11 minute read

Offshore

Siem order for Vard Electro

Norway’s Vard Electro has secured an order with Siem Offshore to deliver its largest battery package to date for a vessel retrofit as the Norwegian shipowner proactively upgrades its fleet with hybrid power in pursuit of greener and safer operations with lower fuel costs.

Advertisement

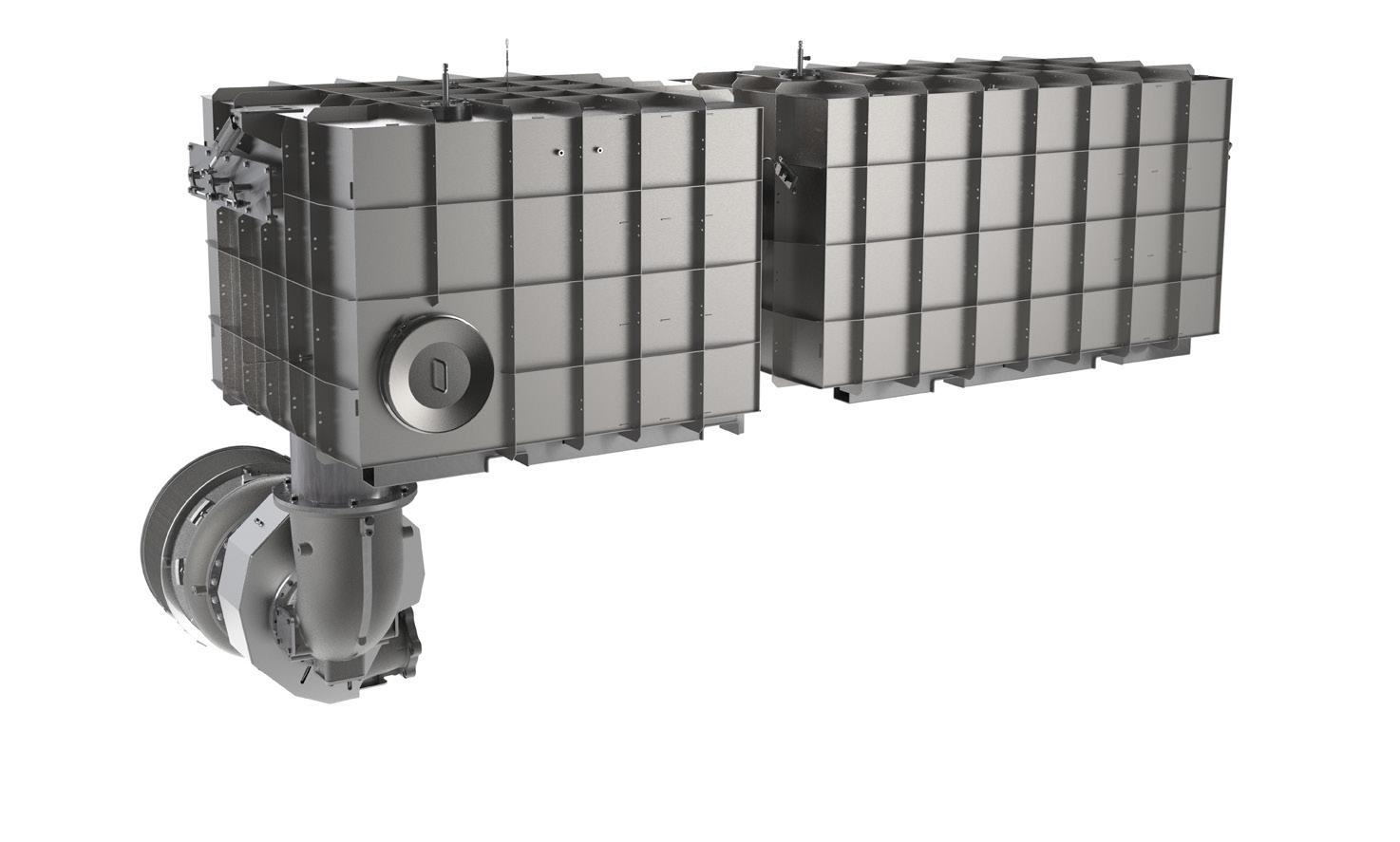

The newly signed contract covers Vard Electro’s SeaQ Energy Storage System (ESS) with two battery packs and a DC link, which will be installed in the first quarter of 2022 on one of Siem Offshore’s subsea construction vessels lined up for work in the wind sector.

