Nothing lasts forever.

But a well-maintained Air Tractor comes close. Perform all recommended maintenance and required inspections.

MAINTENANCE MATTERS

With 36 years of experience, we have perfected the art of guidance for aerial application. But that does not mean we won’t keep innovating and improving. The new Ag-Nav Platinum Lite takes our industry leading technology and combines it with our more economical Guia 153 hardware. Paired with our OLED Transparent Lightbar, and Flow Control, you get the most advanced and cost effect guidance system on the market. The Ag-Nav OLED Lightbar displays all the information of our classic lightbars plus new more information, such as, Flow Rate, Aircraft Heading, Individual Booms On Indicators, Tank Level and more!

IN THIS ISSUE

PRESIDENT:

Graham Lavender - graham@marsaylmedia.com

VICE-PRESIDENT:

Bill Lavender - bill@agairupdate.com

SECRETARY:

Sandy Lavender - sandy@agairupdate.com

ACCOUNTING:

Casey L. Armstrong - casey@marsaylmedia.com

ADVERTISING:

Melanie Woodley - melanie@marsaylmedia.com

CLASSIFIED ADS: classifieds@agairupdate.com

Melanie Woodley - melanie@marsaylmedia.com

PRODUCTION:

Daniela Constantino - daniela@marsaylmedia.com

CIRCULATION: subs@agairupdate.com

Mary Jane Virden - maryjane@marsaylmedia.com

CONTRIBUTING WRITERS:

Ted Delanghe - ted.delanghe@gmail.com

Robert Craymer - robertc@covingtonaircraft.com

Regina Farmer - regina.farmer@chem-man.com

Carlin Lawrence - carlin@agairupdate.com

Ryan Mason - ryan@agairupdate.com

Michelle Miller - michelle@thefarmbabe.com

Josh Alameda - josh.alameda@gmail.com

Tracy Thurman - thurmantracyt@gmail.com

LATIN AMERICAN REPS:

Noelia Burgeus - noeliburgues@gmail.com

Ernesto Franzen - ernesto@agairupdate.com

Guillermo Giordana - aravia@aravia.com.ar

Gina Hickmann - gina@agairupdate.com

Pat Kornegay - pat@svatx.com

Ivan Parra - ivan@agairupdate.com

Marcia Specht - marcia.specht@gmail.com

© Copyright 2023 AgAir Update retains all rights for reproduction of any material submitted, to include but not limited to articles, photographs, emails and bulletin board posts. All material remain the copyright of AgAir Update. No part of this publication may be reproduced, in part or whole, without the written consent of the publisher. Editorial published do not necessary reflect the views of the publisher. Content within AgAir Update is believed to be true and accurate and the publisher does not assume responsibility for any errors or omissions. Unsolicited editorial manuscripts and photos are welcomed and encouraged. We cannot be responsible for return unless submissions are accompanied by a stamped, self-addressed envelope. Advertising deadline is 12 noon, on the 1st of the month preceding the month of publication.

AgAir Update (ISSN 1081-6496) Published monthly by Marsayl Media, 475 Myrtle Field Road, Perry, GA 31069 for $39 USD for one year in the U.S.; International rates are $65 USD for one year. Periodical postage paid at Perry, Georgia and additional mailing offices.

Postmaster: Send address changes to P.O. Box 850, Perry, GA 31069.

AgAir Update, a multiple-award winning publication, is published in three languages and distributed world-wide. AgAir Update is a proud member of:

FROM THE COCKPIT

Bill Lavender bill@agairupdate.com

Grant Erling Lane 1954-2023

Where does one start when writing about the loss of one of your closest friends and an industry leader? I’ve written about many in the ag-aviation industry that have gone before us. This one is tough, my friend Grant Lane.

I first heard of Grant over 35 years ago. Who hadn’t? The Lane family has been instrumental in ag-aviation for over 75 years. It was during a trip to Lane Aviation in Rosenberg, Texas, where I visited Mr. George Lane for an article in the late 1980s, that I met Grant.

Grant’s presence was overwhelming to me at the time. I was still an active ag-pilot trying to get AgAir Update “off the ground.” I soon learned that talking to Grant during that first visit was easy. We hit it off almost immediately. Working the same state trade shows sealed the friendship until his passing on July 12, 2023.

I had been traveling in Latin America for over ten years when I invited Grant to accompany me to Brazil in 2002. That was our first Latin American trip to be followed by at least 50+ more. In those years, we often traveled to Brazil but also to Argentina, Bolivia, Chile, Ecuador, Uruguay, Costa Rica, Guatemala and Mexico. Traveling throughout Latin America was not the only trips we made; they also included Canada, The Bahamas and throughout the U.S.

We were returning home from a trip to Brazil when Grant complained his leg was bothering him. He was always one to tough it out and resisted any medication. His leg bothered him enough to

see a doctor; that was April 2022, when he was diagnosed.

Grant fought his cancer to the end, never giving up hope. We talked at least three times a week and even more often after April of last year. Now, there is an empty void.

Grant was loved and liked by many people. Business-wise, he was the epitome of an intelligent and fair businessman. As a friend, you could not ask for a better one. He will be missed by many. There is no replacing him. I, along with his family and many friends, will have to adapt to life without Grant Lane; not going to be an easy task. Godspeed, my friend, until we meet again.

Until next month, Keep Turning…

October 11-12, 2023

Michigan AAA Convention

AgroLiquid Building, 3055 W. M-21

St. John’s MI 48859

Tim Swanson

989-292-1362 flyingfarmertim@hotmail.com

October 16-17, 2023

Aerial FireFighting 2023

Europe

TBD

Athens, Greece

October 21-22, 2023

2023 Ag Aviation Golf Tournament

Red Apple Inn & Country Club

Heber Springs, AR

Lathan Busby 870-734-7278

Bryant Otto 501-327-7714

Michael Hutchins 870-2413781

Brenda Watts 870-644-3141

October 23-24, 2023

Kansas AAA Convention

Drury Broadview Inn

Wichita, KS

Rhonda McCurry kaaa@ksagaviation.org

316-650-6857

October 23-25, 2023

CAAA 74th Annual Convention

Harvey’s Lake Tahoe

South Lake Tahoe, NV

Terry Gage terry.gage@caaa.net 916-645-9747

November 5-7, 2023

Pacific NW AAA Convention

Coeur D’Alene Resort

115 S 2nd St

Couer d’Alene, ID

Tara Lee Brown

pnwaaa@gmail.com

509-989-9098

CALENDAR OF EVENTS

agairupdate.com/calendar

November 7-9, 2023

Mid-States Ag Aviation Conference

Isle of Capri Casino

Quad Cities Convention Center Bettendorf, IA

Quentin Childs qchilds@insmgmtgrp.com 515-967-3761

November 13-16, 2023

Air Tractor Aircraft Maintenance

Familiarization Course Olney, TX

Brian Hahn bhahn@airtractor.com

November 14-16, 2023

Colorado AAA Convention Island Grove Regional Park Greeley, CO

Jessica Freeman jessica@coagav.org 970-217-5293

December 4-7, 2023

2023 Ag Aviation Expo

Palm Springs Convention Center Palm Springs, CA United States Event Website: http://www. agaviation.org/convention

NAAA Ag Aviation Expo Registration naaaexpo@agaviation.org

202-546-5722

December 7, 2023

Flying in the Wire and Obstruction Environment Course Palm Springs Convention Center Palm Springs, CA United States naaaexpo@agaviation.org

202-546-5722

December 11-14, 2023

Air Tractor Aircraft Maintenance Familiarization Course

Olney, TX

Brian Hahn

bhahn@airtractor.com

January 5-7, 2024

Arkansas AAA Convention

Oaklawn Racing Casino Resort 2705 Central Avenue

Hot Springs, AR 71901

Katherine Holmstrom katherine@araaa.org 501-503-3310

January 8-10, 2024

Louisiana AAA Conference

TBD

Kim Brown LAAGAVIATION@outlook.com (225) 436-3199

January 8, 2024

Arizona AAA Meeting & PAASS Program

Custom Farm Service Hangar

Stanfield, AZ

Brittany Armstrong barmstrong@agairusa.com (520) 705-9692

January 8-11, 2024

Air Tractor Aircraft Maintenance

Familiarization Course

Olney, TX

Brian Hahn bhahn@airtractor.com

January 10-12, 2024

Texas AAA Convention

Corpus Christi, TX

Chris Shields

cshields@thetexascapitol.com (512) 658-8161

January 10-12, 2024

Missouri AAA Convention

Cape Girardeau, MO

Eric Blair

ericb802@yahoo.com

(573) 283-5590

January 14-16, 2024

Northeast AAA Convention

Wyndham Gettysburg

Gettysburg, PA

Ed Carter

businessoffice@northeastaaa.org

(609) 820-7987

January 15-16, 2024

Oklahoma AAA Convention Embassy Suites

Norman, OK United States

Sandy Wells sandy@okaaa.org

(405) 431-0381

January 17, 2024

Ohio AAA Meeting

TJ Willey’s Tiffin, OH

Brian Gibbs gibbsaerospray@gmail.com (419) 332-1724

January 18-20, 2024

Mississippi AAA Convention

Beau Rivage Resort & Casino Biloxi, MS

Vicki Morgan vickimorgan@msaaa.com (662) 299-7836

January 22-23, 2024

Association of Montana Aerial Applicators Convention

Heritage Inn

Great Falls, MT

Alyssa Stromberg

alyssastromberg16@gmail.com (406) 480-3965

January 24-26, 2024

New Mexico AAA Convention Inn at the Mountain Gods Resort

Mescalero, NM United States

Sue Stewart dandsaerial@aol.com (940) 864-2456

February 5-6, 2024

Southeast Aero Cultural Fair (SEAF) FL

Ashley Houston aehouston81@gmail.com 270-293-3843

An AT-802 sprays in Arcadia, Louisiana. Photo by Ron Harper via Facebook.

