CREATIVE SOLUTIONS

Our commitment to exceptional quality and personalized service aligns with our full range of services, all while keeping your budget in mind.

ADVERTISING AND PROMOTIONS:

Creation of niche publications, digital advertising, web development, and commercial printing

DESIGN & MARKETING SERVICES:

Graphic Design, Web Development, Ad Creation, Media Marketing, Digital Marketing

CUSTOM PRINTING:

Printing services for Brochures, Magazines, Business Cards, Postcards, and more!

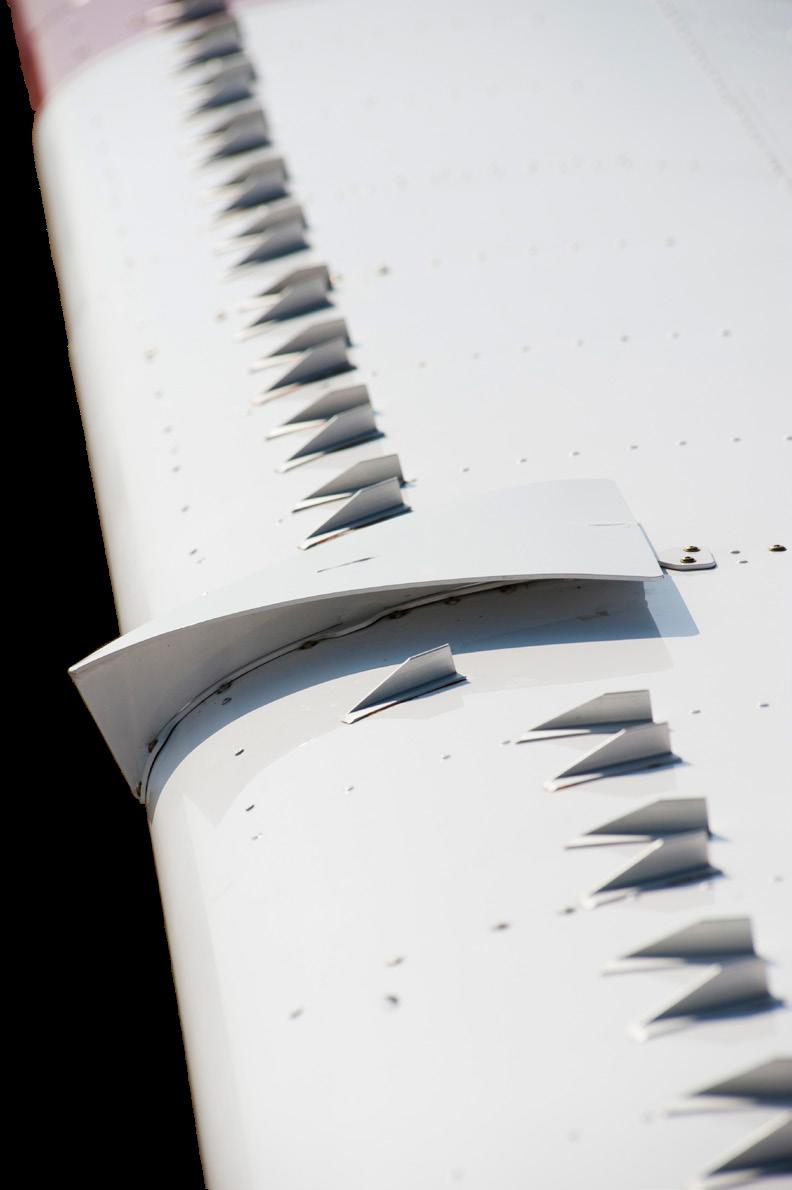

The most crucial function of a garment is to protect the human body from primary outer influences such as wind, rain, sunlight, dust, and mechanical influences. Protective clothing protects individuals exposed to life-threatening or hazardous environments during work. Aerial application ranks high-risk because pilots perform their tasks under drastic working conditions. This is why their clothing should protect against extreme conditions such as high temperature and flame, rain, aggressive and reactive chemicals, hazardous chemicals, etc.

The National Center for Biotechnology Information tested fire-resistant clothing by focusing on the most commonly used body positions (standing, squatting, or sitting) and extreme movements when wearing clothing and performing a job. The following is a summary of their findings.

Essential Functions and Design Considerations

Protective clothing protects individuals from environmental factors like wind, rain, sunlight, dust, and mechanical influences. For professionals in hazardous fields, such as firefighting, the clothing must offer robust protection against extreme conditions, including high temperatures, flames, water, cold, and dangerous chemicals. The design must also accommodate various body positions and movements, such as standing, squatting, and sitting in a cockpit environment.

Creating adequate protective clothing against heat and flame requires a collaborative effort involving designers, engineers, pilots and firefighters. The comprehensive design process covers developing high-tech products from initial concept through feasibility analysis, material selection, prototyping, and manufacturing. Integrating smart technologies with textiles enhances

the functionality of protective clothing, necessitating multidisciplinary collaboration among engineers, fashion designers, and scientists.

Advances in Fire-Resistant Materials

Significant advancements have been made in fire-resistant fibers, high-performance fibers with unique properties, and microporous materials. These innovations extend the life of protective clothing and improve its care while ensuring adequate protection. Various evaluation methods, including thermal manikin tests and hot plate tests under specific conditions, have been established to assess the effectiveness of these materials. Continuous research in textile technology, physiology, ergonomics, and functional design is pivotal in enhancing the durability, moisture transfer, and thermal stress management of protective clothing.

Material Selection

Firefighting gear and fire-resistant flight suits typically incorporate fire-resistant materials such as aramid fibers (e.g., Nomex®), modacrylic fibers, cotton fibers, or textiles treated with flame-retardant finishes. These materials are often blended to enhance comfort and transport moisture and heat. High thermal protection, as in fire turnout gear, is achieved through multilayer or thick textile materials, with each layer contributing significantly to the overall level of protection. For clothing in an aviation application, flight suits are made from aramid fibers such as Nomex®, modacrylic fibers, cotton fibers, or other textile materials with a flame retardant finish to achieve better comfort, which includes the transport of moisture and heat. This is extremely important for comfort when using

(Continued on page 78)

clothing systems in various activities, including extreme conditions. Recently, different techniques for characterizing fire-resistant textile materials have been conducted.

So far, new types of fire resistance fibers, highperformance fibers of unique properties, and microporous materials have been developed, which provide for the long life and easy care of protective clothing as well as, at the same time, providing the user with an adequate level of protection and safety. Special procedures of evaluating the characteristics of protective materials, tests with a thermal manikin and hot plates for the determination of fabric and clothing characteristics under special conditions have been developed. Scientists from different fields (textile technology, physiology, ergonomics, functional design, etc.) are continually working on research such as the development and production of protective clothing and materials, study of their durability during use testing by volunteers in simulated environmental conditions, research

on moisture transfer through clothing and thermal stress, and how to design and implement the appropriate test methods.

Researching Flammability Protection

A paper developed by the National Center for Biotechnology Information investigated the flammability properties of the clothing system for protection against heat and flame and analyzed the damage caused to clothing. A clothing system consisting of underwear comprises 70% wool fiber and 30% modacrylic fiber and overalls for protection against heat and flame, made of 55% modacrylic fiber and 45% cotton fiber, much like an aviator's flight suit.

Results

By testing with a fire manikin and an explosive fire simulator, data on the degree of burns in the case of

(Continued on page 80)

using a clothing system (underwear and overalls) that was exposed to an explosive flame for 4 seconds were obtained.

The clothing system consisting of underwear and singlelayer overalls intended for firefighters to extinguish open fires after exposure to explosive fire for 4 seconds was found to have minor damage. Visual assessment of the damage to the clothing system was performed for 116 seconds after the flame was extinguished in the chamber where the fire manikin test was performed. Based on the observations, it was established that there was no damage to the underwear. There was minor damage to the overalls on the tops of the pockets and the sleeves and part of the trousers below the knee. The visual assessment revealed that there was a shrinkage of material on certain parts of the overalls (shoulder area) and a partial change in color on the material of the overalls (dark brown and black) caused by fire (visible on the folds on the overalls, which appeared during the test.

Damage to the clothing system confirmed the results obtained by the computer display of test results on the fire manikin and microscopic analyses, which did not show damage to the structure. The results of the fire manikin showed that after 17 seconds, the first appearance of first-degree burns was 1% of the total area of human skin in the left forearm. Second-degree burns occurred on

the head but were not considered because the test was performed without head protection (without the use of a helmet and undercap). Four sensors indicating thirddegree burns were identified as invalid because during the calibration of the fire manikin itself, before the test, it was found that the sensors were out of order. Results from fire manikin and damage to the clothing system showed that the user, exposed to fire and heat, would not have injuries dangerous to health and life, thus showing that the clothing system met the expected properties of use/ protection.

If the user used such a clothing system exposed to direct fire for 4 seconds, they would survive without significant health problems. Still, they should immediately move away from further heat and flame exposure.

For the research, an analysis of the primary material from which the overalls were made and an analysis of the material after flame exposure during the fire manikin test were made. The primary material was made from 55% modacrylic fiber and 45% cotton fiber with a built-in antistatic grid, mass per unit area 295 g/m2, woven in canvas. The breaking force in the warp direction was 1049 N and 808 N in the weft direction. After exposing the overalls to explosive fire during the test on the fire

(Continued on page 82)

manikin and visual assessment of the damage, sampling of parts of the overalls in the direction of the warp and weft was performed.

Based on theory and conducted research, except for the critical factor of material selection, great attention should be paid to the functional design of clothing for protection against heat and flame. The tested clothing system provides a high degree of protection, partly due to the adequate use of fire-resistant underwear. The results of testing using the fire manikin showed that when using such a clothing system, the user would not suffer tissue damage, which could pose a danger to health or life if the users are immediately removed from the fire and heat.

If the user continues to use a clothing system exposed to explosive fire, the clothing system will not provide adequate protection due to the damage. Without fire-resistant underwear, the user would obtain burns in more areas than fire-resistant underwear, mainly if they used ordinary cotton underwear, which absorbs moisture faster. The user would "be cooked "when exposed to high temperatures. If the user were exposed to prolonged fire, the damage to the overalls and injuries would be more significant.

Research with the help of a fire manikin and an explosive fire simulator dramatically helps us to predict the degree of burns of users of the clothing systems and the possibility of survival. Such research is fundamental in the first phase of designing clothing systems, which should protect against heat and flame. All of the

materials used must be fireproof so that the failure does not further endanger the health or life of users. In the design and production processes of protective clothing systems, the cooperation of experts in materials and fibers, designers, constructors, technologists, and end users and manufacturers of protective clothing is necessary.

This research underscores the importance of material selection and functional design in developing practical protective clothing against heat and flame. The tested clothing system demonstrated high levels of protection, particularly with fire-resistant underwear. However, the protective properties of the clothing diminish after exposure to fire, emphasizing the need for ongoing improvements.

Collaborative efforts among material scientists, designers, engineers, and end-users are essential in designing and producing effective protective clothing systems. The study highlights the necessity of using fireproof materials and advanced testing methods to ensure user safety in hazardous environments.

The TG-IR and MCC results suggest that while the protective clothing system shows good initial stability against heat, further development is needed to improve its overall thermal resistance. Continuous innovation and rigorous testing are vital to enhancing the performance and safety of protective clothing for individuals working in high-risk environments.

