We are a leading provider of custom solutions for the handling of bulk materials for processing businesses across various industries. Dynamic Air has over five decades of expertise in designing and manufacturing pneumatic conveying systems and equipment for handling dry bulk solids.

At Dynamic Air, we set the standard for excellence in bulk solids handling. With a relentless focus on quality, reliability, and customer satisfaction, we deliver reliable, high-quality pneumatic conveying systems, equipment, and custom solutions that exceed expectations. BULKBUSTERTM

We never take a cookie-cutter approach just to cut costs up front; we know that the right solution will save you money in the many years to come. Our tailored solutions involve thoughtful planning, meticulous engineering and precise manufacturing that optimize efficiency and productivity.

Sales Director: James Scrivens

Production: Sarah Daviner

Accounts Manager: Avery Hudson

Office Manager: Katie Brehm

BULK SOLIDS TODAY is published 6 times a year by Abbey Publishing Ltd

ADVERTISING & EDITORIAL

Please contact us at:

Tel: 01933 316931

Email: editorial@bulksolidstoday.co.uk advertising@bulksolidstoday. co.uk

Web: www.bulksolidstoday.co.uk

Twitter: www.twitter.com/ BulkSolidsToday

CIRCULATION

To receive a copy free of charge, please send your details to subs@bulksolidstoday.co.uk

No part of this publication may be reproduced by any means without prior permission from the publishers. The publishers do not accept any responsibility for, or necessarily agree with, any views expressed in articles, letters or supplied advertisements.

ISSN: 1365/7119

The UK Warehousing Association (UKWA) has hailed the acknowledgement of warehouse rooftop’s potential contribution to the Government’s Clean Power 2030 Action Plan as a ‘breakthrough’ for the sector.

The Clean Power 2030 Plan, published last week, recognises “There is great potential for rooftop solar installation across the UK’s warehouse and industrial sectors.” It references the major research project commissioned by UKWA, which indicates that the UK’s 20% largest warehouses alone can provide 75 million sq m of roof space, with the potential to support up to 15 GW of rooftop solar capacity.

Commenting, UKWA CEO Clare Bottle said: “We

commissioned research into the benefits and barriers of solar power on warehouse rooftops in 2022, against a background of rising prices and compromised energy security due to Russia’s invasion of Ukraine. Our report revealed potential annual savings of £3bn for the warehousing sector, carbon reductions of 2 million tonnes per year, and critically, the opportunity for the sector to double UK’s solar capacity.

“Since then we have engaged tirelessly with Government; including hosting parliamentary receptions, convening a round table discussion with representatives from DESNZ (Department of Energy Security & Net Zero), and our policy team

has responded to various consultations on behalf of members.

“Furthermore, UKWA were represented on the Government’s Solar Task Force Rooftop Subcommittee to make the voice of warehousing heard.

“This reference to our work and the potential our sector offers in the Clean Power 2030 Action Plan is the first time the Government has directly acknowledged the important role we have to play. This breakthrough is hugely encouraging, and we anticipate further progress now that warehousing is firmly on the Government’s agenda.”

The Clean Power 2030 Action Plan can be read here.

The world leader in bulk handling solutions, Martin Engineering, has announced fresh expansion in Central Asia with a new business unit in Kazakhstan.

Based in the country’s largest city and commercial centre, Almaty, in the South East of Kazakhstan, the new venture will act as a regional hub enabling Martin to bring its full range of products and services to the fastgrowing mining sector across Central Asia.

Kazakhstan is the world’s ninth-largest country by land area (approximately 1,000,000 square miles) and has a diverse geology comprising a rich array of metal ores and mineral resources. Consequently mining and minerals production is playing an increasingly important role in the Kazakh economy with most materials exported.

The decision to establish a business unit in Kazakhstan builds on the Martin Engineering’s success in the country to date. That includes delivering innovative conveyor belt cleaning solutions to one of Kazakhstan’s largest copper producers to maximise plant efficiency and productivity.

Now Kazakhstan’s mining and mineral processing companies have access to a broader portfolio of exceptional conveyor products, such as Martin’s revolutionary CleanScrape® belt cleaners, versatile Orion SQC2S™ Secondary Belt Cleaner, and high performance Air Cannons featuring SMART™ Series Nozzles to ensure optimal material flow.

Kazakh customers can also benefit from faster service response times, improved supply

chain logistics and new product trials, as well as enhanced problem-solving services like Walk The Belt™ and tailor-made Foundations™ training for inhouse maintenance teams.

The new business will be led by General Manager Oleg Glukhov, who has worked with Martin Engineering for the past seven years. He says Martin is well placed to support Kazakhstan’s leading minerals processing firms to improve operational performance and safety.

“Kazakhstan is one of the world’s key sources of metals and industrial minerals,” he explained. “Processing materials safely, efficiently and profitably is important, and that’s where Martin Engineering comes in – our market-leading products and services are proven to solve materials handling challenges for the world’s biggest mining and minerals companies.”

Martin Engineering has become synonymous with the development and manufacture of innovations that deliver

cleaner, safer more productive bulk materials processing.

The company holds dozens of patents for engineering designs that have revolutionized workplace safety and production efficiency in foundation sectors like mining, steel, cement and fertilizer production.

Primarily focused on conveyor belt performance and bulk flow technologies, Martin products are proven to eliminate blockages, prevent spillages and reduce dust emissions – a commitment that’s reflected in the company slogan “Problem Solved - Guaranteed”.

The full address of the new business is TOO Martin Engineering Kazakhstan, Abish Kekilbayuly 34, Bostandyk District, Almaty 050000. Enquiries can be made via the website www.martin-eng.kz, by email kz-info@martin-eng.com or on WhatsApp +7 982 283 0204.

To find out more about Martin Engineering visit www.martineng.com.

