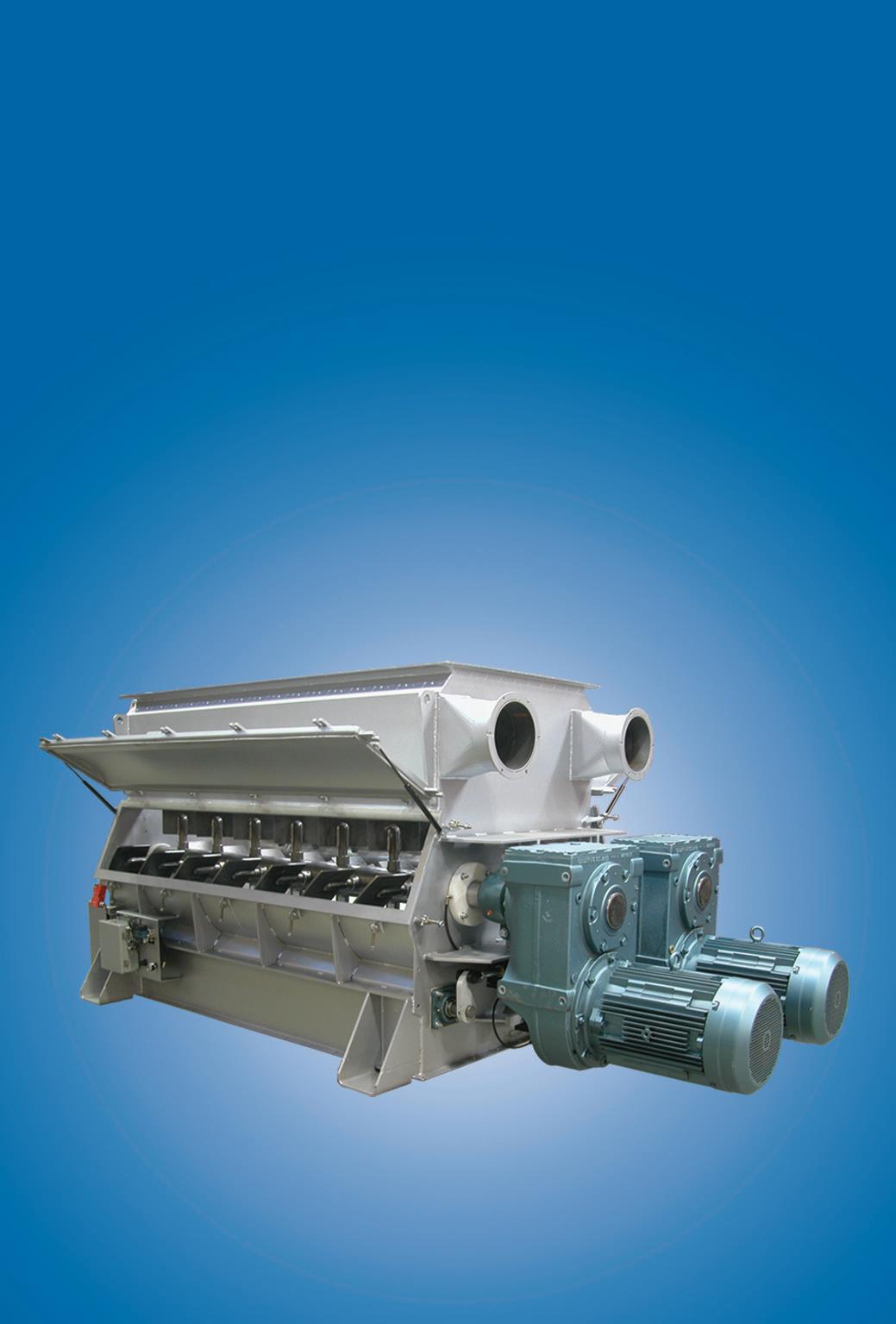

Move your dry granular materials gently, reliably and with significant reductions in product degradation and/or system wear.

Dynamic Air dense phase pneumatic conveying systems have been proven in over 15,000 installations worldwide. They handle a wide range of materials and bulk densities at rates from less than a hundred kilograms per hour to 400 tonnes per hour, over distances exceeding 1500 metres.

Each Dynamic Air system is custom designed from one of our sixteen different conveying concepts. So you get a conveying solution that fits your process perfectly, without compromises.

Our high material-to-air ratios reduce energy and compressed air requirements. Our low conveying velocities provide significant process savings in both operation and maintenance. Initial cost is surprisingly affordable too, thanks to our modular design concept and ease of installation.

Dynamic Air Ltd. Milton Keynes United Kingdom

Phone: +44 (0) 1908 622344 E-mail: sales@dynamicair.co.uk www.dynamicair.com

Sales Director: James Scrivens Production: Sarah Daviner Accounts Manager: Avery Hudson Office Manager: Katie Brehm

BULK SOLIDS TODAY is published 6 times a year by Abbey Publishing Ltd

Please contact us at: Tel: 01933 316931 Email: editorial@bulksolidstoday.co.uk advertising@bulksolidstoday. co.uk Web: www.bulksolidstoday.co.uk Twitter: www.twitter.com/ BulkSolidsToday

To receive a copy free of charge, please send your details to subs@bulksolidstoday.co.uk

No part of this publication may be reproduced by any means without prior permission from the publishers. The publishers do not accept any responsibility for, or necessarily agree with, any views expressed in articles, letters or supplied advertisements.

ISSN: 1365/7119

All contents © Abbey Publishing Ltd 2017

www.bulksolidstoday.co.uk

Dynamic Air BulkBuster bulk bag unloaders provide the solution for effectively emptying large bulk bags and getting the material where you want it in your process. Safety is always a primary concern when handling and maneuvering extremely heavy and cumbersome bulk bags. Dynamic Air takes every precaution to ensure a safe and dust-free operation. A heavyduty framework provides the ultimate in stability and operator safety. Operator efficiency is also maximized due to the simplicity of our designs and ease of operation when lifting, positioning and emptying every bulk bag. Every material has different handling characteristics. Some materials gravity feed easily, but most do not. That is why all bulk bag unloaders need to be engineered for your material. Our many styles and proven designs give us a big advantage in meeting your special process requirements. https://www.dynamicair. com/products/bagunloaders. html

Dynamic Air Ltd Milton Keynes, United Kingdom + 44 1908 622344 E-mail: sales@dynamicair. co.uk www.dynamicair.com

Bulk Solids Today is the bi-monthly digital journal covering the storage, processing and handling of materials ranging from fine powders to the heaviest raw materials. To subscribe to Bulk Solids Today magazine or for more information, please feel free to visit www.bulksolidstoday.co.uk

Trelleborg Marine and Infrastructure launches its latest fixed-installed piloting unit, SafePilot P3, developed in response to the recent advisory issued by the Panama Canal Authority (ACP) requiring a new positioning system for Neopanamax vessels beginning in October 2023.