AIRCRAFT – AG CAT

1971 Grumman AgCat G-164A, s/n 847. TTAF 19551, Geared 1340 w/ only 190 hours since Covington tear down, inspection, and power section replacement. 24v alternator, chip detector, single point fuel, 330 gal hopper upgrade, new fabric tail, extended wings, Hershey wing tips, aileron spades, heavy-duty gear, new 29in tires, Cleveland wheels, and brakes, new battery, new seatbelts, strobe lights, stainless booms, cp nozzles, Satlok Lite GPS system, Lane electric fan brake, rh boom shut off, smoker flagger, also extra yellow tag cylinder ready to install, spare pump, stainless dry spreader. $49,000. Call 509-641-2079

1972 Ag-Cat G-164A. S/N 926, TT Airframe 7,686, P&W R-1340-AN-1 (600 HP), TT SMOH 289, Blower Ratio 10-1, Overhaul by Tulsa Aircraft Engines, Excellent Compressions on all 9 Cylinders, 80 Gallon fuel bottom load, 300-gallon hopper bottom load, Satloc SLXG3 GPS with Light bar, Crophawk 7 flow control, Hershey Wing Extensions and Mods, most Inspections always done by Hershey Flying Service & Wallace Air Repair. Clean Northern Airplane, no Corrosion! Almost $9,000 spent on Fresh Annual Inspection done 09/18/23. Airplane is located in Bassett, Nebraska. It’s Ready to Work! $65,000. For questions and more pictures contact Tim: 432-788-7309

1975 Grumman G164. P&W 985-15B, Time since overhaul 440, Banner Aircraft, Dual Comm, VOR, transponder ADS-B Hershey Wings, extended TW. Hook, Smoke, 500 Letters, all lines, grapples, lead poles & hardware. 80 Gal. Hopper intact if you want to convert. $49,000. Call Mike at 813-390-5402

Ag Cat: G164A+, Export Special: G164A+, Fresh AmAg repair w/factory-jigged frameworks, New 335-Hopper, Ext’d/ Metal Wings, 80-fuel, 24V w/Strobes, E-Servo, TWL, Hybrid Combo. Ready for 1000 hr. service-run. Your certified R985/R1340 E&P installed. $85K includes CofAW4 Export flyaway, $90K in your container.

Contact +1 (870) 886-2418

Ag Cat QueenCat - QueenCat In Progress - S/N 566B Super B+ Mods, ready for Garrett or P&W Turbine, 400-gal, 120fuel, hi wings, heavy struts & wires, T.S. Tail, Heavy Gear, TL DAF Combo. $290K (YOUR FWF).

Contact +1 (870) 886-2418

AIRCRAFT – AIR TRACTOR

2015 Air Tractor AT-502B, N3081V Aircraft: 502B-3029 - Approx TT

2,706.3; Engine: PT6A-34AG - Approx TT 2,706.3; Propeller: Hartzell HC-B3TN-3D. Standard Equipment: 2” spray system, large streamlined booms, 2” bottom loading valve, 500-gallon fiberglass hopper, pump shut-off valve, 3-color polyurethane paint finish, 29X11 highfloation tires and wheels with dual 3-piston brakes, electrically operated high-lift flaps, 3-blade constant-speed reversing Hartzell propeller, 250 amp starter-generator, 170-gallon fuel tanks, strobe lights, turn windows, nose-mounted landing lights, attitude gyro, windshield washer & wiper and hopper rinse tank. Optional Equipment: Stainless Steel Cam Locks, Wingman, Bantam w/Flowcontrol, Smoker, Electric Brake Gr. Adj., GTR 205, GTX 335 & Hatfield Single Point Fuel. 0 Since Propeller Overhaul, 0 Since Starter Generator Overhaul, 0 Since HSI with CT Vane Overhaul, New Segments, Liner Overhaul, 0 Since Fresh Annual and Refurb done at Frost Flying Maintenance. $815K. Call Frost Flying at 870-295-6213

2016 Air Tractor AT-802, New to the market 2016 AT-802 with a -65AG. TTAE 4030, Engine since hot section

750, Hartzell HC-B5MP-3F TT 4030, SatlocFalcon with flow control. Hatfield bottom load fuel. Transland 10 vane spreader. Stainless CP 09 spray Nozzles. Wingman auger system. Garmin radios with ADSB in and out. Annual 4/24 Prop IRAN 4/24. Aircraft to be delivered with fresh hot. $1,200,000. Call Charlie at 318-235-0187

2009 Air Tractor AT-402B, N422RD, PT6A-34AG, Cascade Inlet, Smoker, Right-hand boom shutoff, Night work lights, Stainless spray system, AFTT and ETT is 30hrs. $1,075,000. Call Neal Aircraft at 806-828-5892

1995 Air Tractor 802 -67AG, TTAF 3533.1, TTE 2842.6, SHSI 963.9, Hartzell Prop HC-B5MA-3D TSOH 361.0, Last annual inspection: 10-2022, Eddy current inspection due at TTA 3591.1 (in 58 hours), Spar cap replacement due at TTA 4100 (in 566.9 hours), 374-gallon fuel. NOTES: Wing spar cap center spice can be modified with big butterfly, long splice blocks and cold worked to achieve 8000-hour safe life. Equipment: Air Tractor fire gate, Spray pump with Weathero fan, Ag Nav Guia with flow control, Aluminum booms with CP nozzles, Dual side loader, Single point fuel, RH boom shut off, Dual cockpit with dual controls, KMA 24H audio panel, Garmin GPS 150, Dual KX 155 nav coms, KR87 ADF, KT76A transponder, NPX FM transceiver, AA22-110 radio, S-TEC autopilot. Call South Delta Aviation at 479-935-4891

2024 Air Tractor AT-802A-67AGOctober Delivery. Factory Options Include: Garmin audio panel, radio, transponder, and Smoker.

Call Southeastern Aircraft Sales for details: 772-461-8924

2008 AT-402B -15AG N281LA, Serial No. 402B-1201, Aircraft has been

owned and operated in the Midwest and is very clean. Recent hot section inspection, propeller overhaul, and June 2024 annual. New main gear, tailspring, and hardware installed at annual. Options Included: Lane Electric Brake and Ground Adjustable Fan, Smoker, Bottom loading fuel system, Satloc Bantam with Intelliflow, VHF Comm Radio, Garmin 496, CP Nozzles, AmSafe Inflatable Restraint System, Electronics International Fuel Flow Meter, Vortex Generators, LED Lights All Around with Bayou Pulse Lights, Right Hand Boom Shut-Off, Transland In-Line Strainer, Analog Gauges.

Great aircraft and ready to work. $735K.

Call Lane Aviation at 800-231-6376

2004 AT-802A, PT-67AG, TTAE 9606, TSHS 700, Great shape, Hatfield fuel system on both sides, load system with Reabe hopper gauge on both sides, Reabe canopy, stainless steel AFS nozzles, G4 with flow control, 7”gate, Amsafe belt, pulsating light, 10,000 hrs left on wings, over $600k into it in last 3 years. Fresh annual. $1,100,000.

Call 605-924-6891

2010 AT-402B -15AG, N976CW, Aircraft has been owned and operated in the Midwest and is very clean. Recent hot section inspection and June 2024 annual. FCU Midlife was completed at 2,728 hours, propeller was overhauled at 2,933. New main gear, tailspring, and hardware installed at annual.

Lane Electric Brake and Ground Adjustable Fan, Smoker, Bottomloading fuel system, Satloc Bantam with Intelliflow, VHF Comm Radio, Garmin 496, TeeJet Nozzles, AmSafe Inflatable Restraint System, Electronics International Fuel Flow Meter, Vortex Generators, LED Lights All Around with Bayou Pulse Lights, Right Hand Boom Shut-Off, Transland In-Line Strainer, Analog Gauges. Great aircraft and ready to work. $725,000.

Call Lane Aviation at 800-231-6376

2021 Air Tractor 802-65AG, 1117 Hours, Satloc G4, Flow Control, Transland 7 1/2” Hydraulic Gate, Wingman, CP11’s with swivels, 15,20,25, AFS check valves, Lane Brake, Smoker, A/C, LED Pulse Nose Lights, Fresh Annual, Always Hangared. Additional $8,500 spreader only used 2 seasons also available to purchase. Ready to go! Call Bob Blair at 573-421-2573 for more information

2011 Air Tractor AT-802A, N2039Y Fresh out of annual. THIS AIRCRAFT IS LOADED AND 100% READY FOR ROW CROP, RICE, PINE TREE FERTILIZER, ETC. Air Tractor Fixed Wing Single-Engine PT6A-65AG, TTAF: 7612, Engine TT: 7315, TTSHot 0, CT Blades 2006 TTSN, CT Blades 522 TTS Stretch Test, Start/Gen 0 HRS SINCE OH, Prop 0 HRS SINCE OH, Flat Fan CPs with AFS Check Valves, Vondran computer-controlled 10” Hydraulic Gate with Variable or Constant rate flow with 12 vane Breckenridge spreader, G4 GPS with flow control, Wingman, 5 Bladed adjustable lane fan. Additional pictures available upon request. $915,000. Call 318-552-6533, call or text 318-669-8785, or email monticellofly@gmail.com for more information

1996 AT-502B, TTAF 6367, Cascade Conversion-42, TTE 3174.3, MVP50 engine monitor, TT Avia Prop 726.7, Bantam GPS with Intelliflow, Lane Brake, VGs, storm shield/cutters, fast start, Reabe hopper gage, spreader. fresh annual and hot section inspection. $595K. Call 563-880-9641

2006 Air Tractor 502B, TTAE 7251.7, PT6A-34AG, Time since overhaul 7151.7, Time since hot section 125, Hartzell HCB3BN-3D Propeller, TTProp 7151.7, Prop

since overhaul 300, Cascade Pressure cowl installed, AC and heat, Satloc G4 and flow control with L7 light bar, Lane fan and brake, 10 vane spreader, stainless CP09 nozzles, Garmin radio package (Nav xponder and audio panel. $575,000.

Call Charlie at Adams Flying Service, 318-235-0187

2023 Air Tractor 802A-1001, PT6-67AG, Brackett Air Filter in X-Flow Frame, Hartzell 5 Blade Prop, MVP50T, Kawak Engine Control, 308 Fuel, Hatfield SPF, Stainless Steel Spray System with Aluminum Agrinautics Spray Pump, Large Electric Fan and Brake, Garmin G4 with IF3 Flow Control, 50% Boom Kit, Right Hand Boom Shutoff, Reinforced Boom Hangers, Quick Detach Center Boom Cap, Smoker, 7.5” Hydraulic Gate, Hydraulic Wingman, Black Horizontals, Rear View Mirror. Available Fall of 2024 with fresh annual, fresh HSI, and around 1200 hours TT. $1,925,000.

Call Rick Turner with Neal Aircraft at 940-564-6822

2023 Air Tractor 802A-1006, PT6-67AG, Brackett Air Filter in X-Flow Frame, Hartzell 5 Blade Prop, MVP50T, Kawak Engine Control, 308 Fuel, Hatfield SPF, Stainless Steel Spray System with Aluminum Agrinautics Spray Pump, Large Electric Fan and Brake, Garmin G4 with IF3 Flow Control, 50% Boom Kit, Right Hand Boom Shutoff, Reinforced Boom Hangers, Quick Detach Center Boom Cap, Smoker, 7.5” Hydraulic Gate, Hydraulic Wingman, Black Horizontals, Rear View Mirror. Available Fall of 2024 with fresh annual, fresh HSI, and around 1400 hours TT. $1,925,000.

