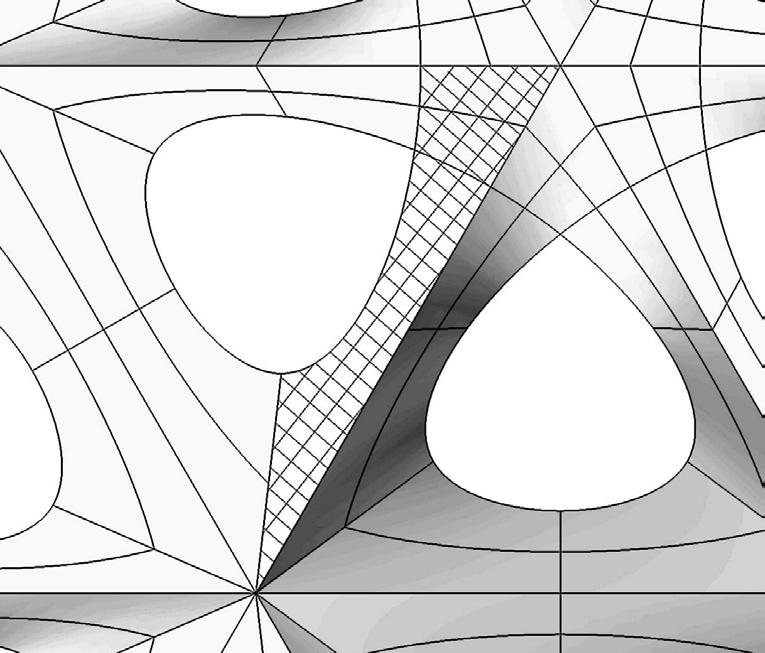

1.5 - Diagram showing the process of Morpho-Mechanical Computation

15

Device

Electrical Signal Filtering Processing Response Behaviour

(Transduction)

16

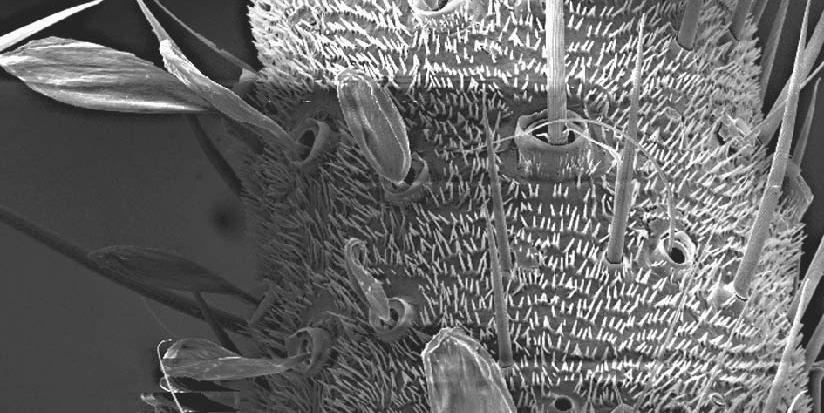

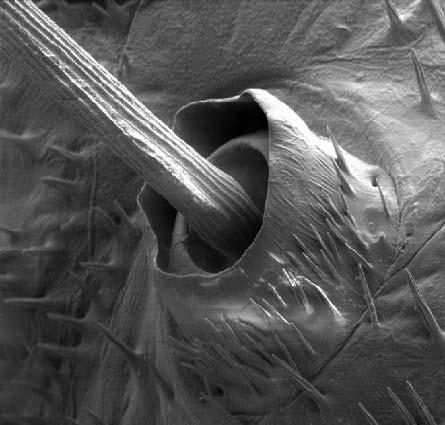

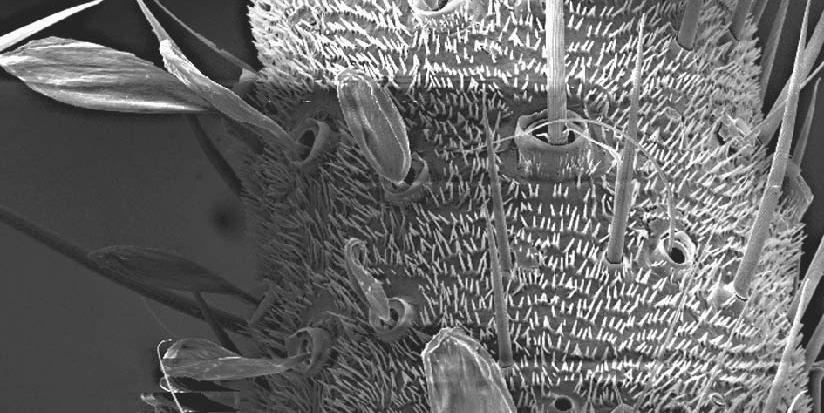

1.6 - Micrograph showing , Sensory filiform hairs of crickets for detection of predators. Filiformhair length varies between 100 and 1500 μm

Biological Sensing Devices

One of the most interesting aspects of multifunctionality and integration in biology is the way in which receptors detect and amplify mechanical strains and displacements. These devices are called as mechanoreceptors. They do exist in all creatures, plants and animals as shown in the table 1.7.

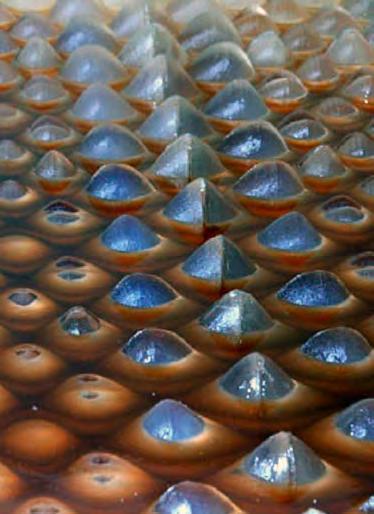

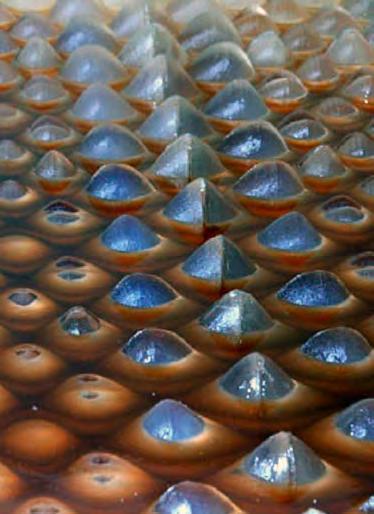

The vibration amplifications in case of insects, arthropods and crustaceans is further elaborated. These species have exoskeletons which, in their rigid state, are stiff laminated composite structures made of chitin fibres embedded in a highly crosslinked matrix of proteins and phenolic substances. The exoskeleton acts also as the load, strain or displacement detector via specialised organs, called sensilla, parts of which are local modification of the laminated structure of the exoskeleton to amplify the strain information for the detector organ connected to the nerve cell. These local modifications are a combination of changes in thickness, material stiffness and fibre orientation function as strain concentrations and mechanical signal amplifiers. These are equivalent to drilling holes into structural

Chemical (most animals and some plants)

Vibration (hair sensors in insects, spiders, scorpions, hearing)

Infrared (beetles, snakes)

Fluid-flow (various insects, spiders, crustaceans, fish, amphibians)

Strain (insects, arthropods)

Pressure (fish)

Touch (most animals and some plants)

Electrical (fish)

Magnetic (fish, birds)

Radiation(most animals –photoreceptors / vision)

Mechano-Receptors

components and embedding strain gauges in the regions near the holes to get an amplification of the remote state of strain of the structure.

The comparison between the vibration graphs shows the efficiency of mechanoreceptors in crickets which have a highly precise vibration sensing as against man-made sensing devices which pick up vibrations. [1.8]

17

1.8 - Comparison between an Input (tapped metal plate) sensor and cricket hair response (frequency range 200-500 Hz) 1.7- Table showing Mechano- Receptors of several organisms

s a e Sensing Actuation Energy

Adaptive systems in nature

Adaptive systems in nature have an incredible Stimulus-Response coordination. The simplest type of response is a direct one-to-one stimulusresponse reaction. A change in the environment is the stimulus; the reaction of the organism to it is the response.

Natural adaptive systems range from simple to complex configurations of sensing devices, actuators, controller logics and inherent energy generators. The adaptive potential is a resultant of continuous evolutionary processes to the environmental pressures under gone by the organism. Lower level organisms such as amoeba, fungi and plants display a simpler process of stimulus response co-ordination as against higher level organisms such as animals which respond to multiple stimuli.

Lower-level Organisms

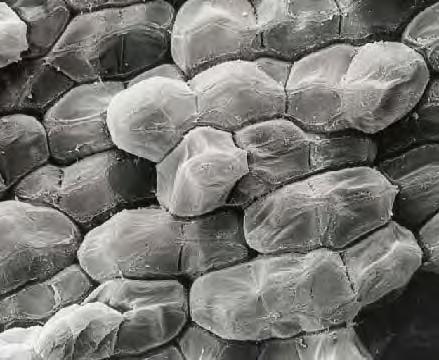

In case of lower level organisms such as nonlignified plants adaptive behavior is entirely dependent on control of turgor pressure inside the cells to achieve structural rigidity, pre-stressing the cellulose fibres in the cell walls at the expense of compression in the fluid. Trees pre-stress their trunks with the outermost layers of cells being prestressed in tension to offset the poor compressive properties of wood. [1.7]

In single-celled organisms, adaptive behavior is the result of a property of the cell fluid called irritability. In simple organisms, such as algae, protozoan’s, and fungi, a response in which the organism moves toward or away from the stimulus is called taxis.

Therefore the sensing and actuation functions are integrated within the definition of the material properties itself. The adaptive behavior emerges through the strategic definition of the fibre material hierarchies in multiple scales.

The energy required for actuation is also generated within the material system, In case of plants, through the process of photosynthesis and distribution of nourishment to alter the osmotic pressure and chemical disintegration in case of single celled organisms.

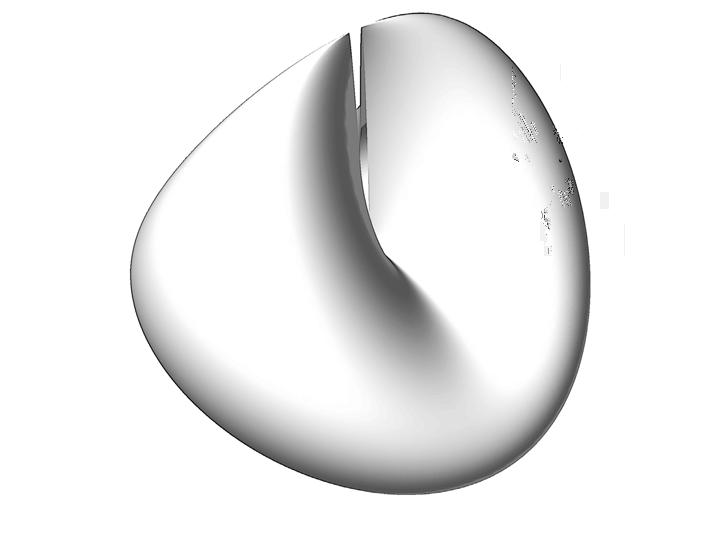

18

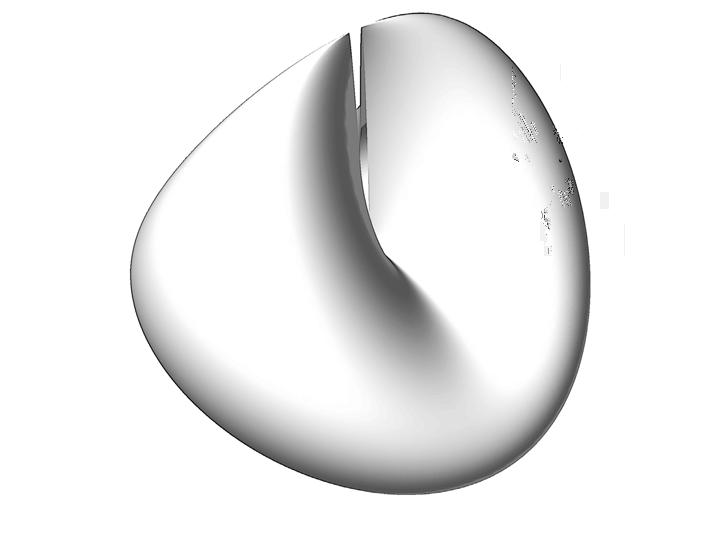

1.9 - Microgaph showing Parenchyma cells in plants which act as mini hydraulic actuators, by changing the osmotic pressure inside their cell walls.

Sensing Actuation Control Energy

Higher-level Organisms

In higher level organisms, adaptive behavior involves the synchronization and integration of events in different parts of the body, a control mechanism, or controller, is located between the stimulus and the response. In multi-cellular organisms, this controller consists of two basic mechanisms by which integration is achieved, chemical regulation and nervous regulation.

In chemical regulation, substances called hormones are produced by well-defined groups of cells and are either diffused or carried by the blood to other areas of the body where they act on target cells and influence metabolism or induce synthesis of other substances. The changes resulting from hormonal action are expressed in the organism as influences on, or alterations in, form, growth, reproduction, and behaviour.

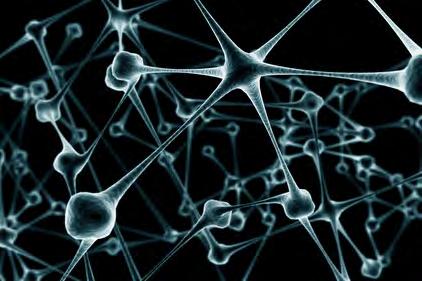

In animals, in addition to chemical regulation via the endocrine system, there is another integrative system called the nervous system. A nervous system can be defined as an organized group of cells, called neurons, specialized for the conduction of an impulse, an excited state from a sensory receptor through a nerve network to an actuator, the site where response occurs.[1.8]

Organisms that possess a nervous system are capable of much more complex behaviour. The nervous system, specialized for the conduction of impulses, allows rapid responses to environmental stimuli. Many responses mediated by the nervous system are directed toward preserving the status

quo, or homeostasis, of the animal. Stimuli that tend to displace or disrupt some part of the organism call forth a response that results in reduction of the adverse effects and a return to a more normal condition. Organisms with a nervous system are also capable of a second group of functions that initiate a variety of behaviour patterns. Animals may go through periods of exploratory or appetitive behaviour, nest building, and migration. Although these activities are beneficial to the survival of the species, they are not always performed by the individual in response to an individual need or stimulus. Finally, learned behaviour can be superimposed on both the homeostatic and initiating functions of the nervous system.[1.9]

Therefore, higher level organisms have far more sophisticated and complex system for sensing and actuation functions. There is a multifarious integration between sensors, controllers and actuators. To maintain homeostasis of the organism, the stimulus generated by multiple sensor inputs, go through filter processing which leads to decision making capabilities in higher level organisms. An equivalent to this in the man-made world would be artificial neural networks which have multiple inputs fed into processors which generated multiple outputs based on predefined rules.

The energy required for actuation is again generated within the organism by the process of metabolism.

19 s

a e c

1.10 - Neurons, forming neural networks in the nervous system and a neuron cell group responsive to multiple stimuli.

Precedents

“The ultimate smart structure would design itself. Imagine a bridge which accretes materials as vehicles move over it and it is blown by the wind. It detects the areas where it is overstretched and adds material until the deformation falls back within a prescribed limit… The paradigm is our own skeleton where material deposition happens in parts which require greater strength.”[1.10]

- Adriaan Beukers and Van Hinte

Architectural structures or building envelopes could be viewed as systems which need to self-regulate, adapt to the environmental changes and respond to natural elements such as sun, wind, rain etc. to achieve a comfortable micro climate. Environmentally responsive buildings, also called as intelligent buildings employing IBMS (Intelligent Building Management Systems) function as a collection of devices such as louvers and shades, controlled by a central computer that receives data from remote sensors and sends back instructions for activation of these mechanical systems.

On the contrary, natural systems are quite different wherein most of the sensing, decision making and reactions are entirely local and the global behavior is the product of these local actions. This is true across all scales, from small plants to large mammals. When we run for a bus, we do not have to make any conscious decisions to accelerate our heartbeat, increase our breathing rate and volume or open our pores to regulate the higher internal temperature generated. This concept of local decision making and reacting to external conditions is termed as cybernetics.[1.11]

Noebert Wiener introduced the term ‘Cybernetics’ in 1949. The concept of cybernetics includes information theory and practice, from transmission to reception, as well as subsequent manipulation and utilization of the information to control regulatory processes of living organisms, societies, buildings and engineering situations. Information plays a decisive role in the operation of both living organisms and buildings. The emissions and transmissions which constantly emanate from infinitely many sources such as the environment are converted into information by the agents which can use them as a basis for action or inaction. Information can reach the receiver without

being passed along and manipulated within; so that the system governs itself by adjusting accordingly. However, information can also have its origin within the living organism or buildings (such as functional and spatial requirements). This feedback within a system is a special form of information in living processes which allows growth, adaptation or rather self-regulation.

Living organisms perceive information through their senses. The senses serve the organism by obtaining information about the environment, like needs for survival, namely food, safety and reproduction. The acquisition of information is partly conscious. Living organisms react to many external as well as internal signals without involving consciousness, by assimilating them unconsciously or subconsciously like the tanning of skin by deposition of melanin when exposed to sunlight does not involve the brain.[1.12]

It is this flexibility, reactive and transformational capacities of biological organisms that scientists are now seeking to replicate in materials, computers, robotics and buildings. In biomimetics, scientists look at everything from the way the brain learns through trial and error, (so that robots may do the same), to the way a fish moves through water (so the submarines can become similarly more flexible and efficient by reducing central control). This level of biomimicry takes into understanding the aspect of self-organization in biological organisms.[1.13]

There are some precedents which have endeavoured to achieve the self -organisational process observed in nature. We shall briefly discuss the system configuration of sensors, actuators, control and energy deployed in these precedents in relation to the higher and lower level organisms discussed in the previous section of adaptive systems in nature.

20

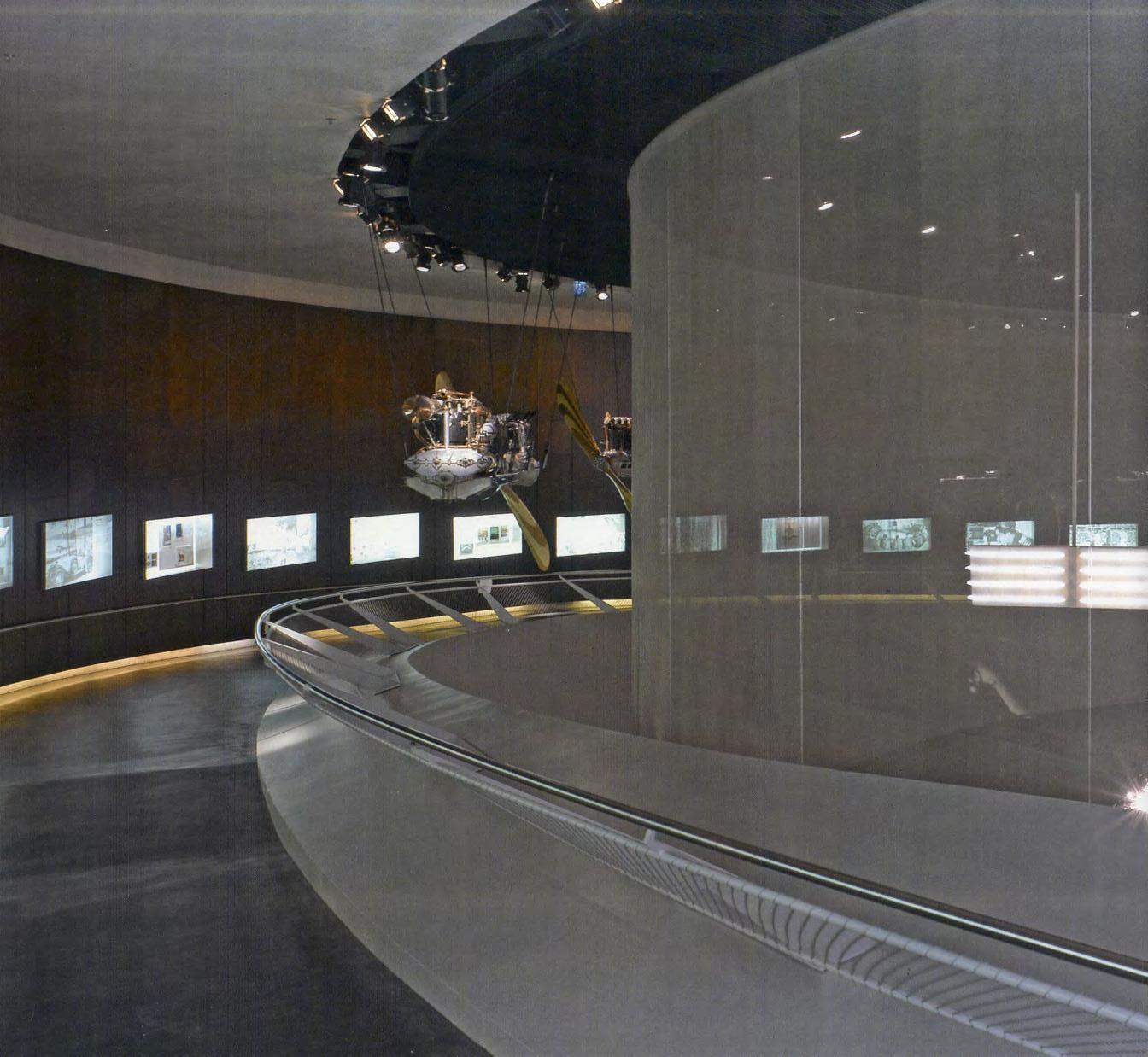

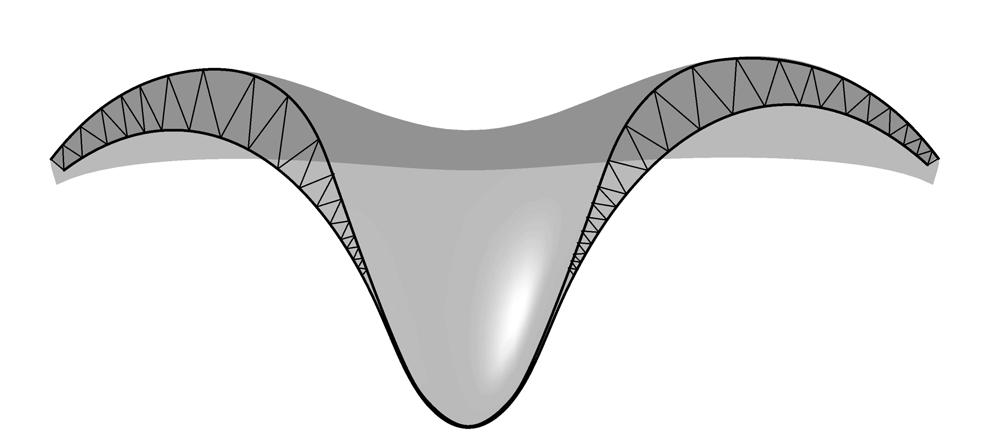

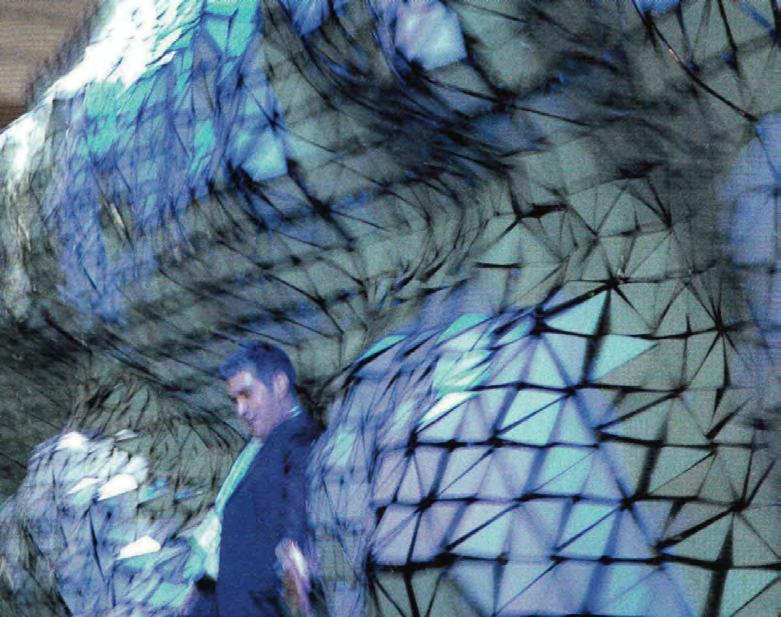

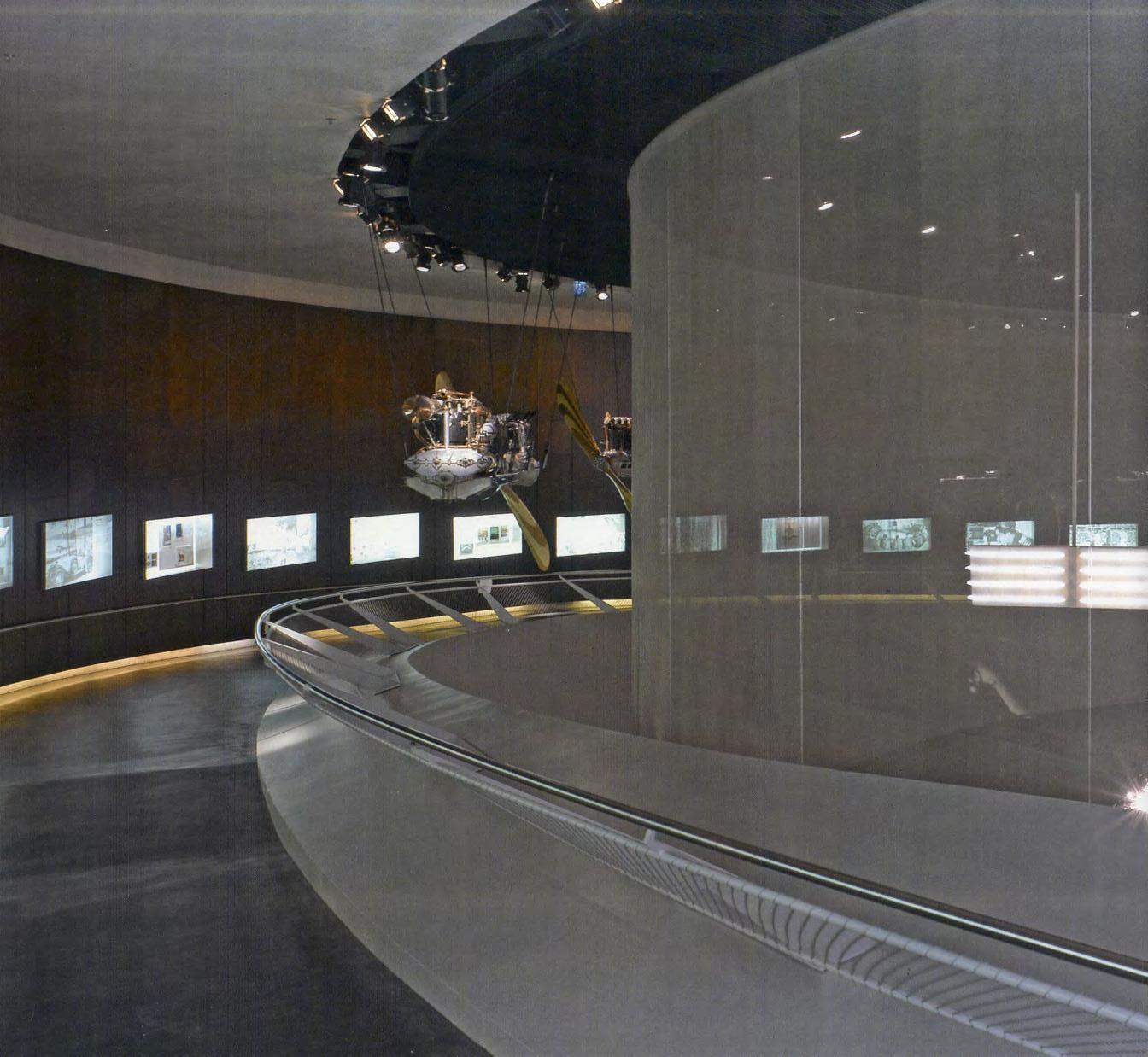

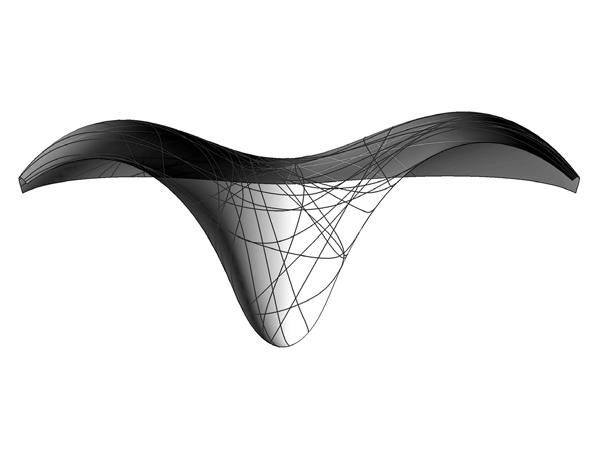

Hypo-Surface

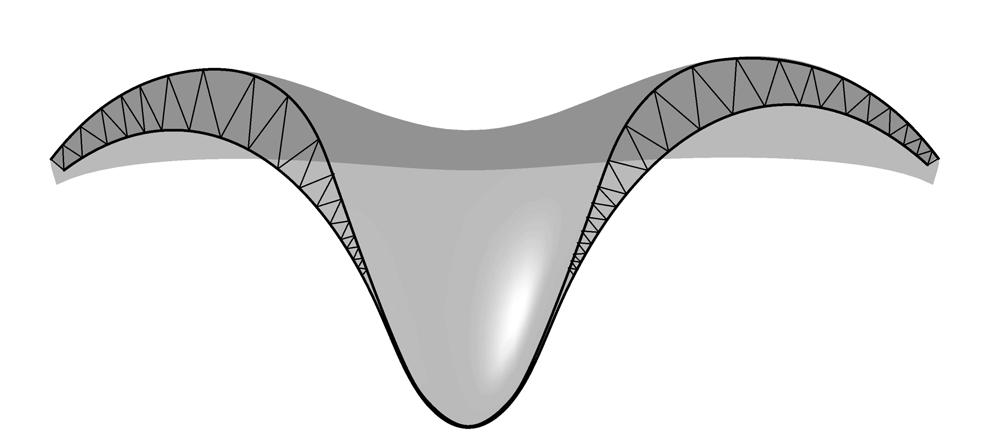

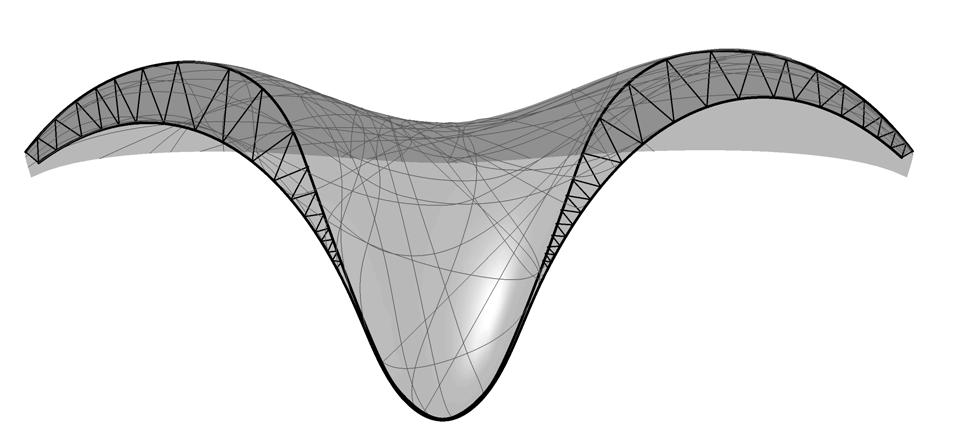

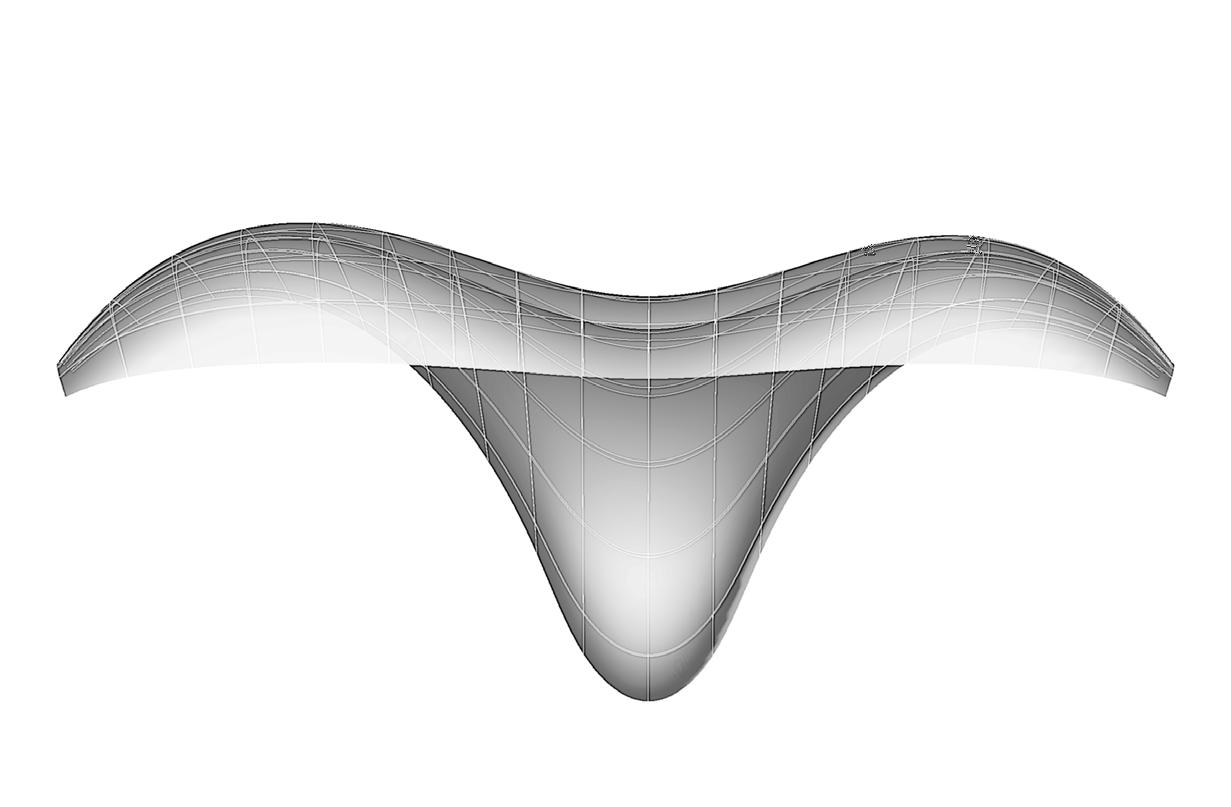

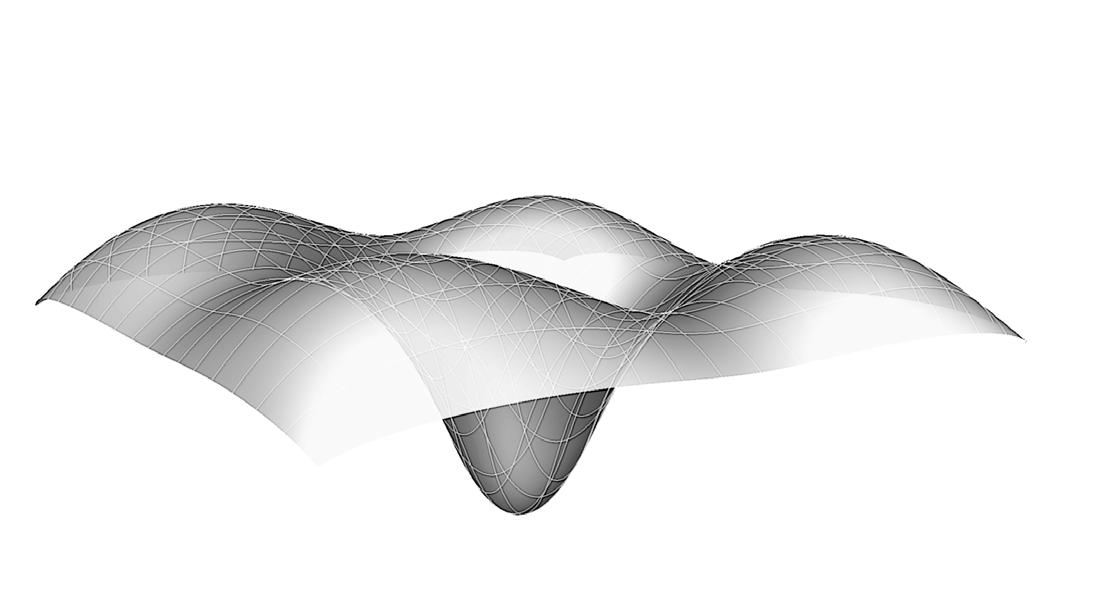

The sensors, actuators and the control technology were developed to react within milliseconds to pulses racing from one side to another at speeds of 50 kilometres an hour. The surface was fractioned into small plates interconnected by rubber squids. The geometry of the curved plane (during actuation) is defined by triangular plates to enable double curvatures.

