THE AG PLANE THAT NEVER WAS

THE AG PLANE THAT NEVER WAS

You have a lot riding on these wings. Follow all service instructions and required inspections.

With 36 years of experience, we have perfected the art of guidance for aerial application. But that does not mean we won’t keep innovating and improving. The new Ag-Nav Platinum Lite takes our industry leading technology and combines it with our more economical Guia 153 hardware. Paired with our OLED Transparent Lightbar, and Flow Control, you get the most advanced and cost effect guidance system on the market. The Ag-Nav OLED Lightbar displays all the information of our classic lightbars plus new more information, such as, Flow Rate, Aircraft Heading, Individual Booms On Indicators, Tank Level and more!

PRESIDENT:

Graham Lavender - graham@marsaylmedia.com

VICE-PRESIDENT:

Bill Lavender - bill@agairupdate.com

SECRETARY:

Sandy Lavender - sandy@agairupdate.com

ACCOUNTING:

Casey L. Armstrong - casey@marsaylmedia.com

ADVERTISING:

Melanie Woodley - melanie@marsaylmedia.com

CLASSIFIED ADS: classifieds@agairupdate.com

Melanie Woodley - melanie@marsaylmedia.com

PRODUCTION:

Felicia (Lisa) Pannell - lisa@marsaylmedia.com

CIRCULATION: subs@agairupdate.com

Mary Jane Virden - maryjane@marsaylmedia.com

CONTRIBUTING WRITERS:

Ted Delanghe - ted.delanghe@gmail.com

Robert Craymer - robertc@covingtonaircraft.com

Regina Farmer - regina.farmer@chem-man.com

Carlin Lawrence - carlin@agairupdate.com

Ryan Mason - ryan@agairupdate.com

Michelle Miller - michelle@thefarmbabe.com

Josh Alameda - josh.alameda@gmail.com

Tracy Thurman - thurmantracyt@gmail.com

LATIN AMERICAN REPS:

Noelia Burgeus - noeliburgues@gmail.com

Ernesto Franzen - ernesto@agairupdate.com

Guillermo Giordana - aravia@aravia.com.ar

Gina Hickmann - gina@agairupdate.com

Pat Kornegay - pat@svatx.com

Ivan Parra - ivan@agairupdate.com

Marcia Specht - marcia.specht@gmail.com

© Copyright 2024 AgAir Update retains all rights for reproduction of any material submitted, to include but not limited to articles, photographs, emails and bulletin board posts. All material remain the copyright of AgAir Update No part of this publication may be reproduced, in part or whole, without the written consent of the publisher.

Editorial published do not necessary reflect the views of the publisher. Content within AgAir Update is believed to be true and accurate and the publisher does not assume responsibility for any errors or omissions. Unsolicited

Bill Lavender

Bill Lavender

Have you noticed the surprising number of ag pilots receiving the FAA’s Master Pilot award? It seems like an inordinate number just recently received this award, including my “old” friend Mark Gary of Mississippi. There have been several others in the last couple of months. It is almost as if the FAA saved up and awarded many ag pilots all at once! I know they did not wait until pilots crossed the 50-year mark to give the award. A good example is Mark. Shoot, he has been flying for a lot more than 50 years!

To say I was wary would better describe my feelings. Even the FAA is not good at “sneaking,” showing up at just the right time! You guessed it. Graham, my son, had a hand in bringing this recognition to fruition. He also coordinated the visit by calling me at home telling me he had an important issue to discuss, could I come by the office at 11:00 am? Of course, what else did I have to do?

“ The next time you talk with an old timer, give him some respect and pick his brain for how he got to where he is today. You will almost certainly learn something! ”

The FAA snuck into AgAir Update ’s office a month ago and surprised me with the Master Pilot award. I crossed the 50-year mark last August 2023. Having the FAA walk into your office unannounced is always a little unnerving. This was even more true this time for me. I only go into the office about once a week to gather any mail that may have reached my old desk. It just so “happened” that the day I stopped by, the FAA came in and asked for me.

As any ag pilot with 50 years of experience will tell you, it wasn’t easy staying out of the trees and wires those years. Fifty years give ample time for the pilot to make mistakes, often ones that make you realize it wasn’t your day to go to the Lord. What you learn from those mistakes makes crossing the 50-year mark obtainable, as well as all the other challenges that life throws at you.

I can imagine the thoughts you beginner ag pilots with only 20 years or so of ag-flying experience are having (joke). You probably think we old-timers need to retire and get out of the way. In some cases, you would be correct, but not all. Some things can be learned from someone who has beaten the odds for 50 years. All ag-pilots should be as fortunate. If you notice, I did not write lucky. You make your luck, and it is called fortune. You do not fly ag safely without adhering to a flying style that will most likely bring you home at the end of the day.

The next time you talk with an old timer, give him some respect and pick his brain for how he got to where he is today. You will almost certainly learn something!

Until next month, Keep Turning…

February 29-March 2, 2024

Canadian AAA Conference

Fairmont Banff Springs

Banff, AB Canada

Shara Tardif

ed@canadianaerialapplicators.com

Phone: 780-413-0078

October 10-12, 2024

NAAA & NAAREF

Oct. 2024 Board Meetings

DoubleTree Chattanooga Chattanooga, TN

Lauren Henretty

Lhenretty@agaviation.org

Phone: 202-546-5722

November 18-21, 2024

2024 Ag Aviation Expo

Fort Worth Convention Center

Fort Worth, TX United States

Lauren Henretty

lhenretty@agaviation.org

Phone: 202-546-5722

November 18-21, 2024

2024 Ag Aviation Expo

Fort Worth Convention Center

Fort Worth, TX United States

Lauren Henretty

lhenretty@agaviation.org

Phone: 202-546-5722

February 20-22, 2025

NAAA & NAAREF

February Board Meetings

Bonaventure Montreal

Montreal, Canada

Lauren Henretty

Lhenretty@agaviation.org

Phone: 202-546-5722

October 9-11, 2025

NAAA & NAAREF

October Board Meetings

Sheraton Flowood The Refuge Flowood (Jackson), MS

Lauren Henretty

Lhenretty@agaviation.org

Phone: 202-546-5722

November 17-20, 2025

2025 Ag Aviation Expo

Atlantis & Reno Convention Center

Reno, NV

Lauren Henretty

Lhenretty@agaviation.org

Phone: 202-546-5722

A Kash Helicopters Bell 206 at work in Connecticut.

- Photo by @conneticut_aviation_spotters on IG

An Air Tractor hard at work in Argentina. - Photo by @matiasferreri on IG

A Kash Helicopters Bell 206 at work in Connecticut.

- Photo by @conneticut_aviation_spotters on IG

An Air Tractor hard at work in Argentina. - Photo by @matiasferreri on IG

Spraying in the land of the long white cloud. - Photo by @pattonairhelicopters on IG

There are very few of these Australian made Air Truk’s left in the world.

- Photo by @austairleague on IG

The Start Stick making it go.

- Photo by @agaviationadventures on IG

A Bell UH-1H takes off after refueling - Photo by @paologianzanti on IG

The view off the wing in Grand Forks, North Dakota. - Photo by @adventurerig on IG

Spraying in the land of the long white cloud. - Photo by @pattonairhelicopters on IG

There are very few of these Australian made Air Truk’s left in the world.

- Photo by @austairleague on IG

The Start Stick making it go.

- Photo by @agaviationadventures on IG

A Bell UH-1H takes off after refueling - Photo by @paologianzanti on IG

The view off the wing in Grand Forks, North Dakota. - Photo by @adventurerig on IG

The NDN-6 Fieldmaster was the brainchild of British aviation legend Nigel Desmond Norman, starting in the mid-1970s. Desmond and his college friend and business partner, John Britten, formed a relationship in the 1950s at the De Havilland Technical School, where they studied aircraft design. In 1954, the two built their first aircraft called the BN1F, a 36hp ultralight.

The aircraft failed from a sales perspective but supplied them with a third partner, Jim McMahon. Together, they formed Crop Culture Aerial, which became highly successful, and along with this new partnership came the early stages of the rotary atomizer spray nozzle. Britten-Norman was formed as a company that specialized in ag operators and supplied ag conversions of Tiger Moths for export to New Zealand. They had taken over the development and sales of spraying equipment, most notably the Micronair Rotary Atomizer. At one point, John and Desmond operated a fleet of approximately 80 aircraft, and the need to consider a replacement ag plane resulted in a partnership with Leland Snow from Texas.