Bonfiglioli’s participation in Bauma China underscores its commitment to the evolving Chinese market, leveraging its innovative technologies to meet local needs. The Chinese market has undergone profound changes in recent years, characterized by rapid growth, intensified competition and a shift towards advanced, niche products and a stronger sustainability. Bonfiglioli has strategically adapted to these changes, focusing on areas where its high-quality, technologically advanced solutions can deliver competitive advantages.

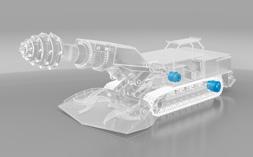

Accelerating Electrification in Construction Machinery

A significant highlight of Bonfiglioli’s showcased at Bauma China was its portfolio of electrification solutions. As the world transitions from traditional systems to electric-powered

machinery, China leads this shift with remarkable speed, supported by government initiatives and market readiness. Bonfiglioli is at the forefront of this transition, presenting advanced solutions for applications such as still loaders, mini-electric excavators and electric systems for 20-ton excavators. Among the products featured are electric motors like the BPM 240, tailored for heavy machinery and multipurpose applications. Combined with an electric swing drive of the 700TE Series and an electric track drive of the 700CE Series, the BPM motor – specifically designed for the pump drive – is featured in a complete super performing kit which has been developed for battery-powered mini-excavators, but suitable also for other compact off-highway machines. An extraordinary innovative

solution that allows for a 20% improvement in energy efficiency. Focus on high performing solutions for the mining sector

Bonfiglioli has identified mining as a key sector where its expertise can drive value. From crushing to earth moving applications, the integrated solutions developed by Bonfiglioli take on the harsh, dusty environments typical of mining activities. Moreover, the range of products is one of the largest available worldwide, with torque values from 13 Nm to 3,000,000 Nm. For mining industry, the flagship products are the travel and track drives of the F Series and the slew drives of the 700T Series. Designed for large excavators, commonly referred to as shovel machines, these compact and highly efficient products demonstrate scalability to cater to a wider range of mining

applications, including stationary machines for conveying and slurry processes. The company also highlights its advanced solutions for road construction and maintenance machinery, including milling machines, road compactors and road pavers. At the trade fair the wheel drive of the 600 Series will be showcased. This Series is the best solution when designing wheeled off-road equipment. With a compact design, high torque and load capacities, a negative multi-disk parking brake and an optional gear disengagement device, this product precisely matches the application requirements.

At Bauma China a focus was dedicated also to Bonfiglioli’s solutions for bulk long distance conveying on overland conveyors in the mining sector. The drive showcased belongs to the HD Series and its output shaft is in the right angle (HDO) configuration. Thanks to high quality materials and an optimized design, this helical bevel gear unit can operate in the harshest environment, as

well as in explosive atmospheres, ensuring low maintenance costs and long time service intervals.

Bonfiglioli’s presence at Bauma China highlights its focus on high-tech, locally produced solutions to meet China’s growing demand for modern, reliable systems. By offering integrated systems with motors, gearmotors and inverters, Bonfiglioli positions itself as a leader in driving technological transformation and as the ideal partner in supporting clients towards more sustainable and efficient innovations.

Unlike other valves that seal with friction, Posi-flate’s unique butterfly valve uses an inflatable seat to seal with air pressure. Thus it requires less torque and a smaller actuator, resulting in lower cost. Plus, the seat automatically compensates for wear, providing longer life. Some users have reported over six million cycles and the valves are still going strong.

Less friction

Low torque

Low maintenance

Lower actuator costs

Longer valve life

More reliable

Process control technology specialist Promtek Ltd is thrilled to announce that it has made it to the list of finalists in the highly esteemed Food Manufacture Excellence Awards 2025. Promtek works with clients to implement systems which improve the efficiency and sustainability of production, which has led to the company being shortlisted for Food Manufacture’s Collaboration and Partnership Award.

The nomination is a testament to Promtek’s commitment to fostering strong, trusted alliances with key partners including the Staffordshire-based companies Trigg Electrical and ADM (previously known as Fuerst Day Lawson). These lasting collaborations have helped Promtek to inspire innovation, expand market reach and promote sustainability, and operational efficiency within the sector.

The award has attracted submissions from an impressive array of leading companies including Arla Foods, Raynor Foods, and RideTandem. The calibre of entries was of an extremely highly standard, so making it onto the shortlist is a huge accomplishment in itself. Everyone in the company feels honoured to be part of it.

“We are incredibly excited to be recognised in this way,” says Lani Scholtz, Marketing Manager at Promtek. “Being shortlisted for the Collaboration and Partnership Award is a testament to our team’s relentless pursuit of quality and innovation. We are so looking forward to joining fellow leaders in the industry as we celebrate the shared commitment to making a difference in the food manufacturing industry.”

The Food Manufacturing Excellence Awards will take place on Thursday 6th February 2025 at the prestigious London Hilton Bankside Hotel. The event promises to be an inspiring evening, showcasing the best and brightest in the industry.

Founded in 1972, Staffordshire-based Promtek has over five decades of expertise designing and integrating process control and automation systems for various bulk material handling industries. The Stoke-On-Trent based company is proud of its heritage and is the go-to provider of solutions which develop, integrate and support process control. Its automated solutions serve with distinction in the production facilities of top-notch companies all around the globe.

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our website - www.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/Distribution, Recycling & Waste Management and more.

www.bulksolidstoday.co.uk

Bobcat will be presenting the company’s expanded range of products for the rental industry at the sold out 2025 edition of the Executive Hire Show (EHS) at the Coventry Building Society Arena in Coventry from 12-13 February 2025.

As can be seen on the company’s Stand Number A72, Bobcat offers one of the widest ranges of products on the market for the rental industry. The Bobcat product portfolio has grown significantly over the past five years, launching more machines during this period than previously in its entire history.

For the rental industry, Bobcat offers extensive line-ups of compact machinery (including loaders, excavators, telehandlers, compact tractors and mowers) and material handling equipment (including forklifts and warehouse solutions), plus a broad range of attachments, parts and services. All Bobcat products are backed by a worldwide network of independent dealers and distributors.

