LIME APPLICATIONS IN

LEADING EDGE

TECHNOLOGIES | | BLOWIN’ IN THE WIND

LAND USE: ARE MOST CROPS JUST USED TO FEED LIVESTOCK? VOLUME 42,

With 36 years of experience, we have perfected the art of guidance for aerial application. But that does not mean we won’t keep innovating and improving. The new Ag-Nav Platinum Lite takes our industry leading technology and combines it with our more economical Guia 153 hardware. Paired with our OLED Transparent Lightbar, and Flow Control, you get the most advanced and cost effect guidance system on the market. The Ag-Nav OLED Lightbar displays all the information of our classic lightbars plus new more information, such as, Flow Rate, Aircraft Heading, Individual Booms On Indicators, Tank Level and more!

P.O. Box 850 • Perry, GA 31069 USA

475 Myrtle Field Rd. • Perry, GA 31069 USA PHONE / Fax: 478-987-2250

aau@marsaylmedia.com • agairupdate.com

AgAir Update is a Marsayl Media Publication

PRESIDENT: Graham Lavender - graham@marsaylmedia.com

VICE-PRESIDENT:

Bill Lavender - bill@agairupdate.com

SECRETARY:

Sandy Lavender - sandy@agairupdate.com

ACCOUNTING:

Casey L. Armstrong - casey@marsaylmedia.com

ADVERTISING:

Melanie Woodley - melanie@marsaylmedia.com

CLASSIFIED ADS: classifieds@agairupdate.com

Melanie Woodley - melanie@marsaylmedia.com

PRODUCTION:

Felicia (Lisa) Pannell - lisa@marsaylmedia.com

CIRCULATION: subs@agairupdate.com

Mary Jane Virden - maryjane@marsaylmedia.com

CONTRIBUTING WRITERS:

Ted Delanghe - ted.delanghe@gmail.com

Robert Craymer - robertc@covingtonaircraft.com

Regina Farmer - regina.farmer@chem-man.com

Carlin Lawrence - carlin@agairupdate.com

Ryan Mason - ryan@agairupdate.com

Michelle Miller - michelle@thefarmbabe.com

Josh Alameda - josh.alameda@gmail.com

Tracy Thurman - thurmantracyt@gmail.com

LATIN AMERICAN REPS:

Noelia Burgeus - noeliburgues@gmail.com

Ernesto Franzen - ernesto@agairupdate.com

Guillermo Giordana - aravia@aravia.com.ar

Gina Hickmann - gina@agairupdate.com

Pat Kornegay - pat@svatx.com

Ivan Parra - ivan@agairupdate.com

Marcia Specht - marcia.specht@gmail.com

© Copyright 2024 AgAir Update retains all rights for reproduction of any material submitted, to include but not limited to articles, photographs, emails and bulletin board posts. All material remain the copyright of AgAir Update No part of this publication may be reproduced, in part or whole, without the written consent of the publisher. Editorial published do not necessary reflect the views of the publisher. Content within AgAir Update is believed to be true and accurate and the publisher does not assume responsibility for any errors or omissions. Unsolicited editorial manuscripts and photos are welcomed and encouraged. We cannot be responsible for return unless submissions are accompanied by a stamped, selfaddressed envelope. Advertising deadline is 12 noon, on the 1st of the month preceding the month of publication. AgAir Update (ISSN 1081-6496) Published monthly by Marsayl Media, 475 Myrtle Field Road, Perry, GA 31069 for $39 USD for one year in the U.S.; International rates are $65 USD for one year. Periodical postage paid at Perry, Georgia and additional mailing offices.

Postmaster: Send address changes to P.O. Box 850, Perry, GA 31069.

AgAir Update, a multiple-award winning publication, is published in three languages and distributed world-wide. AgAir Update is a proud member of:

FROM THE COCKPIT

Bill Lavender . bill@agairupdate.com

Remembering Mr. Leland

As you may know, Air Tractor is celebrating its 50th year manufacturing agricultural aircraft. That is an impressive milestone for any company. It seems like an unusual influx of 50-year celebrations in ag aviation this year, including myself.

Air Tractor began this journey not as “Air Tractor” but as Snow Aeronautical Company, named after its founder Leland Snow. This was in the late 1950s, moving from south Texas to Olney, Texas. He then sold the company to Rockwell-Standard. The Snow S-2A and S-2B became the Thrush, and over 500 of the Snow-designed aircraft were produced. When Rockwell moved the company in 1970 to Albany, Georgia, Mr. Leland resigned and formed Air Tractor in Olney. From that point on, history was made as Air Tractor started its path to become today’s most popular ag plane.

While Mr. Leland was building the first models of AT-300 series Air Tractors in the mid-1970s, I was starting my ag aviation career in a 235 Pawnee in Dawson, Georgia. In the winter of 1980, I upgraded from a 600 hp, B-model Ag-Cat to a more productive turbine-powered ag plane. The choices at the time were a 400-gallon Turbine Thrush or possibly an Air Tractor. I knew that I wanted the reliable P&W PT6A engine; however, at the time, that was not available on the Air Tractor. The decision was made for me: a new Turbine Thrush with the newly introduced PT6A-11AG engine, serial number 1.

Mr. Leland and I became good friends, but understandably, it was not until after I got AgAir Update up and running with national coverage. Since then, Air Tractor and Mr. Leland have always supported the publication, for which I owe much gratitude.

I remember after many interviews, on one occasion, he explained to me how pricing worked. He told me that if

you raise your prices (rates, in my case) a small amount each year in line with ever-present inflation, your customer/client will rarely object. Those that did usually were about to leave you anyway. But, if you did not raise your prices/rates annually and allowed several years to pass, you would have to raise them dramatically. He said this could easily lead to losing that account—excellent and accurate advice.

On another occasion, Mr. Leland called me at my office. A bit surprised to receive his call, I answered the phone. “Bill, this is Leland. I want to talk to you about your pictures in AgAir Update. ” I could not begin to imagine where this conversation was headed. Of course, I said sure, let’s talk.

Mr. Leland said, “I have noticed in the photos you have taken of my aircraft that the prop appears to be stopped while in flight.” Where was he going with this, I asked myself. “I believe it would be better if you could publish these pictures with the prop turning,” he explained. Gee, I had not thought about this. It was an easy enough request to comply with, and I gladly did!

Then there was the time he took me for a drive in his 1996 Lincoln Continental. I recall this very well because it was precisely the same color and model car my parents had at the time. Should I mention that Mr. Leland and my father were born in the same year, 1930? Such a coincidence.

During this drive, Mr. Leland explained to me that this model car would tell him the miles per gallon of gas it could achieve. He would do his best to increase those miles per gallon by altering his driving techniques. This drive had nothing to do with ag aviation except maybe

(Continued on page 8)

highlight his innate desire to be as efficient as possible, something that carried over into his aircraft designs.

It has been 12 years since the passing of Leland Snow. It doesn’t seem like long ago, but that is what happens as you age; time passes quickly. He passed while jogging at 80 years of age. Mr. Leland questioned me about my jogging not too long before his passing. I told him my average time/speed. “Bill, that really is a good rate.” Of course, I was only 50-something at the time.

He never told me his minutes per mile. I often think of him these days when I walk at a reasonable pace. Eighty is not that far off!

Until next month, Keep Turning…

CALENDAR OF EVENTS

September 30 - October 4, 2024

2024 Operation S.A.F.E.

Analyst Training

Delta State University Cleveland, MS

Dr. Dennis Gardisser dgardisser@icloud.com 501-676-1762

October 10-12, 2024

NAAA & NAAREF Oct. 2024 Board Meetings

DoubleTree Chattanooga Chattanooga, TN

Lauren Henretty Lhenretty@agaviation.org 202-546-5722

October 16-17, 2024

Michigan AAA Fall Meeting

AgroLiquid Building 3055 W M-21 St Johns, MI 48879

Tim Swanson flyingfarmertim@hotmail.com 989-292-1362

October 21-23, 2024

Kansas AAA Convention

Drury Broadway Inn Wichita, KS

Rhonda McCurry kaaa@ksagaviation.org 316-650-6857

October 28-30, 2024

California AAA Convention

Embassy Suites, Napa Valley Napa, CA

Terry Gage terry.gage@caaa.net 916-645-9747

November 04-05, 2024

Pacific NW AAA Convention

The Coeur D’Alene Resort 115 S 2nd St Coeur D’Alene, ID 83814

Tara Lea Brown pnwaaa@gmail.com 509-989-9098

November 18-21, 2024

2024 Ag Aviation Expo Fort Worth Convention Center Fort Worth, TX

Lauren Henretty Lhenretty@agaviation.org 202-546-5722

December 10-12, 2024

Mid-States Ag Aviation Conference Isle of Capri/Quad Cities Convention Center Bettendorf, IA