Call Rick Turner with Neal Aircraft at 940-564-6822

2008 Air Tractor AT-602, N602MS, Reduced by $100K, 4210 TTAE, Zero time on engine since $500K spent due to FOD damage. 0 time since new blades,

(PT + CT) Other work done due to FOD damage, Compressor work completed, all records from Dallas Airmotive upon request. New propeller installed at 3,810 hours, Large fuel 280 gallons, Hatfield fuel, SATLOC w/Flow Control, Radio console, Night lights, No airframe damage, hangared & mostly owner flown, fresh annual date of sale. $750K. Call Dow at 573-225-8019

2014 Air Tractor 504, IFR panel. Ready to go to work. Located At KMCK.

AFTT:1609.6, Engine: PT6-34AG, ETT:1609.6, HSI completed 600 hrs ago. PTT: 1609.6 Annual Due March 2024. Asking $850K OBO.

Contact RWA at 308-777-2585 for more info

1987 AT-400, ENGINE TT: 5,900, HSI: 300, PROP TSOH: 400, wings redone at George’s 1,400hrs ago, new paint at 1,400hrs ago, FCU overhauled in 2022, hydraulic wingman, 38”gate box, all new tail spring and hardware, 402 gear, brakes redone from top to bottom, SATLOC, flow control, falcon light bar, lane electric brake, new stainless booms, cp11 nozzles, spreader, all lights are LED, A/C and heat, VGs, smoker, single point fuel, 3 piece windshield, No corrosion. Times may change, this plane is working. Plane is in great shape and ready to go to work, clean plane. $330,000. Call 731-676-2973

2008 AT-502B, S/N 2630, TTAE 5470, PT6-34AG, HSI completed by Covington at 4442.6 TT, Hartzell 3 Blade Prop, 216 Gallon Fuel, VG’s, Single Point Fuel, CP Nozzles, Smoker, Lane Electric Fan and Brake, Satloc Bantam with G4 Screen and G7 Lightbar, Garmin 660 GPS. $695,000.

Call Rick at Neal Aircraft at 940-564-6822

1978 Air Tractor 301 - Bailey conversion 302 Air Tractor with Garrett TPE331-1. Engine is near hot section and wings are 70 hrs away from needing rebuilt. Total time is low 4380. The airframe is in excellent condition. Winglets, tinted side windows, Bantam GPS, reabe hopper gauge, AC, hopper rinse. Could convert back to 1340, or use STC to convert your 301 to turbine or rebuilt motor and wings and continue on. Parting this bird out is an option, too; I can keep the firewall forward. Paint is a solid 8. No corrosion, western KS plane, no dry fertilizer here. It’s not worth much.

Call to make an offer. Flying daily, so times will change. 1-785-657-7400

1997 AT-401B Includes fresh annual. 0 IRAN prop, 0 IRAN engine (Covington), 0 Eddy Current insp. Complete logs since new. Only 16 401Bs currently registered in the U.S. $265K which includes $50,000+ of additional equipment and inventory. See spec sheet for all the details. $265,000.

Contact Bob 507-430-5114

1997 Air Tractor AT-602 - 60AG, N5045S, TTE 11,355.6, TSIRAN 2,277.0 by RT Turbines, TSHOT 998.8 by Geroge’s Aircraft, FCU installed in 2018 - 996.1 since installed, Hobbs 1355.6, Prop TT 11,355.6, TSIRN 998.8, TSOH 2,277.0, TTAF 11,355.6, Spars done at 6643.1 by Frost flying, Spars next due at ACTT 13,143.1 = 1787.5 hrs. left till replacement, New main gear in 2017 at Hobbs 9629.8, New engine mount in 2021 - no AD’s, Storm Shield in 2020, New turtle deck in 2023, New Kawak Throttle Quadrant in 2023, New Reabe Hopper Gauge in 2023, All new AC hose, conducer and dryer in 2022, Load Hawg, Hatfield fuel. $550,000.

Call Aaron at 870-253-8242

1995 Air Tractor 502B-0285 - TTAF 10,557.9, Hobbs 0557.9, TTE 9846.5, Prop TSMOH 3209.2, Annual done in September of 2023 at 10,532 TT. Wing

spars replaced in December of 2013 at 7486.6 TT, 6728.7 time left on 9800-hour spars.PT6-34AG, Hartzell Three Blade Prop, Kawak Throttle Quadrant, Hatfield Single point Fuel, Stainless Steel Spray System with CP Nozzles, Smoker, Storm Cutters, Reabe Transparent Cockpit Top, Air Conditioning, Cockpit Heater. $450,000.00.

Call Rick Turner at Neal Aircraft at 940-564-6822

2023 Air Tractor 802A - 1089 N609LM, PT6A-65AG, 1,000 TT, Stainless Steel Cam Locks, Smoker, 308 Gallon Fuel, Pulse Lights, Fast Start, Amphibious Float Prep, Hatfield Single Point Fuel, Avionics Package, 10” Hydraulic Vondran Gatebox, Falcon w/IF3 Flowcontrol.

Call Frost Flying at 870-295-6213 for the price

2018 Air Tractor 802A - 0768 N80393, PT6A-65AG, 3,500 TT, Stainless Steel Cam Locks, Electric Brake Gr Adj, Smoker, Pulse Lights, Hatfield Single Point Fuel, Air Repair 10” Hydraulic Gate, G4 w/Flowcontrol, Kawak Throttle Quadrant, Wingman, Air Repair Tail Deflector, Trig ADS-B Out System.

Call Frost Flying at 870-295-6213 for the price

2022 Air Tractor 802A - 0949 N11703, PT6A-65AG, 1,700 TT, Stainless Steel

Cam Locks, Electric Brake Gr Adj, Smoker, Pulse Lights, Single Point Fuel, 7 1/2” Hydraulic Gate w/Transland Controller, G4 w/Flowcontrol. Wingman, Tail Deflector, X-Flow System, 308 Gallon Fuel.

Call Frost Flying at 870-295-6213 for the price

2022 Air Tractor 802A - 0944 N347ER, PT6A-65AG, 2,600 TT, Stainless Steel

Cam Locks, Electric Brake Gr Adj, Smoker, Hatfield Single Point Fuel, 10” Hydraulic Vondran Gate, G4 w/ Flowcontrol, Wingman, X-Flow System, 308 Gallon Fuel. Comm Radio. Call Frost Flying at 870-295-6213 for the price

1994 Air Tractor 401 - TTAF 7275, R1340, 117 hrs SMOH Tulsa, Hamilton Standard Propeller 22-D40 Hydromatic, Prop TT 7275, Prop SOH 1179, Vortex generators, Drop boom, Ag Pilot X, Crop Hawk, Smoker, New Landing Gears 2022, Lane Electric Fan Brake, A/C. $250,000. Call Chuck at 320-760-0713

2022 AT-602, N602AF, TTAE 612, PT6-60AG, Hartzell 5 Blade Prop, 234 Gallon Fuel, MVP-50T Engine Monitoring, Kawak Engine Control Quadrant, Hatfield Single Point Fuel, Garmin Com and Transponder, Ag Pilot X with Flow Control, CP-09-3E Spray Nozzles, Smoker, Lane Electric Fan and Brake. See spec sheet for more details. $1,475,000. Call Rick at Neal Aircraft 940-564-6822

1989 AT-401, Cascade Turbine

Conversion M601E-11 AFTT: 8,662.0 hrs

Engine TT: 1,910.4 hrs shop revision completed by GE May 2023 all ADs and SBs complied with. Propeller: 1,881.5 hrs. Wing Spar Replaced December 2017 at 7,642.9 hrs AFTT. Gear Legs replaced in 2014 at 7,025.7 hrs IAW Air Tractor SL. 170 US Gallon fuel with Turbine Conversion Single Point Fuel System AgNav Platinum Guidance and Flow Control ReaBee Hopper Qty System 2 sets of booms ASC-A10 and CP09-3P. $475K.

Call 306-786-3345

1994 AT-401, Cascade Turbine

Conversion M601E-11 AFTT: 4,690.6 hrs

Engine TT: 193.6 hrs Overhauled by GE May 2023. Propeller: 193.6 hrs Wing Spar Modification completed March 2019 at 4,201.3 hrs AFTT 170 US Gallon fuel with Turbine Conversion Single Point Fuel System AgNav Platinum Guidance and Flow Control ReaBee Hopper Qty System 2 sets of booms ASC-A10 Atomizers and CP09-3P. $575K. Call 306-786-3345

1991 AT-401, TTAF 3162.5, P&W R1340, TTE 934.5, Hamilton Standard 3 Blade23D40-51, TTProp 507. Very low hours, well maintained, G4 Satloc Bantam, CP11 nozzles, Reabe Hopper Gauge, Vortex Generators, Garmen Comm, Smoker. $215,000 USD OBO. Contact Reed at 403-793-0949

1992 Air Tractor AT-502 - PT6-15 0SHOT, TTAE 11,752, SPOH 3165. November 2023 annual. Clean Northern plane. Well maintained. Has a SATLOC M3. $425,000. Contact Jim Knox at 218-289-1999 or email jim@agrimaxllc.com

1997 Air Tractor AT-502B - N5063N, PT6A-34AG, TTSN: 14,270.5, TTSHS: 26.2 (8/24/2023 @ 4209.3), HOBBS: 4270.5, Fresh Annual, TTSA: 44, SATLOC G4, Factory Air & Heat, Smoker, ADSB Out, Transponder, Com Radio, Laser Altimeter, Wingman, Side Load Fuel, Kawak Throttle, Reabe Hopper Gauge, A LOT OF TIME LEFT ON THE WINGS, Flown Regularly, Hangared when not in use. $425,000 Price negotiable. For more information, call Duston Bailey at 318-525-5880 or 318-722-0002

Air Tractor AT-802A - March Delivery! New AT-802A, PT6A-65AG, 308 fuel, MVP50, Kawak, radios, Falcon/ FlowControl. Call Farm Air at 877-715-8476

1998 Air Tractor AT-402B -34AG, 7618hrs TT airframe; 484hrs since hot section, willing to do pending sale. Hartzell 3-bladed prop 784hrs since OH. Brand new spars and fresh annual. SATLOC M3 with booms, pump, and electric brake. $675K. Contact +1 (979) 543-5272

1999 AT-602, TTAF 11K, PT6A-65AG, 8886 TTSN, Covington upgrades, FCU 0-since overhaul, new PT blades, new engine mount, fresh spars, 216 fuel, S.P. fuel, Falcon GPS/IF3 flow, wingman, 7 ½” gate, com radio, AM Safe harness, new gear legs, more. Contact Farm Air at 877-715-8476

Wanted: AT 400, 500 & 600 Series Aircraft. Looking for all models of Air Tractor 400, 500 & 600 series aircraft to purchase. The newer, the better but will consider 2006 and newer. Contact 616-837-9428

1986 AT-301 Airframe Only - Parting Out, Approximately 5700 TTSN. NO ENGINE. AT-301: Wings, Tail Feathers, Airframe, Firewall Foreword Less Engine/Prop, Gauges, Gear leg, Hopper, STD Gate Box, Booms, Boom Hangars, Pump, Valve & Plumbing, etc., Flaps, and Ailerons. Contact Farm Air at 877-715-8476

2018 Air Tractor 602. Late model, low time, 2018 AT-602. 3600hrs Total Time. G4, center point fuel, AFS check valves, CP flat fans. Call 979-541-7864

AIRCRAFT – CESSNA

1975 Cessna A188B - AFTT 14,480, IO550D SMOH 133 by Western Skyways, 3-Blade Hartzell SOH 133 TSN 1200. 8:50x10 Cleveland’s, KY97A com, Satloc Bantam, Crophawk 7, hyd spray system with hyd spray valve, stainless booms/ CP’s, Transland 51066 stainless spray pump, smoker, flagman, Robertson STOL, wing leading edge kevlar cuff, Annual 12/23, owned since new. Asking $140K.