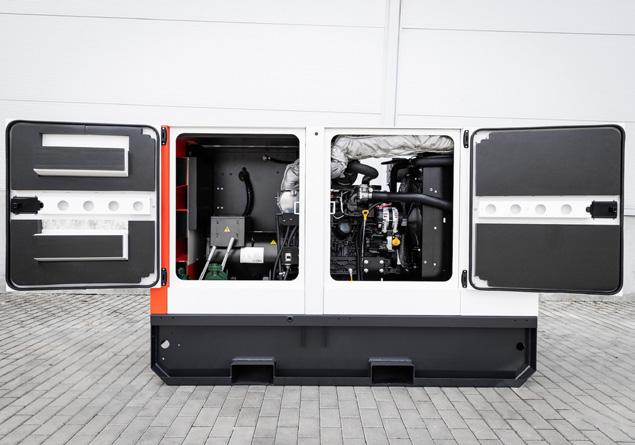

Among the latest additions to the Bobcat

range are a complete line of generators, portable compressors and light towers, building on decades of success and experience in the portable power market.

The very latest portable power products are the new PG40 and PG50 models providing a leap forward in portable generator design. Powered by Stage V D24 engines and Stamford alternators, the new PG40 and PG50 eco-conscious models replace the previous generation Stage IIIA G40 and G60 units, delivering a combination of increased power output and lower fuel consumption compared to their predecessors.

The D24 engine in the new generators is a very impressive unit – more powerful than those in other machines of this size on the market and with a higher capacity. This has allowed Bobcat to offer a true 50 kVA prime unit on the market in the new PG50 model and still be below the Diesel Exhaust Fluid system requirement. Alongside the PG50, the PG40 delivers a prime power output of 40 kVA.

In addition, both generators have a new sleek, compact design, with a selection of novel features including optional factory-mounted running gear, with either fixed or variable height, for easy transportation such as towing behind a car. This upgrade provides unmatched convenience, ensuring mobility on and off the job site.

The new generators also have ‘Liquid Heat’, a low-load management system designed to reduce downtime and deliver peace of mind. Their versatile capabilities allow the new generators to manage

lighter loads while preserving engine life, making them the perfect investment for the rental industry.

The EHS is firmly established as the only annual national event in the UK aimed at tool, equipment and plant hirers and the suppliers serving this dynamic industry. The EHS enables hire professionals to not only see key suppliers they already do business with, in one place, but also to get in front of new companies from around the world who are looking to serve this important market.

Since 1958, Bobcat has been empowering people to accomplish more. As a leading global equipment manufacturer, Bobcat has built a proud legacy of innovation and a reputation for delivering smart solutions to customers’ toughest challenges. The Bobcat brand is owned by Doosan Bobcat.

Doosan Bobcat is a company within the Doosan Group. Doosan Group is a top-tier global enterprise that has proudly served customers and communities for more than a century. Doosan Bobcat is based in Bundang, South Korea.

To learn more about Bobcat’s products, attachments and services, visit www.bobcat.com.

MATERIAL EVOLUTION,

the start-up aiming to radically decarbonise the world’s most common construction material, announced today that its first-ofa-kind ultra-low carbon cement production plant has launched in Wrexham.

The ultra-low carbon cement production facility has been commissioned and is operating on an industrial scale, making it the UK’s biggest producer of ultra-low carbon cement.

The Mevo A1 Production Facility produced its first batch of ultra-low carbon cement in October 2024, on schedule and just 8 months after construction work began onsite. The facility has capacity to produce 120,000 tonnes of Material Evolution’s pioneering MevoCem product, which has up to 85% emissions reductions compared to ordinary Portland cement per year.

under one roof, further lowering the carbon footprint of the end product due to lower transport requirements.

The groundbreaking factory uses no heat or kilns to combine the constituent ingredients of its cement –contrary to the traditional production process that has been scrutinised for its vast carbon output. Instead, the production facility relies on Material Evolution’s patented alkali-fusion process to produce a cement capable of undergoing geopolymerisation.

“This launch takes us one step closer to achieving our goal of removing one gigaton of CO2 by 2040,” said Sam Clark, co-founder and chief operating officer of Material Evolution.

“Constructing a first-of-a-kind facility in just eight months is a massive undertaking. But our modular construction and lean design principles not only allowed us to move rapidly, but also means our approach is highly scalable.”

Clark continued: “We hope this facility proves that cement and concrete decarbonisation is not only a possibility in the future - it’s a reality on the ground today. We look forward to working with government agencies, trade bodies and concrete specifiers to join us on our mission to realise the green transition here in the UK.”

The plant is located in Llay, Wrexham, on the site of CCP Building Products, which produces pre-cast concrete blocks. This co-location marks a first-of-itskind approach to cement and concrete production

Material Evolution funded the Mevo A1 Production Facility’s construction in part through the £15 million Series A funding round it raised in 2023, which included strategic investment from SigmaRoc, CCP Building Products’ parent company.

“We are thrilled to see the Mevo A1 Production Facility up and running, marking a significant milestone in low-carbon cement production in the UK,” said Michael Roddy, RMD North West at SigmaRoc. “This project aligns with SigmaRoc’s commitment to sustainable development, and we are proud to support Material Evolution in driving innovation that transforms the industry.”

The 120 square meter plant was designed to combine and react waste feedstocks using lean manufacturing techniques. Material is transported around the plant using state-of-the-art material handling processes allowing its overall footprint to be far smaller than the average UK cement factory. By using a modular design, the Mevo A1 Production Facility is flexible to the supply chain and raw materials required, allowing for adaptation to new cement technology and innovation.

Founded in 2020 by Dr Liz Gilligan and Sam Clark, Material Evolution aims to help revolutionise the £500 billion concrete industry.