Quintin Childs 515-229-1856

qchilds@insmgmtgrp.com

January 03-05, 2025

Arkansas AAA Convention Oaklawn Racing Casino Resort Hot Springs, AR

Katherine Holmstrom katherine@araaa.org 870-830-2308

January 06-08, 2025

Louisiana AAA Conference

TBA

Kim Brown laagaviation@outlook.com 225-436-3199

January 08-10, 2025

Texas AAA Convention

TBA Chris Shields cshields@thetexascapitol.com 512-476-2644

January 14, 2025

Arizona AAA PAASS Program

Custom Farm Service of Arizona Stanfield, AZ

Brittany Armstrong barmstrong@agairusa.com 520-705-9692

January 15, 2025

Ohio AAA Meeting

TBA Brian Gibbs

gibbsaerospray@gmail.com 419-332-1724

January 15-16, 2025

Missouri AAA Convention Drury Hotel

Cape Girardeau, MO Eric Blair ericb802@yahoo.com 573-283-5590

January 16-18, 2025

Mississippi AAA Convention Beau Rivage Resort & Casino Biloxi, MS Vicki Morgan vickimorgan@msaaa.com 662-455-0070

January 19-21, 2025

Oklahoma AAA Convention Embassy Suites Norman, OK

Sandy Wells sandy@okaaa.org 405-431-0381

January 22-24, 2025

New Mexico AAA Convention Inn at the Mountain Gods Mescalero, NM Seaver Tate seavtate@gmail.com 575-799-2504

AGAV PICS

A gaggle of Air Tractors in South America.

- Photo by @@tudonvelado on IG

Cover crop action in the Thrush.

- Photo by @ejs.photography_ on IG

An Air Tractor spraying cotton in South Africa.

- Photo by @agaviationafrica on IG

Cockpit crop view.

- Photo by @jkcoop_ on IG

An unusual sight as an Autogyro conducts a spray run.

- Photo by @elaaviation on IG

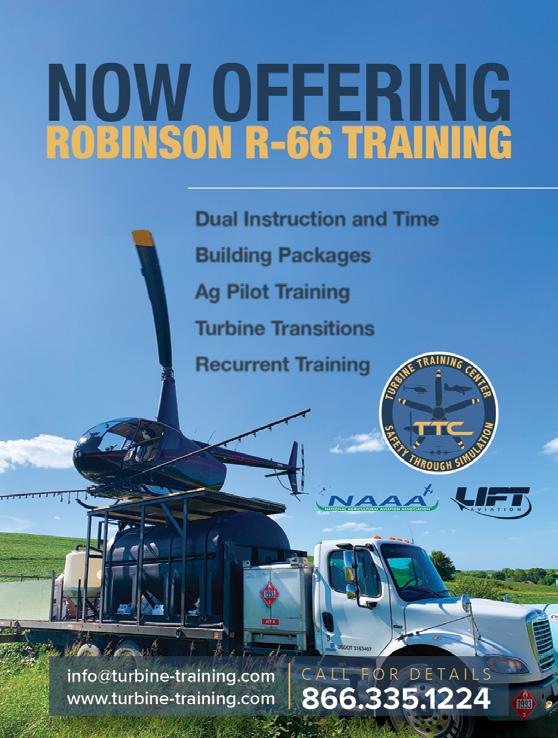

An R66 prepares to take off on the corn run.

- Photo by @parkerwilliams on IG

A gaggle of Air Tractors in South America.

- Photo by @@tudonvelado on IG

Cover crop action in the Thrush.

- Photo by @ejs.photography_ on IG

An Air Tractor spraying cotton in South Africa.

- Photo by @agaviationafrica on IG

Cockpit crop view.

- Photo by @jkcoop_ on IG

An unusual sight as an Autogyro conducts a spray run.

- Photo by @elaaviation on IG

An R66 prepares to take off on the corn run.

- Photo by @parkerwilliams on IG

Doing a little faster than 55 on the corn run in Indiana.

- Photo by @tomojonesfoto on IG

Sunset with the Air Tractor.

- Photo by @adre_le_roux on IG

Head on with an Air Tractor in Moree, New South Wales, Australia.

- Photo by @dust.n.diesel on IG

Taking off in Indiana.

- Photo by @jo_jo_richard on IG

Lifting off in the Thrush in South America.

- Photo by @tudonvelado on IG

Spraying canola in Colfax, Washington.

- Photo by @timgreyphoto on IG

Doing a little faster than 55 on the corn run in Indiana.

- Photo by @tomojonesfoto on IG

Sunset with the Air Tractor.

- Photo by @adre_le_roux on IG

Head on with an Air Tractor in Moree, New South Wales, Australia.

- Photo by @dust.n.diesel on IG

Taking off in Indiana.

- Photo by @jo_jo_richard on IG

Lifting off in the Thrush in South America.

- Photo by @tudonvelado on IG

Spraying canola in Colfax, Washington.

- Photo by @timgreyphoto on IG

LIME APPLICATIONS IN

In New Zealand, aerial lime spreading ensures even distribution, particularly over the country’s diverse topography. This method optimizes the surface area contact between lime particles and soil, enhancing the effectiveness of the neutralization process. By improving soil structure and pH, lime application fosters healthier plant growth, enhances nutrient uptake, and promotes sustainable farming practices across the varied landscapes of New Zealand.

The science of soil chemistry and agronomy underpins the practice of lime spreading, offering a beacon of hope and optimism for enhanced plant growth. The pivotal role of lime application is to regulate soil pH, a key factor that profoundly impacts plant growth and nutrient availability. In New Zealand, especially in high rainfall areas, soils often turn acidic due to the leaching of

(Continued on page 13)

basic ions like calcium and magnesium. This acidity can impede plant growth by restricting the availability of vital nutrients such as nitrogen, phosphorus, and potassium, and by escalating the solubility of toxic elements like aluminum and manganese.

Lime, primarily composed of calcium carbonate (CaCO3), neutralizes soil acidity through a chemical reaction that increases soil pH. When lime is applied to the soil through aerial spreading, it is first broken down into calcium ions (Ca²⁺) and carbonate ions (CO₃²⁻). These ions are then dispersed evenly over the soil surface, ensuring maximum contact

(Continued on page 16)

with the soil particles. The carbonate ions react with hydrogen ions (H⁺) in the soil, forming water (H₂O) and carbon dioxide (CO₂), thus reducing soil acidity. This process, known as aerial topdressing, is a highly efficient and precise method of lime application.

One of the key advantages of lime spreading by air is the substantial time savings it offers to farmers. New Zealand's diverse and often challenging terrain can make ground-based lime application a laborious and timeconsuming task. Aerial topdressing, on the other hand, allows for swift coverage of large areas, significantly reducing the time and

(Continued on page 18)

Agricultural Spray Systems for R22 / R44 Helicopters

• Lightest R22 / R44 Spray Systems

• Certified in the Normal Catergory (R44)

• Rugged / Reliable • Always in Stock

“You never sprayed like this before”

FAA, Canada, EASA, China, Brazil, Mexico STC www.apollospray.com • info@apollospray.com 440-632-1687

labor costs associated with traditional methods. This efficiency empowers farmers to allocate their resources to other crucial aspects of farm management, ultimately leading to a boost in productivity and profitability. Furthermore, the ability to swiftly apply lime during optimal conditions ensures that the soil receives the necessary treatment in a timely manner, thereby enhancing crop yields and pasture growth.

Furthermore, the speed and flexibility of aerial lime spreading make it an ideal solution during peak farming seasons, providing a sense of relief and confidence to farmers. Weather conditions can change rapidly in New Zealand, and the ability to quickly apply lime during optimal weather windows

(Continued on page 20)

can significantly affect soil treatment efficacy. This agility helps farmers maintain their schedules and avoid delays that could impact crop and pasture health.