[1.14]

The responsive behaviour of the hyposurface is different from the self-organisation process of adaptive systems in nature. The system consists of sensors and actuators, but the information processing or control and the energy required for the actuation of the pneumatic pistons are sourced externally.

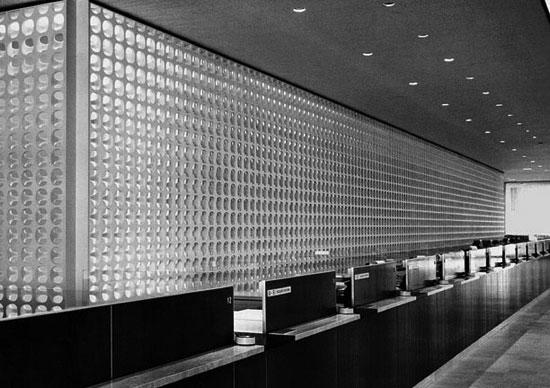

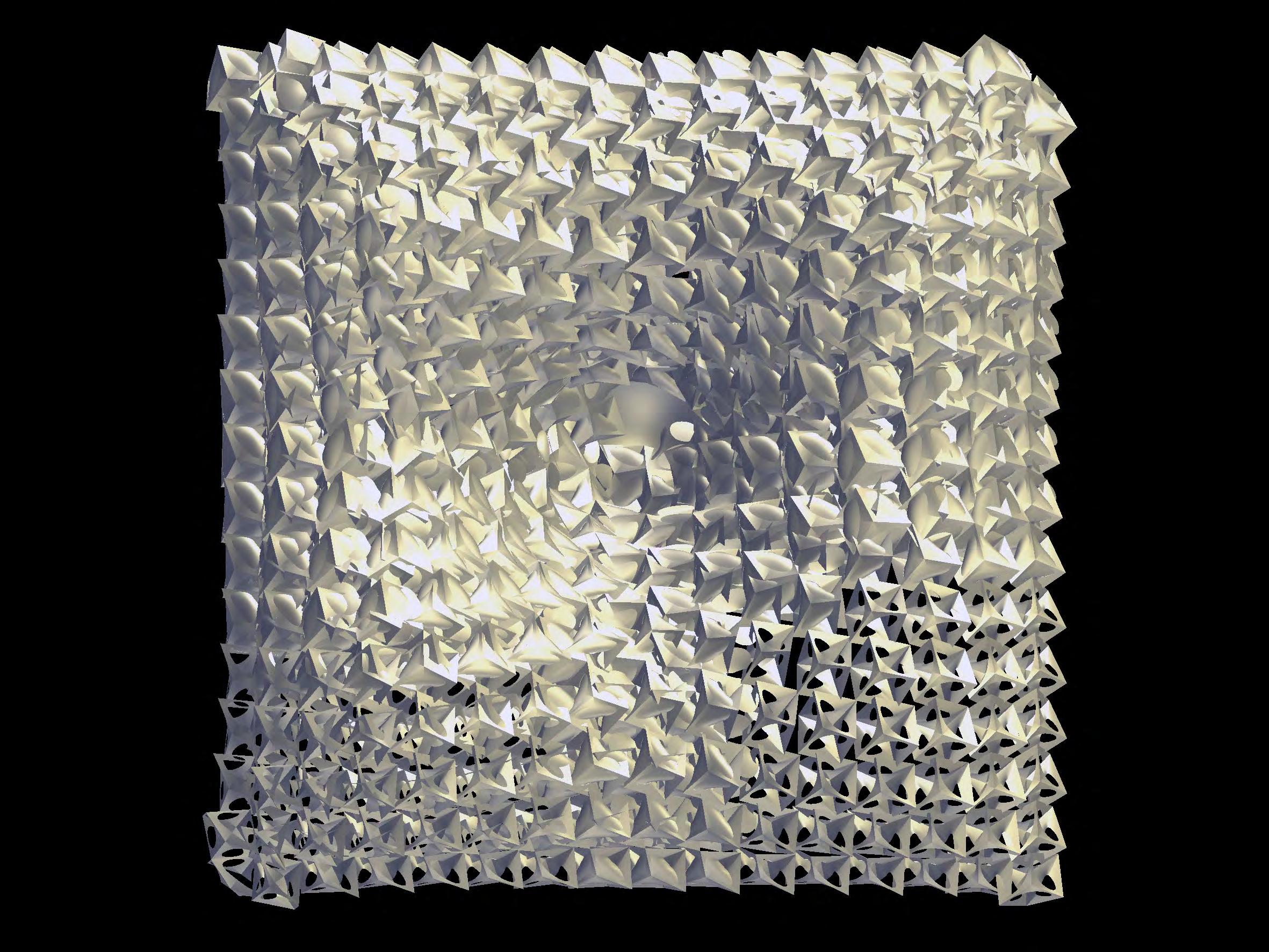

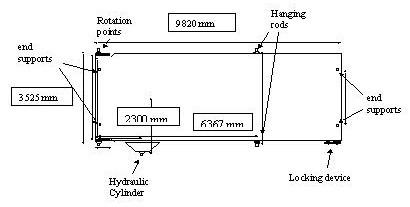

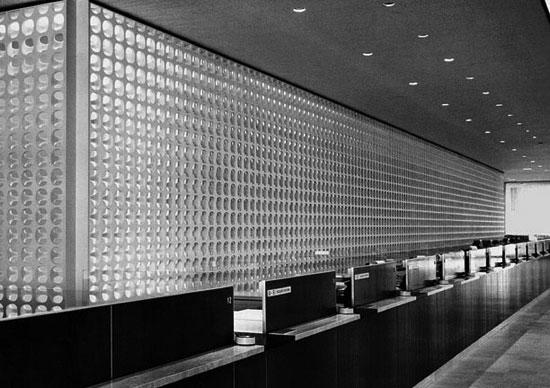

‘Hyposurface’ was developed by Mark Goulthorpe of Decoi architects as an interactive installation in Birmingham Hippodrome in 1999. The responsive wall measures approximately 8 metres wide and 7 meters high. The project was collaboration between architects, mathematicians, computer programmers and multimedia experts. The hyposurface transforms from being a flat plane into a curved plane by moving the components up and down by up to 60cm. The surface, extremely varied in its motions and highly dynamic, reacts to environmental influences. The stimuli are picked up by sensors responsive to video, sound, light, heat, movement and so on. The actuation was carried out through arrays of pneumatic pistons, which are activated in real time to the stimuli. The control system processing the information from sensors calculates and signals to each piston a precise instruction at real-time speed. The wall responds in sympathy with a clap from an observer and does not simply respond as a delayed reaction.

21

a e c

s

1.11 -Active responsive wall ‘Hypo-surface’ developed by Mark Goulthorpe with motion sensors and pneumatic actuators.

1.12 -Diagram showing the configuration of sensors and actuators forming a responsive system with external control and energy input.

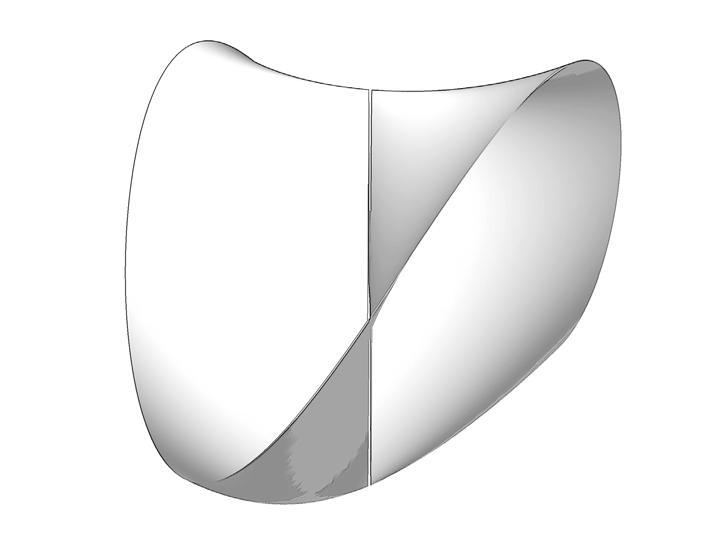

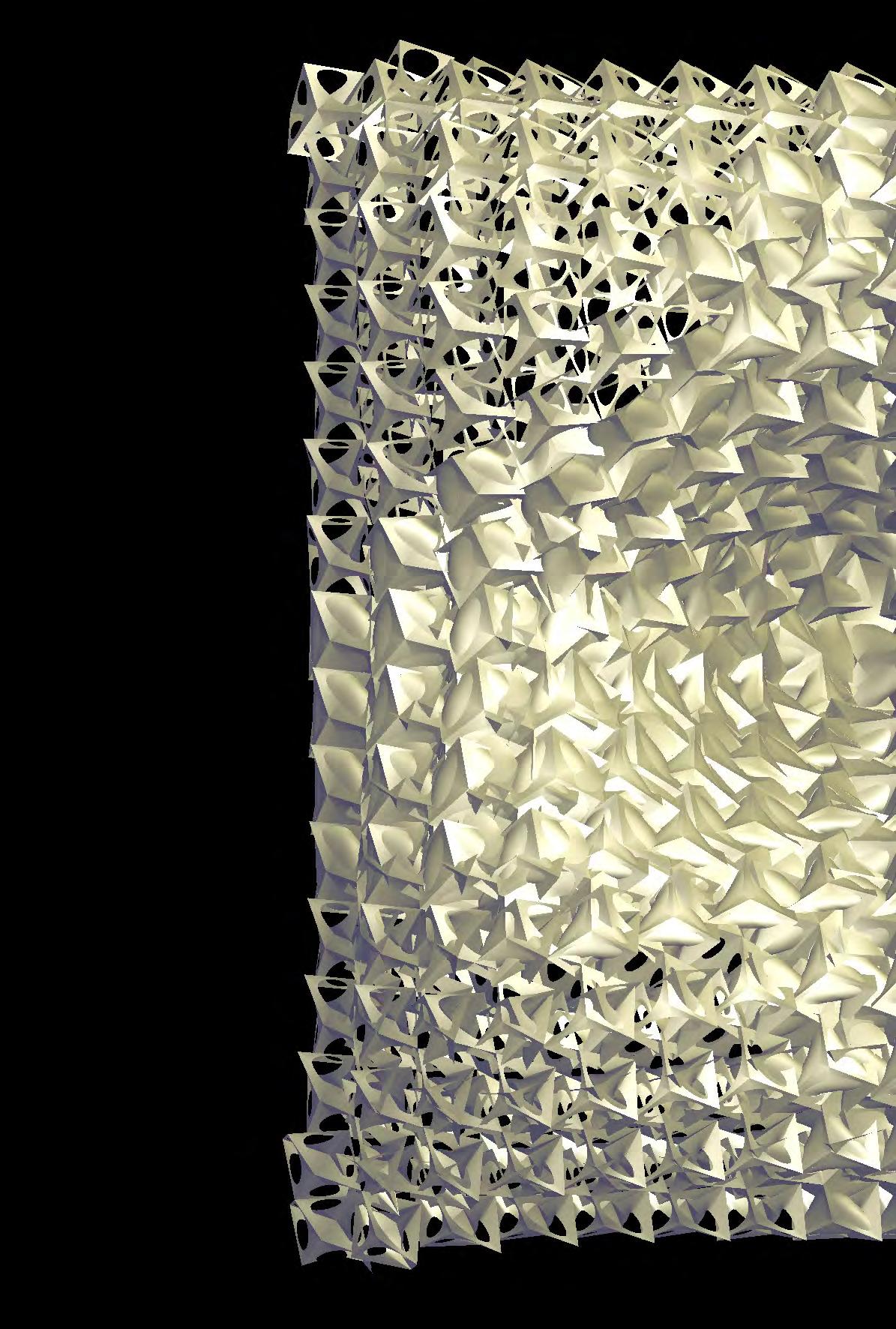

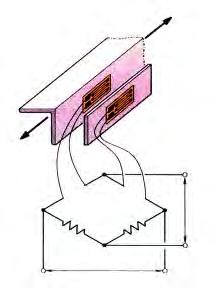

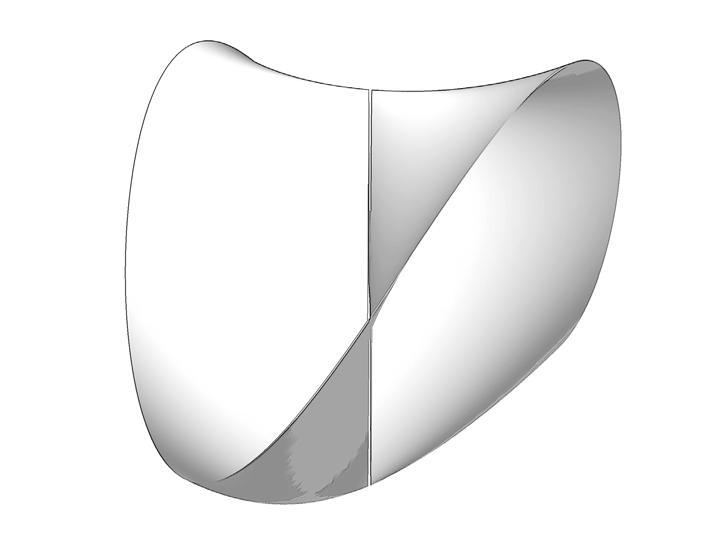

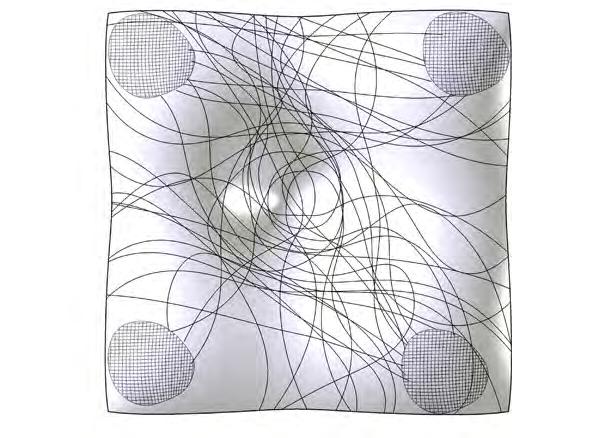

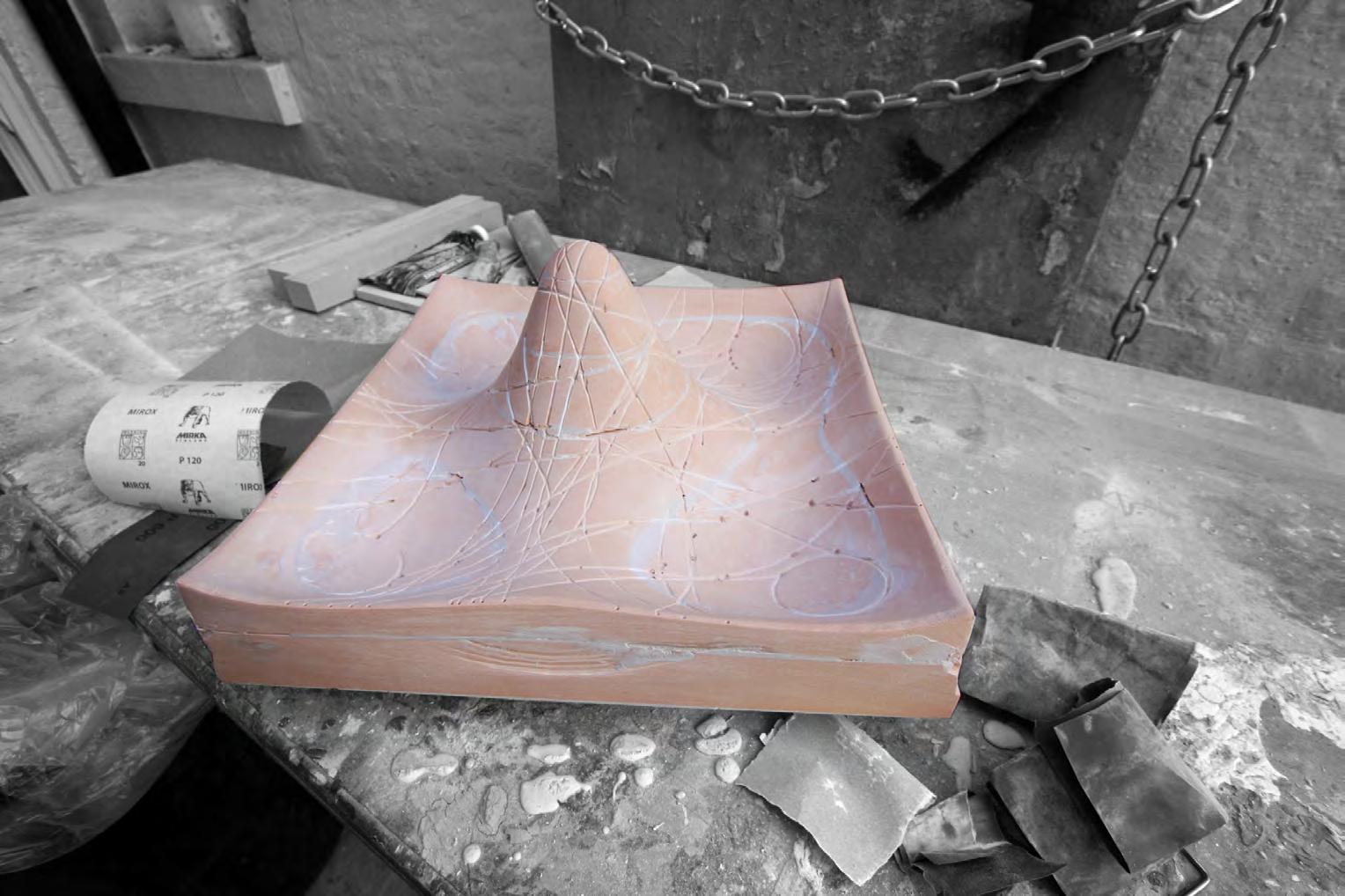

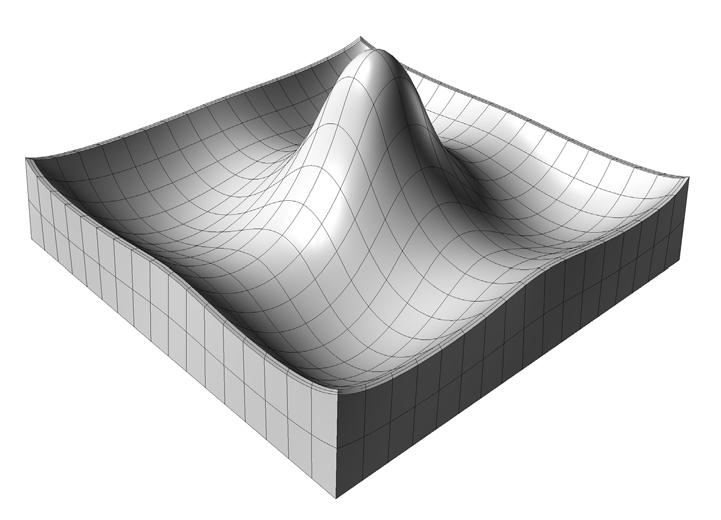

Cartesian wax is a material system developed by Neri Oxman for the exhibition ‘Design and the Elastic Mind’ at the MoMA - Museum of Modern Art in 2008. The project explores the notion of material organization as it is informed by structural and environmental performance. It is a prototype for an environmentally responsive skin and an exploration into building envelope design. The material system defined, integrates structural and environmental elements of the building skin. The structural elements provide for an optimized distribution of load, while the environmental elements allow for the infiltration of light and heat to and from within the skin. Integrated solutions may prove to be more sustainable as they are in the natural and biological world. Less redundant and more custom-fit to their environment, space and structure can now be shaped and manufactured using state-of-the-art fabrication techniques and technologies. It is a well known fact that in nature, shape is cheaper than material. In manmade design, this was never the case. Material is traditionally assigned to a shape by way of post-rationalizing its geometry. By using softwares to create new composite materials Oxman has been able to replicate the processes of nature, creating materials that are able to adapt to light, load, skin pressure, curvature and other ecological elements.[1.15]

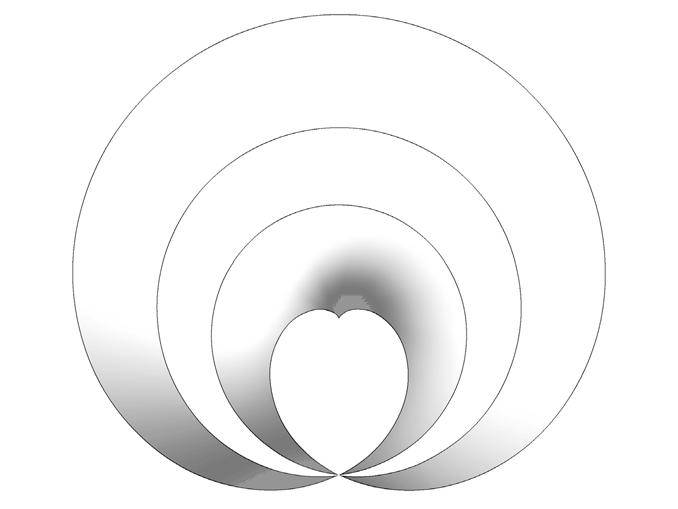

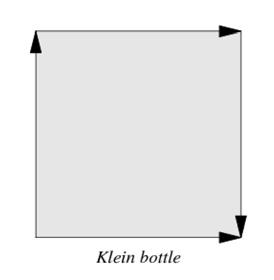

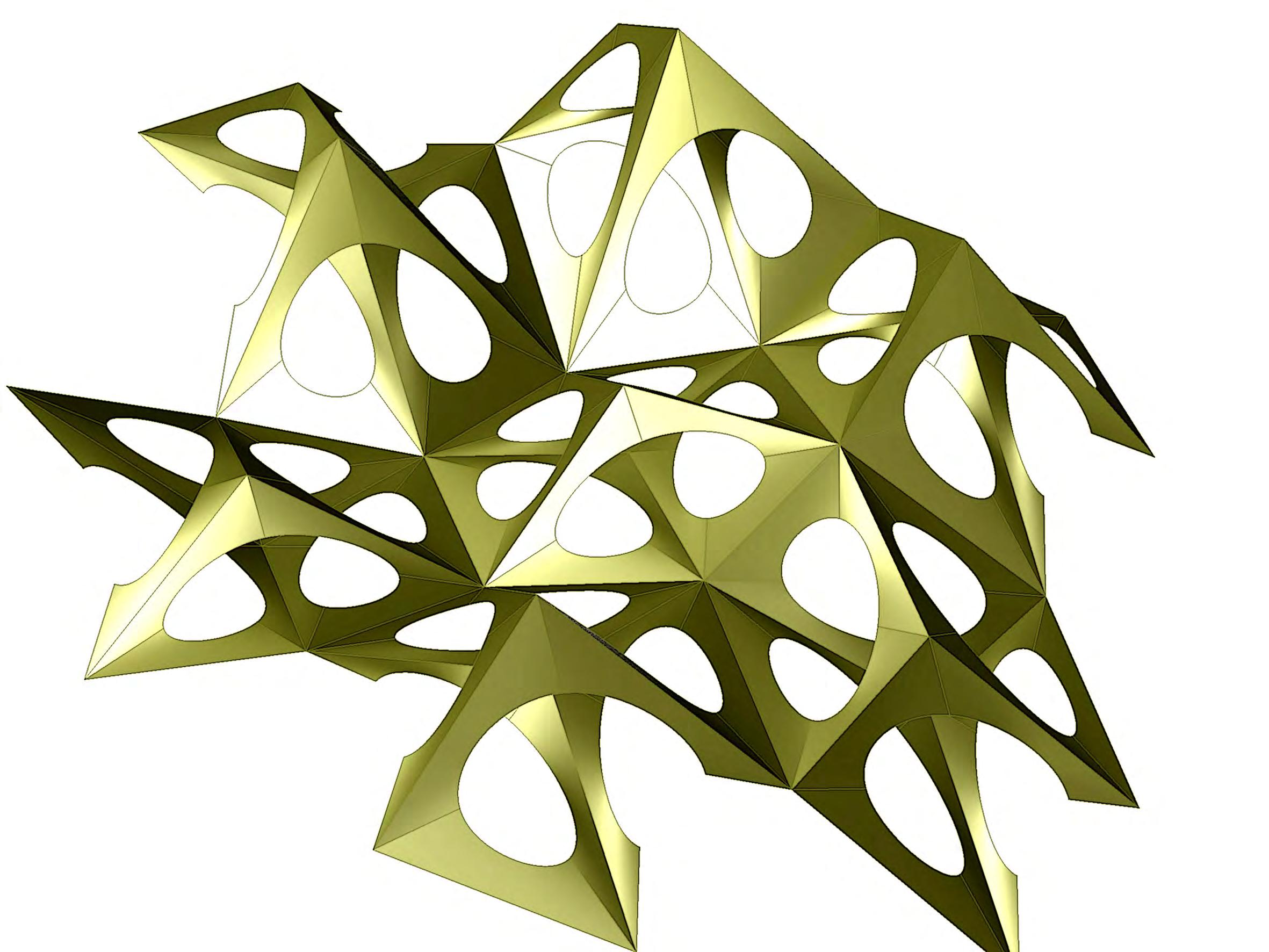

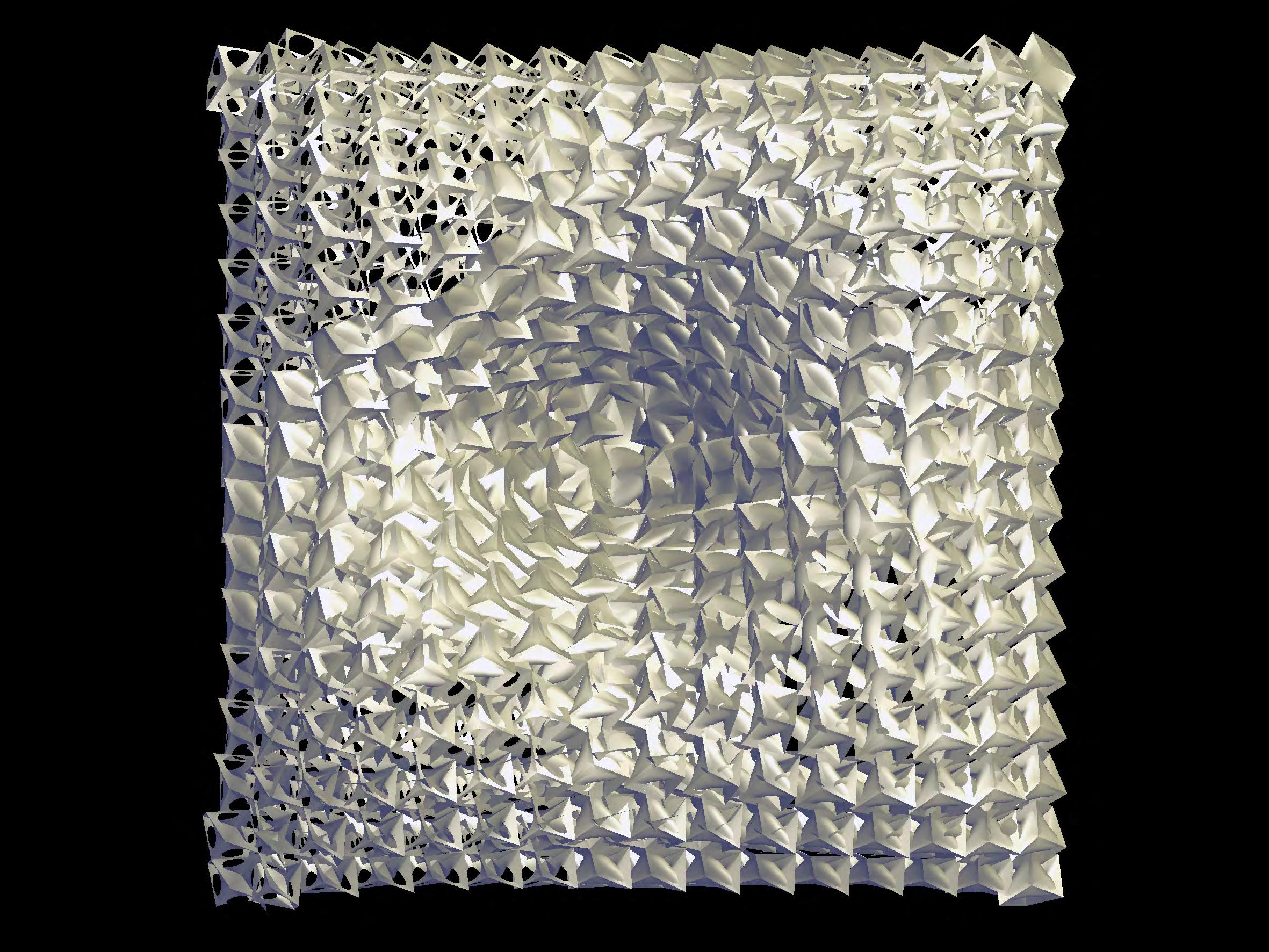

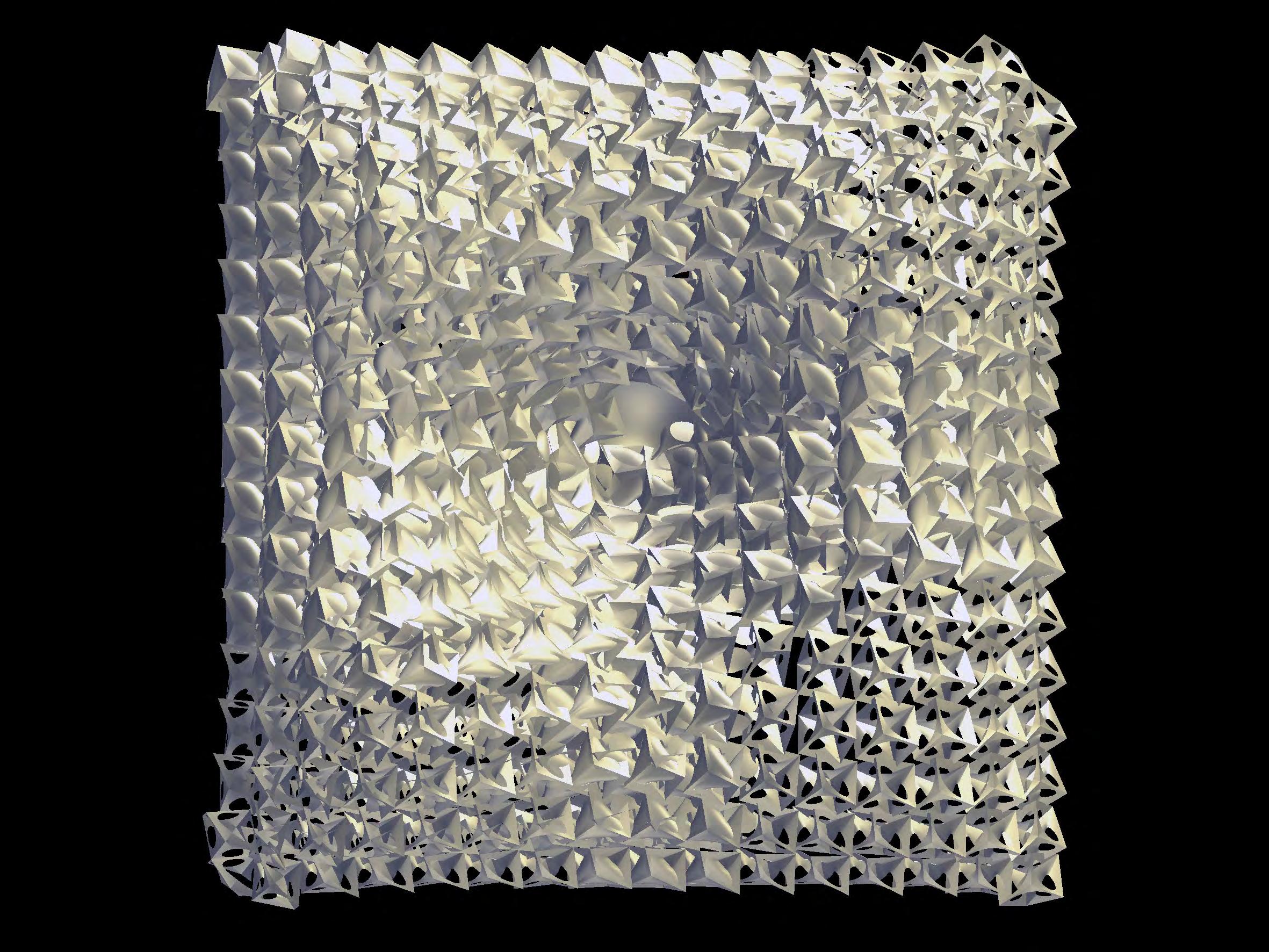

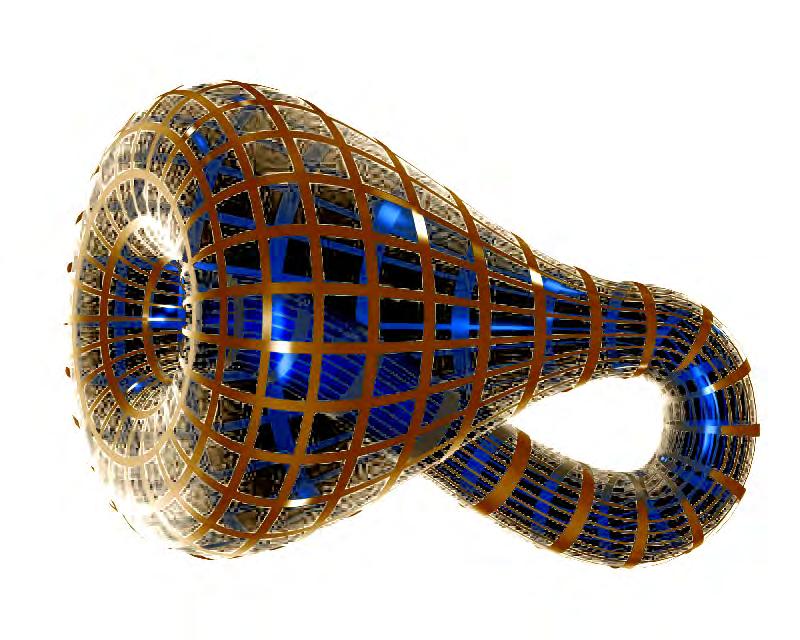

The topology is defined as a continuous tiling system, differentiated across its entire surface area to accommodate for a range of conditions accommodating for light transmission, heat flux, and structural support. The surface is thickened locally where it is structurally required to support itself, and modulates its transparency according to the light conditions of its hosting environment. Twelve tiles are assembled as a continuum comprised of multiple resin types, rigid and flexible. Each tile is designed as a structural composite representing the local performance criteria as manifested in the mixtures of resin. [1.16]

In this case the material system is predefined with sensing and actuation functions. The changes in the environmental heat flux are used to change the state of the resin from flexible to rigid and hence manipulate the transparency of the surface. The adaptive mechanism here is similar to that of lower level organisms, where the sensing, actuation and the energy required for the actuation is generated within the system. There is no information processing or decision making involved and the material seamlessly responds to the changes in the environmental conditions. load, while

22

Cartesian Wax

1.13 -Resposive material system ‘Cartesian Wax’ developed by Neri Oxman.

1.14 -Diagram showing the configuration of sensors, actuators and energy forming an integral part of the material system.