Britten-Norman acquired a 1/3 share of Snow Aeronautical Corp., and when the company was sold to Rockwell, it provided Britten-Norman with the funds to chase their dreams of designing and building their aircraft. Their idea was to build a small island-hopping passenger plane. So, after selling off their shares of Crop Culture to the other Board members in 1963, their efforts were put forth into developing the Britten-

Norman Islander, which made its maiden flight in June of 1965 after only nine months of development. The factory was based at Bembridge on the Isle of Wight (IOW) off the south coast of the UK, and the small island would remain the home of Desmond’s aviation career for years to come.

Over the years, Desmond was involved with numerous other businesses and projects, but in 1971, Britten-Norman went into liquidation and was purchased by Fairey Aviation in 1972. Desmond would remain the managing director until 1976, when he formed his own aviation company, NDN Aircraft Ltd.

The next few years would see the development of three aircraft:

1. NDN Firecracker/Turbo Firecracker – A two-place military trainer

2. NDN-6 Fieldmaster – Agricultural / Firefighting aircraft

3. NAC-1 Freelance – A folding wing fourplace civil aircraft

The NDN-6 Fieldmaster took Desmond back to his ag aviation roots, and his aircraft design was indeed years ahead of its time. He wanted a modern ag aircraft that pushed the boundaries of what was already being manufactured...and pushed the limits he did.

Innovations of the NDN6 Fieldmaster:

• Designed from the beginning to have a Pratt & Whitney PT6A-34 750 HP turboprop and could be easily upgraded to the larger PT6A-65 1250 HP engine if desired .

• Integral titanium 625-gallon hopper as part of the structural airframe .

• Aerofoil ailerons and flaps with spray booms built into the internal structure – tricycle landing gear to aid in ground visibility and the training of new pilots on the type, as most pilots are trained on a tricycle configuration

• Standard dual cockpit with optional controls for training

• Glass canopy for excellent visibility

• Firebombing drop gate

• 40 or 80 nozzle option

• Transland spreader

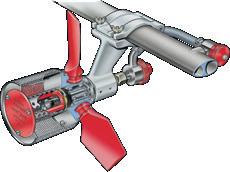

• Micronair Rotary Nozzles (8), Micronair Flowmeter and RPM indicator

• Automatic Flagman

• Lighting packages for navigation, instruments, strobe, beacon, and retractable working lights, both forward and tip mounted, for turning

• IFR instruments

• Heat and air conditioning

• 2-speed windshield wiper and washer system

The Fieldmaster appeared to be a state-of-the-art ag aircraft with every possible option. Desmond performed the first flight on December 17, 1981, at Sandown Airfield in the Isle of Wight, where the aircraft was built in his small hangar factory. As the story goes, he wears his traditional pinstriped suit and sets out to put the aircraft through its paces. A short flight was initially planned, but the flight time gradually grew and grew without Desmond landing at the airfield. After approximately 30-40 minutes, he finally landed unscathed. He promptly stated that the rudder and vertical fin needed to be changed as he could not make the aircraft turn with any real authority, so he had to make a large loop to get back to the airfield.

The Fieldmaster, G-NRDC, got its registration from the project sponsor National Resource Development Corporation. She made her public debut at the Farnborough in February 1982. Again, at the Farnborough 50th Anniversary SBAC in September

1982, test flying, and upgrades continued through 1983, 1984, and 1985, leading to a new production factory being built in Cardiff, Wales, with support from the Welsh Development Agency. On July 22, 1985, NDN officially moved to Cardiff, and at the same time, the name was changed from NDN to NAC (Norman Aeroplane Co.). The factory was staffed, and preparations for production of the NAC-6 Fieldmaster were being finalized. Many notable hires were made at this time, from production line workers to electrical, airframe, and engine engineers, with one notable hire being Vic Osborne. Vic was an electrical engineer, but he would soon become the sole engineer on the Fieldmaster project within a few years. His contributions to the Fieldmaster program cannot be overstated, and his importance will become apparent in the future of the aircraft.

NAC continued using the original aircraft, NRDC, for testing purposes by doing crop dusting tests in Lelystad, Holland (the Netherlands) for Heyboer BV,

working alongside Turboprop Thrush aircraft and Miller Aerials Turboprop Ag-Cats. They were testing and using the Micronair systems mounted to traditional drop booms instead of its internal booms, as the rotary atomizers could not be adapted to the internal boom system. They were also testing the aircraft for firefighting roles during this time. They had developed a water boom/scoop, allowing the aircraft to refill with water by skimming the water with the boom lowered at about 10 feet above it. The rear seat spotter operated the water boom using a hand crank attached to a steel cable. Vic Osborne did much of the back seat work during this testing phase and said cranking that boom up and down was an awful experience and that his arm would go numb from raising the boom. Vic also did photo and video work for the boom testing and fire drops from the NAC Freelance with Desmond at the controls. The back seater was also a lookout for watercraft and debris in the water while on the water scooping passes. The pilot planted the boom scoop firmly in the water, adjusting trim and airspeed as the hopper filled. The filling sequence would take up to 1 minute and 30 seconds as long as the boom wasn’t skipping off the water, but the pilots would only keep the boom in the water for 15 to 20 seconds at a time due to the high level of concentration needed. The system worked but was never implemented commercially, and testing ceased.

The production line at Cardiff was moving along, and in early 1987, the first production aircraft was nearing completion. G-NACL would be the first aircraft produced under the new NAC company name, and on April 28, 1987, they received the type certificate from the UK CAA (Civil Aviation Authority). On the same day, NACL performed its first flight with the prototype NRDC, flying along in formation with Desmond Norman and test pilot Peter Phillips at the controls. NACL flew in primer as Desmond wanted to save the cost of a new paint job in case of an accident.

Through May and June of 1987, NACM & NACN were completed and flight certified. Desmond signed a lease firefighting contract with France Aviation Conseil General Des Alpes Maritimes in Cannes in the South of France for their summer firefighting season. All three completed production aircraft were dispatched along with maintenance staff from Cardiff, including Vic Osborne. The aircraft performed well but was underpowered during high and hot conditions with a big load onboard. The planes were also used for loaded patrols, and they shined in this role as they carried massive amounts of fuel over four internal wing tanks, giving them a loiter time of 7 to 8 hours.

Exeter Airfield enroute to France

NACM Croplease Cannes France

Exeter Airfield enroute to France

NACM Croplease Cannes France

By the end of 1987, aircraft sales had been non-existent, so Desmond leased them to various companies to bring in revenue and test them in real-world situations. The following contract was to Agricair in Zimbabwe, Africa. ODA funded the Tse Tse fly control contract. Agricair Zimbabwe was, at the time, the leading company in Africa when it came to Tse Tse control. Agricair was owned by Field Aviation, which was owned by Hunting Aviation (UK). As the British funded the contract, the contract was awarded to Huntings, and all the equipment to be used was to be British, hence the use of the Fieldmasters.

Only two Fieldmasters were available then, so two Thrush aircraft were used to bring the total number of aircraft to four, which required the area to be sprayed. The Fieldmasters were put into the Zimbabwe register, as Agricair was operating the aircraft, and the aircrew and engineers were all licensed in Zimbabwe. Before the contract started, the crews spent some time in Cardiff so that the engineers could assist with fitting the spray gear, navigation systems, and lights and for the new pilots to do conversions onto the aircraft. The pilots were Rob Tasker (RIP) and Glenn Brunwin. The aircraft required some modifications for the contract with the addition of the spray gear, blind flying instruments, a tiltable instrument panel in the rear cockpit to house the TANS and spray controls, and the manufacture of leading-edge protection panels for the wings and tailplane for bird strikes.

Due to bad weather, the aircraft was ferried to Somalia in December 1987 with a 3-day delay at the Air Force Base in Yeovilton, Ur. The contract was conducted in early 1988, and two aircraft formations conducted the spraying. The Fieldmasters were configured as the lead aircraft, so each formation consisted of a Fieldmaster leading, with a Thrush flying in formation. The spraying was conducted at night at 50 feet or less (tree top). The spray area was about 7000 square km and took about seven nights to complete (one cycle).