Aerial lime spreading in New Zealand not only presents a pragmatic and beneficial approach to soil management but also underscores our collective responsibility towards the environment. The method's economic benefits, such as time and cost savings, are complemented by its environmental advantages. These include precise application and enhanced soil health, making aerial topdressing an attractive option for farmers. Moreover, the logistical hurdles posed by New Zealand's diverse terrain are effectively overcome through this method, ensuring that all agricultural land can receive the necessary treatments. As the agricultural

(Continued on page 22)

PRATT & WHITNEY ENGINES

Complete stock of parts, tools and accessories

0-TIME ENGINES IN STOCK

R985/R1340, R1340 GEARED COVINGTON. AERO RECIP & TULSA

R1830-92, -94, -75

R-2000-7M2 • R2800 VINTAGE & ANDERSON

WE BUY PARTS, INVENTORIES, AND USED ENGINES

R985/R1340 TOP OH TOOL KITS $250.00 TIME RITE KITS

R985 NO BLOW GASKETS ENGINE MOUNTS

TEMPEST SPARK PLUGS

PLUGS

R1340 CAMS,

sector continues to progress, aerial lime spreading emerges as a valuable tool for augmenting productivity and sustainability in New Zealand's farming practices.

One such Lime pilot is Jimbo Burgess, who is responsible for the pictures in this article. Burgess was raised in New Zealand in a small town of about 1,000. His dad was an Air Force mechanic, and Jimbo always had aspirations of being an ag pilot. While driving past the aero club one day, he decided to book a discovery flight, which led to his extensive career in aviation. Burgess began on the ground, loading airplanes in 2004 with Precision Aviation. After about a year, he began survey flights for the company. After the company closed, Burgess continued the survey work, which involved low-level flying using lightbars in the PAC750. After a short hiatus, Burgess went to work with Aeroworks flying the Cresco, powered by the PT6A-34AG. During the New Zealand off-season, he traveled to Canada and did contract work in China with the 510G Thrush. Jimbo works on the South Island, contract flying and taking great photographs.

NAAA INSIGHTS

Fly Safe! Safety Reminders for the Busy Flying Season

NAAA’s sister organization, the National Agricultural Aviation Research & Education Foundation (NAAREF), sends important safety alerts called Fly Safe messages to ag pilots every other Monday in April and May, and every Monday in June, July, and August. Additional safety reminders are issued whenever aviation activity warrants them. This is another invaluable service provided by the two organizations that have resulted in accident and drift incident trends declining over the past quarter of a century. Fly Safe messages are shared with NAAA members and non-members—specifically, all operators and pilots with a valid email address on file with the National Agricultural Aviation Association (NAAA).

If you are a Part 137 operator or ag pilot who has not been getting the Fly Safe messages, please contact NAAA’s Scott Bretthauer at (202) 546-5722 or sbretthauer@ agaviation.org to be added to the recipient list.

Below are a few safety reminders to keep in mind this summer.

Prioritize Avoiding Wires & Obstructions

Wire strikes caused 28% of the ag aviation accidents in 2023 and eight pilots lost their lives last year after hitting a wire. Throughout your 2024 season, no matter how busy you get, do not allow anything to take your focus off wires and other obstacles in the fields you treat. Before applying to fields you’ve treated for years, resist the temptation to rush your reconnaissance efforts. Instead of assuming nothing has changed in those fields, you must start with the assumption there has been a change until a thorough reconnaissance proves otherwise. It’s best to conduct a minimum of two complete orbits around the field in opposite directions. Background and light conditions impact your ability to

(Continued on page 26)

Thirty-five years after the first great historical account of the industry—Mabry Anderson’s Low & Slow: An Insider’s History of Agricultural Aviation—comes a new, updated account of aerial application’s history from the National Agricultural Aviation Association: Agriculture’s Air Force: 100 Years of Aerial Application

Based on a collective history of the agricultural aviation industry sourced from Agricultural Aviation magazine, AgAir Update, Low & Slow and other materials, Agriculture’s Air Force chronicles the agricultural aviation industry’s growth from its infancy in 1921 through the boom times after World War II, and on to today’s modern era of high-tech aerial application.

Whether you are an aviation enthusiast, have an appreciation for agriculture or are simply awed by the aerial ballet of these low-flying aviators, pull up a seat and tag along with Agriculture’s Air Force! (Available in hardback.)

identify obstructions, so making the orbits in different directions changes how you view the site and provides a greater opportunity to see hidden structures.

Obstructions have always been hazardous to low-altitude pilots’ health, and the number of telecommunications towers, GPS differential signal towers, meteorological evaluation towers, wind turbines and other obstructions erected in agricultural regions has increased significantly over the past several years, which increases the risk to ag pilots. Read the Spring 2024 Agricultural Aviation magazine article titled “Turns, Wires, and Nozzles – A Synopsis of the 2023-2024 PAASS Program” for an in-depth review on avoiding wires and obstructions. Learn more by attending the Flying in the Wire & Obstruction Environment Course before the Ag Aviation Expo on Saturday, Nov. 16, in Fort Worth, Texas. Register online at AgAviation.org/ convention. This event will be offered free of charge for those who register in advance.

Don’t Fly Aggressively in an Effort to Get More Work Done

During the busy part of the season, a backlog of work and demanding customers put intense pressure on aerial applicators to push themselves to constantly maximize productivity. This frequently leads pilots to fly as fast as possible, which can eventually lead to flying and turning aggressively, increasing the risk of a stall spin or another type of accident. Flying fast and turning hard puts extra

stress on both you and your aircraft. If you’re not gaining any extra acres, is the extra stress worth it? PAASS is not suggesting you fly your aircraft so slow that you’re at risk of stalling. But if you back off from flying as fast as the aircraft will go and instead fly it at a safe but more reasonable speed, you might see a positive impact on your daily work output. Reducing stress on yourself increases overall safety because you’re better rested and more focused on flying.

Avoid Potential Mid-Air Collisions by Considering Ferrying at 1,000’ & Equipping with ADS-B

PAASS has consistently reminded aerial applicators to “ferry above five (hundred) and stay alive” to reduce the chances of a mid-air collision. However, if turbinepowered ag airplanes are commonly turning at altitudes greater than 500 feet, does this recommendation adequately protect against collisions between ferrying and turning aircraft? Think about how high you go in your ag turns and how high other ag pilots working in your area go in their turns. You may likely realize that ferrying at 500 feet doesn’t provide the safety margin you thought it did. Ferrying closer to 1,000 feet will provide more clearance from aircraft making ag turns.

To further reduce your chances of being in a mid-air collision, consider equipping your ag aircraft with ADS-B In. It will allow you to know where other ADS-B

(Continued on page 28)

equipped aircraft are, as well as provide those aircraft with your location. It can be set to provide audible warnings when another aircraft enters a user-set range, meaning it doesn’t need to be continuously monitored. Communicating on the radio with other ag pilots working in the area can also reduce the risk of a mid-air collision.

New Ag Pilots Should Focus on Safety, Not Productivity

The lack of experience with new ag pilots can put them at a higher risk of having an accident. However, poor mentorship can also significantly increase those risks. New ag pilots need a great deal of training, and it’s their mentor’s job to educate them in a safe manner. New pilots may have many hours in other types of aircraft, but that doesn’t mean their ag flying training should be sped up. How much of that previous flying time was spent flying in the wire environment or working the long days required in ag? If you intend to mentor a new pilot into ag aviation, be ready to devote the time and resources to do it properly, continuously monitor their progress and be available whenever they have questions or concerns.

Sending an inexperienced ag pilot out of their normal area where they are used to flying compounds the danger of a lack of experience in ag flying with the risk of working in unfamiliar territory. New ag pilots need fields specifically selected for them based on their current skills and comfort level. This is not likely to occur when they’re sent out of state during a period of intense spraying activity.

It is sometimes insinuated that inexperienced pilots are at fault for many of the ag accidents. But if these pilots are being turned loose in aircraft that they’re not ready for, to do jobs they’re not prepared to spray yet, whose fault really is it? For the inexperienced ag pilots reading this – when your mentor says you’re not ready yet for a bigger aircraft or a field with wires or other obstacles, listen to them. If you’re in doubt of your abilities to move to a higher performing aircraft or new locale, express those concerns. Mentors, ensure pilots are ready and proven to fly faster and larger aircraft and proven to perform in a new environment.

Funding for NAAREF services and programs, such as PAASS, the Fly Safe campaign and Operation S.A.F.E., comes from NAAA and other donors willing to invest in the future of agricultural aviation; make a donation at AgAviation.org/education/naaref/.

We invite you to join the cause of preserving and protecting the aerial application industry, your livelihood, and your life by joining NAAA if you aren’t a member already. Call (202) 546-5722 or visit AgAviation.org/membership to join online.