A Thrush captured spraying in Hebron, Indiana.

Photo by @tomjonesfoto via Instagram.

A Thrush banks in the summer sun in Stratford, Texas.

Photo by @texas_avgeek on Instagram.

An Embraer Ipanema 202A spotted in South America.

Photo by @ituiutabaspotters on Instagram.

A rear view of a two seat air tractor laying fungicide in Arkansas.

Photo by @deltaplanespotter on Instagram.

A capture of an Air Tractor from Holzwarth Flying Service in Illinois.

Photo by Ken Coleson via Facebook.

An AT-802 sprays in Arcadia, Louisiana. Photo by Ron Harper via Facebook.

A Thrush captured spraying in Hebron, Indiana.

Photo by @tomjonesfoto via Instagram.

A Thrush banks in the summer sun in Stratford, Texas.

Photo by @texas_avgeek on Instagram.

An Embraer Ipanema 202A spotted in South America.

Photo by @ituiutabaspotters on Instagram.

A rear view of a two seat air tractor laying fungicide in Arkansas.

Photo by @deltaplanespotter on Instagram.

A capture of an Air Tractor from Holzwarth Flying Service in Illinois.

Photo by Ken Coleson via Facebook.

AGAV PICS

An Ag Cat sprays Walnuts. Photo by Chris Haile via Facebook.

A Brave weaves its way around windmills.

Photo by @scottpalmair via Instagram.

From the cockpit 500 feet above North Dakota.

Photo by @agaviationadventures on Instagram.

An Air Tractor comes in for a low pass in Chorman, Delaware.

Photo by @agaviationphotography on Instagram.

A Bell 206L3 sprays in Johnstown, Colorado. Photo by @skippyscage on Instagram.

A Cessna 188B lands in Uruana, Goias, Brazil.

Photo by @agro_spotters on Instagram.

An Ag Cat sprays Walnuts. Photo by Chris Haile via Facebook.

A Brave weaves its way around windmills.

Photo by @scottpalmair via Instagram.

From the cockpit 500 feet above North Dakota.

Photo by @agaviationadventures on Instagram.

An Air Tractor comes in for a low pass in Chorman, Delaware.

Photo by @agaviationphotography on Instagram.

A Bell 206L3 sprays in Johnstown, Colorado. Photo by @skippyscage on Instagram.

A Cessna 188B lands in Uruana, Goias, Brazil.

Photo by @agro_spotters on Instagram.

Ag Aircraft Operations Career Pathway Program - Setting Standards for New Ag Pilots

by

Graham Lavender, with contributions from Sheila Millican and Rob Van Namen.

by

Graham Lavender, with contributions from Sheila Millican and Rob Van Namen.

Over the past three decades, the landscape of agricultural aviation has undergone a remarkable transformation. From its early days of radial and piston engine airplanes, we now witness the predominance of advanced agricultural aircraft. The shift to more powerful turbine engines has undoubtedly improved performance but has also led to a significant increase in operating costs.

The purchase price, insurance rates, and training expenses have soared and contributed to a shortage of agriculture pilots. As seasoned ag pilots retire, finding suitable replacements has become challenging. The average age of an agricultural pilot falls between 50 and 60 years, with some still flying well into their late 70s. One of the primary reasons for this scarcity is the high cost and limited availability of ag flight training and insurance premiums for low-time ag pilots.

Acknowledging these concerns, the Mississippi Aerial Applicator Association (MAAA), the National Agricultural Aviation Association (NAAA), and farmers nationwide turned to Senator Cindy Hyde-Smith of Mississippi for assistance. After numerous meetings, studies, and strategic analyses, Senator Hyde-Smith commissioned the Commercial Aviation Department at Delta State University to develop a workforce development plan in the Mississippi Delta to address the shortage of ag pilots.

In response to this call, a collaboration was formed between the director of Flight Operations at Delta State University, Brad MacNealy, a Mississippi ag aviation operator and farmer, Ike Brunetti, and a Workforce Development Consultant, Pam Meeks. Together, they formalized an agriculture flight-training plan and presented it to Senator Hyde-Smith for consideration. Their proposal led to passing legislation granting a 2 million dollar grant to establish an Aerial Applicator Pathway for training Ag pilots at Delta State University. ➤

Senator Hyde-Smith emphasized the importance of partnerships with local businesses, schools, and organizations to realize the idea of Agricultural Aviation Training. Mitzi Woods from South Delta Planning and Economic Development (SDPED) took the initiative and sought assistance from Doug Freeze, Workforce Development Director at Mississippi Delta Community College, and Dr. Courtney Taylor at Accelerate Mississippi for State Workforce Training and Funding. Additionally, Delta State University collaborated with Blues Air, Inc. and Advanced Turbine Training, LLC, experts in Aerial Applicator training. MAAA, the Cleveland Airport, and numerous aerial applicator businesses from Mississippi and neighboring states lent their unwavering support to this initiative.

The next step in the process was to identify prospective students interested in becoming Ag Pilots. There were plenty of interested candidates, but the challenge was to find individuals who were genuinely committed to the program and had a strong work ethic. The program required candidates willing to dedicate long hours in challenging conditions to assist in the daily tasks of keeping the aircraft flying. It needed individuals ready to fly low and face hazardous conditions, who saw ag flying as not just a job, but a way of life they were determined to embrace.

The program devised rigorous selection criteria and processes to ensure the best selection of candidates. The selection committee includes Frank Kimmel, Karl Holcomb, Madison Dixon, Ike Brunetti, and Brad MacNealy.

Three entities are involved in flight instruction for the Ag Aircraft Operations Career Pathway Program (AAOCP). These entities include Delta State University, Blues Air, LLC, and Advance Turbine Training, LLC, all located at Cleveland Airport in Cleveland, MS.

Delta State University primarily handles Instrument and Commercial training—Blues Air covers the slack in case of overbooking from college students. Blues Air is responsible for the Aerial Application training, while Advance Turbine Training manages the Dual cockpit 802 turbine transition.

The program aims to train a minimum of 30 students within three years, at a rate of 10 students per year, but they are open to taking on more students if possible. Successful performance during the initial three-year period could lead to additional funding. The federal funding within AAOCP is available to any U.S. citizen with at least a private pilot's license, and they must have a part 137 operator sponsor. This sponsor acts as a mentor, vouching for the student's capability to become an ag pilot, although they are not financially obligated. ➤

NEW RG-220 BATTERIES DESIGNED FOR THE MOST DEMANDING APPLICATIONS

We love the RG-220. We like that the battery box is clean; it’s a cleaner, friendlier installation without corrosion treatment and preventative maintenance. The mechanic appreciates it and for us it reduces our maintenance costs. There are more amps available for faster, cooler starts.”

For Air Tractor Models AT-402, AT-402A, AT-402B, AT-502, AT-502A, AT-502B, AT-504, AT-602, AT-802 & AT-802A

STC SA01090DE provides for the installation of Concorde RG-220 batteries in Air Tractors.

The TSO-C173a authorized RG-220 was specifically designed to start PT6 turbine engines. It is built with the same components and features that are proven to optimize current output, maximize capacity and sustain turbine engine power requirements. The RG-220 is dependable season after season.

• Faster starts, improved performance and reduced engine wear

• Sealed technology - no electrolyte management or potential contamination

• Proprietary PolyGuard® Separators – for added protection against shock & vibration

• Concorde batteries are 100% recyclable

• Supported by Concorde’s world class customer service

CONCORDE BATTERY CORPORATION

2009 SAN BERNARDINO ROAD, WEST COVINA, CA, 91790 626.813.1234 | ISO 9001 + AS9100 CONCORDEBATTERY.COM

Interested applicants must submit an application to DSU, and after that, they undergo an in-person interview with the program leads. The AAOCP training starts in October and concludes in May of the following year, with a timeframe of approximately 6-8 months for completion, weather permitting. The ag portion of the training typically commences in January. Mississippi residents may be eligible for additional state grant funding.

The training involves a combination of ground and flight instruction. Blues Air provides the Basic Ag Course, which includes 50 hours of ground training covering safety, equipment, and industry aspects. Flight training involves hands-on experience with various aircraft, such as the Ag Pilot X outfitted 150hp Citabria, Scout, Satloc Bantam 188 Ag Truck, and Cessna 172. Furthermore, Advance Turbine Training manages the Dual Cockpit AirTractor 802 for turbine transition training.