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our websitewww.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/ Distribution, Recycling & Waste Management and more.

www.bulksolidstoday.co.uk bst@abbeypublishing.co.uk

Tuf-Lok ring grip pipe and tube couplings are rugged, heavy duty, self-aligning and self-grounded couplings with a high end pull. They can be used for almost any application where pipe or tube ends need to be connected. The Tuf-Lok self-aligning couplings install quickly and easily with little effort.

Features

• Self-aligning

• Self-grounding

• High pressure rated

• Full vacuum rated

• Stainless or mild steel

• Usable on thin or thick wall pipe or tube

• Low cost

• Reusable

• Absorbs vibration

• Externally leakproof

Business group Logistics UK has announced the winners of its eighth annual Logistics Awards at a glittering reception and celebratory gala dinner held at the Park Plaza Westminster Bridge, London on Thursday 12 December. Almost 600 people attended the awards sponsored by Unipart – to celebrate the companies and individuals that have made a significant contribution to the logistics and supply industry in the past year. Shortlisted entrants included representatives of the road, rail, sea and air industries including operators, manufacturers, logistics businesses and supporting sectors, which were recognised for their outstanding commitment, knowledge and expertise.

Award winners included Nestlé UK and Ireland, Tesco, the Fleet Management Team at Powys County Council, The Clancy Group,

Kärcher UK and HSL Chairs. Benz Sirikorn Mecasuwandamrong, Technology Graduate at Ligentia, was named the Rising Star for 2024 and Matt O’Dell, Managing Director – England Logistics, DFDS Logistics, was announced the Logistics Leader of the Year.

The evening also saw Tracy Downend, Distribution Manager at Booker announced as the winner of Logistics UK’s Transport Manager of the Year competition for 2024, sponsored by BP, with Jemma Deans, Transport Manager at Oilfast Ltd named as runner-up.

David Wells OBE, Chief Executive of Logistics UK, commented: “This is the best night of the year, and our Logistics Awards brings the sector together showcasing the skills, expertise and ‘can do’ spirit of our industry. The passion for our profession was

tangible in all the submissions and this year we received our highest number of top-quality entries ever - a clear indicator that the sector continues to innovate and achieve great things for businesses right across the economy.

“All those shortlisted for an award this evening should be very proud of their achievements. The competition was fiercer than ever, generating plenty of ‘heated debates’ among the judges, and all our winners can be justifiably satisfied that they are at the very top of their game.”

The winners of the Logistics Awards 2024 are:

International Logistics Business of the Year (sponsored by CNS Online) - Aramex UK

Highly commended: DFDS Logistics, Metro and Noatum Logistics

Public Services Operator of the Year - Powys County Council - Fleet Management Team

Highly commended: The Clancy Group

Most Innovative Company of the Year (sponsored by Brigade Electronics) - Kärcher UK

Decarbonisation Champion of the Year (sponsored by Allstar) - Nestlé UK&I

Highly commended: Greenergy Flexigrid Ltd and Peel Ports Group

Logistics Technology Provider of the Year (sponsored by Unipart) – Samsara

Highly commended: iCustoms and r2c

Van Business of the Year (sponsored by Logistics UK Recovery) - The Clancy Group

Logistics Partner of the Year (sponsored by M6 Toll) – iCustoms

Highly commended: Clipfine

Air Business of the Year - Metro

Diversity and Inclusion Champion of the Year (sponsored by Port of Dover) - Road to Logistics

Highly commended: CEVA Logistics

Rail Business of the Year - Tesco

People Champion of the Year (sponsored by Howard Tenens) - Reflex Vehicle Hire

Last Mile Delivery Business of the Year - HSL Chairs

Highly commended: Howard Tenens Logistics

Most Innovative Product of the YearOctopus Electroverse for Business

Highly commended: Brigade Electronics Ltd - Backeye®360 AI Intelligent Detection, Deus Robotics and Tesco HGV Routing Platform

Rising Star of the Year - Benz Sirikorn Mecasuwandamrong, Technology Graduate, Ligentia

Highly commended: Jonny Farnhill, Transport Manager, HSL Chairs and Megan Lynch, Transition & Transformation Degree Apprentice UKIN, CEVA Logistics

Logistics Leader of the Year (sponsored by R2C Online) - Matt O’Dell, Managing Director –England Logistics, DFDS Logistics

Highly commended: Chris Welch, Managing Director, Welch’s Transport

Road Transport Operator of the Year (sponsored by Weightmans LLP) - DFDS Logistics

Highly commended: Hovis Logistics

Entries for next year’s Logistics Awards open in March, with Awards night taking place in December. Further details to be published at www. logistics.org.uk/logistics25

Logistics UK is one of the UK’s leading business groups, representing logistics businesses which are vital to keeping the UK trading, and more than seven million people directly employed in the making, selling and moving of goods. With decarbonisation, Brexit, new technology and other disruptive forces driving change in the way goods move across borders and through the supply chain, logistics has never been more important to UK plc. Logistics UK supports, shapes and stands up for safe and efficient logistics, and is the only business group which represents the whole industry, with members from the road, rail, sea and air industries, as well as the buyers of freight services such as retailers and manufacturers whose businesses depend on the efficient movement of goods. For more information about the organisation and its work, please visit www.logistics.org.uk

Whilst machine monitoring is an essential requirement in many manufacturing and industrial applications, not all require the more substantial investment of high-integrity, stand-alone MMS (Machine Monitoring System) or a MPS (Machine Protection System). However, keeping a continuous eye on your critical rotating machinery is still an important requirement, helping to ensure its smooth running and avoiding the potential of a catastrophic failure.

Condition monitoring specialist SENSONICS recognised the increasing demand for continuous protection and monitoring of smaller rotating plant such as; Fans and Blowers, Centrifuges, Pumps, Motors and Conveyors to name a few, which is why they developed their PZDC Accelerometer. Available in a number of options, these 2-wire (+screen) loop- powered 4-20mA sensors have become an established and more affordable means of smaller machine monitoring.