NAAA Board Establishes UAAS Committee for All Mediums

Ensuring Safety, Efficacy, and Compliance in Aerial Applications

The National Agricultural Aviation Association (NAAA) Board of Directors recently voted to establish an Uncrewed Aerial Application System (UAAS) Committee to advise the Association on uncrewed aircraft systems (UAS) – or drone – issues. The decision to establish the committee is to ensure the low-altitude airspace is safe for crewed and uncrewed aircraft as the number of UAS in low-altitude airspace grows. The Committee will also advise the NAAA on ways to ensure aerial application regulatory compliance, efficacy and environmental professionalism is achieved throughout crewed and uncrewed aerial application mediums. These goals are shared by both manned/uncrewed aerial application operations and established, licensed drone operations.

According to the FAA, drones are the fastest-growing segment of aviation in the United States. There are nearly 864,000 drones registered with the FAA and over 330,000 certified Remote Pilots and the numbers are projected to continue growing.

“The purpose of the UAAS Committee is to reach the crewed or legacy ag aircraft operations and operators of the new UAS technology on the imperative issues of airspace safety, environmental professionalism, regulatory compliance and aerial application efficacy—issues of mutual interest to both forms of aerial application,” said Andrew Moore, chief executive officer of NAAA. The formation of the UAAS Committee will be balanced

between crewed and uncrewed NAAA members and all policies proposed will go to the board for final approval. Committee members are required to be NAAA members, and the committee members will be selected by the NAAA President each year.

UAAS Committee members will recommend to the NAAA Board public policy proposals to enhance the safety of the airspace shared by crewed and uncrewed application aircraft, and also provide input facilitating the development and regulatory use of atmospheric models forecasting the movement of applied materials from both crewed and uncrewed aircraft application systems. The Environmental Protection Agency (EPA) has determined the necessity of such models to analyze the atmospheric movement of registered pesticides applied by UAS, just as it currently does for crewed aerial applications and ground and airblast applications via the AgDRIFT atmospheric model.

UAAS Committee members will also recommend to the NAAA Board and its related foundation—the National Agricultural Aviation Research and Education Foundation (NAAREF)—educational curriculum focused on professionalism, regulatory compliance, aviation safety, application efficacy, and environmental stewardship for the uncrewed aerial application systems community. This curriculum will be considered by NAAA and NAAREF at educational events, the annual NAAA Ag Aviation Expo, and within NAAA and NAAREF publications and virtual mediums, ensuring the highest standards in the industry.

SOUTHEASTERN AIRCRAFT SALES

SPRAYING TECHNOLOGY

SPRAY SYSTEMS

Reliable and highly durable

SINCE 1997 ROTARY ATOMIZERS With a standard of excellence for aerial application

FIRE GATES

Versatile and effective in reghting

GROUND SUPPORT EQUIPMENT With great corrosion resistance www.zanoniequipamentos.com.br/en

Delta State Graduates 2nd Class of Ag Pilots

The second class of students from the Commercial Aviation Department at Delta State University to graduate with an Agricultural Aviation Operations Career Pathway Certification were recognized during a ceremony on May 24 in the DSU airport hangar at the Cleveland Municipal Airport. Completion of the program allows graduates to be hired by an aerial applicator business without incurring increased insurance costs, removing one of the largest hurdles for new ag pilots.

The program is the result of DSU’s collaboration with area ag pilots, the Cleveland Airport Board, Blues Air, and many others. The program is 100% funded by the U.S. Department of Education. Sen. Cindy Hyde-Smith, R-Miss., was instrumental in getting the program off the ground and was present at the ceremony to congratulate the graduates.

“It is a great day to be in the Delta,” she said. “I am so excited about this ag pilot program we have here at Delta State University. To see it come together and to be graduating students today is a huge accomplishment.”

Program graduate Anthony Duffin of Glen Alan said, “I’ve wanted to be an ag pilot since I was a kid.” He said that he particularly enjoyed flying the Air Tractor 802 that students train in. “It’s a beast of a plane.” Duffin will be flying an earlier model Air Tractor, the 502, as he begins work for an aerial application company in Louisiana this summer.

Justin Parkey of Charleston also received his certification, saying, “I was training at Blues Air when the program came out, so I tried to get a slot as soon as I could.” When asked what comes next, he said, “I will be working around Charleston flying Ag Cats for Chris Henke at SRB Aerial Applicators.”

Ike Brunetti of Brunetti Flying Service in Shelby has been instrumental in organizing the program and has been a mentor for the new pilots and their instructors as the program has developed. He said, “These 11 young men will fill needs in our industry. We are so proud to have Senator Hyde-Smith here as

(Continued on page 40)

our guest speaker. This program exists because of her passion. She started this ten years ago, and it has taken a tremendous amount of effort from the community and the university to create this much-needed program.”

Phillip Krasner, owner of Blues Air, said, “The students go through the basic ag course while they’re working on their commercial pilot license, then they go to an Air tractor simulator. After that, they move on to Advanced Turbine Training which takes them through AT-802 training and completes the program.”

The Agricultural Aviation Operations Career Pathway Certification attests to a student successfully completing hazmat training, FAA instrument flight certification, FAA commercial certification, tailwheel endorsement and a minimum of 100 hours, 25 hours of which consisting of light bar training in a Citabria, 25 hours of light bar aerial application In an AG Wagon (C-188) and ten-hour typerating and aerial application in an Air Tractor 802.

Hyde-Smith said, “Mississippi is agriculture, through and through. It’s our number one industry. But for the two percent of us that feed the other 98 percent of the country, ag pilots are very important. We could not do it without them.”

Colonel Brad MacNealy, Interim Chair of Delta State’s Commercial Aviation Department said, “We are proud of the 11 men who just completed our second cohort. With a growing population, a shortage of pilots, and aging aerial agricultural applicators, the need for newly trained ag pilots is critical. There’s a huge shortage of training opportunities in the world, and we have the premier aerial

applicator course right here at Delta State. We have been able to bring this program to Cleveland, Mississippi, and make this a one-stop shop with a huge impact.”

Students receiving certification are:

Mason Anderson, Cleveland

Carson Blair, Sidon

Cruse Corso, Taylor

Anthony Duffin, Glen Alan

Curt Dungan, Charleston

Aden Easter, Sumner

Anderson Gentry, Courtland

John Reece Jackson, Isola

Allen Jernigan, Leland

Justin Parkey, Charleston

Blake Rykard, Cleveland

For more information about the Agricultural Aviation Operations Career Pathway and other Commercial Aviation programs at Delta State University, visit https://www.deltastate.edu/college-of-business/ commercial-aviation/.

Blowin’ in the Wind

by Ted Delange

It seems that every time a new forecast comes out, the weather seems to be taking a long walk down the wrong road. Record-breaking temperatures, rainfall, tornadoes, flooding, massive thunderstorms, and staggering drought—there doesn’t appear to be any relief in sight. Coupled with that are new meteorological terms I haven’t heard before, like heat domes, atmospheric rivers, topical plume, Pineapple Express, etc.

More than any other factor, aerial application is dependent on the weather. Sometimes, Mother Nature seems asleep at the wheel or has a nasty mean streak when it comes to helping farmers combat the latest infestation.

Some good news: aerial applicators can always choose to fly in weather suitable for the specific requirements of the job or park the aircraft when the weather is out of limits and wait until things settle down. While it’s challenging to choose to shut down with a lineup of anxious farmers standing in line at the airstrip, hoping to be the next one to get your aerial application services before their crops are toast, don’t press the capricious gods of nature. It seldom pays dividends and, more often than not, will get you into hot water.

“ To paraphrase the famous line from Shakespeare’s Hamlet, to go, or not to go, that is the question. ”

To paraphrase the famous line from Shakespeare’s Hamlet, to go or not to go, that is the question. In the past, it was a matter of looking at the windsock to gauge whether the trip would be safe and effective. That is, if a windsock was present. When I started in the industry decades ago, a lot of flying was done off municipal roads with the attendant lack of weather services.

Today’s aerial applicators have a chest full of new tools, like sophisticated and affordable mobile weather stations that help quantify the decision to fly. Coupled with widespread access to the Internet, you have readily accessible and upto-date weather information whenever needed.

(Continued

on page 44)

“ ... no matter how much you prepare, the skies are ready with challenges that can sneak up on you and spoil a perfectly wonderful day... ”

To those unfamiliar with aerial application, the public notion is of daredevil pilots staging a free and entertaining airshow. Nothing could be further from reality. Compared to the early pioneering cropdusters who spawned a new industry, today’s operators and pilots are better trained, equipped, and managed than ever before.

However, no matter how much you prepare, the skies are ready with challenges that can sneak up on you and spoil a perfectly wonderful day. It is one thing to deal with an issue while you are thousands of feet above ground. It’s a different kettle of fish when you’re skimming over crops at a dozen feet. Here are a few reminders to help keep your guard up.