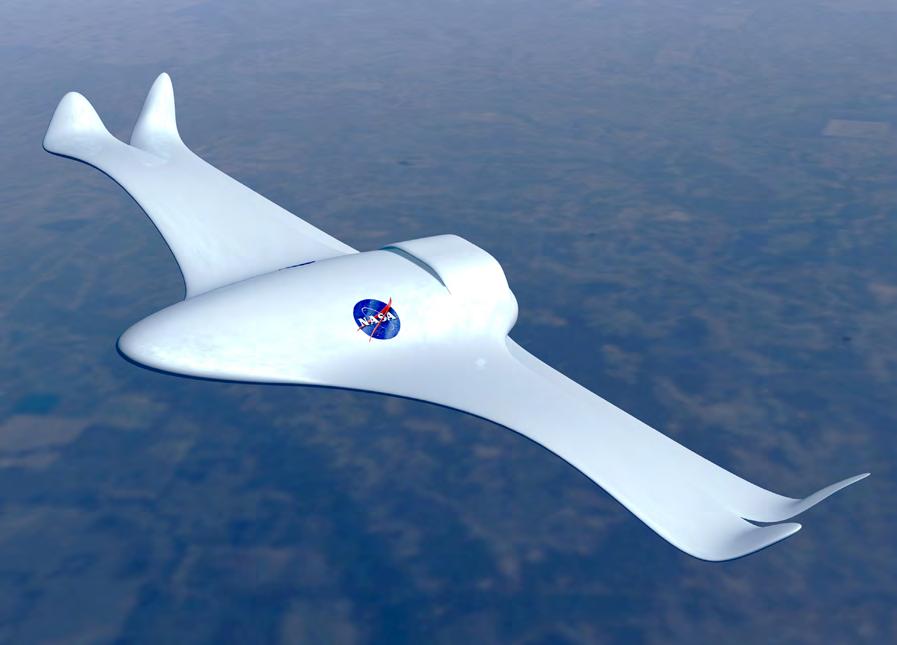

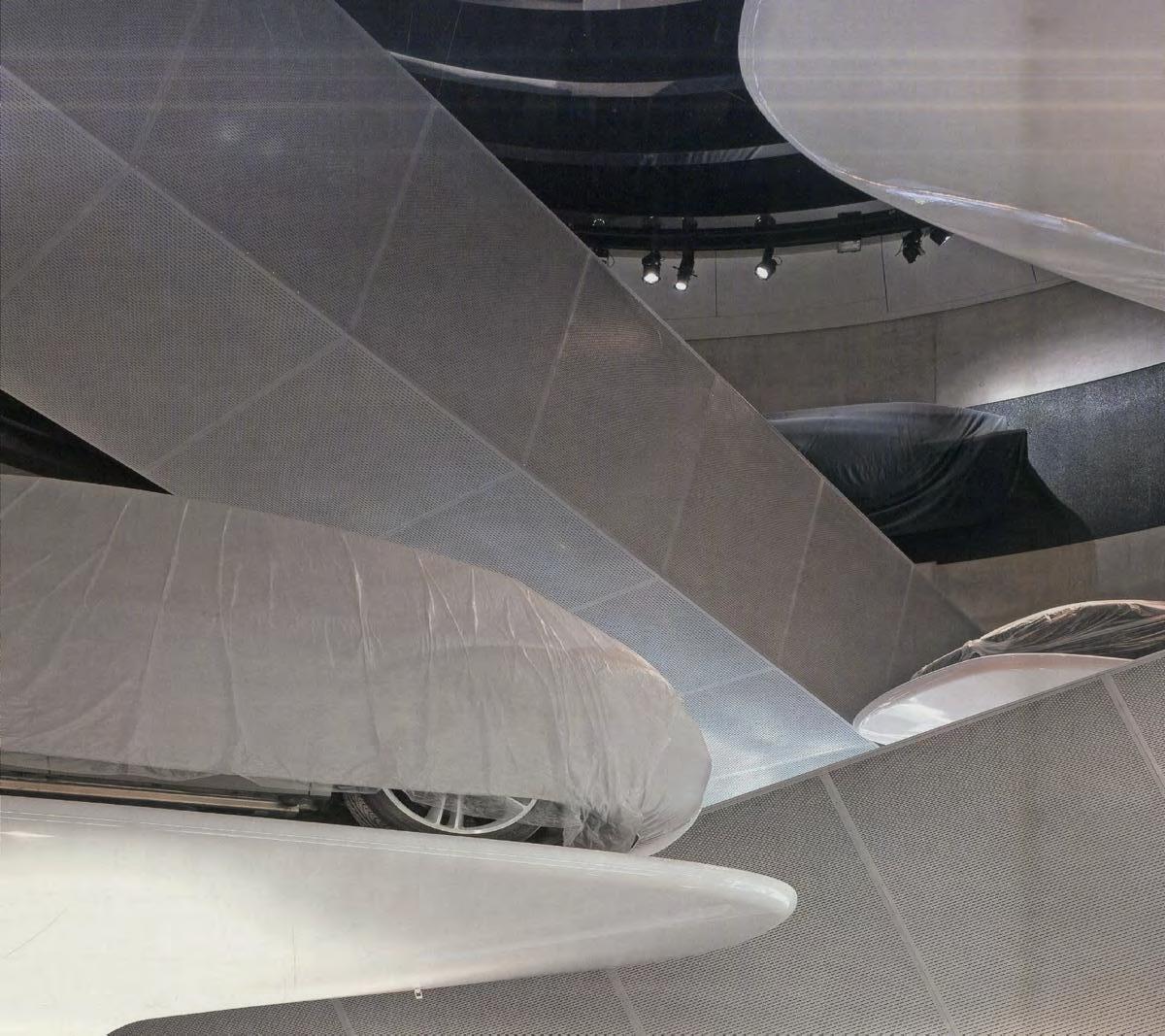

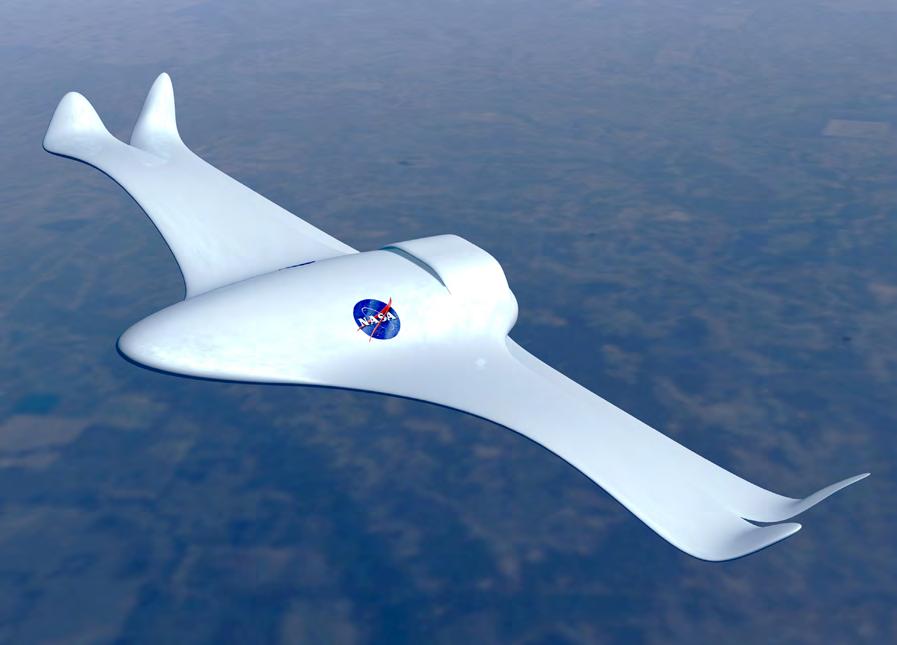

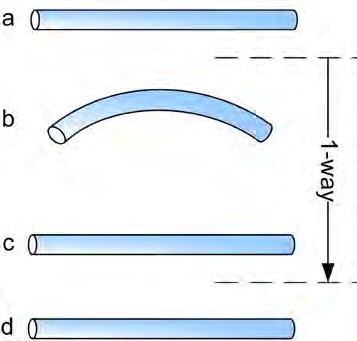

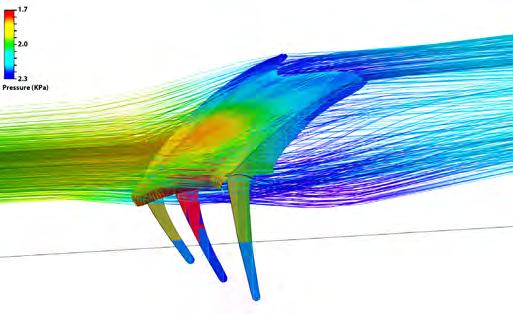

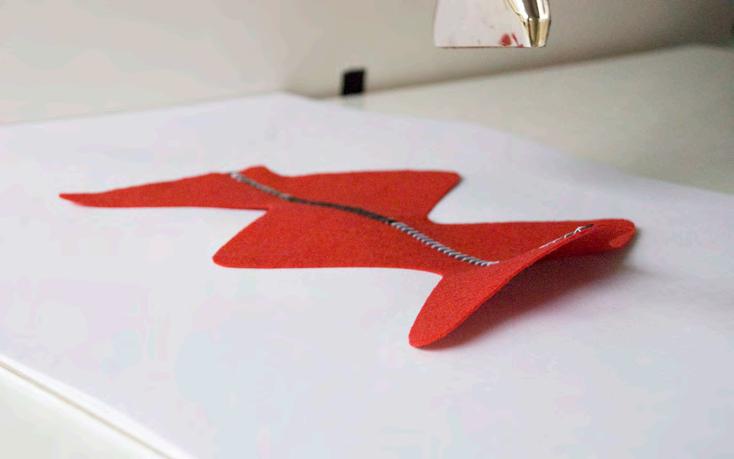

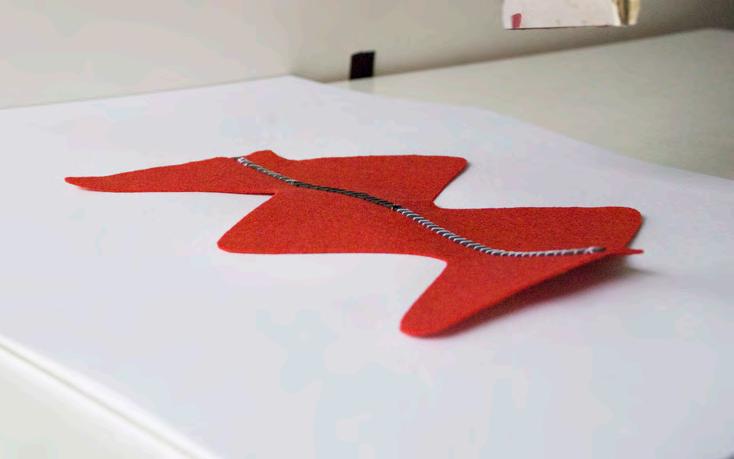

NASA is currently working with Boeing and the U.S. Air Force on the Active Aero-elastic Wing (AAW) F/A-18 project in a quest for developing a morphing aircraft that changes its shape in flight. The Aircraft of the future will not be built of traditional, multiple, mechanically connected parts and systems. Instead, aircraft wing construction will employ fully integrated, embedded “smart” materials and actuators that will enable aircraft wings with unprecedented levels of aerodynamic efficiencies and aircraft control. The availability of strong, flexible composite structures and miniaturized computers and motors point the way toward seamless wings that will one day bend to achieve flight control as effortlessly as a bird does. [1.17]

The smart plane would respond to the constantly varying conditions of flight, sensors will act like the “nerves” in a bird’s wing and will measure the pressure over the entire surface of the wing. The response to these measurements will direct actuators, which will function like the bird’s wing “muscles.” Just as a bird instinctively uses different feathers on its wings to control its flight, the actuators will change the shape of the aircraft’s wings to continually optimize flying conditions. Active flow control effectors will help mitigate adverse aircraft motions when turbulent air conditions are encountered.

Intelligent systems composed of these sensors, actuators, microprocessors, and adaptive controls will provide an effective “central nervous system” for stimulating the structure to affect an adaptive “physical response.”The central nervous system will provide many advantages over current technologies. The proposed AAW Vehicles will be able to monitor their own performance, environment, and even their operators in order to improve safety and fuel efficiency, and minimize airframe noise. They will also have systems that will allow for safe takeoffs and landings. Researchers at NASA Langley Research Center are taking the lead to explore these advanced vehicle concepts and revolutionary new technologies. [1.18]

The process of morpho mechanical computation in the smart plane is similar to that of higher level organisms. There are multiple inputs from the environment such as temperature, drag coefficient, turbulence and so on; these multiple sensor inputs would be processed by controllers similar to that of the central nervous system. Then the actuation would be carried out through the actuators strategically positioned long the surface of the wing span. load, while

23

Smart Plane

of sensors ,

and energy forming and integrated and cohesive smart adaptive

1.15- Morphing smart plane , developed by NASA Dryden Flight Research Centre shows advanced concepts for the aircraft of the future 1.16 -Diagram showing

the configuration

actuators, controllers

system.

Smart systems

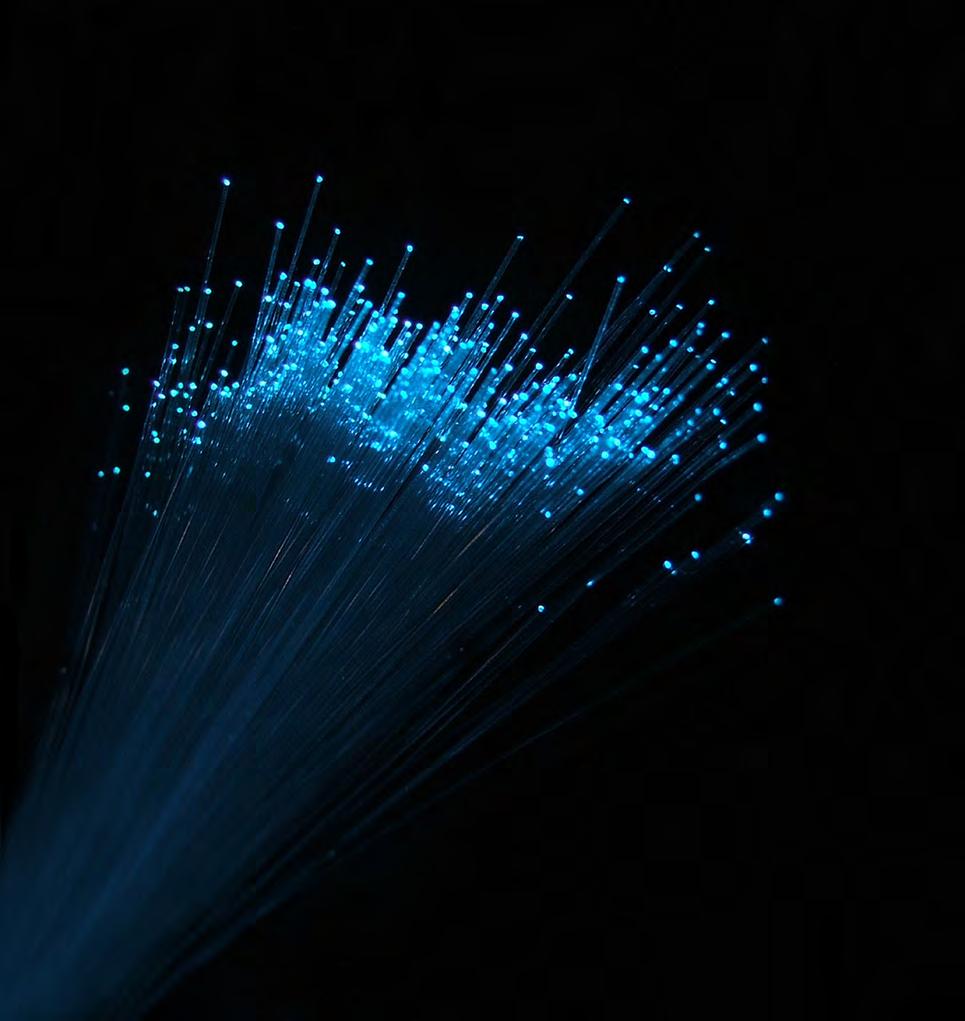

All around us are living things that sense and react to the environment in sophisticated ways. As structures have become more complex and are being asked to perform ever more difficult missions, there has been an ever increasing need to build “intelligence” into them so that they can sense and react to their environment. Examples include buildings that can sense, react and survive earthquakes and spacecraft that can sense and repair damage autonomously. To perform these functions successfully a “nervous system” is required that performs in a manner analogous to those of living things sensing the environment, conveying the information to a central processing unit (the brain) and reacting appropriately. Fiber optic technology has enabled the nerves of the system to be realized. Using hair-thin glass fibers as information carriers and sensors that may be built directly into the fibers with no increase in the overall size, it is possible to create long strands of fibre sensors capable of measuring strain, pressure, temperature, and other key parameters. These sensor “strings” may then be embedded into the structural materials with no degradation in overall strength, resulting in “smart structures” with built in nervous systems. Such structures could achieve active control, where a structure senses environmentally induced structural changes and reacts in real time.[1.19]

The term smart materials and structures are used to describe this unique collaboration of material and their structural properties with fibre optic sensors and actuation control technology. Smart structures constructed from materials with fibre optic nerves could continuously monitor the loads imposed on them as well as their vibration state and deformation. In addition, strain sensing may be capable of assessing damage and warning of impending weakness in structural integrity or improving quality control of thermo set composite materials during fabrication through cure monitoring. This could lead to greater reliance in the use of advanced composite materials and the usage of optimum material based on specific loading conditions.

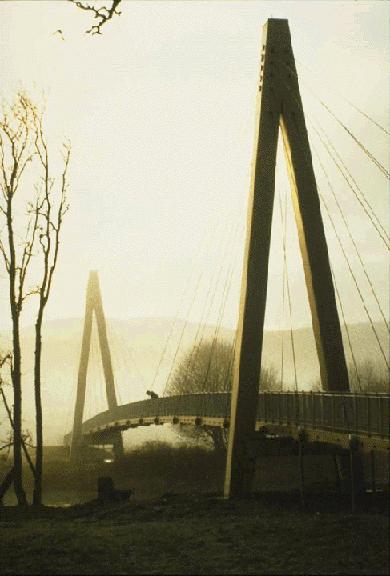

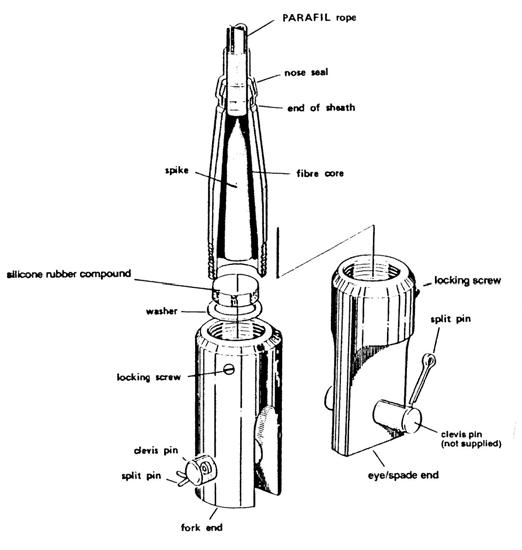

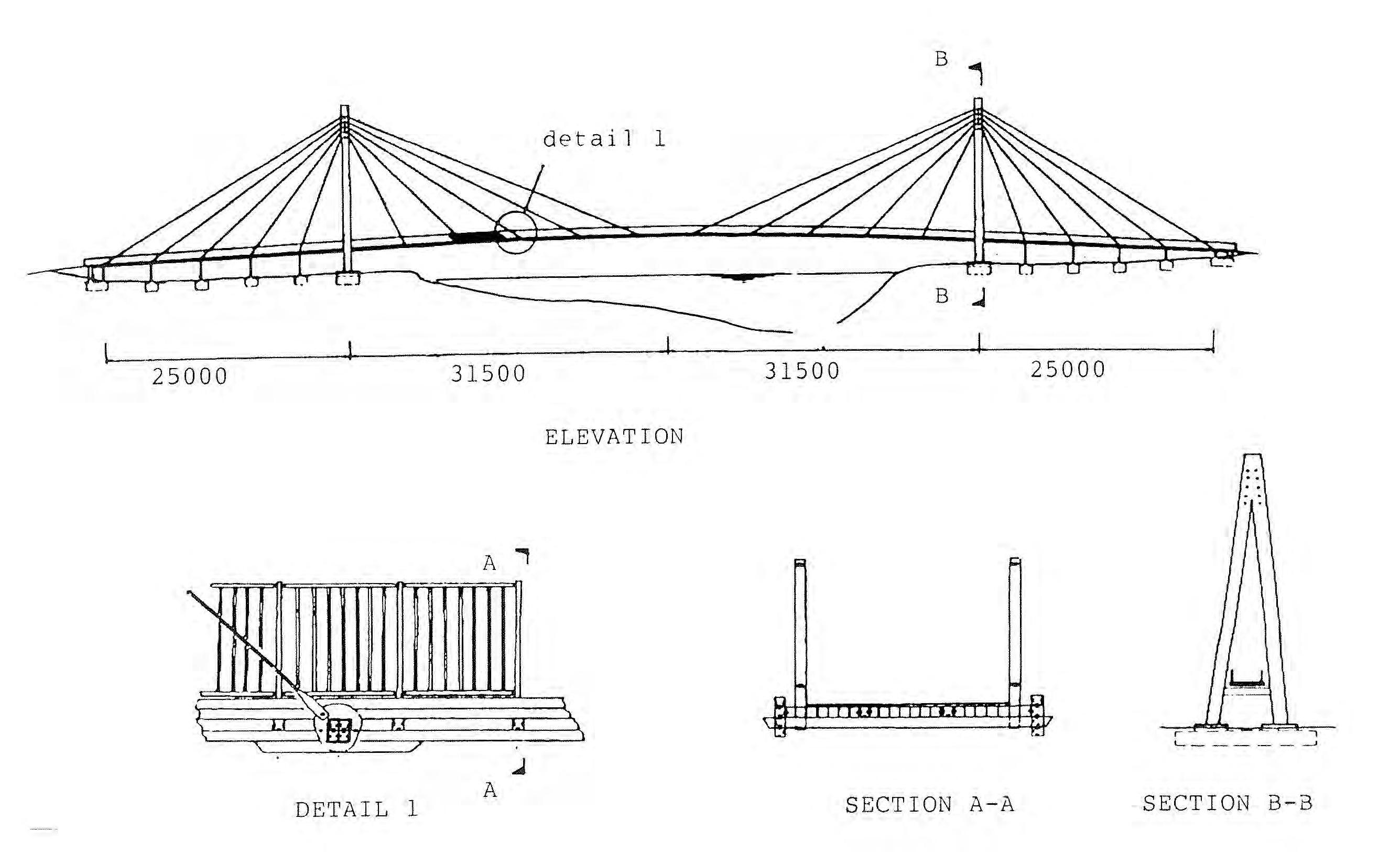

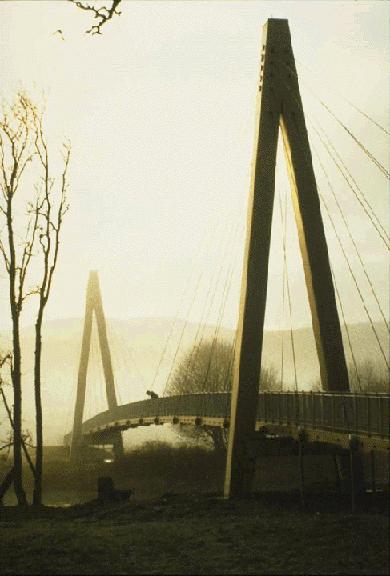

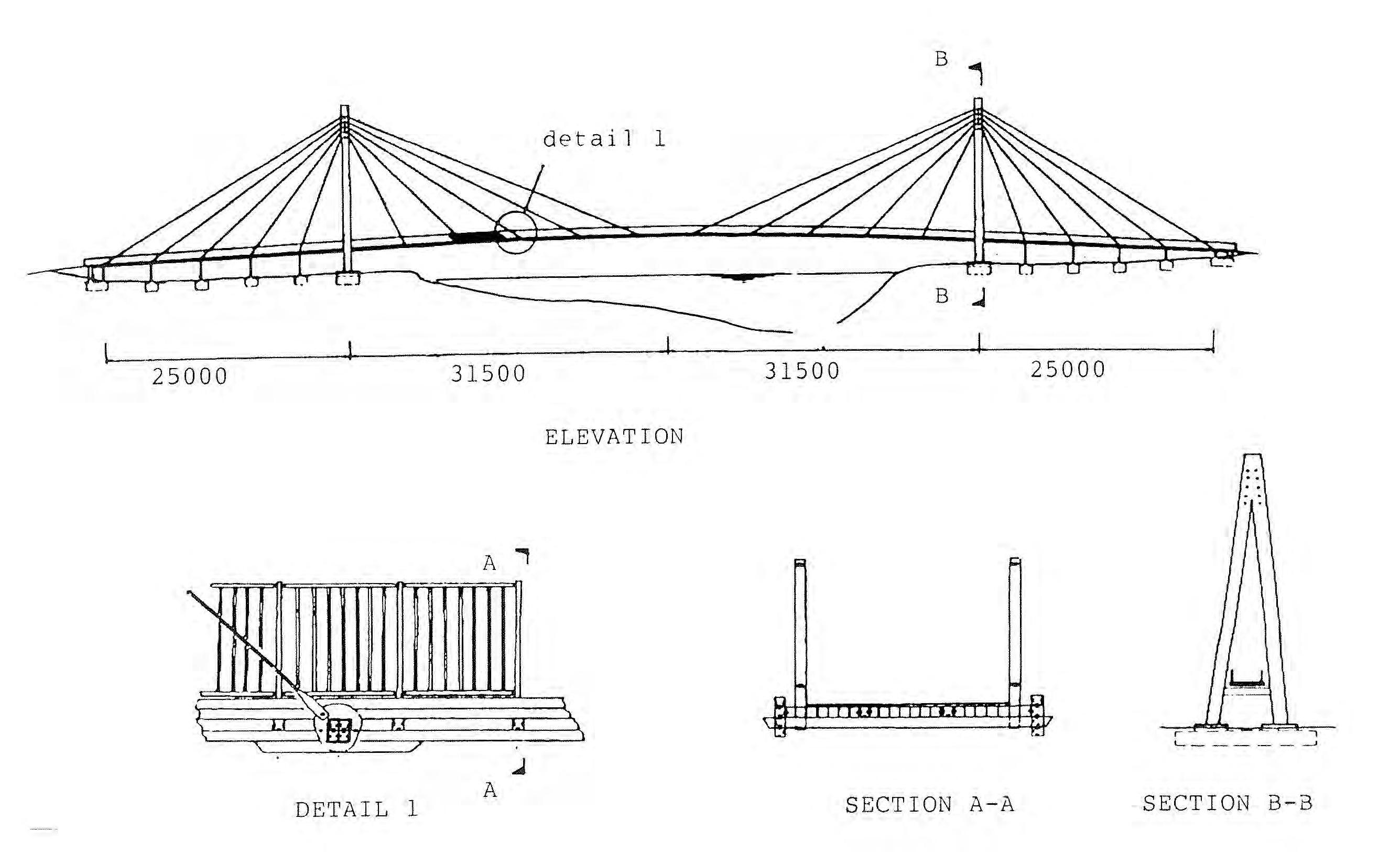

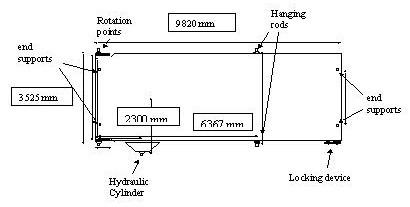

A large scale research effort is currently underway to use advanced composite materials extensively in bridges. This research is addressing issues of corrosion, rehabilitation, and monitoring and involves new concepts and designs in bridge repair and construction. One of the most significant advances is the replacement of steel pre-stressed tendons with ones made of advanced composite materials. These fiber reinforced polymers are practically immune to corrosion and also lead themselves to internal monitoring by means of embedded fiber optic sensors. A structurally integrated sensing system could monitor the state of the structure, throughout its working life. It could determine the strain, deformation, load distribution and temperature or environmental degradation experienced by the structure. The first smart bridge to be built with structurally integrated fiber optic strain and temperature sensors was opened in 1993 in Calgary.

In more advanced smart structures the information provided by the built-in sensor system could be used for controlling some aspect of the structure, such as its stiffness, shape, position or orientation. These systems could be called adaptive (or reactive) smart structures to distinguish them from the simpler passive smart structures. A more appropriate term for structures that only sense their state might be “Sensory Structures”. Smart structures might eventually be developed that will be capable of adaptive learning and these could be termed “Intelligent Structures”. Indeed, if we consider the confluence of the four fields- structures, sensor systems, actuator control systems, and neural network systems- we can appreciate that there is the potential for a broad class of structures such as, Controlled Structures, Self-learning Reactive Structures, Smart Structures and Self-learning Smart Structures. Therefore smart structures open up a new panorama for biomimetic systems.

As Eric Udd says, “This era would see the marriage of fibre optic technology and artificial intelligence with material science and

structural engineering. Major structures constructed in this period would be constructed with built-in optical neuro-systems and active actuation control that would make them more like living entities than the inanimate edifices we are familiar with today. To carry this biological paradigm one step further, it may even be possible to contemplate future structures that have the capacity for limited self-repair. Indeed, if we think of the new frontiers for engineering as being in space or underwater, self-diagnosis, self-control, and self- healing may not be so much esoteric as vital”. [1.20]

24

1.17

-Calgary bridge built with embedded fibre optic sensors.

Structures

Controlled Structures Smart Structures Smart Adaptive Structures

Actuator Systems

Intelligent Adaptive Structures Selflearning Reactive Structures Selflearning Smart Structures

Sensor Systems

Neural Network Systems

25

1.18 -Diagram showing Smart Systems possible by the confluence of four disciplines: materials and structures, sensing systems, actuator control systems, and adaptive learning neural networks.

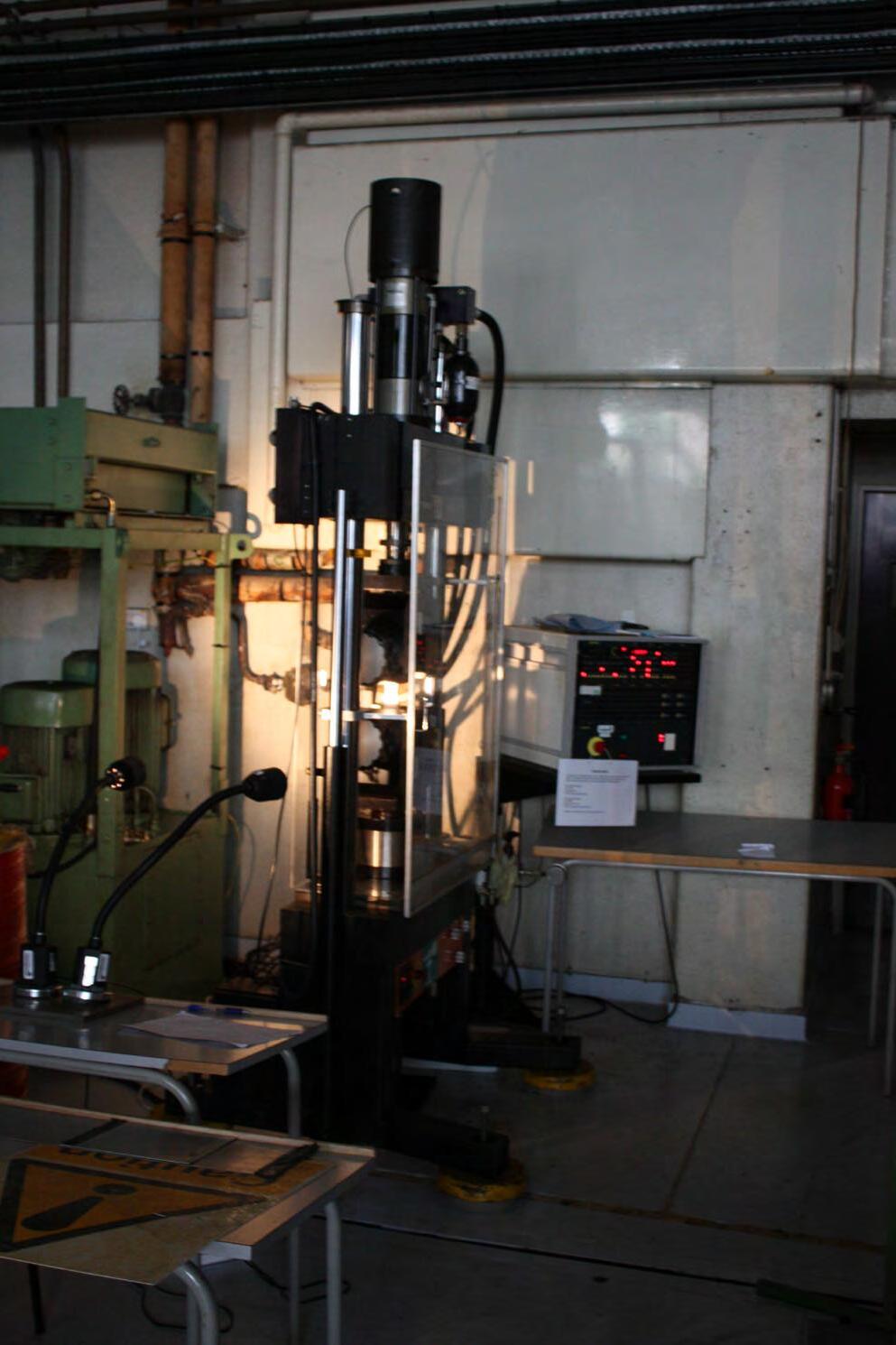

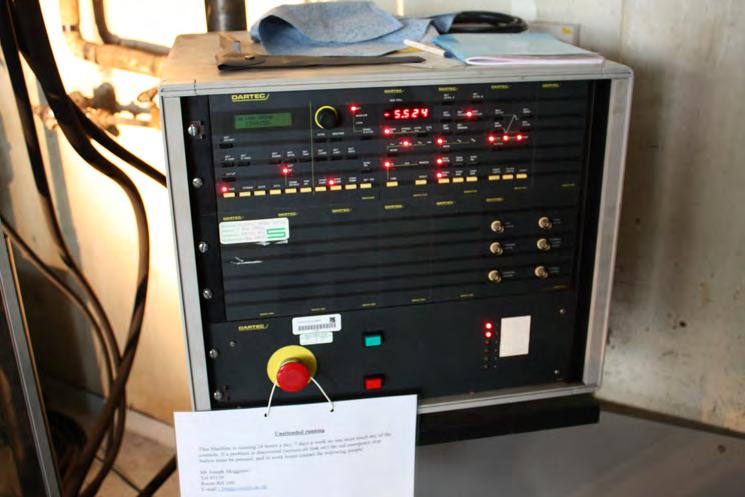

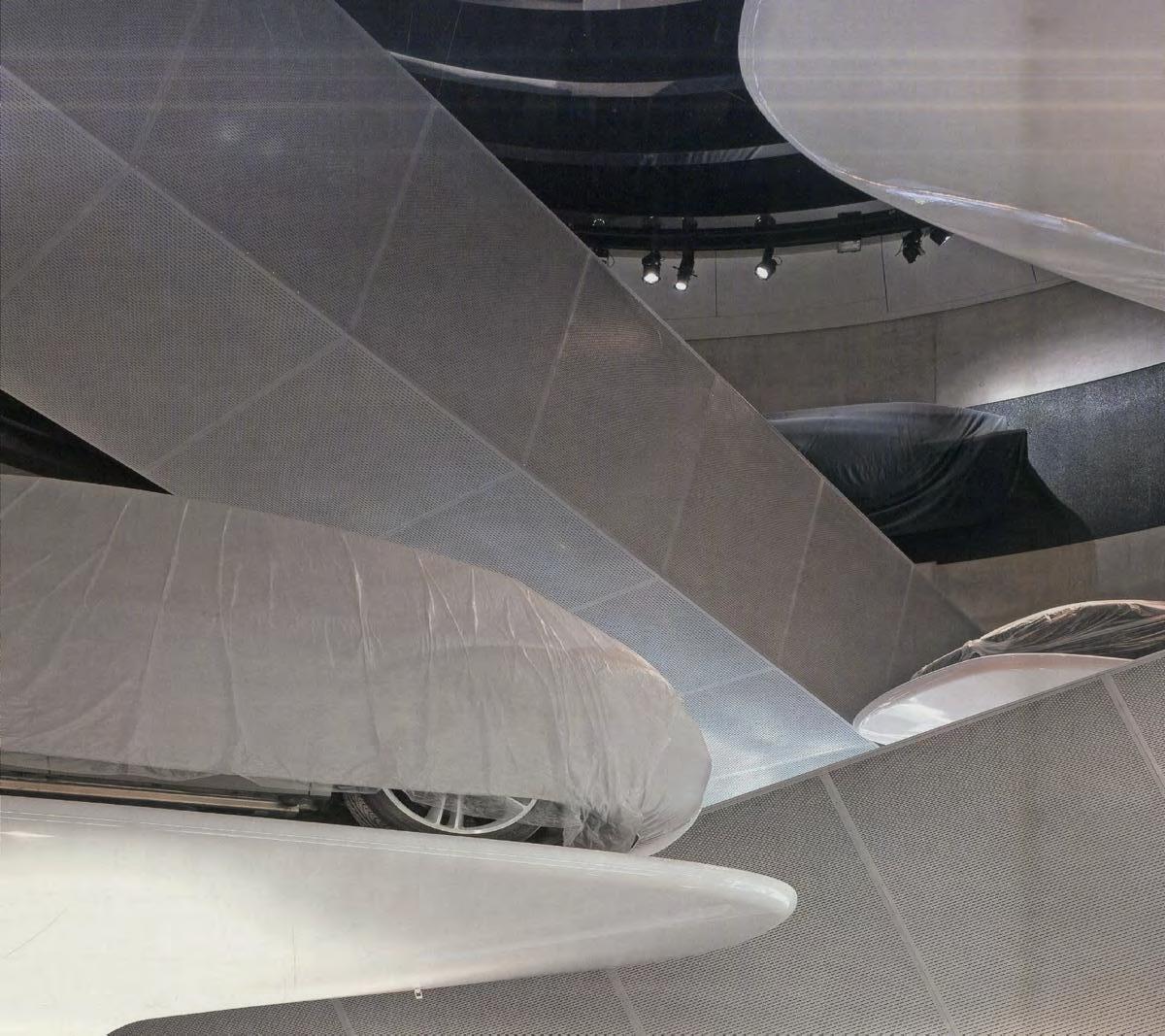

2 Technology

This chapter will explore all the different technologies used for our research and development of the project. For building our physical models and achieving the desired functionality of the system -both in theory and in practice-, many possibilities were open and specific choices had to be made. Here we explain our choices and give a thorough background of the technology behind our material system.