The collaboration between these entities ensures that students receive comprehensive and experienced training to become

competent and safe Ag Pilots. Those interested in self-funding their flight training can pay directly to Blues Air for the course. The focus is on equipping students with the skills and knowledge necessary to excel in their careers as agricultural pilots. The program aims to set a new safety, efficiency, and accuracy standard in aerial application training.

For more information, interested individuals can contact the respective entities involved in the AAOCP program:

Delta State University - AAOCP Grant Program Coordinator: Sheila Millican (Contact: 662-846-4216, Email: Smillican@deltastate.edu)

Blues Air, LLC - Owner/Operator: Phil Krasner (Contact: 504722-3399, Email: Phillipkranser@yahoo.com) and Chief of Ag Ops and Training: Rob Van Namen (Contact: 662-8224151, Email: Robvan502@gmail.com)

Advance Turbine Training, LLC - Owner: Ike Brunetti (Contact: 662-719-2200, Email: Shelbyairservice2@gmail.com)

NAAA is excited to announce the hiring of Lauren Henretty, CMP, as the association’s new Associate Director of Meetings & Marketing. Lauren brings 20 years of experience working for associations in the education, meetings and management space. She most recently worked as associate director and education program planner for the Pediatric Pharmacy Association. Lauren will use her experience to help in the planning and execution of the Ag Aviation Expo, board meetings, other industry events and NAAA marketing initiatives.

Lauren is a graduate of the University of Pittsburgh and lives with her husband and daughter in southern Maryland. Please help us in welcoming Lauren to the NAAA staff.

Pratt & Whitney Expands P&WCSMART™ Portfolio for PT6A-34AG Engines

São Paolo, Brazil, July 18, 2023 – Pratt & Whitney Canada (P&WC), a business unit of Pratt & Whitney, announced today that it has added three new P&WCSMART™ offerings designed specifically for PT6A-34AG operators: Flat Rate Overhaul Program, Propeller Strike Repair Program and Flat Rate Engine Exchange. These additions will better support customers by providing fixed costs for major engine maintenance services, thereby eliminating price uncertainty while delivering original equipment manufacturer (OEM)-level engine maintenance and parts, and world-class service.

“Our P&WCSMART lineup continues to attract new and repeat customers by offering them the best value in the industry,” said Irene Makris, vice president, Customer Service, Pratt & Whitney Canada. “Tailored to the needs of operators with mature engines, P&WCSMART solutions for PT6A-34AG are tailored to help our global aerial application customers optimize their maintenance with well-priced, no-surprise solutions aligned with their business model. For aircraft reaching the end of their lifecycle, maintenance costs become higher and harder to predict – but with our P&WCSMART solutions, operators can keep their mature engines economically viable for longer.”

Flat Overhaul Program

The benefits of the PT6A-34AG Flat Overhaul Program include a guaranteed overhaul price and capped price for optional compressor turbine blade and limited life parts replacement, with no extra charges for engines that exceed the OEM-recommended time between overhauls or engines removed because of a propeller strike event.

Propeller Strike Repair Program

Under the PT6A-34AG Propeller Strike Repair Program, customers whose engines are affected by such an event will receive up to US$395,000 in parts and service for a fixed price of US$175,000 (2023 pricing). This includes labour, new genuine P&WC parts, exchanges and subcontracted parts, and more.

Flat Rate Engine Exchange Program

Finally, the PT6A-34AG Flat Rate Engine Exchange program is a cost-effective alternative to overhauling an engine. For a fixed price, customers benefit from the simplicity of receiving a freshly overhauled engine of the same model in exchange for their existing one. They eliminate the need to rent an engine while theirs is being overhauled; there is only one engine removal and installation, not two. This allows them to reduce downtime and increase aircraft availability.

With the addition of the latest solutions, the P&WCSMART program now includes more than 25 unique offerings spread across three portfolios: PT6A, turboshaft and PW100 engines. It features a variety of options that bring peace of mind to eligible operators, such as capped costs for major maintenance events like overhauls and hot section inspections, engine exchanges and upgrade programs.

P&WC’s P&WCSMART™ program is popular with customers because it provides cost guarantees up front, saves them money and maintains the value of their assets. These new offerings were developed based on feedback from agricultural aviation customers to meet their evolving business needs and support their bottom line.

The Pratt & Whitney team will be at Congresso AVAG July 18 to 20 booth # 67 where a cutaway of a PT6A engine will be on display.

About Pratt & Whitney

Pratt & Whitney is a world leader in the design, manufacture and service of aircraft engines and auxiliary power units. To learn more, visit www.prattwhitney.com. To receive press releases and other news directly, please sign up here.

For further information: Pratt & Whitney, +1 (860) 5659600, media@prattwhitney.com

TURNING DATA INTO ACTION

Our FAST™ solution helps you make informed decisions and optimize operations through full-flight data intelligence delivered wirelessly within minutes of engine shutdown. It helps you see the small details – as well as the bigger picture – so you can stay ahead of the game.

EXPLORE OUR DIGITAL SOLUTIONS AT PRATTWHITNEY.COM/FAST

Remembering the Life and Legacy of Grant Lane

via Air Tractor

The worldwide Air Tractor family is saddened by the loss of Grant Lane, President and CEO of Lane Aviation, Inc.

“Grant was a big presence and influence at Air Tractor, and in the ag aviation industry,” says Air Tractor President Jim Hirsch. “We will miss him and remember him with admiration and respect. Our prayers and condolences are with the Lane family.”

Grant passed away July 12, 2023, after a courageous battle with cancer.

For decades, Grant Lane was a leading voice in the U.S. ag aviation industry. Few could surpass his cheerful, quiet good spirit, and his drive to go the extra mile. “Grant’s standards were always high. He gave his best to help people achieve their goals,” Hirsch said.

The Lane name has been associated with Leland Snow and Air Tractor since 1957. George Lane was a big believer in the work of Leland Snow and paid a deposit on one of the first five Snow S2A ag planes. Shortly thereafter, Lane Aviation became a dealer for Snow Aircraft – and later Air Tractor. Lane Aviation became the first Air Tractor dealer in 1974.

Grant and his brother Mark Lane grew up in the Lane Aviation business and were taught to fly by their father. Both soloed at 16. In 1975, Grant began flying and working fulltime for Lane Aviation. When Grant arrived at an operator’s location, he was there to help.

Lane Aviation continued to grow and thrive, which paved the way for its entrance into international and South American markets in the early 2000s. Agricultural aviation in Latin America had begun gaining significant momentum by then, and Grant formed a partnership with AeroGlobo Aeronaves to bring Air Tractor aircraft into Brazil. In 2007, AeroGlobo Aeronaves became the exclusive Lane Aviation agent in Brazil.

Grant will be remembered for his hands-on approach with customers and his dedication for progress in ag aviation.

Over the year’s Grant accumulated numerous accolades, including the NAAA’s Larsen-Miller Community Service Award. Grant and his father, George received NAAA’s prestigious Agrinaut Award in 2006 for Lane Aviation’s creation in the 1970s of the Lane Brake, a breakthrough in pump fan brake technology.

Grant’s legacy lives on in his son Logan Lane, who now will serve as the company’s president. Logan is a pilot and graduate of Texas A&M University with life-long experience in the ag aviation business. Like his father Grant, Logan has been guided and prepared for a career of service to customers and investing in the lives of other people.

“Lane Aviation is in good hands with Logan to carry on the Lane tradition,” Hirsch says.

Per Grant’s wishes, there will be no funeral service, but a celebration of his life will be held at Lane Aviation, in Rosenberg, Texas at a date yet to be determined. In lieu of flowers, the Lane family requests to either donate blood in his name to a local blood bank or donate to the PAASS Program.

FAA Streamlines UAS Part 137 Certification Process

NAAA is concerned about the competitive advantage the FAA’s streamlined UAS Part 137 certification process gives to new uncrewed Part 137 applicants over those who must follow the standard process with the FSDO.

On June 13, the Federal Aviation Administration (FAA) issued Notice 8900.659, directing its staff with updated guidance on the Part 137 certification process for UAS. The FAA justifies these changes by asserting that uncrewed aircraft system (UAS) Part 137 operations present a lower risk than other certificated operations.

As stated by the agency:

We’ve seen a significant increase in agricultural aircraft operator certificate applicants seeking to use Unmanned Aircraft Systems (UAS) under 14 CFR Part 137. Our data shows that UAS not only have significant commercial and agricultural value, but they also operate in a lower risk category when compared to crewed aircraft; they have no onboard pilot, carry a much smaller payload and 99 percent of the UA carry no flammable fuel.

Since the first agricultural UAS certificate was issued in 2015, there have been no known accidents or injuries among the 178 certificated operators. Given the relatively low risk of agricultural UAS operations and restrictions written into the required exemption, we’ve determined that streamlining the Part 137 UAS certification process will not adversely affect safety.