It is hard to cope with something you can’t see directly, and first and foremost on my list of Mother Nature’s poisoned gifts is the phenomenon of low-level wind shear. It can be a real bummer like its big brother, clear air turbulence. Ask any experienced ag pilot if they’ve ever been bit by wind shear, and you’ll add another story to the next hangar talk session.

The problem with wind shear, a.k.a. steep wind gradient, occurs when a headwind rapidly changes to a tailwind, causing a dramatic decrease in airspeed and performance. This can happen when you’re pulling up into a dramatically increasing tailwind. If severe enough, the perception you get with such a rapid decrease in airspeed is that you’ve just had an engine failure.

No problem if the terrain ahead of you is flat. It’s not so good when you’ve got a powerline, hill or some other obstruction you need to clear. Double that when you have a full load aboard.

Avoidance is the key. Even if it’s lightly gusting on the ground, be on the lookout for a strong wind shear aloft. It’s better to be safe than sorry. Thunderstorms, frontal weather, temperature inversions, or tall trees or buildings can cause localized wind shear.

Although we are taught about wind shear in our commercial ground school, it doesn’t sink in until the phenomena have nipped you. My first and most memorable experience was in a Cessna 188, applying fungicide about 25 miles from my home base. There was a light headwind on takeoff, but on the way to the field, I noticed it was getting bumpier and bumpier as I climbed. At any rate, I could see the field well in advance and decided to enter directly on the first spray run.

All went well until I pulled up at the far end of the field. Luckily, there was only a line of small trees to avoid as I had the awful sinking sensation of mushing during the pull-up, with the airspeed unwinding like a broken spring. Turning back to the field for the next run wasn’t going to happen until I got the AgTruck out of the nearstall condition I found myself in. Only by gently lowering the nose to get out of the wind shear around 300 feet was I able to get back to a fully flyable condition.

I also recall that it took a couple of miles to achieve that goal of doing a 180 to line up with the next swath, all the while feeling like I was trying to balance precariously on a beach ball, trying somehow to maintain stability where any sudden movement could lead to a nose-dive. Or, in the case of the AgTruck, use gentle movements on the stick to avoid a stall and unwanted contact with terra firma.

There is no shortage of events that could lead to a day you’d rather avoid: inversions, mechanical and thermal turbulence, flight into rising ground. The list goes on and on. But when considering whether to go or not to go, remind yourself that it is best to be prudent when faced with a risky situation rather than charging full steam ahead.

Keep the math simple. One of your primary goals is to have the same number of landings as takeoffs so you can avoid becoming an unwanted and preventable statistic.

Air Tractor’s Gene Williams Remembered

Gene Williams, the man who set the standards for Air Tractor customer service throughout his career, passed away May 7 in Wichita Falls, Texas. He was 82.

“Gene was a very smart and perceptive man. He understood human behavior and how to get things done while always remaining a down-to-earth guy from rural Texas. We were lucky that he chose Air Tractor to share his talents with,” says Jim Hirsch, Air Tractor president.

Williams officially retired from Air Tractor in 2007, after 20 years of service at the agricultural aircraft manufacturer, but continued mentoring Jeff Dobbs, who followed in his footsteps as Customer Service Manager. Dobbs says, “Gene practically wrote the book on Air Tractor customer care.”

“Gene spent a lot of time working on an invaluable document called the Air Tractor Customer Service Manual. He recognized that because they were out of production, there were old Tractor AT-300s, 301s, 400s,

and 400As remained in service. But very few people remained at Air Tractor who were familiar with these airplanes. In Gene’s words, ‘The answers to customers’ questions are all found in Air Tractor drawings, engineering reports, and service letters. The research necessary to find these answers can be very timeconsuming unless one already knows the answers.’ Gene collected and preserved that knowledge and passed it along to us. It was this type of foresight that I am grateful for,” Dobbs adds.

Dobbs recalls that Gene was an outstanding mentor who always had a word of encouragement during difficult times.

“Gene was unlike anyone I have ever met. He had a special gift for reading people, an uncanny way with words, and a common-sense approach to problem solving that you just don’t come across very often,” Dobbs says. “I consider it a real honor to be in the role

(Continued on page 48)

of Customer Service Manager here at Air Tractor. It is because of people like Leland Snow, the first unofficial Customer Service Manager, and later Gene Williams, who paved the way for the success we have today.”

Gene Williams was born December 8th in Wichita Falls on the day the US entered World War II. He grew up in Wichita and Young counties.

He served proudly in the U.S. Marine Corps, but his proudest achievements were his children and grandchildren. He is survived by son, Wade Williams (Loving, Texas), and three daughters—Tracie Moore (Graham, Texas), Desi Vicars (Holliday, Texas), and April Palmer (Houma, Louisiana)— eight grandchildren:

Carl Moore (Joshua, Texas), Michael Moore (Graham, Texas), Yves Andress (Spokane, Washington), Thomas Williams (Houston, Texas), Rona Williams (Houston, Texas), Hunter Dalton (Wichita Falls, Texas), Hadley Vicars (Holliday, Texas), and Layton Gober (Holliday, Texas); and one great-grandson, Owen Dalton (Wichita Falls), along with numerous nieces and nephews in California, Boston, Kentucky, and Texas.

During his 82 years Gene made many friends and he and maintained those friendships with delight. His family notes that so many of his friends were part of the agricultural aviation industry. “Gene will be missed, but never forgotten. He made sure of it by leaving his mark on the very fabric that makes Air Tractor special,” Hirsch said.

CRAYMER’S COUNSEL

Robert Craymer | robertc@covingtonaircraft.com

Clean Air

Engine maintenance is crucial for optimal performance. An engine thrives on three things: clean oil, clean fuel, and clean air. While we filter and monitor the oil and fuel, the air requires more attention. Engine washing, when the engine needs cleaner air, can work wonders in maintaining its health and efficiency.

A clean engine is a happy engine. Pratt & Whitney Canada’s maintenance manual provides insight into types of engine washes, guidelines for washing and why they are important. However, the maintenance manual does not explicitly tell us when to wash. How often do you wash your PT6 engine?

It is time to discuss the types of engine washes that you should be doing and my thoughts on how often you might do each type. If you have sat through an engine discussion, washing almost always comes up as a topic of conversation. The maintenance manual defines three internal types of washes: Desalinization, Power Recovery and Turbine. I also remind folks to pay attention to the external engine wash. Not only does it give you a chance to look your engine over, but it also provides an opportunity to make sure you have cables and components lubricated. Not cleaning these components and caring for their proper lubrication can lead to premature wear and failure. You want to be looking for early signs of corrosion as well. The earlier you catch corrosion, the better. I have had several discussions lately troubleshooting worn or parts being affected by the operating conditions (corrosive environment).

All internal engine washes are performed while the engine is running. This process provides two additional things to watch out for: first, ensure that you do not overheat your starter/generator and allow for proper cooling between motoring cycles. The second concern is the potential to siphon the oil from the oil tank and flood the accessory gearbox, which is more common in large PT6 engines. An

indicator of this is oil coming out of the inlet case. When washing a large PT6 engine, we aim to do as few motoring cycles as possible.

Begin your internal washes by engaging your starter. When the Ng is between 10% to 25%, the water or cleaning fluid is injected into the engine at a rate of 2 to 3 gal/minute. Make sure to read your maintenance manual to see the complete washing instructions. All internal

(Continued on page 52)

Proudly supporting operators of:

Proudly supporting operators of:

engine washes are performed while the engine is turning. Let’s define the wash so you can make the best choice as to what type of wash you need.

The first internal wash is the desalinization wash. This wash is performed to remove salts, deposits and light dirt. This wash is performed with drinking-quality water, provided minimum standards are met. People who live in areas with a high mineral content in the water should use demineralized water. Desalinization wash can be a daily or weekly wash, depending on the atmosphere in which you fly. We talk about salt air, pollution, dust, and sand, but what about corrosive products delivered with ag aircraft? Can these materials make it through the air filtration? I suggest checking the cleanliness of your compressor during your 100-hour inspection. This check will let you know if you need to increase the frequency of your desalinization (plain water) washes. If you are doing a lot of fertilizer, run some water through your engine. Some chemicals quickly cause corrosion on and in the engine when not taken care of.

The second internal wash is the performance recovery wash. Pratt & Whitney Canada recommends this level of washing if there is a noticeable difference in engine performance. If you are doing regular desalinization washes and the compressor still shows signs of dirt/ salt/chemicals, add a performance recovery wash to your regular schedule. This wash is like the desalination wash with the addition of a cleaning solution. Important note: ONLY use approved chemicals in the cleaning solution. Several options are available, listed in the engine maintenance manual, along with the proper mix ratios. Don’t put non-approved chemicals in, as this could cause even more damage than not washing.