SafePilot P3 from Trelleborg is a highaccuracy navigation solution that provides real-time certified data to and from the pilot’s display, enabling more efficient operations in constrained waterways. The unit features an advanced motion sensor and an exceptionally precise global navigation satellite system (GNSS) that measures the vessel’s movement in three dimensions. It computes the vessel’s position and heading based on dual GNSS antennas and has a built-in backup battery allowing it to function even during power outages.

Richard Hepworth, President of Trelleborg Marine and Infrastructure, said: “Using a novel approach, we developed a solution that makes pilotage much easier in confined waterways. We’re always striving to innovate, and SafePilot P3 reflects that commitment. It integrates seamlessly with Trelleborg’s SafeCaptain App and is the first of its type evaluated and approved by the ACP. An added benefit of this solution is that it is suitable for use globally in all waterways and

ports in conjunction with the SafePilot App.”

The new unit enables the SafePilot application to operate on vessels, providing pilots with access to the most reliable data related to vessel positioning & movement. As a result, it minimizes the time and complexity associated with lengthy pilotage procedures. Aside from improving situational awareness while transiting the canal and approaching the port, the SafePilot P3 enhances communication between the captain, pilot, tug operators, and canal personnel.

The new unit is the latest addition to Trelleborg’s portfolio of SafePilot solutions, which includes advanced portable navigation systems. These systems provide ports with relevant, real-time navigation information, giving pilots greater control, safety, and accuracy during port approach and maneuvers.

Distinguished by their intuitive and easy-to-use nature, all SafePilot solutions

utilize touchscreen technology. The instant zoom function and intelligent chart structure of the SafePilot software improve response and decision-making times. It is an exceptionally user-friendly maritime piloting software designed by a dedicated group of software developers and maritime pilots.

SafePilot is a critical component of SmartPort. SmartPort, by Trelleborg, is a technology platform that connects disparate, data-driven assets to power communication and decision making in the port environment, giving stakeholders a holistic view of operations.

For more information about SafePilot P3, visit: https:// safepilotp3.com/

For more information about Trelleborg Marine and Infrastructure’s products and solutions, visit: https://www. trelleborg.com/en/marineand-infrastructure

Aggregate Industries has announced the appointment of Garrath Lyons as Chief Financial Officer and member of the Executive team. Garrath has been with the business for four years, having previously held the role of Divisional Finance Director with responsibility for the company’s Aggregates and Asphalt divisions. He brings a wealth of experience to the role, having started his career at Deloitte before moving to FTSE 250, global engineering company IMI plc where he held several senior finance leadership roles.

Garrath replaces longstanding Chief Financial Officer John Bowater who has been with the company for 18 years. John will be taking a step back from a full-time role at the end of the year but will continue to work with Aggregate Industries as a strategic advisor to the CEO, working on strategic initiatives.

Dragan Maksimovic, Chief Executive Officer, comments: “John is well respected in the industry having spent 54 years in the heavy building materials sector and has delivered immense value to the business over nearly two decades. John has played an instrumental role over his career, driving the growth of Aggregate Industries through transformational acquisitions and investments in developing our industry leading portfolio of assets.

I am very excited to be able to accelerate our journey with the appointment of Garrath to our executive team. His role will be instrumental in driving our next phase of greengrowth, including strategic

investments in sustainable opportunities, digital transformation and an evolving geographic footprint, ensuring we remain at the heart of UK construction”.

Garrath Lyons comments: “I’m delighted to have this opportunity to help lead the business at this exciting time for the UK construction sector as we focus on continuing our first-class service offering and delivering a more sustainable future.”

Aggregate Industries, part of the Holcim Group, is a leading supplier of sustainable construction materials with over 200 sites

Unlike other valves that seal with friction, Posi-flate’s unique butterfly valve uses an inflatable seat to seal with air pressure. Thus it requires less torque and a smaller actuator, resulting in lower cost. Plus, the seat automatically compensates for wear, providing longer life. Some users have reported over six million cycles and the valves are still going strong.

Tel: +44 (0) 1908 622366 www.posiflate.com

At Plastindia 2023 (February 1-5, 2023, Pragati Maidan, New Delhi, India), Coperion –technology leader in extrusion and compounding, bulk material handling and feeding systems –will present innovative solutions and new developments at Booth 7H-FP-C-3 to greatly increase the efficiency of polyolefin manufacturing and engineering plastics compounding.

Together with machine manufacturer Herbold Meckesheim – recently merged with Coperion – various processes and plant solutions for reclaiming plastics of all kinds will be on display. These complete systems for mechanical and chemical plastics recycling stand out for their high levels of automation, conscientious use of resources, and the extremely high product quality they achieve.

Whether for continuous stabilization, homogenization and pelletizing of LLDPE, HDPE or PP powders, or for concentrating melt solutions, Coperion possesses comprehensive process expertise in polyolefin manufacturing. From handling and feeding

additives to extrusion and devolatilization, pelletizing and conveying, Coperion has successfully implemented countless polyolefin manufacturing plants with the highest throughput rates and very high product quality.

One new Coperion plant concept now allows the energy-efficient incorporation of recyclate into polyolefin production. Conventional polyolefin manufacturing processes using recyclates require three steps: preparation of new material; mechanical recycling with filtration and pelletizing of the waste plastic; and mixing the two product streams. Coperion’s new process solution allows mechanically recycled and filtered melt to be added directly into the extruder where the new material is manufactured. Energy-intensive mixing and melting of the new material stream and PCR compounds are completely eliminated, significantly dropping investment and operating costs.

