13 minute read

LNG

Høglund technician’s on-board the Horizon Reliance

Høglund wins COSCO award

Advertisement

Norway’s Høglund has announced that it has been awarded a contract to deliver Automation and Fuel Gas Supply System (FGSS) for the 2,400 teu containership Horizon Reliance. In partnership with China’s COSCO Shipyard Group, Høglund will deliver a total integrated solution on the vessel, including the installation of FGSS, Power Management System (PMS), Ship Performance Monitor (SPM) and digital solutions for data collection, as well as the full automation of all the new systems on-board the ship. Rather than recycling this 274 m x 30 m ship built in 1979, owner Sunrise Reliance LLC’s choice to entirely retrofit and refurbish the ship signals the company’s commitment to environmentally conscious action.

Høglund will design, engineer, manufacture, supply and deliver a fully integrated automation solution to support the vessel’s transition from steam propulsion power to a dual-fuel vessel. This includes a high-pressure FGSS - with a design supply pressure of 320 bar - and Høglund’s signature PMS and SPM to effectively drive fuel savings and ensure safer and more reliable vessel operations for Horizon Reliance. The PMS will ensure that the generators onboard function more efficiently, while the SPM will enable and facilitate the analysis of the power usage for its optimisation.

As part of the total automation of the new systems on-board the vessel, Høglund will also incorporate digital solutions for data collection on the ship. By integrating these systems, Høglund enables better access and quality of operational data for owners and crew, and better control over the systems. Following the systems integration, maintenance and future upgrades will become simpler, reducing total lifecycle costs.

The new digital solutions will allow the owner to access detailed performance and operational data from all the systems on-board the vessel and will facilitate informed decision making with regards to operations optimisation. The automation and digital work on the ship will effectively protect and future-proof the asset, improve its management and environmental performance, and prolong the life of the vessel. Høglund will ensure that the Horizon Reliance is adapted to meet the new requirements of the industry and to successfully overcome the new challenges in the market. Høglund’s expertise will allow Sunrise Reliance LLC to operate in a manner which assures a greener future for the Horizon Reliance, where the new systems on-board will help the ship to meet the latest regulations on carbon emissions and significantly reduce its environmental impact, as well as raise the sustainability standards and overall green profile of the vessel.

This project is another example of the increasing recognition in the industry of automation’s role in maximising safety and reliability and improving the environmental performance and the lifespan of shipping assets.

Wärtsilä signs agreement with Simon Møkster

Finland’s Wärtsilä and Norway’s Simon Møkster Shipping have signed a collaboration agreement to carry out a feasibility study on utilising ammonia as the main fuel in dualfuel engines where LNG is the alternative fuel. The aim is to demonstrate the feasibility of converting vessels for dual ammonia – LNG operation, and that it can be carried out safely and efficiently.

“We are excited to join Wärtsilä in this project. We see this as a step towards meeting

The Stril Pioneer

10 GasLog LNG tankers will benefit from being covered by a tailored Wärtsilä OMA

our targets for reducing greenhouse gas emissions, and our ambition is to cut our fleet’s CO2 emissions by 40% by 2030. By 2050 we expect to reach net-zero carbon emissions,” says Anne Jorunn Møkster, Owner and CEO Simon Møkster.

“Decarbonisation is central to the future of shipping, and Wärtsilä is totally committed to helping our customers achieve this goal. This collaboration agreement represents further evidence of this commitment. We are leading the way towards the adoption of alternative cleaner future marine fuels through extensive testing and research, and we see ammonia as an extremely promising option,” says Cato Esperø, Head of Sales Norway, Wärtsilä.

The testing will be carried out on the Stril Pioneer, an OSV currently operating with Wärtsilä 32DF dual-fuel engines using LNG as the primary fuel. Simon Møkster has been one of the pioneers in the use of LNG as a marine fuel, adding the Stril Pioneer to its fleet in 2003. By using a blend of ammonia and LNG, emissions of CO2 from the combustion process will be considerably reduced.

Simon Møkster Shipping is a supplier of modern offshore support vessels with high quality specifications, designed for operations in harsh weather conditions. The company’s head office is located in Stavanger, Norway and main operational area is the North- and the Barents Sea. Møkster has a fleet of 17 vessels and approximately 500 employees onshore and offshore. Simon Møkster Shipping is 100% owned by the Møkster family. Møkster has a long term perspective for both ownership and chartering activities. Strong focus on health, safety, environment and quality are fundamental for all of Møkster’s activities.