The final internal wash is the compressor turbine desalinization wash, which is another wash that is a rinse. This wash sprays clean water directly on the compressor turbine blades. A tool is required to perform the compressor turbine desalinization wash. A water rinse of the turbine is recommended when doing a performance recovery wash as the final step. This wash removes residue from the CT blades and limits the opportunity for sulphidation to attack blade coating and parent material. You need to perform this wash if you notice dirt or other things “sticking” to your compressor turbine (CT) blades. The blades are inspected at each nozzle interval via borescope, so you will watch how they are

doing. If anyone has had to replace CT blades, then you know just how valuable this small amount of preventative maintenance can be.

I encourage everyone to wash their engines based on what they see in and on them. Some customers wash daily, some weekly or every 100 hours. It is all based on condition. Make sure you reference the manual for all the proper steps. Make sure all the drains are open and draining. Make sure to disconnect the air system going to the fuel control from the engine. People should wash before the work day, giving you the best opportunity to dry the engine after the wash - an important step in the process. Cleanliness can make a world of difference not only in the performance of your engine but also in providing an opportunity to save you money as a preventative step.

Robert Craymer has worked on PT6A engines and PT6A-powered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and is an instructor of PT6A Maintenance and Familiarization courses for both pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member.

Robert can be reached at robertc@covingtonaircraft.com or 662-910-9899. Visit us at covingtonaircraft.com.

Michelle Miller | michelle@thefarmbabe.com

Michelle Miller | michelle@thefarmbabe.com

Land Use: Are Most Crops Just Used to Feed Livestock?

It takes a lot of food to feed livestock. There is also a lot of land for crops around the world. Animal rights activists sometimes try to convince you that one of the reasons we shouldn’t raise livestock for meat is because it’s inefficient and that most land that’s producing crops is used to feed livestock. They will also claim that this land could be used to produce a lot more food to feed people instead of animals. So, would it be better to use land and resources to produce things to feed people instead of feeding livestock?

We need to look at whether most crops are used to feed livestock and what type of land is used. So, first off, are most crops used to feed livestock? No! Only 13 percent of global animal feed consists of grain crops. In the United States, this number drops to 7 percent.

86% of global livestock feed intake consists of feed that is not edible to humans. This includes byproducts like grains distillers, soybean meal, citrus pulp, almond hulls,

and much more. Forty percent of ingredients used in animal feeds are direct byproducts of other industries. If we look solely at beef cattle in the United States, just 7 percent of their lifetime feed intake is grain that would otherwise be edible to humans.

For every 0.6 kg of human-edible protein that cattle consume, they produce 1 kg of human-edible protein in the form of beef. This is convincing evidence that cattle are highly efficient at converting things we can’t eat into something we can.

There are two types of land: arable land and marginal land. Arable land can grow crops, while marginal land is unsuitable for growing anything. Thirty-three percent of agricultural land is arable, which means there is a lot of land unsuitable for growing crops. One of the best uses for this land (since it can’t be used to grow human-

(Continued on page 56)

NEW RG-220 BATTERIES DESIGNED FOR THE MOST DEMANDING APPLICATIONS

We love the RG-220. We like that the battery box is clean; it’s a cleaner, friendlier installation without corrosion treatment and preventative maintenance. The mechanic appreciates it and for us it reduces our maintenance costs. There are more amps available for faster, cooler starts.”

For Air Tractor Models AT-402, AT-402A, AT-402B, AT-502, AT-502A, AT-502B, AT-504, AT-602, AT-802 & AT-802A

STC SA01090DE provides for the installation of Concorde RG-220 batteries in Air Tractors.

The TSO-C173a authorized RG-220 was specifically designed to start PT6 turbine engines. It is built with the same components and features that are proven to optimize current output, maximize capacity and sustain turbine engine power requirements. The RG-220 is dependable season after season.

• Faster starts, improved performance and reduced engine wear

• Sealed technology - no electrolyte management or potential contamination

• Proprietary PolyGuard® Separators – for added protection against shock & vibration

• Concorde batteries are 100% recyclable

• Supported by Concorde’s world class customer service

+ AS9100 CONCORDEBATTERY.COM

edible food) is to allow livestock to graze. Livestock are excellent at converting byproducts and inedible products into something we can eat.

It’s claimed that it sacrifices 12 pounds to 20 pounds of feed (human edible and inedible) to produce one pound of beef. This myth also isn’t true. It doesn’t take 5 pounds of grain to produce 1 pound of beef. The 2.5 pounds of grain cattle consume couldn’t be shifted to a human diet.

For example, let’s compare the nutrition from common crops with the nutrition from beef. For one pound of steak and one pound of soybeans, steak has more than twice the amount of protein than soybeans. A serving of steak also has 84% of the recommended vitamin B12 intake and 57% of the recommended zinc intake. Soybeans don’t contain any vitamin B12 or zinc.

Livestock also provide critical essential nutrients. Food from animal sources contributes 18% of global calorie consumption and 25% of global protein consumption. Animal proteins also provide essential micronutrients, including vitamin A, vitamin B-12, riboflavin, calcium, iron and zinc, all of which can be difficult to obtain from plantsource foods alone.

We all know that animal proteins are a great source of protein, but not all proteins are created equal. Only animal proteins provide all of the essential amino acids (protein building blocks) that a person needs for optimal health.

People who consume animal proteins have been shown to have a higher net protein balance and greater protein synthesis than those who consume an equal amount of plant-based proteins.

One last thing to consider is how livestock benefits the land. Using practices like rotational grazing, livestock can help sequester carbon and improve soil health. Livestock also promotes biodiversity and the abundance of plants. Animals like goats and sheep can be used to “clean up” brush and overgrown areas, which is essential in fire prevention.

While some of the diet fed to livestock could be converted to products to feed humans, we’d miss out on essential nutrients. Livestock are also efficient at converting land that can’t be used to grow anything edible to humans into protein that we can eat. Using a small amount of land that could be used to produce food for people is a small price to pay for all of the nutritional and environmental benefits that we get from livestock.

Let’s not forget we get more than just food from animal agriculture; we use thousands of products daily! From lotions and soaps to textiles and leather, renewable energy, life-saving pharmaceuticals and more… animal agriculture has a beautiful sustainability story to share that helps divert waste and non-arable land into products we use every day.

TWENTY YEARS AGO

Stories from AgAirUpdate Featured 20 Years Ago

Aircair Takes on Thrush Aircraft Dealership

by Bill LavenderMOREE, NSW AUSTRALIA — It had been four years since my last trip Down Under. Typically, I try to visit Australasia and New Zealand at least once every three years, and sometimes more often. This year, with the help of Julie Black and Fred Nolan of Aircair, I was able to visit three operations before exhibiting at the Aerial Agricultural Association of Australia’s annual convention on the Gold Coast (eastern coastline of Australia, south of Brisbane). This article is part one of a three-part series of that journey.

Departing from my office in Perry, Georgia Saturday afternoon, traveling through Atlanta, Los Angeles, Sydney, then arriving at my destination, Moree, New South Wales Australia; it was a long trip requiring 40 hours and two days (crossed the International Date Line), and that was the quickest as I could get there. Fred met me at the Moree Airport, 8.00p Monday night. Finally, I had arrived. I was exhausted. The next day promised to be the beginning of a busy week, meeting people and learning more about ag-aviation in Australia.

During my first trip to Australia, more than a decade ago, I also visited Fred Nolan, but at that time things were different. Fred was the General Manager and Chief Pilot or Gwydir Air, a very large ag operation with more than 18 Turbo Thrush aircraft, as well as a distributor for the Ayres Thrush, Transland, Micronair, Gippsland Aeronautics ag aircraft, Satloc GPS, CP Products, Omnistar and Ag Tips. The company flew more than two million acres annually, with the majority flown by night.

Now, all that has changed. The Gwydir Air that I visited 10 years ago is no longer in business. The

company went into receivership over a year ago and its various components split into separate, private companies. Because of the split, Fred an employee of 27 years, now hangs his hat at one-time competitor, Aircair Aviation.

Fred’s addition to Aircair in September 2003 brought to the company an expanded cotton client base, as well as sales dealerships for the Thrush, Dromader M18 and the Gippsland GA200 ag aircraft. Other well-known agaviation product lines such as Transland, CP Products, Satloc GPS systems, Micronair, Spectrum Electrostatic Systems, Fugro Omnistar and Ag Tip Winglets to mention a few, where also transferred.