A key reason for the success of this flexible, costsaving solution is that the PZDC Accelerometer (g) or velocity (mm/s) vibration transmitter can be directly connected to an existing DCS (Distributed Control System), a PLC (Programmable Logic Controller), a BMS (Building Management System), or a SCADA system.

The PZDC is available as a standard general purpose device, or there is an intrinsically safe option for use in hazardous areas with potentially explosive atmospheres including hydrogen or dusts, conductive or non, also for use in mines with methane and dust. Submersible versions are also available with polyurethane cable and IP68 (10bar) sealing, along with specially engineered options for subsea applications, using specialist corrosion resistant materials and over-moulded cable entries to withstand greater pressures.

The PZDC can be supplied with a top, side exit integrated cable, or with an integral connector and separate connector cable assembly, standard (plain) or armoured options as well as more specialist LSZH options.

Bunting has joined forces with Smiley Monroe to modify a ToughFlex® belt for Overband Magnets. The new belt is more resistant to excessive wear in arduous working conditions.

Overband Magnets have a permanent or electromagnetic block mounted between two pulleys over which continuously runs a cleaning belt. In operation, the Overband Magnet is suspended over a conveyor transporting material such as waste, both industrial and household, and quarried rock. The magnetic field of the centrally located magnet block attracts ferrous metals and other magnetic materials up and out of the conveyed material. Between the magnet box face and the separated metal is a moving cleaning belt with upstands, which transfers the captured material away from the conveyor and out of the magnetic field into a separate collection area.

The separated metal is often angular with sharp edges, which can damage the rubber cleaning belt. In certain applications, such as when handling industrial and commercial waste, there is a high content of metal in a form that commonly causes belt damage.

In particular, customers using the ultra-strong but lightweight ElectroMax Overband Magnet are achieving high levels of metal separation which has resulted in a higher rate of belt wear. The lower magnetic power of permanent Overband Magnets separated less metal and, subsequently, had less belt wear.

Whilst assessing methods to extend belt life in difficult applications, Bunting approached Smiley Monroe, a leading producer of endless conveyor belts, cut rubber and plastic parts for the materials processing equipment manufacturing sector. Smiley Monroe routinely test the abrasion resistance, tensile strength and adhesion levels of both the cover rubber and fabric plies of our raw materials and finished products in their well-equipped labs, to ensure conformity to DIN, ISO and company standards.

After considering several options, Smiley Monroe recommended the ‘ToughFlex® Belt’. ToughFlex® conveyor belts are designed to handle the toughest conveying applications, from bulk handling to mobile crushing. The belts are constructed with a special weave of two fabric plies and an additional binder warp. The plies

are reinforced to resist puncturing and are protected with heavy duty, wear resistant top and bottom covers.

The belt material and design met the criteria for less damage from ferrous metal piercing and tearing the belt, even when extremely angular with multiple sharp edges. This meant less maintenance and extended production hours between replacing belts.

Once the belt material was selected, the engineering design teams of Bunting and Smiley Monroe worked together to modify the belt for use on an Overband Magnet, adding integrally moulded cleats for the transfer of captured ferrous metal.

“We [Bunting] are continually looking make improvements that help our customers,” explained Adrian Coleman, Bunting’s Technical Director. “An increasing number of our customers are turning to the ElectroMax Overband Magnet because of the increased magnetic power but compact design. However, for certain applications we identified a benefit of using a belt with better wear characteristics and contacted Smiley Monroe.”