To eradicate the flies, a minimum of five cycles was required, and the scientists determined the time between each cycle, which was approximately 7 to 10 days apart. The flying crews were Rob Tasker as Pilot with Martin Ludlow as navigator in the one Fieldmaster, Hugh Mundy flying formation in a Thrush, Glenn Brunwin as Pilot, Bobby Tasker as navigator in the other Fieldmaster and Johnny Falzoi flying formation in a Thrush. John Robert McLagan Gair and others were part of the engineering team supporting the contract aircraft. Afterward, the two Fieldmasters were ferried back to Cardiff, passing over the Mediterranean Sea and the deserts of Egypt.

While NACM and NACN were working on the Tse Tse fly contract in Somalia, Desmond sent NACL on a sales tour to Australia and Singapore for the airshow in January 1988. Renowned female ferry pilot Janet Ferguson made the long

trek to South Australia from Cardiff, Wales, covering 9000 miles one way. Once Janet arrived safely in Australia, NAC’s second test pilot, Doug Barden, flew on a commercial flight and took CL to various Australian states, showing off its firefighting capabilities. Australia was celebrating its bi-centennial, so the aircraft was painted with a “Happy Birthday Australia” on the aft fuselage. After touring Australia, Janet returned to the UK, stopping in Singapore to participate in the Singapore International Airshow.

By the summer of 1988, the last two production Fieldmasters were completed. NACO & NACP were flight tested and ready to join the other three production aircraft. All five of the aircraft were essentially the same...Pratt & Whitney PT6A-34 turboprops at 750 hp, 625 US gallon titanium hoppers, dual seating, and the other innovations that Desmond had designed. There were minor variations between each aircraft, but nothing major or significant. The layout worked well; all five aircraft went to France in Cannes for the 1988 firefighting season. This would be the only time all the Fieldmasters would work together in one location, minus the original prototype NRDC.

Leading up to 1988, Desmond agreed to have some Fieldmaster fuselages and wings be produced by Utva Aviation in Yugoslavia. The airframes would then be shipped back to Cardiff for final assembly. Utva found some issues with the wing root and redesigned it, providing more strength to the main spar. They also redesigned the nose section to accept a 724 shp M601D-1 Walter Turboprop as a less expensive alternative to the pricey Pratt & Whitney. This project lasted until 199,2 when war broke out in Yugoslavia, and Utva was notified that it was under Western sanctions and work on the British airframes was to cease immediately. The Utva factory suffered severe damage during the war, but miraculously, the airframes survived unscathed and were put into storage till 1999. There is more to this story, but we will continue it later.

In the early fall of 1988, NAC was under serious financial constraints due to the massive amount of money spent to get to this point of production. On July 26, 1988, NAC went into receivership with Price-Waterhouse directing the company. Desmond was out at the company that

1987 April Boom Testing

1987 April Boom Testing

bared his name, but NAC would continue to operate until a buyer for the company could be found or the assets liquidated. As the story goes, Desmond had his Freelance aircraft and the original Fieldmaster prototype NRDC moved out of Cardiff the morning the receivers arrived to take over. For some reason, these aircraft were not to be part of the sale of the company, and Desmond made sure they were not confiscated. Some workers were laid off, while others were paid to merely show up, sweep the floors continuously, and drink coffee. But only two months later, a former financial backer of Desmond purchased NAC’s liquid assets and the rights to the Fieldmaster agricultural and firefighting aircraft, including the five production Fieldmasters.

Andrew MacKinnon and his company, Croplease Ltd., began to plan how to move forward with his new acquisition. However, Andrew was not from the aviation world but instead finance. He lived and worked in London while the aircraft was nowhere in his direct line of sight. All the employees had been let go by this time, but one engineer contacted Andrew and offered his services. At this point, Vic Osborne became the sole engineer for the Fieldmaster aircraft.

After the 1988 summer firefighting ended in France, NACL, NACM, and NACN were off to Morocco in Northern Africa to spray for a massive locust infestation. They were based in Ouarzazate, and once again, Vic was there to keep the aircraft in tip-top shape.

1989 started slowly, and NAC (now Croplease) had moved away from Cardiff to Bournemouth, UK, and began to use Interair as a maintenance and parking facility and as their new home base of operations. The upcoming fire season was on the horizon. At the request of the French pilots, Croplease hired Brooklands Aerospace at Old Sarum to provide CAA M3 oversight for a planned engine upgrade from the -34 to the 1250 shp -65 Pratt & Whitney turboprop. The aircraft was designed to accept this upgrade from its inception with new parts consisting of the engine, engine mount, five-bladed propeller, and a new nose cowling.

The rest of the aircraft would remain untouched except for a gauge or two in the cockpit. Vic Osborne and an assistant from Brooklands did the conversion in an old WW2 hangar at the Old Sarum airfield beginning in late August, with the first flight coming on October 28, 1989. British aviation legend Neville Duke performed the first flight of the newly named Firemaster 65 with Vic riding shotgun in the rear. Duke’s resume was legendary, and his accomplishments and accolades are remarkable. He was a three-tour veteran of WWII, beginning his RAF career at 19 years of age in 1941, flying Spitfires from Biggin Hill over Europe. Duke

was transferred to North Africa, flying the Curtiss, the P-40B Tomahawk, and then the P-40D Kittyhawk.

By September 1944, at 22, he had amassed 27 victories in 486 sorties and 712 operational hours. He was a flight commander by age 21 and a squadron commander officer at 23. After the war, he became an RAF test pilot for Hawker from 1945 through 1948 and, after retiring from the RAF, joined Hawker again as their assistant chief test pilot until October 1956, when he was forced to retire due to injuries sustained in a few heavy and forced landings which fractured his spine leaving him immobile for months. His later life mainly revolved around civil aviation and his company, Duke Aviation, where he was a personal pilot for Sir George Dowty and a test pilot for the Edgley Optica and the Firemaster 65. He wrote several books about his life and experiences, and his legacy has left a lifelong impression on those who met the man.

At this same time, NRDC was also at Old Sarum in late 1989, and Vic was instructed to dismantle the airframe for some unknown reason. He removed the wings, engine, and propeller, and she sat there in that state till she was moved back to her ancestral home at the Sandown Airfield on the IOW on November 11, 1991. She was laid to rest beside Desmond’s old hangar, where she was born some ten years earlier.

NRDC would remain there for the next 20 years, along with the engineering sample and numerous parts. On February 14, 2011, NRDC and all the parts were loaded onto two trucks and shipped to Jim Pearce, a notable aircraft rescue and preservation specialist and a former crop duster. Jim never got to restore the Fieldmaster, and it was rumored to be again sold to some brothers near Wainfleet, UK, who had planned to open a crop dusting museum. That plan never materialized, and it seemed as though NRDC was then lost, and it became a sad note in the history of the Fieldmaster story. We will come back to NRDC later in this article.

Neville and Vic did the flight testing and -65 certification program from Sandown in early 1990, and all went according to plan with no issues to report except for the nose landing gear, which now would flap from left to right from the prop-wash produced by the 5-bladed prop. They devised a simple fix by extending the nose wheel mud guard, which cured the issue. Vic recalls this three-week time spent with Neville as the most rewarding and treasured time in his long, distinguished aviation career.

After the test program was finished on NACL, Vic began the exact -65 conversion on NACM, followed by NACN. Andrew had arranged with Desmond to have Vic use his

old factory hangar at Sandown and hire a previous Cardiff factory worker to help convert the two aircraft. The engine transplant went smoothly, with Andrew and Desmond ensuring all the needed parts were delivered to Sandown. Flight tests were completed again by Neville Duke, who described the performance of the -65 as “a box full of birds” and “homesick angel,” referring to its lift and speed capabilities. The Firemaster 65’s were again ready for the summer firefighting season in Cannes, France. Also, in Portugal, the planes performed exceptionally well with the new engines, according to the pilots. The aircraft was proving extremely capable, and Andrew believed he could get production up and running again based on the new Firemaster 65. NACO and NACP were left as -34’s and were never converted to the more powerful -65.

In 1991, the three -65 Firemasters again went to France for firefighting, and NACP worked for Heyboer BV in Lelystad, Netherlands, in August of that same year. NACO appeared to have not worked at all that summer in 1991.