Stan Robinson ex-Chief Engineer at Gwydir also joined Fred at Aircair heading up the new Thrush Product and Technical Support role as did Bob Knight, Senior Operations Co-Ordinator who now assists the company’s aerial ag operation.

Aircair is a very large aerial operation in its own right, most likely the largest of all of the operations in Australia, operating 12 aircraft made up of nine AT502s, along with a PT6A-34 Thrush, a Cessna C-188 and a Cessna C-182. The fleet size and make up is now being reviewed in line with more favorable climatic and seasonal conditions.

Sue Warburton is the Managing Director of Aircair, a familyorientated company who together with her husband, Pat Warburton, founded the company in 1980. David Black is Chief Pilot of Aircair Aviation Moree, while his wife, Julie (Warburton) Black is head of public relations for the company. Public relations would include handling the media. Hopefully, I wasn’t too much of a challenge for Julie, with her aptly arranging meetings and complex travel plans for me. She did an excellent job, not a flaw anywhere.

It is interesting that before the formation of Aircair in 1980, Pat was the General Manager and Chief

(Continued on page 60)

Pilot for Gwydir Airspray, where Fred flew with him and Sue at the very beginning of the large scale cotton development in Northern NSW. Now events have come full circle and Fred has joined the Aircair team to help plan and consolidate Aircair as the company positions itself for a more diversified future.

Aircair’s main base is in Moree northern NSW with operations in Narrabri, Goondiwindi and a new base in Arthurton, South Australia. The expansion into South Australia was for geographical diversification, helping to ease the strain of a four-year drought that has besieged most of east-central and southeastern parts of Australia. With some rain in January of this year, weather modeling suggests that the drought (El Nino) might come to an end. The South Australia operation is primarily a winter cereal crop region. This allows aircraft that normally work at the New South Wales’s bases on cotton in the summer, to be able to travel south for the winter work generating cash flow and higher aircraft and personnel utilization.

During the summer, mid-December to mid-February, due to hot and arid conditions, 70% of Aircair’s applications on cotton are conducted at night. Better conditions exist at night environmentally and it gives the operation a longer duty shift to get through the work. It’s during this busy time that Aircair ops are basically 24/7. Pilots sleep during the middle of the day, while maintenance crews work on the aircraft and ground crew prepare for the late afternoon, nighttime and early morning applications.

Typical operations are flown at application rates of 30-50 liters per hectare (3-5 gallons/acre). However, Aircair has been experimenting with the Spectrum Electrostatic Spray System mounted on the C-188 last year, with a new system to be installed on a turbine aircraft for 2004/5 season. The evaluations are ongoing, including tests that were conducted in conjunction with Queensland University.

Successful applications have been made with herbicides, insecticides and desiccates on cotton and grain sorghum at rates of 10L/H (one gal/ac).

Fred says several operators in Australia have experienced very positive results, with four electrostatic systems sold to date. Additional R&D projects are planned with the Spectrum ES system over the next 12 months to look at potential for band spraying of chemicals, high efficiency low volume application and drift measuring assessments. However, Australian operators are having some of the same problems that U.S. operators are facing, and that is being able to meet label requirements.

Hopefully, once enough data is collected, the chemical companies will apply to have their labels modified to include an electrostatic application statement. Fred claims it has demonstrated to be a very useful tool offering a very effective and economic way to spray, with equivalent application safety. Importantly, it promises to meet the main objectives of the BMPs (Best Management Programs) developed for the Australian cotton industry.

Aircair’s new Satloc GPS dealership is an important asset giving the company the opportunity to work closely with

Satloc’s new systems and technology development. Sales of M3 and the new Litestar II series systems have been strong into both Australia and New Zealand.

This summer (Southern Hemisphere), Satloc and Aircair will look at emerging variable rate liquid applications, following a three-year experience level using this technology on solids applications in rice at Griffith NSW. Work to date has been with Satloc M3 and an Auto-Cal controller. Variable rate applications were made with urea fertilizer on wheat as well as urea and rice seeding. Greg Guyette, Director of Sales and Marketing at Satloc has been instrumental in assisting with the development of this technique in Australia.

Fred believes one of the exciting developments to come in the future of ag-aviation will be the advancement of variable rate technology (VRT), particularly for Pix and defoliant applications on cotton. This involves the direct injection (DI) of chemicals through a secondary boom, sub-pump and tank on board the aircraft. Aircair will be evaluating in the upcoming season liquid applications using the Satloc M3 and Satloc’s new Aerial ACE controller.

“You need a nice, steady learning curve with this technology, not moving too fast, but allowing yourself time to work the development. It’s about getting satellite or IR images into the plane, onto the crop and back into the office” explains Fred.

When it comes to maintenance, Aircair conducts scheduled 75, 150 and 300-hour inspections on its fleet under a company maintenance schedule. With its own eddy current equipment, Aircair inspects both Thrush and Air Tractor wings and is one of the few Australian aircraft maintenance shops approved to do both Air Tractor and Thrush wing spare

replacements. Graeme Wood who is Aircair Maintenance Chief Engineer, feels personally that aircraft handling may be a major contributor to the ultimate wing spar life issue. Each aircraft tells its own story, he feels.

With a history of successfully operating Air Tractors for over 20 years, Aircair has invested heavily to provide continued Thrush support to operators Down Under.

Fred has always been a Thrush pilot and believes strongly in the aircraft and is delighted that production has restarted with a new series of aircraft from Thrush Aircraft Inc, which will sell well throughout Australasia. A new series T34- 550 is being delivered to the Philippines as this edition goes to press. With a strong relationship with the major power plant manufacturers Pratt and Whitney, as well as Honeywell, the new Thrush series of ag aircraft are set to offer aerial operators the right options in a demanding business.

He pointed out that the TPE-331-10 powered, 510-gallon Thrush (S2R-G10) has been the Australian best seller in the 500-gallon class over the past 10 years and with new 440-gallon and 660-gallon aircraft now available, Thrush Aircraft are offering operators the right aircraft for Australian and New Zealand operators, at the right time. Now with a 550-gallon hopper being married to either the PT6-34 or –60, as well as the TPE331-10, the economics are even better.

Drought, low water storage capacity for irrigation and new government water sharing policies continue to affect rice and cotton operators, the prime activity area for Australian ag aviation. When the drought ends, and a favorable foreign exchange rate for the Australian dollar against the U.S. dollar, the pent-up demand for the Thrush aircraft should release with orders for new Thrush aircraft.

Now in a position to serve all Down Under operators, Aircair can deliver new Thrush aircraft and also offer complete product support to include parts and service.

LOW & SLOW

Mabry I. Anderson . An Insider’s History of Agricultural Aviation

Chapter Two: The Equipment & People (cont.)

Wide-Scale Forest Programs

Mid-Continent was among the first to engage in widescale forest programs, operating budworm control units in Minnesota and New York, and later in the gigantic forest spraying program in New Brunswick. More will be said about these forest programs later. But it is well to note that Reade’s firm one year contracted for 50 Stearmans that helped make up the fleet of over 200 that went into the New Brunswick bush on this project.

Reade’s firm also operated in the cotton growing regions, particularly in Mississippi and was one of the first to use 450 horsepower P & W installations in that area. Although some 450’s had been used in Mississippi as early as 1946, a wholesale changeover did not occur until the early 1950’s with Reade’s units contributing strongly to this change.

Some of Mid-Continent’s early pilots became well-known and contributed greatly to the growth of the industry.

Richard Reade always had a preference for cats-whether they be large animals or ag aircraft. Pilot Al Honeywell (left) and his pet lion visit Reade to promote the Ag-Cat. Reade would probably be more comfortable in the cockpit.

Richard Reade always had a preference for cats-whether they be large animals or ag aircraft. Pilot Al Honeywell (left) and his pet lion visit Reade to promote the Ag-Cat. Reade would probably be more comfortable in the cockpit.

“ Mr. Grumman...wanted to call the plane the ‘Grasshopper,’ but I managed to talk him out of it. When I eulogized on the long line of Grumman fighters, most of them bearing the word cat as a part of their name, he gave in graciously and the plane was officially named the Ag-Cat... ”

They included Bill Mooneyhan, Bill Fennell, Eddie Hughes, Erv Ovick, and Cotton Holifield. Some of these men have passed on, while others continue flying.

Eventually Reade based his operation at Hayti, Missouri, where it is still located. As early as 1953, Reade realized that the industry’s future was predicated on establishing strength and good relations throughout the industry. He began taking an active part in the various associations that were developing. State and national associations will be covered in detail later. Reade was chairman of the membership committee of the National Aviation Trades Association’s ag flying division as far back as 1953. He also served on the association’s Board of Directors from 1964 to 1966.