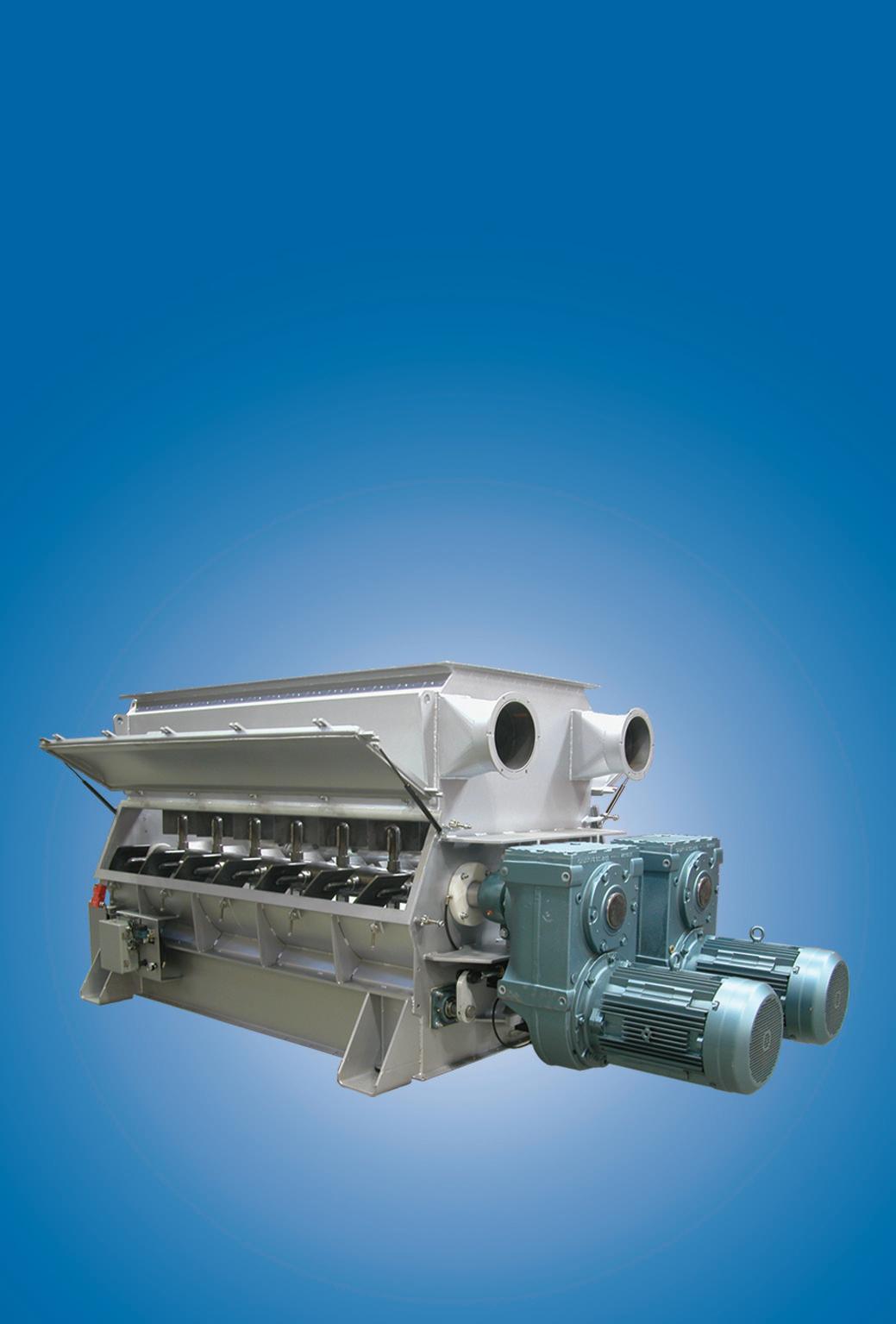

The Blendcon® air blender by Dynamic Air is a fast, efficient blender for mixing batches from 5 cubic feet to over 4000 cubic feet of dry bulk materials. The blender is unique in that it lacks moving parts required to displace the material in the mixing process. Instead of shafts, paddles, or agitators, compressed air is pulsed into the material in an upward circular pattern to lift, turn, and tumble dry materials. This makes the Blendcon air blender especially effective for abrasive blends such as glass batch, tile grout, and concrete mixes. Since the process area is a conebottomed vessel, the Blendcon air blender empties nearly 100%, making cleanup easy. Plus, the Blendcon air blender’s blending method is so effective, the ratio of horsepower to blended material is very low, resulting in high energy efficiency.

https://www.dynamicair.com/product/blendcon-airblender/

The Series 486 inflatable seated butterfly valve from Posi-flate is suitable for many applications, such as food, chemical and pharmaceutical. The stainless steel valve features a fully machined 316L stainless steel housing and a single piece disc and shaft that is available in a number of materials including 316L stainless steel and Hastelloy. The disc may be polished to a mirror finish or coated with PTFE, nylon or other high-performance coating. The Posi-flate Series 486 butterfly valve is ideal for powders, granules, slurries and liquids and is available in sizes 2” (50mm) to 20” (500mm). Typical applications include loading and unloading of process material, sterile air control, and outlet valves for storage containers or hoppers.

The inflatable seat design of the Posi-flate butterfly valve provides a better seal by utilizing air pressure to expand the seat against the disc, providing more sealing area and an even pressure distribution against the disc every time. The seat automatically compensates for wear when it inflates against the disc, extending valve life considerably. Because the Posi-flate disc only makes casual contact with the seat during opening and closing, torque requirements are substantially lower. This ease of movement also allows the disc to come to a perfect 90-degree position every time. Additionally, the smooth profile of the disc helps material flow easier and reduces build-up. For unique fail-safe monitoring, a pressure switch can be utilized to verify a perfect seal.

Posi-flate

Milton Keynes, United Kingdom +44-1908-622366

E-mail: sales@posiflate.co.uk https://www.posiflate.com

One of the most significant developments in forklift truck safety technology turned 25 in 2024.

Toyota’s System of Active Stability (SAS) was launched in 1999 as a unique solution to the problem of trucks rolling or tipping over, which are among the most common forklift accidents that occur within a warehouse or factory environment.

A result of Toyota’s many years of engineering experience in the automotive sector, the SAS deploys several devices that make it considerably harder for trucks to be rolled or tipped as they go about their work.

For example, the rear axle on Toyota’s four-wheel counterbalance trucks features a swing lock cylinder. This provides greater lateral stability

when the truck is turning by locking the rear axle. On the three-wheel Traigo range, the SAS optimises the driving speed while taking curves. This way the truck’s stability always remains under control.

In addition, the SAS uses advanced sensors linked to an on-board controller to monitor and manage the truck’s mast when loads are being put-away or picked. By automatically restricting the mast’s speed and angle, the risk of ‘mast sway’ and a forklift becoming unbalanced is minimised, allowing faster and safer storage and retrieval of pallets at height.

“When it was launched the Toyota System of Active Stability was an industry first and, 25 years on, the multi awardwinning technology remains unique in the industry,” says

Toyota Material Handling’s Product Development Manager, Chris Read.

Chris continues: “Toyota has always been at the forefront of the development of new and advanced safety solutions and a quarter of a century after we first introduced it the Toyota System of Active Stability is still regarded as one of the most iconic and important developments in the material handling industry.”

The patented System of Active Stability is now a standard feature on every model in Toyota’s extensive counterbalance truck range.

To discover more about Toyota’s counterbalance trucks, visit https://toyota-forklifts. co.uk/trucks/counterbalanced/ counterbalance-forklifts/

- DESIGNED TO FURTHER ENHANCE PERFORMANCE AND OPERATOR COMFORT -

Develon, formerly Doosan Construction Equipment, has announced several new features and options for the company’s award-winning DL-7 wheel loader range.

Comprising eleven models, running from the smallest DL200-7, through to the top-of-the-range DL580-7 model, the DL-7 range is designed to provide easier and faster loading with maximum bucket capacities from 2.0 to 6.4 m3, providing increased productivity for a very wide range of material-handling applications.

These include the transport and delivery of soil, sand, aggregates and other materials in industry, recycling, waste, construction, demolition, mining and quarrying. Develon also offers a wide choice of options to provide more work tools for a better match with applications, further increasing output.