OMA with GasLog

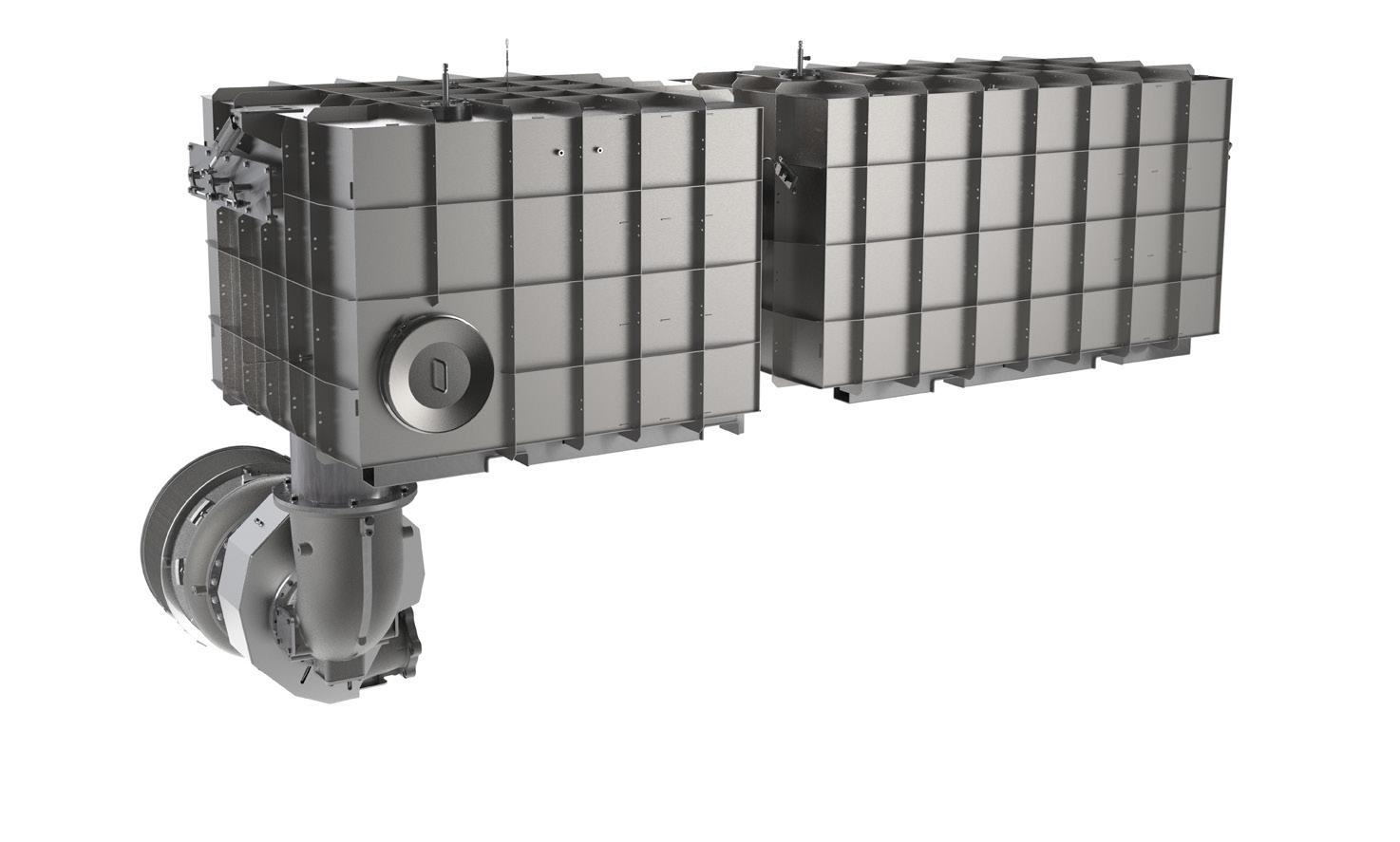

Wärtsilä’s Optimised Maintenance Agreement (OMA) has been selected by Greek shipowner and operator GasLog to cover 10 of the company’s LNG tankers. The agreement is designed to ensure certainty of operations with budgeted maintenance costs. The tailored agreement covers the vessels’ twin two-stroke dual-fuel main engines, enabling them to benefit from the latest condition monitoring and asset diagnostic services.

These include Wärtsilä’s unique Expert Insight solution and remote operational support capabilities. The Expert Insight digital predictive maintenance innovation utilises artificial intelligence (AI) and advanced diagnostics to provide accurate and pro-active advice and recommendations. Together with Wärtsilä’s vast experience and deep in-house knowhow, the system is able to promptly recognise performance deviations, should they occur, thus allowing timely corrective and mitigating actions to be taken, thereby increasing uptime. By ensuring efficient operations, emission levels are lowered.

Expert Insight is estimated to reduce unplanned maintenance by as much as 50%, and to deliver an up to 5% improvement in fuel efficiency, with a corresponding reduction in emissions. The service is delivered via Wärtsilä’s Expertise Centres strategically located around the world.