One of Mid-Continent’s most noteworthy contributions to the industry came with the development of new aircraft. When Grumman introduced its famous AgCat line, Mid-Continent became its first distributor. Actually, Dick Reade gave this aircraft its famous and appropriate name.

“Mr. Grumman,” remarked Reade recently, “wanted to call the plane the ‘Grasshopper,’ but I managed to talk him out of it. When I eulogized on the long line of Grumman fighters, most of them bearing the word cat as a part of their name, he gave in graciously and the plane was officially named the Ag-Cat, reminiscent of the old Hellcat of World War II.”

Mid-Continent continued to expand in all directions. In addition to custom application and aircraft sales,

(Continued on page 64)

it engaged in maintenance, aviation insurance, and the development and production of modem aircraft loading equipment. The company’s Planemate loading units were developed primarily to serve the rice growing areas and have become an industry standard.

Movie Star’s Stearman

A helicopter unit based in California is part of this farflung firm and company maintenance shops in Hayti still completely rebuild the trusty old Stearmans as a service to a nostalgic ag flying public. A few years back, Mid-Continent built a mint-condition Stearman for the late movie star Steve McQueen. It was something to see, hand-rubbed, completely refurbished from the metal work out with genuine leather trimmings and black walnut, hand-carved sticks!

Of all of Mid-Continent’s accomplishments, Reade is perhaps proudest of serving as the first president of the National Aviation Association in 1966 when he helped found it. He was also the recipient of the first Agrinaut A ward in 1968 and although he has received most of the ag aviation awards, he is still 100 percent active in his industry. “Old crop dusters never die,’ Reade philosophizes. “They don’t even fade away!”

Another post-World War II pioneer who contributed strongly to the industry was Robert G. “Bob” Ueding, who still operates Ueding Flying Service at Vincennes, Indiana.

Ueding was an Army primary flight instructor during the war at Fort Stockton, California, and later ferried for the old Ferry Command. After the war, he went to work “cold turkey” as a duster pilot for the legendary Henry “Pop” Elliott. Elliott was one of the original Huff-Daland dusters and in 1946 operated his own service at Cleveland, Mississippi. During the 1946 season Ueding flew Elliott’s beloved Travel-Airs and, after learning the ropes, went into business for himself in Vincennes.

Ueding worked mainly for local farmers and canning firms, and was one of the first to offer regular, dependable service to Indiana farmers. As business developed, he

expanded the size of his fleet and went about obtaining USDA contracts for large-scale grasshopper control work, timber spraying, fire ant control programs, and even boll weevil control programs in the Deep South.

The advent of the miracle material Mirex made controlling the imported fire ant practical and, for a number of seasons, Ueding’s planes and equipment were leaders in this field. They also worked the Canadian spruce budworm programs, beginning in 1953 and continuing into the 1960s.

In 1964 the firm procured and operated two helicopters. But after two years, Ueding returned to fixed-wing Stearmans. Until 1965, the company operated 450 horsepower Stearmans exclusively, but then added Piper Pawnees and later the Thrush line.

Ueding’s firm has a long and honorable history with a great sense of permanence. Such firms have added much to the stature and integrity of the business.

A relatively unsung man who did much to foster the industry was the late Hugh Wheelless, Sr., founder of Dothan Aviation at Dothan, Alabama. Hugh was a World War II pilot who entered the flying business directly after the War flying Stearmans.

Early in his career, he began specializing in government contract work, particularly fire ant control programs and wide-scale grasshopper work in the West. Hugh was a visionary who quickly recognized that single-engine Stearmans were limited in scope. He began purchasing multi -engined surplus war aircraft and converting them for use in agriculture. Huge tank/hoppers were installed and, for some time, Dothan Aviation had almost a monopoly on wide-scale work of this nature. Several B-17s wound up in the fleet and with Stearmans for the small jobs, Wheelless could and did contract for both large and small jobs.

The firm prospered until his untimely passing some years ago. His son, Hugh Wheelless, Jr., took over the business and ran it quite successfully until he divested himself of all of his aircraft holding to devote his full time to other commercial ventures.

The Wheelless firm contributed significantly to the expansion of the ag flying industry, particularly in multi -engine operation and imported fire ant control. Techniques developed by this firm in the fire ant eradication program were used with great efficiency until Mirex was banned by the EPA.

This was one of the industry’s most successful and meaningful programs and contributed enormously to the success and well-being of farming and rural communities in the Deep South. Like DDT, its banishment was built along unsound lines. The general public lost in the long run.

Given the opportunity, the average duster pilot is a traveling man. This penchant for wanting to see what is on the other side of the mountain moves him around. As a result, ag flying jobs in glamorous, out-ofthe-way places never go lacking for applicants.

In the Central American republics, particularly in Nicaragua and Guatemala, a huge build-up in farm acreage took place in the 1950s. This was especially true for cotton land in Nicaragua. The way was quickly paved for massive aerial application programs for insect control. Enterprising businessmen were quick to take advantage of the situation.

Nicaragua was, and still is, a land of contrasts. The cultivated and populated areas were literally chopped out of the jungle by hand. Timber-clad mountains taper off into incredibly fertile valleys and farmers began operating plantations of enormous size and scope.

The tropical climate, with a 12-month growing season and almost daily rain showers, is exactly what the land

(Continued on page 66)

AG AVIATION

QUALITY FERTILIZERS

KUGLER Fertilizers are formulated to the highest quality, making them ideal for aerial application. With KUGLER QUALITY, you don’t have plugging problems. When you apply KUGLER QUALITY Fertilizers, you maximize your airtime.

When foliar applying high quality Kugler Fertilizers, you also don’t have to worry about rust or corrosion on the plane or ground equipment.

This season, make the change to high quality Kugler Fertilizers. We make it. We sell it. And nobody can match our ease of aerial application –Think Local. Think Kugler.

With KUGLER, you can see the QUALITY

Bob Ueding (with goggles) still operates his ag aviation business in Indiana. After WW II he apprenticed under the legendary “Pop” Elliott, an original Huff-Daland duster.

needs to yield astounding amounts of produce, provided that the lush, unwanted vegetation and the overwhelming populations of damaging insects could be controlled. With no dormant season to reduce insect numbers, a constant struggle exists between planter and bugs. In the early 1950s the improved airplane service fought the battle of the bugs.

Sayasa Vanflober had acquired an impressive fleet of Stearmans and Piper PA-18s, all equipped for straight dusting. Liquid spraying had not been initiated in the region.

The Nicaraguan cotton growing season fit nicely into the working schedule of most U.S. pilots, beginning around September 15 or October I, when most stateside pilots were winding up their seasons. As a result, most pilots who traveled to Nicaragua hailed from traditional cotton country such as the Mississippi -Arkansas-Louisiana Delta, and Texas, clear into the Rio Grande Valley. Towns like Harlingen, Texas, became “staging areas” for these Central American operations and pilots would gather there and swoop down on Nicaragua as a group.

Several Mississippi pilots, including Lee Corviss, Chuck Thresto, and Sid Norwood regularly migrated to Central America wrapping up their work in the Delta area by October I.

“It was quite a set-up,” reminisces Lee Corviss. “The tremendous cotton fields were hacked out of the jungle by hand. It wasn’t all level land either. Lots of those big fields followed the contours of hills and mountains and some were so steep that flying them was a real problem. A supercub, or even a Stearman, just couldn’t work them in the conventional manner. The uphill climb was just too steep.

“We had to figure out ways to ‘racetrack’ lots of those fields and, during the course of that operation, a good many planes were wiped out and some really good pilots were injured or killed. Actually, it was pretty remarkable that we didn’t have more trouble. But when you are working that kind of country, most pilots learn to take extra special care of the old bird, so we got by pretty well after all.

“Satellite operations were scattered all over the country,” continued Corviss. More or less permanent strips were set up near the towns of Leone, Chinandega, and Rivas.

“Also, lots of the big farms had their own strips. One of the biggest problems we had was finding the strip we were to work from! Ferrying into these strips was pretty hairy, with nothing under you except mountains and jungle. I used to sit up there and wonder to myself just what I’d do if I had to put that old Stearman down in all of those trees when the next clearing might 20 miles away!”

Pilots, often accompanied by their wives, had relatively plush living arrangements in the towns, usually a spacious apartment. Labor was cheap and full-time cooks and maids were abundant and economical.

Very little outside entertainment was available, and sightseeing was about the only diversion for leisure time. However, the forests and waters teeming with wildlife and fish provided plenty to do for the sportsman types.