PARALLEL LIFT FOR ENHANCED PALLET HANDLING AND LIFTING WORK

One of the most important changes in the DL-7 range is the new parallel lift system now adopted as standard in the six smallest models from the DL200-7 to the DL380-7.

These wheel loaders now feature a parallel lift

system with electro-hydraulic compensation, specifically designed to maintain the horizontal alignment of the pallet forks during lifting. This advanced system automatically adjusts the forks to stay level as they move up and down, ensuring loads remain stable and securely balanced. Ideal for precise pallet handling, Parallel Lift simplifies loading and unloading operations and reduces the risk of spillage or damage. This enhancement not only improves safety but also increases productivity, allowing operators to handle materials with greater confidence and efficiency in any working environment.

ELECTRIC JOYSTICK STEERING EXTENDED

Electric joystick steering integrated on the armrest, a proven feature on large Develon wheel loaders is now available for the smallest models from the DL200-7 to the DL280-7.

Electric joystick steering helps operators to keep their concentration and reduces stress. The comfortable electric joystick allows the operator to drive their machine more easily, especially in repetitive tasks and tight spaces. Designed

to give the operator more precise control with a shorter lever stroke, resulting in less fatigue, the sensitivity of the ergonomic joystick control can be set and altered according to operator preferences using the SmartTouch touchscreen monitor. User-friendly and easy to read in all conditions, the touchscreen provides all the important settings and information the operator needs in one place.

FULL VISIBILITY

Another upgrade for all the models in the DL-7 range is a comprehensive Full LED Lighting Pack designed to improve visibility, safety and operator comfort. This new package includes advanced LED work lights, which provide powerful illumination for optimum visibility during night shifts or in low light conditions, ensuring tasks are completed safely and efficiently.

The LED road lights add an extra layer of safety when transporting materials, improving visibility on roads and in busy working areas.

In addition to the lighting enhancements, this package also includes heated and electrically adjustable door mirrors. The heating function ensures clear vision in cold or frosty conditions by preventing fog and ice build-up. The power adjustment allows the operator to set the optimum angle without leaving the cab, increasing comfort and ease of operation.

With the full LED lighting package in place, Develon wheel loaders can tackle and operate in any environment with improved safety, enhanced functionality and greater operator control.

SPACIOUS ERGONOMIC CAB DESIGN

Inside the cab, there is an option on all models of a new seat with both heating and ventilation. The seat offers fully adjustable horizontal and vertical suspension settings and a pneumatic lumbar function as standard. There is a 3-point safety belt with alarm icons on the SmartTouch touchscreen monitor and on the gauge panel, which offers a clear layout and anti-reflective glass.

DL-7 wheel loaders offer significantly enhanced operating comfort, an enhanced steering system and advanced electronic controls. Using the new Develon Smart Key system on the control panel in the cab, the operator can start the machine using a keyless device, helping to prevent machine theft. The

Smart Key system provides remote door control, door lock and unlock, door release, searching and other functions. The control panel also includes two USB sockets.

DL-7 wheel loaders have smooth and responsive hydraulics and auxiliary hydraulic connections. All of the newly updated DL-7 wheel loaders are equipped as standard with a 3rd spool valve with settable flow and detent function, providing a constant flow for hydraulically driven attachments. Operators can easily and comfortably control hydraulic attachments via the proportional switch on the joystick.

The DL200-7, DL220-7, DL250-7 and DL2807 models now have both quick coupler and 3rd spool piping as standard, with these new features optional on the larger models.

For more on Develon, please visit the website: https://eu.develon-ce.com/en/

Atherton Material Handling has installed a Bunting Suspension Electro Magnet at a calcium carbonate quarry in Melton, UK. The Suspension Electro Magnet removes tramp ferrous metal prior to a metal detector, reducing the number of metal detection trips and increasing productivity.

Bunting is one of the world’s leading designers and manufacturers of magnetic separators, eddy current separators, metal detectors and electrostatic separators, with globally located manufacturing facilities.

Atherton Material Handling originally contacted Bunting to find a solution to the problem of a metal detector in the quarry tripping too frequently. Tom Higginbottom, Bunting’s Technical Sales Engineer, was invited on site by the Atherton team to review

the installation.

Bunting had supplied the original metal detector, a model TN77 series, which was identifying tramp metal that could damage crushers, screens, and conveyors. The metal detector was operating perfectly, but the quantity of tramp metal contamination resulted in frequent tripping, and the need to stop the conveyor for removal of the metal. Even though the metal detector’s performance was providing the ideal protection of processing plant, the frequency of metal-trips was affecting productivity.

Bunting recommended the installation of a Suspension Magnet prior to the metal detector. This would remove all tramp ferrous metal, which is magnetic, leaving the metal detector to focus on

non-ferrous tramp metal such as manganese steel digger teeth.

The troughed conveyor transporting the quarried calcium carbonate was 600mm wide, carrying a densely packed 100mm burden depth of material. This led to the recommendation of a Suspension Electro Magnet, which produces a strong, deep field powerful enough to attract tramp ferrous metal at the bottom of the burden.

The selected Suspension Electro Magnet, model 60 OCW 20, is cooled by oil and weighs just over one tonne. The magnet width is wider than the conveyor, at 925mm, and stretches along the conveyor 925mm. This provides plenty of dwell time under the magnet for the magnetic attractive force to pull the ferrous tramp metal through the burden.

The Suspension Electro Magnet has three suspension points, which connect up to a hand-geared travelling trolley, installed by Atherton Material Handling. This system enables the easy moving of the Suspension Electro Magnet away from the conveyor for safe and effective removal of all captured tramp ferrous metal off the magnet face. In operation, the maintenance crew manoeuvers the Suspension Electro Magnet into position over a chute before turned off the magnetic field and allowing all captured metal to discharge from the face of the magnet, under gravity, into a separate collection area.