Another highlight of Coperion’s presence at Plastindia will be the ZXQ 800 rotary valve. Coperion developed this high performance, low gas leakage valve especially for powder intake into pneumatic conveying up to 3.5 bar. With its enormous

capacity, it is optimally suited for high-throughput polyolefin plants.

Along with polyolefin equipment, Coperion will be demonstrating versatile uses of its technologies and process expertise in various compounding tasks at Plastindia 2023 – from filling and reinforcing engineering plastics and masterbatch preparation to bioplastic manufacturing. Compounding with Coperion’s ZSK and STS twin screw extruders, as well as material conveying and feeding, stand out for their very high degree of automation and efficiency. Thanks to its high specific torque of 18 Nm/cm3, the ZSK extruder achieves very high throughput rates with comparatively low energy consumption. Bulk material handling is extremely gentle on product and raw material feeding is highly accurate. Product changes can be accomplished in no time, increasing overall equipment effectiveness (OEE).

Emblematic of its first-class technologies for compounding, Coperion’s ZRD 200 rotary valve for discharge and metering of powders as well as the WZK

100 two-way diverter valve will be on display.

Additionally, the T35/S60 Quick Change (QC) feeder with the 2415 pellet receiver will be available to view. The QC feeder is suited especially for applications requiring maximum flexibility in feeding and material changeover. It allows the feeder unit, including the screws, to be quickly and easily removed and installed. The single screw feeding design handles free flowing powders, granules, pellets and other free flowing materials. The twin screw design is ideal for floodable powders and more difficult, sticky or hardto-flow materials.

With the preconfigured ProRate PLUS feeder in size S, Coperion offers a robustly constructed, continuous gravimetric feeder at a very good price-to-performance ratio, perfect for economical,

reliable feeding of free-flowing bulk materials.

Coperion and Herbold Meckesheim realize entire plants for plastics recycling. From mechanical processing –shredding, washing, separating, drying and agglomerating of plastics – to bulk material handling as well as feeding and extrusion all the way to compounding and pelletizing, their systems cover the entire process chain for reclaiming plastics.

Coperion and Herbold Meckesheim achieve solutions for mechanical recycling of postindustrial and post-consumer waste, chemical recycling, solvent-based recycling, and deodorization, tailored to the type of plastic being recycled. Together, they will be showing

a PET recycling plant simulation at Plastindia, demonstrating their expertise in numerous plastics recycling processes. Booth visitors can look directly into entire process steps and view the construction and functionality of key technologies.

Coperion’s ultramodern Recycling Innovation Center demonstrates the importance of plastics recycling for Coperion. It is currently under construction right next to Coperion’s existing Test Center for bulk material handling at the Niederbiegen/ Weingarten, Germany, production facility. In this new Test Center, dedicated specifically to recycling applications, Coperion will advance its industry-leading research and development in an environment where every major process stage can be tested under production conditions and put through their paces by customers prior to making an investment.

TorqSense, a non-contact digital torque monitoring system that could guarantee an infinite lightness of touch has proven to be the only way to test the seals of super high performance vacuum systems.

The ultimate fields of precision manufacture, such as electronics, biophysics and thin film deposition where tolerances are measured in atoms, are often conducted in hard vacuum to remove airborne contaminants and avoid the performance reducing effects of tiny air movements.

However the vast majority of vacuum chamber designs require seals for rotary drive shafts (called rotary feedthroughs) and ‘feedthroughs’ for the passage of materials, components, tools and finished products. In high vacuum applications conventional seals are unlikely to be able to achieve the performance specifications required, so magnetic fluid seals are used.

A ferrofluid is a stable colloidal suspension of sub-domain magnetic nano particles in a liquid carrier. The particles, which have an average size of about 100Å (10 nm), are coated with a stabilising dispersing agent (surfactant), which prevents particle agglomeration even when a strong magnetic field gradient is applied to the

ferrofluid.

With over thirty years of experience producing seals for the world’s most demanding applications, Ferrotec of Woolwich in London is able to optimise ferrofluid materials for the most extreme performance requirements and incorporate them into bespoke vacuum system designs.

“About half of our work is to bespoke design,” says Jeff Lewcock of Ferrotec, “and we have to test every seal to the nth degree to meet out customers specifications. To test the feedthrough it is mounted onto a vacuum chamber that is connected to a helium leak detector. Helium is then spayed onto the feedthrough and the leak rate observed during static and dynamic running.

As part of the test the starting and running torque of the seal are measured and the power loss through the seal is calculated. These readings allow Ferrotec to troubleshoot the individual seal, analyse the design’s performance and add to Ferrotec’s knowledge base.

“With the sort of tolerances we work to we needed a torque sensor that didn’t add any extra drag to the whole seal mechanism, so we were delighted to discover Sensor Technology’s noncontact TorqSense,” says Jeff.

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our websitewww.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/ Distribution, Recycling & Waste Management and more. www.bulksolidstoday.co.uk bst@abbeypublishing.co.uk

Tuf-Lok ring grip pipe and tube couplings are rugged, heavy duty, self-aligning and self-grounded couplings with a high end pull. They can be used for almost any application where pipe or tube ends need to be connected. The Tuf-Lok self-aligning couplings install quickly and easily with little effort.

Features

Self-grounding

High pressure rated

Full vacuum rated

Stainless or mild steel

Usable on thin or thick wall pipe or tube

Low cost

Reusable

Absorbs vibration

Externally leakproof

Tuf-Lok (UK) Tel: +44 (0) 1706 822512 Email: sales@tuflok.co.uk • www.tuflok.com

Rushlift, the national full-service provider of materials handling equipment (MHE), has secured a major three-year extension to its successful, long-running MHE contract with the UK & Ireland business of international building solutions and materials manufacturer and supplier, Saint-Gobain. At the end of the three-year arrangement Saint-Gobain (UK&I) has the option to further extend the contract by two more years.

The new £45m deal continues an existing 10-year agreement with Rushlift to supply, manage and maintain SaintGobain (UK&I)’s materials handling fleet across its sites including distant locations such as the Shetland Islands, Isle of Man and Jersey. In total over two thousand mixed-fleet assets will continue to be managed by Rushlift across some 850+ manufacturing and merchant sites operated by Saint-Gobain (UK&I) brands such as Jewson, JP Corry, British Gypsum, Rencol, and many more.