Email Terry Reznicsek at aviation@gervais.com or call 503-393-7401

1967 Cessna 188 Ag Wagon - 230. 2,900 TTAF, 300SMOH/SPOH. Paint, windows 7 yrs old, Satloc Bantam/Intelliflow/ L7 lightbar/G4 screen, WeathAero fan, chem pump, Superbooms, CP-11 nozzles all added in 2020. Have a like-new spreader. New tires, tubes, brakes, lines, cylinders rebuilt. New tailwheel rim. Continental 0-470-R has high comp. pistons. Makes about 245 hp. New float plane engine mount, overhauled starter less than 20 hrs. Rebuilt carburetor less than 50 hrs. Knisley exhaust. Left-hand side loader. This airplane needs nothing. Put it to work. A/D’s current. Annual good through July ‘24. $95,000. Call Brian at 507-848-4755

1974 Cessna 188B, N888BT, SIN 0001782T, Engine IO-520-D11B SIN 1031405, McCauley Prop #D2A34C98 SIN 961474, TTAF 5194.0, Engine TSMOH 1069.8, Prop TSPOH 1263.5. Engine: Factory overhauled on 10/16/15, Comp last annual 60/69/62/62/64/61 over 80, Mag sent off in 2022 for 500-hour inspection, Has Airwolf remote oil filter, Starter drive OH in 2019, Starter OH in 2020. Airframe: All Leading Edge skins were replaced in 2023 due to dents, along with a couple of top skins, and the top of RT Airlerium wings were repainted to match. Wings reinstalled with all new hardware. Installed all new Mich lunging gear attached bolts and saddles. Has Trig comm radio, Hydraulic spray pump, 8.50 x 10 tires, Satloc 99 GPS, New side windows in 2022, New tailwheel assembly in 2014, Engine mount was removed and refurbished in 2022 due to surface rust, New left bladder in 2014, new right bladder in 2016. Prop: Overhauled in 2014, Flushed in 2016 due to new engine, Govenor OH in 2016. $125,000.

Text Aaron Peterson at 870-253-8242 or email aaron@advantageagair.us

1980 Cessna T188C - N9998J, TTAF 6270, Continental T510-520-T, H.P. 310, TMOH 1476, McCauley 3-blade propeller, 1476 TT SIRAN, COMP. Check 1-78, 2-79-3-79, 4-79-5-79,6-78, Installed New Load Engine Mounts, New Mitchell Tachometer, Smoker, VG’s,

New 22X8-6 PLY LH & RH Main Tires, New LH Brake Disc, Hydraulic Manual Spray System w/Boom. Very clean aircraft. No known damage. Annual 5/16/24 by Butterfly Aviation. Call Mid-Continent at 800-325-0885

1971 Cessna 188. October 2023 annual. ACTT 3885, 0 SMOH IO 540, 0 SPOH. Clean northern plane well maintained. Air conditioning, Satloc 99, Agrinautics spray pump, lane Break. $190,000. Call Jim Knox 218-289-1999 or email jim@ agrimaxllc.com

Cessna 185, N185HR, Model: A185F, TTAE: 475 original hours. Comes with fresh annual. Make offer. Located in Springfield, Colorado. $575K.

Contact Neal Aircraft at 806-828-5892

1978 Cessna Ag Truck, 5832 TTAF, 625 TTE, 550 TT on prop, 8.50X10 Clevelands, GPS, field ready. Price reduced to $102,000.

Call Reggie Odom at 850-336-0554

AIRCRAFT – PIPER

Piper Brave PA-36-285, 96.53 on airframe since complete rebuild, refiberglassed hopper, new wing spare

(completed by Johnston Aircraft), and center section!! New MVP 50 and G4!! Total airframe time 8,932.8 hours. Topend overhaul on engine 322.1 hours ago and 924.6 total hours. The propeller has 528.4 hours. $180K.

Contact RWA at 308-777-2585 for more info

1980 Piper Brave PA-36-375, TTAF 7136, Wings 1024 hrs. remaining, Center section 90 hrs. remaining, New center section to be installed, Harbor air conditioner, VG’s, Hooker harness, AgPilot X GPS w/FlowControl, CP Nozzles, Adjustable spray pump, Lane pump brake, Fuel flow indicator, Aircraft com radio, PT6A-20 SMOH 2014.9 and 30 hrs. since 100 hr. inspection, Hartzell prop SMOH 2014.9. $255,000.

Call Shelton at 912-592-5334

1976 Piper PA-25-235, TTAF 6067.0, Lycoming 132C5 TTE 9335.48, TSMOH 540.0, Propeller TT 4306.0, Satloc Lite Star 3, Boom, CP3 Nozzles. Call Mid-Continent 800-325-0885

1982 Piper Super Cub. Lowest time Piper built Cub on the planet, 650 hours TTSN, 0 SMOH, Stits Fabric, beautiful paint, Com Radio, L3 Lynx transponder with ADSB in-out with touchscreen weather, traffic. Call Clyde at 956-202-2094

AIRCRAFT – THRUSH

1972 Aero Commander S2R, N954DM Serial #1683R, TT in service: 13585.1 hrs. Major Airframe Overhaul at 13125.0 hrs., Garrett TPE-331-5-252 Serial #P-22117, TSO 5723.7 (HSI Preformed at 5196/Gearbox Inspection at 5264) Time Remaining on Wings

4156.0 hrs., Hartzell Propeller HC-B4TN5NL, Time Since IRAN 62 hrs. This aircraft is above average for the year and model. It has been maintained and serviced by authorized facilities IAW FAA and Factory Airworthiness Directives and Service Bulletins. Equipped with the following: AgNav GPS Guia Platnum w/Flow Control, Hopper Rinse System / 525 Gallon Hopper, Electric Fan and Spray Pump Brake, Vortex Generators / AFS Nozzles and Check Valve / Aluminum Booms, Harbour STC A/C, Hooker Shoulder Harness, Comm Radio/ADSB, Anti Collision Wing Lights, Smoker, Strobes, Bleed air Heat.

Call Dirk at 334-797-7727 for more information

2022 710 Thrush - with PT6A-65AG, N710NW, S2R-T660, S/N: T660168DC, Dual cockpit single control with standard equipment includes:

Single Point Fuel, MVP-50T, A/C & Heat, Garmin G5, Hartzell 5-Blade Propeller, 3” Side Load System, 2” SS Spray Syatem, Streamlined Aluminum Booms, Hopper Rinse System. See spec sheet for all optional equipment.

Call Mid-Continent at 800-325-0885

2021 710 Thrush - N701NW, TTAE 1439, PT6A-65AG, Hartzell 5-blade Propeller TT 1439, All standard equipment included. Additional options on aircraft are as follows: Ag PilotX GPS, Ag Laser Altimeter, CP11 Nozzles, Lane Brake and Fan, Stainless Steps, AFS Check Valves, Fast Start, Garmin Comm Radio, AFS Booms, Reabe Hopper Gauge, Garmin Transponder ADSB-OUT, Swathmaster Spreader. The aircraft is in like new condition and equipped well.

Call Mid-Continent at 800-325-0885

1978 Thrush S2R - TTAF 12,942, Engine Model 601E11, TTSOH 3470, Avia Prop - V508E-AG/106/A, TT Prop 5977, TT SOH 3470, SS booms, new spray pump, Crophawk, A/C, fabric tail in good condition. 690 hrs left on spars. Needs AD 21-13-07 compliance. Make offer. Call Kirk at 218-478-2247

1977 Turbine Thrush - Cascade conversion M601E-11 AFTT 6,038 TSMOH 1,400, SB& AD’s completed 08/2023 prop 0 since overhaul 2023, Fuel 192 gal, Hatfield fuel loading system. Air conditioning, GPS Satloc G4 with Intelliflow, Reabe hopper gauge, two sets of booms with atomizers, annual with or without sale. $449,000. Call Roland Jenson at 306-860-8172

1997 S-2R G-6, 8954 TSN. Recent rebuild inclusive of Avenger Spars and new paint 228 gal fuel. Aileron servos, single point fuel, air conditioning, heat, smoke

etc. AM Safe restraint system, new seat covers. TPE 331-6, fast start, fresh hot section and gearbox, good remaining cycles, 0 TSO propeller, fresh annual. M-3 Satloc with flow control, electric fan brake, plumbed thru t-booms. Ready to work. $444,900. Possible aircraft trades/terms. Text 541-388-0323, email randygoeringinc@yahoo.com or call 541-388-1323

1990 Thrush S2R-T34, TTAF 13531.5, PT6A-34 TTE 23561.2, TSOH 6410.5, Hartzell HC-B3TN-3D Propeller Prop TSOH 5096.3. It doesn’t have dual controls. I have a seat that can be installed. Comes with a meter from Turbine Conversions for doing seeding. 10 vane spreader is in ok shape. In annual and ready for work. $350,000. Call or text 208-705-9161 may consider doing a partial trade for a smaller plane

2009 Thrush S2HG-T65, 550 with -60. TTAE 7010.8, Time since hot section 469.8, Hartzell Propeller HC-B5MP-3CProp TT 7010.8, Time since overhaul 5.1. Very well-equipped aircraft, including Amsafe restraints and ADSB. This aircraft is currently going through annual, and ready to go shortly. The tail is also being painted to match factory paint. $740,000. Call 605-350-4536

2005 Thrush S2R-T34, N40428, TTAF

7,806.8 Engine Notes: P&W PT6A-34AG

S/N: PCE-PH0293 750 HP ENGINE TIME 7746.2 TT 0.0 SHSI-MARCH 27, 2024 Additional Equipment: SATLOC G4 W/ Intelliflow, Smoker, Air Conditioning / Heat, Bottom Load Fuel, Lane Electric Fan Brake. Inspection Status: Annual June 2024 Prop Notes: HARTZELL HC-B3TN-3D

S/N: T10282N+2 0.0 SIRAN MARCH 3, 2024. 20,000+ hrs. left on Wing Spars. Call Mid-Continent Aircraft at 800-325-0885

1999 Thrush 510, Very clean 1999 510 Thrush. TTAE 7700, P&W -34, TSHS 800. Never fertilized with. It has been in west Texas/eastern New Mexico since new. Ag Pilot X GPS. $495K. Call 575-799-2504

2004 Thrush S2R-65, 60AG 550 gal Thrush, TTAF 6431.7, TTE 6131.7, Time since O/H 1134, TSHS 797, Hartzell HCB5MP-3C Propeller, TT Prop 1631.4, TT since Prop O/H 1522, Satloc Batam, Fuel flow meter, A/C & Heat, 1230 hrs. since O/H power section, Log books available for inspection. $580,000. Call Jamey at 870-697-2744

2004 Thrush 550, 2004 Thrush 550, TTAF 8093, with PT6-45R 0 SHOT, O/H Bleed Valves, 0 SMOH Prop, Hydraulic Gate Box, SATLOC G4, Booms and Spreader. Sale with fresh annual. $510,000. Call 979-257-6695

2024 Thrush 710P, For sale 2024 fresh off the assembly line 710P, PT6A-65AG, 5-blade propeller, all standard options, including single-point fuel system, and a smoker system. This airplane is ready to cover some big acres. It can be sold as equipped, or we can get you a quote and equip it with all your requested options. Call North Star Aviation today at 620-356-4528

2024 Thrush 510P2+ - For sale 2024 fresh off the assembly line 510P2+ dual cockpit, PT6A-140AG, 4 blade propeller, all standard options, dual-cockpit upgrade (includes hopper rinse & rear seat), and a smoker system are already installed. This airplane is ready to cover some acres; it can be sold as equipped, or we can get you a quote and equip it with all your requested options. Call North Star Aviation today 620-356-4528

2023 Thrush 510P2 - TT120, Smoker, Leading Edge Lights, Micro VGs, Falcon GPS, Intelliflow, Sideload fuel, Garmin GTX 327, Garmin GMA 340, Garmin GTR 225. Call Mid-Continent at 800-325-0885