The FAA is moving forward with the following changes:

Part 137 UAS Certification Process

1. Uncrewed Operators (UO) now apply for a Part 137 certificate via the central UAS Operations Office (137UOO) instead of their local Flight Standards District Office (FSDO). They would still need to have applied for and been granted the necessary exemptions from 14 CFR before applying. The new office may be contacted at: UAS137Certificates@faa.gov.

2. The FAA determined UO are lower risk, so § 137.19(e) Knowledge and Skills Tests can now be self-administered. The FAA can request documentation of satisfactory completion.

3. No Letter of Authorization (LOA) issued for UO; Operating Certificate issued by 137UOO.

4. Splitting of Flight Safety Offices:

• 137UOO is responsible for uncrewed-only operations.

• Local FSDO is responsible for mixed operations (having both crewed and uncrewed).

• 137UOO will specifically coordinate with FSDOs to conduct field activities on an asneeded basis (inspections, investigations, etc.).

5. No regular surveillance will be required by the FAA for uncrewed-only operations.

Documentation Requirements

1. Newly required operations manual for UO (includes safety, flight duties/ responsibilities, accident reporting, HAZMAT, etc.). ➤

Thirty-five years after the first great historical account of the industry—Mabry Anderson’s Low & Slow: An Insider’s History of Agricultural Aviation—comes a new, updated account of aerial application’s history from the National Agricultural Aviation Association: Agriculture’s Air Force: 100 Years of Aerial Application.

Based on a collective history of the agricultural aviation industry sourced from Agricultural Aviation magazine, AgAir Update, Low & Slow and other materials, Agriculture’s Air Force chronicles the agricultural aviation industry’s growth from its infancy in 1921 through the boom times after World War II, and on to today’s modern era of high-tech aerial application.

Whether you are an aviation enthusiast, have an appreciation for agriculture or are simply awed by the aerial ballet of these low-flying aviators, pull up a seat and tag along with Agriculture’s Air Force! (Available in hardback.)

2. Newly required self-created/self-administered/selfdocumented training program for UO.

3. (1) and (2) are not submitted to or approved by the FAA but must be made available by request.

Approved Aircraft

1. 49 USC § 44807 previously approved UA are all approved for Part 137 use.

2. All <55 lb. UA are approved for Part 137 use.

Alignment of Policy

1. Uncrewed-only operators need only a Remote Pilot Certificate (not a commercial pilot certificate).

2. Third-class medical certificate required (not a secondclass medical certificate).

NAAA is concerned about the competitive advantage that this gives to new uncrewed Part 137 applicants over those who must follow the standard process with the FSDO. The association is also concerned that the separate centralized approach for UAS may prove to further alienate crewed and uncrewed Part 137 operators, as they would deal with distinctly different FAA officials and oversight, even if treating adjacent fields. When the skies become more crowded with UAS

operations, FAA safety coordination becomes more and more important.

The new process will likely relieve backed-up FSDOs of their UAS burden, and hopefully allow them to better serve crewed and mixed crewed/uncrewed operators. In addition, NAAA does appreciate the FAA’s assertion that at least a third-class medical certificate be required. NAAA has held firm on this requirement for all proposed commercial operations of UAS, commenting as such on countless UAS exemption petitions.

Within 12 months, the FAA will incorporate these changes into Advisory Circular (AC) 137-1. Current Part 137 UAS applicants on the National Applicant List will be automatically transferred to the 137UOO, and applicants in progress will be given the option to continue working the certification with the FSDO or transfer to the new streamlined process. It is also worthy to note that the scope of these changes does not extend to any specialty use cases, such as beyond visual lineof-sight (BVLOS) or swarm operations. Any proposed specialty use cases would still need to be initiated through a Letter of Intent (LOI) with the jurisdictional FSDO.

NAAA continues to meet with industry stakeholders to better evaluate the impacts of these changes to its member operators and is actively formulating a suitable response to the FAA regarding this notice.

Sertãozinho, Brazil Welcomes SINDAG 2023

by Graham LavenderSertãozinho, a vibrant city in Brazil, was abuzz with excitement as it played host a small fleet of aircraft from the 2023 AvAg Congress. The event, organized by SINDAG) drew the attention of ag aviation enthusiasts, industry professionals, and local residents alike.

The AvAg Congress, renowned for showcasing the latest advancements in aerial application technology, chose Sertãozinho as its destination, highlighting the city’s importance in the agricultural sector. Nestled in the heart of São Paulo state,

Sertãozinho boasts a rich history of agricultural excellence, making it an ideal backdrop for this prominent gathering.

The event drew participants from diverse backgrounds, ranging from farmers and agronomists to aviation experts and government officials. Together, they explored innovative solutions to enhance crop monitoring, pest control, and precision agriculture. The AvAg Congress facilitated knowledge exchange, fostering collaboration and paving the way for advancements in sustainable farming practices. ➤

HIGH PERFORMANCE STARTS WITH THE RIGHT PARTS

APS has designed a high quality brake disc that has established itself as the benchmark among aircraft brake discs. A true blend of strength and durability. CNC machined from a rigid one piece design these brakes are built to provide unparalleled performance. Heat treated to give it the appearance, with our name proudly engraved on the side; APS offers the ultimate in braking performance.

Centrally located at KHCD airport in Hutchinson, Minnesota. ASI Jet is an Authorized Thrush Aircraft Dealer, Service Center, and Parts Distributor. Specializing in New and Used Aircraft Sales, Heavy Airframe Maintenance and Installations, Wing Spar AD compliance, Parts support, and much More! Give us a call, we are here to work for YOU!

For over 30 years, ISOLAIR has been manufacturing industry leading helicopter systems for the firefighting, forestry and aerial application industries. With a broad line of certified and custom helicopter equipment, ISOLAIR has the system to fit your company’s needs From agricultural spray systems and bucket spreaders to firefighting systems, forestry grapples and torches, ISOLAIR can and will do it all!

With competitive pricing, quality assurance, easy to install products, and an ongoing commitment to customer service, we welcome you to contact us. Our friendly and knowledgeable staff is ready to answer your questions and help you find the ISOLAIR system that will best meet your operational requirements.

For over 30 years, ISOLAIR has been manufacturingindustry leadinghelicopter systems for the firefighting, forestry and aerial application industries. With a broad line of certified and custom helicopter equipment, ISOLAIR has the system to fit your company’s needs.Fromagricultural spray systems and bucket spreaders to firefighting systems, forestry grapples and torches, ISOLAIR can and will do it all! With competitive pricing, qualityassurance, easy to install products, and an ongoing commitment to customer service, we welcome you to contact us. Ourfriendly andknowledgeablestaff is ready to answer your questionsand help youfind the ISOLAIR system that will best meet youroperational requirements.

Attendees had the opportunity to witness live demonstrations of the aircraft’s capabilities, including precision spraying techniques and remote sensing technologies.

Sertãozinho, with its vast agricultural landscapes, proved to be an ideal location for the AvAg Congress. The event

allowed participants to gain practical insights into the challenges faced by farmers and explore how aviation can contribute to their success. It also showcased the city’s commitment to embracing technological advancements and promoting sustainable practices within the agricultural sector.

The AvAg Congress in Sertãozinho not only served as a platform for innovation but also fostered networking opportunities among industry professionals. Participants engaged in thought-provoking discussions, exchanging ideas and experiences that will shape the future of Brazilian agriculture.

There were over 150 exhibitors from all corners of the globe in attendance.

Sertãozinho’s role as the host of the AvAg Congress served as a testament to the city’s commitment to progress and its recognition of the vital role aviation plays in shaping the future of Brazilian agriculture. By embracing innovation and collaboration, Sertãozinho and the AvAg Congress have set the stage for a promising future in which aerial technology and sustainable agriculture work hand in hand to create a prosperous and environmentally conscious industry.

Testing the Waters

with Economic, Effective Solutions to Improve Spray Quality

by Doug Applegate

by Doug Applegate

Everyone takes a moment to mentally run through your planning process prior to making a herbicide application. Chemical selection, equipment setup and field scouting are all essential to effective weed control.

But where does water quality rank on your list of preapplication priorities? Ideally, it’s near the top, given the detrimental effect that mixing poor-quality water with costly chemicals can have on equipment efficiency and herbicide efficacy. Water hardness, bicarbonates, salinity and pH can influence how effective and economic you are in combatting a waterhemp or Palmer amaranth invasion.

“There is growing awareness that certain herbicides, and glyphosate in particular, can have reduced efficacy when mixed with poor quality water,” says sprayer expert Tom Wolf, co-founder of the website Sprayers101.com.

We’ll explore effective testing methods and treatments in my next post, so stay tuned. But let’s start by understanding what causes poor water quality and how it can cost us yield and equipment efficiency.

Mixing hard water with herbicides can soften their effectiveness in controlling invasive weeds. But glyphosate is particularly sensitive to hard water rich in iron, calcium, magnesium, potassium and sodium ions. The positively charged cations in hard water bind with the negatively charged glyphosate molecules, which weakens the weedkilling ability of the chemical.

Given that many of us have paid at least twice as much for glyphosate during the last few years, the thought of investing more money for less return due to poor water quality is concerning.