Sensing Actuation Energy Control Base Material

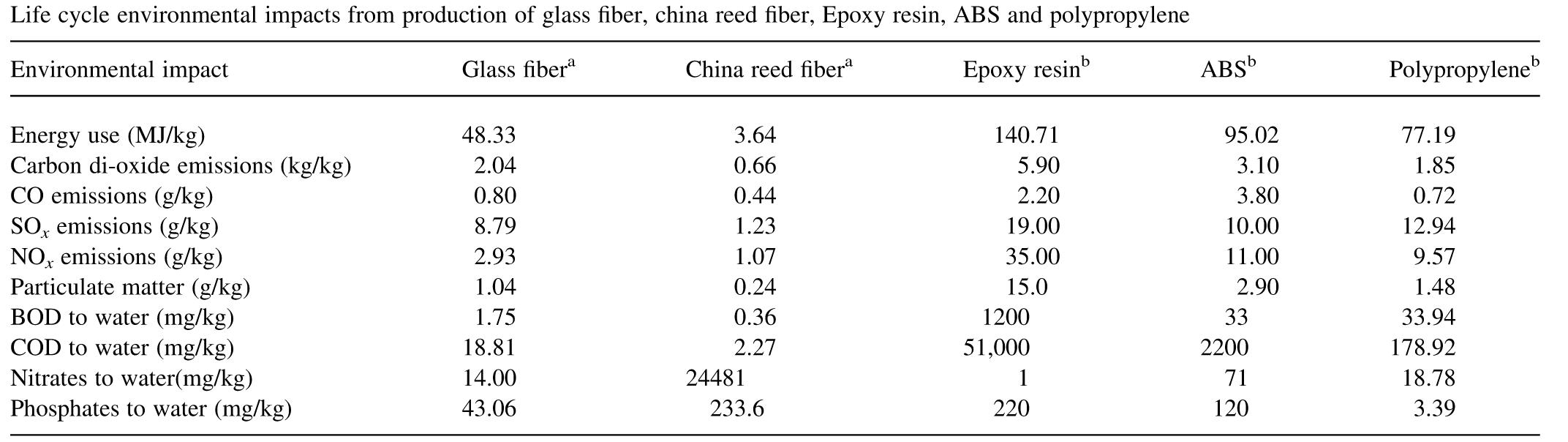

Base Material

Fibre Composites

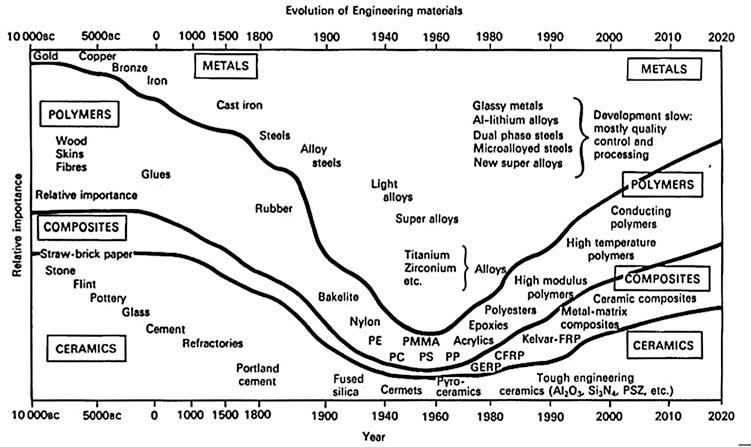

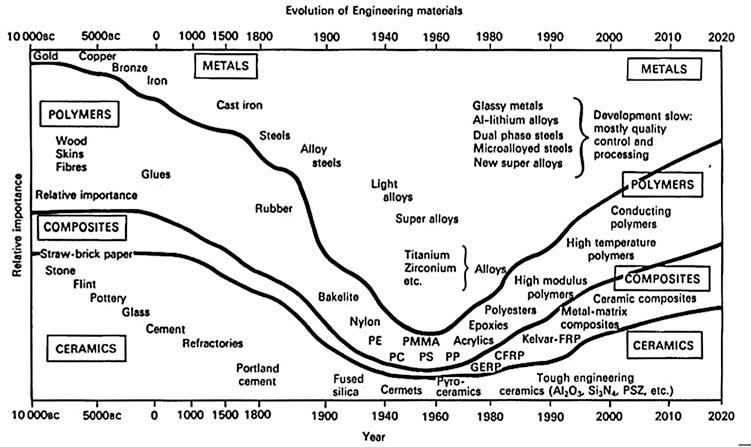

Man made composites are not new. The first composite materials were developed many years ago:

• Mud bricks reinforced with straw (antiquity)

• Glass Reinforced Plastic - GRP (1940s)

• Carbon Fibre Reinforced Plastic – CFRP (1960s)

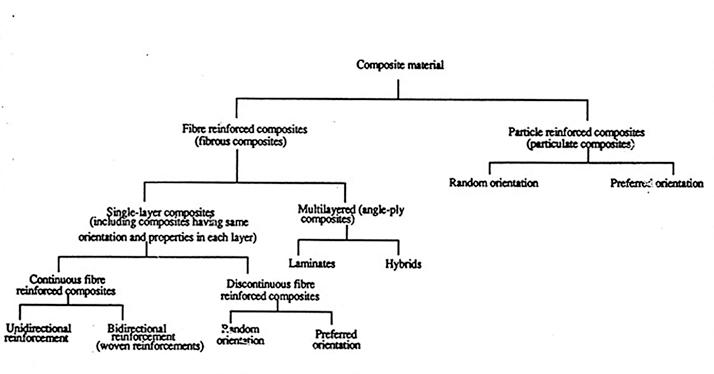

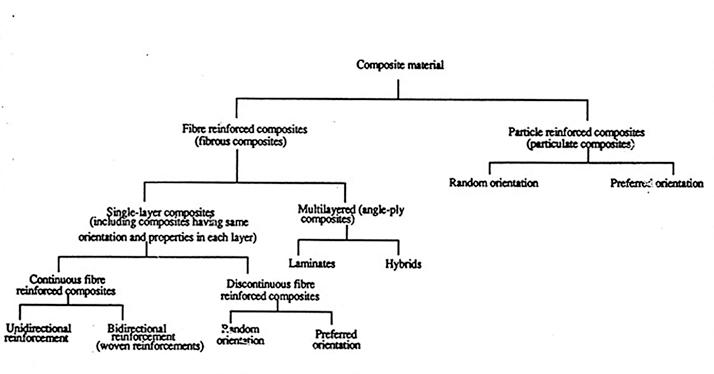

In its most basic form a composite material is one which is composed of at least two elements working together to produce material properties that are different to the properties of those elements on their own [2.1]. In practice, most composites consist of a bulk material (the ‘matrix’), and a reinforcement of some kind, added primarily to increase the strength and stiffness of the matrix [2.2,2.3,2.4]. This reinforcement is usually in fibre form.

Today, the most common man-made composites can be divided into three main groups:

Polymer Matrix Composites (PMC’s): These are the most common and have been selected for the construction of this project. Also known as FRP - Fibre Reinforced Polymers (or Plastics) - these materials use a polymer-based resin as the matrix, and a variety of fibres such as glass, carbon and aramid as the reinforcement.

Metal Matrix Composites (MMC’s) - Increasingly found in the automotive industry, these materials use a metal such as aluminium as the matrix, and reinforce it with fibres such as silicon carbide.

Ceramic Matrix Composites (CMC’s) - Used in very high temperature environments, these materials use a ceramic as the matrix and reinforce it with short fibres, or whiskers such as those made from silicon carbide and boron nitride.

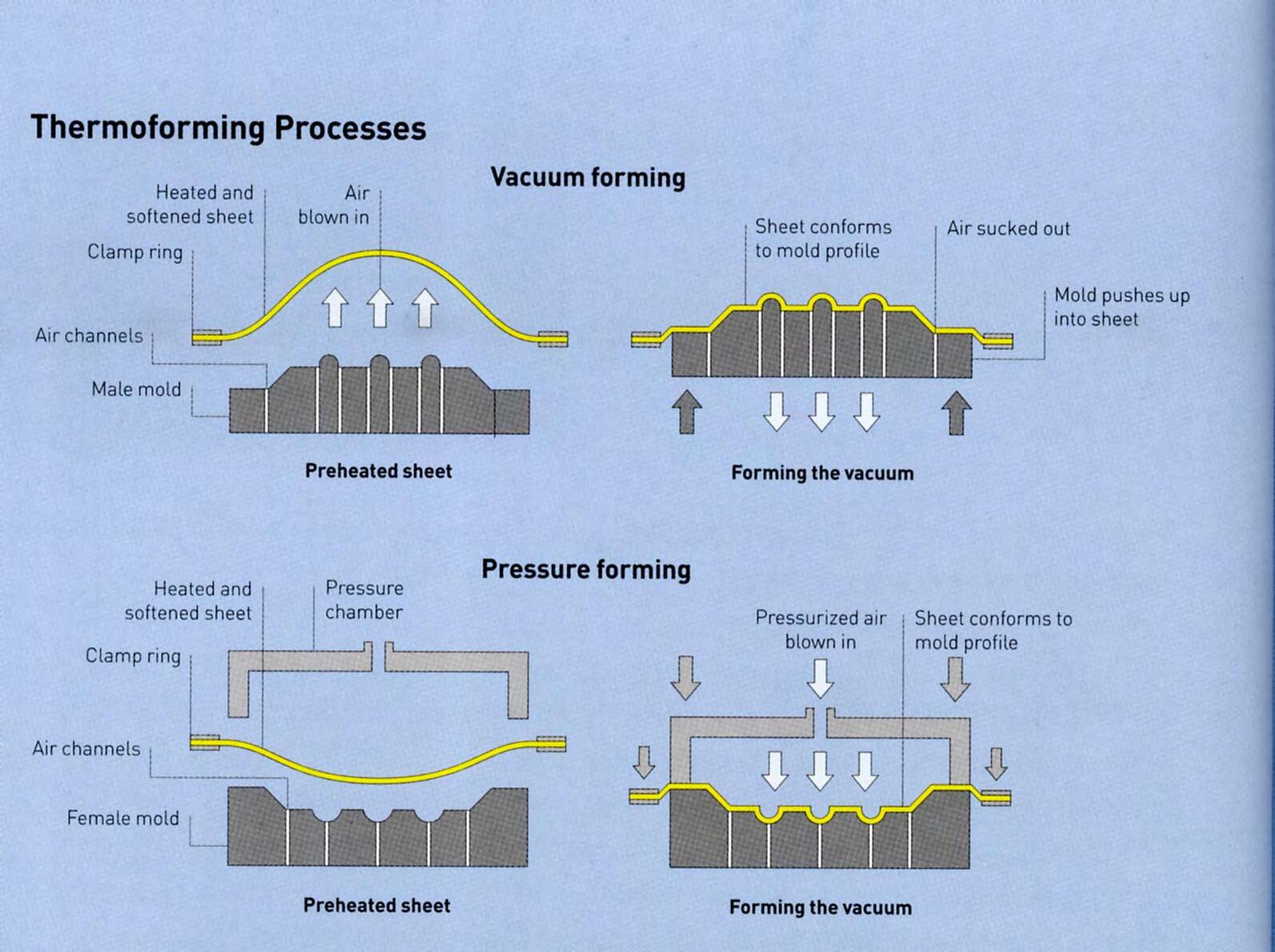

Resins are divided into two major groups known as thermoset and thermoplastic.

Thermoplastic resins become soft when heated, and may be shaped or molded while in a heated semi-fluid state and become rigid when cooled. Thermoset resins, on the other hand, are usually liquids or low melting point solids in their initial form. When used to produce finished goods, these thermosetting resins are “cured” by the use of a catalyst, heat or a combination of the two. Once cured, solid thermoset resins cannot be converted back to their original liquid form. Unlike thermoplastic resins, cured thermosets will not melt and flow but will soften when heated (and lose hardness) and once formed they cannot be reshaped. Heat Distortion Temperature (HDT) and the Glass Transition Temperature (Tg) is used to measure the softening of a cured resin. Both test methods (HDT and Tg) measure the approximate temperature where the cured resin will soften significantly to yield (bend or sag) under load.

The most common thermosetting resins used in the composites industry are unsaturated polyesters, epoxies, vinyl esters and phenolics. There are differences between these groups that must be understood to choose the proper material for a specific application.

Polyester

Unsaturated polyester resins (UPR) are the workhorse of the composites industry and represent approximately 75% of the total resins used. Thermoset polyesters are produced by the condensation polymerization of dicarboxylic acids and difunctional alcohols (glycols). In addition, unsaturated polyesters contain an unsaturated material, such as maleic anhydride or fumaric acid, as part of the dicarboxylic acid component. The finished polymer is dissolved in a reactive monomer such as styrene to give a low viscosity liquid. When this resin is cured, the monomer reacts with the unsaturated sites on the polymer converting it to a solid thermoset structure [2.5].

The primary functions of the resin are to transfer stress between the reinforcing fibers, act as a glue to hold the fibers together, and protect the fibers from mechanical and environmental damage.

A range of raw materials and processing techniques are available to achieve the desired properties in the formulated or processed polyester resin. Polyesters are versatile because of their capacity to

28

PMC | Resins

2.1 Classification of composite materials

2.2

Diagram

showing the evolution of engineering materials

2.3 Examples of composite materials uses

be modified or tailored during the building of the polymer chains. They have been found to have almost unlimited usefulness in all segments of the composites industry. The principal advantage of these resins is a balance of properties (including mechanical, chemical, electrical) dimensional stability, cost and ease of handling or processing.

Unsaturated polyesters are divided into classes depending upon the structures of their basic building blocks. Some common examples would be orthophthalic (“ortho”), isophthalic (“iso”), dicyclopentadiene (“DCPD”) and bisphenol A fumarate resins. In addition, polyester resins are classified according to end use application as either general purpose (GP) or specialty polyesters. [2.5]

Epoxy

Epoxy resins have a well-established record in a wide range of composite parts, structures and concrete repair. The structure of the resin can be engineered to yield a number of different products with varying levels of performance. A major benefit of epoxy resins over unsaturated polyester resins is their lower shrinkage. Epoxy resins can also be formulated with different materials or blended with other epoxy resins to achieve specific performance features. Cure rates can be controlled to match process requirements through the proper selection of hardeners and/or catalyst systems. Generally, epoxies are cured by addition of an anhydride or an amine hardener as a 2-part system. Different hardeners, as well as quantity of a hardener produce a different cure profile and give different properties to the finished composite.

Epoxies are used primarily for fabricating high performance composites with superior mechanical properties, resistance to corrosive liquids and environments, superior electrical properties, good performance at elevated temperatures, good adhesion to a substrate, or a combination of these benefits. Epoxy resins do not however, have particularly good UV resistance. Since the viscosity of epoxy is much higher than most polyester resin, requires a post-cure (elevated heat) to obtain ultimate mechanical properties making epoxies more difficult to use. However, epoxies emit little odor as compared to polyesters.

Epoxy resins are used with a number of fibrous reinforcing materials, including glass, carbon and aramid. This latter group is of small in volume, comparatively high cost and is usually used to meet high strength and/or high stiffness requirements. Epoxies are compatible with most composite manufacturing processes, particularly vacuumbag molding, autoclave molding, pressure-bag molding, compression molding, filament winding and hand lay-up.

Vinyl Ester

Vinyl esters were developed to combine the advantages of epoxy resins with the better handling/faster cure, which are typical for unsaturated polyester resins. These resins are produced by reacting epoxy resin with acrylic or methacrylic acid. This provides an unsaturated site, much like that produced in polyester resins when maleic anhydride is used. The resulting material is dissolved in styrene to yield a liquid that is similar to polyester resin. Vinyl esters are also cured with the conventional organic peroxides used with polyester resins. Vinyl esters offer mechanical toughness and excellent corrosion resistance. These enhanced properties are obtained without complex processing, handling or special shop fabricating practices that are typical with epoxy resins.

Phenolics are a class of resins commonly based on phenol (carbolic acid) and formaldehyde. Phenolics are a thermosetting resin that cure through a condensation reaction producing water that should be removed during processing. Pigmented applications are limited to red, brown or black. Phenolic composites have many desirable performance qualities including high temperature resistance, creep resistance, excellent thermal insulation and sound damping properties, corrosion resistance and excellent fire/smoke/smoke toxicity properties. Phenolics are applied as adhesives or matrix binders in engineered woods (plywood), brake linings, clutch plates, circuit boards and more.

Benefits of using composites

superior mechanical properties compared to the matrix

low density – weight saving

corrosion resistance

fatigue expansion coefficient

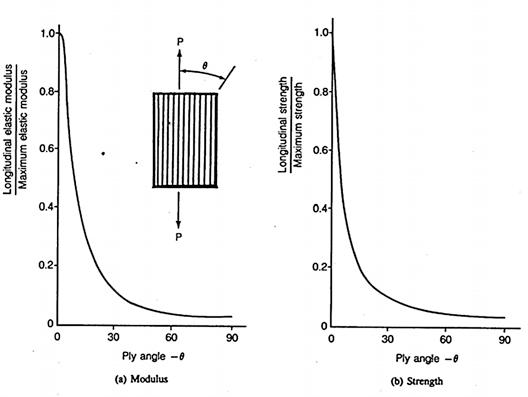

Composite’s properties depend on:

• fibre content (volume fraction)

• fibre alignment (unidirectional gives highest value)

• fibre length (discontinuous OK if l/d > 30)

• fibre distribution

• fibre orientation; multi-axial loads (lay-up, stacking sequence)

29

Phenolic

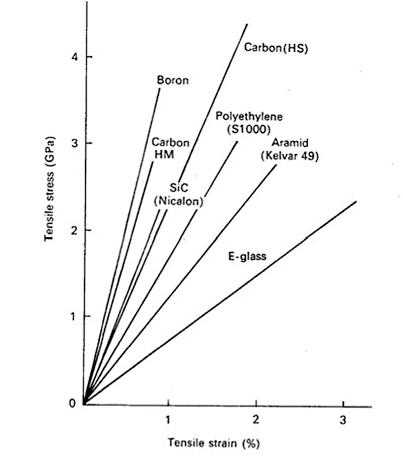

2.5 Stress-strain curves for a selection of fibres 2.6 Directionality of fibres 2.4 Young’s Modulus-Density graph

Polyurethane

Polyurethane is a family of polymers with widely ranging properties and uses, all based on the exothermic reaction of an organic polyisocyanates with a polyols (an alcohol containing more than one hydroxl group). A few basic constituents of different molecular weights and functionalities are used to produce the whole spectrum of polyurethane materials. The versatility of polyurethane chemistry enables the polyurethane chemist to engineer polyurethane resin to achieve the desired properties.

Polyurethanes appear in an amazing variety of forms. These materials are all around us, playing important roles in more facets of our daily life than perhaps any other single polymer. They are used as a coating, elastomer, foam, or adhesive. When used as a coating in exterior or interior finishes, polyurethane’s are tough, flexible, chemical resistant, and fast curing. Polyurethanes as an elastomer have superior toughness and abrasion is such applications as solid tires, wheels, bumper components or insulation. There are many formulations of polyurethane foam to optimize the density for insulation, structural sandwich panels, and architectural components. Polyurethanes are often used to bond composite structures together. Benefits of polyurethane adhesive bonds are that they have good impact resistance, the resin cures rapidly and the resin bonds well to a variety of different surfaces such as concrete.

Thermoplastics

A thermoplastic is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently. Most thermoplastics are highmolecular-weight polymers whose chains associate through weak Van der Waals forces (polyethylene); stronger dipole-dipole interactions and hydrogen bonding (nylon); or even stacking of aromatic rings (polystyrene). Thermoplastic polymers differ from thermosetting polymers (Bakelite; vulcanized rubber) as they can, unlike thermosetting polymers, be remelted and re-moulded.

Thermoplastics are elastic and flexible above a glass transition temperature Tg, specific for each one—

the midpoint of a temperature range in contrast to the sharp melting point and melting point of a pure crystalline substance like water. Below a second, higher melting temperature, Tm, also the midpoint of a range, most thermoplastics have crystalline regions alternating with amorphous regions in which the chains approximate random coils. The amorphous regions contribute elasticity and the crystalline regions contribute strength and rigidity, as is also the case for non-thermoplastic fibrous proteins such as silk.

Thermoplastics can go through melting/freezing cycles repeatedly and the fact that they can be reshaped upon reheating gives them their name. This quality makes thermoplastics recyclable. [2.7]

30

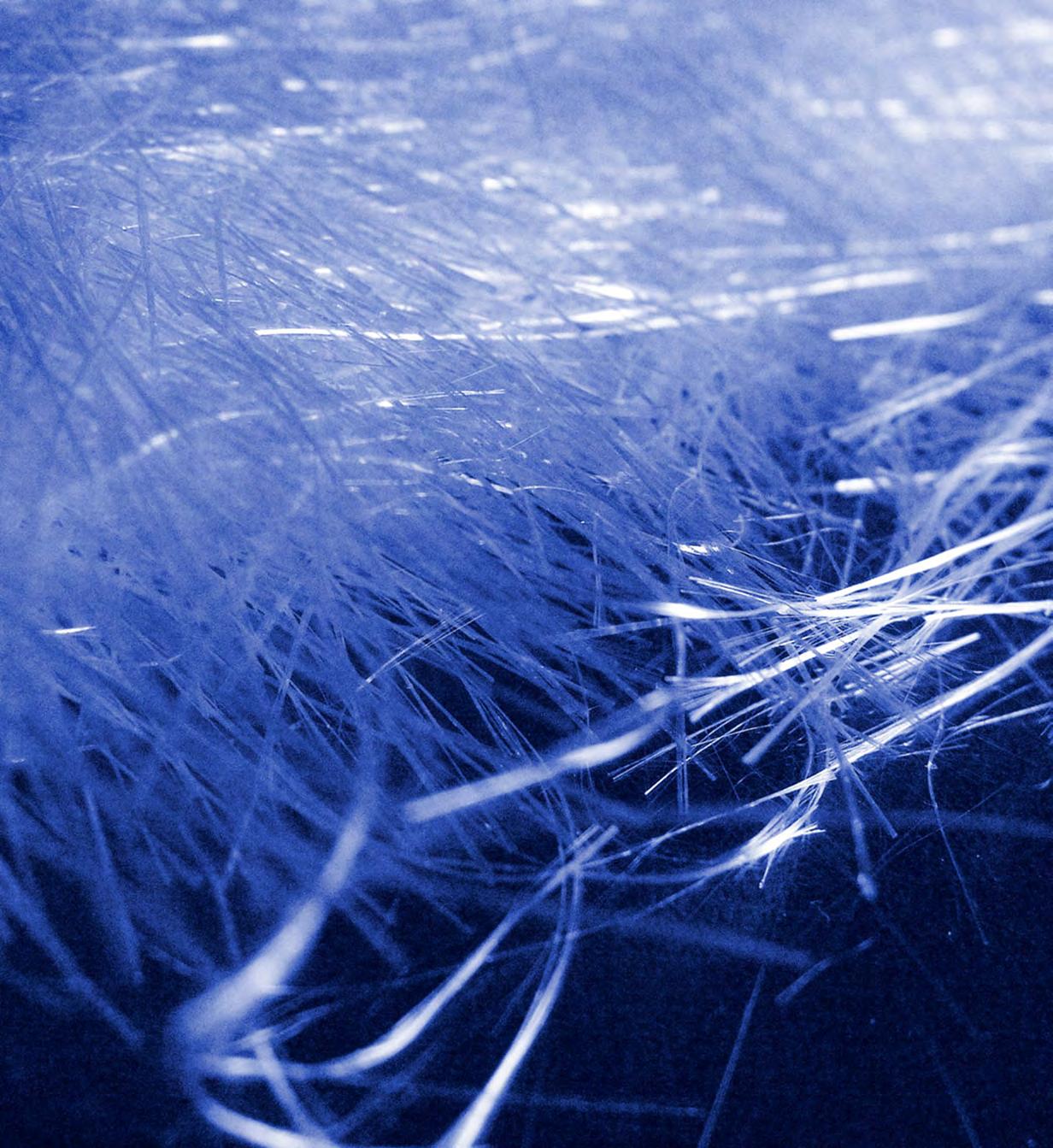

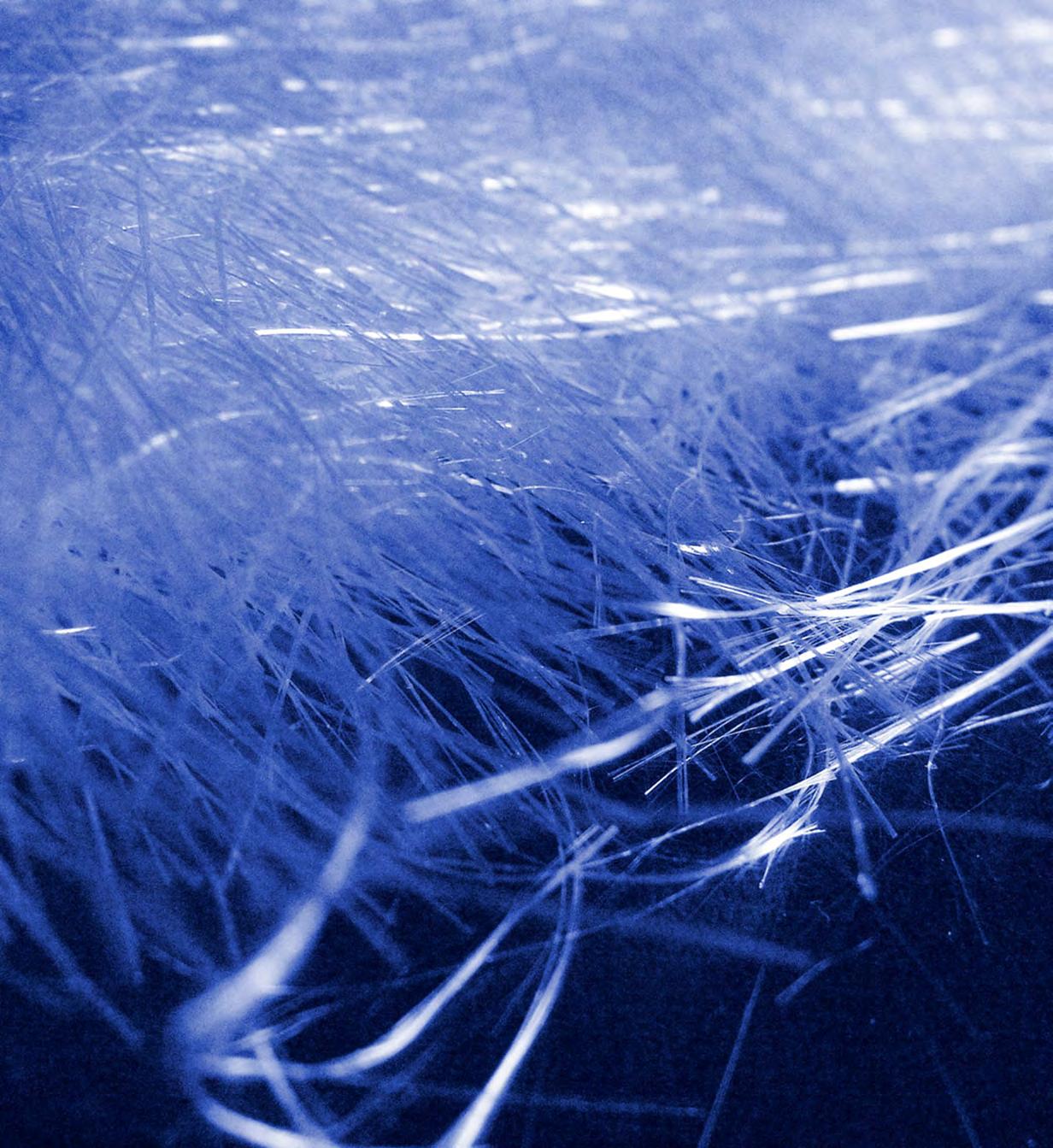

2.7 Close-up of a glass fibre mat

Reinforcements

The primary function of fibers or reinforcements is to carry load along the length of the fiber to provide strength and stiffness in one direction. Reinforcements can be oriented to provide tailored properties in the direction of the loads imparted on the end product. Reinforcements can be both natural (Appendix) and manmade. Many materials are capable of reinforcing polymers. Some materials, such as the cellulose in wood, are naturally occurring products. Most commercial reinforcements, however, are man-made. Of these, by far the largest volume reinforcement measured either in quantity consumed or in product sales, is glass fiber. Other composite reinforcing materials include carbon, aramid, UHMW (ultra high molecular weight) polyethylene, polypropylene, polyester and nylon. Carbon fiber is sometimes referred to as graphite fiber. The distinction is not important in an introductory text, but the difference has to do with the raw material and temperature at which the fiber is formed. More specialized reinforcements for high strength and high temperature use include metals and metal oxides such as those used in aircraft or aerospace applications.

Development of Reinforcements - Fibers

Early in the development of composites, the only reinforcements available were derived from traditional textiles and fabrics. Particularly in the case of glass fibers, experience showed that the chemical surface treatments or “sizings” required to process these materials into fabrics and other sheet goods were detrimental to the adhesion of composite polymers to the fiber surface. Techniques to remove these materials were developed, primarily by continuous or batch heat cleaning. It was then necessary to apply new “coupling agents” (also known as finishes or surface treatments), an important ingredient in sizing systems, to facilitate adhesion of polymers to fibers, particularly under wet conditions and fiber processing.

Most reinforcements for either thermosetting or thermoplastic resins receive some form of surface treatments, either during fiber manufacture or as a subsequent treatment. Other materials applied to fibers as they are produced include resinous binders to hold fibers together in bundles and lubricants to protect fibers from degradation caused by process abrasion. [2.8]

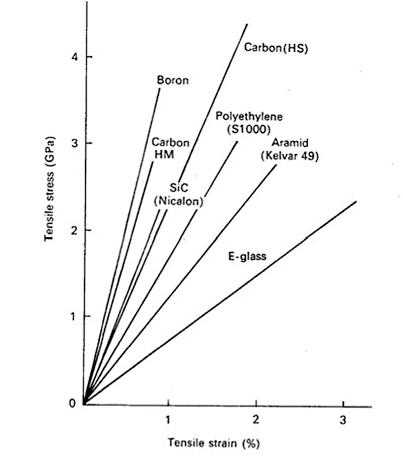

Glass Fibers

Based on an alumina-lime-borosilicate composition, “E” glass produced fibers are considered the predominant reinforcement for polymer matrix composites due to their high electrical insulating properties, low susceptibility to moisture and high mechanical properties. Other commercial compositions include “S” glass, with higher strength, heat resistance and modulus, as well as some specialized glass reinforcements with improved chemical resistance, such as AR glass (alkali resistant).

Glass fibers used for reinforcing composites generally range in diameter from 9 to 23 microns. Fibers are drawn at high speeds, approaching 200 miles per hour, through small holes in electrically heated bushings. These bushings form the individual filaments. The filaments are gathered into groups or bundles called “strands.” The filaments are attenuated from the bushing, water and air cooled, and then coated with a proprietary chemical binder or sizing to protect the filaments and enhance

the composite laminate properties. The sizing also determines the processing characteristics of the glass fiber and the conditions at the fiber-matrix interface in the composite.

Glass is generally a good impact resistant fiber but weighs more than carbon or aramid. Glass fibers have excellent characteristics, equal to or better than steel in certain forms. The lower modulus requires special design treatment where stiffness is critical. Composites made from this material exhibit very good electrical and thermal insulation properties. Glass fibers are also transparent to radio frequency radiation and are used in radar antenna applications.

Carbon Fibers

Carbon fiber is created using polyacrylonitrile (PAN), pitch or rayon fiber precursors. PAN based fibers offer good strength and modulus values up to 85-90 Msi. They also offer excellent compression strength for structural applications up to 1000 ksi. Pitch fibers are made from petroleum or coal tar pitch. Pitch fibers extremely high modulus values (up to 140 Msi) and favorable coefficient of thermal expansion make them the material used in space/satellite applications. Carbon fibers are more expensive than glass fibers, however carbon fibers offer an excellent combination of strength, low weight and high modulus. The tensile strength of carbon fiber is equal to glass while its modulus is about three to four times higher than glass.

Carbon fibers are supplied in a number of different forms, from continuous filament tows to chopped fibers and mats. The highest strength and modulus are obtained by using unidirectional continuous reinforcement. Twist-free tows of continuous filament carbon contain 1,000 to 75,000 individual filaments, which can be woven or knitted into woven roving and hybrid fabrics with glass fibers and aramid fibers.

Carbon fiber composites are more brittle (less strain at break) than glass or aramid. Carbon fibers can cause galvanic corrosion when used next to metals. A barrier material such as glass and resin is used to prevent this occurrence. [2.9]

Aramid Fibers (Polyaramids)

Aramid fiber is an aromatic polyimid that is a man-made organic fiber for composite reinforcement. Aramid fibers offer good mechanical properties at a low density with the added advantage of toughness or damage/impact resistance. They are characterized as having reasonably high tensile strength, a medium modulus, and a very low density as compared to glass and carbon. The tensile strength of aramid fibers are higher than glass fibers and the modulus is about fifty percent higher than glass. These fibers increase the impact resistance of composites and provide products with higher tensile strengths. Aramid fibers are insulators of both electricity and heat. They are resistant to organic solvents, fuels and lubricants. Aramid composites are not as good in compressive strength as glass or carbon composites. Dry aramid fibers are tough and have been used as cables or ropes, and frequently used in ballistic applications.

31

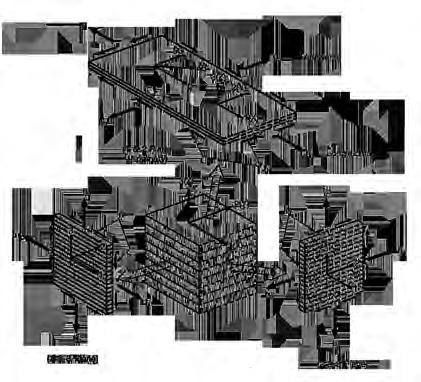

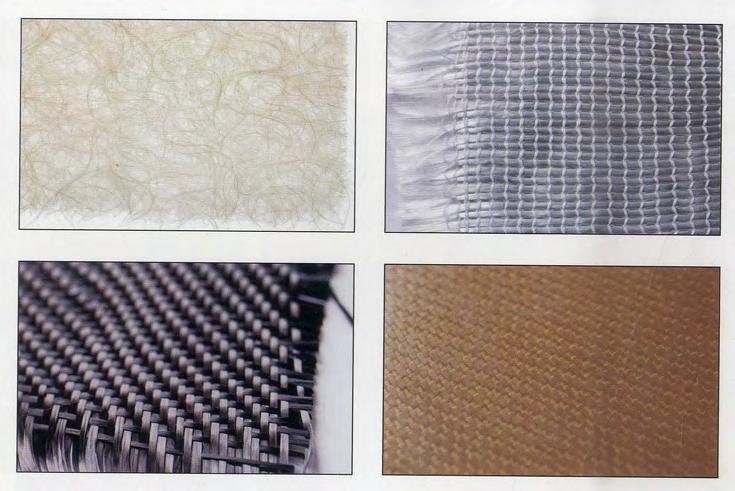

Reinforcement Forms

Regardless of the material, reinforcements are available in forms to serve a wide range of processes and end-product requirements. Materials supplied as reinforcement include roving, milled fiber, chopped strands, continuous, chopped or thermoformable mat. Reinforcement materials can be designed with unique fiber architectures and be preformed (shaped) depending on the product requirements and manufacturing process.