1994 Thrush S2R-T45 - 1994 Thrush Dual Cockpit -45, SN T45-006, TTAF 10,500, TTE 14,270, Fresh Hot, New V-ring segment repaired ext. duct by RT Turbine, Prop OH, Load Hawg, A/C and Heat new, Ag Nav Platinum, Annual Jan. 1, 2023, CP Nozzles. $700,000. Call 229-220-6343

1989 Thrush S2R-T34 - Single Cockpit, N3097K, Serial number T34-115, 17,000 TTAF/engine, OH Prop 5/22, 12-9-2016 Century Wing Spars installed, 9/10/18 Micro Vortex, Generators, 2020 Paint, Load Hawg, Engine work done by R.T Turbines at 14,799.3 hours, 2020 R.T. Turbines new V-ring, blades. $350K. Call 229-220-6343 or email croomaviation@gmail.com

1994 Thrush S2R-G6 510 Super 6Annual January 2024, Current Hobbs 6700, Spar caps replaced at Hobbs 5636. Big butterfly installed. Options include SATLOC G4 with flow control (not pictured or installed), A/C and heater, VG’s, Right boom shutoff, Airfoil booms, Garmin Comm, Single point fuel, 228-gallon tanks, fast start, Transland pump and electric brake, Four battery conversion - new batteries installed July 2023, New tail spring and head installed at annual. Engine: Garrett TPE331-6-511M

Super 6 built by CD Aviation in January 2024, installed in February 2024, 25 hrs SMOH, 25 hrs since CAM, 25 hrs since Hot Section. Prop: 3 blade Hartzell HC-B3TNSE 775 hrs TSOH. CLEAN AIRCRAFT, WELL EQUIPPED AND READY TO WORK! $575K. Contact Jody Perkins at Adcock Flying Service 360-632-5198 for email Jodycperkins@yahoo.com

1992 Thrush Ayres S2R-G6, 1992 Ayres S2R-G6 Airframe, N3105U - No Prop, No Engine - TTAF 6937, MVP-50 Glass Panel, Vortex Generators, 24 Volt Freon Air Conditioner, Aileron Servo, Reabe Hopper Level Indicator, Fabric Tail, Wings - Century Spar Caps 60,000 hrs. life.

Call Mid-Continent at 800-325-0885

1979 S2R-T34-014, C-GMQB. Fuselage Configuration Dual Cockpit / 400 Gallon hopper. Airframe Hours 4389. Engine Serial Number PT6-34AG PCE-56683. Engine TTSN 4389 hrs / 6047 cycles. Engine 4000 hr TSO 1068 hours-Vector Aerospace. Engine Time Since HSI 643.3 hours. Propeller HCB3TN-3C TSO 532 hours. Max Take-off weight TCCA LSTC9120 lbs. Basic Empty Weight 4572 lbs. Comm 1 Garmin SL40. Comm 2 Garmin SL40. Audio Panel Garmin GMA340. Attitude Indicator RCA2600-3-Digital. Transponder / ADS-B L3 NGT-9000D

SBAS. Navigation GPS Garmin Aera 796. Heading Indicator RCA15EKElectric. ME406 ELT 453-6603. Engine Instruments Analog - UMA Tri Gauge. Cascade Cowls complied with. Kawak Engine Controls complied with. Serv Aero Tailwheel Assy complied with. ATS Vortex Generators complied with. Tail Surfaces Fabric. Dual Batteries Gill Complied With. Additional Options: Servo Tabs, Cleveland Wheels and Brakes, SB-AG-34 Wing Attach Beef Up, SB-AG-23 Steel Reinforcement Web Doubler Kit SS2R-FF-002, AG-29, Big Butterfly and Lower Splice Plate Kit. Contact Paul at 506-654-6834

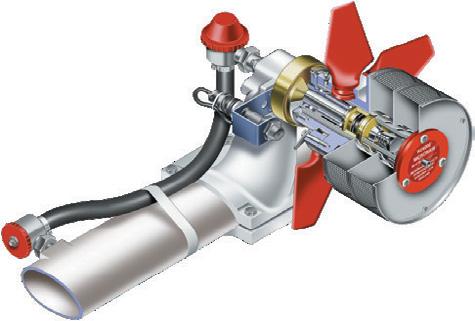

Pratt & Whitney PT6A-140AG 867SHP STC Kit, THRUSH 510P & 510G Aircraft - Complete Firewall forward bolt-on STC kits for the 510G and 510P. Thrush model aircraft. Contact Cascade Aircraft to secure the 867SHP-certified upgrade STC kit for your THRUSH 510 aircraft. Call 509-635-1212

1996 Thrush S2R-G6, 1996 Ayres Corporation S2R-G6, S/N G6-144 N2239V, TT: 6314.6, TTE: 11,990, HSI: 2153, Prop TT: 2332, Factory Spars installed at TT: 5,202, Options include: SATLOC G4/ IntelliFlow, Smoker, AC and heater, VG.s, Winglets, Right boom shut-off, King 96 Comm, Hatfield SPF, Cool Start, SS Booms, CP-11 nozzles, AFS check valves, Agrinautics pump w/ electric brake, Shadin fuel flow, Landing light, Hopper rinse tank, Nav lights with strobes and four new batteries. Aircraft will need an annual inspection. $432K. North Star Aviation is the First Lift Aviation Dealer. 620-356-4528

1991 Thrush S2R-T34, N672EH, 11,349 TTAF, PT6A -42 engine, TSO 3583.6, Load Master 4-blade propeller, Power Pressure Cowling with Quick Change Power Filter System, GPS SATLOC M3, Flow Control, Intelliflow, Spray Pump, Booms, Winglets, New Paint. Call Turbines, Inc at 812-877-2587

AIRCRAFT – OTHER

1968 Citabria 7ECA, clean and solid airplane, TTAE - 2,928, time since complete Top OH - 365 hrs, TSMOH - 1,360 hrs, Last annual inspection09/2023. $60,000.

Contact Kevin Jones 662-292-7541

1938 Boeing A75N1(PT17), N54284, TTAF 6080.7, R985-AN-14B, TTE 520.4, Annual 6/2021, Garmin SL-40COM, Garmin GTX 327 TXP, PS Engineering PM-1200, Installed Oilmatic Pre-oiler, Installed Airwolf remote oil filter, Smoker, Speed ring, total fuel 56 gallons, Redline brakes, Garmin GDL 82 ADSB-OUT. Call Mid-Continent 800-325-0885

B1-A Callair Manufacturing Rights. Available now is the type certificate, drawings, jigs, tooling, aircraft parts, and property associated with this 300 gal Pratt and Whitney 985 powered sprayer. Start your own aircraft company or expand your line. Contact +1 (850) 380-6091

AIRCRAFT – HELICOPTER

Bell 206B and 206L models for sale or lease, spray-ready. Call Hunter Parker at 561-723-3592 or Brian Parker at 561-723-1911

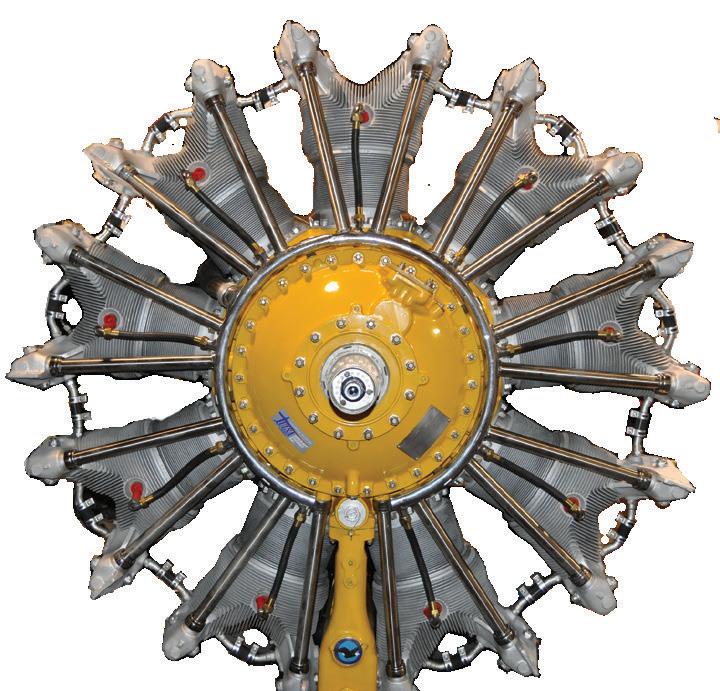

ENGINE - PISTON

Pratt & Whitney R-985 & R-1340 Engines in stock. All with new pistons installed. Overhauled by Aero Recip, Covington, Tulsa and Younkin. Call 661-257-7708

GE/Walter M601E-11 - 1986 Walter M601E-11 Engine. Damaged in a prop strike. Selling as is. $9500. Call 6441-316-9114

Pratt & Whitney R-985 & R-1340

Cylinder Assemblies - R-985 & R-1340

Complete OHC Cylinder Assemblies OHC in stock, all with new pistons installed and all gaskets and seals to install. We also stock new and overhauled magnetos, OHC carbs, starters fuel pumps, etc. Top overhaul tool kits $250 each. Call 661-257-7708

Pratt & Whitney R1340 - R1340 Engine Overhaul - New pistons, new bearings, mags, ignition harness, carb, with warranty outright/exchange. Call Chester Roberts Supply Company at 903-429-6805

Pratt & Whitney R985-AN1-14B - R985AN1-14B Tulsa Overhaul, New pistons, Bosch mags, ignition harness, carb with warranty outright/exchange. For more information call Chester Roberts Supply Company at 903-429-6805

ENGINE - TURBINE

Honeywell/Garrett TPE331-10-511M - For immediate sale. S/N: P-36452C, TSN: 13,155.9, TSCAM: 5606.1, TSHSI: 90.9, TSGBI: 90.9, CSN: 21,919, CSCAM: 1788, CSHSI: 28.0. TS Level II Prop strike inspection: 0.0. Fresh out of Level II prop strike inspection. Surplus to needs. Engine is sitting at TAE(Ag Air turbines), crated, turn-key, ready to ship. Spec sheet is attached. $299,000. Contact: Pete Brawn, Ph. 541-740-5062 (No Texts). Email: peteairways@gmail.com

Pratt & Whitney PT6A-34. PT6A-34 PCE57524 For Sale, TSN 8341.4, FSN 15632, SCN 3912, EOS Overhaul. Contact 817-354-2002

Honeywell/Garrett TPE331-6. (Super conversion STC to -511B) SN: P-27069C. Engine has only 372.2 hours Since MAJOR Overhaul!! And only 4830 hours TT Since NEW! - LOW cycles (status sheet below for download). The following work was just completed at TAE Aerospace: 0 Hours Since - Level 3 Prop strike inspection. 0 Hours Since - Hot section Inspection and Gear box inspection. 0 hours SinceSuper conversion with Bigfoot Mod completed. 0 Hours Since - Overhauled FCU/Prop Governor/Fuel pump installation. Ready to go NOW! Asking $399,000 USD and will consider offers and trades of aircraft and engines! ORRRR...if you have a clean Thrush airframe to sell that would be just begging for this motor, let me know! ASI JET Specializes in Aircraft Sales, Maintenance, and Parts Support. Call ASI Jet Sales at 320-587-7615 for more information! *All specifications are subject to verification upon inspection by buyer.