As under the existing contract, Rushlift will supply, maintain and support a wide variety of forklift trucks of different manufacture, along with related industrial equipment – from counterbalance trucks, telehandlers, and reach trucks to loading shovels, powered access platforms and floor cleaning equipment. All vehicles will be regularly serviced under a set maintenance regime, with fast breakdown response and support.

Ian Berrill, transport & supply chain solutions director for Saint-Gobain (UK&I) says: “Our customer service performance is absolutely vital to the success of our business and, for us, that means having a forklift truck fleet that we know we can depend upon. We need consistently high standards of maintenance and support across every site we run. Over the last ten years, Rushlift has proved to be a reliable partner, maintaining and upgrading our fleet to match our service SLAs and working closely with us to help achieve our environmental targets. With this contract renewal, we have every confidence that Rushlift will continue to deliver the dedicated service and total support that we need to run our business.”

Tom Welland, account director at Rushlift, commented: “We are delighted that Saint-

Gobain (UK&I) has again recognised Rushlift as the best-value solution provider for their MHE needs. This is a significant endorsement of our continued commitment to driving service improvements, fleet performance and uptime across Saint-Gobain (UK&I)’s materials handling operations. Securing a major extension to one of the largest MHE contracts in the market makes us extremely proud.”

As an experienced supplier of counterbalanced and warehouse forklift trucks, Rushlift is able to source the best-suited industrial equipment for the task by accessing back-toback supply chain agreements procured by Saint-Gobain (UK&I)’s central transport team.

Founded in Bishop Auckland in 1978, Rushlift has grown to become a nationwide materials handling service operation with five sites located across the UK – from Cornwall to Aberdeen, and throughout Ireland – employing over 200 people. The business now offers forklift contract hire, short-term rental, new truck sales, and reconditioned equipment, along with full nationwide service engineering, maintenance and parts support. A separate division, Rushlift GSE, provides ground support equipment, financing and servicing for some of the UK’s largest airlines.

For further information on Rushlift go to https://www.rushlift.co.uk

Briggs Equipment has completed the acquisition of Blulift, one of the Republic of Ireland’s leading regional providers of powered access equipment.

From their site in Co. Limerick, Blulift offers full hire, sales, training and maintenance services for all varieties of specialist access equipment. The acquisition sees Briggs Equipment further strengthen its position as the UK and Ireland’s premier Asset Management and Engineering Services specialist, whilst also demonstrating an ongoing commitment to grow the scope and scale of its powered access offering.

As part of the Briggs Equipment Group, Blulift will benefit from targeted investment and support to help fulfil its potential and continue delivering an outstanding service to a diverse portfolio of customers.

Pete Jones, Briggs Equipment’s Group Managing Director, commented: “This purchase of Blulift is another significant milestone in our acquisition strategy. Throughout the acquisition process, we have been extremely impressed with the business’ positive employee culture and proven track record of long-term success. We are delighted to welcome Blulift into the Briggs family and as part of the Group

we will be providing them with all the support and investment they need to thrive and reach new heights.

“The acquisition also highlights our commitment to bolstering our powered access capability within Ireland and ensuring we can continue to provide the best possible service in what is a key market for us.

John Cusack, Blulift’s Managing Director, commented: “This is a really exciting day for the Blulift business and our people. We have worked extremely hard over more than two decades to deliver outstanding service to our loyal customers and before entering into any acquisition discussions, we had to ensure that the philosophy and culture that makes Blulift unique would be preserved. With Briggs Equipment we have a parent company that is proven in delivering on their acquisition promises, delivering appropriate investment, support and guidance.

“We could not be more proud of the journey we have been on as a business to get to this point and we can’t wait for the next chapter as part of the Briggs Equipment Group.”

Carbon fibre is noted for its combination of strength and light weight, however, its low bulk density and fibrous particle shape can make it resistant to flow. Careful handling is therefore required to ensure a reliable feed during production. In 2019 electrical power and advanced materials company, Mersen, approached solids handing equipment specialist, Ajax Equipment, to enhance carbon fibre handling from a milling process at its Eurocentral, UK facility near Glasgow.

Even where the general properties of a material are widely known it is valuable to determine the exact behavioural characteristics of the material to be handled. “Milled carbon fibre is quite low bulk density, which is often a concern for flowability, but it is the other bulk properties like shear strength and wall friction against mild steel which need to be measured so that the correct design of storage and feed control can be established,” commented Eddie McGee, managing director, Ajax Equipment.

“With the knowledge obtained from material testing at Ajax, our engineers designed an integrated carbon fibre storage and feed system, formed of a hopper and screw feeder, that would provide a dependable onward supply of material from the line’s rotary valve and vacuum loader above.”

The new hopper’s steep walled vee shape encourages the flow of carbon fibre powder towards its elongated outlet and the screw feeder below. Once out of the hopper, the screw’s progressive geometry, including variable pitch and stepped shaft, ensures a reliable and controlled flow of reworked fibre powder. In addition, the feeder’s cover is hinged to allow Mersen’s manufacturing team to easily retrieve a sample of carbon fibre powder and inspect the machine internally.

Commenting on the line upgrade, Scott Keil, manufacturing manager at Mersen, said “As one of several partners in this project, Ajax were a delight to deal with. They tested our unusual material in their lab to determine its flow characteristics, before designing and supplying the specified

equipment within tight deadlines. They also coordinated and provided technical support to our other partners. In short, we are very pleased with Ajax’s work.”

Following the completion of the rework line upgrade, Ajax was asked to design and supply a carbon fibre handling system for a new line as part of Mersen’s ongoing projects to enhance and expand its production capacity at the same Eurocentral, UK facility. “After the success of working with Ajax to upgrade the existing line we were happy to work with them again on this new line,” said Scott Keil.

Eddie McGee again, “Working on a new line provides the opportunity to design each component of the system together, ensuring efficiency of process and plant configuration. The carbon fibre product behaves very differently to the milled version, it is extremely low density and very fibrous with long thin particle shapes. Flow property tests were performed and informed the design of the storage and transfer system needs for carbon fibre on Mersen’s additional line. Ajax designed a system comprising silo, six screwed feeder, collecting screw conveyor with declumping features and an inclined screw.”