The system will enable the vessel to operate in fully electric mode with zero emissions while manoeuvring in harbour or other restricted areas and will deliver estimated fuel savings of up to 20%, according to Vard Electro Head of Commercial Sales, Gisle Anderssen.

The SeaQ ESS stores excess energy either generated by the vessel or derived from shore connections with renewable power sources, to replace engines running on fossil-based fuels that drive propulsion and thruster systems.

Battery storage will be used as a spinning reserve in place of generator sets, enabling the vessel to run on fewer engines with more optimal load while still maintaining the requirement for redundancy.

An added benefit with batteries is peak shaving that takes the strain off the engines during big load variations by levelling the power and delaying the need for engines to restart. This results in significantly lower fuel consumption and reduced maintenance costs due to less wear-and-tear on engines.

“A significant benefit of battery storage is that it enhances the responsiveness of propulsion and other systems due to instant power response in line with load variations, offsetting slower ramp speeds with less responsive engines,” Anderssen says. This is particularly useful for offshore support vessels that are heavily dependent on DP systems for fast manoeuvrability in safety-critical situations, he explains.

The batteries for Siem Offshore will be supplied together with a DC grid for power distribution to consumers, with control and monitoring of the battery storage solution handled by the SeaQ Energy Management System (EMS) that interacts with existing control systems on-board.

“The flexibility of the SeaQ ESS system that enables it to be easily integrated with a vessel’s existing systems, as well as its advanced functionality, were key factors in our selection of Vard Electro for this retrofit to reduce our environmental footprint,” says Jon A. Houge, Operations Manager of Siem Offshore.

Vard Electro will act as system integrator for the turnkey project that will entail engineering, installation, integration, testing, and commissioning of the system comprising batteries, DC grid, EMS, energy storage inverter, filter and/or transformer, fire detection, and a cooling & ventilation system.

Anderssen says there is increasing demand for such hybrid retrofits both for offshore support vessels such as PSVs as well as larger ships, with Vard Electro’s modular system highly adaptable for ease of installation on a wide variety of vessels with minimal downtime.

“We are very pleased to have won this initial contract with Siem Offshore and look forward to collaborating with them on this project as well as possible future deliveries of battery systems. The award is further vindication of the proven efficacy of the SeaQ battery technology in optimising engine performance to deliver big fuel efficiency gains for shipowners amid increasing regulatory and market demands for low-carbon vessel operations.”

It is the latest in a string of similar deliveries of battery storage systems from the leading ship technology supplier’s SeaQ range that have demonstrated significant fuel savings for vessel operators while also reducing emissions since the first system was delivered five years ago.

One of the Siem Offshore fleet The Viking free-fall lifeboat

BW Offshore contract for Viking

Norwegian FPSO owner and operator BW Offshore has selected Denmark’s Viking Norsafe Free-fall Lifeboats, Daughter Craft and Davits for a large FPSO project which will operate off northern Australia. Primary means of evacuation will be three Viking Norsafe GES-50 Mk. III Free-fall Lifeboats - each able to carry 70 people - with secondary launch and recovery achieved by corresponding HD-50 Davits.

Also part of the package is a Viking Norsafe Munin-1000 Daughter Craft with capacity for 21 persons and a PLR-12005 Davit for launch and recovery. With a SOLAS crew of three persons, the Munin-1000 boat can recover 18 survivors from the water and is fitted with twin 300 hp engines and waterjets – giving the power and manoeuvrability to fulfil its Search and Rescue role.

The latest order continues the longestablished relationship between Viking and BW Offshore, spanning multiple projects, and

seals a deal that involved nearly two years of discussion of safety requirements. Fully compliant with SOLAS and DNVGL-ST-E406, the free-fall system is verified by ALARP process (as low as reasonably practicable) for operation in Australian waters.