From 1988 to 1992, Andrew changed the corporate name and transferred assets multiple times. Croplease Ltd, Croplease PLC, Croplease Enterprises, and eventually EPA Aircraft Company were all owners of the Fieldmaster assets and its production rights under Andrew MacKinnon’s ownership and direction. Early 1992 saw the Fieldmaster project begin its decline. The Utva Aviation plan Desmond had originally cultivated (which Andrew inherited) was dead due to war and political sanctions in Yugoslavia. The summer firefighting contracts in France had yet to come through

for the 1992 season, and despite taking the aircraft to numerous airshows, Andrew could not secure any future orders and sales. This ended Desmond’s dream ag aircraft and Andrew’s business venture.

Andrew had been hemorrhaging money for the past few years and finally had enough. He decided to try and recoup some of his losses by parking the aircraft and selling off whatever he could. All engines, propellers, and instruments were removed and sold, and the airframes were parked and left for years.

NACM Firemaster 65 (TTAF 1403 hrs), NACN Firemaster 65 (TTAF 1280 hrs) and NACO Fieldmaster -34 (TTAF 279 hrs) were parked at Bournemouth Airfield and NACL Firemaster 65 (TTAF 814 hrs). NACP Fieldmaster -34 (TTAF 543 hrs) was placed at Sandown alongside the already dismantled NRDC and the engineering sample outside Desmond’s old hangar. It was an unfortunate and ironic ending that these aircraft returned to the home of their conception only to be left for dead. 1995 saw Andrew once again try to sell the Fieldmaster and NACM, and NACN was put back into flying condition with -65 engines.

They performed some promotional demonstrations around the UK and went to a few airshows, but nothing became of Andrew’s efforts, and the planes were once again mothballed, and it appeared that the Fieldmaster was dead for good.

Stay tuned for the next installment of the Fieldmaster series in April 2024

Rotor hosted guest of honor New Hampshire Governor Chris Sununu on Wednesday, January 30, 2024, in the first live flight test of its R22 autonomous helicopter test aircraft. The company-hosted event included a tour of Rotor’s new Research & Development Center and a naming ceremony for Rotor’s R550X prototype, which was attended by staff, their families, and invited VIPs.

The live flight of the R220Y, an uncrewed R&D aircraft based on the Robinson R22 2-seat helicopter, took place at Nashua Airport at around 2:30 pm ET on January 30, 2024, before a crowd of around 100 people. The aircraft performed a full startup procedure, hovered in front of the audience, made turning maneuvers, and descended to land after around three minutes in the air. To the company’s knowledge, this historic flight is the first time an uncrewed full-scale helicopter has flown publicly in front of a crowd. It marks an important milestone on Rotor’s path to operational readiness for commercial missions.

The event highlighted the spirit of technological innovation in New Hampshire. It included a tour of Rotor’s campus, located on the former campus of Daniel Webster College, a site steeped in aviation history. Rotor’s newlyrenovated R&D Center serves as the backdrop to Rotor’s revitalization of the aviation industry in New Hampshire, buoyed by the recently-announced R550X commercial helicopter program and the beginning of flight operations from a new Remote Operation Center.

The event concluded with the naming of Rotor’s R550X prototype, a static vehicle that will begin a tour of the US and Canada later this Spring. During the ceremony, Rotor CEO Hector Xu revealed the name of the aircraft “as a tribute to the spirit of innovation and to what I can now proudly call my home state, this R550X will be named the Spirit of New Hampshire.” He and Governor Sununu popped champagne to celebrate.

Governor Sununu emphasized the historical significance of the occasion, stating, “As we embrace the Spirit of New Hampshire, we honor the legacy of American aviation pioneers nearly a century ago while looking to the future. New Hampshire has long been known for our innovative spirit, and today, a new era of aviation was ushered in right here in the Granite State. This is an exciting moment for the future of American-made aircraft!”

Rotor is building the first two R550Xs at its facilities in Nashua, N.H. These aircraft are expected to begin agricultural flights later this year. The R550X is based on the Robinson R44 Raven II. It is designed to lift heavy loads up to 1,212 lbs, or 550 kg, with no pilot onboard. With a flight time of over three hours and a top speed of 150 miles per hour, the R550X offers long-range VTOL capabilities beyond the reach of drones and eVTOLs.

“The R550X is the most technologically advanced and highest capacity commercial uncrewed helicopter in the world. And it’s built right here in this hangar,” said Xu. Rotor has brought scores of high-tech jobs to New Hampshire from across the United States. It intends to add new manufacturing, quality control, sales, and engineering support departments to support the R550X program.”

We love the RG-220. We like that the battery box is clean; it’s a cleaner, friendlier installation without corrosion treatment and preventative maintenance. The mechanic appreciates it and for us it reduces our maintenance costs. There are more amps available for faster, cooler starts.”

SAM ROGGE

JET STREAM AG AVIATION, PRESIDENT & PILOT NAAA COLORADO BOARD MEMBER AT-402B INSTALLATIONS

For Air Tractor Models AT-402, AT-402A, AT-402B, AT-502, AT-502A, AT-502B, AT-504, AT-602, AT-802 & AT-802A

STC SA01090DE provides for the installation of Concorde RG-220 batteries in Air Tractors.

The TSO-C173a authorized RG-220 was specifically designed to start PT6 turbine engines. It is built with the same components and features that are proven to optimize current output, maximize capacity and sustain turbine engine power requirements. The RG-220 is dependable season after season.

• Faster starts, improved performance and reduced engine wear

• Sealed technology - no electrolyte management or potential contamination

• Proprietary PolyGuard® Separators – for added protection against shock & vibration

• Concorde batteries are 100% recyclable

• Supported by Concorde’s world class customer service

CONCORDE BATTERY CORPORATION

2009 SAN BERNARDINO ROAD, WEST COVINA, CA, 91790 626.813.1234 | ISO 9001 + AS9100 CONCORDEBATTERY.COM

The Huff-Daland Duster is now showcased at the National Air and Space Museum, part of the Smithsonian Institution on the National Mall in Washington, DC. This aircraft, originally from Huff-Daland Dusters Inc., the precursor to Delta Air Lines, marked the inception of aerial application businesses. It conducted the pioneering commercial dusting of crops using its specially designed aircraft, the Puffer.

The National Air and Space Museum recently completed a comprehensive $250 million renovation, making it a prominent attraction with approximately 1.9 million annual visitors. Surpassing the Udvar-Hazy Center, the previous home of the Huff-Daland Duster, the downtown DC museum provides increased exposure for visitors to delve into the early history of the aerial application industry. Delta Air Lines generously donated this historic aircraft to the museum in 1968. While the museum is free to visit, a timed entry for the day of your visit is required.

As the largest among the Smithsonian’s 19 museums, the National Air and Space Museum is dedicated to educating and inspiring people about the significance of flight to humanity. The Smithsonian has expanded its collection over the years, acquiring other aircraft related to aerial application work, such as the Curtiss JN-4D Jenny and the Air Tractor 400A Dusty Crophopper, the latter donated by Rusty & Lea Lindemann to commemorate the aerial application’s 100th anniversary. Both these aircraft are currently on display at the Udvar-Hazy Center.

For a deeper dive into the history of the aerial application industry, consider purchasing “Agriculture’s Air Force: 100 Years of Aerial Application,” which commemorates the industry’s centennial. Additionally, explore “Speed, Safety, and Comfort: The Origins of Delta Air Lines” by James John Hoogerwerf, a former Delta Boeing 767 captain and aviation historian, offering insights into the history of Delta. Both are available in the AgAir Update Marketplace, marketplace.agairupdate.com

Austin: 800-370-0557

Dallas: 800-880-0801

Houston: 800-880-8822

Kerrville: 800-880-4545

Lakeland: 800-881-9688

Scottsdale: 800-880-3597

St. Louis: 800-880-8644

It all began in the Guatemalan Air Force. Julio Cesar Reyes Veliz, the son of an aeronautical mechanic, had his first encounter with aviation during his childhood. His father, a descendant of Spaniards from the northern coast of Guatemala, worked in aircraft maintenance in the country’s capital and instilled in him the dream of becoming a pilot. At 18, Julio began his preparation to become an agricultural pilot: with two years of study, he obtained private, commercial, and ag pilot licenses.