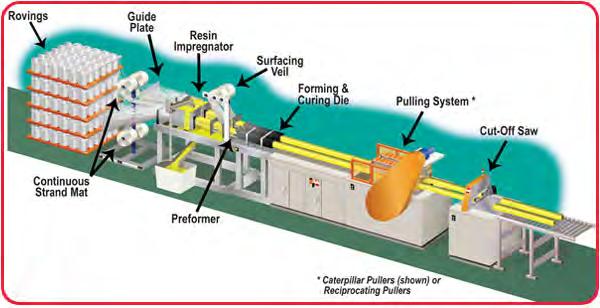

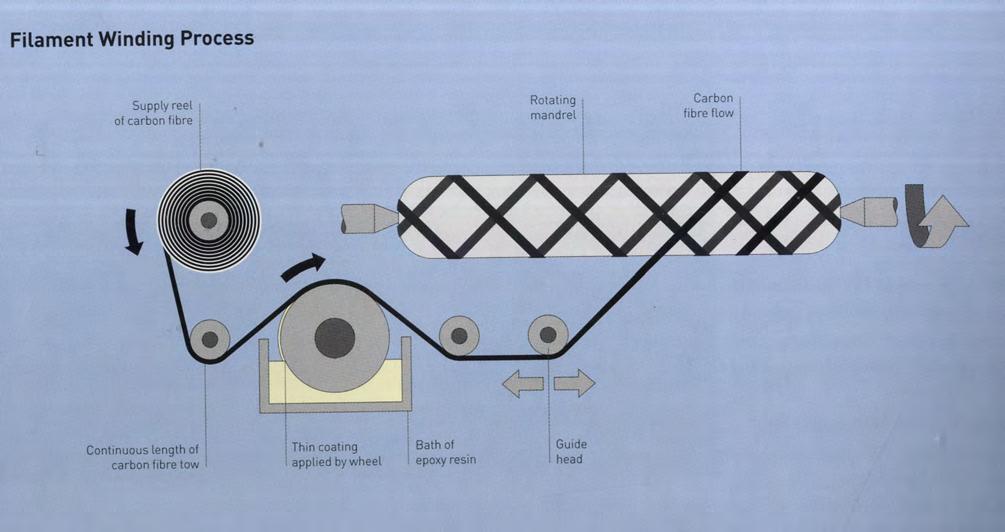

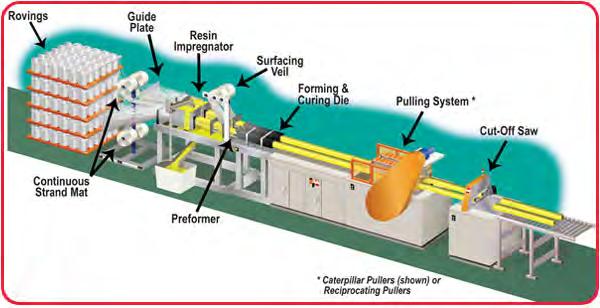

Multi-End and Single-End Rovings

Rovings are utilized primarily in thermoset compounds, but can be utilized in thermoplastics. Multi-end rovings consist of many individual strands or bundles of filaments, which are then chopped and randomly deposited into the resin matrix. Processes such as sheet molding compound (SMC), preform and spray-up use the multi-end roving. Multi-end rovings can also be used in some filament winding and pultrusion applications. The single-end roving consists of many individual filaments wound into a single strand. The product is generally used in processes that utilize a unidirectional reinforcement such as filament winding or pultrusion.

Mats

Reinforcing mats are usually described by weight-per-unit-of-area. The type and amount of binder that is used to hold the mat together dictate differences between mat products. In some processes such as hand lay-up, it is necessary for the binder to dissolve. In other processes, particularly in compression molding, the binder must withstand the hydraulic forces and the dissolving action of the matrix resin during molding. Therefore, two general categories of mats are produced and are known as soluble and insoluble.

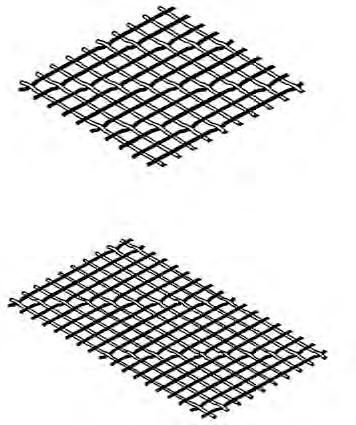

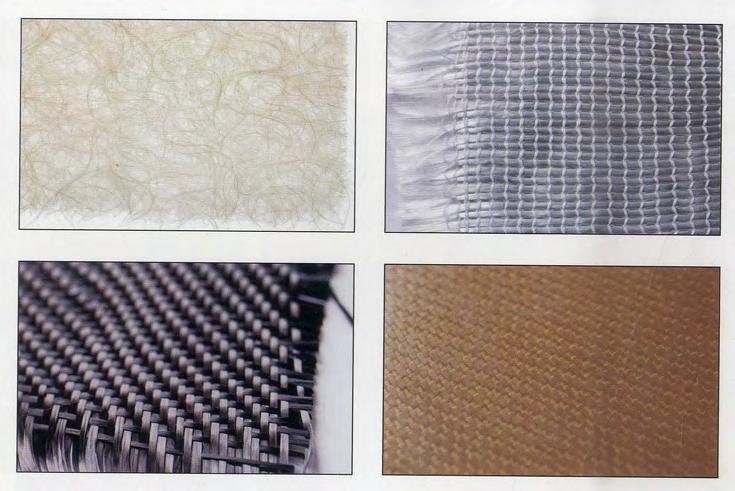

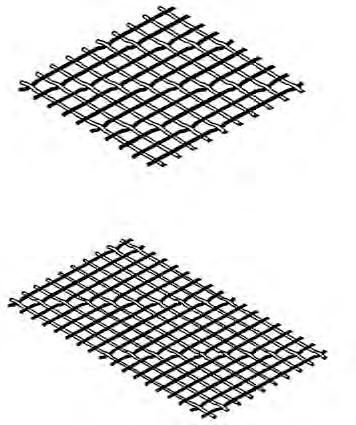

Woven, Stitched, Braided Fabrics

There are many types of fabrics that can be used to reinforce resins in a composite. Multidirectional reinforcements are produced by weaving, knitting, stitched or braiding continuous fibers into a fabric from twisted and plied yarn. Fabrics refer to all flat-sheet, roll goods, whether or not they are strictly fabrics. Fabrics can be manufactured utilizing almost any

reinforcing fiber. The most common fabrics are constructed with fiberglass, carbon or aramid. Fabrics are available in several weave constructions and thickness (from 0.0010 to 0.40 inches). Fabrics offer oriented strengths and high reinforcement loadings often found in high performance applications.

Fabrics are typically supplied on rolls of 25 to 300 yards in length and 1 to 120 inches in width. The fabric must be inherently stable enough to be handled, cut and transported to the mold, but pliable enough to conform to the mold shape and contours. Properly designed, the fabric will allow for quick wet out and wet through of the resin and will stay in place once the resin is applied. Fabrics, like rovings and chopped strands, come with specific sizings or binder systems that promote adhesion to the resin system. [2.10]

Fabrics allow for the precise placement of the reinforcement. This cannot be done with milled fibers or chopped strands and is only possible with continuous strands using relatively expensive fiber placement equipment. Due to the continuous nature of the fibers in most fabrics, the strength to weight ratio is much higher than that for the cut or chopped fiber versions. Stitched fabrics allow for customized fiber orientations within the fabric structure. This can be of great advantage when designing for shear or torsional stability.

Woven fabrics are fabricated on looms in a variety of weights, weaves, and widths. In a plain weave, each fill yarn or roving is alternately crosses over and under each warp fiber allowing the fabric to be more drapable and conform to curved surfaces. Woven fabrics are manufactured where half of the strands of fiber are laid at right angles to the other half (0o to 90o). Woven fabrics are commonly used in boat manufacturing. [2.11]

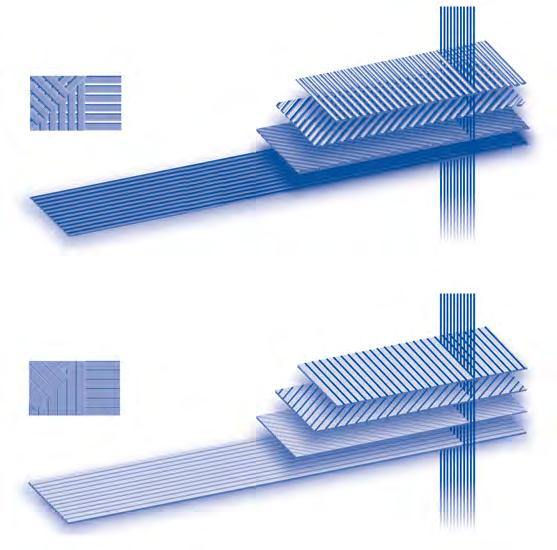

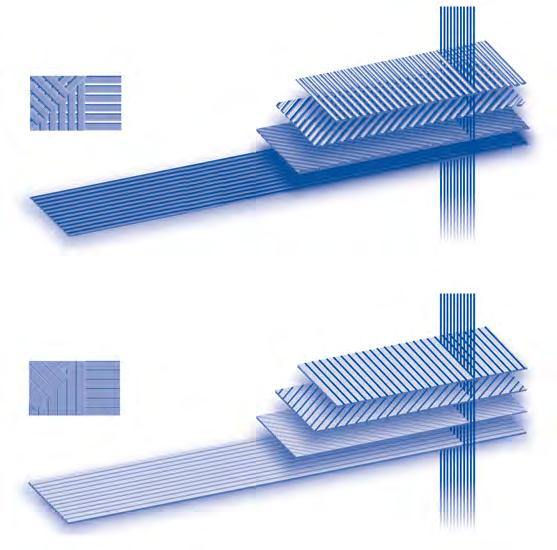

Stitched fabrics, also known as non-woven, non-crimped, stitched, or knitted fabrics have optimized strength properties because of the fiber architecture. Woven fabric is where two sets of interlaced continuous fibers are oriented in a 0o and 90o pattern where the fibers are crimped and not straight. Stitched fabrics are produced by assembling successive layers of aligned fibers. Typically, the available fiber orientations include the 0o direction (warp), 90o direction (weft or fill), and +45o direction (bias).

Economic aspects

Composite materials are expensive:

design costs are higher higher cost of analysis

higher cost of component testing certification and documentation testing but

costs may be lowered by innovative design concepts which consider manufacturing lower part count

reduction in number of fasteners used use of automation

Woven Fabrics (2-D weaving)

Genrally more expensive than UD tapes but significant cost savings during manufacturing fabrics are generally described according to the types of weave and the number of yarns per inch – first in the warp direction (parallel to length of fabric) and then in the fill (or weft) direction (perpendicular to the warp)

Unidirectional Fabric

warp strands are as straight as tape improved drapability over tape minimal reduction of fibre strength improved fibre alignment

Plain Weave Fabric

some loss of properties due to fibre crimping provides reproducible laminate thickness good drapability

speedier lay-up easier to handle

wet-out difficulties with tightly woven fabrics

width limitations thicker than tape

good damage tolerance

Advantages:

enhanced toughness (fewer layers, kinked fibres deflect interlaminar cracking)

damage tolerant due to fibre-interlocking

convenience of handling no weak transverse direction

superior drapability of some weaves

Disadvantages:

more expensive (based on 3K tow to ensure a thin uniform sheet – 6K and 12K tows typical in UD tape)

involve additional manufacturingweaving kinked fibres limit full strength potential

lower fibre volume fraction than ud tape

fabric distortion (bowing and skewing) causes part warpage

32

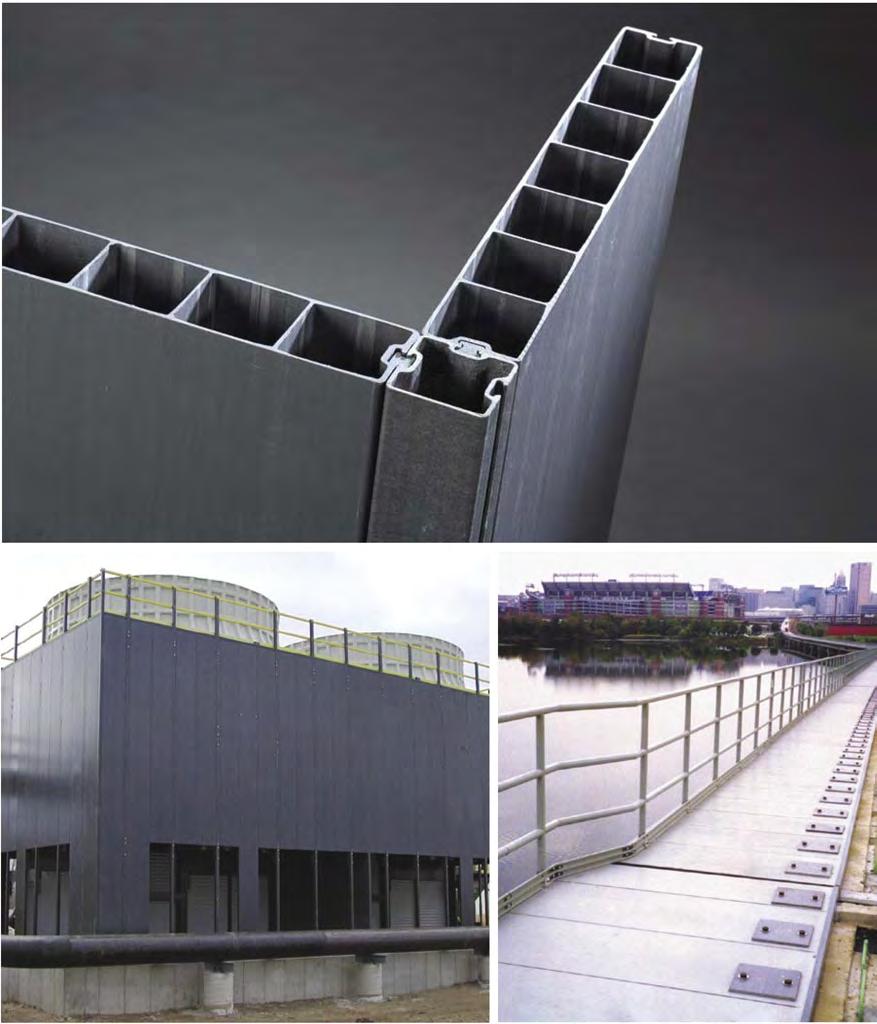

The assembly of each layer is then sewn together. This type of construction allows for load sharing between fibers so that a higher modulus, both tensile and flexural, is typically observed. The fiber architecture construction allows for optimum resin flow when composites are manufactured. These fabrics have been traditionally used in boat hulls for 50 years. Other applications include light poles, wind turbine blades, trucks, busses and underground tanks. These fabrics are currently used in bridge decks and column repair systems. Multiple orientations provide a quasi-isotropic reinforcement.

Braided fabrics are engineered with a system of two or more yarns intertwined in such a way that all of the yarns are interlocked for optimum load distribution. Biaxial braids provide reinforcement in the bias direction only with fiber angles ranging from ± 15o to ± 95o. Triaxial braids provide reinforcement in the bias direction with fiber angles ranging from ± 10o to ± 80o and axial (0o) direction.

Unidirectional

Unidirectional reinforcements include tapes, tows, unidirectional tow sheets and rovings (which are collections of fibers or strands). Fibers in this form are all aligned parallel in one direction and uncrimped providing the highest mechanical properties. Composites using unidirectional tapes or sheets have high strength in the direction of the fiber. Unidirectional sheets are thin and multiple layers are required for most structural applications.

In some composite designs, it may be necessary to provide a corrosion or weather barrier to the surface of a product. A surface veil is a fabric made from nylon or polyester that acts as a very thin sponge that can absorb resin to 90% of its volume. This helps to provide an extra layer of protective resin on the surface of the product. Surface veils are used to improve the surface appearance and insure the presence of a corrosion resistance barrier for typical composites products such as pipes, tanks and other chemical process equipment. Other benefits include increased resistance

to abrasion, UV and other weathering forces. Veils may be used in conjunction with gel coats to provide reinforcement to the resin.

Prepreg

Prepregs are a ready-made material made of a reinforcement form and polymer matrix. Passing reinforcing fibers or forms such as fabrics through a resin bath is used to make a prepreg. The resin is saturated (impregnated) into the fiber and then heated to advance the curing reaction to different curing stages. Thermoset or thermoplastic prepregs are available and can be either stored in a refrigerator or at room temperature depending on the constituent materials. Prepregs can be manually or mechanically applied at various directions based on the design requirements. [2.11]

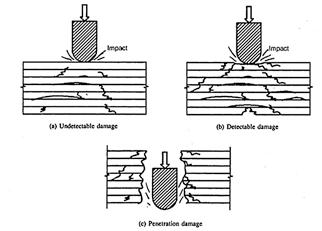

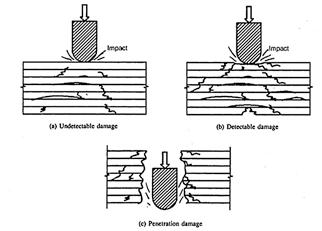

Impact – composites are very susceptible to impact damage.

Impact damage :

caused by dropped tools, runway debris, hail or bird impact damage, ballistics.

more critical in compressively loaded structures

BVID and CAI

damage tolerance may be improved by:

minimising grouping of plies of same orientation using more ±45° plies (soft skin design) using ±45° plies on the outer surfaces thermoplastics

33

2.9 Woven fabrics

2.8 Impact Damage

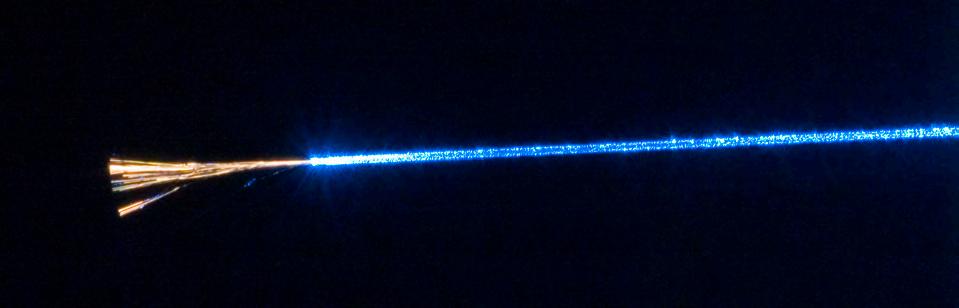

Sensing

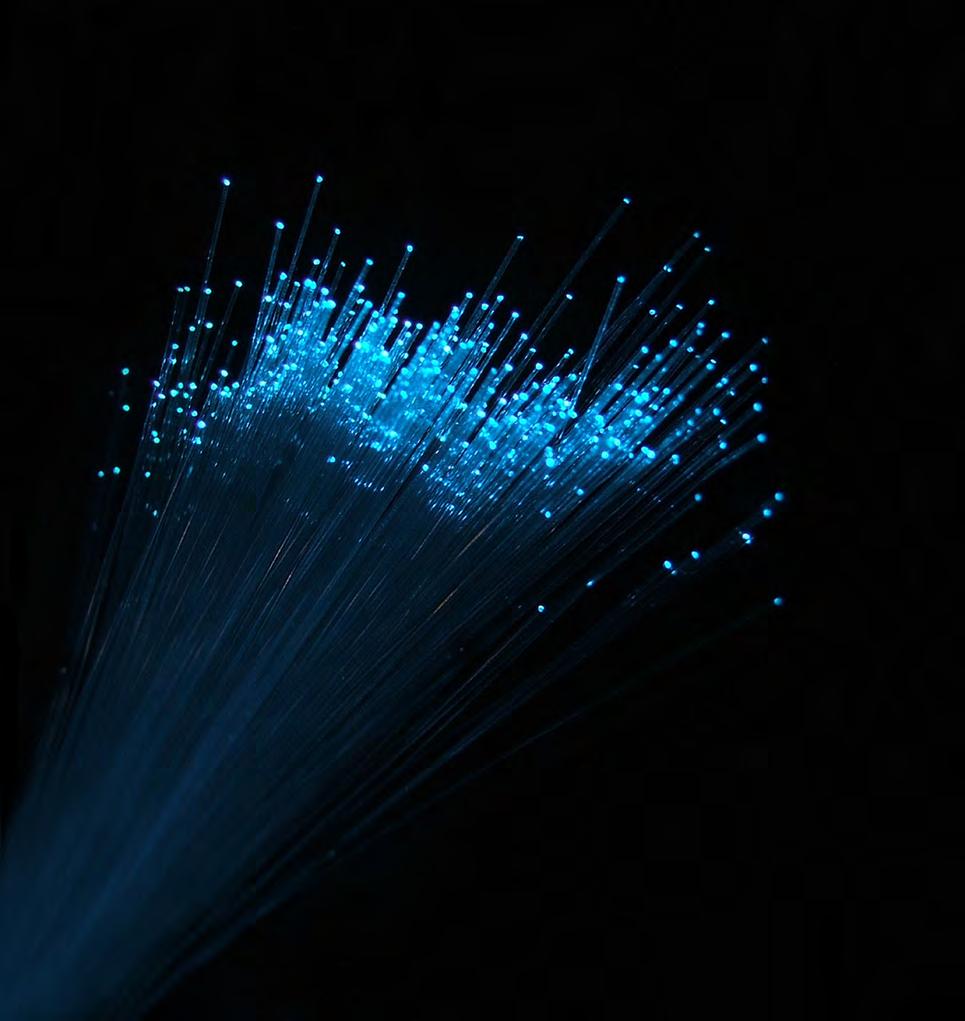

An optical fiber (or fibre) is a glass or plastic fiber that carries light along its length. Fiber optics is the overlap of applied science and engineering concerned with the design and application of optical fibers. Optical fibers are widely used in fiber-optic communications, which permits transmission over longer distances and at higher bandwidths (data rates) than other forms of communications. Fibers are used instead of metal wires because signals travel along them with less loss, and they are also immune to electromagnetic interference. Fibers are also used for illumination, and are wrapped in bundles so they can be used to carry images, thus allowing viewing in tight spaces. Specially designed fibers are used for a variety of other applications, including sensors and fiber lasers. [2.12, 2.14]

Light is kept in the core of the optical fiber by total internal reflection. This causes the fiber to act as a waveguide. Fibers which support many propagation paths or transverse modes are called multi-mode fibers (MMF), while those which can only support a single mode are called single-mode fibers (SMF). Multimode fibers generally have a larger core diameter, and are used for short-distance communication links and for applications where high power must be transmitted. Single-mode fibers are used for most communication links longer than 550 metres

History

Fiber optic technology experienced a phenomenal rate of progress in the second half of the twentieth century. Early success came during the 1950’s with the development of the fiberscope. This image-transmitting device, which used the first practical all-glass fiber, was concurrently devised by Brian O’Brien at the American Optical Company and Narinder Kapany (who first coined the term ‘fiber optics’ in 1956) and colleagues at the Imperial College of Science and Technology in London. Early all-glass fibers experienced excessive optical loss, the loss of the light signal as it traveled the fiber, limiting transmission distances.

This motivated scientists to develop glass fibers that included a separate glass coating. The innermost region of the fiber, or

core, was used to transmit the light, while the glass coating, or cladding, prevented the light from leaking out of the core by reflecting the light within the boundaries of the core. This concept is explained by Snell’s Law which states that the angle at which light is reflected is dependent on the refractive indices of the two materials ‘ in this case, the core and the cladding. The lower refractive index of the cladding (with respect to the core) causes the light to be angled back into the core.

The fiberscope quickly found application inspecting welds inside reactor vessels and combustion chambers of jet aircraft engines as well as in the medical field. Fiberscope technology has evolved over the years to make laparoscopic surgery one of the great medical advances of the twentieth century.

The development of laser technology was the next important step in the establishment of the industry of fiber optics. Only the laser diode (LD) or its lower-power cousin, the light-emitting diode (LED), had the potential to generate large amounts of light in a spot tiny enough to be useful for fiber optics. In 1957, Gordon Gould popularized the idea of using lasers when, as a graduate student at Columbia University, he described the laser as an intense light source. Shortly after, Charles Townes and Arthur Schawlow at Bell Laboratories supported the laser in scientific circles. Lasers went through several generations including the development of the ruby laser and the helium-neon laser in 1960. Semiconductor lasers were first realized in 1962; these lasers are the type most widely used in fiber optics today.

Because of their higher modulation frequency capability, the importance of lasers as a means of carrying information did not go unnoticed by communications engineers. Light has an information-carrying capacity 10,000 times that of the highest radio frequencies being used. However, the laser is unsuited for open-air transmission because it is adversely affected by environmental conditions such as rain, snow, hail, and smog. Faced with the challenge of finding a transmission medium other than air, Charles Kao and Charles Hockham, working at the Standard Telecommunication Laboratory in England in 1966, published a landmark paper proposing that optical fiber

34

conductive paste optical ber inner core outer core 1.5cm 125μm 635μm

2.10 Diagram of a fibre optic cable 2.11 Fibre optic cables

Fibre Optics

might be a suitable transmission medium if its attenuation could be kept under 20 decibels per kilometer (dB/km). At the time of this proposal, optical fibers exhibited losses of 1,000 dB/ km or more. At a loss of only 20 dB/km, 99% of the light would be lost over only 3,300 feet. In other words, only 1/100th of the optical power that was transmitted reached the receiver. Intuitively, researchers postulated that the current, higher optical losses were the result of impurities in the glass and not the glass itself. An optical loss of 20 dB/ km was within the capability of the electronics and optoelectronic components of the day.

Intrigued by Kao and Hockham’s proposal, glass researchers began to work on the problem of purifying glass. In 1970, Drs. Robert Maurer, Donald Keck, and Peter Schultz of Corning succeeded in developing a glass fiber that exhibited attenuation at less than 20 dB/km, the threshold for making fiber optics a viable technology. It was the purest glass ever made. [2.16]

The early work on fiber optic light source and detector was slow and often had to borrow technology developed for other reasons. For example, the first fiber optic light sources were derived from visible indicator LEDs. As demand grew, light sources were developed for fiber optics that offered higher switching speed, more appropriate wavelengths, and higher output power. For more information on light emitters see Laser Diodes and LEDs.

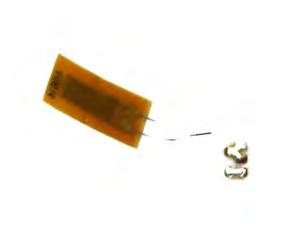

Fibre Optic Sensors

Most people, incorrectly, assume fibre optic cables are only used for telecommunication purposes; there are actually many other uses for fibre optic cables. While telecommunications is a very common, visible, use of fibre optics, it is also very common to use them as sensors. [2.15]