Viking has delivered well over a hundred units of the Viking Norsafe GES-50 lifeboat. The free-fall lifeboat has been installed at 22 locations in Australian waters in recent years, effectively shutting out the competition. While original design attributes play a big part in its on-going success, Dawes explained that continual product development remains pivotal. This specific free-fall boat installation will feature a shortened launch ramp which saves space and weight. Viking’s capabilities in information exchange during the tender process had also helped in securing the order.

Viking will supply pre-tested boats and fully assembled davits for plug and play installation to reduce site activities subsequent to delivery. After the FPSO goes onstream, the Viking team in Perth, Australia will provide complete backup and maintenance support for the boats and davits.

Wärtsilä agreements with Eidesvik and Siem

Finland’s Wärtsilä and Norway’s Eidesvik Offshore ASA have signed a landmark cooperation agreement aimed at converting an offshore supply vessel (OSV) to operate with an ammonia-fuelled combustion engine with required fuel supply and safety system. This project will be the first of its kind ever in the world and has a provisional completion target by the end of 2023.

The OSV considered for a retrofit currently has Wärtsilä dual-fuel engines operating primarily with LNG fuel. The conversion will allow the vessel to operate with a 70%

The PSV Siem Pride

ammonia blend. Wärtsilä has already successfully laboratory tested an engine fuelled with a 70% ammonia blend. The ultimate goal is to achieve operation with 100% ammonia and with a minimum ignition fuel requirement.

As a fuel, ammonia has the potential to drastically reduce emissions of CO2. Both Wärtsilä and Eidesvik have stated their commitment to supporting the industry’s efforts to decarbonise its operations. “Using ammonia as a fuel is seen as a key future contributor to shipping’s energy transition, and we’re excited to be the first offshore ship owner taking this step. This project is yet another confirmation of our strong reputation as a pioneer in implementing new environmental technologies in both newbuilds and the existing fleet,” said Eidesvik CEO & President, Jan Fredrik Meling.

Eidesvik has a strong track record in supporting sustainable innovations, having used LNG fuel in its fleet from as early as 2003, and fuel cells from 2006. The company believes that to achieve the industry’s decarbonisation targets, not only newbuilds will need to have the appropriate technologies, but existing vessels must also be retrofitted accordingly. Furthermore, prolonging the life of existing assets requires less capital and is less energyintensive than building new ones.

Wärtsilä and Eidesvik are also partners in the EU-funded ShipFC project to equip a platform supply vessel, the Viking Energy with a 2 MW fuel cell running on green ammonia. The installation is scheduled to take place in late 2023.

This ammonia conversion project also ties in with one of the on-going work streams of the Wärtsilä-led Zero Emissions Energy Distribution at Sea (ZEEDS) project, aimed at developing ammonia-powered newbuilds and converting suitable existing vessels.

Meanwhile, Wärtsilä will upgrade the Siem Pride, an 89 m-long Platform Supply Vessel (PSV) owned by Siem Offshore, for hybrid engine and battery propulsion. The upgrade will enable the vessel to reduce the number of engines in use during operations, thereby considerably lowering its energy and fuel consumption. The order with Wärtsilä was signed in the second quarter, 2021.

Central to the conversion will be the Wärtsilä HY Module, which is a containerised solution on the deck of the vessel. Its latest-generation energy management system, which acts as the overall brain for the system, creates a high level of interaction with the ship’s other on-board systems. The installation will be connected to the existing 690 volt main switchboard. The engines in operation may run at up to 95% maximum continuous rating (MCR) without risk of overloading or black-outs.

“Decarbonising our operations is central to our strategy going forward, which is why we have taken this important step to convert the Siem Pride for hybrid propulsion. Wärtsilä has industry-leading experience and expertise in this field, and their upgrade solution will deliver considerable added value to the vessel’s performance,” says Jon August Houge, Operations Manager, Siem Offshore.

For the upgrade, Wärtsilä will supply the hybrid drive, the energy management system, the transformer, batteries, and the switchboard modification. The dynamic-positioning system will also be upgraded, while the ship design will be modified for the new arrangement. A deck house containing the equipment will also be installed. Finalisation of the project is projected for April 2022, at which time the vessel will be awarded DNV’s Battery Power notation.