Starting his career in the mid-1970s, Julio flew his first three seasons in the Retalhuleu region, spraying for a Spanish cotton farmer (a crop booming in the country then), initially with a Pawnee and later with a Cessna.

He then began working for Raul Garcia Granados, the largest cotton producer in Guatemala, where he would fly for over 20 years. He piloted the country’s first turbo Thrush and the Snow S-2A.

During the 1980s, Julio met his namesake, Julio Vargas, an agricultural pilot who alternated his work between Guatemala and Mississippi.

A decade later, after the cotton boom had passed, the two friends received a risky but tempting proposal. The largest spraying company in the country had gone bankrupt, leaving eight aircraft (including Turbo Thrush, AT-302, AT-401, and AT402) inoperable. The bank that had acquired the machines approached the two pilots and offered them to take ownership.

In 1997, Conversiones SA was born with a clear purpose: to modernize the Guatemalan agricultural air fleet. The initial focus was on the heart of the aircraft, requiring a revival of their turbines. For this, they brought in Juan Martinez, who is responsible for maintenance, to establish their first base in Tiquisate.

Conversiones established a contract with the U.S. Embassy in Guatemala in its first year of operation through the U.S. Department of Agriculture’s (USDA) whitefly eradication program. This project aimed to control an insect causing enormous economic losses to various agricultural industries (it is estimated that in 1990 alone, the whitefly caused a loss of USD 500 million in the states of Florida, Texas, California, and Arizona).

Although coffee, one of Guatemala’s main crops, was not attacked by the pest, it was one of its primary hosts. It was discovered that spraying over 300,000 hectares of coffee plantations in Guatemala was crucial for the phytosanitary safety of the United States. Thus, Conversiones began its first season contributing to American agriculture as well.

In this way, the company emerged with a particular purpose: to rebuild airplanes (and, in the case of piston aircraft, convert them to turbines) and use them for protecting crops. Some of those eight immobilized aircraft were sold to other regional operators after refurbishment, and the remainder became part of Conversiones’ own spraying operation. In addition to coffee, the company expanded its protection to the sugarcane and banana industries, which are currently the main large-scale crops in Guatemala.

In the early 2000s, the company also began to specialize in providing maintenance services to other operators in the country. To strengthen this endeavor, they gained a heavyweight addition: Juan Francisco Ortiz Mijangos, an expert in aerial agricultural parts. After working for nearly 20 years in the trade of aviation parts in Florida, the “almost gringo Guatemalan” was invited by his then-client to return to his homeland and assist Conversiones in purchasing equipment for both its fleet and other operators in the country.

Subsequently, two more individuals joined the team: Roman (son of Julio Reyes), an engineer responsible for all electronic maintenance aspects of the aircraft, and Jason (son of Julio Vargas), an agricultural pilot currently in charge of coordinating the work of other aviators. As Mr. Juan Martinez aged, he passed the baton to Wilfredo Mejia Sanchez, an aeronautical mechanic from Honduras. After serving in his country’s air force for years, he joined the Conversiones team and became the primary reference for PT6 maintenance in Central America.

The company continued its operations in Tiquisate, on the “Guatemalan Coast.” This region, bathed by the Pacific Ocean, is the country’s leading agricultural producer and is home to the most extensive banana plantations and sugar mills, with a significant portion of the production aimed at the North American market.

The maintenance center and the main operational base of Conversiones are located there (the administrative

office is in the capital, Guatemala City, near the country’s main airport). Five active company aircraft (in addition to several undergoing reconstruction) rest there, departing each day for clients’ farms, which have their own runways and loading stations.

The other three aircraft in Conversiones’ fleet are stationed in Puerto Barrios, located in the country’s northern region, near the Caribbean Sea and the border with Honduras. They exclusively serve a multinational banana group (the second-largest globally), currently controlled by Brazilians. Julio Reyes mentioned that his company shifted to operating almost exclusively in this type of crop due to the perennial nature of the application:

“We need to spray fungicide on bananas once a week, every week of the year. This ensures continuous work, unlike other crops where spraying is seasonal, providing greater profitability and security for both the company and the pilots. Banana is not only the most lucrative for aerial application operations but also for Guatemalan farmers (ensuring higher yields than other largescale crops) and for our country as a whole (being the most exported crop in Guatemala nowadays)”.

During the 2010s, Conversiones shifted its focus beyond the North and began exploring new technologies in South America. Initially, the company solidified a partnership with a turbine parts review and sales company, particularly for PT6 engines. They then initiated an association with the application technology manufacturer Zanoni Equipamentos, which has now been completed for five years. Conversiones became

the authorized and exclusive distributor of the Brazilian brand for the entire Central American agricultural aviation market. Francisco, currently responsible for serving customers with this product line, shares insights about the alliance:

“Initially, we purchased the products for our own use. After confirming the quality of the equipment in practice, we decided to start reselling them to other local operators. Previously, we bought these types of parts from the United States, but we opted for Zanoni for three reasons: product quality, technical support, and work philosophy. These are technologies that sell themselves without much effort in having to promote them. Moreover, we have direct access to the technical and commercial team whenever we need it, and just like our approach here at Conversiones, they know that, above all else, we always put the customer first. Today, we have the largest stock of spraying parts in Central America, allowing us to respond promptly to any needs of agricultural pilots”.

In addition to converting spraying equipment for the Zanoni brand, Conversiones, in partnership with the Brazilians, initiated another innovative project for the region: disseminating Brazil’s most commonly used aerial spraying methods, utilizing rotary atomizers, and reducing spray volumes. Similar to what Zanoni has been doing in the USA through its local resale, Conversiones has shown local operators that, with the advancement of the chemical industry and adjuvants, it is possible to combine phytosanitary safety with greater operational profitability. The initial tests were conducted by Javier Soberano Sanchez,

We specialize in providing a high level of service to our clients. You work in a demanding environment, you can rely on Neal Aircraft to give you the best service and support.

a businessman and agricultural pilot from southern Mexico who also serves banana crops. After equipping his Pawnees with Zanoni pumps, valves, and atomizers, the businessman welcomed agronomist Alan McCracken for a series of assessments and calibrations with the new technology and shared about the project:

“Conversiones and Zanoni financed a research and technical assistance project for us to start this type of work here in Mexico. For those not used to it, the low volume presents a few initial challenges, such as greater care in the choice of adjuvants and preparation of the chemical mix. Still, these are easy issues to solve with the necessary support. We started the tests and showed them to the farmers before anything else. Like any paradigm shift, they were initially apprehensive, but the results were excellent, and customers were very pleased with the applications. The atomizers are excellent”.

Javier’s work quickly spread, and then FBJ Aeroaplicaciones also decided to test the new technology. Jaime Baldenebro’s company, located in Ciudad Obregón in northern Mexico, equipped one of its Braves with Zanoni atomizers through Conversiones

and received support from the agrochemical industry to start low-volume work. FMC sponsored a local seminar for farmers and a calibration job, also conducted by McCracken, focused on potato crops. The pilot and partner of the company, Alejandro Baldenebro, shared some considerations about the project:

“Using low volume brings us some advantages. First, it eliminates drift problems due to evaporation, as the lower water volume means less potential for dissipation through this process. With this technology, we achieve better penetration into the leaves, improved control of pests and diseases, and, consequently, higher crop productivity. We are working to promote this type of operation throughout the country”.

In 2024, Conversiones partnered with one of the authorized Air Tractor dealerships in Latin America to distribute other aviation parts to regional operators. Consequently, it has become crucial in modernizing Central American agricultural aviation, connecting the Brazilian application technology industry with the local agricultural aviation sector.