“To achieve optimal operational efficiency, we need to take advantage of the latest and most advanced technology. Wärtsilä’s OMA provides this. We have worked closely with the Wärtsilä team to create a customised agreement that addresses our main concerns and needs while providing an efficient means for us to manage both costs and risks,” says Kostas Karathanos, General Manager, Innovation & Technology at GasLog.

“This agreement represents the smart way for ensuring the efficient maintenance of complex modern marine engines and related systems. By ensuring optimal engine efficiency, which in turn minimises emissions, it is also a valuable contributor to global efforts to decarbonise shipping,” says Rajeev Janardhan, Sales Manager, 2-stroke engine Lifecycle solutions, Wärtsilä Marine Power.

The OMA is an important element within Wärtsilä’s Lifecycle Solutions offering, which is aimed at strengthening the business performance and competitiveness of its customers. The broad range of services that enable reliable and efficient vessel operations include 24/7 remote technical support, contract management, maintenance planning, and annual engine health audits. The planning and supply of spare parts required for engine overhauls is also included.

GTT wins SHI containership order

France’s GTT has been chosen by South Korea’s Samsung Heavy Industries (SHI) to design the cryogenic fuel tanks of six LNGfuelled containerships. Used as a marine fuel, LNG is today the best industrial tool to preserve air quality, a major public health issue. It reduces sulphur oxide emissions by 99%, fine particles by 91% and nitrous oxide emissions by 92%. It also reduces ship emissions by up to 20% of CO2 compared to a conventional ship.

Each LNG fuel tank will be fitted with the Mark III membrane containment technology developed by GTT, demonstrating that GTT technology is as attractive for mid-size size container vessels as for very large ones. The vessels deliveries are scheduled to occur between the third quarter of 2023 and the

The ABS-classed Rayah

fourth quarter of 2024.

In addition to the engineering services and technical assistance at the shipyard, GTT will assist the operator through every step of its first LNG-fuelled projects - commissioning of the LNG tank, first LNG bunkering operations, as well as further specific LNG operations and maintenance of the vessels. Moreover, GTT will provide LNG training for the crews, supported by its proprietary G-Sim training simulator, which replicates the future LNG operations of the vessels. GTT will also offer its HEARS emergency response service with 24/7 technical assistance.

In addition, GTT will fit these six vessels with its GTT Digital platform, a ‘smart shipping’ solution to monitor and optimise the operational performance of the vessels and further reduce their energy consumption and environmental footprint.

ABS classes VLCC

The ABS-classed Rayah, Bahri’s first LNG-ready very large crude carrier (VLCC), has been delivered. The 319,000 dwt double-hull tanker was built by International Maritime Industries (IMI) and Hyundai Heavy Industries (HHI) at HHI’s shipyard in Ulsan, South Korea. The vessel features the ABS SUSTAIN-1 notation as well as the LNG Ready notation recognising its preparations for a future retrofit for LNG-fuelled operation.

The ABS Sustain notations demonstrate adherence to certain UN Sustainable Development Goals related to vessel design, outfitting and layout that can be controlled, measured and assessed. They establish a pathway for sustainability certification and reporting. Both the SUSTAIN-1 and LNG Ready notations reflect Bahri, IMI, and ABS’ commitment to the environmental protection elements of Saudi Arabia’s 2030 Vision.

“ABS is a world leader in gas as a marine fuel and is committed to helping shipowners on their decarbonisation journey with a flexible approach to fleet modernisation. This is an innovative vessel that is leading the way in terms of its design and its approach to sustainability, and we are proud to have been able to use our expertise to support its development,” said ABS Chairman, President and CEO, Christopher J. Wiernicki.

IMI CEO, Fathi Al-Saleem, said, “The completion of this project is a major milestone for us and a reflection of the hard work and collaboration of everyone involved. Working with our partners, we have successfully delivered the vessel on time and to the highest international shipbuilding standards, in line with the ABS Sustain notations. We aspire to become a global leader in sustainability and environmental excellence - receiving ABS’ notations is a testament to the steady progress we are making towards that goal.”

“ABS is a long-standing business partner of Bahri Ship management and has been very supportive in Bahri’s initiatives of building the first of its kind VLCC vessel with SUSTAIN-1 and LNG Ready notations. Their knowledge in Alternative Fuels and Vessel engineering has tremendously helped Bahri in achieving this remarkable milestone. Going forward, Bahri considers ABS as one of its important business partners in Sustainable growth programmes and the Kingdom’s 2030 vision for environmental protection,” said Bahri Ship Management President, Abdulaziz Sabri.