The vessel currently operates with two Wärtsilä 34DF and two Wärtsilä 20DF dualfuel engines, as well as a complete Wärtsilä electrical package, including the integrated automation and power management systems, and the company’s Low Loss Concept power distribution system which features higher efficiency, lower weight and volume, and high system redundancy.

New notation for drillship

The Ultra-deepwater drillship Valaris DS-12 has become the first vessel in the world to receive the ABS Enhanced Electrical System Notation EHS-E. Valaris upgraded the vessel’s electrical system to secure the notation, which recognises sophisticated system design to improve reliability and enhance protection. The Valaris electrical system is specifically designed to allow the drillship to optimise powerplant performance, enabling operations on fewer generators and reducing emissions.

“It is great to see Valaris become the first to secure this notation, which recognises its commitment to sustainable operations and investment in advanced electrical systems to increase efficiency. As the world’s leading global offshore Class, ABS is well placed to help forward thinking operators such as Valaris achieve next generation operations,” said Matt Tremblay, ABS Vice President, Global Offshore.

“With this enhanced notation, Valaris DS-12 exemplifies our company’s purpose of providing responsible solutions that deliver energy to the world. I want to recognise our engineers, ABS and thank our customer, BP, for their support. This is truly a remarkable team achievement that paves the way to more sustainable deepwater drilling,” said Gilles Luca, Valaris Senior Vice President and Chief Operating Officer.

ABS has surveyed the upgraded system and tested it to ensure it can operate on reduced generator power. The short circuit and fault ride through capability was demonstrated on-board the vessel with ABS in attendance.

The Valaris DS-12

HMC has renewed its LTSSP with KD for an additional five years

KD renews Heerema support contract

Norway’s Kongsberg Digital (KD) has confirmed that Holland’s Heerema Marine Contractors (HMC) has renewed its Long-Term System Support Program (LTSSP) contract with the company for another five years. The LTSSP is in support of a K-Sim Offshore Crane simulation system, which features digital twins of HMC’s semisubmersible construction vessels, ships and barges. HMC’s simulation centre is located at the HMC headquarters in Leiden, the Netherlands.

Renewal of the LTSSP ensures KD’s continued commitment to maintaining HMC’s simulators at the leading edge of available technology, from hardware upgrades through to additional ship models, library objects and equipment models. Installed in 2015 as one of the world’s most advanced offshore heavy lift crane simulators, its usage ranges from confirming feasibility of new methods and equipment to optimising efficiency and safety performance for current execution methods.

“By renewing this LTSSP we are ensuring that our clients, offshore crew and project teams continue to benefit from the most advanced simulation-based training and project preparation on the market, simulating real-world scenarios,” comments Jan Pieter de Vries, Manager Simulations and Visual Products, HMC Academy. “KD has proved a competent partner, working in close collaboration with the team here at HMC to ensure that training and simulation needs are met. We are pleased to confirm our on-going relationship.”

HMC’s simulator platform was developed specifically by KD to meet its requirements, as a leading marine contractor in the offshore renewables and oil and gas markets, specialising in transporting, commissioning, and decommissioning offshore facilities. The Simulation Centre is a real-time offshore environment where offshore crew and project teams examine all project aspects and associated risks. It includes two offshore crane operator domes and a bridge with K-Sim DP simulator, based on the same Kongsberg Maritime K-Pos DP systems used on HMC’s vessels. Detailed models of HMC’s SSCVs, heavy lift vessel, tugs and barges ensure realistic scenarios and enable detailed pre-mission training for heavy-lift projects.

“HMC’s renewal of this LTSSP is a clear endorsement of the capability and longevity of our maritime simulation solutions,” concludes Andreas Jagtøyen, Executive Vice President Digital Ocean, KD. “Our commitment to supporting the maritime industry is not limited to providing the best technology, but also extends to ensuring that our customers gain value from their investment for years to come, through long product lifecycles and extensive service, provided by our 24/7 support network. Our LTSSP programme elevates our relationship with our customers beyond just being a vendor to rather act a trusted partner.” SORJ