The Suspension Electro Magnet, suspended 200mm above the conveyor, generates 650 Gauss on the surface of the belt, which is enough magnetic force to remove a wide range of tramp ferrous metal.

Once installed, the resultant reduction in the number of times the metal detector trips will reduce production downtime without any compromise on protecting the crushers and other processing equipment from tramp metal damage.

“We worked closely with the Atherton Material Handling team to find a solution for their client,” explained Tom. “The final solution not only maintains and improves important protection against tramp metal damage, but also makes it easy and safe to operate and clean the Suspension Electro Magnet.”

For further information, please contact us on press@buntingmagnetics.com or visit our website:

Bunting-Redditch – www.bunting-redditch.com

The Bella dryer/cooler offers thermal efficiencies to 80 percent or better because air flows around material while it is suspended in the weightless zone. The result is a more consistent material.

Quarry Manufacturing & Supplies’ (QMS) long standing Romanian partner Mirfo SRL has recently completed the installation of a 1,000tph aggregate plant in Arad County, Romania. An array of crushing, screening and associated QMS equipment has been installed on behalf of leading Romanian aggregates supplier, Luscan Com SRL. The aggregates will be produced in a multitude of fractions for use on a variety of infrastructure projects in Romania and Hungary.

Comanesti headquartered Mirfo SRL has since its creation become one of Romania’s leading suppliers and installers of high quality quarrying and aggregate production equipment. Working in a highly competitive market place that covers Romania, and increasingly Hungary, the company has gone from strength to strength supplying, designing, installing and supporting quarrying and aggregate plants.

One of the reasons for the success of the company in its ten or so years of operation has been the longstanding partnership forged with UK based QMS. This has enabled Mirfo SRL to supply cost effectively some of the most advanced crushing and screening solutions available, supported by a company that is still focused on the real needs of its customers.

A major project Mirfo SRL has been involved in recently has been the design and installation of a bespoke aggregate plant at Luscan Com SRL’s Batuta Quarry. Luscan began its life as a transport and haulage company but soon began to see the benefits of producing aggregates itself. This led directly to the acquisition in 2017 of the Batuta Quarry, the largest stone quarry in Romania, which has since Luscan’s running of the quarry produced a staggering eight million tons of mainly diabase aggregates.

Due to diabase’s structure, it is ideal when crushed for use as a construction aggregate. This has led to rock from the quarry being used on some of the largest road and railway construction projects in Romania and, increasingly, Hungary. The company’s customers now consist of a who’s who of European construction companies including Astaldi SpA Italia, WeBuild SPA, CRH Romania, Max Boegl, Strabag Romania, Porr Construct, Somaco Prefabricate, Travertec S.R.L., Holcim and Colas.

Since acquiring the Batuta quarry in 2017, Luscan has invested in the facilities, distribution points, haulage and production equipment. It now has three production lines, all with the necessary loading and transport equipment. However, in 2023 it was decided to update the plant with the construction of a new production line. The new line has been designed to produce the same amount of aggregates, but with 40% lower fuel consumption than at present so as to provide a positive impact on the environment. At the same time, the haulage loading system will be automated, thus dispensing with some front loaders, which will further lead to a significant decrease in CO2 emissions.

Due to its excellent reputation for supplying some of the most productive, reliable and environmentally friendly crushing and screening equipment on the market, Mirfo was invited to provide a solution for the new production line. Luscan required new equipment for its entire primary, secondary, tertiary and quaternary crushing. Along with this, the company also required screens and conveyors to produce 0/4 mm, 4/8 mm, 8/16 mm, 16/22,4, 31.5/50 mm, 0/63 mm, and +63 mm fractions to be sold as the quarry’s main products. These products will then be used for asphalt production, road and railway construction along with concrete and concrete precast production.

In order to ensure that Luscan would be provided with the best possible solution, Mirfo contacted QMS for advice on the most suitable equipment. “Zoltán

Olti-Pasca, Mirfo’s general manager, is always in close contact with QMS in order to provide his customers with the best possible solution, and the Batuta Quarry was no different,” explains QMS managing director Jonathan Beck. “Given the importance of the quarry, and the role Luscan plays in supplying aggregates to some of the leading players in European construction, it was vital that the most productive and cost-effective portfolio of equipment was supplied.” After consulting with QMS process experts, Mirfo supplied a selection of QMS cone crushers, screens and associated equipment. The full selection consisted of three cone crushers (B6, B4XC, B4); three 2x7m 3D screens and one 2x6m 2D screen.

The QMS B-Series XC models are purpose designed for secondary crushing applications, boasting a significantly large intake capacity relative to their size, a feature attributed to their uniquely long crushing chamber. To optimise operational economy, the extended chamber is divided into three sections: the upper concave, lower concave and mantle. These sections can be exchanged at different intervals, enhancing both efficiency and adaptability.

The QMS B-Series cone crushers stand out with their unique hydraulic system, a hallmark

of innovation in the field. This system provides automatic overload protection by allowing the head assembly to drop, facilitating the safe passage of tramp iron and other non-crushable materials. This feature is particularly advantageous for maintaining operational efficiency and protecting the crusher from potential damage. Another notable feature is the liner design. The liners do not require any backing material like plastic, epoxy or zinc. This design choice significantly reduces maintenance time as there is no need for mixing, pouring or waiting for curing processes. It also enhances safety for maintenance staff, a testament to QMS’s commitment to both efficiency and safety.

“Mirfo SRL reports that Luscan Com SRL’s Batuta Quarry is now fully operational and producing the accurately sized aggregates its clients require. We are pleased to supply the equipment required and value our long-standing relationship with Zoltán and the rest of the Mirfo team. They know we are always on hand to help deal with any eventuality, providing advice as well as spare parts and any assistance we can provide. I myself look forward to seeing the Batuta quarry in action when I visit Mirfo in the coming weeks,” concludes Quarry Manufacturing and Supplies managing director Jonathan Beck.