“In the past, farmers with hard water problems often spent more on glyphosate and increased the application rate as a solution,” Wolf says. “Today, farmers can’t afford the same approach, and in some cases, have reduced their rate of glyphosate application because it’s been too expensive.”

While some might save a few dollars on front-end weed control, ultimately, Wolf says they could end up paying the price in lost yield and persistent weed problems. “Allowing heartier, more tolerant weeds to survive may speed up development of polygenic resistance,” he says. “This means that subsequent weeds of the same variety will become more and more established and herbicide resistant over time.”

The problems that poor water quality can create aren’t only in the field. For example, hard water can make some

herbicides more difficult to mix or leave a “gummy” residue in the sprayer tank, says Wolf.

“Think of it like shampoo. You want to get a good lather going which can be difficult with hard water,” he says. “It’s the same with your tank mix, where hard water will make it more difficult to get a complete mix.”

One problematic scenario Wolf sees is when farmers mix cold water high in bicarbonates, with Liberty and clethodim plus Amigo, the registered activator in Canada. The combination can create an oily residue.

Mixing turbid water containing clay particles or other suspended solids with herbicides like glyphosate can also reduce potency and create dust in the sprayer tank.

Water with a pH between six and eight is safe to use.

Total water hardness should be below 350 ppm for low rates of glyphosate (the equivalent of a half-liter per acre), and below 700 ppm for the higher rates, according to Bayer.

EC values less than 500 µS/cm are considered safe. For values above 500, a hardness test is necessary to confirm the presence of antagonizing cations.

Now we’ll look at proven methods for testing sources and treating causes.

From cost-effective additives to investing in a commercial reverse osmosis system, it’s worth knowing which options successfully do the dirty work to keep your water clean ahead of chemical applications.

What’s in your water? If you don’t know the answer, it’s worth finding out before mixing your next chemical application.

Softening the Hardness

Think about the soil samples you take and how interpretation of those test results support farm management decisions. The concept applies to testing water quality as well. Farmers can draw valuable insights on hardness, conductivity and bicarbonates.

Water tests calculate hardness with a formula that accounts for the two most common cations, calcium and magnesium (2.497*Ca + 4.118*Mg).

Here’s a couple other contaminant thresholds to consider when interpreting water test results: ➤

Conductivity: Water below 500 microsiemens per centimeter (µS/cm) is likely safe to use as a spray carrier. Values above 1,000 µS/cm require further investigation into the cause.

Bicarbonates: The typical threshold level is 500 ppm that may require a UAN or 28-0-0 liquid fertilizer additive to reduce the impact bicarbonates have allowing weed root development.

Sourcing treated water from a municipality or offsetting the use of poor quality water with a higher volume of herbicides are options. But they aren’t always the most convenient or practical.

A water softener can mitigate hardness by reducing magnesium and calcium that bond with and minimize the effectiveness of glyphosate. But Wolf notes that softeners tend to utilize sodium, which also curbs the efficacy of glyphosate.

“Basically, these systems swap out magnesium and calcium and replace them with sodium from the sodium chloride that needs to periodically be added,” Wolf says. “Although that softens water, sodium is still a slight antagonist for sprays and the approach alone is not practical.”

A popular complementary or stand-alone approach to treating water hardness is mixing ammonium sulfate (AMS)

prior to adding the herbicide to the sprayer tank. The additive can help neutralize the hard water cations that impact herbicide performance.

“We match the amount of AMS to the ppm of the various antagonizing cations. This approach prescribes a certain amount of AMS, even if the hardness is quite low,” says Wolf. “There are different spray grade AMS adjuvants farmers can purchase. It’s affordable and effective, but depending on the severity of the problem, 10-20 pounds of dry AMS per 100 gallons of water in a 1,000 gallon tank can add up.”

“Be conscious of lowering pH through acidification because it will affect the solubility of some herbicides and render the tank mix unusable or lead to clogging issues,” Wolf says.

Water pH can also impact the effectiveness of pesticides the longer they sit in the spray tank. A chemical process, known as hydrolysis, can break down chemicals in a matter of hours and dramatically reduce the efficacy of an application, according to analysis by the University of Purdue Extension.

While manufacturers formulate products to retain effectiveness in slightly acidic water for up to 24 hours, all pesticides are not created equal. The number of hours or days it takes active ingredients in a product to lose potency in water can vary, with pH playing a significant role.

Airworthiness Directive Issued for GE Turboprop Engines

The FAA is adopting a new airworthiness directive (AD) for all GE Aviation Czech s.r.o. (GEAC) (type certificate previously held by WALTER Engines a.s., Walter a.s., and MOTORLET a.s.) Model M601E–11AS, M601E–11S, H75–100, H80–100, and H85–100 engines. This AD is prompted by reports of multiple failures of the needle bearing installed in propeller governors having part numbers (P/Ns) P–W11–1 or P–W11–2, caused by self-generated debris from the

needle bearing, which led to oil contamination. This AD requires the replacement of the affected propeller governors with a redesigned propeller governor and prohibits the installation of the affected propeller governors, as specified in a European Union Aviation Safety Agency (EASA) AD, which is incorporated by reference (IBR). The FAA is issuing this AD to address the unsafe condition on these products. Read the entire AD by scanning the QR code below.

DWA Could Have Changed the Future

Bringing aerial application up-to-date

by Curtis Farnham

by Curtis Farnham

WICHITA, KS – Let’s face it. The world economy is in a slump. Retailers report slow sales. The aviation industry has slowed or stopped production. Aerial applicators struggle to stay out of the red. Just about every industry is feeling the pinch. Is a solution in sight?

Kenneth Razak, president of Razak Engineering, Inc, prefers not to think about it that way. Speaking of his

30-year experience teaching engineering, he writes, “Ordinarily we think of ‘problems’ and seek ‘solutions”. What we should do is say that there are ‘situations’ and we seek ‘options’. Razak has put his premise to work. He has analyzed the aerial application situation and has tabulated options for action. It started in the late 1950s. Razak was then a consultant to Cessna Aircraft Company and was commissioned in September 1958 to study the aerial application industry. He was to report to Cessna on the economic potential of developing and building an ag-plane. ➤

His first step was to analyze all phases of aerial application in agriculture. The goal was to find basic factors and parameters that affected agricultural use of aerial application. Among his findings, three items stood out.

(1) Aerial application was limited to crops that had a field value (in 1960) of at least $100 per acre.

(2) The maximum rate of ejection of material from airplanes in use at that time was about 20 pounds per second.

(3) Ag airplanes were inefficient high-drag machines. The first factor formed a lower limit to crops that could justify aerial application. The second factor eliminated crops that required high rates of fertilizer or liquid application. The third factor limited profits of aerial applicators.

Razak studied the effects of these and other factors by using an operations analysis approach. He wrote a complex computer program that “flew” airplanes through every step of an aerial application mission. He found that by increasing the possible rate of material ejection and by increasing

aerodynamic efficiency, the profit making potential was substantially increased.

This defined the situation. Options were to design a new type of wing and make ag airplanes more efficient.

Razak approached the University of California at Davis where professors Norman Akesson and Wesley Yates had long worked on ag aviation topics. He proposed an approach to a new wing design. They considered it had enough potential to justify initial tests on a semi-span wing. These tests proved his theory and Razak outlined an airplane that included these features. This was the Distributor Wing Airplane (DWA).

Razak submitted his report to Cessna and described four options.

(1) Do nothing. Let ag operators use current production airplanes of 170s, 172s and 180s and hang distributing equipment on them.

(2) Equip current airplanes with features that would make it easier to hang distributing equipment on existing airplanes. ➤

Family Owned /Operated Celebrating Our 53rd Year of Service!

Chester Roberts Supply Company

Overhauled Radial Aircraft Engines - Propellers

Pratt & Whitney and Curtiss Wright Engines and Parts

Carburetors - Magnetos - Alternators - Accessories

Overhauled engines in stock

Top Quality Engines / Props

Tel: 903-429-6805

Fax: 903-429-6047

crs5r@crsaviation.com

661 Pearce St. Collinsville, TX 76233

Lane Aviation is your North American Micronair dealer, providing proven technology that is used in over a hundred countries across the globe. The Micronair family of products are tailored to meet the varying needs of specific industries which include aerial spraying, horticulture and viticulture, agriculture, animal and public health, forestry and migrant pest control.

(3) Design an “on purpose” airplane using existing manufacturing procedures to produce a ‘new’ airplane that could be called an ag airplane.

(4) Design and build a prototype of the DWA.

Cessna chose the third option and built the AgWagon 230 and the AgTruck 300. These airplanes were in production for several years. They were useful machines but neither of them addressed the basic factors that Razak had defined in his analysis.

Cessna released the Distributor Wing principle to Razak and he arranged to conduct further tests at the University of California. A full scale semi-span wing was built and tested. These tests expanded and corroborated initial tests and provided airplane design data. In January 1964, Razak and company negotiated a contract with International Minerals and Chemical Company (IMC) to build N361DW, the first prototype DWA. Its first flight was in January 1965 and was followed by a successful round of flight testing. These flights

further verified the principles and showed that the Distributor Wing approach was practical.