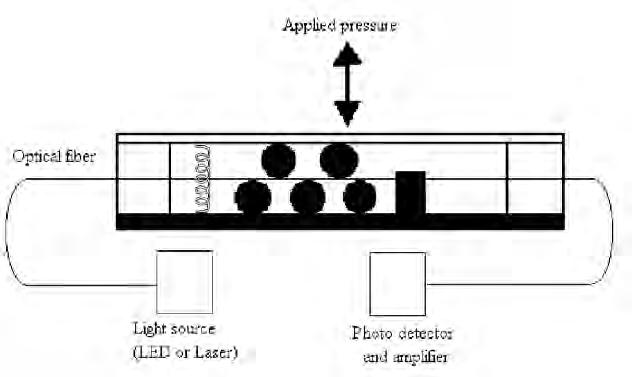

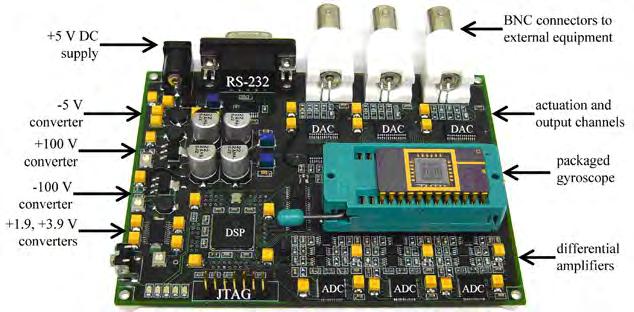

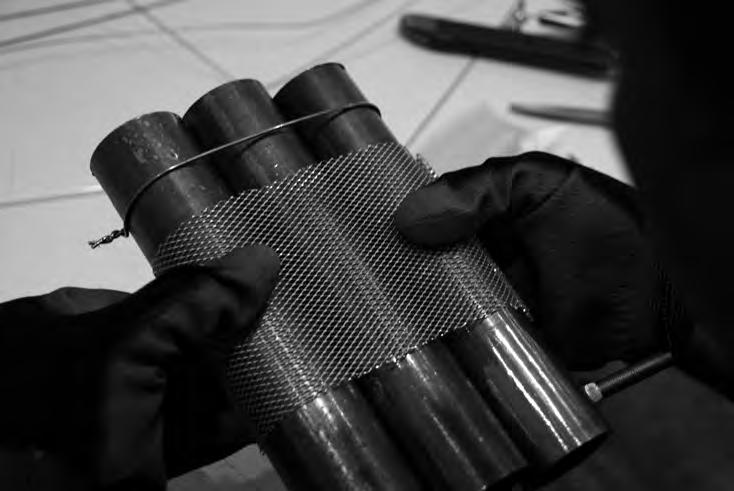

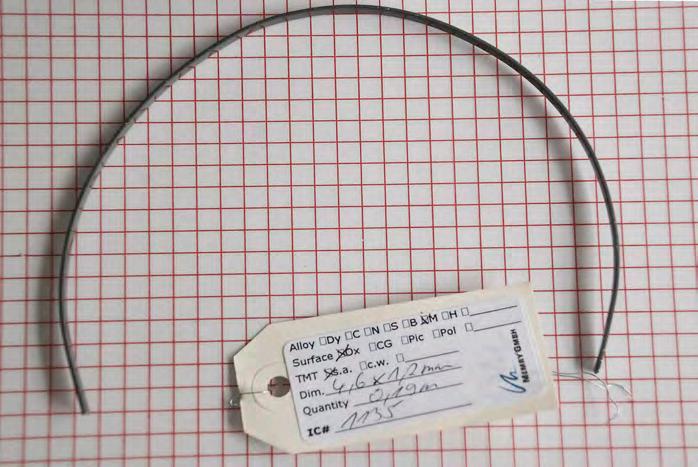

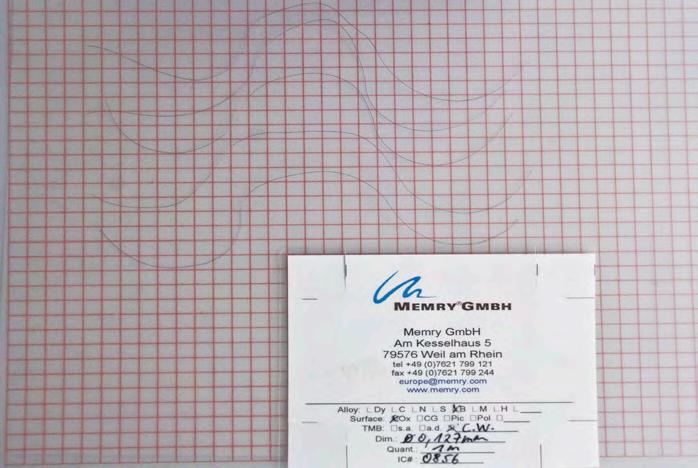

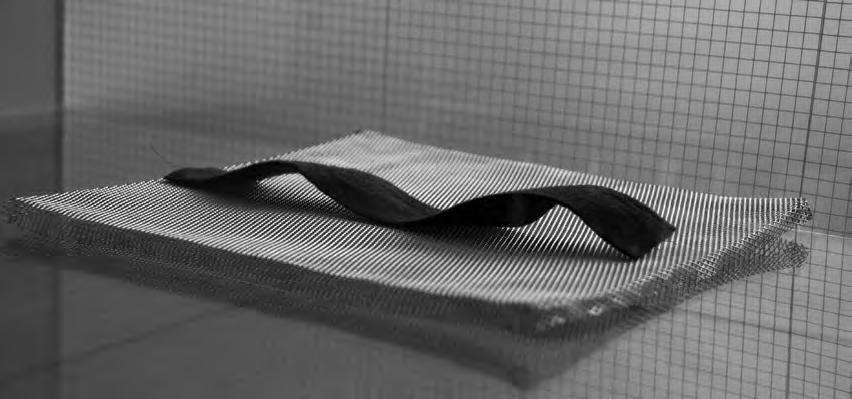

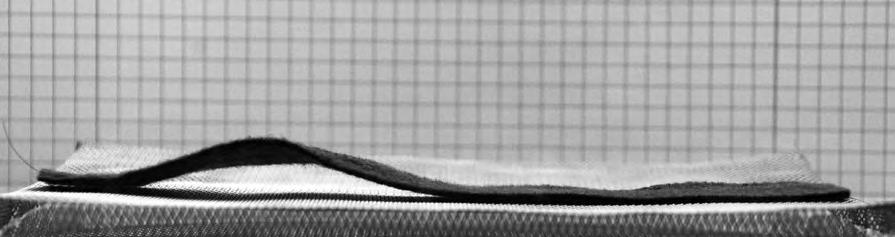

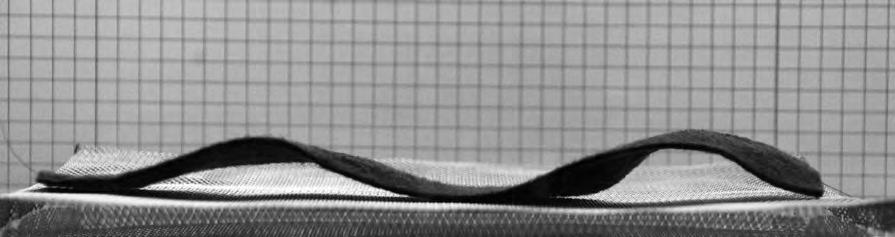

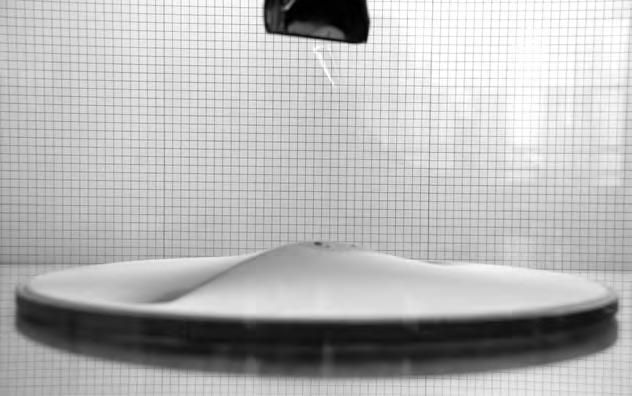

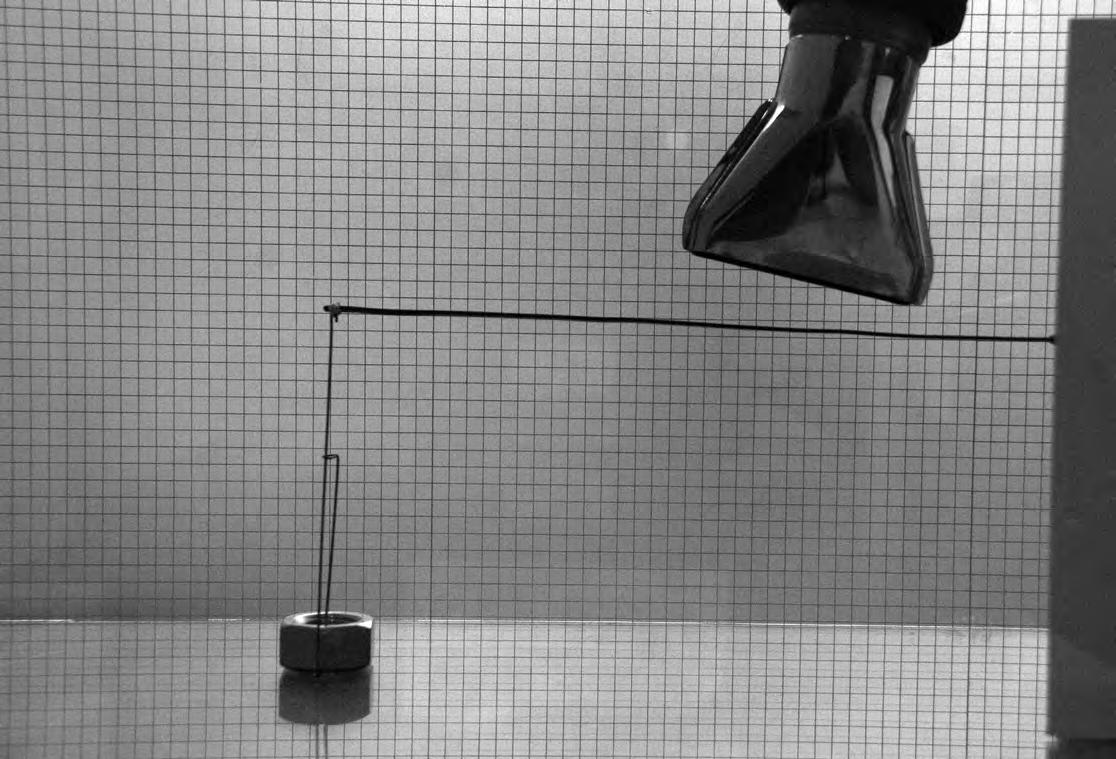

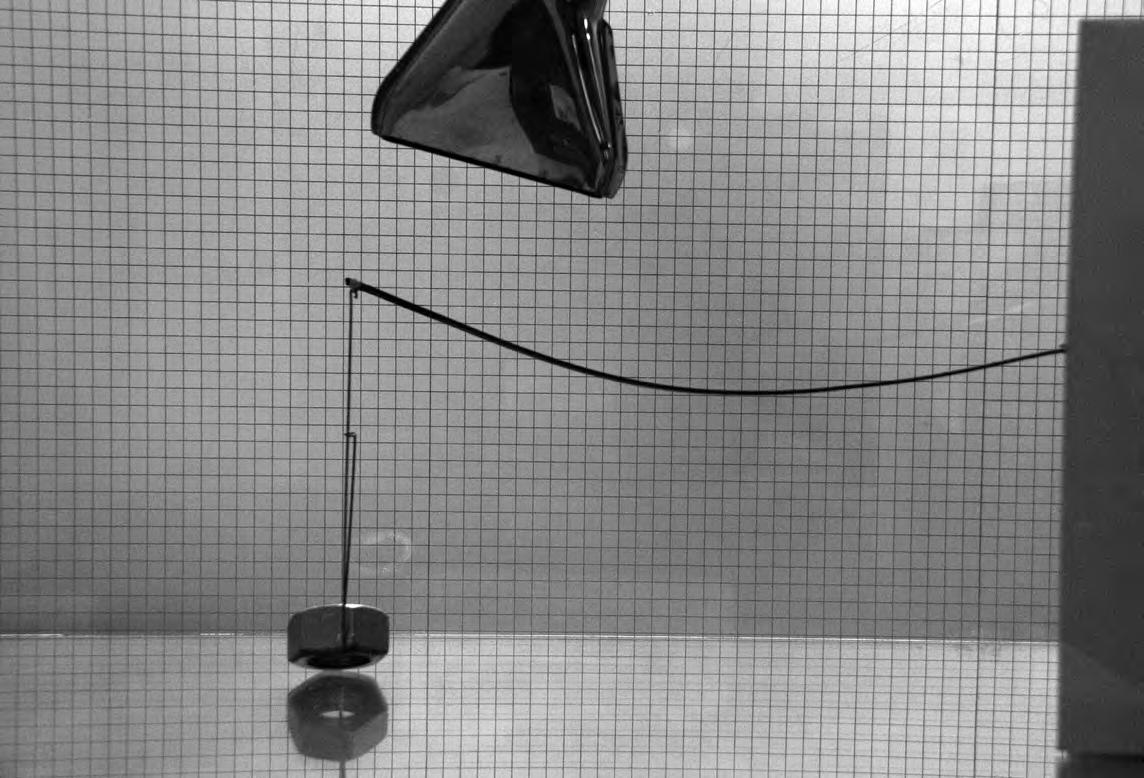

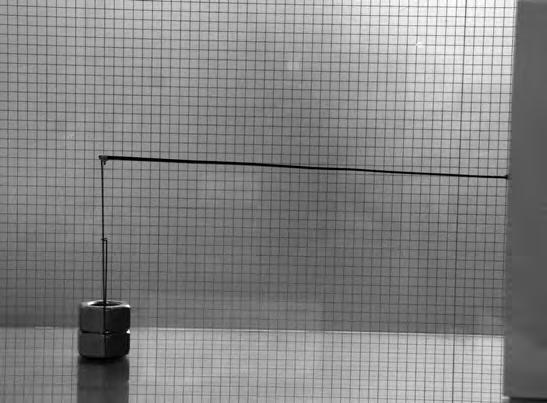

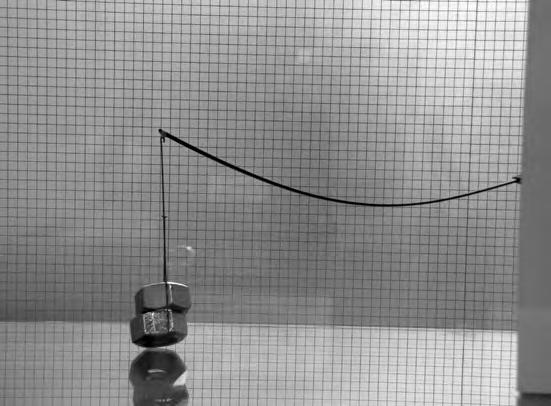

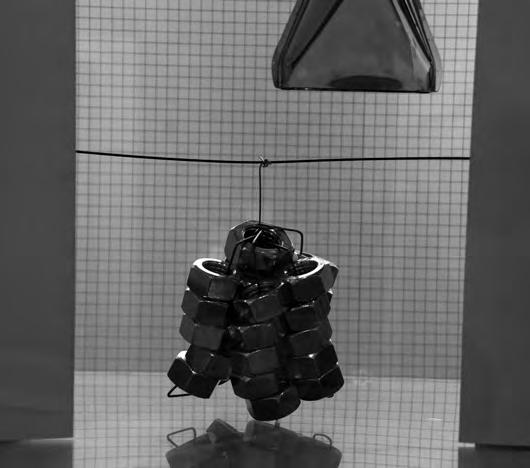

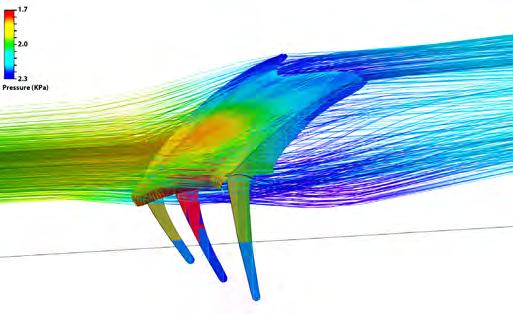

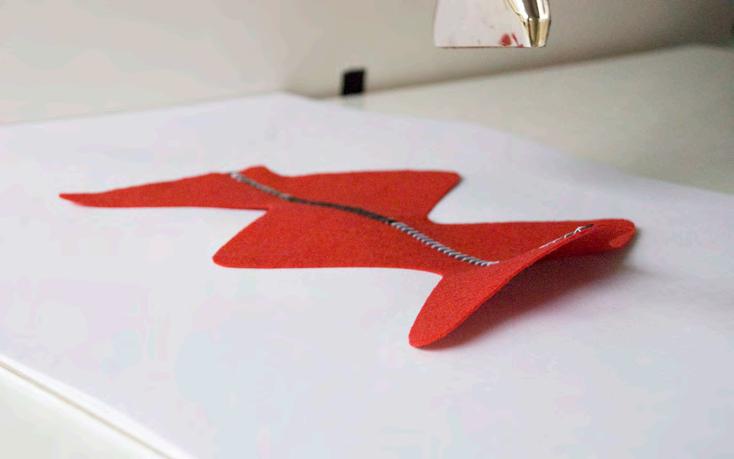

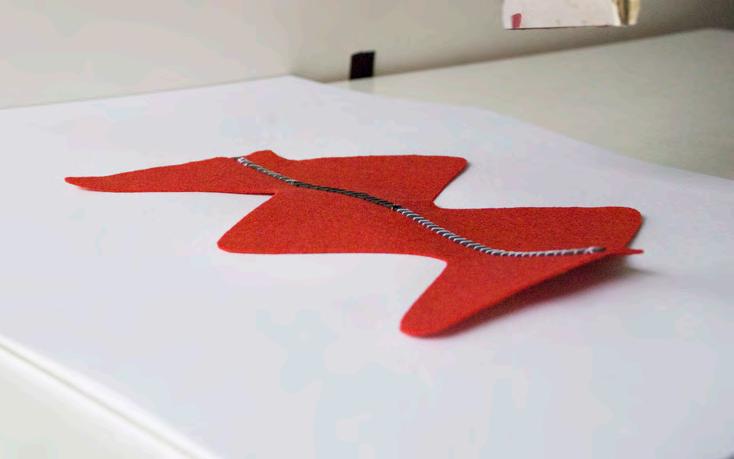

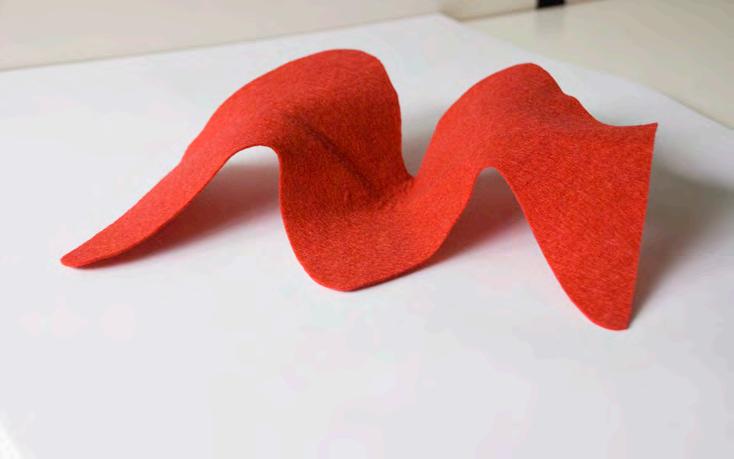

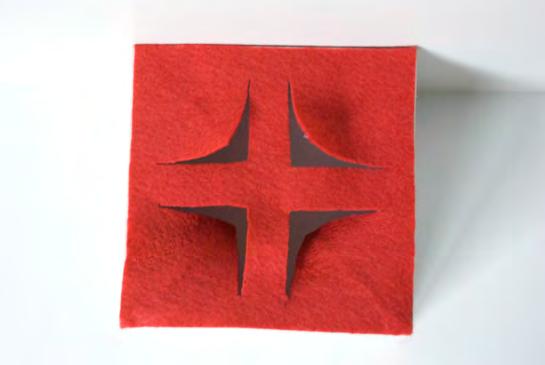

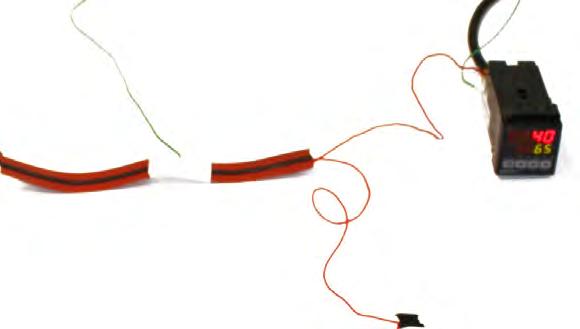

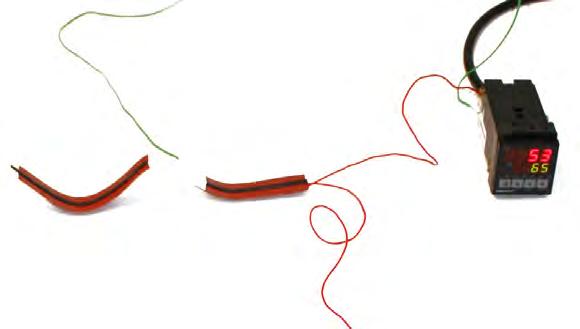

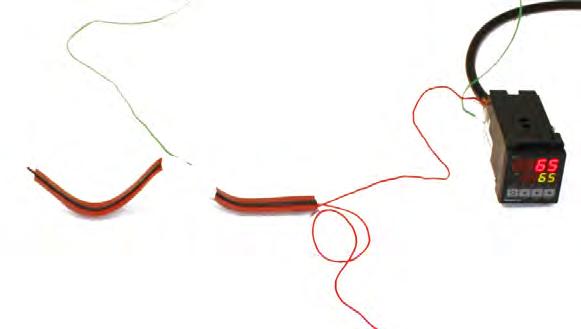

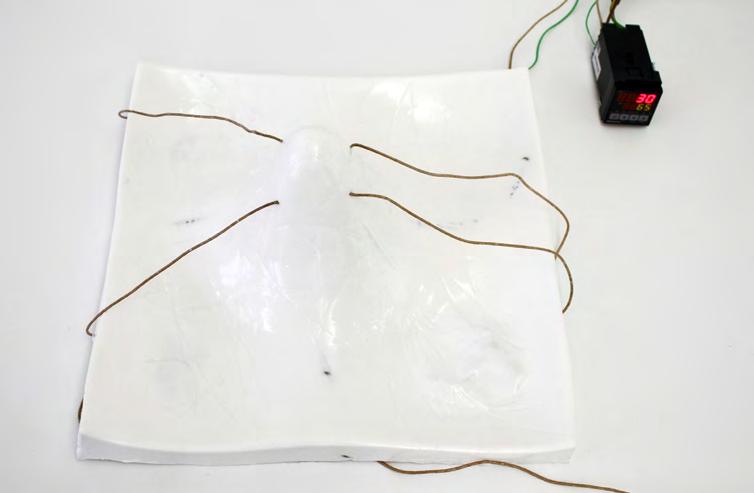

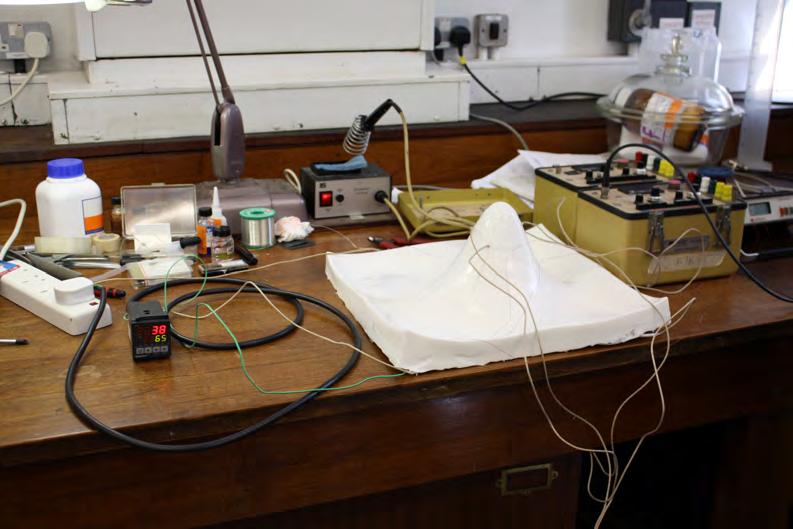

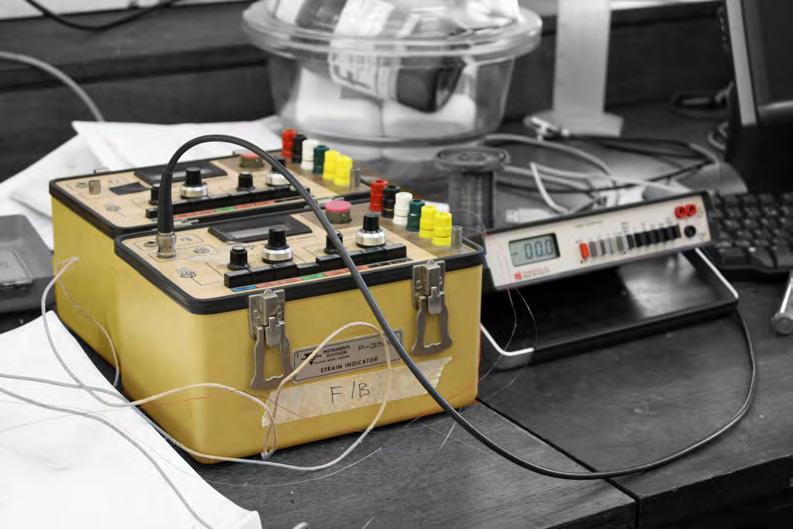

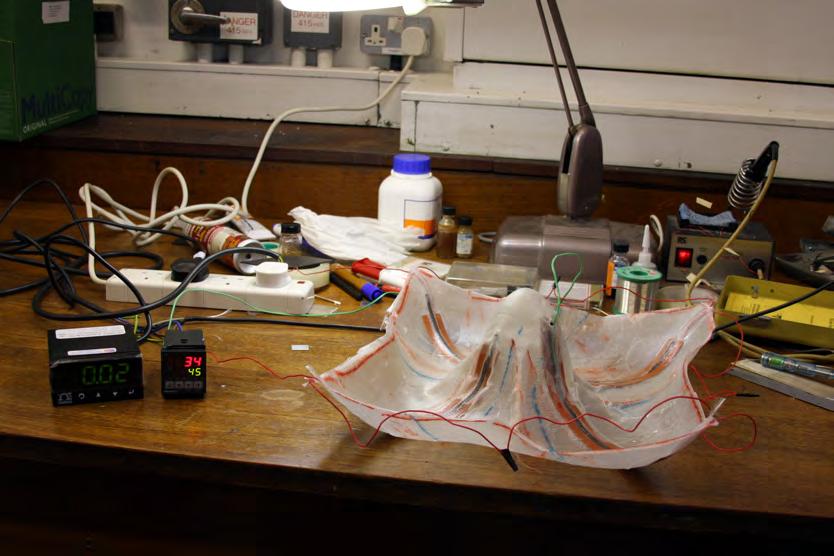

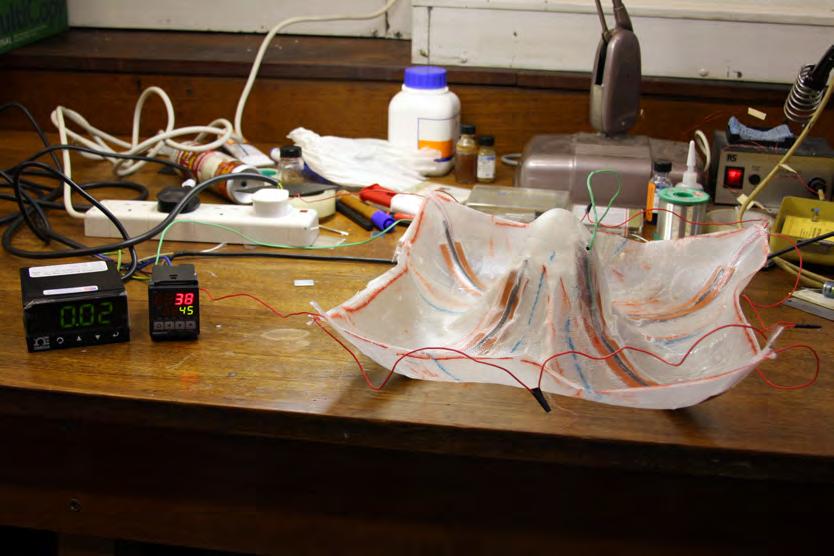

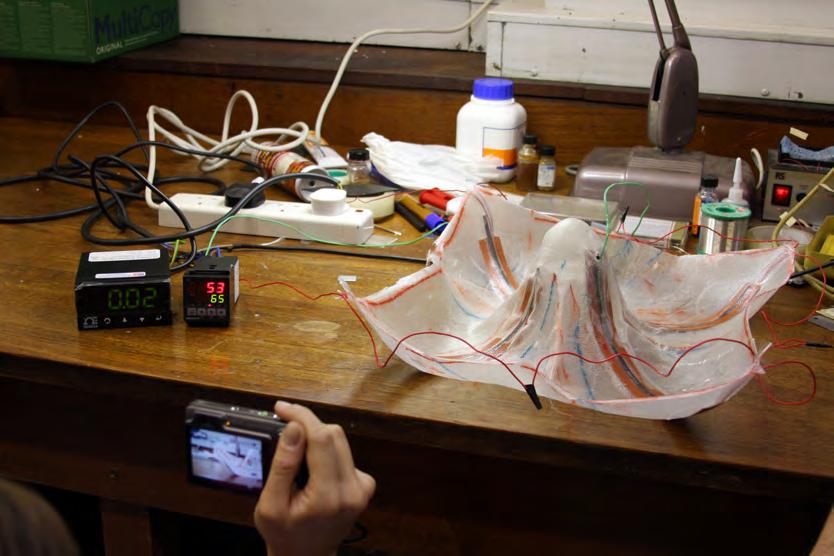