SPRAYING TECHNOLOGY

SINCE 1997

www.zanoniequipamentos.com.br/en

SPRAY SYSTEMS

Reliable and highly durable

ROTARY ATOMIZERS

With a standard of excellence for aerial application

FIRE GATES

Versatile and effective in reghting

GROUND SUPPORT EQUIPMENT

With great corrosion resistance

Micro VG Kits Available for:

Air Tractor: AT-300, AT-301, AT-302, AT-400, AT-400A, AT-401, AT-401A, AT-401B, AT-402, AT-402A, AT-402B, AT-501, AT-502, AT-502A, AT-502B, AT-504

Thrush: S2R, S2R-T11, S2R-T15, S2R-T34, S2RHG-T34, S2R-T45, S2R-T65, S2RHG-T65, S2R-R1340, S2R-R1820, S2R-R3S, S2R-G1, S2R-G5, S2R-G6, S2R-G10, S2R-H80 (510G)

Cessna Models: 188B, A188B, T188C

Dromader : PZL M18, M18A, M18B

Piper Brave: PA-36-285, PA-36-300, PA-36-375

Weatherly: 201, 201A, 201B, 201C, 620, 620A, 620B

Brian Tracy, motivational speaker and author, says, “Complacency is the enemy of success.” When it comes to aircraft maintenance, complacency is the enemy of safety! The Maintenance Personal Minimums Checklist is one tool that can help ward off complacency, make safety the primary objective, and maybe even make your job a little easier.

Developed in the late 1990s by FAASTeam member Richard Mileham, the Maintenance Personal Minimums Checklist is an important risk management tool. Its name, inspired by the Personal Minimums Worksheet for pilots, is a bit of a misnomer since it is more like a condensed version of a code of conduct for mechanics. The list, which is available in pocket size or slightly larger, includes items to consider before and after performing a task. The FAA recommends keeping one handy, where you can see it, like near a toolbox or workbench, and use it for each task you perform.

One of the top causes of complacency is doing repetitive tasks on a continual basis without incident. As a writer, the stakes are lower, and most of my tasks are varied and new. But for mechanics,

complacency is a real hazard. This checklist will help mitigate the risks that complacency creates. It reminds you to consider crucial questions like, “Am I physically prepared to perform the task?” before you get started. Taking a minute to review and answer each question in this section of the checklist honestly before you begin any task can help you avoid a sense of overconfidence — another part of complacency — that could lead to careless mistakes.

Once you’ve completed the task, refer to the list again. Check each of these equally crucial questions to make sure the aircraft is safe for flight. Questions like, “Did I perform the job task without pressures, stress, and distractions?” will help you double-check your own work. You might think that you will always know to check in with yourself on questions like, “Am I willing to fly in the aircraft once it is approved for the return to service?” but the checklist ensures a safety baseline every single time you perform a task. Even if you’ve completed this task hundreds of times — especially if you’ve completed this task hundreds of times — it’s critical to take a moment and check your work. The checklist will help you mitigate the risks that crop up when complacency sets in.

A PDF copy of the FAA’s Maintenance Personal Minimums Checklist is available at bit.ly/MaintenanceHangar or you can reach out to your local FAASTeam Program Manager for hardcopies. If you’re still not sold on the idea that you need to use this checklist, just remember, the work you do impacts lives, not just machinery.

Rebekah Waters is an FAA Safety Briefing associate editor. She is a technical writer-editor in the FAA’s Flight Standards Service. This article was originally published in the January/February 2024 issue of FAA Safety Briefing magazine.

Robert Craymer |

Robert Craymer |

The FAA has issued an emergency Advisory Directive (AD). They are following the lead of Transport Canada and EASA (Transport Canada Emergency AD CF-2024-05). Pratt and Whitney Canada have also issued a corresponding category 1 service bulletin (A14574). To highlight what this means regarding importance, Pratt & Whitney Canada has only issued three other category 1 service bulletins, the last being in 2014.

All of this information applies to the following engine models: All PT6A-64, PT6A-66, PT6A-66A, PT6A-66B, PT6A-66D, PT6A-66T, PT6A-67, PT6A-67A, PT6A-67AF, PT6A-67AG, PT6A-67B, PT6A-67D, PT6A-67F, PT6A-67P, PT6A-67R, PT6A-67RM, PT6A-67T engines.

This AD and service bulletin indicate that they must be complied with before the next flight. For most engine

owners/operators, this will mean a review of the AD and determining applicability. The inspection/replacement of the affected parts is specifically targeted to a batch of blades made from a specific batch of raw materials.

The parts affected are the second-stage power turbine blades (PT2). These blades all have individual serial numbers on each blade, and for new engines, the blade serial numbers should be listed in the logbook on the serialized component list. Suppose you have had your PT2 blades replaced within the last 50 hours of operation. In that case, the installing maintenance provider should have provided or be able to identify for you the serial numbers of the blades that were installed.

This is the critical information that you are looking for. The serial numbers of the affected blades are listed in the service bulletin (A14574). If you find these blades in your

engine, please get in touch with someone within the Pratt & Whitney Canada network. You can contact your field service manager or the Designated Overhaul Facility you work with. Pratt & Whitney Canada has assured me that parts will not be an issue as they know the number of blades affected and have set aside the replacements.

The majority of engines out there won’t be affected by this AD. All that needs to be done is a review of the information and to make a logbook entry stating that the AD does not apply to your engine. This step does need to be done before your next flight. Get with your maintenance provider, and please ensure that you do this. It will keep you out of trouble if an inspector does a review of your logs.

I advise everyone to be aware and review this AD to ensure you are covered.

Robert Craymer has worked on PT6A engines and PT6A-powered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and has been an instructor of PT6A Maintenance and Familiarization courses for pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member.

Robert can be reached at robertc@covingtonaircraft.com or 662-910-9899

Visit us at covingtonaircraft.com

Most of you know that there are specific limits regarding alcohol consumption when you plan to fly. You must abstain from alcohol for at least 8 hours prior (12 hours in the military) and your blood alcohol level must be less than 0.04% (grams/deciliter) per Title 14, Code of Federal Regulations (CFR), section 91.17. The use of alcohol and other drugs (legal or illicit) proximate to flight is simply not safe. Studies have shown that there is an increased mishap rate among pilots who have had a DUI or DWI (driving under the influence or driving while intoxicated). In addition, a significant number of pilots involved in fatal accidents have had alcohol or other impairing drugs found in their system at autopsy.

The FAA is very concerned about this safety risk, and, as such, FAA regulations put an emphasis on the importance of flying unimpaired. You should also know that pilots are required to report alcohol or drug-related incidents to the FAA. Pilots who maintain an FAA medical certificate and operate under part 121 or 135 face additional requirements including random drug and alcohol testing.

Pilots are subject to the reporting requirements of 14 CFR section 61.15. You must provide a written report to the FAA Civil Aviation Security Division within 60 days of any action regarding your driver’s license. This includes suspensions, convictions, etc. Please note that this is required even if charges are subsequently dismissed. Also note that multiple reports might be required for the same offense, for instance, if a suspension is followed by a later conviction. This regulatory requirement reflects how the law was written.

Pilots who maintain FAA medical certification have additional reporting requirements under items 18 and 20 of the medical certificate application (FAA Form 8500–8). This is separate from the reporting due under section 61.15 and neither disclosure satisfies the reporting requirement for the other. Also, applicants for a medical certificate or those choosing the BasicMed pathway grant consent for a review of the National Driver’s Registry (NDR) as part of the application process.

There are also considerations for those who fly ultralights (part 103) and drones (part 107). The use of alcohol or other drugs is limited in section 103.9 and sections 107.23, 107.27, and 107.57, respectively in addition to section 91.17. While there is no specific reporting requirement under part 103 or 107, a pilot who holds

a certificate issued under part 61 must still meet the reporting requirements of section 61.15 even if they no longer exercise that certificate.

Clearly, the take-home message is don’t drink and fly, or drive for that matter. Some that do are repeat offenders before they are caught by law enforcement. If you are going out and plan to drink, also plan to have a designated driver, take a cab, or spend the night at a hotel or with a friend. Some of you already follow this guidance. Hopefully, more of you will. However, some will test the system and get caught. You risk being involved in an accident or losing your pilot certificates with a mandatory grounding period before retesting is permitted.

Let’s assume that the FAA’s legal team has determined enforcement action is unnecessary after reporting. There are still considerations for pilots who hold an FAA medical certificate. Both substance abuse and dependence are specifically disqualifying conditions listed in 14 CFR part 67. While a single event (DUI/DWI) can be relatively straightforward if an underlying dependence is absent, many times it will still require clearance from the FAA. For multiple events and/or cases where dependence is demonstrated, the pilot should anticipate that they will not be flying until the FAA is satisfied that the individual is in good recovery. Even then, years of monitoring is the rule.