The silo needed vertical walls and was fitted with a six screwed feeder which actively extracts poor flow carbon fibre from the large outlet of the silo above. The integrated design of the feeder and silo means that any arching and hold up of fibre is completely avoided and a positive, regulated feed is consistently achieved. The output is fed into a collecting screw which transfers the product towards the outlet. To ensure the most even of feeds to the onward process the outlet section incorporates blades to comb the fibre through a grille, breaking up any tendency for the fibre to clump and hold together.

The conveyor has outlets at each end so that the existing and a future, planned mill can be served. The conveyor has the declumping feature at each outlet, with supply controlled by which direction the collecting screw is run in. When constructing reversible discharge screws, it is essential to ensure the flights are completely uniform otherwise the screw may compact material when running in one of the directions. The elevator features a long single span screw to avoid any potential blockages, effectively configured for pushing the poor flow fibre up the incline and minimise service needs.

“Commissioning with the new multi-screw system has gone exceptionally well with production totally satisfied that the Ajax feed of product to our mill is

consistent and indeed superior to our original Silo set up,” comments, Scott Keil.

For more information on Ajax’s solids handling equipment, call +44 (0)1204 386723, email sales@ajax.co.uk and www.ajax.co.uk.

Hyster® 8-18 tonne capacity lift trucks include Stage V engines to help businesses comply with emissions legislation while heightening productivity and lowering the Total Cost of Ownership.

The new H8-18XD series of Hyster Big Trucks features Stage V engines and delivers low running costs in terms of fuel and AdBlue® consumption, with no compromise on performance or durability.

“We are constantly evolving our range of Hyster solutions, according to technological developments, changes in legislation, and above all, our customers’ needs,” says Jan-Willem van den Brand, Direct Global Market Development Big Trucks. “Customers can expect high uptime and low TCO (Total Cost of Ownership) in demanding applications where cost pressures are having a big impact.”

Tyre repair and replacement is in fact the second largest cost for most materials handling operations. For this reason, the Hyster trucks feature an adjustable maximum steering angle. This decreases friction when the operator selects the reduced angle, resulting in reduced tyre wear and cost.

“A key way to increase productivity and maximise the profitability of an operation is to prevent downtime for service and maintenance,” says Jan-Willem. “Therefore, improved serviceability is built into the design of all models in the series.”

The service intervals on the new Stage V engine have increased from 500 hours to 1000 hours. In accordance with regulations, the new Hyster trucks use a combination of a Selective Catalytic Reduction (SCR), a Diesel Exhaust Fluid (DEF) like AdBlue® and a Diesel Particulate Filter (DPF). For easy access, both after-treatment units are packed in one box and conveniently positioned on the outside of the truck.

To speed up general maintenance and minimise downtime, the truck series is designed with easy service access, with a display providing key truck performance data and on-board diagnostics on one clear screen.

The Hyster® H8-18XD truck series is available with a variety of wheelbase sizes. Businesses can specify a truck for optimal manoeuvrability in tight spaces, boosting productivity and reducing tyre wear. Where space isn’t an issue, applications can select a model with a larger outer turning radius and lower truck weight to help reduce fuel consumption and costs.

Different truck configurations are available, as well as special engineering options, to accommodate other application-specific requirements, from a reversing fan to improve cooling in dusty paper or construction operations, or different handling attachments to accommodate the load variation encountered in the wood industry.

The truck series also features a redesigned front end and operator-friendly XD cabin, for which the Hyster® H16XD-6 lift truck received a 2020 GOOD DESIGN Award*.

“The cab and front-end design focuses on visibility, ergonomics and comfort to help drive operator productivity throughout an entire shift,” says Jan-Willem. “Not only is a comfortable operator often more productive, but comfort also keeps them happy. This is more important than ever as many markets are encountering a shortage of skills in this area.”

The quiet and comfortable cab has the largest

cabin entry area in the industry making it easy to get on and off, and it is spacious enough to wear a hard hat inside.

The cab’s redesigned mast and carriage creates a wider view for the operator, providing greater visibility of fork tips at ground level and trailer height. Operators of the new Hyster® H8-18XD range benefit from an improved sense of stability thanks to the new cast counterweight. This has shifted the trucks’ centre of gravity downwards and towards the rear, minimising bounce.

“Precision handling of fragile, heavy loads in tight spaces is required throughout applications, such as the chemicals, metals and construction industries. These trucks are sometimes required to work closely alongside materials and workers,” says Jan-Willem. “In these operations, a truck needs to deliver powerful performance, but with accuracy, for maximum productivity and less costly damage to loads.”

“With our new series of 8-18 tonne lift trucks, we have simplified the range, while simultaneously offering more choice to customers in their specific application requirements,” adds Jan-Willem.

For more information visit www.hyster.com.