The unique feature of the DWA is a fan that continuously blows air out of a slot ahead of the flap. The air passes over the flaps and gives the plane distinct performance advantages. For aerial applicator planes there is a further advantage. The blowing system functions as a built-in spreader. The air transports material from the hopper through the wings and discharges it from the slot.

Sadly, the fertilizer industry collapsed the same year. The sale price of fertilizer dropped by 50%. IMC was encountering very high costs to develop a new potash mine and was forced to cancel its financial backing for many projects. One of these was the DWA. The project was set aside late in 1965.

The Distributor Wing Airplane is based on a fundamental aircraft design concept. Airplanes must be designed for the missions they are to fly. Existing airplanes were adapted for

the purpose of aerial application; they weren’t designed for the mission. From the very first, spreaders and sprayers were hung outside the airplane. The Stearman is the classic example. This was a high drag, low-power airplane to start with. Adding spreaders and spray booms, plus increasing the payload, made it necessary to use bigger engines. Bigger engines were also required to attain higher ejection rates and wider swaths. But bigger engines cost more money, they are more expensive to overhaul, and they have higher maintenance and fuel costs.

This power race was necessary at first, because the aerial application industry was not big enough for a manufacturer to justify development of a completely new airplane. However, when specialized aerial application planes became available, the legacy continued. Spreaders and sprayers continued to be hung on airplanes, the airplanes still were high drag machines, and bigger and still bigger engines were required. The DWA breaks this cycle. By incorporating a blowing system and using the wing as a built-in spreader, there is no need for externally hung equipment. Profitability increases because the plane has substantially less drag and therefore needs less power.

In 1999, Razak renewed his activities in airplane design. He laid out low-drag configuration with the built-in spreader of the Distributor Wing. He also incorporated new technology. The result is the “DWA Mark X”. To verify its performance, Razak has rewritten his operations analysis program and is offering it to the aerial application industry. More details will be forthcoming in a future editon of AgAir Update. Operators are invited to submit data on (1) their current airplanes, (2) missions they are now flying and (3) missions they would like to fly. These data will be used to compute the earning power of existing airplanes and compare with his new DWA.

Razak’s next move will depend on the results of the operations analysis. If the results show a clear improvement in earning power and the ability to open new markets, Razak says that he will be in touch with major fertilizer and ag chemical companies to determine their interest in assisting with the development of the new model of the Distributor Wing Airplane.

Curtis Farnham is a senior in aerospace engineering at Wichita State University. He has been a Cooperative Education student at NASA Houston for three semesters and now works part-time for Razak Engineering while planning his future career.

What is in a Warranty?

Many things in life come with a warranty, but you can be disappointed and infuriated if you don’t read the terms and conditions or understand them. Hopefully, the Ag engine warranty that Pratt and Whitney Canada provide is clear to you. Let’s ensure that you are getting the most out of the warranty provided to you.

The basic warranty. Pratt & Whitney Canada has a two-part warranty coverage in their enhanced warranty for Ag engines. Just for your information, military-use engines have different warranties. For older Ag engines, the warranty period is the first 1000 engine operating hours from the date of engine shipment. For newer Ag engines, based on the serial number, the warranty period is 2500 operating hours or five years, whichever occurs first. After five years, if TTSN is below 1,000 hours, a basic warranty will still apply up to 1,000 hours. P&WC warrants that the new engine will be free from material and/or manufacturing workmanship defects. The warranty defines a defect as a part’s breakage or failure as determined by P&WC caused by a material defect or manufacturing workmanship. You need to check the warranty coverage information for your coverage and other exclusions.

Alongside this basic warranty exists some additional warranties provided to you—the Primary Parts Service Policy or PPSP and the Extended Engine Service Policy or EESP. The PPSP includes support for a specific group of parts. This coverage extends beyond the 2500 warranty, sometimes to TBO or even 5000 hours. The group of parts is listed in the warranty documentation. This is pro-rated coverage, and the list includes a formula for determining available coverage. If the primary part affected is repaired during the process, it will continue its class life. If the part is replaced with a new one, the primary part warranty starts at zero. This has the potential to be a huge benefit that not many people are aware of.

The EESP or Extended Engine Service Policy was brought about by an engine suffering extensive damage from a warrantable, chargeable event. The P&WC warranty administrator may determine that a premature overhaul is required. If this happens, you may receive a LCO or Limited Cost Overhaul. The other thing that could happen is a like value engine exchange. This coverage is again based on hours and cycles consumed. ➤

Items like engine age, environmental, operational, and maintenance conditions may also be viewed to determine coverage. We have had several engines that have fallen into this coverage. You might be surprised at the level of support P&WC can provide.

P&WC also provides Commercial Support Programs Notices or CSPNs for some events. There are program notices for various parts, for example, an inspection of some fuel nozzle tips and replacing some gear sets in the reduction gearbox. A wide variety of items have been identified as requiring commercial support. P&WC has also provided coverage for the power turbine blade replacement at 5000 hours on the PT6A-67AG through a CSPN. If you are unaware of this coverage, the blades can be replaced at 50% off the list through commercial support coverage. Questions about commercial support? Time to ask them.

Now, let’s review what is not covered. As with every warranty, some things fall into this category. Routine line maintenance and adjustment costs, including other standard maintenance items, are not covered. Engine overhaul or major refurbishment costs are not covered. Hot section inspections and refurbishment costs associated with hot section inspections are not covered. This doesn’t mean that if a part in a hot section prematurely needs repair, it isn’t covered. More times than I can count, P&WC has covered components in a hot section by covering repair costs or replacing them. Items like seal rings or segments are not typically covered; their replacement is normally as a refurbishment to reestablish proper sealing or clearances. This also falls into the category of normal wear, tear and deterioration. P&WC also reserves the right to exclude warranty coverage if other than original or authorized parts are used. Parts used in your engine must have traceability or certification, including filters. If parts have been involved in a previous accident or are not repaired in accordance with P&WC approved process, it can also lead to exclusion. Another group of factors beyond P&WC’s control is listed in the literature, and I strongly recommend reviewing those. If you need a copy of the warranty program, contact your field service manager, or we can help.

Your responsibilities are simple. Operate and maintain your engine in accordance with written instructions, including the maintenance manuals and service bulletins. For instance, document the results of your borescopes when you do your fuel nozzle maintenance. P&WC has asked me for this data before asking for warranty consideration on a hot-section project. This brings me to my next point. Keep adequate maintenance records. You may be requested to provide this data to the warranty administrator. Claims must be made

within 30 days of discovery, and claims must be submitted within 180 days. Claims must include the defective part and must be made through a designated facility or distributor. This is where repair or replacement parts must be procured. If you have a warranty issue, please get in touch with your Pratt & Whitney Canada Field Service Manager. That is the place to begin. Send the engine for repair to an authorized facility, such as Covington Aircraft. For more help, feel free to reach out, and I can help you through the process.

Robert Craymer has worked on PT6A engines and PT6Apowered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and has been an instructor of PT6A Maintenance and Familiarization courses for pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member. Robert can be reached at robertc@ covingtonaircraft.com or 662-910-9899. Visit us at covingtonaircraft.com.

SPREADING THE FACTS

Michelle Miller - michelle@thefarmbabe.com

Conspiracy Theorists

Who are “They?”

The other day I took a flight from the US to Canada and noticed that not everyone was wearing a mask. And I thought, how cool is that? Scientists worked so hard to get us a vaccine so our lives could return to normal. For the first time, I didn’t have to think about whether or not I needed a vaccine, mask or a negative Covid test. I just…flew.

Scientists and farmers have much in common: they’re both very underappreciated. The anti-GMO and anti-vaccine crowd have many similarities but are both very misunderstood sectors. But god bless the scientists; where would our lives be without these scientific advancements?

The anti-vax and anti-GMO crowds usually have something in common: they don’t like/trust big corporations or the government. And in a sense, they bring a good point. Often people fear or don’t trust what they don’t understand,

and big corporations and government are not always at the forefront of people we meet on the street every day. How many people know a scientist? The first time I met someone who worked for the FDA, I looked at them like they were a foreign alien, like… these people EXIST?? Ha. Vaccine and GMO scientists are not people you usually meet every day. Many people don’t know that being a plant breeder is a career. They’re like the “Wizard of Oz: ‘Pay no attention to that man behind the curtain!”

So, if they believe corporations are untrustworthy or are “out to get us,” how can we trust anything? The “organic” food label is still overseen by the big government they rail against and is usually owned by the same giant corporations they don’t like.

This is when I put the communication back on them. ➤

“THEY”

When people say things like… “I don’t trust GMOs. I only buy organic and nonGMO,” I reply, “Well, that’s what they want! The big corporations want you to pay more for non-GMO and Organic; they want you to pay three times more for your groceries!” Let us not forget that “natural and organic” is a $350 billion business.

The Non-GMO project is also a multibillion dollar brand. Think about it. It’s what “they” want you to believe.