Pratt & Whitney PT6A-34. PT6A-34 PCE57524 For Sale, TSN 8341.4, FSN 15632, SCN 3912, EOS Overhaul. Call for pricing at 817-354-2002

EQUIPMENT - DISPERSAL

Mkit 9005 - 2” Electro Magnetic Meter Flow Controler for AgPilot X. 2” stainless steel full port valve with cables. New, still in the box. $4250. Call 530-300-5379

Air Tractor 802A Ram Air Offset Inlet Kit - Complete Air Tractor AT-802A Ram Air Offset Inlet kit. Ferry time only. List price new: $38,493 Sales price: $25,000. Call Neal Aircraft at 806-828-5892

Transland 10” Hydraulic Gate - Used 10” Hydraulic Gate. List price new: $37,765 Sales Price: $17,500. Call Neal Aircraft at 806-828-5892

Sorenson spray tank made for a Piper Super Cub, 80-gallon tank, fiberglass, and stored inside. $500. Call Don Kothe at +1 (308) 692-3315. Please do not email.

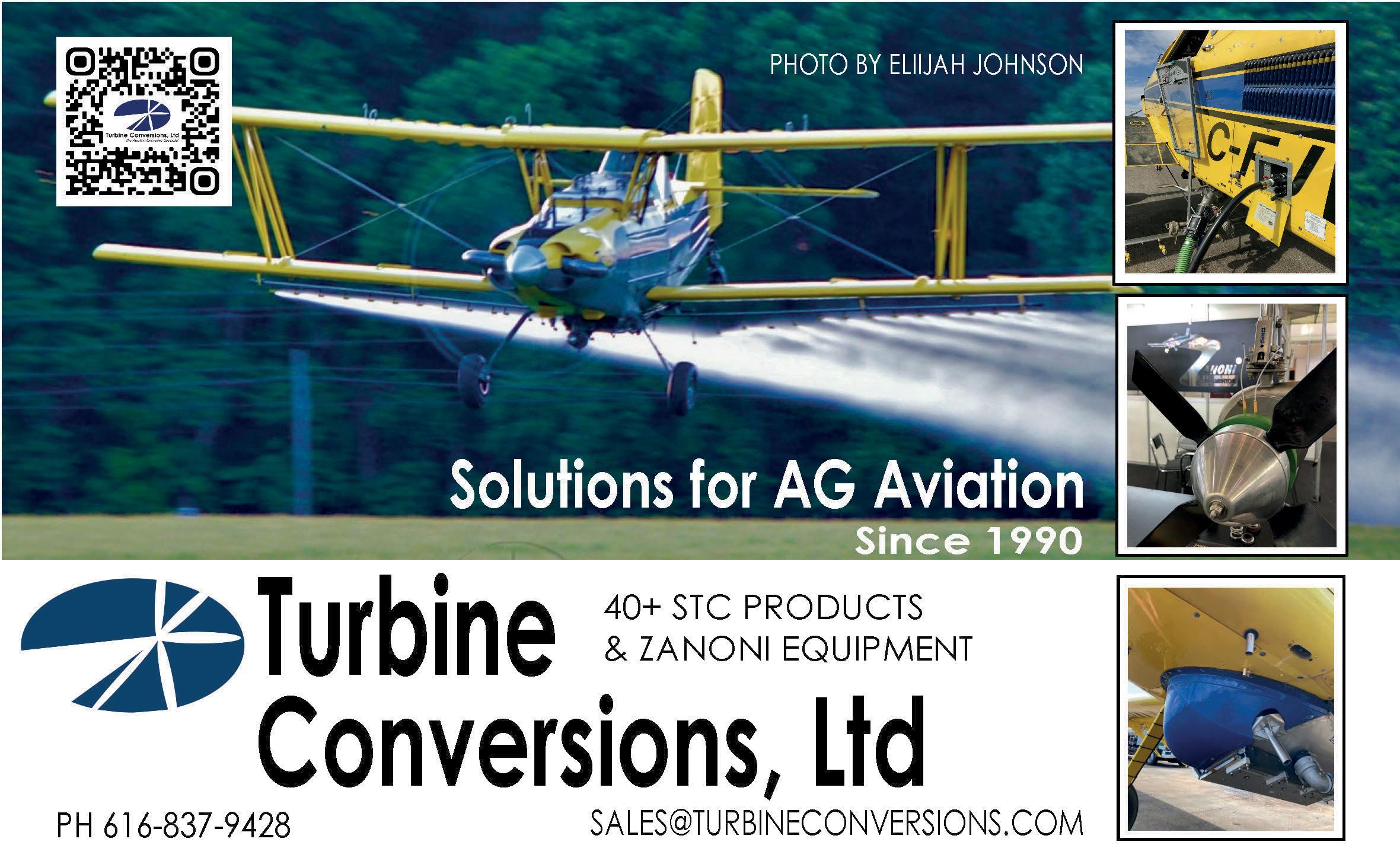

Stainless Steel Booms, Pumps & Nozzles - For Sale - High quality Stainless Steel booms, pumps and nozzles! On the shelf and ready to ship. Contact mark@turbineconversions.com or call +1 (616) 837-9428

Zanoni Equipment Atomizers - New, in stock and ready to ship at Turbine Conversions, Ltd in Michigan. High quality, stainless steel, tested, proven, and US operators are loving these atomizers. Contact 616-837-9428

AT-802 Hatfield Fire Gate - New Production ready to ship! Original Hydraulic Clam Shell Design, STC, BLM & IATB Approved. Proven reliable design, currently fighting fires in North & South America. Built tough, lighter weight, and affordable pricing available options. Other aircraft models available - STC on All models of AT, Thrush, and M18 Dromader with short lead time. Contact 616-837-9428

Transland 10 vane spreader for 38” gate, new, $13,000. Contact 281-342-5451

Transland Spreader, 25” Slimline in fair condition. $750. Contact +1 (478) 494-3757

Fire Gate Hatfield Hydraulic Drop Door, USFS / BLM approved, Fits Thrush, Dromader, can be adapted to Air Tractor 502 or 802, excellent condition, with streamlined fairings, all controls included. $5,000 Any reasonable offer accepted! Needs to go! S.E.A.T. program is expanding. Pilot/contractor training available. Call +1 (530) 345-9919

Ag Cat - Various Ag Cat Spares available.

Please contact us for the price at spares@orsmondaviation.co.za or +27 58 303 5261 or visit our website at https://orsmondaviation.co.za/

Spray Equipment - New without warranty spray equipment for all Air Tractor models, including pumps, booms, and nozzles.

Contact 817-456-5450

SUPERBOOMS, Thrush Servos; Maintenance on Ag & G.A. Aircraft Including Heavy Structural Repairs; Robinson Helicopter Service Center; Machining, Fabricating & Sheet Metal Gurus.

Contact +1 (701) 642-5777

(2)Transland SS 22274 38” to 25” gate box adapters & 21966 Gate Boxes. $2500 Each or $4000 for both plus shipping.

Contact 620-525-6712

Miscellaneous Items For Sale - 50 brass T-Jet nozzles complete with swirl plates $250. Transland gate box for hopper SS good condition, 25 inch $500. Cal Max Helmet large, very good, complete w/ face plates. Wired for headset. $500. One alternator, new, 100 amp, adapter for P&W engines, electrical parts for night spraying $600. Contact Al at 208-569-3407

EQUIPMENT - GPS

Satloc G4 - Selling new Satloc G4 still in the box. L8 lightbar, all hardware wiring new in box. $19,000. Call 530-300-5379

Satloc G4 - Hi we have 5 complete working SATLOC G4 units for sale, one is available immediately, and the other 4 will be available in the next week or so as they are still being used until our new units come in. (more photos available upon request) $12,000. For any interest or questions please contact Wade at 530-570-9412

GPS Trac Map, Ag Nav, Satloc - 3Complete Trac Map Flight 3 systems (lightbar, head unit, cables, antenna etc.) $3,500.00 USD. Miscellaneous Trac Map Flight 3 Parts - Light Bars, Cables, Wireless Dongles. Satloc - Light bar and cable. Ag Nav - Ag Flow 1 Screens (6 total). Screen and mounting brackets only. $500.00 USD. Make me an offer on it all or willing to part out separate. Call 306-786-3345

AgPilotX - Helicopter light bar now available with the new iPad based

guidance system - AgPilotX. Entire system with helicopter light bar is 13 lbs. Call Anthony Fay with Insero for details 480-285-4367

Wanted: SATLOC Bantams, G4 Units & Flow Controllers.

Call Mike at Orsmond Aerial Spray (Pty) Ltd +27 58 303 5261 or email mikep@orsmondaviation.co.za

EQUIPMENT - PARTS

Van Horn 2062200-301 - Van Horn OH 58 Tail Rotor Blades as removed from flying OH58. 981.1 SNEW, Excellent condition. Will send to blade shop for inspection upon sale. Must sell. Model #2062200301. $29,999. Call 910-876-2519

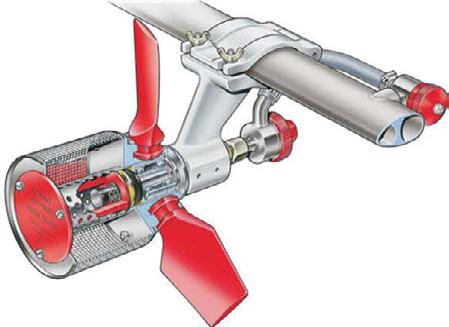

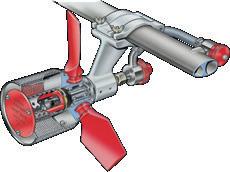

Kawak Electric Spray Pump - Variable speed high output Kawak electric spray pump. Will dramatically increase the productivity with up to double the output vs. existing electric spray pumps. Pilot-controlled variable speed output to pump or automatic speed modulation via GPS/flow control integration.

Call or email for pricing. 541-385-5051 or sales@kawakaviation.com

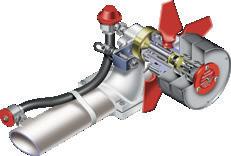

Kawak Power Stop Throttle QuadrantsAir Tractor 5, 6, 8, and 1002 Kawak power stop throttle quadrants. Feature power lever stop, allowing the pilot to manually set max torque, temp, or Ng for the day. The new power “lever lockout” feature prevents engine over torques when the prop is in feather.

Call or email for pricing. 541-385-5051 or sales@kawakaviation.com.

Thrush Top Hat Header Tank Modification

- Thrush H-80 STC SA04485CH Top Hat Header Tank Modification. STC solves issues with FCU and extends the factory recommended replacement of the auxiliary fuel pump from 500 hours to 3,500 hours. Currently have 4 spots open for early 2024 delivery.

Contact your favorite Thrush dealer at +1 (616) 837-9428 or Ann@turbineconversions.com for more details.

Tools for reaming attach bolts wing main (Center wing to outboard wing) Attachment joints for Dromader M-18 per repair service bulletin #e/02.170/2000. Available for rent. Contact ann@turbineconversions.com or 616-837-9428

R-985 & R-1340 Engine Parts - Complete stock of all P&W R-985 & R-1340 engine parts. Also P&W tools, Top OH tool kits, Time Rite kits, engine mounts, Champion & Tempest spark plugs, parts books, OH

and maintenance manuals, Mags, carbs, starters, fuel pumps boost pumps. Also, R-1830, R-200, R-2800 engines and parts. Call Sun Air Parts at +1 (661) 257-7708

Reinforced Thrush Leading Edges - Send your leading edges to us, and we will reinforce them with durable custom extruded aluminum reinforcements. Available directly from Turbine Conversions, Ltd. Call 616-837-9428

Wanted: P&W Engine Parts - Pratt & Whitney Engine Cores, Engine Parts Inventories, Cylinders, Starters, Fuel Pumps and Boost Pumps. Call Sun Air Parts at +1 (661) 257-7708

Air Tractor & Thrush Boost Pumps - New and overhauled Air Tractor and Thrush boost pumps in stock. Delco A4949 motor with 400 GPH AN4101 fuel pump attached. Outright and exchange. We supply these direct to both factories. Call Sun Air Parts at +1 (661) 257-7708

Ag Cat Frameworks, All Models, 4130 weld assys, fixture perfect, ready to install. Struts, wires, hoppers, long fuel, high-wings, dispersal equipment, hardware, all upgrades, components, and spares.