*https://www.chi-athenaeum.org/aboutgood-design.html

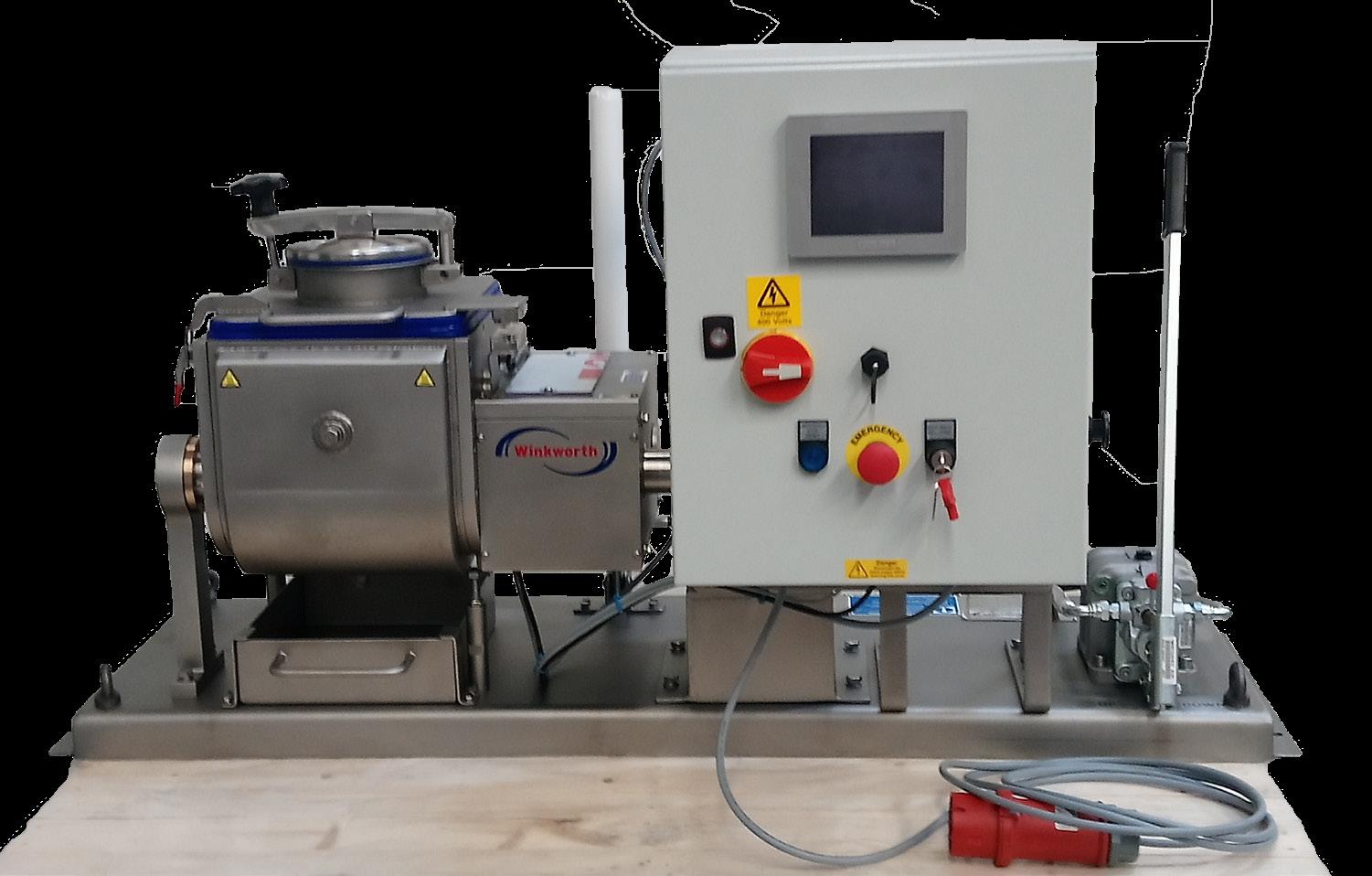

In preparation for the launch of a new protein bar ready-to-mix product, Winkworth, the UK’s leading designer and manufacturer of industrial mixing and blending machinery, has recently worked with a leading whey ingredient supplier to strengthen their capabilities within the category.

With the growth in protein bar retail value expected to double in the coming years to 14% CAGR (2019-2023)¹, the customer needed a pilot size mixer that could conduct trials during their development phase to replicate large scale industrial production methods. The customer’s bakery mixers, used for similar pilots, were not able to mix the dense ingredients of whey protein isolate and dairy proteins sufficiently to be effective. The company required a high torque kneading and folding mixer that could effectively mix 5kg batches.

Winkworth recommended their stainless steel MZ10 high shear mixer, which is ideal for mixing, kneading and blending of dense materials for development. Featuring twin heavy duty Z blades and a manually operated hydraulic tilting mechanism, the 10 litre capacity of Winkworth’s range of laboratory and pilot mixers are small enough to reduce waste, yet large enough to be representative of production reality. This accurate representation of production performance typically provides a scalable outcome prior to full capital investment.

“Throughout this smooth process we had good support from Winkworth - the mixer is ideal for our requirements and is delivering what we hoped for,” commented Winkworth’s customer. “We are frequently showing the mixer to our customers who, like us, are very impressed with its capabilities.”

“The MZ10 is ideal in this case,” added Winkworth’s technical director, Tim Simpson. “Being able to mix small batches means that it is perfect for pilot studies and trials, and with its high torque capability it’s more than capable of mixing dense material. Of course, once the pilot has

successfully concluded, we can provide customers production scale mixers up to 1500 litres batch volumes as required, and larger on request. For the protein/energy bar market specifically, several companies have adopted our larger scale Winkworth Z Blade production mixers, which have proved ideal. ”

Winkworth has been designing and manufacturing world-class industrial mixers, paddle mixers and blenders since 1924. Used for mixing doughs, powders, creams, batters, pastes, sludges, slurries and granules for all industries, Winkworth supply mixing machinery all over the world. Their product range includes: Z Blade, Extruder, Ploughshare, Twin shaft, Ribbon, Double Cone Blenders, Paste Feeders, Process Vessels, Homogenisers and vacuum dryers for use in a wide variety of industries. All their industrial mixers are designed and wholly made in the UK and can be manufactured to suit any ATEX requirements, include CE markings and are manufactured in accordance to their ISO 9001 accreditation.

For further information on Winkworth’s range of laboratory and pilot mixers, or any other product in their portfolio, contact Winkworth on +44 (0)1256 305 600, visit www.mixer.co.uk, or email info@mixer.co.uk.

Kason has upgraded its popular VIBRO-BED fluid bed processor with new features designed to regulate pressure and temperature more efficiently for faster material drying and increased throughput.

Fluid bed processors dry, moisturise, heat or cool bulk material by causing it to vibrate on a screen or perforated surface within a rising column of heated, chilled or moisturised air. In addition to faster drying, Kason’s upgraded controls make it easier for operators with minimal training to run batch or continuous material processing.

“This upgrade makes one of the industry’s most energy- and cost-efficient fluid bed dryers even better,” said Seth Vance, CEO of Advanced Material Processing, Kason’s parent company. “Along with further improving performance to help decrease processing time, the ability to record operational data and troubleshoot issues remotely in real-time helps minimise downtime for an even greater return on investment.”

Kason’s updated VIBRO-BED dryer also offers customers:

An energy-efficient circular design that utilises 100% of surface area to optimise airflow for faster drying, less waste and a more consistent product.

Eight compact models ranging from 610 to 2125 mm (24 to 84 in.) in diameter that provide fast, cost-effective installation and conserve valuable floor space.

A remote control-enabled PLC panel with HMI screen to control temperature and optimise energy use.