Dr. Susan Northrup received a bachelor’s degree in chemistry, a medical degree from The Ohio State University, and a master’s degree in public health from the University of Texas. She is double board-certified by the American Board of Preventive Medicine in Aerospace Medicine and Occupational Medicine. She is a retired U.S. Air Force colonel and a former regional medical director for Delta Air Lines. She is also an active private pilot.The next time you talk with an old timer, give him some respect and pick his brain for how he got to where he is today. You will almost certainly learn something!

The upkeep of an aircraft is a crucial task that requires attention to detail and a comprehensive understanding of the different variables involved . The washing of the plane not only ensures aesthetic appeal but also enhances the performance and longevity of the aircraft .

Paint correction and high-quality protection like industrial ceramic coating play a crucial role in safeguarding the aircraft’s exterior from various elements, including UV rays, harsh weather conditions, and environmental pollutants . A well-maintained paint job significantly reduces the acceleration of corrosion associated with our industry; look for a certified aviation detailer and ask how your aircraft will be protected . Use the previous articles to keep your aircraft in its best condition and get the most longevity in your investment . We have summarized our articles into critical points .

We want to extend a BIG thank you to Ag Air Update for their support over this time, allowing us to share this information with all of you, and finally, our clients over the years for their trust . Without you, none of this would be possible .

1. Never wash the aircraft in direct sunlight as this will lead to quick drying, and depending on your water, mineral content can form mineral deposits on aircraft; given enough repetitions, this can soak deeply into your aircraft paint and may only be removed by heavy polishing, chemical treatment or worse permanent staining and required professional detailing services.

2. Follow the soap manufacturer’s instructions for diluting the wash soap appropriately. Check the MSDS always; a quick, simple reading will save hours working to pay for that new paint job.

3. Use foaming soap with a Foam Gun (for garden hose) or Foam Cannon (for pressure washer) to apply the wash soap. Allow a few minutes for the bugs to soak, then follow up by scrubbing with a soft bristle brush, a two-bucket wash method.

4. Be careful about your brush scrubbing; realize your body is a pendulum, and often, without thinking, we press at the bottom of the action and relieve pressure as the brush extends further up the wing. Look at the flaps and see heavy scratching. You may have developed this habit, or the brush clogs and scratches the surface.

5. An inline water filter can be purchased usually for less than a hundred dollars or a little more. It has enough flow to supply a pressure washer or garden hose and will minimize mineral deposits.

6. Wash as often as you can. A quick foam application with wash soap and pressure wash will neutralize the most contamination, leading to easier cleaning. The more buildup and longer the bugs bake, the more applications will be required to reach below the contamination layer, or the more aggressive soap or patience will be needed to remove the bugs and chemicals.

Please see the October 2023 issue for more information:

Option A:

Look for neutral-scented, non-colored, zero phosphate wash soap, often natural or organic label. These can be purchased at your local supercenter or online.

Option B: Look online for specialized microfiber cleaner packets. These come at a slightly higher cost per unit, provide guidelines for soiling level and dilution ratio, and provide the best opportunity to rejuvenate the towel.

Air drying is the best method for microfiber towels. Excessive heat can damage the fibers, making them stiff and leading to scratches/marks in your paint and windows. If using a dryer, opt for low or no heat settings. Do not use drier sheets as they can leave residue/protectant on the towel, making it lose its absorbency and may repel future protective coatings or dirt, leading to more scrubbing.

Please see the November 2023 issue for more information on microfiber care:

1. Thorough Cleaning: Begin by washing and decontaminating the paint surface to remove dirt, grime, and any loose particles that may further damage the paint with abrasion. After washing, the clay bar may be used with specific wash soaps in a detailed spray formulation to remove surface contamination. We suggest medium-grade clay towels as they are generally larger, more durable, and have fabric on the back for wiping/wetting the surface.

2. Paint Correction: Use an abrasive compound Like IGL F1-F3 series to remove the oxidized layer, restoring the paint’s shine and color. If done correctly, this process will provide the best surface for adhesion with the protection of sealant and wax or ceramic coating. Being too aggressive and using improper polishing methods may permanently damage the paint. While not polishing enough will leave contamination and oxidation on the surface, vastly degrading the ability to protect the surface.

3. Ongoing Maintenance: Regularly washing the aircraft is the best procedure/care for the paint.

Corrosion inhibitors like zinc chromate primer have been implemented to provide protection; you will often notice this process by a green color below the paint surface. Factories like Thrush Aircraft have made this standardized process. Air Tractor has chosen electromagnetic protection using the cathode/anode approach. Both systems have advantages and disadvantages.

Hybrid Wax:

Carnauba wax is derived from the leaves of the Brazilian palm tree and is great for many applications, often suggested for aircraft like Cirrus, made from carbon fiber or synthetic materials.

Hybrid waxes combine the benefits of both carnauba wax and synthetic polymer wax. They provide a slightly faster application and easier removal of application while still providing natural gloss and shine.

Paint sealants offer a longer-lasting solution compared to traditional wax. These sealants are made of synthetic polymers. Most are rated at 6-month protection with proper Ph Neutral wash soaps.

This nanotechnology creates a molecular bond with the substrate, forming a thin, almost zero-weight layer over the paint that is much stronger than traditional waxes and sealants and is designed to handle the chemicals used daily in aerial applications. Not all ceramic coatings are created the same look for a certified aircraft detailer specializing in agricultural/Industrial ceramic coating.

Graphene has been making its way into the market in recent years. Clear coating systems like IGL Coatings Aegis 15-year rated, hydrophobic, self-cleaning, C5 corrosion rated, 6000-hour salt spray test is implemented and brought to the market; corrosion may be slowed and discussion for history books. Frontline Detail, who attends continuing education training in ceramic coating, can install these products with specific guidelines for aerial application aircraft. If you want to learn more or have questions, book a consultation with Frontline Detail at www.frontlinedetailusa.com.

Please see this and February 2024 issues for more information:

Carlin Lawrence

Carlin Lawrence

Jesus said, “For nation will rise against nation, and kingdom against kingdom. And there will be famines, pestilences, and earthquakes in various places. All these are the beginning of sorrows… For then there will be great tribulation, such as has not been since the beginning of the world until this time, no, nor ever shall be. And unless those days were shortened, no flesh would be saved; but for the elect’s sake those days will be shortened.” (Matthew 24:7-8, 21-22). The wars between Ukraine and Russia and between Hamas and Israel could easily spread into other countries. Ezekiel chapters 38-39 tell us that a country from the north will be joined with several Arab countries and will invade Israel, and God will destroy 83 percent of that army (Ezekiel 39:2 KJV).

“I watched as the Lamb opened the first of the seven seals. Then I heard one of the four living creatures say in a voice like thunder, ‘Come!’ I looked, and there before me was a white horse! Its rider held a bow, and he was given a crown, and he rode out as a conqueror bent on conquest” (Revelation 6:1-2). The Anti-Christ will appear to be a peace keeping man, but he will become possessed by the spirit of Satan, and his earthly wisdom and demonic power will fascinate, charm, and deceive much of the non-Christian world (Revelation 13:14).

“When the Lamb opened the second seal, I heard the second living creature say, ‘Come!’ Then another horse came out, a fiery red one. Its rider was given power to take peace from the earth and to make people kill each other. To him was given a large sword” (Revelation 6:3-4). In the process of bringing the world under his control, Anti-Christ will wage war against anyone who opposes him. These wars will cause worldwide food production to fall and people will begin to starve and fight over food and other essentials of life.

“When the Lamb opened the third seal, I heard the third living creature say, ‘Come!’ I looked, and there before me was a black horse! Its rider was holding a pair of scales in his hand. Then I heard what sounded like a voice among the four living creatures, saying, ‘A quart of wheat for a day’s wages, and three quarts of barley for a day’s wages, and do not damage the oil and the wine!’” (Revelation 6:5-6). When the apostle John wrote this, a quart of wheat was barely enough to sustain one person for one day, while a denarius represented one day’s wages for an average worker.

During the tribulation era a day’s wages will barely buy enough food for the worker, but will not be enough to feed their family. A person will be able to purchase three quarts of barley for a denarius, and that will help provide for families, but barley is low in nutritional value. A person’s wages will barely feed three people with low quality food. Both of those scenarios represent the severe famine conditions at that time.