Call +1 (870) 886-2418

AV-KOR1 Helmets Available Now! The AVKOR1 helmet is made out of a fiberglass composite, utilizing Koroyd and an anti-microbial comfort liner making it the lightest aviation helmet on the market. Features Fire Retardant trim and a FIDLOCK buckle system. Works with any aftermarket in-helmet communications devices. North Star Aviation is the First Lift Aviation Dealer.

Contact North Star Aviation at 620-356-4528

Leaf Spring Conversion Kit PA25 - CTS 1109.21 - A-K-009 Leaf Spring Conversion Kit PA25 - CTS 1109.21 - Speed increase, large service life, and minimum maintenance. Kit includes spring, brackets, installation hardware, and certs. Made by Lavia SA, manufacturer of the PA-25 Puelche. Email aravia@aravia.com.ar

Transland Pump Mount.

Call Billy Maxwell at Transland +1 (940) 687-1100

Transland Aluminum Boom ClampsLarge & Small.

Call Billy Maxwell at Transland +1 (940) 687-1100

Transland 4” Delrin Hopper Vents. Call Billy Maxwell at Transland 940-687-1100 or email sales@translandllc.com for more information

Transland Grip Steps for AT aircraft. Call Billy Maxwell at Transland 940-687-1100 or email sales@translandllc.com for more information

Brushless Motor Airframe Fuel Pump

- New Brushless Motor Airframe Fuel Pump - STC kits for PT6 Air Tractor and THRUSH aircraft. Long lasting, solid state, with fail safes.

Call 509-635-1212

2013 AT-502B Firewall forward parts: Engine mount, cowling and Ram Air filter system. All parts with less than 1400 hours total time. Very clean and well maintained AT-502B. Parts are located in Alabama.

Call Cascade Aircraft Conversions for more details 1-509-635-1212

Radial Mounts/Rings - Radial Parts: 2 Fiberglass AT Speed Rings, 1 THRUSH Speed Ring, 1 Radial engine mount with ring. Make offer. Call 509-635-1212

Pratt & Whitney PT6A-140AG 867SHP STC Kit for THRUSH 510P & 510G Aircraft - Complete Firewall forward bolt-on STC kits for the 510G and 510P. Thrush model aircraft. Contact Cascade Aircraft to secure the 867SHP-certified upgrade STC kit for your THRUSH 510 aircraft. Contact 509-635-1212

AT-502 sheet metal. Some new, some used, all airworthy. Mostly fwd. lower fuselage. $500 for all OBO. Will box and ship for materials and labor. Contact 530-345-9919

Ayres Thrush ‘Hoerner’ wing tips. Left and right, no damage. $500 for the pair. Call Gary at 530-345-9919 garyhendricksonn3n@gmail.com

EQUIPMENT - SUPPORT

Ground Support Engine Driven Transfer Pump, Zanoni Equipment’s all stainless steel construction paired with a Honda 13 HP motor.

Contact 616-837-9428

3” load, mix tank, fully contained and lockable, air compressor and storage complete and ready to go.

CallFarm Air at 877-715-8476

Portable Load Pad - Like new portable load pad suitable for an 802. Very little use.

Call Farm Air at 877-715-8476

HELP WANTED

Mechanic/Shop Manager - Farm Air Flying Service is seeking a full-time mechanic/shop manager. The ideal candidate would be an A&P and or IA with experience working on PT6s. However, we are willing to invest in and grow with a person with higher aspirations. Duties include 100-hour inspections, annual inspections on our fleet that includes, 502s, 504, 802, Ag Cat, and Bell 47 Soloy and general maintenance on related equipment (ground rigs loader trucks etc). Shop manager duties include ordering and stocking a shop for maintenance duties. Competitive pay, 12 months of housing and relocation help included. Located in the heart of California’s central valleys rice country, we are uniquely situated, surrounded by country living but close to big city life, with the Sierra Nevadas, the Pacific ocean in our backyard. Email oldcrow1982@gmail.com or call 530-300-5379

502 Pilot Needed Immediately- For a corn run in Nebraska. US pilots only, please.

Please call or text 308-991-3432

Pilots Wanted - Seasonal & Full-TimeIndiana operator looking for pilots to fill seats in 402, 602, and 802 beginning July 2024. Must be able to get pesticide licenses in Indiana, Michigan, Ohio, and Illinois. Send resumes or inquiries to IndianaAgJobs@gmail.com

SEAT Pilots Needed- Seat pilots are needed immediately. Must be a Level I or Level II.

Contact Dain at 806-535-8560

A&P Mechanics Needed- Looking for three A&P Mechanics to maintain five Ag Cats and a Cessna October-December or January-March. Pay commensurate with experience and housing will be provided. Relocation to south Louisiana is required, with time allocated to return during holidays if necessary.

Contact Vincent Flying Service, Kaplan, LA 337-643-3688

Full-Time and Seasonal Pilots NeededGrowing multi-location Kansas operation seeking full-time and seasonal pilots. Herbicide experience is a huge plus. Benefits and guaranteed salary for the right candidates/full-time positions.

Email blindads@agairupdate.com,

Subject: ID#2757

IA AP Mechanic Needed - Northern California operation is looking for a full-time mechanic to set up shop.

Ag cats, Thrushes, Air Tractors, and a few GA airplanes in the off-season. Ag experience is preferred but not required; salary depends on experience. We can help with relocation costs. Please call for more information. Come live in beautiful California and work on airplanes, a dream come true!

Contact Rick at 530-438-2141

R66 Helicopter and Pilot WantedWestern operation looking for an R66 helicopter and pilot. Long-term contract. All inquiries must include a resume or list of total times.

Email blindads@agairupdate.com

Subject: ID#3900

AT-802 & Thrush Pilots Needed - Larnaca, Cyprus operation looking for AT-802 & Thrush pilots.

Please email references and resume to Nicolas at aviators@hotmail.gr

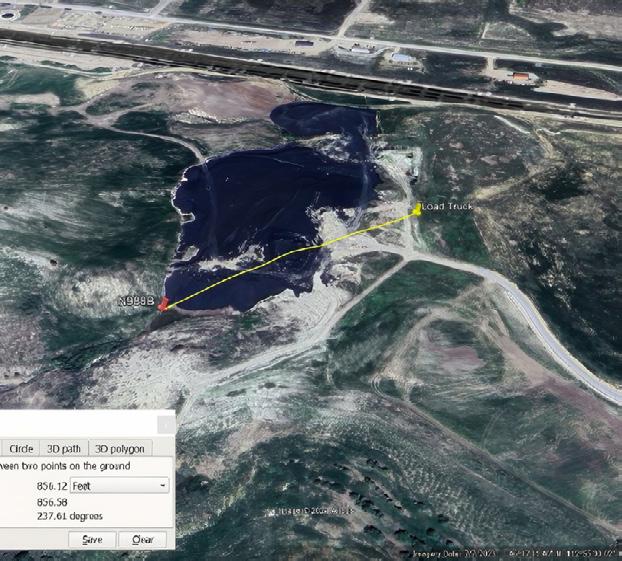

Alternate Application Division Manager - Alternate Application Division Manager - Nebraskaland Aviation is seeking an individual to assist with our vision, creation, and management of a new alternative application division inside of our company. This job is listed on our website at Careers | Nebraskaland Aviation | NE, KS | Ag Aviation, Fertilizer, Chemicals. Use of this equipment will include imagery services, as well as, but not limited to, herbicide, fungicide, biological, and nutritional product applications to row crops and rangeland. This new division will consist of aerial equipment such as rotary drones that are common today, larger unmanned fixed-wing aircraft that are coming to market, and all new technologies that will eventually become available. This division will also include ground applications to be made with UTV and ATV equipment, as well as autonomous ground sprayers and all other new technologies that will be coming to market. Our vision is to create the most technologically advanced and most capable alternate application division in the United States with the purpose of meeting the ever-changing needs of our customers.

Email resume and references to Tye at tye.marquardt@nebav.com

Experienced Pilot Needed - Lakeland Aviation, Inc. Corcoran, CA, is looking for an experienced pilot. Average annual pay $200K+, 90% of work is 1 mile runs -1/2 section fields with few to no obstacles. Mostly newer airplanes, excellent maintenance, and crew. Home every night/day - we do work nights in the summer. Health Insurance, 401K, paid vacation. Fly 500-700 hours per year. Please submit a resume with

references to Reid Potter (559) 289-4649 rpotter@lakelandaviation.net or Chris Nolta (530) 517-1253 cnagpilot@comcast.net

AT-602 Pilot Wanted in MongoliaThomas Air LLC Mongolia is looking for an experienced fixed-wing turbine pilot for forestry flying in Mongolia. From the end of May through September for 3-4 months. Lots of adventure and bush piloting spray jobs in different locations. Throughout the summer. Contact info: burenkh@gmail.com, mobile number +976-8888-1369

Pilot - California, Central Valley Operation looking to hire fixed wing, and Helicopter Pilots. Turbine Trushes, Air Tractor 802’s, Huey’s, and Bell 206’s. Night Flying is prefered.

Please Call Debbie Burgos at 559-816-7244

Experienced Turbine Pilot - Seeking experienced turbine pilots in the Midwest for the upcoming season and beyond (Air Tractor and/or Thrush). June through August mainly, but possibly a couple of weeks of work in the Spring. Email resume or total times to blindads@ agairupdate.com

Subject: ID#2754

AT-802 Timber and Corn Run pilot needed for rotation mid-January through mid-May. AT-802 Corn run pilot needed from mid-June to mid-August. Minimum experience - 500 hours 802 time or hightime 502 or 602 pilot. Email resume to cropdoctoral@hotmail.com or call/text 870-510-6882

Tabula – Eastern United States Regional Aviation Business Development Team Member: Due to continued growth in the United States, Tabula is hiring a new Regional Aviation Business Development Team Members for the Southern Eastern United States region to focus on our AirVision System. This position will be based out of our Melbourne, Florida location. About the role: The Business Development Team is responsible for maintaining our existing sales, growing new business, and technically supporting our products within the Agriculture, Mosquito, Forestry, Horticulture, Fire and Utility industries. We are seeking someone with experience in the Agriculture Aviation Sector. In return, we are offering a role that has the opportunity for growth and development, a base salary of $60k, plus a generous commission and bonus program that will reflect your skills, knowledge, and

overall experience, with total earning potential being well over $100k. To apply, please send your CV and cover letter to recruitment@tabula.live

2 Professional Turbine Ag Pilots for the 2024 spray season. Operating Thrush 510P aircraft from May 15, 2024 to October 15, 2024. Job duties include providing aerial application on fields primarily in Saskatchewan and possibly other provinces. Must be insurable on Thrush 510P aircraft, and capable of operating a Satloc GPS system or able to learn it. Must be able to speak, read, and write proficient English. Accidentfree flight record is preferred. Housing and vehicle can be provided if needed. Wage is $50/hour, 40 hours/week. Performance-based bonus is offered. Workers compensation provided. Call Justin Farr at Farr Air Inc. 306-8616675 or 306-848-1044

Looking to Hire a Long-Term, Experienced AT-502B Pilot - Wellestablished company in California looking to hire a long-term experienced AT-502B Pilot. Insecticide, Fungicide, Seed & Fertilizer. Crops include Orchards, Rice, Vegetables & Row Crops. E-mail resume and references to blindads@agairupdate.com

Subject ID#2095

Full-time Pilot position North Dakota - Looking for an experienced pilot to fly AT-502/602. The season runs from mid-May through September. The main application is fungicide/insecticide; herbicide experience is preferred. The position may include some travel during the season.