Lighter materials and fewer welded seams

to reduce cleaning and maintenance costs. Configurations for scalping, de-dusting, agglomerating or de-agglomerating materials while they are dried, cooled or moisturised to save on the cost of operating separate equipment.

To find out more about Kason’s VIBRO-BED processor, visit https://www.kason.com/fluidbed/

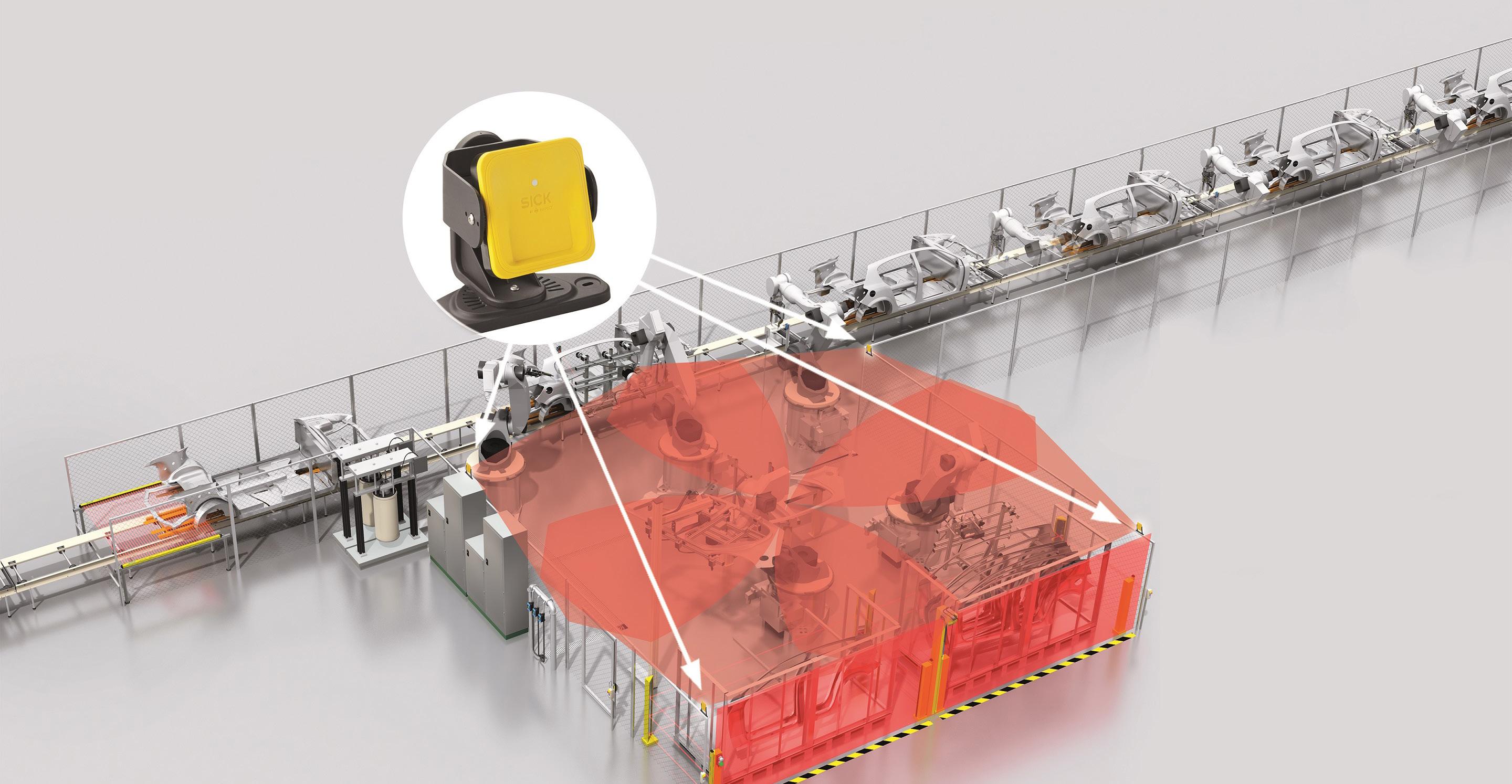

SICK HAS LAUNCHED THE SAFERS3, A NEXT-GENERATION SAFE 3D RADAR SYSTEM DESIGNED TO ENABLE MAXIMUM PRODUCTIVITY WITH HIGHLY-RELIABLE SAFE ACCESS PROTECTION FOR WORKERS IN HAZARDOUS INDUSTRIAL AREAS, INCLUDING ROBOT CELLS. THE ROBUST RADAR DETECTION PRINCIPLE IS IDEAL FOR HEAVY INDUSTRIAL OR HARSH OUTDOOR ENVIRONMENTS, WHICH MAY CHALLENGE CONVENTIONAL OPTICAL DETECTION SYSTEMS.

Incorporating best-in-class safe radar technology, the SICK safeRS3 is an electrosensitive 3D protective device for safe personal detection. With a higher measurement accuracy, it protects personnel in stationary applications to PLd or SIL2 in line with ISO 13849-1 and IEC 62061.

By introducing the safeRS3, SICK has achieved a longer 5m protective field range, with to a 100° opening angle and the ability to set up to four protective fields. A safety-over-networks version has been introduced with PROFINET control for easy integration into a PROFIsafe network.

The safeRS3 extends the versatility of safe radar to more industrial applications. As a category 3 device, the SICK safeRS3 can be used in robotic applications in accordance with ISO 10218-2. With the SICK safeRS3, operators can avoid unnecessary machine downtime while continuing to safeguard personnel. A safe automatic restart function helps to ensure maximum productivity in more complex machine cells, including those with robots. The validation view helps operators to view

where field infringements are in real time, so false trips can be identified quickly.

The SICK safeRS3’s 60GHz radar detection principle ensures it can filter out particles or contamination in dirty or high-humidity conditions. The SICK safeRS3 is not affected by low or bright light. It performs accurately despite dirt, dust clouds, woodchips, plastic particles, flying swarf or sparks or steam, heavy rain or humidity.

Operating at temperatures between -40 °C to +60 °C, the SICK safeRS3 therefore offers reliable protection in heavy industrial facilities including steel production, timber or plastics fabrication or in outdoor environments e.g. where gantry cranes are operating in bulk materials handling facilities, mines or quarries.