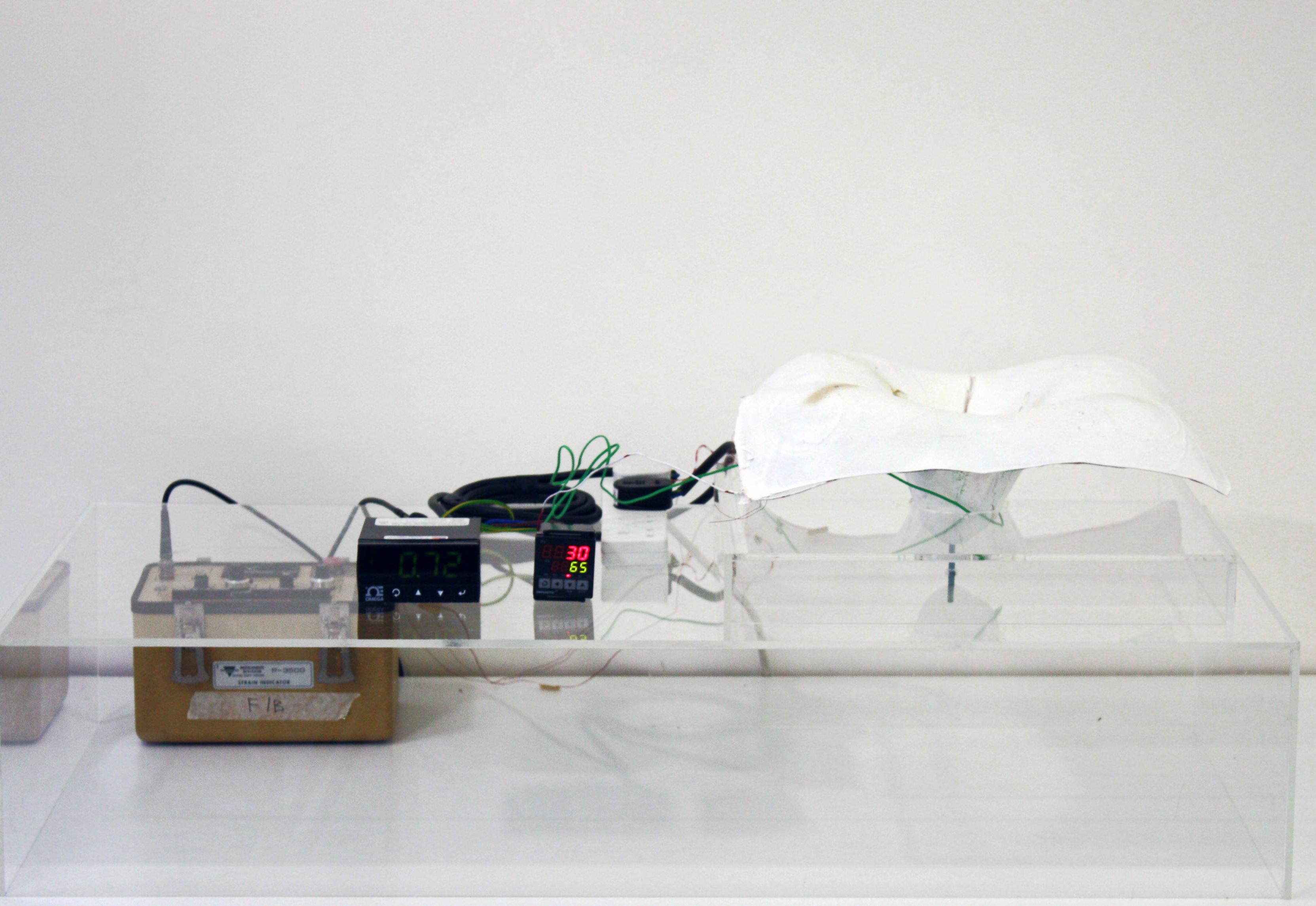

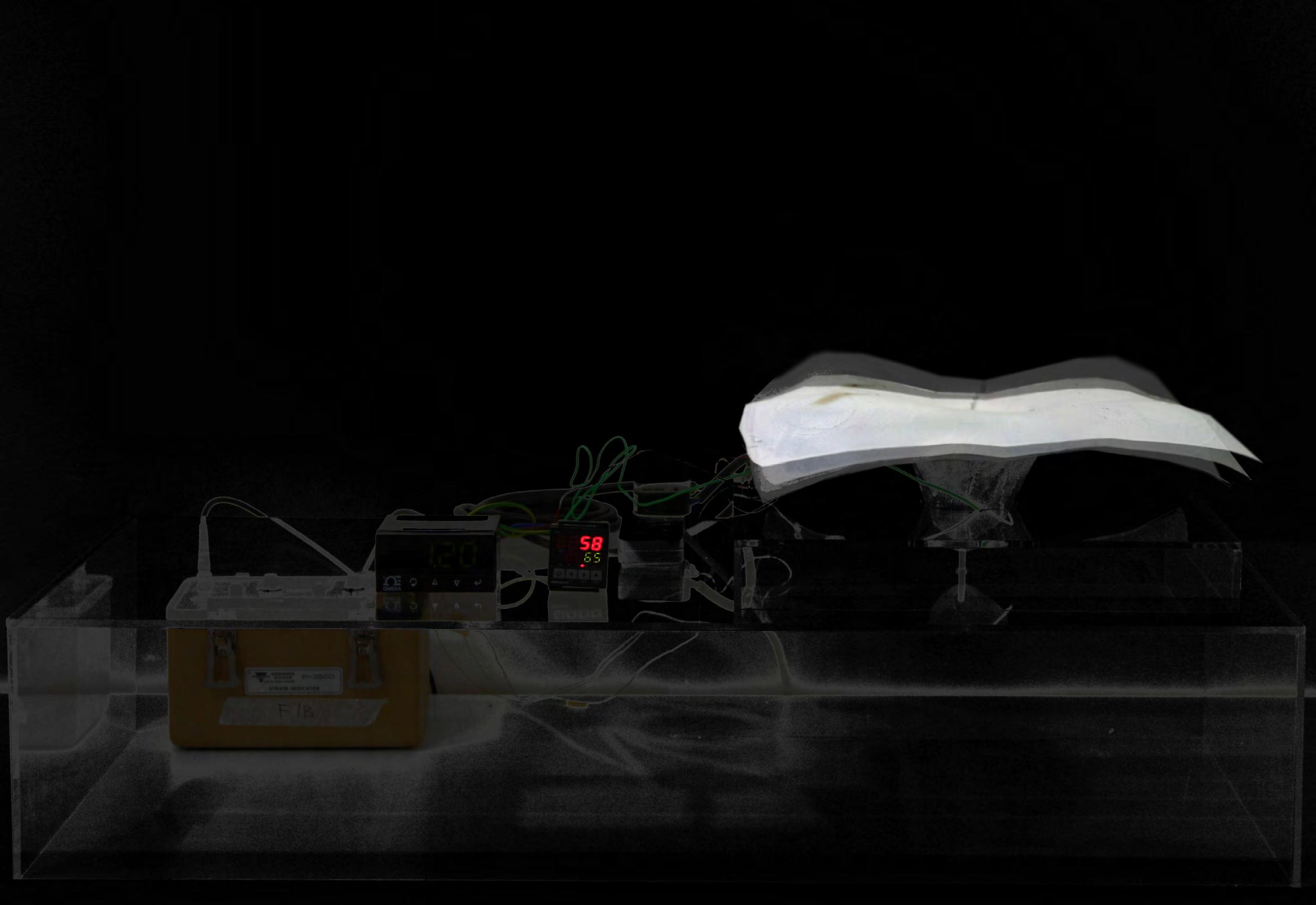

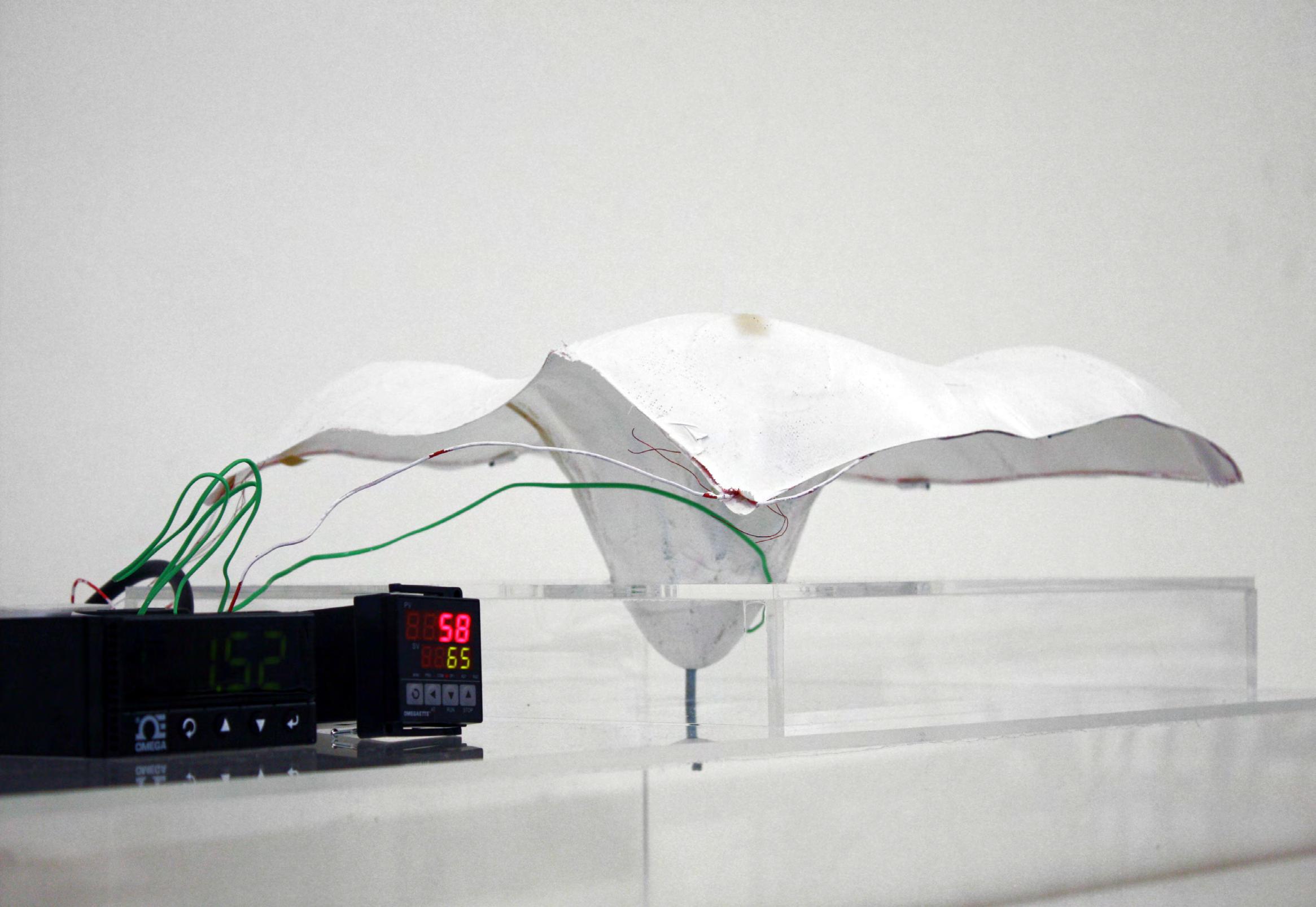

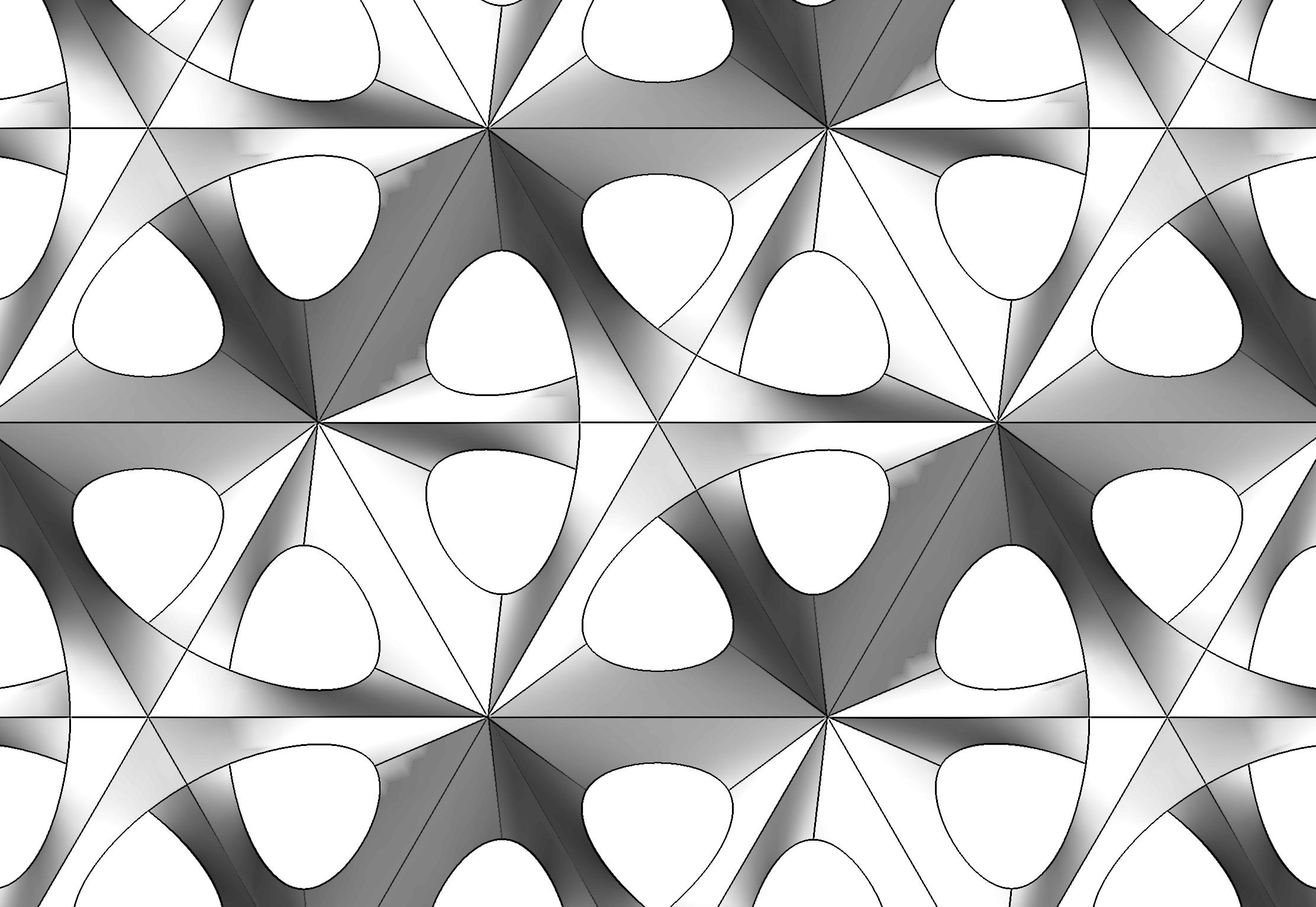

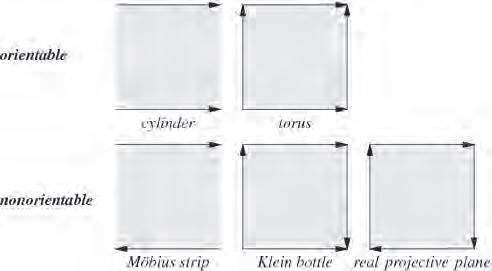

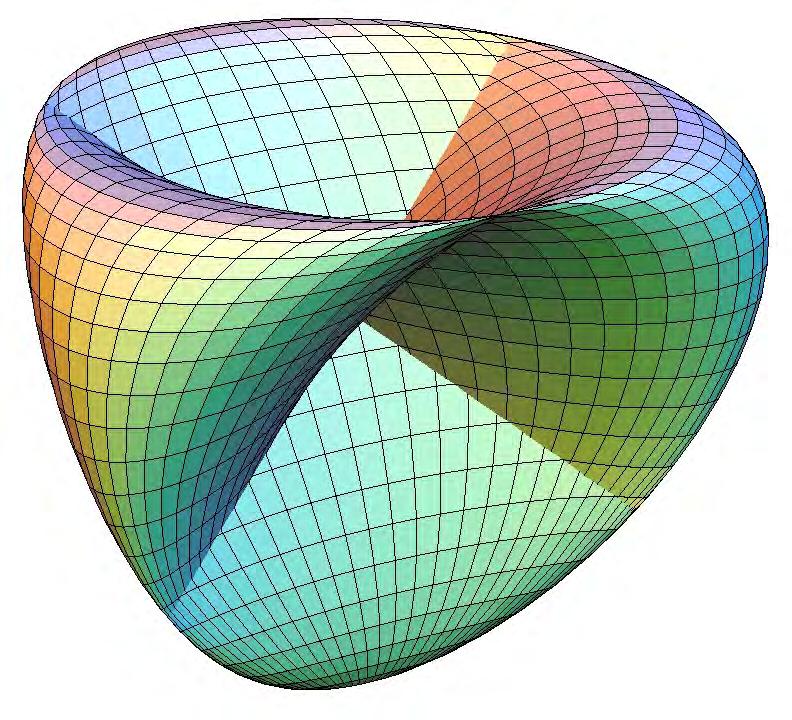

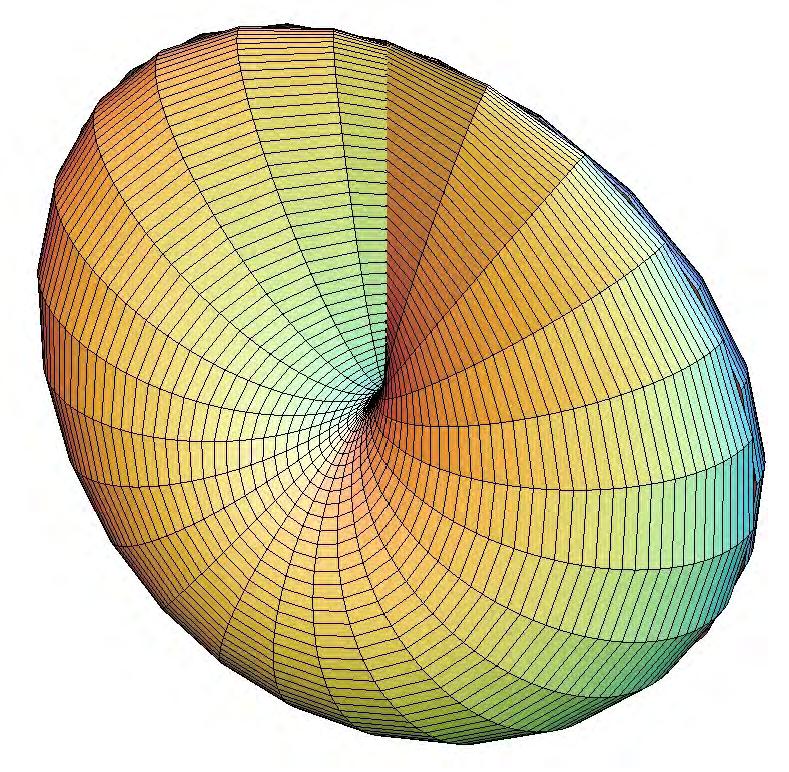

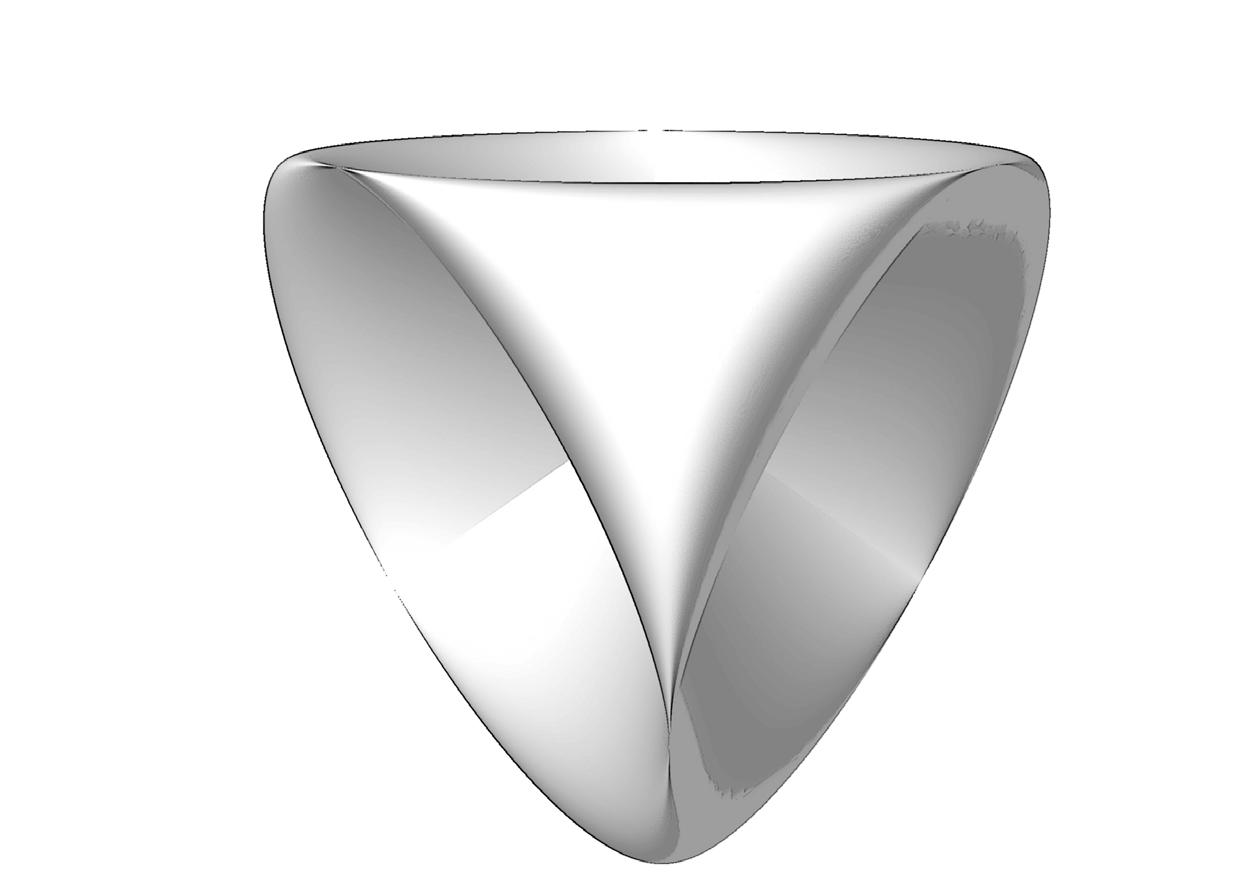

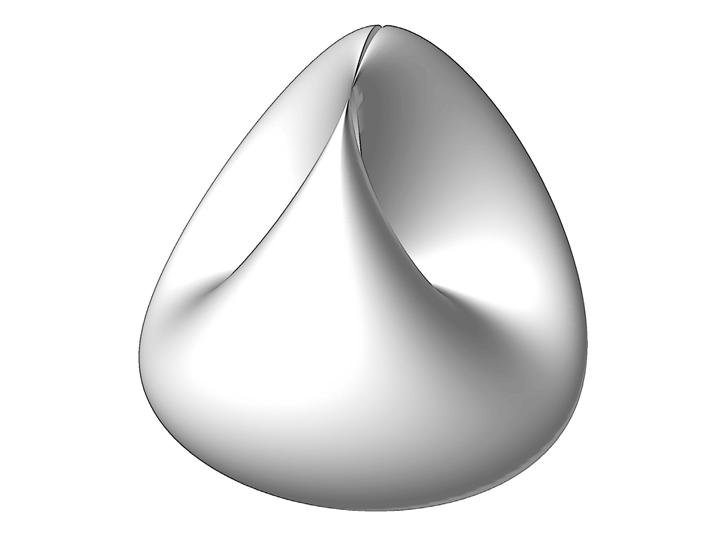

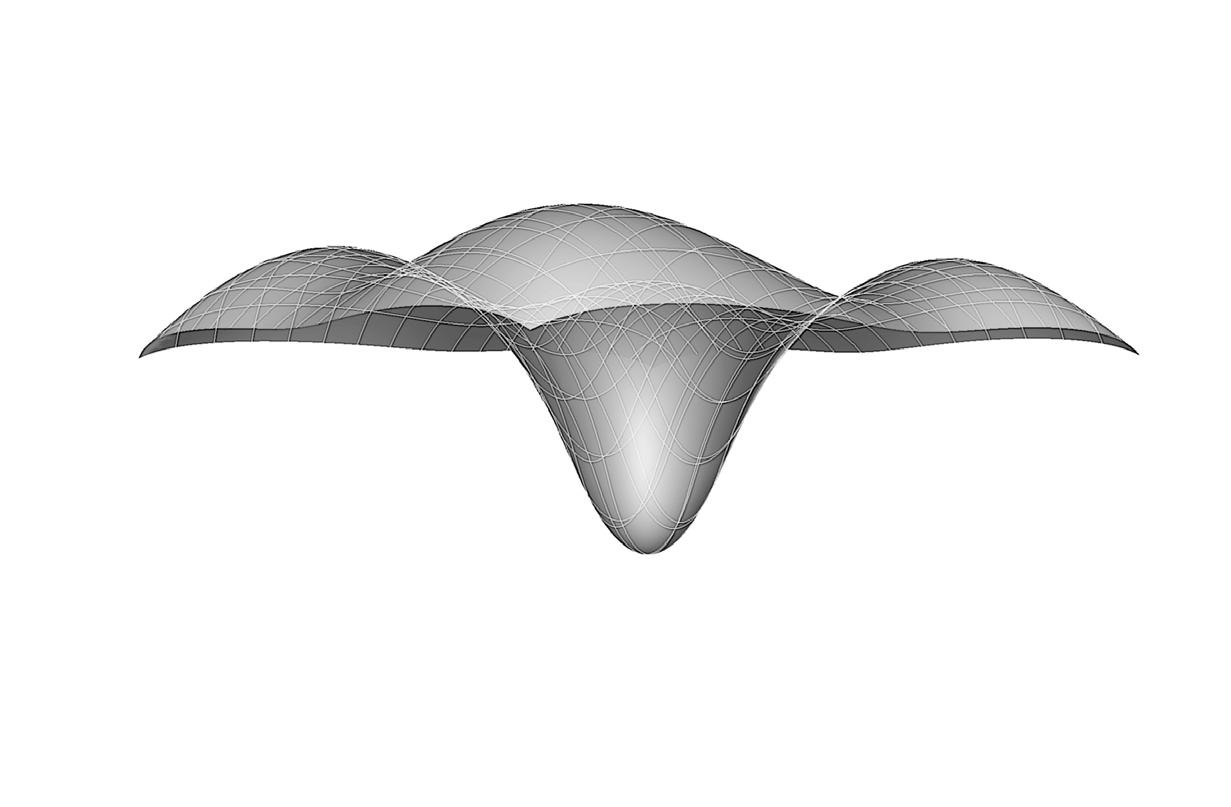

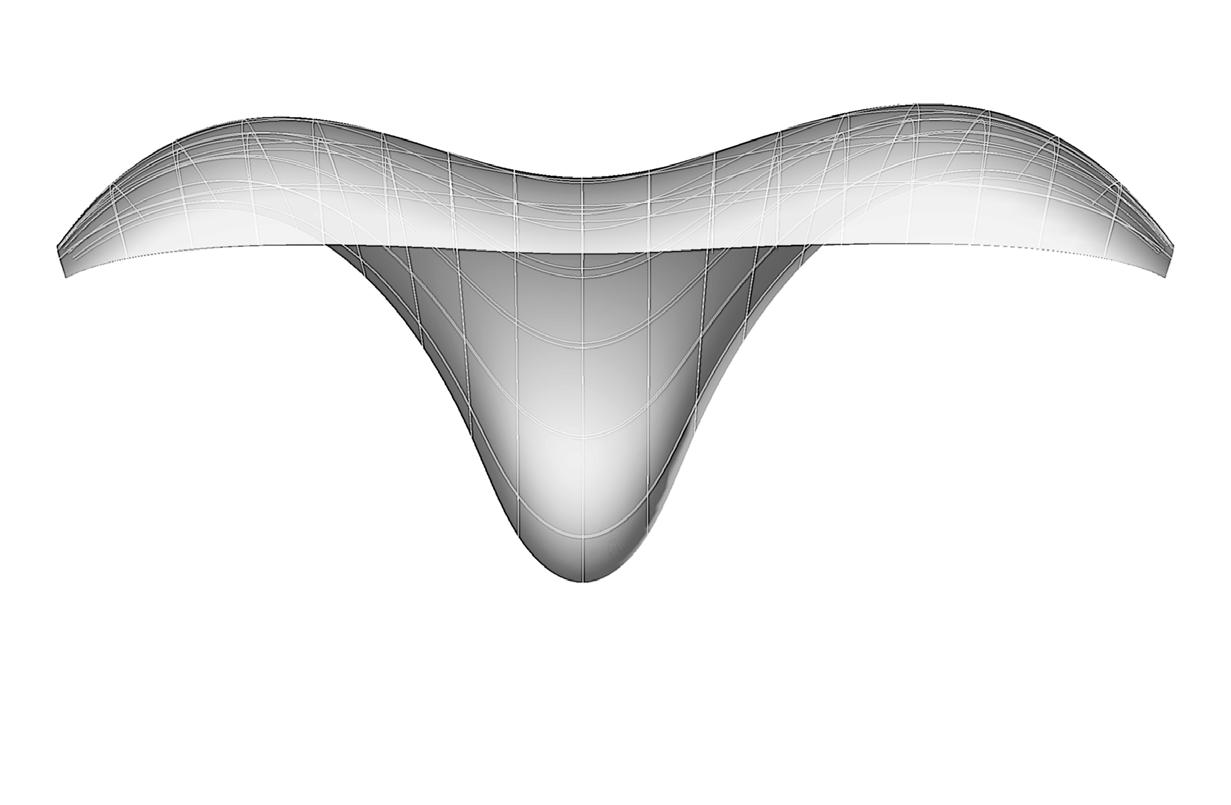

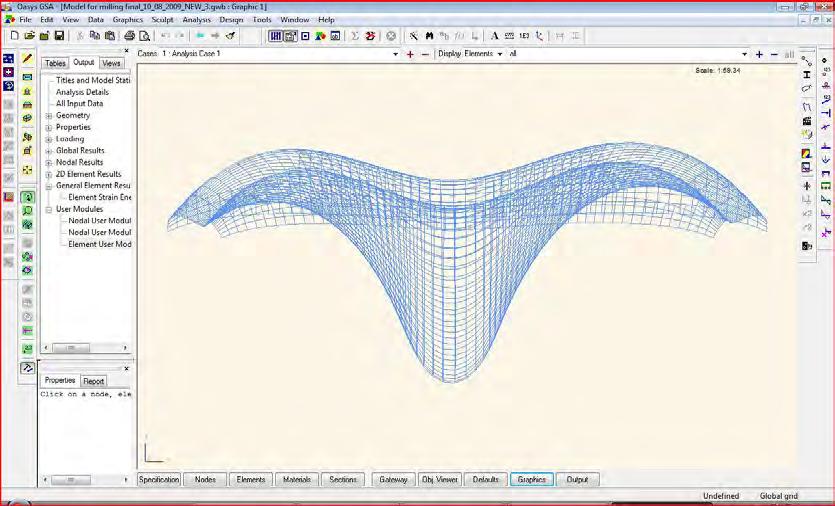

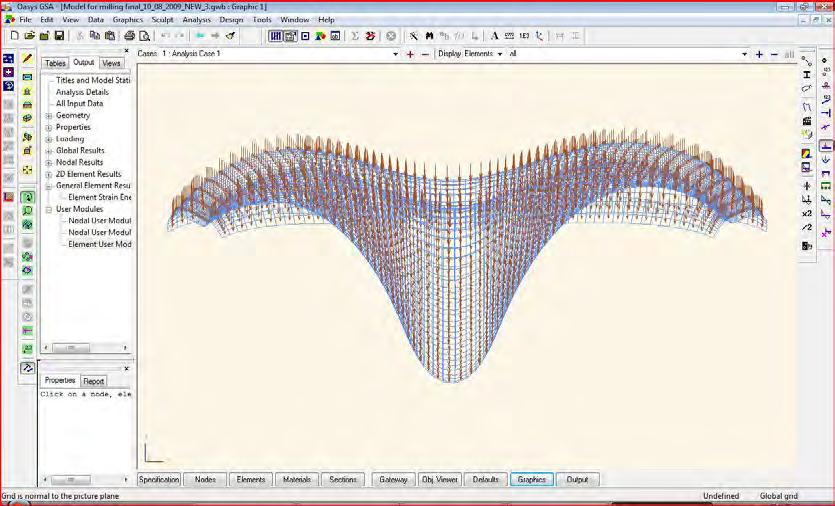

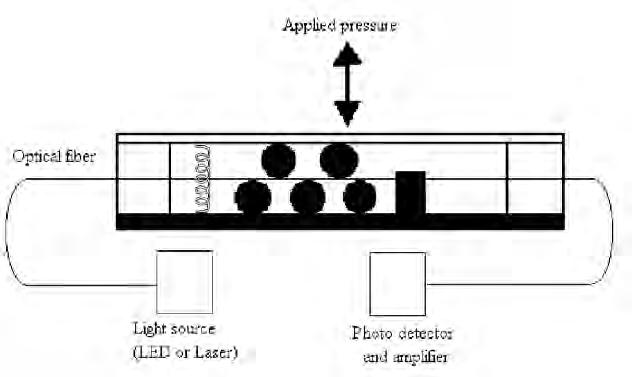

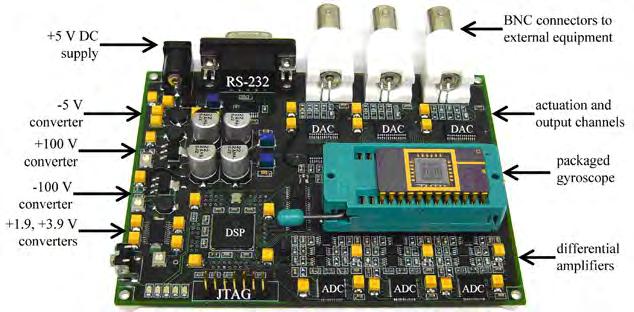

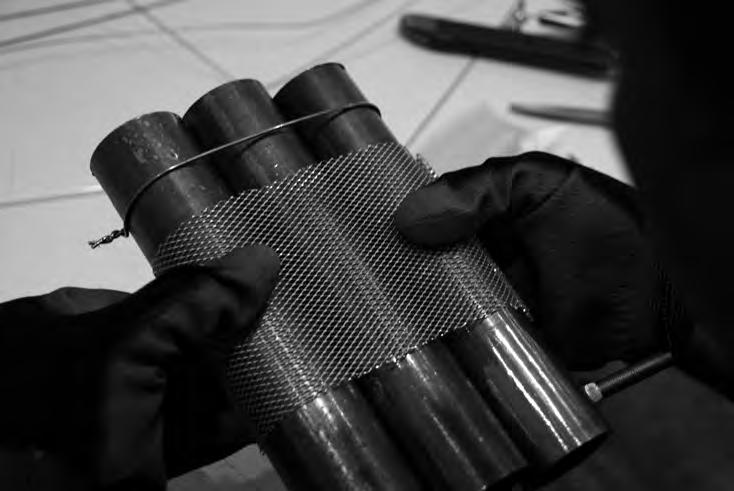

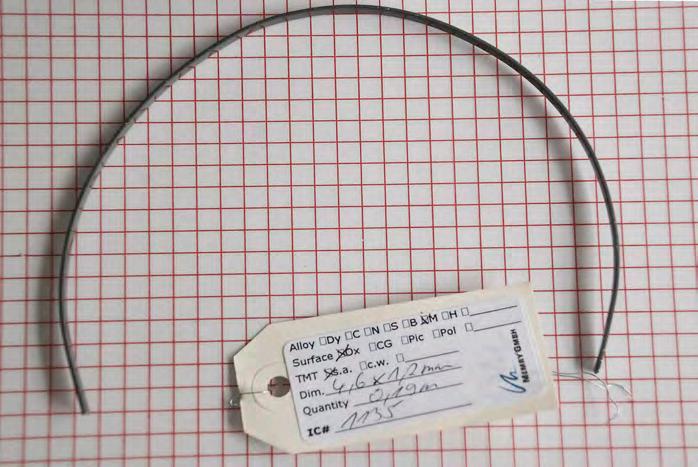

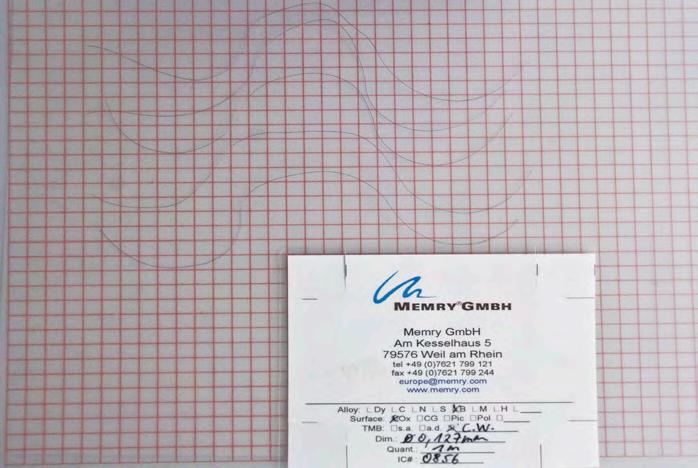

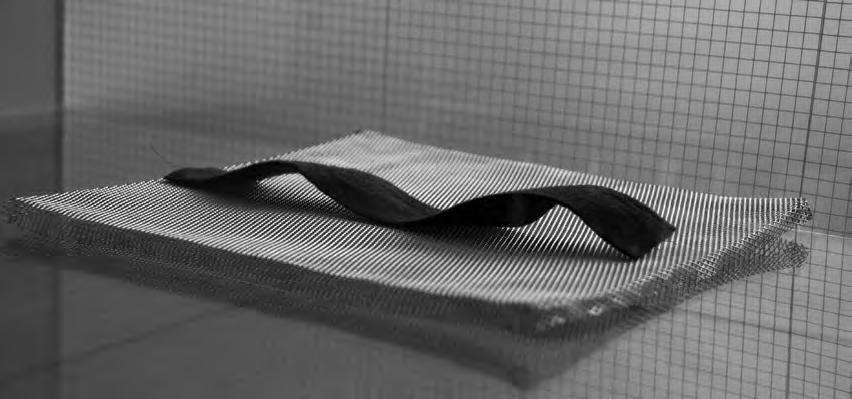

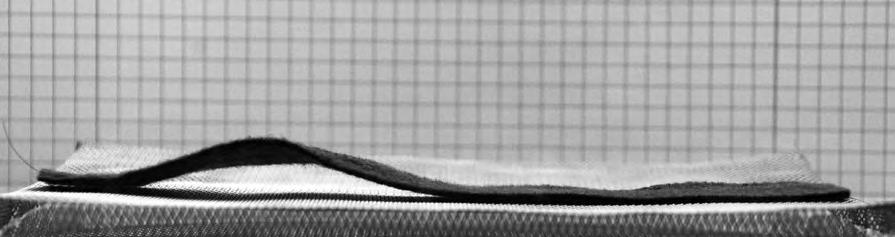

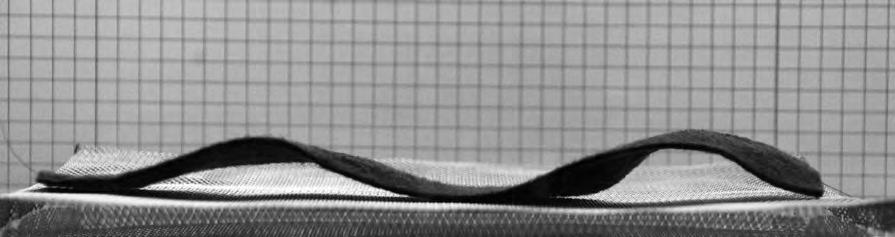

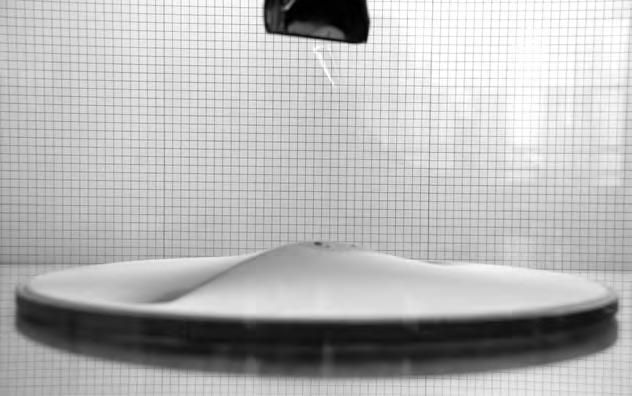

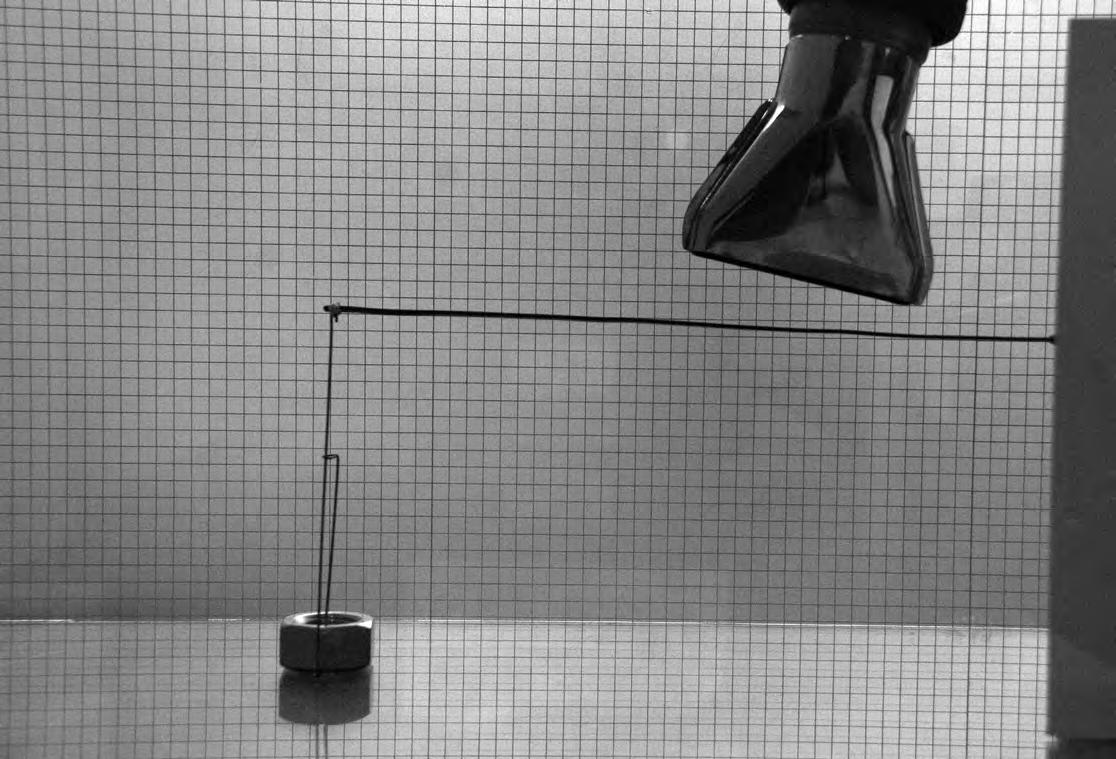

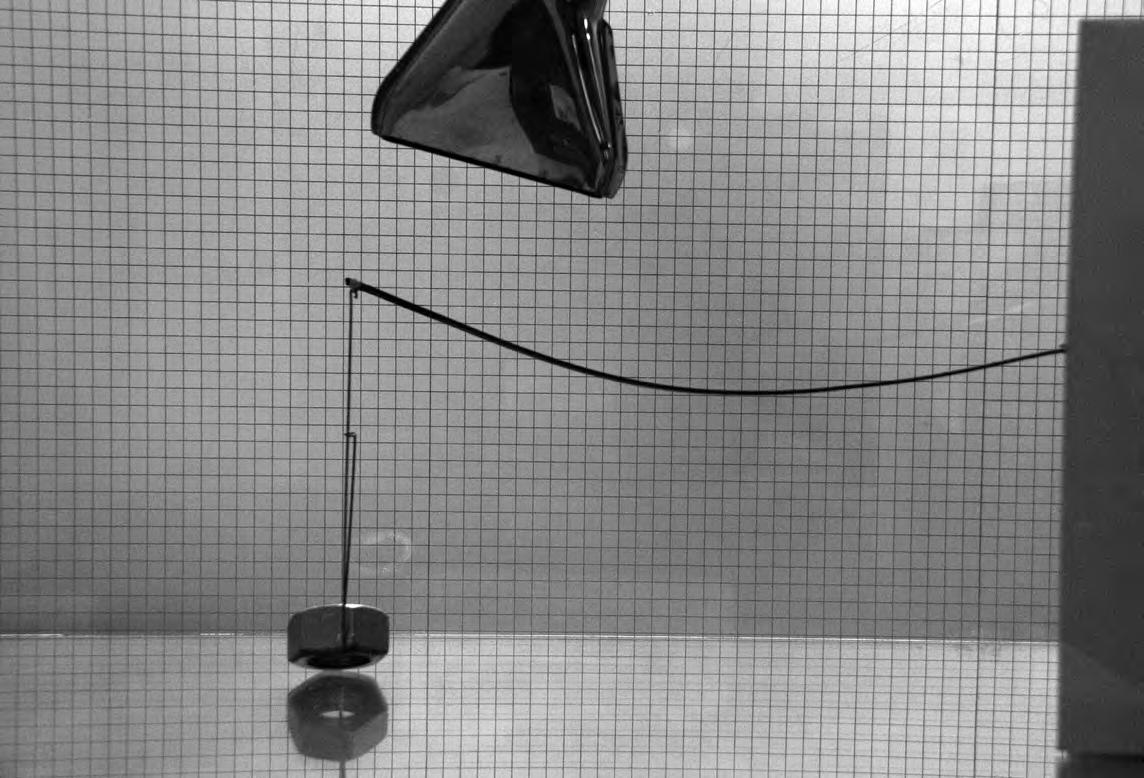

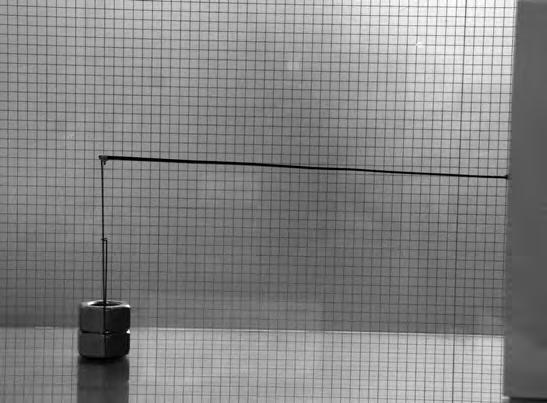

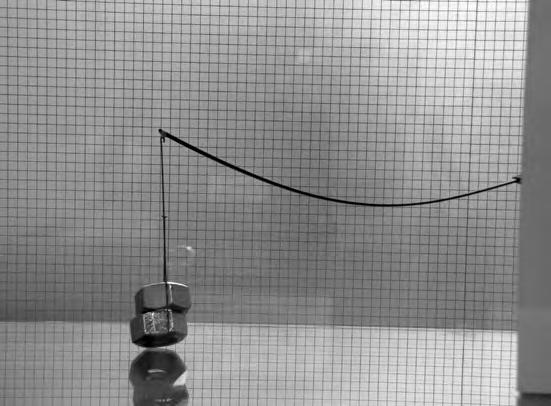

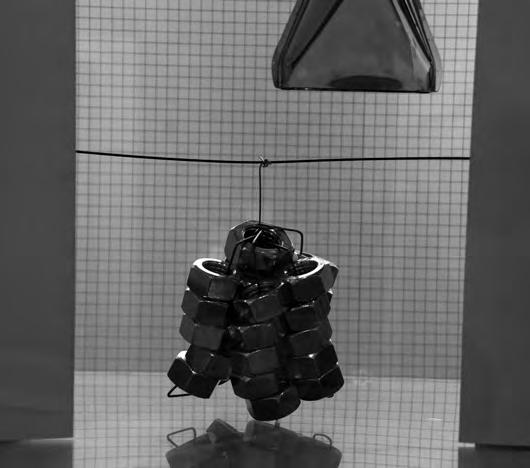

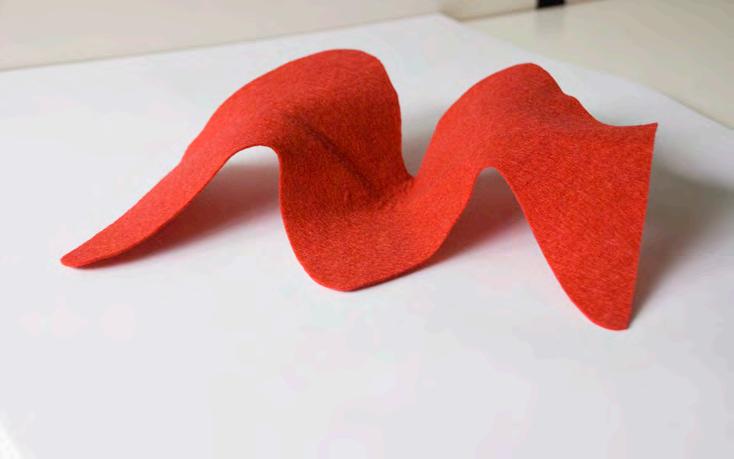