The people making money off the antivaccine and antiGMO movements are doing just that: selling products and making a profit off of fear-based marketing disinformation campaigns. Don’t get me wrong- I respect people’s right to choose regarding food and medicine. When it comes to medicine, there is no shortage of side effects that can often mess with people’s bodies worse than their original problem; that’s well documented. But we should be thankful for the amazing scientists that have made it possible for us to move past the COVID-19 pandemic, mask and fear-free nowadays for a majority. It’s far too well documented to know that vaccines work, and our lives have leveled back out to a decent sense of normalcy.

Conspiracy theorists don’t trust the government and likely think they’re lying and lazy. But if COVID-19 was just a conspiracy, do we believe the government would go through the trouble to stop the entire global economy, pay billions of dollars to people with unemployment programs, and send out billions of vaccines FOR FREE to the general public? Of course not! They didn’t roll

out this program and put the world at a standstill for fun. “The government is lazy,” according to the conspiracy theorists, right? The scientific community wouldn’t just do this to do it. Deaths and illnesses have decreased tenfold since the vaccine was introduced.

Have you ever put fifteen people in a room together and tried to have them all keep a secret? That is not going to happen. So no, the government is not in a big “Illuminati lizard people” and “what they want you to think” conspiracy. Who are “they?”

“They” are real people. “They” are scientists. They are people who care. They’re parents, friends, experts, doctors, brothers and sisters, researchers and more. They are agronomists, plant pathologists, immunologists, epidemiologists, and toxicologists; the list goes on. And as with everything in life, we must go to the source.

We go to our dentists for our teeth, our car manufacturers for our cars, we go to Apple for our iPhones. So doesn’t it make sense to ask real GMO and vaccine scientists about GMOs and vaccines, etc? At least keep an open mind and hear what they have to say. The experts are real, and they can usually be found on LinkedIn or Twitter, ready to answer your questions to set the record straight and help you feel more comfortable in this crazy world.

The next time someone says, “Do your research,” remember that a Google search isn’t research. Researchers do research. And it’s time to give them the respect they deserve.

“

“They” are real people. “They” are scientists. They are people who care. They’re parents, friends, experts, doctors, brothers and sisters, researchers and more.

The Storm Shield™ is the latest advancement in bird/drone strike protection technology for general aviation. The Storm Shield™ is:

• 8 Times Stronger than Factory (OEM) Air Tractor Windshield. Impact tested at National Institute for Aviation Research (NIAR) lab at Wichita State University

• Scratch Resistant with Greater Clarity

• Advancing Safety for the Aviation Industry

• Available for all Air Tractor and Thrush models (Center Windshield)

bluestripdistributing@live.com

International 559-925-5025

Toll Free 877-924-5025

Products for the Agricultural Aviation Industry

HOT STUFF AG AIRCRAFT CLEANER

A triple concentrated ag aircraft cleaner that may be used in steam cleaners, hot or cold washers, foamed on, or applied with a mop or brush. Removes exhaust and chemical stains, even those with a vegetable oil base. Shipped in 5 gallon quantities. One gallon of the triple concentrate with 4 gallons of your water makes 5 gallons of concentrate, which can be further diluted. Used by more than 400 ag aircraft operators.

FORMULA 641 DEGREASER

Triple Concentrate B0010 B0009

A trend setting formula that keeps pace with today’s safety and environmental regulations. Powerful natural degreasers and deodorizers are specially blended to outperform the conventional hazardous solvent degreasers. This multi-purpose concentrate instantly emulsifies grease and oils without the use of harsh acids, alkalise, or petroleum products. This product is ideal for degreasing concrete floors, equipment, trucks, motors, and metal surfaces including radial engines.

Fog or Fires – Avoid Inadvertent Instrument Meteorological Conditions No Matter the Causes

via NAAA's FlySafe Campaign

Pressure to get work done can lead pilots to make decisions that compromise their personal minimums and reduce safety margins. Taking off for a job before foggy weather has fully cleared up is unfortunately a common example of this behavior. Smoke from Canadian wildfires has also become a serious visibility concern this season as large-scale weather patterns move the smoke from Canada down to the Midwest, southeast, and east coast in the U.S. Whether it’s fog or smoke, flying into a situation where you lose visibility is called inadvertent instrument meteorological conditions (IIMC) and should be completely avoided by waiting until conditions for flying have improved.

Use every forecasting tool available to you to determine if it’s safe for you to fly. The Helicopter Emergency Medical Services (HEMS) Weather Tool is designed to provide weather information specifically for short distance and low-altitude flights. Fire and smoke

information can be found on the AirNow Fire and Smoke Map. Set your personal minimums and don’t ever deviate from them, no matter how much pressure is placed on you to fly. For the helicopter air ambulance (HAA) industry, the weather minimums for dispatch are 2 miles of visibility and an 800-foot ceiling. Keep in mind these minimums are for instrument rated pilots flying an aircraft with the proper instruments.

Also important are en route decision triggers – a predetermined set of flight conditions to prevent you from continuing a flight into IMC. If you go IIMC without the correct instruments, most critical being an attitude indicator, and proficiency with them, you will not be able to maintain control of your aircraft. Once you lose visibility, visual and vestibular illusions quickly cause spatial disorientation. Studies have put the time before you have an accident at between 56 and 178 seconds. For ag aviation, IIMC accidents are fatal 92% of the time.

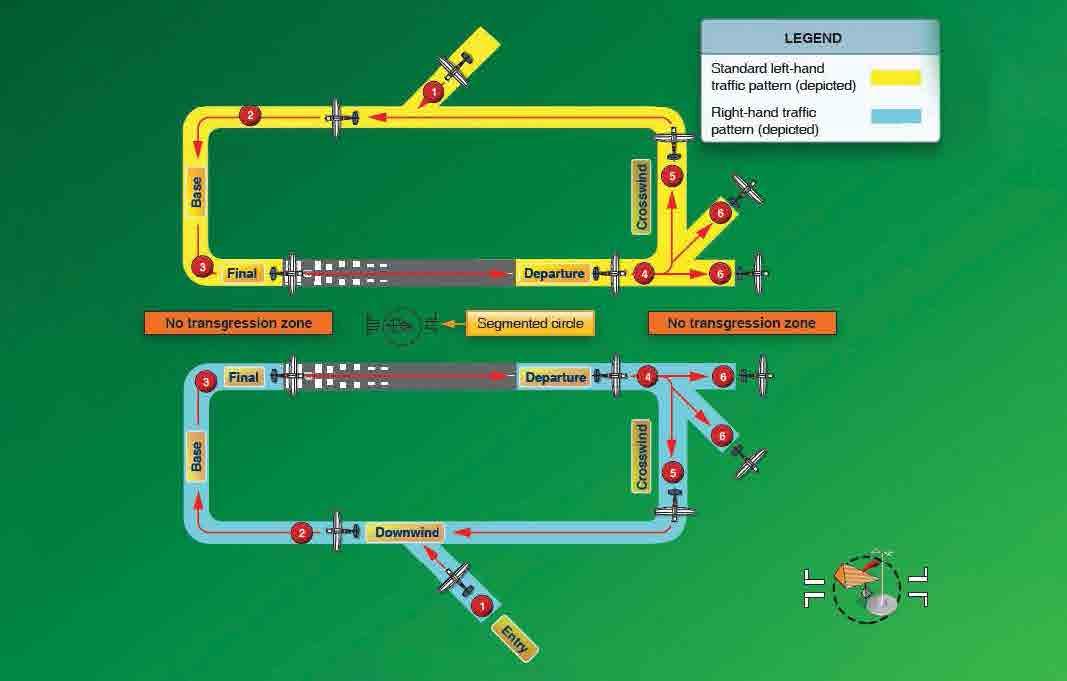

FAA Releases Updated Advisory Circular on Non-Towered Airport Operations

Airport operators play a crucial role in maintaining safety at non-towered airports, and the circular offers guidance on managing these facilities effectively.

The Federal Aviation Administration (FAA) has recently issued an updated advisory circular providing comprehensive guidelines for non-towered airport operations. The circular, which aims to enhance safety and efficiency at these airports, offers valuable information and recommendations for pilots, air traffic controllers, and airport operators.

In response to the increasing number of nontowered airports across the country, the FAA recognizes the importance of clear procedures and effective communication to ensure smooth operations. The advisory circular, AC 9066B, replaces its predecessor AC 90-66A and incorporates updated best practices and technological advancements in the aviation industry.

One of the key focuses of the circular is to promote effective communication between pilots and air traffic controllers. It emphasizes the significance of using standard phraseology, maintaining situational awareness, and utilizing appropriate frequencies to ensure smooth coordination. Pilots are encouraged to be vigilant and actively listen to radio communications, especially when operating in busy airspace.

The updated guidelines also address various aspects of non-towered airport operations, including traffic patterns, collision avoidance, and aircraft separation. The circular provides recommendations for pilots to maintain a safe distance from other aircraft, prioritize collision avoidance procedures, and adapt to the specific traffic patterns of each airport. Furthermore, it emphasizes the importance

of visual scanning techniques to mitigate the risk of mid-air collisions.

Airport operators play a crucial role in maintaining safety at non-towered airports, and the circular offers guidance on managing these facilities effectively. It covers topics such as lighting, signage, marking, and runway maintenance to ensure compliance with industry standards. By implementing these measures, airport operators can enhance visibility and provide clear guidance to pilots during takeoff, landing, and taxiing.