Because of its technology and 3D coneshaped coverage, the SICK safeRS3 is ideal for hazardous areas with more complex topography. Steps, platforms, and supports, for example, can cause shadowing effects and could therefore be difficult to cover comprehensively using laser scanners, which detect in 2D planes.

Each SICK safeRS3 radar sensor has an exceptionally rugged IP67 housing and can be configured with up to six sensors. With an adjustable operating range and selectable opening angle, the system is highly adaptable to almost any environment.

With the PROFINET version, a standard Ethernet connection also enables configuration, diagnostics and Modbus integration. Alternatively, customers can purchase an

economical control with local I/O and 2 pairs of OSSDS for configuration and diagnosis via USB-C.

www.sick.co.uk

The Bella dryer/cooler offers thermal efficiencies to 80 percent or better because air flows around material while it is suspended in the weightless zone. The result is a more consistent material.

JJX Logistics has added a striking new IVECO S-WAY 6x2 (AS260S46Y/P) rigid to its fleet to boost its operational capabilities in urban areas.

JJX Logistics is a specialist in time-critical logistics throughout the UK and Europe.

Transporting a wide range of cargos for over 25 years, JJX Logistics is also licensed to carry all nine classes of hazardous materials and is TAPA certified for high-value assets.

With the need to accommodate a wide variety of cargo types in urban areas JJX has specced up and built the ultimate IVECO S-WAY rigid capable of carrying up to 15 tonnes.

It joins a 510hp IVECO S-WAY tractor unit on the fleet which managing director John Joseph Donovan was so impressed with he has ordered a range-topping 570hp model for long-haul routes from the UK to Italy as part of a new international contract.

The IVECO S-WAY 6x2p is equipped with a rear lift axle which reduces tyre wear on return trips and improves manoeuvrability.

Additionally, rear air suspension has been specified which further improves the ride and handling and adds extra peace of mind when the truck is carrying sensitive cargoes. The Driver Comfort Plus package further optimises driver comfort with door roller blinds, automatic air conditioning and high comfort seats.

To ensure the truck is self-sufficient when loading and unloading at customer sites, a Palfinger forklift has been mounted on the rear of the Fred Smith and Son-built curtain-sided body. This companion vehicle can lift up to two tonnes and is able to load and unload cargo from the back of this IVECO S-WAY. A

full Direct Vision system has also been installed to ensure the truck can operate within the busy confines of London.

This IVECO S-WAY rigid is equipped with a 460hp Cursor 11 diesel engine that delivers strong performance and economy with the help of the optional Aero Plus pack that incorporates a roof spoiler and front cab corner fins.

All JJX Logistics trucks can find themselves travelling into Europe at the drop of a hat, so the IVECO S-WAY infotainment system hosting navigation for the whole of Europe, Russia, Turkey, and Ukraine is invaluable.

The distinctive blue and white JJX Logistics livery enhances the design of the IVECO S-WAY. Highlights trim the bold grille, and vibrant splashes of colour follow the natural contours of the Italian-designed bodywork. This stylish livery applied by Baker Ward Stickers Ltd took three weeks to come to fruition, a design that was further enhanced by the addition of a Premium Style Pack which includes aluminium air intakes, a pneumatic horn, an external sun visor, and eye-catching coloured finishes inside the cab.

Commenting on the continued addition of new IVECO S-WAYs onto its fleet managing

director John Joseph Donovan said: “We eagerly awaited the truck to come down the supply chain, but now it’s here we are over the moon with it!”

JJX’s IVECO S-WAY Rigid is expected to cover 80,000 – 100,000 miles each year and represents a key asset for JJX Logistics. www.iveco.com

If you are interested in submitting editorial to Bulk Solids Today magazine, please send your submission through to editorial@bulksolidstoday.co.uk

To subscribe to Bulk Solids Today magazine or for more information, please feel free to visit www.bulksolidstoday.co.uk

One of the important features of the Doosan stand at Bauma is the dedicated Innovation Center, where the company will unveil the new generation XiteCloud ‘All-in-One Platform’ for Smart Construction under the company’s ‘Powered by Innovation’ banner.

In 2019 in South Korea, Doosan introduced Concept-X, the world’s first unmanned automated and integrated control solution for construction, quarrying and mining sites. XiteCloud is the first stage in commercialising Concept-X.

Doosan is committed to producing innovative products and services for its customers and delivering added value through innovation. Visitors to Bauma will be able to see the latest developments in the XiteCloud system, as the company further expands its business portfolio into the field of construction site management, to complement its existing operations in manufacturing and sales of construction equipment.

With XiteCloud, a customer can manage multiple

tasks such as surveys, terrain analysis, machine purchases, equipment operation and construction management on a single platform, thereby reducing construction costs and saving time, while increasing work accuracy, which in turn raises productivity. XiteCloud also allows customers to manage multiple projects on a single platform, accumulating and managing data that can be utilized for future decision making/business.

At Bauma 2022, visitors to the Innovation Center on the Doosan stand will be able to see the new All-in-One Platform for smart construction, based around the Xitecloud system. The All-in-One Platform introduces a range of new solutions that form part of the XiteCloud system all of which will be demonstrated at Bauma, covering many aspects of construction management, including:

XiteCore

XiteFleet

XiteAnalyst

XiteSIM

XiteSafety

XiteAuto

As suggested by its name, XiteCore is a Cloud-based open integrated dashboard system that connects all of the XiteCloud solutions, providing the information needed to carry out a construction project and enables easy project management and control at a glance.

This system provides opportunities for collaboration/communication among project participants with an open platform that adopts an applied card-type interface that allows the user to set the dashboard flexibly according to the particular characteristics of the project (card type, location, size, etc.) It also incorporates realtime monitoring of weather, manpower, equipment, instruments, CCTV and other aspects, together with connection to the other solutions within XiteCloud such as XiteFleet, XiteAnalyst and so on.

In addition to several contracts awarded in South Korea and elsewhere around the world, XiteCloud has gone through an exhaustive technology

verification process at multiple international construction, mining and quarrying sites. Having successfully implemented XiteCloud in its home market and beyond, Doosan is using Bauma 2022 as an important springboard to continue the international launch of the XiteCloud system.

For more on Doosan construction equipment, please visit the website: www.eu.doosanequipment. com