ABS has introduced an ‘Alternative Fuel Ready’ approach to help shipowners prepare their fleets for the introduction of alternative fuels. Introduced through the Guide for Gas and Other Low-Flashpoint Fuel Ready Vessels, it is designed to support shipowners looking to build a new vessel or convert an existing one to use LNG, methanol, ethane, LPG, hydrogen, ammonia and other gases or low-flashpoint fuels. Download a copy of the Guide for Gas and Other Low-Flashpoint Fuel Ready Vessels here.

UECC takes delivery of Auto Advance

UECC has taken delivery of the world’s first dual-fuel LNG battery hybrid PCTC that is set to provide significant gains in energy efficiency and emissions reduction as it enters service this year to boost the leading European shortsea ro/ro carrier’s bold effort to decarbonise its fleet.

The vessel, to be named Auto Advance, is the first in a series of three newbuild pure car and truck carriers (PCTC) - measuring 169 m by 28 m and with capacity for 3,600 vehicles on 10 cargo decks – that are being delivered from China’s Jiangnan Shipyard. The remaining two sisterships are scheduled for delivery in 2022.

“Having brought into operation the first-ever dual-fuel LNG PCTCs five years ago, UECC is now taking delivery of the first of three of the world’s first dual-fuel LNG battery hybrid PCTC to be built. This is another big step forward in eco-friendly ship operations that shows we walk the talk,” says UECC chief executive Glenn Edvardsen. “This is also a technological milestone as the successful performance of the vessel in sea trials has vindicated our confidence in the viability of this innovative solution.”

UECC has taken the lead in the PCTC segment by developing the pioneering design, together with DNV and Jiangnan’s in-house ship designer Shanghai Merchant Ship Design & Research Institute, to incorporate proven technology in a new configuration geared to enhancing operational and environmental performance.

LNG battery hybrid technology, together with an optimised hull design for better fuel efficiency, will enable these newbuilds to exceed IMO’s requirement to cut carbon intensity by 40% from

2008 levels within 2030. Emissions of carbon dioxide will be reduced by around 25%, SOx and particulate matter by 90% and NOx by 85% from the use of LNG, while the newbuilds will also meet IMO’s Tier 3 NOx emissions limitations for the North Sea and Baltic Sea.

Dual-fuel engine technology has now been combined with an energy storage system (ESS), supplied by Finland’s WE Tech, incorporating a battery package from Corvus Energy that will be charged by a permanent magnet, directly driven shaft generator or dual-fuelled generators.

The ESS, which will provide power to the main switchboard with a DC link for power distribution, will enable peak shaving for the main engine and auxiliaries to reduce fuel consumption and emissions, with a controllable pitch propeller, bulb rudder and dual-fuel boiler also part of the power system.

These vessels will require only two auxiliary dual-fuel gensets, in addition to the main engine, as the ESS and shaft generator provide a spinning reserve to eliminate the need for another genset that would normally be required.

Battery capacity is based on detailed modelling of the vessels’ expected operational profile to economise on installation, with payback time for the ESS estimated at only five years, according to UECC’s head of ship management and newbuilding Jan Thore Foss. The hybrid solution, which has gained DNV’s Battery Safety notation, will be steered by an intelligent energy management system, supplied by Norway’s Kongsberg Maritime, that will serve as a control system for overall energy production and consumption – essentially the ‘energy brain’ of the vessel.

Batteries can be most efficiently charged while at sea using the shaft generator so that they are fully charged when entering port, enabling the vessel to manoeuvre in port using bow thrusters driven solely by battery power that can also supply the ship’s other energy needs while it is docked.

“This will effectively eliminate emissions while in port and these vessels are also equipped to connect to green power from shore that is becoming increasingly available in order to reduce harmful emissions of NOx, SOx and particulate matter,” Foss says.

Operational flexibility can deliver significant fuel efficiency gains and Foss believes this, combined with a low-emissions profile, will give the vessels an advantage in the European market as EU plans to include shipping in the Emissions Trading System are set to hike costs for pollutive vessels.

UECC’s energy and sustainability manager Daniel Gent says, “LNG is presently the most environment-friendly and widely available low-carbon fuel, with an estimated emissions reduction of around 25% compared with other fossil fuels.

“We are therefore taking advantage of the best available fuel solution now and combining this with hybrid technology to further cut emissions. But we are not locked into LNG and these dual-fuel engines are also ready to use alternative low-emission fuels such as biofuel, bio-LNG and synthetic LNG as these become commercially and technically viable.”

Edvardsen claims that UECC, jointly owned by green-focused players NYK and Wallenius Lines, is presently the only shipping company in its regional market segment that is investing in sustainable newbuilds. UECC has already achieved a substantial reduction in the carbon intensity of its fleet, but we aspire to do much more.”

SORJ

UECC’s first newbuild dual-fuel LNG battery hybrid PCTC Auto Advance