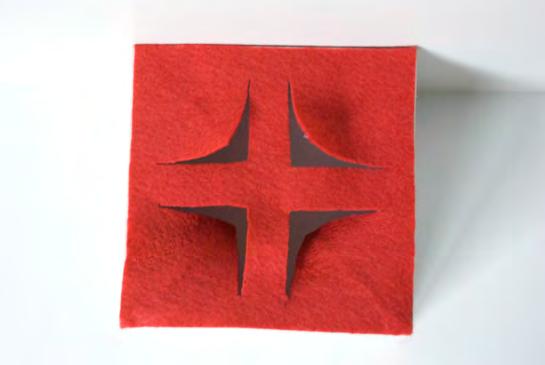

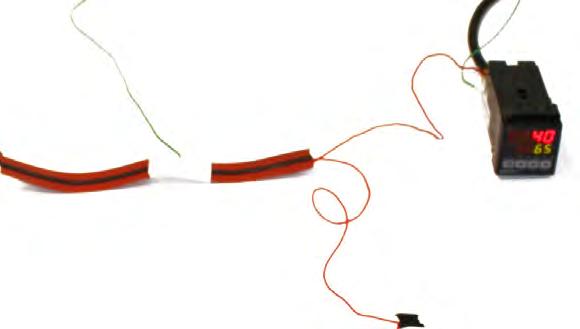

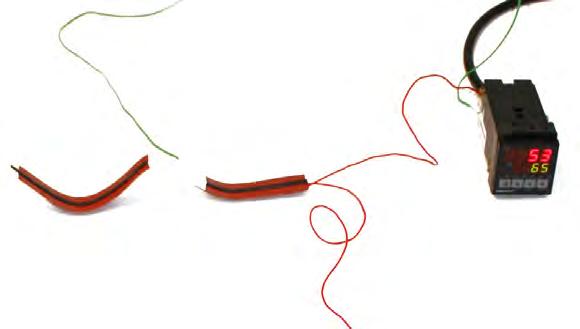

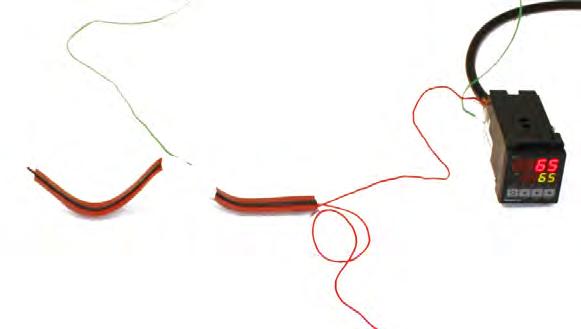

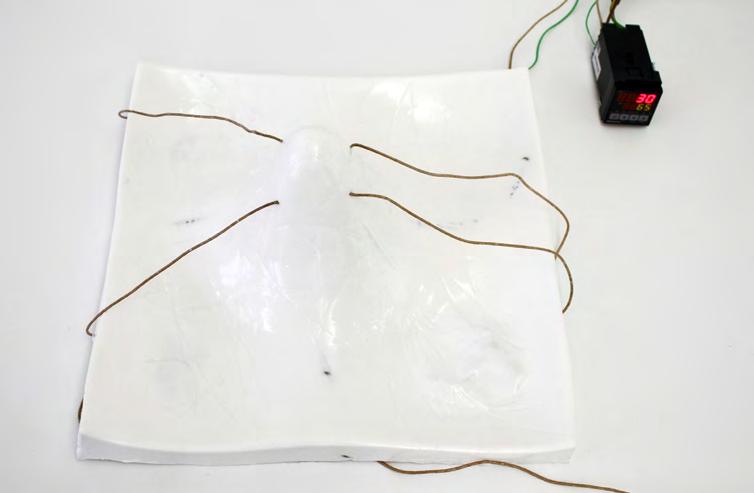

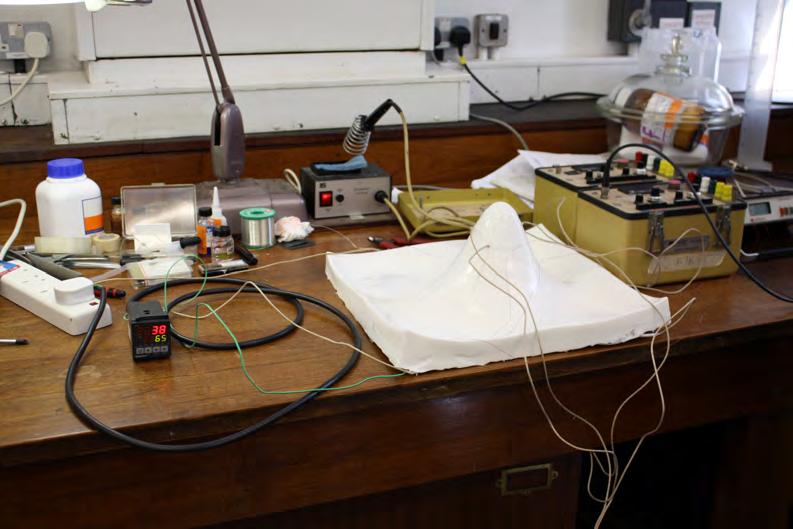

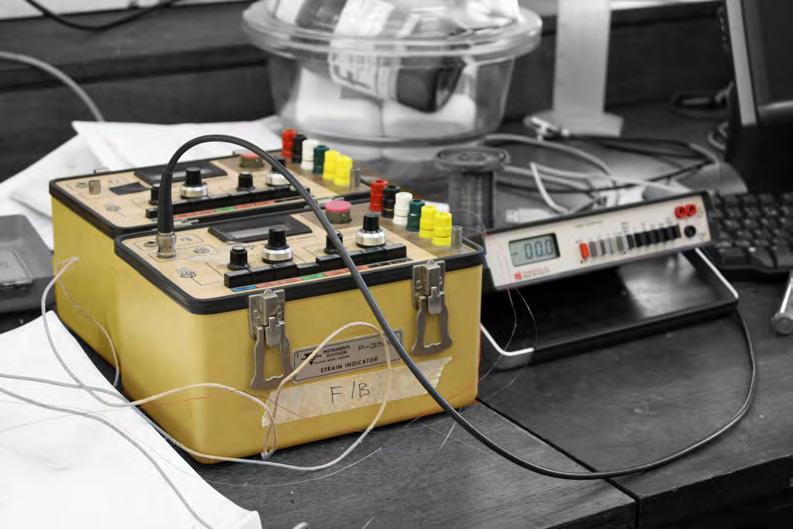

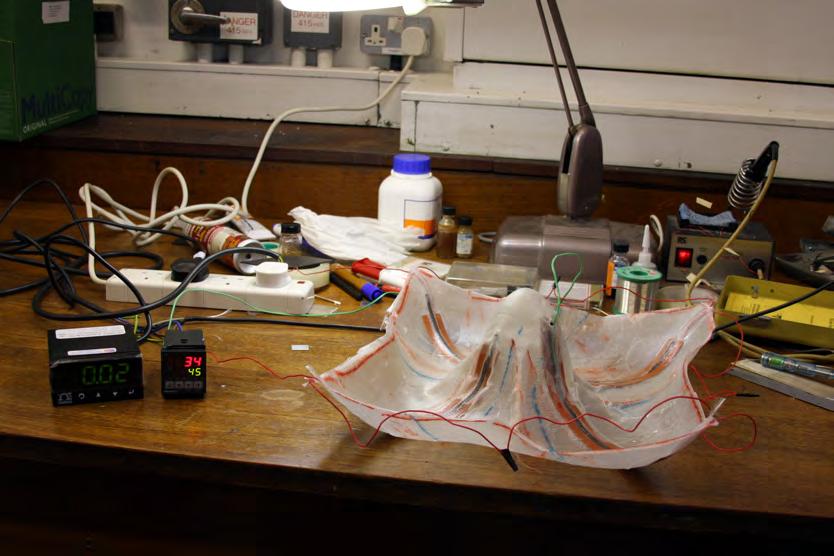

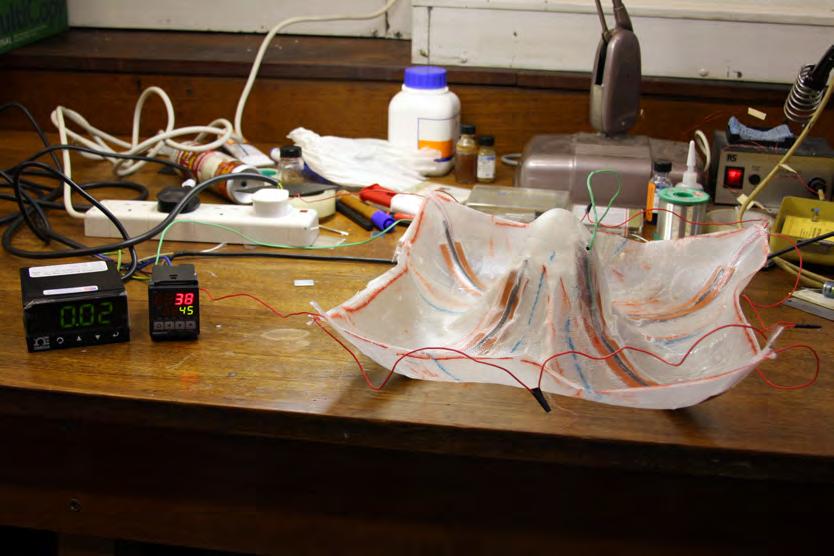

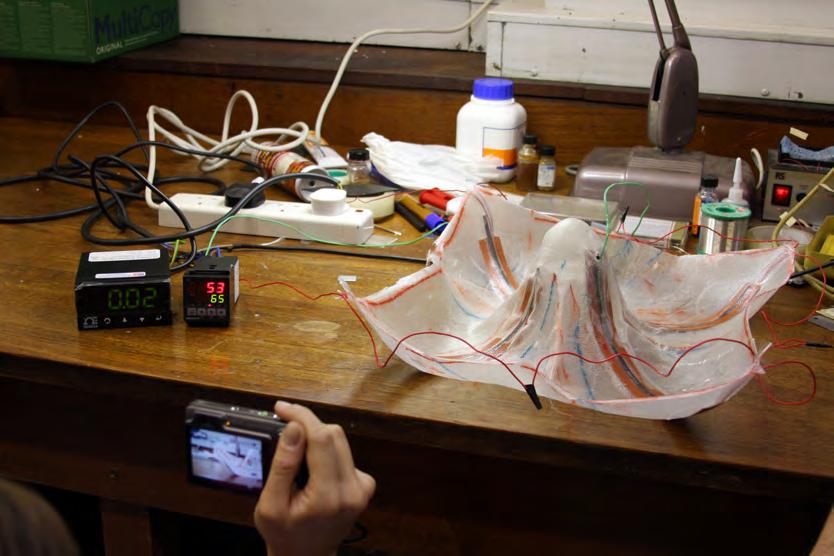

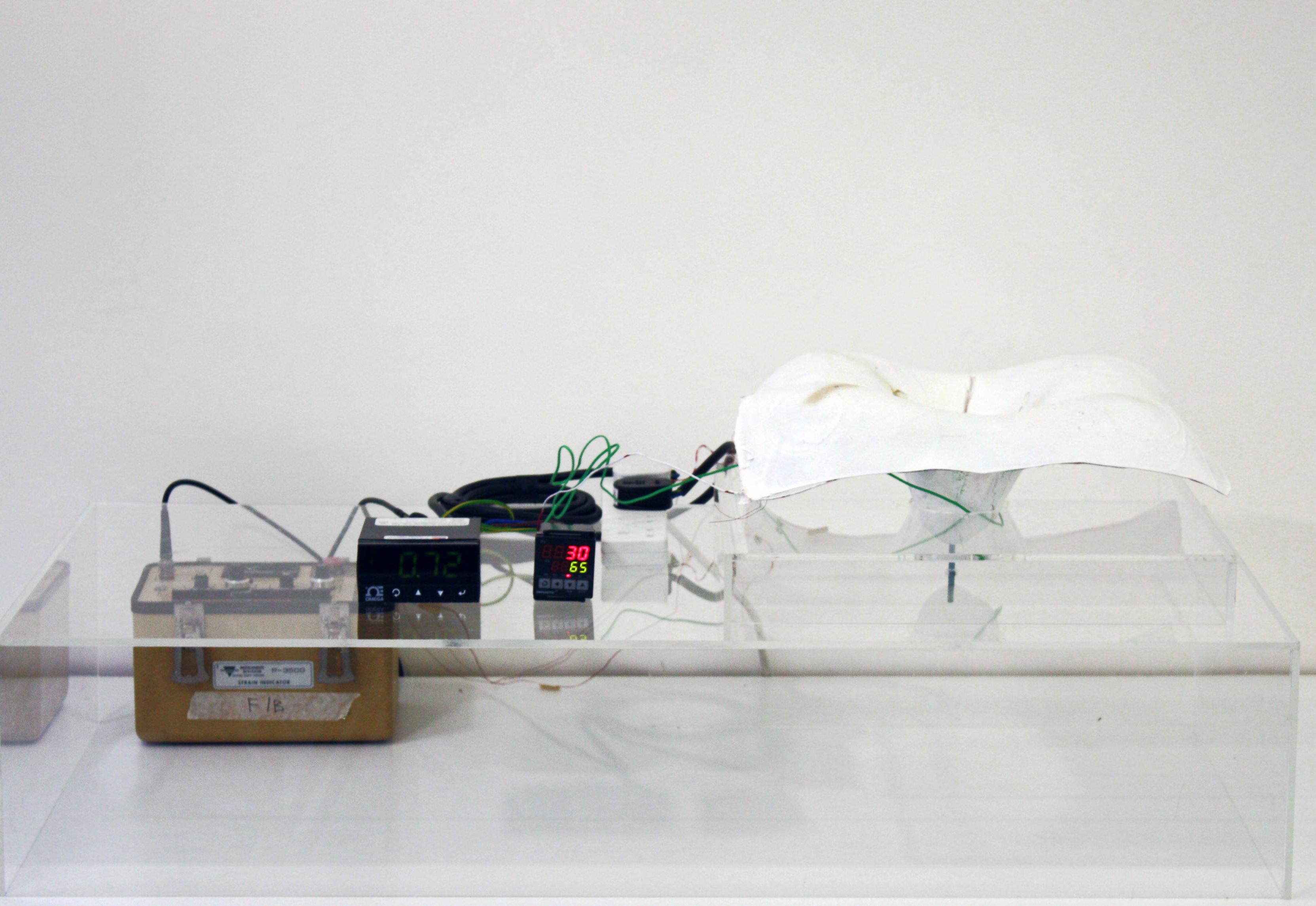

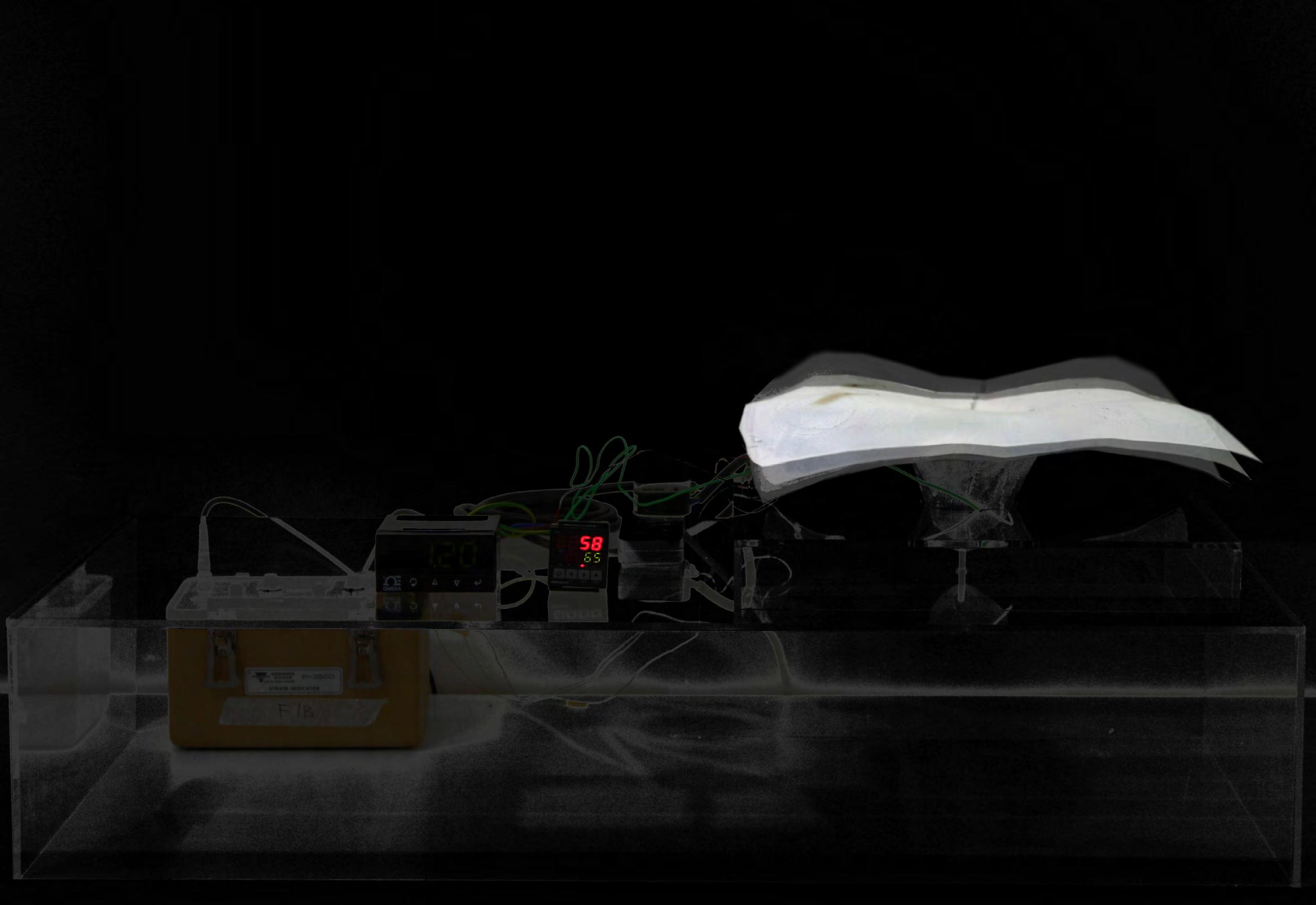

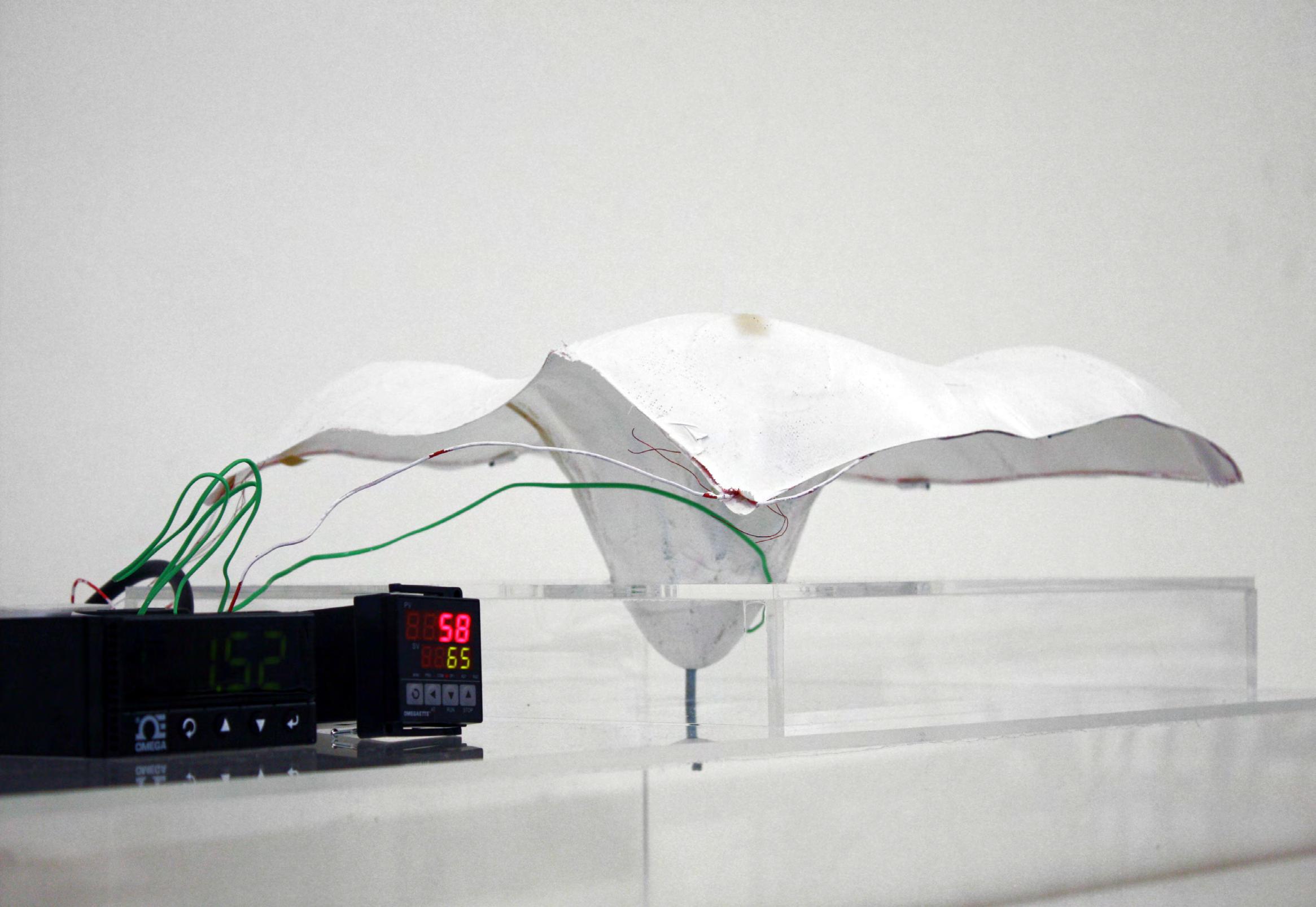

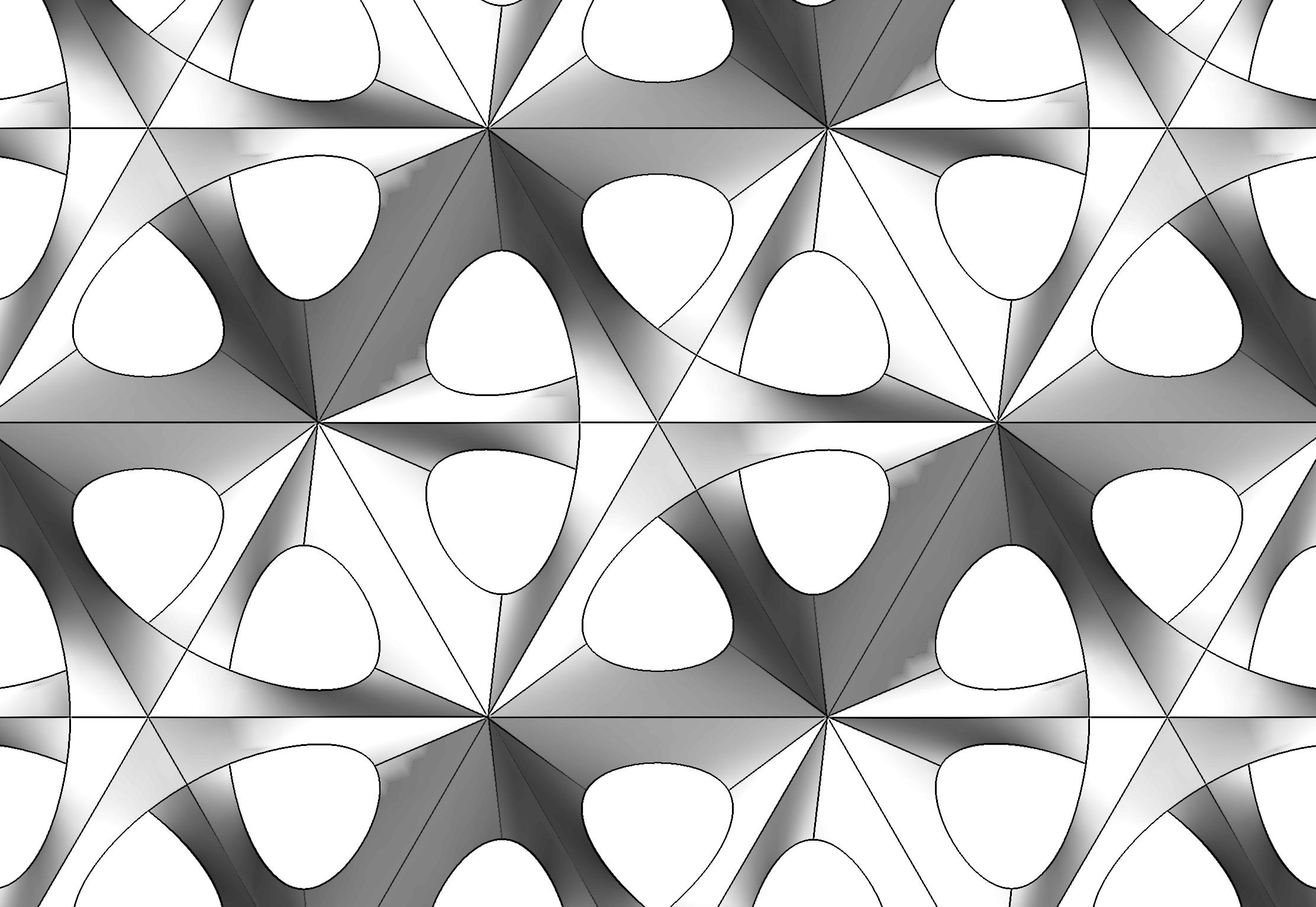

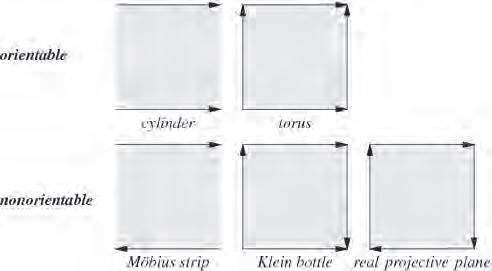

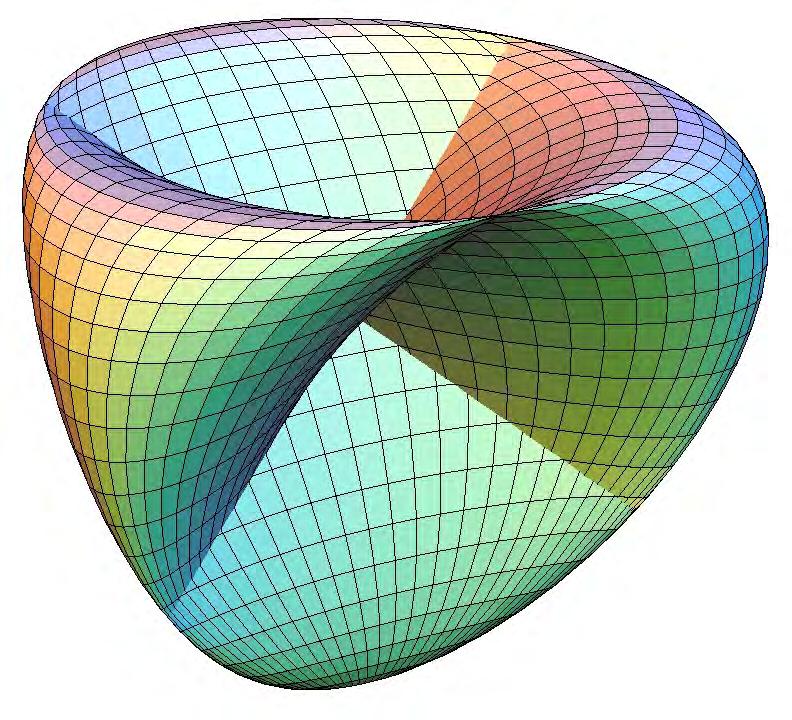

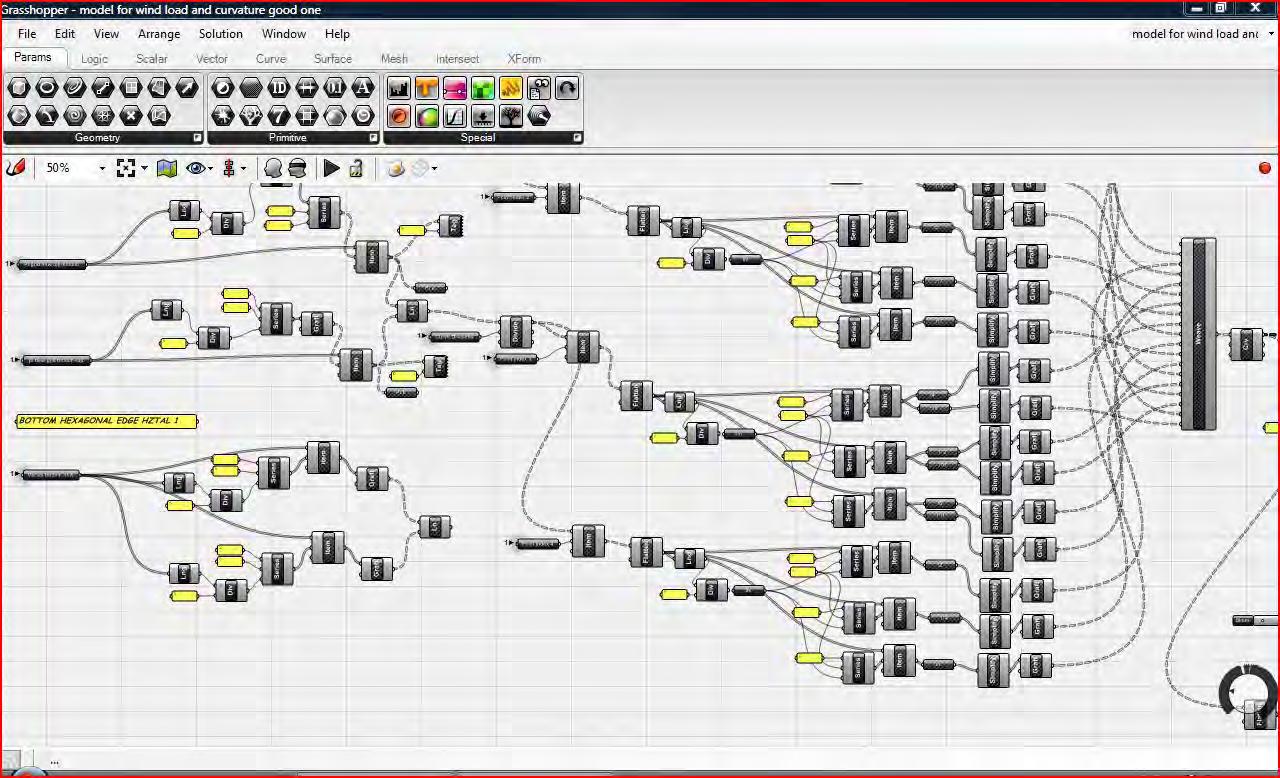

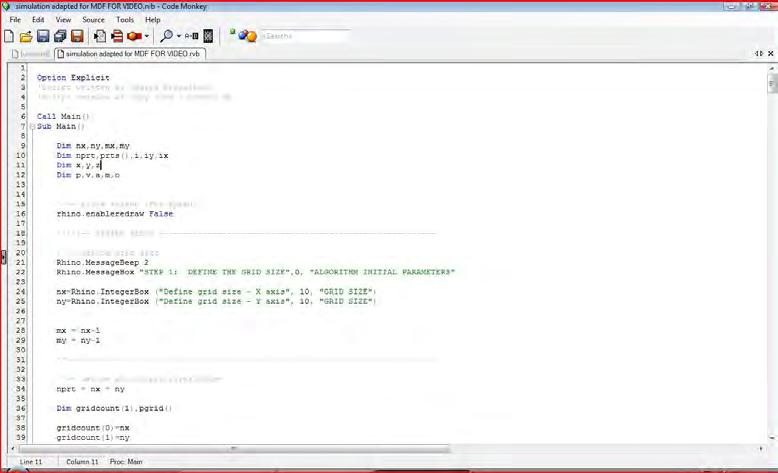

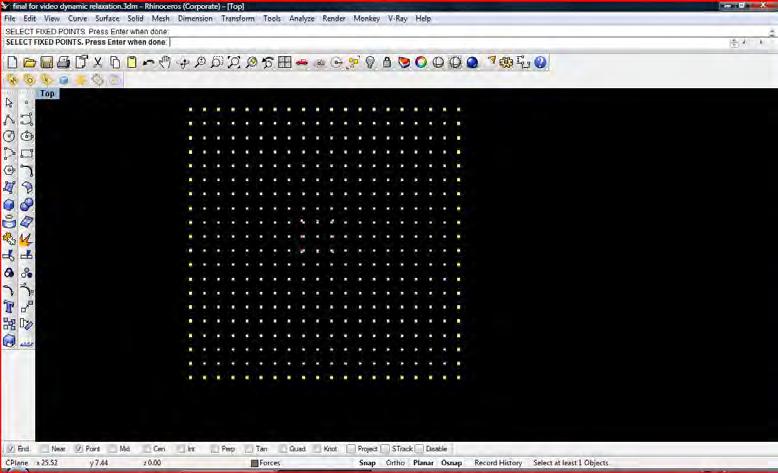

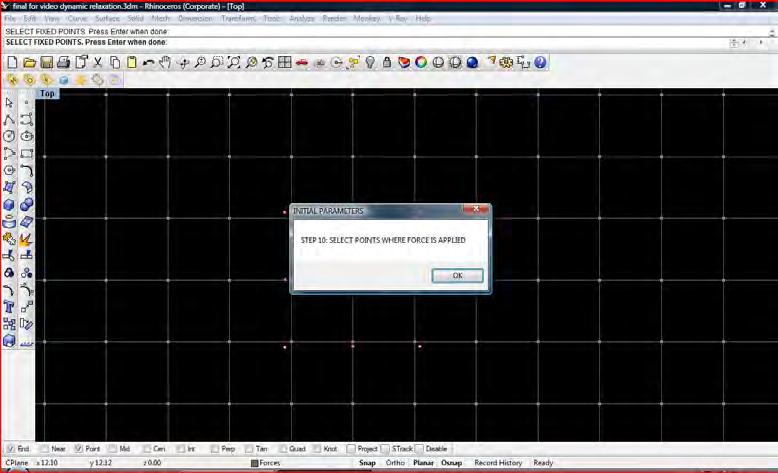

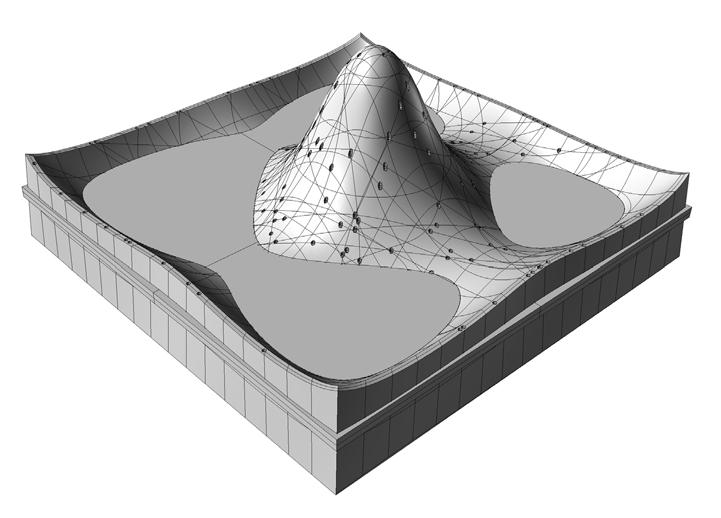

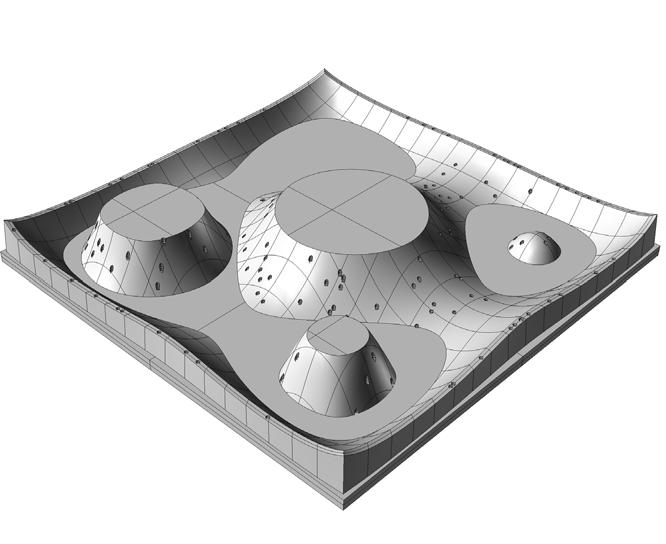

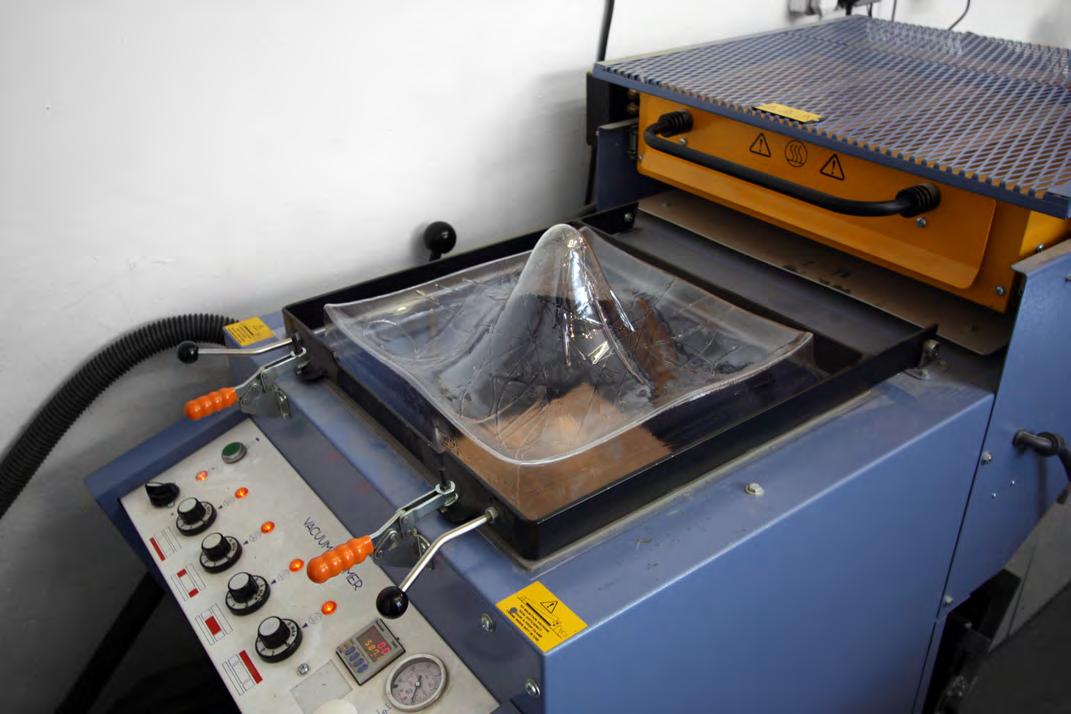

Because of the various properties of light, all of which also occur within a fibre optic cable, fibre optics can be used to measure strain, temperature, or pressure. This can happen