Additionally, the circular highlights the benefits of technology in non-towered airport operations. It discusses the use of Automated Weather Observation Systems (AWOS) and Remote Communications Outlets (RCO) to provide pilots with real-time weather information and efficient communication channels. The FAA encourages pilots and operators to leverage these technological advancements to enhance safety and situational awareness.

The release of this updated advisory circular demonstrates the FAA's commitment to promoting safety and efficiency at non-towered airports. By following the recommended practices outlined in AC 90-66B, pilots, air traffic controllers, and airport operators can collaborate effectively to mitigate risks and ensure smooth operations. The circular serves as a valuable resource for the aviation community, offering comprehensive guidelines that align with current industry standards and advancements.

As the aviation landscape continues to evolve, the FAA remains dedicated to providing up-to-date guidance and fostering a culture of safety. The updated advisory circular serves as a testament to the agency's ongoing efforts to adapt to changing needs and promote safe operations at nontowered airports across the United States.

A link to the updated Advisory Circular can be found at the FAA's website or by scanning the QR Code below.

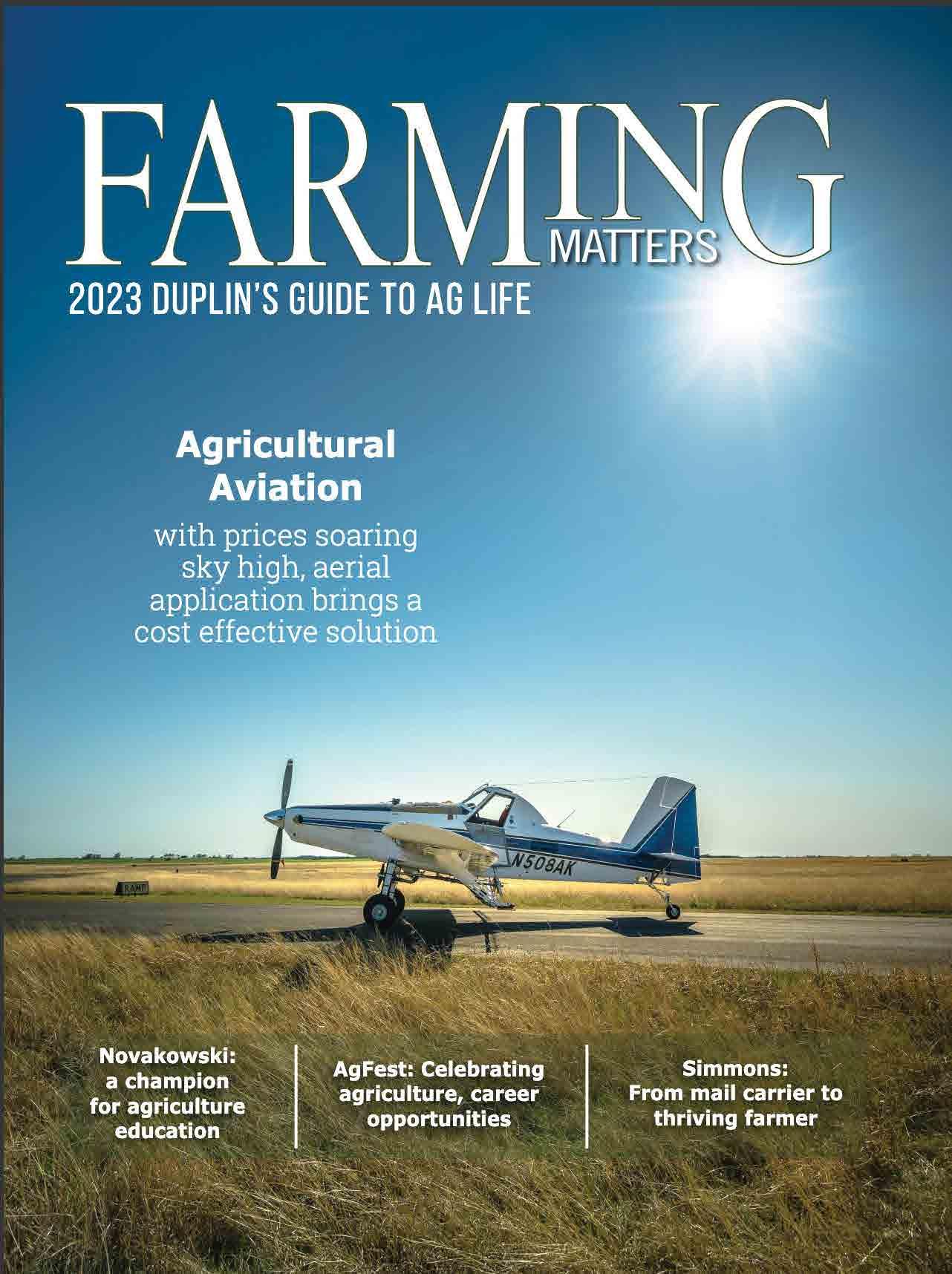

Moore's Aerial Applicators Featured on Two Agricultural Magazine Covers

Mike Rivenbark, the owner and operator of Moore's Aerial Applicators based in North Carolina, recently received the honor of being featured on the cover of two North Carolina publications, bringing positive attention to agricultural aviation and the benefits of aerial crop treatment.

The Summer 2023 issue of Home Grown, an advertising supplement to The Sampson Independent, showcased Moore's Aerial Applicators' ag planes on its cover. Another publication, Farming Matters, based in Dublin County, North Carolina, featured Moore's AT-502XP on its cover as well.

Both articles highlighted the significance of agricultural aviation and the advantages of aerial application in crop treatment. In Farming Matters, Rivenbark and his company were featured under the headline "Agricultural Aviation technology: When timing and cost are of the essence."

Meanwhile, Home Grown titled their article "Agricultural from the air: Moore’s Aerial Applicators of Clinton treats crops from up top."

Based in eastern North Carolina, Moore's Aerial Applicators serves a range of farms, from small to large, covering areas

as small as three acres and as extensive as 3,000 acres in a single job. Blueberries are among their main crops, with approximately 5,000 acres of blueberries treated seven times a year. Moreover, Rivenbark extends his services to Nebraska during summer, covering around 20,000 acres in a two-week span using his AT-502XP. Larger planes like the 502XP can cover an average of 150 to 200 acres per hour, while smaller agricultural planes manage around 75 to 100 acres per hour.

Rivenbark's dedication goes beyond aerial application; he actively educates farmers and residents about the benefits and professionalism of ag pilots. This is especially important in rural areas like Duplin County, where not everyone fully understands the work of aerial applicators. Rivenbark took the initiative to explain to a concerned resident, who wrongly assumed that the spraying had damaged her bushes, that his treatments were safe and

wouldn't cause such harm. He used the opportunity to educate others by seeking permission to post the explanatory video on social media.

Moore's Aerial Applicators was featured in the November 2020 issue of AgAir Update. Read the article by scanning the QR code below:

Crop Duster Pete, a Children's Book that Captures Daily Ag Aviation

The story revolves around Pete, a humble crop duster and his day-to-day operations in an agricultural spraying service.

by Graham LavenderCrop Duster Pete, written by Peter Schellenberger, takes young readers on an enchanting journey through the skies in a tale filled with the daily routine of agricultural aviation. This delightful 22page children's book will surely capture young readers' imagination and leave them yearning for more.

The story revolves around Pete, a humble crop duster and his day-to-day operations in an agricultural spraying service. From the very beginning of the day, Schellenberger captures children’s imaginations as they load the aircraft, taxi, find the field and apply the product.

The book concludes with the standard end-of-workday chores for any operator and brings the children along to see what a busy day is like in the lives of an ag pilot.

The writing style employed by Peter Schellenberger is simple yet captivating for the child’s mind, making it perfect for young readers. The story flows smoothly, effortlessly drawing readers into Pete's world. Schellenberger skillfully weaves in descriptive language, painting vivid pictures of the countryside and the exhilarating experience of flying through the air. Accompanying the charming narrative are beautifully illustrated pages that add to the storyline.

Crop Duster Pete is published by Christian Faith Publishing, available in both digital and paperback formats.

REGINA’S PERSPECTIVE

Recently my husband had knee replacement surgery and said it was the most painful thing he’s ever been through. It hurt me to see what he was going through. After going through so much severe pain, he had a light stroke. This resulted in him getting detailed scanning which revealed that he was a “very sick man,” according to the cardiologist.

This was unexpected because we both walk around the farm, eat healthy and try to live a healthy lifestyle. He never experienced chest pains or typical symptoms of heart issues. However, sometimes genetics plays a role as well. One thing is for sure it has been an eye-opening experience for both of us.

He had a six-hour surgery, and the Dr. told me to say goodnight, go home and let him sleep. He had to have a quadruple bypass, and I was thankful they got him up the following day. After a week, we came home, and I learned how to be a caretaker. Helping him get dressed, doing anything that required lifting and going to Dr. appointments. Amazingly I have such a good team at the office. They were

my backup plan. However, thanks to online technology, I could still work when I needed to get on a computer.