After the February, 2022 Russian invasion of Ukraine wheat rose to over $12.00 dollars a bushel because of the Ukrainian crops were blocked by Russia from being shipped to other countries. We can only imagine what would happen if this was a world-wide war. The U.S. Bureau of the Census, International Data Base, estimates that the population of the world in 2050 will be over 9 billion people. It’s not hard to see how such a massive amount of humanity will have trouble feeding ourselves in the future. Planet earth is fast becoming over-crowded, with over 8,045,311,447 billion people as of 2023, a 0.88% increase from 2022).

“I looked, and there before me was a pale horse! Its rider was named Death, and Hades was following close behind him. They were given power over a fourth of the earth to kill by sword, famine and plague, and by the wild

beasts of the earth” (Revelation 6:8). God reveals to John that wild beasts of the earth are going to be a part of this devastation. But we shouldn’t think on the terms of huge wild beasts such as lions, tigers or bears. But think about rats, mosquitoes, bird flu, infections and disease carriers that are small but dangerous. The fourteenth-century outbreak of bubonic plague, a rat-borne disease called the Black Death, killed between one-fourth and one-third of Europe’s population. The bird flu in 1918-1920 killed 50-100 million people worldwide. These pandemics were a drop in the bucket compared to what’s coming on this earth. In Revelation 9:18 demons kill one-third of the earth’s population

The first four seals of Revelation chapter six reveal to us some of the most frightening things that will ever come upon this earth. But these first four seals are only a prelude to what is coming. Nothing in human history has even comes close to these catastrophic events that are in the future of this world. This is just the beginning of the worldwide wars, hunger and plagues that are in the future for this sinful and rebellious world. Still to come are the remainder of the seal judgments, the trumpet judgments, and the bowl judgments. But because of God’s love for humanity He is patient toward us, not willing that any should perish but that all should come to repentance (2 Peter 3:9).

Jesus said to Martha, “I am the resurrection and the life. He who believes in Me, though he may die, he shall live. And whoever lives and believes in Me shall never die. Do you believe this?” (John 11:25-26). God wants everyone to come to trust in Jesus Christ as their Lord and Savior (1 Timothy 2:3-4). But He has also given each person a free will to choose where he/she wants to spend eternity. Don’t miss your place in heaven while chasing the pleasures and things of this world!

Drake Martin

Drake Martin

It has been remarkable to see the growth Chem-Man has experienced just in my (what feels like a short) time with the company. With the rapid growth, we have amassed several new customers and grown our following who are often unaware just how long Chem-Man has been around serving aerial and ground applicators across the U.S. and Canada.

Regina Farmer started Chem-Man in 1992. The software originated as a DOS program (Disk Operating System) and at the Ame was an advanced billing system utilized by many aerial and ground applicators in the South. As technology evolved and the Ag AviaAon Industry advanced, the equipment and systems used by applicators had to evolve with it. In 2015 ChemMan moved to the online version that would later evolve and become what the program is today.

who played a vital role in the Boll Weevil run that we all know today as the foundation for current ag aviation. Laine has been running the office and taking care of the bookkeeping since 1995. Her initial billing program was another DOS program for a few short years where she then switched to The desktop version of Chem-Man in 2000.

Believe it or not, there are a small handful of operators in existence that are still using the original desktop version of Chem-Man to this day. I would like to introduce someone who until a year ago would fall into that category. This person and I have grown to become great friends after working closely together, which also resonates particularly with me is that he and his family are the first operation I worked with after my career with Chem-Man began.

Wade Lakey of Tri-County Sprayers, the 3rd generation of a family of aerial applicators with deep roots in the Ag Aviation Industry. Wade moved back home after his time in college and stepped up to help run the family business. Wade works alongside his mother Laine, his father Brad, and his uncle Vance who began an ag flying business based in Hamlin, Texas in 1988.

Vance and Brad were the sons of Herbert (Herb) Lakey who began his flying career in Texas in 1964. Herb started out flying a Piper Pawnee and his endeavors only grew after that. Herb was one of the many pioneers of the industry

Laine and Wade utilized the Chem-Man desktop until 2023 when I first met them at the TAAA convention in Lubbock, Texas. After spending some time allowing me to showcase demonstrations and after attending a Chem-Man introductory training class, they decided that after all of these years, it was finally time to make the switch.

Wade jokingly shares that his career began at TriCounty Sprayers at birth however, he assumed more responsibilities and pivotal roles within the company when he returned from college in 2012. Wade wears many hats within the company managing tasks that range from mechanic duties, equipment maintenance, aircraft mixing and loading, inventory management and sales, and scheduling and dispatching. Although the combination of the desktop version of billing with Chem-Man, handwritten notes, and black and white copies of google maps worked well for many years, Wade quickly saw the need to embrace the 21st century

and utilize the latest and most advanced technologies on the market. After years of pleading with his mother to switch to the online version of Chem-Man, Laine began considering the change after noticing her older outdated computer that housed the desktop software was beginning to have issues. The fear of change was overcome with the greater fear of losing all their customer information and current balances should something happen to that computer, especially during the busy season. Laine currently takes care of the billing and bookkeeping, but having Wade around has allowed her the ability to spend more time with her grandchildren.

Over 60 years, Tri-County Sprayers has seen a drastic evolution in the ag aviation industry. Wade recalls stories from his grandfather’s early days with the company and how he used to draw maps on napkins and then fly to fields looking for flags, indicating he was on the right pass. The company grew from a single piston-powered aircraft using handwritten napkin maps to an operation that utilizes four turbine-powered aircraft where they service their area as well as reaching other parts of the country to assist other operations in the Midwest. In their growth, they proudly received the TAAA Operator of the Year Award in 2019.

When asked what Wade has particularly enjoyed the most about the switch his answer to me was... “It wasn’t but a couple of weeks after that we started using ChemMan online that we had a job that was completed but I had forgotten to move it from scheduling to an invoice.

If I would not have had Chem-Man, the job would have inevitably been lost with the way we did things before.”

Wade and Laine were also apprehensive about making a change based on the price. “Before we were used to buying software and we own it with the desktop version of Chem- Man it was a one-and-done purchase. We were hesitant to shift into a yearly subscription pricing point at first. But after a short time of using Chem-Man online, we quickly could see the benefit and the program is well worth what we pay just for the mapping alone, much less all the other features that come with it.” Wade also comments that he particularly likes the ability to know how much chemical is needed and how much chemical he has on hand. Wade goes on to say “Chem-Man has made my life so much easier eliminating the guesswork on figuring product needed for a job or how much product I have in inventory. That feature alone saves me over an hour every day.”

I asked Laine what she has enjoyed about switching to Chem-Man online, and her reply to me was… “Being able

to grab the laptop and take it wherever or even login on my phone and have access to Chem-Man. It allows me to not be confined to the office or one computer. I never realized how much I would use Chem-Man outside of the office; if a customer calls and wants to know if a job has been completed, I can just look at my phone and say, ‘Yes that’s been sprayed, or that job has been finished’. It has prevented me from writing down an order when I get a call if I’m out of the office and accidentally forgetting about the order if I misplace that note.”

It has been very rewarding for me to hear how well implementing Chem-Man online has been for the Lakeys and everyone at Tri-County Sprayers. I hope to reach other operators out there who share some of the similar concerns about switching from the desktop version to the online version like Wade and Laine both had. Although change can be scary sometimes there are advancements and new technologies made to simplify the lives and work of operators in our industry. I take pride in knowing that Chem-Man does just that and I believe wholeheartedly in our program. Spray seasons are beginning in the southern states and before we know it, it will be full throttle for everyone across the country. We hope everyone has a safe and prosperous season and thank everyone for their continued support.

In ag aviation stick and rudder skills become honed to a fine edge. It comes with the territory of repetitive low-level flights at high gross weights with much cranking and banking day in and day out.

by Ted Delange

To make it even more challenging, operations often occur at high-density altitudes from remote airstrips and even at night, where soaring daytime temperatures prohibit daylight-hours applications.

On the other hand, skills tend to gain a bit of rust during the off-season, whether a month or two or longer, depending on the geographic location. It is essential to recognize this decreased level of performance, which naturally accompanies a break in the action. Professional athletes such as Major League Baseball players are well aware of this tendency and have spring training before a new season, where through practice and exhibition games, they can get back into the groove.

Many ag operators have spring training of sorts with refresher programs in place, where everyone – mixer/