Call or email for details. 701-339-8799 gravesen.chad@gmail.com

Level 1 Seat Pilot - Looking for a level 1 seat pilot for 2024 and beyond for an exclusive use contract.

Contact Patrick Mertens at 970-571-0871

Mechanic Wanted - FAA maintenance facility is seeking a skilled mechanic to join the maintenance team at an industry-leading aviation center. Qualified candidates must have Airframe & Powerplant Certificate with at least five years of experience working in Ag Aviation. Must be able to stand, stoop, squat, or kneel for eight or more hours on concrete, lift up to 65 lbs., follow inspection checklists, and fix discrepancies. Self-motivated individuals should be able to see the end goal at the early stages for the maintenance process and be a team player.

Competitive pay, 100% employer-paid health insurance with vision and dental

options, 401k, paid holidays, vacation, and sick time. Interested parties should return a completed application with a current resume.

Contact Joe Risner – Director of Maintenance for more information. 800-325-0885

Pilot Needed in North Dakota: A 2018 AT-502XP pilot is needed to cover up to 122,000 acres. Experience is needed. Travel required.

Call for details. +1 (701) 321-0767

Helicopter A&P mechanic - Jones Aviation is looking for a full time, experienced helicopter A & P mechanic. We are located in northern California. Maintenance will be performed on site. Experience with UH-1H would be preferred. We would be willing to help with relocation costs. Needs to be a team player but not afraid to lead. Overtime might be required during seasonal times of year.

Contact Chris (530)321-1253

A&P, A&P/IA - FAA Part 137 Operator, looking for new A&P’s and experienced A&P’s. Air Tractors & Bell Helicopters. “Aircraft Type” experience not as important as: Conscentious, organized, willing to learn, get things done, team players.Will perform/participate in Sheduled/Unscheduled Maintenance & Inspections. Maintain support equipment/shop. Full time/Year Round. $23-$32 hr DOE. Some Benefits & Vacation. US Citizen or Valid Work Visa. Send Resume: DOM@trirotorllc.com

Ag & King Air Simulator Instructors: Looking for Ag & King Air Simulator Instructors. Instructors are 1099 contractors. Work is on a per-student basis. 1-3 day courses and paid by the day. Work one one-on-one with the students. Classroom and simulator instruction. Days are 9-5 with no weekends. Lodging fees are covered for instructors who travel to our location to teach. Flight instructor certificate is not needed. Looking for someone who has an Ag pilot background/experience. Turbine experience is a must. Could be active or retired. Must have an interest in teaching and passing on their knowledge to others in the industry. Please include a resume when inquiring. Email blindads@agairupdate.com Subject: ID#153

IA and A&P mechanics needed. Call Frost Flying at 870-295-6213 Salary depending on qualifications and experience

Experienced Pilot/Manager - North Dakota aviation operation looking for an Experienced pilot/manager to co-manage FBO, Airport, and Aerial spraying operation. 802 and Turbine Thrush. Season runs mid-June through September. Potential opportunity to partner/purchase operation in the near

future. Start putting your time and efforts into your building your own operation!! FBO and Airport management provide steady income streams to help make it through the slow seasons. Email resume and references to luke@ltenterprisesnd.com

Marketing Assistant Job - Lift Aviation is looking for a motivated person to assist with brand marketing and sales initiatives in conjunction with trade shows, brand building, and sales generation. Previous experience in marketing/sales is preferred. This position requires an excellent work ethic. The candidate will aid in sales, marketing, and tradeshow initiatives. Overall objective – Assist in all facets of sales/marketing. Competitive Wage Health / Dental / Optical Insurance PTO Paid holidays 401k Job Type: Full-time, Onsite Only, Hourly Pay, Travel possible Email resume and references to Todd Lentz at todd@liftaviationusa.com

Experienced Engine & Component Technicians Needed - TAE Aerospace is a global aerospace company, servicing commercial and defense customers worldwide. We create value for customers through innovative thinking, premium quality products, and services in aerospace engineering, manufacturing, turbine engine, and component MRO. Located across the globe, our maintenance facilities in Australia and in America are the leading provider of quality general aviation, aerial agricultural, turboprop engine, and component maintenance. Right now, we are looking for experienced Engine and Component Technicians to join our teams in Adelaide, South Australia, and Scottsdale, Arizona. If you have proven TPE331, PT6A or GE H80 experience or have worked in a similar role, and looking for your next challenge – we want you! Find out more about joining our team.

Email: Hr-support@taeaerospace.com phone: +61(0)881500200 or visit: www.taeaerospace.com

Helicopter Spray Pilot - B&S Air Inc. is looking for an experienced Helicopter Spray Pilot for the 2023 season. 1000 Hours of Turbine Spray time on forestry work is required. Work will be guaranteed from April-November of 2023, with the possibility of a long-term seat.

Please contact Chase Gibson directly at 228-860-2375 to discuss the seat. https:// www.bandsairinc.com/

Mix Truck Driver/Helicopter Loader - QUALIFICATIONS: Class A or B CDL required with tanker and hazmat endorsements. Experience in related field is helpful; clean driving record, must pass regular drug and alcohol screenings; must be willing to travel and work outside in the elements, and some heavy lifting may be required. Immediate permanent relocation is not necessary.

JOB DESCRIPTION: Our company provides silvicultural services for many types of customers throughout the US South and Midwest. This job offers workers a chance to travel and interact with many different types of leaders in the forestry industry. This is a great opportunity to advance with our company or to meet other persons in the industry that may help to further your career. This job will require you to be on the road from March-end of October with off time November-February. Our helicopter crews often work long hours and 7 day work weeks. Duties include: Driving mix truck from one spray location to the next with the help of the crew leader for navigation and filling the helicopter with chemicals. Necessary training will be provided to complete these tasks. Stays at hotel required while working out of town or at company owned apartment when working near our office. Ideal candidate will be willing to work hard with a positive attitude, work long hours and work as a team to help make the crew productive.

PLEASE CONTACT CHASE GIBSON DIRECTLY at 228-860-2375 or email resume to chase@bsairinc.com

Tabula – Regional Aviation Business Development Team Members for the Canadian Market: Due to continued growth in the United States, Tabula is hiring a new Regional Aviation Business Development Team Members for the Canadian Market to focus on our AirVision System. In return, we are offering a role that has the opportunity for growth and development, a base salary of $60k, plus a generous commission and bonus program that will reflect your skills, knowledge, and overall experience, with total earning potential being well over $100k. To apply, please send your CV and cover letter to recruitment@tabula.live

Tabula – Regional Aviation Business Development Team Members for the Southern Central United States: Due to continued growth in the United States, Tabula is hiring a new Regional Aviation Business Development Team Members for the Southern Central United States region to focus on our AirVision System. We are seeking someone with experience in the Agriculture Aviation Sector. About the role:The Business Development Team is responsible for maintaining our existing sales, growing new business, and technically supporting our products within the Agriculture, Forestry, Horticulture and Utility industries. In return, we are offering a role that has the opportunity for growth and development, a base salary of $60k, plus a generous commission and bonus program that will reflect your skills, knowledge, and

overall experience, with total earning potential being well over $100k. To apply, please send your CV and cover letter to recruitment@tabula.live.

Pilots Wanted - Looking for a few good pilots to fly 400-turbine Air Tractors. Willing to help with the turbine transition for the corn run. Perfect opportunity for a piston pilot. Call or text Craig at 815-499-4704

Long-Term Experienced AT-402 PilotWell established company in Ohio looking for a long-term experienced AT-402 pilot - 2023 and beyond. Housing is available. Fungicide, insecticide, fertilizer, seeding work on corn, beans, wheat, and some vegetables. Send resume to chadniese@embarqmail.com Call Chad at 419-235-4182

POSITION WANTED

Pilot Arizona - Pilot Available now. Any state or country. 58 good condition. Recent time on 510P. Licenced in Kansas, Colorado. E mail pawneeguy@hotmail.com

Plane & Pilot Available - Plane & Pilot available from July to August for 4-6 weeks. 510 Thrush. Experienced owner/ operator. Quality work. Shapefile proficient.

Email contact information and operation location to blindads@agairupdate.com Subject: ID#3384

Looking for 2024 Seat and Beyond Georgia: Looking for a 2024 seat and beyond. Willing to travel. Total time 20,200. Turbine time 18,471. Total Ag time 1,255. Licensed in Georgia. Completed NAFA in January 2024. Call Hale Ellis for more details at 678-779-4726

Experienced AG Pilot looking for Seat Georgia: Experienced AG Pilot looking for Seat, 7500TT, 4300AG, flown all Air Tractors models and Trush planes. Resume available on request. Contact IFlyag66@gmail.com

Subcontract for Corn Run South Dakota - Experienced pilot with AT-5, 6, or 802 SATLOC/flow control, extensive SHP time. Contact 701-541-0102

Experienced Tail Wheel Looking for Seat Utah - Experienced Tail Wheel. Most of my time has been in Turbine and Radial Ag Aircraft. Currently flying corporate and have a flexible schedule.Have a clean and safe record. Looking for ferry or contract flying opportunities. Located in Salt Lake City. Call Ty at 801-232-5777

Helicopter Pilot Turbine/Piston

Tennessee - Helicopter pilot turbine/ piston 7000+ flight hours looking for opportunity. Willing to work as a loader and hangar to earn a seat. Hardworking and committed to delivering high-quality results. Reliable and dedicated with an excellent safety record and work ethic. Available on short notice. I appreciate your time. Looking forward to hearing from you. Steve Reach out via call, text or 901-586-7322 or email at Stbrown77@gmail.com

Looking for Ag Pilot or Ground Crewman Position - Mature and teachable Ag Pilot, seeking to learn from other professionals. Either as an Ag Pilot or a ground crewman. Extensive farm and aviation maintenance background. Four seasons loading and Ag pilot experience. Flight time is as follows, 1240 TT, 645 Ag, 40 Turbine. A&P mechanic. Thank you. Please email AgAir41@outlook.com

AK Bush Pilot Looking for AG Pilot Slot, Alaska - 25 yrs AK bush. Central America Missionary pilot. 7500 TT, 1250 DHC3, 250 DHC3T. Train me so I can spray for you. See resume for details or email Will at whframingconsultant2@gmail.com

Looking for Long-Term Seat in the US

Cordoba - Looking for long-term seat in the US. I have an interesting combination of Aviation Engineering, Flight Training and Flight Experience, both Rotary Wing and Fixed Wing. Currently flying Thrush 510, Robinson 44, Robinson 66 and King Air C90. Experience in liquid application, aerial seeding and aerial fertilization. I am also URT (Upset Recovery Training) and aerobatics flight instructor giving instruction for more than 80 pilots already including AG pilots on how to recover airplanes form upset attitudes. Pilot Licenses: ATP, IFR Helicopter, CFI, TT Rotary Wing 1,500 hours. Resume and references are attached. For more information email cerionidiego@gmail.com

Looking for a Seat Missouri: Experienced Loader, CFI - Working on my second year loading now. Trained with Eagle Vistas over the winter on AG with John Becker. Some Ag-Cat and Pawnee time, 25 hours ag, 850 total, 150 tailwheel. I have my CFI, multi, and instrument. Looking for a seat in a plane, willing to load for the right company.

Contact Joseph Dittrich +1 (417) 763-7675

OPERATIONS FOR SALE